3C-1

SC-2

mJUKI

CP-30

'CP-ISO

CP-230'CP-330

ENGINEER'S

MANUAL

1..

4-.

gSil^'^SI

caoo

<r £•

^fV

^ 881

No.

1993.12

CP-330

1-47

PREFACE

This

Engineer's

The Instruction Manual for these machines intended for the maintenancepersonnel and operators at an apparel factory contains

operating

Manual when carrying out the maintenance of thesemachines.

Manualiswritten

instructionsindetail.

for

the

technical

Itis

advisabletouse

personnel

the

relevant

who

are

responsible

Instruction

forthe

Manual

service

and

maintenance

and

Parts

list

together

1. Keep your handt away from the ncedlt uAwn the

power twitch it turned ON or while the machine it

operating.

with

ofthe

this

Engineer's

machines.

Z Do not put your fingers into the thresd takf'Up cover

whtle

the

machineisoperattng.

S. It

your

machine it provided with a

guard or any

machine

with

other

anyofthem

protectori. do not operate

removed.

belt

cover, linger

your

CAUTION

3. Be Kite to

the

machine

turn

the power iwiteh OFF

bead

or rcmo«ing the V

belt.

before

tilting

a

TT

6. To achieve tccurity. be ture that the power tupply

earth wire has been connected before operating the

tawing

machine.

TT

f

C31

C. Outing operation, be careful not to allow your or any

penon't

motor

toundhheard

endofwork.

liead or fsarsdt to come

dote

to them. Doingto mey be

when

not

other

hendwheel. V belt, bobbin winder or motoi. Alto, do

not place enything

dangerout.

7. No

not operating. So, do

OFFatthe

dote

to the

the

tewing

forget to turn the power

machine

it

TT

TT

^ %

8.

When

you

move

the

unit

fromacold

power

tothe

unit

after

you

have

9.Incaseof

10.

Whenever

hand.

BEFORE

1.

Never

2.

Confirm

nameplate located under the motor.

3.Besuretoconnect

4.

After

down,

(The

thunder,

you

OPERATION

operate

the

that

the

voltage

settingupthe

and

turn

the

handwheel

should

besureto stopthe

connect/remove

machine

unless

and

the

power

machine,

power

switchONwhile

turn

itsoil

phase

supply

check

counterclockwiseasobserved

place

directlytowarm

confirmed

the

pan

thereisno

unit

and

power

connectororthe

has

been

filled

(single-or3-phase)

earth

wiretoassure

the

directionofmotor

observing

place,

fear

ofdew

remove

the

power

like,

with

oil.

arc

correctbychecking

safety

either

rotation.Tocheck

the

handwheel.

from

the

handwheel

dew

condensation

may

condensation.

plug

from

the

receptacle

besureto

them

turn

against

OFF

the

the

ratings

forasingle-phaseor3-phase

it,

turn

the

handwheelbyhandtobring

side.)

version.

result.

TurnONthe

forextra

power

switch

shownonthe

m

safety.

before

PSC

the

box

needle

CONTENTS

L

GENERAL

(1)

Features

2.

CONHGURATION

3.

EXPLANATION

(1) Control panels of CP-30, -130, -230 and -330 4

(2) Explanation

4.

EXPLANATIONOFTHE

(1)

Howtoset

(2) PSC function setting table 18

(3) Explanationofthe functions 20

1) Specifying the soft-stan function 20

2) Material edge sensor (ED: Optional) function 20

3) Flicker reducing function 21

4) Bobbin thread counting function 21

5) Number of revolutions for reverse stitching 21

6) Thread trimmingprohibitingfunction 21

7) Specification of the needlebarpositionwhenthe sewingmachinestops 21

8) Click of the key switches on the PSC 22

9) Function setting No. 012 22

10) No.ofpcs. counter 22

11) Bobbinthreadremaining

OF

THE

CONTROL

of

the control panel 6

PSC

for

functions

BOX

amount

PANEL

detecting

function

12) Preventionof tangle-upthreadat the sewingstart 23

13) Intermediate reverse stitching function 24

14) Number of revolutions at low speed 25

15) Number of revolutions for threadtrimming 25

16) One-shotautomaticstitchingspeed 25

17) Adjustmentofpedal stroke 25

18) Compensation of the neutralpointof the pedal 27

19) Functionofauto-lifter 27

20) Selectionof the presser footliftingfunctionof the pedal(PFLtype) 28

21)

Compensation

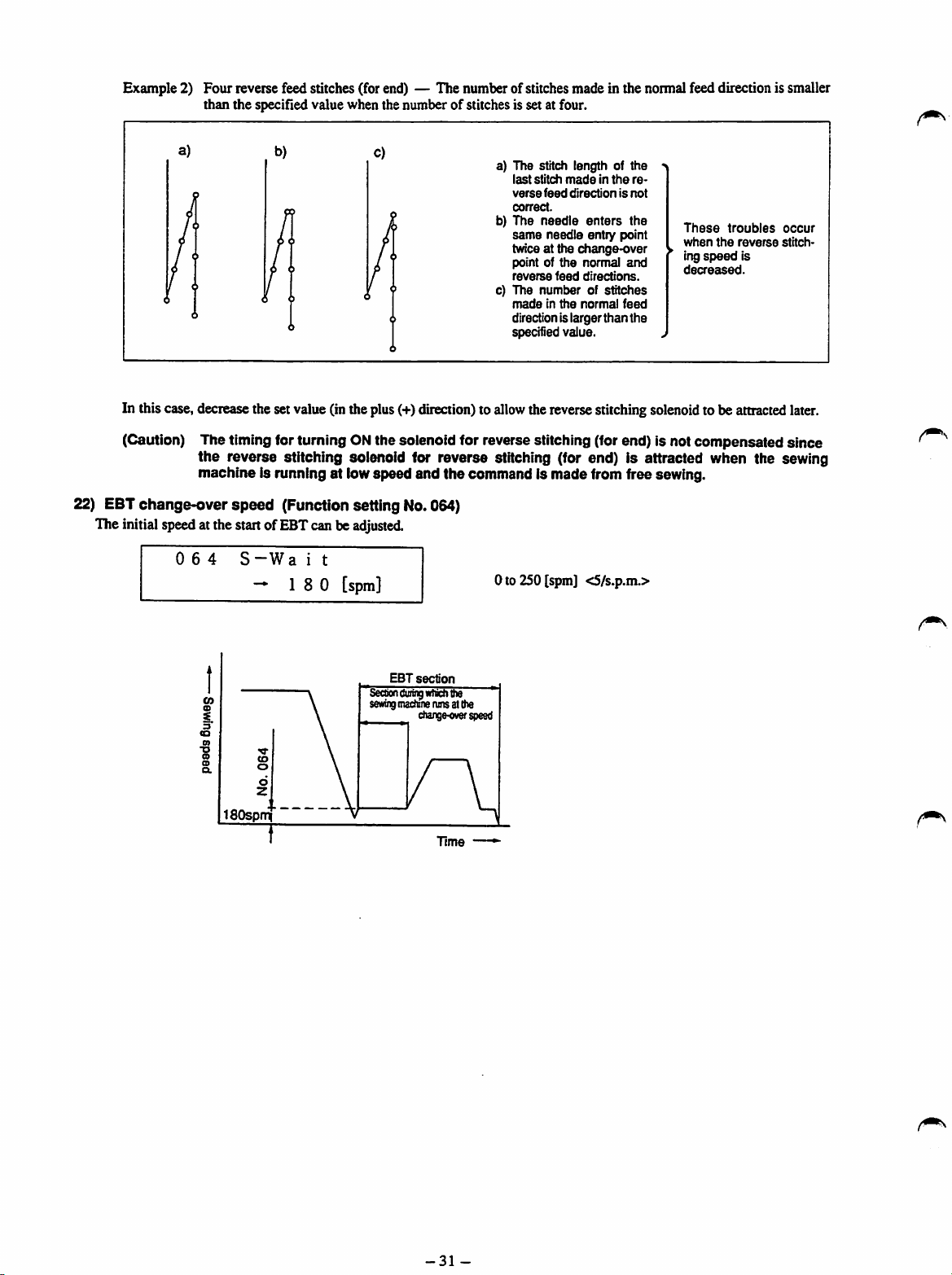

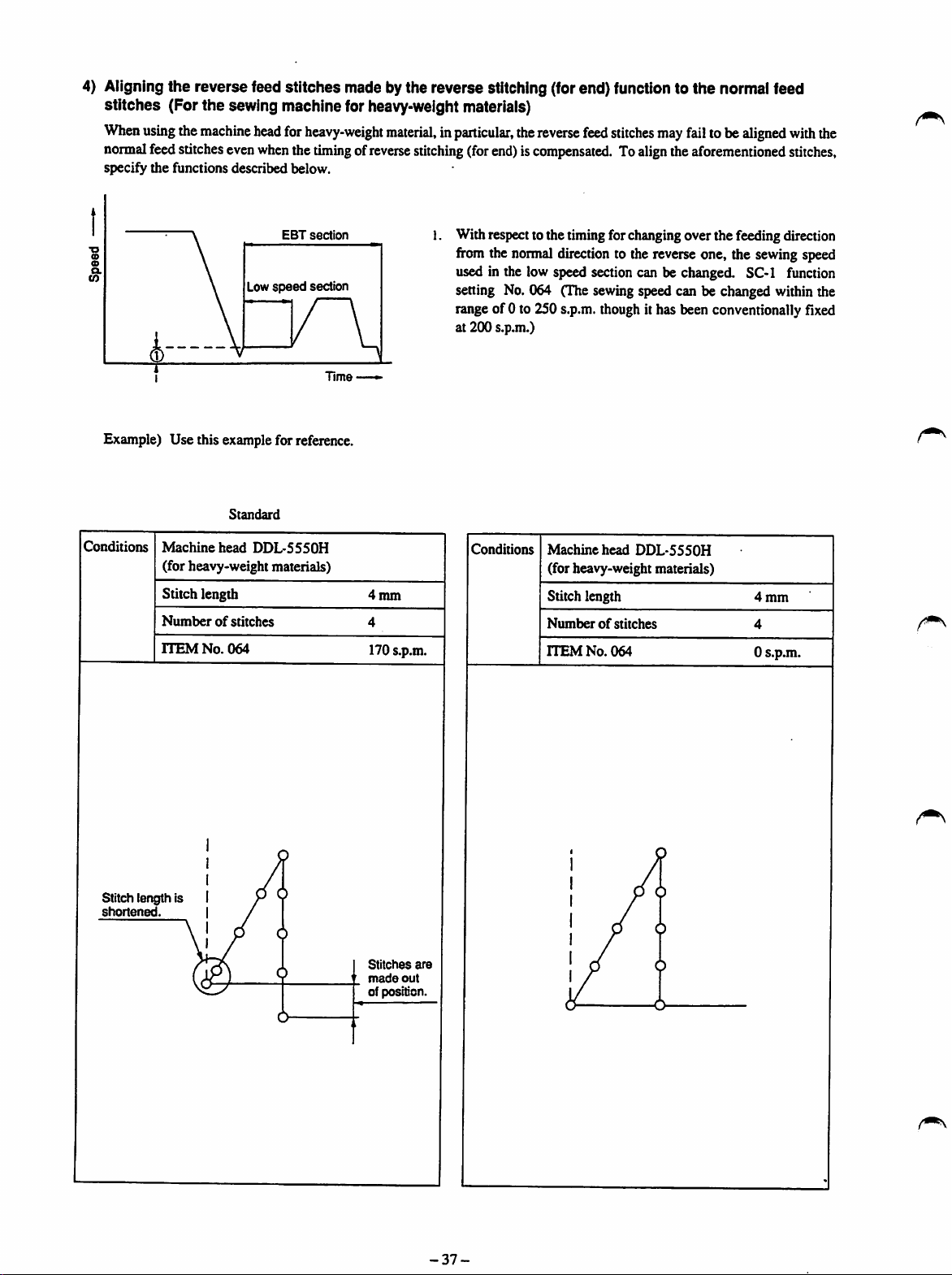

22) EBT change-over speed 31

23) Effective diameterof motorpulley 32

24)

Presser

25)

Reverse

26) Needlebar

27) Reverse stitching (for start) function 32

foot

rotation

up/down

ofthe

lifting

timing

function

function

position

for

after

for

turning

thread

raising

retaining

ONthe

trimming

the

needle

function

solenoid

(for

after

thread

for

KFL

reverse

ofPFL

trimming

stitching

type)

28) Auto/manual change-overfunction for overlapping speed 33

29) Direction of rotation of the motor 33

30)

Accumulated

31)

E^PROM

reset

length

oftime

during

which

the

sewing

machineisenergized

32) Monitorof the state of inputsignal 33

33) Hysteresis of troubles 33

34) Communication facility 33

35) PSC box version management 33

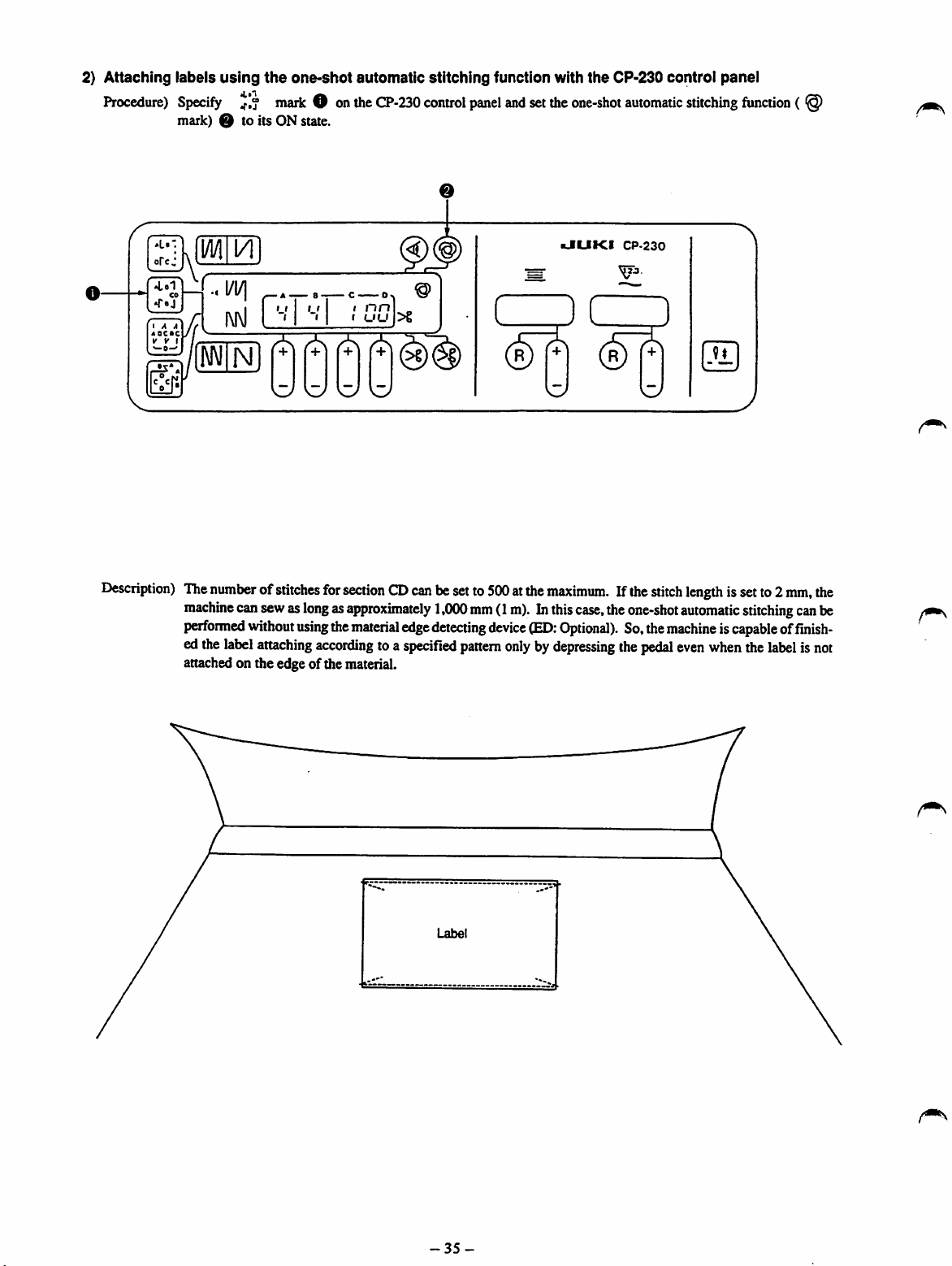

(4) Examplesof applications

.'.

