Page 1

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Panel-mounted Thermostat

DGRL

97/23/EG

EM Series

Special features

• Safety temperature monitor STW (STB)

• Safety temperature limiter STB

• Tested according to DIN EN 14597 and the Pressure Equipment Directive 97/23/EC

Brief description

Panel-mounted thermostats are used to monitor thermal processes. The devices are available

as safety temperature monitor STW (STB) and safety temperature limiter STB. In the event of a

malfunction, the STB switches the monitored machine to a safe operating status.

Data Sheet 602026

Page 1/7

Panel-mounted thermostats operate according to the fluid expansion principle

is used as the electrical switching element.

− a microswitch

Switching function

Safety temperature monitor STW (STB)

If the temperature on the temperature probe exceeds the setpoint value, the microswitch is activated by the transmission mechanics and the electrical circuit is opened or closed. If the temperature falls below the selected setpoint (by the amount of the switching differential), the

microswitch is reset to its initial position.

Restart lock of the safety temperature limiter STB

If the temperature on the temperature probe exceeds the set limit value, the electrical circuit is

opened and the microswitch is mechanically locked. The microswitch can be manually unlocked once the temperature has dropped by approx. 10 °C.

Self-monitoring for the safety temperature limiter STB

and safety temperature monitor STW (STB)

If the measuring system is destroyed (i.e. if the expansion fluid leaks), the pressure in the diaphragm of the STB drops and permanently opens the electrical circuit. Unlocking is then no longer possible. When the probe has cooled down to a temperature below approx. -20 °C, the

electrical circuit is also opened. However, it automatically closes again when the temperature

rises.

Use of the safety temperature monitor STW

as a safety temperature limiter STB

The activation lock required by DIN EN 14597 must be warranted by the following circuit diagram. The circuit diagram must comply with DIN EN 50156.

Approvals/approval marks (see "Technical Data")

