Page 1

Hydrostatic drive for excellent

drive comfort and productivity

Low fuel consumption

Generously designed operator

workplace

Excellent stability during travel

due to extremely low centre

of gravity and high pivot steer

axle

Driver assistance systems

(optional)

DFG/TFG 540s/545s/550s/S50s

Diesel and LPG counterbalanced trucks with hydrostatic drive

(4,000/4,500/4,990/5,000 kg)

Jungheinrich Diesel and LPG counterbalanced trucks with hydrostatic drive give a

productivity particularly in shuttle operations (e.g. trailer and loading bay operations). The power of this drive technology is demonstrated to full advantage:

high acceleration, rapid direction

changes and precise driving characteristics. With 5 operating programmes,

the performance characteristics can be

adapted to the requirements of numerous varied applications.

State-of-the-art engines from the automotive industry give precise operation

and optimum productivity combined

with low fuel consumption minimised

by their electronic control systems. All

engines have low exhaust emissions and

comply with at least the current EU regulations. The diesel truck is fitted with a

diesel particle filter as standard. A closedloop three-way catalytic converter is

available as an option for the LPG trucks.

The workplace is optimally laid out with

the operator in mind. It provides safety,

protects the operator’s health and ensures relaxed and concentrated operation – the best basis for high productivity

throughout the shift. The roof panel,

made out of safety glass, oers ideal

protection against foul weather and small

falling objects. The improved lighting

level makes for a more pleasant working

environment and helps make loading and

unloading operations quicker and safer.

