Page 1

12.12 -

11.14

51289390

DFG/TFG 660-690

Operating instructions G

TFG 680

DFG 670

DFG 680

DFG 690

DFG S80

DFG S90

TFG 660

TFG 670

TFG 690

TFG S80

TFG S90

DFG 660

Page 2

3

11.14 E N

Declaration of Conformity

Jungheinrich AG, Am Stadtrand 35, D-22047 Hamburg

Manufacturer or agent acting in the European Union

Additional information

On behalf of

Date

G

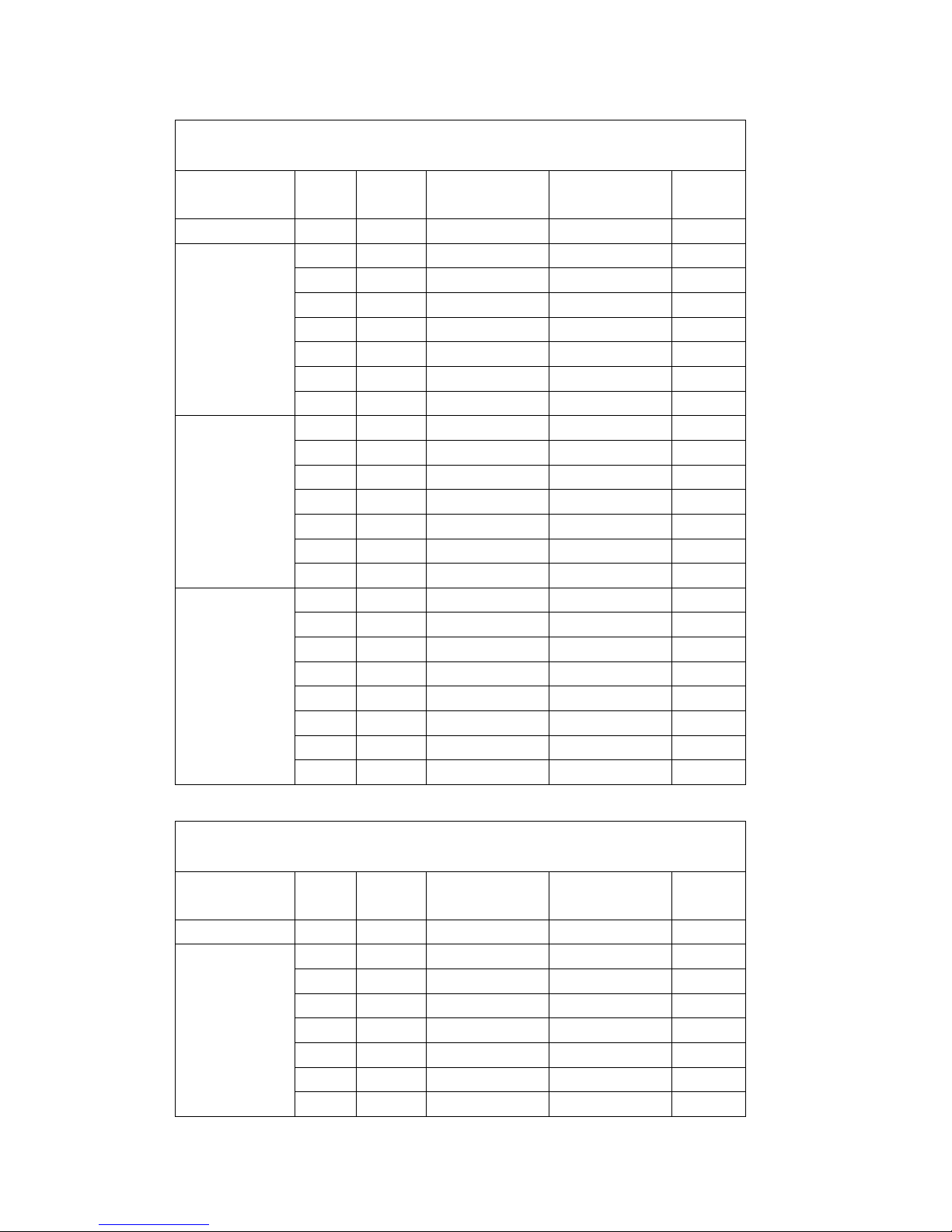

EU Conformity Declaration

The undersigned hereby declare that the powered industrial truck described below in

detail complies with the European Directives 2006/42/EC (Machinery Directive) and

2004/108/EEC (Electromagnetic Compatibility - EMC) including amendments as well

as the legislative decree to incorporate the directives in national law. The signatories

are in each case individually authorized to compile the technical documents.

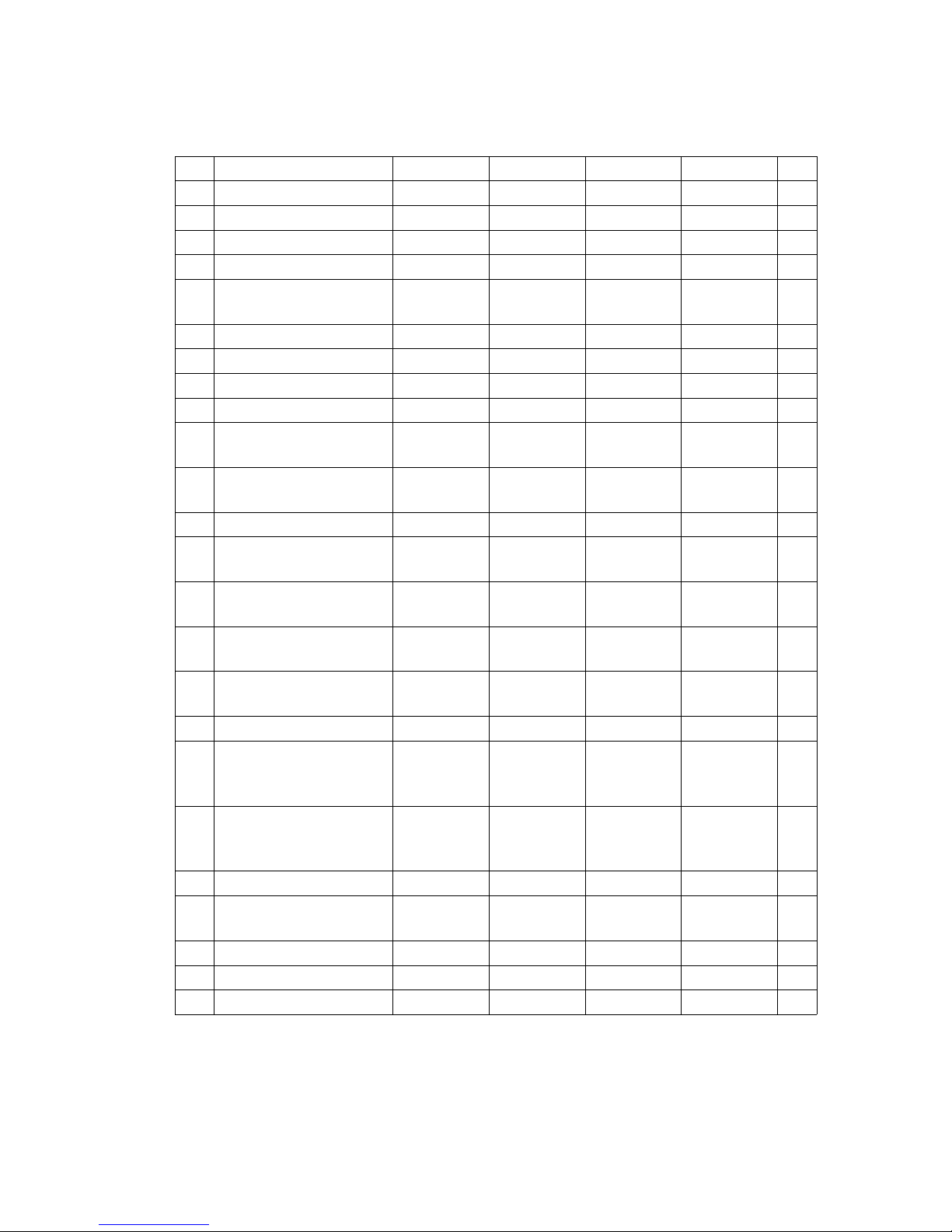

Type Option Serial no. Year of

manufacture

DFG 660

DFG 670

DFG 680

DFG 690

DFG S80

DFG S90

TFG 660

TFG 670

TFG 680

TFG 690

TFG S80

TFG S90

G

Page 3

11.14 E N

4

Page 4

5

11.14 E N

Foreword

Notes on the operating instructions

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide

sufficient instruction for the safe operation of the industrial truck. The information is

provided clearly and concisely. The chapters are arranged by letter and the pages are

numbered continuously.

The operator manual details different industrial truck models. When operating and

servicing the industrial truck, make sure that the particular section applies to your

truck model.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to

alter the design, equipment and technical features of the system. No guarantee of

particular features of the truck should therefore be assumed from the present

operating instructions.

Safety notices and text mark-ups

Safety instructions and important explanations are indicated by the following

graphics:

DANGER!

Indicates an extremely hazardous situation. Failure to comply with this instruction will

result in severe irreparable injury and even death.

WARNING!

Indicates an extremely hazardous situation. Failure to comply with this instruction

may result in severe irreparable injury and even death.

CAUTION!

Indicates a hazardous situation. Failure to comply with this instruction may result in

slight to medium injury.

NOTE

Indicates a material hazard. Failure to comply with this instruction may result in

material damage.

Z Used before notices and explanations.

t Indicates standard equipment

o Indicates optional equipment

Page 5

11.14 E N

6

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - Germany

Tel: +49 (0) 40/6948-0

www.jungheinrich.com

Page 6

7

11.14 E N

Contents

A Correct Use and Application ................................................... 11

1 General.................................................................................................... 11

2 Correct application................................................................................... 11

3 Approved application conditions.............................................................. 12

4 Proprietor responsibilities ........................................................................ 13

5 Adding attachments and/or optional equipment ...................................... 13

B Truck Description .................................................................... 15

1 Application ............................................................................................... 15

1.1 Truck models and rated capacity............................................................. 15

2 Assemblies and Functional Description................................................... 16

2.1 Assembly Overview ................................................................................. 16

2.2 Functional Description ............................................................................. 17

3 Technical Specifications .......................................................................... 19

3.1 Performance data .................................................................................... 19

3.2 Dimensions .............................................................................................. 23

3.3 Weights.................................................................................................... 28

3.4 Mast versions .......................................................................................... 29

3.5 Tyre type.................................................................................................. 33

3.6 Engine Data ............................................................................................. 35

3.7 EN norms................................................................................................. 36

3.8 Conditions of use ..................................................................................... 37

3.9 Electrical requirements ............................................................................ 37

4 Identification points and data plates ........................................................ 38

4.1 Data plate ................................................................................................ 40

4.2 Truck capacity plate................................................................................. 41

4.3 Attachment capacity plate ....................................................................... 42

4.4 Jack attachment point.............................................................................. 42

5 Stability .................................................................................................... 42

C Transport and Commissioning ................................................ 43

1 Transport ................................................................................................. 43

2 Truck laden.............................................................................................. 43

2.1 Centre of gravity of the truck ................................................................... 43

2.2 Lifting the truck by crane ......................................................................... 44

2.3 Loading with another industrial truck ....................................................... 45

3 Securing the truck during transport ......................................................... 46

4 Using the Truck for the First Time ........................................................... 47

Page 7

11.14 E N

8

D Fuelling the Truck.................................................................... 49

1 General.................................................................................................... 49

1.1 Safety regulations for handling diesel fuel and LPG................................ 49

1.2 LPG system relief valve ........................................................................... 51

2 Adding diesel ........................................................................................... 52

2.1 Fuelling .................................................................................................... 52

2.2 Fuelling with fuel containers .................................................................... 53

3 LPG containers........................................................................................ 54

3.1 LPG bottles .............................................................................................. 54

3.2 Liquid gas tank ........................................................................................ 57

4 Fuel level indicator................................................................................... 58

4.1 Display unit .............................................................................................. 58

E Operation ................................................................................ 59

1 Safety Regulations for the Operation of the Forklift Truck....................... 59

2 Displays and Controls.............................................................................. 61

2.1 Multi-task switch ...................................................................................... 61

2.2 SOLO-PILOT ........................................................................................... 63

2.3 MULTI-PILOT .......................................................................................... 64

2.4 Controls ................................................................................................... 65

2.5 Multifunction display ................................................................................ 67

2.6 Operation of the multifunction display ..................................................... 70

3 Dashboard ............................................................................................... 80

3.1 Without air conditioning system ............................................................... 80

3.2 With air conditioning system .................................................................... 80

3.3 With automatic air conditioning................................................................ 81

4 Heater, fan, air conditioning system ........................................................ 82

4.1 Heater ...................................................................................................... 82

4.2 Air conditioning system (o) ..................................................................... 82

5 Preparing the Truck for Operation ........................................................... 86

5.1 Checks and operations to be performed before starting daily operation . 86

5.2 Entry and exit........................................................................................... 88

5.3 Setting up the operator position............................................................... 89

5.4 Seat Belt .................................................................................................. 95

6 Industrial Truck Operation ....................................................................... 96

6.1 Safety regulations for truck operation ...................................................... 96

6.2 Preparing the truck for operation ............................................................. 99

6.3 Operational Checks ................................................................................. 102

6.4 Parking the truck securely ....................................................................... 103

6.5 Emergency Disconnect............................................................................ 105

6.6 Travel....................................................................................................... 106

6.7 Steering ................................................................................................... 108

6.8 Brakes ..................................................................................................... 109

6.9 Adjusting the forks ................................................................................... 111

6.10 Replacing the forks.................................................................................. 112

6.11 Lifting, transporting and depositing loads ................................................ 113

6.12 Operating the lift mechanism and integrated attachments ...................... 115

6.13 Safety instructions for operating additional attachments ......................... 121

6.14 Operating additional attachments for the SOLO-PILOT .......................... 124

Page 8

9

11.14 E N

6.15 Operating additional attachments for the Multi Pilot ................................ 125

6.16 Fitting additional attachments .................................................................. 126

7 Towing trailers ......................................................................................... 128

8 Optional equipment ................................................................................. 130

8.1 Rotating Driver's Seat.............................................................................. 131

8.2 Sliding windows ....................................................................................... 140

8.3 Emergency Exit ....................................................................................... 140

8.4 Driver'S Seat Heater................................................................................ 140

8.5 Fire Extinguisher...................................................................................... 141

8.6 Rockinger Coupling with Hand Lever ...................................................... 141

9 Troubleshooting....................................................................................... 143

9.1 Automatic Emergency Brake ................................................................... 143

9.2 Troubleshooting ....................................................................................... 145

9.3 Operating the truck without its own drive system .................................... 146

F Industrial Truck Maintenance .................................................. 151

