Page 1

SERVICE MANUAL

TV/DVD COMBO

AV-20FD23

AV-20FD23

TV

CATV

POWER

SUBTITLE

DVD

CONTROL

REPEATA-B

ZOOM

TITLE

RETURN

PLAY MODE

SLOW

AUDIO

ANGLE

123

CANCEL

456

DISPLAY

789

TV RETURN

C.C.

0

SLEEP TIMER

INPUT

AUDIO

LIGHT

RM-C394G

SELECT

MUTING

/ENTER

+

CH

VOL

VOL

+

CH

DVD SETUP

TV MENU

TV/DVD

DVD MENU

PREV NEXT

B.SEARCH

PLAY

F.SEARCH

OPEN/CLOSE

STOP

PAUSE/STILL

TV / DVD

CONTENTS

a SPECIFICATIONS ....................................................................................................................................2

¤ OPERATING INSTRUCTIONS (APPENDED)

a SAFETY PRECAUTIONS ........................................................................................................................3

a SPECIFIC SERVICE INSTRUCTIONS ....................................................................................................8

a SERVICE ADJUSTMENTS ....................................................................................................................16

a GUIDE FOR REPAIRING .......................................................................................................................22

¤ STANDARD CIRCUIT DIAGRAM ........................................................................................................ 2-1

a PARTS LIST ...........................................................................................................................................33

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

No. 52014

May 2002

Page 2

AV-20FD23

SPECIFICATIONS

TELEVISION

Picture Tube: 20” (measured diagonally)

Tuner Type: Quartz PLL Frequency Synthesized

Receiving Channels: VHF 2-13

UHF 14-69

CATV 14-36 (A)-(W)

37-59 (AA)-(WW)

60-85 (AAA)-(ZZZ)

86-94 (86)-(94)

95-99 (A-5)-(A-1)

100-125 (100)-(125)

01 (5A)

Antenna Input: VHF/UHF In 75 ohms coaxial

Speaker: 3”, 8 ohms x 2

Audio Output Power: 2.5 + 2.5 W

DVD/CD player

Signal system: NTSC

Applicable disc: 1. DVD (12cm, 8cm)

2. CD (12cm, 8cm)

Audio characteristics: DVD: 4Hz - 22KHz

Frequency response: CD: 4Hz - 20KHz

S/N Ratio: 90dB

Harmonic distortion: 0.06%

Wow and flutter: Below Measurable Level

Dynamic range: 96dB

Input/Output: Inputs : Video : (RCA) 1 Vp-p/75ohm

Audio : (RCA) –8 dB/50Kohm

Outputs : Video : (RCA) 1 Vp-p/75ohm

Audio : (RCA) –8 dB/1Kohm

GENERAL

Power Source: AC 120V 60Hz

Power Consumption: 110 Watts

Dimensions: W 22-5/8” x D 19-1/8” x H 20-3/8”

Weight: 56.1 Ibs/25.5 kg

Inputs: Video: In (RCA) 1Vp-p 75 ohm

Audio: In (RCA) -8 dB/50K ohm

Headphone Jack: 3.5mm mini-jack

Storage Temperature -20 °C ~ 60 °C

Operating Temperature 5 °C ~ 40 °C

Accessories:

Remote Control X 1

Batteries (AA) X 2

Design & specification are subject to change without notice.

2 No. 52014

Page 3

SAFETY PRECAUTIONS

SERVICING NOTICES ON CHECKING

As for the places which need special attentions,

they are indicated with the labels or seals on the

cabinet, chassis and parts. Make sure to keep the

indications and notices in the operation manual.

2. AVOID AN ELECTRIC SHOCK

There is a high voltage part inside. Avoid an

electric shock while the electric current is

flowing.

3. USE THE DESIGNATED PARTS

The parts in this equipment have the specific

characters of incombustibility and withstand

voltage for safety. Therefore, the part which is

replaced should be used the part which has

the same character.

Especially as to the important parts for safety

which is indicated in the circuit diagram or the

table of parts as a mark, the designated

parts must be used.

4. PUT PARTS AND WIRES IN THE

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

5. TAKE CARE TO DEAL WITH THE

CATHODE-RAY TUBE

In the condition that an explosion-proof cathoderay tube is set in this equipment, safety is

secured against implosion. However, when

removing it or serving from backward, it is

dangerous to give a shock. Take enough care to

deal with it.

6. AVOID AN X-RAY1. KEEP THE NOTICES

Safety is secured against an X-ray by considering about the cathode-ray tube and the high

voltage peripheral circuit, etc.

Therefore, when repairing the high voltage peripheral circuit, use the designated parts and

make sure not modify the circuit.

Repairing except indicates causes rising of high

voltage, and it emits an X-ray from the cathoderay tube.

PERFORM A SAFETY CHECK AFTER

7.

SERVICING

Confirm that the screws, parts and wiring which

were removed in order to service are put in the

original positions, or whether there are the

portions which are deteriorated around the

serviced places serviced or not. Check the

insulation between the antenna terminal or

external metal and the AC cord plug blades.

And be sure the safety of that.

(INSULATION CHECK PROCEDURE)

1.

Unplug the plug from the AC outlet.

2.

Remove the antenna terminal on TV and turn

on the TV.

Insulation resistance between the cord plug

3.

terminals and the eternal exposure metal

[Note 2] should be more than 1M ohm by

using the 500V insulation resistance meter

[Note 1].

4.

If the insulation resistance is less than 1M

ohm, the inspection repair should be

required.

[Note 1]

If you have not the 500V insulation

resistance meter, use a Tester.

[Note 2]

External exposure metal: Antenna terminal

Earphone jack

AV-20FD23

HOW TO ORDER PARTS

Please include the following informations when you order parts. (Particularly the VERSION LETTER.)

1. MODEL NUMBER and VERSION LETTER

The MODEL NUMBER can be found on the back of each product and the VERSION LETTER can be

found at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

No. 52014 3

Page 4

AV-20FD23

CAUTION

THIS DIGITAL VIDEO PLAYER EMPLOYS A LASER SYSTEM.

TO ENSURE PROPER USE OF THIS PRODUCT, PLEASE READ THIS SERVICE MANUAL CAREFULLY AND RETAIN FOR FUTURE REFERENCE. SHOULD THE UNIT REQUIRE MAINTENANCE,

CONTACT AN AUTHORIZED SERVICE LOCATION-SEE SERVICE PROCEDURE.

USE OF CONTROLS, ADJUSTMENTS OR THE PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

TO PREVENT DIRECT EXPOSURE TO LASER BEAM, DO NOT TRY TO OPEN THE ENCLOSURE.

VISIBLE LASER RADIATION MAY BE PRESENT WHEN THE ENCLOSURE IS OPENED. DO NOT

STARE INTO BEAM.

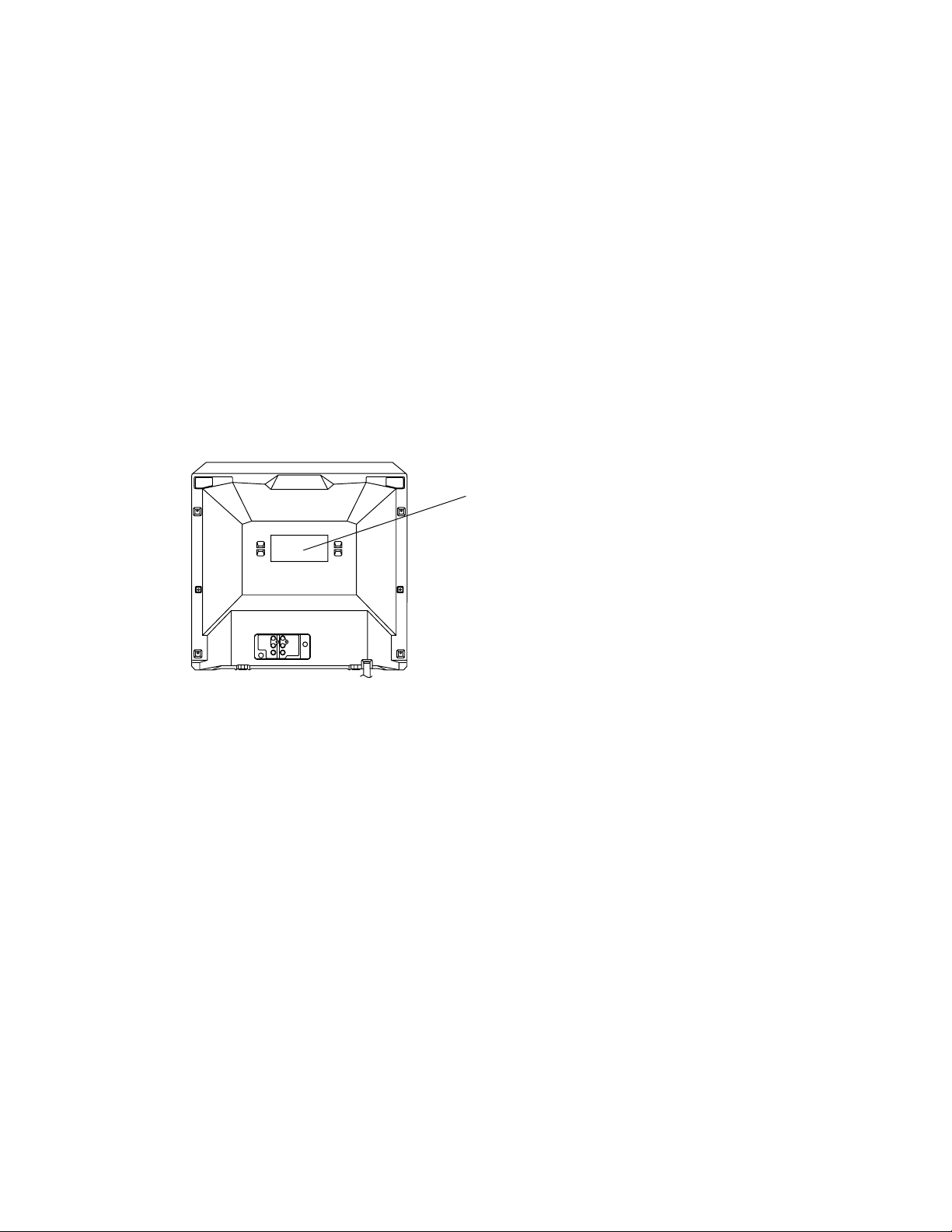

Location of the required Marking

The rating sheet and the safety caution are on the rear of the unit.

CERTIFICATION: COMPLIES WITH FDA

RADIATION PERFORMANCE STANDARDS,

21 CFR SUBCHAPTER J.

4 No. 52014

Page 5

IMPORTANT SERVICE SAFETY INFORMATION

AV-20FD23

Operating the receiver outside of its cabinet or with its

back removed involves a shock hazard. Work on these

models should only be performed by those who are

thoroughly familiar with precautions necessary when

working on high voltage equipment.

