Page 1

AMW 22 / AMW 22p / AMW 22ps

12.14

Operating instructions

51119800

11.19

en-GB

AMW 22

AMW 22p

AMW 22ps

Page 2

2

Page 3

Declaration of Conformity

Manufacturer

Jungheinrich AG, 22039 Hamburg, Germany

Description

Industrial truck

Type Option Serial no. Year of

manufacture

AMW 22

AMW 22p

AMW 22ps

On behalf of

Date

EU DECLARATION OF CONFORMITY

The undersigned hereby declare that the powered truck described in detail complies

with the current versions of European Directives 2006/42/EG (Machinery Directive)

and 2014/30/EU (Electromagnetic Compatibility - EMC). The manufacturer is

authorised to compile the technical documentation.

11.19 en-GB

3

Page 4

11.19 en-GB

4

Page 5

Foreword

Notes on the operating instructions

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide

sufficient instruction for the safe operation of the industrial truck. The information is

provided clearly and concisely. The chapters are arranged by letter and the pages

are numbered continuously.

The operator manual details different industrial truck models. When operating and

servicing the industrial truck, make sure that the particular section applies to your

truck model.

Our trucks are subject to ongoing development. We reserve the right to alter the

design, equipment and technical features of the system. No guarantee of particular

features of the truck should therefore be assumed from the present operating

instructions.

Safety notices and text mark-ups

Safety instructions and important explanations are indicated by the following

graphics:

Z

DANGER!

Indicates an extremely hazardous situation. Failure to comply with this instruction will

result in severe irreparable injury and even death.

WARNING!

Indicates an extremely hazardous situation. Failure to comply with this instruction

may result in severe irreparable injury and even death.

CAUTION!

Indicates a hazardous situation. Failure to comply with this instruction may result in

slight to medium injury.

NOTICE

Indicates a material hazard. Failure to comply with this instruction may result in

material damage.

Used before notices and explanations.

Indicates standard equipment

t

Indicates optional equipment

o

11.19 en-GB

5

Page 6

11.19 en-GB

6

Page 7

11.19 en-GB

Contents

.

A Correct Use and Application 9

.

1 General 9

2 Correct application 9

3 Approved application conditions 9

4 Proprietor responsibilities 10

5 Adding attachments and/or optional equipment 10

.

B Truck Description 11

.

1 Application 11

2 Calibrated weighing system (AMW 22p / AMW 22ps) 11

3 Assemblies and Functional Description 12

3.1 Truck Component Overview 12

3.2 Weighing System Component Overview 13

4 Technical Specifications 14

4.1 Performance data 14

4.2 Weighing System Weight Display 14

4.3 Weighing Variance of the Weighing System 15

4.4 Dimensions 16

4.5 Weights 17

4.6 Batteries 17

4.7 Tyre type 17

4.8 Operating conditions 18

4.9 Identification Points and Data Plates 19

4.10 Wind loads 20

.

C Transport and Commissioning 21

.

1 Lifting by crane 21

2 Transport 22

3 Using the Truck for the First Time 23

.

D Batteries/Accumulators - Replacement/Charging 25

.

1 Safety Regulations for Handling Batteries and Accumulators 25

2 Safety regulations for handling lithium-ion batteries 27

2.1 Safety regulations 27

2.2 Potential hazards 28

2.3 Charging the battery 32

2.4 Battery lifetime and maintenance 33

2.5 Storing the battery 33

2.6 Faults 33

2.7 Disposal and transport of a lithium-ion battery 35

2.8 Hazard and Safety Instruction Phrases 39

3 Power Supply AMW 22 41

3.1 General information 41

3.2 Replacing batteries 41

4 Power Supply AMW 22p 43

4.1 General information 43

4.2 Charging the battery 43

7

Page 8

5 AMW 22ps power supply 45

5.1 General information 45

5.2 Battery charge status 46

5.3 Charging the battery 47

.

E Operation 49

.

1 Safety Regulations for the Operation of Forklift Trucks 49

2 Displays and Controls 51

3 Starting up the truck 52

3.1 Checks and Operations to Be Performed Before Starting Daily Work 52

4 Industrial Truck Operation 53

4.1 Safety regulations for truck operation 53

4.2 Parking the truck securely 54

4.3 Pushing/Pulling 55

4.4 Steering 55

4.5 Brakes 56

4.6 Lifting, transporting and depositing loads 57

4.7

4.8

4.9 AMW 22ps weighing system 76

4.10

5 Troubleshooting 102

5.1 Load cannot be lifted 102

.

AMW 22 / AMW 22p Standard Weigher (t) 60

AMW 22p Weigher, Special Version (o) 66

On-Board Printer (o) 101

F Checking the Industrial Truck 103

.

1 Spare Parts 103

2 Operational Safety and Environmental Protection 103

3 Safety Regulations for Checks 104

4 Lubricants and Lubrication Schedule 106

4.1 Handling consumables safely 106

4.2 Lubrication Schedule 108

4.3 Consumables 108

5 Checks 109

5.1 Preparing the Truck for Checking 109

5.2

6 Decommissioning the Industrial Truck 110

6.1 Prior to decommissioning 110

6.2 Restoring the truck to service after decommissioning 110

7 Safety tests to be performed at intervals and after unusual incidents 111

8 Final de-commissioning, disposal 111

9 Operating Company Checks 112

(o) Check and Adjust Foot-Activated Parking Brake 109

11.19 en-GB

8

Page 9

A Correct Use and Application

1 General

The truck must be used, operated and serviced in accordance with the present

instructions. All other types of use are beyond its scope of application and may result

in damage to personnel, the industrial truck or property.

2 Correct application

NOTICE

The maximum load and the maximum permissible load distance given on the data

plate must be observed.

The load must be fully supported by the load handler, evenly distributed and raised

completely from the ground.

The following operations are in accordance with regulations and are permitted:

– Lifting and lowering loads.

– Transporting lowered loads.

The following operations are prohibited:

– Carrying and lifting passengers.

– Pushing or pulling loads.

– Transverse handling of long loads.

3 Approved application conditions

– Operation in industrial and commercial environments.

– Permissible temperature range see page 18.

– Operation only on secure, level surfaces with sufficient load-bearing capacity.

– Operation only on routes that are visible and approved by the operating company.

– Do not negotiate inclines.

WARNING!

Use under extreme conditions

Using the truck under extreme conditions can result in malfunctions and accidents.

Special equipment and authorisation are required if the truck is to be constantly

u

used in extreme conditions, especially in dusty or corrosive atmospheres.

The truck cannot be used in areas at risk of explosion.

u

In adverse weather conditions (thunder, lightning) the industrial truck must not be

u

operated outside or in endangered areas.

11.19 en-GB

9

Page 10

4 Proprietor responsibilities

For the purposes of the present operating instructions the “operating company” is

defined as any natural or legal person who either uses the industrial truck himself, or

on whose behalf it is used. In special cases (e.g. leasing or renting) the proprietor is

considered the person who, in accordance with existing contractual agreements

between the owner and user of the industrial truck, is charged with operational

duties.

The proprietor must ensure that the industrial truck is used only for the purpose it is

intended for and that danger to life and limb of the user and third parties are

excluded. Furthermore, accident prevention regulations, safety regulations and

operating, servicing and repair guidelines must be followed. The operating company

must ensure that all users have read and understood these operating instructions.

NOTICE

Failure to comply with the operating instructions invalidates the warranty. The same

applies if improper work is carried out on the truck by the customer or third parties

without the permission of the manufacturer.

5 Adding attachments and/or optional equipment

The mounting or installation of additional equipment which affects or enhances the

performance of the industrial truck requires the written permission of the

manufacturer. Local authority approval may also need to be obtained.

Local authority approval however does not constitute the manufacturer’s approval.

10

11.19 en-GB

Page 11

B Truck Description

1 Application

The pallet truck is designed to transport goods on level surfaces. Open bottom

pallets or roll cages can be lifted.

The rated capacity is indicated on the data plate or the capacity plate Qmax.

The weighing system provides the option of weighing loads, adding individual

weights and displaying a total weight. Current weighing data and entered data can

be issued on the on-board printer (o). The date and time are only issued if this option

has been activated.

2 Calibrated weighing system (AMW 22p / AMW 22ps)

The AMW22p / AMW 22ps industrial truck can be equipped with an optional

calibratable weighing system and manufacturer calibration in accordance with OIML

Approval Class III (European Approval No. T2782) in order to perform weighing

operations for commercial purposes.

The calibrated weighing system is approved separately by the notified body with a

serial number and is given an official inspection label. The inspection label confirms

the accuracy within the permissible calibration tolerance. The supplied declaration of

conformity must be retained. The area of validity of the EC calibration comprises the

EU state specified on the declaration of conformity. Weighing systems that are

currently in use are tested in accordance with the statutory provisions of the

respective EU country.

Z

If the validity period of the calibration is limited according to national regulations, the

owner of a truck with a calibrated weighing system bears sole responsibility for its

timely recalibration.

Significant geographical changes in location of the truck require a recalibration to be

performed before the weighing system can be operated.

NOTICE

The validity of the calibration becomes void in the event of damage to the truck,

manual intervention in the operation of equipment such as the housing opening, as

well as any damage or removal of the test plaques.

Calibratable weighing systems with deviations beyond the traffic error limit, an

exceeded reverification date or which have passed their calibration expiry date must

be taken out of service.

