Page 1

SERVICE MANUAL

CD RECEIVER

4983420036

KD-SH9105

Area Suffix

U -------------------- Other Areas

ATT

ANGLE

EQ

CD

DAB

DISC

FM

PRESET

PRESET

R D

AM

CH

AUX SEL

RM-RK100

50Wx4

SRC

DISC

VOLUME

D

DISP

ATT

MOSFET

SEL

KD-SH9105

BBE

3456 M21

MODE

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

6 Description of major ICs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.49834

2003/6

Page 2

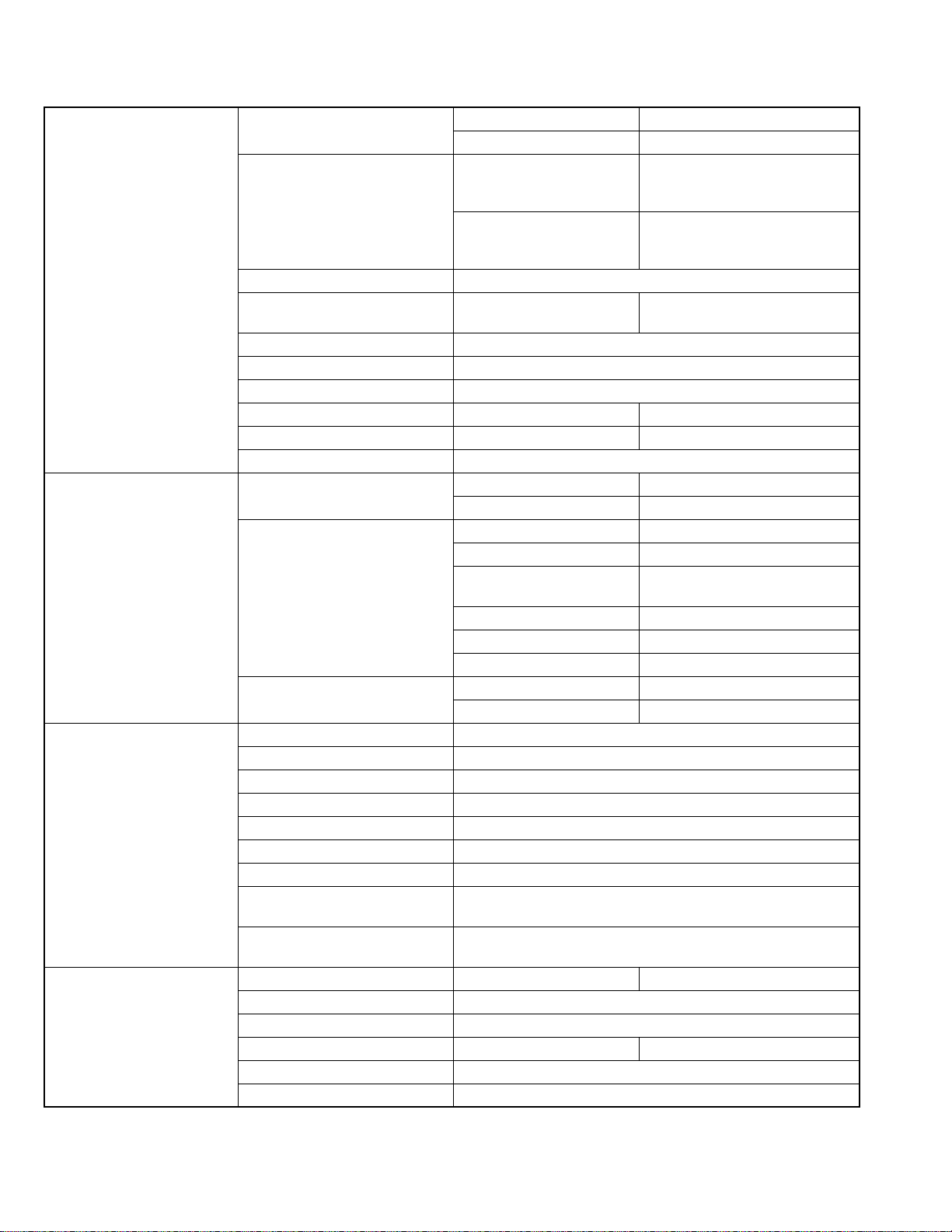

SPECIFICATION

AUDIO AMPLIFIER SECTION Maximum Power Output Front 50 W per channel

Rear 50 W per channel

Continuous Power Output (RMS) Front 19 W per channel into 4 Ω, 40 Hz

to 20 000 Hz at no more than 0.8%

total harmonic distortion.

Rear 19 W per channel into 4 Ω, 40 Hz

to 20 000 Hz at no more than 0.8%

total harmonic distortion.

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Frequencies 60 Hz, 150 Hz, 400 Hz, 1 kHz, 2.4

kHz, 6 kHz, 12 kHz

Level ±10 dB

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-In Level/Impedance LINE IN 1.5 V/20 kΩ load

Line-Out Level/Impedance LINE OUT 4.0 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

TUNER SECTION Frequency Range FM 87.5 MHz to 108.0 MHz

AM 531 kHz to 1 602 kHz

[FM Tuner] Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity

(400 kHz)

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation: 35 dB

Capture Ratio 1.5 dB

[AM Tuner] Sensitivity 20 µV

Selectivity 35 dB

CD PLAYER SECTION Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 98 Db

Signal-to-Noise Ratio 102 dB

Wow and Flutter Less than measurable limit

MP3 (MPEG Audio Layer 3) Max.

Bit rate:

WMA (Windows Media® Audio)

Max. Bit rate:

GENERAL Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size 182 mm × 52 mm × 161 mm

Panel Size 188 mm × 58 mm × 17 mm

Mass 1.8 kg (excluding accessories)

320 Kbps

192 Kbps

65 dB

1-2 (No.49834)

Page 3

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

(No.49834)1-3

Page 4

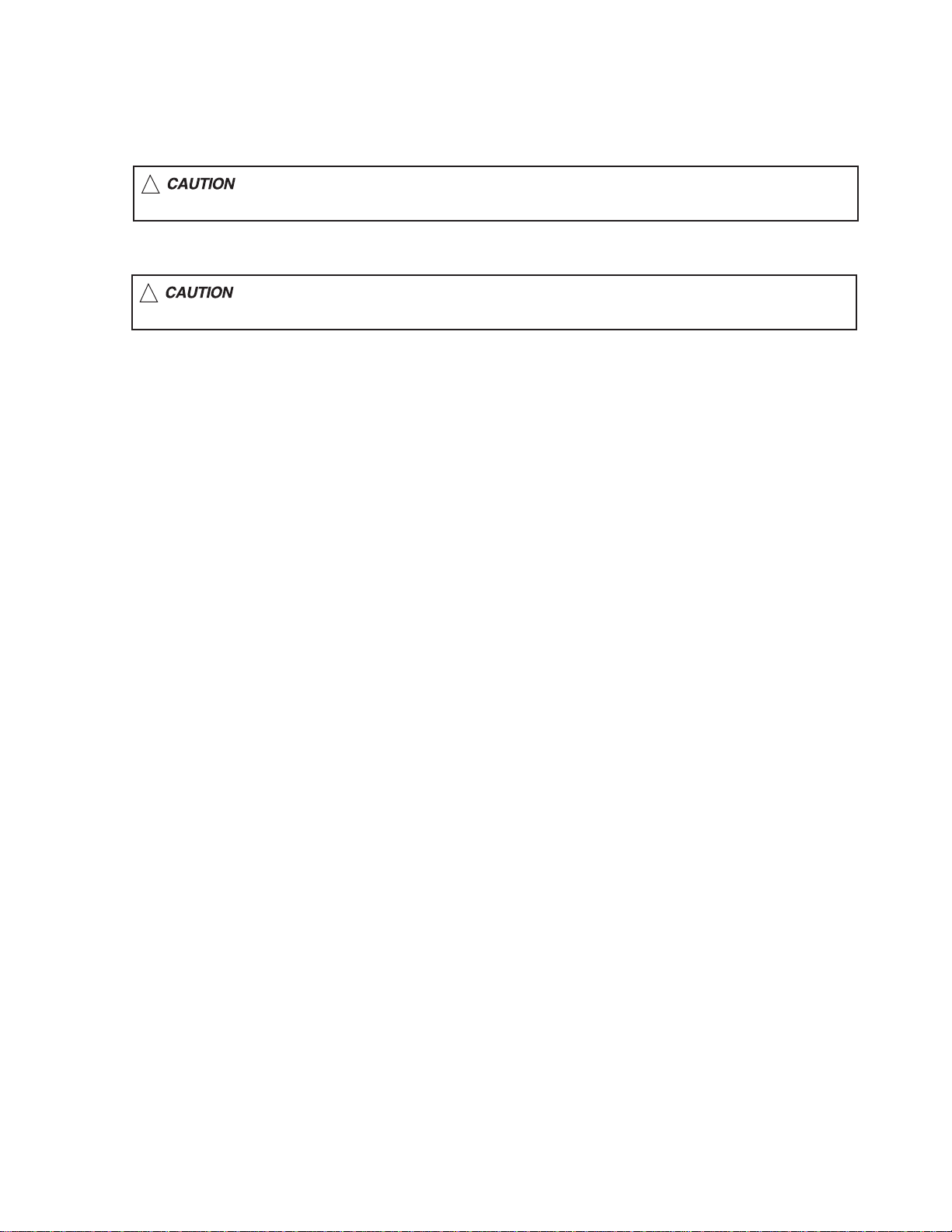

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser dio de) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sh eet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before instal lation, both sides of the laser di ode on the replacement optica l

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed *Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land before the flexible wire is disconnected from the connector on the CD pickup unit.

(If the flexible wire is disconnected without applying solder, the CDpickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the flexible wire.

