Page 1

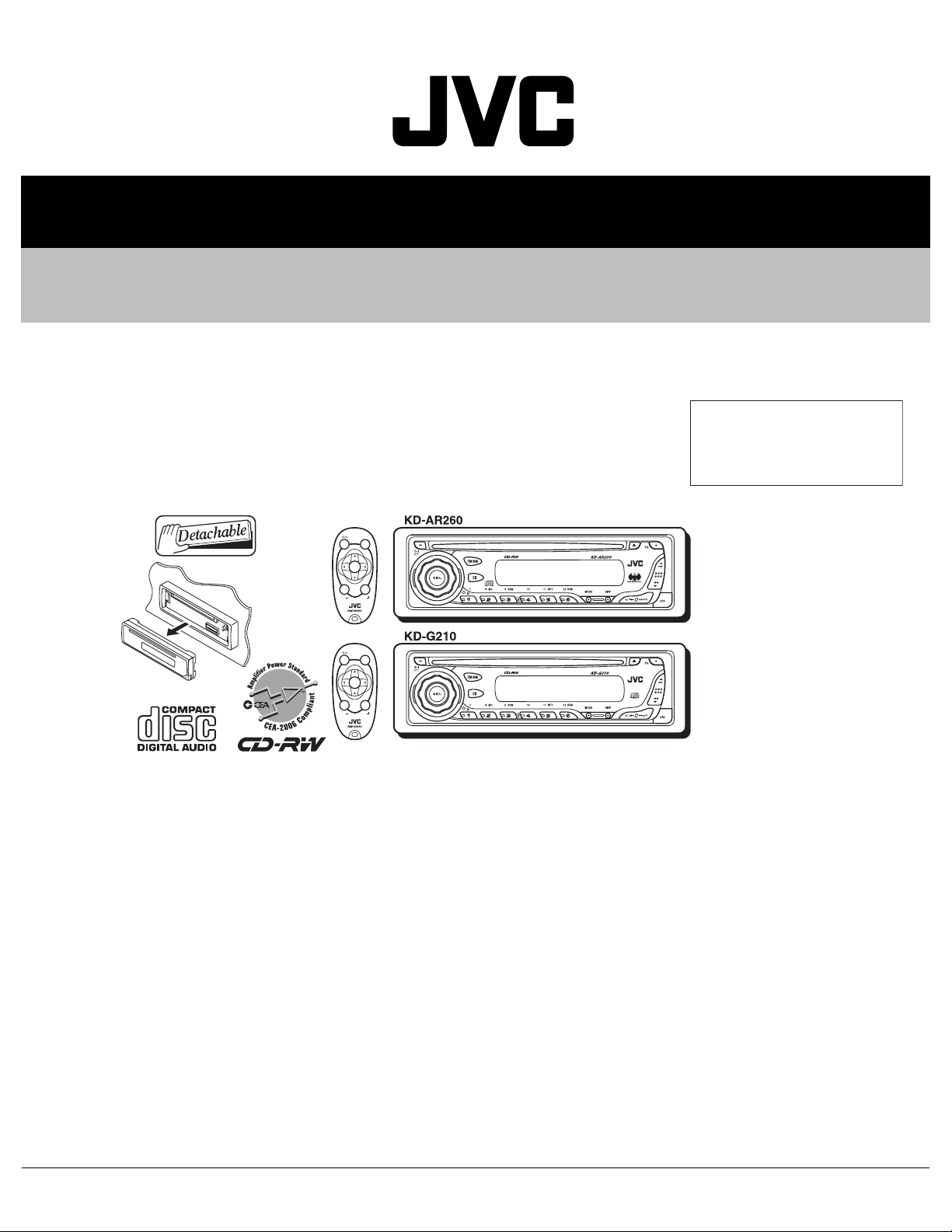

MA111200411

SERVICE MANUAL

CD RECEIVER

KD-AR260,KD-G210

J ------------- Northern America

SOUND

ATT

U

SOURCE

F

R

D

VOL

VOL

SOUND

ATT

U

SOURCE

F

R

D

VOL

VOL

Area suffix

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.MA111

2004/11

Page 2

SPECIFICATION

AUDIO AMPLIFIER SECTION

Power Output 18 W RMS × 4 Channels at 4 Ω and [< or =] 1 % THD + N

Signal to Noise Ratio 80 dBA (reference: 1 W into 4 Ω)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±10 dB at 100 Hz

Treble ±10 dB at 10 kHz

Frequency Response 40 Hz to 20 000 Hz

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

TUNER SECTION

Frequency Range FM 87.5 MHz to 107.9 MHz

AM 530 kHz to 1 710 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Capture Ratio 1.5 dB

AM Tuner Sensitivity 20 µV

Selectivity 35 dB

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0ºC to +40ºC (32ºF to 104ºF)

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 150 mm (7-3/16" × 2-1/16" × 5-15/16")

Panel Size (approx.) 188 mm × 58 mm × 11 mm (7-7/16" × 2-5/16" × 7/16")

Mass (approx.) 1.3 kg (2.9 lbs) (excluding accessories)

Design and specifications are subject to change without notice.

1-2 (No.MA111)

Page 3

1.1 Safety Precautions

SECTION 1

PRECAUTIONS

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

(No.MA111)1-3

Page 4

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

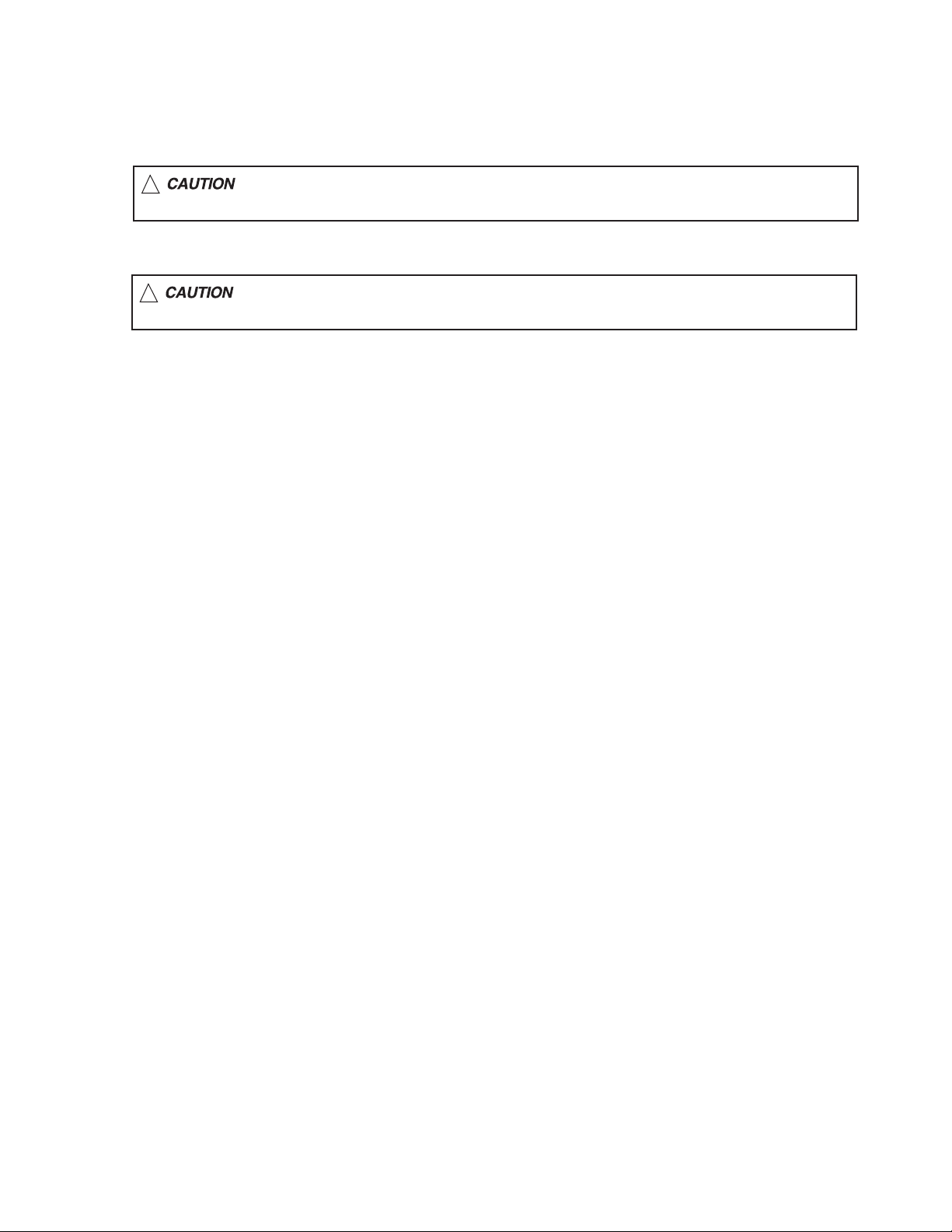

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

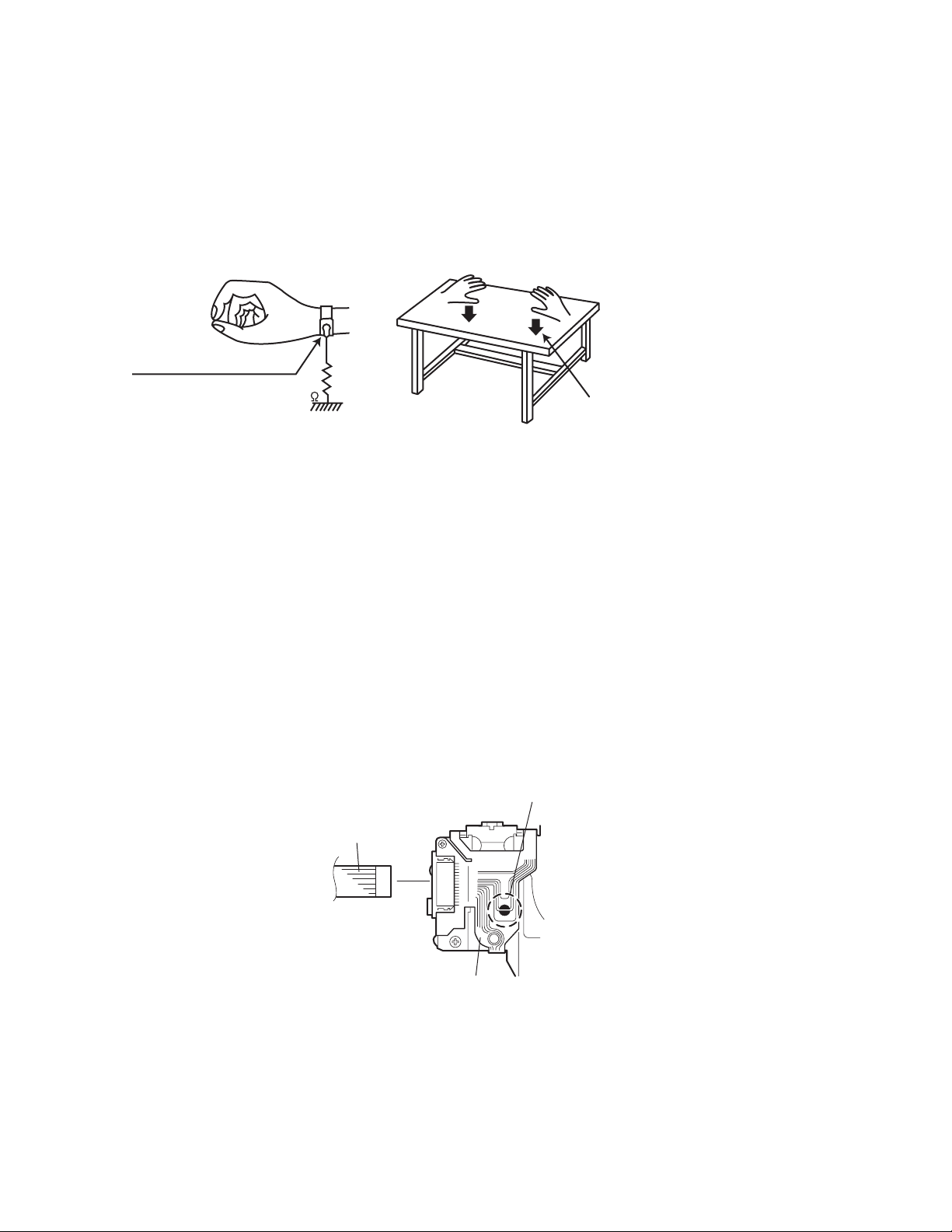

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land before the flexible wire is disconnected from the connector on the CD pickup unit.

(If the flexible wire is disconnected without applying solder, the CD pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the flexible wire.

Short-circuit point

(Soldering)

Flexible wire

1-4 (No.MA111)

Pickup

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MA111)1-5

Page 6

SECTION 3

DISASSEMBLY

3.1 Main body

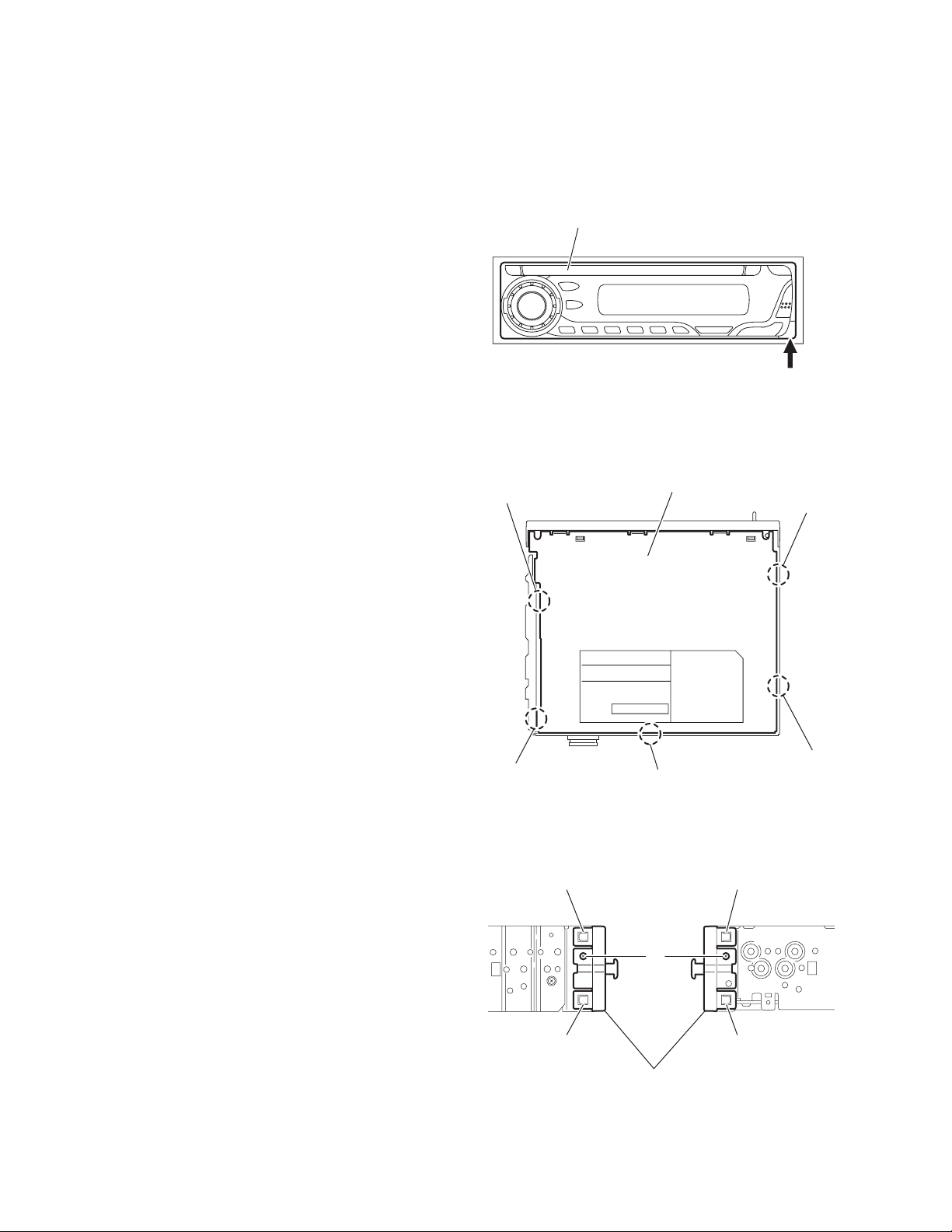

3.1.1 Removing the front panel assembly

(See Fig.1)

(1) Push the detach button in the lower right part of the front

panel assembly and remove the front panel assembly.

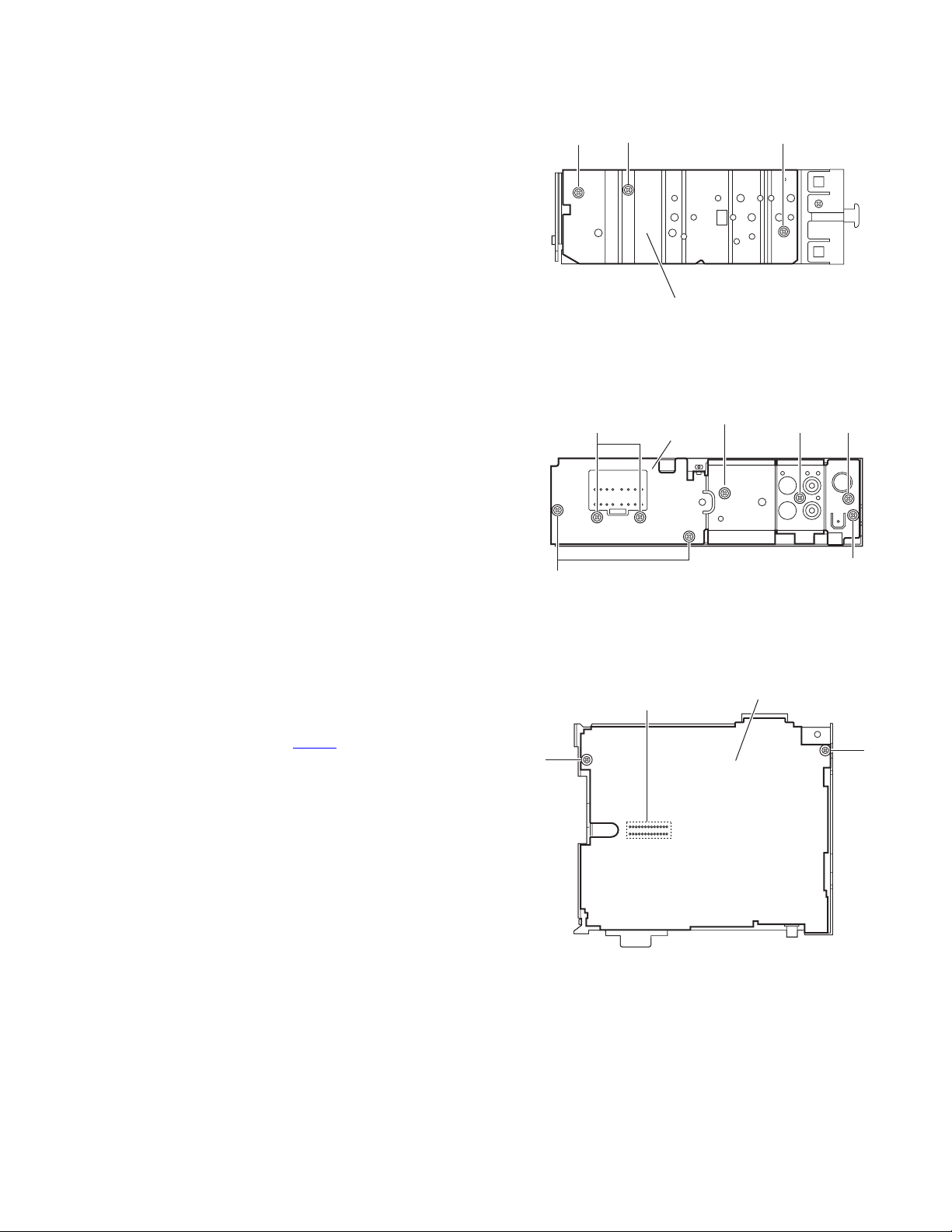

3.1.2 Removing the bottom cover

(See Fig.2)

(1) Turn the main body up side down.

