Page 1

JUMO Wtrans B

Programmable Head Transmitter

with Radio Transmission

B 707060.0

Operating Manual

2011-09-30/00536757

Page 2

Page 3

Content

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.1 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.2 Antenna-battery case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Connection elements and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Identifying the instrument version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.1 Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Order details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Probe preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1 Fitting/exchanging the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Safety information concerning lithium batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Battery service life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Disposal of lithium batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Probe range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.1 General information about radio transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Possible impairment of radio transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.1 Information about fastening, securing and arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Installing the antenna-battery case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Installing the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4 Aligning the antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2 Connection elements and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.3 Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.3.1 Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.3.2 Analog input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3.3 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3.4 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 Setup program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3

Page 4

Content

7.1 General information about the setup program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.2 Required hardware and software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.3 Establishing the connection between PC and probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.4 Probe configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.4.1 Establishing the communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.4.2 Reading the current probe parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.4.3 Editing probe parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.4.4 Transmitting new parameters to the probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.5 Parameters overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8 Supplement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

8.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.1.1 Analog input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.1.2 Output (radio transmission) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.1.3 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.1.4 Environmental influences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.1.5 Casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4

Page 5

1.1 Safety information

General information

This manual contains information that must be observed in the interest of your own safety and

to avoid damage to assets. This information is supported by symbols which are used in this

manual as follows.

Please read this manual before commissioning the device. Keep the manual in a place accessible to all users at all times.

If difficulties occur during commissioning, please refrain from carrying out any manipulations

that could jeopardize your warranty rights.

Warning signs

CAUTION!

This symbol in combination with the signal word indicates that damage to assets or data

loss will occur if suitable precautions are not taken.

Note signs

1 Introduction

TIP!

This symbol refers to important information about the product or its handling or additional

use.

REFERENCE!

This symbol refers to further information in other sections, chapters or manuals.