1 Operational Safety and Environmental Protection................................... 151

2 Maintenance Safety Regulations............................................................. 152

2.1 Working on the electrical system ............................................................. 153

2.2 Consumables and used parts .................................................................. 153

2.3 Wheels..................................................................................................... 153

2.4 Lift Chains................................................................................................ 154

2.5 Hydraulic system ..................................................................................... 154

2.6 Working in the vicinity of the engine ........................................................ 155

3 Lubricants and Lubrication Schedule ...................................................... 156

3.1 Handling consumables safely .................................................................. 156

3.2 Lubrication Schedule ............................................................................... 158

3.3 Consumables........................................................................................... 160

3.4 Coolant specification ............................................................................... 161

4 Maintenance and repairs ......................................................................... 162

4.1 Preparing the truck for maintenance and repairs .................................... 162

4.2 Lifting and jacking up the truck safely...................................................... 163

4.3 Replacing wheels .................................................................................... 164

4.4 Checking the wheel attachments............................................................. 166

4.5 Opening the Service Panel ...................................................................... 166

4.6 Tilting the Cab ......................................................................................... 167

4.7 Replacing wheels .................................................................................... 171

4.8 Checking the wheel attachments............................................................. 173

4.9 Hydraulic system ..................................................................................... 174

4.10 Engine maintenance................................................................................ 177

4.11 Check the transmission oil level .............................................................. 183

4.12 Performing Other Maintenance Work ...................................................... 183

4.13 Closing the Motor Compartment.............................................................. 183

4.14 Checking electrical fuses......................................................................... 184

4.15 Cleaning .................................................................................................. 189

4.16 Starter battery.......................................................................................... 191

4.17 Exhaust system ....................................................................................... 192

4.18 Restoring the truck to service after maintenance and repairs ................. 193

5 Decommissioning the industrial truck ...................................................... 194

5.1 Prior to decommissioning ........................................................................ 195

5.2 During decommissioning ......................................................................... 195

Page 9

11.14 E N

10

5.3 Restoring the truck to service after decommissioning ............................. 196

6 Safety tests to be performed at intervals and after unusual incidents ..... 197

7 Final de-commissioning, disposal............................................................ 198

8 Human vibration measurement ............................................................... 198

9 Servicing and Inspection ......................................................................... 199

10 Maintenance checklist DFG..................................................................... 200

10.1 Operating Company ................................................................................ 200

10.2 Customer Service .................................................................................... 203

11 Maintenance checklist TFG ..................................................................... 212

11.1 Operating Company ................................................................................ 212

11.2 Customer Service .................................................................................... 215

Page 10

11

11.14 E N

A Correct Use and Application

1 General

The truck must be used, operated and serviced in accordance with the present

instructions. All other types of use are beyond its scope of application and may result

in damage to personnel, the industrial truck or property.

2 Correct application

NOTE

The maximum load and load distance are indicated on the capacity plate and must

not be exceeded.

The load must rest on the load handler or be lifted by an attachment approved by the

manufacturer.

The load must be fully raised,see "Lifting, transporting and depositing loads" on

page 113.

The following operations are in accordance with regulations and are permitted:

– Lifting and lowering loads.

– Transporting lowered loads over short distances.

– Occasional towing of trailer loads.

– When towing trailers the load must be secured on the trailer.

– The permissible trailer load must not be exceeded.

The following operations are prohibited:

– Travelling with a raised load (>30 cm).

– Carrying and lifting passengers.

– Pushing or pulling loads.

– Transporting hanging loads. If the truck is to be operated with hanging loads, proof

of sufficient safety distance under local operating conditions must be obtained from

a specialist assessor.

Page 11

11.14 E N

12

3 Approved application conditions

DANGER!

Do not exceed the permissible surface and point loading on the travel lanes.

At blind spots get a second person to assist.

The driver must ensure that the loading dock /dock leveller cannot be removed or

come loose during loading/unloading.

– Operation in industrial and commercial environments.

– Permissible temperature range -20 to 40°C.

– Operation only on secure, level surfaces with sufficient capacity.

– Do not exceed the permissible surface and spot load limits on the travel routes.

– Operation only on routes that are visible and approved by the operating company.

– Negotiating inclines up to a maximum of 15 %.

– Do not travel across or at an angle on inclines. Travel with the load facing uphill.

– Operation in partially public traffic.

– Do not operate LPG trucks under ground level areas.

– The truck may only be operated in areas that are clean and free of oil and similar

substances.

WARNING!

Operating an LPG truck under ground level areas could result in explosions.

LPG is heavier than air. An explosive LPG/air mixture could therefore form under

ground level areas without sufficient ventilation.

XDo not use LPG trucks under ground level areas.

WARNING!

Use under extreme conditions

Using the truck under extreme conditions can result in malfunctions and accidents.

XSpecial equipment and authorisation are required if the truck is to be constantly

used in extreme conditions, especially in dusty or corrosive atmospheres.

XThe truck cannot be used in areas at risk of explosion.

XIn adverse weather conditions (thunder, lightning) the industrial truck must not be

operated outside or in endangered areas.

Page 12

13

11.14 E N

4 Proprietor responsibilities

For the purposes of the present operating instructions the “operating company” is

defined as any natural or legal person who either uses the industrial truck himself, or

on whose behalf it is used. In special cases (e.g. leasing or renting) the proprietor is

considered the person who, in accordance with existing contractual agreements

between the owner and user of the industrial truck, is charged with operational duties.

The proprietor must ensure that the industrial truck is used only for the purpose it is

intended for and that danger to life and limb of the user and third parties are excluded.

Furthermore, accident prevention regulations, safety regulations and operating,

servicing and repair guidelines must be followed. The operating company must

ensure that all users have read and understood these operating instructions.

NOTE

Failure to comply with the operating instructions invalidates the warranty. The same

applies if improper work is carried out on the truck by the customer or third parties

without the permission of the manufacturer.

5 Adding attachments and/or optional equipment

The mounting or installation of additional equipment which affects or enhances the

performance of the industrial truck requires the written permission of the

manufacturer. Local authority approval may also need to be obtained.

Local authority approval however does not constitute the manufacturer’s approval.

Page 13

11.14 E N

14

Page 14

15

11.14 E N

B Truck Description

1 Application

The DFG/TFG 660-690 is a four-wheel IC engine sit-down forklift truck. The DFG

series are diesel engine trucks, while the TFG series are fitted with a petrol engine for

LPG operation.

The DFG/TFG 660-690 is a cantilever counterbalanced truck which can lift, transport

and deposit loads using the load handler attached in front.

Closed bottom pallets can also be lifted.

The DFG/TFG 660-690 is equipped with a hydrodynamic drive.

1.1 Truck models and rated capacity

The rated capacity depends on the model. The rated capacity can be derived from

the model name.

The rated capacity is not generally the same as the permissible capacity. The

capacity can be found on the capacity plate attached to the truck.

DFG660

DFG Model name

6Series

60 Rated capacity x 100 kg

Page 15

11.14 E N

16

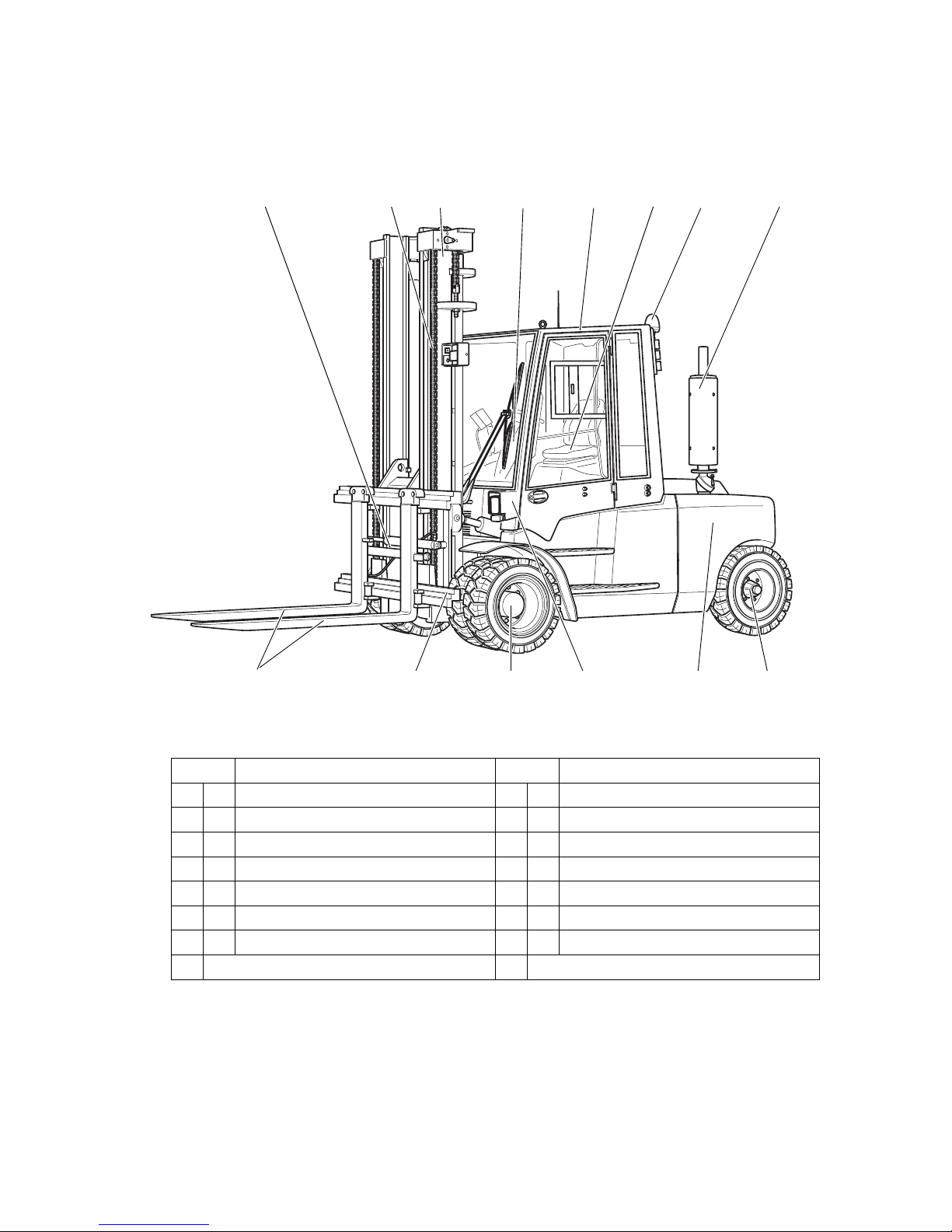

2 Assemblies and Functional Description

2.1 Assembly Overview

6

3

14 13 12 910

12

4

5

78

11

Item Description Item Description

1 o Fork adjustment 8 t Exhaust pipe

2 t Load chains 9 t Steer axle

3 t Mast 10 t Counterweight

4 t Steering column 11 t Illumination

5 t Cab 12 t Drive

6 t Driver's seat 13 t Fork carriage

7 o Beacon 14 t Fork tines

t = Standard equipment o = Optional equipment

Page 16

17

11.14 E N

2.2 Functional Description

Chassis and superstructure

A rigid chassis which protects the units and controls, provides the truck with

maximum static safety. A wide opening cab (5) facilitates service and maintenance

work. The hydraulic oil reservoir is integrated on the right-hand side and the fuel tank

on the opposite side of the chassis. The vertical, free standing front exhaust pipe (8)

is positioned much higher than is common. It prevents vibrations and sound saves

from being transferred and exhaust gases from penetrating into the operator position.

Operator position

The operator position is articulating, which cushions vibrations and noise. Non-slip

steps and a handle on the cab post ensure easy entry and exit. The driver is protected

by the cab (5). To adapt the seat position, the driver can adjust the seat and steering

head both vertically and horizontally. The accelerator pedal and brake pedal are of

"automotive" design.

Steering

The steer cylinder of the hydrostatic steering is integrated in the steer axle (9) and is

controlled by the power steering. The steer axle is fully floating in the chassis to

ensure excellent grip even on non-level surfaces.

Wheels

All wheels are located within the truck geometry. A choice of pneumatic or

superelastic tyres are available.

Diesel engine

Quiet-running, water-cooled diesel engines featuring high performance and low

consumption with very clean fuel combustion under all operating conditions ensure

soot values are below the limit of visibility. An additional particle filter (o) ensures

very low exhaust levels.

LPG engine

Quiet running, water-cooled four-stroke engines featuring high performance and low

consumption. Petrol engines with very low residual exhaust levels are used. A 3-way

catalytic converter ensures very low exhaust levels.

Electrical System

12-volt system with 3-phase alternator. A repeat start block prevents malfunctions

when the truck is powered up. For diesel engines, a rapid pre-heat system is installed;

LPG motors have an electronic ignition system for rapid and trouble-free engine

starting. The key switch is used to start and stop the engine.

Page 17

11.14 E N

18

Drive System

A power shift gear with radiator and torque converter is flanged directly to the engine.

This transfers the force to the drive axle (12).

The travel direction lever, either on the steering column or optionally on the multi-task

handle, controls forward/reverse travel and the neutral position.