11.19 en-GB

11

Page 12

3 Assemblies and Functional Description

6

13452

798

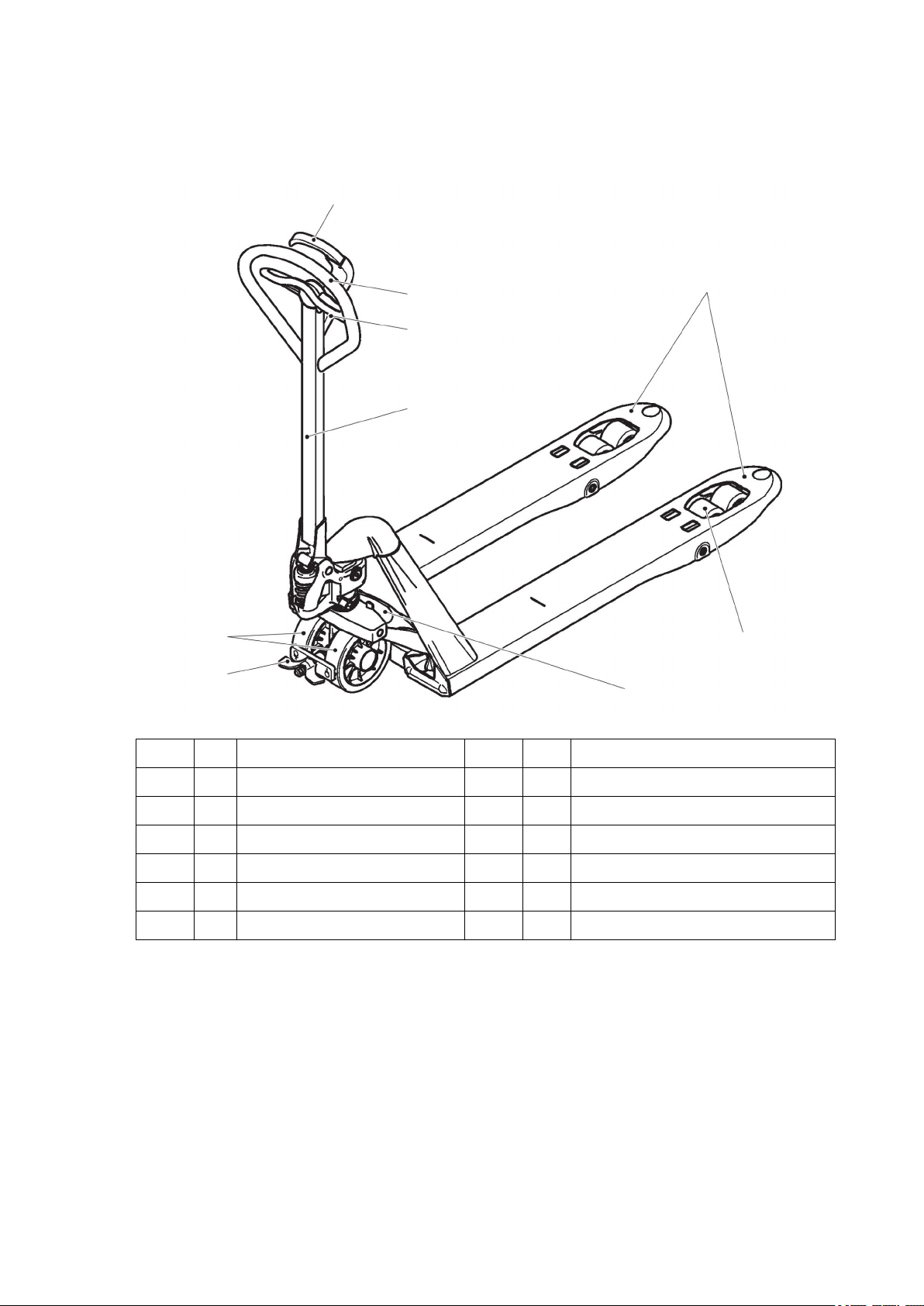

3.1 Truck Component Overview

Item Description Item Description

1

2

3

4

5

Travel and parking brake 6

o

Load handler 7

t

Handle 8

t

“Lift/lower fork” handle 9

t

Tiller

t

Standard equipment

t

Steered wheels

t

Load wheels

t

Foot-activated parking brake

o

Data plate

t

Optional equipment

o

11.19 en-GB

12

Page 13

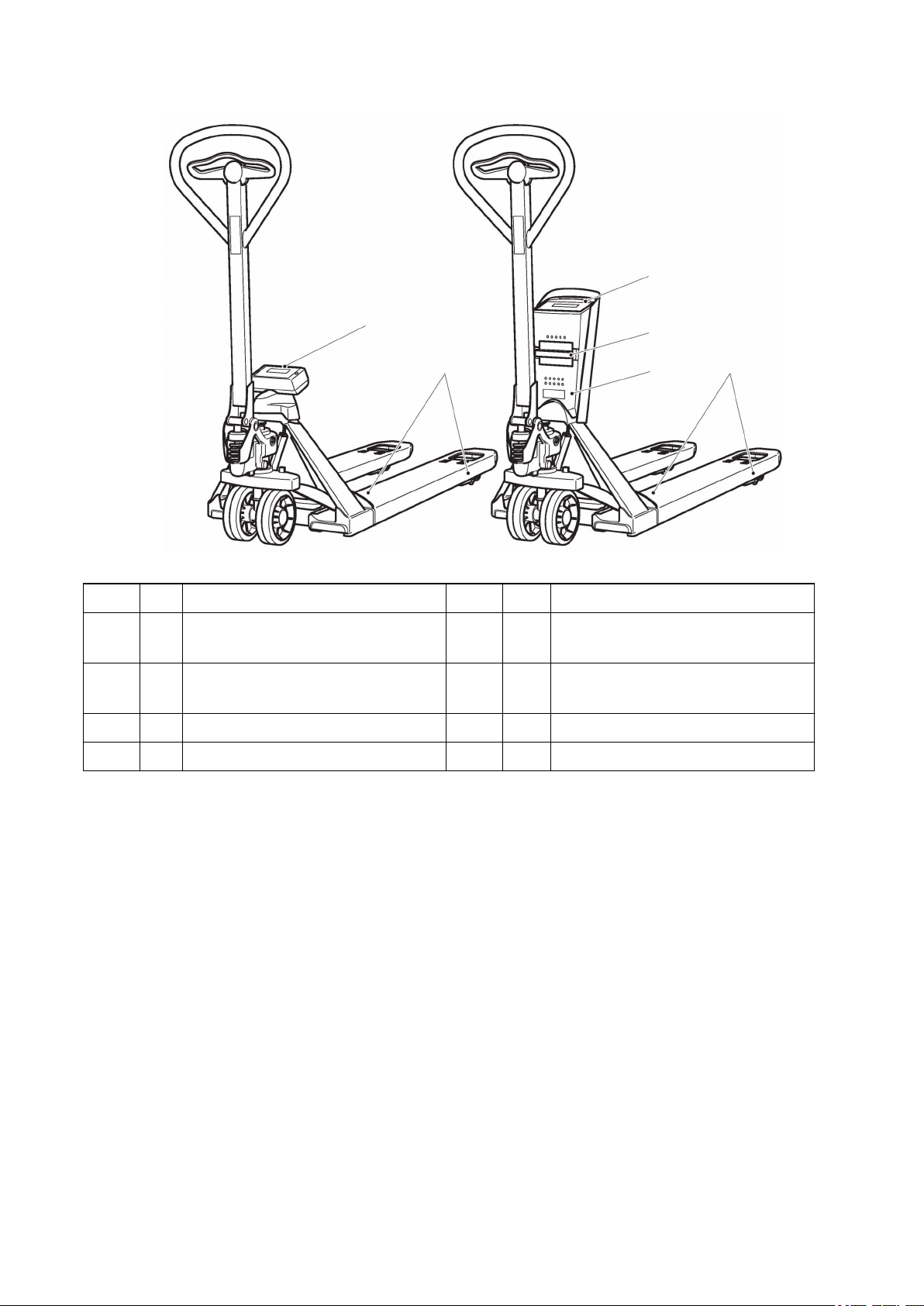

3.2 Weighing System Component Overview

1113101312

14

Item Designation Item Designation

10

Display and evaluation unit

t

13

t

Load cells

(AMW 22p / AMW 22ps)

11

Display and evaluation unit

t

14

On-board printer

o

(AMW 22)

12

Battery

t

Standard equipment

t

Optional equipment

o

3.2.1 Weight Detection

Four load cells are bolted to the load carrying frame and also to the load attachment

head. The load cells and the connection cable to the evaluation and display unit are

installed so that they are protected.

3.2.2 Evaluation and Display Unit

Weights, system statuses and quantities (o) are displayed. All functions of the

weighing system can be called up using the keys below the display. The zero setting

is performed automatically within set limits.

3.2.3

On-Board Printer (o)

11.19 en-GB

Individual weights, tare weights and total weights can be output on thermal paper, as

can quantities (o) with identification code numbers (o) and time of printing (o).

13

Page 14

4 Technical Specifications

Z

The technical specification is given according to the German guideline "Type sheets

for industrial trucks". Technical modifications and additions reserved.

4.1 Performance data

AMW 22 / AMW 22p /

Q Rated capacity 2200 kg

c Load centre distance 600 mm

x Load distance 890 mm

Lowering speed with / without load 90/20 mm/s

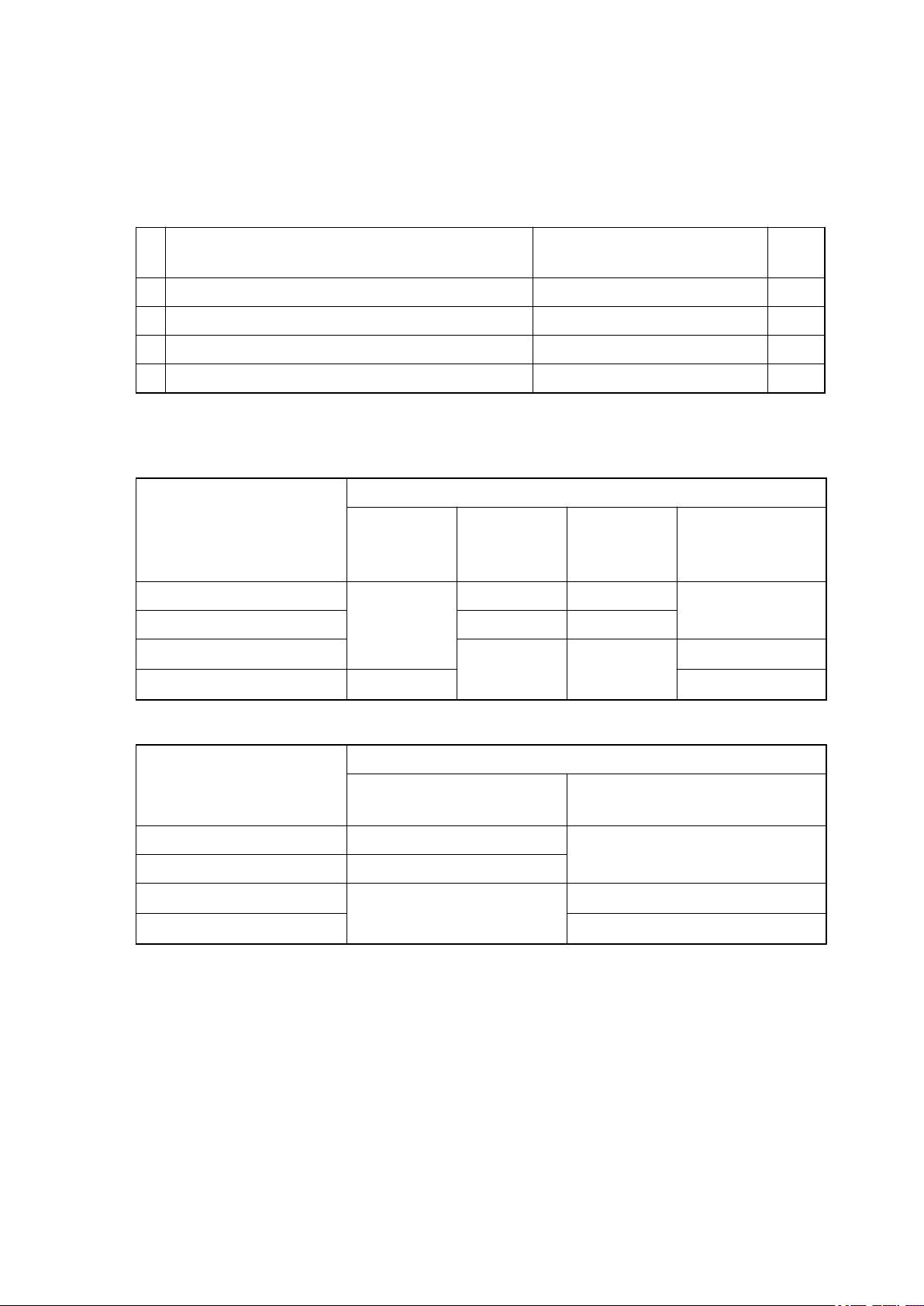

4.2 Weighing System Weight Display

AMW 22 and AMW 22p

Weight range Resolution of weight display

AMW 22 AMW 22p

(t)

AMW 22ps

AMW 22p

1)

(o)

1)

AMW 22p

Calibrated (o)

1)

0 to 200 kg 1.0 kg 0.2 kg 0.1 kg 0.5 kg (o)

200 to 500 kg 0.5 kg 0.2 kg

500 - 2000 kg (t)

500 - 2200 kg (o)

1.0 kg

0.5 kg 1.0 kg

AMW 22ps (from year of manufacture 2020)

Weight range Resolution of weight display

AMW 22ps (t)

1)

AMW 22ps

Calibrated (o)

1)

0 to 200 kg 0.2 kg 0.5 kg

200 to 500 kg 0.5 kg

500 - 2000 kg (t)

500 - 2200 kg (o)

1.0 kg 1.0 kg

1) Multi-range display: The resolution of the weight display depends on the weight.

During weighing out, the resolution does not change on passing the boundary to the

next lower weight range.

14

11.19 en-GB

Page 15

4.3 Weighing Variance of the Weighing System

AMW 22 Within a temperature range of -10 to +40°C, the maximum weighing

variance is 0.1% of the overall weighing range.

Z

AMW 22p

AMW 22ps

Outside the listed temperature range, weighing variances of up to 0.3% can occur.

Within a temperature range of -10 to +40°C the maximum weighing

variance is 0.1% of the measured weight.