(2) Insert a screwdriver under the joints to release the two

joints a on the left side, two joints b on the right side and

joint c on the back side of the main body, then remove the

bottom cover from the main body.

CAUTION:

When releasing the joints using a screwdriver, do not damage

the main board.

Front panel assembly

Joint a

Detach button

Fig.1

Bottom cover

Joint b

3.1.3 Removing the front chassis assembly

(See Fig.3)

• Prior to performing the following procedures, remove the front

panel assembly and bottom cover.

(1) Remove the screw A on the both sides of the main body.

(2) Release the two joints d and two joints e on the both sides

of the main body, then remove the front chassis assembly

toward the front.

1-6 (No.MA111)

Joint a

Joint c

Fig.2

Joint d Joint e

A

Joint d

Front chassis assembly

Fig.3

Joint e

Joint b

Page 7

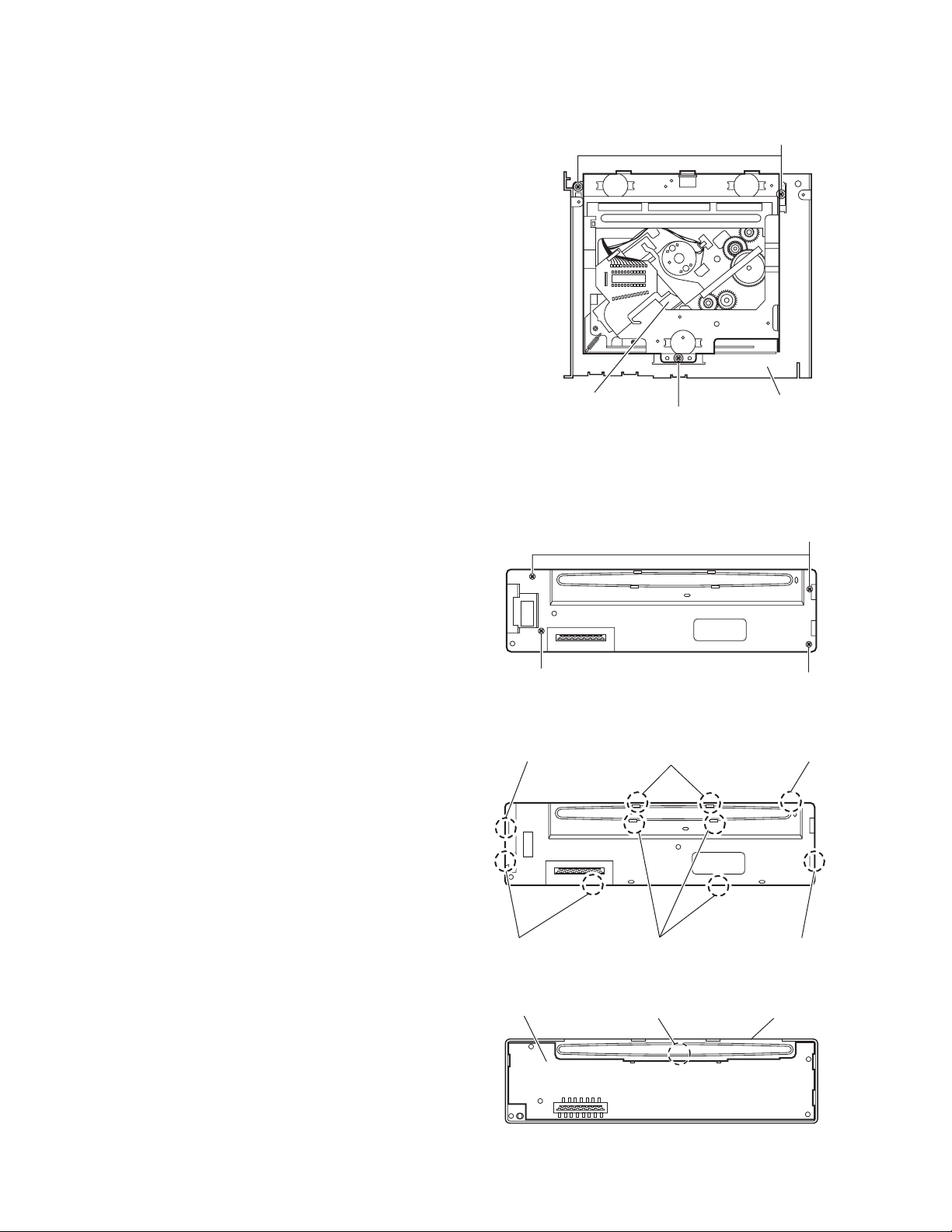

3.1.4 Removing the side panel

(See Fig.4)

• Prior to performing the following procedure, remove the front

panel assembly as required.

(1) Remove the screw B and two screws C attaching the side

panel on the left side of the main body, and remove the side

panel.

3.1.5 Removing the rear bracket

(See Fig.5)

• Prior to performing the following procedure, remove the bottom

cover.

(1) Remove the three screws D, three screws E and two

screws F attaching the rear bracket on the back side of the

main body.

(2) Remove the rear bracket.

BCC

Side panel

Fig.4

EF

Rear bracket

F

E

3.1.6 Removing the main board

(See Fig.6)

• Prior to performing the following procedure, remove the front

panel assembly, front chassis assembly, side panel, bottom

cover and rear bracket.

(1) Remove the two screws G attaching the main board.

(2) Disconnect the connector CN501

board.

and remove the main

G

D

D

Fig.5

Main board

CN501

G

Fig.6

(No.MA111)1-7

Page 8

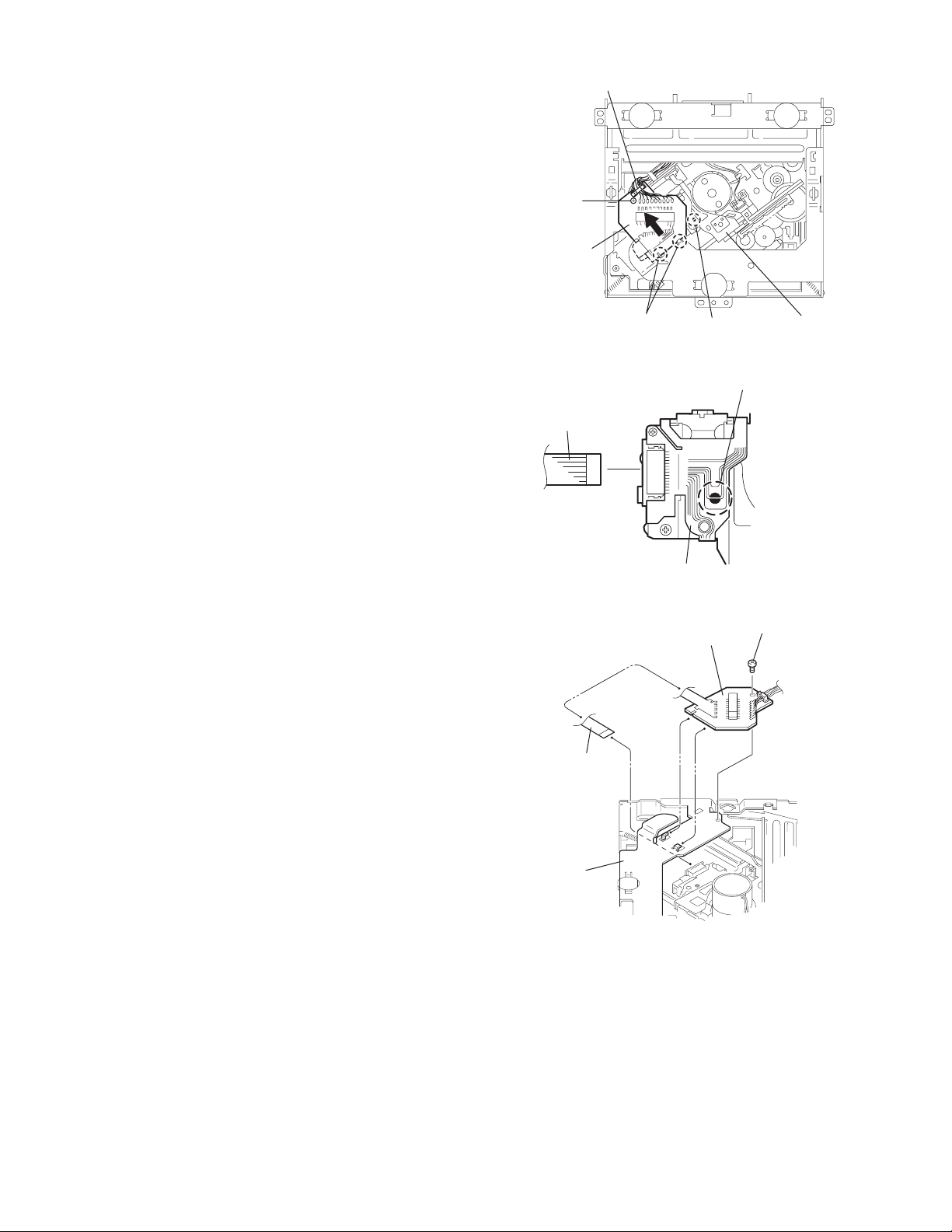

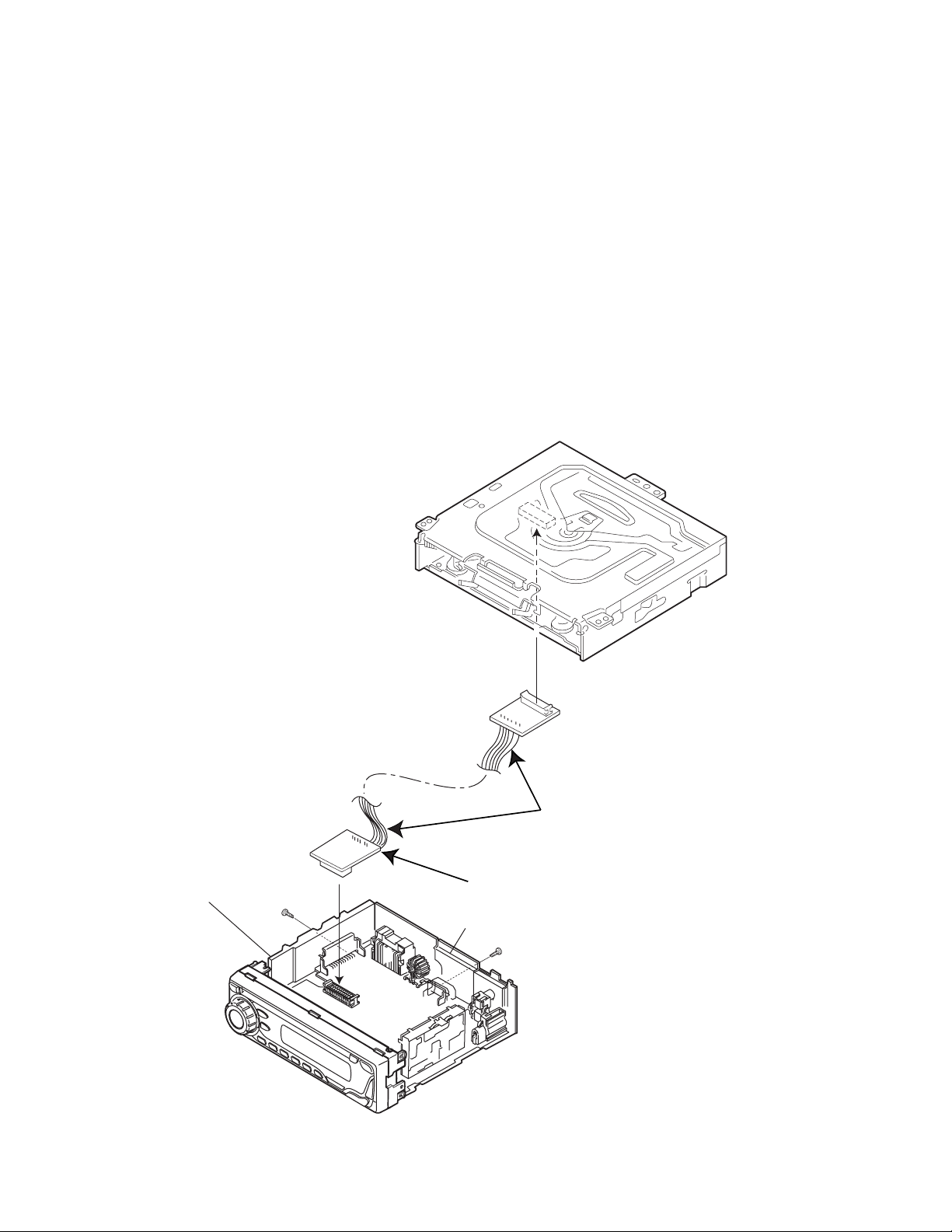

3.1.7 Removing the CD mechanism assembly

f

(See Fig. 7)

• Prior to performing the following procedure, remove the front

panel assembly, front chassis assembly, side panel, bottom

cover, rear bracket, main board and CD mechanism board.

(1) Remove the three screws H attaching the top chassis.

(2) Take out the CD mechanism assembly.

H

3.1.8 Removing the front board

(See Figs.8 to 10)

• Prior to performing the following procedure, remove the front

panel assembly.

(1) Remove the four screws J on the back side of the front pan-

el assembly. (See Fig.8.)

(2) Release the ten joints f. (See Fig.9.)

(3) Release the joint g and take out the front board. (See

Fig.10.)

CD mechanism assembly

Fig.7

J

Fig.8

Joint f Joints f

Top chassis

H

J

J

Joints

1-8 (No.MA111)

Joints f

Front board

Joints f

Fig.9

Joint g

Fig.10

Joint f

Front panel assembly

Page 9

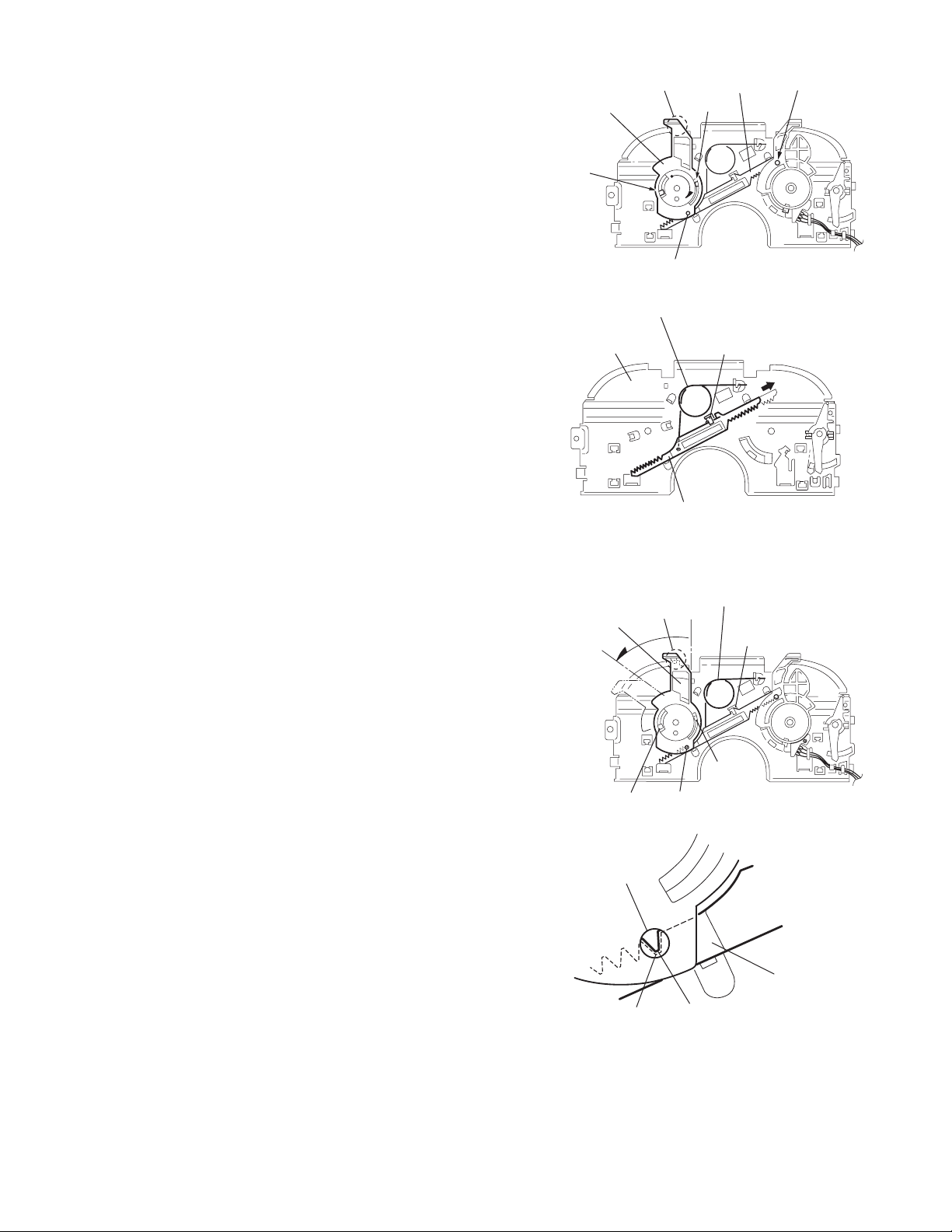

3.2 CD Mechanism Assembly

A

3.2.1 Removing the top cover

(See Figs.1 and 2)

(1) Remove the two screws A on the both side of the body.

(2) Lift the front side of the top cover and move the top cover

backward to release the two joints a.

Top cover

Joints a

A

Joints a

A

Fig.1

Fig.2

Top cover

(No.MA111)1-9

Page 10

3.2.2 Removing the connector board

(See Figs.3 to 5)

CAUTION:

Before disconnecting the flexible wire from the pickup, solder

the short-circuit point on the pickup. No observance of this instruction may cause damage of the pickup.

(1) Remove the screw B fixing the connector board.

(2) Solder the short-circuit point on the connector board.

(3) Disconnect the flexible wire from the pickup.

(4) Move the connector board in the direction of the arrow to

release the two joints b.

(5) Unsolder the wire on the connector board if necessary.

CAUTION:

Unsolder the short-circuit point after reassembling.

