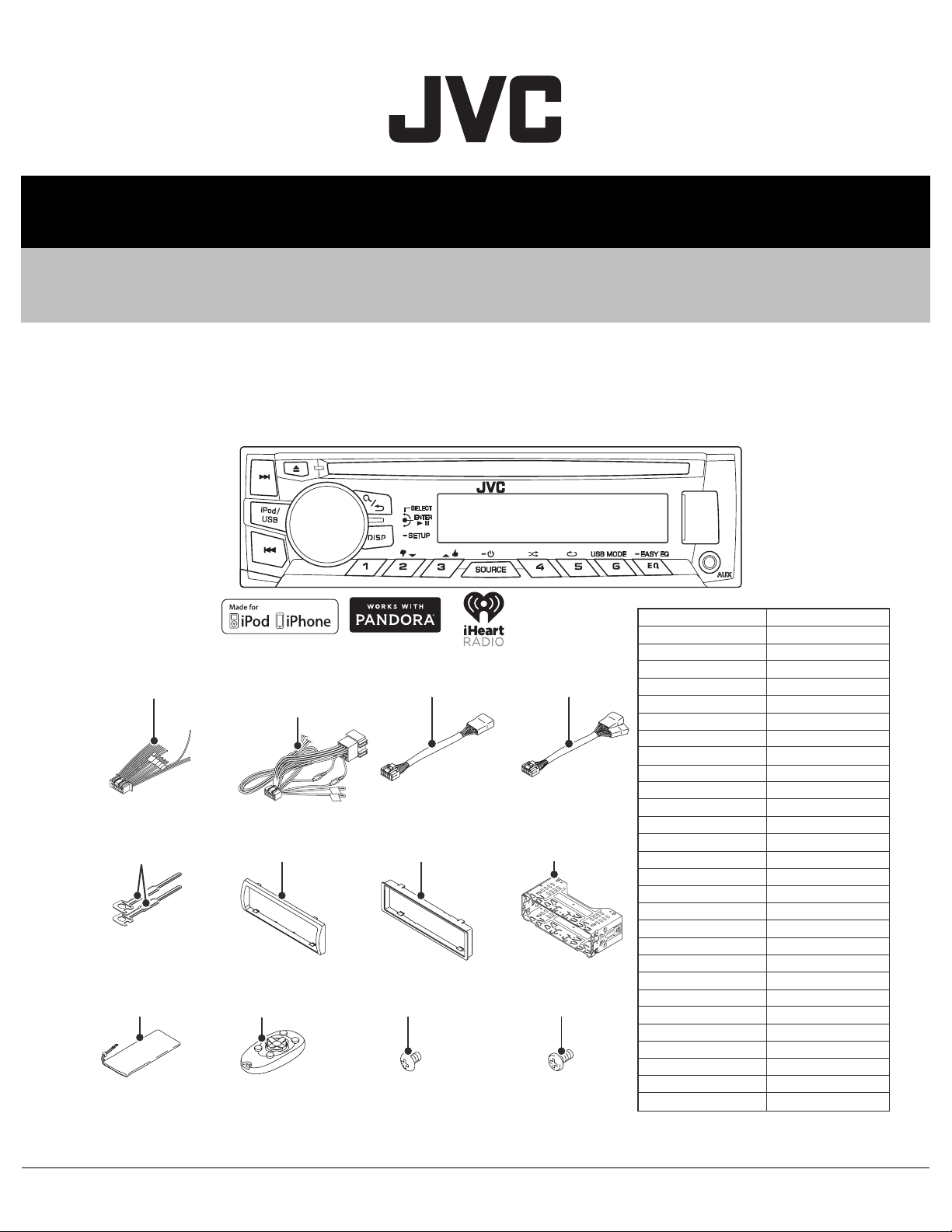

Page 1

SERVICE MANUAL

CD RECEIVER

MA596<Rev.005>20157SERVICE MANUAL

KD-R460J, KD-R461DA9, KD-R461E, KD-R461EN, KD-R461EY,

KD-R461MA9, KD-R461U, KD-R461UT, KD-R462E, KD-R462EN,

KD-R462EY, KD-R463EU, KD-R464E, KD-R464EN, KD-R466U, KD-R467EE,

KD-R469E, KD-R469EY, KD-R469UR, KD-R660J, KD-R661E, KD-R661EN,

KD-R661EY, KD-R661MA9, KD-R661U, KD-R661UT, KD-SR41J, KD-SR61J

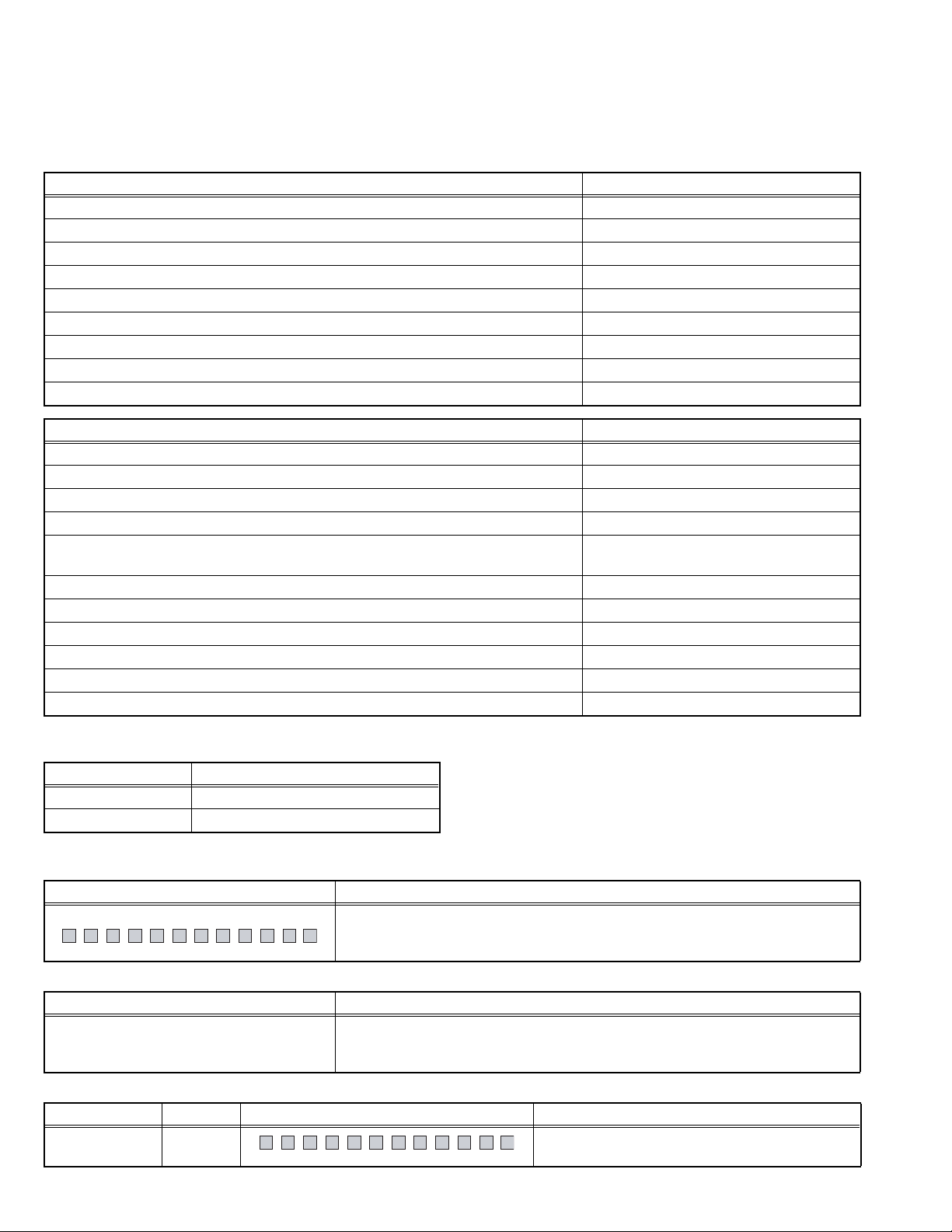

DETACHABLE PANEL

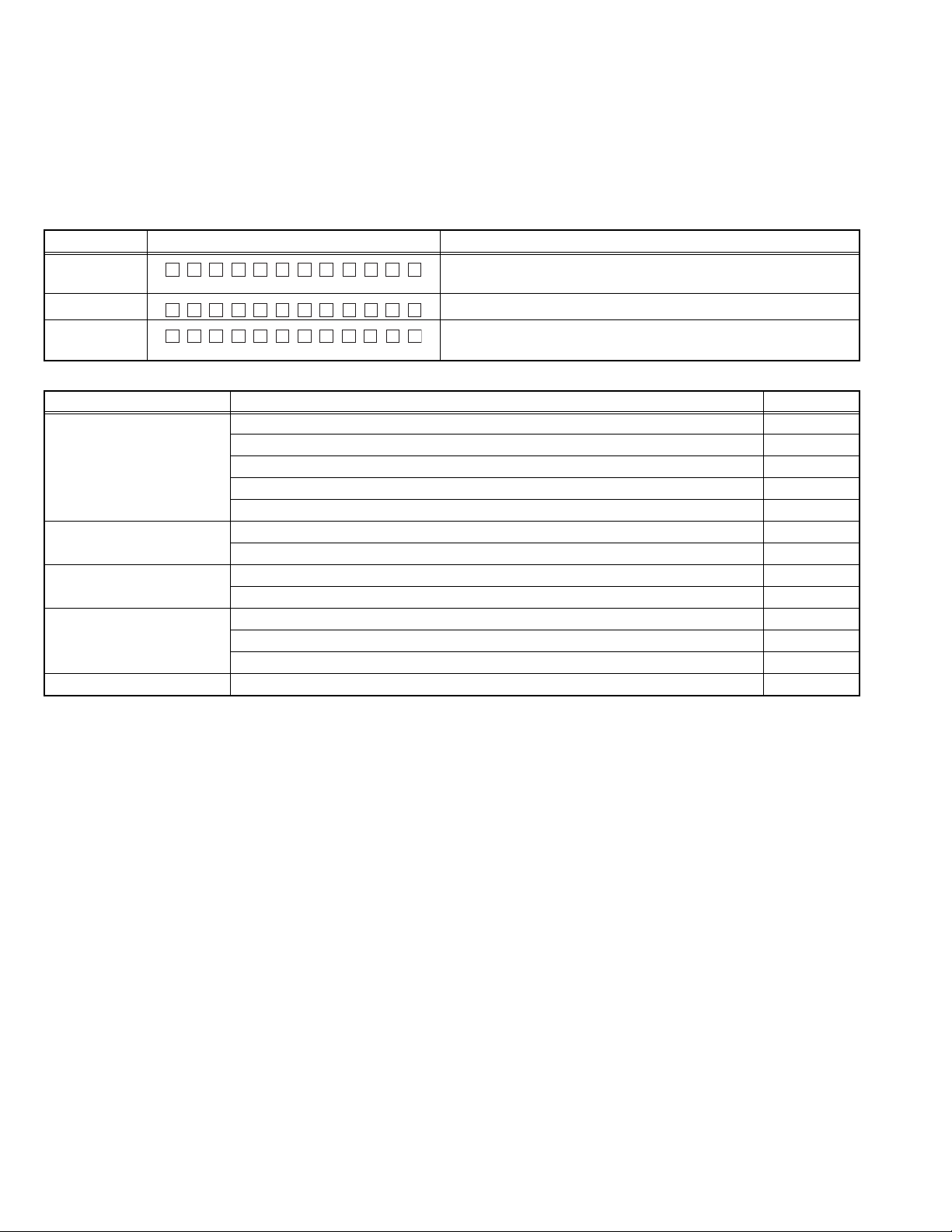

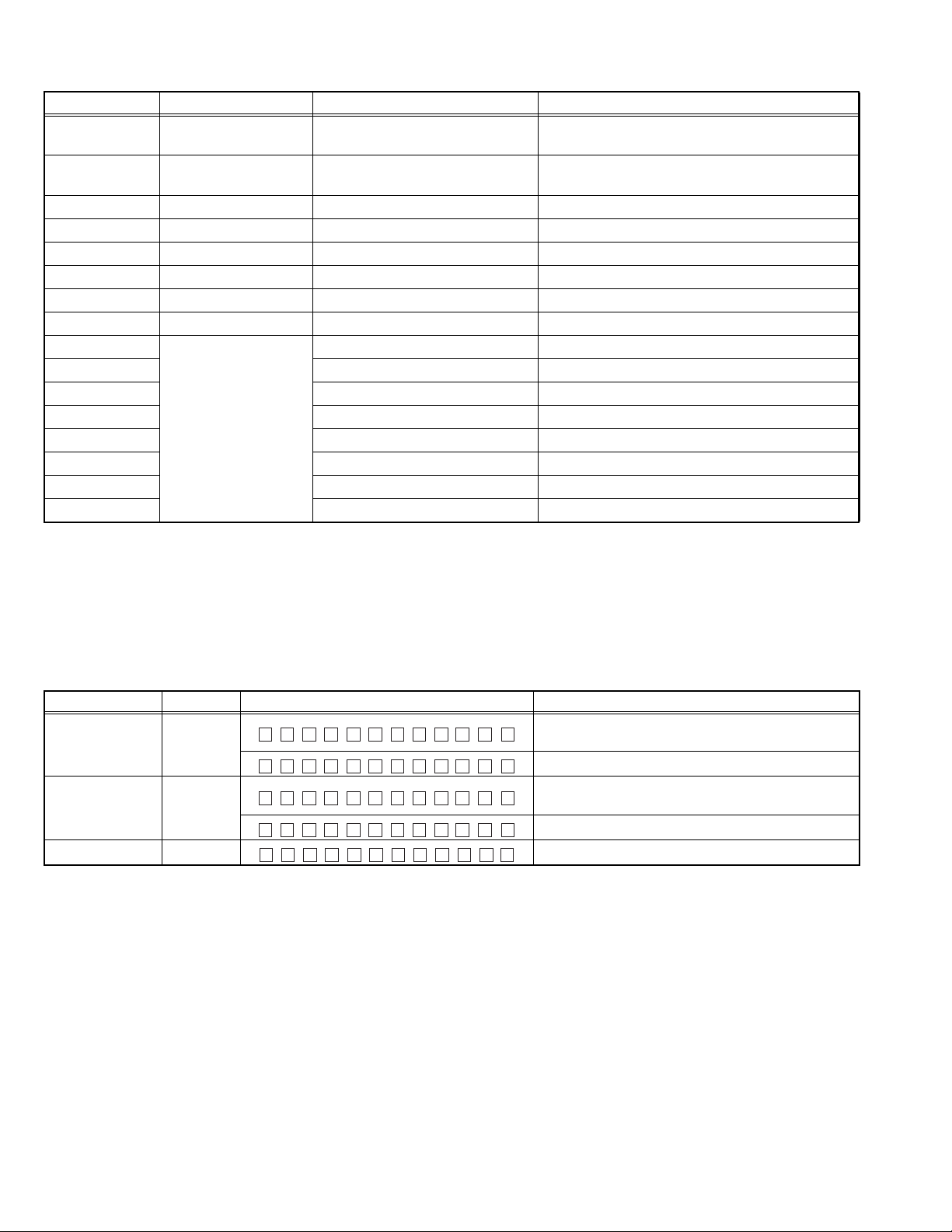

Model Parts number

CP-R460JD

CP-R461ED

CP-R461ED

CP-R461ED

CP-R461UD

CP-R461UD

CP-R462ED

CP-R462ED

CP-R462ED

CP-R463EU

CP-R464ED

CP-R464ED

CP-R466UD

CP-R467EED

CP-R469ED

CP-R469ED

CP-R660JD

CP-R661ED

CP-R661ED

CP-R661ED

CP-R661UD

CP-R661UD

CP-SR41JD

CP-SR61JD

DC cord

(QAM1329-001)

Hook

(GE40685-001A) x2

Carrying case

(GE40521-001A)

COPYRIGHT © 2015 JVC KENWOOD Corporation

DC cord

(QAM1345-003)

(QAM1378-001)

Trim plate

(GE20363-00xA)

Remote control unit

(RM-RK52M)

DC cord assy

(E3A-0181-00)

Escutcheon

(B0H-0021-00)

Screw (M5x8)

(QYSDSP5008ZA) x4

Lead free solder used in the board (material: Sn-Ag-Cu, melting point: 219 Centigrade)

Lead free solder used in the board (material: Sn-Cu, melting point: 230 Centigrade)

DC cord assy

(E3A-0218-00)

Mounting sleeve

(GE20362-002A)

Screw (M5x10)

