M5 and M10 Internet

Routers

Hardware Guide

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Part Number : 530–007247–01, Revision 3

This product includes the Envoy SNMP Engine, developed by Epilogue Technology, an Integrated Systems Company. Copyright

© 1986-1997, Epilogue Technology Corporation. All rights reserved. This program and its documentation were developed

at private expense, and no part of them is in the public domain.

This product includes memory allocation software developed by Mark Moraes, copyright © 1988, 1989, 1993, University of Toronto.

This product includes FreeBSD software developed by the University of California, Berkeley, and its contributors. All of the documentation and

software included in the 4.4BSD and 4.4BSD-Lite Releases is copyrighted by the Regents of the University of California. Copyright © 1979, 1980,

1983, 1986, 1988, 1989, 1991, 1992, 1993, 1994. The Regents of the University of California. All rights reserved.

GateD software copyright © 1995, the Regents of the University. All rights reserved. Gate Daemon was originated and developed through release

3.0 by Cornell University and its collaborators. Gated is based on Kirton’s EGP, UC Berkeley’s routing daemon (routed), and DCN’s HELLO routing

protocol. Development of Gated has been supported in part by the National Science Foundation. Portions of the GateD software copyright © 1988,

Regents of the University of California. All rights reserved. Portions of the GateD software copyright © 1991, D. L. S. Associa tes.

This product includes software developed by Maker Communications, Inc., Copyright © 1996, 1997, Maker Communications, Inc.

Juniper Networks is registered in the U.S. Patent and Trademark Office and in other countries as a trademark of Juniper Networks, Inc. ERX,

ESP, E-series, Internet Processor, J-Protect, JUNOS, JUNOScript, JUNOSe, M5, M7i, M10, M10i, M20, M40, M40e, M160, M-series, NMC-RX, SDX,

T320, T640, and T-series are trademarks of Juniper Networks, Inc. All other trademarks, servicemarks, registered trademarks, or registered

service marks

Copyright © 2003, Juniper Networks, Inc. All rights reserved.

M5 and M10 Internet Routers: Hardware Guide

Copyright © 2003, Juniper Networks, Inc.

All rights rese

are the property of their respective owners. All specifications are subject to change without notice.

rved. Printed in USA.

Writ er : Tony Ma uro

Editor: Stella

Illustrator: Faith Bradford

Covers and Template Design: Edmonds Design

Revision History

30 June 2003—Corrected and added component information.

07 October 2002—Corrected and added new component information.

12 March 2002—New edition—Changed book name and added PIC-related information.

03 Decembe r 2001—Fourth edition—Corrected AC power measurements.

10 May 2001—Third e

29 September 2000—Second edition—Corrected AC plug figure.

27 July 2000—First edition.

The information in this document is current as of the date listed in the revision history.

Juniper Networks a

otherwise revise this publication without notice.

Products made or so

M160, and T320 routers, T640 routing node, and the JUNOS and SDX-300 software) or components thereof might be covered by one or more of the

following patents that are owned by or licensed to Juniper Networks: U.S. Patent Nos. 5,473,599, 5,905,725, 5,909,440, 6,192,051, 6,333,650, 6,359,479,

6,406,312, 6,429,706, 6,459,579, 6,493,347, 6,538,518, 6,538,899, 6,552,918, 6,567,902, 6,578,186, and 6,590,785.

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. The JUNOS software has no known time-related limitations through the year

2038. However, the NTP application is known to have some difficulty in the year 2036.

Hackell

dition—Added four-post rack mounting instructions.

ssumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify, transfer or

ld by Juniper Networks (including the ERX-310, ERX-705, ERX-710, ERX-1410, ERX-1440, M5, M7i, M10, M10i, M20, M40, M40e,

ii

Table of Con

tents

About This Manual .......................................... ............................................... ...... xv

Objectives

Audience.......................................... ............................................... ...... xv

Document Org

Documentation Conventions. ............................................... .........................xvi

List of Techni

Documentation Feedback ............... .............................................. ...............xix

How to Request S

Part 1

Product Overview

Chapter 1

System Overvi

System Description .............. .............................................. ........................ 3

Field-Replac

Safety Requirements, Warnings, and Guidelines ........................ ............................. 4

................................ ............................................ ................. xv

anization ......................... ............................................ .........xvi

General Conve

Notes, Cautions, and Warnings.............................................. ...................xvii

............................... ........................................... ........................ 3

ew

ntions................... .............................................. ............xvi

cal Publications.......................................................... ..............xvii

upport................. ............................................ .................xix

eable Units (FRUs).......................... ............................................ .. 3

Chapter 2

Hardware Component Overview .. ............................................... .......................... 5

Chassis ................... .............................................. ................................ 5

Packet Forwarding Engine.......... .............................................. ..................... 8

Midplane ................. ............................................ ............................. 8

Physical Interface Cards (PICs)........ ........................................... ................ 9

PIC Components................................................... ......................... 10

Flexible PIC Concentrators (FPCs) ............................................. ................. 10

Forwarding Engine Board (FEB)..................... ............................................ 10

FEB Components .............................. ............................................ . 11

Routing Engine........................... .............................................. ............... 12

Routing Engine Components................................................ .................... 13

Craft Interface.............. ............................................... ............................ 14

Alarm LEDs and Lamp Test Button ...................... ....................................... 15

Routing Engine Interface Ports and Status Indicators................... ....................... 15

PIC Offline Buttons ....................... .............................................. ......... 16

Ta b l e o f C on t e nt s

iii

Power Supplies...................... .............................................. .................... 16

AC Power Supply.................................... ............................................. 17

DC Power Supply ...................... .............................................. ............ 18

Power Supply LEDs and Self-test Button.................... .................................... 19

Fan Tray .......................................... ............................................... ...... 19

Cable Management System . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 20

Chapter 3

JUNOS Internet Software Overview ............................. ....................................... 21

Routing Engine Software Components ............... .............................................. . 21

Routing Protocol Process.............. .............................................. ............ 22

IPv4 Routing Protocols ...................... .............................................. . 22

IPv6 Routing Protocols ...................... .............................................. . 24

Routing and Forwarding Tables ..... .............................................. ......... 24

Routing Policy.................................. ............................................. 25

VPNs...................... ............................................... ......................... 26

Interface Process............................... ............................................ ...... 26

Chassis Process ....... ............................................... ............................ 26

SNMP and MIB II Processes ................... ............................................ ...... 26

Management Process. . .. . .. . .. . .. . .. . .. . ... ... ... .. . .. . ... ... ... ... ... ... ... ... ... ... ... ... ... .. 27

Routing Engine Kernel............................................... ............................ 27

Tools for Accessing and Configuring the Software.................................................. .27

Tools for Monitoring the Software..................... .............................................. .27

Software Upgrades.................................. .............................................. .... 28

Chapter 4

System Architecture Overview ... ............................................... ......................... 29

Packet Forwarding E

Data Flow through the Packet Forwarding Engine ............................... .............. 30

RoutingEngineArch

Routing Engine Functions ..................................... .................................. 32

ngine Architecture............ .............................................. .... 29

itecture..................... ............................................... ...... 31

Part 2

Initial Installation

Chapter 5

Prepare for Router Installation......... .............................................. .................... 37

Rack Requirements

Rack Size and Strength ................... .............................................. ......... 37

Spacing of Mounting

Connection to Building Structure ................................... ............................ 39

Clearance Requirem

Router Environmental Tolerances..................... .............................................. . 40

Fire Safety Requirem

Fire Suppression .......................... .............................................. ......... 41

Fire Suppression Equ

................................. ............................................ ...... 37

Holes............................................. ......................... 39

ents for Airflow and Hardware Maintenance.................................. 40

ents............. ............................................... ................. 41

ipment .................................. .................................. 41

iv M5 and M10 Internet Routers Hardware Guide

Power Guidelines, Requirements, and Specifications ................ ............................... 42

Site Electrical Wiring Guidelines ........... ............................................... ...... 43

Distance Limitations for Signaling ............. ............................................ 43

Radio Frequency Interference ................ ............................................ . 43

Electromagnetic Compatibility.............................. ............................... 43

Router Power Requirements ........................................ ............................ 43

AC Grounding and Power Cord Specifications................................. ................. 45

DC Grounding, Connection, and Cable Specifications ................ ......................... 46

Network Cable Specifications and Guidelines ........................... ............................ 48

Fiber Optic and Network Cable Specifications ....... .......................................... 48

Signal Loss in Multimode and Single-Mode Fiber-Optic Cable................................. 48

Attenuation and Dispersion in Fiber-Optic Cable ..................... ......................... 49

Calculating Power Budget for Fiber-Optic Cable....................... ......................... 49

Calculating Power Margin for Fiber-Optic Cable............................ .................... 50

Attenuate to Prevent Saturation at SONET/SDH PICs .......................................... 51

Cable Specifications for Routing Engine Management Interfaces ... ... ... ... ... ... ... ... ... ... ... . 52

Site Preparation Checklist ........................................ .................................... 52

Chapter 6

Unpack the Router............ ............................................... .................................... 55

Tools Required ... .............................................. ....................................... 55

Unpack the Router ............................... ............................................... ...... 55

Choose Front or Cente

r Mounting ....................................... ............................ 57

Chapter 7

Install the Router ................ .............................................. .................................. 59

Tools and Parts Required ...................... .............................................. ......... 59

Install the Chassis into the Rack............................... ....................................... 59

Chapter 8

Connect the Router and Perform Initial Configuration............... ....................... 61

Tools and Parts Required ...................... .............................................. ......... 61

Connect the Router to Management Devices. . .. . ... ... ... ... ... ... ... ... ... ... . .. . .. . .. . .. . .. . .. . .. 61

