40012146

No.E358-01

ENGINEER’S MANUAL

SC-910/SC-910A

®

PREFACE

This Engineer’s Manual is written for the technical personnel.

Operating instructions for the sewing machine are fairly detailed in the Instruction Manual intended for the maintenance personnel and operators at the apparel factory. And this manual describes the contents and individual

parts which are not described in the Instruction Manual. It is advisable to use the Instruction Manuals for IP-100

and SC-910/SC-910A and the relevant Parts Lists with this Engineer’s Manual when carrying out the maintenance

of this sewing machine.

CONTENTS

1. SPECIFICATION .............................................................................................1

2. OUTLINE ........................................................................................................ 1

(1) Features .........................................................................................................................1

3. CONFIGURATION.......................................................................................... 2

(1) DDL-9000/SC-910 ..........................................................................................................2

(2) DDL-8700/SC-910/M91 ..................................................................................................3

4. EXPLANATION OF CONTROL PANEL......................................................... 4

(1) List of control panels of CP-160 and IP-100 ...............................................................4

(2) Explanation of control panel CP-160 ..........................................................................6

(3) Example of application.................................................................................................7

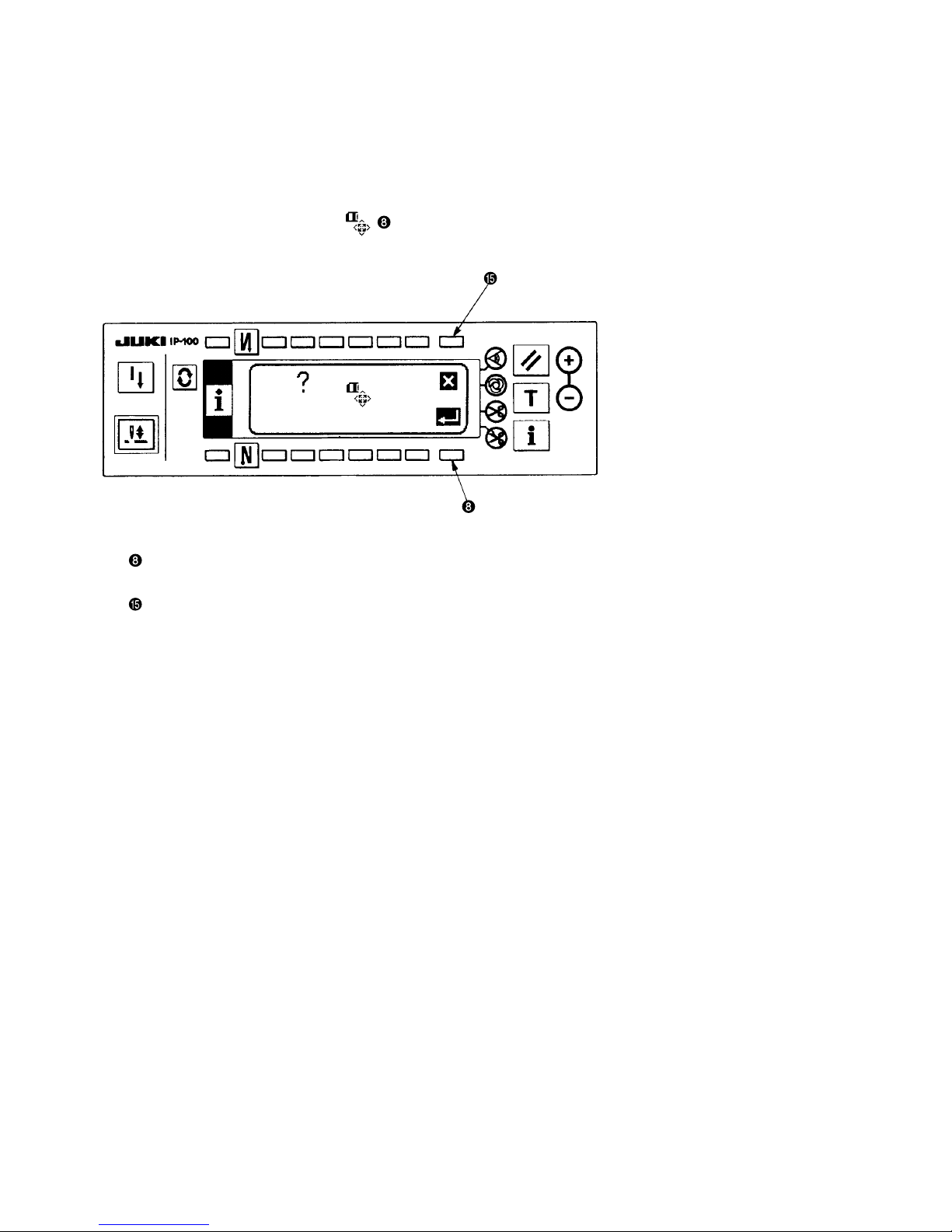

(4) Explanation of control panel IP-100 ..........................................................................10

1) Information...........................................................................................................................................10

2) Matters that demand special attention regarding the operation panel, IP-100 ....................................19

3) Error Display ........................................................................................................................................20

4) Error code list (Error display in panel) .................................................................................................21

5) Warning list ..........................................................................................................................................23

5. CONTROL BOX (SC-910/SC-910A)............................................................ 24

(1) Connecting the cords .................................................................................................24

(2) Setting for functions...................................................................................................25

(3) Function setting list....................................................................................................27

(4) Detailed explanation of selection of functions ........................................................34

6. CHANGING PROCEDURE OF THE PEDAL TYPE..................................... 48

(1) Parts necessary for change .......................................................................................48

(2) Attaching parts............................................................................................................48

(3) Adjusting pedal depressing pressure.......................................................................48

(4) Change-over procedure of the jumper......................................................................49

(5) Automatic compensation of neutral point of the pedal sensor..............................49

7. CONNECTING PROCEDURE OF JUKI OPTIONAL DEVICE..................... 50

(1) Connection of the bobbin thread remaining amount detection device, AE ..........50

(2) Connection of the material end sensor (ED) ............................................................50

(3) Connection of the pedal of standing-work machine (PK) .......................................51

8. SETTING OF THE AUTO LIFTER FUNCTION ............................................ 51

9. EXTERNAL INPUT / OUTPUT CONNECTOR ............................................. 52

10. INITIALIZATION OF THE SETTING DATA ................................................ 53

11. CONNECTOR CONNECTION DIAGRAM.................................................. 54

(1) Solenoid for machine head ........................................................................................54

(2) Solenoid for lifting presser foot ................................................................................54

12. OPTIONAL CORD ...................................................................................... 55

(1)Relay cord A asm. for the standing sewing machine (Part No. M9701351AA0) ...55

(2)Relay cord A asm. for DC24V (Part No. M9703351AA0) ..........................................56

13. MAINTENANCE.......................................................................................... 57

(1) Replacing the fuse......................................................................................................57

(2) Power voltage changeover procedure .....................................................................58

14. Expansibility .............................................................................................. 59

15. REGARDING ERROR DISPLAY (SC-910/SC-910A)................................. 60

(1) Error code list (SC-910/SC-910A)..............................................................................62

15. BLOCK DIAGRAM ..................................................................................... 63

(1) SC-910/SC-910A block diagram ................................................................................63

(2) IP-100 operation panel block diagram......................................................................64

16. DRAWING OF TABLE ................................................................................ 65

(1) For DDL-8700 ..............................................................................................................65

(2) For DDL-9000 ..............................................................................................................66

– 1 –

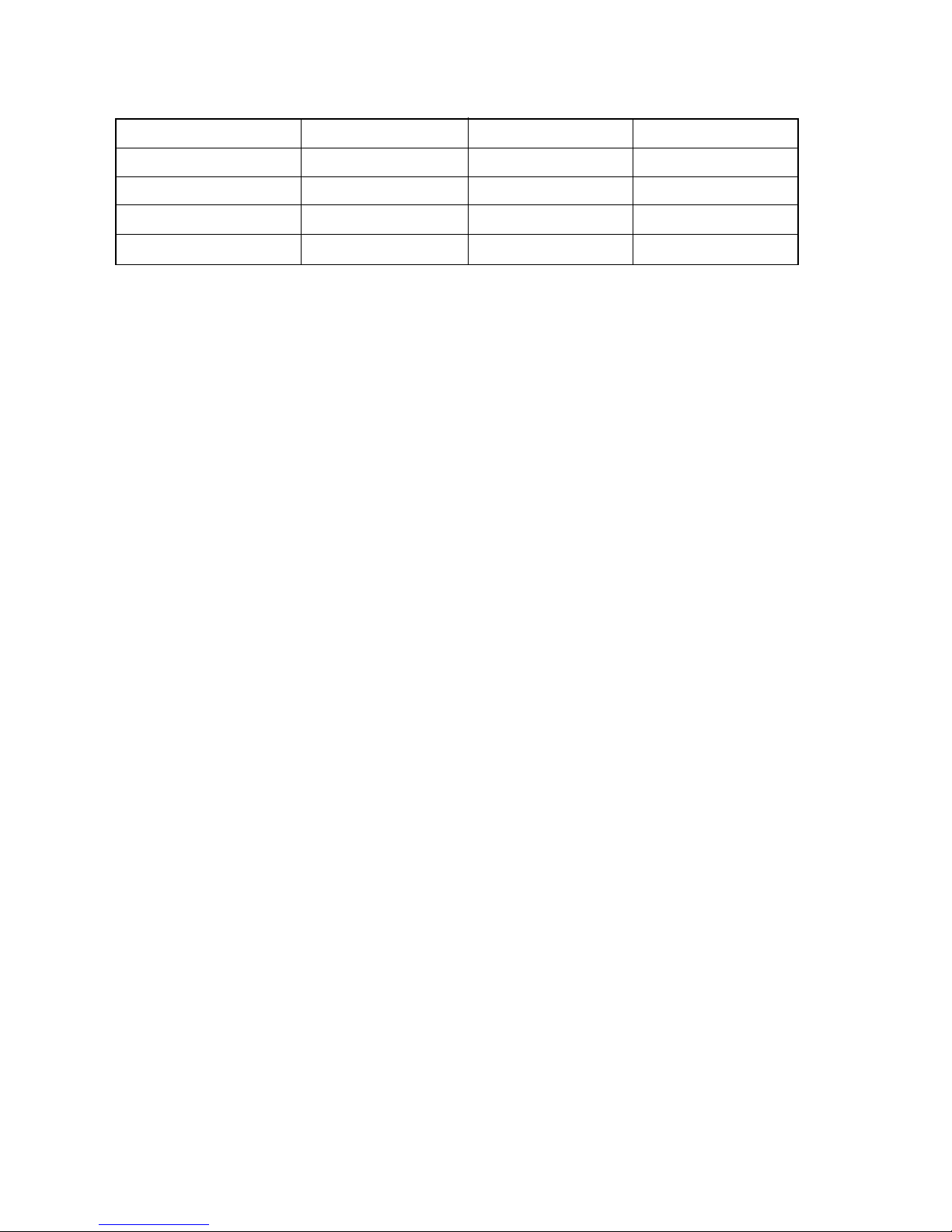

1. SPECIFICATIONS

Supply voltage Single phase 100 to 120V 3-phase 200 to 240V Single phase 200 to 240V

Frequency 50 Hz / 60 Hz 50 Hz / 60 Hz 50 Hz / 60 Hz

Operating temperature range Temperature : 0 to 40°C Temperature : 0 to 40°C Temperature : 0 to 40°C

Operating humidity range Humidity : 90% or less Humidity : 90% or less Humidity : 90% or less

Power consumption 650VA 650VA 650VA

2. OUTLINE

(1)Features

1) Voltage changeover function of single phase 100 to 120V/3-phase 200 to 240V is provided.

The control box with voltage changeover function can be used either for single phase 100 to 120V or for 3phase 200 to 240V by replacing the power cord up to the power switch and changing the voltage changeover

connector inside the box.

In addition, it can be used for single phase 200 to 240V.

2) By using IP-100, the sewing management information such as output display, etc. can be displayed.

3) The conventional JUKI optional devices can be used without any adjustment.

However, when AE (bobbin thread remaining amount detection device) is used, it is necessary to separately

purchase the optional circuit board.

4) By using the flash ROM for CPU, the future version-up can be adapted.

5) SC-910 control box can be used for DD (direct-drive) system machine head and drive system machine head

by connecting the small-sized motor unit (M-91).