5

Page 6

1 Introduction

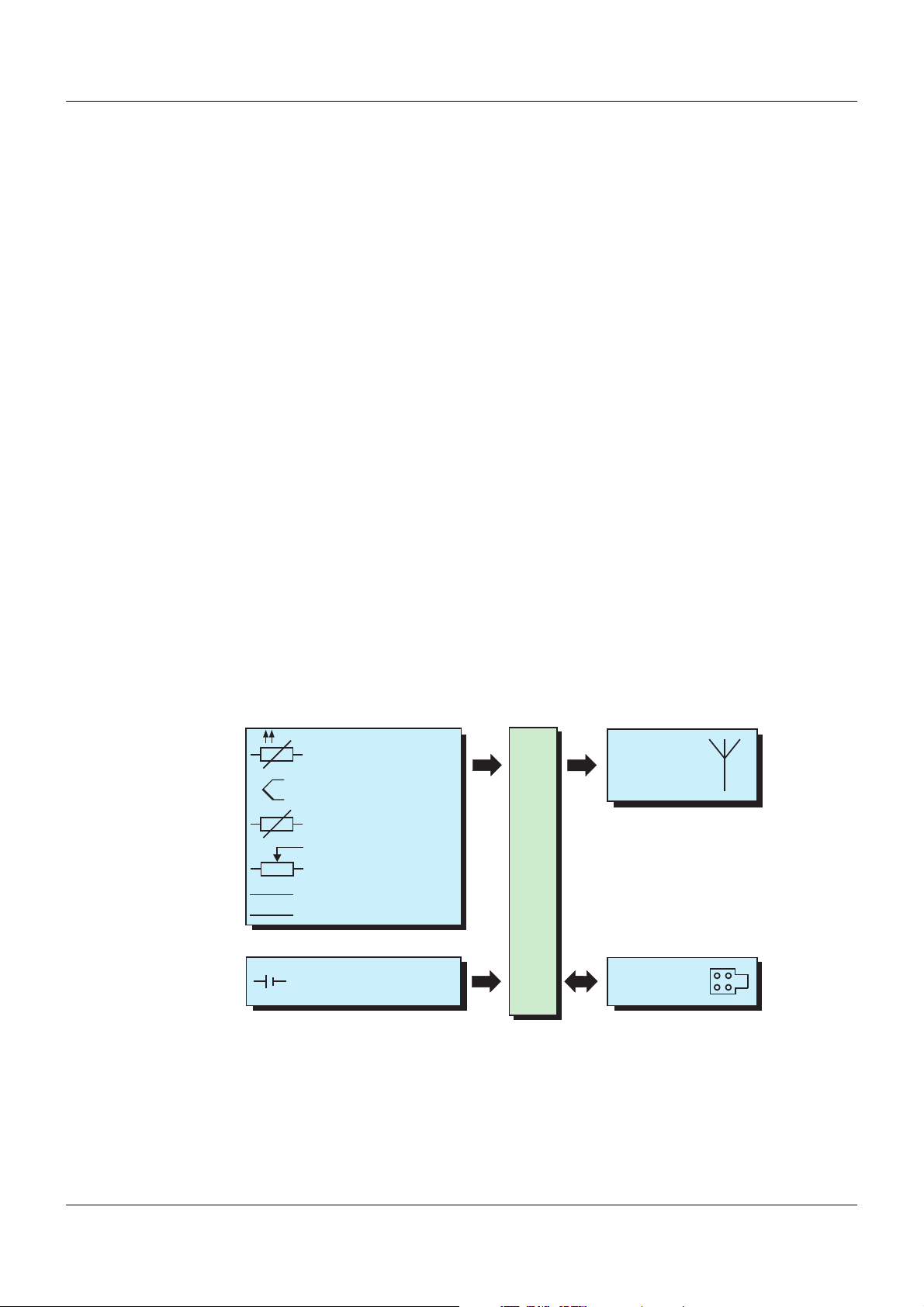

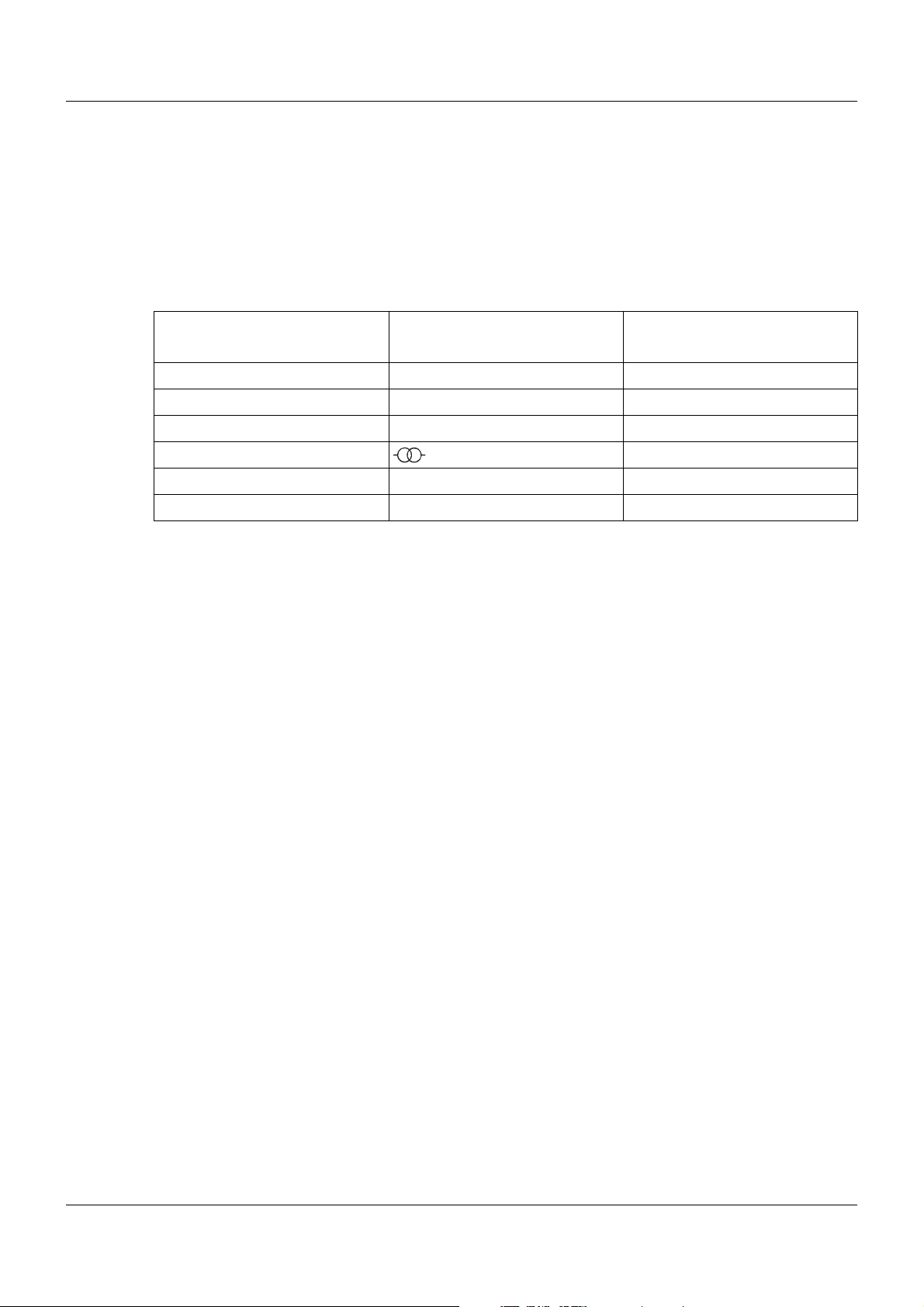

Transmission unit

Transmission

frequency

868.4 MHz

Head transmitter

Power supply

Lithium battery

3.6 V, 2.2 Ah

Interface

Setup

Analog input

+

-

RTD

temperature probe

Thermocouple

Resistance /

Potentiometer

Voltage

Resistance transmitter

1.2 Description

The Wtrans B head transmitter with wireless data transmission is used in connection with a

Wtrans receiver unit for stationary or mobile temperature measuring with RTD temperature

probes or thermocouples. Alternatively, resistors with an ohmic-value of up to 10 kΩ, voltages

up to 50 mV, and currents up to 20 mA that use an external shunt are measurable. Customerspecific linearizations are possible.

The measured values are transmitted wirelessly to the receiver of the Wtrans measuring system. These values are shown on the receiver's LCD display and are digitally available on the

RS485-interface or as analog output(s). Optionally, different alarm types can be indicated with

the two relay outputs.

This head transmitter is designed for industrial applications – it is made up of the transmitter

with an integrated transmission unit and an antenna-battery case. The transmitter is designed

to be installed into type B terminal heads and works in an ambient temperature range from -30

to 85 °C. It is possible to install the transmitter into customer-specific terminal heads. The antenna-battery case is connected to the terminal head through a screw connection (M20 × 1.5).

The transmission frequency of the Wtrans measuring system is 868.4 MHz. This frequency is

unaffected for the most part by external interferences and it allows for transmissions even in a

rough industrial environment. When using the antenna wall-holder with the 3 m antenna line for

the receiver then the maximum open-air range is 300 m.

A 3.6 V, 2.2 Ah (size AA) lithium battery is used as a power supply for the transmitter. For the

easy configuration and parameterization of the head transmitter and the Wtrans receiver on a

PC an optional setup program is available. Additionally, measured values can be recorded on

the PC with the online-chart function.

1.3 Block diagram

6

Page 7

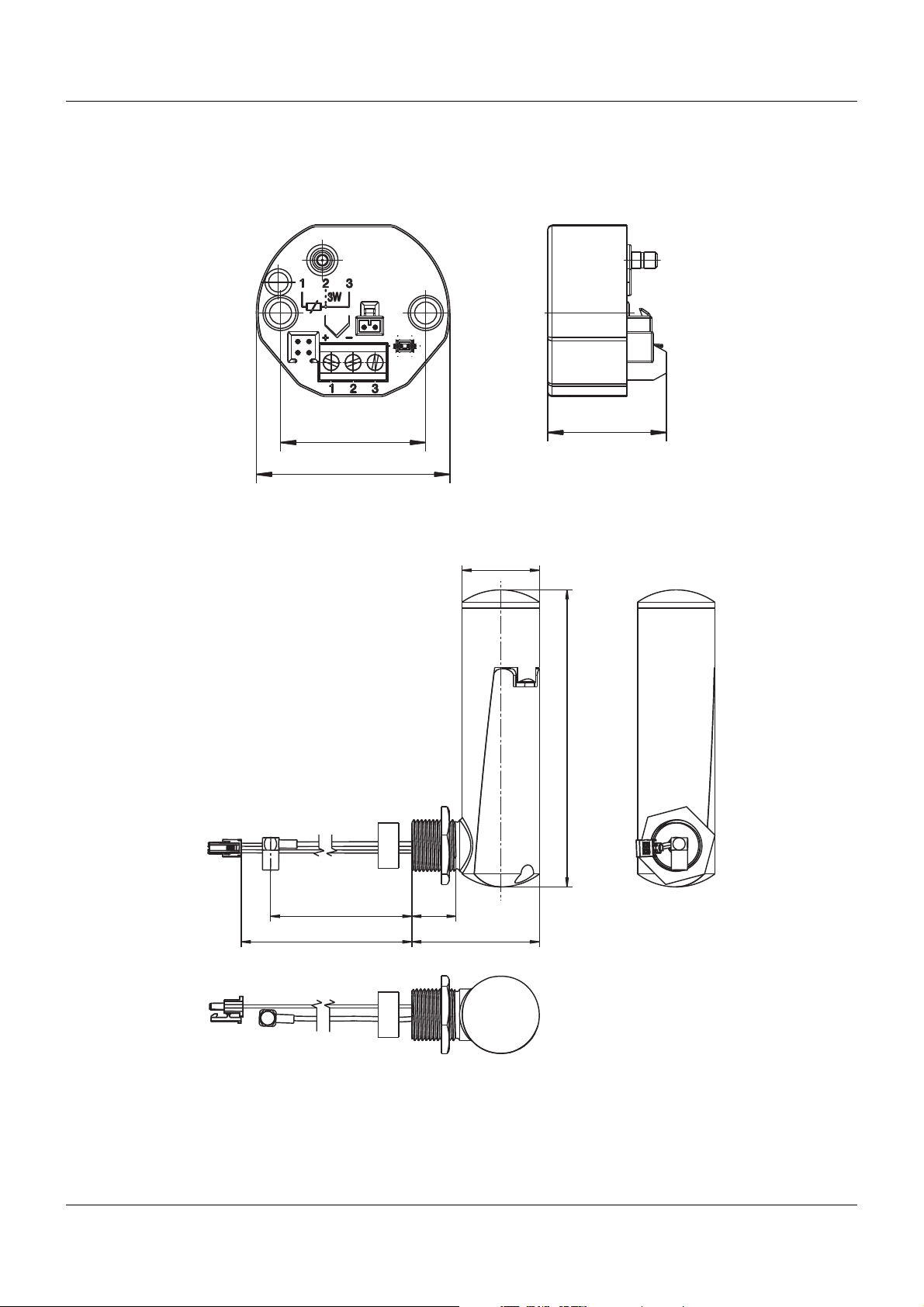

1.4 Dimensions

27

33

Ø44

approx. 105

approx. 125

17

49.5

Ø30

115

1.4.1 Transmitter

1.4.2 Antenna-battery case

1 Introduction

7

Page 8

1 Introduction

(1)

(6)

(6)

(2)

(5)

(4)

(7)

(8)

(3)

(9)

(10)

(11)

