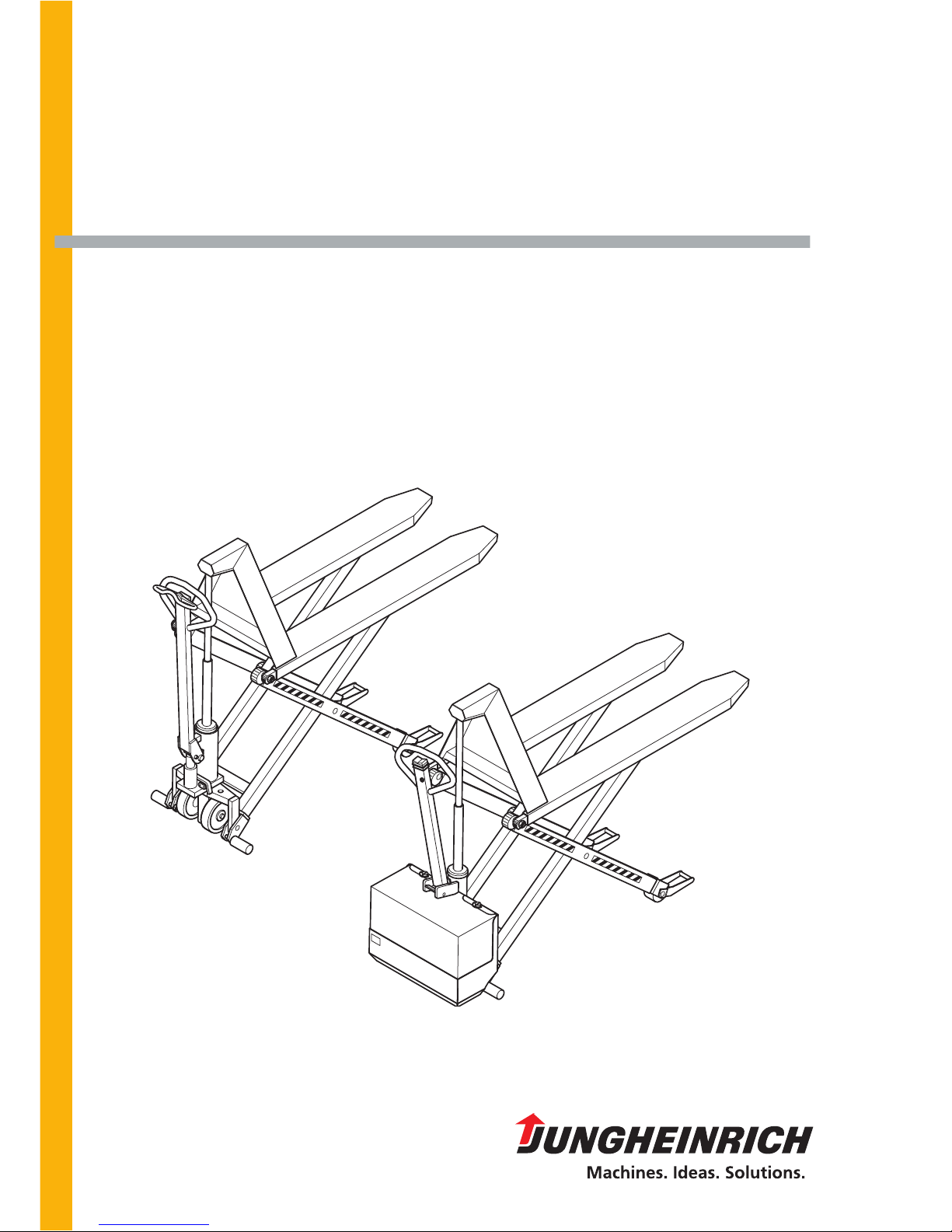

Jungheinrich AMX-E Inox, AMX Inox Pro Ex, AMX 10 Inox, AMX 10 Pro, AMX 10 Inox Pro Ex Operating Instructions Manual

...Page 1

Operating instructions

51021985

AMX/-E 10 INOX/INOX PRO

AMX 10 INOX PRO Ex

G

12.05 -

07.08

Page 2

0108.GB

Foreword

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide

sufficient instruction for the safe operation of the industrial truck. The information is

provided clearly and concisely. The chapters are arranged by letter. Each chapter

starts with page 1. The page identification consists of a chapter letter and a page

number.

For example: Page B 2 is the second page in chapter B.

The operating instructions detail different truck models. When operating and servicing

the truck, make sure that the instructions apply to your truck model.

Safety instructions and important explanations are indicated by the following

graphics:

F

Used before safety instructions which must be observed to avoid danger to

personnel.

M

Used before notices which must be observed to avoid material damage.

Z

Used before notices and explanations.

t Used to indicate standard equipment.

o Used to indicate optional equipment.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to

alter the design, equipment and technical features of the truck. No guarantee of

particular features of the truck should therefore be inferred from the present operating

instructions.

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - GERMANY

Telephone: +49 (0) 40/6948-0

www.jungheinrich.com

0108.GB

Foreword

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide

sufficient instruction for the safe operation of the industrial truck. The information is

provided clearly and concisely. The chapters are arranged by letter. Each chapter

starts with page 1. The page identification consists of a chapter letter and a page

number.

For example: Page B 2 is the second page in chapter B.

The operating instructions detail different truck models. When operating and servicing

the truck, make sure that the instructions apply to your truck model.

Safety instructions and important explanations are indicated by the following

graphics:

F

Used before safety instructions which must be observed to avoid danger to

personnel.

M

Used before notices which must be observed to avoid material damage.

Z

Used before notices and explanations.

t Used to indicate standard equipment.

o Used to indicate optional equipment.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to

alter the design, equipment and technical features of the truck. No guarantee of

particular features of the truck should therefore be inferred from the present operating

instructions.

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - GERMANY

Telephone: +49 (0) 40/6948-0

www.jungheinrich.com

Page 3

0108.GB

0108.GB

Page 4

I 1

0708.GB

Index

A Correct Application

B Truck Description

1 Application ........................................................................................... B 1

2 Materials .............................................................................................. B 1

3 Assemblies and Functional Description .............................................. B 2

4 Standard Version Specifications ......................................................... B 4

4.1 Performance data for standard trucks ................................................. B 4

4.2 Dimensions ......................................................................................... B 4

5 EN norms ............................................................................................ B 7

5.1 Conditions of use ................................................................................ B 7

6 Identification points and data plates .................................................... B 8

6.1 Data plate ........................................................................................... B 10

C Transport and Commissioning

1 Lifting by crane .................................................................................... C 1

2 Securing the truck during transport ..................................................... C 1

3 Using the truck for the first time .......................................................... C 2

D Battery Maintenance, Charging & Replacement

1 Safety regulations for handling acid batteries ..................................... D 1

2 Battery types ....................................................................................... D 2

3 Charging the Battery ........................................................................... D 2

4 Battery discharge indicator .................................................................. D 3

5 Battery Replacement ........................................................................... D 4

E Operation

1 Safety Regulations for the Operation of Forklift Trucks ...................... E 1

1.1 Additional clause to the safety regulations for operating

an explosion-proof industrial truck ( ) ............................................... E 2

2 Controls ............................................................................................. E 3

3 Starting up the truck ............................................................................ E 4

4 Industrial truck operation ..................................................................... E 5

4.1 Safety regulations for truck operation ................................................. E 5

4.2 Travel, Steering, Braking ..................................................................... E 6

4.3 Lifting and depositing loads ................................................................. E 7

4.4 Parking the truck securely ................................................................... E 8

5 Troubleshooting .................................................................................. E 9

I 1

0708.GB

Index

A Correct Application

B Truck Description

1 Application ........................................................................................... B 1

2 Materials .............................................................................................. B 1

3 Assemblies and Functional Description .............................................. B 2

4 Standard Version Specifications ......................................................... B 4

4.1 Performance data for standard trucks ................................................. B 4

4.2 Dimensions ......................................................................................... B 4

5 EN norms ............................................................................................ B 7

5.1 Conditions of use ................................................................................ B 7

6 Identification points and data plates .................................................... B 8

6.1 Data plate ........................................................................................... B 10

C Transport and Commissioning

1 Lifting by crane .................................................................................... C 1

2 Securing the truck during transport ..................................................... C 1

3 Using the truck for the first time .......................................................... C 2

D Battery Maintenance, Charging & Replacement

1 Safety regulations for handling acid batteries ..................................... D 1

2 Battery types ....................................................................................... D 2

3 Charging the Battery ........................................................................... D 2

4 Battery discharge indicator .................................................................. D 3

5 Battery Replacement ........................................................................... D 4

E Operation

1 Safety Regulations for the Operation of Forklift Trucks ...................... E 1

1.1 Additional clause to the safety regulations for operating

an explosion-proof industrial truck ( ) ............................................... E 2