(QYSDSP5010ZA) x4

KD-R460J

KD-R461DA9

KD-R461E

KD-R461EN

KD-R461EY

KD-R461MA9

KD-R461U

KD-R461UT

KD-R462E

KD-R462EN

KD-R462EY

KD-R463EU

KD-R464E

KD-R464EN

KD-R466U

KD-R467EE

KD-R469E

KD-R469EY

KD-R469UR

KD-R660J

KD-R661E

KD-R661EN

KD-R661EY

KD-R661MA9

KD-R661U

KD-R661UT

KD-SR41J

KD-SR61J

COPYRIGHT © 2015 JVC KENWOOD Corporation

No.MA596<Rev.005>

2015/7

Page 2

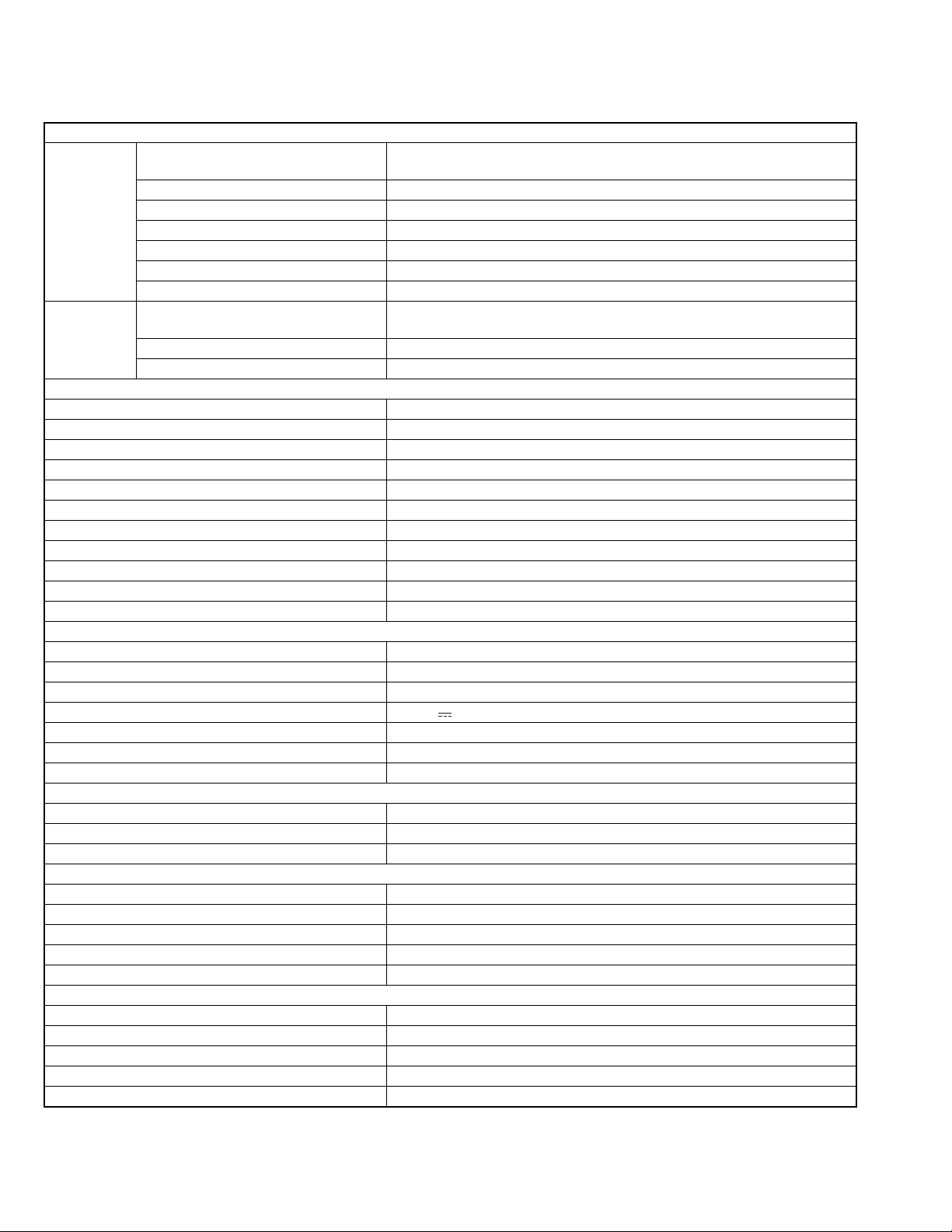

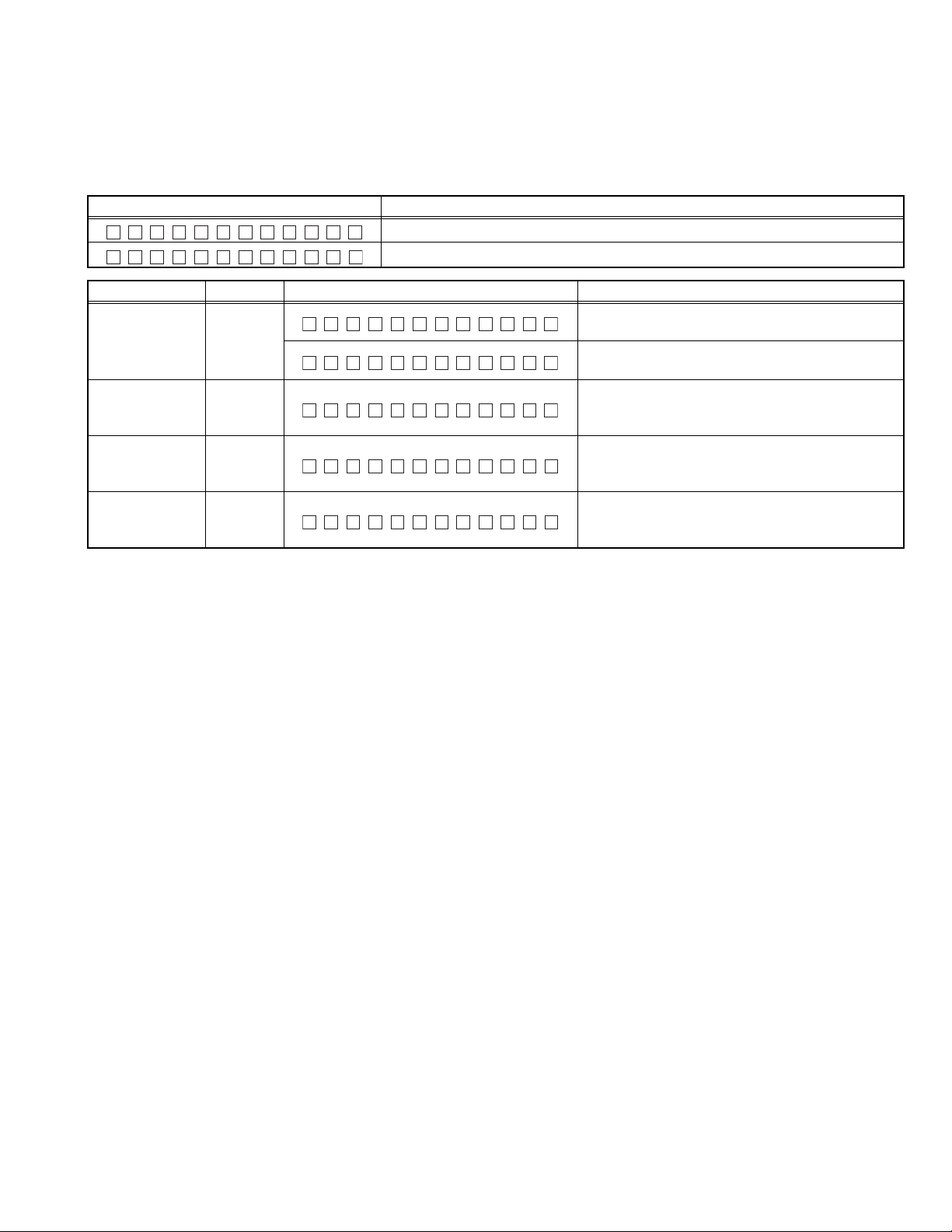

SPECIFICATION

For US

TUNER

FM Frequency Range 87.9 MHz to 107.9 MHz (200 kHz step)

87.5 MHz to 108.0 MHz (50 kHz step)

Channel Space Selection 50 kHz/200 kHz

Usable Sensitivity (S/N = 26 dB) 8.2 dBf (0.71 µV/75 Ω)

Quieting Sensitivity(DIN S/N = 46 dB) 17.2 dBf (2.0 µV/75 Ω)

Frequency Response (±3 dB) 30 Hz to 15 kHz

Signal-to-Noise Ratio (MONO) 64 dB

Stereo Separation (1 kHz) 40 dB

AM Frequency Range 530 kHz to 1 700 kHz (10 kHz step)

531 kHz to 1 611 kHz (9 kHz step)

Channel Space Selection 9 kHz/10 kHz

Usable Sensitivity (S/N = 20 dB) 29 dBµ (28.2 µV)

CD player

Laser Diode GaAIAs

Digital Filter (D/A) 8 times over sampling

Spindle Speed 500 rpm - 200 rpm (CLV)

Wow & Flutter Below measurable limit

Frequency Response (±1 dB) 20 Hz - 20 kHz

Total Harmonic Distortion (1 kHz) 0.01%

Signal-to-Noise Ratio (1 kHz) 105 dB

Dynamic Range 90 dB

Channel Separation 85 dB

MP3 Decode Compliant with MPEG-1/2 Audio Layer-3

WMA Decode Compliant with Windows Media Audio

USB

USB Standard USB 1.1, USB 2.0 (Full speed)

Compatible Devices Mass storage class

File System FAT12/ 16/ 32

Maximum Supply Current DC 5 V 1 A

MP3 Decode Compliant with MPEG-1/2 Audio Layer-3

WMA Decode Compliant with Windows Media Audio

WAV Decode Linear-PCM

Auxiliary

Frequency Response (±3 dB) 20 Hz - 20 kHz

Input Maximum Voltage 1 000 mV

Input Impedance 30 kΩ

Audio

Maximum Output Power 50 W × 4 or 50 W × 2 + 50 W × 1 (Subwoofer = 4 Ω)

Full Bandwidth Power(at less than 1 % THD) 22 W × 4

Speaker Impedance 4 Ω to 8 Ω

Preout Level/Load (CD/USB) 2 500 mV/10 kΩ

Preout Impedance ≤ 600 Ω

General

Operating Voltage (10.5 V - 16 V allowable) 14.4 V

Maximum Current Consumption 10A

Operating Temperature Range 0°C to + 40°C

Installation Size (W × H × D) 182 mm × 53 mm × 158 mm (7-3/16" × 2-1/8" × 6-1/4")

Weight 1.2 kg (2.65 lbs)

• Subject to change without notice.

(No.MA596<Rev.005>)2/28

Page 3

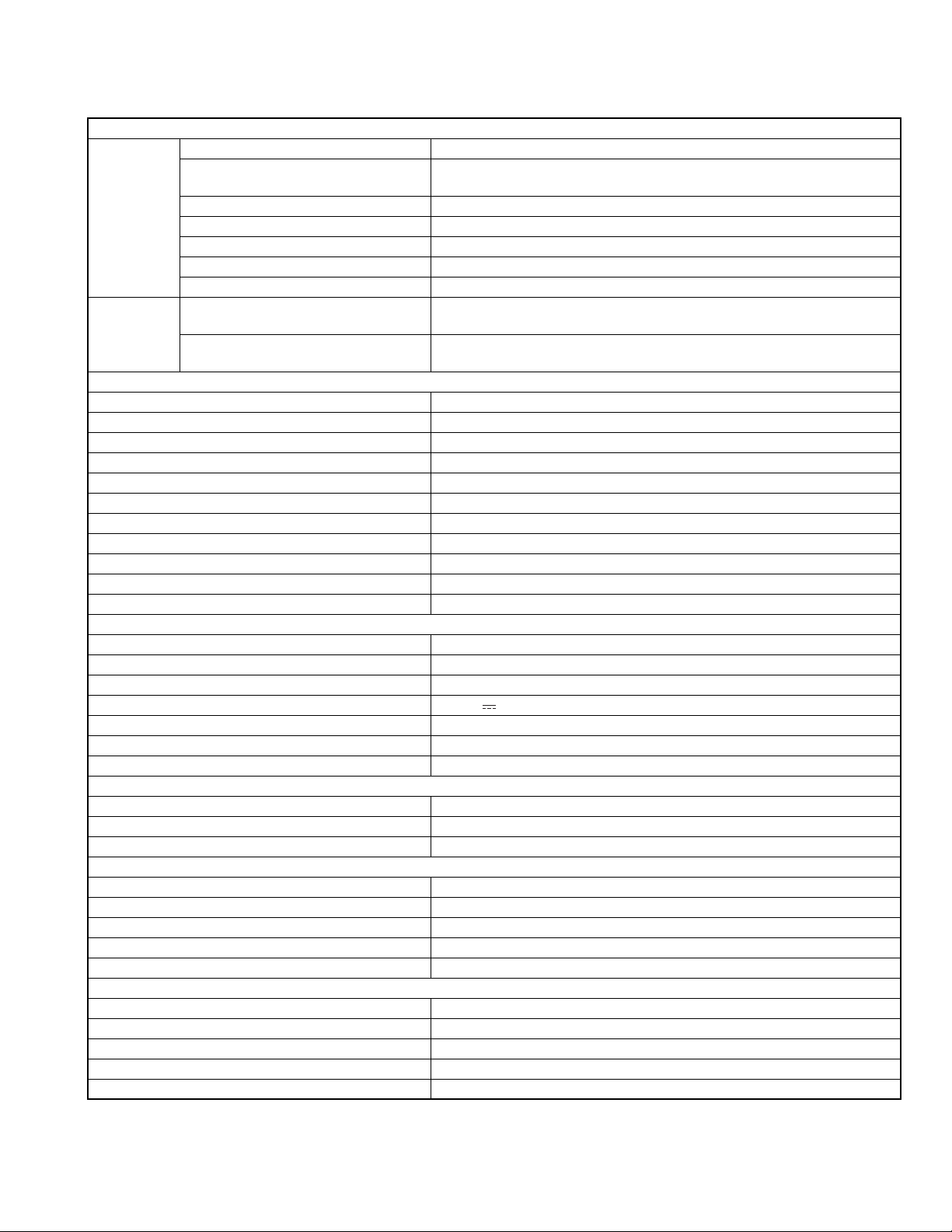

SPECIFICATION

For Europe

TUNER

FM Frequency Range [Except KD-R467] 87.5 MHz to 108.0 MHz (50 kHz step)

Frequency Range [KD-R467] FM: 87.5 MHz to 108.0 MHz (50 kHz step)

FM-Lo: 65.0 MHz to 74.0 MHz (30 kHz step)

Usable Sensitivity (S/N = 26 dB) 0.71 µV/75 Ω

Quieting Sensitivity(DIN S/N = 46 dB) 2.0 µV/75 Ω

Frequency Response (±3 dB) 30 Hz to 15 kHz

Signal-to-Noise Ratio (MONO) 64 dB

Stereo Separation (1 kHz) 40 dB

AM Frequency Range MW : 531 kHz to 1 611 kHz (9 kHz step)

LW : 153 kHz to 279 kHz (9 kHz step)

Usable Sensitivity (S/N = 20 dB) MW : 28.2 µV

LW : 50 µV

CD player

Laser Diode GaAIAs

Digital Filter 8 times over sampling

Spindle Speed 500 rpm - 200 rpm (CLV)

Wow & Flutter Below measurable limit

Frequency Response (±1 dB) 20 Hz - 20 kHz

Total Harmonic Distortion (1 kHz) 0.01%

Signal-to-Noise Ratio (1 kHz) 105 dB

Dynamic Range 90 dB

Channel Separation 85 dB

MP3 Decode Compliant with MPEG-1/2 Audio Layer-3

WMA Decode Compliant with Windows Media Audio

USB

USB Standard USB 1.1, USB 2.0 (Full speed)

Compatible Devices Mass storage class

File System FAT12/ 16/ 32

Maximum Supply Current DC 5 V 1 A

MP3 Decode Compliant with MPEG-1/2 Audio Layer-3

WMA Decode Compliant with Windows Media Audio

WAV Decode Linear-PCM

Auxiliary

Frequency Response (±3 dB) 20 Hz - 20 kHz

Input Maximum Voltage 1 000 mV

Input Impedance 30 kΩ

Audio

Maximum Output Power 50 W × 4 or 50 W × 2 + 50 W × 1 (Subwoofer = 4 Ω)

Full Bandwidth Power(at less than 1 % THD) 22 W × 4

Speaker Impedance 4 Ω to 8 Ω

Preout Level/Load (CD/USB) 2 500 mV/10 kΩ load (full scale)

Preout Impedance ≤ 600 Ω

General

Operating Voltage 14.4 V (10.5 V - 16 V allowable)

Maximum Current Consumption 10A

Operating Temperature Range 0°C to + 40°C

Installation Size (W × H × D) 182 mm × 53 mm × 158 mm

Weight 1.2 kg

• Subject to change without notice.

(No.MA596<Rev.005>)3/28

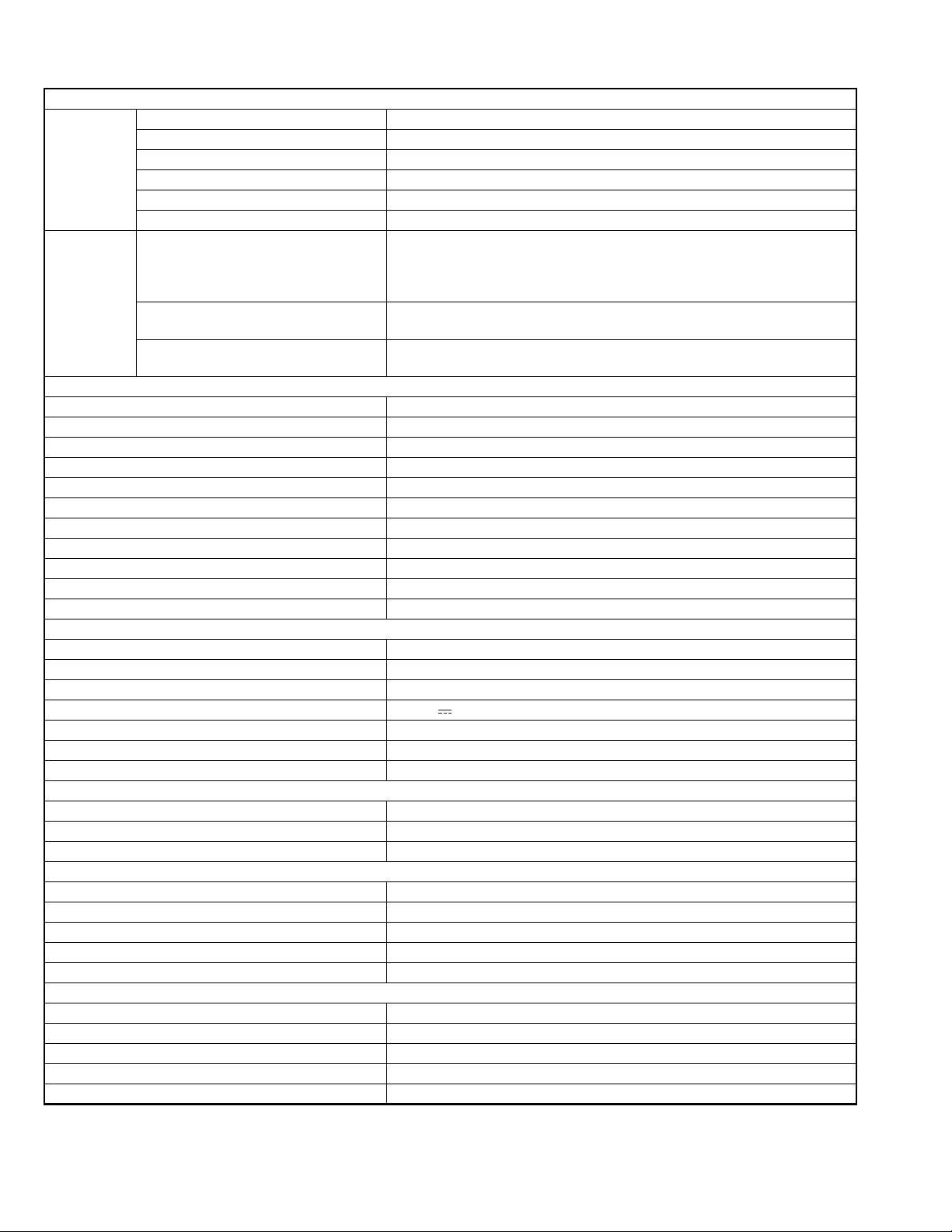

Page 4

For ASIA

TUNER

FM Frequency Range 87.5 MHz to 108.0 MHz (50 kHz step)

Usable Sensitivity (S/N = 26 dB) 8.2 dBf (0.71 µV/75 Ω)

Quieting Sensitivity(DIN S/N = 46 dB) 17.2 dBf (2.0 µV/75 Ω)

Frequency Response (±3 dB) 30 Hz to 15 kHz

Signal-to-Noise Ratio (MONO) 64 dB

Stereo Separation (1 kHz) 40 dB

AM Frequency Range Band 1 (MW): 531 kHz to 1 611 kHz (9 kHz step)

Band 2 (SW1): 2 940 kHz to 7 735 kHz (5 kHz step)

Band 3 (SW2): 9 500 kHz to 10 135 kHz (5 kHz step) / 11 580 kHz to 18 135

kHz (5 kHz step)

Channel Space Selection Band 1: 9 kHz

Band 2/3: 5 kHz

Usable Sensitivity (S/N = 20 dB) 29 dBµ (28.2 µV)

SW: 30 dBµ (32 µV)

CD player

Laser Diode GaAIAs

Digital Filter (D/A) 8 times over sampling

Spindle Speed 500 rpm - 200 rpm (CLV)

Wow & Flutter Below measurable limit

Frequency Response (±1 dB) 20 Hz - 20 kHz

Total Harmonic Distortion (1 kHz) 0.01%

Signal-to-Noise Ratio (1 kHz) 105 dB

Dynamic Range 90 dB

Channel Separation 85 dB

MP3 Decode Compliant with MPEG-1/2 Audio Layer-3

WMA Decode Compliant with Windows Media Audio

USB

USB Standard USB 1.1, USB 2.0 (Full speed)

Compatible Devices Mass storage class

File System FAT12/ 16/ 32

Maximum Supply Current DC 5 V 1 A

MP3 Decode Compliant with MPEG-1/2 Audio Layer-3

WMA Decode Compliant with Windows Media Audio

WAV Decode Linear-PCM

Auxiliary

Frequency Response (±3 dB) 20 Hz - 20 kHz

Input Maximum Voltage 1 000 mV

Input Impedance 30 kΩ

Audio

Maximum Output Power 50 W × 4 or 50 W × 2 + 50 W × 1 (Subwoofer = 4 Ω)

Full Bandwidth Power(at less than 1 % THD) 22 W × 4

Speaker Impedance 4 Ω to 8 Ω

Preout Level/Load (CD) 2 500 mV/10 kΩ load

Preout Impedance ≤ 600 Ω

General

Operating Voltage (10.5 V - 16 V allowable) 14.4 V

Maximum Current Consumption 10A

Operating Temperature Range 0°C to + 40°C

Installation Size (W × H × D) 182 mm × 53 mm × 158 mm

Weight 1.2 kg

• Subject to change without notice.

