Page 1

ENGLISH

Lu-2220N-7

INStructIoN MaNuaL

i

Page 2

CONTENTS

1. SPECIFICATIONS .................................................................................................................... 1

2. INSTALLATION ........................................................................................................................ 1

(1) Attaching the hinge seats and support rubber of the machine head .............................................. 1

(2) Attaching the oil pan ............................................................................................................................1

3. INSTALLING THE WASTE OIL CONTAINER ......................................................................... 2

4. ADJUSTING THE BELT TENSION .......................................................................................... 2

5. INSTALLING THE SYNCHRONIZER SUPPORT ROD ........................................................... 2

6. ATTACHING THE BELT COVER ............................................................................................. 3

7. INSTALLING THE KNEE SWITCH .......................................................................................... 3

8. INSTALLING THE AIR DRIVE UNIT ........................................................................................ 4

(1) Installing the air control unit ............................................................................................................... 4

(2) Connecting the air hose ....................................................................................................................... 5

(3) Adjusting the air pressure ...................................................................................................................6

9. INSTALLING THE THREAD STAND ....................................................................................... 7

10. LUBRICATION ....................................................................................................................... 7

11. ATTACHING THE NEEDLE ...................................................................................................9

12. ATTACHING/REMOVING THE BOBBIN ............................................................................... 9

13. THREADING THE HOOK .................................................................................................... 10

14. INSTALLING THE THREAD GUIDE .................................................................................... 10

(1) Installing the needle thread guide rod .............................................................................................. 10

(2) Installing the bobbin winder thread guide .......................................................................................10

15. WINDING A BOBBIN ........................................................................................................... 11

16. ADJUSTING THE AMOUNT OF OIL IN THE HOOK .......................................................... 11

17. THREADING THE MACHINE HEAD ................................................................................... 12

18. ADJUSTING THE STITCH LENGTH ................................................................................... 13

19. THREAD TENSION ............................................................................................................... 13

(1) Adjusting the length of thread remaining after thread trimming ...................................................13

(2) Adjusting the needle thread tension.................................................................................................13

(3) Adjusting the bobbin thread tension ................................................................................................ 13

20. THREAD TAKE-UP SPRING ............................................................................................... 14

(1) When you want to change the stroke of the spring : ......................................................................14

(2) When you want to change the tension of the spring : ....................................................................14

21. HAND LIFTER / HANDHEBEL ............................................................................................ 14

22. ADJUSTING THE PRESSURE OF THE PRESSER FOOT ................................................ 14

23. NEEDLE-TO-HOOK RELATION .......................................................................................... 15

24. ADJUSTING THE HOOK NEEDLE GUARD ....................................................................... 15

25. ADJUSTING THE BOBBIN CASE OPENING LEVER ........................................................ 16

v

Page 3

26.

ADJUSTING THE THREAD TRIMMING MECHANISM COMPONENTS ...............................16

(1) Positioning the thread trimming cylinder joint ..............................................................................16

(2) Adjusting the position of the feed dog ............................................................................................16

(3)-1. Counter knife

(3)-2. Counter knife (Adjusting the lateral position) ............................................................................. 18

(4) Moving knife (Adjusting the vertical position) ................................................................................ 19

(5) Counter knife (Adjusting the vertical position) ...............................................................................20

(6) Thread guide installing position ....................................................................................................... 20

(7) Adjusting the knife pressure ............................................................................................................ 21

(8)-1. Initial position of the moving knife drive arm and the moving knife ........................................22

(8)-2. Adjusting the clearance between the moving knife drive arm and the moving knife drive arm

stopper .............................................................................................................................................. 23

(8)-3. Installing position of the moving knife return plate ...................................................................23

(9) Adjusting the thread trimming cam timing ...................................................................................... 24

(10) Installing position of the clamp spring .......................................................................................... 25

(11) Adjusting the condensation amount .............................................................................................. 26

(12) Explanation of the solenoid valve .................................................................................................. 27

(Adjusting the travel amount) (Positioning of the counter knife base stopper) ........... 17

27. ADJUSTING THE LIFTING AMOUNT OF THE PRESSER FOOT AND THE WALKING

FOOT ................................................................................................................................... 28

28. SEWING SPEED TABLE ..................................................................................................... 28

(1) Max. sewing speed in accordance with the amount of the alternating vertical movement of the

walking foot and the presser foot ................................................................................................... 28

29. RESETTING THE SAFETY CLUTCH .................................................................................. 28

30. OPERATION SWITCHES .................................................................................................... 29

31. KNEE SWITCH .................................................................................................................... 31

32. CAUTIONS WITH REGARD TO THE SEWING OPERATION ............................................ 31

33. TROUBLES IN SEWING AND CORRECTIVE MEASURES ............................................... 32

vi

Page 4

1. SPECIFICATIONS

Model LU-2220N-7

Applications Car seats, furniture, etc.

Sewing speed Max. 3,500 rpm See “ 28. SEWING SPEED TABLE” on page 28.

Stitch length (max.) Normal feed : 9 mm Reverse feed : 9 mm

Needle SCHMETZ 34 x 35R (Nm 0 to Nm 60)

Hook Vertical-axis, .6-fold hook

Lift of presser foot Hand lifter lever : 9 mm Knee lifter : 6 mm

Lubricating oil JUKI New Defrix Oil No.

Workplace-related noise at sewing speed

Noise

n = 2.500 min- : LPA ≦ 84 dB (A)

Noise measurement according to DIN 45635-48-A-.

