Page 1

JUMO IGBT-Power Converter

70/100 A with amplitude control

B 70.9050.0.1

Operating Manual

02.08

/00440431

Page 2

Page 3

1 Contents

1 Contents ............................................................................................ 3

2 Introduction ....................................................................................... 5

2.1 Preface .................................................................................................................. 5

2.2 Typographical conventions ................................................................................. 6

2.2.1 Warning signs ........................................................................................................ 6

2.2.2 Note signs .............................................................................................................. 6

2.2.3 Performing an action ........................................................................................... 7

2.3 Order details ......................................................................................................... 8

2.3.1 Standard accessories ............................................................................................ 8

2.3.2 Accessories ........................................................................................................... 9

2.4 Brief description ................................................................................................ 10

2.5 Interpretation of the LEDs ................................................................................ 11

3 Installation ....................................................................................... 13

3.1 Important notes on installation ........................................................................ 13

3.1.1 Correctly wire all components ............................................................................. 13

3.2 Filtering and interference suppression ............................................................ 16

3.3 Ambient conditions ........................................................................................... 18

3.4 Spacings ............................................................................................................. 20

3.4.1 Opening the housing ........................................................................................... 21

4 Electrical connection ...................................................................... 23

4.1 Screw connections in the power section ........................................................ 23

4.1.1 Suitable cables and cross-sections ..................................................................... 25

4.1.2 Electrical isolation ................................................................................................ 26

4.1.3 Use of residual current protection devices .......................................................... 26

4.1.4 Replacing the two semiconductor fuses ............................................................. 26

4.1.5 Wiring of the screw terminals .............................................................................. 28

5 Settings ............................................................................................ 31

5.1 Operating principle ............................................................................................ 31

5.2 Setting switches S101, S103, S104, S105, S106 and X106 ............................ 32

5.3 Subordinate control loop .................................................................................. 33

5.4 Load voltage adjustment .................................................................................. 33

5.5 Control inputs .................................................................................................... 34

5.5.1 Combination of external potentiometer and electronic controller ....................... 35

5.6 Firing pulse inhibit ............................................................................................. 36

5.7 Resistance output .............................................................................................. 36

02.08 [IGBT Power Converter 70/100A] 3

Page 4

5.8 Trimmer settings ................................................................................................ 37

5.8.1 Resistance limiting (R-control) ............................................................................. 37

5.8.2 SIC voltage reserve (SIC reserve) ........................................................................ 38

5.8.3 Control input adjustment (max. Power adjust) .................................................... 38

5.8.4 Setting for maximum power (max. Power adjust) ............................................... 39

5.8.5 Input signal attenuation ....................................................................................... 39

5.9 Setting the base load (min. Power adjust) ...................................................... 39

5.10 Setting the current limit (max. current adjust) ................................................ 40

5.11 Total and partial load failure monitoring (load fail adjust) ............................. 40

5.11.1 Setting the load fault indication ........................................................................... 42

5.12 Safety cut-out in the power section ................................................................. 43

5.13 Adjusting the output level signal (output adjust U2, P , I2 ) ............................ 43

6 Technical data ................................................................................. 45

6.1 Voltage supply .................................................................................................... 45

6.2 Control ................................................................................................................ 45

6.3 Fault signal output ............................................................................................. 45

6.4 General characteristics ..................................................................................... 45

6.5 Choke data ......................................................................................................... 47

6.6 EMC filter ............................................................................................................ 47

7 Troubleshooting .............................................................................. 49

4 [IGBT Power Converter 70/100A] 02.08

Page 5

2.1 Preface

B

A

H

2 Introduction

Please read this operating manual before commissioning the instrument. Keep

the operating manual in a place accessible to all users at all times.

Your comments are appreciated and may assist us in improving this operating

manual.

Phone: +49 661 6003 -727

Fax +49 (0)661 6003-508

The IPC must only be used with the original JUMO choke and an original

JUMO supply filter.

Please check that the chosen supply filter is adequate for the maximum

current drawn from the electrical supply to avoid it being overloaded.

All necessary settings are described in this operating manual.

Manipulations not described in the manual or expressly forbidden will

jeopardise your warranty rights.

Please contact the nearest subsidiary or the head office, should you encounter

problems.

Service hotline For technical questions

Phone support in Germany:

Phone: +49 (0)661 6003-300 or -653 or -899

Fax: +49 661 6003 -881729

E-mail: service@jumo.net

Austria:

Phone: +43 1 610610

Fax: +43 1 6106140

E-mail: info@jumo.at

Switzerland:

Phone: +41 1 928 24 44

Fax: +41 1 928 24 48

E-mail: info@jumo.ch

When accessing the inner parts of the unit and returning controller modules,

E

assemblies or components, please observe the regulations according to DIN

EN 61340-5-1 and DIN EN 61340-5-2 „Protection of electrostatic sensitive

devices“. Only use ESD packaging for transport.

Please note that we cannot accept any liability for damage caused by ESD.

ESD=Electro Static Discharge

02.08 [IGBT Power Converter 70/100A] 5

Page 6

2 Introduction

2.2 Typographical conventions

2.2.1 Warning signs

Danger

This symbol is used when there may be danger to personnel if the

instructions are ignored or not followed correctly!

V

Caution:

This symbol is used when there may be damage to equipment or

A

ESD

data if the instructions are ignored or not followed correctly!

This symbol is used where special care is required when handling

components liable to damage through electrostatic discharge.

E

2.2.2 Note signs

Note

Reference

Footnote

H

v

1

abc

This symbol is used when your special attention is drawn to a

remark.

This symbol refers to further information in other manuals,

chapters or sections.

Footnotes are remarks that refer to specific points in the text.

Footnotes consist of two parts:

A marker in the text and the foot note text itself.

The markers in the text are arranged as continuous superscript

numbers.

6 [IGBT Power Converter 70/100A] 02.08

Page 7

2.2.3 Performing an action

Action

instruction

Vital text

h Plug in the

connector

B

2 Introduction

This symbol indicates that an action to be performed is

described. The individual steps are marked by this asterisk.

This text contains important information, and it is vital that you

read it before going any further.