B

Connector board

Flexible wire

Wires

Joints b

Short-circuit point

Fig.3

Short-circuit point

(Soldering)

Pickup

Flexible wire

Frame

Pickup

Fig.4

B

Connector board

Fig.5

1-10 (No.MA111)

Page 11

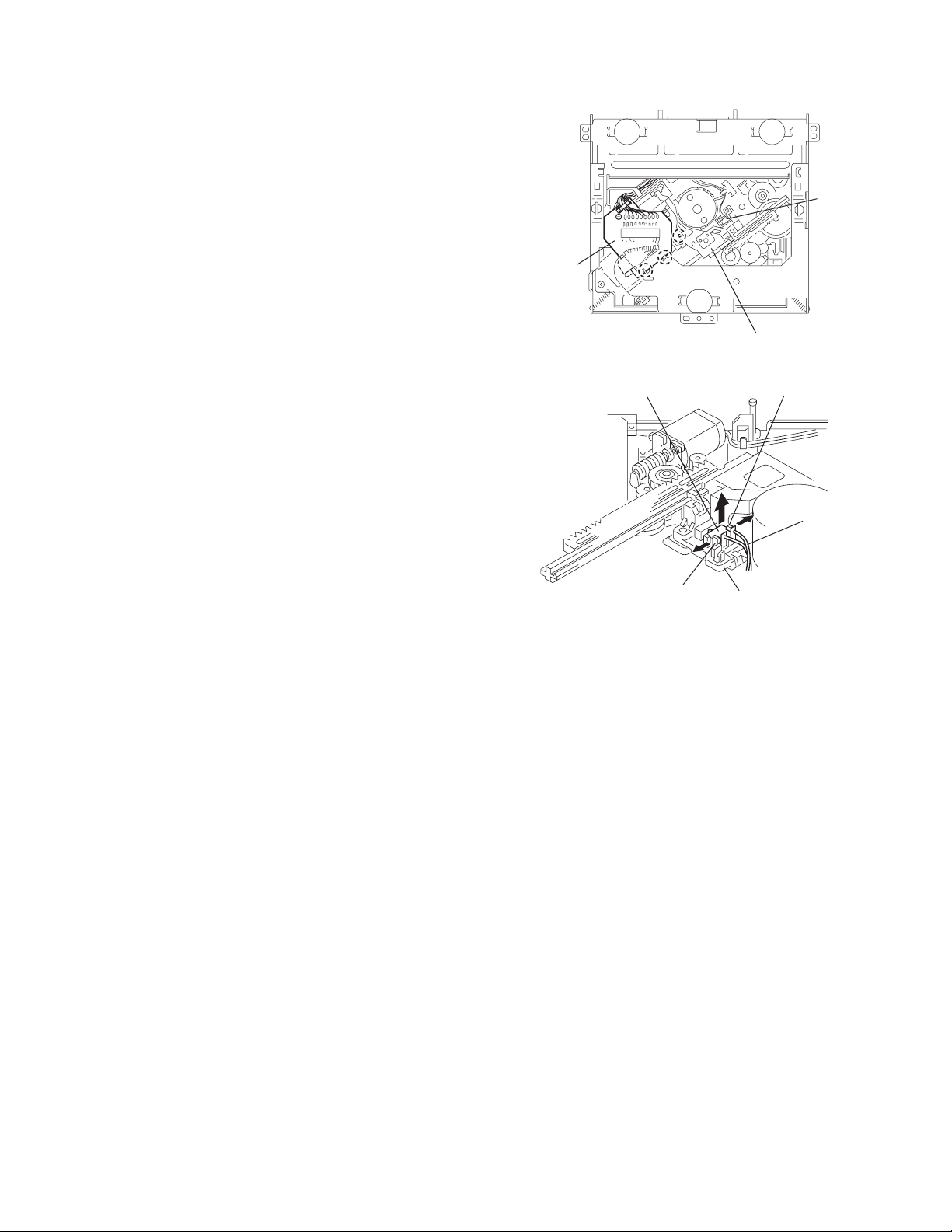

3.2.3 Removing the DET switch

(See Figs.6 and 7)

(1) Extend the two tabs c of the feed sw. holder and pull out

the switch.

(2) Unsolder the DET switch wire if necessary.

Connector

board

DET switch

DET switch

Pickup

Fig.6

Tab c

DET switch wire

Tab c

Feed sw. holder

Fig.7

(No.MA111)1-11

Page 12

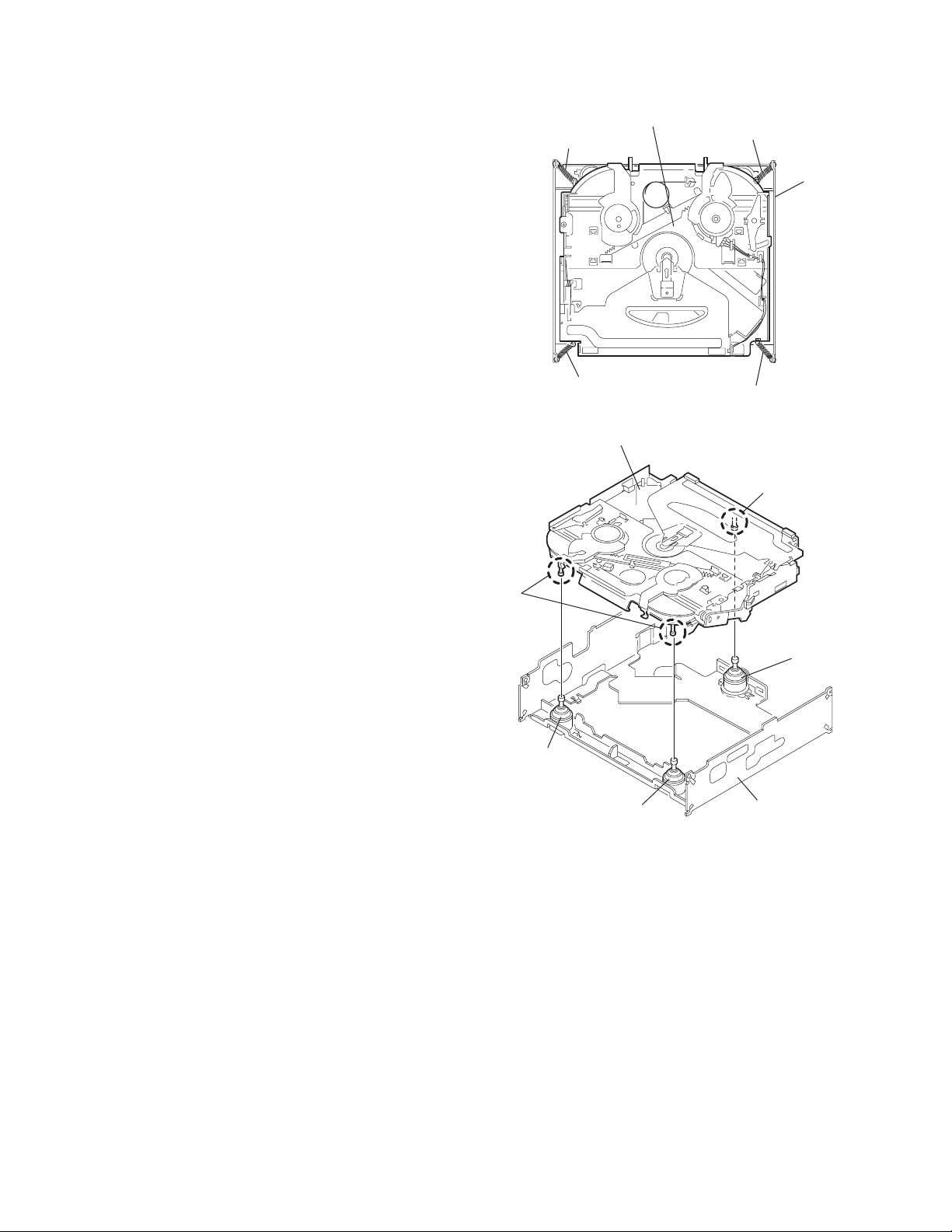

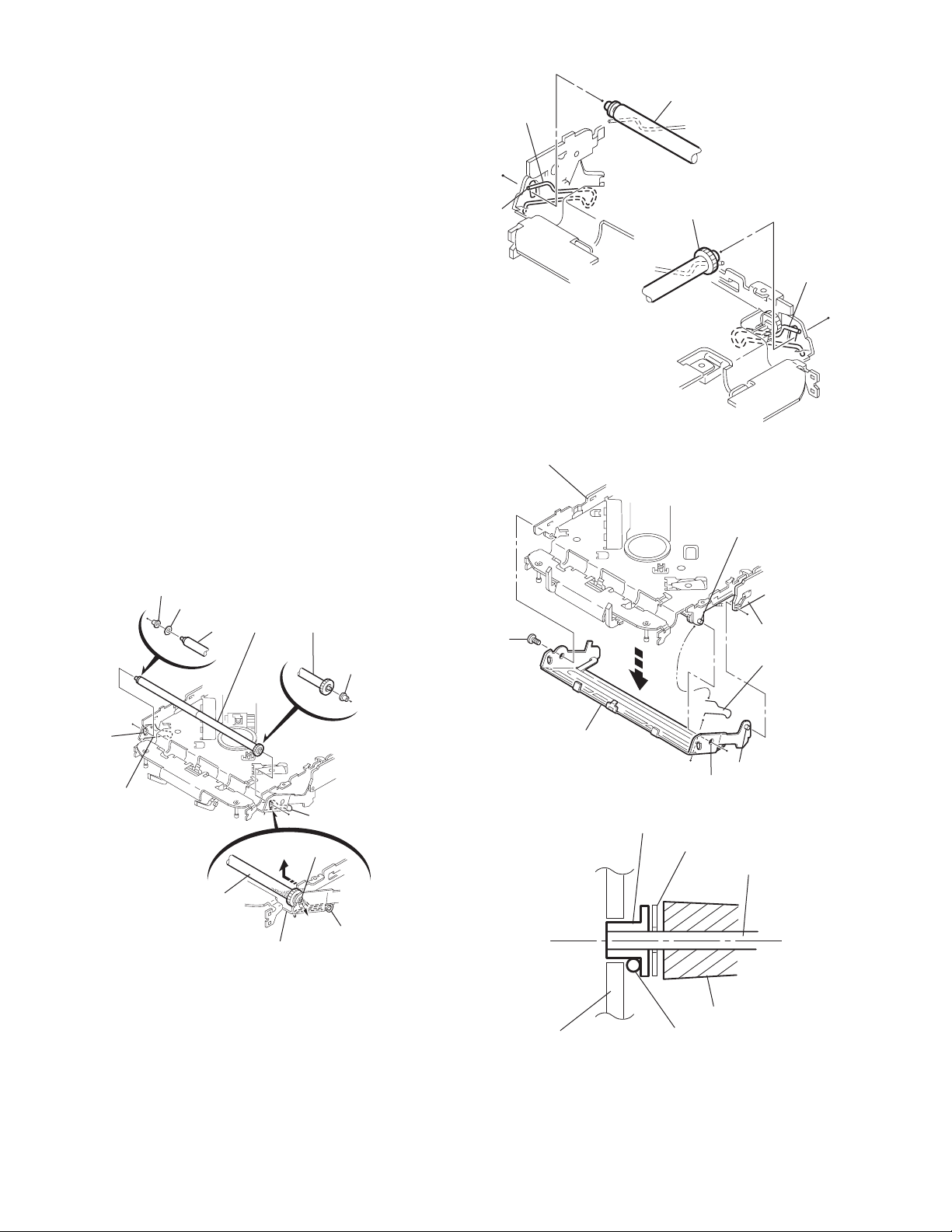

3.2.4 Removing the chassis unit

r

(See Figs.8 and 9)

• Prior to performing the following procedure, remove the top

cover and connector board.

(1) Remove the two suspension springs (L) and (R) attaching

the chassis unit to the frame.

CAUTION:

• The shape of the suspension spring (L) and (R) are different. Handle them with care.

• When reassembling, make sure that the three shafts

on the underside of the chassis unit are inserted to the

dampers certainly.

Suspension spring (R)

Chassis unit

Suspension spring (L)

Frame

Suspension spring (R)

Chassis unit

Shafts

Damper

Damper

Suspension spring (L)

Fig.8

Shaft

Dampe

Frame

Fig.9

1-12 (No.MA111)

Page 13

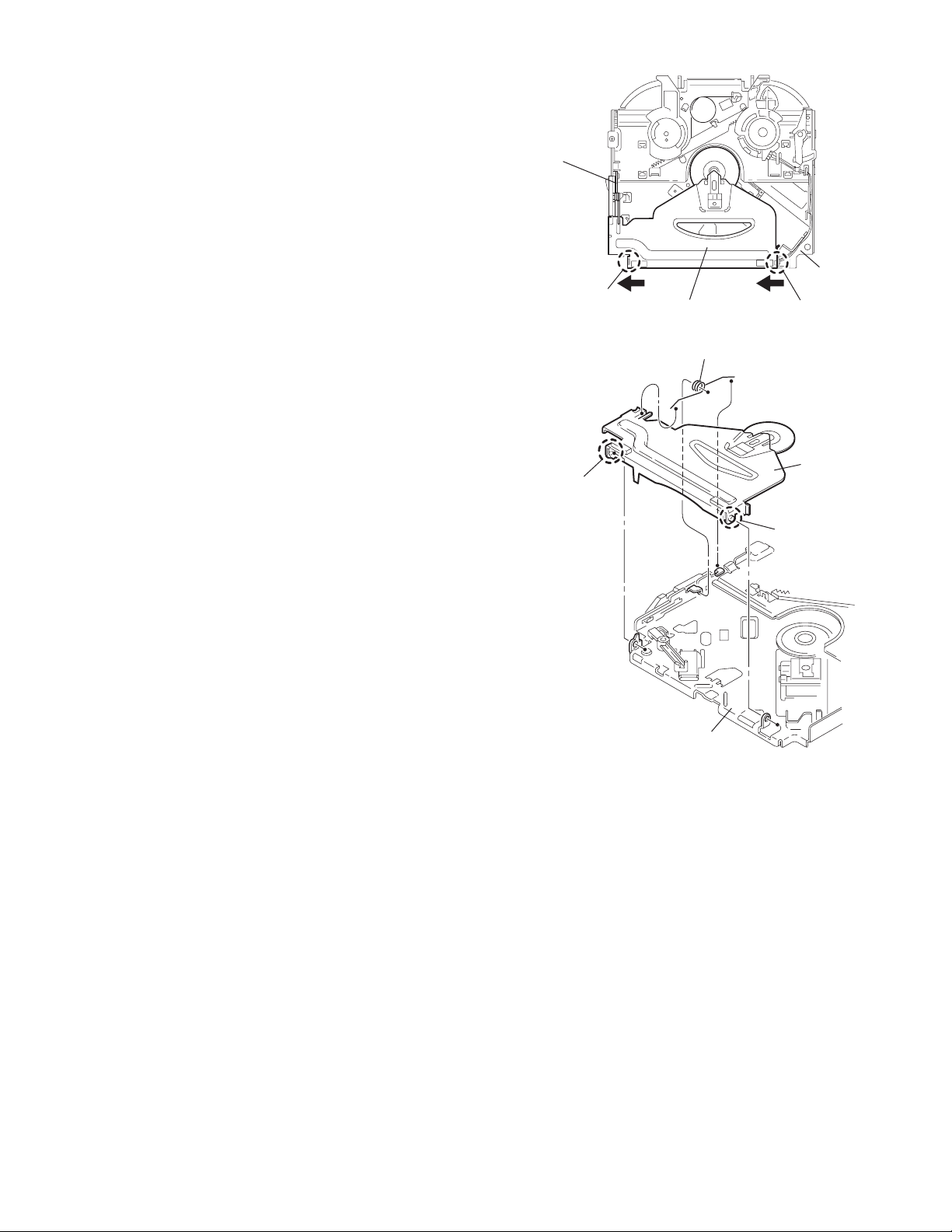

3.2.5 Removing the clamper assembly

(See Figs.10 and 11)

• Prior to performing the following procedure, remove the top

cover.

(1) Remove the clamper arm spring.

(2) Move the clamper assembly in the direction of the arrow to

release the two joints d.

Clamper arm

spring

Joint d

Joint d

Clamper assembly

Fig.10

Clamper arm spring

Chassis rivet

assembly

Joint d

Clamper

assembly

Chassis rivet assembly

Fig.11

Joint d

(No.MA111)1-13

Page 14

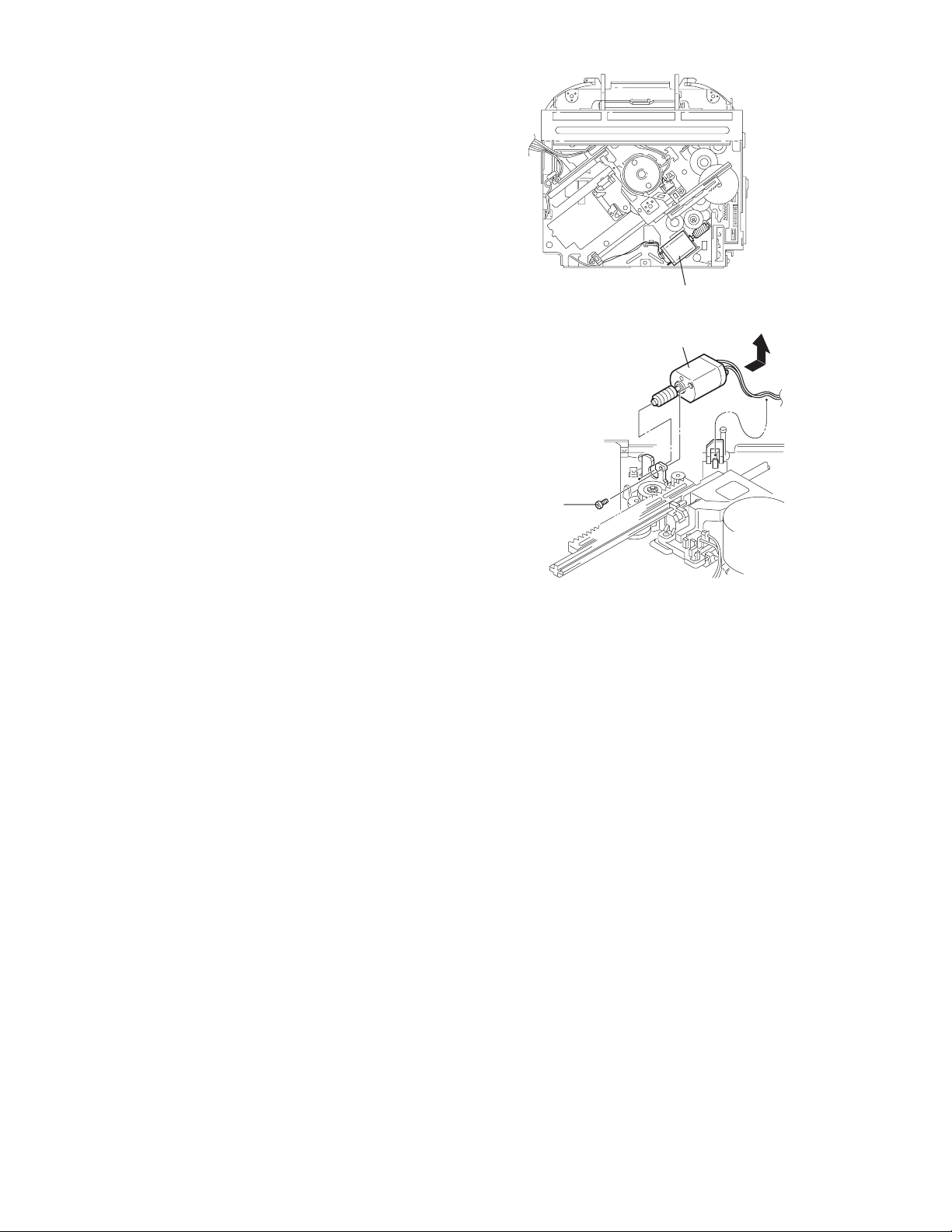

3.2.6 Removing the loading / feed motor assembly

(See Figs.12 and 13)

• Prior to performing the following procedure, remove the top

cover, connector board and chassis unit.

(1) Remove the screw C and move the loading / feed motor

assembly in the direction of the arrow to remove it from the

chassis rivet assembly.

(2) Disconnect the wire from the loading / feed motor assembly

if necessary.

CAUTION:

When reassembling, connect the wire from the loading /

feed motor assembly to the flame as shown in Fig.12.

