Page 1

SERVICE MANUAL

HD MEMORY CARD CAMERA RECORDER

HC044<Rev.001>20124SERVICE MANUAL

GY-HM150U, GY-HM150E,

GY-HM150EC

COPYRIGHT © 2012 JVC KENWOOD Corporation

1 PRECAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1 SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3.1 Removing the bottom cover assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3.2 Removing the upper assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3.3 Removing the view finder assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3.4 Removing the boards and the OP block assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3.5 Removing the upper assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

3.6 Removing the monitor assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3.7 Removing the view finder assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3.8 Removing the OP block assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

3.9 Removing the audio unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

4.1 INSTRUMENTS REQUIRED FOR ADJUSTMENT AND THE SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

4.2 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

5.1 SERVICE MENUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

5.2 HOW TO UPDATE THE FIRMWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

5.3 PRECAUTIONS WHEN CHANGING BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

5.4 Checking emergency history with SSS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

5.5 EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

5.6 SSS (Service Support System) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

* The illustration shows the GY-HM150U/GY-HM150E with the supplied microphone attached.

TABLE OF CONTENTS

COPYRIGHT © 2012 JVC KENWOOD Corporation

No.HC044<Rev.001>

2012/4

Page 2

SPECIFICATION

GY-HM150U GY-HM150E GY-HM150EC

General

Power consumption Approx. 8.3 W (when backlight is set to [STANDARD] while the LCD monitor or viewfinder is in use)

Allowable operating temperature 0 °C to 40 ° C (32 °F to 104 °F)

Allowable operating humidity 35 % RH to 80 % RH

Allowable storage temperature -20 °C to 50 °C (-4 °F to 122 °F)

Filter diameter When the hood is

Video/Audio

Video recording file

Video format NTSC setting HD (HQ mode):1920x1080/59.94i, 29.97p, 23.98p, 1440x1080/59.94i, 1280x720/59.94p, 29.97p, 23.98p

Terminals

Audio INPUT1/

INPUT2 terminals

Accessories

AC Adapter

Allowable operating temperature 0 °C to 40 ° C (32 °F to 104 °F)

Remote Control Unit

Allowable operating temperature 0 °C to 40 ° C (32 °F to 104 °F)

Image pickup device 1/4", Progressive CCD × 3

When the hood is

QuickTime File Format(For Final Cut Pro)

format

MP4 File Format (HD only)

AVI File Format (SD only)

Component terminal Y, P

Headphone jack 3.5 mm mini jack (stereo)

Remote terminal 3.5 mm mini jack (4-pin)

Operating distance Approx. 5 m (16.4 ft) (along front axis)

1-2 (No.HC044<Rev.001>)

Power DC 11 V (using AC adapter)

DC 7.2 V (using battery)

Dimensions 366 mm (W) × 179 mm (H) × 138 mm (D)(14-4/8" x 7-1/8" x 5-4/8")

Mass Approx. 1190 g (2.7 Ibs)

Approx. 1320 g (2.9 Ibs) (incl. battery BN-VF823U, SD card, micorophone)

Lens F1.8 to 2.8

f = 3.7 mm to 37 mm

detached

LCD screen 2.7", 16:9, 230,000 pixels

Viewfinder 0.24", 16:9, 260,000 pixels

Recording time Approx. 25 minutes (8 GB SDHC/SDXC card, 35 Mbps, VBR mode)

Video signal HD (HQ mode):MPEG-2 Long GOP

Audio signal LPCM 2ch, 48 kHz/16 Bit

PAL setting HD (HQ mode):1920x1080/50i, 25p, 1440x1080/50i, 1280x720/50p, 25p

AV terminal Video Analog output 1.0 V (p-p), 75 Ω Audio Analog output (stereo)

HDMI terminal HDMI

USB terminal Mini USB-B type, USB 2.0

Dimensions 49 mm (W) × 26 mm (H) × 64 mm (D)(1-15/16" × 1-1/ 8" × 2-7/8")

Battery life Approx. 1 year (varies according to frequency of use)

Dimensions 42 mm (W) × 14.5 mm (H) × 91 mm (D)(1-6/8" × 9/16" × 3-5/ 8")

46 mm (screw pitch: 0.75 mm)

Compatible with filter (external diameter: 50 mm and below),tele-converter, and wide-converter

72 mm (screw pitch: 0.75 mm)

attached

Compatible with filter (external diameter: 75 mm and below) only

* When removing the filter, do not press on the top and bottom of the hood. Doing so makes it difficult to remove the filter and may

damage the inner surface of the hood.

Zoom Up to 10x (optical zoom)

VBR, 35 Mbps (Max) MPEG-2

HD (SP mode):MPEG-2 Long GOP

CBR, 25 Mbps (1440x1080i) /19 Mbps(1280x720p) MPEG-2

SD DV

CBR, 25 Mbps (720x480i)

HD (SP mode):1440x1080/59.94i, 1280x720/59.94p, 29.97p, 23.98p

SD:720x480/59.94i -

HD (SP mode):1440x1080/50i, 1280x720/50p, 25p

- SD:720x576/50i

-8 dBu, 1 k Ω (when reference level -12 dB is selected)

-16 dBu, 1 k Ω (when reference level -20 dB is selected)

, PR component output

B

Y: 1.0 V (p-p), 75 Ω

, PR: 700 mV (p-p), 75 Ω

P

B

TM

Connector

MIC -60 dBu, 3 kΩ, XLR (balanced), +48 V output (phantom power supply)

LINE +4 dBu, 10 k Ω, XLR (balanced)

AC adapter, Power co rd×2, Battery, Battery

charger, Remote control unit, Audio unit,Microphone,AV cord,Component cable,CDROM,Instruction manual,Warranty card

Power AC 100 V to 240 V, 50 Hz/60 Hz

Output DC 11 V =, 1 A

(excluding cord and AC plug)

Mass Approx. 86 g (0.19 Ibs)

Type DC 3 V (button battery CR2025)

Mass Approx. 30 g (0.07 Ibs)(including button battery)

DV

CBR, 25 Mbps (720x576i)

AC adapter, Power co rd×4, Battery, Battery

charger, Remote control unit, Audio unit,Microphone,AV cord,Component cable,CDROM,Instruction manual

AC adapter, Power cord, Remote control

unit, Audio unit,Microphone,AV cord,Component cable,CD-ROM,Instruction manual,Warranty card

47 mm (W) × 28 mm (H) × 72 mm (D)

(excluding cord and AC plug)

Page 3

SECTION 1

r

PRECAUTION

1.1 SAFETY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding spurious radiation emission.

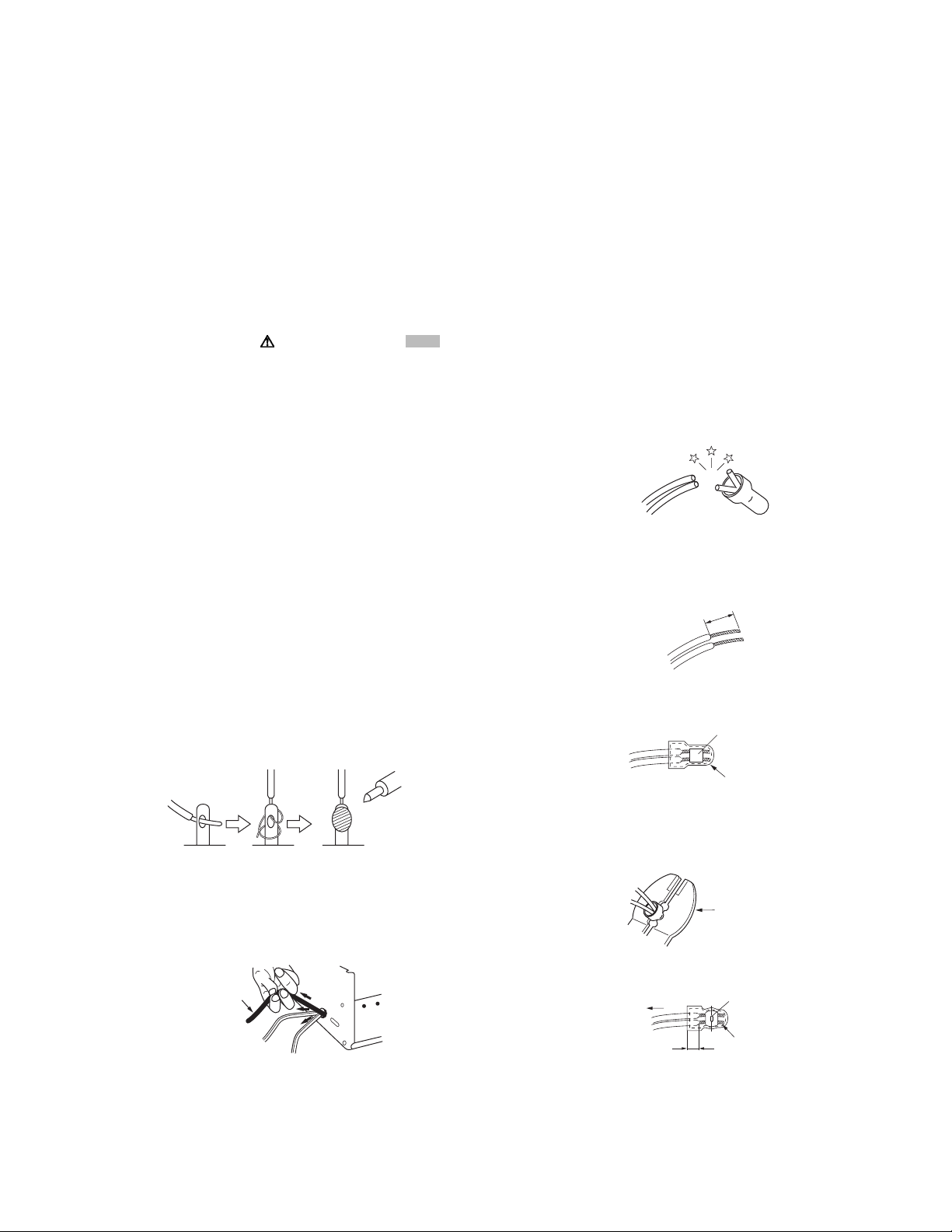

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

• Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

cathode ray tubes and other parts with only the specified

parts. Under no circumstances attempt to modify these circuits.Unauthorized modification can increase the high voltage value and cause X-ray emission from the cathode ray

tube.

(12) Crimp type wire connector In such cases as when replac-

ing the power transformer in sets where the connections

between the power cord and power trans former primary

lead wires are performed using crimp type connectors, if

replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according

to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected. In-

sert the wires fully into the connector.

Metal sleeve

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to

crimp the metal sleeve at the center position. Be

sure to crimp fully to the complete closure of the

tool.

1

.2

2.0

5.5

5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Crimped at approx. cente

of metal sleeve

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs) In regard to such

products, the cathode ray tubes themselves, the high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the

Conductors extended

Wire insulation recessed

more than 4 mm

Fig.1-1-7

(13) Battery replacement caution notice.

CAUTION RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE

INSTRUCTIONS.

