Page 1

Versatile: HGV double-deck

loading or pallet truck

/ stacker operation

3-phase AC motor for

maximum performance and

low energy consumption

ShockProtect to protect the

operator, truck and load

Electric tiller for easy steering

Optimum driving

characteristics with fixed

ProTracLink torsion bar

Fixed operator

platform (optional)

ERD 220

Electric pedestrian stacker (2,000 kg)

The ERD 220 electric pedestrian stacker

is extremely versatile and powerful when

it comes to load handling. A specialist in

HGV double-deck loading, it transports

loads eciently over longer distances

or stacks/retrieves loads up to 2560 mm

high.

The design of the truck is very robust: An

8-mm steel chassis and box section forks

made of sectional steel allow for heavyduty applications with heavy loads.

The ERD 220 is also ideal for both pedestrian and ride-on operation. In ride-on

mode, the ERD achieves a very high

speed of up to 12.5 km/h. This means

that goods can be handled or transported eciently.

This truck also oers maximum operator

safety and operator comfort:

• In addition to the soft suspension of

the platform, the entire drive system is

cushioned with ShockProtect suspension. The advantage:

• Reduces stress on the operator’s spinal

column.

• Considerably less impact on the chassis and all technical components of the

ERD 220.

• Electric steering for fatigue-free travel,

even with heavy loads.

• The maximum speed of the truck is

automatically reduced when cornering,

depending on the steering angle

(Curve Control).

• A fixed stand-on platform (optional)

provides outstanding operator protection with extra-high side components.

Up to 465 Ah high-performance batteries

are available for really demanding applications. Combined with state-of-theart 3-phase AC technology, this ensures

longer operating times with simultaneously minimised power consumption.

For multi-shift operations, the ERD 220 is

equipped with a lateral battery exchange

option. The ERD 220 basic model is

available for less demanding applications

(no lateral battery exchange).