02.08 [IGBT Power Converter 70/100A] 7

Page 8

2 Introduction

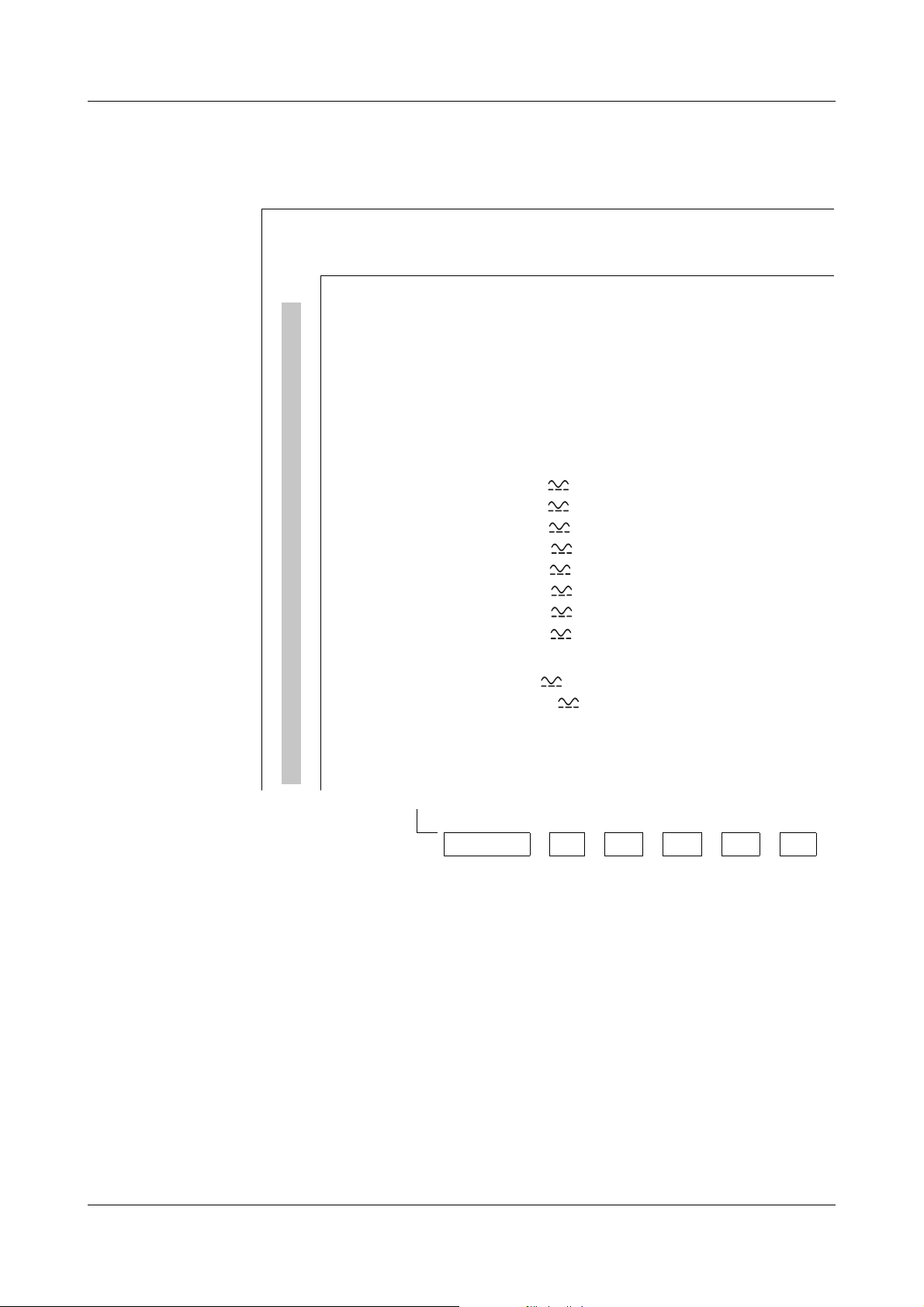

2.3 Order details

The nameplate is glued onto the right panel of the housing.

x

x

x

x

x

(1) Basic version

709050/82

709050/92 Customer-specific version

11 115V AC +15/-20%, 48 ... 63Hz

xx 12 230V AC +15/-20%, 48 ... 63Hz

115 115V AC +15/-20%, 48 ... 63Hz

x 230 230V AC +15/-20%, 48 ... 63Hz

x 400 400V AC +15/-20%, 48 ... 63Hz

x x 020

x x 060

x x 090

x x 120

x x 150

x x 210

x 270

x 380

IGBT power converter 70 or 100A

(max. load voltage 380V) standard version

(2) Voltage supply to the control section

(only for 115V AC in the power section)

(3) Voltage supply to power section

(4) Load voltage

20V DC

60V DC

90V DC

120V DC

150 V DC

210V DC

270V DC

380V DC

xx 070

x

x

xx 100

x x 252 Relay (changeover contact) 3A

x

x

x x 257 Optocoupler Ic

Order code - - - -/

Order example 709050/82 - 12 - 230 - 150 - 100 / 252

2.3.1 Standard accessories

1 Operating Manual

(5) Load current

70A DC

100A DC

(6) Extra code for fault signal output

= 2mA, U

max.

(1) (2) (3) (4) (5) (6)

CEO max.

= 32V

8 [IGBT Power Converter 70/100A] 02.08

Page 9

2.3.2 Accessories

2 Introduction

Choke: L=0.6mH/I

= 100A, protection rating IP 20, as per EN 60 529

N

Dimensions Connection

Height: 208 mm

Width: 200 x 200 mm

Via screw terminals

up to max. 10...50

2

mm

Choke: L=0.6mH/I

= 75A, protection rating IP 20, as per EN 60 529

N

Dimensions Connection cross-

section

Diameter: 155 mm

Height: 135 mm

Diameter of fixing

hole: 10.4 mm

Via screw terminals

up to max. 4...25 mm

2

EMC filter

For voltage supply to power section

Nominal voltage,

nominal current

115V/250V/440V

AC,

I

= 16A

Nom

115V/250V/440V AC,

= 20A

I

Nom

115V/250V/440V

AC,

I

= 32A

Nom

115V/250V/440V

AC,

I

= 63A

Nom

115V/250V/440V

AC,

I

= 100A

Nom

For voltage supply to the control section

115V/250V AC,

= 1A

I

Nom

Dimensions

(L x W x H)

(255 x 60 x 130) mm 0.6 ... 0.8 Nm approx.

(289 x 70 x 140) mm 1.5 ... 1.8 Nm approx. 5.5

(324 x 90 x 160) mm 1.5 ... 1.8 Nm approx.

(380 x 117 x 190) mm 2 ... 2.3 Nm approx.

(445 x 150 x 220) mm 6 ... 8 Nm approx. 26

80 x 45 x 30 mm - approx.

Tightening torque

for

screw terminals

Tightening torque

for screw terminals

max. 6...8 Nm approx.

Tightening torque

for screw terminals

max. 4...4.5 Nm approx.

Weight Sales No.

20kgs

Weight Sales No.

7.5 kgs

Weight Permissibl

4kgs

kgs

9.5kgs

17kgs

kgs

120g

70/00415759

70/00392474

Sales

e ambient

temperatu

No.

re

40°C 70/00399527

40°C 70/00438775

40°C 70/00409831

40°C 70/00409990

40°C 70/00431997

40°C 70/00413620

Semiconductor fuse

2 extra fast semiconductor fuses are installed in the converter, to protect the

IPC in the event of an earth short.

2

The I

t value of the semiconductor fuse must be less than 20000 A2s!

Sales No. 70/00434229

02.08 [IGBT Power Converter 70/100A] 9

Page 10

2 Introduction

2.4 Brief description

Instrument The J IPC is a IGBT power converter for controlling heater loads that

previously required a transformer (either a variable transformer or a

combination of transformer and thyristor power unit).

Its function is that of an electronic transformer with a pulsed DC output.

Advantages It combines the advantages of a conventional variable transformer, such as

amplitude control which is the sinusoidal current loading, with the advantages

of a thyristor power switch, such as current limiting, load monitoring,

subordinate control action, etc.

There is no electrical isolation between the voltage supply and the

A

Application This power converter is employed wherever large resistive loads need to be

load voltage.

switched and no electrical isolation is required between the supply voltage

and the load voltage. Thanks to the amplitude control (the current drawn from

the supply is always sinusoidal), synchronous clock controls (as for burst-firing

operation) and power-factor compensation networks (for the reactive power

resulting from phase-control) are no longer required.

