Page 1

KS-F363R/KS-F360R

SERVICE MANUAL

CASSETTE RECEIVER

KS-F363R/KS-F360R

Contents

KS-F363R

KS-F360R

Different pont Illumination

KS-F363R Amber

KS-F360R Green

KS-F363R

KS-F360R

Area Suffix

EEXContinental Europe

Central Europe

Safety precaution

Disassembly method

Adjustment method

Description of major ICs

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

1- 2

1- 3

1-12

1-16~22

No.49686

Feb. 2002

Page 2

KS-F363R/KS-F360R

Safety precaution

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

Page 3

Disassembly method

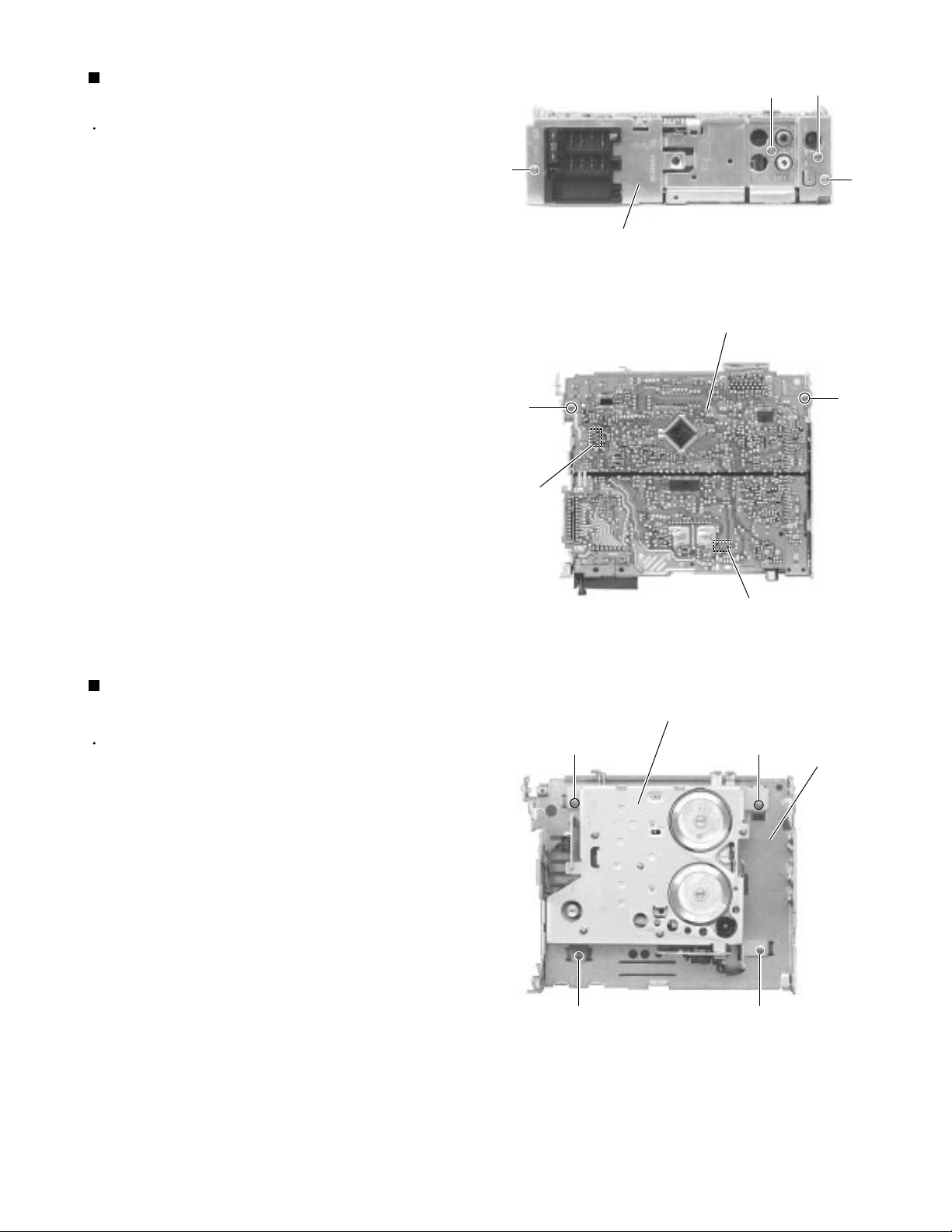

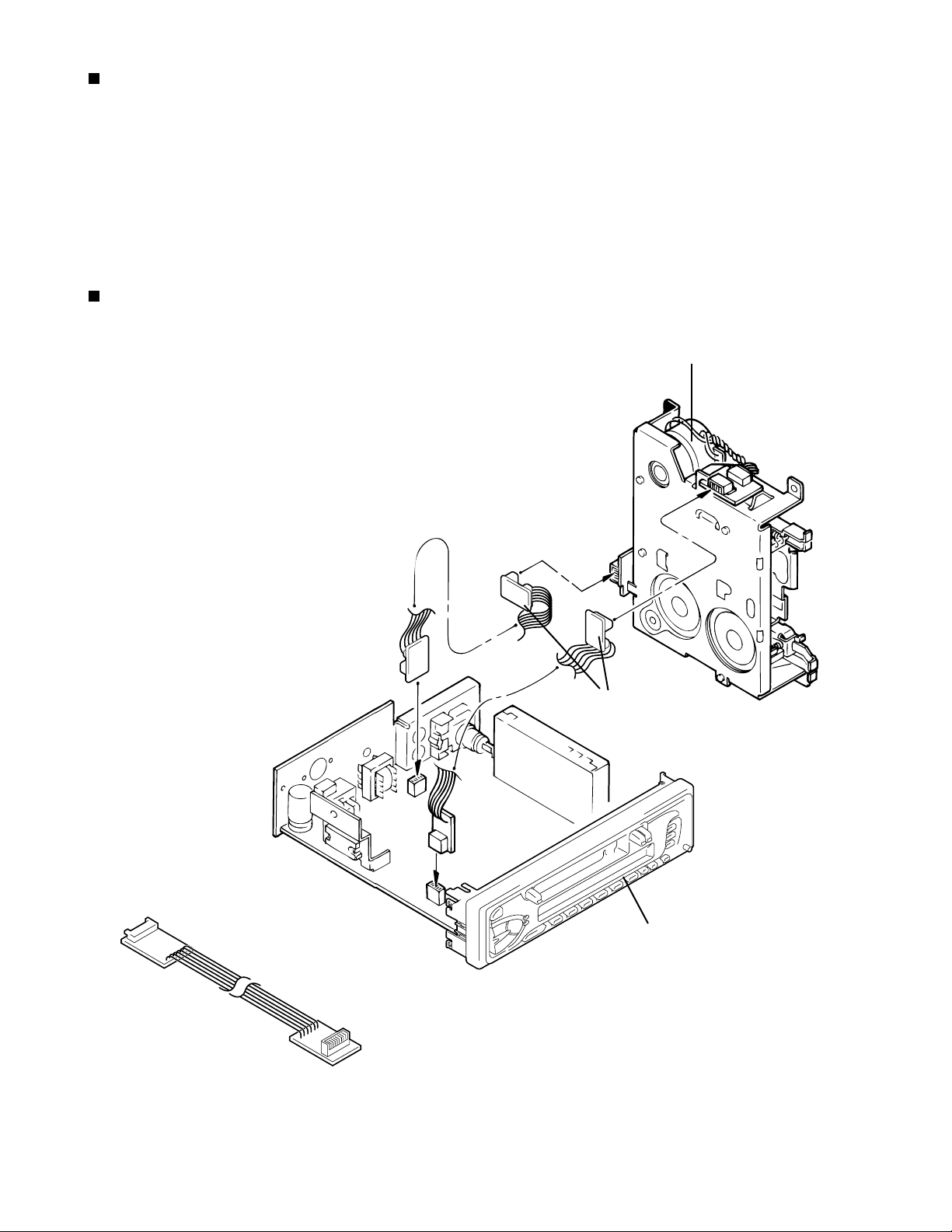

<Main body>

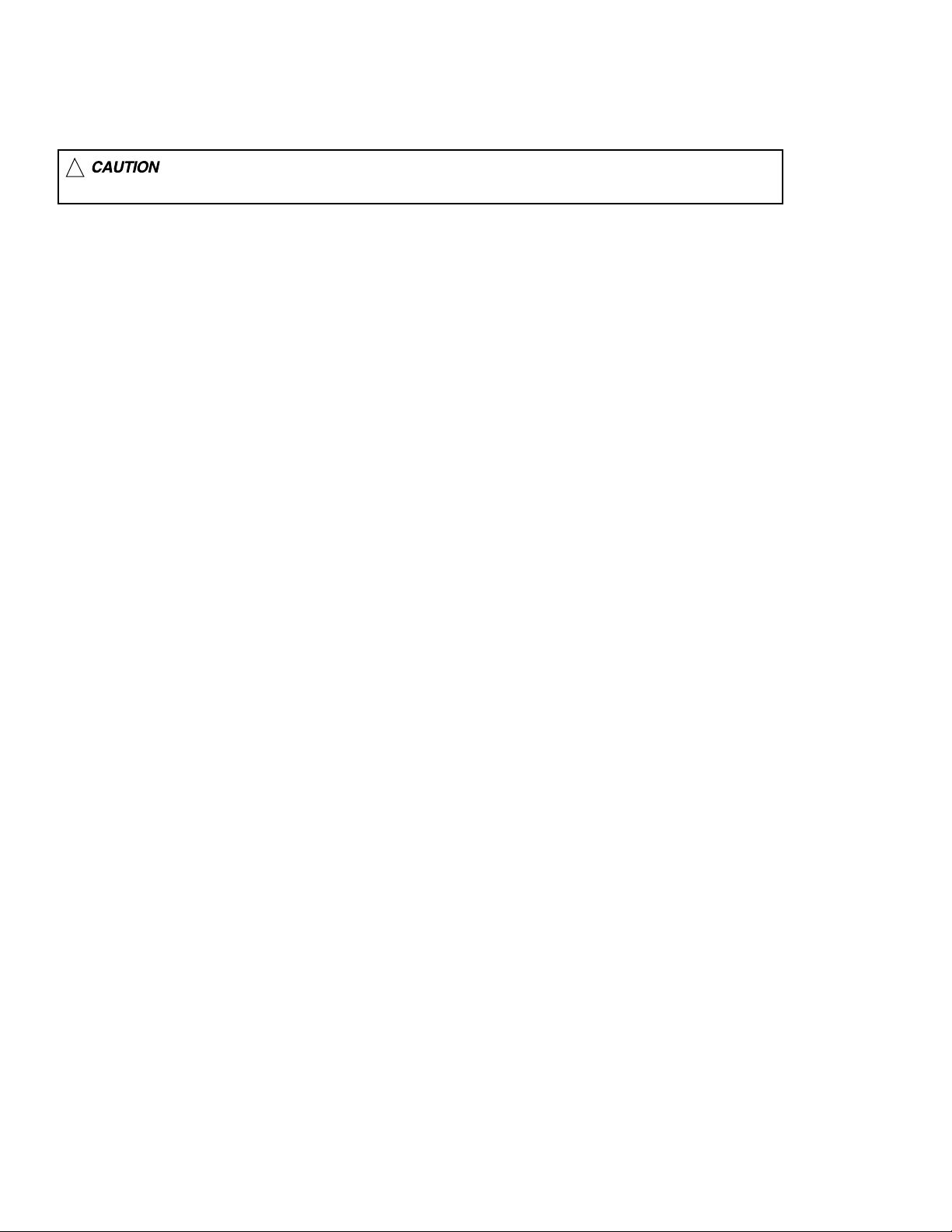

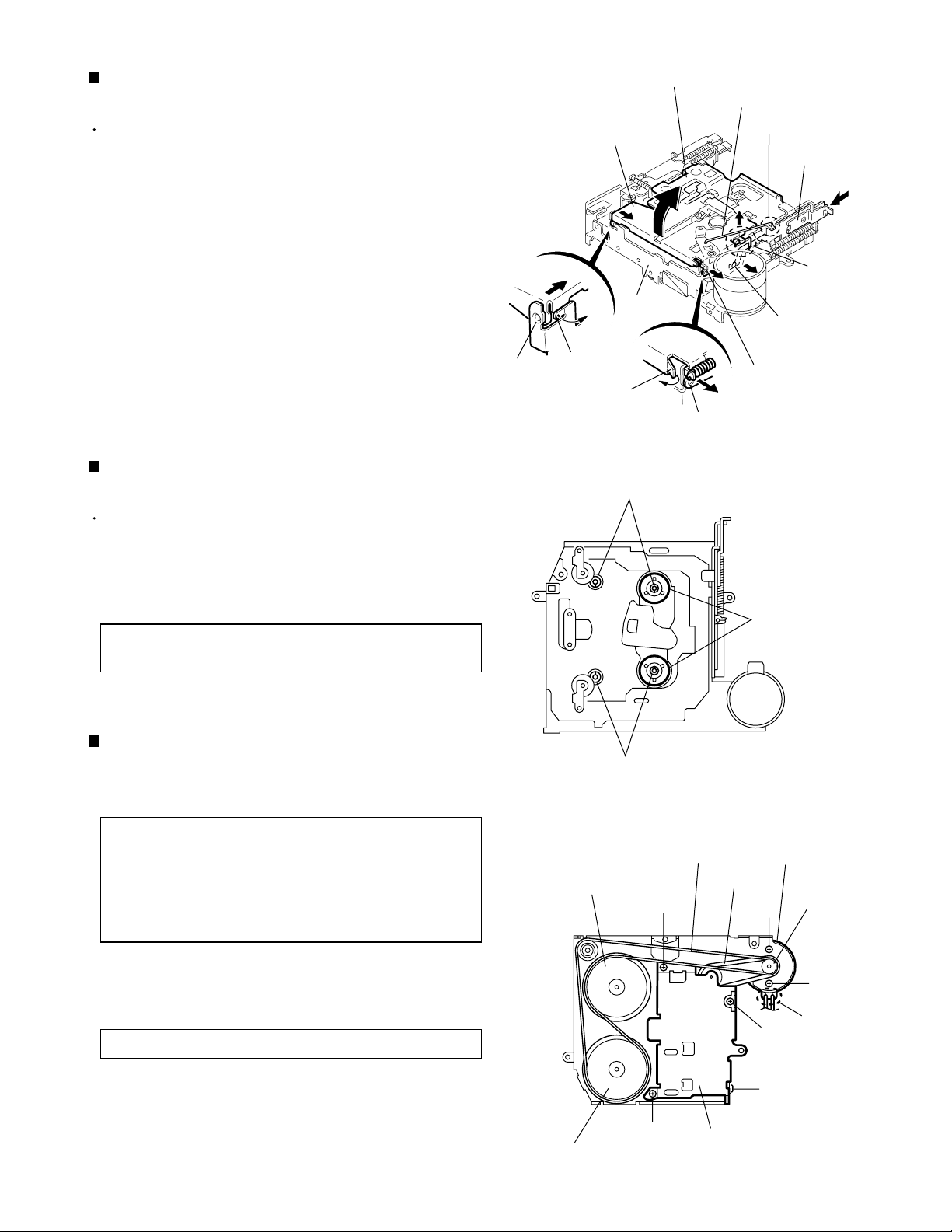

Removing the front panel assembly

(See Fig.1)

1.