Exercise care when servicing this chassis with power

applied. Many B plus and high voltage RF terminals are

exposed which, if carelessly contacted, can cause

serious shock or result in damage to the chassis.

Maintain interconnecting ground lead connections

between chassis, escutcheon, picture tube dag and

tuner cluster when operating the chassis.

These receivers have a "polarized" AC line cord. The

AC plug is designed to fit into standard AC outlets in one

direction only. The wide blade connects to the "ground

side" and the narrow blade connects to the "hot side" of

the AC line. This assures that the TV receiver is properly

grounded to the house wiring. If an extension cord must

be used, make sure it is of the "polarized" type.

Since the chassis of this receiver is connected to one

side of the AC supply during operation, service should

not be attempted by anyone not familiar with the

precautions necessary when working on these types of

equipment.

When it is necessary to make measurements or tests

with AC power applied to the receiver chassis, an

Isolation Transformer must be used as a safety

precaution and to prevent possible damage to

transistors. The Isolation Transformer should be

connected between the TV line cord plug and the AC

power outlet.

Certain HV failures can increase X-ray radiation.

Receivers should not be operated with HV levels

exceeding the specified rating for their chassis type. The

maximum operating HV specified for the chassis used in

these receivers is 32kV±1.0kV at zero beam current with

a line voltage of 120V AC. Higher voltage may also

increase the possibility of failure in the HV supply.

The picture tube used in this receiver employs integral

implosion protection. Replace with a tube of the same

type number for continued safety. Do not lift picture tube

by the neck. Handle the picture tube only when wearing

shatterproof goggles and after discharging the high

voltage completely. Keep others without shatterproof

goggles away.

When removing springs or spring mounted parts from

the tuner, tuner cluster or chassis, shatterproof goggles

must be worn. Keep others without shatterproof goggles

away.

Before returning the receiver to the user, perform the

following safety checks:

1.

Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the receiver.

2.

Replace all protective devices such as nonmetallic

control knobs, insulating fishpapers, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

3.

To be sure that no shock hazard exists, a check for

the presence of leakage current should be made at

each exposed metal part having a return path to the

chassis (antenna, cabinet metal, screw heads, knobs

and/or shafts, escutcheon, etc.) in the following

manner.

Plug the AC line cord directly into a 120V AC receptacle.

(Do not use an Isolation Transformer during these

checks.) All checks must be repeated with the AC line

cord plug connection reversed. (If necessary, a

nonpolarized adapter plug must be used only for the

purpose of completing these checks.)

If available, measure current using an accurate leakage

current tester. Any reading of 0.35mA or more is

excessive and indicates a potential shock hazard which

must be corrected before returning the receiver to the

owner.

It is important to maintain specified values of all

components in the horizontal and high voltage circuits

and anywhere else in the receiver that could cause a

rise in high voltage, or operating supply voltages. No

changes should be made to the original design of the

receiver.

Components shown in the shaded areas on the

schematic diagram and/or identified by

in the

replacement parts list should be replaced only with exact

factory recommended replacement parts. The use of

unauthorized substitute parts may create shock, fire, Xray radiation, or other hazards.

To determine the presence of high voltage, use an

accurate high impedance HV meter connected between

the second anode lead and the CRT dag grounding

device. When servicing the High Voltage System,

remove static charges from it by connecting a 10k ohm

resistor in series with an insulated wire (such as a test

probe) between the picture tube dag and 2nd anode

lead (have AC line cord disconnected from AC supply).

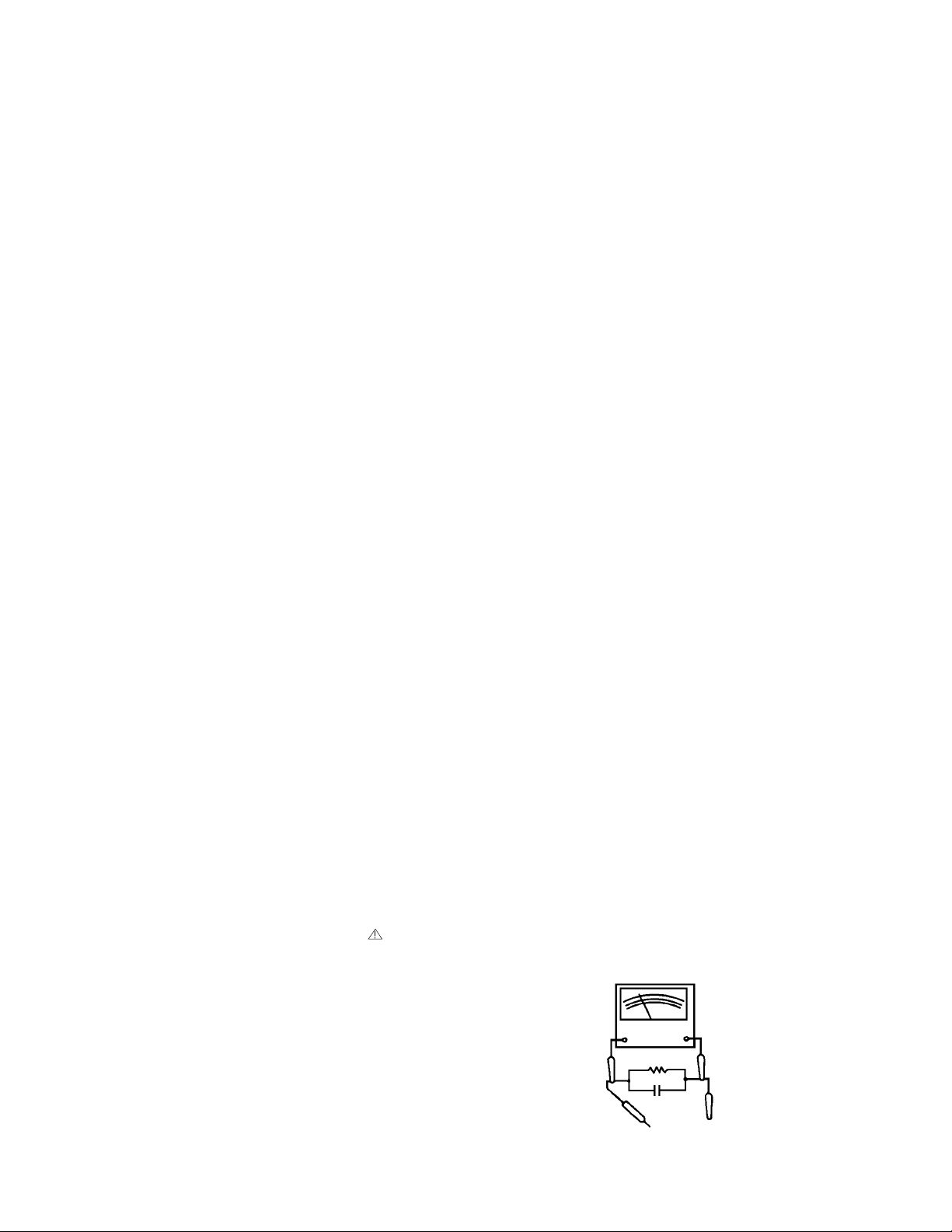

If a reliable leakage current tester is not available, this

alternate method of measurement should be used.

Using two clip leads, connect a 1500 ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with a

known earth ground, such as a water pipe or conduit

and the metal part to be checked. Use a VTVM or VOM

with 1000 ohms per volt, or higher, sensitivity to

measure this AC voltage drop across the resistor. Any

reading of 0.35 volt RMS or more is excessive and

indicates a potential shock hazard which must be

corrected before returning the receiver to the owner.

VT VM

AC SCALE

1.5K OHMS

10W

15µF

TO EXPOSED

METAL PARTS

TEST PROBE

TO KNOWN

EARTH GROUND

No. 52014 5

Page 6

AV-20FD23

IMPORTANT SAFEGUARDS

READ INSTRUCTIONS

1.

All the safety and operating instructions should be read before the unit is operated.

RETAIN INSTRUCTIONS

2.

The safety and operating instructions should be retained for future reference.

HEED WARNINGS

3.

All warnings on the unit and in the operating instructions should be adhered to.

FOLLOW INSTRUCTIONS

4.

All operating and use instructions should be followed.

CLEANING

5.

Unplug this unit from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a damp cloth for cleaning.

ATTACHMENTS

6.

Do not use attachments not recommended by the unit’s manufacturer as they may cause hazards.

WATER AND MOISTURE

7.

Do not use this unit near water. For example, near a bathtub, washbowl, kitchen sink, or laundry tub, in a wet basement, or near a

swimming pool.

ACCESSORIES

8.

Do not place this unit on an unstable cart, stand, tripod, bracket, or table. The unit may fall,

causing serious injury, and serious damage to the unit. Use only with a cart, stand, tripod,

bracket, or table recommended by the manufacturer.

An appliance and cart combination should be moved with care. Quick stops, excessive force,

8A.

and uneven surfaces may cause the appliance and cart combination to overturn.

VENTILATION

9.

Slots and openings in the cabinet and in the back or bottom are provided for ventilation, to ensure reliable operation of the unit, and

to protect it from overheating. These openings must not be blocked or covered. The openings should never be blocked by placing

the unit on a bed, sofa, rug, or other similar surface. This unit should never be placed near or over a radiator or heat source . This

unit should not be placed in a built-in installation such as a bookcase or rack unless proper ventilation is provided or the manufacturer’s instructions have been adhered to.

POWER SOURCES

10.

This unit should be operated only from the type of power source indicated on the rating plate. If you are not sure of the type of

power supply to your home, consult your appliance dealer or local power company. For units intended to operate from battery

power, or other sources, refer to the operating instructions.

GROUNDING OR POLARIZATION

11.

This unit is equipped with a polarized alternating-current line plug (a plug having one blade wider than the other). This plug will fit

into the power outlet only one way. This is a safety feature. If you are unable to insert the plug fully into the outlet, try reversing the

plug. If the plug should still fail to fit, contact your electrician to replace your obsolete outlet. Do not defeat the safety purpose of the

polarized plug. If your unit is equipped with a 3-wire grounding-type plug, a plug having a third (grounding) pin, this plug will only fit

into a grounding-type power outlet. This too, is a safety feature. If you are unable to insert the plug into the outlet, contact your

electrician to replace your obsolete outlet. Do not defeat the safety purpose of the grounding-type plug.

12.

POWER-CORD PROTECTION

Power-supply cords should be routed so that they are not likely to be walked on or pinched by items placed upon or against them,

paying particular attention to cords at plugs, convenience receptacles, and the point where they exit from the appliance.

13.

LIGHTNING

To protect your unit from a lightning storm, or when it is left unattended and unused for long periods of time, unplug it from the wall

outlet and disconnect the antenna or cable system. This will prevent damage to the unit due to lightning and power line surges.

14.