10 [IGBT Power Converter 70/100A] 02.08

Page 11

2 Introduction

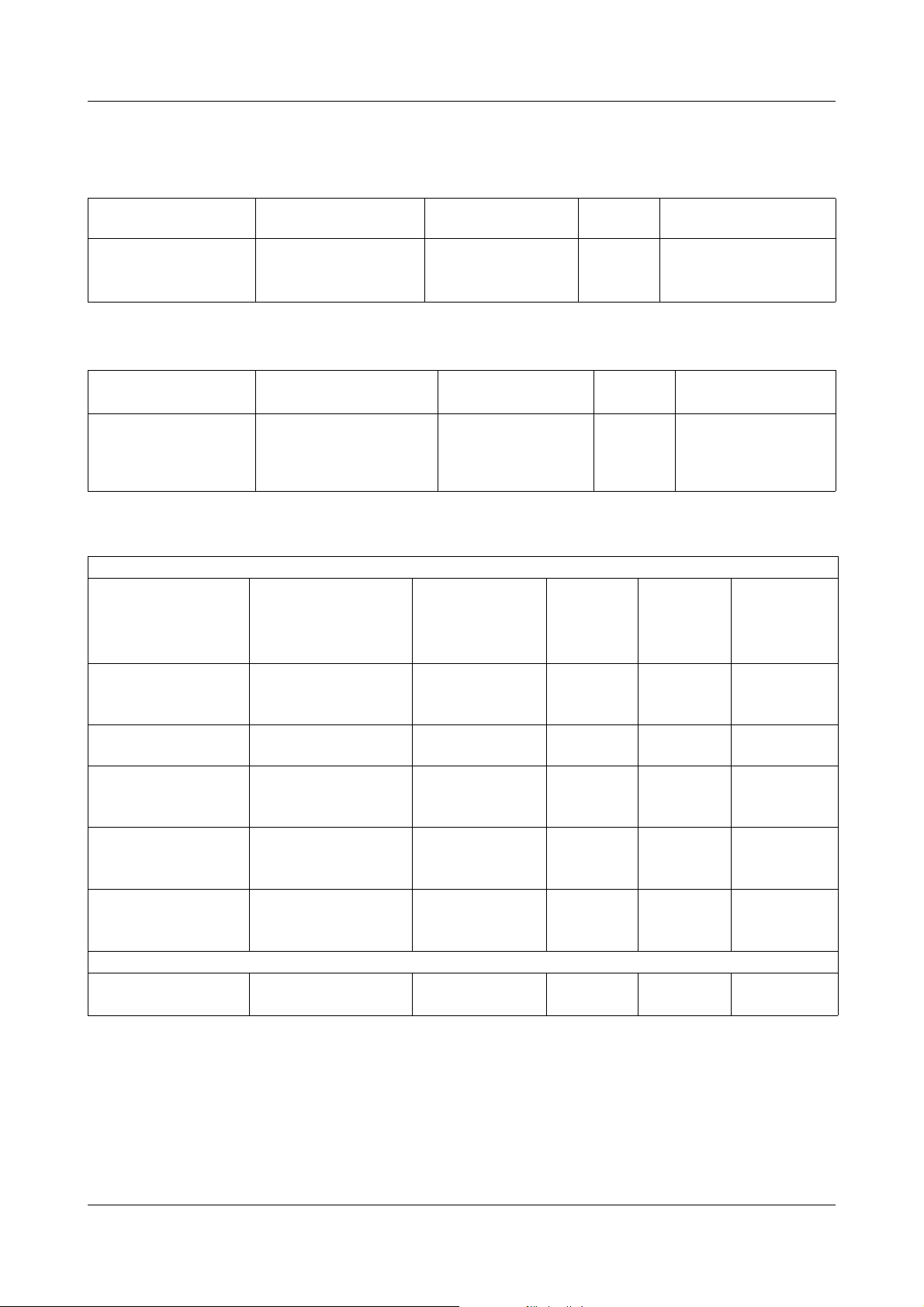

2.5 Interpretation of the LEDs

fuse

Two semiconductor fuses are integrated in the IPC, to protect it in the event of an earth short. If an earth

short occurs, one or both of the semiconductor fuses will trip. Tripping of one or both of the fuses is

indicated by the "Fuse" LED and the drop-out of the fault signal relay.

v Chapter 4.1.4 „Replacing the two semiconductor fuses“

overheat

This LED lights up if the maximum permitted temperature is

exceeded. The fault signal relay drops out at the same time.

The load output remains disconnected until the temperature has

fallen below the limit value again.

v Chapter 3.3 „Ambient conditions“

IGBT

This LED lights up when the electronic safety cut-out of the load circuit

has tripped.

(e.g. because of a wiring fault).

The safety cut-out remains activated until the IPC has been completely

(all-pole) disconnected from the supply and then switched on again.

The fault signal relay drops out at the same time.

v Chapter 5.12 „Safety cut-out in the power section“

current limit

This LED lights up if the converter is working at the current limit.

v Chapter 5.10 „Setting the current limit (max. current

adjust)“

load fail

This LED lights up if a total or partial load failure has been

detected.

The fault signal relay drops out at the same time.

v Chapter 5.11 „Total and partial load failure

monitoring (load fail adjust)“

R-control

This LED lights up if the converter is working at the

resistance limit.

v Chapter 5.8.1 „Resistance limiting (R-

control)“

SIC reserve

This LED lights up when the IPC has reached its

max. load voltage, so there is no longer

automatic compensation for ageing at SIC load.

The fault signal relay drops out at the same time.

v Chapter 5.8.2 „SIC voltage reserve (SIC

reserve)“

This LED indicates that the control section is

connected to the voltage supply.

It does not indicate the status of the power

section!

Power

02.08 [IGBT Power Converter 70/100A] 11

Page 12

2 Introduction

12 [IGBT Power Converter 70/100A] 02.08

Page 13

3.1 Important notes on installation

3 Installation

Safety

regulations

V

k The choice of cable, the installation and the electrical connection of the

instrument must conform to the requirements of VDE 0100 "Regulations on

the Installation of Power Circuits with Nominal Voltages below 1000 V AC"

or the appropriate local regulations.

k The electrical connection must only be carried out by qualified personnel.

k An isolation switch should be wired between the supply and the converter

to be able to disconnect the converter from the voltage supply on all poles

prior to starting internal work.

Caution!

The converter has 2 power supplies (to the control section and to the power

section). Disconnect both supplies (all poles) prior to starting work on the

converter.

Allow 1 minute to elapse after switching off prior to starting work on the

converter, since potentially fatal voltages could be present in the converter

interior and at the terminals.

k Inside the converter, safety gaps meet the requirements for double

insulation.

When installing the connecting cable, ensure that the cables are fitted

according to regulations and that the safety gaps are maintained.

Electrical

supply types

Fuse protection k Fuse protection in accordance with the VDE regulations must be installed

V

The IPC is suitable for operation with TN and TT supply networks.

h Carry out installation in accordance with EN 50178.

for the voltage supply to the power section. The supply protection can also

be achieved by a circuit-breaker in the supply lead. This must be

dimensioned for the power consumption of the power converter and the

rated current of the downstream EMC filter.

k Two semiconductor fuses are incorporated to protect the IPC in the event

of an earth short.

2

(The I

v Chapter 4.1.4 „Replacing the two semiconductor fuses“

k Provide an appropriate control circuit fuse for control section lead

protection. The control section consumes approx. 75 VA.

t value of the semiconductor fuse must be smaller than 20000 A2s)!

3.1.1 Correctly wire all components

EMC filter

The IPC may only be used in conjunction with a suitable filter

A

(accessories). If a different filter is used, it must be of equal or better

characteristics. Otherwise, inductive voltages may be introduced into

the supply network. We decline any liability for damage caused as a

result.

02.08 [IGBT Power Converter 70/100A] 13

Page 14

3 Installation

The EMC filters may only be used for interference suppression of the

H

The earth leakage current of the IPC power converter with a filter wired into the

supply lead is less than 3 mA. If the load conditions result in an earth leakage

current greater than 3.5 mA, a fixed supply connection is required as a

protection against hazardous potentials (also see EN 50178).

Electromagnetic compatibility conforms to the standards and regulations cited

in the technical data.

v Chapter 6 „Technical data“

h Load wiring (thick) and cables for control inputs (thin) should be routed

14 [IGBT Power Converter 70/100A] 02.08

IPC power converter. Other devices, such as controllers, power

supplies etc. must be suppressed, where necessary, with their own

EMC filters. Do not wire these devices in parallel to the IPC power

converter on the load side of the EMC filter.

separately, if possible.

Page 15

3 Installation

Positioning of

the choke

Connection h Check the data given on the nameplate (voltage supply to the control

PE connection/

FB connection

Choke

connection

h The choke should be installed close to the converter.

section, voltage supply to the power section, load voltage and load current)

against the system data.

v Chapter 2.3 „Order details“

h Check the adaptation of the setpoint inputs.

h Check the switch settings.

h Provide a direct connection between the PE of the IPC and the PE of the

supply network. Connect to the PE terminal

of the IPC.

h If necessary, interference emission of the IPC can also be minimised by a

function equipotential bonding. The function equipotential bonding is

connected to the FB terminal of the IPC.

v Chapter 3.1.1 „Correctly wire all components“

h The choke is connected to terminals C and 1C.

Voltage

supply

Load

connection

h Connect the voltage supply to the control section to terminals L1 and N(L2)

(X109).

h Connect the voltage supply of the power section to terminals U and N(V).

An isolation switch should be wired between the supply and the

A

h The load is connected to terminals D and 1D.

h The cable between the load and the IPC should be as short as possible and

not exceed 50 m.