2 Controls ............................................................................................. E 3

3 Starting up the truck ............................................................................ E 4

4 Industrial truck operation ..................................................................... E 5

4.1 Safety regulations for truck operation ................................................. E 5

4.2 Travel, Steering, Braking ..................................................................... E 6

4.3 Lifting and depositing loads ................................................................. E 7

4.4 Parking the truck securely ................................................................... E 8

5 Troubleshooting .................................................................................. E 9

Page 5

0708.GB

I 2

F Industrial Truck Maintenance

1 Operational safety and environmental protection ................................ F 1

2 Maintenance Safety Regulations ........................................................ F 1

3 Servicing and inspection ..................................................................... F 3

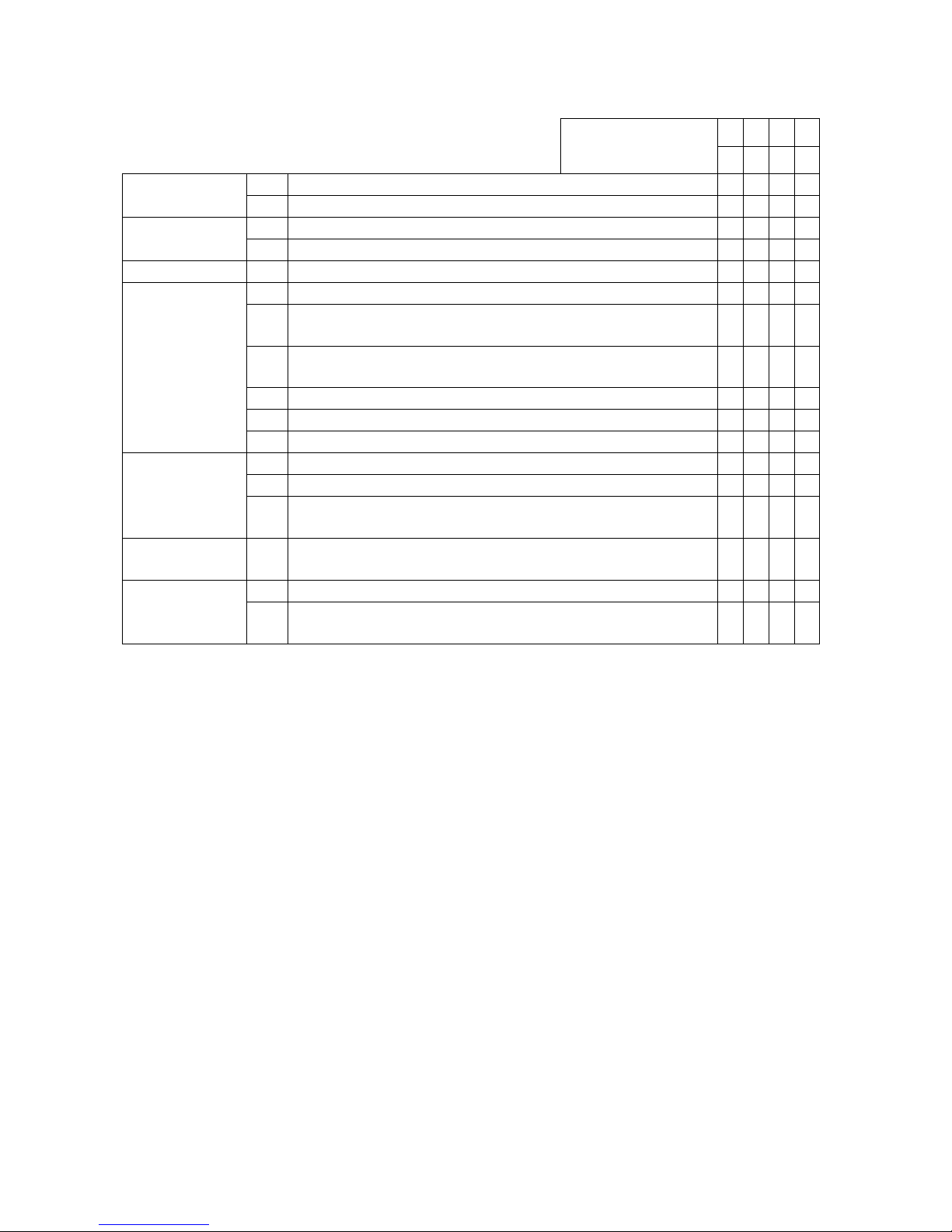

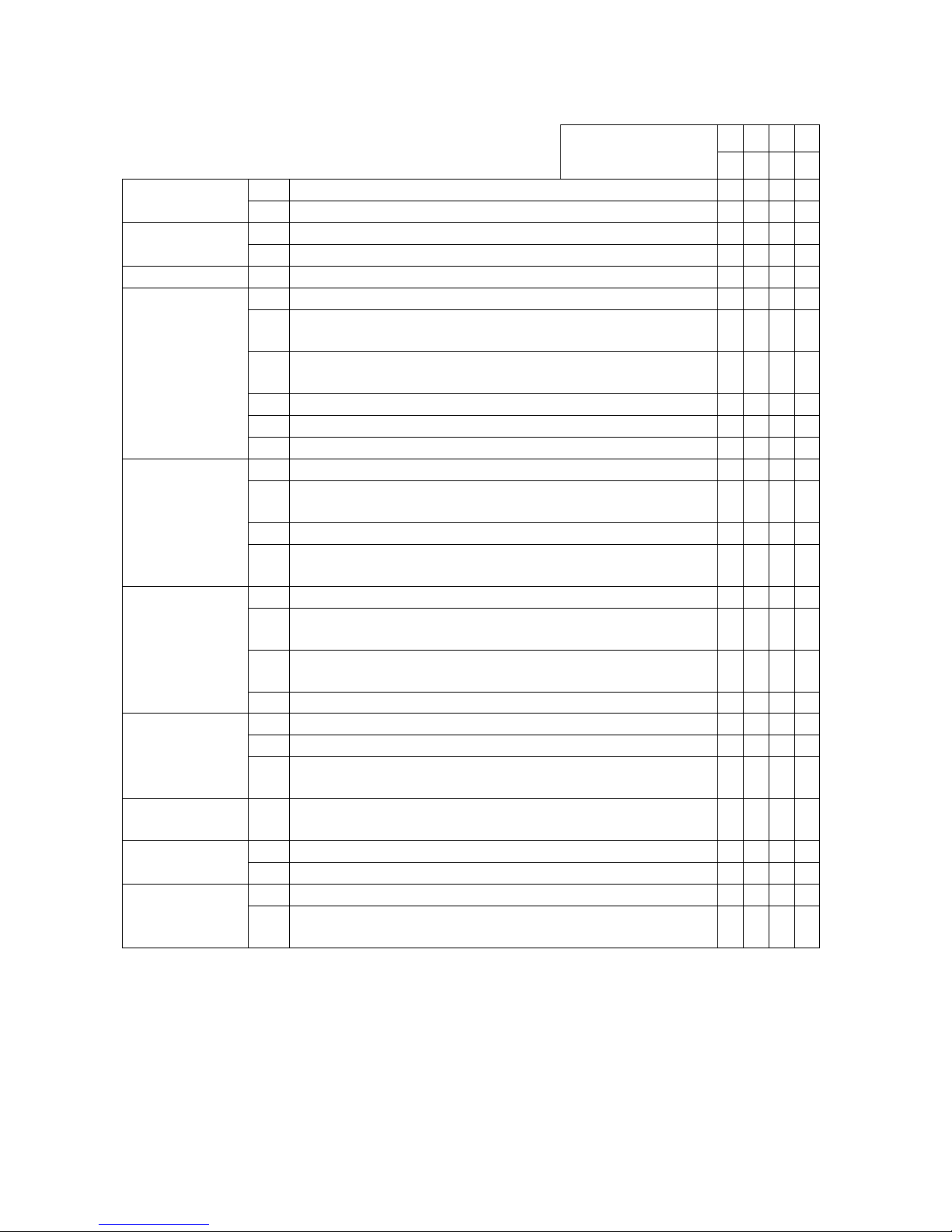

4 Maintenance Checklist AMX ............................................................... F 4

5 AMX-E Maintenance Checklist: ......................................................... F 5

6 Lubrication Schedule .......................................................................... F 6

6.1 Consumables ...................................................................................... F 7

7 Maintenance Instructions .................................................................... F 7

7.1 Preparing the truck for maintenance and repairs ................................ F 7

7.2 Replacing the Hydraulic Oil (AMX) ...................................................... F 8

7.3 Replacing the Hydraulic Oil (AMX-E) .................................................. F 8

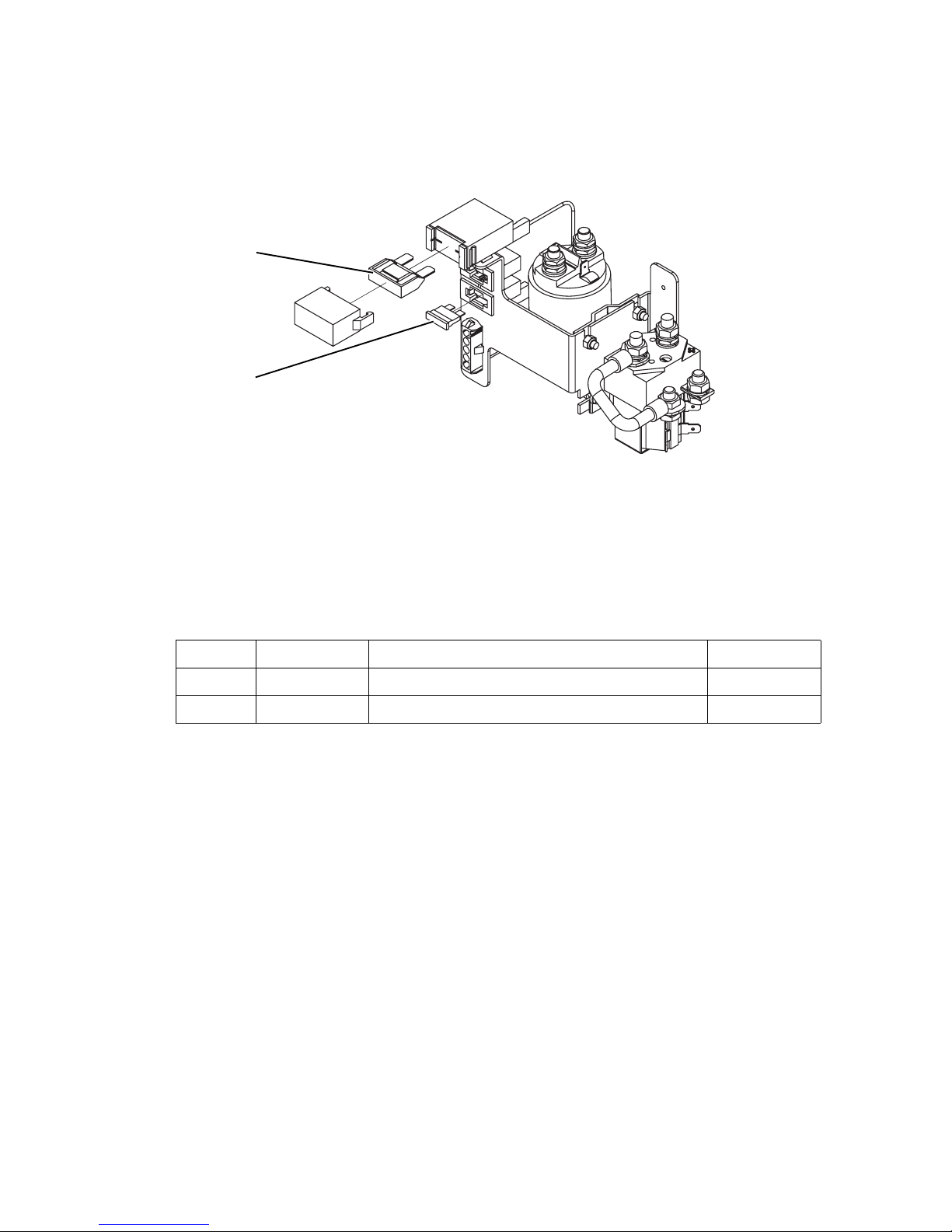

7.4 Checking electrical fuses .................................................................... F 9

7.5 Recommissioning ................................................................................ F 10

8 Decommissioning the industrial truck .................................................. F 10

8.1 Prior to decommissioning: ................................................................... F 10

8.2 Action to be taken while the truck is out of service (AMX-E only) ....... F 10

8.3 Returning the truck to operation after decommissioning ..................... F 11

9 Safety checks to be performed at regular intervals and following

any unusual incidents .......................................................................... F 12

10 Final de-commissioning, disposal ....................................................... F 12

0708.GB

I 2

F Industrial Truck Maintenance

1 Operational safety and environmental protection ................................ F 1

2 Maintenance Safety Regulations ........................................................ F 1

3 Servicing and inspection ..................................................................... F 3

4 Maintenance Checklist AMX ............................................................... F 4

5 AMX-E Maintenance Checklist: ......................................................... F 5

6 Lubrication Schedule .......................................................................... F 6

6.1 Consumables ...................................................................................... F 7

7 Maintenance Instructions .................................................................... F 7

7.1 Preparing the truck for maintenance and repairs ................................ F 7

7.2 Replacing the Hydraulic Oil (AMX) ...................................................... F 8

7.3 Replacing the Hydraulic Oil (AMX-E) .................................................. F 8

7.4 Checking electrical fuses .................................................................... F 9

7.5 Recommissioning ................................................................................ F 10

8 Decommissioning the industrial truck .................................................. F 10

8.1 Prior to decommissioning: ................................................................... F 10

8.2 Action to be taken while the truck is out of service (AMX-E only) ....... F 10

8.3 Returning the truck to operation after decommissioning ..................... F 11

9 Safety checks to be performed at regular intervals and following

any unusual incidents .......................................................................... F 12

10 Final de-commissioning, disposal ....................................................... F 12

Page 6

A 1

1205.GB

A Correct Application

Z

The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are

supplied with the truck. The guidelines form part of these operating instructions and

must be observed. National regulations apply in full.

The truck described in the present operator manual is an industrial truck designed for

lifting and transporting load units.

It must be used, operated and serviced in accordance with the present instructions.

All other types of use lie beyond the scope of application and can result in damage to

personnel, the truck or property. In particular, avoid overloading the truck with loads

which are too heavy or placed on one side. The data plate attached to the truck or the

load chart are binding for the maximum load capacity. The industrial truck must not

be used in fire or explosion endangered areas, or areas threatened by corrosion or

excessive dust.

Proprietor responsibilities: For the purposes of the present operator manual the

“proprietor” is defined as any natural or legal person who either uses the industrial

truck himself, or on whose behalf it is used. In special cases (e.g. leasing or renting)

the proprietor is considered the person who, in accordance with existing contractual

agreements between the owner and user of the industrial truck, is charged with

operational duties.

The proprietor must ensure that the truck is used only for the purpose it is intended

for and that danger to life and limb of the user and third parties are excluded.

Furthermore, accident prevention regulations, safety regulations and operating,

servicing and repair guidelines must be followed. The proprietor must ensure that all

truck users have read and understood this operator manual.

M

Failure to comply with the operator manual shall invalidate the warranty. The same

applies if improper work is carried out on the truck by the customer or third parties

without the permission of the manufacturer’s customer service department.

Attaching accessories: The mounting or installation of additional equipment which

affects or enhances the performance of the industrial truck requires the written

permission of the manufacturer. In some cases, local authority approval shall be

required.

Approval of the local authorities however does not constitute the manufacturer’s

approval.

A 1

1205.GB

A Correct Application

Z

The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are

supplied with the truck. The guidelines form part of these operating instructions and

must be observed. National regulations apply in full.

The truck described in the present operator manual is an industrial truck designed for

lifting and transporting load units.

It must be used, operated and serviced in accordance with the present instructions.

All other types of use lie beyond the scope of application and can result in damage to

personnel, the truck or property. In particular, avoid overloading the truck with loads

which are too heavy or placed on one side. The data plate attached to the truck or the

load chart are binding for the maximum load capacity. The industrial truck must not

be used in fire or explosion endangered areas, or areas threatened by corrosion or

excessive dust.

Proprietor responsibilities: For the purposes of the present operator manual the

“proprietor” is defined as any natural or legal person who either uses the industrial

truck himself, or on whose behalf it is used. In special cases (e.g. leasing or renting)

the proprietor is considered the person who, in accordance with existing contractual

agreements between the owner and user of the industrial truck, is charged with

operational duties.

The proprietor must ensure that the truck is used only for the purpose it is intended

for and that danger to life and limb of the user and third parties are excluded.

Furthermore, accident prevention regulations, safety regulations and operating,

servicing and repair guidelines must be followed. The proprietor must ensure that all

truck users have read and understood this operator manual.

M

Failure to comply with the operator manual shall invalidate the warranty. The same

applies if improper work is carried out on the truck by the customer or third parties

without the permission of the manufacturer’s customer service department.

Attaching accessories: The mounting or installation of additional equipment which

affects or enhances the performance of the industrial truck requires the written

permission of the manufacturer. In some cases, local authority approval shall be

required.

Approval of the local authorities however does not constitute the manufacturer’s

approval.

Page 7

1205.GB

A 2

1205.GB

A 2

Page 8

B 1

0708.GB

B Truck Description

1 Application

The AMX is a scissor lift pallet truck, designed for transporting goods on level

surfaces. Open bottom pallets can be lifted. The capacity of the truck is shown on the

data plate and on the data capacity plate Q

max

. The dimensions of the load forks are

calculated according to the type and number of pallets transported.

