Page 1

SERVICE MANUAL

CD RECEIVER

KD-SH99R

Detachable

ATT

ANGLE

CD

FM

AM

CH

AUX SEL

KD-SH99R

EQ

R D

VOLUME

Contents

Safety precaution

Preventing static electricity

Disassembly method

Adjustment method

Flow unit reading TOC

of CD/CD-R/CD-RW

Maintenance of laser pickup

Replacement of laser pickup

Description of major ICs

RM-RK100

Area Suffix

E ------- Continental Europe

EX ----- Central Europe

1- 2

1- 3

1- 4

1-15

1-18

1-20

1-20

1-21~45

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

No.49645

Jun. 2001

Page 2

KD-SH99R

Safety precaution

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-2

Page 3

KD-SH99R

Preventing static electricity

1.Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2.About the earth processing for the destruction prevention by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

4.Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

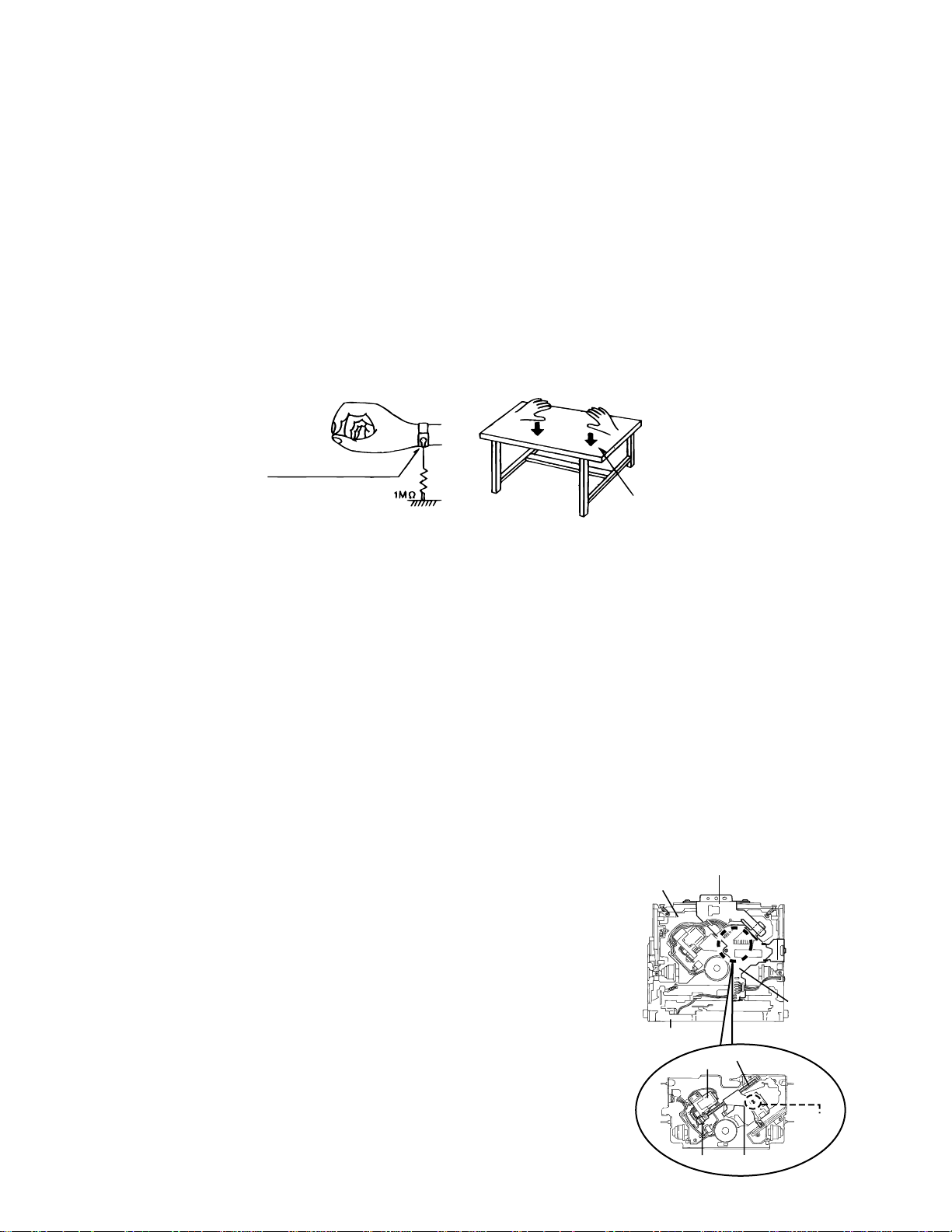

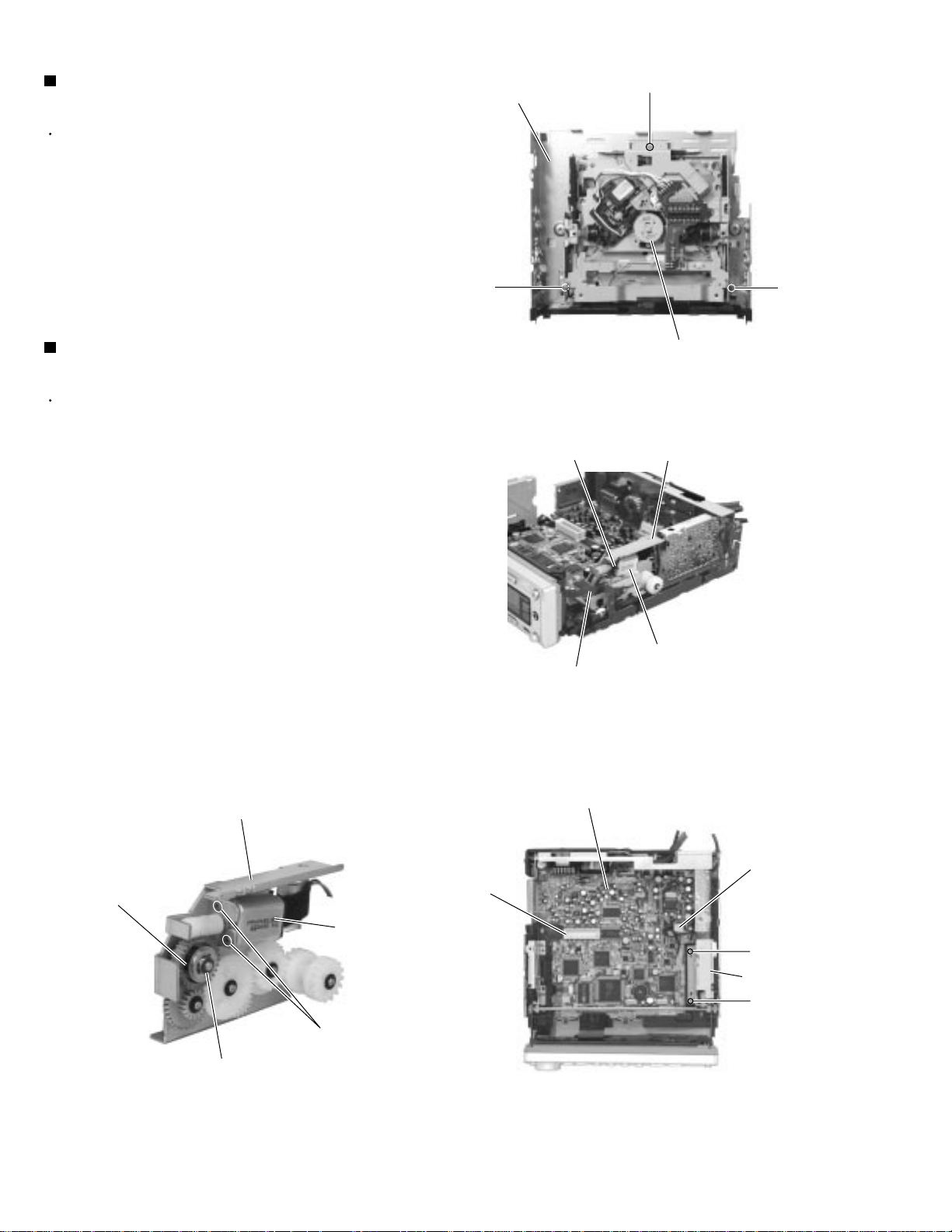

CD mechanism ass’y

Damper bracket

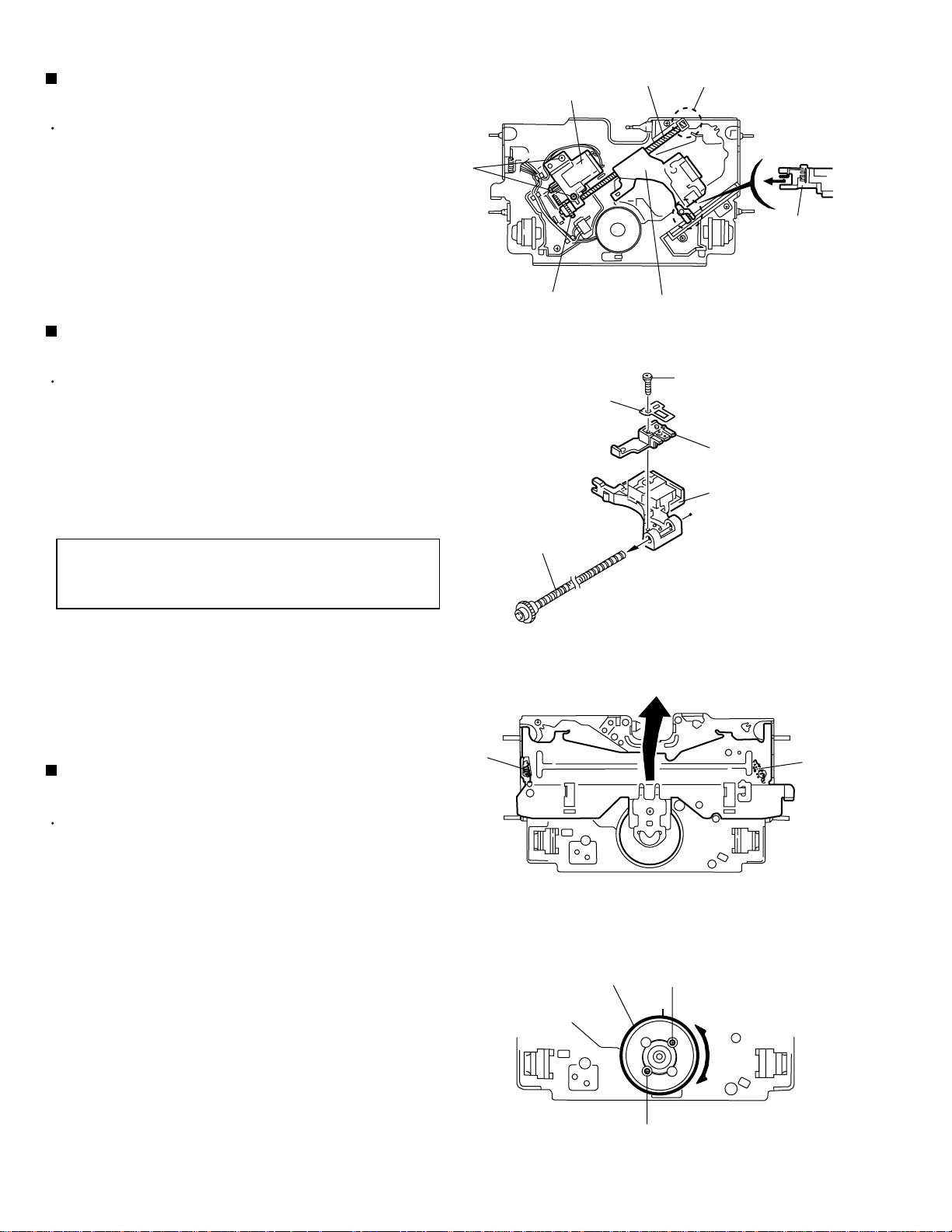

Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for pick-up and how to

detach the substrate.

1.Solder is put up before the card wire is removed from connector on

the CD substrate as shown in Figure.

(When the wire is removed without putting up solder, the CD pick-up

assembly might destroy.)

2.Please remove solder after connecting the card wire with

when you install picking up in the substrate.