11.19 en-GB

15

Page 16

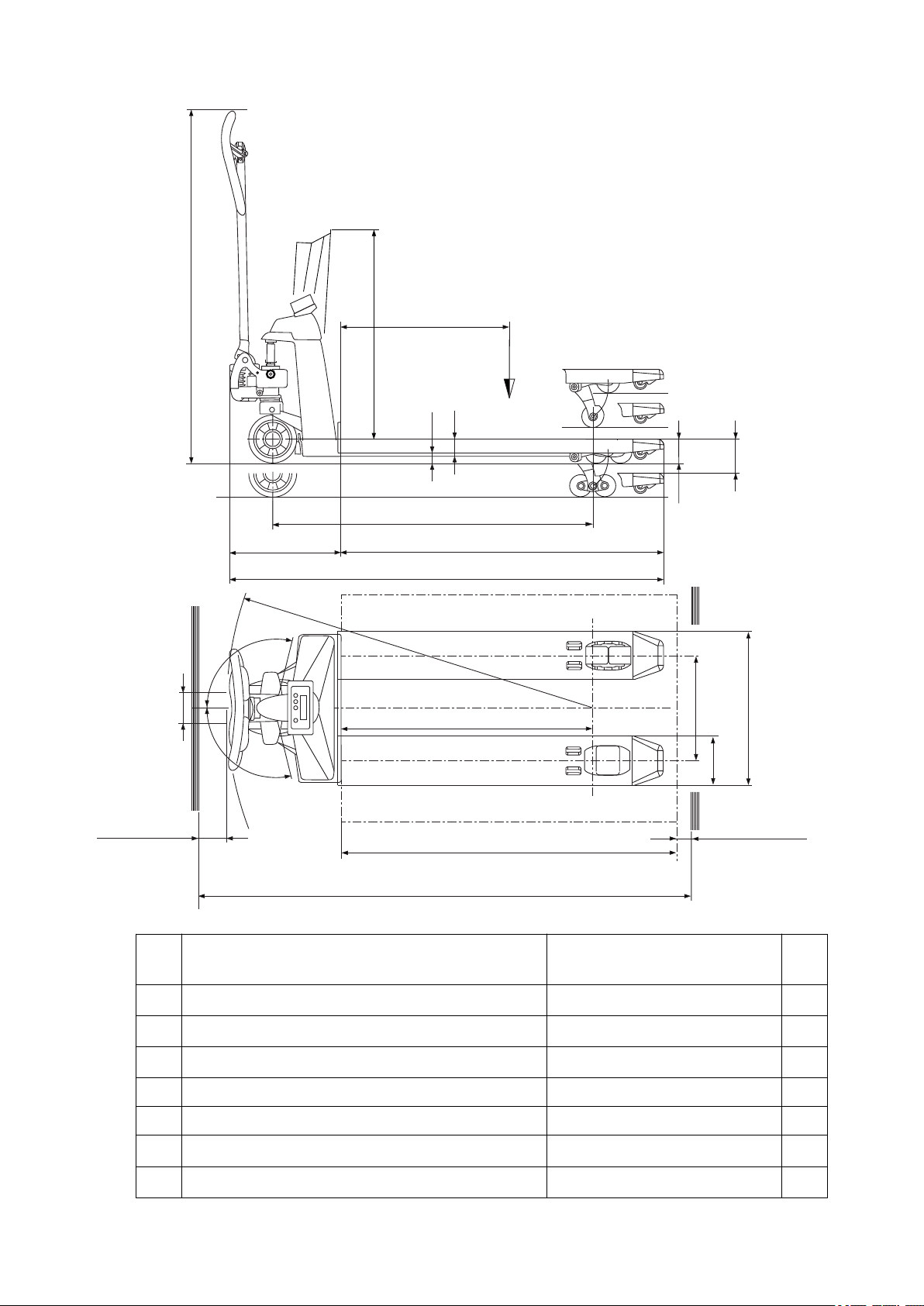

4.4 Dimensions

s

e

W

a

x

h

14

b

11

b

10

b1= b

5

h

3

h

13

l

1

l

6

l

2

l

m

2

674 (AMW 22p / AMW 22ps)

y

c

Q

104°

104°

a/2=100

a/2=100

Ast = W

a+l6

-x+a

Designation AMW 22 / AMW 22p /

h3Lift

h13Lowered height

h14Height of tiller handle

y Wheelbase 1110 mm

s/e/l Fork dimensions 62/170/1150 mm

AMW 22ps

122 mm

86 mm

1234 mm

16

l1Overall length 1546

l2Length to fork face

396 mm

mm

11.19 en-GB

Page 17

Designation AMW 22 / AMW 22p /

AMW 22ps

b1Overall width

b5Outer fork distance

b10Track width, front

b11Track width, rear

Ast Working aisle width 1000x1200 transv. 1763 mm

Ast Aisle width 800x1200 length. 1813 mm

Wa Turning radius 1303 mm

4.5 Weights

Designation AMW 22 / AMW 22p /

Net weight 99/102 kg

Axle load, w.o. load front/rear 61/38 kg

Axle load, w. load front/rear (AMW 22) 578/1721 kg

4.6 Batteries

540 mm

540 mm

109 mm

370 mm

AMW 22ps

Truck Battery type Voltage/capacity

AMW 22 Alkaline (type AA) 4x1.5 V

AMW 22p Lead-gel battery

AMW 22ps Lithium-ion battery

4.7 Tyre type

AMW 22 / AMW 22p /

Tyre size, front Ø 170 x 50 mm

Tyre size, rear Ø 82 x 96 mm

Tyre size, rear (tandem wheels) Ø 82 x 62 mm

12 V/1.2 Ah

(rechargeable)

14.8 V/5 Ah

(rechargeable)

AMW 22ps

11.19 en-GB

17

Page 18

4.8 Operating conditions

– During operation: -10°C to 40°C

Ambient lighting

– - At least 50 Lux during operation

Z

Outside the listed temperature range, weighing variances of up to 0.3% can occur.

NOTICE

Rapid changes in temperature should be avoided as they can cause moisture to

condense within the electronics. When large temperature differences are

encountered, switch the weighing system off whilst it acclimatises.

18

11.19 en-GB

Page 19

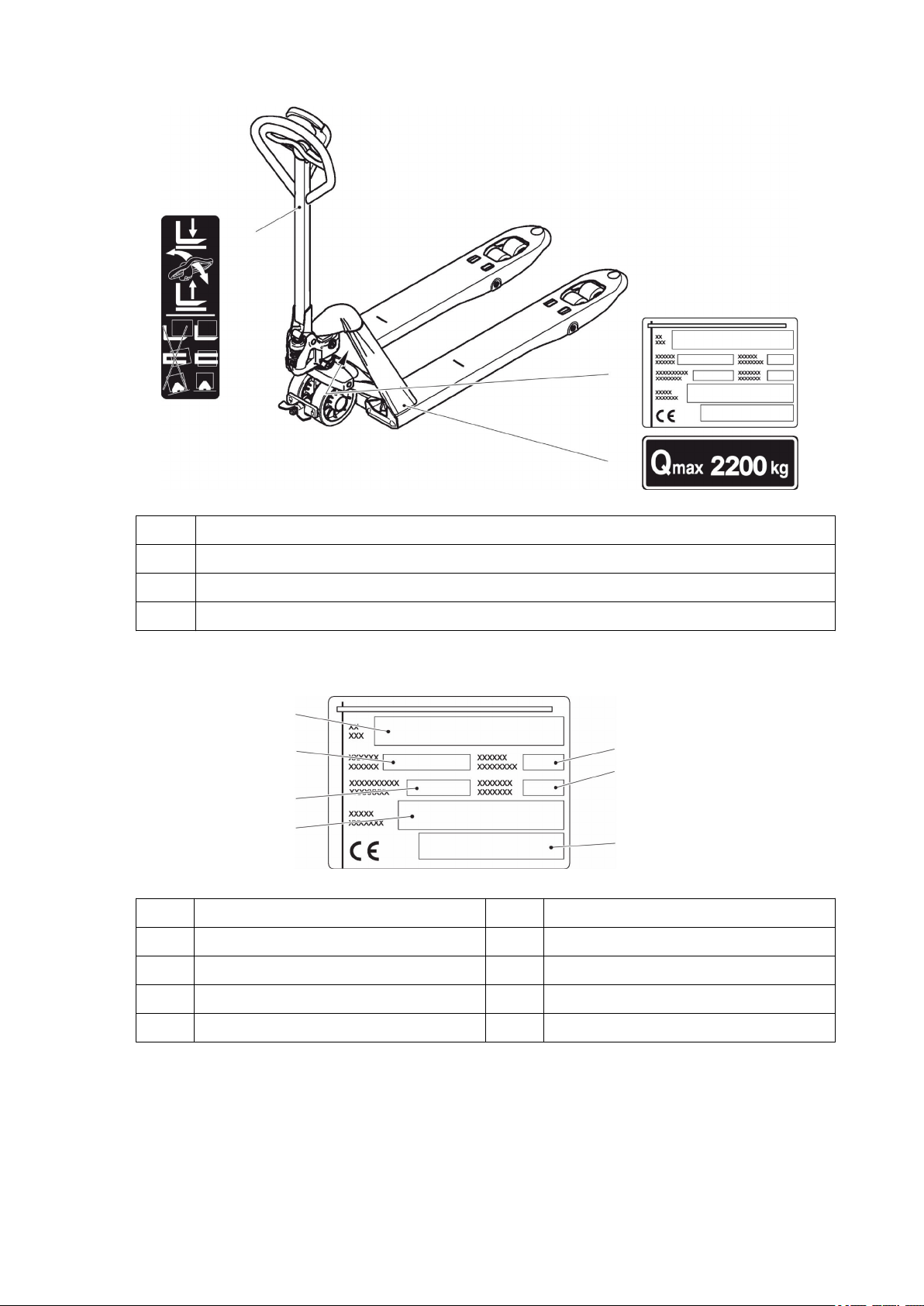

4.9 Identification Points and Data Plates

9

16

15

222117

19

18

23

20

Item Model

9 Truck data plate

15 Plate - Operation / Lifting

16 Capacity Qmax

4.9.1 Data plate

Item Description Item Description

17 Model 21 Rated capacity (kg)

18 Year of manufacture 22 Manufacturer

11.19 en-GB

Z

19 Serial number 23 Manufacturer's logo

20 Net weight in kg

For queries regarding the truck or ordering spare parts always quote the truck serial

number (19).

19

Page 20

4.10 Wind loads

Wind forces can affect the stability of a truck when lifting, lowering and transporting

loads with large surface areas.

Light loads must be especially secured when they are subjected to wind forces. This

will prevent the load from sliding or falling.

Stop the truck in both cases.

