Page 1

Thyristor Power Units

B 70.9040.0

Operating Instructions

02.06

/00089951

Page 2

Page 3

Contents

1 Introduction ......................................................................................... 7

1.1 Preface .................................................................................................................... 7

1.2 Typographical conventions ................................................................................... 8

1.2.1 Warnings .................................................................................................................. 8

1.2.2 Note signs ............................................................................................................... 8

1.3 Description .............................................................................................................. 9

1.4 Type designation .................................................................................................... 9

1.4.1 Type extensions (extra codes) ................................................................................ 10

1.4.2 Standard accessories ............................................................................................ 10

1.4.3 Accessories ............................................................................................................ 11

1.5 Block diagram ...................................................................................................... 11

1.6 Front panel indicators and adjustments ............................................................ 12

2 Operating modes .............................................................................. 13

2.1 Phase-angle control with soft start and current limiting .................................. 13

2.2 Burst-firing operation, for resistive loads .......................................................... 14

2.3 Burst-firing operation for transformer loads and loads with a high positive tem-

perature coefficient TC (mixed operation) 15

3 Installation ......................................................................................... 17

3.1 Important installation notes ................................................................................ 17

3.2 Filtering and interference suppression .............................................................. 18

3.3 Installation site and climatic conditions ............................................................ 18

3.4 Wall mounting ....................................................................................................... 19

3.4.1 TYA-110/3, 025..100 .............................................................................................. 19

3.4.2 TYA-110/3,150 and TYA-110/3, 250 ...................................................................... 20

3.5 DIN rail mounting ................................................................................................. 21

3.5.1 TYA-110/3, 025 ..100 ............................................................................................. 21

4 Electrical connection ........................................................................ 23

4.1 Connection diagram ............................................................................................ 23

4.1.1 Type TYA-110/3, 025, - 050, - 075, - 100, ... .......................................................... 25

4.1.2 Type TYA-110/3, 150, ... ......................................................................................... 25

4.1.3 Type TYA-110/3, 250, ... ......................................................................................... 25

4.2 Single-phase operation: line/phase – N ............................................................. 26

4.3 Single-phase operation: phase – phase ............................................................. 27

4.4 Star configuration: with star point connected to N .......................................... 28

4.5 Open delta configuration (six-wire circuit) ........................................................ 29

Power units 02.06 3

Page 4

Contents

4.6 Free-running economy circuit, purely resistive loads ....................................... 30

4.7 Master-slave economy circuit, with resistive/inductive loads ......................... 31

5 Commissioning ................................................................................. 33

5.1 Adjust control input (full wave) ........................................................................... 33

5.1.1 Setting the maximum power output ....................................................................... 33

5.1.2 Input signal attenuator ........................................................................................... 33

5.2 Setting the base load ........................................................................................... 34

5.3 Setting the current limit ....................................................................................... 35

5.3.1 Alteration of the current limit Imax, as a function of the voltage on Terminal 9 ..... 36

5.4 Setting the phase angle for the first half-wave ................................................. 36

5.5 Load and part-load failure monitoring ............................................................... 37

5.5.1 Setting the threshold for load failure indication ................................................ 37

5.5.2 Setting for master-slave and free-running economy circuit ............................ 38

5.6 External changeover of operating modes ......................................................... 38

5.7 Blown fuse indication .......................................................................................... 38

6 Settings .............................................................................................. 39

6.1 Opening the housing ............................................................................................ 39

6.2 Adjustment switches S1 — 21 and pin headers X503 / X504 .......................... 40

6.3 Summary of possible settings ............................................................................ 42

6.4 Control inputs ....................................................................................................... 43

6.4.1 Combinations of external potentiometer and electronic controller ........................ 44

6.5 Subsidiary control loops ...................................................................................... 45

6.6 Actual (power) output .......................................................................................... 46

6.7 Load current adaptation (only with extra code TR/T0) ..................................... 47

6.8 Select operating modes and load types ............................................................ 47

6.9 Economy circuit .................................................................................................... 48

6.9.1 Free-running economy circuit (asynchronous switching) for resistive loads ......... 49

6.9.2 Master-slave economy circuit (synchronous switching) for resistive and transformer

loads 49

6.10 Firing-pulse inhibit ............................................................................................... 50

7 Technical data ................................................................................... 51

7.1 Load circuit ........................................................................................................... 51

7.2 Control ................................................................................................................... 51

7.3 General data ......................................................................................................... 51

4 Power units 02.06

Page 5

Contents

8 Faults .................................................................................................. 53

8.1 Fault-finding .......................................................................................................... 53

8.2 Replacing the semiconductor fuse .................................................................... 53

8.2.1 Type TYA-110/3, 025 to 100, ... .............................................................................. 53

8.2.2 Type TYA-110/3, 150, ... ......................................................................................... 54

8.2.3 Type TYA-110/3, 250, ... ......................................................................................... 54

Power units 02.06 5

Page 6

Contents

6 Power units 02.06

Page 7

1.1 Preface

B

1 Introduction

Please read these operating instructions before starting up the instrument.

Keep them in a place that is accessible to all users at all times.

Please help us to improve this manual.

Your suggestions will be welcome.

Fax: in Germany (0661) 6003-862

abroad +49 661 6003-607

H

H

If any difficulties arise during commissioning, you are asked not to

carry out any unauthorized manipulation. You could endanger your

rights under the instrument warranty!

Please contact the nearest subsidiary or the main factory in such a

case.

When returning chassis, modules or components, the regulations

of EN 100 015 “Protection of electrostatically sensitive components” must be observed. Use only the appropriate ESD packaging for transport.

Please note that we cannot accept any responsibility for damage

caused by ESD (electrostatic discharge).

Power units 02.06 7

Page 8

1 Introduction

1.2 Typographical conventions

1.2.1 Warnings

The signs for Danger and Caution are used in this manual under the following

conditions:

Danger

This symbol is used where there may be danger to personnel if the instruc-

V

A

E

tions are disregarded or not followed accurately!

Caution

This symbol is used where there may be damage to equipment or data if the

instructions are disregarded or not followed accurately!

Caution

This symbol is used if precautions must be taken when handling electrostati-

cally sensitive components.

1.2.2 Note signs

Note

H

v

1

abc

h Handling instructions

This symbol is used to draw your special attention to a remark.

Reference

This symbol refers to additional information in other manuals, chapters or

sections.

Footnote

Footnotes are comments that refer to specific parts of the text. Footnotes

consist of two parts:

1) The marking in the text, arranged as continuous superscript numbers.

2) The footnote text at the bottom of the page, in a smaller typeface than the

main text, and preceded by a number and a stop.

This symbol marks the description of a required action.

The individual steps are indicated by asterisks, for example:

h Disconnect the instrument completely from the supply

h Remove the instrument cover

8 Power units 02.06

Page 9

1 Introduction

1.3 Description

Application A thyristor power unit can be used wherevere sizeable resistive or inductive

loads are switched frequently – for instance, in industrial furnaces and plastics

processing.

Operating modes

Regulation Variations in the line supply voltage have no effect on the control-loop regula-

Versions The power stage is composed of 2 thyristors connected in anti-parallel, the in-

Standards The thyristor power units meet VDE 0160 5.5.1.3 (5/88) and VDE 0106 Part 100

The thyristor power units can operate under phase-angle control with adjustable current limiting or in burst-firing mode, depending on the setting of the internal switch. An external switch may also be used to change over the operating mode. In burst-firing mode, the phase angle can be cut back for the first

half-cycle, for driving transformer loads.

tion during operation. This is ensured by a subsidiary V

An input signal attentuator (trimmer) permits the restriction of the control

range, and a base load can be set by an external potentiometer. In burst-firing

mode an economy circuit can be used for multi-phase loads. With phase-angle control, the target phase angle that is set by the controller is gradually approached from the initial 180°, thus avoiding high surge currents (soft start).

sulated heatsink, and the control electronics. Thyristor units for up to 50A rated load can either be snapped onto a 35mm DIN rail, or mounted on a basplate fixed to a wall. Units for 75A or higher rated load can only be wallmounted.

(3/83). Earthing must be carried out in accordance with the regulations of the

local electrical supply utility.

2

, P or I2 control loop.

1.4 Type designation

The basic version, TYA-110/3, includes the following features:

- Voltage, current and potentiometer input

- Input signal is freely selectable

- Operating mode is freely selectable

- Phase-angle reduction of 1st half-wave for burst-firing operation

- Supply line voltage monitoring

- Input signal attentuation by trimmer

- Soft start in phase-angle operation

2

-V

-control with adjustable power level output signal

- Master-slave economy circcuit

- Firing-pulse inhibit

Power units 02.06 9

Page 10

1 Introduction

TYA-110/3 , . . . , . . . , . . Thyristor power unit for analog control

025 Load current 25A

050 Load current 50A

075 Load current 75A

100 Load current 100A

150 Load current 150A

250 Load current 250A

024 Rated load voltage 24V

042 Rated load voltage 42V

115 Rated load voltage 115V

230 Rated load voltage 230V

265 Rated load voltage 265V

400 Rated load voltage 400V

460 Rated load voltage 460V

500 Rated load voltage 500V

TR Indication of part-load failure or blown fuse through

built-in relay and LED.