Connect to a Network for Out-of-Band Management ... ... . .. . .. . .. . .. . .. . .. . .. . .. ... . .. . .. . .. 62

Connect to a Management Console or Auxiliary D evice . .. . .. . .. . .. . ... ... ... ... ... ... ... ... .. 63

Connect PIC Cables .................................... ........................................... .... 63

Provide Power to the Router................................... ....................................... 65

Connect Power to an AC-Powered Router ............................. ......................... 65

Connect Power to a DC-Powered Router.................................................. ...... 66

Power On the Router ..................... .............................................. ......... 67

Configure the JUNOS Internet Software............... ........................................... .... 69

Ta b l e o f C o n t e n t s

v

Part 3

Hardware Maintenance, Replacement, and Troubleshooting

Procedures

Chapter 9

Maintain Hardware Components .......................... .............................................. . 75

Routine Maintenance Procedures.......... .............................................. ............ 75

Maintain the Fan Tray.......................... .............................................. ......... 75

Maintain Packet Forwarding Engine Components............................ ....................... 76

Maintain the FEB.......................... .............................................. ......... 76

Maintain PICs and PIC Cables. ........................................... ....................... 76

Maintain the Power Supplies ....................... .............................................. .... 78

Maintain the Routing Engine ............................. ............................................ 79

Chapter 10

Replace Hardw

are Components

Tools and Parts Required ...................... .............................................. ......... 81

Replace the Fa

Remove the Fan Tray .................. ........................................... ............... 82

Install the Fan

Replace Packet Forwarding Engine Components..................... ............................... 84

Replace the FEB

Replace a PIC ..................................... .............................................. . 87

Replace PIC Cable

Replace an SFP.............................. ............................................... ...... 95

Replace Power Syste

Replace an AC Power Supply............................. ....................................... 98

Disconnect and Conne

Replace an AC Power Cord ....................... ........................................... ...103

Replace a DC Power Supp

Disconnect and Connect DC Power............................................... .............108

Replace Routing Engine C

Remove and Insert the PC Card.......................................... ...................... 112

n Tray.............................................. .................................... 82

Tray.......... ............................................ ......................... 83

Remove the FEB .......................... .............................................. .... 85

Install the FEB .................................... .......................................... 8

Remove a PIC.... ............................................... ............................ 87

Install a PIC ............ .............................................. ....................... 89

Remove a PIC Cable... .............................................. ....................... 92

Install a PIC Cable

Remove an SFP ........................................... .................................. 95

Install an SFP .. .............................................. ............................... 96

m Components ........................................ ......................... 98

Remove an AC Power Sup

Install an AC Power Supply............................................. ...................100

Disconnect AC Power from the Router ........................ ...........................102

Connect AC Power to the

Remove a DC Power Supply......................... ......................................104

Install a DC Power Suppl

Disconnect DC Power from

Connect DC Power to the Router ................................. ........................ 110

Remove the PC Card ....... ............................................... ................ 113

................................ .......................................... 81

................................ ............................................ ...... 84

s ......... .............................................. ....................... 92

................................ .......................................... 93

ply ............ .............................................. .... 99

ct AC Power ...................... ...................................... 101

Router............................ ..............................102

ly ......................................... ...........................104

y........... ........................................... ...........106

the Router..... ..............................................109

omponents ........................... ................................... 112

6

vi M5 and M10 Internet Routers Hardware Guide

Insert the PC Card .. ............................................... ........................ 114

Replace the Routing Engine... ........................................... ...................... 115

Remove the Routing Engine ...................................... ........................ 115

Install the Routing Engine..................... ............................................ 116

Replace Connectors to Routing Engine Interface Ports ....................................... 118

Replace the Management E thernet Cable ... ... ... ... ... ... ... ... .. . ... ... ... ... ... ... ... 118

Replace the Console or Auxiliary Cable................................ ................... 119

Chapter 11

Troubleshoot Hardware Components ................... ........................................... ...121

Overview of Trou

Command-Line Interface ...................................... .................................121

LEDs .............................. ............................................... ................122

LEDs on the Craft Interface ............................................ ...................122

LEDs on Hardware C

Hardware and Interface Alarm Messages. . .. . .. . .. . .. . .. . .. . .. . .. . .. . ... ... ... ... ... ... ... ... .122

Juniper Networks T

Troubleshoot the Fan Tray............... .............................................. ..............124

Tro u b le s ho o t Pack

Troubleshoot the FEB............ ............................................ ...................125

Troubleshoot PICs.................................................... ...........................1

Troubleshoot the Power System............................... ......................................125

LED on Both Supplies I

LED on One Supply Is Off.. .............................................. ......................126

bleshooting Resources ...................................... ......................121

omponents.................................. ........................122

echnical Assistance Center ............................................. ...124

et Forwarding Engine Components............... ..............................124

s Off.............. ........................................... ...........126

Part 4

Appendixes

Appendix A

Safety and Regulatory Compliance Information.... ...........................................129

Definition of Safet

Safety Guidelines and Warnings............................................. ........................131

General Safety Guid

Qualified Personnel Warning................................ ..............................132

Restricted Access Ar

Prevent Electrostatic Discharge Damage ...................... ...........................134

Electrical Safety Gu

General Electrical Safety Guidelines ................... ...................................136

AC Power Electrical Sa

DC Power Electrical Safety Guidelines......... ...........................................137

Copper Conductors War

DC Power Disconnection Warning..................... ...................................138

DC Power Grounding Requ

DC Power Wiring Sequence Warning............ .........................................140

DC Power Wiring Terminat

Grounded Equipment Warning ................................... ........................142

In Case of Electrical Acc

Midplane Energy Hazard Warning .......... ..............................................143

Multiple Power Supplies D

y Warning Levels...................... ...........................................129

elines and Warnings ........ ..............................................131

ea Warning .... .............................................. ........133

idelines and Warnings.....................................................135

fety Guidelines ................................. ...................136

ning ..................................... ........................138

irements and Warning .......................................139

ions Warning ................ .................................141

ident ....... ........................................... ...........143

isconnection Warning ............. ...........................144

25

Ta b l e o f C on t e nt s

vii

Power Disconnection Warning...... ........................................... ...........144

TN and IT Power Warning........................... ......................................145

Installation Safety Guidelines and Warnings ............................................. .....146

Chassis Lifting Guidelines ........................ .........................................146

Installation Instructions Warning ........ ............................................ .....147

Rack-Mounting Requirements and Warnings.............................................147

Ramp Warning................................. ............................................151

Laser and LED Safety Guidelines and Warnings...............................................152

General Laser Safety Guidelines........................................ ...................152

Class 1 Laser Product Warning................................. ...........................153

Class 1 LED Product Warning. .............................................. ..............153

Laser Beam Warning .......... .............................................. ..............154

Radiation From Open Port Apertures Warning..................... ......................154

Maintenance and Operational Safety Guidelines and Warnings..............................155

Battery Handling Warning................................... ..............................155

Jewelry Removal Warning ................................... ..............................156

Lightning Activity Warning ........................................ ........................157

Operating Temperature Warning.......................................... ................158

Product Disposal Warning........................................... ......................159

Agency Approvals................ .............................................. ......................160

Compliance Statements for EMC Requirements................................. ...................161

Canada ........................... ............................................... ................161

European Community ....................................... ...................................161

Japan ........................................... .............................................. ...161

Taiwan.................... ............................................... ........................161

United States ................................ ............................................... .....162

Appendix B

Return the Router or Its Components ................................. ..............................163

Tools and Parts Required ...................... .............................................. ........163

Return Procedure ........................ .............................................. ..............163

Locate Component Serial Numbers ............. ............................................... .....164

FEB Serial Number ID Label................................................. ...................165

PIC Serial Number ID Label ...................... ..............................................165

Power Supply Serial Number ID Label............. ............................................166

Routing Engine Serial Number ID Label .......................................... .............167

Pack the Router for Shipment ......................................... ..............................168

Pack Components for Shipment ............................................ ........................169

Appendix C

Cable Connector Pinouts .... ............................................ ...................................171

RJ-45 Connector Pinouts

DB-9 Connector Pinouts for the Routing Engine AUX/MODEM and CONSOLE Ports... ... ... ... .171

RJ-48 Cable Pinouts for E

RJ-21 Cable Pinouts for Fast Ethernet 12-Port PIC..................................................175

for the Routing Engine MGMT Port.................................... ..171

1 and T1 PICs ......................................... ...................172

Part 5

Index ................................. ............................................ ......................................177

viii M5 and M10 Internet Routers Hardware Guide

Index

Index ................................. ............................................ ......................................179

Ta b l e o f C o n t e n t s

ix

x M5 and M10 Internet Routers Hardware Guide

List of Figures

List of Figur

Figure 1: Front of M5 Chassis..................................... .............................................. ................ 6

Figure 2: Fro

Figure 3: Rear of Chassis..................................... .............................................. ..................... 7

Figure 4: Mid

Figure 5: Forwarding Engine Board..................................................... ....................................... 12

Figure 6: Rout

Figure 7: Craft Interface ........................................... ............................................ ................. 14

Figure 8: AC Pow

Figure 9: DC Power Supply..................... ............................................ .................................... 18

Figure 10: Airf

Figure 11: Cable Management System .. . .. . .. . .. . .. . .. . ... ... ... ... ... ... ... ... ... . .. . .. . .. . .. . .. . .. . ... ... ... ... ... ... ... ... 20

Figure 12: Syste

Figure 13: Packet Forwarding Engine Components and Data Flow..... ............................................... ...... 31

Figure 14: Routin

Figure 15: Control Packet Handling for Routing and Forwarding Table Updates .. .......................................... 33

Figure 16: Typical

Figure 17: Chassis Dimensions and Clearance Requirements ................................ ............................... 40