2Materials

1)

AMX-E Inox Pro

2)

AMX Inox Pro/Inox Pro Ex

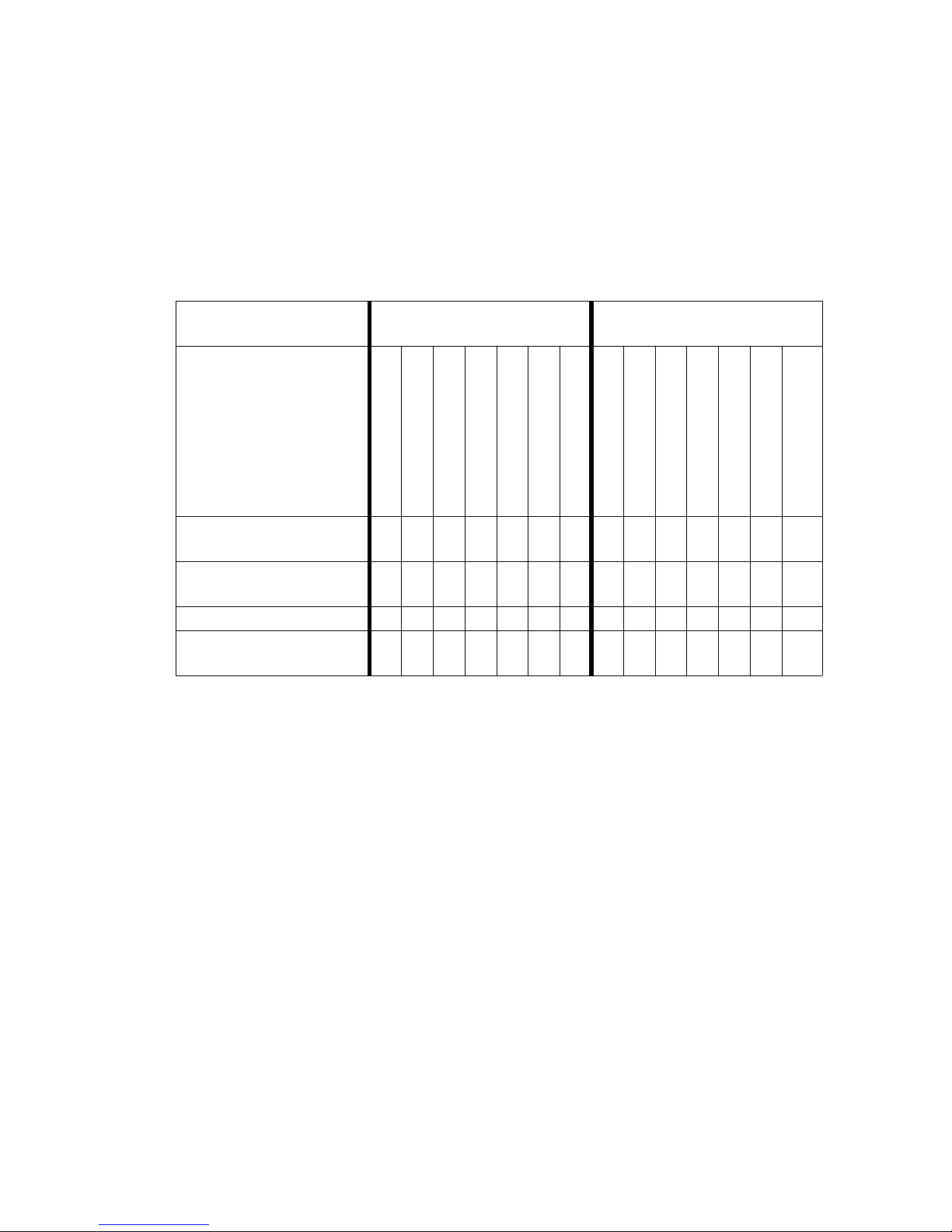

Material Comparison AMX/AMX-E Inox AMX/AMX-E Inox Pro

AMX Inox Pro Ex

Rahmen

Control handle

Axle

Outrigger lever

Yoke/Reversing lever

Plunger rod

Pump

Rahmen

Control handle

Axle

Outrigger lever

Yoke/Reversing lever

Plunger rod

Pump

Acid resistant steel

(AISI 316)

tt

Stainless steel

(AISI 303/304)

ttt tttttt

1)

Hot galvanized tt

Electro-galvanized +

yellow chromate

tt

2)

B 1

0708.GB

B Truck Description

1 Application

The AMX is a scissor lift pallet truck, designed for transporting goods on level

surfaces. Open bottom pallets can be lifted. The capacity of the truck is shown on the

data plate and on the data capacity plate Q

max

. The dimensions of the load forks are

calculated according to the type and number of pallets transported.

2Materials

1)

AMX-E Inox Pro

2)

AMX Inox Pro/Inox Pro Ex

Material Comparison AMX/AMX-E Inox AMX/AMX-E Inox Pro

AMX Inox Pro Ex

Rahmen

Control handle

Axle

Outrigger lever

Yoke/Reversing lever

Plunger rod

Pump

Rahmen

Control handle

Axle

Outrigger lever

Yoke/Reversing lever

Plunger rod

Pump

Acid resistant steel

(AISI 316)

tt

Stainless steel

(AISI 303/304)

ttt tttttt

1)

Hot galvanized tt

Electro-galvanized +

yellow chromate

tt

2)