2013-03-06/00073209

Page 2

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

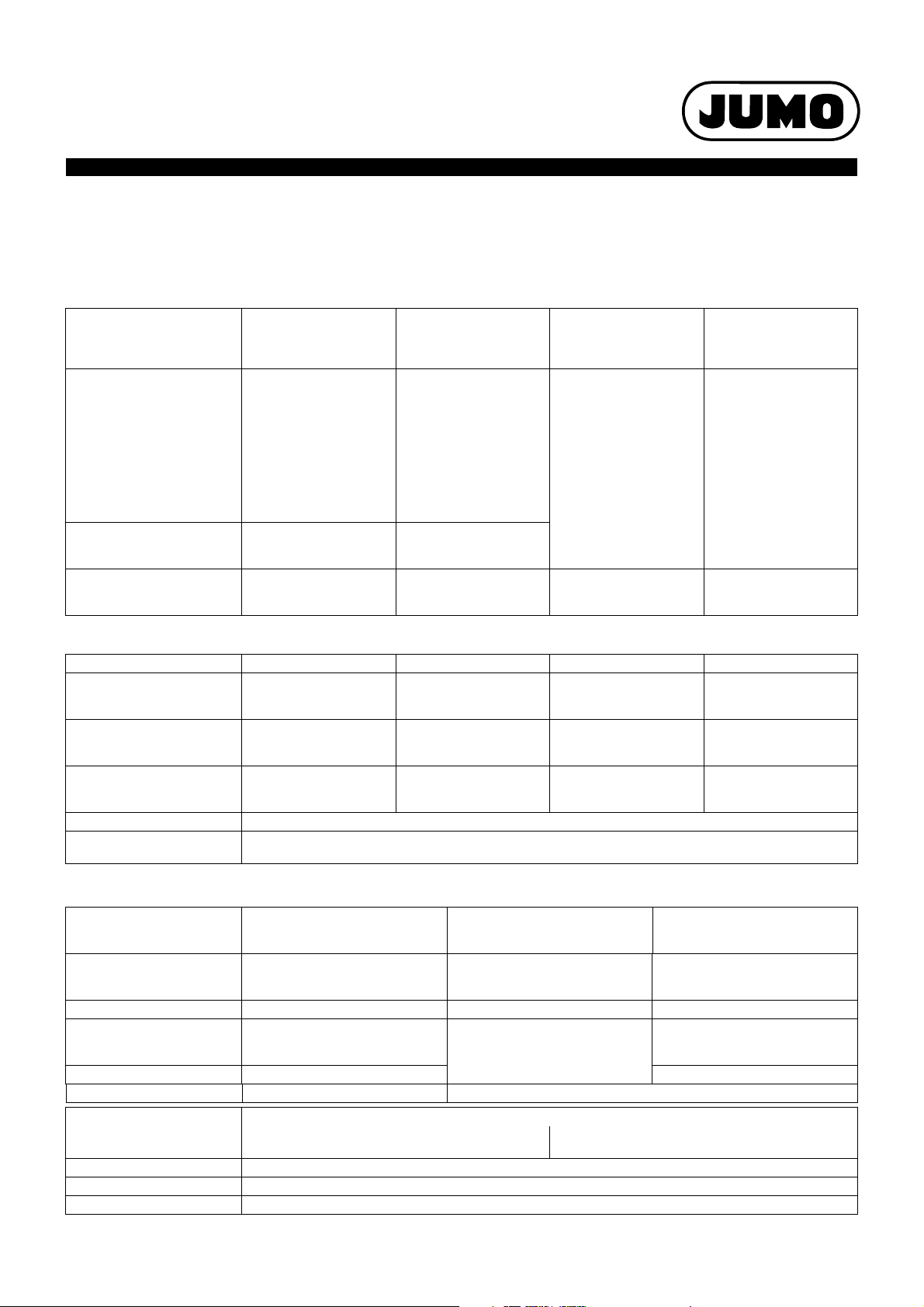

Technical data

General information

Limit value range, limit value range setting, and temperature probe

Type Limit value range

Limit value setting

°C

EM-20-E +40 to +110

+100 to +150

+110 to +170

+180 to +250

+230 to +300

Limit value setting done

prior to mounting with a

screwdriver at the limit

value knob.

EM-30-E Optional limit value

+20 to +300

Permanently factory-set

EM-80 Optional limit value

+60 to +180

Permanently factory-set

Max. allowable

probe temperature

Limit value

Limit value

°C

+135

+173

+195

+288

+345

+15 %

+15 %

Data Sheet 602026 Page 2/7

Limit value tolerance°CProbe length, dimen-

sion "L"

for probe Ø "d"= 6 mm

mm

+0/-9

+0/-8

+0/-9

+0/-13

+0/-14

72

85

72

60

60

+0/-5 84

Capillary and temperature probe

Type Scale limit value Capillary Temperature probe Notes

EM- . . Up to 200 °C Copper (Cu)

ø 1.5 mm

Material no. Cu-DHP

Up to 300 °C Copper (Cu)

ø 1.5 mm

Material no. Cu-DHP

Up to 300 °C Stainless steel (CrNi)

ø 1.5 mm

Copper (Cu)

Material No. Cu-DHP

Hard soldered

Stainless steel (CrNi)

Material No. 1.4571

Hard soldered

Stainless steel (CrNi)

Material no. 1.4571

- -

- -

Available at extra cost

welded

Capillary length Standard: 1000 mm, max. 5000 mm

Min. bending radius of the

capillary

5 mm

Electrical data

Switching element:

Single-pole snap-action

switch

Microswitch with changeover con-

Max. switching capacity Type N/C contact, terminal 2 N/O contact, terminal 4

Contact reliability To ensure a high switching reliability, we recommend a minimum load of:

Rating surge voltage 1500 V (via the switching contacts 400 V)

Overvoltage category I I

Required fuse rating See max. switching capacity

2013-03-06/00073209

Type EM-20-E

Type EM-30-E

Microswitch with N/C contact and

tact

Typ e EM - 80

Standard

restart lock

Typ e EM - 80

with extra code "574"

Microswitch with N/C contact, re-

start lock, and additional signal

contact

EM-20-E

EM-30-E

EM-80/U

AC 230 V +10 %,

10 (2) A, cos ϕ = 1 (0.6)

DC 230 V +10 %, 0.25A

AC 230 V +10 %,

2 (0.4) A, cos ϕ = 1 (0.6)

DC 230 V +10 %, 0.25A

EM-80 - -

Extra code "574" Microswitch with gold plating, AC / DC 24 V, 0.1 A

For silver contacts:

AC / DC = 24 V, 20 mA

For gold-plated contacts (extra code "702"):

AC/DC = 5V, 5mA

Page 3

Data Sheet 602026 Page 3/7

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Electrical connection Standard Tab connector A 6.3 x 0.8 DIN 46244

2

Extra code 699 Screw connection up to 2.5 mm

conductor cross section (available at

extra cost) — also suitable for retrofitting —

Switching differential in %

from the limit value range

Mid ambient temperature

influence

Switching function Rated value Possible actual value

STW (STB) 7 7-8

(In % from the scale range) referring to the limit value.