1

1

2

4

16

16

22

28

32

32

32

33

33

34

5. EXPLANATION OF ERRORS ANDCORRECTIVE

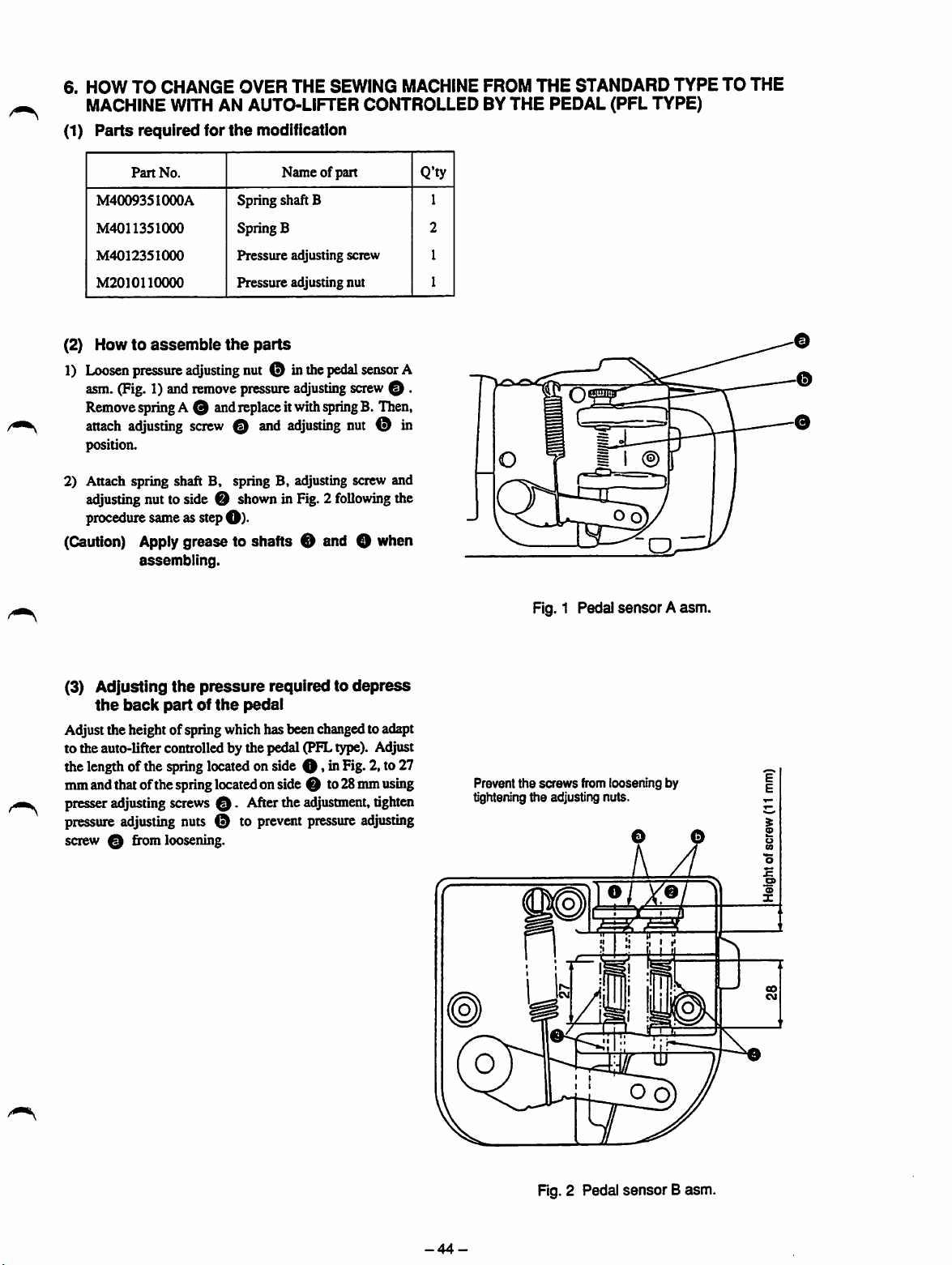

6. HOWTO CHANGE OVER THE SEWINGMACHINEFROMTHE STANDARD TYPE TO

THE

MACHINE

(1) Partsrequired for the modification 44

(2) How to assemble the parts 44

(3)

Adjusting

WITHANAUTO-UFTER

the

pressure

requiredtodepress

CONTROLLED

the

MEASURES

back

partofthe

BYTHE

pedal

PEDAL

(PFL

TYPE)

(4) Settingfor the functionsof thePSCbox 44

(5)

Automatic

compensation

ofthe

neutral

position

ofthe

pedal

sensor

38

44

44

45

7.

AUTOMATIC

(Only

forthe

8.

HOW

TO CHANGE THE

9. EXPLANATION OF FUSES 47

(1)

Replacing

10. CONNECTOR CONNECTION DIAGRAM 48

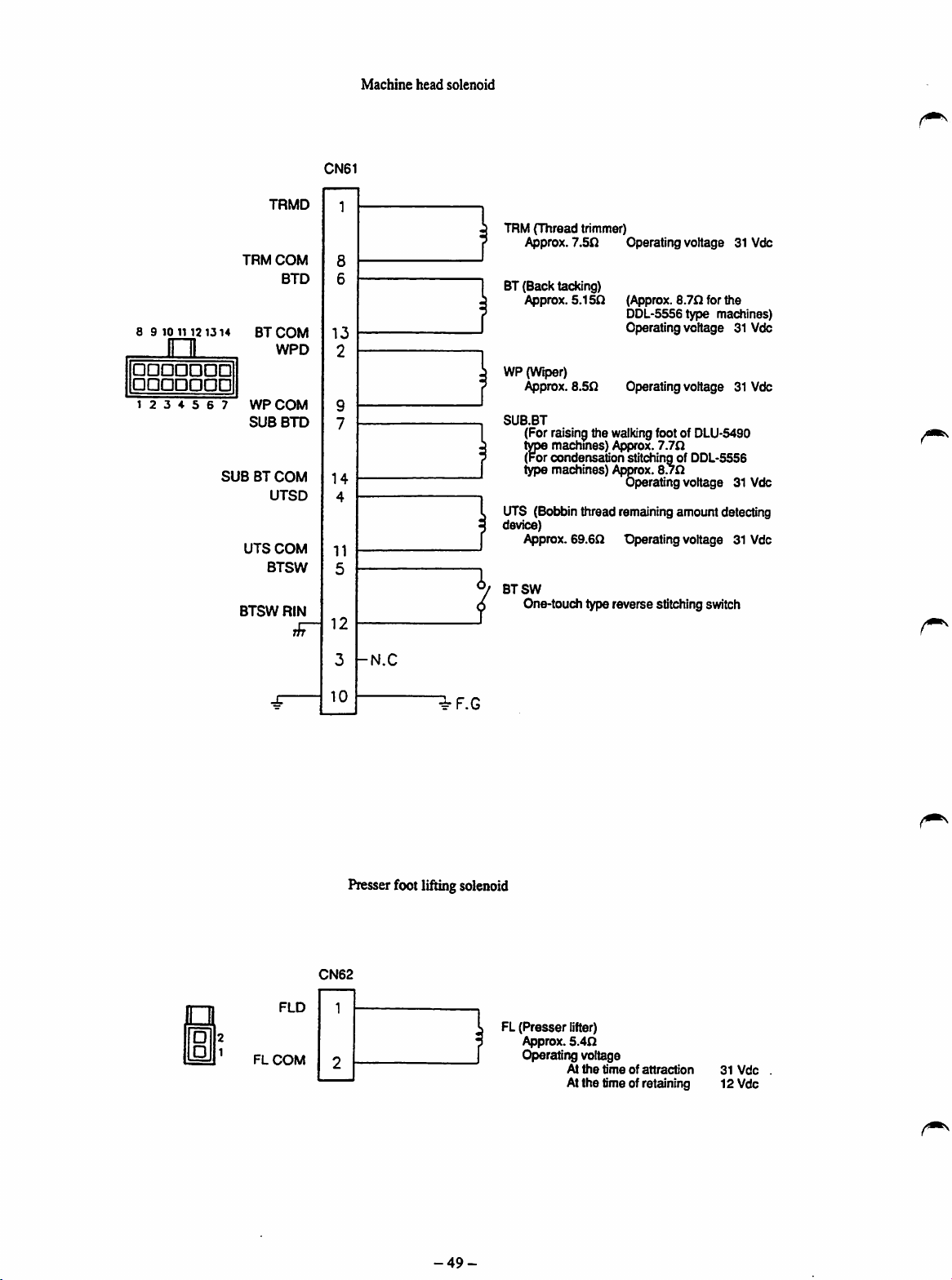

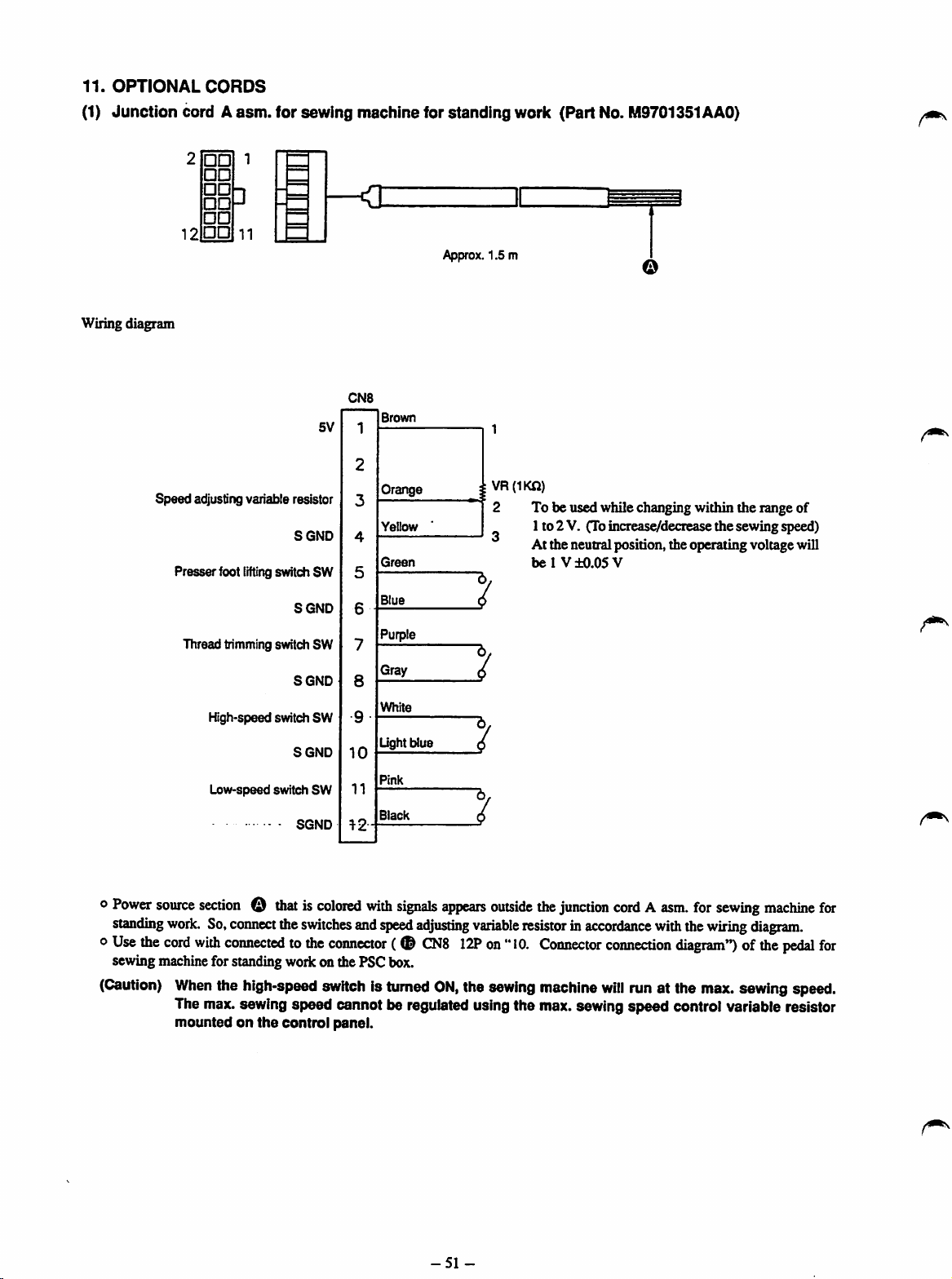

11. OPTIONAL CORDS 51

(1)

Junction

(2)

Junction

(3)

