Page 1

( 2 )

( 1 )

( 3 )

( 4 )

( 6 )

( 5 )

( 1 ) ( 1 )

( 1 ) ( 1 )

( 2 ) ( 3 )

➞

➞

( A )

80

Ø

D

S

G

25

100

100

( A )

80

25

100

100

S

D

Ø 90

Ø91

Ø 30

( A )

100

100

80

66

86

Ø 8

Ø 5

d

L

15

25

( A )

100

100

80

66

86

Ø 8

Ø 5

15

25

L1

G

D

S

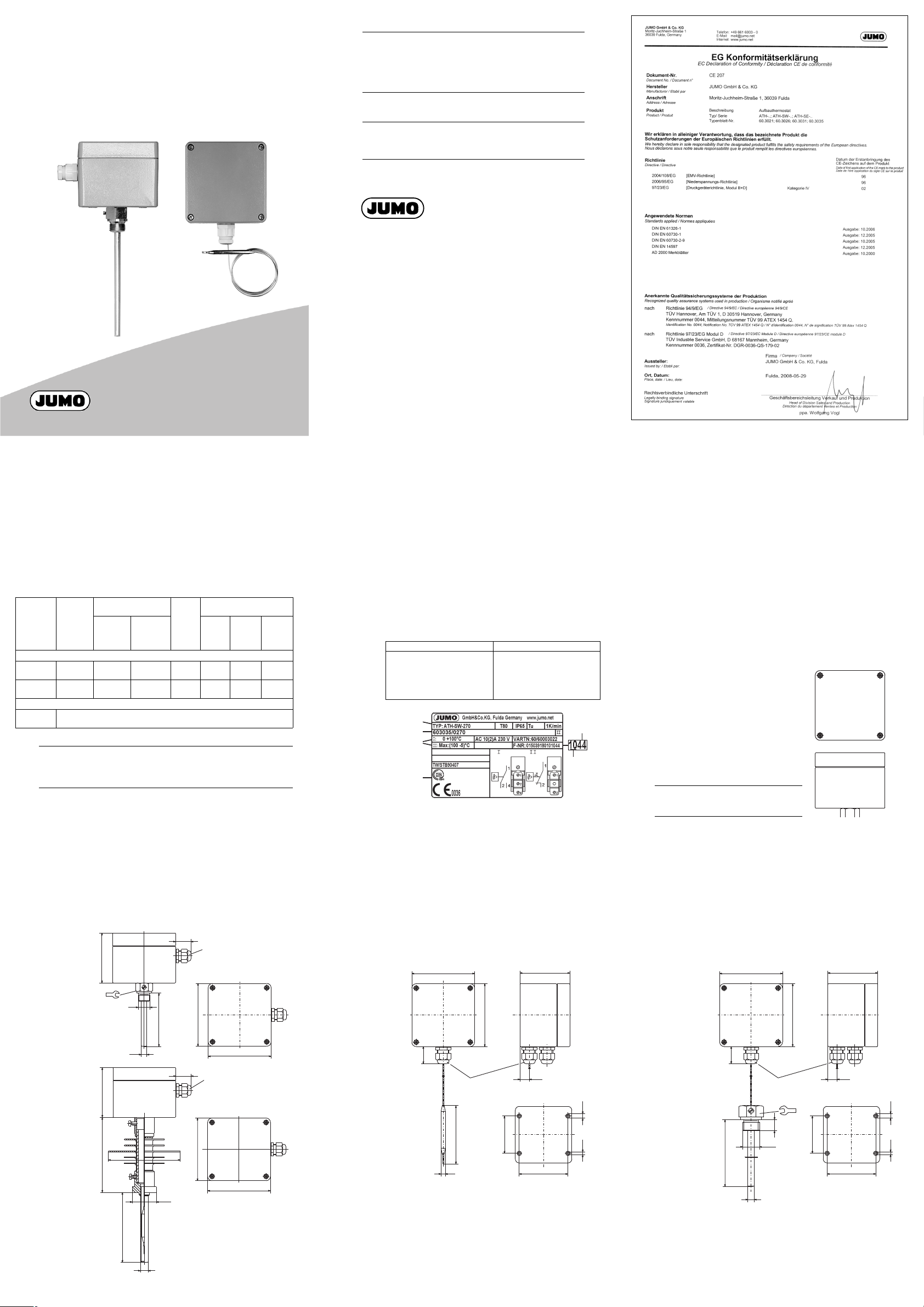

Surface-mounting Thermostats

Series ATH.-SW-...