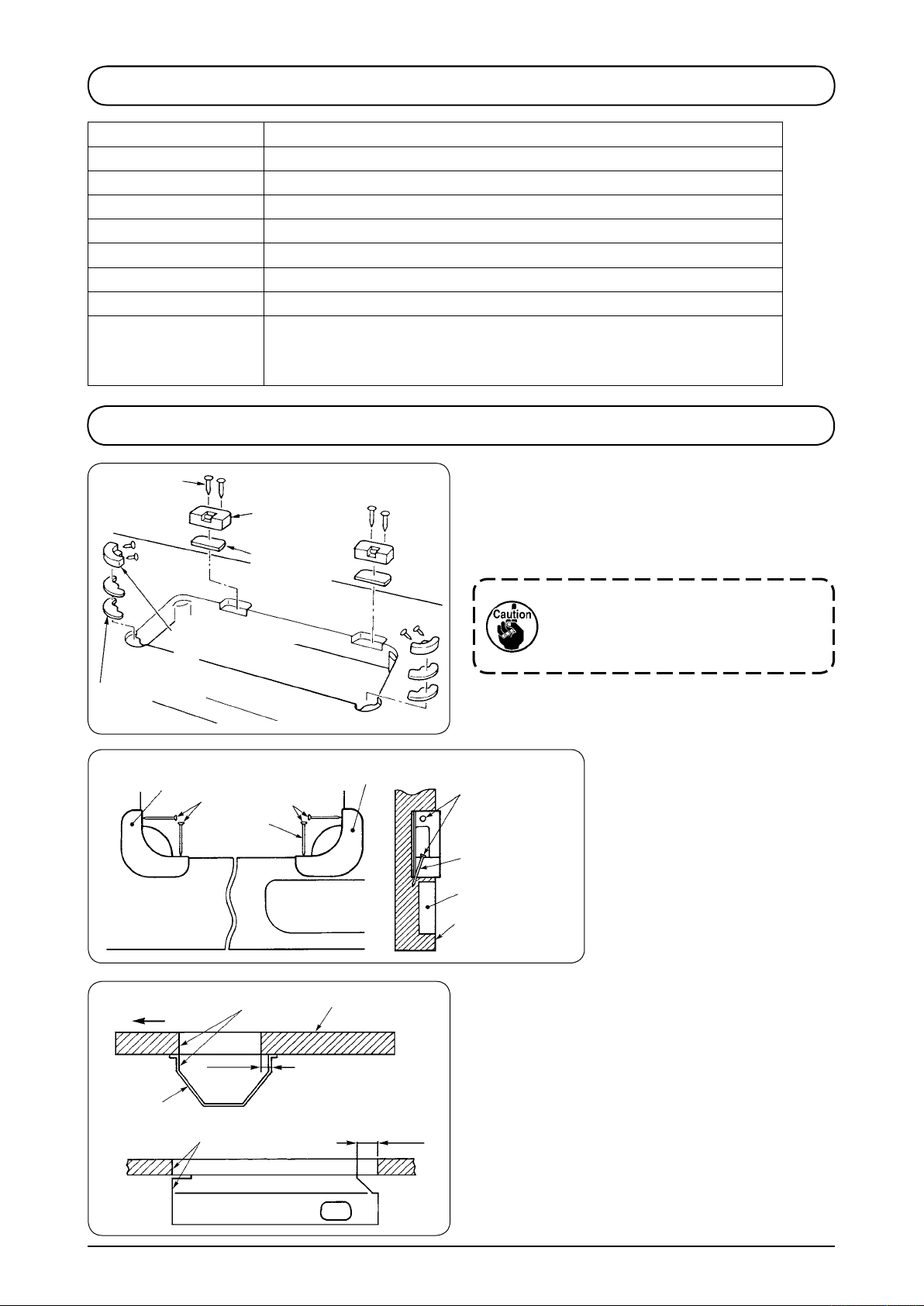

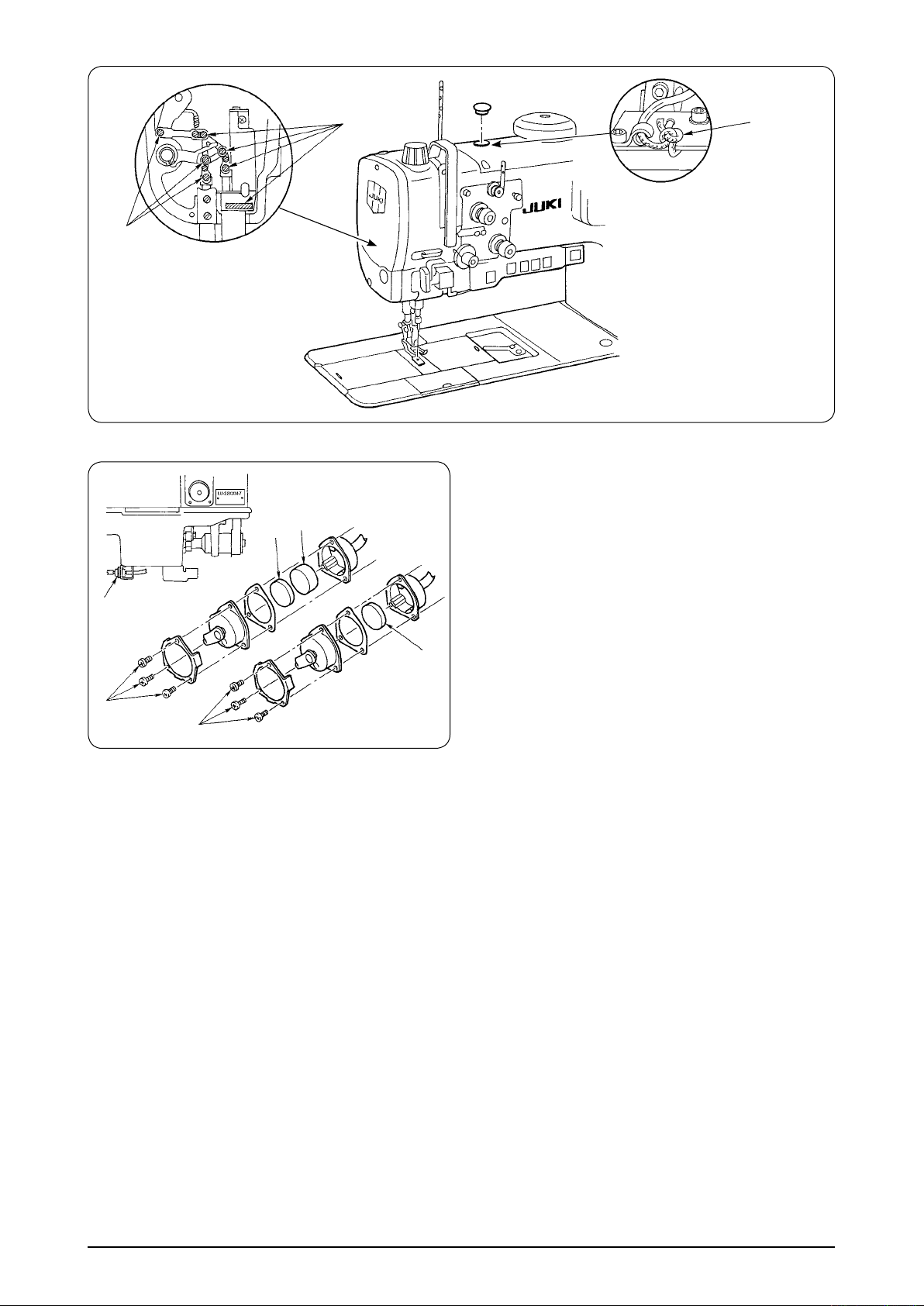

2. INSTALLATION

Nail

Support rubber of

the machine head

Rubber cushion

Support rubber of the

machine head

Nail

Hinge seat

Spacer rubber

Support rubber of the machine head

Nail

A

Small articles

case

(1) Attaching the hinge seats and support

rubber of the machine head

Fix th e hinge seats and th e support ru bbers

supplied with the machine on the table using nails.

When driving nail A, drive it slantingly

so that it does not pass through the

side of the small articles case.

Nail

A

Small articles

case

Top surface of

the machine table

Operator’s side

1

Align

Align

Table

20 mm

(2) Attaching the oil pan

Fix oil pan 1 supplied with the machine on the

table in 8 places with wood screws.

50 mm

− −

Page 5

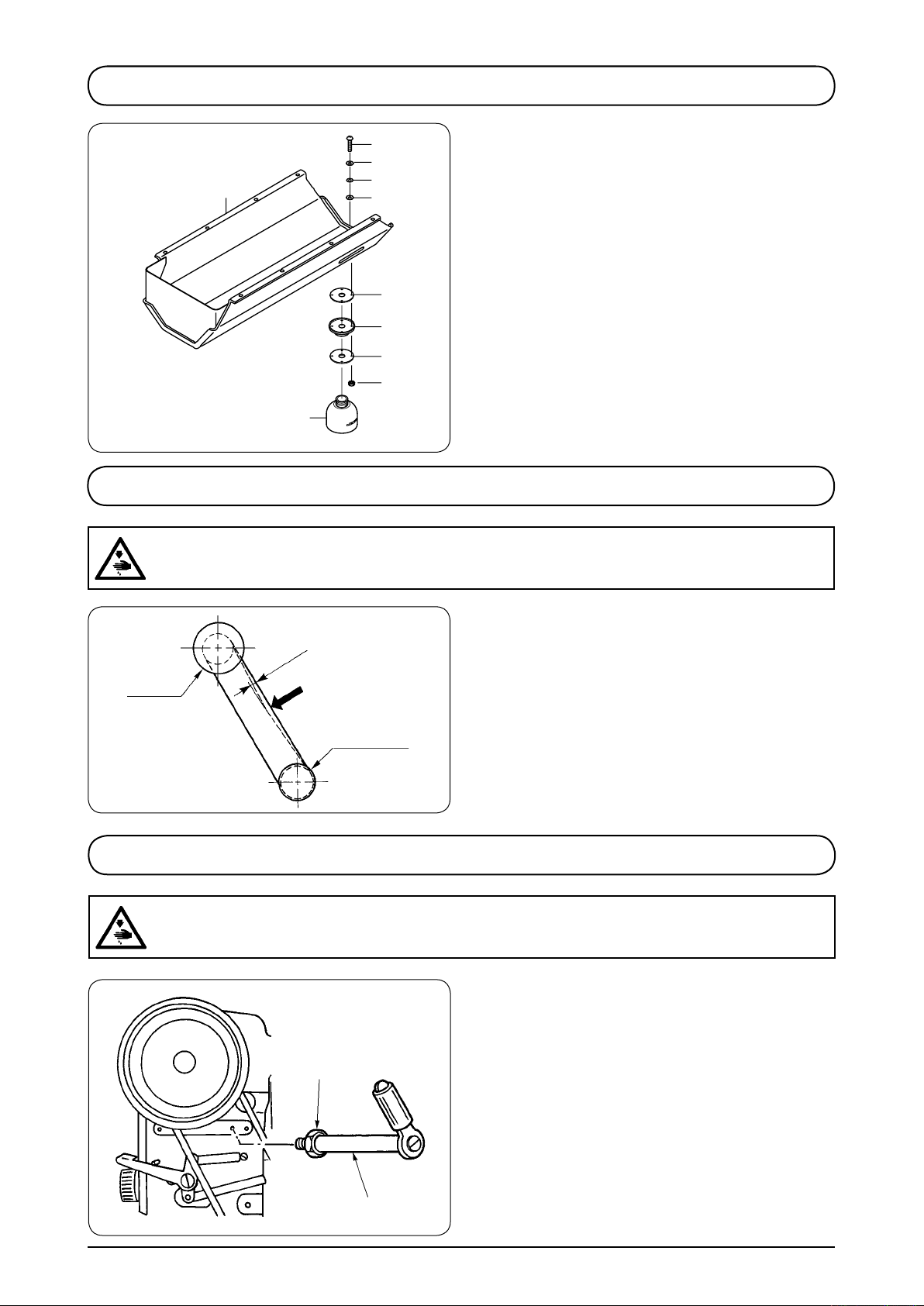

3. INSTALLING THE WASTE OIL CONTAINER

4

5

Oil pan

8

5

2

1

3

6

7

4. ADJUSTING THE BELT TENSION

WARNING :

To avoid possible personal injury due to abrupt start of the machine, turn off the power to the

machine and check to be sure that the motor has totally stopped rotating in prior.

) Attach drain plug 1, oil seal 2 and washer 3 to

the oil pan. Attach packing 5 and washer 8 to

screw 4 and x them with nut 6.

2) After they are xed, screw in waste oil container

into drain plug 1.

7

Adjust the belt tension with the height of the motor so

that the belt sags 5 mm when the center of V belt is

applied with a 9.8N load.