(No.MA596<Rev.005>)4/28

Page 5

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

1.5 Remote control

The Lithium battery is in danger of explosion if replaced incorrectly. Replace it only with the same or equivalent type.

1.6 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the

laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

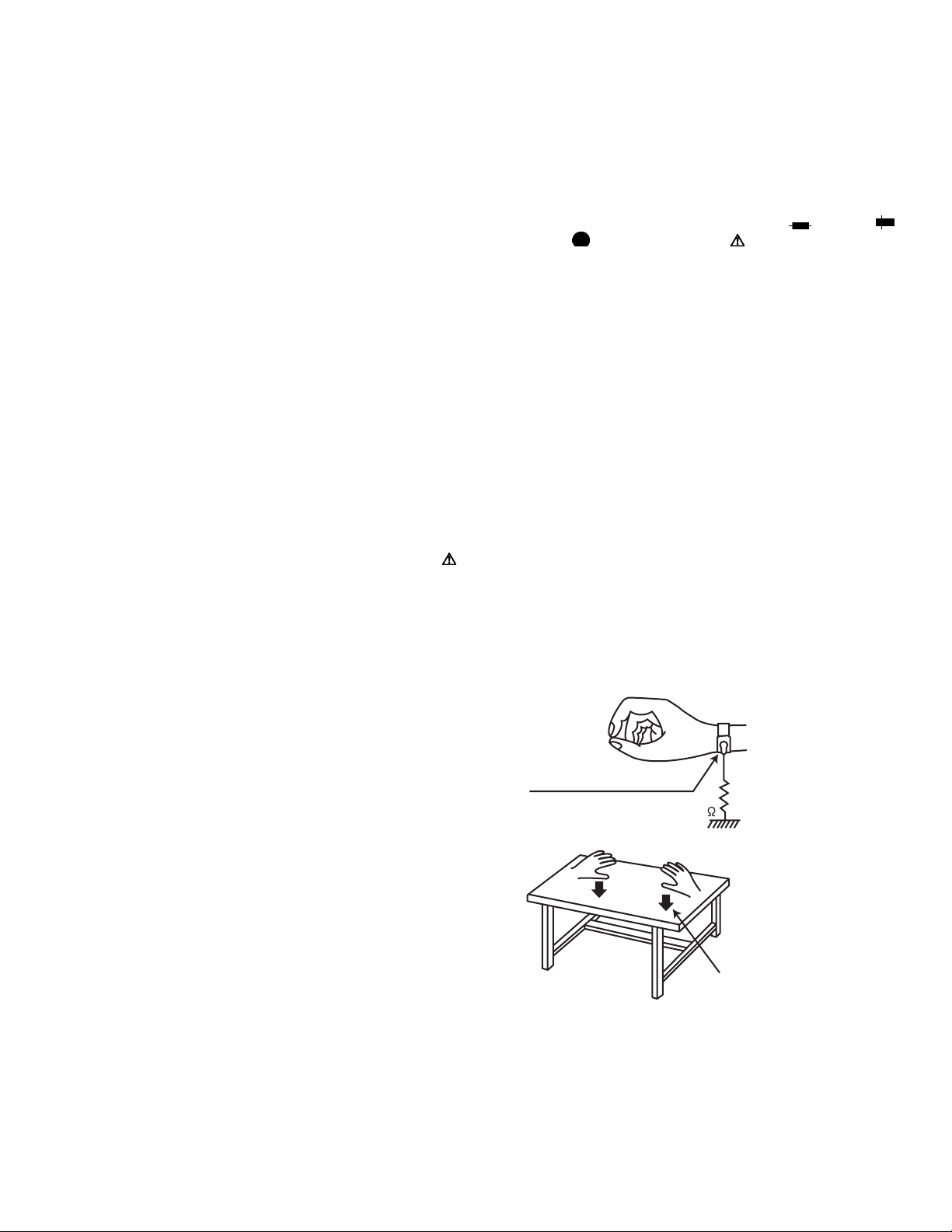

1.6.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup

(laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are

being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such

as a conductive sheet) or an iron plate over it before placing the traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity

built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before

installation, both sides of the laser diode on the replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

(No.MA596<Rev.005>)5/28

Page 6

1.7 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong

shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers,

etc. after replacing the optical pickup. For specific details,

refer to the replacement procedure in the text. Remove the

anti-static pin when replacing the traverse unit. Be careful

not to take too long a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when

subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that ad-

justs the laser power. Do not turn it.

1.9 Important for laser products

1.8 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the

pickup unit.

• Apply solder to the short land sections before the card wire is

disconnected from the connector on the servo board. (If the

card wire is disconnected without applying solder, the pickup

may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land

sections after connecting the card wire.

SOLDER

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

(No.MA596<Rev.005>)6/28

Page 7

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

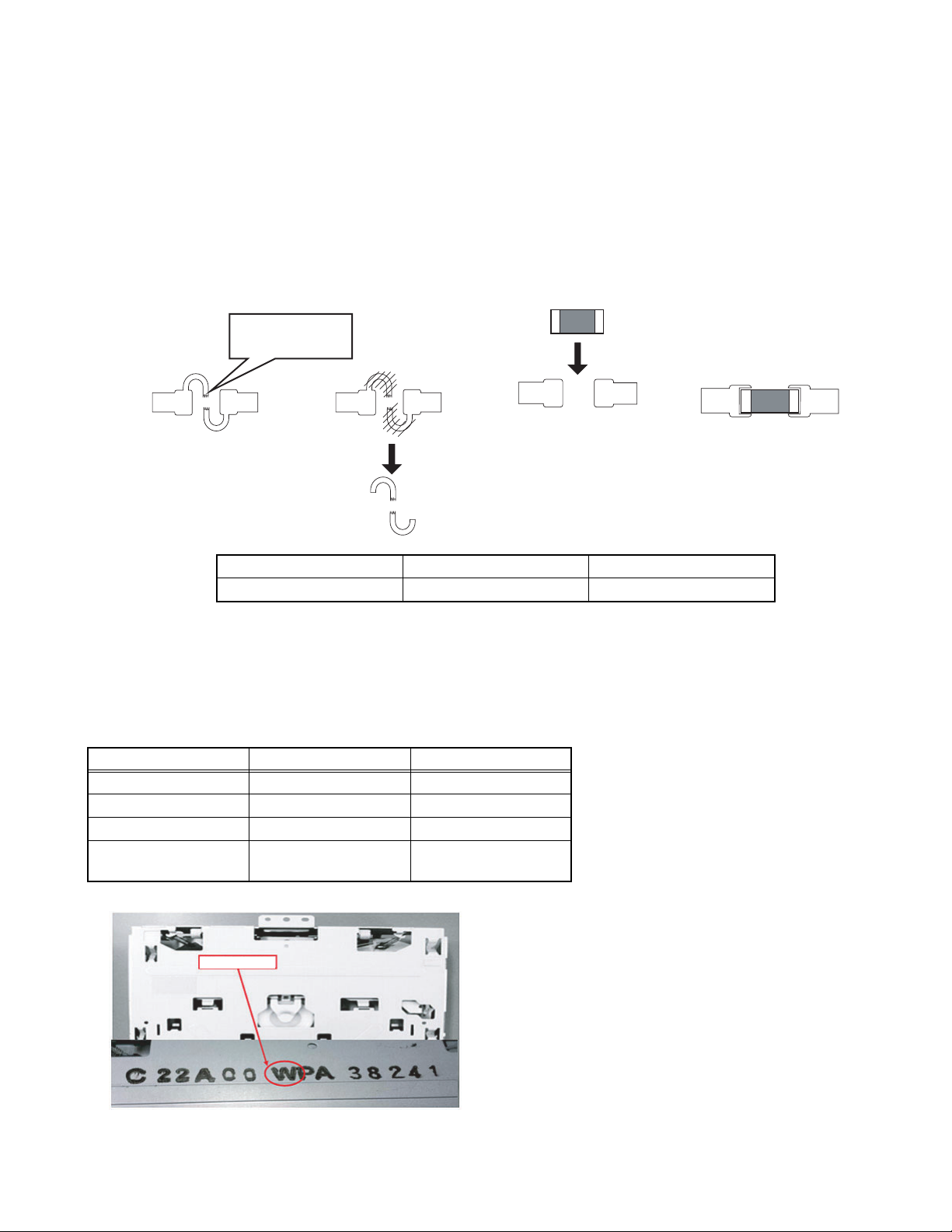

2.1 How to repair a fuse pattern

2.1.1 Purpose of fuse pattern

In order to prevent serious damage on the circuit, fuse pattern is prepared on the GND line of RCA Terminal. This damage may

take due to improper part replacement with a external equipment via RCA line.

2.1.2 Repair Procedure

(1) Check the shorted circuit at the meltdown point.

Need to clean up if the shorted circuit or carbonization happen at the fuse pattern.

(2) Add following part on the fuse pattern.

(3) Check output level.

Meltdown point

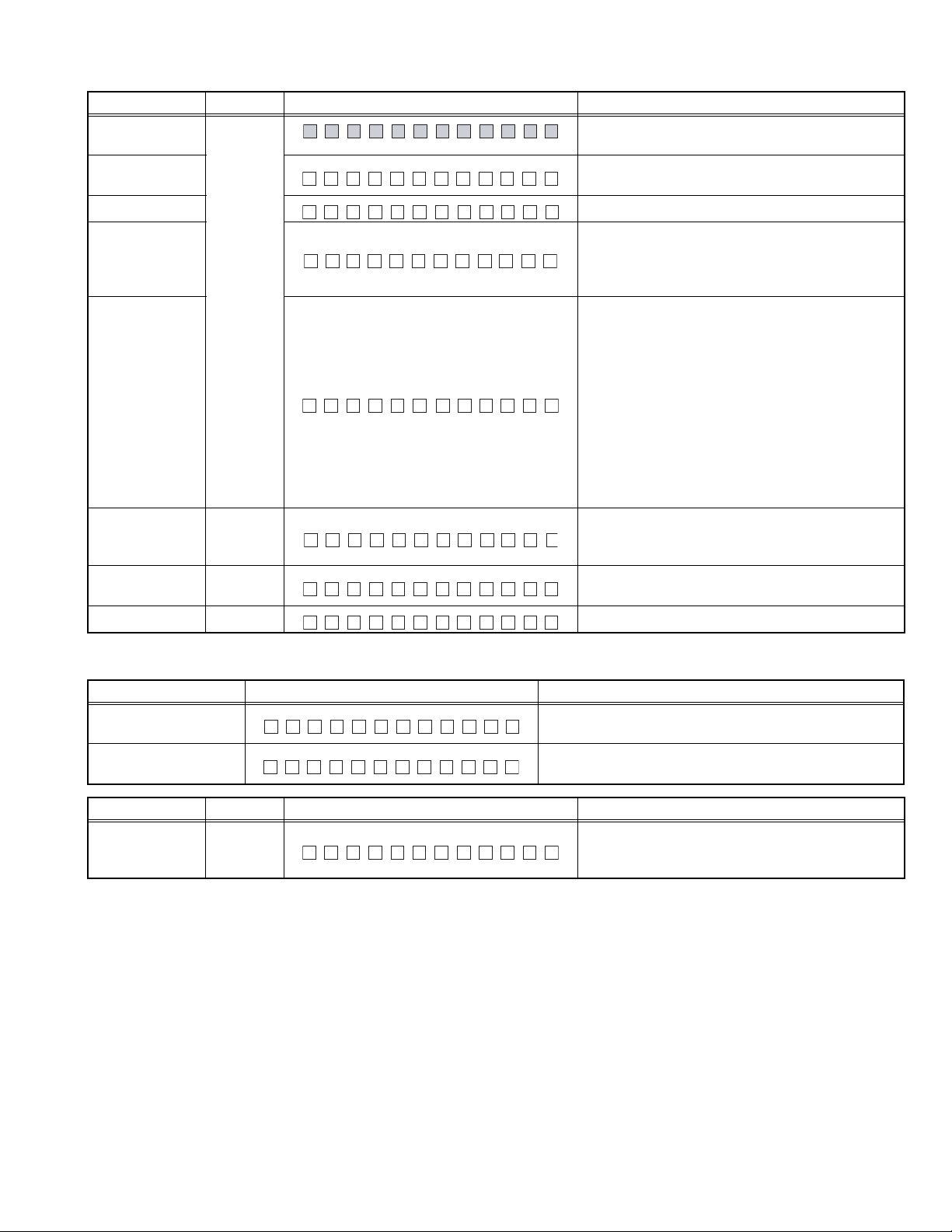

Part Number Part Name SPEC

F53-0513-08 PATTERN FUSE 4A

2.1.3 After finished repair

Due to improper part replacement, this meltdown occurs.

Thus please notice following information when the unit is returned to your customer.

Things to be checked before installing the unit.

(1) Check the GND line of external amplifier or other equipment which must connect properly.

(2) Check whether the GND line is not short-circuited with the battery terminal. (do not short-circuit these lines)

2.2 How to identify the CD mechanism ASSY

Production site Made at JEIN Made at JKEM

CD mechanism ASSY FC2-2A00NXN X92-6820-01

PWB ASSY LVA20106-01A X32-6680-00

PW BOARD LVB20106-001B J76-0898-12

Identification number

Identification number of the 14 characters are printed on the CD mechanism ASSY upper surface.

The 7th character

xxxxxxNxxxxxxx

The 7th character is "N".

xxxxxxWxxxxxxx

The 7th character is "W".

(No.MA596<Rev.005>)7/28

Page 8

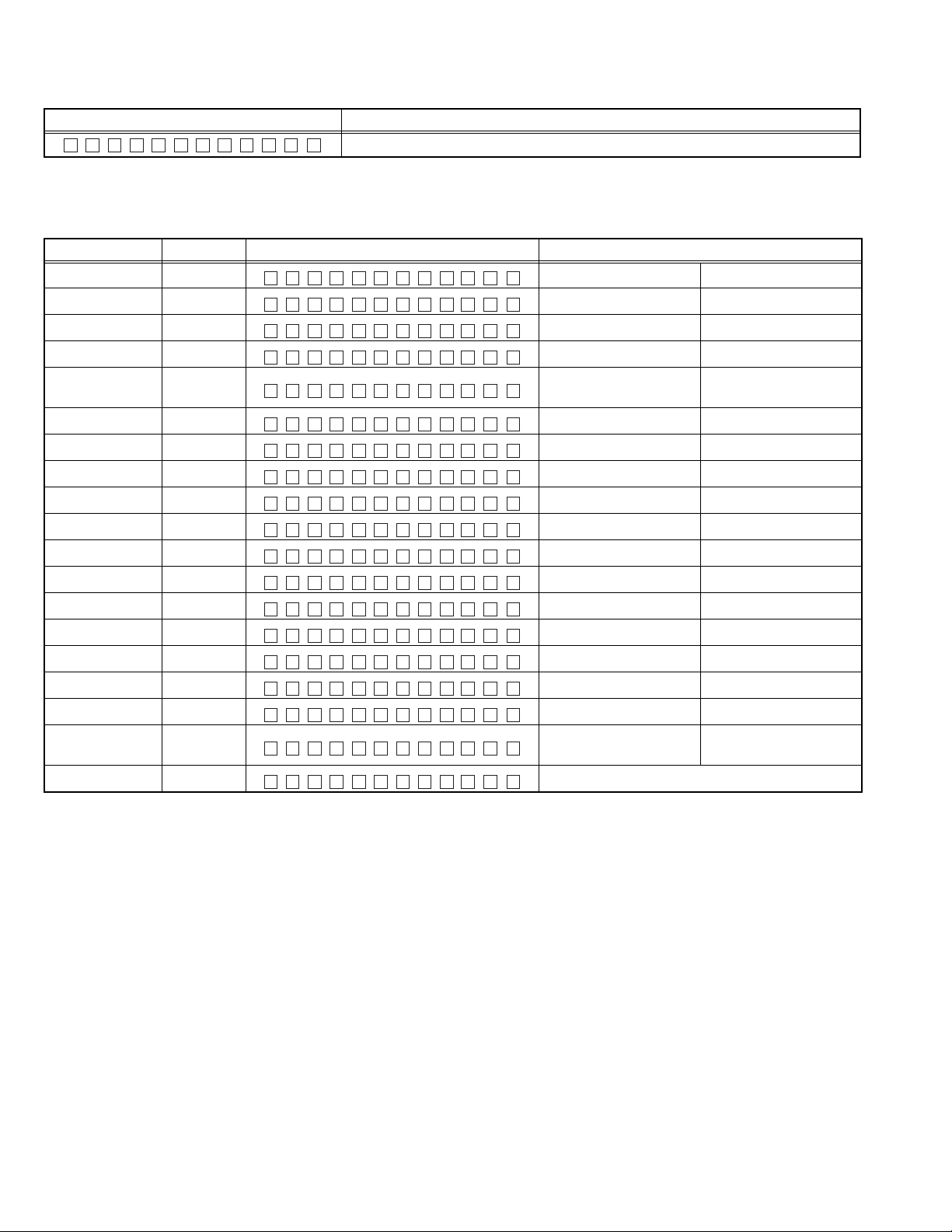

2.3 MICROCOMPUTER’S TERMINAL DESCRIPTION

IC701 (R5S726A0D216FP) on MAIN PWB ASSY

Pin No. Pin Name I/O Application

1 LCD_INH O Display On/Off Control L: Display OFF/

2 DAB_COM_ON O Enable DAB micon (For DAB model) H: ON/L: OFF

2 NC O No Use (for non DAB model)

3 PVcc - Power supply for I/O circuits

4 NRST O LSI Reset Signal (L: Reset) L: Reset ON/

5Vss -GND

6 PANEL_PON O Supply Control to Panel L: ON/H: OFF

7 DC_ERR2 I Detect DC Clip (for ST Power Amp IC) L: DC Error ON/

8 PWIC_MUTE O Muting Output for Power Amp IC L: Mute ON/H: Mute OFF

9 LCD_CE O LCD Driver IC Chip Enable Output (for LCD Model)

10 Vss - GND

11 LCD_CLK O LCD CLK Output

12 Vcc - Power supply

13 RGB_CLK O I2C Clock Output for RGB Driver (For RGB Model)

13 PCB_TEST_MODE

_RX

14 LCD_DATA_SYS O LCD DATA Output (for LCD Model)

14 LCD/

RGB_DATA_SYS

14 PCB_TEST_MODE

_TX

15 USB_PON O Enable Output for High Side Switch L: HisideSW OFF/

16 PVcc - Power supply for I/O circuits

17 BT_DATA_BT I BT Data Input (For BT model only)

17 NC O No Use (for non BT model)

18 Vss - GND

19 BT_DATA_SYS O BT Data Output (For BT model only)

19 NC O No Use (for non BT model)

20 Vcc - Power supply

21 PWIC_STBY O Output to Power On Power Amp IC L: Standby/H: Play

22 SXM_DATA_SXM I SXM Data Input (For SXM model only)

22 NC O No Use (for non SXM model)

23 SXM_DATA_SYS O SXM Data Output (For SXM model only)

23 NC O No Use (for non SXM model)

24 DEBUG_1A O For Debug

24 DAB_CLK_SYS O Clock to DAB (for DAB model only)

24 HD_CLK_SYS O Clock to HD Decoder (for HD model only)

25 DEBUG_1B O For Debug

25 DAB_CS_SYS O Command Request from main micon to DAB micon (for DAB model)

25 HD_CS_SYS O Command Request from SYS-com to HD (for HD model)

26 DEBUG_1C O For Debug

26 DAB_DATA__SYS O DAB Data Output (for DAB model only)

26 HD_DATA_SYS O HD Data Output (for DAB model only)

27 DAB_DATA_DAB I DAB Data Input (for DAB model only)

I PCB Test Mode RX

O LCD and RGB DATA Output (for RGB Model)