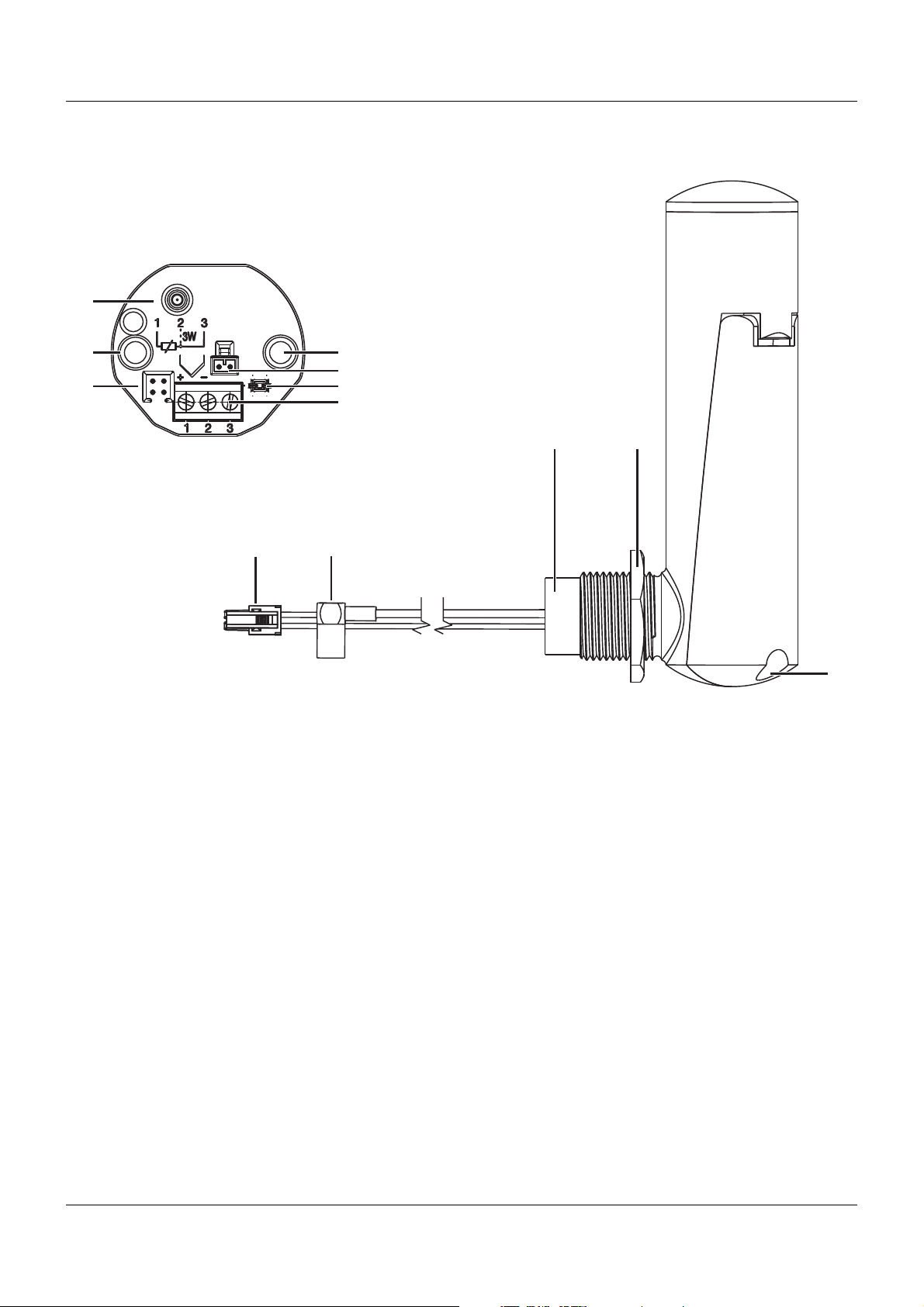

1.5 Connection elements and connectors

(1) SMB antenna connector (antenna connection) (7) Voltage supply socket (battery connection)

(2) Voltage supply connector (battery connection) (8) SMB antenna socket (antenna connection)

(3) Cable guide for antenna cable and voltage supply (9) Seal

(4) Probe connection (10) Locknut

(5) Setup connector (11) Battery lid screw

(6) Fastening holes for installation in the connection

head, form B

8

Page 9

2.1 Rating plate

Position

The rating plate is glued laterally to the transmitter.

The factory set probe ID is additionally stated on a sign fitted on top of the transmitter.

Contents

The rating plate contains important information. This includes:

2 Identifying the instrument version

Description Designation on the rating

Device type Type 707060/8-10/000

Sales No. VARTN 70/XXXXXXXX

Fabrication No. F-No 0070033801210220006

Voltage supply DC 3.6 V

Probe ID 123

Transmission frequency 868.4 MHz

Device type

Compare the specifications on the rating plate to your order documents. The supplied device

version can be identified using the type key in Chapter 2.2 "Order details", page 10.

Sales No. (VARTN)

The Sales No. provides an unambiguous definition of an article from the catalog. It is important

for communication between the sales department and the customer.

Fabrication No. (F-No.)

The fabrication number (F-No.) indicates, among others, the production date (year/week) and

the hardware version number.

Example

plate

Production date

Example: F-No. = 0070033801210220006

The figures concerned are in positions 12, 13, 14, 15 (from the left).

Thus the device was produced in the 22nd calendar week in 2010.

Probe ID

The probe ID is factory set. It must be entered and activated on the receiver to establish communication between the probe and receiver. The probe ID can be changed to customer specific

requirements using the setup program. The user must exclude that several probes with identical probe IDs are active.

Transmission frequency

The transmission frequency identifies the frequency and frequency band used by the device

for transmission. In the 868 MHz band (Europe), the transmission is carried out at 868.4 MHz.

9

Page 10

2 Identifying the instrument version

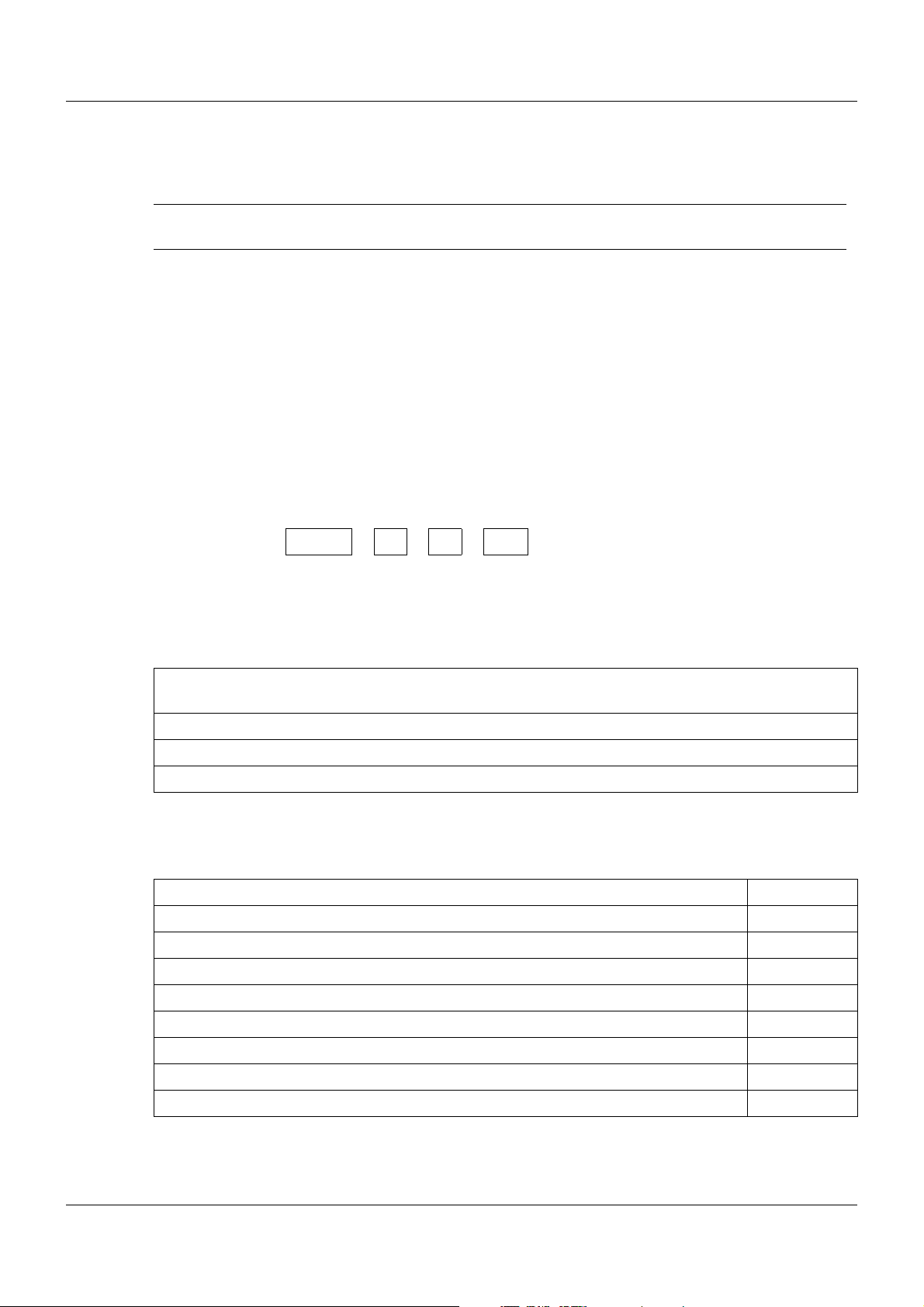

2.2 Order details

(1) Basic type

707060

8 Standard, with factory settings

9 Customized programming according to specification

10 Transmission frequency 868.4 MHz (Europe)

000 none

1

The connection head, form B, is not included in the delivery scope.

2

Please specify the probe ID, transmission interval, measuring range and the probe type in plain text.

