Page 1

M40e Multiservice Edge

Router

Hardware Guide

Published: 2010-10-28

Copyright © 2010, Juniper Networks, Inc.

Page 2

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

This productincludes the Envoy SNMP Engine, developed by EpilogueTechnology,an Integrated Systems Company. Copyright ©1986-1997,

Epilogue Technology Corporation. All rights reserved. This program and its documentation were developed at private expense, and no part

of them is in the public domain.

This product includes memory allocation software developed by Mark Moraes, copyright © 1988, 1989, 1993, University of Toronto.

This product includes FreeBSD software developed by the University of California, Berkeley, and its contributors. All of the documentation

and software included in the 4.4BSD and 4.4BSD-Lite Releases is copyrighted by the Regents of the University of California. Copyright ©

1979, 1980, 1983, 1986, 1988, 1989, 1991, 1992, 1993, 1994. The Regents of the University of California. All rights reserved.

GateD software copyright © 1995, the Regents of the University. All rights reserved. Gate Daemon was originated and developed through

release 3.0 by Cornell University and its collaborators. Gated is based on Kirton’s EGP, UC Berkeley’s routing daemon (routed), and DCN’s

HELLO routing protocol. Development of Gated has been supported in part by the National Science Foundation. Portions of the GateD

software copyright © 1988, Regents of the University of California. All rights reserved. Portions of the GateD software copyright © 1991, D.

L. S. Associates.

This product includes software developed by Maker Communications, Inc., copyright © 1996, 1997, Maker Communications, Inc.

Juniper Networks, Junos, Steel-Belted Radius, NetScreen, and ScreenOS are registered trademarks of Juniper Networks, Inc. in the United

States and other countries. The Juniper Networks Logo, the Junos logo, and JunosE are trademarks of Juniper Networks, Inc. All other

trademarks, service marks, registered trademarks, or registered service marks are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify,

transfer, or otherwise revise this publication without notice.

Products made or sold by Juniper Networks or components thereof might be covered by one or more of the following patents that are

owned by or licensed to Juniper Networks: U.S. Patent Nos. 5,473,599, 5,905,725, 5,909,440, 6,192,051, 6,333,650, 6,359,479, 6,406,312,

6,429,706, 6,459,579, 6,493,347, 6,538,518, 6,538,899, 6,552,918, 6,567,902, 6,578,186, and 6,590,785.

M40e Multiservice Edge Router Hardware Guide

Copyright © 2010, Juniper Networks, Inc.

All rights reserved. Printed in USA.

Writing: Charissa Fleischer, Elizabeth Gardner, Jerry Isaac, Tony Mauro, Sheila Nolte

Editing: Stella Hackell

Illustration: Faith Bradford

Cover Design: Edmonds Design

Revision History

August 2010—Corporate rebranding.

August 2009—Updated product names and revised sections into modular topics for easier customer access.

14 May2007—Correctedthe DCsystemcurrent rating and cable lug specification.Updatedthe DCinput voltage operating range,the nominal

AC input voltage, AC input voltage range, and AC maximum power output.

30 March 2007—Added pinouts for the BITS input connectors. Updated clearance requirements. Corrected manual titles in references.

20 October 2006— Added European Community EMC Declaration of Conformity.

28 June2006—CorrectedFPC throughput information. Added how much torqueto apply when securingthe cables tothe DCpower supplies.

30 May2006—Added powercable warningin Japanese.Added lithium battery statement. Deleted statementsabout converting a DC-powered

router to AC power.

26 September 2005—Added new FPCs and FPC handling and storage procedures.

25 February 2005—Corrected DC power illustration and replacement procedure.

12 November 2004—Added general updates and revised fuse replacement procedure.

30 June 2003—Corrected and added component information.

18 October 2002—Incorporated updated technical information.

10 April 2002—Updated power information.

14 January 2002—Initial release.

Copyright © 2010, Juniper Networks, Inc.ii

Page 3

The information in this document is current as of the date listed in the revision history.

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. The Junos OS has no known time-related limitations through

the year 2038. However, the NTP application is known to have some difficulty in the year 2036.

iiiCopyright © 2010, Juniper Networks, Inc.

Page 4

END USER LICENSE AGREEMENT

READ THIS END USER LICENSE AGREEMENT (“AGREEMENT”) BEFORE DOWNLOADING, INSTALLING, OR USING THE SOFTWARE.

BY DOWNLOADING, INSTALLING, OR USING THE SOFTWARE OR OTHERWISE EXPRESSING YOUR AGREEMENT TO THE TERMS

CONTAINED HEREIN, YOU (AS CUSTOMER OR IF YOU ARE NOT THE CUSTOMER, AS A REPRESENTATIVE/AGENT AUTHORIZED TO

BIND THE CUSTOMER) CONSENTTO BEBOUND BY THISAGREEMENT. IF YOUDO NOTOR CANNOT AGREE TO THE TERMS CONTAINED

HEREIN, THEN (A) DO NOT DOWNLOAD, INSTALL, OR USE THE SOFTWARE, AND (B) YOU MAY CONTACT JUNIPER NETWORKS

REGARDING LICENSE TERMS.

1. The Parties. The parties to this Agreement are (i) Juniper Networks, Inc. (if the Customer’s principal office is located in the Americas) or

Juniper Networks (Cayman) Limited(if the Customer’s principal office islocated outside the Americas) (suchapplicable entitybeing referred

to herein as “Juniper”), and (ii) the person or organization thatoriginally purchased fromJuniper oran authorizedJuniper reseller the applicable

license(s) for use of the Software (“Customer”) (collectively, the “Parties”).

2. The Software. In this Agreement, “Software” means the program modules and features of the Juniper or Juniper-supplied software, for

which Customer has paid the applicable license or support fees to Juniper or an authorized Juniper reseller, or which was embedded by

Juniper in equipment which Customer purchased fromJuniper or an authorized Juniper reseller. “Software” also includes updates, upgrades

and new releases of such software. “Embedded Software” means Software which Juniper has embedded in or loaded onto the Juniper

equipment and any updates, upgrades, additions or replacements which are subsequently embedded in or loaded onto the equipment.