(No.HC044<Rev.001>)1-3

Page 4

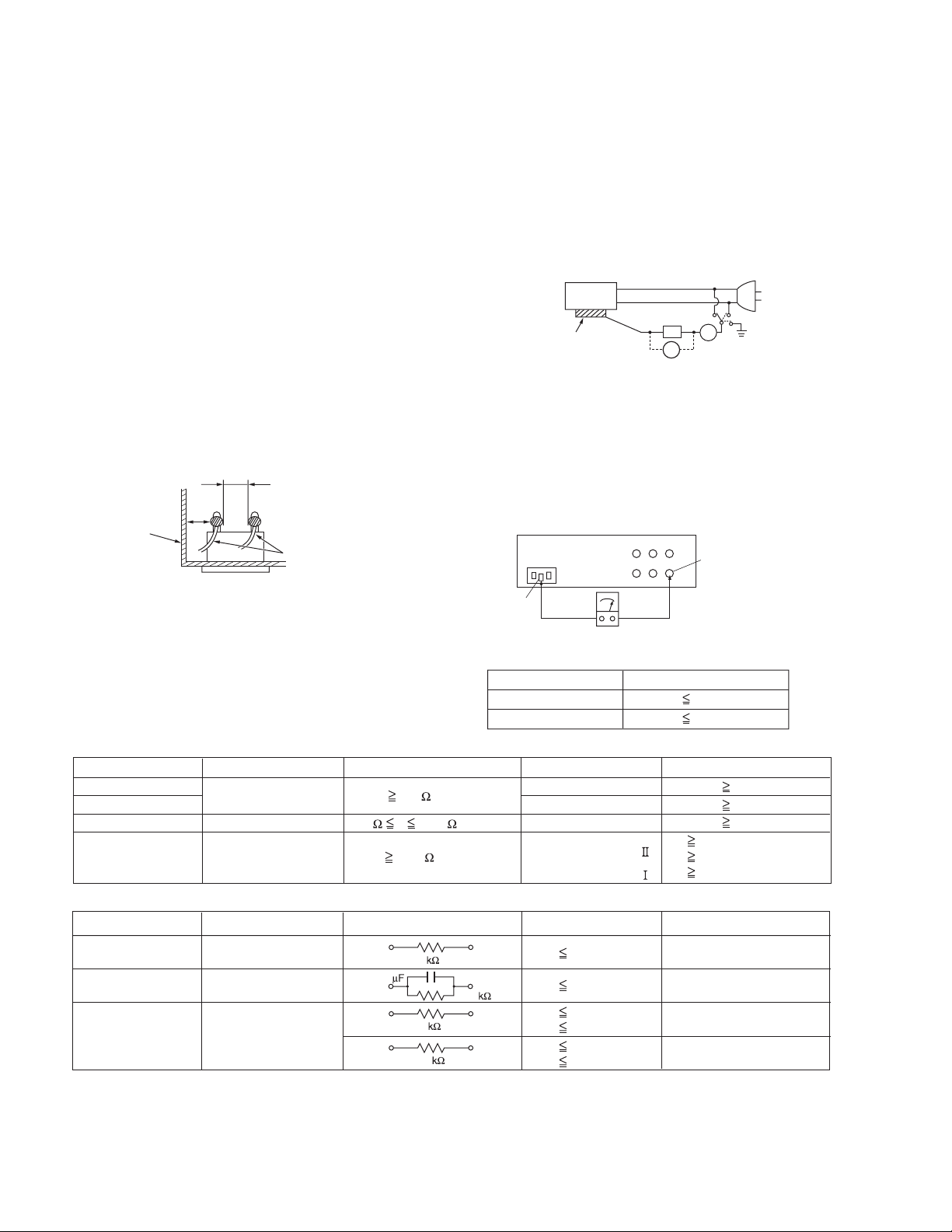

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed accessible parts (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON) Insert load Z between

earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure

across both terminals of load Z. See Fig.1-1-9 and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.HC044<Rev.001>)

Page 5

SECTION 2

r

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

SECTION 3

DISASSEMBLY

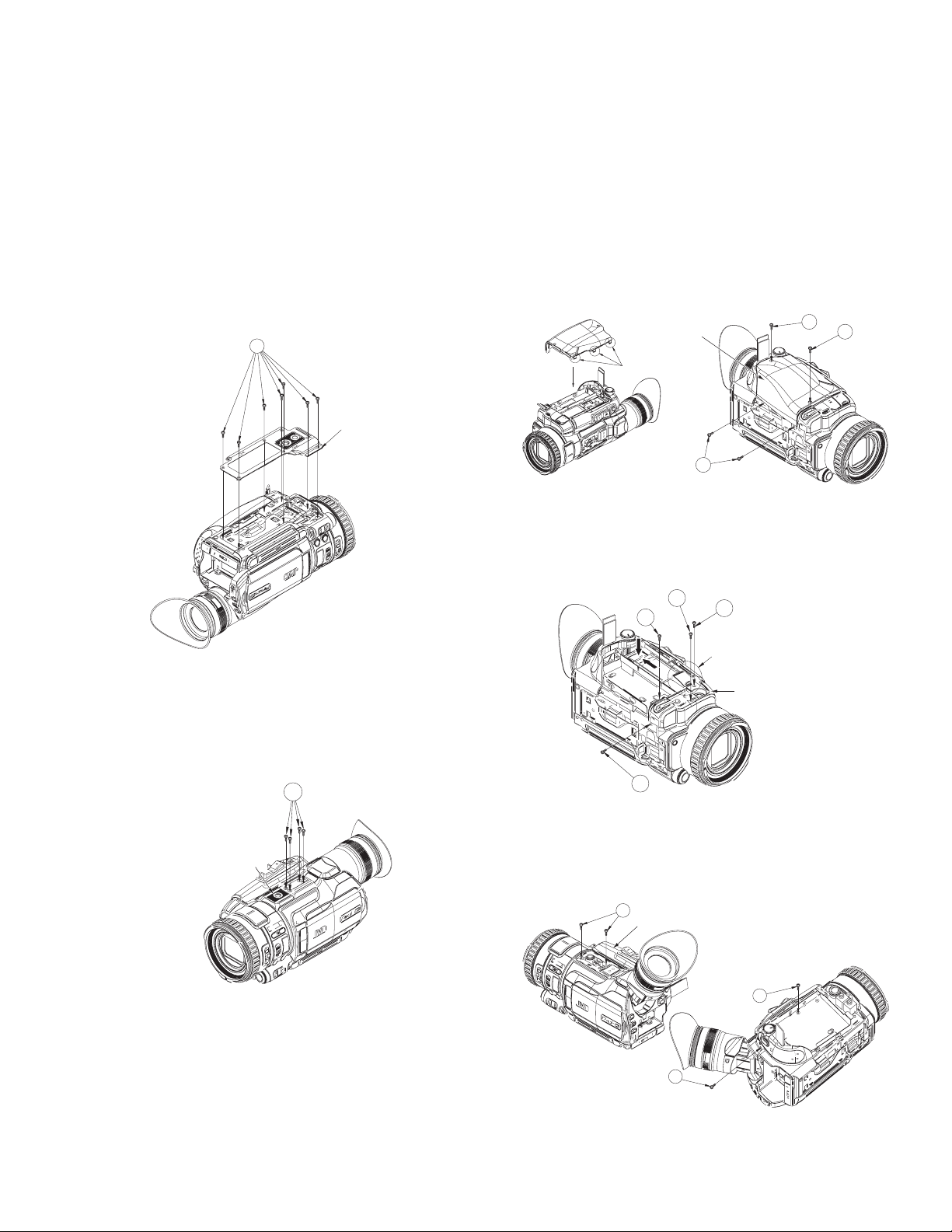

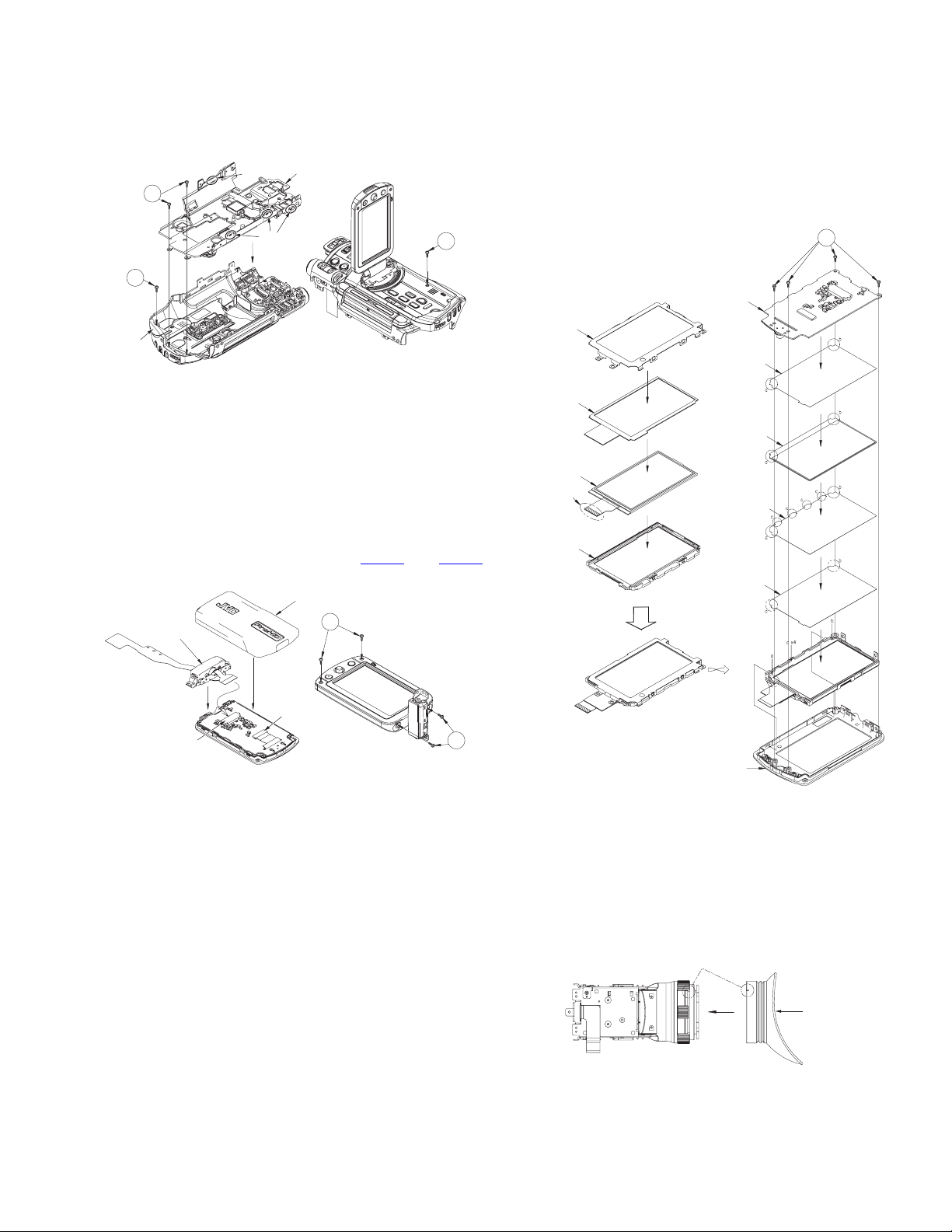

3.1 Removing the bottom cover assembly (See Figure 1)

(1) Remove the seven screws A attaching the bottom cover

assembly.

• The screws indicated with the marks need not be removed.

A

Bottom cove

assembly

Fig.1

3.2 Removing the upper assembly (See Figure 2, Figure 3, Figure 4, Figure 5, Figure 6, Figure 7, Figure 8)

(1) Remove the four screws A attaching the shoe assembly,

then remove the shoe assembly.

A

(2) Remove the four screws B attaching the grip cover, then

remove the grip cover.

• Before attaching the grip cover, attach the three tabs on

the grip cover first.

Grip cover

Tabs

B

B

B

Fig.3

(3) Remove the two screws C and the two screws D attaching

the jack cover, then remove the jack cover.

Screw C: Short Screw D: Long

Open the

mic cover

D

C

aa

C

D

The Jack cover is done in

the slide while pushing arrow

"a" part.

Jack cover assembly

Fig.4

Shoe assembly

Fig.2

(4) Remove the three screws E and the one screw F attaching

the upper cover assembly, then remove the upper cover

assembly.