TO Indication of part-load failure or blown fuse through

optocoupler

MS Master-slave circuit

2 pre-assembled power units on a mounting plate,

ready for connection

1

1

1

1

1

1

1

1

1. Rated load voltage = supply voltage for the control electronics

1.4.1 Type extensions (extra codes)

TR Extended version, with indication of part-load failure (adjustable by trimmer) or

blown fuse through common relay contact and LED.

This version also includes:

- Current limiting (internal, external) and rated current adjustment at I ≤ I

2

- Free selection of the subsidiary control-loop type (V

, I2 or P).

/2

N

A free-running economy circuit can be implemented with P-control!

2

- Power level output signal can be switched to: V

, P, I

2

TO as for TR, but with signaling via optocoupler

MS Master-slave circuit: 2 pre-assembled power units on a mounting plate, ready

for connection.

1.4.2 Standard accessories

1 Mounting plate for wall-mounting

1 Operating Instructions

10 Power units 02.06

Page 11

1.4.3 Accessories

Super-fast semiconductor fuses to protect the thyristors from short-circuits

(no supply line fusing).

1 Introduction

32A for I

80A for I

125A for I

160A for I

350A for I

550 A for I

Assembly kit for DIN rail mounting, for 25A and 50A versions,

Sales No. 70/00067312

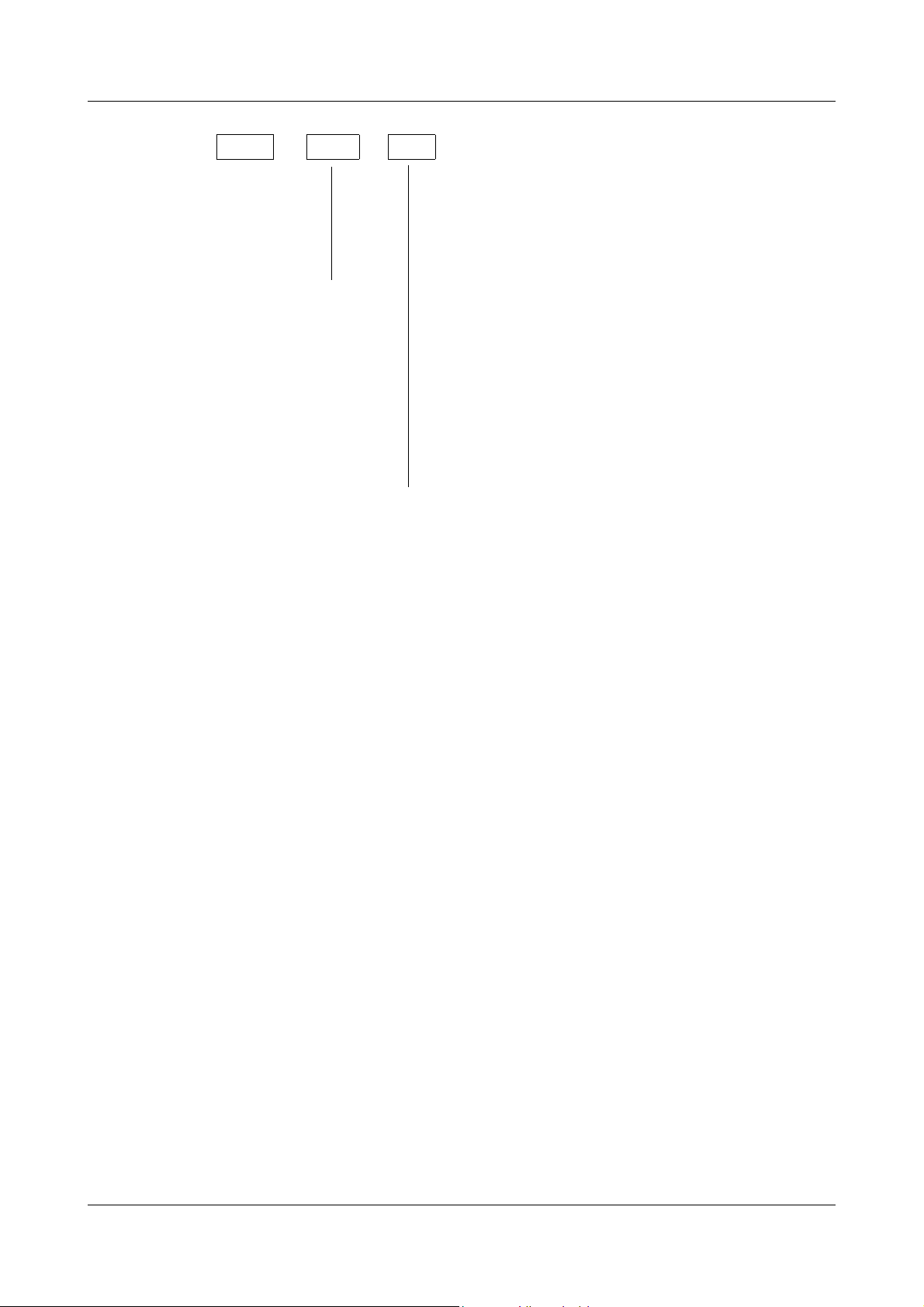

1.5 Block diagram

= 25A, Sales No. 70/00068009

N

= 50A, Sales No. 70/00068011

N

= 75A, Sales No. 70/00081800

N

= 100A, Sales No. 70/00081801

N

= 150A, Sales No. 70/00083318

N

= 250A, Sales No. 70/00371964

N

(

(1) Load (9) Control electronics

(2) Super-fast semiconductor fuse (10) Trimmer on front panel

(3) Thyristor module with RC

protection network

(4) Driver stage for thyristor module (12) Configuration switch

(5) Power supply for control electronics (13) Signal LEDs

(6) Optocoupler (14) Master-slave connections

(7) Voltage converter (15) Output level setting, operating inputs,

(8) Current transformer

(11) Error signal output

via relay or optocoupler

power level output signal

Power units 02.06 11

Page 12

1 Introduction

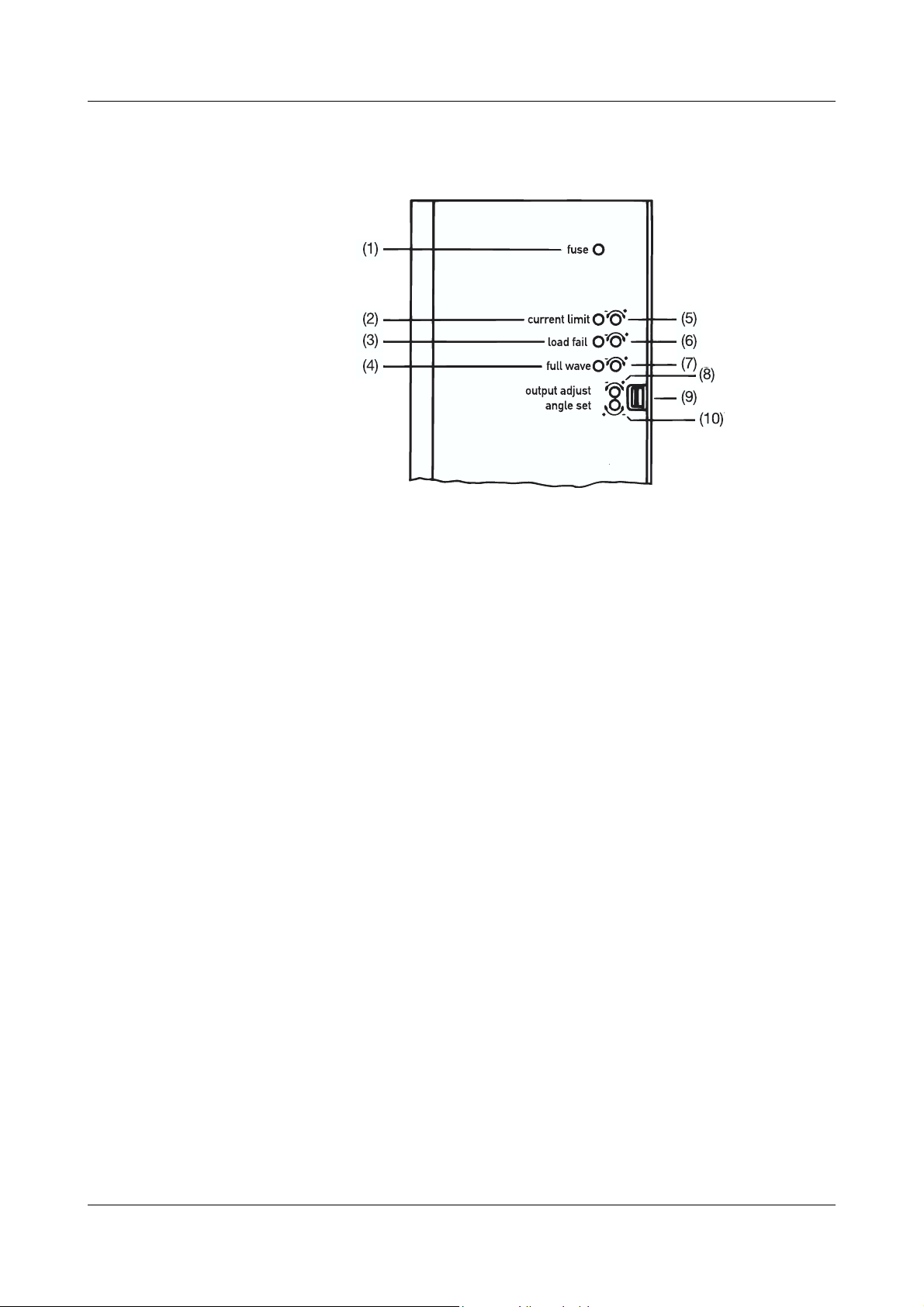

1.6 Front panel indicators and adjustments

Indicator LED for blown semiconductor fuse

(1)