20

11.19 en-GB

Page 21

C Transport and Commissioning

24

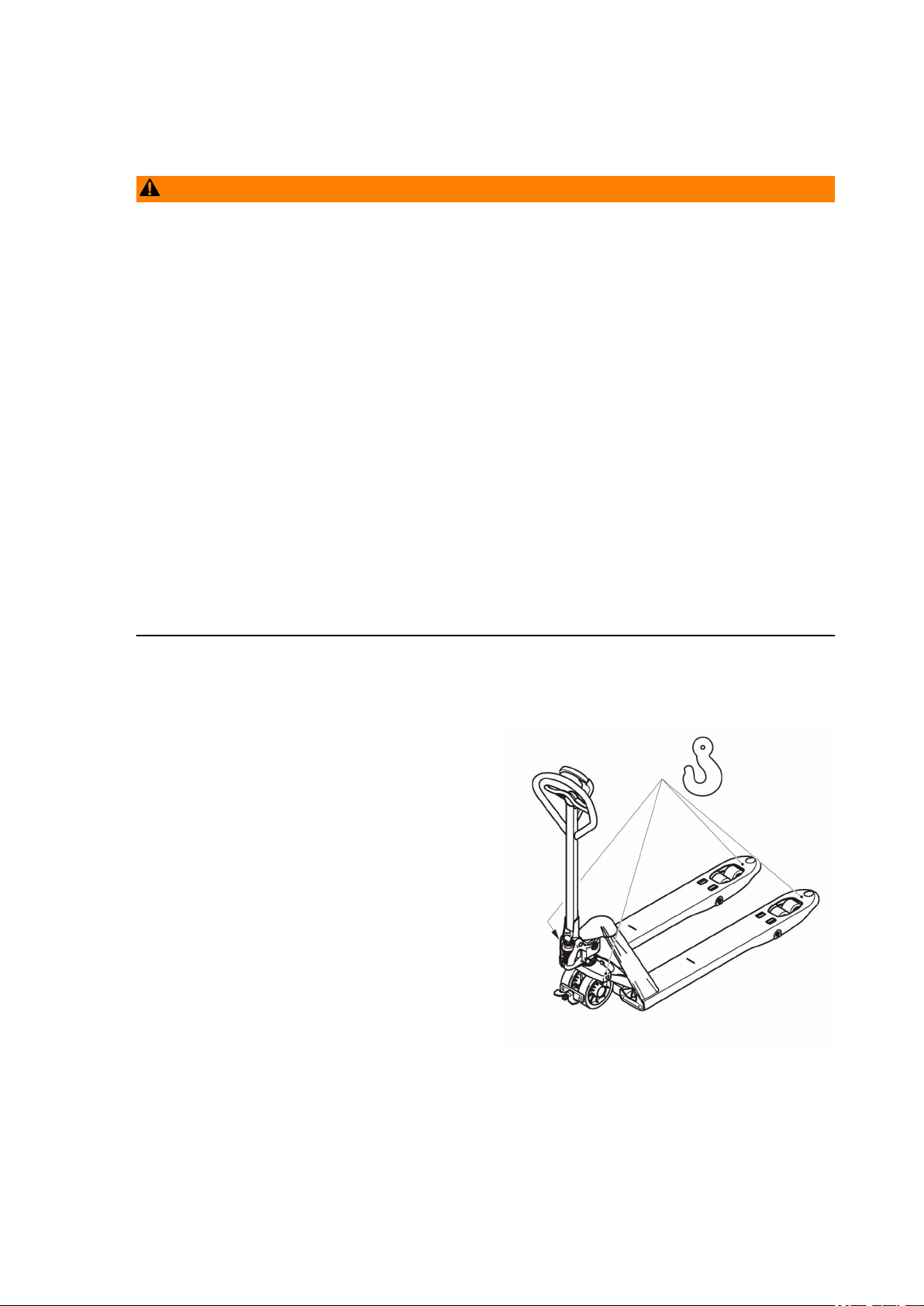

1 Lifting by crane

WARNING!

Improper loading by crane can result in accidents

Improper use or use of unsuitable lifting gear can cause the truck to crash when

being loaded by crane.

Prevent the truck from hitting other objects during lifting, and avoid uncontrolled

movements. If necessary, secure the truck with guide ropes.

The truck may be loaded only by people who are trained in using lifting

u

accessories and lifting gear.

Wear personal protective equipment (e.g. safety shoes, safety helmet, hi-vis

u

jacket, protective gloves) when loading by crane.

Do not stand under suspended loads.

u

Do not walk into or stand in a hazardous area.

u

Always use lifting gear with sufficient capacity (for truck weight, see truck data

u

plate).

Always attach the crane lifting gear to the prescribed attachment points and

u

prevent them from slipping.

Use the lifting accessories only in the prescribed load direction.

u

Crane lifting gear must be fastened in such a way that it does not come into

u

contact with any attachments when lifting.

Lifting the truck by crane

Requirements

– Park the truck securely, see page 54.

Tools and Material Required

– Lifting gear

– Crane lifting gear

Procedure

• Secure the crane lifting gear to the strap

points (24).

The truck can now be lifted by crane.

11.19 en-GB

21

Page 22

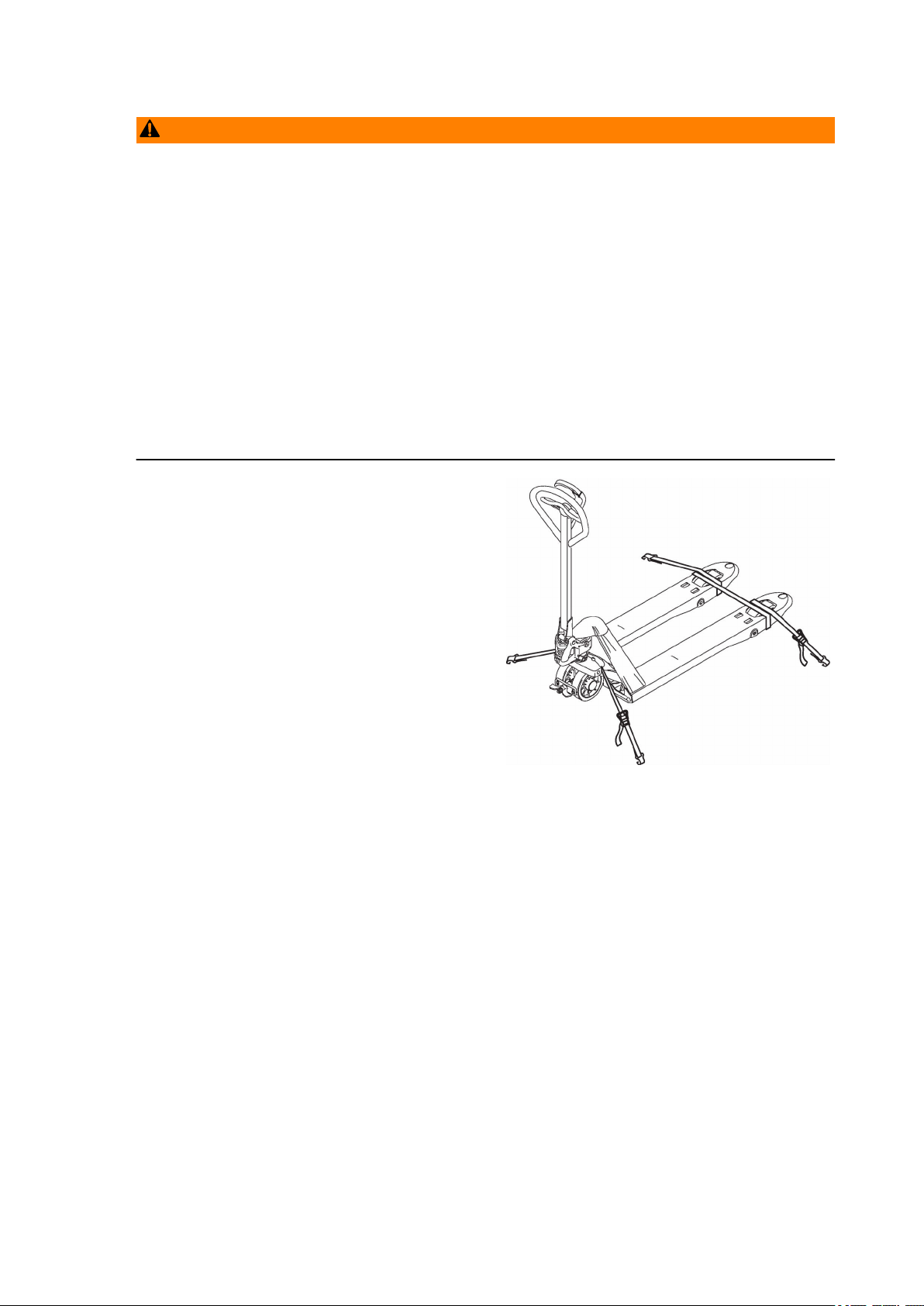

2 Transport

25

25

WARNING!

Accidental movement during transport

Improper fastening of the truck and mast during transport can result in serious

accidents.

Loading must only be performed by specialist personnel trained for this purpose.

u

The specialist personnel must be instructed in securing loads on road vehicles and

handling load securing devices. In each case correct measurements must be

taken and appropriate safety measures applied.

The truck must be securely fastened when transported on a lorry or a trailer.

u

The lorry or trailer must have fastening rings.

u

Use wedges to prevent the truck from moving.

u

Use only fastening belts with sufficient strength.

u

Use non-slip materials to securing the load aids (pallet, wedges, ...) e. g. non-slip

u

mats.

Securing the truck for transport

Requirements

– The truck is now loaded.

– The truck is now parked securely, see

page 54.

Tools and Material Required

– Lashing straps

Procedure

• Attach the lashing straps (25) to the

industrial truck and the transport vehicle

and tension sufficiently.

The truck can now be transported.

11.19 en-GB

22

Page 23

3 Using the Truck for the First Time

Procedure

• Check the equipment is complete.

The truck can now be started, see page 52.

Z

When the vehicle is parked, the surface of the tyres will flatten. The flattening will

disappear after a short period of operation.

11.19 en-GB

23

Page 24

24

11.19 en-GB

Page 25

D Batteries/Accumulators - Replacement/

Charging

1 Safety Regulations for Handling Batteries and

Accumulators

Maintenance personnel

Accumulators must only be charged and batteries only replaced by the operating

company. These operating instructions and the manufacturer’s instructions

concerning batteries and charging stations must be observed when carrying out the

work.

WARNING!

Risk of accidents and injury when handling batteries and accumulators

Batteries and accumulators contain chemicals that are poisonous and corrosive.

Avoid contact at all costs.

Do not dismantle or forcibly open batteries and accumulators.

u

Do not subject batteries and accumulators to heat, fire or direct sunlight.

u

Do not short-circuit batteries and accumulators. Store batteries and accumulators

u

so that no short circuits can occur through other batteries and accumulators or

metal objects.

Never use batteries or accumulators of different makes, capacity, size or type at

u

the same time in one truck.

Failure to comply could result in explosions!

u

Seek medical assistance immediately if you have swallowed a battery or

u

accumulator.

Do not subject batteries and accumulators to impacts.

u

Keep battery terminals and contacts clean and dry.

u

If a battery or accumulator is leaking, do not allow the liquid to come into contact

u

with the skin or eyes. If this has already happened, rinse the affected part with

plenty of water and seek medical assistance immediately.

Keep batteries and accumulators in a clean and dry environment, out of the reach

u

of children.

11.19 en-GB

Park the truck securely before carrying out any work on the batteries/accumulators

(see page 54).

25

Page 26

Battery disposal

NOTICE

Batteries must be disposed of in accordance with the relevant national

environmental protection regulations.

Used batteries are recyclable commodities. As indicated by the marking showing a

crossed-out waste bin, batteries must not be disposed of as domestic waste.

Return or recycling of batteries must be ensured in accordance with the Battery

Directive 2006/66/EG.

Used batteries must be treated as hazardous waste. Batteries marked with the

recycling symbol and the sign showing a crossed-out rubbish bin should not be

disposed of with ordinary household waste.

26

11.19 en-GB

Page 27

2 Safety regulations for handling lithium-ion batteries

2.1 Safety regulations

WARNING!

Unsuitable batteries without manufacturer approval can be dangerous.

Do not use any batteries without approval from the manufacturer.

u

The battery equipment must only be replaced with the manufacturer's

u

authorisation.

When inserting the battery, ensure that it is securely seated in the battery

u

compartment.

– Do not physically machine or modify the battery.

– Do not open, damage, penetrate or bend the battery.

– Do not throw the battery into a fire.

– Protect the battery from high temperatures and overheating.

– Protect the battery from solar irradiation.

– Keep the battery away from radiant sources and strong heat sources.

– The specified charging, operating and storage temperature ranges must be

observed.

Failure to comply with these safety instructions can result in fire and explosion or the

leakage of harmful materials.

11.19 en-GB

27

Page 28

2.2 Potential hazards

+-

2.2.1 Symbols - Safety and Warnings

Used lithium-ion batteries must be treated as hazardous waste.

Lithium-ion batteries marked with the recycling symbol and the sign showing a

crossed-out waste bin must not be disposed of with ordinary household waste.