Front bracket

Feed motor ass’y

FD screw

CD mechanism

control board

Soldering

FD gear

Pickup unit

1-3

Page 4

KD-SH99R

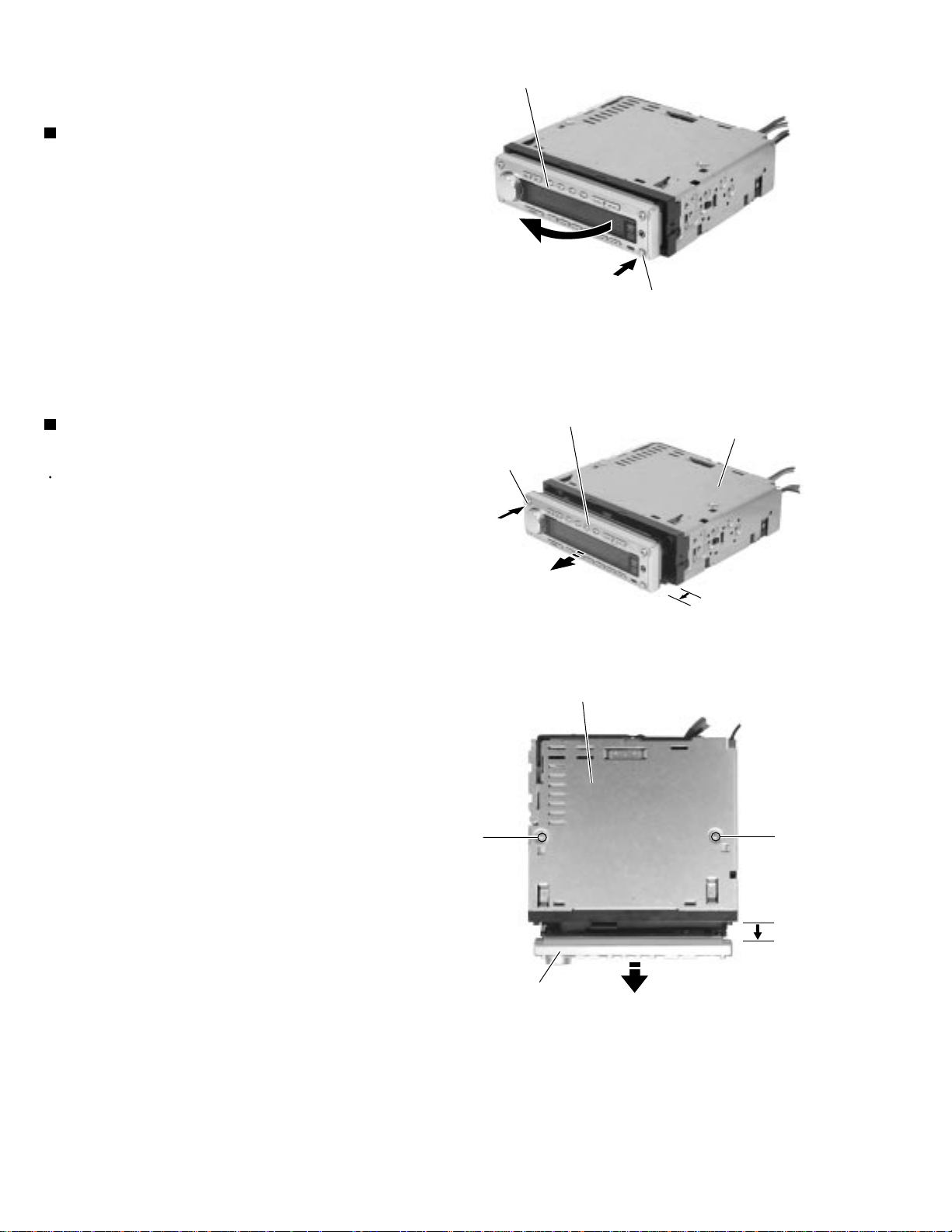

Disassembly method

Removing the front panel assembly

(See Fig.1)

1.

Press the release button in the lower right part of the

front panel assembly to unlock.

2.

Remove the front panel assembly in the direction of

the arrow.

Removing the top chassis

(See Fig.2 to 6)

Turn on power.

1.

Press the eject button in the upper left part of the

front panel assembly to move the assembly as

shown in Fig.2 and turn off power.

Front panel assembly

Front panel assembly

Eject button

Release button

Fig.1

Top chassis

2.

Remove the two screws A on the upper side of the

body.

Top chassis

A

Front panel assembly

Fig.2

A

Fig.3

1-4

Page 5

3.

Remove the three screws B on both sides of the

body.

4.

Remove the screw C and the three screws D on the

left side of the body.

5.

Remove the two screws E and the screw F on the

back of the body.

6.

Move the top chassis upward and remove it with the

CD mechanism assembly. The connector on the CD

mechanism assembly is disconnected from

connector CN601 on the main board.

KD-SH99R

Top chassis

BB

Fig.4

Top chassis

C

Heat sink

E

BD

Fig.5

F

Fig.6

1-5

Page 6

KD-SH99R

Removing the CD mechanism assembly

(See Fig.7)

Prior to performing the following procedure, remove

the top chassis.

1.

Remove the three screws G inside the top chassis

and remove the CD mechanisma ssembly.

Removing the motor assembly

(See Fig.8 to 10)

Prior to performing the following procedure, remove

the top chassis.

1.

Disconnect the wire from connector CN703 on the

main board.

2.

Remove the motor bracket and the spring attached

to the arm braket assembly (R).

Top chassis

G

Spring

G

G

CD mechanisma ssembly

Fig.7

Motor braket

3.

Remove the two screws H attaching the motor

bracket.

4.

Remove the washer attaching the clutch assembly

and pull out the clutch assembly from the shaft.

5.

Remove the two screws I and the motor assembly

from the motor bracket.

Motor braket

Clutch assembly

Motor assembly

Motor assembly

Arm braket assembly (R)

Fig.8

Main board

CN703

CN601

H

Motor braket

H

1-6

Washer

Fig.10

R

Fig.9

Page 7

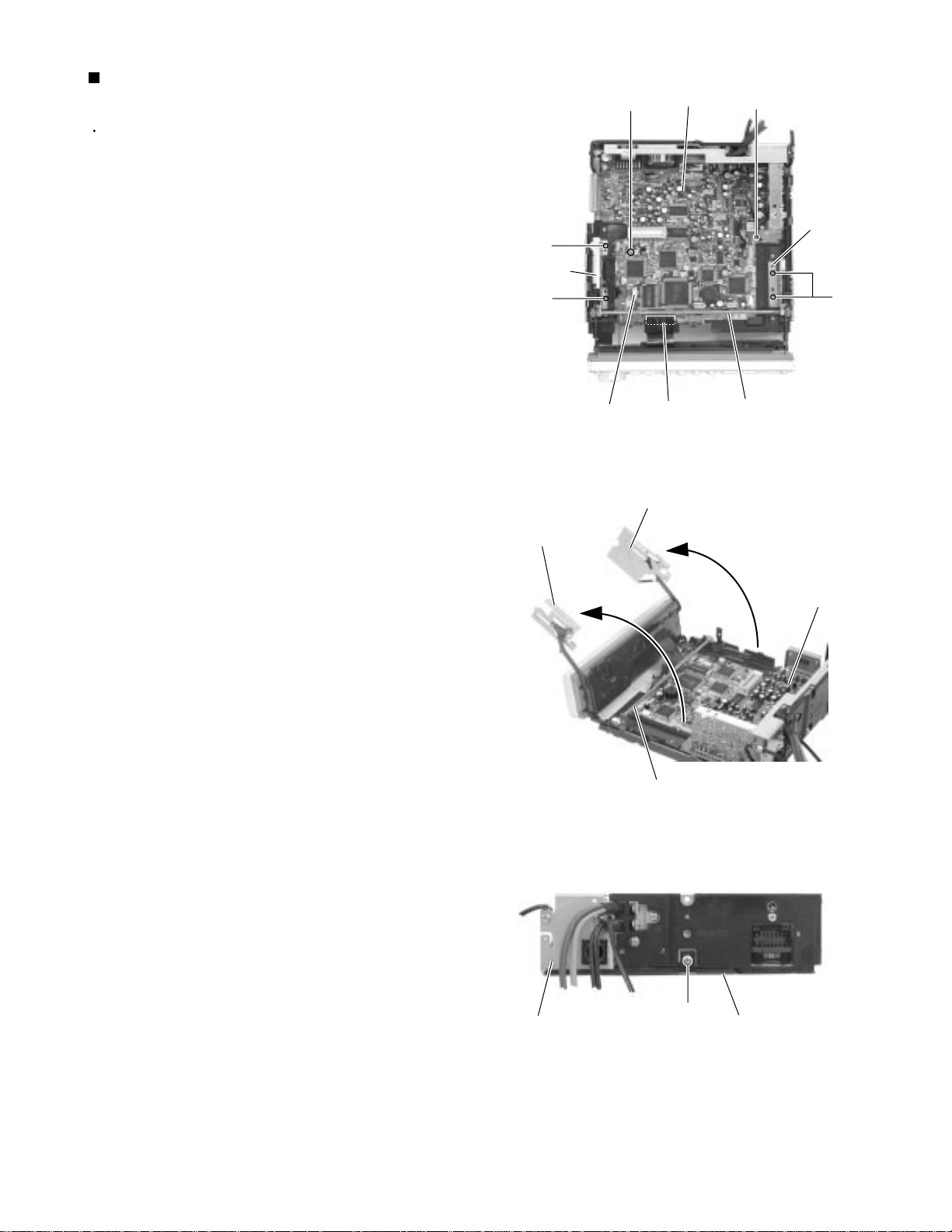

Removing the main board

(See Fig.11 to 15)

Prior to performing the following procedures, remove

the top chassis and the motor bracket.

1.

Disconnect the flexible wire from connector CN701

and CN702 on the main board respectively.

2.

Move the front bracket backward until it stops.

3.

Remove the four screws J attaching the arm

brackets (L) and (R). Move the right and arm lefter

brackets from the rod gear.

4.

Remove the rod gear.

5.

Remove the screw K attaching the rear panel to the

bottom cover on the back of the body.

J

Arm

brackets (L)

J

CN701

L

CN702

Main board

Fig.11

KD-SH99R

L

Arm

brackets (R)

J

Rod gear

Arm brackets (R)

Arm brackets (L)

Main board

Rod gear

Fig.12

Rear panel

K

Fig.13

Bottom cover

1-7

Page 8

KD-SH99R

6.

Remove the two screws L and move the main board

backwards to release the two joints a. (The main

board will be removed with the rear panel and the

rear heat sink)

7.

Remove the screw M and N attaching the rear heat

sink.

8.

Remove the three screws O and the screw P

attaching the rear panel. Remove the main board.