Figure 18: AC Plug T

Figure 19: DC Power and Grounding Cable Connections................... .............................................. .... 47

Figure 20: Unpack th

Figure 21: Routing Engine Management Ports. ... ... ... ... ... ... ... ... ... ... ... . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . ... .. . .. . 62

Figure 22: Routing E

Figure 23: Console and Auxiliary Serial Port Connector................. ............................................... ...... 63

Figure 24: Attach Cab

Figure 25: Connect DC Power and Grounding Cables ...... .............................................. .................... 67

Figure 26: Remove the F

Figure 27: Install the Fan Tray ...... ............................................ .............................................. . 84

Figure 28: Remove the F

Figure 29: Install the FEB ........................... ............................................... ............................ 87

Figure 30: Remove a PIC............ ............................................ .............................................. . 8

Figure 31: Install a PIC ............................................ ............................................ ................. 92

Figure 32: Connect Fibe

Figure 33: Small Form Factor Pluggable (SFP) .. ... . .. ... . .. . .. . ... ... ... ... ... . .. . .. . ... ... ... ... ... ... . .. . .. . ... ... ... ... ... 95

Figure 34: Remove an AC Po

Figure 35: Install an AC Power Supply............................... .............................................. ...........101

Figure 36: Remove a DC Powe

Figure 37: Install a DC Power Supply............................. .............................................. ..............108

Figure 38: Connect Power C

Figure 39: Connect Power Cables to a DC Power Supply..... ............................................... ................ 112

Figure 40: Remove the PC Car

Figure 41: Insert the PC Card .... ............................................... .............................................. 115

Figure 42: Remove the Routi

Figure 43: Install the Routing Engine.................. ............................................... ........................ 118

Figure 44: Routing Engine In

Figure 45: Ethernet Cable Connector................................................ ......................................... 119

Figure 46: Serial Port Connec

Figure 47: Place a Component into an Electrostatic Bag ... .............................................. ...................135

Figure 48: Serial Number ID La

nt of M10 Chassis ............. ............................................ ........................................ 6

plane.................................................... .............................................. ............. 9

ing Engine.................... ............................................... .................................... 14

er Supply ........................................... .............................................. ............ 17

low through the Chassis ........................ ............................................... ................. 19

m Architecture ........................... .............................................. ....................... 29

g Engine Architecture .. .............................................. ....................................... 32

es

Center-Mount Rack.......................................................... ............................... 39

ypes. ............................................... .............................................. ......... 46

e Router..................... .............................................. ............................... 56

ngine Ethernet Cable Connector ......................... .............................................. . 63

le to a PIC ............................. .............................................. .................... 65

an Tray .......................................... ............................................... ...... 83

EB .................................... ............................................... ................. 86

r-Optic Cable to a PIC......................... .............................................. ......... 95

wer Supply ............................ ........................................... ..............100

r Supply................................. ........................................... ...........106

ables to a DC Power Supply........... ............................................ .............108

d ........................................ .............................................. ........ 114

ng Engine ..................................... .............................................. ... 116

terface Ports and Alarm Relay Contacts ................... ................................... 118

tor..................................... ........................................... ..............120

bel ............................... .............................................. ..............165

9

List of Figures

xi

List of Figures

Figure 49: FEB Serial Number ID Label ..................... ........................................... ......................165

Figure 50: PIC

Figure 51: AC Power Supply Serial Number ID Label ............ ............................................ ................166

Figure 52: DC Po

Figure 53: Routing Engine 333 Serial Number ID Label ....................................... ..............................167

Figure 54: Routi

Figure 55: Fast Ethernet 12-port PIC ..... ........................................... .........................................175

Figure 56: VHDCI

Serial Number ID Label ................ ............................................... ........................166

wer Supply Serial Number ID Label.......................................................... ..............167

ng Engine 600 Serial Number ID Label .................................... .................................168

to RJ-21 Cable............................................................. .................................175

xii M5 and M10 Internet Routers Hardware Guide

List of Tables

List of Tables

Table 1: Juniper Networks Technical Documentation ...................................... .....................................

Table 2: Field-Replaceable Units .................. .............................................. ................................ 4

Table 3: Chassis Physical Specifications ............................................. ........................................... 7

Table 4: Alarm LEDs and Lamp Test Button .................. ............................................... ................. 15

Table 5: Electrical Specifications for AC Power Supply...................................... .................................. 18

Table 6: Electrical Specifications for DC Power Supply ..................... .............................................. .... 18

Table 7: States for Power Supply LED................................................ .......................................... 19

Table 8: Router Environmental Tolerances .... .............................................. .................................. 40

Table 9: Component Power Requirements ....................... ............................................... .............. 44

Table 10: AC Power Cord Specifications .......... .............................................. ............................... 45

Table 11: DC Power and Grounding Cable Specifications... .............................................. .................... 46

Table 12: Estimated Values for Factors Causing Link Loss ...................... ........................................... .50

Table 13: Cable Specifications for Routing Engine Management Interfaces ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 52

Table 14: Site Preparation Checklist ................... ............................................ ............................ 52

Table 15: Generic Inventory of Router Components.......... ............................................... ................. 56

Table 16: Tools and Parts Required ............ .............................................. .................................. 81

Table 17: Chassis Alarm Messages.. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . ... .. . .. . .. . .. . .. . .. . ... ... ... ... .. . ..123

Table 18: SONET/SDH Interface Alarm Messages .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . ... ... ... .. . .. . .. . .. . ... ... ... ...123

Table 19: RJ-45 Connector Pinout....................................... .............................................. ........171

Table 20: DB-9 Connector Pinout ......... .............................................. ......................................172

Table 21: RJ-48 Connector to RJ-48 Connector (Straight) Pinout ........................... .................................172

Table 22: RJ-48 Connector to RJ-48 Connector (Crossover) Pinout.................................. ........................173

Table 23: RJ-48 Connector to DB-15 Connector (Straight) Pinout ........................................... ................174

Table 24: RJ-48 Connector to DB-15 Connector (Crossover) Pinout...................... ...................................174

Table 25: RJ-21 Pin Assignments........................................ .............................................. ........176

List of Tables

xiii

List of Tables

xiv M5 and M10 Internet Routers Hardware Guide

About This Manual

This chapter provides a high-level overview of the M5 and M10 Internet Routers Hardware

Guide:

• Objectives on page xv

• Audience on page xv

• Document Organization on page xvi

Objectives

• Documentatio

n Conventions on page xvi

• List of Technical Publications on page xvii

• Documentation Feedback on page xix

• How to Request Support on page xix

This manual explains the hardware installation and basic troubleshooting for the M5 and

M10 Internet routers. It contains procedures for preparing your site for router installation,

unpacking and installing the hardware, starting up the router, performing initial software

configuration, and doing routine maintenance and upgrades. After completing the installation

and basic configuration procedures covered in this manual, refer to the JUNOS Internet

software configuration guides for information about fu rther configuring the JUNOS software.

To obtain additional information about Juniper Networks Internet routers and the Physical

Interface Cards (PICs) they support—either corrections to information in this manual or

information that might have been omitted from this manual—refer to the hardware release

notes.

To obtain the most current version of this manual, the most current version of the

hardware release notes, an d other Juniper Networks technical d ocumentation, refer to

the product documentation page on the Juniper Networks Web site, which is located at

http://www.juniper.net.

Audience

To order printed copies of this manual or to order a documentation CD-ROM, which contains

this manual, please contact your sales representative.

This manual is designed for network administrators who are installing and maintaining a

Juniper Networks router, or preparing a site for router installation. It assumes a broad

understanding o f networks in general, the Internet in particular, networking principles, and

About This Manual

xv

Documentation Co

nventions

network configuration. Any detailed discussion of these concepts is beyond the scope of

this manual.

Document Organization

This manual is divided into several parts:

• Preface "About This Manual" (this chapter), provides a brief description of the contents

• Part 1, "Product Overview," provides an overview of the router, describing its hardware

• Part 2, "Initial Installation," describes how to prepare your site for router installation,

and organization of this manual and describes how to contact customer support.

components, the JUNOS Internet software, and the system architecture.

and how to unpack, install, and power on the router. It describes requirements and

specificati

provides detailed safety guidelines and warnings.

ons for the installation site, power source, rack, wiring, and cabling. It also

Documentat

General Con

• Part 3, "Hard

describes how to maintain, replace, and troubleshoot router components.

This manual

ion Conventions

ventions

This manual uses t he following text conventions:

• Router and router component labels are shown in a sans serif font. In the following

example, ETHERNET is the label for the Ethernet management port on the router:

The 10/100-Mbps Ethernet RJ-45 connector is used for out-of-band management of

the router and is labeled ETHERNET.

• Statements, commands, filenames, directory names, IP addresses, and configuration

hierarchy l evels are shown in a sans serif font. In the following example, stub is a

statement

Toconfigureastubarea,includethestub statement at the [edit protocols ospf area

area-id ] h

ware Maintenance, Replacement, and Troubleshooting Procedures,"

also contains a complete index.

name and [edit protocols ospf area area-id] is a configuration hierarchy level:

ierarchy level.

• In examples, text that you type literally is shown in bold. In the following example, you

type the wo

For example, you can use the following command to get information about the source

of an alar

rds show chassis alarms:

m condition:

user@host> show chassis alarms

xvi M5 and M10 Internet Routers Hardware Guide

Notes, Cautions, and Warnings

List of Technical

Publications

Notes, cautio

ns, and warnings are denoted by the following symbols:

A note indicates information that might be helpful in a particular situation or

that might oth

A caution indicates a situation that requires careful attention. Failure to

observe a cautionary note could result in minor injury or discomfort to

yourself, or serious damage to the router.

A warning indicates a potentially dangerous situation. Failure to follow the

guidelines in a warning could result in severe injury or death.

erwise be overlooked.

