Page 1

SERVICE MANUAL

CASSETTE RECEIVER

KS-FX230

KS-FX230

KS-FX230

Area Suffix

/I

40WX4

ATT

SEL

Multi

Music

Scan

SSM

78 9101112

123456

CD CHANGER CONTROL

MO/RND SCAN/RPT

KS

-FX230

CD-CHTUNER TAPE

PROGBAND

SOUND

LOUD

DISP

UF ------------------ China

Contents

Safety precaution 1-2

Disassembly method 1-3

This service manual is printed on 100% recycled paper.

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN, LTD.

Adjustment method 1-9

Description of major ICs 1-12

No.49565

1-1

Jul. 2000

Page 2

KS-FX230

Safety precaution

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

Page 3

Disassembly method

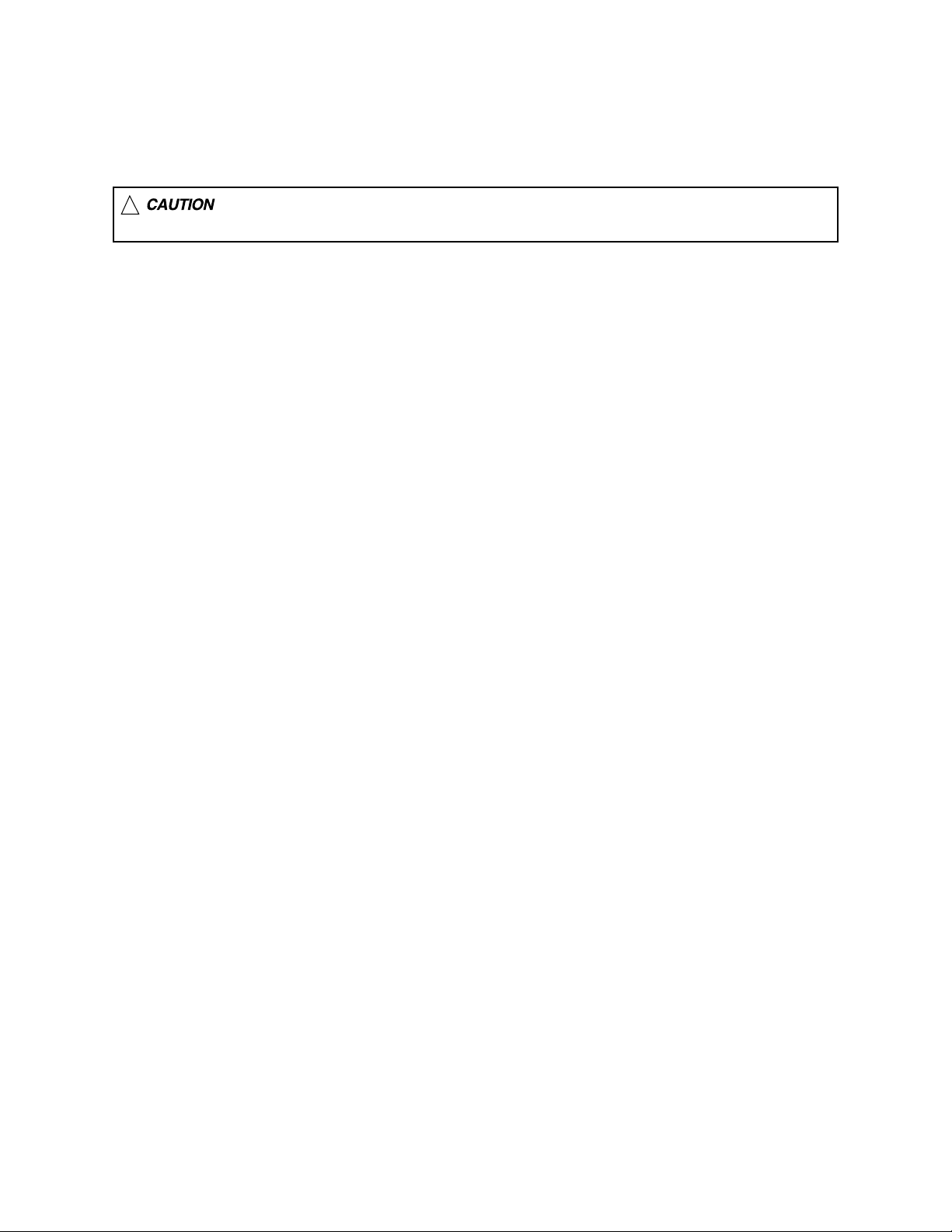

Removing the front chassis (see Fig.1)

1. Disengage the four tabs in the right and left side of

unit and pull the front chassis forward to remove it.

Removing the bottom cover and heat

sink (see Fig.2,3)

1.

Remove one screw A retaining the IC to the heat sink.

2.

Remove two screws B to remove the heat sink.

3.

Turn the upside down, the insert and turn the screwdriver

to remove the bottom cover and protect sheet.

Removing the main board (see Fig.4)

1.

Remove two screws C retaining the rear panel to the

chassis.

2.

Remove two screws D retaining the main board.

KS-FX230

Front chassis

Fig. 1

Bottom cover

Fig. 2

3.

Lift up the main board to remove it. At this time,

remove the connector CP702 connecting the main

board and mechanism assembly.

Removing the rear panel (see Fig.4)

1.

Remove six screws retaining the jacks or the like.

2.

Remove two screws E to the 16-pin jack.

3.

Remove one screw F to remove the line-out jack.

4.

Remove one screw G to remove the antenna jack.

Remove one screw H to remove the changer

controller jack.

Removing the mechanism ass'y (see Fig.5)

1.

Remove four mechanism mounting screws I retaining

the mechanism assembly.

2.

Remove four screws J retaining the cover.

3.

Remove one screw which is the fixation of top cover

and the substrate.

