Page 1

Series ATH.-SE-..

Surface-mounting thermostats

B 603031.0

Operating Instructions

2013-04-15/00073788

Page 2

Please read these Operating Instructions before commissioning the instrument.

Keep the operating instructions in a place which is accessible to all users at all

times. Please assist us to improve these operating instructions. Your suggestions will be welcome.

Phone +49 661 6003-0

Fax +49 661 6003-607

All necessary settings and, where appropriate, alterations inside the instrument

are described in these operating instructions. If, however, any difficulties should

arise during commissioning, you are asked not to carry out any unauthorized

manipulations on the unit. You could endanger your rights under the instrument

warranty! Please contact the nearest subsidiary or the main factory in such a

case.

Page 3

Contents

Page

1 Introduction ............................................................................... 5

1.1 Typographical conventions ...................................................................... 5

1.1.1 Warning signs .............................................................................................. 5

1.1.2 Note signs ................................................................................................... 5

1.2 Application ................................................................................................. 6

1.3 Marking ...................................................................................................... 6

1.4 Safety notes ............................................................................................... 6

2 Instrument identification .......................................................... 7

2.1 Nameplate (example) ................................................................................ 7

2.2 Type designation ....................................................................................... 7

3 Mounting .................................................................................... 8

3.1 Dimensions ................................................................................................ 8

3.2 Opening the case .................................................................................... 10

3.3 Fixing the surface-mounting thermostat .............................................. 10

3.3.1 Code s (rigid stem) .................................................................................... 10

3.3.2 Code f (with capillary) ................................................................................ 10

3.4 Capillary / temperature probe / sheath ................................................. 11

3.4.1 General ...................................................................................................... 11

3.4.2 Approved process connections ................................................................ 11

3.5 Permissible pressure at the sheath ....................................................... 12

3.5.1 Sheaths 20 and 30 .................................................................................... 12

3.6 Mounting the probe ................................................................................. 13

4 Installation ............................................................................... 14

4.1 Regulations and notes ............................................................................ 14

4.2 Electrical connection .............................................................................. 15

4.2.1 Closing the case ....................................................................................... 16

Page 4

Contents

Page

5 Settings .................................................................................... 18

5.1 Setting the limit value ............................................................................. 18

5.2 Resetting the STB ................................................................................... 19

5.3 Self-monitoring ........................................................................................ 19

5.3.1 Behaviour in the event of a measuring system breakage ......................... 19

5.3.2 Response to low temperature ................................................................... 19

5.4 Using the STW(STB) as STB ................................................................... 19

6 Instrument description ........................................................... 20

6.1 Technical data ......................................................................................... 20

Page 5

1.1 Typographical conventions

1.1.1 Warning signs

1 Introduction

V

Danger

This symbol is used where there may be danger to personnel if the instructions are disregarded or not followed accurately.

Caution

A

1.1.2 Note signs

H

v

1

abc

This symbol is used where there may be damage to equipment if the instructions are disregarded or not followed accurately.

Note

This symbol is used to draw your special attention to a remark.

Reference

This symbol refers to additional information in other chapters or sections.

Footnote

Footnotes are comments which refer to specific parts of the text. Footnotes

consist of two parts:

1) The marking in the text, arranged as continuous superscript numbers.

2) The footnote text, at the bottom of the page and preceded by a superscript

number.

✱ Action

This symbol marks the description of a required action.

The individual steps are indicated by an asterisk, e.g.

✱ Select setpoint

5

Page 6

1 Introduction

1.2 Application

Surface-mounting thermostats Series ATH.-SE-.. are approved for monitoring

installations on steel-hulled ocean-going ships (e.g. steam and boiler plant,

indirect heating systems) as:

❏ Temperature monitor (TW)

❏ Safety temperature monitor STW (STB)

❏ Safety temperature limiter (STB).

The versions comply with DIN EN 14597 and are approved as per the guidelines of the Classification Societies:

- Germanischer Lloyd

- Det Norske Veritas

- Bureau Veritas

- Pressure Equipment Directive 97/23/EC CE0036

(ATH.-SE-20 and ATH.-SE-70 only)

Cutting through or kinking the capillary of the surface-mounting thermostats

A

Type ATH.-SE-.. will lead to permanent failure of the instrument!