List of Technical Publications

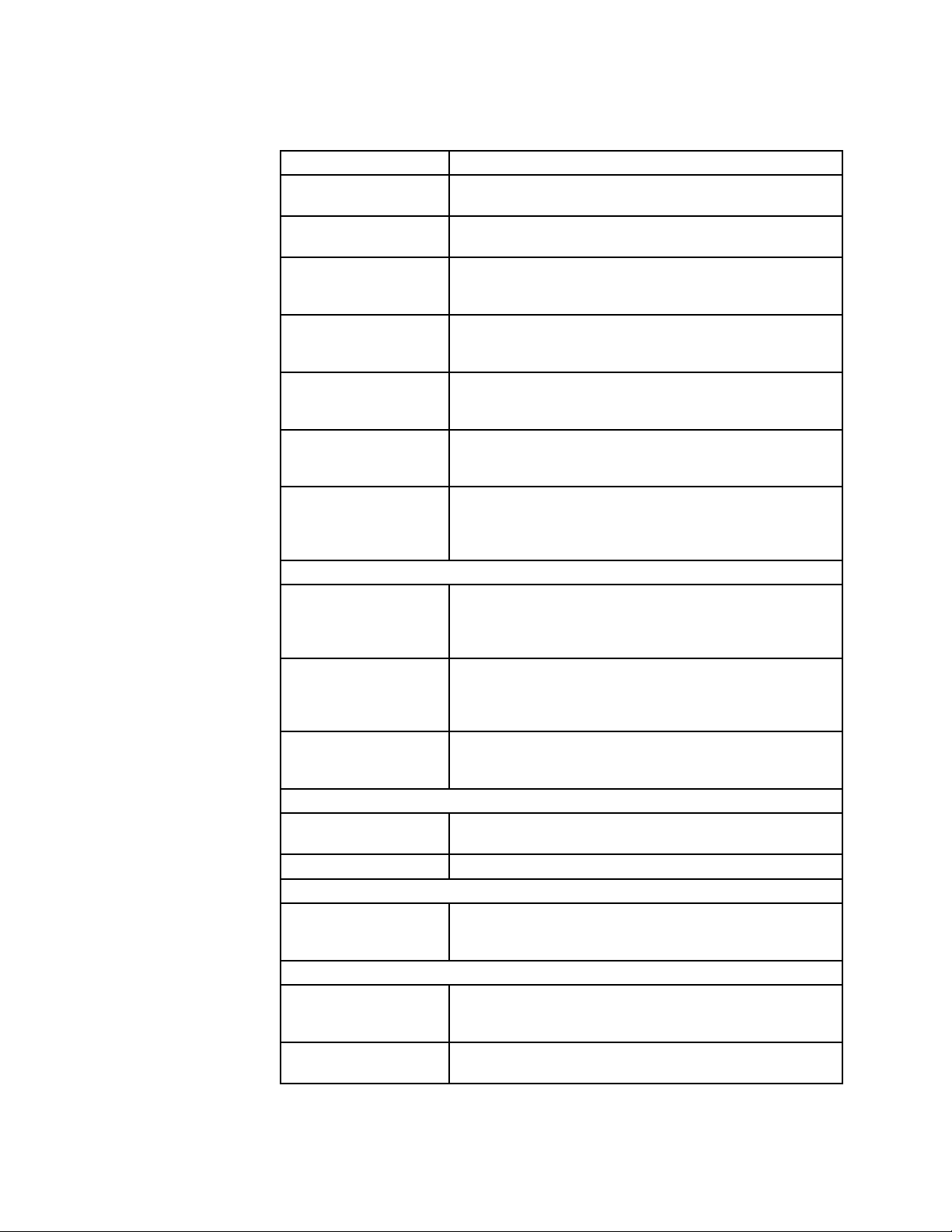

Ta b l e 1 l

contents of each book.

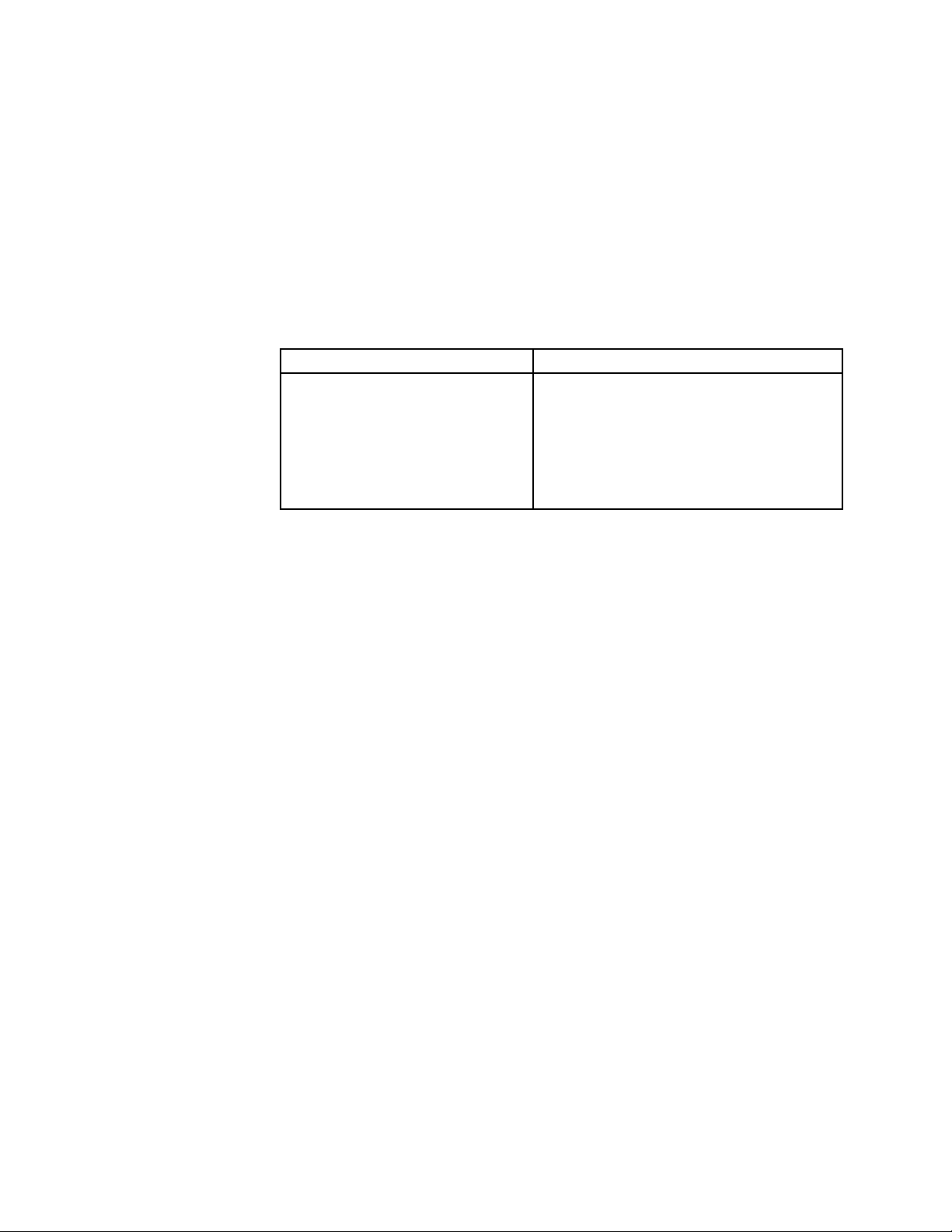

Table 1: Juniper Networks Technical Documentation

ists the software and hardware books for Juniper Networks routers and describes the

Book Description

JUNOS Internet Software Configuration Guides

Feature Guide

Getting Started

Network Interfaces and

Class of Service

s a detailed explanation and configuration examples for

Provide

several of the most complex features in the JUNOS software.

Provides an overview of the JUNOS Internet software and

describes how to install and upgrade the software. This

manual also describes how to configure system management

functions and how to configure the chassis, including user

accounts, passwords, and redundancy.

Provides an overview of the network interface and

class-of-service functions of the JUNOS Internet software and

describes how to configure the network interfaces on the

router.

About This Manual xvii

List of Technical

Publications

Book Description

MPLS Applications

Multicast

Network Management

Policy Framework

Routing and Routing

Protocols

Services Interfaces

VPNs

JUNOS Internet Software References

Operational Mode

Command Reference:

Interfaces

Operational Mode

Command Reference:

Protocols, Class of Service,

Chassis, and Management

System Log Messages

Reference

JUNOScript API Documentation

JUNOScript API Guide

JUNOScript API Reference

JUNOS Internet Software Comprehensive Index and Glossary

Comprehensive Index and

Glossary

Hardware Documentation

Hardware Guide

PIC Guide

Provides an overview of traffic engineering concepts and

describes how to configure traffic engineering protocols.

Provides an overview of multicast concepts and describes how

to configure multicast routing protocols.

Provides an overview of network management concepts and

describes how

to configure various network management

features, such as SNMP, accounting options, and cflowd.

Provides an overview of policy concepts and describes how

to configure routing policy, firewall filters, and forwarding

options.

Provides an overview of routing concepts and describes how

to configure routing, routing instances, and unicast routing

protocols.

Provides an o

verview of the services interfaces functions of the

JUNOSsoftwareanddescribeshowtoconfiguretheservices

interfaces o

ntherouter.

Provides an overview and describes how to configure Layer

2 and Layer 3 Virtual Private Networks (VPNs), Virtual

Private LAN Service (VPLS), and Layer 2 circuits. Provides

configuration examples.

Describes the JUNOS Internet so ftware operational mode

commands yo

u use to monitor and troubleshoot network and

services interfaces on Juniper Networks M-series and T-series

routers.

