Page 1

SERVICE MANUAL

CD RECEIVER

KD-LX333

KD-LX333

Contents

Safety precaution

Preventing static electricity

Disassembly method

Adjustment method

1-2

1-3

1-4

1-13

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

Flow of finctional operation intil opelation

until TOC read

Maintenance of laser pickup

Replacement of laser pickup

Description of Major ICs

Area Suffix

J Northern America

1-14

1-16

1-16

1-17~33

No.49722

Jun. 2002

Page 2

KD-LX333

Safety precaution

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-2

Page 3

KD-LX333

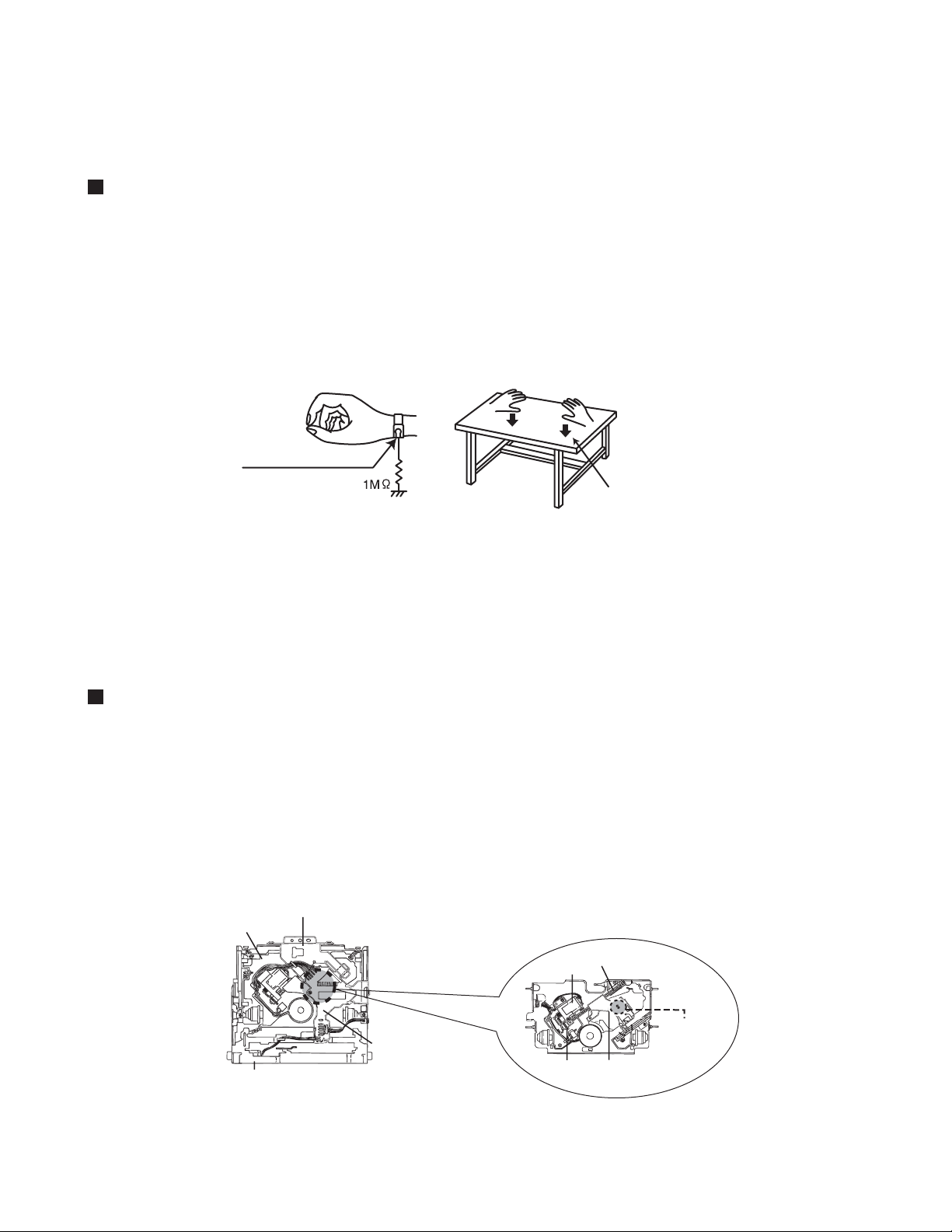

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as mechanism unit.

Be careful to use proper grounding in the area where repairs are being performed.

1. Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2. Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

