Page 1

R

SERVICE MANUAL

HD CAMERA RECORDER

GY-HD100U/GY-HD100E

GY-HD101E

GY-HD101E is added only the DV input function to GY-HD100E.

Note

s Lead free solder used in the board (material : Sn, Ag, In, Bi, melting point : 227 Centigrade)

100% recycled paper

COPYRIGHT © 2005 Victor Company of Japan, Limited

No. HC009

Aug. 2005

Page 2

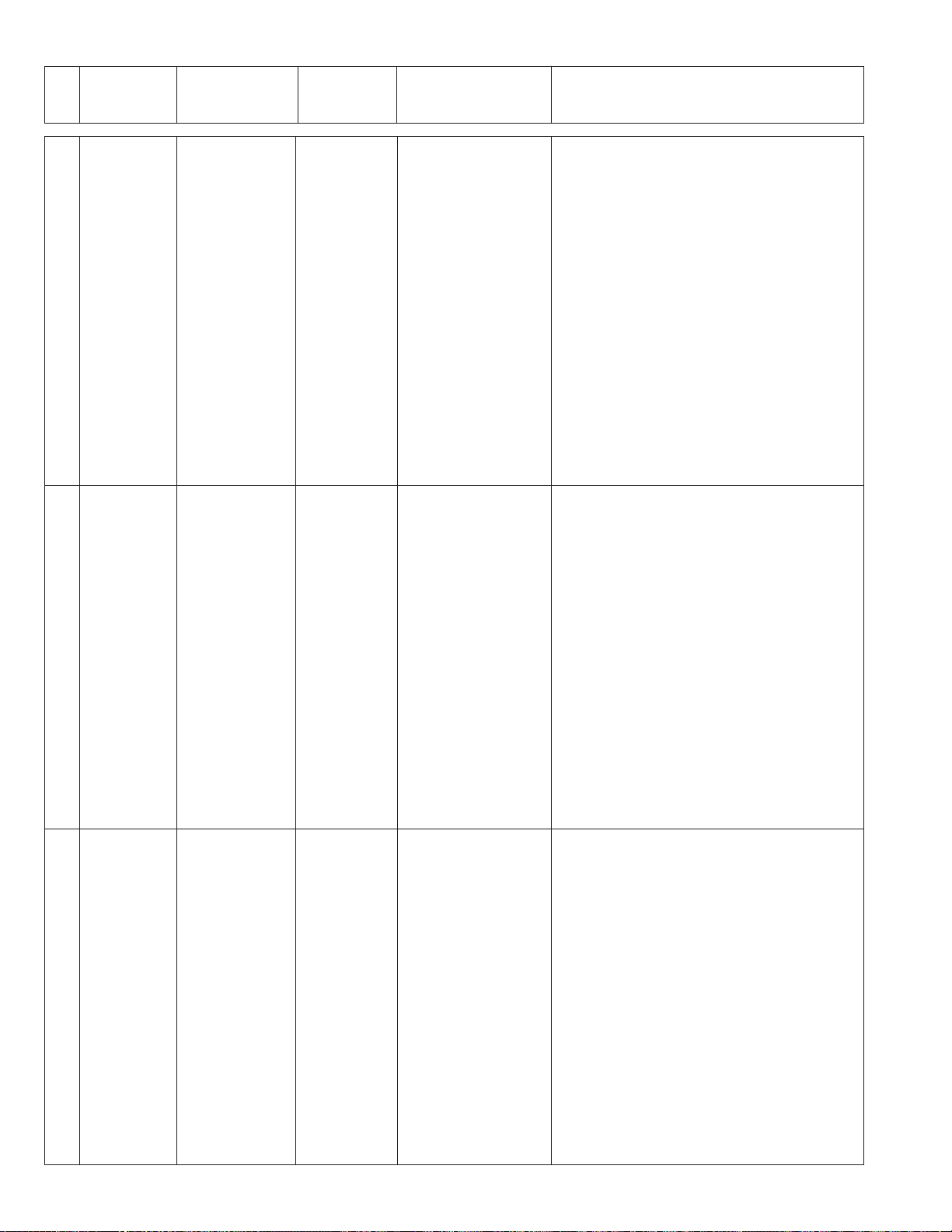

TABLE OF CONTENTS

Section Title Page Section Title Page

Important Safety Precautions

INSTRUCTIONS

SECTION 1 SERVICE CAUTIONS AND DISASSEMBLY

1.1 HOW TO REMOVE THE COSMETIC PARTS ........................... 1-1

1.1.1 Left side cover ................................................................... 1-1

1.1.2 Right side cover ................................................................. 1-1

1.2 HOW TO REMOVE THE OPTICAL BLOCK ASSEMBLY .......... 1-2

1.3 HOW TO REMOVE VCR UNIT ................................................. 1-3

1.3.1 Mechanism unit ................................................................. 1-3

1.3.2 Cassette housing ............................................................... 1-4

1.4 HOW TO REMOVE THE MAJOR BOARDS ............................. 1-5

1.4.1 Audio board ........................................................................1-5

1.4.2 LCD monitor ....................................................................... 1-5

1.4.3 MIF board .......................................................................... 1-6

1.4.4 MAIN board ........................................................................ 1-6

1.4.5 HANDLE assembly ............................................................ 1-6

1.4.6 PS board ............................................................................. 1-8

1.5 SERVICE MENUS ..................................................................... 1-8

1.5.1 Modes required in servicing ............................................... 1-8

1.5.2 Operation in the first-level of the service menu ................. 1-8

1.5.3 CAMERA 1 menu ............................................................... 1-9

1.5.4 CAMERA 2 menu ............................................................. 1-10

1.5.5 CAMERA 3 menu ............................................................. 1-11

1.5.6 VTR 1 menu ..................................................................... 1-11

1.5.7 VTR 2 menu ..................................................................... 1-12

1.5.8 VTR 3 menu ..................................................................... 1-12

1.5.9 DIP SW menu .................................................................. 1-13

1.5.10 HOUR METER ................................................................ 1-15

1.5.11 ERROR HISTORY ........................................................... 1-15

1.5.12 Detail indication of ERROR HISTORY ............................. 1-15

1.5.13 OTHERS menu ............................................................... 1-19

1.5.14 CPU version menu ..........................................................1-20

1.5.15 EEP-ROM ........................................................................ 1-20

1.6 HOW TO UPDATE FIRMWARE ..............................................1-22

1.6.1 Preparation (Copy firmware to SD memory card) ............ 1-22

1.6.2 Update procedure ............................................................ 1-22

SECTION 2 MECHANICAL ADJUSTMENTS

2.1 BEFORE ADJUSTMENTS ........................................................ 2-1

2.1.1 Precautions ........................................................................ 2-1

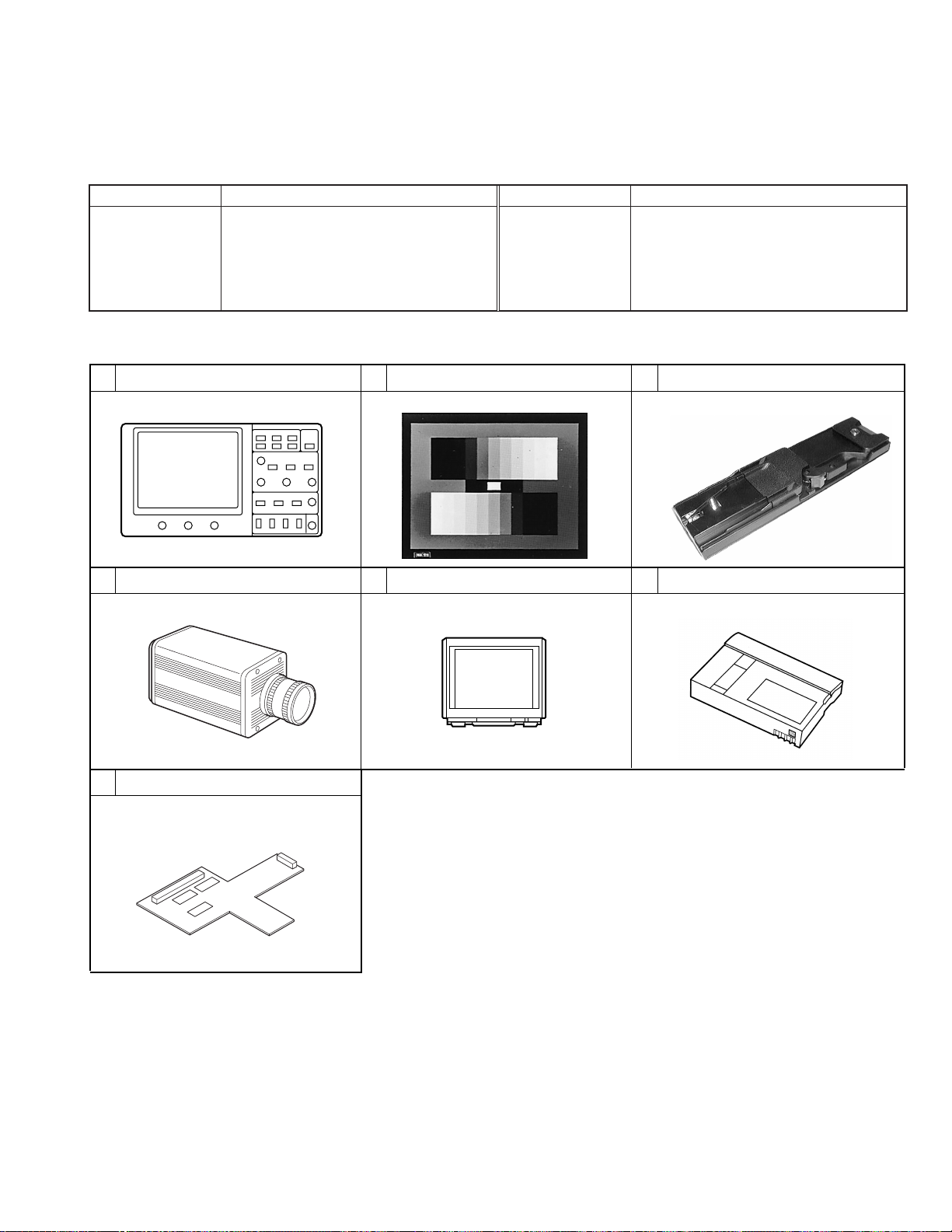

2.1.2 Measuring instruments required for adjustments ............. 2-1

2.1.3 Equipment required for adjustments ................................. 2-1

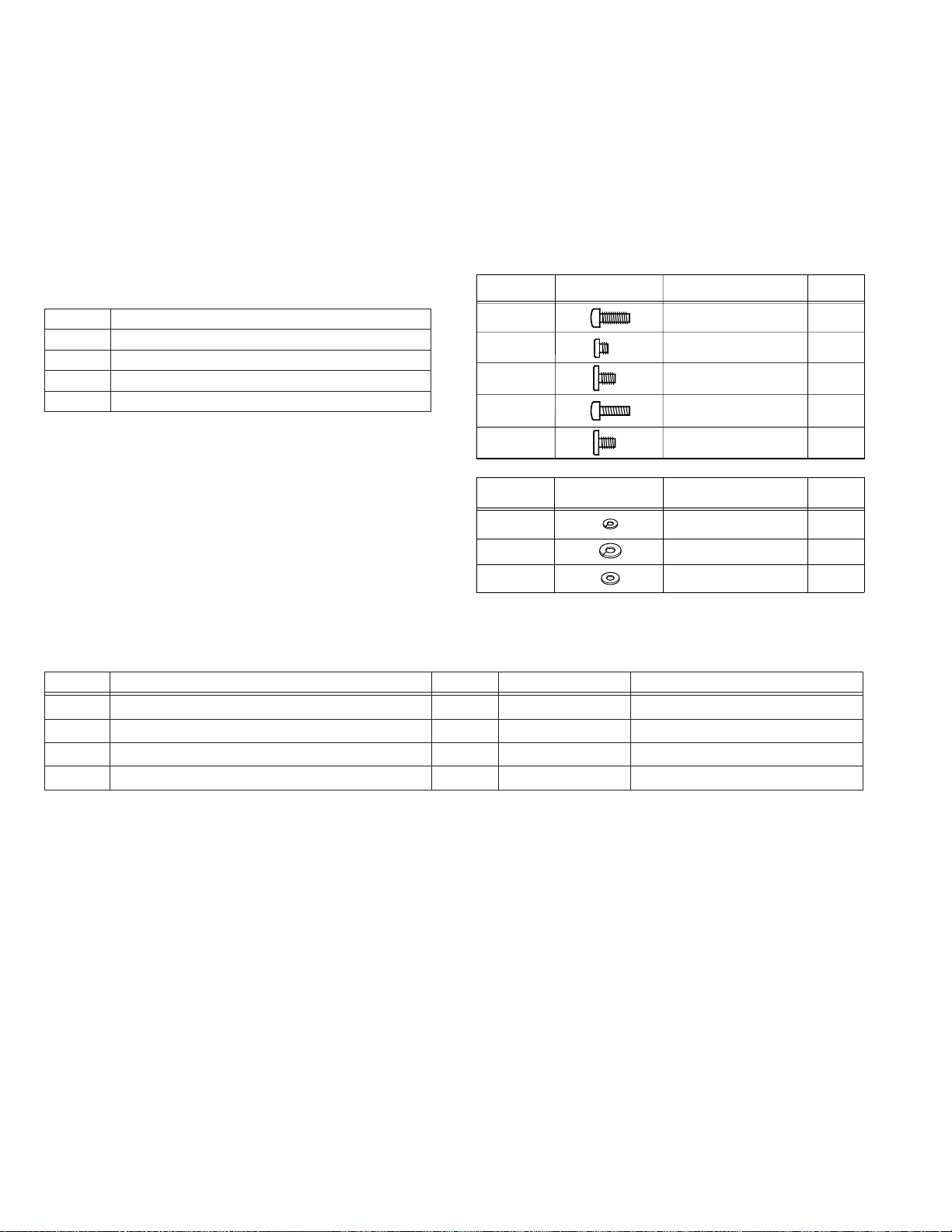

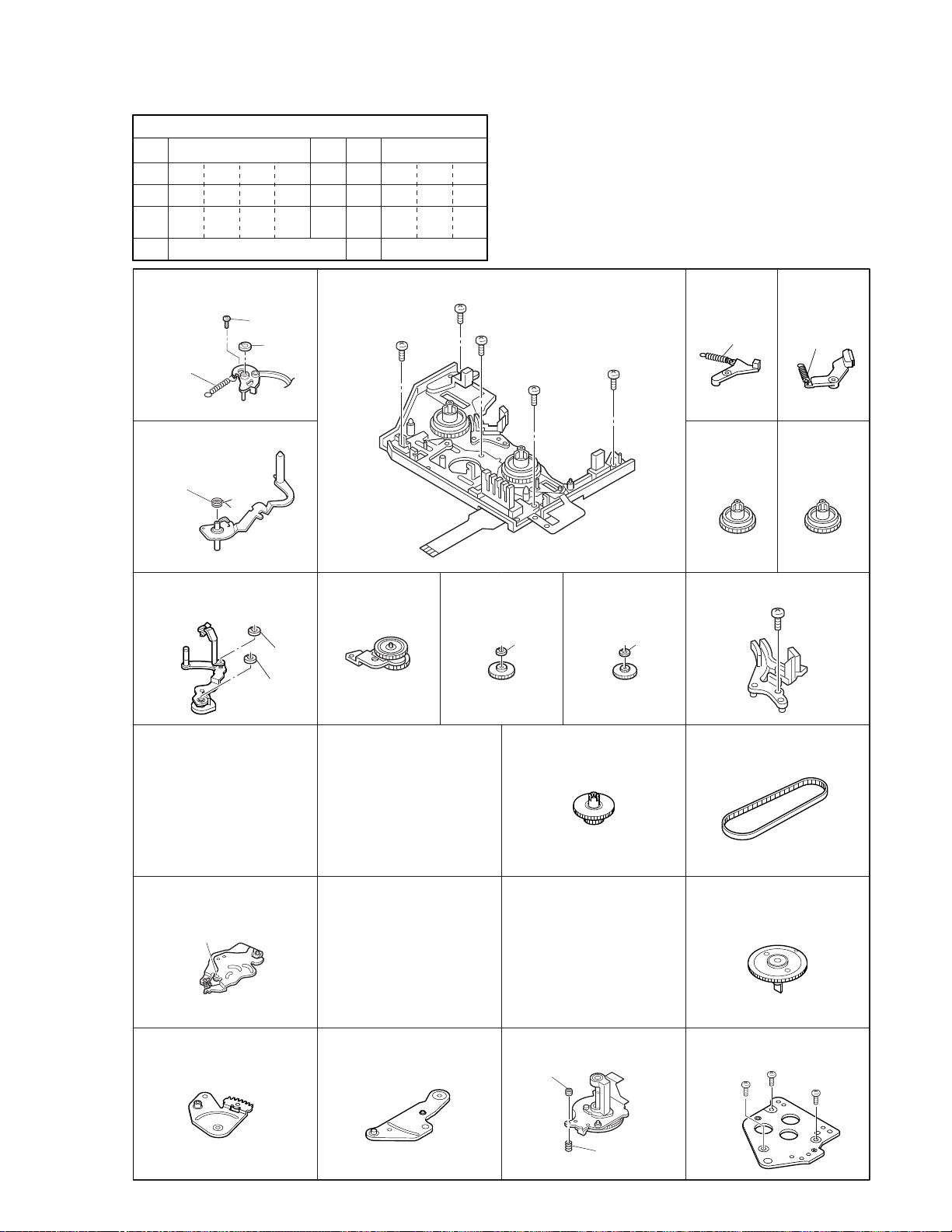

2.2 BASICS OF MECHANISM DISASSAMBLY/ASSEMBLY .......... 2-2

2.2.1 Assembly mode ................................................................. 2-2

2.3 MECHANISM TIMING CHART ................................................. 2-3

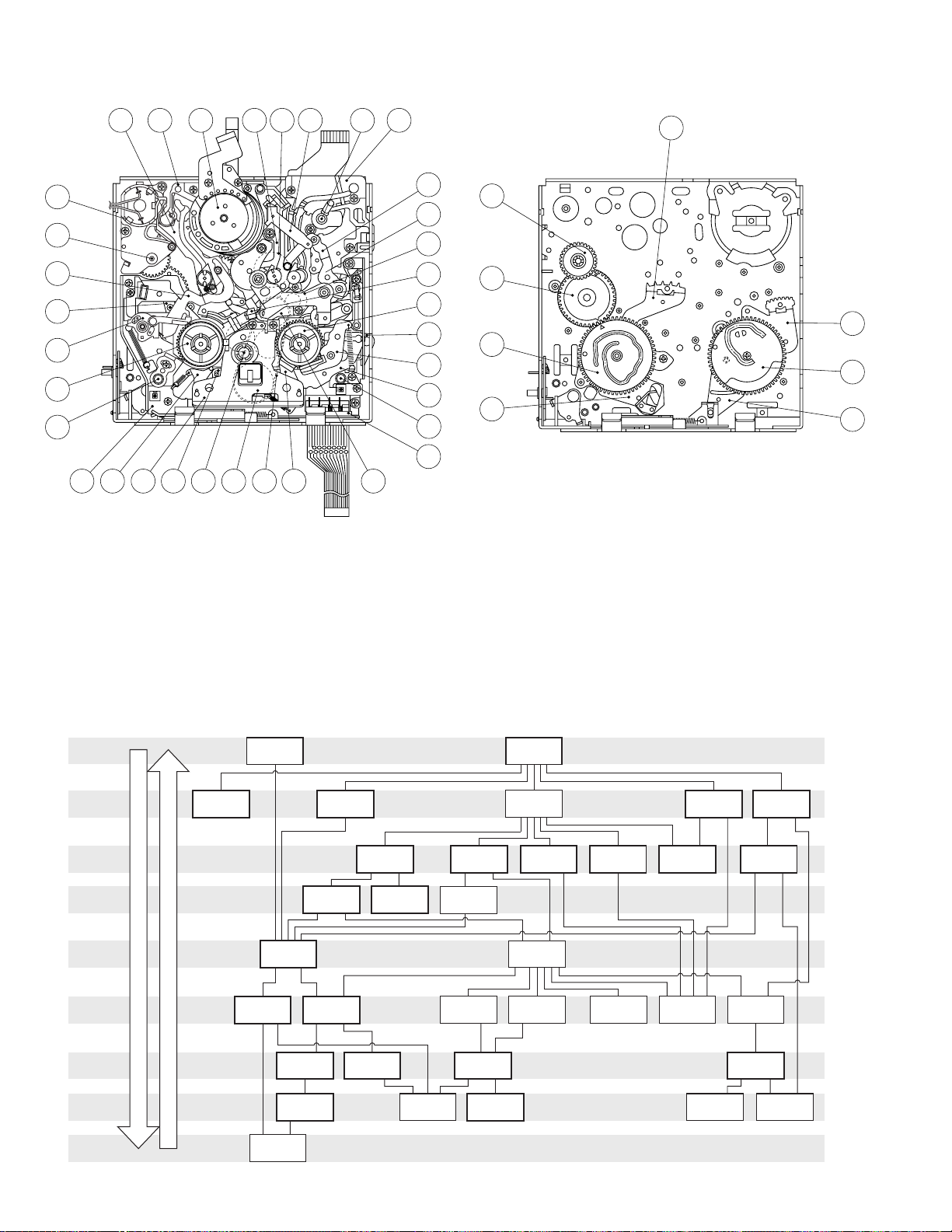

2.4 MAINTENANCE AND INSPECTION OF MAJOR PARTS .......... 2-4

2.4.1 Layout of major parts ......................................................... 2-4

2.4.2 Maintenance and inspection list ........................................ 2-5

2.4.3 Cleaning ............................................................................. 2-6

2.4.4 Oiling and greasing ............................................................ 2-6

2.5 PERIODICAL MAINTENANCE .................................................. 2-7

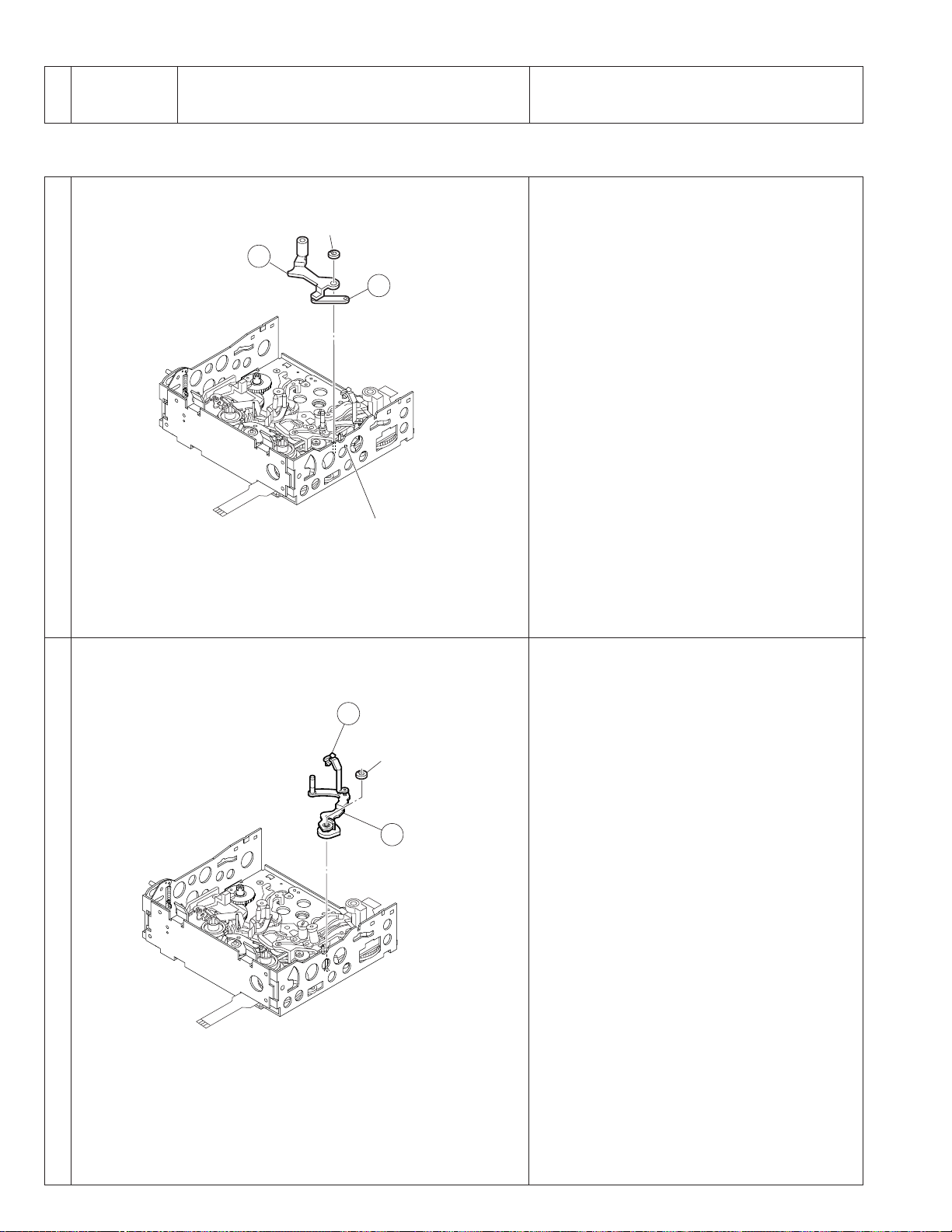

2.6 DISASSEMBLY/ASSEMBLY OF MECHANISM ASSEMBLY ..... 2-8

2.6.1 Assembly/disassembly ...................................................... 2-8

2.6.2 Screws and washers used in mechanism assembly

disassembly/assembly ....................................................... 2-8

2.6.3 Mechanism assembly disassembly procedure table ......... 2-9

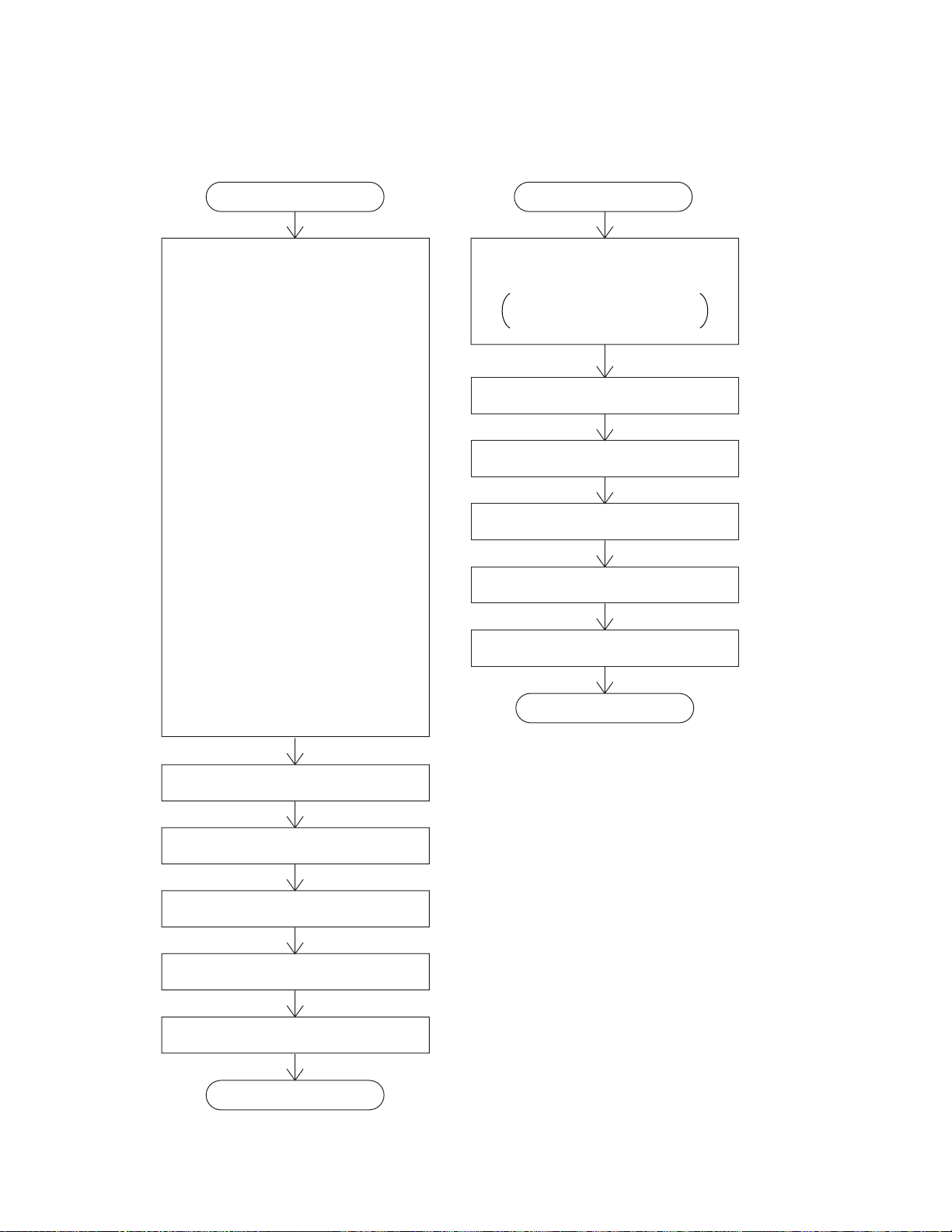

2.6.4 Mechanism disassembly/assembly procedure chart ....... 2-10

2.7 REPLACEMENT OF MAJOR PARTS ...................................... 2-11

2.8

CONFIRMATION AND ADJUSTMENT OF MECHANISM PHASES .....