Loading / feed motor assembly

Fig.12

Loading / feed motor assembly

C

Fig.13

1-14 (No.MA111)

Page 15

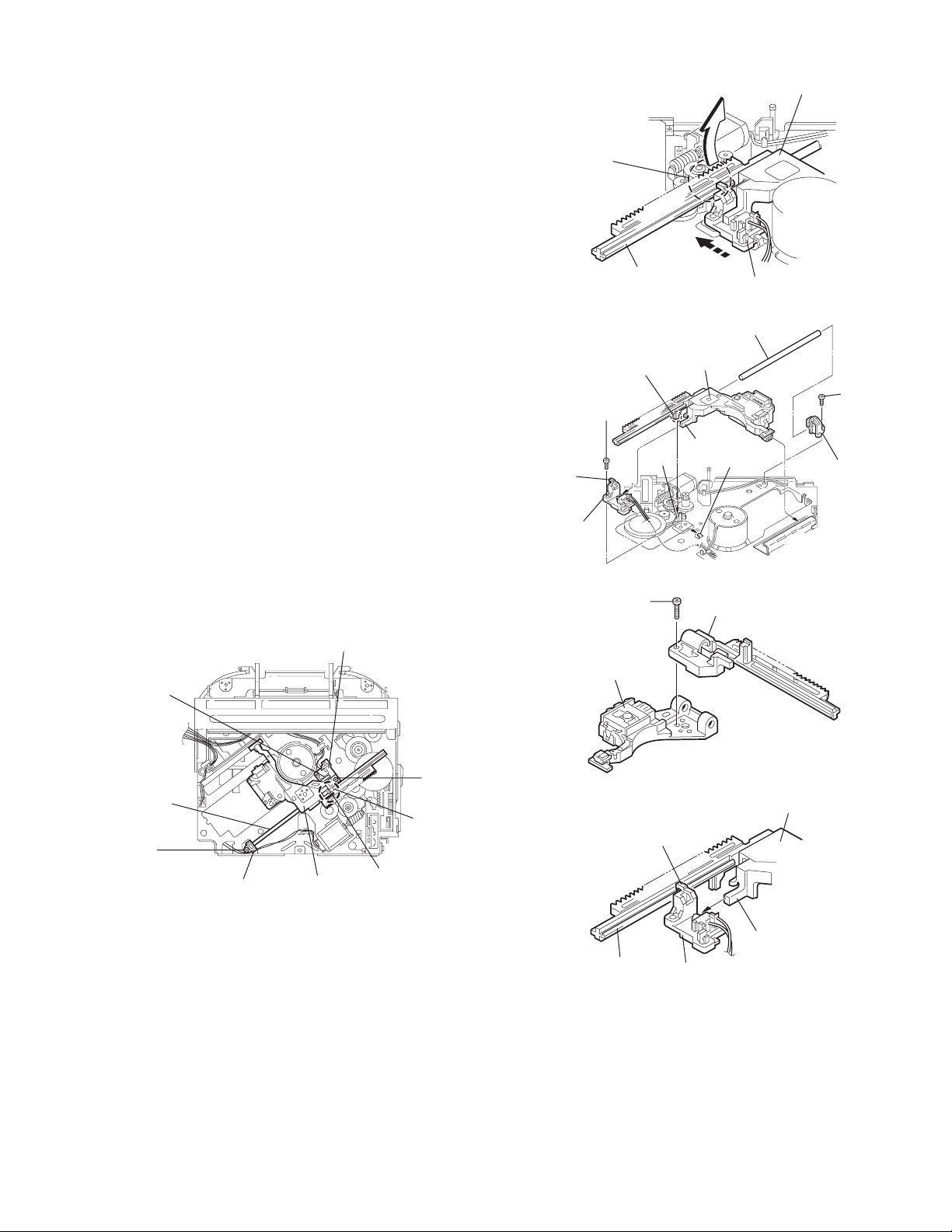

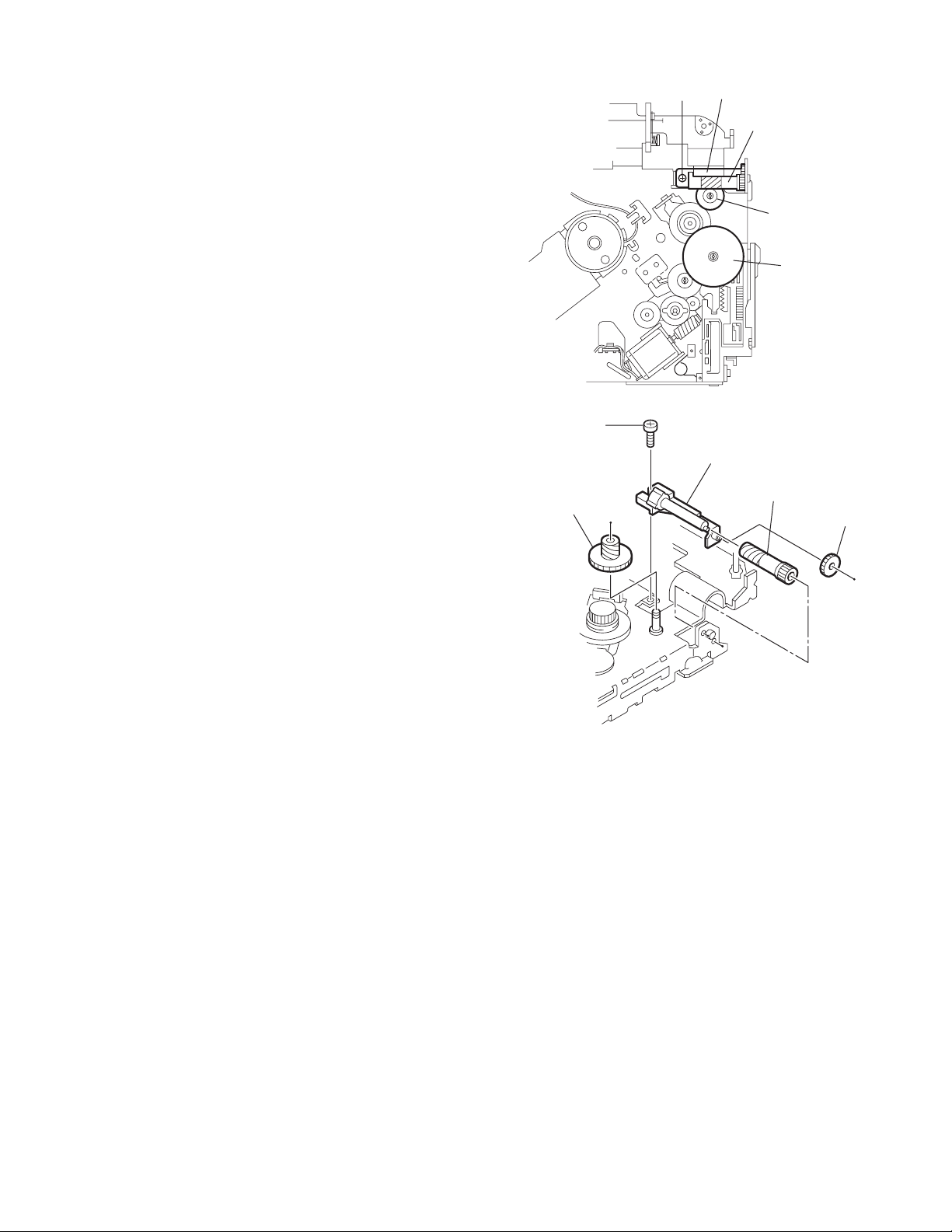

3.2.7 Removing the pickup unit

(See Figs.14 to 18)

• Prior to performing the following procedure, remove the top

cover, connector board and chassis unit.

(1) Remove the screw D and pull out the pu. shaft holder from

the pu. shaft.

(2) Remove the screw E attaching the feed sw. holder.

(3) Move the part e of the pickup unit upward with the pu. shaft

and the feed sw. holder, then release the joint f of the feed

sw. holder in the direction of the arrow. The joint g of the

pickup unit and the feed rack is released, and the feed sw.

holder comes off.

(4) Remove the pu. shaft from the pickup unit.

(5) Remove the screw F attaching the feed rack to the pickup

unit.

3.2.8 Reattaching the pickup unit

(See Figs.14 to 17)

(1) Reattach the feed rack to the pickup unit using the screw F.

(2) Reattach the feed sw. holder to the feed rack while setting

the joint g to the slot of the feed rack and setting the part f

of the feed rack to the switch of the feed sw. holder correctly.

(3) As the feed sw. holder is temporarily attached to the pickup

unit, set to the gear of the joint g and to the bending part of

the chassis (joint h) at a time.

CAUTION:

Make sure that the part i on the underside of the feed

rack is certainly inserted to the slot j of the change lock

lever.

(4) Reattach the feed sw. holder using the screw E.

(5) Reattach the pu. shaft to the pickup unit. Reattach the pu.

shaft holder to the pu. shaft using the screw D.

Feed sw. holder

Joint f

Joint g

Feed sw.

holder

Part e

Feed rack

Part i

E

Pickup unit

Slot j

F

Fig.15

Pu. shaft

Pickup unit

Joint f

Joint h

Fig.16

Feed rack

Pickup unit

Feed sw. holder

D

Pu. shaft

holder

Pu. shaft

D

Pu. shaft holder

Pickup unit

Fig.14

Part e

E

Joint g

Feed rack

Fig.17

Pickup unit

Joint g

Joint f

Feed sw. holder

Fig.18

(No.MA111)1-15

Page 16

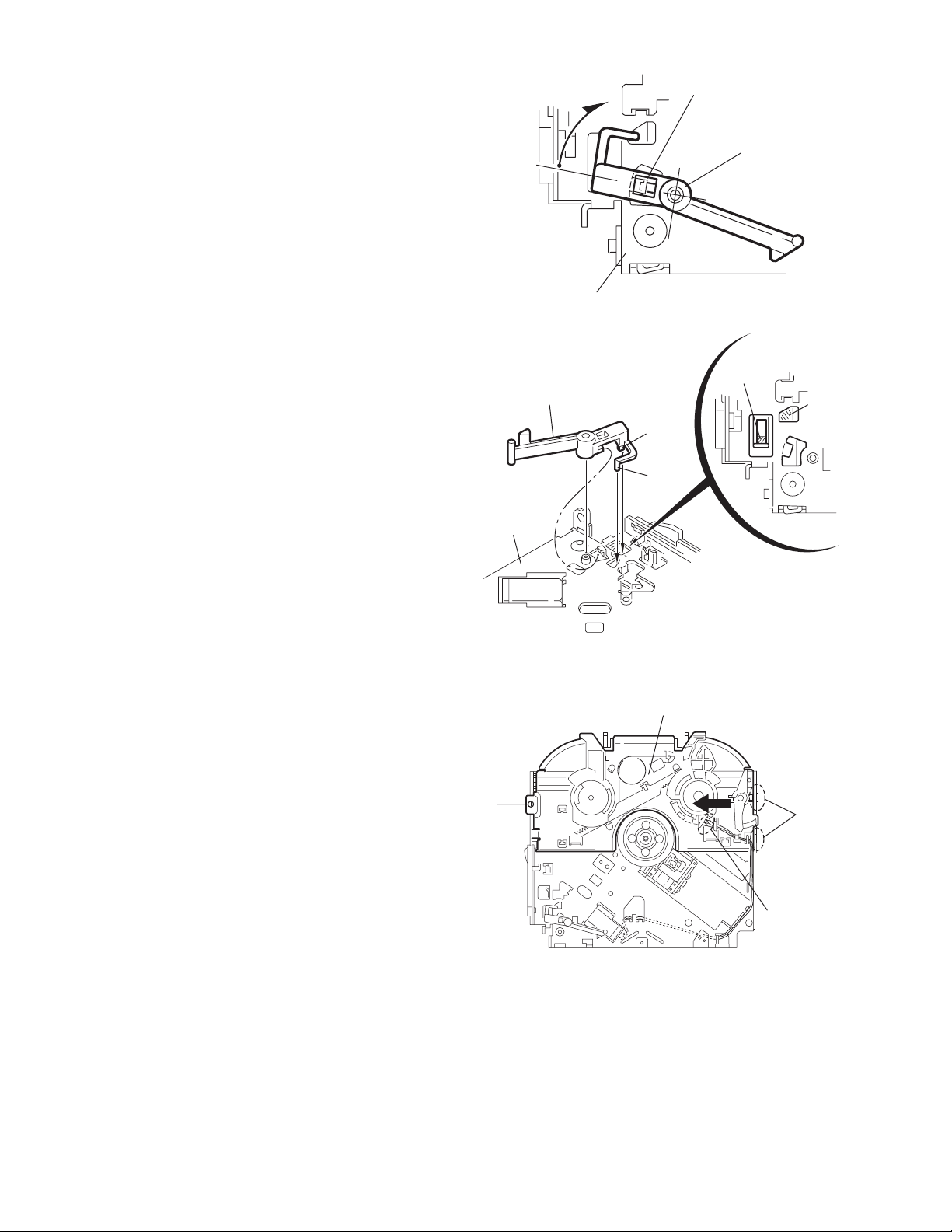

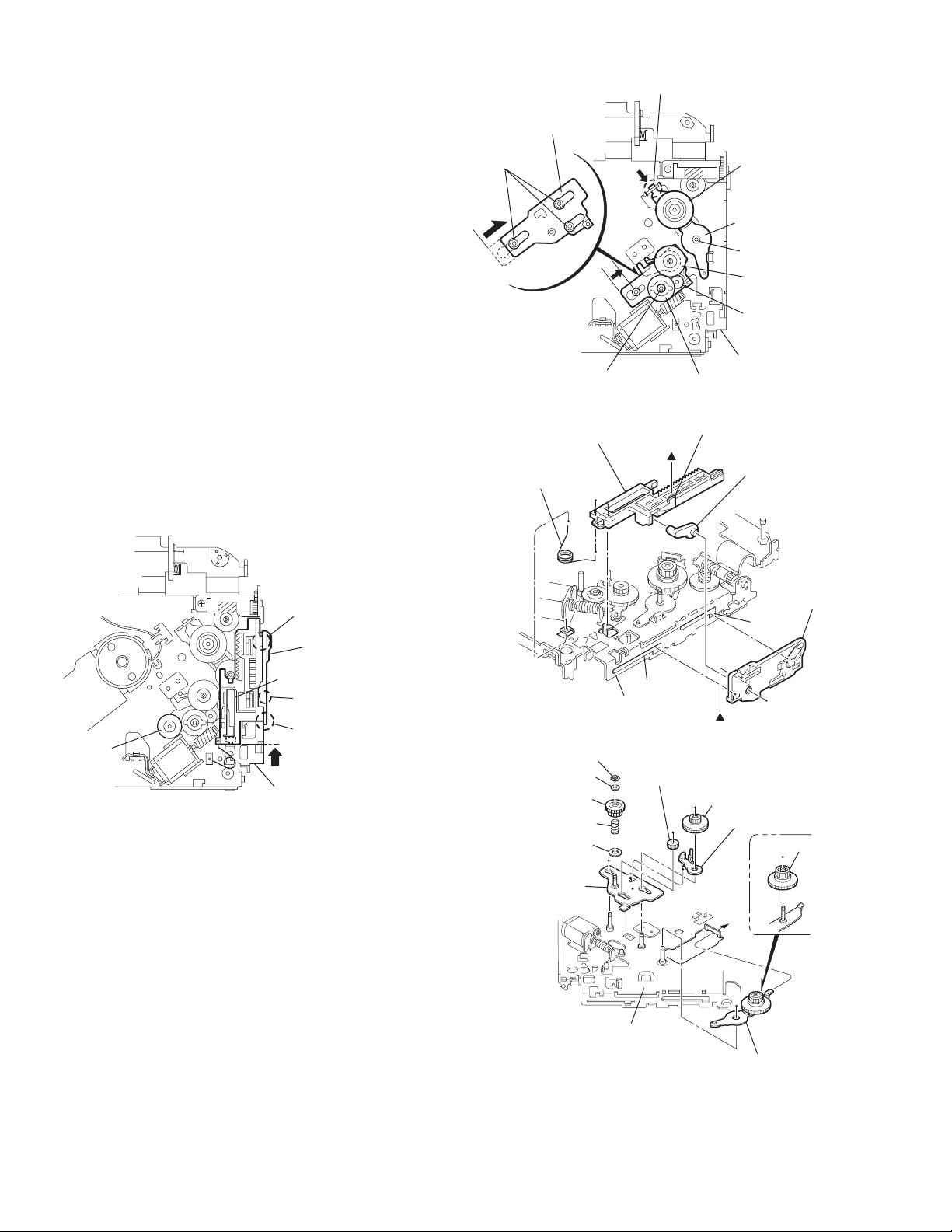

3.2.9 Removing the trigger arm

r

(See Figs.19 and 20)

• Prior to performing the following procedure, remove the top

cover, connector board and clamper unit.

(1) Turn the trigger arm in the direction of the arrow to release

the joint k and pull out upward.

CAUTION:

When reassembling, insert the part m and n of the trigger

arm into the part p and q at the slot of the chassis rivet

assembly respectively and join the joint k at a time.

Chassis rivet assembly

Trigger arm

Chassis rivet

assembly

Joint k

Trigger arm

Fig.19

Part p

Part q

Part m

Part n

3.2.10 Removing the top plate assembly

(See Fig.21)

• Prior to performing the following procedure, remove the top

cover, connector board, chassis unit, and clamper assembly.

(1) Remove the screw H.

(2) Move the top plate assembly in the direction of the arrow to

release the two joints r.

(3) Unsolder the wire marked s if necessary.

H

Fig.20

Top plate assembly

Joints

s

Fig.21

1-16 (No.MA111)

Page 17

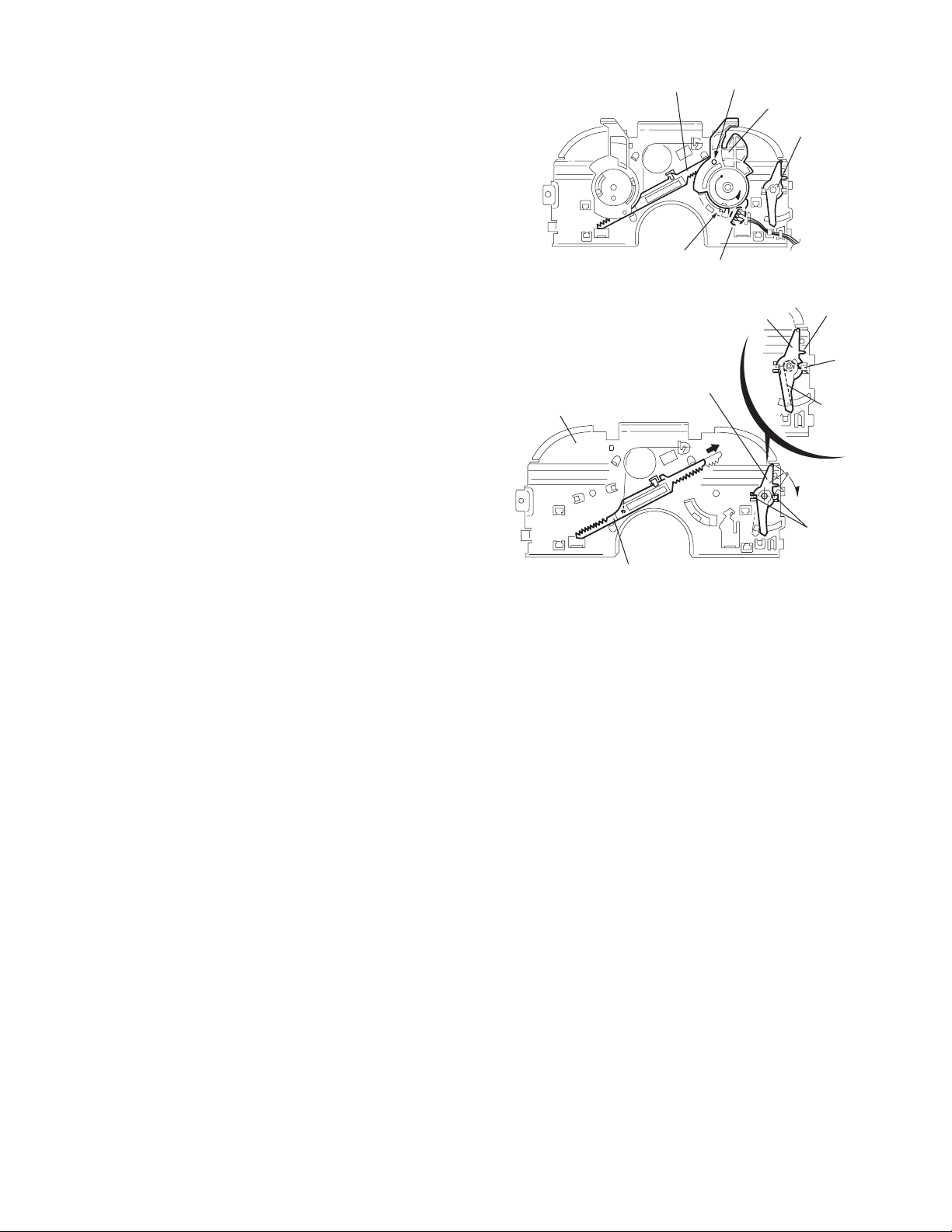

3.2.11 Removing the mode sw. / select lock arm

(See Figs.22 and 23)

• Prior to performing the following procedure, remove the top

plate assembly.