Junction

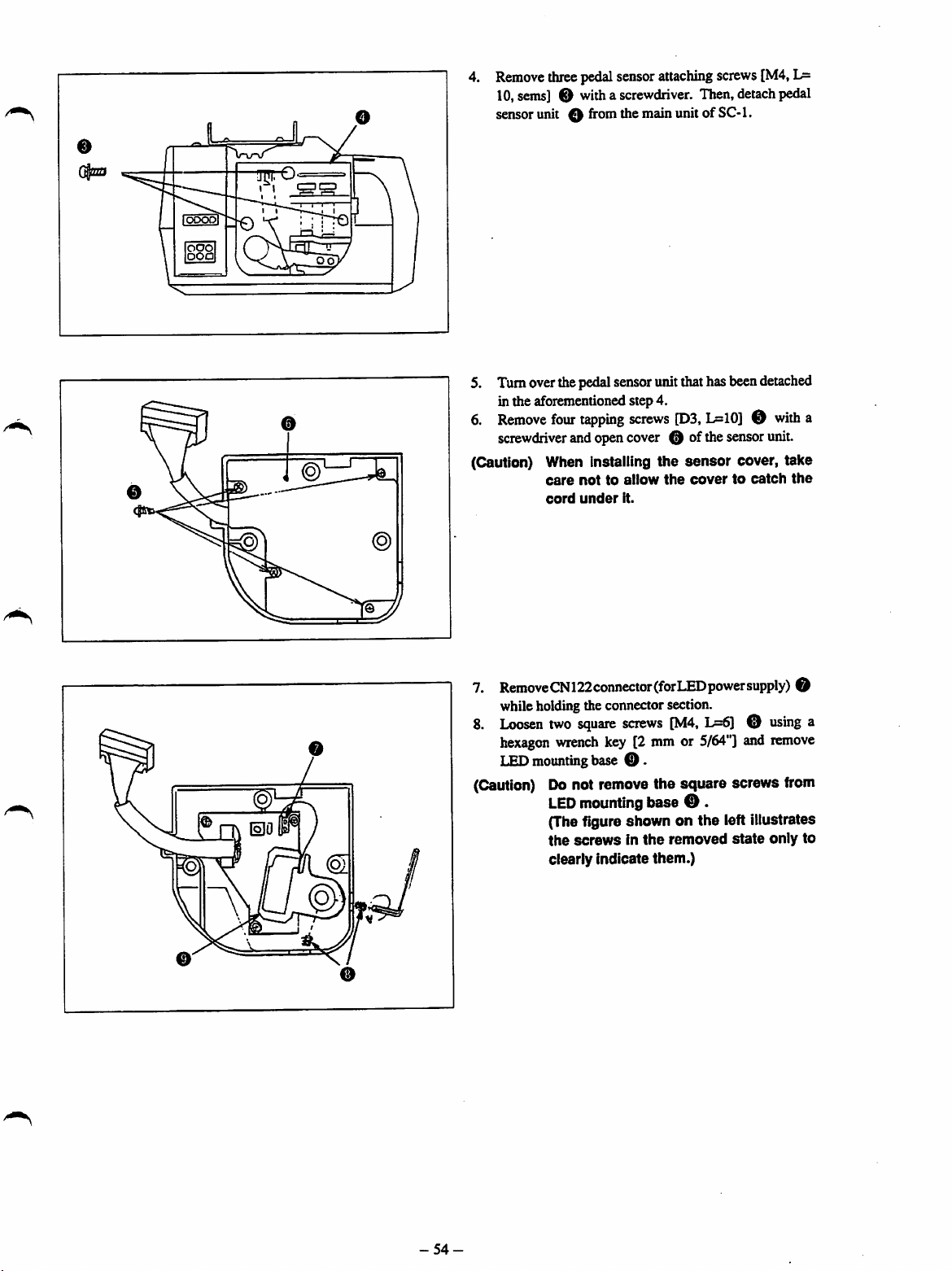

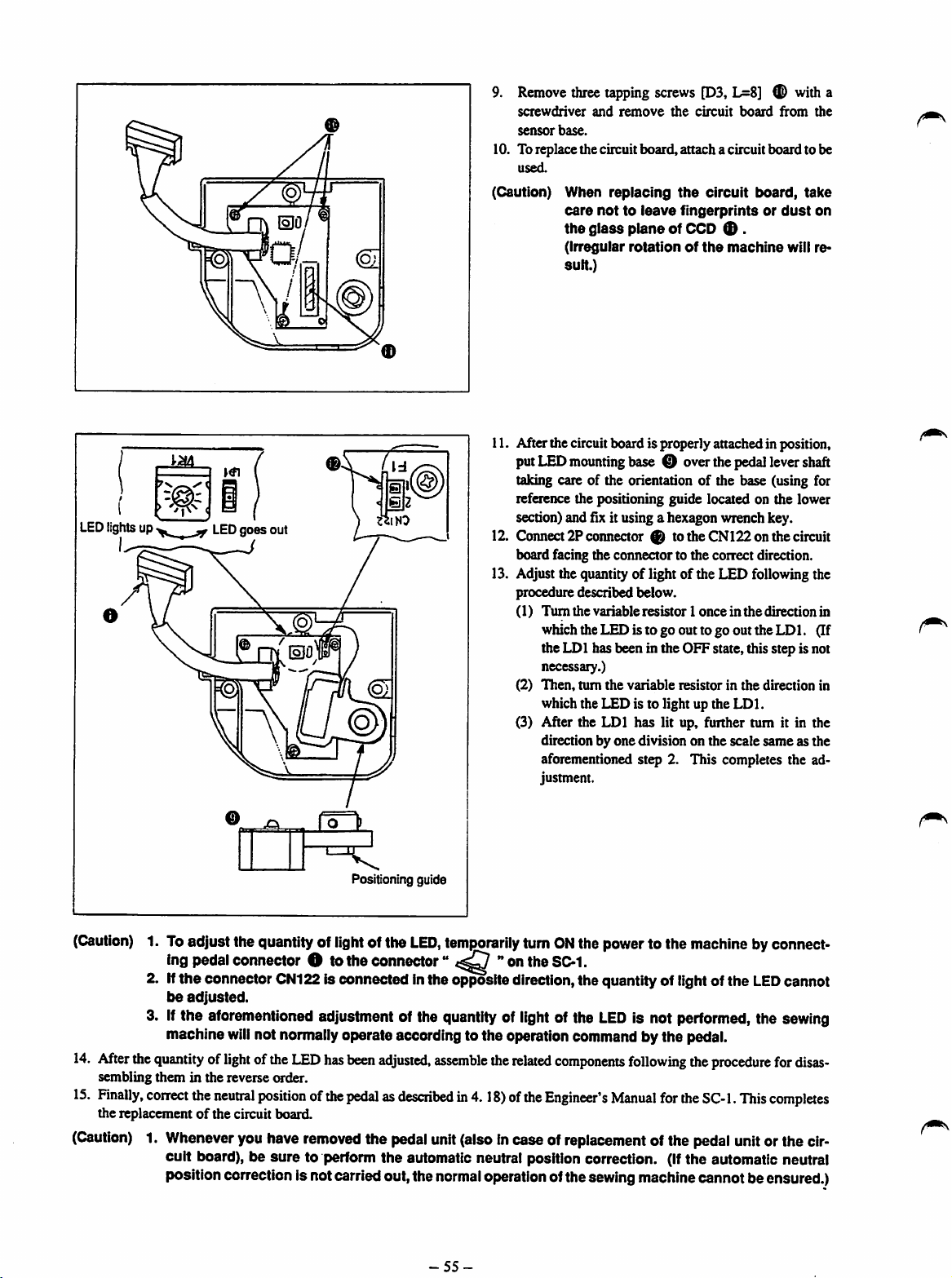

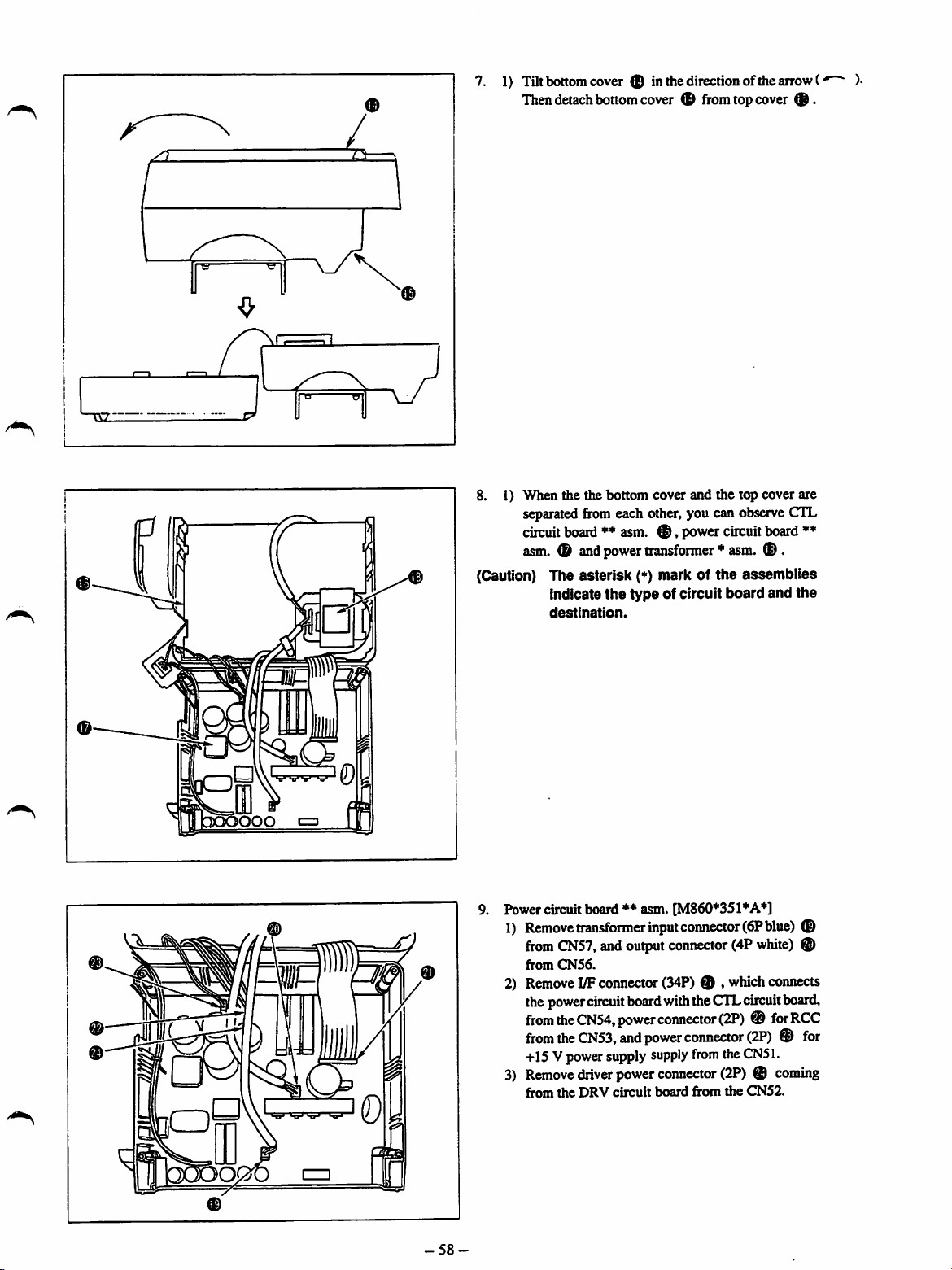

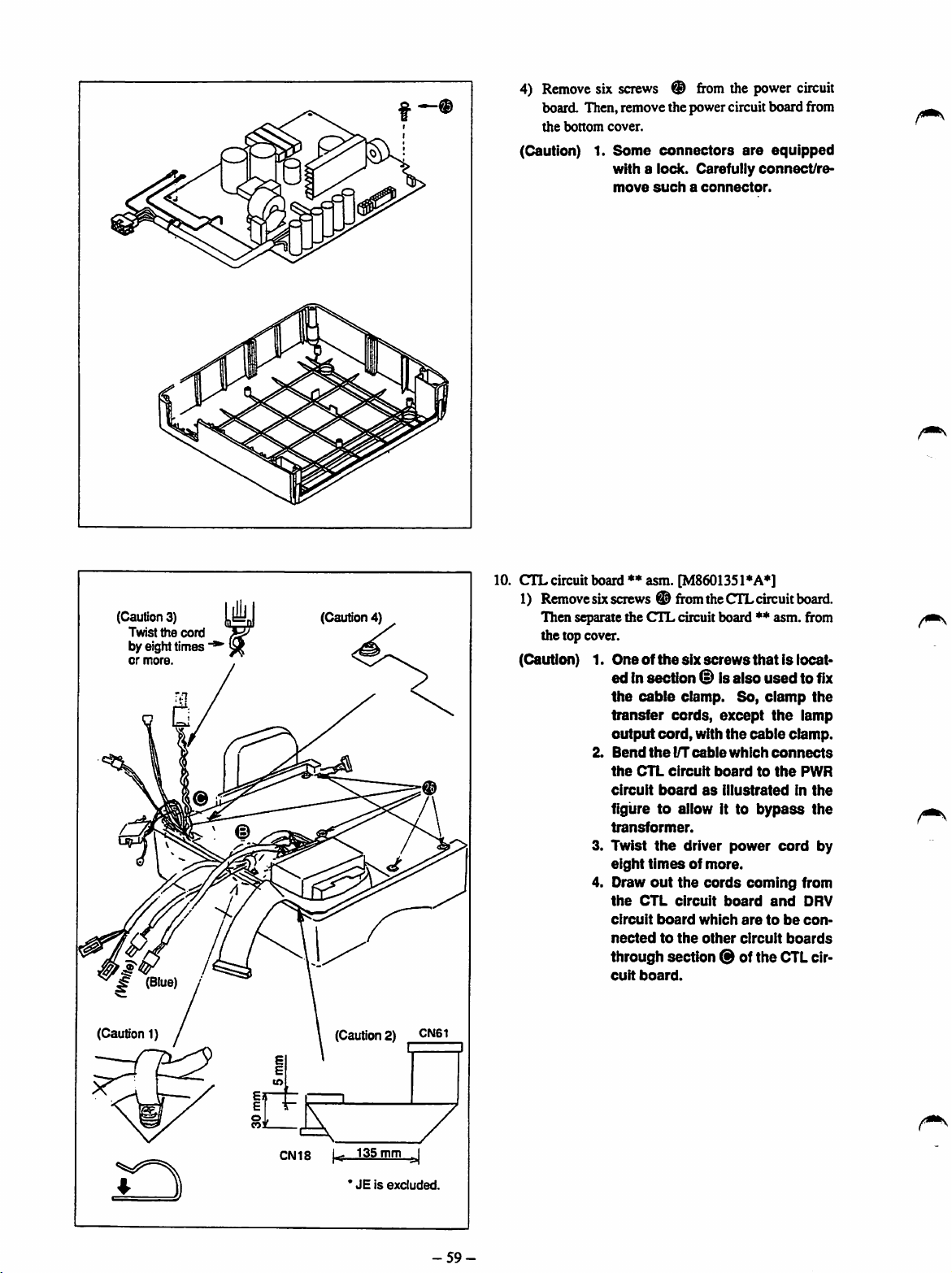

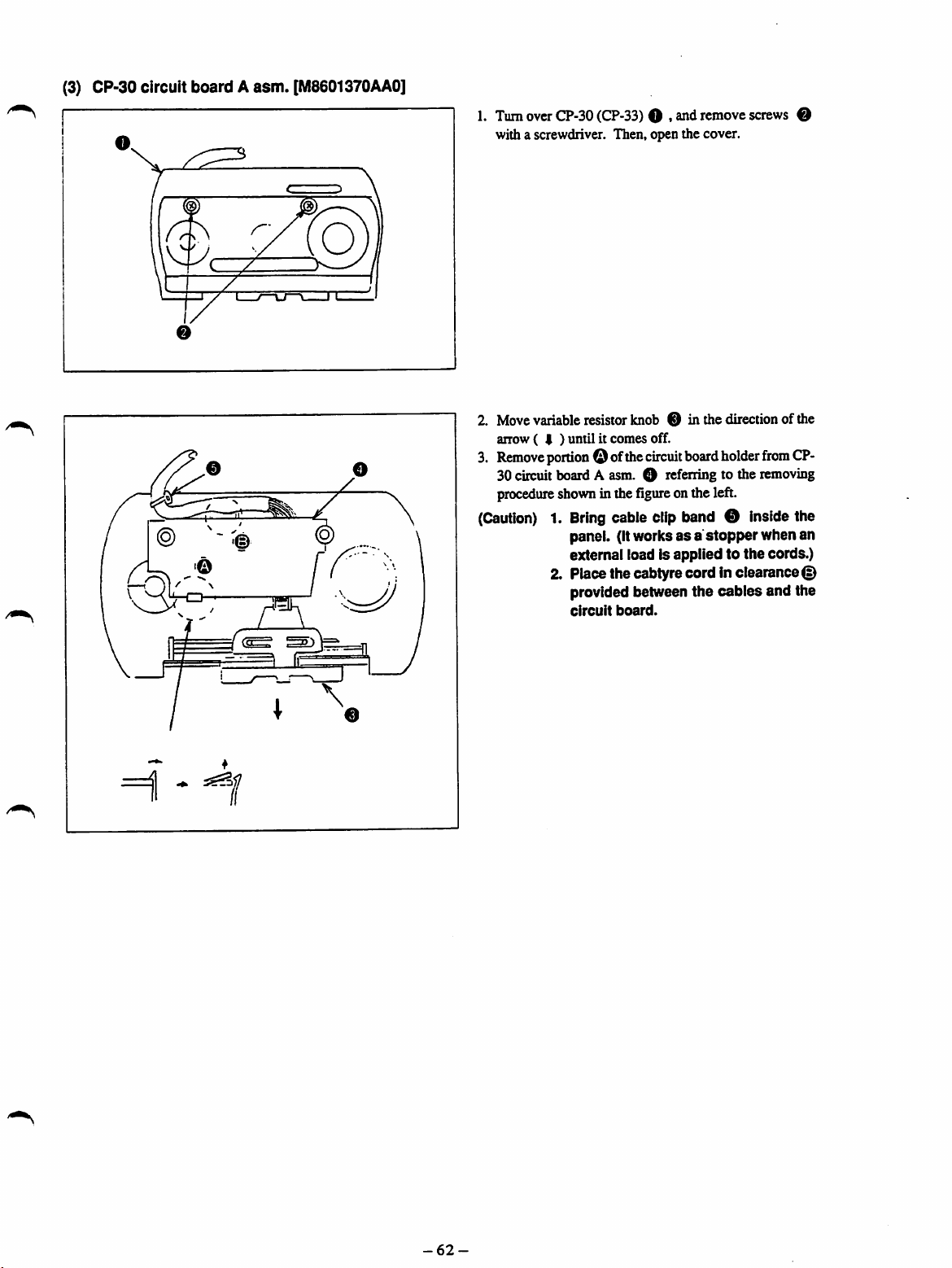

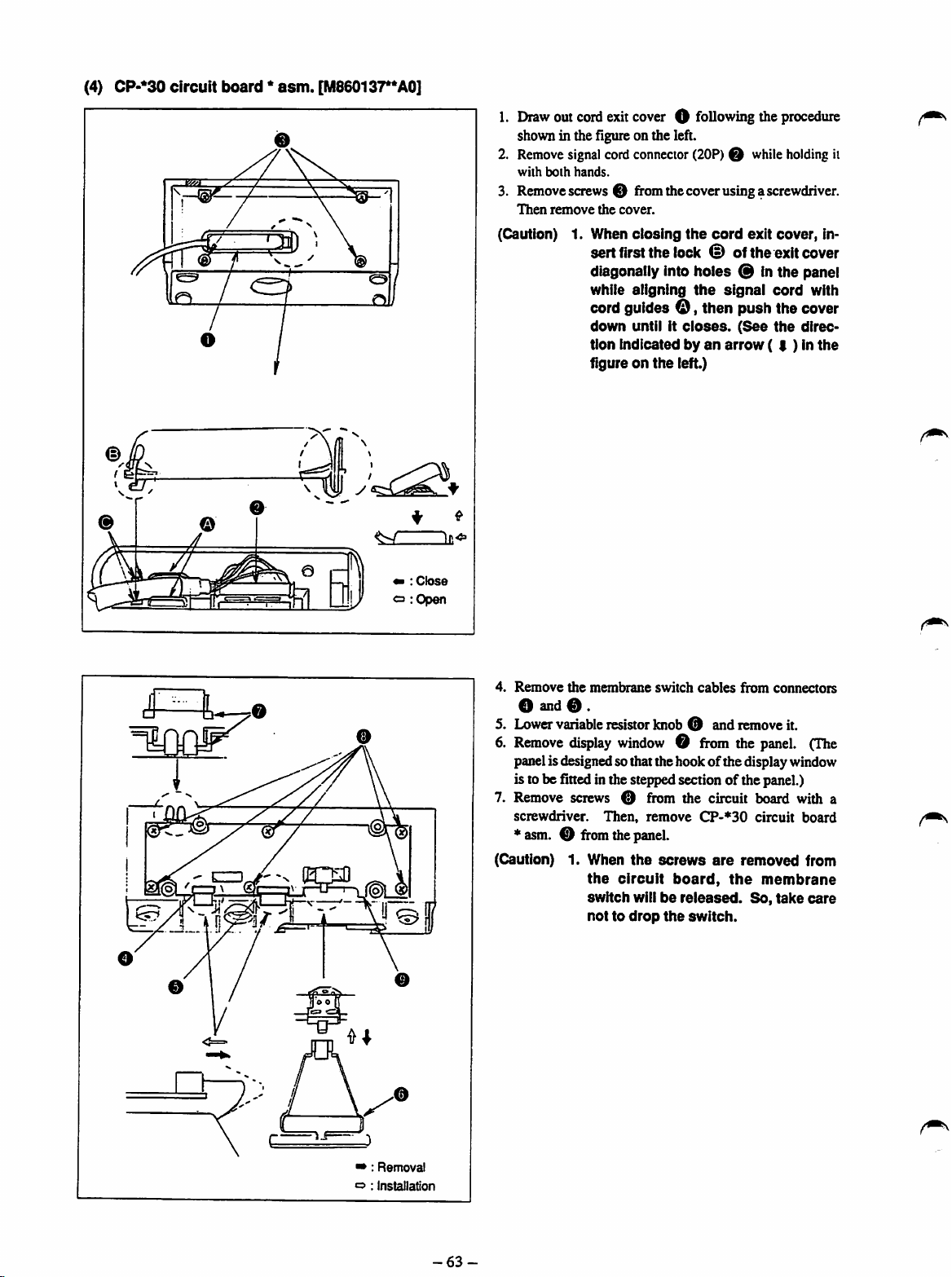

12. HOWTO REPLACETHE CIRCUrrBOARDS - 53

13.

CIRCUIT

14.

BLOCK

15.

BLOCK

16.

BLOCK

PRESSER

sewing

the

fuses

codeA

cordAasm.

cordAasm.

BOARD

MOUNTING

DIAGRAM

DIAGRAM

DIAGRAM

FOOT

machine

SIZE

asm.

for

forthe

for24

(Single

phase

(Single

phase

(3-phasc

LIFTING

equipped

OF MOTOR PULLEY 46

sewing

No.ofpcs.

FUNCTION

withtheAK

machine

counter

for

device)

standing

FROM

work

THE

NEUTRAL

POSITION

Vdc

DIAGRAM

100-120

200-240

200-240

VAC)

VAC)

VAC)

45

47

51

52

52

64

71

72

73

1.

GENERAL

(1)

Features

1) The max.sewing speed control variableresistoris mountedon thecontrolpanel, therebyfacilitating operation.

2) The liquidcrystaldisplaypanelisintroduced astheindicatorofthecontrolpanel. Asa result,numericalcharactersareshown

on the LCD panel in larger size, thereby allowing the operator to read them at a glance.

3) The foot pedal can be operated applyinga light pressure on it whendepressingthe front part or the back part. This helps

achieve easier operation.

4) Material edge sensor (ED), bobbin thread remaining amount detecting device (AH)and foot pedal for standing work are

optionally available.

5)

The

motor is no longer equipped with a mechanical brake.

6) Contactless pedal sensor is introduced, thereby eliminating a contact point.

7)

The

sewing machine controller quickly stops the sewing machine with its needle down.

-1

-

2.

CONFIGURATION

O Power switch

O Control panel

0 Synchronizer

O L-shaped thread stand

0 PSC box

0 Max.sewingspeedcontrolvariable

0 Motor

resistor

O Operationpedal

O

One-touch

(S)

Wiper

0 Standlevelingscrew or caster

typereversefeedswitch

^ Resistorpack(It is not

-2-

equipped

with

theJE type

machine.)

O Power switch

Powerswitch for the motor. PSC and control panel.

9 Control panel

Usedto specifythe automatic reversefeedstitchingfunction, pattemsewingfunction,etc.

® Synchronizer

Incorporatedinthe

sends an input signal to the main circuit board in the PSC box.

O

L-shaped

0 PSC box

thread

Comprisesacircuitrytocontrol

solenoid,

functions.

0

Max.

Allows

0 Motor

Operates

0

Operation

The

presserfootlifter(onlyforthe

0

One-touch

Manually

0

Wiper

Wipes

0

Stand

reverse

sewing

analog

the

pedal

front

and

operatedtomake

the

needle

leveling

Usedtoperform

0

Resistor

Automatically identifies thetypeof

pack

sewing

stand

feed

speed

control

adjustment

sewing

machineathigh

back

parts

type

reverse

thread

screworcaster

adjustmentsothat

(Itisnot

machine

solenoid,

variable

ofthe

of the

feed

switch

the

off

the

equipped

pulley,

the

sewing

etc.),apedal

resistor

maximum

speed,

foot

pedal

sewing

machine

sewing

machine

material

the

stand

with

theJEtype

machine

the

synchronizer

machine

sensortodetect

sewing

speed

medium

are

depressedtocontrol

equipped

perform

after

thread

rests

with

machine.)

head.

detects

and

motor,anoutput

pedal

without

speedorlow

with

AK-85).

reverse

trinuning

responding

securely

the

needle

circuitrytooperate

position,

changing

speed

feed

themotor

responding

the

sewing

stitching.

toa

leveledonthe

position

andapower

wiper

floortominimize

(upordown)

pulley.

toa

signal

speed

andtoactuate