Describes the JUNOS Internet so ftware operational mode

commands you use to monitor and troubleshoot most aspects

of Juniper Networks M-series and T-series routers.

Describes how to access and interpret system log messages

generated by JUNOS software modules and provides a

reference page for each message.

Describes how to use the JUNOScript API to monitor and

configure Juniper Networks routers.

Provides a reference page for each tag in the JUNOScript API.

Provides a complete index of all JUNOS Internet software

books and the JUNOScript API Guide.Alsoprovidesa

comprehensive glossary.

Describes how to install, maintain, and troubleshoot routers

and router components. Each platform has its own hardware

guide.

Describes the router Physical Interface Cards (PICs). Each

router platform has its own PIC guide.

xviii M5 and M10 Internet Routers Hardware Guide

Book Description

JUNOScope Software Documentation

JUNOScope Software

Guide

Release Notes

JUNOS Internet Software

Release Notes

Hardware Release Notes

JUNOScope Software

Release Notes

Describes the JUNOScope software graphical user interface

(GUI), how to install and administer the software, and how

to use the software to manage router configuration files and

monitor router operations.

Provide a summary of new features for a particular software

release. Software release notes also contain corrections and

updates to published JUNOS and JUNOScript manuals, provide

information that might have been omitted from the manuals,

and describe upgrade and downgrade procedures.

Describe the available documentation for the router platform

and summarize known problems with t he hardware and

accompanying software. Each platform has its own release

notes.

Contain corr

manual, provide information that might have been omitted

from the manu

procedures.

How to Request Sup

ections and updates to the published JUNOScope

al, and describe upgrade and downgrade

port

Documentation Feedback

We are always interested in hearing from our customers. Please let us know what you

like and do not like about the Juniper Networks documentation, and let us know of any

suggestions you have for improving the documentation. Also, let us know if you find any

mistakes in the documentation. Send your feedback to techpubs-comments@juniper.net.

How to Request Support

For technical support, contact Juniper Networks at support@juniper.net, or at 1-888-314-JTAC

(within the United States) or 1-408-745-9500 (from outside the United States).

About This Manual

xix

How to Request Sup

port

xx M5 and M10 Internet Routers Hardware Guide

Part 1

Product Overview

• System Overview on page 3

• Hardware Component Overview on page 5

• JUNOS I nternet Software Overview on page 21

• System Architecture Overview on page 29

1

2 M5 and M10 Internet Routers Hardware Guide

Chapter 1

System Overview

This chapter provides an overview of the Juniper Networks M5 and M10 Internet routers,

discussing

• System Description on page 3

• Field-Replaceable Units (FRUs) on page 3

• Safety Requirements, Warnings, and Guidelines on page 4

System Description

The M5 and M10 Internet routers provide high-speed interfaces for medium and large

networks and network applications, such as those supported by Internet service providers

(ISPs). Application-specific integrated circuits (ASICs), a definitive part of the router design,

enable the router to forward data at the high speeds demanded by current network media.

The M5 router supports up to four Physical Interface Cards (PICs), and the M10 router

supports up to eight PICs. Each PIC accepts a specific type of network media, providing up to

16 physical interface ports per system o n the M5 router and up to 32 ports per system on the

M10 router. The router height of 5.25 in. (13.3 cm) enables stacked installation of 14 M5 or

M10 routers in a single floor-to-ceiling rack, for increased port density per unit of floor space.

the following topics:

The router’s maximum aggregate throughput is 6.4 gigabits per second (Gbps), full duplex.

The router provides very high throughput for any combination of PICs that does not exceed 3

Gbps for the M5 router or 6 Gbps for the M10 router. A combination that exceeds these

numbersissupported,butconstitutes oversubscription.

The router architecture cleanly separates control operations from packet forwarding

operations, which helps to eliminate processing and traffic bottlenecks. Control operations in

the router are performed by the Routing Engine, which runs JUNOS Internet software to

handle routing protocols, traffic engineering, policy, policing, monitoring, and configuration

management. Forwarding operations in the router are performed by the Packet Forwarding

Engine, which consists of hardware, including ASICs, designed by Juniper Networks.

Field-Replaceable Units (FRUs)

Field-replaceable units (FRUs) are router components that can be replaced at the customer

site. Replacing most FRUs requires minimal router downtime. The router uses the following

types of FRUs:

System Overview

3

Safety Requireme

nts, Warnings, and Guidelines

• Hot-removable and hot-insertable FRUs—You can remove and replace these

components without powering down the router or disrupting the routing functions.

• FRUs that require powering down the router—You must power down the router before

removing these components.

Table 2 lists the FRUs for the M5 and M10 routers.

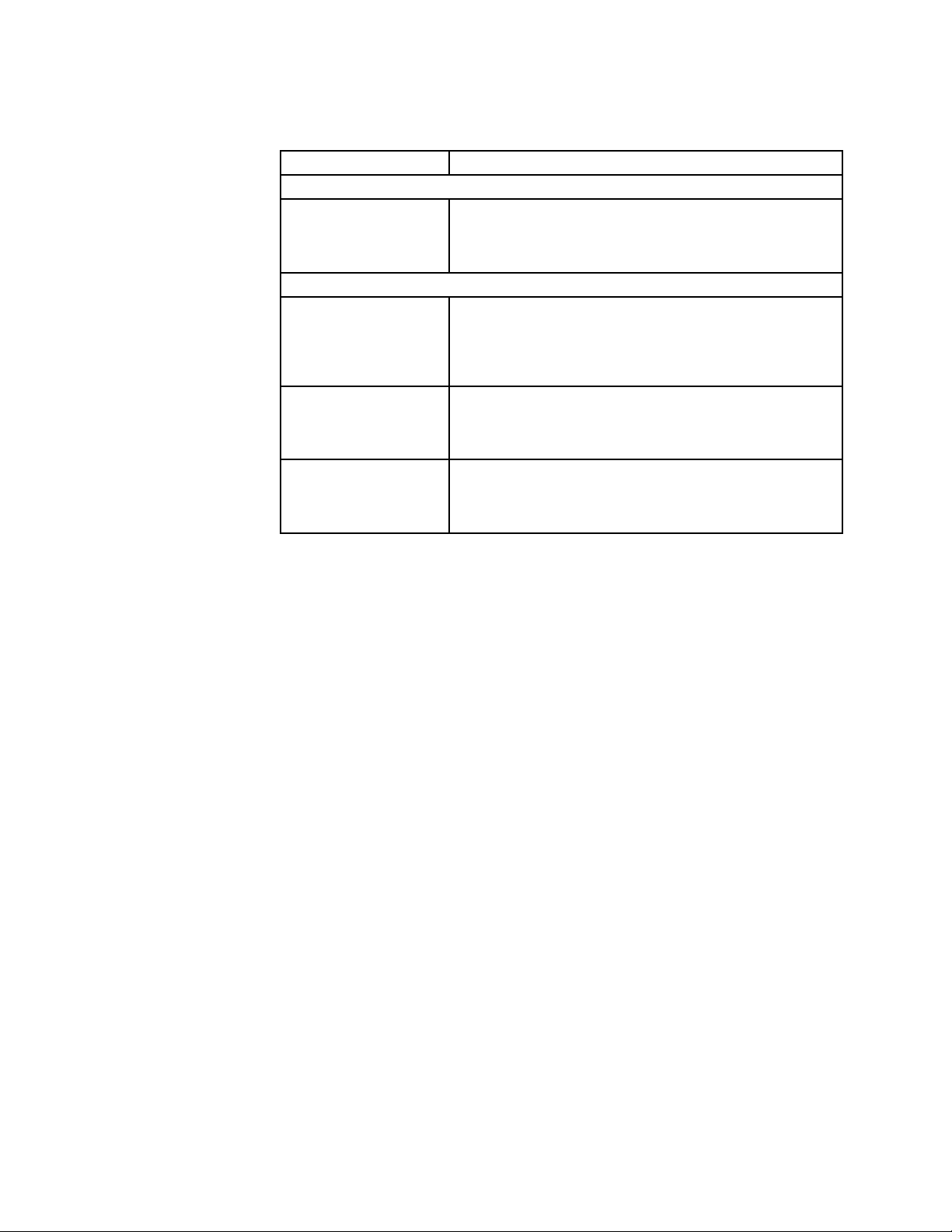

Table 2: Field-Replaceable Units

Hot-Removable and Hot-Insertable FRUs FRUs That Require Powering Down the Router

Fan tray with cable management

system

Physical Interface C ard (PIC)

Power supply (AC or DC)

Forwarding Engine Board FEB)

Routing Engine

Small form factor pluggable (SFP)

For FRU replacement instructions, see “Replace Hardware Components” on page 81.

Safety Requirements, Warnings, and Guidelines

To avoid harm to yourself or the router as you install and maintain it, you need to follow the

guidelines for working with and near electrical equipment, as well as the safety procedures

for working

environment, see “Prepare for Router Installation” on page 37. For a list of safety warnings,

see “Safety and Regulatory Compliance Information” on page 129 and particularly “Electrical

Safety Guid

guidelines for working with electrical equipment is beyond the scope of this manual.

with Internet routers. For a discussion of how to make the installation site a safe

elines and Warnings” on page 135. However, providing an exhaustive set of

4 M5 and M10 Internet Routers Hardware Guide

Chapter 2

Hardware Component Overview

This chapter provides an overview of the hardware components on the M5 and M10

Internet ro

• Chassis on page 5

• Packet Forwarding Engine on page 8

• Routing Engine on page 12

• Craft I nterface on page 14

• Power Supplies on page 16

uters:

Chassis

• FanTrayonpa

ge 19

• Cable Management System on page 20

The router chassis is a rigid sheet metal structure that houses the other hardware

components. The chassis is 17.5 in. (44.5 cm) wide and 24 in. (61 cm) deep. The chassis

height of 5.25 in. (13.3 cm) enables stacked installation of 14 M5 and M10 routers in a single

floor-to-ceiling rack. For more information, see “Rack Requirements” on page 37.