(1) Bring up the mode sw. to release from the link plate (joint t)

and turn in the direction of the arrow to release the joint u.

(2) Unsolder the wire of the mode sw. marked s if necessary.

(3) Turn the select lock arm in the direction of the arrow to re-

lease the two joints v.

(4) The select lock arm spring comes off the select lock arm at

the same time.

Top plate

Link plate

Joint u

Joint t

s

Fig.22

Select lock arm

Select lock arm

Mode sw.

Select lock arm

Top plate

Hook w

Select lock

arm spring

Link plate

Joints v

Fig.23

(No.MA111)1-17

Page 18

3.2.12 Reassembling the mode sw. / select lock arm

(See Figs.24 to 26)

REFERENCE:

Reverse the above removing procedure.

(1) Reattach the select lock arm spring to the top plate and set

the shorter end of the select lock arm spring to the hook w

on the top plate.

(2) Set the other longer end of the select lock arm spring to the

boss x on the underside of the select lock arm, and join the

select lock arm to the slots (joint v). Turn the select lock

arm as shown in the figure.

(3) Reattach the mode sw. while setting the part t to the first

peak of the link plate gear, and join the joint u.

CAUTION:

When reattaching the mode sw., check if the points y and

z are correctly fitted and if each part operates properly.

Select lock arm spring

Hook w

Joint v

Joint v

Select lock arm

Boss x

Fig.24

Joint t

Point y

Link plate

Point z

Link plate

Fig.25

Mode sw.

Select

lock arm

Joint t

Joint u

Fig.26

1-18 (No.MA111)

Page 19

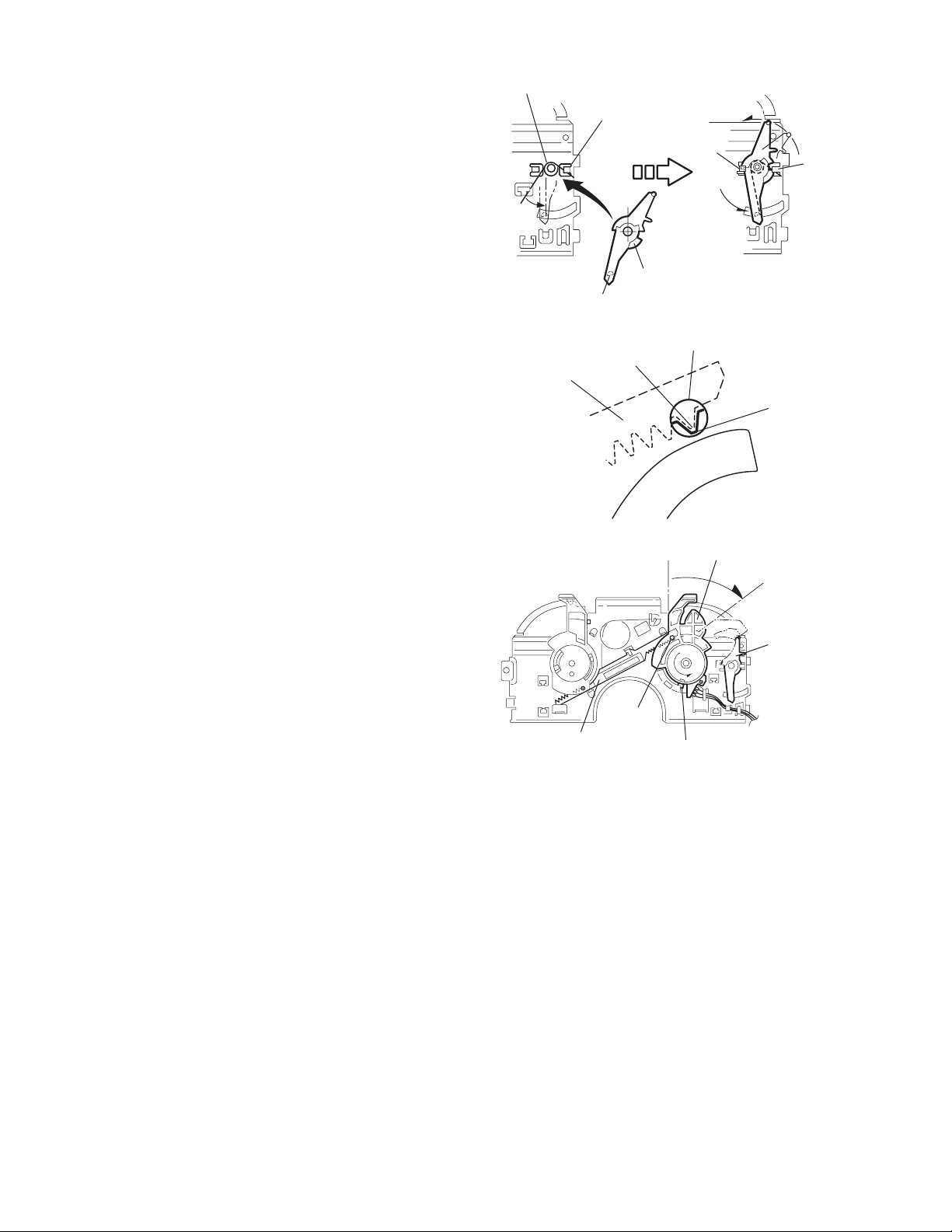

3.2.13 Removing the select arm R / link plate

(See Figs.27 and 28)

• Prior to performing the following procedure, remove the top

plate assembly.

(1) Bring up the select arm R to release from the link plate

(joint a') and turn as shown in the figure to release the two

joints b' and joint c'.

(2) Move the link plate in the direction of the arrow to release

the joint d'. Remove the link plate spring at the same time.

REFERENCE:

Before removing the link plate, remove the mode sw..

Select arm R

Joint b'

Link plate spring

Joint c'

Joint a'

Link plate

Joint b'

Fig.27

Joint r

3.2.14 Reattaching the Select arm R / link plate

(See Figs.29 and 30)

REFERENCE:

Reverse the above removing procedure.

(1) Reattach the link plate spring.

(2) Reattach the link plate to the link plate spring while joining

them at joint d'.

(3) Reattach the joint a' of the select arm R to the first peak of

the link plate while joining the two joints b' with the slots.

Then turn the select arm R as shown in the figure. The top

plate is joined to the joint c'.

CAUTION:

When reattaching the select arm R, check if the points e'

and f' are correctly fitted and if each part operates properly.

Top plate

Select arm R

Joint b'

Joint d'

Link plate

Fig.28

Link plate spring

Joint c'

Joint d'

Joint b'

Joint a'

Fig.29

Joint a'

Point e'

Link plate

Point f'

Fig.30

(No.MA111)1-19

Page 20

3.2.15 Removing the loading roller assembly

(See Figs.31 to 33)

• Prior to performing the following procedure, remove the

clamper assembly and top plate assembly.

(1) Push inward the loading roller assembly on the gear side

and detach it upward from the slot of the joint g' of the lock

arm rivet assembly.

(2) Detach the loading roller assembly from the slot of the joint

h' of the lock arm rivet assembly.

Roller guide

spring

Part k'

Loading roller assembly

Loading roller assembly

The roller guide comes off the gear section of the loading

roller assembly.

Remove the roller guide and the HL washer from the shaft

of the loading roller assembly.

(3) Remove the screw J attaching the lock arm rivet assembly.

(4) Push the shaft at the joint i' of the lock arm rivet assembly

inward to release the lock arm rivet assembly from the slot

of the L side plate.

(5) Extend the lock arm rivet assembly outward and release

the joint j' from the boss of the chassis rivet assembly. The

roller guide springs on both sides come off at the same

time.

CAUTION:

When reassembling, reattach the left and right roller

guide springs to the lock arm rivet assembly before reattaching the lock arm rivet assembly to the chassis rivet

assembly. Make sure to fit the part k' of the roller guide

spring inside of the roller guide. (Refer to Fig.34.)

Roller guide

HL washer

Loading roller assembly

Roller guide

Chassis rivet assembly

J

Roller guide

spring

Fig.32

Boss

L side plate

Roller guide spring

Joint h'

Roller guide spring

Loading roller assembly

Joint g'

Lock arm rivet assembly

Fig.31

Roller guide spring

Roller guide spring

Lock arm rivet assembly

Lock arm rivet assembly

Joint i'

Part j'

Fig.33

Roller guide

HL washer

Roller shaft assembly

Loading roller

Roller guide spring

Fig.34

1-20 (No.MA111)

Page 21

3.2.16 Removing the loading gear 5, 6 and 7

(See Figs.35 and 36)

• Prior to performing the following procedure, remove the top

cover, chassis unit, pickup unit and top plate assembly.

(1) Remove the screw K attaching the loading gear bracket.

The loading gear 6 and 7 come off the loading gear bracket.

(2) Pull out the loading gear 5.

K

Loading gear bracket

K

Loading gear 6

Loading gear 5

Loading gear 3

Fig.35

Loading gear bracket

Loading gear 5

Loading gear 6

Loading gear 7

Fig.36

(No.MA111)1-21

Page 22

3.2.17 Removing the gears

(See Figs.37 to 40)

• Prior to performing the following procedure, remove the top

cover, chassis unit, top plate assembly and pickup unit.

• Pull out the loading gear 3. (See Fig.35.)

(1) Pull out the feed gear.

(2) Move the loading plate assembly in the direction of the ar-

row to release the L side plate from the two slots m' of the

chassis rivet assembly. (See Fig.37.)

(3) Detach the loading plate assembly upward from the chas-

sis rivet assembly while releasing the joint n'. Remove the

slide hook and loading plate spring from the loading plate

assembly.

(4) Pull out the loading gear 2 and remove the change lock le-

ver.

(5) Remove the E ring and washer attaching the changer gear

2.

(6) The changer gear 2, change gear spring and adjusting

washer come off.

(7) Remove the loading gear 1.

(8) Move the change plate rivet assembly in the direction of the

arrow to release from the three shafts of the chassis rivet

assembly upward. (See Fig.38.)

(9) Detach the loading gear plate rivet assembly from the shaft

of the chassis rivet assembly upward while releasing the

joint p'. (See Figs.38 and 40.)

(10) Pull out the loading gear 4.

Change plate

rivet assembly

Shafts

E ring

Loading plate assembly

Loading plate spring

Joint p'

Loading gear 4

Loading gear plate

rivet assembly

Shaft

Loading gear 2

Loading gear 1

Chassis rivet assembly

Change gear 2

Fig.38

Joint n'

Slide hook

Feed gear

Fig.37

Slot m'

L side plate

Loading plate assembly

Joint n'

Slot m'

Chassis rivet assembly

Chassis rivet assembly

E ring

Washer

Change gear 2

Change gear spring

Adjusting washer

Change plate

rivet assembly

Chassis rivet assembly

L side plate

Slot m'

Slot m'

Fig.39

Loading gear 1

Loading gear 2

Change lock lever

Loading gear 4

1-22 (No.MA111)

Loading gear plate rivet assembly

Fig.40

Page 23

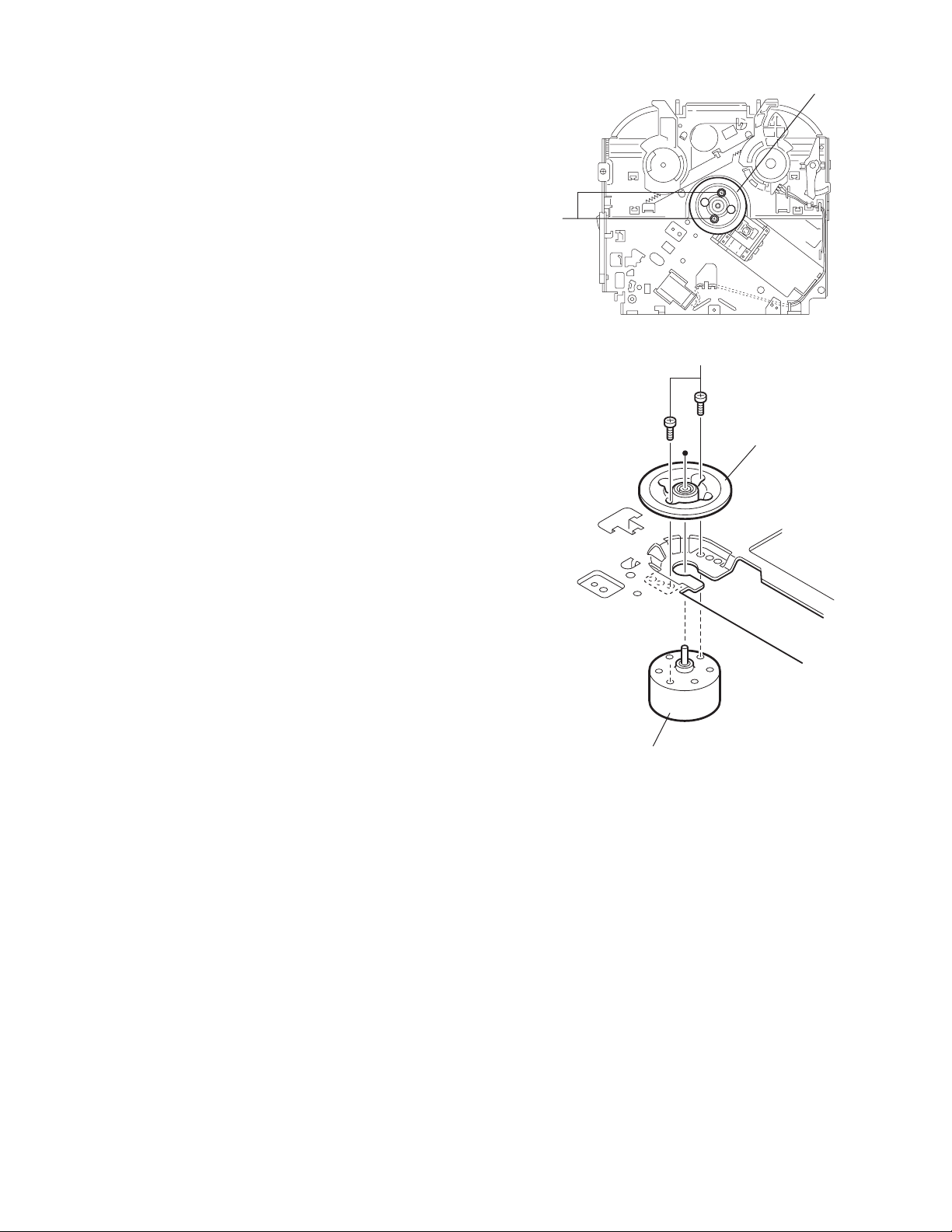

3.2.18 Removing the turn table / spindle motor

(See Figs.41 and 42)

• Prior to performing the following procedure, remove the top

cover, connector board, chassis unit and clamper assembly.

(1) Remove the two screws L attaching the spindle motor as-

sembly through the slot of the turn table on top of the body.

(2) Unsolder the wire on the connector board if necessary.

Turn table

L

Fig.41

L

Turn table

Spindle motor

Fig.42

(No.MA111)1-23

Page 24

SECTION 4

ADJUSTMENT

4.1 Adjustment method

Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Electric voltmeter

(3) Digital tester

(4) Tracking offset meter

(5) Test Disc JVC :CTS-1000

(6) Extension cable for check

EXTSH002-22P × 1

Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

Standard measuring conditions

Power supply voltage DC14.4V(10.5 to 16V)

Load impedance 20KΩ(2 Speakers connection)

Output Level Line out 2.0V (Vol. MAX)

Dummy load

Exclusive dummy load should be used for AM,and FM. For FM

dummy load,there is a loss of 6dB between SSG output and

antenna input.The loss of 6dB need not be considered since

direct reading of figures are applied in this working standard.