1.3 Marking

H

Surface-mounting thermostats Type ATH.-SE-.. are approved as per DIN EN 607302-9.

1.4 Safety notes

In the event of a measuring system breakage, the filling liquid can escape.

H

There is currently no statement by the health authority concerning hazards to

health in the event of short-term exposure and low concentration, e.g. in the

event of a measuring system break.

Physical and toxicological properties of substances which may escape in the

event of a system break:

End of scale Dangerous

reaction

below +200 °C no +355 °C 0.6 - 8 yes yes yes no

+200 °C to +300 °C

6

no +490 °C - - yes yes yes no

Fire/explosion hazard Water

Ignition

temperature

°C

Explosion

limit

% v/v

contami-

nation

Toxicological data

irritant danger to

health

toxic

Page 7

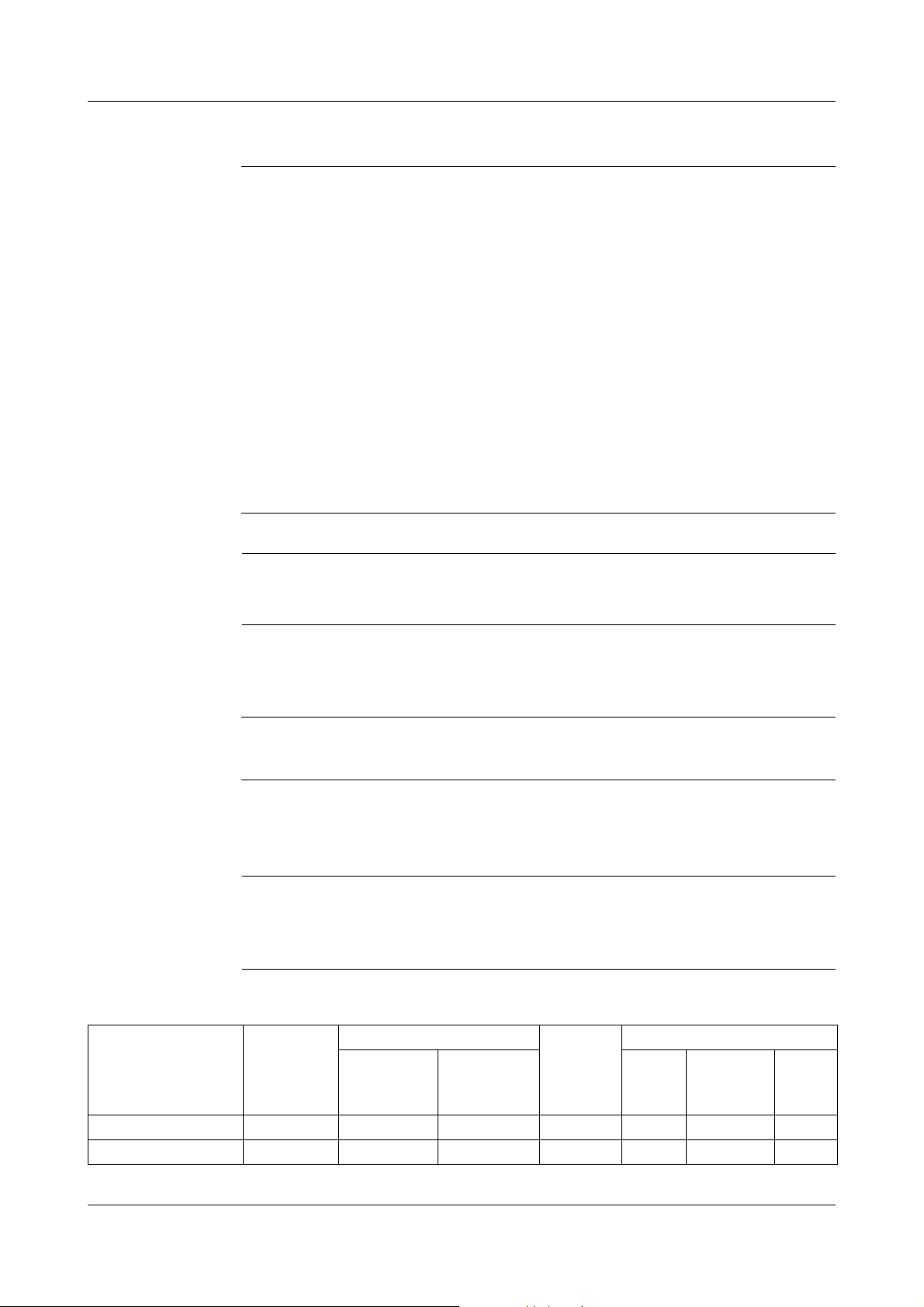

2.1 Nameplate (example)

( 1 )