The two mounting ears (one on each side) extend the chassis width to 19 in. (48.3 cm) and

enable installation into either a front-mount or a center-mount rack.

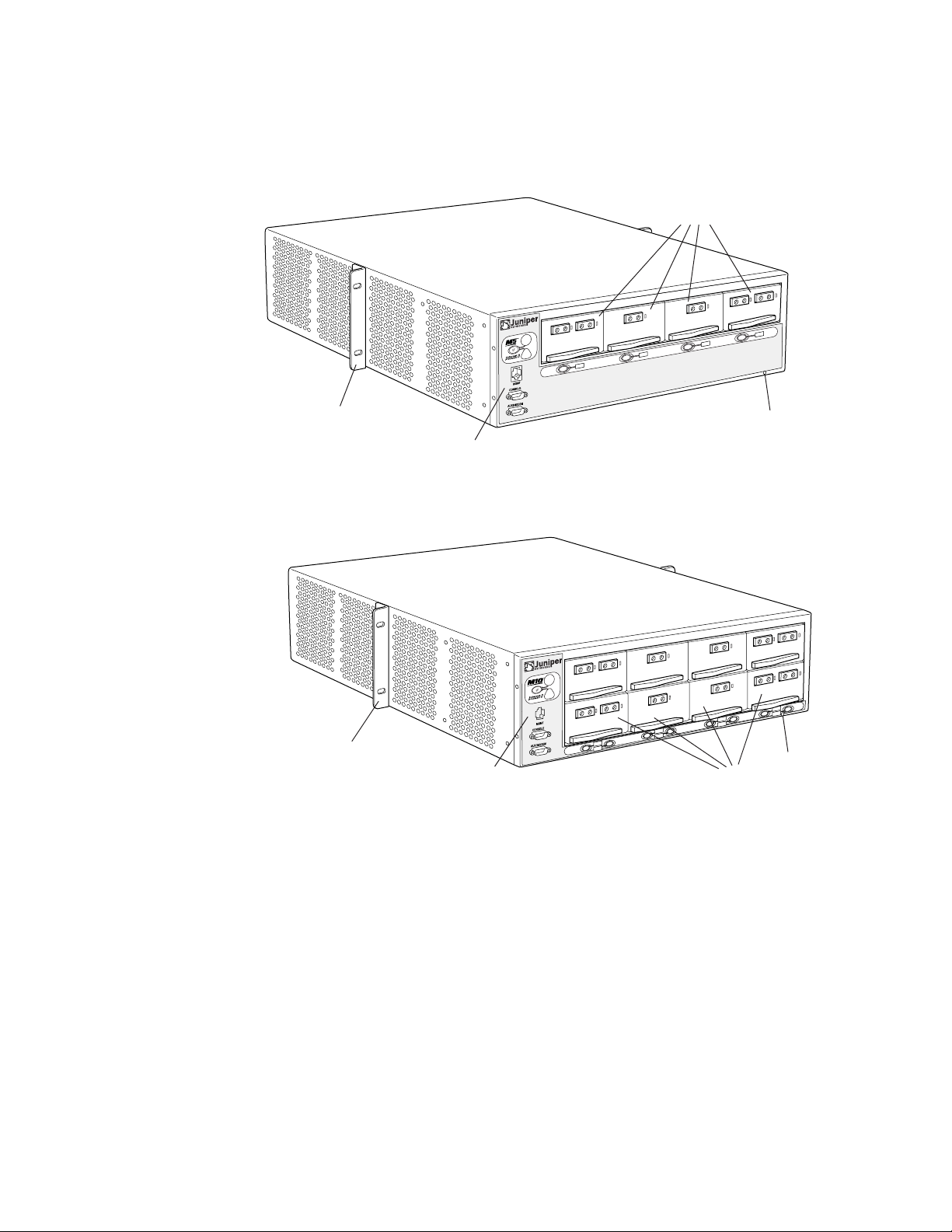

Figure 1, Figure 2, and Figure 3 show front and rear views of the router chassis.

Hardware Component Overview

5

Chassis

Figure 1: Front of M5 Chassis

PICs

1301

R

Mounting ear

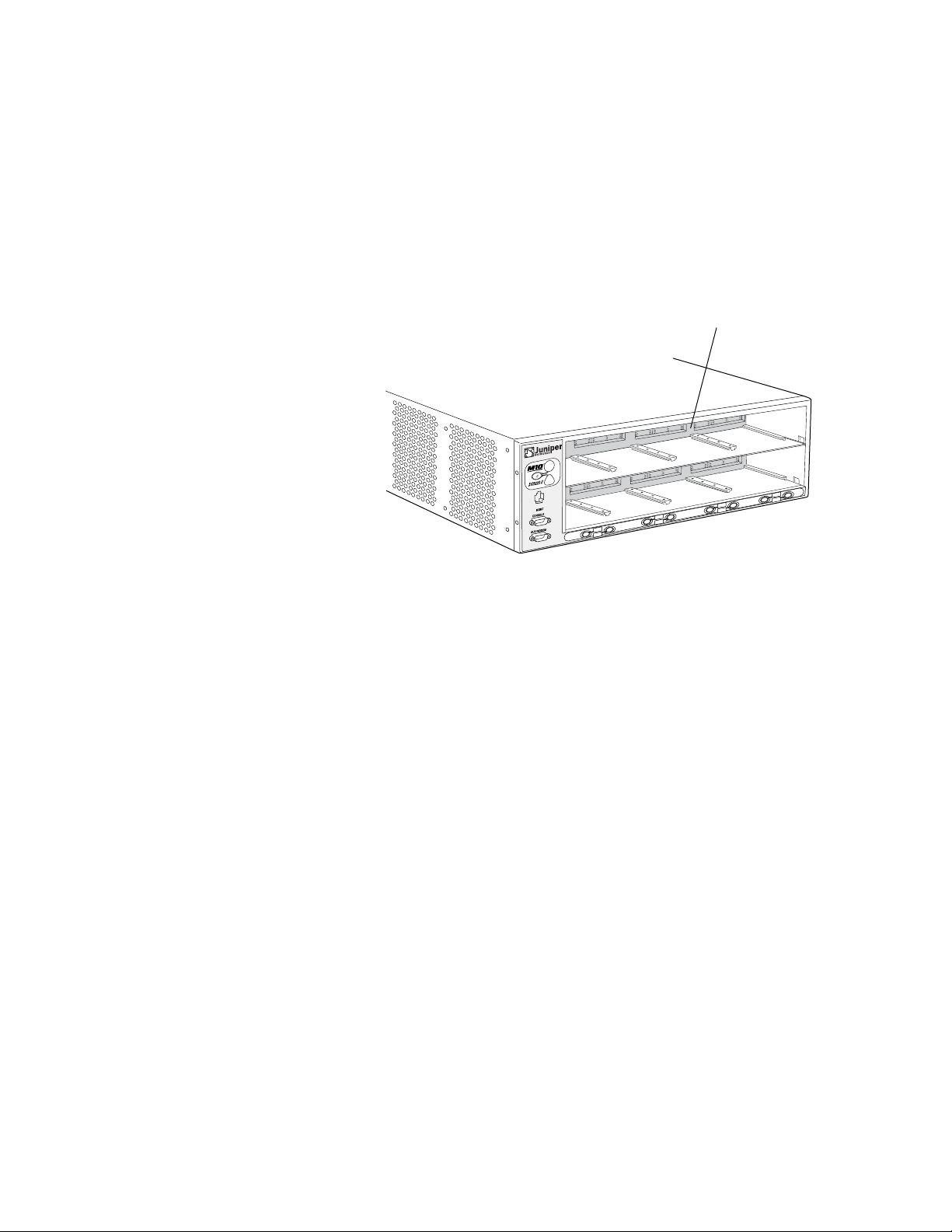

Figure 2: Front of M10 Chassis

Mounting ear

Craft interface

Craft interface

PICs

ESD

point

1300

ESD

point

6 M5 and M10 Internet Routers Hardware Guide

Figure 3: Rear of Chassis

Chassis

Forwarding Engine

Board

Routing Engine

cover

Power supply A

The chass

Power supply B

is includes two electrostatic discharge (ESD) points (banana plug receptacles) for

ESD

point

Fan tray

electrical safety, one front and one rear, as shown in Figure 1, Figure 2, and Figure 3.

Before removing or installing components of a functioning router, attach an

ESD strap to an ESD point and place the other end of the strap around your

bare wrist. Failure to use an ESD strap could result in damage to the router.