2.9 DISASSEMBLY PROCEDURE LIST ........................................ 2-23

2.10 MECHANISM DISASSEMBLY/ASSEMBLY SHEET...............2-24

2.11 TORQUE ADJUSTMENTS .................................................... 2-26

2.12 COMPATIBILITY ADJUSTMENT ........................................... 2-27

2.12.1 Compatibility adjustment flow chart ............................... 2-27

2.12.2 Tape transport restriction ................................................ 2-28

2.12.3 Compatibility adjustment ................................................ 2-29

2-22

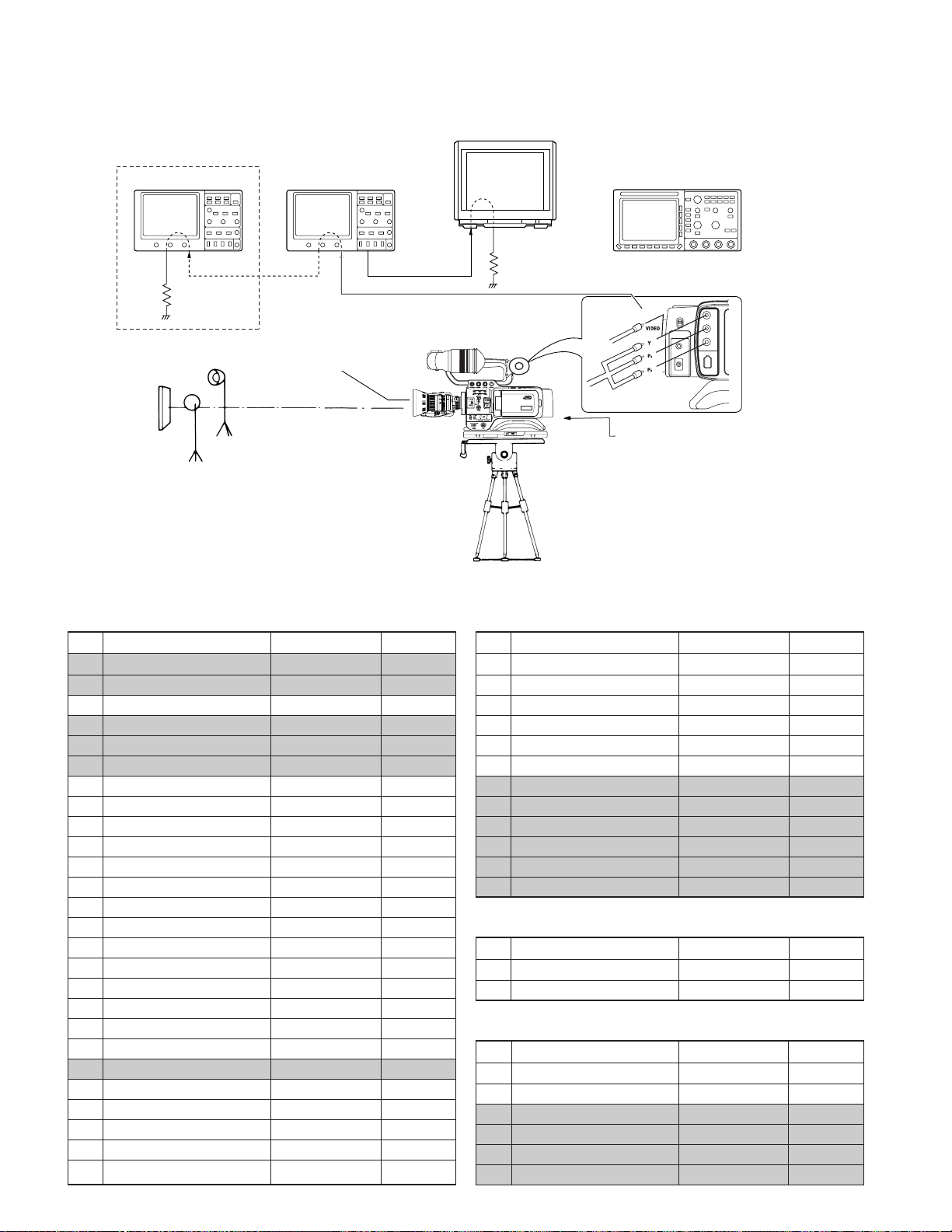

SECTION 3 ELECTRICAL ADJUSTMENTS

3.1 FUNCTIONS REQUIRED FOR ADJUSTMENTS, SETUP .......... 3-1

3.1.1 General instruments necessary for adjustment .................3-1

3.1.2 Special implements required for adjustment ..................... 3-1

3.2 STANDARD SETUP ..................................................................3-2

3.3 ADJUSTMENT MENU ..............................................................3-4

3.3.1 Switches and Functions Used in Adjustments .................. 3-4

3.3.2 Procedure ........................................................................... 3-4

3.3.3 Adjustment mode .............................................................. 3-4

3.4 CAMERA ADJUSTMENTS ....................................................... 3-5

3.4.1 Camera adjustments ..........................................................3-5

3.4.2 AUDIO adjustment ........................................................... 3-13

3.4.3 MONITOR LCD adjustment ............................................. 3-14

3.4.4 VIEWFINDER adjustment ................................................ 3-16

3.5 DVC UNIT ADJUSTMENTS .................................................... 3-18

SECTION 4 CHARTS AND DIAGRAMS

4.1 INDEX TO PAGES OF MAIN BOARDS AND

CIRCUIT BOARD LOCATION ................................................... 4-3

4.1.1 Circuit board location ......................................................... 4-3

4.2 GY-HD100 BLOCK DIAGRAM .................................................. 4-4

4.3 CAMERA PROCESS BLOCK DIAGRAM .................................. 4-5

4.4 OVERALL WIRING DIAGRAM ................................................. 4-6

4.5 ISG SCHEMATIC DIAGRAM .................................................... 4-7

4.6 ISB SCHEMATIC DIAGRAM .....................................................4-8

4.7 ISR SCHEMATIC DIAGRAM .....................................................4-9

4.8 ISG, ISB, ISR CIRCUIT BOARDS ............................................ 4-10

4.9 MAIN SCHEMATIC DIAGRAM ............................................... 4-11

4.10 MAIN CIRCUIT BOARD ........................................................ 4-29

4.11 MIF & PS CIRCUIT BOARDS ...............................................4-30

4.12 MIF SCHEMATIC DIAGRAMS .............................................. 4-31

4.13 PS SCHEMATIC DIAGRAM...................................................4-38

4.14 PRMDA CIRCUIT BOARD .....................................................4-39

4.15 PRMDA SCHEMATIC DIAGRAMS (1/3) ................................ 4-40

4.16 AUDIO CIRCUIT BOARD ...................................................... 4-43

4.17 AUDIO SCHEMATIC DIAGRAMS (1/2) ................................. 4-44

4.18 LINE SELECT SCHEMATIC DIAGRAM ................................. 4-46

4.19 LINE SELECT CIRCUIT BOARDS..........................................4-47

4.20 OPERATION-1 & ETC (MOS, DVOUT, VJK, EAR,

DC IN& SD) SCHEMATIC DIAGRAMS ..................................4-48

4.21 OPERATION-1 & ETC (MOS, DVOUT, VJK, EAR,

DC IN& SD) CIRCUIT BOARDS ............................................. 4-49

4.22 OPERATION-2 (AVR, STA, SWP, MNU, OPE, EJT,

AWB & XLR) SCHEMATIC DIAGRAMS ................................ 4-50

4.23 OPERATION-2 (AVR, STA, SWP, MNU, OPE, EJT,

AWB & XLR) CIRCUIT BOARDS ........................................... 4-51

4.24 OPERATION-3 (FTY, USR, FRL, PBM, AJK, FNC & ZBR)

& MECHA CONNECTOR SCHEMATIC DIAGRAMS ............. 4-52

4.25 OPERATION-3 (FTY, USR, FRL, PBM, AJK, FNC & ZBR)

& MECHA CONNECTOR CIRCUIT BOARDS ........................ 4-53

4.26 VF IF SCHEMATIC DIAGRAM ............................................... 4-54

4.27 VF IF & VF_DR CIRCUIT BOARDS ........................................4-55

4.28 VF DR SCHEMATIC DIAGRAM ............................................. 4-56

4.29 M BL SCHEMATIC DIAGRAM .............................................. 4-57

4.30 M BL CIRCUIT BOARDS .......................................................4-58

4.31 IC BLOCK DIAGRAMS .......................................................... 4-59

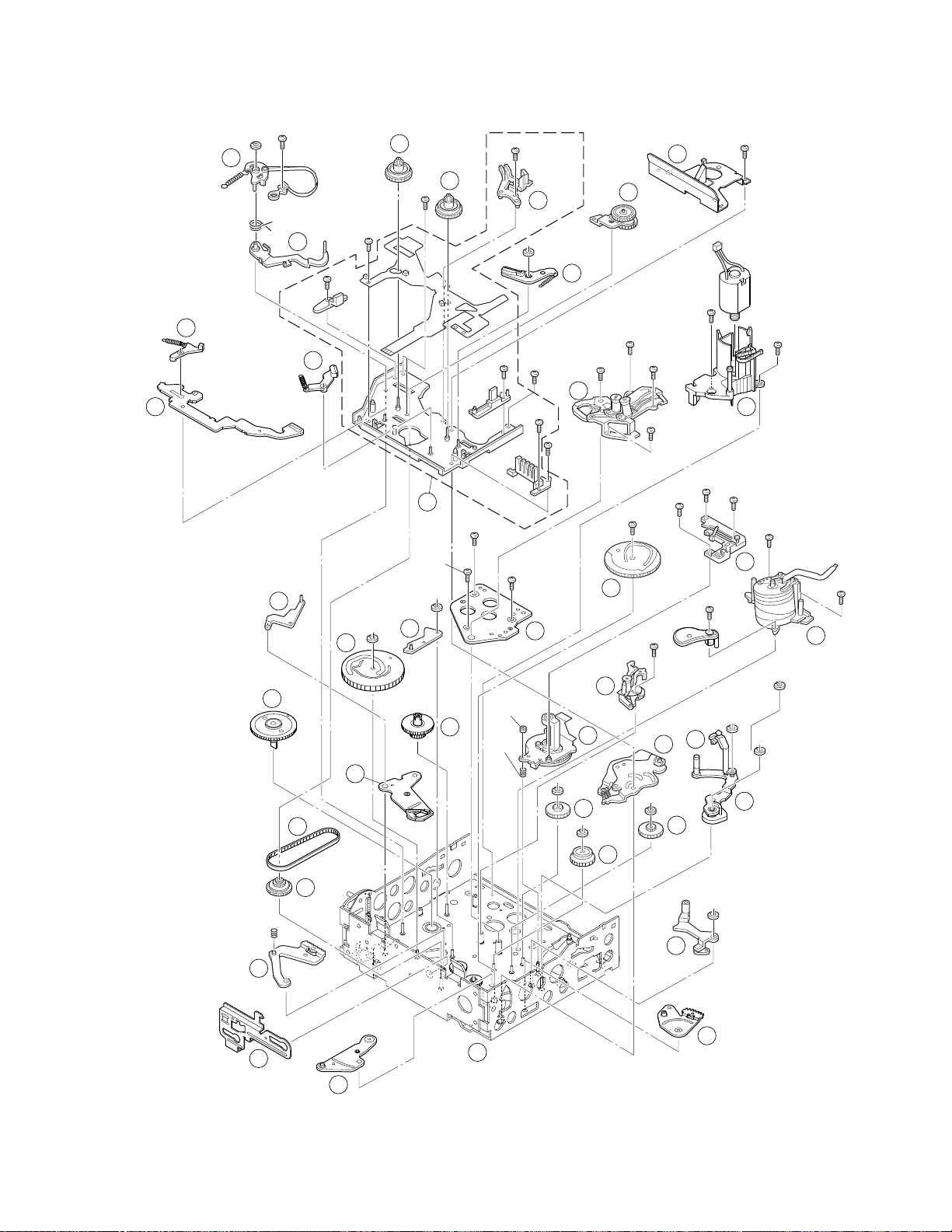

SECTION 5 EXPLODED VIEW AND PARTS LIST

5.1 CABINET ASSEMBLY M2 ....................................................... 5-2

5.2 CHASSIS ASSEMBLY M3 ....................................................... 5-4

5.3 RIGHT SIDE COVER ASSEMBLY M4...................................... 5-6

5.4 MONITOR LCD ASSEMBLY M5 ............................................. 5-7

5.5 HANDLE ASSEMBLY M6....................................................... 5-8

5.6 VF ASSEMBLY M7 ................................................................5-10

5.7 MECHANISM ASSEMBLY M8 ..............................................5-12

Page 3

Section Title Page

SECTION 6 ELECTRICAL PARTS LIST

6.1 ISB BOARD ASSEMBLY PARTS LIST 01 ...............................6-2

6.2 ISG BOARD ASSEMBLY PARTS LIST 02............................... 6-3

6.3 ISR BOARD ASSEMBLY PARTS LIST 03 ...............................6-4

6.4 MAIN BOARD ASSEMBLY PARTS LIST 10 ...........................6-5

6.5 MIF BOARD ASSEMBLY PARTS LIST 20

(GY-HD100U/100E) ................................................................. 6-13

6.6 MIF BOARD ASSEMBLY PARTS LIST 20 (GY-HD101E) ...... 6-16

6.7 PS BOARD ASSEMBLY PARTS LIST 21 .............................. 6-20

6.8 AUDIO BOARD ASSEMBLY PARTS LIST 30 ....................... 6-22

6.9 LINSEL BOARD ASSEMBLY PARTS LIST 31 ...................... 6-24

6.10 SD BOARD ASSEMBLY PARTS LIST 32.............................. 6-25

6.11 PRMDA BOARD ASSEMBLY PARTS LIST 33 ..................... 6-25

6.12 VF DR BOARD ASSEMBLY PARTS LIST 34 ........................ 6-27

6.13 MOS BOARD ASSEMBLY PARTS LIST 35.......................... 6-28

6.14 DC IN BOARD ASSEMBLY PARTS LIST 41......................... 6-28

6.15 VJK BOARD ASSEMBLY PARTS LIST 42 ............................ 6-28

6.16 DV OUT BOARD ASSEMBLY PARTS LIST 43 .....................6-28

6.17 EAR BOARD ASSEMBLY PARTS LIST 44 ........................... 6-28

6.18 MNU BOARD ASSEMBLY PARTS LIST 51.......................... 6-29

6.19 OPE BOARD ASSEMBLY PARTS LIST 52 ........................... 6-29

6.20 EJT BOARD ASSEMBLY PARTS LIST 53 ............................ 6-29

6.21 VF IF BOARD ASSEMBLY PARTS LIST 54 .......................... 6-29

6.22 AWB BOARD ASSEMBLY PARTS LIST 55 .......................... 6-29

6.23 XLR BOARD ASSEMBLY PARTS LIST 56............................ 6-30

6.24 SWP BOARD ASSEMBLY PARTS LIST 57 .......................... 6-30

6.25 STA BOARD ASSEMBLY PARTS LIST 58 ............................6-30

6.26 AVR BOARD ASSEMBLY PARTS LIST 59............................ 6-31

6.27 MON BL BOARD ASSEMBLY PARTS LIST 61 .................... 6-31

6.28 FTY BOARD ASSEMBLY PARTS LIST 62 ............................ 6-31

6.29 USR BOARD ASSEMBLY PARTS LIST 63 ........................... 6-31

6.30 FRL BOARD ASSEMBLY PARTS LIST 64............................ 6-31

6.31 PBM BOARD ASSEMBLY PARTS LIST 65 .......................... 6-32

6.32 ZBR BOARD ASSEMBLY PARTS LIST 66............................ 6-32

6.33 A.JACK BOARD ASSEMBLY PARTS LIST 67 ...................... 6-32

6.34 FNC BOARD ASSEMBLY PARTS LIST 68 ........................... 6-32

6.35 M.CONN. BOARD ASSEMBLY PARTS LIST 70................... 6-32

6.36 TERM. BOARD ASSEMBLY PARTS LIST 80 ....................... 6-32

SECTION 7 PACKING

7.1 PACKING ASSEMBLY M1 ......................................................7-1

SECTION 8 TECHNICAL INFORMATION

8.1 HDV FORMAT .......................................................................... 8-1

8.1.1 HDV Features ..................................................................... 8-1

8.1.2 HD Image Format .............................................................. 8-1

8.1.3 Progressive method ...........................................................8-1

8.1.4 Comparison of HDV format and DV format ....................... 8-2

8.1.5 Tape Format .......................................................................8-3

8.1.6 GY-HD100 & BR-HD50 Compatible Format ....................... 8-3

8.2 RECORDING SIGNAL SYNTAX .................................................. 8-4

8.2.1 720/30P ..............................................................................8-4

8.2.2 720/24P ..............................................................................8-4

8.2.3 720/25P ..............................................................................8-4

8.3 VIDEO CIRCUIT ........................................................................8-5

8.3.1 CCD .................................................................................... 8-5

8.3.2 VIDEO Signals ....................................................................8-6

8.3.3 AUDIO Signals ................................................................... 8-8

8.3.4 SYSTEM CONTROL .........................................................8-10

8.4 GLOSSARY ............................................................................. 8-11

Page 4

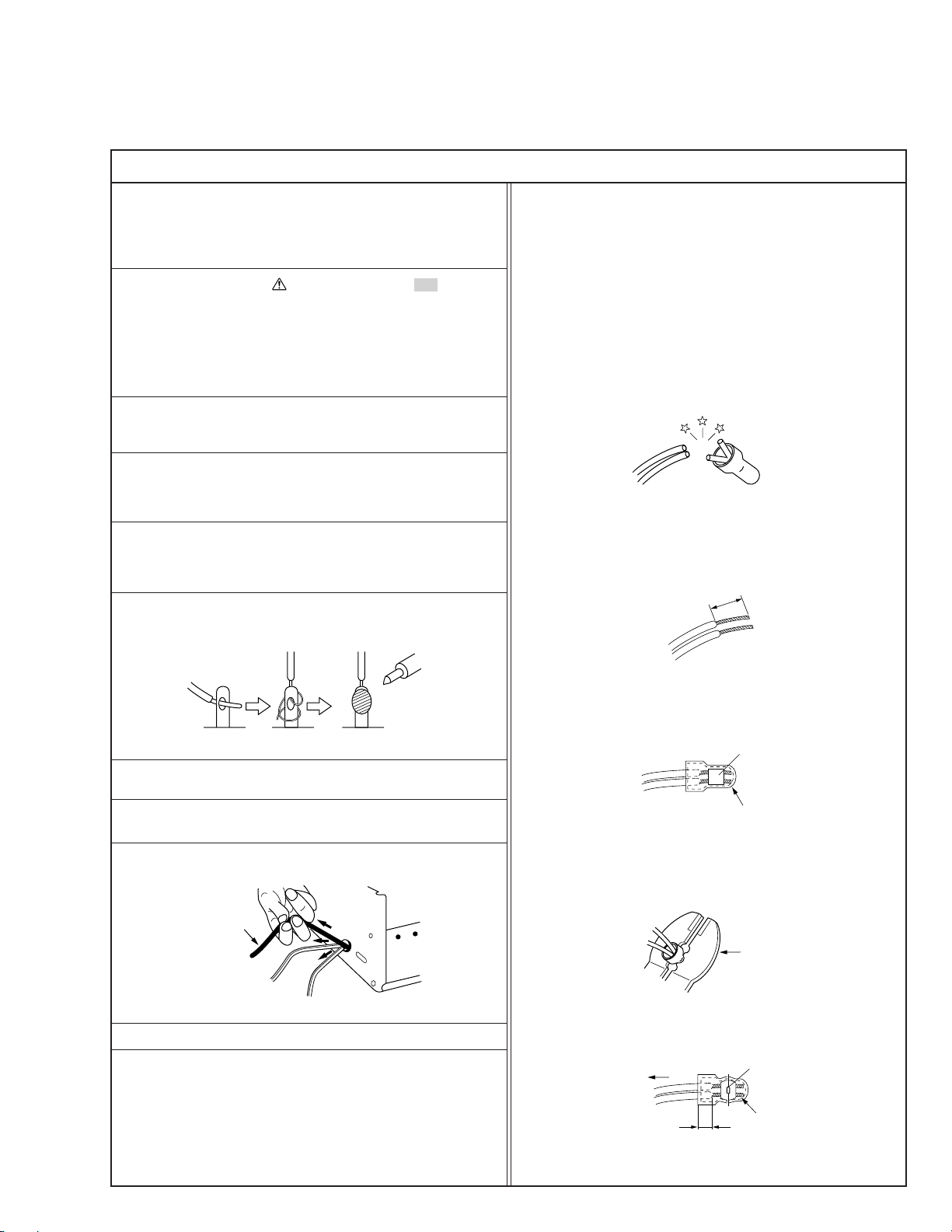

Important Safety Precautions

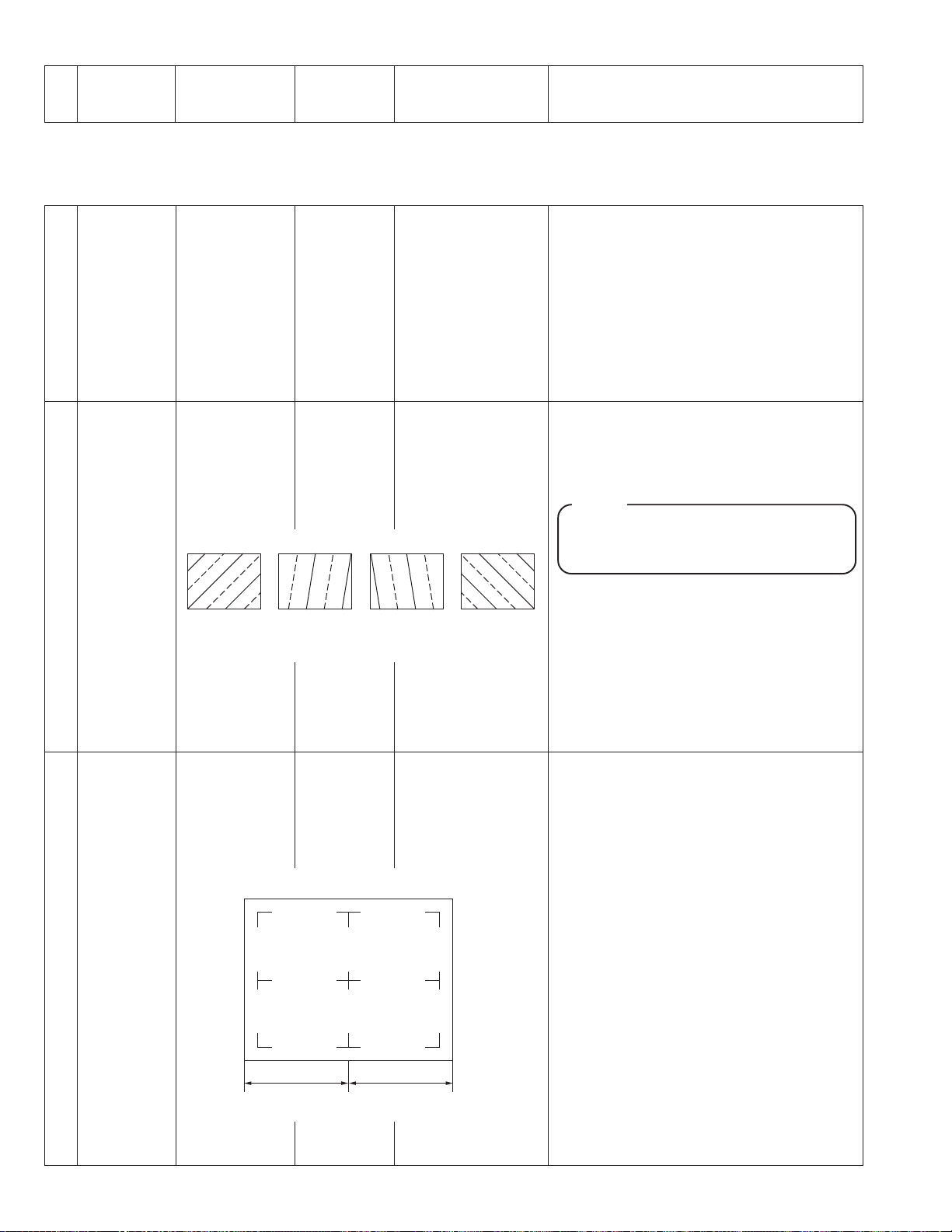

Connector

Metal sleeve

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

symbol and shaded ( ) parts are

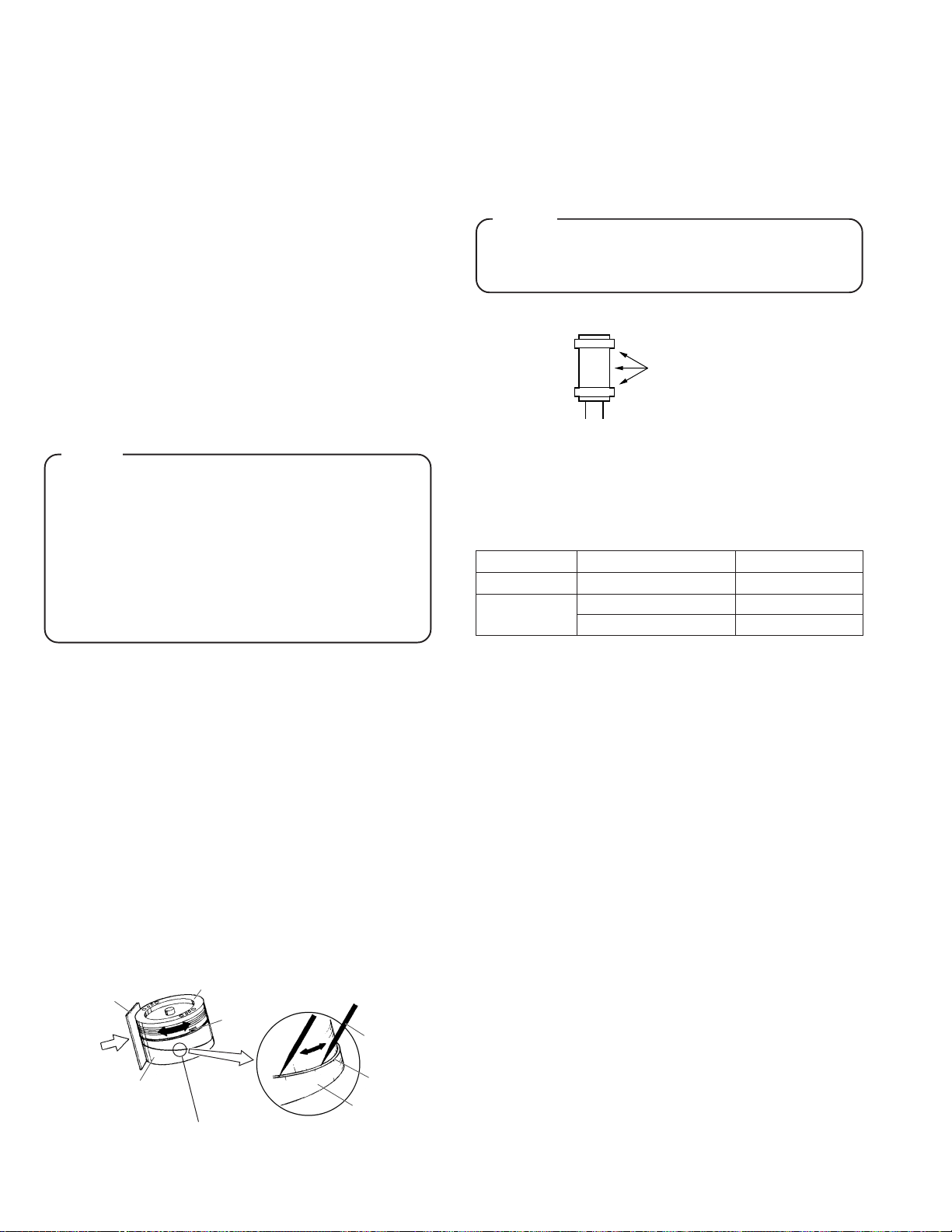

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

7. Observe that wires do not contact heat producing parts

8. Check that replaced wires do not contact sharp edged or

9. When a power cord has been replaced, check that 10-15 kg of

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

Fig.1

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

pointed parts.

force in any direction will not loosen it.