( 2 )

( 3 )

( 4 )

( 6 )

( 2 )

( 1 )

( 5 )

( 7 )

1315

on the case bottom section:

(1) Type code (see type designation, below)

(2) Control range / contact rating

(3) Approval mark

on the thermostat case (inner section):

2 Instrument identification

( 1 ) Type

( 2 ) Type code

( 4 ) Fabrication number

( 5 ) Year of manufacture

( 6 ) Week of manufacture

( 7 ) Connection diagram

2.2 Type designation

Type code

Basic type

603031 ATH.-SE surface-mounted thermostat with microswitch

Basic type extension

02 ATH.-SE-2 Temperature monitor TW with changeover contact

20 ATH.-SE-20 Safety temperature monitor STW (STB),

70 ATH.-SE-70 Safety temperature limiter STB,

with changeover contact

with N/C contact

Design

1ATHs-SE-.. with rigid shaft

2ATHf-SE-.. with capillary

7

Page 8

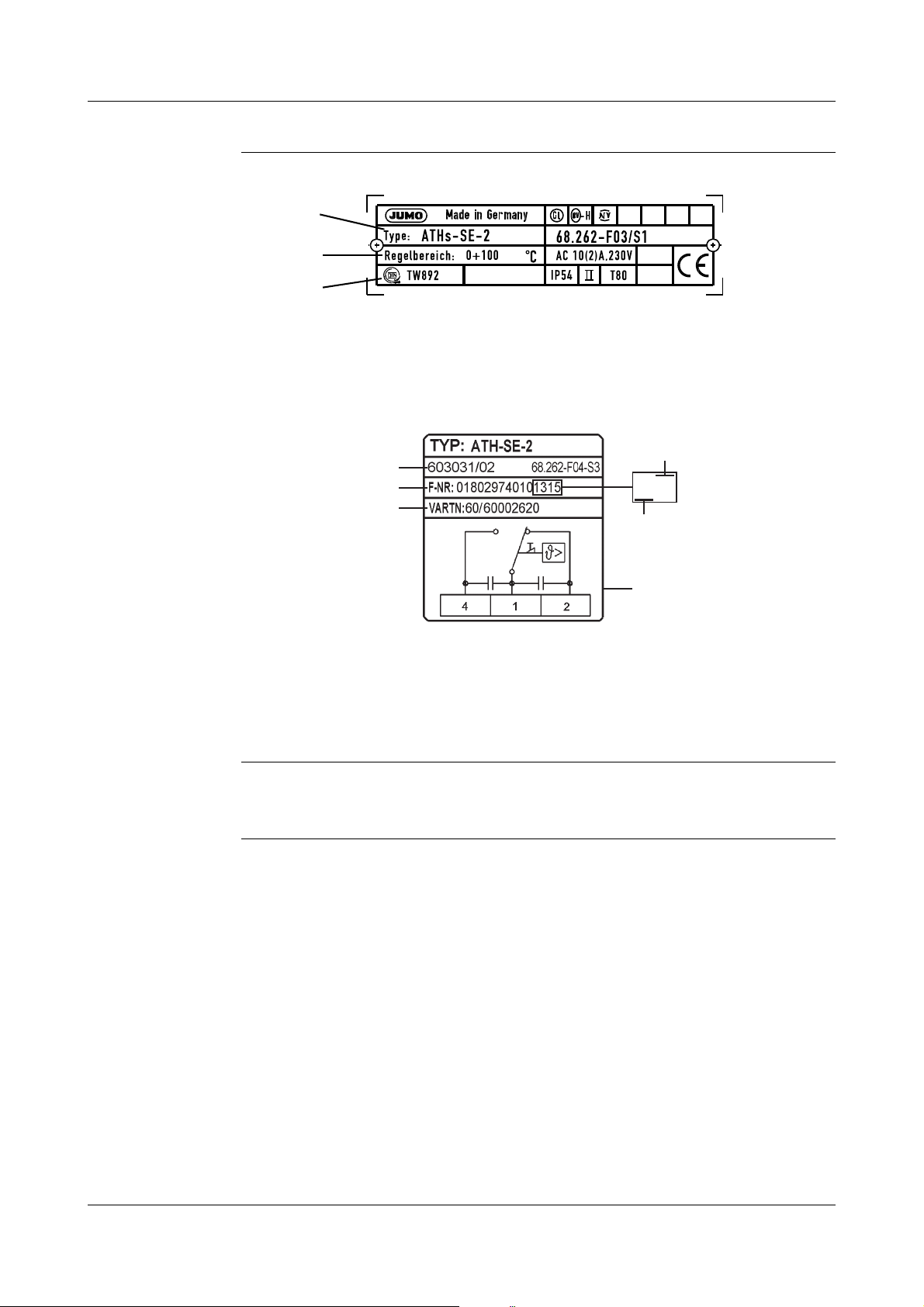

3 Mounting

K M24x1,5

M 20x1,5

DIN 89280-Z14

27

70

66

G1/2

33

14

Ø 26

S = max. 200 (150)

67

94

3.1 Dimensions

ATHs-S E-2,

ATHs-SE-20

with

sheath "20"

(up to +150 °C)

8

Page 9

ATHs-SE-2 (20)

K M24x1,5

M 20x1,5

DIN 89280-Z14

70

66

G 1/2

Ø 26

S = max. 200 (150)

Ø 90

~85

14

27

Ø

K M24x1,5

M 20x1,5

DIN 89280-Z14

70

12

66

G1/2

14

G1/2

Ø 26

S = max. 200 (150)

33

67

94

24

27

Ø

with

sheath "30"

(up to +300 °C)

3 Mounting

ATHf-S E -70 ,

with

sheath "20"

(up to +300 °C)

9

Page 10

3 Mounting

( 1 )

( 5 )

( 5 )

3.2 Opening the case

Opening

V

✱ Unscrew the two lead-sealable cheese-head screws ( 5 )

✱ Remove the upper part of the case ( 1 )

Ensure that the gasket is seated correctly when reassembling!

3.3 Fixing the surface-mounting thermostat

Operating

position

3.3.1 Code s (rigid stem)

3.3.2 Code f (with capillary)

unrestricted

(for open-air mounting on request)

The case journal is secured in the enlarged open end of the sheath by two

fixing screws.

