Page 1

SERVICE MANUAL

DVD/CD RECEIVER

MA17520052

KD-DV6104,KD-DV6103

Area suffix

UI ---------------------------- India

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MA175

2005/2

Page 2

SPECIFICATION

AUDIO AMPLIFIER SECTION

Maximum Power Output Front 50 W per channel

Rear 50 W per channel

Continuous Power Output (RMS) Front 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Frequencies 60 Hz, 150 Hz, 400 Hz, 1 kHz, 2.4 kHz, 6 kHz, 15 kHz

Level ±10 dB

Signal-to-Noise Ratio 70 dB

Audio Output Level Analog (2nd AUDIO OUT) 6 mW (at 16 Ω)

Digital (DIGITAL OUT: Optical) Signal wave length : 660 nm

Output level : -21 dBm to -15 dBm

Line-Out Level/Impedance 5.0 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Subwoofer-Out Level/Impedance 2.0 V/20 kΩ load (full scale)

Color System PAL/NTSC

Video Output (composite) 1 Vp-p/75 Ω

Other Terminals LINE IN, CD changer

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

AM 531 kHz to 1 602 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Capture Ratio 1.5 dB

AM Tuner Sensitivity 20 µV

Selectivity 35 dB

DVD/CD PLAYER SECTION

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

VCD, CD, MP3, WMA 16 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 (MPEG Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media Audio) Max. Bit Rate: 192 kbps

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 158 mm

Panel Size (approx.) 188 mm × 58 mm × 11 mm

Mass (approx.) 1.7 kg (excluding accessories)

Design and specifications are subject to change without notice.

1-2 (No.MA175)