POWER LINES

An outside antenna system should not be located in the vicinity of overhead power lines or other electric light or power circuits, or

where it can fall into such power lines or circuits. When installing an outside antenna system, extreme care should be taken to

keep from touching such power lines or circuits, as contact with them might be fatal.

15.

OVERLOADING

Do not overload wall outlets and extension cords, as this can result in a risk of fire or electric shock.

16.

OBJECT AND LIQUID ENTRY

Do not push objects through any openings in this unit, as they may touch dangerous voltage points or short out parts that could

result in fire or electric shock. Never spill or spray any type of liquid into the unit.

17.

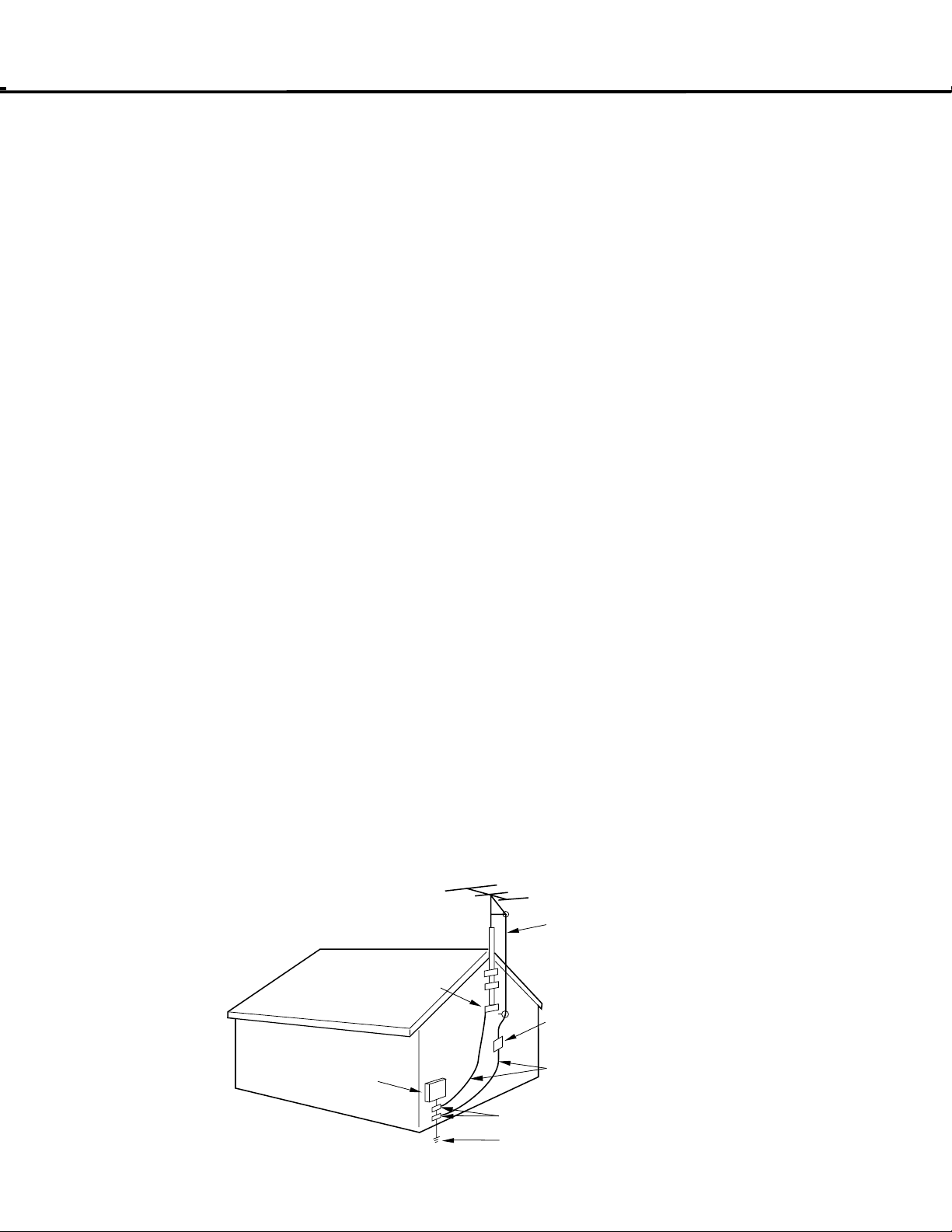

OUTDOOR ANTENNA GROUNDING

If an outside antenna or cable system is connected to the unit, be sure the antenna or cable system is grounded so as to provide

some protection against voltage surges and built-up static charges. Section 810 of the National Electrical Code, ANSI/NFPA 70,

provides information with respect to proper grounding of the mast and supporting structure, grounding of the lead-in wire to an

antenna discharge unit, size of grounding conductors, location of antenna discharge unit, connection to grounding electrodes, and

requirements for the grounding electrode.

18.

SERVICING

Do not attempt to service this unit yourself as opening or removing covers may expose you to dangerous voltage or other hazards.

Refer all servicing to qualified service personnel.

AC)

PORTABLE CART WARNING

(symbol provided by RET

S3126A

6 No. 52014

Page 7

AV-20FD23

IMPORTANT SAFEGUARDS

DAMAGE REQUIRING SERVICE

19.

Unplug this unit from the wall outlet and refer servicing to qualified service personnel under the following conditions:

a.

When the power-supply cord or plug is damaged.

b.

If liquid has been spilled, or objects have fallen into the unit.

c.

If the unit has been exposed to rain or water.

d.

If the unit does not operate normally by following the operating instructions. Adjust only those controls that are covered by

the operating instructions, as an improper adjustment of other controls may result in damage and will often require extensive

work by a qualified technician to restore the unit to its normal operation.

e.

If the unit has been dropped or the cabinet has been damaged.

f.

When the unit exhibits a distinct change in performance, this indicates a need for service.

REPLACEMENT PARTS

20.

When replacement parts are required, be sure the service technician uses replacement parts specified by the manufacturer or

those that have the same characteristics as the original parts.

Unauthorized substitutions may result in fire, electric shock or other hazards.

SAFETY CHECK

21.

Upon completion of any service or repairs to this unit, ask the service technician to perform safety checks to determine that the unit

is in proper operating condition.

WALL OR CEILING MOUNTING

22.

The product should be mounted to a wall or ceiling only as recommended by the manufacturer.

HEAT

23.

The product should be situated away from heat sources such as radiators, heat registers, stoves, or other products (including

amplifiers) that produce heat.

DISC TRAY

24.

Keep your fingers well clear of the disc tray as it is closing. It may cause serious personal injury.

CONNECTING

25.

When you connect the product to other equipment, turn off the power and unplug all of the equipment from the wall outlet. Failure

to do so may cause an electric shock and serious personal injury. Read the owner's manual of the other equipment carefully and

follow the instructions when making any connections.

SOUND VOLUME

26.

Reduce the volume to the minimum level before you turn on the product. Otherwise, sudden high volume sound may cause

hearing or speaker damage.

SOUND DISTORTION

27.

Do not allow the product output distorted sound for a longtime. It may cause speaker overheating and fire.

HEADPHONES

28.

When you use the headphones, keep the volume at a moderate level. If you use the headphones continuously with high volume

sound, it may cause hearing damage.

LEASER BEAM

29.

Do not look into the opening of the disc tray or ventilation opening of the product to see the source of the laser beam. It may cause

sight damage.

DISC

30.

Do not use a cracked, deformed, or repaired disc. These discs are easily broken and may cause serious personal injury and

product malfunction.

NOTE TO CATV SYSTEM INSTALLER

31.

This reminder is provided to call the CATV system installer’s attention to Article 820-40 of the NEC that provides guidelines for

proper grounding and, in particular, specifies that the cable ground shall be connected to the grounding system of the building, as

close to the point of cable entry as practical.

(CONTINUED)

EXAMPLE OF ANTENNA GROUNDING AS PER THE NATIONAL ELECTRICAL CODE

ELECTRIC SERVICE

NEC-NATIONAL ELECTRICAL

S2898A

GROUND CLAMP

EQUIPMENT

CODE

ANTENNA LEAD IN WIRE

ANTENNA DISCHARGE UNIT

(NEC SECTION 810-20)

GROUNDING CONDUCTORS

(NEC SECTION 810-21)

GROUND CLAMPS

POWER SERVICE GROUNDING ELECTRODE SYSTEM

(NEC ART 250, PART H)

No. 52014 7

Page 8

AV-20FD23

SPECIFIC SERVICE INSTRUCTIONS

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

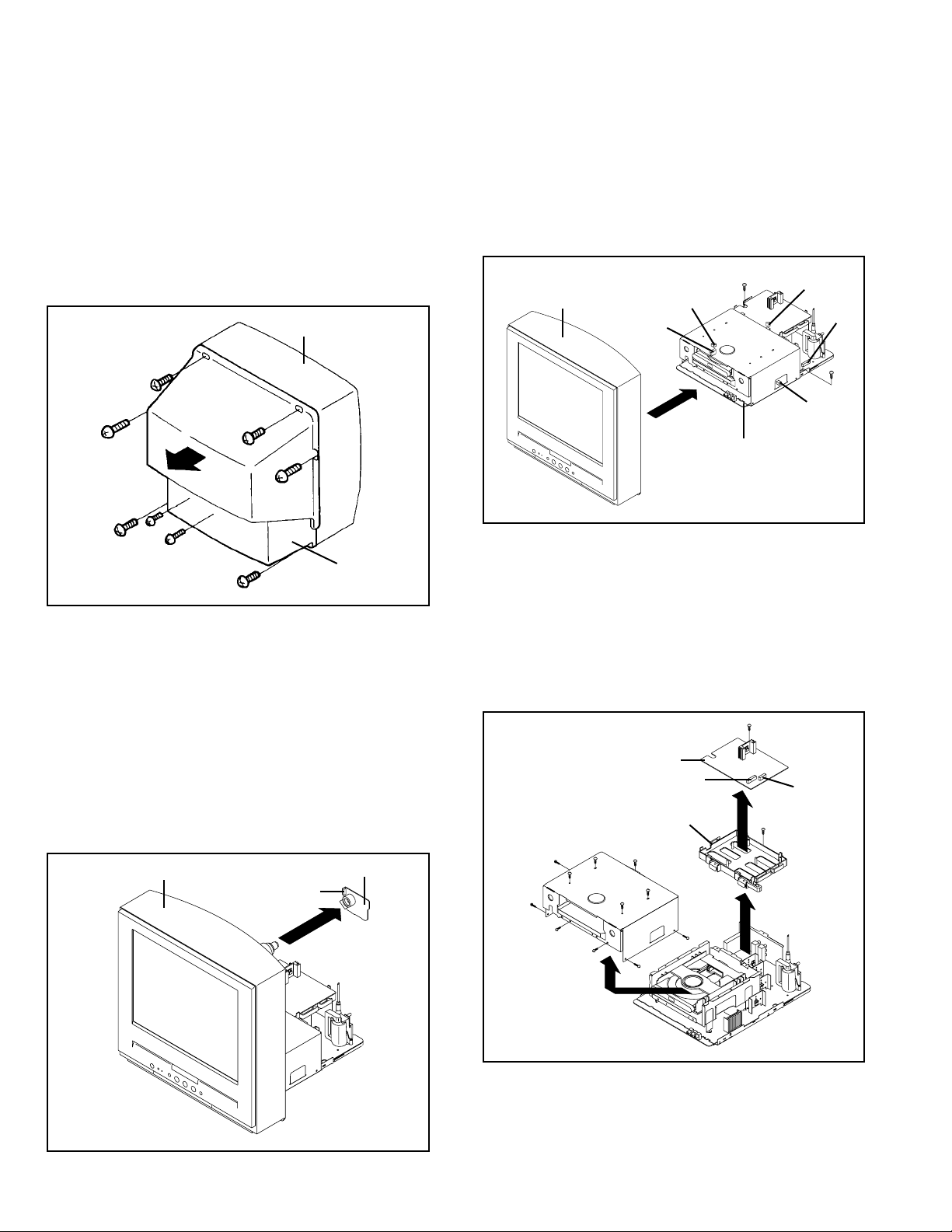

1-1: BACK CABINET (Refer to Fig. 1-1)

1.