signal

and

the

sewing

the

elements

(thread

circuitrytoactuate

output

from

the

the

output

from

the

PSC

vibration

during

the

PSC

thread

box.

speed,

then

trimming

respective

box.

trimmer,

operation.

-3-

3.

EXPLANATION

(1)

Control

(All

the

CP-30

CP-130

OF

THE

panelsofCP-30,

Indicationsonthe

CONTROL

-ISO, -230

control

PANEL

and

panel

-330

are

Illustrated in

•JUtCI

two

theirONstate

for

the

explanation's

sake.)

CP-230

v\

-i.-.—c

M

rs|g|

:N\j

\!8\}3\SS\SSU®

5|

i<®

SU®

•JUKI

(

nnnn

I

fnnnn

1

OUL'L'

I

1 f

uOOOJ(OOOOJ

nnnn^

CP-130

CP-330

UUKI

CP-330

3I/I/1-.

(\(\j

. , 1<® (s

|»01IS|uoi5Sj>{®

IjS

ran

r?fBIOOOoloO<»0

!^^^0OOu|Ot>uu

H

I

i

©

too

® (D ®

-4-

t

PPO

© o

No.

Power

o

0

e

o

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0 No. of

Indicator

Max.

sewing

Reverse

Overlapped stitching pattern

Constant-dimension

Rectangular

Programmed

Programmed

Combinedstitching patternswitch •

Automatic

Asutomatic

Double

reverse

Double

reverse

Switches

Material

Cne-shot

Automatic

Thread trimming prohibition switch •

Bobbin thread counter •

Bobbin

counter

Bobbin thread amount setting switch •

pcs.

lamp

speed

control

stitching

for

edge

automatic

pattern

stitching

stitching

stitching

reverse

stitching

reverse

stitching

stitching

stitching

setting

the

sensor

stitching

thread

trimming switch • Whenthe

reset

counter•Counts

stitching

0 No.of pcs. counter reset switch •

No.of pcs. counter valuecorrection switch •

0

Step setting switch •

0

0

Numberof stitches/sensor change over switch •

0

Numberof stitches Inputswitch •

0

Teachingswitch •

Feedingdirection change-overswitch •

0

0

Stop-stateselectorswitch •

Presserfoot selectorswitch •

0

Used

0 Liftingtime setting switch •

Needleup/down compensating switch •

0

Re-sewing switch • If

0

programmedstitching pattem. this switchis used for re-starting stitchingafter

replacing

intenrupted.

Explanationofthe

(LED) • Lights up whenthepowerswitchis turnedON.

variable

selector

switch

selector

pattern

pattem

selector

pattem1switch

pattem2switch

(for

start)

(for

end)

(for

start)

sviritch • Usedfor

(for

end)

switch

numberofstitches

CN/CFF

switch•Rendered

switch

Comas

downthe

bobbin thread remainingamountdetectingdevice is installed

on

the

machine,

switch • Usedfor

the

initial

upthe

perfoims thread trimming.

numberoffinished

Used

Used

for

changing

Used

stitching

for

setting

the

Used

for

completion of operationsteps.

Used

Used

for

the

bobbin

thread

thebobbinfromthe

components

resistor

combined.

thread

pedal is held depressed.

numberofstitches

specifying

for

setting

runs

• Movethe variableresistor totheleft( ). and

themax. sewingspeed will belimited.

• Used to selecta reverse stitchingpattern.

switch •

selector

switch

Used

switch

switch

• Whenyoustartthe

sewing machine will run automatically untilthe material

edge is detected or the specified numterof stitches are

Used

retuming

over

specifying

Usedtoselectanoverlapped

switch

• Used to select a constant-dimension

sewing pattem.

• Usedto selecta rectanglestitchingpattem.

• Usedto specifytheprogrammedstitchingpattem1.

• Usedtospecifytheprogianuned

for

sewing

stitching

patterns

• Usedto turn ON/OFFthe

stitchingat the start of sewing.

• Usedto turn ON/OFFthe

stitching at the endofsewing.

turning

at the Stan of sewing.

• Usedfor

at the end of sewing.