A

converter to be able to disconnect the converter from the voltage

supply on all poles prior to starting internal work!

The connection must only be carried out by qualified personnel!

Use a shielded cable to connect to the load, ensure that the

shielding is connected to earth on both ends.

v Chapter 3.2 „Filtering and interference suppression“

Choosing the suitable cables

v Chapter 4.1.1 „Suitable cables and cross-sections“

Control inputs The terminal strip for control connections (inputs and outputs) have been laid

out for safe isolation from the supply (SELV). To prevent the safe isolation from

being impaired, ensure that all connected current circuits are also safely

isolated. The required auxiliary supplies must be SELV voltages.

02.08 [IGBT Power Converter 70/100A] 15

Page 16

3 Installation

Switch-on

sequence

The voltage supplies to the control section and to the power section must be

switched on simultaneously.

Under no circumstances may the voltage supply to the control

H

section be switched on before the load voltage. This is especially

important when operating resistive loads that have a high hot/cold

resistance ratio.

3.2 Filtering and interference suppression

System Compliance with the EMC standards can only be achieved through additional

EMC measures.

These include:

- a supply filter in the voltage supply

- a shielded cable for the voltage supply (from the supply filter (load) to the

IPC)

- a shielded cable to the load

- Functional equipotential bonding

Compliance with the EMC standards must be tested for the overall system.

Construction To keep interference emission through conducted and radiated interference

below the permissible levels defined in the pertinent EMC standards,

constructive measures must be taken in the installation and wiring stages in

addition to supply input filtering. Poor earth connection or shielding of the

EMC filter will reduce the effectiveness of the interference suppression

measures.

The following points should be noted in order to achieve good configuration

for EMC purposes:

h All metallic components of the converter or cabinet must be well bonded

for HF currents over a large surface area.

h The EMC filter should be installed close to the IPC, if possible, on a

common metal plate. Route cables for control inputs and signal cables as

far apart from each other as possible, and use shielded cables.

h If possible, do not route power cables in the same cable duct as control or

signal cables.

h The cable between the load and the IPC should be as short as possible and

not exceed 50 m.

Earthing The base plate, the supply filter and the shielding of the supply cable must be

earthed to a star point using HF braiding.

Choosing

a suitable

cable

k If the cable between the filter and the IPC is longer than 300 mm, we

recommend to use a shielded cable with the shielding earthed at both

ends. Route cables inside the switch cabinet as close as possible to

grounded surfaces, otherwise they can act as antennae and radiate

interference.

16 [IGBT Power Converter 70/100A] 02.08

Page 17

3 Installation

k To achieve a good shielding effect for the cable, only use cables that have

shielding made with tinned or nickel-plated copper braiding. The coverage

of the shielding should be at least 70%; the lay angle should be 90°.

Screens made of steel braiding are not suitable. Earth the shielding of the

load cable on both ends.

k The shielding of the control inputs must only be earthed at one end (IPC

side). If potential differences exist, install an additional equipotential

bonding conductor.

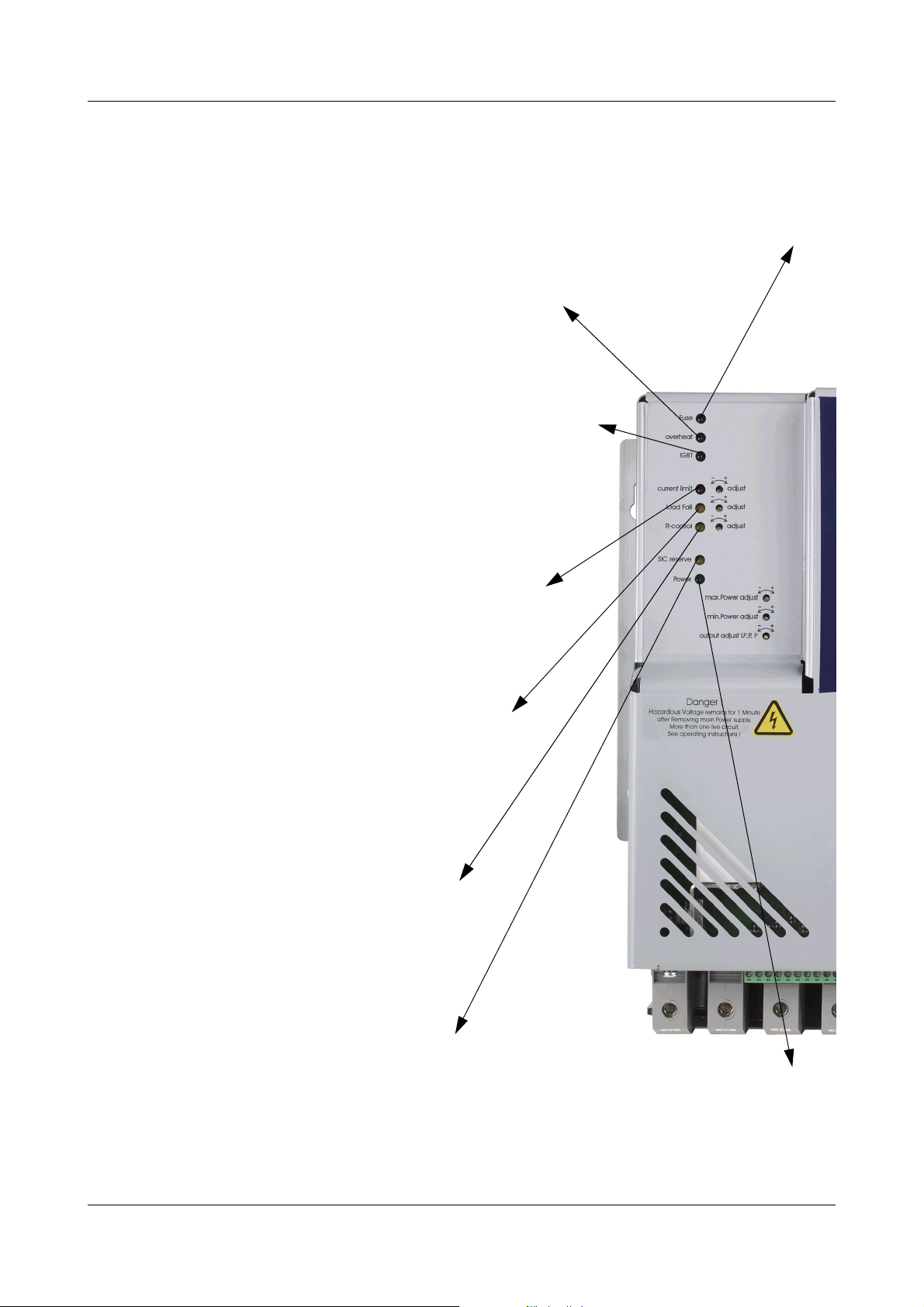

EMV compliant

design

The user/owner is responsible for compliance of the specific application with

the EMC directive. The diagram below illustrates such a design for type

709050/X2-12-400-XXX-100/XXX with a Phase / Phase supply configuration.

02.08 [IGBT Power Converter 70/100A] 17

Page 18

3 Installation

3.3 Ambient conditions

Misuse The instrument is not suitable for use in areas with an explosion hazard (Ex

areas).

Mounting site The installation site should be free from vibration, dust and corrosive media.

Climatic

conditions

Power loss Power loss occurs in the form of thermal discharge at the cooling body of the

- Relative humidity: 5...85 % no condensation (3K3 as per EN 60721)

- Max. air inlet temperature 35°C

- Ambient temperature range: 5 ... 40 °C (3K3 as per EN 60721)

- Storage temperature range: -10...70 °C

power converter and has to be discharged at the place of installation (e.g. in

the switch cabinet) in accordance with the climatic conditions.

Example of the

Molybdenum

Disilicid

heating

elements

IPC type: 709050/82-12-400-150-100/252

Load voltage = 150V

Load current = 100A

Voltage supply to the power section = 400V

Resistive loads and Molybdenum Disilicid heating elements:

Heating element data: Load voltage = 140V; load current = 90A

h Determine the max. load voltage actually taken (e.g. 140 V) and find the

point intersecting with the curve for the voltage supply in the power section.