1302

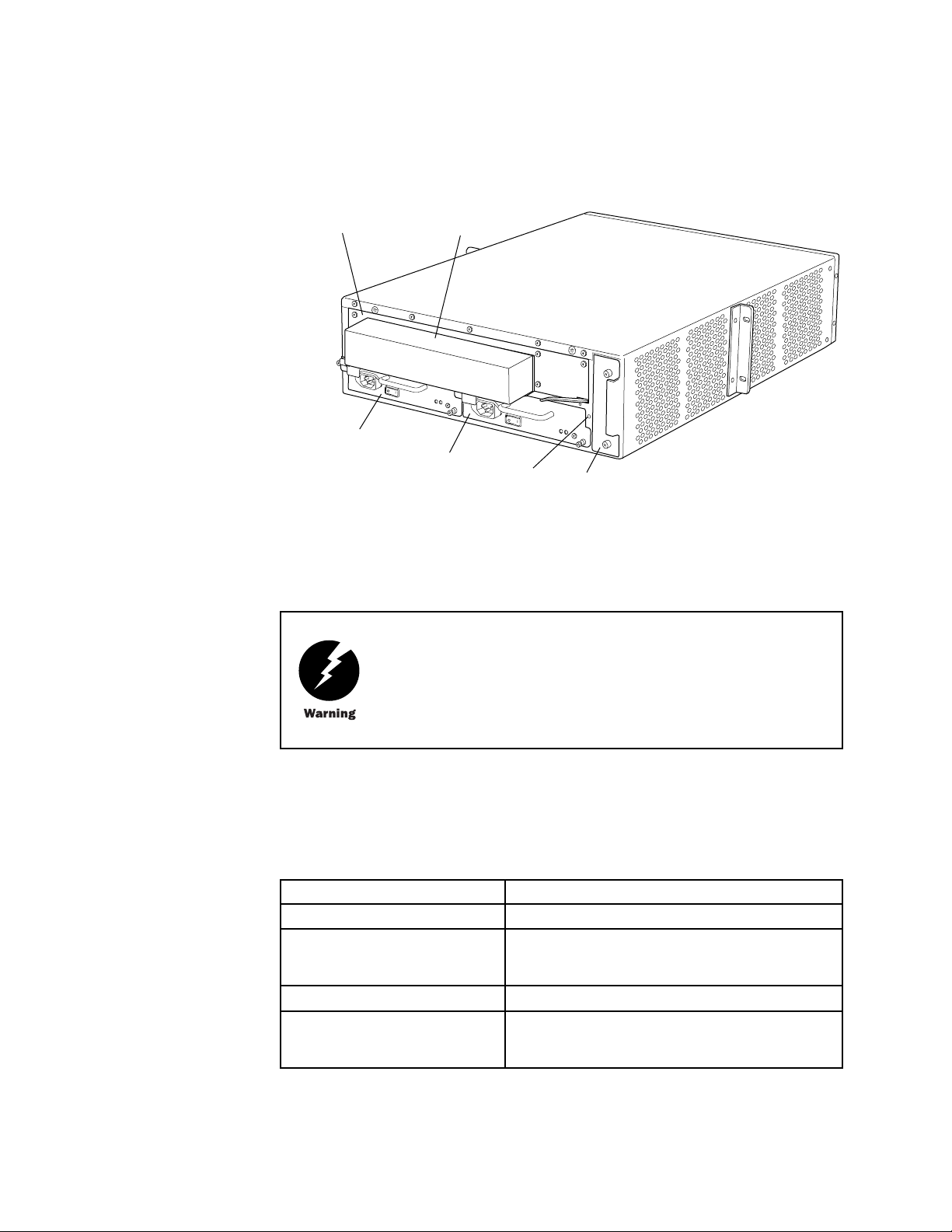

Table 3 summarizes physical specifications for the router chassis.

Table 3: Chassis Physical Specifications

Description Value

Chassis height

Chassis width 17.5 in. (44.5 cm) for sides of chassis

Chassis depth

Weight, maximum configuration M5 router: 61 lb (27.6 kg)

The router must be connected to earth ground during normal operation.

For further safety information, see “Safety and Regulatory Compliance

Informat

ion” on page 129.

5.25 in. (13.3 cm)

19 in. (4

8.3 cm) with mounting ears

24 in. (61 cm)

M10router: 67lb(29.5kg)

Hardware Component Overview 7

Packet Forwardin

gEngine

Description Value

Weight, minimum configuration 57 lb (25.8 kg)

Thermal output 2550 BTU/hour

Packet Forwarding Engine

The Packet Forwarding Engine is a multicomponent system that uses application-specific

integrated circuits (ASICs) to perform Layer 2 and Layer 3 packet switching, route lookups,

and packet fo

Processor II ASIC, I/O Manager ASIC, and media-specific controller ASICs.

rwarding. The ASICs include the Distributed Buffer Manager ASIC, Internet

Midplane

The Packet F

orwardingEnginehasthefollowingcomponents:

• Midplane—Physically separates front and rear cavities inside the chassis, distributes

power from t

components, which plug into it.

• Physical In

as OC-12/STM-4, OC-48/STM-16, Ethernet, and channelized interfaces.

• Flexible PI

built in (cannot be removed from the chassis as on some other M-series platforms).

• Forwardin

installs into the midplane from the rear of the chassis.

For inform

ation about Packet Forwarding Engine components, see t he following sections:

he power supplies, and transfers packets and signals between router

terface Cards (PICs)—Physically connect the router to network media such

C Concentrators (FPCs)—House PICs. On the M5 and M10 routers, FPCs are

g Engine Board (FEB)—Performs route lookup, filtering, and switching. It

• Midplane on page 8

• Physical Interface Cards (PICs) on page 9

• Flexible PIC Concentrators (FPCs) on page 10

• Forwarding Engine Board (FEB) on page 10

The midplan

forming the rear of the PIC card cage (see Figure 4). All router components plug directly

into the midplane. The midplane contains an EEPROM that stores the serial number and

revision l

The midplane performs the following functions:

e is a panel located in the center of the chassis, running from side to side and

evel of the midplane.

• Transfer of packets—After being processed by a PIC, an incoming data packet crosses

themidplanetotheFEB.TheFEBperformsswitchingandforwardingfunctionsand

transfers

to the network.

outgoing packets back across the midplane to the P ICs for transmission

8 M5 and M10 Internet Routers Hardware Guide

Figure 4: Midplane

Packet Forwardin

gEngine

• Power distribution—The midplane distributes power to all router components from the

power supplies attached to it.

• Signal connectivity—The midplane transports the signals exchanged by system

components for monitoring and control pur poses.

Midplane

1304

Physical Interface Cards (PICs)

Physical Interface Cards (PICs) physically connect the router to network media. They are

housed in Flexible PIC Concentrators (FPCs); for more information about FPCs, see “Fl exible

PIC Concentrators (FPCs)” on page 10.

PICsreceiveincomingpacketsfromthenetwork and transmit outgoing packets to the

network, performing framing and line-speed signaling for their media type as required.

PICs also encapsulate outgoing packets received from the FPCs before transmitting them.

The controller ASIC on each PIC performs additional control functions specific to the PIC

media type.

The router supports various PICs, including ATM, Channelized, Gigabit Ethernet, IP Services,

and SONET/SDH interfaces. For complete PIC specifications, see the M5 and M10 Internet

Routers PIC Guide.

Some PICs, such as selected Gigabit Ethernet PICs, accept small form factor pluggables (SFPs),

which are fiber-optic transceivers that can be removed from the PIC. Various SFPs have

different reach characteristics. You can mix them in a single PIC and change the combination

dynamically. SFPs are hot-removable and hot-insertable, as described in “Field-Replaceable

Units (FRUs)” on page 3. For SFP replacement instructions, see “Replace an S FP” on page

95. For information about PICs that use SFPs, see the M5 and M10 Internet Routers PIC Guide.

Up to four regular PICs install into an M5 router and up to eight regular PICs install into an

M10 router, as shown in Figure 1 and Figure 2. The PIC slots on an M5 router and in the upper

FPConanM10routerarenumberedfrom0/0 (zero/zero) through 0/3, right to left. The PIC

slots in the lower FPC on an M10 router are numbered from 1/0 (one/zero) through 1/3,right

to left. The slot number for a PIC appears next to its offline button on the craft interface (see

“PIC Offline Buttons” on page 16). The number of ports on a PIC depends on the type of PIC.

Hardware Component Overview

9

Packet Forwardin

gEngine

Quad-wide PICs, such as the 4-port Gigabit Ethernet and OC-48/STM-16 SONET/SDH PICs,

occupy all four slots in an FPC. Some quad-wide PICs might not be supported on both the M5

and M10 router

Both regular and quad-wide PICs are hot-removable and hot-insertable. A removed PIC

no longer rece

forwarding of traffic through the remaining PICs.

s; for more information, see the M5 and M10 Internet Routers PIC Guide.

ives or transmits data, and removing or inserting a PIC briefly interrupts

For PIC repla

PIC Components

Most PICs supported on the M5 and M10 routers have the following components. For

complete specifications, see the M5 and M10 Internet Routers PIC Guide.Forinformation

about pinouts for PIC cable connectors, see “Cable Connector Pinouts” on page 171.

cement instructions, see “Replace a PIC” on page 87.

• One or more cable connector ports—Accept a network media connector.

• LEDs—Indicate PIC and port status. Most PICs have an LED labeled STATUS on the

PIC faceplate. Some P ICs h ave additional LEDs, often one per port. The meaning of

the LED states differs for various PICs. For more information, see the M5 and M10

Internet Routers PIC Guide.

• Ejector lever—Controls the locking system that secures the PIC in the card cage.

Flexible PIC Concentrators (FPCs)

Flexible PIC Concentrators (FPCs) house the PICs that connect the router to network media

(for information about PICs, see “Physical Interface Cards (PICs)” on page 9). On the M5 and

M10 routers, each FPC is built in (cannot be removed from the chassis as on other M-series

platforms) and corresponds to a horizontal row of PIC slots. The single FPC on the M5 router

is numbered 0 (zero) and the two FPCs on the M10 router are numbered 0 and 1,topto

bottom. Each FPC accommodates up to fourregularPICsoronequad-widePIC.

Forwarding Engine Board (FEB)

The Forwarding Engine Board (FEB) performs route lookup, filtering, and switching

on incoming data packets, then directs outbound packets to the appropriate FPC for

transmission to the network. It can process 40 million packets per second (Mpps).

The FEB installs into the midplane from the rear of the chassis, as shown in Figure 3. It

weighs approximately 7 lb (3.2 kg). The FEB is field-replaceable, but you must power down

the router before removing it from the chassis. Packet forwarding halts until the FEB is

replaced, the router is powered on, and the Routing Engine finishes booting.

