Jungheinrich EFG-Vac 30, EFG-Vac 25L, EFG-Vac 22, EFG-Vac 22-30, 25L Service Manual

...

Operating instructions

50116333

EFG-Vac 22-30 / 25L/S/SL

G

01.01-

12.03

0108.GB

Foreword

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide

sufficient instruction for the safe operation of the industrial truck. The information is

provided clearly and concisely. The chapters are arranged by letter. Each chapter

starts with page 1. The page identification consists of a chapter letter and a page

number.

For example: Page B 2 is the second page in chapter B.

The operating instructions detail different truck models. When operating and servicing

the truck, make sure that the instructions apply to your truck model.

Safety instructions and important explanations are indicated by the following

graphics:

f

Used before safety instructions which must be observed to avoid danger to

personnel.

m

Used before notices which must be observed to avoid material damage.

A

Used before notices and explanations.

t Used to indicate standard equipment.

o Used to indicate optional equipment.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to

alter the design, equipment and technical features of the truck. No guarantee of

particular features of the truck should therefore be inferred from the present operating

instructions.

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - GERMANY

Telephone: +49 (0) 40/6948-0

www.jungheinrich.com

0108.GB

Foreword

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide

sufficient instruction for the safe operation of the industrial truck. The information is

provided clearly and concisely. The chapters are arranged by letter. Each chapter

starts with page 1. The page identification consists of a chapter letter and a page

number.

For example: Page B 2 is the second page in chapter B.

The operating instructions detail different truck models. When operating and servicing

the truck, make sure that the instructions apply to your truck model.

Safety instructions and important explanations are indicated by the following

graphics:

f

Used before safety instructions which must be observed to avoid danger to

personnel.

m

Used before notices which must be observed to avoid material damage.

A

Used before notices and explanations.

t Used to indicate standard equipment.

o Used to indicate optional equipment.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to

alter the design, equipment and technical features of the truck. No guarantee of

particular features of the truck should therefore be inferred from the present operating

instructions.

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - GERMANY

Telephone: +49 (0) 40/6948-0

www.jungheinrich.com

0108.GB

0108.GB

I 1

5082973 - 50116333 GB

Table of contents

A Correct use and application of the truck

B Description of the truck

1 Design and application ........................................................................ B 1

2 Description of assembly groups and functions .................................... B 2

2.1 Truck ................................................................................................... B 3

3 Technical data - standard version ....................................................... B 4

3.1 Performance data ................................................................................ B 7

3.2 Weight (all weights in kg) .................................................................... B 8

3.3 Tyres ................................................................................................... B 8

3.4 Trailer loads ........................................................................................ B 8

3.5 EN standards ...................................................................................... B 9

3.6 Conditions for application .................................................................... B 9

4 Label positions and identification plates .............................................. B 10

4.1 Identification plate, truck ..................................................................... B 12

4.2 Truck load diagram ............................................................................. B 12

4.3 Fork arm load diagram (basic device) ................................................. B 13

4.4 Attachment load diagram .................................................................... B 13

C Transportation and commissioning

1 Transportation by crane ...................................................................... C 1

2 Commissioning .................................................................................... C 2

3 Moving the truck with the drive unit inoperative .................................. C 3

4 Towing the truck .................................................................................. C 3

D Battery - Servicing, recharging, replacement

1 Safety regulations governing the handling of lead-acid batteries ........ D 1

2 Battery types ....................................................................................... D 2

3 Opening the battery hood with support system (optional) ................... D 3

4 Exposing the battery ........................................................................... D 4

5 Charging the battery ............................................................................ D 5

6 Removing and installing the battery .................................................... D 6

7 Closing battery cover .......................................................................... D 7

8 Battery discharge indicator, exhaustive discharge protection

device, operating hour meter .............................................................. D 7

I 1

5082973 - 50116333 GB

Table of contents

A Correct use and application of the truck

B Description of the truck

1 Design and application ........................................................................ B 1

2 Description of assembly groups and functions .................................... B 2

2.1 Truck ................................................................................................... B 3

3 Technical data - standard version ....................................................... B 4

3.1 Performance data ................................................................................ B 7

3.2 Weight (all weights in kg) .................................................................... B 8

3.3 Tyres ................................................................................................... B 8

3.4 Trailer loads ........................................................................................ B 8

3.5 EN standards ...................................................................................... B 9

3.6 Conditions for application .................................................................... B 9

4 Label positions and identification plates .............................................. B 10

4.1 Identification plate, truck ..................................................................... B 12

4.2 Truck load diagram ............................................................................. B 12

4.3 Fork arm load diagram (basic device) ................................................. B 13

4.4 Attachment load diagram .................................................................... B 13

C Transportation and commissioning

1 Transportation by crane ...................................................................... C 1

2 Commissioning .................................................................................... C 2

3 Moving the truck with the drive unit inoperative .................................. C 3

4 Towing the truck .................................................................................. C 3

D Battery - Servicing, recharging, replacement

1 Safety regulations governing the handling of lead-acid batteries ........ D 1

2 Battery types ....................................................................................... D 2

3 Opening the battery hood with support system (optional) ................... D 3

4 Exposing the battery ........................................................................... D 4

5 Charging the battery ............................................................................ D 5

6 Removing and installing the battery .................................................... D 6

7 Closing battery cover .......................................................................... D 7

8 Battery discharge indicator, exhaustive discharge protection

device, operating hour meter .............................................................. D 7

5082973 - 50116333 GB

I 2

E Operation

1 Safety regulations governing the operation of the fork lift truck .......... E 1

2 Description of Operating and Display Elements .................................. E 2

2.1 Switch at instrument panel .................................................................. E 4

2.2 Switches at operating panel ................................................................ E 4

2.3 Multifunction display ............................................................................ E 5

3 Starting up the truck ............................................................................ E 8

3.1 Checks and operations to be performed before starting daily work .... E 8

3.2 Adjusting the driver seat ...................................................................... E 8

3.3 Safety restraint belt ............................................................................. E 10

3.4 Automatic/Mechanical Support System (optional) .............................. E 12

3.5 Adjusting the steering column ............................................................. E 14

3.6 Providing operational readiness .......................................................... E 14

4 Operation of the fork lift truck .............................................................. E 15

4.1 Safety regulations applicable when operating the truck ...................... E 15

4.2 Driving ................................................................................................. E 16

4.3 Steering ............................................................................................... E 19

4.4 Braking ................................................................................................ E 19

4.5 Operating the lifting unit and attachments (MULTIPILOT) .................. E 21

4.6 Operating the lifting equipment and attachments (SOLOPILOT) ........ E 23

4.7 Picking up, transporting, and putting down load units ......................... E 24

4.8 Safe parking of the truck ..................................................................... E 27

4.9 Trailer towing ....................................................................................... E 28

4.10 Trailer loads ........................................................................................ E 28

5 Troubleshooting .................................................................................. E 29

5082973 - 50116333 GB

I 2

E Operation

1 Safety regulations governing the operation of the fork lift truck .......... E 1

2 Description of Operating and Display Elements .................................. E 2

2.1 Switch at instrument panel .................................................................. E 4

2.2 Switches at operating panel ................................................................ E 4

2.3 Multifunction display ............................................................................ E 5

3 Starting up the truck ............................................................................ E 8

3.1 Checks and operations to be performed before starting daily work .... E 8

3.2 Adjusting the driver seat ...................................................................... E 8

3.3 Safety restraint belt ............................................................................. E 10

3.4 Automatic/Mechanical Support System (optional) .............................. E 12

3.5 Adjusting the steering column ............................................................. E 14

3.6 Providing operational readiness .......................................................... E 14

4 Operation of the fork lift truck .............................................................. E 15

4.1 Safety regulations applicable when operating the truck ...................... E 15

4.2 Driving ................................................................................................. E 16

4.3 Steering ............................................................................................... E 19

4.4 Braking ................................................................................................ E 19

4.5 Operating the lifting unit and attachments (MULTIPILOT) .................. E 21

4.6 Operating the lifting equipment and attachments (SOLOPILOT) ........ E 23

4.7 Picking up, transporting, and putting down load units ......................... E 24

4.8 Safe parking of the truck ..................................................................... E 27

4.9 Trailer towing ....................................................................................... E 28

4.10 Trailer loads ........................................................................................ E 28

5 Troubleshooting .................................................................................. E 29

I 3

5082973 - 50116333 GB

F Maintenance of the fork lift truck

1 Operational safety and environmental protection .................................F 1

2 Safety regulations applicable to truck maintenance .............................F 1

3 Servicing and inspection ......................................................................F 3

4 Maintenance checklist EFG-Vac ..........................................................F 4

5 Lubrication schedule EFG-Vac ............................................................F 6

5.1 Fuels, coolants and lubricants ..............................................................F 7

6 Description of servicing and maintenance operations ..........................F 8

6.1 Prepare truck for the servicing and maintenance operations ...............F 8

6.2 Check attachment of tyres ...................................................................F 8

6.3 Tyre pressure .......................................................................................F 8

6.4 Check hydraulic oil level .......................................................................F 9

6.5 Check transmission oil level .................................................................F 10

6.6 Draining oil ...........................................................................................F 10

6.7 Refilling oil ............................................................................................F 10

6.8 Changing the hydraulic filter .................................................................F 10

6.9 Changing the vacuum filter ..................................................................F 11

6.10 Check oil level for brake system ..........................................................F 11

6.11 Restrain safety belt service ..................................................................F 12

6.12 Checking the electric fuses ..................................................................F 13

6.13 Recommissioning after cleaning or maintenance operations ...............F 14

7 Decommissioning the fork lift truck ......................................................F 14

7.1 Operations to be performed prior to decommissioning ........................F 14

7.2 Measures to be taken during decommissioning ...................................F 14

7.3 Recommissioning the truck ..................................................................F 15

8 Safety checks to be performed at regular intervals and following any

untoward incidents (D: Accident prevention check according

to BGV D27) .........................................................................................F 15

I 3

5082973 - 50116333 GB

F Maintenance of the fork lift truck

1 Operational safety and environmental protection .................................F 1

2 Safety regulations applicable to truck maintenance .............................F 1

3 Servicing and inspection ......................................................................F 3

4 Maintenance checklist EFG-Vac ..........................................................F 4

5 Lubrication schedule EFG-Vac ............................................................F 6

5.1 Fuels, coolants and lubricants ..............................................................F 7

6 Description of servicing and maintenance operations ..........................F 8

6.1 Prepare truck for the servicing and maintenance operations ...............F 8

6.2 Check attachment of tyres ...................................................................F 8

6.3 Tyre pressure .......................................................................................F 8

6.4 Check hydraulic oil level .......................................................................F 9

6.5 Check transmission oil level .................................................................F 10

6.6 Draining oil ...........................................................................................F 10

6.7 Refilling oil ............................................................................................F 10

6.8 Changing the hydraulic filter .................................................................F 10

6.9 Changing the vacuum filter ..................................................................F 11

6.10 Check oil level for brake system ..........................................................F 11

6.11 Restrain safety belt service ..................................................................F 12

6.12 Checking the electric fuses ..................................................................F 13

6.13 Recommissioning after cleaning or maintenance operations ...............F 14

7 Decommissioning the fork lift truck ......................................................F 14

7.1 Operations to be performed prior to decommissioning ........................F 14

7.2 Measures to be taken during decommissioning ...................................F 14

7.3 Recommissioning the truck ..................................................................F 15

8 Safety checks to be performed at regular intervals and following any

untoward incidents (D: Accident prevention check according

to BGV D27) .........................................................................................F 15

5082973 - 50116333 GB

I 4

5082973 - 50116333 GB

I 4

A 1

5082973 - 50116333 GB

A Correct use and application of the truck

A

The „Guidelines for the Correct Use and Application of Industrial Trucks“ (VDMA) are

included in the scope of delivery for this truck. The guidelines are part of these

operating instructions and must always be heeded. National regulations are fully

applicable.