Handwheel

15mm

9.8N

Motor pulley

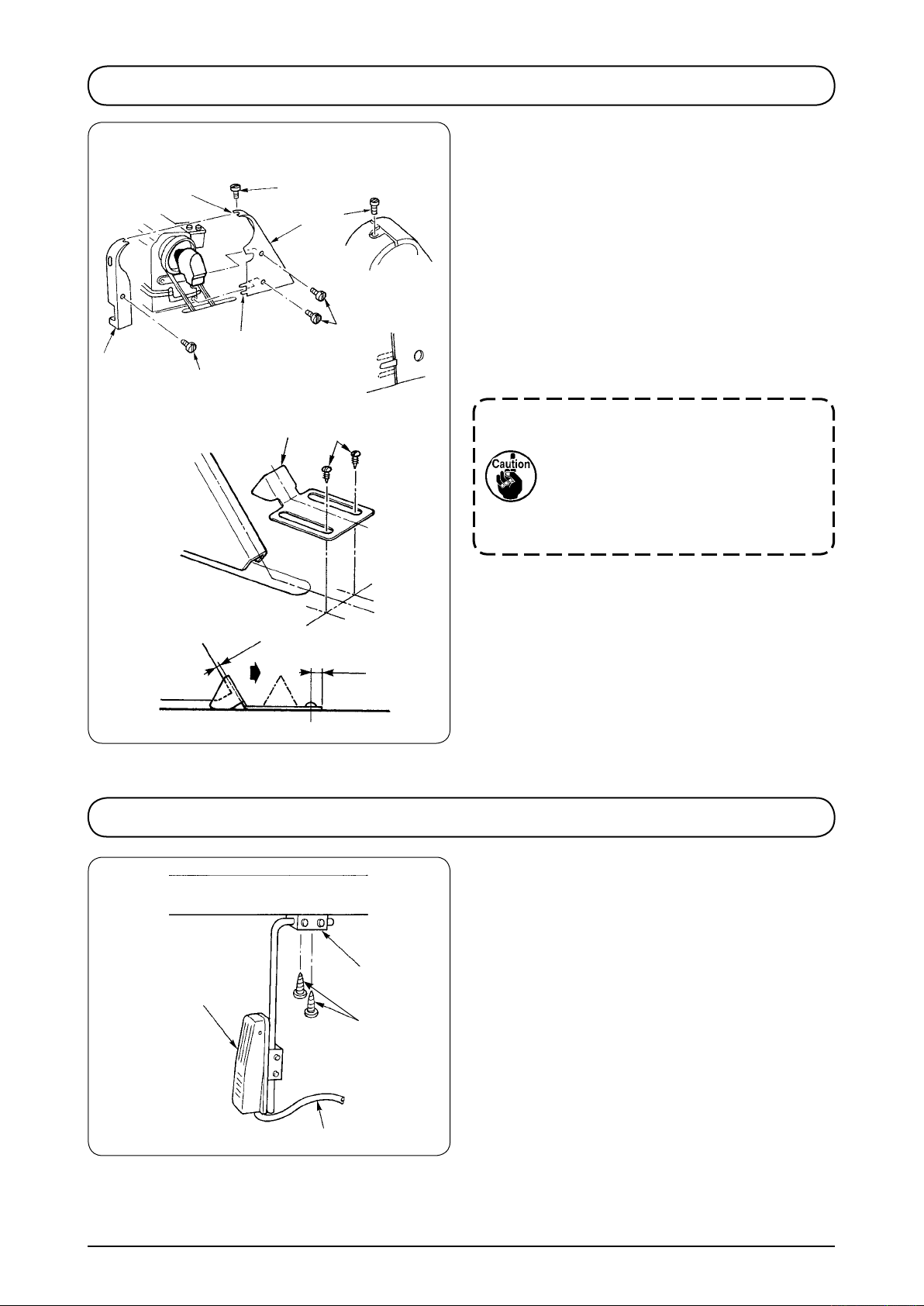

5. INSTALLING THE SYNCHRONIZER SUPPORT ROD

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

) Attach synchronizer support rod 1 to the arm

using attaching nut 2.

2

1

− 2 −

Page 6

6. ATTACHING THE BELT COVER

Notch (upper)

B

4

4

1

2

Notch (lower)

A

3

5

) Fix belt cover (rear) 1 on the arm with screws 2.

2) Fit belt cover (front) 3 to notch (upper) A and

notch (lower) B of the belt cover (rear).

3) Fix belt cover (front) 3 with screws 4 and 5.

4) Fix belt cover auxiliary plate 6 at the position of

0 mm from the rear end with wood screws 7

when there is a clearance of 2.5 mm between the

belt cover and the auxiliary plate.

5) When tilting the machine head, loosen wood

screws 7 and move the belt cover auxiliary plate

in the direction of the arrow until it stops. Then, tilt

the machine head.

6

7

2.5 mm

10 mm

7. INSTALLING THE KNEE SWITCH

2

1

3

Afterattachingthebeltcover,conrm

whether or not the respective cords do

not come in contact with the belt and

the handwheel. Disconnection of the

cords will result when they come in

contact with one another.

) Attach supporting base 2 of knee switch 1 onto

the underside of the table using wooden screws

.

3

2) Fix cord 4 to an appropriate position on the table

using a staple supplied with the machine so as to

prevent the cord from hindering the operation.

4

− 3 −

Page 7

8. INSTALLING THE AIR DRIVE UNIT

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

3

4

Rear view of table

2

1

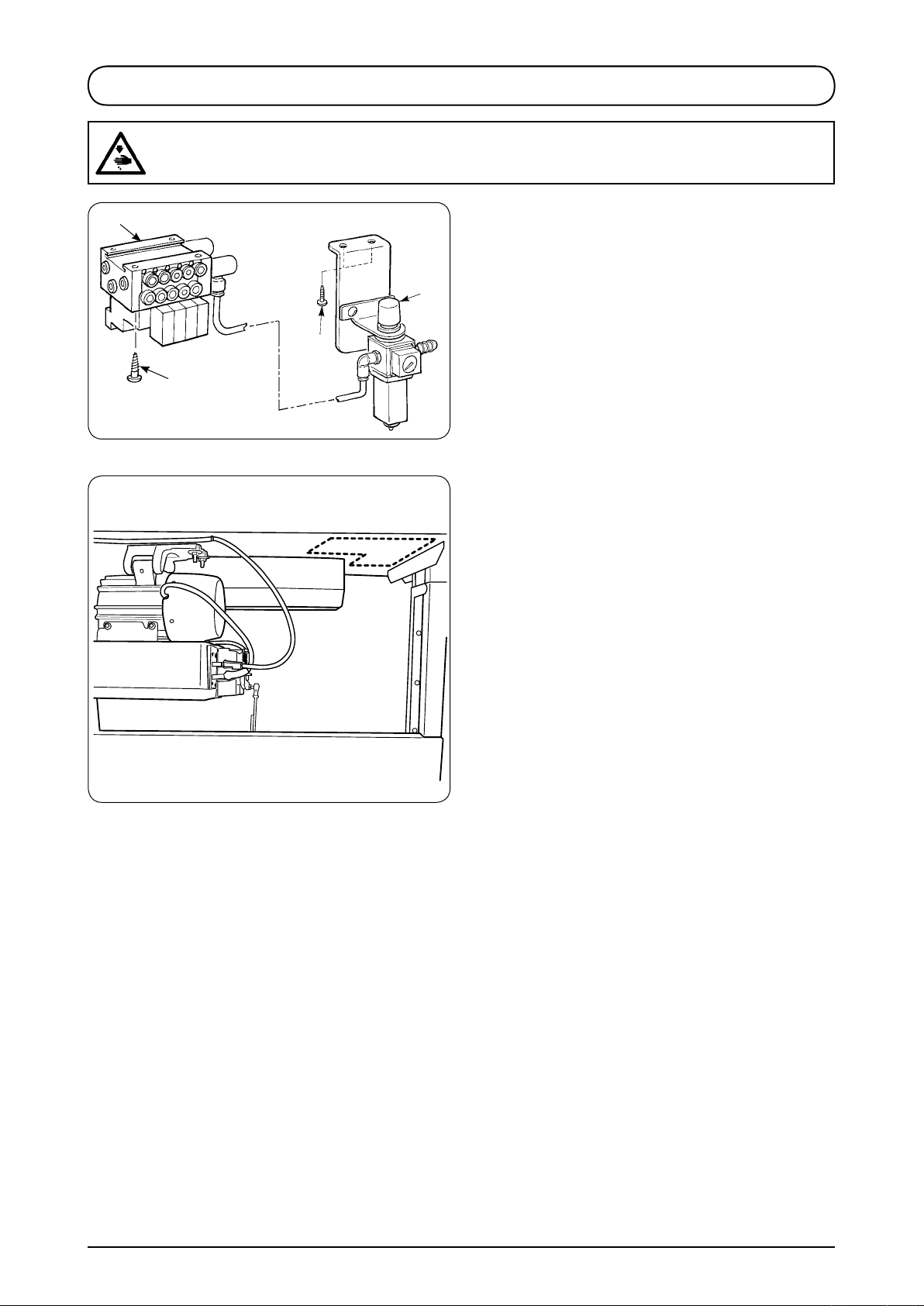

(1) Installing the air control unit

) Install regulator (asm.) 1 on the bottom surface

of the table with wood screw 2 supplied as

accessories.

2) Install air control unit (asm.) 3on the bottom

surface of the table in four places with wood

screws 4 supplied as accessories.

3) Install regulator (asm.) 1 and air control unit

(asm.) 3 in the broken line frame as shown in

the illustration on the left side. Determine the

installing position where it is convenient to the

user.