CD mechanism ass’y

Damper bracket

Front bracket

CD mechanism

control board

Feed motor ass’y

FD gear

FD screw

Soldering

Pickup unit

1-3

Page 4

KD-LX333

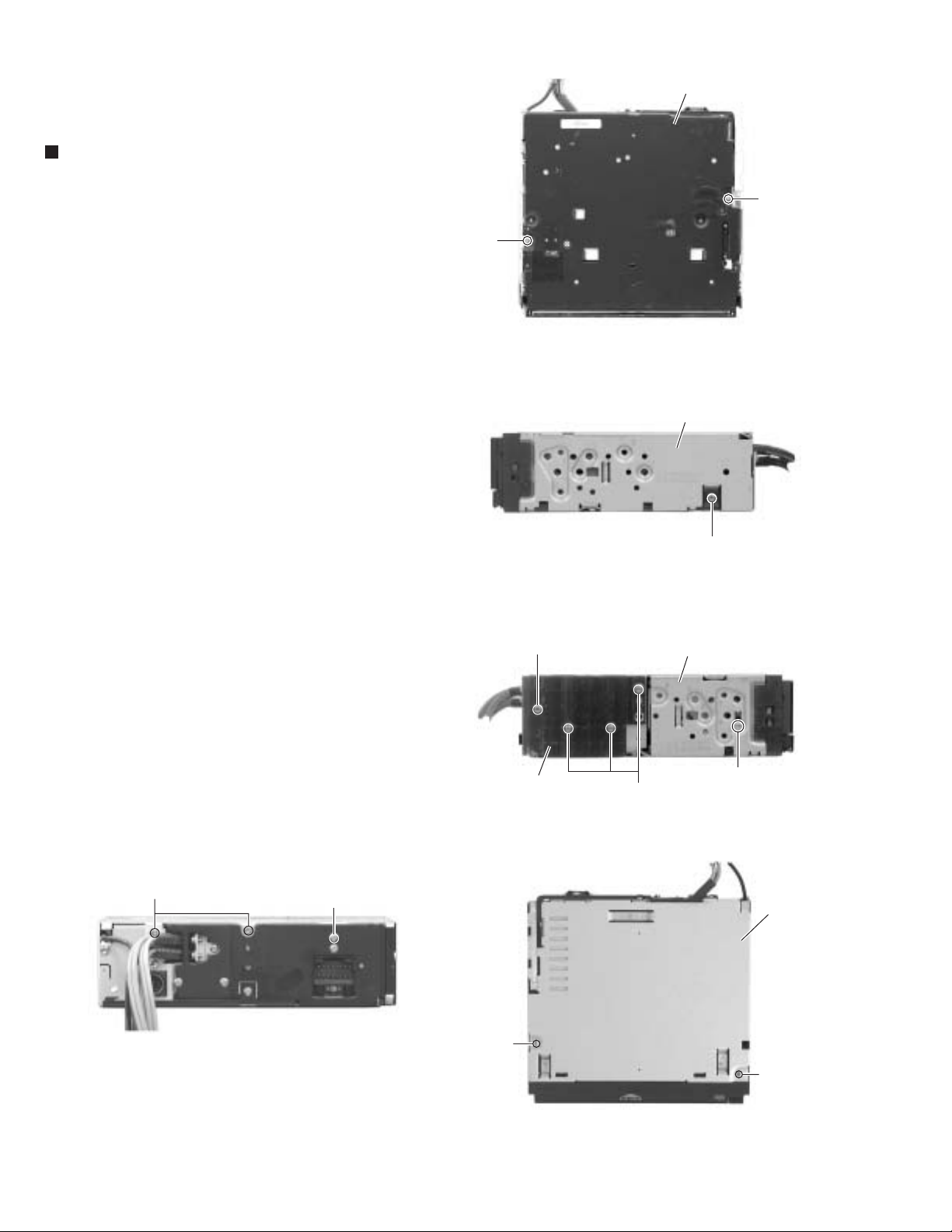

Disassembly method

<Main body>

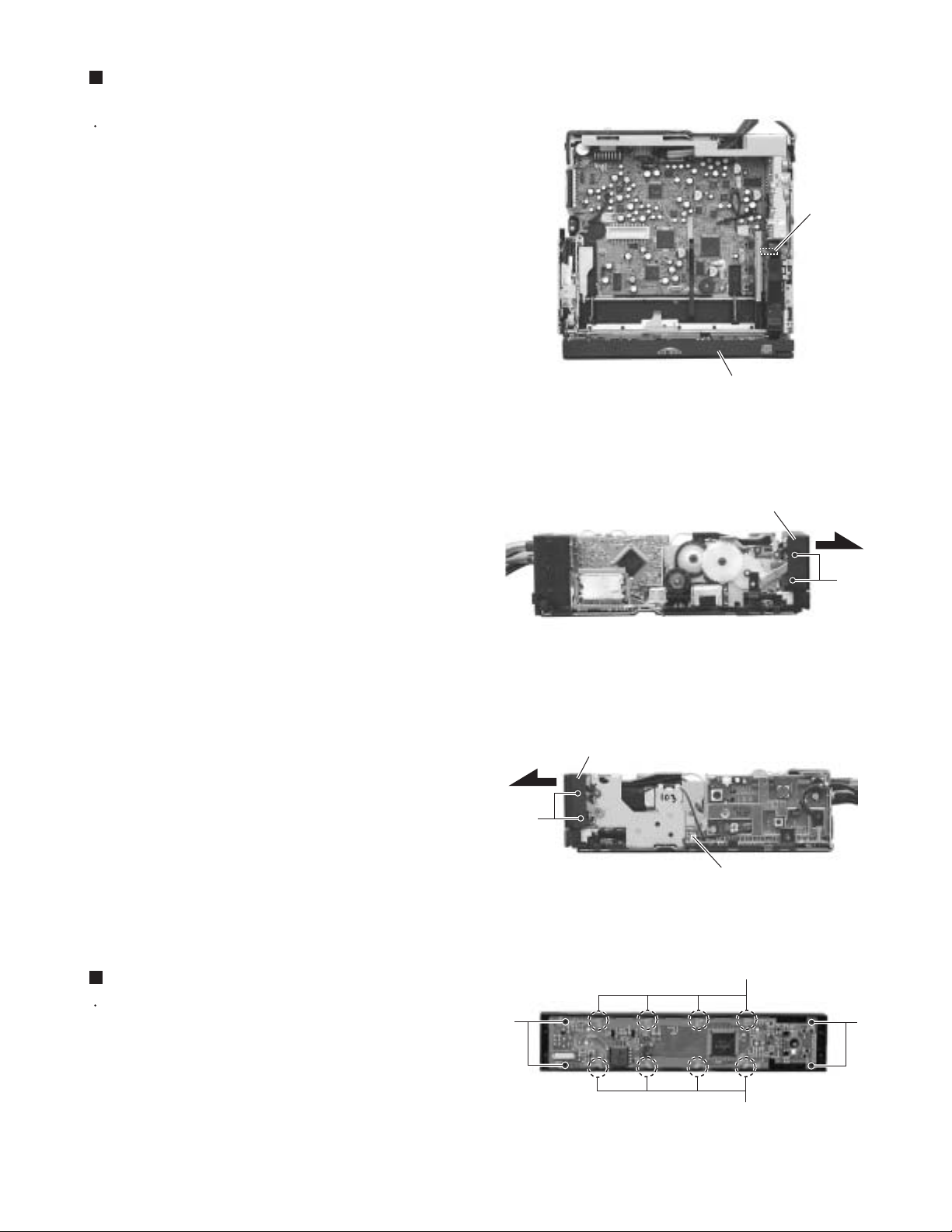

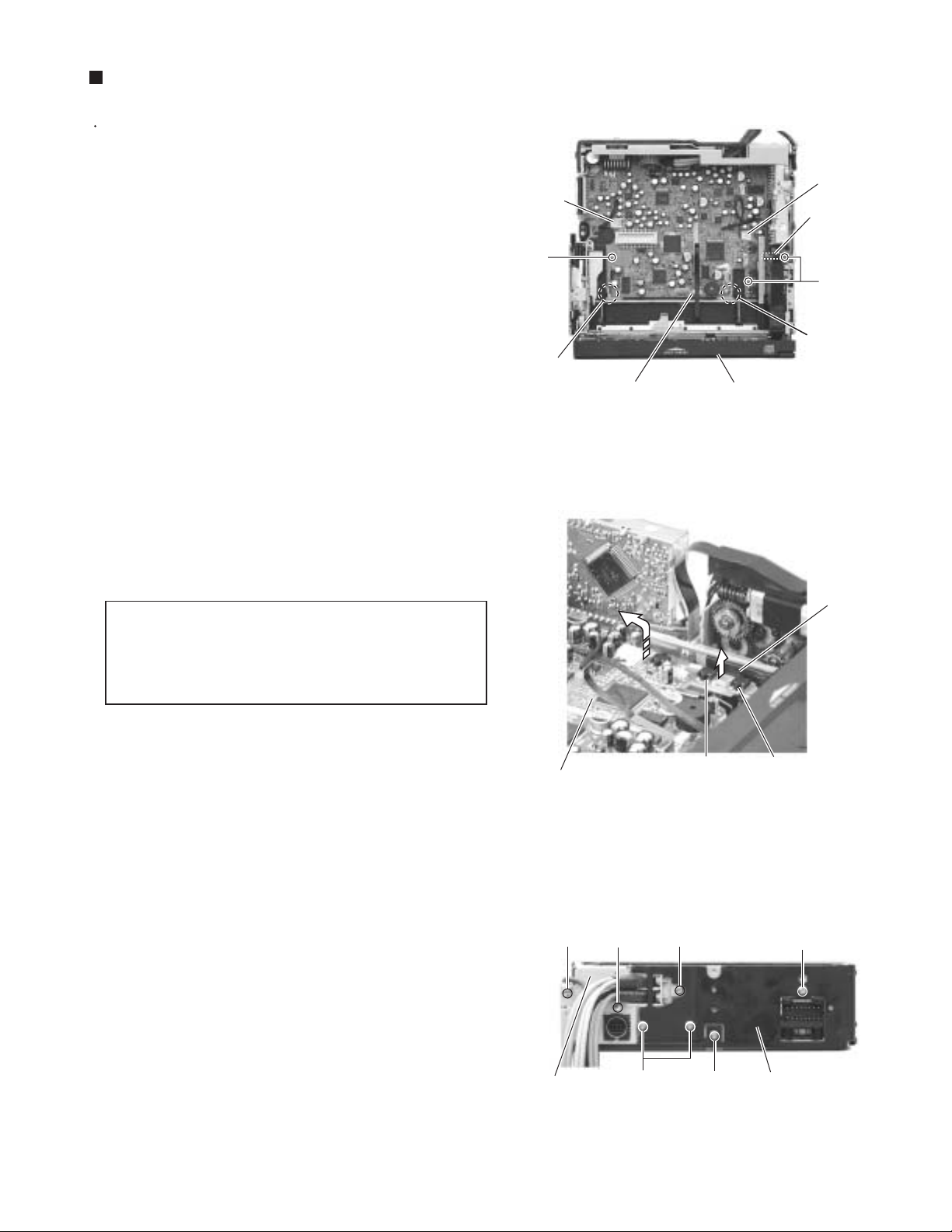

Removing the top chassis

(See Fig.1 to 5)

1.

Remove the two screws A attaching the bottom

cover to the top chassis on the bottom of the body.

2.

Remove the two screws B attaching the top chassis

on both sides of the body.

3.

Remove the two screws C and the two screw D

attaching the heat sink on the left side of the body.

4.

Remove the two screws E and the screw F on the

back of the body.

5.

Remove the two screws G on the upper side of the

body.

6.

Move the top chassis upward and disconnect the CD

mechanism connector from the main board

connector by pulling it. Remove the top chassis from

the body.

Bottom cover

A

A

Fig.1

Top chassis

B

Fig.2

E

Fig.4

F

C

Heat sink

G

Top chassis

B

D

Fig.3

Top chassis

G

1-4

Fig.5

Page 5

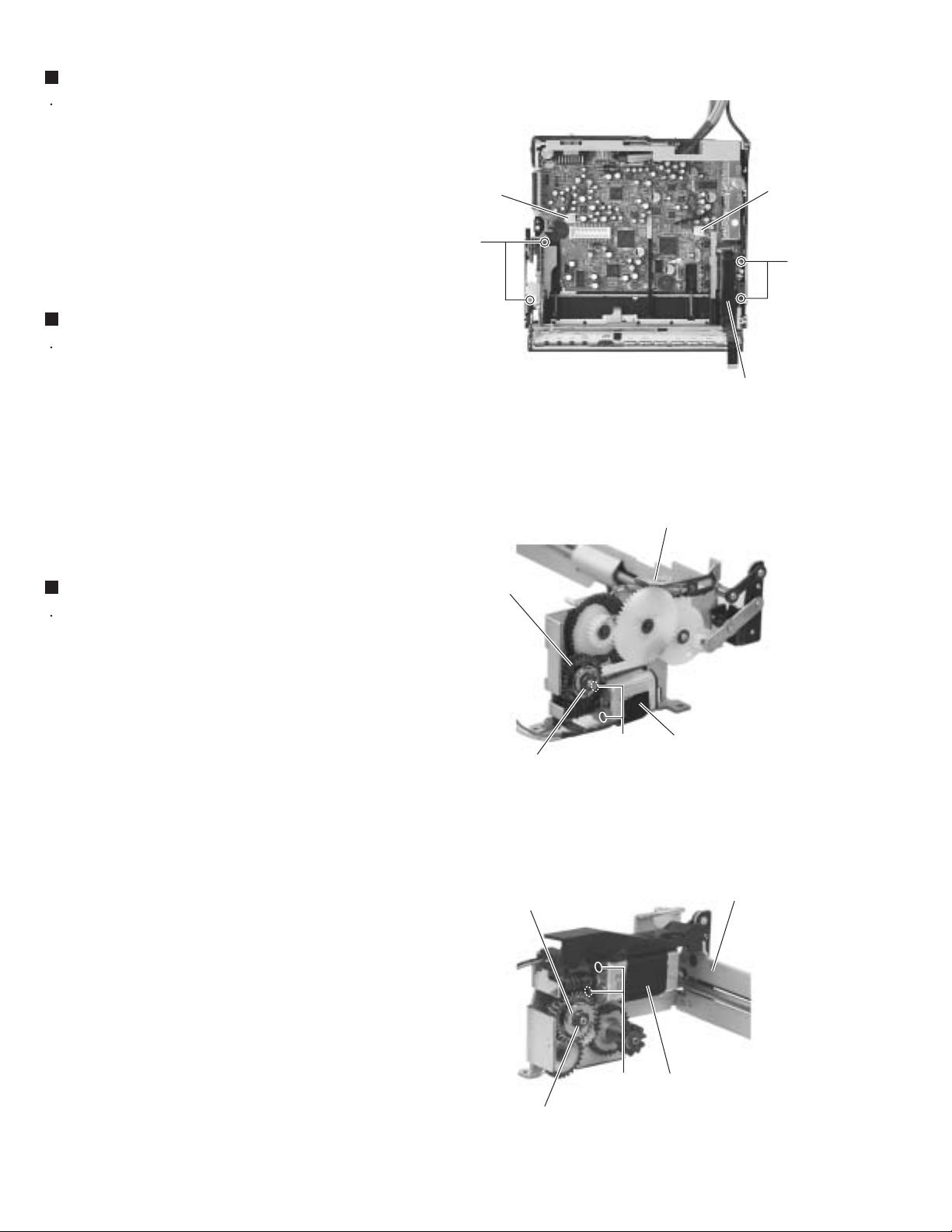

Removing the front panel assembly

(See Fig.6 to 8)

Prior to performing the following procedure, remove

the top chassis assembly.