Removing the front panel unit (see Fig.6)

1. Remove four screws K retaining the rear cover.

A

Left side view

BB

Fig. 3

Connection to the mechanism

connector position

C

E

H

F

G

Fig. 4

Mechanism ass'y

JJ

Heat sink

D

Main board

CP702

C

KK

KK

Fig. 6

JJ

Fig. 5

1-3

Page 4

KS-FX230

<< Cassette mechanism section >>

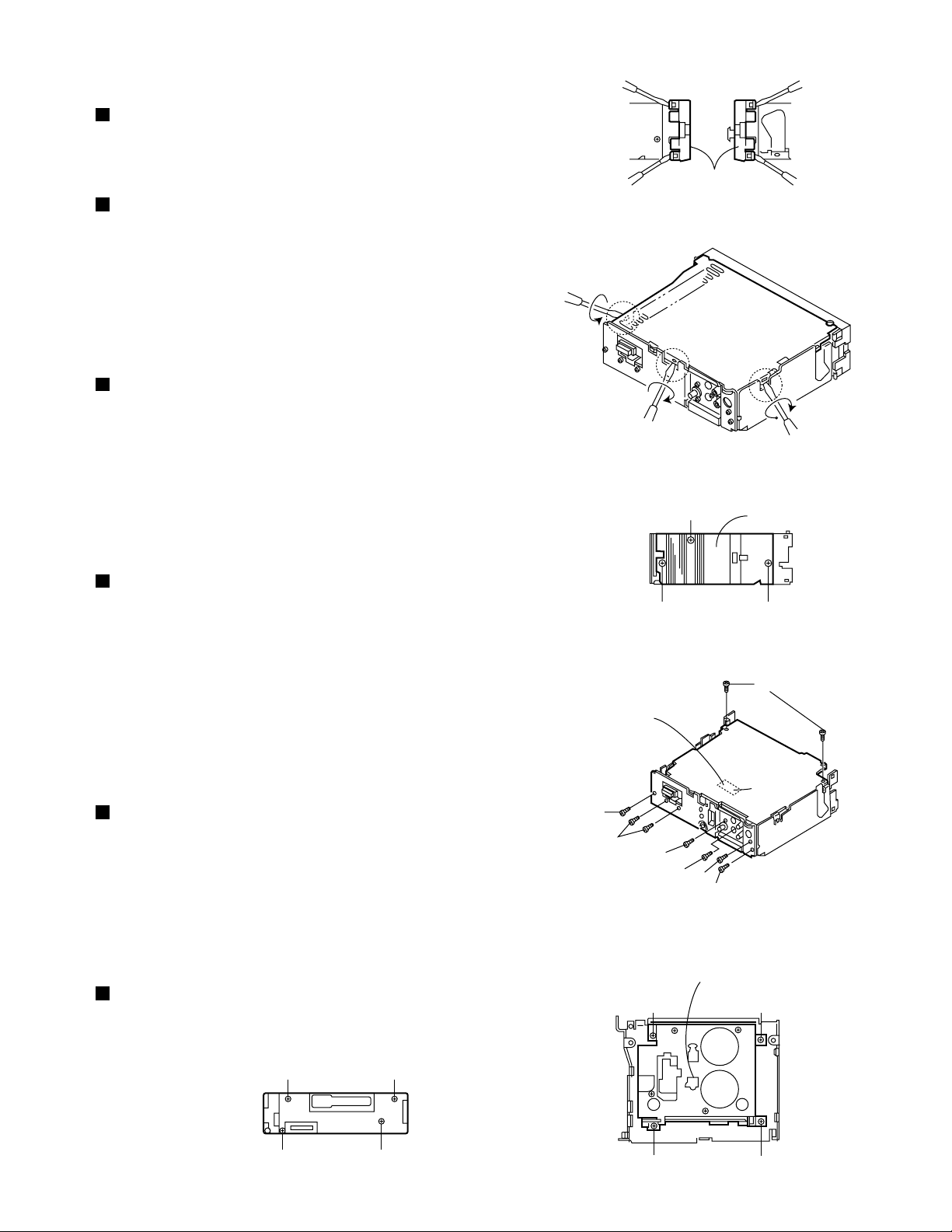

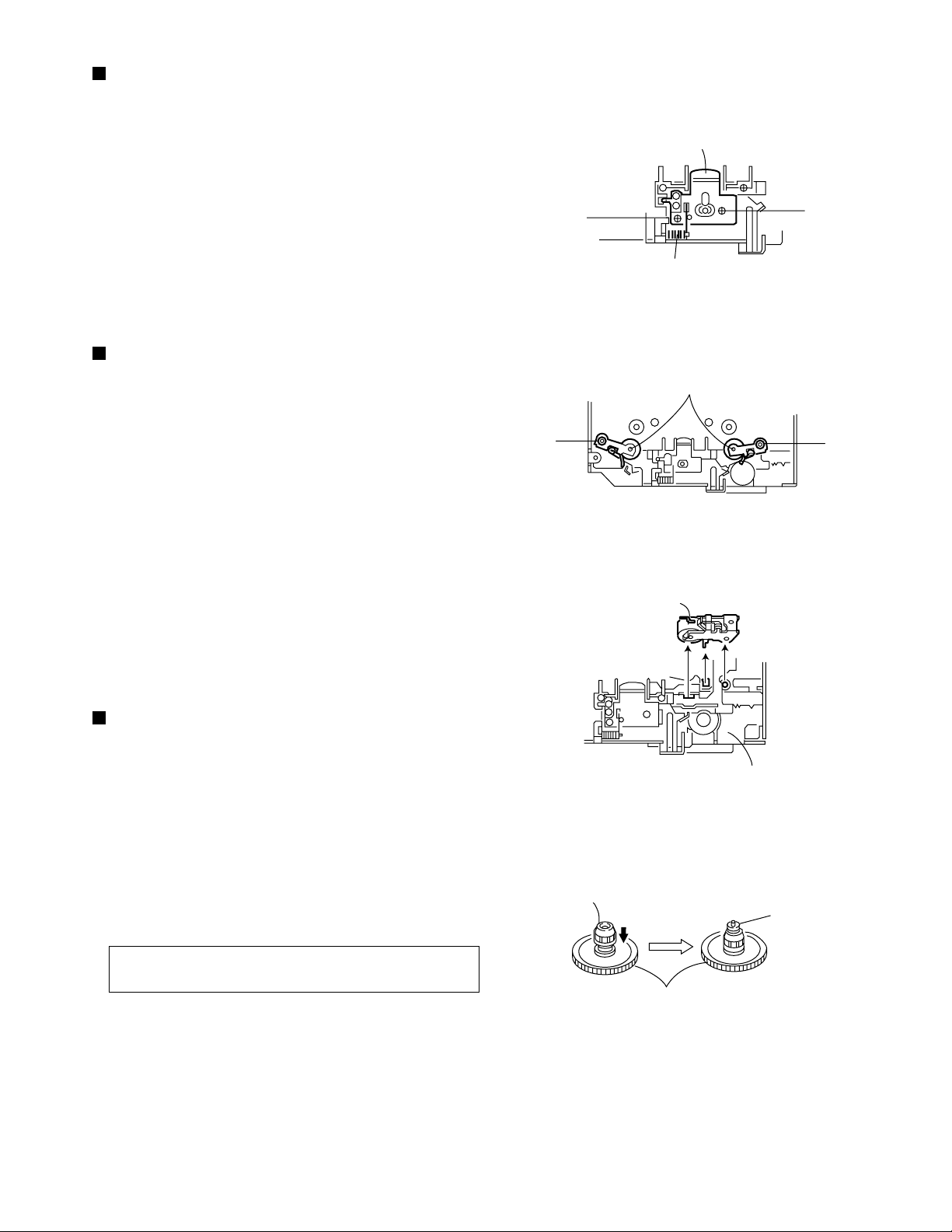

Removing the head relay board (see Fig.1)

1.

Desolder the lead wires of the loading motor at the 2

positions shown (Red and Black).

2.

Desolder the lead wire of the head at the 3 positions

shown (RED, Yellow and Black).

3.

Remove the three screws A securing the head relay

board.

4.

Shift the interlocking section a securing the head

relay board in the direction shown by the arrow to

remove the board.

Removing the load arm ass'y (see Fig.2)

1.

Using tweezers, detach the mylar washer 1 securing

the load arm ass'y and pull out the load arm ass'y.

NOTE : When reassembling, be sure to use a new

mylar washer.

Red

A

Black

Black

Fig. 1

AA

Yellow

a

Red

Head relay board

Catch

2.3.Shift the load arm ass'y counter clockwise.