− 4 −

Page 8

1

2

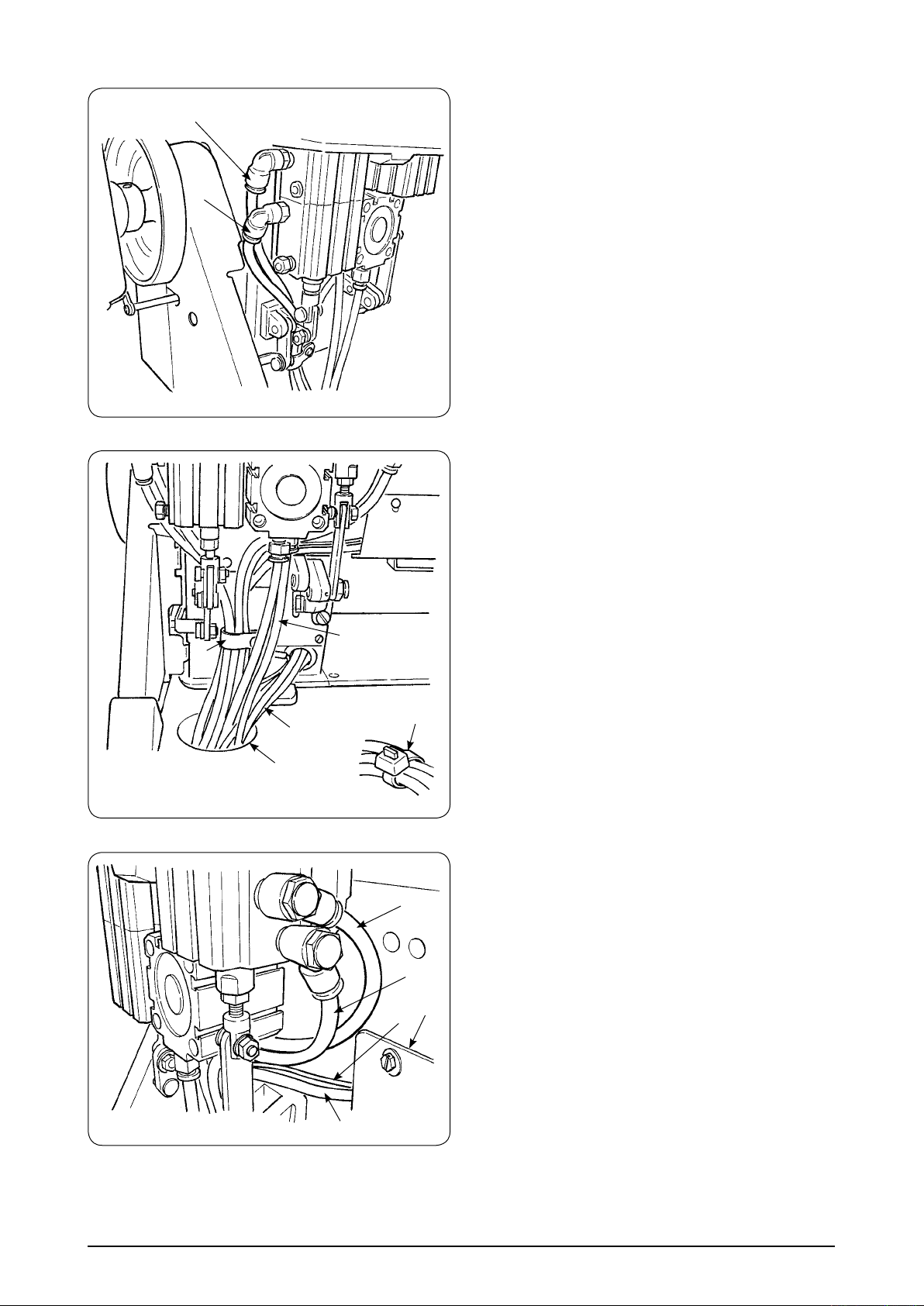

(2) Connecting the air hose

) Connect the air hoses coming from the air control

unit to the air cylinders of the sewing machine

as shown in the illustration. Adjust the seal Nos.

pasted on the hoses to those pasted on the joints,

and connect as described in the list.

Be sure to pass the hoses through hole !0 in the

table.

After connecting them, bundle air hoses 1, 2, 5,

, and C, 6-stage switch cord 6 using cable clip

B

of the machine head.

!1

Directly pass air hoses 7 and 8 through hole !0

in the table.

2) Pass air hoses 3, 4 and 9 coming from the

sewing machine through hole !0 bin the table,

and connect them to the air control unit.

(There are clip bands in the accessories. Use

them to arrange the air hoses if necessary.)

!1

349

!0

78

Clip band

C

B

!2

5

6

− 5 −

Page 9

!3

3) Pass air hoses 5 through cord cover !2 the same

as 6-range switch cord 6, pass them through

clearance A between 6-range switch !3 and the

machine arm, and connect them to the joint of air

hoses 5.

C

5

B

8 9 4

Decrease Increase

5

7 3 1

2

A

1

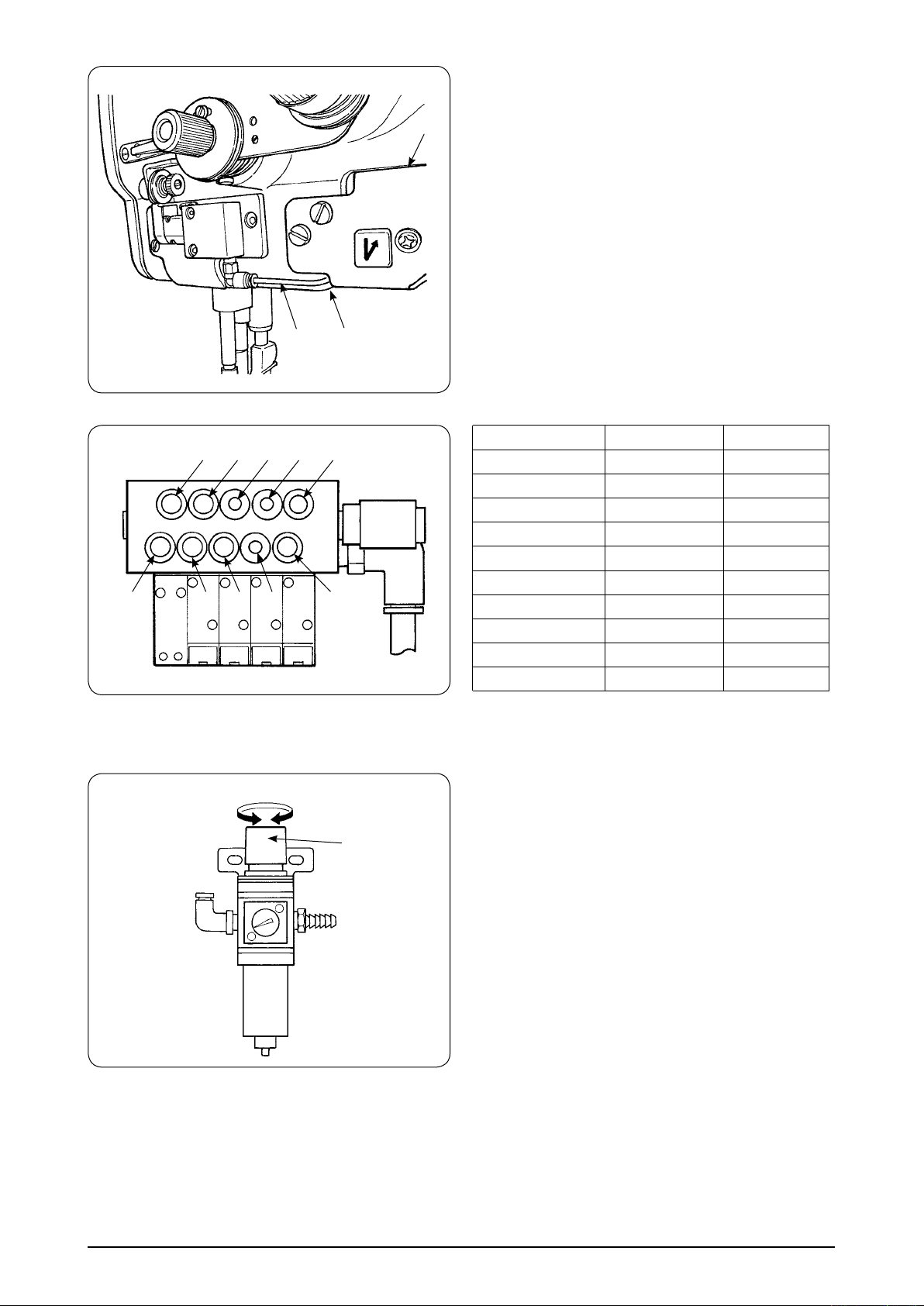

Solenoid valve Cylinder

Condensation

BT

Thread trimming

Thread trimming

Thread clamp

FL

FL

DL

2P

2P

1 1

2 2

3 3

4 4

5 5

7 7

8 8

9 9

B B

C C

(3) Adjusting the air pressure

Adjust the air pressure to 0.4 to 0.5 MPa using air

pressure regulating knob 1 of regulator. Pull knob

up and turn it to properly adjust the operating

1

air pressure. After the adjustment, press the knob

down into the home position.

