Page 1

ATH-EXx

Explosion-protected surface-mounted thermostat

for potentially explosive gas atmosphere Zone 1 and

potentially explosive dust atmosphere Zone 21

B 605051.0

Operating Instructions

2011-04-01/00379556

Page 2

Please read these Operating Instructions before commissioning the instrument.

Keep the manual in a place that is accessible to all users at all times. Please

assist us to improve these operating instructions, where necessary. Your suggestions will be appreciated.

Phone+49 661 6003-0

Fax +49 661 6003-607

All necessary settings and, where appropriate, alterations inside the instrument

are described in these operating instructions. If any difficulties should still arise

during commissioning, you are asked not to carry out any unauthorized manipulations on the unit. You could endanger your rights under the instrument warranty! Please contact the nearest subsidiary or the head office in such a case.

Page 3

Contents

Seite

1 Introduction ............................................................................... 5

1.1 Typographical conventions ...................................................................... 5

1.1.1 Warning signs .............................................................................................. 5

1.1.2 Note signs ................................................................................................... 5

1.2 Application ................................................................................................. 6

1.3 Ex marking ................................................................................................. 6

1.4 Safety notes ............................................................................................... 6

2 Instrument identification .......................................................... 7

2.1 Nameplate .................................................................................................. 7

2.2 Type designation ....................................................................................... 8

3 Mounting .................................................................................... 9

3.1 Dimensions ................................................................................................ 9

3.2 Opening the surface-mounting thermostat .......................................... 10

3.3 Fixing the surface-mounting thermostat .............................................. 10

3.4 Capillary / temperature probe / pocket ................................................. 10

3.4.1 General ...................................................................................................... 10

3.4.2 Approved probes and sheaths .................................................................. 10

3.5 Permissible operating conditions at the pocket .................................. 11

3.5.1 Probe mountings 20 and 22 ...................................................................... 11

3.5.2 Probe mountings 10, 15, 21, 60, 65 .......................................................... 14

3.6 Mounting the probe ................................................................................. 14

4 Installation ............................................................................... 15

4.1 Regulations and notes ............................................................................ 15

4.2 Electrical connection .............................................................................. 16

4.3 Connection diagrams ............................................................................. 16

5 Settings .................................................................................... 17

5.1 Limit setting ............................................................................................. 17

5.1.1 TW, STW, TB (code 7) ............................................................................... 17

5.1.2 STB (code 70) ........................................................................................... 17

5.1.3 TB, STB (code 7-F or 70-F) ....................................................................... 18

5.2 Resetting the TB or STB limiter ............................................................. 19

5.3 Self-monitoring (fail-safe) ....................................................................... 19

5.3.1 Response to a fracture of the measuring system ..................................... 19

5.3.2 Response to low temperature ................................................................... 19

6 Instrument description ........................................................... 20

6.1 Technical data ......................................................................................... 20

7 Appendix .................................................................................. 24

Page 4

Page 5

1.1 Typographical conventions

1.1.1 Warning signs

Danger

This symbol is used when there may be danger to personnel if the instructions are ignored or not followed correctly!

Caution

This symbol is used when there may be damage to equipment if the instruc-

tions are ignored or not followed correctly!

1.1.2 Note signs

Note

This symbol is used when your special attention is drawn to a remark.

1 Introduction

Reference

This symbol refers to further information in other chapters or sections.

1

abc

✱ Action

Footnote

Footnotes are remarks that refer to specific points in the text. Footnotes

consist of two parts:

A marker in the text, and the footnote text.

The markers in the text are arranged as continuous superscript numbers.

The footnote text (in smaller typeface) is placed at the bottom of the page and

starts with a superscript number.

This symbol indicates that an action to be performed is described.

The individual steps are marked by this asterisk, e.g.

✱ Select setpoint

5

Page 6

1 Introduction

1.2 Application

Depending on the version, the explosion-protected surface-mounting

thermostat type ATH-EXx can be used as a

■ TW temperature monitor

■ TB temperature limiter

■ STW fail-safe temperature monitor

■ STB break-proof protection temperature limiter

in areas with an explosion hazard caused by gases, vapors or mists, Zone 1 or

in areas with combustible dust or dust/air mixtures, Zone 21.

If this surface-mounting thermostat is used inside the hazardous area, the

relevant regulations for mounting and operating equipment in such an area

must be observed.

Cutting through or kinking the capillary of the surface-mounting thermostat,

type ATH-EXx, will result in permanent failure of the instrument!

Only use the ATH-EXx with TZ 679 in areas that are classified as areas with

low mechanical risk.