Remove the load arm ass'y from the catch.

Removing the cassette holder and arm

ass'y (see Fig.3)

1.

Remove the head relay board.

2.

Remove the load arm ass'y.

3.

Apply DC 6V to the lead wire of the loading motor

ass'y and turn the load gear ass'y to the position

shown in Fig. 3.

4.

Remove the screw B securing the cassette holder

and holder arm ass'y.

5.

Shift the cassette holder and holder arm ass'y in the

direction shown by the arrow and remove them from

the interlocking section b of the sub chassis ass'y.

Removing the sub chassis ass'y (see Fig.4)

1.

Remove the head relay board.

Load arm ass'y

Cassette holder

C

1

Fig. 2

B

Holder

b

D

2.

Remove the load arm ass'y.

3.

Remove the cassette holder and holder arm ass'y.

4.

Remove the two screw C and D securing the sub

chassis ass'y.

NOTE : When removing the sub chassis ass'y, the

mode gear may become detached. In this

case, set it back to the original position.

1-4

Sub chassis ass'y

Loading gear ass'y

Loading motor ass'y

Fig. 3

Apply DC 6V

Page 5

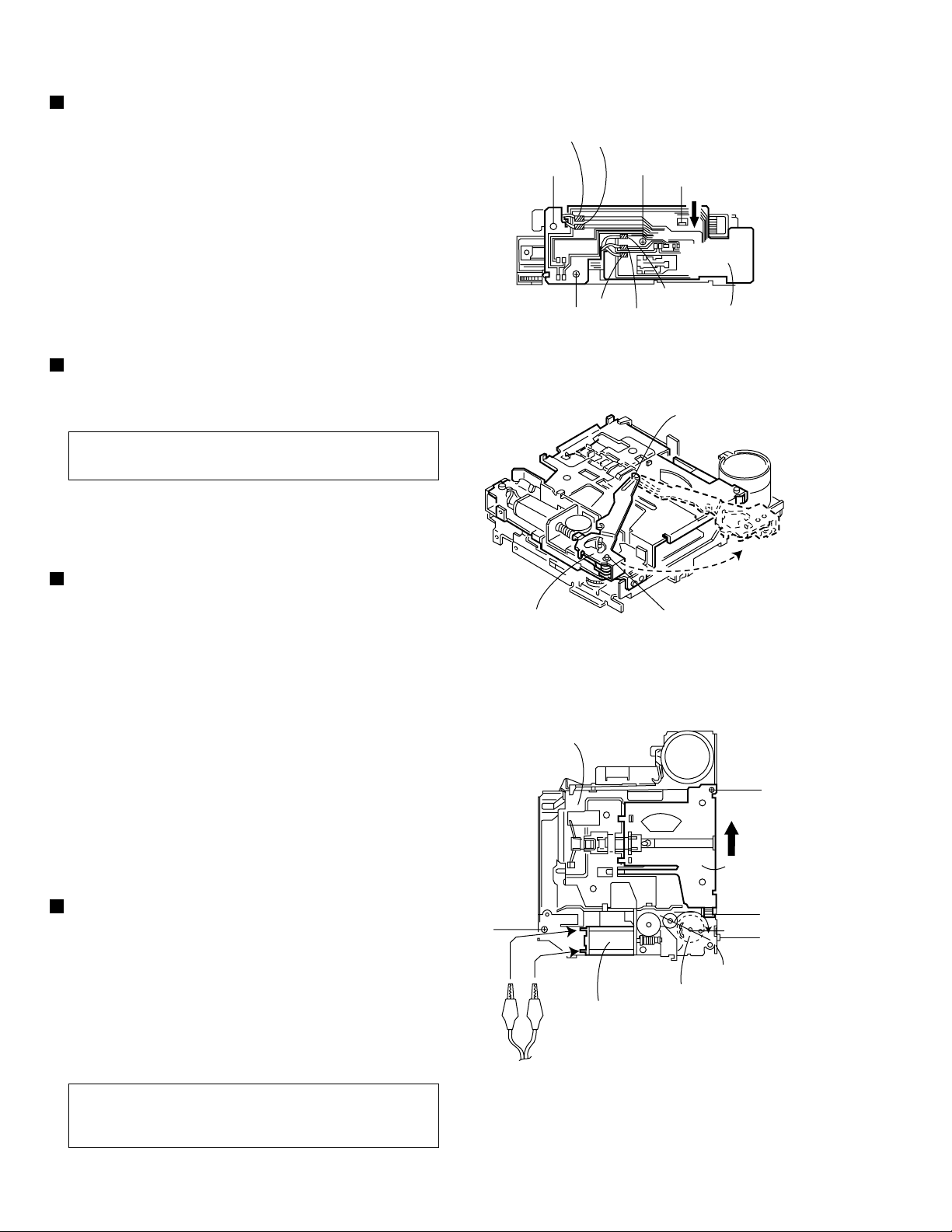

Removing the play head (see Fig.4)

1.