Press the eject button in the lower right part of the

front panel. Remove the front panel assembly from

the body.

Removing the front chassis assembly

(See Fig.2 and 3)

KS-F363R/KS-F360R

Front panel assembly

Eject button

Fig.1

Tab a

Prior to performing the following procedure, remove

the front panel assembly.

1.

Release the four joint tabs a on both sides of the

front chassis assembly and remove the front chassis

assembly toward the front.

Tab a

Front chassis assembly

Heat sink

Fig.2

Tab a

Tab a

Front chassis

assembly

Fig.3

1-3

Page 4

KS-F363R/KS-F360R

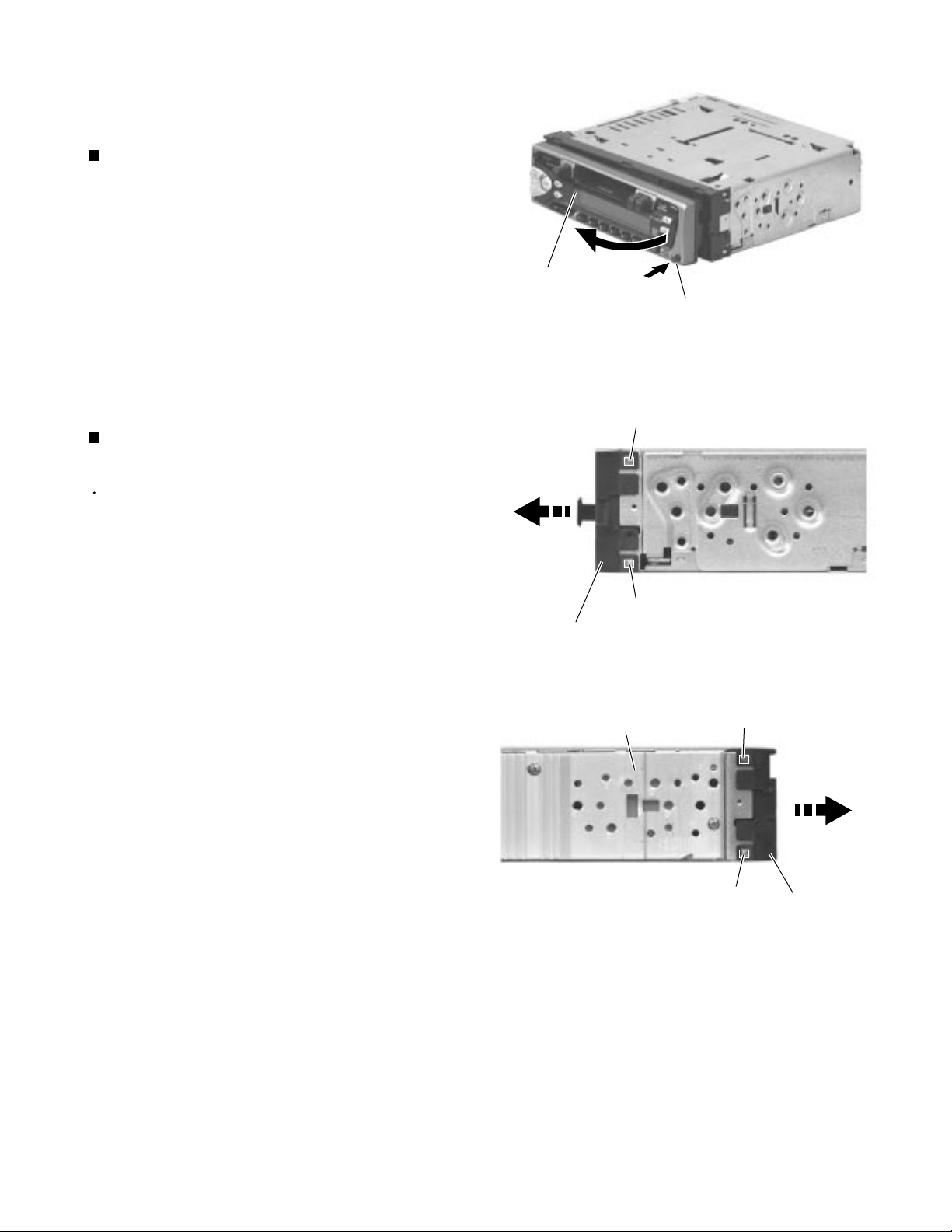

Removing the heat sink (See Fig.4)

1.

Remove the three screws A on the left side of the

body.

Removing the bottom cover

(See Fig.5 and 6)

Prior to performing the following procedure, remove

the front panel assembly, the front chassis assembly

and the heat sink.

1.

Turn over the body and unjoint the five joints b with

the bottom cover and the body using a screwdriver.

Joint b

A

Joints b

Heat sink

Fig.4

Rear panel

Fig.5

A

Bottom cover

Joints b

Joints b

Bottom cover

Joints b

Joint b

Rear panel

Fig.6

1-4

Page 5

KS-F363R/KS-F360R

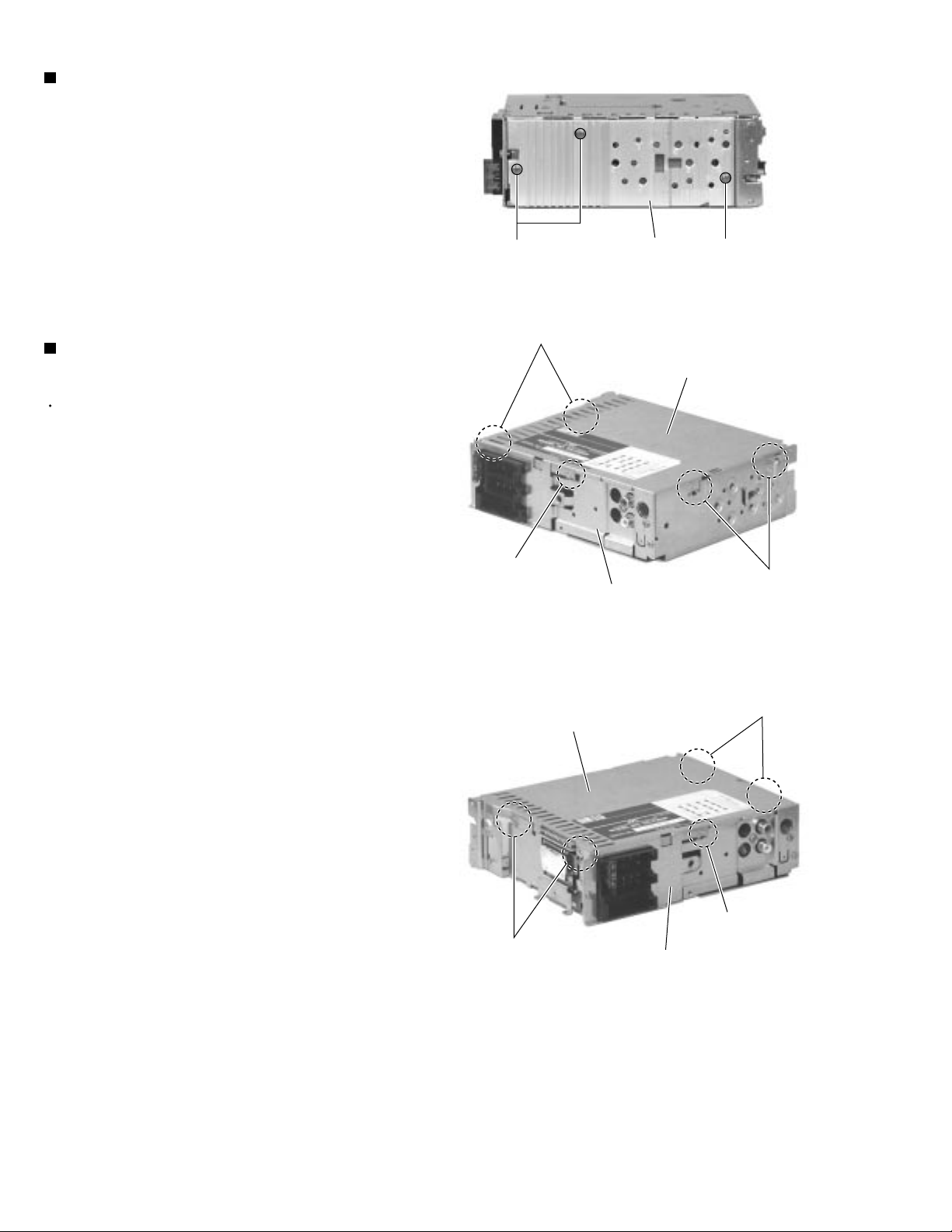

Removing the main board

(See Fig.7 and 8)

Prior to performing the following procedure, remove

the front panel assembly, the front chassis assembly,

the heat sink and the bottom cover.

1.

Remove the screw B, the screw C and the two

screws D attaching the rear bracket on the back of

the body. Remove the rear panel.

2.

Remove the two screws E attaching the main board

on the bottom of the body. Disconnect connector

CN901,CN902 on the main board in the direction of

the arrow.

D

E

CN902

Rear panel

Fig.7

Main board

B

C

D

E

Removing the cassette mechanism section

(See Fig.9)

Prior to performing the following procedure, remove

the front panel assembly, the front chassis assembly,

the heat sink, the bottom cover and the main board.

1.

Remove the four screws F attaching the cassette

mechanism section on the back of the top chassis.

Fig.8

Cassette mechanism section

F

F

Fig.9

CN901

F

F

Top chassis

1-5

Page 6

KS-F363R/KS-F360R

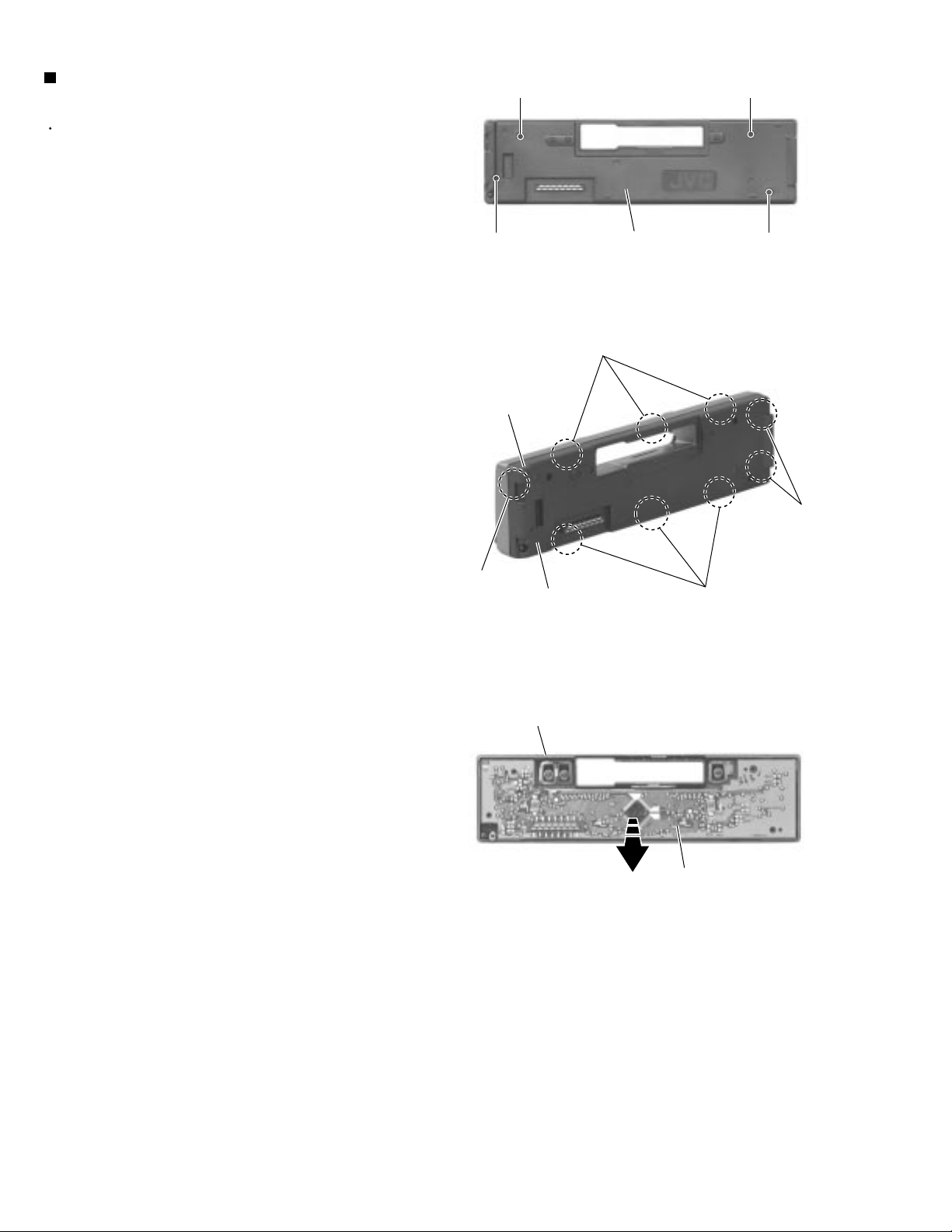

Removing the control switch board

(See Fig.10 to 12)

Prior to performing the following procedure, remove

the front panel assembly.

1.

Remove the four screws G attaching the rear cover

on the back of the front panel assembly.

2.

Unjoint the nine joints c with the front panel and the

rear cover.

3.

Remove the control switch board on the back of the

front panel.