Page 3

1.1 Safety Precautions

SECTION 1

PRECAUTIONS

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

(No.MA175)1-3

Page 4

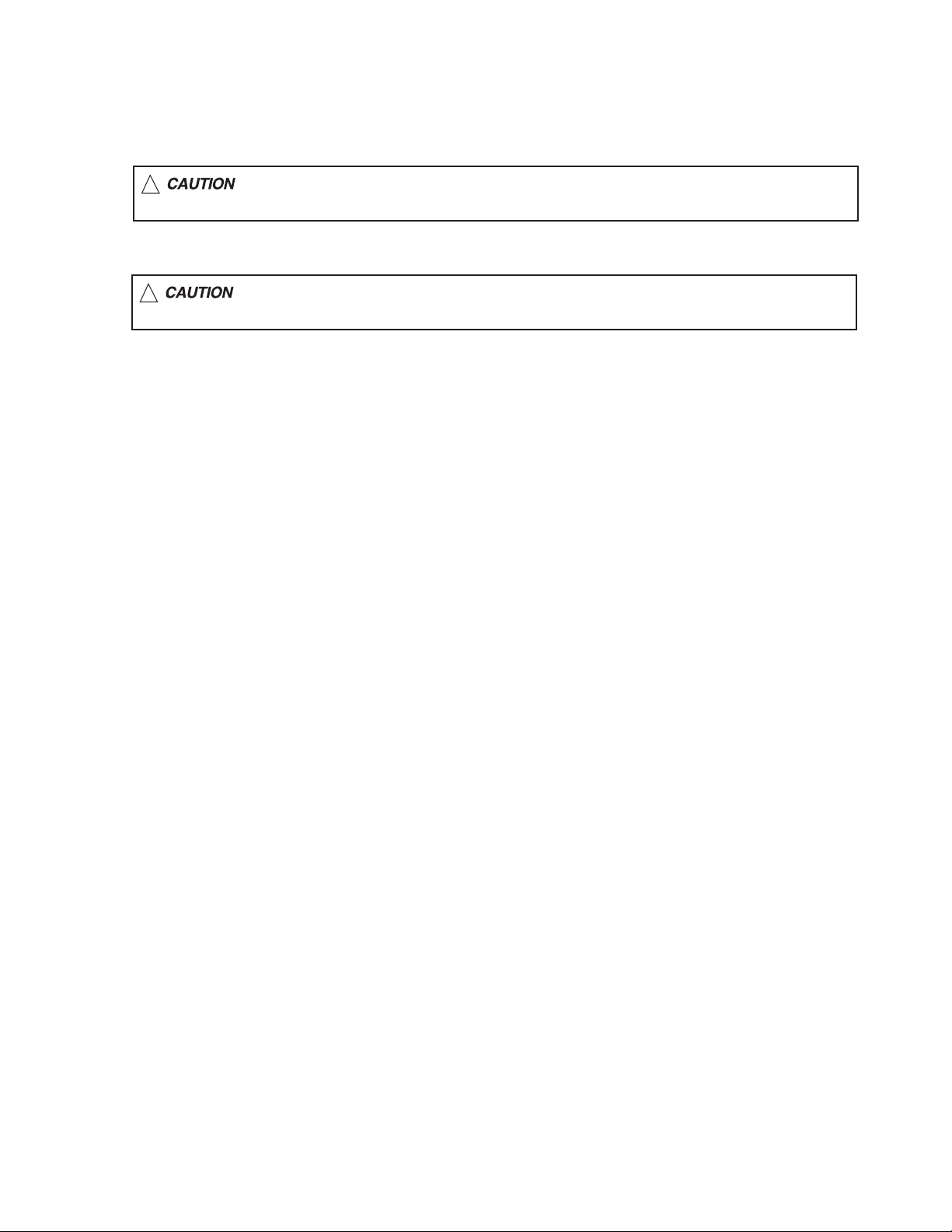

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

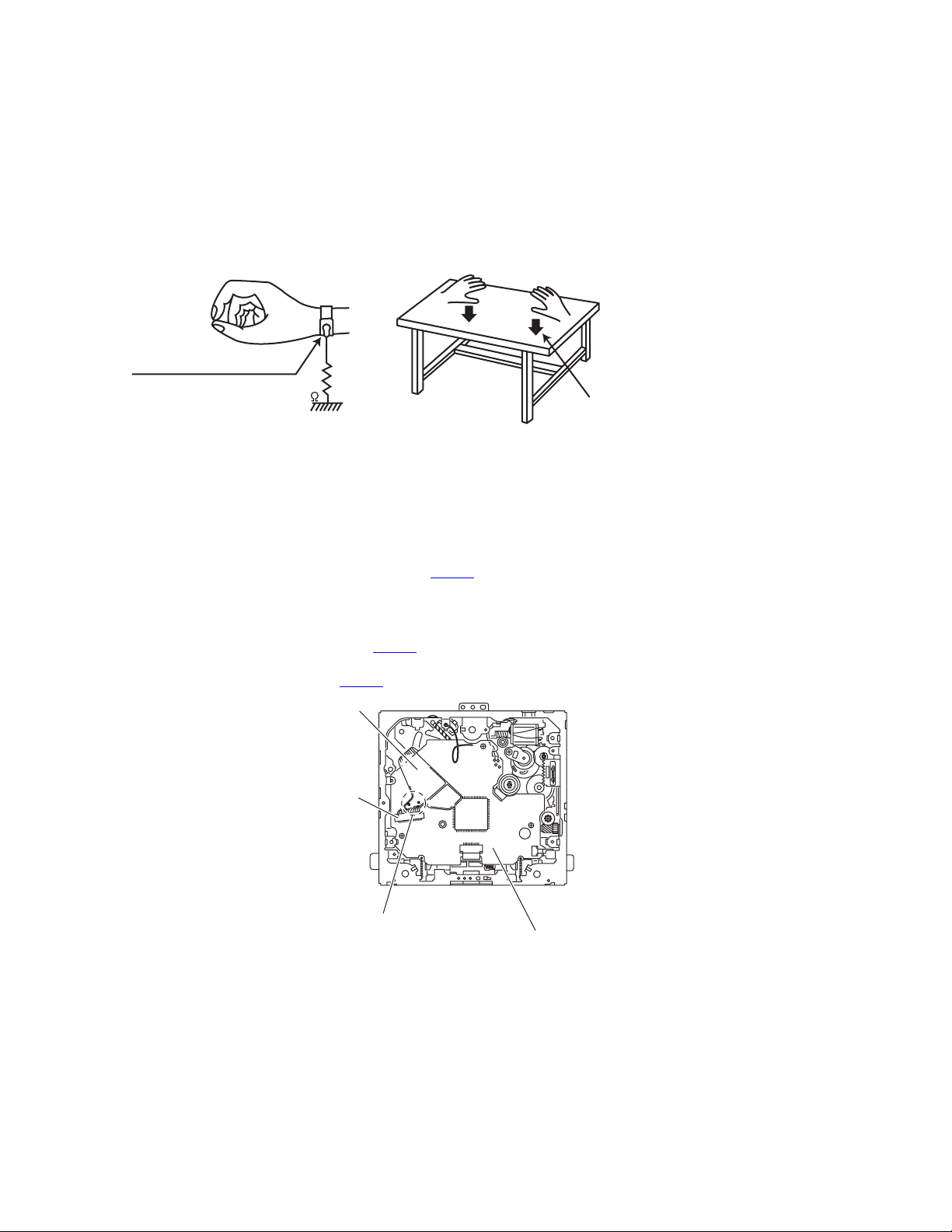

1.3 Handling the traverse unit (optical pickup)

(1) Before disconnecting the flexible wire from the connector CN101

on the flexible wire.

Caution:

If you do not follow this instruction, the DVD pickup may be damaged.

(2) Disconnect the flexible wire from the connector CN101

(3) Remove the solders from the short-circuit points on the flexible wire after replacing the DVD pickup.

(4) Connect the flexible wire to the connector CN101

Flexible wire

CN101

on the mechanism control board.

on the mechanism control board.

on the mechanism control board, solder the short-circuit points

1-4 (No.MA175)

Short-circuit points

Mechanism control board

Page 5

1.4 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CAUTION : Visible and Invisible

CLASS 1

LASER PRODUCT

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

(No.MA175)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MA175)

Page 7

SECTION 3

DISASSEMBLY

3.1 Main body section

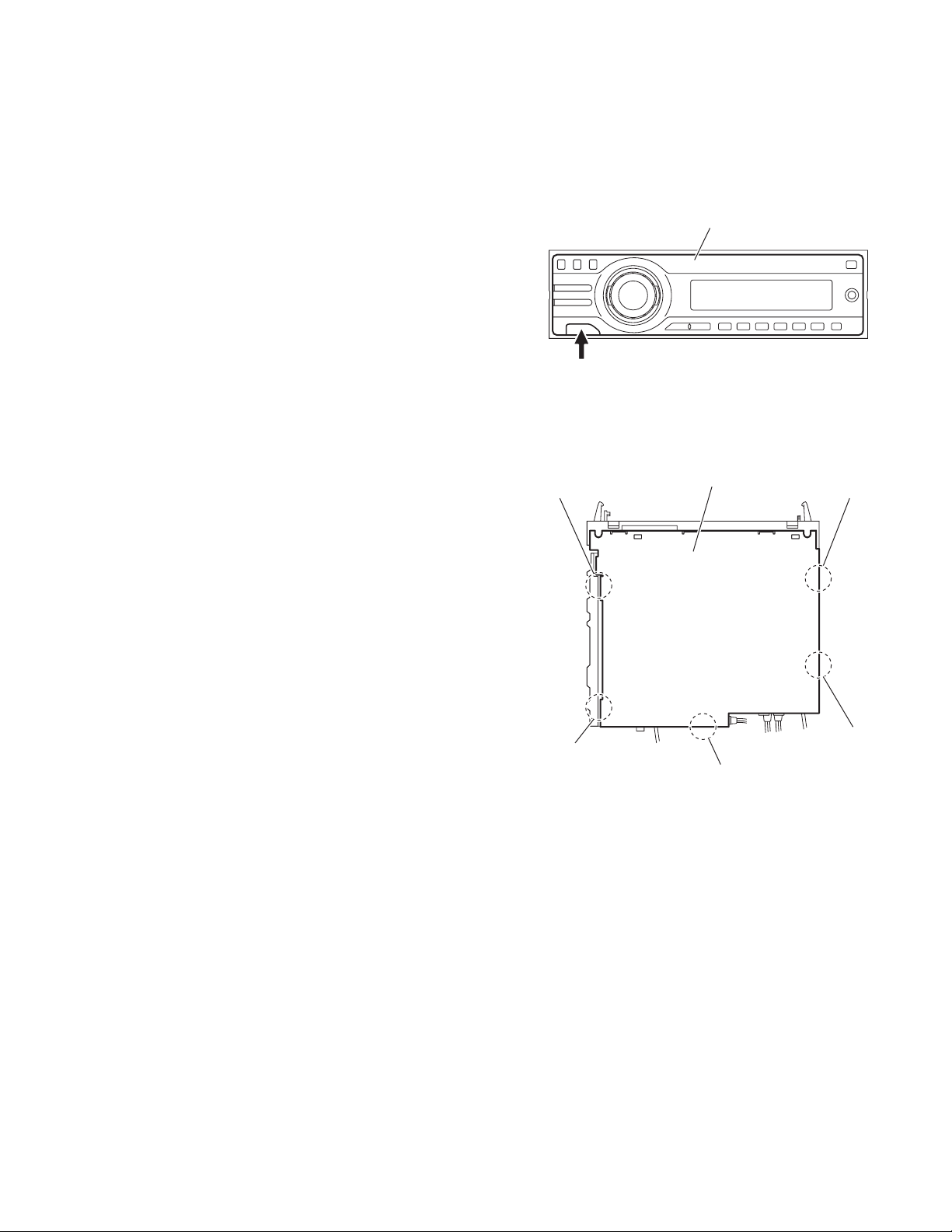

3.1.1 Removing the front panel assembly

(See Fig.1)

Push the detach button in the lower left part of the front panel assembly and remove the front panel assembly.