Short-circuit point

(Soldering)

Flexible wire

1-4 (No.49834)

Pickup

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.49834)1-5

Page 6

SECTION 3

DISASSEMBLY

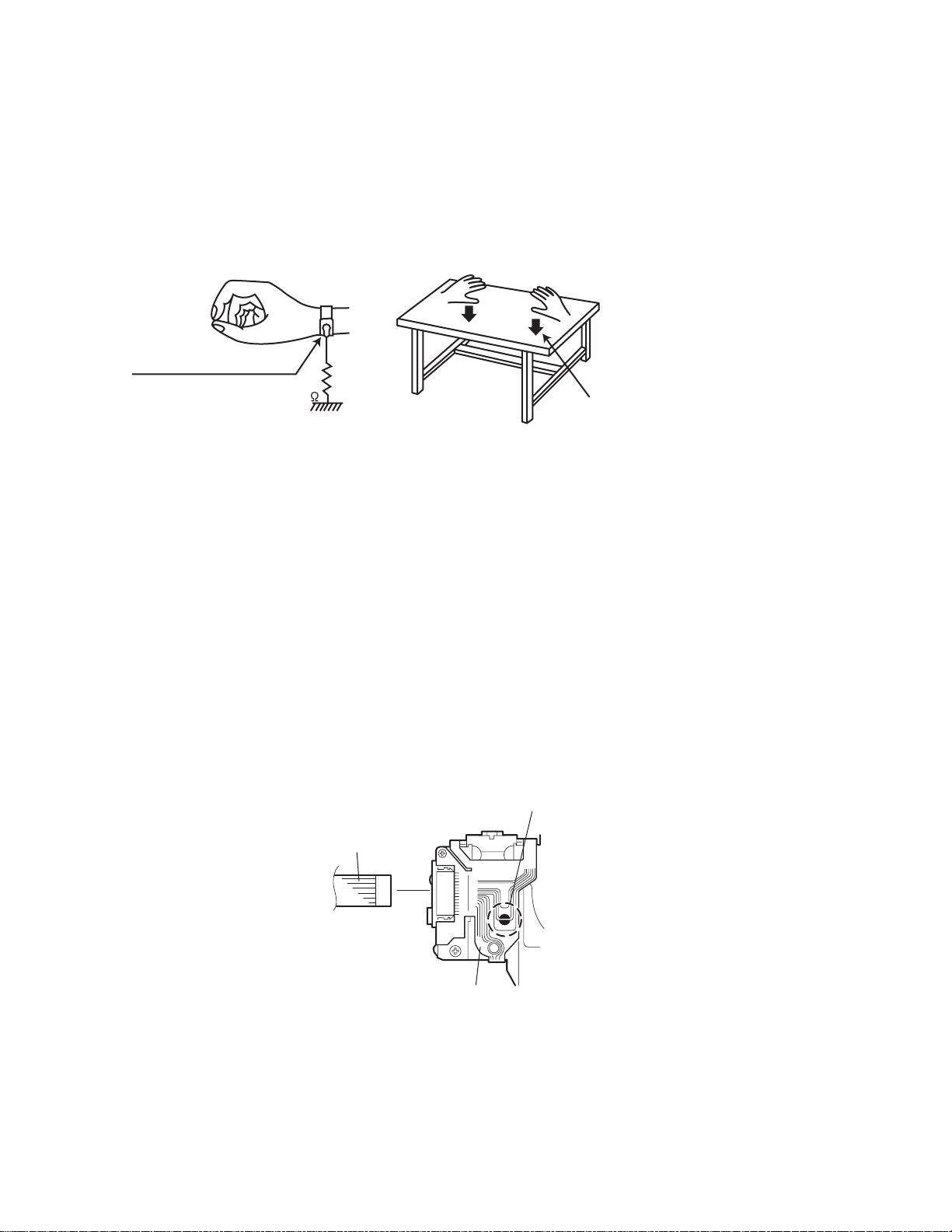

3.1 Main body section

3.1.1 Removing the front panel assembly

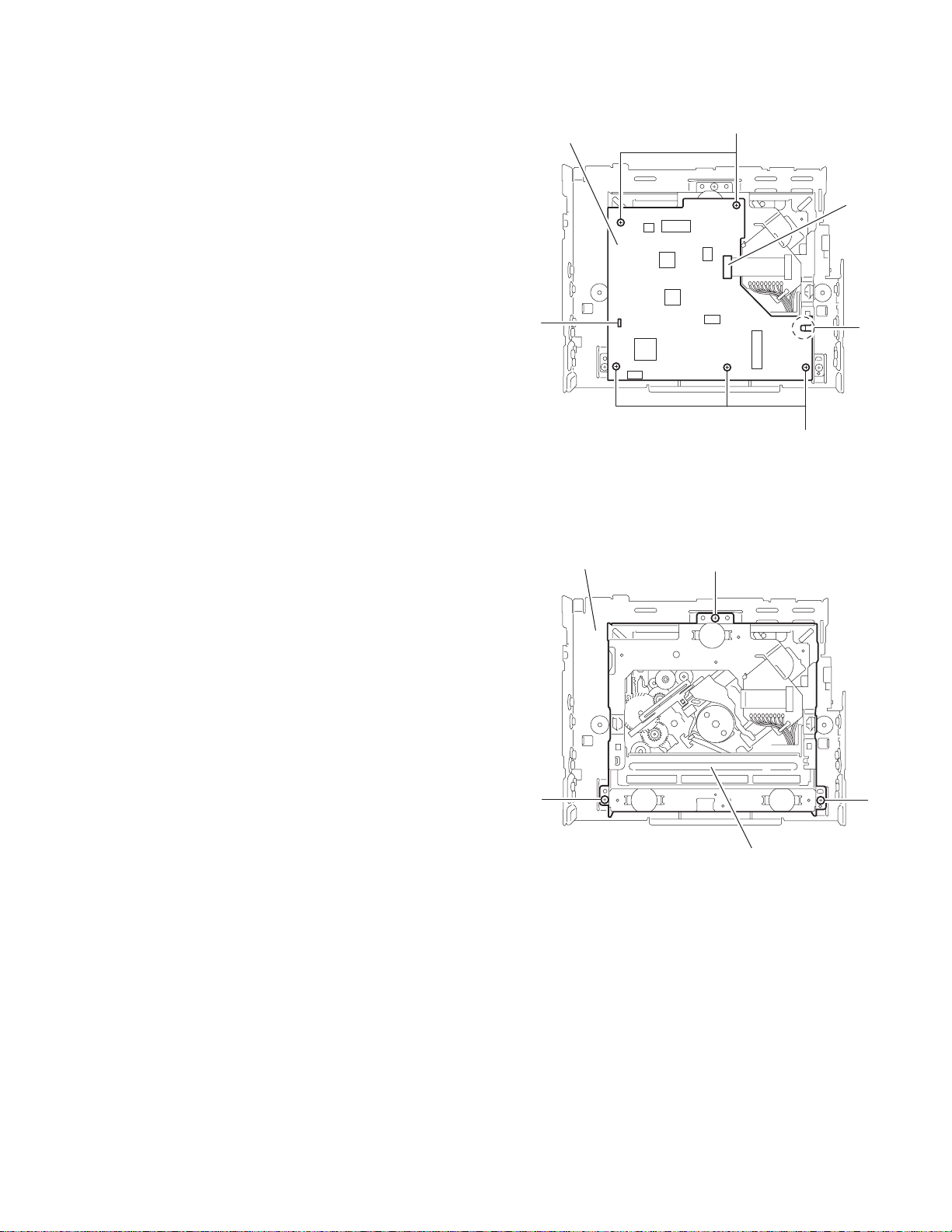

(See Fig.1)

(1) Push the detach button in the lower right part of the front

panel assembly.

(2) Remove the front panel assembly in the direction of the arrow .

3.1.2 Removing the top chassis

(See Figs.2 to 6)

• Turn on power.

(1) Push the eject button in the upper right part of the front pan-

el assembly to move the front panel assembly as shown in

Fig.2 and turn off power.

(2) Remove the two screws A attaching the top chassis from

the top side of the main body. (See Fig.3.)

(3) Remove the three screws B attaching the top chassis from

the both sides of the main body. (See Figs.4 and 5.)

(4) Remove the screw C and three screws D attaching the heat

sink from the left side of the main body. (See Fig.5.)

(5) Remove the two screws E and screw F attaching the top

chassis from the back side of the main body. (See Fig.6 .)

(6) Move the top chassis up ward and remove it with the CD

mechanism assembly. The connector CN501 on the CD

mechanism assembly is disconnected from the connector

CN981 on the main board.

Front panel assembly

Top chassis

Front panel assembly

BB

C

Detach button

Fig.1

Top chassis

Fig.4

Top chassis

A

Front panel assembly

1-6 (No.49834)

