Page 1

SERVICE MANUAL

VCD/CD RECEIVER

4983720036

KD-SV3000

Area Suffix

U --------------------- Other Areas

ATT

FM/AM

CDE

Q

UP

VOL

DOWN

VIDEO CD

P

BC

ENTER

RET

URN

123

OSD

456

AUDI

O

7809

TABLE OF CONTENTS

1 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 Disassembly method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

4 Description of major ICs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.49837

2003/6

Page 2

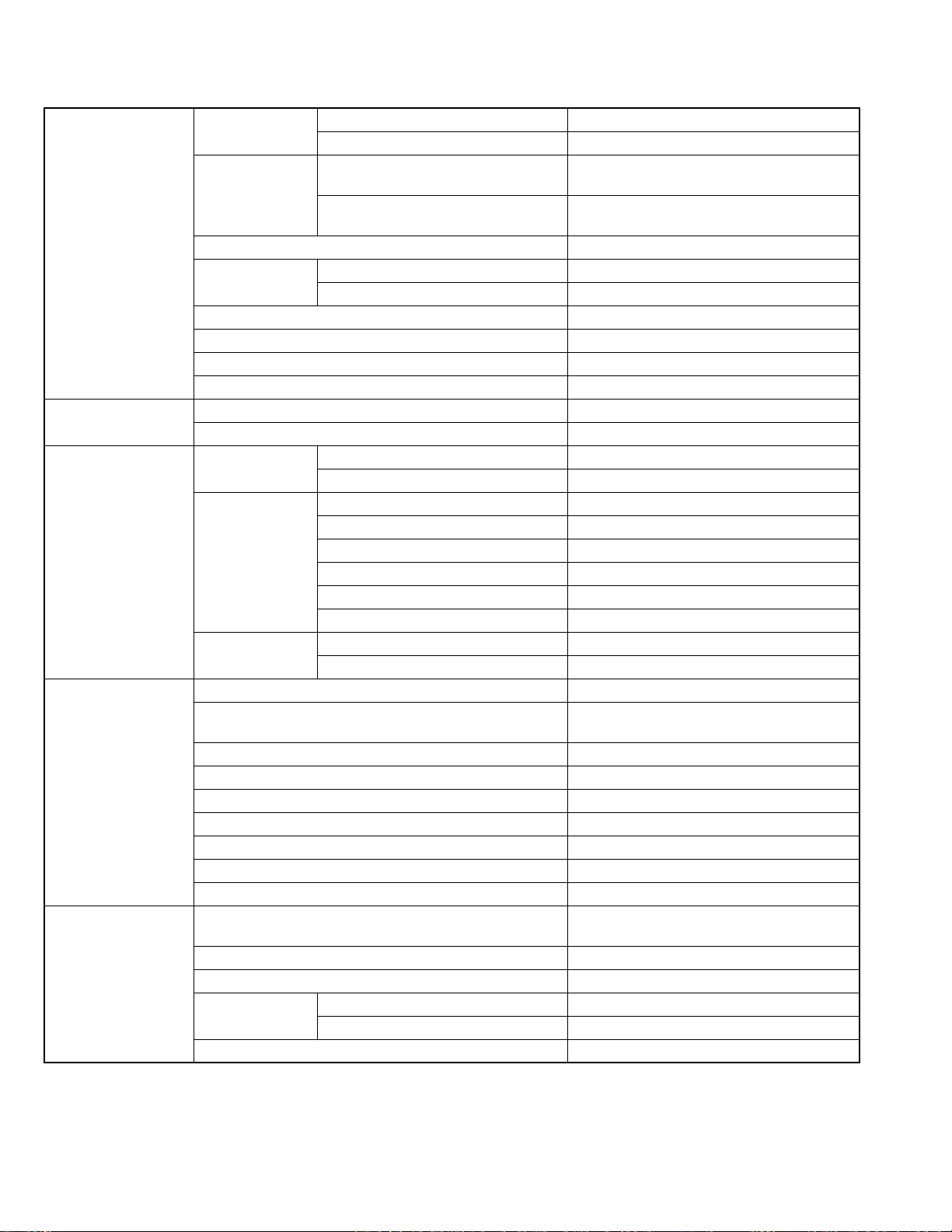

SPECIFICATION

AUDIO AMPLIFIER

SECTION

VIDEO SECTION Color system PAL/NTSC

TUNER SECTION Frequency Range FM 87.5 MHz to 108 MHz

CD PLAYER SECTION Type Compact disc player

GENERAL Power Requirement Operating Voltage: DC 14.4 V (11 V to 16 V al-

Maximum Power

Output

Continuous Power

Output (RMS):

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Rang Bass ±10 dB at 100 Hz

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 2.0 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Video output (composite) 1Vp-p/75Ω

[FM Tuner] Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

[AM Tuner] Sensitivity 20 µV

Signal Detection System Non-contact optical pickup (semiconductor la-

Number of channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 88 dB

Signal-to-Noise Ratio 90 dB

Wow and Flutter Less than measurable limit

MP3 decoding format MPEG1 Audio Layer 3

Max. Bit Rate 320 Kbps

Grounding System Negative ground

Allowable Operating Temperature 0ºC to +40ºC

Dimensions

(W × H × D)

Mass (approx.) 1.3 kg (excluding accessories)

Front 50 W per channel

Rear 50 W per channel

Front 19 W per channel into 4 Ω 40 Hz to 20 000 Hz

at no more than 0.8% total harmonic distortion.

Rear 19 W per channel into 4 Ω 40 Hz to 20 000 Hz

at no more than 0.8% total harmonic distortion.

Treble ±10 dB at 10 kHz

AM 531 kHz to 1 602 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Capture Ratio 1.5 dB

Selectivity 35 dB

ser)

lowance)

Installation Size (approx.) 182 mm × 52 mm × 150 mm

Panel Size (approx.) 188 mm × 58 mm × 11 mm

Design and specifications are subject to change without notice.

1-2 (No.49837)

Page 3

1.1 Safety Precautions

SECTION 1

Precautions

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

(No.49837)1-3

Page 4

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser dio de) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sh eet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handli ng the optical pickup

• In order to ma intain quality during transport and be fore installation, both sides of the laser diode on the re placement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the trav erse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adju st the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed *Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land before the flexible wire is disconnected from the connector on the CD pickup unit.

(If the flexible wire is disconnected without applying solder, the CD pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the flexible wire.

Short-circuit point

(Soldering)

Flexible wire

1-4 (No.49837)

Short-circuit point

Pickup

Pickup

Page 5

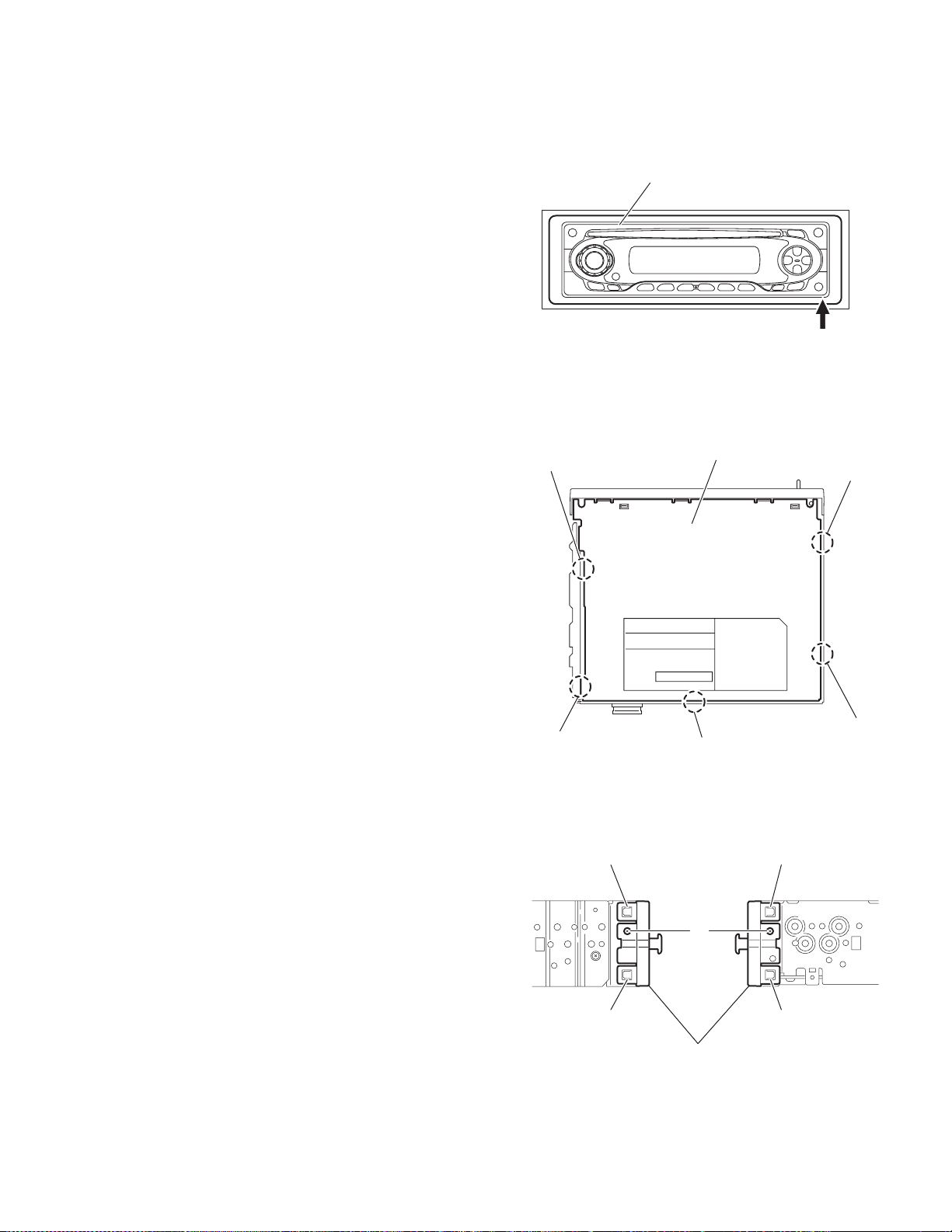

SECTION 2

Disassembly method

2.1 Main body

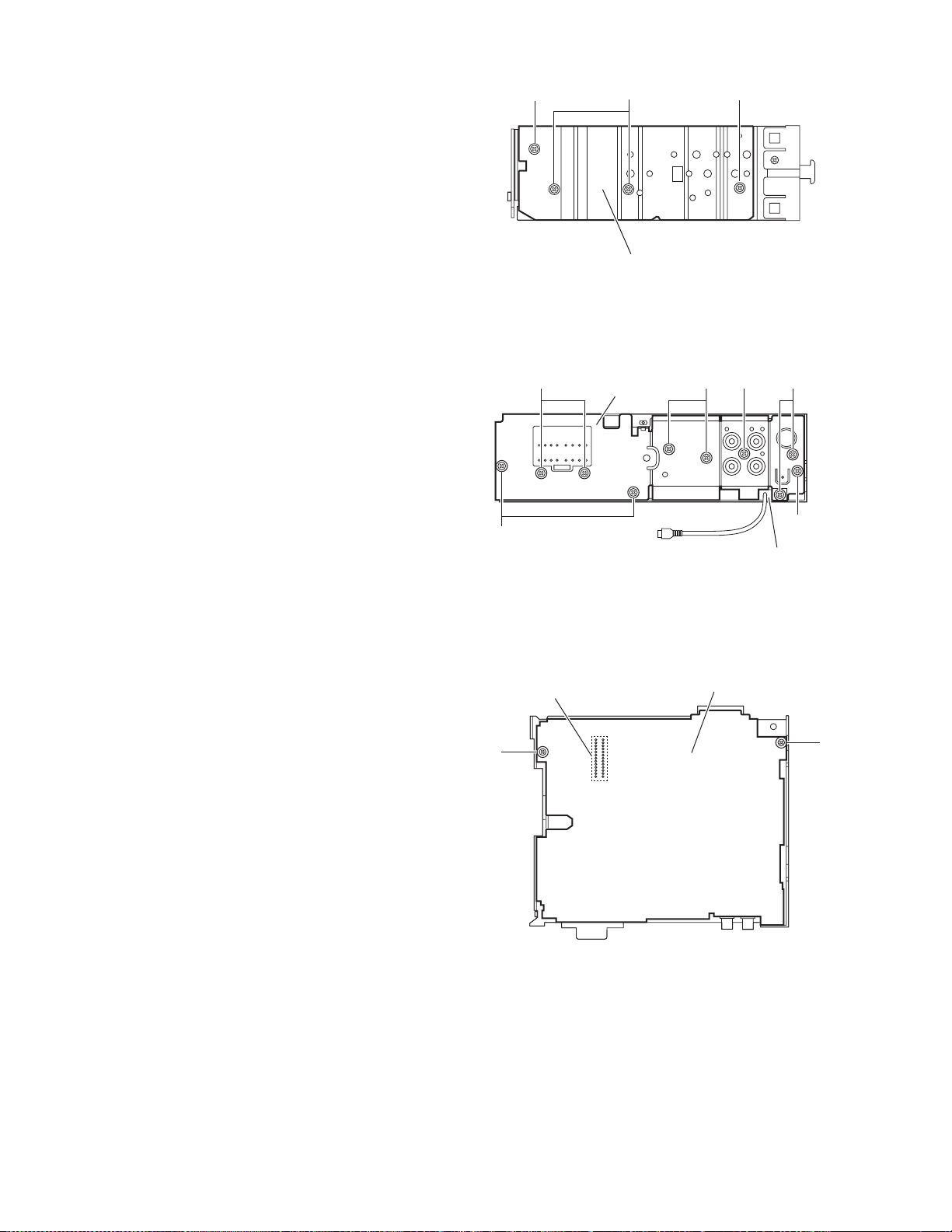

2.1.1 Removing the front panel assembly

(See Fig.1)

(1) Push the rel ease button in the lower right pa rt of the front

panel assembly and remove the front panel assembly.