Page 2

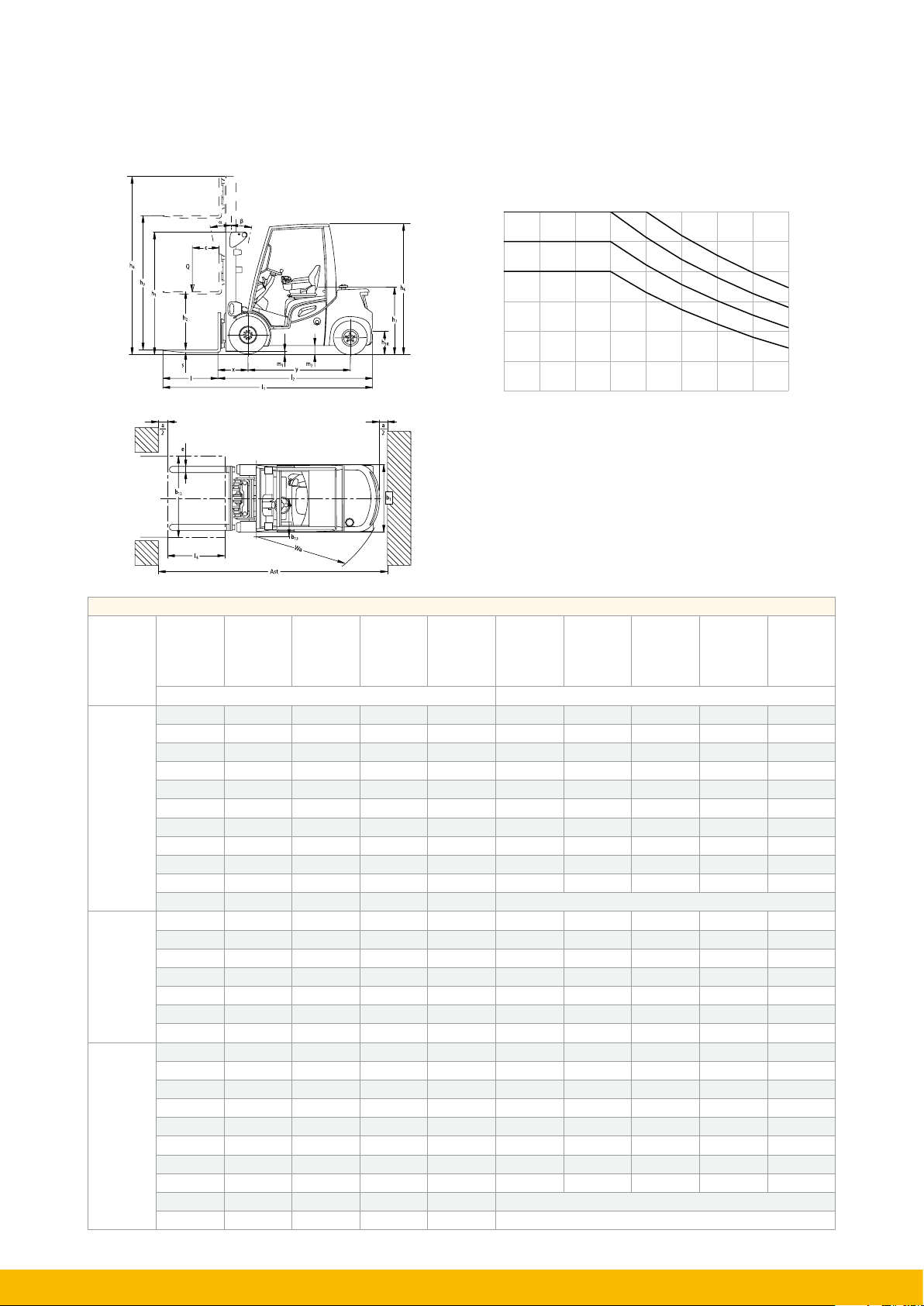

DFG/TFG 540s/545s/550s/S50s

kg

Capacity

5000

4500

4000

3500

3000

2500

2000

200 300 400 500 600 700 800 900 1000

Load centre distance “c” in mm

DFG/TFG S50s

DFG/TFG 550s

DFG/TFG 545s

DFG/TFG 540s

Standard mast types DFG/TFG 540s - S50s

Lift

h3

(mm)

Lowered

mast height

h1

(mm)

Free lift

h2

(mm)

Extended

mast height

h4

(mm)

Mast tilt

forward /

back

a/ß

(°)

Lift

h3

(mm)

Lowered

mast height

h1

(mm)

Free lift

h2

(mm)

Extended

mast height

h4

(mm)

Mast tilt

forward /

back

a/ß

(°)

DFG/TFG 540s/545s DFG/TFG 550s/S50s

Duplex

ZT

2020 1800 150 2735 6/8 2020 1800 150 2883 6/8

2750 2165 150 3465 6/8 2750 2165 150 3613 6/8

3000 2290 150 3715 6/8 3000 2290 150 3863 6/8

3500 2540 150 4215 6/8 3500 2540 150 4363 6/8

3750 2665 150 4465 6/8 4000 2790 150 4863 6/8

4000 2790 150 4715 6/8 4500 3040 150 5363 6/8

4500 3040 150 5215 6/8 5000 3290 150 5863 6/6

5000 3290 150 5715 6/6 5500 3540 150 6363 6/6

5500 3540 150 6215 6/6 6000 3790 150 6863 6/6

6000 3790 150 6715 6/6 6500 4040 150 7363 6/6

6500 4040 150 7215 6/6

Duplex

ZZ

2775 2140 1375 3540 6/8 2725 2140 1225 3640 6/8

3025 2265 1500 3790 6/8 2975 2265 1350 3890 6/8

3525 2515 1750 4290 6/8 3475 2515 1600 4390 6/8

4025 2765 2000 4790 6/8 3975 2765 1850 4890 6/8

4525 3015 2250 5290 6/8 4475 3015 2100 5390 6/8

5025 3265 2500 5790 6/6 4975 3265 2350 5890 6/6

5525 3515 2750 6290 6/6 5475 3515 2600 6390 6/6

Triplex

DZ

4150 2140 1375 4915 6/8 3930 2100 1185 4845 6/8

4525 2265 1500 5290 6/8 4050 2140 1225 4965 6/8

4855 2375 1610 5620 6/6 4425 2265 1350 5340 6/8

5275 2515 1750 6040 6/6 5175 2515 1600 6090 6/6

5650 2640 1875 6415 6/6 5550 2640 1725 6465 6/6

6025 2765 2000 6790 6/6 5925 2765 1850 6840 6/6

6400 2890 2125 7165 6/6 6200 2855 1940 7110 6/6

6775 3015 2250 7540 6/6 6675 3015 2100 7590 6/6

7030 3100 2335 7795 6/6

7180 3150 2385 7945 6/6

Page 3

Issue: 08/2013

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

DFG

DFG

DFG

DFG

TFG

1.2 Model

540s

545s

550s

S50s

1.3 Drive Diesel Diesel Diesel Diesel LPG LPG LPG LPG

1.4 Manual, pedestrian, stand-on, seated, order picker operation seat

1.5 Load capacity/rated load Q t 4 4.5 4.99 5 4 4.5 4.99 5

1.6 Load centre distance c mm 500 500 500 600 500 500 500 600

Identification

1.8 Load distance x mm 564

1)

