Page 1

Corrosion protection through

surface hot dip galvanization

Robust and reliable

Compact and manoeuvrable

Unique controls

AM G20

Electro-plated hand pallet truck (2,000 kg)

The Jungheinrich AM G20 hand pallet

truck is the perfect solution for outdoor operation and in particular humid

environments. A zinc coating provides

the truck’s steel components with a

reliable protection against corrosion. The

main application areas include wholesale

markets and fruit growing operations.

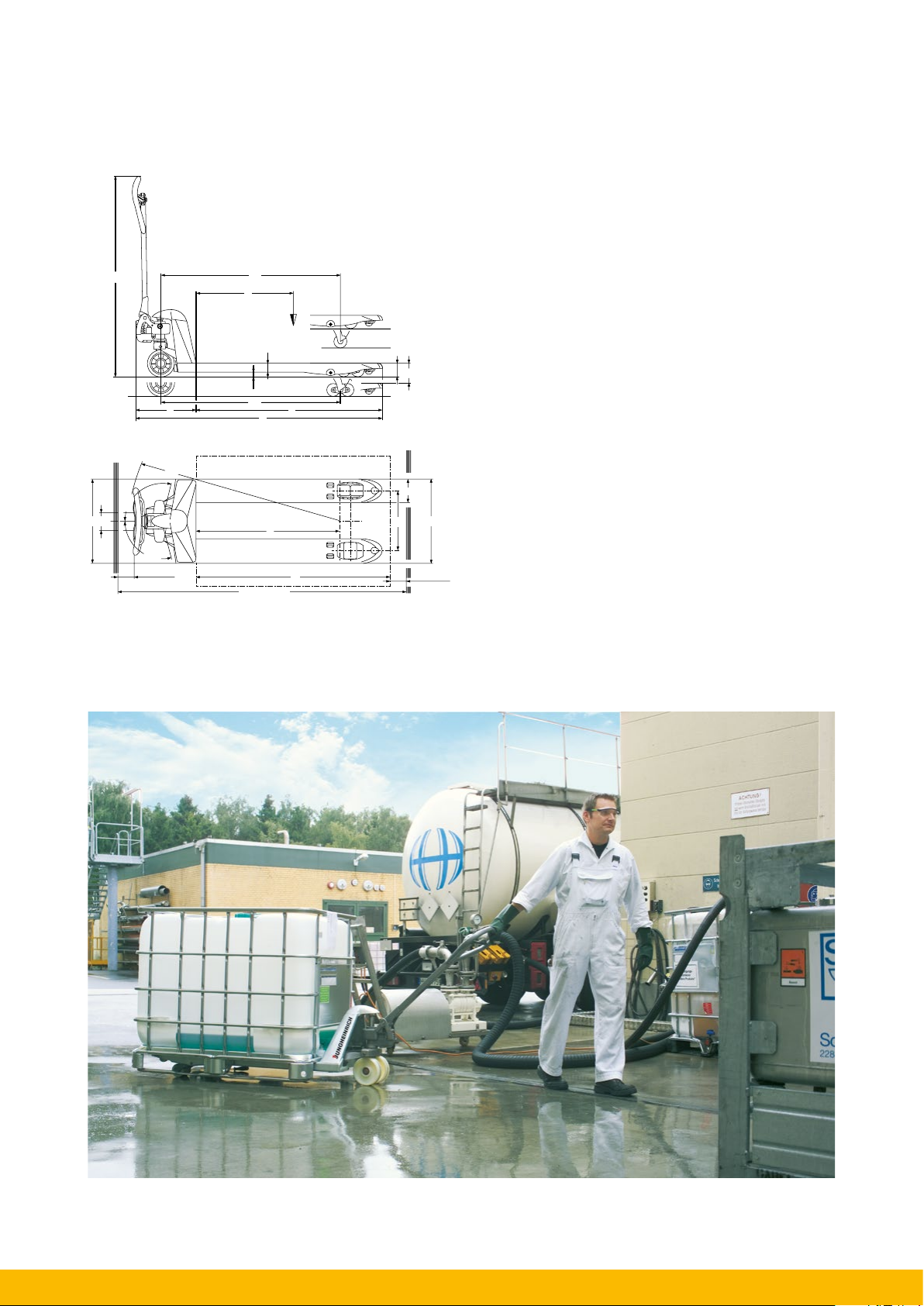

Page 2

AM G20

Ast = Wa+l

6

–x+a

h

14

(y)