2.1.2 Removing the bottom cover

(See Fig.2)

(1) Turn the main body up side down.

(2) Insert a screwdriver under the joints to release the two

joints a on th e left side, two joints b on the right side and

joint c on the back side of the main body, then remove the

bottom cover from the main body.

CAUTION:

When releasing the joints using a screwdriver, do not damage

the main board.

Joint a

Front panel assembly

Release button

Fig.1

Bottom cover

Joint b

2.1.3 Removing the front chassis assembly

(See Fig.3)

• Prior to performing the following procedures, remove the front

panel assembly and bottom cover.

(1) Remove the screw A on the both sides of the main body.

(2) Release the two joints d and two joints e on the both sides

of the main body, then remove the front chassis assembly

toward the front.

Joint a

Joint c

Fig.2

Joint d Joint e

A

Joint d

Front chassis

Fig.3

Joint e

Joint b

(No.49837)1-5

Page 6

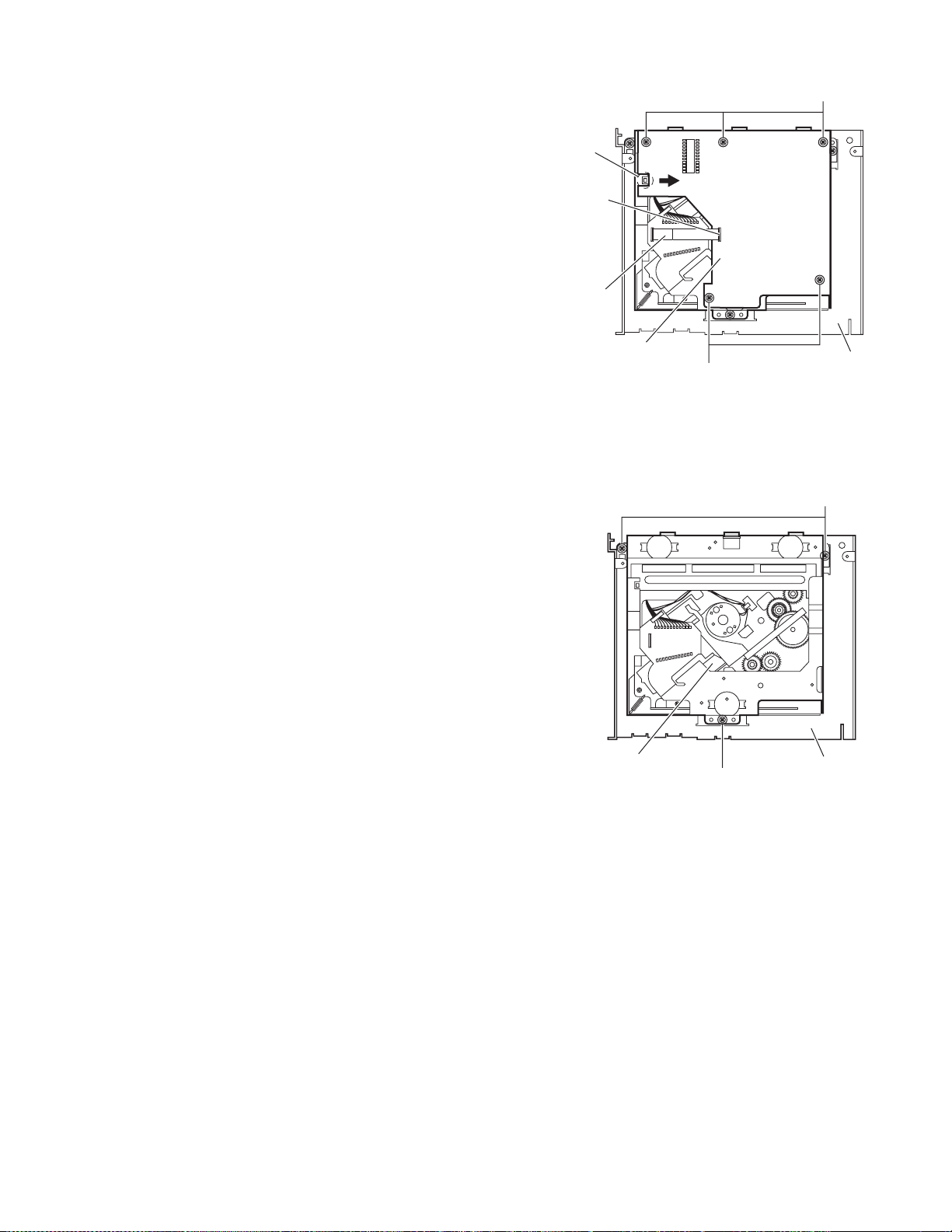

2.1.4 Removing the heat sink

(See Fig.4)

• Prior to performing the follo wing procedure, remove the front

panel assembly as required.

(1) Remove the two screws B and two screws C attaching the

heat sink on the left side of the main body, and remove the

heat sink.

2.1.5 Removing the rear bracket

(See Fig.5)

• Prior to performing the following procedure, remove the bottom

cover.

(1) Remove th e th ree screws D, screw E and six screws F at-

taching the rear bracket on the back side of the main body.

(2) Remove the rear bracket.

Reference:

During reassembly, before fixing the rear bracket onto the

main body, insert the video out cable into the slot.

C

FF

B

Heat sink

Fig.4

Rear bracket

F

C

E

2.1.6 Removing the main board

(See Fig.6)

• Prior to performing the follo wing procedure, remove the front

panel assembly, front chassis assembly, heat sink, bottom

cover and rear bracket.

(1) Remove the two screws G attaching the main board.

(2) Disconnect the connector CN501 and remove the main

board.

G

D

CN501

D

Insert the video out cable

into the slot.

Fig.5

Main board assembly

G

Fig.6

1-6 (No.49837)

Page 7

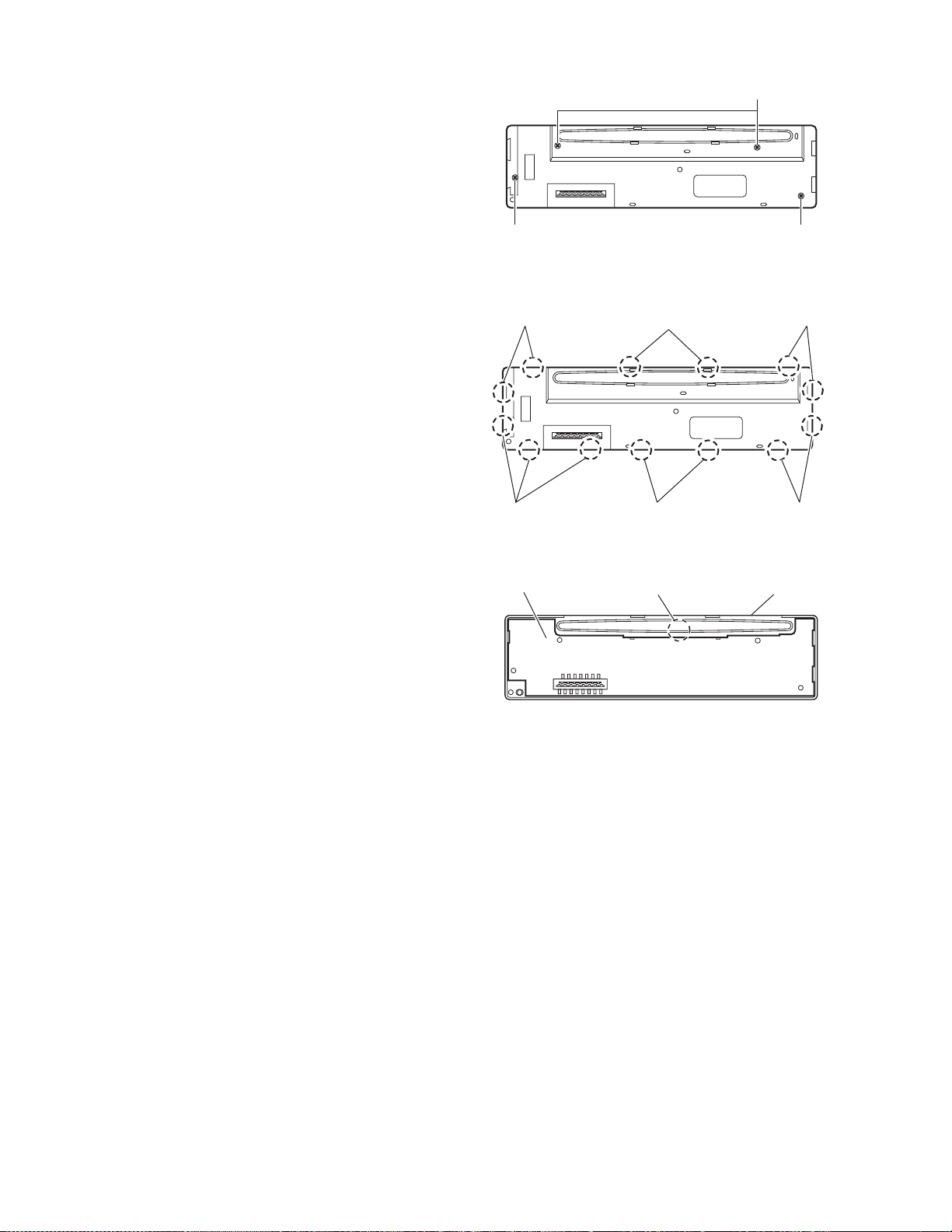

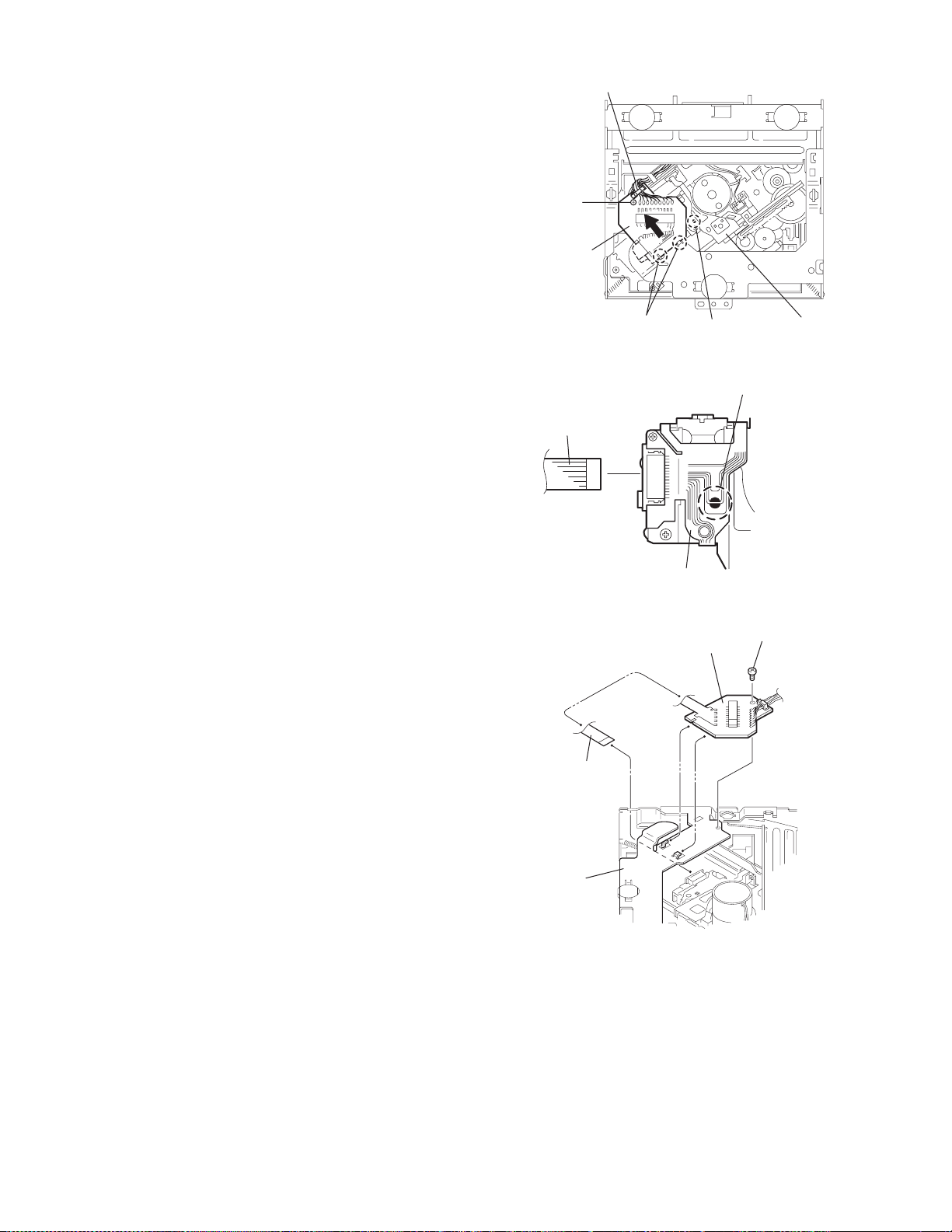

2.1.7 Removing the VCD/CD mechanism board

(See Fig. 7)

• Prior to performing the followin g procedure, remove the front

panel assembly, front chassis assembly, heat sink, bottom

cover, rear bracket and main board.