Eject button

Fig.2

Top chassis

Fig.3

A

Heat sink

E

BD

Fig.5

F

Fig.6

Page 7

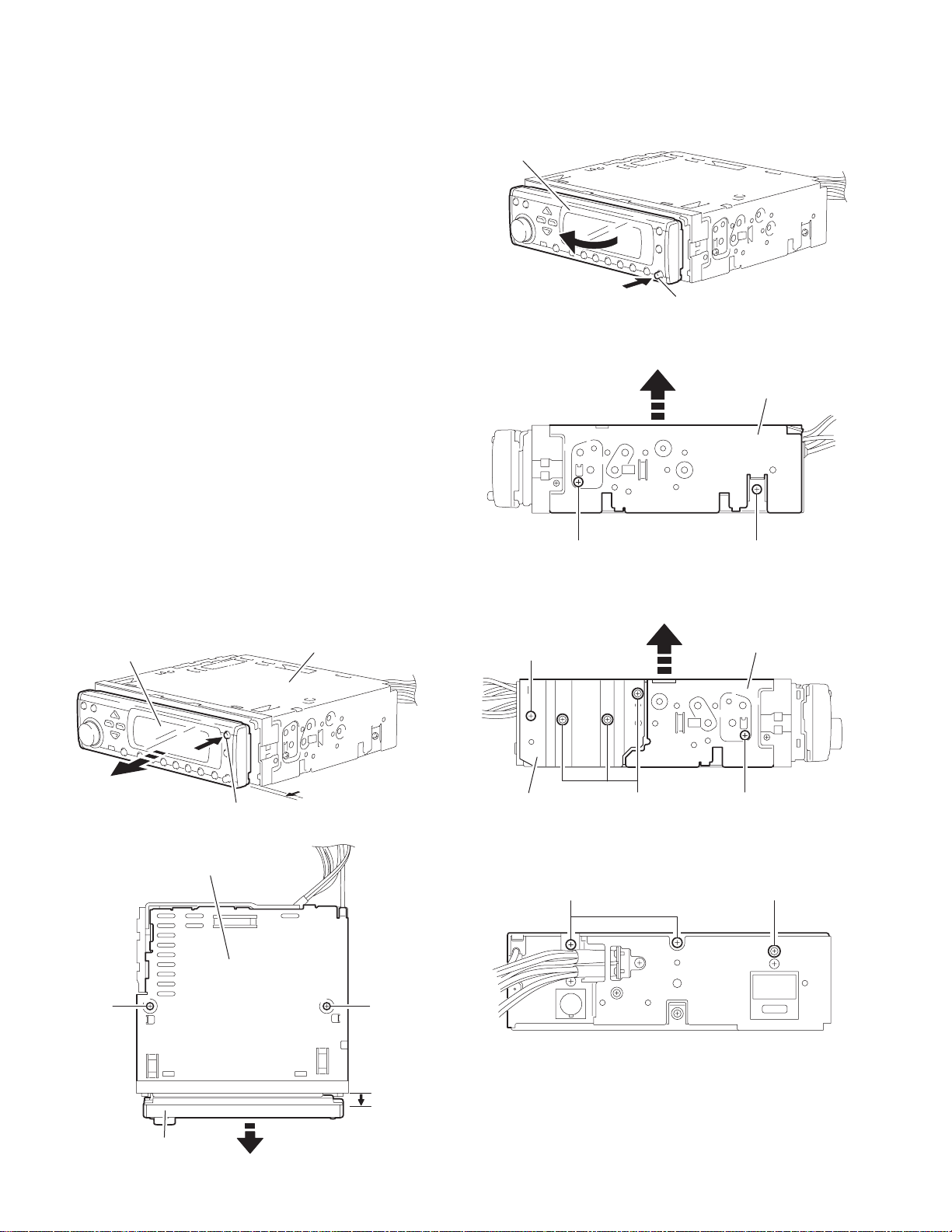

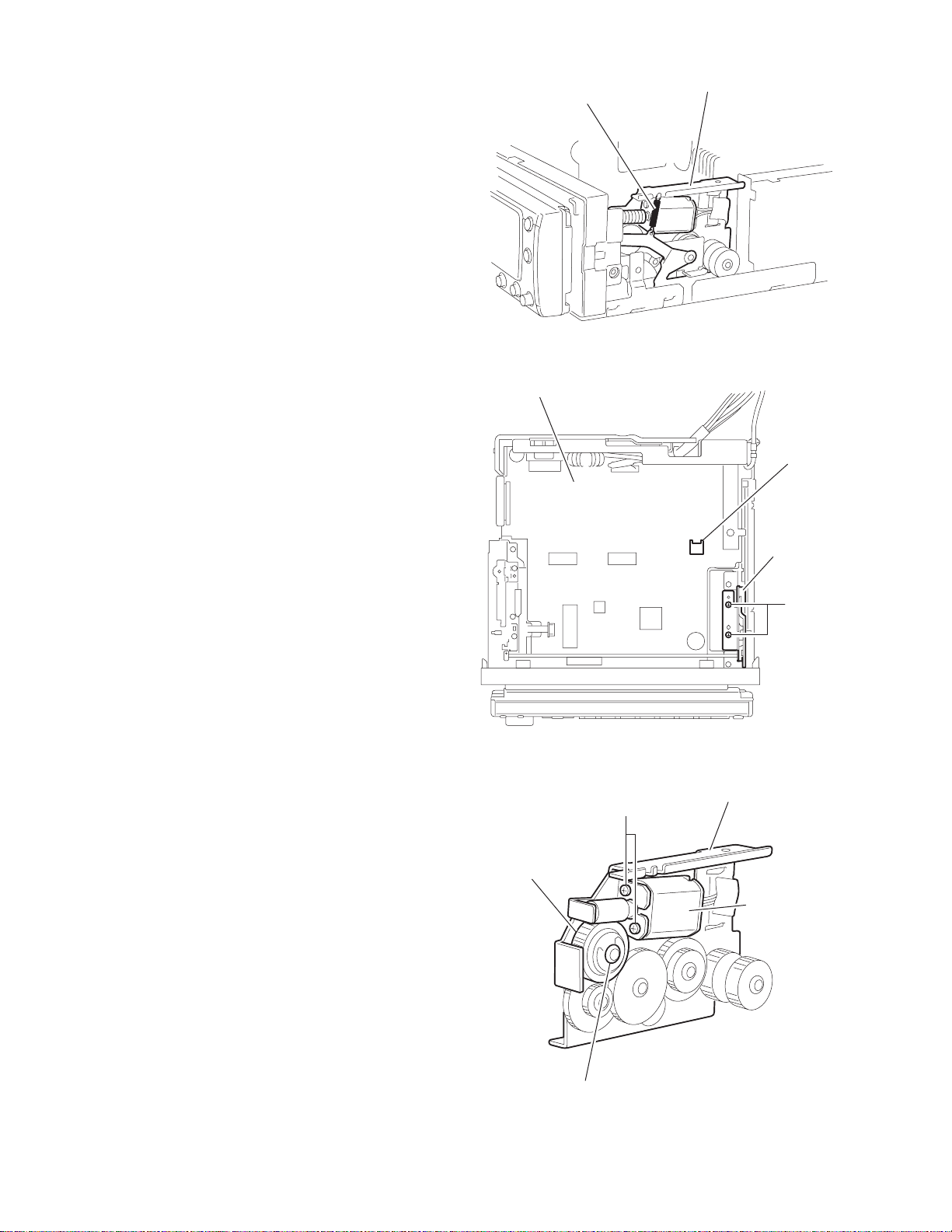

3.1.3 Removing the mecha control board

(See Fig.7)

• Prio r to performing the following procedures, remove the top

chassis.

(1) Disconnect the card wire from the connector CN601 on the

mecha control board.

(2) Remove the five screws G attaching the mecha control

board.

(3) Release the joints a and b, remove the mecha control

board.

Mecha control board

G

CN601

3.1.4 Removing the CD mechanism assembly

(See Fig.8)

• Prio r to performing the following procedure, remove the top

chassis.

(1) Remove the three screws H from the inside of the top chas-

sis and remove the CD mechanism assembly.

a

Top chassis

b

G

Fig.7

H

HH

CD mechanism assembly

Fig.8

(No.49834)1-7

Page 8

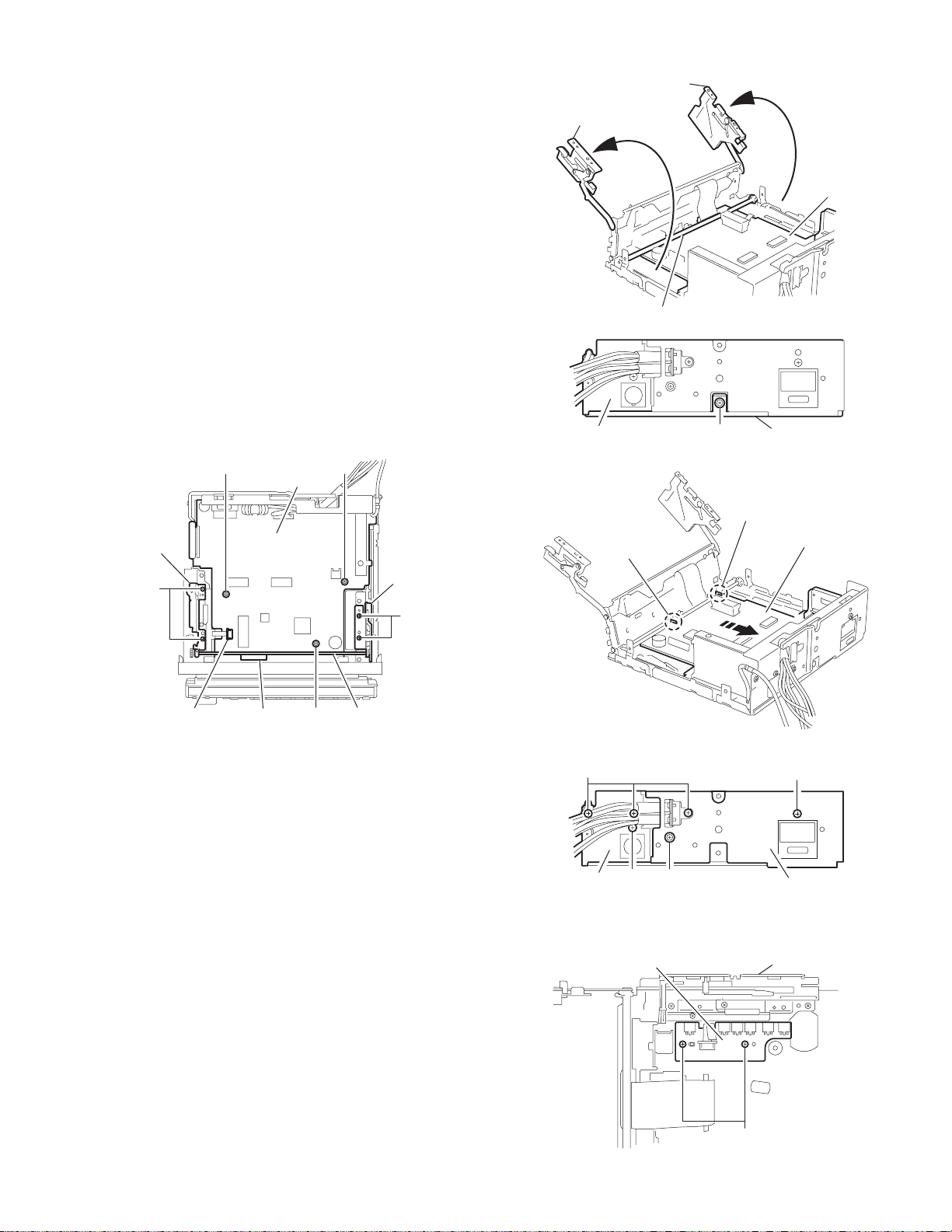

3.1.5 Removing the motor assembly

(See Figs.9 to 11)

• Prior to performing the following procedures, remove the top

chassis.

(1) Remove the spring from the motor bracket. (See Fig.9.)

(2) Disconnect the wire from the connector CN982 on the main

board. (See Fig.10.)

(3) Remove the two screws J attaching the motor bracket.

(See Fig.10.)

(4) Remove the washer attaching the clutch assembly and pull

out the clutch assembly from the shaft. (See Fig.11.)

(5) Remove the two screws K attaching the motor assembly to

the motor bracket. (See Fig.11.)

Main board

Spring

Motor braket

Fig.9

CN982

Clutch assembly

Motor braket

J

Fig.10

Motor braket

K

Motor assembly

1-8 (No.49834)

Washer

Fig.11

Page 9

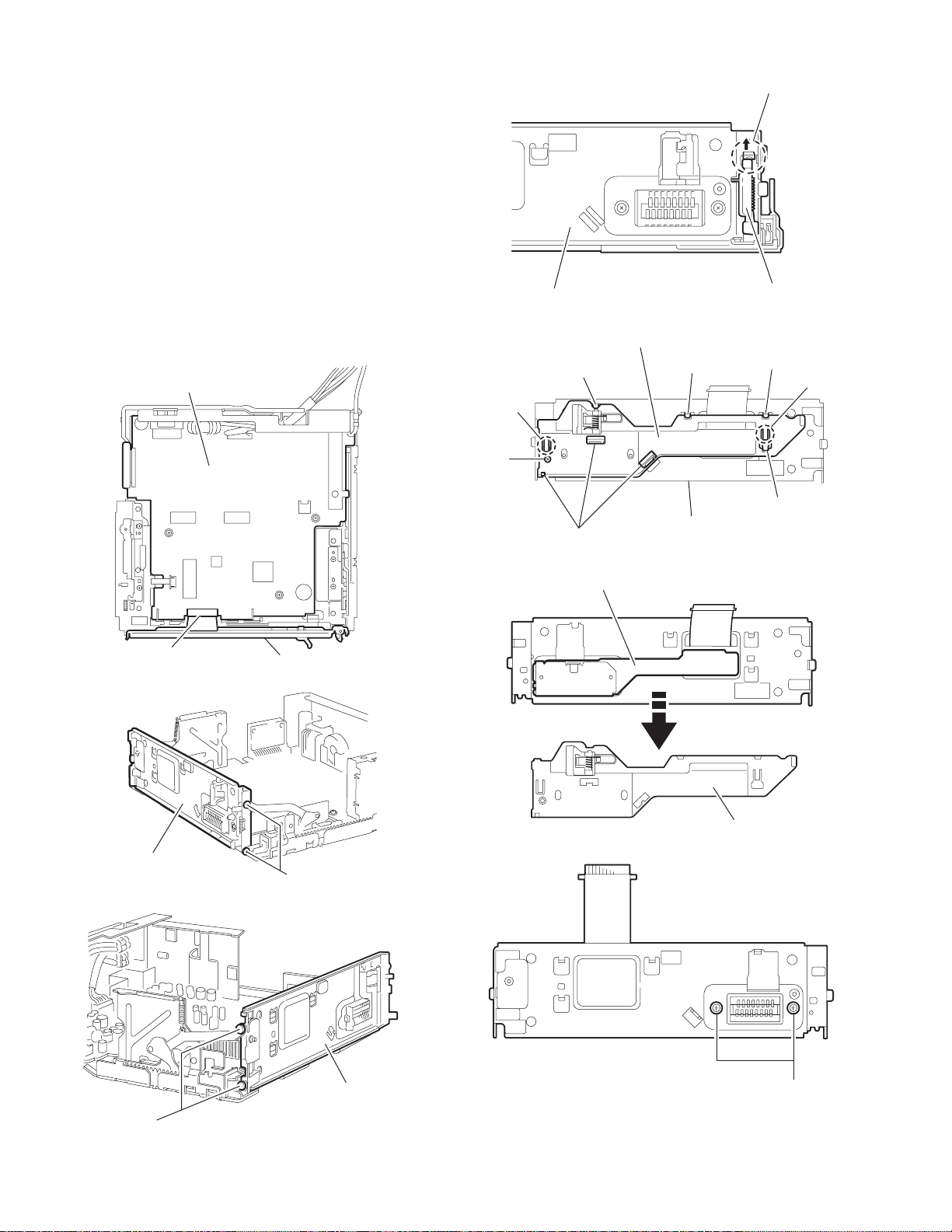

3.1.6 Removing the main board

k

(See Figs.12 to 16)

• Prio r to performing the following procedures, remove the top

chassis and motor assembly.