Power cord

Fig.2

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

Page 5

p

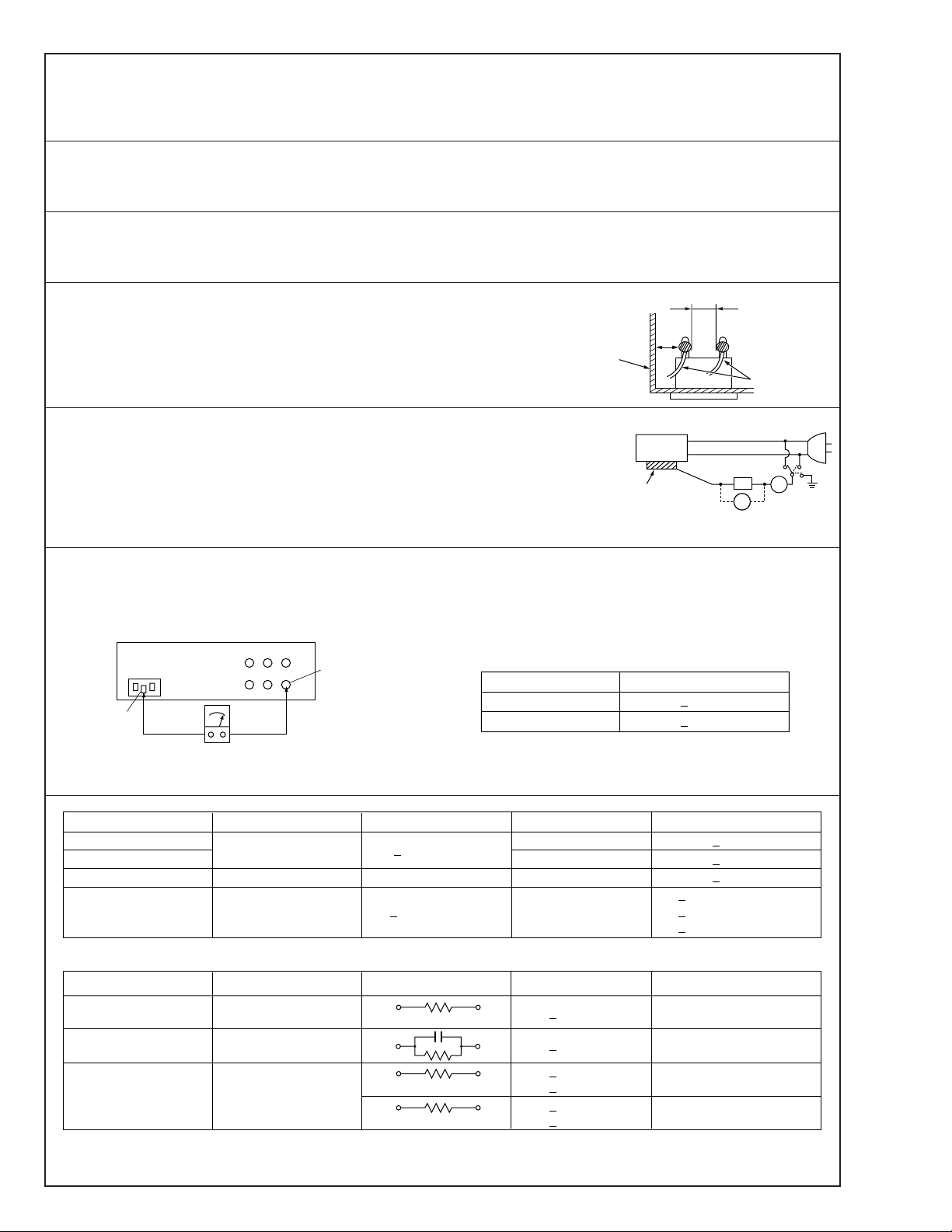

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Chassis

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

AC inlet

Earth pin

Exposed accessible part

Grounding Specifications

Region

USA & Canada

Europe & Australia

Externally

exposed

accessible

Grounding Impedance (Z)

d

d'

art

≤

Z 0.1 ohm

≤

Z 0.5 ohm

Power cord,

primary wire

Z

V

Fig. 9

ab

c

A

Milli ohm meter

Fig. 10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Region

Japan R 1 MΩ/500 V DC

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

Insulation Resistance (R)

≤

–

≤

Table 1 Specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 900 V 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

i1 mA rms Exposed accessible parts

i 0.5 mA rms

i 0.7 mA peak

i2 mA dc

i 0.7 mA peak

i2 mA dc

≤

≤

≤

≤

≤

≤

(Class 2)

(Class 1)

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

Exposed accessible parts

Antenna earth terminals

Other terminals

2

Page 6

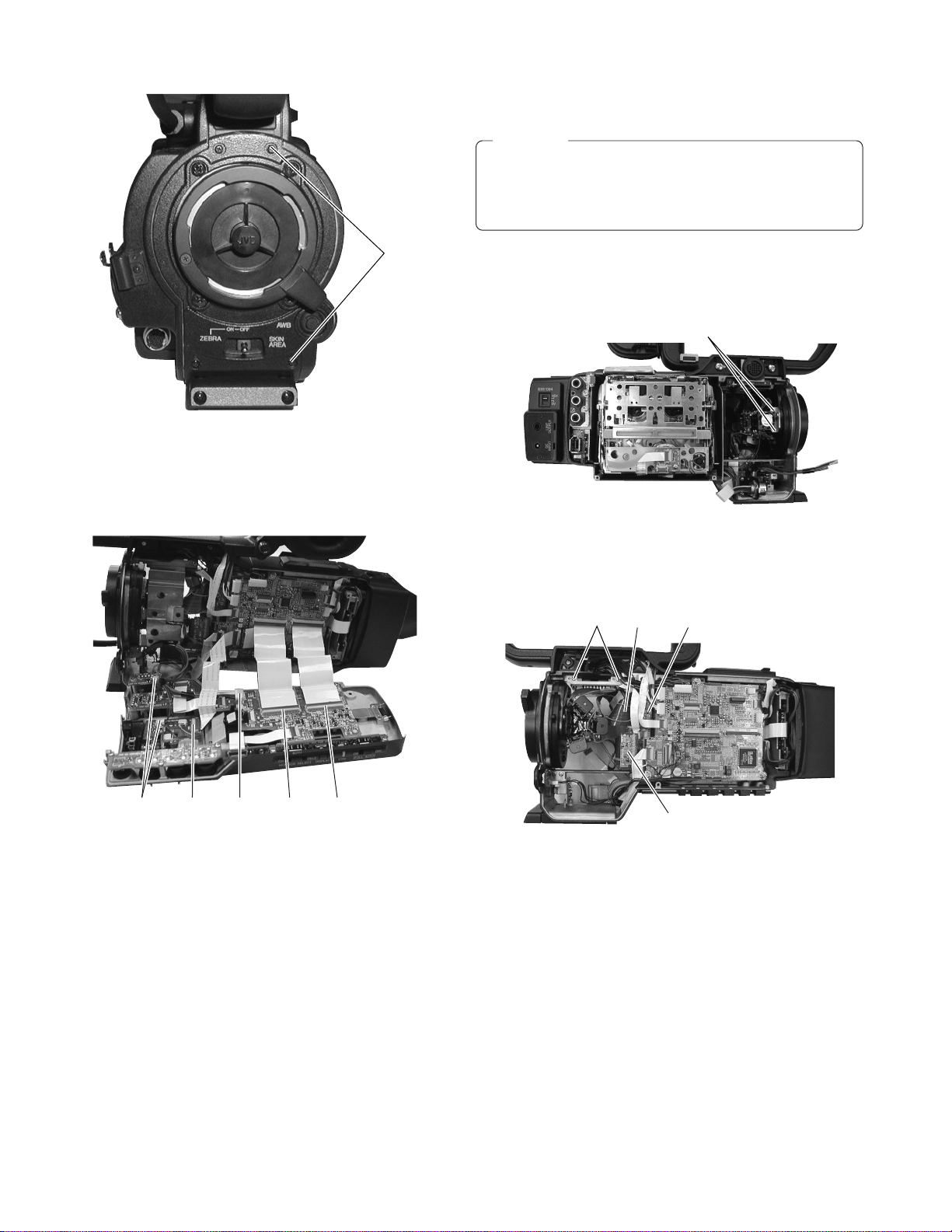

SECTION 1

3

4

SERVICE CAUTIONS AND DISASSEMBLY

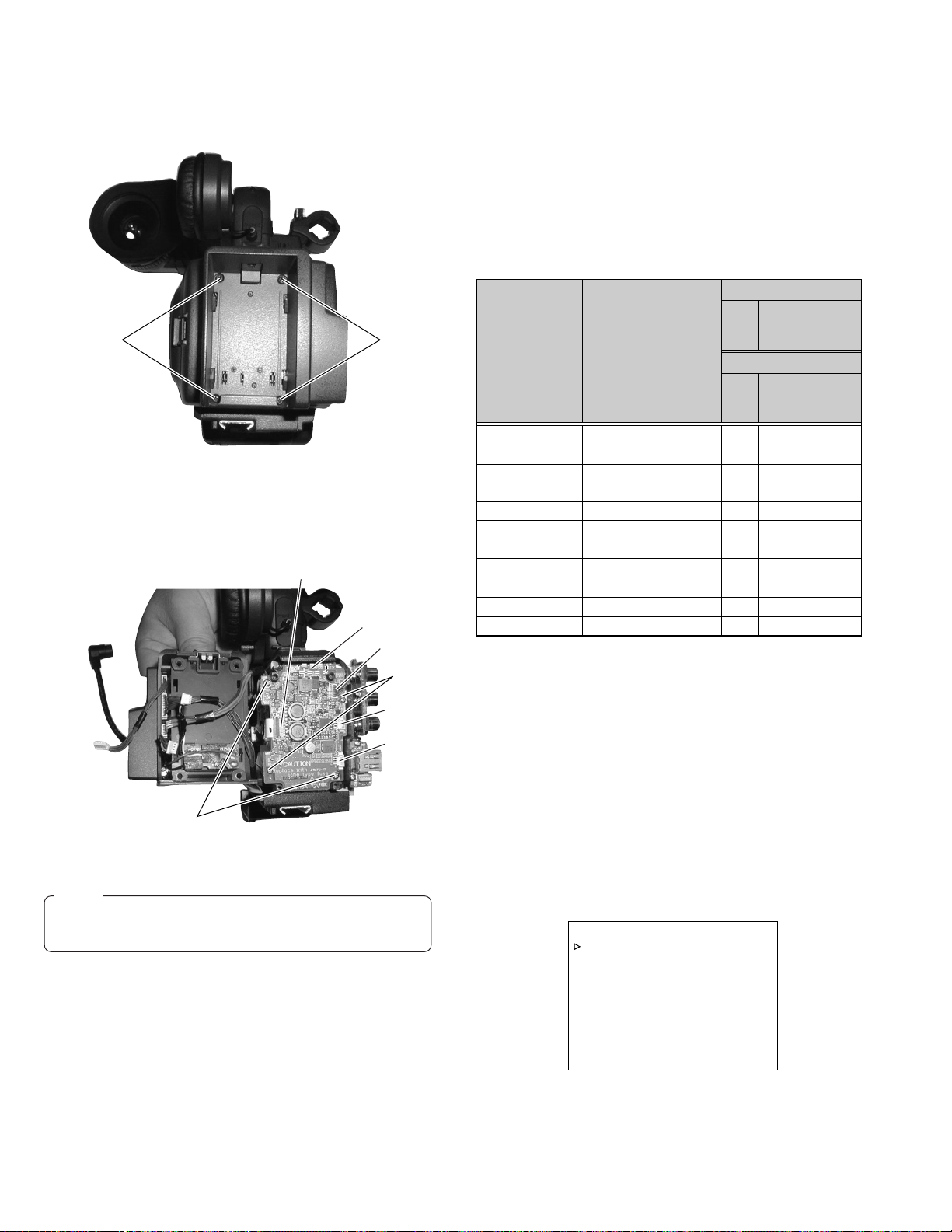

1.1 HOW TO REMOVE THE COSMETIC PARTS

1.1.1 Left side cover

(1) Remove the two screws

ward and pull out to remove.

, slide the cassette cover down-

1

1

Fig. 1.1.1 (1)

Note :

When attaching the cassette cover, make sure to insert the

hook of the cassette cover to the correct position of the

cassette housing.

(3) Remove the two screws

(4) Disconnect the cables CN13 and CN43.

and open the left side cover.

3

Fig. 1.1.1 (3)

(2) Remove the two screws

2

Fig. 1.1.1 (2)

2

.

CN13CN43

Fig. 1.1.1 (4)

1.1.2 Right side cover

(1) Remove the five screws 4 and open the right side cover.

Fig. 1.1.2 (1)

1-1

Page 7

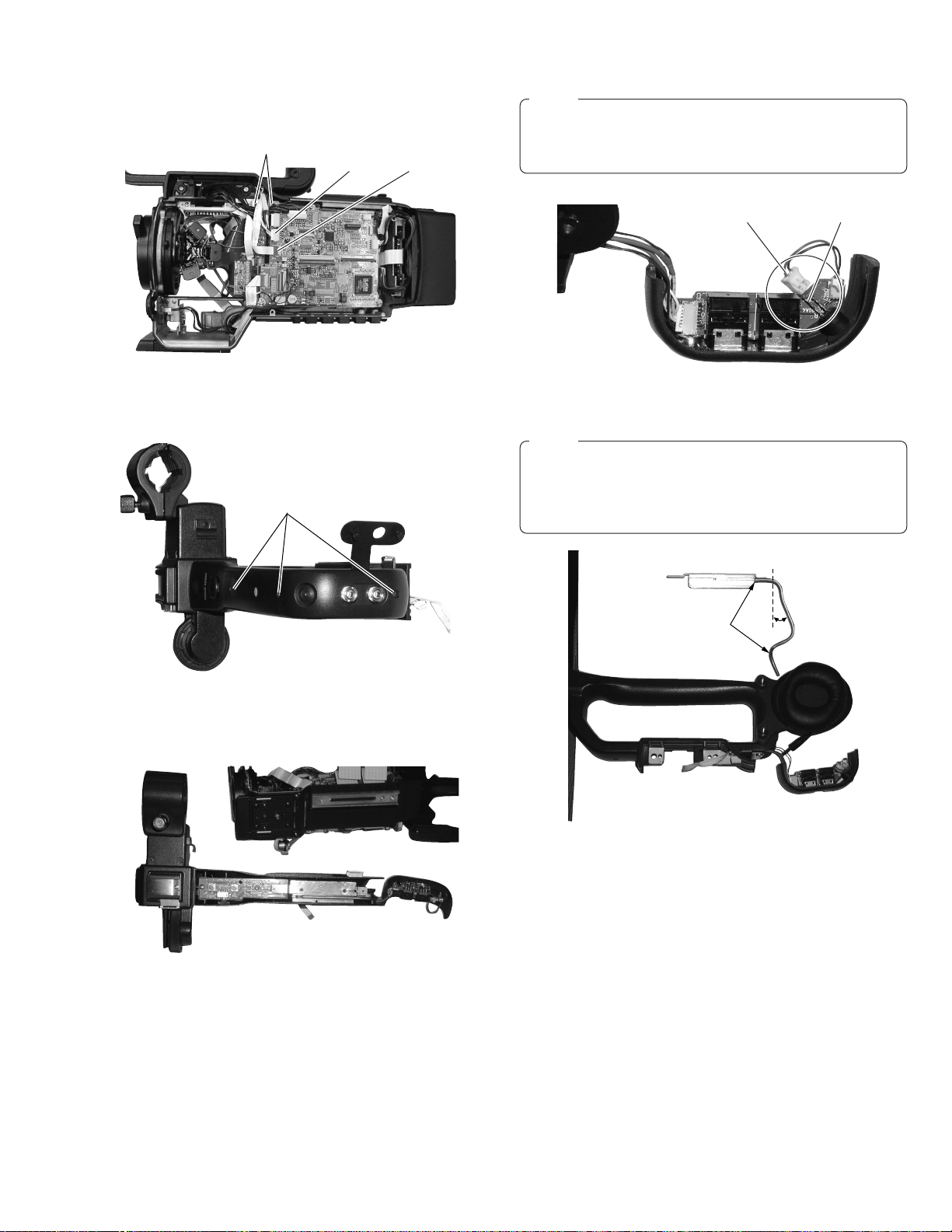

1.2 HOW TO REMOVE THE OPTICAL BLOCK ASSEMBLY

CAUTION

When removing/mounting the optical block assembly in the

camera, take care not to damage cables, also the positioning of the wire assembly is important. A malfunction may

occur if a wire is somehow caught up.

4

Fig. 1.1.2 (2)

(2) Disconnect the cables CN14, CN24 and CN43 on AUDIO

board, CN10 and CN52 on STA board, CN52 on SWP board.

(1) Remove left side cover and the right side cover. (see sec-

tion 1.1.1 and 1.1.2)

(2) Remove the two screws

and remove the FAN motor.

1

1

Fig. 1.2 (1)

(3) Remove the two screws

(4) Disconnect the cables CN26, CN27 and CN28.

CN26 CN27

2

and remove the SD board.

2

1-2

CN52 CN10 CN43 CN24 CN14

Fig. 1.1.2 (3)

CN28

Fig. 1.2 (2)

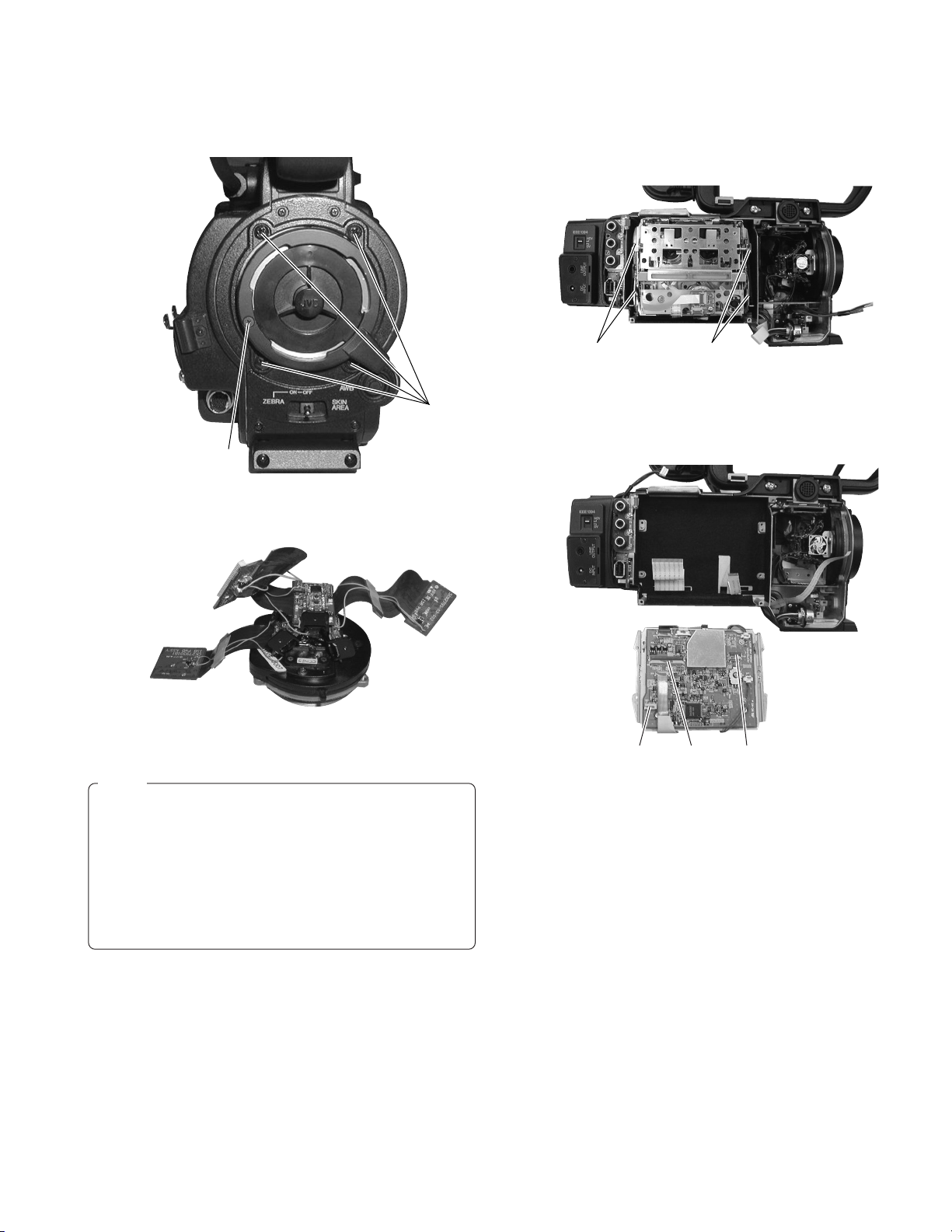

Page 8

(5) Remove the five screws 3 3 and 4 , then remove the opti-

11

CN16CN75 CN17

cal block assembly carefully not to damage boards and cables.

3

4

Fig. 1.2 (3)

1.3 HOW TO REMOVE VCR UNIT

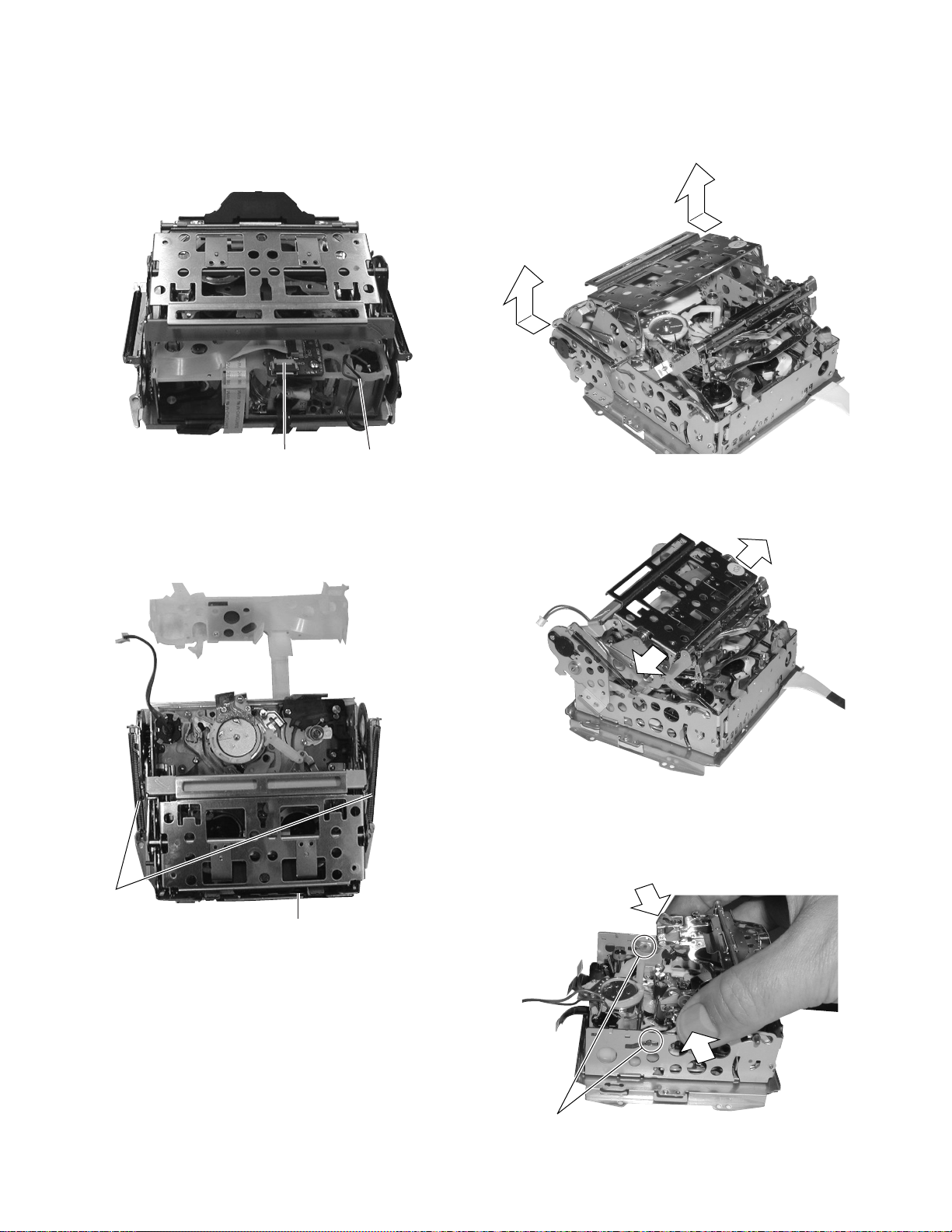

1.3.1 Mechanism unit

(1) Remove the left side cover. (see section 1.1.1)

(2) Remove the four screws

(3) Lift up the mechanism unit gently and disconnect the

cablesCN75, CN16 and CN17.