Brakes

The brake pedal activates the laminated brakes hydraulically. The parking brake is

switched on and off by pressing the parking brake button in the multifunction display.

It acts mechanically on the brake disc of the cardan shaft.

Hydraulic System

All operations can be performed sensitively, proportionally and simultaneously.

Hydraulic functions are controlled by a servo hydraulic controller. Control is possible

via single lever (SOLO-PILOT) or multi-task lever (MULTI-PILOT).

Mast

Two or three-stage masts, optionally with free lift function; narrow mast sections

ensure excellent visibility of the fork tines and attachments. Fork carriages and lift

frames run on lubricating support rollers.

Attachments

The trucks can be optionally fitted with mechanical and hydraulic attachments.

Page 18

19

11.14 E N

3 Technical Specifications

All technical details refer to standard trucks.

Values indicated with *) may vary, depending on the

types of equipment used (e.g. mast, cabin, tyres etc.).

Z The technical specifications comply with the German "Industrial Truck Data Sheet"

Guidelines.

Technical modifications and additions reserved.

3.1 Performance data

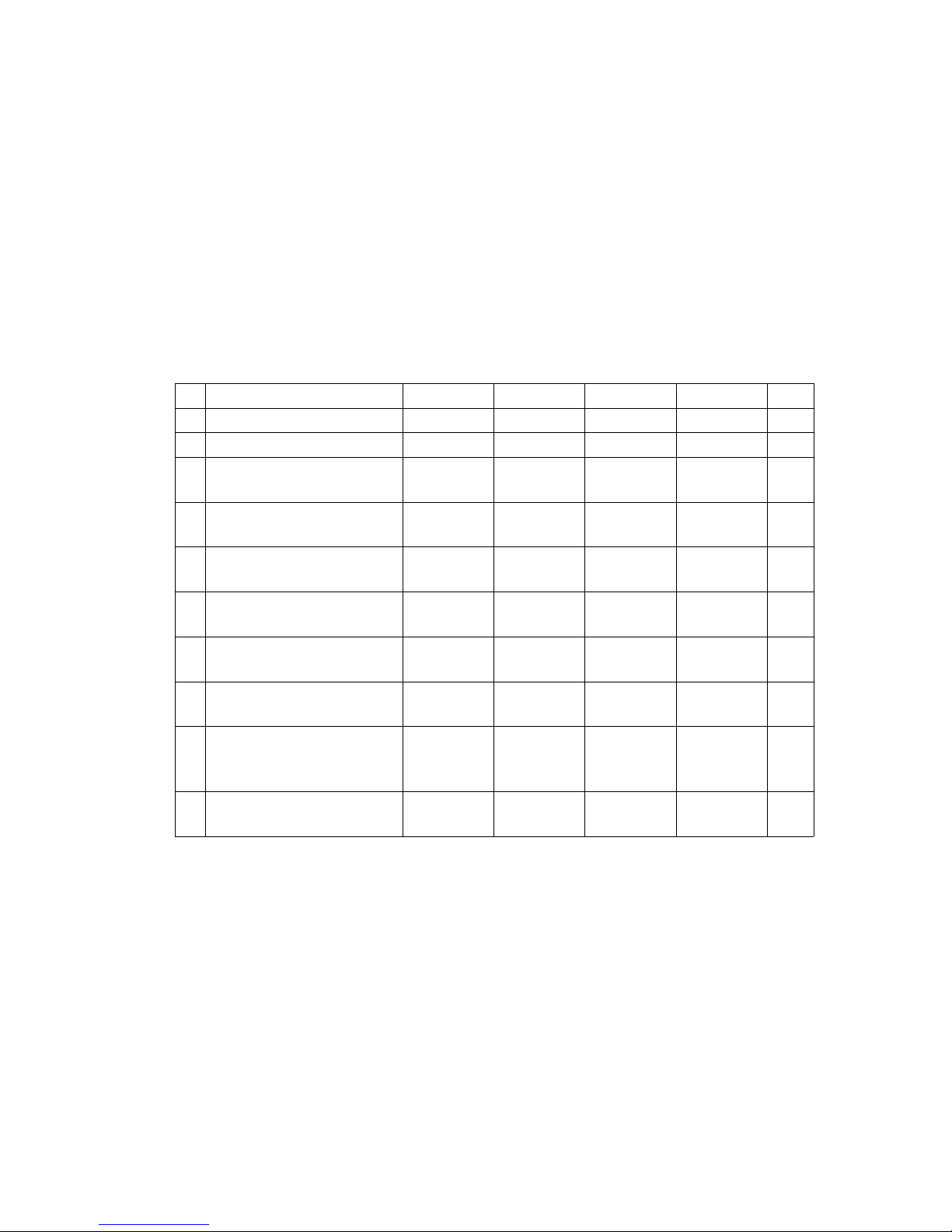

DFG 660-690

1)

for vertical mast.

2)

The values shown represent the maximum gradeability to overcome short

differences in height and surface unevenness (surface edges). The truck must not

operate on inclines of more than 15%.

Component 660 670 680 690

QCapacity

1)

6000 7000 8000 9000 kg

C Load centre distance 600 600 600 600 mm

Travel speed * with /

without load

22.4/22.5 22.4/22.6 22.4/22.5 22.4/22.6 km/h

Lift speed with / without

load

0.50/0.60 0.40/0.60 0.40/0.60 0.40/0.60 m/s

Lowering speed with /

without load

0.60/0.36 0.60/0.36 0.60/0.36 0.60/0.36 m/s

Gradeability

2)

with / without load

30.3/32.0 28.7/31.0 27.1/31.0 24.6/28.0 %

Tow force

with/without load

49.5/49.5 49.5/49.5 49.5/49.5 49.5/49.5 kN

Acceleration* with /

without load to 15 m

6.0/5.0 6.0/5.0 6.0/5.0 7.0/6.0 sec

Available working

pressure

for attachments

160 160 160 160 bar

Oil flow

for attachments

80 80 80 80 l/min

Page 19

11.14 E N

20

DFG S80-S90

1)

for vertical mast.

2)

The values shown represent the maximum gradeability to overcome short

differences in height and surface unevenness (surface edges). The truck must not

operate on inclines of more than 15%.

Component S80 S90

Q Capacity

1)

8000 9000 kg

C Load centre distance 900 900 mm

Travel speed *

with / without load

22.3/22.6 22.3/22.6 km/h

Lift speed

with / without load

0.40/0.60 0.40/0.60 m/s

Lowering speed

with / without load

0.60/0.36 0.60/0.36 m/s

Gradeability

2

with / without load

21.5/25.0 20.9/24.0 %

Tow force with / without load 49.5/49.5 52.9/52.9 kN

Acceleration time *

with / without load to 15 m

7.0/6.0 7.0/6.0 sec

Available working pressure

for attachments

160 160 bar

Oil flow for attachments 80 80 l/min

Page 20

21

11.14 E N

TFG 660-690

1)

for vertical mast.

2)

The values shown represent the maximum gradeability to overcome short

differences in height and surface unevenness (surface edges). The truck must not

operate on inclines of more than 15%.

Component 660 670 680 690

QCapacity

(1

6000 7000 8000 9000 kg

C Load centre distance 600 600 600 600 mm

Travel speed * with /

without load

22.4/22.6 22.4/22.6 22.4/22.6 22.4/22.6 km/h

Lift speed

with / without load

0.40/0.48 0.40/0.48 0.40/0.48 0.40/0.48 m/s

Lowering speed

w / w.o. load

0.60/0.48 0.60/0.36 0.60/0.36 0.60/0.36 m/s

Gradeability

(2

with / without load

27.5/30.0 27.5/30.0 26.5/30.0 23.0/27.0 %

Tow f o r ce

with / without load

45.6/45.6 45.6/45.6 45.6/45.6 45.6/45.6 kN

Acceleration * with /

without load to 15 m

6.0/5.0 6.0/5.0 6.0/5.0 7.0/6.0 sec

Available working

pressure

for attachments

160 160 160 160 bar

Oil flow

for attachments

80 80 80 80 l/min

Page 21

11.14 E N

22

TFG S80-S90

1)

for vertical mast.

2)

The values shown represent the maximum gradeability to overcome short

differences in height and surface unevenness (surface edges). The truck must not

operate on inclines of more than 15%.