LED for current indication

(2)

LED for load-failure indication

(3)

LED for full-output indication

(4)

Adjustment of current limit in phase-angle

(5)

operation (with extra code TR or TO)

Adjustment of threshold for part-load failure

(6)

indication (with extra code TR or TO)

Adjustment of full output

(7)

Adjustment of power level signal

(8)

Spring clip to release cover

(9)

Adjustment of phase-angle reduction for 1st half-

(10)

wave in burst-firing operation

12 Power units 02.06

Page 13

2 Operating modes

2.1 Phase-angle control with soft start and current limiting

In this mode of operation, the power is regulated by altering the phase angle.

This method is suitable for transformer and resistive loads. During the switchon period the phase-angle is gradually advanced by the controller to provide a

soft start. This prevents high surge currents at switch-on.

Current limiting For loads with an initial (cold) resistance that is significantly lower than the re-

sistance after warming up, such as Kanthal-Super heater elements, it is advisable to make use of current limiting (only with extra code TR or TO).

While current limiting is in operation, the phase angle during soft start remains

constant.

The maximum permissible effective (rms) current can be adjusted on the front

panel, by using the “current limit” trimmer.

v Section 5.3 “Setting the current limit”

Power units 02.06 13

Page 14

2 Operating modes

2.2 Burst-firing operation, for resistive loads

In this mode of operation, the power is regulated by changing the number of

full-wave cycles of the supply line voltage which are switched on during each

control period. This method is used for purely resistive loads which have a

cold resistance that is roughly the same as the hot resistance.

Since switching only takes place at the zero-crossing points, this mode of

operation produces very little RF-interference.

The internal switch S20 can be used to adjust the duty cycle to suit the system

being controlled.

v Section 6.2 “Adjustment switches S1 — 21 and pin headers X503 / X504”

Cycle time S 20

Variable cycle time

The control unit uses the shortest available cycle time

(for fast control loops)

Fixed cycle time (≈ 500ms)

Used for transformer loads, slow control loops

1

2

14 Power units 02.06

Page 15

2 Operating modes

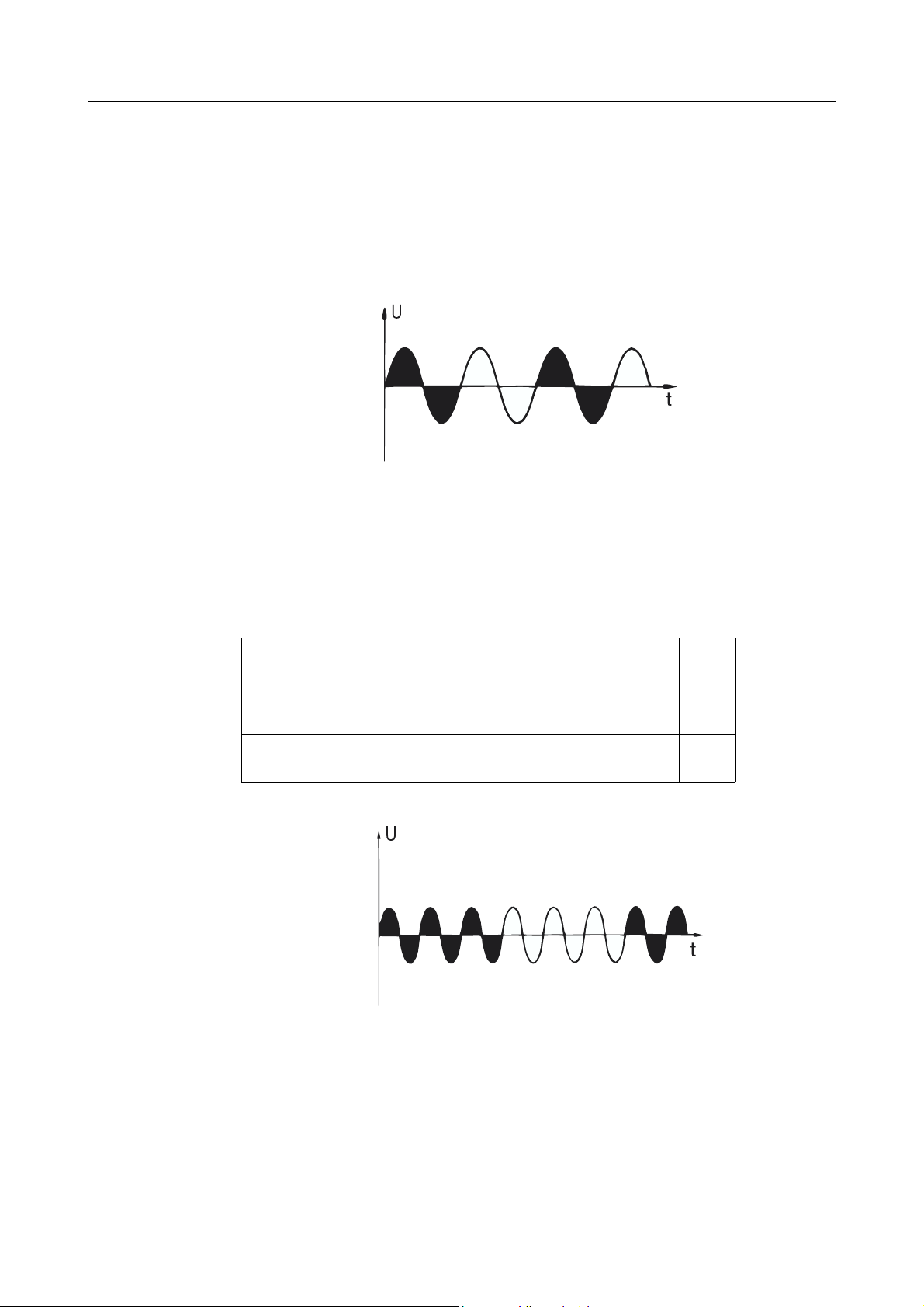

2.3 Burst-firing operation for transformer loads and loads with a high positive temperature coefficient TC (mixed operation)