– 2 –

3. CONFIGURATION

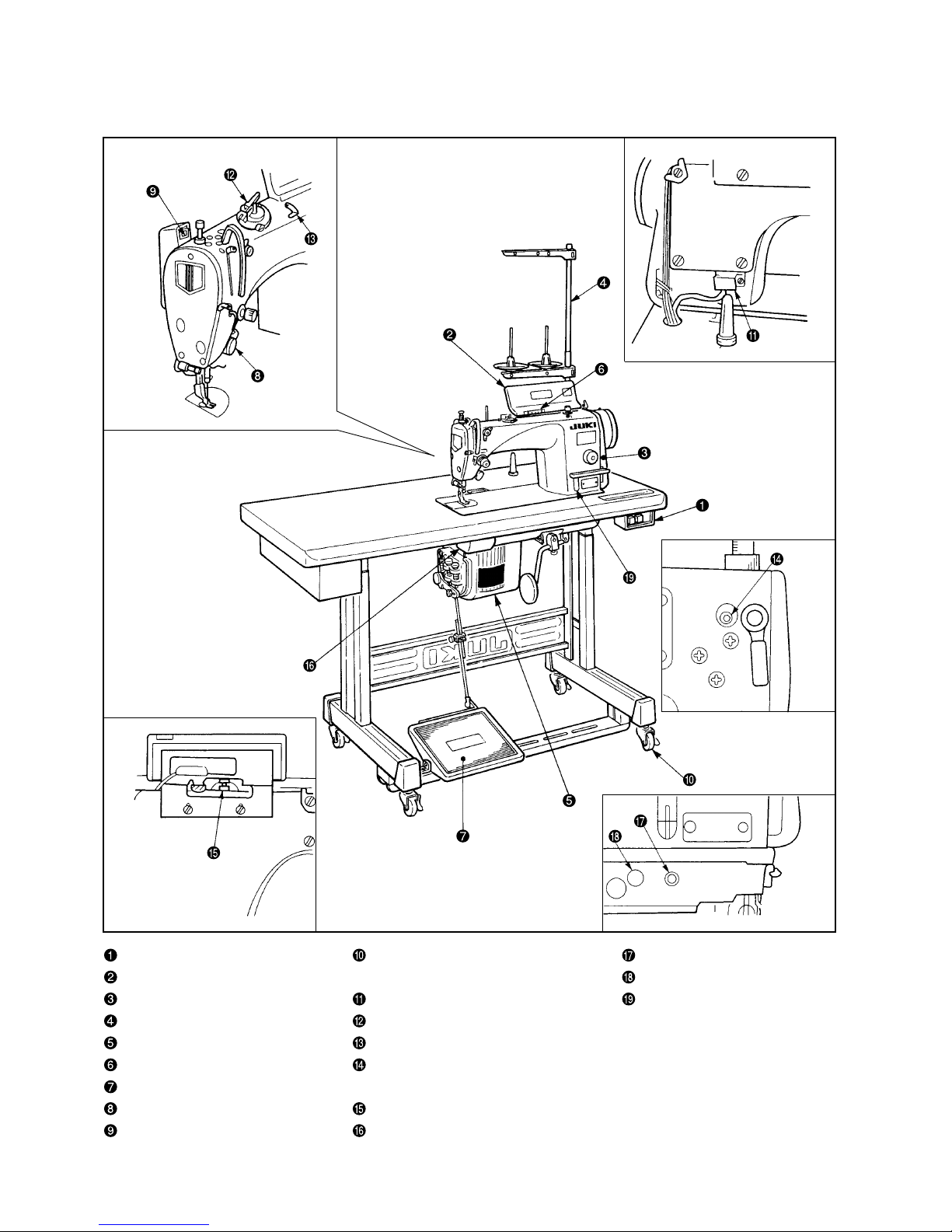

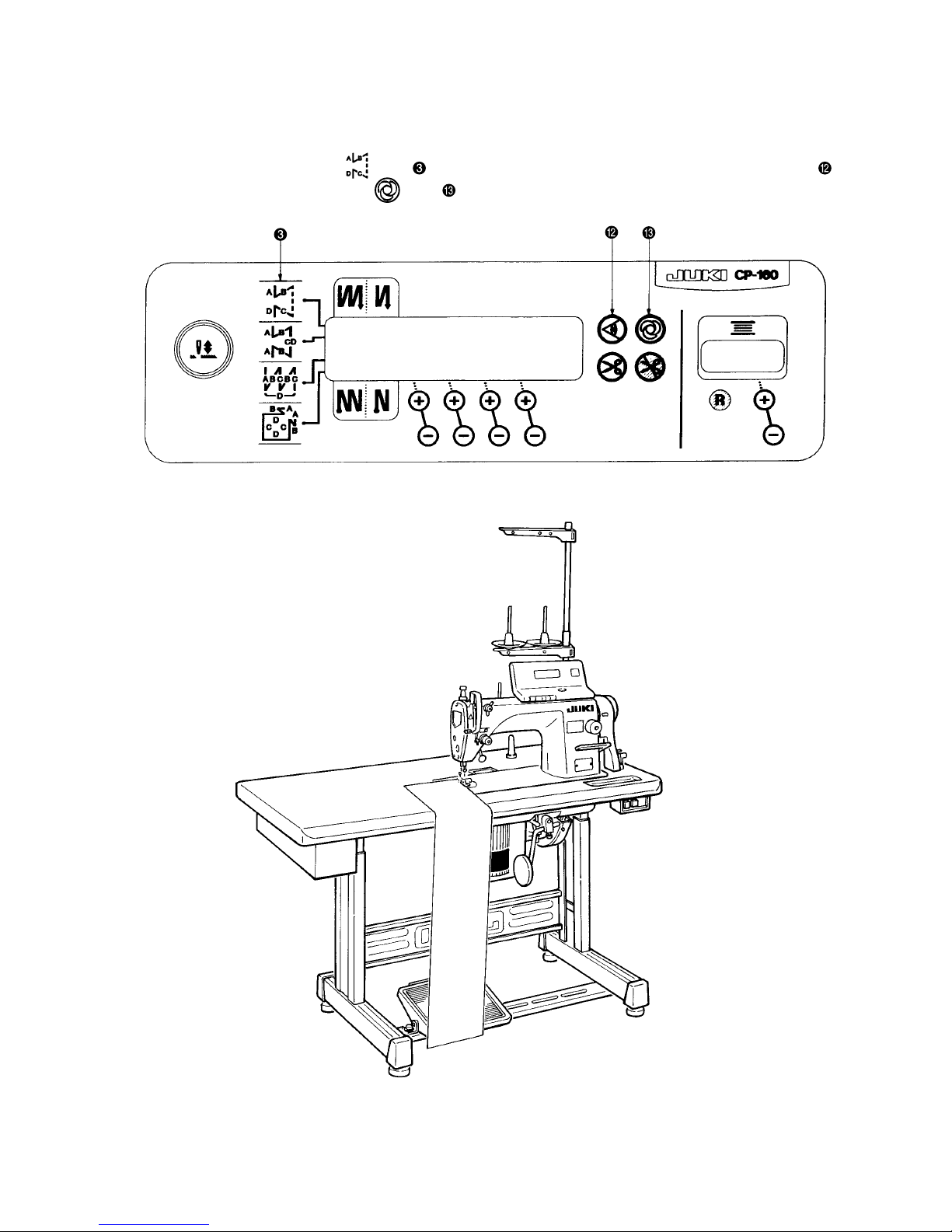

(1)DDL-9000/SC-910

Power switch Screw for leveling table Oil inlet

Operation panel and stand (Caster) Air vent

Pulley cover Resistance pack Oil amount indicating

Thread stand Bobbin winder window (SS, SH)

PSC box (SC-910) Thread cutter retainer

Max. speed control knob Thread release changeover

Operation pedal screw

Touch-back switch Micro lifter screw

Wiper device Under cover

DDL-9000

– 3 –

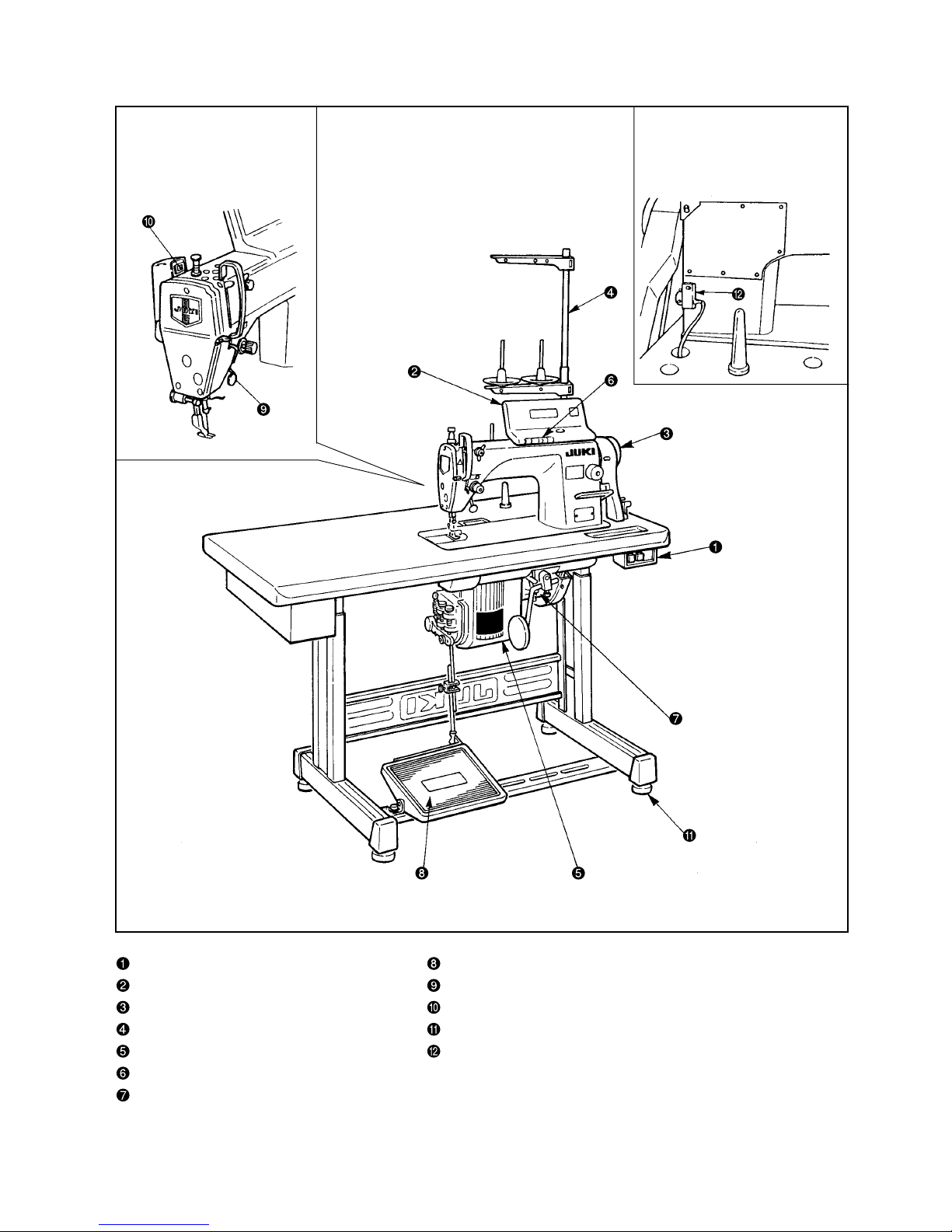

(2)DDL-8700/SC-910/M-91

Power switch Operation pedal

Control panel Touch-back switch

Synchronizer Thread wiping (wiper) device

L-shaped thread stand Screw or caster for level adjustment of table / stand

PSC box (SC-910) Resistor pack

Max. speed control knob

Motor (M-91)

– 4 –

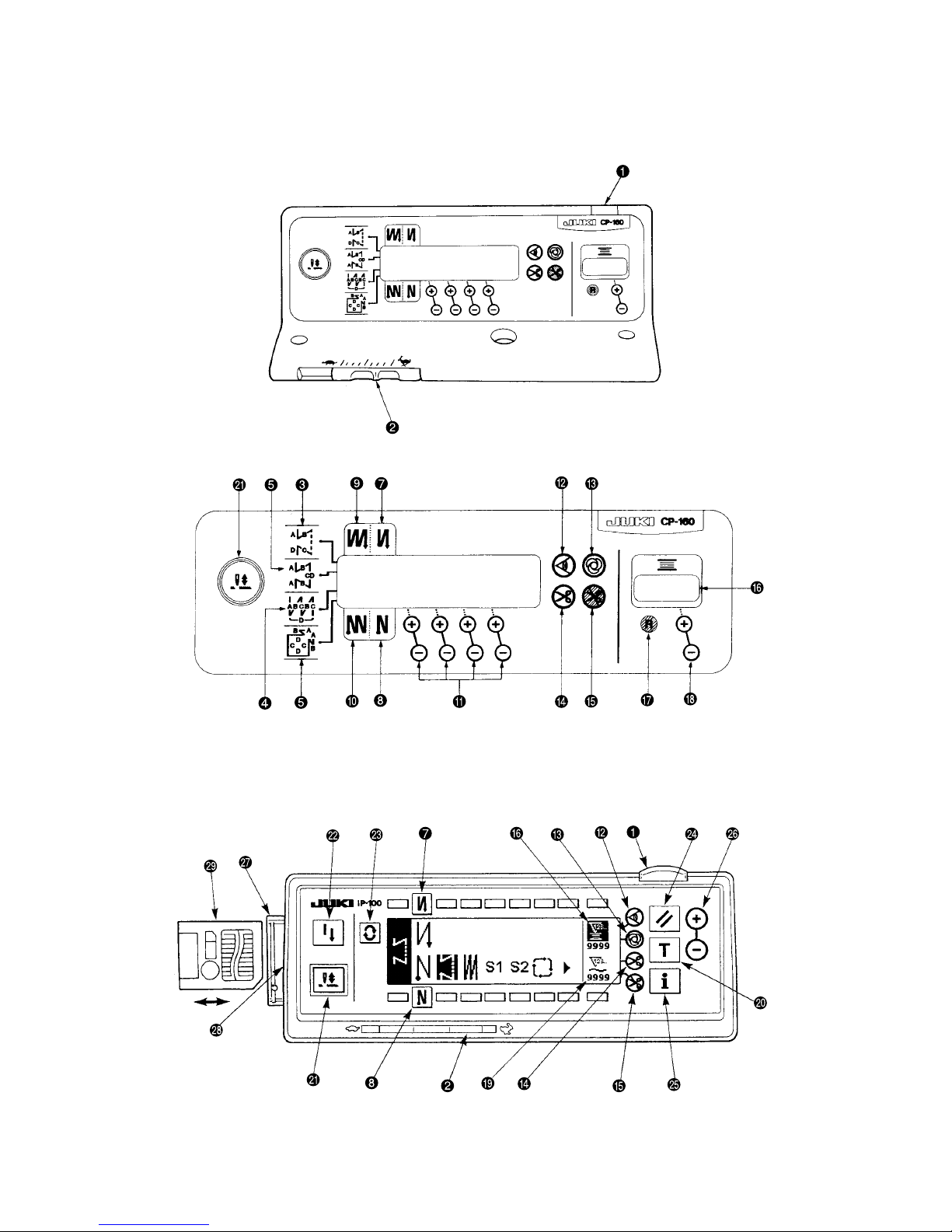

4. EXPLANATION OF CONTROL PANEL

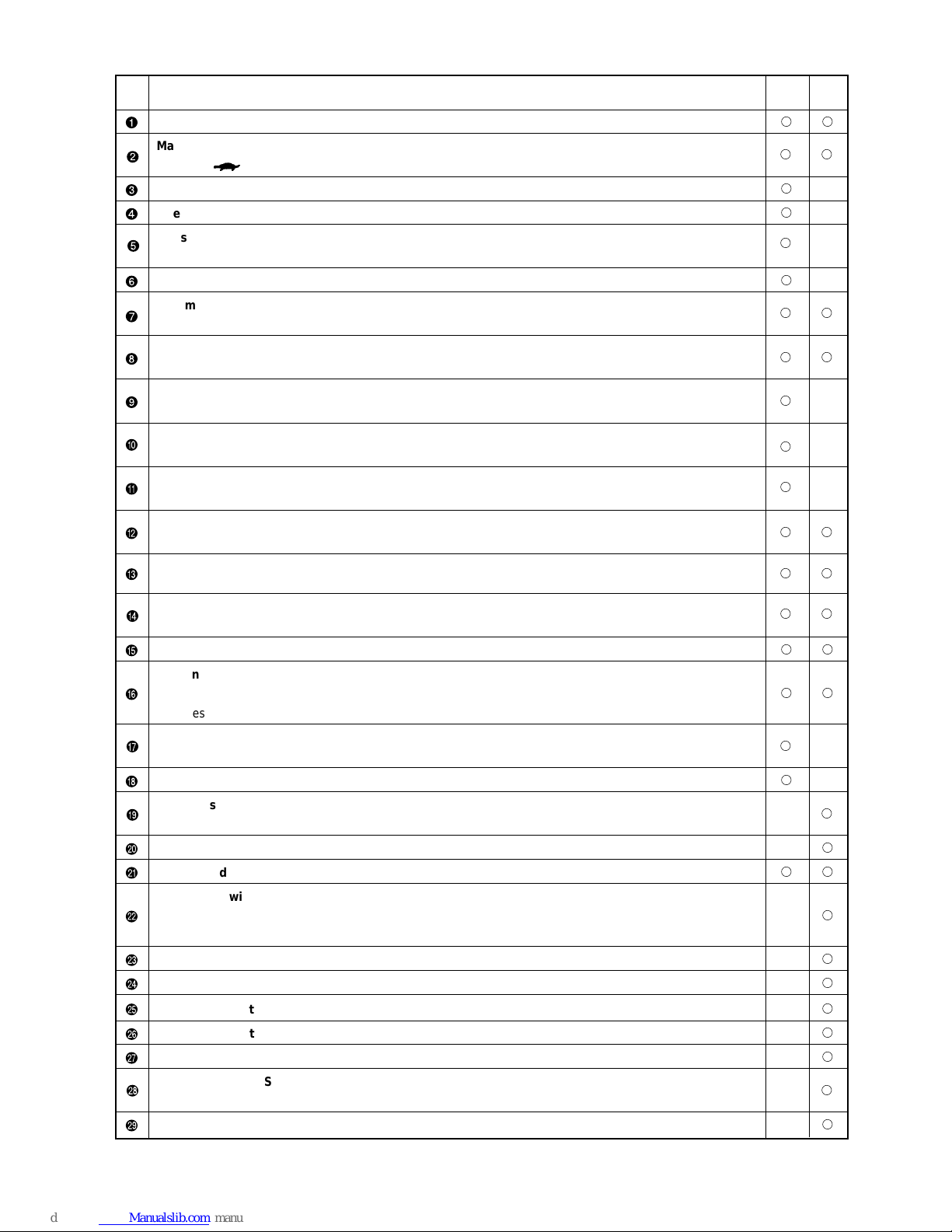

(1) List of control panels of CP-160 and IP-100

CP-160

IP-100

– 5 –

No. Description

Power indication LED : Lights up when the power switch is turned ON.