3. License Grant. Subject to payment ofthe applicablefees andthe limitationsand restrictions set forth herein, Juniper grants to Customer

a non-exclusive and non-transferable license, without right to sublicense, to use the Software, in executable form only, subject to the

following use restrictions:

a. Customer shall use Embedded Software solely as embedded in, and for execution on, Juniper equipment originally purchased by

Customer from Juniper or an authorized Juniper reseller.

b. Customer shall use the Software on a single hardware chassis having a single processing unit, or as many chassis or processing units

for which Customer has paid the applicable license fees; provided, however, with respect to the Steel-Belted Radius or Odyssey Access

Client software only, Customer shall use such Software on a single computer containing a single physical random access memory space

and containing any number of processors. Use of the Steel-Belted Radius or IMS AAA software on multiple computers or virtual machines

(e.g., Solaris zones) requires multiple licenses, regardless of whether such computers or virtualizations are physically contained on a single

chassis.

c. Product purchase documents, paper or electronic user documentation, and/or the particular licenses purchased by Customer may

specify limitsto Customer’s use of the Software. Such limitsmay restrict use to a maximumnumber of seats,registered endpoints, concurrent

users, sessions, calls, connections, subscribers, clusters, nodes, realms, devices, links, ports or transactions, or require the purchase of

separate licenses to use particular features, functionalities, services, applications, operations, or capabilities, or provide throughput,

performance, configuration, bandwidth, interface, processing, temporal, or geographical limits. In addition, such limits may restrict the use

of the Software to managing certain kinds of networks or require the Software to be used only in conjunction with other specific Software.

Customer’s use of the Software shall be subject to all such limitations and purchase of all applicable licenses.

d. For any trial copy of the Software, Customer’s right to use the Software expires 30 days after download, installation or use of the

Software. Customer may operate the Software after the 30-day trial period only if Customer pays for a license to do so. Customer may not

extend or create an additional trial period by re-installing the Software after the 30-day trial period.

e. The Global Enterprise Edition of the Steel-Belted Radius software may be used by Customer only to manage access to Customer’s

enterprise network. Specifically, service provider customers are expressly prohibited from using the Global Enterprise Edition of the

Steel-Belted Radius software to support any commercial network access services.

The foregoing license is not transferable or assignable by Customer. No license is granted herein to any user who did not originally purchase

the applicable license(s) for the Software from Juniper or an authorized Juniper reseller.

4. Use Prohibitions. Notwithstanding the foregoing, the license provided herein does not permit the Customer to, and Customer agrees

not to and shall not: (a) modify, unbundle, reverse engineer, or create derivative works based on the Software; (b) make unauthorized

copies of the Software (except as necessary for backup purposes); (c) rent, sell, transfer, or grant any rights in and to any copy of the

Software,in any form, to any third party;(d) remove any proprietary notices, labels, or markson or in any copy ofthe Softwareor any product

in which the Software is embedded; (e) distribute any copy of the Software to any third party, including as may be embedded in Juniper

equipment sold in the secondhandmarket; (f) use any‘locked’ or key-restricted feature, function, service,application, operation,or capability

without first purchasing the applicable license(s) and obtaining a valid key from Juniper, even if such feature, function, service, application,

operation, or capability is enabled without a key; (g) distribute any key for the Software provided by Juniper to any third party; (h) use the

Copyright © 2010, Juniper Networks, Inc.iv

Page 5

Software in any manner that extends or is broader than the uses purchased by Customer from Juniper or an authorized Juniper reseller; (i)

use Embedded Software on non-Juniper equipment; (j) use Embedded Software (or make it available for use) on Juniper equipment that

the Customer did not originally purchase from Juniper or an authorized Juniper reseller; (k) disclose the results of testing or benchmarking

of the Software to any third party without the prior written consent of Juniper; or (l) use the Software in any manner other than as expressly

provided herein.

5. Audit. Customer shall maintain accurate records as necessary to verify compliance with this Agreement. Upon request by Juniper,

Customer shall furnish such records to Juniper and certify its compliance with this Agreement.

6. Confidentiality. The Parties agree that aspects of the Software and associated documentation are the confidential property of Juniper.

As such, Customer shall exercise all reasonable commercial efforts to maintain the Software and associated documentation in confidence,

which at a minimum includes restricting access to the Software to Customeremployees and contractors having a need to use the Software

for Customer’s internal business purposes.

7. Ownership. Juniper and Juniper’s licensors, respectively, retain ownership of all right, title, and interest (including copyright) in and to

the Software, associated documentation, and all copies of the Software. Nothing in this Agreement constitutes a transfer or conveyance

of any right, title, or interest in the Software or associated documentation, or a sale of the Software, associated documentation, or copies

of the Software.

8. Warranty, Limitation of Liability, Disclaimer of Warranty. The warranty applicable to the Software shall be as set forth in the warranty

statementthat accompanies theSoftware(the “Warranty Statement”). Nothingin this Agreementshall give riseto any obligation tosupport

the Software. Support services may be purchased separately. Any such support shall be governed by a separate, written support services

agreement. TO THE MAXIMUM EXTENT PERMITTED BY LAW, JUNIPER SHALL NOT BE LIABLE FOR ANY LOST PROFITS, LOSS OF DATA,

OR COSTSOR PROCUREMENTOF SUBSTITUTE GOODSOR SERVICES,OR FORANY SPECIAL, INDIRECT,OR CONSEQUENTIALDAMAGES

ARISING OUTOF THIS AGREEMENT,THE SOFTWARE, ORANY JUNIPEROR JUNIPER-SUPPLIED SOFTWARE. INNO EVENT SHALLJUNIPER

BE LIABLE FOR DAMAGES ARISING FROM UNAUTHORIZED OR IMPROPER USE OF ANY JUNIPER OR JUNIPER-SUPPLIED SOFTWARE.

EXCEPT AS EXPRESSLY PROVIDED IN THE WARRANTY STATEMENT TO THE EXTENT PERMITTED BY LAW, JUNIPER DISCLAIMS ANY

AND ALL WARRANTIES IN AND TO THE SOFTWARE (WHETHER EXPRESS, IMPLIED, STATUTORY, OR OTHERWISE), INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR NONINFRINGEMENT. IN NO EVENT DOES

JUNIPER WARRANT THAT THE SOFTWARE, OR ANY EQUIPMENT OR NETWORK RUNNING THE SOFTWARE, WILL OPERATE WITHOUT

ERROR OR INTERRUPTION, OR WILL BE FREE OF VULNERABILITY TO INTRUSION OR ATTACK. In no event shall Juniper’s or its suppliers’

or licensors’ liability to Customer, whether in contract, tort (including negligence), breach of warranty, or otherwise, exceed the price paid

by Customer for the Software that gave rise to the claim, or if the Software is embedded in another Juniper product, the price paid by

Customer for such other product. Customer acknowledges and agrees that Juniper has set its prices and entered into this Agreement in

reliance upon the disclaimers of warranty and the limitations of liability set forth herein, that the same reflect an allocation of risk between

the Parties (including the risk that a contract remedy may fail of its essential purpose and cause consequential loss), and that the same

form an essential basis of the bargain between the Parties.

9. Termination. Any breach of this Agreement or failure by Customer to pay any applicable fees due shall result in automatic termination

of the license granted herein. Upon such termination, Customer shall destroy or return to Juniper all copies of the Software and related

documentation in Customer’s possession or control.