1.

Disconnect the flexible harness from connector

CN701 on the main board assembly.

2.

Remove the four screws H attaching the front panel

assembly on both sides of the body. Remove the

front panel toward the front.

KD-LX333

CN701

Front panel assembly

Fig.6

Front panel assembly

H

Front panel assembly

H

Fig.7

CN701

Fig.8

Removing the Front Board (See Fig.9)

Prior to performing the following procedure, remove

the top chassis assembly and the front panel

assembly.

1.

Remove the four screws I attaching the front board

on the back of the front panel assembly and release

the eight joints a.

Joints a

I

Joints a

Fig.9

I

1-5

Page 6

KD-LX333

Removing the lifter unit (See Fig.10)

Prior to performing the following procedure, remove

the top chassis assembly and the front panel

assembly.

1.

Disconnect the harness from connector CN503and

CN504 on the main board.

2.

Remove the four screws J and detach the lifter unit

from the bottom cover.

Removing the feed motor (L) (See Fig.11)

Prior to performing the following procedure, remove

the lifter unit.

1.

Remove the washer attaching the clutch assembly

and detach the clutch assembly from the shaft of the

lifter unit.

2.

Remove the two screws K attaching the feed motor

(L).

CN503

J

CN504

J

Lifter unit assembly

Fig.10

Lifter unit assembly

Removing the feed motor (R) (See Fig.12)

Prior to performing the following procedure, remove

the lifter unit.

1.

Remove the washer attaching the clutch assembly

and detach the clutch assembly from the shaft of the

lifter unit.

2.

Remove the two screws L attaching the feed motor

(R).

Clutch assembly

Washer

Clutch assembly

Feed motor (L) assembly

K

Fig.11

Lifter unit assembly

1-6

Washer

Feed motor (R) assembly

L

Fig.12

Page 7

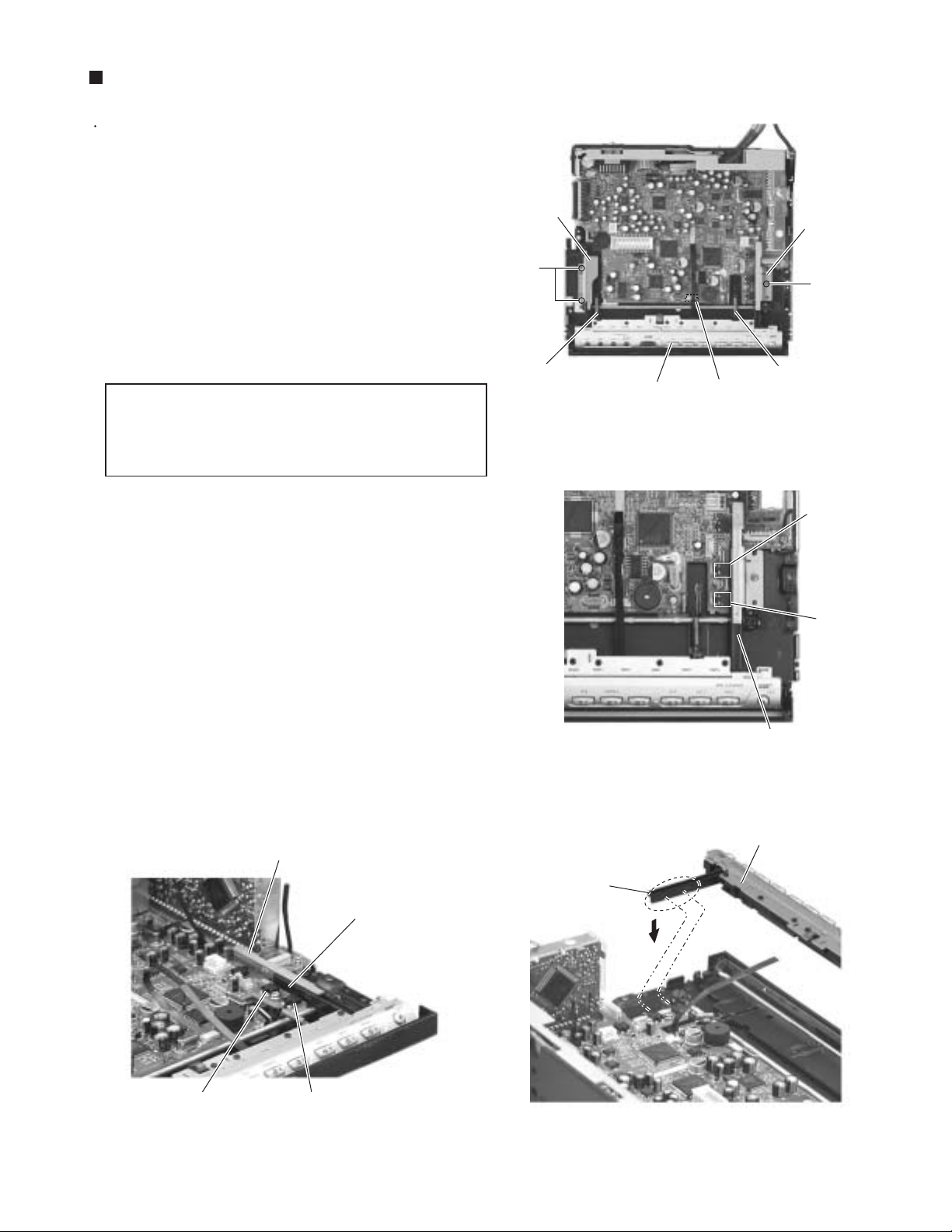

Removing the operation assembly

(See Fig.13 to 16)

Prior to performing the following procedure, remove

the top chassis assembly, the front panel assembly

and the lifer unit.

1.

Disconnect the card wire from connector CN702 on

the main board and remove the operation assembly.

2.

Remove the three screws M attaching the right and

left brackets which fix gears on both sides of the

operation assembly.

3.

Remove the springs 5 and 6 from the operation

assembly.

ATTENTION:

When reassembling, correctly engage

the switch S651 and S652 on the

main board and the right gear with

the part b of the operation assembly.

Bracket (L)

M

Spring 5

Operation assembly

Fig.13

KD-LX333

Bracket (R)

M

Spring 6

CN702

Bracket (R)

Operation assembly b

S652

S651

Operation assembly b

Fig.14

Operation assembly

b

S652

S651

Fig.15Fig.16

1-7

Page 8

KD-LX333

Removing the operation switch board

(See Fig.17 and 18)

Prior to performing the following procedure, remove

the operation assembly.

1.

Remove the six screws N attaching the button panel

on the operation assembly.

2.

Pull out the operation switch board from inside of the

button panel.

NN

Button panel

Fig.17

Operation switch board

Button panel

Removing the CD mechanism assembly

(See Fig.19)

Prior to performing the following procedure, remove

the top chassis.

1.

Remove the three screws O and the CD mechanism

assembly from the top chassis.