O PCB Test Mode TX

Processing/Operation/

Description

H: Display ON

H: Reset OFF

H: DC Error OFF

H: HisideSW ON

(No.MA596<Rev.005>)8/28

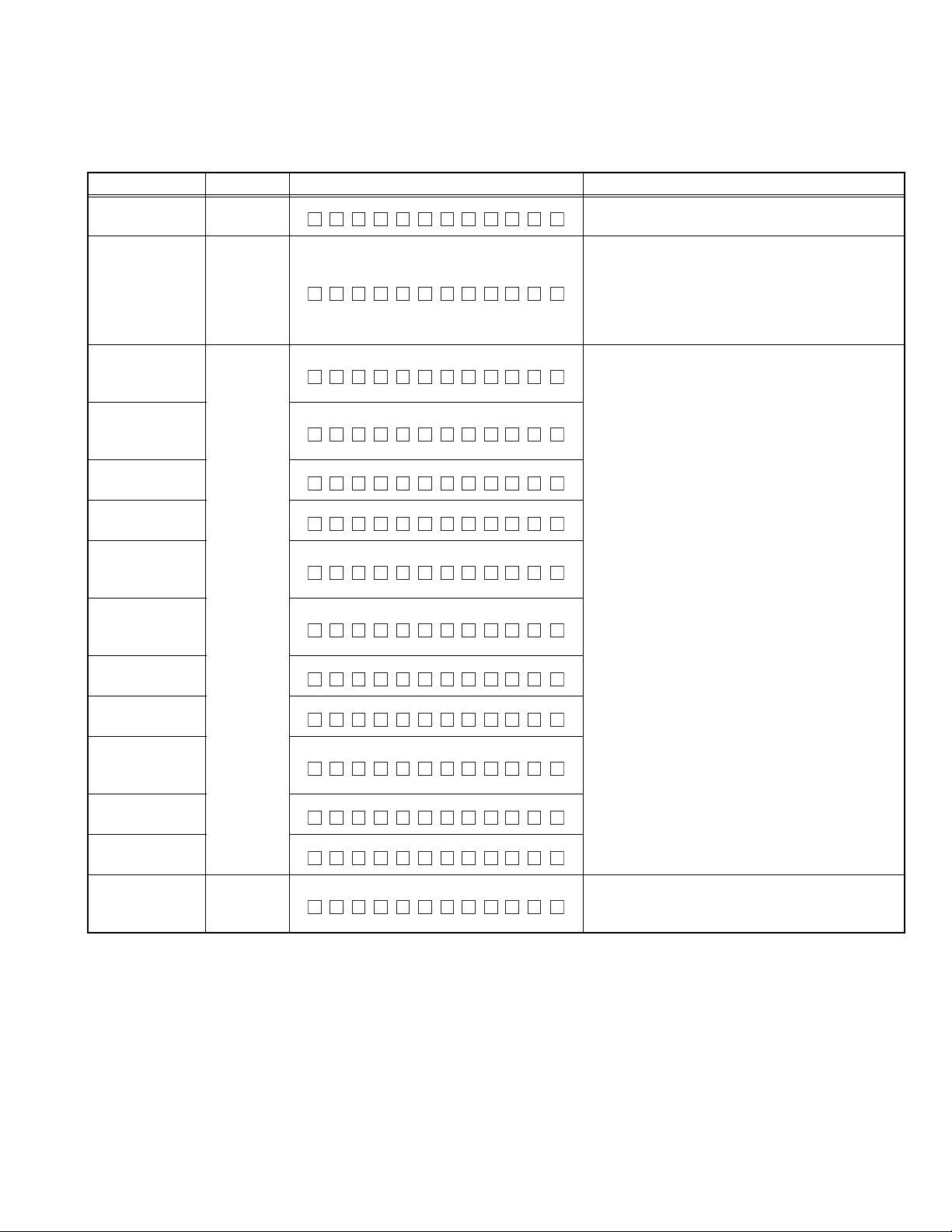

Page 9

Pin No. Pin Name I/O Application

27 HD_DATA_HD I HD Data Input (for HD model only)

28 PVcc - Power supply for I/O circuits

29 FREQ_SEL O Frequency Select Pulse: Power On/

30 Vss - GND

31 ENC2 I Volume Encoder Pulse Input 2

32 ENC1 I Volume Encoder Pulse Input 1

33 REMO I Remocon Input L (Pulse): Remote control

34 STAT I DSP Status Signal

35 SW1 I CD Mecha SW1

35 DEBUG_2A O For Debug

36 PVcc - Power supply for I/O circuits

37 NC O No Use

38 Vss - GND

39 RESET I Reset Input

40 Vss - GND

41 PLLVcc - Power supply for PLL

42 PAN_DET I Panel Detection input L: Panel Attached/

42 NC I No Use (for non detachable model)

43 Vcc - Power supply

44 EXTAL I High Speed Clock 12MHz

45 XTAL O High Speed Clock 12MHz

46 Vss - GND

47 Vss - GND

48 PVcc - Power supply for I/O circuits

49 D-0 I/O USB Data- 0

50 D+0 I/O USB Data+ 0

51 ASEMD I ASE Mode Select Pin

52 PSW I CD Mecha Position Setting SW (Reset Switch)

53 BT_MUTE I BT Mute L: Mute OFF/H: Mute ON

53 NC I No Use (for non BT model)

54 STAGE2 I Model Selecting Input 2

54 STEERING_REMO2I OE Remote In 2 (for DOP models)

Processing/Operation/

Description

L: Power Off

data/H: Standby

H: Panel Detached

55 STAGE1 I Model Selecting Input 1

55 STEERING_REMO1I OE Remote In 1 (for DOP models)

56 TEL_MUTE I Tel Mute Detection Input (for JVC Model)

56 LINE_MUTE I Line Mute Detection Input (For KWD Model)

56 NC I No Use (for non support Tel mute model)

57 DC_ERR1 I Detect DC Offset Error from EVOL IC L: DC Error ON/

H: DC Error OFF

58 Avss - GND

59 Avcc - Power Supply

60 Avref - Reference Power Supply

61 TRST I Debugging Interface. Reset Input.

62 ASEBRKAK/ASE-

BRK

I/O Emulator Break Mode Acknoledge/Break Input

(No.MA596<Rev.005>)9/28

Page 10

Pin No. Pin Name I/O Application

63 TDO O Debugging Interface. Serial Output for Instructions and Data

64 TDI I Debugging Interface. Serial Input for Instructions and Data

65 TMS I Debugging Interface. Test Mode Select Signal Input.

66 TCK I Debugging Interface. Test Clock Input.

67 NC O No Use

68 NC I No Use

69 PVcc - Power supply for I/O circuits

70 SPBCLK O FLASH SPI Multi I/O Bus Clock output

71 Vss - GND

72 SPBSSL O FLASH SPI Multi I/O Bus Slave Select Output

73 SPBIO0 I/O FLASH SPI Multi I/O Bus I/O Data 0

74 SPBIO1 I/O FLASH SPI Multi I/O Bus I/O Data 1

75 SPBIO2 I/O FLASH SPI Multi I/O Bus I/O Data 2

76 Vss - GND

77 SPBIO3 I/O FLASH SPI Multi I/O Bus I/O Data 3

78 Vcc - Power supply

79 MD_CLK I Clock Mode Set (Power ON Reset)

EXTAL Pin Input Clock Ranges from 10 to 12 MHz

80 MD_BOOT I BOOT Mode Set L: Boot mode 0/

81 DRV_MUTE O Motor Driver Control

81 DEBUG_2C O For Debug

82 PVcc - Power supply for I/O circuits

83 DAB_PON O Control 3..3V power for DAB Module (for DAB model only) H: ON/L: OFF

83 HD_PON O Control 3.3V power for HD module (for HD model only) HD source= H: ON/

83 NC O No Use (for non DAB/non HD model)

84 Vss - GND

85 MUTE O Muting Output for Evol & Line Out L: Mute ON/H: Mute OFF

86 Vcc - Power supply

87 BT_RST O BT Reset Output (For BT model) L: Reset ON/

87 NC O No Use (for non BT model)

88 PON_DCDC6V O Enable Output for DC-DC Regulator

89 LCD_DATA_LCD I LCD DATA Intput (for LCD Model)

90 DAB_REQ_DAB I Command Request from DAB micon to main micon

90 NC O No Use (for non DAB model)

91 EVOL_SCL I/O I2C Clock 391kHz for E-Vol

91 EP_SCL I/O I2C Clock 391kHz for E2PROM

91 TU_SCL I/O I2C Clock 391kHz for Tuner

92 EVOL_SDA I/O I2C Data for E-Vol

92 EP_SDA I/O I2C Data for E2PROM

92 TU_SDA I/O I2C Data for Tuner

93 IPOD_SCL O iPod Authentication IC I2C Clock Clock speed 23kHz

93 NC O No Use (For non-iPod Model)

94 IPOD_SDA O iPod Authentication IC I2C Data

94 NC O No Use (For non-iPod Model)

95 REG_SCL O I2C Clock for Regulator IC

96 REG_SDA O I2C Data for Regulator IC

Processing/Operation/

Description

H: Boot mode 1

Other source= L: OFF

H: Reset OFF

(No.MA596<Rev.005>)10/28

Page 11

Pin No. Pin Name I/O Application

97 CD_DSP_SW O CD DSP Switch L: Other sources/

98 DIM_IN I Dimmer Control Input (for JVC Model) L: Dimmer Detect ON/

98 NC O No Use (For KWD Model) keep L output setting

99 REG_FLG I Power Detection L: Detect OFF/

100 Vss - GND

101 PVcc - Power supply for I/O circuits

102 MLD O Microcontroller Command Load Signal

103 BCLK I Servo DSP Data Bit Clock

104 LRCK I Servo DSP Data Word Clock

105 CD_SRDATA_CD I Servo DSP Data Input

106 CD_SRDATA_SYS O Servo DSP Data Output

107 Vss - GND

108 MCLK O Microcontroller Command Clock Signal

109 Vcc - Power supply

110 MDATA O Microcontroller Command Data Signal

111 TU_RST O HELIO/CAYMAN (HD) Reset L: Reset ON/

111 NC O No Use (For non DAB/HD model)

112 PVcc - Power supply for I/O circuits

113 SXM_PWR O Power Supply for SXM (For SXM model only) L: PWR Off/H: PWR On

113 NC O No Use (for non SXM model)

114 Vss - GND

115 DRV_CNT O Loading Motor Control Output

116 BEEP O Output for Beep Tone Generator H (Pulse): BEEP/L: OFF

117 DRV_Lo/Ej O Loading Motor Control Output

118 PCB_TEST_MODE I PCB Test Mode Switch L: Normal Mode/H: Check

118 WDT O Watch Dog Timer output L: Normal Mode /

119 SW2 I CD Mecha SW2

119 DEBUG_2B O For Debug

119 Field Test 2 O RDS data log output (standby for field test)

120 BLKCK I Sub-Code Block Clock Signal

120 Field Test 1 O RDS data log output (standby for field test)

Processing/Operation/

Description

H: CD USB SD source

H: Dimmer Detect OFF

H: Detect ON

H: Reset OFF

Mode (After Reset software need to check the pin

input. If detect high it

should enter Serial Number mode)

H: Reset by WDT

(No.MA596<Rev.005>)11/28

Page 12

SECTION 3

DISASSEMBLY

3.1 Main body

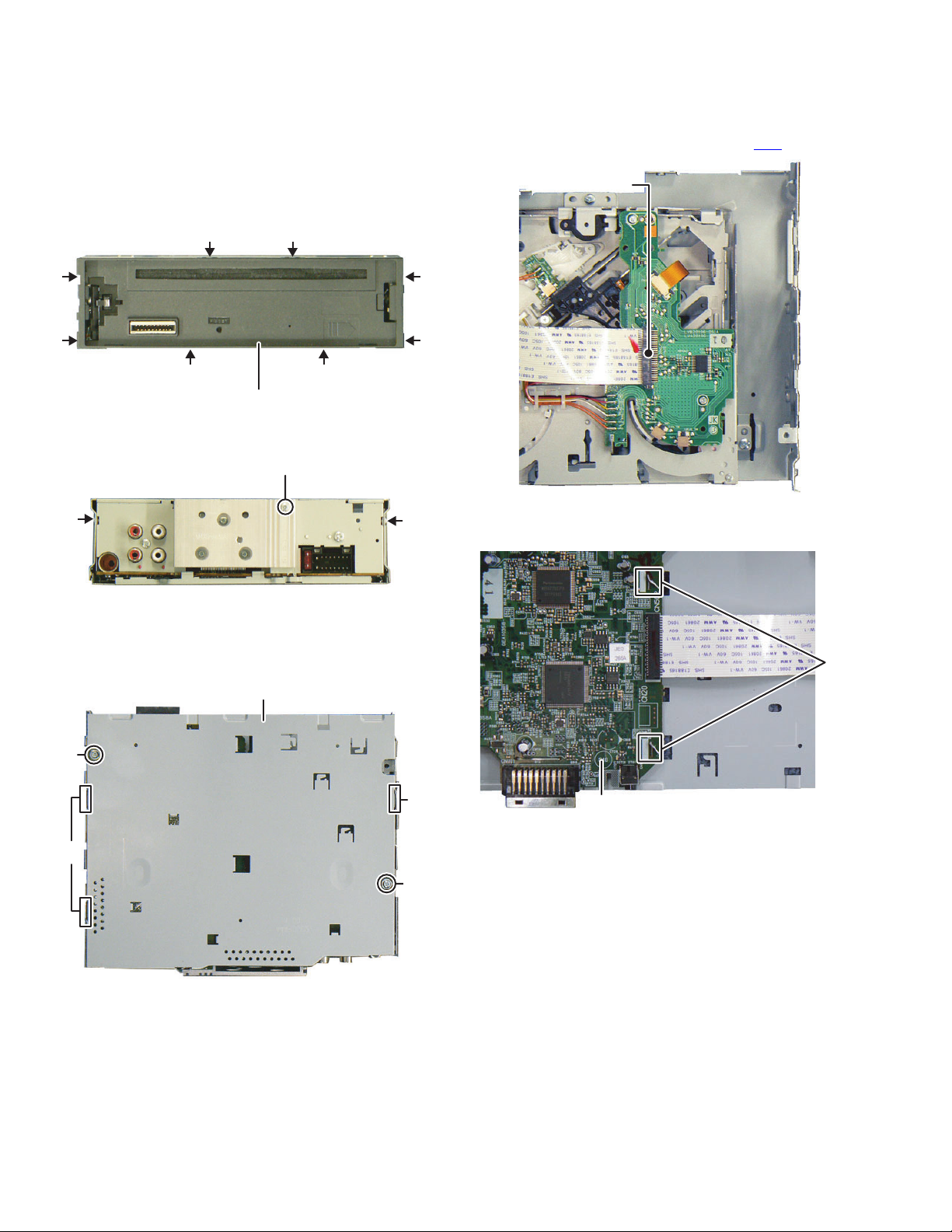

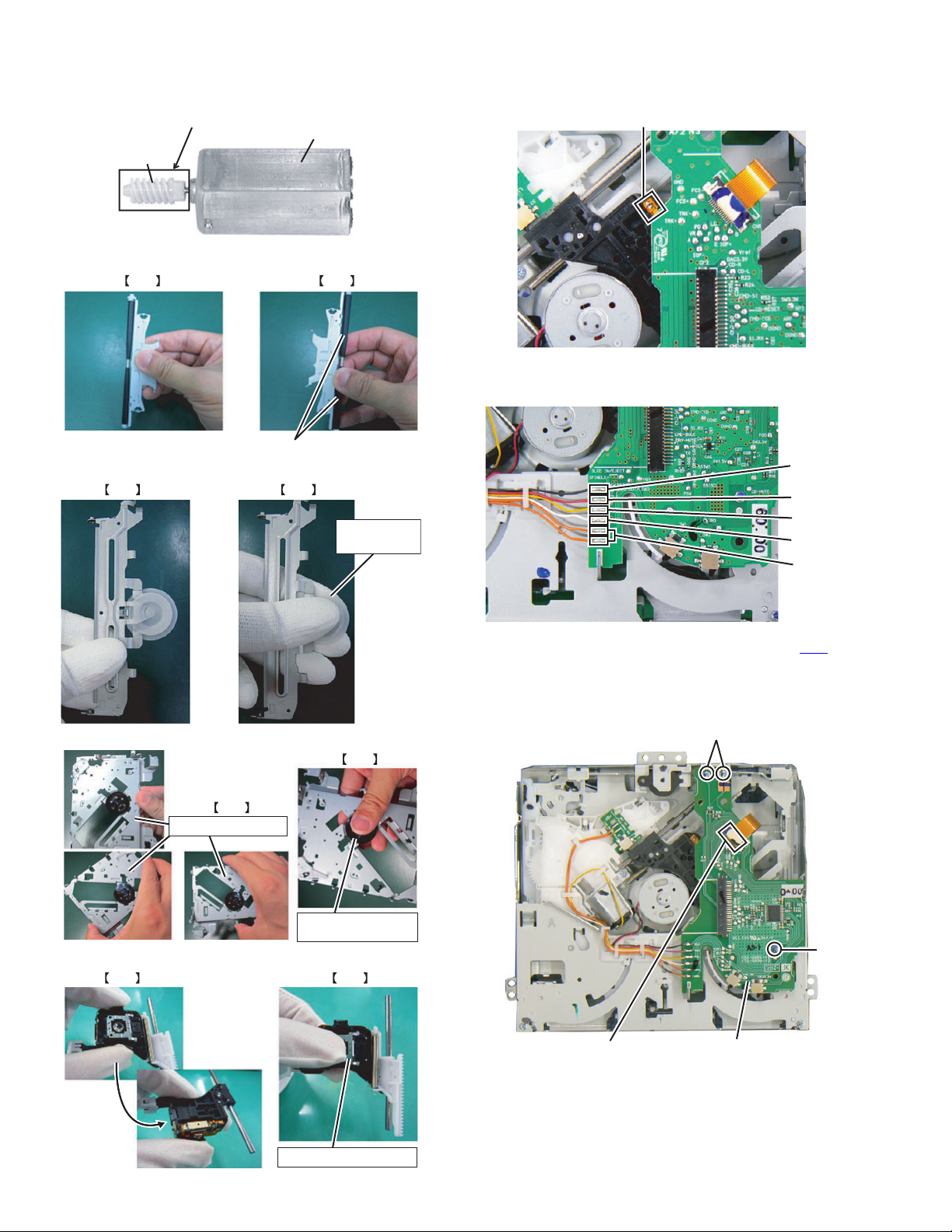

3.1.1 Removing the MAIN PWB (See Fig.1 to 5)

(1) Disengage the 8 hooks a, and remove the FRONT CHAS-

SIS ASSY.