10. Taxes. All license fees payable under this agreement are exclusive of tax. Customer shall be responsible for paying Taxes arising from

the purchase of the license, or importation or use of the Software. If applicable, valid exemption documentation for each taxing jurisdiction

shall be provided to Juniper prior to invoicing, and Customer shall promptly notify Juniper if their exemption is revoked or modified. All

payments made by Customer shall be net of any applicable withholding tax. Customer will provide reasonable assistance to Juniper in

connection with such withholding taxes by promptly: providing Juniper with valid tax receipts and other required documentation showing

Customer’s payment of any withholding taxes; completing appropriate applications that would reduce the amount of withholding tax to

be paid; and notifying and assisting Juniper in any audit or tax proceeding related to transactions hereunder. Customer shall comply with

all applicable tax laws and regulations, and Customer will promptly pay or reimburse Juniper for all costs and damages related to any

liability incurred by Juniper as a result of Customer’s non-compliance or delay with its responsibilities herein. Customer’s obligations under

this Section shall survive termination or expiration of this Agreement.

11. Export. Customer agrees to comply with all applicable export laws and restrictions and regulations of any United States and any

applicable foreign agency or authority, and not to export or re-export the Software or any direct product thereof in violation of any such

restrictions, laws or regulations, or without all necessary approvals. Customer shall be liable for any such violations. The version of the

Software supplied to Customer may contain encryption or other capabilities restricting Customer’s ability to export the Software without

an export license.

vCopyright © 2010, Juniper Networks, Inc.

Page 6

12. Commercial Computer Software. The Software is “commercial computer software” and is provided with restricted rights. Use,

duplication, or disclosure by the United States government is subject to restrictions set forth in this Agreement and as provided in DFARS

227.7201 through 227.7202-4, FAR 12.212, FAR 27.405(b)(2), FAR 52.227-19, or FAR 52.227-14(ALT III) as applicable.

13. Interface Information. To the extent required by applicable law, and at Customer's written request, Juniper shall provide Customer

with the interface information needed to achieve interoperability between the Software and another independently created program, on

payment of applicable fee, if any. Customer shall observe strict obligations of confidentiality with respect to such information and shall use

such information in compliance with any applicable terms and conditions upon which Juniper makes such information available.

14. Third Party Software. Any licensor of Juniper whose software is embedded inthe Software and any supplier of Juniper whose products

or technology are embedded in (or services are accessed by) the Software shall be a third party beneficiary with respect to this Agreement,

and such licensor or vendor shall have the right toenforce this Agreement in its own name as if it were Juniper. In addition, certain third party

software may be provided with the Software and is subject to the accompanying license(s), if any, of its respective owner(s). To the extent

portions of the Software are distributed under and subject to open source licenses obligating Juniper to make the source code for such

portions publicly available (such as the GNU General Public License (“GPL”) or the GNU Library General Public License (“LGPL”)), Juniper

will make such source code portions (including Juniper modifications, as appropriate) available upon request for a period of up to three

years from the date of distribution. Such request can be made in writing to Juniper Networks, Inc., 1194 N. Mathilda Ave., Sunnyvale, CA

94089, ATTN: General Counsel. You may obtain a copy of the GPL at http://www.gnu.org/licenses/gpl.html, and a copy of the LGPL

at http://www.gnu.org/licenses/lgpl.html .

15. Miscellaneous. This Agreement shall be governed by the laws of the State of California without reference to its conflicts of laws

principles. The provisions of the U.N. Convention for the International Sale of Goods shall not apply to this Agreement. For any disputes

arising under this Agreement, the Parties hereby consent to the personal and exclusive jurisdiction of, and venue in, the state and federal

courts within Santa Clara County, California. This Agreement constitutes the entire and sole agreement between Juniper and the Customer

with respect to the Software, and supersedes all prior and contemporaneous agreements relating to the Software, whether oral or written

(including any inconsistent terms contained in a purchase order), except that the terms of a separate written agreement executed by an

authorized Juniper representative and Customer shall govern to the extent such terms are inconsistent or conflict with terms contained

herein. No modification to this Agreement nor any waiver of any rights hereunder shall be effective unless expressly assented to in writing

by the party to be charged. If any portion of this Agreement is held invalid, the Parties agree that such invalidity shall not affect the validity

of the remainder of this Agreement. This Agreement and associated documentation has been written in the English language, and the

Parties agree that the English version will govern. (For Canada: Les parties aux présentés confirment leur volonté que cette convention de

même que tous les documents y compris tout avis qui s'y rattaché, soient redigés en langue anglaise. (Translation: The parties confirm that

this Agreement and all related documentation is and will be in the English language)).

Copyright © 2010, Juniper Networks, Inc.vi

Page 7

Table of Contents

About the Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Junos OS Documentation and Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

Documentation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

Documentation Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

Requesting Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

Self-Help Online Tools and Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

Opening a Case with JTAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvii

Part 1 Overview of the M40e Multiservice Edge Router

Chapter 1 Overview of the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

M40e System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

M40e System Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2 M40e Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

M40e Chassis Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

M40e Midplane Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

M40e PICs Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

M40e PIC Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

M40e PIC Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

M40e Flexible PIC Concentrators (FPCs) Description . . . . . . . . . . . . . . . . . . . . . . . 13

M40e FPC Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

M40e FPC Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

M40e FPC Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Identifying M40e FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

M40e FPCs Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

M40e Packet Forwarding Engine Clock Generators (PCGs) Description . . . . . . . . 18

M40e PCG LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

M40e Switching and Forwarding Module (SFM) Description . . . . . . . . . . . . . . . . 20

SFM Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SFM Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SFM Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SFM Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

M40e SFM LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

M40e Host Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

M40e Routing Engine Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

M40e Routing Engine 333 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

M40e Routing Engine 333 LEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

M40e Routing Engine 600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

viiCopyright © 2010, Juniper Networks, Inc.