.

1

Fig. 1.3.1(1)

Fig. 1.2 (4)

Note :

• The CCDs are bonded precisely to the prism. In case of

trouble with a CCD, it is not possible to replace an individual CCD, but the entire optical block assembly should

be replaced.

• The optical block assembly supplied as a service part.

• When replacing the optical block, attach the original FAN

and FNC board to the new optical block because those

are not included on the optical block assembly.

Fig. 1.3.1(2)

1-3

Page 9

1.3.2 Cassette housing

(1) Remove the mechanism unit. (see section 1.3.1)

(2) Remove CN1 and release the motor wire. Release the lock

sideways and remove the tape guard

CN1 Motor Wire

(4) Slide the outer unit to rear direction and lift up slightly. Pull

out to side direction to release the outer unit. Perform same

manner other side.

Fig. 1.3.2(1)

(3) Pop up the cassette housing by sliding release lever and

remove the two screws

2

.

2

Release Lever

Fig. 1.3.2(3)

Fig. 1.3.2(4)

(5) Slide the cassette housing to the position of fig.1.3.2(5) and

hold the cassette housing slightly to inside direction to release it.

1-4

Fig. 1.3.2(2)

Release Position

Fig. 1.3.2(5)

Page 10

(6) Release bosses of the cassette housing from the mecha-

nism unit.

Fig. 1.4.1(2)

Fig. 1.3.2(6)

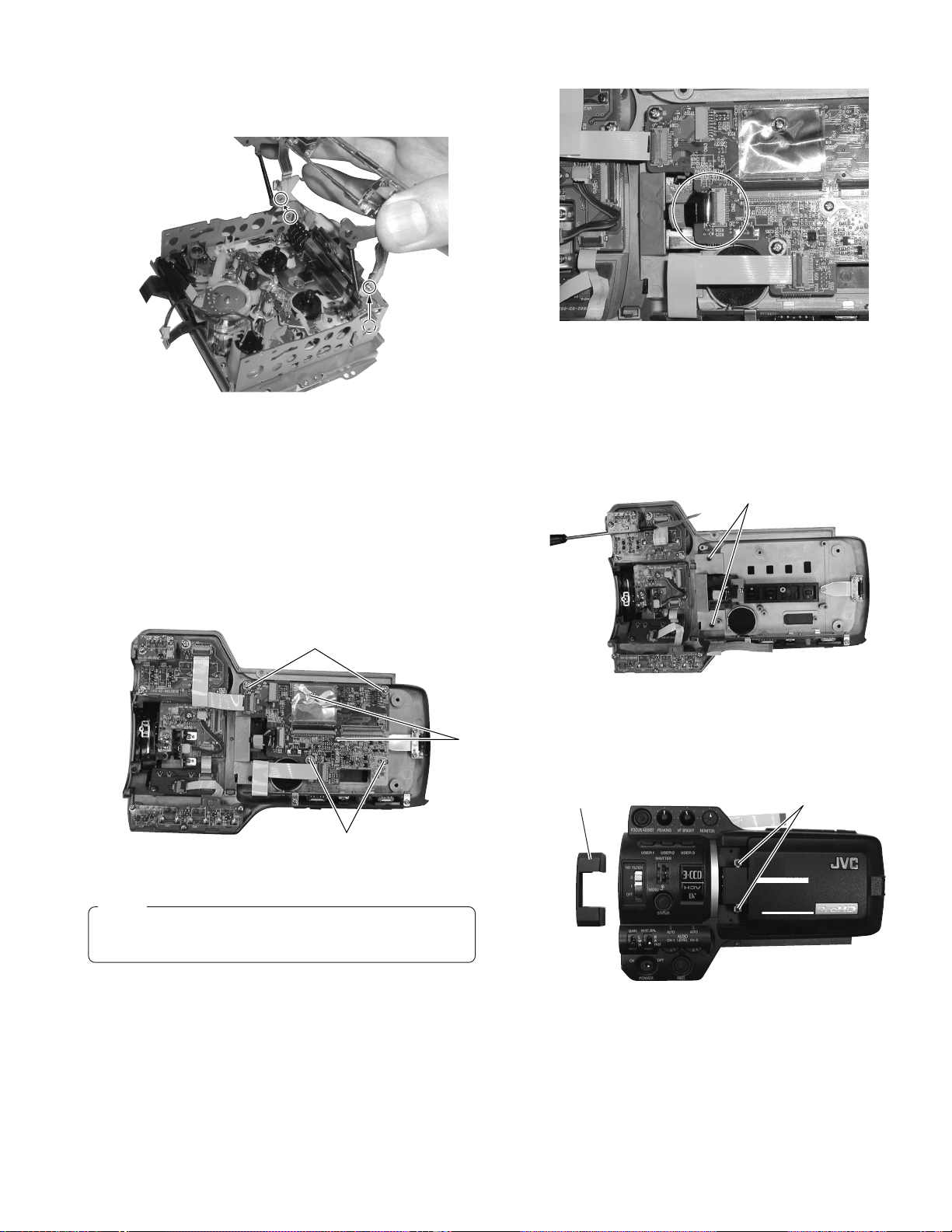

1.4 HOW TO REMOVE THE MAJOR BOARDS

1.4.1 Audio board

(1) Remove right side cover. (see section 1.1.2)

(2) Disconnect cables CN44, CN45 and CN62.

(3) Remove six screws

and 2.

1

1

1

Fig. 1.4.1(1)

2

1.4.2 LCD monitor

(1) Remove Audio board. (see section 1.4.1)

(2) Remove two screws

3

.

3

Fig. 1.4.2(1)

(3) Remove the hinge cover and remove two screws

Hinge Cover

4

4

.

Note :

CN62 may be slightly hard to connect FPC cable. Make sure

to insert the cable to correct position.

Fig. 1.4.2(2)

1-5

Page 11

1.4.3 MIF board

(1) Remove the right side cover. (see section 1.1.2)

(2) Remove four screws

(3) Remove the cables CN4, CN9, CN11, CN12, CN13, CN22,

CN23, 34 and CN48, then lift up MIF board to release B to B

connector between MIF board and MAIN board.

5

.

(4) Slide the MAIN board downward and pull out.

Do not bend the Heat Pipe.

Do not bend the Heat Pipe.

CN12CN13 CN23

CN22CN48

5

CN4

CN34

CN11

CN9

5

Fig. 1.4.3

1.4.4 MAIN board

(1) Remove MIF board. (see section 1.4.3)

(2) Remove six screws 6 and 7.

(3) Remove the cables CN3, CN16, CN17, CN18, CN19, CN26,

CN27, CN28, CN29 and CN30.

7

6

Fig. 1.4.4(2)

(5) Remove the two screws 8. Remove the heat sink carefully

because it is being fitted sticky.

8

CN26

CN27

CN28

CN17CN18 CN3 CN16

Fig. 1.4.4(1)

CN29

CN30

CN19

Fig. 1.4.4(3)

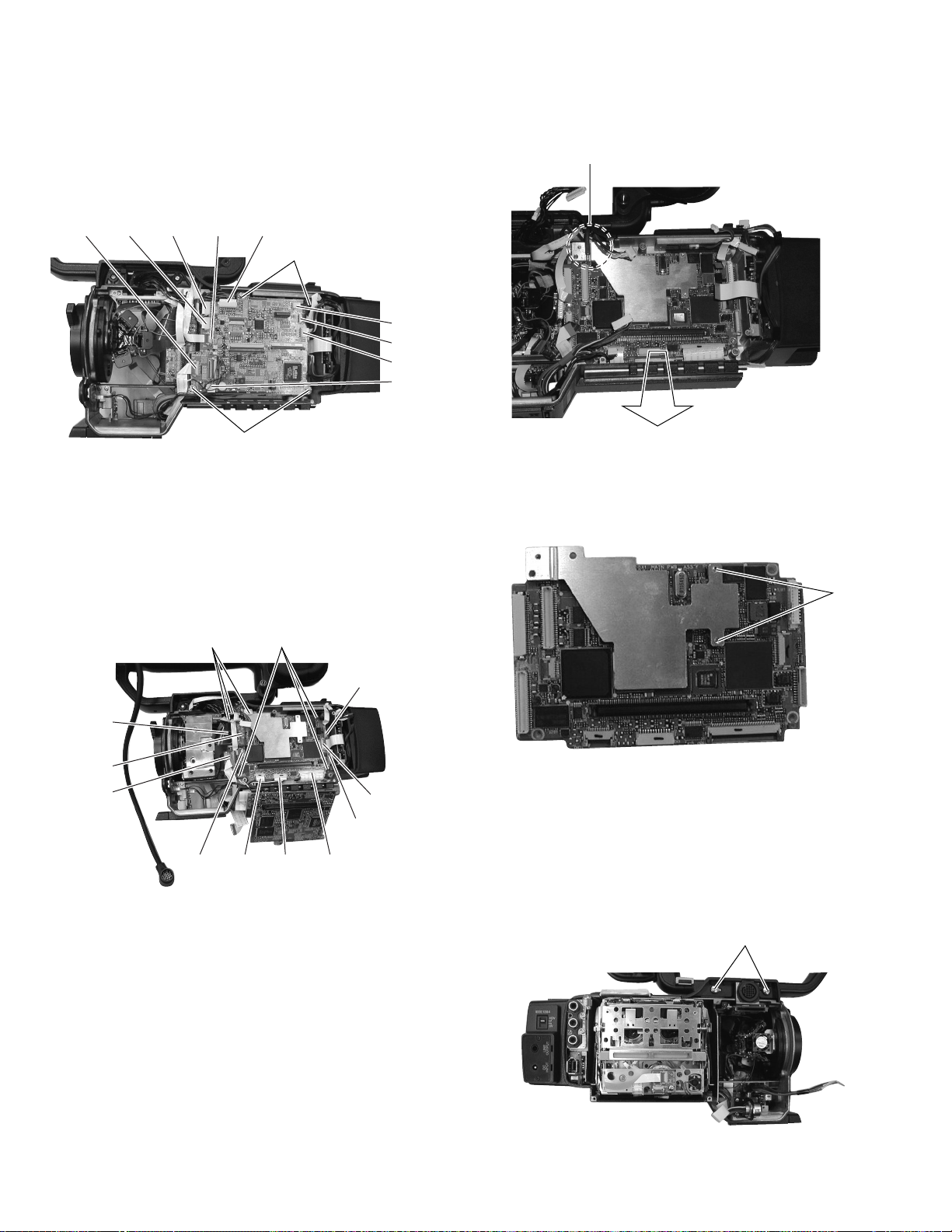

1.4.5 HANDLE assembly

(1) Remove left side cover and right side cover. (see section

1.1.1 and 1.1.2)

(2) Remove two screws

9

.

9

1-6

Fig. 1.4.5(1)

Page 12

Longer PinRed wire

(3) Remove the cables CN12 and CN48. Remove the two screws

and lift up the handle assembly.

0

0

CN12 CN48

Fig. 1.4.5(2)

(4) Remove three screws

!

.

!

Note :

When connecting the LED connector on EAR board, ensure the polarity that the red wire should be connected

longer pin of LED.

Fig. 1.4.5(5)

Note :

When removing the Heat Sink Ass’y, bend the Heat Pipe

slightly like Fig. 1.4.5(6).

Return the bend after attaching the Heat Sink Ass’y.

Do not bend the other portion of Heat Pipe.

Fig. 1.4.5(3)

(5) Remove the handle cover R and handle cover T.

Fig. 1.4.5(4)

Do not bend

Fig. 1.4.5(6)

About

20 degrees

1-7

Page 13

1.4.6 PS board

(1) Remove the four screws

Fig. 1.4.6(1)

(2) Remove the four screws

CN1, 29, CN30, CN53 and CN75.

.

@

@@

and $. Disconnect the cables

#

CN30

CN29

CN75

$

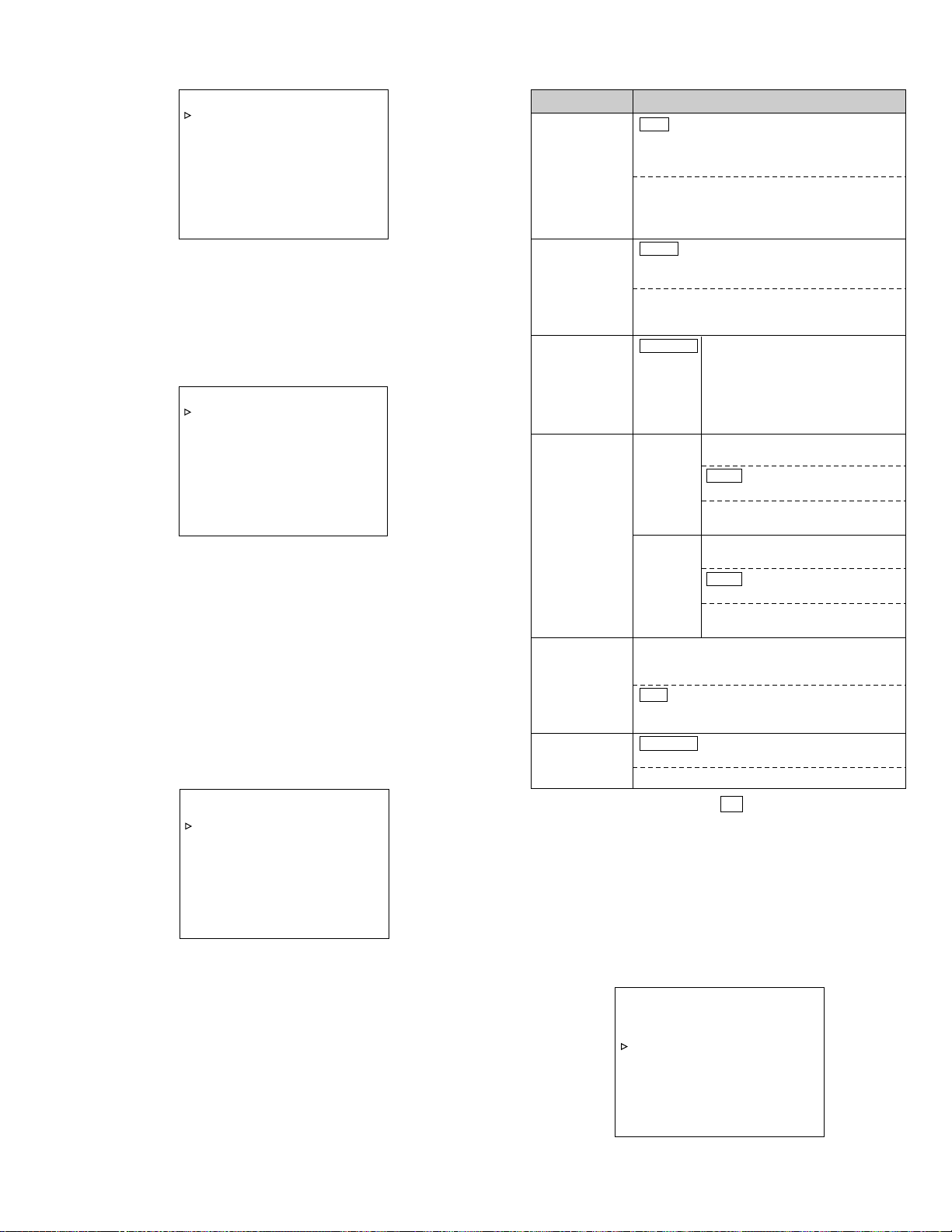

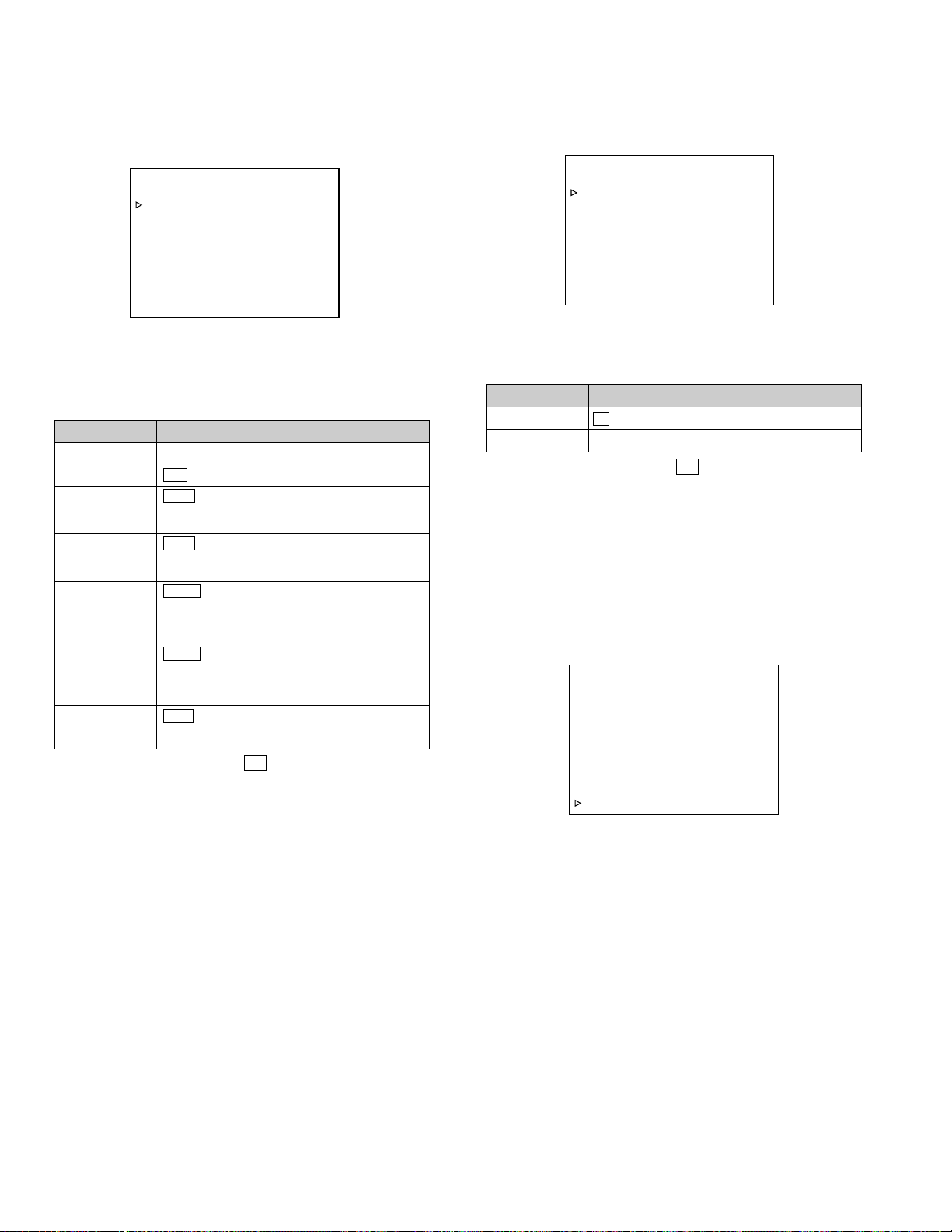

1.5 SERVICE MENUS

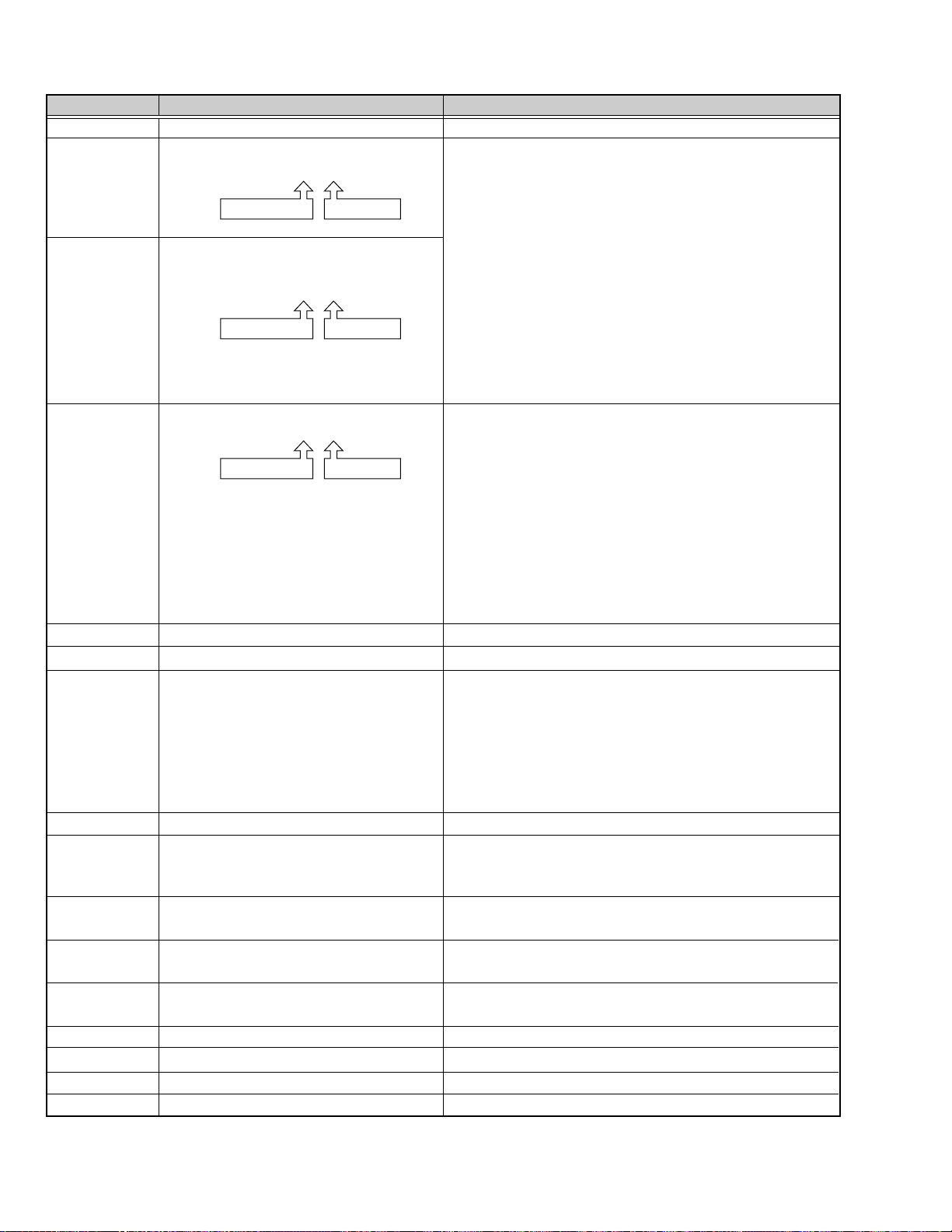

1.5.1 Modes required in servicing

(1) While holding down the specified button(s) (FOCUS ASSIST,

USER 3), press and hold the STATUS button for more than

1 second in order to display the first-level menu of the service menu hierarchy. The items in the first-level menu vary

according to which specified button is being held at the moment the STATUS button is pressed. (Characters are displayed on LCD monitor screen or View finder.)

When power up

Item Displayed Content

CAMERA1 MENU

CAMERA2 MENU

CAMERA3 MENU

VTR1 MENU

VTR2 MENU

VTR3 MENU

DIP SW

HOUR METER

ERROR HISTORY

OTHERS

VERSION

Camera setting, blemish detect

Error correct ON/OFF

AW data reset menu

Repeat, FF/REW speed setting

Long pause, shutdown setting

Reserved, BATT, Info.

DIP SW MENU

Hour Meter indication

Error History

MENU SAVE etc.

CPU Version indication

Holding

ⳮ

DISPLAY

button

Activation Method

FOCUS

USER 3

ASSIST

嘷

ⳮ

ⳮ

嘷

ⳮ

ⳮ

ⳮ

ⳮ

ⳮ

ⳮ

嘷

Holding

DISPLAY

button

FOCUS ASSIST

USER 3

嘷

嘷

ⳮ

嘷

嘷

ⳮ

嘷

嘷

嘷

嘷

ⳮ

+

嘷

嘷

嘷

嘷

嘷

嘷

嘷

嘷

嘷

嘷

ⳮ

Table 1-5-1 Service Menu First Tier List

CN1

CN53

#

Fig. 1.4.6(2)

Note :

When replacing the fuse F1, ensure to replace with same

type fuse. (refer to the parts list)

1.5.2 Operation in the first-level of the service menu

(1) While holding down the specified button(s) (FOCUS ASSIST

or USER 3), press and hold the STATUS button for more

than 1 second.

(2) The first-level of the service menu is displayed.

(3) Rotate the SHUTTER dial to move the cursor ( 3) on to the

item to be modified.

(4) Push into the SHUTTER dial to direct the item on which the

cursor ( 3) is located.

• Pressing the STATUS button returns to the MENU display.

• Can not open the service MENU while recording.

