Page 1

A single lift cylinder

for easy servicing

Enclosed fork tips

Fast lift as standard

(up to 120 kg)

AMX 10/10e

Scissor lift hand pallet truck (1,000 kg)

The truck can be used as a hand pallet

truck as well as a lift table, supply table

and workbench.

• Steering wheels: Ø 170 mm with a

choice of nylon, rubber or polyurethane tyres.

• Load rollers: Ø 82 mm with a choice of

nylon or polyurethane tyres.

• Lift height: Up to 800 mm, with additional support legs for stability.

• Lifting and lowering: Manual or electro-hydraulic with 0.5 kW lift motor.

• Forks: Robust, torsion-resistant construction with closed fork tips.

• Battery (only for AMX 10e): 70 Ah C5,

maintenance-free.

• AMX 10 with manual hydraulics: The

load can be brought to the optimum

work height with just a few movements

of the tiller. Beyond a certain fork

height, the scissor lift hand pallet truck

is secured by additional support legs.

• AMX 10e with electro-hydraulics: Scissor lift hand pallet trucks are recommended for frequently changing work

heights. The work height can be easily

adjusted at the touch of a button.

Page 2

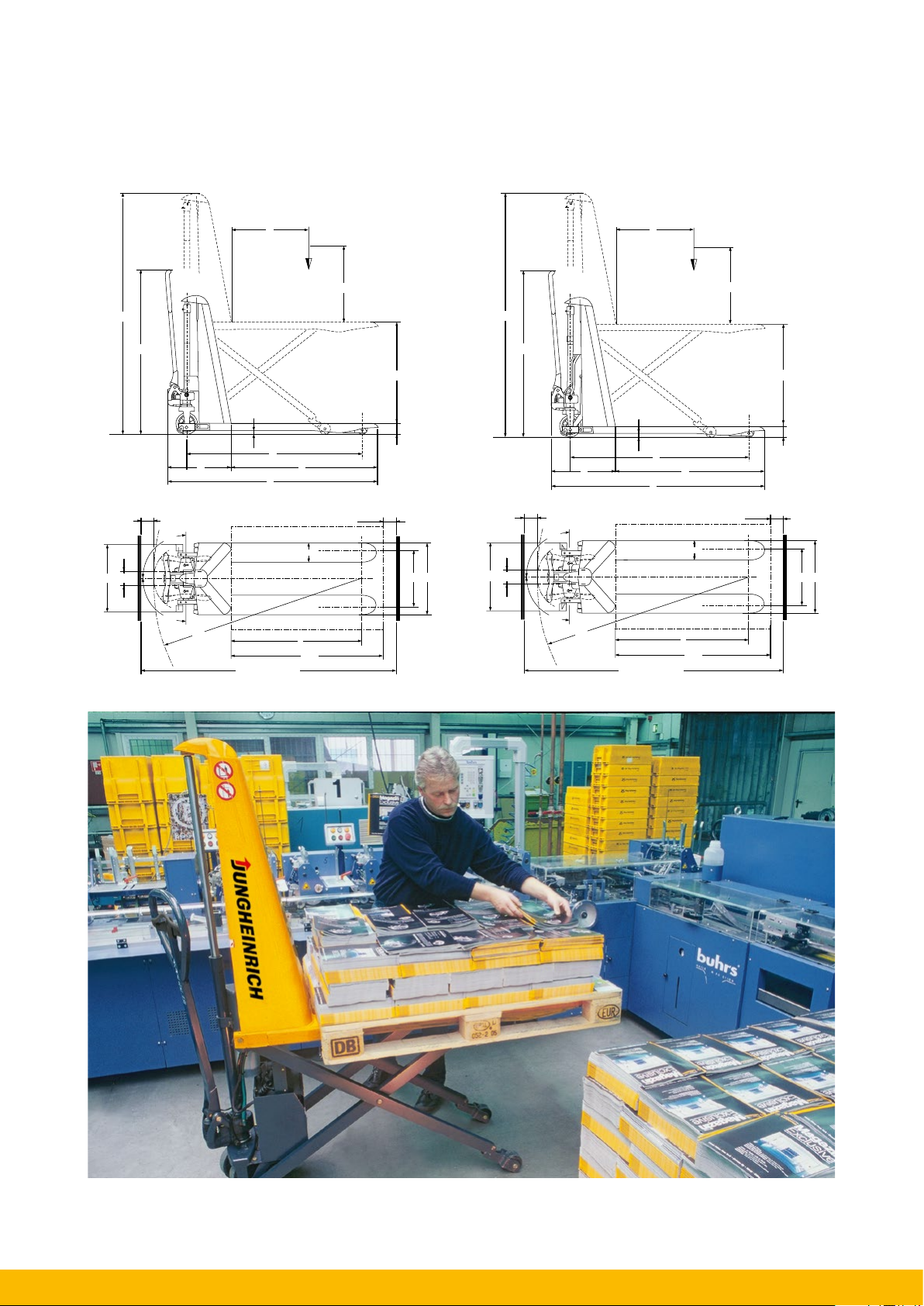

AMX 10/10e

AMX 10

a/2=10 0

b1b

1897

AMX 10e

c

Q

600 Maxi

1897

a/2=100

b

b

1

h

14

l

2

90°

10

90°

Wa

h

14

h

3

m

2

l

2

y

l

l

1

h

13

a/2=100

°

90

10

90

°

Wa

e

b

11b5

x

1200

Ast = Wa + l6– x + a

c

m

2

y

l

1

Ast = Wa + l6– x + a

x

Q

l

1200

600 Maxi

h

3

h

13

a/2=100

e

b

b

11

5

Page 3

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model AMX 10 AMX 10e

1.3 Drive manual Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation hand hand

1.5 Load capacity/rated load Q t 1

1.6 Load centre distance c mm 600

Identification

1.8 Load distance x mm 1030

1.9 Wheelbase y mm 1383

2.1 Service weight kg 157 195

2.2 Axle load, w. load, front / rear kg 406 / 751 443 / 752

2.3 Axle load, w.o. load, front / rear kg 101 / 56 136 / 59

Weights

3.1 Tyres N;C;V

3.2 Tyre size, at front mm Ø 170 x 50

3.3 Tyre size, at rear mm Ø 82 x 62

3.4 Additional wheels (dimensions) mm Ø 82 x 62

3.5 Wheels, number front/rear (× = driven wheels) 2/2

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

mm 109

10

mm 440

11

4.4 Lift h3 mm 714

4.5 Extended mast height h