Page 2

ERD 220

ERD 220

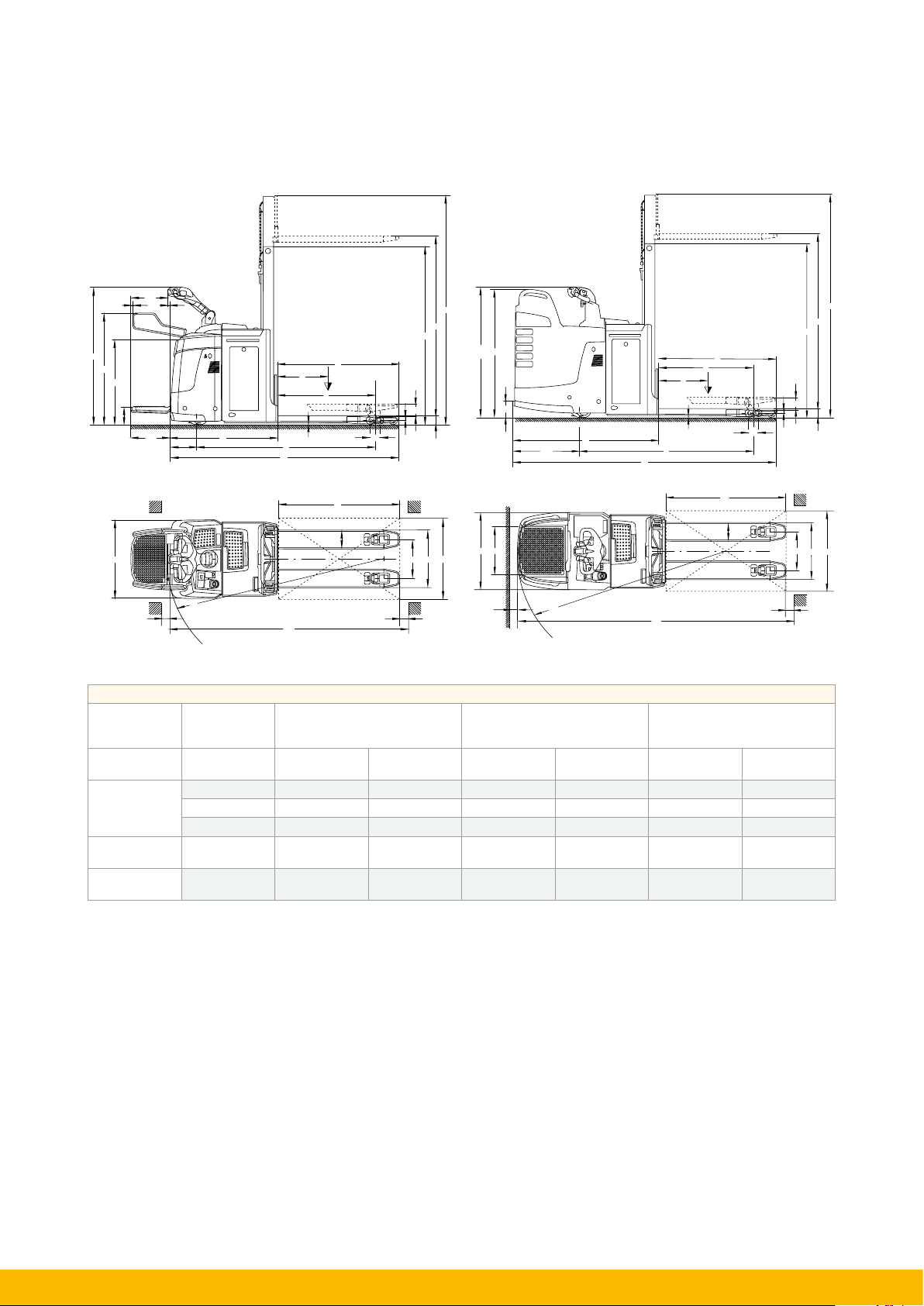

362

20

22

h

14

1098

837

170

384

264

b

1

Foldable platform

ERD 220

h

h

4

h

3

h

1

l

Q

c

x

m

l

2

Wa

a

2

2

y

l

1

l

6

e

Ast

s

h

5

95

b

b

11

a

2

h

14

1270

max

163

h

13

b

b

11

1

b

12

5

a

2

l

2

673

Wa

y

l

1

Ast

l

x

Q

c

m

2

l

6

e

s

95

4

h

3

h

1

h

5

h

13

b

(b12)

b

10

5

a

2

Fixed platform

Duplex

ZT

Duplex

ZZ

Triplex

DT

1)

including basic lift + 122 mm

Standard mast types ERD 220

Lift

h

(mm)

3

Lowered mast height

h

1

(mm)

ERD 220 Basic ERD 220 Fold up

/ Fixed Platform

Free lift

h

2

(mm)

ERD 220 Basic ERD 220 Fold up

/ Fixed Platform

Extended mast height

h

4

(mm)

ERD 220 Basic ERD 220 Fold up

/ Fixed Platform

1660 1350 1350 100 100 2150 2150

2010 1530 1530 100 100 2500 2500

2560 - 1810 - 100 - 3050

2500 - 1700 - 1130 - 3070

2500 - 1366 - 100 - 2990

1)

Page 3

Issue: 10/2010

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model ERD 220

Basis Foldable platform fixed platform

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation

stand-on/pedes-

trian

1.5 Load capacity/rated load Q t 2

1.5.1 Load capacity/mast lift Q t 1

Identification

1.5.2 Load capacity/support arm lift Q t 2

1.6 Load centre distance c mm 600

1.8 Load distance x mm 957

1.9 Wheelbase y mm 1749

6)

2.1.1 Net weight incl. battery (see row 6.5) kg 1186 1110 1168

2.2 Axle load, w. load, front / rear kg 1958 / 1228 1920 / 1190 1920 / 1248

2.3 Axle load, w.o. load, front / rear kg 348 / 838 310 / 800 310 / 858

Weights

3.1 Tyres Vulkollan

3.2 Tyre size, at front mm Ø 230 x 77

3.3 Tyre size, at rear mm Ø 85 x 95 / Ø 85 x 75

3.4 Additional wheels (dimensions) mm Ø 140 x 50

3.5 Wheels, number front/rear (× = driven wheels) 1x +2/2 4

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

4.2 Mast height (lowered) h

4.4 Lift h

4.5 Extended mast height h

4.6 Initial lift h

4.9 Height of tiller in drive position min. / max. h

4.15 Lowered height h

4.19 Overall length l

mm 512

10

mm 385

11

mm 1350

1

mm 1660

3

mm 2150

4

mm 122

5

mm 1158 / 1414

14

mm 90

13

mm 2246 2174

1

4.20 Length incl. back of forks l2 mm 1056 984

4.21 Total width b1/b2 mm 770

4.22 Fork dimensions s/e/l mm 56 / 185 / 1190

Basic dimensions

4.25 Width over forks b

4.32 Floor clearance centre wheelbase m

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 2455

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2465

4.35 Turning radius Wa mm 2022

mm 570

5

mm 20

2

5)

4)

6)