Order code /-/

Order example 707060 / 8 - 10 / 000

JUMO Wtrans B

Programmable head transmitter with radio transmission

(2) Input

(3) Output (probe)

(4) Extra codes

(1) (2) (3) (4)

1

2

2.3 Scope of delivery

1 transmitter in the ordered version (without terminal head form B) inc. mounting parts (2 screws and

2 compression springs)

1 antenna-battery case with reverse battery protection connection cables

1 lithium battery 3.6 V, 2.2 Ah (size AA) already inserted in the antenna-battery case ready for use

1 operating manual B707060.0

2.4 Accessories

Article Sales No.

Lithium battery 3.6 V, 2.2 Ah (size AA) 70/00547559

PC interface with USB/TTL converter, adapter (socket connector) and adapter (pins) 70/00456352

PC interface with TTL/RS232 converter and adapter (socket connector) 70/00350260

Setup program on CD-ROM, multilingual 70/00488887

Setup program including OnlineChart on CD-ROM, multilingual 70/00549067

OnlineChart activation 70/00549188

10

Precision-resistor type 2.5 R / 0.1 % (shunt) 70/00555645

Page 11

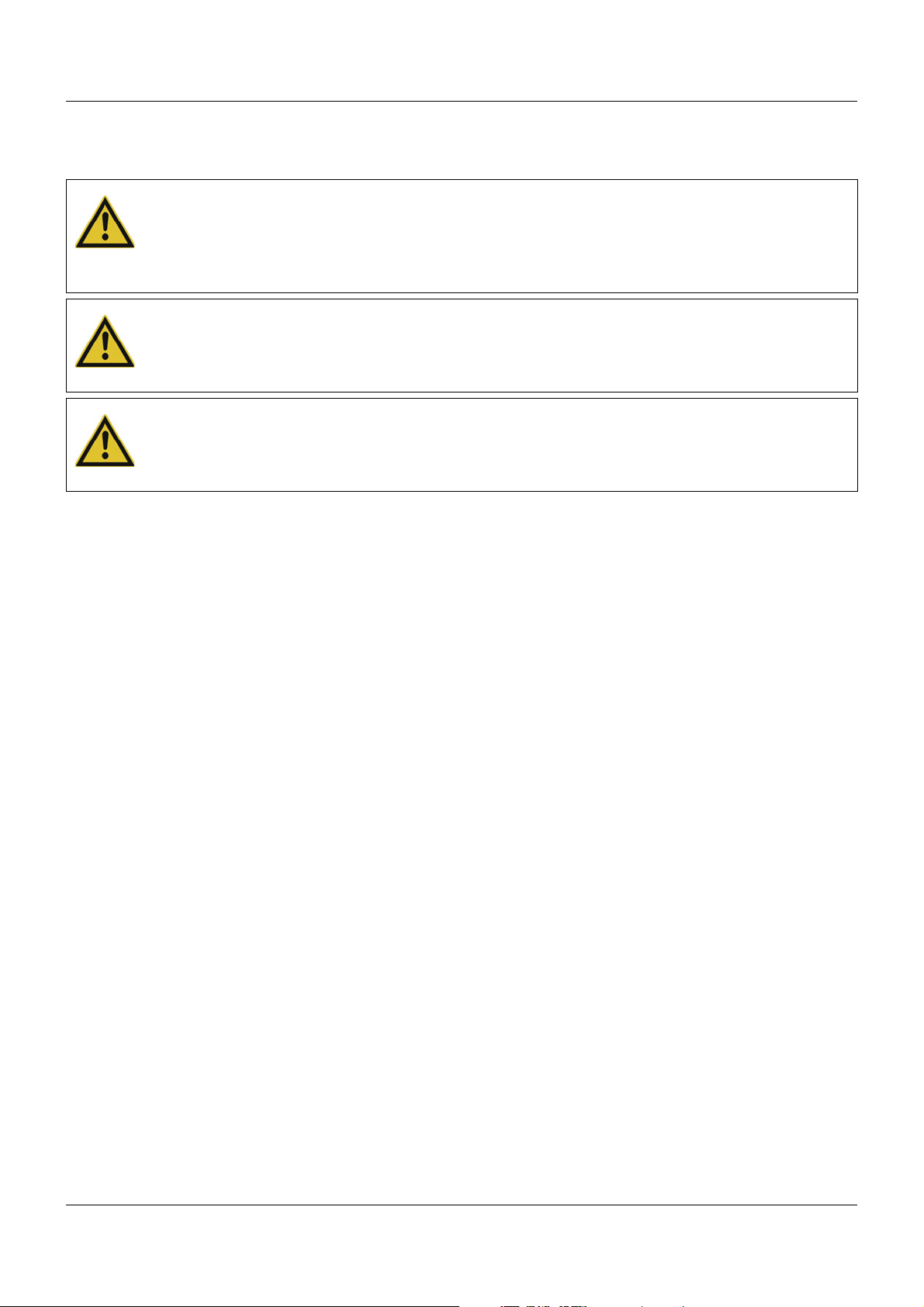

3.1 Fitting/exchanging the battery

CAUTION!

Ensure that soiling, moisture and vapors cannot enter the device.

The device could be destroyed.

When inserting/changing the lithium battery, ensure that the device is not exposed to soiling,

moisture and vapors.

CAUTION!

The probe does not function, if the poles are incorrectly connected.

The battery and the probe electronics could be damaged.

Ensure that the poles are correctly connected.

CAUTION!

Incorrect batteries put safety at risk.

The device could be destroyed when using incorrect batteries.

Only use the lithium battery available as accessories.

Power supply of the probe is provided by the included 3.6 V, 2.2 Ah lithium battery inserted in

the antenna-battery case ready for use.

Battery service life depends on the set transmission interval and the ambient temperature: approx. 1 year with the factory-set values (transmission interval 15 s) and room temperature.

3 Probe preparation

11

Page 12

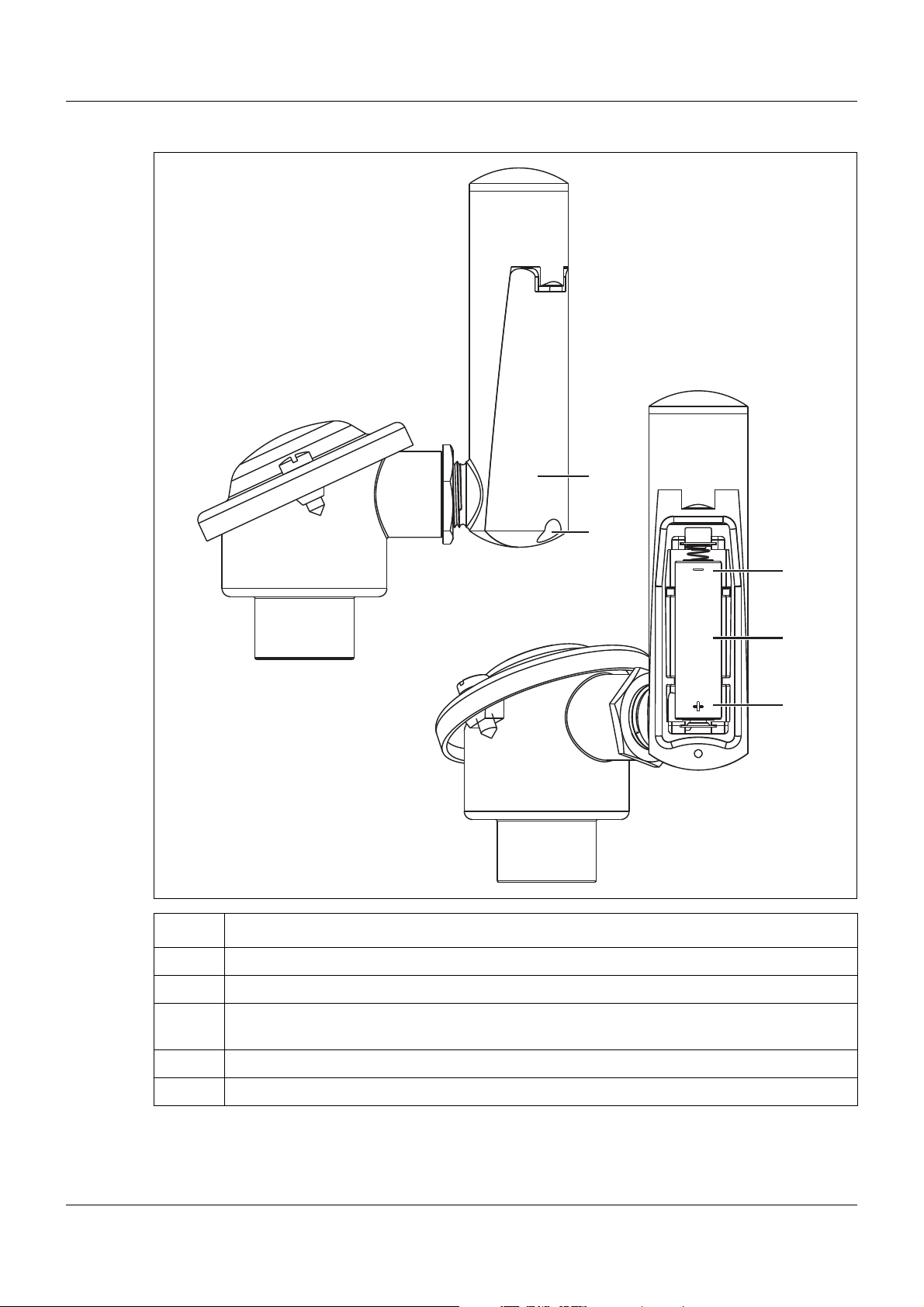

3 Probe preparation

(D)

(A)

(E)

(B)

(C)

If the battery was removed or must be replaced, proceed as follows:

12

Step Activity

1 Undo the battery lid screw (A) on the antenna-battery case and open the case lid (B).

2 Press on the battery in the area of the minus pole (D) to remove the battery (C).

3 When inserting a battery, always insert the minus pole (D) side first followed by the plus

pole (E).