G

G G

Front panel

Rear cover

Fig.10

Joints c

G

Joints c

Joints c

Rear cover

Front panel

Joints c

Fig.11

Control switch board

Fig.12

1-6

Page 7

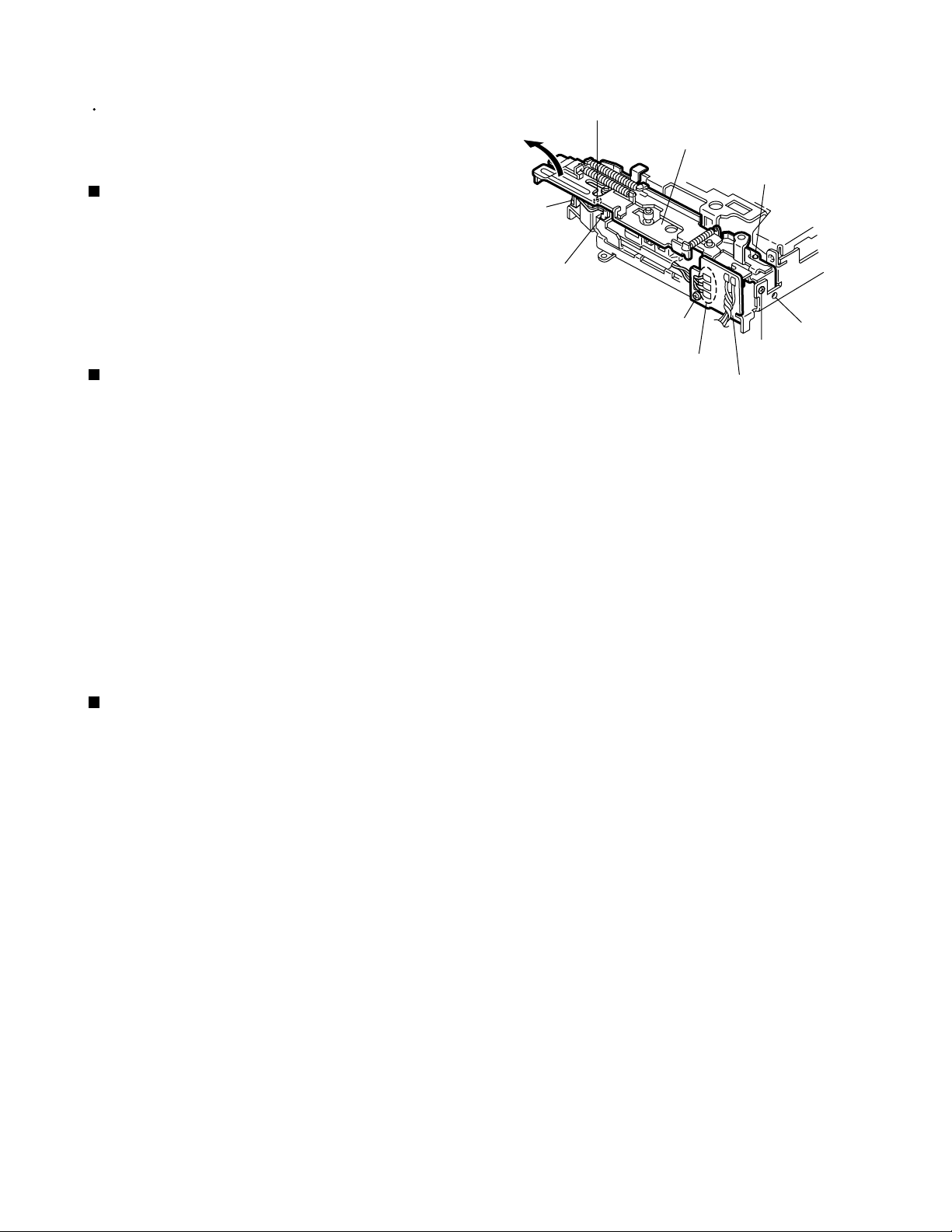

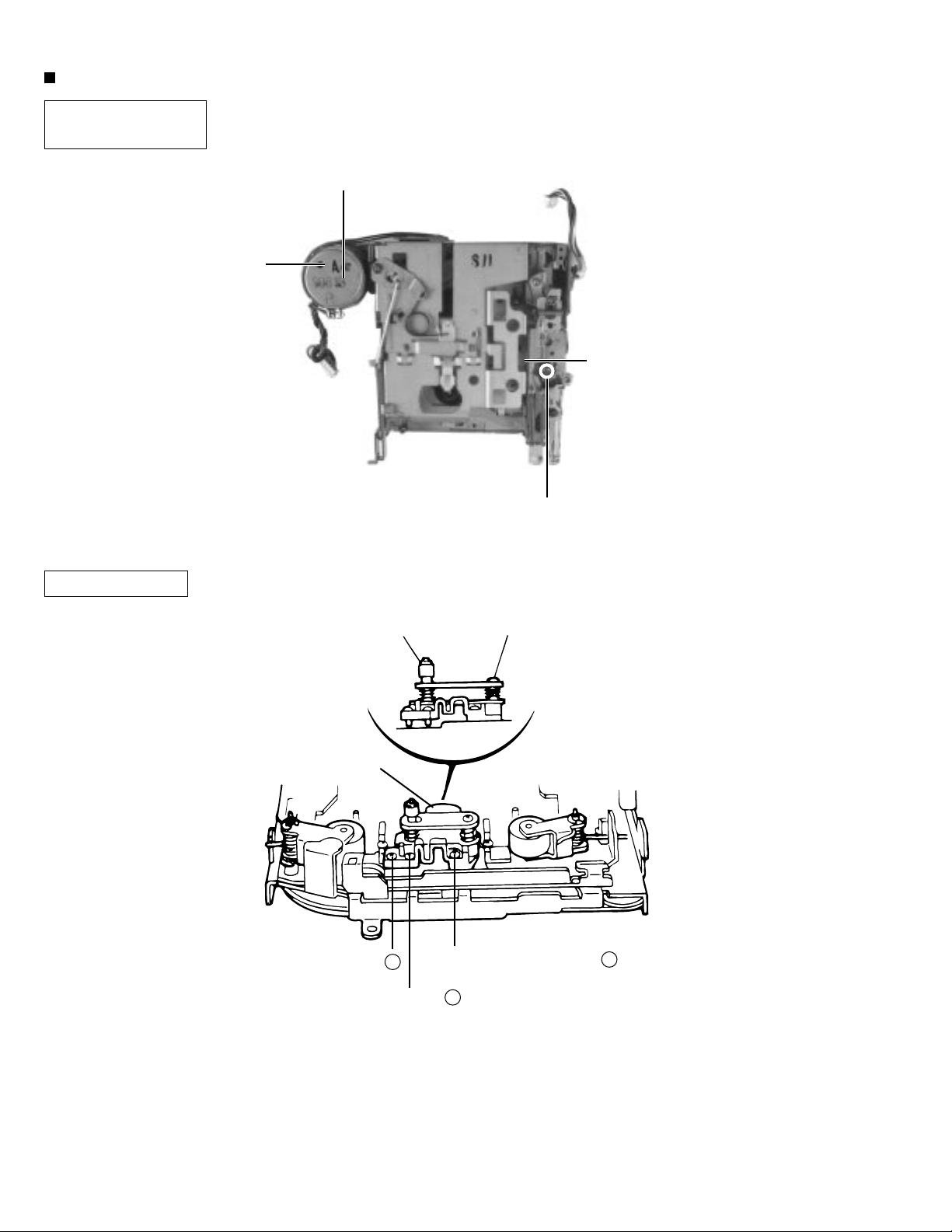

<Cassette mechanism assembly>

KS-F363R/KS-F360R

Prior to performing the following procedures, remove

the head amplifier board, the relay board and the

mechanism bracket.

Removing the direction switch board

(See Fig.1)

1.

Unsolder the three wires a on the direction switch

board.

2.

Remove the one screw A attaching the direction

switch board.

Removing the FF / REW lever assembly

(See Fig.1)

1.

Remove the screw B attaching the FF / REW lever

assembly on the back of the cassette mechanism

assembly.

2.

Remove the screw C on the upper side of the FF /

REW lever assembly.

3.

Lift and pull forward the FF / REW lever assembly to

disengage the joints b, c, d and e.

Joint e

Joint d

C

FF / REW lever assembly

A

Soldering a

Direction switch board

Fig.1

Joint c

Joint b

B

Reattaching the FF / REW lever assembly

(See Fig.1)

1.

Reattach the FF / REW lever assembly to the joint c

on the back of the chassis.

2.

Reattach the pinch-roller shaft e, the change lever d

and the return link e to the chassis.

1-7

Page 8

KS-F363R/KS-F360R

Pinch-roller (R) assembly

A arm spring (b)

Shaft

Remove the P arm spring (r)

from the chassis.

P arm spring (r)

S support plate

C washer

FF roller

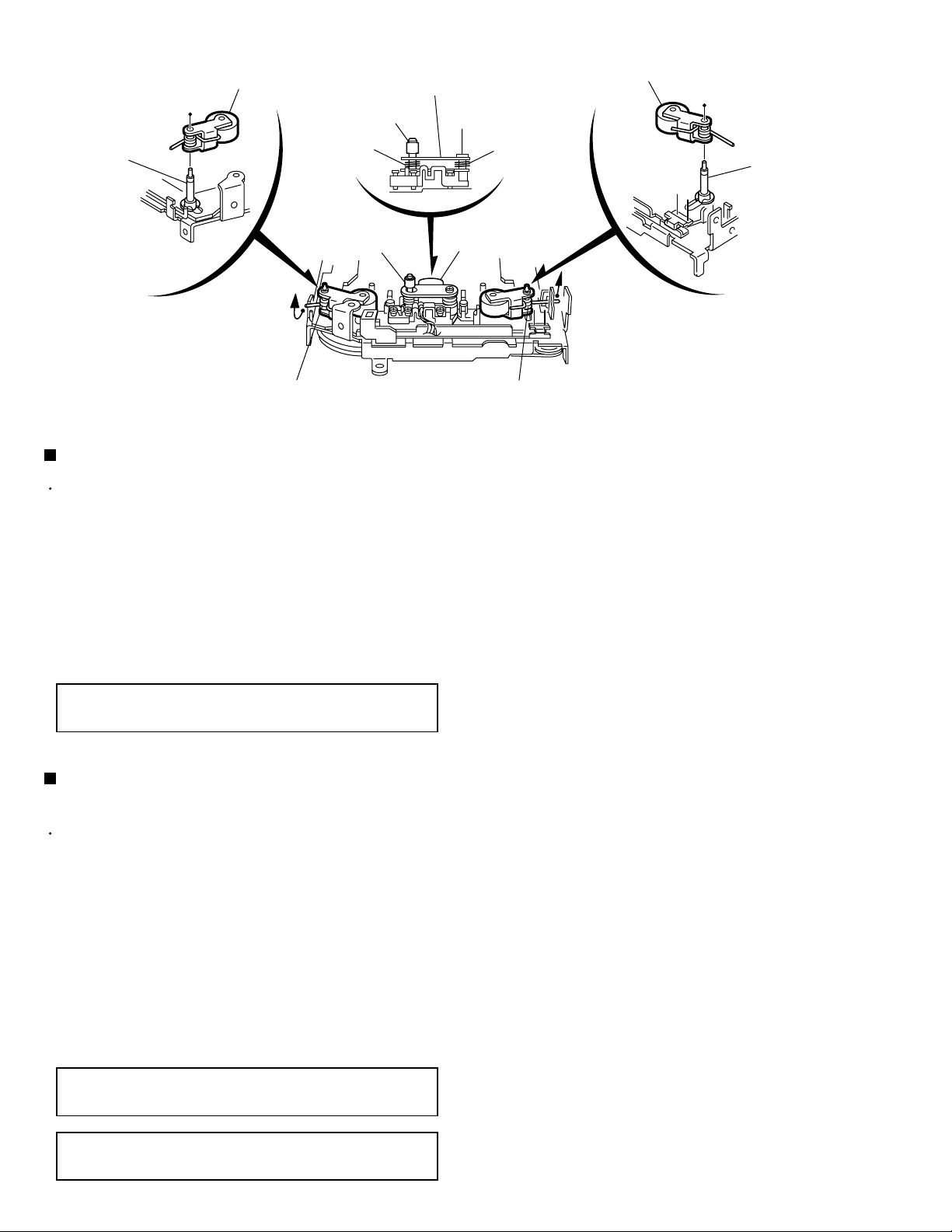

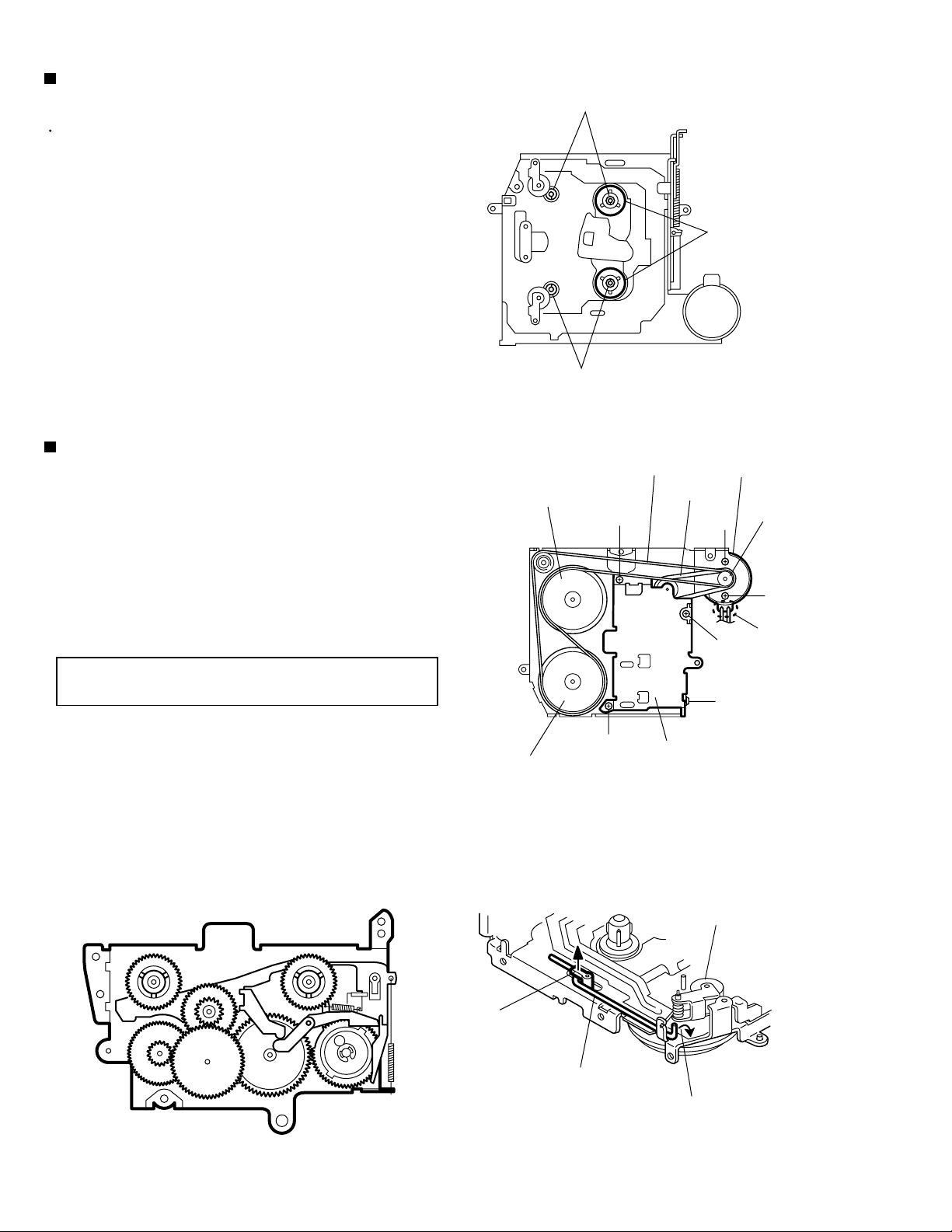

Removing the playback head (See Fig.2)

Prior to performing the following procedure, remove

the direction switch board and the FF / REW lever

assembly.

Pinch-roller (F) assembly

D

A arm spring (a)

Shaft

Playback head

Remove the P arm spring (f)

from the chassis.

P arm spring (f)

Fig.2

1.

Remove the screw D attaching the playback head.

2.

Remove the C washer and pull out the FF roller.

3.

Remove the S support plate, the A arm spring (a)

and (b), the playback head.

ATTENTION:

The A arm spring (a) differs from the A

arm spring (b).

Removing the pinch-roller (R) and (F)

assembly (See Fig.2)

Prior to performing the following procedure, remove

the direction switch board and the FF / REW lever

assembly.