It is not possible to change over to phase-angle control in this

H

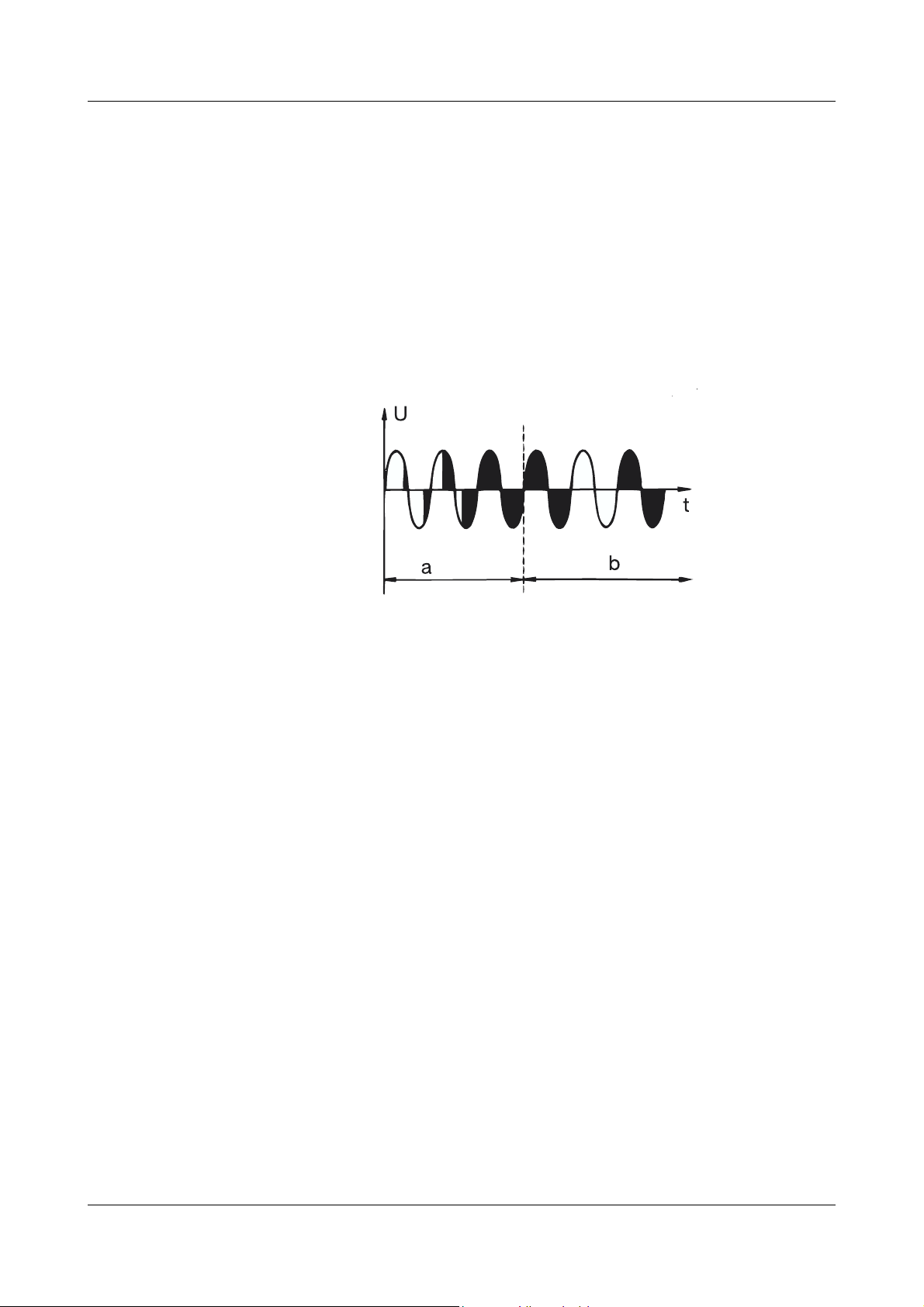

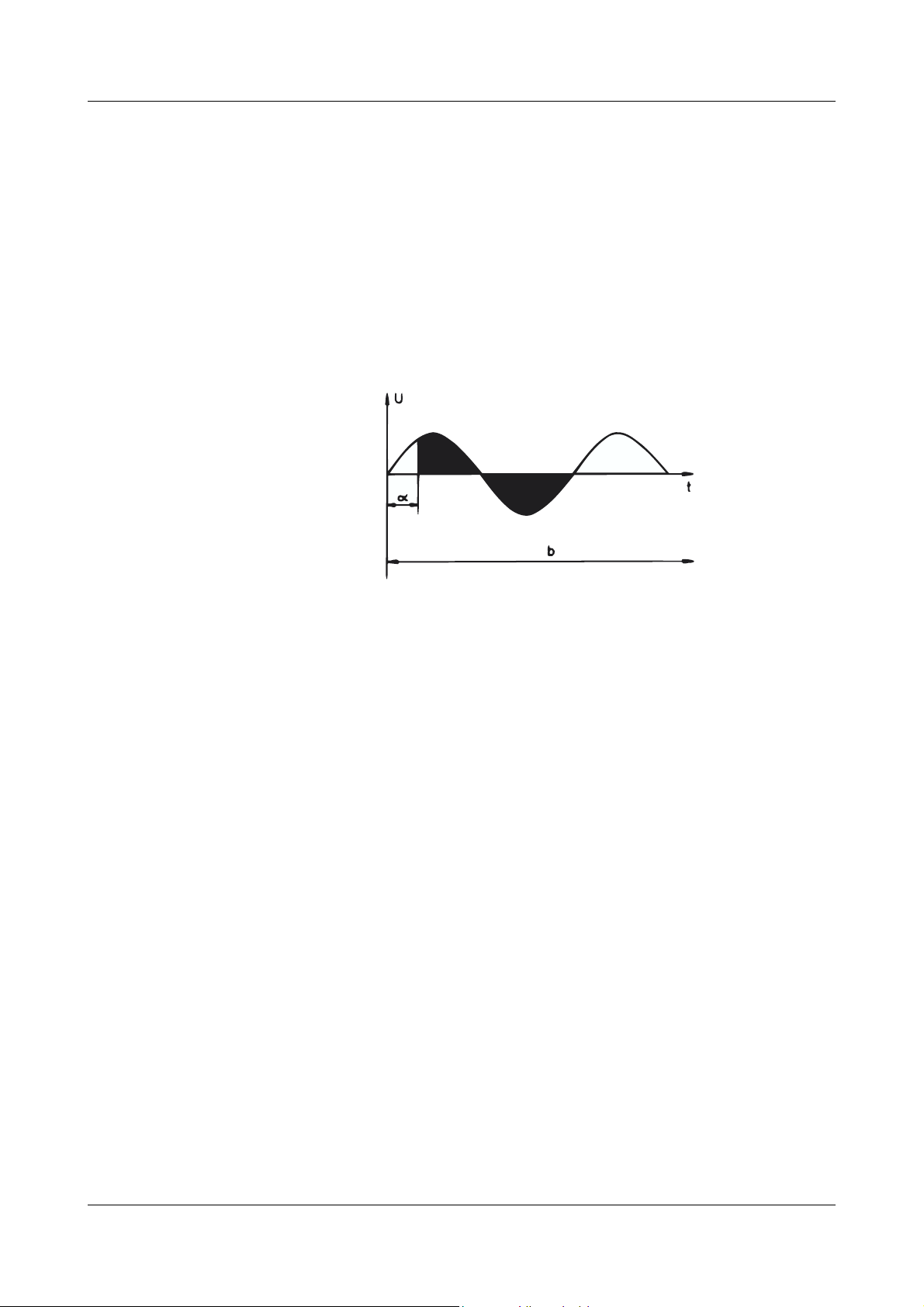

Soft start For the first switch-on of the thyristor power unit, or after being switched off by

inhibiting the firing-pulses, after a supply line interruption, or if the setpoint

was switched off for more than 8seconds, there will always be a short phaseangle controlled start (area a in the diagram).

mode of operation.

After this soft start, the controller switches over automatically to burst-firing

operation if the given setpoint is larger than the minimum setpoint + 10% of

the setpoint range (area b in the diagram).

Example:

Setpoint range 2 — 10V

The changeover to burst-firing operation takes place at

2V + 10% of 8V = 2V + 0.8V = 2.8V

After this changeover, the power output is regulated to follow the setpoint input provided.

H

1. with extra codes TR/TO

If the power unit runs into current limiting1 during the phase-angle

controlled start, then the output is regulated according to the maximum current given by the curent limit setting, even for low levels of

the setpoint input.

Power units 02.06 15

Page 16

2 Operating modes

For transformer loads, the thyristor power unit operates in burst-firing mode

with a cut-back (retarded) phase-angle for the first half-wave. The factory setting is an angle α = 90°. This value can be altered on the front panel over a

range α = 0 — 90°.

v Section 5.4 “Setting the phase angle for the first half-wave”

H

We recommend that this setting is not changed!

16 Power units 02.06

Page 17

3.1 Important installation notes

3 Installation

Safety regulations

Fusing - In the event of a short-circuit in the load circuit, the power unit is protected

V

Interference suppression

Wiring Load and control cables should be laid separately, as far as feasible.

- The choice of cable, installation and electrical connection of the instrument

must meet the requirements of VDE 0100 “Regulations for the Installation of

Power Circuits with nominal voltages below 1000 V AC” or the

corresponding local regulations.

- Electrical installation must only be performed by properly qualified

personnel.

- The unit must be completely disconnected from the supply line (on all

poles) if there is a risk of contact with live parts during work on the unit.

by the built-in semiconductor fuse.

v Section 8.2 “Replacing the semiconductor fuse”

- Do not connect any additional loads to the output load terminals.

- The electromagnetic compatibility (EMC) meets the standards and

regulations cited in the technical data.

v Section 7 “Technical data”

The appropriate fuses for control circuitry (e.g. 2A, type Neozed) should be

used to protect the wiring.

Connections h Check the data given on the nameplate (rated load voltage, load current)

against the data for the system.

h Wire up the connections from supply line – thyristor power unit – load

according to the wiring diagram, and check them

h If the economy circuit configuration is used, check that the rotary electrical

field has clockwise phasing.

h Check the settings for the setpoint inputs

h Check the switch positions

Supply voltage h Connect the supply voltage for the control electronics as shown in the wi-

ring diagram.

h Link “N/L2” to “V”, unless the economy circuit is being used (slave unit).

Load connection

Phasing The supply voltage for the control electronics and the load voltage must

The electronic switching devices (2 antiparallel thyristors) are in circuit between the screw connections “U1” and “U 2”.

have the same phase.

h Terminal “L1” must be connected, via a control circuitry fuse, to the same

supply potential as terminal “U1”!

Power units 02.06 17

Page 18

3 Installation

Switch-on sequence

Control inputs The control connections (inputs and outputs) are designed for safety sepa-

The supply voltages for the load and control circuitry must be switched on

at the same time.