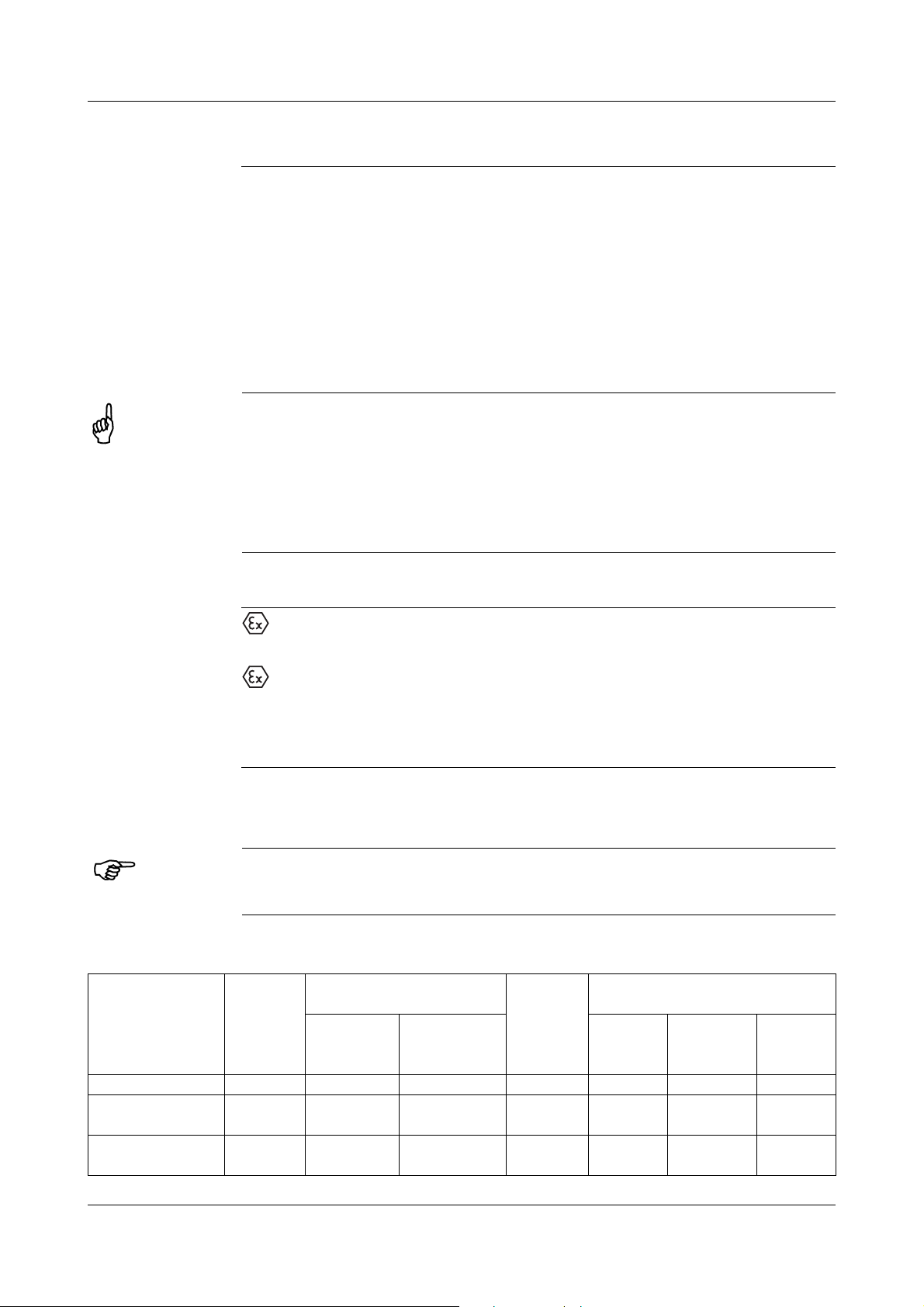

1.3 Ex marking

II 2G Ex ed IIC T5 bzw. T6

for potentially explosive gas atmospheres

II 2D Ex tD A21 IP65 T95°C bzw.T80°C

for potentially explosive dust atmospheres

Test certificate: PTB 03 ATEX 1187

CE marking and No. of notified body: CE 0044.

1.4 Safety notes

Filling liquid may escape in the event of a measuring system fracture. At present there is

no restrictive statement from the health authorities concerning any danger to health over

short periods and at low concentration, e.g. after a fracture of the measuring system.

Physical and toxicological properties of the substances that may escape in the

event of a system fracture.