(1) Disconnect the flexible wires from the con nectors CN703

and CN991 on the main board respectively. (See Fig.12.)

(2) Move the front bracket backward until it stops.

(3) Remove the four screws L attaching the arm brackets (L)

and (R). Move the arm brackets (L) and (R) from the rod

gear. (See Fig.12.)

(4) Remove the rod gear.

(5) Remove the screw M attaching the rear panel to the bottom

cover from the back side of the main body. (See Fig.14.)

(6) Remove the three screws N attaching the main b oard and

move the main board backwards to release the two joints

c. (The main board will be removed with the rear panel and

rear heat sink) (See Figs.12 and 15.)

(7) Remove the screw P and Q attaching the rear he at sink.

(See Fig.16.)

(8) Remove the three screws R and screw S attaching the rear

panel, then remove the main board. (See Fig.16.)

NN

Main board

Arm

brackets (L)

L

Arm

brackets (R)

Arm brackets (L)

Arm brackets (R)

Rod gear

Rear panel

Joint c

Fig.13

M

Fig.14

Main board

Bottom cover

Joint c

Main board

L

CN703

3.1.7 Removing the lifter switch board

(See Fig.17)

• Prio r to performing the following procedure, remove the top

chassis, motor assembly and main board.

(1) Remove the two screws T attaching the lifter switch board

to the bottom chassis.

CN991

Fig.12

M

Rod gear

R

Rear panel

Lifter switch board

S

Q

Fig.15

P

Rear heat sin

Fig.16

Bottom chassis

T

Fig.17

(No.49834)1-9

Page 10

3.1.8 Removing the lifter board

(See Figs.18 to 24)

• Prior to performing the following procedures, remove the top

chassis and front panel assembly.

(1) Disconnect the flexible wire from the connector CN991 on

the main board. (See Fig.18.)

(2) Remove the four screws U attaching the front bracket on

the both sides of the main body. (See Figs.19 and 20.)

(3) Push the pin of the joint d on the front side of the front

bracket to release the detach lever. (See Fig.21.)

(4) Remove the screw V attaching the connector cover in the

rear side of the front bracket. (See Fig.22.)

(5) Release the two joints f while pushing them from the front

side, and then move the connector cover in the direction of the

arrow and release the eight joints e. (See Figs.22 and 23.)

(6) Remove the two screws W attach ing the lifter board from

the front side of the main body. (See Fig.24.)

Main board

Front bracket

Joint f

V

Connector cover

Joint e

Joints e

Lifter board

Fig.21

Joint

Front bracket

Fig.22

e

d

Joint

Datch lever

Joint e

Joint f

Joint e

CN991

Front bracket

U

Fig.18

Fig.19

Fig.20

Front bracket

U

Front bracket

Connector cover

Fig.23

W

Fig.24

1-10 (No.49834)

Page 11

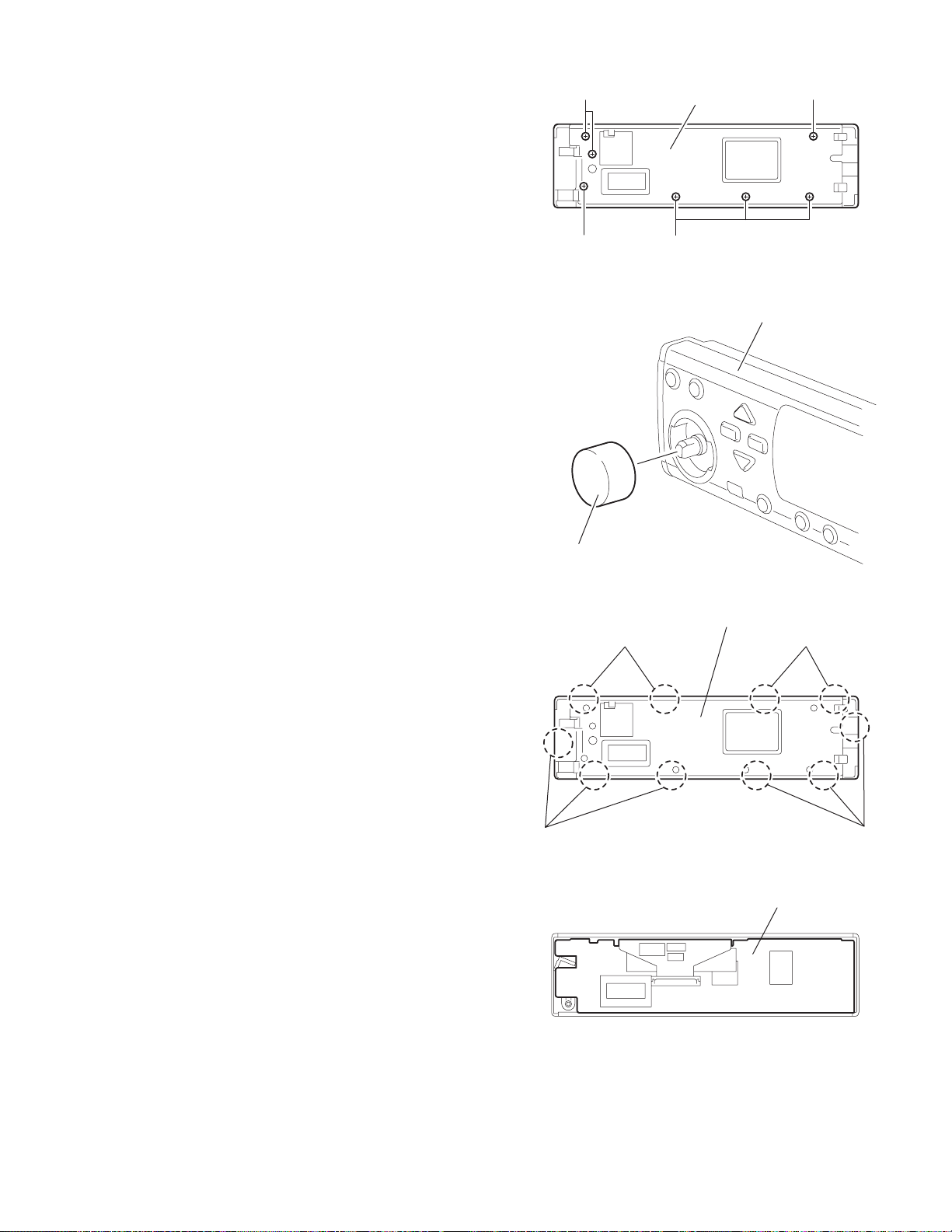

3.1.9 Removing the front board (See Figs.25 to 28)

• Prio r to performing the following procedure s, remove the front

panel assembly.

(1) Remove the six screws X attaching the rear panel to the

front panel assembly. (See Fig.25.)

(2) Pull out the volume knob from the front side of the front

panel assembly. (See Fig.26.)

(3) Release the ten joints g of the front panel and the rear pan-

el. (See Fig.27.)

(4) Take out the front bo ard from the front panel assembly.

(See Fig.28.)

XX

Rear panel

XX

Fig.25

Front panel assembly

Volume knob

Joints g

Joints g

Fig.26

Rear panel

Joints g

Joints g

Fig.27

Front board

Fig.28

(No.49834)1-11

Page 12

3.2 CD Mechanism section

A

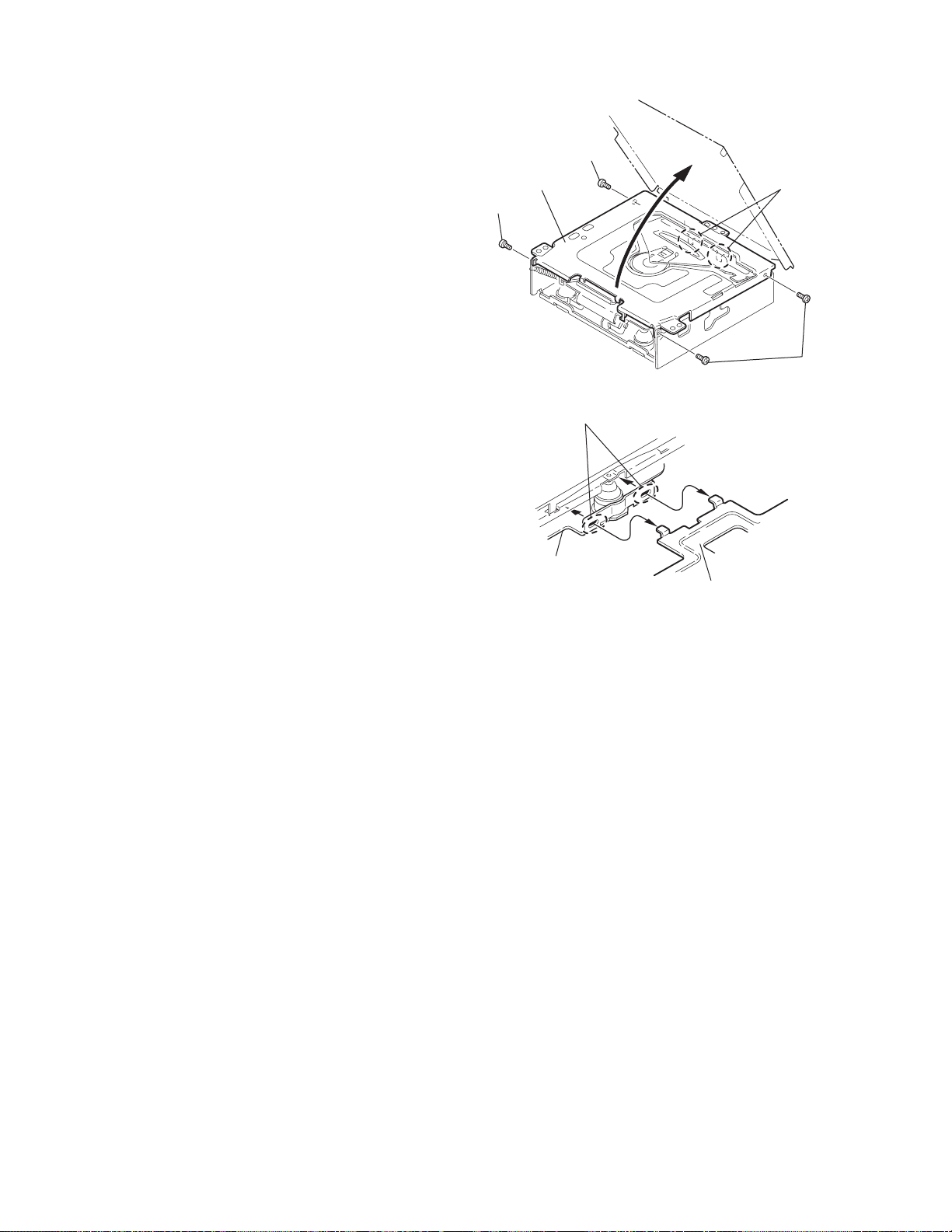

3.2.1 Removing the top cover

(See Figs.1 and 2)

(1) Remove the four screws A on the both side of the body.