(See Fig.

1)

aa

a

a

aa

FRONT CHASSIS ASSY

Fig.1

(2)

Remove the 1 screw A and 2 screws B. (See Fig.

2)

A

B

B

(5) Disconnect the FFC wire from connector CN1

CN1

. (See Fig.4)

a

a

Fig.4

(6) Disengage the 2 hooks c, and remove the MAIN PWB.

(See Fig.5)

Fig.2

(3) Remove the 2 screws C. (See Fig.3)

(4) Disengage the 3 hooks b, and remove the BOTTOM

COVER with MAIN PWB.

(See Fig.3)

BOTTOM COVER

C

b

b

C

Fig.3

c

MAIN PWB

Fig.5

(No.MA596<Rev.005>)12/28

Page 13

3.1.2 Removing the CD MECHANISM (See Fig.6)

(1) Remove the 3 screws D, and remove the CD

MECHANISM. (See Fig.6)

3.2 CD mechanism

• NOTICE FOR HANDRIG OF MECHANISM ASSY

OK

Handle CHASSIS part.

NG

Do not stay MECHANISM ASSY in upside-down condition

for 1 hour and more.

D

CD MECHANISM

Fig.6

3.1.3 Removing the SWITCH PWB (See Fig.7)

(1) Remove the VOLUME KNOB.

(2) Remove the 4 screws E.

(3) Disengage the 14 hooks d, and remove the REAR

COVER.

(4) Remove the SWITCH PWB.

E E

Do not touch P.C.B..

d dd d dd d

d

d

d

Do not touch

PICK UP ASSY.

d ddd

EE

REAR COVER

Fig.7

TOP SIDE BOTTOM SIDE

NG

Do not touch DAMPER.

NG

DO NOT TOUCH AREA

DO NOT TOUCH HOLES, MOTOR, DAMPER, PCB, FFC, OPU AND WIRE.

• THESE PARTS NEED CAUTION OF HANDLING

CAUTION:

Don't touch the following parts in particular by the hand which

touched grease. (It becomes a cause of traction problem)

HC TURN TABLE TRIGGER ARM

(No.MA596<Rev.005>)13/28

CAUTION PARTS

ROLLER DISC GUIDE

Page 14

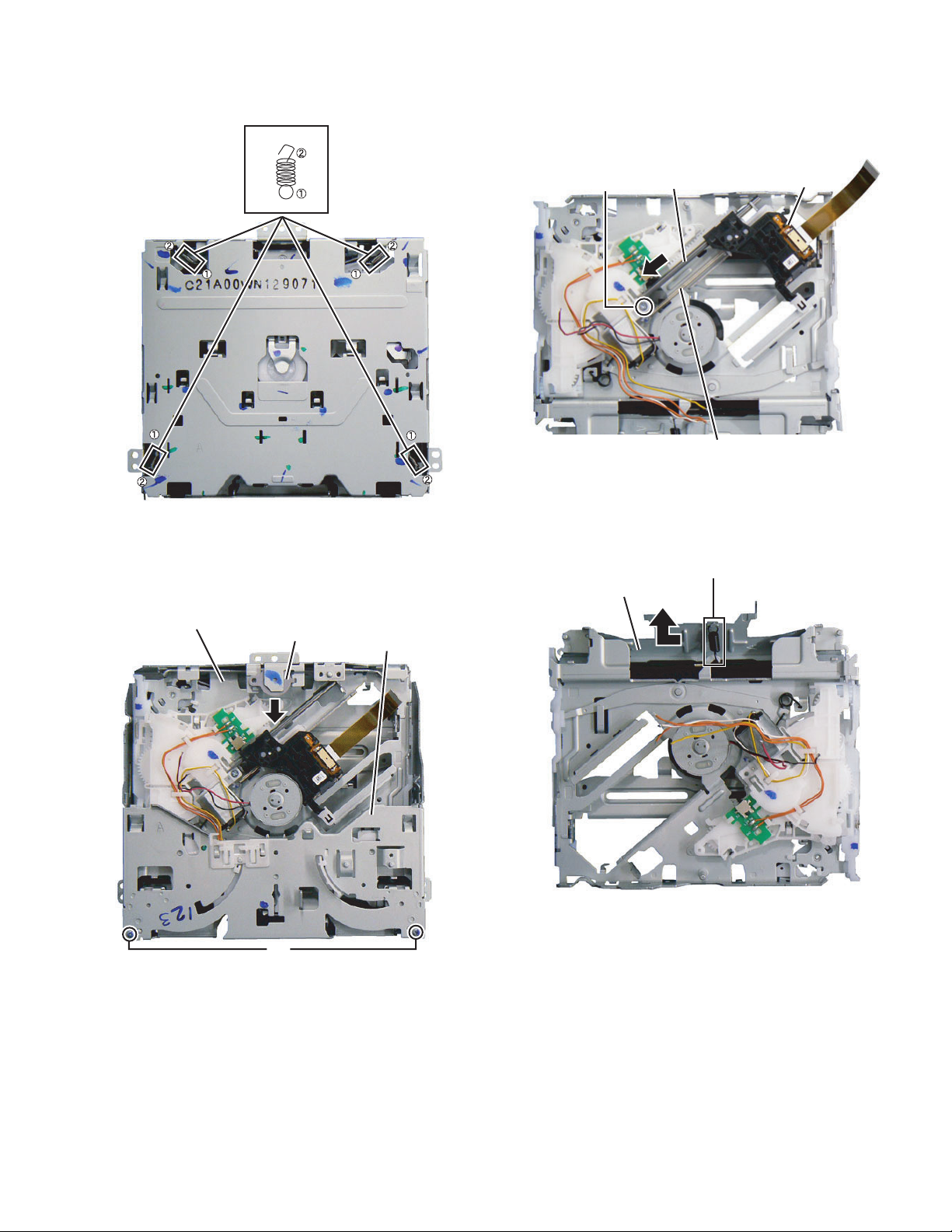

• NOTICE FOR HANDRIG OF FEED MOTR ASSY

CAUTION: For mounting FEEDMOTOR ASSY, DON'T bump this part.

Because handling may cause this part easily deformed.

FEED MOTOR

WORM 1

• NOTICE FOR HANDRIG OF ROLLER LEVER ASSY

OK

Do not handle roller part.

NG

• NOTICE FOR CLAMPER ASSY OF PICK UP ASSY

OK NG

Do not handle

the clamper part.

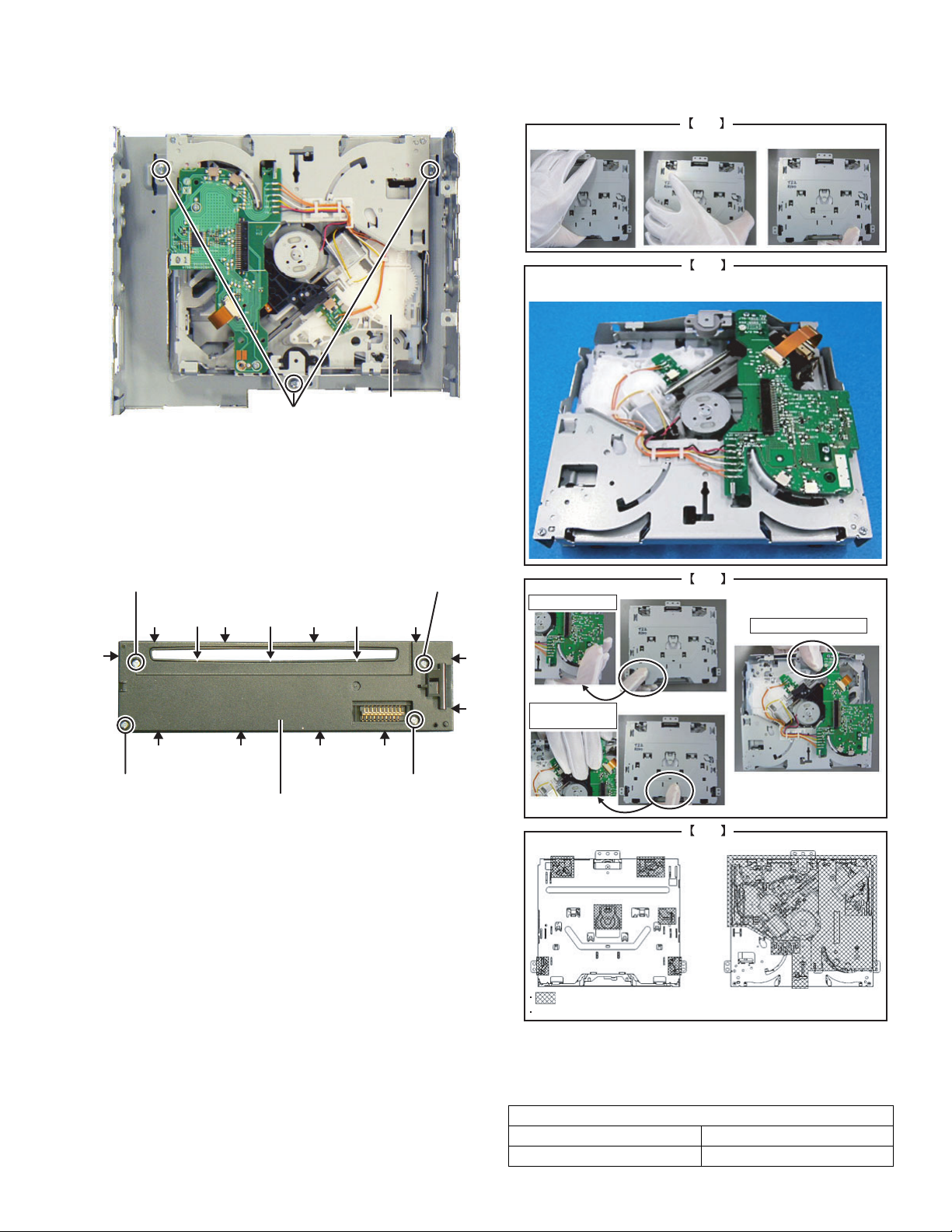

3.2.1 Removing the CD MECHA PWB (See Fig.1 to 3)

(1) Solder the short land on the PICKUP. (See Fig.1)

SOLDER

Fig.1

(2) Remove the 6 wires from the CD MECHA PWB. (See

Fig.2)

Black

Red

Yellow

Orange

White

Orange

• NOTICE FOR HANDRIG OF MD CHASSIS ASSY

NG

OK

Handle CHASSIS part.

Do not handle the

turn table part.

• NOTICE FOR HANDRIG OF PICK UP ASSY

OK NG

Fig.2

(3) Disconnect the FPC wire from the connector CN1 (CD

Player unit). (See Fig.3)

(4) Remove the 3 screws A, and remove the CD MECHA

PWB. (See Fig.3)

A

A

CN1

CD MECHA PWB

Fig.3

Do not handle the lens part.

(No.MA596<Rev.005>)14/28

Page 15

3.2.2 Removing the TRAVERSE MECHANISM (See Fig.4, 5)

(1) Remove the 4 springs from the TRAVERSE MECHANISM.

(See Fig.4)

SPRING

3.2.3 Removing the PICKUP ASSY (See Fig.6)

(1) Remove the 1 screw C.

(2) Remove the MAIN SHAFT in the direction of the arrow.

(3) Remove the SPRING.

(4) Remove the PICKUP ASSY.

Fig.4

(2) Remove the 2 screws B.

(See Fig.5)

(3) Remove the DAMPER in the direction of the arrow.

(See Fig.5)

(4) Remove the TRAVERSE MECHANISM. (See Fig.5)

TRAVERSE MECHANISM

DAMPER

LOWER CHASSIS

MAIN SHAFT

C

SPRING

Fig.6

3.2.4 Removing the ROLLER LEVER ASSY (See Fig.7)

(1) Remove the SPRING.

(2) Remove the ROLLER LEVER ASSY in the direction of the

arrow.

SPRING

ROLLER LEVER ASSY

PICKUP ASSY

B

Fig.5

Fig.7

(No.MA596<Rev.005>)15/28

Page 16

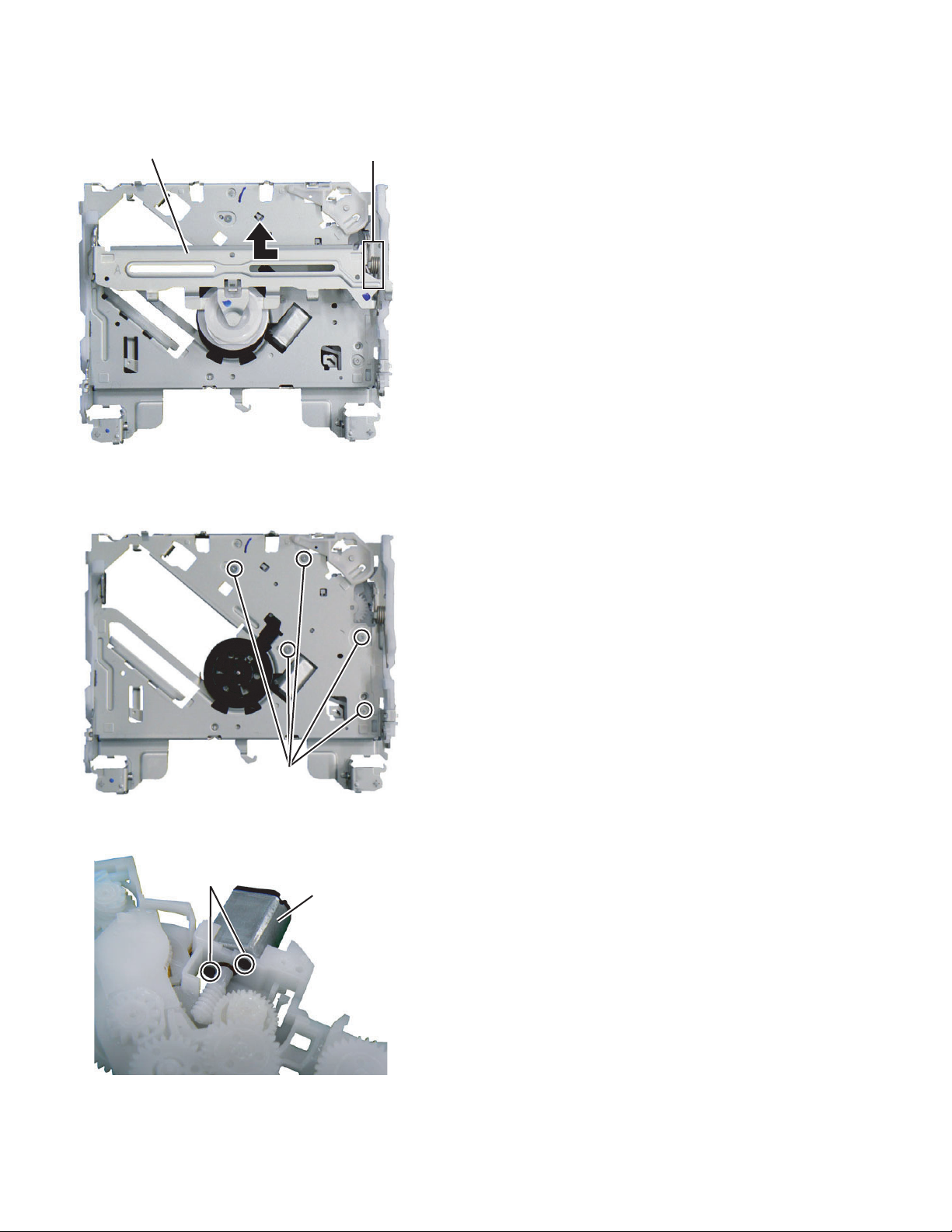

3.2.5 Removing the CLAMP ARM ASSY (See Fig.8)

(1) Remove the SPRING.

(2) Remove the CLAMP ARM ASSY in the direction of the

arrow.

CLAMP ARM ASSY

Fig.8

3.2.6 Removing the FEED MOTOR (See Fig.9, 10)

(1) Remove the 5 screws D, and remove the FEED MOTOR

ASSY. (See Fig.9)

SPRING

D

Fig.9

(2) Remove the 2 screws E, remove the Feed motor.