<<

Max. speed limit variable resister : Maximum speed is limited when this resister is moved in the left

direction ( ).

Reverse stitching pattern switch : Used for specifying the reverse stitching pattern to be sewn.

<

Overlapped stitching pattern switch : Used for specifying the overlapped stitching pattern to be sewn.

<

Constand dimension stitching pattern switch : Used for specifying the constant dimension stitching

pattern to be sewn.

Rectangular stitching pattern switch : Used for specifying the rectangular stitching pattern to be sewn.

<

Automatic reverse stitching at the start of sewing switch : Used for turning ON / OFF the automatic

reverse stitching at the start of sewing.

Automatic reverse stitching at the end of sewing switch : Used for turning ON / OFF the automatic

reverse stitching at the end of sewing.

Automatic double reverse stitching at the start of sewing switch : Used for turning ON / OFF the

automatic double reverse stitching at the start of sewing.

Automatic double reverse stitching at the end of sewing switch : Used for turning ON / OFF the

automatic double reverse stitching at the end of sewing.

Switches for setting the number of stitches : Used for setting the number of stitches to be sewn in

processes A through D.

Material edge sensor ON / OFF switch : Rendered effective when the material edge sensor is

installed on the machine. Used for selecting whether or not the material sensor is used during sewing.

One-shot automatic stitching switch : Start the sewing machine with this switch, and the sewing machine

will run automatically until the material edge is detected or the end of the set number of stitches is reached.

Automatic thread trimming switch : When the material edge is detected, the machine will perform

thread trimming even when keeping depressing the front part of the pedal.

Thread trimming prohibition switch : Used for prohibiting thread trimming at any occasion.

<<

Bobbin thread counter : Indicates the amount of bobbin thread while counting it by subtracting from the set

value. When the bobbin thread remaining amount detecting device is installed on the machine, the counter

<<

indicates the number of times of detecting.

Bobbin counter reset switch : Used for returning the value shown on the bobbin thread counter to

the initial value.

Bobbin thread amount setting switch : Used for setting the amount of bobbin thread.

<

No. of pcs. counter : The indication shown on the counter increases while counting up the number of

finished pieces of garment every time the machine performs thread trimming.

Teaching switch : Used for setting the number of stitches to a value which has been actually sewn.

<

Needle up/down compensating switch : Used when performing needle up / down compensating stitching.

<<

Re-sewing switch : If the bobbin thread runs out before the completion of the operation steps of a

programmed stitching pattern, this switch is used for re-starting stitching from the position where the

<

stitching has been interrupted after replacing the bobbin.

Screen changeover switch : This is the switch to change over the screen.

<

Reset switch : This is the switch to make the value of bobbin thread counter or sewing counter the set value.

<

Information switch : This is the switch to perform various function settings.

<

Counter value setting switch : This is the switch to set the value of bobbin thread counter or No. of pcs. counter.

<

Smart media cover : This is the cover for smart media inserting opening.

<

Smart media slot (Smart media inserting opening) : To set smart media, insert smart media into

smart media slot and push it until it is almost hidden.

Smart media : ( Optional : Part No.HX005750000 )

<

CP160

IP-

100

<<

<

<<

<<

<

<

<

<<

<<

<<

<

<

<

– 6 –

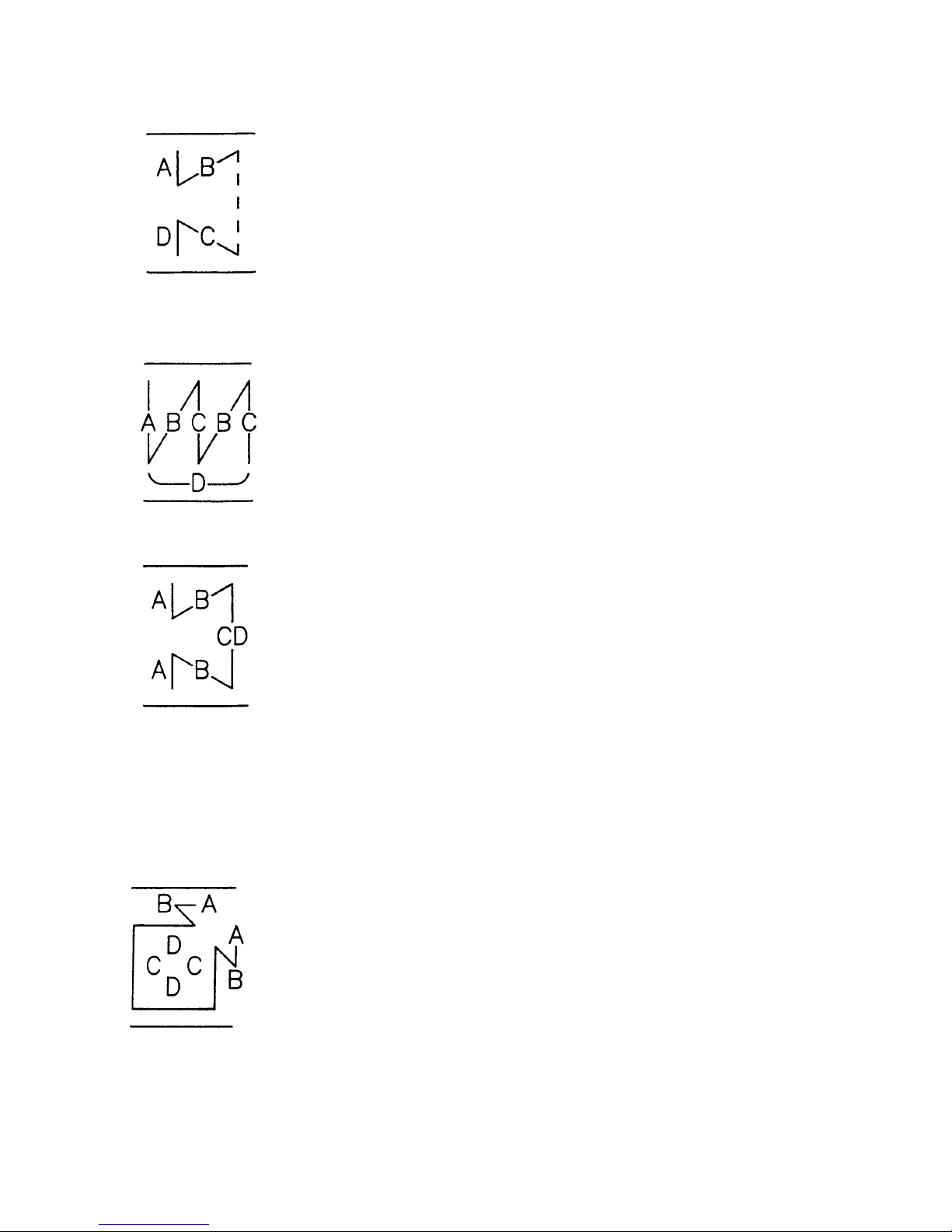

(2) Explanation of control panel CP-160

1) Reverse stitching pattern

When the sewing machine performs the free stitching operation, the

machine performs the reverse stitching operation at the start and end of

sewing.

The reverse stitching operation can set the ON and OFF settings.

Furthermore, single and double reverse stitching patterns can be selected.

Setting of number of stitches or other settings can be performed by operating the control panel.

A, B, C and D = 0 to 19 stitches

2) Overlapped stitching pattern

The sewing machine repeats the normal stitching and reverse stitching

by the predetermined time, and performs the line bartacking. Then, the

machine makes the thread trimmer actuate and stop to complete the

overlapped stitching procedure.

Change of the number of stitches or the number of times of repetition can

be performed by operating the control panel.

A, B and C = 0 to 19 stitches

D = 0 to 9 times

3) Constant-dimension stitching pattern

The free stitching process in the reverse stitching pattern becomes the

set value of the number of stitches. The sewing machine will automatically

stop (automatically perform thread trimming if the automatic thread

trimming is selected.) after the machine finishes the predetermined number

of stitches in the process of CD.

If the automatic thread trimming is not selected, operate the touch-back

switch after the machine has automatically stopped. Then, the machine

runs at a low speed (stitch compensation operation). Also, if the pedal is

returned to its neutral position and depressed its front part again, the

sewing can be continued regardless of the setting of number of stitches.

Setting of number of stitches or selection of automatic thread trimming

can be performed by operating the control panel.

A and B = 0 to 19 stitches CD = 0 to 500 stitches

4) Rectangular stitching pattern

There are 4 operation steps in the process of constant-dimension stitching

pattern. At each operation step the sewing machine automatically stops

after sewing the predetermined number of stitches. At this time, if the

touch-back switch is operated, the sewing machine runs at a low speed

(stitch compensation operation). Also, in case of the last operation step, if

the pedal is returned to its neutral position and depressed its front part

again, the sewing can be continued regardless of the setting of number of

stitches. However, if the automatic thread trimming is set, the machine

will perform thread trimming. Setting of number of stitches or selection of

automatic thread trimming can be performed by operating the control panel.

A and B = 0 to 19 stitches C and D = 0 to 99 stitches

– 7 –

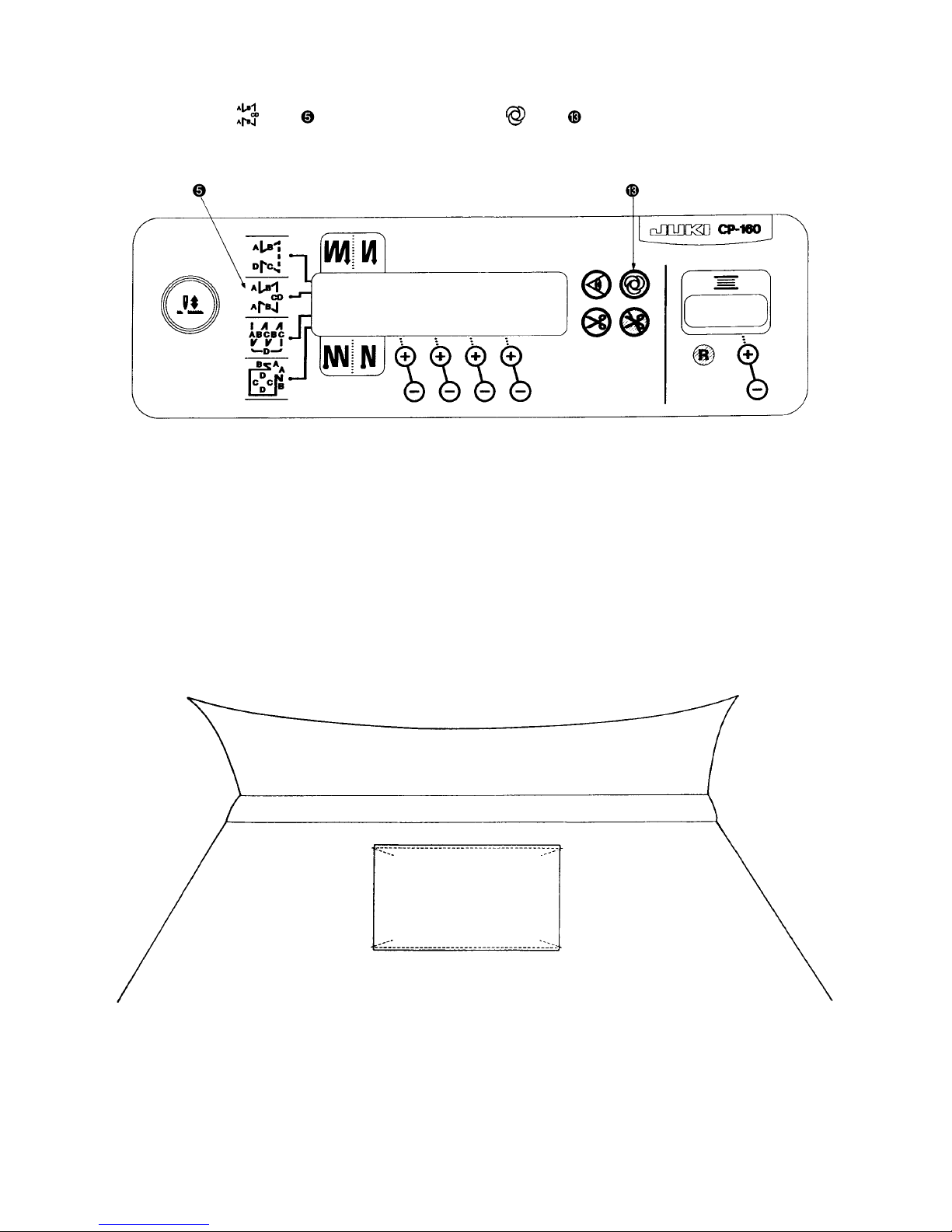

(3) Example of application

1) When the CP-160 is used together with the material end sensor (ED : optional), it can be used as a

small edge-controller.

(Method) Adjust the position to mark of the CP-160, turn ON material end sensor ON/OFF switch of

the CP-160, and turn ON mark of the automatic one-shot stitching.

Caution) Number of rotations of the automatic one-shot stitchig can be changed by the function setting

(No. 38).

– 8 –

2) Label attaching is performed by the automatic one-shot stitching with the CP-160

(Method) Select mark on the CP-160, and turn ON mark of the automatic one-shot stitching.

Explanation) Number of stitches at the section CD can be set up to 500 stitches. If the stitch length is 2 mm, it is

possible to sew approximately 1,000 mm (1 m).

This function can perform the automatic one-shot stitching without using the material end sensor

(ED : optional). Therefore, the sewing machine performs the sewing to the last according to the

sewing pattern even if the label is not located at the end of material when the pedal is depressed

once.