4 Close the case lid (B) again and ensure the correct seal position.

5 Retighten the battery lid screw (A).

Page 13

3 Probe preparation

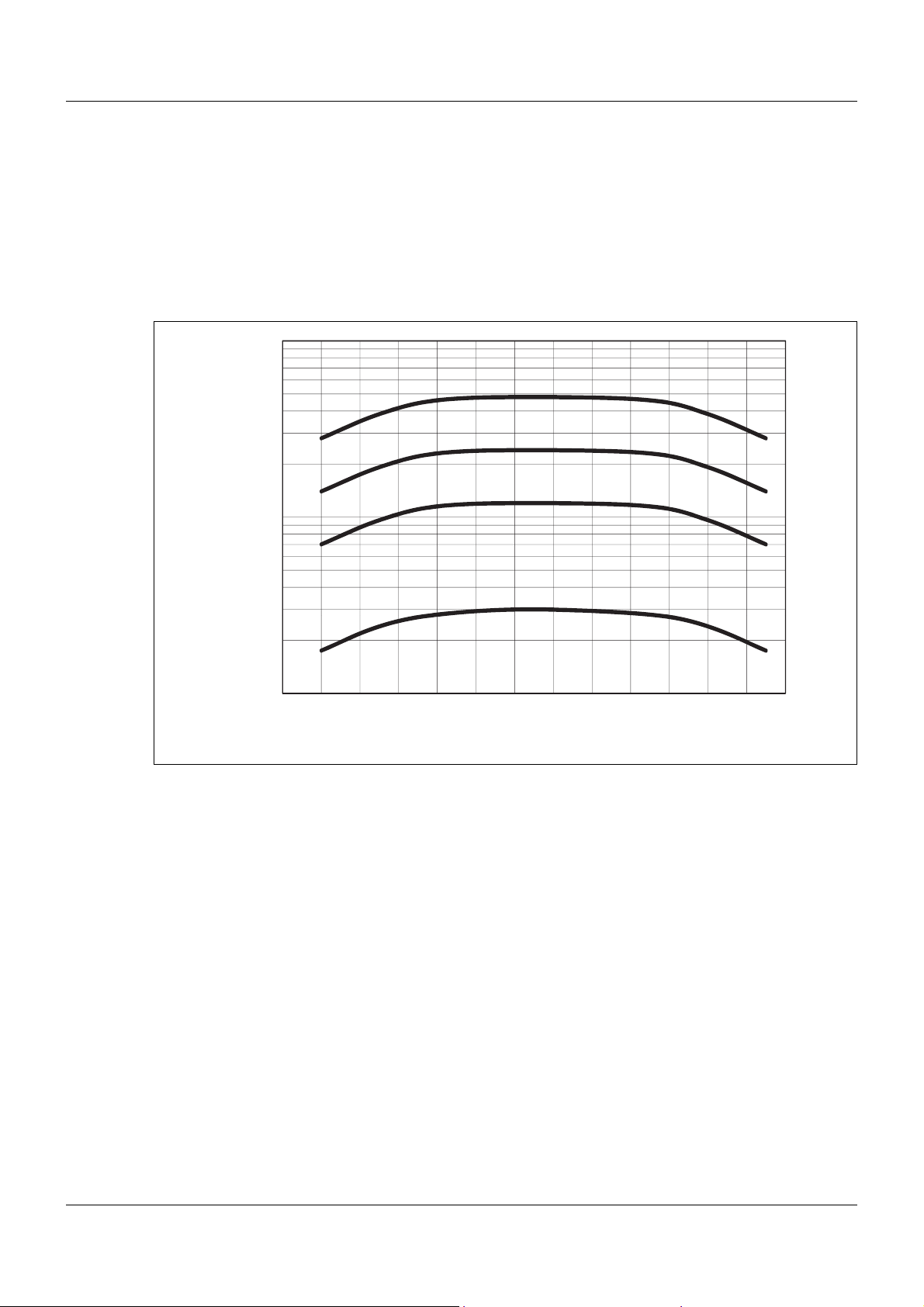

2s

15 s

30 s

90 s

100

80

60

50

40

30

20

10

8

6

5

4

3

2

1

Ambient temperature in °C

-40-30-20-10 0 102030 405060708090

Battery service life in month

3.2 Safety information concerning lithium batteries

http://batterie.jumo.info

3.3 Battery service life

The battery service life, depending on the transmission interval (2 s, 15 s, 30 s, 90 s) and the

ambient temperature, are shown in the following figure.

3.4 Disposal of lithium batteries

Please dispose of all batteries according to the Life-Cycle Resource Management and Waste

Act and the national regulations.

Insulate the contacts of lithium batteries not completely discharged. Disposal of batteries together with domestic waste is expressively prohibited. Batteries can be deposited at communal

waste collection points or the local retailers.

13

Page 14

3 Probe preparation

14

Page 15

4 Probe range

4.1 General information about radio transmission

Radio signals are electromagnetic waves the signal of which will become weaker on their path

from the probe to the receiver (this is termed as path attenuation). The field strength reduces

inversely proportional in relation to the square of the distance between the probe and receiver.

In addition to this natural range restriction, a reduced range can also be the result of the following causes:

• Ferroconcrete walls, metallic objects and surfaces, heat insulation or windows with vapor

deposited metal layer reflect and absorb electromagnetic waves and, for this reason, a

deadspot is formed behind.

• Metal tubes, chains, etc. on the probe housing, for this reason, do not fasten any metallic

objects on the probe housing.

• Insufficient spacing between several probes, for this reason, ensure a minimum spacing of

20 cm.

• The antenna is installed at an insufficient height; install as high as possible above the floor

and ensure visual contact between the probe and receiver.

The following values are reference values concerning permeability of radio signals:

Material Permeability

Wood, plaster, glass uncoated 90 to 100 %

Brickwork, press boards 65 to 95 %

Armored concrete 10 to 90 %

Metal, aluminum lamination 0 to 10 %

The range between the probe and the receiver is 300 m in open air and when using the antenna

wall holder for the receiver. The optimum reception can be achieved, if visual contact can be

established between the probe and receiver.

If the receiver is installed into a switch cabinet, behind concrete walls or concrete ceilings, the

antenna must always be installed with the wall holder and antenna cable for the receiver pointing in the direction of the probes.

15

Page 16

4 Probe range

4.2 Possible impairment of radio transmission

Collisions when using an excessive number of probes

When using a large number of probes, do not select a transmission interval which is too low,

otherwise the radio channel will be unnecessarily occupied. A too low transmission interval

means a very high data volume on the selected frequency which can lead to collisions with other probes. Telegrams can be destroyed during radio transmission caused by collisions.

Figure 1: The telegrams of a probe reach the receiver without collisions.

Figure 2: Telegrams of several probes can collide.

16

Page 17

4 Probe range

16 18 20 22 24 26 28 30

Number of probes

Fault increase

Figure 3: Collisions depending on the number of probes

at a transmission interval of 1s

As the figure 3 shows, the error curve increases sharply once 24 probes are reached.

For this reason, we recommend using a maximum of 16 probes for the smallest transmission

interval of 1 s. For the factory setting of 15 s, a considerably larger number of probes is possible.

Estimation of the maximum number of probes

If more than the recommended 16 probes are to be used at a transmission interval of 1 s, select

a higher transmission interval to prevent an increased error quota.