Remove the head relay board.

KS-FX230

2.

Remove the load arm ass'y.

3.

Remove the cassette holder and holder arm ass'y.

4.

Remove the sub chassis ass'y.

5.

Disengage the spring holding the play head down.

6.

Remove the two screws E securing the play head.

Removing the pinch roller ass'y (see Fig.5,6)

1.

Remove the head relay board.

2.

Remove the load arm ass'y.

3.

Remove the cassette holder and holder arm ass'y.

4.

Remove the sub chassis ass'y.

5.

Detach the mylar washers c at the two positions

securing the right and left pinch roller ass'y.

Play head

E

Spring

Fig.4

Pinch roller ass'y

c

Fig.5

E

c

NOTE : When reassembling, be sure to use new

mylar washers. Also, make sure that grease

is not adhering to the pinch rollers.

6. Pull out the pinch rollers.

Removing the reel disk ass'y (see Fig.7)

1.

Remove the head relay board.

2.

Remove the load arm ass'y.

3.

Remove the cassette holder and holder arm ass'y.

4.

Remove the sub chassis ass'y.

5.

Detach the mylar washer d from the tip by first

pressing down the reel feather to expose it.

NOTE : When reassembling, be sure to use a new

mylar washer

Pinch roller ass'y

Reel feather

push

Reel disk ass'y

Sub chassis

Fig.6

d

Fig.7

1-5

Page 6

KS-FX230

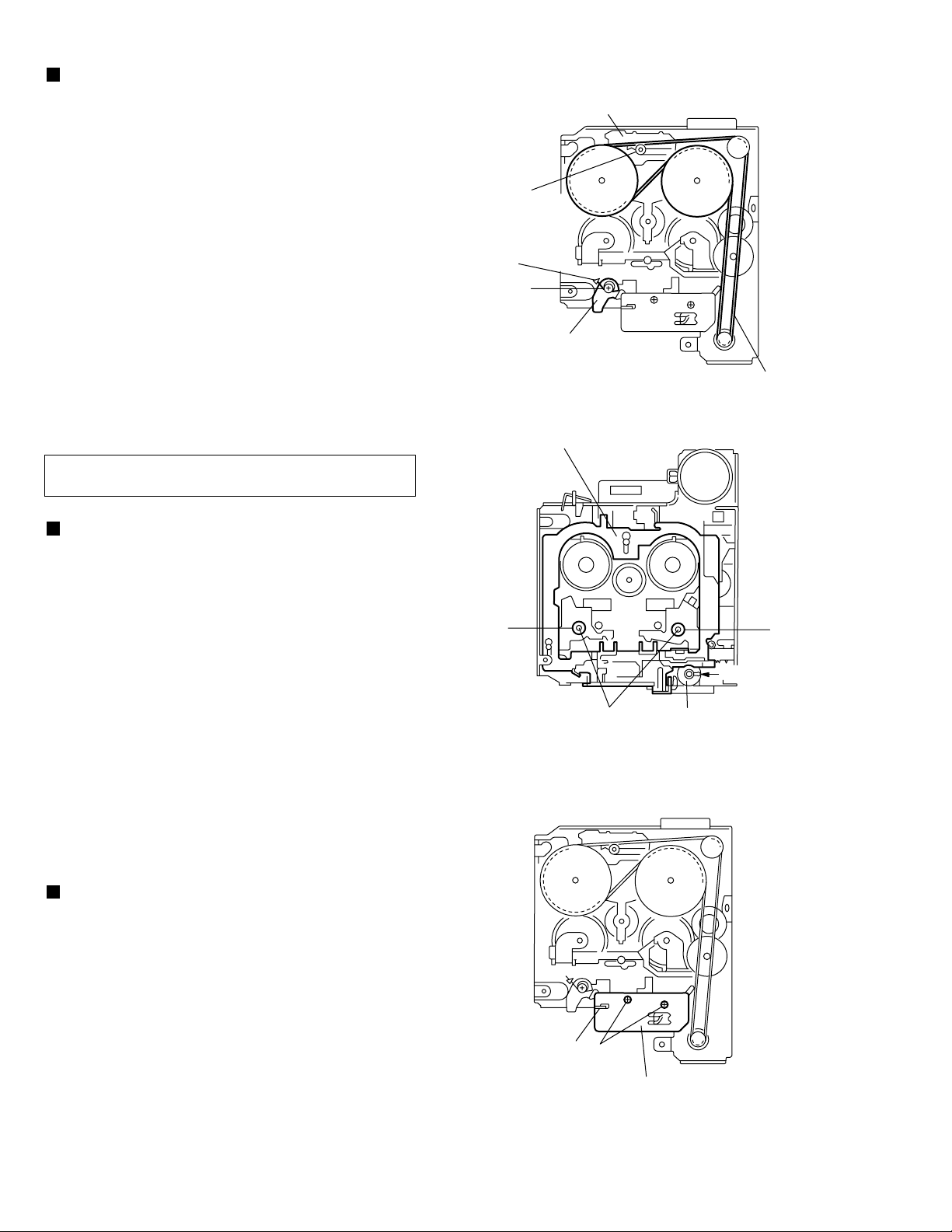

Removing the head plate (see Fig. 8,9)

1.

Remove the head amp PCB.

2.

Remove the load arm ass'y.

3.

Remove the cassette holder and holder arm ass'y.

4.

Remove the sub chassis ass'y.

5.

Remove the right and left pinch roller ass'y.

6.

From the rear of the head plate, detach the mylar

washer e and the washer pressing the forward/

reverse plate down. (see Fig. 8)

Forward/reverse plate

e

Spring

F

7.

Remove the screw F fixing the metal detection lever

and removal spring as shown in Fig. 8.

8.

Remove the head plate.

9.

Pull out the mode gear. (see Fig. 9)

NOTE : When installing the mode gear, set it to the

arrow mark.

Removing the flywheel ass'y (see Fig. 9)

1.

Remove the head relay PCB.

2.

Remove the load arm ass'y.

3.

Remove the cassette holder and holder arm ass'y.

4.

Remove the sub chassis ass'y.

5.

Remove the head plate.

6.

