Page 1

ENGLISH

ii

Page 2

CONTENTS

1. SPECIFICATIONS .................................................................................... 1

2. SET-UP ..................................................................................................... 1

1. Installing the motor unit ......................................................................................... 1

2. Installing the control box ....................................................................................... 1

3. Installing the belt .................................................................................................... 2

4. Adjusting the pulley cover ..................................................................................... 2

5. Installation and adjustment for the protecting pin

and the belt slip-off preventing bracket................................................................ 3

6. Connecting the cords .............................................................................................. 4

7. Attaching the connecting rod ............................................................................... 11

3. FOR THE OPERATOR ........................................................................... 11

1. Operation of SC-500 ............................................................................................. 11

2. Explanation of the operation panel ..................................................................... 13

3. Setting for functions of SC-500 ........................................................................... 18

4. Function setting list .............................................................................................. 20

5. Detailed explanation of selection of functions .................................................. 24

6. Automatic compensation of neutral point of the pedal sensor ........................ 32

7. Bobbin thread remaining amount detection device, AE ................................... 32

8. Connection of the pedal of standing-work machine ......................................... 32

9. Setting of the auto lifter function ........................................................................ 33

10. Connection of the material end sensor (ED) ..................................................... 33

11. Initialization of the setting data .......................................................................... 34

4. MAINTENANCE ...................................................................................... 34

1. Replacing the fuse ................................................................................................ 34

2. Changing procedure between 100V to 120V and 200V to 240V

(Possible only for the voltage changeover type) ............................................... 36

3. Error codes ............................................................................................................ 37

Page 3

1. SPECIFICATIONS

Supply voltage Single phase 100 to 120V 3-phase 200 to 240V Single phase 200 to 240V

Frequency 50 Hz / 60 Hz 50 Hz / 60 Hz 50 Hz / 60 Hz

Operating environment

Input 390VA (LZ-228* : 460VA) 390VA (LZ-228* : 460VA) 390VA (LZ-228* : 460VA)

(Caution) 1. Indication of the power consumption is the mean power consumption when DDL-8700

is mounted in accordance with the operating conditions JUKI specifies.

2. The power consumption changes in accordance with the operating conditions and the

mounted machine head. So, be careful.

3. Instantaneous maximum power consumption may become 1.5 times or more than the

mean power consumption.

Temperature : 0 to 40˚C Temperature : 0 to 40˚C Temperature : 0 to 40˚C

Humidity : 90% or less Humidity : 90% or less Humidity : 90% or less

2. SET-UP

Install the motor unit to the control box following the instructions below.

1. Installing the motor unit

Install the motor unit on the table with the fitting bolt

asm. supplied with the unit as accessories.

1

Convex

washer

Nat

Spring

washer

At this time, insert the nuts and washers supplied with

the unit as accessories as shown in the figure so that

the motor unit can be securely fixed on the table.

1) Press three bolts 1 supplied with the unit as

accessories into the motor hanging bolt hole in the

table and fix them.

2) Temporarily tighten convex washer, spring washer

and nut on the side where two bolts are attached.

3) Hang the motor unit to the washer which has been

temporarily tightened, and attach convex washer,

spring washer and nut to the other bolt on the

opposite side.

4) After adjusting the installing position of the motor,

securely tighten the respective nuts.

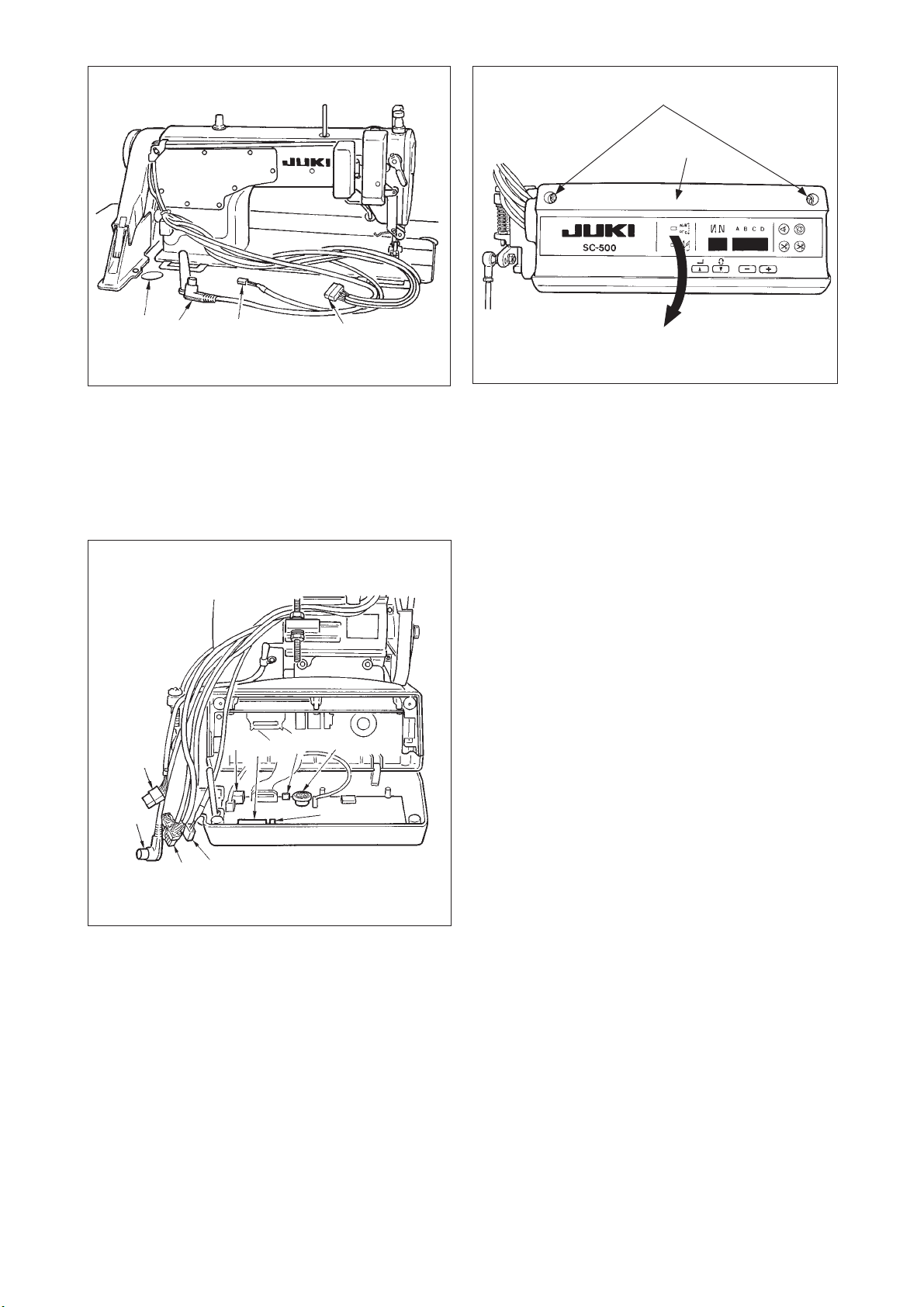

2. Installing the control box

2

3

1) Loosen four screws 2 supplied with the motor unit

as accessories, tighten screws 2 after hanging

control box unit 3 to the screws, and fix control

box unit 3.

− 1 −

Page 4

3. Installing the belt

15mm (9.8N)

Tension

adjust nuts

4. Adjusting the pulley cover

b

Belt

a

1

1) The belt distance, between sewing machine pulley

and motor pulley, must be parallel.

2) The belt tension should be adjusted by turning the

tension adjust nuts to change height of the motor,

so that the belt sinks down by about 15 mm (9.8N)

when it is depressed by band at the center of the

belt span.