The fork-lift truck described in these operating instructions is a truck that is suitable

for lifting and transporting loads.

It must be used, operated and maintained according to the information in these

operating instructions. Any other uses are outside the design envelope and can lead

to injury to persons or damage to equipment and property. Above all, overloading

caused by excessively heavy or unbalanced loads must be avoided. The max.

admissible load to be picked up is indicated on the identification plate or load diagram

label shown on the truck. The operator must ensure that damaged and/or poorly

readable load diagrams are renewed. The fork-lift truck must not be operated in

spaces subject to fire or explosion hazards, or in spaces where corrosive or very

dusty atmospheres prevail.

Duties of the user: A „user“ within the meaning of these operating instructions is

defined as any natural or legal person who either uses the fork-lift truck himself, or on

whose behalf it is used. In special cases (e.g. leasing or renting), the user is

considered the person, who, in accordance with existing contractual agreements

between the owner and the user of the fork-lift truck, is charged with the observance

of the operating duties.

The user must ensure that the truck is not abused and only used within its design

limits and that all danger to life and limb of the operator, or third parties, is avoided.

In addition to this, it must be ensured that the relevant accident prevention regulations

and other safety-related provisions, as well as the operating, servicing and

maintenance guidelines, are observed. The user must also ensure that all persons

operating the truck have read and understood these operating instructions.

m

If these operating instructions are not observed the warranty becomes void. The

same applies if improper works are carried out at the device by the customer and/or

third parties without permission of our Customer Service.

Mounting of attachments: The mounting or installation of any attachments which

will interfere with, or supplement, the functions of the truck is permitted only after

written approval by the manufacturer has been obtained. If necessary, the approval

of local authorities has to be obtained.

Any approval obtained from local authorities does not, however, make the approval

by the manufacturer unnecessary.

Trailing and slipping loads: The truck may only be used for trailing or slipping loads

for which the truck has been approved.

A 1

5082973 - 50116333 GB

A Correct use and application of the truck

A

The „Guidelines for the Correct Use and Application of Industrial Trucks“ (VDMA) are

included in the scope of delivery for this truck. The guidelines are part of these

operating instructions and must always be heeded. National regulations are fully

applicable.

The fork-lift truck described in these operating instructions is a truck that is suitable

for lifting and transporting loads.

It must be used, operated and maintained according to the information in these

operating instructions. Any other uses are outside the design envelope and can lead

to injury to persons or damage to equipment and property. Above all, overloading

caused by excessively heavy or unbalanced loads must be avoided. The max.

admissible load to be picked up is indicated on the identification plate or load diagram

label shown on the truck. The operator must ensure that damaged and/or poorly

readable load diagrams are renewed. The fork-lift truck must not be operated in

spaces subject to fire or explosion hazards, or in spaces where corrosive or very

dusty atmospheres prevail.

Duties of the user: A „user“ within the meaning of these operating instructions is

defined as any natural or legal person who either uses the fork-lift truck himself, or on

whose behalf it is used. In special cases (e.g. leasing or renting), the user is

considered the person, who, in accordance with existing contractual agreements

between the owner and the user of the fork-lift truck, is charged with the observance

of the operating duties.

The user must ensure that the truck is not abused and only used within its design

limits and that all danger to life and limb of the operator, or third parties, is avoided.

In addition to this, it must be ensured that the relevant accident prevention regulations

and other safety-related provisions, as well as the operating, servicing and

maintenance guidelines, are observed. The user must also ensure that all persons

operating the truck have read and understood these operating instructions.

m

If these operating instructions are not observed the warranty becomes void. The

same applies if improper works are carried out at the device by the customer and/or

third parties without permission of our Customer Service.

Mounting of attachments: The mounting or installation of any attachments which

will interfere with, or supplement, the functions of the truck is permitted only after

written approval by the manufacturer has been obtained. If necessary, the approval

of local authorities has to be obtained.

Any approval obtained from local authorities does not, however, make the approval

by the manufacturer unnecessary.

Trailing and slipping loads: The truck may only be used for trailing or slipping loads

for which the truck has been approved.

5082973 - 50116333 GB

A 2

5082973 - 50116333 GB

A 2

B 1

5082973 - 50116333 GB

B Description of the truck

1 Design and application

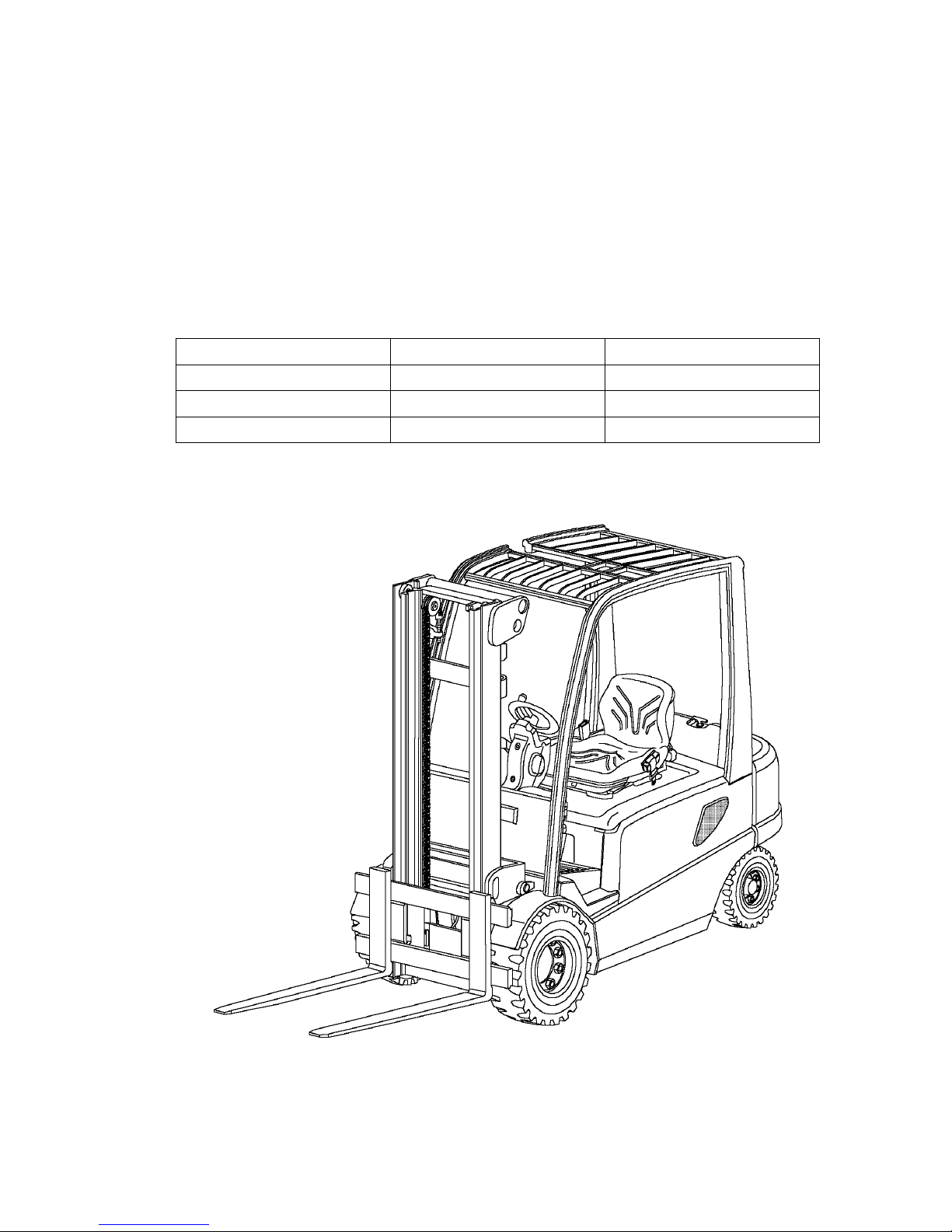

EFG-Vac is an electric rider-controlled fork lift truck in four-wheel construction with

front drive which picks up, transports, and lifts its load outside the wheelbase. It is a

cantilevered counterbalance truck which can – due to its load lifting device being

located in front of the lift truck – unload lorries and deliver the load on ramps or in

racks unimpededly. It can be used to stack and transport DIN 15142 pallets,

DIN 15144 lattice box pallet, and other palletised loads.

Truck types and maximum carrying capacity:

*) The load diagrams attached to the trucks are binding for the carrying capacity

Type max. carrying capacity *) Load centre

EFG-Vac 22 2,200 kg 500 mm

EFG-Vac 25 2,500 kg 500 mm

EFG-Vac 30 3,000 kg 500 mm

B 1

5082973 - 50116333 GB

B Description of the truck

1 Design and application

EFG-Vac is an electric rider-controlled fork lift truck in four-wheel construction with

front drive which picks up, transports, and lifts its load outside the wheelbase. It is a

cantilevered counterbalance truck which can – due to its load lifting device being

located in front of the lift truck – unload lorries and deliver the load on ramps or in

racks unimpededly. It can be used to stack and transport DIN 15142 pallets,

DIN 15144 lattice box pallet, and other palletised loads.