Page 8

M40e Multiservice Edge Router Hardware Guide

M40e Routing Engine 600 LEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

M40e Miscellaneous Control Subsystem (MCS) Description . . . . . . . . . . . . . . . . . 31

M40e MCS LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

M40e Craft Interface Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

M40e Craft Interface Alarm LEDs and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

M40e Craft Interface LCD Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

LCD Idle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

LCD Alarm Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Host Module LEDs on the M40e Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

FPC LEDs and Controls on the M40e Craft Interface . . . . . . . . . . . . . . . . . . . . . . . 38

M40e Connector Interface Panel (CIP) Description . . . . . . . . . . . . . . . . . . . . . . . . 39

Routing Engine Management Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

BITS Input Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Alarm Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

M40e Power System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Circuit Breaker Box on a DC-Powered Router . . . . . . . . . . . . . . . . . . . . . . . . . 47

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

M40e Cooling System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Cooling System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Airflow Through the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

M40e Cable Management System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 3 Junos OS Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

M40e Junos OS Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

M40e Routing Engine Software Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Routing Protocol Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

VPNs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Interface Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Chassis Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

SNMP and MIB II Processes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Management Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Routing Engine Kernel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Tools for Accessing and Configuring the M40e Software . . . . . . . . . . . . . . . . . . . . 57

Tools for Monitoring the M40e Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

M40e Software Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 4 M40e System Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

M40e System Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

M40e Packet Forwarding Engine Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Packet Forwarding Engine Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Data Flow Through the Packet Forwarding Engine . . . . . . . . . . . . . . . . . . . . . 60

M40e Routing Engine Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Routing Engine Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

IPv4 Routing Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

IPv6 Routing Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Routing and Forwarding Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Routing Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Copyright © 2010, Juniper Networks, Inc.viii

Page 9

Table of Contents

Part 2 Setting Up the M40e Router

Chapter 5 Preparing the Site for M40e Router Installation . . . . . . . . . . . . . . . . . . . . . . . 67

M40e Site Preparation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

M40e Rack Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

M40e Rack Size and Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Spacing of the M40e Mounting Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

M40e Connection to Building Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

M40e Clearance Requirements for Airflow and Hardware Maintenance . . . . . . . . 71

Chapter 6 Unpacking the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Tools and Parts Required to Unpack the M40e Router . . . . . . . . . . . . . . . . . . . . . . 73

Unpacking the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Verifying the M40e Parts Received . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Chapter 7 Installing the M40e Router Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . 77

Rack-Mounting M40e Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Installing the M40e Mounting Hardware for a Four-Post Rack . . . . . . . . . . . . . . . 78

Installing Cage Nuts, If Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Installing the Mounting Shelf in a Four-Post Rack or Cabinet . . . . . . . . . . . . . 78

Removing the Center-Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Installing the M40e Mounting Hardware for an Open-Frame Rack . . . . . . . . . . . . 78

Installing Cage Nuts, If Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Installing the Mounting Shelf in an Open-Frame Rack . . . . . . . . . . . . . . . . . . 79

Removing the Center-Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Chapter 8 Installing the M40e Router Using a Mechanical Lift . . . . . . . . . . . . . . . . . . . . 81

Tools and Parts Required to Install the M40e Router Using a Mechanical Lift . . . 81

Installing the M40e Router Using a Mechanical Lift . . . . . . . . . . . . . . . . . . . . . . . . 81

Chapter 9 Installing the M40e Router Without a Mechanical Lift . . . . . . . . . . . . . . . . . 83

Tools and Parts Required to Install the M40e Router Without a Lift . . . . . . . . . . . 83

Removing Components from the Chassis Before Installing the M40e Router

Without a Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Removing the Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Removing the Rear Component Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Removing the SFMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Removing the MCSs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Removing the PCGs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Removing the Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Removing the Rear Upper Impeller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 90

Removing the Rear Lower Impeller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 91

Removing the Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Removing the FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Removing the Front Impeller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Installing the M40e Chassis into the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Reinstalling the M40e Components into the Chassis . . . . . . . . . . . . . . . . . . . . . . . 97

Reinstalling the Front Impeller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Reinstalling the FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Reinstalling the Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Reinstalling the Rear Lower Impeller Assembly . . . . . . . . . . . . . . . . . . . . . . . 101

ixCopyright © 2010, Juniper Networks, Inc.

Page 10

M40e Multiservice Edge Router Hardware Guide

Reinstalling the Rear Upper Impeller Assembly . . . . . . . . . . . . . . . . . . . . . . . 102

Reinstalling the Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Reinstalling the PCGs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Reinstalling the MCSs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Reinstalling the SFMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Reinstalling the Rear Component Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Reinstalling the Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Chapter 10 Grounding the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Connecting the M40e Grounding Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Chapter 11 Connecting the M40e Router to External Devices . . . . . . . . . . . . . . . . . . . . . . 111

Tools and Parts Required to Connect the M40e Management Devices . . . . . . . . . 111

Connecting the M40e Router to Management and Alarm Devices . . . . . . . . . . . . 111

Connecting the M40e Router to a Management Console or Auxiliary

Connecting the M40e Router to a Network for Out-of-Band

Connecting the M40e Router to an External Alarm-Reporting Device . . . . . . 115

Connecting the M40e PIC Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Chapter 12 Providing Power to the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Connecting AC Power to the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Connecting DC Power to the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Chapter 13 Configuring Junos OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Initially Configuring the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Part 3 Hardware Maintenance, Troubleshooting, and Replacement

Procedures

Chapter 14 Maintaining M40e Router Hardware Components . . . . . . . . . . . . . . . . . . . . 129

Routine Maintenance Procedures for the M40e Router . . . . . . . . . . . . . . . . . . . . 129

Maintaining the M40e Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Maintaining the M40e Fan Tray and Impellers . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Maintaining the M40e Host Module Components . . . . . . . . . . . . . . . . . . . . . . . . . 131

Maintaining M40e FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Holding and Storing M40e FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Holding an M40e FPC Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Holding an M40e FPC Vertically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Holding an M40e FPC Horizontally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Storing an M40e FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Maintaining M40e PICs and PIC Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Maintaining the M40e PCGs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Maintaining M40e SFMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Maintaining M40e Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Copyright © 2010, Juniper Networks, Inc.x

Page 11

Table of Contents

Chapter 15 Troubleshooting M40e Hardware Components . . . . . . . . . . . . . . . . . . . . . . 145

Overview of Troubleshooting Resources for the M40e Router . . . . . . . . . . . . . . . 145

M40e Router Troubleshooting Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

M40e Router LED Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Craft Interface LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Hardware Components LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

M40e Chassis and Interface Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . 147

Using Blown Fuse Indicators to Troubleshoot the M40e Router . . . . . . . . . . 149

Troubleshooting the Cooling System on the M40e Router . . . . . . . . . . . . . . . . . . 150

Troubleshooting FPCs on the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Troubleshooting PICs on the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Troubleshooting the M40e Power System When All LEDs on Both Supplies Are

Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Troubleshooting the M40e Power System When All LEDs on One Supply Are

Off or LED States Are Not Correct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Chapter 16 Replacing M40e Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

M40e Field-Replaceable Units (FRUs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Tools and Parts Required to Replace M40e Hardware Components . . . . . . . . . . 158

Replacing the CIP on the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Removing the M40e CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Installing the M40e CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Replacing Connections to the M40e Routing Engine Interface Ports . . . . . . . . . . 163

Replacing the M40e Management Ethernet Cable . . . . . . . . . . . . . . . . . . . . 163

Replacing the M40e Console or Auxiliary Cable . . . . . . . . . . . . . . . . . . . . . . 166