(1) Remove th e five screws H attaching the VCD/CD mecha-

nism board.

(2) Disconnect the card wire from the connector CN601 on the

VCD/CD mechanism board.

(3) Move the VCD/CD mechanism board in the direction of the

arrow to release it from the joint f.

H

Joint f

CN601

Card wire

2.1.8 Removing the CD mechanism assembly

(See Fig. 8)

• Prior to performing the followin g procedure, remove the front

panel assembly, front chassis assembly, heat sink, bottom

cover, rear bracket, main board and VCD/CD mechanism

board.

(1) Remove the three screws J attaching the top chassis.

(2) Take out the CD mechan ism as sembly.

VCD/CD mechanism board

CD mechanism assembly

Top chassis

H

Fig.7

J

Top chassis

J

Fig.8

(No.49837)1-7

Page 8

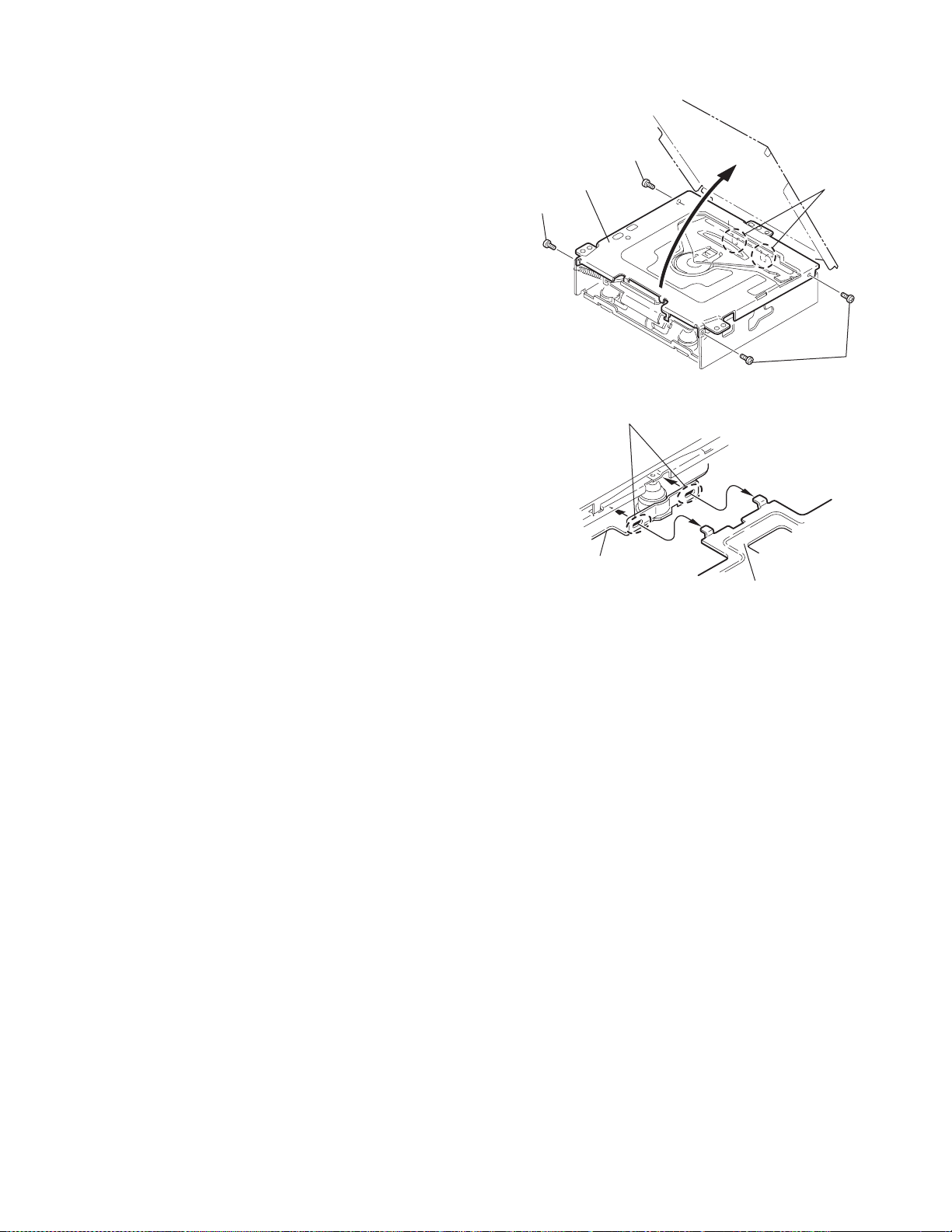

2.1.9 Removing the front board

(See Figs.9 to 11)

• Prior to performing the follo wing procedure, remove the front

panel assembly.

(1) Remove the four screws K on the back side of the front

panel assembly. (See Fig.9.)

(2) Release the thirteen joints g. (See Fig.10.)

(3) Release the joint h and take out the front board. (See

Fig.11.)

K

K

Fig.9

Joints g Joints g

Joints g

Front board

Joints g

Fig.10

Joint h

K

Joints g

Joints g

Front panel assembly

Fig.11

1-8 (No.49837)

Page 9

2.2 CD Mechanism section

A

2.2.1 Removing the top cover

(See Figs.1 and 2)

(1) Remove the four screws A on the both side of the body.

(2) Lift the front side of the top cover an d move the top cover

backward to release the two joints a.

Top cover

Joints a

A

Joints a

A

Fig.1

Fig.2

Top cover

(No.49837)1-9

Page 10

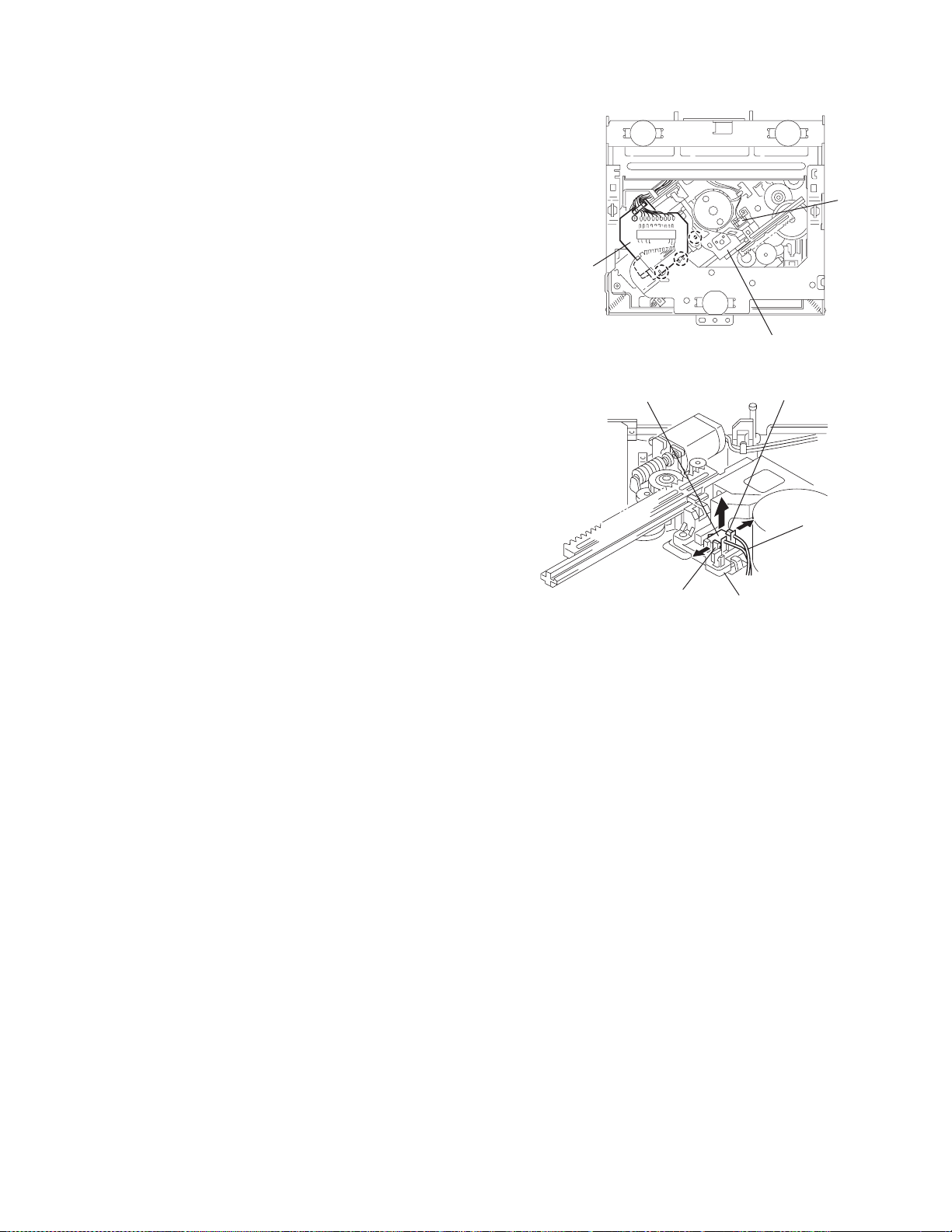

2.2.2 Removing the connector board

(See Figs.3 to 5)

CAUTION:

Before disconnecting the flexible wire from the pickup, solder

the short-circuit point on the pickup. No observance of this instruction may cause damage of the pickup.

(1) Remove the screw B fixing the connector board.

(2) Solder the short-circuit point on the pickup.

(3) Disconnect the flexible wire from the pickup.

(4) Move th e connector board in the direction of the arrow to

release the two joints b.

(5) Unsolder the wires on the connector board if necessary.

CAUTION:

Unsolder the short-circuit point after reassembling.

B

Connector board

Flexible wire

Wires

Joints b

Short-circuit point

Fig.3

Short-circuit point

(Soldering)

Pickup

Flexible wire

Frame

Pickup

Fig.4

B

Connector board

Fig.5

1-10 (No.49837)

Page 11

2.2.3 Removing the DET switch

(See Figs.6 and 7)

(1) Exten d the two tabs c of the feed sw. hol der and pull out

the switch.

(2) Unsolder the DET switch wire if necessary.

DET

switch

Connector

board

Pickup

Fig.6

DET switch

Tab c

Tab c

DET switch wire

Feed sw. holder

Fig.7

(No.49837)1-11

Page 12

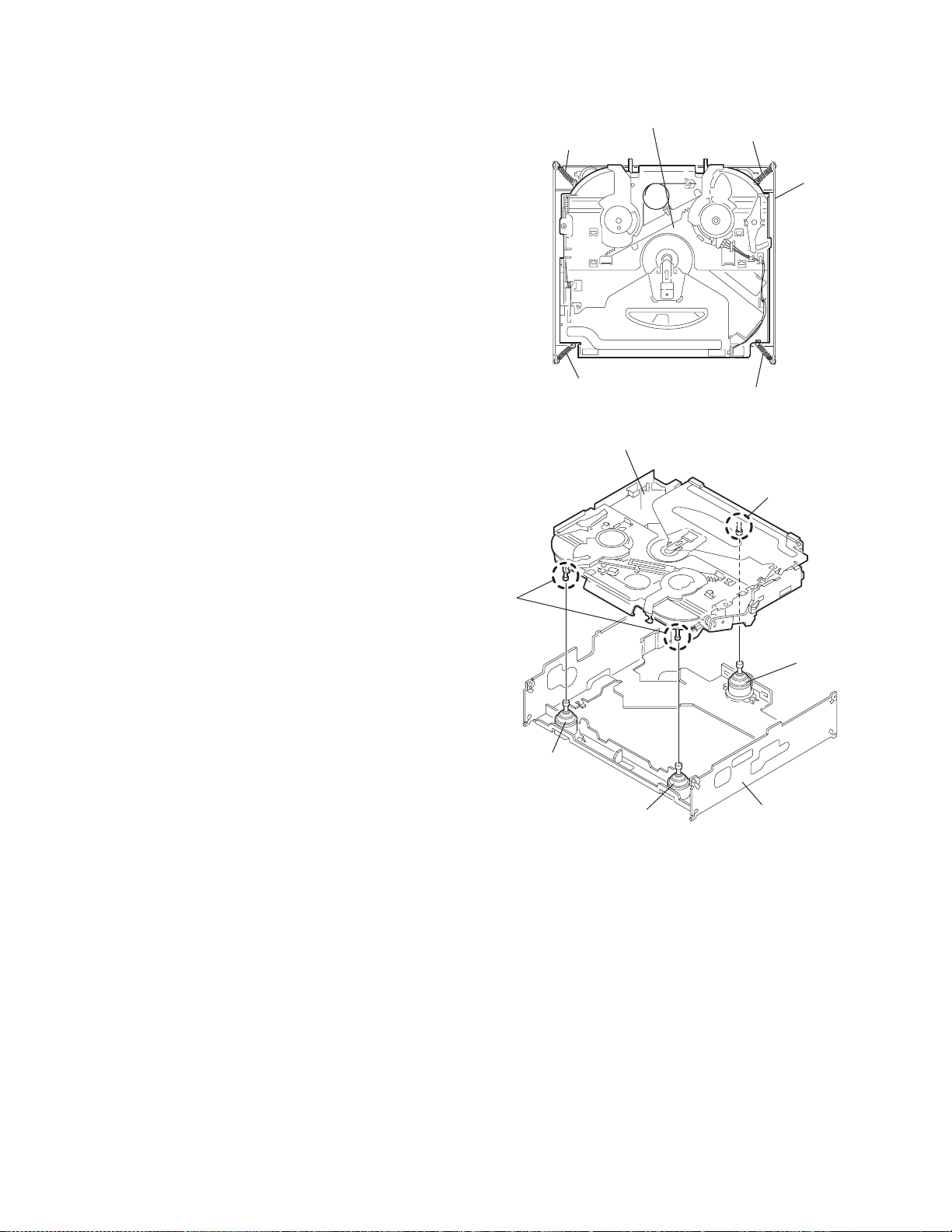

2.2.4 Removing the chassis unit

r

(See Figs.8 and 9)

• Prior to performing the following procedure, remove the top

cover and connector board.