Page 9

0708.GB

B 2

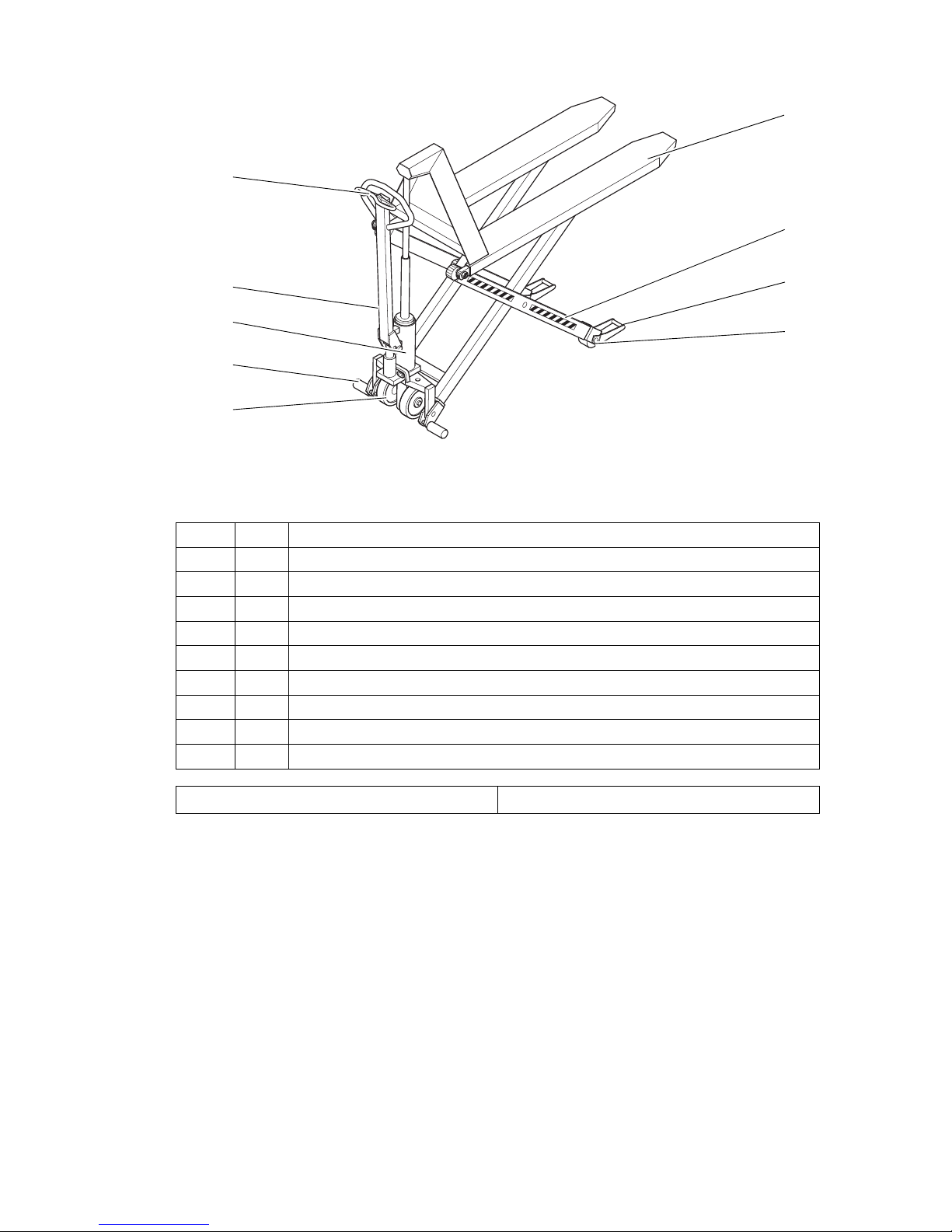

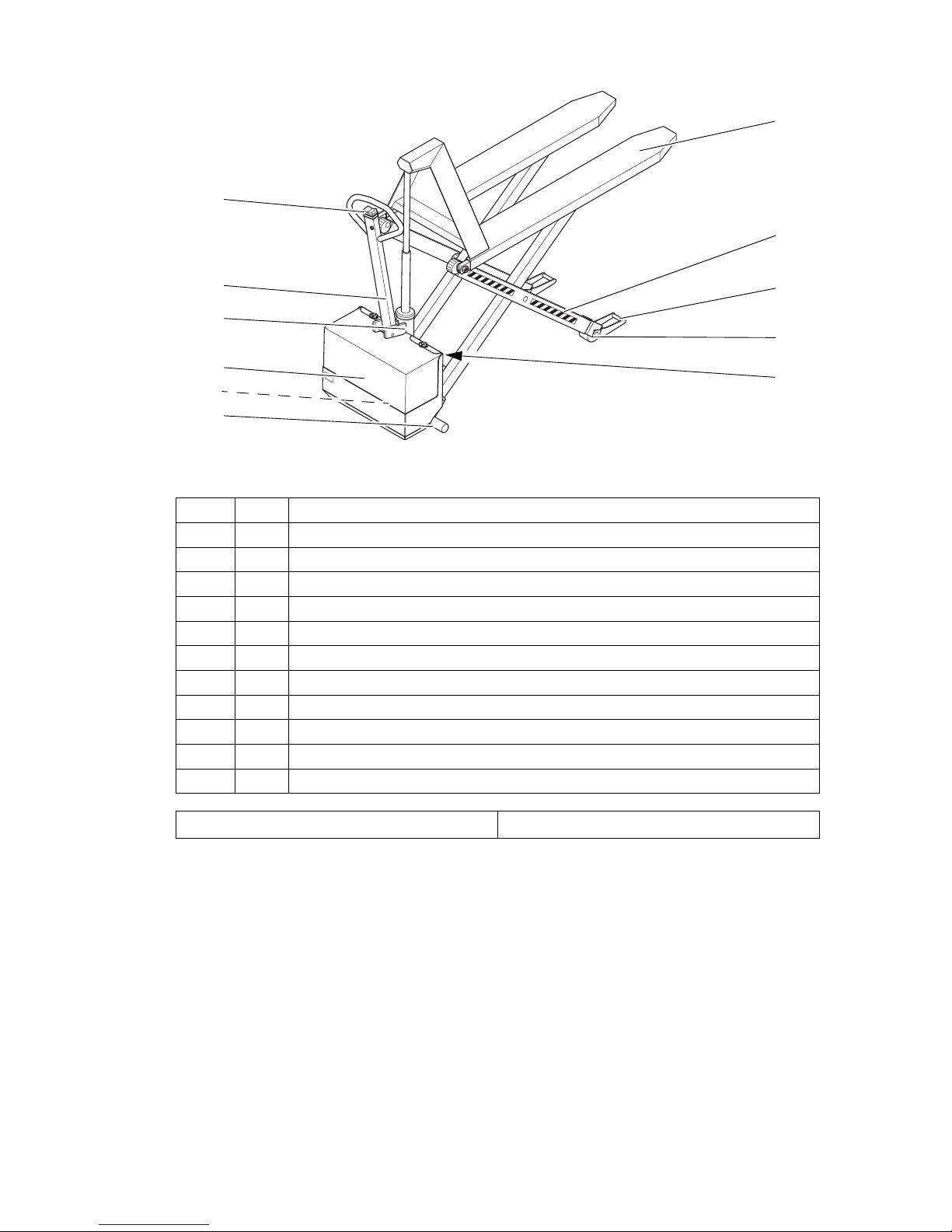

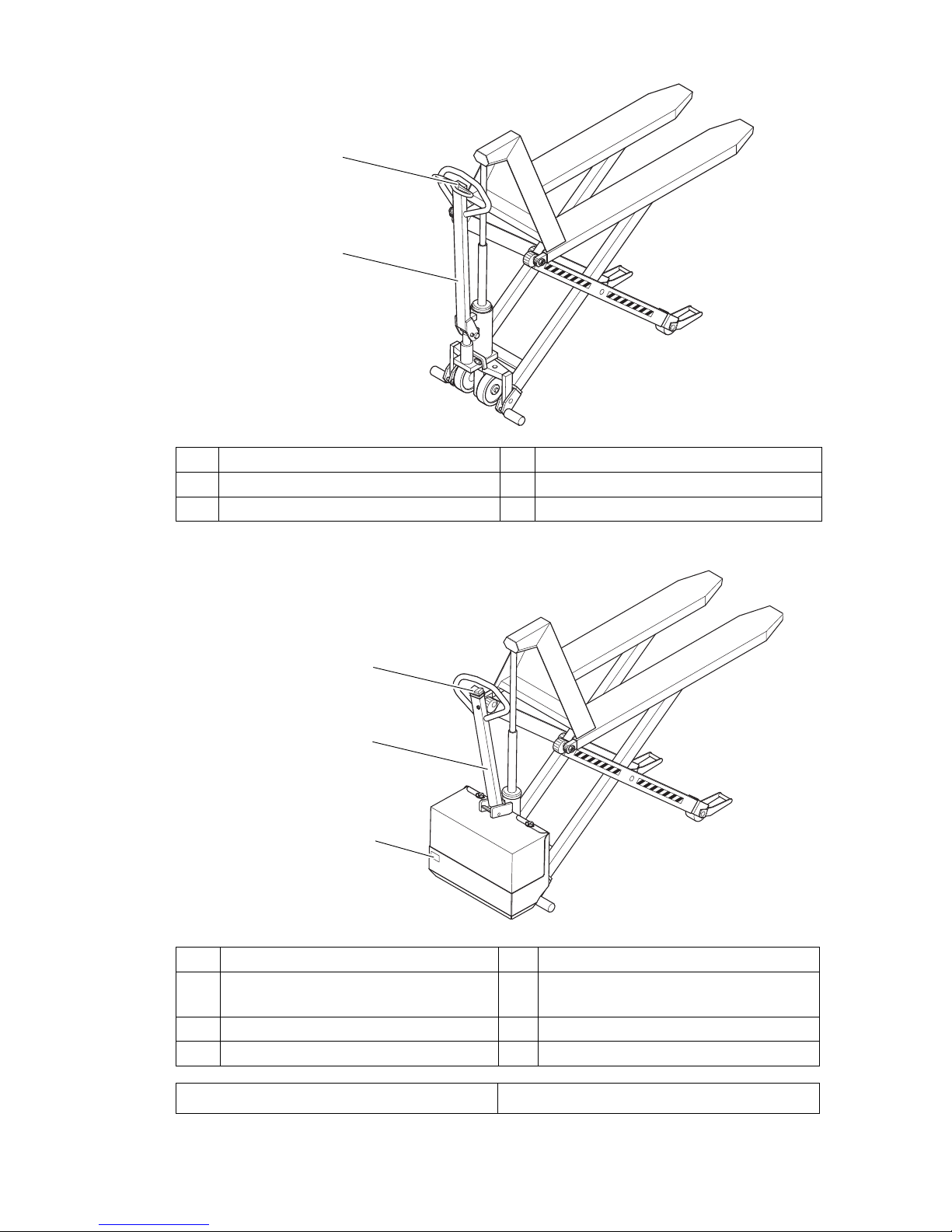

3 Assemblies and Functional Description

Item Description

1 t Load fork

2 t Scissors

3 t Bearing thrust strap

4 t Load wheels

5 t Steer wheels

6 t Support leg

7 t Hydraulic cylinder

8 t Control handle

9 t “Lift/lower load fork” handle

t = Standard equipment o = Optional equipment

1

2

3

4

5

6

7

8

9

AMX Inox/Inox Pro/Inox Pro Ex

0708.GB

B 2

3 Assemblies and Functional Description

Item Description

1 t Load fork

2 t Scissors

3 t Bearing thrust strap

4 t Load wheels

5 t Steer wheels

6 t Support leg

7 t Hydraulic cylinder

8 t Control handle

9 t “Lift/lower load fork” handle

t = Standard equipment o = Optional equipment

1

2

3

4

5

6

7

8

9

AMX Inox/Inox Pro/Inox Pro Ex

Page 10

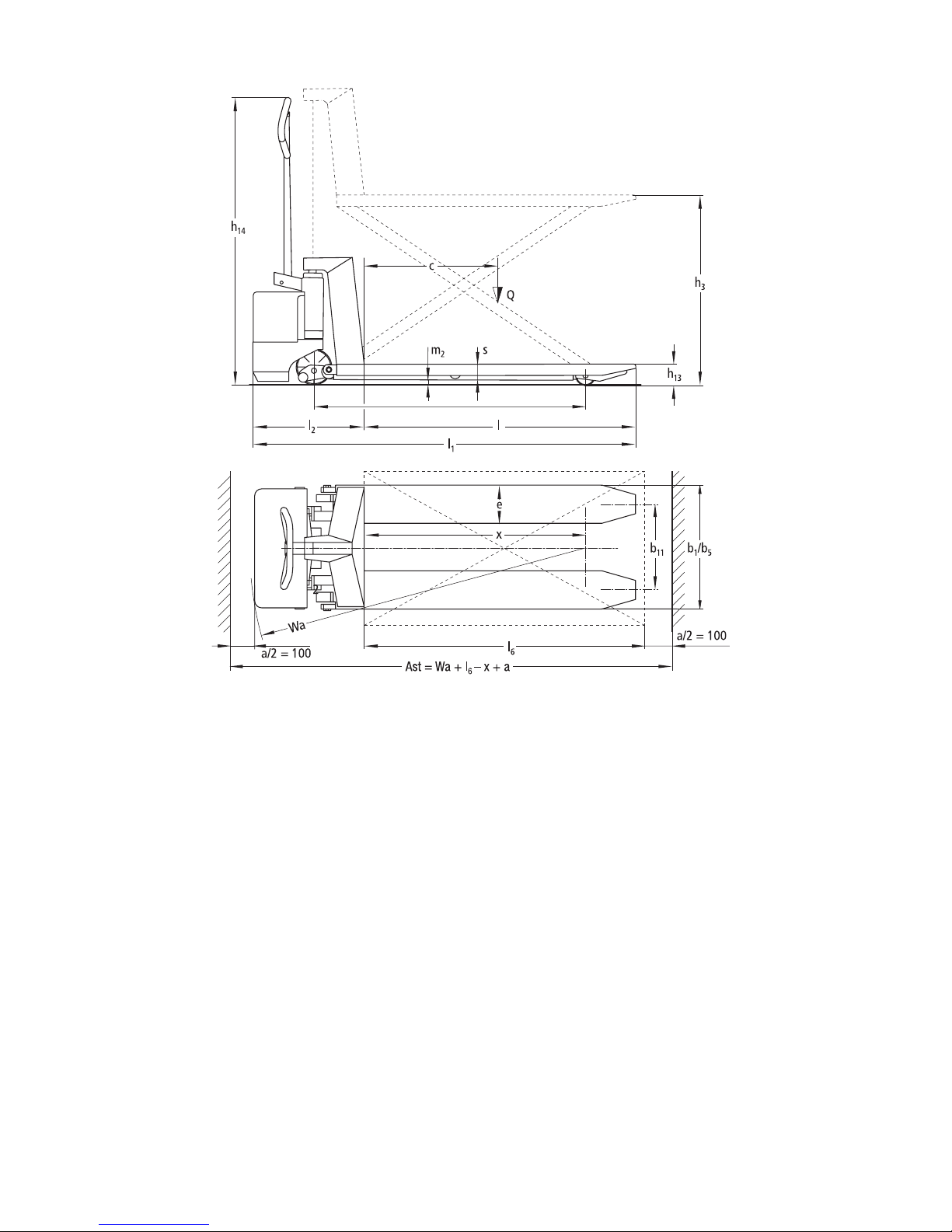

B 3

0708.GB

Item Description

10 t Load fork

11 t Scissors

12 t Bearing thrust strap

13 t Load wheels

14 t Battery connector

15 t Support leg

16 t Steer wheels

17 t Hydraulic unit

18 t Hydraulic cylinder

19 t Control handle

20 t “Lift/lower fork” button

t

=

Standard equipment o = Optional equipment

10

11

12

13

14

15

16

17

18

19

20

AMX-E Inox/Inox Pro

B 3

0708.GB

Item Description

10 t Load fork

11 t Scissors

12 t Bearing thrust strap

13 t Load wheels

14 t Battery connector

15 t Support leg

16 t Steer wheels

17 t Hydraulic unit

18 t Hydraulic cylinder

19 t Control handle

20 t “Lift/lower fork” button

t

=

Standard equipment o = Optional equipment

10

11

12

13

14

15

16

17

18

19

20

AMX-E Inox/Inox Pro

Page 11

0708.GB

B 4

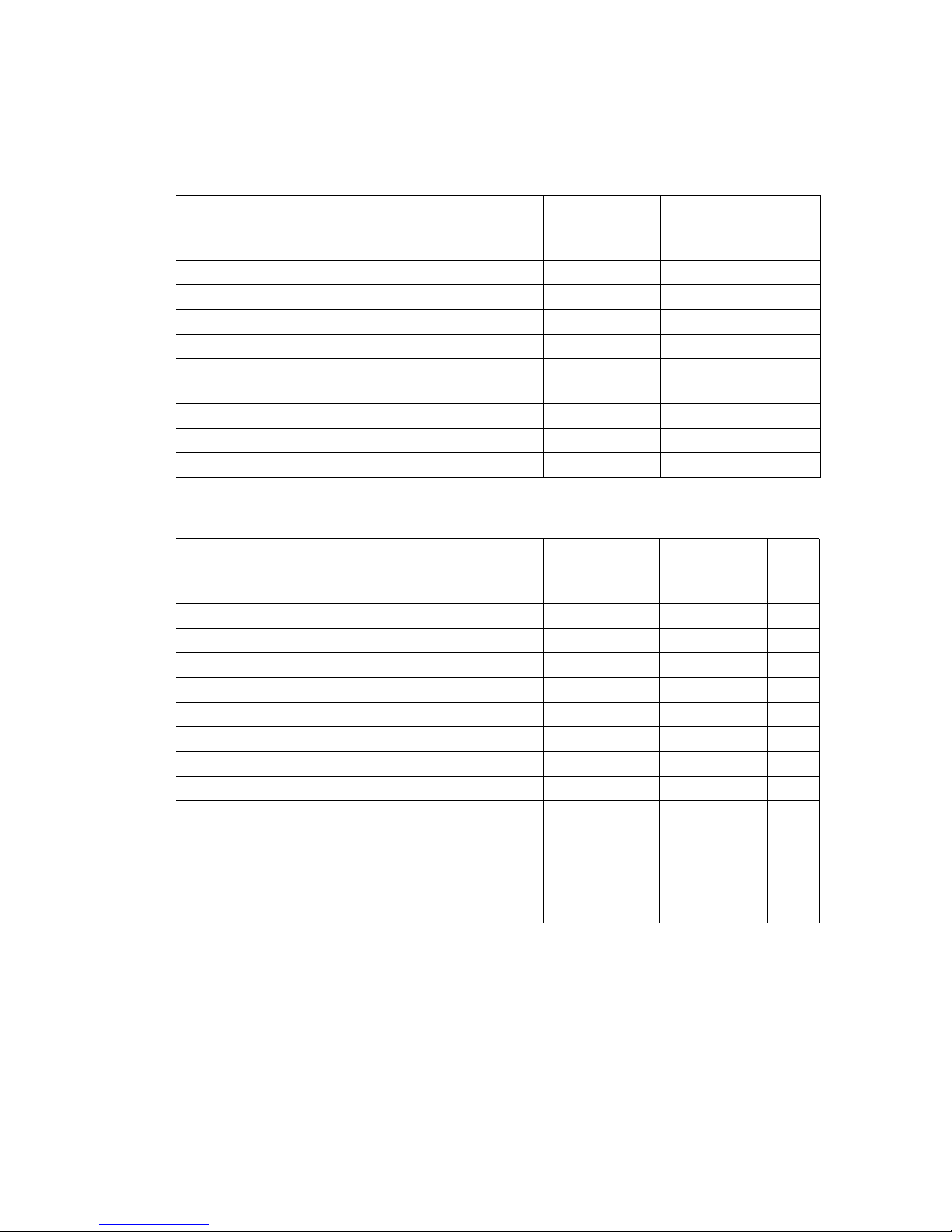

4 Standard Version Specifications

Z

Technical data specified in accordance with VDI 2198.

Technical modifications and additions reserved.

4.1 Performance data for standard trucks

4.2 Dimensions

Description AMX 10 Inox/

Inox Pro/

Inox Pro Ex

AMX-E 10

Inox/Inox Pro

Drive unit: Manual Electric (lift)

Q Rated capacity 1000 1000 Kg

c Load centre of gravity 600 600 mm

x Load distance 925 925 mm

Lowering speed

with / without load 0.15/0.093 0.08/0.05 m/s

Lift motor, output where s3 10% - 0,9 kW

Battery voltage, rated capacity k

5

- 12/60 V / Ah

Battery weight - 20 Kg

Description AMX 10 Inox/

Inox Pro/

Inox Pro Ex

AMX-E 10

Inox/Inox Pro

h3Lift 800 800 mm

h

13

Lowered height 85 85 mm

h

14

Tiller in neutral position. 1195 1195 mm

y Wheelbase 1140 1140 mm

s/e/l Fork dimensions

50/163/1140 50/163/1140

mm

l

1

Overall length 1480 1580 mm

l

2

Length incl. fork shank 340 440 mm

b

1

/ b2Overall width 540/680 540/680 mm

b

5

Outer load fork distance 540 540 mm

b

1

Load bearing part track width 540 540 mm

m2Ground clearance 28 28 mm

A

st

Aisle width 800x1200 longit. 1830 1890 mm

Wa Turning radius 1300 1396 mm

0708.GB

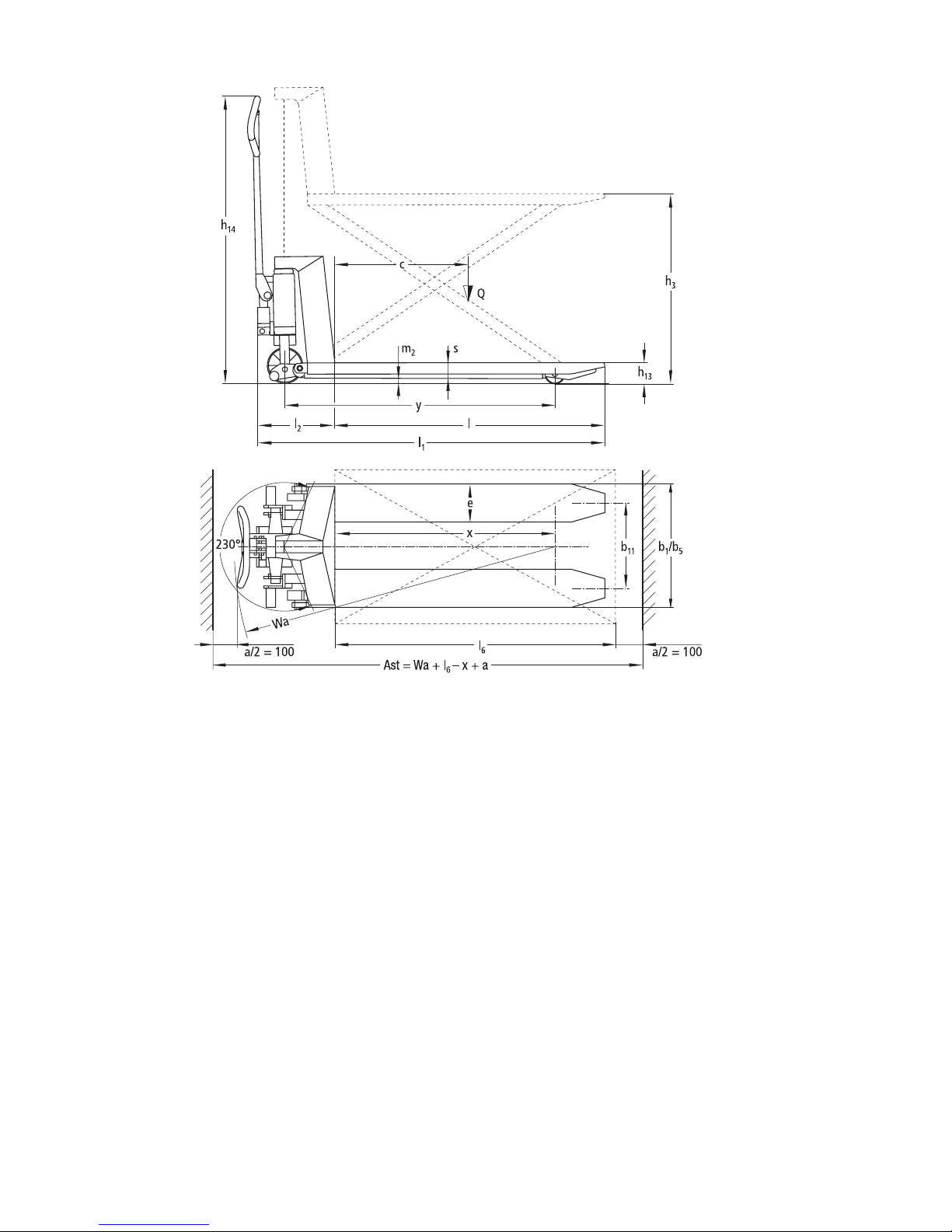

B 4

4 Standard Version Specifications

Z

Technical data specified in accordance with VDI 2198.