Joint a

Joint a

Main board

Fig.14

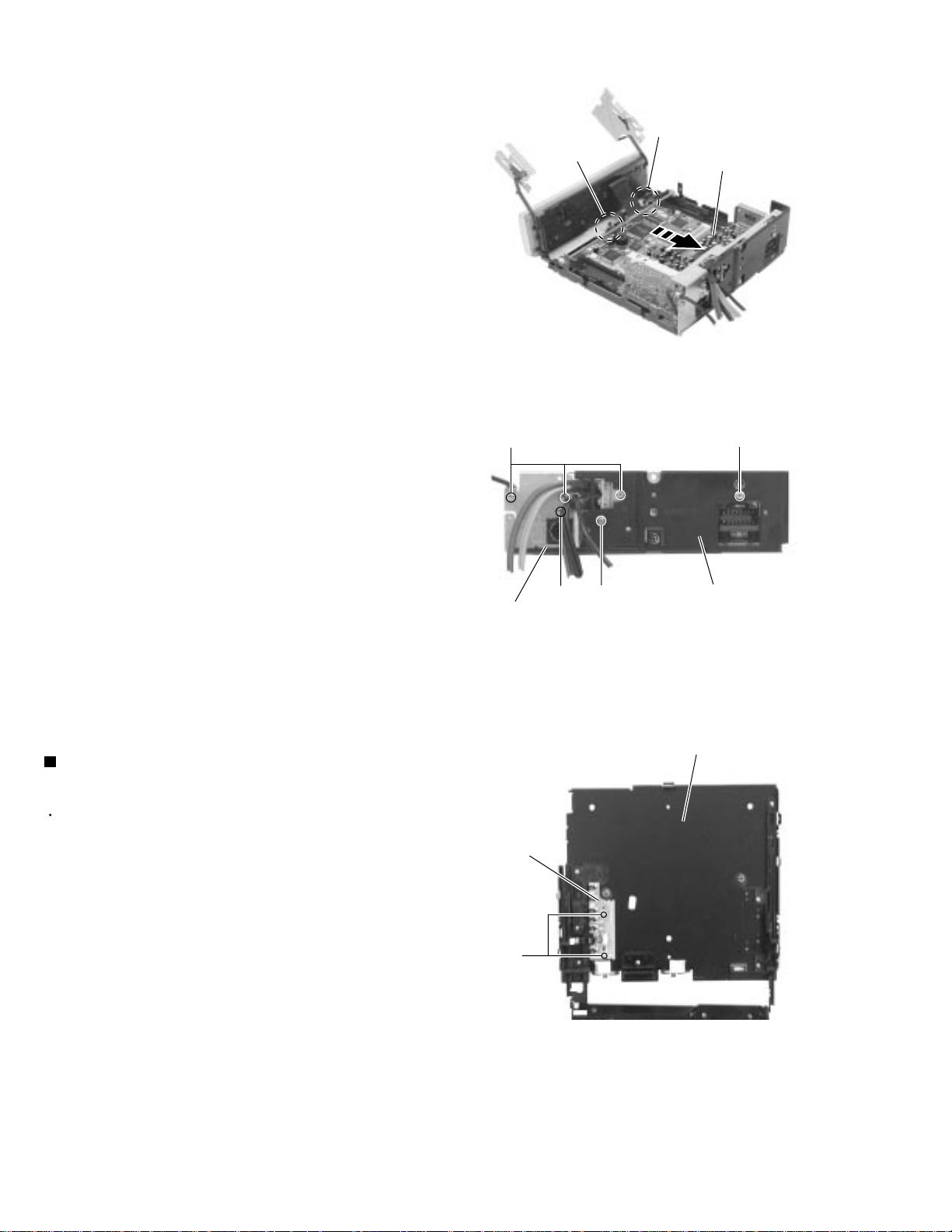

Removing the lifter switch board

(See Fig.16)

Prior to performing the following procedures, remove

the top chassis, the motor bracket and the main

board.

O

Rear panel

Lifter switch board

P

N

M

Rear heat sink

Fig.15

Bottom cover

1.

Remove the two screws Q attaching the lifter switch

board.

1-8

Q

Fig.16

Page 9

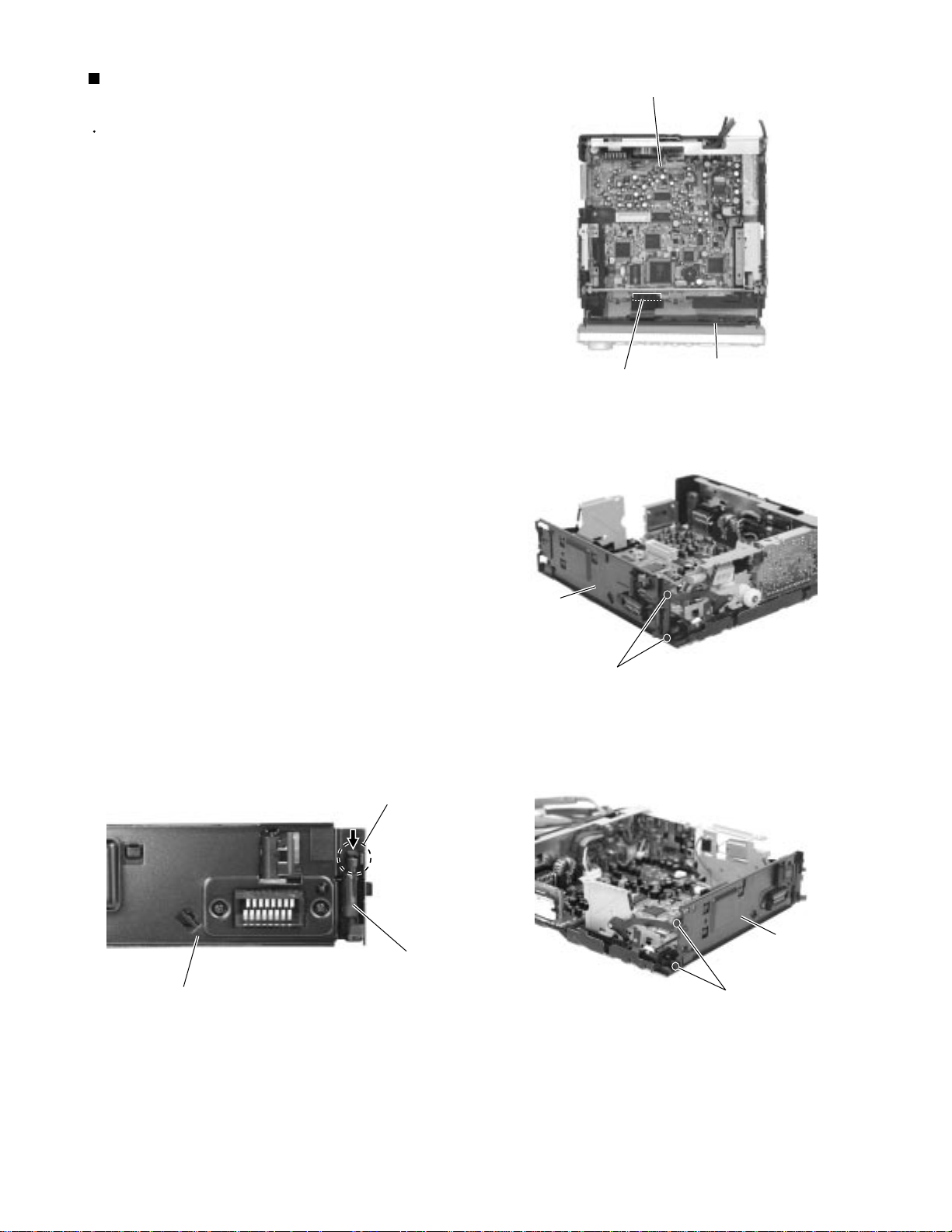

KD-SH99R

Removing the lifter board

(See Fig.17 to 23)

Prior to performing the following procedure, remove

the top chassis assembly and thefront panel

assembly.

1.

Disconnect the flexible wire from connector CN702

on the main board.

2.

Remove the four screws R attaching the front

bracket on both sides of the body.

3.

Push the pin of the joint c on the front of the front

bracket to release the lock lever.

Main board

CN702

Front bracket

Fig.17

Front bracket

Front bracket

R

Fig.18

Joint c

Front bracket

Lock lever

R

Fig.19Fig.20

1-9

Page 10

KD-SH99R

4.

Remove the screw S attaching the lifter board cover

in the rear of the front bracket.

5.

Release the two joints d while pushing the front side.

Move the lifter board cover inthe direction of the

arrow and release the eight joints e.

Joint d

Joints e

Lifter board cover

Joints e

Joint d

6.

Remove the two screws T attaching the lifter board

on the front of the body.

S

Joints e

Lifter board

Joint e

Front bracket

Fig.21

Lifter board cover

Fig.22

1-10

Fig.23

T

Page 11

KD-SH99R

<Front panel assembly>

Prior to performing the following procedure, remove

the front panel assembly.

Removing the front board

(See Fig.24 and 25)

1.

Remove the four screws U attaching the rear panel

to the front panel assembly.

2.

Release the eleven joints f of the front panel and the

rear panel.

3.

Disconnect the wire from connector CN503 on the

front board.

4.

If necessary, unsolder connector CN502 on the front

board.

Removing the volume board

(See Fig.25 and 26)

Prior to performing the following procedure, remove

the rear panel.

U

Line in board

U

Joint f 11

Front board

V

Rear panel

Fig.24

Soldering

(CN502)

CN503

Fig.25

Soldering

W

V

U

U

Volume board

W

1.

Remove the two screws W attaching the volume

board.

2.

Disconnect the volume knob, ring lens and volume

ring from the volume board.

3.

If necessary, unsolder the volume board.

Removing the line in board

(See Fig.25 and 27)

Prior to performing the following procedure, remove

the rear panel.

1.

Disconnect the wire from connector CN503 on the

front board.

2.

Pull out the line in board from the front panel

assembly.

Volume board

Volume lens, Volume ring

Rng knob

Fig.26

Line in board

Fig.25

1-11

Page 12

KD-SH99R

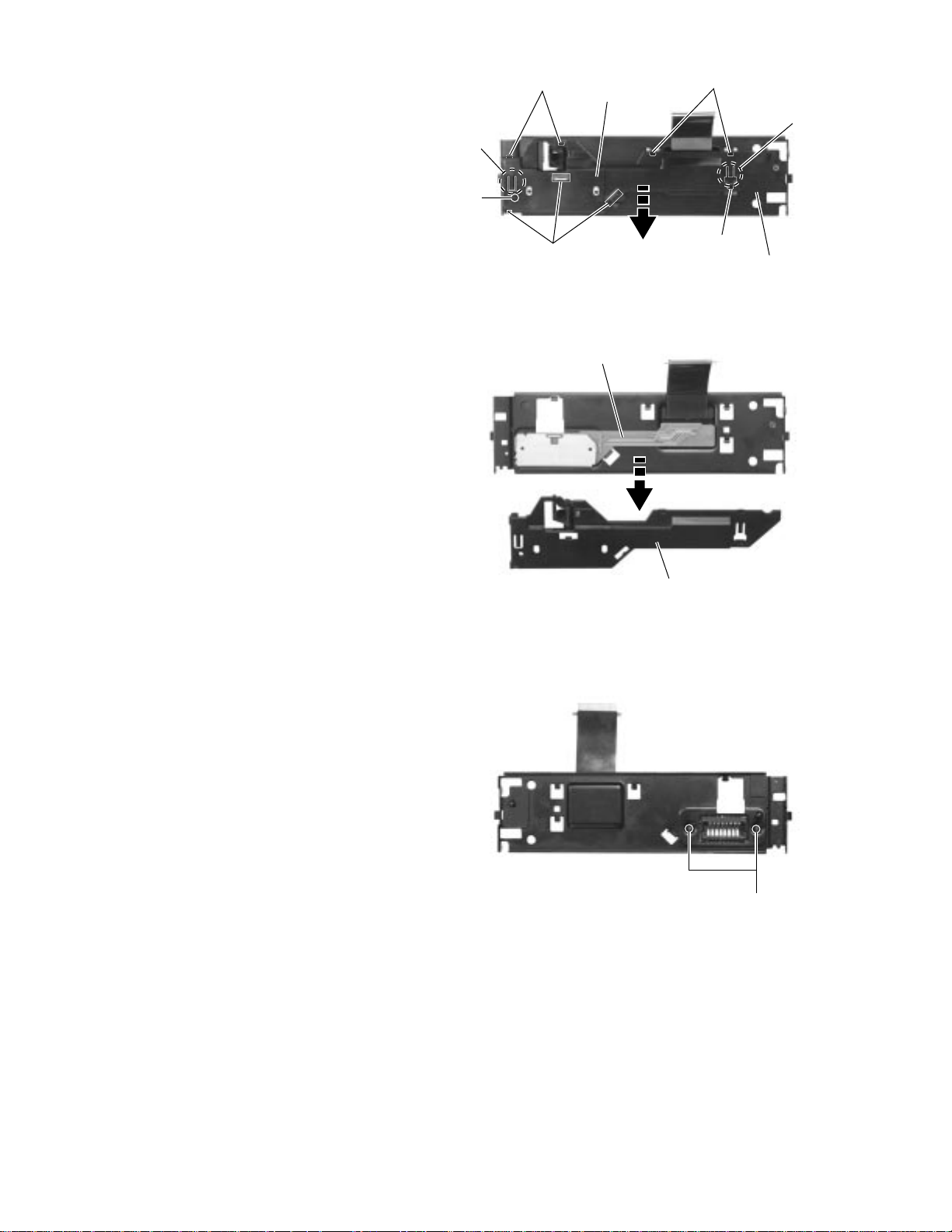

<CD mechanism section>

Removing the CD mechanism control

board (See Fig.1 and 2)

1.

Unsolder the part a and b on the CD mechanism

control board.

2.

Remove the stator fixing the CD mechanism control

board and the damper bracket (To remove the stator

smoothly, pick up the center part).

3.

Remove the screw A attaching the CD mechanism

control board.

4.

Remove the CD mechanism control board in the

direction of the arrow while releasing it from the two

damper bracket slots d and the front bracket slot e.

5.

Disconnect the flexible wire from connector on the

pickup unit.