Replacing Alarm Relay Wires on the M40e Router . . . . . . . . . . . . . . . . . . . . . 167

Replacing the M40e Cooling System Components . . . . . . . . . . . . . . . . . . . . . . . . 167

Replacing the Fan Tray on an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Removing the Fan Tray on an M40e Router . . . . . . . . . . . . . . . . . . . . . . 168

Installing the M40e Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Replacing the M40e Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Removing the M40e Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Installing the M40e Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Replacing the M40e Front Impeller Assembly . . . . . . . . . . . . . . . . . . . . . . . . 172

Removing the M40e Front Impeller Assembly . . . . . . . . . . . . . . . . . . . . 172

Removing the M40e Craft Interface from the Front Impeller

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Installing the M40e Craft Interface on the Front Impeller Assembly . . . 174

Installing the M40e Front Impeller Assembly . . . . . . . . . . . . . . . . . . . . . 175

Replacing the M40e Rear Lower Impeller Assembly . . . . . . . . . . . . . . . . . . . 175

Removing the M40e Rear Lower Impeller Assembly . . . . . . . . . . . . . . . 176

Installing the M40e Rear Lower Impeller Assembly . . . . . . . . . . . . . . . . 176

xiCopyright © 2010, Juniper Networks, Inc.

Page 12

M40e Multiservice Edge Router Hardware Guide

Replacing the M40e Rear Upper Impeller Assembly . . . . . . . . . . . . . . . . . . . 177

Replacing the M40e Host Module Components . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Replacing an MCS in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Removing and Inserting the PC Card in an M40e Router . . . . . . . . . . . . . . . . 182

Replacing a DIMM Module in M40e Routing Engines . . . . . . . . . . . . . . . . . . . 185

Replacing a Routing Engine in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . 186

Replacing the M40e Packet Forwarding Engine Components . . . . . . . . . . . . . . . 190

Replacing an FPC in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Replacing a PCG in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Replacing a PIC in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Replacing PIC Cables in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Replacing an SFM in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Replacing an SFP in an M40e PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Replacing M40e Power System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Replacing an M40e AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Replacing an AC Power Cord on an M40e Power Supply . . . . . . . . . . . . . . . 215

Replacing an M40e DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Replacing the Circuit Breaker Box on a DC-Powered M40e Router . . . . . . . . 218

Replacing a Fuse on an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Removing the M40e Rear Upper Impeller Assembly . . . . . . . . . . . . . . . 178

Installing the M40e Rear Upper Impeller Assembly . . . . . . . . . . . . . . . . 178

Removing an MCS from an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . 180

Installing an MCS in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Removing the M40e PC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Inserting the M40e PC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Removing a M40e DIMM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Installing a M40e DIMM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Removing a Routing Engine from an M40e Router . . . . . . . . . . . . . . . . . 187

Installing a Routing Engine in an M40e Router . . . . . . . . . . . . . . . . . . . . 189

Removing an FPC in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Installing an FPC in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Removing a PCG in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Installing a PCG in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Removing a PIC in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Installing a PIC in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Removing a PIC Cable from an M40e Router . . . . . . . . . . . . . . . . . . . . . 203

Installing a PIC Cable in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . 204

Removing an SFM in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Installing an SFM in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Removing an SFP from an M40e PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Installing an SFP in an M40e PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Removing an M40e AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Installing an M40e AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Removing an M40e DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Installing an M40e DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Removing the Circuit Breaker Box from a DC-Powered M40e

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Installing the Circuit Breaker Box in a DC-Powered M40e Router . . . . . 220

Copyright © 2010, Juniper Networks, Inc.xii

Page 13

Table of Contents

Part 4 Appendixes

Appendix A Safety and Regulatory Compliance Information for the M40e Router . . . 227

Definition of Safety Warning Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Safety Guidelines and Warnings for the M40e Router . . . . . . . . . . . . . . . . . . . . . 229

M40e General Safety Guidelines and Warnings . . . . . . . . . . . . . . . . . . . . . . 229

General Safety Guidelines and Warnings for M Series, MX Series, and

T Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Qualified Personnel Warning for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Restricted Access Area Warning for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Preventing Electrostatic Discharge Damage to an M Series, MX Series,

or T Series Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Fire Safety Requirements for the M40e Router . . . . . . . . . . . . . . . . . . . . . . . 233

Fire Safety Requirements for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

M40e Router Installation Safety Guidelines and Warnings . . . . . . . . . . . . . 234

M40e Chassis Lifting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Installation Instructions Power Warning for M Series, MX Series, and T

Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Rack-Mounting Requirements and Warnings for M Series, MX Series,

and T Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Ramp Warning for M Series, MX Series, and T Series Routers . . . . . . . . 240

Laser and LED Safety Guidelines and Warnings for the M40e Router . . . . . 240

General Laser Safety Guidelines for M Series and T Series Routers . . . 240

Class 1 Laser Product Warning for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Class 1 LED Product Warning for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Laser Beam Warning for M Series, MX Series, and T Series Routers . . . 242

Radiation from Open Port Apertures Warning for M Series, MX Series,

and T Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Maintenance and OperationalSafetyGuidelines andWarnings for theM40e

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Battery Handling Warning for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Jewelry Removal Warning for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Lightning Activity Warning for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Operating Temperature Warning for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Product Disposal Warning for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

xiiiCopyright © 2010, Juniper Networks, Inc.

Page 14

M40e Multiservice Edge Router Hardware Guide

Electrical Safety Guidelines and Warnings for the M40e Router . . . . . . . . . 250

Agency Approvals and Compliance Statements for the M40e Router . . . . . . . . 264

Agency Approvals for M40e Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Compliance Statements for NEBS for M Series, MX Series, and T Series

Compliance Statements for EMC Requirements for the M40e Router . . . . 266

Compliance Statements for Environmental Requirements for M Series, MX

Compliance Statements for Acoustic Noise for the M40e Router . . . . . . . . 268

Appendix B M40e Router Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

M40e Router Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Appendix C M40e Router Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 271

M40e Router Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Appendix D Power Guidelines, Requirements, and Specifications for the M40e

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Site Electrical Wiring Guidelines for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

M40e Router Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

M40e Chassis Grounding Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

M40e AC Power, Connection, and Power Cord Specifications . . . . . . . . . . . . . . . 277

M40e DC Power, Connection, and Cable Specifications . . . . . . . . . . . . . . . . . . . 279

M40e DC Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Appendix E Cable and Wire Guidelines and Specifications for the M40e Router . . . . 283

Fiber-Optic Specifications and Guidelines for the M40e Router . . . . . . . . . . . . . 283