3.1.2 Removing the bottom cover

(See Fig.2)

Reference:

Remove the front panel assembly as required.

(1) Release the two joints a, two joints b and joint c.

(2) Remove the bottom cover from the main body.

Caution:

Do not damage the main board when releasing the joints using

a screwdriver or a similar tool.

Detach button

b

Front panel assembly

Fig.1

Bottom cover

a

a

b

c

Fig.2

(No.MA175)1-7

Page 8

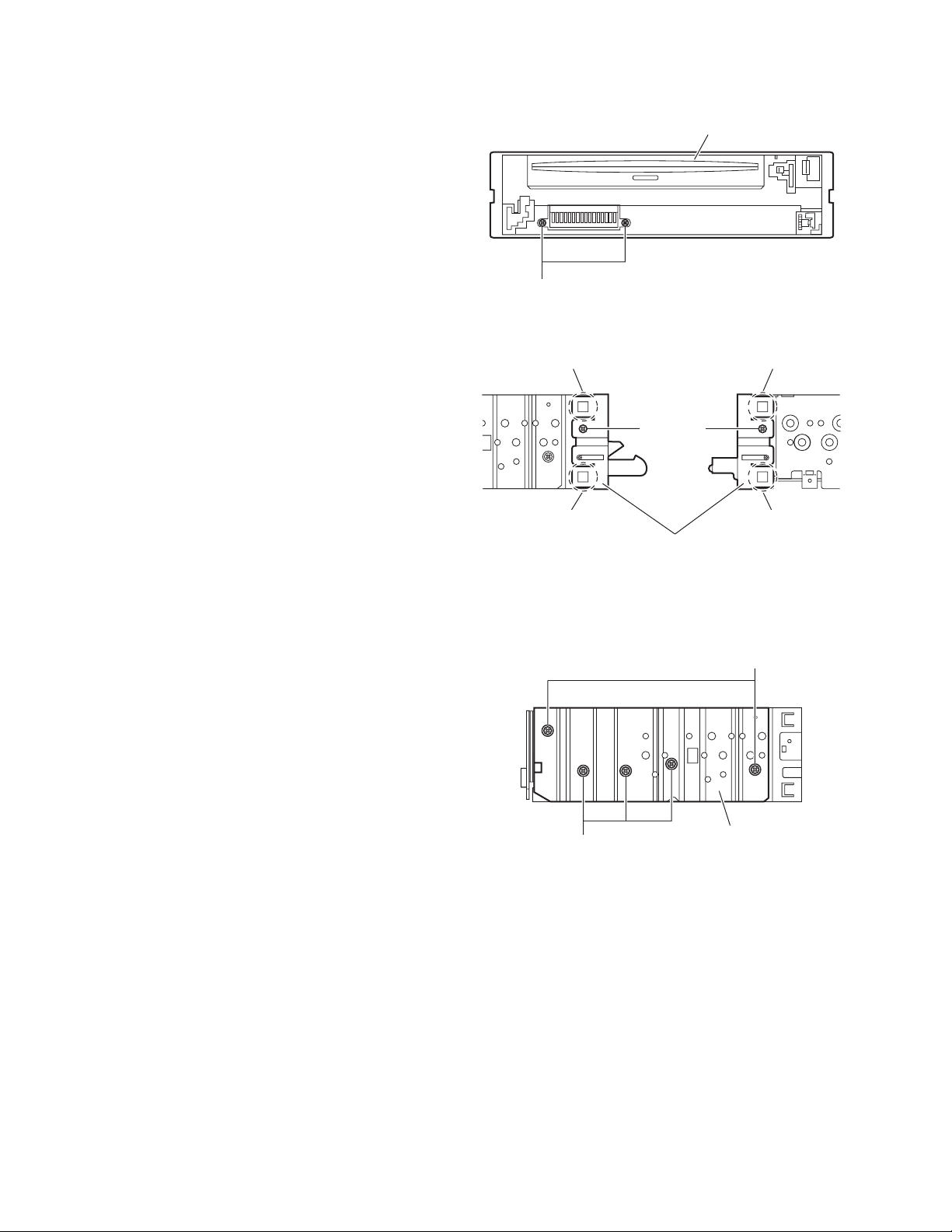

3.1.3 Removing the front chassis assembly

(See Figs.3 and 4)

• Remove the front panel assembly and bottom cover.

(1) From the front side of the main body, remove the two

screws A attaching the front chassis assembly. (See

Fig.3.)

(2) From the both sides of the main body, remove the two

screws B attaching the front chassis assembly. (See

Fig.4.)

(3) Release the two joints d and two joints e. (See Fig.4.)

Front chassis assembly

A

Fig.3

3.1.4 Removing the side heat sink

(See Fig.5)

Reference:

Remove the front panel and front chassis assemblies as re-

quired.

From the left side of the main body, remove the two screws C and

three screws D attaching the side heat sink.

d

B

d

Front chassis assembly

Fig.4

e

B

e

C

1-8 (No.MA175)