If the belt tension is not tight, speed is unstable at

low-speed or medium-speed operation, and the

needle will not stop exactly in position.

1) After adjusting the belt tension, adjust the pulley

cover 1 so that the clearances between the belt

and the pulley cover 1, a and b should be the

same.

2) After the completion of adjustment, tighten screws

2 located on the side of pulley cover 1 and

securely fix the pulley cover 1 so that it does not

slip out of position.

1

2

− 2 −

Page 5

5. Installation and adjustment for the protecting pin and the belt slip-off preventing bracket

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1) Attaching hole for the protecting pin

To attach protecting pin 1, select either attaching

hole A or attaching hole B in the motor pulley cover

2

3

1

Belt

in accordance with the direction of rotation of the

sewing machine and attach the pin in the selected

hole using screw 2 and washer 3 supplied with

the unit.

a) If the motor shaft rotates in direction A in the

figure on the above:

/ Attach protecting pin 1 in attaching hole A .

b) If the motor shaft rotates in direction B in the

figure on the above:

/ Attach protecting pin 1 in attaching hole B .

Attaching

hole A

A

4 mm or less

Belt

4 mm or less

Adjusting position for protecting pin

Pulley

cover

1

Belt

3 mm or less

Attaching

hole B

B

Motor

pulley

5

4

Adjusting position for belt slip-off preventing braket

2) Adjustment for the protecting pin and the belt slip-

off preventing bracket

Adjust the position of protecting pin 1 and belt slip-

off preventing bracket 4 in accordance with the

figure on the left.

a) Adjusting the protecting pin

Loosen screw 2 and adjust so that protecting

pin 1 is positioned at the location indicated in

the figure on the left.

b) Adjusting belt slip-off preventing bracket

Loosen screw 5 and adjust so that belt slipoff preventing bracket 4 is positioned at the

location indicated in the figure on the left.

If protecting pin 1 is not properly adjusted, it

is possible that your fingers may be caught in

the clearance provided between the pulley and

the belt resulting in injury. If belt slip-off

preventing bracket 4 is not properly adjusted,

it is possible to allow the belt to slip off causing

safety hazard.

3) After the adjustment, tighten screws 2 and 5 so

as to secure protecting pin 1 and belt slip-off

preventing bracket 4 to prevent these components

to fluctuate because of vibration.

4) Before starting the operation of the sewing

machine, ascertain that protecting pin 1 and belt

slip-off preventing bracket 4 do not come in contact

with the pulley and the belt.

− 3 −

Page 6

6. Connecting the cords

WARNING :

• To prevent personal injury caused by abrupt start of the sewing machine, carry out the work after

turning OFF the power switch and a lapse of 5 minutes or more.

• To prevent damage of device caused by maloperation and wrong specifications, be sure to connect

all the corresponding connectors to the specified places.

• To prevent personal injury caused by maloperation, be sure to lock the connector with lock.

• As for the details of handling respective devices, read carefully the Instruction Manuals supplied

with the devices before handling the devices.

Following connectors are prepared when loosening the front cover fixing screws A of SC-500 and opening the

cover. Connect the machine head connectors to the positions corresponding to each other so as to fit the

devices mounted on the machine head.

OPC circuit board A (asm.)

A

1

Front cover

4

5

2

6

3

A

9

!0

!1

7

!2

!3

!4

!5

!6

8

1 CN30 Motor signal connector

2 CN32 Machine head connector

3 CN33 Needle bar position detector connector

4 CN36 Machine head solenoid connector

5 CN37 Presser foot lifter solenoid connector

6 CN38 CP-160 panel connector

7 CN39 Standing machine pedal connector

8 CN40 Signal for extension connector (For the details, refer to Engineer's Manual.)

9 CN51 Not used

!0 CN52 Not used

!1 CN53 Bobbin thread remaining amount detection solenoid connector

!2 CN189 External interface signal connector

!3 CN59 Bobbin thread count-up output connector

!4 CN55 Material end detection sensor (ED) connector

!5 CN58 Standing machine pedal connector

!6 CN57 Bobbin thread remaining amount detection sensor connector

− 4 −

Page 7

5

4

A

2

3

1

1) Pass the cords 笊 of the thread trimming solenoid,

reverse-stitching solenoid, etc., and the cords of

the synchronizer 笆, machine head 4P connector

3through hole A in the table to route them down

under the machine table.

!0

7

8

9

6

2

1

3

!1

2) Loosen setscrew 5 in front cover 4.

3) Pressing the side of front cover 4 in the direction

of the arrow, open the front cover toward you.

Note : Be sure to open / close the front cover with

your hands.

4) Connect 14P code 1 coming from the machine

head to connector 7 (CN36).

5) Connect 4P connector coming from the machine

head 3 to connector 8 (CN32).

6) Connect 7P connector 2 coming from the machine

head to connector 9 (CN33).

7) When the optional AK device is attached, connect

2P connector coming from the AK device to

connector !1(CN37) .

8) Connect the connector 6 coming from the motor

to connector !0 (CN30) on the circuit board.

(Caution)

1. When using the AK device, set whether to

use the AK device after confirming how to

select the auto-lifter function. (Refter to

page 33.)

2. Be sure to securely insert the respective

connectors after checking the inserting

directions since all connectors have the

inserting directions.

(When using a type with lock, insert the

connectors until they go to the lock.)

The sewing machine is not actuated unless

the connectors are inserted properly.

In addition, not only the problem of error

warning or the like occurs, but also the

sewing machine and the control box are

damaged.

3. Perform the insertion of the connector by

lending your hands to the front cover.

− 5 −

Page 8

!4

!3

!2

[ Connection of the connector for CP panel ]

Exclusive connectors are prepared for connection of

the connector for CP-160.

Paying attention to the orientation of the connector

!2, connect it to connector !3 located on the circuit

board. After connecting, securely lock the connector.

9) After inserting the connector, put all cords together

with cable clip band !4 located on the side of the

box.

(Caution)

1. Fix the cord clamp and the cable clip band

following the attaching procedure.

2. When removing the cable clip band,

remove it while pressing the hook of the

cable clip band.

How to fix cable clip band !4

Pull

Pull

How to remove cable clip band

Push

Push

Pushing the hook portion, push the band to remove it.

Push

Push the hook.

(Caution) 1. Fix the cable clip band following the attaching procedure as shown in the figure.

2. To remove the cable clip band, push the cable clip band until it comes off while pressing

the hook of the band following the removing procedure as shown in the figure.

− 6 −

Page 9

5

!5

4

!6

!8

!7

10) Close front cover 4 while paying attention to

pinching of the wire.

11) After that, fix it with the screw 5.

!9

!9

12)Connect connector 4P !5 to connector !

6 locat

on the side of the box.

13)Connect motor

outpu

t cord !7 of the power switch

to connector !8.

14)Binding of the cords coming from machine head

Bind the cable attached to the machine head at

two places with the cable clip band !9 supplied with

the unit as accessories as shown in the figure.

(Do not bind the motor signal cable together.)

ed

@0

15)Make sure that the power switch is turned OFF

and insert power supply cord @0 coming from the

power switch into the power plug socket.

(Caution)

1. Check again the supply voltage indicated

on the control box before connecting the

power cord.

2. Prepare the power switch conformed to the

safety standard.

3. Be sure to connect the ground wire ( green

/ yellow).

− 7 −

Page 10

[ For CE specifications only ]

2

1) Remove three screws 1 located on the side of the

control box.

1

2) Set power source cover installing plate 2 supplied

with the unit as accessories to the control box main

unit with the three screws which have been

removed.

4

Crimp style terminal section

3

3) Remove nut section 4 from cord bush 3 supplied

with the unit as accessories.