Truck types and maximum carrying capacity:

*) The load diagrams attached to the trucks are binding for the carrying capacity

Type max. carrying capacity *) Load centre

EFG-Vac 22 2,200 kg 500 mm

EFG-Vac 25 2,500 kg 500 mm

EFG-Vac 30 3,000 kg 500 mm

5082973 - 50116333 GB

B 2

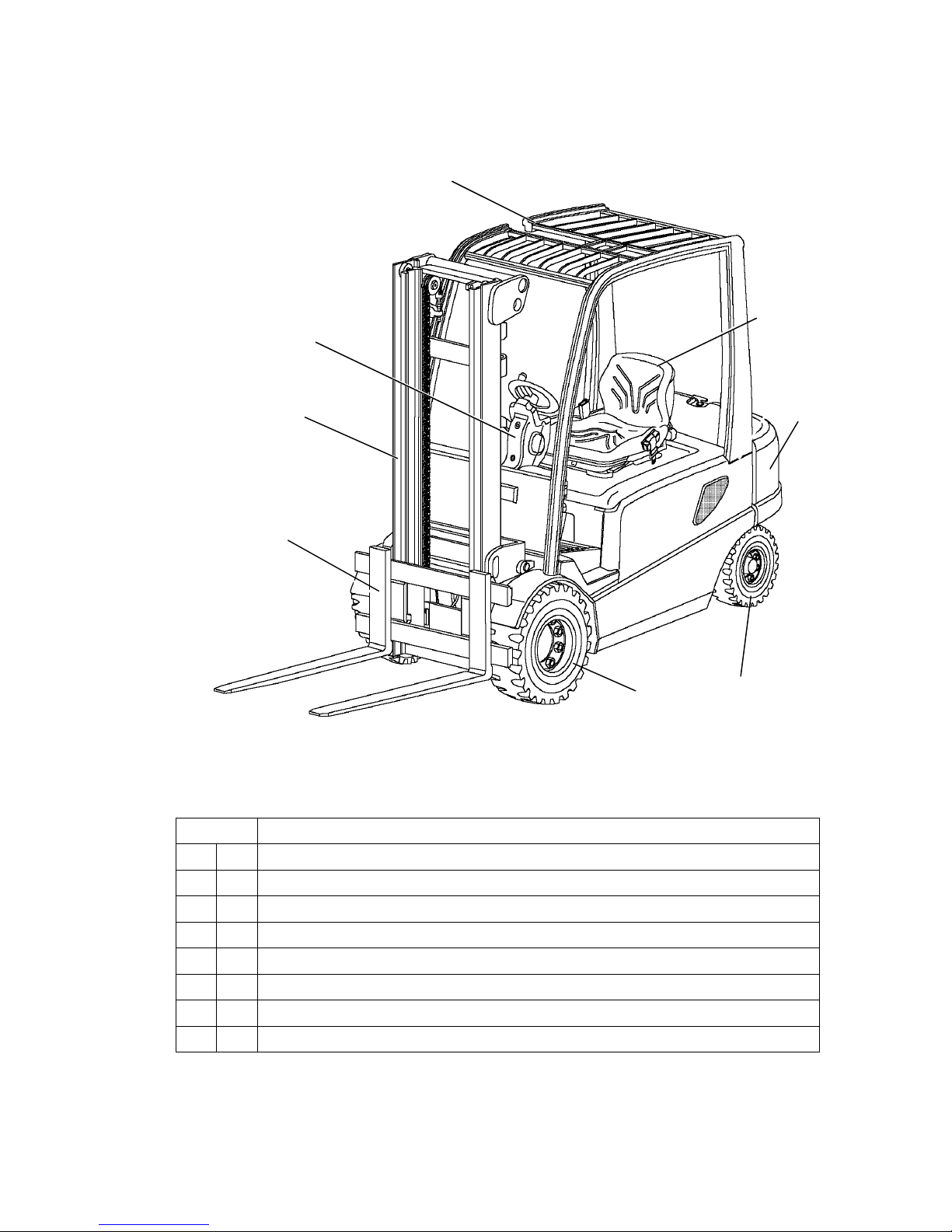

2 Description of assembly groups and functions

Item Designation

1 t Overhead guard

2 t Driver seat

3 t Counterweight

4 t Steering axle

5 t Drive axle

6 t Fork arm carriage

7 t Lifting mast

8 t Steering

1

2

3

4

5

6

7

8

5082973 - 50116333 GB

B 2

2 Description of assembly groups and functions

Item Designation

1 t Overhead guard

2 t Driver seat

3 t Counterweight

4 t Steering axle

5 t Drive axle

6 t Fork arm carriage

7 t Lifting mast

8 t Steering

1

2

3

4

5

6

7

8

B 3

5082973 - 50116333 GB

2.1 Truck

Steering (8): When a load is applied to the driver seat the steering is switched to

Standby. The steering unit runs at a preset idle speed. Depending on the steering

request the steering pump is increased and the travel speed is reduced depending on

the steering arc (“CurveControl”). The steering angle is indicated in the display.

Driver seat (2): The driver seat is a comfort seat and the steering column is

adjustable. There are storage places for documents or personal belongings of the

driver. The MULTI-PILOT combines all hydraulic functions and the travel direction

switch in one single lever. The overhead guard (1) is prepared for a cabin installation

and thus can be easily retrofitted.

Electric/electronic system: Sophisticated three-phase AC technology enables data

transfers with few cables only (CAN bus). Thus we achieve decreased susceptibility

to faults caused be broken cables as well as considerably faster fault isolation. The

complex TC system (Total Control) is designed for simply, safe, and flexible usage.

Depending on the load the driver can select from different operating programmes:

from high-performance to energy-saving. Convenient and very fast fault analysis and

programming can be performed via PC.

Drive and brake system: The front drive offers ideal traction to the drive wheels at

all times.

The hydraulically actuated oil-bath multi-disk brake used a service brake is practically

maintenance-free. The encapsulation in the transmission allows applications even in

aggressive environments. In addition, the lift truck is generatively braked via the travel

motor. Thus the energy consumption is minimised.

After approximately 15 sec standstill of the truck or 1 to 15 sec (adjustable) after the

driver seat is relieved the spring-loaded brake engages.

When actuating the accelerator the spring-loaded brake is automatically disengaged.

Hydraulic system: All functions must be executed sensitively, proportionally, and

simultaneously (only if this does not impair the safety). For higher efficiency a

hydraulic unit and a steering booster motor function separately from each other. The

micro pressure filter can be changed from the top (without spilling hydraulic oil).

Lifting mast (7): Our goal is optimising the view. The high-strength steel profiles are

narrow, which is especially notable in the three-stage lifting mast with its good view

to the fork arms. The same good results are achieved for the fork arm carriage.

The lifting mast as well as the fork arm carriage move on prelubricated and thus

maintenance-free cocked support rollers.

B 3

5082973 - 50116333 GB

2.1 Truck

Steering (8): When a load is applied to the driver seat the steering is switched to

Standby. The steering unit runs at a preset idle speed. Depending on the steering

request the steering pump is increased and the travel speed is reduced depending on

the steering arc (“CurveControl”). The steering angle is indicated in the display.

Driver seat (2): The driver seat is a comfort seat and the steering column is

adjustable. There are storage places for documents or personal belongings of the

driver. The MULTI-PILOT combines all hydraulic functions and the travel direction

switch in one single lever. The overhead guard (1) is prepared for a cabin installation

and thus can be easily retrofitted.

Electric/electronic system: Sophisticated three-phase AC technology enables data

transfers with few cables only (CAN bus). Thus we achieve decreased susceptibility

to faults caused be broken cables as well as considerably faster fault isolation. The

complex TC system (Total Control) is designed for simply, safe, and flexible usage.

Depending on the load the driver can select from different operating programmes:

from high-performance to energy-saving. Convenient and very fast fault analysis and

programming can be performed via PC.

Drive and brake system: The front drive offers ideal traction to the drive wheels at

all times.

The hydraulically actuated oil-bath multi-disk brake used a service brake is practically

maintenance-free. The encapsulation in the transmission allows applications even in

aggressive environments. In addition, the lift truck is generatively braked via the travel

motor. Thus the energy consumption is minimised.

After approximately 15 sec standstill of the truck or 1 to 15 sec (adjustable) after the

driver seat is relieved the spring-loaded brake engages.

When actuating the accelerator the spring-loaded brake is automatically disengaged.

Hydraulic system: All functions must be executed sensitively, proportionally, and

simultaneously (only if this does not impair the safety). For higher efficiency a

hydraulic unit and a steering booster motor function separately from each other. The

micro pressure filter can be changed from the top (without spilling hydraulic oil).

Lifting mast (7): Our goal is optimising the view. The high-strength steel profiles are

narrow, which is especially notable in the three-stage lifting mast with its good view

to the fork arms. The same good results are achieved for the fork arm carriage.

The lifting mast as well as the fork arm carriage move on prelubricated and thus

maintenance-free cocked support rollers.