Screw E: Short Screw F: Long

E

Upper cover assembly

E

F

Fig.5

(No.HC044<Rev.001>)1-5

Page 6

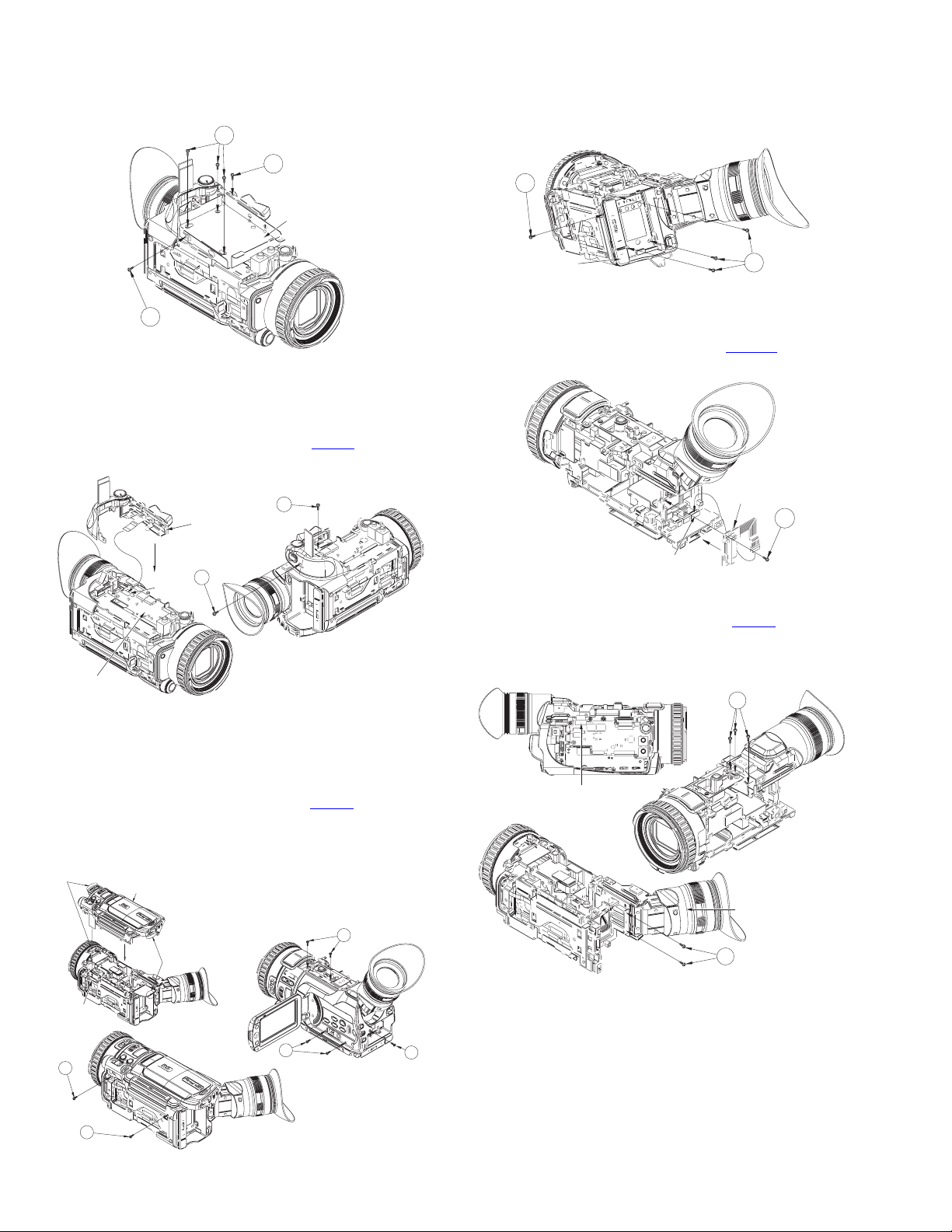

(5) Remove the four screws G and the one screw H attaching

the case (HDD), then remove the case (HDD).

Screw G: Short Screw H: Long

G

H

Case (HDD)

3.3 Removing the view finder assembly (See Figure 9, Figure 10, Figure 11)

(1) Remove the four screws A attaching the rear cover assem-

bly, then remove the rear cover assembly.

A

G

Fig.6

(6) Remove the one screw J and the one screw K attaching

the OPE unit.

Screw J: Short Screw K: Long

(7) Pull out the wire from the connector CN204

on the ANA-

LOG board, then remove the OPE unit.

J

OPE Unit

K

CN204

ANALOG

Board

Fig.7

Rear cover

assembly

A

Fig.9

(2) Remove the one screw B attaching the REAR board.

(3) Pull out the wire from the connector CN6001

on the MAIN

board, then remove the REAR board.

REAR Board

B

CN6001

MAIN Board

Fig.10

(4) Pull out the wire from the connector CN205

on the ANA-

LOG board.

(5) Remove the five screws C attaching the view finder assem-

bly, then remove the view finder assembly.

C

(8) Remove the six screws L and the one screw M attaching

the upper assembly.

Screw L: Short Screw M: Long

(9) Pull out the wire from the connector CN107 on the MAIN

board, then remove the upper assembly.

• When attaching the upper assembly, be sure to set the

two tabs firmly.

Set the tabs firmly

CN107

MAIN Board

L

L

Upper assembly

L

Set the tabs firmly

L

Fig.8

1-6 (No.HC044<Rev.001>)

CN205

ANALOG Board

View finder assembly

C

Fig.11

M

Page 7

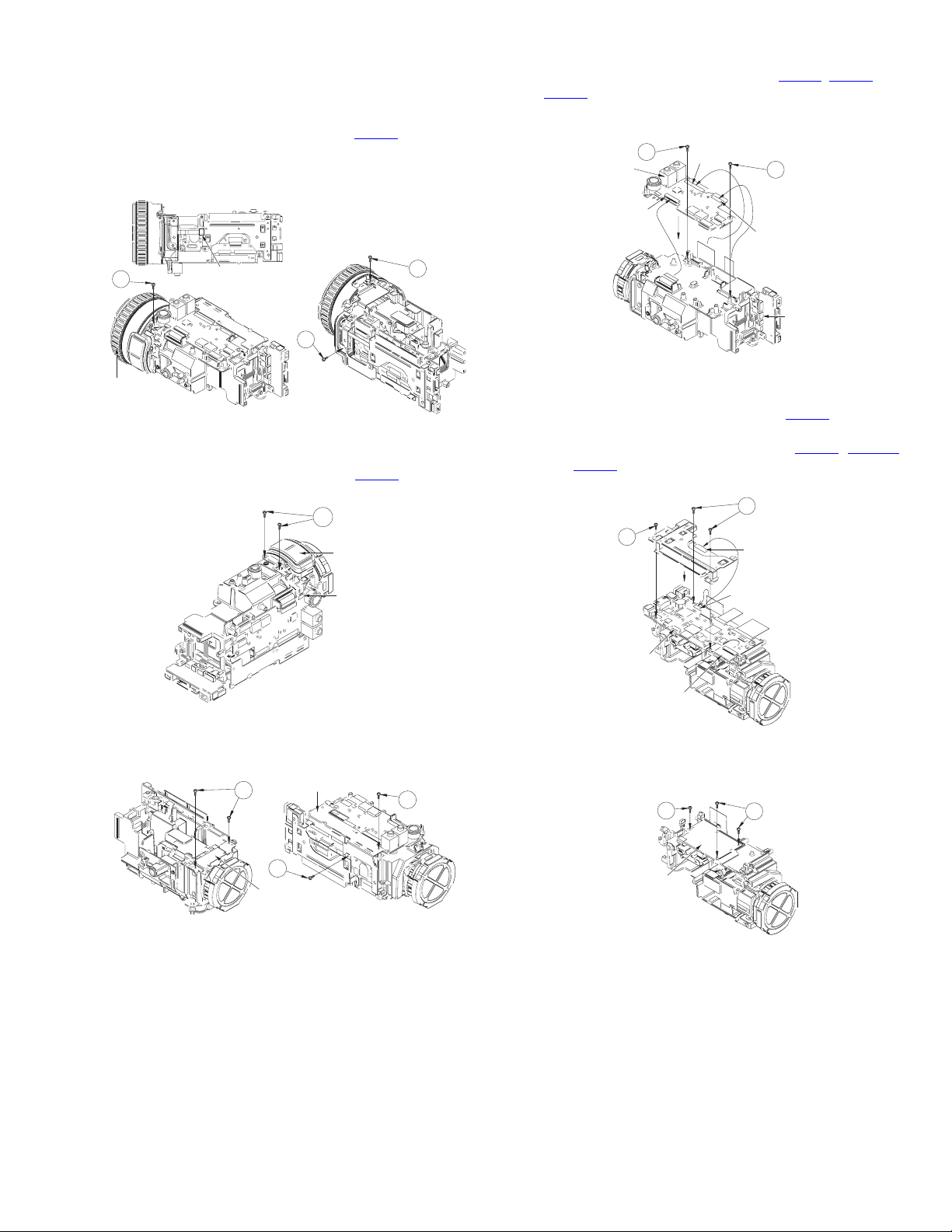

3.4 Removing the boards and the OP block assembly (See

A

Figure 12, Figure 13, Figure14, Figure 15, Figure 16,

Figure 17, Figure 18, Figure 19, Figure 20)

(1) Pull out the wire from the connector CN108

on the MAIN

board.

(2) Remove the three screws A attaching the focus ring as-

sembly, then remove the focus ring assembly.

(6) Pull out the wires from the connectors CN201

on the ANALOG board.

CN203

, CN202, and

(7) Remove the two screws D attaching the ANALOG board,

then remove the ANALOG board.

D

NALOG

Board

CN203

CN201

D

CN202

A

Focus ring

assembly

CN108

MAIN Board

A

A

Fig.12

(3) Remove the two screws B attaching the MIC assembly.

(4) Pull out the wire from the connector CN206

on the ANA-

LOG board, then remove the MIC assembly.

B

MIC Assembly

CN206

Fig.13

(5) Remove the four screws C attaching the bracket (bottom)

and the bracket (frame), then remove each bracket.

Bracket (Bottom)

C

C

CN6003

Fig.15

(8) Remove the three screws E attaching the bracket (MAIN).

(9) Pull out the wire from the connector CN901

on the SD

board, then remove the bracket (MAIN) and the SD board.

(10) Pull out the wires from the connectors CN103

and CN110

on the MAIN board, then remove the MAIN

, CN6003,

board.

E

E

CN110

MAIN

Board

CN901

SD Board

CN103

Fig.16

(11) Remove the three screws F attaching the heat sink (MAIN),

then remove the heat sink (MAIN).

F

F

C

Bracket (Frame)

Heat sink

(MAIN)

Fig.14

Fig.17

(No.HC044<Rev.001>)1-7

Page 8

(12) Disconnect the B to B connector from the connector

CN5001 on the CDS board.

(13) Remove the three screws G attaching the OP block assem-

bly, then remove the OP block assembly.

G

OP Block

assembly

CN5001

CDS Board

G

Fig.18

(14) Remove the two screws H attaching the JACK board, then

remove the JACK board.

H

JACK

Board

Fig.19

(4) Pull out the wires from the connectors CN621

and CN626 on the OPE4 board.

CN622

, CN624,

(5) Remove the one screw C and the two screws D attaching

the OPE4 board, then remove the OPE4 board.

Screw C: Silver Screw D: Black

D

CN621

D

CN626

CN624

C

CN622

OPE4 Board

Fig.22

(6) Remove the two screws E attaching the cover (upper), then

remove the cover (upper).

(7) Remove the two screws F attaching the monitor assembly,

then remove the monitor assembly.

E

F

Cover (upper)

(15) Remove the two screws J attaching the CDS board and the

bracket (CDS), then remove the CDS board and the bracket (CDS).