In no circumstances should the supply voltage for the control

A

ration from the supply line input (SELV). In order not to diminish this safety

separation, all connected circuits must also have safety separation. The

auxiliary voltages which are required must be safe extra-low voltages

(SELV).

electronics be switched on before the voltage for the load!

This is especially important for operating transformer loads and re-

sitive loads with a large variation between hot and cold resistance!

Connections must only be wired up by properly qualified

personnel!

V

3.2 Filtering and interference suppression

In order to prevent radio-frequency interference, such as would occur with

phase-angle control, electrical apparatus and systems must have interference

suppression implemented.

The control electronics of the thyristor power units conforms to the EMC Directive EN 61 326.

However, modules such as thyristor power units have no use by themselves,

but only as a component function within a system. For this reason, the load

circuit of the power unit must have suitable interference suppression filters fitted by the system provider.

Specialist companies have appropriate ranges of filters available to deal with

these problems. Such filters are normally supplied as complete modules that

are ready to be connected up.

3.3 Installation site and climatic conditions

The installation site should be, as far as possible, free from vibration. Electromagnetic fields, caused by equipment such as motors and transformers,

should be avoided. The ambient temperature at the installation site must be

within the range 0 to 45°C (measured about 100 mm below the unit) and the

relative humidity must be

in dry rooms. The inside of the unit must be kept free from conductive dirt and

corrosive gases.

≤ 75%. The thyristor power unit is intended for use

The thyristor power unit must be mounted vertically, to ensure good convection cooling. If it is mounted in a switchgear cabinet, adequate ventilation must

be provided. There must be at least 100 mm free space below, and 150 mm

18 Power units 02.06

Page 19

3 Installation

above the unit. The thyristor power unit has enclosure protection IP00, and so

it must be mounted in such a way that bodily contact is prevented (built-in

unit).

V

The heatsink can become very hot in operation!

Incorrect use - The unit is not suitable for installation in areas with an explosion hazard

(Ex areas).

- The installation site should be free from vibration, dust, and corrosive

media.

Ambient conditions

3.4 Wall mounting

- Side-by-side mounting of units is permitted

- Relative humidity ⱕ 75 %, no condensation

- Ambient temperature range: 0 to 45 °C

Storage temperature range: -10 to 70 °C

h Fix the aluminium mounting plate to the heatsink, using the cheese-head

screws provided.

h Fix the thyristor power unit with its mounting plate to the wall, using four

screws.

3.4.1 TYA-110/3, 025..100

Power units 02.06 19

Page 20

3 Installation

3.4.2 TYA-110/3,150 and TYA-110/3, 250

20 Power units 02.06

Page 21

3.5 DIN rail mounting

h Fix the DIN rail

h Snap the thyristor power unit and its mounting plate onto a standard rail (to

DIN EN 50 022) and lock it in place with the lever. This type of mounting is

only possible for thyristor power units up to 50A rated current.

3.5.1 TYA-110/3, 025 ..100

3 Installation

Power units 02.06 21

Page 22

3 Installation

22 Power units 02.06

Page 23

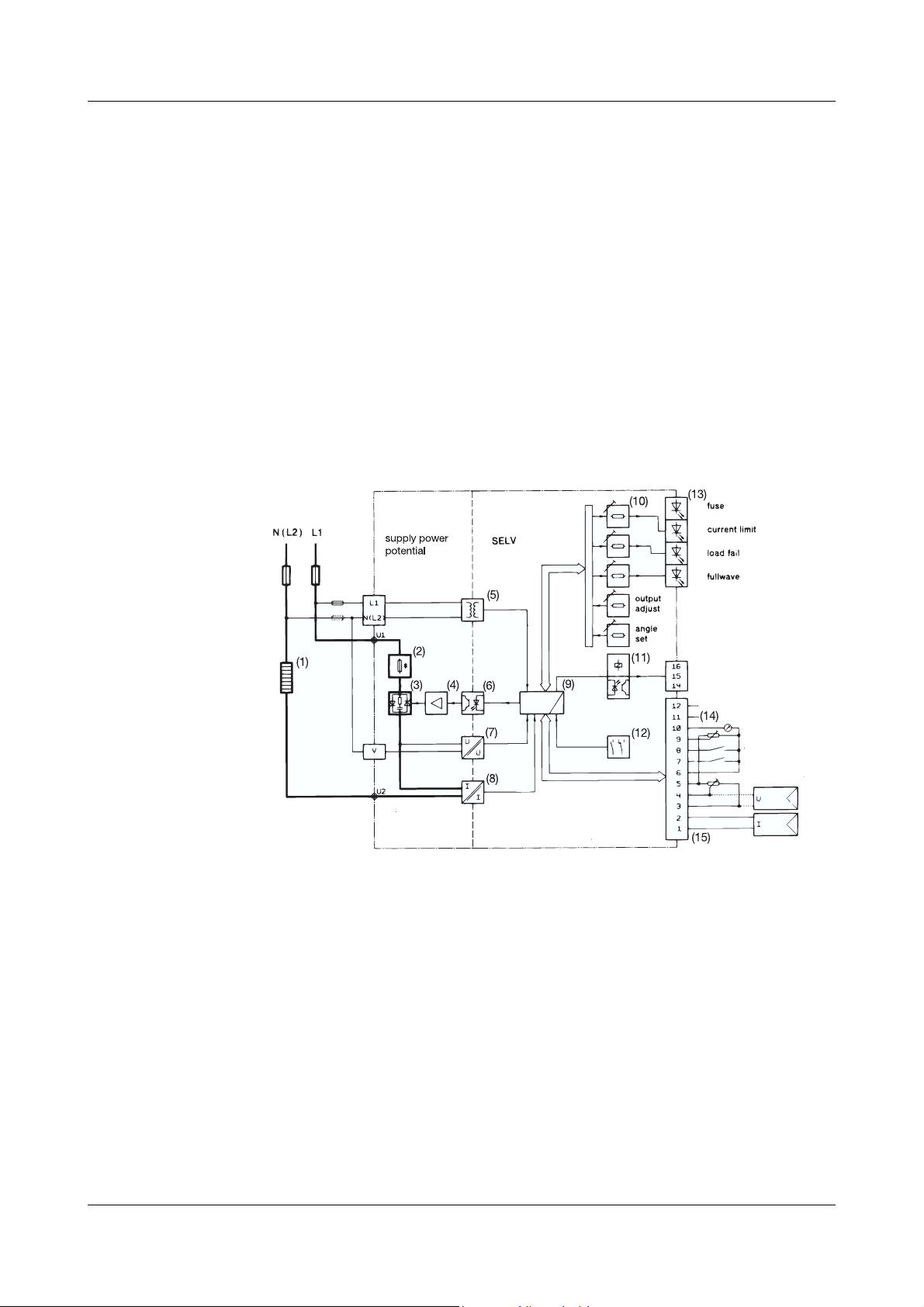

4.1 Connection diagram

V

The diagram shows the various connections that are available at the plug-in

screw terminals.

4 Electrical connection

Only properly qualified personnel are permitted to make electrical

connections!

h Disconnect the equipment completely (on all poles) from the supply line

h Connect the control cables (conductor cross-section 0.2 — 2.5 mm

screw terminals. Use cable lugs to DIN 46 212 for the load connections.

Tools required 1 screwdriver, 3 mm blade (max.)

1 socket wrench, 10 mm (for TYA-110/3, 100)

1 socket wrench, 13 mm ( for TYA-110/3,150 and TYA-110/3, 250)

Power units 02.06 23

2

) to the

Page 24

4 Electrical connection

Connection for Pin assignment Symbol

Supply voltage for control electronics;

link V to N/L2, unless economy circuit is being used

Load connection U1

L1 (line / phase 1)

N/L2 (neutral / phase 2)

V

U2

Current input

(differential input)

Voltage input

(referred to ground)

Logic input Current signal 0/20 mA 1-

Voltage signal 0/10 V 3⊥

Floating contact 4+

External manual adjustment with 5 kΩ potentiometer

(via voltage input)

Firing-pulse inhibit input I

(make or break contact)

Load-failure output with relay,

switching capacity 5A at 230 V AC, resistive load.

Relay drops out if fault occurs.

(extra code TR)

≈ 1mA

K

12+

3⊥

4+

2+

4+

5 (+10V, 2 mA)

3Start (⊥)

4Slider

5 End (+10V, 2mA)

6⊥

7+

16 P pole

15 O break contact

14 S make contact

or

Load failure output with optocoupler

I

= 2mA U

Cmax.

(extra code TO)

External changeover of operating mode

(phase-angle or burst-firing operation)

Actual (power) output 0 — 10V

I

≈ 2mA

max

Master-slave connection for

master-slave economy circuit

External current limiting

with 5 kΩ potentiometer

CEO max.