• Usedforsettingthe

processes A through D.

effective

installedon the machine. Used for settingwhetheror not

the material edge sensor is used during sewing.

finished.

material

trinnming

for

prohibiting

amountofbobbin

the

counter

indicates

tlw

value.

for

setting

resetting

value

the

set

Used

for

Used

counter.

the

operation

Used

finishessewing whenthe specifiednumber of

stitches is reached or it finishes sewing when the

material edge sensoractuates.

for

inputting

putem.

Used

for

specifying

be

fed

either

the

stop-stateofthe

the

the

lengthoftinte

U»ed

when

stitching. 1 o

out

before

operation

ON/OFFthe

turning

ONA)FFthe

numberofstitches

whenthe

sewing

machine

edgeis

detected,

processevenwhen thefrontpartof thefoot

thread

trimmingatany

threadinsubtracting

the

numberoftimesofdetections.

shown

onthe

the

amountofIrobbtn

pieces

ofgannentseveiy

value

onthe

for

conecting

steps

the

numberofstitches

toa

nonnal

the

ofa

programmed

for

selecting

value

which

the

directioninwhich

directionorreverse

sewing

state

ofthe

presser

during

performing

the

needle

completionofthe

stepwherethe

stitching

stitching

0.0,

automatic

automatic

double

double

material

edgesensoris

withthis

the

machine

bobbin

thread.

time

No.ofpcs.

valueonthe

whether

foraprogrammed

has

been

machineatthe

foot.

which

the

up/down

operation

stitching

pattern.

pattem2.

0

and0with

reversefeed

reversefeed

reversestitching

reversestitching

tobesewnin

switch,

willstartthe

time.

method.

When

thread

counter

the

machine

counter

tozero

No.ofpcs.

sdtching

pattern.

the

sewing

machine

actually

sewn.

the

material

direction.

time

presser

footisraised.

compensating

steps

ofa

has

been

the

the

to

(0).

isto

of

CP-

30

o

o

j

j o

1

!

i

i

i

i

CP-

CP-

130

230

o 0 0

o

0

o o o

o c 0

o

o i

1 ^

! o

! o

c 0 o

c 0 o

o o

o o

o o o

0 o o

0 o o

0

o o

o

o

o o

o o

o o o

o

o 0

o 0

o

CP330

o

0

o

o

o

o

o

o

o

o

o

o

o

o

-5-

(2)

Explanationofthe

1)

Reverse

stitching

control

pattern

panel

(CP-130/-230/-330)

In the stitching mode, the machine performs reverse feed stitching at the start and

endofsewing.

The reverse feed stitching can be set to ON/OFF state. Furthermore, either single re

versestitchingordoublereversestitching (CP-230/-330)canbespecified. The number

of

reverse feed stitches and otherdata on the reverse stitching can be set by operating

the switches on the control panel.

A=B=C=D=0to19stitches

2) Overlapped stitching pattern (CP-130/-230/-330)

The machineperformsnormal feed stitching and reversefeedstitchingby theprede

termined number of times, performs straight line tacking, automatically performs

thread trimming and finishes the sewing.

The numberofstitches and the number of times by which the sewing is repeated can

bechangedby operatingtheswitcheson the controlpanel.

A=B=C=

D=0to9times

A=B=C=0to19stitches

D=0to9times

0to9

0 to 9

stitches

stitches

•

CP-230/-330

CP-130

c:p-130

CP-230

CP-330

3) Constant-dimension sewing pattern (CP-230)

Thefree

the number of stitches. When the specified number of stitches for process CD is

completed,

is specified, the

If theautomaticthreadtrimmingis not

cally

machine will run at low speed (perform compensating stitching).

If

pedal,

stitches.

Thenumber of stitchesandautomaticthread trimmingarespecifiedby operating the

switches on the control panel.

you

A=B=

stop.

return

the

stitching

the

sewing

Now,

the

machine

0 to 19

process

machine

ifyou

foot

pedal

will

stitches,

-6-

ina

reverse

machine

operate

automatically

willautomatically

the

One-touch

toits

neutral

continue

sewing

CD=0to

feed

stitching

stops

perform

speciHed,

type

position,

regardlessofthe

500

stitches

patternisused

(ifthe

automatic

threadtrimming).

the sewingmachine will automati

reverse

stitching

then

depress

specified

the

astheset

thread

switch,

front

number

value

trimming

the

sewing

partofthe

of

of

foot

4) Rectangular

5) Programmed stitching pattern (CP-330)

The

constant-dimension

the

numberofstitches

loweringofpresser

liftingofpresser

< How to set data on a program >

stitching

D

c c

D

pattern (CP-230)

A

A

N

B

sewing

(Max.

500),

foot

and

normal/reverse

footisspecified

The constant-dimension sewingprocess has four operationsteps. The machine auto

matically stops running upon completion of the sewing of the number of stitches

specifiedforeachstep ofoperation. If you operatethe One-touchtype reverse stitch

ingswitchafterthe sewing

(performscompensating stitching). For the last operation step, you can make the

sewingmachinecontinuesewing regardless of the specified number of stitches by

returningthe foot pedalto its neutral position then depressingthe from part of the

pedal. Note thatthe machinewill automaticallyperformthread trimmingif the auto

matic thread triimner is specified.

Thenumberofstitchesand

switches on the control panel.

process

canbeprogrammedasmanyas15

needle

up/down

feed

(for

KFLorPFL

A=B=

0 to 19

stop

mode,

stitching

type),

machine

automatic

stitches,

C=I>= 0 to 99

automatic

canbeseparately

the

time

during

hasstopped,themachinewillrun at low speed

threadtrimming arespecifiedby operatingthe

stitches

operation

thread

specified

which

0 O O

steps.

trimming,

for

the

presser

The

sewing

continuous

the

respective

footisraised

conditions

operation

steps,

operation

can

alsobespecified.

including

lifting/

steps.Ifthe

Example of a pattern

10

4lJl

20

Step 1

10

Steps

Datasettingstatefor step 1

/—

s 1

f

1

LU

Step

1

U

X

Step'

%

20

Steps

EQ>§

-'-(D

Nf

0 0

•JUKI

'v'n'I

kE|

•tc

cooa

uuuu

X

CP-330

-i-Hgte

I s

'-•!

s'U

__W

0 o

Data

programming

illustrated ontheleftas an

(Step 1)

1.

Press

grammedstitchingpattern 1.

2.

Programmed

number

3.

Confirm

of

stitches

4. Setthe

rectionchange-over switch

5. Setthe

Stop-stateselectorswitch

(Caution) Ifthe stop-state of the sewing machine is

6. Setthe

the upperpositionusingPresser foot selector switch 0 .

If

you

footis in the

using

Lifting

which

specified, it will be set to 60 sec.

k

Data

setting

procedureisdescribed

example.

Programmed

ofstitchesanddataon step 1are shownonthe LCD.

thatdataonstep1areshownontheLCD. Thensetthenumber

to20usingNumberofstitchesinput

feeding

stop-state

automatic

dure is not allowed to go forward to the next

position

wanttospecify

the

presser

stitching

stitching

direction

ofthe

sewing

pattern

thread

ofthe

presser

the

highest

positionin particular, setit to adesiredvalue

time

setting

footis in the

range:

0.10

¥

0

panem1switch

1 is

specified

to the

normal

0.

machine

0.

trimming

foot

when

lengthoftime

switch

@ . Ifthe

highest

sec.to99.95

below

direction

tothe

^ ,

the

during

position

sec.

sewing

GD

9»

while

taking

O to select pro

andthe

predetermined

switch

O .

using

Feeding

needle-down

data

setting

machine

which

the

length

oftime

isnotparticularly

thepattern

stop

using

set

to the

proce

step.

stops

presser

during

di

to

^

-7-

(Step 2)

7. Make the LCD indicate step 2 by pressing

of Step settingswitch 0 once.

/•

s

1 n

1 u

L

EQ>s

1

3^

8. Set the number of stitches to 10 using

stitches input switch 0 .

9. As in the data setting procedure for step 1, set the

feeding direction to the normal direction, the stop-state

to the needle-down stop state and the presser foot

position to the upper position.

the+switch

Number

of

Step

steps

m

©

1

1

a

BQ>«

-•-iD

(Step 3)

10. MaketheLCDindicatestep 3 bypressing the+switch

of Step setting switch 0 once.

11

Set the numberofstitches to 20 using

stitches

input

switch

O.

12

As in the data settingprocedure for step 1 and step 2,

set

tb.

feedingdirection to the normal direction, the

stop-statetotheneedle-down stopstateandthepresser

foot position to the upper position.

Number

of

2

¥

o o

/•—

s 1

:>

j

LU

5)

O O

(Step 4)

13. Makethe LCDindicatestep4bypressingthe+switch

of

Step

settmg

switch0once.

Set the number of stitches to 10 using Number of

w

I n

I u

-l-§|kE3

-L|Xi

14.

stitches

Setthe

15.

Feeding

Set the

16

maticthread

input

switch

feeding

direction

stop-state

trimming

O.

direction

tothe

normal

change-over

of the

usingStop-state selectorswitch

switch

sewing

machineto the auto

direction using

0 .

17.

Set the

position

machine

selectorswitch o

Specify

Step

4

©

18.

stitching

0 0

1

r*-

{M'

Dataonanother

sewing

process

^

canbeprogrammed,

taking

the

aforementioned

-8-

stitching

setting procedure.

19. Furthermore,itispossibletospecifythedoublereverse

stitching

start)switch 0 andDoublereversestitching(forend)

switch

(Caution) Ifyou operate the One-touch type reverse

procedure,

of the

presser

stops

totheupper

the

reverse

(for

start)

(forend)

feature

0.

stitchingsvi/itchatthe completionofevery

operation step, the sewing machine will

run at low

stitching).

switch0.This

using

for

position

stitching

switch0and

Double

speed

(perform

programmed

footwhenthe

usingPresserfoot

feature

using

Automatic

completes

reverse

stitching

compensating

stitching

sewing

Reverse

reverse

thedata

pattern

(for

2.

< Teaching

Lithe

been actually sewn.

mode

teaching

>

mode,itispossibletosetthe

g)#

/

1

s

EQ>e

< One-shotautomatic stitching>

The

one-shot

automaticstitchingfunction can be

numberofstitches

(g(g)(i)

1

1

--ill

separately

ina

programmed

setby steps.

stitching patterntothenumberof stitchesthathas

1. In a programmed stitching pattern, press Teaching

switch O to

2.

The

indication

cator changes

machine has entered

3. Depress the front part of the pedal to make the sew

ing machine perform sewing until the last stitch of

the current operation step is reached.

(Caution)

4. Return the foot pedal to its neutral position to make

the sewing machine stop running. Now, the number

of

stitches

trol panel.

5. Proceed to the subsequent step using Step setting

switch O or make the sewing machine perform

thread trimming. This completes the input of the

number of stitches for operation step 1.

specify

shownonthe

to"—T."

the

The

numberofstitches

when

the

sewing

operated

stitching

which

or

switch.

has

been

the

teaching

This shows that the sewing

teaching

using

mode.

numberofstitches

r

mode.

will

notbeinput

machineismanually

the

Compensating

sewnisshownonthe

indi

con

<

/—

j

L-,

< Continuousstitching mode >

In

this

mode,

itis

possibletomake

-|->S

-'4fl

In the programmed stitching pattern process, press

One-shot automatic stitching switch O to specify

the one-shot automatic stitching function.

is shown on the control panel, which shows the

one-shot automatic stitching function has been speci

S

@1

r

1

LU

EQ>g

J.fTl

fied.

In the step where the one-shot automatic stitching

function has been specified, the sewing machine will

automatically continue sewing, once the sewing ma

chinestarts running,until theend ofthe stepis reached.

©

the

sewing

machine

0^^

execute

the

subsequent

step

after

the

completionofthe

In the programmed stitching pattern process, press

Stop-stateselectorswitch

stitching mode.

Aslong as the continuousstitching mode is specified,

you can make the sewing machine execute the subse

quent step after the completionof the current step by

depressing the front part ofthe foot pedal.

Oto

current

step.

specifythecontinuous

<To

operate

the

control

panelincombination

•

When

the

control

panelisusedincombination

predetermined

•

Carefully

numberofstitches

read

the

Instruction

butbyan

Manual

for

with

input

the

the

with

signal

material

material

the

material

ofthe

edge

-9-

edge

material

sensor

sensor

edge

before

>

sensor,

edge

using

the

sensor.

the

sewing

material

process

edge

canbecompleted

sensor.

notbythe

6) Combined stitching pattern

Reverse

^

canbesewn

stitching

pattern,

with

overlapped

combinedasdesired.

stitching

(As

pattern,

programmed

manyaseight

stitching

different

pattern^and

patterns

programmed

canbecombined.)

stitching

panem

Programmed pattern indication

Selected

•JUKI

Combined-stitching

indicator (flashes on and

Executed pattem indication

pattem

Indicationof the programmed pattem

thatisbeing

and

off)

•JUKI

pattern indicator (fights up)

CP-330

ofO

Step

execute

CP-330

No

(flashes

on

Programming

Press

the

mode

for the combined stitching

[Indications shown on the LCD panel go out excluding

a partofthem (only the step No. indication and the

selected

Now, press the keys corresponding to the pattems to

becombinedinthe order of sewing. (Every timeapattem

is

selected,

located on

to the selected

the step No. increasesas

If

you want to execute the same pattem twice continu

ously, press the pattem switch twice.

2

Execution

a. Upoii completion of the programming procedure, press

mode

(^)

key

twicetoselect

pattem

indication stays ON.)]

the

the

sideofthe

pattem

mode

pattern

pattem,

lights up

1,2,3

the

programming

pattem

indicator

which corresponds

and,

at the same time,

and so on.)

program.

" "

the key again, and the machine will enter the

combined program executing mode.

b. Every time the thread trimmer actuates, the machine

proceeds to the subsequent pattem which has been se

lected. (The selected pattem indicator " " flashes

on and

off

to indicate the pattern that is being execut

ed.)

c. To Hnish the combined pattem stitching program, press

anotherpattem selectingkey after thread trimming.

(Caution) If

the

thread

trimmer

completion of a pattern,

proceedtothe

subsequent

actuates

the

machine will

program.

before

Combined stitching

Indicator (lights up)

pattem

Program No.that is

being executed

-10-

7)

Howtouse

the

bobbin

thread

counter

(CP-130A230/-330)

The machine detects the number of stitchesfinished. The preset value on the bobbinthread counter is subtracted in accord

ance with the number of stitches finished (Every time the detectordetects that the sewingmachine has finished 10 stitches,

1 is subtracted from the preset value on the bobbin thread counter.) When the value on the counter becomes a minus value as

" 1 0

-1,"

the buzzer peeps three times to wam the operator that the time to change the bobbin thread has come.

1. Pressbobbin thread counter reset switch O to return

Preset

key

n

u

thevalue indicatedon bobbin thread counter 0 to the

initialvalue (it has beenfactoiy-set to

delivery).

(Caution)

The

bobbin

during

thread

thread

sewing.

trimmer

actuate

In

counter

this

"0"

case,

once.

at the

cannot

make

K

2. Specify an initial value desired using bobbin thread

amountsettingswitch 0 .