1.

Remove the P arm spring (f) in the pinch-roller (F)

assembly from the chassis.

2.

Remove the P arm spring (r) in the pinch-roller (R)

assembly from the chassis.

3.

Draw out the pinch roller (F) and (R) assembly from

the shaft.

ATTENTION:

The P arm spring (f) differs from the P

arm spring (r).

ATTENTION:

The pinch roller (F) assembly differs

from the pinch roller (R) assembly.

1-8

Page 9

KS-F363R/KS-F360R

Removing the cassette hanger / cassette

holder (See Fig.3)

Prior to performing the following procedure, remove

the FF / REW lever assembly.

1.

From the rear of the unit, bend the two tabs f

outwards and disengage the two joints g in the

direction of the arrow.

2.

Push the eject lever and remove the cassette holder

from the playback head. Disengage the two joints h

of the cassette hanger / cassette holder and the eject

lever in the direction of the arrow.

3.

Lift the cassette hanger / cassette holder and disengage

the joint i of the return link and the eject lever.

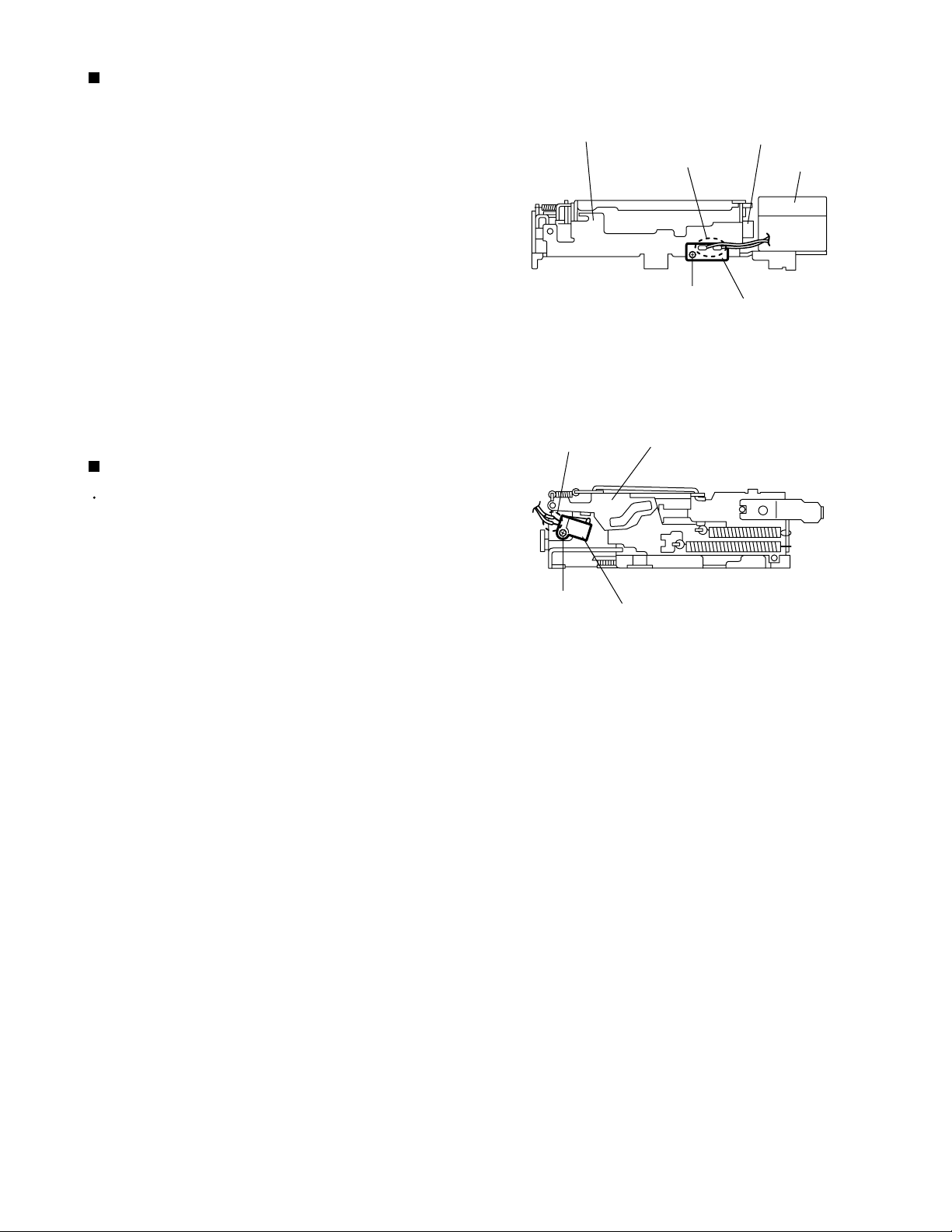

Removing the reel disc assembly

(See Fig.4)

Prior to performing the following procedure, remove

the FF / REW lever assembly and the cassette

hanger / cassette holder.

Joint g

Cassette holder

Return link

Joint i

Cassette hanger

Eject lever

Joint h

Chassis

Joint h

Tab f

Tab f

Joint g

Fig.3

C washer

1.

Remove the C washer and pull out reel disc assembly.

ATTENTION:

Replace with a new C washer when

reattaching.

Removing the motor assembly

(See Fig.5)

1.

Unsolder the two wires j on the motor assembly.

ATTENTION:

2.

Turn over the cassette mechanism assembly and

remove the main belt and the sub-belt from the

motor pulley.

ATTENTION:

To replace the sub-belt, remove the

main belt and the sub-belt from the

motor pulley. Then remove the three

screws E and one screw F. Replace

with a new sub-belt while lifting the reel

base assembly slightly.

The main belt can now be removed.

C washer

Flywheel (BF)

Fig.4

Main-belt

E

Reel disc assembly

Motor assembly

Sub-belt

G

E

Motor pulley

G

Soldering j

3.

Remove the two screws G attaching the motor

assembly.

Flywheel (BR)

Reel base assembly

E

Fig.5

F

1-9

Page 10

KS-F363R/KS-F360R

Removing the Flywheel (BF) and (BR)

assembly (See Fig.4 and 5)

Prior to performing the following procedure, remove

the cassette hanger / cassette holder.

1.

From the upper side of the cassette mechanism

assembly, remove the C washer from each shaft of

the flywheel (BF) and (BR).

2.

Turn over the cassette mechanism assembly and

remove the main belt. Pull out the flywheel (BF) and

(BR) downward respectively.

Removing the reel base assembly

(See Fig.5 and 6)

1.

Raise the part k of the reel base assembly slightly

and remove the selector link (B) on the front side of

the cassette mechanism assembly by turning it as

shown in Fig.10.

C washer

C washer

Flywheel (BF)

Fig.4

Main-belt

E

Reel disc assembly

Motor assembly

Sub-belt

G

Motor pulley

2.

Remove the three screws E and the one screw F

on the underside of the cassette mechanism

assembly.

ATTENTION:

The reel base assembly is not

repairable. Handle with care.

Inside of the reel base assembly

Flywheel (BR)

k

Reel base assembly

E

Fig.5

Pinch-roller (R) assembly

G

Soldering j

E

F

1-10

Selector link (B).

Turn the selector link (B).

Fig.6Fig.7

Page 11

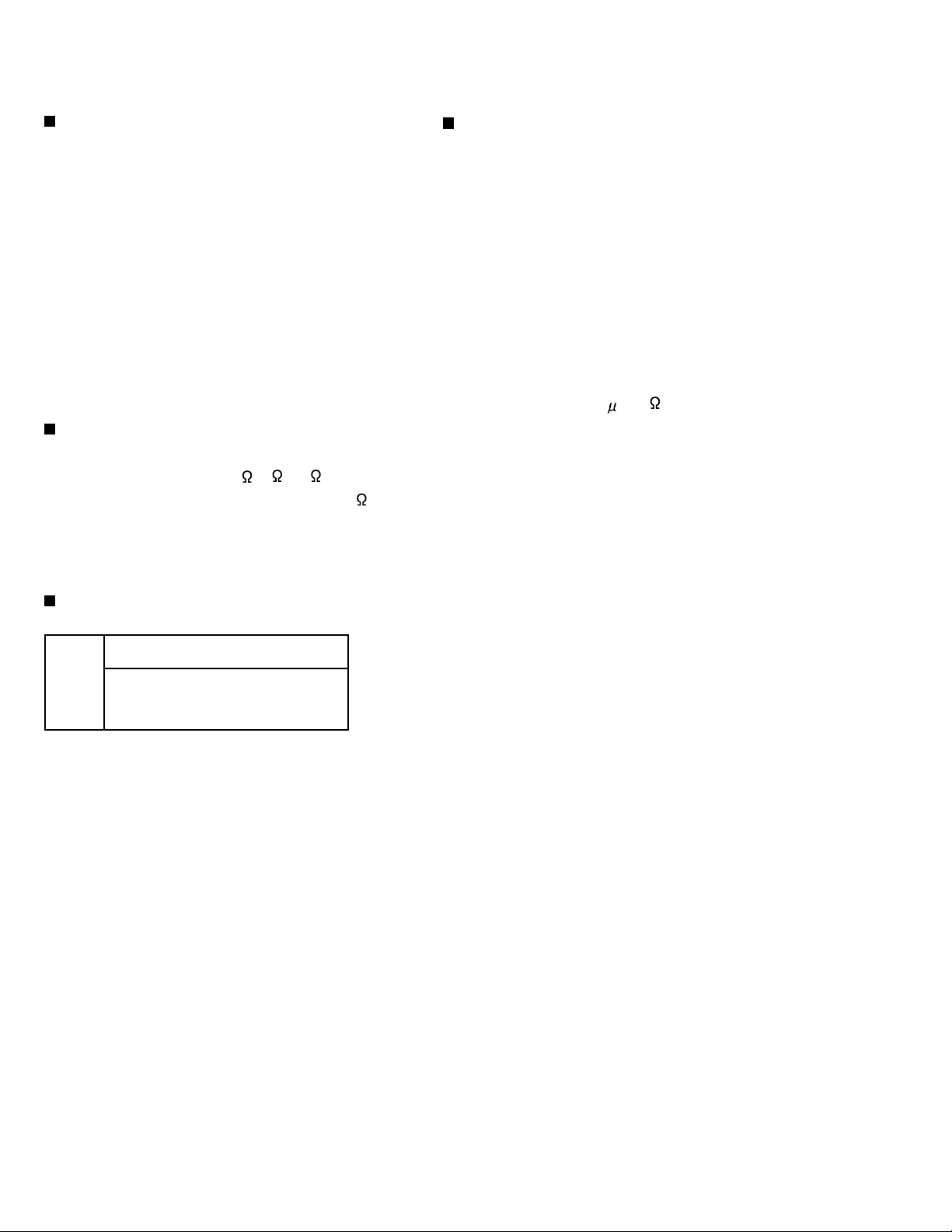

Removing the mute switch board

(See Fig.8)

1.

Unsolder the two wires l on the mute switch board on

the back of the cassette mechanism assembly.

2.

Remove the screw H attaching the mute switch

board.

Cassette mechanism assembly

Soldering l

Fig.8

H

KS-F363R/KS-F360R

Rower switch

Motor assembly

Mute

switch board

Removing the power switch (See Fig.9)

Prior to performing the following procedure, remove

the motor assembly.

1.

Unsolder the two wires m on the power switch on the

side of the cassette mechanism assembly.

2.

Remove the screw I attaching the power switch.

Soldering m

I

Cassette mechanism assembly

Power switch

Fig.9

1-11

Page 12

KS-F363R/KS-F360R

Adjustment method

Test instruments reqired for adjustment

1. Digital oscilloscoe(100MHz)

2.Frequency counter meter

3.Electric voltmeter

4.Wow & flutter meter

5.Test tapes

VT724.......................for DOLBY level measurement

VT739............For playback frequency measurement

VT712....For wow flutter & tape speed measurement

VT703.....................For head azimuth measurement

6.Torque gauge...................Cassette type for CTG-N

(Mechanism adjustment)

Standard volume position

Balance and Bass, Treble volume, Fader

:Center(Indication"0")

Loudness,Dolby NR,Sound,Cruise:Off

Volume position is about 2V at speaker output with

following conditions,Playback the test tape VT721.

AM mode 999kHz/62dB,INT/400Hz,30%

FM mono mode

FM stereo mode 1kHz,67.5kHz dev.pilot 7.5kHz dev

Output level 0dB(1 V,50 /open terminal)

Measuring conditions(Amplifier section)

Power supply voltage.............. DC14.4V(11V - 16V allowance)

Load impedance............ 4 (4 to 8 allowance)

Line out level/Impedance..............1.0V/20k load (250 nWb/m)

modulation signal on recieving.

97.9MHz/66dB,INT/400Hz,22.5kHz

deviation pilot off mono

Frequenc

Frequency band

FM: 87.5 MHz to 108.0 MHz

Band

AM : 522 kHz to 1620 kHz(MW)

144 kHz to 279 kHz(LW)

1-12

Page 13

KS-F363R/KS-F360R

Information for using a car audio service jig

1. For 1995 and 1996 , we're advancing efforts to make our extension cords common for all car audio products.

Please use this type of extension cord as follows.

2. As a U-shape type top cover is employed, this type of extension cord is needed to check operation of the

mechanism assembly after disassembly.

3. Extension cord : EXTKSRT002-6P ( 6 pin extension cord ) For connection between mechanism assembly

and main board assembly.

Check for mechanism driving section such as motor ,etc..

Disassembly methodl

1. Remove the bottom cover.

2. Remove the front panel assembly.

3. Remove the top cover .

4. Install the front panel.

5. Confirm that current is being carried by connecting

an extension cord jig.

Note

Available to connect to the CN701 connector when installing the front panel.

Cassette mechanism

EXTKSRT002-6P

Extension cord

: EXTKSRT002-6P

Main board

Front panel assembly

1-13

Page 14

KS-F363R/KS-F360R

Arrangement of adjusting & test points

Cassette mechanism

(Surface)

Motor assembly

Tape speed adjust

Playback head

Head section view

Head azimuth screw

Playback head

Azimuth screw

Fixed screw

1-14

Height adjusting screw

Height adjusting screw

c

Height adjusting screw

b

a

Page 15

KS-F363R/KS-F360R

Mechanism adjustment section

Item Adjusting & Confirmation Methods Adjust Std. Value

1.Head azimuth

"Head Height Adjustment"

Note

Adjust the azimuth directly. When you adjust the height using a mirror tape, remove the cassette housing from the

mechanism chassis.

After installing the cassette housing, perform the azimuth

adjustment.

1.Load the mirror tape ( SCC-1659 ). Adjust with height

adjustment screw (a) and azimuth adjustment screw (b) so

that line "A" of the mirror tape runs in the center between

Lch and Rch in the reverse play mode.

2.After switching from REV to FWD then to REV, check that

the head position set in procedure "1" is not changed.

*If the position has shifted, adjust again and check.

3.Adjust the azimuth screw (b) so that line "B" of the mirror

tape runs in the center between Lch and Rch in the forward

play mode.

"Head Azimuth Adjustment"

1.Load the test tape ( VT724: 1kHz ) and play it back in the

reverse play mode. set the Rch output level to maximum.