Disengage the main belt from the flywheel ass'y.

(see Fig. 8)

7.

Remove E washers f at the two positions which

secure the capstan shaft away from the surface.

(see Fig. 9)

Metal tape detection lever

Fig.8

Head plate

f

Capstan shaft

Fig.9

Main belt

f

Marking

Mode gear

8.

Pull out the flywheel ass'y from the rear.

Removing the reel disk PCB (see Fig. 10)

1.

Remove the head relay PCB.

2.

Remove the load arm ass'y.

3.

Remove the cassette holder and holder arm ass'y.

4.

Remove the sub chassis ass'y.

5.

Straighten the curved tab g securing the reel disk

PCB. (see Fig. 10)

6.

Remove the two screws G fixing the reel disc PCB.

7.

Remove the reel disk PCB.

1-6

g

G

Reel desk PCB

Fig.10

Page 7

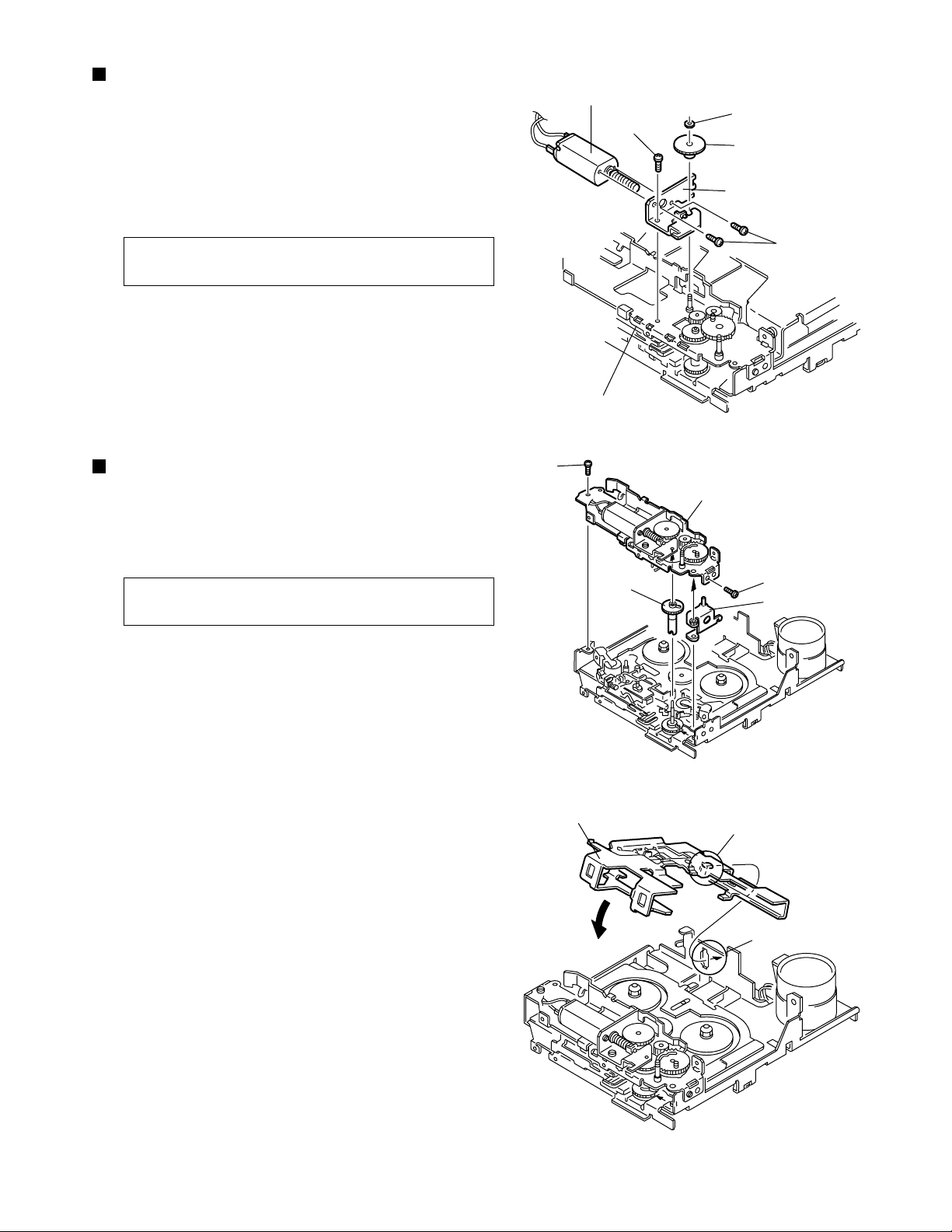

Removing the loading motor ass'y

1.

Remove the head relay ass'y.

2.

Remove the load arm ass'y.

(see Fig. 11)

KS-FX230

Loading motor ass'y

h

H

Worm gear

3.

Remove the Mylar washer h fixing the worm gear.

(see Fig.11)

NOTE : When reassembling, be sure to use a new

mylar washer.

4.5.Remove the screw H fixing the loading motor ass'y.

(see Fig.11)

Remove the two screws I fixing the loading motor

ass'y. (see Fig 11)

(Procedures for reassembling)

1.2.Insert the mode gear into the sub chassis ass'y.

Install the sub chassis ass'y and secure it with the

two screws C and D as shown in Fig.12.

NOTE : The set arm ass'y and the mode gear

should be positioned as shown in Fig.12.

Sub chassis ass'y

C

Mode gear

Motor bracket

I

Fig.11

Sub chassis ass'y

D

Set arm ass'y

3. Attach the cassette holder as shown in Fig.13. In this

case, first pass the tab of the section i through the

mechanism j, then attach the cassette holder in the

direction shown by the arrow.

Fig.12

Cassette holder

i

j

Fig.13

1-7

Page 8

KS-FX230

4. Set the catch to the holder arm ass'y as shown in

Fig.14.

Holder arm ass'y

5.

While attaching the holder arm ass'y to the cassette

holder, insert the shaft of the holder arm ass'y into

the interlocking section k of the sub chassis ass'y as

shown in Fig.15.

6.

Install the spring attached to the folder arm ass'y

shaft over the set arm ass'y as shown in Fig.16.

7.

After the holder arm ass'y is installed, secure it with

the screw B. (see Fig.15)

Holder arm ass'y

Spring

Catch

Cassette holder

Fig.14

Holder arm ass'y

B

k

Fig. 16

After the installation, apply DC 6V to the lead wires

8.

of the loading motor ass'y to locate the load gear

ass'y as shown in Fig.17.