4.9 Height of tiller in drive position min. / max. h

4.15 Lowered height h

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

mm 1897

4

mm 1299

14

mm 86

13

mm 1650

1

mm 500

2

mm 560

1/b2

4.22 Fork dimensions s/e/l mm 53 / 150 / 1150

4.25 Width over forks b

Basic dimensions

mm 560

5

4.32 Floor clearance centre wheelbase m2 mm 30

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2005

4.35 Turning radius W

mm 1635

a

5.2 Lift speed, w. / w.o. load m/s 0.03 / 0.05

5.3 Lower speed, w. / w.o. load m/s 0.11 / 0.04 0.13 / 0.05

3)

1)

Issue: 11/2012

2)

Perform-

ance data

6.2 Lift motor rating at S3 15% kW 0.5

6.3 Battery according to DIN 43531/35/36 A,B,C, no maintenance-free

6.4 Battery voltage/nominal capacity K5 V/Ah 12 / 70

Electrics

6.5 Battery weight kg 24

4)

1)

680 mm also possible

2)

Electric and manual lift

3)

Lateral support rollers

4)

On-board charger

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Easy handling

The easy-to-use controls are equally

suitable for both left and right-handed

operators. The special lowering valve enables loads to be lowered precisely or in

small increments.

Adjustable lift height reduces strain

on the back

Jobs which involve a great deal of

bending and heavy lifting can soon have

a detrimental eect on health. The work

height of the AMX 10 / AMX 10e can be

varied by a height of up to 800 mm. This

ensures back strain is reduced during

operation. The scissor lift hand pallet

truck can also be equipped with lateral

support rollers, so that travel is also possible in the raised position.

Eortless lifting and lowering

Lifting can be by either manual hydraulic

lift (AMX 10) or electro-hydraulic lift (AMX

10e) with a 0.5 kW lift motor. The pump

unit has an integrated reservoir. The

lowering valve integrated in the pump

unit facilitates precise lowering via hand

lever. The hydraulic system is protected

against overloading by a pressure relief

valve.

Battery and charger (AMX 10e)

A built-in electronic charger is fitted as

standard. The maintenance-free battery

(70 Ah) can be charged at any standard

240-V socket. The charger automatically

switches o when the charging process

is completed.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_AMX 10/10e_042014_en_UK_000

Loading...

Loading...