ATTENTION:

Turn the FD gear in the direction of the

arrow to move the entire pickup unit to

the appropriate position where the

flexible wire of the CD mechanism unit

can be disconnected easily.

(Refer to Fig.2)

CD mechanism assembly

D

h

Front bracket

Pickup unit

Damper bracket

D

A

Fig.1

e

b

Flexible wire

a

h

c

D

d

CD mechanism

control board

Shift the lock

Removing the loading motor

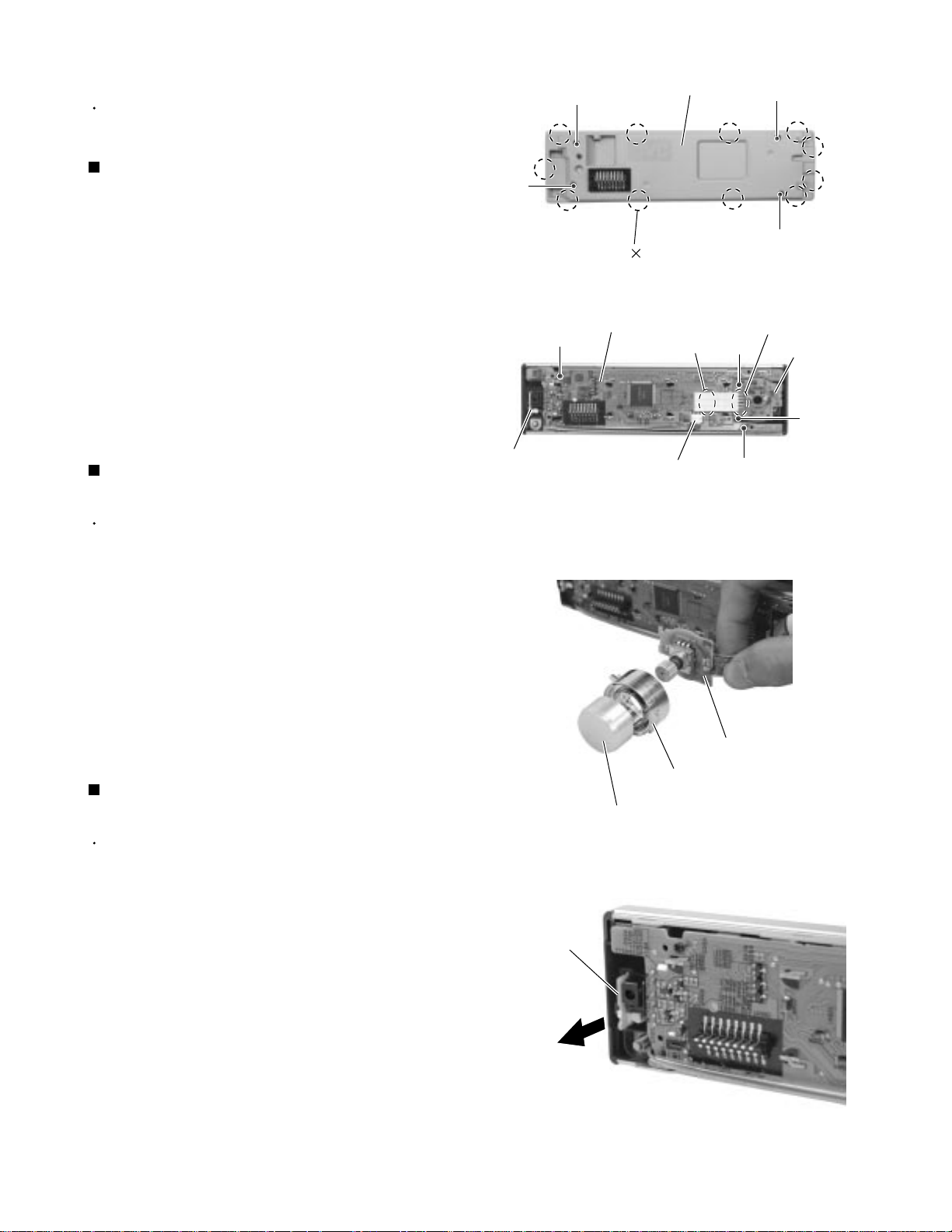

(See Fig.3 to 5)

Prior to performing the following procedure, remove

the CD mechanism control board.

1.

Remove the two springs f attaching the CD

mechanism assembly and the front bracket.

2.

Remove the two screws B and the front bracket

while pulling the flame outward.

3.

Remove the belt and the screw C from the loading

motor.

Loading motor

C

FD gear

f

B

Loading motor

Pull outward

Fig.2

CD mechanism control board

f

B

Front bracket

Fig.3

Front bracket

Pull outward

1-12

Fig.5

Belt

Flame

Fig.4

Page 13

KD-SH99R

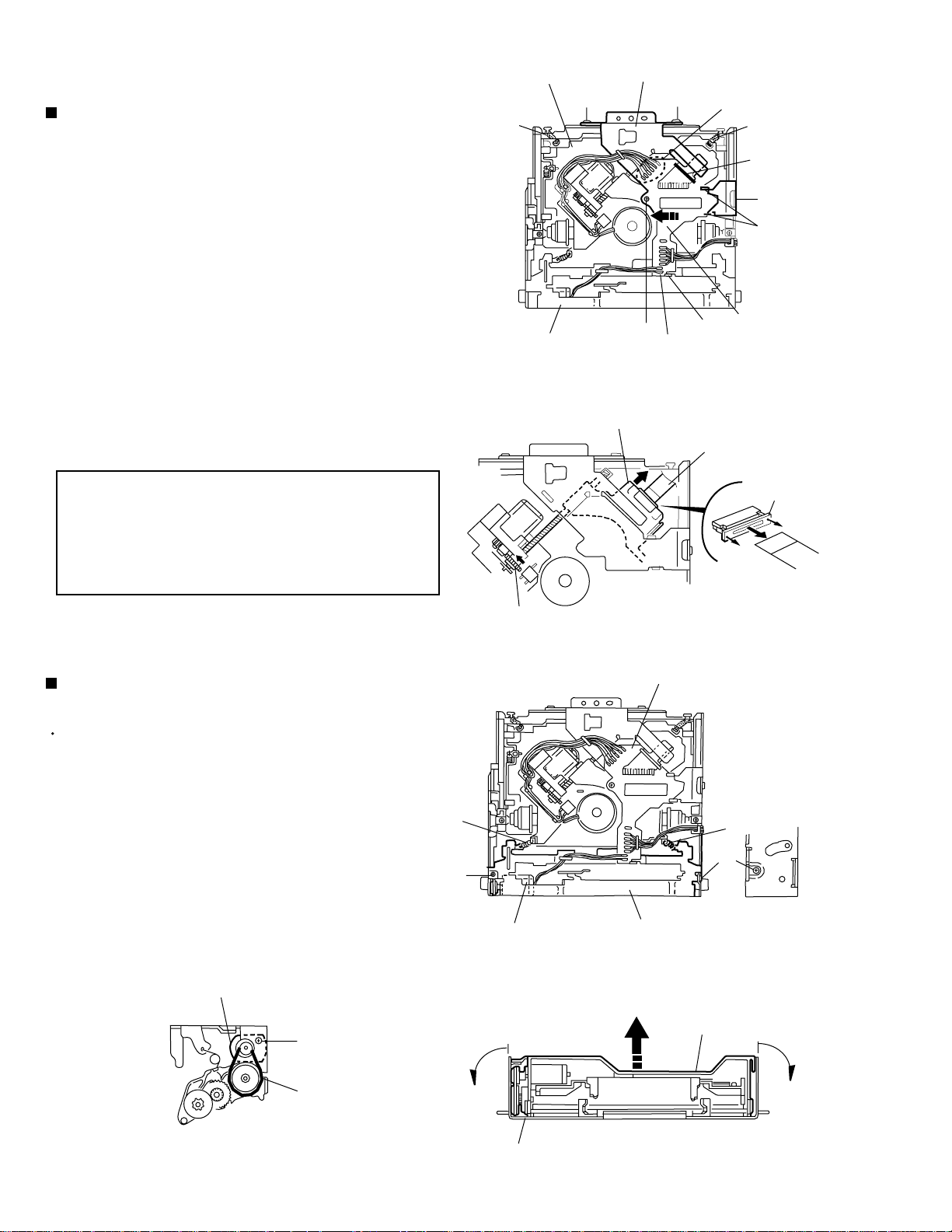

Removing the CD mechanism assembly

(See Fig.1, 6 to 9)

Prior to performing the following procedure, remove

the CD mechanism control board and the front

bracket (loading motor).

1.

Remove the three screws D and the damper

bracket.

2.

Raise the both sides fix arms and move the fix plates

in the direction of the arrow to place the four shafts g

as shown in Fig.8 and 9.

3.

Remove the CD mechanism assembly and the two

springs h attaching the flame.

4.

Remove the two screws E and both sides rear

damper brackets from the dampers. Detach the CD

mechanism assembly from the left side to the right

side.

ATTENTION:

The CD mechanism assembly can be

removed if only the rear damper

bracket on the left side is removed.

CD mechanism

h

Front bracket

CD mechanism

D

Flame

assembly

D

assembly

h

D

Damper bracket

D

A

Fig.1

e

b

Damper bracket

D

Fig.6

a

h

c

D

d

CD mechanism

control board

h

Fix plate (L)

g

Fix arm (R)

D

Fig.7

Rear damper bracket

g

Fig.8

Rear damper bracket

E

Fix plate(R)

E

Fix arm (L)

Damper

Damper

g

g

Fig.9

1-13

Page 14

KD-SH99R

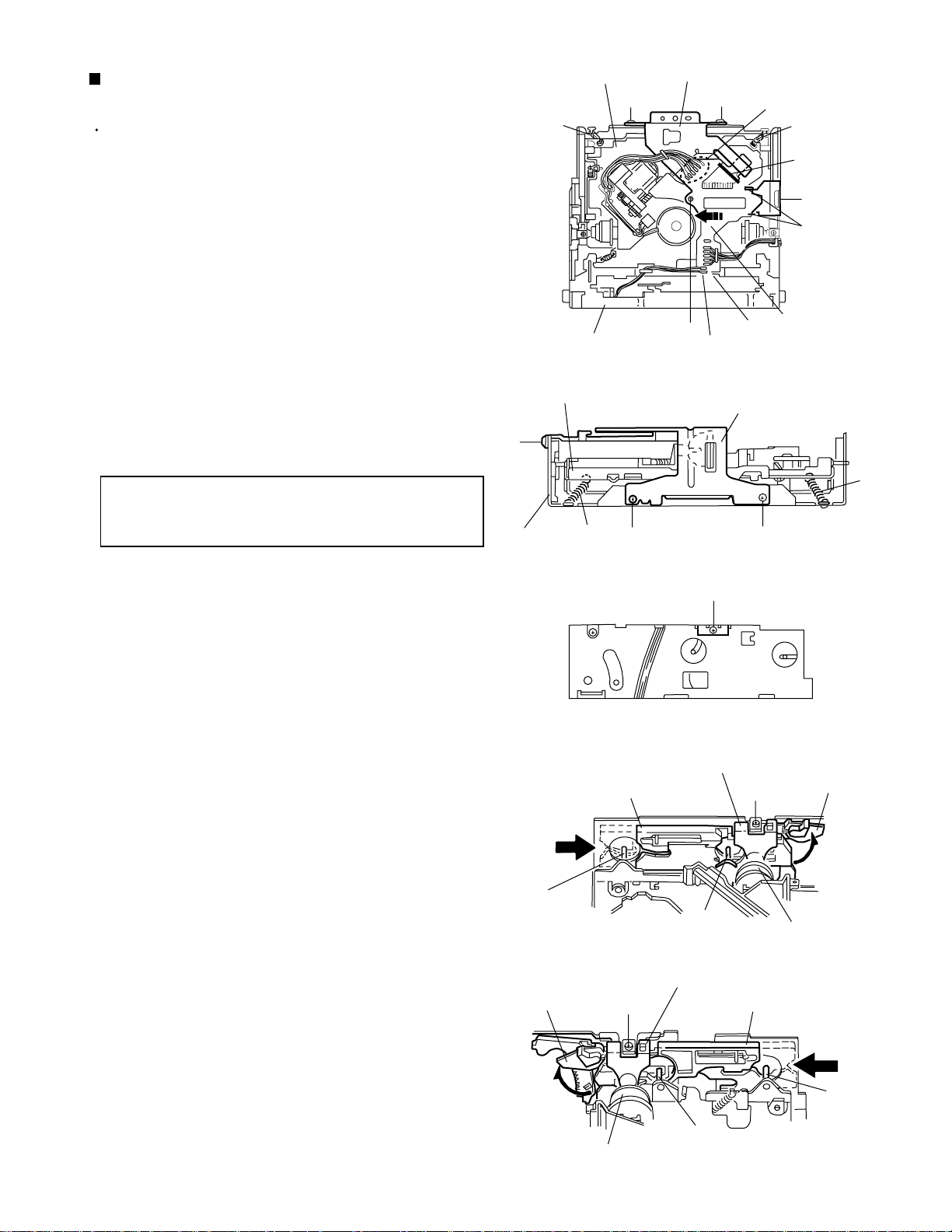

Removing the feed motor assembly

(See Fig.10)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor) and the CD mechanism assembly.