Remove the 7 screws 1.

2.

Remove the screw 2 which are used for holding the Back

Cabinet.

3.

Remove the AC cord from the AC cord hook 3.

4.

Remove the Back Cabinet in the direction of arrow.

Front Cabinet

1

1

1

1

2

1-2: CRT PCB (Refer to Fig. 1-2)

CAUTION: BEFORE REMOVING THE ANODE CAP,

DISCHARGE ELECTRICITY BECAUSE IT

CONTAINS HIGH VOLTAGE.

BEFORE ATTEMPTING TO REMOVE OR

REPAIR ANY PCB, UNPLUG THE POWER

CORD FROM THE AC SOURCE.

1.

Remove the Anode Cap.

(Refer to REMOVAL OF ANODE CAP)

2.

Disconnect the following connector:

(CP805).

3.

Remove the CRT PCB in the direction of arrow.

Front Cabinet

1

1

3

Back Cabinet

1

CP805

Fig. 1-1

CRT PCB

1-3: POWER PCB/DVD BLOCK (Refer to Fig. 1-3)

1.

Remove the 2 screws 1.

2.

Disconnect the following connectors:

(CP104, CP301, CP302, CP401 and CP3800).

3.

Remove the POWER PCB/DVD Block in the direction of

arrow.

1

CP3800

Front Cabinet

CP301

CP104

CP302

Power PCB/DVD Block

Fig. 1-3

1-4: POWER PCB (Refer to Fig. 1-4)

1.

Remove the 11 screws 1.

2.

Remove the Top Shield in the direction of arrow (A).

3.

Disconnect the following connectors:

(CP3802 and CP3803).

4.

Remove the screw 2.

5.

Remove the PCB Cover Ass'y in the direction of arrow (B).

6.

Remove the screw 3.

7.

Remove the Power PCB in the direction of arrow (C).

3

Power PCB

CP3803

PCB Cover Ass'y

1

1

1

1

1

1

1

1

1

1

1

(A)

CP3802

(C)

2

(B)

CP401

1

Fig. 1-2

8 No. 52014

Fig. 1-4

Page 9

DISASSEMBLY INSTRUCTIONS

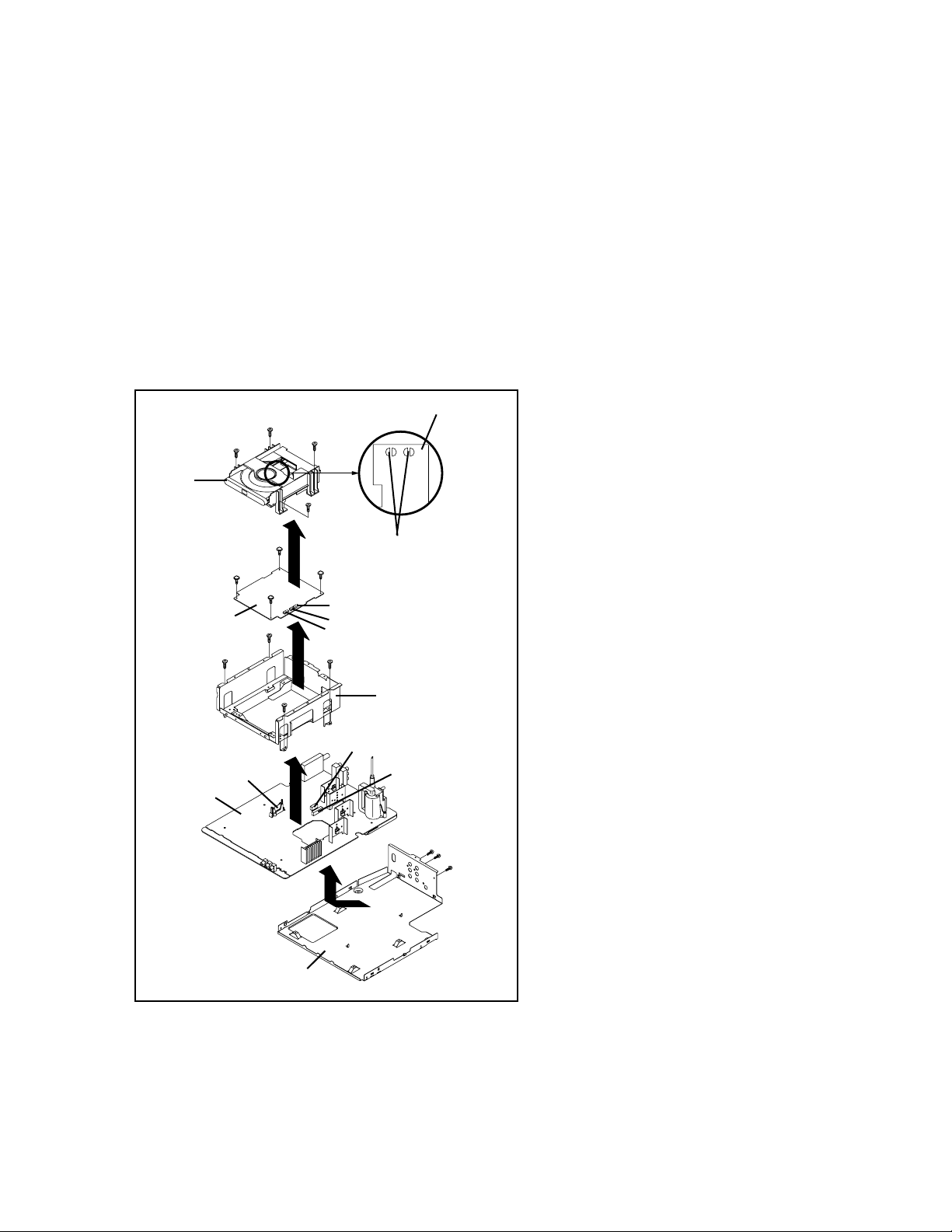

1-5: AV PCB/DVD PCB/DECK CD (Refer to Fig. 1-5)

1.

Make the short circuit on the position as shown Fig. 1-5

using a soldering. If you remove the Deck CD with no

soldering, the Laser may be damaged.

2.

Disconnect the following connectors:

(CP8001, CP8002 and CP8005).

3.

Remove the 4 screws 1.

4.

Remove the Deck Angle in the direction of arrow (A).

5.

Disconnect the following connectors:

(CP2301, CP2302 and CP2601).

6.

Remove the 4 screws 2.

7.

Remove the Deck CD in the direction of arrow (B).

8.

Remove the 4 screws 3.

9.

Remove the DVD PCB in the direction of arrow (C).

10.

Remove the 3 screws 4.

11.

Remove the AV PCB in the direction of arrow (D).

Pick Up PCB

2

2

Deck CD

2

AV-20FD23

3

DVD PCB

1

AV PCB

CP8002

2

3

(B)

3

1

(C)

1

(A)

(D)

Make the sort circuit

using a soldering.

3

CP2601

CP2301

CP2302

1

CP8002

Deck Angle

CP8005

4

4

4

Bottom Plate

Fig. 1-5

NOTE

When the installation of the Deck CD, remove all the

soldering on the short circuit position after the connection of

Pick Up PCB and DVD PCB connector.

No. 52014 9

Page 10

AV-20FD23

DISASSEMBLY INSTRUCTIONS

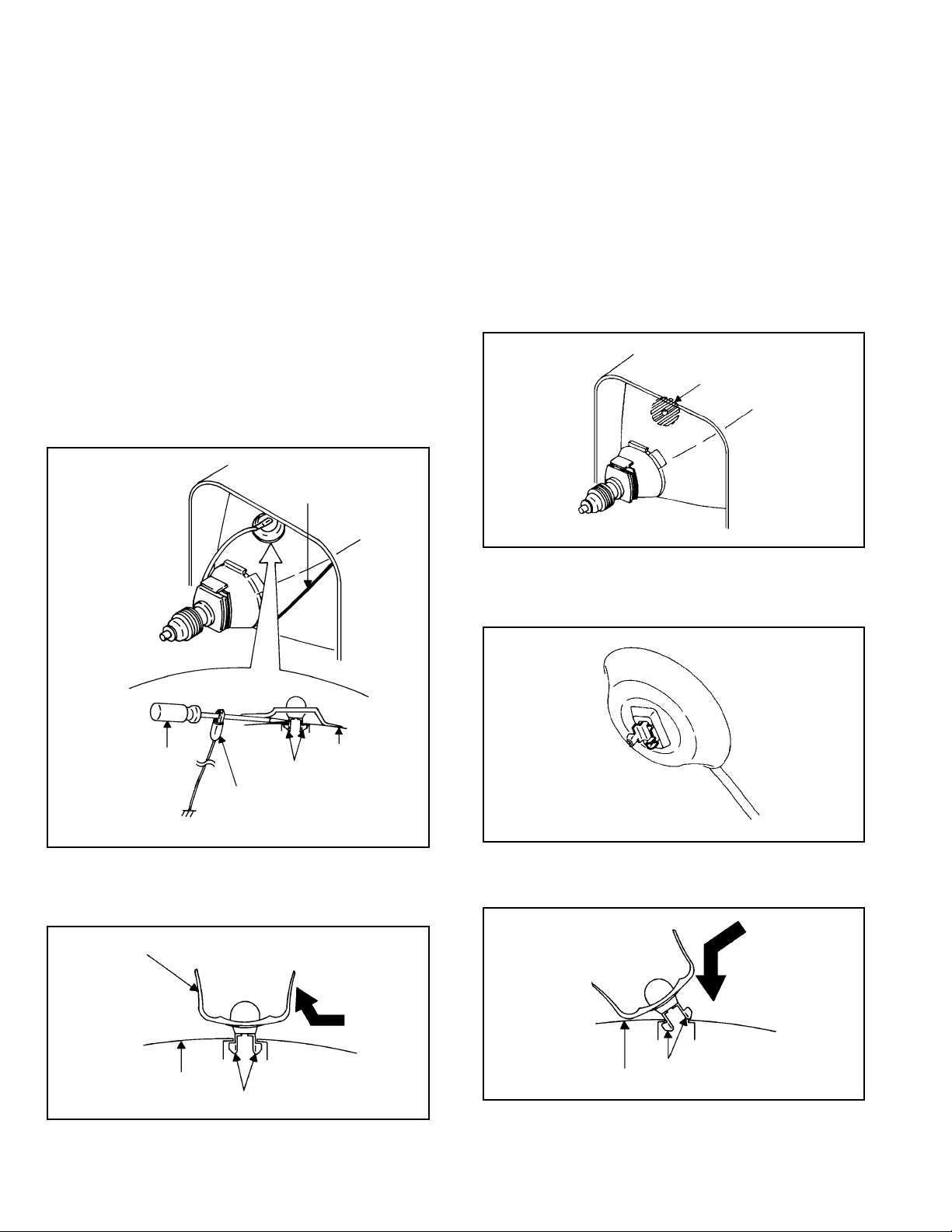

2. REMOVAL OF ANODE CAP

Read the following NOTED items before starting work.