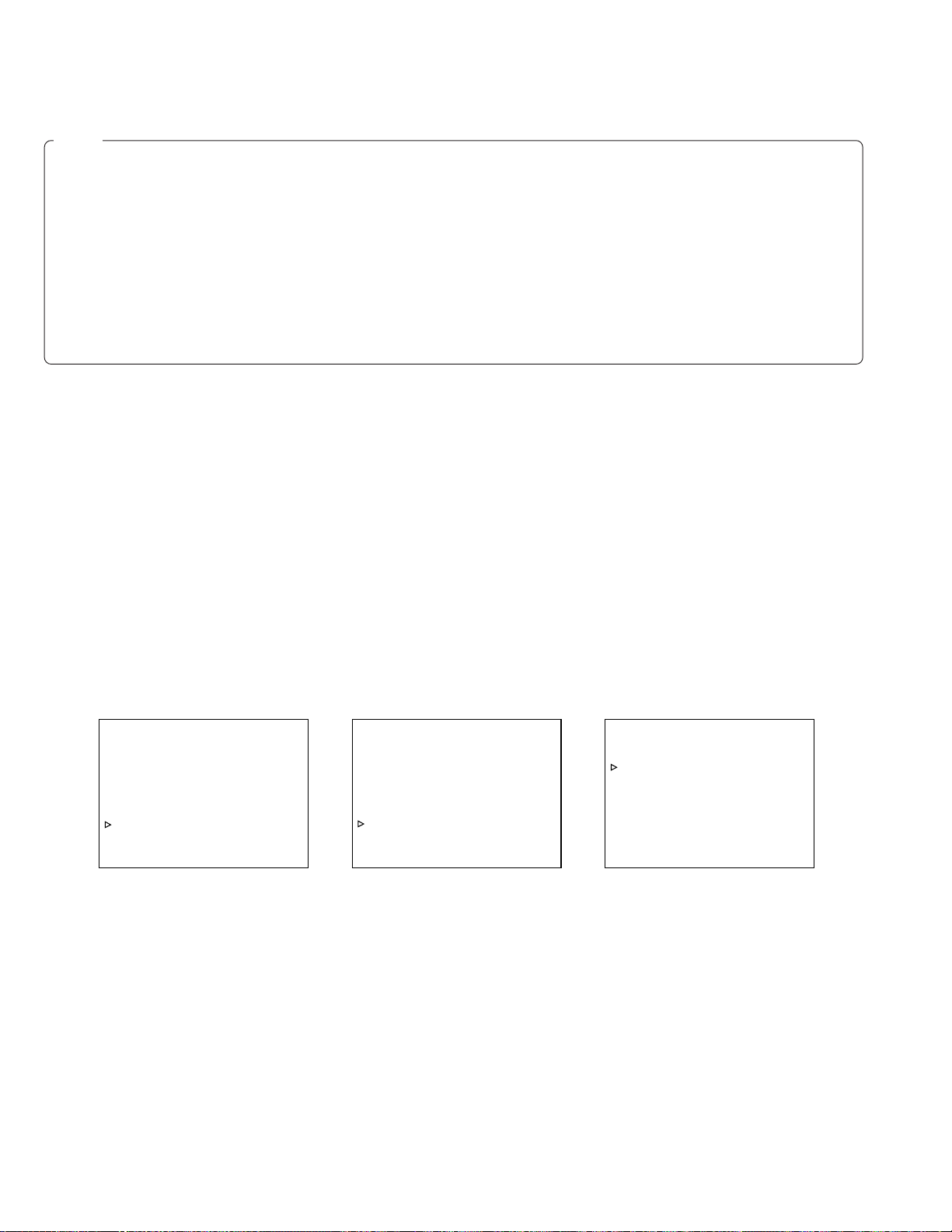

– – – A DV A NC E D M EN U – – –

V ERS ION CHECK . .

CAMERA 1 . .

VTR1 . .

EX I T

Fig. 1-5-2 (1)

While holding down the FOCUS ASSIST button, press and

hold STATUS button for more than 1 second,this MENU

screen is shown on the monitor. (Refer to Fig. 1-5-2(1))

1-8

Page 14

– – – S ER V I C EMENU–––

OFF When the face of LCD screen is

turned toward the camera subject,

does not invert the left and right of

the LCD display. (normal image)

ON When the face of LCD screen is

turned toward the camera subject,

inverts the left and right of the LCD

display. (mirror image)

AUTO When selected FAS mode, audio

recording Level will be

automatically set to AUTO mode.

SW SET When selected FAS mode, audio

recording level will be depending

on switch setting.

ALC + EEI

When selected ALC mode

including FAS mode, EEI function

will be activated.

ONLY ALC

When selected ALC mode

including FAS mode, EEI function

will not be activated.

U MODEL

1/240 Maximum shutter speed is

set to 1/240 second.

1/480 Maximum shutter speed is

set to 1/480 second.

1/960 Maximum shutter speed is

set to 1/960 second.

E MODEL

1/200 Maximum shutter speed is

set to 1/200 second.

1/400 Maximum shutter speed is

set to 1/400 second.

1/800 Maximum shutter speed is

set to 1/800 second.

OFF When selected FULL AUTO mode,

IRIS mode will be depeng on IRIS

MODE switch of the lens.

ON When selected FULL AUTO mode,

Auto Iris mode will be activated

even Manual Iris mode is selected.

CANCEL Does not execute blemish

detection.

EXECUTE

Execute blemish detection.

Item Parameter

LCD L/R

REVERSE

FAS

AUDIO

ALC MODE

EEI MAX

( indicates the factory setting.)

PIXEL

COMPEN DET

IRIS ENF.

AUTO

CAMERA 1 . .

CAMERA 2 . .

VTR1 . .

VTR2 . .

DIP S

HOUR ME T E R

ERROR H I STORY . .

OTHERS . .

EX I T

At first, while holding down the DISPLAY button, turn ON

the power switch, and then, while holding down the USER

3 button, press and hold STATUS button for more than 1

second, this MENU screen is shown on the monitor. (Refer

to Fig. 1-5-2(2))

– – – F A C T O R YMENU–––

CAMERA 1 . .

CAMERA 2 . .

CAMERA 3 . .

VTR1 . .

VTR2 . .

VTR3 . .

DIP S

HOUR ME T E R

ERROR H I STORY . .

At first, while holding down the DISPLAY button, turn ON

the power switch, and then, While holding down the FOCUS ASSIST and USER 3 button, press and hold STATUS

button for more than 1 second, this MENU screen is shown

on the monitor. (Refer to Fig. 1-5-2(3))

1.5.3 CAMERA 1 menu

(1) In a service menu, place the cursor ( 3) on “CAMERA 1”

and push the SHUTTER dial to display the CAMERA1 menu.

OTHERS . .

EX I T

LCD L / R REVERSE OFF

FAS AUD IO AUTO

ALC MODE ALC+EEI

EE I MAX 1 / 2 40

IRIS ENF AUTO ON

PIXEL COMPEN DET CANCEL

P AGE BACK

(2) Rotate the SHUTTER dial to move the cursor ( 3) on the

mode to be adjusted.

(3) Push the SHUTTER dial so that the parameter blinks.

(4) Rotate the SHUTTER dial to vary the parameter.

(5) After completing the parameter setting, push the SHUTTER

dial to stop the blinking of the parameter and store the set-

ting in memory.

(6) After completing the setting, move the cursor ( 3) to “PAGE

BACK” and push the SHUTTER dial to return to the display

at the higher hierarchy level.

W

..

Fig. 1-5-2 (2)

W

..

Fig. 1-5-2 (3)

– – – C AM ER A 1 – – –

Fig. 1-5-3 (1)

Table 1-5-3 (1)

䡵 White blemish detection

Open the User MENU, select "VIDEO FORMAT", "REC", set

to "HDV-HD24P" and push the SHUTTER dial.

Select "FRAME RATE", set to "24" and push the SHUTTER

dial. Select "EXECUTE", push the SHUTTER dial, then GYHD100 is automatically rebooted.

– – – V I D EO F OR M A T – – –

FRAME RATE 24

REC HDV - HD 2 4 P

ASPECT - - - PB OUTPUT 7 2 0P

PB T APE DVCAM

OUT P UT T ERM I NA L COMPOS I T E

SET UP 0 . 0

P AGE BACK

EXECUTE

EXECUTE

%

Fig. 1-5-3 (2)

1-9

Page 15

Open the Service MENU, select "CAMERA1", "PIXEL

COMPEN DET", "EXECUTE" and push the SHUTTER dial, then

CCD white blemish detect operation start automatically.

At this time, the lens is closed and the camera is in the SLOW

SHUTTER

mode.

– – – C AME RA 1 – – –

LCD L / R REVERSE OFF

FAS AUD IO AUTO

ALC MODE ALC+EE I

EE I MAX 1/240

IRIS ENF AUTO ON

PIXEL COMPENDET EXECUI T

P AGE BACK

Fig. 1-5-3 (3)

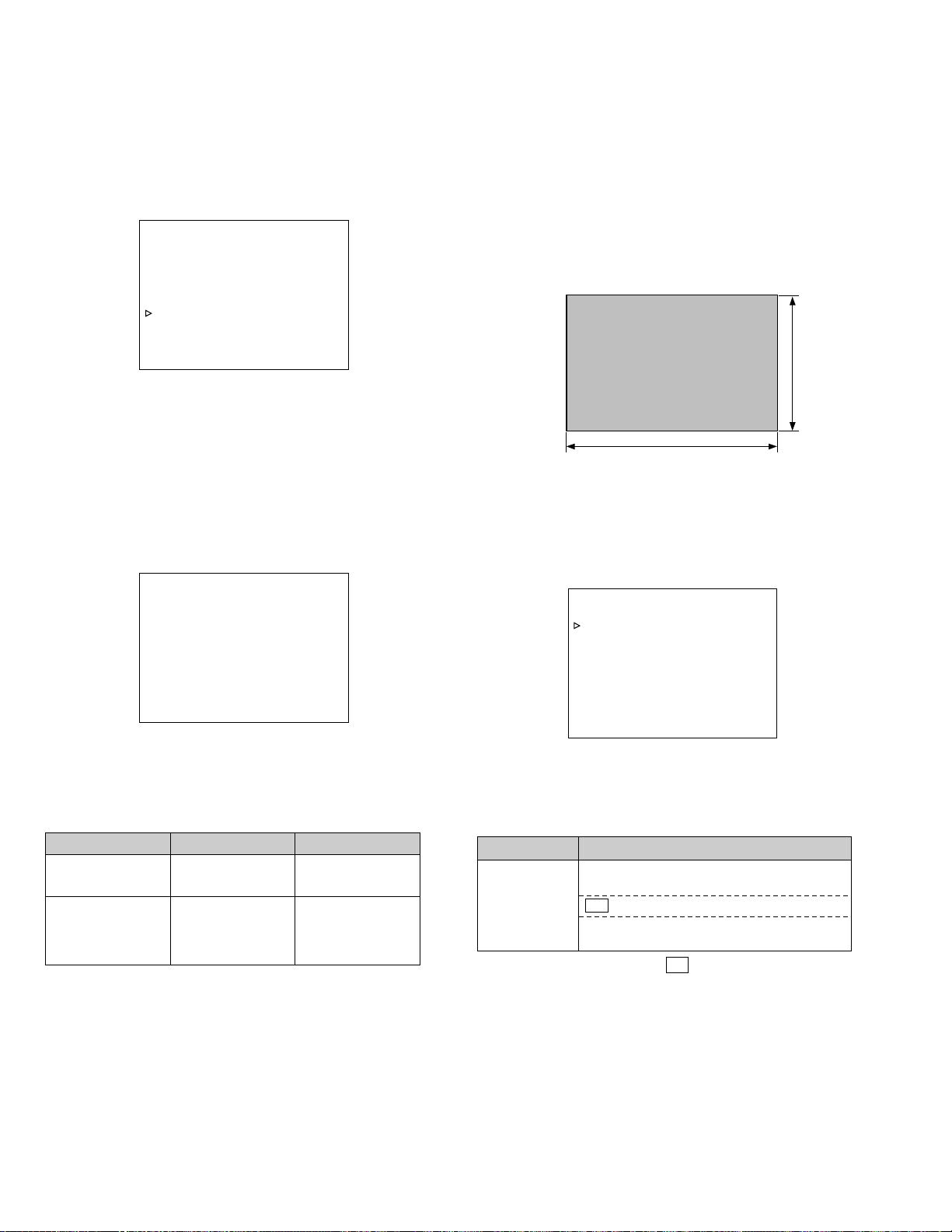

䡵 Details on correctable white blemish

Up to 127 errors with composite video levels of 50mV or

more can be corrected. No limitation of errors per line within

127 however, the maximum consecutive errors are 4 and

the correction results may be inferior to the case of single

error correction.

Oblique noise may be observed on the screen during white

blemish detection. This is due to the principles of error correction and is not a malfunction.

White blemish can be detected in the following area.

100%

After completing white blemish detection, return "REC" and

"FRAME RATE" setting to original one's.

When the white blemish detection completes, the result data

is stored in the memory of CPU,

end message is shown as below, then please turn off.

PIXEL COMPEN

END

TURN PO

AND ON AGA I N

W

ER OFF

Fig. 1-5-3 (4)

If any errors occurs during the detection operation, an error message is displayed , and return to MENU display.

Message TreatmentError details

LENS NOT

CLOSED?

COUNT OVER

The lens does not

close for detection.

The number exceeds

the specified count.

No result is stored in

the EEPROM.

Only the specified

count of data is

stored in the

EEPROM.

Table 1-5-3 (2)

100%

Fig. 1-5-3 (5)

1.5.4 CAMERA 2 menu

(1) In a service menu, place the cursor on “CAMERA 2” and

push the SHUTTER dial to display the CAMERA2 menu.

– – – C A MERA2 – – –

PIXEL COMPE N ON

TEST S I GNAL OFF

P AGE BACK

Fig. 1-5-4

Operation ways are almost same as CAMERA 1 MENU, so

please refer it.

Item Parameter

PIXEL

COMPEN *1

OFF Does not correct the detected white

blemish.

ON Corrects the detected white blemish.

CHECK

Light up the pixels which are the

detected white blemish.

( indicates the factory setting.)

Table 1-5-4

1-10

*1: This mode is automatically set to ON when the power

is turned on.

The OFF mode is enabled only after it is set to OFF at

this screen until the power is turned off.

Page 16

1.5.5 CAMERA 3 menu

OFF Does not indicate the Battery

information.

AUTO Show the Battery information as

Battery Info of VTR3 MENU.

OFF Disable repeat recording

2 Perform repeat recording 2 times.

5 Perform repeat recording 5 times.

12 Perform repeat recording 12 times.

ON Enable full repeat recording.

OFF Disable repeat playback.

ON Enable repeat playback.

FF/REW When FF/REW command is

received from REMOTE, it runs as

FF/REW mode.

SEARCH When FF/REW command is

received from REMOTE, it runs as

search FWD/REV mode.

FIELD

FRAME

X5 Maximum FF/REW speed is limited up

to x5.

X7.5 Maximum FF/REW speed is limited up

to x7.5.

X10 Maximum FF/REW speed is limited up

to x10.

MAX *1No limitation

DV Horizontal effective pixels are 720.

STANDARD Horizontal effective pixels are

710 at 60/30 frame rate and 702 at

50/25 frame rate.

Item Parameter

BATT.

DISPLAY

REC REPEAT

PLAY REPEAT

REMOTE

FF/REW

STEP

SLOW [DV]

FF/REW

SPEED

VIDEO OUT

HBLANK

( indicates the factory setting.)

In a service menu, place the cursor on “CAMERA 3” and push

the SHUTTER dial to display the CAMERA3 menu.

Operation ways are almost same as CAMERA 1 MENU, so

please refer it.

Item Parameter

AW/SKIN RESET

PIXEL COMP

RESET

CCD ADJ

RESET

CAM EEPROM

RESET

– – – C A ME R A 3 – – –

W

/SKIN RESET CANCEL

A

PIXEL COMP RESET CANCEL

CCD A D J RES E TCANCEL

CAN EE PROM RESET CANCEL

P AGE BACK

Fig. 1-5-5

CANCEL Does not reset the auto white

EXECUTE Resets the auto white data and

CANCEL Does not reset the detected white

EXECUTE Resets the detected white

CANCEL Does not reset the CCD

EXECUTE Resets the CCD adjustment data.

CANCEL Does not reset the EEPROM data

EXECUTE Resets the EEPROM data for

data and the skin detect data.

the skin detect data.

blemish data.

blemish data.

adjustment data.

for CAMERA CPU.

CAMERA CPU.

( indicates the factory setting.)

Table 1-5-5

1.5.6 VTR 1 menu

In a service menu, place the cursor on “VTR 1” and push the

SHUTTER dial to display the VTR 1 menu.

––– VTR1–– –

BATT . D I SPL AY AUTO

REC REPE AT OF F

PLAY REPEAT OFF

REMOTE FF /RE

STEP SLOW[DV] FRAME

FF / RE

W

VIDEO OUT HBLANK DV

P AGE BACK

W

FF / RE

SPEED MAX

W

Fig. 1-5-6

Operation ways are almost same as CAMERA 1 MENU, so

please refer it.

Table 1-5-6

*1: Maximum speed is x20 at VTR mode, but no function

at CAM mode.

1-11

Page 17

0 Normal setting

Refer to next page.

Item Parameter

RESERVED

BATTERY INFO

( indicates the factory setting.)

1.5.7 VTR 2 menu

In a service menu, place the cursor on “VTR 2” and push the

SHUTTER dial to display the VTR 2 menu.

1.5.8 VTR 3 menu

In a service menu, place the cursor on “VTR 3” and push the

SHUTTER dial to display the VTR 3 menu.

––– VTR2–– –

L ONG PAUSE ON

BATT . SHUT DO

B ATY.ALARM 6.9V

ANTON SHUT DO

ANTON ALARM 13 . 5V

DF MASK [ DV ] OFF

P AGE BACK

W

N6.0V

W

N12.6V

Fig. 1-5-7

Operation ways are almost same as CAMERA 1 MENU, so

please refer it.

Item Parameter

LONG PAUSE

OFF Disable the long pause function.

ON Enable the long pause function.

BATT.

SHUTDOWN *1

BATT.

ALARM *1

ANTON SHUT

DOWN

6.8V Setting of the battery voltage when

shutdown should occur. (Setting in

0.1V steps between 6.3V and 7.5V.)

6.9V Setting of the battery voltage when

battery alarm is indicated. (Setting in

0.1 V steps between 6.3V and 8.0V.)

12.0V Setting of the ANTON battery voltage

when shutdown should occur. (Setting

in 0.1V steps between 10.5V and

13.6V.)

ANTON

ALARM

13.5V Setting of the ANTON battery voltage

when battery alarm is indicated.

(Setting in 0.1 V steps between 10.5V

and 13.6V.)

DV DF MASK *2

OFF "1" is recorded as per format.

ON "0" is always recorded.

( indicates the factory setting.)

Table 1-5-7

––– VTR3–– –

RESERVD 0

BATTELY I NFO . .

PAG BACK

Fig. 1-5-8 (1)

Changing of setting is prohibited.

Table 1-5-8 (1)

䡵 BATTERY INFO Display

Display method

Move the cursor to the “BATTERY INFO..” in “VTR3” screen

and press SHUTTER dial. BATTERY INFO screen (right figure) will be displayed.

– – – B A T T E R Y I N F O – – –

T YPE ANTON SMART

R EMA I N 1 2 5M i n / 9 5

<12.8V 1.25A 30° C>

FUL L CAPACI TY 3 2 . 6Ah

PRESENT CAPAC I TY 3 0 . 5 A h

SER I A L NO. 5 5 5 2 0

MANU F AC T UR E2004/04

SOF TWARE REV . 1 2 . 5

CAL I BRAT I ON REQU I RED OFF

P AGE BACK

%

*1 : When operating by DC input, then “SHUT DOWN” will be

set to 6.0V, and “ALARM” will be set to 6.9V automatically, and these setting will not relate to menu setting.

*2 : FRAME RATE 50/25 only

1-12

Fig.1-5-8 (2) BATTERY INFO

(When the Anton/Bauer Smart Battery is detected)

Page 18

Item Descriptions

TYPE

ANTON SMART When ANTON/BAUER SMART BATTERY is connected

AFG When BATTERY with I/F of AFG (AnalogFuelGauge) is connected

OTHERS When other BATTERY is connected

NO DETECT When no BATTERY is connected

REMAIN Minute

%

Voltage

Current

Temperature

FULL CAPACITY

PRESENT CAPACITY

SERIAL NO.

MANUFACTURE

SOFTWARE REV.

CALIBRATION

REQUIRED

Remaining battery lasting time [min] calculated based on current power consumption

Current remaining capacity [%] corresponding to total battery capacity

Output voltage of battery

Output current of battery

Temperature of battery

Capacity [Ah] when the BATTERY is fully charged

Current BATTERY capacity [Ah]

Manufactured serial number

Manufactured date

Software revision number

OFF Calibration not required

ON Calibration required

Table 1-5-8 (2)

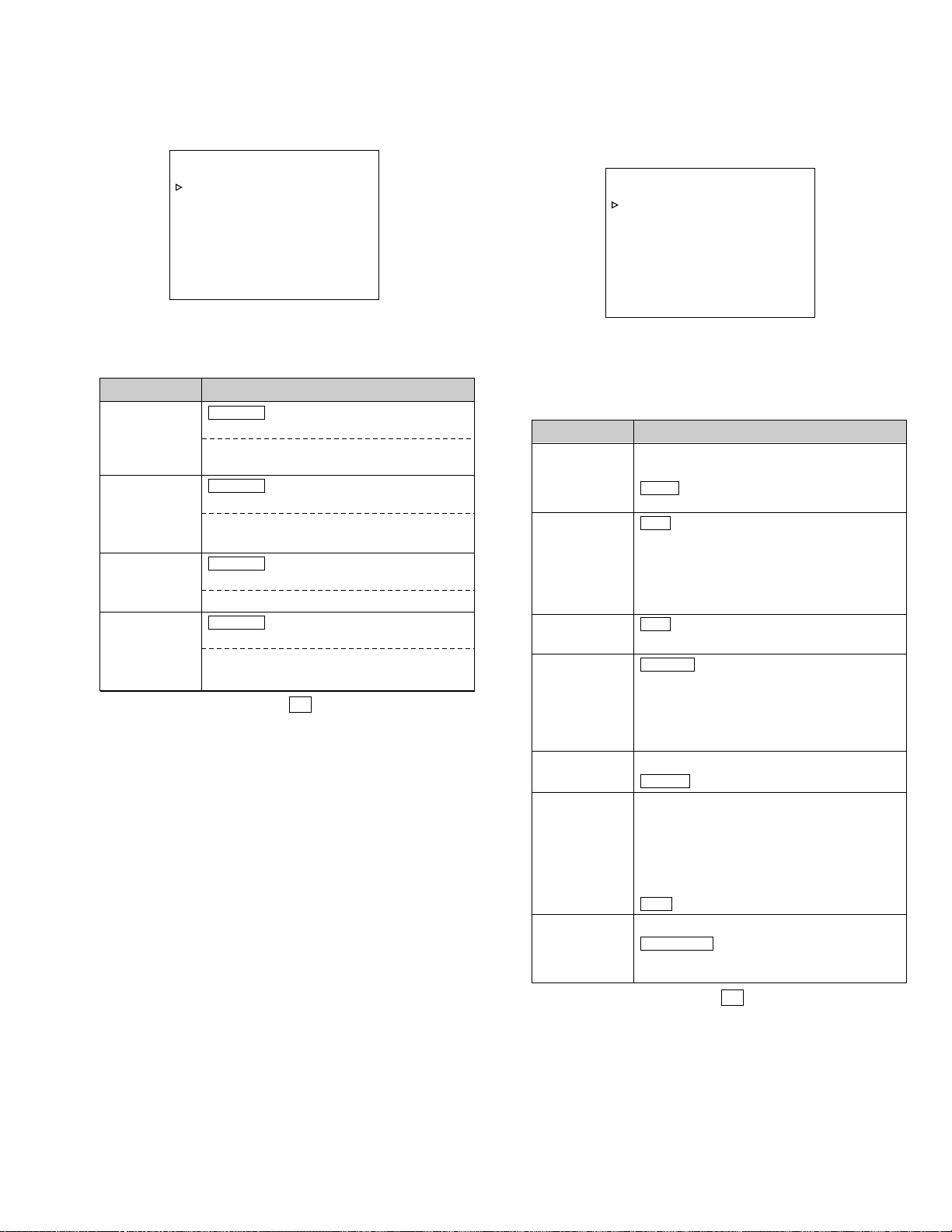

1.5.9 DIP SW menu

(1) In a service menu, place the cursor on “DIP SW ” and push the SHUTTER dial to display the DIP SW menu.

– – – D I P SW [ 1 / 6 ] – – –

W

ALL RESET CANCEL

DIPS

NEXT PAGE

P AGE BACK

Fig. 1-5-9 (1)

– – – D I P SW [ 4 / 6 ] – – –

W

16 OFF

DIPS

DIPS

W

17 OFF

DIPS

W

18 OFF

W

19 OFF

DIPS

DIPS

W

20 OFF

DIPS

W

21 OFF

DIPS

W

22 OFF

DIPSW23 OFF

NEXT PAGE

P AGE BACK

Fig. 1-5-9 (4)

– – – D I P SW [ 2 / 6 ] – – –

W

00

DIPS

DIPS

W

1OFF

DIPS

W

2OFF

W

3OFF

DIPS

DIPS

W

4OFF

DIPS

W

5OFF

DIPS

W

6OFF

DIPSW7OFF

NEXT PAGE

P AGE BACK

Fig. 1-5-9 (2)

– – – D I P SW [ 5 / 6 ] – – –

W

24 OFF

DIPS

DIPS

W

25 OFF

DIPS

W

26 OFF

W

27 OFF

DIPS

DIPS

W

28 OFF

DIPS

W

29 OFF

DIPS

W

30 OFF

DIPSW31 OFF

NEXT PAGE

P AGE BACK

Fig. 1-5-9 (5)

– – – D I P SW [ 3 / 6 ] – – –

W

8OFF

DIPS

DIPS

W

9OFF

DIPS

W

10 OFF

W

11 OFF

DIPS

DIPS

W

12 OFF

DIPS

W

13 OFF

DIPS

W

14 OFF

DIPSW15 OFF

NEXT PAGE

P AGE BACK

Fig. 1-5-9 (3)

– – – D I P SW [ 6 / 6 ] – – –

W

32 0

DIPS

DIPS

W

33 0

DIPS

W

34 0

W

35 OFF

DIPS

DIPS

W

36 OFF

DIPS

W

37 OFF

DIPS

W

38 OFF

DIPSW39 OFF

P AGE BACK

Fig. 1-5-9 (6)

1-13

Page 19

Operation ways are almost same as CAMERA 1 menu, so please

--- DIP SW 6/6 --0

0

0

OFF

OFF

OFF

OFF

OFF

DIP SW 32

DIP SW 33

DIP SW 34

DIP SW 35

DIP SW 36

DIP SW 37

DIP SW 38

DIP SW 39

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

gp

refer it.

All DIP Switch settings which are shown below should

not be changed ecxept for repair or maintenance. And

do not forget to return original position after repair.

Item Parameter

--- DIP SW 1/6 ---

DIP SW

ALL

RESET

CANCEL Cancel to reset all

DIPSW settings.

EXECUTE Execute to reset all

DIPSW settings.

--- DIP SW 2/6 ---

DIP SW 0

1:Displays error rate monitor

and CPU port information

DIP SW 1

ON : Disable warning message

display

DIP SW 2

DIP SW 3

DIP SW 4

DIP SW 5

DIP SW 6

DIP SW 7

Change prohibited

ON : Disable DEW warning

Change prohibited

Change prohibited

Change prohibited

Change prohibited

--- DIP SW 3/6 ---

DIP SW 8

DIP SW 9

DIP SW 10

Change prohibited

Change prohibited

ON :

Displays error rate solely

for audio block on the error rate

monitor screen

DIP SW 11

DIP SW 12

DIP SW 13

DIP SW 14

DIP SW 15

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Factory

setting

CANCEL

0

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Table 1-5-9

ERROR RATE MONITOR screen

By setting "DIP SW 0" to "1", error rate and each CPU port information display screen will appear on the LCD monitor, View

finder and monitor.