Install the load arm ass'y.

9.

10.

Install the head relay PCB.

NOTE : Install it so that the slide switch lever of the

head relay PCB is set in the PCB stay hook

of the sub chassis ass'y. (see Fig.18)

11.

Solder the loading motor and head lead wires to the

head relay PCB, respectively. (see Fig.19)

Head PCB

Set arm ass'y

Refer to Fig.16

Fig.15

Loading motor

Apply DC 6V

Fig. 17

Slide switch

1-8

Fig.19

PCB stay

Fig.18

Page 9

Adjustment method

KS-FX230

Equipment and measuring instruments

used for adujustment

Electoronic voltmeter

Audio frequency osillator

(range ; 50 20kHz and outp ut 0 dB with impedance of

660 )

Attenuator (impedance;600 )

Frequency counter

AM Standard signal generator

FM Standard signal generator

Wow flutter mater

Torqu testing cassette gauge

CTG N (mechanical adjusting)

TW 2111A (FWD play)

TW 2121A (REV play)

Standard tape

VT712 or VTT712 (tape speed,wow & flutter adj.)

VT724 or VTT724 (reference level)

VT738 or VTT736 (playback frequency response)

VT721 or VTT721 (output level)

VT703 or VTT703 (azimuth) (10kHz part only)

Preset Memory Initialization

For ver.U

Condition for measurement

Power Spupply DC14.4V

(Reduced voltage ; 10.5V)

Load 4

(4-speakers connection)

BASS / TRE,FADER Indication 0

Main volume Position with an output level

of 2V during VT721 playback

Tuner section

FM ; 400Hz,22.5kHz deviation (MONO)

FM STEREO ; 1kHz,6.5kHz deviation,

pilotsignal 7.5kHz,66dB V

AM ; 400Hz,30% modulation,74dB V

Output impedznce ; 50

Dummy antenna

SSG Level

66dB

FM SSG 50

SSG Level

74dB

AM SSG 50

Coaxial Cable

10

4.5

60

FM DUMMY ANTENNA

Coaxial Cable

15pF

30

60pF

AM DUMMY ANTENNA

Plug to fit

antenna jack

Input Level

60dB

Plug to fit

antenna jack

Metal shield

must be attached to plug

Band

FM(MHz)

AM(kHz)

M1

87.5

531

Preset Memory

M2

M3

89.9

97.9

603

999

M4

105.9

1404

M5

108.0

1602

M6

87.5

531

Manual Tuning Up/Down Frequency

FM: 50kHz

AM: 9kHz

1-9

Page 10

KS-FX230

< Information for using a Car Stereo service jig (for adjustment and checking) >

For 1995 and 1996,we're advancing eff orts to make our extension cords common f or all Car Stereo products .

Please use this type of extension cord as follows.

As a U shape type top cover is emplo yed,this type of extension cord is needed to check operation of the

mechanism assembly after disassembly.

Extension cords

EXT KSRT002 18P (18 pin extension cord)

For connection between mechanism assembly and main

PCB assembly.

Check for mechanism-driving section such as motor , etc.

Disassembly method (Refer to method to remove main parts)

1.

Remove the bottom cover.

2.

Remove the front panel assembly.

3.

Remove the top cover. (Remove the screws at each side of heat sink and rear panel.)

4.

Install the front panel (whose assembly was removed in step 2) to the main unit.

5.

Confirm that current is being carried by connecting an extension cord jig.

Connection diagram

Extension cord

Mechanism assembly

1-10

KS-FX230/KS-F130

Main board assembly

Front panel assembly

Available to connect to the CN701 connector

when installing the front panel.

Page 11

KS-FX230

Item

1.

Head

azimuth

adjustment

Conditions

Test tape:

SCC-1659

VT703(10kHz)

Adjustment and Confirmation methods

Head height adjustment

Adjust the azimuth directly. When you

adjust the height using a mirror tape,

remove the cassette housing from the

mechanism chassis. After installing the

cassette housing, perform the azimuth

adjustment.

Load the SCC-1659 mirror tape. Adjust with

1.

height adjustment screw A and azimuth

adjustment screw B so that line A of the

mirror tape runs in the center between Lch

and Rch in the reverse play mode.

After switching from REV to FWD then to

2.

REV, check that the head position set in

procedure 1 is not changed. (If the position

has shifted, adjust again and check.)

Adjust with azimuth adjustment screw B so

3.

that line B of the mirror tape runs in the

center between Lch and Rch in the forward

play mode.

Head azimuth adjustment

Load VTT724 (VT724) (1kHz) and play it

1.

back in the reverse play mode. Set the Rch

output level to max.

Load VTT703 (VT703) (10kHz) and play it

2.

back in the forward play mode. Adjust the

Rch and Lch output levels to max, with

azimuth adjustment screw B. In this case,

the phase difference should be within 45 .

Engage the reverse mode and adjust the

3.

output level to max, with azimuth

adjustment screw C.

(The phase difference should be 45 or

more.)

When switching between forward and

4.

reverse modes, the difference between

channels should be within 3dB. (Between

FWD L and R, REV L and R.)

S.Values Adjust

A line

Head shield

The head is at low position

during.

B line

Head shield

The head is at High position

during REV.

Output

level:

Maximum

PBHead

FWD Adj B

REV Adj C

(0 ) (45 )

HEIGHT Adj A

phase

Tape speed

2.

and wow

flutter

confirmation

Play back

3.

frequency

response

confiramation

When VTT721 (VT721) (315Hz) is played

5.

back, the level difference between channels

should be within 1.5dB.

Test tape: VTT712

(3kHz)

Test tape: VTT724

(1kHz)

VTT739

(63Hz / 1kHz / 10kHz)

The tuner section is of an adjustment-freedesign. In case the tuner is in trouble, replace the tuner pack.

Check to see if the reading of the F, counter /

1.

wow flutter meter is within 3015 3045(FWD

/ REV), and less than 0.35% (JIS RMS).

In case of out of specification, adjust the

2.

motor with a built-in volume resistor.

Play test tape VTT724, and set the volume

1.

position at 2V.

Play test tape VTT739 and confirm.

2.

1kHz / 10kHz: -1 3dB,

1kHz / 63Hz: 0 3dB,

When 10kHz is out of specification, it will be

3.

necessary to read adjust the azimuth.