*

After turning the power off there might still be a potential

voltage that is very dangerous. When removing the

Anode Cap, make sure to discharge the Anode Cap's

potential voltage.

Do not use pliers to loosen or tighten the Anode Cap

*

terminal, this may cause the spring to be damaged.

REMOVAL

1. Follow the steps as follows to discharge the Anode Cap.

(Refer to Fig. 2-1.)

Connect one end of an Alligator Clip to the metal part of a

flat-blade screwdriver and the other end to ground.

While holding the plastic part of the insulated Screwdriver,

touch the support of the Anode with the tip of the

Screwdriver.

A cracking noise will be heard as the voltage is discharged.

GND on the CRT

3. After one side is removed, pull in the opposite direction to

remove the other.

NOTE

Take care not to damage the Rubber Cap.

INSTALLATION

1. Clean the spot where the cap was located with a small

amount of alcohol. (Refer to Fig. 2-3.)

NOTE

Confirm that there is no dirt, dust, etc. at the spot where

the cap was located.

Location of Anode Cap

Fig. 2-3

Screwdriver

Alligator Clip

GND on the CRT

Flip up the sides of the Rubber Cap in the direction of the

2.

arrow and remove one side of the support.

(Refer to Fig. 2-2.)

Rubber Cap

Support

CRT

Fig. 2-1

2.3.Arrange the wire of the Anode Cap and make sure the

wire is not twisted.

Turn over the Rubber Cap. (Refer to Fig. 2-4.)

Fig. 2-4

4. Insert one end of the Anode Support into the anode

button, then the other as shown in Fig. 2-5.

CRT

Support

10 No. 52014

Fig. 2-2

Support

CRT

5.6.Confirm that the Support is securely connected.

Put on the Rubber Cap without moving any parts.

Fig. 2-5

Page 11

DISASSEMBLY INSTRUCTIONS

AV-20FD23

3. REMOVAL AND INSTALLATION OF FLAT

PACKAGE IC

REMOVAL

1. Put the Masking Tape (cotton tape) around the Flat

Package IC to protect other parts from any damage.

(Refer to Fig. 3-1.)

NOTE

Masking is carried out on all the parts located within

10 mm distance from IC leads.

IC

Masking Tape

(Cotton Tape)

Fig. 3-1

2. Heat the IC leads using a blower type IC desoldering

machine. (Refer to Fig. 3-2.)

NOTE

Do not add the rotating and the back and forth directions force on the IC, until IC can move back and forth

easily after desoldering the IC leads completely.

Blower type IC

desoldering machine

3. When IC starts moving back and forth easily after

desoldering completely, pickup the corner of the IC using

a tweezers and remove the IC by moving with the IC

desoldering machine. (Refer to Fig. 3-3.)

NOTE

Some ICs on the PCB are affixed with glue, so be

careful not to break or damage the foil of each IC

leads or solder lands under the IC when removing it.

Blower type IC

desoldering machine

Tweezers

IC

4.5.Peel off the Masking Tape.

Absorb the solder left on the pattern using the Braided

Shield Wire. (Refer to Fig. 3-4.)

NOTE

Do not move the Braided Shield Wire in the vertical

direction towards the IC pattern.

Fig. 3-3

Braided Shield Wire

Soldering Iron

IC

Fig. 3-2

IC pattern

Fig. 3-4

No. 52014 11

Page 12

AV-20FD23

DISASSEMBLY INSTRUCTIONS

INSTALLATION

1. Take care of the polarity of new IC and then install the

new IC fitting on the printed circuit pattern. Then solder

each lead on the diagonal positions of IC temporarily.

(Refer to Fig. 3-5.)

Soldering Iron

Solder temporarily Solder temporarily

Fig. 3-5

2. Supply the solder from the upper position of IC leads

sliding to the lower position of the IC leads.

(Refer to Fig. 3-6.)

4. When bridge-soldering between terminals and/or the

soldering amount are not enough, resolder using a Thintip Soldering Iron. (Refer to Fig. 3-8.)

IC

Thin-tip Soldering Iron

Fig. 3-8

5. Finally, confirm the soldering status on four sides of the

IC using a magnifying glass.

Confirm that no abnormality is found on the soldering

position and installation position of the parts around the

IC. If some abnormality is found, correct by resoldering.

NOTE

When the IC leads are bent during soldering and/or

repairing, do not repair the bending of leads. If the

bending of leads are repaired, the pattern may be

damaged. So, be always sure to replace the IC in this

case.

Solder

IC

Supply soldering

from upper position

to lower position

Soldering Iron

Fig. 3-6

3. Absorb the solder left on the lead using the Braided

Shield Wire. (Refer to Fig. 3-7.)

NOTE

Do not absorb the solder to excess.

Soldering Iron

IC

Braided Shield Wire

Fig. 3-7

12 No. 52014

Page 13

AV-20FD23

SERVICE MODE LIST

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter to the SERVICE MODE function, press and hold both buttons simultaneously on the main unit and on the remote control

for more than a standard time (second).

Set Key OperationsRemocon Key

VOL. (-) MIN

VOL. (-) MIN 1

VOL. (-) MIN 4

VOL. (-) MIN 5

VOL. (-) MIN 6

0

Standard Time

(seconds)

1

1

1

1

Releasing of V-CHIP PASSWORD.1

Initialization of the factory on TV.

NOTE:

Initialization of the factory on DVD.

NOTE: Do not use this for the normal servicing.

DVD Write mode.

Refer to the “RE-WRITE FOR DVD FIRMWARE”.

NOTE: The function will only work at the DVD stop mode.

POWER ON total hours and PLAY/REC total hours are displayed on

the screen.

Refer to the "PREVENTIVE CHECKS AND SERVICE INTERVALS"

(CONFIRMATION OF HOURS USED).

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the "WHEN REPLACING EEPROM (MEMORY) IC".

Do not use this for the normal servicing.

If you set a factory initialization, the memories are reset such as the

channel setting, and the POWER ON total hours.

The function will only work without the setting of DVD disc at DVD

mode.

While pressing the Remocon Key for more than the Standard Time,

press the Set Key simultaneously.

Do not use this for the normal servicing.

VOL. (-) MIN 8

VOL. (-) MIN 9

VOL. (-) MIN LIGHT 1

STOP 1 3

STOP 7 3

1

1

Writing of EEPROM initial data.

NOTE: Do not use this for the normal servicing.

Display of the Adjustment MENU on the screen.

Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display Adjustment).

Remocon format selection. (JVC format NEC format)

NOTE: Supplied remocon can not be operated at NEC format.

(The “N” is always displayed on the monitor.)

Do not use this for the normal servicing.

Check for the firmware version.

Refer to the “RE-WRITE FOR DVD FIRMWARE”.

NOTE: The function will only work at the DVD stop mode.

Do not use this for the normal servicing.

Releasing of PARENTAL LOCK.

Refer to the “PARENTAL CONTROL - RATING LEVEL”.

NOTE:

The function will only work without the setting of DVD disc at DVD

mode.

No. 52014 13

Page 14

AV-20FD23

PARENTAL CONTROL - RATING LEVEL

4 DIGIT PASSWORD CANCELLATION

If the stored 4 digit password in the Rating Level menu needs to be cancelled, please follow the steps below.

Turn Unit ON.

1.

Confirm that no sisc on the disc tray.

2.

Press and hold the '7' key on the remote control unit.

3.

Simultaneously press and hold the 'STOP' key on the front panel.

4.

Hold both keys for more than 3 seconds.

5.

The On Screen Display message 'PASSWORD CLEAR' will appear.

6.

The 4 digit password has now been cleared.

7.

NB: The above procedure will reset ALL of the player's settings to the default factory state.

CONFIRMATION OF HOURS USED

POWER ON total hours can be checked on the screen. Total hours are displayed in 16 system of notation.

NOTE: If you set a factory initialization, the total hours is reset to "0".

1.

Set the VOLUME to minimum.

2.

Press both VOL. DOWN button on the set and Channel

button (6) on the remote control for more than 1 second.

3.

After the confirmation of using hours, turn off the power.

ADDRESS DATA

INIT 00 F8

CRT ON 0010

FIG. 1

Initial setting content of MEMORY IC.

POWER ON total hours.

= (16 x 16 x 16 x thousands digit value)

+ (16 x 16 x hundreds digit value)

+ (16 x tens digit value)

+ (ones digit value)

WHEN REPLACING EEPROM (MEMORY) IC

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to

ensure correct data settings while making reference to TABLE 1.

Note: No need setting for the position of the mark @ due to the adjustment value.

+0 +1 +2 +3 +4 +5 +6 +7 +8 +9 +A +B +C +D +E +FINI

F8 43 25 01 F1 27 27 D3 81 CD

00 DD 3F BF F0 61 63

64 67 69 2A 6B 6C 6D 6E 6F10 26 70 71 52 72 53 73

54 55 75 75 56 56 76 76 5720 74 57 77 77 58 58 78

78 59 79 79 5A 5A 7A 7A 5B30 59 5B 7B 7B 5C 5C 7C

7C 5D 7D 7D 5E 5E 7E 7E 5F40 5D 5F 5F 7F 7F @ @

@ @@@@@@@@50 @ @@@@@@

@ @@@@@@@@60 @ @ 10 00 52 09 45

84 --- --- --- --- --- --- --- ---70 --- --- --- --- --- --- ---

Table 1

1.

Enter DATA SET mode by setting VOLUME to minimum.

2.

Press both VOL. DOWN button on the set and Channel button (6) on the remote control for more than 1 second.