5641)5641)5791)5641)5641)5641)579

1.9 wheelbase y mm 1970 1970 1970 2000 1970 1970 1970 2000

2.1 Service weight kg 6310 6550 7200 7400 6360 6600 7250 7450

9050 /

9660 /

10940

2.2 Axle load, w. load, front / rear kg

Weights

2.3 Axle load, w.o. load, front / rear kg

1260

2920 /

3390

1390

2730 /

3820

/ 1260

3240 /

3960

10900

/ 1500

3000 /

4400

3.1 Tyres SE

3.2 Tyre size, at front mm

8.25300-15 300-15 300-15

15

3.3 Tyre size, at rear mm 28x9-15

3.5 Wheels, number front/rear (× = driven wheels) 2x/2

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

mm 1195 1160 1160 1160 1195 1160 1160 1160

10

mm 1150

11

4.1 Tilt of mast/fork carriage forward/backward α/β ° 6/8

4.2 mast height (lowered) h

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8 Seat height/stand height h

4.12 Coupling height h

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 fork dimensions s/e/l mm

Basic dimensions

4.23 Fork carriage ISO 2328, class/type A, B 3A 3A 3A 4A 3A 3A 3A 4A

4.24 fork carriage width b

4.31 floor clearance with load under mast m

4.32 Floor clearance centre wheelbase m

mm 2540

1

mm 150

2

mm 3500

3

mm 4215 4215 4365 4365 4215 4215 4365 4365

4

mm 2405

6

mm 1230

7

mm 510

10

mm 4145 4220 4240 4310 4145 4220 4240 4310

1

mm 2995 3070 3090 3160 2995 3070 3090 3160

2

mm 1450

1/b2

mm 1260

3

mm 175

1

mm 200

2

50 /

125 /

1150

50 /

150 /

1150

50 /

150 /

1150

60 /

150 /

1150

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 4405 4465 4475 4530 4405 4465 4475 4530

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 4605 4665 4675 4730 4605 4665 4675 4730

4.35 turning radius W

4.36 Smallest pivot point distance b

mm 2640 2700 2710 2750 2640 2700 2710 2750

a

mm 730

13

5.1 Travel speed, w. / w.o. load km/h 21

0.53 /

0.51 /

0.49 /

5.2 Lift speed, w. / w.o. load m/s

5.3 Lower speed, w. / w.o. load

m/s 0.57 / 0.54

0.56

0.55

0.53

0.49 /

0.53

5.5 Drawbar pull w. / w.o. load N 23000 22000 22000 22000 23000 22000 22000 22000

5.7 Gradeability laden/unladen % 25 / 27 23 / 26 22 / 26 21 / 25 25 / 27 23 / 26 22 / 26 21 / 25

5.9 Acceleration time w. / w.o. load S 5.7 / 5 6 / 5.2 6 / 5.2

Performance data

5.10 Service brake hydrostatic

6.2 /

5.5

5.11 parking brake Automatic activated multi disc brake

VW /

VW /

VW /

7.1 Motor manufacturer / type

2,0 CR

2,0 CR

2,0 CR

VW /

2,0 CR

7.2 motor output according to ISO 1585 kW 55 55 55 55 59 59 59 59

7.3 rated revolutions per minute /min 2700

7.4 No. of cylinders 4 4 4 4 6 6 6 6

7.4.1 cubic capacity cm³ 1968 1968 1968 1968 3597 3597 3597 3597

7.5 fuel consumption acc. to VDI cycle l/h 4.4 4.8 5 5.2

Combustion engine

7.5.1 fuel consumption acc. to VDI cycle kg/h 4.3 4.5 4.7 4.8

8.1 type of drive control hydrostatic

8.2 working pressure for attachments bar 170

8.3 oil flow for attachments l/min 48

Misc.