End of scale°CDanger-

ous

reaction

< +200°C – +355°C 0,6 - 8 V X X X –

+200°C

+350°C

> 350°C

+500°C

– +490°C - - X X X –

– – – ––––

Ignition

Fire and

explosion hazard

Explosion

temp.

°C

% v/v

limit

Water

conta-

mination

Toxicological data

irritant danger to

health

– = no; X = yes

toxic

6

Page 7

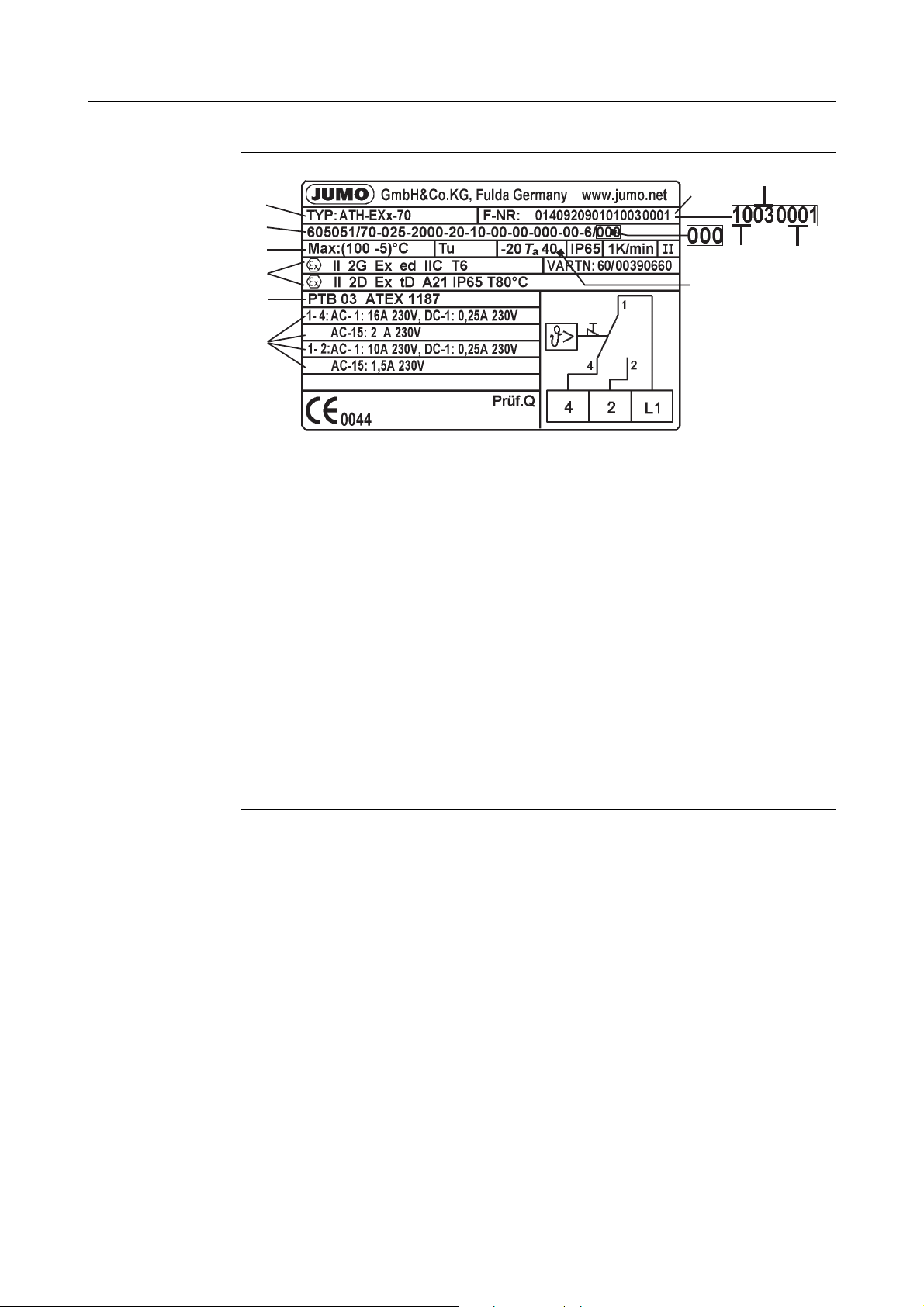

2.1 Nameplate

( 4 )

( 3 )

( 2 )

( 1 )

( 5 )

( 6 )

( 8 )

( 9 )

(10)

(11)

( 7 )

( 12 )

( 1 ) Type ➩ Chapter 2.2 "Type designation", page 8

( 2 ) Type code

( 3 ) Control range or limit value range / ambient temperature at which this

( 4 ) Ex-protection marking

( 5 ) Testing laboratory / certification

2 Instrument identification

thermostat was calibrated (option)

( 6 ) Switching capacity

( 7 ) Permissible ambient temperature

( 8 ) Serial number

( 9 ) Year of production

(10) Week of production

(11) Running serial device number

(12) Extra code

7

Page 8

2 Instrument identification

2.2 Type designation

ATH-EXx- . .- .