Please read these operating instructions before commissioning the

instrument. Keep these operating instructions in a place which is

H

accessible to all users at all times. Please assist us to improve these

operating instructions, where necessary. Your comments will be

appreciated.

Phone+49 661 6003-0

Fax+49 661 6003-607

If any difficulties should arise during starting up, please refrain from

any unauthorized manipulations or actions. The warranty will

H

become null and void! Please contact the supplier or the head office.

The instruments are maintenance-free. In the event of malfunction,

please return the instrument to the supplier, with precise details of

H

the fault. The staff at our field offices, branches and agencies are

always available to provide service and advice.

ATH s-S W-. .

ATHf-SW-..

B 603035.0

Operating Instructions

2012-06-18/00408320

1. Introduction / Application

ATH-SW series surface-mounting thermostats are approved as:

■

temperature monitors (TW)

■

safety temperature limiters (STB)

■

safety temperature monitors STW (STB)

■

Type examination to:

- DIN EN 14597

- Pressure Equipment Directive 97/23/EC (all types, apart from ATH.-SW-2 and

ATH .- SW -2 2)

Safety notes

Physical and toxicological properties of substances which may escape, should the

system fracture:

End of

scale

≥

+200°C

<+200

≥

+200°C

≤

+350°C

≥

+400°C

≤

+500°C

H

Danger-

ous

reactions

no +355°C 0.6 - 8 yes yes

°

C

no +490°C- - yesyes

1

Should the measuring system fracture, the fill fluid may escape. At present,

there is no restrictive statement from the health authorities concerning danger

to health in the event of short-term exposure at low concentration, for

example, should the measuring system fracture.

Fire /

explosion hazard

Ignition

tempera-

ture

°C

Explosion

liquid-filled

limit

% v/v

gas-filled

Water

conta-

mina-

no

tion

irritant

To xi c ol o gy

danger

to health

1

1

toxic

no

no

JUMO GmbH & Co. KG

Street address:

Moritz-Juchheim-Straße 1, 36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14, 36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

e-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd. JUMO House

Temple Bank, Riverway, Harlow, Essex CM 20 2 TT, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

e-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

8 Technology Boulevard, Canastota, NY 13032, USA

Phone: 315-697-5866

Fax: 315-697-5867

e-mail: info@jumo.us

Internet: www.jumo.us

1-800-554-JUMO

2. Instrument identification / type

declaration

Type designation

ATH . -S W /

ATH Surface-mounting thermostat with microswitch

s with screw-in pocket, attached to housing (rigid stem)

f with capillary

-SW dustproof and jet-proof housing

-20 temperature monitor (TW) with changeover contact

-20 safety temperature monitor STW (STB),

-70 safety temperature limiter (STB),

Typ es

Nameplate

(prime example)

("20" or "30" pockets)

made from diecast aluminum, IP65 protection

with changeover contact

with break contact and lock-out

/au gold-plated snap-action switch contact

Single thermostats Twin thermostats

AT H. -S W- 2

AT H. -S W- 20

AT H. -S W- 70

ATH .- SW -2 2

ATH .- SW -2 20

ATH .- SW -2 70

ATH.-SW-2020

ATH.-SW-2070

ATH.-SW-7070

3. Mounting / General information

Capillary / temperature probe / pocket

General information

■

If the capillary of the surface-mounting thermostat is cut through or becomes

kinked, this could result in permanent device failure!

■

The minimum bending radius allowed for the capillary is 5 mm.

■

JUMO pockets must be used when installing the temperature probe, if the approval

for the surface-mounting thermostat is to remain valid.

■

The temperature probe must be fully immersed in the measurement medium.

■

When air is the measurement medium, you must choose a process connection

without a pocket.

■

To ensure the general accuracy of the operating value, the instruments must only

be used with the pockets supplied on delivery (diameter D = 8, 10 mm).

