Page 1

86700200304

SERVICE MANUAL

MECHANISM ASSEMBLY

DVC MECHANISM

VHS-C MECHANISM

VHS MECHANISM

<DVC MECHANISM> <VHS MECHANISM><VHS-C MECHANISM>

TABLE OF CONTENTS

1 JIGS AND TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3 PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.86700

2003/04

Page 2

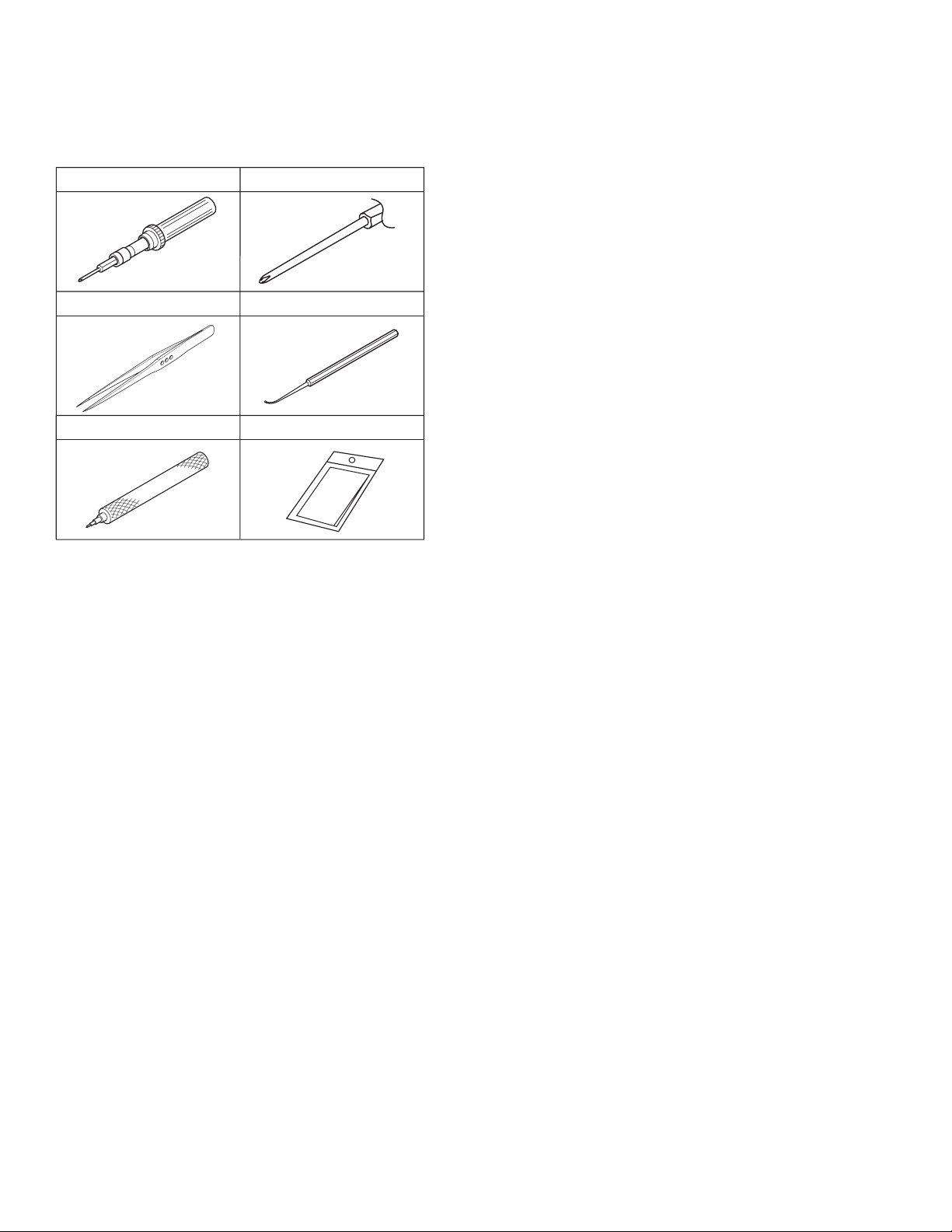

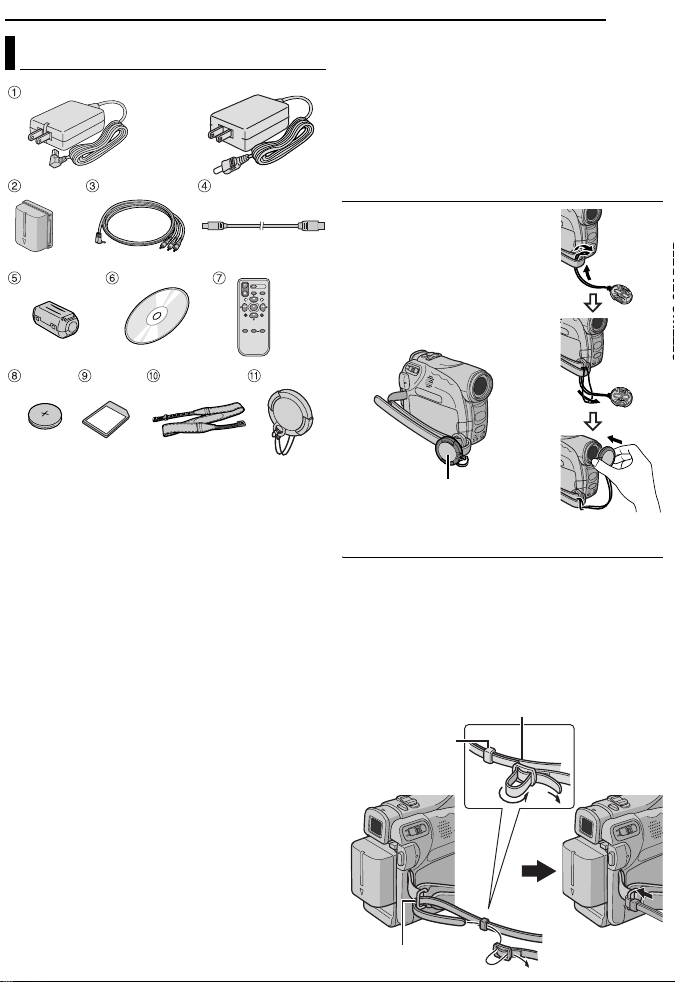

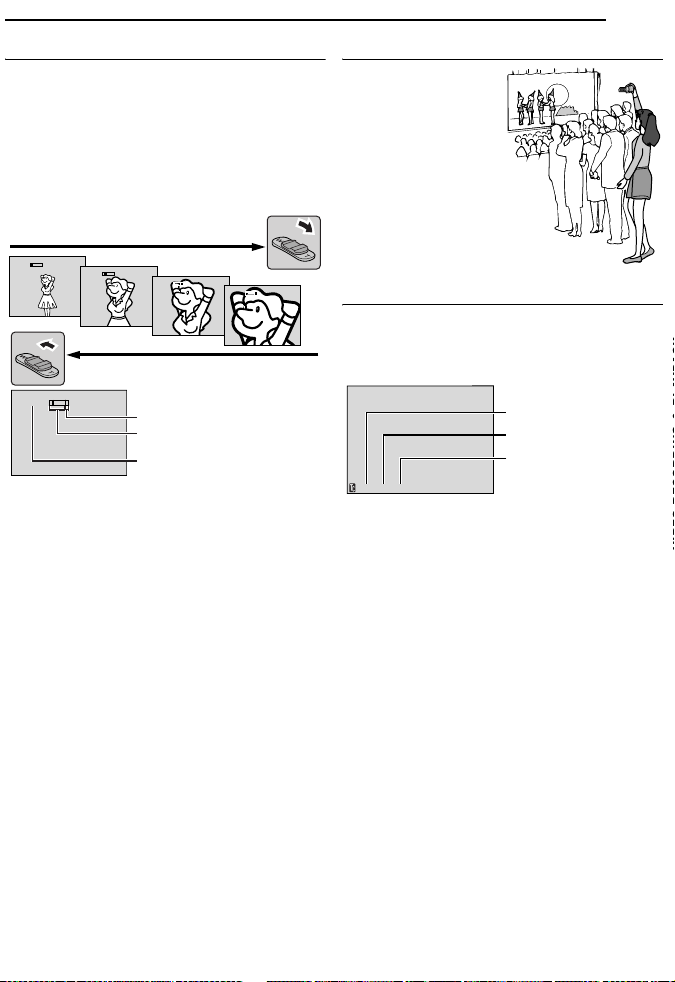

1.1 TOOLS REQUIRED FOR ADJUSTMENTS

1.

3.

5. 6.

Torque driver

YTU94088

Tweezers

P-895

Slit washer installation jig

YTU94121A

2.

Chip IC replacement jig

4.

Bit

YTU94088-003

PTS40844-2

Cleaning cloth

KSMM-01

SECTION 1

JIGS AND TOOLS

1. Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

Torque setting value of torque driver is limited. At the values

over the maximum torque setting value, fasten a screw

manually not to damage the screw thread.

2. Bit

This bit is slightly longer than those set in conventional torque

drivers.

3. Tweezers

To be used for removing and installing parts and wires.

4. Chip IC replacement jig

To be used for replacement of part.

5. Slit washer installation jig

To be used to install slit washers.

6. Cleaning cloth

Recommended cleaning cloth to wipe down the video heads,

mechanism (tape transport system), optical lens surface.

Fig.1-1-1

1-1 (No.86700)

Page 3

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

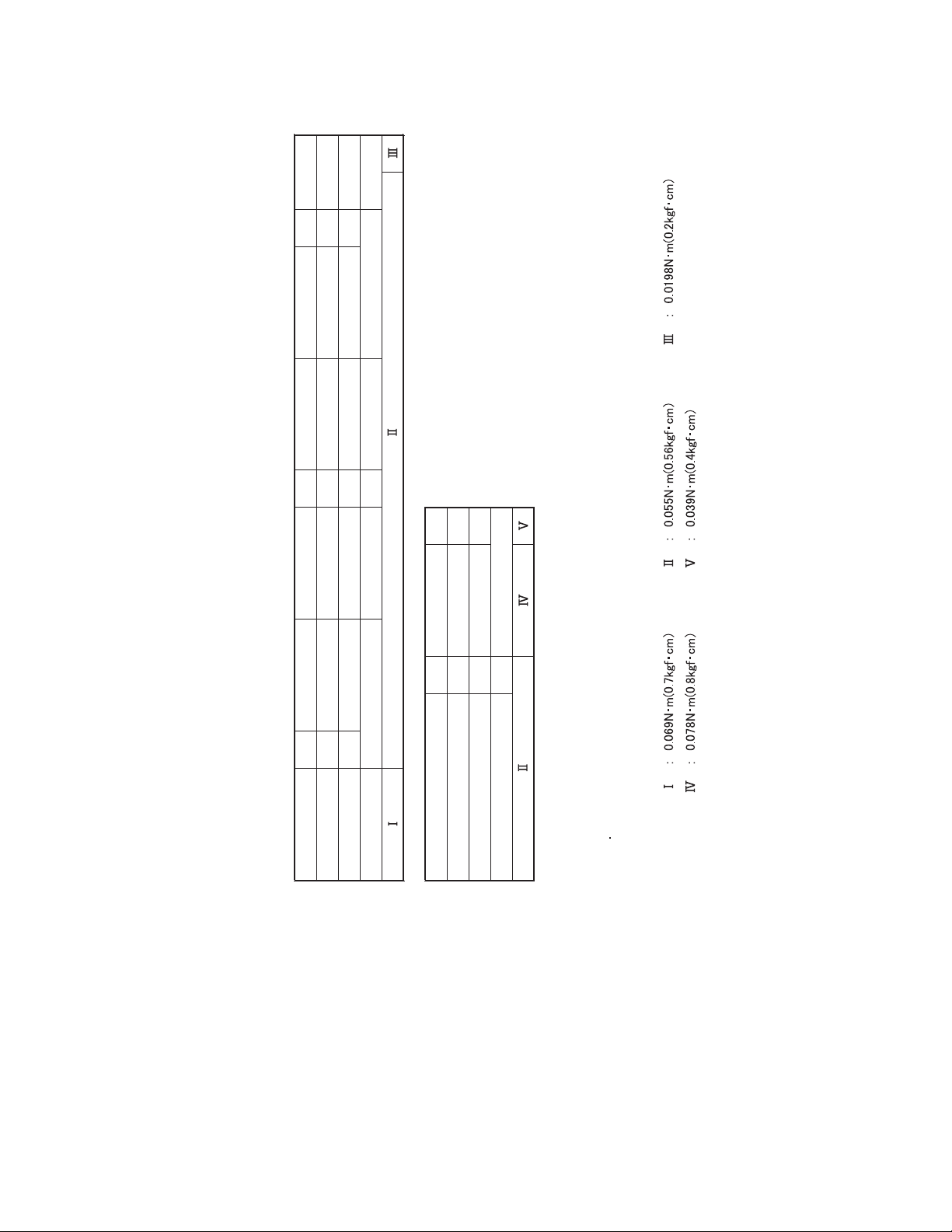

2.1 DVC MECHANISM

2.1.1 Precautions

(1) When fastening parts, pay careful attention to the tighten-

ing torque of each screw. Unless otherwise specified, tighten a screw with the torque of 0.055 N•m (0.56 kgf•cm).

(2) Be sure to disconnect the set from the power supply before

fastening and soldering parts.

(3) When disconnecting/connecting wires, be careful not to get

them and their connectors damaged.

(4) When replacing parts, be very careful neither to damage

other parts nor to fit wrong parts by mistake.

2.1.2 Notes on procedure for disassembly/assembly

The disassembling procedure table (Fig. 2-1-10 on page 2-4,a

part of the table is shown below for reference)shows the procedure to disassemble/reassemble mechanism parts.

Carefully read the following explanation before starting actual

disassembling/reassembling work. The item numbers(circled

numbers)in the following explanation correspond to those appearing under respective columns of the table.

Example

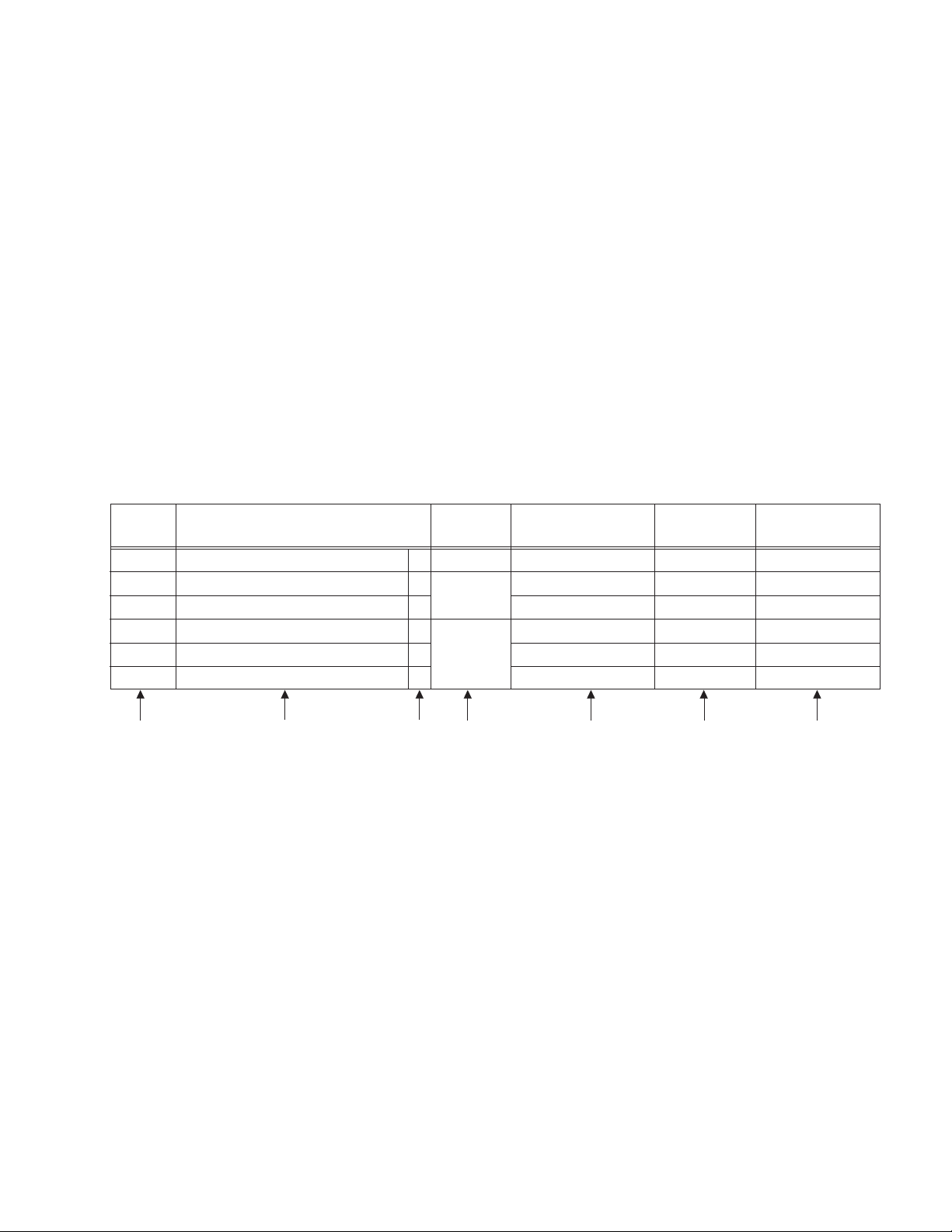

NO. PART NAME FIG. POINT NOTE REMARKS

[1]

[2]

[3]

[4]

[5]

[6]

*1 *2 *3 *4 *5 *6 *7

*1 Numbers appearing in this column indicate the order to re-

move parts. When reassembling, follow these numbers in

the reverse order. Circled numbers in this column correspond to those appearing in drawings of this section.

*2 This column shows part names corresponding to numbers

in the left column.

*3 The symbol (T or B)appearing in this column shows the

side which the objective part is mounted on.

T =the upper side, B =the lower side

*4 Symbols appearing in this column indicate drawing num-

bers.

*5 This column indicates parts and points such as screws,

washers,springs,and others to be removed/fitted for disassembling/reassembling the mechanism. Besides such the

parts, this column occasionally indicates working points.

P= Spring

W= Washer

S= Screw

* = Lock (L),soldering (SD),shield,connector (CN),etc.

Example

CASSETTE HOUSING ASSY T Fig.2-4-3 3(S1),(L1a)-(L1e)

UPPER BASE ASSY T Fig.2-4-4 (S2),(L2a),(L2b)

DRUM ASSY T (S3a),2(S3b)

REEL DISK ASSY(SUP) T Fig.2-4-5 (W4)

REEL DISK ASSY(TU) T

REEL COVER ASSY T

• Remove (W1)=Washer W1.

• Remove the solder at (SD1)=Point SD1.

• Disconnect A = Connector A.

(W5a),(W5b),(W5c)

(W6),(S6a),2(S6b)

*6 Numbers in this column represent the numbers of notes in

the text.

(For parts that need phase adjustment after reassembling,

refer to “MECHANISM ADJUSTMENTS”.)

*7 This column indicates required after-disassembling/-reas-

sembling work such as phase adjustment or mechanism

adjustment.

NOTE 1 a,b,c,d

NOTE 2

NOTE 3 a,b

NOTE 4 a

NOTE 5 a,b

NOTE 6

ADJUSTMENT

ADJUSTMENT

(No.86700)2-1

Page 4

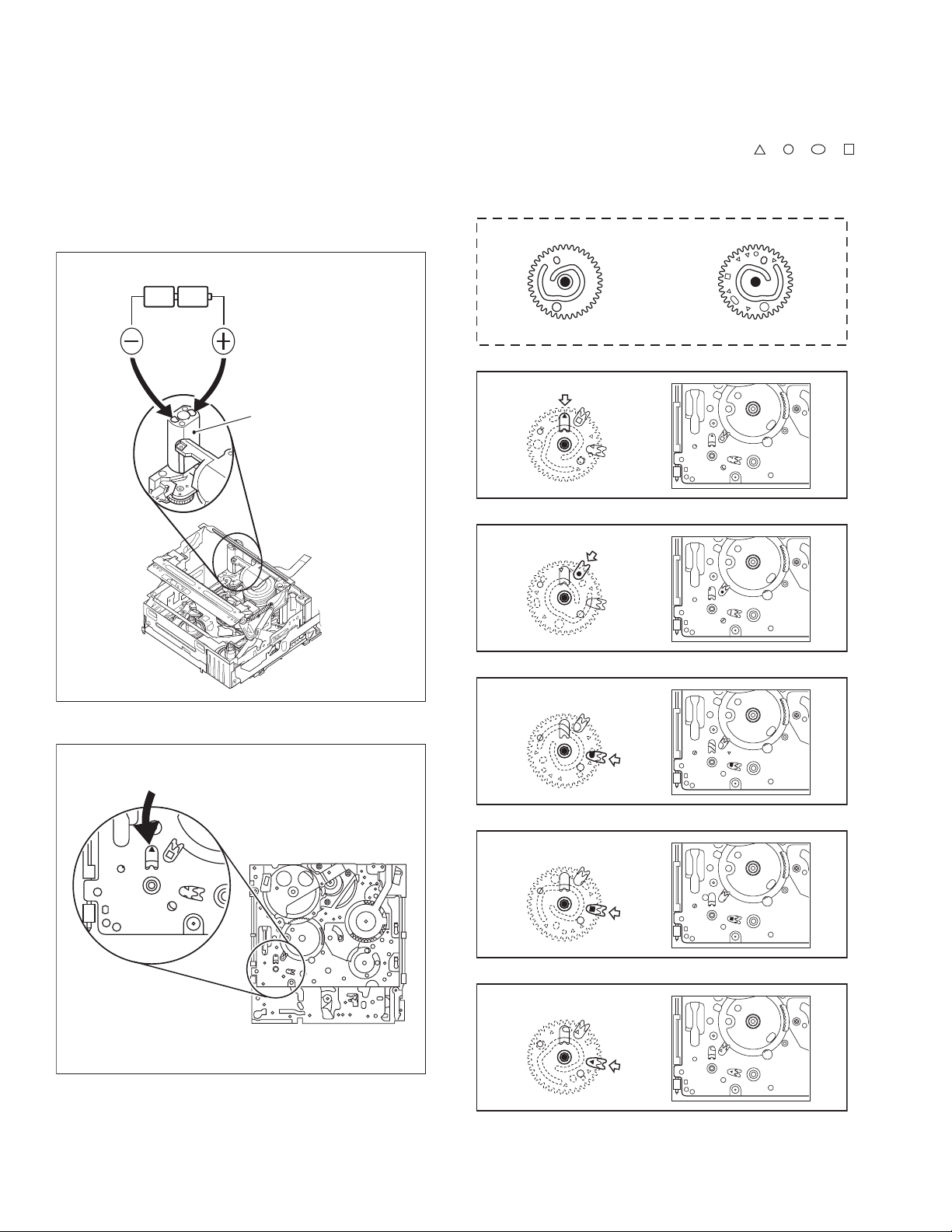

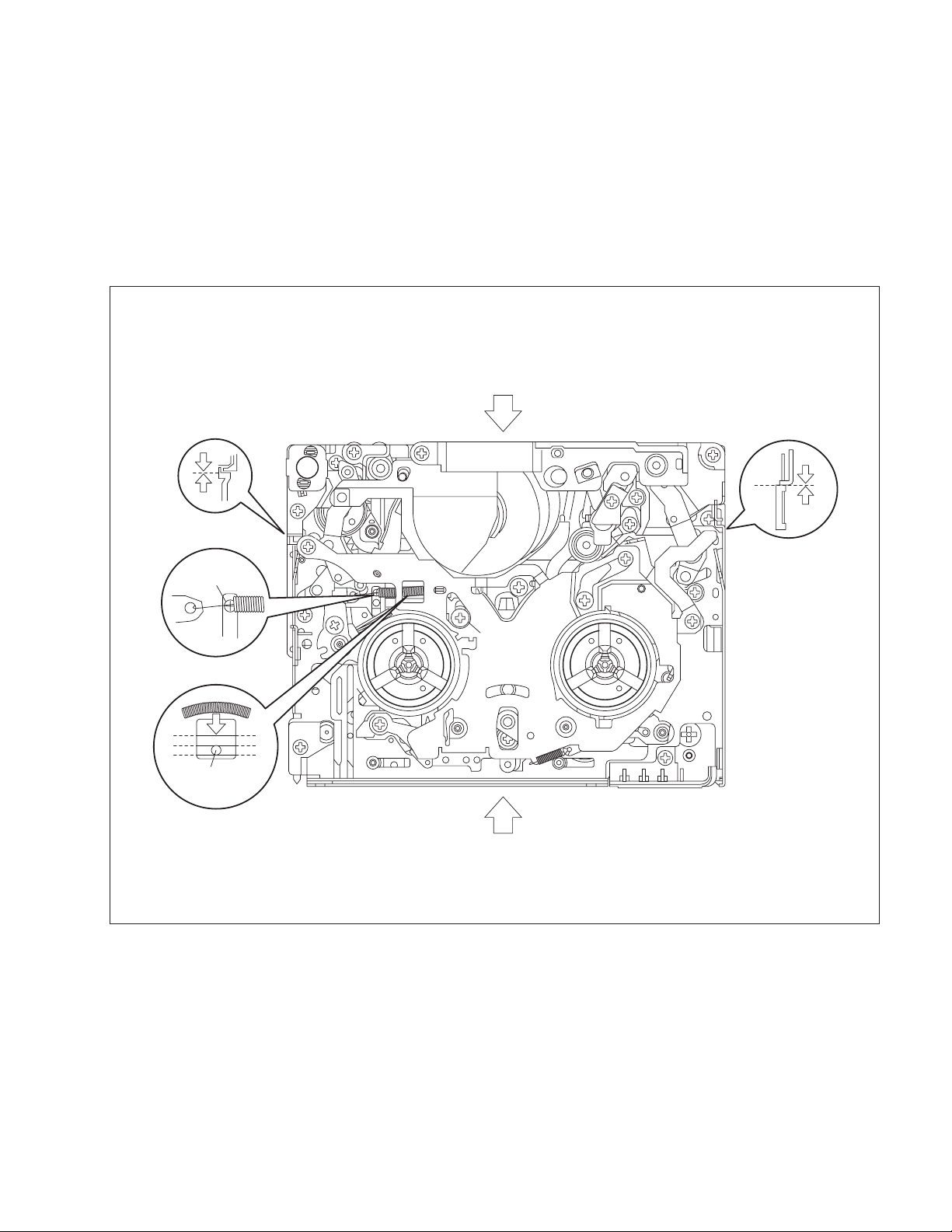

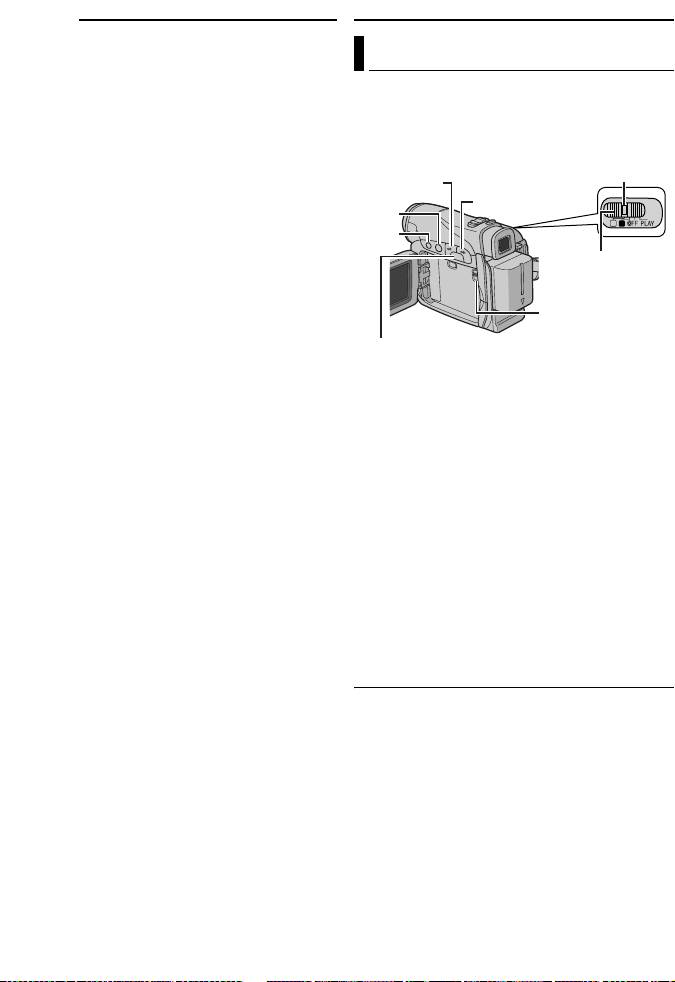

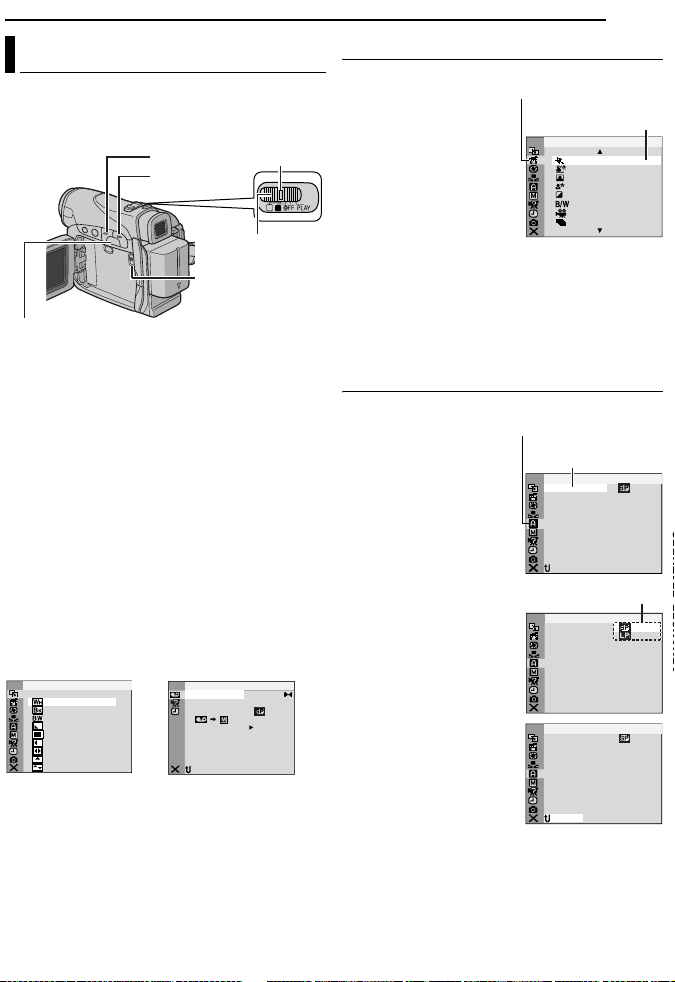

2.1.3 DISASSEMBLY AND ASSEMBLY OF MECHANISM ASSEMBLY

2.1.3.1 General statement

The mechanism should generally be disassembled/assembled in

the C.IN mode (ASSEMBLY mode). (Refer to Fig. 2-1-1,2-1-2.)