(1) Remove the two suspension springs (L) and (R) attaching

the chassis unit to the frame.

CAUTION:

• The shape of the suspension spring (L) and (R) are different. Handle them with care.

• When reassembling, make sure that the three shafts

on the underside of the chassis unit are inserted to the

dampers certainly.

Suspension spring (R)

Chassis unit

Suspension spring (L)

Frame

Suspension spring (R)

Chassis unit

Shafts

Damper

Damper

Suspension spring (L)

Fig.8

Shaft

Dampe

Frame

Fig.9

1-12 (No.49837)

Page 13

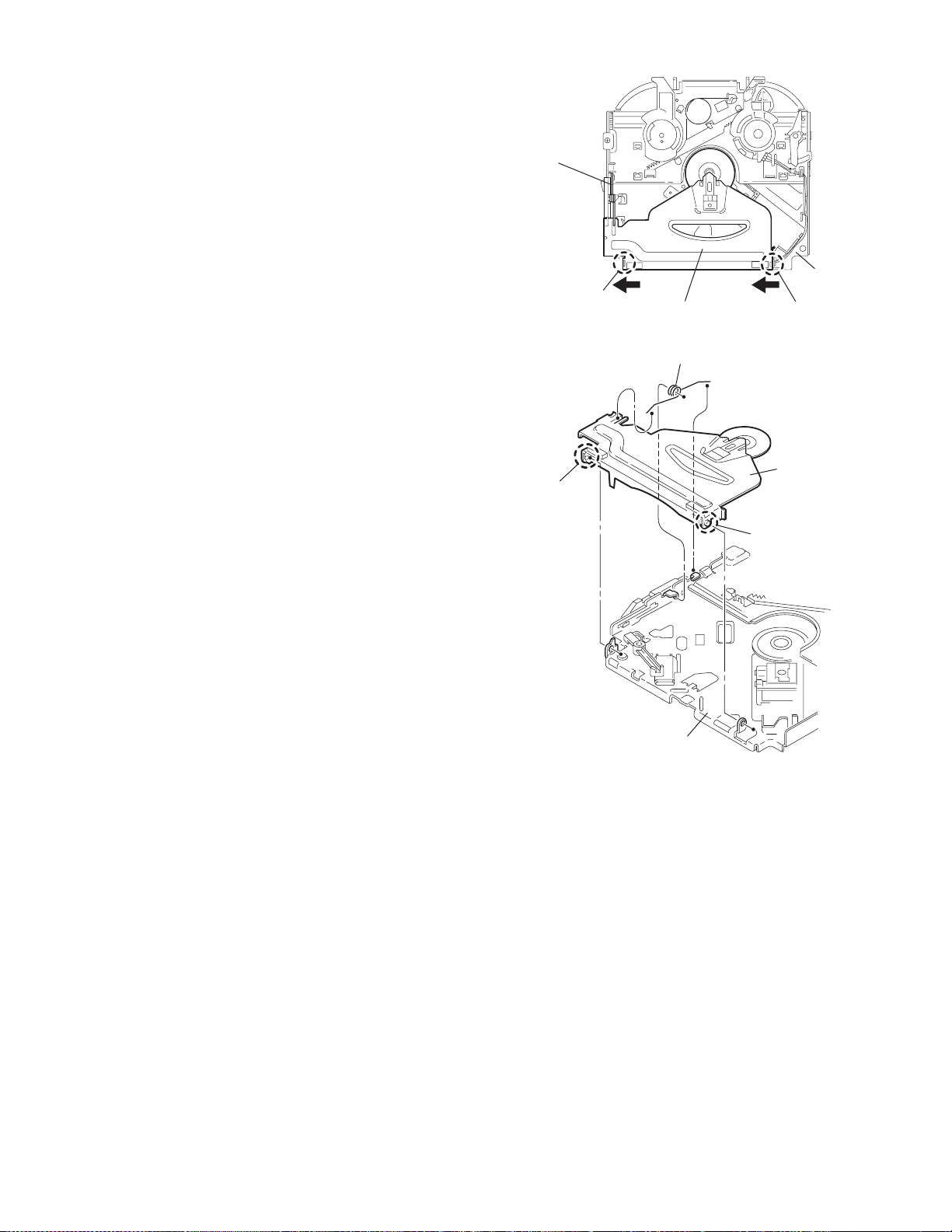

2.2.5 Removing the clamper assembly

(See Figs.10 and 11)

• Prior to performi ng the following procedure, remove the top

cover.

(1) Remove the clamper arm spring.

(2) Move the clamper assembly in the direction of the arrow to

release the two joints d.

Clamper arm

spring

Joint d

Joint d

Clamper assembly

Fig.10

Clamper arm spring

Chassis rivet

assembly

Joint d

Clamper assembly

Chassis rivet assembly

Joint d

Fig.11

(No.49837)1-13

Page 14

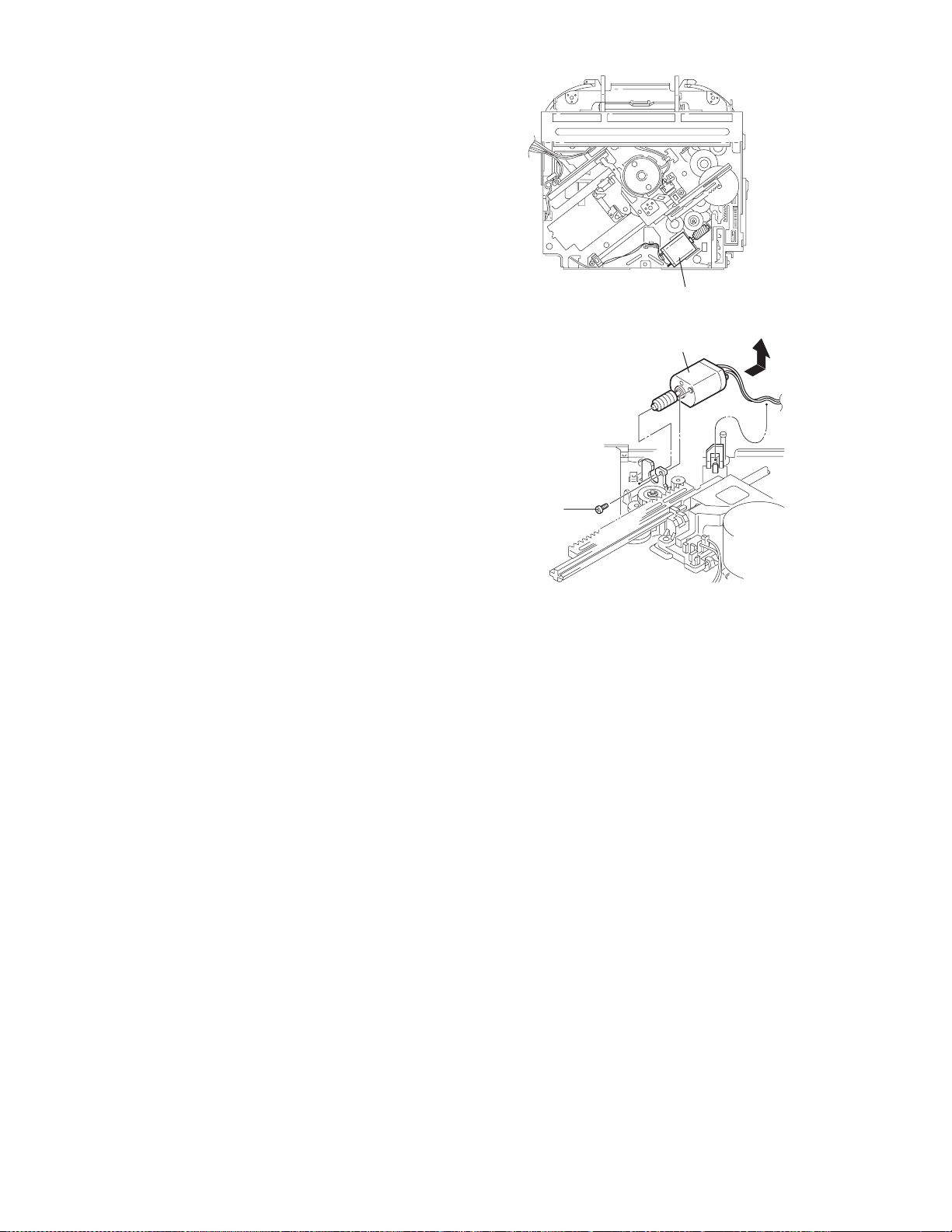

2.2.6 Removing the loading / feed motor assembly

(See Figs.12 and 13)

• Prior to performing the following procedure, remove the top

cover, connector board and chassis unit.

(1) Remove the screw C and move the loading / feed motor as-

sembly in the direction of the arrow to remove it from the

chassis rivet assembly.

(2) Disconnect the wire from the loading / feed motor assembly

if necessary.

CAUTION:

When reassembling, connect the wire from the loadin g /

feed motor assembly to the flame as shown in Fig.12.

Loading / feed motor assembly

Fig.12

Loading / feed motor assembly

C

Fig.13

1-14 (No.49837)

Page 15

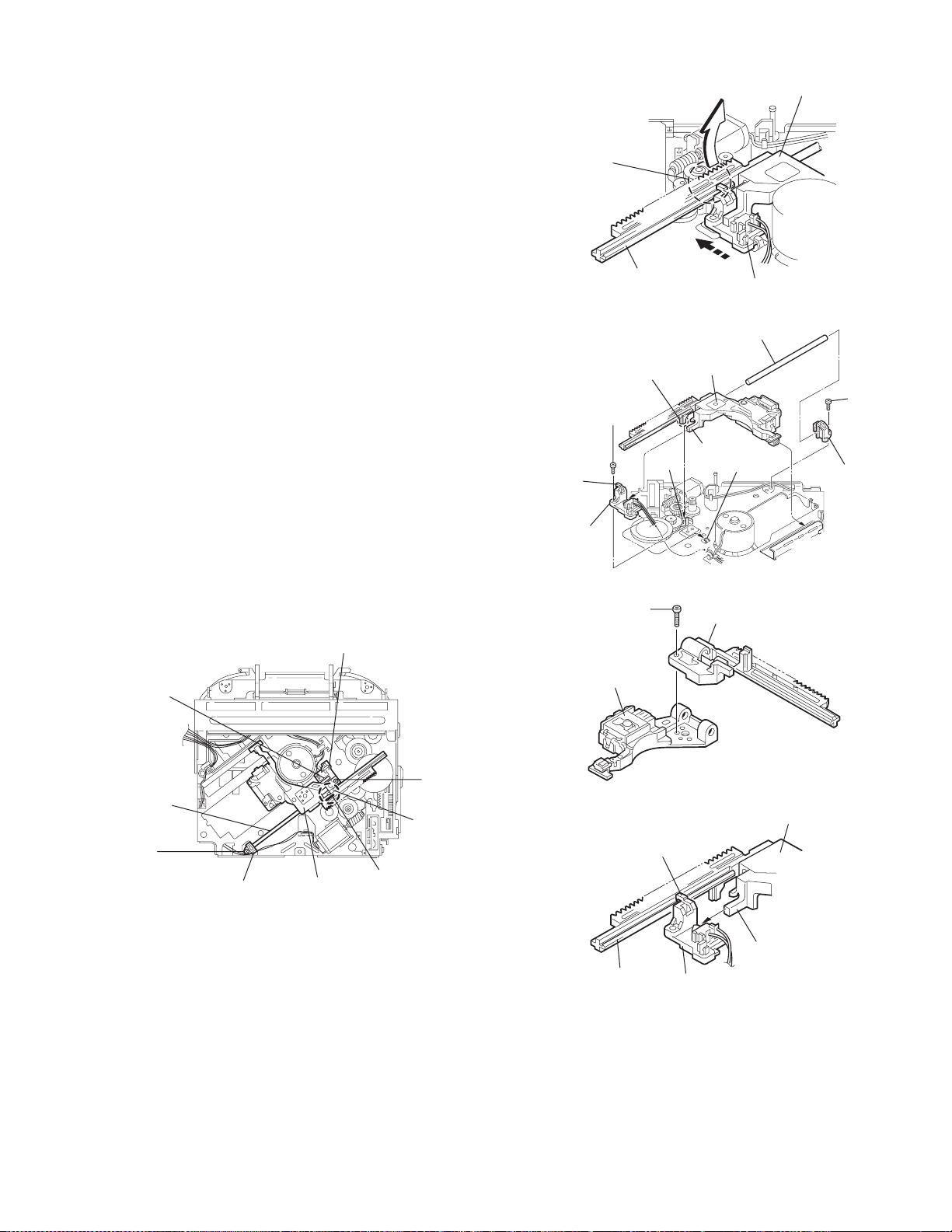

2.2.7 Removing the pickup unit

r

(See Figs.14 to 18)

• Prior to performi ng the following procedure, remove the top

cover, connector board and chassis unit.