Buy-back terms and type of recycling are to be agreed with the manufacturer in

accordance with the Battery Directive 2006/66/EG.

Avoid fire and short circuits due to overheating.

Do not ignite or position an open flame, glowing embers, or sparks near the

lithium-ion battery.

Keep lithium-ion batteries away from strong heat sources.

Hot surfaces.

Battery cells can generate very high short-circuit currents, causing them to

become hot.

Dangerous electrical voltage!

Battery cells can generate very high short-circuit currents, causing them to

become hot.

Caution!

The metal parts of the battery cells are constantly under voltage, so do not

place any foreign objects or tools on the lithium-ion battery.

Observe the accident prevention regulations and DIN EN 50272-3.

Wear personal protective equipment (e.g. safety goggles and safety gloves)

when handling damaged battery cells and lithium-ion batteries. Use only

insulated tools.

If the contents leak out, do not inhale the fumes.

Always wash your hands after completing the work.

Do not mechanically machine the lithium-ion battery, strike, crush, compress,

notch, dent or modify it in any way.

Do not open, damage, penetrate, bend, heat the lithium-ion battery or allow it to

become hot, do not throw it into a fire, short circuit it or immerse it in water. Do

not store it or operate it in pressurised containers.

Follow the operating instructions and keep them in a visible position in the

charging area.

If any faults are found on the lithium-ion battery, contact the manufacturer's

customer service department immediately.

Do not carry out any actions on your own.

Do not open the lithium-ion battery.

Protect the lithium-ion battery from solar radiation or other forms of heat

radiation.

Do not expose the lithium-ion battery to heat sources.

11.19 en-GB

28

Page 29

2.2.2 Explosion and fire hazard

WARNING!

Physical damage, thermal effects or incorrect storage in the event of a defect can

result in explosions or fire.

The battery materials can be flammable.

2.2.2.1 Particular hazard from combustion products

The lithium ion battery may be damaged by a fire in the vicinity of the lithium ion

battery. When fighting a lithium-ion battery fire, the following dangers and information

must be taken into consideration.

WARNING!

Contact with combustion products can be hazardous

Fires produce combustion products.

Combustion is a chemical process by which a flammable material combines with

oxygen under heat and light (fire).

The resulting combustion products can occur in the form of smoke, through leaking

fluids, escaping gases, debris as well decomposition products of certain chemicals.

These combustion products are substances that enter the body through the

respiratory tract and / or the skin, where they can produce and adverse effects such

as choking.

Avoid contact with combustion products.

u

Use protective equipment.

u

– Hydrogen fluoride (HF) Hydrofluoric acid = extremely corrosive

– Risk of toxic substances produced by pyrolysis

– Risk of highly flammable gas mixtures.

– Other combustion products: Carbon monoxide & -dioxide, manganese, nickel and

cobalt oxides.

11.19 en-GB

29

Page 30

2.2.2.2 Special fire fighting protective equipment

– Use self-contained breathing apparatus.

– Wear protective overalls.

2.2.2.3 Additional fire fighting instructions

To prevent secondary fires from occurring, the lithium-ion battery must be cooled

from the outside. Fluids or solids must never be directed into the lithium-ion battery.

Suitable extinguishing agents

– Carbon dioxide extinguisher (CO2)

– Water (not on mechanically opened or damaged batteries!)

Unsuitable extinguishing agents

– Foam

– Grease fire extinguishing agents

– Powder extinguishers

– Metal fire extinguishers (PM 12i extinguishers)

– Metal fire powder PL-9/78 (DIN EN 3SP-44/95)

– Dry sand

2.2.2.4 Instructions for cooling an overheated, non physically damaged battery

This type of damage may be caused by a short circuit inside the battery, which may

result in harmful materials leaking, fire or battery explosion.

Endangered unopened batteries can be cooled using a water

jet.

2.2.3 Material discharge

WARNING!

Battery electrolyte fluid can be hazardous

Electrolyte fluid can be discharged if the battery is physically damaged. Electrolyte

fluid is harmful and must not come into contact with the skin or eyes.

If it does, rinse the affected parts with plenty of water and seek medical assistance

u

immediately.

In the event of skin irritation or if any substances are breathed in, seek medical

u

assistance immediately.

In the event of inhalation bring the affected person into the fresh air and keep them

u

still.

2.2.3.1 Precautionary measures for personnel

– Keep personnel away and facing the wind.

– Block off the affected area.

30

11.19 en-GB

Page 31

– Ensure there is adequate ventilation.

– Wear personal protective equipment.

– If vapours / dust / aerosols are present, use self-contained

breathing apparatus.

2.2.3.2 Precautionary measures for the environment

Do not allow spilled fluids to enter the water system, drainage system or the

underground

water.

2.2.3.3 Cleaning measures

The leaked fluid must be removed professionally by the operating company on the

basis of a risk assessment and disposed of in the correct manner. The fire brigade,

the Agency for Technical Relief or similar institutions must be used. Absorb residues

with liquid-absorbent material (such as vermiculite, sand, universal binders and

pebble grain).

2.2.4 Touch voltage hazard

WARNING!

Hazardous contact voltages only arise in the event of a technical or physical defect.

The batteries are normally charged. There is still some residual voltage in a

discharged battery. This must be considered as a hazardous contact voltage.

With this kind of defect the battery must not be touched and must not come into

contact with metal objects see page 28.

11.19 en-GB

31

Page 32

2.3 Charging the battery

The operating instructions are a major component of the charger.

The owner shall ensure that the operating instructions are kept permanently in the

vicinity of the charger, and that operating personnel shall be aware of the guidelines

mentioned in the instructions.

The owner shall add further instructions regarding national accident prevention and

environmental protection regulations to the operating instructions, including

information on supervisory and reporting obligations, taking into account particular

company practices e.g. in terms of work organization, work processes and the

personnel employed.

Apart from the operating instructions and the current accident prevention regulations

in force in the country and place of use, generally recognised technical regulations

for safe and proper use shall be observed.

DANGER!

Explosion risk when charging unsuitable battery types

Charging a battery that is not suitable for this charger can result in damage to the

charger and battery. The battery could expand or burst.

The lithium-ion battery must only be charged with the battery charger provided for

u

this battery.

WARNING!

Warning: hazardous electrical voltage!

The charger is an electric component conducting voltages and currents that are

hazardous to people.

The charger must only be operated by trained technicians.

u

Disconnect the mains supply and the battery connector before carrying out any

u

work on the charger.

The charger should only be opened and serviced by trained electricians.

u

WARNING!

Any damage and other defects to the charger can result in accidents.

If any safety-related modifications, damage or other defects are discovered on the

charger or during operation, the charger must be taken out of service until it has

been repaired.

Report any defects immediately to your supervisor.

u

Tag out and decommission a faulty charger.

u

Only return the charger to service when you have identified and rectified the fault.

u

32

11.19 en-GB

Page 33

NOTICE

Intermediate charging of the lithium-ion battery

Intermediate charging of the lithium-ion battery is possible, i.e. a battery that is not

fully discharged can be charged or partially charged at any time.

The lithium-ion battery should be fully charged before use.

u

To ensure reliable operation of the lithium-ion battery, it must be fully charged at

u

least every 26 weeks with frequent intermediate charging.

Turn off the battery charger before disconnecting the lithium-ion battery from the

u

charger.

NOTICE

Full discharge can damage the battery

Self-discharge can cause the battery to fully discharge. Full discharge shortens the

service life of the battery.

Before a long period of inactivity, the battery must be fully charged.

u

Charge the battery at least every 26 weeks, see page 47.

u

Z

If the battery is fully discharged or if the battery temperature is below the permissible

level, the battery will not charge. Fully discharged batteries cannot be charged by the

user (faulty). Contact the manufacturer's customer service department.

2.4 Battery lifetime and maintenance

The lithium-ion battery is wear-free. The components are maintenance-free, as a

result there are no maintenance intervals planned for this battery.

2.5 Storing the battery

NOTICE

Discharge can damage the battery

If the battery is not used for a long period of time, it can become damaged through

discharge.

Before a long period of inactivity, the battery must be fully charged.

u

To ensure a long battery life, we recommend checking and charging the battery

u

every 4 weeks when it is not being used.

2.6 Faults

11.19 en-GB

If any damage is found to the battery or battery charger

contact the manufacturer's customer service department immediately.

The operating company must not carry out any remedial work on its own.

Independent attempts to tamper with or repair the battery may invalidate the

warranty. A service agreement with the manufacturer will help identify faults.

WARNING!

Do not open the battery.

In order to avoid fire, explosion and leakage of harmful materials, a safe place for

storing batteries until the manufacturer's customer service department arrives on site

must satisfy the following criteria:

33

Page 34

– Do not store in places often frequented by personnel.

– Do not store in places where valuable objects (e.g. cars) are stored.

– A PM12i burning metal fire extinguisher or a Co2 fire extinguisher must be

available to put out any fires.

– There should not be any fire or smoke detectors in the vicinity in order to ensure

that an automatic fire detection system is only activated in the event of actual

danger (e.g. naked flames).

– Small amounts of discharge from a single battery are not critical to the

environment. Above-average natural ventilation is required in this case.

– No ventilation intake pipes should be in the vicinity, as discharged content could

spread within a building.

Examples of where to store a non-functional battery:

– Roofed outdoor position.

– Ventilated container.

– Covered box with pressure and smoke discharge option.

34

11.19 en-GB

Page 35

2.7 Disposal and transport of a lithium-ion battery

2.7.1 Instructions for disposal

NOTICE

Lithium-ion batteries must be disposed of in accordance with the relevant national

environmental protection regulations.

For lithium-ion battery disposal, contact the manufacturer's customer service

u

department.

Used cells and lithium-ion batteries are recyclable economic goods. In accordance

with the marking showing a crossed-out waste bin, these lithium-ion batteries may

not be disposed of as domestic waste.

Return or recycling of batteries must be ensured in accordance with the Battery

Directive 2006/66/EG.

Used lithium-ion batteries must be treated as hazardous waste.

Lithium-ion batteries marked with the recycling symbol and the sign showing a

crossed-out waste bin must not be disposed of with ordinary household waste.

Buy-back terms and type of recycling are to be agreed with the manufacturer.

11.19 en-GB

35

Page 36

2.7.2 Marking of packages with lithium-ion batteries

UN 3171

9

26

27

The lithium-ion battery is a hazardous material. The applicable ADR regulations

must be observed during transport.

Z

ADR = Accord européen relatif au transport international des marchandises

Dangereuses par Route

Item Description

26 Danger label class 9A for lithium-ion batteries

Marking of packages with lithium-ion batteries in accordance with the

27

dangerous goods regulations GGVS/ADR appendix 9 for the transport of

hazardous goods

36

11.19 en-GB

Page 37

2.7.3 Shipping information

UN 3171

9

UN 3171

9

The lithium-ion battery is a hazardous material. The applicable ADR regulations

must be observed during transport.

Z

2.7.3.1 Shipping functional batteries

Classification according

to ADR (road transport)

- Classification code M4 lithium battery

- Danger label

ADR = Accord européen relatif au transport international des marchandises

Dangereuses par Route

Functioning batteries can be shipped in accordance with the following regulations:

UN 3171 lithium-ion battery class 9

- ADR limited quantity LQ:0

IMDG classification (sea

transport)

- EMS F-A, S-I

- Danger label

- IMDG limited quantity LQ: -

UN 3171 lithium-ion battery class 9

11.19 en-GB

37

Page 38

IATA classification (air

UN 3171

9

transport)

- Danger label

Exposure scenario Not specified.

Substance safety rating Not specified.

Marking Product does not require marking under EC Directive /

2.7.3.2 Shipping faulty batteries

UN 3171 lithium-ion battery class 9

HazMatR.

To transport these faulty lithium-ion batteries, contact the manufacturer's customer

service department. Faulty lithium-ion batteries must not be transported

independently.

38

11.19 en-GB

Page 39

2.8 Hazard and Safety Instruction Phrases

Hazard and safety instruction phrases are codified hazard and safety instruction

phrases for hazardous materials used as part of the globally harmonised system for

the grading and identification of chemicals.