Label

CD

CD

– 9 –

Condition Machine head of DDL-8700H (for thick materials)

Stitch length 4 mm

Number of stitches 4 stitches

ITEM No. 64 “0” rpm

Standard

Condition Machine head of DDL-8700H (for thick materials)

Stitch length 4 mm

Number of stitches 4 stitches

ITEM No. 64 170rpm

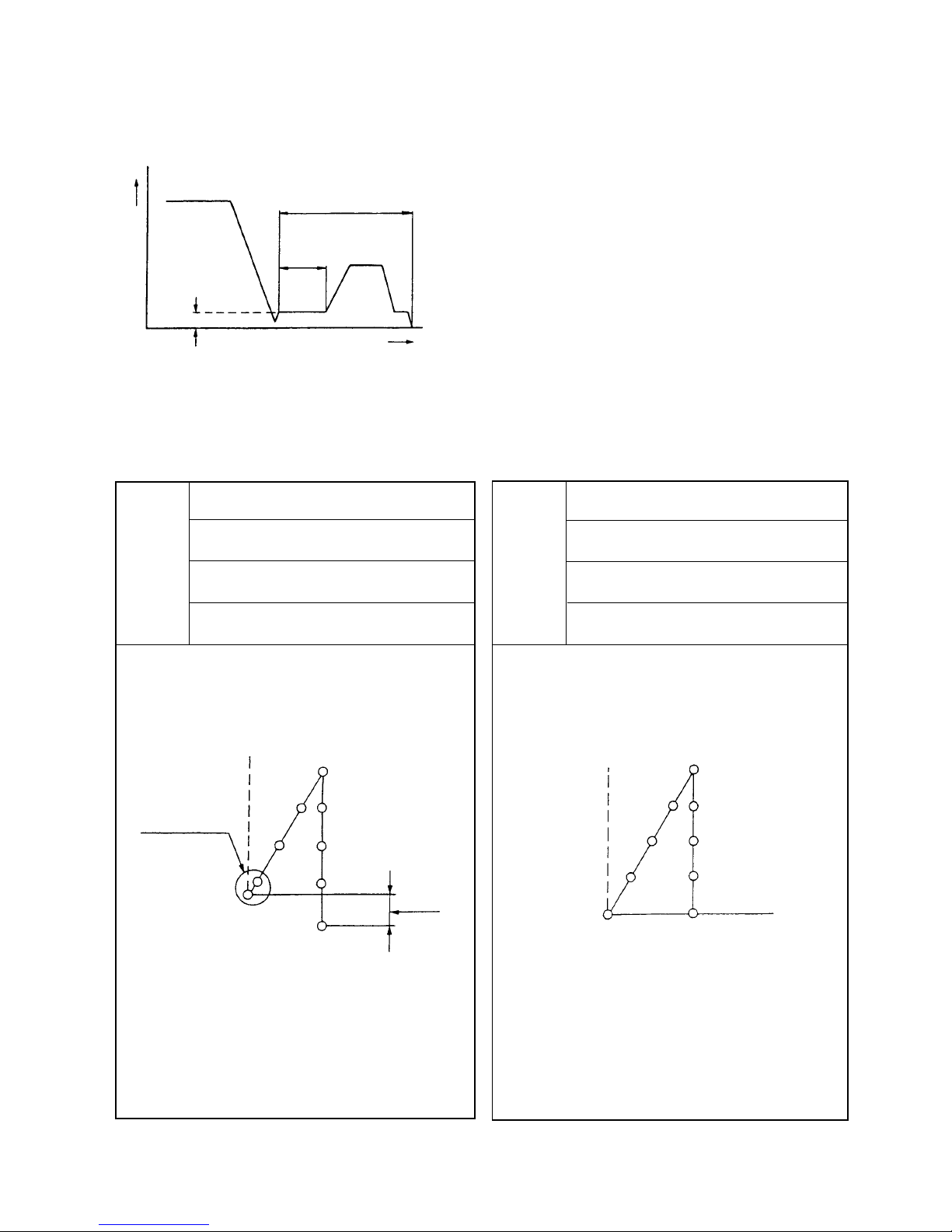

3) Seam joining of the reverse feed stitching at the end of sewing (For thick materials)

Especially some sewing machine heads for thick materials are likely to fail joining the seam at the section of the

following figure even if the timing of reverse feed stitching at the end of sewing is compensated.

1 At the timing to move to the reverse feed stitching action,

the rotating speed at the section where the sewing machine

is rotated at a low speed can be changed.

SC-910 function setting No. 64

(0 to 250 rpm changeable : 200 rpm was fixed in the past.)

Example) Use for reference.

Section of EBT

Section of low

speed

Time

1

Speed

Stitch lenth

becomes small.

Stitch

length

slips off.

– 10 –

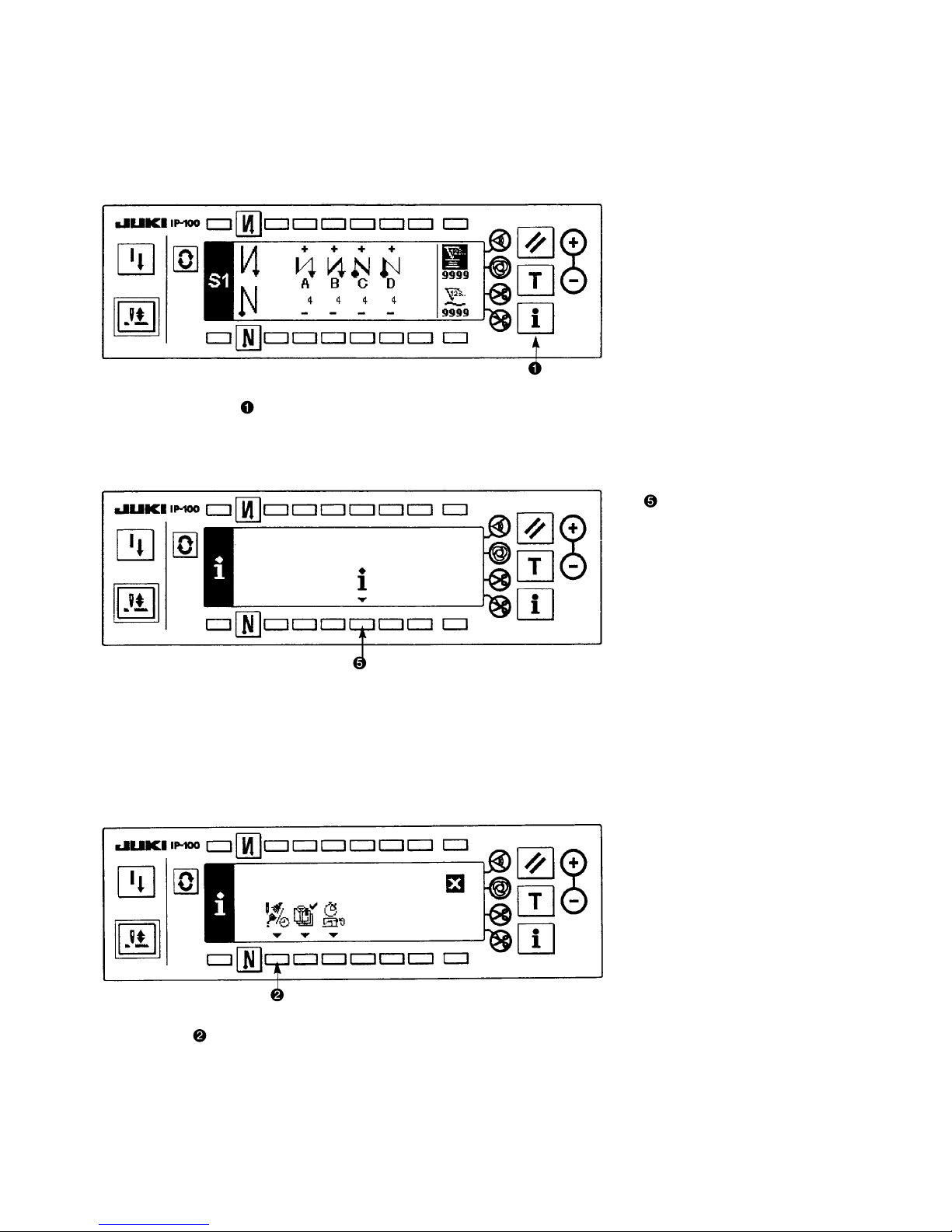

(4)Explanation of control panel IP-100

1) Information

Setting and checking of various data can be performed with the information.

For the information, there are the operator level and the maintenance personnel level.

[Operator level]

1) Turn ON the power.

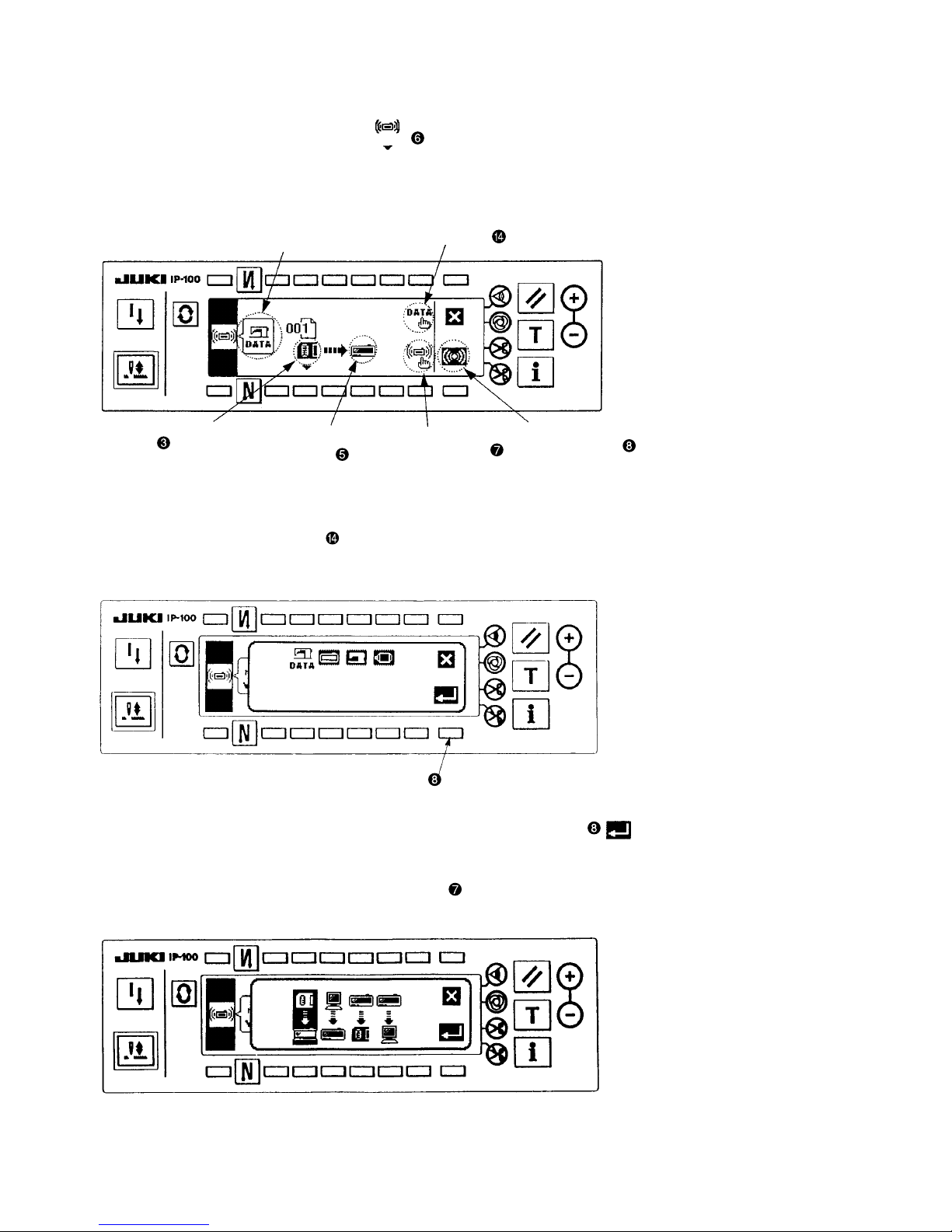

2) Press switch to display the information screen.

Information screen (operator level)

1. Sewing management information

For the sewing management information, there are the maintenance management function, production control

function and working measurement function.

[Maintenance management function]

: Sewing management

information

1) Press to display the maintenance function screen.

– 11 –

Information screen (Maintenance personnel level)

: Ver display

: Function setting

: Sewing management

information

: Communication mode

: Smart media format

[Maintenance personnel level]

1) Turn ON the power. When the needle bar is not in the UP position, turn the handwheel to bring the needle bar

to its UP position.

2) Press switch for approximately three seconds to display the information screen.

3) Press switches , , , and corresponding to the various functions.