Component S80 S90

Q Capacity 8000 9000 kg

C Load centre distance 900 900 mm

Travel speed *

with / without load

22.4/22.6 22.4/22.6 km/h

Lift speed

with / without load

0.40/0.48 0.40/0.48 m/s

Lowering speed

with / without load

0.60/0.36 0.60/0.36 m/s

Gradeability*

with / without load

20.2/23.0 17.6/20.0 %

Tow f or ce

with / without load

45.6/45.6 45.6/45.6 kN

Acceleration time *

with / without load to 15 m

7.0/6.0 7.0/6.0 sec

Available working

pressure

for attachments

160 160 bar

Oil flow

for attachments

80 80 l/min

Page 22

23

11.14 E N

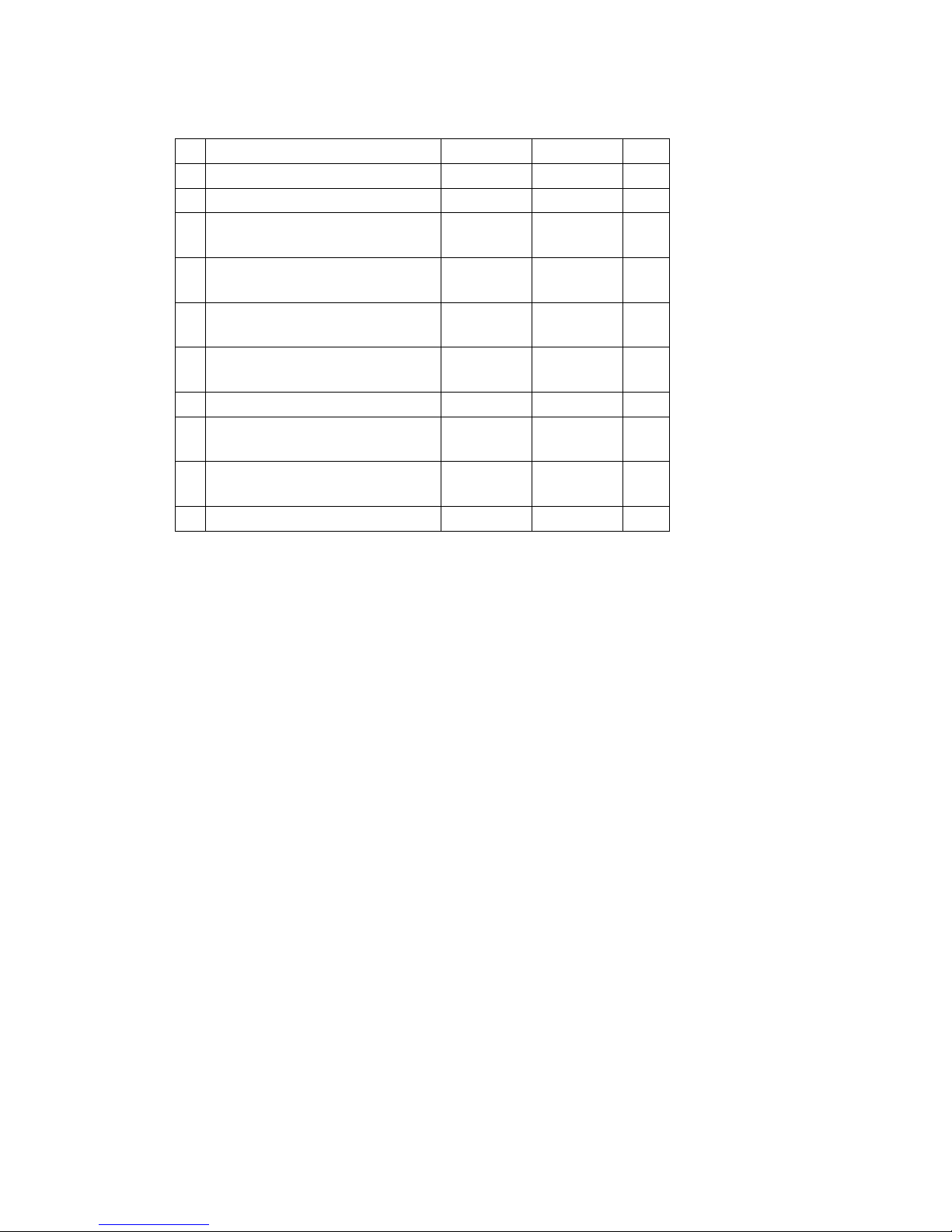

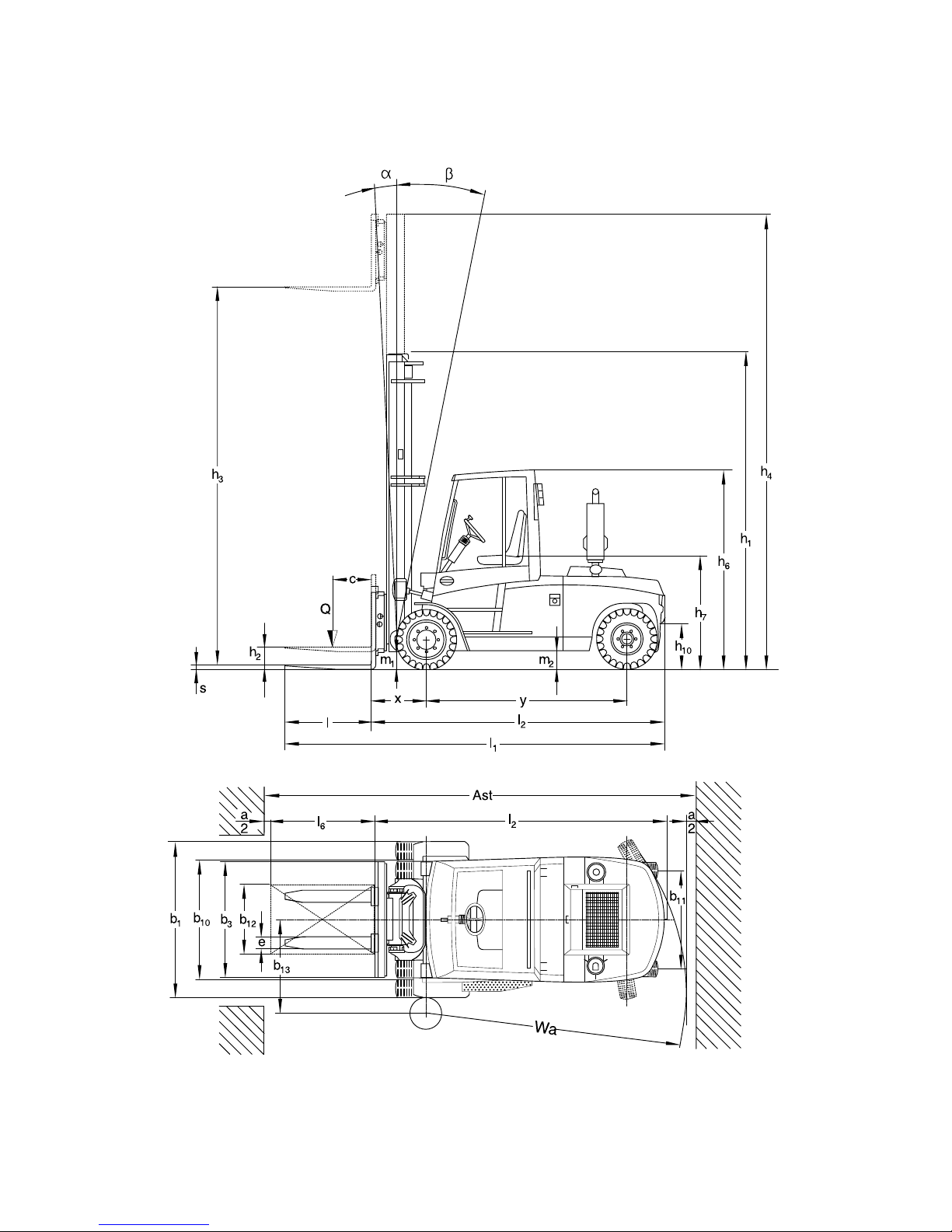

3.2 Dimensions

DFG 660-690

*) The data listed in the table corresponds to the standard version.

Model 660 670 680 690

a/2 Safety distance 100 100 100 100 mm

h

1

Collapsed height* 2710 2710 3010 3160 mm

h

3

Lift* 3600 3600 3600 3600 mm

h

4

Extended height* 4510 4510 4810 4960 mm

h

6

Overhead guard

height*

2705 2705 2705 2705 mm

h7Seat height* 1600 1600 1600 1600 mm

h

10

Coupling height 500 500 500 500 mm

Į

Mast tilt, fwd.* 6 6 6 6 °

ȕ

Mast tilt, back* 9 9 9 9 °

l1Length, including

forks*

4760 4770 4880 5035 mm

l

2

Length, including fork

shank*

3560 3570 3680 3835 mm

b1Overall width* 1820 2002 2002 2100 mm

s/e/l Fork dimensions* 60/150/

1200

60/150/

1200

70/150/

1200

70/150/

1200

mm

m

1

Ground clearance,

laden, below mast*

230 230 230 230 mm

m2Ground clearance

centre wheelbase*

250 250 250 250 mm

Fork carriage ISO

2328 class / type A, B

4 A4 A4 A4 Amm

b

3

Fork carriage width 1800 1800 2000 2100 mm

Ast Working aisle width for

pallets 800 x 1200

lengthways

5320 5330 5440 5745 mm

Ast Working aisle width for

pallets 1000 x 1200

traverse

5120 5130 5240 5545 mm

Wa Turning radius 3250 3250 3350 3650 mm

b

13

Smallest turning

radius

1270 1270 1320 1390 mm

x Load distance* 680 680 700 700 mm

c Load centre of gravity 600 600 600 600 mm

y Wheelbase 2295 2295 2395 2545 mm

Page 23

11.14 E N

24

DFG S80-S90

*) The data listed in the table corresponds to the standard version.

TFG 660-690

Model S80 S90

a/2 Safety distance 100 100 mm

h

1

Collapsed height* 3160 3310 mm

h

3

Lift* 3600 3600 mm

h4Extended height* 4960 5110 mm

h

6

Overhead guard

height*

2705 2705 mm

h7Seat height* 1600 1600 mm

h10Coupling height 500 500 mm

Į

Mast tilt, fwd.* 6 6 °

ȕ

Mast tilt, back* 9 9 °

l

1

Length, including

forks*

5640 5840 mm

l2Length, including fork

shank*

3840 4040 mm

b

1

Overall width* 2150 2150 mm

s/e/l Fork dimensions* 70/180/

1800

70/180/

1800

mm

m1Ground clearance,

laden, below mast*

230 230 mm

m

2

Ground clearance

centre wheelbase*

250 250 mm

Fork carriage ISO

2328 class / type A, B

4 A 4 A mm

b

3

Fork carriage width 2100 2100 mm

Ast Working aisle width for

pallets 800 x 1200

lengthways

5745 5995 mm

Ast Working aisle width for

pallets 1000 x 1200

traverse

5545 5795 mm

Wa Turning radius 3900 3900 mm

b

13

Smallest turning

radius

1490 1490 mm

x Load distance* 700 700 mm

c Load centre of gravity 900 900 mm

y Wheelbase 2545 2745 mm

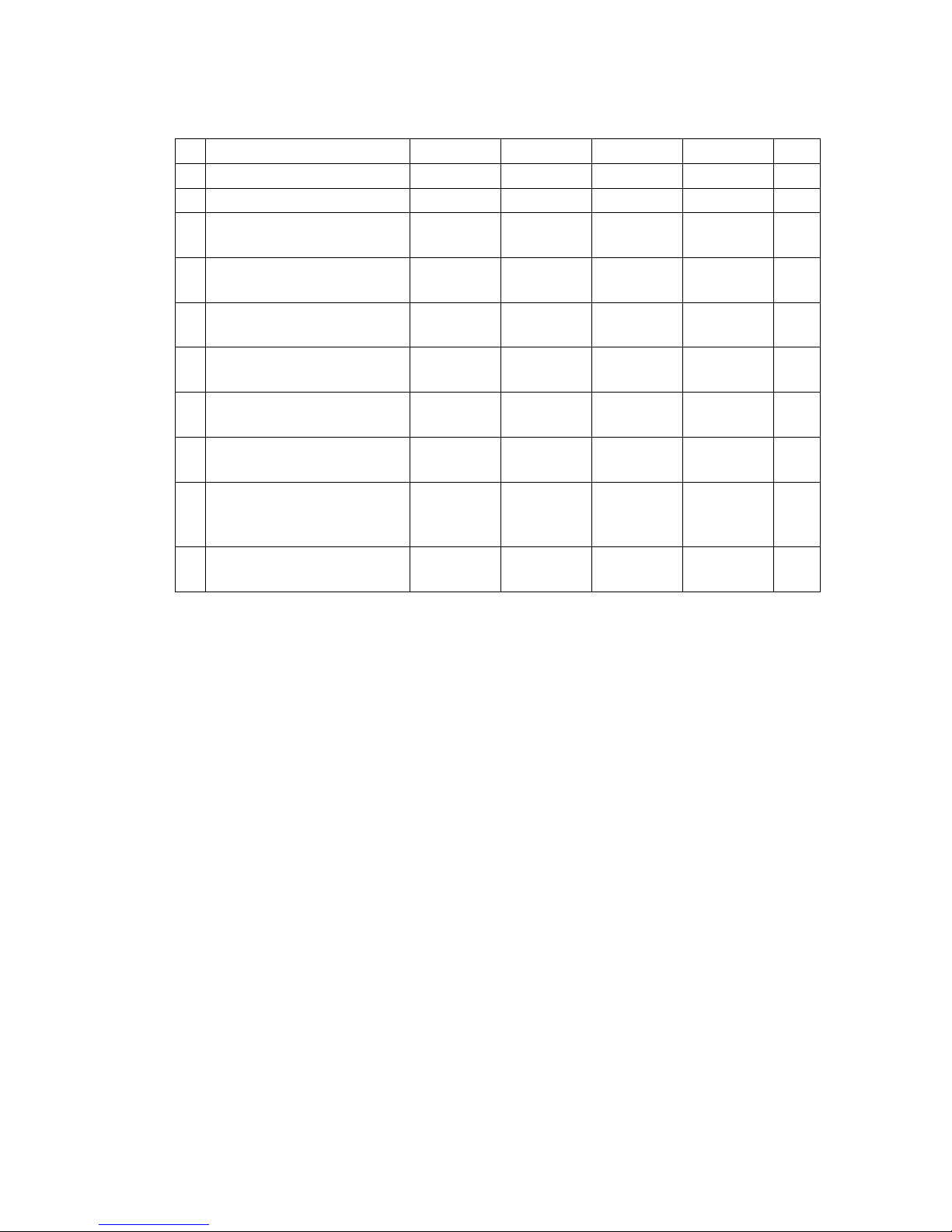

Type 660 670 680 690

a/2 Safety distance 100 100 100 100 mm

Page 24

25

11.14 E N

*) The data listed in the table corresponds to the standard version.

TFG S80-S90

h

1

Collapsed height* 2710 2710 3010 3160 mm

h

3

Lift* 3600 3600 3600 3600 mm

h

4

Extended height* 4510 4510 4810 4960 mm

h

6

Overhead guard

height*

2705 2705 2705 2705 mm

h

7

Seat height* 1600 1600 1600 1600 mm

h

10

Coupling height 500 500 500 500 mm

Į

Mast tilt, fwd.* 6 6 6 6 °

ȕ

Mast tilt, back* 9 9 9 9 °

l1Length, including

forks*

4860 4870 4980 5135 mm

l

2

Length, including fork

shank*

3660 3670 3780 3935 mm

b1Overall width* 1820 2002 2002 2150 mm

s/e/l Fork dimensions* 60/150/

1200

60/150/

1200

70/150/

1200

70/150/

1200

mm

m

1

Ground clearance,

laden, below mast*

230 230 230 230 mm

m2Ground clearance

centre wheelbase*

235 250 250 250 mm

Fork carriage ISO

2328 class / type A, B

4 A4 A4 A4 Amm

b

3

Fork carriage width 1800 1800 2000 2100 mm

Ast Working aisle width for

pallets 800 x 1200

lengthways

5420 5430 5640 5895 mm

Ast Working aisle width for

pallets 1000 x 1200

traverse

5220 5230 5440 5695 mm

Wa Turning radius 3350 3350 3550 3800 mm

b

13

Smallest turning

radius

1320 1320 1370 1440 mm

x Load distance* 680 680 700 700 mm

c Load centre of gravity 600 600 600 600 mm

y Wheelbase 2395 2395 2495 2645 mm

Component S80 S90

a/2 Safety distance 100 100 mm

h

1

Mast height retracted* 3160 3310 mm

h

3

Lift* 3600 3600 mm

h

4

Mast height extended* 4960 5110 mm

Type 660 670 680 690

Page 25

11.14 E N

26

*) The data listed in the table corresponds to the standard version.