O

Fig.18

O

O

CD mechanism assembly

1-8

Fig.19

Page 9

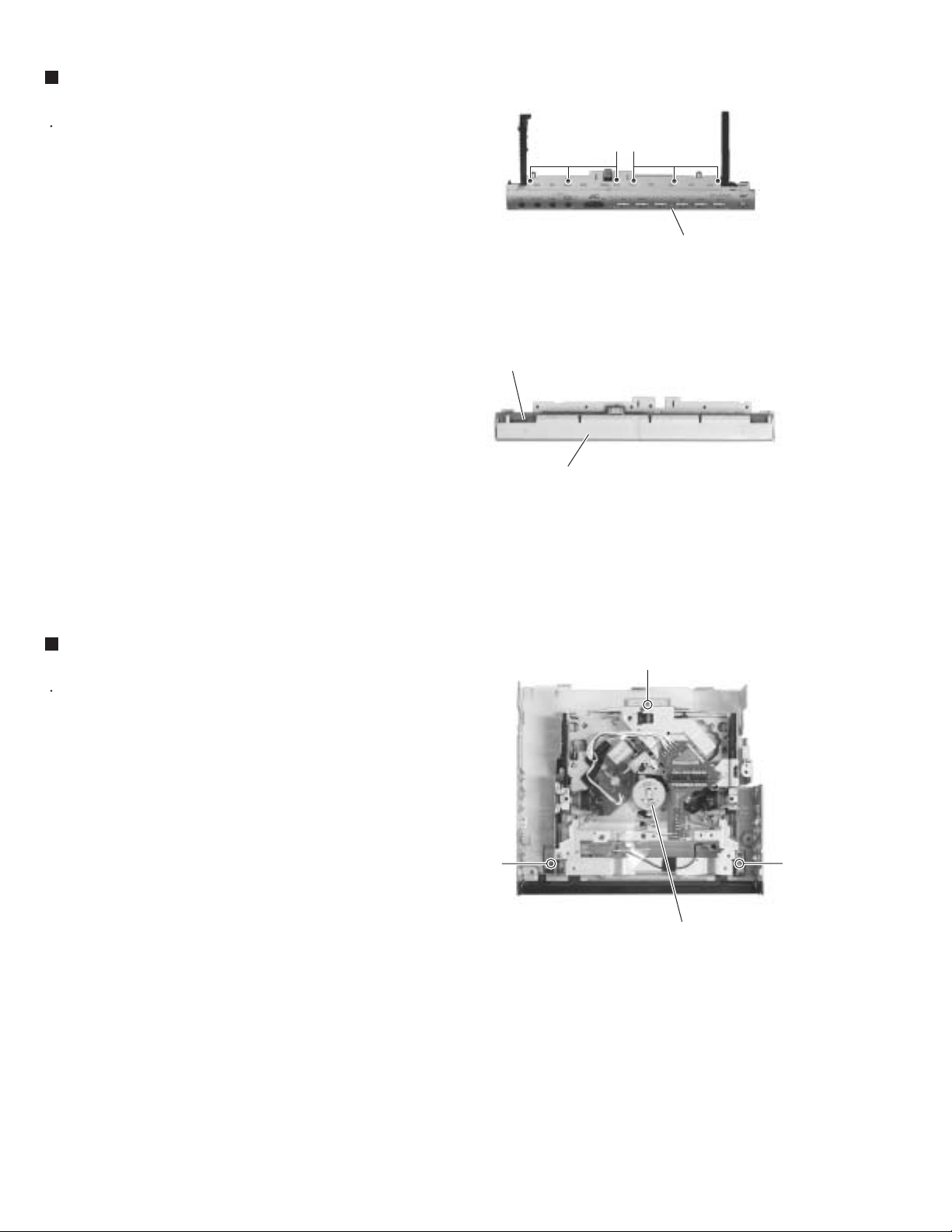

Removing the main board assembly

(See Fig.20 to 22)

Prior to performing the following procedure, remove

the top chassis.

KD-LX333

1.

Disconnect the flexible harness from connector

CN701, the card wire from CN702 on the main board

and the harness from CN503 and CN504

respectively.

2.

Remove the three screws P attaching the main

board assembly to the bottom cover on the upper

side of the body.

3.

Remove the screw Q attaching the rear panel and

the bottom cover on the back of the body. Move the

main board in the direction of the arrow and release

the two joints c. (At this point, the main board can be

removed with the rear panel and the rear heat sink.)

4.

Remove the three screws R attaching the rear heat

sink on the back of the body.

5.

Remove the two screws S and the screw T

attaching the rear panel. Now, the main board

assembly will be removed.

ATTENTION:

When reassembling, correctly engage

the switch S651 and S652 on the

main board and the right gear with

the part b of the operation assembly

(Refer to Fig.21).

CN503

P

Joint c

CN702

CN504

CN701

P

Joint c

Front panel assembly

Fig.20

b

Main board

S

Rear panel

T

S652

Fig.21

S

Fig.22

QR

S651

R

Rear heat sink

1-9

Page 10

KD-LX333

<CD mechanism section>

Removing the CD mechanism control

board (See Fig.1 and 2)

1.

Unsolder the part a and b on the CD mechanism

control board.

2.

Remove the stator fixing the CD mechanism control

board and the damper bracket (To remove the stator

smoothly, pick up the center part).

3.

Remove the screw A attaching the CD mechanism

control board.

4.

Remove the CD mechanism control board in the

direction of the arrow while releasing it from the two

damper bracket slots d and the front bracket slot e.

5.

Disconnect the flexible wire from connector on the

pickup unit.

ATTENTION:

Turn the FD gear in the direction of the

arrow to move the entire pickup unit to

the appropriate position where the

flexible wire of the CD mechanism unit

can be disconnected easily.

(Refer to Fig.2)

CD mechanism assembly

D

h

Front bracket

Pickup unit

Damper bracket

D

A

Fig.1

e

b

Flexible wire

a

h

c

D

d

CD mechanism

control board

Shift the lock

Removing the loading motor

(See Fig.3 to 5)

Prior to performing the following procedure, remove

the CD mechanism control board.

1.

Remove the two springs f attaching the CD

mechanism assembly and the front bracket.

2.

Remove the two screws B and the front bracket

while pulling the flame outward.

3.

Remove the belt and the screw C from the loading

motor.

Loading motor

C

FD gear

f

B

Loading motor

Pull outward

Fig.2

CD mechanism control board

f

B

Front bracket

Fig.3

Front bracket

Pull outward

1-10

Fig.5

Belt

Flame

Fig.4

Page 11

KD-LX333

Removing the CD mechanism assembly

(See Fig.1, 6 to 9)

Prior to performing the following procedure, remove

the CD mechanism control board and the front

bracket (loading motor).

1.

Remove the three screws D and the damper

bracket.

2.

Raise the both sides fix arms and move the fix plates

in the direction of the arrow to place the four shafts g

as shown in Fig.8 and 9.

3.

Remove the CD mechanism assembly and the two

springs h attaching the flame.

4.

Remove the two screws E and both sides rear

damper brackets from the dampers. Detach the CD

mechanism assembly from the left side to the right

side.

ATTENTION:

The CD mechanism assembly can be

removed if only the rear damper

bracket on the left side is removed.

CD mechanism

h

Front bracket

CD mechanism

D

Flame

assembly

D

assembly

h

D

Damper bracket

D

A

Fig.5

e

b

Damper bracket

D

Fig.6

a

h

c

D

d

CD mechanism

control board

h

Fix plate (L)

g

Fix arm (R)

D

Fig.7

Rear damper bracket

g

Fig.8

Rear damper bracket

E

Fix plate(R)

E

Fix arm (L)

Damper

Damper

g

g

Fig.9

1-11

Page 12

KD-LX333

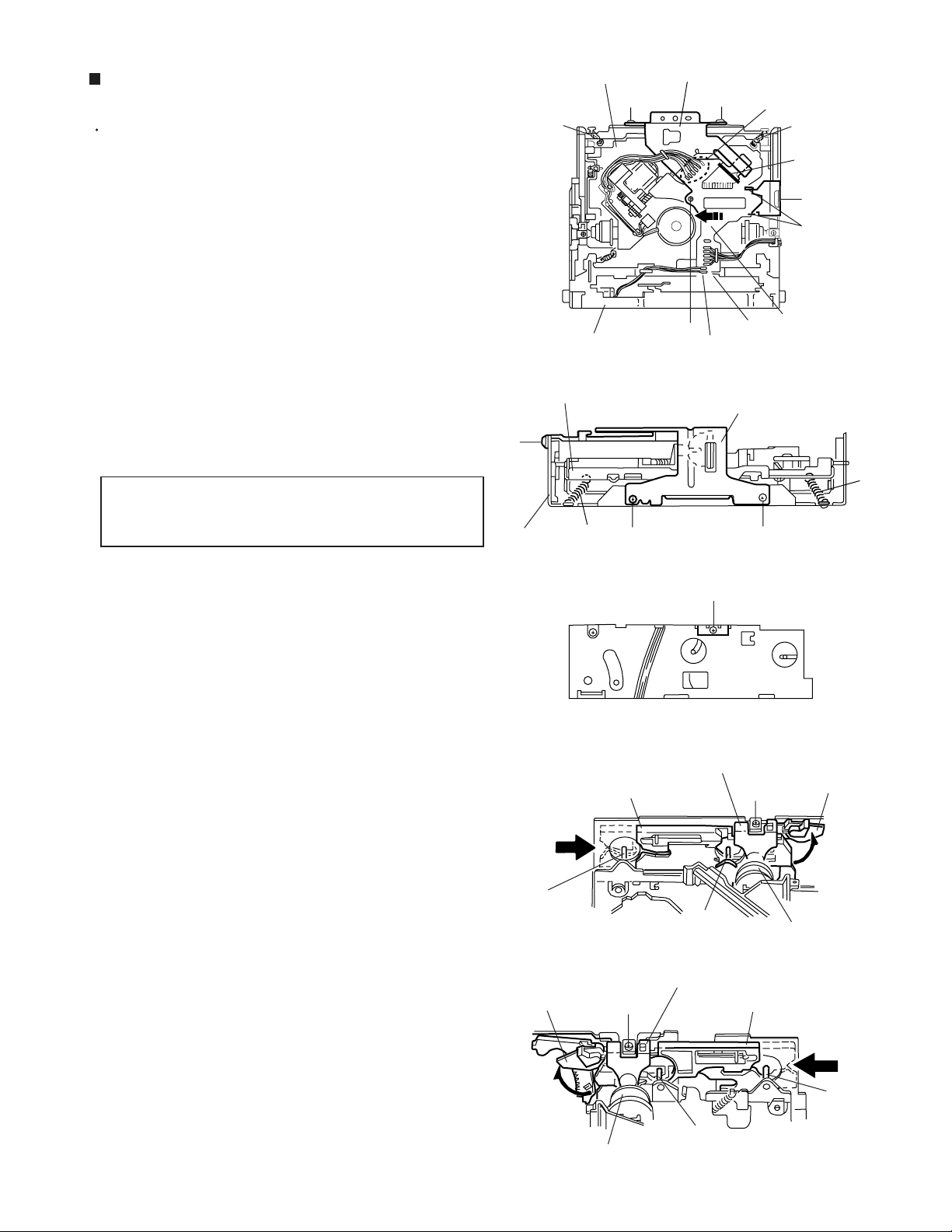

Removing the feed motor assembly

(See Fig.10)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor) and the CD mechanism assembly.

1.

Remove the two screws F and the feed motor

assembly.

Removing the pickup unit

(See Fig.10 and 11)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism assembly and

the feed motor assembly.

1.

Detach the FD gear part of the pickup unit upward.

Then remove the pickup unit while pulling out the

part i of the FD screw.

