Page 1

•JUKI

SWING-TYPE

SEWING

MACHINES

SHIRRING

MO-2400N

ATTACHMENTS

AND

S057-8058

8097.8098

IN8TRUCTI0N

-2500N

SERIES

MANUAL

No.05

BES05730B0A

Page 2

These shirring attachments, S057, S058, S097 and S098 are designed for use with JUKI overedgers and

safety stitchers MO-2400N and -2500N series.

Please read this manual carefully before using these units in order to get the most

outofit and to enjoy

using it for a long time.

1.

MODELS

Swing-type Shirring Attachments for MO-2400N and -2500N series

5057 : Swing-type Shirring Attachment (pedal-operated) for safety stitchers

5097 : Swing-type Shirring Attachment (manually-operated) for safety stitchers

5058 : Swing-type Shirring Attachment (pedal-operated) for overedgers

5098 : Swing-type Shirring Ajtachment (manually-operated) for overedgers

2.

APPLICABLE

SEWING

MACHINES

—--.-^^Attachment

Series

MO-2400N

MO-2500N

3.

SPECIFICATION

Application

~~~~~—

MO-2416N

BD4,

DD4, DD6,

MO-2443N

MO-2516N

BD4, DD4, DD6, DE4,

MO-2543N

To provide shirring partially or continuously on light-weight articles

S057,

DBD6

DBD6

DE4,

S097

DF6,

DF6,

such as ribbed knit, light-weight knit and broadcloth garments.

Sewing speed

Differential

feed

ratio

5,000 through 5,500 s.p.m.

Overedger

-1:3,

Safety stitcher

materials)

Liftofpresser foot

4.

REPLACEMENT

The

gauge

set of a

sewing

Overedger - 5

GAUGE

SETS

mm.

Safety stitcher - 6.5 mm

machine must be changed when a shirring attachment S057, S058, S097 or

S098 isinstalledto the machine Select the most suitable

DH6,

FF6,

RH6

MO-2412N-DF6

MO-2414N-BD6,

MO-2504N-0D6,

MO-2404N-0D6,

DH6,

FF6,

RH6

MO-2512N-DF6

MO-2514N.BD6,

-1:3

gauge

set out of those listed below.

(Adjustable for each type

S058,S098

0F6,

BE6

0F6,

BE6

0H6

0H6

of

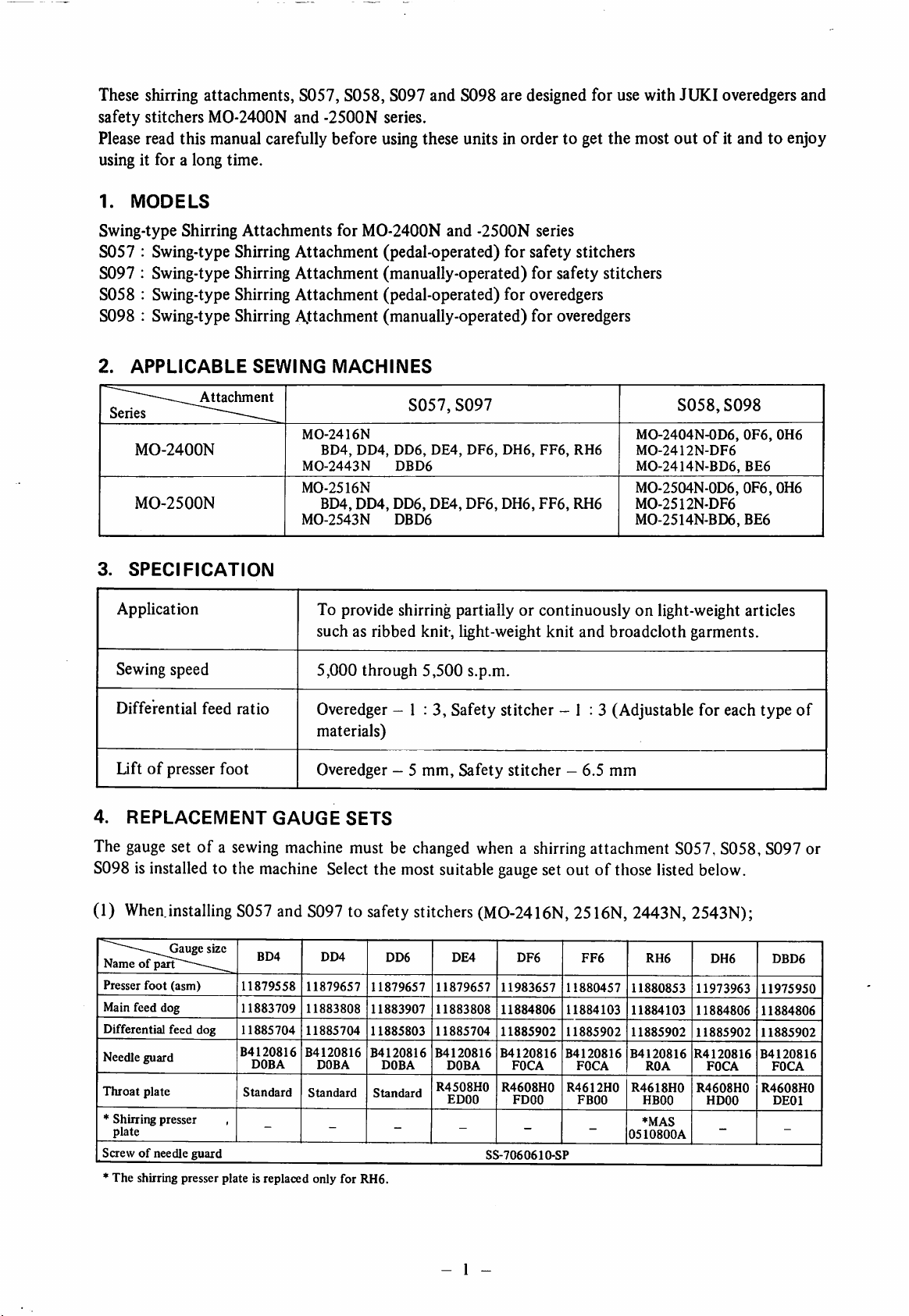

(1)

When

installing

•—-..^^Gauge

Nameof parT

Presser

foot

(asm)

Main feed dog

Differential feed dog

Needle

guard

Throat

plate

* Shirring presser ,