4) After checking the direction of the nut, pass the

nut through the power source cord supplied with

the unit as accessories.

(Caution) Note that the flat face of the nut should

face the power source cover installing plate

side.

5) Pass the terminal of the power source cord through

the hole from the inside of the power source cover

installing plate.

6) Pass the cord bush, while paying attention to the

direction, through the power source cord from the

power source cord terminal side.

4

5

b

7) Insert connector 5 of the power source cord to

the connector (top) of the control box.

(Caution) Securely insert the connector while

paying attention to the direction.

8) Tighten nut 4 and securely fix the cord bush to the

installing plate.

9) Clamp section b of the cord bush and securely fix

it to the cord.

− 8 −

Page 11

6

7

10) Insert connector 6 coming from the motor to the

connector of the control box from the inside.

11) Securely fix power source cover 7 supplied with

the unit as accessories to power source cover

installing plate 2 with two screws 8 supplied with

the unit as accessories while being careful that the

cord is not caught by the cover.

8

* For handling the cable, refer to 14) and 15) of 6. Connecting the cords.

− 9 −

Page 12

[ For LA specifications only ]

1

2

1) Remove three screws 1 located on the side of the

control box.

3

4

2) Set power source cover installing plate 2 supplied

with the unit as accessories to the control box main

unit with the three screws which have been

removed.

3) Pass the terminal of the power source cord through

the hole from the inside of the power source cover

installing plate.

4) After checking the direction of the nut 3, pass the

nut through the power source cord supplied with

the unit as accessories and insert it into the conduit.

(Caution) Note that the flat face of the nut should

face the power source cover installing plate

side.

5) Securely fix it to the installing fittings with nut 3

from both sides.

5

6

6) Insert connector 4 of the power source cord to the connector (top) of the control box.

(Caution) Securely insert the connector while paying attention to the direction.

7) Securely fix power source cover 5 supplied with the unit as accessories to power source cover installing

plate 2 with two screws 6 supplied with the unit as accessories while being careful that the cord is not

caught by the cover.

* For handling the cable, refer to 14) and 15) of 6. Connecting the cords.

− 10 −

Page 13

7. Attaching the connecting rod

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and a lapse of 5 minutes or more.

1) Fix connecting rod 1 to installing hole B of pedal

lever 2 with nut 3.

2) Installing connecting rod 1 to installing hole A will

lengthen the pedal depressing stroke, and the pedal

operation at a medium speed will be easier.

2

1

3

A

B

3. FOR THE OPERATOR

1. Operation of SC-500

笊

笆

1) Press ON button 笊 of the power switch to turn ON

the power.

(Caution) When the buzzer is kept beeping

immediately after turning ON the power,

press OFF button 2 on the sewing machine

to turn OFF the power since connection of

the cord or power voltage may be wrong.

2) When the needle bar is not in its UP position, it

automatically rotates to reach the UP position.

(Caution)

1. When turning ON the power for the first

time, it will be slightly delayed since

initialization is performed.

2. When turning ON the power, do not place

your hands under the needle.

4

5

6

3) When depressing front part 4 of the pedal, the

sewing machine rotates at the number of

revolutions in accordance with the depressing

amount.

When the pedal is returned to the neutral position,

the sewing machine stops.

4) When lightly depressing back part 5 of the pedal,

the presser goes up. (PFL type only)

5) When strongly dpressing back part 6 of the pedal,

thread trimming is performed.

(Caution) For KFL and PFL types, thread trimming

entering point is different from each other.

− 11 −

Page 14

7

8

6) When operation panel 7 is connected, various

sewing patterns such as reverse feed stitching at

sewing start, reverse feed stitching at sewing end,

etc. can be set.

Refer to the Instruction Manual for the operation

panel for the details.

7) When pressing touch-back switch 8, reverse feed

can be performed.

2

8) When sewing is completed, make sure that the

sewing machine has stopped.

Then, press the OFF button 2of the power switch

to turn OFF the power.

− 12 −

Page 15

2. Explanation of the operation panel

5

1 / switch : Used for determining the contents of setting.

2 / switch : Used for changing the contents of setting.

3 switch : Used for changing the contents of the selected display (flashing

4 switch : Used for changing the contents of the selected display (flashing

6

1

2

When this switch is pressed, flashing stops and the contents of setting

are determined.

When this switch is pressed, changeable positions flash on and off.

By pressing the switch, flashing position shifts in the right direction.

section).When this switch is pressed, the contents of the display

increase.

section).

When this switch is pressed, the contents of the display decrease.

7

4

8

3

9

!1

!0

!2

5 PATTERN SELECTION display : The selected pattern is displayed.

6 REVERSE STITCHING : Rendered effective when reverse stitching pattern is selected.

AT START display “ ” Without reverse stitching display / “ ” Reverse stitching display/

“ ” Double reverse stitching display

7 REVERSE STITCHING : Rendered effective when reverse stitching pattern is selected.

AT END display “ ” Without reverse stitching display / “ ” Reverse stitching display/

“ ” Double reverse stitching display

8 NUMBER OF STITCHES display : Number of stitches of reverse stitching or overlapped stitching is

displayed.

9 MATERIAL EDGE SENSOR : Lights up when the material edge sensor setting is selected.

display Function setting No. 2

!0 ONE-SHOT AUTOMATIC : Lights up when the one-shot automatic stitching is selected.

STITCHING display Function setting No. 76

!1 AUTOMATIC : Lights up when the automatic thread trimming by depressing the

THREAD TRIMMING display front part of the pedal is selected.

Function setting No. 3

!2 THREAD TRIMMING : Lights up when the thread trimming prohibition is selected.

PROHIBITION display Function setting No. 9

− 13 −

Page 16

Operating procedure of the sewing pattern

(1) Reverse stitching pattern

Reverse stitching patterns below can be set by using the operation panel.

Reverse stitching patterns that can be set

Reverse stitching

at start display

Sewing pattern

Reverse stitching

at end display

Reverse stitching pattern

2

1

A

B

D

C

Overlapped stitching pattern

⇔

2

1

A

A

B

D

C

A

A

BB

D

D

C

A

B

D

D

C

C

A

B

C

B

D

CDC

[ Setting procedure of the reverse stitching ]

1) Hold pressing / switch 1, and press

/ switch 2 to select the reverse

stitching pattern.

(Every time / switch 2 is pressed,

reverse stitching pattern/overlapped stitching

pattern change over alternately.)

A

A

B

B

D

C

6

6

Flash

1

Flash

7

Shift direction

Contents of reverse

stitching slection

7

updating with swith3

updating with swith4

2) Press / switch 1 to make reverse

stitching at start display 6 flash on and off.

Every time / switch 1 is pressed, the

flashing position shifts in the right direction.

(Caution) The sewing machine does not start in

the flashing state.

3) Press switch 3 or switch 4 and

select the reverse stitching pattern.

Reverse stitching patterns and displays are as

follows.

: Reverse stitching

: Double reverse stitching

: Without reverse stitching

1

4

3

4) Press / switch 1 to make reverse

stitching at end display 7 flash on and off, and set

the pattern in the same way as step 3).

− 14 −

Page 17

5) Press / switch 1 to make number of

6

8

stitches display 6 flash on and off, and set the

number of stitches for the respective processes of

the stitching.

6) Press

switch 3 or switch 4 to

change the number of stitches.

The number of stitches can be changed up to as

many as 15 stitches for the A, B, C, and D

processes respectively.

2

1

4

3

However, displays are as follows.

10 stitches = A, 11 stitches = b, 12 stitches = c, 13

stitches = d, 14 stitches =E and 15 stitches = F

7) When the setting of all items has been completed,

press

/ switch 2 to determine the

contents of the setting. (Flashing stops.)

