Page 1

Powerful and ecient with

maintenance-free AC drive

motor

Manoeuvrable and compact

for tight aisles

Sensitive lifting with

speed-controlled hydraulic

motor

Comfortable working

environment with practical

storage trays for pencils and

documents

Fast, easy charging at any

socket with on-board charger

(optional)

EJC 110/112

Electric pedestrian stacker (1,000/1,200 kg)

The EJC range 1 pedestrian stackers

show their strength in transporting over

short distances and stacking or retrieving

up to 3600 mm high. The compact chassis of the EJC ensures especially easy and

safe operation even in the most confined

spaces. Another useful feature is the

option of driving in crawl mode with the

tiller in upright position. The combination

of 3-phase AC drive motor and our own

internally developed electronic con-

troller ensures maximum eciency. The

advantage is high speed and powerful

acceleration with minimum energy

consumption, which in turn ensures

fast, ecient throughput. Operators will

also be pleased with precise lifting and

gentle lowering (optional for EJC 110)

of loads. The controlled lift motor and

conveniently positioned buttons on the

tiller head allow the operator to stack

loads to high heights. The power is sup-

plied to the EJC 110/112 via batteries with

capacities of up to 200 Ah. An on-board

charger (optional) protected against

moisture and dust ensures fast and easy

charging at any 13 Amp plug socket.

Optional fast charging is available. Practical storage compartments on the dashboard and front of the truck give you

easy access to all the resources you need

such as pencils, knives or documents.

Page 2

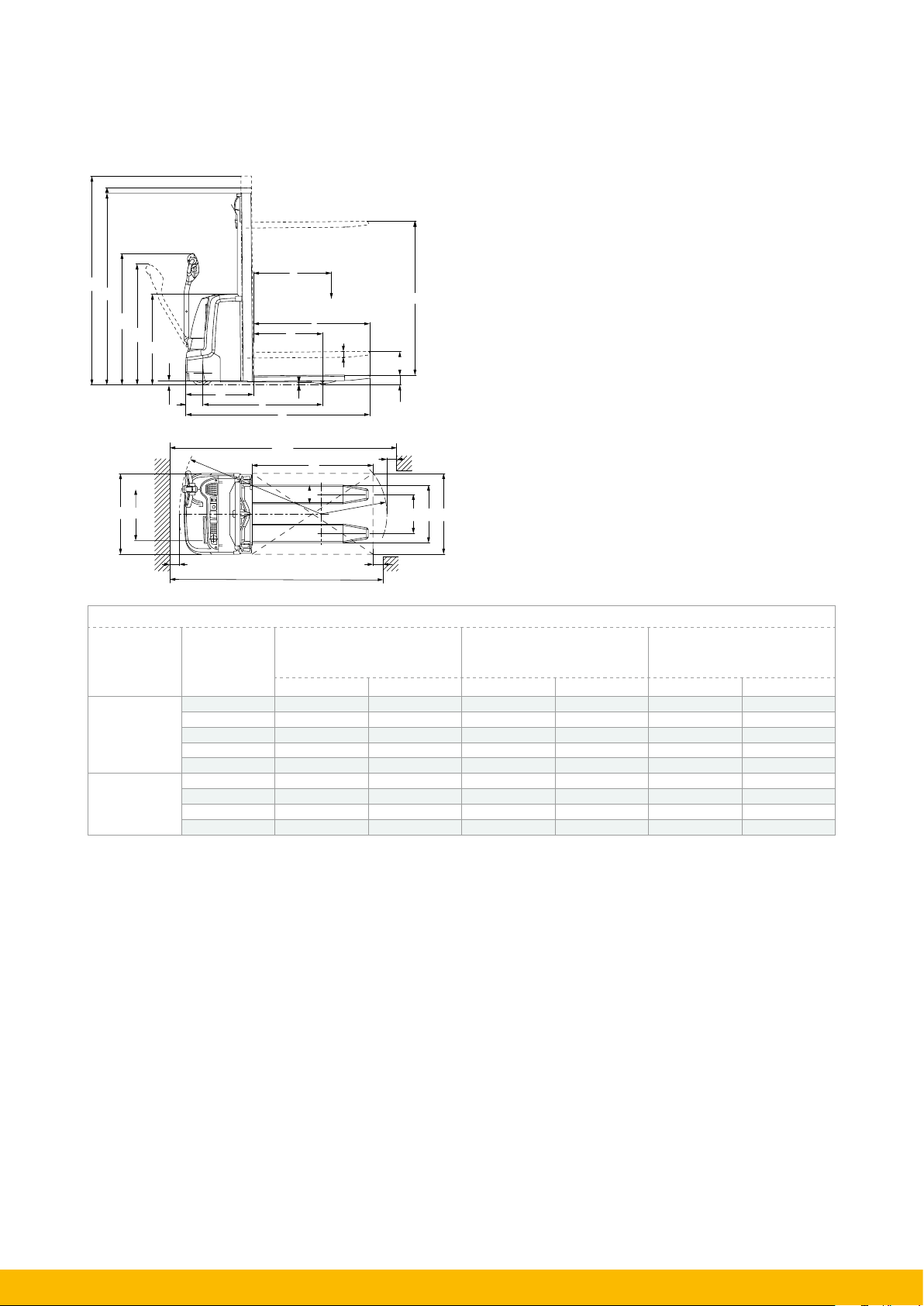

EJC 110/112

h₄

₂

h₁

h₁₄

max.

h₁₄

min.