The values which are pointed by arrow are the error rate value.

Error rate of CH-1 shown in upper row, and CH-2 shown in lower

row, and these value are indicated total AUDIO/VIDEO error rate.

When the error rate increase , the warning message "HEAD

CLEANING REQUIRED" is displayed. And this message is indicate when the error rate value is over 4,500 (one-channel AUDIO/VIDEO total) for 7 seconds consecutively.

ERROR RATE indicator

XXXX

65535 XX XX XX XX XX XX

65535 XX

FI L1

F5.68

STBY

XX

T

XX

D

XX XX XX

XX

XX XX XXXX

CHCH12---------+-+--

01/ 02/ 03 AM01: 23: 45

00: 00: 00: 00

XX XX XX

XX

--

SP 2 0 mir

ADP

FAS

-3 d B

XX

FA

12. 2V

W

I

SD

B

--- DIP SW 4/6 ---

DIP SW 16

DIP SW 17

DIP SW 18

DIP SW 19

DIP SW 20

DIP SW 21

DIP SW 22

DIP SW 23

--- DIP SW 5/6 ---

DIP SW 24

DIP SW 25

DIP SW 26

DIP SW 27

DIP SW 28

DIP SW 29

DIP SW 30

DIP SW 31

1-14

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

Change prohibited

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Fig. 1-5-9 (7)

Page 20

1.5.10 HOUR METER

In a service menu, place the cursor on “HOUR METER ” and

push the SHUTTER dial to display the HOUR METER menu.

– – – H O U R M ETER [ 1 / 2 ] – ––

DRUM CL E AR

TOTALDRUM 000000H

N

FA

PO

W

ER 000000H

C APSTAN 000000H

SEACH 000H00M

W

FF / RE

NEXT PAGE

P AGE BACK

000000H

000H00M

Fig. 1-5-10 (1)

– – – H O U R M ETER [ 2 / 2 ] –––

LOAD ING 0000000

EJECT 0000000

F

W

D/REV 0000000

CLEANING TAPE 0000000

P AGE BACK

Fig. 1-5-10 (2)

Operation ways are almost same as CAMERA 1 menu, so please refer it.

Item Parameter

DRUM

TOTAL DRUM

FAN

POWER

CAPSTAN

SEARCH

FF/REV

LOADING

EJECT

FWD/REV

CLEANING TAPE

000000 Displays the drum hour

meter(maintenance for drum)

CLEAR Resets the drum hour meter.

000000 Displays the total hour meter.

CLEAR Resets the total drum hour meter.

(This does not work unless the special

setting)

000000 Displays the fan hour meter.

CLEAR Resets the fan hour meter.

000000 Displays the power hour meter.

CLEAR Resets the power hour meter.

000000 Displays the capstan hour meter.

CLEAR Resets the capstan hour meter.

000000 Displays the search hour meter.

CLEAR Resets the search hour meter.

000000 Displays the FF/REW hour meter.

CLEAR Resets the FF/REW hour meter.

000000 Displays the loading count.

CLEAR Resets the loading count.

000000 Displays the eject count.

CLEAR Resets the eject count.

000000 Displays the forward/reverse

switching count.

CLEAR Resets the forward/reverse switching

count.

000000 Displays the cleaning tape working

count.

CLEAR Resets the cleaning tape working

count.

1.5.11 ERROR HISTORY

In a service menu, place the cursor on “ERROR HISTORY ” and

push the SHUTTER dial to display the ERROR HISTORY menu.

– – – E RR O R H ISTORY –––

(HISTORY - 1 ) 7101

CAP MOTOR FA I L URE

(HISTORY - 2 ) 7101

CAP MOTOR FA I L URE

(HISTORY - 3 ) 7101

CAP MOTOR FA I L URE

(HISTORY - 4 ) 7101

CAP MOTOR FA I L URE

CLEAR CANCEL

P AGE BACK

Fig. 1-5-11

(1) Rotate the SHUTTER dial to move the cursor onto the item

to show details.

(2) Push the SHUTTER dial so that the details of ERROR HIS-

TORY is shown.

(3) Rotate the SHUTTER dial to move cursor onto the “CLEAR”,

push the SHUTTER dial, then ERROR HISTORY will be deleted.

Note :

ERROR HISTORY was stored from “HISTORY-1” box to

“HISTORY-4”box. Latest error was stored “HISTORY-4”

box, and if there will be occur another error then latest error

history will be rewrite on “HISTORY-4”. From “HISTORY1” to “HISTORY-3” will not rewrite, except to “CLEAR”

operation.

1.5.12 Detail indication of ERROR HISTORY

In a ERROR HISTORY display, place a cursor onto the item and

push SHUTTER dial, then detail display (MECHANISM INFO)

picture will be shown.

MECHANISM INFO has 2 pages.

– – – M E CHAN I SM I NF 0 1 / 2 – –

P.TM 000000H

SYS MODE:PLAY(01. 00)

MSD MODE : P L A Y ( 0 1 . 00 )

LAST KEY:PLAY(01.00)

T APE REM[ 0 0 0 0 ]

DE

W

DIAMETER TU[00]SP[00]

NEXT PAGE

P AGE BACK

–>STOP( 00 . 00 )

[00] TEMP[00]

Fig. 1-5-12 (1)

– – – M E CHAN I SM I NF 0 2 / 2 – –

M.POSI BRK2FAST>BRK2FAST

H.POSI INI T >CASS IN

CAP [ OF F F

TU [ ON ] SP [ OFF ] DRM[ OFF ]

DRV [ 00 ] CAPV [ 0 0 ] RELV [ 00 ]

MCV [ 0 0 ] RE L I [ 0 0 ]

BGN [ OF F ] END [ ON ] CAS [ OFF ]

STD[OFF ] HW[OFF] HW2[OFF]

SPL [ OF F ] TH IN[ON]

P AGE BACK

W

D]REL [OFF FWD]

Table 1-5-10

Fig. 1-5-12 (2)

1-15

Page 21

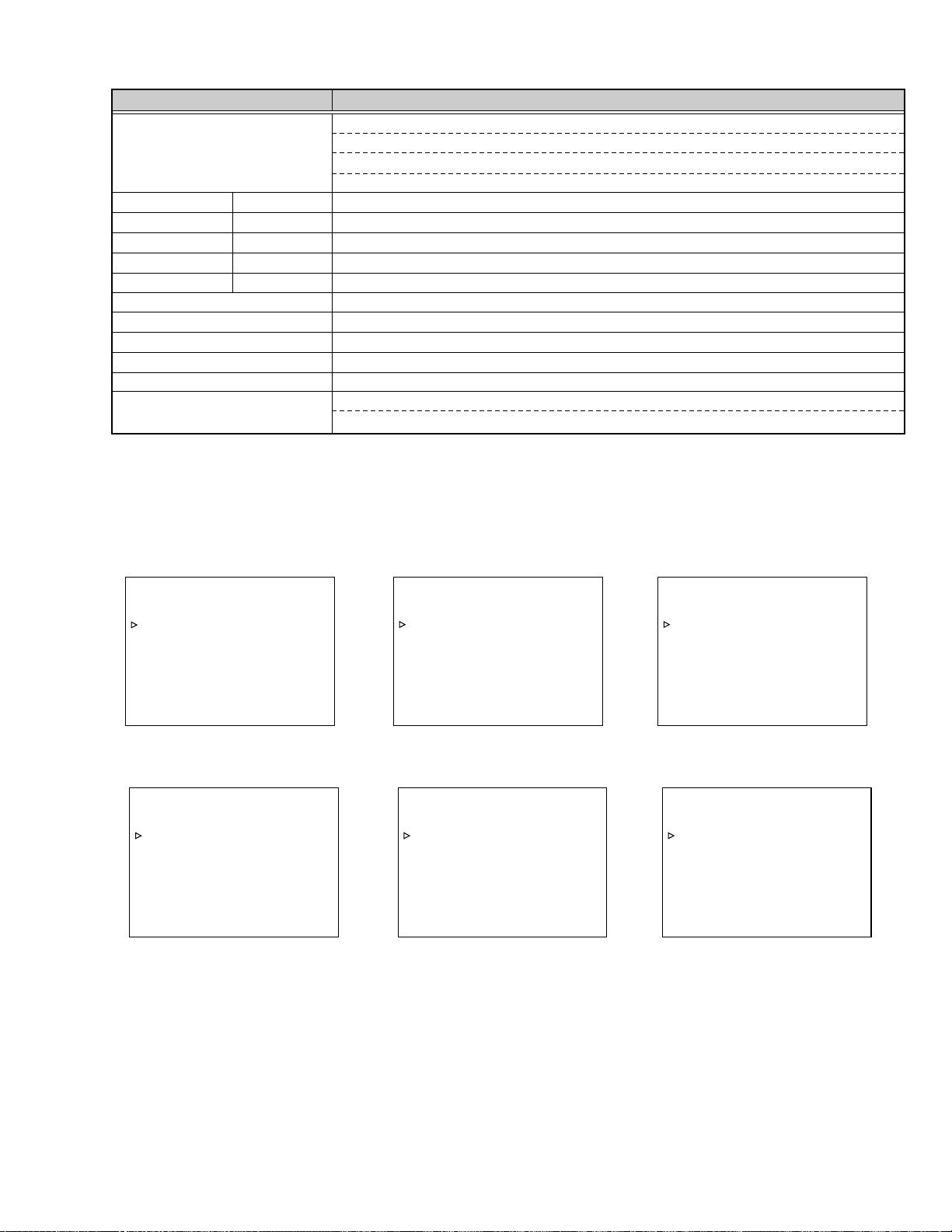

Item Content Displayed Content

P.TM

SYS MODE

MSD MODE

LAST KEY

TAPE REM

DEW

TEMP

DIAMETER

M. POSI

CAP

REL

DRM

DIR

DRV

CAPV

RELV

POWER HOUR METER

SYSCON CPU mode when error occurred

PLAY (03, 00)

ParameterMODE DATA

MSD CPU mode and target mode when

error occurred

PLAY (01, 00)

ParameterMODE DATA

Final Key code when error occurred

PLAY (E7, 01)

ParameterMODE DATA

TAPE REMAIN

DEW sensor A/D intake value

Temperature sensor A/D intake value

The value “49” [5°C] is threshold of

detecting low temperture. The value “DC”

[60°C] is the threshold of displaying “OVER

HEATING” message.

Displays wound tape diameter (Take-up, Supply)

Mechanism position and target mechanism

position

Capstan status

Reel status

Drum status

Direction of tape running (Direction of target)

Drum control voltage

Capstan control voltage

Reel control torque value

Power hour meter is displayed.

SFF/SREW parameter is speed display.

(Refer to Table 1-9-11 (2) Speed parameter)

Parameters of other modes are irrelevant.

EJECT (01) : Eject

STOP (02) : Stop

PLAY (03) : Play REC (13) : Rec

STL (04) : Still RECP (14) : Rec Pause

FF (05) : FF DVRC (15) : DV Rec

REW (06) : Rew DVRP (16) : DV Rec Pause

SFF (07) :

SREW (08) :

SFF/SREW parameter is speed display (See Table 1-9-11 (2))

Other parameters are 01: ON, 00: OFF

REC (E0) : Rec SFF (EB) : Search Fwd

RECP (E1) : Rec Pause SREW (EC) : Search Rev

DVRP (E2) :

ADUB (E5) : Audio Dub EJECT (F1) : Eject

ADBP (E6) :

PLAY (E7) : Play HWDN (F3) : Housing Down

STL (E8) : Still POFF (F4) : Power Off

FF (E9) : FF DVRC (F5) : DV Rec

REW (EA) : Rew PON (FA) : Power on

Displays tape remaining in minutes ([FFFF] : not detected)

DEW display at over [48]

Temperature is displayed in hexadecimal value.

-10°Ca[22] 20°Ca[7C] 50°Ca[CC]

a

- 5°C

a

0°C

a

5°C

10°Ca[59] 40°Ca[B7] 65°Ca[E1]

a

15°C

[00]—[FF] : 0mm-82mm (Diameter) ([00] is non-detected)

[2EJ], [EJ], [EJ2CAIN], [CAIN], [CAIN2HLD], [HLD],

[HLD2REV], [REV], [REV2FWD], [FWD], [FWD2STP], [STP],

[STP2], [CLNOFF], [INIT]

[ON] : Rotate [FWD/REV]: Direction display

[OFF] : Stop

[ON] : Rotate [FWD/REV]: Direction display

[OFF] : Stop

[ON] : Rotate

[OFF] : Stop

[FWD/REV]: Direction display

[00-FF] : 0—3V

[00-FF] : 0—3V

[00-FF] : 0—3A

Search Fwd

Search Rev

DV Rec Pause

Audio Dub Pause

[2D] 25°Ca[8C] 55°Ca[D4]

[3A] 30°Ca[9C] 60°Ca[DC]

[49] 35°Ca[AA]

[6A] 45°Ca[C2] 70°Ca[E6]

POFF (1A) : Power Off

NDEF (1F) :

STOP (F0) : Stop

HWUP (F2) : Housing Up

“OVER HEATING” message

During initial operation

1-16

Page 22

Item Content Displayed Content

MCV/SPD

RELI

BGN

END

CAS

THIN

Loading/cassette housing control voltage

(when error code 4xxx and error code 3xxx

is displayed.)

Tape speed (When the code excepting

error code 4xxx and error code 3xxx is

displayed.)

Reel current (Cassette housing motor current

only during housing-related warning)

Begin sensor

End sensor

Cassette SW status

Thin tape detection

[00-FF] : 0—8V (Displays mode motor control voltage

during error code 3xxx)

(Displays cassette motor control voltage

during error code 4xxx)

[00-FA] : 0—25X (FF is displayed when the speed is faster

than this.)

“Tape speed” is a function to convert the

hexadecimal value into a decimal value,

and no speed parameter of the tape.

(ex. FAh = 250 → The speed is 25.0X.)

[00-FF] : 0—1.2A

[ON] : Leader tape detected

[OFF] : Magnetic tape detected

[ON] : Trailer tape detected

[OFF] : Magnetic tape detected

[ON] : No cassette

[OFF] : Cassette detected

[ON] : THIN

[OFF] : NORMAL

Table 1-5-12 (1) MECHANISM INFO content

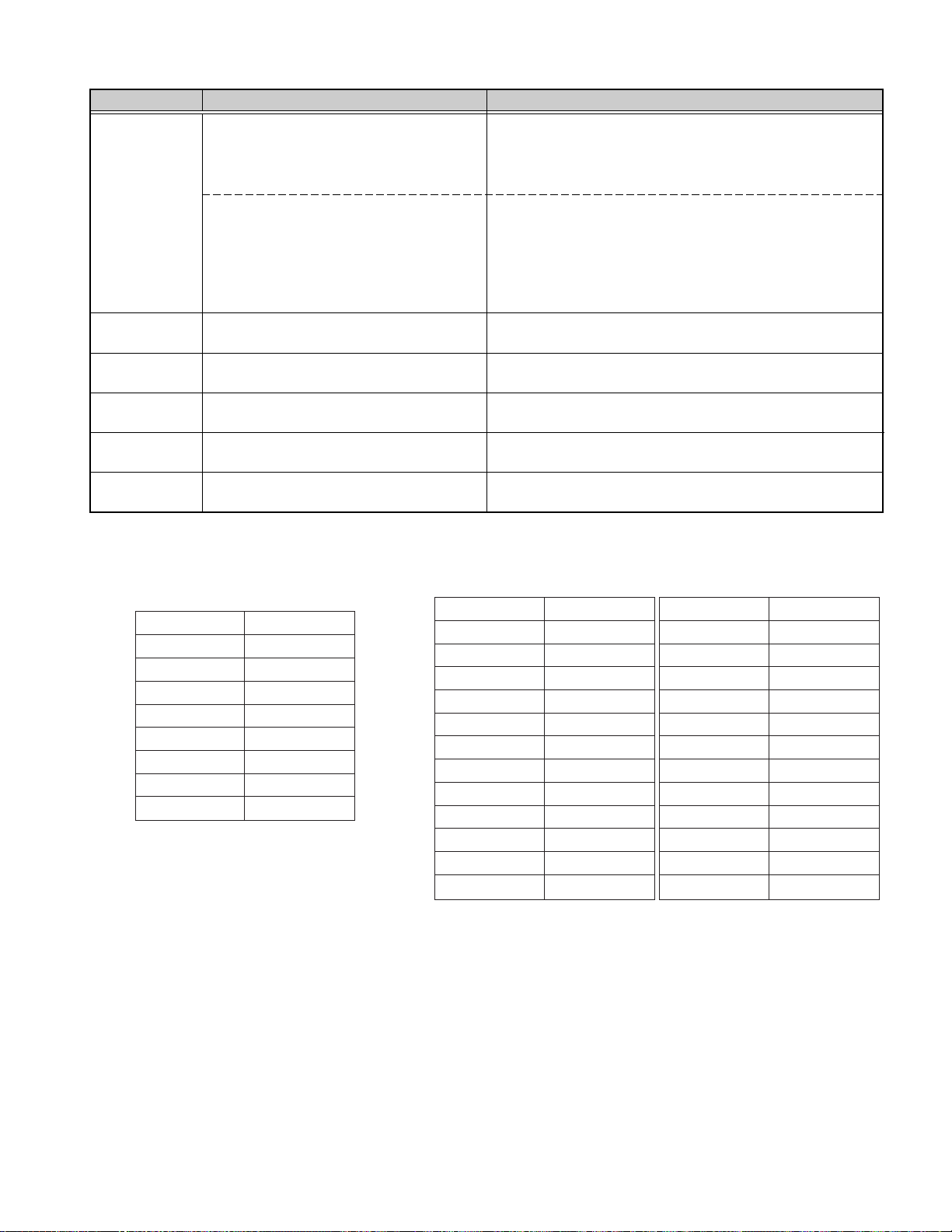

Parameter Speed

BD + 8.5

A9 + 5.5

91 + 2.5

80 + 1

81 – 1.5

91 – 2.5

A9 – 4.5

BD – 6.5

Table 1.5.12 (2) HDV Speed parameter

Parameter Speed Parameter Speed

00 x 0 82 x 1.08

1F x 0.03 83 x 1.11

40 x 0.10 84 x 1.12

53 x 0.20 85 x 1.16

61 x 0.30 91 x 2.00

6D x 0.50 A9 x 5.00

7A x 0.80 BD x 9.00

7B x 0.84 C0 x 10.0

7D x 0.90

7F x 0.96

80 x 1.00

81 x 1.04

Table 1-5-12 (3) DV Speed parameter

1-17

Page 23

Error code

0201

3200

3300

4100

5605

5606

5607

5608

5609

5702

5802

7001

7101

7202

7203

7302

7303

7305

Display

CONDENSATION ON DRUM

LOADING FAILURE

UNLOADING FAILURE

No display

CASSETTE EJECT FAILURE

DEFECTIVE TAPE

DEFECTIVE TAPE

DEFECTIVE TAPE

DEFECTIVE TAPE

DEFECTIVE TAPE

TAPE END DET. ERROR

TAPE BEGIN DET. ERROR

DRUM MOTOR FAILURE

CAP MOTOR FAILURE

SUPPLY REEL FAILURE

SUPPLY REEL FAILURE

TAKE UP REEL FAILURE

TAKE UP REEL FAILURE

TAKE UP REEL FAILURE

Content of occurrence

DEW detected

Does not load

Does not unload

Does not intake

Does not eject

Tape abnormality

during intake

Tape tear during

unloading

Tape tear during

loading

Tape tear on the

loading side

Tape tear during

slack takeup

End sensor

abnormality

Begin sensor

abnormality

Drum motor does

not rotate

Capstan motor

does not rotate

SUP reel does not

rotate

SUP side tape slack

TU reel does not

rotate

TU side tape slack

Tape slack during

unloading

Method of detection Detected signal

If DEW sensor detects

condensation

If mechanism position does

not move in loading direction

within 5 seconds

If mechanism position does

not move in unloading

direction within 5 seconds

If intake is not completed

within 5 seconds (Ejects

without warning)

If eject is not completed

within 5 seconds

If begin or end side sensor is

ON after intake

If reel FG is excessive during

unloading

If reel FG is insufficient during

loading

If only supply side reel does

not rotate during FWD/REV

If tape slack takeup is not

completed within 10 seconds

If trailer tape sending is not

completed within 3 seconds

If leader tape sending is not

completed within 3 seconds

If drum motor does not rotate

for over 4 seconds

If capstan motor does not

rotate for over 2 seconds

If SUP reel does not rotate for

over 3 seconds

If only SUP reel does not

rotate during REV

If TU reel does not rotate for

over 3 seconds

If only TU reel does not rotate

during FWD

If TU reel FG is insufficient

during unloading

IC71 (MSD) –detects voltage

of pin E16

IC71 (MSD) –detects output

of pin F14, rotary encoder

IC71 (MSD) –detects output

of pin F14, rotary encoder

IC71 (MSD) –pin M9,

CASSETTE SW is not

detected within 5 seconds

IC71 (MSD) –pin P9,

HOUSING SW is not

detected within 5 seconds

IC71 (MSD) –pin E15, START

sensor and pin E14,

END sensor are both detected

IC71 (MSD) –pin R14, TU

REEL FG is detected

IC71 (MSD) –pin R14, TU

REEL FG is detected

IC71 (MSD) –pin R13, SUP

REEL FG is not detected

IC71 (MSD) –pin R14, TU

REEL FG and pin R13, SUP

REEL FG are both detected

IC71 (MSD) –pin E14, END

sensor is detected for over 3

seconds

IC71 (MSD) –pin E15, START

sensor is detected for over 3

seconds

IC71 (MSD) –pin T14, DRUM

FG is not detected for over 4

seconds

IC71 (MSD) –pin T13, CAP

FG is not detected for over 2

seconds

IC71 (MSD) –pin R13, SUP

REEL FG is not detected for

over 3 seconds

IC71 (MSD) –pin R13, SUP

REEL FG is not detected

IC71 (MSD) –pin R14, TU

REEL FG is not detected for

over 3 seconds

IC71 (MSD) –pin R14, TU

REEL FG is not detected

IC71 (MSD) –pin R14, TU

REEL sensor is detected

1-18

Table 1-5-12 (4) Error Code Contents

Page 24

1.5.13 OTHERS menu

In a service menu, place the cursor on “OTHERS” and push the SHUTTER dial to display the OTHERS menu.

– – –

OTHERS

M E M O R Y S

M E M O R Y S

A L L R E SE

MEM . ED I T AD R : 3 9 8

D ATA: 4 F

P AGE BACK

W L O A D

W S A V E

T

–––

:OFF

:OFF

:CANCEL

Fig. 1-5-13

Operation ways are almost same as CAMERA1 MENU, so please refer it.

Item Parameter

MEMORY SW

LOAD

MEMORY SW

SAVE

ALL RESET

OFF Standard setting

START Menu SW information is loaded from a store area.

OFF Standard setting

START Menu SW information is saved to a store area.

CANCEL Standard setting

EXECUTE Resets all EEP-ROM data to default settings except adjustment data, hour meter data, and

IEEE1394 ID data.

Default settings at time of shipment differ by market region.

I: for Japan, U: for USA, E: for EU, EC: for China

MEM.EDIT

Contents of the EEP-ROM can be edited directly

x

ADR: Address (0

000-0x7DF) display

DATA: Display of data embedded in address shown by ADR

Operation procedure

1. Rotate the SHUTTER dial to move the cursor to MEM.EDIT.

2. Push the SHUTTER dial to blink the “ADR” parameter.

3. Then rotate the SHUTTER dial to adjust the specified value.

4. Next, push the SHUTTER dial to blink the DATA parameter.

5. Rotate the SHUTTER dial to adjust the specified value.

6. Finally, push the SHUTTER dial to store the data.

(NOTE)

Data that is crucial for the system is stored in the EEP-ROM, and making unadvised changes to it can cause the

unit to stop operating correctly. Please do not use anything other than the IEEE1394 ID setting.

(䡺 is default setting when shipped from factory)

Table 1-5-13 OTHERS Menu Setting Items List

1-19

Page 25

1.5.14 CPU version menu

Displays version of SYSCON CPU, Camera CPU , VTR CPU, ENC CPU, PACKAGE, FPGA2, FPGA3 and FPGA4.

– – – V E RS I O N C H EC K – – –

SYS CPU C1590 V00–00

CAM CPU C15 9 1 V0 0 – 0 0

VTR CPU C1594 V00–00

ENC CPU L1187 V00–00

P ACKAGE C1 6 1 5 V 0 0 – 0 0

FPGA2 C1595 V00–00

FPGA3 C1596 V00–00

FPGA4 C1597 V00–00

P AGE BACK

Software version

Fig. 1-5-14 CPU Version

1.5.15 EEP-ROM

(1) EEP-ROM and maintenance data

GY-HD100 is equipped with three EEP-ROMS for the purpose of data maintenance, and their contents are as per the following list.

When the circuit board or EEP-ROM is replaced, there will be no data in the EEP-ROM. When the unit is powered up, and the

SYSCON CPU recognizes that there is no data in the EEP-ROM, it automatically writes initial data into the EEP-ROM to initialize it.

The memory data shown in Table 1-5-15 will all be reset back to default settings, so it will be necessary to perform necessary

adjustments and settings again.