(2) Overlapped stitching pattern

Overlapped stitching patterns below can be set by using the operation panel.

A : Number of stitches of normal stitching setting

A

C

C

0 to 15 stitches

B : Number of stitches of reverse stitching setting

0 to 15 stitches

C : Number of stitches of normal stitching setting

0 to 15 stitches

B

B

D

D : Number of times of repetition

0 to 9 times

(Caution) When process D is set to 5 times, the

sewing is repeated as A / B / C / B / C.

Reverse stitching pattern

Overlapped stitching pattern

[Setting procedure of the overlapped stitching]

1) Hold pressing / switch1, and press

⇔

/ switch 2 to select the overlapped stitching

pattern.

2

2

1

1

4

3

2

1

(Every time / switch 2 is pressed,

reverse stitching pattern/overlapped stitching

pattern change over alternately.)

2) The number of stitches for process A becomes in

flashing state.

3) Every time / switch 1 is pressed, the

flashing position shifts in the right direction and the

display of the process where setting can be

changed flashes on and off.

4) Press switch 3 or switch 4 to

change the number of stitches.

5) When the setting of all processes has been

completed, press / switch 2 to

determine the contents of the setting. (Flashing

stops.)

(Caution) When the overlapped stitching is

selected, the automatic operation display

flashes on and off. It is not possible to

release the automatic operation.

− 15 −

Page 18

(3) Special setting

For material end sensor function, automatic thread trimming function, one-shot automatic stitching function and thread

trimming prohibition function which are displayed in the front panel, it is possible to change the set value by directly

moving to the function setting mode while the power is turned ON in addition to the normal function setting procedure.

[ Moving procedure to the function setting mode ]

1) Hold pressing / switch 1, and press

switch 3 to move to the function setting

mode.

(Caution) Function setting No. 2 is displayed

immediately after the changeover.

2) When returning to the normal mode, press /

switch 2 and determine the contents of

2

1

3

the setting.

1 Material end sensor function setting (Function

setting No. 2)

It is rendered effective when connecting the

optional material end sensor.

It is possible to change the set value with

switch 3 or switch 4

0 : Material end sensor function is prohibited.

1 : Material end sensor function is effective.

1

4

3

a

When "1" is selected, material

end sensor display lights up

when the mode has returned to

the normal one.

1

1

4

4

3

3

2 Thread trimming operation after material end stop

setting (Function setting No. 3)

Press / switch 1 to advance to the

function setting No. 3.

It is possible to change the set value with

switch 3 or switch 4.

0 : Material end stop

1 : Automatic thread trimming after detection

of material end

When "1" is selected, the

a

automatic thread trimming

display lights up when the mode

is returned to the normal one.

3 Number of stitches to stop the sewing machine after

detection of material end setting (Function setting

No. 4)

Press / switch 1 to advance to the

function setting No. 4.

It is possible to change the set value with

switch 3 or switch 4.

Specified number of stitches : 0 to 19 stitches

− 16 −

Page 19

1

4

3

(Caution) When the specified number of stitches

is insufficient, there is a case where the

sewing machine cannot stop within the

specified number of stitches depending on

the speed of rotation of the sewing

machine.

4 One-shot automatic stitching setting function

(Function setting No. 76)

Press

/ switch 1 to advance to the

function setting No. 76.

It is possible to change the set value with

switch 3 or switch 4.

0 : Pedal designated speed is prior.

1 : Automatic operation

(Caution) It is rendered effective when the material

end sensor function is set.

It is not possible to prohibit the one-shot

operation at the time of the overlapped

stitching operation.

Speed of rotation is the speed set at the

function setting No. 38.

When "1" is selected, the one-

a

shot automatic stitching display

lights up when the mode is

returned to the normal one.

1

4

3

5 Thread trimming prohibition function setting

(Function setting No. 9)

Thread trimming operation at normal stitching and

overlapped stitching can be prohibited by selecting

the thread trimming prohibition.

Press / switch 1 to advance to the

function setting No. 9.

It is possible to change the set value with

switch 3 or switch 4.

0 : Thread trimming is effective.

1 : Thread trimming is prohibited.

When "1" is selected, the thread

a

trimming prohibition display lights

up when the mode is returned to

the normal one.

− 17 −

Page 20

3. Setting for functions of SC-500

Functions can be selected and specified by means of the four setting switches and light emitting diode located

inside the front cover of the SC-500.

Specified No.

1

1 Switch for entering specified value changed

and updating setting No. in DOWN direction

2 Switch for entering specified value changed

and updating setting No. in UP direction

Specified value

2

34

3 Down switch (DOWN)

4 Up switch (UP)

(Caution) • Do not perform switch operations other than those described in the following explanations.

• Be sure to re-turn the power switch ON after one second or more has passed. If the power

is turned ON immediately after turning it OFF, the sewing machine may not work normally.

In this case, turn ON the power again.

6

5

How to change over to the function setting modo

1) Turn OFF the power to the unit.

2) Pressing switch 4, turn ON the power to the unit.

4

3) Indication 5, 6 will be shown on the display. (If

the indication fails to change, re-perform the

procedures 1) and 2).

4

− 18 −

Page 21

Specified

No.

1

2

5

4) When you want to advance the setting No., press

switch 2 to advance the setting No.

When you want to return the setting No., press

switch 1 to return the setting No.

(Caution) When switch 1 (switch 2) is held

pressing, the setting No. will return (will

advance) continuously. When the setting

No. is advanced (returned), the contents

which are before by one (after by one) will

be determined. So, be careful when

changing the contents (up/down switch is

touched).

EXAMPLE) CHANGING THE FLICKER

REDUCING FUNCTION (SETTING No. 5)

Press switch 2 five times to set the setting No. to “5”.

Press switch 4 five times to change the set No. to “5”

since the current set value is displayed on LED 5.

(Standard : “0”)

1

1

2

2

3

3

4

4

5

(Caution) Keep pressing switch 4 or switch 3,

and the setting vaue can be changed

continuously.

5) When the change has been completed, press

switch 1 or 2 to specify the changed value.

(Caution)

1. When turning OFF the power before

performing this work, the contents which

have been changed are not updated.

2. Press switch 1, and screen display will

change to the contents of the setting No.

which is before by one.

3. Press switch 2, and screen display will

change to the contents of next setting No.

After completing the operation, turn OFF

the power and turn ON the power again to

return to the normal operation.

After completing the operation, turn OFF the power

and turn ON the power again to return to the normal

operation.

− 19 −

Page 22

4. Function setting list

No.

1

2

3

4

5

6

7

8

*

9

10

11

12

13

14

15

Item

Soft start

function

Material end

sensor function

Thread trimming

function by

material end

sensor

Number of

stitches for

material end

sensor

Flicker

reducing

function

Bobbin thread

counting

function

Unit of bobbin

thread

counting down

Number of

rotation of

reverse feed

stitching

Thread

trimming

prohibiting

function

Setting of

needle bar

stop position

when the

sewing

machine stops.

Click sound of

key switch

mounted on

PSC

Optinal switch

function

selection

Function of

prohibiting start

of the sewing

machine by

bobbin thread

counter

Sewing

counter

Number of times

of detection of

run-out of bobbin

thread remaining

amount

The number of stitches to be sewn at a low speed when the soft-start

function is used at the start of sewing.

0 : Soft-start function is not operative.

Material end sensor function (used in case of without panel).

0 : Material end detection function is not operative.

1 : After detecting material end, the specified number of stitches (No.

4) will be sewn, and the sewing machine will stop.

Thread trimming function by material end sensor (used in case of without

panel).

0 : Automatic thread trimming function after detection of material end

is not operative.

1 : After detecting material end, the specified number of stitches (No.

