Page 1

Enclosed fork tips

Unique controls

Acid-resistant chassis

Robust and reliable

Compact and manoeuvrable

Grease nipples on all moving

parts

AM I20/I20p

Stainless steel hand pallet truck (2,000 kg)

The Jungheinrich AM stainless steel hand

pallet truck is ideal for use in damp and

hostile environments. The stainless steel

construction provides unrivaled hygiene.

Jungheinrich’s decades of experience

in stainless steel hand pallet trucks is

reflected today in its reliable and robust

trucks. In meat or fish processing,

chemical or pharmaceuticals sectors,

Jungheinrich stainless steel hand pallet

trucks oer the right solution.

Page 2

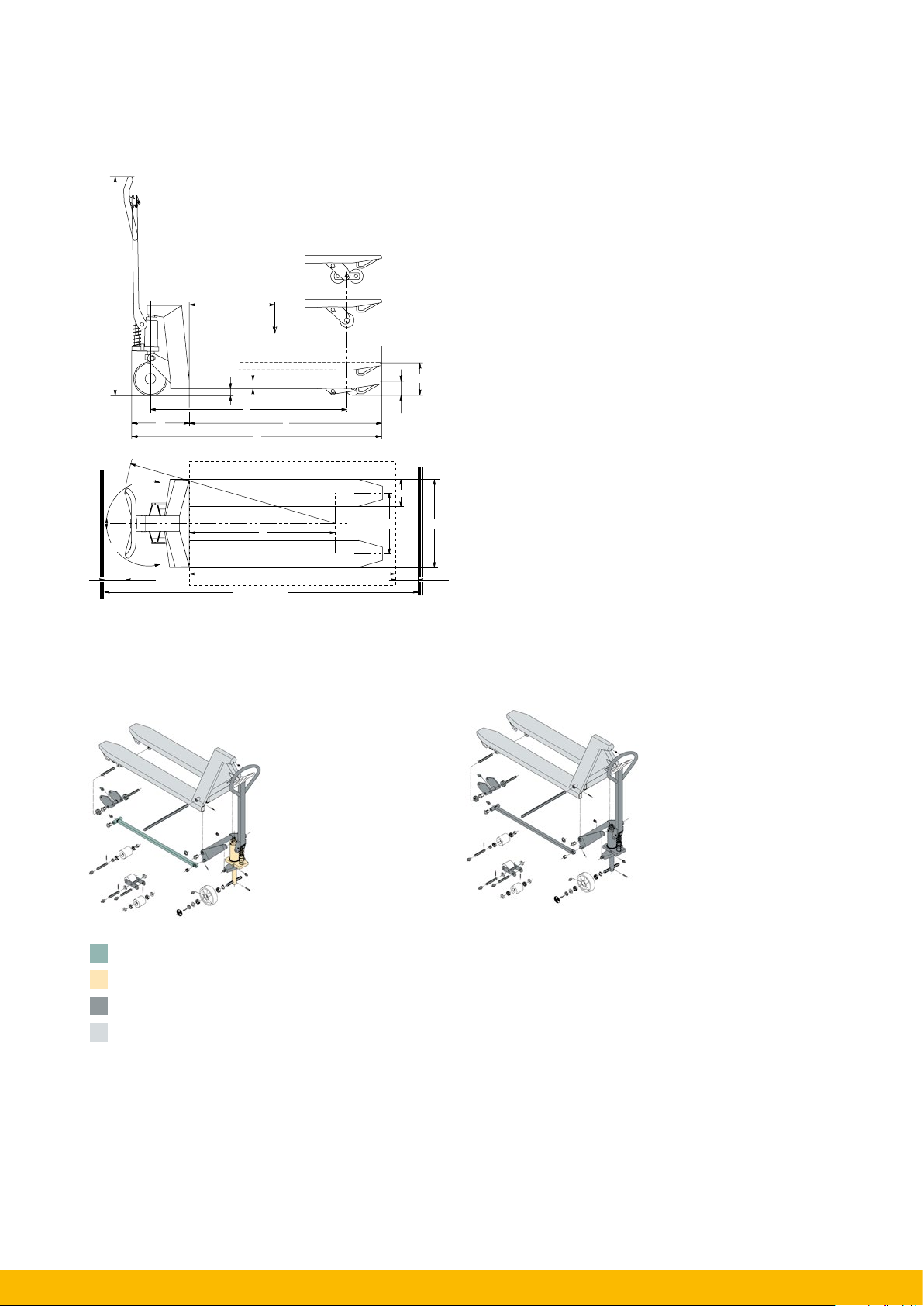

AM I20/I20p

a/2=100

5

Ast

= Wa+l6–x+a

h

14

c

s

m

2

y

l

1

x

115°

Wa

115°

a/2=100

l

2

Q

h

12

h

l

l

6

13

e

b

b1/b

11

AM I20

Not all environments require trucks to be made of 100% stainless

steel. Only those parts which come into direct contact with food

must be made of stainless steel. Many components however

need only be moisture-repellent. Consequently, the components

of the AM I20 consist of a number of dierent surfaces.

AM I20

Autophorese

Chromite coating

Stainless steel (AISI 303/304)

Acid resistant stainless steel (AISI 316)

AM I20p

The AM I20p is 100% rust-proof and has been designed especially for applications where hygiene is of the essence and for

use in particularly hostile environments. The hydraulics are protected; no foreign bodies or water can penetrate the truck.

AM I20p

Page 3

Issue: 06/2011

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model AM I20 AM I20p AM I20 AM I20p AM I20 AM I20p

1.3 Drive manual

1.4 Manual, pedestrian, stand-on, seated, order picker operation hand

1.5 Load capacity/rated load Q t 2

1.6 Load centre distance c mm 400 400 500 500 600 600

Identification

1.8 Load distance x mm 645 645 805 805 975 975

1.9 Wheelbase y mm 875 875 1035 1035 1170 1170

2.1 Service weight kg 64 64 66 66 68 68

2.2 Axle load, w. load, front / rear kg

Weights