Technical modifications and additions reserved.

4.1 Performance data for standard trucks

4.2 Dimensions

Description AMX 10 Inox/

Inox Pro/

Inox Pro Ex

AMX-E 10

Inox/Inox Pro

Drive unit: Manual Electric (lift)

Q Rated capacity 1000 1000 Kg

c Load centre of gravity 600 600 mm

x Load distance 925 925 mm

Lowering speed

with / without load 0.15/0.093 0.08/0.05 m/s

Lift motor, output where s3 10% - 0,9 kW

Battery voltage, rated capacity k

5

- 12/60 V / Ah

Battery weight - 20 Kg

Description AMX 10 Inox/

Inox Pro/

Inox Pro Ex

AMX-E 10

Inox/Inox Pro

h3Lift 800 800 mm

h

13

Lowered height 85 85 mm

h

14

Tiller in neutral position. 1195 1195 mm

y Wheelbase 1140 1140 mm

s/e/l Fork dimensions

50/163/1140 50/163/1140

mm

l

1

Overall length 1480 1580 mm

l

2

Length incl. fork shank 340 440 mm

b

1

/ b2Overall width 540/680 540/680 mm

b

5

Outer load fork distance 540 540 mm

b

1

Load bearing part track width 540 540 mm

m2Ground clearance 28 28 mm

A

st

Aisle width 800x1200 longit. 1830 1890 mm

Wa Turning radius 1300 1396 mm

Page 12

B 5

0708.GB

AMX Inox/Inox Pro/Inox Pro Ex

B 5

0708.GB

AMX Inox/Inox Pro/Inox Pro Ex

Page 13

0708.GB

B 6

AMX-E Inox/Inox Pro

0708.GB

B 6

AMX-E Inox/Inox Pro

Page 14

B 7

0708.GB

5 EN norms

Electromagnetic compatibility (EMC)

The manufacturer confirms that equipment complies with

tolerance levels for electromagnetic emissions and

resistance as well as static electricity discharge testing in

accordance with EN 12895 including the normative

procedures contained therein.

Z

No changes to electric or electronic components or their arrangement may be made

without the written agreement of the manufacturer.

5.1 Conditions of use

Ambient temperature

AMX Inox/Inox Pro - at temperatures from -35 °C to 40 °C

Ambient temperature

AMX-E Inox/Inox Pro - at temperatures from 5 to 40 °C

Ambient temperature

AMX Inox Pro Ex - at temperatures from -20 to 40 °C

B 7

0708.GB

5 EN norms

Electromagnetic compatibility (EMC)

The manufacturer confirms that equipment complies with

tolerance levels for electromagnetic emissions and

resistance as well as static electricity discharge testing in

accordance with EN 12895 including the normative

procedures contained therein.

Z

No changes to electric or electronic components or their arrangement may be made

without the written agreement of the manufacturer.

5.1 Conditions of use

Ambient temperature

AMX Inox/Inox Pro - at temperatures from -35 °C to 40 °C

Ambient temperature

AMX-E Inox/Inox Pro - at temperatures from 5 to 40 °C

Ambient temperature

AMX Inox Pro Ex - at temperatures from -20 to 40 °C

Page 15

0708.GB

B 8

6 Identification points and data plates

Item Description

21 Warning decals: “Do not stand under the load handler” / “Do not stand on

the load handler”

22 Capacity Q

max

23 “Load centre of gravity” decal

24 Truck data plate

25 “Correct operation/loading” decal

26 “Danger of trapping” warning

21

22

23

24

25

26

AMX Inox/Inox Pro

21

22

24

23

26

AMX-E Inox/Inox Pro

0708.GB

B 8

6 Identification points and data plates

Item Description

21 Warning decals: “Do not stand under the load handler” / “Do not stand on

the load handler”

22 Capacity Q

max

23 “Load centre of gravity” decal

24 Truck data plate

25 “Correct operation/loading” decal

26 “Danger of trapping” warning

21

22

23

24

25

26

AMX Inox/Inox Pro

21

22

24

23

26

AMX-E Inox/Inox Pro

Page 16

B 9

0708.GB

Item Description

27 Warning decals: “Do not stand under the load handler” / “Do not stand on

the load handler”

28 Capacity Q

max

29 “Load centre of gravity” decal

30 Truck data plate

31 “Correct operation/loading” decal

32 “Danger of trapping” warning

33 Explosion proof decal

XXX XX ATEX XXXXXX X

27

28

29

30

31

32

AMX Inox Pro Ex

II 2G IIB T4

33

B 9

0708.GB

Item Description

27 Warning decals: “Do not stand under the load handler” / “Do not stand on

the load handler”

28 Capacity Q

max

29 “Load centre of gravity” decal

30 Truck data plate

31 “Correct operation/loading” decal

32 “Danger of trapping” warning

33 Explosion proof decal

XXX XX ATEX XXXXXX X

27

28

29

30

31

32

AMX Inox Pro Ex

II 2G IIB T4

33

Page 17

0708.GB

B 10

6.1 Data plate

Z

For queries relating to the truck or spare parts orders, please state the truck

serial no. (40, 48).

Item Description

34 Type

35 Year of manufacture

36 Net weight in kg

37 Manufacturer

38 Manufacturer’s logo

39 Rated capacity (kg)

40 Serial no.

Item Description

41 Type

42 Reference (ATEX)

43 Year of manufacture

44 Net weight in kg

45 Manufacturer

46 Manufacturer’s logo

47 Rated capacity (kg)

48 Serial no.

34

35

36

37

38

39

40

AMX Inox/Inox Pro

47

XXX XX ATEX XXXXXX X

41

42

43

44

45

48

AMX Inox Pro Ex

46

0708.GB

B 10

6.1 Data plate

Z

For queries relating to the truck or spare parts orders, please state the truck

serial no. (40, 48).

Item Description

34 Type

35 Year of manufacture

36 Net weight in kg

37 Manufacturer

38 Manufacturer’s logo

39 Rated capacity (kg)

40 Serial no.

Item Description

41 Type

42 Reference (ATEX)

43 Year of manufacture

44 Net weight in kg

45 Manufacturer

46 Manufacturer’s logo

47 Rated capacity (kg)

48 Serial no.

34

35

36

37

38

39

40

AMX Inox/Inox Pro

47

XXX XX ATEX XXXXXX X

41

42

43

44

45

48

AMX Inox Pro Ex

46

Page 18

C 1

1205.GB

C Transport and Commissioning

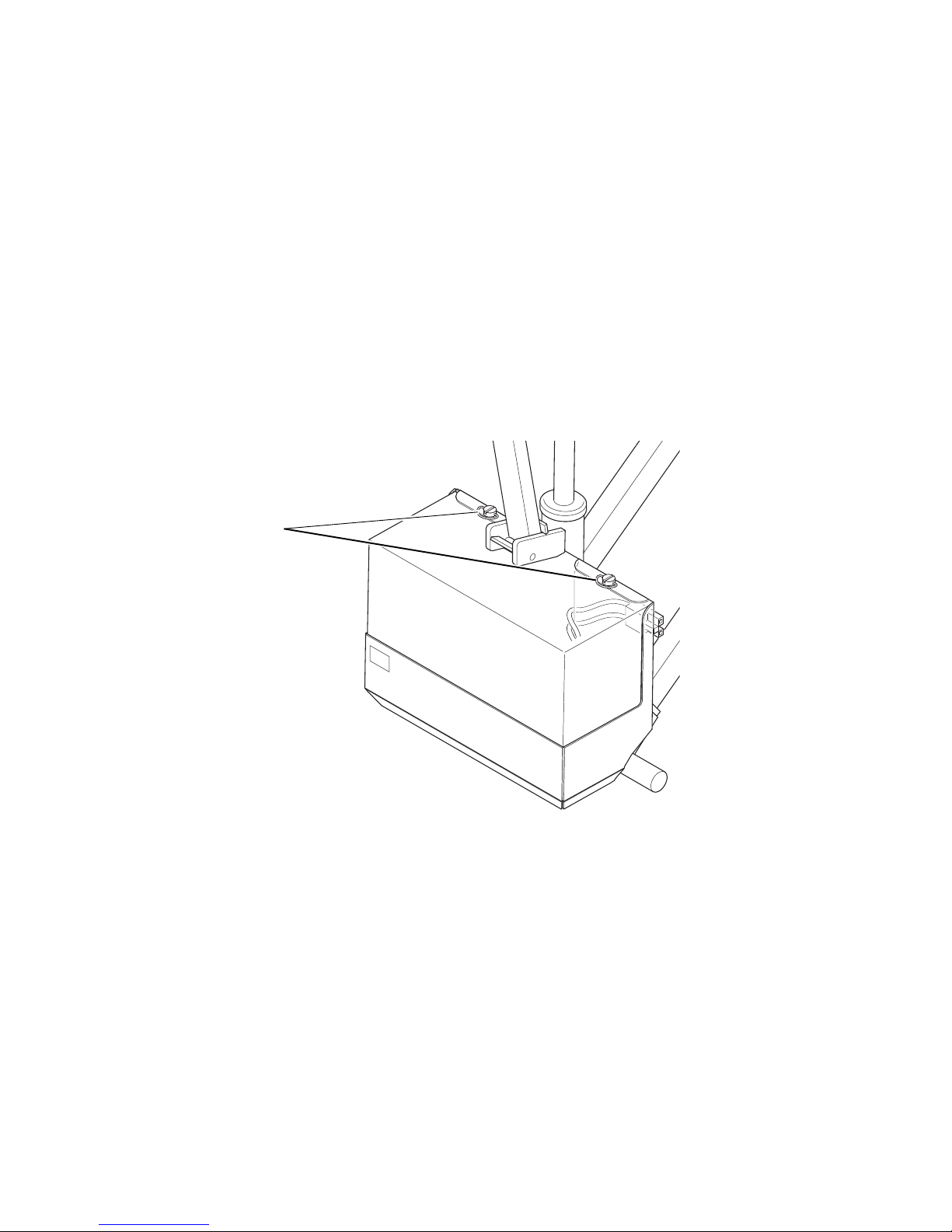

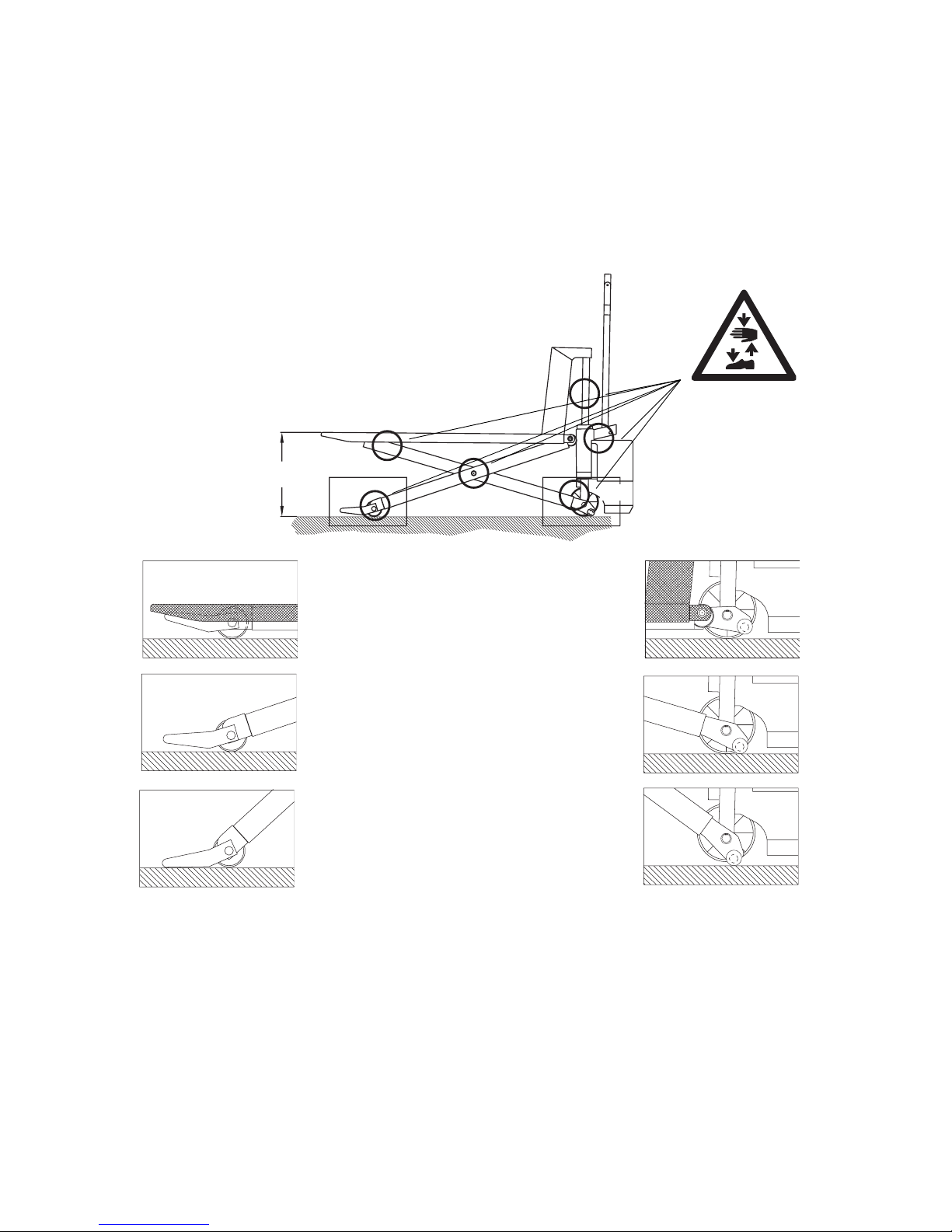

1 Lifting by crane

M

Only use lifting gear with sufficient capacity.

(AMX-E: Transport weight = net weight + battery weight; see truck data plate)

Z

Strap points are provided for transporting the truck with crane lifting gear.

– Park the truck securely (see

Chapter E).

– Secure the lifting slings to the

attachment points.