4) will be sewn, and the sewing machine will stop and perform

automatic thread trimming.

Number of stitches for material end sensor (used in case of without panel).

Number of stitches from detection of material end to stop of the sewing

machine.

Flicker reducing function (If the hand lamp flickers).

0 : Flicker reducing function is not operative.

1 : Less effective 蜚 8 : Highly effective

Bobbin thread counting function

0 : Bobbin thread counting function is not operative.

1 : Bobbin thread counting function is operative.

Unit of bobbin thread counting down

0 : Count/10 stitches

1 : Count/15 stitches

2 : Count/20 stitches

Sewing speed of reverse feed stitching

Thread trimming prohibiting function (used in case of without panel).

0 : Thread trimming prohibiting function is not operative.

1 : Thread trimming is prohibited.

(Output of solenoid is prohibited. : Thread trimmer and wiper)

Position of needle bar is specified when the sewing machine stops.

0 : Predetermined lowest position

1 : Predetermined highest position

Click sound of key switch mounted on PSC is specified.

0 : Click is not operative.

1 : Click is operative.

Switching of function of optional switch.

0 : No function

1 : Needle up/down compensating stitching

2 : Back compensating stitching

3 : Function of canceling once reverse feed stitching at the end of sewing

4 : Thread trimming function

5 : Presser foot lifting function

6 : One stitch compensating stitching

7 : Function of simultaneously canceling reverse feed stitching at the

start and end of sewing

8 : Presser foot lifting function when pedal is neutral

Function of prohibiting start of the sewing machine by bobbin thread counting

0 : When counting is out (-1 or less) Function of prohibiting start of the

sewing machine is not operative.

1 : When counting is out (-1 or less) Function of prohibiting start of the

sewing machine after thread trimming is operative.

2 : When counting is out (-1 or less), the sewing machine stops once.

Function of prohibiting start of the sewing machine after thread

trimming is operative.

Counting function of sewing (number of completion of process)

0 : Sewing counter function is not operative.

1 : Sewing counter function is operative.

Number of times of detection of run-out of bobbin thread remaining amount

1 to 19 : Number of times during which the signal is not made even if

Description

0 : Function of bobbin thread remaining amount is not operative.

run-out of bobbin thread remaining amount is detected.

Setting

range

0 to 9

(Stitches)

0/1

0/1

0 to 19

(Stitches)

0 to 8

0/1

0 to 2

150 to 3,000

(r.p.m.)

0/1

0/1

0/1

0 to 8

0 to 2

0/1

0 to 19

Indication of

function setting

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

0

0

0

5

0

1

0

1900

0

0

1

0

0

1

1

Ref.

page

24

24

24

ENGLISH

24

24

24

24

24

25

25

25

Function of

neutral presser

21

lifting

Function of lifting presser foot when the pedal is in neutral position.

0 : Function of neutral automatic presser lifting is not operative.

1 : Selection of function of neutral presser lifting.

0/1

21

25

0

* Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

(Descriptions of setting in this list are the standard values at the time of delivery of DDL-8700.)

However, contents of function setting are subject to change for improvement of function and performance without notice.

− 20 −

Page 23

No.

22

*

24

25

*

26

27

29

30

31

32

33

35

*

37

38

*

39

40

*

41

*

*

42

43

*

Item

Function of

changeover of

compensating

switch on the

operation panel

function

Function of fine

adjustment of

number of

rotation

Thread

trimming

motion

condition

Function of

setting the

holding force

after stop

Function of

setting the

reaction force

at the time of

retry

Suction time of

the first start of

the back

solenoid

Function of

reverse feed

stitching on the

way

Number of

stitches of

reverse feed

stitching on the

way

Effective

condition of

reverse feed

stitching on the

way when the

sewing

machine is

stopping.

Thread

trimming

function by

reverse feed

stitching on the

way

Number of

rotation at a

low speed

Number of

rotation of softstart

One-shot

speed

Pedal stroke at

the start of

rotation

Low speed

section of

pedal

Starting

position of

lifting presser

foot by pedal

Starting

position of

lowering

presser foot

Pedal stroke 2

for starting

thread trimming

Description

Function of needle up/down compensating switch on the operation panel

can be changed.

0 : Needle up/down compensation

1 : One stitch compensation

Number of rotation can be compensated.

Be sure to normally use this function with "0".

This function sets the thread trimming motion after DOWN position has

been off by turning handwheel by hand.

0 : Thread trimming after turning handwheel by hand is permitted.

1 : Thread trimming after turning handwheel by hand is prohibited.

This function prevents the sewing machine from the reverse rotation after it

has stopped.

0 : Initial value

1 : Less effective / 9 : Highly effective

This function sets the magnitude of return force of the needle bar before

the retry motion.

1 : Less return force / 15 : High return force

This function sets the suction motion time of the back-tack solenoid.

50 ms to 300 ms

Function of reverse feed stitching on the way

0 : Function of reverse stitching on the way is not operative.

1 : Function of reverse feed stitching on the way is operative.

Number of stitches of reverse feed stitching on the way.

Effective condition of reverse feed stitching on the way

0 : Function is not operative when the sewing machine stops.

1 : Function is operative when the sewing machine stops.

Thread trimming function by reverse feed stitching on the way

0 : Automatic thread trimming function after completion of reverse feed

stitching on the way is not operative.

1 : Automatic thread trimming after completion of reverse feed stitching

on the way is performed.

Lowest speed by pedal

Sewing speed at the start of sewing (soft-start)(The max. value depends

on the number of rotation of the sewing machine head.)

One-shot speed (The max. value depends on the number of rotation of

the sewing machine head.)

Position where the sewing machine starts rotating from pedal neutral

position (Pedal stroke)

Position where the sewing machine starts accelerating from pedal neutral

position (Pedal stroke)

Position where the cloth presser starts lifting from pedal neutral position

(Pedal stroke)

Starting position of lowering presser foot

Stroke from the neutral position

Position 2 where the thread trimming starts from pedal neutral position

(When the function of lifting presser foot by pedal is provided.) (Pedal

stroke)

Setting

range

0/1

–1.5% to

1.5%

(0.1 %)

0/1

0 to 9

0 to 15

50 to 300

(ms)

0/1

0 to 19

(Stitches)

0/1

0/1

150 to 250

(r.p.m.)

150 to MAX

(r.p.m.)

150 to MAX

(r.p.m.)

10 to 50

(0.1 mm)

10 to 100

(0.1 mm)

–60 to –10

(0.1mm)

8 to 50

(0.1 mm)

–60 to –10

(0.1 mm)

Indication of

function setting

22

24

25

26

27

29

30

31

32

33

35

37

38

39

40

41

42

43

Ref.

page

0

26

0

1

26

26

0

26

3

250

26

27

0

27

4

0

27

27

0

200

800

2500

24

28

30

60

–21

10

–51

* Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

(Descriptions of setting in this list are the standard values at the time of delivery of DDL-8700.)

However, contents of function setting are subject to change for improvement of function and performance without notice.

− 21 −

Page 24

No.