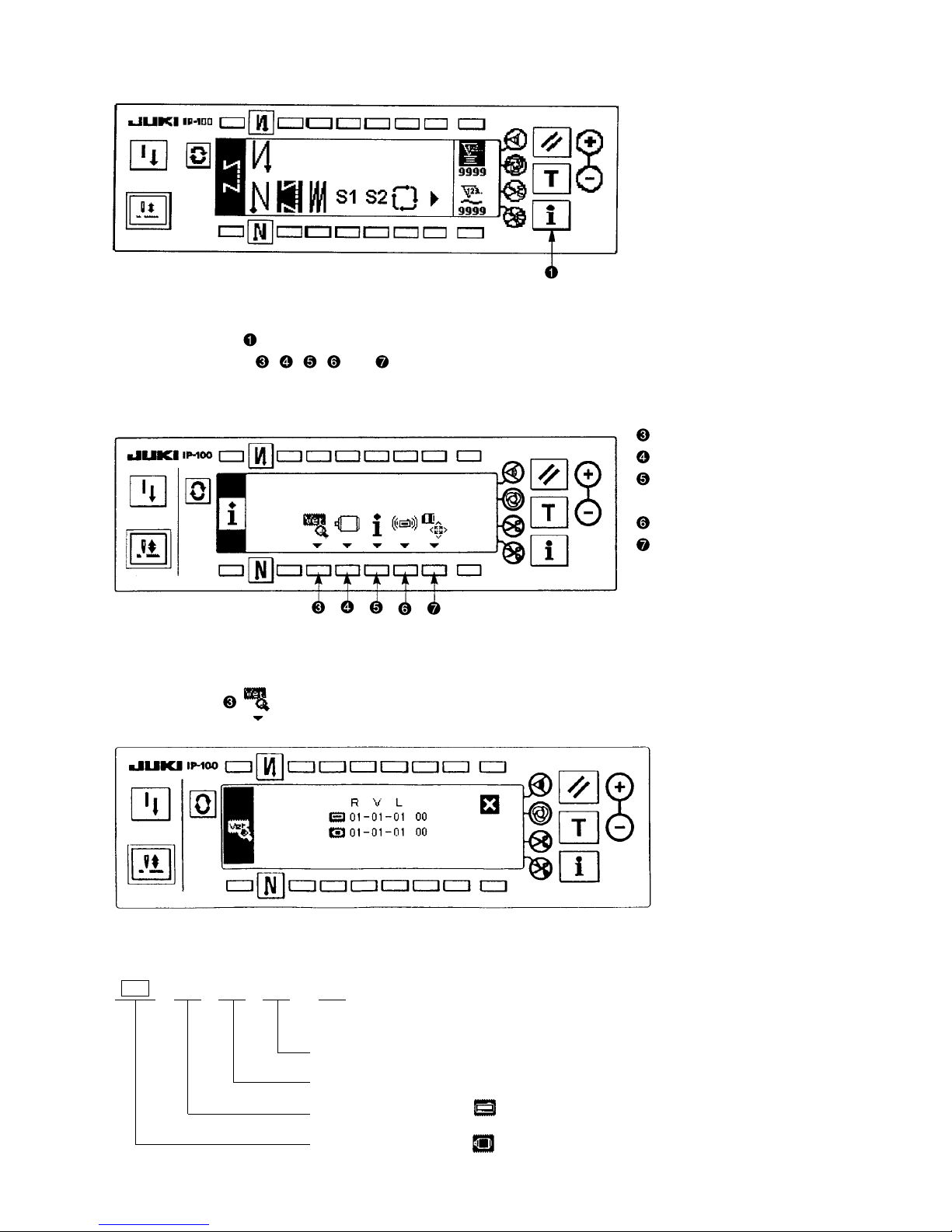

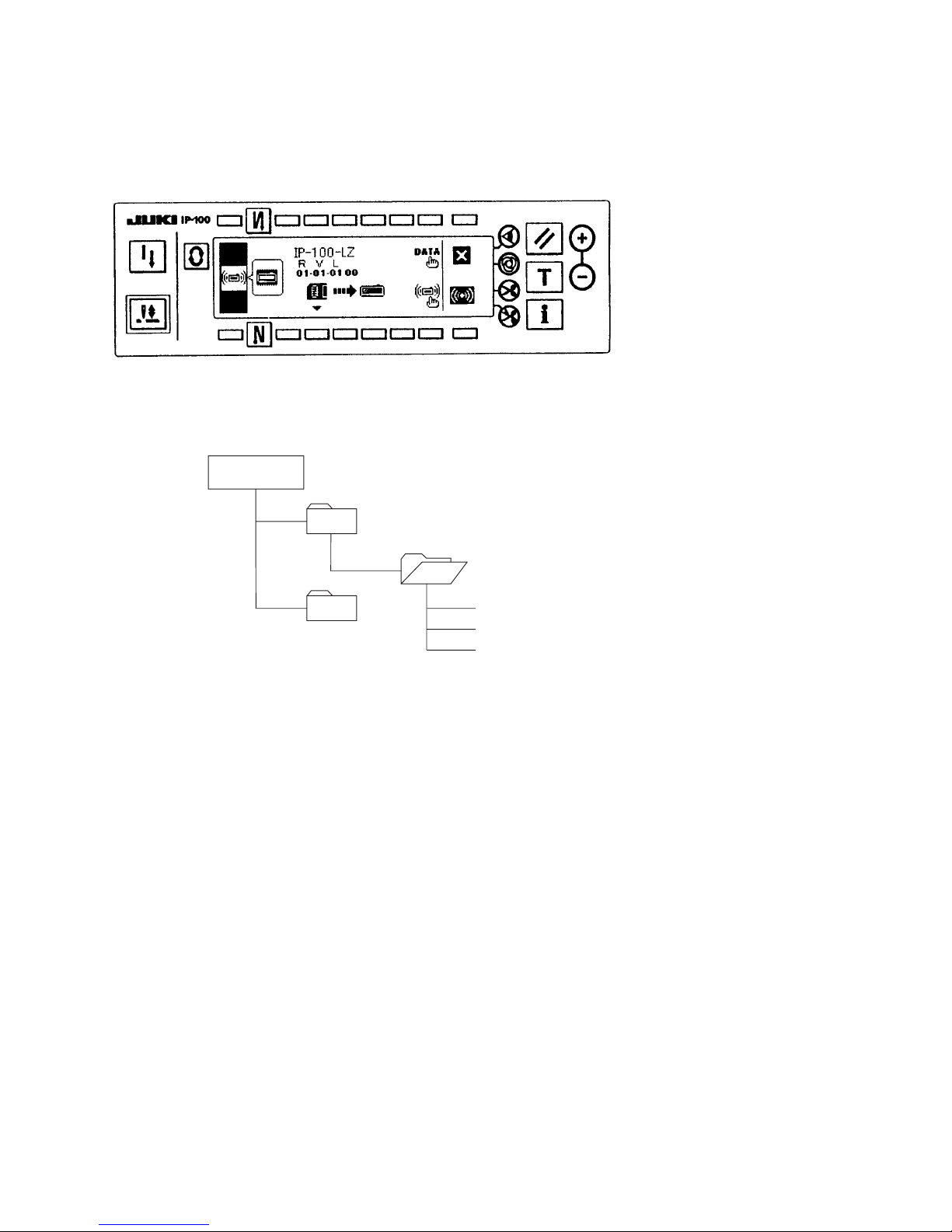

2. Ver display

Software version of each CPU is displayed.

Press switch in the information screen (maintenance personnel level).

Ver display screen

Explanation of display

Others

Level

Version

Revision

Kind of CPU

01- 01 01 00

RVL

Panel software

Servo motor software

– 12 –

3. Sewing management information

For the sewing management information, there are the operator level and the maintenance personnel level.

[Operator level]

Press switch in the information screen.

[Maintenance personnel level]

Press switch for approximately three seconds in the information screen.

Pictograph on the left end of the sewing management information is shown in reverse video.

Sewing management information screen (Maintenance personnel level)

4. Operation status screen

The total record of the sewing machine is displayed.

: Total operation time of the sewing machine (hour)

: Total number of times of thread trimming of the sewing machine (number of times)

: Total current-carrying time of the sewing machine (hour)

: Total number of stitches of the sewing machine (1,000 stitches)

: Maintenance function

: Production control function

: Operation measurement

function

: Operation status

: Error record

– 13 –

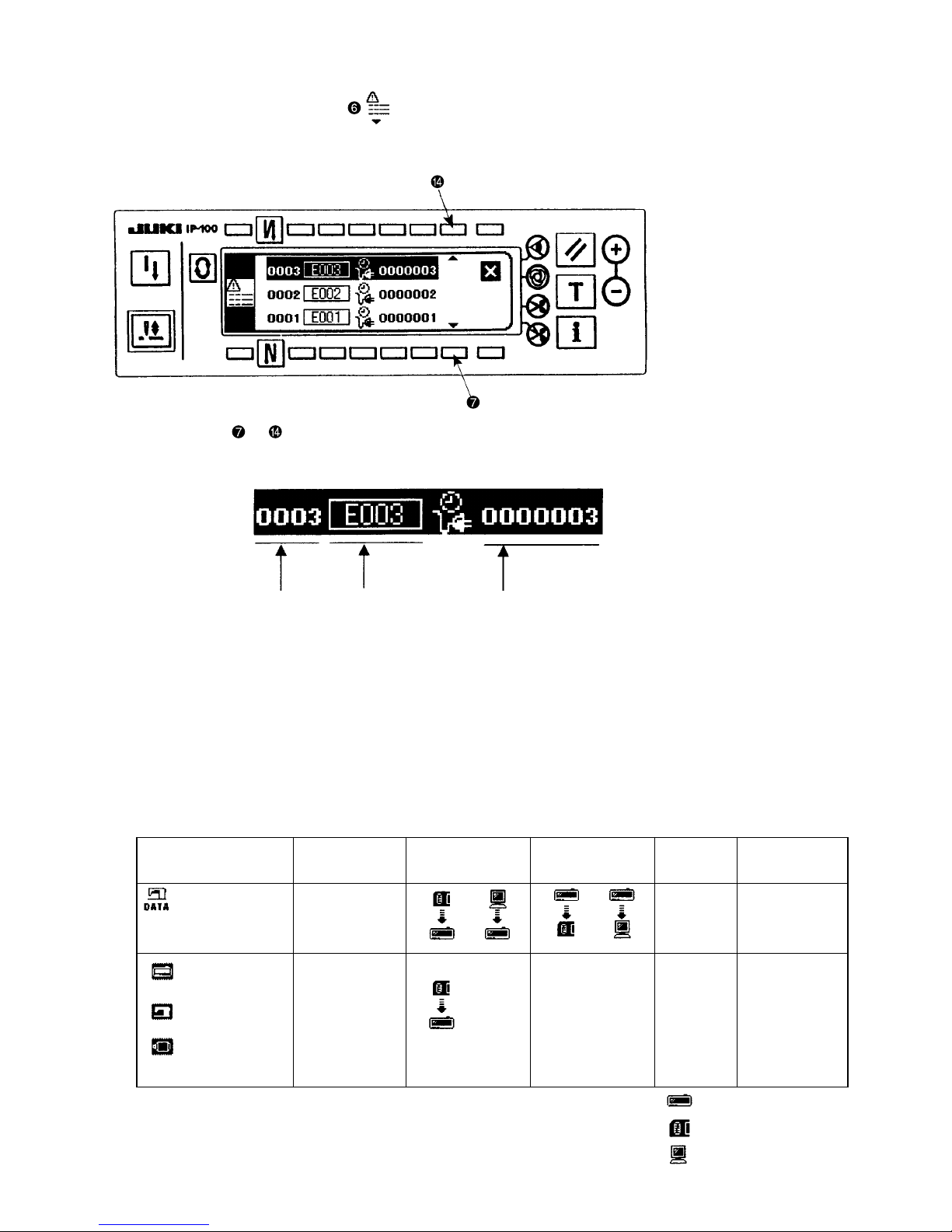

5. Error record display

Press error record display switch in the sewing management information screen (maintenance personnel

level).

Error record screen

When switch or is pressed, the error record scrolls up or down.

Explanation of display

Error record of approximately 100 cases (depending on the memory capacity) can be stored in memory in the

order of the latest.

6. Communication mode

Uploading and downloading of various data with the sewing machine server utility (hereinafter called SU- 1) or

the smart media can be performed in the communication mode.

For the communication mode, there are the operator level and the maintenance personnel level.

The kind of data which can be handled with the operator level is different from that with the maintenance personnel level.

Kind of data Operation level Download Upload Extension Remarks

of file

Maintenance MSP

All sewing machine personnel

data

Panel Maintenance NG PRG

personnel

Main

Servo motor

Each program data

Communication function table

: Panel

: Smart media

: SU-1

Record No.

Error No.

ime occurred (Unit : time)

– 14 –

Operating procedure

[Maintenance personnel level]

Press communication mode switch for approximately three seconds in the information screen.

ictograph on the left end of the communication screen is shown in reverse video.

Communication screen (Maintenance personnel level)

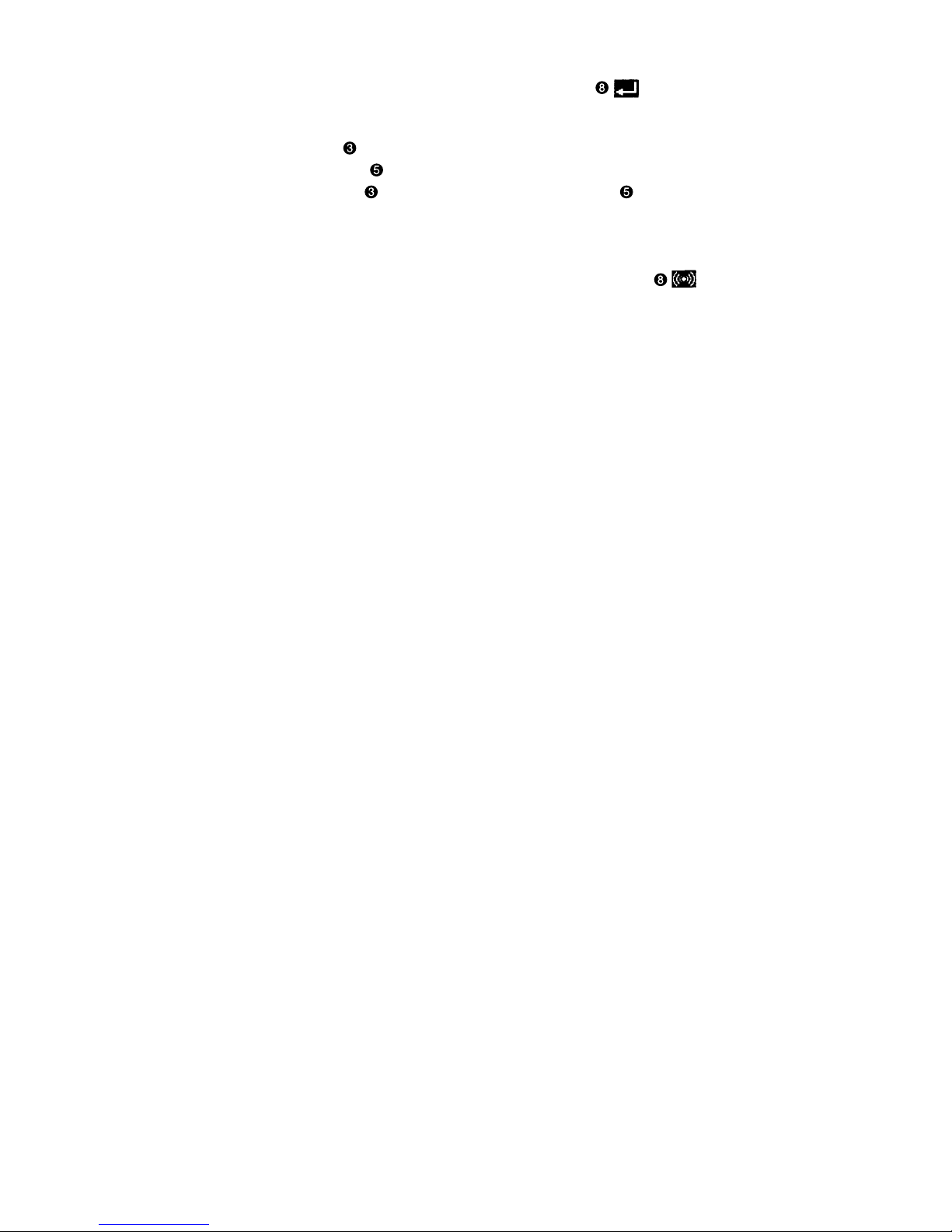

7. Communication setting

1 Data selection

Press data selection switch in the communication screen.

Data selection screen

Select the data to perform communication, and press set key switch .

2 Communication method selection

Press communication method selection switch in the communication screen.

Communication method selection screen

Kind of selected data

Data selection

Data communication

source

Data

communication

destination

Communication

method selection

Start of

communication

– 15 –

Select the method to perform communication and press set key switch .

Reference : Communication method cannot be selected by downloading of program.

3 Data communication source

4 Data communication destination

Set data communication source and data communication destination in the ten key screen, or "+" or "–

" key.

(Ten key input, or "+" or "-" key input is changed according to the kind of data.)

5 Start of communication

After all settings have been completed, press communication start key switch to start communication.

When the screen returns to the communication setting screen after display of the during communication

screen, communication is completed.

(Caution) Never turn OFF the power during communication.

Motion in case of OFF cannot be guaranteed.