D

Side heat sink

Fig.5

Page 9

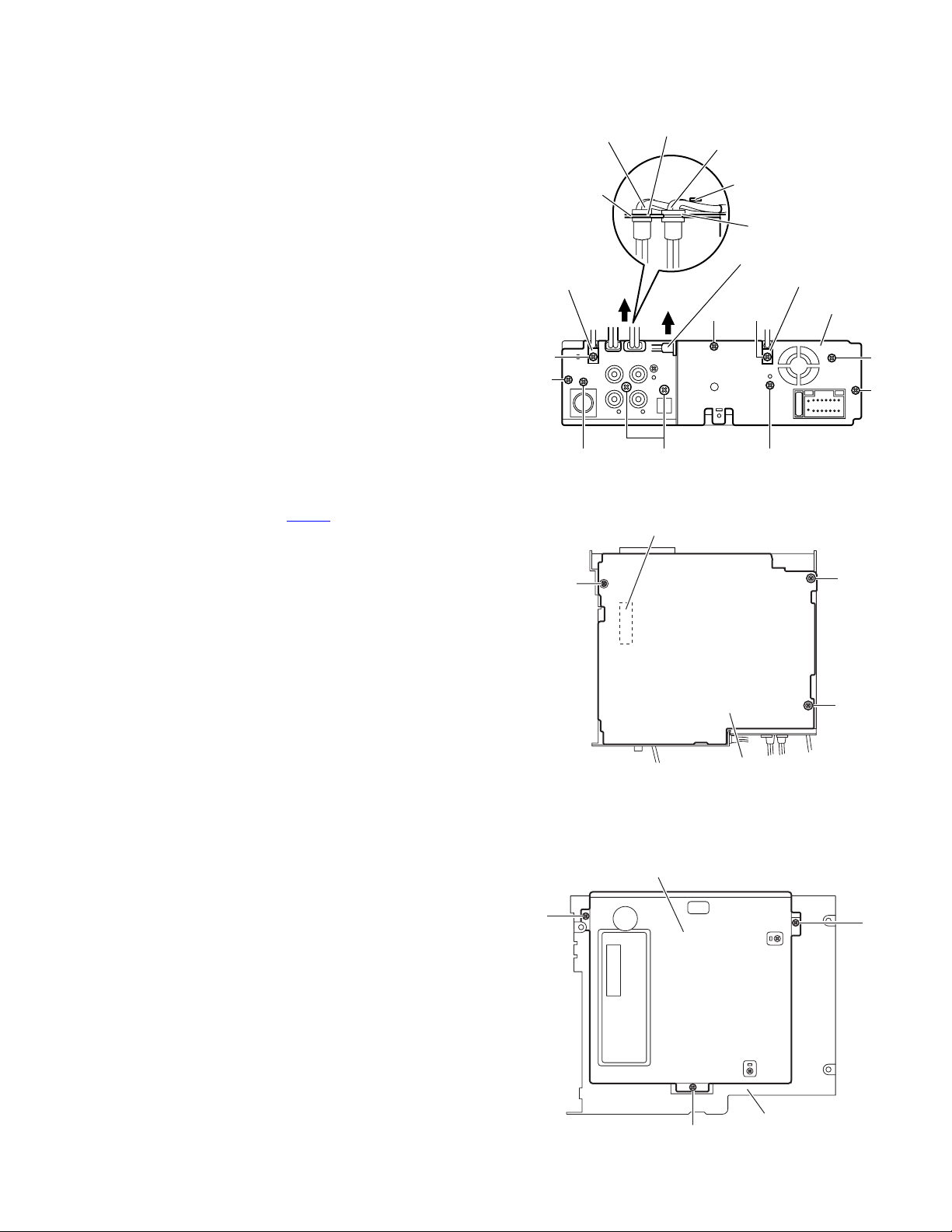

3.1.5 Removing the rear bracket

(See Fig.6)

• Remove the bottom cover.

(1) From the back side of the main body, remove the two

screws E, two screws E', screw F, two screws G and three

screws H attaching the rear bracket.

(2) Remove the LINE IN, SUBWOOFER and AUDIO OUT ca-

bles from the rear bracket in the direction of the arrow.

Reference:

• When attaching the LINE IN and SUBWOOFER cables, insert them in the slots of the rear bracket and hang them on

a wire holder.

• When attaching the screws E', attach the cable holders with

them.

3.1.6 Removing the main board

(See Figs.6 and 7)

• Remove the front panel assembly, bottom cover, front chassis

assembly and side heat sink.

Reference:

Remove the rear bracket as required.

(1) From the back side of the main body, remove the three

screws H attaching the main board. (See Fig.6.)

(2) From the bottom side of the main body, remove the three

screws J attaching the main board. (See Fig.7.)

(3) Disconnect the connector CN961

the DVD mechanism assembly and take out the main

board from the main body. (See Fig.7.)

on the main board from

SUBWOOFER cable

Rear bracket

Cable holder

E'

H

F

CN961

G

Slot

LINE IN cable

Wire holder

AUDIO OUT cable

HEE'

Fig.6

Slot

Cable holder

Rear bracket

E

H

3.1.7 Removing the DVD mechanism assembly

(See Fig.8)

• Remove the front panel assembly, bottom cover, front chassis

assembly, side heat sink and main board.

(1) From the inside of the top chassis, remove the three

screws K attaching the DVD mechanism assembly.

(2) Take out the DVD mechanism assembly from the top chas-

sis.

J

DVD mechanism assembly

K

J

J

Main board

Fig.7

K

K

Fig.8

Top chassis

(No.MA175)1-9

Page 10

3.1.8 Removing the main sub board

(See Figs.9 to 11)

• Remove the front panel assembly, bottom cover, front chassis

assembly, side heat sink, main board and DVD mechanism assembly.

(1) From the top side of the DVD mechanism assembly, re-

move the two screws L attaching the dust cover. (See

Fig.9.)

(2) Remove the dust cover from the DVD mechanism assem-

bly. (See Fig.9.)

Reference:

When attaching the dust cover, align the joints f in the

holes of the dust cover before attaching the screws L.

(See Fig.9.)

(3) Release the lock of the connector CN962

board and disconnect the card wire. (See Fig.10.)

(4) Bend the joint g in the direction of the arrow. (See Fig.10.)

(5) Remove the two screws M attaching the main sub board

and remove the main sub board from the DVD mechanism

assembly. (See Fig.10.)

Reference:

• When attaching the main sub board, align the joints h in the

holes of the main sub board before attaching the screws M.

(See Fig.10.)

• When the resolution of DVD mechanism assembly is done

sequentially, remove the two screws N attaching the support

bracket. (See Fig.11.)

• Remove the card wire from the connector CN401

quired. (See Fig.11.)

on the main sub

as re-

DVD mechanism assembly

Dust cover

Fig.9

DVD mechanism assembly

CN962

h

L

Lock

f

L

f

g

M

N

h

Main sub board

Fig.10

Support bracket

Fig.11

Card wire

CN401

Card wire

1-10 (No.MA175)

Page 11

3.1.9 Removing the switch board

(See Figs. 12 to 14)

• Remove the front panel assembly.

(1) From the back side of the front panel assembly, remove the

five screws P attaching the rear cover. (See Fig.12.)

(2) Release the ten joints i attaching the rear cover to the front

panel assembly. (See Fig.13.)

(3) Take out the switch board while lifting the switch board

from the front panel assembly little by little. (See Fig.14.)

Reference:

Remove the volume knob from the front side of the front panel

assembly at the same time.

Note:

Do not lose the compression springs when removing the

switch board. (See Fig.14.)

Rear cover

P

Front panel assembly

P

P

Fig.12

i

i

Rear cover

Switch board

Compression spring

i

i

Fig.13

Front panel assembly

Compression spring

Fig.14

(No.MA175)1-11

Page 12

3.2 DVD mechanism assembly

3.2.1 Removing the mechanism control board

(See Fig.1)

Caution:

Before disconnecting the flexible wire extending from the DVD

pickup, solder the short-circuit point on the flexible wire using

a grounding soldering iron. If you do not follow this instruction,

the DVD pickup may be damaged.