− 6 −

Page 10

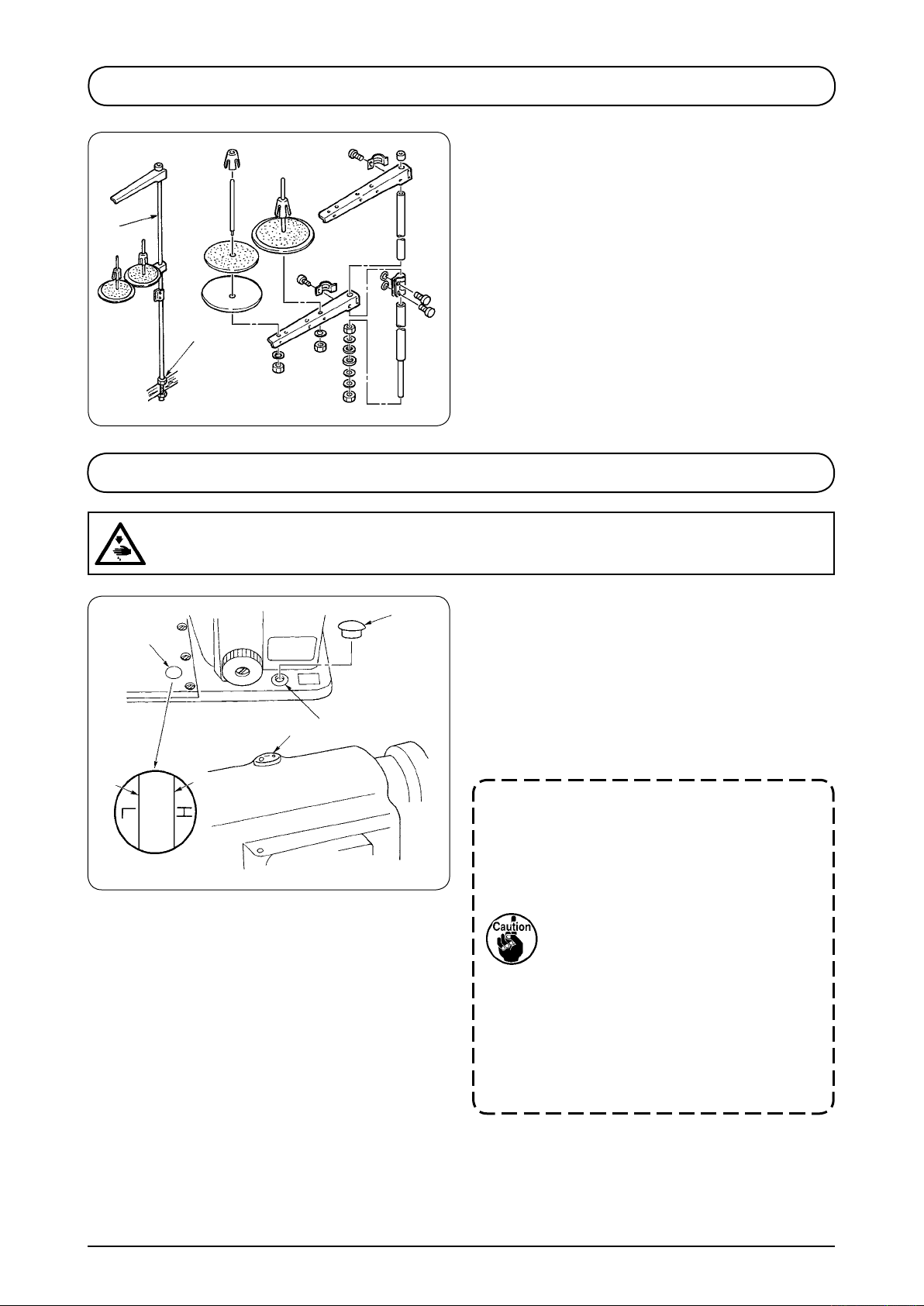

9. INSTALLING THE THREAD STAND

) Assemble the thread stand and set it to the hole

2) Tighten locknut 1 to x the thread stand.

3) When ceiling wiring is possible, pass the power

2

1

10. LUBRICATION

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

of the table.

cord through spool rest rod 2.

4

2

3

LU-2220N-7

Oil window

1

5

) Pour the JUKI New Defrix Oil No. into the oil

tank in the bed from lubrication hole 1 until H

level 3 of oil gauge 2 is reached.

2) Add the same lubricating oil as soon as the oil

level has come down to L level 4.

3) After the lubrication, operate the sewing machine

and check that the oil rises up to the oil sight

window.

1. Do not use any lubrication oil other

thanthespeciedtype.Besureto

close cap 5 of the oil hole.

2. When you operate your machine

forthersttimeaftertheset-upor

after an extended period of disuse,

apply two or three drops of oil to

the sections indicated with arrows.

(Refer to Fig. 1 on the next page.)

3. To use the machine that has been

disused for an extended period

of time, run in the machine for

approximately 10 minutes at 1,800

rpm.

− −

In the case where the machine is operated with

¡

the hook lled with normal amount of oil, the

oil level descends from H level to the L level in

approximately 00 hours .

Page 11

Supply oil

Filter

7

8

Supply oil

Supply oil

Flg.1

[Cleaningthelter]

) Approximately once a month, remove screws 6

from the lter case and clean magnet 7 and lter

element 8 inside the lter.

2) If the lter is clogged with soil, circulation failure

will result.

This will give rise to oil leakage from the upper

portion of the hook driving shaft saddle.

6

7

6

− 8 −

Page 12

11. ATTACHING THE NEEDLE

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

Use a SCHMETZ 34 x 35R needle.

) Turn the handwheel to bring the needle bar to the

2

1

Long groove

highest position of its stroke.

2) Loosen needle clamp screw 2, and hold needle

so that the long groove in the needle is facing

1

exactly to the left.

3) Push the needle 1 deep into the needle clamp

hole until it will go no further.

4) Tighten needle clamp screw 2 rmly.

12. ATTACHING/REMOVING THE BOBBIN

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

) Lift latch 1 of hook, and take out the bobbin.

2) Put the bobbin into the shaft in the hook correctly

and release the latch.

1

− 9 −

Page 13

13. THREADING THE HOOK

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

) Pass the thread through thread path 1 in the

hook and thread hole 2 in the lever, and draw the

thread.

Now, the thread will be brought to the thread hole

via the tension spring.

2

Make sure that the bobbin revolves in the

•

direction of the arrow when you draw the thread.

2

1

14. INSTALLING THE THREAD GUIDE

(1) Installing the needle thread guide rod

1

2

) Install needle thread guide rod 1 with nut 2.

2

1

(2) Installing the bobbin winder thread

guide

) Attach bobbin winder thread guide 1 to the

bobbin winder on the machine arm using screws

.

2

2) Adjust the position of the thread guide referring to

“15. WINDING A BOBBIN”

.

− 0 −

Page 14

15. WINDING A BOBBIN

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

A

5

F

D

4

3

G

H

B

C

1

E

2

) Pass the thread in the order, A through H. Then

wind it several turns round the bobbin.

2) Tilt bobbin presser 1.

3) Adjust bobbin thread amount adjustment screw 2

to wind a bobbin about 90% of its capacity.

Turn the screw counterclockwise to increase the

amount of thread to be wound round the bobbin,

or clockwise to decrease it.

4) If the bobbin is wound unevenly, correct it by

moving thread guide 3 of the bobbin winder back

or forth.

Then tighten screws 4.

5) When the bobbin is lled up, the bobbin presser

automatically releases the bobbin and the bobbin

winder stops running.

16. ADJUSTING THE AMOUNT OF OIL IN THE HOOK

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

) Adjust the amount of oil in the hook by turning

oil amount adjustment screw 1 mounted on the

hook.

2) Turning the adjustment screw clockwise will

decrease the amount of oil in the hook or

counterclockwise will increase it.

3) Place a piece of paper near the periphery of the

hook, and run the machine for approximately ve

seconds. The proper amount of oil in the hook is

obtained when the oil spots lightly make stripes

on the paper as shown in the gure.

1

A piece of paper

− −

Page 15

17. THREADING THE MACHINE HEAD

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

Needle thread

Threading method :

draw the thread to the operator's side.

L

Thread the machine head following the order of A

through to P as shown in the illustration given above.

A

G

B

E

K

M

C

D

F

N

N

P

H

I

J

O

− 2 −

Page 16

18. ADJUSTING THE STITCH LENGTH

Tu r n standard f e e d adjusting di a l 1 or 2P feed

adjusting dial 3 counterclockwise or clockwise so that

3

2

1

the number corresponding to the desired number is

brought to the top of the dial until the marking spot is

reached.

When turning 2P feed adjusting dial

,besuretoconrmthat2Pswitchis

3

OFF.

The scale 3 or less of 2P feed adjusting

dial (place where the dial stops with

the dial stopper) is for adjusting the 2P

feedadjustingdialto"0"point.

The scale 3 or less cannot be used.

For the details of 2P device, refer to

"30.OPERATIONSWITCHES".

19. THREAD TENSION

B

B

A

1

A

2

3

C

D

[Reversefeedstitching]

) Press down reverse feed control lever 2.

2) Reverse feed stitching can be performed as long

as you keep pressing the lever down.

3) Release the lever, and the machine will run in the

normal feed direction.

(1) Adjusting the length of thread

remaining after thread trimming

Turn thread tension nut No.

to shorten the length of thread remaining after

thread trimming. Turn the nut counterclockwise B

to lengthen it.

clockwise A

1

(2) Adjusting the needle thread tension

Turn thread tension nut No. 2

to increase the needle thread tension, or

A

counterclockwise Bto decrease it.

clockwise

2

(3) Adjusting the bobbin thread tension

Turn tension adjustment screw

to increase the bobbin thread tension, or

C

counterclockwise Dto decrease it.

clockwise

3

− 3 −

Page 17

20. THREAD TAKE-UP SPRING

(1) When you want to change the stroke

5

3

1

4

2

IncreaseDecrease

21. HAND LIFTER / HANDHEBEL

of the spring :

) Loosen screw 2 in the stopper, and move

stopper 3 to the right or left to change stroke of

thread take-up spring 1.

2) Move the stopper to the right to increase the

stroke of the thread take-up spring, or the left to

decrease it.

