Page 1

3 Phase AC drive system

Outstanding ergonomics with

multi-functional tiller head

Operation with tiller in upright

position using the crawl speed button

Compact and manoeuvrable

Integrated charger with 13 Amp

plug socket for easy charging

Sensitive lowering function places

loads gently (optional)

EMC 110/EMC B10

Electric pedestrian stacker (1000 kg)

The Jungheinrich electric pedestrian stacker

EMC 110/EMC B10 combines productivity,

user-friendly controls and safety for the

operator. It offers a wide array of options

for almost any application. Two of the best

examples are placing goods in racking and

feeding machines. Palletised goods are

simply raised to the required picking height

Then they can be deposited into the racking or removed from the pallet without

placing stress on the operator’s back.

Ergonomic and engineering advantages

make the EMC especially easy to operate:

The long tiller provides the operator with

low operating forces and a high safety fac-

at the same time. The sensitive lower-

tor

ing function (optional) ensures gentle de positing of especially delicate materials on

the racking or floor.

All drive and lift functions are easily accessible from the multi-functional tiller head

without having to reach around. The creep

.

speed button allows the truck to operate

even in very confined spaces with the tiller

upright.

The EMC also offers impressive features

for easy power management: The nomaintenance 70 ah batteries can be recharged simply by connecting the integrated charger into any 13 Amp plug

socket. The battery discharge indicator

continually displays the batteries state of

charge.

The innovative 3 phase AC drive motor

gives outstanding performance in this

truck class and creates ideal conditions for

efficient, productive work.

The EMC B10 is also capable of lifting

perimeter based pallets and can also be

fitted with an FEM / ISO fork carriage. A

wide selection of attachments can be

mounted on the fork carriage, further

expanding the already broad range of

applications.