ATH Surface-mounting thermostat (with capillary)

ATH-EXx Marking for explosion-protected version

ATH-EXx- ..-. Code number for the function:

2=0Temperature monitor (TW)

with changeover contact.

Limit adjustable within the housing.

7=0Temperature limiter (TB)

with changeover contact and restart lock-out.

Limit adjustable within the housing.

7-F =0Temperature limiter (TB)

with changeover contact and restart lock-out.

Limit is factory-set.

20 =0Fail-safe temperature monitor (STW)

with changeover contact.

Limit adjustable within the housing.

70 =0Break-proof protection temperature limiter (STB)

with change-over contact and restart inhibit.

The limit value can be set by the installing engineer–

before commissioning the plant – within the housing.

70-F =0Break-proof protection temperature limiter (STB)

with change-over contact and restart inhibit.

Limit value set to a fixed value at the factory.

ATH-EXx- . .- .F=0Designation for factory-set limit setting.

Extra code (TZ) 679: Min. operating temperature: -50°C

8

Page 9

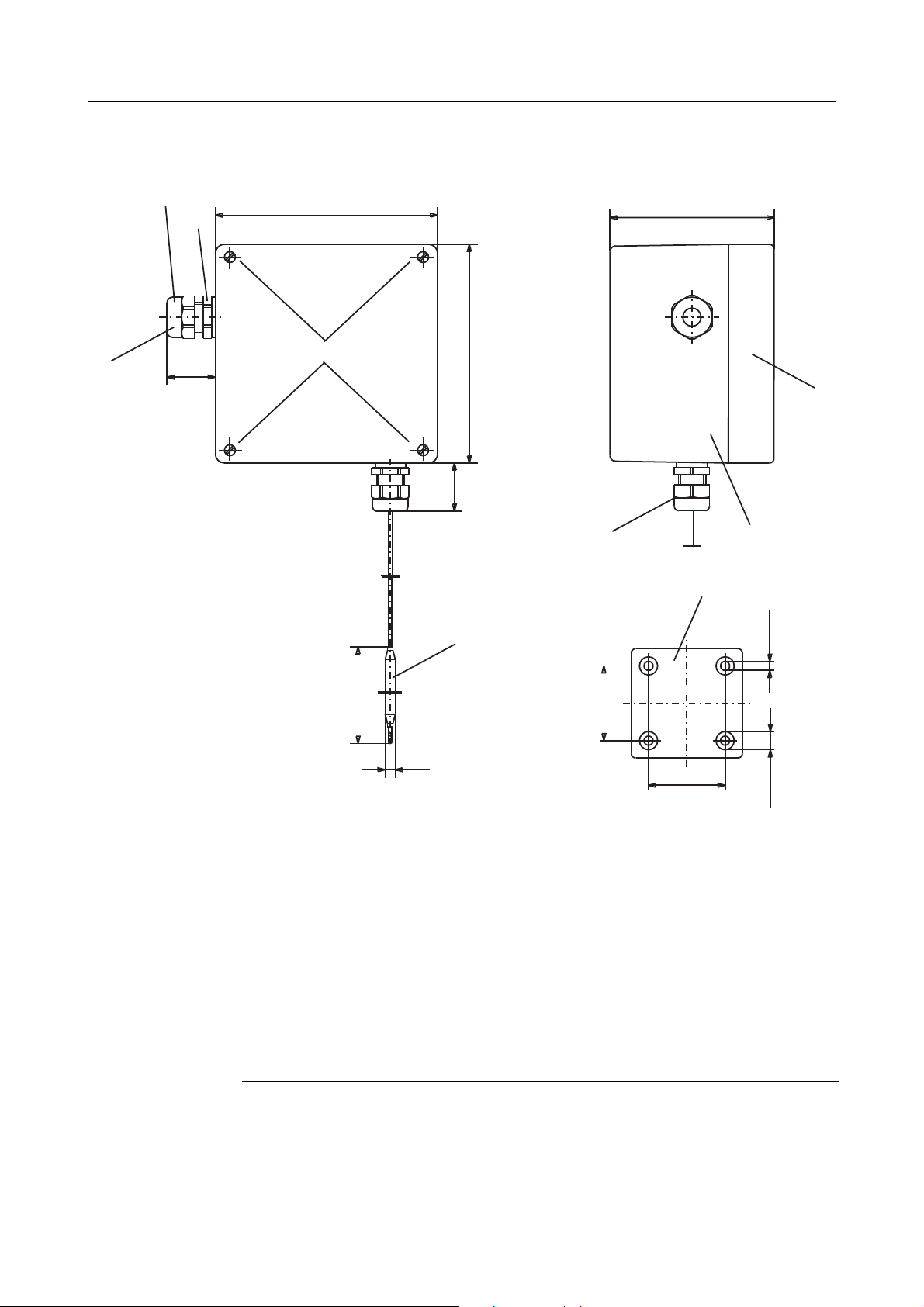

3.1 Dimensions

90

d

122

120

82

6.4

10.4

106

L

29

25

( 1 )

( 2 )

( 1.1 )

( 1.2 )

( 7 )

( 5 )

( 6 )

( 4 )

( 3 )

3 Mounting

(1) Ex cable gland M 20 x 1.5 x 6-12

(1.1) Screw-in thread Tightening torque: 3,75 Nm

(1.2) Compression screw Tightening torque: for cable dia. 06mm=3.5Nm

(2) Cover screws

(3) Cover

(4) Housing base

(5) Drilling diagram

(6) Ex cable gland for sealing the capillary exit

(7) Temperature probe

Tightening torque: for cable dia. 12 mm = 2.5 Nm

9

Page 10

3 Mounting

3.2 Opening the surface-mounting thermostat

✱ Unscrew the 4 cover screws (2)

✱ Remove cover (3) with seal (not visible)

Make sure that the seal is seated correctly when reassembling!

3.3 Fixing the surface-mounting thermostat

Mounting

position

To DIN 16257, NL 0 — NL 90 (other NL on request)

✱ Drill fixing holes according to the drilling diagram.