– 16 –

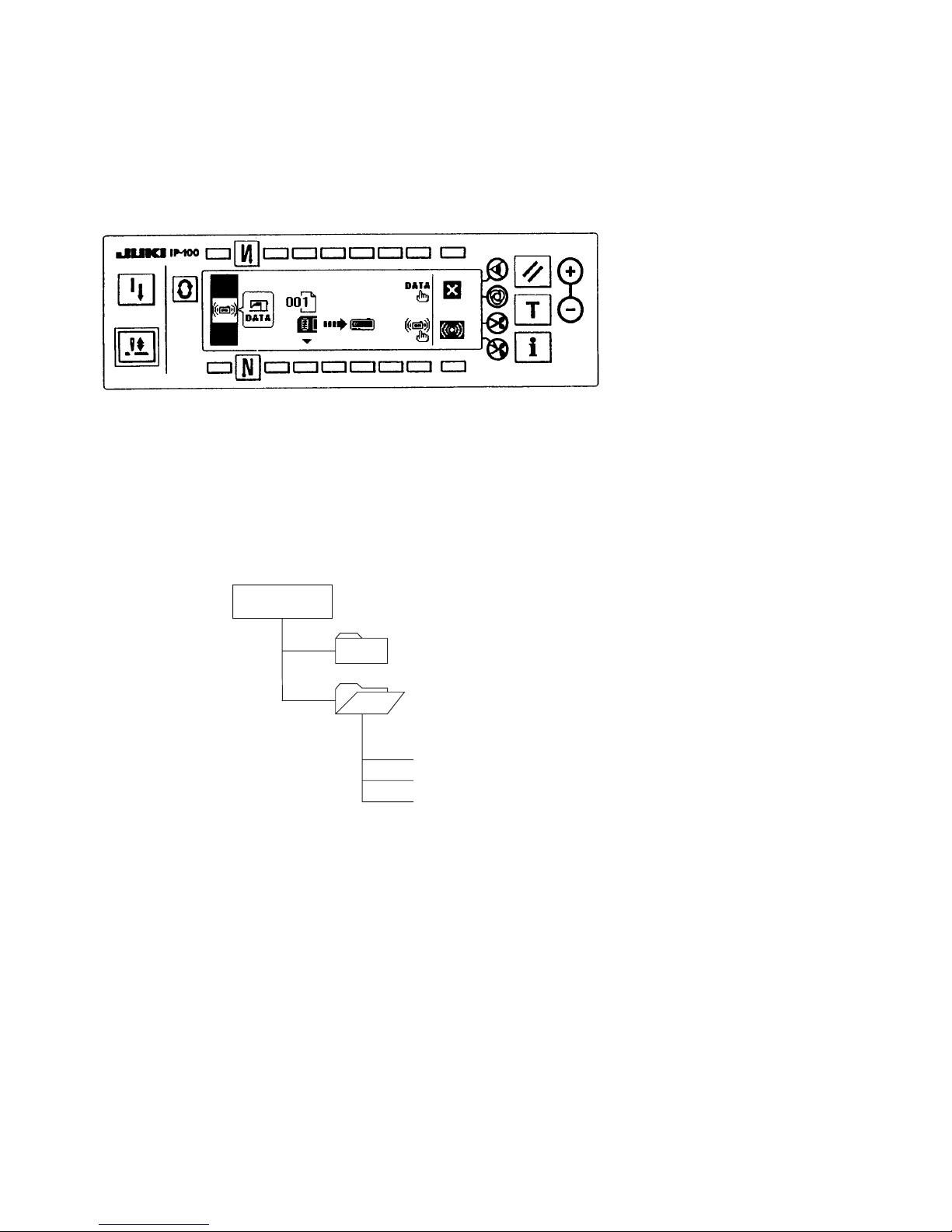

8. All sewing machine data

1. Data such as sewing setting data, adjustment data, etc. which are memorized in the sewing machine can be

stored in one package.

2. It is possible to download the all sewing machine data to the other sewing machines to make the same

setting.

Communication screen (Download of all sewing machine data)

Reference : When downloading the all sewing machine data, it is necessary that the file and the Ver of the sewing

machine have to agree with each other. An error occurs when the file of different Ver is downloaded.

(Caution) It is not possible to store and copy the function setting of the servo motor.

Folder structure of all sewing machine data (* .MSP) file in the smart media

Upload :

Uploading to the smart media is written in the folder of "SC910".

In case there is no folder, the folder of "SC910" is automatically created.

Download :

Downloading from the smart media is read from the folder of "SC910".

Store the copy from other media or the like in the folder of "SC910".

1 Create folder "SC910" in the smart media.

(It is not necessary to create the folder when it already exists.)

2 Copy the file (extension MSP).

Smart media

PROG

SC910

SC00001.EPD

SC00001. MSP

– 17 –

9. Program data

1. When the change of software occurs in the future due to Ver-up or the like, rewriting of the program can be

performed.Rewriting of the program is performed with each CPU.

Communication screen (Download of IP-100 program data)

Folder structure of program (* .PRG) file in the smart media

Download :

Downloading from the smart media is read from the folder of "PROG\SC910".

Store the copy from other media or the like in the folder of "PROG\SC910".

1 Create folder "PROG" in the smart media.

2 Create folder "SC910" in the PROG folder.

(It is not necessary to create the folder when it already exists.)

3 Copy the program file (extension PRG).

Smart media

PROG

SC910

SC910

IP010101.PRG

MT010101.PRG

– 18 –

10. Smart media format

Perform formating of the smart media.

The media formated with the personal computer or the like may not be used.

When using the media with IP-100, be sure to perform formating with IP-100.

Press smart media format switch in the information screen (maintenance personnel level)

Smart media format confirmation screen

: Formating is performed.

Confirm again whether formating can be performed before pressing the switch.

: The screen returns to the information screen.

(Caution)When formating is performed, all data stored in the smart media are deleted. Take the backup

of necessary data beforehand.

– 19 –

2) Matters that demand special attention regarding the operation panel, IP-100

1. Kind of IP-100

For the operation panel, IP-100, there are several kinds of types in accordance with the specifications.

Types that can be used for SC-910 are TYPE-B and TYPE-C. The product is TYPE B0A or TYPE C0A which is

indicated on the name plate seal located in the rear of the panel case.

Brackets for installing panel for both types are different from each other.

There is the jumper wire W1 (side of RVR1 variable resistor) on the circuit board. Set the W1 setting to 2-3 for

both types.

Type name plate seal Setting of W1

TYPE B0A 2-3 pin setting (lower side)

TYPE C0A 2-3 pin setting (lower side)

(Caution) When setting is wrong, LCD screen display is not properly performed.

2. Matters that demand special attention when disassembling the operation panel

Operation panel, IP-100 is constructed with precision components.

Leave the action such as disassembling the panel case or the like to our service department since injury by

electric shock or failure of panel will be caused.

If the force more than expected is applied when disassembling the panel case, it may be damaged since it is

made of the plastic molding.

Especially when performing disassembling (opening/closing) the front panel and the rear panel in the state that

the smart media cover attached to the rear case is closed, the small-sized switch mounted on the inside of the

printed circuit board interferes with the smart media cover and may be damaged. So, be careful.

It is necessary to assemble all screws used in the operation panel with tightening torque of 0.56Ncm.

(Excluding screws to fix it on the machine head and to fix the earth wire.)

3. Prohibition of the change of DIP switch setting

Do not perform the changeover of DIP switches since the guarantee of control program and stored data cannot

be performed.

It is not necessary to operate these switches since they are all changeover switches for the production by the

manufacturers.

(Caution) The 4-string DIP switches are not exposed unless the operation panel case is disassembled.

W1

1

2

3

TYPE B0A, C0A

– 20 –

3) Error Display

1. Error display

* Error is informed by means of the panel display, machine head mirror LED blink and control box

buzzer.

Two different kinds of screens of the panel display screen appear due to the difference of the procedures.

1. Error screen disappears when the operator

removes the cause.

Example) The needle position is not in its UP

position.

Make the needle position UP by turning the

handwheel by hand.

2. Remove the cause of error after turning OFF

the power.

– 21 –

4) Error code list (Error display in panel)

There are the following error codes in this device. These error codes interlock (or limit function) and inform the

problem so that the problem is not enlarged when any problem is discovered. When you request our service, please

confirm the error codes.

— UP position detection error when turn- 1.When needle position is not UP position at the 1. Set to UP position by turning handwheel by hand.

ing ON the power time of turning ON the power. 2. Connect synchronizer connector.

— Smart media cover open 1. Lid of smart media slot is open. Close the lid.

E000 EEPROM initialization 1. EEPROM initialization is executed. —

2. Resistor pack is replaced.

E003 Disconnection of synchronizer connector 1. When position detection signal is not inputted from 1. Check the synchronizer connector (CN30) for loose connection and disconnection.

the sewing machine head synchronizer.2.Check whether the synchronizer cord has broken since the cord is caught in the

2. When the synchronizer has broken. machine head or the like.

E005 Synchronizer upper position sensor failure

E007 Overload of motor 1. When the machine head is locked. 1. Check whether the thread has been entangled in the motor pulley.

2. When sewing extra-heavy material beyond the 2. Check the motor output connector (4P) for loose connection and disconnection.

guarantee of the machine head.

3. When the motor does not run.

E008 Undefined machine head When the machine head connector is not properly read. Check the machine head connector (CN31) for loose connection and disconnection.

E011 Smart media not inserted Smart media is not inserted. Return after reset operation.

E012 Read error Data read from smart media is not possible. Return after reset operation.

E013 Write error Data write to smart media is not possible. Return after reset operation.

E014 Write protect Smart media is in write prohibition state. Return after reset operation.

E015 Format error Formatting cannot be performed. Return after reset operation.

E016 External media capacity over Media capacity of smart media is short. Return after reset operation.

E019 File size over File is too big. Return after reset operation.

E021 Access error Abnormality of access of file Return after reset operation.

E302 Fall detection switch failure When fall detection switch is inputted in the state that 1. Check whether the machine head is tilted without turning OFF the power switch (sewing

the power is turned ON. machine operation is prohibited for safety sake).

2. Check whether the fall detection switch cord is caught in the sewing machine or the like

and has broken.

E343 Bobbin thread remaining amount sensor 1. The device is not connected when bobbin thread 1. Check whether the device is connected.

unit trouble remaining detection function is ON. 2. Check whether bobbin thread remaining amount detection connector (CN58) is loosened

2. Failure of position sensor of the device or disconnected.

3. Failure of position solenoid of the device

E730 Motor encoder trouble (AB phase) When the motor signal is not properly inputted. 1. Check the motor signal connector (CN38 and CN39) for loose connection and

disconnection.

2.

Check whether the motor signal cord has broken since the cord is caught in the machine head

or the like.broken since the cord is caught in the machine head or the like.

E733 Reverse rotation of main shaft motor State that the sewing machine is rotating in the Turn OFF the power.

different direction from the normal rotating direction

at 500 rpm or more continues 40 times or more while

motor is running (excluding holding of needle

position).

No. Description of error detected Cause Item to be checked or corrective measure

E004 Synchronizer upper position sensor failure

E731 Motor sensor error (UVW phase)

– 22 –

E810 Solenoid short-circuit When the short-circuited solenoid is desired to be driven. Check whether the solenoid is short-circuited.

E811 Overvoltage 1. When voltage upper than guaranteed one is 1. Check whether the applied power voltage is higher than the rated voltage + (plus)

inputted. 10% or more.

2. When 200V is inputted for 100V setting. 2. Check whether 100V/200V changeover connector is set by mistake.

In the above cases, POWER circuit board has broken.

E813 Low voltage 1. When voltage lower than guaranteed one is 1. Check whether the votage is lower than the rated voltagw - (minus) 10% or less.

inputted. 2. Check whether 100V/200V changeover connector is set by mistake.

2. When 100V is inputted for 200V setting.

E920 GA failure Abnormality of gate array When return is not performed even after turning OFF the power, the possibility of gate

array breakage is large.

E922 Main shaft motor control is impossible. When main shaft motor cannot be controlled. Turn OFF the power.

E924 Motor driver failure Motor driver has broken. Turn OFF the power.

E940 Bird's nest sequence error Bird's nest prevention sequence is not completed. Turn OFF the power.

E941 GA failure Abnormality of gate array When return is not performed even after turning OFF the power, the possibility of gate

array breakage is large.

E942 EEPROM failure Writing is not completed even after the lapse of 10 Turn OFF the power.

[ms] or more.

E944 Left needle is uncontrollable. In case of LH sewing machine with organized split Check whether needle control connectors (CN55 and CN56) are loosened or discon

needle bar mechanism nected.

1. Same error is not detected yet.

2. Home position signal is ON when left needle is

locked.

3. Home position signal is OFF when left needle is

released.

E945 Right needle is uncontrollable. In case of LH sewing machine with organized split Check whether needle control connectors (CN55 and CN56) are loosened or discon

needle bar mechanism nected.

1. Same error is not detected yet.

2. Home position signal is ON when right needle is

locked.

3. Home position signal is OFF when right needle is

released.

No. Description of error detected Cause Item to be checked or corrective measure

– 23 –

5) Warning list

No. Contents and display of warning Corrective measure Remarks

A201 Replacement of oil warning • Press to close warning screen, and Refer to

perform replacement of needle. Then clear Instruction Manual

the value in the clear screen. 6-15-(2) Sewing

•Press to clear the value, and perform management

replacement of needle. information.

A202 Cleaning warning • Press to close warning screen, and Refer to

perform cleaning. Then clear the value in the Instruction Manual

clear screen. 6-15-(2) Sewing

•Press to clear the value, and perform management

cleaning. information.

A203 Replacement of needle warning • Press to close warning screen, and Refer to

perform replacement of oil. Then clear the Instruction Manual

value in the clear screen. 6-15-(2) Sewing

•Press to clear the value, and perform management

replacement of oil. information.

– 24 –

5. CONTROL BOX (SC-910/SC-910A)

(1)Connecting the cords

WARNING :

•To prevent personal injury caused by abrupt start of the sewing machine, carry out the work after turning OFF the

power switch and a lapse of 5 minutes or more.

•To prevent damage of device caused by maloperation and wrong specifications, be sure to connect all the corresponding connectors to the specified places.

•To prevent personal injury caused by maloperation, be sure to lock the connector with lock.

• As for the details of handling respective devices, read carefully the Instruction Manuals supplied

with the devices before handling the devices

Following connectors are prepared on the front face of SC-910. Connect the connectors coming from the machine

head to the corresponding places so as to fit the devices mounted on the machine head.

Optional unit A

IO circuit board A (asm.)

CN30 Synchronizer : it detects the needle bar position.

CN35 CP-160 panel : V arious kinds of programmed sew-

ing can be executed.

(Refer to the Instruction Manual for each

CN33 Not used

CN31 Machine head connector 4P

CN42 External input/output connector : input/output of

up/down detection signal, rotation

prohibition signal, etc. is prepared.

CN48 Safety switch (standard) : When tilting the sewing

machine without turning the power

OFF, the op-

eration of the sewing machine is

prohibited so as

to protect against danger.

Optional switch : by changing over the

internal

functions, 6 kinds of functions can

be selected.

CN40 Presser foot lifter solenoid. (For automatic presser

foot lifter type only)

CN46 Machine head solenid : Thread trimming, reverse-

stitching solenoid, touch-back switch, etc.