1-24 (No.MA111)

Heat sink

Extension cable

EXTSH002-22P

Rear bracket

Page 25

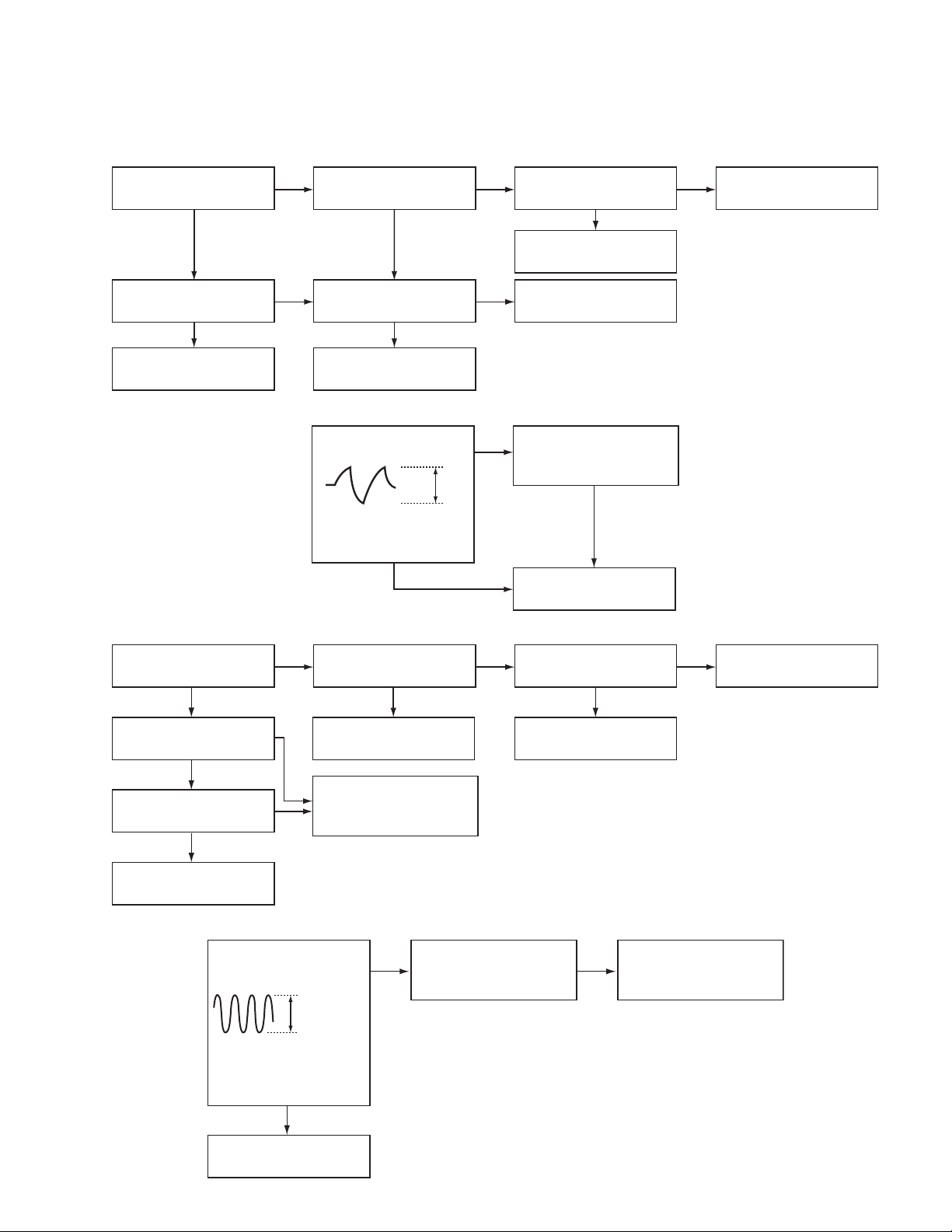

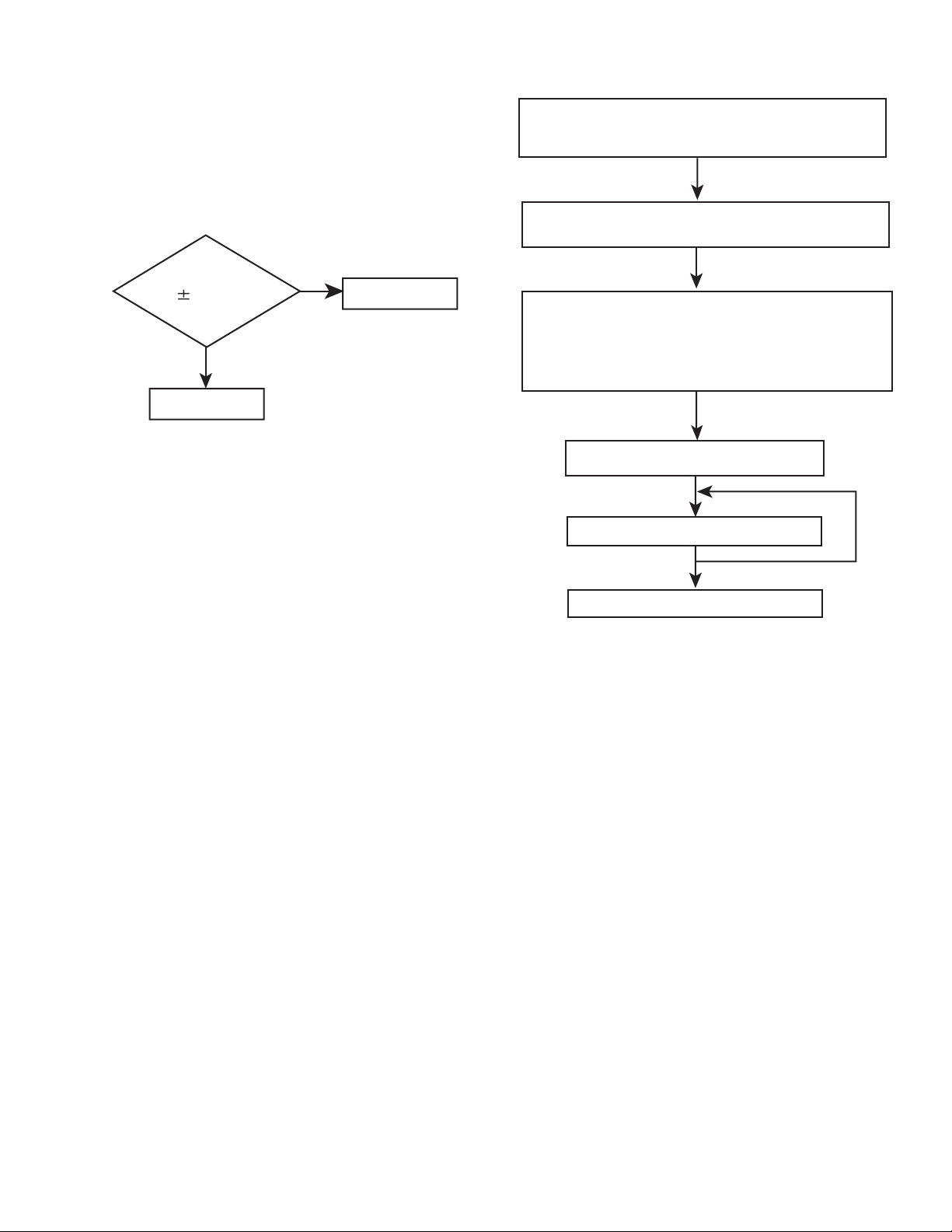

5.1 Feed section

SECTION 5

TROUBLESHOOTING

Is the voltage output at

IC561 pin 22 5v or 0V

YES

Is 4V present at both

sides of the feed motor?

YES

Check the feed motor.

5.2 Focus section

5.3 Spindle section

NO

Is the wiring for IC561

pin 22 correct?

NO

Is 6V or 2V present at

IC541 pins 4 and 5?

Check IC541.

When the lens is

moving:

Does the S-search

waveform appear at

IC541 pins 8 and 9?

NO

NO

YES

4V

YES

YES

NO

Is 5V present at IC541

pin 27?

Check the vicinity of

IC561.

Check the feed motor

connection wiring.

Check the circuits in

the vicinity of IC541

pins 15 and 16.

Check the pickup and

its connections.

NO

Check CD 8V.

YES

YES

Is the disk rotated?

YES

Does the RF signal

appear at TP RF?

YES

Is the RF waveform

at TP RF distorted?

YES

Proceed to the Tracking

section

5.4 Tracking section

When the disc is rotated

at first:

Is the tracking error

signal output at TP TE?

NO

Is 4V present between

IC541 pins 6 and 7?

Check the spindle motor

and its wiring.

NO

Check the circuits in

the vicinity of IC501

or the pickup.

NO

NO

Approx. 1.2V

NO

YES

Check the circuits in

the vicinity of IC501

pins 25 and 26.

Is 4V present at IC561

pins 24 and 25?

YES

Check the vicinity of

IC541

NO

Check the pickup and

its connections.

NO

Check IC561.

YES

Check IC561.

(No.MA111)1-25

Page 26

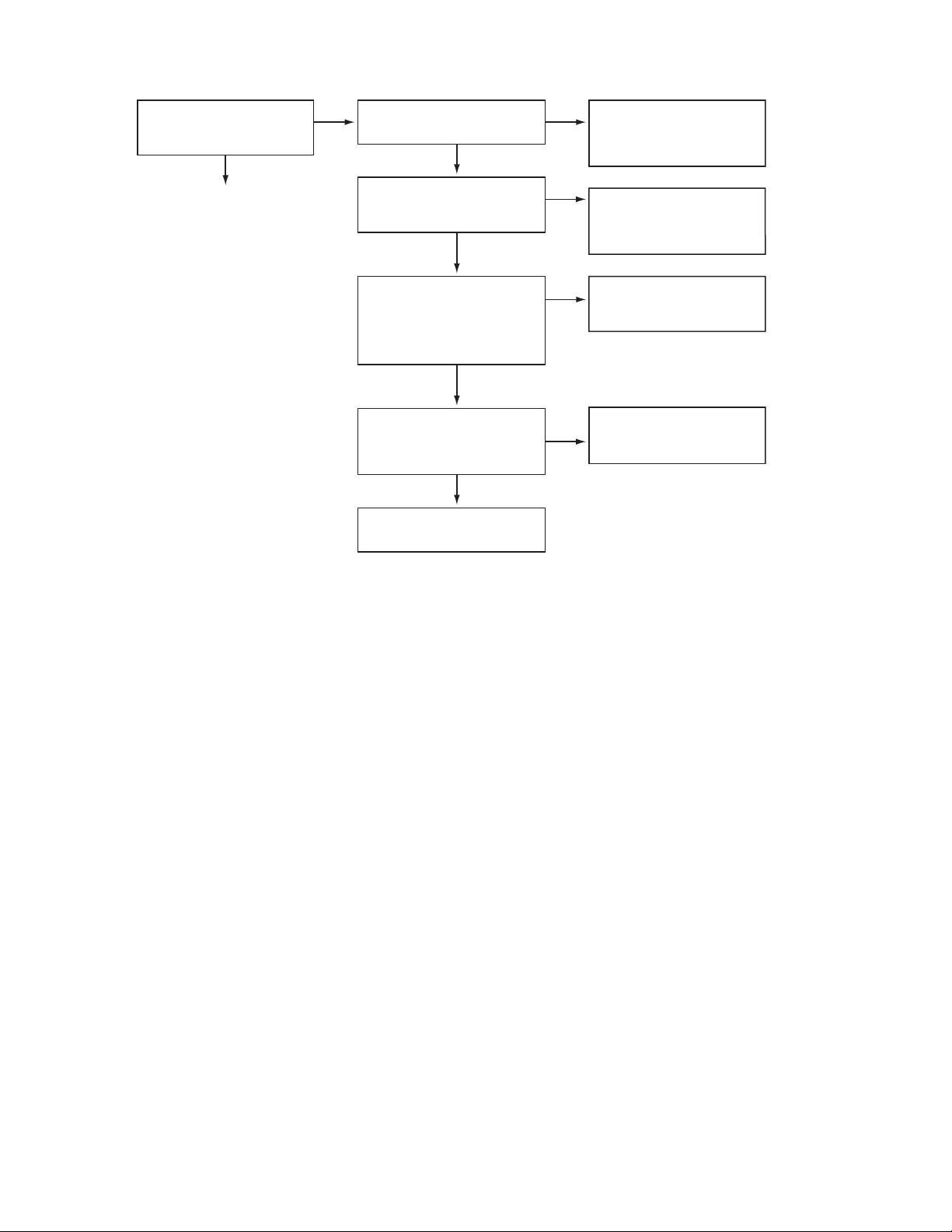

5.5 Signal proccessing section

Is the sound output from

both channels (L, R)?

YES

Normal

No sound from either

channel.

YES

Is 9V present at IC301 pin

31?

YES

NONO

Compare the L-ch and

R-ch to locate the

defctive point.

NO

Check the viciniyt of the

Q321 audio power

supply.

Is the audio signal

(including sampling output

components) output to

IC151 pins 1 and 7 during

playback?

YES

Is the audio signal output

at IC301 pins 3 and 30

during playback?

YES

Check the muting circuit.

NO

NO

Check IC151 and its

peripheral circuits.

Check IC301 and its

peripheral circuits.

1-26 (No.MA111)

Page 27

5.6 Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to clean the lens

with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

• The level of RF output (EFM output: amplitude of eye

pattern) will be low.

5.7 Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Is RF output

1.0 0.35Vp-p?

NO

Replace it.

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board

which is attached to the pickup is used to adjust the laser

power.Since this adjustment should be performed to match

the characteristics of the whole optical block, do not touch

the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced. If the semi-fixed resistor is adjusted while the

pickup is functioning normally, the laser pickup may be

damaged due to excessive current.

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at TP1.

Finish.

(No.MA111)1-27

Page 28

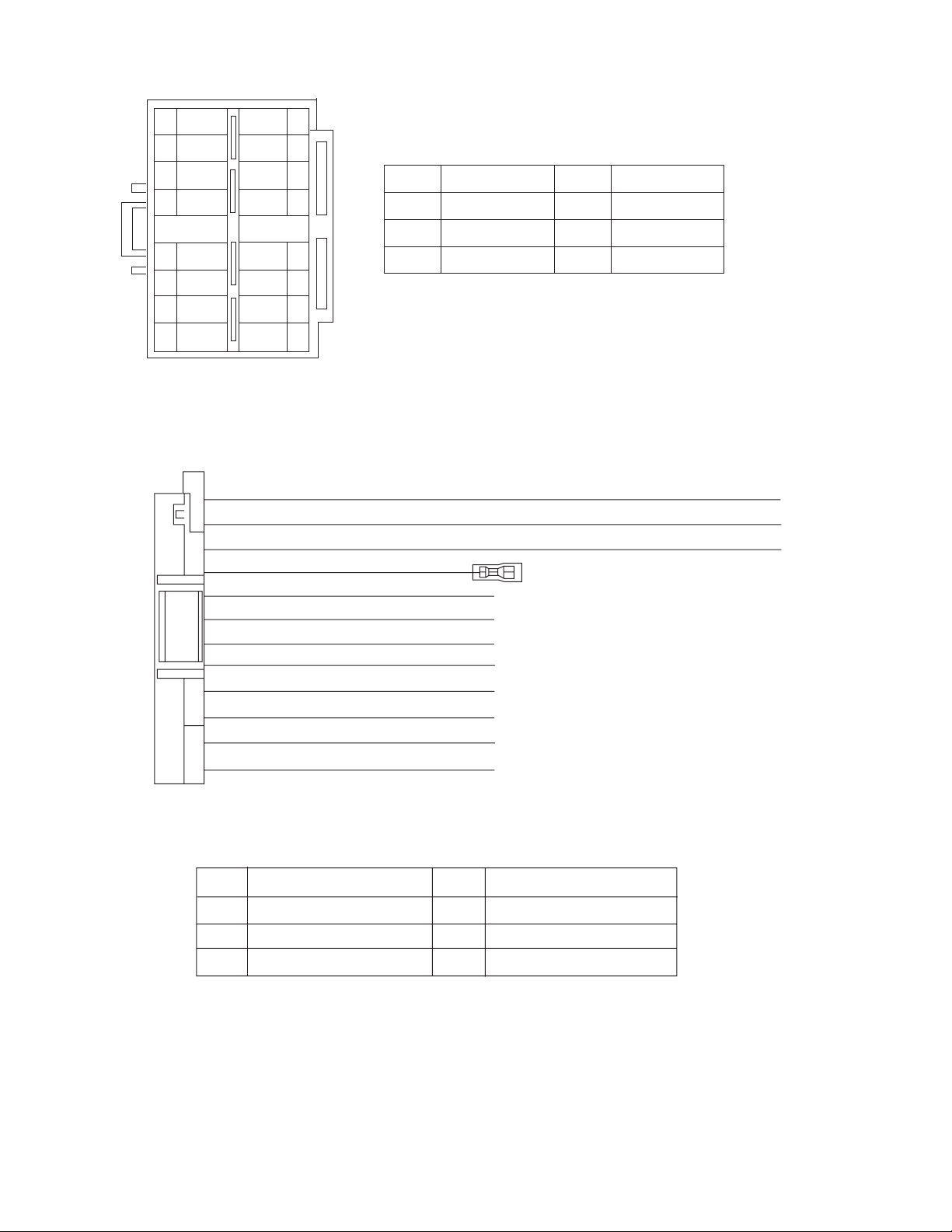

5.8 16 PIN CORD DIAGRAM

8

7

6

BL/WH

5

4

3

2

1

BK

RD

NC

WH

GN

VI

GY

WH/BK

GN/BK

GY/BK

16 YL

8 BK

7 RD

5 BL/WH REMOTE

4 WH

12 WH/BK

3 GN

11 GN/BK RL-

2 VI RR+

10 VI/BK

1 GY FR+

YL

NC

NC

NC

VI/BK

16

15

14

13

12

11

10

9

MEMORY

GND

ACC

FL+

FL-

RL+

RR-

BK

RD

BL

WH

Black

Red

Blue

White

GN

VI

GY

YL

Green

Violet

Gray

Yellow

1-28 (No.MA111)

9 GY/BK

RR

FR

FL

RL

Rear Right

Front Right

Front Left

Rear Left

FR-

REMOTE

ACC

MEMORY

GND

Remote out

ACC Line

Memory Backup Battery +

Ground

Page 29

(No.MA111)1-29

Page 30

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY CAR ELECTRONICS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA111)

Printed in Japan

VPT

Page 31

CD RECEIVER KD-AR260/KD-G210

ENGLISH

RECEPTOR CON CD KD-AR260/KD-G210

RECEPTEUR CD KD-AR260/KD-G210

SOUND

ATT

U

SOURCE

F

R

D

VOL

VOL

SOUND

ATT

U

SOURCE

F

R

D

VOL

VOL

• This unit is equipped with the display demonstration. To cancel it, see page 8.

• Esta unidad está equipada con demostración en la pantalla. Para cancelarla, consulte la página 8.

• Cet appareil est équipé d’une fonction de démonstration des affichages. Pour l’annuler, référezvous à la page 8.

For installation and connections, refer to the separate manual.

Para la instalación y las conexiones, refiérase al manual separado.

Pour l’installation et les raccordements, se référer au manuel séparé.

For customer Use:

Enter below the Model No. and

Serial No. which are located on

INSTRUCTIONS

MANUAL DE INSTRUCCIONES

MANUEL D’INSTRUCTIONS

the top or bottom of the

cabinet. Retain this information

for future reference.

Model No.

Serial No.

GET0246-001A

ESPAÑOL

FRANÇAIS

[J]

Page 32

FRANÇAIS

IMPORTANT POUR PRODUITS LASER

1. PRODUIT LASER CLASSE 1

2. ATTENTION: N’ouvrez pas le couvercle supérieur. Il n’y a aucune pièce réparable par l’utilisateur à

l’intérieur de l’appareil; confiez toute réparation à un personnel qualifié.

3. ATTENTION: Risque de radiations laser visible et invisible quand l’appareil est ouvert et que le

système de verrouillage ne fonctionne pas ou a été mis hors service. Évitez toute exposition directe

au rayon.

Avertissement:

Si vous souhaitez opérer l’appareil pendant que vous conduisez, assurez-vous de bien regarder devant vous afin

de ne pas causer un accident de la circulation.

Comment réinitialiser votre autoradio

Maintenez pressées les deux touches en

même temps.

• Cette procédure réinitialise le microordinateur. Vos ajustements préréglés sont

aussi effacés.

• Si un disque est en place, il est éjecté.

Faites attention, dans ce cas, de ne pas le

faire tomber.

2

Comment forcer l’éjection d’un disque

Si un disque ne peut pas être reconnu ou ne

peut pas être éjecté par l’autoradio, forcez

l’éjection de la façon suivante.

Maintenez pressées les deux touches en

même temps.

• Si cela ne fonctionne pas, essayez de

réinitialiser l’autoradio.

• Faites attention de ne pas faire tomber le

disque quand il est éjecté.

Page 33

Merci pour avoir acheté un produit JVC. Veuillez lire attentivement toutes les instructions avant d’utiliser

l’appareil afin de bien comprendre son fonctionnement et d’obtenir les meilleures performances possibles.