5082973 - 50116333 GB

B 4

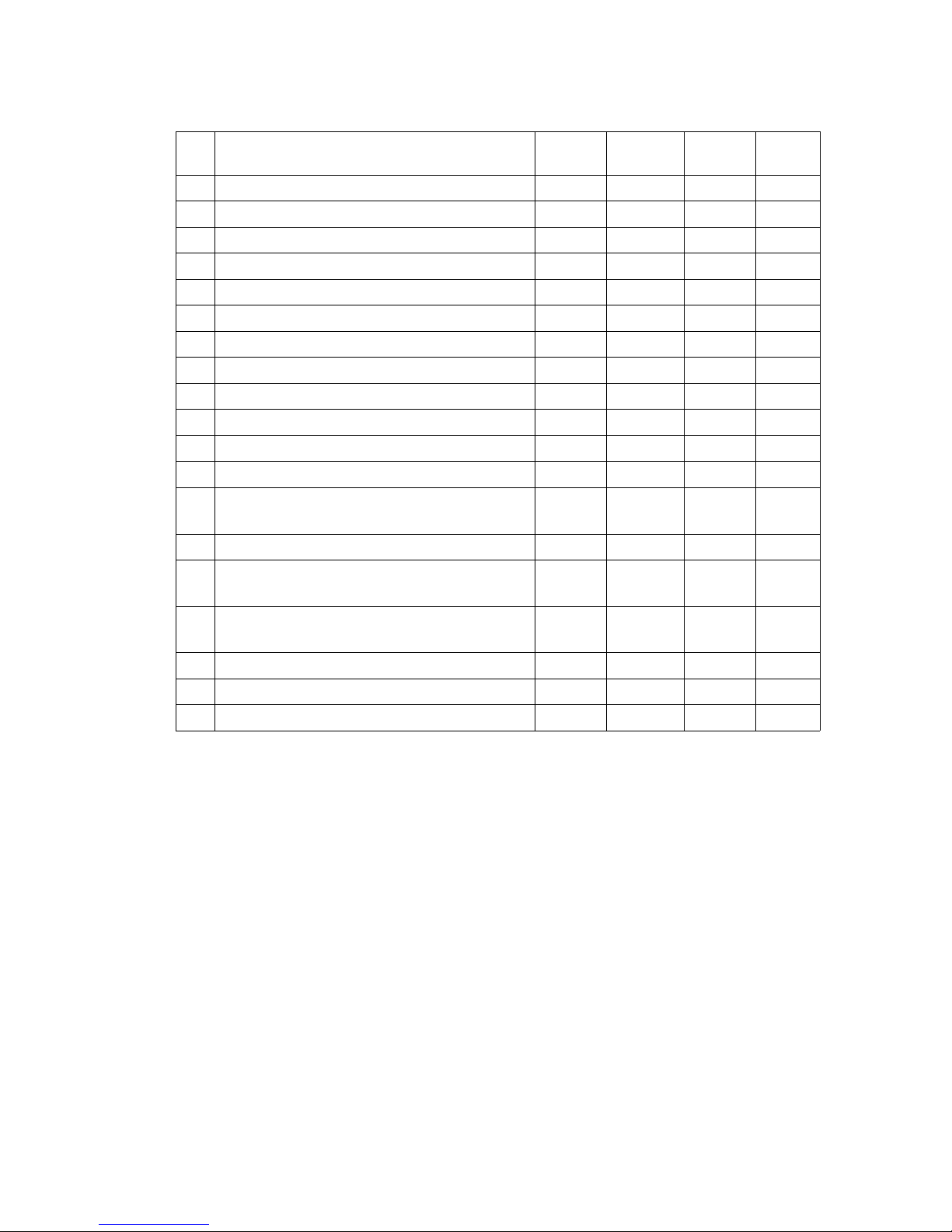

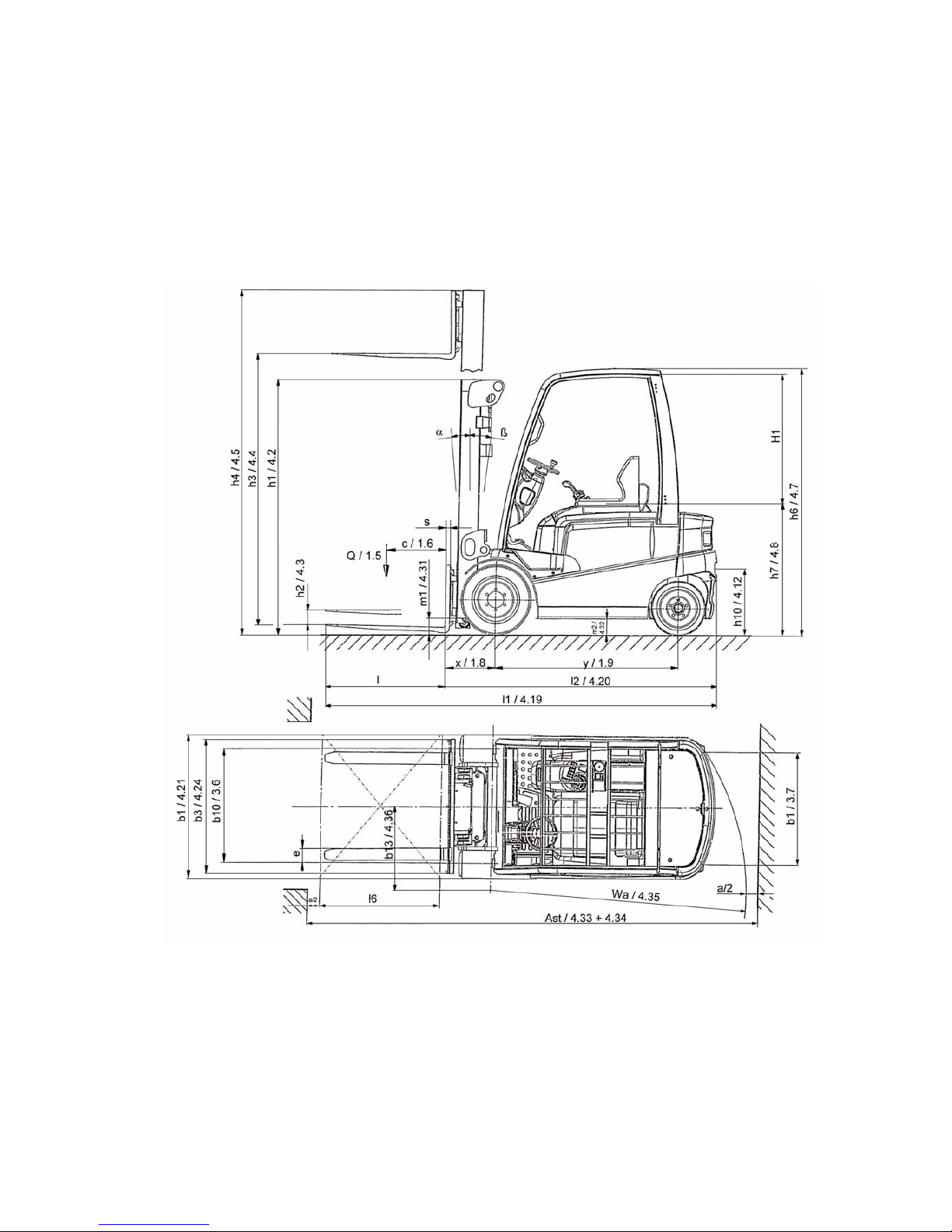

3 Technical data - standard version

1)

= +25 mm DZ mast

Designation

EFG-

Vac 22

EFG-

Vac 25

EFG-

Vac 25L

h1Height with mast retracted 2,200 2,200 2,200 mm

h

2

Free lift height 150 150 150 mm

h

3

Lift 3,100 3,100 3,100 mm

h

4

Height with mast extended 3,696 3,696 3,696 mm

h

6

Height above overhead guard 2,215 2,215 2215 mm

h

7

Seating height/standing height 1,060 1,060 1,060 mm

Seating room H1 1,105 1,105 1,105

h

10

Coupling height

390/

550

390/

550

390/

550

mm

L

1

Overall length including fork 3,428 3,428 3,572 mm

L2Length including fork back 2,278 2,278 2,422 mm

b1 Overall width 1,196 1,196 1,196 mm

b3 Width of fork arm carriage 1,120 1,120 1,120 mm

m1Ground clearance with load under lifting mast 110 110 110 mm

m2Ground clearance at centre of wheelbase 125 125 125 mm

Ast

Width of aisle

with pallets 800 × 1,200 lengthwise

3,875 3,875 4,025 mm

Ast

Width of aisle

with pallets 1,000 × 1,200 crossways

3,675 3,675 3,825 mm

W

a

Turning radius 2,050 2,050 2,200 mm

x Load distance 425

1)

425

1)

425

1)

mm

y Wheel-base 1,537 1,537 1,681 mm

5082973 - 50116333 GB

B 4

3 Technical data - standard version

1)

= +25 mm DZ mast

Designation

EFG-

Vac 22

EFG-

Vac 25

EFG-

Vac 25L

h1Height with mast retracted 2,200 2,200 2,200 mm

h

2

Free lift height 150 150 150 mm

h

3

Lift 3,100 3,100 3,100 mm

h

4

Height with mast extended 3,696 3,696 3,696 mm

h

6

Height above overhead guard 2,215 2,215 2215 mm

h

7

Seating height/standing height 1,060 1,060 1,060 mm

Seating room H1 1,105 1,105 1,105

h

10

Coupling height

390/

550

390/

550

390/

550

mm

L

1

Overall length including fork 3,428 3,428 3,572 mm

L2Length including fork back 2,278 2,278 2,422 mm

b1 Overall width 1,196 1,196 1,196 mm

b3 Width of fork arm carriage 1,120 1,120 1,120 mm

m1Ground clearance with load under lifting mast 110 110 110 mm

m2Ground clearance at centre of wheelbase 125 125 125 mm

Ast

Width of aisle

with pallets 800 × 1,200 lengthwise

3,875 3,875 4,025 mm

Ast

Width of aisle

with pallets 1,000 × 1,200 crossways

3,675 3,675 3,825 mm

W

a

Turning radius 2,050 2,050 2,200 mm

x Load distance 425

1)

425

1)

425

1)

mm

y Wheel-base 1,537 1,537 1,681 mm

B 5

5082973 - 50116333 GB

1)

= +25 mm DZ mast

Designation

EFG-

Vac 25S

EFG-Vac

25SL

EFG-

Vac 30

h1Height with mast retracted 2,200 2,200 2,200 mm

h

2

Free lift height 150 150 150 mm

h3Lift 3,100 3,100 3,100 mm

h4Height with lifting mast extended 3,696 3,696 3,806 mm

h

6

Height above overhead guard 2,215 2,215 2,215 mm

h7Seating height/standing height 1,060 1,060 1,060 mm

Seat clearanceH1 1,105 1,105 1,105

h

10

Coupling height 390/550 390/550 390/550 mm

L1Overall length including fork 3,428 3,572 3,577 mm

L2Overall length including fork back 2,278 2,422 2,427 mm

b1 Overall width 1,196 1,196 1,196 mm

b3 Width of fork arm carriage 1,120 1,120 1,120 mm

m

1

Ground clearance under lifting mast

with load

110 110 110 mm

m

2

Ground clearance at centre of wheelbase 125 125 125 mm

Ast

Width of aisle

with pallets 800 × 1,200 lengthwise

3,875 4,025 4,030 mm

Ast

Width of aisle

with pallets 1,000 × 1,200 crossways

3,675 3,825 3,830 mm

W

a

Turning radius 2,050 2,200 2,200 mm

x Load distance 425

1)

425

1)

430

1)

mm

y Wheel-base 1,537 1,681 1,681 mm

B 5

5082973 - 50116333 GB

1)

= +25 mm DZ mast

Designation

EFG-

Vac 25S

EFG-Vac

25SL

EFG-

Vac 30

h1Height with mast retracted 2,200 2,200 2,200 mm

h

2

Free lift height 150 150 150 mm

h3Lift 3,100 3,100 3,100 mm

h4Height with lifting mast extended 3,696 3,696 3,806 mm

h

6

Height above overhead guard 2,215 2,215 2,215 mm

h7Seating height/standing height 1,060 1,060 1,060 mm

Seat clearanceH1 1,105 1,105 1,105

h

10

Coupling height 390/550 390/550 390/550 mm

L1Overall length including fork 3,428 3,572 3,577 mm

L2Overall length including fork back 2,278 2,422 2,427 mm

b1 Overall width 1,196 1,196 1,196 mm

b3 Width of fork arm carriage 1,120 1,120 1,120 mm

m

1

Ground clearance under lifting mast

with load

110 110 110 mm

m

2

Ground clearance at centre of wheelbase 125 125 125 mm

Ast

Width of aisle

with pallets 800 × 1,200 lengthwise

3,875 4,025 4,030 mm

Ast

Width of aisle

with pallets 1,000 × 1,200 crossways

3,675 3,825 3,830 mm

W

a

Turning radius 2,050 2,200 2,200 mm

x Load distance 425

1)

425

1)