CN47 Optional circuit board connection connector : Re-

quired when using JUKI standard bobbin thread

remaining amount detection sensor, etc.

CN38, CN39

Motor signal connector

CN32 Standing machine pedal : JUKI standard PK-70,

etc. Sewing machine can be controlled with the

external signal.

CN34 IP-100 panel (LCD panel) : Various kinds of pro-

grammed sewing can be executed.

CN45 Material end detection sensor ED-4, etc.

CN43 Fan

* By adding the optional unit A, the following optional devices

of JUKI standard can be connected.

CN128 Left/right needle detection

CN127 Thread holding, thread suction, thread drawing

CN122 Needle cooler (bottom fan)

CN121 Bobbin thread remaining amount detection

CN120 +24V external power source

CN123 Needle/bobbin thread remaining amount detec-

tion sensor

CN125 External interface I/F D/A Input

CN126 Left/right lock SW, LED

CN129 Thread holding, thread suction, thread drawing,

bobbin thread remaining amount detection

– 25 –

Specified No.

Specified value

(2) Setting for functions

Functions can be selected and specified by means of the four setting switches and light emitting diode located

inside the front cover of the SC-910/SC-910A.

(Caution) • Do not perform switch operations other than those described in the following explanations.

• Be sure to re-turn the power switch ON after one second or more has passed. If the power is

turned ON immediately after turning it OFF, the sewing machine may not work normally. In

this case, turn ON the power again.

WARNING :

To avoid possible personal injuries caused by movement other than that you desired, do not operate the switches in the

procedure other than those required, as described below, to specify the functions.

How to change over to the function setting modo

1) Turn OFF the power to the unit.

2) Open the front cover.

3) Pressing switch , turn ON the power to the unit.

4) Indication will be shown on the display. (If the

indication fails to change, re-perform the procedures 1) to 3).

Switch for entering specified value changed and

updating setting No. in UP direction

Switch for entering specified value changed and

updating setting No. in DOWN direction

Up switch (UP)

Down switch (DOWN)

– 26 –

5) When you want to advance the setting No., press

switch to advance the setting No.

When you want to return the setting No., press

switch to return the setting No.

(Caution) Keep pressing switch or switch ,

and the setting No. will advance (return) continuously.

When the setting No. is advanced (returned), the contents which are before

by one (after by one) will be etemined.

So be careful when changing the Setting No.

EXAMPLE) CHANGING THE FLICKER REDUC-

ING FUNCTION (SETTING No. 5)

Press switch four times to set the setting No. to “5”.

Press switch five times to change the set No. to “5”

since the current set value is displayed on LED .

(Standard : “0”)

(Caution) Keep pressing switch or switch ,

and the setting vaue can be changed

continuously.

6) When the change has been completed, press

switch or to specify the changed value.

(Caution) 1. When turning OFF the power before

performing this work, the contents

which have been changed are not

updated.

2. Press switch , and screen display

will change to the contents of next

setting No.

3. Press switch , and screen display

will change to the contents of previous setting No.

After completing the operation, turn

OFF the power, and return the front

cover to the original position.

The machine returns to the normal

operation by turning ON the power

again.

Setting No.

– 27 –

(3)Function setting list

No. Item Description Setting range

1 Soft start The number of stitches to be sewn at a low speed when the soft-start 0 to 9 34

function function is used at the start of sewing. (Stitches)

0 : Soft-start function is not operative.

2 Material end Material end sensor function (used in case of without panel). 0/1 34

sensor 0 : Material end detection function is not operative

function 1 : After detecting material end, the specified number of stitches (No. 4) will

be sewn, and the sewing machine will stop.

3 Thread trimming Thread trimming function by material end sensor (used in case of without panel). 0/1 34

function by 0 : Automatic thread trimming function after detection of material end is not

material end operative.

sensor 1 : After detecting material end, the specified number of stitches (No. 4) will

be sewn, and the sewing machine will stop and perform automatic

thread trimming.

4 Number of Number of stitches for material end sensor (used in case of without panel). 0 to 19 34

stitches for Number of stitches from detection of material end to stop of the sewing (Stitches)

material end machine.

sensor

5 Flicker reducing Flicker reducing function (If the hand lamp flickers). 0 to 8 34

function 0 : Flicker reducing function is not operative.

1 : Less effective . 8 : Highly effective

6 Bobbin thread Bobbin thread counting function 0/1 34

counting 0 : Bobbin thread counting function is not operative.

function 1 : Bobbin thread counting function is operative.

7 Unit of bobbin Unit of bobbin thread counting down 0 to 2

thread counting 0 : Count/10 stitches

down 1 : Count/15 stitches

2 : Count/20 stitches

8 Number of Sewing speed of reverse feed stitching 180 to 3000

rotation of (r.p.m)

reverse feed

stitching

9 Thread Thread trimming prohibiting function (used in case of without panel). 0/1 34

trimming 0 :Thread trimming prohibiting function is not operative.

prohibiting 1 : Thread trimming is prohibited.

function (Output of solenoid is prohibited. : Thread trimmer and wiper)

10 Setting of Position of needle bar is specified when the sewing machine stops. 0/1 34

needle bar 0 : Predetermined lowest position

stop position 1 : Predetermined highest position

when the sewing

machine stops.

11 Click sound of Click sound of key switch mounted on PSC is specified. 0/1 34

key switch 0 : Click is not operative.

mounted on 1 : Click is operative.

PSC

12 Optinal switch Switching of function of optional switch. 0 to 8 35

function 0 : No function

selection 1 : Needle up/down compensating stitching

2 : Back compensating stitching

3 : Function of canceling once reverse feed stitching at the end of sewing

4 : Thread trimming function

5 : Presser foot lifting function

6 : One stitch compensating stitching

7 : Function of simultaneously canceling reverse feed stitching at the start

and end of sewing

8 : Neutral presser lifting changeover function

13 Function of Function of prohibiting start of the sewing machine by bobbin thread counting 0 to 2 43

prohibiting 0 : When counting is out (-1 or less) Function of prohibiting start of the

start of the sewing machine is not operative.

sewing 1 : When counting is out (-1 or less) Function of prohibiting start of the

machine by sewing machine is operative.

bobbin thread 2 : When counting is out (-1 or less) Function of forcibly prohibiting start of

counter the sewing machine is operative.

14

Sewing Counting function of sewing (number of completion of process)

0/1

35

counter 0 : Sewing counter function is not operative.

1 : Sewing counter function is operative.

15

Number of times Number of times of detection of run-out of bobbin thread remaining amount

0 to 19

of detection of 0 : Function of bobbin thread remaining amount is not operative.

run-out of 1 to 19 : Number of times during which the signal is not made even if run-out

bobbin thread of bobbin thread remaining amount is detected.

remaining

amount

1

0

2

0

3

0

4

5

5

0

6

1

7

0

8

1900

9

0

10

0

11

1

12

0

13

0

14

0

15

1

Indication of Ref.

function setting page

– 28 –

No. Item Description Setting range

18 Bird’s nest This function is effective in combination with the machine head with bird's nest 0 to 2 35

prevention prevention function (optional unit A is necessary).

function 0 : Bird's nest prevention function is not operative.

1 : Bird's nest prevention function is operative.

2 : Bird's nest prevention function is operative.(with tension release)

19 Needle thread This function is effective in combination with the machine head with bird's nest 0 to 1 35

release prevention function (optional unit A is necessary).

function at the 0 : Needle thread release function is not operative.

sewing start 1 : Needle thread release function is operative.

20 Number of This function is effective in combination with the machine head with bird's nest 0 : Function 35

condensation prevention function (optional unit A is necessary). OFF

stitches 0 : Condensation function is not operative. 1 to 9 stitches

1 to 9 : Number of condensation stitches

21 Function of Function of lifting presser foot when the pedal is in neutral position. 0/1 35

neutral 0 : Function of neutral automatic presser lifting is not operative.

presser lifting 1 : Selection of function of neutral presser lifting.

22 Function of Function of needle up/down compensating switch on the operation panel can 0/1 35

changeover of be changed.

compensating 0 : Needle up/down compensation

switch on the 1 : One stitch compensation

operation

panel function

24 Function of fine Number of rotation can be compensated. -1.5% to 1.5% 43

adjustment of Be sure to normally use this function with "0". (0.1%)

number of

rotation

25 Thread trimming This function sets the thread trimming motion after DOWN position has been 0/1 36

motion condition off by turning handwheel by hand.

0 : Thread trimming after turning handwheel by hand is permitted.

1 : Thread trimming after turning handwheel by hand is prohibited.

26 Function of This function prevents the sewing machine from the reverse rotation after it 0 to 9 36

setting the has stopped.

holding force 0 : Initial value

after stop 1 : Less effective -> 9 : Highly effective

27 Function of This function sets the magnitude of return force of the needle bar before the 1 to 100 36

setting the retry motion.

reaction force 1 : Less return force -> 100 : High return force

at the time of

retry

28 Number of This function is effective in combination with the machine head with bird's nest 0 to 30 36

stitches of prevention function (optional unit A is necessary). (Stitches)

needle thread This function sets the number of stitches grasping thread at the sewing start.

release 0 to 30 stitches

29 Suction time of This function sets the suction motion time of the back-tack solenoid. 50 to 300 36

the first start of 50 ms to 300 ms (ms)

the back

solenoid

30 Function of Function of reverse feed stitching on the way 0/1 37

reverse feed 0 : Function of reverse stitching on the way is not operative.

stitching on 1 : Function of reverse feed stitching on the way is operative.

the way

31 Number of Number of stitches of reverse feed stitching on the way. 0 to 19 37

stitches of (Stitches)

reverse feed

stitching on

the way

32 Effective condition Effective condition of reverse feed stitching on the way 0/1 37

of reverse feed 0 : Function is not operative when the sewing machine stops.

stitching on the 1 : Function is operative when the sewing machine stops.

way when the

sewing machine

is stopping.

33 Thread trimming Thread trimming function by reverse feed stitching on the way 0/1 37

function by 0 : Automatic thread trimming function after completion of reverse feed

reverse feed stitching on the way is not operative.

stitching on 1 : Automatic thread trimming after completion of reverse feed stitching on

the way the way is performed.

35 Number of Lowest speed by pedal 20 to 400 43

rotation at a (r.p.m.)

low speed

36 Number of Thread trimming speed 20 to 250

rotation of (Caution) Do not change the set value. (r.p.m.)

thread When it is changed, the sewing machine is apt to be broken.

trimming

18

1

19

0

20

0

21

0

22

0

24

0

25

1

26

0

27

50

28

1

29

250

30

0

31

4

32

0

33

0

35

200

Indication of Ref.

function setting page

36

210

– 29 –

37 Number of Sewing speed at the start of sewing (soft-start) 150 to 5500 34

rotation of (r.p.m.)

soft-start

38 One-shot One-shot speed (The max. value depends on the number of rotation of the 200 to MAX 37

speed sewing machine head.) (r.p.m.)

39 Pedal stroke at Position where the sewing machine starts rotating from pedal neutral position 1.0 to 5.0 38

the start of (Pedal stroke) (0.1mm)

rotation

40 Low speed Position where the sewing machine starts accelerating from pedal neutral 1.0 to 10.0 38

section of position (0.1mm)

pedal (Pedal stroke)

41 Starting position Position where the cloth presser starts lifting from pedal neutral position

-6.0 to 5.0 38

of lifting presser (Pedal stroke) (0.1mm)

foot by pedal

42 Starting position Starting position of lowering presser foot 0.8 to 5.0 38

of lowering Stroke from the neutral position (0.1mm)

presser foot

43 Pedal stroke 2 Position 2 where the thread trimming starts from pedal neutral position (When

-6.0 to -1.0 38

for starting the function of lifting presser foot by pedal is provided.) (Pedal stroke) (0.1mm)

thread trimming

44 Pedal stroke for Position where the sewing machin reaches its highest sewing speed from 1.0 to 15.0 39

reaching the pedal neutral position (Pedal stroke) (0.1mm)

maximum number

of rotation

45 Compensation Compensation value of the pedal sensor -15 to 15 39

of neutral point

of the pedal

46 Auto-lifter Auto-lifter selection 0/1

selecting 0 : Solenoid drive system

function 1 : Pneumatic drive system

47 Holding time of Limitation time of waiting for lifting solenoid type auto-lifter device 10 to 600 39

lifting auto-lifter (second)

48 Pedal stroke 1 Position where thread trimming starts from pedal neutral position (Standard -6.0 to -1.0 39

for starting pedal) (Pedal stroke) (0.1mm)

thread trimming

49 Lowering time Lowering time of presser foot after the pedal has been depressed. 0 to 250 41

of presser foot (Start of rotation of the sewing machine is delayed during this time.) (10ms)

51 Compensation Compensation of starting the solenoid for reverse feed stitching when reverse -36 to 36 39

of solenoid-on feed stitching at the start of sewing is performed. (10°)

timing of reverse

feed stitching at

the start of sewing

52 Compensation Compensation of releasing the solenoid for reverse feed stitching when reverse -36 to 36 39

of solenoid-off feed stitching at the start of sewing is performed. (10°)

timing of reverse

feed stitching at

the start of sewing

53 Compensation Compensation of releasing the solenoid for reverse feed stitching when reverse -36 to 36 40

of solenoid-off feed stitching at the end of sewing is performed. (10°)

timing of reverse

feed stitching at

the end of sewing

55 Foot lift after Function of lifting presser foot at the time of (after) thread trimming 0/1 40

thread trimming 0 : Not provided with the function of lifting presser foot after thread trimming

1 : Provided with the function of lifting presser foot automatically after thread

trimming

No. Item Description Setting range

37

800

38

2500

39

30

40

60

41

-21

42

10

43

-51

44

150

45

0

46

0

47

60

48

-35

49

140

51

-6

52

-4

53

-9

55

1

Indication of Ref.

function setting page

– 30 –

No. Item Description Setting range

56 Reverse Function of reverse revolution to lift the needle at the time of (after) thread 0/1 40

revolution to lift trimming

the needle after 0 : Not provided with the function of reverse revolution to lift the needle

thread trimming after thread trimming

1 : Provided with the function of reverse revolution to lift the needle after

thread trimming

57 Bobbin thread Function of detecting bobbin thread remaining amount at the time of (after 0/1 40

remaining thread trimming

amount 0 : Not provided with the function of detecting bobbin thread remaining

detection amount

function 1 : Provided with the function of detecting bobbin thread remaining amount

58 Function of Function of holding predetermined upper/lower position of the needle bar 0/1 40

holding 0 : Not provided with the function of holding predetermined upper/lower

predetermined position of the needle bar

upper/lower 1 : Provided with the function of holding predetermined upper/lower position

position of the of the needle bar

needle bar

59 Function of This function can specify the sewing speed of reverse feed stitching at the start 0/1 40

Auto/Manual of sewing.

change-over of 0 : The speed will depend on the manual operation by pedal, etc.

reverse feed 1 : The speed will depend on the specified reverse feed stitching speed

stitching at the (No. 8).

start of sewing

60 Function of stop Function at the time of completion of reverse feed stitching at the start of sewing 0/1 41

immediately 0 : Not provided with the function of temporary stop of the sewing machine

after reverse at the time of completion of reverse feed stitching at the start of sewing

feed stitching at 1 : Provided with the function of temporary stop of the sewing machine at

the start of the time of completion of reverse feed stitching at the start of sewing.

sewing

61

Function of starting

Function of starting prohibition of the sewing machine by detection of bobbin 0/1 40

prohibition of thread remaining amount

the sewing 0 : This function does not stop the sewing machine when counting is out

tmachine by (-1 or less).

detection of 1 : This function stops the sewing machine when counting is out (-1 or less).

bobbin thread

remaining amount

64 Change-over Initial speed when starting condensation stitch or EBT 0 to 250 43

speed of (rpm)

condensation

stitch or EBT

(end back tack)

65 On-timing of Starting (compensation) timing of solenoid for compensation stitch : -1 -36 to 0 35

solenoid for Compensation value of starting the solenoid when condensation stitch is (10°)

condensation performed by 1 stitch.

stitch (when

condensation

stitch is performed

by 1 stitch.)