M

Attach the crane slings to the

strap points so that the truck

cannot slip.

Lifting slings should be

fastened to the harness in such

a way that they do not come

into contact with any parts of

the truck when it is being

raised.

2 Securing the truck during transport

F

The truck must be securely fastened when transported on a lorry or a trailer.

The lorry / trailer must have fastening rings.

– Tighten the tensioning belts

over the forks to secure the

truck. Attach tensioning belts

to the fastening rings.

– Tighten the tensioning belt

with the tensioner.

M

Loading must be carried out by

specially trained staff in

accordance with

recommendations contained in

Guidelines VDI 2700 and

VDI 2703. In each case correct

measurements shall be

determined and appropriate

safety measures adopted.

C 1

1205.GB

C Transport and Commissioning

1 Lifting by crane

M

Only use lifting gear with sufficient capacity.

(AMX-E: Transport weight = net weight + battery weight; see truck data plate)

Z

Strap points are provided for transporting the truck with crane lifting gear.

– Park the truck securely (see

Chapter E).

– Secure the lifting slings to the

attachment points.

M

Attach the crane slings to the

strap points so that the truck

cannot slip.

Lifting slings should be

fastened to the harness in such

a way that they do not come

into contact with any parts of

the truck when it is being

raised.

2 Securing the truck during transport

F

The truck must be securely fastened when transported on a lorry or a trailer.

The lorry / trailer must have fastening rings.

– Tighten the tensioning belts

over the forks to secure the

truck. Attach tensioning belts

to the fastening rings.

– Tighten the tensioning belt

with the tensioner.

M

Loading must be carried out by

specially trained staff in

accordance with

recommendations contained in

Guidelines VDI 2700 and

VDI 2703. In each case correct

measurements shall be

determined and appropriate

safety measures adopted.

Page 19

1205.GB

C 2

3 Using the truck for the first time

To prepare the truck after delivery or transport the following tasks must be carried out:

– Check the truck for completeness and satisfactory condition of the equipment.

– Install battery (where required). Do not damage battery cables (only AMX-E).

– Charge the battery (only AMX-E, see Chapter D).

– Commission the truck in accordance with instructions (see Chapter E).

Z

When the truck is parked, the surface of the tyres will flatten. The flattening will

disappear after a short period of operation.

1205.GB

C 2

3 Using the truck for the first time

To prepare the truck after delivery or transport the following tasks must be carried out:

– Check the truck for completeness and satisfactory condition of the equipment.

– Install battery (where required). Do not damage battery cables (only AMX-E).

– Charge the battery (only AMX-E, see Chapter D).

– Commission the truck in accordance with instructions (see Chapter E).

Z

When the truck is parked, the surface of the tyres will flatten. The flattening will

disappear after a short period of operation.

Page 20

D 1

1205.GB

D Battery Maintenance, Charging &

Replacement

1 Safety regulations for handling acid batteries

Park the truck securely before carrying out any work on the batteries (see Chapter E).

Maintenance personnel: Batteries may only be charged, serviced or replaced by

trained personnel. The present operator manual and the manufacturer’s instructions

concerning batteries and charging stations must be observed when carrying out the

work.

Fire protection: Smoking and naked flames must be avoided when working with

batteries Wherever a truck is parked for charging there shall be no inflammable

material or operating fluids capable of creating sparks within 2 metres around the

truck. The area must be well ventilated. Fire protection equipment must be provided.

Battery maintenance: The battery cell covers must be kept dry and clean.

The terminals and cable shoes must be clean, secure and have a light coating of

dielectric grease. Batteries with non insulated terminals must be covered with a non

slip insulation mat.

Battery disposal: Batteries may only be disposed of in accordance with national

environmental protection regulations or disposal laws. The manufacturer’s disposal

instructions must be followed.

M

Before closing the battery cover make sure that the battery lead cannot be damaged.

F

Batteries contain an acid solution which is poisonous and corrosive. Therefore,

always wear protective clothing and eye protection when carrying out work on

batteries. Above all avoid any contact with battery acid.

Nevertheless, should clothing, skin or eyes come in contact with acid the affected

parts should be rinsed with plenty of clean water - where the skin or eyes are affected

call a doctor immediately. Immediately neutralise any spilled battery acid.

M

Only batteries with a sealed battery container may be used.

F

The weight and dimensions of the battery have considerable affect on the operational

safety of the truck. Battery equipment may only be replaced with the agreement of the

manufacturer.

D 1

1205.GB

D Battery Maintenance, Charging &

Replacement

1 Safety regulations for handling acid batteries

Park the truck securely before carrying out any work on the batteries (see Chapter E).

Maintenance personnel: Batteries may only be charged, serviced or replaced by

trained personnel. The present operator manual and the manufacturer’s instructions

concerning batteries and charging stations must be observed when carrying out the

work.

Fire protection: Smoking and naked flames must be avoided when working with

batteries Wherever a truck is parked for charging there shall be no inflammable

material or operating fluids capable of creating sparks within 2 metres around the

truck. The area must be well ventilated. Fire protection equipment must be provided.

Battery maintenance: The battery cell covers must be kept dry and clean.

The terminals and cable shoes must be clean, secure and have a light coating of

dielectric grease. Batteries with non insulated terminals must be covered with a non

slip insulation mat.

Battery disposal: Batteries may only be disposed of in accordance with national

environmental protection regulations or disposal laws. The manufacturer’s disposal

instructions must be followed.

M

Before closing the battery cover make sure that the battery lead cannot be damaged.

F

Batteries contain an acid solution which is poisonous and corrosive. Therefore,

always wear protective clothing and eye protection when carrying out work on

batteries. Above all avoid any contact with battery acid.

Nevertheless, should clothing, skin or eyes come in contact with acid the affected

parts should be rinsed with plenty of clean water - where the skin or eyes are affected

call a doctor immediately. Immediately neutralise any spilled battery acid.

M

Only batteries with a sealed battery container may be used.

F

The weight and dimensions of the battery have considerable affect on the operational

safety of the truck. Battery equipment may only be replaced with the agreement of the

manufacturer.

Page 21

1205.GB

D 2

2Battery types

The truck is equipped with the following battery types:

The battery weight is indicated on the battery data plate.

F

When replacing/installing the battery make sure the battery is securely located in the

battery compartment of the truck.

3 Charging the Battery

When the green LED (100%) on the battery discharge indicator is lit, the battery is

fully charged.

F

When the red LED on the battery discharge indicator is lit, the battery is discharged.

The truck must be charged with a stationary charger.

– Park the truck securely (see Chapter E).

M

Only connect and disconnect the battery and the charger when the charger is

switched off.

– Connect the charger to the battery. Then connect the charger to a suitable mains

socket (230 V ±10%).

– Charge the battery until the green LED (100%) on the battery discharge indicator

is lit.

– Pull the mains connector of the charger out of the mains socket, and remove the

charger connector from the battery connector.

Z

Do not undertake a lift operation during charging.

M

To ensure a long battery life, it is advisable to run a regular compensation charge (1 x

a week). The charger must be connected to the mains for at least 12 hours.

Mains connection

Mains supply: 230 V (± 10%)

Mains frequency:50 Hz ± 4%

Charging times

The charging time can take up to 12 hours depending on the battery discharge status.

12 volt battery 60AhC5

1205.GB

D 2

2Battery types

The truck is equipped with the following battery types:

The battery weight is indicated on the battery data plate.

F

When replacing/installing the battery make sure the battery is securely located in the

battery compartment of the truck.

3 Charging the Battery

When the green LED (100%) on the battery discharge indicator is lit, the battery is

fully charged.

F

When the red LED on the battery discharge indicator is lit, the battery is discharged.

The truck must be charged with a stationary charger.

– Park the truck securely (see Chapter E).

M

Only connect and disconnect the battery and the charger when the charger is

switched off.

– Connect the charger to the battery. Then connect the charger to a suitable mains

socket (230 V ±10%).

– Charge the battery until the green LED (100%) on the battery discharge indicator

is lit.

– Pull the mains connector of the charger out of the mains socket, and remove the

charger connector from the battery connector.

Z

Do not undertake a lift operation during charging.

M

To ensure a long battery life, it is advisable to run a regular compensation charge (1 x

a week). The charger must be connected to the mains for at least 12 hours.

Mains connection

Mains supply: 230 V (± 10%)

Mains frequency:50 Hz ± 4%

Charging times

The charging time can take up to 12 hours depending on the battery discharge status.

12 volt battery 60AhC5

Page 22

D 3

1205.GB

4 Battery discharge indicator

The battery discharge status is indicated by the LED.

M

For light applications (load < 300 kg) charge the battery when the LED is flashing

yellow.

Charge the battery when the LED is flashing red.

Further operation will damage the battery.

Battery depletion occurs and the voltage drops below the minimum level.

Z

Lifting is cut out when 20% residual capacity is reached (LED goes red).

Charge Colour Status

100% Green Truck operational

75% Green Truck operational

50% Green Truck operational

25% Yellow Charge battery

<25% Red Charge battery, truck not operational

D 3

1205.GB

4 Battery discharge indicator

The battery discharge status is indicated by the LED.

M

For light applications (load < 300 kg) charge the battery when the LED is flashing

yellow.

Charge the battery when the LED is flashing red.

Further operation will damage the battery.

Battery depletion occurs and the voltage drops below the minimum level.

Z

Lifting is cut out when 20% residual capacity is reached (LED goes red).

Charge Colour Status

100% Green Truck operational

75% Green Truck operational

50% Green Truck operational

25% Yellow Charge battery

<25% Red Charge battery, truck not operational

Page 23

1205.GB

D 4

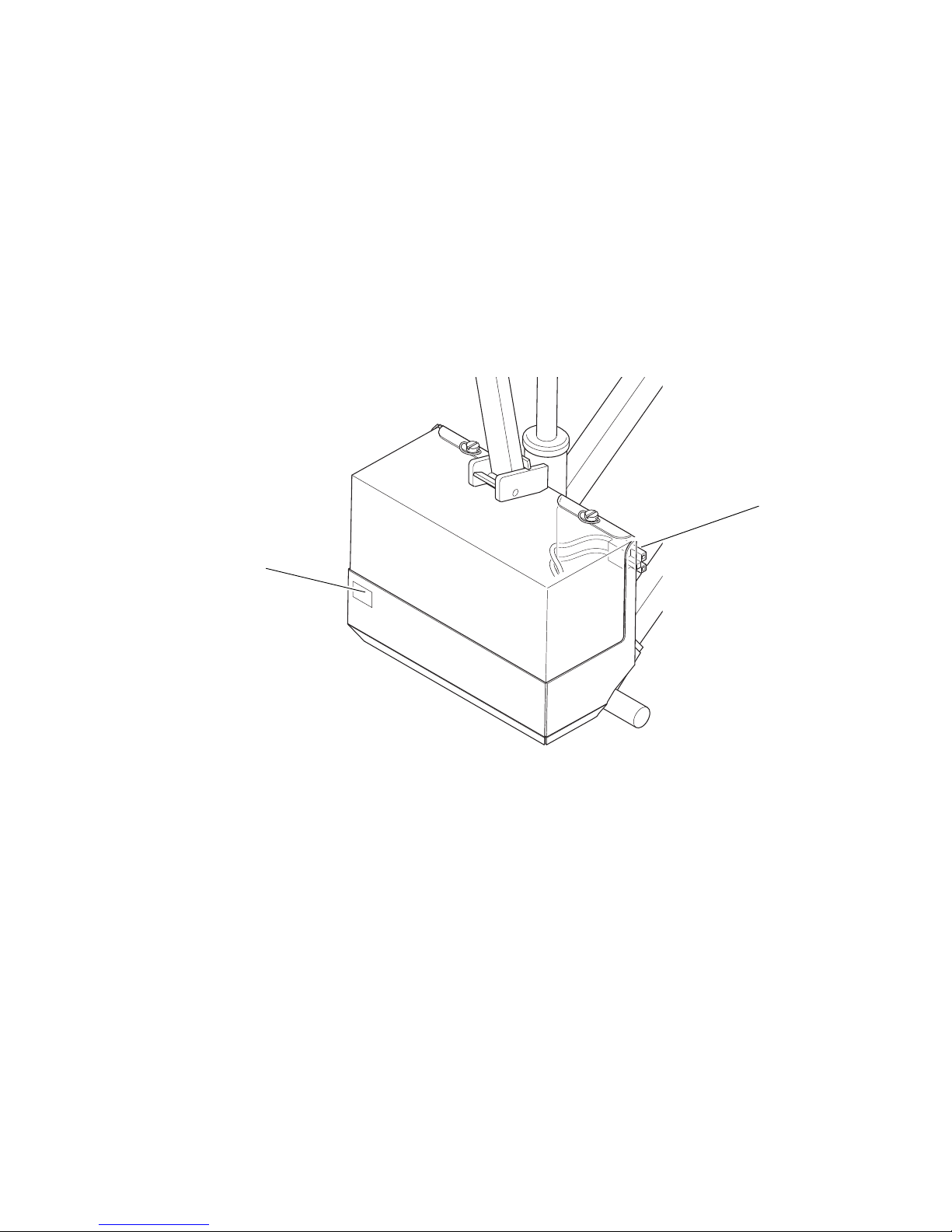

5 Battery Replacement

F

The truck must be parked on level ground. To prevent short circuits, batteries with

exposed terminals or connectors must be covered with a rubber mat. Place the

battery connector or the battery cable in such a way that they will not get caught on

the truck when the battery is removed.

F

When replacing a battery always use the same battery type. Extra weights must not

be removed and must remain in the same position.

– Turn the turn-lock fasteners (1) 90°.

– Remove the battery panel.

– Undo the terminal screws and remove the battery cable from the terminals.

M

Place the battery connector or the battery cable in such a way that they will not get

caught on the truck when the battery is removed.

– Remove the battery.

M

Installation is the reverse order. When reinstalling the batteries, make sure they are

installed in the correct position and properly connected.

– Red cable: + terminal

– Black cable: - terminal

– After installing the battery again, check all cables and plug connections for visible

signs of damage.

F

Before starting the truck, the battery panel must be firmly closed. Close the battery

panel carefully and slowly. Do not reach between the battery panel and the chassis.