The Y axis shows the attendant power loss factor of, e.g., 8.5.

The power loss (W) is obtained by multiplying this power loss factor by the

load current (e.g. 90A)

18 [IGBT Power Converter 70/100A] 02.08

Page 19

3 Installation

that flows at max. load voltage (e.g. 140V) through the load resistor

Power loss = 90(A) x power loss factor

Power loss = 90(A) x 8.5 = 765W

Example of the

SIC heating

elements

Wall

fixing

IPC type: 709050/92-12-400-150-100/252

Load voltage = 150V

Load current = 100A

Voltage supply to the power section = 400V

P control, P = 6300W

SIC heating elements

SIC heating element data: new: 70V/90A, old 140V/45A; P = 6300W

h Determine the maximum load voltage actually (e.g. 70V) of the new SIC

heating element and find the point intersecting with the curve for the

voltage supply in the power section. The Y axis shows the attendant power

loss factor of, e.g., 6.8.

The power loss (W) is obtained by multiplying this power loss factor by the

load current (e.g. 90A)

that flows at max. load voltage (e.g. 70V) through the new SIC heating element

Power loss = 90(A) x power loss factor

Power loss = 90(A) x 6.8 = 612W

h Use 4 hexagonal M6 bolts (at least quality 8.8) to fix the converter vertically

on a heat-resistant switch cabinet back panel.

H

The temperature of the air drawn in through the ventilation grille

must not exceed 35° C. Ensure that the inlet air for the built-in

ventilators can be taken in from below and escape at the top

without obstruction!

02.08 [IGBT Power Converter 70/100A] 19

Page 20

3 Installation

V

Dimensions Type 709050/X2...

3.4 Spacings

Caution! Hot cooling body!

The cooling body can reach very high temperatures during

operation!

h Allow a clearance of 10 cm from the floor.

h Allow a clearance of 15 cm from the ceiling.

h When fitted next to each other, no spacing between the units is required.

20 [IGBT Power Converter 70/100A] 02.08

Page 21

3.4.1 Opening the housing

Caution!

V

The converter has 2 power supplies (to the control section and to the power

section). Disconnect both supplies (all poles) prior to starting work on the

converter.

Allow 1 minute to elapse after switching off prior to starting work on the

converter, since potentially fatal voltages could be present in the converter

interior and at the terminals.

Caution! Hot cooling body!

h Disconnect the built-in converter from the voltage supply on all poles

h Wait for 1 minute

h Check that no voltage is present

h Undo the 2 screws from the bottom of the converter

3 Installation

h Swing up the housing cover from the bottom of the converter

02.08 [IGBT Power Converter 70/100A] 21

Page 22

3 Installation

h Lift the cover out of the groove and take it off forward

22 [IGBT Power Converter 70/100A] 02.08

Page 23

4 Electrical connection

V

4.1 Screw connections in the power section

Tool - Screwdriver

- Allen key, width across flats 5 mm

The electrical connection must only be carried out by qualified

personnel!

h Disconnect the system from the electrical supply on all poles.

h Make the connections to the screw terminals in the power section using

cable lugs and cable cross sections from 10 to 50mm

Maximum tightening torque from 6 to 8 Nm.

2

.

02.08 [IGBT Power Converter 70/100A] 23

Page 24

4 Electrical connection

Phase / N The diagram shows the wiring for single-phase operation Phase / N for

type 709050/X2.

I

Phase / Phase The diagram shows the wiring for single-phase operation Phase / Phase for

type 709050/X2.

24 [IGBT Power Converter 70/100A] 02.08

Page 25

4 Electrical connection

4.1.1 Suitable cables and cross-sections

PE conductor The cross-section of the PE conductor must be at least as large as the cross-

section of the voltage supply conductors to the power section. If the

protective earth (PE) conductor is not part of the supply cable or its sheathing,

the chosen conductor must have a cross-section of at least 2.5 mm

2

mechanically protected) or at least 4mm

mechanically protected).

v see VDE 0100 Part 540

Control section The screw terminals for the voltage supply to the control section are laid out

for a conductor cross-section between 0.5mm

conductor cross-section must not be less than 0.5

must correspond to the selected conductor cross-section.

Power consumption is approx. 75 VA.

Power section

The minimum conductor cross-section chosen must be adequate

H

for the maximum conductor current. The electrical connection is

made via screw terminals on the converter. We recommend the use

of a shielded cable to reduce EMC interference emission.

(if the PE conductor is not

2

and 2.5mm2. The minimum

2

mm. Fusing of the cable

2

(if

Calculation

formula

Example

A

I

I

I

Supply

Supply

Supply

v Chapter 3.2 „Filtering and interference suppression“ Choosing

the suitable cables

The cable cross-section in the load and choke circuits must not be

smaller than the cross-section of the supply leads to the power

section!

=

=

=

maximum load power consumption

+ 2A

Voltage supply to power section

3000 W (heater load)

+ 2A =

230V (voltage supply to the power section)

13A + 2A = 15A

02.08 [IGBT Power Converter 70/100A] 25

Page 26

4 Electrical connection

4.1.2 Electrical isolation

The control section, including the inputs and outputs, as well as all operator

controls can be connected to SELV circuits.

The fault signal relay can be connected to SELV or supply potential, without

prejudicing the electrical isolation arrangements of the other inputs and

outputs.

There is no electrical isolation between the voltage supply of the

A

4.1.3 Use of residual current protection devices

The converter is equipped with an internal input rectifier. A short to the housing

can result in a residual DC current that blocks the tripping of the conventional

residual current protection device. For this reason, any RCD used must be an

„all-current sensitive“ version of Type B.

When defining the trip current for the RCD, the leakage currents of the EMC

filter caused by the Y capacitors (<3mA) as well as the capacitive currents

from the cable shielding have to be taken into account.

power section and the load.

Ensure that the metal housing of the oven or combustion chamber

is properly earthed.

v Chapter 3.2 „Filtering and interference suppression“ Installation

must comply with EVC requirements.

See also EN 50178 (VDE 0160):

H

Protection of electrical equipment through residual current

protection devices.

4.1.4 Replacing the two semiconductor fuses

h Disconnect (all poles) the converter from the voltage supply.

h Wait 1 minute to allow hazardous voltages to discharge.

h Check that no voltage is present on the screw terminals.

h Open the housing as described in Chapter 3.4.1 „Opening the housing“.

h Undo 2 screws of the semiconductor fuse, remove fuses from the holder by

turning laterally, and replace with new fuses.

h Tighten the screws with a maximum tightening torque of 20 Nm.

26 [IGBT Power Converter 70/100A] 02.08

Page 27

4 Electrical connection

h Check the cause that led to the semiconductor fuse tripping (e.g. earth

short in the power section).

h Only use original JUMO replacement parts, item No. 70/00434229.

v Chapter 2.3.2 „Accessories“

02.08 [IGBT Power Converter 70/100A] 27

Page 28

4 Electrical connection

4.1.5 Wiring of the screw terminals

Position The following diagram shows the position of the screw connections in the

power section, the screw terminals on the PCB as well as the general

connection arrangement.

Only tighten the green screw terminals in the control section with a

A

tightening torque of 0.5 to 0.6 Nm!

Connection for terminal screw X109 Detail

Voltage supply

Control section

Connection for Screw connections in

Voltage supply to power section U

Protective earth PE

Functional equipotential bonding

v Chapter 3.1.1 „Correctly wire all

components“

28 [IGBT Power Converter 70/100A] 02.08

L1

N (L2)

Detail

the power section

N(V)

FB

Page 29

4 Electrical connection

Choke connection 1C

C

Load connection 1D -

D +

Connection for terminal screw X102 Detail

Current input

(differential input)

12+

Voltage input

(referred to ground)

External manual adjustment

Potentiometer 5 k⍀

Firing pulse inhibit

(inhibit input) I

approx. 1mA

K

3 ground

4+

3 Start (ground)

4 slider

5 end (+10V)

6 ground

7+

(break or make contact)

2

Output level 0 to 10V (U

approx. 2mA

I

max

, P, I2 )

Resistance output 0 to 5 V (R)

approx. 2mA

I

max

10+

6 ground

8 +

6 ground

–

Connection for Screw terminal X103 Detail

Load fault output with relay

contact rating 230V AC/3A

resistive load

1 make contact

2 break contact

3 common

relay drops out at fault

8

+

6

Load fault output with

optocoupler Ic

U

CEO max

= 32 V

max

= 2mA

3 collector

1 emitter

02.08 [IGBT Power Converter 70/100A] 29

Page 30

4 Electrical connection

30 [IGBT Power Converter 70/100A] 02.08

Page 31

5.1 Operating principle

The J IPC can be used wherever a transformer was previously used to

reduce the voltage level.