(2) Lift the front side of the top cover and move the top cover

backward to release the two joints a.

Top cover

Joints a

A

Joints a

A

Fig.1

Fig.2

Top cover

1-12 (No.49834)

Page 13

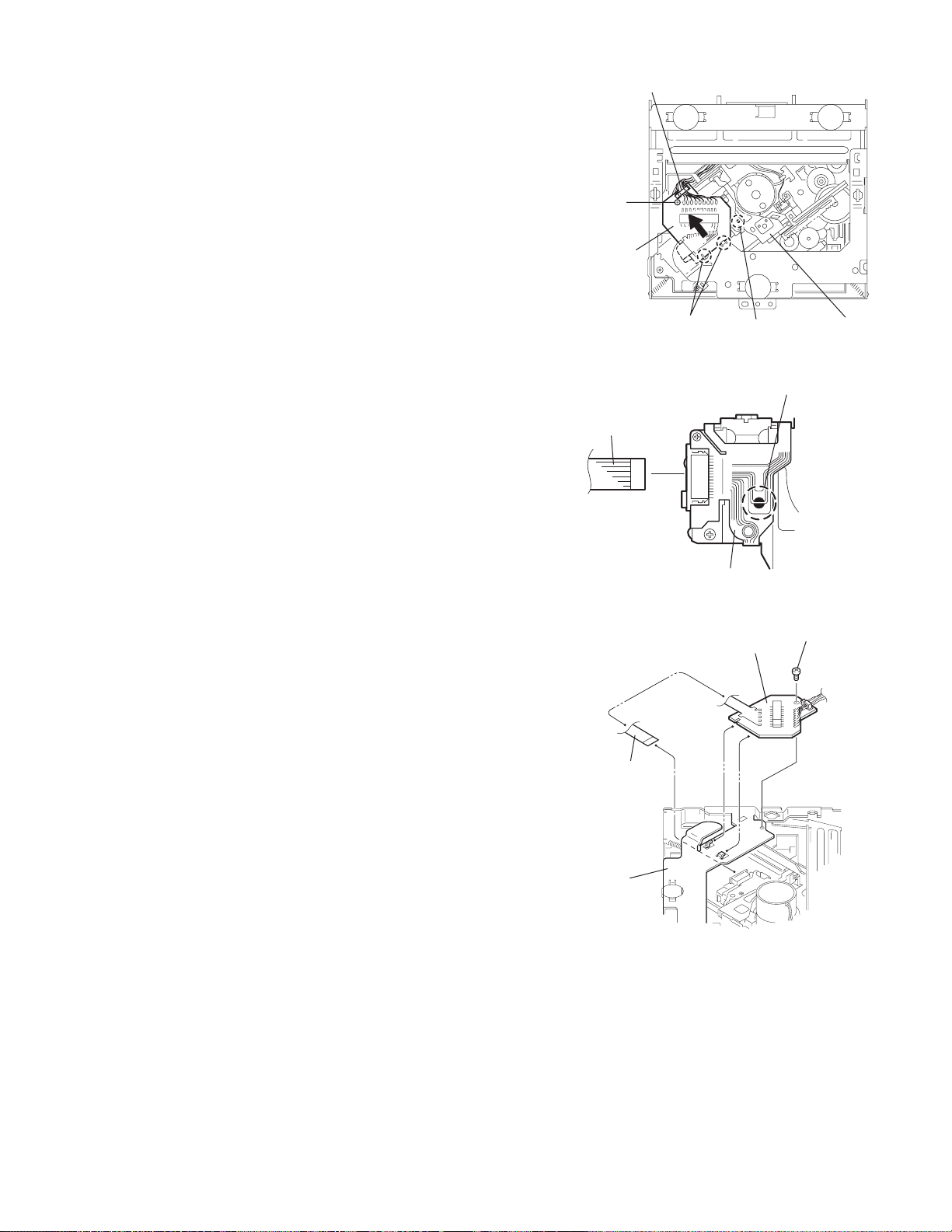

3.2.2 Removing the connector board

(See Figs.3 to 5)

CAUTION:

Before disconnecting the flexible wire from the pickup, solder

the short-circuit point on the pickup. No observance of this instruction may cause damage of the pickup.

(1) Remove the screw B fixing the connector board.

(2) Solder the short-circuit point on the pickup.

(3) Disconnect the flexible wire from the pickup.

(4) Move the connector board in the direction of the arrow to

release the two joints b.

(5) Unsolder the wires on the connector bo ard if necessary.

CAUTION:

Unsolder the short-circuit point after reassembling.

B

Connector board

Flexible wire

Wires

Joints b

Short-circuit point

Fig.3

Short-circuit point

(Soldering)

Pickup

Flexible wire

Frame

Pickup

Fig.4

B

Connector board

Fig.5

(No.49834)1-13

Page 14

3.2.3 Removing the DET switch

(See Figs.6 and 7)

(1) Extend the two tabs c of the feed sw. holder and pull out

the switch.

(2) Unsolder the DET switch wire if necessary.

DET

switch

Connector

board

Pickup

Fig.6

DET switch

Tab c

Tab c

DET switch wire

Feed sw. holder

Fig.7

1-14 (No.49834)

Page 15

3.2.4 Removing the chassis unit

r

(See Figs.8 and 9)

• Prio r to performing the following procedure, remove the top

cover and connector board.

(1) Remove the two suspensi on springs (L) an d (R) attaching

the chassis unit to the frame.

CAUTION:

• The shape of the suspension spring (L) and (R) are different. Handle them with care.

• W hen reassembling, make sure that the three shafts

on the underside of the chassis unit are inserted to the

dampers certainly.

Suspension spring (R)

Chassis unit

Suspension spring (L)

Frame

Suspension spring (R)

Chassis unit

Shafts

Damper

Damper

Suspension spring (L)

Fig.8

Shaft

Dampe

Frame

Fig.9

(No.49834)1-15

Page 16

3.2.5 Removing the clamper assembly

(See Figs.10 and 11)

• Prior to performing the following procedure, remove the top

cover.

(1) Remove the clamper arm spring.

(2) Move the clamper assembly in the direction of the arrow to

release the two joints d.

Clamper arm

spring

Joint d

Joint d

Clamper assembly

Fig.10

Clamper arm spring

Chassis rivet

assembly

Joint d

Clamper assembly

Chassis rivet assembly

Joint d

Fig.11

1-16 (No.49834)

Page 17

3.2.6 Removing the loading / feed motor assembly

(See Figs.12 and 13)

• Prio r to performing the following procedure, remove the top

cover, connector board and chassis unit.

(1) Remove the screw C and move the loading / feed motor as-

sembly in the direction of the arrow to remove it from the

chassis rivet assembly.

(2) Disconnect the wire from the loading / feed motor assembly

if necessary.

CAUTION:

When reassembling, connect the wire from the loading /

feed motor assembly to the flame as shown in Fig.12.

Loading / feed motor assembly

Fig.12

Loading / feed motor assembly

C

Fig.13

(No.49834)1-17

Page 18

3.2.7 Removing the pickup unit

r

(See Figs.14 to 18)

• Prior to performing the following procedure, remove the top

cover, connector board and chassis unit.

(1) Remove the screw D and pull out the pu. shaft holder from

the pu. shaft.

(2) Remove the screw E attaching the feed sw. holder.

(3) Move the part e of the pickup unit upward with the pu. shaft

and the feed sw. holder, then release the joint f of the feed

sw. holder in the direction of the arrow. The joint g of the

pickup unit and the feed rack is released, and the feed sw.

holder comes off.

(4) Remove the pu. shaft from the pickup unit.

(5) Remove the screw F attaching the feed rack to the pickup

unit.

3.2.8 Reattaching the pickup unit

(See Figs.14 to 17)

(1) Reattach the feed rack to the pickup unit using the screw F.

(2) Reattach the feed sw. holder to the feed rack wh ile setting

the joint g to the slot of the feed rack and setting the joint f

of the feed rack to the switch of the feed sw. holder correctly.

(3) As the feed sw. holder is temporarily attached to the pickup

unit, set to the gear of the joint g and to the bending part of

the chassis (joint h) at a time.

CAUTION:

Make sure that the part i on the underside of the feed

rack is certainly inserted to the slot j of the change lock

lever.

(4) Reattach the feed sw. holder using the screw E.

(5) Reattach the pu. shaft to the pickup unit. Reattach the pu.

shaft holder to the pu. shaft using the screw D.

Part e

Joint g

Feed sw. holder

Feed rack

Part i

E

Slot j

F

Feed sw. holder

Fig.15

Pu. shaft

Pickup unit

Joint f

Joint h

Fig.16

Feed rack

Pickup unit

D

Pu. shaft holde

Joint f

Pu. shaft

D

Pu. shaft holder

Feed sw. holder

Pickup unit

Fig.14

Part e

E

Joint g

Pickup unit

Feed rack

Fig.17

Pickup unit

Joint g

Joint f

Feed sw. holder

Fig.18

1-18 (No.49834)

Page 19

3.2.9 Removing the trigger arm

r

(See Figs.19 and 20)

• Prio r to performing the following procedure, remove the top

cover, connector board and clamper unit.

(1) Turn the trigger arm in the direction of the arrow to release

the joint k and pull out upward.

CAUTION:

When reassembling, insert the part m and n of the trigger

arm into the part p and q at the slot of the chassis rivet

assembly respectively and join the joint k at a time.

Chassis rivet assembly

Trigger arm

Chassis

rivet

assembly

Joint k

Trigger arm

Fig.19

Part p

Part q

Part m

Part n

3.2.10 Removing the top plate assembly

(See Fig.21)

• Prio r to performing the following procedure, remove the top

cover, connector board, chassis unit, and clamper assembly.

(1) Remove the screw H.

(2) Move the top plate assembly in the direction of the arrow to

release the two joints r.

(3) Unsolder the wire marked s if necessary.

H

Fig.20

Top plate assembly

Joints

s

Fig.21

(No.49834)1-19

Page 20

3.2.11 Removing the mode sw. / select lock arm

(See Figs.22 and 23)

• Prior to performing the following procedure, remove the top

plate assembly.

(1) Bring up the mode sw. to release from the link plate (joint t)

and turn in the direction of the arrow to release the joint u.

(2) Unsolder the wire of the mode sw. marked s if necessary.

(3) Turn the select lock arm in the direction of the arrow to re-

lease the two joints v.

(4) The select lock arm spring comes off the select lock arm at

the same time.

Link plate

Joint u

Fig.22

Joint t

Mode sw.

Select lock arm

s

Top plate

Select lock arm

Link plate

Select lock arm

Fig.23

Top plate

Hook w

Select lock

arm spring

Joints v

1-20 (No.49834)

Page 21

3.2.12 Reassembling the mode sw. / select lock arm

(See Figs.24 to 26)

REFERENCE:

Reverse the above removing procedure.

(1) Reattach the select lock arm spring to the top plate and set

the shorter end of the select lock arm spring to the hook w

on the top plate.