✱ Use the 4 screws to secure the housing base.

3.4 Capillary / temperature probe / pocket

3.4.1 General

Cutting through or kinking the capillary of the surface-mounting thermostat will

lead to permanent instrument failure!

Minimum permissible bending radius of the capillary is 5 mm.

The temperature probe must be mounted in a JUMO pocket, otherwise the

approval of the surface-mounting thermostat becomes invalid.

The temperature probe must completely immersed in the medium to be

measured.

To ensure their overall accuracy, the thermostats must only be used together

with the pockets supplied by the factory (diameter D = 8, 10 or 15 mm).

Pockets with a diameter D = 10 mm must only be fitted with probes with

diameter d = 8 mm.

Fitting several probes into a common pocket is only permitted with 2 or 3

probes (mounting type "10", diameter d = 6 mm) and 15 x 0.75 mm pockets.

When fitting 2 probes in a common pocket, the factory-supplied spring clip

must be fitted in the pocket.

For operation in air, probe mounting type "10" (without pocket) must be chosen.

3.4.2 Approved probes and sheaths

see current data sheet 606710

10

Page 11

3 Mounting

3.5 Permissible operating conditions at the pocket

3.5.1 Probe mountings 20 and 22

The values given below refer to the maximum loading on the probe mounting

concerned. The maximum pressure which can be sealed depends on the

mounting conditions and may possibly be lower.

3.5.1.1 Steel pockets

Materials Tube: St 35.8 I

Weld-in nipple: 16 Mo 3 (no turned groove)

Loading

Temperature Tube diameter

8 x 0.75 mm or

conical

max. permissible

pressure

100°C 89 bar 72 bar 48 bar

150°C 83 bar 67 bar 45 bar

200°C 78 bar 63 bar 42 bar

300°C 59 bar 47 bar 32 bar

400°C 46 bar 37 bar 25 bar

450°C 24 bar 19 bar 13 bar

With operating temperatures above 420°C, the permissible operating time is

limited to 200,000 hours. TRD 508 must be observed in this respect.