= 32V

15 Collector

16 Emitter

6⊥

8+

10+

6⊥

6⊥

11

12

5 Start (+10V, 2mA)

6 End (⊥)

9 Slider

24 Power units 02.06

Page 25

4.1.1 Type TYA-110/3, 025, - 050, - 075, - 100, ...

4.1.2 Type TYA-110/3, 150, ...

4 Electrical connection

4.1.3 Type TYA-110/3, 250, ...

Power units 02.06 25

Page 26

4 Electrical connection

4.2 Single-phase operation: line/phase – N

UL = phase-phase voltage P

= phase-neutral voltage IL = current in phase conductor

U

N

U

= voltage on thyristor power unit I

Thy

= total controlled power

tot

= current in thyristor power unit

Thy

26 Power units 02.06

Page 27

4 Electrical connection

4.3 Single-phase operation: phase – phase

UL = phase-phase voltage P

U

= phase-neutral voltage IL = current in phase conductor

N

= voltage on thyristor power unit I

U

Thy

= total controlled power

tot

= current in thyristor power unit

Thy

Power units 02.06 27

Page 28

4 Electrical connection

4.4 Star configuration: with star point connected to N

UL = phase-phase voltage P

U

= phase-neutral voltage IL = current in phase conductor

N

U

= voltage on thyristor power unit I

Thy

= total controlled power

tot

= current in thyristor power unit

Thy

28 Power units 02.06

Page 29

4 Electrical connection

4.5 Open delta configuration (six-wire circuit)

UL = phase-phase voltage P

= phase-neutral voltage IL = current in phase conductor

U

N

U

= voltage on thyristor power unit I

Thy

= total controlled power

tot

= current in thyristor power unit

Thy

Power units 02.06 29

Page 30

4 Electrical connection

4.6 Free-running economy circuit, purely resistive loads

Only possible in burst-firing mode with P-control

U

= phase-phase voltage P

L

U

= phase-neutral voltage IL = current in phase conductor

N

= voltage on thyristor power unit I

U

Thy

= total controlled power

tot

= current in thyristor power unit

Thy

30 Power units 02.06

Page 31

4 Electrical connection

4.7 Master-slave economy circuit, with resistive/inductive loads

Only possible in burst-firing mode

UL = phase-phase voltage P

= phase-neutral voltage IL = current in phase conductor

U

N

U

= voltage on thyristor power unit I

Thy

= total controlled power

tot

= current in thyristor power unit

Thy

Power units 02.06 31

Page 32

4 Electrical connection

32 Power units 02.06

Page 33

5.1 Adjust control input (full wave)

The trimmer (7) “full wave” on the front panel can be used to adjust the thyristor power unit so that the 100% (full wave) firing point is reached at the maximum output signal of the preceding controller.

5 Commissioning

5.1.1 Setting the maximum power output

h Apply the maximum controller output signal

h Turn the “full wave” trimmer clockwise or counter-clockwise until the green

LED for “full wave” just light up in phase-angle control, and does not light

up in burst-firing mode.

H

When using a logical control output (e.g. from a single-setpoint

controller) the “full wave” trimmer must be turned fully clockwise.

5.1.2 Input signal attenuator

h Turning the “full wave” trimmer counter-clockwise limits the maximum

power output of the thyristor power unit.

When using the free-running economy circuit, both thyristor power units

must be adjusted as described above.

When using the master-slave economy circuit, the adjustment is only made

on the master power unit.

v Section 4.6 “Free-running economy circuit, purely resistive loads” und

Section 4.7 “Master-slave economy circuit, with resistive/inductive loads”

Power units 02.06 33

Page 34

5 Commissioning

5.2 Setting the base load

A base load can be set, in addition to the analog current input and the potentiometer input. Since these input signals are added together, the input signal

gain must be corrected by adjusting the “full wave” trimmer (7).

For instance, if a heating system is to be operated with a 33% base load, with

the other 66% of the output being regulated by the controller, then the procedure is as follows:

Calculate the reduction factor of the controller signals.

In this example it would be 100% : 66% = 1.5.

Multiply this factor by the intended base load setting.

In this case: 1.5 x 33% = 50%.

The factor 0.5 means that the external potentiometer must be set to 50% of

the full-scale value.

Adjustment:

h Set the potentiometer to the calculated fraction of the full scale (e.g. 50%)

h Apply the maximum current (e.g. 20mA) to the current input

h Turn the “full wave” trimmer clockwise or counter-clockwise until the green

LED for “full wave” just light up in phase-angle control, and does not light

up in burst-firing mode.

34 Power units 02.06

Page 35

5.3 Setting the current limit

5 Commissioning

Internal current limiting

Current limiting is only possible in the phase-angle mode of control.

h The trimmer (5) “current limit” on the front panel can be used to limit the

effective (rms) value of the load current over a range from 10 — 100% of

the rated current for the thyristor control unit (I

1.5 turns clockwise correspond to increasing the threshold by about 10%

of the rated current.

The red LED lights up when the current limit is reached. Current limiting is

achieved by limiting the “ON” phase angle so that the set value for effective

current is not exceeded.

ThyN

).

External current limiting

An external voltage signal in the range 0 — 10 V can be applied to Terminal 9

to influence the internal current limit I

0V means no effect, 10 V means the maximum effect (the threshold is reduced

to the smallest value possible).

set by the “current limit” trimmer.

max

Power units 02.06 35

Page 36

5 Commissioning

5.3.1 Alteration of the current limit Imax, as a function of the voltage on Ter m i n al 9

With an internal limit of, for example, I

variation is only 0 to 8V.

= 0.8 x I

max

5.4 Setting the phase angle for the first half-wave

In the mode “burst-firing with phase-angle controlled start” the thyristor power

unit retards the firing point for the first half-wave after the start in burst-firing

mode.

The factory setting is an angle α = 90°(electrical). This value can be altered

over the range α = 0 — 90°by the trimmer (10) “angle set”.

The factory setting will be satisfactory in most cases.

, the external range of

Thy

If it is nevertheless necessary to make an adjustment, then the

H

Counter-clockwise (left) = advance the firing angle α

Clockwise (right) = retard the firing angle α

36 Power units 02.06

minimum switch-on current at the start of the burst is the criterion

for setting the angle α.

Page 37

5.5 Load and part-load failure monitoring

This function is only available with the extra code TR or TO. If there is a

change in the load resistance during operation, this is detected and indicated

by the part-load failure monitoring.

The signal output is available either as a floating contact (extra code TR) or an

optocoupler (extra code TO). If a part-load fault occurs, the relay drops out or

the collector-emitter of the optocoupler goes high-impedance. The signal output is also produced if there is a blown fuse.

The response threshold can be set by the front-panel trimmer (6) “load fail” to

a value between 20 and 100% of the rated current for the power unit. Partload failure monitoring functions in all operating modes.

5 Commissioning

H

v Section 6.2 “Adjustment switches S1 — 21 and pin headers X503 / X504”

The load/part-load failure monitoring (low current monitoring) can

also be used for overcurrent monitoring. To implement this, remove

the two jumpers on pin header X504, next to the “angle set” trimmer, turn them through 90° and replace.

5.5.1 Setting the threshold for load failure indication

(Factory setting is 50% of rated load)

h Connect up the load

h Apply full power

h Set the “load fail” trimmer so that the yellow “load fail” LED just goes out.

- turn clockwise (right) = LED lights up

- turn counter-clockwise (left) = LED goes out

h If necessary, the threshold can be reduced by further counter-clockwise ro-

tation, whereby 1.5 turns of the trimmer potentiometer correspond to a load

change of about 10% of the rated curent for the thyristor power unit.

If the load current is below the rated current of the power unit, then the number of turns required is reduced in the same proportion.

If load current I

v Section 6.3 “Summary of possible settings”

< 0.5 x I

L

then internal switch S15 must be in position 0.

ThyN

Power units 02.06 37

Page 38

5 Commissioning

Alternative setting:

Simulate a load failure, and then adjust the “load fail” trimmer so that the yellow “load fail” LED just lights up.

5.5.2 Setting for master-slave and free-running economy circuit

When using master-slave and free-running economy circuits, the

H

H

5.6 External changeover of operating modes

For this to be possible, an external switch must be wired between Terminal 8

and Terminal 6.

settings must be made in both thyristor power units.

The smallest change of resistance that can be detected is 5% of

the nominal load resistance (10% in an economy circuit).

Switch Operating mode

open burst-firing mode

closed phase-angle control

The external switch can only be used to change from burst-firing to

H

If the switches S12 and S13 are closed, an external changeover to phaseangle control is not possible.

v Section 6.3 “Summary of possible settings”

phase-angle control when the internal switch S3 is open, since this

switch is in parallel with the external switch S.

5.7 Blown fuse indication

If a short-circuit occurs, the built-in semiconductor fuse switches within half a

supply cycle, to protect the thyristors. When the fuse is blown, the “fuse” LED

lights up,

v Section 8.2 “Replacing the semiconductor fuse”

With extra code TR or TO, an output signal is also available.

v Section 4.1 “Connection diagram”

38 Power units 02.06

Page 39

6.1 Opening the housing

Adjustments must only be made while the unit is disconnected

from the supply power!

V

It is easier if these adjustments are carried out before the unit is installed.

h Use a screwdriver to lever the spring fixing lug outwards.