plate

Screwofneedle

The

shirring presser plate is replaced only

size

guard

S057

BD4

11879558

11883709

11885704

B4120816

DOBA

Standard

-

and

S097tosafety

DD4

11879657

11883808

11885704

B4120816

DOBA

Standard

-

DD6

11879657 11879657

11883907

11885803

B4120816

DOBA

Standard

-

for

RH6.

stitchers

DE4

11883808

11885704

B4120816

DOBA

R4508H0

EDOO

-

(MO-2416N,

DF6

11983657

11884806

11885902

B4120816

FOCA

R4608H0

FDOO

-

SS-7060610-SP

2516N,

FF6

11880457

11884103 11884103

11885902

B4120816

FOCA

R4612H0

FBOO

2443N,

RH6

11880853

11885902

B4120816

ROA

R4618H0

HBOO

-

♦MAS

0510800A

2543N);

DH6

11973963

11884806 11884806

11885902

R4120816

FOCA

R4608H0

HDOO

-

DBD6

11975950

11885902

B4120816

FOCA

R4608H0

DEOl

-

Page 3

(2)

When

installing S058 and S098 to overedgers (MO-2404N, 2412N, 2414N, 2504N, 2512N, 2514N);

Gauge size

Name

ofparts \

Presser

foot

Main feed dog

Differential

dog

Throat

plate

5.

ADJUSTING

(asm)

feed

0D6

11878857

11883402

B1657814B0L

R4300H0DD0A

THE

0F6

11974268

11883402

B1657814B0L

R430OHOFEOB

SHIRRING

11974268

11883402

B1657814B0L

R4300H0HE0A

PRESSER

0H6

PLATE

BD6

11879350

11883402

B1657814B0L

R4305H0DE0A

5

BE6

11879350

11883402

B1657814B0L

R4305H0EE0B

DF6

(2A12N)

11974060

11884608

11886603

R4308H0FE00

lT

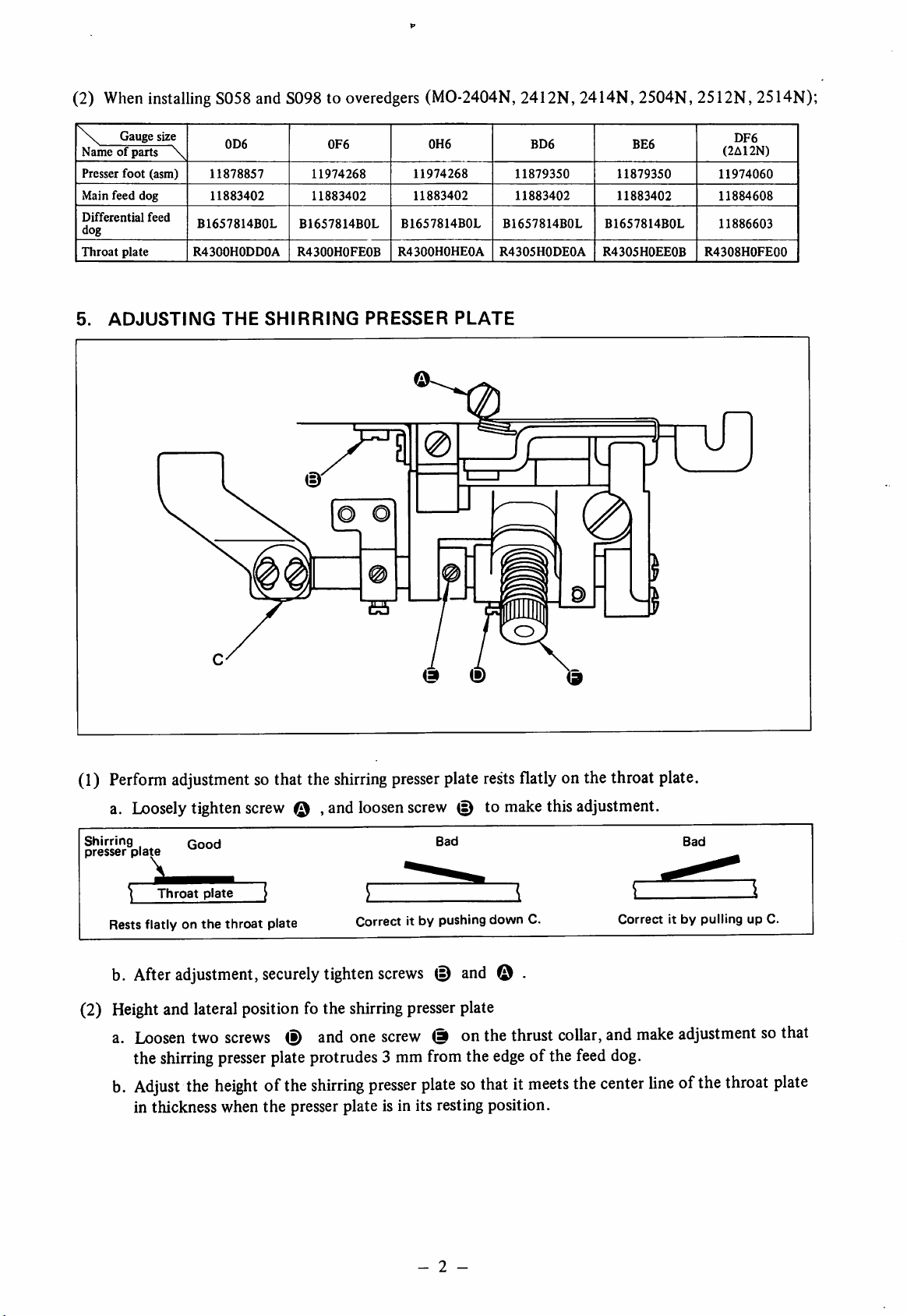

(1)

Perform

adjustment

sothat the

shirring

presser

plate

rests

flatly

onthe throat

a. Loosely tighten screw , and loosenscrew (s) to makethis adjustment.

Shirring

presser

Rests

b.

(2)

Height

a.

plate

After

Loosen

the shirring

Adjust

in thickness when

Qood

Throat

plate

flatlyonthe

adjustment,

throat

plate

securely

[ 1

Correct it by pushing

tighten

screws

Bad

and lateral positionfo the shirring presser plate

two

screws

presser

the

heightofthe

(D

and

one

screw

© onthe

plate protrudes 3 mmfrom the

shirring

the

presser plate is in its resting position.