1.

Remove the two screws F and the feed motor

assembly.

Removing the pickup unit

(See Fig.10 and 11)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism assembly and

the feed motor assembly.

1.

Detach the FD gear part of the pickup unit upward.

Then remove the pickup unit while pulling out the

part i of the FD screw.

Feed motor assembly

F

FD gear

Nut push spring plate

FD screw

Pickup unit

Fig.10

Part i

Part j

Pickup unit

G

Pickup mount nut

Pickup unit

ATTENTION:

2.

Remove the screw G attaching the nut push spring

plate and the pickup mount nut from the pickup unit.

Pull out the FD screw.

When reattaching the pickup unit,

reattach the part j of the pickup unit,

then the part i of the FD screw.

Removing the spindle motor

(See Fig.12 and 13)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism assembly and

the feed motor assembly.

1.

Turn up the CD mechanism assembly and remove

the two springs k on both sides of the clamper arms.

Open the clamper arm upward.

2.

Turn the turn table, and remove the two screws H

and the spindle motor.

k

FD screw

Spindle motor

Fig.11

k

Fig.12

H

1-14

H

Fig.13

Page 15

Adjustment method

KD-SH99R

Test instruments required for adjustment

1. Digital oscilloscope (100MHz)

2. AM Standard signal generator

3. FM Standard signal generator

4. Stereo modulator

5. Electric voltmeter

6. Digital tester

7. Tracking offset meter

8. Test Disc JVC :CTS-1000

9. Extension cable for check

EXTGS004-26P 1

Standard measuring conditions

Power supply voltage DC14.4V(11 V to 16V allowance)

Load impedance 4 (4 to 8 allowance)

Line-Out Level/Impedance 4.0V/20k load(fuull scall)

How to connect the extension cable for adjusting

Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

BBE : OFF

Frequency Band

FM 87.5MHz ~107.9MHz

FM 87.5MHz 108.0 MHz

AM 530kHz ~ 1710 kHz(with channel interval set to 10kHz)

AM 531 kHz 1602 kHz(with channel interval set to 9 kHz)

Dummy load

Exclusive dummy load should be used for AM,and FM. For

FM dummy load,there is a loss of 6dB between SSG output

and antenna input.The loss of 6dB need not be considered

since direct reading of figures are applied in this working

standard.

(with channel interval set to 200kHz)

(with channnel interval set to 50kHz)

EXTLX003-20PC

EXTLX003-7PC

EXTLX003-20P

EXTGS004-26P

EXTLX003-7P

EXTLX003-2P

1-15

Page 16

KD-SH99R

< Service mode >

The menu in the service mode can be switched with UP/DOWN.

The menu selected by the SEL button input is executed.

The ordinary mode

"UP" + "DOWN" + VR counterclockwise rotation.

DEL EEPROM EEPROM data all clear (changer is connected).

CH CH ERR CD changer error career call (changer is connected).

DELL CH ERR CD changer EEPROM clear (EEPROM career)

RUNNING CD CD running mode (Do not use in service).

RUNNING SH Running mode of front panel (Do not use in service).

DEL DATA CD ERROR MECHA ERR error career deletion.

CD ADJ R Self adjustment value call (It is a display switch with VR).

MEKACON WR Sub-microcomputer writing (Do not use in service).

TEMP DATA Temperature data call.

VERSION Microcomputer version confirmation.

The display changes in the up/down key.

The main microcomputer : SH99 J203

The Sub-microcomputer : SH99S 122

CD ERROR CD relation error career reading

< Error display >

Item Content

DISC_ERROR_0

DISC_ERROR_1

DISC_ERROR_2

DISC_ERROR_3

DISC_ERROR_4

DISC_ERROR_5

EJECT_ERR

Others

FOCUS NG

Self adjustment NG

CLV NG

TOC reading NG

or

MP3 FILE CHECK NG

BLANK DISC

1-16

MECHA ERR Panel relation error career reading

Page 17

<ERROR CODE of Panel mechanism>

Memory to EEPROM of 6 digits, 1st and 2nd digit are indicate the operation mode when occur the error,

3rd to 6th digit are indicate details of error.

LCD indication time is use lower 2digits of details of error.

This series is indicate ERR XX (XX is error code).

<ex.> When details of error is 0A0001 , it is indicate ERR 01, details of error is 0E0031 , it is ERR 31.

Switch is from this side sequentially PSW1, PSW2,.....PSW6.

Details of error Error code

1. Error of door open (fault of PSW1)

(1) Time out by PSW1 not changed

(2) PSW1 change during waiting 300ms after open position detected

2. Error of door close (fault of PSW6)

(1) Time out by PSW6 not changed

(2) PSW6 change during waiting 300ms after close position detected

3. Error of shift to DETACH position (fault of PSW5)

(1) Time out by PSW5 not changed to open side

(2) Shift to open side, pass the DETACH position then detect ANGLE1

(3) Time out by PSW5 not changed to close side

(4) Shift to close side, pass the DETACH position then detect close position

4. Error of angle adjustment

4-1 Shift to ANGLE1 (fault of PSW4)

(1) Time out by PSW4 not changed to shift for open side

(2) Shift to open side, pass the ANGLE1 then detect ANGLE2

(3) Time out by PSW4 not changed to shift for close side

(4) Shift to close side, pass the ANGLE1 then detect DETACH position

4-2 Shift to ANGLE2 (fault PSW3)

(1) Time out by PSW3 not change to shift for open side

(2) Shift to open side, pass the ANGLE2 then detect ANGLE3

(3) Time out by PSW3 not changed to shift for close side

(4) Shift to close side, pass the ANGLE2 then detect ANGLE1

4-3 Shift to ANGLE3 (fault PSW2)

(1) Time out by PSW2 not changed to shift for open side

(2) Shift to open side, pass the ANGLE3 then detect OPEN position

(3) Time out by PSW2 not changed for shift for close side

(4) Shift to close side, pass the ANGLE3 then detect ANGLE2

5. PSW fault condition at initialize

When all PSW is checked immediately after RESET, and the state of SWITCH which

cannot be originally is detected, it is displayed as ERR 00.

0A0001

0A0002

0B0006

0B0007

0C0011

0C0012

0C0013

0C0014

0D0021

0D0022

0D0023

0D0024

0E0031

0E0032

0E0033

0E0034

0F0041

0F0042

0F0043

0F0044

000000

KD-SH99R

1-17

Page 18

KD-SH99R

Flow until reading TOC of CD/CD-R/CD-RW

FEED RETURN

OFFSET SELF ADJUSTMENT

LASER ON

Pre SP KICK

LENS UP

FOCUS ON

THE SPINDLE START

TRAKING BALANCE

RF GAIN

FOCUS GAIN

TRACKING

TOC READING

Becomes DRVMUTE=H and the output of the IC604 driver becomes possible.

Picking up is moved to surroundings on the inside until becoming REST SW=L.

Afterward, moves in the direction of outer again and stops in the place in which

became REST SW=H.

FOCUS OFFSET, TRACKING OFFSET, and RF OFFSET are done, and

OFFSET of RF AMP in IC603 is corrected.

400ms turns the spindle motor before the focus search starts.

Lens UP of the pick is done. At this time, S character curve becomes about

2.0Vp-p by CTS-1000.

The down of the lens and FOCUS ONing are made.

Changes into CD-RW MODE, and serches for FOCUS in case of no FOCUS ON

even if FOCUS search(UP DOWN) is done three times.

The spindle motor is rotated up to the number of necessary rotations.

In the state of tracking OFF, do the self adjustment of wavy OFFSET of TE2 to 0.

It takes time to adjust the one with a large gap of the traking balance of picking up.

At this time, the racking error becomes about 2.8Vp-p by CTS-1000.

In the state of traking OFF, do the self adjustment of the RF level of RF(TP601)

to 1.0-1.2Vp-p. After adjusts,traking ON is done.

Do th eself adjustment of the gain intersection of the focus servo to 1.2kHz

(300ms).

Do the self adjustment of the gain intersection of the focus servo to 1.2kHz.

(300ms).

Time expands in DISC that the number of total tracks with CD-TEXT is a lot of.

1-18

1Tr. HEAD

TP603

TE2

TP605

FEED

TP634

SP0

TP636

It is a head of 1Tr., and the reproduction begins.

Shape of waves when based on Vref(TP602)

FE

2.0Vp-p

2.8Vp-p

FE : Focus error signal

TE : T Tracking error signla

FEED : FEED deive signal

SPO : Spindle drive signal

Page 19

Adjustment part

KD-SH99R

IC941

C143

C144

TE2

TE

FE

C142

C944

D942

FOD

R630

C632 C633

C635

C631

C634

C636

C630

C629

R629

R636

C626

C628

R942

Q941

C637

R637

C678

C841

R876

C860

R134

C308

R941

R944

C622

R620 R621

C620 C621

C623

C627

C625

C624

C638

X602

R678

C677

C614

C615

IC603

R634

C680

C616

CN601

R677

C945

R853

R661

R695

R696

C639

C304

IC607

C307

R687

R688

R689

R855

R627

C641

X603

C302

R647

C643

R643

R857

R856

C642

C301

R690

C640

R697

R694

C305

R691

R698

C303

R667

R699

R665

R666

R668

R669

C669

R663

C687

R693

R676

TRD

C913

C686

R840

R839

IC606

R624

R838

R672

R673

R674

R675

R877

SPO

IC604

C676

C651

R662

C679

R633

X602

R619

R639

R651

R654

R650

R631

R644

R652

C351

C350

Q683

IC605

R655

IC803

C916

R211

C653

R649

IC805

R642

C450

R653

IC806

R659

C852

C851

R658

R111

R660

R641

C952

L622

R656R657

C161

C451

C654

IC804

C352

C321

FEED

C961

D402

D412

D416

D408

D401

C948

C947

C943

C941

C946

C949

C927

C141

IC941

C944

C143

C144

D942

L961

CN301

CN901

C926

CN302

D961

R977

C968

R978

C329

C921C922

D332

R231

R232

C928

D410

D414

R337

R976

C408

D967

Q232

R131

D962

C924

Q132

Q131

Q231

R132

C409

C272

D231

B1

IC401

R233

C404

C172

R243

R237

C323

C407

C410

R238

C244

D131

C405

B2

C273

R234

R244

IC171

R277

C173

C401

C243

C403

C241 C242

C220

R220

C402

C406

C309

R137

R143

C306

R120

R138

R133

C917

C120

C310

IC301

R144

C912

R134

C142

C302

C308

R942

C304

C305

R877

Q941

C307

R941

C301

C303

C945

R624

R944

C913

C622

R620R621

C643

C620C621

CN601

IC604

C623

R643

C626

C627

R627

R647

C687

C686

R857

R687

R688

R856

R840

C625

R689

R695

R855

R663

R691

R696

C641

R690

R661

C629

IC603

C630

R693

C624

R694

C642

R630

C628

R629

R697

R698

C676

C631

C632 C633

R699

R665

R666

R672

C637

C635

R839

R673

R669

R674

R838

C669

R675

IC606

R667

R668

C640

C634

R676

C636

X603

C638

R636

C639

R637

CN701

R679

R686

IC602

R680

R685

R681

R684

R682R683

IC601

D723

D724

D725

D726

D727

D728

D729

C721

D730

C722

C725

R933

R930

R923

R932

R924

R931

D914

D912

D722

C723

D721

CN702

C724

D796

CN771

IC961

C964

R963

C967

R962

Q755

R961

C330

R343

R436

R336

D701

C331

R344

C969

R325

R328

R331

C328

C327

R327

Q983

C971

R437

R340

C962

R329

Q35

R964

C965

C986

IC323

C977

D986

X51

C982

IC322

C332

R341

C334

C333

C978

R332

R342

R330

C325

C910

C175

R854

C452

IC911

C915

L852

R851

L851

R833

R911

R834

C203

C817

C818

D964

C450

C451

C103

C57

C163

R162

C25

D161

R164

D111

R163

D162

R161

PP2

R631

R644

C916

R617

R954

C321

C352

C351

R625

C951

C650

R645

IC951

R615

R618

C952

C350

R616

R111

R817

R813

C657

C811

R811

C164

C804

R823

C655

C656

C809

R211

R827

C653

C821

R821

R822

C803

R824

IC801

C161

C162

L622

C651

C812

R639

R812

R649

C822

C820

R814

R656R657

R658

R659

R660

R642

Q683

IC703

R641

C808

C814

C654

R784

C824

R662

R783

IC605

R633

C816

IC771

C772

C826

X602

R776

R655

IC802

IC804

R835

C819

C679

R619

R651

C710

R653

R775

R778

C852

R729

C771

R777

R654

C851

R725

R746

R779

R780

R650

R652

R723

R831

IC803

IC806

IC805

R832

R830

R766

D702

C714

BZ791

IC701

R759

R768

R702

X801

C713

C791

C708

X601

X701

R757

R758

R603R606

R798

R623

R648

R646

R628

R797

R626

D795

Main board

(Forward side)