The following H phrases describe the hazards arising from the battery cells and their

contents.

The P phrases describe the safety measures to be applied.

2.8.1 Hazard Instruction Phrases (H phrases)

2.8.1.1 Physical hazards (H200 range)

H242 Heating can result in fire.

2.8.2 Safety Instruction Phrases (P phrases)

2.8.2.1 General (P100 range)

P102 Keep out of reach of children.

2.8.2.2 Prevention (P200 range)

P201 Obtain special instructions before use.

P202 Read and understand all safety instructions before use.

P233 Keep containers sealed.

P235 + P410 Keep cool. Protect against direct sunlight.

P251 Do not penetrate or burn, even after use.

P261 Avoid inhalation of dust, smoke, gas, steam, vapours or aerosols.

2.8.2.3 Reaction (P300 range)

P314 Seek medical advice or assistance if feeling unwell.

In case of inhalation:

P304 + P340

Bring the person into fresh air and ensure he or she can breath

unhindered.

P313 + P332 For skin irritation: Seek medical advice or assistance.

P313 + P337 For persistent eye irritation: Seek medical advice or assistance.

P370 + P378

In the event of fire:

Use CO2 to extinguish.

P370 + P380

In the event of fire:

Clear the area.

2.8.2.4 Storage (P400 range)

P410 + P412

Protect against direct sunlight and do not subject to temperatures in

excess of 40 °C.

P411 + P235 Keep cool and do not store in temperatures in excess of 50 °C.

11.19 en-GB

39

Page 40

2.8.2.5 Disposal (P500 range)

P502

Obtain information on recycling or reuse from the manufacturer or

supplier.

40

11.19 en-GB

Page 41

3 Power Supply AMW 22

3.1 General information

Power is supplied via four 1.5 V alkaline batteries of type AA. If the unit is not used

for 3 minutes, it will shut down automatically. Under normal conditions, the system

can perform weighing operations for around 1 year. If the battery charge status

becomes too low, the display will show "LOW BAT". When the batteries are

discharged, the weighing system will shut down automatically.

3.2 Replacing batteries

Z

11.19 en-GB

Replacing batteries (up to year of manufacture 2013)

Procedure

• Undo the two lateral retaining screws on the upper part of the housing and

carefully take off the upper part of the housing.

The upper and lower parts of the housing remain linked by connecting cables.

• Take all the used batteries out of the battery compartment in the lower part of the

housing and insert new batteries, ensuring their polarity matches the markings.

• Re-apply the upper part of the housing, taking care not to trap the connecting

cables, and tighten the retaining screws.

41

Page 42

Replacing batteries (from year of manufacture 2013)

Procedure

• Undo the retaining screws of the battery holder and pull out the battery holder.

• Take all the used batteries out of the battery holder and insert new batteries,

ensuring their polarity matches the markings.

• Re-insert the battery holder and tighten the retaining screws.

42

11.19 en-GB

Page 43

4 Power Supply AMW 22p

28 28 28 28

4.1 General information

Power is supplied by a 12 V / 1.2 Ah battery module, which is protected against

reverse polarity.

If the unit is not used for 30 minutes, it will shut down automatically. Under normal

conditions, the system can be used for up to 35 hours of uninterrupted weighing

(weighing system without built-in printer).

If the battery module charge status becomes too low, the display will show "LOW

BAT" or, on some models (o), will only display one remaining battery segment. In

this case, the battery must be charged or replaced immediately as the weighing

system will soon shut down automatically.

Z

To avoid a loss in battery capacity, we recommend that the battery module be

charged for at least 6 hours. If the weighing system is used in multi-shift operation,

or if it is fitted with a built-in printer (o), procurement of an additional battery module

is recommended.

4.2 Charging the battery

Charging the battery

Requirements

– Truck is parked securely.

11.19 en-GB

– Weighing system is switched off – see page 66.

Tools and Material Required

– Charger for lithium-ion batteries (28)

Procedure

• Remove the battery (29) from the weighing system (30).

• Place the battery in the charger.

• Connect the charger to the power supply.

Z

The LED on the charger lights up red while charging is active.

43

Page 44

• Disconnect the charger from the power supply once charging is completed.

Z

Z

The charger switches off and the LED lights up green once charging is completed.

A deep discharge of the battery can occur if it is not removed from a charger the

power supply of which has been interrupted.

• Place the battery in the weighing system.

The weighing system is ready for use again.

44

11.19 en-GB

Page 45

5 AMW 22ps power supply

5.1 General information

Charging process

The weighing system is equipped with a rechargeable lithium-ion battery and an

intelligent battery charger. New lithium-ion batteries must be charged for at least

8 hours before first use. The battery can subsequently also be used when not fully

charged. In this case, the remaining operating time is reduced.

It takes 6 to 7 hours to fully charge the battery. In the case of partially discharged

batteries, the charging time is reduced accordingly. Charging continues automatically

after a power failure.

The charging process can be interrupted and continued as a partial charge. To do

so, disconnect the charger from the power supply.

Once the battery is fully charged, the charger stops automatically. The LED on the

charger lights up green.

In this case:

– Disconnect the charger from the power supply.

– Remove the battery from the charger.

– Place the battery in the weighing system – see page 47.

If the battery has not been fully charged after 8 hours, the charger stops

automatically. The LED on the charger lights up red.

In this case:

– Disconnect the charger from the power supply.

– Have the battery and/or charger repaired or replaced – see page 102 and see

page 103.

Battery service life

The charge capacity of the battery will gradually diminish over time and with

repeated use. If the operating time with a fully charged battery gets shorter and

shorter, it is time to replace the battery – see page 103. Correct use and charging

will extend the service life.

Permissible temperatures

The service life of the battery will be extended if the permitted temperature ranges

are observed.

During operation: -10°C to +50°C

During charging: 0°C to +40°C

During storage: +10°C to +20°C

11.19 en-GB

45

Page 46

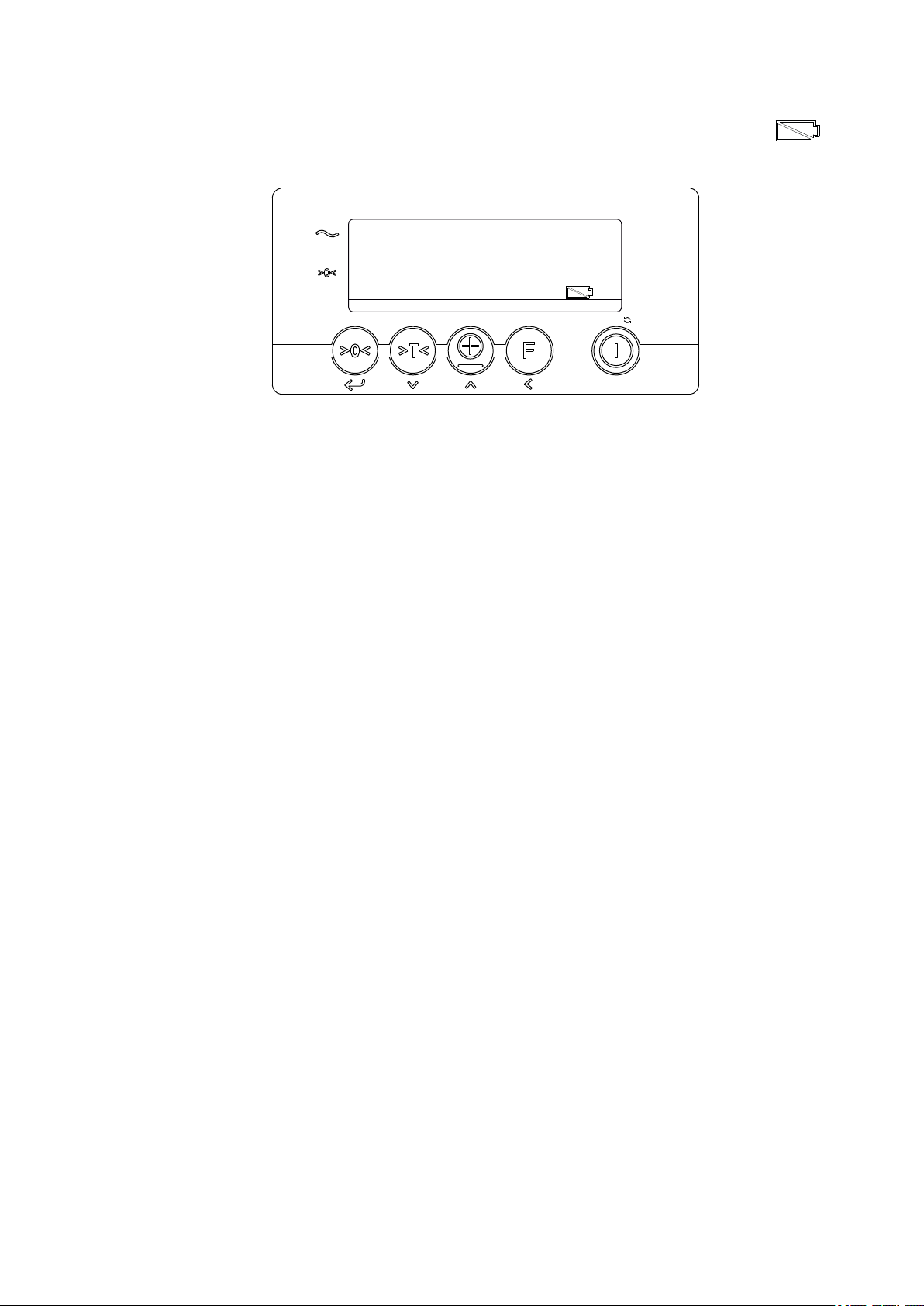

5.2 Battery charge status

NET

ID CODE PT TOTAL KG/LB

CLR

e1 e2 e3 STP1 STP2

Z

If the battery voltage is too low, the battery icon on the display lights

up. The weighing system switches off automatically after 2 minutes.

Checking the battery charge status

Procedure

• Check the display and, if necessary, charge the battery – see page 47.