Page 2

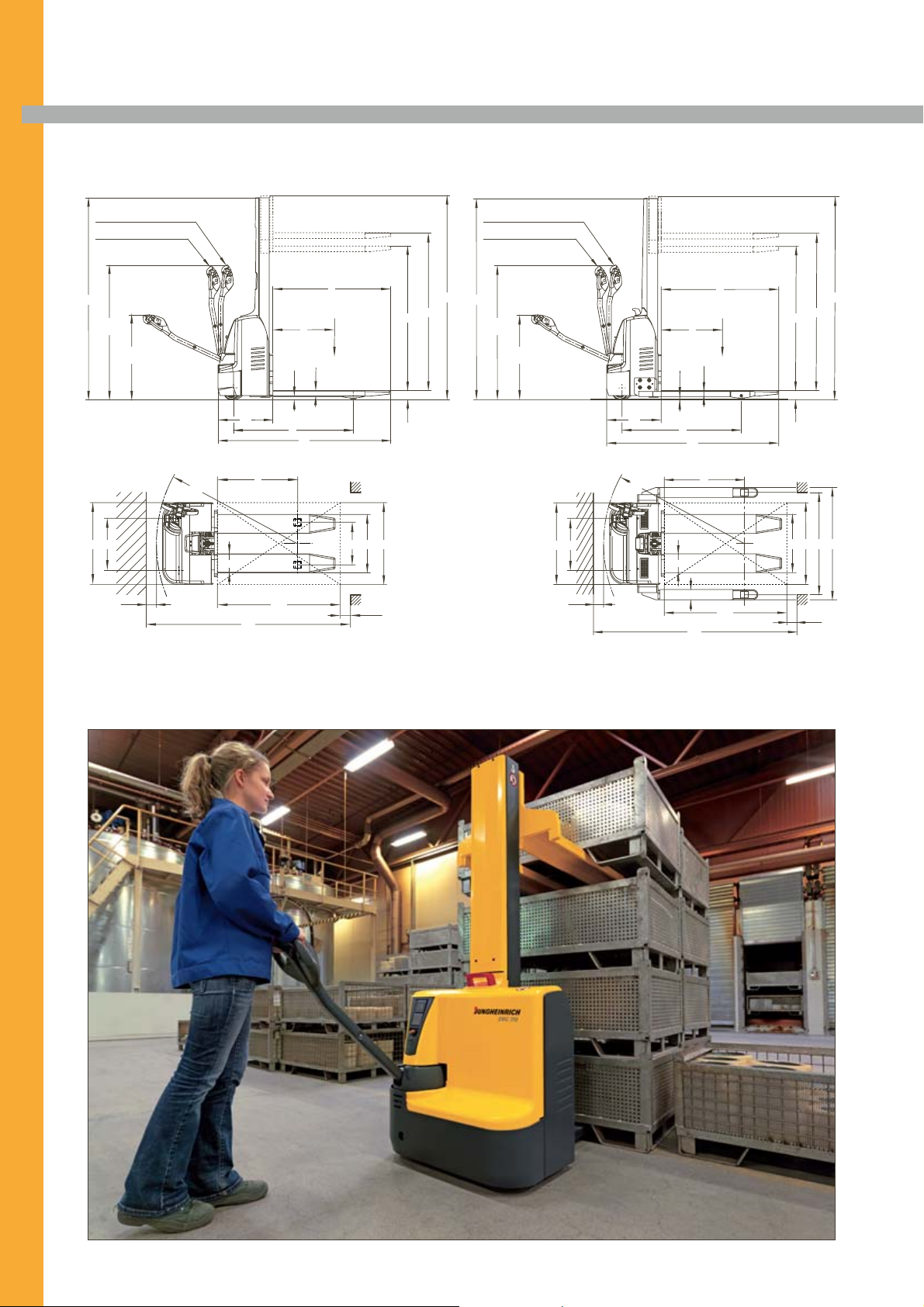

EMC 110/EMC B10

EMC 110 EMC B10

Travel position, crawl speed

Travel position, normal

h

1

h

14

max.

h

14

min.

b1b

10

a

2

Travel position, crawl speed

Travel position, normal

l

c

Q

s

m

2

l

2

y

l

1

Wa

x

b

(b12)

b

11

5

h

4

h

h

3

h

2

h

13

1

h

14

max.

h

14

min.

l

2

Wa

b1b

10

ee

(l6)

Ast

a

2

a

2

l

c

Q

s

m

2

y

l

1

h

4

h

3

h

2

h

13

x

b

b

2(b12)b11

5

e

100

(l6)