However, when the mechanism is removed from the main body,

it is set in the STOP mode. Therefore, after the mechanism is removed from the main body, supply 3 V DC to the electrode on the

top of the loading motor to enter the mechanism mode into the C

IN mode compulsory.

<Mechanism assembly/Cassette housing assembly>

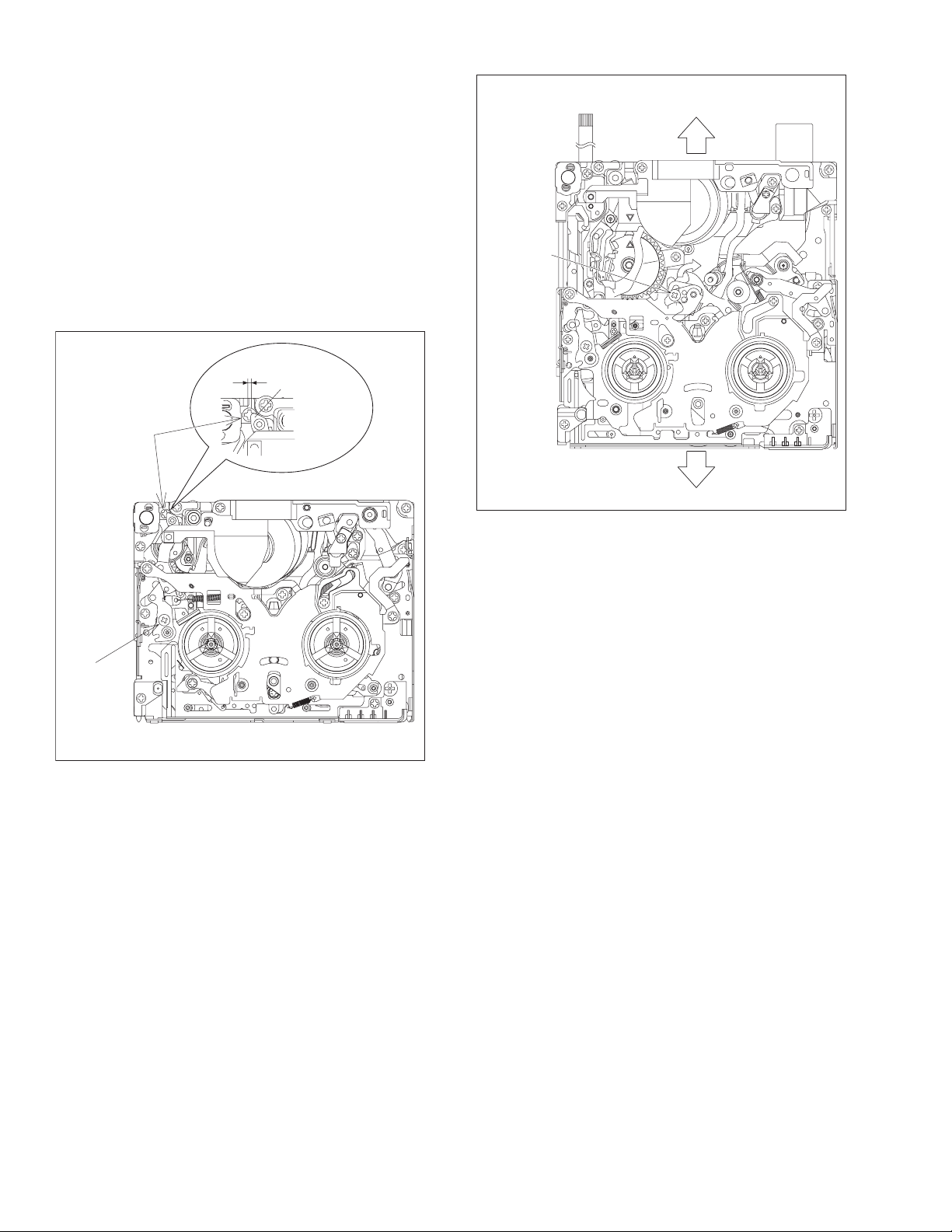

2.1.3.2 Explanation of mechanism mode

The mechanism mode of this model is classified into five modes

as shown in Fig. 2-1-9. Each mechanism mode can be distinguished from others by the relative position of “ ”, “ ”, “ ”, “ ”

marks on the sub cam gear to the inner or outer protrusion on the

main deck.

Refer to Fig. 2-1-3 to 2-1-8 below.

DC3V

LOADING MOTOR

<SUB CAM GEAR>

TOP VIEW BOTTOM VIEW

Fig.2-1-3

<C IN mode>

Fig.2-1-4

Fig.2-1-1

<Back side of the mechanism assembly>

C IN mode

<SHORT FWD mode>

Fig.2-1-5

<STOP mode>

Fig.2-1-6

<REV mode>

Fig.2-1-7

2-2 (No.86700)

<PLAY mode>

Back side of deck

Fig.2-1-2

Fig.2-1-8

Page 5

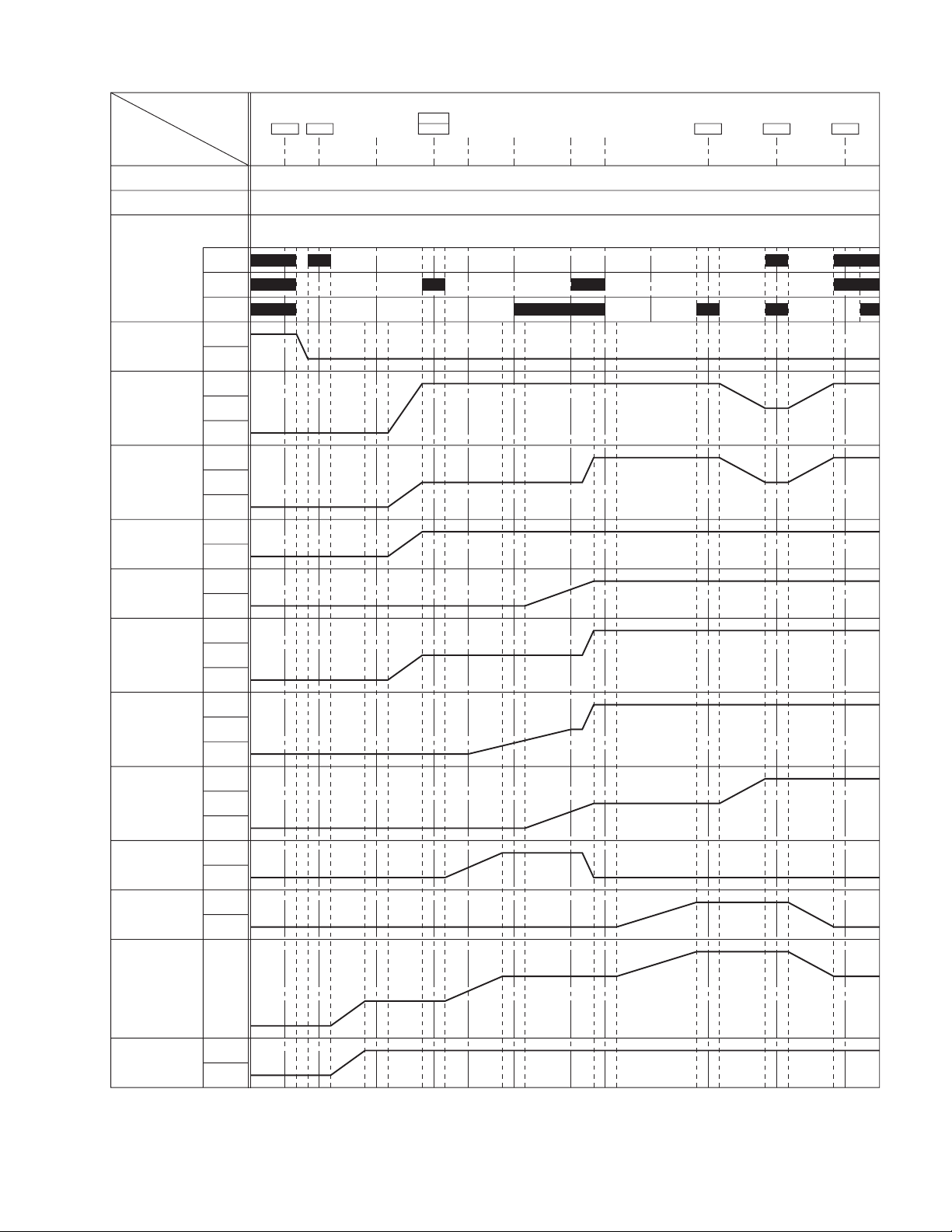

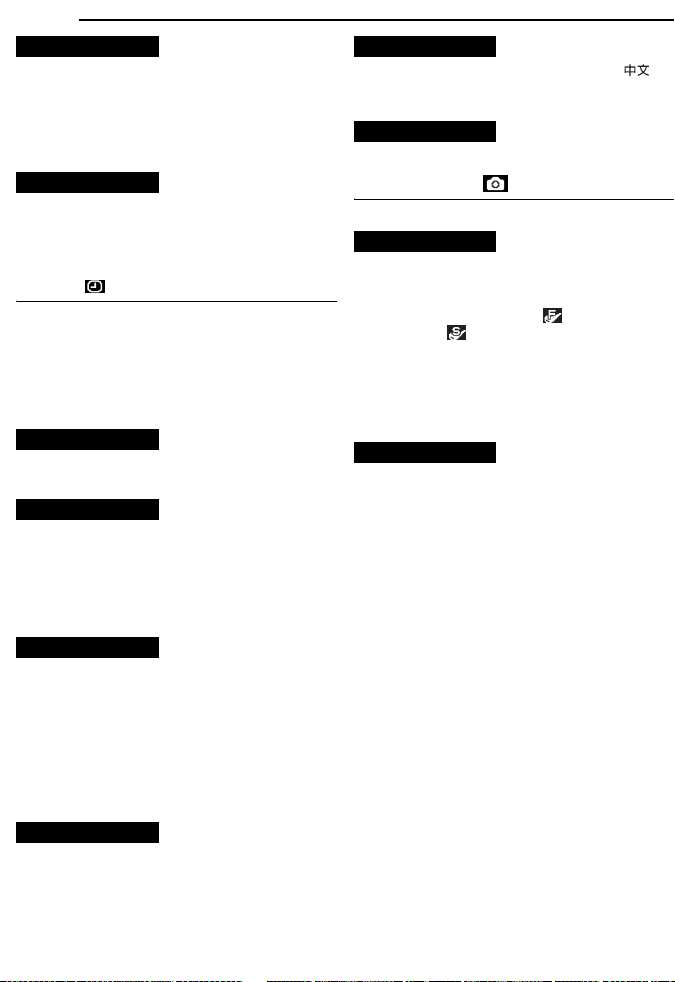

2.1.3.3 Mechanism timing chart

PARTS

MAIN CAM

SUB CAM

ROTARY

ENCODER

EJECT LEVER

TENSION ARM

PAD ARM

TU ARM

SLIDE DECK

SUP. L. ARM

TU. L. ARM

P. ROLLER

BRAKE (S)

BRAKE (T)

MODE

a

b

c

ON

OFF

L. END

LOCK

UL

L. END

OFF

UL

ON

OFF

LOAD

UL

L. END

LOAD

UL

L. END

LOAD

UL

PRESS

LOAD

UL

ON

OFF

ON

OFF

R

SHORT

o

68

o

0

o

0

o

0

o

RELEASE

(30.71o) (95.14o) (110.06o) (206.06o) (210.05o)80.34

(27.14o) (84.08o) (97.35o) (182.10o) (185.63o)71

EJECT

C IN

-12.40o (22.44o) (69.53o) (80.5o) (150.58o) (153.5o)58.71

o

-16.97

o

-15

-13o-3o3

o

74

o

o

o

TU. P. B

START

SLIDE

START

TU. P. B

END

SLIDE

END

STOP PLAYREVFWD

177.79

243.29

o

215

212o218

o

o

o

o

212.77

o

291.16

o

257.3

254.3o260.3

o

243.94

333.82

o

295

292o310

o

o

o

CTL PLATE

RELEASE

LEVER

C

L

ON

OFF

Fig.2-1-9

(No.86700)2-3

Page 6

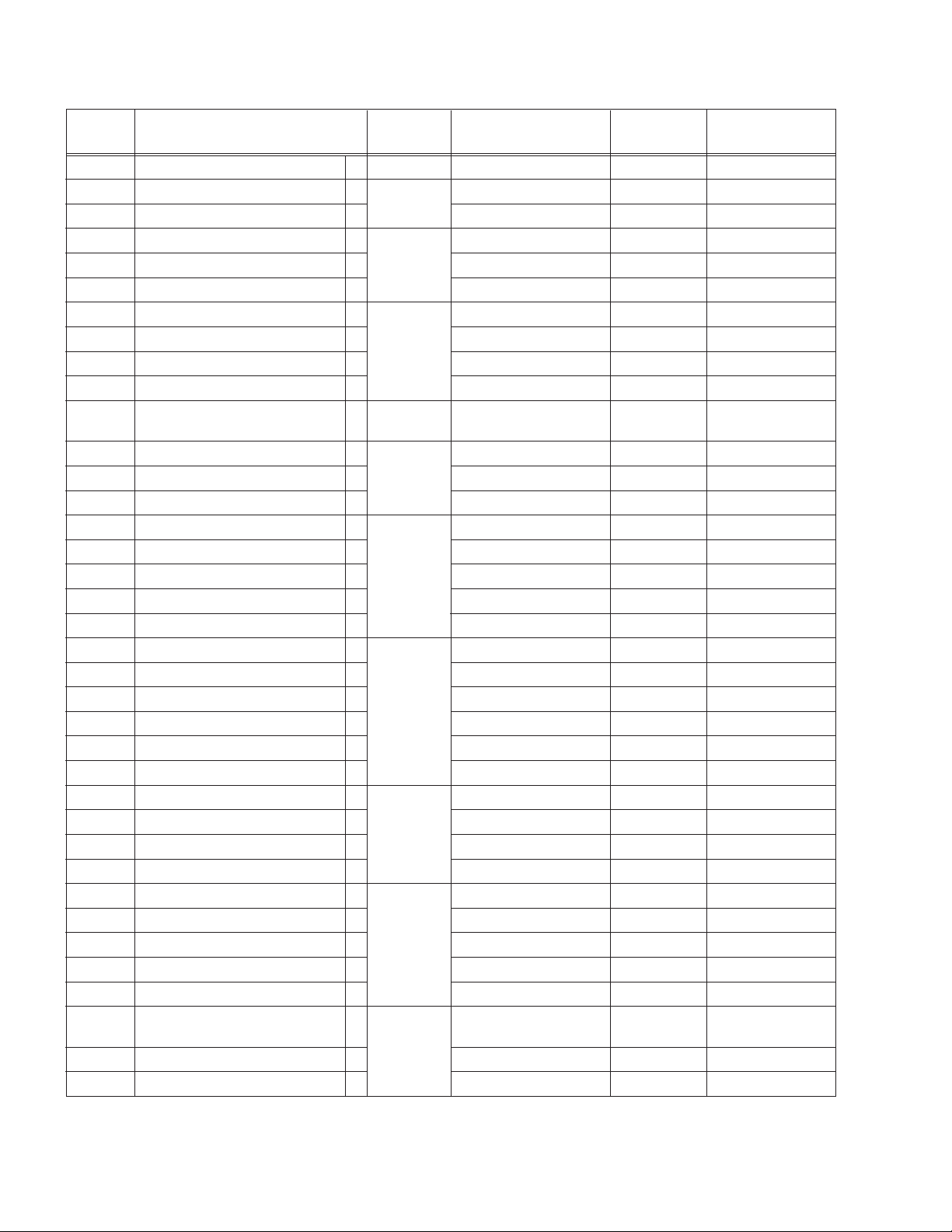

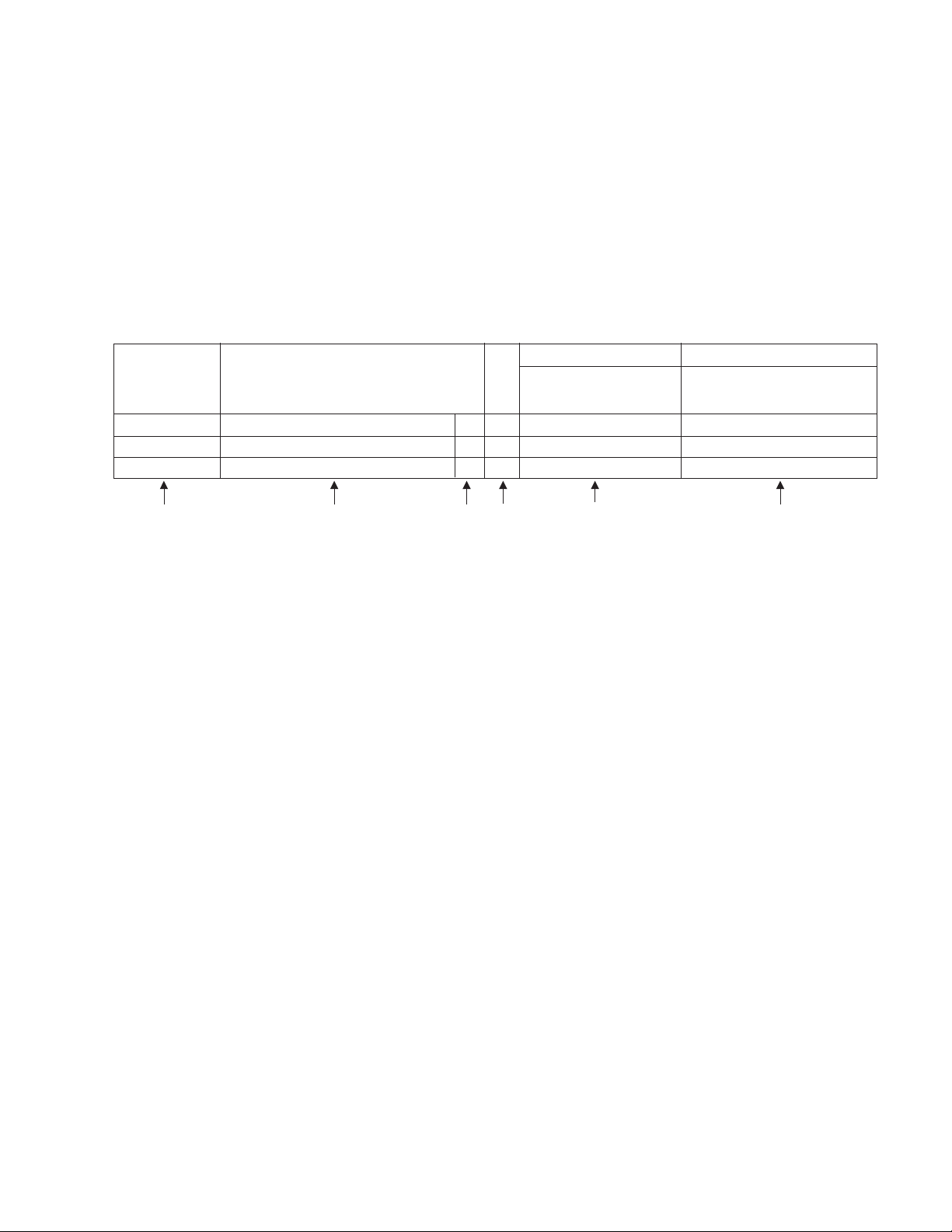

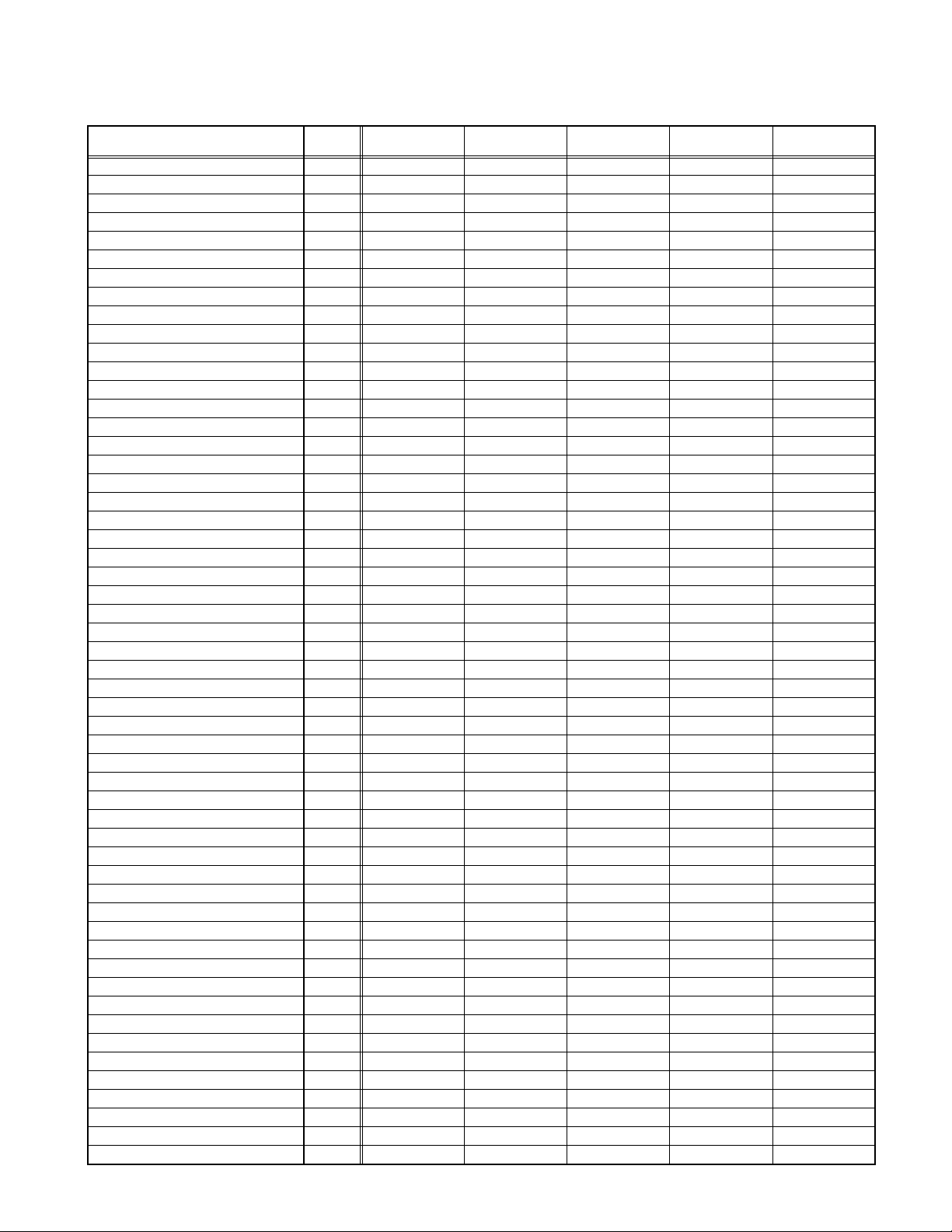

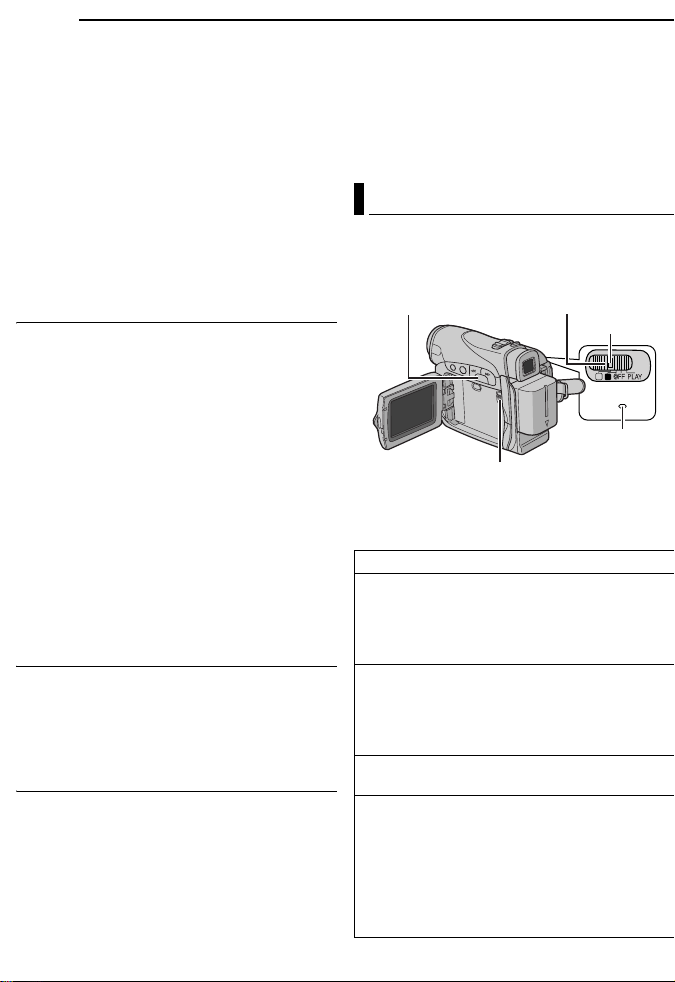

2.1.4 DISASSEMBLY PROCEDURE TABLE

MARK: # After assembly, perform adjustments.