J1

C117

L1

CN705

C998

C2

C4

Q34

D11

C34

C9

Q91

R83

R93

C81

Q81

C91

IC51

C5

C55

C53

C7

CN703

C32

TU1

R614

PP1

B3

IC608

R773

R781

R765

R782

R774

R772

R763

R764

R762

R770

R736

R761

R709

R722

R721

R724

R720

R719

R718

R717

R715R716

R714

TH951

R713

X702

BZ791

IC961

C931

C991 C992 C993

C997

C990

D1

D2

J1

R837

R692

C671

R671

R844

R843

B14

RF

B10

R664

R670

C645

R635

C617

C618

R852

B15

C644

R638

R632

X603

C612

R640

C646

C647

Vref

Q636

C996

CN771

B4

C773

C754

C774

C1

C3

R754

C755

B17

B5

C2

Q13

C11

CN705

D754

C10

C4

C84

R11

R4

C94

R5

Q11

C9

R14

R12

B18

R81

R13

X51

C82

R82

C45

C81

C6

C92

C44

C91

R92

C46

R35

R34

Q52

R56

R91

R55

C42C43

C41

R3

C5

R1

R51

C40

L51

Q1

C7

C53

PP2

Q51

R2

C47

Q32

C8

R33

Q33

B6

C56

C32

R32

R36

Q22

CN703

TU1

R23

PP1

R26

Q23

R726

C48

R727

C22

C21

C23

R24

R739

C719

R734

R735

C712

R745

R753

R728

R731

R732

R733

R707

R708

R710

R711

R701

R751

X702

C707

C702

C701

IC702

C964

C972

C973

R971

R975

C971

C967

Q966

C966

C969

R968

C965

R969

R10

R986

Q965

R15

R970

Q979

R987

Q12

C977

D978

C978

Q977

C51

C52

R53

R913

D980

R52

R54

R219

C54

R218

C25

C57

R118

R119

Q24

R21

R22

R28

R816

R167

C809

C24

R25

R825

R767

C164

R826

C804

C803

R27

R815

C808

C820

B8

C49

C807

C711

C806

C805

C815

C825

C826

D965

B9

L701

D963

R866

C710

R951

R738

R965

R743

R740

R868

R730

R864

C864

R796 R852

R999

R863

R865

R867

C714

R794

R793

Q701

R795

R792

R755

R769

R747 R748

R737

R742

R741

C706

C713

X701

C708

C705

C703 C704

C715

R705

R706

R927

R703

D711

R925

R135

C995

CN301

R136

R338

CN302

R961

R339

C337

R178

Q423

C987

C962

R335

Q323

Q321

C329

R276

R274

C323

R984

C982

R333

Q322

R176

C273

Q986

R334

C994

C325

C336

R275

R435

R985

C174

C175

C910

C452

C918

C911

C915

R175

C203

C212

R352

C210

C450

C451

C103

C916

C352

B7

Q642

C112

R177

R912

C321

C351

R351

C952

C350

Q161

R165

R622

C652

C161

C162

R166

C653

Q641

R634

X602

C816

C853

C680

R678

C660

L606

R677

B606

C678

C677

R870

C866

R869

R871

R872

R874

C841

C876

R876

R853

C878

C614

C615

C616

C860

C863

R859

X801

R861

R862

C862

BZ791

C605

R860

C861

B16

C606

R604

C792

C601

R791

C604

R602

R605

C791

X601

R601

C602

C726

Q791

R926

CN704

R922

Main board

(Reverse side)

D404

C961

CN901

C925

C923

L961

R235

D406

R236

D405

D961

B11

R172

C901

R272

R273

C272

C173

R173

R174

D911

C914

C912

D913

C913

C110

C671

IC607

R670

C617

C618

C609

C603

C942

D407

B12

D415

C409

C408

D403

R242

R241

R245

R402

C410

R404

C172

R401

C943

R403

R145

C242

C407

R141

C941

C401

C405

R146

R142

R405

C241

C403

C406

R246

D409

D411

C305

C402

C306

C310

R305

R301

C309

C141

IC941

C142

C308

D413

R943

C302

C303

C944

Q942

C307

C945

R304

R302

D941

B13

C301

R303

R836

R842

R841

R837

R844

R843

B14

B10

R692

R671

R664

C646

B15

C647

C644

C645

R638

R635

R632

Q636

X603

C612

R640

C619

R607

R608R609

L601

C611

C613

R928

R929

R613

C610

R612

R611

CN602

R610

RF shape of waves

1.0 1.2Vp-p

1-19

Page 20

KD-SH99R

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

(1) The level of RF output (EFM output:ampli

tude of eye pattern) will be low.

Is RF output

0.8

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed

circuit board which is attached to the pickup

is used to adjust the laser power.Since this

adjustment should be performed to match the

characteristics of the whole optical block,

do not touch the semi-fixed resistor.

If the laser power is lower than the specified

value,the laser diode is almost worn out, and

the laser pickup should be replaced.

If the semi-fixed resistor is adjusted while

the pickup is functioning normally,the laser

pickup may be damaged due to excessive current.

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

1-20

Play a disc.

Check the eye-pattern at measures

between TP601 and TP602.

Finish.

Page 21

Description of major ICs

UPD784215AGC146(IC701):MAIN CPU

1.Pin layout

75 51

76

50

KD-SH99R

2.Block diagram

INTP2/NMI

INTP0,INTP1

INTP3-INTP6

TI5/TO5

TI6/TO6

TI7/TO7

TI8/TO8

RTP0-RTP7

AV R

ANI0-ANI7

AV R

TI00

TI01

TO0

TI1

TO1

TI2

TO2

ANO0

ANO1

EF1

AV

EF0

AV

DD

AV

PCL

BUZ

100

125

PROGRAMMABEL

INTERRUPT

CONTROLLER

TIMER/COUNTER

TIMER/COUNTER1

TIMER/COUNTER2

TIMER/COUNTER5

TIMER/COUNTER6

TIMER/COUNTER7

TIMER/COUNTER8

WATCH TIMER

OUTPUT PORT

D/A

CONVERTER

SS

A/D

CONVERTER

SS

CLOCK OUTPUT

CONTROL

BUZZER OUTPUT

(16 BITS)

(8 BITS)

(8 BITS)

(8 BITS)

(8 BITS)

(8 BITS)

(8 BITS)

WATCHDOG

TIMER

REAL-TIME

26

78K/IV

CPU CORE

RAM

ROM

UART/IOE1

BAUD-RATE

GENERATOR

UART/IOE2

BAUD-RATE

GENERATOR

CLOCKED

SERIAL

INTERFACE

BUS I/F

PORT 0

PORT 1

PORT 2

PORT 3

PORT 4

PORT 5

PORT 6

PORT 7

PORT 8

PORT 9

PORT 10

PORT 12

PORT 13

SYSTEM

CONTROL

RxD1/SI1

TxD1/SO1

ASCK1/SCK1

RxD2/SI2

TxD2/SO2

ASCK2/SCK2

SI0

SO0

SCK0

AD0-AD7

A0-A7

A8-A15

A16-A19

RD

WR

WAIT

ASTB

P00-P06

P10-P17

P20-P27

P30-P37

P40-P47

P50-P57

P60-P67

P70-P72

P80-P87

P90-P95

P100-P103

P120-P127

P130,P131

RESET

X1

X2

XT1

XT2

V

DD

SS

V

TEST

1-21

Page 22

KD-SH99R

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

PREQ

AMUTE

DIMMER-OUT

ANT PEM

VDD

X2

X1

VSS

XT2

XT1

RESET

BUS-INT

PS2

RDS-SCK

RDS-DA

REMOCON

AVDD

AVREF0

SD-ST

MRC DATA

KEY0

KEY1

TEMP

LEVEL

SQ

S.METER

AVSS

INLOCK

NC

AVREF

BUS-SI

BUS-SO

BUS-SCK

(STAGE)

LCD-DA

LCD-CL

LCD-CE

BUZZER

EPDAI

EPDAD

EPCLK

BUS-I/O

PM0

PM1

O

Mechanism power supply ON/OFFdemand output("L":On demand)

O

Audio output MUTE control signal output ("L" :MUTE ON)

O

Non connected

O

Non connected

O

Non connected

O

Non connected

O

Unused output port

O

Antenna remote output

-

5V connection

Sub-clock 32.738MHz

I

Sub-clock 32.738MHz

-

GND connection

Sub-clock 12.5MHz

I

Sub-clock 12.5MHz

Reset detection terminal

I

Non connected

O

J-BUS signal interrupt input

I

POWER SAVE2 BACK UP synchronization. It is H input and stop mode.

I

Unused input port

I

RDS clock input

I

RDS data input

I

Remote control signal input

-

5V connction

-

5V connection

I

Station detector, stereo signal input.

It is H and broadcasting station havingBroadcasting station,L:stereo

I

MRC DATA input

I

Key input 0

I

Key input1

I

Temperature data input for contrast correction

I

Level meter input

I

S.QUALITY level input

I

S.METER level input

-

GND connection

O

The LOCK detection output. At LOCK:H

O

Unused output port

-

5V connection

I

J-BUS data input

O

J-BUS data output

I/O

J-BUS clock I/O

I

H:L:Initialization port

O

Data output to LCD driver

O

Clock output to LCD driver

O

Chipenable output to LCD driver

O

Buzzer output

I

Communication data input of 12C

O

Communication data input of 12C

O

Communication data input of 12C

O

The J-BUS I/O switch output. When outputting :H,When inputting :L

O

Panel close side motor control signal output

O

Panel opening side motor control signal output

UPD784215AGC146(1/2)

1-22

Page 23

Pin No. Symbol I/O Function

51

52

53

54

DETACH

Non connected

O

Non connected

O

Non connected

O

The detach signal input. It is L of 200ms or more and operation mode.

I

It is H and POWER SAVE.

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

VCR CONT

PNL SW1

PNL SW2

PNL SW3

PNL SW4

PNL SW5

PNL SW6

AFCK

SEEK/STOP

S MUTE

FM/AM

PLL-CE

PLL-DO

PLL-CLK

PLL-DI

TEL-MUTE

AMP KILL

VSS

DIMMER-IN

PS1

Signal output for VCR control

O

Panel position detection switch one signal input.

I

Panel position detection switch two signal input.

I

Panel position detection switch three signal input.

I

Panel position detection switch four signal input.

I

Panel position detection switch five signal input.

I

Panel position detection switch six signal input

I

The Af check output. When you check AF:L.

O

The auto seek stop switch output. At SEEK:H, STOP:L.

O

Software mute output for CF switch noise.

O

FM and the AM switch output. At FM:H,At AM:L

O

CE output for IC control for PLL.

O

Data output for IC control for PLL.

O

Clock output for IC control for PLL.

O

Data input for IC control for PLL.

I

Telephone ,ute detection input.

I

POWER-AMP, ON/OFF switch output. H:OFF

O

GND connection

Dimmer detection input. L:Dimmer ON

I

At POWER SAVE of POWER SAVE1.ACC and synchronization:L.