2.Load the test tape ( VT703: 10kHz ) and play it back in the

forward play mode. Adjust the Rch and Lch output levels

to maximum, with azimuth adjustment screw (b).

In this case, the phase difference should be within 45 .

3.Engage the reverse mode and adjust the output level to

maximum, with azimuth adjustment screw (c).

*The phase difference should be 45 or more.

4.When switching between forward and reverse modes, the

difference between channels should be within 3dB.

*Between FWD Lch and Rch, REV Lch and Rch.

5.When the test tape ( VT721 : 315Hz ) is played back, the

level difference between channels should be within 1.5dB.

Head shield

The head is at low position

during FWD.

Head shield

The head is at height position

during REV.

Head azimuth

screw

screw (c)

screw (b)

0

Phase

A Line

B Line

Fixed screw

screw (a)

45

2.Tape Speed and

Wow & Flutter

3.Playback

Frequency

response

1.Check to see if the reading of the frequency counter & Wow

flutter meter is within 2940-3090 Hz( FWD/REV ), and less

than 0.35% ( JIS RMS ).

2.In case of out of specification, adjust the motor with a builtin volume resistor.

1.Play the test tape ( VT724 : 1kHz ) back and set the volume

position at 2V.

2.Play the test tape ( VT739 )back and confirm 0 + 3dB at1kHz/

-

8kHz and -4+2dB at 1kHz/125Hz.

3.When 8kHz is out of specification, it will be necessary to

readjust the azimuth.

Built-in

volume resistor

Tape Speed

2940-3090Hz

Wow&Flutter

Less than

0.35%

(JIS RMS)

Speaker out

1kHz/8kHz

: 0dB_}3dB,

125Hz/1kHz

: -4dB+2dB,

1-15

Page 16

KS-F363R/KS-F360R

Description of major ICs

UPD178018AGC555 (IC701) : CPU

1. Pin layout

80 ~ 61

1

60

2. Pin function

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

~

20

21 ~ 40

~

41

Port Name I/O Descriptions

KEY 0

KEY 1

KEY 2

LEVEL

SM

SQ

LCDCE

LCDDA

LCDSCK

BUSI/O

UNLOCK

BUSSI

BUSSO

BUSSCK

NC

NC

NC

NC

NC

NC

GNDPORT

VDDPORT

AM

AFCK

MONO

FM

SEEK/STOP

NC

IFC

VDDPLL

FMOSC

AMOSC

GNDPLL

AMEO

FMEO

IC

SD/ST

STAGE0

NC

F/R

I

I

I

I

I

I

O

O

O

I

-

I

O

I/O

-

-

-

-

-

-

-

O

O

O

O

O

-

I

-

I

-

O

O

-

I

I

O

Key input 0

Key input 1

Key input 2

Level meter input

S.meter level input

S.Quality level input

CE output to LCD driver

Data output to LCD driver

Clock output to LCD driver

I/O selector output for J-BUS, H : OUT, L: INPUT

Non connect

J-BUS Data input

J-BUS Data output

J-BUS Clock in/output

Non connect

Non connect

Non connect

Non connect

Non connect

Non connect

Port GND

Port Vdd

Non connect

AF check output, L: AF check

Monaural on /off selecting output, H:mono on

FM/AM switching output L : FM H : AM

Auto seek /stop selecting output, H: Seek, L:Stop

Non connect

FM/AM midle frequency counter input

PLL Vdd

FM/AM limited generator frequency input

None connect

PLL GND

AM error out output

FM error out output

GND

Station detector, Stereo signal input, H:Find Station, L:Stereo

Pull up

Non connect

Main motor output

1-16

Page 17

KS-F363R/KS-F360R

Pin No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Port Name I/O Descriptions

NC

NC

TELMUTE

TAPEIN

I2CCLK

I2CDAO

I2CDAI

NC

NC

T-MUTE

NC

NC

NC

NC

TAPE

TUNER

CD

NC

NC

MUTE

POWER

NC

NC

NC

NC

NC

ON

STOP

RDSCK

RDSDA

REMOCON

DETACH

BUSINT

REGCPU

GND

X2

X1

REGOSC

VDD

NC

-

-

O

I

O

O

I

-

-

I

-

-

-

-

-

-

-

-

O

O

-

-

-

-

-

I

O

I

I

I

I

I

-

-

-

I

-

-

-

Non connect

Non connect

Telephone mute signal detection input

TAPE input

I2C information clock output

I2C information data output

I2C information clock input

Non connect

Non connect

Telephone mute signal detection input

Non connect

Non connect

Non connect

Non connect

Non connect

Non connect

Non connect

Non connect

Non connect

Mute output

Power ON /OFF switching output , H : power on

Non connect

Non connect

Non connect

Non connect

Non connect

CPU power supply

STOP signal output terminal

Clock input for RDS

RDS data input

Remocom input

Detach signal input H : Power save

Cut-in input for J-BUS signal

Regulator for CPU power supply, Connect the GND with 0.1 F.

Ground

Connecting the crystal oscillator for system clock

Connecting the crystal oscillator for system clock

Regulator for oscillator circuit.Connect the GND with 0.1 F.

Vdd

Pull up

1-17

Page 18

KS-F363R/KS-F360R

AN80T05LF (IC961) : Regulator

1.Pin layout & Block diagram

Reference Voltage

Thermal

Protection

ASO & Peak

Current Protection

Pre

Drive

1 2 3 4 5 6 7 8 9 10 11 12

ILL

10V

2.Pin function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

Pre

Drive

MODE2 MODE1 STB VDD

5.6V

AMP

Out

AMP VCC ANT COM

Symbol Function

ILL

MODE2

MODE1

STB

VDD

AMP

VCC

ANT

COM

AM

FM

GND

10V power supply for illumination.

When 5V is input,becomes AM. and the antenna output is turned on.

When 5V is input,becomes AM. and the output of FM is switched.

When 5V is input, outputs to ILL,COM,and AMP. It is 0V usually.

5.6V power supply.

Power supply supply to remote amplifier

Back up. connects with ACC with it.

Power supply supply to auto antenna.

8.7V power supply.

The power supply of 8.7V to AM.

The power supply of 8.7V to FM.

Ground

AMP

Out

Pre

Drive

Pre

Drive

8.7VAM8.7VFM8.7V

Pre

Drive

GND

1-18

Page 19

HA13158A (IC941) : Power amp

1. Pin layout 2. Block diagram

2

STBY

IN1

1

14 18 6

INVCC

INPUTBUFFER1

KS-F363R/KS-F360R

PVCC1PVCC2

+

AMP1

-

3

4

5

1 ~ 23

UPC1228HA (IC901) : Head amp

IN2

IN3

IN4

11

13

23

10

MUTE

INPUTBUFFER2

INPUTBUFFER3

INPUTBUFFER4

PROTECTOR (ASO

SURGE, TSD)

12 22

AMP2

AMP3

AMP4

TA B

+

7

8

-

9

15

+

16

-

17

19

+

20

-

21

1

IN1

ANP1

2

NFB1

3

OUT1

4

VCC

5

GND

6

OUT2

ANP2

7

NFB2

UPC1228HA

8

IN2

1-19

Page 20

KS-F363R/KS-F360R

LC75823W (IC651) : LCD driver

1. Pin Layout & Symbol

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

DICLCE

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

S17

S18

S19

OSC

S20

Vss

S21

VDD2

VDD1

S22

S23

INH

S24

VDD

S25

COM3

COM2

S26

S27

COM1

S52

S28

S29

S51

S30

S50

S31

S49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

S32

S48

S47

S46

S45

S44

S43

S42

S41

S40

S39

S38

S37

S36

S35

S34

S33

2. Pin Function

Pin No.

1 to 52

53 to 55

S1 to S52

COM1 to COM3

56

57

58

59

60

61

62

63

Symbol

VDD

INH

VDD1

VDD2

Vss

OSC

CE

CL

I/O

O

Segment output pins used to display data transferred

Function

by serial data input.

O

Common driver output pins. The frame frequency is given

by : t0=(fosc/384)Hz.

--

Power supply connection. Provide a voltage of between

4.5 and 6.0V.

I

Display turning off input pin.

INT="L" (Vss) ----- off (S1 to S52, COM1 to COM3="L"

INT="H" (VDD)----- on

Serial data can be transferred in display off mode.

I

Used for applying the LCD drive 2/3 bias voltage

externally.

Must be connected to VDD2 when a 1/2 bias drive scheme

is used.

I

Used for applying the LCD drive 1/3 bias voltage

externally.

Must be connected to VDD1 when a 1/2 bias drive scheme

is used.

--

Power supply connection. Connect to GND.

I/O

Oscillator connection.

An oscillator circuit is formed by connecting an external

resistor and capacitor at this pin.

Serial data CE : Chip enable

interface connection

I

to the controller. CL : Sync clock

1-20

64

DI

DI : Transfer data

Page 21

SAA6579T-X (IC761) : RDS

1.Pin layout

SCOUT

2.Block diagram

QUAL

RDDA

Vref

MUX

ODA

V

V

SSA

CIN

1

2

3

4

5

6

7

8

RDCL

16

T57

15

OSCO

14

OSCI

13

0DD

V

12

V

SSD

11

TEST

10

MODE

9

KS-F363R/KS-F360R

121413

3.Pin function

4

8

7

CLOCKED

COMPARATOR

5

3

REFERENCE

VOLTAGE

Pin No.

1

2

3

4

ANTIALIASING

FILTER

6 11

Symbol

VP1

QUAL

RDDA

Vref

MUX

57 kHz

BANDPASS

(8th ORDER)

COSTAS LOOP

VARIABLE AND

FIXED DIVIDER

CLOCK

REGERATION

AND SYNC

Quality indication output

RDS data output

Reference voltage output (0.5VDDA)

Multiolex signal input

RECONSTRUCTION

FILTER

TEST LOGIC AND OUTPUT

SELECTOR SWITCH

Description

OSCILATOR

AND

DIVIDER

BIPHASE

SYMBOL

DECODER

910

QUALITY BIT

GENERATOR

DIFFERENTIAL

DECODER

1

2

15

15

5

6

7

8

9

10

11

12

13

14

15

16

VDDA

VSSA

CIN

SCOUT

MODE

TEST

VSSD

VDDD

OSCI

OSCO

T57

RDCL

+5V supply voltage for analog part

Ground for analog part (0V)

Subcarrier input to comparator

Subcarrier output of reconstruction filter

Oscllator mode / test control input

Test enable input

Ground for digital part (0V)

+5V supply voltage for digital part

Oscillator input

Oscillator output

57 kHz clock signal output

RDS clock output

1-21

Page 22

KS-F363R/KS-F360R

TEA6320T-X (IC911) : E.volume

1.Pin layout

2.Block diagram

10 8 9 7 6

5

12

SDA

1

GND

2

OUTLR

OUTLF

MUTE

TL

B2L

B1L

IVL

ILL

QSL

IDL

ICL

IMD

IBL

IAL

3

4

5

6

7

8

9

10

11

12

13

14

15

16

3.Pin functions

Pin

Symbol

No.

SDA

1

SCL

32

VCC

31

OUTRR

30

OUTRF

29

TR

28

B2R

27

B1R

26

IVR

25

ILR

24

QSR

23

IDR

22

Vref

21

ICR

CD-CH

TAPE

TUNER

20

19

18

17

CAP

IBR

IAR

I/O

Serial data input/output.

I/O

MUTE

21

31

2

19

16

15

13

11

14

22

20

18

17

Functions Functions

POWER

SUPPLY

SOURCE

SELECTOR

23 25 24 26 27 28

VOLUME 1

+20 to -31 dB

LOUDNESS

LEFT

VOLUME 1

+20 to -31 dB

LOUDNESS

RIGHT

Pin

No.

17

Symbol

IAR

BASS

LEFT

+15 dB

LOGIC

BASS

RIGHT

+15 dB

I/O

I

Input A right source.

TREBLE

LEFT

+12 dB

TREBLE

RIGHT

+12 dB

FUNCTION

ZERO CROSS

DETECTOR

VOLUME 2

0 to 55 dB

BALANCE

FENDER REAR

VOLUME 2

0 to 55 dB

BALANCE

FENDER FRONT

HC BUS

REC

VOLUME 2

0 to -55dB

BALANCE

FENDER FRONT

VOLUME 2

0 to -55dB

BALANCE

FENDER REAR

3

4

32

1

29

30

10

11

12

13

14

15

16

2

3

4

5

6

7

8

9

GND

OUTLR

OUTLF

TL

B2L

B1L

IVL

ILL

QSL

IDL

MUTE

ICL

IMO

IBL

IAL

Ground.

-

output left rear.

O

output left front.

O

Treble control capacitor left channel or

I

input from an external equalizer.

Bass control capacitor left channel or

-

output to an external equalizer.

Bass control capacitor left channel.

-

Input volume 1. left control part.

I

Input loudness. left control part.

I

Output source selector. left channel.

O

Not used

-

Not used

-

Input C left source.

I

Not used

-

Input B left source.

I

Input A left source.

I

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

IBR

CAP

ICR

Vref

IDR

QSR

ILR

IVR

B1R

B2R

TR

OUTRF

OUTRR

Vcc

SCL

I

Input B right source.

-

Electronic filtering for supply.

I

Input C right source.

-

Reference voltage (0.5Vcc)

-

Not used

O

Output source selector right channel.

I

Input loudness right channel.

I

Input volume 1. right control part.

-

Bass control capacitor right channel

Bass control capacitor right channel or

O

output to an external equalizer.

Treble control capacitor right channel or

I

input from an external equalizer.

O

Output right front.

O

Output right rear.

-

Supply voltage.

I

Serial clock input.

1-22

Page 23

< MEMO >

KS-F363R/KS-F360R

1-23

Page 24

KS-F363R/KS-F360R

VICTOR COMPANY OF JAPAN, LIMITED

MOBILE ELECTRONICS DIVISION

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.49686)

200202

Page 25

KS-F363R/KS-F360R

PARTS LIST

[ KS-F363R ]

[ KS-F360R ]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

E ----------- Continental Europe

EX --------------- Central Europe

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

Cassette mechanism assembly and parts list (Block No.MP)

Electrical parts list (Block No.01~02)

Packing materials and accessories parts list (Block No.M3,M5)

3- 2

3- 5

3-10

3-14

3-1

Page 26

KS-F363R/KS-F360R

Exploded view of general assembly and parts list

Block No.