(2) When you want to change the tension

of the spring :

) Loosen nut 4, and move spring stud 5

counterclockwise to increase the tension of the

spring, or clockwise to decrease it.

) When you want to keep the presser foot in the

lifted position, turn hand lifter

the arrow. This makes the presser foot rise 9 mm

and stay at that position.

2) To make the presser foot come down to its home

position, lower the hand lifter.

in the direction of

1

1

22. ADJUSTING THE PRESSURE OF THE PRESSER FOOT

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

) Turn presser spring regulating dial 1 clockwise

to increase the pressure of the presser foot, or

counterclockwise to decrease it.

(Be sure to operate the sewing machine with the

pressure of the presser foot minimized as long as

the presser foot securely holds the material.)

1

Decrease

Increase

− 4 −

Page 18

23. NEEDLE-TO-HOOK RELATION

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

2

4

1.4 mm

1

2.0 mm

0.02 - 0.1 mm

) Adjust the standard feed adjusting dial to "0".

2) Loosen hook driving shaft set collar clamping screw 3, and turn the handwheel counterclockwise to make

the needle bar ascend by 2.0 mm from the lowest position of its stroke.

3) In the state described in 2), align blade point 1 of the hook with the center of needle 2, and tighten hook

driving shaft set collar clamping screw 3. At this time, a clearance of .4 mm is provided between the blade

point of the hook and the top end of the needle eyelet. (As reference, the handwheel pointer meets the

marker line of the scale L on the handwheel.)

4) Loosen screw 4 in the top face of the bed and screw 5 in the hook driving shaft saddle, and adjust so

that a clearance of 0.02 to 0. mm is provided between the blade point of hook and the needle by moving

the hook driving shaft saddle to the right or left. Once the specied clearance is obtained, securely tighten

screws 4 and 5.

5) Set the standard feed adjusting dial to maximum value, and check that the blade point of the hook does not

come in contact with the needle.

3

5

The operation panel could come in contact with the thread stand when tilting the machine

head. To protect the relevant parts from contact, shift the thread stand to a position at which

the thread stand does not interfere with the control panel.

24. ADJUSTING THE HOOK NEEDLE GUARD

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

When a hook has been replaced, be sure to check

1

0.15 - 0.2 mm

2

2

3

the position of the hook needle guard.

As the standard position of the hook needle guard,

hook needle guard 2 must push the side face of

needle 1 to lean the needle by 0.5 to 0.2 mm away

from its straight position. If not, adjust the hook

needle guard by bending it.

) If you want to move the hook needle guard

inwards, turn adjusting screw 3 clockwise.

2) If you want to move the hook needle

guard outwards, turn adjusting screw 3

counterclockwise.

− 5 −

Page 19

25. ADJUSTING THE BOBBIN CASE OPENING LEVER

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

) Turn the handwheel to move bobbin case opening

lever 1 in the direction of the arrow A, and

loosen screw 2.

6

C

E

5

A

B

D

3

26.

ADJUSTING THE THREAD TRIMMING MECHANISM COMPONENTS

4

1

E

2

F

0.1 - 0.3 mm

2) Turn the handwheel to move bobbin case opening

lever 1 in the direction of arrow B, and loosen

screw 3.

3) Turn bobbin case 4 in the direction of arrow C

to until bobbin case stopper 5 rests in groove D

on throat plate 6. In this state, adjust so that a

clearance of 0. to 0.3 mm is provided between

top end E of bobbin case opening lever and

protrusion F on the bobbin case when they

approach most. Then, tighten screws 2 and 3.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

(1) Positioning the thread trimming cylinder joint

Th read tr immi ng cylinder 1 and thread trimm ing

cylinder joint 2 have to be assembled as shown in the

gure on the left side.

2

1

7.0 ± 0.5 mm

(2) Adjusting the position of the feed dog

Install the feed dog in terms of the window hole of the

throat plate to the position below on condition that the

standard feed dial : P = 0.

Lateral direction : Clearance between the left and

5.7 ± 0.2 mm

P=0

A

A = B

B

•

right is equal (center of the window hole of throat

plate)

Longitudinal direction : Clearance on the operator

•

side is 5.7 ± 0.2 mm.

− 6 −

Page 20

(3)-1. Counter knife

3

4

9.0 ± 0.5 mm

(Adjusting the travel amount) (Positioning of the counter knife base stopper)

) Turn the handwheel to adjust the thread take-up

lever to the lower dead point, loosen counter knife

base stopper setscrew 4 and counter knife drive

arm clamp screw 2, and adjust the clearance

between thread trimming cylinder joint 3 and

joint stopper 4 to 9.0 ± 0.5 mm.

(At this time, the gauge for adjustment supplied

as accessories can be used.)

2) When the distance between the tip of counter

knife and the groove of machine bed is 3.8 ± 0.

mm, make the counter knife base and counter

1

knife base stopper come in contact a with each

other.

(At this time, gauge for adjustment supplied as

accessories can be used.)

37.8 ± 0.1 mm

Top surface of machine bed

37.8 ± 0.1 mm

Groove section

of slide plate

2

3) Tighten counter knife base stopper setscrew 1

and counter knife drive arm clamp screw 2.

a

Counter knife

Gauge for adjustment supplied as accessories

2.4 mm

43 mm

− −

Thickness : 0.6 mm

29 mm

26.8 mm

37.8 mm

9 mm

Page 21

(3)-2. Counter knife (Adjusting the lateral position)

) Loosen counter knife setscrews 1.

1

2

4

2.4 ± 0.15 mm

Counter knife

base

3

2) Set the feed dial to "0", adjust the thread take-

(Press the manual switch of solenoid valve

3) Keeping the state of 2), move counter knife 2 to

(At this time, the gauge for adjustment supplied

4) Release the manual switch of solenoid valve that

up lever to the lower dead point, and actuate the

solenoid valve by hand to mate the state that the

thread trimming cylinder is drawn.

No. 3 to make the state of lock. Refer to

Explanationofthesolenoidvalve"

"(12)

.)

the right and left. Then adjust the distance from

feed dog 3 to thread guide 4 to 2.4 ± 0.5 mm

and tighten counter knife setscrews 1.

as accessories can be used.)

has been actuated in (3) – 2 – 2). (Refer to

Explanationofthesolenoidvalve"

"(12)

.)

When installing the counter knife,

tighten the screws while pressing the

counter knife to the anti-operator side.

Gauge for adjustment supplied as accessories

2.4 mm

43 mm

Thickness : 0.6 mm

29 mm

26.8 mm

37.8 mm

9 mm

Conrmation:Actuatethesolenoidvalvebyhandtomovethethreadtrimmingaircylinderand

conrmthefollowingsinthestatethatthecounterknifebasecomesincontactwiththecounterknife

base stopper :

Distance between the tip of counter knife and the machine bed is 37.8 ± 0.1 mm.

•

Clearance between the cylinder joint and the joint stopper is 9.0 ± 0.5 mm.

•

Distance from the left end of feed dog to the thread guide is 2.4 ± 0.1 mm.

•

− 8 −

Page 22

(4) Moving knife (Adjusting the vertical position)

) Loosen moving knife drive arm clamping screw 1

1

and moving knife shaft thrust collar setscrew 2

and tighten them again after adjusting the vertical

direction of moving knife 3. When tightening

moving knife drive arm clamping screw 1,

perform the items (), (8), (9) and (0) that are

mentioned later.

0.5 to 0.6 mm

2

Throat plate

3

2) The vertical position of moving knife is the

position where the clearance between the bottom

surface of throat plate (reverse side) and the top

surface of moving knife 3 is 0.5 to 0.6 mm.

(At the time of adjustment, the gauge for

adjustment supplied as accessories can be used.)

Gauge for adjustment supplied as accessories

2.4 mm

43 mm

Thickness : 0.6 mm

− 9 −

29 mm

26.8 mm

37.8 mm

9 mm

Page 23

(5) Counter knife (Adjusting the vertical position)

) Loosen counter knife base clamping screw 1,

1

To align with the

top surface of

moving knife

adjust it to the position where the upper end of

the blade section of counter knife 2 aligns with

the top surface of moving knife 3, and tighten the

screw again. (At this time, be careful of the blade

point of hook. It is safe to work while adjusting the

main shaft angle to the position near L engraved

marker line.)

2

3

(6) Thread guide installing position

To align the top

surface of thread

guide with the top

surface of moving

knife.

3

1

2

) Loosen thread guide setscrews 1 and tighten

them again after adjusting the position of thread

guide 2.

Installing position : The top surface of thread

guide 2 should align with the top surface of

moving knife 3 in the vertical direction and the

thread guide should be xed after fully moving it

to the direction of the arrow mark as shown in the

gure in the longitudinal direction.

− 20 −

Page 24

(7) Adjusting the knife pressure

29.0 to 30.0 mm

1

) Adjust the thread take-up lever to its lower dead

point, and actuate the solenoid valve by hand to

make the state that the thread trimming cylinder

is drawn.

(Press the manual switch of solenoid valve

No. 3 to make the state of lock. Refer to

Explanationofthesolenoidvalve"

"(12)

.)

2) Keeping the state of ), slowly turn the handwheel

by hand, and adjust the distance of R section of

the moving knife and the end of machine bed to

the position of 29 to 30 mm.

(At this time, the gauge for adjustment supplied

as accessories can be used.)

3) Loosen moving knife setscrews 1 and tighten

them again after adjusting the knife pressure.

4) Release the manual switch of solenoid valve that

has been actuated in () – ). (Refer to

Explanationofthesolenoidvalve"

"(12)

.)