(1) Turn over the body, and solder the short-circuit points on

the flexible wire extending from the DVD pickup.

(2) Disconnect the flexible wire from connector CN101

mechanism control board.

(3) Disconnect the card wire from connector CN201

mechanism control board.

(4) Disconnect the flexible wire from connector CN202

mechanism control board.

(5) Unsolder two soldered points a on the mechanism control

board and remove the wire extending from the feed motor.

(6) Remove the screw A attaching the lug wire.

(7) Remove the two screws B and screw C attaching the

mechanism control board.

Caution:

• As the flexible wire to be connected to CN101

attach it to the mechanism control board using a double

tape.

• After reassembling, unsolder the short-circuit points.

on the

on the

on the

, make sure to

Flexible wire

Double tape

CN101

B

Short-circuit points

A

Lug wire

B

CN201

Feed motor

a

C

CN202

Mechanism control board

Fig.1

1-12 (No.MA175)

Page 13

3.2.2 Removing the top cover

(See Fig.2)

(1) Remove the two screws D attaching the top cover on the

back of the body.

(2) Remove the top cover upward.

Reference:

When reassembling, set part b of the top cover under the

bending part c of the chassis frame.

3.2.3 Removing the mechanism section

(See Fig.2 to 4)

• Remove the top cover.

(1) From the bottom of the body, remove the screw E attaching

the lug wire. (See Fig.2.)

(2) Remove the two screws F attaching the right and left stop-

pers on the front side. (See Fig.2.)

(3) Remove the two floating springs on the bottom of the body.

(See Fig.3.)

(4) Move the mechanism section upward and remove from the

chassis frame.

The three damper springs come off from the dampers.

(See Fig.4.)

Caution:

• When reassembling, reattach the damper spring to the

damper respectively and insert the three shafts on the bottom of the mechanism to the dampers.

• Before inserting the shaft to the dampers, apply IPA to the

hole of damper.

Floating spring

Fig.3

Mechanism section

Stopper

F

Top cover

Stopper

F

D

D

b

c

E

Lug wire

Damper SP.(F)

(Silver)

Damper (F)

(Black)

Damper SP.(F)

(Silver)

Damper (F)

(Black)

Fig.4

Damper SP.(R)

(Red)

Damper (R)

(Purple)

Chassis frame

Fig.2

(No.MA175)1-13

Page 14

3.2.4 Removing the clamper unit

(See Fig.5 to 7)

• Remove the top cover and the mechanism section.

(1) Remove the clamper2 spring on the bottom of the mecha-

nism section. (See Figs.5.and 6.)

(2) Release the part d of the clamper spring from the bending

part of the chassis base assembly. (See Fig.7.)

(3) Move the clamper unit in the direction of the arrow and turn.

Release the two joints e and f, then remove the clamper

unit upward. (See Fig.6.)

3.2.5 Reattaching the clamper unit

(See Fig.5 to 9)

(1) Attach the clamper spring to the clamper unit. (See Fig.8.)

(2) Move the clamper unit to set the side joints e and f to each

boss of the chassis base assembly. Make sure that part g

is inserted to the notch of the chassis base assembly. (See

Figs.5 and 9.)

(3) Move the part d of the clamper spring to the outside of the

bending part of the chassis base assembly. (See Fig.7.)

(4) Attach the clamper2 spring to the chassis base assembly.

(See Figs.5 and 6.)

Caution:

When reattaching, temporarily hook the end of the clamper

spring as shown in the figure to make the work easy. (See

Fig.8.)

Clamper unit

Clamper2 spring

Chassis base assembly

Fig.6

Clamper spring

Clamper spring

f

Clamper2 spring

Chassis base assembly

g

d

Chassis base assembly

Fig.7

e

Fig.5

1-14 (No.MA175)

Page 15

Clamper unit

Clamper unit

Clamper spring

Fig.8

Fig.9

g

Notch

(No.MA175)1-15

Page 16

3.2.6 Removing the front unit

(See Fig.10 to 12)

• Remove the top cover and the mechanism section.

(1) Disconnect the flexible wire from connector CN202 on the

mechanism control board at the bottom of the body. (See

Fig.10.)

(2) Remove the screw G attaching the front unit on the top of

the body. (See Fig.11.)

(3) Move the front unit toward the front to release joint h, and

release two joints i and j on the right side of the chassis

base assembly. Then remove the front unit upward. (See

Figs.11 and 12.)

(4) Remove the two screws H attaching the switch board. (See

Fig.12.)

Reference:

You can remove the switch board only without removing the

front unit.

Caution:

When reassembling, attach the flexible wire extending from

the switch board using the double tape. (See Figs.10 and 12.)

Mechanism control board

G

Front unit

h

Fig.11

CN202

Double tape

Fig.10

Flexible wire

Double tape

j

i

H

Switch board

Front unit

G

1-16 (No.MA175)

h

Fig.12

Page 17

3.2.7 Removing the loading arm assembly

(See Fig.13 , 14)

• Remove the top cover, the mechanism section and the front

unit.

(1) From the top of the body, move the loading arm assembly

from the front side upward, and release the bosses from

the right and left joints k and m of the chassis base assembly.

(2) Release the boss from notch n of the connect arm on the

right side of the body, and release the boss from notch p of

the slide cam assembly on the left side.

m

Loading arm assembly

Side cam

assembly

p

m

k

Fig.13

Loading arm assembly

k

n

n

Connect arm

Fig.14

(No.MA175)1-17

Page 18

3.2.8 Removing the rod (L)(R)/roller assembly

(See Fig.15 and 16)

• Remove the top cover, the mechanism section, the front unit

and the loading arm assembly.

(1) Release the rod (L) and (R) from the joints q at the bottom

of the loading arm assembly (See Fig.15.)

(2) Remove the roller assembly from the loading arm assem-

bly. (See Fig.16.)

(3) Remove the two collars and washer from the roller assem-

bly. (See Fig.16.)

Caution:

After attaching the loading arm assembly to the roller assembly, attach the rod (L) and (R). Attach the rods to the right and

left collars of the roller. (See Fig.15.)

When reattaching the rod (L) and (R) to the loading arm assembly, engage each joint as shown in Fig.15. As joints q of

the rod (L), let the rod through q before reattaching it.

Collar

Collar

Rod(R) Rod(L)

q

q

q

Collar

Rod(L)

Rod(R)

q

Loading arm assembly

Fig.15

Roller assembly

Loading arm assembly

q

Rod(L)

q

Collar

Washer

Rod(R)

1-18 (No.MA175)

Fig.16

Page 19

3.2.9 Removing the DVD pickup assembly

(See Fig.17 to 19)

• Remove the mechanism control board.