EEP-ROM Board name Memory data content

IC70

MAIN board

(MSD CPU)

• Adjusted data (DVC section)

• IEEE1394 ID data

• HOUR METER data

IC57

MAIN board

• Blemish data

(Camera CPU)

IC61

MIF board

(SYSCON CPU)

• Adjusted data (Camera section)

• User menu and Service menu settings data

• ERROR HISTORY

Table 1-5-15 EEP-ROM Memory Data Content

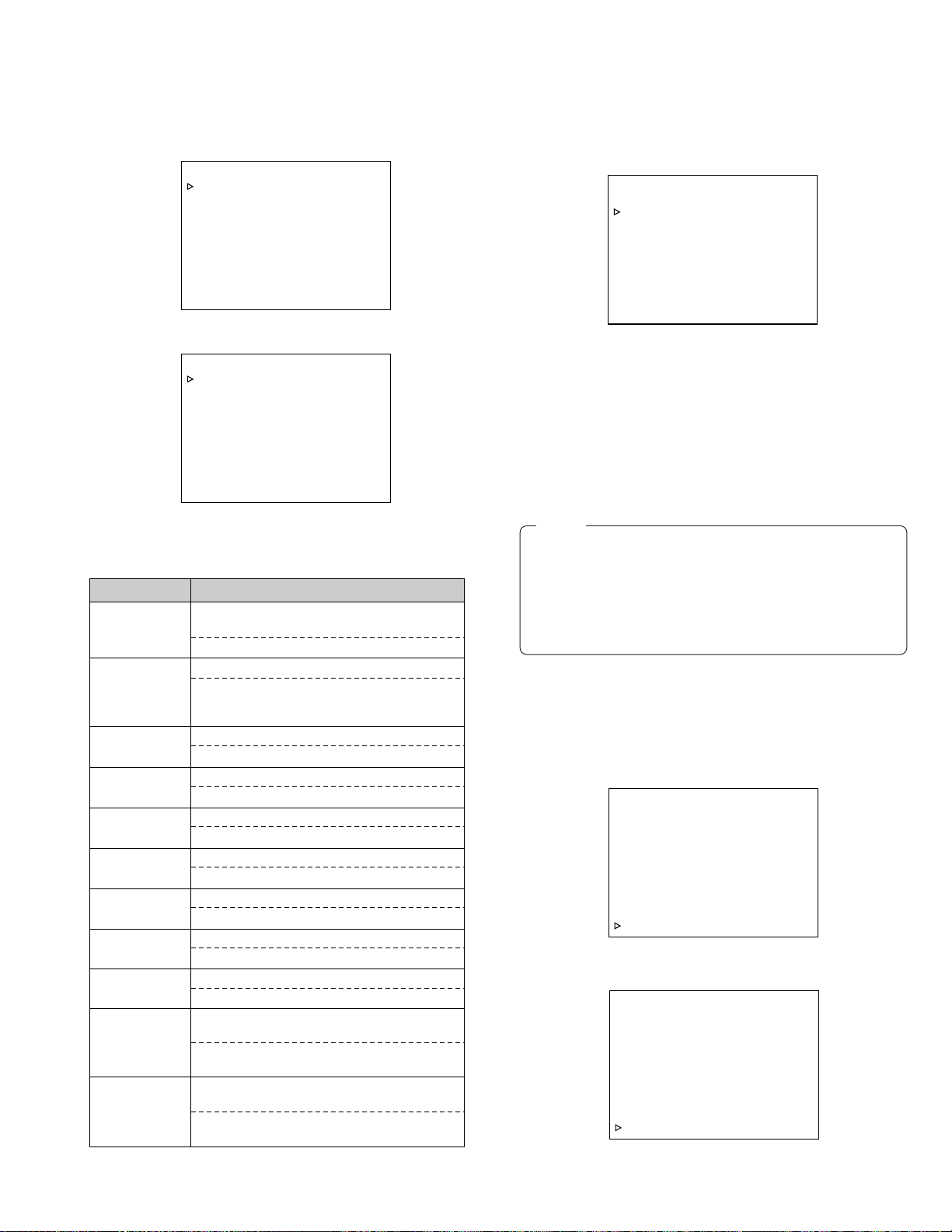

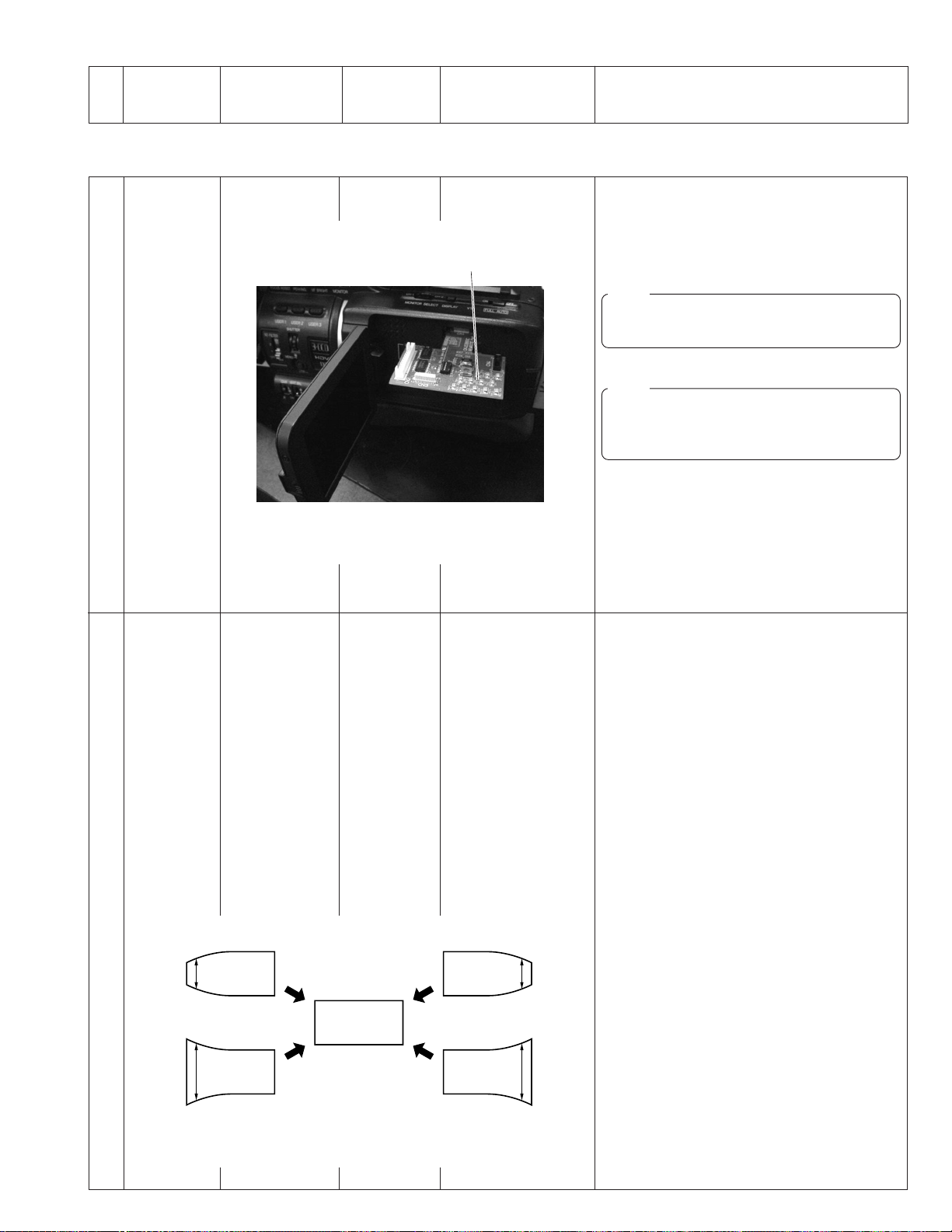

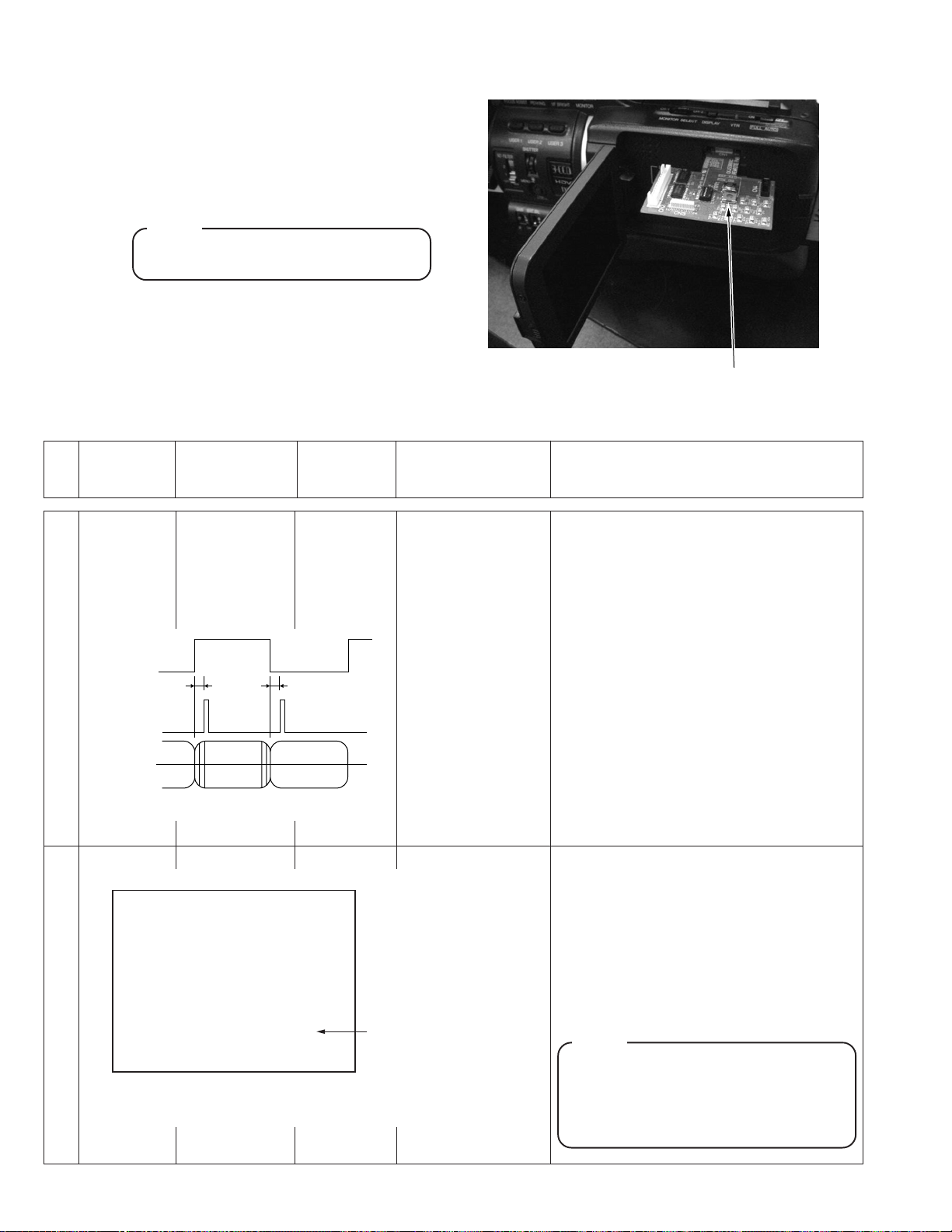

(2) IEEE1394 ID setting method

IEEE1394 equipped units have an ID, as defined by the IEEE1394 standard, stored in the internal EEP-ROM (IC 70. At the time of

production, the ID numbers allotted to each individual unit are written into the unit’s memory, and a sticker bearing the ID is affixed

inside the unit. When the EEP-ROM or MAIN circuit board is replaced, the ID needs to be set again.

Procedure for setting IEEE1394 ID

The ID is an 8 digit, hexadecimal code, with 1 high-end Byte being the model code, and 3 low-end Bytes being unique to the unit.

The model code is automatically initialized, so only the lower 3 Bytes of unique code need to be set manually. Go from Service

Menu → OTHERS Menu → MEM. EDIT (Memory Edit) to select the address in the ID data section and make the setting directly.

The 3 low-end Byte address is as follows. Make the setting while confirming the ID printed on the label (GY-HD100U/E ID: 4Fxxxxxx,

GY-HD101E ID: 4Exxxxxx) pasted on the inside of the GY-HD100 (See Fig. 1-5-15).

IEEE1394 ID data : 4F xx xx xx (Indicates on the label of GY-HD100 inside.)

hhh

MEMORY Address number “391” “392” “393” (Each 1 Byte ID data are stored for every one Memory Address number.)

1-20

Page 26

Setting procedure

(1) Rotate the SHUTTER dial to move the cursor to MEM.

EDIT.

(2) Push the SHUTTER dial to make the ADR parameter blink.

(3) Select ADR parameter “391”.

(4) Push the SHUTTER dial to make the DATA parameter

blink.

(5) Rotate the SHUTTER dial to set the ID data for ADR =

“391”.

(6) Push the SHUTTER dial to confirm the DATA parameter.

(7) In the same manner, select ADR parameter “392” and

“393” to set the ID data.

ID Label

Fig. 1-5-15 ID Label Attachment Position

1-21

Page 27

1.6 HOW TO UPDATE FIRMWARE

Note :

• When replacing MIF board or MAIN board, firmware update is essential.

• Do not turn the power off during the update, otherwise CPU may be destroyed and replacement of CPU or board will be

required.

• Under the battery operation firmware update can not be allowed, use the AC adapter.

• When update is failed audio AUTO LED’s are flashing alternately. In this case try again after removing SD memory card.

• Remove the IEEE1394 cable, otherwise it may cause some troubles on GY-HD100.

• Do not format the SD memory card by PC.

The SD memory card formatted by PC will not work correctly due to wrong formatting. In this case format the SD memory card

on GY-HD100.

You can also format the SD memory card using the general digital still camera equipped SD memory card slot, or formatting

software supplied from SD memory card manufacturer such as Pnasonic.

1.6.1 Preparation (Copy firmware to SD memory card)

Note: 32MB - 512 MB of Panasonic SD memory card is recommended.

(1) Download the update file from JS-NET and unzip it to a PC.

(2) Insert the SD memory card to the PC and confirm that no file is in the SD memory card. If there are some files, delete them.

(3) Copy the unzipped update file(s) to the SD memory card.

1.6.2 Update procedure

(1) Eject and take out the cassette if loaded, and close the cassette cover.

(2) While pressing USER2 and USER3 buttons, turn on the power. Both HDV and DV LED will turn on a light.

(3) Insert the SD memory card to the card slot of GY-HD100.

(4) Rotate the SHUTTER dial, move the cursor to UPGRADE and press SHUTTER dial.

(5) Rotate the SHUTTER dial, select EXECUTE and press SHUTTER dial.

(6) Rotate the SHUTTER dial, move the cursor to CONTINUE? and press SHUTTER dial.

(7) Rotate the SHUTTER dial, select EXECUTE and press SHUTTER dial.

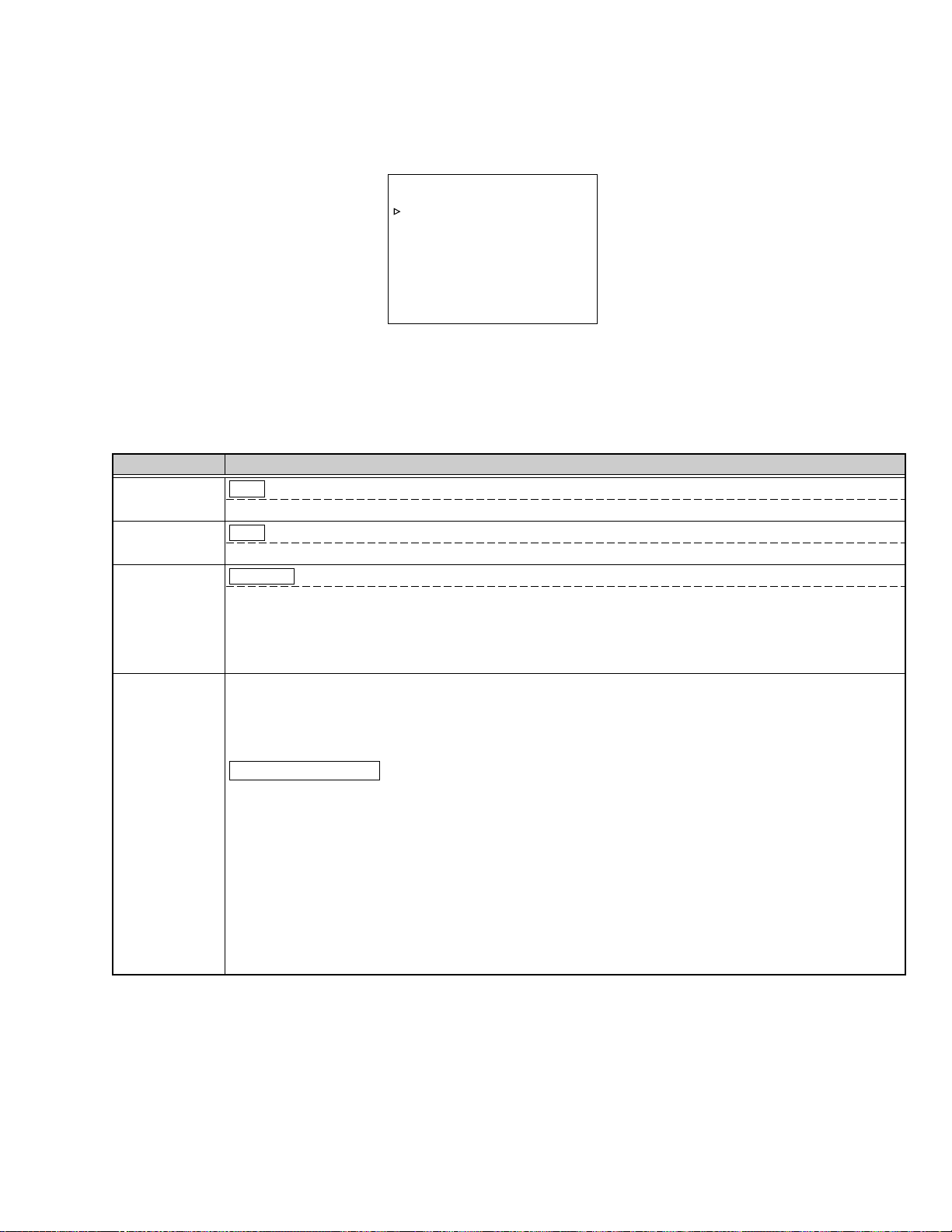

– – – S Y S T E M U PG RA DE – – –

UPGRADE SYS TEM F I RM

UPGRADE CANCEL

EX I T

W

ARE?

– – – S Y S T E M U PG RA DE – – –

W

UP GRADE

CURRENT F I RM

CONT I NUE ? CANCEL

B ACK

ILL ERASE

W

ARE !!!

– – – S Y S T E M U P D A T E – – –

UPDAT I NG . . .

Fig.1.6.2 SYSTEM UPDATE Menu Screen

(8) When update is completed, audio AUTO LED’s of AUDIO CH-1 and CH-2 are blinking slowly. It will take about seven minutes to

complete.

(9) Remove the SD memory card, then GY-HD100 will reboot automatically.

(10) Turn off the power and turn on again.

(11) Enter the Service Menu to check CPU VERSION.

1-22

Page 28

SECTION 2

MECHANICAL ADJUSTMENTS

2.1 BEFORE ADJUSTMENTS

2.1.1 Precautions

1) Be sure to apply a screw securing torque when attaching a

part.

The securing torque should be 0.04 N-m (0.4 kgf-cm) unless

otherwise specified.

2) Always unplug the power cord of the set before attaching,

removing or soldering a part.

3) When unplugging a connector, do not pull the wire but grasp

the connector body.

4) Do not make an adjustment or rotate a potentiometer blindly

while the source of trouble is not identified.

5) Before adjusting electrical circuitry, be sure to wait for more

than 10 minutes after turning the power on.

2.1.3 Equipment required for adjustments

Alignment tape

1

MC-1 (NTSC)

MC-2 (PAL)

2

DV tape

For use

in self-recording/playback.

(M-DV 63PRO BU)

2.1.2 Measuring instruments required for adjustments

Instrument

Oscilloscope

Torque screwdriver

5

YTU94088 YTU94088-003

Slit washer attaching tool

6

YTU94121A

Calibrated instrument with measuring

bandwidth of 100 MHz or more.

Table 2-1-1

Condition

Replaceable bit

(long type)

Cassette torque meter

3

YTU94150A (or YTU94151A)

Guide screwdriver

4

YTU94085

CK453800C

PTS40844-2

Table 2-1-2

7

Connector board (REWRITE PWB)