430

1)

mm

y Wheel-base 1,537 1,681 1,681 mm

5082973 - 50116333 GB

B 6

5082973 - 50116333 GB

B 6

B 7

5082973 - 50116333 GB

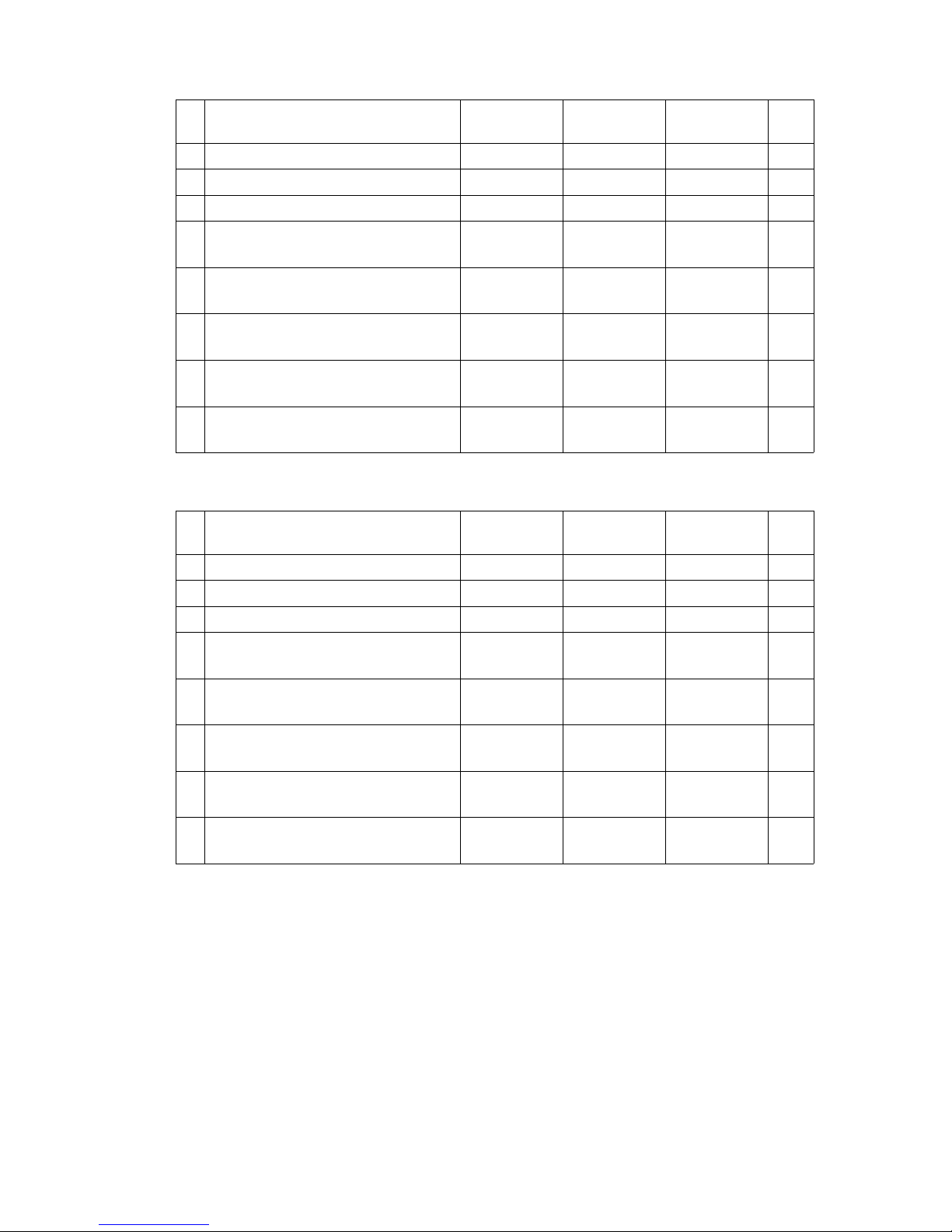

3.1 Performance data

Designation

EFG-Vac

22

EFG-Vac

25

EFG-Vac

25L

Q Carrying capacity/load 2.2 2.5 2.5 t

c Load centre 500 500 500 mm

Travel speed with/without load 17/18 17/18 17/17 km/h

Lifting speed

with/without load

0.46/0.54 0.44/0.54 0.44/0.54 m/s

Lowering speed

with/without load

0.58/0.56 0.58/0.56 0.58/0.56 m/s

Negotiable gradient

with/without load S2 30 min.

10/15 8.5/14 7.5/13 %

Max. negotiable gradient

with/without load S2 5 min.

20/31 18/29 17/27 %

Acceleration time

with/without load for 10 m

4.2/3.9 4.3/4,0 4.4/4.1 s

Designation

EFG-

Vac 25S

EFG-Vac

25SL

EFG-Vac

30

Q Carrying capacity/load 2.5 2.5 3.0 t

c Load centre 500 500 500 mm

Travel speed with/without load 20/20 20/20 20/20 km/h

Lifting speed

with/without load

0.55/0.60 0.55/0.60 0.50/0.60 m/s

Lowering speed

with/without load

0.58/0.56 0.58/0.56 0.58/0.56 m/s

Negotiable gradient

with/without load S2 30 min.

12/19 11/17 10/17 %

Max. negotiable gradient

with/without load S2 5 min.

21/35 20/32 18/29 %

Acceleration time

with/without load for 10 m

4.1/3.7 4.1/3.7 4.2/3.8 s

B 7

5082973 - 50116333 GB

3.1 Performance data

Designation

EFG-Vac

22

EFG-Vac

25

EFG-Vac

25L

Q Carrying capacity/load 2.2 2.5 2.5 t

c Load centre 500 500 500 mm

Travel speed with/without load 17/18 17/18 17/17 km/h

Lifting speed

with/without load

0.46/0.54 0.44/0.54 0.44/0.54 m/s

Lowering speed

with/without load

0.58/0.56 0.58/0.56 0.58/0.56 m/s

Negotiable gradient

with/without load S2 30 min.

10/15 8.5/14 7.5/13 %

Max. negotiable gradient

with/without load S2 5 min.

20/31 18/29 17/27 %

Acceleration time

with/without load for 10 m

4.2/3.9 4.3/4,0 4.4/4.1 s

Designation

EFG-

Vac 25S

EFG-Vac

25SL

EFG-Vac

30

Q Carrying capacity/load 2.5 2.5 3.0 t

c Load centre 500 500 500 mm

Travel speed with/without load 20/20 20/20 20/20 km/h

Lifting speed

with/without load

0.55/0.60 0.55/0.60 0.50/0.60 m/s

Lowering speed

with/without load

0.58/0.56 0.58/0.56 0.58/0.56 m/s

Negotiable gradient

with/without load S2 30 min.

12/19 11/17 10/17 %

Max. negotiable gradient

with/without load S2 5 min.

21/35 20/32 18/29 %

Acceleration time

with/without load for 10 m

4.1/3.7 4.1/3.7 4.2/3.8 s

5082973 - 50116333 GB

B 8

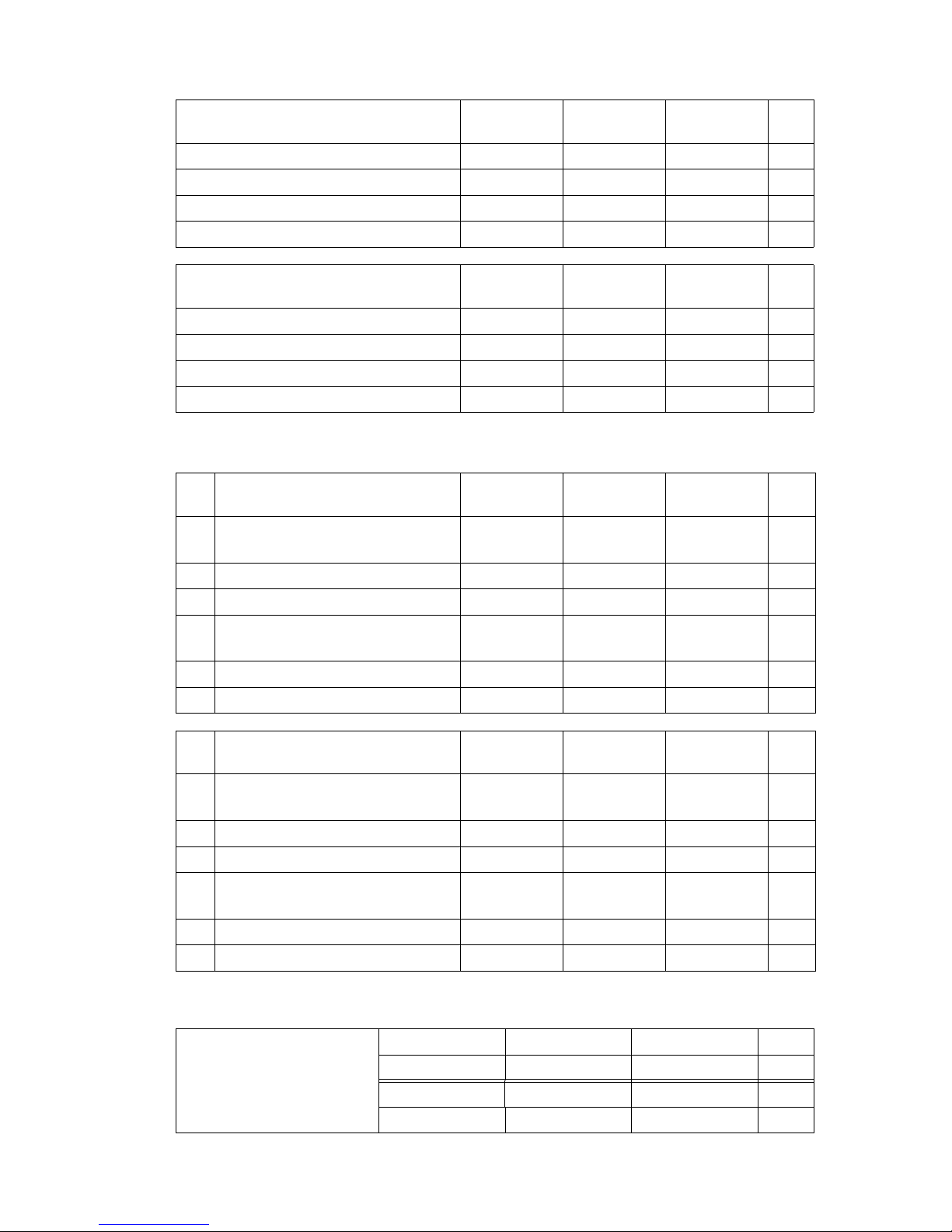

3.2 Weight (all weights in kg)

3.3 Tyres

3.4 Trailer loads

Designation

EFG-Vac

22

EFG-Vac

25

EFG-Vac

25L

Dead weight (incl. battery) 4,300 4,600 4,750 kg

Battery weight 1,558 1,558 1,872 kg

Load per axle with load front/rear 5,800/700 6,300/800 6,400/850 kg

Load per axle without load front/rear 2,300/2,000 2,300/2,300 2,530/2,220 kg

Designation

EFG-Vac

25 S

EFG-Vac

25 SL

EFG-Vac

30

Dead weight (incl. battery) 4,600 4,750 5,100 kg

Battery weight 1,558 1,872 1,872 kg

Load per axle with load front/rear 6,300/800 6,400/850 7,250/850 kg

Load per axle without load front/rear 2,300/2,300 2,530/2,220 2,600/2,500 kg

Designation

EFG-Vac

22

EFG-Vac

25

EFG-Vac

25L

Solid rubber tyres,

SE (= solid), air

Solid Solid Solid

Tyre size, front 23 x 9-10 23 x 9-10 23 x 9-10

Tyre size, rear 18 x 7-8 18 x 7-8 18 x 7-8

Number of wheels, front/rear

(x=driven)