(1) Remove the screw D and pull out the pu. shaft holder from

the pu. shaft.

(2) Remove the screw E attaching the feed sw. holder.

(3) Move the part e of the pickup unit upward with the pu. shaft

and the feed sw. holder, then release the joint f of the feed

sw. holder in the direction of the arrow. The joint g of the

pickup unit and the feed rack is released, and the feed sw.

holder comes off.

(4) Remove the pu. shaft from the pickup unit.

(5) Remove the screw F attaching the feed rack to the pickup

unit.

2.2.8 Reattaching the pickup unit

(See Figs.14 to 17)

(1) Reattach the feed rack to the pickup unit using the screw F.

(2) Reattach the feed sw. holder to the feed rack while setting

the joint g to the slot of the feed rack and setting the joint f

of the feed rack to the switch of the feed sw. holder correctly.

(3) As the feed sw. holder is temporarily attached to the pickup

unit, set to the gear of the joint g and to the bending part of

the chassis (joint h) at a time.

CAUTION:

Make sure that the part i on the underside of the feed

rack is certainly inserted to the slot j of the change lock

lever.

(4) Reattach th e feed sw. holder using the screw E.

(5) Reattach th e pu. shaft to the pickup unit. Reatta ch the pu.

shaft holder to the pu. shaft using the screw D.

Part e

Joint g

Feed sw. holder

Feed rack

Part i

E

Slot j

F

Fig.15

Pu. shaft

Pickup unit

Joint f

Joint h

Fig.16

Feed rack

Pickup unit

Feed sw. holder

D

Pu. shaft holde

Joint f

Pu. shaft

D

Pu. shaft holder

Feed sw. holder

Pickup unit

Fig.14

Part e

E

Joint g

Pickup unit

Feed rack

Fig.17

Pickup unit

Joint g

Joint f

Feed sw. holder

Fig.18

(No.49837)1-15

Page 16

2.2.9 Removing the trigger arm

r

(See Figs.19 and 20)

• Prior to performing the following procedure, remove the top

cover, connector board and clamper unit.

(1) Turn the trigger arm in the direction of the arrow to release

the joint k and pull out upward.

CAUTION:

When reassembling, insert the part m and n of the trigger

arm into the part p and q at the slot of the chassis rivet

assembly respectively and join the joint k at a time.

Chassis rivet assembly

Trigger arm

Chassis

rivet

assembly

Joint k

Trigger arm

Fig.19

Part p

Part q

Part m

Part n

2.2.10 Removing the top plate assembly

(See Fig.21)

• Prior to performing the following procedure, remove the top

cover, connector board, chassis unit, and clamper assembly.

(1) Remove the screw H.

(2) Move the top plate assembly in the direction of the arrow to

release the two joints r.

(3) Unsolder the wire marked s if necessary.

H

Fig.20

Top plate assembly

Joints

s

Fig.21

1-16 (No.49837)

Page 17

2.2.11 Removing the mode sw. / select lock arm

(See Figs.22 and 23)

• Prior to performi ng the following procedure, remove the top

plate assembly.

(1) Bring up the mode sw. to release from the link plate (joint t)

and turn in the direction of the arrow to release the joint u.

(2) Unsolder the wire of the mode sw. marked s if necessary.

(3) Turn the select lock arm in the dire cti on of the arrow to re-

lease the two joints v.

(4) The select lock arm spring comes off the select lock arm at

the same time.

Link plate

Joint u

Fig.22

Joint t

Mode sw.

Select lock arm

s

Top plate

Select lock arm

Link plate

Select lock arm

Fig.23

Top plate

Hook w

Select lock

arm spring

Joints v

(No.49837)1-17

Page 18

2.2.12 Reassembling the mode sw. / select lock arm

(See Figs.24 to 26)

REFERENCE:

Reverse the above removing procedure.

(1) Reattach the select lock arm spring to the top plate and set

the shorter end of the select lock arm spring to the hook w

on the top plate.

(2) Set the other longer end of the select lock arm spring to the

boss x on the underside of the select lock arm, and join the

select lock arm to the slots (joint v). Turn the select lock

arm as shown in the figure.

(3) Reattach the mode sw. while setting the part t to th e first

peak of the link plate gear, and join the joint u.

CAUTION:

When reattaching the mode sw., check if the points y and

z are correctly fitted and if each part operates properly.

Select lock arm spring

Hook w

Joint v

Joint v

Select lock arm

Boss x

Fig.24

Joint t

Point y

Link plate

Point z

Link plate

Fig.25

Mode sw.

Select

lock arm

Joint t

Joint u

Fig.26

1-18 (No.49837)

Page 19

2.2.13 Removing the select arm R / link plate

(See Figs.27 and 28)

• Prior to performi ng the following procedure, remove the top

plate assembly.

(1) Bri ng up the select arm R to release from the link plate

(joint a') and turn as shown in the figure to release the two

joints b' and joint c'.

(2) Move the link plate in th e direction of the arrow to release

the joint d'. Remove the link plate spring at the same time.

REFERENCE:

Before removing the link plate, remove the mode sw..

Select arm R

Joint b'

Link plate spring

Joint c'

Joint a'

Link plate

Joint b'

Fig.27

Joint r

2.2.14 Reattaching the Select arm R / link plate

(See Figs.29 and 30)

REFERENCE:

Reverse the above removing procedure.

(1) Reattach th e link plate spring.

(2) Reattach the li nk plate to the link pla te spri ng while j oini ng

them at joint d'.

(3) Reattach the joint a' of the select arm R to the first peak of

the link plate while joining the two joints b' with the slots.

Then turn the select arm R as shown in the figure. The top

plate is joined to the joint c'.

CAUTION:

When reattaching the sele ct arm R, check if the points e'

and f' are correctly fitted and if each part operates properly.

Top plate

Select arm R

Joint b'

Joint d'

Link plate

Fig.28

Link plate spring

Joint c'

Joint d'

Joint b'

Joint a'

Fig.29

Joint a'

Point e'

Link plate

Point f'

Fig.30

(No.49837)1-19

Page 20

2.2.15 Removing the loading roller assembly

(See Figs.31 to 33)

• Prior to performing the following procedure, remove the

clamper assembly and top plate assembly.

(1) Push inw ard the loading roller assembly on the gear side

and detach it upward from the slot of the joint g' of the lock

arm rivet assembly.

(2) Detach the loading roller assembly from the slot of the joint

h' of the lock arm rivet assembly.

The roller guide comes off the gear section of the loading

roller assembly.

Remove the roller guide and the HL washer from the shaft

of the loading roller assembly.

(3) Remove the screw J attaching the lock arm rivet assembly.

(4) Push th e shaft at the joint i' of the lock arm rivet assembly

inward to release the lock arm rivet assembly from the slot

of the L side plate.

(5) Extend the lock arm rivet assembl y outward and release

the joint j' from the boss of the chassis rivet assembly. The

roller guide springs on both sides come off at the same

time.

CAUTION:

When reassembling, reattach the left and right roller

guide springs to the lock arm rivet assembly before reattaching the lock arm rivet assembly to the chassis rivet

assembly. Make sure to fit the part k' of the roller guide

spring inside of the roller guide. (Refer to Fig.34.)

Roller guide

spring

Part k'

Chassis rivet assembly

Loading roller assembly

Loading roller assembly

Roller guide

spring

Fig.32

Boss

Roller guide

Joint h'

Roller guide spring

Loading roller assembly

HL washer

Loading roller assembly

Joint g'

Lock arm rivet assembly

Fig.31

Roller guide

Roller guide spring

Roller guide spring

J

Lock arm rivet assembly

Lock arm rivet assembly

L side plate

Roller guide spring

Joint i'

Joint j'

Fig.33

Roller guide

HL washer

Roller shaft assembly

Loading roller

Roller guide spring

Fig.34

1-20 (No.49837)

Page 21

2.2.16 Removing the loading gear 5, 6 and 7

(See Figs.35 and 36)

• Prior to performi ng the following procedure, remove the top

cover, chassis unit, pickup unit and top plate assembly.

(1) Remove the screw K atta ching the loading gear bracket.

The loading gear 6 and 7 come off the loading gear bracket.

(2) Pull out the loading gear 5.

K

Loading gear 5

Loading gear bracket

K

Loading gear 6

Loading gear 5

Loading gear 3

Fig.35

Loading gear bracket

Loading gear 6

Loading gear 7

Fig.36

(No.49837)1-21

Page 22

2.2.17 Removing the gears

(See Figs.37 to 40)

• Prior to performing the following procedure, remove the top

cover, chassis unit, top plate assembly and pickup unit.

• Pull out the loading gear 3. (See Fig.35.)

(1) Pull out the feed gear.

(2) Move the load ing pl ate assembly i n the dire ctio n of the ar-

row to release the L side plate from the two slots m' of the

chassis rivet assembly. (See Fig.37.)

(3) Detach the loading pla te assembly upward from the chas-

sis rivet assembly while releasing the joint n'. Remove the

slide hook and loading plate spring from the loading plate

assembly.

(4) Pull out the loading gear 2 and remove the change lock le-

ver.

(5) Remov e the E ring and wa sher atta ching th e change gear

2.

(6) The change gear 2, change gear spring and adjusting

washer come off.

(7) Remov e the loading gear 1.

(8) Move the change plate rivet assembly in the direction of the

arrow to release from the three shafts of the chassis rivet

assembly upward. (See Fig.38.)

(9) Detach the loading gear plate rivet assembly from the shaft

of the chassis rivet assembly upward while releasing the

joint p'. (See Figs.38 and 40.)

(10) Pull out the loading gear 4.

Change plate

rivet assembly

Shafts

E ring

Loading plate assembly

Loading plate spring

Joint p'

Loading gear 4

Loading gear plate

rivet assembly

Shaft

Loading gear 2

Loading gear 1

Chassis rivet assembly

Change gear 2

Fig.38

Joint n'

Slide hook

Feed gear

Fig.37

Slot m'

L side plate

Loading plate assembly

Joint n'

Slot m'

Chassis rivet assembly

Chassis rivet assembly

E ring

Washer

Change gear 2

Change gear

spring

Adjusting

washer

Change plate

rivet assembly

L side plate

Slot m'

Slot m'

Fig.39

Loading gear 1

Loading gear 2

Change lock lever

Loading gear 4

1-22 (No.49837)

Chassis rivet assembly

Loading gear plate rivet

assembly

Fig.40

Page 23

2.2.18 Removing the turn table / spindle motor

(See Figs.41 and 42)

• Prior to performi ng the following procedure, remove the top

cover, connector board, chassis unit and clamper assembly.

(1) Remove the two screws L a ttaching the spindle motor as-

sembly through the slot of the turn table on top of the body.

(2) Unsolder the wire on the connector board if necessary.

Turn table

L

Fig.41

L

Turn table

Spindle motor

Fig.42

(No.49837)1-23

Page 24

SECTION 3

Adjustment

3.1 Adjustment method Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) AM Standard sign al generator

(3) FM Standard signal generator

(4) Stereo modulator

(5) Electric voltmeter

(6) Digital tester

(7) Tracking offset meter

(8) Test Disc JVC :CTS-100 0

(9) Extension ca ble for check

EXTSH002-22P × 1

Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

Standard measuring conditions

Power supply voltage DC14.4V(11 to 16V)

Load impedance 20KΩ(2 Speakers connection)

Output Level Line out 2.0V (Vol. MAX)

Dummy load

Exclusive dummy load should be used for AM,and FM. For FM

dummy load,there is a loss of 6dB between SSG output and

antenna input.The loss of 6dB need not be considered since

direct reading of figures are applied in this working standard.

1-24 (No.49837)

Extension cable

EXTSH002-22P

Heat sink

(Attach the heat sink

using the two screws.)

Rear bracket

(Attach the rear bracket

using the screw.)

CN501

Page 25

3.2 Service mode

Operation method

Insert the test disc

"TOC read" starts

Press the [CD], [SEL]

and [POWER] keys

simultaneously for 2 seconds.

"VERSION" is

indicated on the LCD.

Press the [SEL] key

"MAIN 400" is

indicated on the LCD.

Press the [F.SKIP] key

"SUB 225" is

indicated on the LCD.