J

CDS Board and

bracket (CDS)

Fig.20

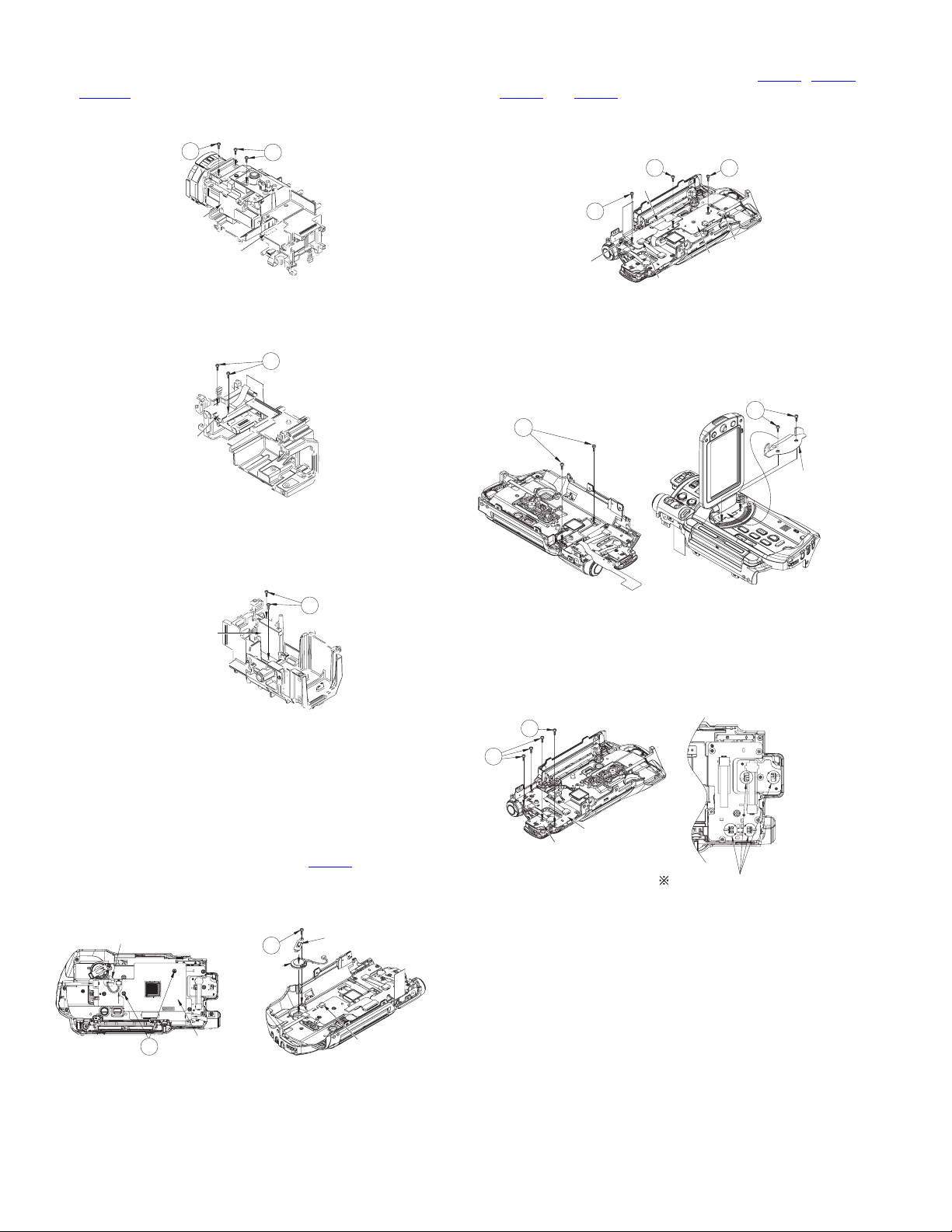

3.5 Removing the upper assembly (See Figure 21, Figure 22, Figure 23, Figure 24, Figure 25)

• Remove the upper assembly from the main unit.

(1) Remove the two screws A attaching the CU sheet, then re-

move the CU sheet.

(2) Pull out the wire from the connector CN623

on the OPE4

board.

(3) Remove the one screw B attaching the speaker, then re-

move the speaker and the bracket (SPK).

Process wire to this notch.

B

Speaker

Bracket (SPK)

Fig.23

(8) Remove the four screws G attaching the OPE2 board and

the OPE3 board, then remove each board.

• When attaching the OPE2 board and OPE3 board, make

sure that each pair of switches and knobs aligns at four

positions.

G

G

OPE3 Board

OPE2 Board

Fix the screws after confirming the

position of switch and knob.

Fig.24

CU Sheet

A

1-8 (No.HC044<Rev.001>)

CN623

Fig.21

Page 9

(9) Remove the two screws H and the one screw J attaching

the frame (upper).

(10) Remove the four tabs, then remove the frame (upper).

(11) Remove the one screw K attaching the OPE1 board as-

sembly, then remove the OPE1 board assembly.

Tab

H

K

Frame (upper)

Tabs

J

(3) Removing the four screws C attaching the bracket (LCD)

enables to release each part.

• When assembling the parts, be careful with the assembling order and direction of each part.

• Do not push the LCD surface as it may be damaged.

• Be careful in handling the surface of the LCD and the

monitor, and do not damage, soil, or leave fingerprints. If

the surfaces are soiled, gently wipe them off with soft

cloth.

C

MONI Board

OPE1

Board

assembly

Fig.25

3.6 Removing the monitor assembly (See Figure 26, Figure

27)

• Removing the monitor assembly from the upper assembly.

(1) Remove the two screws A and the two screws B attaching

the monitor cover assembly, then remove the monitor cover assembly.

Screw A: Narrow Screw B: Thick

(2) Pull out the wires from the connectors CN701

, and CN703

on the MONI board, then remove the hinge unit assembly.

Monitor cover assembly

Hinge unit

assembly

CN703

A

CN701

B

Fig.26

LCD Bracket

Spacer (LCD)

LCD Module

Support plate

side

LCD Case

Sheet (M.REF)

Light guide

Sheet (M.DIFF)

Sheet BEF

Turn

Put it on slit

of MONI case.

MONI Case assembly

Fig.27

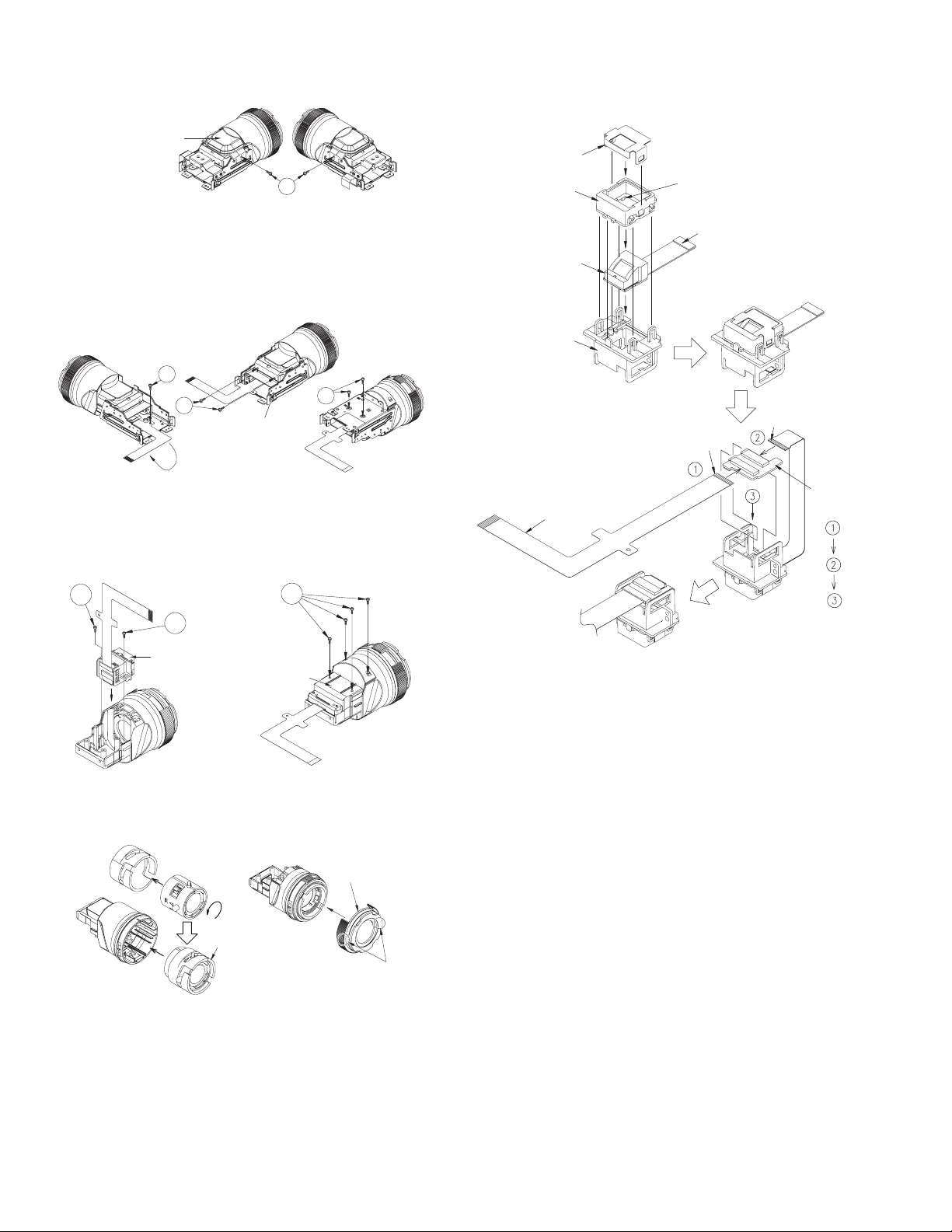

3.7 Removing the view finder assembly (See Figure 28, Figure 29, Figure 30, Figure 31, Figure 32, Figure 33)

• Remove the view finder assembly from the main unit.

(1) Remove the eye cap.

• When attaching the eye cap, align the positions as

shown in the figure.

Match and attach this position.

Eye cap

Fig.28

(No.HC044<Rev.001>)1-9

Page 10

(2) Remove the two screws A attaching the upper cover (VF),

then remove the upper cover (VF).

Upper cover (VF)

A

Fig.29

(3) Remove the one screw B attaching the wire.

(4) Remove the two screws C and the two screws D attaching

the holder (VF) assembly, then remove the holder (VF) assembly.

Screw C: Short Screw D: Long

B

C

Holder (VF)

assembly

D

(8) The parts on the LCD module assembly are fixed only with

the tabs. When assembling the parts, be careful with the attaching order and direction of each part.

LCOS Bracket

LCOS Cover

LCD Module

LCOS Holder

Note the boss breaking.

Support plate side

Terminal side

Terminal side

Fig.30

(5) Remove the four screws E attaching the bottom case (VF),

then remove the bottom case (VF).

(6) Remove the two screws F attaching the LCD module as-

sembly, then remove the LCD module assembly.

F

F

LCD Module assembly

Bottom case (VF)

E

Fig.31

(7) Remove the two tabs, then remove the front cover (VF).

• Removing the front cover (VF) enables to release the

lens and other parts.

Front cover (VF)

Lens holder

assembly

VF Board

FPC

Fig.33

1-10 (No.HC044<Rev.001>)

Tabs

Fig.32

Page 11

3.8 Removing the OP block assembly (See Figure 34, Fig-

r

ure 35, Figure 36, Figure 37)

• Remove the OP block from the main unit.

(1) Pull out the wire connected to the ROIS unit.

(2) Remove the two screws A attaching the ROIS unit, then re-

move the ROIS unit.

• Do not blow the lens inside the ROIS (on the OP

block) with air. Never touch the lens.

ROIS Unit

Connector

A

Fig.34

(3) Unsolder the soldered points on the CCD board, then re-

move the CCD board.

(4) Remove the one screw B attaching the heat sink (CCD) as-

sembly, then remove the heat sink (CCD) assembly.

B

(6) Unsolder the soldered points on the zoom motor unit and

the focus motor unit.

• Be careful not to break or damage the wire by solder-

ing (overheated).

(7) Remove the six screws D and the one screw E attaching

the iris motor unit, zoom motor unit, and the focus motor

unit, then remove each part.

• As the spring comes off when the zoom motor unit and

the focus motor unit are removed, be careful not to loose

the spring.

• See the figure when attaching the spring.

E

D

Iris motor unit

D

Focus moto

unit

Slide part (Motor side)

Slide part

(OP Block side)

Zoom motor unit

Hook

Hook

D

Spring

Spring

Spring

Fig.37

Heat sink (CCD)

assembly

Fig.35

(5) Remove the three screws C attaching the prism assembly,

then remove the prism assembly.