Deviation of the ambient temperature at the switching head and/or capillary from the +22 °C calibration ambient temperature produces a switching head offset.

Higher ambient temperature = lower switching point

Lower ambient temperature = higher switching point

For temperatures with scale limit value / limit value

< +200 °C ≥ +200 °C ≤ +350 °C

STW (STB) Switching differential in %

77

Ambient temperature influence on the switching head in %/°C

0.43 0.35

Ambient temperature influence on the capillary in %/m

0.09 · °C · m 0.07 · °C · m

STB Ambient temperature influence on the switching head: 0.35 °C/°C

Ambient temperature influence on the capillary in °C/m 0.07 °C/°C·m

Temperature compensation Extra code "707"

For detailed information please refer to the graphical diagram on page 5.

Allowable storage tempera-

-50 to +50 °C

ture

Allowable ambient temperature when in use on the

switching head and capillary

Rated position (NL)

Min. +18 °C (0 °C for extra code "707")

Max. +80 °C

Any

Switching head

Case material Sheet steel, galvanized

Mounting Extra code 704 with 2 M4 screws, spaced 28 mm

Extra code 705 with 2 M3 screws, spaced 33 mm

Extra code 706 with 2 M3 screws, spaced 22 mm (standard for EM-20-E and EM-30-E)

Extra code 710, central mounting M10 x 1 with acorn nut (only for STB, standard for EM-80)

Protection type EN 60 529-IP 00

Weigh t Approx. 0.3 kg

Process connection

EM series

with capillary

Material Thermowell Up to +150 °C CuZn as a standard

a

Plain cylindrical probe "10" (standard)

Screw-in thermowell "20" (upon request)

Screw-in sleeve with screw-in spigot G 1/2 form A according to DIN 3852/2

and clamping piece with fixing screw for securing the probe

Over +150 °C CrNi

Insertion length S Standard lengths: 100, 120, 150, 200, or 300 mm (different lengths upon request)

Immersion tube Ø D = 8 mm

a

For different process connections and thermowells refer to data sheet 606710.

Note: Physical and toxicological properties of the expansion medium that may escape in the event of a measuring system facture.

Control range

with scale limit value

≤ +200 °C No +355 °C 0.6 - 8 V % Yes Yes

a

At present, no statement concerning health hazards in the event of short-term and low concentration exposure (e.g. measuring system rupture) has been made by

the health authority.

2013-03-06/00073209

Hazardous

reactions

Fire and explosion hazard Hazardous to

Ignition

temperature

Explosion

limit

water

Irritant Health risks Toxic

Information about toxicology

a

No

Page 4

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Approvals / approval marks

Data Sheet 602026 Page 4/7

Approval marks Testing agency Certificates / certification

Inspection basics Valid for

number

DIN DIN CERTCO / TÜV Süd STB 78208 DIN EN 14597 EM-80

STW (STB) 77508S EM-20-E, EM-30-E

DIN TÜV Süd B

= 250.000

10d

a

DIN EN ISO 13849-1 EM-20-E, EM-30-E,

EM-80

DGRL TÜV Süd IS-TAF-MUC 08 05 73377 020 97/23/EG EM-20-E, EM-30-E,

EM-80

DVGW DVGW / TÜV CE-0085AR0124 90/396/EWG EM-20-E, EM-30-E,

EM-80

UL UL E66358 UL 873,

EM-80

CSA-C22.2 No. 24

MH45736 UL 353,

EM-80

CSA-C22.2 No. 24

GOST Moskau GOST Standard, Russland EM-...

a

nähere Angaben siehe: Sicherheitshandbuch JUMO EM 602021, 602026.