2.3 Axle load, w.o. load, front / rear kg

2) 2) 2) 2)

3.1 Tyres N;V

3.2 Tyre size, at front mm Ø 200x50

3.3 Tyre size, at rear mm Ø 80x90

3.5 Wheels, number front/rear (× = driven wheels) 2/2 or 2/4

3.6 Track width, front b

3.7 Track width, rear b

Wheels / chassis

mm 130

10

mm 360

11

4.4 Lift h3 mm 115

4.9 Height of tiller in drive position min. / max. h

4.14 Standing height raised h

4.15 Lowered height h

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 Fork dimensions s/e/l mm

4.25 Width over forks b

Basic dimensions

4.32 Floor clearance centre wheelbase m2 mm 38

mm 1220

14

mm 200

12

mm 85

13

mm 1150 1150 1310 1310 1480 1480

1

mm 340 340

2

mm 520

1/b2

mm 520

5

45 / 160

/ 810

45 / 160

/ 810

45 / 160

/ 970

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 1610

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 1810

4.35 Turning radius W

mm 934 934 1094 1094 1774 1774

a

5.3 Lower speed, w. / w.o. load m/s

1)

45 / 160

/ 970

1)

636 /

1432

21 / 472)21 / 47

3)

45 / 160

/ 1140

0.09 /

0.04

636 /

1432

2)

45 / 160

/ 1140

0.09 /

0.04

Perform-

ance data

1)

680 mm also possible

2)

Width 520 mm

3)

Ø 80x70 tandem tyres

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Controls Enclosed fork tips In operation

Easy to operate

The easy to operate handle is suitable for

both left and right-handers. The special

lowering valve enables loads to be

lowered precisely.

Optimum hygiene

The enclosed fork tips ensure that no dirt

can spray up through the fork tips to the

load. Freely accessible or fully enclosed

cavities allow for eective cleaning with

no ‘hiding spots’ for bacteria. Grease

nipples on all moving parts and foodgrade grease (class H1 and H2) complete

the solution.

Fast operation

The very short chassis length of 340 mm

allows for safe and easy operation even

in confined spaces. Brackets on the fork

tips enable the forks to extend and retract easily.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_AM I20/I20p_012014_en_UK_000

Loading...

Loading...