Ast

a

2

Page 3

Technical data in line with VDI 2198 as at: 06/2009

1.1 Manufacturer (abbreviation) Jungheinrich Jungheinrich 1.1

1.2 Manufacturer’s type designation EMC 110 EMC B10 1.2

1.3 Drive electric electric 1.3

1.4 Operator type pedestrian pedestrian 1.4

1.5 Load capacity/rated load Q (t) 1.0 1.0 1.5

1.6 Load centre distance c (mm) 600 600 1.6

Identification

1.8 Load distance (Centre of load axle to fork face) x (mm) 784 784 1.8

1.9 Wheelbase y (mm) 1168 1168 1.9

2.1 Service weight incl. battery (see line 6.5) kg 545 590 2.1

2.2 Axle loading, laden front/rear kg 555 / 990 575 / 1015 2.2

2.3 Axle loading, unladen front/rear kg 400 / 145 435 / 155 2.3

Weights

3.1 Tyres PU / Pevopur PU / Pevopur 3.1

3.2 Tyre size, front mm 230 x 70 230 x 70 3.2

3.3 Tyre size, rear mm 77 x 70 77 x 70 3.3

3.4 Additional wheels (dimensions) 150 x 54 125 x 40 3.4

3.5 Wheels, number front rear (× = driven wheels) 1x +2 / 2 or 4 1x +2 / 2 3.5

3.6 Track width, front b10 (mm) 510 510 3.6

Wheels, Chassis

3.7 Track width, rear b11 (mm) 415 1000 / 1170 / 1370 3.7

4.2 Closed mast height h1 (mm) 19702) 19702) 4.2

4.3 Free lift h

4.4 Lift h

4.5 Height, mast extended h

(mm) 15072) 15072) 4.3

2

(mm) 15402) 15402) 4.4

3

(mm) 1992 2) 1992 2) 4.5

4

4.9 Height of tiller in drive position min./max. h14 (mm) 821 / 1305 821 / 1305 4.9

4.19 Overall length l1 (mm) 1685 1685 4.19

4.20 Length to face of forks l

4.21 Overall width b

4.22 Fork dimensions s / e / l (mm) 56 / 185 / 1150 56 / 185 / 1150 4.22

Basic Dimensions

4.25 Width across forks b

(mm) 535 535 4.20

2

/ b2 (mm) 800 / – 800 / 1100 1) 4.21

1

(mm) 570 570 / 660 4.25

5

4.32 Ground clearance, centre of wheelbase m2 (mm) 30 30 4.32

3

4.33 Aisle width for pallets 1000 × 1200 crossways Ast (mm) 1944

4.34 Aisle width for pallets 800 × 1200 lengthways Ast (mm) 1994

) 1944 3) 4.33

4

) 1994 4) 4.34

4.35 Turning radius Wa (mm) 1378 1378 4.35

5.1 Travel speed, laden/unladen km / h 4.2 / 5.0 4.2 / 5.0 5.1

5.2 Lift speed, laden/unladen m / s 0.09 / 0.13 0.09 / 0.13 5.2

5.3 Lowering speed, laden/unladen m / s 0.12 / 0.11 0.12 / 0.11 5.3

5.7 Gradeability, laden/unladen % 3.5 / 15 3.5 / 15 5.7

Performance Data

5.10 Service brake electric electric 5.10

6.1 Drive motor rating S2 60 min. kW 0.5 0.5 6.1

6.2 Lift motor rating at S

10% kW 1.2 1.2 6.2

3

6.3 Battery acc. to DIN 43531/35/36 A, B, C, no no no 6.3

6.4 Battery voltage, nominal capacity K

E-Motor

6.5 Battery weight kg 63 63 6.5

5

V / Ah 2 x 12 / 70 2 x 12 / 70 6.4

6.6 Energy consumption acc. to VDI cycle kWh/h 0.55 0.55 6.6

8.1 Type of drive control AC SpeedControl AC SpeedControl 8.1

Others

8.4 Sound level at the driver‘s ear according to EN 12 053 dB(A) 70 70 8.4

1) Straddle legs available in 3 overall widths

2) Version with high mast: + 460 mm

3) Diagonal method acc. to VDI: + 262 mm

4) Diagonal method acc. to VDI: + 159 mm

This specification sheet according to VDI regulation 2198 only provides technical values for the standard truck. Non-standard tyres, different masts, additional equipment, etc. could produce

other values. Right reserved for technical changes and improvements.

Page 4

Make use of the advantages

Safe and comfortable stacking

and retrieval

All lifting and lowering functions are easily

controlled from the multi-functional tiller

head, allowing the operator to focus entire-

on stacking and retrieval. Further features

ly

make stacking and retrieval particulary

safe and productive:

Long safety tiller

쐍

Precise and gentle depositing of loads

into the racking or on the floor. The

lowering speed is electro-hydraulically

controlled (in 2 stages) sensitively by

button on the tiller head (optional).

쐍

High lifting speed increases productivity.

쐍

Automatic regulation of the lift height

with

intelligent lift positioning (option-

al).

Working ergonomically

The recently developed tiller head is perfectly adapted to the ergonomic needs of

the operator:

쐍

Colour scheme for intuitive operation

and buttons with wear-resistant icons.

쐍

Grip angle to suit the hand position of

the operator.

쐍

Rocker switch for consistently good

operation in all tiller positions.

쐍

Horn button placed in the centre of the

tiller where it can be reached quickly.

Wide track version of EMC B10

쐍

Ideal for lifting perimeter based pallets.

쐍

Use of attachments (e. g. cranehooks or

barrel turners) with optional FEM / ISO

fork carriage.

Operating as a lifting table

쐍

One-piece front cover provides quick

access to all components.

Long operating times

The battery, when used together with the

energy-saving 3 Phase system, gives long

operating times.

쐍

Maintenance-free 24 V / 70 ah batteries

(gel fleece).

쐍

Integrated 230 V charger for easy charg-

at any 13 Amp mains socket.

ing

쐍

Integrated 110

V charger (optional).

Working in very confined spaces

The EMC is an especially compact pedestri-

stacker. The extremely short chassis

an

length and low vehicle weight allowing

extremely confined spaces, in the lift

use in

on mezzanines. The EMC is also

and

equipped with a crawl speed button. A

press of the button is all that‘s needed for

the EMC to manoeuvre safely, even with

the tiller up right.

Jungheinrich UK Ltd.

Head Office:

Sherbourne House · Sherbourne Drive

Tilbrook · Milton Keynes MK7 8HX

Phone 01908 363100

Fax 01908 363180

EMC B10 with FEM / ISO fork carriage (optional)

and forged forks

Lower maintenance costs

Service-friendly components ensure lower

maintenance costs in the long-term:

쐍

Maintenance-free 3 phase drive motor.

Additional equipment

쐍

Tandem load wheels

쐍

CanCode for PIN activation (instead of

key switch) and automatic shut-off function.

쐍

Discharge indicator and CanDis operat-

ing hours counter.

쐍

FEM / ISO fork carriage with forged

forks.

Jungheinrich

Plants, Sales and

Services Europe

ISO 9001/ ISO 14001

Jungheinrich trucks

conform to the European

Safety Requirements.

8758.GB.6.2009.r.s.

info@jungheinrich.co.uk

www.jungheinrich.co.uk

Loading...

Loading...