Tape speed:

3015

3045Hz

Wow

flutter: less

than 0.35%

Speaker out

1kHz / 63Hz

: 0 3db

1kHz / 10kHz

: -1 3db

Built-in volume

resistor

1-11

Page 12

KS-FX230

Descrption of major ICs

TEA6320T-X (IC931) : E.volume

1.Pin layout

2.Block diagram

10 8 9 7 6

5

12

SDA

1

GND

2

OUTLR

OUTLF

MUTE

TL

B2L

B1L

IVL

ILL

QSL

IDL

ICL

IMD

IBL

IAL

3

4

5

6

7

8

9

10

11

12

13

14

15

16

3.Pin functions

Pin

Symbol

No.

SDA

1

SCL

32

VCC

31

OUTRR

30

OUTRF

29

TR

28

B2R

27

B1R

26

IVR

25

ILR

24

QSR

23

IDR

22

Vref

21

ICR

CD-CH

TAPE

TUNER

20

19

18

17

CAP

IBR

IAR

I/O

Serial data input/output.

I/O

MUTE

21

31

2

19

16

15

13

11

14

22

20

18

17

Functions Functions

POWER

SUPPLY

SOURCE

SELECTOR

23 25 24 26 27 28

VOLUME 1

+20 to -31 dB

LOUDNESS

LEFT

VOLUME 1

+20 to -31 dB

LOUDNESS

RIGHT

Pin

No.

17

Symbol

IAR

BASS

LEFT

+15 dB

LOGIC

BASS

RIGHT

+15 dB

I/O

I

Input A right source.

TREBLE

LEFT

+12 dB

TREBLE

RIGHT

+12 dB

FUNCTION

ZERO CROSS

DETECTOR

VOLUME 2

0 to 55 dB

BALANCE

FENDER REAR

VOLUME 2

0 to 55 dB

BALANCE

FENDER FRONT

HC BUS

REC

VOLUME 2

0 to -55dB

BALANCE

FENDER FRONT

VOLUME 2

0 to -55dB

BALANCE

FENDER REAR

3

4

32

1

29

30

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

GND

OUTLR

OUTLF

TL

B2L

B1L

IVL

ILL

QSL

IDL

MUTE

ICL

IMO

IBL

IAL

Ground.

output left rear.

O

output left front.

O

Treble control capacitor left channel or

I

input from an external equalizer.

Bass control capacitor left channel or

-

output to an external equalizer.

Bass control capacitor left channel.

Input volume 1. left control part.

I

Input loudness. left control part.

I

Output source selector. left channel.

O

Not used

Not used

Input C left source.

I

Not used

Input B left source.

I

Input A left source.

I

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

IBR

CAP

ICR

Vref

IDR

QSR

ILR

IVR

B1R

B2R

TR

OUTRF

OUTRR

Vcc

SCL

I

Input B right source.

-

Electronic filtering for supply.

I

Input C right source.

-

Reference voltage (0.5Vcc)

-

Not used

O

Output source selector right channel.

I

Input loudness right channel.

I

Input volume 1. right control part.

-

Bass control capacitor right channel

Bass control capacitor right channel or

O

output to an external equalizer.

Treble control capacitor right channel or

I

input from an external equalizer.

O

Output right front.

O

Output right rear.

-

Supply voltage.

I

Serial clock input.

1-12

Page 13

LC75823E(IC651):LCD driver

KS-FX230

1.Pin layout

48 to 33

49

to to

64

1 to 16

3.Pin function

PIN

No.

1 to 9

10 to 52

32

17

Symbol I/O

S10 to S52

2.Block diagram

COM1 COM2 COM3 S52 S51 S1

VDD1

VDD2

INH

OSC

COMMON

DRIVER

CLOCK

GENERATOR

DI CL CE

LATCH & DRIVER

SHIFT REGISTER

ADDRESS

DETECTOR

Functions

-

NOT USED

O

Segment outputs that display data transferred from

VDD VSS

53 to 55

56

57

58

59

60

61

62

63

64

COM1 to COM3

VDD

/INH

VSS

OSC

CE

CL

DI

serial data.

O

The frame frequency (fo) for the common driver output is

(fosc/384)Hz.

-

Power supply

I

Forcibly terns off the display. regardless of internal data.

Serial data can be input. whether this pin is high or low

-

NOT USED

-

-

To GND

I

Oscillator connection (for the common segment alternating

waveform)

I

Serial data transfer

I

pins.connected to a

I

microprocessor.

CE : Chip enable

CL : Sync.clock

DI : Transfer data

1-13

Page 14

KS-FX230

LC72362N-9388 (IC701) : System control

1. Pin layout

80 to 65

1

64

to to

24

25 to 40

2. Pin function

Pin No. Symbol I/O

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15~18

19~22

23~26

27~30

31

32

33~36

37~40

41~43

44

45~48

49~52

53,54

55,56

57~60

61,62

63~66

67

68

69

70

71

72

73

74

75

76

77,78

79

80

PK1/INT1, PK0/INT0

PJ3/DAC3~PJ0/DAC0

PI1/ADI5, PI0/ADI4

PH3/ADI3~PH0/ADI0

XIN

TEST2

PG3/SI0

PG2/SO0

PG1/SCK0

PG0

PF3/SI1

PF2/SO1

PF1/SCK1

PF0

PE3/SI2

PE2/SO2

PE1/SCK2

PE0

PD3~PD0

PC3~PC0

PB3~PB0

PA3~PA0

V DD

PQ0

PP3~PP0

PO3~PO0

PN3~PN1

PN0/BEEP

PM3~PM0

PL3~PL0

PK3, PK2

HOLD

SNS

LCTR

HCTR

EO3

SUBPD

V DD

AMIN

FMIN

V SS

EO2,EO1

TEST1

XOUT

41

Function

I

4.5MHz crystal oscillator connections

LSI test pin.

General-purpose input/output and serial input/output shared ports.

I/O

Output only port.

O

Key source signal output only ports.

O

Key return signal input only port, of which threshold voltage is designed to be

I

low.

Power supply connections.

O

General-purpose input/output port.

O

Output only port.

O

General-purpose output port/BEEP tone shared output pins.

O

I/O

General-purpose input/output ports.

General-purpose input-output/external interrupt shared port.

I/O

O

General-purpose output port/DAC shared output pins.