TABLE DES MATIÈRES

Comment réinitialiser votre autoradio ....... 2

Comment forcer l’éjection d’un disque ...... 2

Comment utiliser la touche MODE............ 3

EMPLACEMENT DES TOUCHES .......... 4

Panneau de command .............................. 4

Télécommande ......................................... 5

Préparation de la télécommande .............. 6

FONCTIONNEMENT DE BASE ............ 7

Mise sous tension ..................................... 7

Annulation de la démonstration des

affichages ............................................... 8

Réglage de l’horloge ................................. 9

FONCTIONNEMENT DE LA RADIO ....... 10

Ecoute de la radio ..................................... 10

Mémorisation des stations ........................ 12

Accord d’une station présélectionnée ....... 13

FONCTIONNEMENT DU LECTEUR CD ... 14

Lecture d’un CD ........................................ 14

Localisation d’une plage ou d’un point

particulier sur un CD .............................. 15

Sélection des modes de lecture de CD..... 15

Interdiction de l’éjection de CD ................. 16

AJUSTEMENT DU SON .................... 17

Sélection des modes sonores préréglés

(C-EQ: égaliseur personnalisé) .............. 17

Ajustement du son .................................... 18

AUTRES FONCTIONS PRINCIPALES..... 19

Sélection du mode de gradateur ............... 19

Sélection de la commande de gain de

l’amplificateur ......................................... 19

Détachement du panneau de commande ... 20

DÉPANNAGE ................................ 21

ENTRETIEN ................................. 22

Manipulation des disques ......................... 22

SPÉCIFICATIONS........................... 23

Comment utiliser la touche MODE

Si vous appuyez sur MODE, l’appareil entre en mode de fonctions et les touches numériques

peuvent être utilisées comme touches de fonction.

Ex.: Quand la touche numérique 2 fonctionne comme touche MO (monaural).

FRANÇAIS

Indicateur de durée restante

Pour utiliser de nouveau ces touches comme touches numériques après avoir appuyer sur

MODE, attendez 5 secondes sans appuyer sur aucune touche, jusqu’à ce que le mode de

fonctions soit annulé.

• Appuyer de nouveau sur MODE annule aussi le mode de fonctions.

AVANT D’UTILISER L’APPAREIL

*

Par sécurité....

• N’augmentez pas trop le volume car cela bloquerait

les sons de l’extérieur rendant la conduite

dangereuse.

• Arrêtez la voiture avant de réaliser toute opération

compliquée.

*

Température à l’intérieur de la voiture....

Si votre voiture est restée garée pendant longtemps

dans un climat chaud ou froid, attendez que la

température à l’intérieur de la voiture redevienne

normale avant d’utiliser l’appareil.

3

Page 34

EMPLACEMENT DES TOUCHES

Panneau de command

Fenêtre d’affichage

FRANÇAIS

1 Touche (attente en service/sourdine)

2 Touche SEL (sélection)

3 Touche FM/AM

4 Touche CD

5 La fente d’insertion

6 Fenêtre d’affichage

7 Touche 0 (éjection)

8 Capteur de télécommande

9 Touche EQ (égaliseur)

p Touche 5 (haut)

Touche ¡ (avance rapide)

q Molette de commande

w Touches numériques

e Touche MO (monaural)

r Touche SSM (Mémorisation automatique des

meilleures stations)

t Touche RPT (répétition)

y Touche RND (aléatoire)

u Touche MODE

i Touche DISP (affichage)

o Touches

; Touche (déblocage du panneau de

commande)

4/¢

4

a Touche ∞ (bas)

Touche 1 (retour rapide)

Fenêtre d’affichage

s Indicateurs de réception du tuner

—MO (monaural), ST (stéréo)

d Indicateur CD

f Indicateur RND

g Indicateur RPT (répétition)

h Indicateur LOUD (contour)

j Indicateur EQ (égaliseur)

k Indicateurs du mode sonore (C-EQ: égaliseur

personnalisé)—ROCK, CLASSIC, POPS, HIP

HOP, JAZZ, USER

l Affichage principal

/ Affichage de la source

Indicateur du niveau de volume

(disque aléatoire)

Page 35

Télécommande

RM-RK50

SOUND

ATT

U

SOURCE

R

VOL

1 • Met l’appareil sous tension si vous appuyez

sur cette touche quand l’appareil est hors

tension.

• Maintenez pressée jusqu’à ce que

“SEE YOU” apparaisse sur l’affichage pour

mettre l’appareil hors tension.

• Appuyez brièvement sur cette touche pour

couper le volume momentanément.

Appuyez de nouveau le rétablir.

F

D

VOL

4 Fonctionne de la même façon que la molette

de commande de l’appareil principal.

Remarque:

Ces touches ne sont pas utilisées pour

ajuster “DEMO”, “CLOCK H”,

“CLOCK M”, “DIMMER” et “AMP

GAIN” (voir les pages 8, 9 et 19).

5 Sélectionne le mode sonore (C-EQ: égaliseur

personnalisé).

Chaque fois que vous appuyez sur la touche,

le mode sonore (C-EQ) change.

6 Sélectionner la source.

Chaque fois que vous appuyez sur la touche,

la source change.

7 • Recherche des stations en écoutant la

radio.

• Fait défiler rapidement en avant ou en

inverse la plage si est maintenue pressée

en écoutant le CD.

• Saute au début de plage suivante ou revient

au début des plages courante (ou

précédentes) si est brièvement pressée en

écoutant le CD.

FRANÇAIS

2 Choisit la bande lors de l’écoute de la radio.

Chaque fois que vous appuyez sur la touche,

la bande change.

3 Choisit les stations préréglées lors de l’écoute

de la radio.

Chaque fois que vous appuyez sur la touche,

le numéro de station préréglée augmente et

la station choisie est accordée.

5

Page 36

Préparation de la

télécommande

Avant d’utiliser la télécommande:

• Pointez la télécommande directement sur le

capteur de télécommande de l’appareil

principal. Assurez-vous qu’il n’y a pas

d’obstacle entre les deux.

Capteur de télécommande

FRANÇAIS

• Ne pas exposer la télécommande à un

éclairage puissant (en plein soleil ou un

éclairage artificiel).

Mise en place de la pile

Lorsque la portée ou l’efficacité de la

télécommande diminue, remplacez la pile.

1. Retirez le porte-pile.

1) Poussez le porte-pile dans la direction de

la flèche en utilisant la pointe d’un

stylo-bille ou un objet similaire.

2) Retirez le porte-pile.

3. Remettez le porte-pile en place.

Insérez le porte-pile en le poussant jusqu’à

ce que vous entendiez un déclic.

(face arrière)

AVERTISSEMENT:

• Conservez la pile hors de la portée des enfants.

Si un enfant venait à avaler une pile, consultez

immédiatement un médecin.

• Ne rechargez pas, ne court-circuitez pas, de

démontez pas, ne chauffez pas la pile et ne les

jetez pas dans le feu.

Le faire, pourrait amener la pile à émettre de la

chaleur, se fragmenter ou causer un incendie.

• Ne mélangez pas la pile avec d’autres objets

métalliques.

Le faire, pourrait amener la pile à émettre de la

chaleur, se fragmenter ou causer un incendie.

• Pour vous débarrassez des pile ou les

conserver, entourez-les de ruban adhésif et

isolez-les. Ne pas le faire, pourrait amener la

pile à émettre de la chaleur, se fragmenter ou

causer un incendie.

• Ne piquez pas la pile avec une broche

métallique ou un objet similaire.

Le faire, pourrait amener la pile à émettre de la

chaleur, se fragmenter ou causer un incendie.

(face arrière)

2. Placez la pile.

Insérez la pile dans le porte-pile avec le pole

+ dirigé vers le haut de façon que la pile soit

bien fixée dans le porte-pile.

Pile bouton au

lithium (Produit

référencé: CR2025)

6

ATTENTION:

NE LAISSEZ pas la télécommande pendant

longtemps dans un endroit exposé aux rayons

directs du soleil (tel que le tableau de bord).

Sinon, elle risque d’être endommagée.

Page 37

FONCTIONNEMENT DE BASE

1

3

2

Mise sous tension

1

Mettez l’appareil sous tension.

Remarque sur le fonctionnement monotouche:

Quand vous choisissez la source à l’étape

ci-dessous, l’appareil se met automatiquement

sous tension. Vous n’avez donc pas besoin

d’appuyer d’abord sur cette touche pour mettre

l’appareil sous tension.

2

Choisissez la source.

Pour utiliser le tuner (FM ou AM),

voir les pages 10 – 13.

Pour reproduire un CD,

voir les pages 14 – 16.

3

Ajustez le volume.

4

Ajustez le son comme vous le

souhaitez. (Voir les pages 17 et 18).

Pour baisser le son instantanément

Appuyez brièvement sur pendant

l’écoute de n’importe quelle source. “ATT ”

2

commence à clignoter sur l’affichage, et le

niveau de volume est baissé instantanément.

Pour revenir au niveau de volume précédent,

appuyez de nouveau brièvement sur la touche.

• Si vous tournez la molette de commande, vous

pouvez aussi rétablir le son.

FRANÇAIS

Pour mettre l’appareil hors tension

Maintenez pressée pendant plus d’une

seconde.

“SEE YOU” apparaît et l’appareil se met hors

tension.

• Si vous mettez l’appareil hors tension lors

de l’écoute d’un CD, la lecture du CD

débutera à partir de l’endroit où elle a été

interrompue la prochaine fois que vous mettez

l’appareil sous tension.

Pour augmenter le

volume

Pour diminuer le

volume

Le niveau de volume apparaît.

Indicateur du niveau de volume

PRECAUTION sur le réglage du volume:

Les CD produisent très peu de bruit comparé avec

les autres sources. Si le niveau de volume est

ajusté, par exemple, pour le tuner, les enceintes

risquent d’être endommagées par l’augmentation

soudaine du niveau de sortie.

Par conséquent, diminuez le volume avant de

reproduire un CD et ajustez-le comme vous le

souhaitez pendant la lecture.

7

Page 38

Annulation de la

DEMO OFF

DEMO ON

démonstration des affichages

À l’expédition de l’usine, la démonstration est en

service et celle-ci démarre automatiquement

FRANÇAIS

quand aucune opération n’est effectuée pendant

environ 20 secondes.

• Il est recommandé d’annuler la démonstration

des affichages avant d’utiliser l’appareil pour la

première fois.

Pour annuler la démonstration des

affichages, suivez la procédure ci-dessous:

1

Maintenez pressée SEL (sélection)

pendant plus de 2 secondes.

“DEMO”, “CLOCK H”, “CLOCK M”,

“DIMMER”, ou “AMP GAIN” apparaît sur

l’affichage.

2

Choisissez “DEMO” s’il n’apparaît

pas sur l’affichage.

3

Choisissez “DEMO OFF”.

4

Terminez le réglage.

Pour mettre en service la démonstration des

affichages, répétez la même procédure et

choisissez “DEMO ON” à l’étape

3

.

8

Page 39

Réglage de l’horloge

Fréquence

Horloge

1

Maintenez pressée SEL (sélection)

pendant plus de 2 secondes.

“DEMO”, “CLOCK H”, “CLOCK M”,

“DIMMER”, ou “AMP GAIN” apparaît sur

l’affichage.

2

Réglez les heures.

1 Choisissez “CLOCK H” (heures) s’il

n’apparaît pas sur l’affichage.

2 Ajustez les heures.

12

4

Terminez le réglage.

Pour vérifier l’heure actuelle ou changer le

mode d’affichage

Appuyez sur DISP (affichage)

répétitivement.

Chaque fois que vous appuyez sur

la touche, le mode d’affichage

change comme suit:

• Pendant l’utilisation du tuner:

• Pendant l’utilisation du CD:

HorlogeDurée de lecture écoulée

FRANÇAIS

3

Réglez les minutes.

1 Choisissez “CLOCK M” (minutes).

2 Ajustez les minutes.

12

• Quand l’appareil est hors tension:

L’appareil se met sous tension et l’horloge

apparaît pendant 5 secondes. Puis, l’appareil

se remet hors tension.

9

Page 40

FONCTIONNEMENT DE LA RADIO

Ecoute de la radio

Vous pouvez utiliser la recherche automatique ou

l’accord manuel pour accorder une station

particulière.

FRANÇAIS

Recherche d’une station

automatiquement:

Recherche automatique

1

Choisissez la bande (FM1 – 3, AM).

Chaque fois que vous

appuyez sur la touche, la

bande change comme suit:

FM1 FM2 FM3 AM

S’allume lors de la réception d’une émission

FM stéréo de signal suffisamment for.

La bande choisie apparaît.

Remarque:

Cet appareil a trois bandes FM (FM1, FM2,

FM3). Vous pouvez utiliser n’importe laquelle

pour écouter une station FM.

2

Commencez la recherche d’une

station.

Pour rechercher des

stations de fréquences

supérieures

Pour rechercher des stations de fréquences

inférieures

Quand une station est accordée, la

recherche s’arrête.

Pour arrêter la recherche avant qu’une

station ne soit accordée, appuyez sur la même

touche que vous avez utilisée pour la recherche.

10

Page 41

Recherche manuelle d’une station:

Recherche manuelle

1

Choisissez la bande (FM1 – 3, AM).

Chaque fois que vous

appuyez sur la touche, la

bande change comme suit:

FM1 FM2 FM3 AM

Remarque:

Cet appareil a trois bandes FM (FM1, FM2,

FM3). Vous pouvez utiliser n’importe laquelle

pour écouter une station FM.

2

Maintenez pressée ¢ ou 4

jusqu’à ce que “M” (manuel) clignote

sur l’affichage.

3

Accordez une station souhaitée

pendant que “M” (manuel) clignote.

Pour accorder des stations

de fréquences supérieures

Quand une émission FM stéréo est

difficile à recevoir:

1 Appuyez sur MODE pour entrer

en mode de fonction pendant

l’écoute d’une station FM.

2 Appuyez sur MO (monaural)

pendant que “MODE” clignote

sur l’affichage, de façon que

“MONO” apparaisse sur

l’affichage.

Chaque fois que vous appuyez

sur la touche, le mode monaural

se met alternativement en et

hors service.

Indicateur MO (monaural)

Lorsque l’indicateur MO est allumé sur

l’affichage, le son que vous entendez est

monaural mais la réception est améliorée.

FRANÇAIS

Pour accorder des stations de fréquences

inférieures

• Si vous relâchez la touche, le mode

manuel est mis automatiquement hors

service après 5 secondes.

• Si vous maintenez la touche pressée, la

fréquence continue de changer (par

intervalle de 200 kHz pour la bande FM et

par intervalle de 10 kHz pour la bande

AM) jusqu’à ce que vous la relâchiez.

11

Page 42

Mémorisation des stations

Vous pouvez utiliser l’une des deux méthodes

suivantes pour mémoriser les stations reçues.

• Présélection automatique des stations FM:

SSM (Mémorisation automatique des

meilleures stations)

• Présélection manuelle des stations FM et AM

Présélection manuelle

Vous pouvez présélectionner manuellement un

maximum de 6 stations pour chaque bande

(FM1, FM2, FM3 et AM).

Ex.: Mémorisation de la station FM située à

92,5 MHz sur le numéro de présélection 1

de la bande FM1.

Présélection automatique des stations

FM: SSM

Vous pouvez présélectionner 6 stations locales

dans chaque bande FM (FM1, FM2 et FM3).

1

Choisissez le numéro de la bande

FM (FM1 – 3) où vous souhaitez

FRANÇAIS

mémoriser la station.

Chaque fois que vous

appuyez sur la touche, la

bande change comme suit:

FM1 FM2 FM3 AM

2

Appuyez sur MODE pour entrer en

mode de fonction.

3

Maintenez pressée SSM pendant

environ 2 secondes.

1

Choisissez le numéro de la bande

(FM1 – 3, AM) où vous souhaitez

mémoriser la station (dans cet

exemple, FM1).

Chaque fois que vous

appuyez sur la touche, la

bande change comme suit:

FM1 FM2 FM3 AM

2

Accordez une station (dans cet

exemple à 92,5 MHz).

Pour accorder des stations

de fréquences supérieures

Pour accorder des stations de fréquences

inférieures

3

Maintenez pressée la touche

numérique (dans cet exemple, 1)

pendant plus de 2 secondes.

“SSM” clignote, puis disparaît quand le

préréglage automatique est terminé.

Les stations locales FM avec les signaux les plus

forts sont recherchées et mémorisées

automatiquement dans le numéro de bande que

vous avez choisi (FM1, FM2 ou FM3). Ces

stations sont mémorisées sur les touches de

présélection de station—No.1 (fréquence la plus

basse) à No.6 (fréquence la plus haute).

Quand la présélection est terminée, la station

mémorisée automatiquement sur la touche de

présélection de station 1 est accordée

automatiquement.

12

Le numéro préréglé clignote pendant un

instant.

Page 43

4

Répétez la procédure ci-dessus pour

mémoriser d’autres stations sur

d’autres numéros de présélection.

Remarques:

• La station précédemment présélectionnée est

effacée quand une nouvelle station est mémorisée

sur le même numéro de présélection.

• Les stations présélectionnées sont effacées si

l’alimentation du circuit mémoire est interrompue

(par exemple, pendant le changement de la

batterie). Si cela se produit, présélectionnez de

nouveau les stations.

Accord d’une station

présélectionnée

Vous pouvez accorder facilement une station

présélectionnée.

Rappelez-vous que vous devez d’abord

mémoriser les stations. Si vous ne les avez pas

encore mémorisées, référez-vous à

“Mémorisation des stations” à les pages 12 et

13.

1

Choisissez la bande (FM1 – 3, AM).

Chaque fois que vous

appuyez sur la touche, la

bande change comme suit:

FM1 FM2 FM3 AM

2

Choisissez le numéro (1 – 6) de la

station présélectionnée souhaitée.

FRANÇAIS

Remarque:

Vous pouvez aussi utiliser les touches 5 (haut) ou ∞

(bas) sur l’appareil pour choisir les stations

présélectionnées suivantes ou précédentes.

Chaque fois que vous appuyez les touches 5 (haut)

ou ∞ (bas), les stations présélectionnées suivantes ou

précédentes sont accordées.

13

Page 44

FONCTIONNEMENT DU LECTEUR CD

Lecture d’un CD

Insérez un disque dans la fente de

d’insertion.

FRANÇAIS

Remarque sur le fonctionnement monotouche:

Si un CD se trouve déjà dans la fente d’insertion,

appuyer sur CD met l’appareil sous tension et

commence la lecture automatiquement.

Indicateur CD

Indication de la source actuelle

Durée de lecture

totale du disque

inséré

Durée de lecture

écoulée

Toutes les plages sont reproduites répétitivement

jusqu’à ce que vous arrêtiez la lecture.

L’appareil se met en

marche, tire le CD et

commence la lecture

automatiquement.

Nombre total de

plages du disque

inséré

Numéro de la

plage actuelle

Remarque:

Quand un CD est inséré à l’envers, “EJECT”

apparaît sur l’affichage et le CD est éjecté

automatiquement.

Pour arrêter la lecture et éjecter le CD

Appuyez sur 0.

La lecture du CD s’arrête et le CD est

automatiquement éjecté de la fente d’insertion.

La source change sur le tuner (vous entendez la

dernière station reçue).

• Si vous changez la source, la lecture de CD

s’arrête aussi (sans éjecter le CD).

La prochaine fois que vous choisissez “CD”

comme source, la lecture du CD commence à

partir de l’endroit où elle a été interrompue.

Remarques:

• Si le CD éjecté n’est pas retiré avant environ 15

secondes, le CD est automatiquement réinséré dans

la fente d’insertion pour le protégé de la poussière.

(Dans ce cas, la lecture du CD ne commence pas).

• Vous pouvez éjecter le CD quand l’appareil est hors

tension.

A propos du désaligement:

Un désalignement peut être la conséquence d’une

conduite sur un terrain accidenté. Cela

n’endommage pas l’appareil ni le CD, mais cela

peut être agaçant.

Nous vous recommandons d’arrêter la lecture de

CD lors d’une conduite sur un tel terrain.

14

Page 45

Localisation d’une plage ou

d’un point particulier sur un CD

Sélection des modes de

lecture de CD

Pour avancer rapidement ou inverser une

plage

Maintenez pressée ¡,

pendant la reproduction d’un

CD, pour avancer rapidement la

plage.

Maintenez pressée 1, pendant la reproduction

d’un CD, pour inverser la plage.