Prism

assembly

C

Fig.36

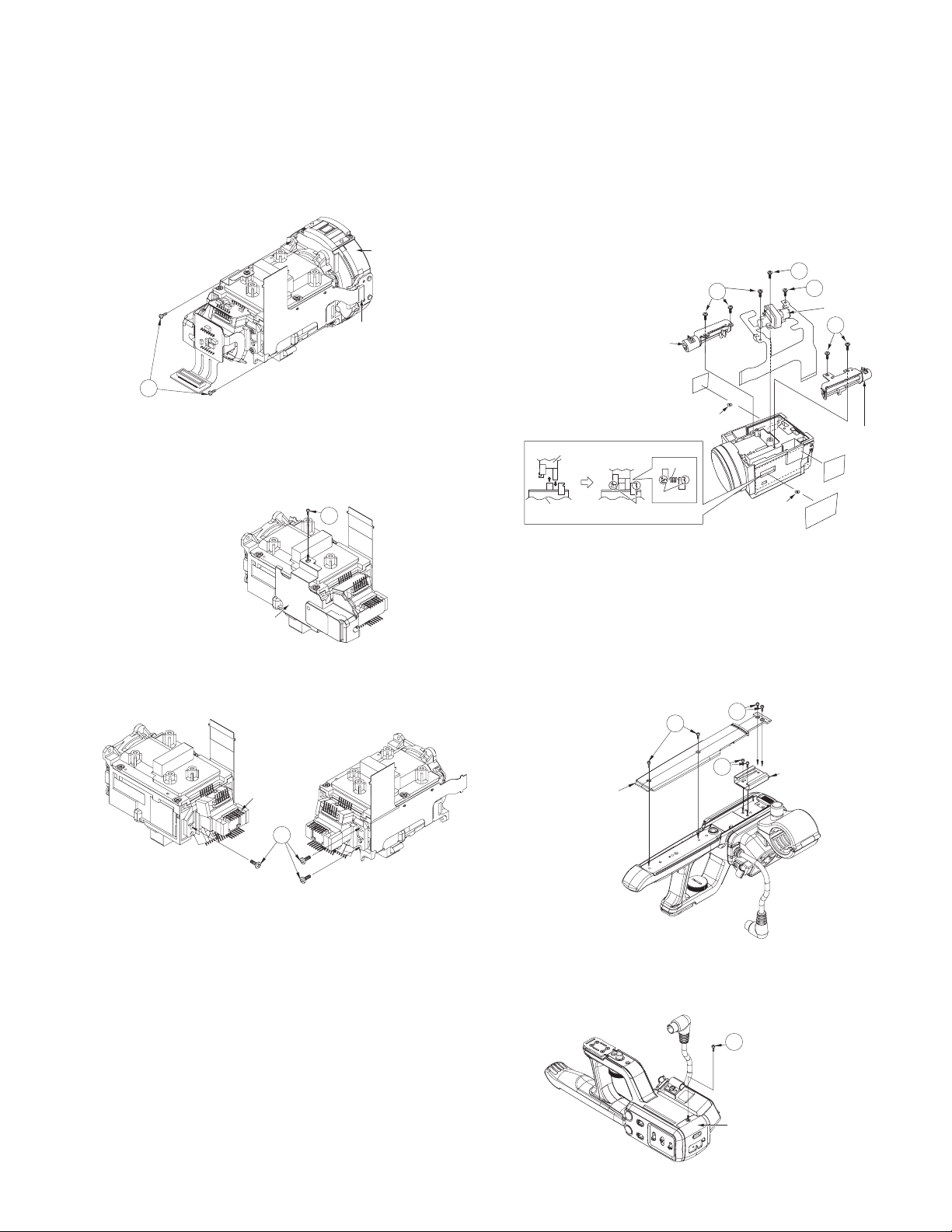

3.9 Removing the audio unit (See Figure 38, Figure 39, Figure 40, Figure 41, Figure 42, Figure 43, Figure 44, Figure 45)

(1) Remove the four screws A attaching the cover (TOP), then

remove the cover (TOP).

(2) Remove the two screws B attaching the shoe assembly,

then remove the shoe assembly.

A

Cover (TOP)

A

B

Shoe assembly

Fig.38

(3) Remove the one screw C attaching the AU cover (FR) as-

sembly, then remove the AU cover (FR) assembly.

C

AU Cover (FR) assembly

Fig.39

(No.HC044<Rev.001>)1-11

Page 12

(4) Remove the four screws D attaching the XLR board.

X

r

(5) Pull out the wire from the connector CN2802 on the XLR

board, then remove the XLR board assembly.

D

D

CN2802

D

(9) Remove the two screws H attaching the AU cover (BTM),

then remove the AU cover (BTM).

H

AU Cover (BTM)

Fig.44

XLR Board assembly

Fig.40

(6) Remove the three screws E attaching the AU cover (SW),

then remove the AU cover (SW).

• The slide knob comes off at the same time. When attaching the AU cover (SW), be careful with the direction of the

slide knob.

E

Slide knob

Slide knob

AU Cover (SW)

Fix convex shape of

knob with mark.

Fig.41

(7) Remove the two screws F attaching the audio VR knob,

then remove the audio VR knob.

(10) Remove the four screws J attaching the shoe plate, then

remove the shoe plate, lock screw, and the lock spring.

• See the figure when attaching the shoe plate, the lock

screw, and the lock spring.

J

Shoe plate

Detail of how to fix

Pass the screw a part of

extended slit.

A

Lock spring

Slide screw like arrow afte

pass A of the lock screw

Lock screw

Fig.45

Suppress the outside of knob,

and fix the screw.

attach the knob so that the print

side may become right.

(8) Remove the three screws G attaching the XLR2 board,

then remove the XLR2 board.

1-12 (No.HC044<Rev.001>)

LR2 Board

G

Audio VR knob

F

Fig.42

Fig.43

Page 13

SECTION 4

(

)

(

)

_R_

_G_

_

_

_B_

_

_

_

_

_

_

_

_HD_

_

_

_

_

_R_

_B_

_

_

_

_

_HD_

_

_

_

_

_

_

_G_

_

_

ADJUSTMENT

4.1 INSTRUMENTS REQUIRED FOR ADJUSTMENT AND THE SETUP

4.1.1 Measuring instruments required for adjustment

Instrument Condition Instrument Condition

PC (Windows) With an RS-232C compliant serial

communication port.

Color TV monitor Supporting HD, with an HDMI input. Speaker ----------

Oscilloscope 100 MHz or higher (300 MHz is recom-

mended), calibrated instrument.

Frequency counter With threshold level adjustment. Cali-

brated instrument.

Digital volt meter Calibrated instrument.

4.1.2 Jigs and tools required for adjustment

Self-diagnostic software

PC cable Communication cable Jig connector cable Charging battery

(Service Support System)

YTU94057-121

QAM0099-002 KSJ1742 KSJ1740 KSJ1741

Download from JS-NET

Audio tester Calibrated instrument.

DC power source 12V/1.7A or more, power source for light box.

AC adapter Used as a power source for the unit.

(Accessory : AP-V21)

adjustment jig

Light box INF adjustment lens

Focus chart Step down ring Filter

(Collimator)

YTU93096B YTU92001D YTU92001-018 YTU92001-102

ø46mm→ø36mm

4.1.3 Jig connector cable connection

(1) Remove the seven screws, then remove the bottom cover.

(2) Connect the jig connector cable to the MAIN board CN111.

IC CLIP WIRING

JIG Connector

TO MM0D

TO AL_3.1V

TO IF_RX

TO IF_TX

TO GND

Slide Switch of the Communication Cable

Communication

Cable

Green

Blue

Red

White

Black

Communication

Cable

Normally switched to the mini jack side.

(SSS communication for adjustment)

Only when updating CAM CPU,

switched to the IC clip side.

PC Cable

CAUTION

Before connecting the jig cable, be sure to turn “OFF” the power.

If the jig connector cable is connected while the power is “ON”,

communication error may occur.

When the error occurs, the power supply of unit is turned “OFF”.

JIG Connector Cable (KSJ1740)

JIG CONN

Service

Support

System

121

PC(Windows)

XDSPTRST

XDSPSRST

VF

VF

VF

VF

REG_3.1V

UA

UA

AL_3.1VSYS

DSP

SYS

OCD

VF

DRV

OCD

DSP

DSP

DSP

EXTRGO

DSP

MMOD

KENTO

11

16 2

JIG

23

JIG

17 4

JIG

35

COM_JIG

RXDO

TXDO

TX

IF

IF

RX

RSTL

GND

GND

RTCK

IRU

MVD

GND

18 6

47

19 8

59

20 10

611

21 12

TDI

713

22 14

SCL

815

JIG

23 16

3.0V

917

24 18

SDA

10 19

25 20

11 21

26 22

12 23

TCK

27 24

TDO

13 25

28 26

TMS

14 27

29 28

15 29

30 30

• Color temperature conversion filter.(LBB12)

YTU94152-LBB12

• ND filter (ND1.5)

YTU94152-ND1.5

• ND filter (ND0.3)

YTU94152-ND0.3

JIG CONN BOARDMAIN CN111

PIN No.

XDSPTRST

JIG

VF

JIG

VF

REG

3.1V

TXDO

UA

TX

IF

DSP_TDI

OCD

SCL

3.0V

DRV

OCD_SDA

DSP

RTCK

MVD

DSP

TDO

DSP

TMS

GND

XDSPSRST

VF

JIG

VF_COM_JIG

UA

RXDO

AL_3.1VSYS

IF

RX

SYS_RSTL

VF

JIG

GND

GND

IRU

TCK

DSP

EXTRGO

MMOD

KENTO

(No.HC044<Rev.001>)1-13

Page 14

4.1.4 Set up for adjustment

(1) Connect appropriate measuring instruments, jigs, and tools required for the adjustment item.

Color TV Monitor

Audio Tester

Light Box

Filter

Oscilloscope

Frequency Counter

Audio Signal

75 resistor for termination

Focus Chart

(Insert the filter into the light box.)

Collimator

Step Down Ring

Oscilloscope

Video Signal

Service

Support

System

121

4.2 ADJUSTMENT

The adjustment for this model is a special adjustment using a

PC.

Use the self-diagnostic software SSS (Service Support System)

for adjustment.

4.2.1 Basic usage of the SSS for adjustment

(1) Click [Adjustment Utility] on the main screen of the SSS.

(2) The Adjustment Utility screen is displayed.

• The adjustment items are categorized into the following

six groups.

Click the tab on the Adjustment Utility screen to select.

1) Setting Serial No.

2) Deck Adjustment

3) Camera Adjustment

4) Optical Adjustment

5) Color View Finder (C.VF) Adjustment

6) ROIS Adjustment

(3) Select the item to adjust.

a) Click the [Procedure], then select the adjustment

item from the pulldown menu.

b) Click the selected adjustment item.

(The display shows White Drop Out Pixel of CCD is selected)

(4) Click the [Start] button.

(5) Required procedure for adjustment is displayed on the

screen.

Follow the direction for adjustment.

(6) When the adjustment is completed normally, the box on the

left of the adjustment item is checked.

1-14 (No.HC044<Rev.001>)

Page 15

4.2.2 Setting Serial No.

Measuring

No. Item

Instrument &

Input Signals

1 Setting se-

--- EE

rial number

4.2.3 Deck Adjustment

Measuring

No. Item

Instrument &

Input Signals

1 Built-in MIC

L/R level

• Audio tester

• Speaker

balance

Mode

Mode

EE/Video mode

Measuring Point (A)

Adjustment Points (B)

Adjustment Level (C)

(A)--(B)EEPROM Menu

(C)Serial number

Measuring Point (A)

Adjustment Points (B)

Adjustment Level (C)

(A)A/V OUT (Audio OUT)

(B)60 Hz(NTSC):1710h

50 Hz(PAL) :6710h

(C)Minimize the level differ-

ence between the left and

the right sides.(Should be

within ±2.5dB)

Adjustment Procedure

(1) Input the serial number.

Input a number into the item of "Serial No."

in EEPROM Menu in SERVICE MENU.

(Refer to 5.1.6 EEPROM Menu. A serial

number is 8 figures.)

Adjustment Procedure

• Adjust in 60 Hz(NTSC), the value is also written in the 50 Hz(PAL) address.

(1) Set the unit 20 cm or more distance from

the speaker, facing the built-in MIC

straight to the speaker.

(2) Output about 300 Hz sine-wave sound.

Set the output level so that the audio output of the unit stays 400 to 700mVrms.

(3) Adjust to minimize the level difference be-

tween Lch and Rch.

20 cm or more

Speaker: 300 Hz sine wave

(No.HC044<Rev.001>)1-15

Page 16

4.2.4 Camera Adjustment

Measuring

No. Item

1 White Drop

Out Pixel of

CCD

NOTE

• For white blemish detection, the CCD must be fully warmed up.

- White blemish cannot be detected when the CCD is cold.