Example:

16 probes at a transmission interval of 1s = 32 probes at a transmission interval of 2s

When the number of probes is to be increased additionally, the following calculation results in

the next example:

Example:

16 probes at a transmission interval of 1s = 48 probes at a transmission interval of 3s (theoretically)

However, from a transmission interval of ≥ 3 s, the telegram is transmitted twice. For this reason, the number of probes to be used is cut in half.

16 probes at a transmission interval of 1s = 24 probes at a transmission interval of 3s (effectively)

The identical behavior occurs from a transmission interval of ≥ 60s. From this transmission interval, the telegram is transmitted three times.

External probes

The ISM band can also be used freely by other devices. External probes can transmit on the

same frequency. If, for example, the probe and an external probe transmit their radio telegrams

at the same time, the telegrams are destroyed. Due to the fact, that the probes are not able to

check their own active transmission, no error is detected.

Electrical devices

In a rough industrial environment, radio telegrams can be destroyed, for example, by frequency

converters, electrical welding equipment or poorly shielded PCs, audio/video devices, electronic transformers, electronic ballasts, etc.

17

Page 18

4 Probe range

Error map-out

The radio transmission timeout parameter on the receiver can be used to map out lost telegrams (either by external influence or collisions caused by a large number of probes) and no

error message appears. The value received last is retained over 2...10 transmission intervals

and the alarm radio transmission timeout is only then activated (display "----").

TIP!

In the event of collisions caused by an excessive number of probes, observe and, if necessary, correct the factors "number of probes", "transmission intervals" and, on the receiver, "radio transmission timeout".

18

Page 19

5 Installation

5.1 Information about fastening, securing and arrangement

TIP!

Install the antenna-battery case vertically to the top and, if possible, with free view to the receiver antenna.

TIP!

Never cover or coat the antenna-battery case with metallic objects. Otherwise, the probe

range is impaired.

TIP!

For optimum probe function ensure a minimum spacing of 200 mm between the probes.

19

Page 20

5 Installation

(H)

(B)

(C)

(G)

(D)

(F)

(A)

(E)

5.2 Installing the antenna-battery case

Proceed as follows to install the antenna-battery case:

Step Activity

1 Guide the voltage supply socket (B) and SMB antenna socket (C) of the antenna-

battery case (A) through the opening (G) of the connection head (H).

2 Push seal (D) into the opening (G).

3 Screw the thread (E) into the opening (G). Turn the antenna-battery case until it

makes contact with the seal (D). To ensure impermeability, continue turning for at

least 1/2 to max. 1 1/2 revolutions.

For an optimum transmission performance, the antenna-battery case should be positioned vertically (to the top) independent of the connection head position. Ensure

that the cables also turn when the sockets (B) and (C) are turned while installing the

antenna-battery case. Avoid twisting of the cables.

4 Tighten the locknut (F) and secure the antenna-battery case against loosening.

20

Page 21

5.3 Installing the transmitter

(B)

(E)

(A)

(F)

(D)

(C)

Proceed as follows to install the transmitter:

Step Activity

5 Installation

1 Let all connection cables hang out of the connection head.

2 Insert the transmitter (A) into the connection head (D).

3 Fit the transmitter (A) in the connection head (D) using the screws and pressure

springs (included in the delivery scope).

4 Connect the probe cables to the connector (C) as per connection diagram.

5 Guide the antenna and voltage supply connection clockwise in a large arc.

6 Connect the SMB antenna socket to the connector (E) without tensile stress.

7 Connect the voltage supply socket to the connector (F) without tensile stress.

8 Insert the antenna and voltage supply connection into the cable guide (B).

9 Fit the lid of the connection head.

21

Page 22

5 Installation

5.4 Aligning the antenna

The recommended and unfavorable antenna alignment possibilities are shown in the following

figure. The best possible reception is ensured when the recommended alignment possibilities

are used.

Recommended installation:

Connection head vertical and

antenna-battery case vertical to the top

Recommended installation:

Connection head horizontal and

antenna-battery case vertical to the top

Recommended installation:

Connection head horizontal and

antenna-battery case vertical to the top

Unfavorable installation:

Never install the antenna-battery case horizontally.

Unfavorable installation:

Never install the antenna-battery case horizontally.

22

Page 23

6.1 Safety information

• The electrical connection must only be carried out by qualified personnel.

• When installing and operating the transmitter ensure that no electro-static charging can

take place.

• The transmitter is not suitable for installation and application in explosion endangered areas.

• Never expose the transmitter to magnetic or electrical fields (e.g. caused by transformers,

walkie-talkies or electro-static discharge).

• An electrical connection deviating from the connection diagram can destroy the transmitter.

6 Electrical connection

23

Page 24

6 Electrical connection

(1)

(6)

(6)

(2)

(5)

(4)

(7)

(8)

(3)

(9)

(10)

(11)

+-

6.2 Connection elements and connectors

(1) SMB antenna connector (antenna connection) (7) Voltage supply socket (battery connection)

(2) Voltage supply connector (battery connection) (8) SMB antenna socket (antenna connection)

(3) Cable guide for antenna cable and voltage supply (9) Seal

(4) Probe connection (10) Locknut

(5) Setup connector (11) Battery lid screw

(6) Fastening holes for installation in the connection

head, form B

6.3 Connection diagram

6.3.1 Voltage supply

Connection Connector Terminals Symbol and terminal designation

Lithium battery, DC 3.6 V 2

24

Page 25

6 Electrical connection

1

3

J

1

3

J

2

3

2

+

-

1

3

J

1

3

2

1

3

2

E

S

A

3

2

+

-

3

2

Shunt

+

-

6.3.2 Analog input

Connection Connector Terminals Symbol and terminal designation

RTD temperature probe

4 1 and 3

2-wire circuit

RTD temperature probe

4 1 to 3

3-wire circuit

Thermocouple 4 2 and 3

Resistance / potentiometer

4 1 and 3

2-wire circuit

Resistance / potentiometer

4 1 to 3

3-wire circuit

Resistance transmitter

4 1 to 3

A=Start

S = Slider

E=End

Voltage (0 to 50 mV) 4 2 and 3

Current (0 to 20 mA) 4 2 and 3

Measuring range: Voltage

(0 to 50 mV)

with shunt 2.5 Ω (see „Accessories“)

6.3.3 Output

Connection Connector Terminals Symbol and terminal designation

Antenna connector 1

25

Page 26

6 Electrical connection

6.3.4 Interface

Connection Connector Terminals Symbol and terminal designation

Setup 5

26

Page 27

7 Setup program

7.1 General information about the setup program

The setup program serves to configure probes and receivers by means of a PC. The configuration data can be archived on data carriers and printed.

Configurable parameters are:

• Probe ID

• Transmission interval

• Configuration of the probe used

The factory settings are:

• Probe ID consecutively

• Transmission interval (15s)

• Probe setting as per order specifications

(Example: Pt100 in 3-wire circuit, -200 ... +600 °C)

The connection between probe and PC is established via a PC interface (USB/TTL or TTL/

RS232 converter).

27

Page 28

7 Setup program

7.2 Required hardware and software

The following hardware and software prerequisites must be fulfilled for operation and software

installation:

Minimum configuration

• Intel Pentium III

• Microsoft Windows 2000 or XP

• 256 MB central memory

• CD drive

• Mouse

• one free USB port or

• one free serial interface (depending on the interface/port used)

• 120 MB free hard disk memory

Recommended configuration

• Intel Pentium 4

• Microsoft Windows XP

• 512 MB central memory

1

or higher

1

2

2

Information about Windows 2000 or XP

If several users are managed on the computer, ensure that the user is logged in, who will work

with the program later. Ensure that the user has administrator rights while installing the software. After installation, the rights can be restricted again.

In the event of non-observance of this information, correct and complete installation cannot be

guaranteed!

TIP!

If no communication with the transmitter (probe) or the receiver is possible through the setup

program, update the setup program.

The latest setup program is available as download on the manufacturer's internet page.

28

1

Intel and Pentium are registered trademarks of Intel Corporation.

2

Microsoft and Windows are registered trademarks of Microsoft Corporation.

Page 29

7 Setup program

7.3 Establishing the connection between PC and probe

The connection between probe and PC is established via a PC interface TTL/RS232 converter

and adapter (socket) or USB/TTL converter and adapter (socket).

CAUTION!

Permanent interface operation!

The PC interface TTL/RS232 converter or USB/TTL converter is only designed for a time-limited interface connection.

Please ensure that the interface connection is disconnected and the probe correctly closed

once the setup data transfer is completed.

CAUTION!

Disconnect and remove the voltage supply!

Malfunctions can occur, if the connection between battery and transmitter is disconnected

while the setup connector is still connected.