13

54

55

M

M

1

M

13

12

19

51

18

10

21

14

17

20

43

23

22

50

9

45

49

46

47

44

48

A

53

56

52

Main board

B

15

C

8

12

A

14

16

43

42

27

5

1

7

B

C

3

2

11

4

5

11

11

Front board

34

29

41

40

31

25

38

28

37

36

26

33

39

35

32

6

30

11

6

24

3-2

Page 27

KS-F363R/KS-F360R

Parts list (General assembly)

Item

A

1 --------------2 VKL7821-001

3 QYSPSPT2625Z

4 FSKM2005-002

5 QYSDST2605Z

6 QYSDSP2604Z

7 FSJC1029-305

8 FSMH3001-201

9 FSKM3011-002

10 FSMA3004-203

11 QYSDST2605Z

12 FSKZ4005-001

13 QYSDST2604Z

14 QYSDST2606Z

15 FSKZ4005-001

16 ZCKSF150J-FB

17 FSJC1055-001

18 FSJC4003-029

19 VKW4947-002

20 FSKS3010-001

21 FSKW4005-003

22 FSXP3026-002

23 FSKW3002-004

24 FSJC1053-006

25 FSJD3022-00P

26 FSJK3014-001

27 FSXP2035-110

28 FSYH4036-031

29 FSXP2034-039

30 FSXP3053-002

31 FSXP4005-026

32 FSXP2044-001

33 FSXP3068-004

34 FSXP3066-001

35 FSXP3065-001

36 FSXP3067-001

37 FSKW3002-003

38 FSKW3002-003

39 FSKW3002-003

40 FSXP3055-001

41 FSKW3002-012

42 FSJC1054-001

43 VKZ4777-001

44 QLD0145-001

45 QNZ0439-001

46 FSJK3034-001

47 FSYH4076-001

Parts number Parts name Area

FSJD3022-00N

CASSETTE MECHA

EJECT LEVER

MINI SCREW

MECHA BRACKET

SCREW

SCREW

TOP CHASSIS

SIDE PANEL

BOTTOM COVER

INSULATOR

SCREW

SCREW

SCREW

SCREW

SCREW

FRONT CHASSIS A

FRONT CHASSIS

CASSETTE LID

DOOR SPRING

LOCK LEVER

TORSION SPRING

RLS KNOB

COMP.SPRING

FRONT PANEL

FINDER ASSY

FINDER ASSY

LIGHT LENS

PRESET BUTTON

SHEET

D.FUNC BUTTON

POWER BUTTON

BBE BUTTON

COMBO BUTTON

PUSH BUTTON

FF BUTTON

EJECT BUTTON

REW BUTTON

COMP. SPRING

COMP. SPRING

COMP. SPRING

DETACH BUTTON

COMP. SPRING

REAR COVER

MINI SCREW

LCD MODULE

RUBBER CONNE

LCD LENS

LIGHTING SHEET

Q'ty

1

CDS-363SJ1

1

1

1

2

PCB+MECHA

4

MECHA+M.BKT

1

1

1

1

4

CHASSIS+MECHA BKT

2

CHASSIS+SIDE PANEL

2

CHASSIS+REAR BKT

2

CHASSIS+MAIN PW

1

SIDE PANEL+IC BKT

1

17,18,19

1

1

1

1

1

1

1

1

1

KS-F363R

1

KS-F360R

1

1

1-6,RDS,PTY

1

PRESET BUTTON

1

FM/AM/TP

1

1

1

1

DISP,MO

1

1

1

1

FOR REW BUTTON

1

FOR FF BUTTON

1

FOR EJECT BUTTON

1

1

FOR DETACH BUTTON

1

4

F.PANEL+REAR COVER

1

1

1

1

Block No. M1MM

Description

3-3

Page 28

KS-F363R/KS-F360R

Parts list (General assembly)

Item

A

48 FSYH3022-002

49 FSKS3021-001

50 GE30329-002A

51 VMA4652-001SS

52 FSKL4018-00B

53 FSKM3012-012

54 QYSDST2606Z

55 QYSDSF3006Z

56 QMFZ047-100-T

A

Parts number Parts name Area

GE30330-002A

LCD CASE

LENS CASE

NAME PLATE

NAME PLATE

EARTH PLATE

IC BRACKET

REAR BRACKET

SCREW

SCREW

FUSE

Q'ty

1

1

1

KS-F360R

1

KS-F363R

1

1

1

1

REAR BKT+ANT JACK

1

REAR BKT+PIN JACK

1

Block No. M1MM

Description

3-4

Page 29

Cassette mechanism assembly and parts list

KS-F363R/KS-F360R

30

12

66

81

109

49

72

24

32

CDS-363SJ1

89

120

100

57

Block No.

107

53

23

96

123

31

119

45

46

2

109

121

68

69

47

109

61

61

110

25

65

58

67

M

19

107

118

M

P

M

109

20

22

62

5

73

109

54

42

70

40

107

43

44

63

38

79

78

39

106

37

35

41

21

7

77

107

117

10

116

1

97

82

106

105

48

50

93

114

26

3

87

115

106

86

71

122

85

94

76

117

83

6

8

95

101

15

4

117

9

74

16

80

3-5

Page 30

KS-F363R/KS-F360R

Parts list (Cassette mechanism)

Item

A

1 X-0363-1001S

2 X-0363-1002S

3 X-0363-1004S

4 X-0363-6001S

5 X-0363-6007S

6 X-0363-6003S

7 X-0363-6004S

8 X-0363-6005S

9 X-0363-6006S

10 X-0363-2005S

12 X-0363-1019S

15 1-0363-6010S

16 1-0363-6011S

19 1-0036-1065S

20 1-0036-1066S

21 1-0036-1007S

22 1-0036-1013S

23 1-0036-1015S

24 1-0036-1018S

25 1-0036-1023S

26 1-0036-1026S

30 1-0138-1002S

31 1-0138-1006S

32 1-0138-1010S

35 1-0363-1003S

37 1-0036-2001S

38 1-0036-2003S

39 1-0036-2004S

40 1-0036-2007-5S

41 1-0036-2009S

42 1-0036-2010S

43 1-0036-2014S

44 1-0038-2014S

45 1-0038-2018S

46 1-0363-2006S

47 1-0138-2005-3S

48 1-0036-2005S

49 1-0032-2007S

50 1-0058-2021-5S

53 1-0363-3018S

54 1-0036-3018S

57 1-0363-3007S

58 1-0363-3011S

61 1-0036-4001S

62 1-0036-4002S

63 1-0036-4003S

65 1-0036-4006S

66 1-0036-4007S

Parts number Parts name Area

MAIN CHASSIS AS

HEAD PLATE ASSY

FR CONV ARM (A)

REEL BASE ASSY

LEVER BRKT ASSY

TU GEAR ARM ASS

PINCH ARM(R) AS

PINCH ARM(F) AS

DETECTOR CAM AS

REEL SPINDLE AS

EJ.CAM LOCK ASY

FLYWHEEL ASSY F

FLYWHEEL ASSY R

FF LEVER(JVC)

REW LEVER(JVC)

EJECT LEVER

LOCK ARM

SPG SUPPORT PLT

CENTER PLATE

CHANGE LEVER(B)

FR ARM(B)

CASSETTE HANGER

ADJUSTER SHIN(X

CASSETTE HOLDER

EJECT CAM

IDLE GEAR

REDUCT.GEAR(B)

REDUCT.GEAR(A)

RATCHET

SENSOR ARM

SELECTOR GEAR

DETECTOR GEAR

GEAR LOCK ARM

TAPE GUIDE

ADJUSTER LINK(B

ADJUSTER ARM(B)

PULLEY GEAR

TAPE HOOKER

IDLER PULLEY(A)

FF ROLLER

COLLER

HP ROLLER(A)

PROGRAM ROLLER

FF/REW LEVER SP

LOCK LEVER SPG

GEAR LOCK ARM S

HEAD PLATE SPG

EJ.CAM LOCK SPG

Q'ty

Block No. MPMM

Description

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

3-6

Page 31

KS-F363R/KS-F360R

Parts list (Cassette mechanism)

Item

A

67 1-0036-4008S

68 1-0036-4010S

69 1-0036-4011S

70 1-0036-4015S

71 1-0036-4017S

72 1-0036-4023S

73 1-0038-4014S

74 1-0138-4001S

76 1-0363-4003S

77 1-0363-4004S

78 1-0363-4005S

79 1-0036-4005S

80 1-0036-5020S

81 1-0363-5007S

82 1-0036-5001S

83 1-0363-5003S

85 1-0036-7002S

86 1-0036-7003S

87 1-0036-7073S

89 X-0363-7006S

93 1-0363-7001S

94 1-0363-7002S

95 1-0363-7008S

96 1-0036-7016S

97 1-0363-7005S

100 1-0036-7089S

101 1-0036-7088S

105 2-1816-0032-E8S

106 2-1812-0030-D2S

107 1-0036-5024S

109 2-1712-0050-16S

110 2-1712-5060-16S

114 1-0363-7015S

115 2-1331-7040-C2S

116 2-1331-7060-C2S

117 2-1382-0030-C2S

118 2-1332-0040-C1S

119 2-1032-0070-C2S

120 2-1032-0025-C2S

121 2-1012-0040-C2S

122 2-1012-0030-F2S

123 1-0138-5002S

Parts number Parts name Area

Q'ty

PROGRAM ARM SPG

ADJUST ARM SP(A

ADJUST ARM SP(B

DASH SPG 1

CHANGING ARM SP

CENTER PLT SP(B

RATCHET SPG

BACK TEMSION SP

PINCH ARM SPG F

PINCH ARM SPG R

EJECT LEVER SPG

EJECT CAM SPG

MAIN BELT(AL)

RETURN LINK

SUB BELT

SELECTOR LINK B

WIRE(A)

WIRE(B)

WIRE(AL)

MOTOR ASSY

MUTE SW

SLIDE SW

SLIDE SW PWB

HEAD

POWER SW

6P WIRE ASY(JVC

5P WIRE ASY(JVC

MYLAR WASHER(S)

POLY WASHER(S)

PSW(REEL)

E RING

E RING

MUTE SW PWB

SCREW S

SCREW S

SCREW B

SCREW S

SCREW

SCREW

SCREW

SCREW

AZIMUTH SCREW

Block No. MPMM

Description

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

3

5

5

1

1

1

1

5

1

2

2

1

1

3

3-7

Page 32

KS-F363R/KS-F360R

Grease point 1/2

Grease

FL-942

SW-902

SW-522B

FG-84M

C68

1

Reverse side

A

24

3-8

2

72

Page 33

Grease point 2/2

KS-F363R/KS-F360R

19

20

5

35

30

12

3

38

16

39

42

37

43

4

15

3-9

Page 34

KS-F363R/KS-F360R

e

Electrical parts list (Main board)

Item

A

C 1 QEKJ1HM-104Z E CAPACITOR .10MF 20% 50V

C 6 NCB21EK-563X C CAPACITOR

C 7 NCB21EK-123X C CAPACITOR

C 9 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 17 NCS21HJ-151X C CAPACITOR

C 18 QERF1HM-224Z E CAPACITOR .22MF 20% 50V

C 20 NCS21HJ-102X C CAPACITOR

C 21 QEQF1HM-225Z NP E CAPACITOR 2.2MF 20% 50V

C 24 NCB21EK-473X C CAPACITOR

C 25 NCB21EK-104X C CAPACITOR

C 30 NDC21HJ-470X C CAPACITOR

C 101 NCS21HJ-821X C CAPACITOR

C 102 QEKJ1HM-474Z E CAPACITOR .47MF 20% 50V

C 103 NCS21HJ-101X C CAPACITOR

C 104 QEKJ0JM-476Z E CAPACITOR 47MF 20% 6.3V

C 105 QFV61HJ-103Z MF CAPACITOR .010MF 5% 50V

C 111 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 112 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 113 QFLA1HJ-822Z M CAPACITOR 8200PF 5% 50V

C 114 QFV61HJ-154Z MF CAPACITOR .15MF 5% 50V

C 115 QERF1HM-224Z E CAPACITOR .22MF 20% 50V

C 116 QFV61HJ-333Z MF CAPACITOR .033MF 5% 50V

C 117 QFLA1HJ-562Z M CAPACITOR 5600PF 5% 50V

C 118 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 119 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 143 NCS21HJ-471X C CAPACITOR

C 144 NCS21HJ-471X C CAPACITOR

C 151 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 152 NCB21HK-122X C CAPACITOR

C 153 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 154 NCB21HK-153X C CAPACITOR

C 201 NCS21HJ-821X C CAPACITOR

C 202 QERF1HM-474Z E CAPACITOR .47MF 20% 50V

C 203 NCS21HJ-101X C CAPACITOR

C 204 QEKJ0JM-476Z E CAPACITOR 47MF 20% 6.3V

C 205 QFV61HJ-103Z MF CAPACITOR .010MF 5% 50V

C 211 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 212 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 213 QFLA1HJ-822Z M CAPACITOR 8200PF 5% 50V

C 214 QFV61HJ-154Z MF CAPACITOR .15MF 5% 50V

C 215 QERF1HM-224Z E CAPACITOR .22MF 20% 50V

C 216 QFV61HJ-333Z MF CAPACITOR .033MF 5% 50V

C 217 QFLA1HJ-562Z M CAPACITOR 5600PF 5% 50V

C 218 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 219 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 243 NCS21HJ-471X C CAPACITOR

C 244 NCS21HJ-471X C CAPACITOR

C 251 QEKJ1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 252 NCB21HK-122X C CAPACITOR

C 253 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 254 NCB21HK-153X C CAPACITOR

C 301 NCB21HK-331X C CAPACITOR

C 302 NCB21HK-103X C CAPACITOR

C 303 NCB21EK-472X C CAPACITOR

C 304 NCB21EK-104X C CAPACITOR

C 305 QEKJ1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 701 NDC21HJ-270X C CAPACITOR

C 702 NDC21HJ-270X C CAPACITOR

C 703 NCB21EK-104X C CAPACITOR

C 704 NCB21EK-104X C CAPACITOR

C 705 NCB21HK-102X C CAPACITOR

C 707 NCB21EK-104X C CAPACITOR

C 708 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

Parts number Parts name Ar

Block No. 01

Remarks

Item

a

A

C 709 QERF0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 710 NCS21HJ-121X C CAPACITOR

C 711 NCB21CK-224X C CAPACITOR

C 712 NCB21HK-104X C CAPACITOR

C 761 NCB21EK-223X C CAPACITOR

C 762 NCS21HJ-561X C CAPACITOR

C 763 QEKJ1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 764 NDC21HJ-820X C CAPACITOR

C 765 NDC21HJ-470X C CAPACITOR

C 766 QERF1CM-476Z E CAPACITOR 47MF 20% 16V

C 767 NCB21HK-103X C CAPACITOR

C 901 QEKJ1AM-107Z E CAPACITOR 100MF 20% 10V

C 911 QERF1CM-476Z E CAPACITOR 47MF 20% 16V

C 912 QERF1CM-107Z E CAPACITOR 100MF 20% 16V

C 913 QERF1CM-107Z E CAPACITOR 100MF 20% 16V

C 932 NCB21EK-104X C CAPACITOR

C 941 NCB21EK-104X C CAPACITOR

C 942 NCB21EK-104X C CAPACITOR

C 943 NCB21EK-104X C CAPACITOR

C 944 NCB21EK-104X C CAPACITOR

C 945 QEKJ1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 961 QETM1CM-228 E CAPACITOR 2200MF 20% 16V

C 962 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 963 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 964 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 965 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 966 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 967 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 969 NCB21EK-473X C CAPACITOR

C 970 NCB21EK-473X C CAPACITOR

C 971 NCB21EK-104X C CAPACITOR

C 977 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 978 QEKJ1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 979 QEKJ1CM-106Z E CAPACITOR 10MF 20% 16V

C 980 NCB21HK-473X C CAPACITOR

C 981 QEKJ0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 982 QEKJ1CM-106Z E CAPACITOR 10MF 20% 16V