- Apply power for more than 60 minutes, then check the internal temperature is 47.5°C or higher (EEPROM data : 43h or

less) with the SSS main screen [Option]→[About Temperature(OP)].

- When the room temperature is low, the CCD may not be fully warmed up. Warm up the internal temperature by wrapping

the unit with antistatic aircap or similar material.

• Inserting an SD card to slot A is required.

(An SD card is required to temporary store the white blemish data obtained from the CCD. When the adjustment is finished,

the data is written in the EEPROM, and the temporary data on the SD card is deleted.)

• Before checking the white blemish correction, unplug the power cord and plug it back in.

(The adjustment only writes the correction data, and actual correction data reading and correction is performed when the

power is turned ON.)

2 Hall gain,

Offset

3 ND Hall

gain, Offset

4 White bal-

ance

Instrument &

Input Signal

--- Internal temper-

--- EE/Video mode

--- EE/Video mode

• Light box

• Collimator

•Filter

(Color temperature conversion LBB12)

Mode

ature of the unit

is 47.5°C or

higher (43h or

less)

EE/Video mode

Measuring Point (A)

Adjustment Point (B)

Adjustment Level (C)

(A)HDMI output

(B)2000h to 3FFFh

(C)Automatic adjustment

(A)--(B)60 Hz(NTSC)

:12C0h,12C1h

136Ah,136Bh

50 Hz(PAL): 62C0h,62C1h

636Ah,636Bh

(C)Automatic adjustment

(A)--(B)60 Hz(NTSC):1330h,1331h

4102h,4103h

50 Hz(PAL): 6330h,6331h

7102h,7103h

(C)Automatic adjustment

(A)--(B) 60 Hz(NTSC)

:122Ah~1239h

50 Hz(PAL): 622Ah~6239h

(C)Automatic adjustment

Adjustment Procedure

(1) Apply power to the unit for more than 60

minutes, then check the internal temperature is 47.5°C or higher (43h or less) using

the SSS.

(2) Start the adjustment.

(3) When the adjustment is completed, the in-

formation screen shows the completion of

the adjustment.

(4) Before checking the white blemish, unplug

the power cord and plug it back in.

• Adjust in 60 Hz(NTSC), the value is also written in the 50 Hz(PAL) address.

(1) Start the adjustment.

(2) When the adjustment is normally finished,

the information screen shows the completion of the adjustment. The color bar is displayed in the unit.

• Adjust in 60 Hz(NTSC), the value is also written in the 50 Hz(PAL) address.

(1) Start the adjustment.

(2) When the adjustment is normally finished,

the information screen shows the completion of the adjustment. The color bar is displayed in the unit.

• Adjust in 60 Hz(NTSC), the value is also written in the 50 Hz(PAL) address.

(1) Attach the collimator (without chart) to the

camera lens.

(2) Shoot the light box.

(3) After the start of the adjustment, the ad-

justment on the low color temperature is

completed, and the confirmation screen

for the continuing adjustment is displayed.

(4) Attach the LBB12 filter, then click OK.

(5) Start the adjustment.

(Adjustment on high color temperature

starts.)

(6) When the adjustment is normally finished,

the information screen shows the comple-

tion of the adjustment. The color bar is dis-

played in the unit.

1-16 (No.HC044<Rev.001>)

Page 17

No. Item

5Minimum/

Maximum

gain

Measuring

Instrument &

Input Signal

• Oscilloscope

•Light box

•Collimator

• ND filter

(ND0.3 ×

2pcs)

(or ND0.6 filter)

Mode

EE/Video mode

Measuring Point (A)

Adjustment Point (B)

Adjustment Level (C)

(A)COMPONENT OUT (Y)

[Minimum gain]

(B) 60 Hz(NTSC)

:12C2h,12C3h

50 Hz(PAL): 62C2h,62C3h

[Maximum gain]

(B) 60 Hz(NTSC)

:12C4h,12C5h

50 Hz(PAL): 62C4h,62C5h

(C)0.70±0.03Vpp

Adjustment Procedure

• Adjust in both 60 Hz(NTSC) and 50 Hz(PAL).

• Adjustment is performed only for the minimum

gain. The value of the minimum gain+1F6h is

written as the maximum gain.

[60 Hz(NTSC) adjustment]

(1) Attach the collimator (without chart) to the

camera lens.

(2) Attach the two ND0.3 filters (or one ND0.6

filter), then shoot the light box.

(3) The component Y output adjusts to the

specified value.

[50 Hz(PAL) adjustment]

(4) Adjust the component Y output to the

specified value in the same way as the

procedure (3).

6 AF filter • Light box

•Collimator

• ND filter

(ND1.5)

• ND filter

(ND0.3)

EE/Video mode

(A)---

(B)60 Hz(NTSC): 13A0h to

13A3h

(C)Automatic adjustment

(B)50 Hz(PAL) :63A0h to

63A3h

(C)Automatic adjustment

• Adjust in both 60 Hz(NTSC) and 50 Hz(PAL).

[60 Hz(NTSC) adjustment]

(1) Attach the collimator (without chart) to the

camera lens.

(2) Attach the ND1.5 filter, then shoot the light

box.

(3) After the start of the adjustment, the ad-

justment on the AGC ON is completed,

and the confirmation screen for the continuing adjustment is displayed.

(4) Change the filter from ND1.5 to ND0.3,

then click OK. (Adjustment of AGC OFF

starts.)

(5) When the adjustment of AGC OFF is com-

pleted, the screen for the continuing adjustment is displayed.

[50 Hz(PAL) adjustment]

(6) Change the filter from ND0.3 to ND1.5,

then, adjust in the same procedure from

(2) to (5).

(7) When the adjustment is normally finished,

the information screen shows the completion of the adjustment. The color bar is displayed in the unit.

(No.HC044<Rev.001>)1-17

Page 18

4.2.5 OP Adjustment

No. Item

1OP adjust-

ment

a)Infinity

sensor

b)Zoom

sensor

c) Multi

points adjustment

d) Backlash

(Focus)

e) Backlash

(Zoom)

f)Tele end

adjustment

g)Sensor

position focus pulse

number

h) Sensor

position

zoom pulse

number

Instrument &

Input Signals

• Light box

• Collimator

• Focus chart

Measuring

Mode

EE/Video mode

Measuring Point (A)

Adjustment Points (B)

Adjustment Level (C)

(A)---

(B)60 Hz(NTSC)

:14E0h,14E1h

50 Hz(PAL)

: 64E0h,64E1h

(B)60 Hz(NTSC)

:14E2h,14E3h

50 Hz(PAL)

: 64E2h,64E3h

(B)60 Hz(NTSC)

: 14E4h to 14EDh

50 Hz(PAL)

: 64E4h to 64EDh

(B)60 Hz(NTSC)

: 14EEh to 14F0h

50 Hz(PAL)

: 64EEh to 64F0h

(B)60 Hz(NTSC)

: 14F1h to 14F3h

50 Hz(PAL)

: 64F1h to 64F3h

(B)60 Hz(NTSC) : 14F7h

50 Hz(PAL): 64F7h

(B)60 Hz(NTSC) : 14F8h

50 Hz(PAL): 64F8h

(B)60 Hz(NTSC) : 14F9h

50 Hz(PAL): 64F9h

(C)Automatic adjustment

Adjustment Procedure

• Adjust in 60 Hz(NTSC), the value is also written in the 50 Hz(PAL) address.

• Items from a) to h) are automatically adjusted.

(1) Attach the collimator + focus chart to the

camera lens.

(2) Shoot the light box.

(3) Start the adjustment.

(4) When the adjustment is normally finished,

the information screen shows the comple-

tion of the adjustment. The color bar is dis-

played in the unit.

1-18 (No.HC044<Rev.001>)

Page 19

4.2.6 ROIS Adjustment

Measuring

No. Item

Instrument &

Input Signals

1 Center po-

--- ---

sition

Mode

Measuring Point (A)

Adjustment Points (B)

Adjustment Level (C)

(A)Label on the ROIS

(B)60 Hz(NTSC)

YAW(Lower digit): 16AAh

YAW(Higher digit): 16ABh

50 Hz(PAL)

YAW(Lower digit): 66AAh

YAW(Higher digit): 66ABh

(C)Write the value in the label

on the ROIS.

Adjustment Procedure

• Adjust in 60 (NTSC), the value is also written

in the 50 Hz(PAL) address.

(1) Note down the value in the label attached

to the ROIS.

(2) Write the 13th, 14th, and the 15th values

to each address.

(3) Write the 20th, 21st, and the 22nd values

in the same way.

2 YAW Hall

--- EE/Video mode

gain, Offset

3 PITCH Hall

--- EE/Video mode

gain, Offset

4 ROIS gain Color TV monitor EE/Video mode

(B)60 Hz(NTSC)

PITCH(Lower digit): 16ACh

PITCH(Higher digit):16ADh

50 Hz(PAL)

PITCH(Lower digit): 66ACh

PITCH(Higher digit):66ADh

(C)Write the value in the label

on the ROIS.

(A)--(B)60 Hz(NTSC):1694h,

1695h, 1698h to 169Bh

50 Hz(PAL): 6694h, 6695h,

6698h to 669Bh

(C)Automatic adjustment

(A)--(B)60 Hz(NTSC): 1696h,

1697h, 169Ch to 169Fh

50 Hz(PAL): 6696h,

6697h, 669Ch to 669Fh

(C)Automatic adjustment

(A)HDMI (or A/V OUT)

[YAW]

(B)60 Hz(NTSC)

YAW(Lower digit): 1690h

YAW(Higher digit): 1691h

50 Hz(PAL)

YAW(Lower digit): 6690h

YAW(Higher digit): 6691h

(C)Minimize lateral image

trembles.

[PITCH]

(B)60 Hz(NTSC)

PITCH(Lower digit): 1692h

PITCH(Higher digit):1693h

50 Hz(PAL)

PITCH(Lower digit): 6692h

PITCH(Higher digit):6693h

(C)Minimize lengthwise image

trembles.

1111098765432

12 22212019181716151413

Higher digit

Lower digit

YAW

Higher digit

Lower digit

PITCH

The higher digit of YAW and PITCH inputs

the value of one digit.

The lower digit of YAW and PITCH inputs

the value of two digits.

• Adjust in 60 Hz(NTSC), the value is also written in the 50 Hz(PAL) address.

(1) The adjustment is started.

(The automatic adjustment is done.)

• Adjust in 60 Hz(NTSC), the value is also written in the 50 Hz(PAL) address.

(1) The adjustment is started.

(The automatic adjustment is done.)

• Adjust in 60 (NTSC), the value is also written

in the 50 (PAL) address.

(1) While vibrating the unit to the YAW direc-

tion, adjust to minimize the tremble of the

TV monitor screen.

(2) While vibrating the unit to the PITCH direc-

tion, adjust to minimize the tremble of the

TV monitor screen.

(No.HC044<Rev.001>)1-19

Page 20

SECTION 5

TROUBLE SHOOTING

5.1 SERVICE MENUS

5.1.1 Modes required serviceing

Press the buttons by the combination of the following table, and press the [MENU] button. Will display the following service menus.

The items in the first layer vary according to the specified buttons being held when the [MENU] button is pressed.

(Characters are displayed on LCD monitor screen or view finder.)

MENU Item Displayed content Activation method

FIRMWARE Firmware (Package) version indi-

cation

VERSION CHECK CPU and Program version indica-

tion

ADVANCED FUNCTION White blemish and camera set-

tings

SERVICE FUNCTION Not used

DIP SW Settings of DIP SW

HOUR METER Power hour meter and slot eject

count

EEPROM Serial number input

IEEE1394ID input

While holding down the [OIS] button and the [MENU] button, turn ON the

power.

Turn ON the power. The following operations are performed while holding down the [OIS] button.

• While holding down the [USER1] button and the [USER2] button,

press the [MENU] button (less than 1 second).

• And the [MENU] button is pressed again.

Turn ON the power. The following operations are performed while holding down the [OIS] button.

• While holding down the [USER1] button and the [USER2] button,

press the [MENU] button (less than 1 second).

• And while holding down the [AF/MF] button, press the [MENU] button.

5.1.2 Operation in the first layer of the service menu

(1) While holding down the specified buttons, press the

[MENU] button.

(2) The first layer of each service menu is displayed.