by ½" pipe thread on the case journal

10

Page 11

3.4 Capillary / temperature probe / sheath

3.4.1 General

Cutting through or kinking the capillary will lead to permanent failure of the

A

H

instrument!

Minimum permissible bending radius of the capillary is 5 mm.

The temperature probe must be fitted in a JUMO sheath, otherwise the

approval of the surface-mounting thermostat becomes invalid.

The temperature probe must be completely submerged in the medium.

In order to ensure the general accuracy of response, the instruments must only

be used with the sheaths supplied from the factory (diameter D = 8, 10 mm).

Only probes with a diameter d = 8 mm may be fitted in sheaths with a diameter

D = 10 mm.

When the operating medium is air, connection type "10" (without sheath) must

be selected.

3 Mounting

3.4.2 Approved process connections

Te mp er at ur e

probe

Sheaths 20, 30

H

10

refer todata sheet 606710 !

11

Page 12

3 Mounting

3.5 Permissible pressure at the sheath

3.5.1 Sheaths 20 and 30

The following values refer to the maximum pressure of the probe mounting

A

3.5.1.1 Stainless steel sheath

concerned. The maximum pressure which can be sealed depends on the

mounting conditions and may possibly be lower.

Material

Permitted flow

velocities

3.5.1.2 Sheath "20" made of brass

l

Tube and nipple material: X 6 CrNiMoTl 17 122

Temperature Tube diameter

100°C 92bar 74bar

150°C 88bar 71bar

200°C 83bar 67bar

300°C 72bar 58bar

on request

Temperature Tube diameter

8 x 0.75 mm or conical 10 x 0.75 mm

Max. permissible pressure Max. permissible pressure

Sheath "20" tube and nipple material: brass

8 x 0.75 mm 10 x 0.75 mm

Emitted flow

velocities

H

A

12

Max. permissible pressure Max. permissible pressure

100 °C 50 bar 40 bar

150 °C 48 bar 39 bar

on request

The plain cylindrical probe, Form 10 must only be used in pressureless

medium.