h

6

Overhead guard

height*

2705 2720 mm

h

7

Seat height* 1600 1600 mm

h

10

Coupling height 500 500 mm

Į

Mast tilt, fwd.* 6 6 °

ȕ

Mast tilt, back* 9 9 °

l

1

Length, including

forks*

5740 5740 mm

l2Length, including fork

shank*

3940 3940 mm

b1Overall width* 2150 2150 mm

s/e/l Fork dimensions* 70/180/

1800

70/180/

1800

mm

m

1

Ground clearance,

laden, below mast*

240 240 mm

m

2

Ground clearance

centre wheelbase*

240 240 mm

Fork carriage ISO

2328 class / type A, B

4 A 4 A mm

b3Fork carriage width 2100 2100 mm

Ast Aisle width for pallets

800 x 1200

lengthways

5895 5895 mm

Ast Working aisle width for

pallets 1000 x 1200

traverse

5695 5695 mm

Wa Turning radius 3800 3800 mm

b

13

Smallest turning

radius

1440 1440 mm

x Load distance* 700 700 mm

c Load centre of gravity 900 900 mm

y Wheelbase 2645 2645 mm

Component S80 S90

Page 26

27

11.14 E N

Page 27

11.14 E N

28

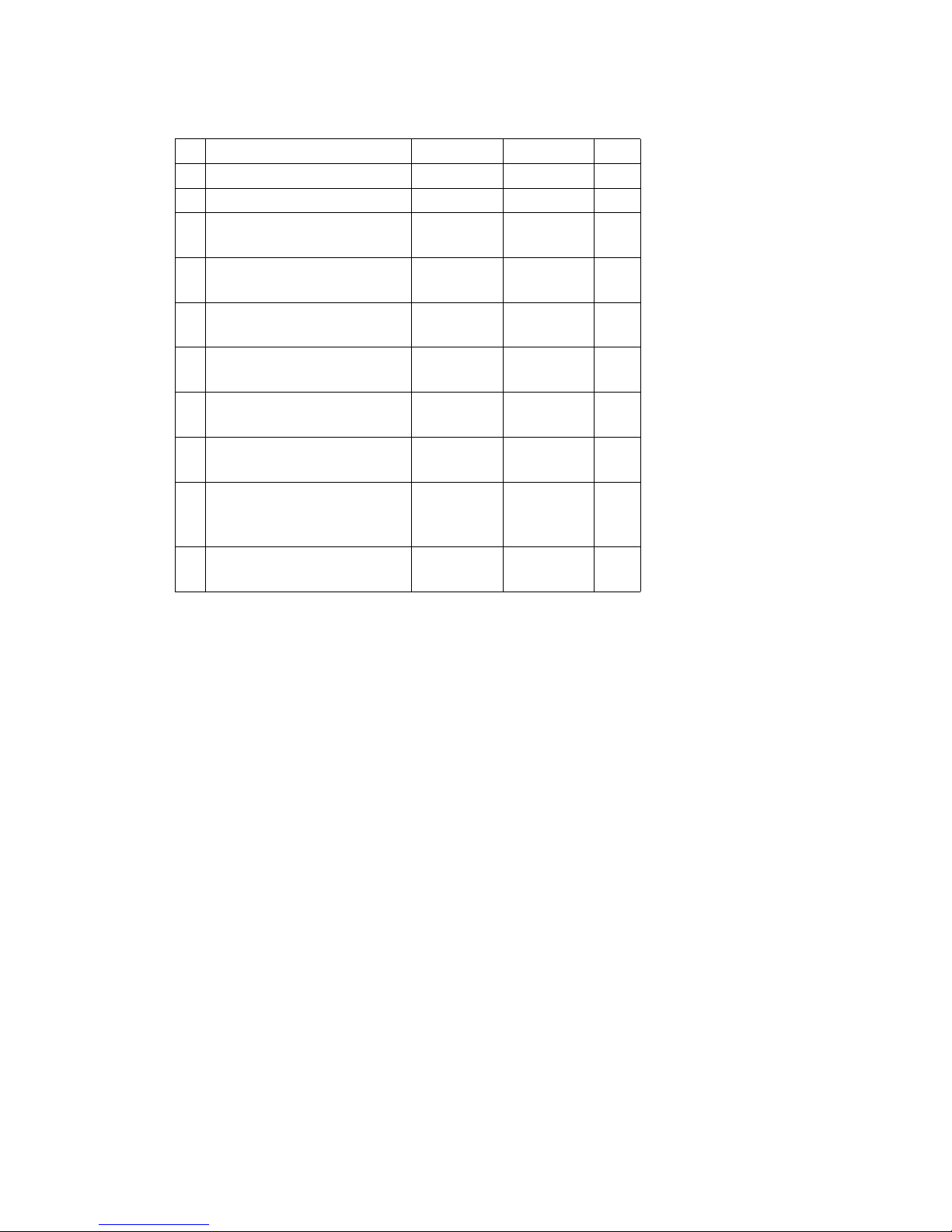

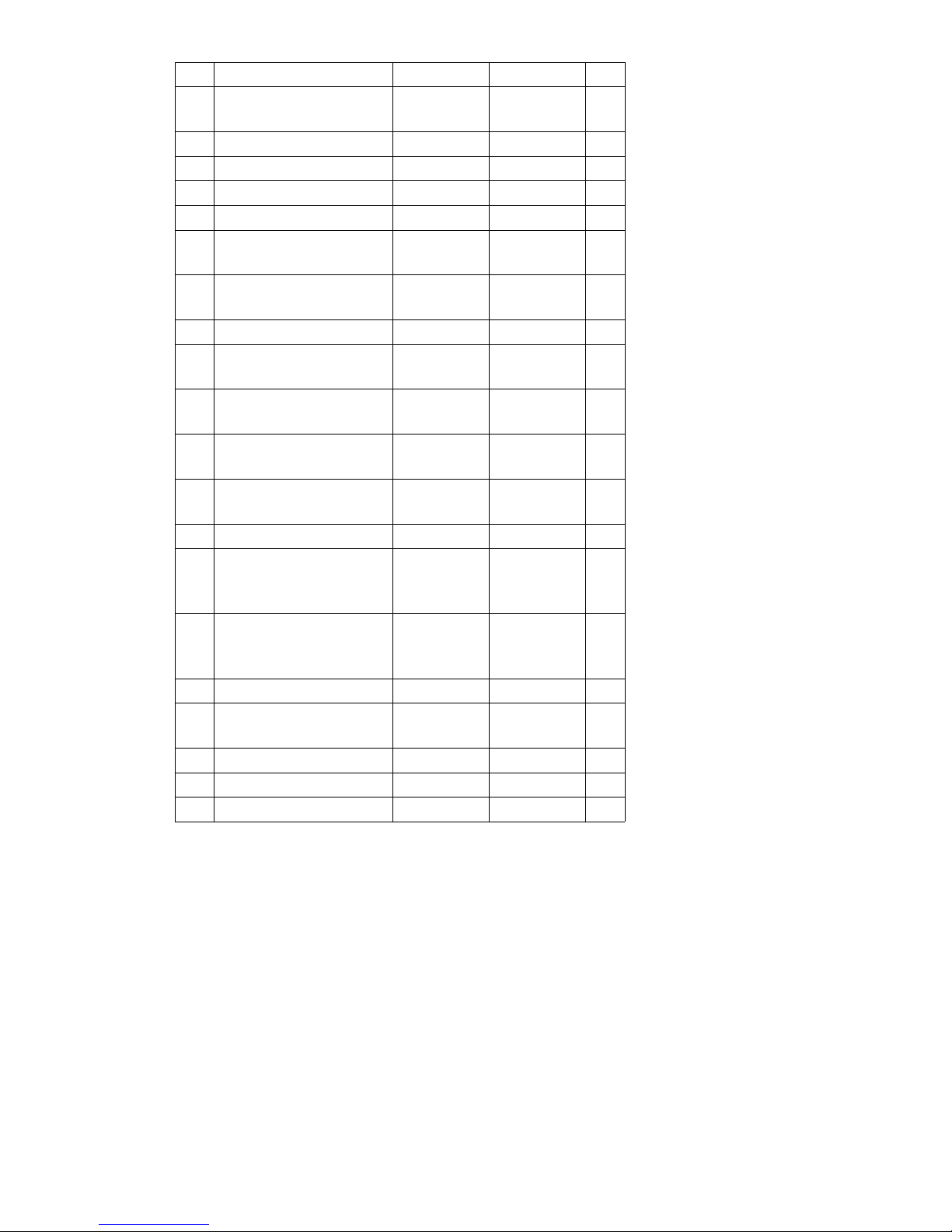

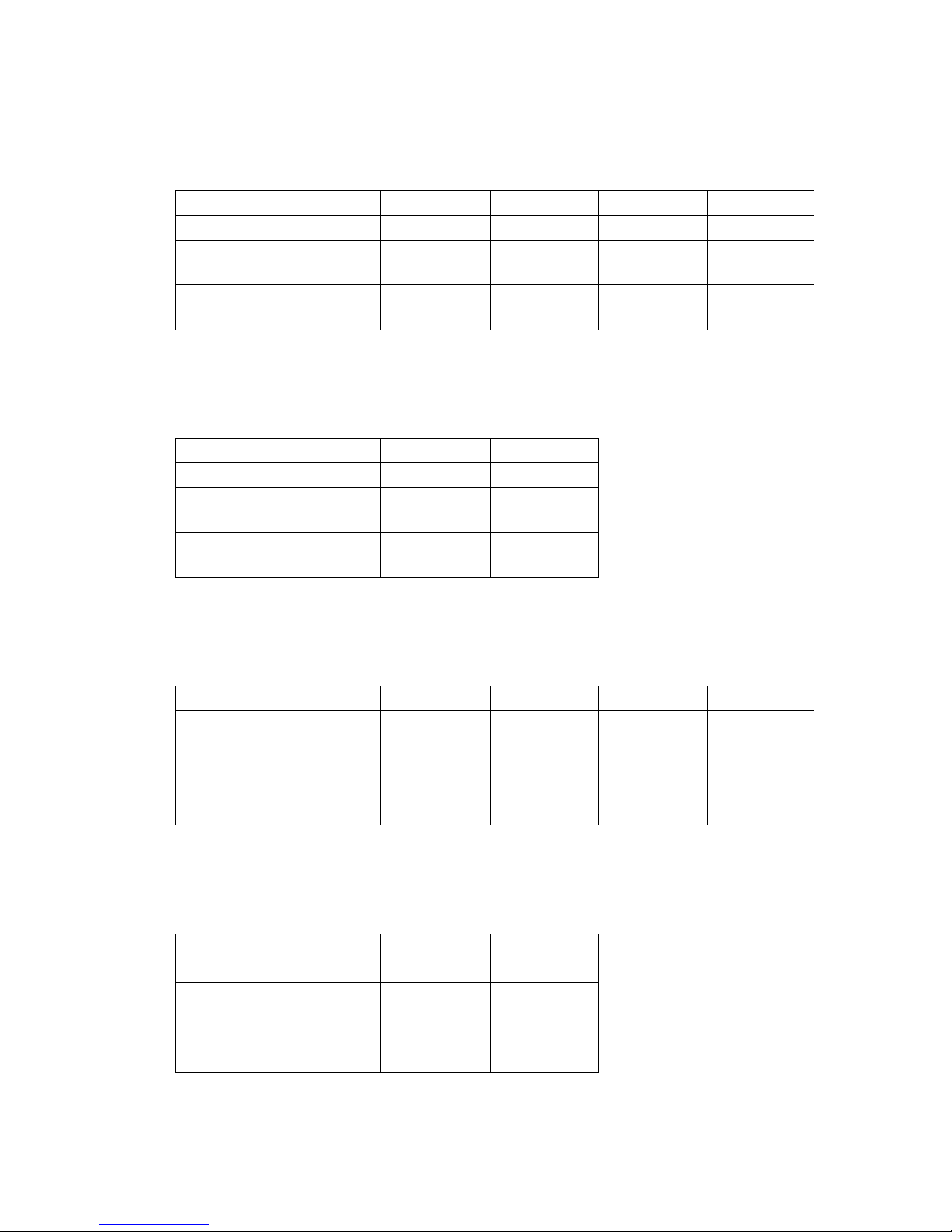

3.3 Weights

Z All dimensions in kg.

DFG 660-690

*) The data listed in the table corresponds to the standard version.

DFG S80-S90

*) The data listed in the table corresponds to the standard version.

TFG 660-690

*) The data listed in the table corresponds to the standard version.

TFG S80-S90

*) The data listed in the table corresponds to the standard version.