1

1205.GB

D 4

5 Battery Replacement

F

The truck must be parked on level ground. To prevent short circuits, batteries with

exposed terminals or connectors must be covered with a rubber mat. Place the

battery connector or the battery cable in such a way that they will not get caught on

the truck when the battery is removed.

F

When replacing a battery always use the same battery type. Extra weights must not

be removed and must remain in the same position.

– Turn the turn-lock fasteners (1) 90°.

– Remove the battery panel.

– Undo the terminal screws and remove the battery cable from the terminals.

M

Place the battery connector or the battery cable in such a way that they will not get

caught on the truck when the battery is removed.

– Remove the battery.

M

Installation is the reverse order. When reinstalling the batteries, make sure they are

installed in the correct position and properly connected.

– Red cable: + terminal

– Black cable: - terminal

– After installing the battery again, check all cables and plug connections for visible

signs of damage.

F

Before starting the truck, the battery panel must be firmly closed. Close the battery

panel carefully and slowly. Do not reach between the battery panel and the chassis.

1

Page 24

E 1

1205.GB

E Operation

1 Safety Regulations for the Operation of Forklift Trucks

Driver’s rights, obligations and responsibilities: The driver must be informed of

his duties and responsibilities and be instructed in the operation of the truck and shall

be familiar with the operator manual. The driver shall be afforded all due rights.

Unauthorised Use of Truck: The driver is responsible for the truck during the time

it is in use. The drive must prevent unauthorised persons from driving or operating the

truck. Do not carry passengers or lift other people.

Damage and Faults:The supervisor must be immediately informed of any damage

or faults to the forklift truck or attachment. Trucks which are unsafe for operation

(e.g. wheel or brake problems) must not be used until they have been rectified.

Repairs: The driver must not carry out any repairs or alterations to the forklift truck

without the necessary training and authorisation to do so. The driver must never

disable or adjust safety mechanisms or switches.

Hazardous area: A hazardous area is defined as the area in which a person is at risk

due to truck movement, lifting operations, the load handler (e.g. forks or attachments)

or the load itself. This also includes areas which can be reached by falling loads or

lowering operating equipment.

F

Unauthorised persons must be kept away from the hazardous area. Where there is

danger to personnel, a warning must be sounded with sufficient notice.

If unauthorised personnel are still within the hazardous area the truck shall be

brought to a halt immediately.

Safety Devices and Warning Signs: Safety devices, warning signs and warning

instructions shall be strictly observed.

E 1

1205.GB

E Operation

1 Safety Regulations for the Operation of Forklift Trucks

Driver’s rights, obligations and responsibilities: The driver must be informed of

his duties and responsibilities and be instructed in the operation of the truck and shall

be familiar with the operator manual. The driver shall be afforded all due rights.

Unauthorised Use of Truck: The driver is responsible for the truck during the time

it is in use. The drive must prevent unauthorised persons from driving or operating the

truck. Do not carry passengers or lift other people.

Damage and Faults:The supervisor must be immediately informed of any damage

or faults to the forklift truck or attachment. Trucks which are unsafe for operation

(e.g. wheel or brake problems) must not be used until they have been rectified.

Repairs: The driver must not carry out any repairs or alterations to the forklift truck

without the necessary training and authorisation to do so. The driver must never

disable or adjust safety mechanisms or switches.

Hazardous area: A hazardous area is defined as the area in which a person is at risk

due to truck movement, lifting operations, the load handler (e.g. forks or attachments)

or the load itself. This also includes areas which can be reached by falling loads or

lowering operating equipment.

F

Unauthorised persons must be kept away from the hazardous area. Where there is

danger to personnel, a warning must be sounded with sufficient notice.

If unauthorised personnel are still within the hazardous area the truck shall be

brought to a halt immediately.

Safety Devices and Warning Signs: Safety devices, warning signs and warning

instructions shall be strictly observed.

Page 25

1205.GB

E 2

1.1 Additional clause to the safety regulations for operating an explosion-proof

industrial truck ( )

Explosion-proof trucks are indicated as follows:

Trucks with this reference can be used in zone 1 areas at risk from explosion due to

gas, steam or fog of explosion group IIB and temperature group T4.

F

Dust, contamination and paint, acids and caustic solutions can cause a reduction or

complete failure of electrical/electronic energy conducted to the ground.

The truck and transport routes must be treated accordingly.

It is the sole responsibility of the user to check the safety mechanisms, such as testing

the electrically conductive wheel(s).

When replacing wheels always use new wheels with the same level of functionality.

At least one wheel must be antistatic.

Z

Enter and exit the pallet truck into the load handler opening without load to avoid

grating on sharp edges.

II 2G IIB T4

1205.GB

E 2

1.1 Additional clause to the safety regulations for operating an explosion-proof

industrial truck ( )

Explosion-proof trucks are indicated as follows:

Trucks with this reference can be used in zone 1 areas at risk from explosion due to

gas, steam or fog of explosion group IIB and temperature group T4.

F

Dust, contamination and paint, acids and caustic solutions can cause a reduction or

complete failure of electrical/electronic energy conducted to the ground.

The truck and transport routes must be treated accordingly.

It is the sole responsibility of the user to check the safety mechanisms, such as testing

the electrically conductive wheel(s).

When replacing wheels always use new wheels with the same level of functionality.

At least one wheel must be antistatic.

Z

Enter and exit the pallet truck into the load handler opening without load to avoid

grating on sharp edges.

II 2G IIB T4

Page 26

E 3

1205.GB

2 Controls

Item Control / Display Function

1 Control handle t Moves and steers the truck.

2 “Lift/lower load fork” handle t Manually lifts / lowers load fork.

Item Control / Display Function

3 Battery discharge indicator t Indicates the battery charge status

(see Chapter D).

4 Control handle t Used to steer and brake the truck.

5 “Lift/lower fork” button t Lifts / lowers the forks.

t = Standard equipment o = Optional equipment

1

2

AMX Inox/Inox Pro/Inox Pro Ex

3

4

5

AMX-E Inox/Inox Pro

E 3

1205.GB

2 Controls

Item Control / Display Function

1 Control handle t Moves and steers the truck.

2 “Lift/lower load fork” handle t Manually lifts / lowers load fork.

Item Control / Display Function

3 Battery discharge indicator t Indicates the battery charge status

(see Chapter D).

4 Control handle t Used to steer and brake the truck.

5 “Lift/lower fork” button t Lifts / lowers the forks.

t = Standard equipment o = Optional equipment

1

2

AMX Inox/Inox Pro/Inox Pro Ex

3

4

5

AMX-E Inox/Inox Pro

Page 27

1205.GB

E 4

3 Starting up the truck

F

Before the truck can be commissioned, operated or a load unit lifted, the driver must

ensure that there is nobody within the hazardous area.

Checks and operations to be performed before starting daily work

– Inspect the entire truck (especially the wheels and the load handler) for visible signs

of damage.

AMX-E only:

– Check whether charge connector is connected (6). Remove if necessary.

Z

The battery discharge monitor (7) shows the available battery capacity.

The truck is now operational.

6

7

1205.GB

E 4

3 Starting up the truck

F

Before the truck can be commissioned, operated or a load unit lifted, the driver must

ensure that there is nobody within the hazardous area.

Checks and operations to be performed before starting daily work

– Inspect the entire truck (especially the wheels and the load handler) for visible signs

of damage.

AMX-E only:

– Check whether charge connector is connected (6). Remove if necessary.

Z

The battery discharge monitor (7) shows the available battery capacity.

The truck is now operational.

6

7

Page 28

E 5

1205.GB

4 Industrial truck operation

4.1 Safety regulations for truck operation

Travel routes and work areas:Only use lanes and routes specifically designated for

truck traffic. Unauthorised third parties must stay away from work areas. Loads must

only be stored in places specially designated for this purpose.

Driving conduct:The driver must adapt the travel speed to local conditions. The

truck must be driven at slow speed when negotiating bends or narrow passageways,

when passing through swing doors and at blind spots. The driver must always

observe an adequate braking distance between the forklift truck and the vehicle in

front and must be in control of the truck at all times. Abrupt stopping (except in

emergencies), rapid U turns and overtaking at dangerous or blind spots are not

permitted.

Travel visibility:The driver must look in the direction of travel and must always have

a clear view of the route ahead. Loads that affect visibility must be positioned at the

rear of the truck. If this is not possible, a second person must walk in front of the truck

as a lookout.

Negotiating slopes and inclines:Slopes or inclines may only be negotiated if they

are designated traffic routes, are clean and have a non-slip surface and providing

they can be safely negotiated in accordance with the technical specifications of the

truck. The truck must always be driven with the load unit facing uphill. The industrial

truck must not be turned, operated at an angle or parked on inclines or slopes.

Inclines must only be negotiated at slow speed, with the driver ready to brake at any

moment.

Negotiating lifts and docks:Lifts and docks must only be used if they have sufficient

capacity, are suitable for driving on and authorised for truck traffic by the owner. The

driver must satisfy himself of the above before entering these areas. The truck must

enter lifts with the load in front and must take up a position which does not allow it to

come into contact with the walls of the lift shaft. People travelling in the lift with the

forklift truck must only enter the lift after the truck has come to a halt and must exit the

lift before the truck.

Type of loads to be carried: The operator must make sure that the load is in a

satisfactory condition. Do not carry loads unless they are positioned safely and

carefully. Use suitable precautions to prevent parts of the load from tipping or falling

down,

E 5

1205.GB

4 Industrial truck operation

4.1 Safety regulations for truck operation

Travel routes and work areas:Only use lanes and routes specifically designated for

truck traffic. Unauthorised third parties must stay away from work areas. Loads must

only be stored in places specially designated for this purpose.

Driving conduct:The driver must adapt the travel speed to local conditions. The

truck must be driven at slow speed when negotiating bends or narrow passageways,

when passing through swing doors and at blind spots. The driver must always

observe an adequate braking distance between the forklift truck and the vehicle in

front and must be in control of the truck at all times. Abrupt stopping (except in

emergencies), rapid U turns and overtaking at dangerous or blind spots are not

permitted.

Travel visibility:The driver must look in the direction of travel and must always have

a clear view of the route ahead. Loads that affect visibility must be positioned at the

rear of the truck. If this is not possible, a second person must walk in front of the truck

as a lookout.

Negotiating slopes and inclines:Slopes or inclines may only be negotiated if they

are designated traffic routes, are clean and have a non-slip surface and providing

they can be safely negotiated in accordance with the technical specifications of the

truck. The truck must always be driven with the load unit facing uphill. The industrial

truck must not be turned, operated at an angle or parked on inclines or slopes.

Inclines must only be negotiated at slow speed, with the driver ready to brake at any

moment.

Negotiating lifts and docks:Lifts and docks must only be used if they have sufficient

capacity, are suitable for driving on and authorised for truck traffic by the owner. The

driver must satisfy himself of the above before entering these areas. The truck must

enter lifts with the load in front and must take up a position which does not allow it to

come into contact with the walls of the lift shaft. People travelling in the lift with the

forklift truck must only enter the lift after the truck has come to a halt and must exit the

lift before the truck.

Type of loads to be carried: The operator must make sure that the load is in a

satisfactory condition. Do not carry loads unless they are positioned safely and

carefully. Use suitable precautions to prevent parts of the load from tipping or falling

down,

Page 29

1205.GB

E 6

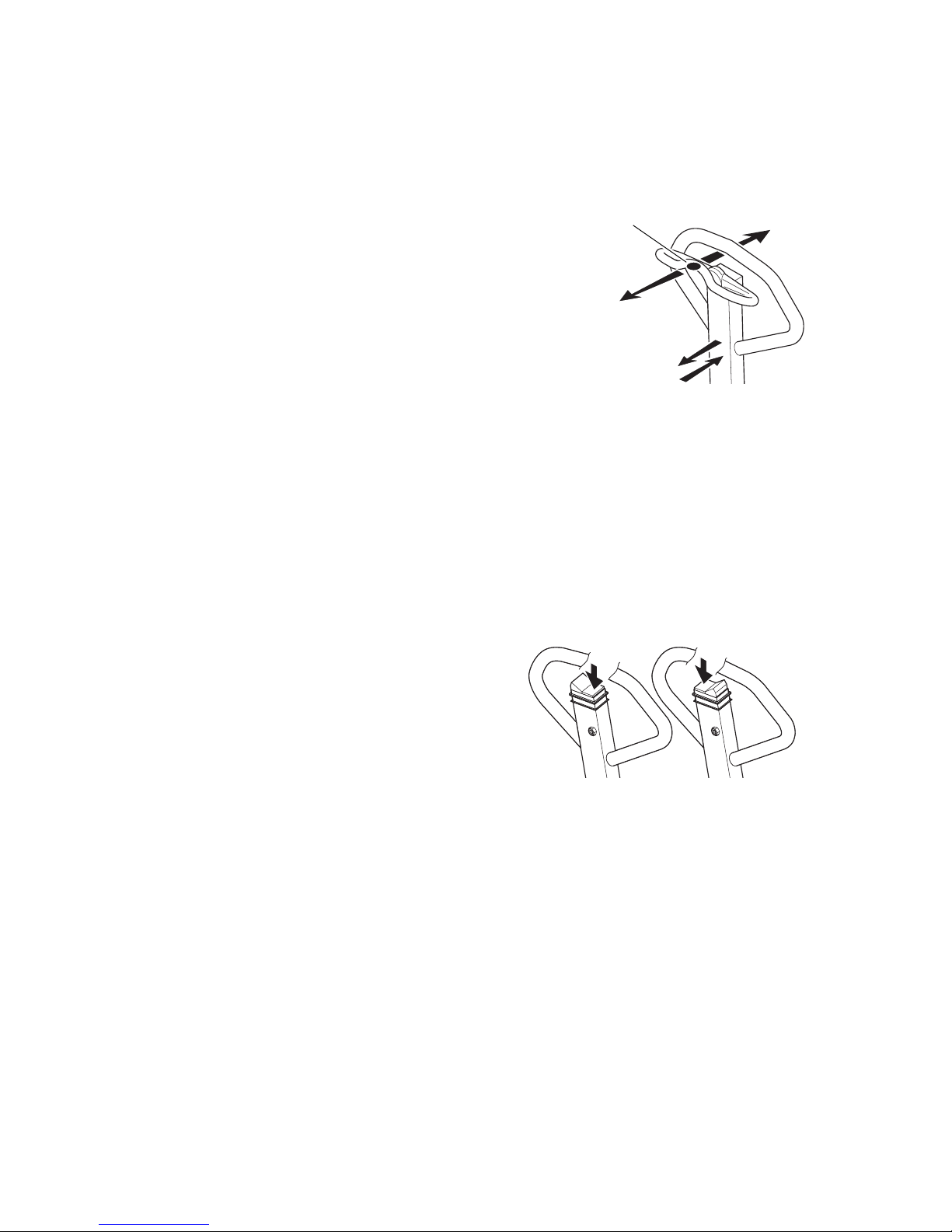

4.2 Travel, Steering, Braking

F

Never carry passengers.