900

35

c

Q

l

x

s

h₃

h₂

b₁₀

b₁

Duplex ZT

Duplex ZZ

1)

with 100 mm free lift

l₂

170

Wa

a

2

m₂

y

l₁

Ast

l₆

e

(Ast)

h₁₃

a

2

R

b₁₁b₅b₁

a

2

Standard mast types EJC 110/112

Lift

h

Lowered mast height

3

h

1

1)

Free lift

h

2

Extended mast height

(mm) (mm) (mm) (mm)

EJC 110 EJC 112 EJC 110 EJC 112 EJC 110 EJC 112

2500 1750 1750 100 100 2975 2975

2700 1850 1850 100 100 3175 3175

2900 1950 1950 100 100 3375 3375

3200 2100 2100 100 100 3675 3675

3600 2300 2300 100 100 4075 4075

2500 - 1700 - 1225 - 2975

2900 - 1900 - 1425 - 3375

3200 - 2050 - 1575 - 3675

3600 - 2250 - 1775 - 4075

h

4

Page 3

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EJC 110

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation pedestrian

1.5 Load capacity/rated load Q t 1 1.2

1.6 Load centre distance c mm 600

Identification

1.8 Load distance x mm 681 688

1.9 Wheelbase y mm 1184 1191

2.1.1 Net weight incl. battery (see row 6.5) kg 750 830

2.2 Axle load, w. load, front / rear kg 570 / 1180 650 / 1380

2.3 Axle load, w.o. load, front / rear kg 510 / 240 580 / 250

Weights

3.1 Tyres PU

3.2 Tyre size, at front mm Ø 230 x 70

3.3 Tyre size, at rear mm Ø 77 x 75 Ø 85 x 110

3.4 Additional wheels (dimensions) mm Ø 150 x 54 Ø 140 x 54

3.5 Wheels, number front/rear (× = driven wheels) 1x +1/2 4

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

mm 507

10

mm 415 400

11

4.2 Mast height (lowered) h1 mm 1950

4.2.1 Total height h15 mm

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.9 Height of tiller in drive position min. / max. h

4.15 Lowered height h

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

Basic dimensions

4.22 Fork dimensions s/e/l mm 56 / 185 / 1150

4.25 Width over forks b

4.32 Floor clearance centre wheelbase m

mm 100

2

mm 2900

3

mm 3375

4

mm 850 / 1305

14

mm 90

13

mm 1822

1

mm 672

2

mm 800

1/b2

mm 570

5

mm 30

2

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 2071

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2121

4.35 Turning radius Wa mm 1402 1409

5.1 Travel speed, w. / w.o. load km/h 6 / 6

5.2 Lift speed, w. / w.o. load m/s 0.12 / 0.22 0.13 / 0.22

5.3 Lower speed, w. / w.o. load m/s 0.33 / 0.33 0.43 / 0.37

data

5.8 Max. gradeability, laden/unladen % 8 / 16

Performance

5.10 Service brake generated

6.1 Drive motor rating S2 60 min. kW 1.0

6.2 Lift motor rating at S3 10% kW 1.7

6.2 Lift motor, output at S3 (on time) 12 % kW 2

6.3 Battery according to DIN 43531/35/36 A,B,C, no British Standard

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 200

Electrics

6.5 Battery weight kg 185

6.6 Energy consumption according to VDI cycle kWh/h 0.83 0.93

8.1 Type of drive control AC SpeedControl

8.4

Misc.

Sound pressure level at operator’s ear according to EN

12053

dB (A) 62

3)

2)

1)

Issue: 05/2012

3)

EJC 112

1)

Diagonal in accordance with VDI: + 137 mm

2)

Diagonal in accordance with VDI: + 212 mm

3)

Values for 290 ZT standard mast with battery

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Excellent view of the load for precise positioning

Good storage options for pens,

tools and documents

Innovative drive technology and

control

Our 3-phase AC motors oer improved

performance with lower running costs

thanks to linking with our electronic

controllers. Make the most of these advantages:

• High level of eciency with excellent

energy management.

• Powerful acceleration.

• Rapid direction change.

• Maintenance-free drive motor.

Manoeuvrable and compact

With its compact chassis, the EJC is ideal

for operating in confined areas. In addition you can continue working safely

by pressing the crawl speed button with

the tiller upright.

Precise and comfortable stacking and

retrieval

Loads can be stacked and retrieved safely

and eciently thanks to:

• Precise and gentle lifting of the load by

speed-controlled hydraulic motors.

The castor wheel is easy to replace,

lowering maintenance costs

• Gentle depositing of the load via

2-stage lowering speed (EJC 110)

and proportional hydraulics (EJC 112,

optional with EJC 110).

• Long safety tiller ensures sucient

distance between the operator and the

truck.

• Less noise produced with slow lifting

via lift control.

Practical storage areas

The EJC 110/112 provides excellent

storage space for the operator:

• Paper storage on the chassis cover.

• Extra storage areas next to control

panel.

• Clip board (combined with the optional

metal cover).

Service-friendly technology

• Service access ports on the front of the

chassis for fast tyre change.

• Wheel can be changed with the truck

only slightly raised by using the castor

wheel with a bayonet mechanism.

• Tiller electronics protected against

moisture and dirt with IP65 protection.

• Electronic controller and built-in

charger (optional) protected against

moisture and dirt with IP54 protection.

Long operating time

• Battery capacities up to 200 Ah ensure

a long operational life.

• Built-in charger (optional) for straightforward charging at any standard 13

Amp socket (also available with quick

charging function for charging during

a shift).

Additional equipment

• CanDis: Discharge indicator and hourmeter.

• CanCode: Access control via PIN.

• Load guard.

• Connection option e.g. for terminal,

scanner or printer.

• Special robust metal battery lid for

heavy-duty applications.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EJC 110/112_012014_en_UK_000

Loading...

Loading...