660 670 680 690

Net weight* 10500 11400 12400 14000

Axle loading, unladen

load front / rear*

5000/5500 5500/5900 6000/6400 6800/7200

Axle loading, laden front /

rear*

14900/1600 16400/2000 18100/2300 20500/2500

S80 S90

Net weight* 14400 15500

Axle loading, unladen

load front / rear*

7200/7200 7800/7700

Axle loading, laden front /

rear*

20400/2000 22500/2000

660 670 680 690

Net weight* 10970 11570 12700 14200

Axle loading, unladen

load front / rear*

5360/5610 5660/5910 5800/6100 6900/7300

Axle loading, laden front /

rear*

14810/2160 16670/1900 18600/2100 20700/2500

S80 S90

Net weight* 14600 15200

Axle loading, unladen

load front / rear*

7300/7300 7500/7700

Axle loading, laden front /

rear*

20100/2500 22100/2100

Page 28

29

11.14 E N

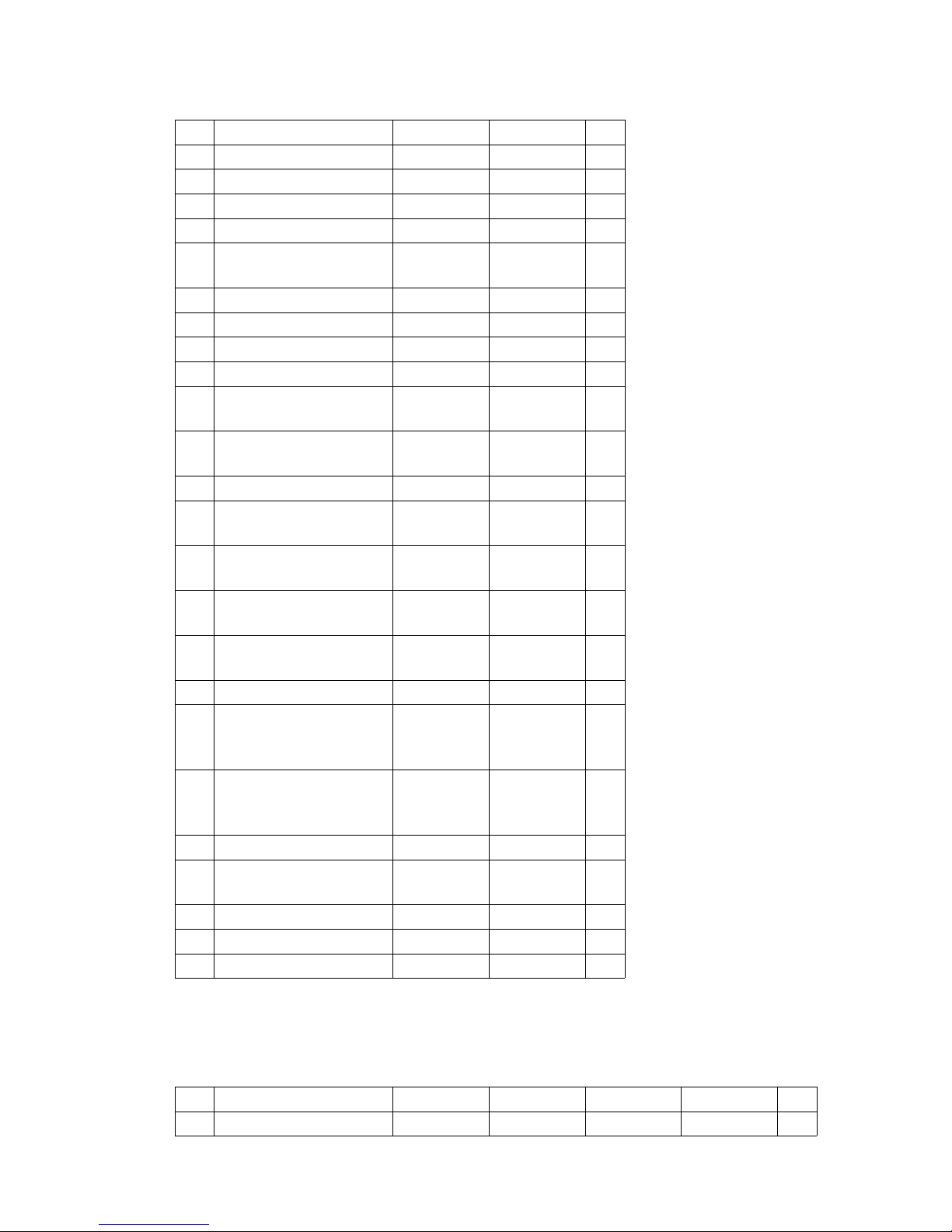

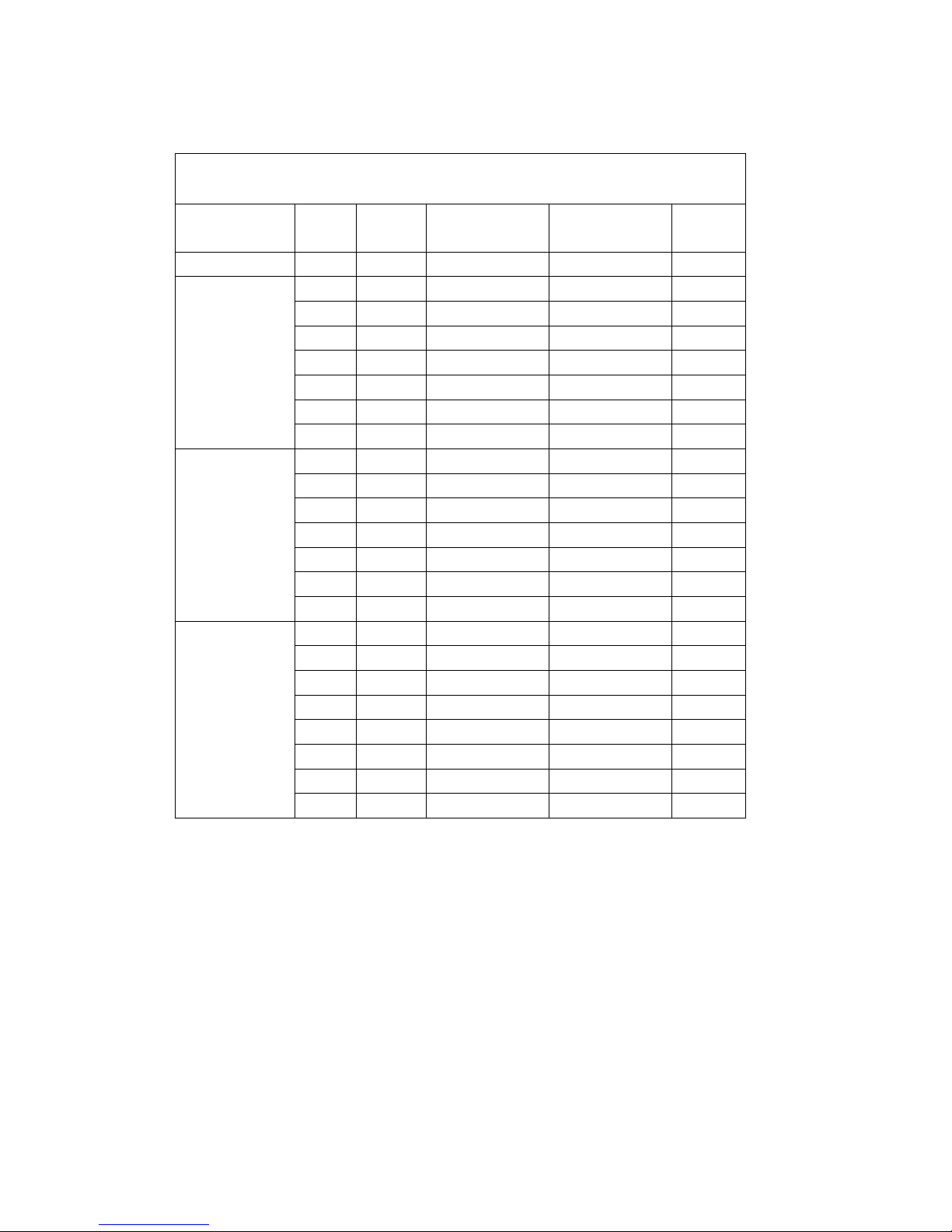

3.4 Mast versions

Z All dimensions in mm.

Mast chart

V D I 3 5 9 6

Description

Lift h

3

Free lift

h

2

Retracted

height h

1

Extended

height h

4

Weight

(kg)

660/670 660/670

ZT

3600 0 2710 4510 2080

4000 0 2910 4910 2140

4500 0 3160 5410 2240

5000 0 3410 5910 2335

5500 0 3660 6410 2460

6000 0 3910 6910 2585

6500 0 4160 7410 2735

ZZ

3600 1800 2875 4675 2278

4000 2000 3075 5075 2350

4500 2250 3325 5675 2422

5000 2500 3575 6075 2542

5500 2750 3825 6575 2652

6000 3000 4075 7075 2772

6500 3300 4325 7575 2892

DZ

4500 1500 2585 5585 2671

5000 1667 2752 6086 2754

5500 1833 2918 6586 2837

6000 2000 3085 7086 2920

6500 2167 3252 7586 3045

7000 2333 3418 8086 3191

7500 2500 3585 8586 3295

8000 2667 3752 9086 3397

Page 29

11.14 E N

30

Special trucks are not included in this overview.

Mast chart

V D I 3 5 9 6

Description

Lift h

3

Free lift

h

2

Retracted

height h

1

Extended

height h

4

Weight

(kg)

680 680

ZT

3600 0 3010 4810 2180

4000 0 3210 5210 2261

4500 0 3460 5710 2360

5000 0 3710 6210 2485

5500 0 3960 6710 2610

6000 0 4210 7210 2757

6500 0 4460 7710 2910

ZZ

3600 1800 3025 4825 2326

4000 2000 3225 5225 2350

4500 2250 3475 5725 2422

5000 2500 3725 6225 2604

5500 2750 3975 6725 2724

6000 3000 4225 7225 2847

6500 3300 4475 7725 2964

DZ

4500 1500 2735 5736 2733

5000 1667 2902 6236 2816

5500 1833 3068 6736 2900

6000 2000 3235 7236 3024

6500 2167 3402 7736 3170

7000 2333 3568 8236 3274

7500 2500 3735 8736 3377

8000 2667 3902 9236 3459

Page 30

31

11.14 E N

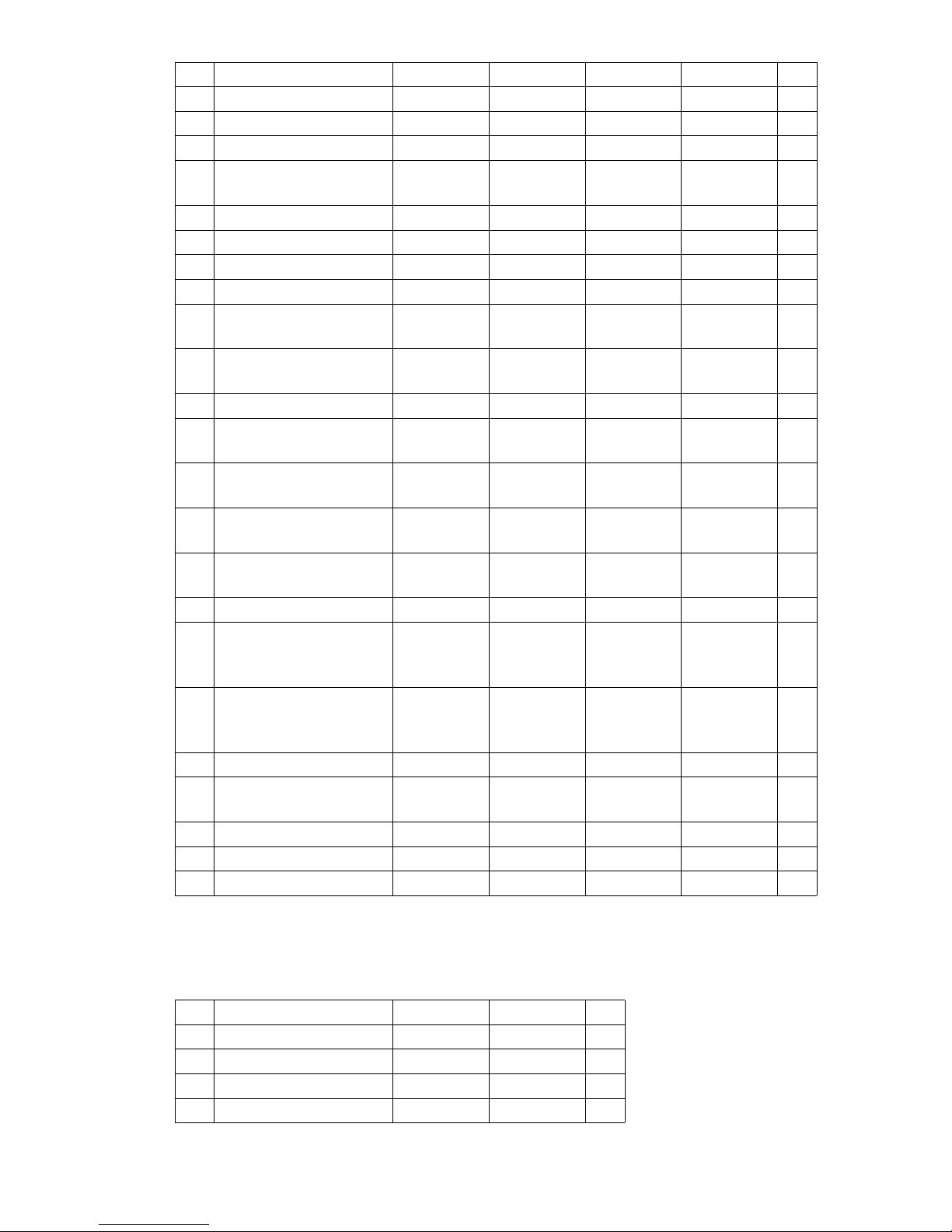

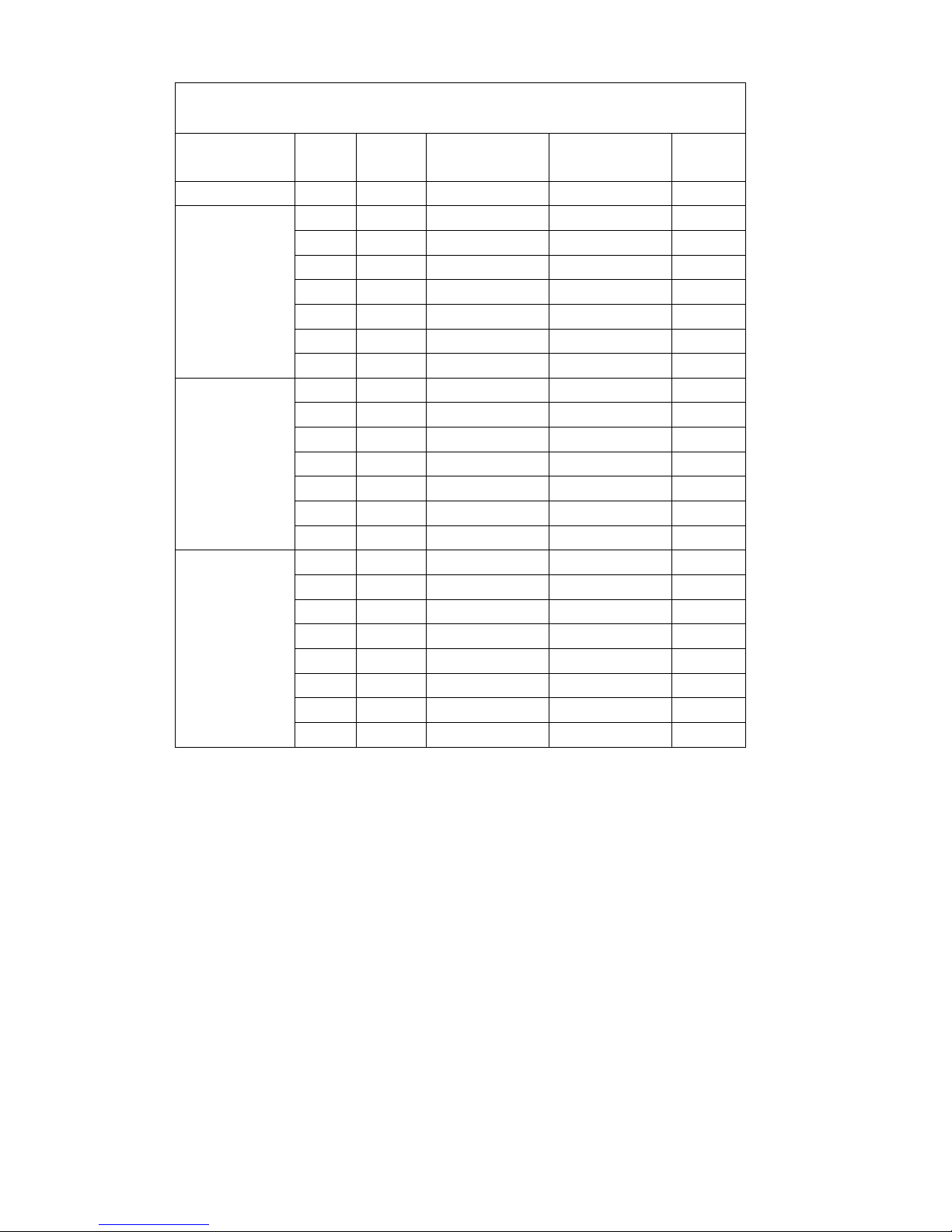

DFG/TFG 690-S90

Mast chart

V D I 3 5 9 6

Description

Lift h

3

Free lift

h

2

Collapsed

height h

1

Extended

height h

4

Weight

(kg)

690/S80 690/S80

ZT

3600 0 3160 4960 2240

4000 0 3360 5360 2310

4500 0 3610 5860 2435

5000 0 3860 6360 2560

5500 0 4110 6860 2710

6000 0 4360 7360 2860

6500 0 4610 7860 2985

ZZ

3600 1800 3175 4975 2374

4000 2000 3375 5375 2446

4500 2250 3625 5875 2556

5000 2500 3875 6375 2676

5500 2750 4125 6875 2796

6000 3000 4375 7375 2916

6500 3300 4625 7875 3036

DZ

4500 1500 2885 5886 2796

5000 1667 3052 6386 2879

5500 1833 3218 6886 3004

6000 2000 3385 7386 3149

6500 2167 3552 7886 3253

7000 2333 3718 8386 3357

7500 2500 3885 8886 3439

8000 2667 4052 9386 3522

Mast chart

V D I 3 5 9 6

Description

Lift h

3

Free lift

h

2

Collapsed

height h

1

Extended

height h

4

Weight

(kg)

S90 S90

ZT

3600 0 3310 5110 2285

4000 0 3510 5510 2385

4500 0 3760 6010 2510

5000 0 4010 6510 2635

5500 0 4260 7010 2810

6000 0 4510 7510 2935

6500 0 4760 8010 3060

Page 31

11.14 E N

32

Special trucks are not included in this overview.