44

*

45

*

46

*

47

48

*

49

51

52

53

55

56

57

58

59

60

61

Item

Pedal stroke for

reaching the

maximum

number of

rotation

Compensation of

neutral point of

the pedal

Auto-lifter

selecting function

Holding time of

lifting auto-lifter

Pedal stroke 1

for starting

thread trimming

Lowering time of

presser foot

Compensation of

solenoid-on

timing of reverse

feed stitching at

the start of

sewing

Compensation of

solenoid-off

timing of reverse

feed stitching at

the start of

sewing

Compensation of

solenoid-off

timing of reverse

feed stitching at

the end of

sewing

Foot lift after

thread trimming

Reverse

revolution to lift

the needle after

thread trimming

Bobbin thread

remaining

amount detection

function

Function of

holding

predetermined

upper/lower

position of the

needle bar

Function of Auto/

Manual changeover of reverse

feed stitching at

the start of

sewing

Function of stop

immediately after

reverse feed

stitching at the

start of sewing

Function of

starting

prohibition of the

sewing machine

by detection of

bobbin thread

remaining

amount

Description

Position where the sewing machin reaches its highest sewing speed from

pedal neutral position (Pedal stroke)

Compensation value of the pedal sensor

Auto-lifter selection

0 : Solenoid drive system

1 : Pneumatic drive system

Limitation time of waiting for lifting solenoid type auto-lifter device

Position where thread trimming starts from pedal neutral position (Standard

pedal) (Pedal stroke)

Lowering time of presser foot after the pedal has been depressed.

(Start of rotation of the sewing machine is delayed during this time.)

Compensation of starting the solenoid for reverse feed stitching when

reverse feed stitching at the start of sewing is performed.

Compensation of releasing the solenoid for reverse feed stitching when

reverse feed stitching at the start of sewing is performed.

Compensation of releasing the solenoid for reverse feed stitching when

reverse feed stitching at the end of sewing is performed.

Function of lifting presser foot at the time of (after) thread trimming

0 : Not provided with the function of lifting presser foot after thread

trimming

1 : Provided with the function of lifting presser foot automatically after

thread trimming

Function of reverse revolution to lift the needle at the time of (after) thread

trimming

0 : Not provided with the function of reverse revolution to lift the needle

after thread trimming

1 : Provided with the function of reverse revolution to lift the needle

after thread trimming

Function of detecting bobbin thread remaining amount at the time of

(after) thread trimming

0 : Not provided with the function of detecting bobbin thread

remaining amount

1 : Provided with the function of detecting bobbin thread remaining

amount

Function of holding predetermined upper/lower position of the needle

bar

0 : Not provided with the function of holding predetermined upper/

lower position of the needle bar

1 : Provided with the function of holding predetermined upper/lower

position of the needle bar

This function can specify the sewing speed of reverse feed stitching at

the start of sewing.

0 : The speed will depend on the manual operation by pedal, etc.

1 : The speed will depend on the specified reverse feed stitching

speed (No. 8).

Function at the time of completion of reverse feed stitching at the start

of sewing

0 : Not provided with the function of temporary stop of the sewing

machine at the time of completion of reverse feed stitching at the

start of sewing

1 : Provided with the function of temporary stop of the sewing

machine at the time of completion of reverse feed stitching at the

start of sewing.

Function of starting prohibition of the sewing machine by detection of

bobbin thread remaining amount

0 : This function does not stop the sewing machine when counting

is out (-1 or less).

1 : This function stops the sewing machine when counting is out (-1

or less).

Setting

range

10 to 150

(0.1 mm)

–15 to 15

0/1

10 to 600

(second)

–60 to –10

(0.1 mm)

0 to 250

(10 ms)

–36 to 36

(10˚)

–36 to 36

(10˚)

–36 to 36

(10˚)

0/1

0/1

0/1

0/1

0/1

0/1

0/1

Indication of

function setting

44

45

46

47

48

49

51

52

53

55

56

57

58

59

60

61

150

0

0

60

35

140

10

16

18

1

0

0

0

1

0

1

* Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

(Descriptions of setting in this list are the standard values at the time of delivery of DDL-8700.)

However, contents of function setting are subject to change for improvement of function and performance without notice.

− 22 −

Ref.

page

28

30

28

28

28

29

29

29

29

29

30

29

ENGLISH

Page 25

No.

64

70

71

72

73

75

*

76

84

*

87

Item

Change-over

speed of EBT

(end back tack)

Function of softdown of presser

foot

Function of

limitation of reacceleration from

reduction of

speed

Function of

limitation of

acceleration at

the start of

rotation

Retry function

Rotating direction

of motor

One-shot

function up to

end of material

Presser lifter

solenoid initial

motion suction

time

Function of

pedal curve

selection

Description

Initial speed when starting reverse feed stitching at the sewing end

Presser foot is slowly lowered.

0 : Presser foot is rapidly lowered.

1 : Presser foot is slowly lowered.

Speed limitation is performed at the time of re-acceleration on the way

of reducing speed of the sewing machine.

It is effective when operating inching sewing.

Speed limitation is performed at the time of start-up of the sewing

machine (excluding the start of sewing).

It is effective when operating inching sewing.

This function is used when needle cannot pierce materials .

0 : Normal

1 : Retry function is provided.

Normal rotating direction of motor

0 : Clockwise

1 : Counterclockwise

One-shot automatic stitching up to end of material is performed. (Used

in case of without panel)

0 : Without one-shot function

1 : With one-shot function

Suction motion time of presser lifter solenoid

50 to 300 ms

Pedal curve is selected. (Improving pedal inching operation)

Number of rotations

2

0

1

Setting range

0 to 250

(r.p.m.)

0/1

0 to 5

0 to 5

0/1

0/1

0/1

50 to 300

(ms)

0/1/2

Indication of

function setting

64

70

71

72

73

75

76

84

87

180

0

0

0

1

1

0

250

0

Ref.

page

30

30

30

31

31

31

Pedal stroke

89

*

91

*

92

93

94

*

96

Tension

release

function

Function of

prohibiting

compensation

operation after

turning

handwheel by

hand

Function of

reducing speed

of reverse feed

stitching at the

start of sewing

Function added

to needle up/

down

compensating

switch

Manufacturer's

function

Max. number of

rotation setting

It is effective in combination with the machine head provided with tension

release function.

0 : Tension release function is ineffective.

1 : Tension release function is effective.

Function of compensating stitching when turning handwheel by hand at

the time of completion of constant-dimension stitching

0 : Function of compensating stitching is effective.

1 : Function of compensating stitching is prohibited.

Function to reduce speed at the time of completion of reverse feed

stitching at the start of sewing.

0 : Speed is not reduced.

1 : Speed is reduced.

Operation of needle up/down compensating switch is changed after

turning ON the power or thread trimming.

0 : Normal (needle up/down compensating stitching only)

1 : One stitch compensating stitching is performed only when

aforementioned changeover is made. (Upper stop ıî upper stop)

Do not change the set value.

It is very dangerous to change the set value since it causes damage to

the machine.

Max. number of rotation of the sewing machine head can be set.

* Setting varies in accordance with resistance pack to be connected.

0/1

0/1

0/1

0/1

0/1

150 to MAX

(rpm)

89

91

92

93

94

96

0

1

0

0

0

4000

* Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

(Descriptions of setting in this list are the standard values at the time of delivery of DDL-8700.)

However, contents of function setting are subject to change for improvement of function and performance without notice.

30

31

31

− 23 −

Page 26

5. Detailed explanation of selection of functions

1 Selection of the soft-start function (Function setting No. 1)

The needle thread may fail to interlace with the bobbin thread at the start of sewing when the stitching pitch

(stitch length) is small or a thick needle is used. To solve such problem, this function (called “soft-start”) is

used to limit the sewing speed, thereby assuring successful formation of the starting stitches.

1

0

0 : The function is not selected.

1 to 9 : The number of stitches to be sewn under the soft-start mode.

The sewing speed limited by the soft-start function can be changed. (Function setting No. 37)

37

2 Material end sensor (ED : optional) function (Function setting No. 2 to 4)

This function is possible when the material end sensor (ED) is attached.

As for the details, refer to the instruction manual for the material end sensor.

(Caution) Setting will be invalid when the material end sensor is not attached, or CP-160 is connected.

3 Flicker reducing function (Function setting No. 5)

The function reduces flickering of the hand lamp at the start of sewing. The higher the set value increases,

the more effective the function will work.