Pour aller aux plages suivantes ou

précédentes

Appuyez brièvement sur

lors de la reproduction d’un CD,

pour avancer jusqu'au début de

la plage suivante.

Chaque fois que vous appuyez

consécutivement sur la touche,

le début des plages suivantes est

localisé et celle-ci est reproduite.

Appuyez brièvement sur

reproduction d’un CD, pour revenir au début de la

plage actuelle.

Chaque fois que vous appuyez consécutivement

sur la touche, le début des plages précédentes est

localisé et celle-ci est reproduite.

4

lors de la

¢

Pour aller directement à une plage

particulière

Appuyez sur la touche numérique

correspondante au numéro de plage souhaité

pour commencer sa reproduction.

Pour reproduire les plages dans un ordre

aléatoire (Lecture aléatoire de disque)

Vous pouvez reproduire toutes les plages du

disque dans un ordre aléatoire.

1 Appuyez sur MODE pour entrer

en mode de fonction pendant

l’écoute d’un CD.

2 Appuyez sur RND (aléatoire)

pendant que “MODE” clignote

sur l’affichage, de façon que

“DISC RND” apparaisse sur

l’affichage.

Chaque fois que vous appuyez

sur la touche, le mode de

lecture aléatoire de disque se

met alternativement en et hors

service.

Indicateur RND

Quand la lecture aléatoire de disque est mise en

service, l’indicateur RND

l’affichage. Puis, une plage choisie aléatoirement

est reproduite.

(disque aléatoire)

s’allument sur

FRANÇAIS

• Pour choisir un numéro de plage de 1 – 6:

Appuyez brièvement sur 1 (7) – 6 (12).

• Pour choisir un numéro de plage de 7 – 12:

Maintenez pressé 1 (7) – 6 (12) pendant plus

d’une seconde.

15

Page 46

Pour reproduire les plages répétitivement

(Lecture répétée de plage)

Vous pouvez reproduire la plage actuelle

répétitivement.

1 Appuyez sur MODE pour entrer

en mode de fonction pendant

l’écoute d’un CD.

2 Appuyez sur RPT (répétition)

pendant que “MODE” clignote

sur l’affichage, de façon que

“TRK RPT” apparaisse sur

l’affichage.

Chaque fois que vous appuyez

sur la touche, le mode de

lecture répétée de plage se met

FRANÇAIS

Quand la lecture répétée de plage est mise en

service, l’indicateur RPT s’allume sur l’affichage.

Puis, la plage en cours de lecture est reproduite

répétitivement.

alternativement en et hors

service.

Indicateur RPT

Interdiction de l’éjection de CD

Vous pouvez interdire l’éjection d’un CD et le

verrouiller dans la fente d’insertion.

Tout en maintenant pressée CD,

maintenez pressée 0 pendant plus de

2 secondes.

“NO EJECT” clignote sur l’affichage pendant

environ 5 secondes, le CD est verrouillé et ne

peut plus être éjecté.

Pour annuler l’interdiction et

déverrouiller le CD

Tout en appuyant sur CD, maintenez de nouveau

pressée 0 pendant plus de 2 secondes.

“EJECT” apparaît sur l’affichage et le CD est

éjecté de la fente d’insertion.

16

Page 47

AJUSTEMENT DU SON

Sélection des modes sonores

préréglés (C-EQ: égaliseur

personnalisé)

Vous pouvez choisir un mode sonore préréglé

(C-EQ: égaliseur personnalisé) convenant à

votre genre de musique.

Choisissez le mode sonore que vous

souhaitez.

Chaque fois que vous

appuyez sur la touche, le

mode sonore change comme

suit:

CLASSICROCKUSER

JAZZ

Le modèle d’affichage change pour

chaque mode sonore sauf pour “USER”.

HIP HOP

POPS

Indication Pour: Valeurs préréglées

BAS TRE LOUD

USER (Son plat) 00 00 OFF

ROCK Musique +03 +01 ON

rock ou disco

CLASSIC Musique +01 –02 OFF

classique

POPS Musique +04 +01 OFF

légère

HIP HOP Musique +02 00 ON

funk ou rap

JAZZ Musique +02 +03 OFF

Jazz

Remarque:

Vous pouvez ajuster chaque mode sonore selon vos

préférences. Une fois que vous avez réalisé un

ajustement, il est mémorisé automatiquement pour le

mode sonore actuellement choisi. Référez-vous à

“Ajustement du son” à la page 18.

FRANÇAIS

Ex.: Quand vous choisissez “ROCK”

17

Page 48

Ajustement du son

Vous pouvez ajuster les caractéristiques du son

à votre préférence.

1

Choisissez l’élément que vous

souhaitez ajuster.

Chaque fois que vous

appuyez sur la touche,

l’élément ajustable change

comme suit:

BAS

(graves)

VOL

(volume)

FRANÇAIS

Indication Pour: Plage

1

BAS*

TRE*

FAD *

BAL Ajuster l’équilibre L06 (Gauche

LOUD*1Relève les

VOL*

Ajuster les graves. –06 (min.)

1

Ajuster les aigus. –06 (min.)

2

Ajuster l’équilibre R06 (Arrièrer

entre les enceintes | seulement)

avant et arrière. F06 (Avant

entre les enceintes seulement)

gauche et droite. |

fréquences basses

et élevées pour LOUD ON

produire un son |

bien équilibré LOUD OFF

à faible niveau de

volume.

3

Ajuster le volume. 00 (min.)

TRE

(aigus)

LOUD

(contour)

(balance)

|

+06 (max.)

|

+06 (max.)

seulement)

R06 (Droit

seulement)

|

30 ou 50 (max.)

FAD

(fader)

BAL

1

*

Quand vous ajustez les graves, les aigus ou le

loudness, l’ajustement réalisé est mémorisé pour le

mode sonore actuellement choisi (C-EQ) y compris

“USER”.

2

*

Si vous utilisez un système à deux enceintes, réglez

le niveau de fader sur “00”.

3

*

Normalement, la molette de commande fonctionne

comme commande de volume. Alors, vous n’avez

pas besoin de choisir “VOL” pour ajuster le

niveau de volume.

4

*

En fonction du réglage de commande du gain de

l’amplificateur. (Référez-vous à la page 19 pour les

détails).

2

Ajustez le réglage.

Pour augmenter le

niveau ou pour mettre

en service le loudness

Pour diminuer le niveau

ou pour mettre hors

service le loudness

Le modèle d’affichage change quand

vous ajustez les grave ou les aigus.

Ex. 1: Quand vous ajustez les “TRE” (aigus)

Ex. 2: Quand vous mettez en service le

loudness

3

Répétez les étapes 1 et 2 pour

ajuster d’autres éléments.

Pour réinitialiser chaque mode sonore aux

réglages de l’usine, répétez la même procédure

et réaffectez les valeurs préréglées données

4

dans le tableau de la page 17.

*

18

Page 49

AUTRES FONCTIONS PRINCIPALES

Sélection du mode de gradateur

Vous pouvez assombrir l’affichage la nuit (en

fonction de vos préférences).

À l’expédition de l’usine, le gradateur est hors

service.

1

Maintenez pressée SEL (sélection)

pendant plus de 2 secondes.

“DEMO”, “CLOCK H”, “CLOCK M”,

“DIMMER”, ou “AMP GAIN” apparaît sur

l’affichage.

2

Choisissez “DIMMER” s’il n’apparaît

pas sur l’affichage.

3

Choisissez le mode souhaité—

“OFF” ou “ON”.

Sélection de la commande de

gain de l’amplificateur

Vous pouvez changer le niveau de volume

maximum de l’appareil. Quand la puissance

maximum des enceintes est inférieure à 50 W,

choisissez “LOW PWR” pour éviter qu’elles

soient endommagées.

À l’expédition de l’usine, “HIGH PWR” est choisi.

1

Maintenez pressée SEL (sélection)

pendant plus de 2 secondes.

“DEMO”, “CLOCK H”, “CLOCK M”, “DIMMER”

ou “AMP GAIN” apparaît sur l’affichage.

2

Choisissez “AMP GAIN” s’il

n’apparaît pas sur l’affichage.

3

Choisissez le mode souhaité

—“HIGH PWR” ou “LOW PWR”.

FRANÇAIS

• OFF: Met le gradateur hors service.

• ON: Met le gradateur en service.

4

Terminez le réglage.

• LOW PWR: Vous pouvez ajuster le niveau

• HIGH PWR: Vous pouvez ajuster le niveau

4

Terminez le réglage.

Remarque:

Si vous changez le réglage de “HIGH PWR” sur

“LOW PWR” pendant une écoute avec un niveau de

volume supérieur à 30, l’appareil change le niveau de

volume automatiquement sur “VOL 30”.

de volume de “VOL 00” à

“VOL 30”.

de volume de “VOL 00” à

“VOL 50”.

19

Page 50

Détachement du panneau de

commande

Vous pouvez détacher le panneau de commande

quand vous quittez la voiture.

Lors du détachement ou de la remise en place

du panneau de commande, faites attention de ne

pas endommager les connecteurs situés à

l’arrière du panneau et sur le porte-panneau.

Comment détacher le panneau de

commande

Avant de détacher le panneau de commande,

assurez-vous de mettre l’appareil hors tension.

FRANÇAIS

1

Déverrouillez le panneau de

commande.

Comment attacher le panneau de

commande

1

Insérez le côté gauche du panneau

de commande dans la rainure située

du côté droit du porte-panneau.

2

Appuyez sur le côté droit du

panneau de commande pour le fixer

au porte-panneau.

20

2

Levez et tirez le panneau de

commande de l’appareil.

3

Mettez le panneau de commande

détaché dans la boîte fournie.

Remarque sur le nettoyage des connecteurs:

Si vous détachez fréquemment le panneau de

commande, les connecteurs se détérioreront.

Pour réduire cette détérioration, essuyez

périodiquement les connecteurs avec un coton-tige

ou un tissu imprégné d’alcool, en faisant attention

de ne pas endommager les connecteurs.

Connecteurs

Page 51

DÉPANNAGE

Ce qui apparaît comme un problème n’est pas toujours très sérieux. Vérifier les points suivants avant

d’appeler un centre de réparation.

Symptoms

•

Le son ne peut pas être

entendu des enceintes.

•

Cet appareil ne fonctionne pas

du tout.

Général

•

La présélection automatique

SSM (Mémorisation

automatique des meilleures

stations) ne fonctionne pas.

FM/AM

•

Il y a du bruit statique lors de

l’écoute de la radio.

•

Le CD est éjecté

automatiquement.

•

Le CD-R/CD-RW ne peut pas

être reproduit.

•

Les plages sur un CD-R/

CD-RW ne peuvent pas être

sautées.

Causes

Le niveau de volume est réglé au

niveau minimum.

Les connexions sont incorrectes.

Le micro-ordinateur intégré peut

fonctionner incorrectement à

cause de parasites, etc.

Les signaux sont trop faibles.

L’antenne n’est pas connectée

fermement.

Le CD est inséré à l’envers.

Le CD-R/CD-RW n’est pas

finalisé.

Remèdes

Ajustez-la sur le niveau optimum.

Vérifiez les cordons et les

connexions.

Tout en maintenant SEL

(sélection) pressée, appuyez sur

sourdine) pendant plus de 2

secondes pour réinitialiser

l’appareil.

préréglés seront aussi effacés).

(Voir la page 2).

Mémorisez les stations

manuellement.

Connectez l’antenne fermement.

Insérez-le CD correctement.

•

•

(attente en service/

(Vos ajustements

Insérez un CD-R/CD-RW finalisé.

Finalisez le CD-R/CD-RW avec

l’appareil utilisé pour

l’enregistrement.

FRANÇAIS

•

Le CD ne peut être ni

reproduit ni éjecté.

Lecture de CD

•

Le son du CD est interrompu

par moment.

•

“NO DISC” apparaît sur

l’affichage.

Le CD est verrouillé.

Le lecteur de CD fonctionne

peut-être incorrectement.

Vous conduisez sur une route

accidentée.

Le CD est rayé.

Les connexions sont incorrectes.

Il n’y a pas de CD dans la fente

d’insertion.

Le CD n’est pas inséré

incorrectement.

Déverrouillez le CD.

(Voir la page 16).

Tout en maintenant

(attente en service/sourdine),

pressée, appuyez sur 0 (éjection)

pendant plus de 2 secondes. Faites

attention de ne pas faire tomber le

CD quand il est éjecté.

Arrêtez la lecture quand vous

conduisez sur des routes accidentées.

Changez le CD.

Vérifiez les cordons et les connexions.

Insérez un CD dans la fente

d’insertion.

Insérez-le CD correctement.

21

Page 52

ENTRETIEN

Manipulation des disques

Cet appareil est conçu pour reproduire les CD,

CD-R (enregistrables) et CD-RW (réinscriptibles).

• Cet appareil n’est pas compatible avec les

disques MP3.

Manipulation des disques

Pour retirer un disque de

son boîtier, faites pression

sur e support central du boîtier

et retirez le disque en le tenant

par ses arêtes.

• Tenez toujours le disque par ses arêtes. Ne

touchez pas la surface enregistrée.

Pour remettre un disque dans son boîtier,

insérez délicatement le CD autour du support

central (la surface imprimée dirigée vers le haut).

FRANÇAIS

• Remettez les disques dans leur boîtier après

utilisation.

Pour garder propres vos disques

Un disque sale peut ne pas être

reproduit correctement. Si un

disque devient sale, essuyez-le

avec un chiffon doux, en ligne

droite, du centre vers les arêtes.

Avant de reproduire un disque neuf

Les disques neufs peuvent avoir

des ébarbures sur les arêtes

intérieures et extérieures. Si un tel

disque est utilisé, cet appareil

risque de rejeter le disque.

Pour retirer ces ébarbures, frottez les arêtes

avec un crayon, un stylo, etc.

Condensation d’humidité

De l’humidité peut se condenser sur la lentille à

l’intérieur du lecteur de disque dans les cas

suivants:

• Après avoir mis le chauffage dans la voiture.

• Si l’intérieur de la voiture devient très humide.

Si cela se produit, le lecteur de disque peut ne

pas fonctionner correctement. Dans ce cas,

éjectez le disque et laissez l’appareil sous

tension pendant quelques heures, jusqu’à ce que

l’humidité se soit évaporée.

Support central

Lors de la reproduction d’un CD-R ou CD-RW

Avant de reproduire un CD-R ou CD-RW, lisez

attentivement leurs instructions et précautions.

•

Utilisez uniquement des CD-R ou CD-RW

“finalisés”.

•

Certains CD-Rs ou CD-RWs ne peuvent pas être

reproduits sur cet appareil à cause de leurs

caractéristiques et pour les raisons suivantes:

– Les disques sont sales ou rayés.

– De l’humidité s’est condensée sur la lentille,

à l’intérieur de l’appareil.

– La lentille du capteur, à l’intérieur de l’appareil,

est sale.

•

Les CD-RW peuvent nécessiter une durée de

mise en service plus longue car le facteur de

réflexion des CD-RW est inférieur à celui des CD

ordinaires.

•

Les CD-R ou CD-RW sont sensibles aux hautes

températures ou à une humidité importante. Ne

les laissez pas à l’intérieur de la voiture.

•

N’utilisez les CD-R ou CD-RW suivants.

– Disques avec des autocollants, des étiquettes

ou des cachets de protection collés sur leur

surface.

– Disques sur lesquels une étiquette peut être

imprimée directement avec, par exemple,

une imprimante à jet d’encre.

L’utilisation de ce type de disque par haute

température ou humidité peut entraîner un

mauvais fonctionnement de l’appareil ou

endommager le disque. Par exemple:

– L’autocollant ou l’étiquette peut rétrécir et

gondoler le disque.

– L’autocollant ou l’étiquette peut se détacher

et le disque ne peut plus être éjecté.

– L’impression sur le disque peut devenir collante.

Lisez attentivement les instructions et les

précautions sur les étiquettes et les disques

imprimables.

ATTENTION:

•

N’insérez pas des disques de 8 cm (3-3/16 pouces)

disque (CDs single) dans la fente d’insertion. (De tels

disques ne peuvent pas être éjectés).

•

N’insérez pas des disques avec une forme

inhabituelle—comme le cœur d’une fleur; cela

pourrait causer un mauvais fonctionnement.

•

N’exposez pas les disques à la lumière directe du soleil

ou à toute source de chaleur, ni ne les placez pas dans

un endroit soumis à des hautes températures ou à

l’humidité. Ne les laissez pas dans la voiture.

•

N’utilisez aucun solvant (comme par exemple: un

nettoyant pour disque analogique, un diluant en

bombe, de la benzine, etc.) pour nettoyer les disques.

22

Disque

gondolé

Autocollant

Reste

collant

Disque

Etiquette

spécialisée

Page 53

SPÉCIFICATIONS

SECTION AMPLIFICATEUR AUDIO

Puissance de sortie:

18 W RMS x 4 canaux à 4 Ω

et avec ≤ 1% THD+N

Rapport signal sur bruit:

80 dBA (référence: 1 W pour 4 Ω)

Impédance de charge: 4 Ω (4 Ω à 8 Ω tolérés)

Plage de commande de la tonalité:

Graves: ±10 dB à 100 Hz

Aigus: ±10 dB à 10 kHz

Réponse en fréquence: 40 Hz à 20 000 Hz

Niveau de sortie de ligne/Impédance:

2,5 V/20 kΩ en charge (pleine échelle)

Impédance de sortie: 1 kΩ

SECTION TUNER

Plage de fréquence:

FM: 87,5 MHz à 107,9 MHz

AM: 530 kHz à 1 710 kHz

[Tuner FM]

Sensibilité utilisable:

11,3 dBf (1,0 µV/75 Ω)

Sensibilité utile à 50 dB:

16,3 dBf (1,8 µV/75 Ω)

Sélectivité de canal alterné (400 kHz):

65 dB

Réponse en fréquence: 40 Hz à 15 000 Hz

Séparation stéréo: 35 dB

Rapport de synchronisation: 1,5 dB

[Tuner AM]

Sensibilité: 20 µV

Sélectivité: 35 dB

SECTION LECTEUR CD

Type: Lecteur de disque compact

Système de détection de signal: Capteur sans

contact optique (semiconducteur laser)

Nombre de canaux: 2 canaux (stéréo)

Réponse en fréquence: 5 Hz à 20 000 Hz

Plage dynamique: 96 dB

Rapport signal sur bruit: 98 dB

Pleurage et scintillement: Inférieur à la limite

mesurable

GÉNÉRAL

Alimentation:

Tension de fonctionnement:

CC 14,4 V (11 V à 16 V tolérés)

Système de mise à la masse: Masse négative

Température de fonctionnement admissible:

0°C à +40°C (32°F à 104°F)

Dimensions (L × H × P):

Taille d’installation (approx.):

182 mm × 52 mm × 150 mm

(7-3/16 pouces × 2-1/16 pouces ×

5-15/16 pouces)

Taille du panneau (approx.):

188 mm × 58 mm × 11 mm

(7-7/16 pouces × 2-5/16 pouces ×

7/16 pouces)

Masse (approx.):

1,3 kg (2,9 livres) (sans les accessoires)

La conception et les spécifications sont sujettes à

changement sans notification.

Si un kit de montage est nécessaire pour

votre voiture, consultez votre annuaire

téléphonique pour trouver le magasin

spécialisé en autoradio le plus proche de

chez vous.

FRANÇAIS

23

Page 54

Having TROUBLE with operation?

Please reset your unit

Refer to page of How to Reset

Still having trouble??

USA ONLY

Call 1-800-252-5722

http://www.jvc.com

We can help you!

EN, SP, FR

© 2004 Victor Company of Japan, Limited

0904DTSINTJEIN

Page 55