(1) From the bottom of the body, turn the feed gear in the di-

rection of the arrow to move the DVD pickup outwards.

(See Fig.17.)

(2) Remove the screw J attaching the thrust spring. (See

Fig.17.)

(3) Remove the DVD pickup assembly upward on the L.S.gear

side and release from sub shaft at joint r. Move the lead

screw of the DVD pickup assembly in the direction of the

arrow to release from joint s. (See Fig.18.)

Caution:

• When releasing the lead screw at joint s, the L.S.collar

comes off at the end of the lead screw. When reassembling, reattach the L.S.collar to the lead screw and

engage joint s. (See Fig.18.)

• When reattaching the L.S.collar, reattach it to the point

s of the lead screw, and to the rod (M). Make sure that

the L.S.collar is set on the rod (M) spring. (See Fig.18.)

(4) Remove the screw K attaching the rack spring/ rack plate

on the DVD pickup. (See Fig.19.)

(5) Pull out the lead screw. (See Fig.19.)

Caution:

Perform adjustment after replacing the pickup.

DVD Pickup assembly

DVD Pickup assembly

Feed gear

J

Thrust spring

Fig.17

s

L.S.collar

Rod(M)

Lead screw

Sub shaft

L.S.collar

r

L.S.gear

Fig.18

K

Rack spring

Lead screw

Rack plate

DVD Pickup

Fig.19

(No.MA175)1-19

Page 20

3.2.10 Removing the spindle motor

r

(See Fig.20)

• Remove the mechanism control board.

Remove the two screws L attaching the spindle motor on the

bottom of the body.

Caution:

Perform adjustment when reattaching the spindle motor.

3.2.11 Removing the feed motor assembly

(See Fig.21 and 22)

• Remove the mechanism control board.

(1) Remove the feed TRI. spring on the bottom of the body.

(See Fig.21.)

(2) Remove the two screws M attaching the feed motor as-

sembly. (See Fig.21.)

(3) Remove the slit washer from the motor H. assembly and

pull out the worm wheel. (See Fig.22.)

Remove the two screws N attaching the feed motor. (See

Fig.22.)

Spindle motor

Feed TRI. spring

L

Fig.20

M

Feed motor assembly

1-20 (No.MA175)

Fig.21

Slit washer

Worm wheel

Feed moto

N

Motor H. assembly

Fig.22

Page 21

SECTION 4

ADJUSTMENT

4.1 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Jitter meter

(3) Digital tester

(4) Electric voltmeter

(5) Tracking offset meter

(6) Test Disc : VT501 or VT502

(7) Extension studs : STDV001-3P

(8) Extension cable : EXTDV002-30P

4.3 Connection method

Connection procedure

(1) Attach the front chassis assembly to the main board.

(2) Connect the front panel assembly to the main board.

(3) Attach the heat sink and rear bracket to the main board.

(4) Attach the extension studs to the DVD mechanism assembly.

(5) Connect the DVD mechanism assembly and the main board with a extension cable.

4.2 Standard measuring conditions

Power supply voltage DC14.4V(11 to 16V)

Load impedance 4Ω(2 Speakers connection)

Line Output 20KΩ

Caution:

Be sure to attach the heat sink and rear bracket onto the power

amplifier IC and regulator IC respectively, before supply the

power. If voltage is applied without attaching these parts, the

power amplifier IC and regulator IC will be destroyed by heat.

Extension cable

EXTDV002-30P

Heat sink

Rear bracket

Main board

Extension stud

STDV001-3P

Extension studs

STDV001-3P

(No.MA175)1-21

Page 22

After replacing the pickup, set the unit in the service mode to display a jitter value on the LCD. Confirm that the jitter value measured

with a jitter meter is within 12% of the jitter value displayed on the LCD. If it is within 12%, then adjustment is not necessary. Please

note that a jitter value displayed on the LCD is hex data. Refer to the corresponding decimal notation value using the Jitter Conversion

Table and confirm it with the measured value.

Fix the screws "a", "b" and "c" with screw lock paint.

If the measured jitter value is outside the 12% tolerance range, perform the following adjustments.

c

b

a

Jitter value adjustment procedure (Pickup horizontal level adjustment relative to the DVD recording surface)

(For the adjustment tool use a 3 mm wrench and not a screwdriver, this procedure will make the adjustment easier.)

3 mm wrench

(1) Set the unit to the service mode and display a jitter value (hex data) on the LCD.

(2) Turn each of the screws a, b and c, by a half-turn per step, in the direction that reduces the jitter value in order to minimize it.

(Do not turn a screw more than a half turn at a time, but adjust the screws in the cycle of a → b → c → d → a.)

(3) After completing the adjustment, secure the screws with screw lock paint.

1-22 (No.MA175)

Page 23

4.4 Jitter value conversion table

Load the test DVD and set the unit to the service mode. A jitter value converted to the hex value is displayed on the LCD. Refer to the

corresponding decimal notation value shown in the following Jitter Conversion Table.

The adjustment is OK if the jitter value measured with a jitter meter is within 12% of the jitter value displayed on the LCD.

If the measured jitter value is outside the 12% tolerance range, adjust it to minimize the difference between the measured value and

the displayed value.

Indicated

on the LCD

20A7

2072

203D

2008

1FD2

1F9D

1F68

1F33

1EFE

1EC8

1E93

1E5E

1E29

1DF4

1DBE

1D89

1D54

1D1F

1CEA

1CB4

1C7F

1C4A

1C15

1BE0

1BAA

1B75

1B40

1B0B

1AD6

1AA0

1A6B

1A36

1A01

19CC

1996

1961

192C

18F7

JIT OUT

1957.98

1955.32

1952.66

1950

1947.34

1944.68

1942.02

1939.36

1936.7

1934.04

1931.38

1928.72

1926.06

1923.4

1920.74

1918.08

1915.42

1912.76

1910.1

1907.44

1904.78

1902.12

1899.46

1896.8

1894.14

1891.48

1888.82

1886.16

1883.5

1880.84

1878.18

1875.52

1872.86

1870.2

1867.54

1864.88

1862.22

1859.56

Jitter value

(%)