On the 150 A and 250 A versions: press both spring lugs inwards.

h Pull off the cover from the front.

6 Settings

Power units 02.06 39

Page 40

6 Settings

6.2 Adjustment switches S1 — 21 and pin headers X503 / X504

The switches S1 to 21 can be found on the back of the printed circuit board.

It is easier to access switches S15, S16 and S21 if the plug-in

H

40 Power units 02.06

screw terminals are first pulled off downwards.

Page 41

6 Settings

Power units 02.06 41

Page 42

6 Settings

6.3 Summary of possible settings

Switch position

Switch number

1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

factory setting 1 0 0 1 0 0 1 0 0 1 0 0 0 1 1 0 1 1 1 1 1

job-specific setting

Control input

0 — 20mA 1 0 0 1

4 — 20 mA 0 0 0 2

0 — 10V 1 0 0 1

2 — 10V 0 0 0 2

0 — 5V 1 0 1 1

1 — 5V 0 0 1 2

Logic signals 0/10V, 0/5V,

0 1 1 2 1

0/20mA or floating contact

Subsidiary control loop

2

V

1 0 0

P 0 1 0

2

I

0 0 1

Actual power output

2

V

1 0 0

P 0 1 0

2

I

Load current adaptation I

IL < 0.5 · I

IL ⱖ 0.5 · I

ThyN

ThyN

L

0 0 1

0

1

Firing-pulse inhibit

-external make contact 1

-external break contact

Operating mode:

Phase-angle control

for transformer/resistive load 1 1 0 0 0 1 1 1

Burst-firing mode:

■ for resistive load 0 1 0 1 1 1

■ for transformer load 0 0 1 1 1 1 1 1 2

- R ≈ constant 0 0

R

w

- > 1(soft start)

-----R

K

1 1

- fixed cycle (500ms) 2

- variable cycle 1

Economy circuit

(free-running)

■ for resistive load 0010 1 0001 11

(Master-slave)

-master, resistive load 0 1 0 1 1 1 1

2

-slave

, resistive load 0 1 0 0 22 1

-master, transformer load

2

-Slave

1. S5, S6, S8, S9, S15 only have an effect with extra code TR or TO.

2. The jumpers on pin header X503 must be turned through 90°. Section 6.2 “Adjustment switches S1 — 21 and pin headers

X503 / X504”. A changeover to phase-angle control is not possible for burst-firing mode with a transformer load and soft start.

, transformer load 0 0 1 1 1 0 2 2 2 1

0 0 1111 11 2 1

v Section 2.3

2

42 Power units 02.06

Page 43

6.4 Control inputs

The internal switches S1, S2, S 16, S19, S20 can be used to adapt the thyristor power unit to suit the available control signal (controller output signal).

There are separate voltage and current control inputs. The current inputs (+,-)

are designed for a differential current signal, i.e. they can have a common potential that is up to 10V above or below the ground reference potential (⊥).

If the current and voltage inputs are used simultaneously, they have an additive effect. Both analog and logical controller output signals may be used.

Control signal Internal switch

Signal start Signal end S1 S2 S16 S19 S20

0 mA 20 mA 1 0 0 1

4 mA 20 mA 0 0 0 2

0 V 10 V 1 0 0 1

2 V 10 V 0 0 0 2

0 V 5 V 1 011

1 V 5 V 0012

logic levels 0/10V 0/5V, 0/20mA or

floating contact

6 Settings

01121

Analog control inputs

The thyristor power unit can be operated by the following signals (for analog

power regulation):

- voltage signal (Terminals 3, 4)

- current signal (Terminals 1, 2)

-5 kΩ potentiometer (Terminals 3, 4, 5)

A 10 V source is provided at Terminal 5 for use with a potentiometer. The

switch settings are the same as for a 0 — 10 V signal.

Power units 02.06 43

Page 44

6 Settings

Logic control inputs

The thyristor power unit can also be operated by the following logical signals

(e.g. two-state/single-setpoint controller outputs):

(switching pulse bursts on or off):

- current signal 0/20mA (Terminals 1, 2)

- voltage signal 0/10V (Terminals 3, 4)

- floating contact (Terminals 4, 5)

6.4.1 Combinations of external potentiometer and electronic controller

Controller with current output

The voltage input (Terminals 3, 4) can be used together with the internal 10 V

source and a 5 kΩ potentiometer to provide manual setting.

Switch S

Automatic open open

Manual closed closed

a

S

b

To prevent unintended overdriving on the changeover to manual

H

operation, S

two signal sources will be added together for a moment.

should be mechanically coupled to Sb. Otherwise the

a

44 Power units 02.06

Page 45

6 Settings

Controller with voltage output

This only uses the voltage input of the thyristor power unit. A 5 kΩ potentionmeter is required on Terminals 3 and 5 for manual operation.

Switch S

Automatic operation position 1

Manual operation position 2

c

6.5 Subsidiary control loops

Subsidiary control loops are primarily used to eliminate or compensate external disturbances, such as supply-line fluctuations and changes in resistance

which would have a negative effect on the regulation. A subsidiary V

loop is set up ex-factory. With extra code TR or TO this can be changed to P

2

control. The free-running economy circuit must operate with a P control

or I

loop.

v Section 6.2 “Adjustment switches S1 — 21 and pin headers X503 / X504”

H

v Section 6.7 “Load current adaptation (only with extra code TR/T0)”

Control

type

2

V

With P or I2 control loops (extra code TR/TO) a load current adaptation must be made for operating currents that are less than half

the rated load current.

Internal switches Application

S4 S5 S6

100- positive TC,

2

control

- R ≈ constant

- brightness controls

Power units 02.06 45

Page 46

6 Settings

P 0 1 0 - temperature-dependent TC

- free-running economy circuit

2

I

0 0 1 - negative TC

6.6 Actual (power) output

The factory setting is that the actual (power) signal output corresponds to the

2

signal at the output of the power unit, and is therefore proportional to the

V

power in the load (R = constant). With the extra code TR/TO it can be switched

2

over to a P or I

v Section 6.3 “Summary of possible settings”

Actual (power) signal output Internal switches

2

V

P010

2

I

signal.

S7 S8 S9

100

001

Adjust output The signal at the actual (power) output is a voltage in the range 0 — 10V (cor-

responding to 0 — 100% of the particular measurement range). The trimmer

(8) “output adjust” can be used to adjust the range end value:

Action Response

Turn trimmer fully clockwise (right)

Turn trimmer fully counter-clockwise

(left)

H

v Section 6.7 “Load current adaptation (only with extra code TR/T0)”

With P or I2 control loops, a load current adaptation must be made

for operating currents that are less than half the rated load current!

Measurement range 0 — 100 %

corresponds to a signal 0 — 10V

Measurement range 0 — 100 %

corresponds to a signal 0 — 5V

46 Power units 02.06

Page 47

6 Settings

6.7 Load current adaptation (only with extra code TR/T0)

With P or I2 control, switch S15 must be in position 0 if the operating current is

less than half the rated current. This is to ensure proper measurement of the

load current for the subsidiary control loop, the current limiting, and the overcurrent / low current detection.

The factory setting must not be altered on the 150A and 250A

A

Load current adaptation Internal switch S 15

versions!

(Reserved for service purposes: 1A test mode)

< 0.5 x I

I

L

LL > 0.5 x I

ThyN

ThyN

k factory setting

6.8 Select operating modes and load types

The internal switches S3, S10 — S 13 and S20 are used to set the required

mode of operation.

In both phase-angle and burst-firing modes the thyristor power unit basically

operates with a subsidiary V

be changed over from V

v Section 6.5 “Subsidiary control loops”

Switch S3 S10 S11 S12 S13 S14 S17 S18 S19

Operating mode:

Phase-angle control

■ for resistive or

transformer load

2

control loop. With extra code T0 or TR this can

2

to P or I2 control.

1 1 0 0 0 1 1 1

0

1

Burst-firing operation

■ resistive load

■ transformer load

- R ≈ constant

R

w

------

- > 1

R

K

- fixed cycle (500ms)

- variable cycle

0 1 0 1 1 1

0 0 1 1 1 1 1 1 2

0 0

1 1

2

1

Power units 02.06 47

Page 48

6 Settings

It is not possible to change over to phase-angle control if S12 and S13 are

closed.

v Section 2.3 “Burst-firing operation for transformer loads and loads with a

high positive temperature coefficient TC (mixed operation)”

6.9 Economy circuit

Two single-phase units can be used at any time to implement an “economy

circuit” in a 3-phase system.

The switch settings that are required for this, depending on the type of load

and circuit, can be found in the table.

V

The thyristor power units must always be dimensioned for the

phase-phase voltage, regardless of whether the load is wired in a

star or delta configuration.

It is vital to ensure that the roating electrical field is right-handed,

i.e. clockwise rotation.