I

General-purpose output port/ADC shared input pins.

I

PLL control, CLOCK STOP mode control pin.

I

Voltage sense/general-purpose input pin shared port.

Universal counter (frequency, cycle measurement)/general-purpose input

I

shared input port.

Universal counter/general-purpose input shared input port.

I

O

2nd PLL charge pump output pin.

Sub-charge pump output pin.

O

Power supply connections.

O

AM VCO (local oscillator) input pin.

I

FM VCO (local oscillator) input pin.

I

O

Power supply connections.

Main charge pump output pins.

O

LSI test pin.

4.5MHz crystal oscillator connections

O

1-14

Page 15

3.Block diagram

KS-FX230

XIN

XOUT

FMIN

AMIN

SNS

VDD

VSS

HCTR

LCTR

HOLD

TEST1

TEST2

PA0

PA1

PA2

PA3

PB0

PB1

PB2

BP3

PC0

PC1

PC2

PC3

PD0

PD1

PD2

PD3

PE0

SCK2/PE1

PO2/PE2

SI2/PE3

PF0

SCK1/PF1

SO1/PF2

SI1/PF3

V-DET

DIVIDER REFERENCE DIVIDER SELECTOR

1/16, 1/17

SNSFF

1/2

BUS

DRIV.

LATCH

BUS

DRIV.

LATCH

BUS

DRIV.

LATCH

BUS

DRIV.

LATCH

BUS

DRIV.

LATCH

BUS

DRIV.

PROGRAMMABLE DIVIDER

1/114, 1/124

LATCH

UNIVERSAL

COUNTER

(20bits)

RAM

512 4bits

ROM

12K 16bits

ADDRESS DECODER

PROGRAM COUNTER

STACK

ALU

ADDRESS

DECODER

BUS

DRIVER

INSTRUCTION

DECODER

JUDGE

PHASE

DETECTOR

UNLOCK

F/F

PHASE

DETECTOR

LATCH

LATCH

BUS

DRIV.

LATCH

BUS

DRIV.

LATCH

BUS

DRIV.

BEEP

LATCH

BUS

DRIV.

LATCH

BUS

DRIV.

LATCH

BUS

DRIV.

LATCH

BUS

DRIV.

BUS

DRIV.

SUB

C.P.

MPX

INTERRUPT

E01

E02

SUBPD

EO3

PQ0

PP3

PP2

PP1

PP0

PO3

PO2

PO1

PO0

PN3

PN2

PN1

PN0/BEEP

PM3

PM2

PM1

PM0

PL3

PL2

PL1

PL0

PK3

PK2

PK1/INT1

PK0/INT0

PJ3

PJ2

PJ1

PJ0

PI1/ADI5

PI0/ADI4

PF0

SCK1/PF1

SO1/PF2

SI1/PF3

SIO

LATCH

BUS

DRIV.

ADC

MPX

BUS

DRIV.

PH3/ADI3

PH2/ADI2

PH1/ADI1

PH0/ADI0

1-15

Page 16

KS-FX230

HD74HC126P (IC751) : Changer control

1.Pin arrangement 2. Pin function

11C

21A

31Y

42C

52A

62Y

7GND

3. Block diagram

1A

( TOP VIEW )

14

13

12

11

10

9

8

Vcc

4C

4A

4Y

3C

3A

3Y

Input Output

CA

X

LLH

HH H

Y

ZL

1Y

1C

2A

2C

3A

3C

4A

2Y

3Y

4Y

1-16

4C

Page 17

HA13158A (IC981) : Power amp

1. Pin layout

1 ~ 23

2. Block diagram

14 18 6

INVCC

INPUTBUFFER1

IN1

2

STBY

1

PVCC1PVCC2

AMP1

KS-FX230

3

+

4

-

5

IN2

IN3

IN4

11

13

23

10

MUTE

INPUTBUFFER2

INPUTBUFFER3

INPUTBUFFER4

PROTECTOR (ASO

SURGE, TSD)

12 22

AMP2

AMP3

AMP4

TAB

7

+

8

-

9

15

+

16

-

17

19

+

20

-

21

1-17

Page 18

KS-FX230

BA3918-V1 (IC781) : Regulator

1.Block diagram

REGULATOR

NC TUNER

2.Pin functions

Pin

Symbol

No.

1

2

3

4

5

6

7

8

9

10

11

12

NC

TUNER

FM/AM

POWER

5V

REMOTE

VP

NC

9V

NC

TUNER-9V

GND

FM/AM

I/O

GND

+

+

POWER

OIVPC

5V REMOTE VP

+

NC 9V

+

NC TUNER-9V

Functions

Not used

Output selector of AM and ANT.

O

Output selector for AM or FM or both outputs is off.

O

Output selector of COM and AMP. Only VDD output is on at STAND BY.

O

Output level is 5.6v. Output current is 100mA(min). It is voltage supply

for micro computer. Whenever Vcc terminal is connected, output always

keep running

Voltage which is about 1V lower than Vcc unit voltage. Output current is

500mA(min). Voltage supply for Remote Amp.

To be continued to BACK UP and ACC of car.

O

Not used

Output level is 8.7V. Output current is 150mA(min). It can be used for

system common power supply ; tone control, volume control, balance control,

equalize amplifier.

Not used

Output level is 8.7V. Output current is 250mA(min). Voltage supply for

FM Radio Tuner.

To GND

-

1-18

Page 19

CXA2509AQ(IC901):Cassette mecha controler

1.Block diagram and pin configuration

KS-FX230

LB1641 (IC501) : DC motor driver

1. Pin layout

1 2 3 4 5 6 7 8 9

GNDOUT1 P1

VZ IN1 IN2

2. Pin functions

Input Output

IN1 IN2 OUT1 OUT2

0 0 0 0

1 0 1 0

0 1 0 1

1 1 0 0

VCC1

VCC2 P2

10

OUT2

Mode

Brake

CLOCKWISE

COUNTER-CLOCKWISE

Brake

1-19

Page 20

KS-FX230

<<MEMO>>

1-20

Page 21

KS-FX230

KS-FX230

VICTOR COMPANY OF JAPAN, LIMITED

MOBILE ELECTRONICS DIVISION

PERSONAL & MOBILE NETWORK B.U. 10-1,1Chome,Ohwatari-machi,Maebashi-city,Japan

(No.49565)

1-21

Printed in Japan

200007(O)

Loading...

Loading...