Chip IC replacement tool

8

2-1

Page 29

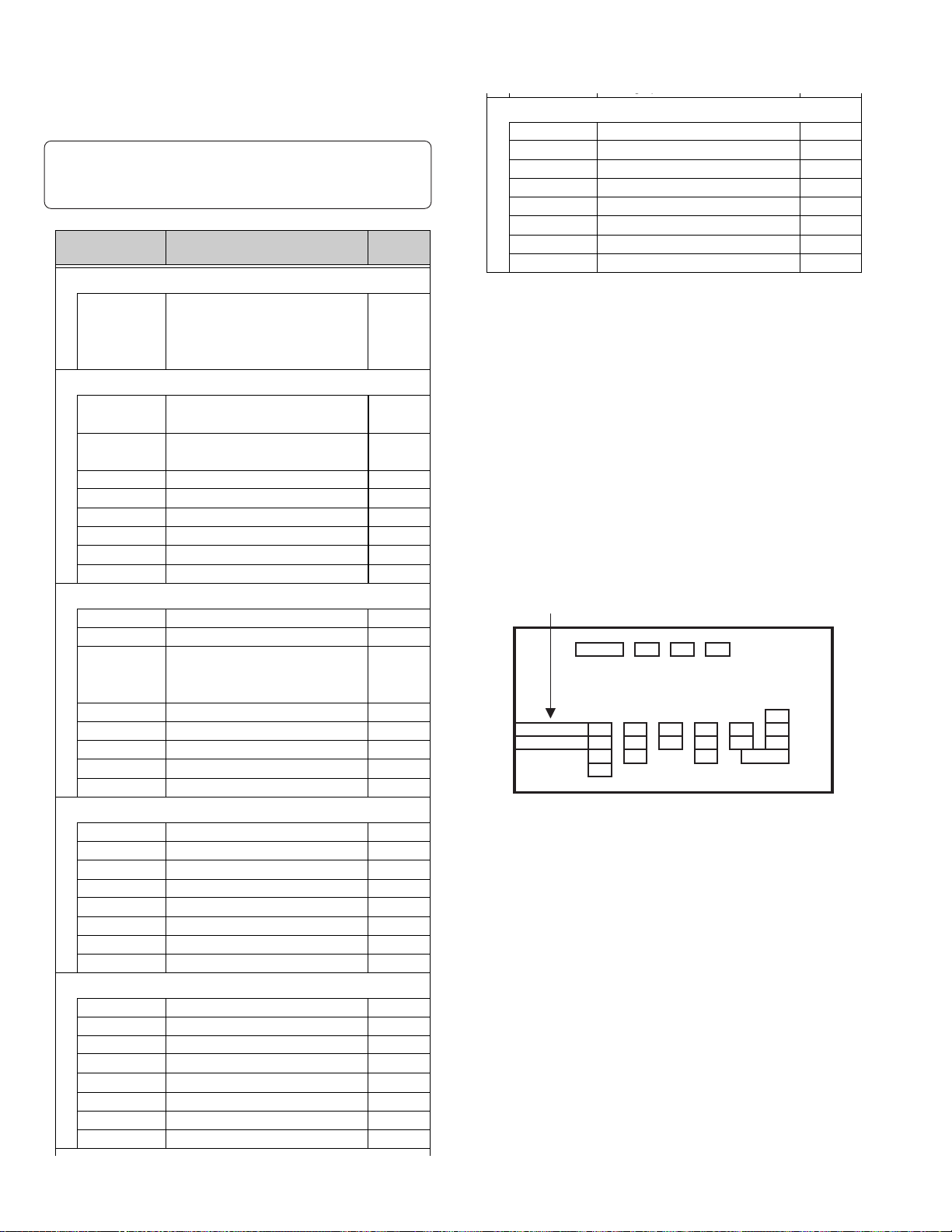

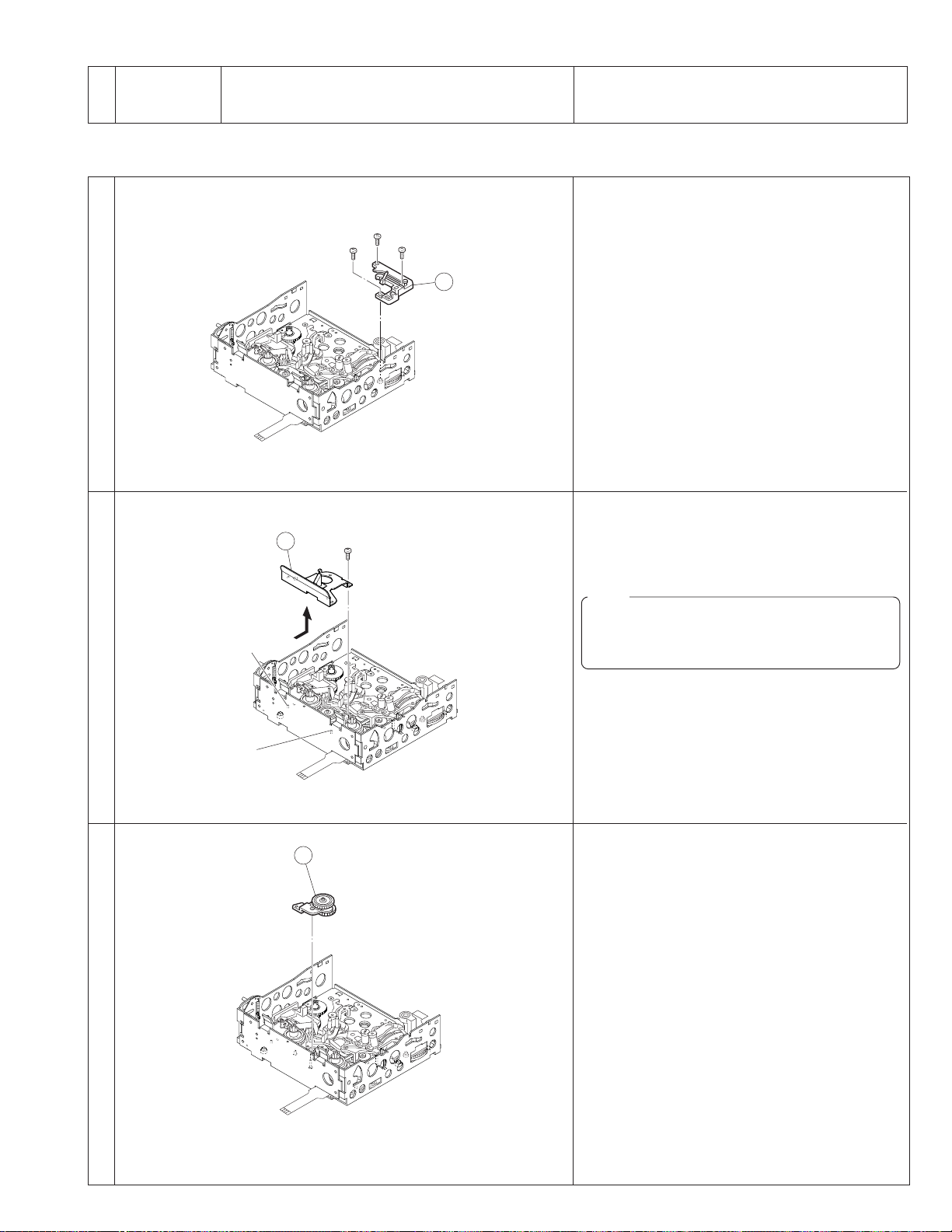

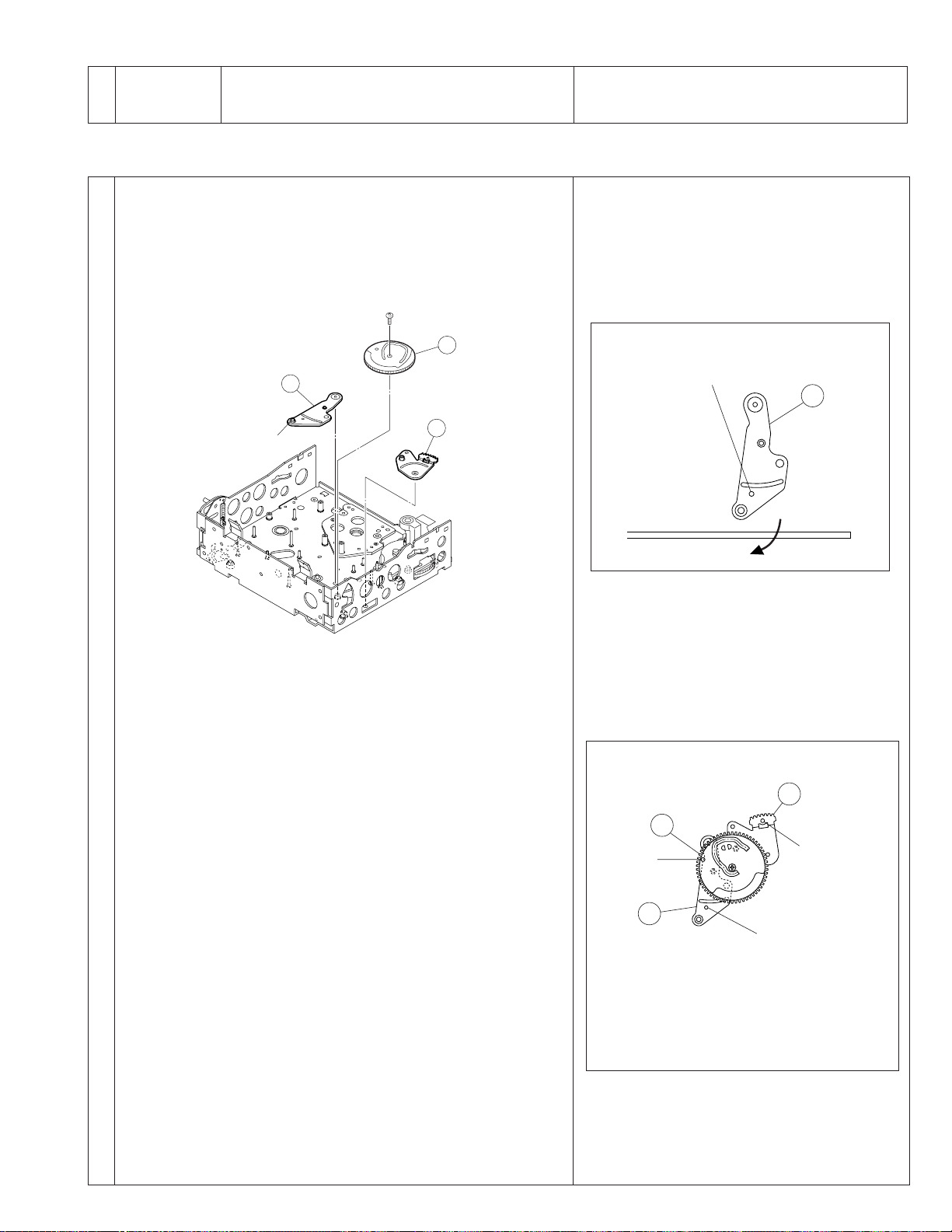

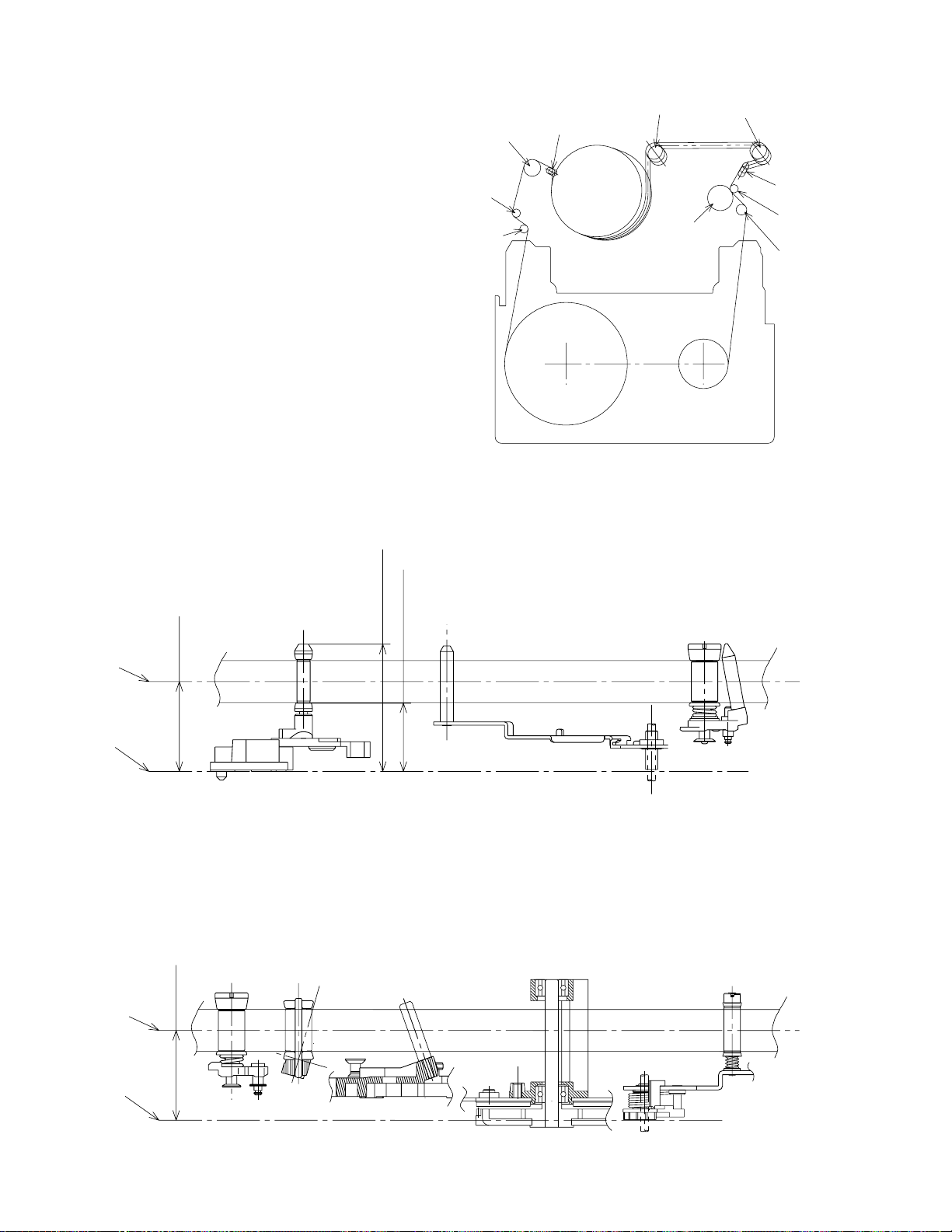

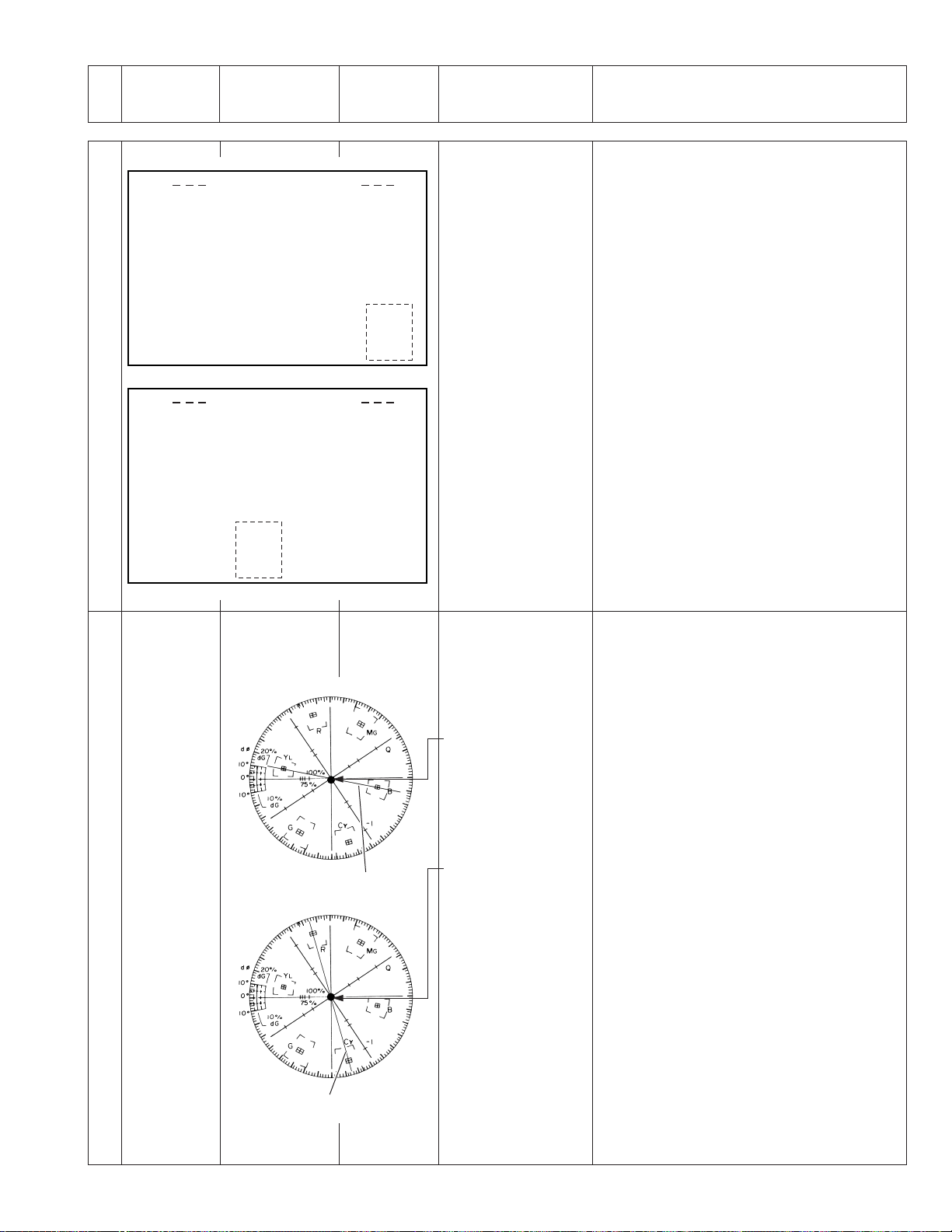

2.2

BASICS OF MECHANISM DISASSAMBLY/ASSEMBLY

2.2.1 Assembly mode

The disassembly and assembly of the mechanism can be done

in the ASSEMBLY mode (see Table 2-2-1).

The ASSEMBLY mode is provided in the intermediate position

between C-IN and Harf LOAD. As the C-IN (Cassette IN) mode

is usually set when a cassette tape is ejected, the ASSEMBLY

mode should be entered after entering the C-IN mode.

ASSEMBLY

39

Arm gear 2 assembly

See section 2.7.17

Main deck

H. LOAD

Table 2-2-1

POLE BASE

CTL PLATE

MAIN BRAKE(S)

Encorder gear

34

assembly

See section 2.7.16

EJECT C-IN

ON

OFF

OFF

OFF-OFF

ON-OFF

ON-ON

OFF-ON

ON

36

Arm gear 1 assembly

See section 2.7.16

There are 2 ways to set to ASSEMBLY mode as shown below:

1) Apply DC 3 V to the motor.

2) Remove the motor from the bracket (Gear cover) and turn

the wheel gear 2 using screwdriver.

As shown in Fig. 2-2-1, the ASSEMBLY mode position refers to

where the hole position of 7 cm component matches the hole

position of the main deck.

Hole of Arm gear

2 assembly

L-END

Hole of Sub cam

gear assembly

REV FWD STOP

Hole of Arm gear

1 assembly

Hole of Encode gear

Main deck

Main cam

35

See section 2.7.16

2-2

Centering arm assembly

37

See section 2.7.16

40

Top view Bottom view

Sub cam See

38

section 2.7.17

Clutch lock lever assembly

See section 2.7.17

Hole of Main cam gear

Phase alignment

Hole of Centering arm assembly

Hole of Clutch lock

lever assembly

Fig. 2-2-1

Page 30

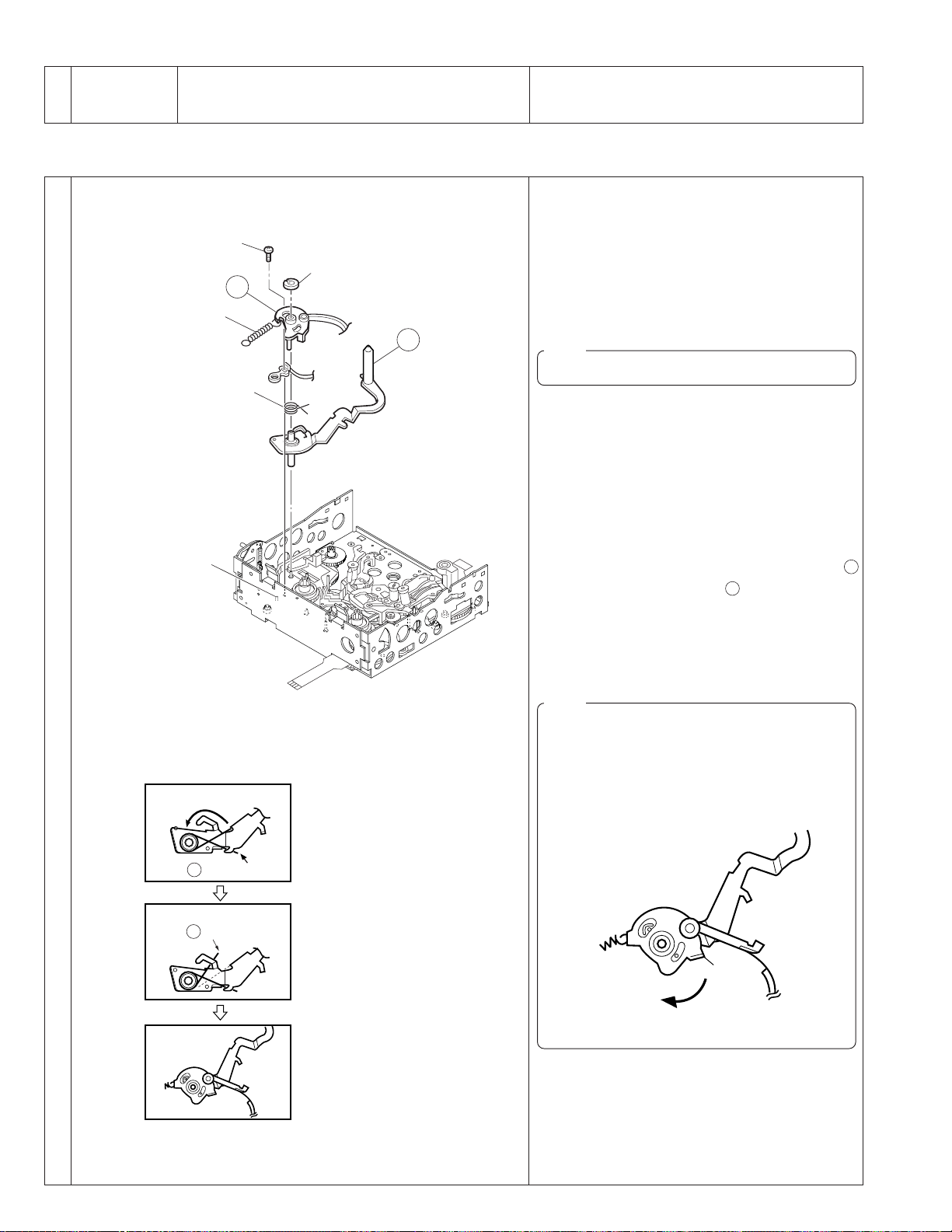

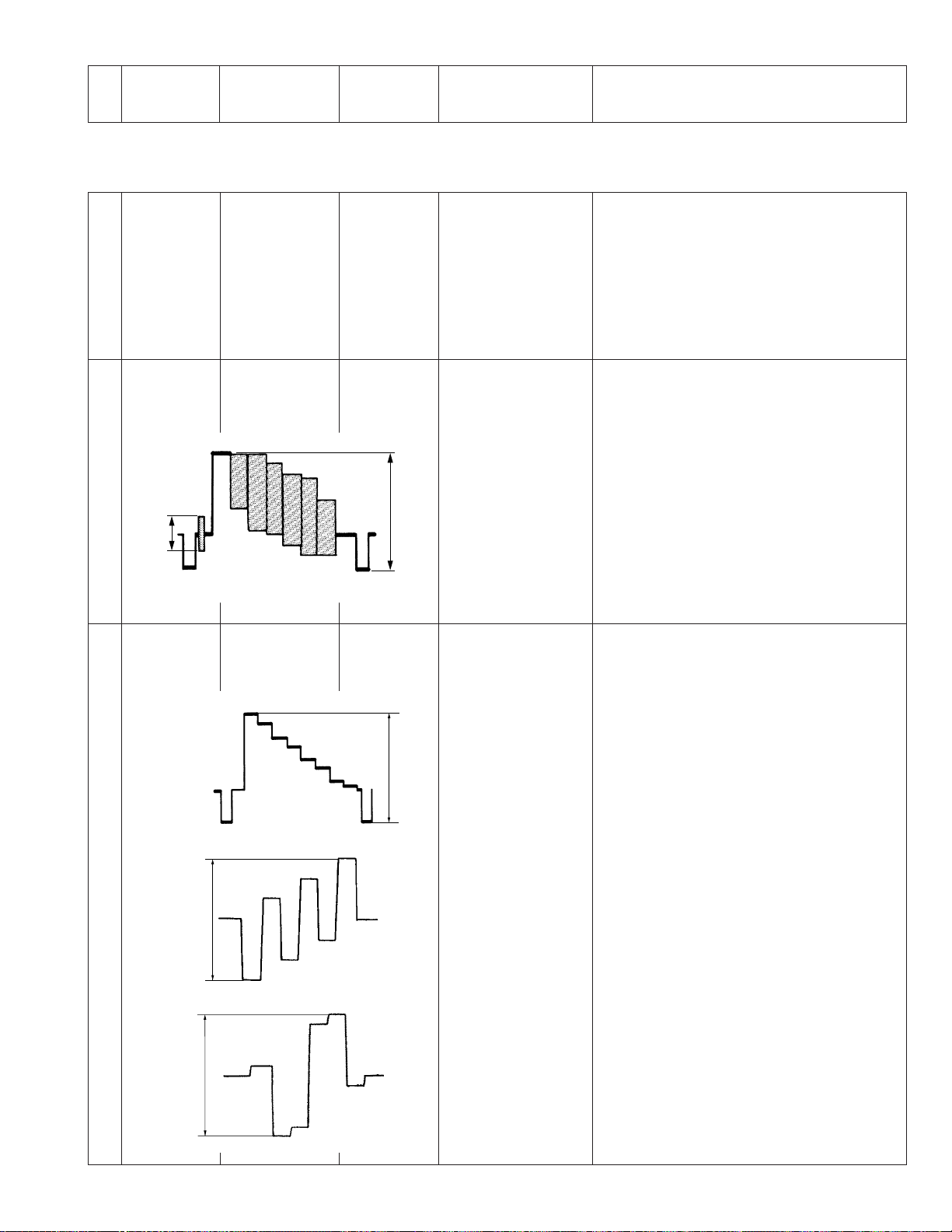

2.3 MECHANISM TIMING CHART

See following table (Table 2-3-1).

EJECT C-IN H. LOAD

ON

POLE BASE

OFF

OFF

OFF-OFF

CTL PLATE

MAIN BRAKE(S)

MAIN BRAKE(T)

SUB BRAKE

ON-OFF

ON-ON

OFF-ON

ON

OFF

ON

OFF

ON

ASSEMBLY

L-END

REV FWD STOP

ON(REV MODE)

ON(PLAY MODE)

PINCH ROLLER

EXIT GUIDE ARM

TENSHION ARM

BAND ARM PLATE

CENTERRING ARM

OFF1

HALF LOADING

ASSEMBLY

CLEANER ON

OFF1

OFF1

OFF1

TU CENTERRING

FREE

SUP CENTERRING

S. REV

C. HOUSING LOCK

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Table 2-3-1

2-3

Page 31

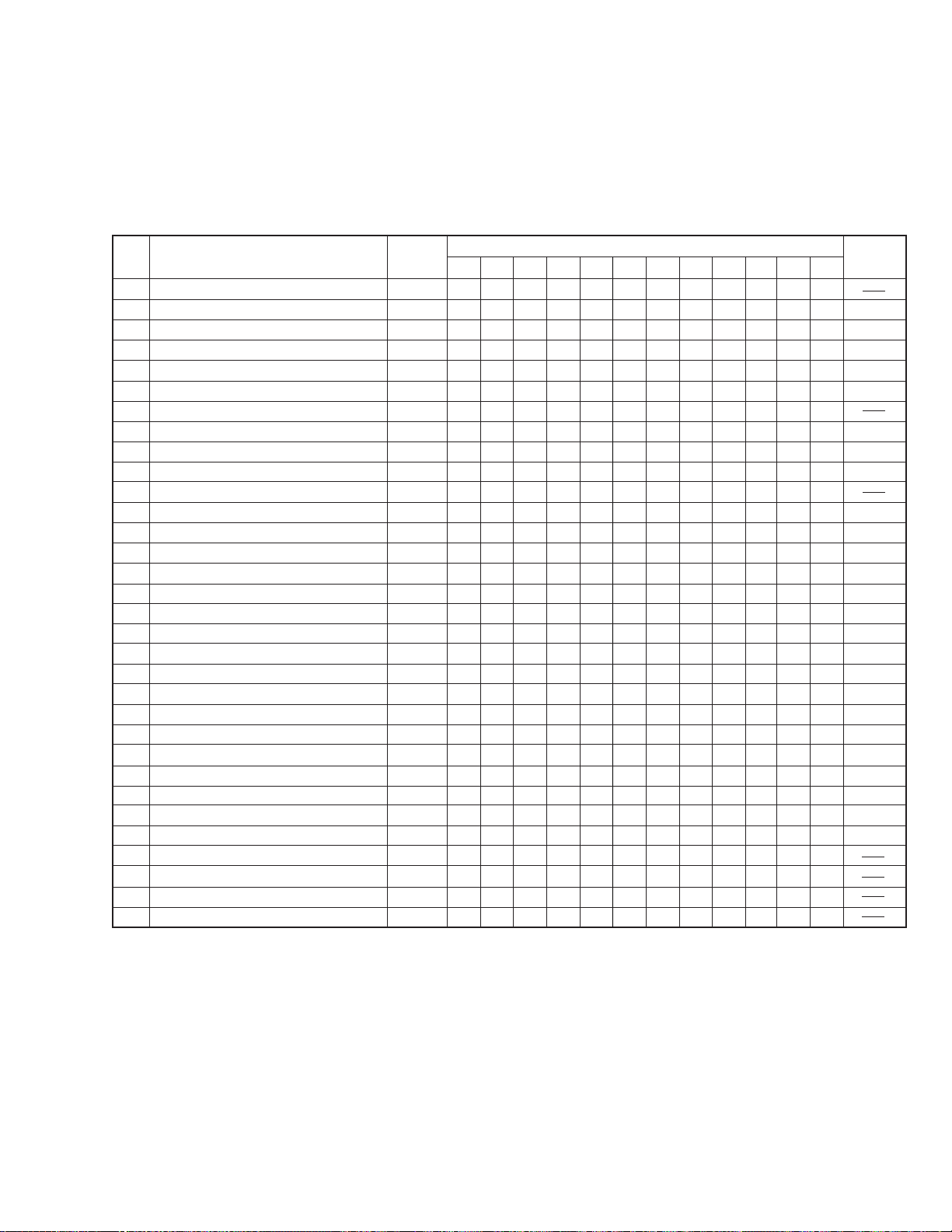

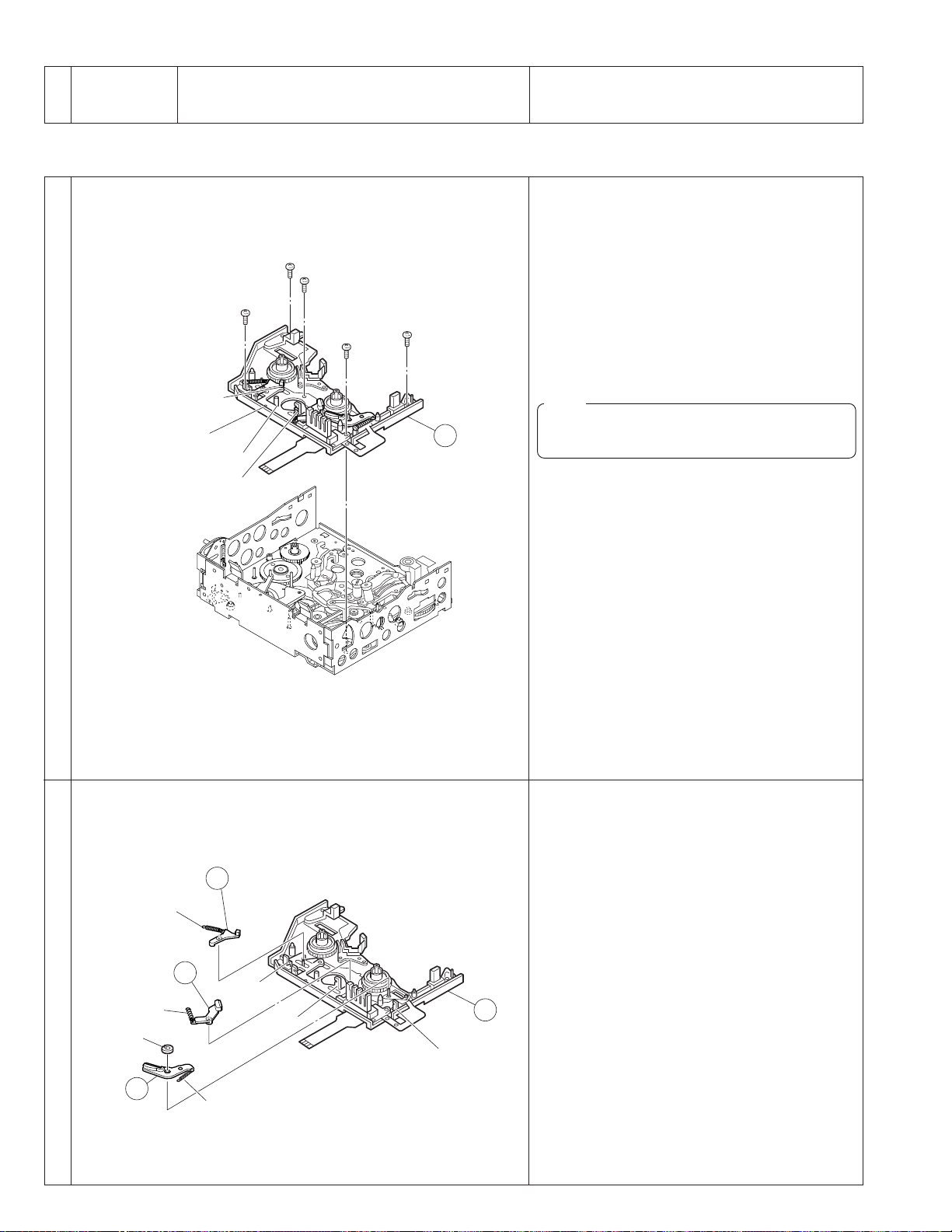

2.4 MAINTENANCE AND INSPECTION OF MAJOR PARTS

Periodical inspection and maintenance are requisite to maintain

the initial performance and reliability of the product. Table 2-4-1

(Maintenance & Inspection List) has been compiled assuming