(2) Set the other longer end of the select lock arm spring to the

boss x on the underside of the select lock arm, and join the

select lock arm to the slots (joint v). Turn the select lock

arm as shown in the figure.

(3) Reattach the mode sw. while setting th e part t to the first

peak of the link plate gear, and join the joint u.

CAUTION:

When reattaching the mode sw., check if the points y and

z are correctly fitted and if each part operates properly.

Select lock arm spring

Hook w

Joint v

Joint v

Select lock arm

Boss x

Fig.24

Joint t

Point y

Link plate

Point z

Link plate

Fig.25

Mode sw.

Select

lock arm

Joint t

Joint u

Fig.26

(No.49834)1-21

Page 22

3.2.13 Removing the select arm R / link plate

(See Figs.27 and 28)

• Prior to performing the following procedure, remove the top

plate assembly.

(1) Bring up the select arm R to release from the link plate

(joint a') and turn as shown in the figure to release the two

joints b' and joint c'.

(2) Move the link plate in the direction of the arrow to release

the joint d'. Remove the link plate spring at the same time.

REFERENCE:

Before removing the link plate, remove the mode sw..

Select arm R

Joint b'

Link plate spring

Joint c'

Joint a'

Link plate

Joint b'

Fig.27

Joint r

3.2.14 Reattaching the Select arm R / link plate

(See Figs.29 and 30)

REFERENCE:

Reverse the above removing procedure.

(1) Reattach the link plate spring.

(2) Reattach the link plate to th e lin k plate sprin g whil e joi ning

them at joint d'.

(3) Reattach the joint a' of the select arm R to the first peak of

the link plate while joining the two joints b' with the slots.

Then turn the select arm R as shown in the figure. The top

plate is joined to the joint c'.

CAUTION:

When reattaching the select arm R, check if the points e'

and f' are correctly fitted and if each part operates properly.

Top plate

Select arm R

Joint b'

Joint d'

Link plate

Fig.28

Link plate spring

Joint c'

Joint d'

Joint b'

Joint a'

Fig.29

1-22 (No.49834)

Joint a'

Point e'

Link plate

Point f'

Fig.30

Page 23

3.2.15 Removing the loading roller assembly

(See Figs.31 to 33)

• Prior to performing the following procedure, remove the

clamper assembly and top plate assembly.

(1) Push inward the loading roller assembly on the gear side

and detach it upward from the slot of the joint g' of the lock

arm rivet assembly.

(2) Detach the loading roller assembly from the slot of the joint

h' of the lock arm rivet assembly.

The roller guide comes off the gear section of the loading

roller assembly.

Remove the roller guide and the HL washer from the shaft

of the loading roller assembly.

(3) Remove the screw J attaching the lock arm rivet assembly.

(4) Push the shaft at the joint i' of the lock arm rivet assembly

inward to release the lock arm rivet assembly from the slot

of the L side plate.

(5) Extend the lock arm rivet assembly outward and release

the joint j' from the boss of the chassis rivet assembly. The

roller guide springs on both sides come off at the same

time.

CAUTION:

When reassembling, reattach the left and right roller

guide springs to the lock arm rivet assembly before reattaching the lock arm rivet assembly to the chassis rivet

assembly. Make sure to fit the part k' of the roller guide

spring inside of the roller guide. (Refer to Fig.34.)

Roller guide

spring

Part k'

Chassis rivet assembly

Loading roller assembly

Loading roller assembly

Roller guide

spring

Fig.32

Boss

Roller guide

Joint h'

Roller guide spring

Loading roller assembly

HL washer

Loading roller assembly

Joint g'

Lock arm rivet assembly

Fig.31

Roller guide

Roller guide spring

Roller guide spring

J

Lock arm rivet assembly

Lock arm rivet assembly

L side plate

Roller guide spring

Joint i'

Joint j'

Fig.33

Roller guide

HL washer

Roller shaft assembly

Loading roller

Roller guide spring

Fig.34

(No.49834)1-23

Page 24

3.2.16 Removing the loading gear 5, 6 and 7

(See Figs.35 and 36)

• Prior to performing the following procedure, remove the top

cover, chassis unit, pickup unit and top plate assembly.

(1) Remove the screw K attaching the loading gear bracket.

The loading gear 6 and 7 come off the loading gear bracket.

(2) Pull out the loading gear 5.

K

Loading gear 5

Loading gear bracket

K

Loading gear 6

Loading gear 5

Loading gear 3

Fig.35

Loading gear bracket

Loading gear 6

Loading gear 7

Fig.36

1-24 (No.49834)

Page 25

3.2.17 Removing the gears

(See Figs.37 to 40)

• Prio r to performing the following procedure, remove the top

cover, chassis unit, top plate assembly and pickup unit.

• Pull out the loading gear 3. (See Fig.35.)

(1) Pull out the feed gea r.

(2) Move the loading plate a ssemb ly in the d irection o f the ar-

row to release the L side plate from the two slots m' of the

chassis rivet assembly. (See Fig.37.)

(3) Detach the loading plate assemb ly upward from the chas-

sis rivet assembly while releasing the joint n'. Remove the

slide hook and loading plate spring from the loading plate

assembly.

(4) Pull out the loading gear 2 and remove the change lock le-

ver.

(5) Remove the E ring and washer attaching the change gear

2.

(6) The change gear 2, change gear spring and adjusting

washer come off.

(7) Remove the loading gear 1.

(8) Move the change plate rivet assembly in the direction of the

arrow to release from the three shafts of the chassis rivet

assembly upward. (See Fig.38.)

(9) Detach the loading gear plate rivet assembly from the shaft

of the chassis rivet assembly upward while releasing the

joint p'. (See Figs.38 and 40.)

(10) Pull out the loading gear 4.

Change plate

rivet assembly

Shafts

E ring

Loading plate assembly

Loading plate spring

Joint p'

Loading gear 4

Loading gear plate

rivet assembly

Shaft

Loading gear 2

Loading gear 1

Chassis rivet assembly

Change gear 2

Fig.38

Joint n'

Slide hook

Feed gear

Fig.37

Slot m'

L side plate

Loading plate assembly

Joint n'

Slot m'

Chassis rivet assembly

Chassis rivet assembly

E ring

Washer

Change gear 2

Change gear

spring

Adjusting

washer

Change plate

rivet assembly

L side plate

Slot m'

Slot m'

Fig.39

Loading gear 1

Loading gear 2

Change lock lever

Loading gear 4

Chassis rivet assembly

Loading gear plate rivet

assembly

Fig.40

(No.49834)1-25

Page 26

3.2.18 Removing the turn table / spindle motor

(See Figs.41 and 42)

• Prior to performing the following procedure, remove the top

cover, connector board, chassis unit and clamper assembly.

(1) Remove the two screws L attaching the spindle motor as-

sembly through the slot of the turn table on top of the body.

(2) Unsolder the wire on the connector board if necessary.

Turn table

L

Fig.41

L

Turn table

1-26 (No.49834)

Spindle motor

Fig.42

Page 27

SECTION 4

le

ADJUSTMENT

4.1 Adjustment method Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) AM Standard signal generator

(3) FM Standard signal generator

(4) Stereo modulator

(5) Electric voltmeter

(6) Digital tester

(7) Tracking offset meter

(8) Test Disc JVC :CTS-1000

(9) Extension cable for check

EXTSH002-22P × 1

Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

Standard measuring conditions

Power supply voltage DC14.4V(11 to 16V)

Load impedance 20KΩ(2 Speakers connection)

Output Level Line out 2.0V (Vol. MAX)

Dummy load

Exclusive dummy load should be used for AM,and FM. For FM

dummy load,there is a loss of 6dB between SSG output and

antenna input.The loss of 6dB need not be considered since

direct reading of figures are applied in this working standard.

Extension cab

EXTSH002-22P

(No.49834)1-27

Page 28

4.2 Service mode

When entering the service mode, "DATA CLEAR" is displayed without fail.

: Initial display

SEL

POWER

SOURCE

A

DATA_CLEAR

DISC+/-:CATEGORY

: SEEK UP

: SEEK DOWN

: DISC UP

: DISC DOWN

EPROM_CLEAR

NAME_CLEAR

CD_ERROR_CLEAR

CH_ERROR_CLEAR

SH_MECHA_ERROR_CLEAR

EPROM_CLEAR

NAME_CLEAR

CD_ERROR_CLEAR

CH_ERROR_CLEAR

SH_MECHA_ERROR_CLEAR

EPROM_CLEAR

NAME_CLEAR

CD_ERROR_CLEAR

CH_ERROR_CLEAR

SH_MECHA_ERROR_CLEAR

EPROM_CLEAR

NAME_CLEAR

CD_ERROR_CLEAR

CH_ERROR_CLEAR

SH_MECHA_ERROR_CLEAR

EPROM_CLEAR

NAME_CLEAR

CD_ERROR_CLEAR

CH_ERROR_CLEAR

SH_MECHA_ERROR_CLEAR

PICTURE_CLEAR

DSP_ERROR_CLEAR

PICTURE_CLEAR

DSP_ERROR_CLEAR

___NOW

___ERROR_CLEAR

SEL

*Letter turn on and off

(Turn on: 0.5sec, Turn off: 0.5sec)

___NOW

___NAME_CLEAR

SEL

*Letter turn on and off

(Turn on: 0.5sec, Turn off: 0.5sec)

___NOW

___CD_ERROR_CLEAR

SEL

*Letter turn on and off

(Turn on: 0.5sec, Turn off: 0.5sec)

___NOW

___CH_ERROR_CLEAR

SEL

*Letter turn on and off

(Turn on: 0.5sec, Turn off: 0.5sec)

___NOW

___SH_MECHA_ERROR_CLEAR

SEL

*Letter turn on and off

(Turn on: 0.5sec, Turn off: 0.5sec)

___NOW

___PICTURE_CLEAR

SEL

*Letter turn on and off

(Turn on: 0.5sec, Turn off: 0.5sec)

___NOW

___DSP_ERROR_CLEAR

SEL

*Letter turn on and off

(Turn on: 0.5sec, Turn off: 0.5sec)

EPROM all clear & Flash ROM all clear

(Following all contents are cleared.)