2x / 2 2x / 2 2x / 2

b

10

Track, front 990 990 990 mm

b

11

Track, rear 920 920 920 mm

Designation

EFG-Vac

25S

EFG-Vac

25SL

EFG-Vac

30

Solid rubber tyres,

SE (= solid), air

Solid Solid Solid

Tyre size, front 23 x 9-10 23 x 9-10 23 x 10-12

Tyre size, rear 18 x 7-8 18 x 7-8 18 x 7-8

Number of wheels, front/rear

(x=driven)

2x / 2 2x / 2 2x / 2

b

10

Track, front 990 990 956 mm

b11Track, rear 920 920 920 mm

Max. permissible trailer

loads

EFG-Vac 22 EFG-Vac 25 EFG-Vac 25L

12,900 13,800 13,800 kg

EFG-Vac 25S EFG-Vac 25SL EFG-Vac 30

13,800 13,800 15,300 kg

5082973 - 50116333 GB

B 8

3.2 Weight (all weights in kg)

3.3 Tyres

3.4 Trailer loads

Designation

EFG-Vac

22

EFG-Vac

25

EFG-Vac

25L

Dead weight (incl. battery) 4,300 4,600 4,750 kg

Battery weight 1,558 1,558 1,872 kg

Load per axle with load front/rear 5,800/700 6,300/800 6,400/850 kg

Load per axle without load front/rear 2,300/2,000 2,300/2,300 2,530/2,220 kg

Designation

EFG-Vac

25 S

EFG-Vac

25 SL

EFG-Vac

30

Dead weight (incl. battery) 4,600 4,750 5,100 kg

Battery weight 1,558 1,872 1,872 kg

Load per axle with load front/rear 6,300/800 6,400/850 7,250/850 kg

Load per axle without load front/rear 2,300/2,300 2,530/2,220 2,600/2,500 kg

Designation

EFG-Vac

22

EFG-Vac

25

EFG-Vac

25L

Solid rubber tyres,

SE (= solid), air

Solid Solid Solid

Tyre size, front 23 x 9-10 23 x 9-10 23 x 9-10

Tyre size, rear 18 x 7-8 18 x 7-8 18 x 7-8

Number of wheels, front/rear

(x=driven)

2x / 2 2x / 2 2x / 2

b

10

Track, front 990 990 990 mm

b

11

Track, rear 920 920 920 mm

Designation

EFG-Vac

25S

EFG-Vac

25SL

EFG-Vac

30

Solid rubber tyres,

SE (= solid), air

Solid Solid Solid

Tyre size, front 23 x 9-10 23 x 9-10 23 x 10-12

Tyre size, rear 18 x 7-8 18 x 7-8 18 x 7-8

Number of wheels, front/rear

(x=driven)

2x / 2 2x / 2 2x / 2

b

10

Track, front 990 990 956 mm

b11Track, rear 920 920 920 mm

Max. permissible trailer

loads

EFG-Vac 22 EFG-Vac 25 EFG-Vac 25L

12,900 13,800 13,800 kg

EFG-Vac 25S EFG-Vac 25SL EFG-Vac 30

13,800 13,800 15,300 kg

B 9

5082973 - 50116333 GB

3.5 EN standards

Continuous sound pressure:

EFG-Vac 22/25/25L = 70 dB(A)

EFG-Vac 25S/25SL/30 = 71 dB(A)

according to EN 12053 as stipulated in ISO 4871

A

The continuous sound level is a value averaged according to standard regulations,

taking the sound pressure level into account when driving, lifting and idling. The

sound pressure level is measured at the ear.

Vibration: EFG-Vac 22-30 = aw,zS = 0.45 m/s

2

According to EN 13059

A

The swinging acceleration acting on the body in its operating position is, according to

standard regulations, the linear integrated, weighted acceleration in the vertical

plane. It is determined by driving over bumps with a constant speed.

Electromagnetic compatibility (EMC)

The manufacturer confirms compliance with the limit values for electromagnetic emission and interference immunity as well as testing of static electricity discharge according to EN 12895 and the references to other

standards contained therein.

A

Electrical or electronic components and their arrangement may only be modified after

written approval by the manufacturer has been obtained.

3.6 Conditions for application

Ambient temperature:

- during operation: -20°C to 40°C

A

Industrial trucks must be specially equipped and approved for continuous use in

environments with temperatures below 5°C or in cold stores respectively with

extreme temperatures or humidity changes.

B 9

5082973 - 50116333 GB

3.5 EN standards

Continuous sound pressure:

EFG-Vac 22/25/25L = 70 dB(A)

EFG-Vac 25S/25SL/30 = 71 dB(A)

according to EN 12053 as stipulated in ISO 4871

A

The continuous sound level is a value averaged according to standard regulations,

taking the sound pressure level into account when driving, lifting and idling. The

sound pressure level is measured at the ear.

Vibration: EFG-Vac 22-30 = aw,zS = 0.45 m/s

2

According to EN 13059

A

The swinging acceleration acting on the body in its operating position is, according to

standard regulations, the linear integrated, weighted acceleration in the vertical

plane. It is determined by driving over bumps with a constant speed.

Electromagnetic compatibility (EMC)

The manufacturer confirms compliance with the limit val-

ues for electromagnetic emission and interference immu-

nity as well as testing of static electricity discharge ac-

cording to EN 12895 and the references to other

standards contained therein.

A

Electrical or electronic components and their arrangement may only be modified after

written approval by the manufacturer has been obtained.

3.6 Conditions for application

Ambient temperature:

- during operation: -20°C to 40°C

A

Industrial trucks must be specially equipped and approved for continuous use in

environments with temperatures below 5°C or in cold stores respectively with

extreme temperatures or humidity changes.