ADDRESS and DATA should appear as FIG 1.

3.

ADDRESS is now selected and should "blink". Using the VOL. UP/DOWN button on the remote, step through the ADDRESS

until required ADDRESS to be changed is reached.

4.

Press ENTER to select DATA. When DATA is selected, it will "blink".

5.

Again, step through the DATA using VOL. UP/DOWN button until required DATA value has been selected.

6.

Pressing ENTER will take you back to ADDRESS for further selection if necessary.

7.

Repeat steps 3 to 6 until all data has been checked.

8.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

The unit will now have the correct DATA for the new MEMORY IC.

14 No. 52014

Page 15

AV-20FD23

SERVICING FIXTURES AND TOOLS

X-JG176 Up-Date Disc

RE-WRITE FOR DVD FIRMWARE

Turn on the power, and set the DVD mode.

1.

Open the DVD tray.

2.

Press both VOL. DOWN button on the set and Channel button (5) on the remote control for more than 1 second.

3.

Press OPEN/CLOSE button on the unit to check if all the keys on the unit do not function.

4.

NOTE: To check if DVD Write mode is set.

When inserting Up-Date Disc at Non DVD Write mode, the read error will happen.

5.

Place the Up-Date Disc and close the tray by hand. (Refer to SERVICING FIXTURE AND TOOLS)

6.

Automatic read will start and "CD-R UPDATE PROCESS" will be displayed on the screen.

At this time, the horizontal noise lines may appear. But no problem.

7.

Approxi. 20 seconds later, the tray will open automatically. Remove the Up-Date Disc.

8.

Then, Approxi. 40 seconds later, the above indication will disappear and the tray will close automatically.

When the "No Disc" appears on the screen, the write will end.

NOTE: Do not turn off the unit on the way or push the tray by hand to close it.

Up-Date error will happen and can not be done with the Up-Date of Up-Date Disc.

9.

Unplug the AC cord, then plug it in.

10.

After the write, set to the initializing of shipping.

Set to the DVD mode, press both VOL. DOWN button on the set and Channel button (1) on the remote control for more than 1

second.

11.

The "INITIALIZE 5 ---> COMPLETE" will appear on the screen.

Then unplug the AC cord, and plug it in.

12.

CHECK FOR THE FIRMWARE VERSION

Set to the DVD mode, press both Channel button (1) on the remote control and the STOP button on the set for more than 3

seconds.

Firmware version will be displayed on the top left of the screen.

When the changed version displays, the Re-write will be completed.

13.

Turn off the power

Version OSD : ZTA25010

DISC REMOVAL METHOD AT NO POWER SUPPLY

1.2.Remove the Back Cabinet and Power PCB/DVD Block.

(Refer to item 1 of the DISASSEMBLY INSTRUCTIONS.)

Rotate the black gear of Deck CD section in the direction of

the arrow by hand, remove the disc from Deck CD.

Z T A 2 5 0 1 0

Fixed

Release date (Example: 2002.5.1)

No. 52014 15

Released times on the same date

A = October

B = November

C = December

Gear (Black)

Deck CD

Page 16

AV-20FD23

SERVICE ADJUSTMENTS

ELECTRICAL ADJUSTMENTSELECTRICAL ADJUSTMENTS

1.

BEFORE MAKING ELECTRICAL

ADJUSTMENTS

Read and perform these adjustments when repairing the

circuits or replacing electrical parts or PCB assemblies.

CAUTION

•

Use an isolation transformer when performing any service

on this chassis.

•

Before removing the anode cap, discharge electricity

because it contains high voltage.

•

When removing a PCB or related component, after

unfastening or changing a wire, be sure to put the wire

back in its original position.

•

When you exchange IC and Transistor for a heat sink,

apply the silicon grease (YG6260M) on the contact section

of the heat sink. Before applying new silicon grease,

remove all the old silicon grease. (Old grease may cause

damages to the IC and Transistor).

Prepare the following measurement tools for electrical

adjustments.

1. Oscilloscope

2. Digital Voltmeter

3. AC Voltmeter

4. Pattern Generator

5. Multi-Sound Signal Generator

NO.

FUNCTION

01

R CUT OFF

02

G CUT OFF

03

B CUT OFF

04

G DRIVE

05

B DRIVE

06

BRIGHTNESS(CENT.)

07

BRIGHTNESS(MAX)

08

BRIGHTNESS(MIN)

09

COLOR(CENT.)

10

COLOR(MAX)

11

COLOR(MIN)

12

TINT

13

SUB CONTRAST

14

CONTRAST(CENT.)

15

CONTRAST(MAX)

16

CONTRAST(MIN)

17

SHARPNESS

18

RGB CONTRAST

19

H POSITION

20

V POSITION

21

V SIZE

22

V LINEARITY

23

V S CORRECTION

24

EW PARABOLA CORR.

25

EW TRAPEZIUM CORR.

26

H SIZE

27

V EHT

28

H EHT

29

RF AGC

30

V CENTERING

31

CORNER CORR. TOP

32

CORNER CORR. BTM

33

OSD H

34

FM LEVEL

35

TEST PWM

36

TEST TONE CONTROL

FUNCTION

NO

.

37

BRI. AV(CENT.)

38

BRI. AV(MAX)

39

BRI. AV(MIN)

40

COL. AV(CENT.)

41

COL. AV(MAX)

42

COL. AV(MIN)

43

TINT AV

44

SUB CONTRAST AV

45

CONT. AV(CENT.)

46

CONT. AV(MAX)

47

CONT. AV(MIN)

48

SHARPNESS AV

49

BRI. DVD(CENT.)

50

BRI. DVD(MAX)

51

BRI. DVD(MIN)

52

COL. DVD(CENT.)

53

COL. DVD(MAX)

54

COL. DVD(MIN)

55

TINT DVD

56

SUB CONTRAST DVD

57

CONT. DVD(CENT.)

58

CONT. DVD(MAX)

59

CONT. DVD(MIN)

60

SHARPNESS DVD

61

BRI. GAME(CENT.)

62

BRI. GAME(MAX)

63

BRI. GAME(MIN)

64

CONT. GAME(CENT.)

65

CONT. GAME(MAX)

66

CONT. GAME(MIN)

67

TUNING V MUTE

68

POWER ON V MUTE

69

INPUT LEVEL

70

SEPARATION L

71

SEPARATION H

72

CUT OFF

Fig. 1-2

On-Screen Display Adjustment

In the condition of NO indication on the screen.

1.

Press the VOL. DOWN button on the set and the Channel

button (9) on the remote control for more than 1 second

to appear the adjustment mode on the screen as shown

in Fig. 1-1.

Function

Step No.

01 RCUT

7D

Fig. 1-1

Use the Channel UP/DOWN button or Channel button (1-

2.

0) on the remote control to select the options shown in

Fig. 1-2.

Press the MENU button on the remote control to end the

3.

adjustments.

2. BASIC ADJUSTMENTS

2-1: CONSTANT VOLTAGE

Set condition is AV MODE without signal.

1.

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Connect the digital voltmeter to TP3801.

Adjust the VR3800 until the digital voltmeter is 114 ± 0.5V.

4.

2-2: RF AGC

1.

Receive the VHF HIGH (63dB).

2.

Place the set with Aging Test for more than 15 minutes.

3.

Connect the digital voltmeter between the pin 5 of

CP101 and the pin 1 of CP101.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (29) on the remote control to

select "AGC".

5.

Press the VOL. UP/DOWN button on the remote control

until the digital voltmeter is 2.4 ± 0.05V.

2-3: FOCUS

1.

Receive the monoscope pattern.

2.

Turn the Focus Volume fully counterclockwise once.

3.

Adjust the Focus Volume until picture is distinct.

16 No. 52014

Page 17

ELECTRICAL ADJUSTMENTS

AV-20FD23

2-4: CUT OFF

1.

Adjust the unit to the following settings.

R CUT=7F, G CUT=7F, B CUT=7F, G DRV=3F,

B DRV=3F

2.

Place the set with Aging Test for more than 15 minutes.

3.

Set condition is AV MODE without signal.

4.

Using the remote control, set the brightness and contrast

to normal position.

5.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (72) on the remote control to

select "CUT OFF".

6.

Adjust the Screen Volume until a dim raster is obtained.

2-5: WHITE BALANCE

NOTE: Adjust after performing CUT OFF adjustment.

1.

Place the set with Aging Test for more than 15 minutes.

2.

Receive the gray scale pattern from the Pattern

Generator.

3.

Using the remote control, set the brightness and contrast

to normal position.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (04) on the remote control to

select "G DRV".

5.

Press the CH. UP/DOWN button on the remote control to

select the "R CUT", "G CUT", "B CUT", "G DRV" or "B

DRV".

6.

Adjust the VOL. UP/DOWN button on the remote control

to whiten the R CUT, G CUT, B CUT, G DRV, and B DRV

at each step tone sections equally.

7.

Perform the above adjustments 5 and 6 until the white

color is looked like a white.

2-6: HORIZONTAL POSITION

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (19) on the remote control to

select "HPOSI".

4.

Press the VOL. UP/DOWN button on the remote control

until the SHIFT quantity of the OVER SCAN on right and

left becomes minimum.

2-8: VERTICAL SIZE

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (21) on the remote control to

select "VSIZE".

4.

Press the VOL. UP/DOWN button on the remote control

until the Up/Down OVER SCAN Quantity becomes equal

to the Right/Left OVER SCAN Quantity.

2-9: VERTICAL LINEARITY

NOTE: Adjust after performing adjustments in section 2-8.

After the adjustment of Vertical Linearity, reconfirm

the Vertical Position and Vertical Size adjustments.

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (22) on the remote control to

select "VLIN".

4.

Press the VOL. UP/DOWN button on the remote control

until the SHIFT quantity of the OVER SCAN on upside

and downside becomes minimum.

2-10: OSD HORIZONTAL

Activate the adjustment mode display of Fig. 1-1 and

1.

press the channel button (33) on the remote control to

select "OSD".

Press the VOL. UP/DOWN button on the remote control

2.

until the difference of A and B becomes minimum. (Refer

to Fig. 2-1)

33 OSD

15

2-7: VERTICAL POSITION

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (20) on the remote control to

select “VPOSI”.

4.

Check if the step No. of V. POSITION is “02”.

5.

Adjust the VR402 until the horizontal line becomes fit to

the notch of the shadow mask.

BA

No. 52014 17

Fig. 2-1

Page 18

AV-20FD23

ELECTRICAL ADJUSTMENTS

2-11: SEPARATION

Please do the method (1) or method (2) adjustment.

Method (1)

1.

Set the multi-sound signal generator for each different Lch and R-ch frequency (Ex. L-ch=2KHz, R-ch=400Hz)

and receive the RF signal.

2.

Connect the oscilloscope to the Audio Out Jack.

3.

Press the AUDIO button on the remote control to set to

the stereo mode.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (70) on the remote control to

select “SEPAL”.