Execute by "SEL" key

Normal

display

EPROM (DISC/LINE NAME) clear

Execute by "SEL" key

Normal

display

EPROM (CD ERROR) clear

Execute by "SEL" key

Normal

display

EPROM (CH ERROR) clear

Execute by "SEL" key

Normal

display

EPROM (SH DOOR MECHA ERROR) clear

Execute by "SEL" key

Normal

display

Flash ROM (all PICTURE) clear

Execute by "SEL" key

Normal

display

Flash ROM (all DSP retry count number) clear

Execute by "SEL" key

Normal

display

RUNNING_MODE

DISC+/-:FUNCTION

B

C

1-28 (No.49834)

RUNNING_CD

RUNNING_SH_MECHA

RUNNING_CD

RUNNING_SH_MECHA

RUNNING_CD

COUNT :

ERROR :

SEL

RUNNING_SH_MECHA

COUNT :

ERROR :

SEL

CD running mode (SH mecha open)

Running number

CD error during running mode

by error code chart

Door mecha running mode (No retry action)

Running number

Door error during running mode

by error code chart

Page 29

B

C

CD_DATA_READ

DISC+/-:FUNCTION

ERROR_READ

DISC+/-:FUNCTION

ADJ_NOW

ADJ_INT

OTHERS

ADJ_NOW

ADJ_INT

OTHERS

ADJ_NOW

ADJ_INT

OTHERS

CD_ERROR_READ

CH_ERROR_READ

SH_MECHA_ERROR_READ

CD_ERROR_READ

CH_ERROR_READ

SH_MECHA_ERROR_READ

ADJ_NOW

FEB__ ____TEB__

FGA__ ____TGA__

SEL

FEO__ ____RFG__

TEO__

ADJ_INT

FEB__ ____TEB__

FGA__ ____TGA__

SEL

FEO__ ____RFG__

TEO__

OTHERS

IOP__TEMP____I T

IOP__INT__

SEL

TEMP__MAX__

P_TOTAL_ H

TOTAL_ERROR :

E1_ _____2_

E2_ _____3_

SEL

E3_ _____4_

1__ 5_

TOTAL_ERROR :

E1_ _____2_

E2_ _____3_

SEL

E3_ _____4_

1__ 5_

CD data display

Hex. code display

Total running time display

(Four figures (to 9999), hour only, omit)

CD error display

Total error number

Display by error code chart

CH error display

Total error number

Display by error code chart

VERSION

MAIN_V

CD_V

CH_V

A

CD_ERROR_READ

CH_ERROR_READ

SH_MECHA_ERROR_READ

CD_ERROR_READ

CH_ERROR_READ

SH_MECHA_ERROR_READ

E1_

E2_

SEL

E3_

1__

INIT_RETRY____TOTAL_

INIT_RETRY_NG_TOTAL_

SEL

SH door mecha error display

Display by error code chart

DSP initial setting data error

Retry total number of initial setting

Error number: NG after retry two times

(First transmit NG Retry first transmit NG

Second transmit NG : 1 count)

(No.49834)1-29

Page 30

4.3 Flow of functional operation unit TOC read

When the pickup correctly moves

to the inner area of the disc

$82

Microprocessor

commands

FMO

TC94A14FA "40"

FEED MOTOR

+TERMINAL

IC681 "17"

REST SW

When correctly focused

FEO

TA2157 "15"

$83

$81

Focus Servo Loop ONo

v

3.3V

Hi-Z

0V

6V

4V

2V

OFF

ON

Pickup feed to the inner area

2.2V

RF signal eye-pattern

remains closed

RF signal eye-pattern

opens

Power ON

Set Function CD

Disc inserted

YES

Laser emitted

Focus search

Disc rotates

n

Tracking loop closed

TOC read out

YES

When the laser diode correctly

emits

Microprocessor

commands

SEL

TC94A14FA "38"

LD

CN601 "10"

"No disc"

display

When the disc correctly rotates

Microprocessor

commands

DMO

TC94A14FA "41"

Spindle

motor(-)

IC681 "16"

$84 $86 $ A200

Acceleration Servo CLV

Rough

Servo

0.5 Sec 0.5 Sec

$84

3.3V

0V

4V

0V

3.3V

2.2V

0V

6V

3.2

2V

1-30 (No.49834)

Jump to the first track

Play

Tracking Servo Loop ON

RF signal

Rough Servo Modev

CLV Servo Mode

(Program Area)

CLV Servo Mode

(Lead-In Area;

Digital :0)

Page 31

4.4 Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to clean the lens

with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

• The level of RF output (EFM output: amplitude of eye

pattern) will be low.

4.5 Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Is RF output

1.3 0.4Vp-p?

NO

Replace it.

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board

which is attached to the pickup is used to adjust the laser

power.Since this adjustment should be performed to match

the characteristics of the whole optical block, do not touch

the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced. If the semi-fixed resistor is adjusted while the

pickup is functioning normally, the laser pickup may be

damaged due to excessive current.

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at RF test point.

Finish.

(No.49834)1-31

Page 32

5.1 Feed section

NO

NO

n

SECTION 5

TROUBLE SHOOTING

Is the voltage output at

IC621 pin "40" 5V or 0V?

Is 4V present at both

sides of the feed motor?

Check the feed motor.

5.2 Focus section

5.3 Spindle section

YES

YES

NO YES NO

Is the wiring for IC621

pin "40"?

NO

NO

Does the S-search

waveform appear at

IC681 pins "13" and "14"?

Is 6V or 2V present at

IC681 "16" and "17"?

NO

Check IC681.

When the lens is

moving:

4V

YES

Is 3.3V present at IC681

pin "6"?

Check the vicinity of

IC621.

YES

Check the feed motor

connection wiring.

Check the circuits in

the vicinity of IC681

pins "13","14"and"1".

YES

Check the pickup and

its connections

YES

Check CD 8V

and 5V.

Is the disk rotated?

Does the RF signal

appear at IC601 pin "19"?

Is the RF waveform at

IC601 pin "19" distorted?

Proceed to the Tracking

section

5.4 Tracking section

When the disc is rotated

at first:

Is the tracking error signal

output at IC601 "11"?

YES

YES

YES

NO

NO

Approx. 1.2V

Is 4V present at IC681

pins "15" and "16"?

YES

Check the spindle motor

and its wiring

Check the circuits in the

vicinity of IC601 pin "19"

or the pickup

YES YES

Check the circuit in the

vicinity of IC601 pins

"2" to "7".

NO

Is 4V present at IC621

pins "41" ?

YES

Check the vicinity of

IC681.

Check the pickup and

its connections

NO

Check the circuits i

the vicinity of IC621

or IC621

1-32 (No.49834)

YES

Check IC621.

Page 33

Description of major ICs

+

+

-

-

+

+

-

-

-

+

+

6.1 BA3220FV-X (IC171,IC271) : Line out amp

•Pin layout

SECTION 6

• Block diagram

14

8

3220

17

CL-

14

LGND

13

OUTL OUTR RGND

1112

10

CR-

9

CR+

8

REFL

REFR

FILTER

1

2

Vcc

3

INL

4

NFLCL+

56

FIL

NFR

7

INR

(No.49834)1-33

Page 34

6.2 AK7740VT (IC101) : Audio DSP with AD/DA converter

• Pin layout

AINR3

AINL4

AINR4

AINL+

AINL-

AINR+

AINR-

AVS S

VCOM

AVD D

AOUTL1

AOUTR1

• Block diagram

SDOUTA

SDINA

SDIN

RQ

SO

SCLK

RDY

DRDY

JX

AINL3

AINR2

AINL2

AINR1

AINL1

VREFH

AVD D

AVS S

DVSS

DVDD

XTI

XTO

4847464544434241403938

1

2

3

4

5

6

7

48 pin LQFP

(TOP VIEW)

8

9

10

11

12

1314151617181920212223

JX

CLKO

SMODE

LRCLK

BITCLK

SDIN

SDINA

SDOUTA

SDOUT

DVSS

DRDY

37

36

35

34

33

32

31

30

29

28

27

26

25

24

DVDD

AOUTL2

AOUTR2

BVSS

DVSS

DVDD

INT_RESET

S_RESET

RQ

SCLK

SI

SO

RDY

Note) JX , SDIN and SDINA are Pull-down pins

SMODEXTOXTICLKOUTBITCLKLRCLK

SMODEXTOXTICLKOUTBITCLKLRCLK

OUTAE

SW3

RQ

SI

SI

SO

SCLK

RDY

DRDY

JX

72kbit DLRAM

DSP

SDINA

SDIN

ISEL[2:0]

SDOUTD1

SDOUTD1

SDOUT

*SW1,SW2,SW3,ISEL[2:0],

OUTAE control register

SW0

CONTROLLER

SD ATA

SW2

SW2

SW1

ADC

AINL-

AINL+

AINR-

AINR+

SDATA AOUTL

SD ATA

INT_RESET

VREFF

DAC1

DAC2

AOUTR

AOUTL

AOUTR

INT_RESET

S_RESETS_RESET

AINL-

AINL+

AINL1

AINL2

AINL3

AINL4

AINR-

AINR+

AINR1

AINR2

AINR3

AINR4

VREFF

VCOM

AOUTL1

AOUTR1

AOUTL2

AOUTR2

SDOUT

1-34 (No.49834)

Note)

C

A

B

When C is "L" (0) then A connects with Q

Q

Page 35

• P in function

Pin No. Symbol I/O Function

1 AINL3 I ADC single-ended analog Lch input pin No.3

2 AINR2 I ADC single-ended analog Rch input pin No.2

3 AINL2 I ADC single-ended analog Lch input pin No.2

4 AINR1 I ADC single-ended analog Rch input pin No.1

5 AINL1 I ADC single-ended analog Lch input pin No.1

6 VREFH I Analog Reference voltage input pin.

Normally connect to AVDD (pin 7) and connect 0.1mF and 10mF capacitors between this pin and AVSS.

7 AVDD - Power supply pin for analog section 3.3V (typ)

8 AVSS - Analog ground 0V

9 DVSS - Ground pin for digital section 0V

10 DVDD - Power supply pin for digital section 3.3V (typ)

11 XTI I Master clock input pin

Connect a crystal oscillator between this pin and the XTO pin or input the external CMOS clock signal XTI pin.

12 XTO O Crystal oscillator output pin

When a crystal oscillator is used it should be connected between XTI and XTO.

When the external clock is used keep this pin open

13 CLKO O Clock output pin Outputs the XTI clock. Allow s the output to be set to "L" by control register setting.

14 JX I External condition jump pin (Pull down)

15 SMODE I Slave/master mode selector pin

Set LRCLK and BITCLK to input or output mode.

SMODE-"L": Slave mode (These are set to input mode.)

SMODE-"H": Master mode (These are set to output mode.)

16 LRCLK I/O LR channel select Clock pin

SMODE-"L": Slave mode : Inputs the fs clock.

SMODE-"H": Master mode : Outputs the fs clock.

17 BITCLK I/O Serial bit clock pin

SMODE-"L": Slave mode : Inputs 64 fs or 48 fs clocks.

SMODE-"H": Master mode : Outputs 64 fs clocks.

18 SDIN I DSP Serial data input pin (Pull down)

Compatible with MSB/LSB justified 24 20 and 16 bits.

19 SDINA I DSP Serial data input pin (Pull down)

Leave opens or connect to DVSS at using the internal ADC.

Compatible with MSB justified 24 bits.