Feed motor assembly

F

FD gear

Nut push spring plate

FD screw

Pickup unit

Fig.10

Part i

Part j

Pickup unit

G

Pickup mount nut

Pickup unit

ATTENTION:

2.

Remove the screw G attaching the nut push spring

plate and the pickup mount nut from the pickup unit.

Pull out the FD screw.

When reattaching the pickup unit,

reattach the part j of the pickup unit,

then the part i of the FD screw.

Removing the spindle motor

(See Fig.12 and 13)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism assembly and

the feed motor assembly.

1.

Turn up the CD mechanism assembly and remove

the two springs k on both sides of the clamper arms.

Open the clamper arm upward.

2.

Turn the turn table, and remove the two screws H

and the spindle motor.

FD screw

k

Spindle motor

Fig.11

k

Fig.12

H

1-12

H

Fig.13

Page 13

Adjustment method

KD-LX333

Test instruments required adjustment

1.Digital oscilloscope (100MHz)

2.AM Standard signal generator

3.FM Standard signal generator

4.Stereo modulator

5.Electric voltmeter

6.Digital tester

7.Test disc(CTS-1000)

8.Extension cable for check

EXTGS004-22P

Standard volume position

Balance and Bass & Treble volume : Indication "0"

Loudness : OFF

requency Band

F

FM: 87.5 MHz to 107.9 MHz

(with channel interval set to 200 kHz)

87.5 MHz to 108.0 MHz

(with channel interval set to 50 kHz)

AM: 530 kHz to 1710kHz

(with channel interval set to 10 kHz)

531 kHz to 1602 kHz

(with channel interv

Dummy load

Exclusive dummy load should be used for AM, and FM.

For FM dummy load, there is a loss of 6dB between SSG output

and antenna input. The loss of 6dB need not be considered

since direct reading of figures are applied in this workingo

standard.

Standard measuring conditions

Power supply voltage DC 14.4V(11V to 16V allowance)

Load impedance 4 (4 to 8 allowance)

Line-out Level/Impedance

: 2.0 V/20k load(full scale)

Output impedance : 1k

al set to 9 kHz)

EXTLX002-JIG : Kit including the following 8 extension parts.

No.

1

2

3

4

5

6

7

Parts number Quantity Description

EXTLX001-2P

EXTLX001-6PF

EXTLX001-6PC

EXTLX002-16PF

EXTLX002-16PC

EXTLX002-SWPWB

EXTLX002-4P

2

1

1

1

1

1

1

EXTGS004-26P

EXTLX001-16PF

2Pin, 30cm extension cord

6Pin, 30cm flat wire

6Pin x 2, interlocking connector

16Pin flat wire

16Pin, interlocking connector

3 switch PWB

4Pin, 30cm extension cord

EXTLX002-4P

EXTLX002-SWPWB

EXTLX002-16PC

EXTLX001-2P

EXTLX001-6PC

EXTLX001-2P

EXTLX001-6PF

1-13

Page 14

KD-LX333

Flow of functional operation until TOC read

Power ON

When the pickup correctly moves

v

to the inner area of the disc

Set Function CD

When the laser diode correctly

emits

Microprocessor

commands

FMO

TC94A14FA" 40"

FEED MOTOR

+TERMINAL

IC501"4"

REST SW

When correctly focused

FEO

TA2157" 15"

Focus Servo Loop ONo

$83

$82

$81

3.3V

Hi-Z

0V

6V

4V

2V

OFF

ON

Pickup feed to the inner area

2.2V

RF signal eye-patternn

remains closed

RF signal eye-pattern

opens

Disc inserted

YES

Laser emitted

Focus search

Disc rotates

Tracking loop closed

TOC read out

YES

Microprocessor

commands

SEL

TC94A14FA"38"

LD

CN501"15"

"No disc"

display

When the disc correctly rotates

Microprocessor

commands

DMO

TC94A14FA"41"

Spindle

motor(-)

IC501"7"

$84 $86 $ A200

Acceleration Servo CLV

Rough

Servo

0.5 Sec 0.5 Sec

$84

3.3V

0V

4V

0V

3.3V

2.2V

0V

6V

3.2

2V

1-14

Jump to the first track

Play

Tracking Servo Loop ON

RF signal

Rough Servo Modev

CLV Servo Mode

(Program Area)

CLV Servo Mode

(Lead-In Area;

Digital :0)

Page 15

Feed section

Is the voltage output at

IC541 pin "40" 5V or 0V?

YES

Is 4V present at both

sides of the feed motor?

YES

NO YES NO

NO

Is the wiring for IC541

(56)~(64) correct?

NO

Is 6V or 2V present at

IC501 "4" and "5"?

NO

Is 3.3V present at IC501

pin "20"?

Check the vicinity of

IC541.

YES

Check the feed motor

connection wiring.

YES

Check CD 8V

KD-LX333

and 5V.

Check the feed motor.

Focus section

When the lens is

moving:

4V

Does the S-search

waveform appear at

IC501 pins "8" and "9"?

Spindle section

Is the disk rotated?

YES

Does the RF signal

appear at TP1?

YES

Is the RF waveform at TP1

distorted?

YES

Proceed to the Tracking

section

Check IC501.

NO

YES

NO

NO

NO

Check the circuits in

the vicinity of IC501

pins "8","9"and"15".

Check the pickup and

its connections

Is 4V present at IC501

pins "6" and "7"?

Check the spindle motor

and its wiring

Check the circuits in the

vicinity of IC521 "19"~

"24" or the pickup

YES

YES

NO

Is 4V present at IC541

pins "41" ?

Check the vicinity of

IC501.

NO

YES

Check IC541 and

IC521.

racking section

T

When the disc is rotated

Is the tracking error signal

output at IC521 "11"?

Check IC541.

at first:

Approx. 1.2V

YES

YES YES

Check the circuit in the

vicinity of IC521 pins

"2"~"12".

Check the pickup and

its connections

1-15

Page 16

KD-LX333

Maintenance of laser pickup

(1) Cleaning the pickup lens

Before you replace the pickup,please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired.

the following symptoms will appear..

(1) The level of RF output (EFM output:amplitude

of eye patterrn) will be low.

Is RF output

1.3 0.4Vp-p?

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed

circuit board which is attached to the pickup

is used to adjust the laser power.Since this.

adjustment should be performed to match the

characteristics of the whole optical block,

do not touch the semi-fixed resistor..

If the laser power is lower than the specified

value, the laser diode is almost worn out, and

the laser pickup should be replaced.

If the semi-fixed resistor is adjusted while

the pickup is functioning normally, the laser

pickup may be damaged due to excessive current.

NO

Replace it.

Replacement of laser pickup

Turn of the power switch and, disconnect the

power cord.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in, and turn the power on.

At this time, check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly..

1-16

Play a disc.

Check the eye-pattern at TP1.

Finish.

Page 17

Description of major ICs

/

TC9490FA (IC521) : DSP & DAC

1.Pin layout & Block daiagram

KD-LX333

DV

SS3

RO

DV

DD3

DVR

LO

DV

SS3

ZDET

SS5

V

BUS0

BUS1

BUS2

BUS3

BUCK

/CCE

/RST

VXDD3XOXI

SS3

XV

TEIN

DD3VSS3

V

DMO

FMO

DD3

AV

SEL

TEBC

RFGC

48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33

49

50

51

52

LPF

Clock

generator

1-bit

DAC

PWM

Servo control

A/D

53

54

55

56

Address

circuit

ROM

RAM

Digital equalizer

automatic

adjustment circuit

57

58

59

60

61

62

Micro-

controller

interface

circuit

Correction

Audio output

circuit

16k

RAM

Digital output

CLV servo

Sync signal

protection

EFM

Sub code

detector

TMAX

63

VCO

PLL

REF

V

D/A

Data

slicer

TRO

FOO

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

TEZI

TEI

SBAD

FEI

RFRP

RFZI

RFCT

DD3

AV

RFI

SLCO

AV

SS3

VCOF

REF

RV

LPFO

LPFN

64

DD5

V

17

TMAX

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

BCK

LRCK

AOUT

DOUT

IPF

DD3

V

V

SBOK

CLCK

DATA

SFSY

SBSY

/HSO

UHSO

DD3

PV

PDO

SS3

1-17

Page 18

KD-LX333

2.Pin function (1/2)

Pin No.

1

2

3

4

Symbol

BCK

LRCK

AOUT

DOUT

5

6

7

8

9

10

11

12

13

14

VDD3

VSS3

SBOK

CLCK

DATA

SFSY

SBSY

/HSO

/UHSO

IPF

I/O

O

O

O

O

O

-

-

O

I/O

O

O

O

O

O

TC9490FA(2/3)

Function

Bit clock outputpin 32fs, 48fs, or 64fs selectable by command.

L/R channel clock output pin."L" for L channe and "H" for R channel.

Output polarity can be inverted by command.

Audio data output pin. MSB-first or LSB-first selectable by command.

Digital data output pin. Outputs up to double-speed playback.

Correction flag output pin.When set to "H",AOUT output cannot be corrected

by C2 correction processing.

Digital 3.3V power supply voltage pin.

Digital GND pin.

Subcode Q data CRCC result output pin."H" level when result is OK.

Subcode P-W data read clockI/O pin. I/O polarity selectable by command.

Subcode P-W data output pin.

Playback frame sync signal output pin.

Subcode block sync signal output pin. "H" level at S1 when subcode sync is

detected.

Playback speed mode flag output pins.

/HSO

H

H

L

--

H

L

L

--

Playback speed/UHSO

Normal

Double

4 times

---

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

PVDD3

PDO

TMAX

LPFN

LPFO

PVREF

VCOF

SS3

AV

SLCO

RFI

AV

RFCT

RFZI

RFRP

FEI

SBAD

TEI

TEZI

FOO

TRO

REF

V

-

PLL-only 3.3V power supply voltage pin.