66 On-timing of Starting (compensation) timing of solenoid for condensation stitch : -2 -36 to 0 35

solenoid for Compensation value of starting the solenoid when condensation stitch is (10°)

condensation performed by 2 stitches.

stitch (when

condensation

stitch is performed

by 2 stitches.)

67 Number of Not used. 0 to 9

times of (Stitches)

drives of airpurge

68 Start-up Not used. 0 to 35

position of (10°)

airpurge

69 Pause Not used. 0 to 35

position of (10°)

airpurge

70 Function of Presser foot is slowly lowered. 0/1 41

soft-down of 0 : Presser foot is rapidly lowered.

presser foot 1 : Presser foot is slowly lowered.

71 Function of Speed limitation is performed at the time of re-acceleration on the way of 0 to 5 41

limitation of re- reducing speed of the sewing machine.

acceleration It is effective when operating inching sewing.

from reduction

of speed

56

0

57

0

58

0

59

1

60

0

61

1

64

180

65

-15

66

-15

67

2

68

27

69

12

70

0

71

0

Indication of Ref.

function setting page

– 31 –

72 Function of Speed limitation is performed at the time of start-up of the sewing machine 0 to 5 41

limitation of (excluding the start of sewing).

acceleration at It is effective when operating inching sewing.

the start of

rotation

73 Retry function This function is used when needle cannot pierce materials . 0/1 41

0 : Normal

1 : Retry function is provided.

75 Rotating Normal rotating direction of motor 0/1 43

direction of 0 : Clockwise

motor 1 : Counterclockwise

76 Function to Starting curve of the sewing machine is selected. 0/1 42

select the start- 0 : Normal curve

up speed of the 1 : More sharp curve

sewing machine

87 Function of Pedal curve is selected. (Improving pedal inching operation) 0/1/2 42

pedal curve

selection

89 Tension Not used 0/1 36

release

function

91 Function of Function of compensating stitching when turning handwheel by hand at the 0/1 43

prohibiting time of completion of constant-dimension stitching

compensation 0 : Function of compensating stitching is effective.

operation after 1 : Function of compensating stitching is prohibited.

turning

handwheel by

hand

92 Function of Function to reduce speed at the time of completion of reverse feed stitching 0/1 41

reducing speed at the start of sewing.

stitching at the 0 : Speed is not reduced.

start of sewing 1 : Speed is reduced.

93 Function added Operation of needle up/down compensating switch is changed after turning 0/1 42

to needle up/ ON the power or thread trimming.

down compen- 0 : Normal (needle up/down compensating stitching only)

sating switch 1 : One stitch compensating stitching is performed only when aforementioned

changeover is made. (Upper stop / upper stop)

94

Continuous In IP-100 program functions, a function that does not stop the sewing machine 0/1 42

stitching + one- by combining continuous stitching with one-shot stitching when the step is

shot stitching changed.

non-stop function 0 : Normal (The sewing machine stops when a step is completed.)

1 : The sewing machine does not stop when a step is completed and

proceeds to next step.

96 Max. number of Max. number of rotation of the sewing machine head can be set. 50 to MAX 42

rotation setting * Setting varies in accordance with resistance pack to be connected. (r.p.m.)

100 Number of Not used 0 to 2 36

stitches of

tension release

motion at the

sewing start

101 Sewing This function selects the input destination of the sewing counter. 0/1 42

counter input 0 : Every time thread trimming is performed, the counter automatically

function counts up.

1 : The counter counts up by inputting of the external sewing counter SW

104 PWM when Not used. (Do not change the set value.) 30 to 200

start of

rotation is

locked

105 Touch back When the IP-100 is connected and a corner pattern is selected, this function 0/1 44

switch 1 needle provides the capability of stitch compensation during in-cornersewing with

compensation the aid of a touch back switch.

function 0: OFF Compensation sewing disabled with the touch back switch

1: ON Compensation sewing enabled with the touch back switch

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine

head.

104

40

87

0

No. Item Description Setting range

76

0

89

0

91

1

92

0

93

0

94

0

96

4000

100

0

101

0

72

0

Indication of Ref.

function setting page

73

0

75

0

Number of rotations

2

0

Pedal stroke

1

105

0

– 32 –

No. Item Description Setting range

106 Presser lifter When the IP-100 is connected and a corner pattern is selected, this function 0/1 44

switch 1 needle provides the capability of stitch compensation during in-corner sewing the

compensation the aid of a presser lifter switch.

function 0: OFF Compensation sewing disabled with the presser lifter switch

1: ON Compensation sewing enabled with the presser lifter switch

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine

head.

* When using this function, it is necessary to set up the presser lifter function

selection (No.117) at 0 (function disabled).

107 In-corner sewing When the IP-100 is connected and a corner pattern is selected, this function 0/1 44

one-shot function is used to perform automatic one-shot sewing for in-corner sewing.

0: OFF Automatic one-shot sewing disabled during in-corner sewing

1: ON Automatic one-shot sewing enabled during in-corner sewing

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine

head.

108 In-corner presser When the IP-100 is connected and a corner pattern is selected, this function 0/1 44

lifter function is used to perform automatic presser rising after the completion of in-corner

sewing.

0: OFF

Automatic presser rising disabled after the completion of in-corner sewing

1: ON

Automatic presser rising enabled after the completion of in-corner sewing

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine head.

* This function is available only if the automatic presser lifter unit (AK) is connected.

109 Re-sewing When the IP-100 is connected, this function is used to stop/start sewing again 0/1 45

function (sewing retried in the middle of operation).

0: OFF Re-sewing function disabled

1: ON Re-sewing function enabled

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine head.

110 Unilateral needle When a reverse or overlapped stitching pattern is selected, this function is 0/1 45

selection function used to stop/start the unilateral needle selection. When 0 (disable) is selected,

(Free stitching/ unilateral needle selection is disabled for the reverse or overlapped stitching

overlapped pattern.

stitching) 0: OFF Unilateral needle selection function (during free stitching) disabled

1: ON Unilateral needle selection function (during free stitching) enabled

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine head.

111 Unilateral needle When the IP-100 is connected and a corner pattern is selected, this function is 0/1 45

selection function used to stop/start the unilateral needle selection. When 0 (disable) is selected,

(Corner pattern) arbitrary unilateral needle selection is disabled for the corner pattern.

0: OFF Unilateral needle selection function (during corner pattern) disabled

1: ON Unilateral needle selection function (during corner pattern) enabled

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine head.

112 Selection of Selection of operation available when the teaching switch is pressed. 0 to 2 45

teaching 0: Normal (Teaching operation is performed under the conditions of teaching

operation + unilateral needle selection.)

1: Teaching operation only by unilateral needle selection (It is unnecessary

to press the teaching switch in order to start up the teaching operation.)

2: Teaching operation disabled in the bilateral needle selection (Press the

teaching switch after the unilateral needle state has been assumed.)

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine head.

113 Number of Selection of the number of reproduced stitches when corner teaching 0/1 46

stitches for (measuring the number of stitches for unilateral needle sewing) is carried out.

teaching replay 0: The number of replay stitches coincides with that of measured stitches.

1: The number of replay stitches is less by 1 than that of measured stitches.

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine head.

114Left bobbin When the IP-100 is connected, this function is used to stop/start the left 0/1 46

thread counter bobbin thread counter.

function 0: OFF Left bobbin thread counter function disabled

1: ON Left bobbin thread counter function enabled

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine head.

115 Right bobbin When the IP-100 is connected, this function is used to stop/start the right 0/1 46

thread counter bobbin thread counter.

function 0: OFF Right bobbin thread counter function disabled

1: ON Right bobbin thread counter function enabled

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine head.

107

0

108

1

109

1

110

1

111

1

112

0

113

0

114

1

115

1

Indication of Ref.

function setting page

106

1

– 33 –

No. Item Description Setting range

116 Selection of When the IP-100 is connected, switch selection is performed to start in-corner 0 to 6 46

corner teaching sewing in the case of corner pattern sewing.

start switch 0: No function

1: Left needle selector switch

2: Right needle selector switch

3: Teaching switch

4: Optional switch

5: Knee switch, presser lifter switch

6: No function (Don’t care.)

* When 1: left needle selector switch, 2: right needle selector switch, or

3: teaching switch is selected for the in-corner selector switch, set No.111

unilateral needle selection function (corner pattern) at 0 (function disabled),

without fail.

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine head.

117 Selection of When the knee switch is connected, selection is performed to stop/start the 0/1 47

presser lifter automatic presser lifter function by means of the knee switch.

switch function 0: OFF The automatic presser lifter is stopped with the knee switch.

1: ON The automatic presser lifter is used with the knee switch.

* Setting is possible only if LH-4168 or LH-4188 is selected for the machine head.

* When using this function, it is necessary to set up the presser lifter switch 1

(No.106) at 0 (function disabled).

118 Grease up error In the case of grease-up error (E220, E221), this error is cleared by setting 0/1 47

reset the setup description at 1.

0: Normal condition

1: Grease-up error reset when the power is turned on for the next time

(After grease-up error has been reset, this function is also canceled.)

* Prior to resetting the grease-up error, grease-up treatment is always needed.

* Setting is possible only for the machine head (part of the LH-4100 or

LH-3500 Series) where grease-up treatments are needed.

116

5

117

0

118

0

Indication of Ref.

function setting page

– 34 –

(4)Detailed explanation of selection of functions

11

11

1

Selection of the soft-start function (Function setting No. 1)

The needle thread may fail to interlace with the bobbin thread at the start of sewing when the stitching pitch

(stitch length) is small or a thick needle is used. To solve such problem, this function (called “soft-start”) is used

to limit the sewing speed, thereby assuring successful formation of the starting stitches.

0 : The function is not selected.

1 to 9 : The number of stitches to be sewn under the soft-start mode.

The sewing speed limited by the soft-start function can be changed. (Function setting No. 37)

Data setting range

150 to 5,500 rpm <50 rpm>

22

22

2

Material end sensor (ED : optional) function (Function setting No. 2 to 4)

This function is possible when the material end sensor (ED) is attached.

As for the details, refer to the instruction manual for the material end sensor.

(Caution) Setting will be invalid when the material end sensor is not attached, or CP-160 or higher class

model is connected.

33

33

3

Flicker reducing function (Function setting No. 5)

The function reduces flickering of the hand lamp at the start of sewing. The higher the set value increases, the

more effective the function will work.

Setting range

0 to 8

0 : Flicker reducing function does not work.

to

8 : Flickering is effectively reduced.

(Caution) The more effective the flicker reducing function works (the more the set value is made), the

lower the start-up speed of the sewing machine will become.

44

44

4

Bobbin thread counting function (Function setting No. 6)

When the control panel (CP-160 or higher class model) is used, the function subtracts from the predetermined

value and indicates the used amount of bobbin thread.

For the details, refer to the instruction manual for the control panel.

(Caution) If “0” is set, the LCD indication on the control panel will go out and the bobbin thread counting

function will be invalid.

55

55

5

Thread trimming prohibiting function (Function setting No. 9)

This function turns OFF thread trimming solenoid output and wiper solenoid output when thread trimming is

actuated. [If the control panel (CP-160 or higher class model) is used with the sewing machine, this function will

work in accordance with the function setting on the control panel.]

By this function, separate sewing material can be spliced and sewn without trimming thread.

0 : off Thread trimming is operative. (thread can be trimmed).

1 : on Thread trimming is inoperative. (thread can not be trimmed).

66

66

6

Setting of the needle bar stop position when the sewing machine stops (Function setting No. 10)

The position of the needle bar when the pedal is in its neutral position is specified.

0 : Down The needle bar stops in the lowest position of its stroke.

1 : Up The needle bar stops in the highest position of its stroke.

(Caution) If the stop position of the needle bar is set to the highest position, the thread trimming action

will be taken after the needle bar comes down once to the lowest position.

77

77

7

Sound of click of the key switch mounted on the PSC box (Function setting No. 11)

This function selects whether the sound is effective or ineffective when operating the four key switches mounted

on the PSC box.

0 : off The sound of click is ineffective.

1 : on The sound of click is effective.

1

0

37

800

5

0

9

0

10

0

11

1

– 35 –

88

88

8

Optional switch function selection (Function setting No. 12) : It is used only when it is combined with the

machine head provided with the optional switch.

Functions to be assigned to the optional switch can be selected from the following functions.

0 : No function (Standard setting)

1 : Needle up / down compensating stitching : Every time the switch is pressed, normal feed

stitching by half stitch is performed. (Same operation as that of up / down compensating

stitching switch on the panel.)

2 : Back compensating stitching : Reverse feed stitching is performed at low speed while

the switch is held pressing. (It is effective only when constant dimension sewing pattern

is selected with the CP-160 or higher class model.)

3 : Function of canceling once reverse feed stitching at the end of sewing : By depressing

the back part of the pedal after pressing the switch, operation of reverse feed stitching is

canceled once.

4 : Thread trimming function : This function is actuated as the thread trimming switch.

5 : Presser foot lifting function : This function is actuated as the foot lifter switch.

6 : One stitch compensating stitching : Every time the switch is pressed, one stitch stitching

operation is executed.

7 : Function of simultaneously canceling reverse feed stitching at the start and end of sewing :

By operating the optional switch, ineffective/effective can be alternately changed over.

8 : Function of neutral presser lifting change-over : By operating the optional switch, ON/

OFF can be changed over alternately.

(Note) Indication of reverse feed stitching at the start and

end of sewing on the operation panel is the same

even when the function is canceled. So, be careful.

99

99

9

Sewing counting function (Function setting No. 14)

The function counts up every time thread trimming is completed and counts the number of completion of the

sewing process.

This can be realized together with the IP-100 control panel. Refer to the explanation of the control panel.

0 : Sewing counter function is not operative.

1 : Sewing counter function is operative.

(Indication on the IP-100 control panel will go out as well.)

00

00

0

Bird’s nest prevention function (Function setting No. 18 to 20, 28, 65, 66, 89, 100)

This function prevents the thread from being entangled at the sewing start.

This function is used only when it is combined with the sewing machine head with bird’s nest prevention specifications.

(When using this function, the optional unit A is necessary.)

1. Bird’s nest prevention function (Function setting No. 18)

0 : Bird’s nest prevention function is ineffective.