NO. PART NAME

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[23]

[24]

[25]

[26]

[27]

[28]

[29]

[30]

[31]

[32]

[33]

[34]

[35] / [36]

[36]

[37]

CASSETTE HOUSING ASSY

UPPER BASE ASSY

DRUM ASSY

REEL DISK ASSY(SUP)

REEL DISK ASSY(TU)

REEL COVER ASSY

TENSION ARM ASSY

SLANT POLE ARM ASSY

TU ARM ASSY

SWING ARM ASSY

SLIDE DECK ASSY

PAD ARM ASSY

TU BRAKE ASSY

TENSION CTL LEVER ASSY

CENTER GEAR

PINCH ROLLER ARM F. ASSY

TENSION CTL PLATE ASSY

BRAKE CTL LEVER ASSY

MOTOR BRACKET ASSY

GUIDE RAIL ASSY

SLIDE LEVER 2 ASSY

LOADING PLATE ASSY

MODE GEAR

EJECT LEVER

BASE R ASSY

ROTARY ENCODER

GEAR COVER ASSY

MAIN CAM ASSY

SLIDE ARM ASSY

CONNECT GEAR 2

SUB CAM ASSY

CONTROL ARM ASSY

REEL GEAR 1

DRUM BASE ASSY/

CAPSTAN MOTOR

CAPSTAN MOTOR

MAIN DECK ASSY

FIG. POINT NOTE REMARKS

T Fig.2-1-14

T Fig.2-1-15

T

T Fig.2-1-16

T

T

T Fig.2-1-17

T

T

T

T Fig.2-1-18

3(S1),(L1a)-(L1e)

(S2),(L2a),(L2b)

(S3a),2(S3b)

(W4)

(W5a),(W5b)

(W6),2(S6a),(S6b)

(L7)

(P8)

(L9)

(S10)

2(S11a),(S11b),2(L11a),

NOTE 1 a,b,c,d

NOTE 2

NOTE 3 a,b

NOTE 4

NOTE 5 a,b

NOTE 6

NOTE 7

NOTE 8

NOTE 9

NOTE 10

NOTE 11a,b

2(L11b),(L11c)

T Fig.2-1-19

T

T Fig.2-1-20

T

T

T

T

T Fig.2-1-21

T

T

T

T

T

T Fig.2-1-22

T

T

T

T Fig.2-1-23

T

T

T

T

T Fig.2-1-24

T

T

(P12),(L12),(W12)

(P14),(L14),(W14)

(W15)

(W17)

-

3(S20),(L20a),2(L20b)

2(W21),(S21),2(L21a),(L21b)

(W23)

(W25)

(S26a),(S26b),2(L26)

2(S27)

(S28a),2(S28b)

-

-

(S32)

-

3(S35)

(S36)

-

Fig.2-1-10

NOTE 12

-

NOTE 14

NOTE 15

NOTE 16

NOTE 17

NOTE 18

NOTE 19

NOTE 20

NOTE 21

NOTE 22

NOTE 23

NOTE 24

NOTE 25

NOTE 26

NOTE 27

-

NOTE 29

NOTE 30

NOTE 31

NOTE 32

NOTE 33

NOTE 34

NOTE 35a,b

NOTE 36

-

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT / #

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT / #

ADJUSTMENT / #

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT / #

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

PHASE ADJUSTMENT

PHASE ADJUSTMENT

ADJUSTMENT

PHASE ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

2-4 (No.86700)

Page 7

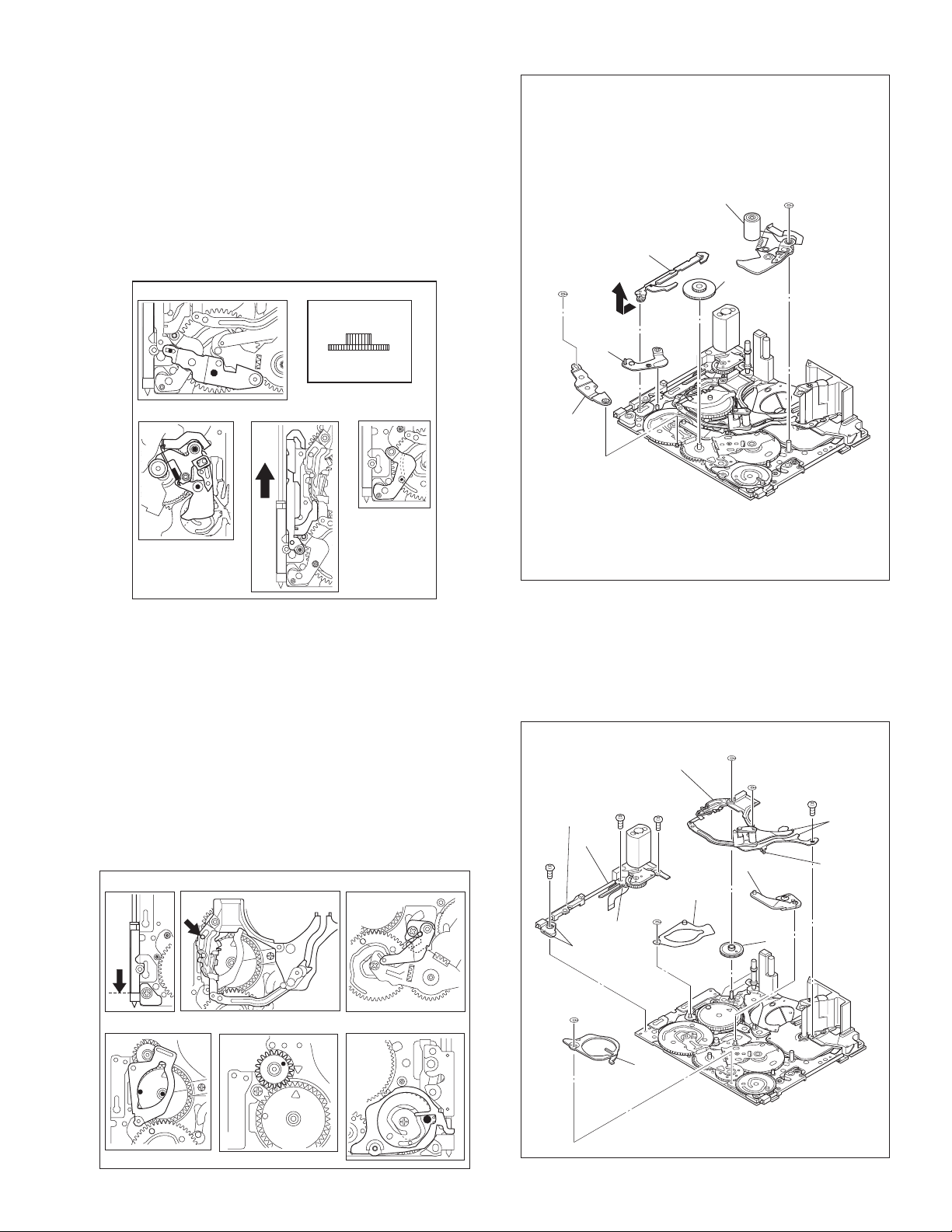

2

(S1)

[1]

17

(S20)

(W12)

[14]

(S20)

[20]

16

[12]

[8]

(P8)

(W14)

(P14)

14

(S11b)

(P12)

(S20)

15

(W4)

[4]

(S6a)

[6]

[7]

(W23)

21

(S27)

[18]

27

[35]

7

5

28

(S35)

[17]

4

(S2)

[36]

[2]

(S36)

(W17)

[3]

30

29

(S35)

1

(S1)

(W5a)

8

(W6)

[27]

[30]

[23]

(W5b)

11

(S10)

22

(S27)

[5]

10

(S6b)

13

(S11a)

3

(S1)

[34]

9

(S6a)

[10]

(S11a)

[11]

(W21)

12

[22]

(W21)

(S21)

[21]

[9]

(S35)

(S3b)

(S3a)

6

(S3b)

18

(W15)

(S28b)

[15]

24

[29]

[16]

[31]

25

(S28b)

[28]

23

(S28a)

[19]

[24]

[37]

Fig.2-1-11

20

(S26b)

(W25)

[25]

19

(S26a)

26

(S32)

[26]

[32]

[33]

(No.86700)2-5

Page 8

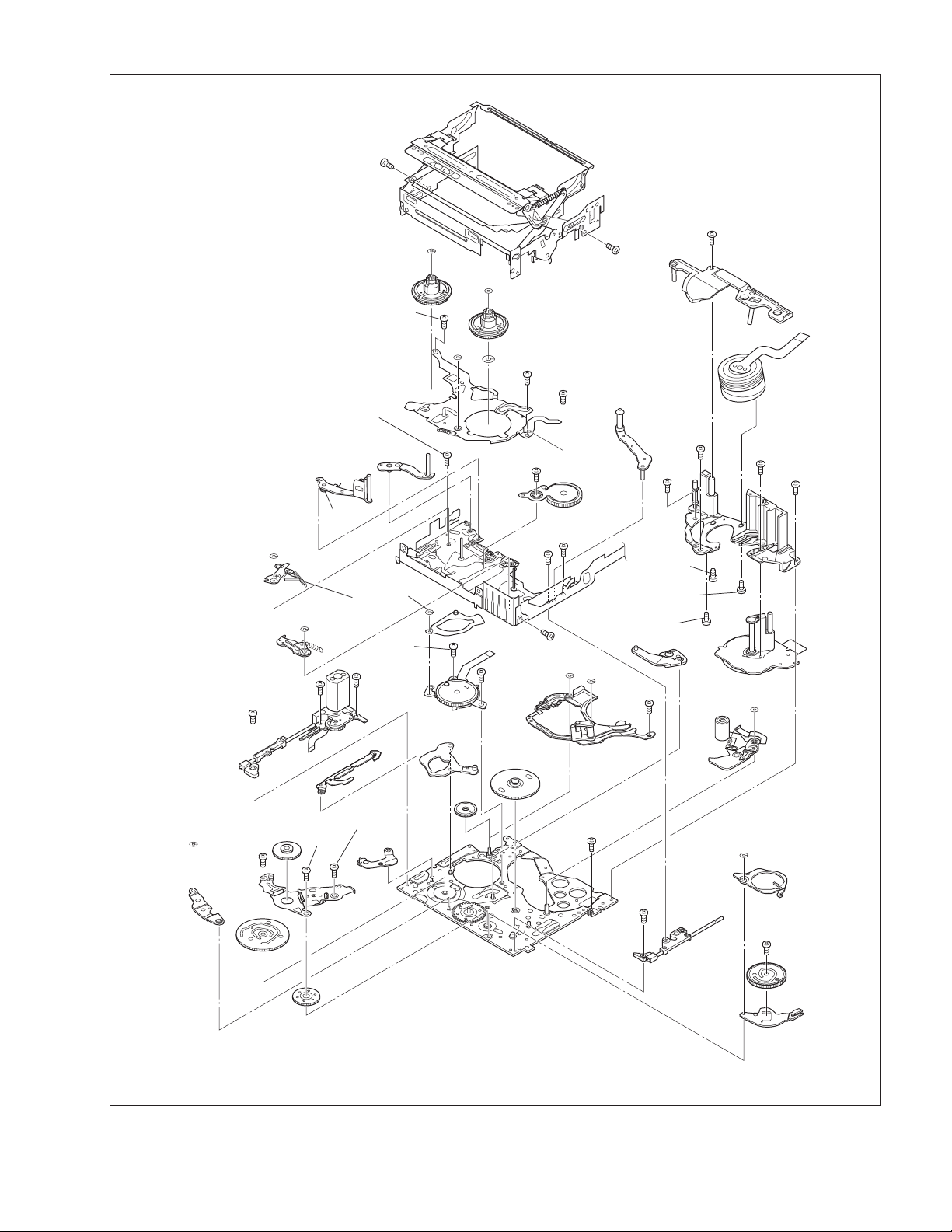

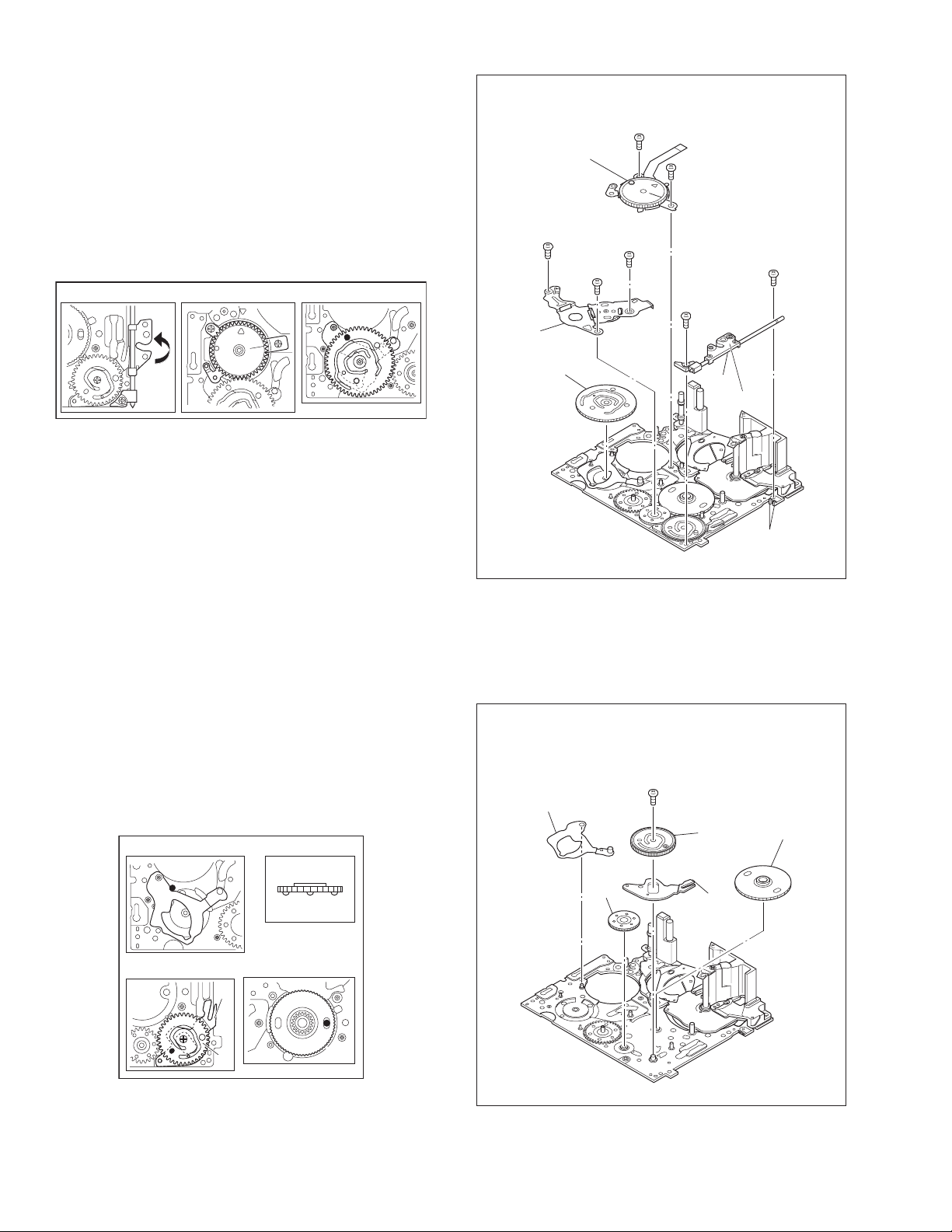

< TOP VIEW >

[24] [27] [ 2 ] [ 3 ] [36] [35][21]

[17]

< BOTTOM VIEW >

[20]

[23]

[18]

[8]

[7]

[22]

[12]

[4]

[29]

[19]

[34]

[14][31][28][16][15][30]

[5]

Fig.2-1-12

[36] [3] [22]

[26]

[34]

[9]

[10]

[33]

[26]

[6]

[37]

[25]

[32]

[11]

[26]

[32]

[25]

[31] [16] [6]

Fig.2-1-13

[37]

[11]

[27]

[20]

[30]

[18]

[19]

[29]

[30]

2-6 (No.86700)

Page 9

2.1.5 DISASSEMBLY/ASSEMBLY

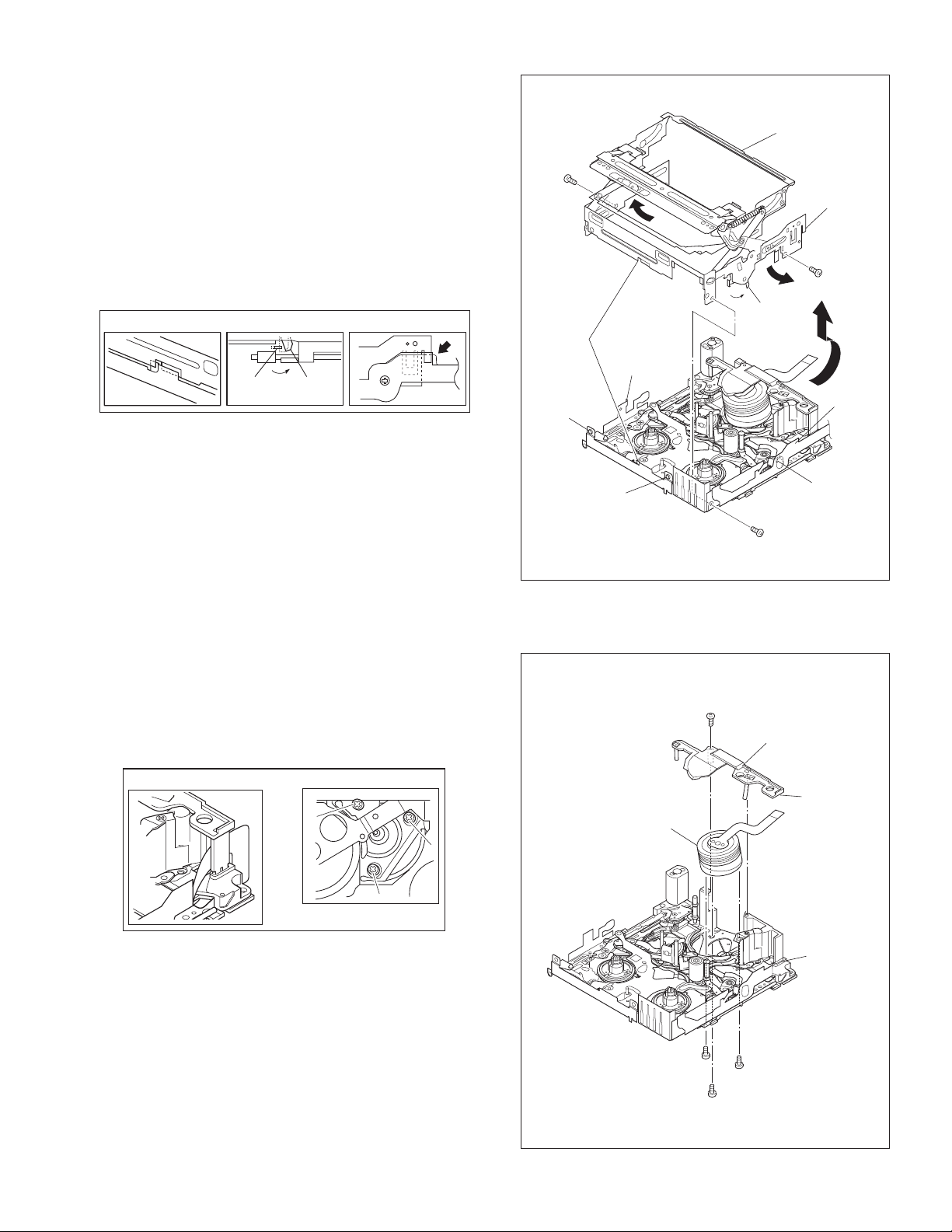

2.1.5.1 [ 1 ] CASSETTE HOUSING ASSY

NOTE 1a:

Be careful not to damage any of the parts during work.

NOTE 1b:

Special care is required in mounting.

NOTE 1c:

When mounting, the CASSETTE HOUSING ASSY should be

attached in the Eject status. Pay heed to the positions of the

LOCK LEVER and EJECT LEVER during mounting.

NOTE 1d:

When mounting, be sure to locate the FPC in the gap.

NOTE 1b

NOTE 1c

EJECT

LEVER

LOCK

LEVER

NOTE 1d

*

2

(S1)

NOTE 1b

(L1d)

(L1c)

(L1b)

NOTE 1a

[1]

LOCK

LEVER

NOTE 1c

NOTE1d

*

1

(S1)

NOTE 1d

2.1.5.2 [ 2 ] UPPER BASE ASSY

[ 3 ] DRUM ASSY

NOTE 2:

When mounting, be sure to insert the FPC reinforcing sheet.

NOTE 3a:

Be mindful of scratches or damage during work.

NOTE 3b:

Be careful not to attach screws incorrectly.

NOTE 2

NOTE 3b

5

7

6

(L1e)

* 0.069 N.m (0.7 kgf.cm)

Fig.2-1-14

NOTE 3a

[3]

4

(S2)

3

(S1)

(L1a)

*

[2]

NOTE 2

(L2b)

6

(S3b)

7

(S3b)

Fig.2-1-15

(L2a)

NOTE 2

5

(S3a)

NOTE 3b

(No.86700)2-7

Page 10

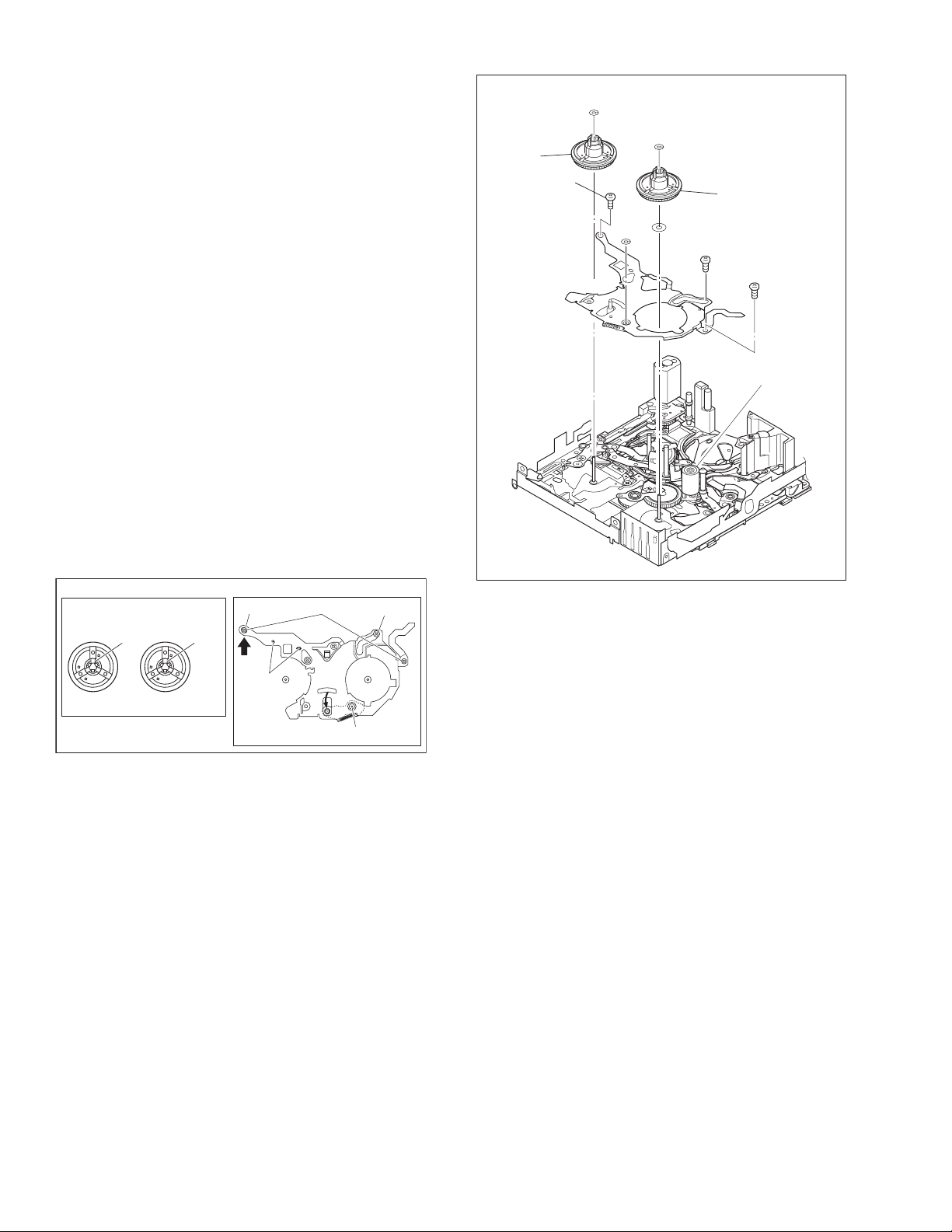

2.1.5.3 [ 4 ] REEL DISK ASSY(SUP)

[ 5 ] REEL DISK ASSY(TU)

[ 6 ] REEL COVER ASSY

NOTE 4:

Be careful not to attach the REEL DISK wrongly. The Supply

side can be identified by the white color at the center.

NOTE 5a:

Be careful not to attach the REEL DISK wrongly. The Take-up

side can be identified by the black color at the center.

NOTE 5b

The washer is inserted under the REEL DISK.

Be carefull not to lose the washer.

Two washers are inserted under the REEL DISK in some products manufactured earlier, but one washer is inserted in the

products manufactured recently and in the future.

See the parts list, and use the parts written in the parts list.

NOTE 6:

Perform the following steps for mounting.

(1) Align the hole with the pin.

(2) Attach the [17] PINCH ROLLER ARM FINAL ASSY by

aligning the positions.

(3) Attach the SLIDE DECK ASSY (POINT[A]) by aligning

the positions.

(4) Check that the parts below them are located in the cor-

rect positions.

(5) Tighten the 2 screws.

(6) Tighten the screw.

(7) Attach the 1 SLIT WASHER parts.

NOTE 4

[4]

[6]

NOTE 6

8

(S6a)

(W4)

(W6)

(W5a)

(W5b)

NOTE 5a

[5]

NOTE 5b

10

(S6b)

9

(S6a)

[17]

NOTE 4, 5

REEL DISK ASSY

WHITE

SUP

TU

BLACK

NOTE 6

(3)

[A]

(4)

(5)

Fig.2-1-16

(2),(6)

(1), (7)

2-8 (No.86700)

Page 11

2.1.5.4 [ 7 ] TENSION ARM ASSY

[ 8 ] SLANT POLE ARM ASSY

[ 9 ] TU ARM ASSY

[10] SWING ARM ASSY

NOTE 7:

When detaching, remove the spring of the [12] PAD ARM

ASSY in advance.

Pay attention to the attachment position.

NOTE 8:

When mounting the SLANT POLE ARM ASSY, hook the

spring onto the lug as in diagram A, and fit the combination

onto the SLIDE DECK ASSY. After fitting, hook the spring onto

the lug of the SLIDE DECK ASSY as in diagram B.

Be careful not to lose the spring.

NOTE 9:

Pay attention to the attachment position.

NOTE 10:

When detaching, remove the screw then remove the SWING

ARM ASSY by pulling it up and turning it.

NOTE 7

(L7)

[7]

(P8)

NOTE 8

NOTE 10

[10]

[8]

NOTE 9

[9]

11

(S10)

(L9)

NOTE 7

NOTE 9

SPRING

NOTE 8

AB

SPRING

NOTE 10

NOTE 7

Fig.2-1-17

(No.86700)2-9

Page 12

2.1.5.5 [11] SLIDE DECK ASSY

NOTE 11a:

Each of the parts on the SLIDE DECK ASSY can be replaced

separately.