O

EFM and PLCK phase difference signal output pin.

O

TMAX detection result output pin.

TMAX OutputTMAX Detection result

Longer than fixed period

Within fixed period

Shorter than fixed period

I

Inverted input pin for PLL LPF amp.

O

Output oin for PLL LPF amp.

-

PLL-only V

VCO filter pin.

O

Analog GND pin.

DAC output pin for data slice level generation.

O

RF signal input pin.Zin selectable by command.

I

Analog 3.3V power supply voltage pin.

RFRP signal center level input pin.

I

RFRP signal zero-cross input pin.

I

RF ripple signal input pin.

I

Focus error signal input pin.

I

Sub-beam adder signal input pin.

I

Tracking error input pin. Inputs when tracking servo is on.

I

Tracking error signal zero-cross input pin.

I

Focus equalizer output pin.

O

Tracking equalizer output pin.

O

Analog reference power supply voltage pin.

-

REF pin.

"PVDD3"

"HIZ"

"AV

SS3"

1-18

Page 19

KD-LX333

2.Pin function (2/2)

Pin No.

36

37

38

39

40

41

42

43

44

45

Symbol

RFGC

TEBC

SEL

AV

FMO

DMO

V

V

TESIN

XV

46

47

48

49

XV

DV

50

51

52

DV

DVR

53

54

55

56

57

58

59

60

61

62

63

64

DV

ZDET

V

BUS0

BUS1

BUS2

BUS3

BUCK

/CCE

/RST

V

DD3

SS3

DD3

XI

XO

DD3

RO

DD3

LO

SS5

DD5

SS3

SS3

SS3

I/O

O

O

O

O

O

-

-

I

-

I

O

-

O

-

O

O

-

I/O

I

I

I

-

TC9490FA(3/3)

Function

RF amplitude adjustment control signal output pin.

Tracking balance control signal output pin.

APC circuit ON/OFF signal output pin. At laser on,high impedance with

UHS="L" ,H output with UHS="H".

Analog 3.3V power supply voltage pin.

Feed equalizer output pin.

Disc equalizer output pin.

Digital GND pin.

Digital 3.3V power supply voltage pin.

Test input pin. Normally,fixed to "L".

System clock oscillator GND pin.

System clock oscilatoe input pin.

System clock oscillator output pin.

System clock oscillator 3.3V power supply voltage pin.

DA converter GND pin.

R-channel data forward output pin.

DA converter 3.3V power supply pin.

Reference voltage pin.

L-channel data forward output pin.

DA converter GND pin.

1 bit DA converter zero data detection flag output pin.

Microcontroller interface GND pin.

Microcontroller interface data I/O pins.

Microcontroller interface clock input pin.

Microcontroller interface chip enable signal input pin.At "L".

Bus0 to BUS3 are active.

Reset signal input pin. At reset,"L".

Microcontroller interface 5V power supply pin.

NJM4565MD (IC151,IC171,IC323) : Operational amp

+

A OUTPUT

-

A INPUT

+

A INPUT

V

1

2

3

-

4

8

V

B OUTPUT

7

B INPUT

-

6

5

+

B INPUT

1-19

Page 20

KD-LX333

UPD784215AGC101 (IC701) : Main micon

1.Pin layout

100 ~ 76

1

75

~

25

26 ~ 50

2.Pin functions(1/3)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Symbol

SW2

SW3

SW4

RST-SW

LMO

LM1

DIM-OUT

ILLUM1

VDD

X2

X1

VSS

XT2

XT1

RESET

SW1

BUS-INT

PS2

CRUISE

NC

NC

REMOCON

AVDD

AVREFO

TEM1

KEY0

KEY1

KEY2

LEVEL

NC

SQ

SM

AVSS

W-VOL

DOT-CNT

AVREF

BUS-SI

BUS-SO

BUS-SCK

STAGE2

LCD-DA

LCD-SCK

~

51

I/O

Function

I

CD mechanical switch 2 detection signal input

I

CD mechanical switch 3 detection signal input

I

CD mechanical switch 4 detection signal input

I

Rest switch detection signal input

O

Motor signal control signal output at loading

O

Motor signal control signal output at leject

O

DIMMER pulse control output

O

POWER ON:H,FLAT PANEL:L

-

5V

-

-

-

GND

-

I

Reset detection teaminal

I

CD mechanical switch 1 detection signal input

I

J-BUS int

I

POWER SAVE2. Operating together with BACKUP.H input:STOP

I

Pulse signal for CRUISE input(only in 330R)

-

I

Remocon input

-

5V

-

5V

I

Temperature detection input

I

Key input 0

I

Key input 1

I

Key input 2

I

Level meter input

I

S.QUALITY level input

I

S.METER level input

-

GND

O

Subwoofer volume control analog output

O

Dot matrix contrast adjustment analog output

-

5V

I

J-BUS data input

O

J-BUS data output

I/O

J-BUS clock input and output

I

H:LX300 L:LX100

O

Data output to LCD driver

O

Clock output to LCD driver

1-20

Page 21

2.Pin functions(2/3)

KD-LX333

Pin No.

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

Symbol

LCD-CE1

BUZZER

12C-DAI

12C-DAO

12C-CLK

BUS-I/O

TMO

TM1

DMO

DM1

ST

NC

MONO

C-SW1

C-SW2

C-SW3

C-SW4

C-SW5

VOL1

VOL2

SEEK/STP

NC

FM/AM

PLL-CE

PLL-DO

PLL-CLK

PLL-DI

NC

AMP-KILL

VSS

DIM -IN

PS1

POWER

CD-ON

MUTE

W-LPF1

W-LPF2

W-MUTE

VDD

VOL-DA

VOL-CLK

NC

GVSW

LCD RST

NC

DMK

TMK

NC

BUCK

CCE

RST

TEST

I/O

Function

O

Chip enable output 1 to LCD driver

O

Buzzer output

I

12C communication data input

O

12C communication data output

O

12C communication clock output

O

J-BUSI/O signal terminal

O

Tray motor negative signal output terminal

O

Tray motor positive signal output terminal

O

Motor control signal output in door down

O

Motor control signal output in door up

I

Stereo detector stereo signal input H:Brordcasting station L:Stereo

O

O

Monaural ON/OFF selection output MONO ON:H

I

Chameleon machanical switch 1 detection signal input

I

Chameleon machanical switch 2 detection signal input

I

Chameleon machanical switch 3 detection signal input

I

Chameleon machanical switch 4 detection signal input

I

Chameleon machanical switch 5 detection signal input

I

Rotary volume signal 1 input

I

Rotary volume signal 2 input

O

Auto seek/stop selection output SEEK:H STOP:L

O

-

FM/AM selection output FM:H AM:L

O

IC control CE output

O

IC control data output

O

IC control clock output

I

IC control data input

O

Telephone mute detection input

O

POWER AMP ON/OFF selection output

-

GND

I

Dimmer detection input L:dimmer ON

I

Power save 1 Operating together with ACC.Power save :L Operating :H

O

Power ON/OFF selection output Power ON:H

O

CD power supply control signal output CD:H

O

Mute output MUTEON:L

O

Subwoofer cut off frequency control output 1

O

Subwoofer cut off frequency control output 2

O

Subwoofer mute output MUTE ON:H

-

5V

O

data output terminal

O

clock signal output terminal

O

O

CD-DA/CD-RW selection control output CD-RW:L

O

Reset signal output to LCD driver

-

O

Door motor kick signal output

O

Tray motor kick signal output

-

O

Data cmmunication clock output with CDLSI

O

Data cmmunication clock CE with CDLSI

O

CDLSI reset signal output

-

GND

1-21

Page 22

KD-LX333

+

+

-

-

+

+

-

-

-

+

+

2.Pin functions(3/3)

Pin No.

95

96

97

98

99

100

Symbol

BUSO

BUS1

BUS2

BUS3

DISCSEL

NC

I/O

Function

I/O

Data communication input and output port 0 with CDLSI

I/O

Data communication input and output port 1 with CDLSI

I/O

Data communication input and output port 2 with CDLSI

I/O

Data communication input and output port 3 with CDLSI

I

H:not for 8cm DISC L:for 8cm DISC

O

BA3220FV-X (IC301,IC401) : Line out amp

1.Pin layout

14

3220

17

8

2.Block diagram

1

CL-

14

LGND

13

REFL

2

Vcc

OUTL OUTR RGND

3

INL

1112

4

NFLCL+

10

REFR

FILTER

56

FIL

CR-

9

NFR

CR+

8

7

INR

1-22

Page 23

BD3860K (IC911) : E.Vol & Loud

1.Terminal layout

33 23

KD-LX333

2.Block diagram

GND FIL VCC SEL1

6 5 9 40 36 35 343328323130 2919 15 14

POWER

SUPPLY

A1

41

B1

42

C1

43

D1

44

INPUT

1

2

3

4

SELECTOR

A2

B2

C2

D2

34

44

1 11

INPUT

GAIN

0 18 dB

INPUT

GAIN

0 18 dB

22

12

VIN1 LOUD1 HF1 LF1 DET1 TIN1 TNF1 BNF1

MAIN

VOLUME

0 -40 dB

LOUDNESS

MAIN

VOLUME

0 -40 dB

LOUDNESS

LOW(f=50Hz) 6dB

PROCESS CONTROL +3 to 12dB

(f=10kHz)

LOGIC

LOW(f=50Hz) 6dB

PROCESS CONTROL +3 to 12dB

(f=10kHz)