(No.49834)1-35

Page 36

6.3 BA6956AN (IC981) : Reversible motor driver

• Block diagram

TSD

CONTROL LOGIC

1 2 3 4 5 6 7 8 9

REF

OUT2

RNF

VM

OUT1

Vcc

FIN

GND

• Pin function

Pin No. Symbol Function

1 VREF Output high voltage level control terminal

2 OUT2 Output terminal for motor

3 RNF GND of driver division

4 OUT1 Output terminal for motor

5 VM Power supply for driver division

6 Vcc Power supply for signal division

7 FIN Input terminal for control logic

8GNDGND

9 RIN Input terminal for control logic

6.4 BU4066BCFV-X (IC322,IC351) : Quad analog switch

• Pin layout & Block diagram

VDD C1 C4 I/O4 I/O3O/I4 O/I3

14 13 12 11 810 9

RIN

• Truth table

FIN RIN OUT1 OUT2 MODE

H L H L Forward rotation mode

L H L H Reverse rotation mode

H H L L Break Mode

L L OPEN OPEN Stand-by mode

1-36 (No.49834)

1234 756

I/O1 O/I1 O/I2 I/O2 VssC2 C3

Page 37

6.5 HD74HCT126T-X : (IC503) Buffer

• Pin arrangement • Pin function

Input Output

1C

1A

1Y

2C

2A

2Y

GND

• Block diagram

1

2

3

4

5

6

7

14

13

12

11

10

Vcc

4C

4A

4Y

3C

9

3A

8

3Y

CA Y

LX Z

HL L

HH H

H : High level

L : Low level

X : Irrelevant

Z : Off (Hhigh-impedance)state of a 3-stage output

1A

1C

2A

2C

3A

3C

4A

1Y

2Y

3Y

4Y

4C

(No.49834)1-37

Page 38

6.6 LH28F160BJHET93 (IC803) : 16M flash memory

A

• Pin layout

• Block diagram

A15 1

14 2

A

A

13 3

12 4

A

A

11 5

A

10 6

A

9 7

8 8

A

19 9

A

NC 10

WE# 11

RP# 12

V

CCW 13

WP# 14

RY/BY# 15

A

18 16

A

17 17

7 18

A

A

6 19

A

5 20

A

4 21

A

3 22

A

2 23

A1 24

Output

buffer

48-LEAD TSOP

STANDARD PINOUT

12mm x 20mm

TOP VIEW

DQ0 to DQ15

Input

buffer

48

47

46

44

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A

16

BYTE#

GND

DQ

15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

VCC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

GND

CE#

A0

-1-A19

Input

buffer

Address

latch

Address

counter

Y

decoder

X

decoder

Output

Multiplexer

Boot block 0

Boot block 1

Parameter block 0

Parameter block 1

Parameter block 2

ID code

register

Status

register

comparator

Y gate

Main block 0

Parameter block 3

Parameter block 4

Parameter block 5

Data

32k word

(64k byte)

Main block

x 31

Main block 1

register

Command

interface

Data

machine

Main block 29

Main block 30

user

Write

state

I/O logic

Write/Erase

voltage

selecter

VCC

BYTE#

CE#

WE#

OE#

RP#

WP#

RY/BY#

VCCW

VCC

GND

1-38 (No.49834)

Page 39

• P in function

Pin No. Symbol I/O Function

1 to 8 A

9A

15

to A

19

I Address input for memory address

8

I Address input for memory address

10 NC - Non connection

11 WE# I Write enable

12 RP# I Reset

13 VCCW - Power supply for write/erase

14 WP# I Write prot ect

15 RY/BY# O Ready/Busy

16,17 A

18 to 25 A

18,A17

to A

7

I Address input for memory address

I Address input for memory address

0

26 CE# I Chip enable

27 GND - Ground

28 OE# I Output enable

29 DQ

30 DQ

31 DQ

32 DQ

33 DQ

34 DQ

35 DQ

36 DQ

0

8

1

9

2

10

3

11

I/O Data input/output

I/O Data input/output

I/O Data input/output

I/O Data input/output

I/O Data input/output

I/O Data input/output

I/O Data input/output

I/O Data input/output

37 VCC - Power supply

38 DQ

39 DQ

40 DQ

41 DQ

42 DQ

43 DQ

44 DQ

45 DQ

45 A

4

12

5

13

6

14

7

15

-1

I/O Data input/output

I/O Data input/output

I/O Data input/output

I/O Data input/output

I/O Data input/output

I/O Data input/output

I/O Data input/output

I/O Data input/output

I Address input for memory address

46 GND - Ground

47 BYTE# I Byte enable

48 A

16

I Address input for memory address

(No.49834)1-39

Page 40

6.7 IC-PST3424U-X (IC803) : Reset

T

• Pin layout

VOUT

VDD

• Block diagram

1

2

VDD

43VSS

NC

2

Vref

3

VSS

• Pin function

No. Pin Name Function

1 Vout Reset Signal Output PIN

2 VDD VDD PIN / Voltage Detect PIN

3 NC Non connect

4 VSS VSS PIN

+

-

1 VOU

1-40 (No.49834)

Page 41

6.8 NJM2360AM-X (IC921) : DC-DC convertor

•Pin layout

1. Cs

1

2

3

4

• Block diagram

8

7

6

5

2. Es

3. C

4. GND

5. INV

6. Vcc

7. S

8. C

T

IN

I

D

Switch

collector

Switch

emitter

Timing

capacitor

1

Q

2

3

4GND

6.9 NJM4565V-X (IC132,IC171) : Dual ope amp

• Terminal layout & Pin function

1

A

2

-

3

4

1

+

Q

2

V

REF

1.25V

B

-

QS

R

C OSC

T

+

Ipk

COMP

+

-

Driver

8

collector

Ipk sense

7

+

6

V

Comparator

5

reversal input

1

8

7

6

AOUTPUT

2

A-INPUT

3

A+INPUT

4

V

5

B+INPUT

6

B-INPUT

7

B OUTPUT

8

V

5

(No.49834)1-41

Page 42

6.10 NJU7241F33-X (IC504,IC804) : Voltage regulator

D

T

D

PIN FUNCTION

1

2

5

1. GND

IN

2. V

3. VOUT

4. +NC

5. STB

3

4

6.11 RPM6938-SV4 (IC602) : Remote control receiver

• Block diagram

I/V

conversion

PD

AMP

for

trimming circuit

magnetic shield

6.12 TDA7404D-X (IC911):Carradio signal processor

• Terminal layout

1

28

BPF

AGC

Detector

Vcc

Comp

22k

ohm

3

VD

OU

1

2

GN

• Block diagram

14

15

MIX

Gain/Auto Zero

Input Multiplexer

Mono/Beep

Mixing Stage

Beep

Supply

Loudness

Volume

Soft Mute

Digital Control I C-Bus

Treble

2

Bass

Mono Fader

Mono Fader

Mono Fader

Mono Fader

Mono Fader

Mono Fader

Zero Cross

1-42 (No.49834)

Page 43

6.13 TDA7560-8 U (IC301) : Car radio amplifier

•Pin layout

1 25

IN1

IN2

IN4

TAB

P-GND2

ST-BY

OUT2-

Vcc

OUT2+

OUT1-

P-GND1

SVR

OUT1+

S-GND

IN3

OUT3+

C-GND

OUT3-

P-GND3

• Block diagram

Vcc1 Vcc2

ST-BY

Vcc

MUTE

OUT4+

OUT4-

P-GND4

HSD

100nF470uF

IN1

IN2

IN3

IN4

MUTE

0.1µF

0.1µF

0.1µF

0.1µF

AC-GND

0.47uF 47uF

SVR TAB S-GND

HSD

HSD/V

OUT1+

OUT1-

PW-GND

OUT2+

OUT2-

PW-GND

OUT3+

OUT3-

PW-GND

OUT4+

OUT4-

PW-GND

OFF

DET

(No.49834)1-43

Page 44

6.14 UPD784217AGC227 (IC701) : CPU

• Pin layout

75 51

76 50

100 26

125

• Block diagram

Pin No Symbol I/O Function

1 S.SELECT O E-VOL selection output, H: REAR L: FRONT

2 DSP.SELECT O DSP or Source direct selection output, H: Source direct L: DSP

3 LINE IN ON O OTHER

4 AMP KILL O Internal amplifier ON/OFF selection, H: OFF L: ON

5 to 7 NOT USE - Not connect

8 ANT CONT O Antenna remote control

9 VDD - Power supply

10 X2 11 X1 I

12 VSS - Ground

13 XT2 14 XT1 15 RESET I System reset

16 REMOCON I Remocon input

17 BUS-INT I J-BUS INT

18 PS2 I Power save2, H means STOP mode

19 CD-REQ I CD REQ INPUT

20 RDS-SCK - Not use

21 STEERING

I Steering remocon input

REMOCON

22 KEY DATA I KEY DATA

23 AVDD - A/D converter power supply

24 AVREF0 - A/D reference voltage

25 VOL1 I Volume encoder pulse input 1

26 VOL2 I Volume encoder pulse input 2

27 to 29 NOT USE - Connect to ground

30 MRC I MRC input

31 SQ I Not use, pull down

32 SM I S.METER input

33 AVSS - Ground

34 NOT USE - Not connect

35 STAGE3 I Feature selection, H: SH9750 L: SH9700

36 AVREF 37 BUS-SI I J-BUS data input

38 BUS-SO O J-BUS data output

39 BUS-SCK I/O J-BUS clock input/output

40 BUS-I/O O J-BUS I/O selection output: H input: L

41 DISP DA O DISPLAY DATA output

42 DISP SCK O DISPLAY SCK

43 DISP CE O DISPLAY CE

44 BUZZER O Buzzer output

45 E2PROM-DI I I2C data input

46 E2PROM-DO O I2C data output

47 E2PROM-CLK O I 2C clock output

48 NOT USE - Not connect

1-44 (No.49834)

Page 45

Pin No Symbol I/O Function

49 DETACH I Detach detect input; H means detaching

50 RDY I DSP data writing ready input

51 INPUT OVER I lLINE,AUX input over detecting port, L: Input over

52 S.RESET O DSP system reset output

53 INIT.RESET O DSP initialize reset output

54 RQ O DSP request input, RQ=L: Interface to micom

55 DSP SCK O DSP CLOCK OUTPUT

56 DSP DA O DSP data output

57 DSP SI I DSP data input

58 BBE O BBE ON/OFF selecting output, H: BBE1,2,3,FIX L: OFF

59 NOT USE - Not connect

60 RDS DA - Not use

61 SD/ST I Station detector or stereo indicator input;

H means a station is there, L means the program is stereo.

62 AFCK - Not use

63 SEEK/STOP O Auto seek and stop selecting output; H means seeking, L means receiving.

64 CF SEL O Wide & Narrow

65 FM/AM O FM,AM band selecting output; H=FM, L=AM

66 PLL-CE O CE output for PLL IC

67 PLL-DO O Data output for PLL IC

68 PLL-CLK O Clock output for PLL IC

69 PLL-DI I Data input from PLL IC

70 TEL-MUTING I Telephone muting detection input; Active level can be selected H or L in PSM

71 DIM-OUT O Dimmer detector output

72 VSS - Ground

73 DIM-IN I Dimmer detector input L=dimmer on

74 PS1 I Power save1 L=ACC off

75 POWER O Power ON/OFF control output H=power on

76 NOT USE O Not connect

77 MUTING O Muting output L=muting on

78 CD MUTING I CD mute input L=mute on

79 CD RESET O CD reset control out H=reset on

80 NOT USE - Not connect

81 VDD - Power supply

82 VOL-MUTE - Not use

83 VOL-DA O Data output for e-vol IC

84 VOL-CLK O Clock output for e-vol IC

85 NOT USE O Not connect

86 SUB MUTING O Muting control output for subwoofe r

87 LPF1 O LPF control1

88 LPF2 O LPF control2

89 STAGE2 I Feature selection H: R or Do L: J or U

90 STAGE1 I Feature selection H: R or U L: J or Do

91 PM0 O Panel motor close control output

92 PM1 O Panel motor open control output

93 PMKICK O Panel motor kick control output

94 TEST For rewriting flash memory

95 PNL-SW1 I Panel position sw1

96 PNL-SW2 I Panel position sw2

97 PNL-SW3 I Panel position sw3

98 PNL-SW4 I Panel position sw4

99 PNL-SW5 I Panel position sw5

100 PNL-SW6 I Panel position sw6

(No.49834)1-45

Page 46

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY MOBILE ENTERTAINMENT CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.49834)

Printed in Japan

WPC

Loading...

Loading...