When detaching the assembly, if there is no need to replace

any of its parts, remove the SLIDE DECK ASSY as it is.

NOTE 11b:

When mounting, pay attention to the positions of the [22]

SLIDE LEVER 2 ASSY studs and the [19] BRAKE CTL LEVER ASSY.

When mounting, position the CONTROL PLATE on the left

side.

Pay attention to the position of the SLIDE GUIDE PLATE during mounting.

NOTE 11b

SLIDE GUIDE

PLATE

(L11b)

14

(S11b)

NOTE 11b

(L11c)

13

(S11a)

12

(S11a)

NOTE 11a

[11]

(L11a)

2.1.5.6 [12] PAD ARM ASSY

[13] [14] TU BRAKE ASSY

NOTE 12:

The spring may have already been disengaged when the [ 8 ]

SLANT POLE ARM ASSY was removed.

NOTES 14:

When mounting, pay attention to the correct positioning.

Mount the CONTROL PLATE by moving it fully toward the left

side.

NOTE 12,14

[12]

CONTROL

PLATE

SPRING

[14]

(W12)

Fig.2-1-18

[12]

NOTE 12

(P12)

(W14)

(L12)

Fig.2-1-19

(P14)

[14]

NOTE 14

(L14)

2-10 (No.86700)

Page 13

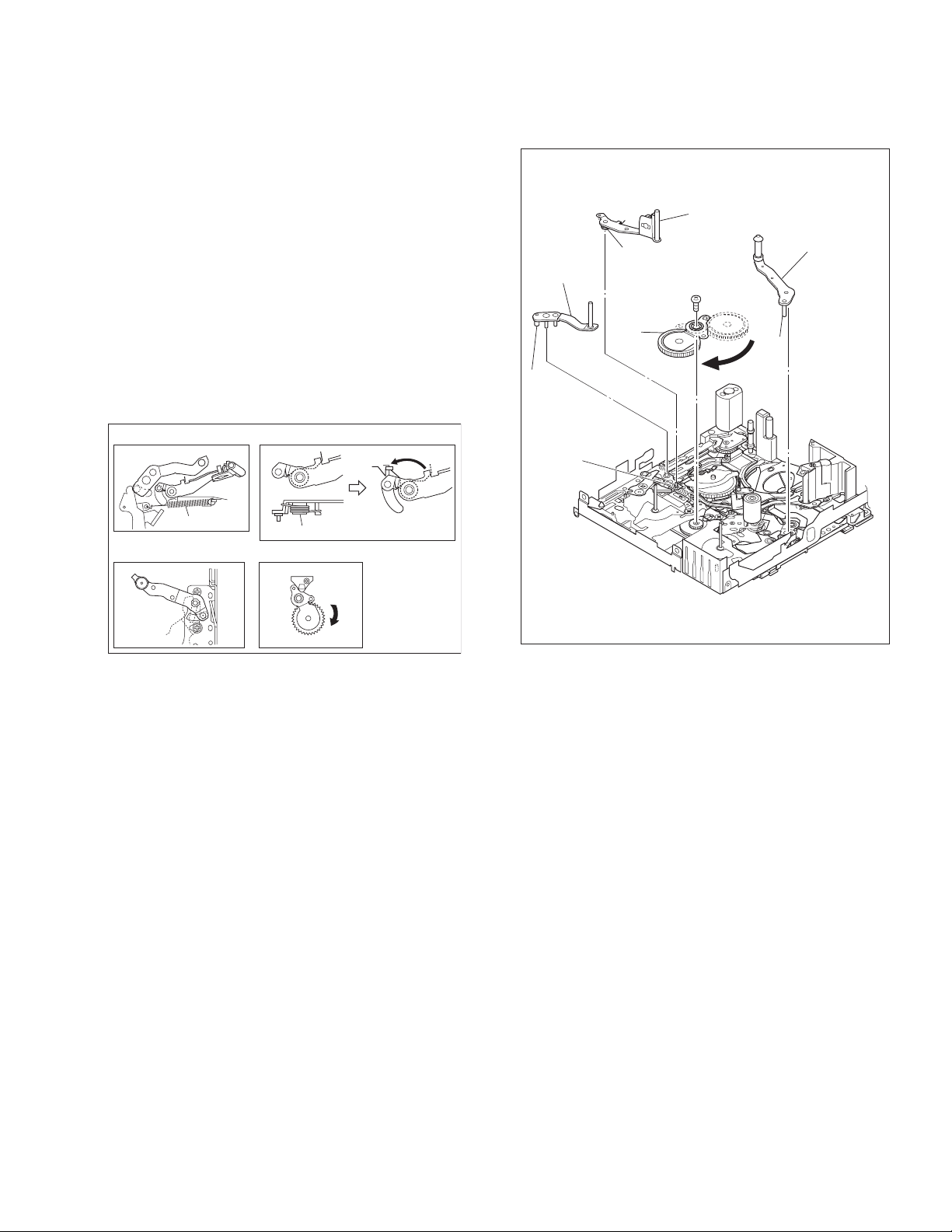

2.1.5.7 [15] TENSION CTL LEVER ASSY

[16] CENTER GEAR

[17] PINCH ROLLER ARM FINAL ASSY

[18] TENSION CTL PLATE ASSY

[19] BRAKE CTL LEVER ASSY

NOTES 15/16:

When mounting, pay attention to the correct positioning.

NOTE 17:

Take care against grease attachment during work.

NOTES 18/19:

When mounting, pay attention to the correct positioning.

NOTE 15

NOTE 16

(TOP)

(BOTTOM)

(W15)

NOTE 18

NOTE 19

[19]

[18]

NOTE 17

[17]

[16]

NOTE 16

(W17)

NOTE 17

2.1.5.8 [20] MOTOR BRACKET ASSY

[21] GUIDE RAIL ASSY

[22] SLIDE LEVER 2 ASSY

[23] LOADING PLATE ASSY

[24] MODE GEAR

[25] EJECT LEVER

NOTE 20:

When mounting, pay attention to the positi oning of the slidi ng

parts.

NOTE 21:

When mounting, take care that no part is allowed to float or rattle.

NOTES 22/23/24/25:

When mounting, pay attention to the correct positioning.

NOTE 20 NOTE 21

NOTE 18

NOTE 19

NOTE 22

[15]

NOTE 15

NOTE 20

17

(S20)

(S20)

[20]

(L20a)

(L20b)

16

Fig.2-1-20

NOTE 21

[21]

15

(S20)

NOTE 23

(W23)

[23]

(W21)

(W21)

[22]

NOTE 24

18

(S21)

(L21a)

(L21b)

NOTE 22

[24]

NOTE 23

NOTE 24

(W25)

NOTE 25

[25]

NOTE 25

Fig.2-1-21

(No.86700)2-11

Page 14

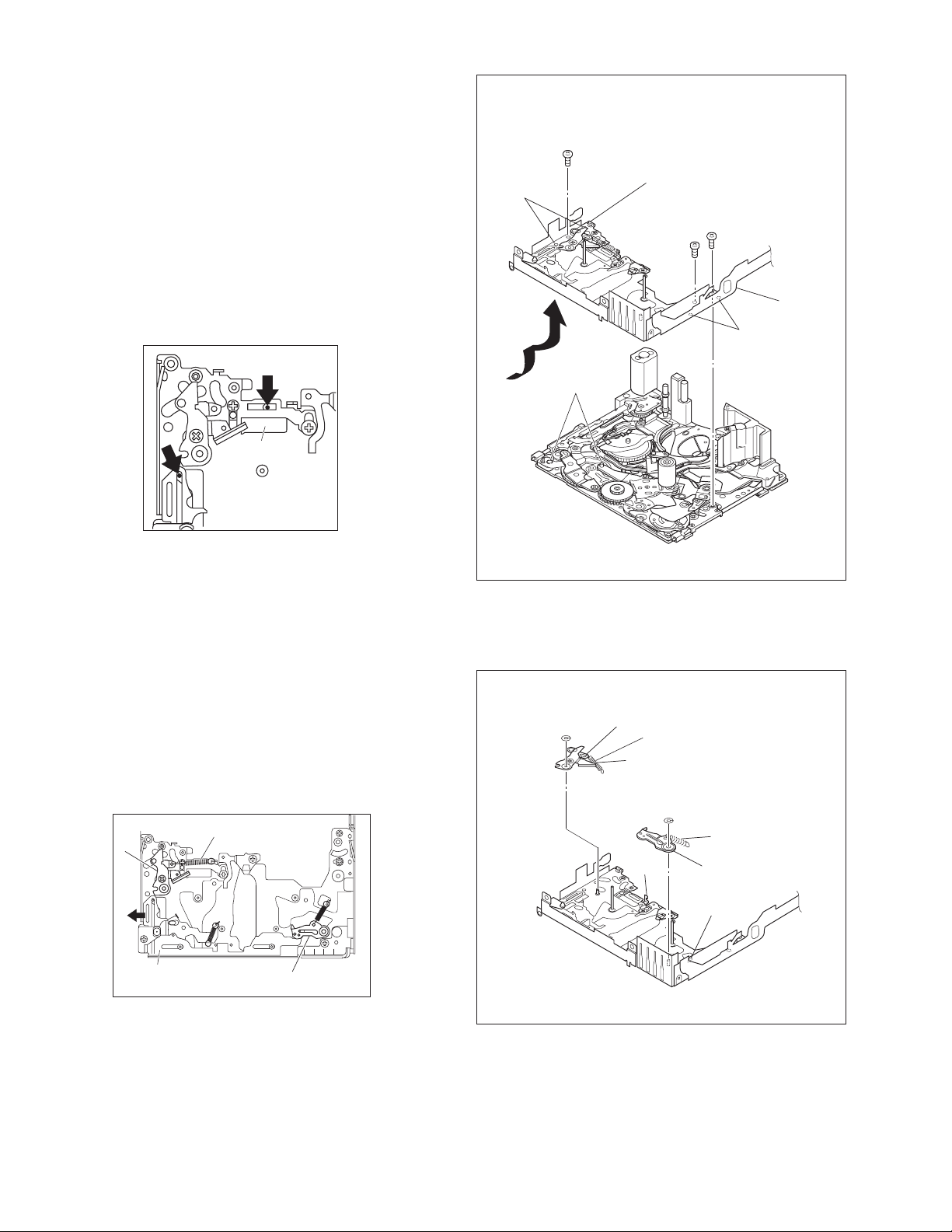

2.1.5.9 [26] BASE R ASSY

[27] ROTARY ENCODER

[28] GEAR COVER ASSY

[29] MAIN CAM ASSY

NOTE 26:

When mounting, fold the sliding part to the inner side.

NOTE 27:

When mounting, pay attention to the correct positioning and

the FPC layout.

NOTE 29:

When mounting, pay attention to the correct positioning.

NOTE 26 NOTE 27 NOTE 29

(S28b)

[28]

NOTE 27

[27]

24

25

(S28b)

21

(S27)

23

(S28a)

22

(S27)

(S26a)

19

*

20

(S26b)

2.1.5.10 [30] SLIDE ARM ASSY

[31] CONNECT GEAR 2

[32] SUB CAM ASSY

[33] CONTROL ARM ASSY

[34] REEL GEAR 1

NOTE 30:

When mounting, pay attention to the correct positioning.

NOTE 31:

When mounting, pay attention to the position of the front and

back.

NOTES 32/33/34:

When mounting, pay attention to the correct positioning.

NOTE 30 NOTE 31

(TOP)

(BOTTOM)

[29]

NOTE 29

* 0.0198N

NOTE 30

[30]

.

m (0.2kgf.cm)

NOTE 31

[31]

Fig.2-1-22

26

(S32)

NOTE 32

[26]

NOTE 26

[32]

[33]

NOTE 33

(L26)

NOTE 34

[34]

NOTE 32/33

2-12 (No.86700)

NOTE 34

[33]

[32]

Fig.2-1-23

Page 15

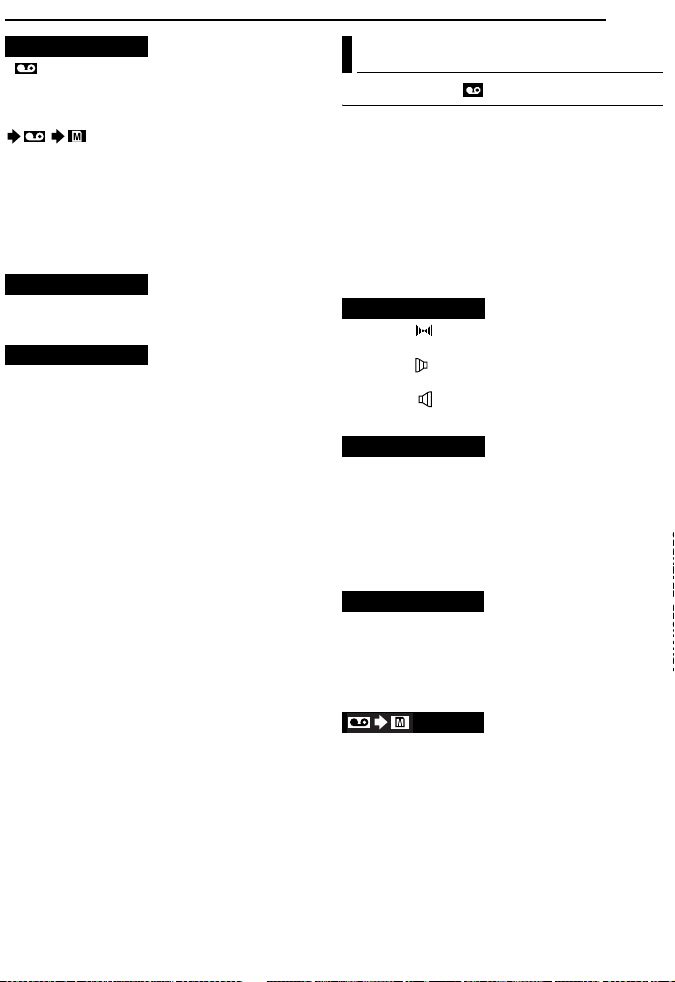

2.1.5.11 [35] DRUM BASE ASSY

[36] CAPSTAN MOTOR

[37] MAIN DECK ASSY

NOTES 35a/36:

Since [36]CAPSTAN MOTOR is attached to [35]DRUM BASE

ASSY, remove [36]CAPSTAN MOTOR together with

[35]DRUM BASE ASSY when removing [36]CAPSTAN MOTOR.

[36]CAPSTAN MOTOR should not be separated from

[35]DRUM BASE ASSY except when replacing them.

NOTE 35b:

It is very important to attach [35]DRUM BASE ASSY to the

proper position.

Especially, improper engagement of [36]CAPSTAN MOTOR

with [34]REEL GEAR 1 causes operational defection or abnormal sound. Therefore, confirm the attachment position before

disassembly procedure.

See the following figure as for the proper attachment position.

NOTE 35b

NG

OK

When [35]DRUM BASE ASSY

is properly attached, the screw

hole tends to be located at the

center of the oval.

NG

When the screw hole is

located far from the center of

the oval, operational defection

or abnormal sound may occur.

*

28

(S35)

*

27

(S35)

[35]

NOTE 35a

[36]

NOTE 36

* 0.078 N.m (0.8 kgf.cm)

** 0.039 N.m (0.4 kgf.cm)

30

(S36)

[37]

**

29

(S35)

*

NOTE 35b

Fig.2-1-24

(A)

Before removing [35]DRUM

BASE ASSY, confirm the

position of [35]DRUM BASE

ASSY by seeing the length

(A), as shown in the left figure.

When reattaching [35]DRUM

BASE ASSY, confirm the

position to reattach [35]DRUM

BASE ASSY by seeing the

length (A). Be sure to reattach

[35]DRUM BASE ASSY to the

same position as it has been

before the removing procedure.

(No.86700)2-13

Page 16

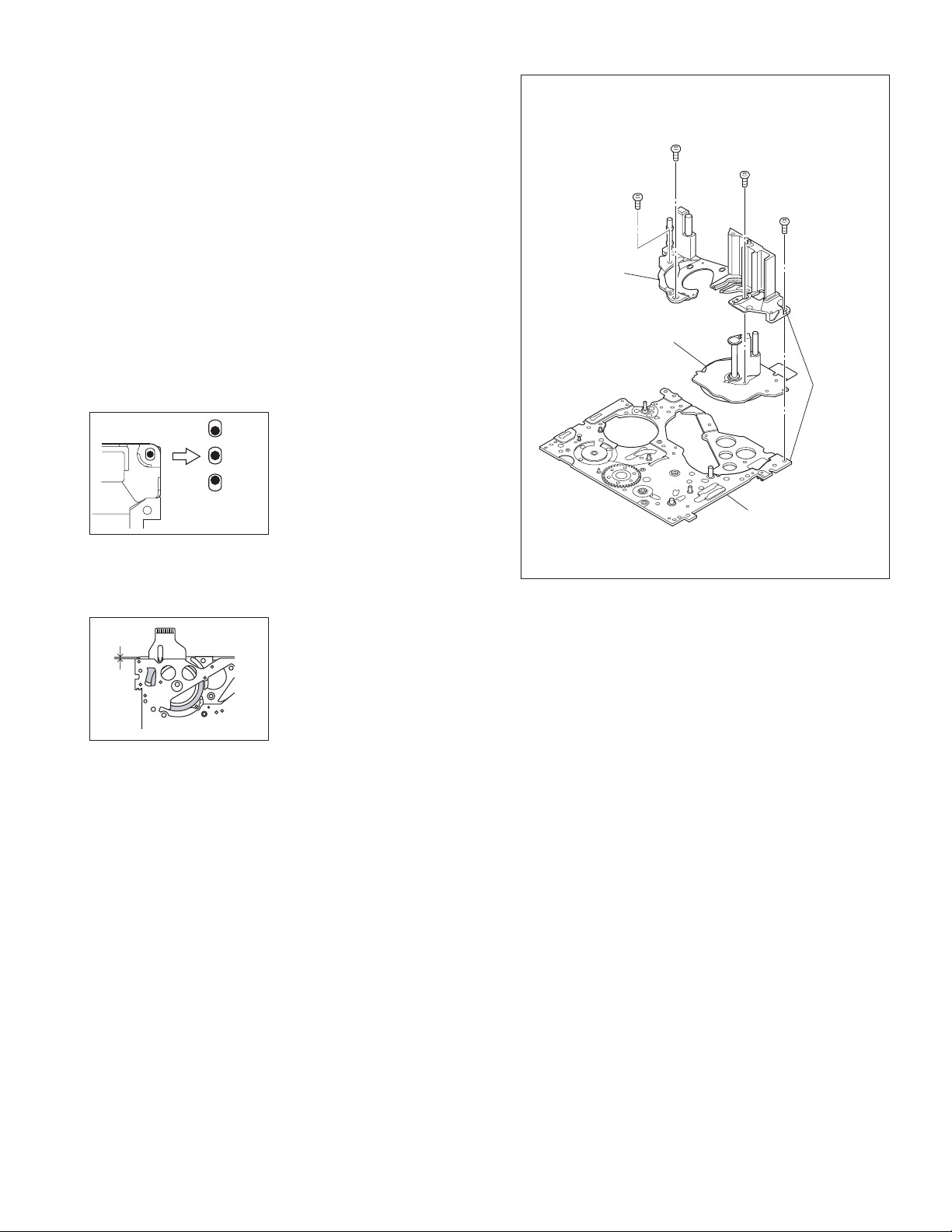

2.1.6 CHECKUP AND ADJUSTMENT OF MECHANISM PHASE

MODE GEAR

[24]

Align the MODE GEAR with the Main Deck

Assembly hole.

Note:

The MODE GEAR may

be displaced during the

mechanism operation,

however it can be

checked from the rear

and realigned during

manual assembly.

[27]

ROTARY ENCODER

Mount the ROTARY ENCODER by aligning its mark ( )

and the mark ( ) of the Main Deck Assembly.

Note:

Be careful when handling the FPC during mounting.

[34]

REEL GEAR 1

Align the REEL GEAR 1 with

the Main Deck Assembly hole.

Note:

The REEL GEAR 1 may be

displaced during mechanism

operation, however this can

be checked from the rear and

realigned during manual

assembly.

[29]

MAIN CAM ASSY/[30]SLIDE ARM ASSY

When mounting the SLIDE ARM ASSY align it with the

Main Deck Assembly and MAIN CAM ASSY holes.

Note:

During the mounting procedure, make sure that the[32]

SUB CAM ASSY is in the correct mounting position.

[32]

Fig.2-1-25

SUB CAM ASSY/[33] CONTROL ARM ASSY

Mount the SUB CAM ASSY hole to align with the CONTROL

ARM ASSY and Main Deck Assembly holes and then tighten

them all together with a screw.

Note:

When mounting it, make sure that the[29]MAIN CAM ASSY is

in the correct mounting position.

2-14 (No.86700)

Page 17

2.1.7 MECHANISM ADJUSTMENTS

2.1.7.1 Adjustment of the slide guide plate

Use Fig. 2-1-26 as the reference unless otherwise specified.

(1) Set the PLAY mode. See Fig. 2-1-8.

(2) Loosen the screws (A, B).

(3) With the Main Deck and Slide Deck Assemblies pushed into the unit, tighten the screws (A, B) while applying pressure to the

stud (shaft) on the Slide Guide plate.

The pressure applied should be enough to enable utilization of the rebounding force of the springs.

The tightening torque should be 0.069 N•m (0.7 kgf•cm).

(4) Check the operation.

Repeat unloading and loading several times and make sure that these operations can be performed smoothly without producing

rattles.

(3)

(

2)(3

)

SCREW A

(3)

STUD

(SHAFT)

(3)

2)(3

)

(

SCREW B

(3)

(3)

Fig.2-1-26

(No.86700)2-15

Page 18

2.1.7.2 Adjustment of the Tension Arm and Pad Arm Assemblies

Use Fig. 2-1-27 as the reference unless otherwise specified.

(1) Set the PLAY mode.

See Fig. 2-1-8.

(2) Loosen the screw A.

(3) With the take-up side at the bottom, align the extreme end

of the Tension Arm Assembly with the crossed grooves on

the screw B that retains the Loading Motor Assembly and

then tighten the screw A.

The tightening torque should be 0.069 N•m (0.7 kgf•cm).

(4) Check the operation.

Repeat unloading and loading several times and make

sure that the Tension Arm Assembly is located within the

normal range.

TENSION

ARM ASSY

SCREW B

(

2)(3

)

SCREW A

Fig.2-1-28

(

(3)

3)

(

2)(3

)

SCREW A

Fig.2-1-27

2.1.7.3 Adjustment of the Slide Lever 2

Use Fig. 2-1-28 as the reference unless otherwise specified.

(1) Set the C IN mode.

See Fig. 2-1-4.

(2) Loosen the screw A.

(3) Set the Main Deck and Slide Deck Assemblies apart so that

they do not rattle, then tighten the screw A by screwing it

fully toward the Drum Assembly.

The tightening torque should be 0.069 N•m (0.7 kgf•cm).

(4) Check the operation.

Repeat unloading and loading several times and make

sure that these operations can be performed smoothly

without producing rattles.

2-16 (No.86700)