5082973 - 50116333 GB

B 10

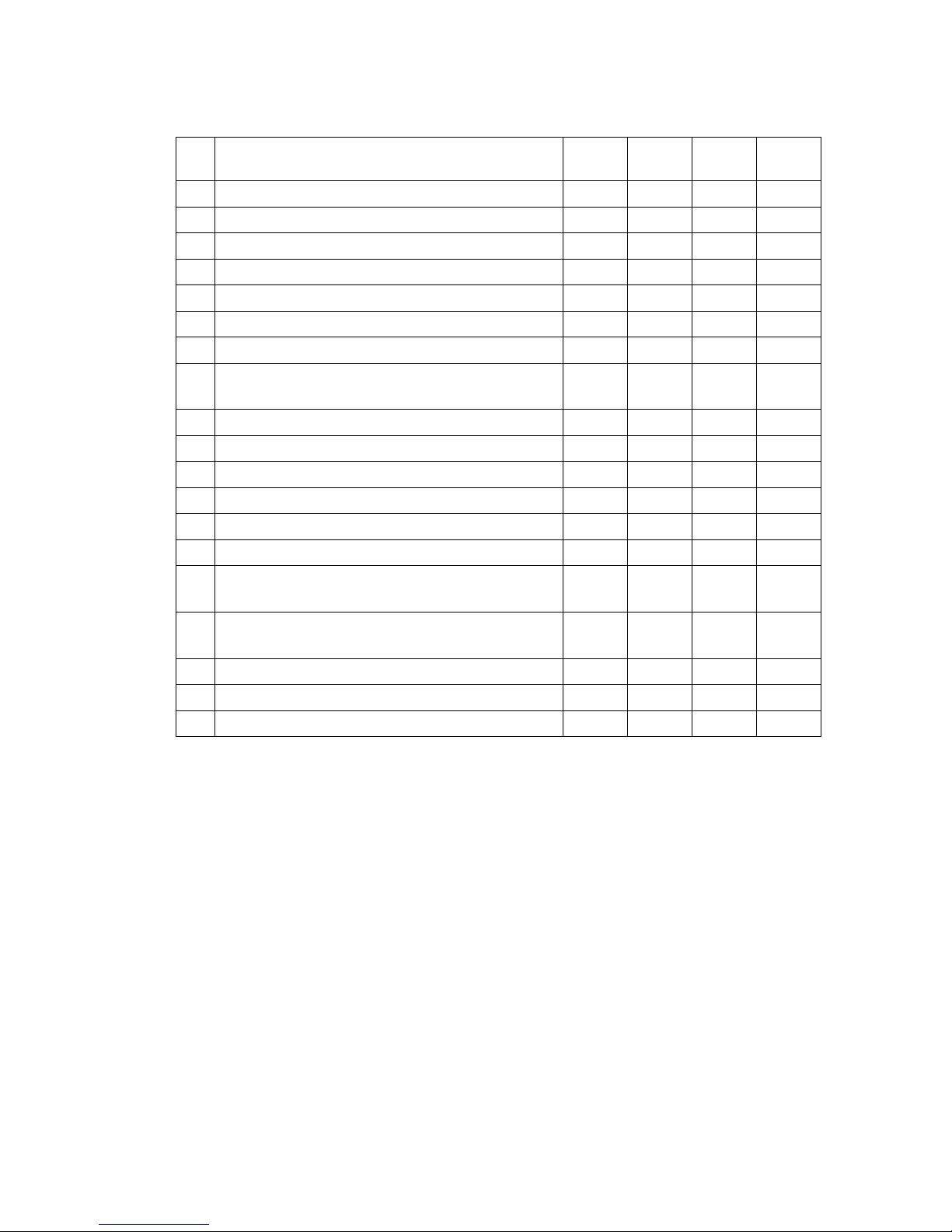

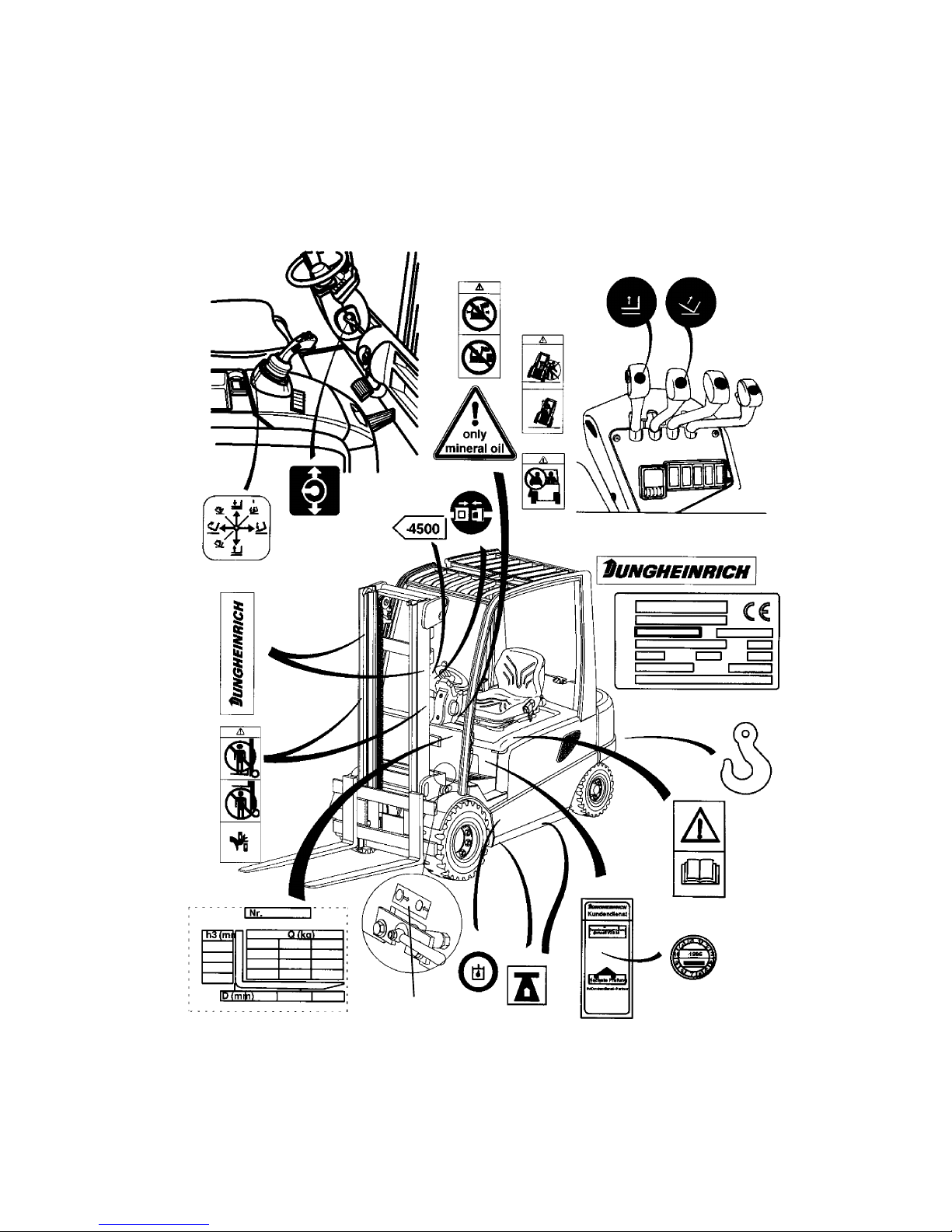

4 Label positions and identification plates

f

Warning and information labels such as load diagrams, sling points, and ID plates

must be readable at all times and must be renewed, if necessary.

2

3

4

1

5

6

7

8

9

10

11

12

13

20

21

18

17

16

15

21

19

14

4

5082973 - 50116333 GB

B 10

4 Label positions and identification plates

f

Warning and information labels such as load diagrams, sling points, and ID plates

must be readable at all times and must be renewed, if necessary.

2

3

4

1

5

6

7

8

9

10

11

12

13

20

21

18

17

16

15

21

19

14

4

B 11

5082973 - 50116333 GB

Item Designation

1 Label, sling points

2 Label, hydraulic functions (MULTI-PILOT)

3 Label, safety belt

4 Label, No passengers allowed

5 Label, observe operating instructions

6 Label, refill hydraulic oil

7 Label, capacity

8 Label, do not step on or under load, danger of crushing

9 Label, do not drive with elevated load, forward mast tilt with

elevated load prohibited

10 Label, warning when turning over

11 Label, lifting/lowering

12 Label, tilt forward/backward

13 Identification plate

14 Label, mineral oil

15 Label, spring-loaded brake

16 Label, lifting point

17 Accident prevention inspection label

18 Label, inspection plate

19 Label, lift limitation

20 Label, steering column adjustment

21 Label, Jungheinrich

B 11

5082973 - 50116333 GB

Item Designation

1 Label, sling points

2 Label, hydraulic functions (MULTI-PILOT)

3 Label, safety belt

4 Label, No passengers allowed

5 Label, observe operating instructions

6 Label, refill hydraulic oil

7 Label, capacity

8 Label, do not step on or under load, danger of crushing

9 Label, do not drive with elevated load, forward mast tilt with

elevated load prohibited

10 Label, warning when turning over

11 Label, lifting/lowering

12 Label, tilt forward/backward

13 Identification plate

14 Label, mineral oil

15 Label, spring-loaded brake

16 Label, lifting point

17 Accident prevention inspection label

18 Label, inspection plate

19 Label, lift limitation

20 Label, steering column adjustment

21 Label, Jungheinrich

5082973 - 50116333 GB

B 12

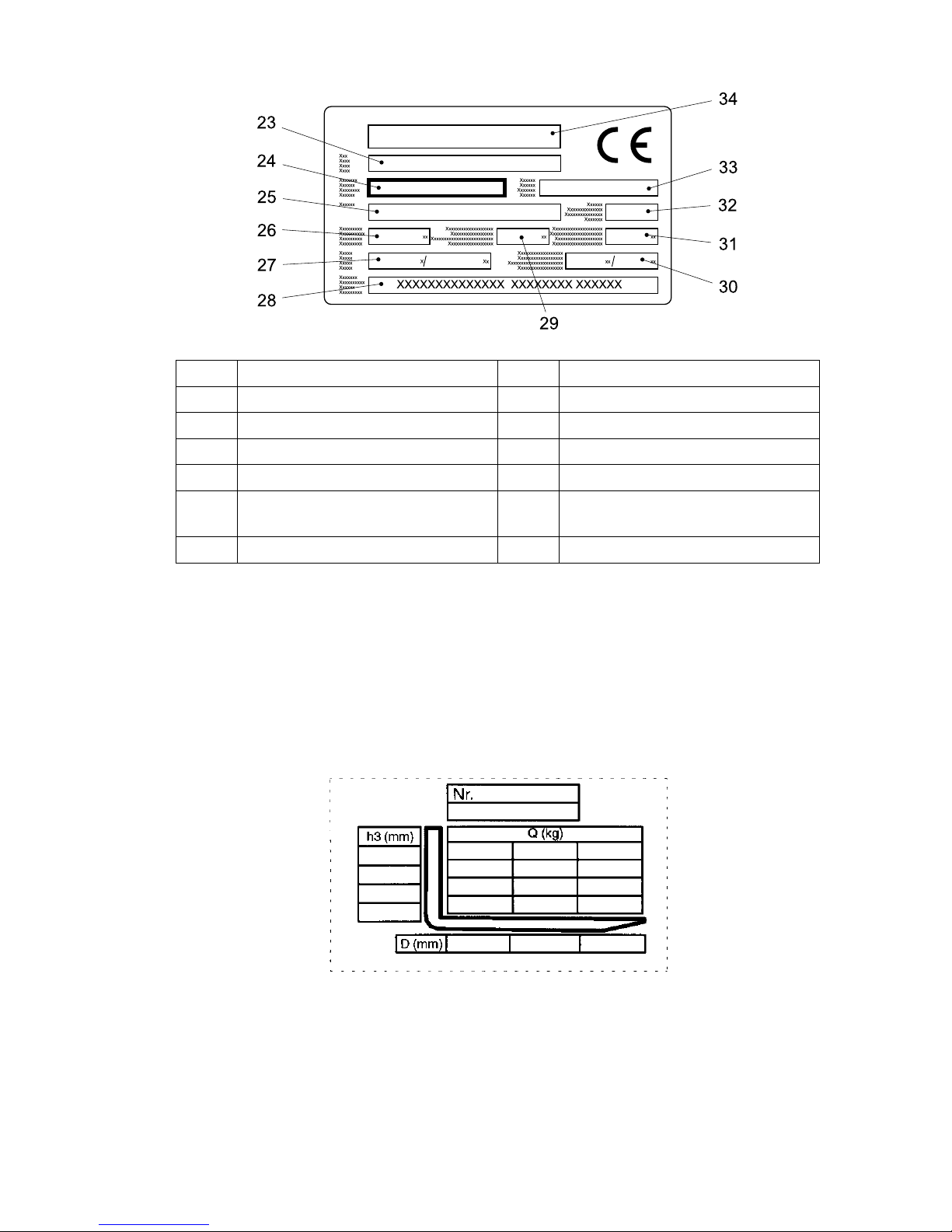

4.1 Identification plate, truck

A

In the event of queries relating to the truck or spare part orders, please state the serial

No. (24) of the truck.

4.2 Truck load diagram

The truck load diagram indicates the carrying capacity Q kg of the truck with the lifting

mast in vertical position. The table shows the maximum carrying capacity at a

standard load centre distance D (in mm) and the desired lifting height H (in mm).

Example for determining the maximum carrying capacity:

At a load centre distance of D = 600 mm and maximum lifting height H = 3,600 mm

the maximum carrying capacity Q = 1,105 kg.

Item Designation Item Designation

23 Type 29 Load centre distance in mm

24 Serial no. 30 Min./max. battery weight in kg

25 Order No. 31 Dead weight without battery in kg

26 Carrying capacity in kg 32 Year of manufacture

27 Battery: Voltage V

Ampere hours Ah

33 Type No.

28 Manufacturer 34 Manufacturer's logo

4,250

3,600

2,900

1,250 1,250

850

500

600 700

1,105

1,105

850

850

850

600

Example:

5082973 - 50116333 GB

B 12

4.1 Identification plate, truck

A

In the event of queries relating to the truck or spare part orders, please state the serial

No. (24) of the truck.

4.2 Truck load diagram

The truck load diagram indicates the carrying capacity Q kg of the truck with the lifting

mast in vertical position. The table shows the maximum carrying capacity at a

standard load centre distance D (in mm) and the desired lifting height H (in mm).

Example for determining the maximum carrying capacity:

At a load centre distance of D = 600 mm and maximum lifting height H = 3,600 mm

the maximum carrying capacity Q = 1,105 kg.

Item Designation Item Designation

23 Type 29 Load centre distance in mm

24 Serial no. 30 Min./max. battery weight in kg

25 Order No. 31 Dead weight without battery in kg

26 Carrying capacity in kg 32 Year of manufacture

27 Battery: Voltage V

Ampere hours Ah

33 Type No.

28 Manufacturer 34 Manufacturer's logo

4,250

3,600

2,900

1,250 1,250

850

500

600 700

1,105

1,105

850

850

850

600

Example:

B 13

5082973 - 50116333 GB

4.3 Fork arm load diagram (basic device)

The fork arm load diagram indicates the carrying capacity Q of the truck in kg. In the

diagram the maximum carrying capacity for different load centres D (in mm) is shown.