46

11.19 en-GB

Page 47

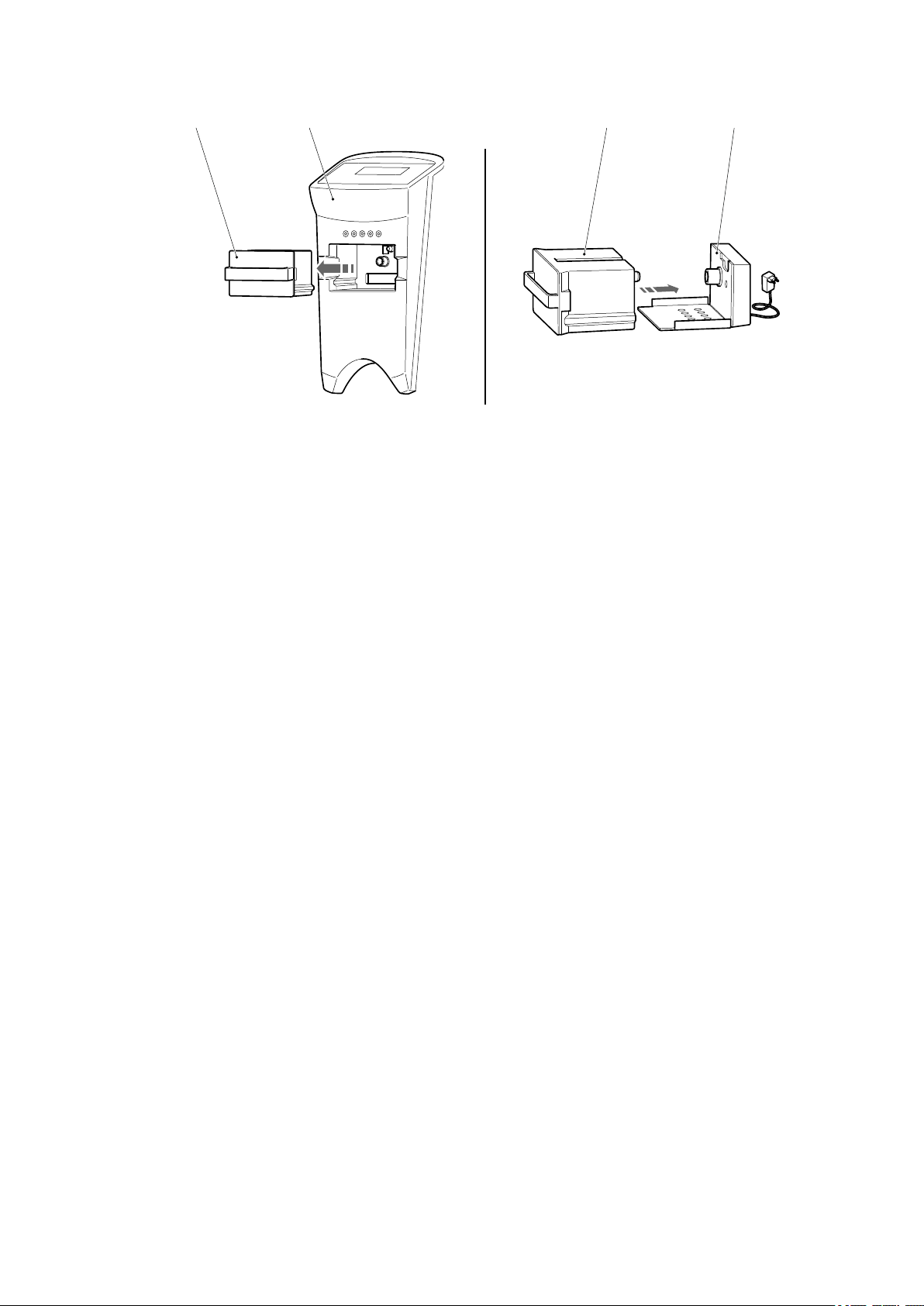

5.3 Charging the battery

3029 29 28

Charging the battery

Requirements

– Truck is parked securely.

– Weighing system is switched off – see page 79.

Tools and Material Required

– Charger for lithium-ion batteries (28)

Procedure

• Remove the battery (29) from the weighing system (30).

• Place the battery in the charger.

• Connect the charger to the power supply.

Z

Z

Z

The LED on the charger lights up red while charging is active.

• Disconnect the charger from the power supply once charging is completed.

The charger switches off and the LED lights up green once charging is completed.

A deep discharge of the battery can occur if it is not removed from a charger the

power supply of which has been interrupted.

• Place the battery in the weighing system.

The weighing system is ready for use again.

11.19 en-GB

47

Page 48

48

11.19 en-GB

Page 49

E Operation

1 Safety Regulations for the Operation of Forklift Trucks

Driver authorisation

The truck may only be used by suitably trained personnel, who have demonstrated

to the proprietor or his representative that they can drive and handle loads and have

been authorised to operate the truck by the proprietor or his representative.

Operator’s rights, responsibilities and rules of conduct

The driver must be informed of his duties and responsibilities and be instructed in

the operation of the truck and shall be familiar with the operating instructions. Safety

shoes must be worn on pedestrian-operated trucks.

Unauthorised use of truck

The operator is responsible for the truck during the time it is in use. The operator

must prevent unauthorised persons from moving or operating the truck. Do not carry

passengers or lift other people.

Damage and faults

The supervisor must be informed immediately of any damage or faults to the truck or

attachment. Trucks which are unsafe for operation (e.g. wheel or brake problems)

must not be used until they have been rectified.

Repairs

The operator must not carry out any repairs or alterations to the truck without

authorisation and the necessary training to do so. The operator must never disable

or adjust safety mechanisms or switches.

11.19 en-GB

49

Page 50

Hazardous area

WARNING!

Risk of accidents/injury in the hazardous area of the truck

A hazardous area is defined as the area in which people are at risk due to travel or

lifting operations of the truck, its load handler or the load. This also includes the area

within reach of falling loads or lowering/falling operating equipment.

Instruct unauthorised persons to leave the hazardous area.

u

In case of danger to third parties, give a warning signal in good time.

u

If unauthorised persons are still within the hazardous area, stop the truck

u

immediately.

Safety devices, warning signs and warning instructions

Safety devices, warning signs (see page 19) and warning instructions in the present

operating instructions must be strictly observed.

50

11.19 en-GB

Page 51

2 Displays and Controls

5

483

1

Item Control /display Function

1 Travel and parking brake

– Prevent the truck from rolling away.

o

– Decelerates the truck.

3 Handle

– To pull the truck.

t

– To push the truck.

4 “Lift//neutral/lower load

handler” handle

– In position "H" (lifting): Moving the tiller

t

raises the load handler.

– In position "neutral": Travel

– Press to position "S" (lowering): Lowers

the load handler.

5 Tiller

– Steers the truck.

t

– Raises the load handler.

8 Foot-activated parking

– Prevent the truck from rolling away.

o

brake

11.19 en-GB

51

Page 52

3 Starting up the truck

3.1 Checks and Operations to Be Performed Before Starting Daily Work

WARNING!

Damage and other truck or attachment (optional equipment) defects can result

in accidents.

If damage or other truck or attachment (optional equipment) defects are discovered

during the following checks, the truck must be taken out of service until it has been

repaired.

Report any defects immediately to your supervisor.

u

Mark defective truck and take out of service.

u

Do not return the industrial truck to service until you have identified and rectified

u

the fault.

Inspection before daily operation

Procedure

• Check the whole of the outside of the truck for signs of damage and leaks.

• Check the load handler for visible signs of damage such as cracks, bent or

severely worn forks.

• Check the load wheels for damage.

• Check that the markings and labels are present, clean and legible, see page 19.

• Test the brakes.

52

11.19 en-GB

Page 53

4 Industrial Truck Operation

4.1 Safety regulations for truck operation

Travel routes and work areas

Only use lanes and routes specifically designated for truck traffic. Unauthorised third

parties must stay away from work areas. Loads must only be stored in places

specially designated for this purpose.

The truck must only be operated in work areas with sufficient lighting to avoid danger

to personnel and materials. Additional equipment is necessary to operate the truck in

areas of insufficient lighting.

DANGER!

Do not exceed the permissible surface and point loading on the travel lanes.

At blind spots get a second person to assist.

The driver must ensure that the loading dock /dock leveller cannot be removed or

come loose during loading/unloading.

Conduct when pulling/pushing

The operator must adapt the travel speed to local conditions. The truck must be

pushed/pulled at slow speed when negotiating bends or narrow passageways, when

passing through swing doors and at blind spots. The operator must always observe

an adequate braking distance between the forklift truck and the vehicle in front and

must be in control of the truck at all times. Abrupt stopping (except in emergencies),

rapid U turns and overtaking at dangerous or blind spots are not permitted. Do not

lean out or reach beyond the working and operating area.

Visibility when pulling/pushing

The operator must look in the direction of travel and must always have a clear view

of the route ahead. If the truck is carrying loads that affect visibility, the truck must be

pulled against the load direction. If this is not possible, a second person must walk

alongside the truck as a lookout to observe the travel route while maintaining eye

contact with the operator. Move the truck only at walking pace and with particular

care. Stop the truck as soon as you lose eye contact.

11.19 en-GB

53

Page 54

Negotiating slopes and inclines

WARNING!

Do not negotiate slopes or inclines.

Negotiating lifts and dock levellers

Lifts may only be negotiated if they have sufficient capacity, are suitable for driving

on and authorised for truck traffic by the owner. The driver must satisfy himself of the

above before entering these areas. The truck must be pushed into lifts with the load

in front and must take up a position which does not allow it to come into contact with

the walls of the lift shaft. Persons riding in the lift with the forklift truck must only

enter the lift after the truck has come to a rest and must leave the lift before the

truck.

4.2 Parking the truck securely

WARNING!

An unsecured truck can cause accidents

Always park the truck on a level surface. In special cases the truck may need to be

u

secured with wedges.

Always fully lower the load handler.

u

Select a place to park where no other people are at risk of injury from the lowered

u

load handler.

54

11.19 en-GB

Page 55

4.3 Pushing/Pulling

153

8

Z

To avoid abrasion and wear, travelling without load should be with the load handler

raised.

Requirements

– Start up the truck, see page 52.

Procedure

• Release the parking brake by applying the footactivated parking brake (8, o) or the travel and

parking brake (1, o).

Using the handle (3) on the tiller (5), the truck can be

pushed or pulled in the required direction.

4.4 Steering

Procedure

• Swing the tiller (5) to the left or right.

Z

In tight bends the tiller extends beyond the truck geometry.

11.19 en-GB

55

Page 56

4.5 Brakes

153

8

8

The truck's braking characteristics depend largely on the surface condition of the

lanes. The driver must take this into account when travelling.

Manual braking

Procedure

• Pull or push against the direction of movement.

The truck brakes.

Braking with the foot-activated parking brake

(

o

)

Procedure

• Apply the foot-activated parking brake (8) in

direction B.

The truck brakes.

Braking with the travel and parking brake (o)

Procedure

• Applying the travel and parking brake (1).

The truck brakes.

11.19 en-GB

56

Page 57

4.6 Lifting, transporting and depositing loads

WARNING!

Unsecured and incorrectly positioned loads can cause accidents

Before lifting a load, the operator must make sure that it has been correctly

palletised and does not exceed the truck’s capacity.

Instruct other people to move away from the hazardous area of the truck. Stop

u

using the truck if people do not vacate the hazardous area.

Only carry loads that have been correctly secured and positioned. Use suitable

u

precautions to prevent parts of the load from tipping or falling down.

Damaged loads must not be transported.

u

Never exceed the maximum loads specified on the load chart.

u

Never stand underneath a raised load handler.

u

Do not stand on the load handler.

u

Do not lift other people on the load handler.

u

Insert the load handler as far as possible underneath the load.

u

NOTICE

Adapt a slower speed when stacking and retrieving.

11.19 en-GB

57

Page 58

4.6.1 Raising a load

H

4

5

1000

kg

1000

kg

Requirements

– Load correctly palletised.

– Load weight matches the truck's capacity.

– Load handler evenly loaded for heavy loads.

Z

In the case of eccentric loading, the forks are

slightly bent and twisted, which leads to variations

in the weighing results. In the case of inclinations

greater than 2°, holes and unevenness in the floor,

the accuracy of the weighing system decreases by

approx. 0.1% per degree.

Precise weighing results are obtained only when

the load centre is between the forks. A smooth flat

floor is required to ensure optimum weighing

accuracy.

Calibrated weighing system (o) (only AMW 22p

and AMW 22ps):

In the case of eccentric loading or inclinations

greater than 2°, the display is blocked. The truck

must be centrally loaded and standing on level

ground.

Procedure

• Drive the truck slowly up to the pallet.

• Push the handle (4) in the "H" direction.

• Slowly insert the load handler into the pallet until the

fork shank touches the pallet.

Z

Z

The load must not extend more than 50 mm beyond the

fork tips.

• Lift the load handler by moving the tiller (5) up and

down until you reach the desired lift height.

With rapid lift (up to 120 kg load, (t)), tiller movements

generate significantly greater lift movements.

11.19 en-GB

58

Page 59

4.6.2 Transporting a load

4

Requirements

– Load raised correctly.

– Good ground conditions.

Procedure

• Adapt your travel speed to the conditions of the route and the load you are

transporting.

• Move truck at a constant speed.

• Watch out for other traffic at crossings and passageways.

• Always move the truck with a lookout at blind spots.

WARNING!

Do not negotiate slopes or inclines.

4.6.3 Depositing a load

NOTICE

Loads must not be deposited on travel or escape routes, in front of safety

mechanisms or operating equipment that must be accessible at all times.

Requirements

– Storage location suitable for storing the load.

Procedure

• Drive the truck carefully up to the storage location.

• Push the handle (4) in direction S (lower) to lower the

load handler.

Z

Do not set the load down abruptly in order to avoid

damaging the load and the load handler.