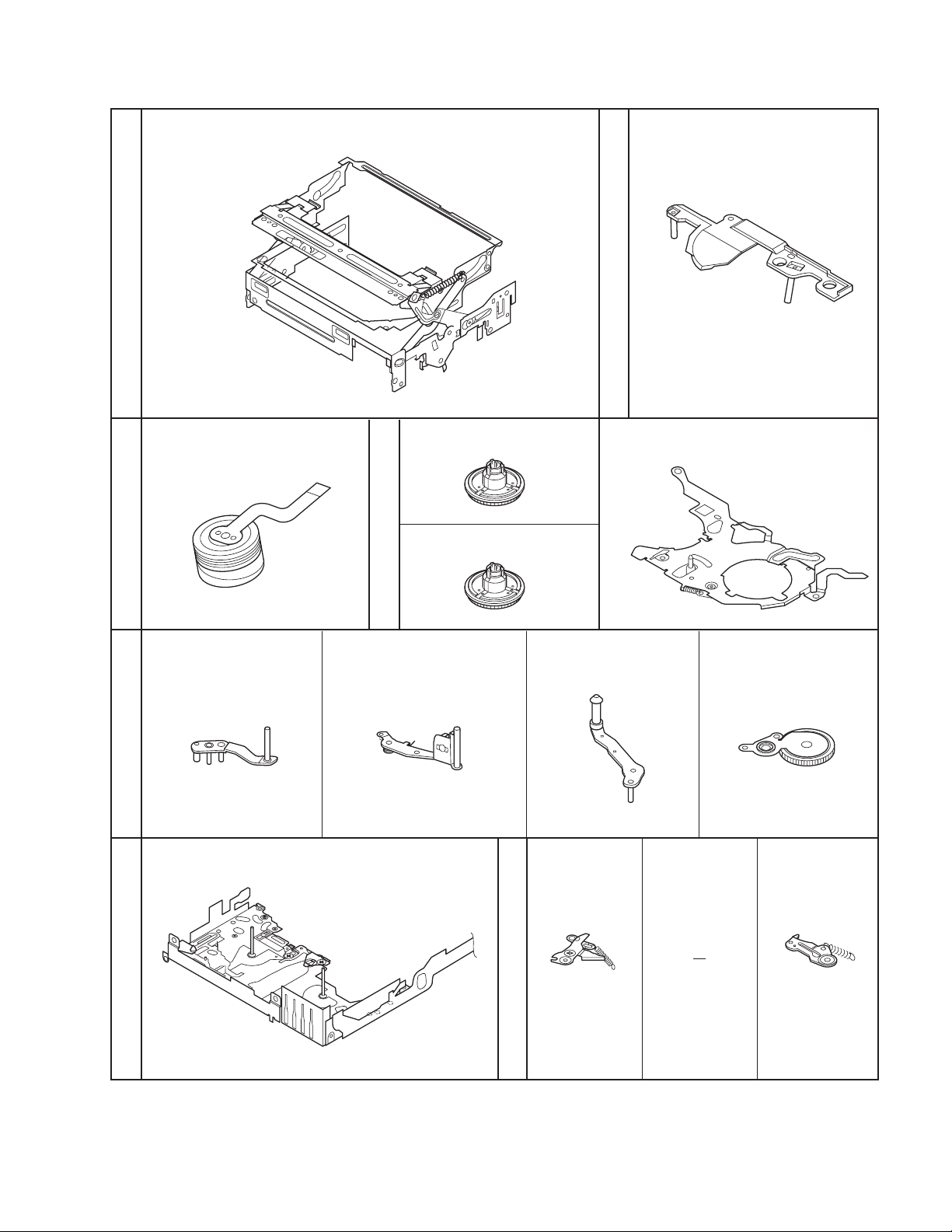

Page 19

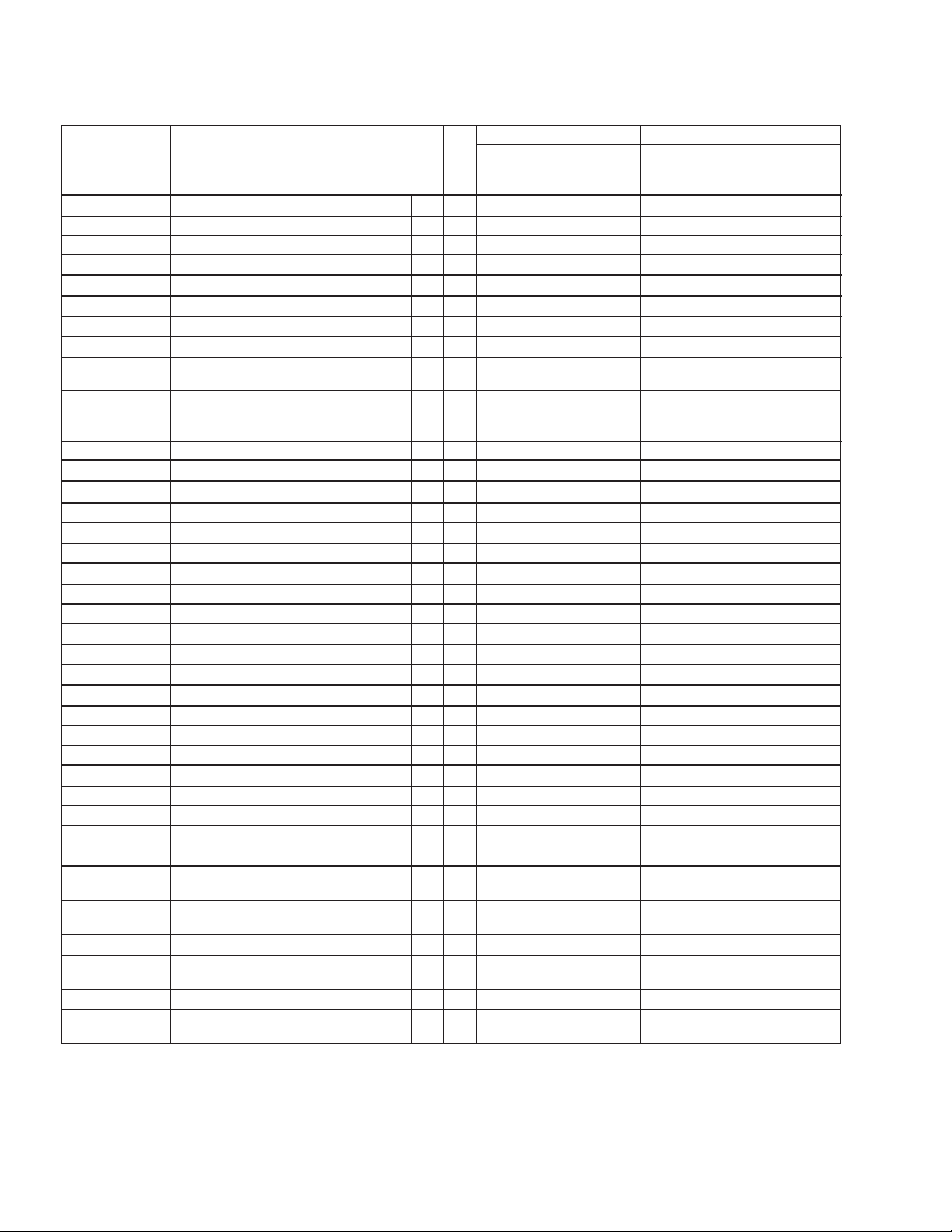

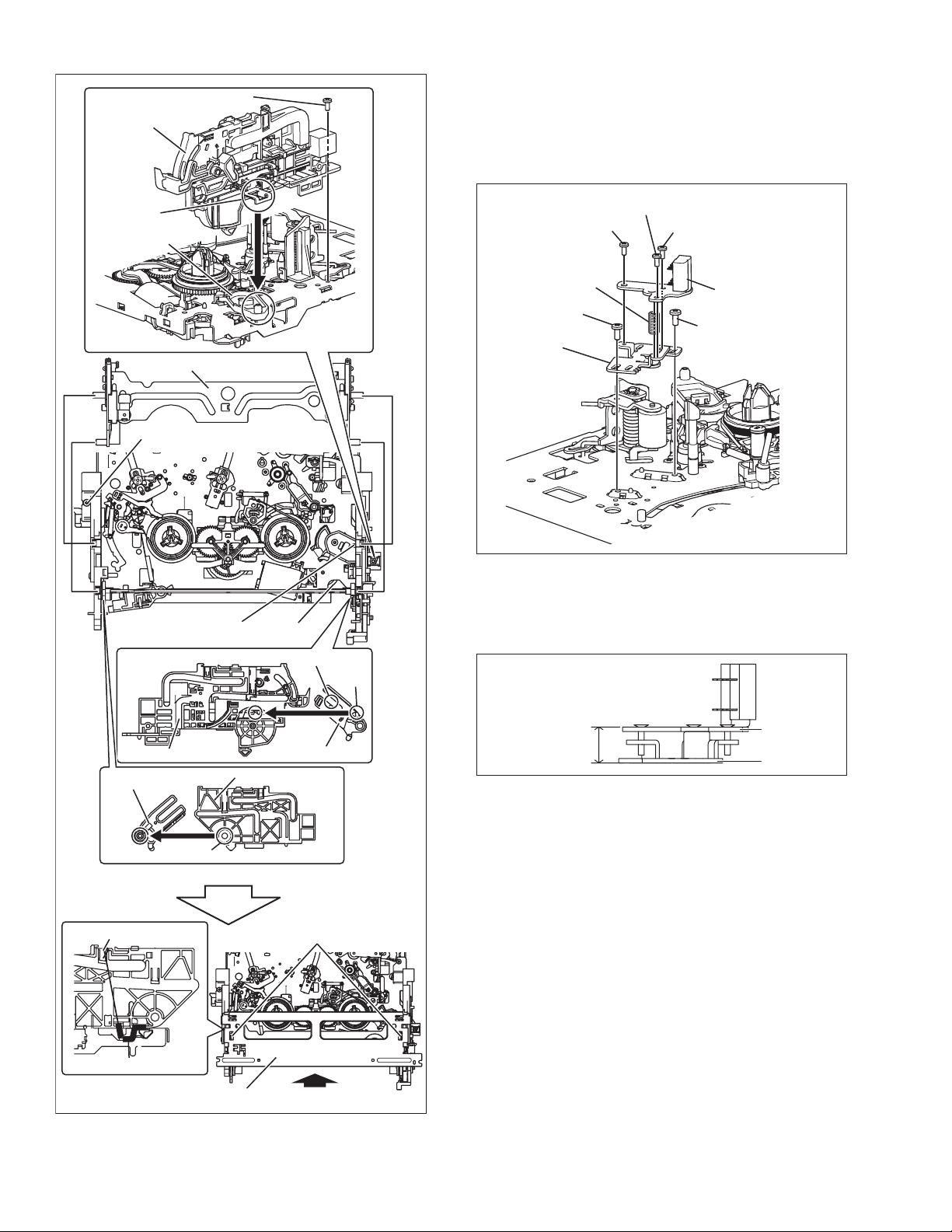

2.1.8 SERVICE NOTE

Use the following chart to manage mechanism parts that are removed for disassembling the mechanism.

[1]

CASSETTE HOUSING ASSY UPPER BASE ASSY

[2]

Fig.2-1-14

[3]

Fig.2-1-15

[7]

DRUM ASSY

TENSION ARM ASSY

Fig.2-1-15

REEL DISK ASSY(SUP)

[4]

Fig.2-1-16

SLANT POLE ARM ASSY SWING ARM ASSYTU ARM ASSY

[ 8 ] [ 9 ] [10]

REEL DISK ASSY(TU)

[5]

REEL COVER ASSY

[6]

Fig.2-1-17

[11]

Fig.2-1-18

SLIDE DECK ASSY

Fig.2-1-19

Fig.2-1-29

PAD ARM

ASSY

[13][12]

TU BRAKE

[14]

ASSY

(No.86700)2-17

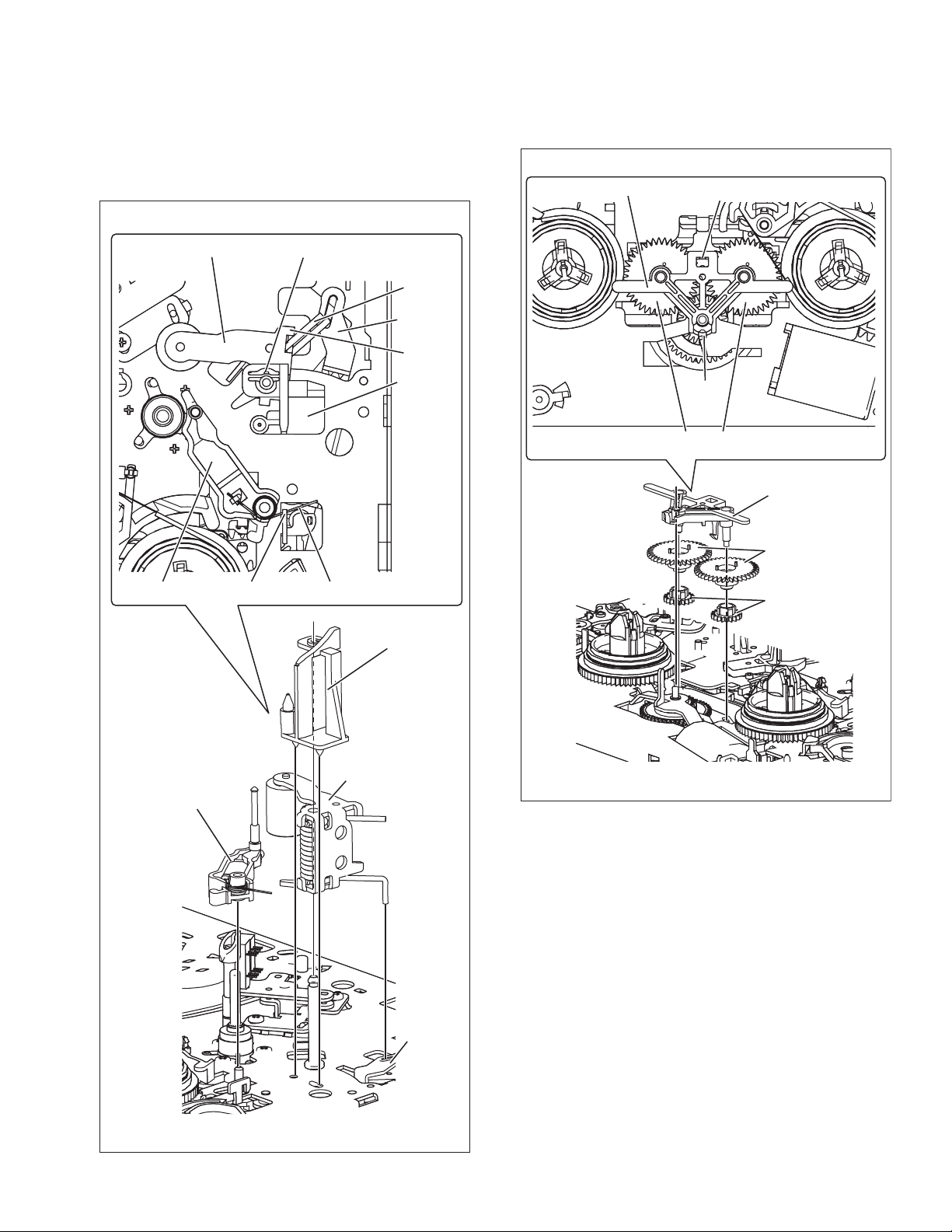

Page 20

[15]

Fig.2-1-20

TENSION CTL

LEVER ASSY

CENTER GEAR

[16]

PINCH ROLLER

[17]

ARM F ASSY

TENSION

.

[18]

CTL PLATE

ASSY

[19]

BRAKE CTL

LEVER

ASSY

[20]

Fig.2-1-21Fig.2-1-22Fig.2-1-23Fig.2-1-24

[26]

[30]

MOTOR

BRACKET

ASSY

BASE R ASSY

SLIDE ARM

ASSY

[31]

[21]

ROTAR Y

[27]

ENCODER

CONNECT

GEAR 2

GUIDE

RAIL ASSY

[32]

[28]

SUB CAM

ASSY

[22]

[24]

GEAR COVER

ASSY

[33]

SLIDE LEVER 2

ASSY

MODE GEAR EJECT LEVER

MAIN CAM ASSY

[29]

CONTROL

ARM ASSY

[23]

[25]

[34]

LOADING

PLATE ASSY

REEL GEAR 1

[35]

2-18 (No.86700)

DRUM BASE ASSY

CAPSTAN MOTOR MAIN DECK ASSY

[36]

Fig.2-1-30

[37]

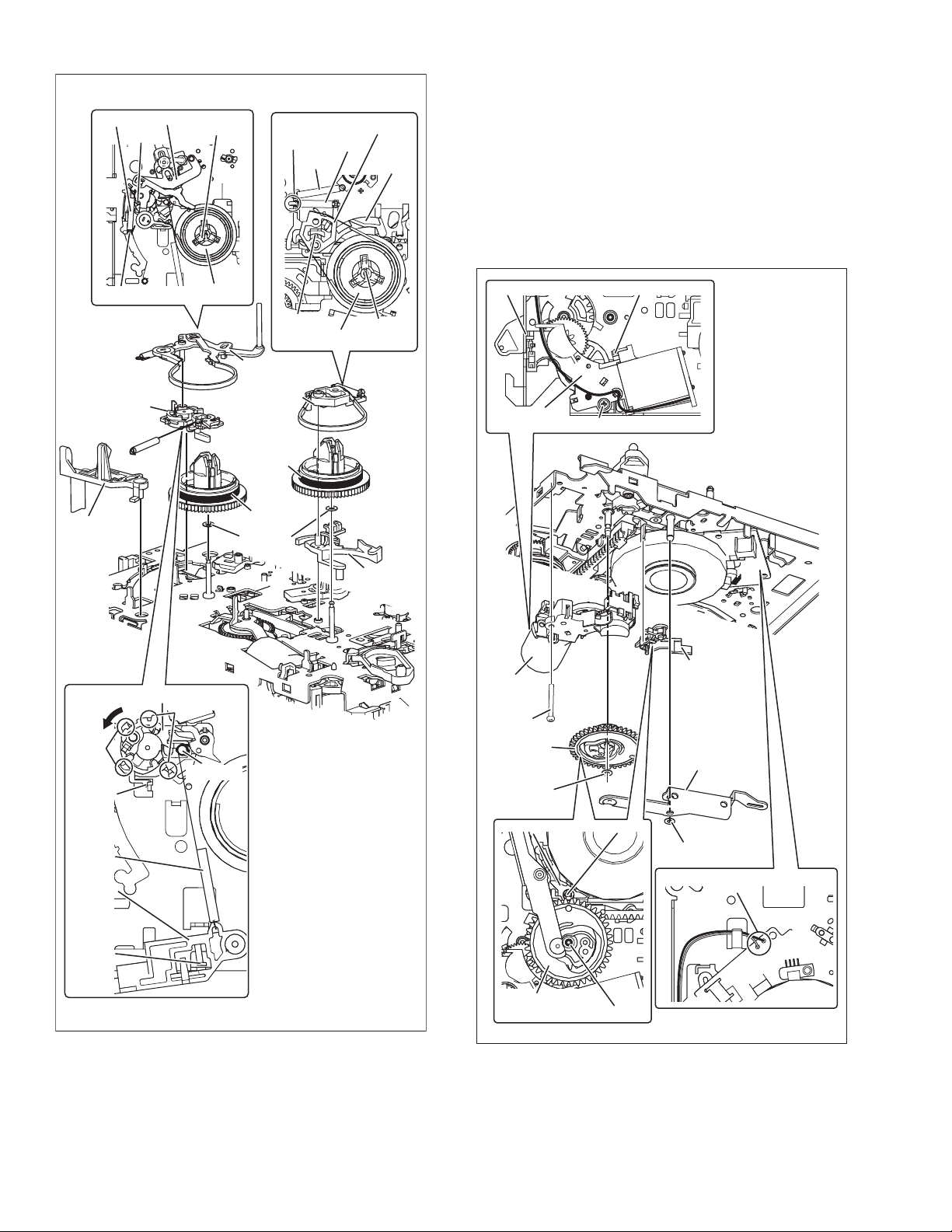

Page 21

2.1.9 SERVICE NOTE

Use the following chart to manage screws.

[22]

21 2215

Symbol No. [1] [2] [3] [6] [10] [11] [20] [21]

Removing order of screw 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Place to stick screw

24

Pay careful attention to tightening t or que for each screw.

[27]

<NOTE>

Symbol No. [28] [32] [35] [36]

Place to stick screw

Screw tightening torque

Removing order of screw 21 22 23 24 25 26 27 28 29 30

Screw tightening torque

Reference drawing (Fig. No.2-1-**) 14 16 17 18

Reference drawing (Fig. No.2-1-**) 22 23

Fig.2-1-31

(No.86700)2-19

Page 22

2.1.10 REMARKS

2.1.10.1 Cleaning

(1) For cleaning of the upper drum (particularly video heads),

use fine-woven cotton cloth with alcohol soaks through. Do

not move the cloth but turn the upper drum counterclock-

wise.

NOTE:

Make sure not to move the cloth in the vertical directi o n

to the video head, since it may cause damage of the video

heads.

(2) For cleaning of parts of the tape transport system except

the upper drum, use fine-woven cotton cloth or cotton swab

soaked alcohol.

(3) After cleaning, confirm that the cleaned parts are complete-

ly dry before loading the deck with cassette tape.

2.1.10.2 Applying oil and grease

(1) Periodical oiling and greasing are not required but should

be done to new parts when replacing. If oil and grease on

the other parts of the other party are old and dirty, wipe

them clean and apply new oil or grease.

(2) For parts and points to apply oil and grease, refer to the ex-

ploded view of the 3.1 DVC MECHANISM ASSEMBLY.

Fig.2-1-32 specifies oil and grease to be used.

(3) When oiling, clean the objective parts with alcohol first and

apply one or two drop(s) of oil. Too much oiling causes ro-

tary parts to slip because of oil leakage.

Classification Part No. Symbol in drawing

Grease KYODO-SH-JB AA

Oil YTU94027 BB

Grease (HANARL)

RX-410R CC

specifies oil and grease to be used

Fig.2-1-32

2-20 (No.86700)

Page 23

2.2 VHS-C MECHANISM

2.2.1 Precautions

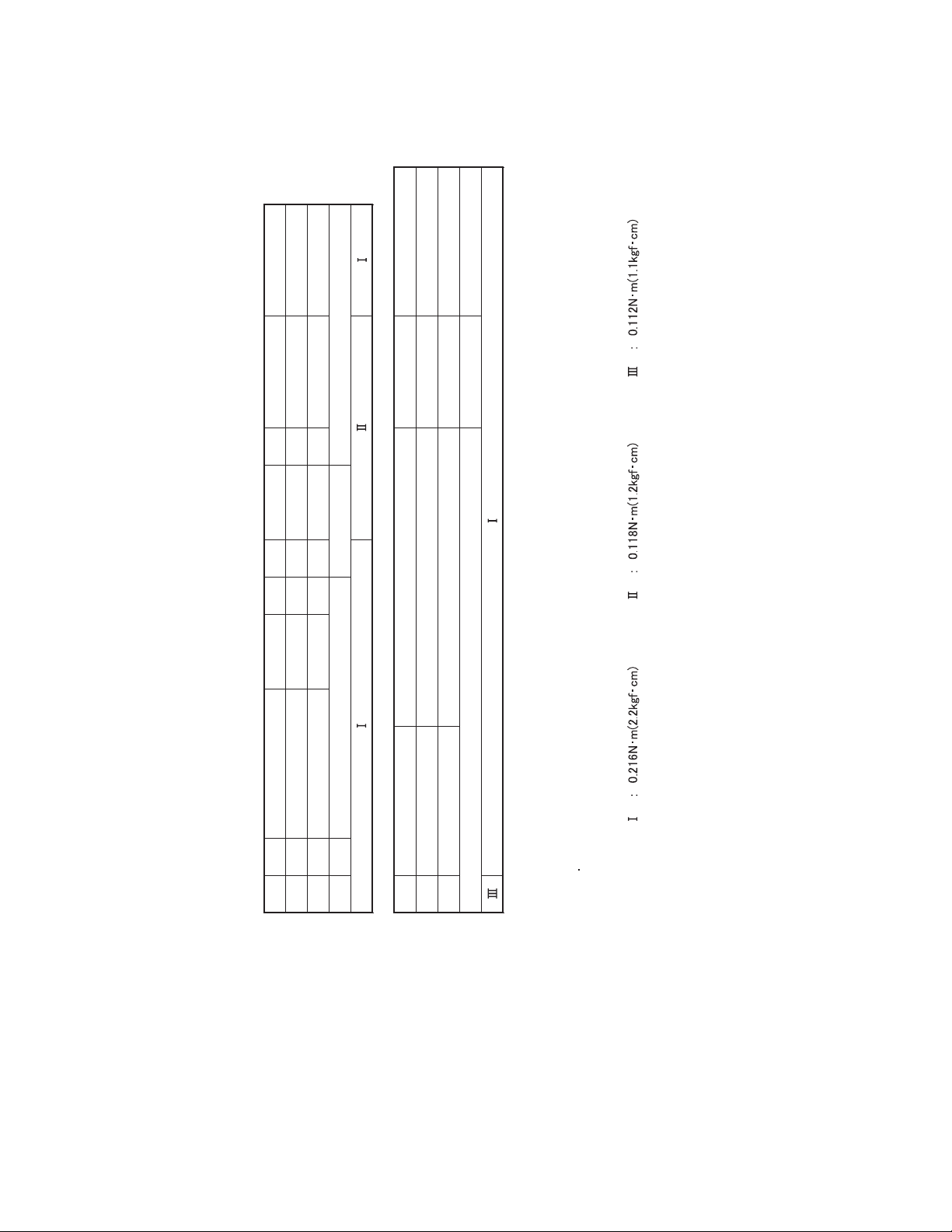

(1) When fastening parts, pay careful attention to the tighten-

ing torque of each screw. Unless otherwise specified, tighten a screw with the torque of 0.216 N•m (2.2 kgf•cm).

Torque setting value of torque driver is limited. At the values over the maximum torque setting value, fasten a screw

manually not to damage the screw thread.

(2) Be sure to disconnect the set from the power supply before

fastening and soldering parts.

(3) When disconnecting/connecting wires, be careful not to get

them and their connectors damaged.

(4) When replacing parts, be very careful neither to damage

other parts nor to fit wrong parts by mistake.

Example

STEP/LOC.

No.

[1]

[2]

[3]

ROLLER BASE ASSEMBLY T M1 (S1) –

TENSION ARM ASSEMBLY T M1 (P1), (W1a) –

REEL DISC (SUP) T M1 (W1a), (W1b) _

PART NAME

*1 *2 *3 *4 *5 *6

FIG.

REMOVAL INSTALLATION

ADJUSTMENT

POINT CONDITION

NOTE

2.2.2 How to read the disassembly and assembly

*1 Order of steps in Procedure

When reassembling, perform the step(s) in the reverse order. These numbers are also used as the identification (lo-

cation) No. of parts Figures.

*2 Part to Name be removed or installed.

*3 Location of part.

T = The Upper side

B = The Lower side

*4 Fig. No. showing Procedure or Part Location.

M = Mechanism

*5 Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

P= Spring

W= Washer

S= Screw

* = Unhook, unlock, release, unplug or unsolder.

Example

• Remove (W1)=Washer W1.

• Remove the solder at (SD1)=Point SD1.

• Disconnect A = Connector A.

*6 Adjustment information for installation.

(+) = Refer to Exploded Views for Lubrication information.

(No.86700)2-21

Page 24

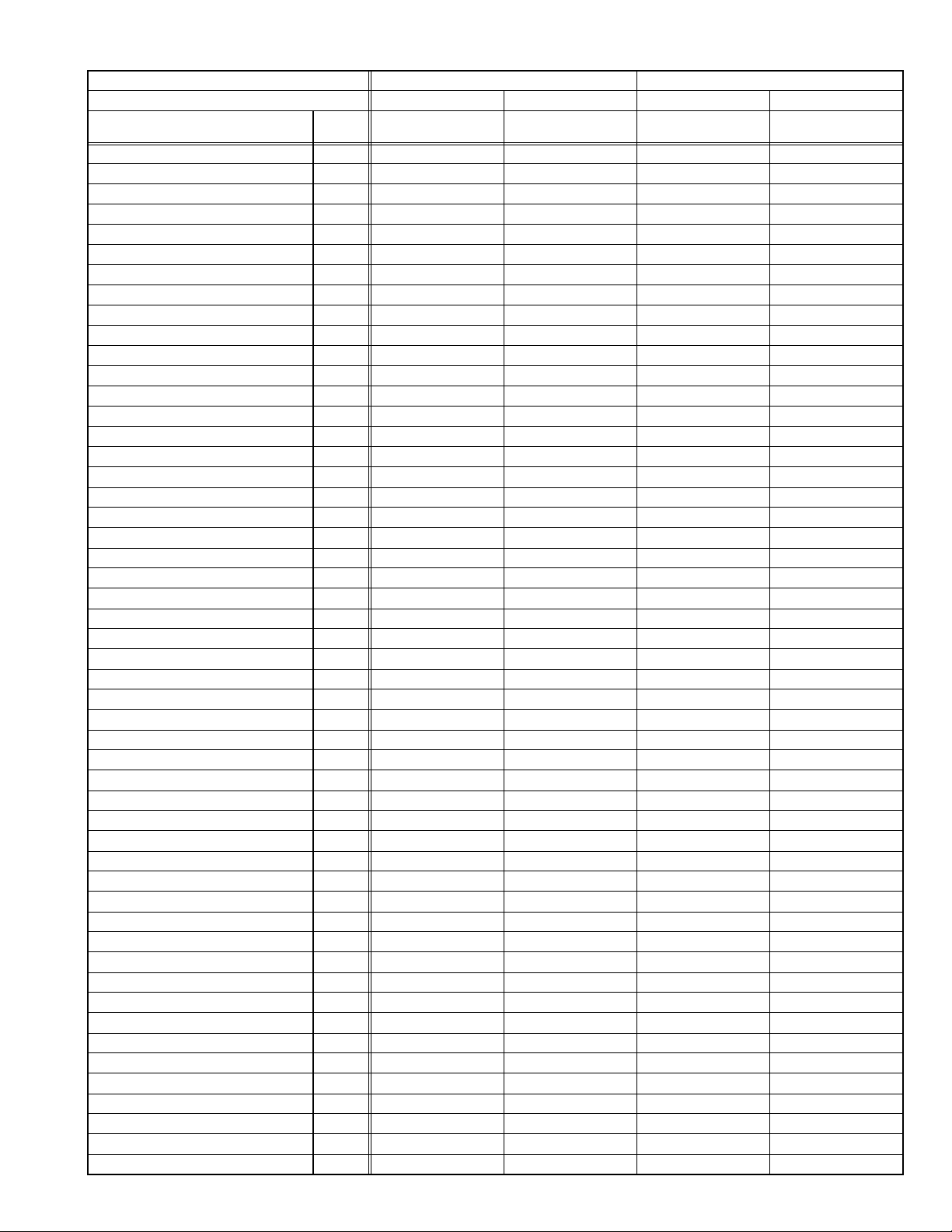

2.2.3 DISASSEMBLY/ASSEMBLY PROCEDRURE TABLE

This procedure starts with the condition that the cabinet parts and deck parts. Also, all the fo llowing procedures for adjustment and

parts replacement should be performed in STOP mode. When reassembling, perform the step(s) in the reverse order.

REMOVAL INSTALLATION

STEP/LOC.

No.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[23]

[24]

[25]

[26]

[27]

[28]

[29]

[30]

[31]

[32]

[33]

[34]

[35]

[36]

[37]

PART NAME

ROLLER BASE ASSY T M1 (1) –

TENSION ARM ASSY M1 (P1), (W1a) –

REEL DISC T M1 (W1a), (W1b) –

SLANT ARM ASSY M1 (W1a) –

CANCEL LEVER ASSY M2 (W2) –

EJECT LEVER ASSY M2 (W2) –

CASSETTE GUIDE (LEFT) M2 (2) –

SUPPLY CLUTCH ASSY M2 (W2) –

WHEEL GEAR T M2 (W2) See, Adjustment procedure for

ROTARY ENCODER

TIMING BELT B M3 – –

CENTER PULLEY UNIT T/B M3 2(S3a) –

CASSETTE GUIDE (R) ASSY T M3 (S3b), (P3) (Only use SVHS model)

TAKE UP GEAR T M3 (W3a) –

BRAKE SUB GEAR T M3 (W3a) –

PINCH ROLLER ARM ASSY

TAKE UP GUIDE ARM ASSY T M3 (W3a) –

LINK ARM ASSY T M4 (W4) –

LED GUIDE T M4 (S4a) –

A/C HEAD UNIT

SLANT POLE BASE ASSY T M5 (S5a) –

CAPSTAN MOTOR

MOTOR BASE M5 2(S5b), (S5c) –

BRUSH M6 (S6a) –

DRUM FINAL ASSY T/B M6

GUIDE RAIL M6 7(S6d)

POLE BASE (S)ASSY

POLE BASE (T)ASSY T M6

COVER PLATE T M7

DRIVE LEVER ASSY

MOTOR BRACKET ASSY

CONTROL CAM T M8 (W8a) See, Adjustment procedure for

LINK LEVER M8

MIDDLE GEAR M8 –

LOADING GEAR(T) ASSY T

LOADING GEAR(S) ASSY T M8 (W8b) –

LOADING RING ASSY T M8 4(S8) See, Adjustment procedure for

FIG.