(The initial value can be set to 9999 at the maximum.)

<Initial

Preset key

CP-130,

valueonthe

o

-230

bobbin

thread

counter

CP-330

for

reference>

3. Once the initial value is specified properly, start the

sewing machine.

4.

Whenaminus

buzzer peeps three times, replace the bobbin

valueisshownonthe

counter

5. After the bobbin thread has been properly replaced,

press bobbinthreadcounter reset switch O to return

the

valueonthe

value. Now, re-start the sewing machine.

6. If the

remaining

or

the

bobbin

counter indicates a minus value, adjust the initial value

appropriately using the

thread

amount

bobbin

thread

countertothe

amountof bobbinthreadisexcessive

thread

runs

out

before

the

bobbin

"+"

or switchofbobbin

adjusting switch 0 .

time

l>e

and

thread

initial

thread

of

rest

the

the

Thetablebelowgivestheinitialsetting

bobbiniswound

outsideofthe

Thread

Spun Uiread#50

Conon

thread

♦

Actually,

thickness

the

bobbin

ditions.

(Caution)Ifthe

with

thread

bobbin

caseisreached

Lengthofthread

wound

round

#50

the

bobbin

thread

and the sewing

thread

counterinaccordance

bobbin

device,

the

bobbin

tothe

the

bobbin

36

m

31

in

counterisaffected

speed.

thread

counterisusedincombination

thread

amount detecting device. So,be sure to use thedeviceafter

values

forreference

extent

thatthe

Valueonbobbin

counter

1200(stitch length: 3 mm)

10(X)

(stitch length: 3 mm)

Thread

So,

adjust

the initial

with

the

counter

when

pinholeinthe

thread

tension

rate

by the

material

value

operating

indicates

the

100%

of

con

the

If the remaining amount of bobbin thread is excessive

.... Increase the initial value using the'Vswitch.

Iftheremainingamountofbobbin threadis insufHcient

....Decreasetheinitialvalue usingthe switch.

with

the

bobbin

numberofdetections

carefully

thread

remaining

ofthe

bobbin

readingthe Instruction

the bobbin thread remaining amount detecting device.

-11

-

amount

thread

detecting

remaining

Manual

for

8) No.

off

pcs.

Reset

counter

key

(CP-230/-330)

Reset

key

It

u

No/

(+.-)key

The No. of pcs. counter counts up the number of finished

productseverytimethemachineperformsthread trimming.

(0-»l-»2

R

Thevalueon theNo.ofpcs.countercan be modifiedusing

No.ofpcs.

thecontrolpanel. The valueon the No. of pcs. counteris

reset

to"0"by

counter

pressing

-»9999)

value

No.ofpcs.

correction

switchOmounted

counter

reset

switchO'

on

9) Re-sewIng

The

re-sewing

Slept

CP-230

switch

switchisused

(p

gi;

W

V

(CP-330)

when

(g>(^

.a

£

n

n

u

u

Vw/

W

D

Step

Step

2

CP-330

the

bobbin

thread

runs

out

during

the

programmed

The bobbin threadrunsout during the operationsteps

forsewing. 0

Bringthefoot

sewing

foot

pedaltomake

TurnON

A

j

Replace

headand

reverse direction to return the material to the position

where

machine

Depress

5.

position

6.

TurnONre-sewing

Then,

The

sewing

grammed stitching pattern.

» Ifthe needle thread breakswhile the sewing machine is

runninginthe

4

steps

pressing

its

neutral

foot

pedaltoactuate

machineheadandslightly feed the materialin there

verse

enables

thefree

as described in the aforementioned steps 5) and 6).

(Caution)

stitch

pattern

sewing

steps.

pedal

toits

neutral

position to

machine

the

the

direction,

stop.

Now,

depress

the

the

thread

trimmer

re-sewing

the

slightly

sewing

tosewoverthefinished seam. 0

the

O of

next

re-sewing

position.

the

sewing

switch

bobbin

withanew

feedthe

was

interrupted

front

part of the foot

step

2is

switch

stepisindicated

machine

sewing

free

switch

and

machine

mode.

continues

sewing

Then,

the

press

O • O

material

reached.

O at

mode

0 ,

depress

thread

re-sewing

tocontinue

Then,

one,

thread

onthe

toallowthe

pedal

stop

on the

the

sewing

( ®

bring

the

thebackpartofthe

trimmer.

switch0.This

operate

the

back

actuate.

machine

position

control

Toreturntothefirstoperation step

make

partofthe

O

the

machine

inthe

sewing

until

panel.

ofthepro

O)

foot

pedal

Re-thread

sewing

under

control

panel

off

the

stop

O •

after

to

the

the

programmed stitching pattern without

using

re-sewing

switchO,depress the

back part ofthe foot pedal to actuate the

thread

o

oo

trimmer.

panel give the step indication 1.

youcanstart

the

programmed stitching pattern.

This

makes

sewing

fromthefirststep of

the

control

Now,

-12-

10) Needle up/down

83^

compensation

T:

n

n

u

u

'+

switch (CP-130/-230/-33G)

GD

Eveiy

time

needle

up/down

pressed, the needle goes up when it is in its lowest position

or comes down when it is in its highest position. This

compensates the stitch by a

stitch length. However,

run continuously at

held pressed.

Also, note that the needle up/down compensation switch is

rendered ineffective after you have turn the handwheel by

hand.

The thread trimmer is operative only in the case of needle

up/down compensation after the front part of the foot

pedal has been once depressed.

low

compensation

halfofthe

note

that the

speed

evenifyou

switch

predetermined

machine

keep

the switch

O is

does not

11) Key

lock

function (CP-130/-230/-33D)

In

ordertoprevent

by

mistake,

thevalueon thebobbinthreadcountercanbechanged.)

*1'". (]

TTT1

Atcic

the

\

L Vj

the

setting

m

specified

switch

\A

dataonthe

canbe

•JUKI

numberofstitchesorthe

locked.

(Even

CP-330

'I

m

1/1

withthe

setting

stitching

switches

processes

areinthe

After the completionofthe setting of data on the

number of stitches, etc., turn OFF the power to the

machine

Turn ON the powerto the machinewhile simultaneous

lypressing automatic reverse stitching (for end) switch

O and the switchof

switch

O forprocessA with

Key

mark

completes the key-locking of the switches.

(Ifthekeymarkisnotshownonthecontrolpanel,carry

outtheaforementionedsteps 1 through 3 again.)

To release the switches from the key-locked state,

performthe aforementioned steps 1 and 2 .

(The key mark will go out and the switches will be

released h-omthe key-locked state.)

once.

® is

(A,

key-lock

shown

B,C

andD)from

state,the

onthe

pattern

number

fingers.

of stitches

control

being

tobe

panel.

changed

sewn

setting

This

and

:

l\l

+

-13-

12)

^ •

(Caution)Ifthe

ON/OFF

When

material edge sensor becomes effective.

• If

when

the

the

material

the

Manual for

switch

material

sensor

@ofthe

edge

sensor,

edge

sensorisspecified,

detects the material edge.

material

edgesensor is usedin

the

material

material

whichisoptionally

edge

edge

the

sensor

sensor

available,isconnectedtothe

sewing

machine

combination

beforehand.

will

with

automatically

the

control

4

control

panel,

stop

runningorperform

panel,

carefully

/—

<

s

f

in

1

lU

W

the

ON/OFF

read

h

&

switchofthe

thread

trimming

the

Instruction

13)

Automatic

thread

CP-130,

trimming

-230

switch

14) Threadtrimmingprohibition switch

4

@

CP-330

• This switch is used to automaticallyactuate the thread

trimmer

matically

(Ifthe

the thread trimmer will actuate after the sewing machine

completes

• This

• If

in a

process

stopsorwhen

automatic

the

switch

isusedtotemporarily makethe

ming function inoperative.

The

other

performance

affected by this switch.

the

automatic

thread

trimming

specified,

but stop with its needle up.

the

wherethe

the

reverse

automatic

thread

prohibition switch are both

machine

will

sewing

material

stitching

reverse

stitching

of the

sewing

trimming

not

perform

machine

edge

sensorisused.

(forend)is

specified,

(for

end).)

thread

machine

switch^and

thread

trimming

auto

trim

is not

the

15)

One-shot

•

This

make

driving the sewing machine once.

autonnatic stitching switch

switchisused,

the

sewing

machine

inthe

constant-dimension

automatically

stitching

perform

sewing

mode

atthe

orinthe

specified

process

speed

where

until

theendofthe

m

the

material

edge

sensorisspeciHed,

processisreached

only

to

by

CP-130,-230

CP-330

-15-

4.

EXPLANATION

(1) Howtoset

Various

faceofthe

functions

PSC

qDDDCSD

OF

for

functions

canbeselected

box.

<^l

THE

PSC

and

BOX

specified

using

J

the

four

setting

switches

DDL-5550

*

After

the powerto the sewingmachineis turnedON,the model

ofsewing machine used is shown on the

and

liquid

crystal

c ••••

display

12

LCD.

mounted

3 4

onthe

front

(Caution)

1)

Setting

Functions

that

canbespecifiedislarger

User

Service

1. TurnOFF the power to the machine once.

2. Call the user level or service level for the setting of

functions.

<

Howtocall

Pressing the 2 [•]

chine.

<

Howtocall

Pressing

chine.

Then,press the 3 [ITEM]switch.

Never

for

functions

canbesetin

level

level

the

the

the 1 [•)

operate

two

(ITEM

(ITEM

103,105

user

switch,

service

switch,

the

switchesInany

different

No.

No.

and

level

levels,

than

thatinthe

001to006,008to010,012,018to020,030to

007,011,013to015,035,036,039to049,051to054,058,060,062,064to066,075,100

107inaddition

>

turnON thepowerto the ma

level

>

turnONthe

power

i.e.,

user

way

user

level

level.

tothe

items

tothe ma

other

thanthe

and

service

Set

for

functionsineither

accepted

procedure

level.

Inthe

descril>ed

service

level,

level

accordingtosewing

033,037,038,050,055to057,

under

theuser

Switchoperation

Callingthe user level

Callingthe servicelevel

level)

below.

the

numberoffunction

conditions.

059,061

Indicationonthe

ITEM

NO.

001

and

LCD

N-SOFT

items

108)

to

.

•DP

3. Indication shown in the illustration on the right will be

given

onthe

LCD.

(If

the

indication

LCD,re-perform theprocedure fromstep 1 .)

does

not

appear

onthe

DDL-5550

••QD

-16-

ITEM

NO.

001

N-SOFT

,

Then, select the item No. corresponding to the function

you want to specify by pressing the 1 [•] switch or 2

[A]

switch.

(Refer to the function setting table for the description of

items.)

5. Once the item No. corresponding to the function desired

has been selected, press the 4 [SET] switch.

Example)

Function for changing the number of stitches for the

soft-start function (0 to 5)

* For example, the numberofstitches for the soft-start

function is changed to five.

6. The indication shown on the LCD will

change

as illus

trated in the figure on the right. Now, the set value can

be changed.

7.

Press

the2 [•] switchfivetimesto

stitches

for

the

starttoto

five.

change

the

number

(To decrease the number of stitches, press the 1 [•]

switch.)

of

Switch operation

1 2

D

or

Example)

Changingthe numberof

stitches

for

function

the

12

3 4

Cflop:

1 2 3 4

(••••

D

soft-start

Indicationonthe

Selected

item

indicated.

ITEM

001

001

N-SOFT

001

N-SOFT

NO.

No.

is

-»

N-SOFT

LCD

- 0

(N)

- 5

(N)

8. After the completion of data

the

4 [SET] switch to enter

changing

the

modifiedvalue.

procedure,

(Caution) If you omit this procedure, the modified

value

wiil

notbeentered.

9. The

10.

11.

indication

givenontheLCDwill

change

toshowthat

data onthe subsequent functionitem No.can be modified.

Toput

forward

[ITEM] switch to return the indication on the

function

the 1

[T]

After

the

orput backtheitem

setting,

andcalltheitem

switch or 2

[A]

switch.

completionofoperation

No.,

press

LCD

No.

desiredbypressing

described

instep 8 ,

turn OFF the power to the machine, then turn it ON. This

will

return

the

machine

tothe

normal

operation

press

firstthe3

to the

mode.

cnnoQ;,

10

CQDQQ

II

12

3 4

T A

"I"

12

1 2

[©a

•O-

3 4

001

002

ITEM

Selected

indicated.

DDL-SS50

N-SOFT-5

•0

ED

NO.

-

item

No.

(N)

—0:off

Iron

002

ED

is

T7

(2)

•-*shows

PSC

function

the

setting

set

value.

table

(Refertothepagesforrefereitce for details.)

Numberofstitchesforthesoft-staitfunction (See 1)onpage20.)

A

001

Mateiial

edgesensor

N-SOFT

function

— 0

(See2)onpage20.)

002 ED — 0 :

inaierial

edge

1 I

sensor

A

Thieid

tiiimninit

functioninaceonJance

wiA

the

003 EDTRM — 0 : off

A

Numberof

stitches

forthematerialedgesensor(See2)onpage20.)

1 ;

004 ED (N) ^ 5

A

Flickerleducine function (See 3) on page 21.)

005 T-Acc ^ 0

A

Bobbin thread countingfimctitm (See4) on page 21.)

006

A

Unitusedfor

007 Ratio —

Numberofrevolutions

008

A

Thread

trimming

009

A

Stxci&aticoofthe

010

A

CUick

(See 8) on page 22.)

Oil

SW2on the simpliftedpanel (See9) on page 22.)

012

A

Sewing

machine

013 AsCnt — 0 :

No.ofDCS.

counter

014 NTO — 1 : on

Numberoftimesofdetectionsofrun-out

015

SCBob

count-down

ofthe

for

iBveisestitdiing

S-BT

prohibiting

TRMINH

needle

bar

position

NFS

Sound

SW2

stopinaocoidance

(See

10)onpage

BIDS

— 1 : on

bobbin

thread(See4) onpage21.)

—

function

(See

— 0 :

when

the

sewing

—

^

with

the

bobl^

22.)

ofbobim

— 1

0 :

1/10

1/

(SeeS)on

1900

6)on

page

machine

Down

Up

NF

FFeed

thread

counter

thread

1 I

stops

1 I on

0 :

1 I

0

(See

[N]

off

on

(See2)on

on

[N]

1

off

15

page

[spm]

21.)

off

on

(See

off

(See4)on

off

on

:off

11)onpage

[N]

21.)

7)n

page

page

page

20.)

21.)

21.)