■

Only a probe of diameter d = 8 mm may be used in pockets of D = 10 mm.

■

Multiple assignments of pockets are only allowed with 2 or 3 cylindrical probes of

Ø 6 mm and pockets of 15 x 0.75 mm.

■

If two probes are assigned, the spring clip provided on delivery must be installed in

the pocket.

■

With pockets 22, 32, 41, 42 and 45 made from St 35.8I/16Mo 3 materials, the

allowed operating period at operating temperatures above 420°C is limited to

200,000 hours. Compliance with TRD 508 is essential for applications in this range.

Fixing the surface-mounting

thermostat

Nom. position (NL)

to DIN 16 257,

NL 0 ... NL 90 (other NLs on request)

Opening the housing

1.

Loosen the 4 cover screws ( 1 )

2.

Remove the top of the housing ( 2 )

4. Dimensions

Thermostats with rigid stem ATHs-SW-..

Code s (rigid stem)

The housing spigot is secured in the enlarged open end of the pocket by a fixing

screw.

ATHs-SW-..,

with "20"

pocket

ATHs-SW-..,

with "32"pocket

( 1 ) Type / max. housing temperature / protection

( 2 ) Order code

( 3 ) Control range / contact rating / sales number/

serial number

( 4 ) Mark of approval / connection diagram

( 5 ) Week of production

( 6 ) Year of production

Thermostats with capillary ATHf-SW-..

Code "f" (with capillary)

Mounting bracket with 4 screws through the housing base,

capillary exit at side of housing

ATHf-SW-..,

with plain

"10" cylindrical

probe,

without

pocket

When re-assembling, make sure the seal is

H

properly seated ( 3 )!

Thermostats with capillary ATHf-SW-..

Code "f" (with capillary)

Mounting bracket with 4 screws through the housing base,

capillary exit at side of housing

ATH f-S W-. .,

with "20"

pocket

( A ) Threaded coupling M 20x1.5

Page 2

Permissible loading on the pocket

(1)

( 2 )

(1)

(3)

( 2 )

(4)

(5)

(A)

(B)

( 1 ) ( 1 )

( 1 ) ( 1 )

( 2 )

( 4 )

( 3 )

➞

➞

(B)

20, 21, 30, 32, 40, 42 and 45 pockets

The values below refer to the maximum loading on the probe mounting

concerned. The actual maximum sealable pressure depends on the mounting

A

conditions and may possibly be lower.

Steel pocket

Materials:

Tub e

:St 35.8 I

Screw-in nipple up to

Welding nipple

:

300°C: 1.0038

Steel

1.5415

Loading

Temperature Tube diameter "D"

100

°

C 89bar 72bar 48bar

°

C 83bar 67bar 45bar

150

°

C 78bar 63bar 42bar

200

°

C 59bar 47bar 32bar

300

°

C 50bar 40bar 27bar

350

8 x 0.75 mm

or conical

10 x 0.75 mm 15 x 0.75 mm

maximum permissible pressure

Permissible incident flow velocity

Temperature: +200

Heat carrier: air ( 1 ), water, oil ( 2 )

Tube diameter "D". 08mm

Permissible incident flow

velocity (m/sec)

at maximum permitted

pressure loading and

different immersion

tube lengths ( S ).

( 1 ) air

( 2 ) water, oil

( S ) immersion tube length

°

C

. . . . . . . . . . . . . .

10 mm

15 mm

The values below refer to the maximum loading on the probe mounting

concerned. The actual maximum sealable pressure depends on the mounting

A

conditions and may possibly be lower.

Immersion tube length

200 mm:

Temperature: +200

Heat carrier: air ( 1 ), water, oil ( 2 )

Tube diameter "D". 08mm

Permissible incident flow

velocity (m/sec)

at maximum permitted

pressure loading and

different immersion

tube temperatures ( t ).

( 1 ) air

( 2 ) water, oil

( t ) temperature

Material: steel

°

C

. . . . . . . . . . . . . .