Connection diagrams

EM-20-E

EM-30-E

EM-80 EM-80/U

2013-03-06/00073209

Page 5

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Dimensions

EM-80

with central mounting

(standard)

EM-20-E

EM-30-E

EM-80

with fixing brackets

Data Sheet 602026 Page 5/7

( 1 ) + ( 2 ) = standard: Tab

connector A 6.3 x 0.8 mm

(DIN 46244)

( 4 ) = only for

extra code /574:

Tab connector A 6.3 x 0.8 mm

(DIN 46244)

Temperature compensation

(TK) (707)

If changes occur to the

switching head temperature in

relation to the calibration

ambient temperature

(= 22 °C), a switching point

deviation occurs. For highly

fluctuating ambient temperatures, we recommend the use

of thermostats with temperature compensation (extra

code 707)

2013-03-06/00073209

Abbreviation B G

704 28 M4

705 33 M3

706 22 M3

EM-.. "without" temperature compensation (707)

Switching point deviation depends on the ambient

temperature at the switching head taking the probe

temperature into account.

EM-../TK "with" temperature compensation (707)

Switching point deviation depends on the ambient

temperature at the switching head taking the probe

temperature into account.

The temperature influence on the capillary is not yet

taken into account and can result in an additional

error of approx. 0.07 °C°C/°C· m.

( A ) = Switching point deviation ( B ) = Probe temperature in °C ( C ) = Ambient temperature in °C

Page 6

Data Sheet 602026 Page 6/7

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Stock versions

Part no. Type Limit value °C Capillary mm Process connection Probe Ø x length mm

60000775 EM-80 +110

60000753 EM-80 +95

1000 Plain cylindrical probe 10 6 x ~ 84

(Delivery within 3 working days after receipt of order)

Order details

EM series as STW (STB) and STB

Order code (1) Basic type

602026 Panel-mounted thermostat, EM series

(2) Basic type extensions

20 EM-20-E Safety temperature monitor, limit value adjustable

30 EM-30-E Safety temperature monitor, limit value permanently set

80 EM-80 Safety temperature limiter, limit value permanently set

(3) Limit value ranges for EM-20-E STW (STB)

000 For permanently set limit value (EM-30-E and EM-80)

055 +40 to +110 °C

506 +100 to +150 °C

508 +110 to +170 °C

575 +180 to +250 °C

606 +230 to +300 °C

(4) Permanently set limit values for EM-30-E and EM-80

000 For adjustable limit value range

... Specified in °C

(5) Capillary length

1000 1000 mm

2000 2000 mm

3000 3000 mm

4000 4000 mm

5000 5000 mm

.... (Special length, specified in mm, min. 500 mm, max. 5000 mm)

a

(6) Capillary material

40 Cu (Copper)

20 CrNi (Stainless steel)

(7) Process connection

10 Plain cylindrical probe

20 Screw-in sleeve

(8) Thread of process connection

00 Without thread (process connection "10")

13 External thread G 1/2

2013-03-06/00073209

Page 7

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

(9) Material of process connection

00 Only with process connection "10"

46 CuZn (Brass)

20 CrNi (Stainless steel 1.4571)

(10) Fitting length "S" (immersion tube length)

000 Without thermowell

100 100 mm

120 120 mm

150 150 mm

200 200 mm

300 300 mm

... (Special length, specification in mm)

(11) Diameter "D" (immersion tube diameter)

00 Without thermowell

88mm

(12) Diameter "d" (probe diameter)

00 Without thermowell

66mm

Data Sheet 602026 Page 7/7

) Extra codes

(13

000 Without extra codes

574 "U" Microswitch with N/C contact, restart lock, and additional signal contact (only STB)

702 "au" Snap-action switch with gold plating (cannot be combined with extra code "574")

2

699 "X" Screw-connection with 2.5 mm

conductor cross section

704 "b1" Switching head mounting with 2 M4 screws, spaced 28 mm

705 "b2" Switching head mounting with 2 M3 screws, spaced 33 mm

706 "b3" Switching head mounting with 2 M3 screws, spaced 22 mm

710 "b7" Central mounting with acorn nut (only for STB)

707 "TK" Temperature compensation

a

Different control / limit ranges upon request

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13)

Order code 602026 /--- ----- - - / ,...

a

Order example 602026 / 80 - 000 - 120 - 2000 - 40 - 10 - 00 - 00 - 000 - 00 - 00 / 000

a

State extra codes one after another, separated by commas

, ...

2013-03-06/00073209

Loading...

Loading...