I

When operating :H.

75

76

77

78

79

80

81

82

83

84

85

86

87

88

POWER

CD-ON

MUTE

W-LPF1

W-LPF2

W-MUTE

VDD

VOL-DA

VOL-CLK

CF-SEL

PMKICK

EMPH

VOL-1

The POWER ON/OFF switch output. At the time of the POWER ON:H.

O

The CD power supply control signal output. At CD:H.

O

The mute output. At the time of the MUTE ON:L.

O

Sub woofer cutoff frequency control output 1

O

Sub woofer cutoff frequency control output 2

O

The mute output for the sub woofer. At the time of the MUTE ON:H.

O

5V connection.

O

Data output for IC control for electronic volume.

O

Clock output for IC control electronic volume.

O

Signal output for FM belt region filter switch.

O

Signal output for panel motor kick

O

The CD emphasis output. When turning.At On:H.

O

Non connected

O

Pulse which rotation volume pulse signal inputs, and becomes

I

judgment of change actually.

89

90

91

92

93

94

95

96

97

98

99

100

VOL-2

(J/R)

BUCK

CCE

LSI RST

TEST

(DISC SEL)

SW1

rotation volume pulse signal input

I

H:J version and L:R version

I

Non connected

O

Non connected

O

CDLSI reset signal output

O

GND connection

Non connected

O

Non connected

O

Non connected

O

Non connected

O

Non connected

O

Panel SW1

I

KD-SH99R

UPD784215AGC146(2/2)

1-23

Page 24

KD-SH99R

UPD63711AGC(IC603):RF Servo amp

1.Pin layout

144 109

1

108

36

37 72

73

2.Pin function

Pin No. Symbol I/O Function

1

2

3

4

VSSO

ZRASO

ZCASO

ZCAS1

-

It is GND of the logic circuit.

O

It is RFOK signal output terminal.

I

Reset signal input terminal. (Active row)

I

Command/parameter identification signal input terminal

A0=L:STB active=Address register set. A0=H:STB active= Parameter set.

5

VSSO

I

The data strove signal input terminal. It is signal to de the latch in LSI as

for the cereal data.

6

ZOE

I

The clock signal input terminal to input and output the cereal data. Input

data from terminal SI is taken by standing up about this signal, and the

cereal data from the terminal SO is output with go down.

7

8

9

ZUWE

ZLWE

VSSO

O

The cereal data and the status signal are output.

I

Cereal data input terminal.

I

The crystal oscillation control terminal. Please input the reset signal

before stopping the crystal oscillation. Moreover, the crystal oscillation is

steady and input the reset signal, please when moves from the state of

the crystal oscillation stop to the ordinary mode.

XTALEN=L:ordinary mode XTALEN=H:Crystal oscillation stop.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

RA0

RA1

RA2

RA3

RA4

RA5

RA6

RA7

VDD0

VSS0

RA8

IO0

IO1

IO2

IO3

IO4

IO5

VSSO

-

Positive power supply supply terminal to logic circuit.

-

Positive power supply supply terminal to D/A converter.

O

R-ch audio signal output terminal.

-

It is D/A converter GND.

-

The outside credit capacitor connection terminal for SCF regulator.

-

It is D/A converter GND.

O

L-ch audio signal output terminal.

-

Positive power supply supply terminal to D/A converter.

O

Output terminal of right channel voice data. PWM output.

O

Left channel voice data audio output terminal. PWM output.

-

Positive power supply supply terminal to crystal oscillation circuit.

O

Crystal departure pendulum connection terminal (Output)

I

Crystal departure pendulum connection terminal (Input)

-

It is GND of the crystal oscillation circuit.

-

Positive power supply supply terminal to logic circuit.

O

The output terminal of priemphasis information in sub code Q.

When the emphasis is added, high level is output. Polarity can be

switched by the command.

F6H LSB EP=0:Normal output EP=1:Reversing output.

28

IO6

O

Flag output terminal which shows that data under output is composed by

data which cannot be corrected.(active high)

29

IO7

I

The cereal data input terminal to building DAC into. When DSP etc. are

not connected with latter part, it should be short with the terminal DOUT.

30

31

IO8

IO9

O

It is an output terminal of the cereal voice data.

I

Cereal clock input terminal to building DAC into.

The output voice data changes from DOUT by standing up about this

clock. The system connected with latter part must take data by standing

up about this signal.

32

IO10

O

The output voice data changes from DOUT by standing up about this

clock.The system connected with latter part must take data by standing

up about this signal.

UPD63711AGC(1/3)

1-24

Page 25

Pin No. Symbol I/O Function

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

IO11

IO12

IO13

VSSO

VDD1

IO14

IO15

DREQ

DRESP

IOP7

IOP6

IOP5

IOP4

IOP3

IOP2

IOP1

IOP0

HDBDIR

DVDD

PACK

TSO

TSI

TSCK_B

TSTB_B

DGND

TEST0

TEST1

ATEST

AGND

FD

TD

SD

MD

DACO

FBAL

TBAL

TEVCA

AVDD

EFM

ASY

C3T

RFI

AGCO

AGCI

RFO

I

LRCK signal input terminal to building DAC into.

O

Signal which distinguishes left channel/right channel of voice data output

from DOUT.

O

Terminal (88.2kHz)(WDCK)of the output of the frequency signal twice

defect detection output terminal(HOLD) LRCK HOLD/WDCK can be

switched with the microcomputer.

O

Terminal of output of data of Digital audio interface.

-

It is GND of the logic circuit.

O

Buffer ring output terminal of oscillation.

I

The state of this terminal is output to Bit5 of the status output.

-

Positive power supply supply terminal to logic circuit.

O

It is EFM-synchronous detection signal.becomes high-level when the

O

output of the synchronous pattern detection signal and the frame

counter is corresponding by the EFM recovery part, and becomes a row

level at the disagreement.

O

Mirror output terminal. (MIRR).It is a frame synchronous signal of PLL

system. The one that a basic frequency (44.1kHz)of the reading signal

obtained in PLL system was divided makes almost equally to the

synchronization(7.35kHz) of one frame. (WFCK)MIRR/WFCK can be

switched with the microcomputer.

O

the terminal for the monitor of the bit clock. When PLL is locked, the

go down edge of the EFM signal and this signal locks.

-

it is GND of the logic circuit.

O

The output terminal which shows the C1 error correction result. Even

go down of RFCK is fixed.

O

It is an output terminal which shows the C2 error correction result. Even

of RFCK is fixed.

-

Positive power supply supply terminal to logic circuit.

O

It is PACK synchronous signal shows the head of packing.

O

It is a cereal output terminal of the CD-TEXT data.

I

It is a serial input terminal of the CD-TEXT control parameter.

I

Cereal clock input terminal of CD-TEXT.

I

Terminal of input of parameter strove signal of CD-TEXT.

-

It is GND of the logic circuit.

I

It is a test terminal. Please connect with GND usually.

O

It is a test terminal. Please make to the opening usually.

-

It is GND of an analog circuit.

O

Focus drive output terminal.

O

Tracking drive output terminal.

O

Thread drive output terminal.

O

Spindle drive output terminal.

O

It is DAC output terminal for the adjustment. A set value of CRAM7FH is

output.

O

It is DAC output terminal for the adjustment. A set value of CRAM7CH is

output (built-in RF FE amplifier offeset).

O

It is DAC output terminal for the adjustment. A set value of CRAM7DH is

output.

O

It is DAC output terminal for the adjustment. A set value of CRAM7EH is

output (built-in RF TE amplifier offset).

-

It is a positive power supply supply terminal to an analog circuit.

O

EFM signal output terminal.

I

It is a standard voltage input terminal of the EFM comparator.

-

Capacitor connection terminal for 3T detection.

I

RF signal input terminal for EFM data generation.

O

RF signal output terminal after gain is adjusted.

I

Input terminal of RF-AGC amplifier.

O

Output terminal of RF saming amplifier.

KD-SH99R

UPD63711AGC(2/3)

1-25

Page 26

KD-SH99R

Pin No. Symbol I/O Function

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

EQ2

EQ1

RF

AGND

A

C

B

D

F

E

AVDD

REFOUT

FE

FEO

TE

TEO

TE2

TEC

AGND

PD

LD

PN

AVDD

-

Equalizer part connection terminal of RF amplifier.

I

Reversing input terminal of RF saming amplifier.

-

It is GND of an analog circuit.

I

Photo detector A input terminal.

I

Photo detector B input terminal.

I

Photo detector C input terminal.

I

Photo detector D input terminal.

I

Photo detector F input terminal.

I

Photo detector E input terminal.

-

Positive power supply supply terminal to analog circuit.

O

reference potential output terminal.

I

Focus make an error amplifier reversing input terminal.

O

Focus Allah amplifier output terminal.

I

Tracking make an error amplifier reversing input terminal.

O

Tracking error amplifier output terminal.

O

Terminal to which tracking error after amplifies is output.

I

The tracking comparator input terminal. The tracking error signal which

cuts the DC element is input. The tracking 0 crossing is detected by

using this signal in LSI.

-

it is GND of an analog circuit.

I

It is a terminal of the input of the detection signal of PD for the LD output

monitor.

O

LD control current output terminal.

I

It is a control polarity set value of the APC circuit.

-

Positive power supply supply terminal to analog circuit.

UPD63711AGC(2/2)

TC74VHC157FT-X(IC803):DAC SW

1.Pin lauout 2.Pin function

SELECT

1A

1B

1Y

2A

2B

2Y

GND

1

2

3

4

5

6

7

ASG

B

Y

A

B

YYB

A

B

Y

A

8

16

15

14

13

12

11

10

Vcc

ST

4A

4B

4Y

3A

3B

3Y

9

ST

H

L

L

L

L

X:Don't Care

INPUTS

X

L

L

H

H

ABSELECT

X

L

H

X

X

X

X

X

L

H

OUTPUT

L

L

H

L

H

1-26

Page 27

UPD70F3033AC015(IC606):SUB CPU

1.Pin layout

100 76

1

75

KD-SH99R

25

26 50

51

2.Pin function

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

TSI

TSCK

JBSO

JBSI

JBCK

EVDD

EVSS

TSTB

XRESET

MIRR

AO

SO

SI

SCK

WSEN

DSPRST

SWAIT

VPP

SA4

SA5

SA6

STB

DRVMUTE

LOAD1

LOAD2

SA0

SA1

SA2

SA3

RESET

XT1

XT2

VSS

VDD

CLKOUT

WR

---

---

RD

---

JBCONT

PON

AD0

AD1

AD2

AD3

O

CD TEXT control parameter cereal output.

O

CD TEXT control cereal clock output.

O

JBUS cereal data output.

I

JBUS cereal data input.

I/O

Cereal clock I/O.

-

5V(power supply for port for I/O).

-

GND(GND for port for I/O).

O

CD TEXT parameter strobe signal output.

O

LSI reset output.

I

MIRR signal input(H:Speculer).

O

Command:/parameter:H switch signal output.

I

DSP cereal data input.

O

DSP cereal data input.

O

DSP cereal data clock output.

O

Internal CD/DC operation of MP3 operation & beginning.

O

DSP RESET:L.

I

WAIT signal input from DECODER.

-

FLASH writing power supply.

O

DECODER address passing output.

O

DECODER address passing output.

O

DECODER address passing output.

(Non connected)

O

DSP cereal data latch output.

O

Servo deriver MUTE control signal output(L:MUTE:ON)

O

Loading drive.

O

Loading drive.

O

DECODER address passing output.

O

DECODER address passing output.

O

DECODER address passing output.

O

DECODER address passing output.

I

Microcomputer reset terminal(L:Reset)

I

Sub-clock

-

Sub-clock

-

-

The main clock crystal oscillation machine.

I

The main clock crystal oscillation machine(20MHz).

-

5V

-

GND

O

Internal system clock output(Non connecte)

O

DECODER data writing.

O

(Non connected)

O

(Non connected)

O

DECODER data reading.

O

Address bus enable.

O

JBUS I/O switch.

I

Mechanism power supply ON:L.