22)

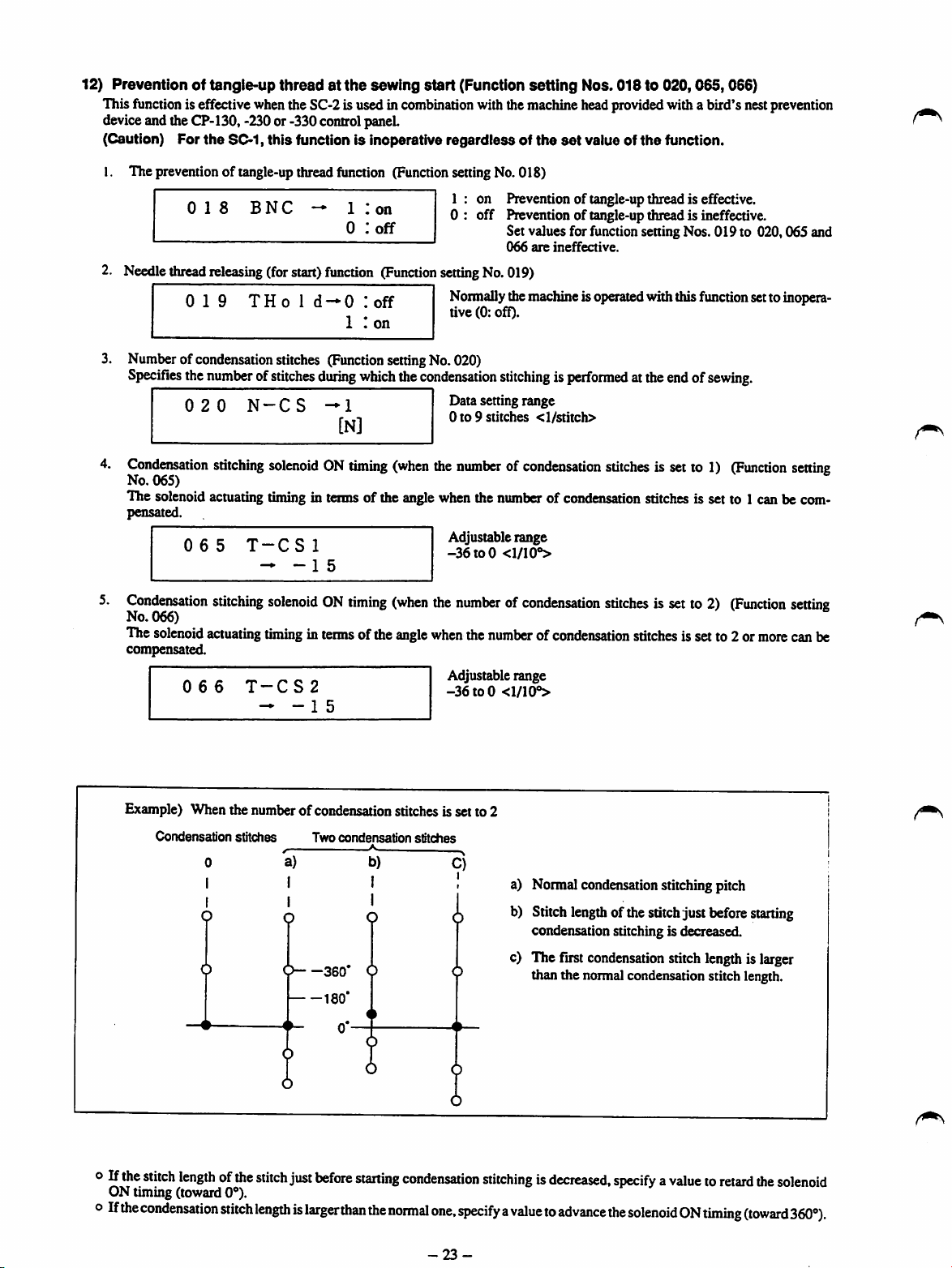

Preventionof tangle-upthreadat the sewingstart (See 12)onpage 23.)

018

A

Needlethread releasing(for start) function (See 12)on page 23.)

019

A 1 :

Numberof condensation stitches (See 12) on page 23.)

020

A

Numberof intennediate reverse feed

030

A

Number of inrennediate reverse feed stitches (See 13) on page 24.)

031

A

Conditions

required(omake

the

sewing

machine

032 OBTS ^ 0 :

A

Thread

trimming

13)on page 24.)

BNC

THold

N-CS

OBT

N-OBT

the

intentieditie

isinthesiopstate (See13)on

functioninaecordanoe

with

— 1

0 :

— 0 :

- 1

function

(See 13)on page 24.)

— 0 :

1 I

^ 4

revtne

tUKhing

page

24.)

1 I

die

intenxdiate

:on

off

off

on

[N]

off

on

[N]

function

off

on

tevene

033 OBTT - 0 : off

1 !

A

Ntunberxf

035

revolutions

atlowspeed (See14)onpage25.)

S-Pos

-•

Numberof

036

revolutions

forthread

S-TRM

trimming

—

Numberof revolutionsfor soft start function (See1) on page20.)

A

A

037

One-shot

038

Ftedal

stndtefor

039

automatic

stitching

starting

S-SOFT

speed

S-ASS

the

machine

P-SSP

(See

(See

—

16)on

—

17)on

on

200

[spm]

(SeeIS)onpage25.)

210

[spm]

800

[spm]

page

25.)

2500

[spm]

page

25.)

— 3.0 [mm]

Low-speed

040

opeiaiion

sectionofthe

P-LSA

pedal

(See

17)onpage

— 6.0 [mm]

Presser

foot

lift

staiting

041

Presser

042

foot

descending

positionofthe

P-FLW

starting

P-FLD

pedal

—

positionofthe

(See

—2.1

pedal

17)

page

[mm]

(See

17)onpage

— 1.0 [mm]

effective

stitching

25.)

25.)

wliil

(See

le

5.)

2

-18-

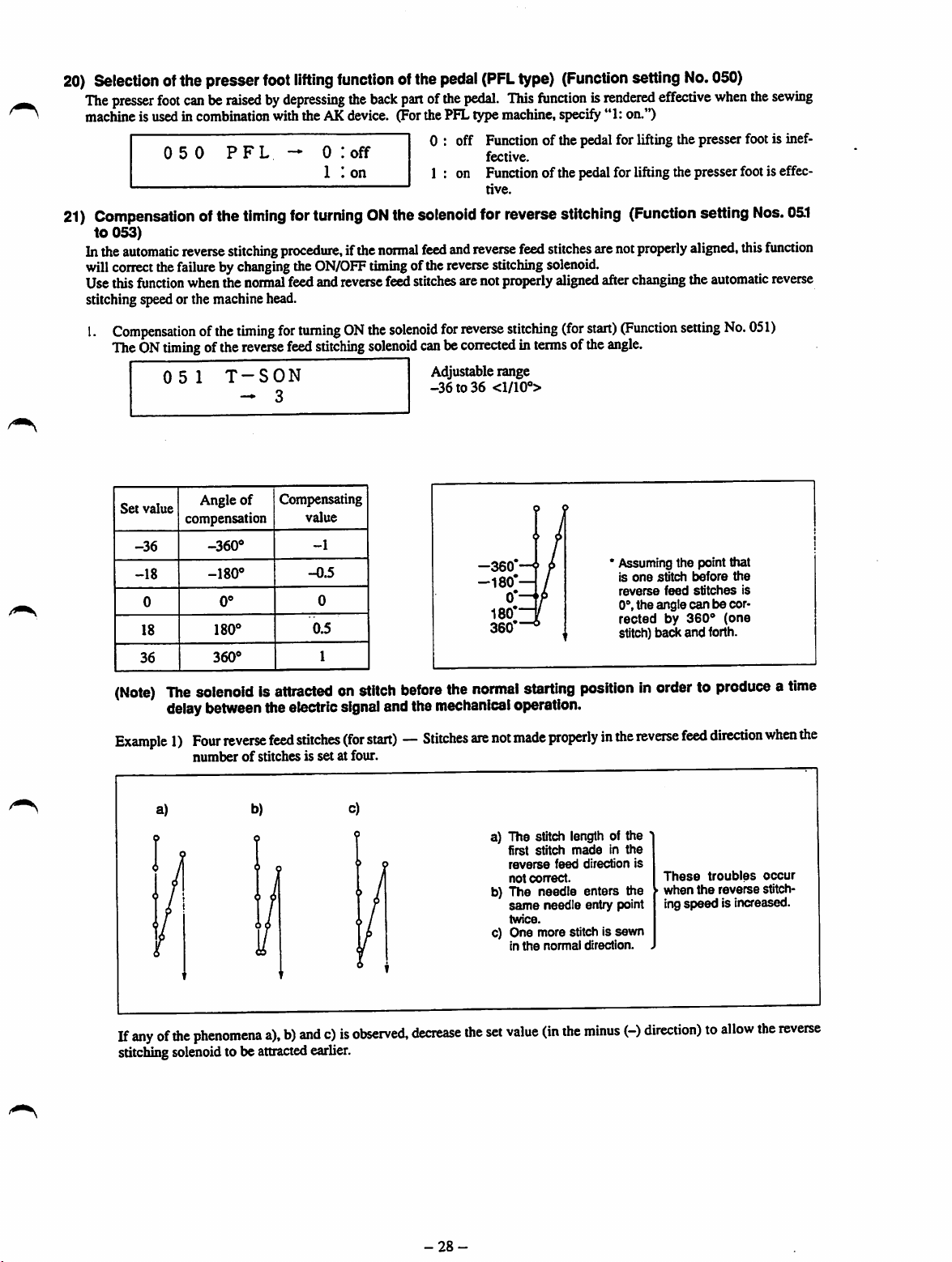

Pedalstroke 2 for making the thread trimmerstart (See 17) onpage25.)

Pedal

043

sMke

044

for

maldng

the

machine

P.TRM2

tcKh

P-MAX

die

largest

—

—5.1

nnmhcrofrevobdioos

[mm]

(See]7)onpige25.)

— 15.0 [mm]

Compensation

Selecticm

Lengthoftinte

ofthe

neutral

pointofthe

045

of auto-lifter (See19)onpage27.)

046

during

047

which

P-ANP

FLScl

the

T-FL

presser

pedal

- 0

— 0 :

footisheld

(See18)onpage27.)

sol

1 I

air

raised

(See

19)onpage

— 60 [sec]

Pedal

stroke

1for

making

the

thread

trimmer

start

(See

17)on

^gth

footis

048

ofdme

desceadittg

049

dufing

P-TRMl

which

thenatton ofthe

(See19)onpage27.)

T-FLWT

—

—3.5

inacfaineispmiiibtted

[mm]

while

-* 140 [msec]

Presser

footlifting

050

A

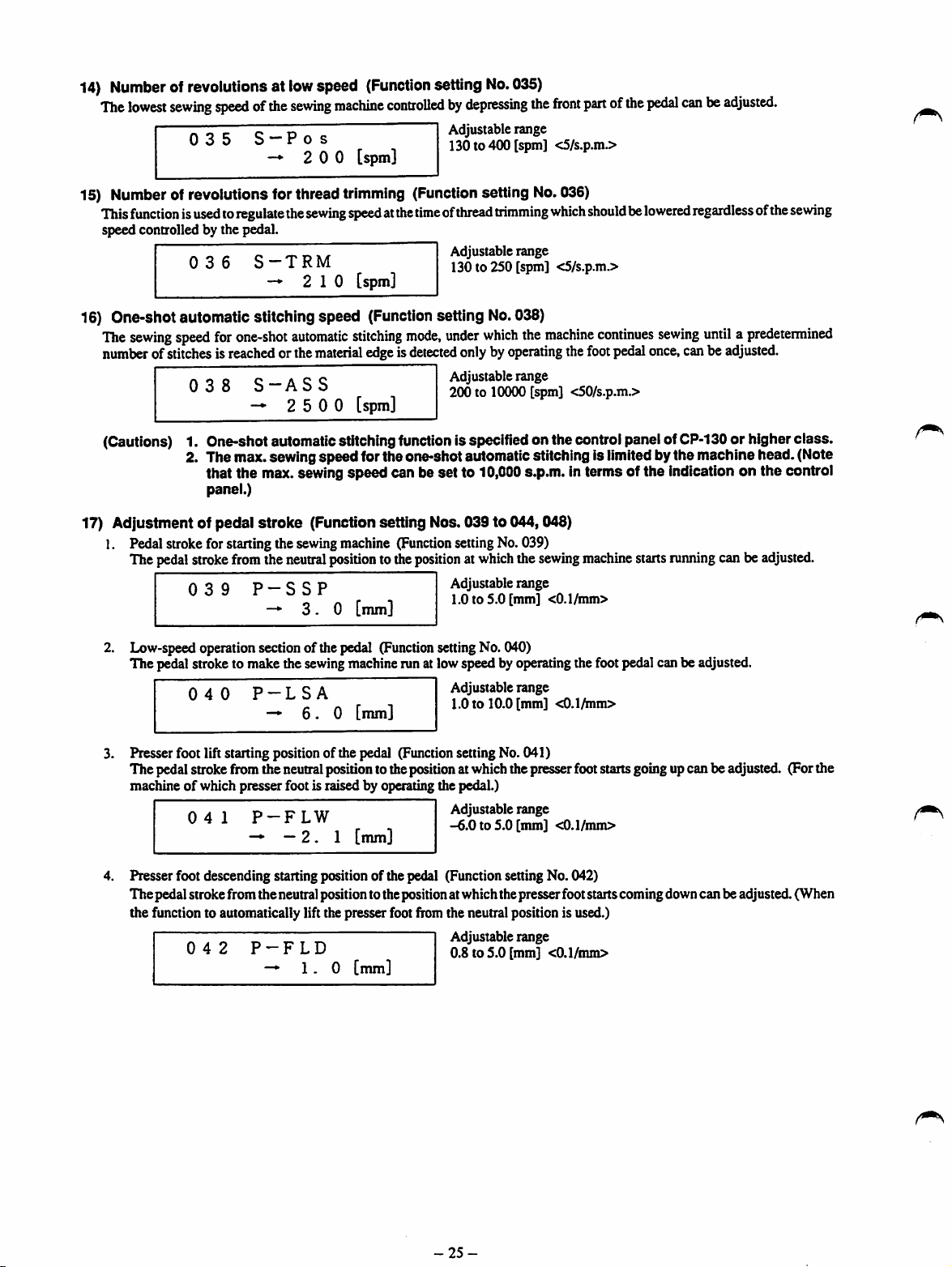

Compensasioa

(forstin) (See 21) oo page 28.)

051

Compensation

(liorsiart)(Sce21)onpage28.)

052

Condensation

(forend)(See21) on page28.)

053

function

ofthepedal (See20)onpage28.)

PFL

of dielinuogfortuningONthe

T-SON

ofthe

timing

for

turning

OFFthe

T-SOFF

ofthe

liming

for

turning

OFFthe

T-EOFF

— 0 :

1 .'

salenoid

lorrevtne stitdiiiii

^ 3

tidcaotd

(or

vcvenc

—

12

solenoid

forlevene

—

18

off

on

stitching

sdrehing

page

the

27.)

25.)

ptesser

Auto/nanuj]

Sewing

Scwutg

device (See 11)00 page 21) *

Auto/tnanual

EBT

Condensation

is set to 1 (See12)on page23.)

Condensation

isseito2

Directionofrotation

Aocnnndatedlengihoflinie

E2PR0M

Monitor

change-over

059

nBdrineaop

060

inichinc

stop

061

change-over

062

change-over

064

stitching

065

stitching

(See12)on page23.)