(See Fig.10)

E

Feed motor

Fig.10

(No.MA596<Rev.005>)16/28

Page 17

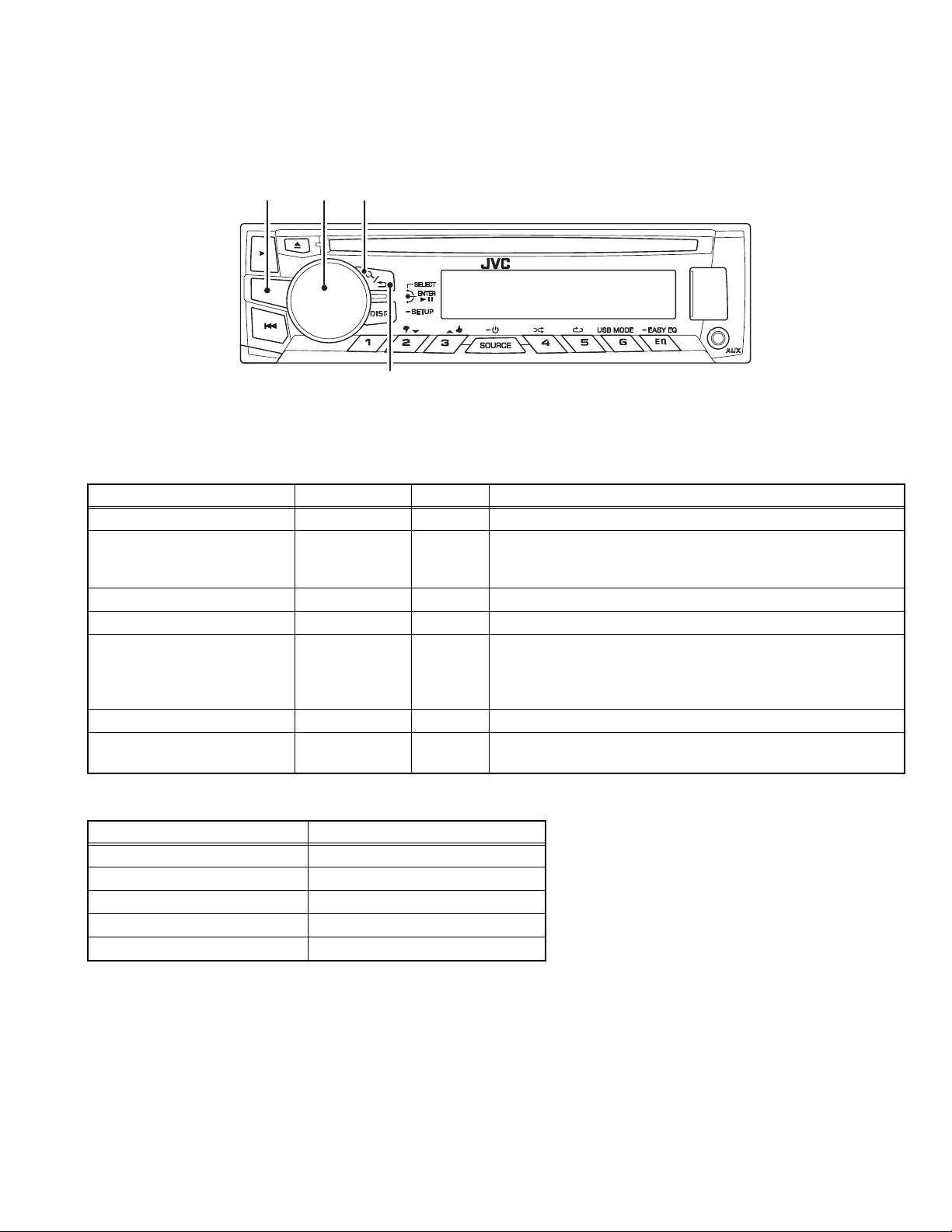

SECTION 4

ADJUSTMENT

4.1 Outline

4.1.1 Panel

ACCENT SEARCHVOL

RETURN

A symbol "" in the key column indicates that the key should be pressed and held for 1 second or longer.

4.1.2 Test Modes

These test modes are available in normal production ROM.

Transition to Test Mode shall be available during DC Error detection.

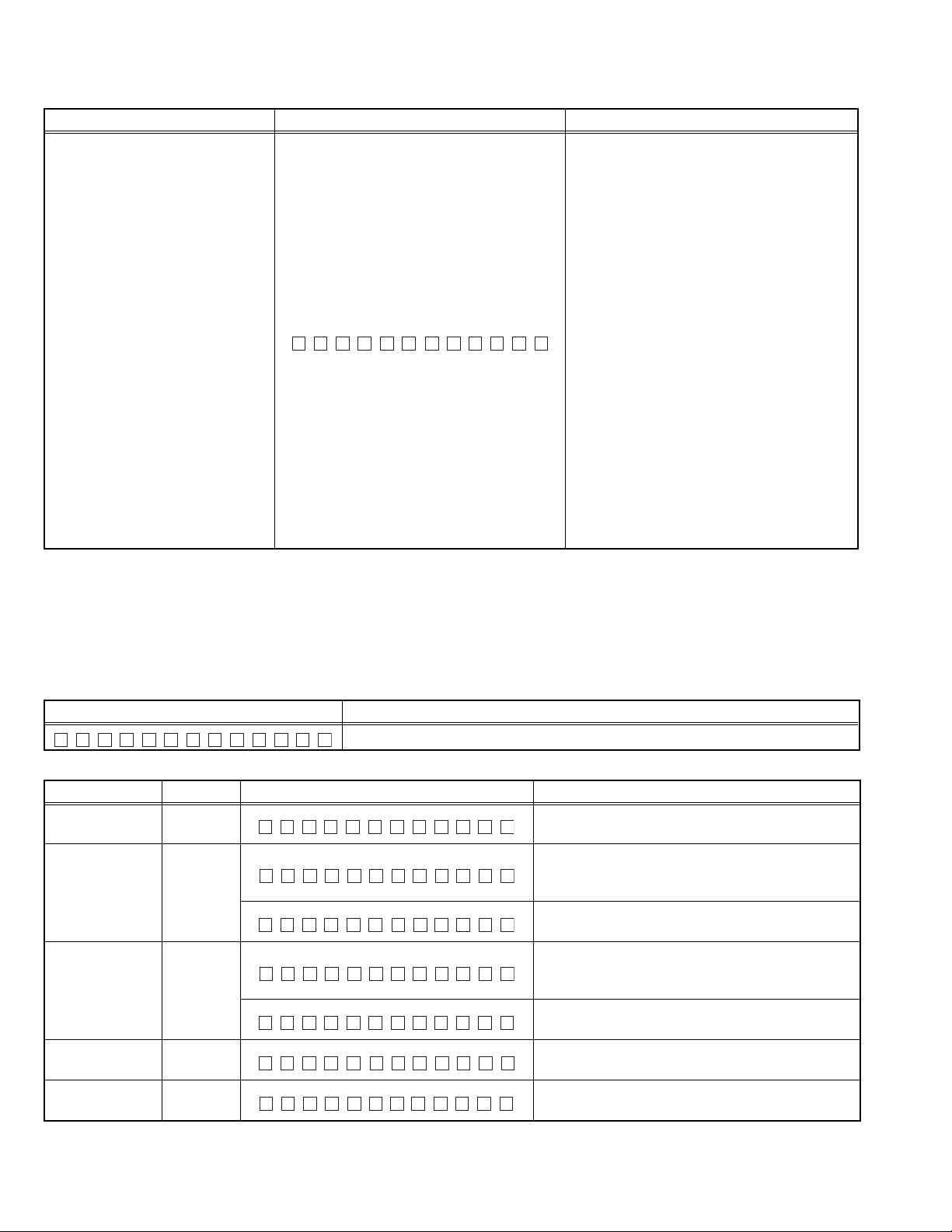

Test Mode Mode Source Operation

Production Test Mode - All Press and hold [DISP] key and [SOURCE] key and reset.

Service Test Mode Normal Mode /

Production Mode

Service Information Clear Mode - All Press and hold [RETURN] key and [SOURCE] key and reset.

DC Error Information Mode - All Press and hold [DISP] key and [] key and reset.

DOP Test Mode Normal Mode All Pressing and holding [SELECT] key, press [DISP] key for 7 sec-

HC Mecha Running Mode - All Press and hold [SOURCE] key and [EJECT] key and reset.

Tunisia Area /

Tuner Span Change Mode

4.1.3 Release from Test Mode

These actions will release the Test Mode and transit back to Normal Mode

Normal Mode All Pressing and holding [VOL] key, press [RETURN] key for 3 sec-

All Pressing and holding [DISP] key, press [] key for 7 seconds.

(Starting to press [DISP] key and [] key at the same time can not

be entered into the mode)

onds.

(Starting to press [SELECT] key and [DISP] key at the same time

can not be entered into the mode)

onds.

Method Remarks

Reset All Modes

Momentarily voltage drop All Modes

ACC OFF All Modes

POWER OFF All Modes

Panel Detach All Modes

(No.MA596<Rev.005>)17/28

Page 18

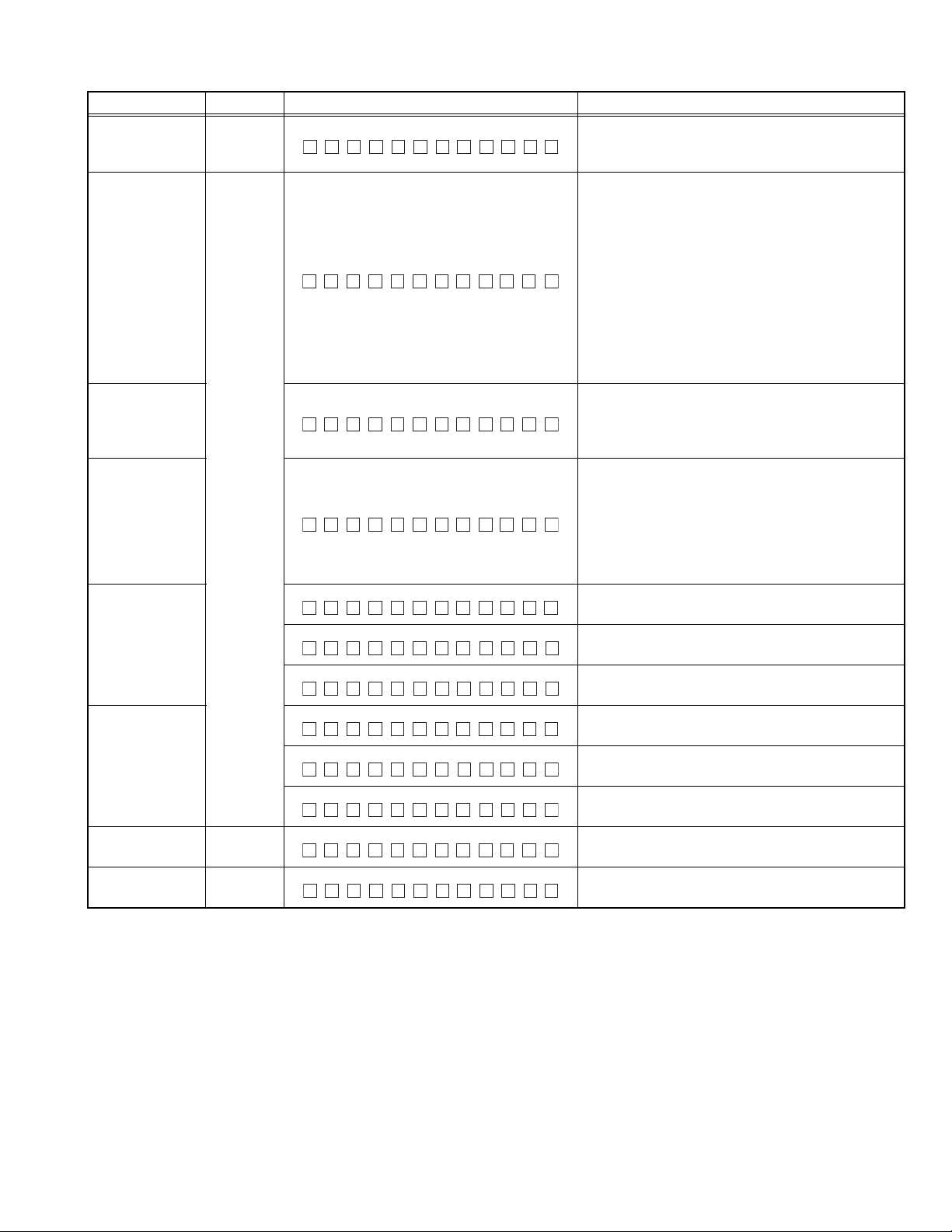

4.2 Production Test Mode

Press and hold [1] key and [3] key and reset.

4.2.1 Test Mode Defaults

During Production Test Mode, the following settings defer from the Normal Mode.

The settings will change immediately after mode activation.

Difference in action Setting value

Period to prohibit TEL/LINE MUTE function (Normal Mode: 10 secs) 1 second

Mecha Initialize Action Prohibited

Writing-in to E2PROM when DC error is detected Prohibited

"DEMO" item in Setup Menu OFF

Power supply during ACC OFF (Back Up On) MUTE terminal turns OFF after 2 seconds

"BEEP" item in Setup Menu ON

Volume range 0 to 44

Source change interval timer 0 seconds

When detected the 0 bit mute Mute off

Various setting item Setting value

Default Volume 15

"BASS BOOST" OFF

"LOUDNESS" OFF

"TEL MUTING" ON

Initial Source FM (Mechaless Models) /

CD (Non-Mechaless Models)

Language English

EQ FLAT

Fader / Balance Center

Digital Track Expander / Sound Reconstruction Set OFF

"VOL ADJUST" / "VOLUME OFFSET" 0

DEMO Mode Setting OFF

4.2.2 Mode structure

The following table shows the test modes that can be accessed from the different sources in Production Test Mode.

Source Test mode

Tuner TUNER Test Mode

USB USB Test Mode

4.2.3 Mode content

Syscon shall display the following information after entering Production Test Mode.

Display content Details

All lights on (BOTH LCD & LED including dual color switchable)

Set should not be able to power on if sub clock is not functioning.

The display is released when another operation is executed.

4.2.4 Special Operation by Key Input

Behaviour Details

Volume Adjustment to 44

Only during Normal display

(Invalid during Menu)

4.2.5 How to transit to Version Display Mode

Item Operation Display content Details

Transit to Display

Mode

RETURN

Pressing and holding [DISP] key, press [] key for 0.5 seconds.

(Starting to press [DISP] key and [] key at the same time can not be entered into

the mode)

Transit to Version Display Mode

(Default status: All Lights ON)

(No.MA596<Rev.005>)18/28

Page 19

4.2.6 Version Display Mode

Item Operation Display content Details

All Lights ON/

All lights ON

TEST

Syscom version

display

Stage Setting ##: Stage Setting for current hardware

Y–SS##@@@

TSAGE :21 ##

## = File Number

@@@ = Syscon Version Number

Serial No. Display (8 digits)

Serial No. display

SN 00000000

Display to support ASCII characters

********: Blank

@@@@@@@@: EEPROM Read Error

DISP

(Toggle)

## = Blank: Verifying

OK: IC mounted

NG: IC not mounted

iPod IC Mount

Verification Status

Display

(USB models

only)

iPod ##

**: Non iPod support model

In addition, upon entering this mode, P-CON is

turned ON.

When a result is OK, P-CON is turned off.

Upon exit, P-CON remains OFF.

When a result is NG, P-CON is kept ON condition.

Upon exit, P-CON remains ON.

Pre-out Switch

(1 Pre-out / 2 Pre-

EQ

L/O SU B.W

Switch Pre-out with toggle

out model only)

Mode release

SOURCE

Transition

Mode release RETURN

Return to Normal mode

Return to Normal mode

4.2.7 Tuner Test Mode Specification

The following display shall be indicated according to the TUNER status.

Status Display content Details

TUNER IC

Communication Error

RDS/RBDS Specified

data reception

TUN CON NG

DRS STTE

Communication to TUNER IC not available

(indicated unless the mode is in Clock Display Mode).

Turn OFF P-CON forcibly if PS=RDS TEST is received.

P-CON recovers with Power OFF/ON.

Item Operation Display content Details

Display TUNER IC version

TUNER IC display EQ

TA2********

'AT2 ********' is eg "AtomIC2 57V1B101" indicating

"AtomIC2 TEF6657V1B 1.01"

*Not applicable and no function for HD and DAB models

(No.MA596<Rev.005>)19/28

Page 20

4.2.8 USB Test Mode Specification

Applicable for iPod model only.

Status Display content Details

## = Blank: Verifying

NG: IC not mounted

**: Non iPod support model

Upon source change to USB source or USB

device plug in:

Verifying: Show "iPod: ##"

NG: Always show "iPod: NG" even during "NO

DEVICE" or playback.

**: Always show "iPod: **" even during "NO

iPod IC Mount Verification Status

Display

iPod ##

DEVICE"

OK: Change back to nomal display ("NO DE-

VICE / normal playback display).

In addition, upon enter to this mode, P-CON is

turned ON.

When a judgment result is OK, P-CON is

turned off.

Upon exit, P-CON still remain OFF.

When a judgment result is NG, P-CON is kept

ON condition.

Upon exit, P-CON still remain ON.

4.3 Service Test Mode

In the STANDBY source, while pressing and holding [2] key, press [6] key for 7 seconds.

(Starting to press [2] key and [6] key at the same time can not be entered into the mode)

4.3.1 Default status immediately after the mode activation

It shall be same as the normal activation.

4.3.2 Mode content

Syscon shall display the following information after entering this mode.

Display content Details

RSVT TES

Display is released when an operation is executed.

4.3.3 Common operation mode for only STANDBY sources

Item Operation Display content Details

Syscom version

display

6

Y–SS##@@@

## = File Number

@@@ = Syscon Version Number

00 to 50 are displayed in "XX".

Power ON

duration display

OPNTM HX0X

2

OPNTM XXXXX

For less than 1 hour, the display is indicated per 10

minutes.

00001 to 10922 are displayed in "XXXXX".

MAX 10922 (hours)

00 - 50 are displayed in "XX".

Disc action

duration display

Disc Eject No. of

times

Disc Eject No. of

times clear

1 (*1)(*2)

DISP (*2)

DISP (*2)

DCTM HX0X

DCTM XXXXX

JECNT XXXXX

JECNT 00000

For less than 1 hour, the display is indicated per 10

minutes.

00001 to 10922 are displayed in "XXXXX".

MAX 10922 (hours)

00001 to 99999 are displayed in "XXXXX"

Clear Disc Eject number of times by pressing for 2

seconds when it is displayed.

*1 This includes all media (CD, USB, iPod, SD) action duration.

*2: Not applicable for mechaless models

(No.MA596<Rev.005>)20/28

Page 21

4.3.4 CD Error Information Display Mode (Not applicable for mechaless models)

Item Operation Display content Details

CD error

information

display mode

CD Mecha error

log display

ACCENT

(*2)

Transit to CD error information display mode.

Mecha error history 1,2,3 (latest)

#:History No. (1,2,3)

XX: kind of errors, "--" when there is none

00: No Error

EMCHAE # XXR

04: TOC read Error

05: Unknown CD

06: Heat Error

0A: Update Error

0D: Hold Error

15: Unknown Disc

99: Mecha Error

CD Load error

info display

CD Eject error

info display

DISP

(Toggle)

Move

between

items with

/

OLAD E#XXR

JEECT E#XXR

Load error switch 1,2

#: Switch No. (1,2)

XX: numbers of errors, "--" when there is none

History No. 2 is un-used

Eject error switch 1,2,3,4

#: History No. (1,2,3,4)

XX: numbers of errors, "--" when there is none

History No.3 is un-used

History No.1: Eject before SW1 is on.

History No.2: Eject until SW1 and SW2 is on.

History No.3: Eject between SW2 on and Eject end

CD time code

error count

information

display (count

skip)

CD time code

error count

information

display

(no count update)

CD error

information clear

ACCENT

(*2)

Mode release ACCENT

(*2)

NCT OLSE

DCDA XX

DCROM XX

NCT TAYS

DCDA XX

DCROM XX

EMCHA E # --R

CD time code error count information (count skip)

mode display

CD-DA error count numbers

XX: numbers of errors and "--" when there is none

CD-ROM (compressed file) error count numbers

XX: numbers of errors and “--” when there is none

CD time code error count information

(count not updated) mode display

CD-DA error count numbers

XX: numbers of errors and "--" when there is none

CD-ROM (compressed file) error count numbers

XX: numbers of errors and "--" when there is none

Clear CD error information by pressing for 2 seconds

when it is displayed.