Terminal V must be linked to phase L2 on both power units.

v Section 4.6 “Free-running economy circuit, purely resistive loads” and

Section 4.7 “Master-slave economy circuit, with resistive/inductive loads”

48 Power units 02.06

Page 49

6 Settings

6.9.1 Free-running economy circuit (asynchronous switching) for resistive loads

A free-running economy circuit has the advantage that the average loading of

the supply network is reduced. Both power units operate independently and

regulate the required 3-phase power quite precisely. Even a possible part-load

failure will not necessarily have an effect on the temperature stability of the

control loop.

A subsidiary P control loop is required for both power units.

Switch S3 S4 S5 S6 S10 S11 S12 S13 S14 S17 S18 S20 S21

Economy circuit

(free-running)

■ resistive load 001010001112

(master-slave)

■ resistive load

- master function 0 1 0 1 1 1 1

- slave function 0 1 0 0 2 2 1

■ transformer load

- master function 0 011111121

- slave function 0 011102221

If S12 and S13 are closed, it is not possible to change over to phase-angle control.

v Section 2.3 “Burst-firing operation for transformer loads and loads with a

high positive temperature coefficient TC (mixed operation)”

6.9.2 Master-slave economy circuit (synchronous switching) for resistive and transformer loads

In the standard version, the master-slave economy circuit operates with a V

control. With extra code TO/TR it is also possible to use a P control and partload regulation. The control electronics of the master unit takes on the actual

power control function, and drives the slave unit in synchronization. This

makes it possible to drive transformer loads.

The combination of the fixed cycle time of the V

configuration makes it possible to achieve good voltage regulation for the individual load resistances, even in the event of a part-load failure.

v Section 4.7 “Master-slave economy circuit, with resistive/inductive loads”

The jumpers on pin header X503 of the slave unit must be turned

H

through 90° !

v Section 6.2 “Adjustment switches S1 — 21 and pin headers X503

/ X504”

2

control and the delta load

2

Power units 02.06 49

Page 50

6 Settings

6.10 Firing-pulse inhibit

Inhibiting the firing pulses is a simple way of switching high powers. In phaseangle control, the thyristor power unit commences with a soft start after firingpulse inhibit has been used. In burst-firing operation with a transformer load,

the power unit first starts up in phase-angle control and then switches over to

burst-firing.

In order to be able to disconnect a system, a contactor or main

switch must be fitted in the supply line circuit!

V

A contact can be wired between Terminals 6 and 7 to shut off the thyristors at

the next zero-crossing point. This external contact can be a make contact or a

break contact, depending on the position of S21.

v Section 6.2 “Adjustment switches S1 — 21 and pin headers X503 / X504”

Only a make contact can be used as the external contact for a

H

master-slave economy circuit.

External

contact

make (a) 1 Load is continuously shut off while the

break (b) 2 Load is continuously shut off while the

Internal switch

S21

Response

external contact is closed.

external contact is open.

50 Power units 02.06

Page 51

7.1 Load circuit

Nominal load voltage 24V-20%/+15% AC 45 — 63Hz

Continuous load

current I

Load types resistive and resistive-inductive loads (B ≤ 1.2 Tesla)

Current limiting With phase-angle control, the load current can be adjusted over the range

Fusing super-fast semiconductor fuse

TSE circuit RC network as standard

Power loss ≈ 1.3V x I

Control accuracy Supply voltage fluctuations within the tolerance range (-20%/+15%)

7 Technical data

42V-20%/+15% AC 45 — 63Hz

115V-20%/+15% AC 45 — 63 Hz

230V-20%/+15% AC 45 — 63 Hz

265V-20%/+15% AC 45 — 63 Hz

400V-20%/+15% AC 45 — 63 Hz

460V-20%/+15% AC 45 — 63 Hz

500V-20%/+15% AC 45 — 63 Hz

(supply voltage for control electronics = nominal load voltage)

25A, 50A, 75A, 100 A, 150A, 250A

L

10 — 100% I

The limiting is based on the rms value of the load current.

by a trimmer on the front panel.

N

(A)

L

are accurately compensated.

Fluctuations ≤ 0.5%.

7.2 Control

Control signal 0 (4) — 20mA RI = 50 Ω

Input signal

attenuation

7.3 General data

Circuit variants - single-phase operation

Operating modes - phase-angle control for resistive and transformer loads, with soft start

Features Two single-phase units can be linked to form an economy circuit for burst-firing

Subsidiary control

types

0 (2) — 10V R

0 (1) — 5V R

0/10V (0/5V) R

0/20mA R

floating contact

or

manual control by an external 5 kΩ potentiometer

adjustment range 100 — 20%

- star circuit with accessible star point

- open delta circuit

- economy circuit using master-slave principle and subsidiary V

in burst-firing operation

- free-running economy circuit (star or delta) only with subsidiary P control

in burst-firing operation

(with current limiting for extra codes TR, TO)

- burst-firing operation for resistive or transformer load

operation.

- free-running economy circuit for resistive loads

- master-slave economy circuit for resistive and transformer loads

With extra code TR or TO: free choice of V

2

V

control as standard.

2

, P, I2 control via internal switches.

= 25kΩ

I

= 12kΩ

I

= 12kΩ

I

= 50Ω

I

2

control

Power units 02.06 51

Page 52

7 Technical data

Actual (power) output V2 signal as standard.

With extra code TR or TO: free choice between V

switches, adjustable from 0 — 5V to 0 — 10V. I

Electrical connection Control wiring by screw terminals for conductor cross-sections 0.2 — 2.5mm

Load connections by cable lugs to DIN 46 212.

Protection IP00 as per EN 60 529, heatsink is grounded

Permitted ambient

temperature range

Permitted storage

temperature range

Climatic conditions rel. humidity ≤ 75% annual mean, no condensation

Cooling natural convection

Operating position vertical

Operating conditions The thyristor power unit is designed as a built-in unit to:

Test voltage to VDE 0160 Table 4 (6/88)

Electromagnetic

compatibility

Creepage distance control electronics to load circuit ≥ 10mm

Housing TYA110/3, 25 (50) 110 x 195 x 152mm

Weight TYA110/3, 25 (50) 2.8 kg

Standard

accessories

Permitted current derated by 2% for each °C increase in ambient temperature;

the maximum permissible ambient temperature must not exceed 60°C.

pollution degree 2 to VDE 0110 Part 1 4.2 (1/89)

overvoltage category Ü III to VDE 0160 5.7 (5/88)

Control electronics to EN 61 326

control electronics to housing ≥ 10mm

Unit can be connected to SELV circuits.

SELV = Seperate Extra Low Voltage

TYA110/3, 75 (100) 125 x 195 x 170mm

TYA110/3, 150 (250) 150 x 220 x 280mm

TYA110/3, 75 (100) 3.7 kg

TYA110/3, 150 8.6 kg

TYA110/3 250 9.0 kg

1 mounting plate for wall-mounting

1 Operating Instructions B 70.9040

0 — 45°C

-10 to +70°C

VDE 0160 5.5.1.3 (5/88)

VDE 0106 Part 100 (3/83)

2

, P, or I2 signal via internal

≈ 2mA.

max

2

.

52 Power units 02.06

Page 53

The thyristor power unit does not require any maintenance.

In the event of a fault, the following points should be observed:

8.1 Fault-finding

If faults occur during commissioning, we recommend that you first check the

positions of the internal switches.

v Section 6.3 “Summary of possible settings”

If the fault persists, check the following items:

- Is the supply voltage present for the thyristor power unit?

Check the phase sequence as well.

- Are all other connections also correct?

- Is the controller operating properly?

Check the operation manually, by using an external potentiometer.

v Section 6.4 “Control inputs”

8.2 Replacing the semiconductor fuse

8 Faults

If the red LED “fuse” lights up, this means that a semiconductor fuse has

blown.

h Disconnect the system from the supply voltage.

v Section 6.1 “Opening the housing”

8.2.1 Type TYA-110/3, 025 to 100, ...

Wrench 10 mm a/f

Power units 02.06 53

Page 54

8 Faults

8.2.2 Type TYA-110/3, 150, ...

Wrench 13 mm a/f

8.2.3 Type TYA-110/3, 250, ...

Wrench 13 mm a/f

h Remove the two hexagonal head fixing screws (1) for the semiconductor

fuse, and take out the fuse.

h Insert a new semiconductor fuse!

54 Power units 02.06

Page 55

h Replace the fixing screws.

h Re-assemble the housing

Use only original replacement fuses. If other fuses are used, this

A

will invalidate the warranty!

8 Faults

Replacement fuses

v Section 1.4.3 “Accessories”

The pcbs carry supply line voltages. Work on the circuitry must

V

therefore only be carried out while the equipment is completely

disconnected from the supply!

To avoid dangerous situations, follow the regulations for “Working

on live equipment“ (VDE 0100 Part 410).

Power units 02.06 55

Page 56

JUMO GmbH & Co. KG

Street address:

Moltkestraße 13 - 31

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2TT, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

8 Technology Boulevard

Canastota, NY 13032, USA

Phone: 315-697-JUMO

1-800-554-JUMO

Fax: 315-697-5867

E-mail:

Internet: www.jumo.us

info@jumo.us

Loading...

Loading...