TREBLE

-14 +14dB

TREBLE

-14 +14dB

-14 +14dB

-14 +14dB

BASS

BASS

BOUT1VCA1 MIX1 BBOUT1

FADER

CH1 FRONT

0 -5 dB

FADER

CH1 REAR

0 -5 dB

FADER

CH2 REAR

0 -5 dB

FADER

CH2 FRONT

0 -5 dB

13

12

37

10

11

7

8

OUTF1

OUTR1

SI

SC

OUTR2

OUTF2

3.Pin function

Pin

Symbol Function

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

A2

B2

C2

D2

FIL

GND

SI

SC

VCC

OUTR2

OUTF2

OUTR1

OUTF1

BOUT1

BNF1

BOUT2

BNF2

TNF2

TNF1

TIN2

BBOUT2

MIX2

CH2 Input Pin A

CH2 Input Pin B

CH2 Input Pin C

CH2 Input Pin D

1/2 VCC Pin

Ground Pin

Serial Data Receiving Pin

Serial Clock Receiving Pin

Power Supply Pin

CH2 Rear Output Pin

CH2 Front Output Pin

CH1 Rear Output Pin

CH1 Front Output Pin

CH1 Bass Filter Setting Pin

CH1 Bass Filter Setting Pin

CH2 Bass Filter Setting Pin

CH2 Bass Filter Setting Pin

CH2 Treble Filter Setting Pin

CH1 Treble Filter Setting Pin

CH2 Treble Input Pin

CH2 BBE II Signal Output Pin

CH2 Output MIX Amplifier

Inverse Input Pin

39 38 37 25 24 26 23 22 21 20 18 17 16

Pin

Symbol Function

No.

23

24

25

26

27

28

29

30

BBOUT1

31

32

33

34

35

36

37

38

39

40

41

42

43

44

VCA2

LF2

HF2

DET2

DEF

DET1

TIN1

MIX1

VCA1

LF1

HF1

LOUD1

VIN1

LOUD2

VIN2

SEL2

SEL1

A1

B1

C1

D1

CH2 High Pass VCA Output Pin

CH2 Low Pass Filter Setting Pin

CH2 High Pass Filter Setting Pin

CH2 High Pass Attack/Release Time Setting Pin

BBE ON/OFF switching time constant pin

CH1 High Pass Attack/Release Time Setting Pin

CH1 treble Input Pin

CH1 BBE II Signal Output Pin

CH1 Output MIX Amplifier Inverse Input Pin

CH1 High Pass VCA Output Pin

CH1 Low Pass Filter Setting Pin

CH1 High Pass Filter Setting Pin

CH1 Loudness Filter Setting Pin

CH1 Main Volume Input Pin

CH2 Loudness Filter setting Pin

CH2 Main Volume Input Pin

CH2 Input Gain Output Pin

CH1 Input Gain output Pin

CH1 Input Pin A

CH1 Input Pin B

CH1 Input Pin C

CH1 Input Pin D

BOUT2BNF2TNF2TIN2BBOUT2MIX2VCA2DET2LF2HF2LOUD2VIN2SEL2

1-23

Page 24

KD-LX333

TA2147F-X (IC501) : RF amp.

1.Terminal layout

2.Block diagram

VRO

FEO

FEN

RFRP

RFRPIN

RFGO

RFGC

AGCIN

RFO

RFN

13GVSW

14

15

16

17

18

19

20

21

22

23

10pF

40k

30k

20k 20k

20k

20k

3k

15k

50 A

12k

12k

BOTTOM

PEAK

20k

180k

40pF

20k

20k

PEAK

1.3V

180k

40k

240k

15pF

240k

15pF

60k

40k

40pF

60k

50k

2k

20 A

20k

60 A

50k

14k

k

1

80k

80k

20k

20k

15k

x0.5

x2

x0.5

x2

1k

2k

1.75k

10pF

12 RFDC

11

TEO

10

TEN

TEBC

9

8

SEL

7

LDO

MDI

6

5

TNI

4

TPI

3

FPI

2

FNI

1-24

GND

24

3k

1

Vcc

Page 25

3.Pin function

Pin No.

1

2

3

4

5

6

7

8

Symbol

Vcc

FNI

FPI

TPI

TNI

MDI

LDO

SEL

I/O

Function

-

3.3V Power supply pin

I

Main-beam amp input pin

I

Main-beam amp input pin

I

Sub-beam amp input pin

I

Sub-beam input pin

I

Monitor photo diode amp input pin

O

Laser diode amp output pin

I

APC circuit ON/OFF control signal,laser diode (LDO) control signal input or

bottom/peak detection frequency change pin.

KD-LX333

9

10

11

12

13

TEBC

TEN

TEO

RFDC

GVSW

APC

circuit

GND OFF

HIZ

Vcc

I

Tracking error balance adjustment signal pin

Adjusts TE signal balance by eliminating carrier component from

PWM signal(3-state output, PWM carrier = 88.2kHz) output from

TC9490F/FA TEBC pin using RC-LPF and inputting DC.

TEBC input voltage:GND~Vcc

I

Tracking error signal generation amp negative-phase input pin

O

Tracking error signal generation amp output pin.

Combining TEO signal and RFRP signal with TC9490F/FA configures

tracking search system.

O

RF signal peak detection output pin

I

AGC/FE/TE amp gain change pin

GND

HIZ

Vcc

Connected to Vcc

through 1k resistor

Control signal output

ON

Control signal output

ON

ModeGVSW

CD-RW

CD-DA

CD-DA

LDOSEL

14

15

16

17

18

19

20

21

22

23

24

VRO

FEO

FEN

RFRP

RFRPIN

RFGO

RFGC

AGCIN

RFO

RFN

GND

Reference voltage (VRO) output pin *VRO = 1/2 Vcc when Vcc = 3.3V

O

Focus error signal generation amp output pin

O

Focus error signal generation amp negative-phase input pin

I

Signal amp output pin for track count

O

Combining RFRP signal TEO signal with TC9490F/FA configures tracking

search system.

Signal generation amp input pin for track count

I

RF signal amplitude adjustment amp output pin

O

RF amplitude adjustment control signal input pin

I

Adjusts RF signal amplitude by eliminating carrier component from PWM

signal (3-state output, PWM carrier = 88.2kHz) output from TC9490F/FA

RFGC pin using RC-LPF and inputting DC.

*RFGC input voltage : GND-Vcc

RF signal amplitude adjustment amp input pin

I

RF signal generation amp output pin

O

RF signal generation amp input pin

I

GND pin

-

1-25

Page 26

KD-LX333

F

TA8273H (IC941) : Power amp

1.Block diagram

INRF

0.22 F

AC CONT1

INRR

0.22 F

+

Vcc 1/2 Vcc 3/4

2200 F 0.022

6 20

+

11

-

+

+

-

9

7

OUT RF+

OUT RF-

1

Protective

circuit

+

-

+

12

+

-

GND

8

OUTRR+

5

OUTRR-

3

GND

2

ST BY

REF

47 F

INLF

AC CONT2

PRE GND

INLR

+5V

ST ON

+

0.22 F

+

0.22 F

4

Stand by

Switch

Mute

10

+

Ripple

Filter

Mute

22

circuit

3.3 F

+

15

-

+

-

17

19

10K

+

OUTLF+

OUTLF-

Low Level

Mute ON

25

18

21

23

GND

OUTLR+

OUT LR-

13

14

Protective

circuit

-

+

+

-

1-26

ON TIME

22 F

Muting &

16

+

ON Time Control

Circuit

GND

24

Page 27

2.Terminal layout

KD-LX333

3.Pin function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

SymbolPin No. Function

AC CONT 1

GND

OUTRRSTBY

OUTRR+

VCC1/2

OUTRFGND

OUTRF+

REF

INRF

INRR

PREGND

INLR

INLF

ONTIME

OUTLF+

GND

OUTLFVCC3/4

OUTLR+

MUTE

OUTLRGND

AC CONT 2

Header of IC

Power GND

Outpur(-) for Rear Rch

Stand by input

Output (+) for Rear Rch

Power input

Output (-) for Front Rch

Power GND

Output (+) for Front Rch

Ripple filter

Front Rch input

Rear Rch input

Signal GND

Rear Lch input

Front Lch input

Power on time control

Output (+) for Front Lch

Power GND

Output (-) for Front Lch

Power input

Output (+) for Rear Lch

Muting control input

Output (-) for Rear Lch

Power GND

Header of IC

TA8273H

RPM6938-SV4 (IC602) : Remote sensor

1.Block diagram

AMP

I/V

conversion

PD

magnetic shield

BPF

fo

trimming

circuit

AGC

Detector

Vcc

Comp

Vcc

22k

Rout

GND

1-27

Page 28

KD-LX333

BR24C16F-X (IC703) : EEPROM

1. Pin layout

VCC WP SCL SDA

A0 A1 A2 GND

3. Block diagram

2. Pin function

Symbol

VCC

GND

A0,A1,A2

SCL

SDA

WP

I/O

-

Power supply.

-

GND

I

No use connect to GND.

I

Serial clock input.

I/O

Serial data I/O of slave and ward address.

I

Write protect terminal.

Function

A0 1

A1 2

A2 3

GND 4

11bit

Address

decoder

Control circuit

High voltage osc circuit

16kbit EEPROM allay

11bit

START

Slave W ard

Address resister

Power supply

voltage det.

STOP

BU4066BCFV-X (IC322) : Quad analog switch

1. Pin layout & Block diagram

VDD C1 C4 I/O4 I/O3O/I4 O/I3

14 13 12 11 810 9

ACK

8bit

Data

resister

8 Vcc

7 WP

6 SCL

5 SDA

1-28

1234 756

I/O1 O/I1 O/I2 I/O2 VssC2 C3

Page 29

FAN8037 (IC581) : CD driver

1. Pin layout & Block diagram

48 47 46 45 44 43 42 41 40 39 38 37

KD-LX333

2. Pin function

Pin

Symbol

No.