Fiber-Optic and Network Cable Specifications for the M40e Router . . . . . . 283

Signal Loss in Multimode and Single-Mode Fiber-Optic Cable for the M40e

Attenuation and Dispersion in Fiber-Optic Cable on M Series, MX Series,

Calculating Power Budget for Fiber-Optic Cable for M Series, MX Series,

Calculating Power Margin for Fiber-Optic Cable for M Series, MX Series, and

Routing Engine Interface Cable and Wire Specifications for the M40e Router . . 288

In Case of an Electrical Accident . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

General Electrical Safety Guidelines and Warnings Electrical Codes for

the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

M40e AC Power Electrical Safety Guidelines and Warnings . . . . . . . . . 256

M40e DC Power Electrical Safety Guidelines and Warnings . . . . . . . . . 256

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

European Community . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Japan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Series, and T Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

and T Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

and T Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

T Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Copyright © 2010, Juniper Networks, Inc.xiv

Page 15

Table of Contents

Appendix F M40e Cable Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

RJ-45 Connector Pinouts for the M40e Routing Engine MGMT Port . . . . . . . . . . 289

DB-9 Connector Pinouts for the M40e Routing Engine AUX/MODEM and

CONSOLE Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

RJ-48 Cable Pinouts for E1 and T1 PICs on the M40e Router . . . . . . . . . . . . . . . 290

DB-9 Connector Pinouts for the M40e CIP BITS Input Ports . . . . . . . . . . . . . . . . 293

M40e X.21 and V.35 Cable Pinouts for EIA-530 PIC . . . . . . . . . . . . . . . . . . . . . . . 294

M40e Fast Ethernet PIC 48-port Cable Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . 296

Appendix G Contacting Customer Support and Returning M40e Hardware . . . . . . . . 299

Locating M40e Component Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Displaying M40e Router Components and Serial Numbers . . . . . . . . . . . . . 299

M40e AC Power Supply Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . 300

M40e CIP Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

M40e Craft Interface Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . 302

M40e DC Power Supply Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . 303

M40e FPC Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

M40e MCS Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

M40e PCG Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

M40e PIC Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

M40e Routing Engine Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . 306

M40e SFM Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Contacting Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Returning a Hardware Component to Juniper Networks, Inc. . . . . . . . . . . . . . . . 308

Tools and Parts Required to Remove Components from an M40e Router . . . . . 309

Packing the M40e Router for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Packing M40e Components for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Part 5 Index

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

xvCopyright © 2010, Juniper Networks, Inc.

Page 16

M40e Multiservice Edge Router Hardware Guide

Copyright © 2010, Juniper Networks, Inc.xvi

Page 17

List of Figures

Part 1 Overview of the M40e Multiservice Edge Router

Chapter 2 M40e Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 1: Front of M40e Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 2: Rear of M40e Chassis with Component Cover in Place . . . . . . . . . . . . . . 10

Figure 3: Rear of M40e Chassis with Component Cover Removed . . . . . . . . . . . . 10

Figure 4: M40e Midplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5: Front of M40e Chassis with Four-PIC FPC Installed in Slot FPC0 . . . . . . 15

Figure 6: M40e FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 7: M40e Enhanced Plus FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 8: M40e Packet Forwarding Engine Clock Generator . . . . . . . . . . . . . . . . . . 19

Figure 9: M40e and M160 Router PCG Location . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 10: M40e Packet Forwarding Engine Clock Generator . . . . . . . . . . . . . . . . . 20

Figure 11: M40e Switching and Forwarding Module . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 12: M40e Switching and Forwarding Module . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 13: M40e and M160 Router Host Module Location . . . . . . . . . . . . . . . . . . . 25

Figure 14: M40e and M160 Router Redundant Host Modules . . . . . . . . . . . . . . . . 26

Figure 15: M40e Router Routing Engine Location . . . . . . . . . . . . . . . . . . . . . . . . . . 27

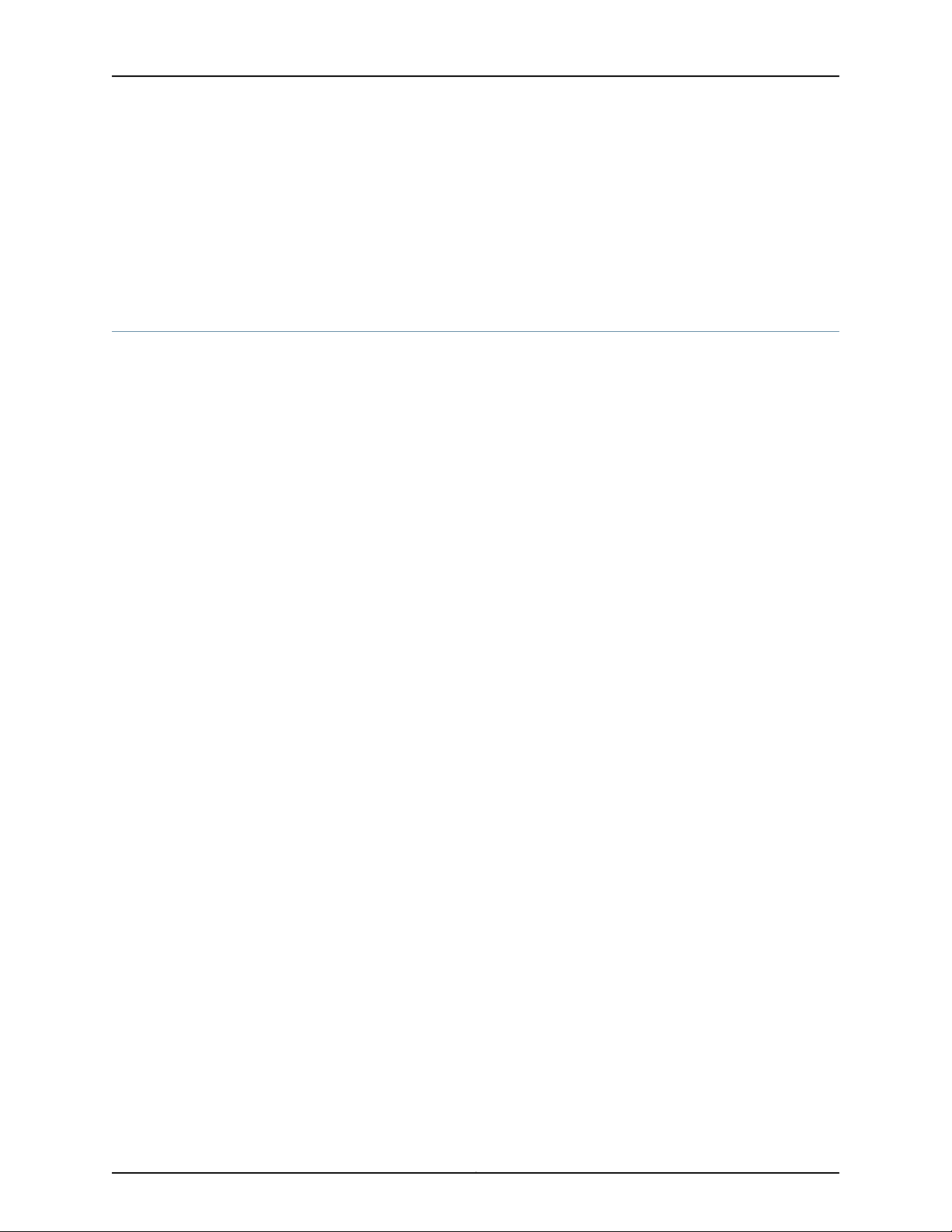

Figure 16: M40e Routing Engine 333 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 17: M40e Routing Engine 600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