5.1 Travel speed, w. / w.o. load km/h 7.2 / 8.2 9.5 / 12.5 9.5 / 12.5

5.2 Lift speed, w. / w.o. load m/s 0.13 / 0.22 0.14 / 0.24 0.14 / 0.24

5.3 Lower speed, w. / w.o. load m/s 0.25 / 0.21 0.27 / 0.25 0.27 / 0.25

data

5.8 Max. gradeability, laden/unladen % 8 / 15 8 / 16 8 / 16

Performance

5.10 Service brake generated

6.1 Drive motor rating S2 60 min. kW 2.8

6.2 Lift motor kW rating at S3 7% kW 2.0

6.2 Lift motor, output at S3 (on time) 12 % kW 2 2

6.3 Battery according to DIN 43531/35/36 A,B,C, no B 43535

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 375 24 / 250

6.5 Battery weight kg 288 220

Electrics

6.6 Energy consumption according to VDI cycle kWh/h 0.51 0.67 0.67

6.7 Throughput eciency t/h 94 94

6.8 Energy consumption at max. throughput kWh/h 0.61 0.61

8.1 Type of drive control AC SpeedControl

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 63 67 67

Misc.

stand-on/pedes-

trian

6)

6)

1677

2)

2)

5)

2383

4)

2393

6)

1950

3)

1)

stand-on

6)

1677

2)

2584

2)

1394

5)

2831

4)

2841

6)

2398

24 / 250

1)

220

3)

1)

375 Ah = 288 kg, 465 Ah = 368 kg

2)

Battery compartment L + 27 mm / L high + 72 mm

3)

Battery compartment L = 375 Ah, L high = 465 Ah

4)

Diagonal in accordance with VDI: + 225 mm

5)

Diagonal in accordance with VDI: + 369 mm

6)

Load section lowered: +48 mm

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may result in

different values.

Page 4

Benefit from the advantages

Fixed operator platform for maximum driver safety

Precise operation with the pallet

stop

Dynamic and ecient travel

The 3-phase AC drive technology and

control electronics (SpeedControl)

guarantee dynamic and energy-saving

handling which can be tailored to the

requirements of any application:

• Powerful 2.8-kW drive motor with

3-phase AC controller.

• Jungheinrich SpeedControl – roll-back

protection on gradients.

• Individually adjustable drive parameters

enable the truck to be tailored to

individual requirements (optional).

• Energy recovery through regenerative

braking on deceleration.

Outstanding handling and lift performance

• Jungheinrich ShockProtect: Protection for the operator, truck and load

through additional drive suspension.

The suspension cushions the operator

and frame against harder impacts.

• Sprung and cushioned support wheels

– linked via the ProTracLink torsion bar

– ensure safe handling under all driving

conditions.

• Controlled hydraulics (optional) for

gentle depositing of the load and

for precise pallet positioning in the

racking.

Flexible and safe operation

Flexible and safe operation

• Depending on the application, it can

be used in ride-on or pedestrian mode

by folding the platform out or in. The

travel speed is automatically reduced

when in pedestrian mode.

• A fixed platform with an enclosed

operator position is available (optional)

where more stringent safety requirements are in place.

• In double-deck operation, two pallets

each weighing 1000 kg can be transported on top of each other at a maximum speed of 8 km/h (ERD 220 entry

model: 5 km/h).

Information at all times

Comprehensive control instrumentation

gives the operator information at a

glance at all times:

• CanDis information display (optional)

with hour-meter and service code

storage.

• Activation of truck via PIN and automatic shutdown with CanCode

(optional).

Outstanding ergonomics

The moisture-proof tiller arm has rocker

switches on both sides and a clear red/

green colour code to match the ergonomic requirements of the operator. The

ERD 220 also has the following features:

• Fatigue-free electric steering.

• Height-adjustable tiller arm on fixed

platform (optional).

• Additional pallet stop on chassis ensures precise positioning of two pallets

stacked on top of each other.

• Detachable storage compartment on

battery lid.

Long operating times

Large battery capacities ensure long

operating times.

• Battery compartment M: 3 PzS 250 Ah

• Battery compartment L: 3 PzS 375 Ah

• Battery compartment L high: 3 PzS

465 Ah

• Side battery removal option for multishift environments

• Built-in charger (24 V/30 A for wet

cell batteries and maintenance-free

batteries) for easy charging at any

mains socket (optional).

Optional equipment

• Load backrest.

• Lowering speed reduction for pallet

lowering.

• Cold store version.

• Entry skids for lifting perimiter based

pallets.

• High-performance lift.

• Slow travel with lowered forks (fork

wear reduction)

• ERD 220 entry model with reduced

performance levels.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_ERD 220 _042014_en_UK_000

Loading...

Loading...