066

075

100

reset

ITEM

ofthe

stateofinput

fPO*]

funaioo

for

reverse

aiuhing

SBTO

function

iaane<fitielyaftgtevtrietgtching(fg

-

SBTQ —

fuocooo

usingthe

bobbin

thmd ittBtininc

ASBob

function

for

overlapped

—»

stttching

BTOp -

speed

(See22)onpage31.)

S-Wait

-•

solenoidONdming

T-CSl

solenoidONliitiing

T-CS2

ofthemotor (See29)on page33.)

DM

doing

STO

(See31)onpage33.)

NO. — •

-

when

the

—

when

the

—

—

whicb

(be

sewing

midiinebaxrgiaed

—

101

signal

for

ITEM

7 0

11111111

(for

slot)

(See

27)onpage

Auto

Manu

Stan)

(S«27)ooptef7?)

0 :

off

1 I

on

1 I

on

0 :

off

speed

(See

28)onpage

Auto

Manu

180

[spm]

numberofcondensation

-15

numberofooodensadon

-15

ccw

cw

(See

30)onpage

0 [min]

ResEEP

No.

102

(See

32)on

deteccinc

satcfaes

$titd«s

page

31)

33.)

33.)

33.)

Effective

diameterofmotor

054

Prcsscr

foot

lifting

055

A

Reveiserocationluncticnroriitsing

056

A

BoNnn

thread

remaining

057

A

Predetermined

upper/lower

058

PCDMP

fimction

FLAT

RATRM

amount

BTDF

HPos

pulley

after

the

needle

position

thread

detecting

(See23)on

page

trimming

(See

— 0 :

aiierthiudtiiiiiTiing

— 0 I

funaion

— 0 :

ofthe

needle

bar

— 0 :

32.)

105.0 [mm]

24)onpage

off

1 I

on

(See

25)on

off

1 I

on

(See

11)on

off

1 I

on

(See

26)on

off

1 I

on

page

page

page

31)

31)

21)

32.)

Registered

—

Receiving

ITEM

troublesofITEM

modeof

No.103 (See33)onpage33.)

EG

EXIT

E2PR0M

(Sec34)onpage33.)

NO. — •

105 RxCopy

Transmission

Version

A)

User

*) Thefunctionis renderedeffectivewhentheSC-2 istisedin combination

the sewingmachinewhichisequippedwitha bird's nestpreventiondevice.

(Caution) The function

-

19-

modeofE2PR0M (See34)cnpage 33.)

ITEM

management

Version

level

modelofsewing

NO.

No.of ITEMNo. IPS (See 35)on page33.)

setting

tableisprepared

machine.

107

TxData

for

0

the

with*

DDL-5550

(3)

Explanationofthe

1)

Specifying

1.

Numberofstitches for the soft-start function (Function setting No. 001)

The needlethread mayfailto interlacewiththebobbinthreadatthestartof sewingwhenasmallerstitchlengthor athicker

needleis used. To solvesuchproblem, this

successful formaiion of the starting stitches.

2.

The

Thelimitof

2)

Material

This

functionisrendered

for the material edge sensor for details.

(Caution)

I.

ON/OFF

Selects

the

the

numberofrevolutions for

edge sensor

The

sensorand whenthe

ofthe

either

material

functions

soft-start

sewing

speed

effective

specified

material

the

material

edge

sensor

function (Function

N-SOFT-

the

soft-start (Function setting No. 037)

whilethe

S-SOFT

(ED:

Optional)

data

edge

edge

ON/OFF

soft-start

when

the

willbeineffective

sewing

sensor

(Function

sensorismade

switch

setting

function

function

material

isusedto limitthesewingspeedat thesewingstart,therebyensuring

function

works

(Function

edge

sensor

when

machine

isequipped

setting

operativeorinoperative.

(J)

mountedonthe

No. 001,037)

The soft-start function is not speciHed.

The

numberofstitchestowhich

isalso

changed.

Datasetting range

130 to 2000 [spm] <10/s.p.m.>

setting

(ED)isattached

the

sewing

No.002)

off:

Material edgesensoris

ineffective.)

on : Materialedge sensor is effective.

No.

002to

tothe

machine

with

control

isnot

the controlpanelof

(When

the

panelisgiven

004)

machine.

Refer

equipped

CP-130/-230/-330

priority.)

inoperative.

the

soft-function

tothe

Instruction

with

the

CP-130

or higher class.

control

(Nos.003 and 004 are

works.

Manual

material

edge

panelisused,

Thread

trimming

Selects

either

CP-130/-230/-330

priority.)

Numberofstitches

Specifies

material.

(Caution)Ifthe

functioninaccordance

the

thread

control

forthe

the

numberofstitchestobe

sewing

sewing

s.p.m.,atleast

thatthe

setto1or2.Inthiscase,

without fail in consideration of the sewing speed or lowerthe sewing speed.

trimming

panelisused,

EDTRM^O

material

N]

speedishigh,

machine

stops.

five

sewing

machine

function

the

edge

sewn

-5

For

stitches

with

the

using

automatic

sensor

(Function

until

the

there

example,

are

required

will

not

specify

Afterthe

sewing

004)and

willautomatically performthread

material

the

material

thread

machine

0 to 19

isa

minimum

when

stop

according

the

numberofstitches

material

machine

stop.

edge

sensor

edge

trimming

Automatic

has

been

The

004)thenautomatically

material edge has been detected.

setting

stops

stitches

edge sensor

willsewa

If"1:on"is

(Function

sensor

switch@mountedonthe

thread

detectedisineffective.

machine

sewsapredetermined

No.

004)

after

the

<l/stitch>

numberofstitches

the

tobe

sewing

sewn

machine

until

tothe

numberofstitches

thatis

detects

predetermined

selected

forNo.003,the

trirruning.

setting

made

trimming

material

No.

effectiveorineffective.

function

performs

edge

sensor

required

perform

the

sewing

machine

sufficienttomake

the edge of material, the

numberofstitches

sewing

machine

003)

(When

control

panelisgiven

afterthe materialedge

numberofstitches

threadtrimmingafter the

has

tobe

sewing

specified

detected

ata

stops.

the

sewn

until

speedof4,000

This

ifithas

the

machine

(No.

the

(No.

edge

of

the

means

been

stop

ED

sensor

(Material

edge

sensor)

-20-

3) Flicker reducing function (Function

This

functionisusedtoprevent

the

more

effective

(Caution)

4)

Bobbin

1- This function is used, when the control panel (CP-130 or higher class) is used with the machine, to indicate the remaining

2.

thread

amount of the bobbin thread while subtracting one from a predetermined set value every time the sewing machine finishes a

predeterminednumber of stitches. Referto the explanationof the controlpanel (on page II).

Unit used for count-downofthe bobbin thread (Function setting No. 007)

The imit used for the count-down (subtraction)ofthe bobbin thread counter can be changed.

the

function

0 0 5

The

more

speedofthe

counting

0 0 6 S C B o

the

will

work.

T-Acc-*

the

flicker reducing function works (the larger

sewing

function

hand

lamp

machine

(Function

b—1

setting

from

will t>ecome).

on

0

off

No. 005)

flickering

setting

atthe

stait-up

Data sening range

Oto

8

0 : Flicker reducing function does not work.

8 : Flicker reducing function works most effectively.

Nos.

006,007,013)

(Caution) If

ofthe

the

set

the

bobbin

the

OFF

control

counting

sewing

value

state,

panel

function

machine.

becomes),

thread

the

indicationonthe

willgoout

is inoperative.

The

the

counting

and

larger

the

lower

function is

the

bobbin

value

the

LCDofthe

isset.

start-up

set

to

thread

007

Ratio—

1/10

1/15

1/10 : 1count-down for every 10 stitches

1/15 : 1 count-down for every IS stitches

1/20 : 1 count-down for every 20 stitches

3. Sewingmachine stop functionin accordancewith the bobbinthread counter (Function setting No. 013)

This function is used to stop the sewingmachine when the value shown on the bobbin thread counter becomes "-1" or less.

0 : off Sewing machine stop function is inoperative even when

0

13

A s c

t-

0

off

1

on

1 : on Sewing machine stops when the bobbin thread counter

the

bobbin

value.

indicates

thread

"-1"ora

counter

smaller

indicates

value.

(Caution) Ifthe bobbinthread counter indicate "~1" or a smallervalue during a sewing process, the sewing

machinewill

stop

after

the

completion of the

process

(after

thread

trimming).

5) Number of revolutions for reverse stitching (Function setting No.008)

Specifies thenumberof

end) and overlapped stitching.

008

(Caution) if any value other than the standard

sewn

previously

item

revolutions

S-BT

— 1 9 0 0

one

with

sewn

Nos.

051,052

(sewing

speed)ofthe

[spm]

accuracy.

seambychanging

and

In

this

053

for

howtocompensate

sewing

machine

Data setting range

forreversestitching(forstart),

180to 3000 (spm] <10/s.p.m.>

set

value, the finished seam may not overlap the previously

case,

adjust

the

numberofstitches

so

the

that

seam.

the

finished

for

processesAthrough

seam

neatly

6) Thread trimming prohibiting function (Function setting No.009)

This

function

When

panel is given priority.

isusedto

the

CP-130/-230/-330

0 0 9

temporarily

control

TRMI

prohibit

thread

panelisused,

NH-0

1 '

:

off

on

trimming

the

incaseofjoining

thread

trimming

seams,

prohibiting

0 : off Threadtrimming is effective.

1 : on Thread trimming is prohibited.

(Themachinewill notperformthreadtrimmingbutstops

with its needle up when depressing the back

foot pedal.)

etc.

switch

^

mountedonthe

7) Specification of the needle bar positionwhen the sewing machine stops (Function setting

Specifies

the

stop

010

position

NFS

ofthe

needle

-

bar

when

Down

Up

the

foot

pedal

restinthe

Down

neutral

position.

Theneedlebar stops initslowestposition.

Up : Theneedlebarstopsin itshighestposition.

"-1"ora

reverse

No.

smaller

stitching (for

overlap

the

D. Refer to

control

pan

of the

010)

(Caution) Ifthe upper

to

the

lowest

stop

position Isspecified,the thread trimmer

position.

-21

actuates

-

afterthe needlebar

has

descended

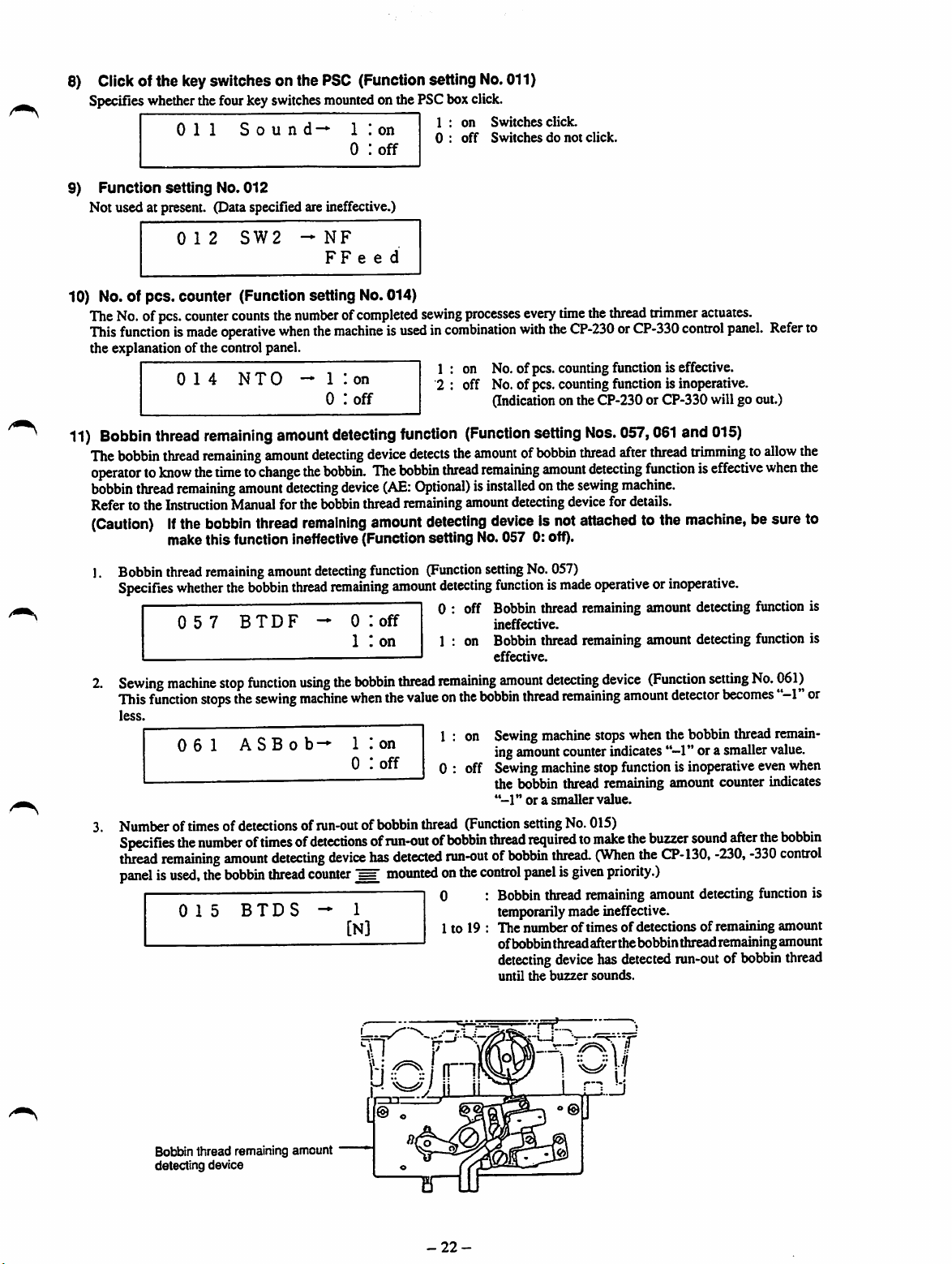

8) Clickof the keyswitches on the PSC (Function setting No.011)

Specifieswhetherthe fourkey

9)

Function

Not used at present. (Data specified are ineffective.)

setting

No. 012

switches

mounted

on the PSCboxclick.

Switches

Switchesdonot

click.

click.

SW2

10) No. of

The

This

the explanation of the control panel.

11)

The

operatortoknow

bobbin

Refer to the InstructionManual for the bobbinthread remaining amountdetectingdevicefor details.

(Caution)Ifthe

1. Bobbin

2.

pcs.

No.ofpcs.

functionismade

Bobbin

bobbin

thread

thread

thread

make this function ineffective (Function setting No.057 0: off).

thread

Specifies

Sewing

machine

This

function

counter (Function setting No.014)

counter

counts

operative

NTO

remaining

remaining

the

timetochange

remaining

amount

bobbin

remaining

whether

stop

stops

the

bobbin

BTDF