5

(Caution) The more effective the flicker reducing function works (the more the set value is made),

800

0

the lower the start-up speed of the sewing machine will become.

Data setting range

150 to MAX rpm <50 rpm>

Setting range

0 to 8

0 : Flicker reducing function does not work.

to

8 : Flickering is effectively reduced.

ENGLISH

4 Bobbin thread counting function (Function setting No. 6)

When the control panel (CP-160) is used, the function subtracts from the predetermined value and indicates

the used amount of bobbin thread.

For the details, refer to the instruction manual for the control panel.

(Caution) If “0” is set, the LCD indication on the control panel will go out and the bobbin thread

counting function will be invalid.

5 Thread trimming prohibiting function (Function setting No. 9)

This function turns OFF thread trimming solenoid output and wiper solenoid output when thread trimming is

actuated. [If the control panel (CP-160) is used with the sewing machine, this function will work in accordance

with the function setting on the control panel.]

By this function, separate sewing material can be spliced and sewn without trimming thread.

9

6 Setting of the needle bar stop position when the sewing machine stops (Function setting No. 10)

The position of the needle bar when the pedal is in its neutral position is specified.

10

(Caution) If the stop position of the needle bar is set to the highest position, the thread trimming

action will be taken after the needle bar comes down once to the lowest position.

0

0

0 : off Thread trimming is operative. (thread can be trimmed).

1 : on Thread trimming is inoperative. (thread can not be trimmed).

0 : Down The needle bar stops in the lowest position of its stroke.

1 : Up The needle bar stops in the highest position of its stroke.

− 24 −

Page 27

7 Sound of click of the key switch mounted on the PSC box (Function setting No. 11)

This function selects whether the sound is effective or ineffective when operating the four key switches

mounted on the PSC box.

11

1

0 : off The sound of click is ineffective.

1 : on The sound of click is effective.

8 Optional switch function selection (Function setting No. 12) : It is used only when it is combined with

the machine head provided with the optional switch.

Functions to be assigned to the optional switch can be selected from the following functions.

0 : No function (Standard setting)

12

0

1 : Needle up / down compensating stitching : Every time the switch is pressed,

normal feed stitching by half stitch is performed. (Same operation as that of

up / down compensating stitching switch on the panel.)

2 : Back compensating stitching : Reverse feed stitching is performed at low

speed while the switch is held pressing. (It is effective only when constant

dimension sewing pattern is selected with the CP-160.)

3 : Function of canceling once reverse feed stitching at the end of sewing : By

depressing the back part of the pedal after pressing the switch, operation of

reverse feed stitching is canceled once.

4 : Thread trimming function : This function is actuated as the thread trimming

switch.

5 : Presser foot lifting function : This function is actuated as the foot lifter switch.

6 : One stitch compensating stitching : Every time the switch is pressed, one

stitch stitching operation is executed.

7 : Function of simultaneously canceling reverse feed stitching at the start and

end of sewing : By operating the optional switch, ineffective/effective can

be alternately changed over.

8 : Presser foot lifting function when pedal is neutral : Every time the switch is

pressed, the function whether automatically lifting the presser foot when

the pedal is neutral or not can be selected.

(Note) Indication 1 of reverse feed stitching

at the start and end of sewing on the

operation panel is the same even

1

when the function is canceled. So, be

careful.

9 Sewing counting function (Function setting No. 14)

The function counts up every time thread trimming is completed and counts the number of completion of the

sewing process.

This can be realized together with the CP-160 control panel. Refer to the explanation of the control panel.

1 : on Sewing counting function is operative.

14

1

0 : off Sewing counting function is inoperative.

(Indication on the CP-160 contorl panel will go out as well.)

(Caution) Setting will be invalid when the material end sensor is not attached, or CP-160 control

panel is connected.

!0 Neutral automatic presser lifting function (with AK device only) (Functionsetting No. 21)

This function can automatically lift the presser foot when the pedal is in the neutral position.

Automatic lifting time of the pedal depends on the automatic lifting time after thread trimming and when the

presser foot is automatically lowered, it is automatically lifted at the second neutral position after it has come

off the neutral position once.

0 : off Function of neutral automatic presser lifting is not operative.

21

0

1 : on Selection of function of neutral automatic presser lifting

− 25 −

Page 28

!1Function of changeover of compensating switch on the operation panel function (Function setting

No. 22)

Function of compensation switch on the operation panel of CP-160 can be changed over to needle up /

down compensating stitching or one stitch compensating stitching.

22

!2Thread trimming motion condition (Function setting No. 25)

This function makes the thread trimming motion ineffective when depressing the back part of the pedal after

DOWN detection position has been off by turning handwheel by hand or the like.

25

!3Function of setting the holding force after stop (Function setting No. 26)

Function to prevent the increased amount of reverse rotation after stop when the machine has been used for

a long time and the machine head torque has become light. When the set value is increased, the prevention

effect becomes large. However, when the set value is excessively increased, on the contrary, there is a

danger that the machine normally rotates. Adjust the function while checking the motion of the needle bar.

26

!4Function of setting the reaction force at the time of retry (Function setting No. 27)

This function changes the magnitude of the reversing force before moving to the retry motion.

0

1

0

0 : Needle up / down compensating stitching

1 : One stitch compensating stitching

0 : Thread trimming motion is effective.

1 : Thread trimming motion is prohibited.

Setting range : 0 to 9

ENGLISH

27

!5 Setting of the suction time of the back-tack solenoid(Function setting No. 29)

This function can change the suction time of the back-tack solenoid.

It is effective to decrease the value when the heat is high.

(Caution) When the value is excessively decreased, failure of motion or defective pitch will follow.

Be careful when changing the value.

29

250

3

Setting range : 1 to 15

1 : Less reversing force to 15 : More reversing force

Setting range : 50 to 300 ms <10 / ms>

− 26 −

Page 29

!6 Function of reverse feed stitching on the way (Function setting Nos. 30 to 33)

Functions of the limit of number of stitches and thread trimming command can be added to the touch back

switch on the sewing machine head.

Function setting No. 30 Function of reverse feed stitching on the way is selected.

30

0

0 : off Normal back-tack function

1 : on Function of reverse feed stitching on the way

Function setting No. 31 Number of stitches performing reverse feed stitching is set.

Setting range

31

4

0 to 19 stitches

Function setting No. 32 Effective condition of reverse feed stitching on the way

0 : off Inoperative when the sewing machine stops.

(Reverse feed stitching on the way functions only when the sewing

32

0

machine is running.)

1 : on Operative when the sewing machine stops.

(Reverse feed stitching on the way functions both when the sewing

machine is running and stops.)

(Caution) Either condition is operative when the sewing machine is running.

Function setting No. 33 Thread trimming is performed when reverse feed stitching on the way is

completed.

33

0

0 : off Without thread trimming

1 : on Thread trimming is executed.

Actions under each setting state

Application

1

2

3

4

5

Function setting

No.30

No.32

0

0 or 1

1

1

1

1

No.33

0 or 1

0

1

0

1

It works as normal touch-back switch.

When operating touch-back switch at the time of depressing front part of the

0

pedal, reverse feed stitching as many as the number of stitches specified by the

function setting No. 31 can be performed.

When operating touch-back switch at the time of either stop of the sewing machine

0

or depressing front part of the pedal, reverse feed stitching as many as the number

of stitches specified by the function setting No. 31 can be performed.

When operating touch-back switch at the time of depressing front part of the pedal,

1

automatic thread trimming is performed after reverse feed stitching as many as the

number of stitches specified by the function setting No. 31 has been performed.

When operating touch-back switch at the time of either stop of the sewing machine

or depressing front part of the pedal, automatic thread trimming is performed

1

after reverse feed stitching as many as the number of stitches specified by the

function setting No. 31 has been performed.