I/O

DECODER I/O data bus

I/O

DECODER I/O data bus

I/O

DECODER I/O data bus

I/O

DECODER I/O data bus

UPD70F3033AC015(1/2)

1-27

Page 28

KD-SH99R

Pin No. Symbol I/O Function

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

AD4

AD5

AD6

AD7

BVDD

BVSS

---

---

---

---

---

---

---

--MD

MC

ML

MP3SEL

PREQ

AMUTE

AVDD

AVSS

AVREF

PDET

SW2

SW3

SW4

REST

RFOK

REQ

EXP

ADIN0

ADIN1

ADIN2

ADIN3

---

CONT+B

SW1

PACK

INT0

INT1

JBINT

TESTMODE

12CD

---

12CC

RXDO

SID

SIC

TSO

I/O

DECODER I/O data bus.

I/O

DECODER I/O data bus.

I/O

DECODER I/O data bus.

I/O

DECODER I/O data bus.

-

5V

-

GND

O

(Non connected)

O

(Non connected)

O

(Non connected)

O

(Non connected)

O

(Non connected)

O

(Non connected)

O

(Non connected)

O

(Non connected)

O

DAC mode control data.

O

DAV mode control clock.

O

DAC mode control latch.

O

MP3/CD-DA switch SW L:Cd H:MP3

O

Mechanism power supply ON/OFF demand output(L:ON demand)

O

Audio output MUTE control signal output(L:MUTE ON)

-

5V(Power supply for AD converter)

-

GND(GND for AD converter)

-

5V(Standard voltage for AD converter)

I

BACKUP power supply detection(L:BACKUP power supply ON)

I

SW2 mechanism switch.

I

SW3 mechanism switch.

I

SW4 mechanism switch.

I

Surroundings position detection switch(L:Surroundings)

I

RFOK signal input.

I/O

Data demand.

I

H:Export L:For country 8cm CD.

I

Test key input 0 (A/D input)

I

Test key input (A/D input of one)

I

Test key input (A/D input of two)

I

Test key input (A/D input of three)

O

(Non connected)

I

LSI5V ON power supply control signal and JBUS control signal input.

I

SW1 mechanism switch.

I

PACK synchronous signal of CD-TEXT.

I

DECODER interrupt request.

I

DECODER interrupt request.

I

J-BUS interrupt signal input.

I

L: test mode shift.

I/O

12C data line.

O

(Non connected)

I/O

12C clock line.

I

FLASH writing cereal data input.

O

MP3 cereal data output and FLASH writing cereal data output.

O

MP3 cereal clock output and FLASH writing cereal clock output.

I

CD-TEXT data serial input.

UPD70F3033AC015(2/2)

1-28

Page 29

MAS3507D-QG-G10 (IC806) :MP3 decoder

1.Pin layout

SID

SII

SIC

PI3

PI2

PI1

PI0

CLKO

PUP

WSEN

WRDY

AVDD

CLKI

AVSS

PI4

33 32 31 30 29 28 27 26 25 24 23

34

35

36

37

38

39

40

41

42

43

44

1

234567891011

XVSS

XVDD

PI8

SOC

SOI

SOD

22

21

20

19

18

17

16

15

14

13

12

KD-SH99R

PI12

PI13

PI14

PI15

PI16

PI17

PI18

PI19

RCS

PR

VSENS

DCSO

2.Block diagram

MPEG Bit Stream

Digital Audio Output

TE

POR

I2CC

Volume

Tone

Control

VSS

VDD

I2CD

(TOP VIEW)

EOD

DCEN

Sync

MPEG

Decoder

RTR

RTW

DCSG

Ancillary

Data

C

Decoder

to

Status

Config.Reg.

PIO

Status Start-up Config.

1-29

Page 30

KD-SH99R

3.Pin function

Pin no. Symbol I/O Function

MAS3507D-QG-G10(1/2)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

TE

POR

I2CC

I2CD

VDD

VSS

DCEN

EOD

RTR

RTW

DCSG

DCSO

VSENS

PR

PCS

PI19

PI18

PI17

PI16

PI15

PI14

PI13

PI12

SOD

SOI

SOC

PI18

XVDD

XVSS

SID

SII

SIC

PI4

PI3

PI2

I

I

I/O

I/O

Supply

Supply

I

OUT

OUT

OUT

Supply

O

I

IN

IN

IN/OUT

IN/OUT

IN/OUT

IN/OUT

IN/OUT

IN/OUT

IN/OUT

IN/OUT

O

O

O

IN/OUT

Supply

Supply

I

I

I

IN/OUT

IN/OUT

IN/OUT

Test Enable

Reset, Active Low

2

I C Clock Line

2

I C Data Line

Positive Supply for Digital Parts

Ground Supply for Digital Parts

Enable DC/DC Converter or Voltage Supervision

PIO End of DMA, Active Low

PIO Ready to Read, Active Low

PIO Ready to Write, Active Low

DC Converter Transistor Ground

DC Converter Transistor Open Drain

DC Converter Voltage Sense

PIO DMA Request Read/Write

PIO Chip Select, Active Low

PIO Data(19)

i)Demand Pin in SDI mode

ii)data bit(7),MSB in PIO DMA input mode

PIO Data(18)

i)MPEG header bit11-MPEG ID(SDI mode)

ii)data bit(6) in PIO DMA input mode

PIO Data (17)

i)MPEG header bit 12-MPEG ID(SDI mode)

ii)data bit(5) in PIO DMA input mode

PIO Data(16)

i)SIC,alternative input for SIC(SDI mode)

ii)data bit(4) in PIO DMA input mode

PIO Data(15)

i)SII, alternative input for SII(SDI mode)

ii)data bit(3) in PIO DMA input mode

PIO Data(14)

i)SID, alternative input for SID (SDI mode)

ii)data bit(2) in PIO DMA input mode

PIO data(13)

i)MPEG header bit 13-Layer ID (SDI mode)

ii)data bit(1) in PIO DMA input mode

PIO Data (12)

i)MPEG header bit 14-Layer ID (SDI mode)

ii)data bit(0) in PIO DMA input mode

Serial Output Data

Serial Output Frame Identification

Serial Output Clock

Start-up : Clock output scaler on/off

1)

Operation : MPEG CRC error

Positive Supply of Output Buffers

Ground of Output Buffers

Serial Input Data

Serial Input Frame Identification

Serial Input Clock

Start-up : Select SDI/PIODMA input mode

1)

Operation : MPEG-Frame Sync

Start-up : Enable Layer 3 / Disable Layer 3 decoding

1)

Operation : MPE Gheader bit 20(Sampling Frequency)

Start-up : Enable Layer 2 / Disable Layer 2 decoding

1)

Operation : MPEG header bit 21(Sampling Frequency)

1-30

Page 31

3.Pin function

Pin no. Symbol I/O Function

36

PI1

IN/OUT

Start-up : SDO Select 32 bit mode / 16 bit I S mode

1)

Operation : MPEG header bit 30(Emphasis)

37

P0

IN/OUT

Start-up : Select Multimedia mode / Broadcast mode

1)

Operation MPEG header bit 31 (Emphasis)

38

39

40

41

CLKO

PUP

WSEN

ERDY

O

O

I

O

Clock Output (normal 24.576 MHz)

Power Up, i.e.Status of Voltage Supervision

WS Enable : Enable DSP

WSEN=0 : Valid clock input at CLKI

WSEN=1 : Clock synthesizer PLL locked

42

43

44

AVDD

CLKI

AVSS

1)

Start-up configuration see Table 2.7.3. in (1)

Supply

I

Supply

Supply for Analog Circuits

Clock Input

Ground Supply for Analog Circuits

KD-SH99R

MAS3507D-QG-G10(2/2)

2

BU4066BCFV-X (IC322) : Quad analog switch

1. Pin layout & Block diagram

VDD C1 C4 I/O4 I/O3O/I4 O/I3

14 13 12 11 810 9

1234 756

I/O1 O/I1 O/I2 I/O2 VssC2 C3

1-31

Page 32

KD-SH99R

LC895199K-ND2(IC601):CD-ROM decoder

1.Pin layout

144 109

1

108

36

37 72

73

2.Pin function

Pin No. Symbol Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

VSSO

ZRASO

ZCASO

ZCAS1

VSSO

ZOE

ZUWE

ZLWE

VSSO

RA0

RA1

RA2

RA3

RA4

RA5

RA6

RA7

VDD0

VSS0

RA8

IO0

IO1

IO2

IO3

IO4

IO5

VSSO

IO6

IO7

IO8

IO9

IO10

IO11

IO12

IO13

VSSO

VDD1

IO14

IO15

DREQ

DRESP

IOP7

IOP6

IOP5

IOP4

IOP3

IOP2

IOP1

IOP0

HDBDIR

RAS signal output terminal to buffer DRAM

CAS signal output 0 terminal to buffer DRAM(0 is used usually)

CAS signal output terminal 1 to buffer DRAM

Buffer DRAM output enable

Buffer DRAM upper write enable

Buffer DRAM lower write enable

Address signal output terminal to data buffer DRAM

5.0V

Address signal output terminal to data buffer DRAM

Data I/O terminal to data buffer DRAM. With built-in pull-up resistor

Data I/O terminal to data buffer DRAM. With built-in pull-up resistor

3.3V

Data I/O terminal to data buffer DRAM.With buolt-in pull-up resistor

General-purpose I/O port

LC895199K-ND2(1/3)

1-32

Page 33

Pin No. Symbol Function

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

TEST0

XTALCK

XTAL

VDD0

VSS0

MCK

TEST1

DSDATA

DLRCK

DBCK

C2PO

SDATA

BCK

LRCK

EXCK

WFCK

SBSO

SCOR

PLL1

PLL2

PLL3

VSS0

VDD1

ZRESET

MCK3

CSCTRL

ZRO

ZWR

ZCS

SUA0

SUA1

SUA2

SUA3

SUA4

SUA5

SUA6

D0

D1

D2

VDD0

VSS0

D3

D4

D5

D6

D7

ZINTO

ZINT1

ZSMAIT

ZRSTCPU

CSEL

ZHRST

ATPINSEL

ZDASP

ZCS3FX

ZCS1FX

DA2

VSS1

VDD1

The terminal TEST.Please connect with VSS

X'tal oscillation circuit input terminal

X'tal oscillation circuit output terminal

5.0V

1/1,2/2,STOP output terminal of XTALCK

The terminal TEST. Please connet with VSS

DAC output terminal

Terminal for CD-DSP I/F

SUB-CODE I/O terminal

Relation connection of PLL terminal

(It is analog VSS in version LC895199 with built-in PLL)

3.3V (It is analog VDD in version LC895199 with buikt-in PLL)

LSI reset terminal

1/1, 1 /5, 2/5, 1/512, and STOP output terminal of XTALCK

Active Lo and Hi selection terminal on MC(microcontroller) side CS

Reading data of MC(microcontroller) signal input terminal

Writing data of MC(microcontroller) signal input terminal

Register chip selection signal input terminal from MC(microcontroller)

MC(microcontroller) register selection signal terminal

MC(microcontroller) data signal terminal.With buit-in puul-up resistor.

5.0V

MC(microcontroller) data signal terminal. With buit-in pull-up resistor.

Interrupt request signal output terminal to MC(microcontroller)

WAIT signal to MC(microcontroller)

Reset signal to CPU

ATAPI control signal

ATAPi data bus

Terminal ATAPI arrangement select terminal. Connects with VDD0

ATAPI data bus

3.3V

KD-SH99R

LC895199K-ND2(2/3)

1-33

Page 34

KD-SH99R

Pin No. Symbol Function

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

DAO

ZPDIAG

DA1

ZIOCS16

HITRQ

ZDMACK

VSS1

IORDY

ZDIOR

ZDIOR

DMARQ

VSS1

DD15

DDO

DD14

DD1

VDDO

VSS1

DD13

DD2

DD12

DD3

VSS1

DD11

DD4

DD10

VSS1

VDD0

DD5

DD9

DD6

VSS1

DD8

DD7

VDD1

ATAPI data bus

ATAPI data bus

ATAPi data bus

ATAPi control signal

ATAPI control signal

5.0V

ATAPI control signal

ATAPI control signal

5.0V

ATAPI control signal

3.3V

LC895199K-ND2(3/3)

1-34

Page 35

HA13164 (IC961) : Regulator

1.Pin layout

KD-SH99R

2.Block diagram

123456789101112131415

ANT OUT

EXT OUT

ANT CTRL

CTRL

CD OUT

AUDIO OUT

C3

0.1u

C4

0.1u

C5

0.1u

C6

10u

2

1

11

12

10

MEMORY

7

VCC ACC

8

Surge Protector

BIAS TSD

15

3

C1

100u

C2

0.1u

13

ILM AJGND

+B

ACC

BATT.DET OUT

9

COMPOUT