ZZ

3600 1800 3325 5125 2422

4000 2000 3525 5525 2518

4500 2250 3775 6025 2628

5000 2500 4025 6525 2748

5500 2750 4275 7025 2868

6000 3000 4525 7525 2988

6500 3300 4775 8025 3108

DZ

4500 1500 3035 6036 2858

5000 1667 3202 6536 2983

5500 1833 3368 7036 3128

6000 2000 3535 7536 3232

6500 2167 3702 8036 3336

7000 2333 3868 8536 3418

7500 2500 4035 9036 3501

8000 2667 4202 9536 3574

Mast chart

V D I 3 5 9 6

Description

Lift h

3

Free lift

h

2

Collapsed

height h

1

Extended

height h

4

Weight

(kg)

S90 S90

Page 32

33

11.14 E N

3.5 Tyre type

WARNING!

The use of tyres that do not match the manufacturer's specifications can result

in accidents.

The quality of tyres affects the stability and performance of the truck.

Uneven wear affects the truck's stability and increases the stopping distance.

X

When replacing tyres make sure the truck is not skewed.

X

Always replace tyres in pairs, i.e. left and right at the same time.

Z When replacing rims and tyres fitted at the factory, only use the manufacturer’s

original spare parts. Otherwise the manufacturer’s specifications cannot be

ensured. If you have any queries contact the manufacturer's customer service

department.

DFG/TFG 660-690

Model DFG/TFG

660 670 680 690

Front

tyres

SE* 355/65 - 15 8.25 - 15 8.25 - 15 300 - 15

Pneumatic*

355/65 - 15

18 PR

8.25 - 15

18 PR

8.25 - 15

18 PR

300 - 15

18 PR

Tyre pressure bar 10 10 10 10

Torque Nm 650 650 650 650

Rear

tyres

SE* 8.25 - 15 8.25 - 15 8.25 - 15 300 - 15

Pneumatic*

8.25 - 15

18 PR

8.25 - 15

18 PR

8.25 - 15

18 PR

300 - 15 18

PR

Tyre pressure bar 10 10 10 10

Torque Nm 450 450 450 450

Page 33

11.14 E N

34

DFG/TFG S80-S90

*) The models listed in the table correspond to the standard version. Other tyres can

be used depending on the truck's equipment.

Model DFG/TFG

S80 S90

Front

tyres

SE* 300 - 15 300 - 15

Pneumatic*

300 - 15

18 PR

300 - 15

18 PR

Tyre pressure bar 10 10

Torque Nm 650 650

Rear

tyres

SE* 300 - 15 300 - 15

Pneumatic*

300 - 15

18 PR

300 - 15

18 PR

Tyre pressure bar 10 10

Torque Nm 450 450

Page 34

35

11.14 E N

3.6 Engine Data

DFG 660-680

DFG 690-S90

TFG 660-680

TFG 690-S90

Model DFG 660 DFG 670 DFG 680

Cylinders/cubic capacity 4/4400 4/4400 4/4400 cm³

Rated speed (without load) 2200 2200 2200 rpm

Idle speed 850 850 850 rpm

Engine output 91 91 91 kW

Fuel consumption

60 VDI duty cycles/h

7.7 8.1 8.5 l/h [kg/h]

Model DFG 690 DFG S80 DFG S90

Cylinders/cubic capacity 4/4400 4/4400 6/6600 cm³

Rated speed (without load) 2200 2200 2200 rpm

Idle speed 850 850 850 rpm

Engine output 91 91 90 kW

Fuel consumption

60 VDI duty cycles/h

8.8 8.8 10.3 l/h [kg/h]

Model TFG 660 TFG 670 TFG 680

Cylinders/cubic capacity 8/5700 8/5700 8/5700 cm³

Rated speed (without load) 2200 2200 2200 rpm

Idle speed 850 850 850 rpm

Engine output 85 85 85 kW

Fuel consumption

60 VDI duty cycles/h

8 8.5 8.9 l/h [kg/h]

Model TFG 690 TFG S80 TFG S90

Cylinders/cubic capacity 8/5700 8/5700 8/5700 cm³

Rated speed (without load) 2200 2200 2200 rpm

Idle speed 850 850 850 rpm

Engine output 85 85 85 kW

Fuel consumption

60 VDI duty cycles/h

10.2 10.2 10.7 l/h [kg/h]

Page 35

11.14 E N

36

3.7 EN norms

Noise emission level

– DFG 660-690, S80: 73 dB (A)*

– DFG S90: 70 dB (A)*

– TFG: 71 dB(A)*

*+/- 4 dB(A) depending on the truck's equipment

in accordance with EN 12053 as harmonised with ISO 4871.

Z The noise emission level is calculated in accordance with standard procedures and

takes into account the noise level when travelling, lifting and when idle. The noise

level is measured at the level of the driver's ear.

Vibration

in accordance with EN 13059.

Z The vibration acceleration acting on the body in the operating position is, in

accordance with standard procedures, the linearly integrated, weighted

acceleration in the vertical direction. It is calculated when travelling over thresholds

at constant speed (standard truck version). These recordings were taken on a

single occasion and must not be confused with the human vibrations of the "2002/

44/EC/Vibrations" operator directive. The manufacturer offers a special service to

measure these human vibrations, see "Human vibration measurement" on

page 198.

Z The vibration that is characteristic for vibrations of the body cannot be used to

determine the actual load caused by vibrations during operation. That depends on

the operating conditions (condition of the travel routes, method of operation, etc.)

and should therefore be determined on site at a suitable location. Hand/arm

vibration must always be determined without exception, even if the values do not

indicate any hazard at all, as in this case.

Whole-body vibration

Motor type Vibration Uncertainty

TFG 1.0 m/s

2

0.2 m/s

2

DFG S90 0.9 m/s

2

0.2 m/s

2

DFG 660-690, S80 1.3 m/s

2

0.2 m/s

2

Hand/arm vibration

Vibration <2.5 m/s

2

Page 36

37

11.14 E N

Electromagnetic compatibility (EMC)

The manufacturer confirms that the truck adheres to the limits for electromagnetic

emissions and resistance as well as the static electricity discharge test in accordance

with EN 12895 as well as the standardised instructions contained therein.

Z No changes to electric or electronic components or their arrangement may be

made without the written agreement of the manufacturer.

WARNING!

Medical equipment can be damaged by non-ionised radiation

Electrical equipment on the truck emitting non-ionised radiation (e.g. wireless data

transmission) can affect operators' medical equipment (pacemakers, hearing aids

etc.) and result in malfunctions. Consult with a doctor or the medical equipment

manufacturer to clarify whether it can be used near the industrial truck.

3.8 Conditions of use

Ambient temperature

– operating at -20 to 40°C

Z Special equipment and authorisation are required if the truck is to be used

continually in conditions of extreme temperature or condensing air humidity

fluctuations.

3.9 Electrical requirements

The manufacturer certifies compliance with the requirements for the design and

manufacture of electrical equipment, according to EN 1175 "Industrial Truck Safety Electrical Requirements", provided the truck is used according to its purpose.

Page 37

11.14 E N

38

4 Identification points and data plates

Z Warnings and notices such as capacity charts, strap points and data plates must

be legible at all times. Replace if necessary.

XXXXXX

xxx xxxxxx

1

0

21

24

35

27

22

29

15

15

16 17 1918

36

20

26

28

33

31

39 40 42

38

23

30

15

4137

25

34

32

25

19

Page 38

39

11.14 E N

Item Component

15 Attachment points for loading by crane (o)

16 Read operating instructions

17 Wear seat belt

18 Test plaque (o)

19 Hot surface warning

20 Trailer coupling

21 Capacity plate

22 Tipover hazard

23 No passengers

24 Do not drive or tilt the mast forward with a load raised

25 Turn the exhaust pipe back before tilting the cab

26 Air pressure

27 Do not stand on load handler / Do not stand under load handler / Risk of

trapping when mast extended

28 Hydraulic oil

29 Jack contact points

30 Emergency exit

31 Battery main switch

32 Warning

33 Coolant notice

34 Noise level

35 Truck data plate

36 Fuel

37 Lift load cushioning (o)

38 Fire extinguisher (o)

39 Add engine oil

40 Windscreen fluid

41 Coolant

42 Check engine oil

Page 39

11.14 E N

40

4.1 Data plate

Z For queries regarding the truck or ordering spare parts always quote the truck serial

number (44).

43 44 4645

52

49

51

48

47

50

Item Component Item Component

43 Type 48 Year of manufacture

44 Serial number 49 Load centre distance (mm)

45 Rated capacity (kg) 50 Net weight in kg

46 Output 51 Manufacturer

47 Option 52 Manufacturer's logo

Page 40

41

11.14 E N

4.2 Truck capacity plate

CAUTION!

Accident risk from fork replacement

If you replace the forks with ones that differ from the originals, the capacity will

change.

X

When replacing the forks you must attach an additional capacity plate to the truck.

X

Trucks supplied without forks are given a capacity plate for standard forks (length:

1150 mm).

The capacity plate (21) gives the capacity (Q in kg) of the truck for a vertical mast.

The maximum capacity is shown as a table with a given load centre of gravity D (in

mm) and the required lift height H (in mm).

The capacity plate (21) of the truck indicates the truck's capacity with the forks as

originally supplied.

Example of how to calculate the maximum capacity:

With a load centre distance D of 700 mm and a maximum lift height h

3

of 5000 mm.

the max. capacity Q is 6940 kg.

Lift height restriction

The arrow shaped markings (53 and

54) on the inner and outer masts show

the operator when the prescribed lift

limits have been reached.

6960

7470

8340

6460

6940

7740

5660

6080

6770

6000

5000

4000

600 700 900

21

53 54

Page 41

11.14 E N

42

4.3 Attachment capacity plate

The attachment capacity plate is next to the truck's capacity plate and gives the

truck’s capacity Q (in kg) in conjunction with the respective attachment. The serial

number for the attachment indicated on the capacity plate must match the data plate

of the attachment.

4.4 Jack attachment point

The "Jack contact point" decal (29) indicates

where the truck may be lifted and jacked up.

5 Stability

The truck's stability has been tested according to latest technological standards.

These take into account the dynamic and static tipover forces that can occur if used

correctly.

Stability can also be affected by the following factors:

– Tyre type

–Mast

– Attachment

– Transported load (size, weight and centre of gravity)

WARNING!

Loss of stability can cause accidents

Changing the components can alter the stability.

29

Page 42

43

11.14 E N

C Transport and Commissioning

1 Transport

Transport can be carried out in two different ways, depending on the height of the

mast and the local conditions.

– Vertically, with the mast assembled (for low heights)

– Vertically, with the mast dismantled (for large heights), all mechanical connections

and hydraulic lines between the basic truck and the mast separated.

2 Truck laden

2.1 Centre of gravity of the truck

WARNING!

An altered centre of gravity can result in tipovers when cornering.

The overall centre of gravity can vary depending on the truck's equipment (especially

the mast version).

For trucks without a mast the centre of gravity will move significantly in the direction

of the counterweight.

XDrive carefully and with modified speed to avoid tipping over.

The picture shows the approximate centre of

gravity location.

Page 43

11.14 E N

44

2.2 Lifting the truck by crane

CAUTION!

The mast can get damaged

X

Loading by crane is only intended for the initial transport before the truck is used

for the first time.

X

Loading must be carried out by specially trained staff in accordance with

recommendations contained in Guidelines VDI 2700 and VDI 2703

DANGER!

Crane slings can tear, resulting in accidents

X

Only use crane lifting gear with sufficient capacity.

X

Loading weight = Net weight of truck (+ battery weight for electric trucks).

X

The mast must be tilted back fully.

X

The crane lifting gear on the mast must have a minimum clear length of 2 m.

X

Crane slings should be fastened in such a way that they do not come into contact

with any attachments or the overhead guard when lifting.

XDo not stand under a swaying load.

XThe truck should only be handled by people who are trained in using lifting slings

and tools.

XWear safety shoes when lifting the truck by crane.

XDo not walk into or stand in a hazardous area.

XAlways attach the crane lifting gear to the prescribed strap points and prevent them

from slipping.

Z Truck net weight: see "Data plate" on page 40.

Lifting the truck by crane

Requirements

– Park the truck securely, see "Parking the

truck securely" on page 103.

Procedure

• Secure the crane slings to the attachment

points (55) and (56.

• Raise and load the truck.

• Lower and deposit the truck carefully (see

"Parking the truck securely" on page 103).

• Secure the truck with wedges to prevent it

from rolling away.

This concludes the loading by crane.

56

55

Page 44

45

11.14 E N

2.3 Loading with another industrial truck

DANGER!

Slipping can cause accidents

X

Do not use another Industrial truck to load the truck!

Page 45

11.14 E N

46

3 Securing the truck during transport

WARNING!

Accidental movement during transport

Improper fastening of the truck and mast during transport can result in serious

accidents.