10 mm

15 mm

Pocket

Stainless steel

Temperature Tube diameter "D"

100

°

150

°

200

°

300

°

400

°

Brass

Temperature Tube diameter "D"

100

°

150

°

Tube and nipple: X 6 CrNiMoTl 17 122

8x0.75mm

or conical

C92bar74bar50bar

C88bar71bar48bar

C83bar67bar45bar

C72bar58bar39bar

C67bar54bar36bar

Tube and nipple: CuZn

8 x 0.75 mm 10 x 0.75 mm 15 x 0.75 mm

C50bar40bar27bar

C48bar39bar26bar

- permissible incident flow velocity: on request -

10 x 0.75 mm 15 x 0.75 mm

maximum permissible pressure

maximum permissible pressure

Probe mountings 50, 52 and 54

(probe in direct contact with medium)

Copper

(CuZn)

200°C 300°C 400°C

Probe material Ø mm Device function

Cu-DHP 04 06bar 2bar

1.4571; St 35 04 - 10 10 bar 2 bar

Process connections

media.

10, 15, 21, 31, 60 and 65

Nipple material

Steel

(St)

Max. temperature

TW STB, STW (STB)

05 05bar

06 04bar

07 03bar

08 03bar

09 03bar

10 03bar

must only be used in unpressurized

Stainless steel

Mounting the probe

The temperature probe ( 2 ) must be fully immersed in the medium,

H

otherwise there will be appreciable variations in the switching point.

(1) Clamp

2

) Temperature probe

(

(3) Capillary

(4) Pocket

(5) Spring clip

In the "20" and "22" probe

mountings of thermostats with

capillary, the temperature probe is

held in position by sliding a clamping

clip over the capillary and clamping it

with a screw in the enlarged open

end of the pocket.

With "50, 52, 54, 40, 41, 60 and 65"

probe mountings, the probe is held in

position by the fitting attached to the

capillary at the factory.

(CrNi)

Approved temperature probes, screw-connections and sheaths

Temperature probes

Screw-connections

Sheaths

see data sheet 606710

10 and 15

50, 52, 54, 60 and 65

20, 21, 22, 30, 31, 32, 40, 41, 42, 45 and 46

5. Installation

Regulations and notes

■

The electrical connection must only be carried out by qualified personnel.

V

■

The choice of cable, the installation and the electrical connection must

conform to the requirements of VDE 0100 “Regulations on the Installation of

Power Circuits with Nominal Voltages below 1000 V” and the appropriate

local regulations.

■

If contact with live parts is possible when working on the device, it must be

completely disconnected from the electrical supply.

■

Ground the instrument to the protective earth at the PE terminal. The cross-

section of this cable must be at least the same as that of the supply cables.

Wire the grounding conductors in a star configuration to a common earth

point that is connected to the PE conductor of the electrical supply. Do not

loop the grounding cables, that is, do not run them from one instrument to

another.

■

Apart from faulty installation, incorrect settings on the thermostat may also

adversely affect the proper functioning of the subsequent process or cause

other damage. It should only be possible for qualified personnel to make

these settings. Please observe the relevant safety regulations for such

matters.

Electrical connection

The instrument complies to Protection

H

Class

I

.

1.

Remove safety protection.

2.

Pass the connection cable

(cable diameter 5 to 10 mm)

through the compression gland

Screw connection up to 2.5 mm

conductor cross-section.

3.

Make the connection to the terminals

( 1, 2 and 4 ), as shown in the relevant

connection diagram.

4.

Connect the protective earth conductor

to terminal

"PE" .

5.

Replace the safety protection.

6.

The reset button

on the STB must be free to move.

(B)

(A)

2

Connection diagrams

Single thermostats

TW, STW (STB)

with changeover contact

Twin thermostat

I

andII:

Systems

with changeover contact

switching function: TW,

STW

.

Closing the housing

1.

Check that the plastic seal ( 3 )

in the housing base ( 2 )

is correctly seated.

2.

Place the top of the housing ( 2 )

onto the base ( 4 )

3.

Tighten the cover screws ( 1 ).

STB

with break contact and lock-out

System

I:

with changeover contact

switching function: TW,

STW

System

II:

with break contact and

lock-out switching

function: STB

Systems

with break contact and

lock-out

switching function: STB

I

and

II:

6. Setpoint and limit setting

TW, STW (STB) and STB

Open the housing

1.

2.