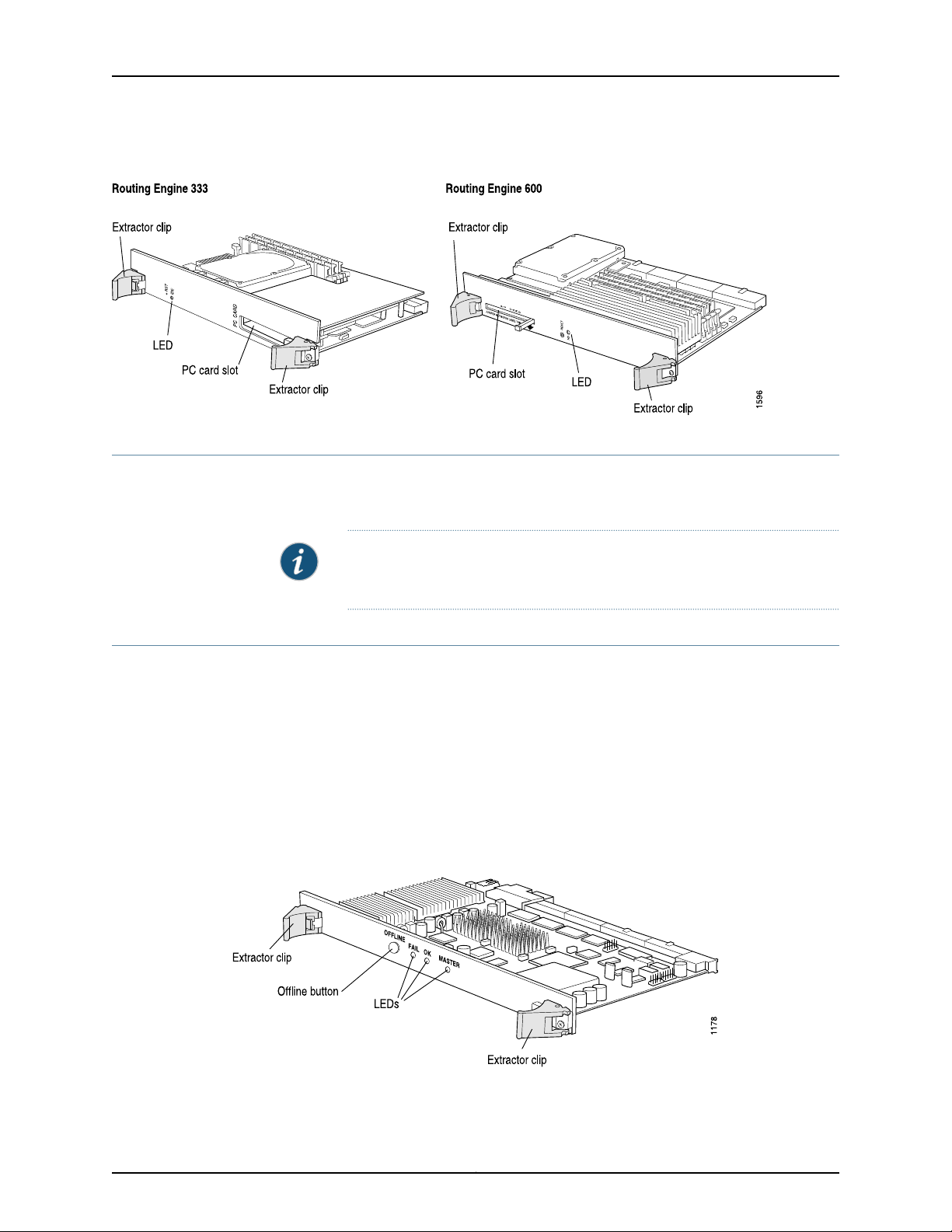

Figure 18: M40e Miscellaneous Control Subsystem . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 19: M40e and M160 Router MCS Location . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 20: M40e Miscellaneous Control Subsystem . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 21: M40e Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 22: LCD in Idle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 23: M40e LCD in Alarm Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 24: Connector Interface Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 25: M40e and M160 Router CIP Location . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 26: M40e Routing Engine Interface Ports for Host Module 0 . . . . . . . . . . . 41

Figure 27: M40e Alarm Relay Contacts and BITS Input Ports . . . . . . . . . . . . . . . . 42

Figure 28: M40e Router Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 29: M40e AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 30: M40e DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 31: M40e Circuit Breaker Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 32: Airflow Through the M40e Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 33: M40e Cable Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 4 M40e System Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 34: System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 35: Packet Forwarding Engine Components and Data Flow . . . . . . . . . . . . 61

Figure 36: M40e Routing Engine Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

xviiCopyright © 2010, Juniper Networks, Inc.

Page 18

M40e Multiservice Edge Router Hardware Guide

Figure 37: Control Packet Handling for Routing and Forwarding Table

Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Part 2 Setting Up the M40e Router

Chapter 5 Preparing the Site for M40e Router Installation . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 38: Typical Open-Frame Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 39: M40e Chassis Dimensions and Clearance Requirements . . . . . . . . . . . 72

Chapter 6 Unpacking the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 40: Unpacking the Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Chapter 9 Installing the M40e Router Without a Mechanical Lift . . . . . . . . . . . . . . . . . 83

Figure 41: Removing a M40e Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 42: Removing an M40e SFM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 43: Removing an M40e MCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 44: Removing a M40e PCG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Figure 45: Removing a M40e Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 46: Removing the M40e Rear Upper Impeller Assembly . . . . . . . . . . . . . . 90

Figure 47: Removing the M40e Rear Lower Impeller Assembly . . . . . . . . . . . . . . . 91

Figure 48: Removing the M40e Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 49: Removing an M40e FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 50: Removing the M40e Front Impeller Assembly . . . . . . . . . . . . . . . . . . . 95

Figure 51: Attaching the Lifting Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 52: Installing the Chassis in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 53: Reinstalling the M40e Front Impeller Assembly . . . . . . . . . . . . . . . . . . 99