5.

Press the VOL. UP/DOWN button on the remote control

to adjust it until the audio output wave becomes a fine

sine wave.

6.

Press the CH UP button 1 time to set to "SEPAH" mode.

7.

Press the VOL. UP/DOWN button on the remote control

to adjust it until the audio output wave becomes a fine

sine wave.

Method (2)

Set the multi-sound signal generator L-ch=1KHz, R-ch

1.

=Non input and receive the RF signal.

Connect the oscilloscope to the Audio Out Jack (R-ch).

2.

Press the AUDIO button on the remote control to set to

3.

the stereo mode.

Activate the adjustment mode display of Fig. 1-1 and

4.

press the channel button (70) on the remote control to

select “SEPAL”.

Press the VOL. UP/DOWN button on the remote control

5.

to adjust it until the R-ch output becomes minimum.

Press the CH UP button 1 time to set to "SEPAH" mode.

6.

Press the VOL. UP/DOWN button on the remote control

7.

to adjust it until the R-ch output becomes minimum.

Set the multi-sound signal generator L-ch=Non input,

8.

R-ch=1KHz and receive the RF signal.

Connect the oscilloscope to the Audio Out Jack (L-ch).

9.

Then perform the above adjustments 3~7.

2-12: LEVEL

1.

Receive the VHF HIGH (70dB).

2.

Connect the AC voltmeter to pin 6 of CP101.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (69) on the remote control to

select "LVL".

4.

Press the VOL. UP/DOWN button on the remote control

until the AC voltmeter is 72 ± 2mV.

2-13: BRIGHT CENTER

1.

Receive the monoscope pattern. (RF Input)

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (06) on the remote control to

select "BRTC".

4.

Press the VOL. UP/DOWN button on the remote control

until the white 15% is starting to be visible.

5.

Receive the monoscope pattern. (Audio Video Input)

6.

Press the INPUT button on the remote control to set to

the AV mode.

7.

Using the remote control, set the brightness and contrast

to normal position.

8.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (37) on the remote control to

select "BRTCA".

9.

Press the VOL. UP/DOWN button on the remote control

until the white 15% is starting to be visible.

10.

Press the TV/DVD button on the remote control to set to

the DVD mode.

11.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (49) on the remote control to

select "BRTCD".

12.

Press the VOL. UP/DOWN button on the remote control

to set the same step numbers as the AV.

2-14: SUB TINT CENTER

1.

Receive the color bar pattern. (RF Input)

2.

Using the remote control, set the brightness, contrast,

color and tint to normal position.

3.

Connect the oscilloscope to TP024.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (12) on the remote control to

select "TNTC".

5.

Press the VOL. UP/DOWN button on the remote control

until the section "A" becomes a straight line.

(Refer to Fig. 2-2)

6.

Receive the color bar pattern. (Audio Video Input)

7.

Press the INPUT button on the remote control to set to

the AV mode.

8.

Using the remote control, set the brightness, contrast,

color and tint to normal position.

9.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (43) on the remote control to

select "TNTCA".

10.

Press the VOL. UP/DOWN button on the remote control

until the section "A" becomes a straight line.

(Refer to Fig. 2-2)

11.

Press the TV/DVD button on the remote control to set to

the DVD mode.

12.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (55) on the remote control to

select "TNTCD".

13.

Press the VOL. UP/DOWN button on the remote control

until the tint step No. becomes "49"

18 No. 52014

Page 19

ELECTRICAL ADJUSTMENTS

“A”

2-15: SUB COLOR CENTER

1.

Receive the color bar pattern. (RF Input)

2.

Using the remote control, set the brightness, contrast,

color and tint to normal position.

3.

Connect the oscilloscop to TP022.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (09) on the remote control to

select "COLC".

5.

Adjust the VOLTS RANGE VARIABLE knob of the

oscilloscope until the range between white 100% and 0%

is set to 4 scales on the screen of the oscilloscope.

6.

Press the VOL. UP/DOWN button on the remote control

until the red color level is adjusted to 105 ± 5% of the

white level. (Refer to Fig. 2-3)

7.

Receive the color bar pattern. (Audio Video Input)

8.

Press the INPUT button on the remote control to set to

the AV mode.

9.

Using the remote control, set the brightness, contrast,

color and tint to normal position.

10.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (40) on the remote control to

select "COLCA".

11.

Adjust the VOLTS RANGE VARIABLE knob of the

oscilloscope until the range between white 100% and 0%

is set to 4 scales on the screen of the oscilloscope.

12.

Press the VOL. UP/DOWN button on the remote control

until the red color level is adjusted to 105 ± 5% of the

white level. (Refer to Fig. 2-3)

13.

Press the TV/DVD button on the remote control to set to

the DVD mode.

14.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (52) on the remote control to

select "COLCD".

15.

Press the VOL. UP/DOWN button on the remote control

to set the same step numbers as the AV.

Fig. 2-2

AV-20FD23

2-16: CONTRAST MAX

1.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (15) on the remote control to

select "CNTX".

2.

Press the VOL. UP/DOWN button on the remote control

until the contrast step No. becomes "72"

3.

Receive a broadcast and check if the picture is normal.

Press the INPUT button on the remote control to set to

4.

the AV mode.

5.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (46) on the remote control to

select "CNTXA".

Press the VOL. UP/DOWN button on the remote control

6.

until the contrast step No. becomes "76"

7.

Receive a broadcast and check if the picture is normal.

8.

Press the TV/DVD button on the remote control to set to

the DVD mode.

Activate the adjustment mode display of Fig. 1-1 and

9.

press the channel button (58) on the remote control to

select "CNTXD".

10.

Press the VOL. UP/DOWN button on the remote control

to set the same step numbers as the AV mode.

2-17: Confirmation of Fixed Value (step No.)

Please check if the fixed values of the each adjustment

items are set correctly referring below.

NO.

FUNCTION

07

BRIGHTNESS(MAX)

08

BRIGHTNESS(MIN)

10

COLOR(MAX)

11

COLOR(MIN)

13

SUB CONTRAST

14

CONTRAST(CENT.)

16

CONTRAST(MIN)

17

SHARPNESS

18

RGB CONTRAST

20

V POSITION

23

V S CORRECTION

24

EW PARABOLA CORR.

25

EW TRAPEZIUM CORR.

26

H SIZE

27

V EHT

28

H EHT

30

V CENTERING

31

CORNER CORR. TOP

32

CORNER CORR. BTM

34

FM LEVEL

35

TEST PWM

36

TEST TONE CONTROL

38

BRI. AV(MAX)

DATA

60

20

7F

00

0F

40

10

1E

14

02

09

00

20

00

00

00

32

00

00

3F

00

51

60

NO.

FUNCTION

39

BRI. AV(MIN)

41

COL. AV(MAX)

42

COL. AV(MIN)

44

SUB CONTRAST AV

45

CONT. AV(CENT.)

47

CONT. AV(MIN)

48

SHARPNESS AV

50

BRI. DVD(MAX)

51

BRI. DVD(MIN)

53

COL. DVD(MAX)

54

COL. DVD(MIN)

56

SUB CONTRAST DVD

57

CONT. DVD(CENT.)

59

CONT. DVD(MIN)

60

SHARPNESS DVD

61

BRI. GAME(CENT.)

62

BRI. GAME(MAX)

63

BRI. GAME(MIN)

64

CONT. GAME(CENT.)

65

CONT. GAME(MAX)

66

CONT. GAME(MIN)

67

TUNING V MUTE

68

POWER ON V MUTE

DATA

20

7F

00

0F

40

10

1E

60

20

7F

00

0F

40

10

1E

=AV

60

20

40

=AV

10

08

90

White 0%

White 100%

Red Level

0%

100%

Fig. 2-3

No. 52014 19

Page 20

AV-20FD23

ELECTRICAL ADJUSTMENTS

3.

PURITY AND CONVERGENCE

ADJUSTMENTS

NOTE

Turn the unit on and let it warm up for at least 30

1.

minutes before performing the following adjustments.

Place the CRT surface facing east or west to reduce the

2.

terrestrial magnetism.

Turn ON the unit and demagnetize with a Degauss Coil.

3.

3-1: STATIC CONVERGENCE (ROUGH ADJUSTMENT)

1.

Tighten the screw for the magnet. Refer to the adjusted

CRT for the position. (Refer to Fig. 3-1)

If the deflection yoke and magnet are in one body,

untighten the screw for the body.

2.

Receive the green raster pattern from the color bar

generator.

3.

Slide the deflection yoke until it touches the funnel

side of the CRT.

4.

Adjust center of screen to green, with red and blue on the

sides, using the pair of purity magnets.

5.

Switch the color bar generator from the green raster

pattern to the crosshatch pattern.

6.

Combine red and blue of the 3 color crosshatch pattern

on the center of the screen by adjusting the pair of

4 pole magnets.

7.

Combine red/blue (magenta) and green by adjusting the

pair of 6 pole magnets.

8.

Adjust the crosshatch pattern to change to white

by repeating steps 6 and 7.

3-2: PURITY

NOTE

Adjust after performing adjustments in section 3-1.

3-3: STATIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 3-2.

1.

Receive the crosshatch pattern from the color bar

generator.

2.

Combine red and blue of the 3 color crosshatch pattern

on the center of the screen by adjusting the pair of

4 pole magnets.

3.

Combine red/blue (magenta) and green by adjusting the

pair of 6 pole magnets.

3-4: DYNAMIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 3-3.

1.2.Adjust the differences around the screen by moving

the deflection yoke upward/downward and right/left.

(Refer to Fig. 3-2-a)

Insert three wedges between the deflection yoke and

CRT funnel to fix the deflection yoke.

(Refer to Fig. 3-2-b)

R G B

R

G

B

UPWARD/DOWNWARD SLANT RIGHT/LEFT SLANT

R

G

B

Fig. 3-2-a

R G B

1.

Receive the green raster pattern from color bar

generator.

2.

Adjust the pair of purity magnets to center the

color on the screen.

Adjust the pair of purity magnets so the color at the

ends are equally wide.

3.

Move the deflection yoke backward (to neck side)

slowly, and stop it at the position when the whole

screen is green.

4.

Confirm red and blue colors.

5.

Adjust the slant of the deflection yoke while watching the

screen, then tighten the fixing screw.