MAIN 400

SUB 225

(Note)

If "SUB 000" and "VCD 000"

are indicated on the LCD,

these operations are required.

Main micon software version

Space

Sub micon software version

Press the [F.SKIP] key

"SUB 144" is

indicated on the LCD.

Press the [F.SKIP] key

Sequence of LCD diaplay

Press the [F.SKIP] . . . . . . . . MAIN SUB VCD/CD MAIN

Press the [B.SKIP] . . . . . . . . MAIN VCD/CD SUB MAIN

Cancellation of service mode

No operation for ten seconds Return to normal display

Press the key except for [F.SKIP] or [B.SKIP] key Return to normal display

VCD 144

VCD/CD control IC software version

(No.49837)1-25

Page 26

3.3 Maintenance of laser pickup

(1) Cleani ng the pick up lens

Before you replace the pick up, please try to clean the lens

with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

• The level of RF output (EFM output: amplitude of eye

pattern) will be low.

3.4 Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Is RF output

1.3 0.4Vp-p?

NO

Replace it.

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board

which is attached to the pickup is used to adjust the laser

power.Since this adjustment should be performed to match

the characteristics of the whole optical block, do not touch

the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced. If the semi-fixed resistor is adjusted while the

pickup is functioning normally, the laser pickup may be

damaged due to excessive current.

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at RF test point.

Finish.

1-26 (No.49837)

Page 27

SECTION 4

A

A

A

A

A

A

A

A

O

4

3

1

0

P

A

Description of major ICs

4.1 AT27C020-70JCU5 (IC102) : 2M-bit (256K x 8) OTP EPROM

• Pin Layout

• Block Diagram

A12

432

5

7

6

6

7

5

8

4

9

3

10

2

11

1

12

0

13

0

14151617181920

O1

VCCPGMA17

A15

A16

VP

1

323130

O3O4O5

O2

ND

VCC

GND

VPP

CE

PGM

A0 - A17

DDRESS

INPUTS

OE

29

28

27

26

25

24

23

22

21

O6

A1

A1

A8

A9

A1

OE

A1

CE

O7

OE,CE AND

PROGRAM LOGIC

Y DECODER

X DECODER

DATA OUTPUTS

O0 - O7

OUTPUT

BUFFERS

Y-GATING

CELL MATRIX

IDENTIFICATION

• Pin function

Pin No. Symbol Function

1 VPP Power supply

2 A16 Address input

3 A15 Address input

4 A12 Address input

5 to 12 A7 to A0 Address inputs

13 to 15 O0 to O2 Outputs

16 O3 to O7 Outputs

17 to 21 GND Ground

22 CE Chip enable

23 A10 Address input

24 OE Output enable

25 A11 Address input

26 A9 Address input

27 A8 Address input

28 A13 Address input

29 A14 Address input

30 A17 Address input

31 PGM Program strobe

32 VCC Power supply

(No.49837)1-27

Page 28

4.2 ES3880FM (IC101) : Video CD processor

• Pin Layout

75 ~ 51

76

50

• Block Diagram

100

~

1 ~ 25

Serial Audio

TDM

Interface

Interface

~

26

Transport

Parser

32-Bit

RISC Processor

8KB cache

On-Screan

Display

Gateway and

DMA Controller

CRT

Controller

Huffman

Decoder

DRAM

Interface

Video

Processor

• Pin function

Pin No. Symbol I/O Descriptions

1 VDD I 2.85V power supply.

2 RAS# O Memory row address strobe (active-low).

3 DWE# O Memory write enable (active-low).

4~12 MA[8:0] O Multiplexed memory row and column address.

13~28 DBUS[0:15] I/O Memory data.

29 RESET# I System reset (active-low)

30 VSS I Ground.

31 VDD I 2.85V power supply.

32~39 YUV[0:7] O B-bit YUV output.

40 VSYNC I/O Vertical sync; programmable for rising or falling edge.

41 HSYNC I/O Horizontal sync; programmable for rising or falling edge.

42 CPUCLK I RISC and system clock input.

43 PCLK2X I/O Doubled pixel clock I/O for screen video interface.

44 PCLK I/O 27-MHz pixel clock qualifier I/O for screen video interface.

45~49 AUX[0:7] I/O Auxillary control (AUX0 and AUX1 are open collectors).

50 VSS I Ground.

51 VDD I 2.85V power supply.

52~54 AUX[0:7] I/O Auxillary control (AUX0 and AUX1 are open collectors).

55~62 LD[0:7] I/O RISC interface data.

1-28 (No.49837)

Page 29

Pin No. Symbol I/O Descriptions

63 LWR# O RISC interface write enable (active-low).

64 LOE# O RISC interface output enable (active-low).

65~67 LCS[3,1,0]# O RISC interface chip select (active-low).

68~79 LA[0:17] O RISC interface address.

80 VSS I Ground.

81 VPP I 5.0V power supply.

82~87 LA[0:17] O RISC interface address.

88 ACLK I/O Master clock for external audio DAC (8.192MHz, 11.2896MHz,

12.288MHz, 16.9344MHz, and 18.432MHz).

89 AOUT O Audio interface serial data.

SEL_PLL0 I Used with SEL_PLL1 pin 91 to select phase-lock loop (PLL) clock

frequency of CPUCLK pin 42:

00 = bypass PLL.

01 = 54MHz PLL.

10 = 67.5MHz PLL.

11 = 81MHz PLL.

90 ATCLK I/O Audio transmit bit clock.

91 ATFS O Audio interface transmit frame sync.

SEL_PLL1 I Used with SEL_PLL0 pin 89 to select phase-lock loop (PLL) clock

frequency of CPUCLK pin 42,

92 MA9 O Multiplexed memory row and column address.

DOE# O Memory output enable (active-low).

93 AIN I Audio interface serial data.

94 ARFS I Audio receive bit clock.

95 ARCLK I Audio interface receive frame sync.

96 TDMCLK I TDM serial clock.

97 TDMDR I TDM serial data receive.

98 TDMFS I TDM frame sync.

99 CAS# O Memory colomn address strobe (active-low).

100 VSS I Ground.

4.3 TC7 W08FU-X (IC107) : Nand gate

• Pin layout & Block diagram • Truth table

1A

1

8

Vcc

ABY

LLL

1B

2Y

GND

2

3

4

7

1Y

6

2B

5

2A

LHL

HLL

HHH

(No.49837)1-29

Page 30

4.4 ES3883F(IC104):VCD Companion chip

• Pin function

80

81

~

~

51

50

~

100

31

1

• Blockdiagram

30~

CD-ROM Controller

CD ROM

Kit

Remote

Control

Interrupt

Control

Audio DAC

Vista ES3880

(Video CD)

DSC

NTSC/PAL Video

PLL

ROM

Mic 1

DRAM

• Pin function

Pin No. Symbol I/O Function

1,25:26,31,72,75,77,91,100 VSS I Ground.

5,16,32,66,73,78,90 VCC I Voltage supply 5v.

6 DSC_C I Clock programming to access internal registers.

7 AUX0 I/O Servo Foward or Control Pin.

9 AUX1 I/O Servo Reverse or Control Pin.

11 AUX2 I/O Servo LDON or Control Pin.

70 AUX3 I/O Servo CW/Limit or Control Pin.

69 AUX4 I/O Servo CCW/Close or Control Pin.

68 AUX5 I/O Servo Data or Control Pin.

67 AUX6 I/O Servo XLAT or Control Pin/VFD_DO.

14 AUX7 I/O Servo BRKM/Sense or Control Pin/VFD_DI.

18 AUX8 I/O Servo Mute/Open or Control Pin/VFD_CLK.

20 AUX9 I/O Servo SQS0 or Control Pin.

34 AUX10 I/O Servo SQCK or Control Pin.

35 AUX11 I/O 3880 IRQ or Interrupt Output or Control Pin.

36 AUX12 I/O CD C2PO or Interrupt input or Control Pin.

38 AUX13 I/O Serial Interrupt/CD-Mute or Control Pin.

39 AUX14 I/O Servo SCOR(S0S1) or Interrupt Input or Control Pin.

40 AUX15 I/O Interrupt Input or Control Pin.

81,83,85,93,95,97,99,8 DSC_D[7:0] I/O Data for programming to access Internal registers.

10 DSC_S I Strobe for programming to access Internal registers.

12 DCLK O Dual-purpose pin DCLK is the MPEG decoder clock.

EXT_CLK I EXT_CLK is the external clock EXT_CLK is an input during bypass PLL mode.

13 RESET_B I Video reset(active-low).

15 MUTE O Audio mute.

17 MCLK I Audio master clock.

19 TWS I Dual-purpose pin TWS is the transmit audio frame sync.

SPLL_OUT O SPL L_OUT is the select PLL output.

21 TSD I Transmit audio data input.

22 TBCK I Transmit aud io bit clock.

Mic 2

Echo/Surround/Vocal Assist

Preamp

Volume Control

Preamp

Volume Control

VFD

Driver

Remote

receiver

Speakers

Television

VFD

Panel

1-30 (No.49837)

Page 31

Pin No. Symbol I/O Function

23 RWS O Dual-purpose pin RWS is the audio frame sync.

SEL_PLL1 I Pins SEL_PLL[1.0] select the PLL clock frequency for the DCLK output.

SEL_PLL1 SEL_PLL0 DCLK

0 0 Bypass PLL(input mode)

0 0 27 MHz(output mode)

1 0 32.4 MHz(output mode)

1 1 40.5 MHz(output mode)

24 RSTOUT_B O Reset output(active-low).

2:4,27:30,76 NC No connect.Do not connect to these pins.

33 RSD O Dual-purpose pin. RSD is the receive audio data input.

SEL_PLL0 I SEL_PLL0 along with SEL_PLL1 select the PLL clock frequency for the

DCLK output.See the table for pin number 23.

37 RBCK O Dual-purpose pin.RBCK is the receive audio bit clock.

SER_IN I SER_IN is the serial input DSC mode.

0-Parallel DSC mode.

1-Serial DSC mode.

41,51 VSSAA I Audio Analog Ground.

42 VCM I ADC Common Mode Reference(CMR) buffer output.CMR is approximately

2.25V.Bypass to analog ground with 47µF electrolytic in parallel with 0.1µF.

43 VREFP I DAC and ADC maximum reference.

Bypass to VCMR with 10µF in parallel with 0.1µF.

44 VCCAA I Analog VCC, 5V.

45:46 AOR+,AOR- O Right channel output.

47:48 AOL-,AOL+ O Left channel input.

49 MIC1 I Microph one input 1.

50 MIC2 I Microphone 2.

52 VREF I Internal resistor divider generates Common Mode Reference(CMR) voltage.

Bypass to analog ground with 0.1µF.

53 VREFM I DAC and ADC minimum reference.

Bypass to VCMR with 10µF in parallel with 0.1µF.

54 RSET I Full scale DAC current adjustment.

55 COMP I Compensation pin.

56:57,62:63 VSSAV I Video Analog Ground

58 CDAC O Modulates chrominance output.

59,60 VCCAV I Video VCC, 5V

61 YDAC O Y Iuminance data bus for screen video port.

64 VDAC O Composite video output.

65 ACAP I Audio CAP.

71 XOUT O Crystal output.

74 XIN I 27 MHz crystal input.

79 PCLK I/O 13.5 MHz pixel clock.

80 2XPCLK I/O 27 MHz(2 times pixel clock).

82 HSYN_B O Horizontal sync(active-low).

84 VSYN_B O Vertical sunc(active-low).

86:89,92,94,96,98 YUV[7:0] I YUV data bus for screen video port.

(No.49837)1-31

Page 32

4.5 AN22000A (IC601) : RF & SERVO AMP

• Terminal layout

ACBDPDF

323130292827262524232221201918

123456789

LD

PD

VCC

RFN

PDE

RFIN

RFOUT

TBAL

FBAL

GCTRL

FEOUT

10111213141516

ARF

CEA

CAGC

3TOUT

FEN

TEN

BDO

CBDO

TEOUT

TEBPF

OFTR

COFTR

• Block diagram

32

31

30

29

27

28

RFOUT

RF_EQ

AMP

AMP

AMP

AMP17GCA BCA

+

-

624754 8

RFIN

AGC

NRFDET

GCA BCA

GCA BCA

GCA BCA

11 12

BDO

SUBT

SUBT

VDET

VREF

17

GND

RFDET

13 14

OFTR

3TENV

VDET

• Pin function

Pin

Symbol I/O Function

No.

1 PD I APC Amp. input terminal

2 LD O APC Amp. output terminal

3 VCC - Power supply terminal

4 RFN I RF adder Amp. inverting input terminal

5 RFOUT O RF adder Amp. output terminal

6 RFIN I AGC input terminal

7 CAGC I Input terminal for AGC loop filter capacitor

8 ARF O AGC output terminal

9 CEA I Capacitor connecting terminal

for HPF-Amp.