4.7

3818

4.8

3825

4.9

3832

5.0

3840

5.1

384D

5.2

385A

5.3

3867

5.4

3875

5.5

3882

5.6

388F

5.7

389D

5.8

38AA

5.9

38B7

6.0

38C5

6.1

38D2

6.2

38DF

6.3

38EC

6.4

38FA

6.5

3907

6.6

3914

6.7

3922

6.8

392F

6.9

393C

7.0

394A

7.1

3957

3964

7.2

3971

7.3

397F

7.4

398C

7.5

3999

7.6

39A7

7.7

39B4

7.8

39C1

7.9

39CF

8.0

39DC

8.1

39E9

8.2

39F6

8.3

3A04

8.4

Indicated

on the LCD

18C2

188C

1857

1822

17ED

17B8

1782

174D

1718

16E3

16AE

1678

1643

160E

15D9

15A4

156E

1539

1504

14CF

149A

1464

142F

13FA

13C5

1390

135A

1325

12F0

12BB

1286

1250

121B

11E6

11B1

117C

1146

1111

JIT OUT

1856.9

1854.24

1851.58

1848.92

1846.26

1843.6

1840.94

1838.28

1835.62

1832.96

1830.3

1827.64

1824.98

1822.32

1819.66

1817

1814.34

1811.68

1809.02

1806.36

1803.7

1801.04

1798.38

1795.72

1793.06

1790.4

1787.74

1785.08

1782.42

1779.76

1777.1

1774.44

1771.78

1769.12

1766.46

1763.8

1761.14

1758.48

Jitter value

(%)

3A11

8.5

3A1E

8.6

3A2C

8.7

3A39

8.8

3A46

8.9

3A54

9.0

3A61

9.1

3A6E

9.2

3A7B

9.3

3A89

9.4

3A96

9.5

3AA3

9.6

3AB1

9.7

3ABE

9.8

3ACB

9.9

3AD9

10.0

3AE6

10.1

3AF3

10.2

3B00

10.3

3B0E

10.4

3B1B

10.5

3B28

10.6

3B36

10.7

3B43

10.8

3B50

10.9

3B5E

11.0

3B6B

11.1

3B78

11.2

3B85

11.3

3B93

11.4

3BA0

11.5

3BAD

11.6

3BBB

11.7

3BC8

11.8

3BD5

11.9

3BE3

12.0

3BF0

12.1

3BFD

12.2

Indicated

on the LCD

10DC

10A7

1072

103C

1007

FD2

F9D

F68

F32

EFD

EC8

E93

E5E

E28

DF3

DBE

D89

D54

D1E

CE9

CB4

C7F

C4A

C14

BDF

BAA

B75

B40

B0A

AD5

AA0

A6B

A36

A00

9CB

996

961

92C

JIT OUT

1755.82

1753.16

1750.5

1747.84

1745.18

1742.52

1739.86

1737.2

1734.54

1731.88

1729.22

1726.56

1723.9

1721.24

1718.58

1715.92

1713.26

1710.6

1707.94

1705.28

1702.62

1699.96

1697.3

1694.64

1691.98

1689.32

1686.66

1684

1681.34

1678.68

1676.02

1673.36

1670.7

1668.04

1665.38

1662.72

1660.06

1657.4

Jitter value

(%)

12.3

3C0A

12.4

3C18

12.5

3C25

12.6

3C32

12.7

3C40

12.8

3C4D

12.9

3C5A

13.0

3C68

13.1

3C75

13.2

3C82

13.3

3C8F

13.4

3C9D

13.5

3CAA

13.6

3CB7

13.7

3CC5

13.8

3CD2

13.9

3CDF

14.0

3CED

14.1

3CFA

14.2

3D07

14.3

3D14

14.4

3D22

14.5

3D2F

14.6

3D3C

14.7

3D4A

14.8

3D57

3D64

14.9

3D72

15.0

3D7F

15.1

3D8C

15.2

3D99

15.3

3DA7

15.4

3DB4

15.5

3DC1

15.6

3DCF

15.7

3DDC

15.8

3DE9

15.9

3DF7

16.0

(No.MA175)1-23

Page 24

4.5 Service mode

4.5.1 Standard input/output conditions

Power supply voltage DC14.4V(11 to 16V)

Load impedance 4Ω(2 Speakers connection)

Line Output 20KΩ

4.5.2 Service mode setting procedure

(The DVD does not need to be loaded before starting the following procedure.)

[SEL] button

[STANDBY/ON ATTENUATOR] button

[DISC UP] button

[DISC DOWN] button

(1) Press a [STANDBY/ON ATTENUATOR] button on a main unit and switch it on.

(2) Keep this state more than 2 seconds while continuing pressing the [SEL] button, [STANDBY/ON ATTENUATOR] button and

[SOURCE] button sequentially.

(3) This unit is set by a service mode.

*Exchanging it operate a menu of a service mode with the [DISC UP] button and [DISC DOWN] button.

Operate choice of a menu with a [SEL] button.

[SOURCE] button

1-24 (No.MA175)

Page 25

4.5.3 Operation procedures

Keep this state more than 2 seconds while

continuing pressing the [SEL] button,

[STANDBY/ON ATTENUATOR] button and

[SOURCE] button sequentially.

The unit enters the service mode.

"INIT ALL" is

indicated on the LCD.

"VERSION" is

indicated on the LCD.

"AREA/RGN" is

indicated on the LCD.

"VIDEO" is

indicated on the LCD.

Press the [SEL] key

Press the [SEL] key

Press the [SEL] key

Press the [SEL] key

Initialize all data to the factory setting

: The system control EEPROM is initialized entirely.

Microcomputer version display

************

************

Exchanging it operate each indication with the

[DISC UP] button and [DISC DOWN] button.

Destination area/region display

************

************

************

Exchanging it operate each indication with the

[DISC UP] button and [DISC DOWN] button.

Setting of NTSC or PAL

"NTSC" or "PAL" are indicated on the LCD.

Exchanging it operate each indication with the

[DISC UP] button and [DISC DOWN] button.

System control microcomputer version

DVD version

System control destination

DVD unit destination

DVD unit region

Note:

There is the model that is not equipped with

this mode by a version.

"CLR ERR" is

indicated on the LCD.

A B

Press the [SEL] key

Clear loading/ejection error history

: The error history stored in the EEPROM is cleared.

(No.MA175)1-25

Page 26

A B

"CD ERROR" is

indicated on the LCD.

Frror code (1 byte)

First byte [01] Eject error

Detailed error codes (2 bytes) Displayed with loading/ejection errors only.

First byte

Second byte

(Example) When a switch status error occurs during loading route 3 and

the switch status is L/L/H/H/H (00111B = 07H), the error code

and detailed error code become: [09 3207].

Press the [SEL] key

[09] Loading error

Higher 4 bits

Lower 4 bits

[1] Time out

[2] Switch status error

[3] Swinging error

bit7

bit6,5

bit4

bit3

bit2

bit1

bit0

Route No. (EJECT route No.)

-

1(2)

1(2)

Read loading and ejection error history

: The error history saved in the system control

is read and displayed.