• Carefully remove the load handler from the pallet.

The load has been set down.

11.19 en-GB

59

Page 60

4.7

33343132353637

38

AMW 22 / AMW 22p Standard Weigher (t)

4.7.1 Display and Controls

Z

Item Indicator Meaning

31 – Weight display in kg, messages

32 - – The displayed weight has a negative value.

33 (~) – The weighing system including the load is stable.

34 (NET) – The displayed weight is a net weight.

Only if the load is stable and the "Stable load" segment (33) is activated will key

commands be accepted and functions executed.

Item Operating function key Input function key

35 Zero setting,

– Confirm, Skip to next

Automatic tare

36 Enter tare weight – Reduce the value

37 Add a weight – Increase value.

38 On / Off – Adjustment

11.19 en-GB

60

Page 61

4.7.2 Display Messages

HELP 1 The weighing system has been overloaded.

NOTICE

The weight to be weighed exceeds the maximum setting. To avoid damage,

immediately relieve the weighing system of the load.

HELP 2 Negative signal from the load cells to the AD converter / inclination.

HELP 3 Negative signal from the load cells to the AD converter / inclination.

HELP 4 The tare weight entered is too high.

Z

Press key (36) to clear the display message. Enter a lower tare weight.

HELP 7 The signal from the load cells to the AD converter is too high.

LOW BAT The charge status is too low. The batteries must be replaced (AMW

22). The battery module must be charged (AMW 22p).

11.19 en-GB

61

Page 62

4.7.3 Operation

33343132353637

38

Z

After the load is raised, the display shows the gross value of the weighed weight.

Before each weighing operation, make sure that the system is unloaded and is free

to move. The weighing system has an automatic zero correction and automatically

compensates for small variations in the zero point. For larger variations in the zero

point, the correction must be performed manually using the 0/T key (35).

The weighing system offers the facility to make manual allowances for tare weights

and to track changes in the net weight:

Z

Procedure

• Raise the load.

• Press the 0/T key (35). The display indicates zero. The NET segment (31) shows

the activated tare weight.

• Loading or unloading the net load.

The net value of the weighed weight is displayed. On unloading, the a negative value

is shown for the net weight.

Performing a zero correction in the unloaded condition causes the system to return

to the standard weighing mode. A tare weight can be entered manually, in either the

loaded or unloaded condition. Tare weights higher than the first weight range (in the

standard version up to 200 kg) will not be accepted and will lead to the display

message HELP 4.

Checking the current tare weight:

Procedure

• Press the ENTER key (36). The most recently used tare value will appear. The

segment on the right side will flash.

• To continue to use the displayed value, keep the Confirm key (35) pressed for

three seconds.

To input a new tare weight:

11.19 en-GB

62

Page 63

Procedure

• Press the ENTER key (36).

• Press the Increase value key (37) or Decrease value key (36) to change the tare

weight. Press the Skip (35) to skip to the next field. Repeat this operation until the

desired value is displayed.

Activate or save the tare weight:

Procedure

• To confirm the value, keep the Confirm key (35) pressed for three seconds.

The tare weight is now activated (NET segment (31) active). If at this time the

system is laden, the net value for the weighed weight will appear in the display. If

at this time the system is unloaded, the display will show the entered tare weight

as a negative value.

Z

Z

The entered value will remain active until the weighing system is switched off, a new

tare weight is entered, a new load is tared or a new zero setting is performed.

Activate and save the tare weight:

Procedure

• Confirm all segments by pressing the Confirm key (35). The tare weight is now

activated (NET segment (34) active) and is saved. If at this time the system is

laden, the net value for the weighed weight will appear in the display. If at this time

the system is unloaded, the display will show the entered tare weight as a

negative value.

The entered value will remain active even after the system is switched off, until a

new tare weight is entered, a new load is tared or a new zero setting is performed.

Deactivating the tare weight by performing a Zeroing:

Procedure

• If the weighing system is loaded: Keep the PT key (36) pressed for two seconds.

The tare weight is reset. The system reverts to standard weighing mode.

• If the weighing system is unladen: Press the 0/T key (35).

A zero correction will be performed. The system reverts to standard weighing

mode.

11.19 en-GB

63

Page 64

33343132353637

38

Addition of individual weighings:

Procedure

• Load the system with the load to be added.

• Press the (37) key to add the weighed weight to the saved total weight.

The display shows the number of weighings recorded alternating with the total

weight. If the system is fitted with a built-in printer (o), the displayed value will be

printed out. After a few seconds the system reverts to standard weighing mode.

Z

If a tare weight is active, the net weights will be totalled.

To display the total weight:

Procedure

• Keep key (37) pressed for three seconds; the total weight calculated thus far will

be displayed.

The display shows the current number of weighings alternating with the total

weight. After a few seconds the system reverts to standard weighing mode.

Resetting the total of individual weighings:

Procedure

• Press the (37) key whilst the total weight is being displayed.

If the system is fitted with a built-in printer (o), a cumulative printout is performed

before the total is reset.

After resetting, the display shows the number of weighings recorded as 00 and

the starting value for the total weight as 0 kg (AMW 22) or 0.0 kg (AMW 22p).

After a few seconds the system reverts to standard weighing mode.

Printing (o)

11.19 en-GB

64

Page 65

Z

A gross weight will be identified on the printout by "B/G", a net weight by "N". If a tare

weight has been input, this will also be printed out and identified by "PT". The total

net weight is identified by "TOT" (Total).

Example of a printout:

01 B/G 6.8 kg

02 B/G 158.2 kg

03 N 426.5 kg

04 N 1200.0 kg

04 PT 150.0 kg

04 TOT 1791.5 kg

11.19 en-GB

65

Page 66

4.8

443940414243464547

4849505152

53

AMW 22p Weigher, Special Version (o)

4.8.1 Display and Controls

Z

Item Indicator Meaning

39 - – The displayed weight has a negative value.

40 (e1) – The displayed weight lies in weight range 1.

41 (e2) – The displayed weight lies in weight range 2.

42 (e3) – The displayed weight lies in weight range 3.

43 (Stp1) – The limit value 1 is activated.

44 (Stp1) – The limit value 2 is activated.

45 – Weight display in kg or lb, messages, quantities

46 (~) – The weighing system including the load is stable.

47 (ZERO) – The displayed weight is within the zero range.

48 (NET) – The displayed weight is a net weight.

Only if the load is stable and the "Stable load" segment (46) is activated will key

commands be accepted and functions executed.

11.19 en-GB

66

Page 67

Item Operating function

level 1

(Press key briefly)

49 Zero offset – Input the code – Confirm

50 Tare the weight – Enter tare weight – Reduce the value

Operating function

level 2

(Press key for a longer

time)

Input function

press the

51 Print out the weight and

total it

52 Calculate piece weight

Relay control (o)

53 On / Off – Change over units of

4.8.2 Display Messages

Err01 Weighing cell signal not stable.

Err02 The weighing system has been overloaded.

NOTICE

The measured weight exceeds the maximum setting. To avoid damage, remove the

load from the weighing system immediately.

Err03 Negative gross weight. This action is not permitted.

Err04 Outside zero range. Acknowledge with any key.

Err05 Accuracy of the piece calculation too low. Acknowledge with any key.

– Check subtotal, print

out final total

– Input the piece weight – Skip to next, activate

measure

– Increase value.

the value

– Adjustment

Z

Err06 Load cell signal too high. Automatic for correction of the input.

Err07 Load cell signal too low. Automatic for correction of the input.

Err08 Calibration out of range (negative).

Err09 Calibration out of range (signal too low).

Err10 Calibration value of point 2 or 3 lower than point 1 or 2.

Err11 Calibration from piece counting mode

Err14 Limit value 2 < limit value 1 (not permitted)

Err97 Calibration blocked (jumper JP1 present)

Err98 The calibration value must be higher than the previous one.

Err99 Confirmation only permitted on power-up unit.

LOW BAT The charge status is too low. The battery module must be charged.

The following additional messages may appear on the display and printout:

Err00 Error message

AddEd Addition confirmation

Add10 Add quantity

11.19 en-GB

Adj08 Adjustment value display

TarE Tare setting of metering operation performed

67

Page 68

DonE Confirmation of metering operation performed

443940414243464547

4849505152

53

PA 00 Parameter number display

StoP Metering operation aborted

ho 00 Hour setting display

m 00 Minute setting display

dA 00 Day setting display

m 00 Month setting display

yE 00 Year setting display

4.8.3 Operation

Z

After the load is raised, the display shows the gross value of the weighed weight.

Before each weighing operation, make sure that the system is unloaded and is free

to move. The weighing system has an automatic zero correction and automatically

compensates for small variations in the zero point. For larger variations in the zero

point, the correction must be performed manually using the >0< key (49).

The weighing system offers the facility to make manual allowances for tare weights

and to track changes in the net weight:

Procedure

• Lift the load.

• Press the T key (50). The display indicates zero. The NET segment (31) shows

the activated tare weight.

• Loading or unloading the net load.

11.19 en-GB

68

Page 69

Z

The net value of the weighed weight is displayed. On unloading, the a negative value

is shown for the net weight.

Press the T key (50) to read off the gross weight. The NET segment (48) is

deactivated. Press the T key (50) again to perform a new net weighing.

A tare weight can be entered manually, in either the loaded or unloaded condition.

The tare weight is input at high resolution, irrespective of weight range and value. A

tare weight that is greater than the capacity of the weighing system will not be

accepted.

Checking the current tare weight:

Procedure

• Keep the PT key (50) pressed for three seconds. The most recently used tare

value will appear. The segment on the right side will flash.

• Press Confirm (49) to continue to use the displayed value.

To input a new tare weight:

Procedure

• Keep the PT key (50) pressed for three seconds.

• Press the Increase value key (51) or Decrease value key (50) to change the tare

weight. Press the Skip (52) to skip to the next field. Repeat this operation until the

desired value is displayed.

Z

Z

Activate or save the tare weight:

Procedure

• Press the Confirm key (49) to confirm the value.

The tare weight is now activated (NET segment (48) active). If at this time the

system is laden, the net value for the weighed weight will appear in the display. If

at this time the system is unloaded, the display will show the entered tare weight

as a negative value.

The value that is input will remain active until a new tare weight is entered.

Press the T key (50) to read off the gross weight.

Checking the identity code number:

The weighing system offers the facility to assign identity code numbers to weighings,

to identify them for subsequent processing. These identity code numbers may be up

to five digits long.

Procedure

• Keep the No key (49) pressed for three seconds.

The identity code number most recently input will be displayed. The last position

on the right of the display will flash.

• Press Confirm (49) to continue to use the displayed value.

Z

11.19 en-GB

The identity code number will be accepted. The weighing system reverts to weighing

mode.

69

Page 70

Inputting a new identity code number:

Procedure

• Keep the No key (49) pressed for three seconds. The identity code number most

recently input will be displayed. The last position on the right of the display will

flash.

• Press the Increase value key (51) or Decrease value key (50) to change the

identity code number . Press the Skip (52) to skip to the next field.

Repeat this operation until the desired value is displayed.

• Press Confirm (49) to load the displayed value.

The identity code number will be accepted. The weighing system reverts to

weighing mode.

Z

Z

The identity code number "00000" is not reported separately on the print-out.

Piece Counting by Calculating the Piece Weights

Pieces can be counted using a known or weighed piece weight. Larger differences in

weight and larger quantities for determining the piece weight result in more accurate

piece weights. The piece weight and the calculated quantity of pieces can be printed

out.

The difference in weight for calculating the piece weight should not be less than 4 to

5 kg.

Piece counting over a piece weight to be weighed, preset to 10 pieces:

Procedure

• Press the piece weight key (52).

The message “Add10“ is displayed. The unit displayed changes from "kg" to

"pcs".

• Increasing or reducing the number of goods placed on the load handler by 10

pieces.

• Press the Confirm key (49).

The calculation of the piece weight will be performed. The quantity of pieces

determined by the weighing will be displayed.

70

11.19 en-GB

Page 71

443940414243464547

4849505152

53