10 3TOUT O 3 TENV output terminal

9

11 CBDO I Capacitor connecting terminal for envelope

detection on the darkness side

10

12 BDO O BDO output terminal

13 COFTR I Capacitor connecting terminal for envelope

15

detection on the light side

14 OFTR O OFTR output terminal

22

-

+

23

15 NRFDET O NRFDET output terminal

16 GND - Ground

17 VREF O VREF output terminal

18 VDET O VDET output terminal

21

-

+

20

19 TEBPF I VDET output terminal

20 TEOUT O TE Amp. output terminal

21 TEN I TE Amp. inverting input terminal

22 FEN I FE Amp. inverting input terminal

23 FEOUT O FE Amp. output terminal

19

18

24 GCTL O GCTL & APC terminal

25 FBAL O FBAL control terminal

26 TBAL O TBAL control terminal

27 E I Tracking signal input terminal 1

28 F I Tracking signal input terminal 2

29 D I Focus signal input terminal 4

-

+

2

LD

30 B I Focus signal input terminal 3

31 C I Focus signal input terminal 2

32 A I Focus signal input terminal 1

1-32 (No.49837)

GCTL26TBAL

25 16 3

FBAL

PD

1

Page 33

4.6 GLT44016-35J4-X (IC103) : Dram

A

A

A

A

A

•Pin layout •Pin function

A

A1

A2

A3

1

1

2

3

4

5

4

6

7

5

8

6

9

7

10

8

11

12

13

14

15

16

0

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

Vss

16

DQ

DQ

15

14

DQ

DQ

13

Vss

12

DQ

DQ

11

DQ

10

DQ9

NC

LCAS

UCAS

OE

A

8

7

A

A

6

5

A

A

4

Vss

Pin Name Functi on

A

0~A8

RAS

UCAS

LCAS

WE

OE

~DQ16Dara inputs / outputs

DQ

1

Vcc +5V power supply

Vss Ground

NC No connection

Vcc

DQ

DQ2

DQ3

DQ

Vcc

DQ

DQ

DQ

DQ

NC

NC

WE

RAS

NC

Vcc

• Block diagram

OE

WE

UCAS

LCAS

RAS

RAS

CLOCK

GENERATOR

CAS

CLOCK

GENERATOR

WE

CLOCK

GENERATOR

Address inpits

Row address strobe

Columu address strobe / upperbyte control

Columu address strobe / lower byte control

Write enable

Output enable

OE

CLOCK

GENERATOR

Vcc

Vss

Data I/O BUS

COLUMN DECODERS

REFRESH

COUNTER

Y

9

0

1

7

8

ADDRESS BUFFWRS

AND PREDECODERS

X0 - X

8

SeNSE AMPLIFIERS

- Y

0

8

512 16

512 16

ROW

DECODERS

MEMORY

ARRAY

512

4.7 TC7S08F-W (IC106) : Buffer

• Pin layout • Block diagram

IN B

IN A

1

2

5 4VDD

I/O

BUFFER

Vcc

I/O1

I/O2

I/O3

I/O4

I/O5

I/O6

I/O7

I/O8

I/O9

I/O10

I/O11

I/O12

I/O13

I/O14

I/O15

I/O16

Y

3

Vss

OUT X

B

GND

(No.49837)1-33

Page 34

4.8 LA47505 (IC321) : Power amp.

• Terminal layout

206

11

1

12

4

10

Stand by

Switch

Ripple

Filter

Protective

circuit

Mute

circuit

9

7

8

5

3

2

22

15

25

13

14

16

Muting &

On Time Control

Circuit

protective

circuit

17

19

18

21

23

24

1-34 (No.49837)

Page 35

• Terminal layout

AC CONT1

GND1

OUTFR-

STBY

OUTFR+

Vcc1/2

OUTRR-

GND2

OUTRR+

VREF

INRR

INFR

SGND

INFL

INRL

ONTIME

OUTRL+

GND3

OUTRL-

Vcc3/4

OUTFL+

MUTE

OUTFL-

GND4

NC

• Pin function

Pin No. Symbol Function

1 AC CONT1 Header of IC

2 GND1 Power GND

3 OUTFR- Outpur(-) for front Rch

4 STBY Stand by input

5 OUTFR+ Output (+) for front Rch

6 Vcc1/2 Power input

7 OUTRR- Output (-) for rear Rch

8 GND2 Power GND

9 OUTRR+ Output (+) for rear Rch

10 VREF Ripple filter

11 INRR Rear Rch input

12 INFR Front Rch input

13 SGND Signal GND

14 INFL Front Lch input

15 INRL Rear Lch input

16 ONTIME Power on time control

17 OUTRL+ Output (+) for rear Lch

18 GND3 Power GND

19 OUTRL- Output (-) for rear Lch

20 Vcc3/4 Power input

21 OUTFL+ Output (+) for front

22 MUTE Muting control input

23 OUTFL- Output (-) for front

24 GND4 Power GND

25 NC No connection

4.9 NJM4565V-X (IC151) : Dual ope amp

• Terminal layout & Pin function

1

2

3

4

1

8

A

+

-

7

B

+

-

6

AOUTPUT

2

A-INPUT

3

A+INPUT

4

V

5

B+INPUT

6

B-INPUT

7

B OUTPUT

8

V

5

(No.49837)1-35

Page 36

4.10 LA6589H-X (IC501) : BTL driver

• Pin layout & Block diagram

VIN1-A

1

+

VIN1+A

VCCP1

2

3

VIN1_SW

H : OP-AMP_A

L : OP-AMP_B

H

28

VIN1

L

27

VIN1-B

+

26

VIN1+B

VO1+

VO1-

VO2+

VO2-

FR

VO3+

VO3-

VO4+

4

5

6

7

Power system

FR

8

9

10

GND

Level shift Level shift

+

Level shift Level shift

33k

11k

+

It is ON/OFF as for all outputs.

5VREG(PNPTr External)

Signal system

GND

H : ON

L : OFF

Signal system

power supply

MUTE

Power system GND

+

25

24

23

22

FR

21

20

19

S-GND

VIN1-SW

MUTE

VREF_IN

FR

VCC_S

REG-OUT

REG_IN

VCCP2

VIN4G

1-36 (No.49837)

VO4-

VIN4

11

12

13

14

11k

+

33k

33k

33k

18

VIN2G

11k

+

11k

+

17

16

15

VIN2

VIN3G

VIN3

Page 37

• Pin function

S

O

V

D

G

T

I

Pin No. Symbol Function

1 VIN1-A CH1 input AMP_A reversing input

2 VIN1+A CH1 input AMP_A non-reversing input

3 VCCP1 CH1 and CH2 power steps power supply

4 VO1+ CH1 Output terminal (+)

5 VO1- CH1 Output terminal (-)

6 VO2+ CH2 Output terminal (+)

7 VO2- CH2 Output terminal (-)

8 VO3+ CH3 Output terminal (+)

9 VO3- CH3 Output terminal (-)

10 VO4+ CH4 Output terminal (+)

11 VO4- CH4 Output terminal (-)

12 VCCP2 CH3 and CH4 power steps power supply

13 VIN4 CH4 Input terminal

14 VIN4G CH4 Input terminal(For gain adjustment)

15 VIN3 CH3 Input terminal

16 VIN3G CH3 Input terminal(For gain adjustment)

17 VIN2 CH2 Input terminal

18 VIN2G CH2 Input terminal(For gain adjustment)

19 REGIN External PNP transistor base connection

20 REG-OUT 5VREG output terminal and external PNP transistor collector connection

21 VCCS Signal system power supply

22 VREFIN Standard voltage impression terminal

23 MUTE Output ON/OFF terminal

24 VIN1_SW CH1 input OP_AMP switch terminal

25 S_GND Signal system GND

26 VIN1+B CH1 AMP_B non-reversing input terminal

27 VIN1-B CH1 AMP_B reversing input terminal

28 VIN1 CH1 input terminal and input OP_AMP output terminal

*1 Frame (FR) at the center becomes system GND(P-GND) power . Please give (*O) as the lowest potential with system GND(S-

GND) signal.

*2 Be short-circuited of VCC_S (signal system power supply) and VCCP1 and VCCP2 (output steps power supply) o n the out-

side.

4.11 MN1510XN-X (IC550) : Driver

• Pin Layout • Block Diagram

VCC PS

AG

1

PS

6

3

6

Clamp

SA

2

UT

CC

3

5

GN

N

42

4

IN

bias

DRV.

6dB

5

GND

1

OU

(No.49837)1-37

Page 38

4.12 HA13164A (IC901) : Regulator

• Terminal layout

123456789101112131415

• Block diagram

ANT OUT

EXT OUT

ANT CTRL

CTRL

CD OUT

AUDIO OUT

C3

0.1u

C4

0.1u

C5

0.1u

C6

10u

2

1

7

11

12

10

VCC ACC

8

Surge Protector

BIAS TSD

15

3

TAB

C1

100u

C2

0.1u

13

ILM AJGND GND

+B

BATT.DET OUT

9

COMPOUT

6

VDD OUT

4

SW5VOUT

5

14

ACC

ILMOUT

R1

C7

0.1u

C8

0.1u

UNIT R:

C:F

note1) TAB (header of IC)

connected to GND

• Pin function

Pin No. Symbol Function

1 EXTOUT Output voltage is VCC-1 V when M or H level applied to CTRL pin.

2 ANTOUT Output voltage is VCC-1 V when M or H level to CTRL pin and H level to ANT-CTRL.

3 ACCIN Connected to ACC.

4 VDDOUT Regular 5.7V.

5 SW5VOUT Output voltage is 5V when M or H level applied to CTRL pin.

6 COMPOUT Output for ACC detector.

7 ANT CTRL L:ANT output OFF H:ANT output ON

8 VCC Connected to VCC.

9 BATT DET Low battery detect.

10 AUDIO OUT Output voltage is 9V when M or H level applied to CTRL pin.

11 CTRL L:BIAS OFF M:BIAS ON H:CD ON

12 CD OUT Output voltage is 8V when H level applied to CTRL pin.

13 ILM AJ Adjustment pin for ILM output voltage.

14 ILM OUT Output voltage is 10V when M or H level applied to CTRL pin.

15 GND Connected to GND.

1-38 (No.49837)

Page 39

4.13 MN101C30ACK1 (IC251) : Unit micon

8

3

T

• Pin Layout

64 49

1

4

16

3

17 32

• Pin function

Pin No. Symbol I/O Function

1,2 /SW1, /SW2 I SW1,SW2 input

3 /SW3 I Conne ct to ground

4 PCHKCD I Connect to ground

5 PCHKVCD I Connect to groun d

6 VREF+ I Connect to VDD

7 VDD - Power supply

8 OSC2 O Xtal output

9 OSC1 I Xtal input

10 VSS - Ground

11 XI I Connect to groun d

12 NC - Not connect

13 MMOD I Connect to ground

14 MSTAT O Status output

15 KCMD I Command input

16,17 NC - Not connect

18 SUBQ I/O SubQ. data

19 SQCK I/O SubQ. clock

20 /VCDRST I/O VCD reset

21 /CDMRST I Micon reset

22 NC - Not connect

23 UDSASTB I/O ES3883 STB for uDSA

24 UDSADAT I/O ES3883 DAT for uDSA

25 UDSAACK I/O ES3883 ACK for uDSA

Pin No. Symbol I/O Function

26 NC - Not connect

27 BLKCK I SubQ. blk. clk

28 GND - Ground

29 PS2 I PS2

30,31 GND - Ground

32 DSASTB I/O ES3880 STB for DSA

33 DSADAT I/O ES3880 DAT for DSA

34 DSAACK I/O ES3880 ACK for DSA

35 PS1 I/O PS1 slave

36 to 48 NC - Not connect

49 REST I/O Rest SW

50 LM O Loading motor control

51 MSW I/O Motor control SW

52 to 55 NC - Not connect

56 /LSIRST O CD LSI reset output

57 STAT I/O Status

58 MDATA I/O Com.data

59 MCLK I/O Com.clock

60 MLD I/O Com.load

61 VREF- I Connect to ground

62 /TLOCK I Tracking lock signal input

63 /FLOCK I Focus lock signal input

64 SENSE I Sense signal input

4.14 RPM6938-V4 (IC602) : Remocon reseiver

• Block diagram

AMP

I/V

conversion

PD

magnetic shield

AGC

BPF Detector

for

trimming

circuit

Vcc

Comp

Vcc

22k

ROU

GND

(No.49837)1-39

Page 40

4.15 MN6627482WA (IC651) : DSP & DAC

A

R

• Pin layout

20 ~ 1

• Block diagram

LRCKIN(MSEL)

BCLK(SSEL)

SRDATAIN

(PSEL)

IOSEL

CLVS

CRC

BLKCK

CLDCK

SBCK

SUBC

DEMPH

RESY

FLAG6(RESY)

SSEL

SQCK

SUBQ

AVDD2

AVDD2

PCK

EFM

PLLF

DSLF

IREF

DRF

ARF

RSEL

PSEL

MLD

MCLK

MDATA

CK384(EFM)

VCOF

BYTCK

SMCK

FCLK

CSEL

MSEL

X2

X1

ÊSTAT

21

~

40

41 ~ 60

DIGITAL

DEEMPHSIS

SUB

CODE

BUFFER

DSL.