Figure 54: Reinstalling an M40e FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 55: Reinstalling the Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 56: Reinstalling the Rear Lower Impeller Assembly . . . . . . . . . . . . . . . . . . 101

Figure 57: Reinstalling the Rear Upper Impeller Assembly . . . . . . . . . . . . . . . . . . 102

Figure 58: Reinstalling a Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Figure 59: Reinstalling a PCG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 60: Reinstalling an MCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 61: Reinstalling an SFM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 62: Reinstalling a Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Chapter 10 Grounding the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure 63: Connecting the M40e Grounding Cable . . . . . . . . . . . . . . . . . . . . . . . . 110

Chapter 11 Connecting the M40e Router to External Devices . . . . . . . . . . . . . . . . . . . . . . 111

Figure 64: Routing Engine Management Ports and Alarm Relay Contacts . . . . . . 112

Figure 65: Console and Auxiliary Serial Port Connector . . . . . . . . . . . . . . . . . . . . . 113

Figure 66: Routing Engine Management Ports and Alarm Relay Contacts . . . . . . 114

Figure 67: Routing Engine Ethernet Cable Connector . . . . . . . . . . . . . . . . . . . . . . . 115

Figure 68: Routing Engine Management Ports and Alarm Relay Contacts . . . . . . 115

Figure 69: Attaching Cable to an M40e PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Chapter 12 Providing Power to the M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Figure 70: Connecting DC Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Copyright © 2010, Juniper Networks, Inc.xviii

Page 19

List of Figures

Part 3 Hardware Maintenance, Troubleshooting, and Replacement

Procedures

Chapter 14 Maintaining M40e Router Hardware Components . . . . . . . . . . . . . . . . . . . . 129

Figure 71: Do Not Grasp the Connector Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 72: Do Not Carry an FPC with Only One Hand . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 73: Do Not Rest the FPC on an Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 74: Holding an FPC Vertically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Figure 75: Holding an FPC Horizontally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Figure 76: Do Not Stack FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Chapter 15 Troubleshooting M40e Hardware Components . . . . . . . . . . . . . . . . . . . . . . 145

Figure 77: Fuse Locations in the Fuse Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Chapter 16 Replacing M40e Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Figure 78: Removing the M40e CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Figure 79: Installing the M40e CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Figure 80: Routing Engine Interface Ports and Alarm Relay Contacts . . . . . . . . . 164

Figure 81: Ethernet Cable Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Figure 82: Routing Engine Interface Ports and Alarm Relay Contacts . . . . . . . . . 166

Figure 83: Removing the Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Figure 84: Installing the Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Figure 85: Removing the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Figure 86: Installing the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Figure 87: Removing the Front Impeller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 173

Figure 88: Removing the Screws Along the Top Front Edge of the Front Impeller

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Figure 89: Removing the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Figure 90: Installing the M40e Front Impeller Assembly . . . . . . . . . . . . . . . . . . . . 175

Figure 91: Removing the Rear Lower Impeller Assembly . . . . . . . . . . . . . . . . . . . . 176

Figure 92: Installing the Rear Lower Impeller Assembly . . . . . . . . . . . . . . . . . . . . 177

Figure 93: Removing the Rear Upper Impeller Assembly . . . . . . . . . . . . . . . . . . . 178

Figure 94: Installing the Rear Upper Impeller Assembly . . . . . . . . . . . . . . . . . . . . 179

Figure 95: Rear of M40e Chassis with Component Cover Removed . . . . . . . . . . 180

Figure 96: Removing an MCS from an M40e Router . . . . . . . . . . . . . . . . . . . . . . . 181

Figure 97: Installing an MCS in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Figure 98: Removing the PC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Figure 99: Inserting the PC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Figure 100: Installing the DIMM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Figure 101: Rear of M40e Chassis with Component Cover Removed . . . . . . . . . . 187

Figure 102: Removing a Routing Engine from an M40e Router . . . . . . . . . . . . . . . 189

Figure 103: Installing a Routing Engine in an M40e Router . . . . . . . . . . . . . . . . . . 190

Figure 104: Removing an FPC from an M40e Router . . . . . . . . . . . . . . . . . . . . . . . 193

Figure 105: Installing an FPC in an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Figure 106: Connecting Fiber-Optic Cable to a PIC in an M40e Router . . . . . . . . 196

Figure 107: Removing a PCG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Figure 108: Installing a PCG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Figure 109: Removing a PIC from an M40e Router . . . . . . . . . . . . . . . . . . . . . . . 200

Figure 110: Installing a PIC from an M40e Router . . . . . . . . . . . . . . . . . . . . . . . . . 202

Figure 111: Connecting Fiber-Optic Cable to a PIC in an M40e Router . . . . . . . . . 203

xixCopyright © 2010, Juniper Networks, Inc.

Page 20

M40e Multiservice Edge Router Hardware Guide

Figure 112: Connecting Fiber-Optic Cable to a PIC . . . . . . . . . . . . . . . . . . . . . . . . 205

Figure 113: Removing an SFM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Figure 114: Installing an SFM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Figure 115: Small Form-Factor Pluggable (SFP) . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Figure 116: Small Form-Factor Pluggable (SFP) . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Figure 117: Removing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Figure 118: Rear of AC Power Supply Showing Midplane Connectors . . . . . . . . . . 213

Figure 119: Installing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Figure 120: Removing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Figure 121: Rear of DC Power Supply Showing Midplane Connectors . . . . . . . . . . 217

Figure 122: Installing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Figure 123: Removing the Circuit Breaker Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Figure 124: Installing the Circuit Breaker Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Figure 125: Fuse Locations in the Fuse Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Part 4 Appendixes

Appendix A Safety and Regulatory Compliance Information for the M40e Router . . . 227

Figure 126: Placing a Component into an Electrostatic Bag . . . . . . . . . . . . . . . . . 233

Figure 127: M40e Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Appendix D Power Guidelines, Requirements, and Specifications for the M40e

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Figure 128: M40e DC Power and Grounding Cable Lug . . . . . . . . . . . . . . . . . . . . . 277

Figure 129: AC Plug Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Figure 130: M40e DC Power and Grounding Cable Connections . . . . . . . . . . . . . 281

Appendix F M40e Cable Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Figure 131: EIA-530 PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Figure 132: Fast Ethernet 48-port PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Figure 133: VHDCI to RJ-21 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Appendix G Contacting Customer Support and Returning M40e Hardware . . . . . . . . 299

Figure 134: Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Figure 135: AC Power Supply Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . 301

Figure 136: CIP Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Figure 137: Craft Interface Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . 302

Figure 138: DC Power Supply Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . 303

Figure 139: FPC Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Figure 140: MCS Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Figure 141: PCG Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Figure 142: PIC Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305