CD error information display mode release, back to

Common Mode Operation

*2: Not applicable for mechaless models

(No.MA596<Rev.005>)21/28

Page 22

4.4 Service Information Clear Mode

Press and hold [2] key and [5] key and reset.

4.4.1 Default status immediately after the mode activation

It shall be same as normal activation.

4.4.2 Mode content

After entering this mode, Syscon shall clear the information stored for service and output the result to the display.

CD will be ejected upon process end.

Cleared information changes will take place only after reset.

Display Display content Details

Data Clear in

IIINTALIZE

Data Clearing in Progress

Progress

Data Clear OK Data cleared successfully

Data Clear NG Data cleared with error

TDA A CLR OK

TDA A CLR NG

Display Blinks (250ms interval)

CD is ejected out after the data is being cleared.

The following table shows the data that is cleared.

Information to Clear Details Storage area

CD mecha log display E2PROM

CD load error information display E2PROM

CD mecha information

CD eject error information display E2PROM

CD time code error count information display (count skip) E2PROM

CD time code error count information display (no count update) E2PROM

Service information

DC error information

CD EJECT number of times display E2PROM

Forced Power OFF information display E2PROM

DC error 1 display (wrong connection & other detection information in detecting duration) E2PROM

DC error 2 display (capacitor leakage detection number information) E2PROM

Tuner Area Setting E2PROM

Tuner information

Preset Frequency E2PROM

Preset PI code E2PROM

Tagging information Token data memory index E2PROM

(No.MA596<Rev.005>)22/28

Page 23

4.5 DC Error Information Mode

Press and hold [3] key and [6] key and reset.

4.5.1 Default status immediately after the mode activation

It shall be same as normal activation.

4.5.2 Mode content

Syscon shall display the following information after entering this mode.

Display content Details

DC ERR

DC OK

When DC error is detected

When DC error is not detected

Item Operation Display content Details

DC 1 E R R

DC ERR1display

DC1 OK

When wrong connection & DC error in other detection duration is detected

When wrong connection & DC error in other detection duration is not detected

Clear detection information when wrong connection

DC ERR1 clear

DC1 OK

& DC error in other detection duration is displayed.

(Clear data flash)

Display detecting number of times in capacitor leak-

DC ERR2 display

DC2 4

age detection duration

#: 0 to 4

Clear number of times for detection information in

DC ERR2 clear

DC 2 0

capacitor leakage detection duration. (Clear data

flash)

4.6 DOP Test Mode

Pressing and holding [SELECT] key, press [DISP] key for 7 seconds.

4.6.1 DOP Mode Common Setting

Common settings for all car makers are as follows:

Demo: No demo animation

Remove all DEMO related items

Power on animation: Show carmaker's name

Only opening animation will show "Car maker's name"

Setup menu: Delete Demo

Color setting for RGB model: Refer to manufacturer preference below:

4.6.2 EEPROM DOP Read Error Display

In the case of an EEPROM read error or EEPROM DOP read error, the unit will behave accordingly.

(1) No Power on animation

(2) No Demo animation

(3) Demo removed in setup menu

(4) Color settings set to default

(5) Serial number display replaced by "SN @@@@@@@@"

(No.MA596<Rev.005>)23/28

Page 24

4.6.3 Mode content

1) Enter DOP Mode. Pressing and holding [SELECT] key, press [DISP] key for 7 seconds.

Display content Details

PDO T E ST

2) Select manufacturer setting.

Note: RGB color save as USER color. DEFAULT color set to USER.

The order is priority. Lower Priority brand need to press and hold(2 secs)

: press and hold (2 second) on button mentioned as follow

Display content Operation Display content Color

No Demo 1

Toyota 2

Honda 3

Ford 4

Suzuki 5

Hyundai 6

Mitsubishi

FIAT

Iveco DISP

Alfa Romeo 1

KIA 2

Volkswagen 3

Chevrolet 4

Peugeot 5

Nissan 6

Isuzu

Skoda

Daihatsu DISP

Default RETURN

JVC

TOYOTA

HONDA

FORD

SUZUKI

HYUNDA I

MI TSUBISHI

FIAT

IVECO

ALFA ROMEO

KIA

VOL KSWAGEN

CHE VRO L E T

PEUGEOT

NISSAN

ISUZU

SKODA

DA IHATSU

DEFAUL T

(same as Daihatsu)

Blue

Lime

Blue

Greenish Blue

Yellow Amber

Blue

Apple

White

White

Red

Blue

White

Red

Green

Orange

Red

Yellowish Green

Yellow Amber

(Same as Suzuki)

Return to default JVC normal setting.

7

25

5

3

16

7

14

User

User

13

7

User

13

24

16

13

User (R=22, G=31, B=0)

15

(No.MA596<Rev.005>)24/28

Page 25

4.7 HC Mecha Running Mode

Press and hold [SRC] key and [EJECT] key and reset.

The software specification for evaluating HC Mecha is described.

This mode is set for the general operation test and the endurance running test.

4.7.1 Mode Display Specification for Evaluation

Display content Operation Display content Details

Run Test Display

Running Mode

count display

Enter the

mode

Pressing

and holding

[RETURN]

key and

insert the

RUN T EST

RMOD# *****

Indicated “Running Mode”

*****: Indicated number display

Repeated the eject.

disc

Tracking_gain

adjusted value

TR - GA ####

####: Indicated hex value

display

Focus_gain

adjusted value

FO - G A ####

display

Te_agc adjusted

value display

Rf_agc adjusted

value display

TEAGC ####

RFAGC ####

Te_balance

adjusted value

display

Focus_balance

adjusted value

DISP

(Toggle the

DISP)

TEBAL ####

FOBA L ####

display

TNI offset adjusted

value display

TPI offset adjusted

value display

TN I O F ####

TP I OF ####

TPI_TNI offset

adjusted value

TPTNO ####

display

TEO offset adjusted

value display

FEO offset adjusted

value display

Error Code

display when no

DISP

TE - OF ####

FE - OF ####

Indicated “NO ERROR”

NO E RROR

error

(No.MA596<Rev.005>)25/28

Page 26

4.7.2 ERROR CODE for MODEL with FLM-HCI MECHA (Ver1.1)

DISPLAY SIGN ERROR Item Condition Details

LI-E LOADING TIME OVER

EJ-E EJECT TIME OVER

In LOAD operating. Anomaly detection of SW state at LOADING.

Or 5 sec TIME OVER from LOAD start.

In EJECT operating. Anomaly detection of SW state at EJECT.

Or 5 sec TIME OVER from EJECT start.

E-04 READ ERROR In RUNNING MODE operating TOC read error.

E-14 FOCUS ERROR In RUNNING MODE operating Focus Error. No complete Focus ON.

E-05 UNKNOWN DISC In RUNNING MODE operating No reflection.

E-20 NODISC ERROR In RUNNING MODE operating In case of DISC distinction.

E-21 DSP ACCESS ERROR In RUNNING MODE operating fails in the access to DSP.

E-22 LIM SW ERROR In RUNNING MODE operating Time over in case of that moves to an inner side.

AE-01

In RUNNING MODE operating Focus Gain Error

AE-02 In RUNNING MODE operating Tracking Gain Error

AE-03 In RUNNING MODE operating RF Gain Error

AE-04 In RUNNING MODE operating Tracking Balance Error

AE-05 In RUNNING MODE operating Focus Balance Error

AUTO ADJUSTMENT

ERROR

AE-06 In RUNNING MODE operating Focus Offset Error

AE-07 In RUNNING MODE operating Tracking Offset Error

AE-08 In RUNNING MODE operating RF Offset Error

4.8 Tuner Span Change Mode

Pressing and holding [VOL] key, press [RETURN] key for 3 seconds.

4.8.1 Default status immediately after the mode activation

It shall be same as normal activation.

After selection of the setting item, the receiver should exit this mode and return to the display before entering this mode.

This setting will be stored in EEPROM.

4.8.2 Mode content

Syscon shall display the following information after entering this mode.

Item Operation Display content Details

Tuner Span

Change Mode

VOL +/-

(*1)

Tuner Span

Change Mode

VOL +/-

(*2)

Release Mode VOL

ARE A AS I A

AREA TUNISIA

AREA E UROPE

AREA TUNISIA

Default setting for Asia models.

Change to 'Asia' area type.

Change to 'Tunisia' area type.

Default setting for Europe models.

Change to 'Europe' area type.

Change to 'Tunisia' area type.

Depending on display pattern in normal mode.

*1: Only applicable for Asia ('U') models

*2: Only applicable for Europe ('E') models

(No.MA596<Rev.005>)26/28

Page 27

4.9 DC Offset error description

A

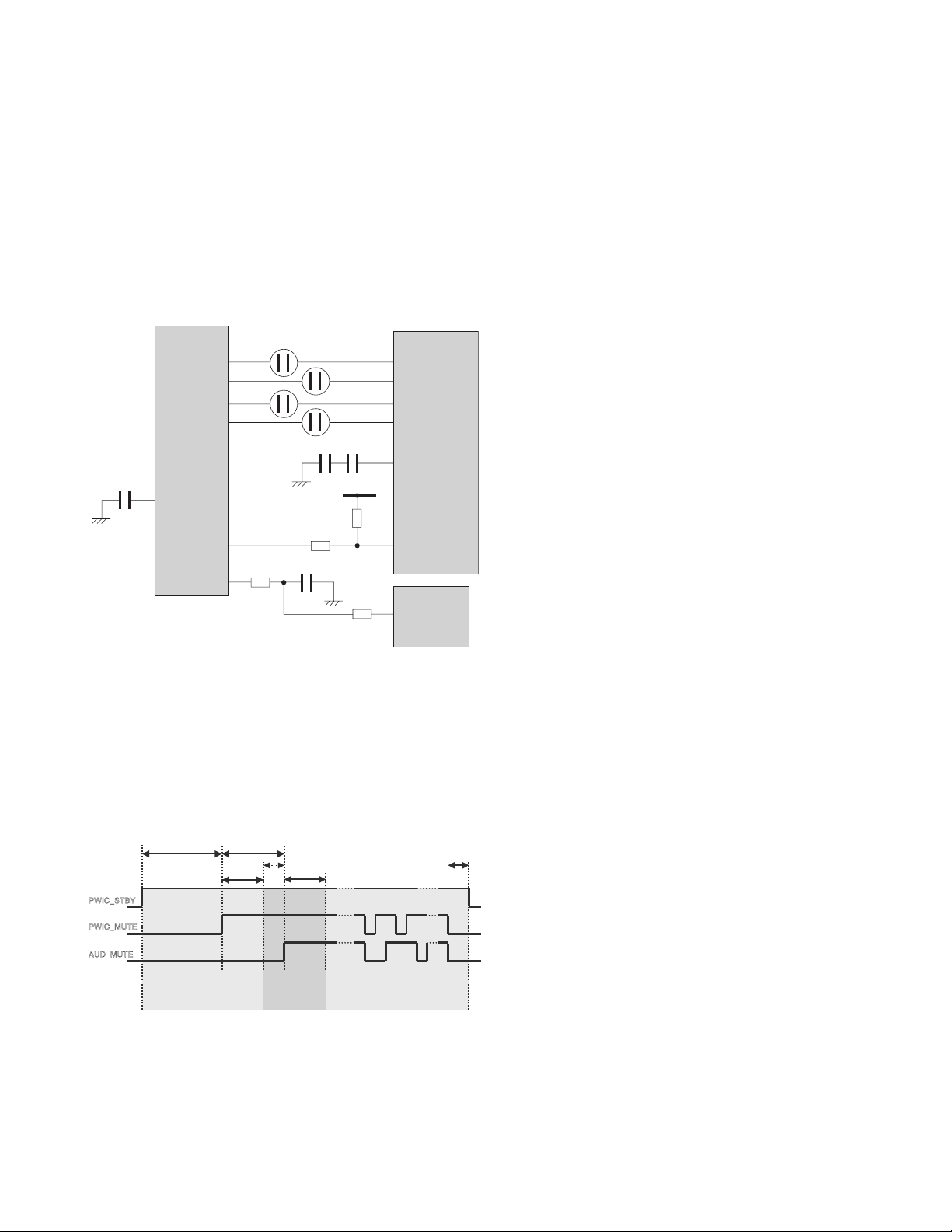

4.9.1 DC Offset detection circuit design

• Purpose:

To prevent breakdown, when occur DC offset between speaker output "+" and "-".

• Target:

Detect DC offset, then stop the Power Amp operation and shift

to specified condition.

4.9.2 Possible causes of DC offset at speaker output lines

(1) Mis-connection for Speaker output for example touch to car

body or battery line.

(2) Current leak of coupling capacitor for Power IC input.

(3) Current leak of AC-GND capacitor for Power IC AC-GND.

(4) Capacitor shorted of above parts due to foreign object.

C-tc

E-Vol

Win_TC

Win_In

DC Error

C-in

C-in

R3

C-in

C-in

C-ac2C-ac1

Sw5V

R2

R1

C3

R4

Audio Pwr Amp

In 1

In 2

In 3

In 4

AcGnd

Offset Detect

Out

Micon

ADC In

4.9.5 Manipulate after detect DC Offset

• If detected error 10 consecutive times, and 10th error occurred

in "Mis-connect detection period", judge as "Mis-connect".

• If detected error 10 consecutive times, and 10th error occurred

in "Capacitor leak detection period", judge as "Capacitor leak ".

• If detected error 10 consecutive times, and 10th error occurred

in "Other detection period" and detected another 10 errors consecutively, then judge as "Other".

• If judge as "Mis-connect".

- turn off speaker output.

- - display "MISWIRING", check wiring connection then reset.

- key access disable except button of Eject, Reset and service

mode

- record error in EEPROM "DC1 ERR"

- the product is able to be recovered by Reset button.

• If judge as "Capacitor leak ".

- turn off speaker output.

- display "WIRING", check wiring connection then reset.

- key access disable except button of Eject, Reset and service

mode

- record error in EEPROM "DC2 #" (# means counter number)

- the product can be recovered by pressing the Reset button

before the capacitor leak error counter reach "DC2 4".

After that, only clear the counter back to "0" can recover the

product.

• If judge as "Other" (manipulation same as mis-connect)

SECTION 5

TROUBLESHOOTING

4.9.3 Type of checking

4.9.3.1 To detect DC Offset Error

• Mis-connection

- Short any one speaker out line to GND or Vcc

• Capacitor leak

- Parallel 330kΩ to either any one of coupling cap or AC-GND

capacitor (to simulate current leakage of capacitor)

- Shorted either any one of coupling capacitor or AC-GND capacitor.

4.9.4 Detection Timing chart

PWIC_STBY

PWIC_MUTE

UD_MUTE

2.0sec or more

Missconnect

detection period

1.5sec or more

0.8sec

0.7sec or more

1.0sec

Capacitor leak

detection period

Other (miss detection etc.)

detection period

50ms

or more

5.1 How to cancel DC offset error

Check to be sure the terminals of the speaker leads are covered

with insulating tape properly, then reset the product.

If an error message does not disappear even after a reset, there

is a need for internal repair.

5.2 How to clear DC offset error recorded in EEPROM

Refer to “4.5 DC Error Information Mode”.

(No.MA596<Rev.005>)27/28

Page 28

JVC KENWOOD Corporation

Automotive Consumer Business Unit 2967-3, Ishikawa-machi, Hachioji-shi, Tokyo, 192-8525, Japan

(No.MA596<Rev.005>)

Printed in Japan

VSE

Page 29

SCHEMATIC DIAGRAMS

30

CD RECEIVER

KD-R460J KD-R461DA9 KD-R461E

KD-R461EN KD-R461EY KD-R461MA9

KD-R461U KD-R461UT KD-R462E

KD-R462EN KD-R462EY KD-R463EU

KD-R464E KD-R464EN KD-R466U

KD-R467EE KD-R469E KD-R469EY

KD-R469UR KD-R660J KD-R661E

KD-R661EN KD-R661EY KD-R661MA9

KD-R661U KD-R661UT KD-SR41J

KD-SR61J

(No.MA596<Rev.005>)1/

Page 30

■ PRECAUTIONS ON SCHEMATIC DIAGRAMS

z Due to the improvement in performance, some part numbers shown in the circuit diagrams

may not agree with those indicated in the Parts List.

z The parts numbers, values and rated voltage etc. in the Schematic Diagrams are for

reference only.

z Since the circuit diagrams are standard ones, the circuits and circuit constants may be

subject to change for improvement without any notice.

■ PRECAUTIONS ON PARTS LIST

z

The parts identified by the symbol are critical for safety. Whenever replacing these parts, be sure to

use specified ones to secure the safety.

z

The parts not indicated in this Parts List and those which are filled with lines --- in the Parts No.

columns will not be supplied.

z

P.W. BOARD Ass'y will not be supplied, but those which are filled with the Parts No. in the Parts No.

columns will be supplied.

z

When ordering chips, screws etc., place bulk orders (unit of tens) whenever possible to improve

shipping efficiency.

z

There are cases where the actual implemented parts in the sets and the service parts are different.

When ordering parts, make sure to refer to the Parts List.

■

PRECAUTIONS ON SERVICE

Certain parts of the power circuits and the GNDs differ according to the models. Care must be

taken for the following points as the differences are indicated separately in the LIVE GND ( ) and

the ISOLATED (NEUTRAL) GND ( ).

1. Do not touch the LIVE GND, or do not touch the LIVE GND and the ISOLATED (NEUTRAL)

GND at the same time. It may cause an electric shock.

Before pulling out the chassis or other parts, make sure to pull out the power cord from the

wall outlet first.

2. Do not short circuit between the LIVE GND and ISOLATED (NEUTRAL) GND, or never

measure the LIVE GND and ISOLATED (NEUTRAL) GND at the same time using measuring

instruments (oscilloscope, etc.). It may blow fuses or damage other parts.