PLL

VCO

VCO

ITUNING

GENERATION

PITCH

CONTROL

80

~

61

8TIMES

OVER SAMPUNC

DIGITAL FILTER

EFM

DEMODULATION

SYNC

INTERPOLATION

SUBCODE

DEMODULATION

MICRO

COMPUTER

INTERFACE

A/D

COVERTER

1BIT

DAC

LOGIC

S

16k

SRAM

CIRC

ERROR

CORRECTION

DEINTERLEVE

CLV

SERVO

INPUT

PEM

(R)

PEM

(L)

D/A

CONVERTER

OUTPUT

DIGITAL

AUDIO

INTERFASE

DIGITAL

AUDIO

INTERFASE

INTER POLATION

SOFT MUTING DIGITAL

ATTENUATION

PEAK DETECTIVE

AUTO CUE

PORT

SERVO

TIMING GENERATOR

AVSS1

AVDD1

OUTR

OUTL

FLAG

IPFLAG

TX

ECM

PC

LRCK

SRDAT

BCLK

DMUTE

TRKV

KICK

VREF

TRVST

ECS

TVD

TRD

FOD

TBAL

FBAL

TOFS

TES

/TLOCK

/FLOCK

PLAY

LDON

WVEL

SENSE

1-40 (No.49837)

D

/

D

V

V

V

R

V

S

D

D

S

S

S

D

D

T

S

1

1

F

/

E

T

E

S

T

R

T

F

E

E

N

V

T

R

C

R

S

B

V

D

D

O

E

T

/

R

F

D

E

O

F

T

Page 41

• Pin function

Pin No. Symbol I/O Function

1 BCLK O Not used

2 LRCK O Not used

3 SRDATA O Not used

4 DVDD1 - Power supply (Digital)

5 DVSS1 - Connected to GND

6 TX O Not used

7 MCLK I CPU command clock signal input(Data is

latched at signal's rising point)

8 MDATA I CPU command data input

9 MLD I CPU command load signal input

10 SENSE O Sense signal output

11 FLOCK O Focus lock signal output Active: Low

12 TLOCK O Tracking lock signal output Active: Low

13 BLKCK O sub-code/block/clock signal output

14 SQCK I Outside clock for sub-code Q resister in-

put

15 SUBQ O Sub-code Q -code output

16 DMUTE Connected to GND

17 STAT O Status signal(CRC,CUE,CLVS,

TTSTOP,ECLV,SQOK)

18 RST I Reset signal input (L:Reset)

19 SMCK - Not used

20 PMCK - Not used

21 TRV O Traverse enforced output

22 TVD O Traverse drive output

23 PC - Not used

24 ECM O Spindle motor drive signal (Enforced

mode output) 3-State

25 ECS O Spindle motor drive signal (Servo error

signal output)

26 KICK O Kick pulse output

27 TRD O Tracking drive output

28 FOD O Focus drive output

29 VREF - Reference voltage input pin for D/A out-

put block (TVD,FOD,FBA,TBAL)

30 FBAL O Focus Balance adjust signal output

31 TBAL O Tracking Balance adjust signal output

32 FE I Focus error signal input (Analog input)

33 TE I Tracking error signal input (Analog input )

34 RF ENV I RF envelope signal input (Analog input)

35 VDET I Vibration detect signal input (H:detect)

36 OFT I Off track signal input (H:off track)

37 TRCRS I Track cross signal input

38 RFDET I RF detect signal input (L:detect)

39 BDO I BDO input pin (L:detect)

Pin No. Symbol I/O Function

40 LDON O Laser ON signal output (H:on)

41 PLLF2 - Not used

42 TOFS O Tracking error shunt signal output

(H:shunt)

43 WVEL - Not used

44 ARF I RF signal input

45 IREF I Reference current input pin

46 DRF I Bias pin for DSL

47 DSLF I/O Loop filter pin for DSL

48 PLLF I/O Loop filter pin for PLL

49 VCOF - Not used

50 AVDD2 - Power supply (Analog)

51 AVSS2 - Connected to GND (Analog)

52 EFM - Not used

53 PCK - Not used

54 VCOF2 - PLL data slice output

55 SUBC - Not used

56 SBCK - Not used

57 VSS - Connected to GND (for X'tal oscillation

circuit)

58 XI I Input of 16.9344MHz X'tal oscillation cir-

cuit

59 X2 O Output of X'tal oscillation circuit

60 VDD - Power supply (for X'tal oscillation circuit)

61 BYTCK - Not used

62 CLDCK - Not used

63 FCLK - Not used

64 IPFLAG - Not used

65 FLAG - Not used

66 CLVS - Not used

67 CRC - Not used

68 DEMPH - Not used

69 RESY - Not used

70 IOSEL - pull up

71 TEST - pull up

72 AVDD1 - Power supply (Digital)

73 OUT L O Lch audio output

74 AVSS1 - Connected to GND

75 OUT R O Rch audio output

76 RSEL - pull up

77 CSEL - Connected to GND

78 PSEL - Connected to GND

79 MSEL - Connected to GND

80 SSEL - Pull up

(No.49837)1-41

Page 42

4.16 NJM78M05FA (IC931) : Regulator

T

• Terminal layout

1.INPUT

2.GND

3.OUTPU

1 2 3

• Block diagram

INPUT

OUTPUT

4.17 RT9161 / A-27CG-X (IC105) : Regulator

• Pin layout • Block diagram

VIN

123

GND VIN

(TAB)

• Pin function

Pin Name Function

VOUT Output Voltage

GND Ground

VIN Power Input

VOUT

Error Amp

1.2V

Reference

GND

VOUT

+

-

GND

1-42 (No.49837)

Page 43

4.18 PT6523LQ (IC601) : LCD driver

•Pin layout

48 ~ 33

49

32

• Block diagram

64

1 ~ 16

17

COMMON

DRIVER

CLOCK

GENERATOR

ADDRESS

DETECTOR

SEGMENT DRIVER & LATCH

SHIFT REGISTER

• Piin function

Pin No. Pin Name I/O Description

1~ 52 SG1 ~ SG52 O Segment Output Pins

53~55 COM1 ~ COM3 O Common Driver Output Pins

56 VDD - Power Supply

57 INH

I Display OFF Control Input Pin

When this pin is "Low", the Display is forcibly turned OFF. (SG1 to SG52, COM1 to COM3 are

set to "LOW"). (See Note 1)

When this pin is set to "High", the Displa is ON.

58 VDD1 I Used for the 2/3 Bias Voltage when the Bias Voltages are provied externally. Connect to VDD2

when 1/2 Bias is used.

59 VDD2 I Used for 1/3 Bias Voltage when the Bias Voltages are provided externally. Connect to VDD1

when 1/2 Bias is used.

60 VSS - Ground Pin.

61 OSC I/O Oscillation Input /Outout Pin

62 CE I Chip Enable Pin

63 CLK I Synchronization Clock

64 DI I Transfer Data Pin

Note 1:

When INH = "LOW" : Serial data trensfers can be performed when the display is forcibly OFF.

(No.49837)1-43

Page 44

4.19 UPD178078GF-642 (IC801) : System CPU

130

80 51

1

0

1

• Pin Layout

81

00

5

3

• Pin function

Pin No. Symbol I/O Function

1 to 8 NC - Not connect

9 E.VOL.DATA_OUT O E.VOLUME data output

10 E.VOL.SCK O E.VOLUME cl ock output

11 NC - Not connect

12 LCD SO O LCD data ou tput

13 LCD SCK O LCD driver clock output

14 MECHA POWER O Linked with MECHA ON

15 LCD CE O LCD driver chip enable signal output

16 to 18 NC - Not connect

19 ENC1 I Rotary volume signal A input

20 ENC2 I Rotary volume signal B input

21,22 NC - Not connect

23 KEY0 I Key input 1

24 KEY1 I Key input 2

25 KEY2 I Key input 3

26 to 29 AVDD - Power supply for A/D converter (Connect to VDD)

30 LEVEL IND I Level meter A/D input

31 SM I S meter (electric field strength) input

32 AVSS - Ground for A/D converter (Connect to ground)

33 REGCPU - Regulator for CPU power supply

34 VDD - Power supply

35 REGOSC - Power supply for oscillator circuit

36 XOUT O Crystal oscillator connect terminal for system clock

37 XIN I Crystal oscillator connect terminal for system clock

38 GND - Connect to ground

39 IFCCONT O IFC output prohibition signal

40 GND - Connect to ground

41 NC - Not connect

42 IF COUNT I FM/AM IF count signal input

43 VDDPLL - Connect to VDD

44 OSC IN I FM/AM local oscillation signal input

45 NC - Not connect

46 GNDPLL - Connect to ground

47 EQ O PLL error signa l output

48 NC - Not connect

49 VPP - Connect to ground through the resistor

50 RESET I Main micon reset input

51 REMOCON I Optical remocon signal input

52 NC - Not connect

53 MECHA.RESET O CD micon reset signal output

54 to 65 NC - Not connect

1-44 (No.49837)

Page 45

Pin No. Symbol I/O Function

66 VIDEO ON/OFF O L: VIDEO OFF, H: VIDEO ON

67 BAND O Tuner receive band switching signal (H: FM, L: AM)

68 NC - Not connect

69 RXD0 I For flas h ROM writing / UART(VCD sta tu s input)

70 TXD0 O For flash ROM writing / UART(VCD command ou tput)

71 SD/ST I Station detection / FM stereo input

72 /MONO O FM monaural control output

73 IF/AGC O IF count request output

74 NC - Not connect

75 ANT.REMOTE O Antenna remote control output (H: tuner)

76 PARKING BRAKE I L: VIDEO OFF, H: VIDEO ON

77 NC - Not connect

78 SW1 I/O S1 input, Disc insert detection on power OFF

79 P.SAVE1 I Power save 1(ACC) detection, L: Power save

80 P.SAVE2 I Power save 2(BATTERY) detection, L: Power save

81 P.SAVE.SLAVE O Power save 1 control signal output to mecha micon

82 GND - Connect to ground

83 to 91 NC - Not connect

92 MUTE O Mute control signal output

93 TEL MUTING I Tel muting input

94 POWER CONT O Power supply IC control signal output

95 to 97 NC - Not connect

98 DETACH I Panel connector detection

99 VDDPORT - Connect to VDD

100 GNDPORT - Connect to ground

4.20 MM1565AF-X (IC108, IC261, IC551) : Regulator

• Block diagram

Vin

Bias

Cont

Thermal

shutdown

GND

• Pin function

Pin No. Symbol Function

1 Vout Output terminal

2 NC Non connect

3 GND Connect to ground

4 Cn Noise decrease terminal

5 Cout Control terminal

6 Sub Substrate (Connect to ground)

7 Vin Input terminal

Driver

Current

limiter

Vo

Reference

Cn

(No.49837)1-45

Page 46

4.21 TEA6320T-X (IC301) : E.volume

• Pin layout

TAPE

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

SDA

GND

OUTLR

OUTLF

TL

B2L

B1L

IVL

ILL

QSL

IDL

MUTE

ICL

IMD

IBL

IAL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CD-CH

TUNER

• Block diagram

10 8 9 7 6

SCL

VCC

OUTRR

OUTRF

TR

B2R

B1R

IVR

ILR

QSR

IDR

Vref

ICR

CAP

IBR

IAR

5

12

21

31

2

19

POWER

SUPPLY

VOLUME 1

+20 to -31 dB

LOUDNESS

LEFT

16

15

13

11

14

22

20

SOURCE

SELECTOR

VOLUME 1

+20 to -31 dB

LOUDNESS

RIGHT

18

17

23 25 24 26 27 28

• Pin functions

Pin

No.

Symbol I/O Functions

1 SDA I/O Serial data input/output.

2 GND - Ground.

3 OUTLR O output left rear.

4 OUTLF O output left front.

5 TL I Treb le control capacitor left channel

or input from an external equalizer.

6 B2L - Bass control capacitor left channel or

output to an external equalizer.

7 B1L - Bass control capacitor left channel.

8 IVL I Input volume 1. left control part.

9 ILL I Input loudness. left control part.

10 QSL O Output source selector. left channel.

11 IDL - Not used

12 MUTE - Not used

13 ICL I Input C left source.

14 IMO - Not used

15 IBL I Input B left source.

16 IAL I Input A left source.

BASS

LEFT

+15 dB

LOGIC

BASS

RIGHT

+15 dB

VOLUME 2

0 to 55 dB

BALANCE

FENDER REAR

VOLUME 2

0 to 55 dB

BALANCE

FENDER FRONT

HC BUS

REC

3

4

32

TREBLE

LEFT

+12 dB

MUTE

FUNCTION

ZERO CROSS

DETECTOR

1

VOLUME 2

TREBLE

RIGHT

+12 dB

Pin

No.

Symbol I/O Functions

0 to -55dB

BALANCE

FENDER FRONT

VOLUME 2

0 to -55dB

BALANCE

FENDER REAR

29

30

17 IAR I Input A right source.

18 IBR I Input B right source.

19 CAP - Electronic filtering for supply.

20 ICR I Input C right source.

21 Vref - Reference voltage (0.5Vcc)

22 IDR - Not used

23 QSR O Output source selector right channel.

24 ILR I Input loudness right channel.

25 IVR I Input volume 1. right control part.

26 B1R - Bass control capacitor right channel

27 B2R O Bass control capacitor right channel

or output to an external equalizer.

28 TR I Treble control capacitor right channel

or input from an external equalizer.

29 OUTRF O Output right front.

30 OUTRR O Output right rear.

31 Vcc - Supply voltage.

32 SCL I Serial clock input.

1-46 (No.49837)

Page 47

(No.49837)1-47

Page 48

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY MOBILE ENTERTAINMENT CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.49837)

Printed in Japan

WPC

Loading...

Loading...