(3) Press the [Cross-Shaped] buttons to move the cursor ()

to the item to be displayed.

(4) Press the [Set] button or the [Cross-Shaped] button (right)

to select the item.

NOTE :

• During recording, the service menu does not start up.

• To go back to the upper layer, press the [Cross-Shaped]

button (left).

• To cancel the service menu, press the [MENU] button.

5.1.2.1 FIRM WARE VERSION MENU Display

(1) Turn ON the power. (DC power supply and a battery are

necessary. )

(2) While holding down the [OIS] button and the [MENU] but-

ton, turn ON the power. Then, the version of firmware is

displayed.

Update Ready

Firmware SPL2470 V0002

Exit

1-20 (No.HC044<Rev.001>)

Page 21

5.1.2.2 Version of CPU and program display

(1) Turn ON the power. (CAM mode, MENU is undisplayed)

(2) The following operations are performed while holding down

the [OIS] button.

(3) While holding down the [USER1] button and the [USER2]

button, press the [MENU] button (less than 1 second).

(4) While holding down the [OIS] button, the [MENU] button is

pressed again.

(5) Move the cursor to [VERSION CHECK], then press the

[SET] button. Then the version of each CPU and a program

is displayed.

Version Check

Package SPL2470 V0002

CAM SPL2471 V0001

MBE SPL2472 V0002

MBE Loader SPL2473 V0001

EEPROM SPL2476 V0001

FPGA SPL2458 V830A

Back

5.1.2.3 SERVICE MENU display

(1) Turn ON the power. (CAM mode, MENU is undisplayed)

(2) The following operations are performed while holding down

the [OIS] button.

(3) While holding down the [USER1] button and the [USER2]

button, press the [MENU] button (less than 1 second).

(4) While holding down the [OIS] button and the [AF/MF] but-

ton, press the [MENU] button.

Service Menu

Advanced Function...

Service Function...

DIP SW...

Hour Meter...

EEPROM...

Exit

Advanced Function

Pixel Compen Det

OP Temperature 40.0

need over 47.5

Loop Rec Off

Back

o

C

o

C(104.0oF)

Item Parameter

PIXEL

COMPEN

DET*

OP TEMPERATURE

NEED OVER

47.5°C

The temperature information on

OP block is displayed.

In the case of a white blemish adjustment start, it recommends that

it is over this temperature.

LOOP REC OFF Loop REC is OFF.

ON Loop REC is carried out infinitely.

*Available only when the Camera Resolution setting is

1920x1080, and the Frame & Bit Rate setting is 60i(HQ). Otherwise, it becomes a gray display and no selection is available.

5.1.3.1 White blemish detection

(1) Open the MAIN MENU, then set [Camera Resolution] in

[Record Format] to 1920x1080, and [Frame & Bit Rate] to

60i(HQ).

Record Format

System Definition HD(MPEG2)

File Format Quick Time

Camera Resolution 1920x1080

Frame & Bit Rate 60i(HQ)

Aspect Ratio 16:9

Set

Cancel

5.1.3 ADVANCED FUNCTION Menu operation

(1) Refer to 5.1.1 to display the SERVICE MENU.

(2) Move the cursor to [ADVANCED FUNCTION], then press

the [Set] button or the [Cross-Shaped] buttons (up/down) to

change the parameter.

(3) ADVANCED FUNCTION Menu is displayed.

(4) Move the cursor to the item to be changed, then press the

[Set] button or the [Cross-Shaped] button (right).

(5) The parameter blinks. Press the [Cross-Shaped] buttons

(up/down) to change the parameter.

(6) Press the [Set] button to set the parameter. The parameter

lights up.

(7) Move the cursor to [BACK], then press the [Set] button or

the [Cross-Shaped] button (right) to go back to the upper

layer and finish the setting.

NOTE :

• To cancel the parameter setting change, press the [CrossShaped] button (left) while the item is chosen.

(2) Open the ADVANCED FUNCTION Menu, choose the [PIX-

EL COMPEN DET], and then press the [Set] button.

[PIXEL COMPEN DET]

Since it is displayed as Detect Pixel Compensation?, [Detect] is chosen and the [SET] button is pressed.

Advanced Function

Pixel Compen Det

OP Temperature 42.5

need over 47.5

Loop Rec Off

Detect Pixel Compensation?

Back

o

C

Advanced Function

Detect

Cancel

o

C(108.5oF)

NOTE:

An error is displayed when SD card is not inserted.

(No.HC044<Rev.001>)1-21

Page 22

PIXEL COMPEN

ERROR

SD CARD

TURN POWER OFF

AND ON AGAIN.

(3) [PIXEL COMPEN EXECUTING] is displayed and the de-

tection required for white blemish correction automatically

starts.

At this time, the camera lens is closed and the mode

changes to the SLOW SHUTTER mode.

PIXEL COMPEN

EXECUTING

5.1.4 DIP SW Menu Operation

(1) Refer to 5.1.1 to display the SERVICE MENU.

(2) Move the cursor to [DIP SW], then press the [Set] button or

the [Cross-Shaped] button (right).

(3) The DIP SW MAIN Menu is displayed.

--- DIP SW ---

DIPSW ALL RESET

DIP SW 0-7..

DIP SW 8-15..

DIP SW 16-23..

DIP SW 24-31..

DIP SW 32-39..

DIP SW 40-47..

DIP SW 48-55..

DIP SW 56-63..

BACK

--- DIP SW 1/8 ---

DIP SW 0 0

DIP SW 1 Off

DIP SW 2 Off

DIP SW 3 Off

DIP SW 4 Off

DIP SW 5 Off

DIP SW 6 Off

DIP SW 7 Off

BACK

(4) When the white blemish detection completes, the result

data is stored in the CPU memory, and an end message is

displayed as shown below. Turn OFF the power.

(After completing white blemish detection, the "Camera

Resolution" and "Frame & Bit Rate" settings return to the

original settings.)

PIXEL COMPEN

END

TURN POWER OFF

AND ON AGAIN

(5) If any errors occur during the detection, an error message

is displayed, then the screen returns to the MENU display.

Message Error details Operation

LENS NOT

CLOSED?

COUNT

OVER

The lens does not close

for detection.

The number exceeds

the specified count.

No result is stored in the

EEPROM.

Only the specified

count of data is stored

in the EEPROM.

--- DIP SW 2/8 ---

DIP SW 8 Off

DIP SW 9 Off

DIP SW 10 Off

DIP SW 11 Off

DIP SW 12 Off

DIP SW 13 Off

DIP SW 14 Off

DIP SW 15 Off

BACK

--- DIP SW 3/8 ---

DIP SW 16 Off

DIP SW 17 Off

DIP SW 18 Off

DIP SW 19 Off

DIP SW 20 Off

DIP SW 21 Off

DIP SW 22 Off

DIP SW 23 Off

BACK

--- DIP SW 4/8 ---

DIP SW 24 Off

DIP SW 25 Off

DIP SW 26 Off

DIP SW 27 Off

DIP SW 28 Off

DIP SW 29 Off

DIP SW 30 Off

DIP SW 31 Off

BACK

1-22 (No.HC044<Rev.001>)

Page 23

--- DIP SW 5/8 ---

DIP SW 32 Off

DIP SW 33 Off

DIP SW 34 Off

DIP SW 35 Off

DIP SW 36 Off

DIP SW 37 Off

DIP SW 38 Off

DIP SW 39 Off

BACK

--- DIP SW 6/8 ---

DIP SW 40 Off

DIP SW 41 Off

DIP SW 42 Off

DIP SW 43 Off

DIP SW 44 Off

DIP SW 45 Off

DIP SW 46 Off

DIP SW 47 Off

BACK

--- DIP SW 7/8 ---

DIP SW 48 Off

DIP SW 49 Off

DIP SW 50 Off

DIP SW 51 Off

DIP SW 52 Off

DIP SW 53 Off

DIP SW 54 Off

DIP SW 55 Off

BACK

--- DIP SW 8/8 ---

DIP SW 56 Off

DIP SW 57 Off

DIP SW 58 Off

DIP SW 59 Off

DIP SW 60 Off

DIP SW 61 Off

DIP SW 62 Off

DIP SW 63 Off

BACK

Refer to 5.1.3 ADVANCED FUNCTION Menu because the operations are almost the same.

NOTE :

ALL DIP switches are factory use only.

These DIP switches are not used for repair or maintenance.

Therefore all DIP Switch settings which are shown below

should not be changed. And do not forget to return to the initial

position, if setting was changed.

Item Parameter

DIP SW

ALL RESET

CANCEL

RESET

Cancel to reset all DIPSW

settings.

Execute to reset all DIPSW

settings.

DIP SW 1/8 DIP SW 0 0 Change prohibited.

DIP SW 1 to 7 OFF Change prohibited.

DIP SW 2/8 DIP SW 8 to 15 OFF Change prohibited.

DIP SW 3/8 DIP SW 16 to 23 OFF Change prohibited.

DIP SW 4/8 DIP SW 24 to 31 OFF Change prohibited.

DIP SW 5/8 DIP SW 32 to 39 OFF Change prohibited.

DIP SW 6/8 DIP SW 40 to 47 OFF Change prohibited.

DIP SW 7/8 DIP SW 48 to 55 OFF Change prohibited.

DIP SW 8/8 DIP SW 56 to 63 OFF Change prohibited.

(Bold is the factory setting.)

5.1.5 HOUR METER Menu Operation

(1) Refer to 5.1.1 to display the SERVICE MENU.

(2) Move the cursor to [HOUR METER], then press the [Set]

button or the [Cross-Shaped] button (right).

(3) The HOUR METER Menu is displayed.

Hour Meter

Power 000006

Slot Eject A 000001

Slot Eject B 000001

Back

Refer to 5.1.3 ADVANCED FUNCTION Menu because the operations are almost the same.

Item Parameter

POWER 000000 Displays the power hour meter.

RESET Resets the power hour meter.

SLOT

EJECT

000000 Displays the slot A and B eject count.

RESET Resets the slot A and B eject count.

(No.HC044<Rev.001>)1-23

Page 24

5.1.6 EEPROM Menu Operation

(1) Refer to 5.1.1 to display the SERVICE MENU.

(2) Move the cursor to [EEPROM], then press the [Set] button

or the [Cross-Shaped] button (right).

(3) The EEPROM Menu is diaplayed.

Item Parameter

Model ID 0 01h Factory use.

1 4F Factory use.

2 8B Factory use.

Node Uniq 0 00h Not use.

1 00h to FFh The left of a serial number to the 1st

figure, and the 2nd figures.

2 The left of a serial number to the 3rd

figure.

3 The left of a serial number to the 4th

figure, and the 5th figures.

4 The left of a serial number to the 7th

figure, and the 8th figures.

Serial No. 0 00h to FFh The left of a serial number to the 1st

figure. (*1)

1 The left of a serial number to the 2nd

figure. (*1)

2 The left of a serial number to the 3rd

figure. (*1)

3 The left of a serial number to the 4th

figure. (*1)

4 The left of a serial number to the 5th

figure. (*1)

5 The left of a serial number to the 6th

figure. (*1)

6 The left of a serial number to the 7th

figure. (*1)

7 The left of a serial number to the 8th

figure. (*1)

All Reset CANCEL Does not reset.

Reset * The data of EEP-ROM is returned

to a setup at the time of factory shipments. (Adjustment data and hour

meter data are excluded.)

* A setup at the time of shipment

changes with sale areas. (I: Japan,

U: America, E: Europe, EC: China)

(*1):It sets to the code changed according to the conversion table of the following table.

Number Input code

030h

131h

232h

333h

434h

535h

636h

737h

838h

939h

G47h

M4Dh

V56h

1-24 (No.HC044<Rev.001>)

Page 25

5.2 HOW TO UPDATE THE FIRMWARE

NOTE:

• When replacing MAIN board, the firmware update is required to maintain combination with other CPU versions.

• Do not turn OFF the power during the update, Otherwise the CPU may be destroyed and replacement of IC or board may be

required.

• Use both an AC adapter and a battery during update. (Do not connect the USB cable.)

• When update is failed, it is displayed on LCD as "UPDATE ERROR!" and LED of SLOT A and SLOT B blinks simultaneously.