C 984 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

CJ701 VMC0334-001 CONNECTOR

CJ901 QGA2002C1-05 CONNECTOR

CJ902 QGA2002F1-06 CONNECTOR

CN901 QGB1214J1-06S CONNECTOR

CN902 QGB1214J1-06S CONNECTOR

CP901 QGB1214K1-06S CONNECTOR

CP902 QGB1214K1-06S CONNECTOR

CP961 QNZ0112-001 CAR CONNECTOR

D 1 1SS119-041 SI DIODE

D 2 1SS119-041 SI DIODE

D 3 MA152WK-X SI DIODE

D 5 1SS119-041 SI DIODE

D 6 MTZJ9.1C-T2 Z DIODE

D 701 RB721Q-T2 S.B.DIODE

D 741 1SS119-041 SI DIODE

D 742 1SS119-041 SI DIODE

D 744 DSK10C-T1 DIODE

D 776 DSK10C-T1 DIODE

D 931 MA152WA-X DIODE

D 951 1SS133-T2 SI DIODE

D 961 1N5401-TU-15 DIODE

D 963 MA152WA-X DIODE

D 965 DSK10C-T1 DIODE

D 966 DSK10C-T1 DIODE

D 977 MA152WK-X SI DIODE

Parts number Parts name Ar

Remarks

a

3-10

Page 35

KS-F363R/KS-F360R

e

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Electrical parts list (Main board)

Item

A

D 978 MTZJ11B-T2 ZENER DIODE

D 980 MA152WA-X DIODE

D 981 MA152WA-X DIODE

D 982 MA152WK-X SI DIODE

IC701 UPD178016AGC555 IC

IC761 SAA6579T-X IC

IC901 UPC1228HA IC

IC911 TEA6320T-X IC

IC941 HA13158A IC

IC961 AN80T05LF IC

J 1 QNZ0009-001 ANTENNA JACK

J 931 QNN0183-001 PIN JACK

L 1 QQL231K-4R7Y INDUCTOR

L 701 QQL231K-470Y INDUCTOR

L 961 QQR0528-002 CHOKE COIL

R 3 NRSA02J-472X MG RESISTOR

R 4 NRSA02J-473X MG RESISTOR

R 5 NRSA02J-332X MG RESISTOR

R 7 NRSA02J-473X MG RESISTOR

R 8 NRSA02J-472X MG RESISTOR

R 9 NRSA02J-102X MG RESISTOR

R 10 NRSA02J-392X MG RESISTOR

R 12 NRSA02J-102X MG RESISTOR

R 14 NRS181J-471X MG RESISTOR

R 24 NRSA02J-102X MG RESISTOR

R 25 NRSA02J-102X MG RESISTOR

R 26 NRSA02J-103X MG RESISTOR

R 27 NRSA02J-102X MG RESISTOR

R 29 NRSA02J-152X MG RESISTOR

R 30 NRS181J-8R2X MG RESISTOR

R 32 NRSA02J-0R0X MG RESISTOR

R 34 NRSA02J-223X MG RESISTOR

Parts number Parts name Ar

1 DTC114EKA-X TRANSISTOR

2 DTC114EKA-X TRANSISTOR

3 2SC2412K/R/-X TRANSISTOR

4 DTA114EKA-X D.TRANSISTOR

5 2SA1037AK/RS/-X TRANSISTOR

6 2SA1037AK/RS/-X TRANSISTOR

7 2SC3661-X TRANSISTOR

10 2SC3661-X TRANSISTOR

11 2SC2412K/R/-X TRANSISTOR

12 2SC2412K/R/-X TRANSISTOR

131 2SC2412K/R/-X TRANSISTOR

151 2SC2412K/R/-X TRANSISTOR

231 2SC2412K/R/-X TRANSISTOR

251 2SC2412K/R/-X TRANSISTOR

301 2SD601A/R/-X TRANSISTOR

302 2SD601A/R/-X TRANSISTOR

701 2SC2412K/R/-X TRANSISTOR

951 DTA114EKA-X D.TRANSISTOR

959 DTC114EKA-X TRANSISTOR

960 2SA1037AK/RS/-X TRANSISTOR

961 2SA1037AK/RS/-X TRANSISTOR

962 2SB1322/RS/-T TRANSISTOR

963 2SA1037AK/RS/-X TRANSISTOR

964 DTC114EKA-X TRANSISTOR

965 DTC114EKA-X TRANSISTOR

966 DTC114EKA-X TRANSISTOR

967 2SA1037AK/RS/-X TRANSISTOR

978 DTC114EKA-X TRANSISTOR

979 DTA114EKA-X D.TRANSISTOR

980 DTC114EKA-X TRANSISTOR

981 DTA114EKA-X D.TRANSISTOR

Block No. 01

Remarks

Item

a

A

R 101 NRSA02J-153X MG RESISTOR

R 103 NRSA02J-101X MG RESISTOR

R 104 NRSA02J-334X MG RESISTOR

R 112 NRSA02J-223X MG RESISTOR

R 113 NRSA02J-222X MG RESISTOR

R 132 NRSA02J-222X MG RESISTOR

R 135 NRSA02J-101X MG RESISTOR

R 136 NRSA02J-102X MG RESISTOR

R 141 NRSA02J-153X MG RESISTOR

R 142 NRSA02J-153X MG RESISTOR

R 143 NRSA02J-393X MG RESISTOR

R 144 NRSA02J-393X MG RESISTOR

R 151 NRSA02J-103X MG RESISTOR

R 152 NRSA02J-223X MG RESISTOR

R 153 NRSA02J-472X MG RESISTOR

R 201 NRSA02J-153X MG RESISTOR

R 203 NRSA02J-101X MG RESISTOR

R 204 NRSA02J-334X MG RESISTOR

R 212 NRSA02J-223X MG RESISTOR

R 213 NRSA02J-222X MG RESISTOR

R 232 NRSA02J-222X MG RESISTOR

R 235 NRSA02J-101X MG RESISTOR

R 236 NRSA02J-102X MG RESISTOR

R 241 NRSA02J-153X MG RESISTOR

R 242 NRSA02J-153X MG RESISTOR

R 243 NRSA02J-393X MG RESISTOR

R 244 NRSA02J-393X MG RESISTOR

R 251 NRSA02J-103X MG RESISTOR

R 252 NRSA02J-223X MG RESISTOR

R 253 NRSA02J-472X MG RESISTOR

R 301 NRSA02J-473X MG RESISTOR

R 302 NRSA02J-473X MG RESISTOR

R 303 NRSA02J-103X MG RESISTOR

R 304 NRSA02J-222X MG RESISTOR

R 305 NRSA02J-153X MG RESISTOR

R 306 NRSA02J-471X MG RESISTOR

R 307 NRSA02J-103X MG RESISTOR

R 701 NRSA02J-271X MG RESISTOR

R 702 NRS181J-271X MG RESISTOR

R 703 NRS181J-271X MG RESISTOR

R 704 NRSA02J-271X MG RESISTOR

R 705 NRSA02J-103X MG RESISTOR

R 706 NRSA02J-473X MG RESISTOR

R 708 NRSA02J-104X MG RESISTOR

R 709 NRSA02J-104X MG RESISTOR

R 710 NRS181J-472X MG RESISTOR

R 711 NRSA02J-391X MG RESISTOR

R 712 NRS181J-103X MG RESISTOR

R 713 NRSA02J-103X MG RESISTOR

R 715 NRS181J-103X MG RESISTOR

R 716 NRS181J-103X MG RESISTOR

R 717 NRS181J-103X MG RESISTOR

R 718 NRS181J-472X MG RESISTOR

R 719 NRSA02J-472X MG RESISTOR

R 720 NRSA02J-472X MG RESISTOR

R 721 NRS181J-472X MG RESISTOR

R 722 NRSA02J-472X MG RESISTOR

R 723 NRS181J-472X MG RESISTOR

R 724 NRS181J-472X MG RESISTOR

R 725 NRS181J-472X MG RESISTOR

R 726 NRS181J-472X MG RESISTOR

R 727 NRSA02J-472X MG RESISTOR

R 733 NRS181J-472X MG RESISTOR

Parts number Parts name Ar

Remarks

a

3-11

Page 36

KS-F363R/KS-F360R

e

Electrical parts list (Main board)

Item

A

R 734 NRSA02J-472X MG RESISTOR

R 736 NRSA02J-103X MG RESISTOR

R 737 NRSA02J-473X MG RESISTOR

R 738 NRSA02J-473X MG RESISTOR

R 740 NRSA02J-473X MG RESISTOR

R 743 NRSA02J-103X MG RESISTOR

R 746 NRSA02J-473X MG RESISTOR

R 747 NRSA02J-473X MG RESISTOR

R 750 NRSA02J-473X MG RESISTOR

R 751 NRSA02J-104X MG RESISTOR

R 752 NRSA02J-334X MG RESISTOR

R 753 NRSA02J-223X MG RESISTOR

R 757 NRSA02J-104X MG RESISTOR

R 759 NRSA02J-334X MG RESISTOR

R 761 NRSA02J-222X MG RESISTOR

R 762 NRSA02J-222X MG RESISTOR

R 763 NRSA02J-222X MG RESISTOR

R 773 NRSA02J-473X MG RESISTOR

R 911 NRSA02J-271X MG RESISTOR

R 912 NRSA02J-271X MG RESISTOR

R 913 NRS181J-100X MG RESISTOR

R 941 NRSA02J-473X MG RESISTOR

R 959 NRSA02J-222X MG RESISTOR

R 960 NRSA02J-273X MG RESISTOR

R 961 QRE141J-470Y C RESISTOR 47 5% 1/4W

R 962 NRSA02J-682X MG RESISTOR

R 963 NRS181J-123X MG RESISTOR

R 966 NRSA02J-473X MG RESISTOR

R 967 NRSA02J-222X MG RESISTOR

R 969 NRS181J-222X MG RESISTOR

R 970 NRS181J-473X MG RESISTOR

R 974 NRSA02J-123X MG RESISTOR

R 975 NRSA02J-243X MG RESISTOR

R 977 NRS181J-181X MG RESISTOR

R 978 NRSA02J-473X MG RESISTOR

R 979 NRSA02J-473X MG RESISTOR

R 980 NRSA02J-102X MG RESISTOR

TU 1 QAU0222-001 TUNER

X 701 QAX0406-002Z CRYSTAL

X 761 QAX0263-001Z CRYSTAL

Parts number Parts name Ar

Block No. 01

Remarks

a

3-12

Page 37

KS-F363R/KS-F360R

e

Electrical parts list (Front board)

Item

A

C 651 NCB21EK-103X C CAPACITOR

C 652 NBE20JM-475X TS E CAPACITOR

C 653 NCB21HK-681X C CAPACITOR

CP701 VMC0335-001 CONNECTOR

D 601 LNJ308G81/1-3/X LED KS-F360R

D 601 SML-310DT/KL/-X LED KS-F363R

D 602 SML-310DT/KL/-X LED KS-F363R

D 602 LNJ308G81/1-3/X LED KS-F360R

D 603 LNJ308G81/1-3/X LED KS-F360R

D 603 SML-310DT/KL/-X LED KS-F363R

D 604 SML-310DT/KL/-X LED KS-F363R

D 604 LNJ308G81/1-3/X LED KS-F360R

D 605 LNJ308G81/1-3/X LED KS-F360R

D 605 SML-310DT/KL/-X LED KS-F363R

D 609 SML-310DT/KL/-X LED KS-F363R

D 609 LNJ308G81/1-3/X LED KS-F360R

D 610 LNJ308G81/1-3/X LED KS-F360R

D 610 SML-310DT/KL/-X LED KS-F363R

D 611 LNJ308G81/1-3/X LED KS-F360R

D 611 SML-310DT/KL/-X LED KS-F363R

D 612 LNJ308G81/1-3/X LED KS-F360R

D 612 SML-310DT/KL/-X LED KS-F363R

D 613 SML-310DT/KL/-X LED KS-F363R

D 613 LNJ308G81/1-3/X LED KS-F360R

D 614 LNJ308G81/1-3/X LED KS-F360R

D 614 SML-310DT/KL/-X LED KS-F363R

D 615 SML-310DT/KL/-X LED KS-F363R

D 615 LNJ308G81/1-3/X LED KS-F360R

D 616 LNJ308G81/1-3/X LED KS-F360R

D 616 SML-310DT/KL/-X LED KS-F363R

D 618 SML-310DT/KL/-X LED KS-F363R

D 618 LNJ308G81/1-3/X LED KS-F360R

D 619 LNJ308G81/1-3/X LED KS-F360R

D 619 SML-310DT/KL/-X LED KS-F363R

D 620 SML-310DT/KL/-X LED KS-F363R

D 620 LNJ308G81/1-3/X LED KS-F360R

D 621 LNJ308G81/1-3/X LED KS-F360R

D 621 SML-310DT/KL/-X LED KS-F363R

D 622 SML-310DT/KL/-X LED KS-F363R

D 622 LNJ308G81/1-3/X LED KS-F360R

D 623 SML-310LT/MN/-X LED

D 624 LNJ308G81/1-3/X LED KS-F360R

D 624 SML-310DT/KL/-X LED KS-F363R

D 654 MA152WK-X SI DIODE

IC651 LC75823W IC

PL601 QLL0092-001 PILOT LAMP KS-F360R

PL601 QLL0076-001 PILOT LAMP KS-F363R

PL603 QLL0076-001 PILOT LAMP KS-F363R

PL603 QLL0092-001 PILOT LAMP KS-F360R

R 601 NRSA02J-561X MG RESISTOR

R 602 NRSA02J-821X MG RESISTOR

R 603 NRSA02J-122X MG RESISTOR

R 604 NRSA02J-182X MG RESISTOR

R 605 NRSA02J-272X MG RESISTOR

R 606 NRSA02J-561X MG RESISTOR

R 607 NRSA02J-821X MG RESISTOR

R 608 NRSA02J-122X MG RESISTOR

R 609 NRSA02J-182X MG RESISTOR

R 610 NRSA02J-272X MG RESISTOR

R 611 NRSA02J-392X MG RESISTOR

R 612 NRSA02J-561X MG RESISTOR

R 613 NRSA02J-821X MG RESISTOR

R 614 NRSA02J-122X MG RESISTOR

Parts number Parts name Ar

Block No. 02

Remarks

Item

a

A

R 615 NRSA02J-182X MG RESISTOR

R 616 NRSA02J-272X MG RESISTOR

R 617 NRSA02J-392X MG RESISTOR

R 621 NRSA02J-332X MG RESISTOR

R 622 NRSA02J-332X MG RESISTOR

R 623 NRSA02J-332X MG RESISTOR

R 632 NRSA02J-821X MG RESISTOR

R 633 NRSA02J-821X MG RESISTOR

R 640 NRSA02J-331X MG RESISTOR

R 641 NRSA02J-331X MG RESISTOR

R 642 NRSA02J-821X MG RESISTOR

R 644 NRSA02J-821X MG RESISTOR

R 646 NRSA02J-821X MG RESISTOR

R 648 NRSA02J-821X MG RESISTOR

R 650 NRSA02J-511X MG RESISTOR

R 651 NRSA02J-511X MG RESISTOR

R 661 NRSA02J-152X MG RESISTOR

R 662 NRSA02J-473X MG RESISTOR

R 663 NRSA02J-154X MG RESISTOR

S 601 NSW0124-001X TACT SWITCH

S 602 NSW0124-001X TACT SWITCH

S 603 NSW0124-001X TACT SWITCH

S 604 NSW0124-001X TACT SWITCH

S 605 NSW0124-001X TACT SWITCH

S 606 NSW0124-001X TACT SWITCH

S 607 NSW0124-001X TACT SWITCH

S 608 NSW0124-001X TACT SWITCH

S 609 NSW0124-001X TACT SWITCH

S 610 NSW0124-001X TACT SWITCH

S 611 NSW0124-001X TACT SWITCH

S 612 NSW0124-001X TACT SWITCH

S 613 NSW0124-001X TACT SWITCH

S 614 NSW0124-001X TACT SWITCH

S 615 NSW0124-001X TACT SWITCH

S 616 NSW0124-001X TACT SWITCH

S 617 NSW0124-001X TACT SWITCH

S 618 NSW0124-001X TACT SWITCH

S 619 NSW0124-001X TACT SWITCH

S 620 NSW0124-001X TACT SWITCH

Parts number Parts name Ar

Remarks

a

3-13

Page 38

KS-F363R/KS-F360R

Packing materials and accessories parts list

P4

A1~A5

P1

Block No.