10 x 0.75 mm 15 x 0.75 mm

max. permissi-

ble pressure

max. permissi-

ble pressure

11

Page 12

3 Mounting

Permissible

incident flow

velocity

Temperature: +200°C

Thermal medium:

Tube diameter D:

Permissible incident flow velocity “v” at the maximum permissible

pressure loading and different immersion tube lengths “S”

air (1)

water, oil (2)

08mm

10 mm

15 mm

Permissible incident flow velocity “v” at the maximum permissible

pressure loading and different immersion tube temperatures “t”

12

Page 13

3.5.1.2 Stainless steel pocket

Materials Tube: X 6 CrNiMoTi 17122

Screw-in/weld-in nipple: X 6 CrNiMoTi 17122

Loading

Temperature Tube diameter

3 Mounting

100°C 92 bar 74 bar 50 bar

150°C 88 bar 71 bar 48 bar

200°C 83 bar 67 bar 45 bar

300°C 72 bar 58 bar 39 bar

400°C 67 bar 54 bar 36 bar

Permissible

incident flow

velocity

3.5.1.3 Brass pocket

Material CuZn (nickel-plated)

Loading

on request

Temperature Tube diameter

8 x 0.75 mm or

conical

max. permissible

pressure

10 x 0.75 mm 15 x 0.75 mm

max. permissi-

ble pressure

max. permissi-

ble pressure

Permissible

incident flow

velocity

100°C 50 bar 40 bar 27 bar

150°C 48 bar 39 bar 26 bar

on request

8 x 0.75 mm 10 x 0.75 mm 15 x 0.75 mm

max. permissible

pressure

max. permissi-

ble pressure

max. permissi-

ble pressure

13

Page 14

3 Mounting

( 1 )

( 2 )

3.5.2 Probe mountings 10, 15, 21, 60, 65

Materials Choice of steel, stainless steel or brass

Loading Only for use in unpressurized media.

Probe mounting 15 60, 65 10, 21

Maximum temperature +55°C +200°C

*

depending on the control range

3.6 Mounting the probe

The temperature probe (2) must be immersed in the medium for its entire

length, otherwise there will be appreciable deviations from the switching point.

In the case of probe mountings 20, 21 and 23, the temperature probe is

secured in the pocket by a clamping clip (1).

*

+500°C

*

14

Page 15

4.1 Regulations and notes

In case of electrical connections in a potentially explosive area, it is necessary

to comply with the relevant specifications.

■ The electrical connection must only be carried out by qualified personnel.

■ The choice of cable, the installation and the electrical connection must

conform to the requirements of VDE 0100 “Regulations on the Installation

of Power Circuits with Nominal Voltages below 1000 V” or the appropriate

local regulations.

■ If contact with live parts is possible while working on the instrument, it must

be completely disconnected from the electrical supply.

■ Earth the instrument at the PE terminal to the protective earth conductor.

This cable must have at least the same cross-section as used for the supply

cables. Earthing cables must be wired in a star configuration to a common

earth point that is connected to the protective earth conductor of the

electrical supply. Do not loop earthing cables, i.e. do not run them from one

instrument to another.

4 Installation

■ Apart from faulty installation, incorrect settings on the thermostat can also

affect the proper functioning of the subsequent process or lead to damage.

Setting up must therefore be restricted to qualified personnel. Please

observe the relevant safety regulations for such matters.

15

Page 16

4 Installation

2

4L12

4

1

PE N

12

4

42

L1

N

N

PE

PE

*

1

42

142

(2)

NPE

1

4

2

4L12

4.2 Electrical connection

✱ Open the housing.

➩ "Opening the surface-mounting thermostat", page 9

✱ Pass the connection cable (cable diameter 6 to 12 mm) through the Ex

cable compression gland (1).

➩ "Dimensions", page 8

✱ Make the connection to the terminals (2) in accordance with the connection

diagram.

✱ Fitting type X (no special tools).

✱ The connecting cable must have a fixed installation

✱ Connect the protective earth conductor to the PE terminal.

✱ Position the connecting cable in the housing and tighten the Ex cable com-

pression gland (1), using the tightening torque given below:

➩ "Dimensions", page 8.

Screw-in thread (1.1) into housing = 3.75 Nm

Compression screw (1.2). = 3.50 Nm for 06 mm cable diameter

Compression screw (1.2). = 2.50 Nm for 12 mm cable diameter

Ensure that connection line for operating temperatures up to -50°C

are low-temperature resistant.

4.3 Connection diagrams

TW / STW

TB / STB

16

Page 17

5.1 Limit setting

05

05

°C

( 1 )

5.1.1 TW, STW, TB (code 7)

✱ Open the housing.

➩ "Opening the surface-mounting thermostat", page 9

✱ Set the limit on the setpoint spindle (1).

5 Settings

5.1.2 STB (code 70)

Setting the limit

according to

the scale

Important note for setup and operation!