For FEB replacement instructions, see “Replace the FEB” on page 84.

The FEB communicates with the Routing Engine using a d edicated 100-Mbps Fast Ethernet

link that transfers routing table data from the Routing Engine to the forwarding table in the

Internet Processor II ASIC. The link is also used to transfer from the FEB to the Routing

10 M5 and M10 Internet Routers Hardware Guide

Packet Forwardin

Engine routing link-state updates and other packets destined for the router that have been

received through the router interfaces.

The ASICs and other components on the FEB provide the following functions:

gEngine

• Route lookups

using the forwarding table stored in SSRAM.

• Creation and r

into 64-byte data cells for easier processing, and reassembles the cells for each packet

after the forwarding decision is made for it. There is one I/O Manager ASIC on the

M5 router and

—The Internet Processor II ASIC on each FEB performs route lookups

eassembly of data cells—The I/O Manager ASIC divides incoming packets

two on the M10 router.

• Management of memory on the FEB—One Distributed Buffer Manager ASIC receives

the 64-byte d

uniformly allocates the cells throughout the memory buffers on the FEB.

• Transfer of o

notification of the forwarding decision for each packet to an I/O Manager ASIC so that

data cells for the outgoing packet can be reassembled for transmission to the network.

ata cells into which t he I/O M anager ASIC divides incoming packets, and

utgoing data packets—The second Distributed Buffer Manager ASIC passes

• Transfer of exception and control packets—The Internet Processor II ASIC passes

exception packets to the microprocessor on the FEB, which processes almost all of

them. The FE

further processing. When the FEB detects an error originating in the Packet Forwarding

Engine, it sends it to the Routing Engine using system logging (syslog) messages.

B sends any remaining exception packets to the Routing Engine for

• Monitoring of system components—The FEB monitors other system components for

failure and alarm conditions. It collects statistics from all sensors in the system and

relays the

the temperature of a component exceeds the lower of two internally defined thresholds,

the Routing Engine issues a “high temperature” alarm. If the temperature exceeds the

higher thr

m to the Routing Engine, which sets alarms as appropriate. For example, if

eshold, the Routing Engine initiates a system shutdown.

FEB Components

• Providing SONET/SDH clock source—The FEB generates a 19.44-MHz clock signal for

use by SON

An FEB has the following components (see Figure 5):

ET/SDH interfaces.

• I/O Manager ASIC (one on the M5 router and two on the M10 router)—Divide incoming

packets into 64-byte data cells for easier processing, and reassemble the cells for each

packet after the forwarding decision is made for it.

• Two Distributed Buffer Manager ASICs—Process incoming and outgoing packets: one

distributes data cells (which the I/O Manager ASIC derives from incoming packets) to

the memory buffers on the FEB, while the second forwards notification of routing

decisions to an I/O Manager ASIC.

• One Internet Processor II ASIC—Performs route lookups and makes routing decisions.

• Parity-protected synchronous SRAM (SSRAM)—Stores the forwarding table.

Hardware Component Overview

11

Routing Engine

• Processor subsystem—Manages FEB functions and handles exception packets. The

processor has the following components:

• OnePowerPC603eprocessor

• EEPROM—Stores the serial number and revision level.

• 19.44-MHz str

2

• I

C controller—Monitors the status of router components.

• Ejector levers—Control the locking system that secures the FEB in the chassis.

Figure 5: Forwarding Engine Board

• Parity-prote

cted Level 2 cache

• Parity-protected DRAM

atum 3 reference clock—Generates clock signal for SONET/SDH PICs.

For specific information about FEB components (for example, the amount of

DRAM), issue the show chassis feb command.

Routing Engine

The Routing Engine is an Intel-based PCI platform that runs JUNOS Internet software.

Software processes that run on the Routing Engine maintain the routing tables, manage the

routing protocols used on the router, control the router’s interfaces, control some chassis

components, and provide the interface for system management and user access to the router.

12 M5 and M10 Internet Routers Hardware Guide

1307

The Routing Engine installs into a slot in the FEB at the rear of the chassis. The Routing

Engine is field-replaceable, but you must power down the router before removing it from

the chassis. P

powered on. For replacement instructions, see “Replace the Routing Engine” on page 115.

acket forwarding halts until the Routing Engine is replaced and the router is

Routing Engine Components

The Routing Engine (shown in Figure 6) is a two-board system with the following components:

Routing Engine

• CPU—Runs JUN

protocols. It has a Pentium-class processor.

• SDRAM—Provi

Engine processes.

• Compact flas

and microcode. The drive is fixed and inaccessible from outside the router.

• Hard drive—P

the system if the flash drive fails.

• PC card slot

upgrades.

• LED—Indica

indicate routing-related activity.

• Interfaces

Routing Engine status to devices (console, laptop, or terminal server) that can be

attached to access ports located on the craft interface.

OS Internet software to maintain the router’s routing tables and routing

des storage for the routing and forwarding tables and for other Routing

h drive—Provides primary storage for software images, configuration files,

rovides secondary storage for log files, memory dumps, and rebooting

—Accepts a removable PC card, which stores software images for system

tes disk activity for the internal IDE interface. It does not necessarily

for out-of-band management access—Provide information about

• EEPROM—Stores t he serial number of the Routing Engine.

• Reset butt

on—Reboots the Routing Engine when pressed.

• Extractor clips—Control the locking system that secures the Routing Engine in the

chassis.

The appear

on your Routing Engine might differ from Figure 6 and other figures in this

document

Routing Engine installation and removal or functionality.

ance and position of electronic components or the PC card slot

that depict the Routing Engine. These differences do not affect

Hardware Component Overview 13

Craft Interface

For specific information about Routing Engine c om ponents (for example, the

capacity of th

Figure 6: Routing Engine

Routing Engine 333 Routing Engine 600

eharddrive),issuetheshow chassis routing-engine command.

Extractor clipExtractor clip

LED

PC card slot

Craft Interface

Figure 7: Craft Interface

Lamp test button

Link status LED

Routing Engine

ports

P

C

C

A

R

JUNIPER NETWORKS LABEL THIS SIDE

D

RESET

HD

PC card slot

Extractor clip

LED

Extractor clip

The craft interface provides status and troubleshooting information at a glance and has

buttons for deactivating alarms and preparing FPCs for removal. The L-shaped craft interface

is located along the left and bottom edges of thefrontofthechassis,asshowninFigure1

and Figure 2. It includes the elements shown in Figure 7. (The LEDs for the power supplies

are located on the power supply faceplate, rather than on the craft interface. For more

information, see “Power Supply LEDs and Self-test Button” on page 19.)

R

Red alarm LED

Yellow alarm LED

Activity status LED

1596

PIC0/3

PIC1/3

14 M5 and M10 Internet Routers Hardware Guide

PIC0/2

PIC1/2

PIC online/offline buttons

PIC0/1

PIC1/1

PIC0/0

PIC1/0

1336

Craft Interface

For information about the elements on the craft interface, see the following sections:

• Alarm LEDs and Lamp Test Button on page 15

• Routing Engine

Interface Ports and Status Indicators on page 15

• PIC Offline Buttons on page 16

AlarmLEDsandLampTestButton

Two large alarm LEDs are located at the top of the craft interface. The circular red LED lights

to indicate a critical condition that can result in a system shutdown. The triangular yellow

LED lights to indicate a less severe condition that requires monitoring or maintenance. Both

LEDs can be lit simultaneously. The button labeled LT (for “lamp test”), located to the left of

the alarm LEDs, causes all LE Ds on the c raft interface to light when pressed and held; use it

to test that LEDs are functional.

Table 4 describes the alarm LEDs and lamp test button in more detail.

Table 4: Alarm LEDs and Lamp Test Button

Shape Color State Description

Red On steadily Critical alarm LED—Indicates a critical condition

Yellow On steadily Warning alarm LED—Indicates a serious but

——

that can cause the router to stop functioning.

Possible causes include component removal,

failure, or overheating.

nonfatal error condition, such as a maintenance

alert or a significant increase in component

temperature.

Lamp test button—Causes all LEDs on the craft

interface t

pressed and held.

o light (for testing purposes), when

Routing Engine Interface Ports and Status Indicators

Below the alarm LEDs on the craft interface are ports for connecting the Routing Engine

to one or more external devices on which system administrators can issue JUNOS

command-line interface (CLI) commandstomanagetherouter(seeFigure7).Theportswith

the indicated label in each set function as follows:

• MGMT—Connects the Routing Engine through an Ethernet connection to a

management LAN (or any other device that plugs into an Ethernet connection) for

out-of-band management. The port uses an autosensing RJ-45 connector to support

both 10- and 100-Mbps connections.

Totheleftoftheportisalinkstatusindicator, which lights to show that a link has

been established over the Ethernet connection. To the r ight of the port is an activity

indicator, which flashes when data is being transferred.

Hardware Component Overview

15

Power Supplies

• CONSOLE—Connects the Routing Engine to a system console through an RS-232

(EIA-232) serial cable.

• AUX/MODEM— Connects the Routing Engine to a laptop, modem, or other auxiliary

device through an RS-232 (EIA-232) serial cable.

For information about the pinouts for the connectors, see “Cable Connector Pinouts”

on page 171.

PIC Offline B

uttons

Power Supplies

An offline button for each PIC is located below the PIC slot along the bottom edge of the

craft interf

when pressed. The buttons are labeled with the PIC slot numbers. The PIC slots on an M5

router and in the upper FPC on an M10 router are numbered from 0/0 (zero/zero) through

0/3,rightto

1/0 (one/zero) through 1/3,righttoleft.

The router uses either AC or DC power. There are two load-sharing, isolated power supplies