Do not disconnect the battery from the transmitter as long as the setup connector is still connected.

CAUTION!

Low battery!

A low battery can lead to interface problems and result in an incorrect configuration or data

loss.

Please ensure that the battery used for the connection between PC and probe never reaches

the "Low battery" status.

29

Page 30

7 Setup program

(1)

(2)

(3)

(4)

TTL/RS232

(1) Laptop/PC (3) Adapter socket, 4-pin

(2) RS232 connector (4) Probe interface

For the setup via the TTL/RS232 converter, establish the following connections:

Step Activity

1 Insert the RS232 connector (2) into the laptop/PC (1).

2 Connect the adapter socket, 4-pin, (3) to the probe interface (4).

TIP!

For probe configuration, ensure that the probe is connected to the voltage supply of the antenna-battery case.

30

Page 31

USB/TTL

USB/TTL

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

7 Setup program

(1) Laptop/PC (5) Modular jack RJ-45

(2) USB connector (6) Adapter of the modular cable

(3) USB socket (7) Adapter socket, 4-pin

(4) USB/TTL converter (8) Probe interface

For the setup via the USB/TTL converter, establish the following connections:

Step Activity

1 Insert the USB connector (2) of the USB cable into the laptop/PC (1).

2 Insert the USB bush (3) of the USB cable into the connector of the USB/TTL converter (4).

3 Connect the RJ-45 connector (5) of the modular line to the RJ-45

socket of the USB/TTL converter (4).

4 Connect the 4-pin adapter socket (7) to the adapter of modular

line (6).

5 Connect the adapter socket, 4-pin, (7) to the probe interface (8).

TIP!

For probe configuration, ensure that the probe is connected to the voltage supply of the antenna-battery case.

31

Page 32

7 Setup program

7.4 Probe configuration

This chapter explains the configuration of a probe via the setup program. Prerequisite being

that the probe and the PC are connected via an interface.

7.4.1 Establishing the communication

A differentiation is made between two different way of proceeding when establishing the communication between probe and setup program:

• Establish the communication with "Device settings assistant”.

This is the case when the setup program is used for the first time

(list of devices empty).

• Establish the communication without "Device settings assistant”.

This is the case when the receiver/probe and setup program have already communicated

(list of devices with entries).

Establishing the communication using the assistant

How to proceed:

Step Activity

1 Start the setup program.

2 Select the "Establish connection" function in the "Data transfer” menu.

The "Assistant for the device settings" appears.

3 Select the probe under the "Device version" and confirm by pressing "Continue".

4 Confirm the PC communication interface "Serial interface" by pressing "Continue".

5 Select the serial interface (e.g. COM1) and confirm with "Continue”.

6 Confirm the MU protocol (transmitter) by pressing "Continue".

7 Exit the assistant by pressing "Finish".

The device list with the selected probe appears.

8 Click on the "Connect" button.

The device list is closed, the assistant terminated and the communication between

probe and setup program established.

32

Page 33

Establishing the communication without using the assistant

How to proceed:

Step Activity

1 Start the setup program.

2 Select the "Establish connection" function in the "Data transfer” menu.

The device list containing all devices entered is mapped in.

3 Select the desired probe by clicking with the left mouse key.

4 Click on the "Connect" button.

The device list is closed, the assistant terminated and the communication between

probe and setup program established.

7.4.2 Reading the current probe parameters

How to proceed:

Step Activity

7 Setup program

1 In the "File" menu select the "New" function.

The "Device assistant” starts.

2 Confirm the "User-defined setting" by pressing the "Continue" button.

3 Select the "Frequency band" and confirm with "Continue".

4 Select the receiver variant and confirm by pressing "Continue".

5 Exit the overview of the selected settings by pressing "Finish".

The current settings are displayed in the setup program.

6 Select the desired probe from the navigation tree by clicking with the left mouse key.

7 In the "Data transfer" menu select the "Data transfer from device" function.

8 Exit the inquiry "Save file" by selecting "Skip".

The current probe parameters are downloaded to the setup program.

7.4.3 Editing probe parameters

How to proceed:

Step Activity

1 Select the probe to be edited from the navigation tree by double clicking with the left

mouse key.

The "Probe configuration" is opened.

2 Edit the desired parameters.

3 Confirm editing with "OK”.

4 Save the parameters in the "File” menu with the "Save” function.

33

Page 34

7 Setup program

7.4.4 Transmitting new parameters to the probe

How to proceed:

Step Activity

1 In the "Data transfer" menu select the "Data transfer to device" function.

The current parameters are transmitted to the probe.

2 Finish the communication between setup program and probe in the "Data transfer"

menu using the "Disconnect connection" function.

7.5 Parameters overview

Parameters Factory setting Value range/Selection

Probe ID inactive 1 ... 99999

Transmission interval 15 s 1 ... 3600 s

Transmission frequency

Probe type RTD temperature

Sensor Pt100 Depending on the probe type,

Connection type 3-wire circuit 3-wire circuit,

Lead resistance R

Resistance R

Resistance R

Resistance R

Resistance R

X

0

A

S

868.4 MHz 868.4 MHz

Display only, cannot be edited!

RTD temperature probe

probe

0Ohm 0 to 22 Ohm

l

10000 Ohm 5 to 10000 Ohm

0Ohm 0 to 4000 Ohm

0Ohm 0 to 10000 Ohm

10000 Ohm 5 to 10000 Ohm

Thermocouple

Resistance/potentiometer

Resistance transmitter

Voltage

Pt100 DIN EN 60751 -200 ... +600 °C

2-wire circuit

Only with 2-wire circuit!

Only for resistance/potentiometer sensortype!

Only for resistance/potentiometer

sensor type!

Only for linearization 0 to 100 %

Only for resistance transmitter

sensor type!

Only for resistance transmitter

sensor type!

34

Resistance R

E

0Ohm 0 to 10000 Ohm

Only for resistance transmitter

sensor type!

Page 35

Parameters Factory setting Value range/Selection

TAG number 10-digit number, freely selectable

Information text 10-digit number, freely selectable

Installation date current date any date

TIP!

At a transmission interval of > 15 s, the probe transmits a so-called link telegram (after a setup transmission), i. e. the telegrams are transmitted at the factory-set interval of 15 s for a

period of 30 minutes, and only then at the set transmission interval.

TIP!

Once the setup connector is connected, the probe automatically transmits telegrams at a

transmission interval of 1s to ensure that changes can be immediately detected by the receiver. After the setup connector is removed, the telegrams are transmitted again at the set transmission interval.

Term definition

Probe ID

The probe ID is an unmistakable ID with max. 5 characters which is recognized by the receiver.

The ID can be individually changed, for example, to achieve a better overview of a system. Ensure that an ID is not used simultanously by two probes within the reception range to avoid malfunctions.

7 Setup program

Transmission interval

This parameter is used to define the time intervals used to transmit data to a receiver. The setting of the "Transmission interval" parameter affects the battery service life. For this reason, act

with caution and do not only consider the transmission quality when selecting the interval.

Transmission frequency

The transmission frequency defines the frequency band used to transmit data to a receiver. The

transmission frequency is defined at 868.4 MHz for Europe because special regulations are defined concerning transmission interval and transmission capacity for the ISM band (Industrial,

Scientific and Medical Band).

35

Page 36

7 Setup program

36

Page 37

8 Supplement

8.1 Technical data

8.1.1 Analog input

RTD temperature probe

Designation Standard Measuring range Measuring accuracy

Pt100 DIN EN 60751 -100 to +200 °C ± 0.1 K

(TK value = 3.85 × 10

Pt500 DIN EN 60751 -100 to +200 °C ± 0.1 K

(TK value = 3.85 × 10

Pt1000 DIN EN 60751 -100 to +200 °C ± 0.1 K

(TK value = 3.85 × 10

Ni 100 DIN 43760 -60 to +250 °C ± 0.2 K

(TK value = 6.18 × 10

Ni 500 DIN 43760 -60 to +150 °C ± 0.2 K

(TK value = 6.18 × 10

Ni 1000 DIN 43760 -60 to +150 °C ± 0.2 K

(TK value = 6.18 × 10

-3

1/K) -200 to +600 °C ± 0.2 K

-3

1/K) -200 to +600 °C ± 0.2 K

-3

1/K) -200 to +600 °C ± 0.2 K

-3

1/K)

-3

1/K)

-3

1/K)

Pt100 JIS 1604 -100 to +200 °C ± 0.1 K

(TK value = 3.917 × 10

-3

1/K) -200 to +600 °C ± 0.2 K

Pt50 ST RGW 1057 1985-200 to +600 °C ± 0.2 K

-3

(TK value = 3.91 × 10

Pt100 GOST 6651-

1/K)

-100 to +200 °C ± 0.1 K

94 A.1

(TK value = 3.91 × 10

Cu50 GOST 6651-

-3

1/K) -200 to +600 °C ± 0.2 K

-50to+200 °C ± 0.2 K

94 A.4

(TK value = 4.26 × 10

Cu100 GOST 6651-

-3

1/K)

-50to+200 °C ± 0.2 K

94 A.4

-3

(TK value = 4.26 × 10

1/K)

Connection type 2-wire or 3-wire circuit

Sensor current < 0.5 mA

Lead compensation Not required for 3-wire circuit (admissible max. 11 Ω per line).