1

IN2+

2

IN2-

3

OUT2

4

IN3+

5

IN3-

6

OUT3

7

IN4+

8

IN4-

9

OUT4

10

CTL1

11

FWD1

12

REV1

13

CTL2

14

FWD2

15

REV2

16

SGND

17

FWD3

18

REV3

19

CTL3

20

SB

21

PS

22

MUTE

23

PVCC2

24

DO7-

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15 16 17 18 19 20 21 22 23 24

I/O

Function

I

CH2 op-amp input(+)

I

CH2 op-amp input(-)

O

CH2 op-amp output

I

CH3 op-amp input(+)

I

Ch3 op-amp input(-)

O

CH3 op-amp output

I

CH4 op-amp input(+)

I

CH4 op-amp input(-)

O

CH4 op-amp output(+)

I

CH5 motor speed control

I

CH5 forward input

I

CH5 reverse input

I

CH6 motor speed control

I

CH6 forward input

I

CH6 reverse input

-

Signal ground

I

CH7 forward input

I

CH7 reverse input

I

CH7 motor speed control

I

Stand by

I

Power save

I

All mute

-

Power supply voltage

O

CH7 drive output(-)

M

s

S

w

C

M

s

S

w

C

M

s

S

w

C

T.S .D

D

D

D

D

D

D

STAND BY

ALL MUTE

POWER SAVE

Pin

No.

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Symbol

DO7+

DO6-

DO6+

PGND2

DO5-

DO5+

DO4-

DO4+

DO3-

DO3+

PGND1

DO2-

DO2+

DO1-

DO1+

PVCC1

REGOX

REGX

RESX

VREF

SVCC

IN1+

IN1-

OUT1

36

35

34

33

32

31

30

29

28

27

26

25

Function

I/O

O

CH7 drive output(+)

O

CH6 drive output(-)

O

CH6 drive output(+)

-

Power ground2

O

CH5 drive output(-)

O

CH5 drive output(+)

O

CH4 drive output(-)

O

CH4 drive output(+)

O

CH3 drive output(-)

O

CH3 drive output(+)

-

Power ground1

O

CH2 drive output(-)

O

CH2 drive output(+)

O

CH1 drive output(-)

O

CH1 drive output(+)

-

Power supply voltage

I

Regulator feedback input

O

Regulator output

I

Regulator reset input

I

Bias voltage input

-

Signal supply voltage

I

CH1 op-amp input(+)

I

CH1 op-amp input(-)

O

CH1 op-amp output

1-29

Page 30

KD-LX333

HA13164A (IC961) : Regulator

1.Terminal layout

123456789101112131415

2.Block diagram

ANT OUT

C3

0.1u

EXT OUT

C4

0.1u

ANT CTRL

CTRL

CD OUT

C5

0.1u

AUDIO OUT

C6

10u

11

12

10

BATT.DET OUT

9

COMPOUT

6

VDD OUT

4

SW5VOUT

5

14

UNIT R:

+B

ACC

ILMOUT

R1

C7

0.1u

C8

0.1u

C1

100u

VCC ACC

8

2

1

7

Surge Protector

BIAS TSD

15

3

TAB

note1) TAB (header of IC)

connected to GND

ILM AJGND GND

13

C2

0.1u

C:F

1-30

3.Pin function

Pin No. Symbol Function

1

2

EXTOUT

ANTOUT

Output voltage is VCC-1 V when M or H level applied to CTRL pin.

Output voltage is VCC-1 V when M or H level to CTRL pin and H level

to ANT-CTRL.

3

4

5

6

7

8

9

10

11

12

13

14

15

ACCIN

VDDOUT

SW5VOUT

COMPOUT

ANT CTRL

VCC

BATT DET

AUDIO OUT

CTRL

CD OUT

ILM AJ

ILM OUT

GND

Connected to ACC.

Regular 5.7V.

Output voltage is 5V when M or H level applied to CTRL pin.

Output for ACC detector.

L:ANT output OFF , H:ANT output ON

Connected to VCC.

Low battery detect.

Output voltage is 9V when M or H level applied to CTRL pin.

L:BIAS OFF, M:BIAS ON, H:CD ON

Output voltage is 8V when H level applied to CTRL pin.

Adjustment pin for ILM output voltage.

Output voltage is 10V when M or H level applied to CTRL pin.

Connected to GND.

Page 31

KD-LX333

T

HD74HC126FP (IC771) : Changer control

OE1

A1

Y1

OE2

A2

Y2

Vss

1

2

3

4

5

6

7

HD74HC126

14

13

12

11

10

9

8

Vcc

OE4

A4

Y4

OE3

A3

Y3

NJM2100M (IC821) : Operational amp

A OUT

A IN–

A IN+

VEE

1

A

+–

2

B

+–

3

4

8

7

6

5

VCC

B OUT

B IN–

B IN+

NJM2904M (IC951) : Ope amp

1.Pin layout

1A OUT

2A -IN

8

7

+

V

B OU

M5282FP-X (IC321) : E. volume

1. Pin layout

1

2

3

4

5

3. Pin function

Pin

Symbol Function

No.

1

Vcc/2

2

Amp+IN

3

Amp-IN

4

Amp OUT

5

GND

6

7

VCA IN

8

9

VCA OUT

10

NC

Vc

Vcc

10

9

8

7

6

Vcc/2 output for microphone amp.

Microphone amp. positive input terminal.

Microphone amp. negative input terminal.

Microphone amp. output terminal.

Ground.

Non connection.

VCA input terminal.

VCA control terminal.

VCA output terminal.

Power supply.

2. Block diagram

3A +IN

4

10

1

2

3

457

9

8

6

5GND

B -IN

B +IN

1-31

Page 32

KD-LX333

LC75878W (IC601) : LCD driver

1. Pin layout

100 ~ 76

2. Block diagram

OSC

VLCD

VLCD0

VLCD1

VLCD2

VLCD3

VLCD4

VDD

VSS

1

~

25

26 ~ 50

P1

GENERAL

PORT

CLOCK

GENERATOR

CONTRAST

ADJUSTER

P4

75

~

51

COM1

COMMON

DRIVER

COM8

S75/COM9

S74/COM10

S73

SEGMENT DRIVER & LATCH

CONTROL

REGISTER

SHIFT REGISTER

CCB

INTERFACE

S1

3. Pin function

No. Symbol

1~73

74

75

76~83

84~87

88

89

90

91

92

93

94

95

96

97

98

99

100

1-32

SEG1~SEG73

SEG74

SEG75

COM8~COM1

P1~P4

VDD

VLCD

VLCD0

VLCD1

VLCD2

VLCD3

VLCD4

VSS

OSC

LCD RESET

CE

CL

DI

DI

INH

I/O

O

Segment driver output pin.

O

Segment driver output pin.

O

Segment driver output pin.

O

Common driver output pin.

O

General-purpose output pin.

-

Logic block power supply pin.

-

LCD driver power supply pin.

O

LCD driver bias 4/4 voltage (H-level) power pin.

I

LCD driver bias 3/4 voltage (intermediate level) power pin.

I

LCD driver bias 2/4 voltage (intermediate level) power pin.

I

LCD driver bias 1/4 voltage (intermediate level) power pin.

I

LCD driver bias 0/4 voltage (L-level) power pin.

-

Power supply pin to connect to ground.

I/O

Oscillator pin.

I

Display off, general-purpose output port L fixed input pin.

I

Chip enable

I

Synchronization clock

I

Transfer data

Function

CL

CE

Page 33

TB2118F-X (IC21) : PLL

1.Terminal Layout

2423222120191817161514

KD-LX333

13

2.Block diagram

osc

2

1

XO

24

XI

FM VCO

AMVCO

IFC

CE

DIN

CK

DOUT

15

16

13

3

4

5

6

123456789

Buff.

ON/OFF

OSC circuit

AMP

AMP

AMP

Serial

Interface

101112

Reference Counter

Prescaler

20-bit BINARY COUNTER

Resistor 1

Resistor 2

I/O PORT

Phase

Comparator

4-bit

Swallow counter

12-bit

Programmable counter

22-bit

40bit shift register

OUTPUT PORT

Constant

power supply voltage

switch

Vdd

Vcc

switch

AM CP.

20

+

+

-

RF

22

19

Vt

18

FM cp

3.Pin Function

Pin

Symbol I/O Function

No.

XOUT

10

11

12

1

2

3

4

5

6

7

8

9

OSC

CE

DI

CK

DOUT

SR

I/01

I/02

OUT1

OUT2

VDD2

Crystal oscillator pin

O

Non connect

Chip enable input

I

Serial data input

I

Clock input

I

Serial data output

O

Register control pin

O

I/O ports

I/O

I/O ports

I/O

Non connect

Non connect

Single power supply for REF. frequency block

-

7

SL

8

9

I/O -2I/O -1

10 11

12

out-2out-1

vdd2

Pin

Symbol I/O Function

No.

IFC

13

VDD

14

FMIN

15

AMIN

16

DGND

17

FMCP

18

Vt

19

AMCP

20

VCC

21

RF

22

AGND

23

XIN

24

17

14

IF signal input

I

Power pins for digital block

FM band local signal input

I

AM band local signal input

I

Connect to GND (for digital circuit)

Charge pump output for FM

O

Tuning voltage biased to 2.5V.

Charge pump output for AM

O

Power pins for analog block

Ripple filter connecting pin

I

Connect to GND (for analog circuit)

Crystal oscillator pin

I

21

23

a-gnd

vccd-gndvdd

1-33

Page 34

KD-LX333

VICTOR COMPANY OF JAPAN, LIMITED

MOBILE ELECTRONICS DIVISION

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.49722)

200206

Loading...

Loading...