Travel

M

Do not drive the truck unless the panel is closed and properly locked.

– Start up the truck (refer to section 3)..

– The truck can be pulled or pushed from the tiller (8) handle (11).

Z

AMX: When moving a laden truck, the handle (9) must be in the “neutral” position.

Steering

– Move the control handle (1) to the left or right.

M

On narrow bends the tiller extends outside the truck’s geometry.

Braking

In an emergency the truck can be braked by lowering the load.

– AMX: Press handle (9) in direction “S” to lower the load.

– AMX-E: Press handle in “Lower” direction “S” to lower the load.

AMX tiller AMX-E tiller:

8

9

10

11

1205.GB

E 6

4.2 Travel, Steering, Braking

F

Never carry passengers.

Travel

M

Do not drive the truck unless the panel is closed and properly locked.

– Start up the truck (refer to section 3)..

– The truck can be pulled or pushed from the tiller (8) handle (11).

Z

AMX: When moving a laden truck, the handle (9) must be in the “neutral” position.

Steering

– Move the control handle (1) to the left or right.

M

On narrow bends the tiller extends outside the truck’s geometry.

Braking

In an emergency the truck can be braked by lowering the load.

– AMX: Press handle (9) in direction “S” to lower the load.

– AMX-E: Press handle in “Lower” direction “S” to lower the load.

AMX tiller AMX-E tiller:

8

9

10

11

Page 30

E 7

1205.GB

4.3 Lifting and depositing loads

M

Before picking up a load, the driver must ensure that it is correctly palletised and that

the capacity of the truck is not exceeded.

Do not lift long loads at an angle.

– AMX: Lower the fork if necessary by pressing the

handle in the “Lower” direction and then return the

handle to the neutral (N) position.

– AMX-E: Lower the fork if necessary by pressing the

button in the “Lower” direction.

– Fully insert the forks of the truck underneath the load.

Raise/Lower

Lift AMX

– Push handle in the “Lift” direction.

– Lift the fork by moving the tiller up and down until you reach the desired lifting

height.

Lower AMX

– Push handle in the “Lower” direction to lower the load.

Z

When moving a laden truck, the handle must be in the neutral (N) position.

AMX-E lift:

Press button (Lift) until you reach the

desired height.

–

AMX-E lower:

– Press “Lower” button to lower the load.

S

H

N

AMX-E tiller:

S

H

AMX-E tiller:

E 7

1205.GB

4.3 Lifting and depositing loads

M

Before picking up a load, the driver must ensure that it is correctly palletised and that

the capacity of the truck is not exceeded.

Do not lift long loads at an angle.

– AMX: Lower the fork if necessary by pressing the

handle in the “Lower” direction and then return the

handle to the neutral (N) position.

– AMX-E: Lower the fork if necessary by pressing the

button in the “Lower” direction.

– Fully insert the forks of the truck underneath the load.

Raise/Lower

Lift AMX

– Push handle in the “Lift” direction.

– Lift the fork by moving the tiller up and down until you reach the desired lifting

height.

Lower AMX

– Push handle in the “Lower” direction to lower the load.

Z

When moving a laden truck, the handle must be in the neutral (N) position.

AMX-E lift:

Press button (Lift) until you reach the

desired height.

–

AMX-E lower:

– Press “Lower” button to lower the load.

S

H

N

AMX-E tiller:

S

H

AMX-E tiller:

Page 31

1205.GB

E 8

Stability at Height

M

Risk of trapping from moving parts!

The support legs (13) and bearing thrust strap (12) combine to stabilise the truck.

When the forks are above a height of 400 mm, the support legs and bearing thrust

strap automatically lower to prevent the scissor lift truck from travelling. The support

legs are eccentric, so that they can be adjusted according to their gradual state of

wear.

4.4 Parking the truck securely

F

Always park the truck securely.

Do not park the truck on an incline.

The load fork must always be lowered to the ground.

– Lower the load forks.

h

13

12

13

h13 = 90 mm

Raise the bearing thrust strap (12) and

support leg (13) off the ground.

h13 = 400 mm

The support leg (13) brakes the truck.

h

13

= 800 mm

The bearing thrust strap (12) raises the

steer wheel, the support leg (13) raises

the load wheel.

1205.GB

E 8

Stability at Height

M

Risk of trapping from moving parts!

The support legs (13) and bearing thrust strap (12) combine to stabilise the truck.

When the forks are above a height of 400 mm, the support legs and bearing thrust

strap automatically lower to prevent the scissor lift truck from travelling. The support

legs are eccentric, so that they can be adjusted according to their gradual state of

wear.

4.4 Parking the truck securely

F

Always park the truck securely.

Do not park the truck on an incline.

The load fork must always be lowered to the ground.

– Lower the load forks.

h

13

12

13

h13 = 90 mm

Raise the bearing thrust strap (12) and

support leg (13) off the ground.

h13 = 400 mm

The support leg (13) brakes the truck.

h

13

= 800 mm

The bearing thrust strap (12) raises the

steer wheel, the support leg (13) raises

the load wheel.

Page 32

E 9

1205.GB

5 Troubleshooting

This chapter is designed to help the user identify and rectify basic faults or the results

of incorrect operation. When locating a fault, proceed in the order shown in the table.

Z

If the fault cannot be rectified after carrying out the remedial procedure, notify the

manufacturer’s service department, as any further troubleshooting can only be

performed by specially trained and qualified service personnel.

Fault Probable Cause Action

Load cannot be lifted

or is not lifted on first

pump stroke.

– Hydraulic oil level too low

– Air in hydraulic system

– Seals leaking, valves do not

close.

– Check hydraulic oil level.

– Pump load handler fully

upwards to bleed the

hydraulic system.

– Inform manufacturer’s

service department.

AMX only:

– Handle in “neutral” position or

pushed in “Lower” direction.

AMX only:

– Push handle in “Lift”

direction.

AMX-E only:

– Battery charge too low.

– Faulty fuse.

AMX-E only:

– Recharge the battery.

– Check fuses.

Load cannot be

lowered

– Lift cylinder damaged. – Inform manufacturer’s

service department.

AMX-E only:

– Battery charge too low.

– Faulty fuse.

AMX-E only:

– Recharge the battery.

– Check fuses.

E 9

1205.GB

5 Troubleshooting

This chapter is designed to help the user identify and rectify basic faults or the results

of incorrect operation. When locating a fault, proceed in the order shown in the table.

Z

If the fault cannot be rectified after carrying out the remedial procedure, notify the

manufacturer’s service department, as any further troubleshooting can only be

performed by specially trained and qualified service personnel.

Fault Probable Cause Action

Load cannot be lifted

or is not lifted on first

pump stroke.

– Hydraulic oil level too low

– Air in hydraulic system

– Seals leaking, valves do not

close.

– Check hydraulic oil level.

– Pump load handler fully

upwards to bleed the

hydraulic system.

– Inform manufacturer’s

service department.

AMX only:

– Handle in “neutral” position or

pushed in “Lower” direction.

AMX only:

– Push handle in “Lift”

direction.

AMX-E only:

– Battery charge too low.

– Faulty fuse.

AMX-E only:

– Recharge the battery.

– Check fuses.

Load cannot be

lowered

– Lift cylinder damaged. – Inform manufacturer’s

service department.

AMX-E only:

– Battery charge too low.

– Faulty fuse.

AMX-E only:

– Recharge the battery.

– Check fuses.

Page 33

1205.GB

E 10

1205.GB

E 10

Page 34

F 1

0708.GB

F Industrial Truck Maintenance

1 Operational safety and environmental protection

The servicing and inspection duties contained in this chapter must be performed in

accordance with the intervals indicated in the maintenance checklists.

F

Any modification to the forklift truck assemblies, in particular the safety mechanisms,

is prohibited. The operational speeds of the truck must not be changed under any

circumstances.

M

Only original spare parts have been certified by our quality assurance department.

To ensure safe and reliable operation of the forklift truck, use only the manufacturer's

spare parts. Used parts, oils and fuels must be disposed of in accordance with the

relevant environmental protection regulations. For oil changes, contact the

manufacturer’s specialist department.

Upon completion of inspection and servicing, carry out the activities listed in the

“Recommissioning” section (see chapter F 7.5).

2 Maintenance Safety Regulations

Maintenance personnel: Industrial trucks must only be serviced and maintained by

the manufacturer’s trained personnel. The manufacturer’s service department has

field technicians specially trained for these tasks. We therefore recommend a

maintenance contract with the manufacturer’s local service centre.

Lifting and jacking up: When an industrial truck is to be lifted, the lifting gear must

only be secured to the points specially provided for this purpose. When jacking up the

truck, take appropriate measures to prevent the truck from slipping or tipping over

(e.g. wedges, wooden blocks). You may only work underneath a raised load handler

if it is supported by a sufficiently strong chain.

Cleaning: Do not use flammable liquids to clean the industrial truck. Prior to cleaning,

implement all necessary safety measures to prevent sparking (e.g. through short

circuits). For battery-operated trucks, the battery connector must be removed.

Only weak suction or compressed air and non-conductive antistatic brushes may be

used for cleaning electric or electronic assemblies.

M

If the truck is to be cleaned with a water jet or a high-pressure cleaner, all electrical

and electronic components must be carefully covered beforehand as moisture can

cause malfunctions.

Do not clean with pressurised water.

After cleaning the truck, carry out the activities detailed in the “Recommissioning”

section.

F 1

0708.GB

F Industrial Truck Maintenance

1 Operational safety and environmental protection

The servicing and inspection duties contained in this chapter must be performed in

accordance with the intervals indicated in the maintenance checklists.

F

Any modification to the forklift truck assemblies, in particular the safety mechanisms,

is prohibited. The operational speeds of the truck must not be changed under any

circumstances.

M

Only original spare parts have been certified by our quality assurance department.

To ensure safe and reliable operation of the forklift truck, use only the manufacturer's

spare parts. Used parts, oils and fuels must be disposed of in accordance with the

relevant environmental protection regulations. For oil changes, contact the

manufacturer’s specialist department.

Upon completion of inspection and servicing, carry out the activities listed in the

“Recommissioning” section (see chapter F 7.5).

2 Maintenance Safety Regulations

Maintenance personnel: Industrial trucks must only be serviced and maintained by

the manufacturer’s trained personnel. The manufacturer’s service department has

field technicians specially trained for these tasks. We therefore recommend a

maintenance contract with the manufacturer’s local service centre.

Lifting and jacking up: When an industrial truck is to be lifted, the lifting gear must

only be secured to the points specially provided for this purpose. When jacking up the

truck, take appropriate measures to prevent the truck from slipping or tipping over

(e.g. wedges, wooden blocks). You may only work underneath a raised load handler

if it is supported by a sufficiently strong chain.

Cleaning: Do not use flammable liquids to clean the industrial truck. Prior to cleaning,

implement all necessary safety measures to prevent sparking (e.g. through short

circuits). For battery-operated trucks, the battery connector must be removed.

Only weak suction or compressed air and non-conductive antistatic brushes may be

used for cleaning electric or electronic assemblies.

M

If the truck is to be cleaned with a water jet or a high-pressure cleaner, all electrical

and electronic components must be carefully covered beforehand as moisture can

cause malfunctions.

Do not clean with pressurised water.

After cleaning the truck, carry out the activities detailed in the “Recommissioning”

section.

Page 35

0708.GB

F 2

Electrical System: Only suitably trained personnel may operate on the truck’s

electrical system. Before working on the electrical system, take all precautionary

measures to avoid electric shocks. For battery-operated trucks, also de-energise the

truck by removing the battery connector.

Welding: To avoid damaging electric or electronic components, remove these from

the truck before performing welding operations.

Settings: When repairing or replacing hydraulic, electric or electronic components or

assemblies, always note the truck-specific settings.

Tyres: The quality of tyres affects the stability and performance of the truck. When

replacing wheels/rollers fitted at the factory, only use manufacturer’s original spare

parts. Otherwise the truck's rated performance cannot be ensured.

When changing wheels and tyres, ensure that the truck does not slew (e.g. when

replacing wheels always left and right simultaneously).

Hydraulic hoses: The hoses must be replaced every six years. When replacing

hydraulic components, also replace the hoses in the hydraulic system.

0708.GB

F 2

Electrical System: Only suitably trained personnel may operate on the truck’s

electrical system. Before working on the electrical system, take all precautionary

measures to avoid electric shocks. For battery-operated trucks, also de-energise the

truck by removing the battery connector.

Welding: To avoid damaging electric or electronic components, remove these from

the truck before performing welding operations.

Settings: When repairing or replacing hydraulic, electric or electronic components or

assemblies, always note the truck-specific settings.

Tyres: The quality of tyres affects the stability and performance of the truck. When

replacing wheels/rollers fitted at the factory, only use manufacturer’s original spare

parts. Otherwise the truck's rated performance cannot be ensured.

When changing wheels and tyres, ensure that the truck does not slew (e.g. when

replacing wheels always left and right simultaneously).

Hydraulic hoses: The hoses must be replaced every six years. When replacing

hydraulic components, also replace the hoses in the hydraulic system.

Page 36

F 3

0708.GB

3 Servicing and inspection

Thorough and expert servicing is one of the most important requirements for the safe

operation of the industrial truck. Failure to perform regular servicing can lead to truck

failure and poses a potential hazard to personnel and equipment.

M

The application conditions of an industrial truck have a considerable impact on the

wear of the service components.

We recommend that a Jungheinrich customer service adviser carries out an

application analysis on site to work out specific service intervals to prevent damage

due to wear.

The service intervals stated are based on single shift operation under normal