DEFLECTION YOKE

DEFLECTION YOKE SCREW

MAGNET SCREW

6 POLE MAGNETS

4 POLE MAGNETS

PURITY MAGNETS

Fig. 3-1

WEDGE

WEDGE

WEDGE

WEDGE POSITION

Fig. 3-2-b

20 No. 52014

Page 21

ELECTRICAL ADJUSTMENTS

4. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE (Connector Connections)

CRT PCB

CP805

CD805

CRT

J801

CP802B

TP024

TP022

CP803B

AV-20FD23

AC IN

POWER PCB

CRT

L3800

CP3803

CP3800

CD751

VR3800

TP3801

CP3802

SPEAKER

CD301

CP301

CP104

TU001

CD402

CD8001

CP802A

CD802

CP101

J4203

CP8005

CP8002

CD8002

J4202

J4201

CP803A

CP8001

CD803

CP402

CP8004

FB401

CP401

CP302

VR402

CRT

CD302

SPEAKER

CP751

OPERATION PCB

DECK CD

AV PCB

CD8501CD8502

CP8502

CP2601

CP2301

CP2302

DVD PCB

CD2301

CD2601

CD2302

No. 52014 21

Page 22

AV-20FD23

GUIDE FOR REPAIRING

IC DESCRIPTION

AV PCB OEC6070B (IC101)

No. Symbol I/O Logic Function

1 VSS - - Negative power supply (Ground)

2 X-RAY TEST Output 1 X-RAY test output

3 PROTECT Output 1

4 TV MUTE Output 1 Volume muting output

5 EXT MUTE Output 1 External picture/volume muting output

6 DVD RESET Output 0 Enforced reset output for DVD

7 TV POWER Output 1 Power control output

Output terminal for protect from high-voltage remaining

VOL.PWM/

8

STBY-H

9 UART CLOCK Output 1 The asynchronous clock output

10 UART START BIT Input 1 The entry for the asynchronous Start bit detection

11 RX Input - The communication DATA entry from the side of DVD

12 TX Output - The communication DATA output to the side of DVD

13 UART CLOCK IN Input - The asynchronous clock Input

14 H CONTROL Output 1

15 X-RAY IN Input - X-RAY detection input (nom. 0V)

16 AFT Input 1 Voltage of tuning input

17 KEY1 Input 0 Voltage of the TV button input

18 KEY2 Input 0 Voltage of the TV button input

19 TV/DVD Output 1

20 DEGAUSS Output 1 Degauss output

21 IIC BUS OFF Input 0 Serial clock/data stop input

22 OSD R Output 1 Red output of RGB image output

23 OSD G Output 1 Green output of RGB image output

24 OSD B Output 1 Blue output of RGB image output

25 OSD Y/BLK Output 1 Fast blanking control signal

26 Hsync Input 0 Horizontal synchronization input

27 Vsync Input 0 Vertical synchronization input

28 OVDD - - Positive power supply (+5V nom.)

29 OVCC - - Negative power supply (Ground)

30 TEST Input - Test input (connects with Ground)

31 XIN Input - Connect the main crystal.

32 XOUT Output - Connect the main crystal.

33 RESET Input 0 System reset voltage input

34 POWER FAIL Input 0 Power failure detection input

35 REMOCON Input 0 Remote control input

36 SD Input 0 Synchronization detector input

37 SCL Output - Serial clock output

38 SDA In/Output - Serial data Input/output

39 VSS - - Negative power supply (Ground)

40 VIDEO IN 1 Input - Picture signal input for the Closed Caption (2Vp-p)

41 VIDEO IN 2 Input - Picture signal input for the Closed Caption (2Vp-p)

42 VDD - - Positive power supply (+5V nom.)

Output 1

Puls width modulation output for the volume control /

Output High-Z at power off

Output terminal for Horizontality Control

TV/DVD picture signal changing output

22 No. 52014

Page 23

(DVD SECTION)

DVD DECK NO OPEN/CLOSE

AV-20FD23

TROUBLESHOOTING GUIDE

CHECK DISPLAY DVD

OSD.

No

CHECK CONNECTION

CD2302.

Yes

CHECK INPUT SIGNAL

IC1001 73, 74 PIN?

Yes

Yes

No

No

CONECTION TRY

AGAIN CD2302.

CHECK THE CIRCUIT

AROUND IC1001.

POSSIBLE TO

OPEN/CLOSE BY

MECHANIC.

Yes

DVD MODE

STABILITY.

No

CHANGE DVD

DECK.

No

CHANGE DVD DECK.

Yes

REFER TO

"INSTABILITY DVD

MODE".

CHECK OUTPUT SIGNAL

IC1001 64, 68 PIN?

Yes

CHECK THE CIRCUIT AROUND

IC2301.

No

CHANGE IC1001.

No. 52014 23

Page 24

AV-20FD23

TROUBLESHOOTING GUIDE

DVD NO PICTURE

CHECK CONNECTION

CD8002.

Yes

CHECK CONNECTION

CD8501, CD8502.

Yes

CHECK INPUT SIGNAL

5~8, 10, 11 PIN OF

CD8501 AND 1, 3, 5 PIN

OF CD8502.

Yes

No

No

No

CONNECTION TRY AGAIN

CD8002.

CONNECTION TRY AGAIN

CD8501, CD8502.

CHECK P.CON +5V LINE AND

P.CON+9V LINE, P.CON+3.3V

LINE.

CHECK OSILLATION

OF X1001.

Yes

CHANGE IC4001.

Yes

CHANGE IC2001.

Yes

CHANGE IC2602.

Yes

CHANGE IC1001.

No

24 No. 52014

CHANGE X1001.

Page 25

DVD, CD NO PLAY

("BLUE BACK LOGO" SHOW ON

SCREEN.)

AV-20FD23

TROUBLESHOOTING GUIDE

AFTER READING,CHECK

"INCORRECT DISC" DISPLAY.

Yes

No

WHEN PLAY,CHECK THE

DECK MOTOR MOVING.

No

CHECK CONNECTION

CD2301.

No

CONNECTION TRY AGAIN

CD2301.

Yes

Yes

CHANGE DVD DECK.

CHANGE DVD DECK.

CHECK CONNECTION

CD2601.

Yes

CHECK DVD DECK CONNECTION

BEND OR SHORT?

No

CONNECTION TRY AGAIN

CD2601.

No. 52014 25

Page 26

AV-20FD23

TROUBLESHOOTING GUIDE

INSTABILITY DVD MODE

CHECK CONNECTION

CD8002.

Yes

CHECK DVD DECK

CONNECTOR BAND

OR SHORT?

Yes

CHECK CONNECTION

CD2301,CD2601.

Yes

No

No

No

CONNECTION TRY AGAIN CD8002.

CHANGE DVD DECK.

CONNECTION TRY AGAIN

CD2301,CD2601.

CHANGE DVD DECK.

26 No. 52014

Page 27

(TV SECTION)

NO POWER(2)

AV-20FD23

TROUBLESHOOTING GUIDE

F501 OK?

YES

Is the voltage at

C3815 DC138V?

YES

Is the voltage at C3826

DC115V?

YES

Is the voltage at

pin28, 33, 34, 42 of

IC101 DC5V?

NO

NO

NO

NO

Change of F501.

Check R3817 and associated

circuit.

Check Q3803, D3810 and

associated circuit.

Check of AT5.6V line and

POWER FAIL line.

YES

Is DIGITAL signal

output from pin37, and

38 of IC101?

YES

Check IC199 ROM DATA and

IC101 associated circuit.

NO

Check of IC101 and

associated circuit.

No. 52014 27

Page 28

AV-20FD23

TROUBLESHOOTING GUIDE

NO SOUND

CD301&CD302 INSERT OK?

YES

Is the voltage at

pin1 of IC302

DC8V?

YES

Is the voltage at

pin5 of IC302

DC4.5V?

YES

Q301 OK?

NO

NO

NO

NO

INSERT CD301 & CD302.

Check SOUND +B Line.

Check POWER ON H Line

and associated circuit.

Check Q301 and A_MUTE Line.

YES

Is audio signal

input from pin14 of

IC902?

YES

Is audio signal

output from pin21

and 22 of IC902?

YES

Is audio signal

output from pin23

and 24 of IC902?

YES

Check IC301 and associated

circuit.

NO

NO

NO

Check SIF Line and associated

circuit.

Check IC902 and associated

circuit.

Check IC4203 and associated

circuit.

28 No. 52014

Page 29

NO PICTURE

AV-20FD23

TROUBLESHOOTING GUIDE

Is the setting of

the BRIGHT center

and CONTRAST max?

YES

Is the voltage at

pin23,36,53 of

IC601 DC9V?

YES

Is the voltage at

pin2,13 of IC601

DC5V?

YES

Is VIDEO signal

input from pin31 of

IC4203?

NO

NO

NO

NO

BRIGHT is adjusted to center,

CONTRAST is adjusted to max.

Check P.CON+9V Line.

Check P.CON+5V Line.

Check TV VIDEO line and

associated circuit.

YES

Is CHROMA signal

output from pin13 and

SYNC signal output

from pin15 of IC1501?

YES

Is CHROMA signal

output from pin6 and

SYNC signal output

from pin5 of IC602?

YES

Check R out line, G out line, B

OUT line and associated circuit.

NO

NO

Check MONITOR VIDEO line

and associated circuit.

Check IC602 and associated

circuit.

No. 52014 29

Page 30

AV-20FD23

TROUBLESHOOTING GUIDE

NO COLOR

Is the setting of the

COLOR central?

YES

Is the receiving of

the color signal?

YES

Is the waveform at

pin42 of IC601

normal?

YES

Check IC601 and associated

circuit

NO

NO

NO

Adjust the COLOR setting.

Receive the color signal.

Check X601 associated circuit.

30 No. 52014

Page 31

NO VERTICAL

AV-20FD23

TROUBLESHOOTING GUIDE

Is the normal signal

output to 38PIN of

IC601?

YES

Is the voltage at pin2

of IC401 DC25.5V?

YES

Check IC401 and associated

circuit.

NO

NO

Check IC601 associated

circuit.

Check FB401 and associated

circuit.

NO OSD

Is there the waveform

of 19, 20, 21 and also

22PIN of IC601?

YES

Check IC601 associated

circuit.

NO

Check IC101 associated

circuit.

No. 52014 31

Page 32

AV-20FD23

SERVICE NOTE :

32 No. 52014

Page 33

JVC SERVICE & ENGINEERING COMPANY OF AMERICA

DIVISION OF JVC AMERICAS CORP.

Head office :

East Coast :

Midwest :

West Coast : 5665 Corporate Avenue, Cypress, California 90630 (714)229-8011

Southwest : 10700 Hammerly, Suite 105, Houston, Texas 77043 (713)935-9331

Hawaii : 2969 Mapunapuna Place, Honolulu, Hawaii 96819 (808)833-5828

Southeast : 1500 Lakes Parkway, Lawrenceville, Georgia 30243 (770)339-2582

1700 Valley Road, Wayne, New Jersey 07470 (973)317-5000

10 New Maple Avenue, Pine Brook, New Jersey 07058 (973)396-1000

705 Enterprise St. Aurora, Illinois 60504

(630)851-7855

JVC CANADA INC.

Head office : 21 Finchdene Square Scarborough, Ontario M1X 1A7 (416)293-1311

Vancouver : 13040 Worster Court Richmond B.C. V6V 2B3 (604)270-1311

®

Printed in Japan

VP0205

SW

Loading...

Loading...