TOT-xxxx : Total error count.

Total error count

(A figure between 0 and 9999 is

displayed. 10000 or more is also

displayed as 9999.)

Enyyzzzz : Latest three error codes.

Detailed error code

Error code

Counter

0nyyzzzz : First five error codes

Detailed error code

Error code

Counter

Exchanging it operate each indication with the

[DISC UP] button and [DISC DOWN] button.

Route No. (Process of error occurrence)

Refer to charts 1.1 and 1.2.

Error type

Disc type (0: 12 cm. 1: 8 cm)

Fixed at 0

SW1 status

SW2 status

SW3 status

SW4 status

REST SW status

SW1/2/3/4

1,1,1,1

0,1,1,1

0,0,1,1

[Rest SW]

[0]

[0]

[0]

Loading

No Disc

Disc insert

detection

Eject

No Disc

Eject

completion

Reload

Disc push in

C D

1-26 (No.MA175)

2(2)

2(2)

2(2)

2(2)

3(1)

3(1)

0,0,0,1

0,0,1,1

0,1,1,1

1,1,1,1

1,1,1,0

1,1,1,0

[0]

[0]

[0]

[0]

[0]

[1]

Load completion

Chart 1.1 12cm Disc switch status transition

Route No. (EJECT route No.)

-

1(2)

1(2)

2(2)

2(2)

3(1)

3(1)

Transition in the center loading (Similar to 12cm in the side loading)

SW1/2/3/4

1,1,1,1

0,1,1,1

0,0,1,1

0,1,1,1

1,1,1,1

1,1,1,0

1,1,1,0

[Rest SW]

[0]

[0]

[0]

[0]

[0]

[0]

[1]

Loading

No Disc

Disc insert

detection

Load completion

Chart 1.2 8cm Disc switch status transition

Eject start

Eject

No Disc

Eject

completion

Eject start

Reload start

Load completion

Reload

Disc push in

Reload start

Load completion

Page 27

C D

"SYS-TEMP" is

indicated on the LCD.

"CHK MODE" is

indicated on the LCD.

"RUNNING" is

indicated on the LCD.

"MEMCHECK" is

indicated on the LCD.

"INIT" is

indicated on the LCD.

Press the [SEL] key

Press the [SEL] key

Press the [SEL] key

Press the [SEL] key

Press the [SEL] key

Thermistor's temperature data readout

: Data in the temperature sensor in the system control

is read every 5 seconds and displayed in hex numbers.

DVD unit check mode

(See section "5.1.4 DVD unit check mode" for details.)

Running mode: For use in running tests.

Memory check

: The remaining data capacity of the disc is displayed on the LCD.

Initialize user set data

: The system control EEPROM is initialized except for the

loading/ejection error history.

(No.MA175)1-27

Page 28

4.5.4 DVD unit check mode

Change LCD indication with a [FF ] button and a [REW ] button.

Check item list

No. A/D key

[1]

1

[2]

2

[3]

3

[4]

4

[5]

5

[6]

6

[DISP]

7

[SOURCE]

8

[SEL]

9

[MODE]

10

[BAND]

11

[DISC UP ]

12

[DISC DW ]

13

[EJECT]

14

Start at normal speed

(After start, it is measured JITTER on the

internal position)

Tracking off on the outermost position of CD

Tracking off on the innermost position of CD

CD_LD lights and laser current is displayed

DVD_LD lights and laser current is displayed

DVD x1 jitter measuring mode

(for use in mechanism measurement)

Indication of EEPROM contents

Initialization of EEPROM contents

Indication of temperature

Search & jitter measurement to an appointed

position of DVD

Setting of MONITOR terminal

DVDx1 double speed start

(After start, it is measured JITTER on the

internal position)

Disc stopped & LD-OFF

OPEN

DVD unit operation

Example of

LCD indication

NORMPLAY

CUR

JIT

EF-BAL

OUTRKOFF

EF-BAL

INTRKOFF

CDLD ON

CUR

JIT

DVDLD ON

CUR

JIT

DVD JITR

CUR

JIT

ROM DATA

ADDR

DATA

ROMCLEAR

JD4-TEMP

TEM

DVD-DL

PLC

JIT

MONITOR

M1

M2

PLAY

CUR

JIT

STOP

DSC OPEN

Indication contents

Laser current value

Jitter value

For EF phase error

For EF phase error

Laser current value

Jitter value

Laser current value

Jitter value

Laser current value

Jitter value

EEPROM address

EEPROM contents

Temperature

(Position measured with VT-501)

Jitter value

Laser current value

Jitter value

Note

1-28 (No.MA175)

Press key [1] of No.1 before an item in which the No.2 or 3 key is pressed.

Press key [1] of No.1 or key [12] of No.12 before an item in which the No. 10 key is pressed and confirm

the indication of jitter value on the LCD.

No.6 starts only a DVD1 layer disk. Even other disks start DVD1 layer.

When No.1 and No.12 are pushed after jitter indication, a focus jump is executed. (only DVD2 layer)

Stop a disk before OPEN, CLOSE by all means. (OPEN and CLOSE are not executed in a disk turn.)

The check mode can be exited either by pressing the [POWER] key or by resetting the unit.

Page 29

5.1 16 PIN CORD DIAGRAM

8

GN

GN/BK

7

6

5

4

3

2

1

VI/BK

VI

BL

BL/WH

RD

BK

WH/BK

GY/BK

OR/WH

WH

GY

BR

YG

YL

10

11

12

13

14

15

16

SECTION 5

TROUBLESHOOTING

9

BK

RD

BL

WH

BR

YG

Black

Red

Blue

White

Brown

Yellow Green

GN

VI

GY

YL

OR

Green

Violet

Gray

Yellow

Orange

1 BK

16 YL

2 RD

15 OR/WH

9 WH

10 WH/BK

12 GY

11 GY/BK

8 GN

7 GN/BK

5 VI

6 VI/BK

3 BL/WH

13 BR

4 BL

GND

MEMORY

ACC

ILL

FL+

FL-

FR+

FR-

RL+

RL-

RR+

RR-

REMOTE

TEL

ANT

REMOTE OUT

TEL MUTING

ILLUMINATION

CONTROL

GND

14 YG

RR

FR

FL

RL

REMOTE

ILL

PARKING

Rear Right

Front Right

Front Left

Rear Left

Remote

Illuminations Control

POWER ANTENNA

ANT

ACC

TEL

GND

MEMORY

PARKING

Auto Antenna

ACC Line

Telephone Muting

Ground

Memory Backup Battery+

Parking Brake

PARKING

BRAKE

(No.MA175)1-29

Page 30

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY CAR ELECTRONICS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA175)

Printed in Japan

VPT

Loading...

Loading...