It functions as an electronic transformer that produces a pulsed DC output.

Block diagram

5 Settings

02.08 [IGBT Power Converter 70/100A] 31

Page 32

5 Settings

5.2 Setting switches S101, S103, S104, S105, S106 and X106

32 [IGBT Power Converter 70/100A] 02.08

Page 33

5.3 Subordinate control loop

Subordinate control loops are primarily used to eliminate or compensate for

external disturbances, such as fluctuations in the supply voltage and

alterations in resistance that have a negative effect on the operation of the

control loop.

2

Factory setting A subordinate U

however, also the P or I

control loop is factory set,

2

control loop is possible.

5 Settings

Control

type

2

U

P 0 1 0 - general application,

2

I

k factory setting

Internal switch S101 Application

S1 S2 S3

1 0 0 - positive TC, Molybdenum Disilicid

0 0 1 - negative TC

5.4 Load voltage adjustment

Switch S101-7 can be used to adjust the load voltage.

If the max. load voltage required is less than 75% of the

load voltage U

If the maximum required load voltage is 75% or more of the nominal load

voltage U

L Nom

as per type code, then S 101-7 must be opened.

L Nom

as per type code, then S 101-7 must be closed.

- R ≈ constant

- brightness controls

required for SIC loads and

automatic compensation for ageing.

Factory setting S101-7 is closed.

02.08 [IGBT Power Converter 70/100A] 33

Page 34

5 Settings

5.5 Control inputs

The internal switches S8, S9 and S104 are used to adapt the converter to the

available control signal (controller output signal).

The voltage and current inputs are separated from one another. The current

inputs (+,-) are arranged as differential inputs, i.e. they can have a maximum

common mode voltage of 7V with respect to the common ground potential (⊥).

If the current and voltage inputs are used at the same time, their effect will be

cumulative.

Control signal Internal switches

Signal start Signal end S8 S9 S104

0 mA 20 mA 0 1 1

4 mA 20 mA 0 0 2

0 V 10 V 0 1 1

2 V 10 V 0 0 2

0 V 5 V 1 1 1

1 V 5 V 1 0 2

k factory setting

Analog

control inputs

The converter can be controlled through the following signals

(continuous power control):

- voltage signal (terminals 3, 4)

- current signal (terminals 1, 2)

-5 kΩ potentiometer (terminals 3, 4, 5)

For this purpose, a 10 V source is provided on terminal 5.

(switch settings are as for a 0 ... 10 V signal)

34 [IGBT Power Converter 70/100A] 02.08

Page 35

5 Settings

5.5.1 Combination of external potentiometer and electronic controller

Controller with

current output

The voltage input (terminals 3, 4) in conjunction with the internal 10 V source

and a 5 kΩ potentiometer is used as a manual control input.

Switch S

a

S

b

Controller with

voltage output

Automatic mode open open

Manual mode closed closed

To prevent unintended oversteering when switching over to the

H

Only the voltage input of the converter is used. Manual operation requires a 5

kΩ potentiometer connected to terminals 3 and 5.

Switch S

Automatic mode Position 1

Manual mode Position 2

manual mode, S

both signals will briefly cumulate.

should be mechanically linked to Sb. Otherwise

a

c

02.08 [IGBT Power Converter 70/100A] 35

Page 36

5 Settings

5.6 Firing pulse inhibit

The firing pulse inhibit function provides a simple way of switching

to high power levels.

In order to be able to disconnect a system from the supply voltage,

V

A

A contact between connections 6 and 7 can be used to switch off the load.

The external contact can be a make or break contact, depending on the

position of S105.

a circuit-breaker or main switch for all-pole disconnection must be

wired into the supply feed!

If the output power is simply removed by inhibiting the firing

pulses, this does not provide electrical isolation from the voltage

supply! The terminals D or 1D may still carry dangerous voltage

from the supply.

External contact Internal switch S 105 Response

Make (a) Position 1 The Load is permanently

Break (b) Position 2 The Load is permanently

k factory setting

Factory setting S105 is in position 1

5.7 Resistance output

When the converter is operating within rated limits, the resistance output has a

voltage of 4 ... 5 V.

switched off when the contact

is closed

switched off when the contact

is open

36 [IGBT Power Converter 70/100A] 02.08

Page 37

5.8 Trimmer settings

The converter has 6 trimmers that can be adjusted by inserting a screwdriver

blade (maximum blade width: 2 mm) through openings in the housing.

current limit adjust

load fail adjust

resistance control adjust

max. Power adjust

min. Power adjust

output adjust P I

5 Settings

2

2

U , ,

5.8.1 Resistance limiting (R-control)

The switch S101-10 can be used to activate a limiting of the output power

depending on the resistance value R when operating Molybdenum Disilicid

heating elements, to avoid overheating of the elements in the upper

temperature range. Direct measurement of the resistance of the elements

allows precise determination of the element temperature. When switch S10110 is closed, the converter limits its output power as soon as the element

resistance (the element temperature) is reached that was set by the trimmer for

„resistance control adjust“. In this manner, the heating element is protected

from overheating. The "R-control" LED signals the active status of the

resistance limiting.

Factory setting The R-control trimmer is not factory-set. An appropriate adjustment must be

carried out on site to set the maximum temperature limit for the heating

element. This can be carried out with the aid of load voltage and current

measurement (resistance measurement) or with the help of a thermal imaging

camera.

A true-rms meter must be used for measuring voltage, power or

A

current, because the load current is pulsating DC.

A meter calibrated for alternating current (AC) and sinusoidal

waveforms will produce false readings!

02.08 [IGBT Power Converter 70/100A] 37

Page 38

5 Settings

The adjustment range of the resistance limiting can be set by the R-control

trimmer between R

= nominal voltage / nominal current

R

Nom

Action Response

Turn „resistance control“

trimmer clockwise

Turn „resistance control“

trimmer counter-clockwise

Factory setting S101-10 is open, R-control is inactive

5.8.2 SIC voltage reserve (SIC reserve)

When SIC heating elements are used, ageing of the elements is automatically

compensated for when P-control is chosen for the subordinate control loop

(Chapter 5.3).

The resistance of the SIC heating element increases with the operational time.

The IPC converter adjusts the load voltage automatically to match the required

power output. As soon as the maximum load voltage from the IPC is no longer

sufficient to produce the required output power for the SIC heating element,

this condition will be signaled by the „SIC reserve“ LED. This indication

appears time delayed after approx. 7 minutes.

The fault signal relay drops out at the same time.

and 10xR

Nom

Nom

.

Limiting at a higher resistance value

(higher temperature)

Limiting at a lower resistance value

(lower temperature)

The SIC reserve display as well as the fault signal function can be activated by

opening the S101-12.

Factory setting S101-12 is closed, and the function is inactive.

5.8.3 Control input adjustment (max. Power adjust)

The „max. Power adjust“ trimmer at the front can be used to adapt the power

output of the converter to the maximum output signal of the controller

connected before.

Action Response

Turn the „max. Power adjust“ trimmer

clockwise

Turn the „max. Power adjust“ trimmer

counter-clockwise

Factory setting The trimmer is adjusted so that a 100% controller output signal produces the

2

maximum load voltage (U

control loop).

control is the factory setting for the subordinate

more power

less power

38 [IGBT Power Converter 70/100A] 02.08

Page 39

Correct

measurement

A

A true-rms meter must be used for measuring voltage, power or

current, because the load current is pulsating DC.

A meter calibrated for alternating current (AC) and sinusoidal

waveforms will produce false readings!