*1 : When the knife pressure is low, tighten

moving knife setscrews 1 while lightly

pressing the moving knife to the counter

knife. When the knife pressure is high, worn-

out or damage of the blade section will be

caused . So, adjust the knife pressure as low

as possible.

*2 : When thread cannot be cut even when the

knife pressure is increased, change the height

of moving knife or counter knife within the

range of adjustment and adjust so that the

blade sections meet together. The height of

moving knife and counter knife should be a

clearance of 0.5 to 0.6 mm between the knife

and the bottom surface of throat plate.

Gauge for adjustment supplied as accessories

2.4 mm

43 mm

− 2 −

Thickness : 0.6 mm

29 mm

26.8 mm

37.8 mm

9 mm

Page 25

(8)-1. Initial position of the moving knife drive arm and the moving knife

) Tilt the sewing machine and actuate the solenoid

valve by hand in the state that the thread trimming

cam roller is not entered the cam groove to make

the state that the thread trimming cylinder is

pushed out.

(Press the manual switch of solenoid valve

No. 4 to make the state of lock. Refer to

Explanationofthesolenoidvalve"

2) Loosen moving knife return plate setscrews 1

and remove moving knife return plate 2.

3) Loosen moving knife drive arm stopper nut 3 and

loosen moving knife drive arm stopper screw 4.

4) Loosen moving knife drive arm clamping screw 5.

5) Adjust the clearance between the thread trimming

cam roller and the periphery of thread trimming

cam to 0.05 to 0.5 mm, and adjust moving knife

to the initial position.

6

The initial position of moving knife is the position

where the distance between the top end of

moving knife and the machine bed is 26.8 ± 0.

mm.

(At this time, the gauge for adjustment supplied

as accessories can be used.)

6) Keeping the state of 5), tighten moving knife drive

arm clamping screw 5.

(Tightening torque : 5.9 to 6.9 N•m)

At this time, for the vertical direction of moving

knife drive arm, both ends of the bottom surface

of moving knife drive arm and the lower end of

moving knife shaft align with each other.

1

26.8 ± 0.1 mm

2

3

4

5

Clearance between the

periphery of thread trimming

cam and the thread trimming

cam roller is 0.05 to 0.15 mm.

"(12)

.)

Top surface of machine bed

26.8 ± 0.1 mm

Groove section of slide plate

6

To be continued to (8) – 2 Adjusting the clearance

between the moving knife drive arm and the

moving knife drive arm stopper

Gauge for adjustment supplied as accessories

2.4 mm

43 mm

Thickness : 0.6 mm

29 mm

26.8 mm

37.8 mm

− 22 −

9 mm

Page 26

(8)-2. Adjusting the clearance between the moving knife drive arm and the moving knife

drive arm stopper

) Maintaining the clearance of 0.05 to 0.5 mm

1

2

Clearance between the moving knife

drive arm and the moving knife drive

arm stopper is 0.05 to 0.1 mm.

between the thread trimming cam roller and the

periphery of thread trimming cam, adjust moving

knife drive arm stopper screw 1 to make a

clearance of 0.05 to 0. mm between the moving

knife drive arm and the moving knife drive arm

stopper, and tighten it with moving knife drive arm

stopper nut 2.

To be continued to (8) – 3. Installing position of

the moving knife return plate

(8)-3. Installing position of the moving knife return plate

) Maintaining the clearance of 0.05 to 0. mm

between the moving knife drive arm and the

moving knife drive arm stopper, make the moving

knife return plate come in contact with the return

pin and x it with moving knife return plate

setscrew 1.

2) Release the manual switch of solenoid valve that

has been actuated in (8) – - . (Refer to

1

Moving knife return plate aligns

with the returning pin. (Contact)

Whenthemachinelockhasoccurredduringthreadtrimmingoperation,conrmwhetheror

not the adjustment values of (8)-1 to 3 are proper.

When they are not proper, it is necessary to perform re-adjustment.

Explanationofthesolenoidvalve"

"(12)

.)

− 23 −

Page 27

(9) Adjusting the thread trimming cam timing

Pointer on handwheel

Scale on handwheel

1

Close

contact

) Loosen thread trimming cam setscrews 1 and

tighten them again after adjusting the position of

thread trimming cam 2.

2) The position of thread trimming cam is the

position where thread trimming cam roller 3

comes in contact with R section where it starts

entering the cam groove when the position of

handwheel is at L engraved marker line.

Conrmation:Makesureagainofthepositionof

L engraved marker line and R section where

the roller starts entering the cam groove after

xingthethreadtrimmingcam.

2

3

− 24 −

Page 28

(10) Installing position of the clamp spring

1

43.0 to 43.5 mm

When there is a clearance between the clamp

spring and the moving knife at the initial

position of moving knife, bobbin thread

cannot be clamped after thread trimming.

) When the moving knife is at the initial position,

loosen clamp spring setscrews 1, make the

clamp spring come in contact with the moving

knife and tighten it with clamp screw setscrews 1.

(Tightening torque : 0.2 to 0.3 N•m)

The distance between the clamp spring and the

end of machine bed becomes 43.0 to 43.5 mm.

(At this time, the gauge for adjustment supplied

as accessories can be used.)

At the time of adjustment, be careful of the

contact of the clamp spring and the hook, and the

contact of the clamp spring and the moving knife

when it moves to its forward travel end.

* When using the clamp spring for optional thin

thread, adjust the adjustment value to 43.5

mmandxtheclampspringwhilemaking

it strongly come in contact with the side of

moving knife.

Move of moving

knife

Be careful of the contact of clamp

spring and moving knife when it

moves to its forward travel end.

Gauge for adjustment supplied as accessories

2.4 mm

43 mm

Thickness : 0.6 mm

29 mm

26.8 mm

37.8 mm

* When the position of the clamp spring cannot

be adjusted even clamp spring setscrews 1 are

loosened, loosen clamp spring base setscrews 2

and move clamp spring base 3 to the operator's

side to adjust.

(The position in vertical direction of the clamp

spring base has to be placed to the hook shaft

base. Therefore, tighten the clamp spring base

with setscrews 2 while lightly pressing it in

downward direction.

9 mm

3

2

− 25 −

Page 29

(11) Adjusting the condensation amount

1

3

A

) Loosen lock nut 3 of reverse feed cylinder

knuckle joint 2.

2) Adjust the clearance between the top end of

reverse feed cylinder rod 1 and the end of

reverse feed cylinder knuckle joint 2 referring to

the standard of the table. (It is possible to adjust

by turning rod 1.)

3) After the adjustment, tighten lock nut 3.

Conrmation:

1. Perform the thread trimming sewing in

practice.

2. Conrmthatthecondensationamount(pitch

before one stitch of thread trimming) is proper

( * ) in accordance with the sewing conditions.

2

Dimension A

Condensation

amount

(Standard)

.5 mm .5 mm

2.0 mm 2.0 mm

* The length of thread remaining on the

cloth side is shortened by decreasing the

condensation amount. When the amount is

excessively decreased, however, the cloth is

tore by the seams and the stitch skips. As a

result, thread trimming trouble occurs.

In addition, when the amount is excessively

increased, thread-handling trouble occurs. As

a result, thread trimming trouble occurs.

Condensation amount of 1.5 to 2 mm is

recommended.

− 26 −

Page 30

(12) Explanation of the solenoid valve

8

9 4 2

Condensation

1

BT

2

Thread trimming ON (Cylinder is drawn.)

3

Thread trimming OFF (Cylinder is pushed out.)

4

Thread clamp (Cylinder is pushed out.)

5

AK (Presser foot rises.)

7

AK (Presser foot lowers.)

8

DL (Cylinder is pushed out.)

9

) 2P

B(C

C

BC7 5 3 1

With regard to the switch of solenoid valve (Manual)

) By pressing the switch (green) inside the cover,

the solenoid valve can be actuated by hand.

B

57 3 1

8 9 4

2

2) By turning the switch in the direction of the arrow

mark while pressing it, it is possible to lock.

By turning the switch in the reverse direction of

the arrow mark, it is possible to release the lock.

* WhenturningONthepower,conrmthatall

covers of the solenoid valve are closed.

(Under the state that the manual switch is

locked, the covers are not closed and it is

possible to prevent the malfunction of the

solenoid valve.)

− 2 −

Page 31

27. ADJUSTING THE LIFTING AMOUNT OF THE PRESSER FOOT AND THE WALKING FOOT

1

The lifting amount of the presser foot and the walking

foot is adjusted using dial 1. Turn the dial clockwise

to increase the lifting amount or counterclockwise to

decrease it.

28. SEWING SPEED TABLE

The maximum sewing speed has been specied in accordance with sewing conditions as shown in the table

below. Set the maximum sewing speed appropriately in accordance with the sewing conditions given taking

care not to exceed the corresponding specied value.

(1) Max. sewing speed in accordance with the amount of the alternating vertical

movement of the walking foot and the presser foot

) When stitch length is 6 mm or less, the max. speed

has to be the upper limit value or lower limit value.

4000

3500

3000

2500

2000

1500

1000

500

0

Revolutions per minute (rpm)

1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5

Amount of alternate vertical movement

of walking foot and presser foot (mm)

Upper

limit

value

Lower

limit

value

2) When stitch length is more than 6 mm and 9

mm or less

Amount of alternate vertical

movement of walking foot

and presser foot

Revolutions

per minute

to 6.5 mm 2000 rpm

29. RESETTING THE SAFETY CLUTCH

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

The safety clutch functions when an excessive load

is applied to the hook or the other components during

sewing.

While the safety clutch if functioning, the hook will

never rotate even if turning the handwheel.