Use a screwdriver

to set the limit on the

setpoint adjuster ( 5 ).

3

. Close the housing

Resetting the STB

Once the temperature has fallen below the set limit (safe temperature limit) by about

10% of the scale range, the microswitch can be reset.

1.

Open the housing

2.

Press the reset button

until the microswitch is

reset.

3.

Close the housing

Self-monitoring

Response to a fracture of the measuring system

With the STB and STW (STB), a fracture of the measuring system (leaking)

causes the circuit to stay open permanently. With the STB, the microswitch is

H

also locked.

Response to low temperature

H

Using the STW (STB) as an STB

V

With the STW (STB) and STB, if the probe temperature falls below the

minimum value of -20°C, the circuit opens. Once the probe temperature has

risen above the minimum value, the STB must be reset manually .

With the STW, reset is automatic.

The required lock-out facility must be ensured by the subsequent circuit. This

circuit must comply with VDE 0116.

(1) upper stop

( 2 ) setpoint pointer

( 3 ) lower stop

( 4 ) scale graduation

( 5 ) setpoint adjuster

(B)

The connection is suitable for fixed wiring. Cable entry is without fixed strain

H

relief. Attachment type "X" (no special tools).

Cu capillary tube with PE function

With CrNi capillary tubes it is the user's responsibility to provide the requisite

V

protective measures against electric shock.

7. Technical data

Mode of operation

STW (STB)

STB

Permissible ambient temperature in operation

max. +80

min. -40

Permissible probe temperature:

Permissible storage temperature:

Switching point accuracy:

to EN 60730-1, EN 60730-2-9 and EN 14597

TW

2BL

2BKLNP

2BFHKLNPV

Capillary Thermostat head At end of scale

°

C+80

°

C-40

-20

°

C-20

-40

°

C-40

TW: in the upper third of the scale ± 1.5 %,

STB, STW (STB): in the upper third of the scale +0/-5 %,

TW STW (STB), STB

°

C+80

°

C +80°C< 200

°

C +80°C

°

C +80°C> 350

max. end of scale +15%

max. 50°C, min. -50°C

Switching point accuracy

in % of the control / limit value range

at scale beginning ± 6 %

at scale beginning +0/-10 %

°

C

≥

200°C ≤ 350°C

°C ≤

°

C

500°C

Mean ambient temperature effect

as % of scale range, relative to limit value. If the ambient temperature at the

thermostat head housing and / or the capillary deviates from the calibration ambient

temperature value of +22

Higher ambient temperature = lower switching point

Lower ambient temperature = higher switching point

TW STB/STW (STB) TW STB/STW (STB)

0.08% per °C 0.17% per °C 0.06% per °C 0.13% per °C

0.047 % per °C 0.054 % per °C 0.09 % per °C 0.11 % per °C

0.14% per °C 0.12% per °C

0.04 % per °C 0.03 % per °C

Maximum permissible contact rating

230 V AC +10%, 10(2) A, cos

230 V DC +10%, 0.25 A or

230 V AC +10%, 6(1.2) A, cos

for gold-plated microswitch, code /au

24 V AC/DC, 0.1 A

Contact reliability

To ensure maximum switching reliability, we recommend a minimum loading of:

24 V AC/DC, 20 mA for silver contacts (standard)

10 V AC/DC, 10 mA for gold-plated contacts (code /au)

Rated surge voltage

Overvoltage category II

Operating medium

Time constant t

Enclosure protection

°

C in, this shifts the switching point.

Surface-mounting thermostats with end of scale

< +200

°

C

Effect on the thermostat head

Effect on capillary per meter

Surface-mounting thermostats with end of scale

TW STB/STW (STB)

0.632

≥

+350°C ≤ +500°C

Effect on the thermostat head

Effect on capillary per meter

(additional info to details on nameplate)

ϕ

= 1(0.6)

ϕ

= 1(0.6)

2500 V

For required fusing, see maximum switching current

Wa t e r, o i l , a i r, super h e a t e d s t e a m

in water in oil in air / superheated

≤

45 s

EN 60 529 - IP 65, use under normal conditions

≥

+200°C ≤ +350°C

≤

60 s

steam

≤

120 s

Loading...

Loading...