Due to the general accuracy of response, the instrument must only be used

with the factory-supplied sheaths.

Page 13

3.6 Mounting the probe

( 1 )

( 2 )

Submerge the sheath and the temperature probe (2) into the medium and

H

ensure that the temperature probe (2) is completely submerged in the medium

because otherwise, greater switching point deviations will occur.

For thermostats with longdistance line (abbreviation

"f"), the temperature probe

is fastened in the sheath by

means of the clamping

piece (1) for connection

types "20".

3 Mounting

13

Page 14

4.1 Regulations and notes

4 Installation

V

❏ The electrical connection must only be made by qualified personnel.

❏ The choice of cable, the installation and the electrical connection must

conform to the requirements of VDE 0100 “Regulations for the installation

of power circuits with nominal voltages below 1000 V”, or the appropriate

local regulations.

❏ If contact with live parts is possible while working on the unit, it must be

completely disconnected from the supply.

❏ Earth the instrument at the PE terminal to the protective conductor. This

cable must have a cross-section that is at least as large as the supply

cables. Earth cables must be run in a star configuration to a common earth

point which is connected to the protective earth of the supply. Do not loop

earth cables, i.e. do not run them from one instrument to another.

❏ Apart from faulty installation, incorrect settings on the thermostat can affect

the proper functioning of the following process or lead to damage. Setting

up must therefore be restricted to qualified personnel. Please observe the

appropriate safety regulations in this respect.

14

Page 15

4.2 Electrical connection

( 4 )

( 5 )

✱ Open the case.

➈ Section 3.2 “Opening the case”, page 10.

✱ Pass the connection cable (cable diameter 10 — 16,5 mm) through the

screw connection (3). Fitting type"X" (no special tools), screw connection

up to 2.5 mm

✱ Remove the protective cover ( 4 ).

✱ Establish the connection to the terminals ( 1 ) in accordance with the appro-

priate connection diagram.

✱ Connect the protective conductor to terminal PE ( 2 ).

✱ Refit the protective cover ( 4 ) and snap it onto the guide lug ( 5 ).

2

conductor cross-section.

4 Installation

15

Page 16

4 Installation

H

( 1 )

( 2 )

( 3 )

( 4 )

( 5 )

( 5 )

Connection

diagrams

TW / STW (STB) STB as N/C contact

4.2.1 Closing the case

✱ Make sure that the plastic gasket in the lower part of the case ( 2 ) is seated

correctly.

On thermostats with code -70, the external reset button ( 3 ) must be located

H

precisely on top of the internal reset button ( 4 ) for the microswitch, since this

is the only way the reset button ( 3 ) can be operated from the outside.

✱ Place the upper part of the case ( 1 ) onto the lower part ( 2 ).

with signal contact

STB

with (N/C) break contact

16

✱ Tighten the lead-sealable cheese-head screws ( 5 ).

Page 17

4 Installation

Cable relief ✱ Turn the screw connection ( 1 ) clockwise until the cable inlet is sealed and

the cable is secured against pulling out. The cable has to be protected

against vibration overload by leaving sufficient extra cable length ( 2 ).

✱ Close the case.

17

Page 18

5 Settings

(1) Top stop

( 2 ) Bottom stop

( 3 ) Set point indicator

( 4 ) Scale division

( 5 ) Set point setter

5.1 Setting the limit value

✱ Open the case.

➈ Section 3.2 “Opening the case”, page 10.

✱ Set the limit value on the set point setter ( 5 ) using a screwdriver.

18

Page 19

5.2 Resetting the STB

After the temperature has fallen below the set limit value (safe temperature

limit) by about 10% of the scale range, the microswitch can be reset.

Action

1. 2. 3.

5 Settings

✱ Unscrew the cap nut

(1).

✱ Press the reset but-

ton (2) until the micro

switch is reset.