Output function

1 Used as the normal reverse feed stitching touch-back switch.

2 Used for reinforcing seam (press sewing) of the pleats. (It works only when the sewing machine is running.)

3 Used for reinforcing seam (press sewing) of the pleats.

(It works either when the sewing machine stops or when the sewing machine is running.)

4 Used as starting switch for reverse feed stitching at the sewing end.

(Used as the substitute for thread trimming by depressing back part of the pedal. It works only when the sewing

machine is running. It is especially effective when the sewing machine is used as the standing-work machine.)

5 Used as starting switch for reverse feed stitching at the sewing end.

(Used as the substitute for thread trimming by depressing back part of the pedal. It works either when the

sewing machine stops or when the sewing machine is running. It is especially effective when the sewing

machine is used as the standing-work machine.)

− 27 −

Page 30

!7 Number of rotation of one-shot stitching (Function setting No. 38)

This function can set, by the pedal operation of one time, the sewing speed of one-shot stitching when the sewing

machine continues stitching until completing the number of stitches specified or detecting the material end.

38

2 500

Setting range

150 to MAX. rpm. <50 / rpm>

(Caution) 1. Setting of one-shot stitching is made by the operation panel of the CP-160, or the

function setting No. 76.

2. The max. number of rotation of one-shot stitching is limited by the model of the sewing machine head.

!8 Holding time of lifting presser foot (Function setting No. 47)

Solenoid type presser foot lifter (No. 46 0) can adjust the holding time control of lifting presser foot.

This function automatically lowers the presser foot when the time set with the setting No. 47 has passed

after lifting the presser foot.

When the pneumatic type presser foot lifter (No. 46 1) is selected, the holding time control of lifting presser

foot is limitless regradless of the set value.

47

60

Setting range

10 to 600 sec <10 / sec>

!9 Compensation of timing of the solenoid for reverse feed stitching (Function setting No. 51 to 53)

When the normal and reverse feed stitches are not uniform under the automatic reverse feed stitching action, this

function can change the ON / OFF timing of the solenoid for back tack and compensate the timing.

1 Compensation of on-timing of solenoid for reverse feed stitching at the start of sewing (Function setting No. 51)

On-timing of solenoid for reverse feed stitching at the start of sewing can be compensated by the unit of angle.

51

10

Adjusting range

– 36 to 36 <1 / 10˚>

Set value Compensation angle

– 36 – 360˚ – 1

– 18 – 180˚ – 0.5

00˚ 0

18 180˚ 0.5

36 360˚ 1

Number of sitches of compensation

–360˚

–180˚

180˚

360˚

* When the point

before 1 stitch is

regarded as 0˚ ,

compensation is

0˚

possible by 360˚ (1

stitch) in front and

in the rear.

ENGLISH

2 Compensation of off-timing of solenoid for reverse feed stitching at the start of sewing (Function setting No. 52)

Off-timing of solenoid for reverse feed stitching at the start of sewing can be compensated by the unit of angle.

52

16

Set value Compensation angle

– 36 – 360˚ – 1

– 18 – 180˚ – 0.5

00˚ 0

18 180˚ 0.5

36 360˚ 1

Adjusting range

– 36 to 36 <1 / 10˚>

Number of sitches of compensation

360˚

180˚

0˚

– 180˚

– 360˚

3 Compensation of off-timing of solenoid for reverse feed stitching at the end of sewing (Function setting No. 53)

Off-timing of solenoid for reverse feed stitching at the start of sewing can be compensated by the unit of angle.

Adjusting range

53

Set value Compensation angle

– 36 – 360˚ – 1

– 18 – 180˚ – 0.5

00˚ 0

18 180˚ 0.5

36 360˚ 1

18

– 36 to 36 <1 / 10˚>

Number of sitches of compensation

360˚

180˚

0˚

– 180˚

– 360˚

− 28 −

Page 31

@0 Foot lift function after thread trimming (Function setting No. 55)

This function can automatically lift the presser foot after thread trimming.This function is effective only when

it is used in combination with the AK device.

0 : off Function of automatically lifting the presser foot is not provided.

55

1

(Presser foot does not automatically go up after thread trimming.)

1 : on Function of automatically lifting the presser foot is provided.

(Presser foot automatically goes up after thread trimming.)

@1 Reverse revolution to lift the needle after thread trimming (Function setting No. 56)

This function is used to make the sewing machine rotate in the reverse direction after thread trimming to lift

the needle bar almost to highest position. Use this function when the needle appears under the presser foot

and it is likely to make scratches on the sewing products of heavy-weight material or the like.

0 : off Function of making the sewing machine rotate in the reverse direction to

56

0

lift the needle after thread trimming is not provided.

1 : on Function of making the sewing machine rotate in the reverse direction to

lift the needle after thread trimming is provided.

(Caution) The needle bar is raised, by rotating the machine in the reverse direction, almost to the

highest dead point. This may result in slip-off of the needle thread. It is therefore necessary

to adjust the length of thread remaining after thread trimming properly.

@2 Bobbin thread remaining amount detection function (Function setting No. 57 and No. 61)

This function detects the amount of the bobbin thread used and informs of the time of replacement of the

bobbin.

This function is used when the bobbin thread remaining amount detection device (AE) is attached.

As for the details, refer to the instruction manual for the bobbin thread remaining amount detection device.

57

0

(Caution) Be sure to set the setting No. 57 to ineffective (“0”) when the AE device is not attached.

(“E43” is displayed, and the sewing machine is not actuated.)

@3 Function of holding predetermined upper / lower position of the needle bar (Function setting No. 58)

When the needle bar is in the upper position or in the lower position, this function holds the needle bar by

applying a brake slightly.

0 : off Function of holding predetermined upper/lower position of the needle

58

0

bar is ineffective.

1 : on Function of holding predetermined upper/lower position of the needle

bar is effective.

@4 Change-over function of AUTO / Pedal for sewing speed of the reverse feed stitching at the start of

sewing (Function setting No. 59)

This function selects whether the reverse feed stitching at the start of sewing is performed without a break at

the speed set by the function setting No. 8 or the stitching is performed at the speed by the pedal operation.

59

1

0 : Manu The speed is indicated by the pedal operation.

1 : Auto Automatic stitching at the specified speed

(Caution) 1. The max. sewing speed of the reverse feed stitching at the start of sewing is limited to

the speed set by the function setting No. 8 regardless of the pedal.

2. When “0” is selected, stitches of reverse feed stitching may not match those of normal

feed stitching.

− 29 −

Page 32

@5

Function of stop immediately after the reverse feed stitching at the start of sewing (Function setting No. 60)

This function temporarily stops the sewing machine even when keeping depressing the front part of the

pedal at the time of completion of process of reverse feed stitching at the start of sewing.

It is used when sewing a short length by reverse feed stitching at the start of sewing.

0 : Not provided with the function of

temporary stop of the sewing

machine immediately after the

60

reverse feed stitching at the start

0

of sewing

1 : Provided with the function of

Stop the sewing machine

temporarily to change direction

of sewing products.

temporary stop of the sewing

machine immediately after the

reverse feed stitching at the start

of sewing

@6 Function of soft-down of presser foot (with AK device only) (Function setting Nos. 70 and 49)

This function can softly lower the presser foot.

This function can be used when it is necessary to decrease contact noise, cloth defect, or slippage of cloth

at the time of lowering the presser foot.

Note : Change the time of function setting No. 49 together at the time of selecting the function of

soft-down since the sufficient effect cannot be obtained unless the time of function

setting No. 49 is set longer when lowering the presser foot by depressing the pedal.

ENGLISH

49

70

140

0

10 ms/Step