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 77 77 77 77 78 78 78 78

8.5 Trailer coupling, model/type DIN DIN 15170 Typ H

TFG

540s

545s

9070 /

9680 /

1290

1420

2950 /

2760 /

3410

3840

8.25300-15 300-15 300-15

15

50 /

50 /

125 /

150 /

1150

1150

0.53 /

0.51 /

0.56

0.55

5.7 / 5 6 / 5.2 6 / 5.2

VW /

VW /

3.6VR6

3.6VR6

TFG

550s

10960

/ 1290

3270 /

3980

50 /

150 /

1150

0.49 /

0.53

VW /

3.6VR6

TFG

S50s

10920

/ 1530

3030 /

4420

60 /

150 /

1150

0.49 /

0.53

6.2 /

5.5

VW /

3.6VR6

1)

1)

+10 mm with DZ mast

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Maximum throughput Comfort and productivity promot-

Ergonomic operator workplace

• Easy and safe access due to a large

step easily visible from above.

• Floating Cab: vibration isolation with

damped power train mountings and

operator workplace module.

• Height and rake adjustable, slim steering column with memory function.

• Easy entry to the cab: the steering column tilts forward by means of a simple

pull on the memory function lever.

• Excellent all-round visibility due to special roof and scuttle design.

ing workplace

• Access Control: Allows operation of

the forklift only if “seat occupied” and

“safety belt locked” recognition are

activated in a defined sequence.

• Drive Control: Automatic travel speed

reduction when cornering. Additional

travel speed reduction occurs with lift

heights in excess of approx. 1.500 mm.

• Lift Control (includes “Drive Control”):

Automatic mast tilt speed reduction

occurs with lift heights in excess of approx. 1.500 mm. Tilt angle is displayed

via an individual display unit.

• The special roof and scuttle designs

including a strut-free safety glass roof

panel ensuring excellent all-round

visibility.

• SOLO-PILOT, Comfort Display and operating console are integrated into the

right hand armrest and are particularly

easy to operate and read.

Handling eciency and drive characteristics

Key advantages of hydrostatic drive:

• Electronic control for precise adjustment of drive and hydraulic functions.

• Optimum handling performance particularly in shuttle operations.

• 5 electronically selectable operating

Assistance systems

• Deactivation of hydraulic functions if

seat is unoccupied.

• No uncontrolled roll-back on ramps or

inclines due to the automatic parking

brake, even with the engine switched

o.

• Excellent stability due to extremely low

centre of gravity and high pivot steer

programmes ensure optimum performance parameters for every application.

• Automatic engine speed increase during lifting and lowering.

• Optional double pedal operation.

• Low maintenance costs due to direct

drive without wearing parts, such as

clutch, dierential and gears.

axle.

A range of optional driver assistance

systems provide even more safety for the

operator, the forklift and the load:

Intelligent electronics

• Splash-proof electronic drive and hydraulic controllers (IP 64) in CAN-Bus

design.

• Electronically controlled motors.

VW engines with low energy consumption

• TFG with maintenance-free, electronic

ignition system.

• Sensitive adjustment of hydraulic functions via electromagnetic valves.

Brakes

The hydrostatic drive allows completely

wear free braking:

• Frequent brake pedal operation is no

longer necessary.

• Parking brake: sprung-loaded laminated oil immersed parking brake as a

maintenance-free, enclosed system.

• Safety on ramps: the parking brake is

activated automatically when the truck

stands still or the engine is switched

o.

Hydraulics

The high performance filter system

ensures clean hydraulic oil and a long

service life of all components.

• Combined suction and return flow filter

system for optimum cold running.

• Hydraulic tank integrated in chassis.

• Ventilation of hydraulic tank via the

filter.

• Pressure relief valves protect against

excess pressure and overloading.

Mast

All mast components are designed for

optimum visibility, maximum stability and

long service life:

• Slender mast profiles with lift cylinders

behind for maximum visibility.

• Damping on mast and tilt cylinders for

increased handling safety.

Outstanding all-round visibility

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

Jungheinrich Plants, Sales and

Services Europe ISO 9001/

ISO 14001

Jungheinrich fork lift trucks

meet European safety require-

ments.

T_DFG/TFG 540s/545s/550s/S50s_102013_en_UK_000

Loading...

Loading...