Block No.

M

M

3

M

M

5

M

M

P2

A14

1/2

A15

A12

P3

A13

P2

2/2

KIT:A6~A10

P5

A11

3-14

A1

P4

E version only

Page 39

KS-F363R/KS-F360R

Parts list (Packing)

Item

A

P 1 GE30123-051A

P 2 LV10448-001A

P 3 QPC03004315P

P 4 FSPG4002-001

P 5 QPA00801205

Parts number Parts name Area

GE30123-052A

FSPG4002-001

Parts list (Accessories)

Item

A

A 1 GET0054-001A

A 2 GET0054-002A

A 3 GET0054-003A

A 4 GET0054-004A

A 5 BT-54013-2

A 6 VKZ4027-202

A 7 VKH4871-001SS

A 8 VKZ4328-001

A 9 WNS5000Z

A 10 FSKL4010-002

A 11 FSJB3002-30C

A 12 FSKM2004-202

A 13 QAM0175-001

A 14 FSJD2034-001

A 15 LV40978-001A

KIT KDGS717K-SCREW1

Parts number Parts name Area

PACKING CASE

PACKING CASE

PACKING CUSHION

POLY BAG

POLY BAG

POLY BAG

POLY BAG

INST.BOOK

INST.BOOK

INSTALL MANUALL

INSTALL MANUALL

W.CARD

PLUG NUT

MOUNT BOLT

LOCK NUT

WASHER

HOOK

HARD CASE

MOUNTING SLEEVE

POWER CORD

TRIM PLATE

CAUTION SHEET

SCREW PARTS KIT

Q'ty

1

KS-F360R

1

KS-F363R

1

1

2

INST.BOOK

1

INST.BOOK

1

SCREW

Q'ty

1

ENG,GER,FRE,DUT

1

SPA,ITA,SWE,RUS

1

ENG,GER,FRE,DUT

1

SPA,ITA,SWE,RUS

1

1

1

1

FOR M5

1

2

1

1

1

1

1

1

A6~A10

Block No. M3MM

Description

E

EX

Block No. M5MM

Description

E,EX

E

E,EX

E

3-15

Page 40

Block diagram

KS-F363R/KS-F360R

P. B .

HEAD

RADIO/TAPE

SWITCH

CJ901

FED-L

FWD-R

REV-L

REV-R

MOTOR

MUTE

SWITCH

IC901

HEAD

MOTOR

T-MUTE

TAPEIN

AMP

TAPE-L

TAPE-R

CJ902

CP901

CP902

CN901 CN902 CJ701

F/R

MOTOR

T-MUTE

TAPEIN

J1

ANT

TU1

FM/AM

TUNER

MUX

IC761

RDS

DETECTOR

RDSCK

RDSDA

IC701

CPU

TU-L,TU-R

SM

SQ

AFCK

MONO

FM

SEEK/STOP

IFC

FMOSC

AMOSC

AMEO

FMEO

SD/ST

E.VOLUME

TAPE-L

TAPE-R

IC911

I2CSCK

I2CDAO

REAR-L

REAR-R

OUTFL

OUTFR

OUTRL

OUTRR

IC941

POWER AMP

FLOUT+

FLOUT-

FROUT+

FROUT-

RLOUT+

RLOUT-

RROUT+

RROUT-

IC961

REGULATOR

COM1

LCD

COM2

COM3

S8~S52

KEY

MATRIX

S601~S620

IC651

LCD

DRIVER

KEY0~KEY2

LCDDA

LCDCK

LCDCE

CP701

KEY0

KEY1

KEY2

LCDCE

LCDCK

LCDDA

J931

LINE OUT

CP961

SPK

BATT

-

Page 41

Standard schematic diagrams

Main amp section

TU1

QAU0222-001

KS-F363R/KS-F360R

KS-F363R/KS-F360R

IC941

HA13158A

R9

1k

R10

3.9k

Q7

CN901

QGB1214J1-06S

CN902

QGB1214J1-06S

R701

R702

R703

R704

C7

0.012

Q10

D776

DSK10C-T1

270

270

270

270

D744

DSK10C-T1

0.056

C6

J1

QNZ0009-001

Q11

1k

R12

TAPE-L

TAPE-R

T-MUTE

TAPE-IN

J751

QNZ0095-001

R141

0.022

C761

R251

1/50

L1

4.7U

D1

D2

1SS119-041

1SS119-041

C18

C17

150P

1k

R24

R25

1k

R26

10k

R27

1k

2.2/50

C20

0.001

Q12

R14

470

F/R

0.22/50

C21

2SA1037AK/RS/-X

R8

4.7k 47k

D6

MTZJ9.1C-T2

220/10

C9

Q1

DTC114EKA-X

1.5k

R29

9V

TAPE-IN

KS-F463R/KS-F460R only

R755

R756

100k

R757

100k

R758

100

HD74HC126FP-X

R759

330k

R306

R736R737

0

R32

Q2

C29

10p

DTC114EKA-X

C24

0.047

Q5

R4R5

D3

MA152WK-X

R303

C303

Q13

R754

0.1

100

47K

R301

R302

C751

0.01

C302

47K

0.1

TAPEIN

R773

D5

C301

LCDCE

LCDCK

LCDDA

47k

47k

2SA1037AK/RS/-X

3.3k 1SS119-041

330p

R749

10K

SO

I/O

SCK

22k

R753R752

330k

22K

R34

SI

C30

47p

Q6

R7

10K

R305

15K

2SD601A/R/-X

470

C304

2SD601A/R/-X

Q302

Q301

0.1

C305

10K

2.2K

2.2/50

R307

R304

R743

10K

DTC114EKA-X

10K47K

2SC2412K/R/-X

Q701

10k

IC751

KEY0

KEY1

KEY2

LCDCE

LCDDA

LCDCK

KEY2

KEY1

KEY0

C1

2SC2412K/R/-X

R3

4.7k

D951

1SS133-T2

8.2

R30

C701

C702

0.1/50

Q4

RB721Q-T2

27P

27P

C709

C151

1/50

Q3

0.015

C154

DTA114EKA-X

C766

C767

C765

47p

C764

82p

R708

100k

R713

10k

D701

R710

4.7K

C703

X701

C704

0.1

QAX0406-002Z

100/6.3

C251

R151

10k

Q151

2SC2412K/R/-X

4.7k

R153

Q951

DTA114EKA-X

47/16

0.01

X761

0.1

R711

390

22k

0.0015

C152

R152

R761

2.2k

R762

2.2k

QAX0263-001Z

R709

R720

4.7k

R719

4.7k

R718

4.7k

0.015

C254

SAA6579T-X

100k

10k

Q251

2SC2412K/R/-X

R253

4.7k

IC761

R706

1/50

C253

C153

1/50

22k

0.0015

C252

R252

C25

0.1

CH.L

TAPE.L

C762

560P

TAPE.R

CH.R

C763

2.2/50

R763

2.2k

47K

R715

10k

R716

10k

R717

10k

R712

10k

R724

4.7k

R725

4.7k

R726

4.7k

R116

R216

R117R217

10k10k

22k

C112

1/50

C212

1/50

22k

C911

T-MUTE

4.7k

4.7k

4.7k

4.7k

R721

R722

R723

R727

SI

I/0

SCK

SO

47/16

4.7k

R733

C211

R113

2.2k

22k22k

R112

C114

0.15

C113

1/50

0.0082

C116

C115

C111

0.22/50

C215

1/50

0.22/50

0.0082

C216

C213

C214

0.15

R212

R213

C912

100/16

2.2k

4.7k

R734

TAPEIN

TELMUTE

C117

0.033 0.033

C217

0.0056

0.0056

100/16

C913

IC701

270

R911

270

R912

10

R913

Q965

DTC114EKA-X

0.001

C705

C119

C118

IC911

TEA6320T-X

F/R

R705

C218

C219

C707

1/50

1/50

0.1

10k

1/50

1/50

R975

24K

Q967

2SA1037AK/RS/-X

R740

47k

47K

R979

47k

R750

47K

R748

R746

47K

R738

47k

47K

R747

C708

220/10

R980

1K

MA152WA-X

R974

12K

2SA1037AK/RS/-X

DTC114EKA-X

D980

DTC114EKA-X

Q961

R959

2.2K

Q959

TELMUTE

Q980

1k

1k

R136

R236

27K

R960

Q960

2SA1037AK/RS/-X

12K

R963

MA152WK-X

D981

MA152WA-X

D982

L701

47u

2SA1037AK/RS/-X

Q964

DTC114EKA-X

2SB1322/RS/-T

Q962

R970

47K

MA152WK-X

Q963

R967

R969

2.2K

R966

2.2k

DTC114EKA-X

9V

Q979

C984

220/6.3

D963

MA152WA-X

47k

C982

10/16

C964

220/6.3

C963

Q966

15k

R142

15k

R241

15K

R242

15K

R132D931

MA152WA-X

2.2k

R232

2.2k

R962 R961

6.8K

R977

D977

Q981

DTA114EKA-X

D978

C981

C977

100/6.3 DTA114EKA-X

220/6.3

IC961

10/16

AN80T05LF

DSK10C-T1

C967

10/16

D966

MTZ11BT-77

C965

220/10

39k

R144

39k

39k

R243

R244

180

Q978

DTC114EKA-X

10/16

C966

39k

R143

R235

R135

Q131

2SC2412K/R/-X

Q231

2SC2412K/R/-X

470p

C144

470p

C243

470p

C143

470p

C244

100

100

0.1

C971

0.047

C970

D965

4.7/25

C945

C962

DSK10C-T1

10/16

C932

0.22

J931

C944

0.1

0.1

0.1

C943

R941

C942

C978

4.7/25

C969

C961

D961

47

R978

4.7k

47K

QMFZ047-100-T

L961

QQRO528-002

!

0.047

2200/16

1N5401-TU-15

C980

0.047

C979

10/16

TUNER SIGNAL

TAPE SIGNAL

CD CHANGER SIGNAL

FRONT SIGNAL

REAR SIGNAL

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

C941

0.1

QAM0158-001

2-2

Page 42

LCD & Key control section

3

R633

R631

820

820

D623

VMC0335-001

CP701

QLD0145-001

LCD1

S8S9S10

KS-F363R/KS-F360R

COM2

COM3

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

S31

S32

S33

S34

S35

S36

S37

S38

S39

S40

S41

S42

S43

S44

S45

S46

S52

COM1

S51

S47

S48

S49

S50

R641

R640

R634

R632

C652

C653

C651

R662

R661

1.5k

S602

S615

S608

0.1

4.7/6.3

47k

680p

R607

R603R602

390330

S603

330

S609

S616

R608

R614

390

390

IC651

LC75823W

S604

S610

S617

R604

R609

R615

470

470

470

S605

S618

S611

R605

R610

R616

560

560

560

S606

S619

S612

R611

R617

820

820

S613

S620

820

D603

D602

820

5

820

820

R643

330

820

R642

330

D621

D622

D618

D619

D620

R644

R64

D601

820

820

820

820

820

D614

D615

D616

R646

R647

D611

D613 D612

R648

R649

D609

D610

D624

R650

R651

510

510

D604

D605

10K

R621

QLL0092-001

PL601

10K

10K

R622

R623

QLL0092-001

PL603

D655

MA152WK-X

D654

MA152WK-X

D653

MA152WA-X

150k

D652

MA152WA-X

R601

270

S601

R606

270

S607

R612 R613

270 330

S614

-

Page 43

Head amp & Mecha control section

KS-F363R/KS-F360R

KS-F363R/KS-F360R

IC901

UPC1228HA

CJ901

QGA2002C1-05

CJ902

QGA2002F1-06

CP902

QGB1214K1-06S

C201

C202

820p

C203

100p

0.47/50

R203

C204

R204

330k

47/6.3

C205

100

0.01

R201

15k

C901

100/10

120

R901

R101

R104

330k

15k

C105

C104

C103

100p

0.01

100

R103

47/6.3

CP901

QGB1214K1-06S

C102

C101

0.47/50

820p

TAPE SIGNAL

2-4

Page 44

ed circu

boards

KS-F363R/KS-F360R

5

Print

Main board

J1

J931

T02

L2

C2

C28

B747

L1

B750

1

D2

D1

R302

C302

C303

R304

R307

C304

Q302

R306

R303

R305

S601

S602

R602

S603

Q7

Q10

5

R4

R5

C17

C29

C24

10

R32

C30

15

C301

R34

C254

B757

Q3

Q301

R301

C761

IC761

B704

B756

C305

D623

R601

R640

R641

R642

D618

S607

D620

R605

FSMW1077A

it

C105

FSMW1075B

C203

R204

R201

B774

R135

R136

Q131

C932

R235

Q231

R236

R232

R132

D931

D6

R24

R9

C9

R10

C7

Q5

C6

R12

Q1

R8

D5

R26

R7

Q6

D3

Q13

R25

Q12

C18

R749

R252

C151

B724

C154

R251

C251

R253

Q4

R3

Q951

R153

C1

C764

R761

R762

X761

1

C763

C762

R763

R703

C968

R606

D619

R702

R701

D740

D731

1

2

D732

D733

S03

R643

R603

R604

D621

S604

D622

S605

D604

S606

C111

C211

R14

R30

B87

B74

B708

C21

R27

B742

C20

Q11

R29

B707

C252

R152

R151

B706

D951

Q251

B703

B702

Q151

R712

C25

C765

R704

Q2

B741

R714

C708

R743

B758

C767

D735

C707

D744

C766

B740

R726

R724

R725

14

D736

Front board (Forward side)

PL601

D605

LCD1

R607

S608

S609

R970

C965

CN901

1

2

C966

IC961

B72

C112

B772

B711

C153

C253

C212

C911

C152

R746

B744

R738

B771

C710

B745

R751

C705

R705

B746

R721

D701

R715

R716

R720

R719

15

C712

C711

D603

R608

R717

R718

C768

D738

D961

Q962

Q966

R969

B5

B6

C967

R113

R112

C113

C114

C115