■ DEVIATION TOLERANCE RANGE

DEVIATION TOLERANCE RANGE

F G J K M N R H Z P

± 1% ± 2% ± 5% ±10% ±20% ±30%

+30%

-10%

+50%

-10%

+80%

-20%

+100%

-0%

30

(No.MA596<Rev.005>)2/

Page 31

LDO3.3V

IC941

Regulator

IC901

HSS

IC891

DC-DC

IC861

EEPROM

IC841

Reset

IC831

Flash

IC821

MICON

IC701

TUNER

IC601

PROCESSING

CD SIGNAL

IC540

IC471

Level Shiftor

IC470

iPOD

IC411

POWER AMP

IC301

E-VOLUME

IC161

REMOCON

IC90

RGB

Driver IC

IC2

LCD

DRIVER

IC1

BLOCK DIAGRAM-1 (SIGNAL BLOCK)

SWITCH PWB

MAIN PWB

PWB

CD MECHA

Connector

Connector

Connector

Connector

CN701

Mute Circuit

FR OUT/SWR

FL OUT/SWL

SW (Mono)

FR OUT

FL OUT

TU_R

SCL_EV_EP_TU

SDA_EV_EP_TU

F_AUXG

F_AUXR

CDR

TRO

VF2

LD

CD_MD

VT2

VT1

VF1

DMO

FMO

FOO

Vref

CDL

RC LPF

F_AUXL

TU_L

DC P.CORD

S

FR

Ant

Jack

J601

SCL_EV_EP_TU

MCLK

MLD

MDATA

NRST

SRDATIN

SPBICLKSPBIO2

SPBISSL

SPBIO3SPBIO1

SPBIO0

BLKCK

SRDATA

LRCK

BCLK

STAT

SDA_EV_EP_TU

SXM_PWR

SXM_TxD

SXM_RxD

DIM IN

iPOD_SDA

ANT

EXT

RESET

MUTE

DC_ERR1

DC_ERR2

LINE_MUT

ACC

FLAG

SDA_REG

SCL_REG

iPOD_SCL

TU_3.3V

SW3.3V

PON_DCDC

TEL

MUTE

FREQ_SEL

REMOTE

ANT

Panel_3.3V

SW

LCD_INH

LCD_CE

LCD_CLK

LCD_DATA_IN

LCD_RGB_DATA_OUT

*RESET(2 DIN)

*PAN_DET(1 DIN)

RGB_CLK

REMO

ENC2

D-0

Regulator

F_AUXG

F_AUXR

F_AUXL

3.3V

CD_

PON

D+0

ENC1

LCD_DATA_OUT/

PON_PANEL

PON USB

DIMMER

CN1

CD MECHA_FC2-2A

CN501

DC_ERR1

J321

CN901

SXI

SXM_PWR

SXM_TxD

SXI_G

SXI_R

REMOTE/

P.CONT

ANT.CONT

MUTE

MUTE

MUTE

ACC

FR+

FR-

FL-

RL-

RR-

RR+

RL+

BEEP

PWIC_STBY

PWIC_MUTE

RR

FR

RL

FL

FL+

SXI_L

SXM_RxD

-

J471

P4

P3

P2

P1

P3

P2

P1

LCD_DATA_IN

LCD_RGB_DATA_OUT

LCD_DATA_OUT /

LCD_INH

LCD_CE

LCD_CLK

ENCODER

EN1

Single Color

LED

RGB LEDs

KSl

Kl4

LCD_DATA_OUT /

LCD_RGB_DATA_OUT

RGB_CLK

RGB

LCD (1.5Line / 1Line)

ED1

ENC2

D-0

SWITCH

(2 DIN)

RESET

F_AUXG

F_AUXR

D-0

D+0

F_AUXL

AUX

USB

CN80

J100

RESET

F_AUXG

F_AUXR

F_AUXL

*S1 TO S51(S90)

COM4

COM3

COM2

COM1

KEY MATRIX

Kl5

Kl4

Kl3

Kl2

KS6

KS3

KS2

KS1

Kl1

D+0

ENC1

REMO

CN701

created date:2015-04-22No.MA596

30

(No.MA596<Rev.005>)3/

Page 32

Q471

Q470

LDO3.3V

IC941

Regulator

IC901

HSS

IC891

DC-DC

IC861

LDO1.25V

IC851

IC841

EEPROM

Reset

IC831

Flash

IC821

MICON

IC701

TUNER

IC601

PROCESSING

CD SIGNAL

IC540

iPod

IC411

POWER AMP

IC301

E-VOLUME

IC161

REMOCON

IC90

RGB

Driver IC

IC2

LCD

DRIVER

IC1

BLOCK DIAGRAM-2 (SUPPLY BLOCK)

SWITCH PWB

MAIN PWB

PWB

CD MECHA

Connector

Connector

Connector

Connector

TEL MUTEDIMMER

Mute Circuit

CN701

VDDA_RF

VDDA_IFADC

VDDD

3.3V

DC P.CORD

S

FR

Ant

Jack

J601

CD7.2V

IOVDD2

IOVDD1

RFVDD2

VIN

AVDD1

RFVDD1

VCC

Panel_3.3V

USB_5V

USB_5V

IN

5.2V

V6IN

VCC2

VCC1

ACC

EXT

(13)

(6)

(1)

(1)

(8)

(7)

(8)

(6)

(24)

(21)

(9)

(7)

(1)(1)

(1)

0.35mA

(2)

(5)

(1)

(8)

(8)

(8)

(11)

0.3mA

(3)

1.3A

(5)

0.25mA

(4)

0.45mA

(13)

(9)(2)

ANT

MEM14.4V

BU3.3V

ILM_10.5V

ILM_10.5V

CD_8V

AU_9/12V

TU_3.3V

GND

GNDACC

VCC

SW_3.3V

PLLVCC

VCC

PVCC

VCC

VCC

VCC

VCC2VCC1

VCCVCC

SW3.3V

Panel_3.3V

SW

Regulator

VDD

VIN

CD3.3V

3.3V

CN1

CD MECHA_FC2-2A

CN502

J321

CN901

SXI

J471

Single Color

LED

RGB LED

5V

Regulator

Gate

SW

AND

ENCODER

EN1

LCD (1.5Line / 1Line)

ED1

SWITCH

(2 DIN)

RESET

5V

USB_5V

USB_5V

AUX

USB

CN80

J100

KEY MATRIX

ILM_10.5V

ILM_10.5V

PANEL_3.3V

PANEL_3.3V

3.3V

CN701

created date:2015-04-22No.MA596

30

(No.MA596<Rev.005>)4/

Page 33

KD-SR41J, KD-SR61J

3.

AM MODECONDITION---FM MODE.

1. VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER

ALL CAPACITORS ARE 50V OR 25V CERAMIC CAPACITOR.

ALL RESISTORS ARE 1/10W 5% METAL GLAZE RESISTOR.

UNLESS OTHERWISE SPECIFIED.2.

ALL RESISTANCE VALUES ARE IN OHM.

COMPONENTS WITH ? IN FRONT INDICATE NOT USE

( )CD MODE.

WITHOUT INPUT SIGNAL

KD-R469E Series, KD-R463EU, KD-R467EE, KD-AR565J, KD-R561U Series,

KD-R460J, KD-R461U Series, KD-R466U Series, KD-R461E Series, KD-R462E Series,

KD-R561E Series, KD-R561EU, KD-R567EE, KD-R660J, KD-R661U Series,

KD-R661E Series, KD-R760J, KD-AR765SJ, KD-R761E Series, KD-R464E Series,

Model list

0V

0V

12MHz

3.3V

14.3V

1.5V0V1.5V

1.5V

1.25V

0V

1.6V

3.3V0V0V0V0V0V3.3V

1.25V

0V

3.3V

3.3V0V0V

1.25V

2.0V0V0V

3.3V

3.3V0V0V0V3.3V

3.3V

3.3V0V3.3V

3.3V

3.3V0V1.25V

3.3V

0V

0V0V3.3V0V3.3V

3.3V

3.3V

1.2V

1.2V

0V

1.8V

0V

3.3V

3.3V

0V

0V

3.3V

0V

3.3V

0V

1.25V

0V

1.25V

1.6V

1.6V

0V

0V

3.3V

0V

3.0V

3.3V

3.3V

1.5V

3.3V

0V

3.3V

3.3V

(0V)

(0V)

0V

(0V)

0V

0V

(1.6V)

3.3V

3.3V

(2.2V)

1.25V

(3.2V)

0V

(0V)

(0V)

(0V)

(0V)

(3.3V)

3.3V

3.3V

0V

0V

(3.3V)

3.3V

3.3V

3.3V

3.3V

3.0V

3.0V

0V0V0V0V0V0V1V

0.85V

3.0V0V0V

3.3V

1.5V

1.5V

3.3V

0V

3.0V

0V

3.3V

0V

0V

0V

0V

0V

0V

3.3V

1.2V

1.2V

1.2V

2.6V

3.3V

0V

0V

0V

0V

3.3V

3.3V

3.3V

3.3V

3.3V

3.0V

0V

3.0V

0V

0V

0V

0V

0V0V3.3V

3.3V

3.3V

5.1V

3.3V

3.3V

3.3V

0V

14.1V

13.9V

6.0V

7.0V

8.5V

10.5V

9.8V

1.6V

4.8V

0.8V

0V

5.2V

14.0V

0V

0V

7.0V

3.3V

3.3V

7.0V

14.2V

7.0V

7.0V0V7.0V

6.9V

6.9V

6.9V

6.8V

7.0V

7.0V

7.0V

14.2V

7.0V

3.3V

7.0V0V0V

0V

3.3V

0V

5.0V

0V

*

3.3V

3.3V

3.3V

LTA024EEB-X

22K

22K

LTC024EEB-X

47K

10K LTA014YEB-X

4.7K

LTC043TEB-X

22K

22K

0V

3.3V

FZB10BT-100

F901

FUSE 10A

0V

1.5V

3.3V

3.3V0V

0V

1.5V

0V

1.5V

1.25V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

3.3V

0V

0V

3.3V

0V3.3V

*

3.3V

* POWER CORD ASS'Y

0V

3.3V

5.2V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

0V

4.0V

4.0V

4.0V

4.0V

4.0V

4.0V

4.0V

8.5V

3.3V

3.0V

3.0V

3.3V

3.3V

AGND

CD_GND

REMOTE OUT

MAIN PWB:J7J-0020-00

LDO_1.25V

LINE MUTE

P.IC MUTE

SW3.3V

HSS_USB

IPOD

EEPROM

RESET

0V

3.3V

3.3V

DCDC

DEBUGGING

FLASH

MGND

SXM_RX_M

M_TX_SXM

PAN_DET

RGB_CLK

CD_SRDATA_M

DRV_MUTE

DCDC5V

SXI_AL

LCD/RGB_DATA_SYS

RGB_CLK

AUX-L

AUX-R

SPBIO0

SPBIO1

REMO

FREQ_SEL

SDA_REG

SCL_REG

MLD

SDA_REG

SCL_REG

SPBCLK

PWIC_STB

SDA_EET

SCL_EET

DC_ERR2

DRV_LO_EJ

SCL_EET

SDA_EET

REMO

D-

ENC1

D+

ENC2

LCD_CLK

LCD_DATA_LCD

LCD_CE

LCD/RGB_DATA_SYS

SCL_IPOD

SDA_EET

SCL_EET

SDA_EET

SCL_EET

M_TX_SXM

SXM_RX_M

ENC1

RROUT

DC_ERR1

CD8V

LCD_INH

RLOUT

RROUT

FLG_REG

LCD_INH

FLG_REG

STAT

SXM_PWR

LCD_DATA_LCD

SDA_IPOD

SCL_IPOD

BLKCK

M_SRDATA_CD

FLG_REG

RL/SUBL

RR/SUBR

FLOUT

DIM_IN

MUTE

REMO

PON_USB

TU.L

TU.R

PON_USB

SPBIO3

SPBSSL

SPBIO2

FL+

SXM_PWR

PON_PANEL

DIM_IN

D-

ENC2

PSW

SW1

RESET

RESET

RR-

FR-

FL+

RL+

BCLK

DRV_CNT

PON_CD

SW2

DC_ERR1

MDATA

MCLK

LRCK

PON_CD

FL-

RL-

RR+

FR+

OFFSET

SDA_IPOD

FROUT

TEL_MUTE

RESET

CD.R

SXI_AR

TEL_MUTE

PON_PANEL

CD.L

M_SRDATA_CD

CD_SRDATA_M

BLKCK

CD.R

STAT

MLD

MDATA

MCLK

LRCK

BCLK

SW2

SW1

MUTE

E_MUTE

DRV_MUTE

PSW

NRST

DRV_LO_EJ

DRV_CNT

FREQ_SEL

BEEP

NRST

DC_ERR2

PAN_DET

PWIC_MUTE

SPBCLK

LCD_CE

LCD_CLK

D+

SPBSSL

SPBIO0

SPBIO1

SPBIO2

SPBIO3

RL/SUBL

SXI_AG

SXI_AL

CD.L

AUX-G

OFFSET

AUX-R

AUX-G

AUX-L

RR/SUBR

SXI_AG FLOUT

SXI_AR

E_MUTE

RLOUT

TU.R

FROUT

RROUT

E_MUTETU.L

RL+

FL-

RL-

FR-

RR-

FR+

RR+

PWIC_MUTE

PWIC_STB

BEEP

RLOUT

FLOUT

FROUT

GND6

GND4

GND3

GND5

GND2

GND1

GND5

GND1

!

!

!

sure to use the specified one.

When replacing those parts make

Parts are safety assurance parts.!

!

!

!

!

!

!

NAX1251-001X

X701

9.216MHZ

QAX0969-001Z

X600

F0K-0014-00

VA600

V

TL901

(SIG)

TL58

(TU.R)

TL50

(TU.L)

TL51

TL625

TL624

(PIN10)

TL45

(SXI.L)

TL56

(SXI.R)

TL57

TL475

TL472

TL476

TL480

(AC)

TL44

TL340

TL350

TL320

TL330

TL260

TL250

TL360

TL370

(FLG)TL17

TL907

(VDD)TL05

(V6)TL14

(TU33)TL09

TL902

(EXT)TL11

(ILM)TL02

(AUD)TL04

(CD)TL03

(MEM)

TL01

TL995

(GND2)

TL25

(A.ANT)

TL19

(OE)

TL21

(REM)

TL20

(SW33)

TL08

(FB)

TL16

(FB1)

TL40

(AL)

TL52

TL60

(AR)

TL53

TL61

(P33)

TL07

TL63

TL64

TL62

TL65

TL67

(GND1)

TL24

TL66

TL68

TL70

TL71

(TXM)

TL41

TL69

(ANT)TL10

(5V)

TL15

(DI) TL30

(CLK) TL22

(HOLD) TL26

(CS)

TL31

(DO)

TL23

(WP)

TL29

(ASEBRK)

TL39

(TDO)

TL33

(TCK)

TL36

(TMS)

TL35

(TDI)

TL34

(ASEMD)

TL38

(TRST)

TL37

TL716

(IP1)

TL46

(IP2)

TL47

(IP3)

TL48

(IP4)

TL49

TL717

(TM)

TL43

(RXM)

TL42

TL704

TL703

TL702

TL705

(V1.25)

TL06

(RST1)

TL27

(RST2)

TL28

TL708

TL72

(PDET)

TL18

TL73

43

2 1

S830

1/16W

10

*RA470

1/16W

47k

RA701

1/8W150

R600

?R1860

0

R1071

0

*R708

?R373

330

*R333

?R1714

0R170

68kR370

12kR371

?R1006

10k

R372

1/4W

0

*R381

1/8W150

C600

16kR1007

?R162

_0.5%

?R782

1/4W

0

R1861

1/4W

6.8k

R903

1kR753

330

R262

0

*R253

_0.5%

?R783

?R780

?R785

?R784

_0.5%

?R781

330

*R343

1/8W

220

*R483

?R401

100

R168

0

R1091

0

R1080

100

R840

100

R611

390

R892

?R402

100

R841

0

*R163

?R164

100

R601

0

R167

1/4W4.7k

R390

1/4W47k

R900

?R904

1/4W

47k

R901

47k

R820

10R754

_0.5%

68k

R865

?R891

_0.5%

39k

R867

_0.5%

20k

R890

_0.5%

18k

R868

910

R722

910

R719

82

R602

?R866

39k

R864

4.7

R605

47k

R751

47k

R749

47k

R720

100k

*R470

47kR744

47kR743

47k

R821

47k

R822

*R735

*R734

*R733

*R732

47kR731

47kR730

47k

R723

47k

R721

47k

R760

47k

R421

30kR403

?R1090

?R1000

?R1001

?R1002

47k

R104

47k

R103

47k

R756

47k

R304

47k

R758

47k

R757

47kR762

47k

R761

4.7k*R414

4.7k

R364

4.7k

R363

4.7kR747

4.7k

R763

4.7k

R702

4.7k*R412

4.7k*R413

4.7k

R748

?R765

4.7k

R746

4.7k

*R482

4.7k

R764

470

R100

33k

R361

33k

R718

3.3k

R709

?R1011

330

R271

330

*R353

330

*R252

390R862

5.1

R303

330

*R323

1.6k

R705

100

R169

22k

R261

22k

*R251

22k

*R321

22k

*R341

?R932

22k

*R351

22k

R273

22k

*R331

22k

R362

22k

R360

22k

*R476

2.2k

R711

1/4W

2.2kR745

2.2kR713

2.2kR715

2.2k

R302

2.2k

R716

?R612

22R726

22R728

20

R861

180

*R340

180

*R320

180

*R350

180

*R250

180

R260

180

*R330

1.6k

R707

1.6k

R704

1.6k

R703

1.6kR701

15k

R727

15kR729

?R610

?R606

?R608

1M

R604

1M

R603

1M

R724

?R607

100k

R270

100k

R717

?R366

100kR365

10k

R171

?R930

1k

R712

1k

R400

1/4W

6.8k

R902

1k

R1070

?R931

1k

R725

1k

R714

100

R905

100

*R471

100

*R472

100R752

100R750

100

R830

100

*R410

100

*R411

?R1052

?R1051

10

R1064

?R1050

?R1067

10

R1065

10

R755

?R609

0

*R161

?R1022

0

*R1043

LTC043TEB-X

Q260

LTC043TEB-X

*Q471

LTC043TEB-X

*Q350

LTC043TEB-X

*Q340

LTC043TEB-X

*Q250

LTC043TEB-X

*Q330

LTC043TEB-X

*Q320

LTA024EEB-X

Q270

LTA014YEB-X

Q701

LTA024EEB-X

Q273

LTC024EEB-X

Q272

LTC014EEB-X

*Q470

?Q930

LSCR523UB-X

Q360

?Q931

LSAR523UBFS8

Q271

?F2

F1

10u

L860

QQR1927-001

L990

4.7u

L600

4.7u

L861

1.0u

L604

0.12u

L606

4.7u

L601

0.1u

L603

0.47u

L602

0.15u

L607

0.22u

L605

LB73G0BK-006

L827

LB73G0CA-002

L825

LB73G0BK-006

L701

NQR0713-001X

L824

NQR0403-003X

L826

NQR0713-001XL710

NQR0713-001XL820

NQR0713-001XL823

NQR0713-001XL822

NQR0713-001X

L700

NQR0713-001XL709

NQR0713-001XL821

2221

F_AUXL

20

F_AUXG

19

F_AUXR

18

GND

17

Panel3.3V

16

ILM10.5

15

LCD/RGB_DATA_SYS

14

LCD_CE

13

LCD_DATA_LCD

12

RGB_CLK/USB_GND

11

LCD_CLK

10

USB_GND

9

ENC2

8

D+

7

ENC1

6

D-

5

LCD_INH

4

USB5V

3

REMO

2

PAN_DET

1

CN701

QGZ2006J1-20

18 17

MEMORY

16

DIMMER

15

TEL MUTE

14

OE REMOTE

13

REAR RIGHT (+)

12

REAR RIGHT (-)

11

REAR LEFT (-)

10

REAR LEFT (+)

9

FRONT LEFT (+)

8

FRONT LEFT (-)

7

FRONT RIGHT (-)

6

FRONT RIGHT (+)

5

*ANTENNA

4

REMOTE/P-CON

3

ACC

2

GND

1

QNZ0607-001

CN990

1211

T10

10T99T88

T7

7T66T55T44

T3

3T22T11