presser

platesothatitmeets

and

down

C.

© .

thrust

edge

of the feed dog.

collar,

the

Correctitby

and

make

center

plate,

Bad

pullingupC.

adjustmentsothat

lineofthe

throat

plate

- 2 -

Page 4

Shirring

presser

3

mm

plate

(3-ro.wfeed dog)

3

mm

(2-ro\A/

Shirring

presser

feed dog)

plate

Throat

Contact

Shirring

plate

presser

without

plate

gap

®

(3) Longitudinal positioning of the shirring presser plate

When

the differential feed dog has completed its

feeding

motion, the top end of the shirring plate

must be about three teeth behind (overedger) or 1 or 2 teeth behind (safety stitcher)ofthe

the differential feed dog as illustrated below.This is the adjustment for the standard pitch shirring.

By changing the longitudinal position of the shirring presser plate, different shirring pitch is

obtained. Adjust the longitudinal position by the typeoffabrics.

3-teeth (overedger)

When

the stitch lengthis

2.2

mm

and

the

differential

feed ratio is

maximum.

Main

feed

dog

Differential

feed

dog

top

of

(4)

Pressure

a.

6.

INSTALLING

of the

The

shirring

standard

presser

pressure

the presser plate is 1.5

THE

SHIRRING

applied

Kg.

Fix the shirring wire (asm) to the

plate

by the

Adjust

top

cover by the two thread tension posts.

the

pressure

WIRE

shirring

(ASM)

presser

plate to the

by knob (9 for the type of

Shirring

wire

(asm)

Thread

workpiece

tension

posts

at the top end of

fabrics.

- 3 -

Page 5

7.

ADJUSTING

THE

LIFTING

AMOUNT

(8057,

3058)

a. Loosen screw

standard

8.

ADJUSTING

lift

<D

and move up or down to adjust the liftofthe shirring presser plate. The

is 3

mm.

Presser

foot

Throat

V=2=^

!5 mm

plate

3

T7"

mm

rc

D

0

THE

MANUAL

LEVER

(S097,

S098)

Adjust

the

protrusion

of the

whenthe manual leverhas

9. CUTTING

When

stalled

S057

toamachine

THE

MACHINE TABLE (Fully-sunken

or

S058

is

in

head

set up on a fully-sunken

type table, modify the