Max. configurable lead-wire resistance for 2-wire circuit: 22 Ω.

37

Page 38

8 Supplement

Thermocouples

Designation Standard Measuring range Measuring accuracy

Fe-CuNi „L“ DIN 43710 -200 to +900 °C ± 0.1 %

Fe-CuNi „J“ DIN EN 60584 -210 to +1200 °C ± 0.1 % as of -100 °C

Cu-CuNi „U“ DIN 43710 -200 to +600 °C ± 0.1 % as of -100 °C

Cu-CuNi T DIN EN 60584 -270 to +400 °C ± 0.1 % as of -150 °C

NiCr-Ni K DIN EN 60584 -270 to +1372 °C ± 0.1 % as of -80 °C

NiCr-CuNi „E“ DIN EN 60584 -270 to +1000 °C ± 0.1 % as of -80 °C

NiCrSi-NiSi „N“ DIN EN 60584 -270 to +1300 °C ± 0.1 % as of -80 °C

Pt10Rh-Pt „S“ DIN EN 60584 -50 to +1768 °C ± 0.15 % as of 20 °C

Pt13Rh-Pt „R“ DIN EN 60584 -50 to +1768 °C ± 0.15 % as of 50 °C

Pt30Rh-Pt6Rh „B“ DIN EN 60584 0 to 1820 °C ± 0.15 % as of 400 °C

W5Re-W26Re „C“ 0 to 2320 °C ± 0.15 %

W3Re-W25Re „D“ 0 to 2495 °C ± 0.25 %

W3Re-W26Re 0 to 2400 °C ± 0.15 %

Chromel-Copel -200 to +800 °C ± 0.1 % as of -80 °C

Chromel-Alumel -200 to +1372 °C ± 0.1 % as of -80 °C

PLII (Platinel II) 0 to 1395 °C ± 0.15 %

MoRe5-MoRe41 0 to 2000 °C ± 0.2 %

Cold junction Pt1000 internal

a

Cold junction accuracy ± 1 K

a

All accuracies given in % refer to the maximum measuring range

Resistance / potentiometer

Designation Measuring range Measuring accuracy

Resistance / potentiometer

Linearization: 0 to 100 %

Resistance / potentiometer

Linearization: Resistance in Ω

Connection type 2-wire or 3-wire circuit

Lead compensation Not required for 3-wire circuit (admissible max.11 Ω per line).

a

All accuracies given in % refer to the maximum measuring range

> 50 Ω to ≤ 400 Ω

> 400 Ω to ≤ 4000 Ω

> 4000 Ω to ≤ 10000 Ω

>50Ω to ≤ 10000 Ω±0.1 %

Max. configurable lead-wire resistance for 2-wire circuit: 22 Ω.

± 400 mΩ

± 4 Ω

± 10 Ω

a

38

Page 39

Resistance transmitter

8 Supplement

Designation Measuring range Measuring accuracy

Resistance transmitter > 50 Ω to ≤ 400 Ω

> 400 Ω to ≤ 4000 Ω

> 4000 Ω to ≤ 10000 Ω

Connection type 3-wire connection

Requirement R

a

All accuracies given in % refer to the maximum measuring range

e+Ra+Rs

≤ 10000 Ω and Re+Ra≤ 1/3 R

± 400 mΩ

± 4 Ω

± 10 Ω

Volta g e

Designation Measuring range Measuring accuracy

Voltage 0 to 50 mV ± 0.1 %

a

All accuracies given in % refer to the maximum measuring range

Measuring circuit monitoring

Measuring probe Detection of

overrange / underrange

Detection of

probe /

cable short-circuit

Detection of

probe /

cable break

a

s

a

The r m ocou p l e Yes / Ye s No Yes

RTD temperature probe Yes / Yes Yes Yes

Resistance / potentiometer Yes / Yes Yes Yes

Resistance transmitter No / No No No

Voltage Yes / Yes No Yes

8.1.2 Output (radio transmission)

Probe ID Max. 5-digit ID, factory-set, can be configured to customer-request

Transmission interval Adjustable from 1 to 3600 s (factory setting: 15 s)

Transmission frequency 868.4 MHz (Europe)

Transmission power +10 dBm

Open air range Max. 300 m when using the antenna wall-holder of the receiver and

the 3 m antenna line. When installing the antenna directly on the

receiver, a reduced range of approx. 40 % must be taken into

account.

Output signal

Thermocouple Voltage (mV)

RTD temperature probe Resistance (Ω)

Resistance / potentiometer Percent (%) or resistance (Ω)

Resistance transmitter Percent (%)

Voltage Voltage (mV)

39

Page 40

8 Supplement

Configuration With setup program

Configurable parameters Probe ID (max. 5-digit ID) and transmission interval

8.1.3 Electrical data

Voltage supply

Lithium battery Rated voltage: 3.6 V, rated capacity: 2.2 Ah; size AA

Operating life Approx. 1 year with the factory-set values (transmission interval =

15 s) and at room temperature (brief transmission interval and high

or low ambient temperature reduce the battery operating life)

Battery change Only use the lithium battery available as an accessory

8.1.4 Environmental influences

Transmitter in the B head with antenna-battery case

Ambient temperature range -30 to +85 °C

Storage temperature range / storage humidity

Temperature influence

Thermocouple ≤ ± 0.005 % / K deviation from 22 °C plus accuracy of the cold junc-

RTD temperature probe ≤ ± 0.005 % / K deviation from 22 °C

Resistance / potentiometer ≤ ± 0.01 % / K deviation from 22 °C

Resistance transmitter ≤ ± 0.01 % / K deviation from 22 °C

Voltage ≤ ± 0.005 % / K deviation from 22 °C

Climate class 10 cycles at 10 °C / 80 °C, according to IEC 68-2-30,

Vibration resistance According to GL characteristic line 2

Admissible mechanical shock resistance 10 g / 6 ms, according to DIN IEC 68-2.29

Electromagnetic compatibility (EMC) According to DIN EN 61326-1

Interference emission Class B

Interference immunity Industrial requirements

Radio frequency spectrum ETSI EN 300 220-1 (V 2.3.1) and ETSI EN 300 220-2 (V 2.3.1)

a

All accuracy values in % refer to the maximum measuring range.

a

-40 to +85 °C / relative humidity ≤ 95 %

tion

relative humidity 95 %, during operation

40

Page 41

8 Supplement

8.1.5 Casing

Transmitter

Type Plastic case to be installed in connection head, form B

Material Polycarbonate

Flammability class UL 94 V2

Dimensions

Diameter 44 mm

Height with/without connectors 31 mm / 27 mm

Protection type IP00: For open installation

IP65: When installed in a suitable head form B

Connections

Sensor 3-pole connection terminal RM 5 mm, conductor cross-section

1.5 mm²

Antenna SMB connector

Voltage supply 2-pin header RM 2.54 mm

Setup 4-pin connector

Weight Approx. 35 g

Antenna-battery case

Type Plastic case with M20x1.5 thread for connection head, form B

Material Polyetherimide

Flammability class UL 94 HB or UL 94 V-0

Dimensions

Diameter 30 mm

Height 115 mm

Protection type IP65, according to DIN EN 60529

Connection

Antenna SMB cable socket, 50 Ω

Battery connection 2-pole connector RM 2.54 mm

Mounting orientation Preferably vertical (optimum alignment is to the receiver antenna)

Weight (including battery) Approx. 80 g

41

Page 42

8 Supplement

42

Page 43

Page 44

JUMO GmbH & Co. KG

Street address:

Moritz-Juchheim-Straße 1

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

e-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Es

sex CM20 2DY, UK

P

hone: +44 1279 635533

Fax: +44 1279 635262

e-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

8 Technology Boulevard

Canastota, NY 13032, USA

Phone: 315-697-JUMO

1-800-554-JUMO

Fax: 315-697-5867

e-mail: info@jumo.us

Internet: www.jumo.us

Loading...

Loading...