T

T

T

T

T

T

B

M3 4(S3a)

M3 (W3b) –

T

M4 2(S4b) –

T

T

M5 3(S5a) –

T

B

T

M6 –

T

T

M7 –

T

M7 3(S7) –

T

T

M8 (W8b) See, Adjustment procedure for

POINT CONDITION

Section 2.2.5

The function of this part varies according

to the ASSY (VHS/SVHS) which this

part is rporated in.

2(S6b), 2(S6c) *

, 8(S6d)

–

–

–

–

CATCHER

(Refer to part list.)

Section 2.2.5

See, Adjustment procedure for

Section 2.2.5

Section 2.2.5

Section 2.2.5

ADJUSTMENT

NOTE

(Refer to fig. 2-2-6)

–

–

–

–

–

Fig.2-2-1

2-22 (No.86700)

Page 25

(S7)

[20]

11

21

(S5a)

34

(S7)

35

j

g

(W1a)

[2]

[31]

33

(S7)

h

x

[25]

y

(S6b)

22

(S6b)

14

(S5a)

15

(S5a)

13

(S5a)

[21]

16

(S5a)

12

(S5a)

[8]

(W2)

[9]

(P1)

(W2)

2

(S2a)

a

c

10

(S4a)

18

(S5b)

d

[19]

[12]

[22]

d

8

(S3a)

[11]

19

(S5c)

(W3a)

[17]

a

j

17

(S5b)

[28]

25

m

(S6d)

[23]

(W4)

[18]

AA

(S6d)

38

(S8)

31

[27]

(S6d)

26

n

28

(S6d)

[26]

36

(S8)

39

(S8)

m

32

27

(S6d)

30

(S6d)

37

(S8)

(S6d)

(S6d)

29

n

(W1a)

(W2)

[3]

[5]

[34]

[4]

(W8b)

[36]

(W1b)

[29]

(W8b)

[35]

(W8a)

b

(W1a)

[30]

[33]

[32]

1

(S1)

[1]

[7]

g

b

(W2)

[6]

[10]

23

(S6c)

3

(S3a)

4

(S3a)

5

(S3a)

6

(S3a)

x

(S6a)

[37]

h

y

[16]

[14]

c

(W3b)

7

(S3a)

(W3a)

(W3a)

9

(S3b)

24

(S6c)

[24]

20

[15]

(P3)

[13]

Fig.2-2-2

(No.86700)2-23

Page 26

<TOP VIEW>

[31]

[37]

[25]

[26]

<BOTTOM VIEW>

[1]

[29]

[28]

[27]

[4]

[36]

[2]

[5]

[9]

[3]

[34]

Fig.2-2-3

[20]

[21]

[19]

[22]

[23]

[17]

[16]

[14]

[15]

[18]

[12]

[13]

[33][32][6][8][30][35][7]

NOTE:

In removing the ROTARY ENCODER,

please remove the BRACKET(MECHA).

2-24 (No.86700)

BRACKET (MECHA)

[11]

NOTE:

When reinstalling the cassette housing to

pay careful attention to the switch

Fig.2-2-4

not to damage it.

[24]

[10]

the set,

Page 27

1

(S1)

[1]

(W1a)

[2]

(P1)

[4]

(W1a)

(W1a)

[3]

(W1b)

9

(S3b)

(P3)

[13]

[12]

7,8

(S3a)

[16]

(W3b)

[17]

(W3a)

(W3a)

[14]

(W3a)

[15]

[11]

(S2)

(W2)

[9]

2

[5]

(W2)

Fig.M1

[6]

(W2)

[7]

[8]

[18]

3

(S3a)

(S4a)

(W4)

10

4

(S3a)

5

(S3a)

Fig.M3

6

(S3a)

[19]

*

11

(S4b)

[10]

[20]

*

12

(S4b)

Fig.M2

* 0.118 N.m (1.2 kgf.cm)

Fig.M4

(No.86700)2-25

Page 28

[22]

**

14,15

(S5a)

*

13

(S5a)

[21]

*

16

(S5a)

[31]

33,34,35

(S7)

17,18

(S5b)

* 0.118 N.m (1.2 kgf.cm)

21,22

Catcher

(S6b)

[28]

[27]

25,26

(S6b)

32

(S6b)

NOTE:

Refer to part list.

31

(S6b)

Fig.M5

(S5c)

27,28,29

(S6b)

19

[25]

[23]

30

(S6b)

[36]

36,37

(S8)

[29]

(W8b)

[30]

Fig.M7

38,39

(S8)

[37]

(W8a)

[32]

* 0.112 N.m (1.1 kgf.cm)

2-26 (No.86700)

23

(S6c)

24

(S6c)

Fig.M6

[26]

[24]

*

20

(S6c)

(W8b)

Fig.M8

[35]

[33]

[34]

Page 29

2.2.4 CHECKUP AND ADJUSTMENT OF MECHANISM PHASE

NOTE:

Pay careful attention to the installing order and phase of mechanism parts of the loading system.

[37] LOADING RING ASSEMBLY

Align the two holes of the LOADING RING

[35] LOADING GEAR(T) ASSEMBLY

Align the hole of the LOADING GEAR

(T) ASSEMBLY to that of the MAIN

DECK hole.

[9] WEEL GEAR

Align one of the three holes of

WHEEL GEAR to MAIN DECK hole.

ASSEMBLY to those of MAIN DECK.

[33] LINK LEVER

Align the hole of the

LINK LEVER to MAIN

DECK hole.

[33] LINK LEVER/CONTROLL CAM

Align each one LINK LEVER

assembly hole and MAIN DECK hole

to the hole at the CONTROL CAM

position.

Align this part to each

“Triangle” mark.

MAIN DECK

Fig.2-2-5 Top of main deck

Align this part to each

“Triangle” mark.

REC SAFTY SW

S-CASS SW

CASS SW

Fig.2-2-6 Rotary encoder

(No.86700)2-27

Page 30

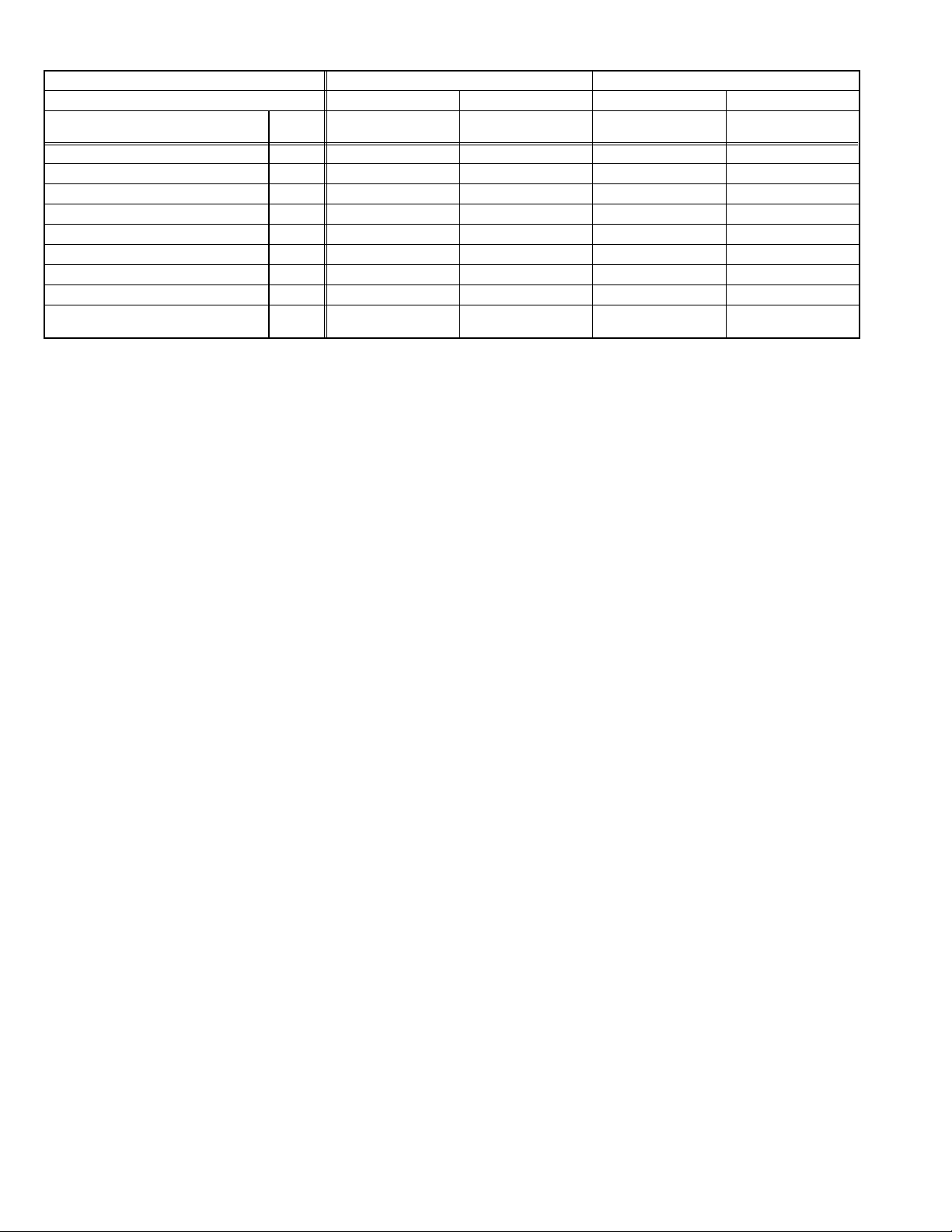

2.2.5 SERVISE NOTE

Use the following chart to manage screws.

M8

2-28 (No.86700)

[10] [12] [20]

Symbol No. [1] [7] [13] [19] [21] [22] [23]

Place to stick screw

Removing order of screw12345678910111213141516171819

Reference dra wing (Fig. No.) M1 M2 M3 M4 M5

Screw tightening torque

[25] [26] [37]

Symbol No. [24] [31]

Removing order of screw 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39

Fig.2-2-7

Place to stick screw

Reference drawing (Fig. No.) M6 M7

Screw tightening torque

Pay careful attention to tightening t or que for each screw.

Torque setting value of torque driver is limited. At the values over the maximum torque setting value, fasten a screw manually

not to damage the screw thread.

<NOTE>

Page 31

2.2.6 REMARKS

2.2.6.1 Cleaning

(1) For cleaning of the upper drum (particularly video heads),

use fine-woven cotton cloth with alcohol soaks through. Do

not move the cloth but turn the upper drum counterclockwise.

NOTE:

Make sure not to move the cloth in the vertical direction

to the video head, since it may cause damage of the video

heads.

(2) For cleaning of parts of the tape transport system except

the upper drum, use fine-woven cotton cloth or cotton swab

soaked alcohol.

(3) After cleaning, confirm that the cleaned parts are complete-

ly dry before loading the deck with cassette tape.

2.2.6.2 Applying oil and grease

(1) Periodical oiling and greasing are not required but should

be done to new parts when replacing. If oil and grease on

the other parts of the other party are old and dirty, wipe

them clean and apply new oil or grease.

(2) For parts and points to apply oil and grease, refer to the ex-

ploded view of the 3.2 VHS-C MECHANISM ASSEMBLY.

Fig.2-2-8 specifies oil and grease to be used.

(3) When oiling, clean the objective parts with alcohol first and

apply one or two drop(s) of oil. Too much oiling causes rotary parts to slip because of oil leakage.

Classification Part No. Symbol in drawing

Grease KYODO-SH-JB AA

Oil YTU94027 BB

specifies oil and grease to be used

Fig.2-2-8

(No.86700)2-29

Page 32

2.3 VHS MECHANISM

2.3.1 Notes

This model’s mechanism relates closely to the rotary encoder

and system control circuit (the rotary encoder is meshed with the

control cam).

The system control circuit detects the mechanism condition using the rotary encoder’s phase (internal switch phase). The refore, the parts such as the rotary encoder, control plate, loading

gear and control cam need to be installed correctly in order for

the mechanism to operate properly. (For the mechanism phase

adjustment, refer to the installation of each part.)

• Before using a soldering iron, be sure to disconnect the power

plug from the AC outlet.

• Do not touch any of the adjustment points until a defect position is specified.

• When plugging or unplugging the connector, be sure not to

damage the wire.

• Be sure the springs are hooked all the way around and in the

correct direction.

• When performing repairs, take care not to damage a catch,

etc.

OK NG

not hooked all the

()

way around

Fig.2-3-1

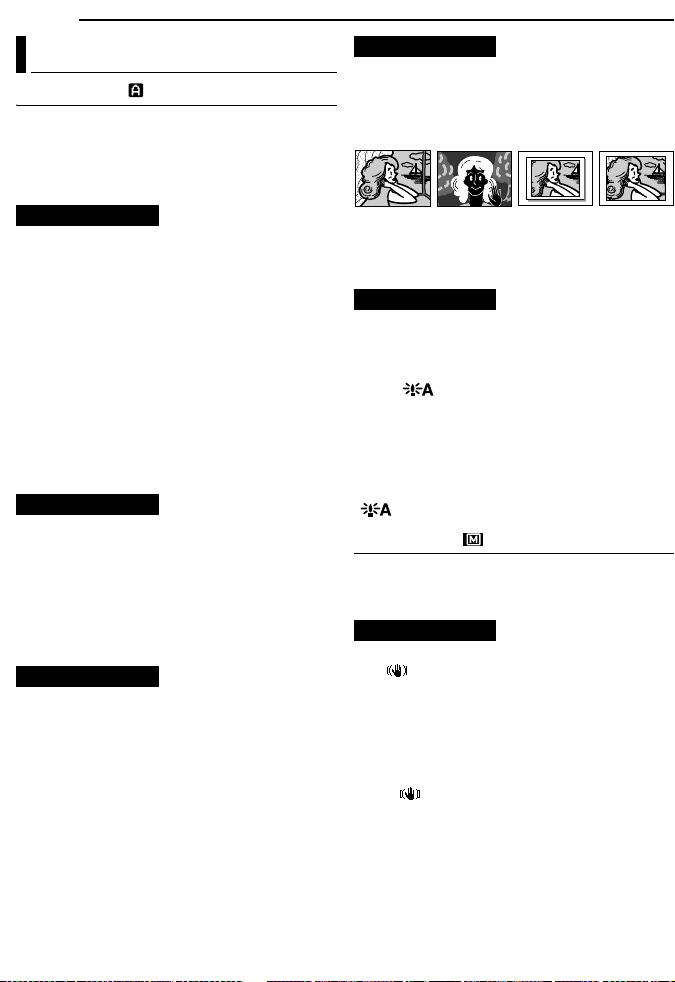

2.3.2 Mechanism operation check

When the mechanism is operated without a cassette loaded, operate the mechanism in the mechanism service mode.

2.3.3 Setting the mechanism assembling mode

The mechanism-assembling mode is provided with thi s mechanism. When disassembling and assembling, it is required to engage this mode.

Set the mode by adopting the following procedures.

(1) Remove the mechanism assembly using the disassem-

bling procedure.

(2) Turn gear (a) of the loading motor manually to set the

mechanism assembly to the eject end mode. Make sure

that the main deck is connected to the guide hole (a) of the

drive lever and the seal (a) of the main deck is connected

to the mark “E” of the control plate. This condition is called

the mechanism-assembling mode.

Seal (a)

"E" mark

CONTROL PLATE

Guide hole (a)

DRIVE LEVER

2-30 (No.86700)

LOADING MOTOR

Loading

Gear (a)

Unloading

Fig.2-3-2

Page 33

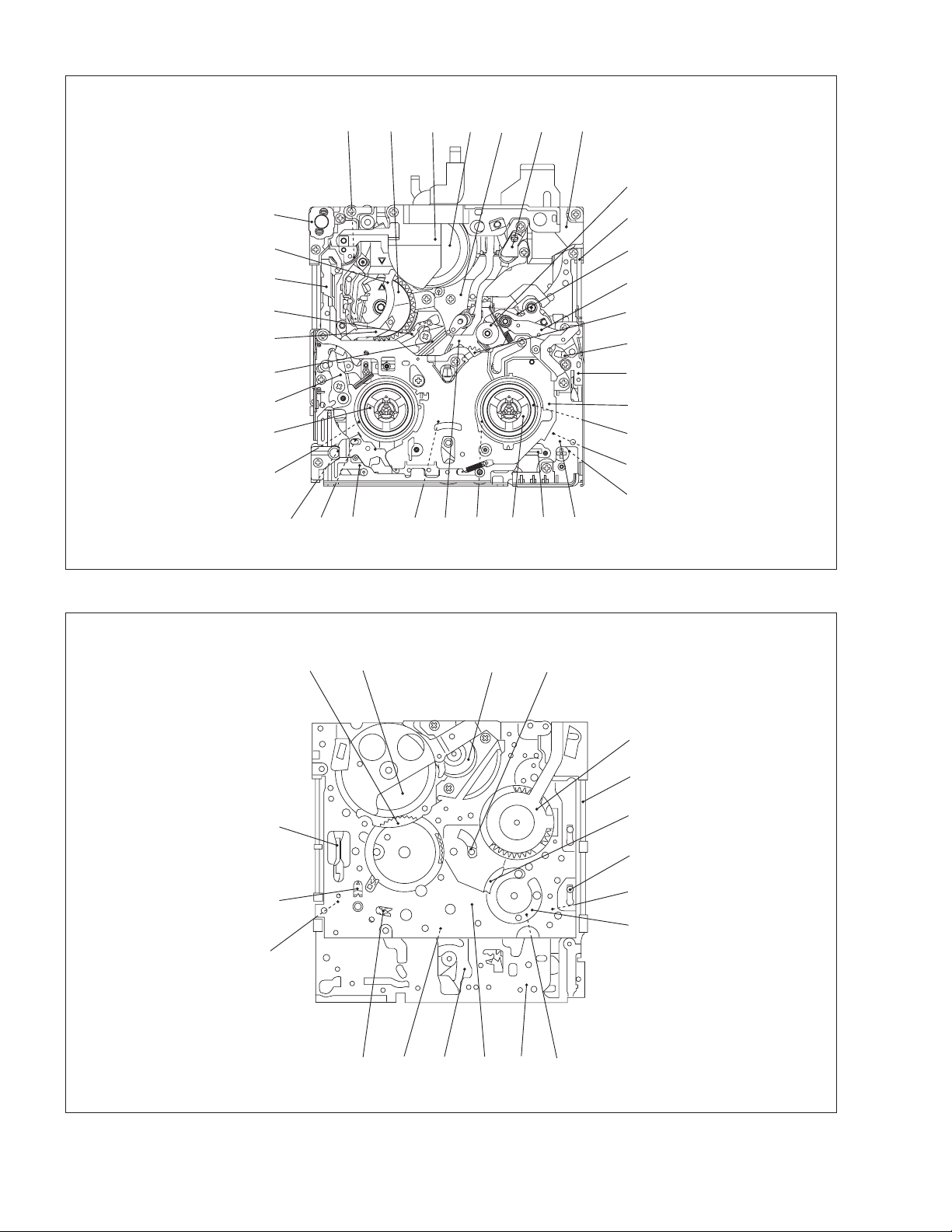

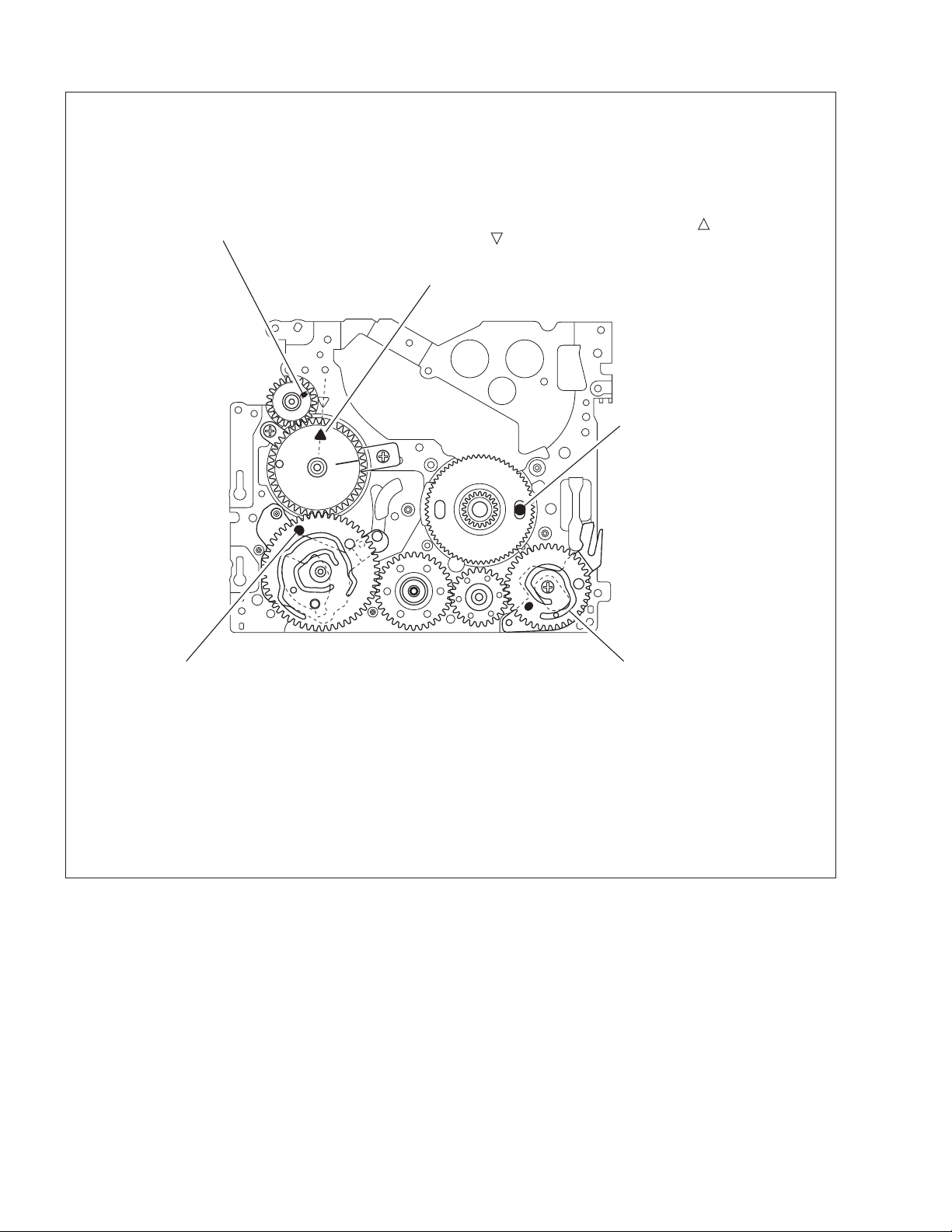

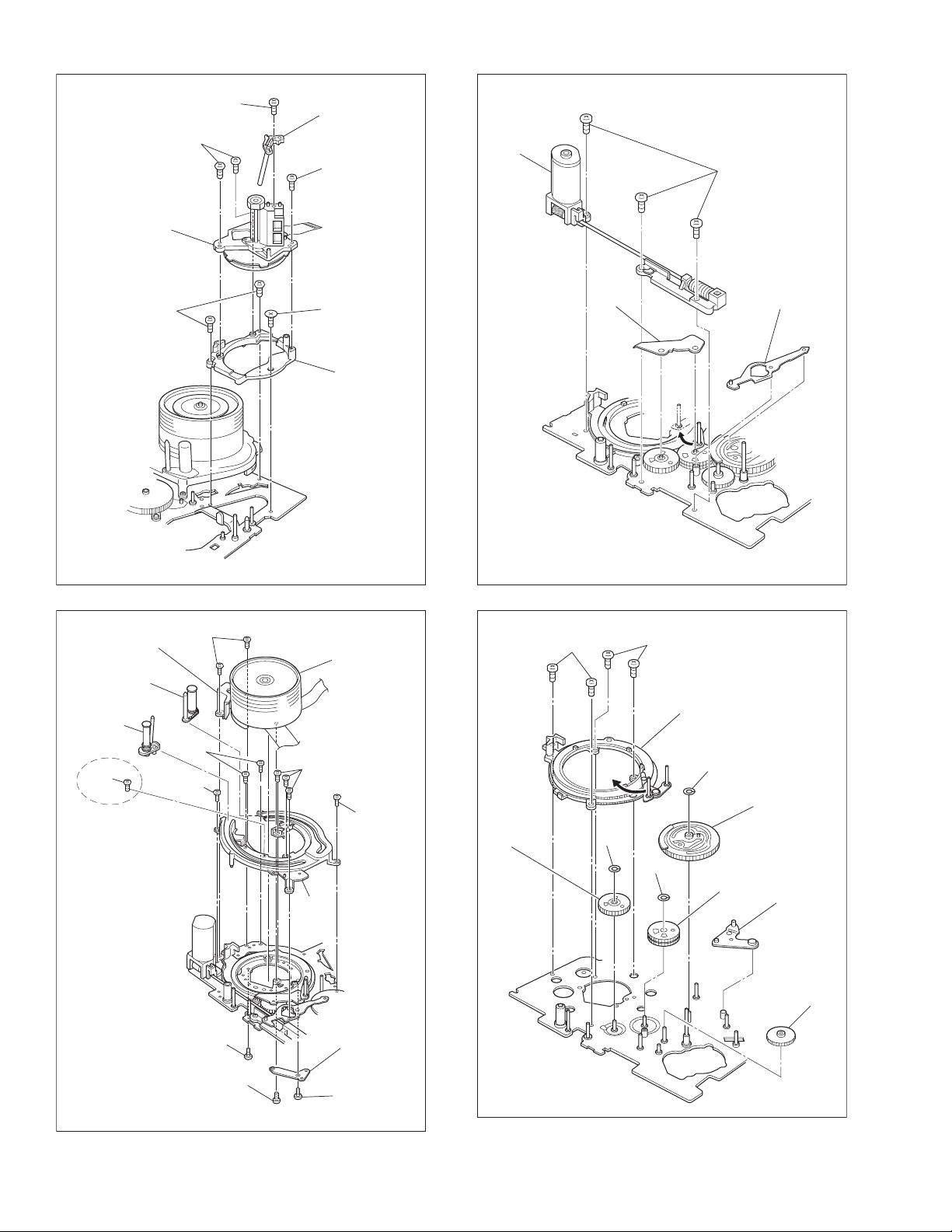

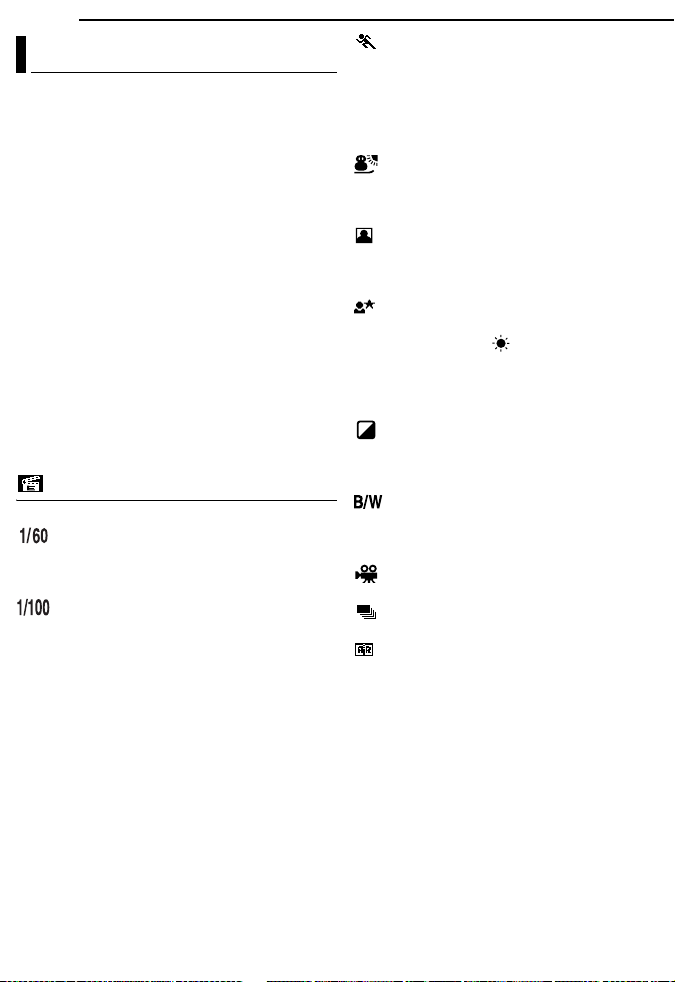

2.3.4 Layout of the main mechanism parts

Full erase head

Pole base assy

(supply side)

Tension arm assy

Tension arm base

Rec safety lever

T17

T1

T16

T15

T14

T2

Reel disk

(supply side)

Pole base assy

(take-up Side)

T13

Load gear assy

(take-up side)

T12

Idler arm

T3

Fig.2-3-3

B1

A/C head

B15

Direct gear

B2

Main brake assy

T4

(take-up side)

T11

Fixing plate

T10

Ider gear 1/2

Load gear assy

B3

(supply side)

T5

Pinch roller arm assy

T6

Lid guide

Guide arm assy

T7

T8

Brake lever

T9

Drive lever

Reel disk

(take-up side)

Side frame(L)

Capstan motor

Capstan brake

Press lever

Control cam

L2

B11

Belt

B14

B13

B12

B10

Loading motor assy

B9

B8

Clutch unit assy

Fig.2-3-4

B7

Change lever

B4

Load gear

B5

Control plate

B6

Tension arm lever

Side frame(R)

R1

Earth spring(1)

Fig.2-3-5 Fig.2-3-6

L1

(No.86700)2-31

Page 34

2.3.5 Disassembling procedure table

This table shows the order o f parts removal wh en replacing each part. For replacement, remove the parts in the order of 1 to 13 shown

in the table and install the parts in the reverse order.