If write protected of SD card is opened at this time (write-in permission), the log file "UPDLOG.TXT" will be written out.

Therefore, it understands which device was NG.

• Remove the IEEE1394 cable, or it may cause troubles on the GY-HM150.

• Do not format the SD memory card by PC.

The SD memory card formatted on the PC may not work correctly. Format the SD memory card on the GY-HM150 if formatting

is required.

• You can also use the SD memory cards formatted with digital still cameras, or formatted using formatting software supplied from

SD memory card manufacturer such as Panasonic.

5.2.1 Preparation (Copy the firmware to SD memory card)

NOTE:

• The update file is named as "GY-HM150.UPD".

• The update file should be put on the directory "//PRIVATE/JVC/GY-HM150", otherwise the update is not executed.

(1) Download the update file from JS-NET SMIS and unzip it to a PC.

(2) Insert the SD memory card to the PC and confirm that no file is in the SD memory card. If there are some files, delete them.

(3) Below the "PRIVATE" folder of an update file is copied to SD memory card.

5.2.2 Update procedure

(1) A battery (10-minute or more use is possible) and an AC adaptor are connected to a main unit.

(2) While pressing the [MENU] and [OIS] buttons, turn ON the power. The UPDATE READY menu is displayed and version of firm-

ware is displayed.

Update Ready

Firmware SPL2470 V0002

Exit

Push the [SET] button.

A

UPDATE READY

(3) Insert the SD memory card into the card slot B.

Note:

Can not be updated with slot A.

(4) The updating is started automatically, after the SD memory card was inserted.

Progress bar is displayed on the LCD display while updating.

The LED of SD card slot B blinks and LED of the slot A turned off.

LCD display

Updating

Don't Turn Power Off

...

----

MF

(No.HC044<Rev.001>)1-25

Page 26

(5) When the update is completed, LEDs of SD card slot A and slot B blink slowly. It takes about 3 minutes to complete the update.

Complete is displayed on the LCD display.

LCD display

Complete

(6) After complete the updating, remove the SD memory card.

(7) Turn OFF the power and an AC adapter and a battery are removed.

(8) Connect a battery and an AC adapter again and check the CPU version.

Note :

Confirm the firmware in the SD card if the "update can't be Executed !" was displayed on the LCD display.

(The LEDs of SD card slot A and slot B blink alternately, when update can not be executed.)

LCD display

Update can't be Executed !

Note:

Check the defect of board or the connection of each board, if the "update error !" was displayed.

LCD display

Update Error !

5.3 PRECAUTIONS WHEN CHANGING BOARDS

After changing the board in service, firmware version update and adjustment may be required.

Make sure to perform version update after changing the MAIN board.

1-26 (No.HC044<Rev.001>)

Page 27

5.4 Checking emergency history with SSS

Emergency history can be checked using SSS.

(1) On the SSS main screen, click [Emergency Utility].

5.4.2 Deleting emergency history

(1) Click [Erase All] on the Emergency Utility screen to delete

emergency history.

(2) Click [Read] on the Emergency Utility screen.

(3) Emergency history is displayed.

NOTE

• Emergency history is recorded in HISTORY-1 to HISTORY-4 in the occurrence order. After the 5th error, HISTORY-4 is overwritten.

• Emergency history is recorded in the EEPROM data. When

all relevant repair work is completed, delete the ERROR

HISTORY.

5.4.3 Emergency display detail

Emergency detail Cause

V INFO ERROR

(Video management file

error)

→When data recovery is

possible, recovery

screen is displayed.

Press [OK] to execute

the recovery.

If recovery is impossible, formatting is required.

MEDIA ERROR

(Media initialization error)

Buffer over flow

• Only the number.

• Can be checked with

SSS (No display on the

unit).

(1)During video recording:

•SD card is removed.

•Power is disconnected or interrupted.

(2)During video editing (Delete/OK

mark/Copy):

•SD card is removed.

•Power is disconnected or interrupted.

(3)Data failure in the card due to

other cause.

• SD card failure.

• SD card terminal connection fail-

ure.

• Card removal right after insertion.

• Due to fragmentation of the SD

card, writing speed deteriorates.

• Copy the necessary data, then

format the SD card.

5.4.1 Saving emergency history

(1) Click [Save] on the SSS main screen.

(2) Save the file with a proper name in a proper location.

(3) To open the saved file, [OPEN] is clicked.

5.4.4 Countermeasure on emergency

If the above emergencies occur, check the SD card or the handling of the SD card.

(1) Check if the SD card terminal is dirty or there is any foreign

material.

(2) After copying the necessary data, format the SD card.

(3) Use recommended SD cards.

(Panasonic, TOSHIBA, or SanDisk)

Using cards other than those specified above may prevent

data from being recorded correctly or result in loss of data.

(4) Do not remove the SD card until card recognition is com-

pleted. (The SD card is not extracted until changing lighting

the access lamp of the card slot.)

(5) While the access lamp is blinking, do not remove the SD

card. Data could be broken.

*If the error is not corrected after checking/replacing

(using normal SD card), or properly handling the SD

card, failure in the main unit is considered.

(No.HC044<Rev.001>)1-27

Page 28

5.5 EEPROM

GY-HM150 has an EEPROM (MAIN board IC1005) for data storage.

When the MAIN board or the EEPROM is replaced, initial value

data writing is required. Readjustment is also required because

the adjustment data is reset.

Using SSS (Service Support System) enables writing, reading

(backup), and changing EEPROM data.

Fixed data Data that not change by CPU.

(Model code, etc.)

Adjusting data Data that is changed by adjustment.

(Adjustment data)

No Fixed data Data that may be changed by CPU.

(Focus/Zoom position memory, etc.)

Default setting data Data that is changed by usage

(Menu setting, emergency data, etc.)

Doctor data Doctor program (Data that not change.)

PE data Data that is used during production.

5.5.1 EEPROM initial data writing

Caution

• Before starting EEPROM data writing, be sure to turn OFF

the power dial of the unit.

• The initial value data is reset, except the fixed value and the

doctor program. Therefore, it is necessary to readjust SECTION 4.

• When the backup data writing of EEPROM, the initial value

data need not be written.

(3) When the Initial and Original file navigator screen appears,

select the SSS folder. Selecting an Object Model automat-

ically displays files that conform to each CPU version.

(4) Click the Conformity file [M9H7-HM100**-MP-*.ROM].

(5) Click [OK].

(6) “Initial data for "GY-HM150**" was loaded on the map.” is

displayed. Click [OK].

(7) The initial data is displayed on the EEPROM Utility screen.

Make sure that the power dial of the unit is turned OFF,

then click [Write].

(1) Click [EEPROM Utility] on the SSS main screen.

(2) Click [Open].

(8) Although the initial data is written, the adjustment data is

reset. Readjust the unit.

5.5.2 EEPROM data backup

EEPROM data can be backed up using SSS. The backed up EEPROM data can be rewritten in the unit.

(1) Click [EEPROM Utility] on the SSS main screen.

(2) When the EEPROM Utility screen appears, click [Read].

1-28 (No.HC044<Rev.001>)

Page 29

(3) After reading the EEPROM data, click [Save].

(4) Save the file as a proper name with a serial number in a

proper location. (Extension is XXXXXX.rom)

5.5.3 EEPROM backup data (original file) writing

Caution

• Before starting EEPROM data writing, be sure to turn OFF

the unit.

• The EEPROM data is the one at the time of the backup. The

adjustment data and the EEPROM version are also the

ones at the time of backup. It is likely to differ from an original version, Adjust the unit or update the EEPROM version

as required.

(1) Specify the location of the backup file saved in 5.2.1 EE-

PROM initial value data writing procedure (3) on the Initial

and Original file navigator screen.

(2) Click Original in Object Model.

(3) Find the target file by the file name from among the dis-

played files.

Select the Conformity file, then click [OK].

5.5.4 EEPROM version check

(1) On the SSS main screen, click [EEPROM Utility].

(2) When the EEPROM Utility screen appears, click [Read].

(3) The EEPROM data is read, and the EEPROM version is

displayed in the right bottom of the screen. (CAM and ARM

versions are also displayed.)

(4) The backup data is displayed in the EEPROM Utility

screen. Make sure that the power dial of the unit is turned

OFF, then click [Write].

(No.HC044<Rev.001>)1-29

Page 30

5.6 SSS (Service Support System)

5.6.1 Installation

(1) Download SSS (Service Support System) from JS-NET.

(2) As the downloaded file is a Zip file, extract the file on the PC.

(3) SS121_*** folder is created. Double click the SETUP.EXE in the SS121_*** folder.

(4) Follow the instruction to install the SSS.

5.6.2 Start up

(1) Connect the unit and a PC. (For the connection, refer to 4.1.3 JIG connector cable connection.)

(2) Select [Start]-[All Programs]-[Service Support System]-[SSS121 GY-HM100].

(3) Select the COM port, then click [OK].

(4) The SSS main screen appears.

(5) If there is an error in the communication with the unit, a “Communication error” message is displayed at the bottom of the screen

(status bar).

Recheck the connection between the unit and the PC.

1-30 (No.HC044<Rev.001>)

Page 31

5.6.3 Main screen structure and functions

(1) The main screen consists of Menu bar, Tool bar, and Status bar.

Menu bar Tool bar

Status bar: SSS button explanation and other items are displayed.

(2) Menu Bar

(1)File

Inspector Opens the Inspector screen. Views internal information of the unit.

Controller DSP (Opens the DSP controller screen). Switches ON/OFF the built-in color bar, grayscale.

Information Emergency Utility. Opens the emergency utility screen.

Total Time Information. Checks/Deletes the media access total time, power on total time.

OP information.

EEPROM Utility Opens the EEPROM Utility screen.

Adjustment Utility Opens the Adjustment Utility screen.

Exit Exits the SSS.

(2)Option

Set Clock Sets the clock of the unit. Sets the time of the connected PC to the unit.

About CPU Checks the CPU version. Checks the versions of camera CPU and ARM CPU.

About Temperature(OP) Checks the internal temperature of the unit.

About Frame No Checks the frame No. Checks the model name, frame No.

(3)Help Checks the SSS version.

(3) Tool bar

(1) Inspector Rx : Received data. Checks the zoom/focus operations. communication condition.

Rxd120 : Received data (120). Displays area level of the screen divided into 120.

Z.Track. Checks zoom tracking (The left side is a curve of infinity.).

(2) DSP Controller Switches ON/OFF the built-in color bar, grayscale.

(3) EEPROM Utility Opens the EEPROM Utility screen.

(4) Emergency Utility Opens the Emergency Utility screen.

(5) Total Time Information Checks/Deletes media access (record & playback) total time, power on total time.

(6) Adjustment Utility Opens the Adjustment Utility screen.

(7) Zoom Control (Tele) Moves zoom to Tele end. Using both [CTRL] & [SHIFT] enables variable speed zoom.

(8) Zoom Control (Wide) Moves zoom to Wide end.

Simultaneous clicking the left & right enables move to the Wide end.

(9) Focus Control (Far) Moves the focus to the Far end. Using both [CTRL] & [SHIFT] enables variable focus.

(10)Focus Control (Near) Moves the focus to the Near end.

Simultaneous clicking the left & right enables move to the Far end.

(11)Auto Focus Giving check in Auto Focus enables auto focus.

(No.HC044<Rev.001>)1-31

Page 32

5.6.4 EEPROM Utility

(1) EEPROM Utility screen structure and functions.

Menu bar

(2) Menu bar

Status bar

(9)(7)(5)(3)(1)

(10)(8)(6)(4)(2)

(1) Initial Rom Data Navigator Open Opens data saved in the disk. * For details refer to 5.5 EEPROM.

(2) Open Opens data saved in the disk.

(3) Save Saves data to the disk. * For details refer to 5.5 EEPROM.

(4) Read Reads data from the EEPROM of the unit. * For details refer to 5.5 EEPROM.

(5) Write Writes data to the EEPROM of the unit. * For details refer to 5.5 EEPROM.

(6) Edit Edits the EEPROM data.

(7) Comparison Compares with the data saved in the disk. Difference is displayed in dark color.

(8) Load Doctor Date Downloads only the doctor data from the saved data in the disk.

(9) Print Prints data.

(10)Copy Copies data to the clipboard.

(3) Status bar