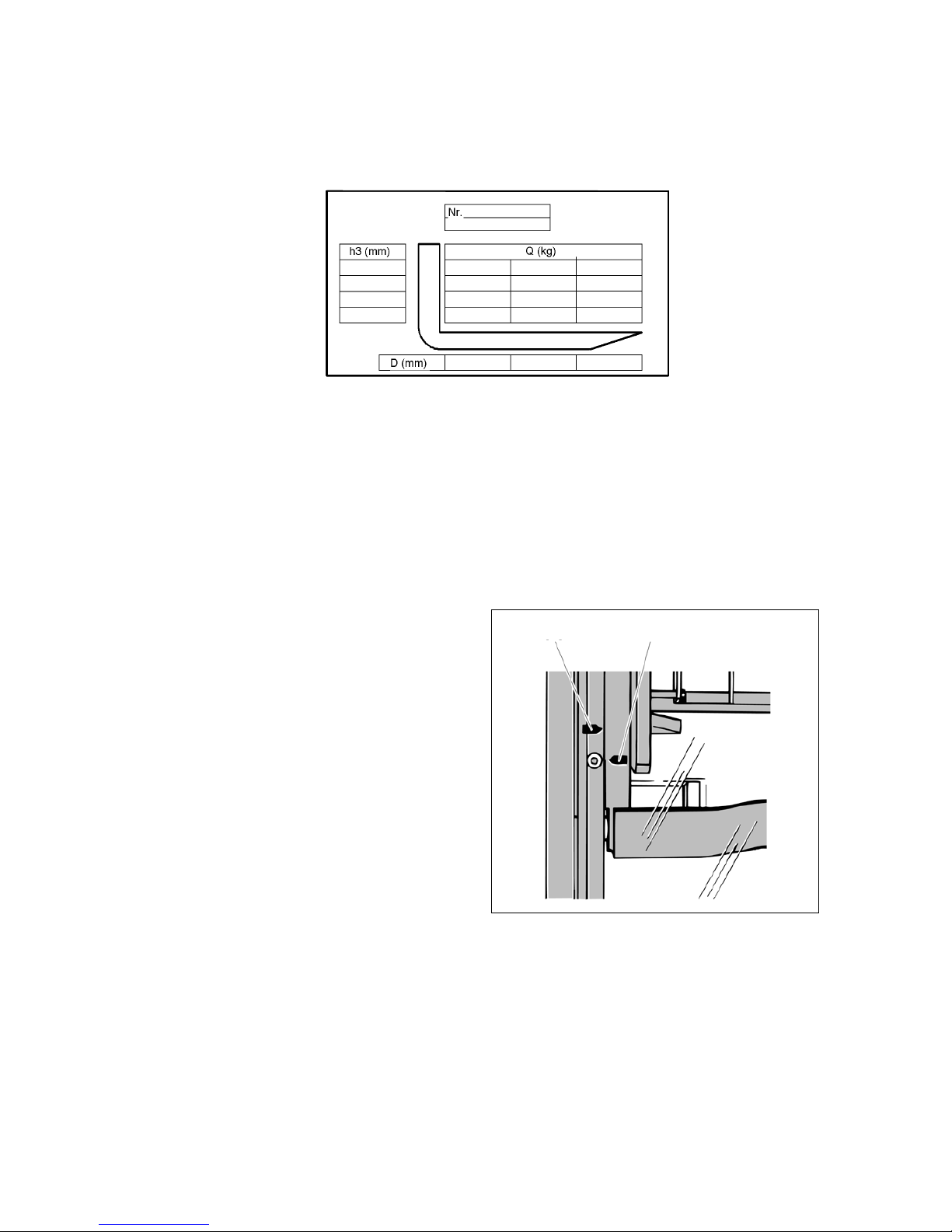

4.4 Attachment load diagram

The attachment load diagram indicates the carrying capacity Q of the truck in

connection with the respective attachment in kg. The attachment serial number

indicated in the load diagram must correspond to the ID plate of the attachment, since

the manufacturer must state the carrying capacity specially for each attachment. It is

indicated in the same way as the carrying capacity of the truck itself and must be

determined accordingly.

The arrow markings (46 and 47) at the

inner respectively outer mast indicate to

the driver that the lift limitations

prescribed in the load diagram have

been reached.

46 47

B 13

5082973 - 50116333 GB

4.3 Fork arm load diagram (basic device)

The fork arm load diagram indicates the carrying capacity Q of the truck in kg. In the

diagram the maximum carrying capacity for different load centres D (in mm) is shown.

4.4 Attachment load diagram

The attachment load diagram indicates the carrying capacity Q of the truck in

connection with the respective attachment in kg. The attachment serial number

indicated in the load diagram must correspond to the ID plate of the attachment, since

the manufacturer must state the carrying capacity specially for each attachment. It is

indicated in the same way as the carrying capacity of the truck itself and must be

determined accordingly.

The arrow markings (46 and 47) at the

inner respectively outer mast indicate to

the driver that the lift limitations

prescribed in the load diagram have

been reached.

46 47

5082973 - 50116333 GB

B 14

5082973 - 50116333 GB

B 14

C 1

5082973 - 50116333 GB

C Transportation and commissioning

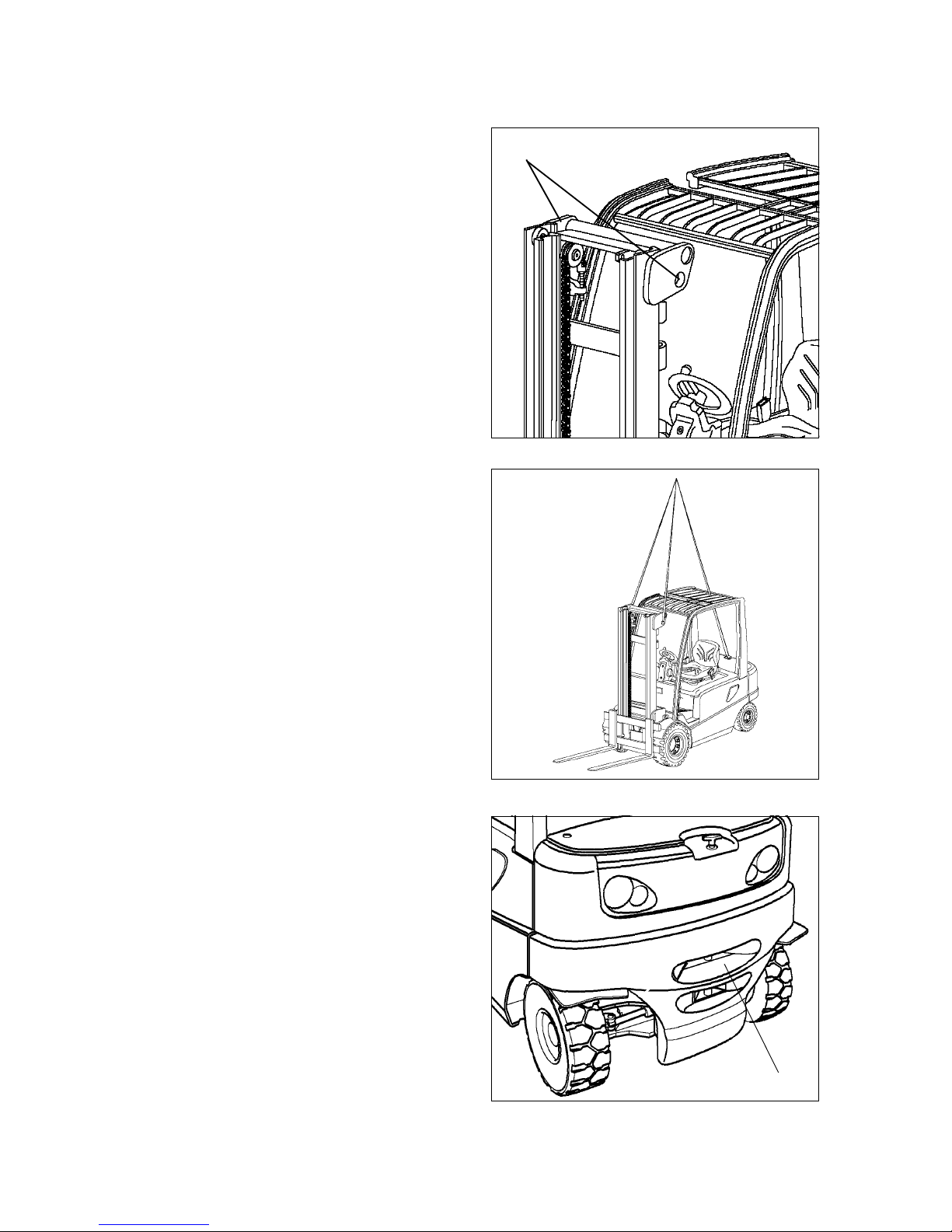

1 Transportation by crane

m

Only lifting gear of adequate capacity

must be used

(loading weight = own weight + battery

weight; see identification plate of the

truck).

– Safe parking of the truck

(refer to chapter E)

– Fasten hoisting gear at lifting mast

crossbeam (1) and at trailer coupling

(2).

m

Transporting by crane is only provided

for transport for first commissioning.

For application conditions that require

frequent shipment (changing usage

locations) it is required to consult the

manufacturer.

m

Hoisting belts or chains may only be

hooked into the top lug of the

counterweight and the lugs of the end

crosshead (lifting mast).

The lifting mast must be fully tilted back.

The hoisting belt or chain at the mast

must have a minimum free length of

2m.

m

The crane hoisting gear must be

attached in such a way that it cannot

touch any attached components or the

overhead guard during lifting.

1

2

C 1

5082973 - 50116333 GB

C Transportation and commissioning

1 Transportation by crane

m

Only lifting gear of adequate capacity

must be used

(loading weight = own weight + battery

weight; see identification plate of the

truck).

– Safe parking of the truck

(refer to chapter E)

– Fasten hoisting gear at lifting mast

crossbeam (1) and at trailer coupling

(2).

m

Transporting by crane is only provided

for transport for first commissioning.

For application conditions that require

frequent shipment (changing usage

locations) it is required to consult the

manufacturer.

m

Hoisting belts or chains may only be

hooked into the top lug of the

counterweight and the lugs of the end

crosshead (lifting mast).

The lifting mast must be fully tilted back.

The hoisting belt or chain at the mast

must have a minimum free length of

2m.

m

The crane hoisting gear must be

attached in such a way that it cannot

touch any attached components or the

overhead guard during lifting.

1

2

5082973 - 50116333 GB

C 2

2 Commissioning

f

Commissioning and instructing drivers may only be performed by appropriately

trained personnel. If several trucks are delivered, care must be taken that only load

carrying units, lifting masts, and basic truck with identical serial numbers are

assembled.

m

The truck must only be operated on

battery current. Rectified alternate

current will damage the electronics.

Cables connected to the battery (trailing

cables) must be less than 6 meters in

length.

In order to prepare the truck for work

following delivery or transportation, the

following operations must be performed:

– Check equipment for completeness.

– Check battery connections and acid

level (refer to chapter D, section 6).

– Check tightening torque of wheel nuts

(refer to chapter F, section 6.3).

– Bring the truck into service as

prescribed

(refer to chapter E, section 3).

5082973 - 50116333 GB

C 2

2 Commissioning

f

Commissioning and instructing drivers may only be performed by appropriately

trained personnel. If several trucks are delivered, care must be taken that only load

carrying units, lifting masts, and basic truck with identical serial numbers are

assembled.

m

The truck must only be operated on

battery current. Rectified alternate

current will damage the electronics.

Cables connected to the battery (trailing

cables) must be less than 6 meters in

length.

In order to prepare the truck for work

following delivery or transportation, the

following operations must be performed:

– Check equipment for completeness.

– Check battery connections and acid

level (refer to chapter D, section 6).

– Check tightening torque of wheel nuts

(refer to chapter F, section 6.3).

– Bring the truck into service as

prescribed

(refer to chapter E, section 3).

Loading...

Loading...