The symbol number before each part name shows the number in the figure “Layout of the main mechanism parts”. T and B on the

right of each part name show the side from which the part should be removed (T: From the front of the mechanism, B: From the rear

of the mechanism, T/B: From both sides).

Symbols and numbers

Removal parts

(Reference items)

Symbols and numbers

Replacement parts

L1

2.1 T 1

Earth spring (1)

Top frame

-

2.1 T 2 1

-

2.1 Cassette holder T 3 1 2

L2

R1

T3

T17

T7

T6

T5

T12

T11

T4

T10

T16

T13

T15

T8

T14

B12

B11

B13

B9

B10

B14

B2

B4

B3

B1

T1

T2

B5

T9

B8

B15

B7

B6

Side frame (L)

2.1 T 3 1 2

-

2.1. Drive arm T 51234

Side frame (R)

2.1 T 3 1 2

A/C head

2.2 T 1

- FE head T/B 1

Guide arm assy

2.3 T 1

Lid guide

2.3 T 1

Pinch roller arm assy

2.3

2.4 T4123

Idler arm

Idler gear 1/2

2.4 T5123 4

Main brake assy (T)

2.5 T6123 45

2.5 Reel disk (T) T 7123 456

Tension arm

2.5 T6123 45

2.5 Reel disk (S) T 7123 45

Tension arm base

2.5 T7123 45

-

T-up head

-

-

T-up lever

Brake lever

2.5 T8123

Rec safety lever

2.5 T7123456

Press lever

2.6 B 1

2.6 Control cam B 2

2.6 Capstan brake assy B 3

2.6 Loading motor assy B 4

2.7 Belt B 1

2.7 Capstan motor T/B 2

Wire holder

-

- T/B 1

Fixing plate

2.7 B 1

2.7 Load gear B 2

2.7

Loading gear assy(S)

2.7

Loading gear assy(T)

Pole base assy(S)

-T/B4

Pole base assy(T)

-T/B5

-

- Load gear base B 5

2.7 Control plate B 6

- T/B10123456

Drive lever

2.8 B 2

Clutch unit

Direct gear

2.8 B 3

-T/B6 12

Change lever

- T/B14123 45

Tension arm lever

L1 - - L2 - R1 T6 T12 T11 T4 T10 T16 T15 B12B11B13 B9 B10 B2 B4 B3 B1 B5 B8 B15

Front(T)/Back(B) of mechanism

Number of removal steps

Earth spring (1)

Top frame

Cassette holder

Side frame (L)

Drive arm

Side frame (R)

Lid guide

Idler arm

Idler gear 1/2

Main brake (T)

Reel disk (T)

Tension arm

Tension arm base

Press lever

Control cam

Capstan brake assy

Loading motor assy

Belt

Fixing plate

Load gear

T2 1

6

6

T8123 45

T8123 45

456

67

67

7

1

12

123

1

1

B3

B4

12

123

123

1234

1234

12 345

78 9

1

1

3

6789 101112 13

Loading gear assy (S)

Loading gear assy (T)

Control plate

Clutch unit

Direct gear

2

4

5

2-32 (No.86700)

Page 35

2.3.6 REPLACEMENT OF THE MAIN MECHANISM PARTS

2.3.6.1 Cassette holder

2.3.6.1.1 Removal

(1) Remove the screws (a) and (b).

(2) Hold up the top frame, cassette holder assembly, drive arm

assembly and side frames (L/R) all together and remove

them by releasing the hooks (a) and (b).

Screw (a)

Screw (b)

2.3.6.1.3 Disassembling

(1) Release hook (a) to remove the earth spring (1) from the

top frame.

(2) Release the catches (a) and (b) and pull the top frame in

the direction shown by the arrow (a) to remove it.

(3) Pull out the side frame (R).

(4) Pull out the cassette holder assembly and drive arm as-

sembly from the side frame (L).

Hook (a)

Catch (a)

Catch (b)

Hook (a)

Hook (b)

Fig.2-3-7

2.3.6.1.2 Installation (phase adjustment)

(1) Turn gear (a) of the loading motor assembly so that the

main deck connects to the guide hole (a) of the drive lever.

(2) Hook the main deck to hooks (a) and (b).

(3) Place the projection of the drive lever to section (a) of the

side frame (R) and install the cassette holder to the main

deck. Make sure that the bosses of the side frame (L/R)

connect with the holes (a) and (b) of the main deck.

(4) Secure screws (a) and (b).

Screw (a)

Screw (b)

Hook (a)

Hook (b)

Hole

(a)

Section

(a)

Hole (b)

Guide hole (a)

DRIVE

LEVER

EARTH SPRING(1)

Arrow (a)

TOP FRAME

SIDE

FRAME(L)

CASSETTE HOLDER

Assembly

DRIVE ARM Assembly

SIDE FRAME(R)

Fig.2-3-9

2.3.6.1.4 Assembling (installation and phase adjustment)

(1) Turn gear (a) of the loading motor assembly so that the

main deck connects to the guide hole (a) of the drive lever.

(2) Place the projection of the drive lever on section (a) of the

side frame (R) and install the side frame (R) to the main

deck.

(3) Secure screw (b).

(4) Place section (b) of the drive arm on the gear of the side

frame (R). Make sure that the pin of the door opener con-

nects with section (c) of the drive arm.

(5) Place the drive arm on section (d) of the side frame (L) and

install the side frame (L) on the main deck. Be sure to con-

nect the earth spring (1) to the side frame (L).

(6) Secure screw (a).

(7) Turn gear (a) of the loading motor assembly until the drive

arm is vertical.

(8) Place the slit of the side frame (L/R) at the foot of the cas-

sette holder assembly and install the cassette holder.

(9) Place the top frame on the position guide (a) of the side

frame (L/R) and push it in the direction shown by the arrow

(a) for installation.

(10) Hook the earth spring (1) to the hook (a) of the top frame.

Fig.2-3-8

Gear (a)

(No.86700)2-33

Page 36

SIDE FRAME(R)

Screw (b)

2.3.6.2 A/C head

2.3.6.2.1 Removal

(1) Remove screws (a) and (b).

(2) Remove the A/C head together with the head base.

(3) Remove the screws (c), (d) and (e) to remove the spring (a)

and the A/C head from the Head base.

Section (a)

DRIVE LEVER

Cassette Holder Assembly

Screw (a)

Guide hole (a)

Gear (a)

Section (c)

Section

(b)

Screw (e)

Screw (c)

Spring (a)

Screw (a)

HEAD BASE

Screw (d)

A/C HEAD

Screw (b)

Fig.2-3-11

2.3.6.2.2 Installation (initial setting)

To install the A/C head to the head base, secure the screws in

the order of (c), (d) and (e). To make the adjustment easy, temporarily elevate the A/C head.

SIDE FRAME(R)

DRIVE ARM(L)

Section (d)

Hook (a)

EARTH SPRING(1)

SIDE FRAME(L)

TOP FRAME

Fig.2-3-10

DRIVE ARM(R)

Position guide (a)

Arrow (a)

(Temporary height)

11mm

A/C HEAD

HEAD BASE

Fig.2-3-12

2-34 (No.86700)

Page 37

2.3.6.3 Guide arm, pinch roller arm

2.3.6.3.1 Removal

(1) Remove the spring (a) from the hook (a) and detach the

guide arm assembly.

(2) Release the catch (a) to remove the lid guide.

(3) Remove the spring (b) from the hook (b) and detach the

pinch roller arm assembly.

2.3.6.4 Idler arm, idler gear 1/2

2.3.6.4.1 Removal

(1) Release the catches (a) and (b) to detach the idler arm.

(2) Detach the idler gear 1/2.

IDLER ARM

Catch (b)

Pinch roller arm assembly

Guide arm assembly Spring (a)

Catch (a)

Hook (a)

Spring (b)

PRESS

LEVER

Hook (b)

LID GUIDE

LID GUIDE

Catch

(a)

IDLER GEAR 1/2

IDLER ARM

IDLER GEAR 2

IDLER GEAR 1

Guide arm assembly

Fig.2-3-13

Pinch roller arm

assembly

PRESS

LEVER

Fig.2-3-14

2.3.6.5 Main brake (T), brake lever, tension arm,

reel disk (S/T), Rec safety lever

2.3.6.5.1 Removal

(1) Remove the spring (a). (Detach section (b) of the spring

(a).)

(2) Release the catch (a) to detach the main brake (T).

(3) Release the catch (b) to detach the reel disk (T) and the

spacer.

(4) Lift up and turn section (b) of the brake lever counterclock-

wise to remove the brake lever.

(5) Remove the spring (b) from the hook (a).

(6) Release the catch (c) to detach the tension arm.

(7) Release the catch (d) to detach the reel disk (S) and the

spacer.

(8) Remove the spring (c) from the hook (b).

(9) Turn the tension arm base in the direction shown by arrow

(a) to release catch (e). Place the projections of the tension

arm base to the holes (a) to detach the tension arm base.

(10) While releasing the catch (f), turn the Rec safety lever

counterclockwise to remove it.

(No.86700)2-35

Page 38

Tension arm assembly

Spring (b)

Catch (c)

Catch (d)

Main brake (T) assembly

Section (b)

Spring (a)

Spring (a)

BRAKE

LEVER

2.3.6.6 Press lever, control cam, capstan brake assembly,

loading motor assembly

2.3.6.6.1 Removal

(1) Remove the slit washer (a) to detach the press lever.

(2) Release the slit washer (b) to detach the control cam.

(3) Release the catch (b) to detach the capstan brake assem-

bly.

(4) Remove the solder (a).

(5) Remove the screw (a).

(6) Release the catches (c) and (d) to detach the loading motor

assembly.

Hook (a)

Tension arm base

assembly

REC SAFETY

LEVER

Tension arm base assembly

Arrow (a)

Hole (a)

Catch (e)

REEL DISK(S)

REEL DISK(T)

REEL DISK(S)

Hole (a)

Hook (b)

Catch (a)

Tension arm

assembly

Main brake (T)

assembly

SPACER

REEL DISK(T)

Catch (b)

BRAKE

LEVER

Catch (d)

Loading motor

assembly

Loading

motor

assembly

Screw (a)

CONTROL

CAM

Slit washer

(b)

Catch (c)

Screw (a)

Capstan

brake assembly

PRESS LEVER

Spring (c)

REC

SAFETY

LEVER

Catch (f)

2-36 (No.86700)

Fig.2-3-15

Capstan brake assembly

CONTROL CAM

Slit washer (b)

Catch (b)

Slit washer (a)

Solder (a)

Fig.2-3-16

Page 39

2.3.6.6.2 Installation (phase adjustment)

(1) Attach the loading motor assembly to the main deck.

(2) Secure the screw (a).

(3) Solder the wire to section (a).

(4) Arrange the wire along with the position guide (b).

(5) Attach the capstan brake assembly to the main deck.

(6) Place the main deck on the guide hole (a) of the control

plate.

(7) Place the main deck on the guide hole (b) of the drive lever.

(8) Place the main deck no guide hole (c) of the control cam to

install the control cam.

(9) Move the capstan brake in the direction shown by the ar-

row (a) to attach the press leve r to the shaft (a). Make sure

that the boss of the press lever fits in the control cam, and

that the shaft (b) of the pinch roller arm assembly connects

with the hole of the press lever.

(10) Attach slit washer (a) to shaft (a).

Position

guide (b)

DRIVE

LEVER

Guide hole (b)

Arrow (a)

Wire (black)Wire (red)

Section (a)

Capstan brake assembly

CONTROL

Shaft (a)

Guide hole (a)

PLATE

Screw (a)

CONTROL CAM

PRESS LEVER

Fig.2-3-17

Guide hole (c)

Loading motor assembly

Shaft (a)

Shaft (b)

Slit washer (a)

(No.86700)2-37

Page 40

Note:

• When replacing the worm bearing of the loading motor

assembly, attach it according to the following specification.

If worm bearing is not attached correctly, a mechanism

noise may occur. (See Fig. 2-3-18)

LOADING MOTOR

WORM BEARING

6.8 ± 0.2 mm

Fig.2-3-18

2.3.6.7 Capstan motor, load gear, control plate

2.3.6.7.1 Removal

(1) Detach the belt.

(2) Check that the FFC connector on the drum is disconnect-

ed.

(3) Release the catch (a) to remove the FFC wire.

(4) Remove the screws (a) to detach the capstan motor.

(5) Remove the screws (b) to detach the fixing plate.

(6) Release the catch (b) to detach the load gear.

(7) Turn the load gear (S/T) in the loading direction to detach it.

(8) Remove the control plate.

CONTROL

PLATE

Screws (a)

Load gear (T) assembly

Load gear (S) assembly

LOAD GEAR

FIXING PLATE

Capstan motor assembly

Screws (b)

Catch (b)

LOAD GEAR

BELT

Fig.2-3-19

Catch (a)

FFC

2-38 (No.86700)

Page 41

2.3.6.7.2 Installation (phase adjustment)

(1) Place the main deck on the guide hole (a) of the tension

arm lever.

(2) Place the main deck on the guide hole (b) of the brake le-

ver.

(3) Attach the control plate to align with the position guide (a).

(4) Place the hole (c) of the load arm (T) on the pole base (T)

and the load gear (T) on the load gear base.

(5) Place the hole (d) of the load arm (S) on the pole base (S)

and the load gear (S) on the load gear base. Be sure to

align the guide mark (e) of the load gear (T) to tha t of the

load gear (S).

(6) Turn the load gear (S/T) in the unloading direction to place

the main deck on the guide hole (f) of the load gear (T).

(7) Place the main deck on the guide hole (g) of the control

plate.

(8) Attach the load gear on the load gear base so that the con-

trol plate is placed on the edge (h) of the load gear.

(9) Place the fixing plate on the shaft of the load gear base and

secure the screws (b).

2.3.6.8 Clutch unit assembly, direct gear

2.3.6.8.1 Removal

(1) Remove the slit washer (a) to detach the clutch unit assem-

bly.

(2) Remove the spring (a) and the direct gear.

DIRECT GEAR

POLE

BASE(T)

Hole (c)

Load gear (T) assembly

Insertion direction

Guide hole (g)

Guide marks (e)

LOAD GEAR BASE

Load gear (T)

assembly

CONTROL PLATE

Guide hole (f)

(From the top)

Load gear (S) assembly

Edge (h)

Position guide (a)

POLE

BASE(S)

Hole (d)

Load gear (S)

assembly

Screws (b)

FIXING

PLATE

LOAD GEAR

Spring (a)

CLUTCH UNIT

Slit washer (a)

Fig.2-3-21

Guide hole (b)

BRAKE LEVER

Fig.2-3-20

Guide hole (a)

TENSION ARM LEVER

(No.86700)2-39

Page 42

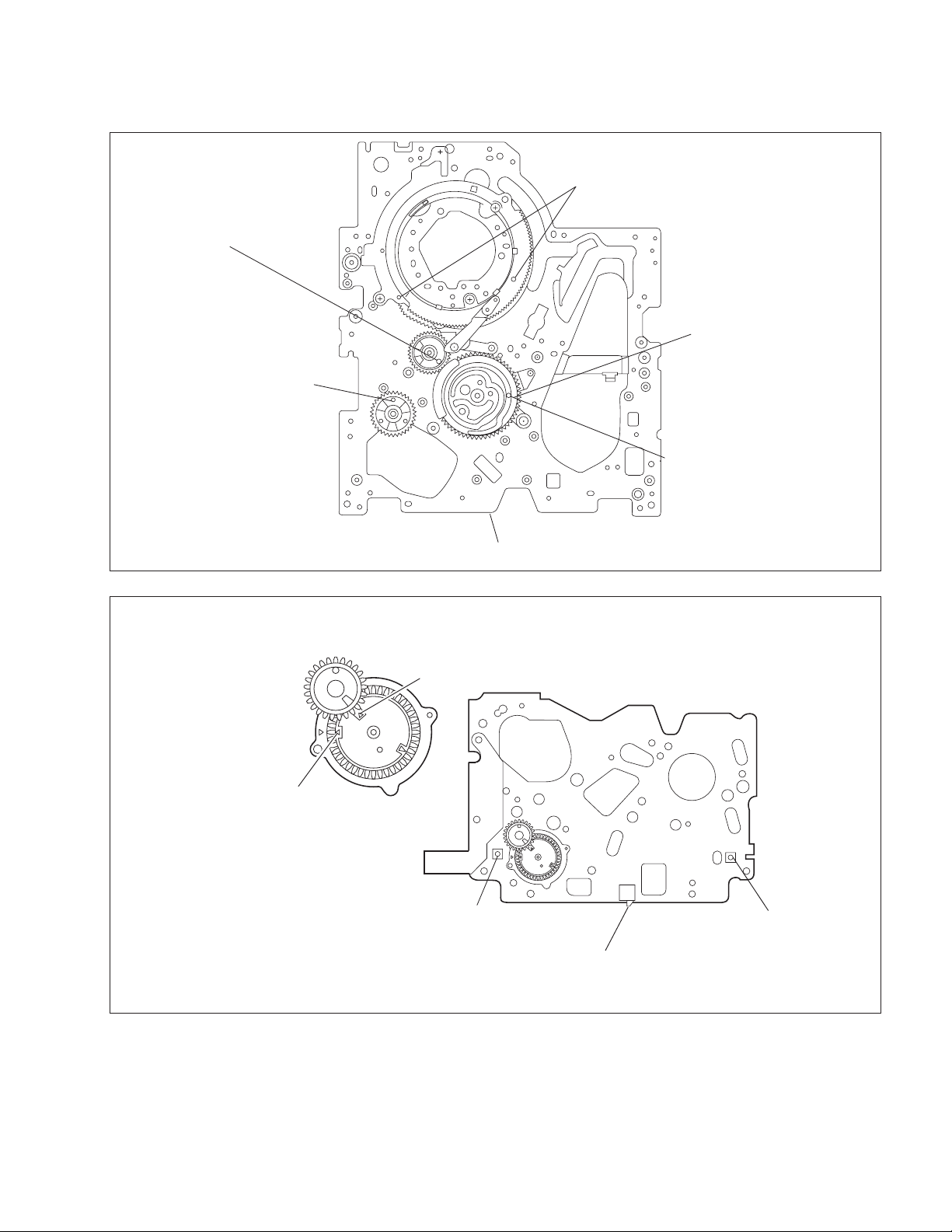

2.3.7 MECHANISM TIMING CHART

MECHANISM MODE

CONTROL PLATE

MARK

POLE BASE

REEL LOCK

TENSION ARM

TENSION

ARM LEVER

(STOP MODE PRESS UP)

ON

BRAKE

LEVER

ON

OFF

LOCK

FREE

ON

OFF

PLAY

STOP

FF/REW

REV

OFF

ON

OFF

REV

SERCH

/SLOW

/STILL

STOP

REEL

BRAKE

EJECT

PLAY

FOR

SLOW

/STILL

E P SL R ST B FR

FF

/REW

GUIDE ARM

PINCH

ROLLER

CONTACT

CAPSTAN BRAKE

TU LEVER

DIRECT GEAR

Movements of a

CONTROL PLATE

ON

OFF

ON

OFF

ON

OFF

OFF2

OFF1

ON

OFF

DIRECT

CLUTCH

(m/m)

0 5 15 20 25 30 35 40 45 50 5510

2-40 (No.86700)

Page 43

2.3.8 REMARKS

2.3.8.1 Cleaning

(1) For cleaning of the upper drum (particularly video heads),

use fine-woven cotton cloth with alcohol soaks through. Do

not move the cloth but turn the upper drum counterclock-

wise.

NOTE:

Make sure not to move the cloth in the vertical direction to

the video head, since it may cause damage of the video

heads.

(2) For cleaning of parts of the tape transport system except

the upper drum, use fine-woven cotton cloth or cotton swab

soaked alcohol.

(3) After cleaning, confirm that the cleaned parts are complete-

ly dry before loading the deck with cassette tape.

2.3.8.2 Applying oil and grease

(1) Periodical oiling and greasing are not required but should

be done to new parts when replacing. If oil and grease on

the other parts of the other party are old and dirty, wipe

them clean and apply new oil or grease.

(2) For parts and points to apply oil and grease, refer to the ex-

ploded view of the 3.3 VHS MECHANISM ASSEMBLY.

Fig.2-3-22 specifies oil and grease to be used.

(3) When oiling, clean the objective parts with alcohol first and

apply one or two drop(s) of oil. Too much oiling causes ro-

tary parts to slip because of oil leakage.

Classification Part No. Symbol in drawing

Grease

Oil

KYODO-SH-JB

COSMO-HV56

AA

BB

specifies oil and grease to be used

Fig.2-3-22

(No.86700)2-41

Page 44

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY CAMCORDER CATEGORY 12, 3-chome, Moriya-cho, kanagawa-ku, Yokohama, kanagawa-prefecture, 221-8528, Japan

(No.86700)