5.8.4 Setting for maximum power (max. Power adjust)

h Apply the maximum controller output signal

h Turn the „max. Power adjust“ trimmer clockwise or counter-clockwise until

the required power is achieved.

h Turning the „max. Power adjust“ trimmer clockwise will increase the

maximum power output.

h Take care that the red „current limit“ LED remains off, otherwise the circuit

is operating in current limiting (current limit), which leaves turning the

trimmer clockwise without effect, as the power output will not increase.

5.8.5 Input signal attenuation

5 Settings

h Turning the „max. Power adjust“ trimmer counter-clockwise will decrease

the maximum power output of the converter.

5.9 Setting the base load (min. Power adjust)

Base load

setting

Example: A heating system is operated with a base load set to 1/3. The remaining 2/3 of

Correct

measurement

Open switch S11 to be able to set a base load.

Turning the „min. Power adjust“ trimmer clockwise will increase the base load

setting.

The settable range covers the complete range from 0 to 100%.

the power are regulated by the controller.

A true-rms meter must be used for measuring voltage, power or

A

current, because the load current is pulsating DC.

A meter calibrated for alternating current (AC) and sinusoidal

waveforms will produce false readings!

Factory setting S101-11 is closed, no base load is set

02.08 [IGBT Power Converter 70/100A] 39

Page 40

5 Settings

5.10 Setting the current limit (max. current adjust)

h The front „max. current adjust“ trimmer can be used to limit the rms value

of the load current over a range of 10 to 100% of the rated converter

current.

1.5 clockwise turns correspond to increasing the response threshold by

approx. 10% of the rated converter current.

Action Response

Correct

measurement

Turn the „max. current

adjust“ trimmer clockwise

Turn the „max. current

adjust“ trimmer counterclockwise

A true-rms meter must be used for measuring voltage, power or

A

current, because the load current is pulsating DC.

A meter calibrated for alternating current (AC) and sinusoidal

waveforms will produce false readings!

The current limit will increase

The current limit will reduce

The red „current limit“ LED is on when current limiting is active.

Factory setting The trimmer is set to the maximum rated current.

H

The activation of the current limit can also be used to operate the

fault signal relay.

For this purpose, open switch S 101/13.

Factory setting: The activated current limit is only indicated by the red

LED ( S 101/13 closed)

v Chapter 5.2 „Setting switches S101, S103, S104, S105, S106 and

X106“

5.11 Total and partial load failure monitoring (load fail adjust)

Total and partial load failure monitoring for different types of load.

The factory setting of the converter is such that the total and partial load failure

states can be detected for resistive loads and loads connected in series. For

short-wave infrared radiators, turn switch S106 to position 2.

Factory setting Switch S106 is in position 1

If the load resistance changes during operation, this will be detected by the

partial load monitoring and indicated through the signal output.

The response threshold can be adjusted by the „load fail adjust“ trimmer on

the front panel (load fail adjust) between 20 and 100% of the rated converter

current.

40 [IGBT Power Converter 70/100A] 02.08

Page 41

The smallest change in resistance that can be detected is 5 % of

H

Factory setting The trimmer is set to approx. 20 %.

The signal output provided is a floating contact or an optocoupler, depending

on the extra code.

Typ e : re lay

709050 / X2 - XX - XXX - XXX - XXX / 252

Typ e :

optocoupler

709050 / X2 - XX - XXX - XXX - XXX / 257

In the case of a load fault, the floating contact drops out, or the collectoremitter path of the optocoupler goes high-resistance.

The signal output is also active if the maximum temperature of the converter is

exceeded (overheat), if the safety cut-out in the power section has been

triggered or if the semiconductor fuse has blown (fuse).

the nominal load resistance.

5 Settings

H

v Chapter „“

Jumper setting Response

k factory setting

H

The functions „SIC voltage reserve exhausted“ or „Current limit

active“ can also be applied to the signal output if they are activated

as described in the following sections:

v Chapter 5.8.2 „SIC voltage reserve (SIC reserve)“

v Chapter 5.10 „Setting the current limit (max. current adjust)“

Underload detection

Overload detection

The total and partial load failure monitoring (underload) also allows

overload monitoring. For this purpose, both jumpers on the pin

strip X106 must be turned through 90°.

v Chapter 5.2 „Setting switches S101, S103, S104, S105, S106

and X106“

02.08 [IGBT Power Converter 70/100A] 41

Page 42

5 Settings

5.11.1 Setting the load fault indication

The partial load setting must be made after the current limit has

H

h Connect the load

h Provide a full control signal (e.g. 20 mA at the control input)

h Adjust the „load fail adjust“ trimmer such that the yellow „load fail“ LED just

extinguishes.

- Turn clockwise = LED lights up

- Turn counter-clockwise = LED extinguishes

h If necessary, continue turning counter-clockwise to reduce the activation

threshold. 1.5 turns of the potentiometer change the load current by

approx. 10% of the converter rated current.

been set. If the current limit setting is changed, this will also affect

the setting of the partial load fault detection.

This must be corrected accordingly, if necessary.

Alternative

setting option:

To simulate a load fail, adjust the „load fail adjust“ trimmer such that the yellow

„load fail“ LED lights up.

The smallest change in resistance that can be detected is 5 % of the

H

nominal load resistance.

42 [IGBT Power Converter 70/100A] 02.08

Page 43

5 Settings

5.12 Safety cut-out in the power section

If there is a fault in the choke or the control electronics, the output voltage is

switched off between terminals D and 1D.

However, terminals D and 1D may still carry dangerous voltage from

A

This state is indicated by the „IGBT“ LED, and the fault signal relay drops out.

This safety cut-out remains activated even when the fault has been remedied.

It can only be reset by disconnecting the voltage supply.

h Switch the device off briefly, and then on again

5.13 Adjusting the output level signal (output adjust U2, P , I2 )

In the factory settings, the output level signal corresponds to the I2 signal at

the output of the converter. It is thus proportional to the power in the load

(R=constant).

the supply. They are not electrically isolated from the supply!

Output adjust

2

, P, I

2

U

However, setting P or U

v Chapter 5.2 „Setting switches S101, S103, S104, S105, S106 and X106“

Power level output Internal switches

2

U

P010

2

I

The output level signal provides a voltage in the range of 0 to 10V

(corresponding to 0 to 100% of the variable being measured). The trimmer

„output adjust U

end value:

Action Response

Tur n „o utput adjust U

clockwise

Tur n „o utput adjust U

counter-clockwise

2

2

instead of the I2 signals is also possible

S4 S5 S6

100

001

, P , I2 “ on the front panel can be used to set the required

2

, P , I2 “ trimmer

2

, P , I2 “ trimmer

End value increases

End value reduces

02.08 [IGBT Power Converter 70/100A] 43

Page 44

5 Settings

44 [IGBT Power Converter 70/100A] 02.08

Page 45

6.1 Voltage supply

6 Technical data

Voltage supply

Power section

Voltage supply

Control section

Power consumption, control section approx. 75 VA

Load voltage U

Load current U

Load type Resistive loads

L rms

L rms

115V AC +15%/-20% 48 ... 63Hz

230V AC +15%/-20% 48 … 63Hz

400V AC +15%/-20% 48 … 63Hz

115V AC +15%/-20% 48 ... 63Hz, (only with 115V AC in the power

section)

230V AC +15%/-20% 48 … 63Hz

20 V DC, 60 V, 90V, 120 V, 150 V, 210 V, 270V, 380V

70, 100A DC

6.2 Control

Control signal 0 (4) … 20mA Ri = 50 Ω

0 (2) … 10V R

0 (1) … 5V R

Manual control through an external 5 kΩ potentiometer

Input signal attenuation Adjustment range 100 to 20%

Base load setting 0 ... 100 %

= 25kΩ

i

= 12kΩ

i

6.3 Fault signal output

Relay (changeover contact)

without contact suppression

Optocoupler output I

150000 switching actions at a contact rating of 3A/230V 50Hz (resistive

load)

Cmax

= 2mA, U

CEOmax

= 32V

6.4 General characteristics

Circuit variants Single-phase operation

Operating modes Amplitude control

Subordinate

control

Current limiting In operation, the load current can be set in the range of 10 … 100% I