✱ Screw the cap nut (1)

back on

5.3 Self-monitoring

5.3.1 Behaviour in the event of a measuring system breakage

On the STB and STW (STB), the circuit stays open permanently in the event of

H

5.3.2 Response to low temperature

H

a measuring system breakage (leakage).

On the STB, the microswitch is additionally locked.

If the probe temperature goes below the minimum value of -10 °C, the circuit is

opened.

After the minimum probe temperature is exceeded, the STB must be manually

reset.

➈ Section 5.2 “Resetting the STB”, page 19.

The TW and STW reset automatically.

5.4 Using the STW(STB) as STB

V

The restart lock as per DIN EN 14597 must be ensured by the subsequent circuit. This circuit must be in accordance with VDE 0116.

19

Page 20

6 Instrument description

6.1 Technical data

Permissible

ambient

temperature

in operation

maximum +80 °C +80 °C

minimum

Capillary Thermostat head with scale limit value

-40 °C -40 °C below +200°C

-20 °C -20 °C >

200 °C to < 350 °C

Permissible

overtemperature safety

Permissible

storage

temperature

Case Cover: aluminium die casting with screws for lead sealing

Connection

cable

Switching

differential

in % of

limit value

range

on the probe during use

max. scale end value +15%

maximum +50 °C, minimum -50 °C

Base: die-cast aluminium, painted

Diameter 10 — 16.5 mm, maximum conductor cross-section 2.5 mm

Code

nominal value possible actual value

S 1

S 2

S 3

only on types 2 and 20

3

6

1.5

2

3-4

6-8

1-2

Max.contact

rating

230 V, 10 (2) A AC, p.f. = 1 (0.6) 230 V, 0.25 A DC

Fusing required see contact rating

Protection IP54 as per EN 60 529, operation under normal conditions

Operating

medium

Time constants

t

0.632

Water, oil, air, superheated steam

in water in oil in air / superheated steam

<

45 sec. < 60 sec. < 120 sec.

TW, STW (STB) with hysteresis 3% and 6%

TW, STW (STB) with hysteresis 1.5%

230 V, 6 (1.2) A AC, p.f. = 1 (0.6)

20

Page 21

6 Instrument description

+0

-5

%

+0

-10

%

Operating

mode

as per EN 60 730-1

TW: Type 2BL = automatic mode

STB, STW (STB): Type 2BK = automatic mode

Operating position

unrestricted (with open-air mounting on request)

Weight approx. 0.65 kg

Capillary and

probe materials

End of scale Capillary Probe

up to +200 °C copper Mat. Ref. 2.0090

up to +300 °C copper Mat. Ref. 2.0090

up to +500 °C stainless steel,

with microswitch disconnection in operation,

which requires no auxiliary energy source.

with microswitch disconnection in operation,

with fail-safe facility.

tin-plated, 1.5 mm dia.

tin-plated, 1.5 mm dia.

1.5 mm dia.

copper Mat. Ref. 2.0090

tin-plated, brazed

stainless steel

Mat. Ref. 1.4571, brazed

stainless steel

Mat. Ref. 1.4571, welded

Minimum

bending radius

Switching point

accuracy

Mean ambient

temperature

influence

5mm

(in % of scale range;

in relation to the set point or limit value at +22 °C ambient temperature)

TW in upper third of scale

at start of scale

± 1.5%

± 1.5%

STB, STW (STB) in upper third of scale

at start of scale

(in % of scale range) in relation to the limit value

There is a displacement of the switching point if the ambient temperature at

the thermostat head and/or the capillary deviates from the +22 °C calibration

ambient temperature.

higher ambient temperature = lower switching point

lower ambient temperature = higher switching point

for temperatures with end of scale:

below +200 °C +200 °C to +350 °C

TW STB/STW (STB) TW STB/STW (STB)

influence on thermostat head, % per °C

0.08 0.17 0.06 0.13

influence on capillary, % per °C per m length

0.047 0.054 0.09 0.11

21

Page 22

Page 23

Page 24

JUMO GmbH & Co. KG JUMO Instrument Co. Ltd. JUMO Process Control, Inc.

Street address:

Moritz-Juchheim-Straße 1

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO House

Temple Bank, Riverway

Harlow - Essex CM20 2DY, UK

Phone: +44 1279 63 55 33

Fax: +44 1279 63 52 62

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Loading...

Loading...