When the thermostat is used as a safety device for explosion protection in

accordance with EU Directive 94/9/EC Annex II Sec. 1.5, a functional test is

required that conforms to the applicable regulations.

The switching point must be fixed by the installation engineer after thermally

testing individual items, and secured against alteration. Several aspects

must be observed:

- the probe geometry and thermal coupling

- the maximum ambient temperature

- the maximum product temperature

✱ Open the housing.

➩ "Opening the surface-mounting thermostat", page 9

✱ Set the limit on the setpoint spindle (1) against the internal scale.

✱ Secure this setting by sealing the setpoint spindle ( 1 ), for instance with

“red” thread sealing wax, temperature resistant to at least +80°C)

17

Page 18

5 Settings

(A)

(1)

(1)

(2)

Setting the limits according to

specific system

characteristic

✱ Open the housing. ➩ "Opening the surface-mounting thermostat", page 9

✱ Warm up the temperature probe – in the system – to the intended limit

temperature (allow at least 5 minutes for the temperature to equalize), while

using a calibrated reference measuring device to measure and observe the

precise temperature at the temperature probe.

✱ Determine the required switching position (circuit 1-4 opens and circuit 1-2

closes) by rotating the setpoint spindle ( 1 ) from the end of the scale in the

direction of the start of the scale.

✱ Secure this setting by sealing the setpoint spindle ( 1 ), for instance with

“red” thread sealing wax, temperature resistant to at least +80°C.

A = secure the limit setting by sealing the setpoint spindle

with “red” thread sealing wax.

( 2 ) reset arm

5.1.3 TB, STB (code 7-F or 70-F)

Important note for setup and operation!

When the thermostat is used as a safety device for explosion protection in

accordance with EU Directive 94/9/EC Annex II Sec. 1.5, a functional test is

required that conforms to the applicable regulations.

In addition, suitable measures (such as calculation, thermal testing of

individual items) must be used to document that the switching point set by the

manufacturer prevents the temperature exceeding the given limit. The specific

local and operating conditions must be taken into account, such as:

- the probe geometry and thermal coupling

- the maximum ambient temperature

- the maximum product temperature

- The limit setting is fixed at the factory.

- Alteration is not permitted.

18

Page 19

5.2 Resetting the TB or STB limiter

If the temperature at the probe goes above the limit that has been set, the

electrical circuit 1-4 is opened and remains mechanically locked out. When the

critical temperature has fallen to about 9-15% below the set limit, the TB or

STB can be reset manually.

✱ Open the housing.

➩ "Opening the surface-mounting thermostat", page 9

✱ Press the reset arm ( 2 ) in the direction of the arrow.

➩ "( 2 ) reset arm", page 18

5.3 Self-monitoring (fail-safe)

5.3.1 Response to a fracture of the measuring system

On the STW or STB, in the event of a fracture of the measuring system (leakage)

the circuit 1-4 will remain permanently open.

On the STB, the microswitch is also mechanically and permanently locked out.

5 Settings

5.3.2 Response to low temperature

If the probe temperature of approx. -30°C (-60°C for the TZ 679) of the STW

and STB is gone below, the power circuit is opened.

When the temperature rises above the minimum probe temperature, the STW

resets itself automatically. The STB requires a manual reset.

➩ "Resetting the TB or STB limiter", page 19

19

Page 20

6 Instrument description

6.1 Technical data

Ex

marking

Explosion

protection

Explosion

protection type

II 2G Ex ed IIC T5 bzw. T6

for potentially explosive gas atmospheres

II 2D Ex tD A21 IP65 T95°C bzw. T80°C

for potentially explosive dust atmospheres

II 2G Equipment group II, Category 2,

equipment for potentially explosive gas atmospheres

II 2D Equipment group II, Category 2,

equipment for potentially explosive dust atmospheres

Ex General requirements

European Standard EN 60079-0

e Increased safety

European Standard EN 60079-7

d Flameproof enclosure

European Standard EN 60079-1

IIC Gas group

T5 or T6 Temperature class

Te st

certificate

Application in combustible dusts

European Standard EN 61241-0

EN 61241-1

IP65 Protection to EN 60529-IP65

T95°C or T80°C max. permissible surface temperature

(application in combustible dusts)

PTB 03 ATEX 1187

20

Page 21

Permissible

ambient temperature in

operation

Permissible

probe temperature

6 Instrument description

Capillary

°C

max. +40 +40

+55 +55

min. -20 (-50 et TZ 679)

Max operating temperature of the cable screw-connection for the TZ 679:

70°C.

max. limit +15% (+550°C with limit > 450°C)

Thermostat head °C

T6 T5

Permissible storage

temperature

Connecting

cable

Switching differential

in % of control/

limit range

Contact rating

max. +50°C, min. -20°C

max. +50°C, min. -50°C et TZ 679

diameter 6 to 12 mm, conductor cross-section up to 2.5 mm

Thermostats with end of scale

350°C

Switching

action

TW 3 3-5 TW 5 5-9

STW 5 5-7 STW 6 6-11

TB / STB – – – – TB / STB – – – –

Terminals 1-4 (break) Terminals 1-2 (make)

AC1: 230 V +10%, 10 A AC1: 230 V +10%, 5 A

AC15: 230 V +10%, 2 A AC15: 230 V +10%, 0.8 A

Nominal

value

Possible

actual

value

TW, STW

DC1: 230 V +10%, 0.25 A

Thermostats with end of scale

350°C

Switching

action

Nominal

2

Possible

value

actual

value

Terminals 1-4 (break) Terminals 1-2 (make)

AC1: 230 V +10%, 16 A AC1: 230 V +10%, 10 A

AC15: 230 V +10%, 2 A AC15: 230 V +10%, 1.5 A

Fusing required see contact rating

TB, STB

DC1: 230 V +10%, 0.25 A

21

Page 22

6 Instrument description

Enclosure protection

Operating

medium

Time constant

t

0.632

Mode of operation

Operating position (NL)

EN 60 529 - IP 65

Water, oil, air, superheated steam

in water in oil in air / superheated

steam

45 s 60 s 120 s

according to EN 60 730-1

TW,TB: Type 2BL = automatic action with micro-disconnection in

operation, no auxiliary supply required.

STW: Type 2BKL = automatic action with micro-disconnection in

operation, fail-safe.

STB: Type 2BFKL = automatic action with micro-disconnection in

operation, fail-safe, reset only permissible by means of a tool.

To DIN 16257, NL 0 — NL 90 (other NL on request)

Weight approx. 1.2 kg

Capillary and

probe material

Min. bending

radius of the

capillary

End of scale Capillary Probe

up to +200°C copper, Mat. Ref. 2.0090

up to +300°C copper, Mat. Ref. 2.0090

up to +500°C stainless steel,

up to +300°C stainless steel,

5mm

electro-tinned

1.5 mm diameter

electro-tinned

1.5 mm diameter

Mat. Ref. 1.4571

1.5 mm diameter

Mat. Ref. 1.4571

1.5 mm diameter

copper, Mat. Ref. 2.0090

electro-tinned

brazed

stainless steel,

Mat. Ref. 1.4571

brazed

stainless steel,

Mat. Ref. 1.4571

welded

stainless steel,

Mat. Ref. 1.4571

welded

22

Page 23

6 Instrument description

Switching point

accuracy

Mean ambient

temperature

effect

in % of scale span, referred to the limit value at Ta +22°C.

in upper third of scale

TW, TB

at start of scale

in upper third of scale

STW, STB

at start of scale

in % of scale span, referred to the limit value.

A deviation of the ambient temperature at the thermostat head and/or the cap-

illary from the +22°C calibration ambient temperature produces a shift in the

switching point:

higher ambient temperature = lower switching point

lower ambient temperature = higher switching point

Surface-mounting thermostats with end of scale

< +200°C +200°C +350°C > 350°C

TW

TB

STW

STB

TW

TB

+0

-4

+0

-6

+0

-5

+0

-7

%

%

%

%

STW

STB

TW

TB

STW

STB

effect due to the thermostat head, % per °C

0.08%/K 0.17%/K 0.06%/K 0.13%/K 0.14%/K 0.12%/K

effect due to capillary, % per °C per meter

0.047%/K 0.054%/K 0.09%/K 0.11%/K 0.04%/K 0.03%/K

23

Page 24

7 Appendix

24

Page 25

7 Appendix

25

Page 26

7 Appendix

26

Page 27

7 Appendix

27

Page 28

7 Appendix

28

Page 29

7 Appendix

29

Page 30

7 Appendix

30

Page 31

Page 32

JUMO GmbH & Co. KG

Street address:

Moritz-Juchheim-Straße 1

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

e-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2TT, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

e-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

8 Technology Boulevard

Canastota, NY 13032, USA

Phone: 315-697-5866

1-800-554-JUMO

Fax: 315-697-5867

e-mail:

Internet: www.jumo.us

info@jumo.us

Loading...

Loading...