X

Loading must be carried out by specially trained staff in accordance with

recommendations contained in Guidelines VDI 2700 and VDI 2703 In each case

correct measurements must be made and appropriate safety measures adopted.

X

The truck must be securely fastened when transported on a lorry or a trailer.

X

The loading area must have clamp rings and a wooden floor to secure the retaining

wedges.

X

Use wedges to prevent the truck from moving.

X

Use only tensioning belts or tie-down straps or with sufficient strength.

Securing with a mast Securing without a mast

Securing the industrial truck for transport

Requirements

– Position the industrial truck securely on a lorry or trailer, see "Parking the truck

securely" on page 103.

Tools and Material Required

– 2 fastening belts with a tensioner

– Retaining wedges

Procedure

• Secure the truck with the fastening belt (58) at the top cross member of the mast

(55) and the trailer coupling (56) or over the front axle cross member (57) and the

trailer coupling (56).

• Tighten the fastening belts (58) with the tensioner.

The truck is now secured for transport.

58

58

58

58

55

56

57

Page 46

47

11.14 E N

4 Using the Truck for the First Time

Safety Instructions for Assembly and Commissioning

WARNING!

Incorrect assembly can result in accidents

The assembly of the truck at the application site, commissioning and operator training

must only be performed by the manufacturer's customer service representatives who

have been specially trained for these tasks.

X

The hydraulic lines may only be connected to the basic truck / mast interface when

the mast has been properly assembled.

X

Only then can the truck be started.

X

If several trucks have been delivered, make sure that the serial numbers of the load

handlers, masts and basic trucks always match.

Preparing the truck for operation after delivery or transport

Procedure

• Check the equipment is complete.

• Check the engine oil level.

• Check the hydraulic oil level.

• Check the transmission oil level.

• Check the brake fluid level.

• Test the battery connections.

• Check the battery acid level (not for maintenance-free batteries).

The truck can now be started, see "Preparing the Truck for Operation" on page 86.

Page 47

11.14 E N

48

Page 48

49

11.14 E N

D Fuelling the Truck

1 General

1.1 Safety regulations for handling diesel fuel and LPG

WARNING!

An unsecured industrial truck can cause accidents

The truck can suddenly start to move.

X

Switch off the truck securely before filling up or replacing the LPG bottle, see

"Parking the truck securely" on page 103.

WARNING!

Accident risk from ignition

X

Fuels and liquefied petroleum gas can ignite.

X

Smoking, naked flames and other ignition sources are strictly prohibited in the

immediate vicinity when handling fuels and LPG.

XLabels indicating the hazard are must be positioned where they are clearly visible.

XDo not store flammable materials in this area.

XPowder fire extinguisher must be provided within easy reach of the filling area.

XUse only category A, B or C type powder fire extinguishers to fight LPG fires.

XBring any unsealed LPG bottles immediately outside, attach visible markings and

notify the supplier.

Storage and Transport

The diesel and LPG storage and transport devices must comply with statutory

requirements.

If there is no filling point available, the fuel must be stored and transported in clean,

approved containers.

The contents must be clearly indicated on the container.

Page 49

11.14 E N

50

NOTE

Fuel can cause environmental damage

X

Bind any spilled diesel fuel with suitable methods.

X

Then dispose of the diesel and fuel filter in accordance with environmental

regulations.

Fuel filling and LPG bottle replacement personnel

Personnel filling the trucks or replacing LPG bottles must have sufficient knowledge

of the nature of fuels to ensure safe operation.

CAUTION!

Liquid gas can cause frostbite

X

Liquid gas produces frostbite when it comes into contact with bare skin.

X

Avoid direct contact with the skin.

X

Wear gloves.

Filling up LPG containers

LPG containers remain attached to the truck and are filled up at LPG stations. Always

follow the instructions of the tank system and LPG container manufacturer as well as

statutory and local regulations when filling up.

NOTE

Instructions for the safe operation of LPG systems

XAll maintenance and repair work on LPG systems and containers should be carried

out by qualified personnel who have been trained to work on LPG systems.

XThe owner must comply with all legal requirements, technical standards and health

and safety regulations applicable to liquid gas.

XBefore starting work, the operator must check that all accessible components of the

LPG system are in good working order, in accordance with the regulations of the

country of use.

XDo not operate the truck if there is any damage, corrosion, wear or degradation to

individual components of the LPG system.

Page 50

51

11.14 E N

1.2 LPG system relief valve

LPG powered trucks are fitted with a

relief valve. This is located on the rear

cover next to the gas bottle.

– In the event of a fault the pressure in

the gas system is restricted to a

maximum level. The relief valve is

fitted with a plastic cover (59).

– When the valve is activated the plastic

cover comes off, thereby clearly

indicating a fault in the gas system.

– In this case the truck must not be

operated.

– The gas system must be check by

suitably qualified and trained

personnel.

– The operator must check that the plastic cover is in place each time he uses the

truck.

– Models with a liquid gas tank have the

relief valve (61) in the drive

compartment. The relief valve is fitted

with a hose (60) that diverts the LPG if

the relief valve is opened.

– When the valve is activated the plastic

cover comes off, thereby clearly

indicating a fault in the gas system.

– In this event the truck must not be

operated.

– The gas system must be check by

suitably qualified and trained

personnel.

– The user must check that the plastic

cover is present each time he uses the

truck.

DANGER!

Danger from escaping liquid gas.

Liquid gas can escape from faulty gas hoses.

XUse only gas bottles with an integrated line break safety valve.

XThe gas bottle connection is also fitted with a line break safety valve which prevents

the gas from escaping accidentally during operation.

XWhen replacing, always use a gas bottle connection with an integrated line break

safety valve.

59

6061

Page 51

11.14 E N

52

2 Adding diesel

CAUTION!

Air in the fuel system will result in malfunctions.

X

Never allow the fuel tank to run dry.

2.1 Fuelling

WARNING!

Diesel fuel can be hazardous

X

Diesel fuel can cause irritation if it comes into contact with the skin. Rinse any

affected areas thoroughly.

X

If it comes into contact with the eyes rinse them immediately with flowing water and

call for a doctor.

X

Wear safety gloves when handling diesel fuels.

NOTE

XFuelling must always be performed in designated areas by trained and authorised

personnel.

NOTE

XCapacity: DFG 660-690 = 125 l.

XUse only diesel in accordance with DIN 590 or DIN 51628 with a cetane rating

above 51.

2.1.1 Fuelling the tank system

Procedure

• Park the truck securely before fuelling,

see "Parking the truck securely" on

page 103.

• Unscrew the tank cap (62).

• Insert the pump nozzle into the open

tank filler neck.

• Add the fuel.

• Do not overfill the tank.

• Tighten the cap (62) back on after

fuelling.

Fuelling is now complete.

62

Page 52

53

11.14 E N

The fuel gauge (63) indicates the fuel level.

NOTE

X

Never allow the fuel tank to run dry. Air

in the fuel system will result in

malfunctions.

2.2 Fuelling with fuel containers

Procedure

• Unscrew the filler cap (62) and open the

fuel container.

• Fit the spout onto the fuel container.

• Insert the spout into the open tank filler

neck.

• Make sure the fuel container and spout

are connected tightly to each other.

• Raise the fuel container carefully and

slowly add the diesel.

• Do not overfill the tank.

• Screw the cap (62) back on tightly after

fuelling.

Fuelling is now complete.

63

62

Page 53

11.14 E N

54

3 LPG containers

Z Only use liquid gas that complies with DIN 51622 or comparable national

regulations.

3.1 LPG bottles

DANGER!

Risk of explosion

X

The LPG bottle must only be replaced at designated areas by trained and

authorised personnel.

CAUTION!

Using unsuitable LPG bottles can cause accidents.

X

Use only approved LPG bottles.

X

The LPG bottle must always rest on an engaged bottle holder so that the hose

connection of the shutoff valve is facing vertically down.

XFor bottle types of other countries note the national regulations.

XNote the indications and markings on the LPG bottle.

3.1.1 Using an LPG bottle

Replace the LPG bottle

Procedure

• Park the truck securely before replacing

the LPG bottle, see "Parking the truck

securely" on page 103

• Close the shut-off valves (64) securely.

• Start the motor and allow the LPG system

to run empty in neutral.

64

Page 54

55

11.14 E N

Remove the LPG bottle

CAUTION!

The connection has a left thread

Procedure

• The LPG bottle console is released with

the finger screw (65).

• Unfold the console (66) as far as the stop.

• Unscrew the union nut (68).

• Remove the hose (60) and immediately

screw the valve cap onto the empty LPG

bottle.

• Loosen the toggle-type fastener with the

handle (67).

• Carefully remove the LPG bottle from the

bracket and place it down securely.

Inserting a new LPG bottle

Procedure

• Insert the LPG bottle into the bracket

• Align the hose connection downwards.

• Clamp the toggle-type fastener with the

handle (67).

• Unscrew the valve cap.

• Fit the hose (60) in accordance with

instructions.

• Carefully open the shut-off valve (64).

• Check the hose connection for leaks using

a foam-forming agent.

The replacement is now complete.

65

66

67

6864606864

Page 55

11.14 E N

56

3.1.2 Operating the Twin Bottle System and Liquid Gas Tank

Changing the LPG Supply

Procedure

Z The (71) switch controls the release of the LPG bottle

or tank.

• Open the shut-off valves (64) of both LPG bottles by

turning anticlockwise.

• Apply the (71) switch.

• The left LPG bottle (69) is activated by the middle

switch position.

• The right LPG bottle (70) is activated by the lower

switch position.

• Close the LPG bottles and open the LPG tank by

applying the top switch position.

LPG supply changed.

S4

S7 S8 S24

S12 S13 S15

S20 S26 S30

64

71

69 70

Page 56

57

11.14 E N

3.2 Liquid gas tank

The filling valve (72) is located on the left side of the truck.

Filling refillable liquid gas tanks

DANGER!

Risk of explosion

X

Fuelling must always be performed in

designated areas by trained and

authorised personnel.

Requirements

– Park the truck securely (see "Parking the

truck securely" on page 103).

– Note all guidelines and regulations

concerning the filling of LPG bottles on the

LPG pump.

Procedure

• Unscrew the tank cap (62).

• Lock the filling adapter of the tank system in

place on the filling valve (72).

• Enabling filling on the tank system

Z The integrated filling stop valve prevents

the tank from overfilling.

• When the filling process is complete,

release the filling adapter of the filling system from the filling valve (72).

• Screw on the tank cap (62).

Z The level of the tank is shown by the fuel indicator.

62

72

Page 57

11.14 E N

58

4 Fuel level indicator

4.1 Display unit

The level indicator (63) shows the capacity

of the tank.

63

Page 58

59

11.14 E N

E Operation

1 Safety Regulations for the Operation of the

Forklift Truck

Driver authorisation

The truck may only be used by suitably trained personnel, who have demonstrated to

the proprietor or his representative that they can drive and handle loads and have

been authorised to operate the truck by the proprietor or his representative.

Operator’s rights, responsibilities and rules of conduct

The driver must be informed of his duties and responsibilities and be instructed in the

operation of the truck and shall be familiar with the operating instructions. Safety

shoes must be worn on pedestrian-operated trucks.

Unauthorised use of truck

The operator is responsible for the truck during the time it is in use. The operator must

prevent unauthorised persons from driving or operating the truck. Do not carry

passengers or lift other people.

Damage and faults

The supervisor must be informed immediately of any damage or faults to the truck or

attachment. Trucks which are unsafe for operation (e.g. wheel or brake problems)

must not be used until they have been rectified.

Repairs

The operator must not carry out any repairs or alterations to the truck without

authorisation and the necessary training to do so. The operator must never disable or

adjust safety mechanisms or switches.

Page 59

11.14 E N

60

Hazardous area

WARNING!

Risk of accidents/injury in the hazardous area of the truck

A hazardous area is defined as the area in which people are at risk due to travel or

lifting operations of the truck, its load handler or the load. This also includes the area

within reach of falling loads or lowering/falling operating equipment.

X

Instruct unauthorised persons to leave the hazardous area.

X

In case of danger to third parties, give a warning signal in good time.

X

If unauthorised persons are still within the hazardous area, stop the truck

immediately.

WARNING!

Falling objects can cause accidents

Falling objects can injure the operator while the truck is being operated.

X

The operator must remain within the protected area of the overhead guard while

the truck is being operated.

Safety devices, warning signs and warning instructions

Safety devices, warning signs (see "Identification points and data plates" on page 38)

and warning instructions in the present operating instructions must be strictly

observed.

Page 60

61

11.14 E N

2 Displays and Controls

2.1 Multi-task switch

Item Control /

Display

Function

73 Multi-task switch t

– Travel function switch – Sets automatic gear shifting

– Travel direction

switch

– Selects travel direction / neutral position

t

= Standard equipment

o

= Optional equipment

73

74

Einzelpedalsteuerung

76 75

to

Page 61

11.14 E N

62

74 Multi-task switch

t

– Travel direction

indicator

– Switches the travel direction indicator on

and off

– Dipped lights/main

beam

– Switch spot lights from dipped lights to

main beam

– Windscreen wiper – Switches the windscreen wiper on and off

– Switches interval speed on and off

– Windscreen washing

system

– Switches windscreen washing system on

and off

– Horn – Activates an audible warning

76 Brake pedal

t

When activated, causes the truck to brake to

a halt immediately.

75 Accelerator pedal

t

Infinite travel speed control.

Item Control /

Display

Function

t

= Standard equipment

o

= Optional equipment

to

Page 62

63

11.14 E N

2.2 SOLO-PILOT

A

B

77 78 79 80 81

82

Item Control /

Display

Function

77 Lever t Load handler raise / lower

78 Lever t Mast forward / reverse tilt

79 Auxiliary hydraulics lever

1

o 1. Activate 1st attachment

80 Auxiliary hydraulics lever

2

o 2. Activate 2nd attachment

81 Auxiliary hydraulics lever

3

o 3. Activate 3rd attachment