mounting opening in the

table as shown in

right.

the

figure

manual

raised

leverbymeans

of its

locknut

so that

clearanceAis

the shirring presserplate 3 mm abovethe throat plate surface.

iyw"''Xl

3^^Noclearance

^ at point A

•>T

Manual

lever

Manual

Point

lever

A

locknut

type

table)

eliminated

10 10

- 4 -

Page 6

10.

INSTALLING

THE

KNEE

LIFTER

(1) Installthe leverinstalling basemounting plate asillustrated below.

Table

Bolt

Setscrew

Frame

Lever

mounting

base

support

plate

O O

Tl

plate

(Note)

For

table-top

Fix

the

lever

platebythe

For

the

table-top

replace

support

with

the

the

plate

unit.

base

bolt

bolt

and

with

bolt

type

mounting

setscrew.

type

table,

the

supplied

Setscrew

For

fully-sunken

Fix

the

lever

platebythe

base

two

type

mounting

setscrews.

Page 7

(2) Attach the knee lifter to the lever base mounting plate according to the following procedures.

a. Attach lever base O to

the

frame support plate using screws @ and washers o

b. Insert shaft © into lever O , and fasten it by screw © .

c. Insert one endofconnecting rod ® into the holeofthe differential feed contort lever from

inside, and insert

the

other

end into the holeoflever © . Then lock the connecting rod to

the

lever with split pin © .

d. Attach the knee press plate © to rod © and tighten screw © at a convenient height.

Side

viewofA

- 6 -

Page 8

To

order

or for further information,

please

contact;

•JUKI

JUKI

CORPORATION

HEAD

OFFICE

8-2-1

KOKURYO-CHO.

CHOFU-CITY. TOKYO 182. JAPAN

BUSINESS

1-23-3

SHINJUKU-KU. TOKYO 160.

PHONE : 03(3205)1188. 1189. 1190

FAX:03(3203)8260. (3205)9131

TELEX;

OFFICE

KABUKI-CHO

J22967,

232-2301

JAPAN

Please do not hesitate to contact our distributors or agents inyourarea for

*The

description covered in this instruction manual is subject to

commodity

without

notice.

further

information

change

for improvement of

1992.12PrintedinJapan

when

necessary.

the

Loading...

Loading...