c

Q

s

h

13

h

m

2

l

2

(y)

l

l

1

3

Wa

°

104

b

b

10

1

104

°

a/2=100

x

l

6

e

b

b

5

11

a/2=100

Page 3

Issue: 04/2010

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model AM G20

1.3 Drive manual

1.4 Manual, pedestrian, stand-on, seated, order picker operation hand

1.5 Load capacity/rated load Q t 2

1.6 Load centre distance c mm 400 500 600

Identification

1.8 Load distance x mm 535 690 890

1.9 Wheelbase y mm 755 910 1110

2.1 Service weight kg 51

2.3 Axle load, w.o. load, front / rear kg 38 / 20

Weights

3.1 Tyres V;N

3.2 Tyre size, at front mm Ø 170x50

3.3 Tyre size, at rear mm Ø 82x96

3.5 Wheels, number front/rear (× = driven wheels) 2/2 or 2/4

3.6 Track width, front b

3.7 Track width, rear b

Wheels / chassis

4.4 Lift h3 mm 122

4.9 Height of tiller in drive position min. / max. h

4.14 Standing height raised h

4.15 Lowered height h

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 Fork dimensions s/e/l mm 53 / 150 / 795 53 / 150 / 950 53 / 150 / 1150

4.25 Width over forks b

Basic dimensions

4.32 Floor clearance centre wheelbase m2 mm 30

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 1584 1584 1734

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 1784

4.35 Turning radius W

5.3 Lower speed, w. / w.o. load m/s 0.09 / 0.02

mm 109

10

mm 370

11

mm 1234

14

mm 205

12

mm 83

13

mm 1165 1320 1520

1

mm 373

2

mm 520

1/b2

mm 520

5

mm 919 1074 1274

a

1)

54

1)

4)

2)

2)

1)

61

3)

Perform-

ance data

1)

+ 5 kg at 680 mm width across forks

2)

680 mm also possible

3)

Width 520 mm

4)

Ø 82x62 mm tandem tyres

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

AM G20 - corrosion protection

through galvanisation

Maintenance-free hydraulics Permanently lubricated joints for

Galvanised surface

High level of corrosion protection

oered by surface hot dip galvanisation.

Easy to operate

The easy to operate control handle is

suitable for both left and right-handers.

The special lowering valve enables loads

to be lowered precisely.

More compact and manoeuvrable

The chassis length of 373 mm allows the

truck to be used safely and easily in confined areas.

maintenance-free operation

Eortless and simple

The further optimised hydraulic system

reduces the pumping action required.

The bushes on the wheels reduce the

required drawbar pull.

Quiet and robust

The chromed bushes on the wheels

and joints ensure quiet running and an

exceptionally long service life. Joints no

longer require lubrication; the AM G20

still runs smoothly.

Clear and safe

Markings on the truck show the exact

pallet position required for crossways

lifting.

Contoured fork tips for easy pallet

entry

Durable

The best guarantees for maximum

stability and durability:

• More stable forks.

• Contoured shapes.

• Welded tiller mounting.

• Protected entry rollers.

• High Quality Hardened steel.

• 2000 kg capacity for the basic model.

Optional equipment

The AM G20 can be equipped for any

application thanks to a extensive range

of optional equipment. This includes a

range of fork lengths, various widths,

wheel combinations and brake systems.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_AM G20_042014_en_UK_000

Loading...

Loading...