Partial load failure 20 ... 100% of nominal current

R-control Adjustment range from R

Power level output As standard: free choice between U

As standard: free choice between U

trimmer on the front panel. This limits the rms-value of the load current.

to 10x R

R

= nominal voltage / nominal current

Nom

adjustable 0 … 5V to 0 … 10V , I

offset deviation: ≤ ± 5%

Nom

2

-, P-, I2 control via internal switches

Nom

2

-, P-, or I2 signal via internal switches,

≈ 2mA,

max

by a

N

02.08 [IGBT Power Converter 70/100A] 45

Page 46

6 Technical data

Power loss P

(W) It occurs in the form of thermal discharge at the cooling body of the power

tot

converter.

v Chapter 3.3 „Ambient conditions“

Control accuracy The regulation will eliminate supply voltage variations within the tolerances range

(+15%/-20%) with an accuracy of

Electrical connection Control leads via plug-in screw terminals for conductor cross-sections from

0.5 to 2.5mm

protection rating IP 20 as per EN 60 529

Protection class Protection class I, with isolated control circuitry for connection to SELV circuits

Permissible ambient

temperature range

Permissible storage

temperature range

Cooling forced convection, maximum inlet air temperature 35°C

Climatic conditions Rel. humidity ≤ 5 to 85 % annual average, no condensation

Installation position vertical

Operating conditions The converter is designed as a built-in device as per EN 50178

Test voltage as per EN 50178

Creepage distances Control section to load circuit ≥ 5.5 mm

Earth leaking current The earth leakage current of the IPC power converter used with an EMC filter in

Housing Metal housing

Weight approx. 17 kgs

5 … 40°C (3K3 as per EN 60721-3-3)

-10 … +70°C (1K3 as per EN 60 721-3-1)

3K3 as per EN 60721

Pollution degree 2, overvoltage category Ü III

Control section to housing ≥ 5.5 mm

The converter can be connected to SELV circuits.

SELV = Separate Extra Low Voltage (safe low voltage)

the supply cable is less than 3 mA (excluding any leakage current in the load).

2

, in the power section via screw terminals 10 to 50mm2.

⫾0.5 %

46 [IGBT Power Converter 70/100A] 02.08

Page 47

6.5 Choke data

6 Technical data

Type Dimensions Connection

cross section

L = 0.6 mH / I

protection IP 20 as per

EN 60529

L = 0.6 mH / I

protection IP 20 as per

EN 60529

= 75A

N

= 100A

N

Choke diameter: 155 mm

Height: 135 mm

Diameter of fixing

hole: 10.4 mm

Height: 208 mm

Width: 200 x 200 mm

4...25 mm

10...50 mm

6.6 EMC filter

For voltage supply to power section

Nominal voltage,

Nominal current

115V/250V/440V AC,

I

= 16A

Nom

115V/250V/440V AC,

I

= 20A

Nom

115V/250V/440V AC,

I

= 32A

Nom

115V/250V/440V AC,

I

= 63A

Nom

115V/250 V/440 V AC,

I

= 100A

Nom

For voltage supply to the control section

115V/250V AC,

I

= 1A

Nom

Dimensions

(length x width x

height)

(255 x 60 x 130) mm 0.25...4 mm

(289 x 70 x 140) mm 0.5...10 mm

(324 x 90 x 160) mm 0.5...10 mm

(380 x 117 x 190) mm 0.5...16 mm

(445 x 150 x 220) mm 10...50 mm

(80 x 45 x 30) mm via

Connection

cross-section

tab connector

6.3 x 0.8mm

Tightening torque

for

screw terminals

2

0.6 ... 0.8 Nm approx. 4

2

1.5 ... 1.8 Nm approx. 5.5

2

1.5 ... 1.8 Nm approx. 9.5

2

2 ... 2.3 Nm approx. 17

2

6 ... 8 Nm approx. 26

- approx. 120 g40°C 70/00413620

Tightening torque

for screw terminals

2

max. 4...4.5 Nm approx.

2

max. 6...8 Nm approx.

Weight Permissible

kgs

kgs

kgs

kgs

kgs

Weig ht Sales

number

70/00392474

7.5 kgs

70/00415759

20 kgs

Sales

ambient

temperature

40°C 70/00399527

40°C 70/00438775

40°C 70/00409831

40°C 70/00409990

40°C 70/00431997

No.

02.08 [IGBT Power Converter 70/100A] 47

Page 48

6 Technical data

48 [IGBT Power Converter 70/100A] 02.08

Page 49

7 Troubleshooting

What is happening? Cause / Remedy Information

Green power LED does

not light up

IPC is not producing any

output power although

green LED

Power is lit and a

setpoint value has been

provided.

- Voltage supply to control section not

connected

- Voltage supply to power section not

connected

- Analog control input not connected

correctly

- Switch positions for control input S 101/8

and 9 or S104 set incorrectly

h Check switch for firing pulse inhibit

S 105

-Load break

- Load short circuit („current-limit“ LED is

lit)

v Chapter 4 „Electrical

connection“

v Chapter 4.1 „Screw

connections in the

power section“

v Chapter 4.1.5

„Wiring of the screw

terminals“

v Chapter 5.5 „Control

inputs“

v Chapter 5.6 „Firing

pulse inhibit“

h Check load and load connections

IPC is not producing any

output power although

green power LED is lit, a

setpoint value is set and

the load fail LED is lit.

-Load break

- Load short circuit („current-limit“ LED is

lit at the same time)

h Check load and load connections

- Safety cut-out in the power section

fuse LED is lit - Semiconductor fuse blown by

earth short in the power section/

h remedy wiring fault or earth short in the

load

IPC is not producing any

output power although

green power LED is lit, a

setpoint value is set and

the overheat LED is lit.

- Switch off caused by overheating

(clogged or faulty fan)

h Check the fan and replace, if necessary

- Insufficient supply of fresh air

- Inlet air temperature > 35°C

h Ensure sufficient ventilation

v Chapter 5.12

„Safety cut-out in

the power section“

v Chapter 4.1.4

„Replacing the two

semiconductor

fuses“

v Chapter 3.3

„Ambient

conditions“

02.08 [IGBT Power Converter 70/100A] 49

Page 50

7 Troubleshooting

What is happening? Cause / Remedy Information

IPC does not produce

full power, although

setpoint is set to 100%

IPC is producing power,

although no setpoint

value is set

- Switch positions for control input S 101/8

and 9 or S104 set incorrectly

- Control input (max. Power adjust) is not

turned clockwise to the stop

h Check adjustment

- Current limiting active (when the red

„current limit“ LED is lit)

h Turn the „max. current adjust“ trimmer

clockwise

- Resistance limiting (R-control) active

h Check switch S 101/10

h Check switch S 103

h Check switch S 101/7

- Check switches S 101/ 8 and 9 or S104

for control input

- Base load setting (max. Power adjust) is

not turned counter-clockwise to the stop

h Check switch S 101/11

v Chapter 5.5 „Control

inputs“

v Chapter 5.8.3

„Control input

adjustment (max.

Power adjust)“

v Chapter 5.10

„Setting the current

limit (max. current

adjust)“

v Chapter 5.2 „Setting

switches S101,

S103, S104, S105,

S106 and X106“

v Chapter 5.5 „Control

inputs“

v Chapter 5.9 „Setting

the base load (min.

Power adjust)“

50 [IGBT Power Converter 70/100A] 02.08

Page 51

7 Troubleshooting

02.08 [IGBT Power Converter 70/100A] 51

Page 52

JUMO GmbH & Co. KG JUMO Instrument Co. Ltd. JUMO Process Control, Inc.

Street address:

Moritz-Juchheim-Straße 1

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

e-mail: mail@jumo.net

Internet: www.jumo.net

JUMO House

Temple Bank, Riverway

Harlow, Essex CM 20 2 TT, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

e-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

8 Technology Boulevard

Canastota, NY 13032, USA

Phone: 315-697-JUMO

1-800-554-JUMO

Fax: 315-697-5867

e-mail: info@jumo.us

Internet: www.jumo.us

Loading...

Loading...