Printed in Japan

200304WPC

Page 45

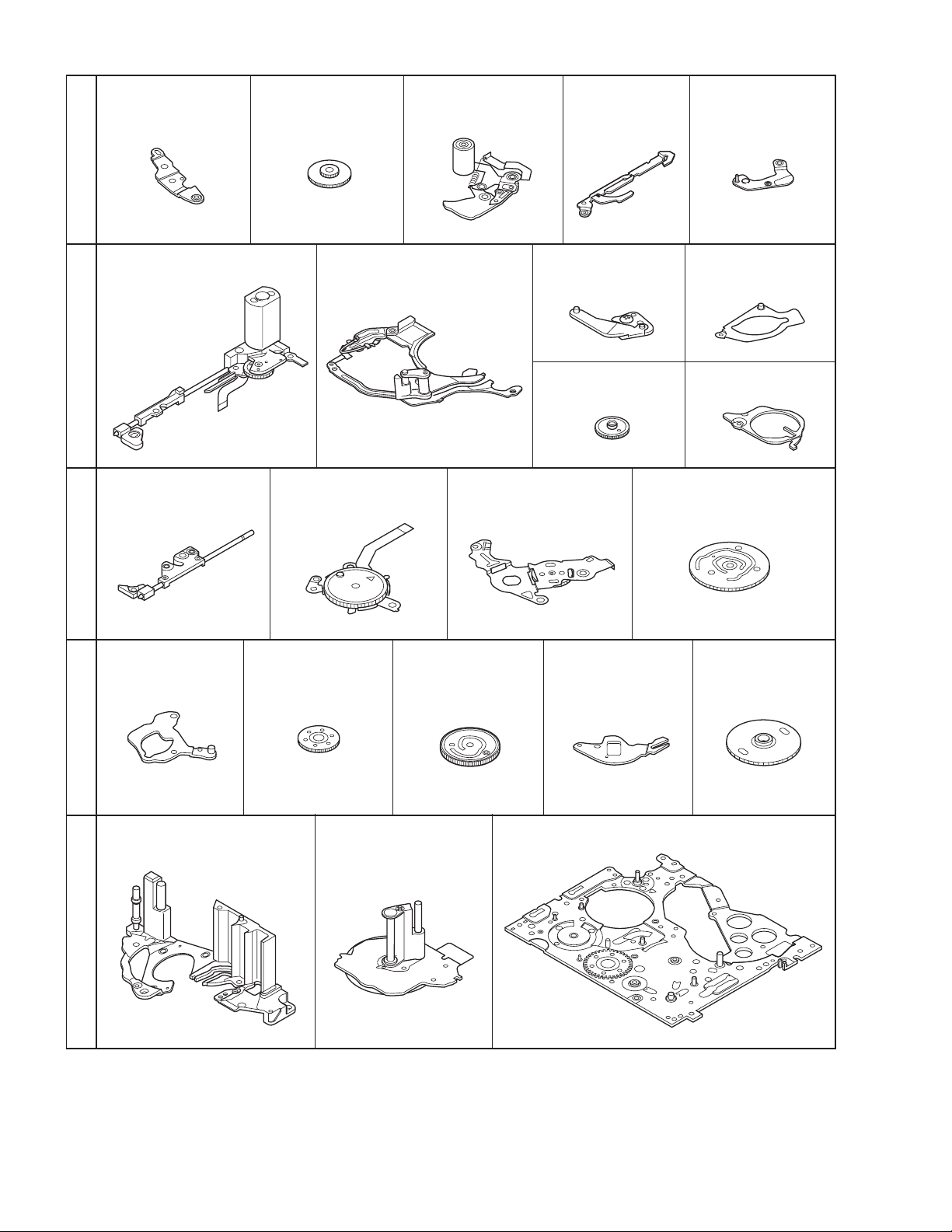

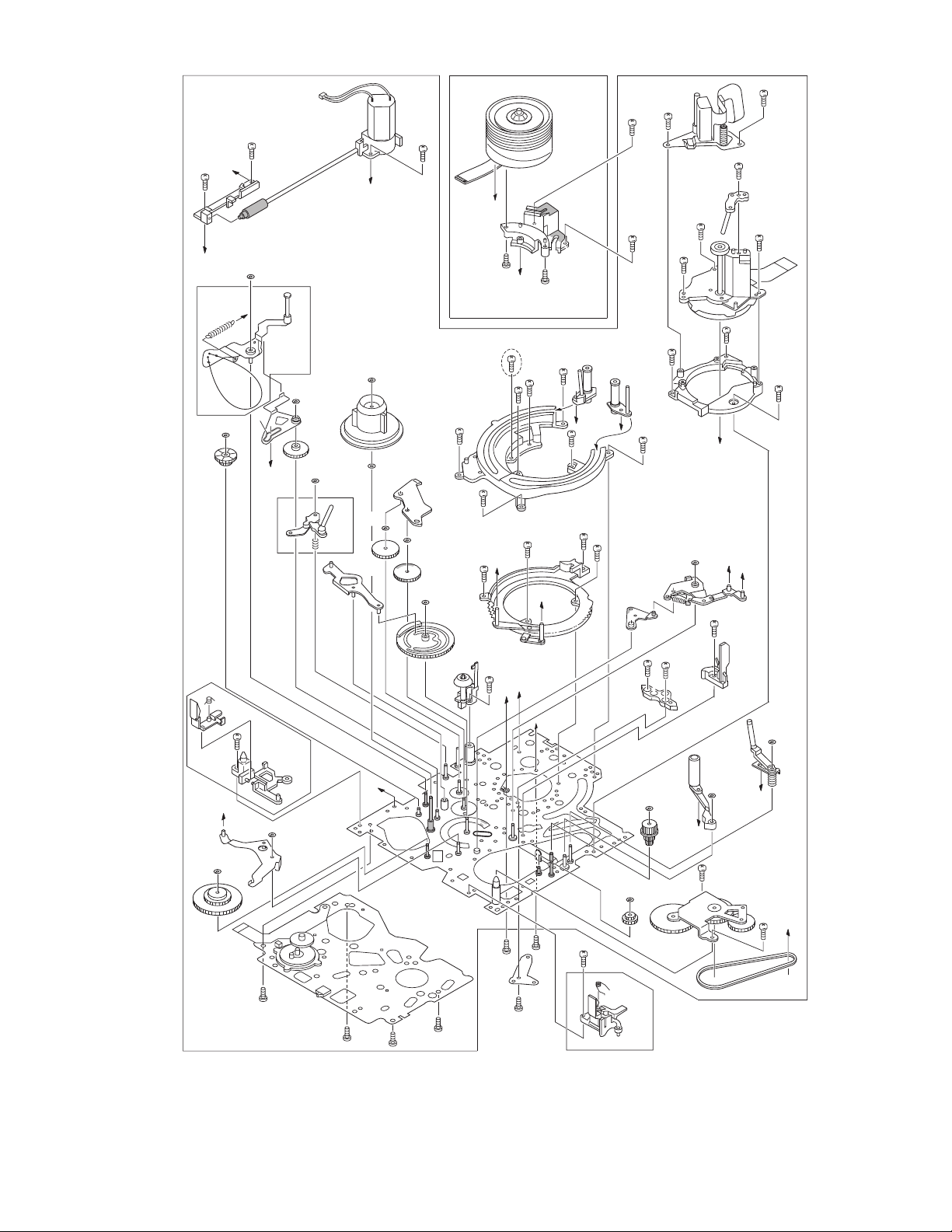

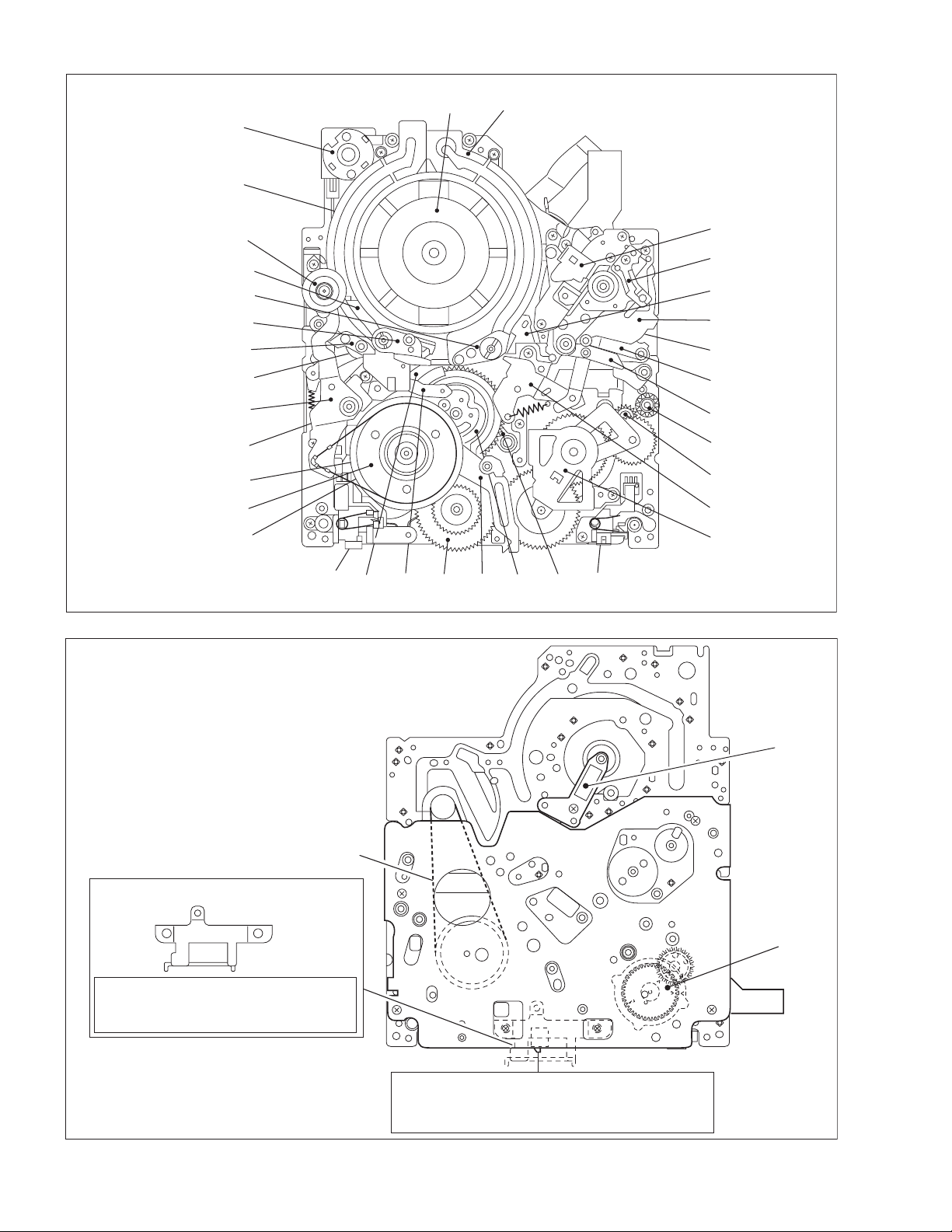

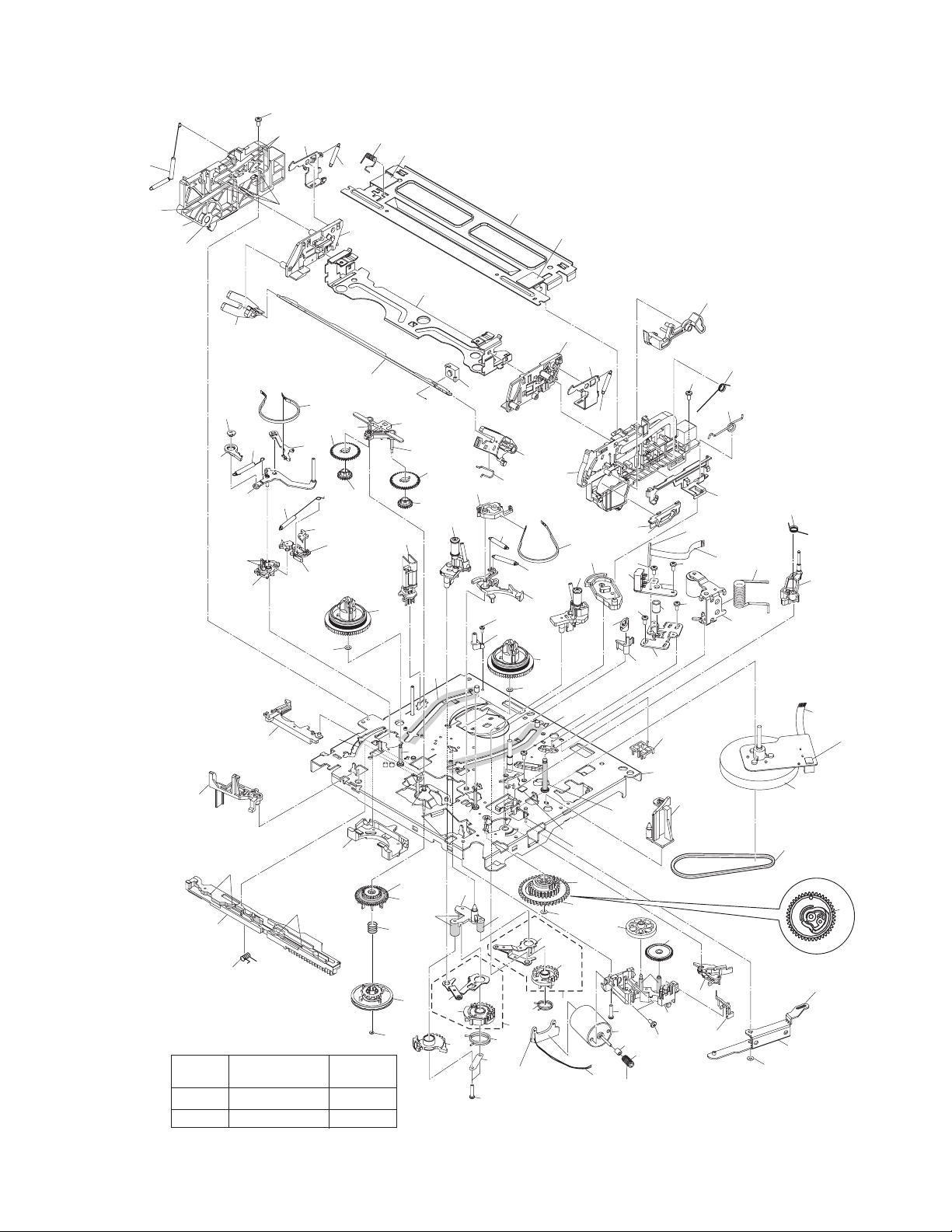

3.1 DVC MECHANISM ASSEMBLY

SECTION 3

PARTS LIST

400/900

900A

401/901

402/902

Classification Part No. Symbol in drawing

Grease KYODO-SH-JB AA

Oil YTU94027

Grease (HANARL)

NOTE1: The section marked in AA, BB and CC

indicate lubrication and greasing areas.

NOTE2: Mark

476/976

430/930

RX-410R CC

ޓis not contained in 900A.

436/936

479/979

437/937

453/953

AA

436B/936B

437/937

431/931

453/953

455/955

457/957

436B/936B

436A/936A

434/934

454/954

452/952

BB

425/925

424/924

428/928

437/937

AA

408/908

429/929

410/910

CC

AA

BB

449/949

435/935

413/913

422/922

440/940

CC

AA

414/914

AA

440/940

438/938

410/977

AA

409/909

478/978

CC

411/911

439/939

412/912

443/943

441/941

466/966

413/913

419/919

421/921

402/902

456/956

418/918

421/921

420/920

442/942

450/950

415/915

451/951

448/948

402/902

416/916

417/917

451/951

461/961

447/947

463/963

406/906

463/963

462/962

406/906

446/946

404/904

405/905

432/932

CC

407/907

445/945

403/903

465/965

433/933

464/964

459/959

460/960

463/963

CC

444/944

AA

458/958

Fig.3-1-1

(No.86700)3-1

Page 46

3.1.1 DVC MECHANISM ASSEMBLY PART LIST

• Since parts numbers described here are the numbers at the time of manualissue, they are subject to change without notice. Therefore, be sure to see a parts list in the service manual of each model as for parts numbers.

• To distinguish the mechanism assembly with the symbol number of 400-499 from the mechanism assembly with the symbol number

of 900-999, see the following procedures.

(1) See the numbers on the backside of the MAIN DECK ASSY.

For example, "29D******" is printed on the backside of the mechanism assembly with the symbol number of 900-999 (YMA0029D

in this example). See the first three characters and numbers from the left.

(2) See the color of the SLIT WASHER on the REEL DISK (TU).

A red slit washer is used (the same color as a slit washer of CASSETTE GUIDE (SUP)) in the mechanism assembly with the

symbol number of 400-499. A black slit washer is used in the mechanism assembly with the symbol number of 900-999.

However, the black slit washer may be changed into a red one for the purpose of parts unifi cation.

(3) See the color of the CASSETTE GUIDE(SUP).

Light-brown CASSETTE GUIDE(SUP) is used in the mechanism assembly with the symbol number of 400-499.

Black CASSETTE GUIDE(SUP) is used in the mechanism assembly with the symbol number of 900-999.

(4) See the shape of the LED PRISM. LED PRISM consists of only resin in the mechanism assembly with the symbol number of

400-499.

Upper part of the LED PRISM is covered with black metal in the mechanism assembly with the symbol number of 900-999.

< TOP VIEW > < BOTTOM VIEW >

MAIN DECK ASSY

(4) LED PRISM

(2) SLIT WASHER

(3) CASSETTE GUIDE (SUP)

Part Name

MECHA(A) ASSY 400 YMA0029C YMA0029M YMA0029L 900 YMA0029H YMA0029E

MECHA(A)ASSY - - - - 900A YMA0029D CASSETTE HOUSING ASSY 401 LY31543-002E* LY31543-002H ← 901 LY32870-001G* LY32870-001J

MINI SCREW,X3 402 YQ43893-8 ←←902 ←←

UPPER BASE ASSY 403 LY31542-001J ←←903 LYH30420-001A ←

MINI SCREW 404 YQ43893* QYSPSPU1425M ← 904 ←←

DRUM ASSY 405 ** ** ** 905 ** **

DAMP.SCREW ASSY,X2 406 LY42820-001A ←←906 ←←

DAMP.SCREW ASSY 407 LY42820-002A ←←907 ←←

REEL DISK ASSY (SUP) 408 LY31538-001B* LY31538-001F ← 908 ←←

REEL DISK ASSY (TU) 409 LY31538-002B* LY31538-002H LY31538-002G 909 LY31538-002H ←

SLIT WASHER,X2 or X1

REEL COVER ASSY 411 LY10217-001A* LY10217-001F ← 911 LY10372-001D ←

MINI SCREW 412 LY42120-001A* LY42120-002A ← 912 ←←

MINI SCREW,X2 413 LY41945-003A ←←913 ←←

SLIT WASHER 414 YQ44246 ←←914 ←←

TENSION ARM ASSY 415 LY42025-001C ←←915 LY43725-001D ←

SLANT POLE ARM ASSY 416 LY31535-001F ←←916 LYH40269-001A ←

TU ARM ASSY 417 LY42031-001G* LY42031-001K ← 917 LY43731-001F ←

SWING ARM ASSY 418 LY31531-001D ←←918 ←←

MINI SCREW 419 YQ43893 ←←919 ←←

SLIDE DECK FINAL ASSY 420 LY20530-003B* LY20530-003E ← 920 LYH30424-001A ←

Symbol

No.

410 YQ44246,(x2) ←,(x2) ←,(x2) 910 ←*,(x1) ←,(x2)

Part No. Part No. Part No.

Symbol

No.

(1) 29D

Part No. Patr No.

3-2 (No.86700)

Page 47

Part Name

MINI SCREW,X2 421 YQ43893 ←←921 ←←

MINI SCREW 422 LY43023-001A ←←922 ←←

PAD ARM ASSY 424 LY31533-001E ←←924 LYH30419-001A ←

SLIT WASHER 425 YQ44246 ←←925 ←←

TU BRAKE ASSY 428 LY42016-001B ←←928 LYH40270-001A ←

SLIT WASHER 429 YQ44246 ←←929 ←←

TENSION CONTROL LEVER ASSY 430 LY41959-001B ←←930 LY43684-001A ←

CENTER GEAR 431 LY31525-001B ←←931 LY32861-001A ←

PINCH ROLLER ARM FINAL ASSY 432 LY31516-001E ← LY31516-001F 932 ←←

SLIT WASHER 433 YQ44246 ←←933 ←←

TENSION CONTROL PLATE ASSY 434 LY41956-001C ←←934 LY43681-001A ←

BRAKE CONTROL LEVER ASSY 435 LY41962-001B* LY41962-001C ← 935 LY43687-001A ←

MOTOR BRACKET ASSY 436 LY20525-002C ←←936 LYH30421-001A ←

LOADING MOTOR 436A QAR0138-001 ←←936A ←←

TAPPING SCREW,x2 436B LY41940-001A ←←936B ←←

MINI SCREW,x3 437 YQ43893 ←←937 ←←

GUIDE RAIL ASSY 438 LY20528-001R* LY20528-001U ← 938 LYH30422-001A ←

MINI SCREW 439 YQ43893 ←←939 ←←

SLIT WASHER,X2 440 YQ44246 ←←940 ←←

SLIDE LEVER2 ASSY 441 LY31498-001C ← LY31498-001D 941 LY32843-001A ←

LOADING PLATE ASSY 442 LY41965-001A ←←942 LY43690-001A ←

SLIT WASHER 443 YQ44246 ←←943 ←←

EJECT LEVER 444 LY31522-001B ←←944 LY32858-001A ←

SLIT WASHER 445 YQ44246 ←←945 ←←

BASE R ASSY 446 LY41929-001E* LY41929-001F ← 946 LYH40271-001A ←

MINI SCREW 447 YQ43893 ←←947 ←←

MINI SCREW 448 LY41945-001B ←←948 ←←

MODE GEAR 449 LY41930-001A ←←949 LY43665-001A ←

ROTARY ENCODER 450 QSW0876-003 ←←950 ←←

MINI SCREW,X2 451 YQ43893 ←←951 ←←

GEAR COVER ASSY 452 LY31524-001A ←←952 LY32860-001A ←

MINI SCREW,X2 453 YQ43893 ←←953 ←←

MINI SCREW 454 YQ43893-4 ←←954 ←←

MAIN CAM ASSY 455 LY41948-001C ←←955 LY43676-001A ←

SLIDE ARM ASSY 456 LY41941-001B ←←956 ←←

CONNECT GEAR 2 457 LY41951-001B ←←957 LY43678-001A ←

SUB CAM ASSY 458 LY41954-001B ← LY41954-001E 958 ←←

MINI SCREW 459 LY42120-001A ←←959 ←←

CONTROL ARM ASSY 460 LY41952-001A ←←960 LY43692-001A ←

REEL GEAR 1 461 LY31523-001B ←←961 LY32859-001A ←

DRUM BASE ASSY 462 LY31508-002A* LY31508-002B LY33372-001A 962 LY31508-002B ←

SCREW,X3 463 QYSPSPU1425M ←←963 ←←

CAPSTAN MOTOR 464 QAR0142-001 ←←964 ←←

MINI SCREW 465 YQ43893 ←←965 ←←

MAIN DECK ASSY 466 LY10210-001D* LY10210-001G ← 966 LY10367-001D* LY10367-001E

SLIT WASHER 476 YQ44246 ←←976 ←←

SLIT WASHER 477 - - - 977 YQ44246-6 WASHER 478 - - - 978 LY42047-005A ←

SPACER 479 -* LY43987-001B ← 979 ←←

NOTE:

MARK ← is same as left.

MARK - is not used.

MARK * reference model was also changed.

MARK ** shows different parts number, depending on models.

Symbol

No.

Part No. Part No. Part No.

Symbol

No.

Part No. Patr No.

(No.86700)3-3

Page 48

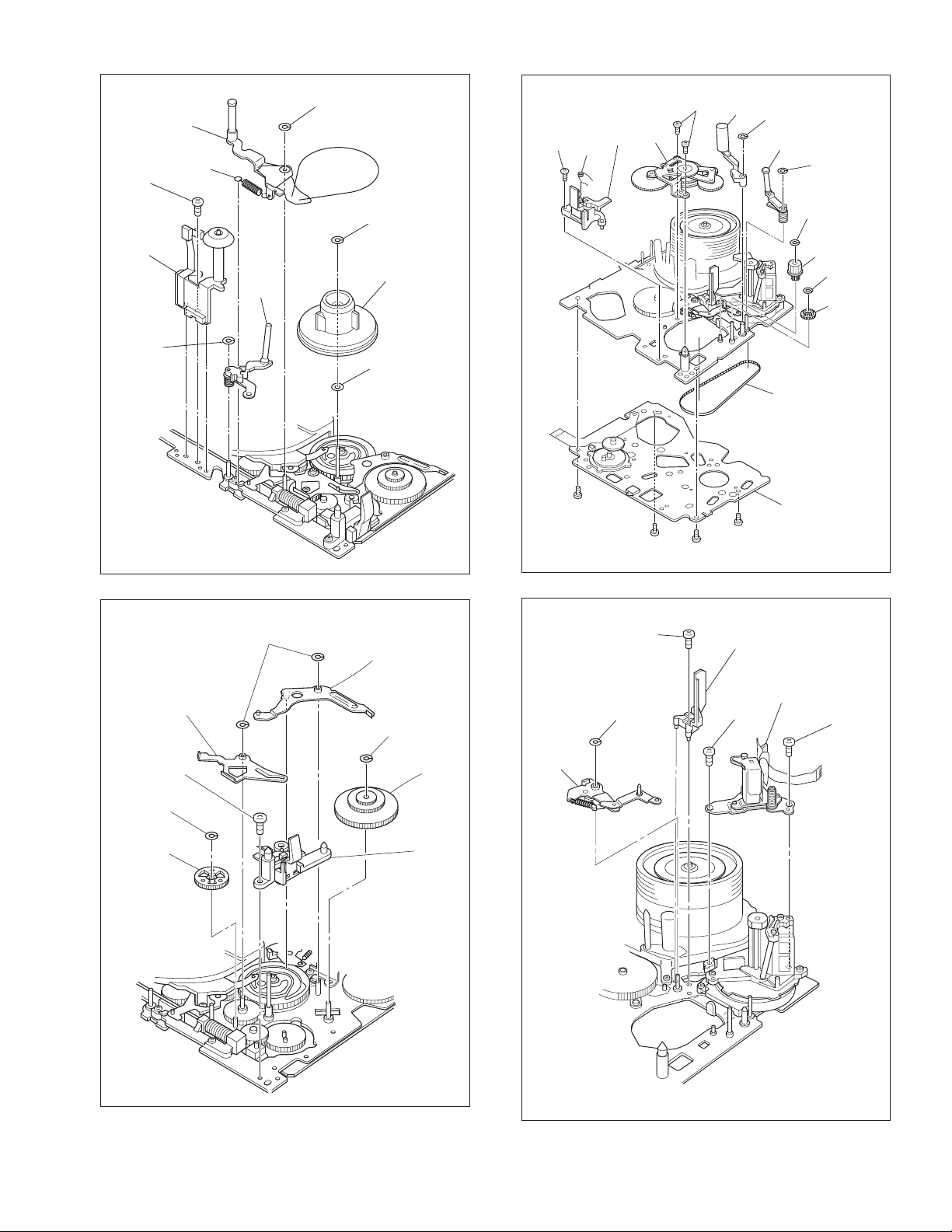

3.2 VHS-C MECHANISM ASSEMBLY

411

451

410

g

439A

404

452

405

414

400

408

410

j

409

AA

440

j

439

402

414

413

412

b

430

429A

461

460

AA

403

b

467

428

467

429

h

457

420

419

410

453

454

BB

g

466

467

418

421

417

BB

AA

416

415

467

425

425

423

431

AA

AA

469B

432

471

AA

x

425

n

425

423

x

469

h

433

a

463

436

435

459

447

446

445

444

442

443

c

d

462

438

437

d

449

450

a

448

458

459

470

AA

469A

470

AA

469B

y

426

425

425

AA

423

m

422

y

471

472

473

425

424

BB

407

427

n

m

425

423

AA

468

465

464

401

457

456

406

406B

406A

442

457

455

445

445

441

434

465

c

450

Classification Part No. Symbol in drawing

Grease KYODO-SH-JB AA

Oil YTU94027 BB

3-4 (No.86700)

NOTE:The section marked in AA and BB indicate

lubrication and greasing areas.

Fig.3-2-1

Page 49

3.2.1 VHS-C MECHANISM ASSEMBLY PARTS LIST

• Since parts numbers described here are the numbers at the time of manualissue, they are subject to change without notice. Therefore, be sure to see a parts list in the service manual of each model as for parts numbers.

Part Name

MECHA(B) ASSY 400 YMA0033A-E YMA0042A-E YMA0034A-E YMA0036A-E YMA0040A-E

MAIN DECK ASSY 401 LY20612-001B ←←←←

CASSETTE GUIDE (LEFT) 402 LY31817-001A ←←←←

SW LEVER (LEFT) 403 LY31815-001A ←←←←

TORSION SPRING 404 LY42581-001A ←←←←

SCREW 405 LY42722-001A ←←←←

CASSETTE GUIDE ASSY(RIGHT) 406 - - YQ44339A-7 ←←

SW.LEVER(RIGHT) 406A - - YQ32162-1-3 ←←

TORSION SPRING 406B - - YQ44340-1-4 ←←

SCREW 407 - - LY42819-001A ←←

MOTOR BRACKET ASSY 408 LY31826-001A ←←←←

WORM BRACKET 409 YQ20793 LY20951-001A YQ20793 ← LY20951-001A

SCREW,X3 410 LY42722-001A ←←←←

WHEEL GEAR 411 LY31925-001A ←←←←

MIDDLE GEAR 412 LY42730-001A ←←←←

CANCEL LEVER ASSY 413 LY42521-001A ←←←←

SLIT WASHER,X2 414 LY42754-003A ←←←←

CONTROL CAM 415 YQ20827-2-1 ←←←←

SLIT WASHER 416 PQM30017-25 ←←←←

LOADING GEAR(T)ASSY 417 LY42733-001A ←←←←

SLIT WASHER 418 LY42754-003A ←←←←

LOADING GEAR(S)ASSY 419 LY42732-001A ←←←←

SLIT WASHER 420 LY42754-003A ←←←←

COVER PLATE 421 LY42403-001A ←←←←

LOADING RING ASSY 422 LY42452-001A ←←←←

SCREW,X4 423 LY42728-001A ←←←←

GUIDE RAIL 424 LY10239-001A ←←←←

SCREW,X8 or X7 425 LY42728-001A,(X8) ←,(X7) ←,(X8) ←,(X8) ←,(X7)

POLE BASE(S)ASSY 426 LY30161-001B ←←←←

POLE BASE(T)ASSY 427 LY30162-002A ←←←←

DRIVE LEVER ASSY 428 LY42523-001A ←←←←

SLANT ARM ASSY 429 LY42545-001B LY44000-001B LY42545-001B ← LY44000-001B

TORSION SPRING(S) 429A LY42547-001A LY43992-001A LY42547-001A ← LY43992-001A

SLIT WASHER 430 LY42754-003A ←←←←

ROLLER BASE ASSY 431 LY42739-003A ←←←←

SCREW 432 LY42722-001A ←←←←

LINK ARM ASSY 433 LY42494-001A ←←←←

SLIT WASHER 434 PQM30017-25 ←←←←

PINCH ROLLER ARM ASSY 435 LY40018-002A ←←LY40018-005A ←

SLIT WASHER 436 PQM30017-25 ←←←←

TAKE UP GUIDE ARM ASSY 437 LY42541-001B ←←←←

SLIT WASHER 438 LY42754-003A ←←←←

TENSION ARM ASSY 439 LY42571-001A ←←←←

TENSION SPRING 439A LY42669-001A ←←←←

SLIT WASHER 440 LY42754-003A ←←←←

MOTOR BASE 441 YQ20797-1-5 ←←←←

SCREW,X2 442 LY42722-001A ←←←←

SCREW 443 YQ44460 ←←←←

CAPSTAN MOTOR 444 QAR0212-001 QAR0212-002 QAR0212-001 QAR0212-002 ←

TAPPING SCREW,X3 445 YQ44304 ←←←←

SLANT POLE BASE ASSY 446 LY42731-001A ←←←←

TAPPING SCREW 447 YQ44304 ←←←←

TIMING BELT 448 YQ43710-2 ←←←←

CENTER PULLEY UNIT 449 LY42678-001A ←←←LY42678-003A

Symbol

No.

Part No. Part No. Part No. Part No. Part No.

(No.86700)3-5

Page 50

Part Name

SCREW,X2 450 LY42722-002A ←←←←

SUPPLY CLUTCH ASSY 451 LY42670-001A ←←←←

SLIT WASHER 452 LY42754-003A ←←←←