) Reset the safety clutch with the sewing machine

2

1

A

2) Fit screwdriver (medium) 2 supplied with the

3) Holding screwdriver 2 by hand to prevent

4) The resetting procedure completes when the

− 28 −

tilted.

machine as an accessory in hole A in safety

clutch bushing 1.

safety clutch bushing 1 from rotating, turn the

handwheel in the reverse direction of rotation.

handwheel clicks.

Page 32

30. OPERATION SWITCHES

One-touch type reverse feed switch

1

• While the machine is in operation, the machine

performs reverse feed stitching as long as this

switch is held pressed, and resumes normal feed

stitching when the switch is released.

• If this switch is pressed while the machine is at

rest, the feed will be set to the reverse feed state.

31 2 4 6

Alternating vertical movement amount change-over switch

2

If this switch is pressed the amount of the alternating vertical movement of the walking foot and the presser

foot will be maximized. (Lamp above the switch lights up)

Use this switch when a multilayered portion of the sewing product is not smoothly fed.

When performing the alternating vertical movement amount change-over with the knee switch, x the

knee switch supplied with the machine on the table with wood screws and use it. For the wiring, refer to

“INSTRUCTION MANUAL (SUPPLEMENT) for sewing machines for leather and heavy-weight materials”.

Automatic reverse feed stitching cancellation/addition switch

3

• If this switch is pressed when the following automatic reverse feed stitching has been specied, the reverse

stitching will not take place (for once immediately after it is pressed). (Example )

• If this switch is pressed when no automatic reverse feed stitching has been specied, the reverse feed

stitching will take place (once immediately after it is pressed). (Example 2)

5

(The sewing machine does not run.)

If it is released, the feed will return to the normal

feed state.

(Example 1) In the case where both automatic reverse feed stitching for start and that for end have

beenspecied:

A

B

C

D

If the switch is pre ssed befor e st artin g

sewing, the automatic reverse feed stitching for

start (between A and B) will not be carried out.

(Example 2) In the case where neither automatic reverse feed stitching for start nor that for end

havebeenspecied:

C

D

If the switch is pressed during sewing, the

automatic reverse feed stitching for end (between

C and D) will not be carried out.

A

B

A

B

C

D

A

B

If the switch is pre ssed befor e st artin g

sewing, the automatic reverse feed stitching for

start (between A and B) will be carried out.

− 29 −

C

D

If the switch is pressed during sewing, the

automatic reverse feed stitching for end (between

C and D) will be carried out.

Page 33

Needle lifting switch

4

If this switch is pressed, the machine will travel from the needle-down stop position to the needle-up stop

position.

When raising the machine head which has been tilted, do not hold the operation switch to

raise it.

Example

2P feed adjusting dial scale : 6

¡

Standard feed adjusting dial scale : 9

¡

If this switch is pressed, stitch length is changed

¡

over from 9 to 6.

2P switch

5

If this switch is pressed, the stitch length is

changed over to that of the scale on the feed

adjusting dial. (Lamp in the button is lit up.)

Be sure to make the number of 2P feed

adjusting dial less than that of the

standard feed adjusting dial.

OFF ON

\

If this switch is pressed again, stitch length

¡

returns from 6 to 9.

− 30 −

Page 34

ON OFF

Needle thread clamp switch

6

When the needle thread clamp switch is turned

ON, the needle thread clamp motion is performed

at the start of sewing, and when it is turned OFF,

the needle thread clamp motion is not performed.

However, the needle thread clamp device as well

as the presser foot lifting motion does not function

until the thread trimming is performed after turning

ON the power.

In addition, when the presser foot is lifted after

thread trimming motion, the needle thread is

clamped with the needle thread clamp device, but

when the needle thread clamp switch is turned

OFF, the needle thread is released.

Needle thread clamp switch can be set

to effective or ineffective by setting of

the motor.

For the details, refer to the Instruction

Manual (Supplement) for SC-510.

31. KNEE SWITCH

If k n ee sw i t ch 1 is pr e ssed, the am o u nt of the

alternating vertical movement of the walking foot and

the presser foot will be maximized. (Same with the

performance carried out by pressing the alternating

vertical movement amount change-over switch “ ”

1

on the machine head.)

The knee switch can be used as the

presser lifting switch by setting of the

motor. (When the switch is used as

the presser lifting switch, the function

as the alternating vertical movement

amount changeover switch is lost.)

For the details, refer to the Instruction

Manual (Supplement) for SC-510.

32. CAUTIONS WITH REGARD TO THE SEWING OPERATION

. Be sure to perform the sewing operation after conrming that the needle bar position (needle UP stop

position/needle DOWN stop position) when the sewing machine stops is properly positioned.

(For the setting of the designation of needle bar position, refer to the Instruction Manual (supplement) for SC-50.)

2. Perform a trial sewing and conrm the nished state of sewing since the state at the start of sewing is

different from that at the end of sewing in accordance with the sewn product (material and thread).

3.

When using the needle thread clamp device, use it together with the reverse feed stitching at the start of sewing.

4. Be sure to perform the thread trimming motion on the cloth.

− 3 −

Page 35

33. TROUBLES IN SEWING AND CORRECTIVE MEASURES

Troubles Causes Corrective measures

. Thread

breakage

(Thread frays

or is worn out.)

(Needle thread

trails 2 to 3 cm

from the wrong

side of the

fabric.)

2. Stitch skipping

Thread path, needle point, hook

1

blade point or bobbin case resting

groove on the throat plate has

sharp edges or burrs.

Needle thread tension is too high.

2

Bobbin case opening lever

3

provides an excessive clearance at

the bobbin case.

Needle comes in contact with the

4

blade point of hook.

Amount of oil in the hook is too

5

small.

Needle thread tension is too low.

6

Thread take-up spring works

7

excessively or the stroke of the

spring is too small.

Timing between the needle and the

8

hook is excessively advanced or retarded.

Timing between the needle and the

1

hook is excessively advanced or

retarded.

Pressure of the presser foot is too low.

2

The clearance provided between

3

the top end of the needle eyelet and

the blade point of hook is not correct.

Hook needle guard is not functional.

4

Improper type of needle is used.

5

Remove the sharp edges or burrs on the

藺

blade point of hook using a ne emery

paper. Buff up the bobbin case resting

groove on the throat plate.

Decrease the needle thread tension.

藺

Decrease the clearance provided between

藺

the bobbin case opening lever and the

bobbin. Refer to

BOBBIN CASE OPENING LEVER.”

Refer to

藺

RELATION.”

Adjust the amount of oil in the hook

藺

properly. See

AMOUNT OF OIL IN THE HOOK.”

Increase the needle thread tension.

藺

Decrease the tension of the spring and

藺

increase the stroke of the spring.

Refer to

藺

RELATION.”

Refer to

藺

RELATION.”

Tighten the presser spring regulator.

藺

Refer to

藺

RELATION.”

Refer to

藺

NEEDLE GUARD.”

Replace the needle with one which is thicker

藺

than the current needle by one count.

“23. NEEDLE-TO-HOOK

“23. NEEDLE-TO-HOOK

“23. NEEDLE-TO-HOOK

“23. NEEDLE-TO-HOOK

“24. ADJUSTING THE HOOK

“25. ADJUSTING THE

“16. ADJUSTING THE

3. Loose stitches

Bobbin thread does not pass through

1

the tension spring of the inner hook.

Thread path has been poorly

2

nished.

Bobbin fails to move smoothly.

3

Bobbin case opening lever provides

4

too much clearance at the bobbin.

Needle thread tension is too low.

5

Bobbin thread tension is too low.

6

Bobbin has been wound too tightly.

7

Thread is thick.

8

Thread supplying amount of thread

9

take-up lever is excessively large.

− 32 −

Thread the bobbin thread correctly.

藺

Remove rough parts with a ne emery

藺

paper or buff it up.

Replace the bobbin or hook with a new

藺

one.

Refer to

藺

CASE OPENING LEVER.”

Increase the needle thread tension.

藺

Increase the bobbin thread tension.

藺

Decrease the tension applied to the bobbin

藺

winder.

Replace the feed dog with one for thick

藺

thread.

Remove the pre-tension of needle thread

藺

clamp device.

Increase the needle count.

藺

Move the thread take-up thread guide to

藺

the right side to decrease the supplying

amount by the thread take-up lever.

“25. ADJUSTING THE BOBBIN

Page 36

Troubles Causes Corrective measures

4. Thread slips off

the needle eyelet

simultaneously with

thread trimming.

5. Thread slips off the

needle eyelet at the

start of sewing.

6. Defective sharpness

at the time of thread

trimming.

Thread tension given by the

1

tension controller No. 1 is too

high.

Thread tension given by the

1

tension controller No. 1 is too

high.

Clamp spring has improper

2

shape.

Bobbin thread tension is too low.

3

The blades of moving knife and

1

counter knife have been

improperly adjusted.

The knives have blunt blades.

2

Needle thread tension is too low.

3

Bobbin thread tension is too low.

4

Decrease the thread tension given by the

藺

tension controller No. 1.

Decrease the thread tension given by the

藺

tension controller No. 1.

Replace the clamp spring with a new one

藺

or correct the current one.

Increase the bobbin thread tension.

藺

Refer to

藺

THREAD TRIMMING MECHANISM

COMPONENTS”

Replace the moving knife and counter

藺

knife with new ones, or correct the current

ones.

Increase the needle thread tension.

藺

Increase the bobbin thread tension.

藺

“26. ADJUSTING THE

.

7. Thread is not

trimmed.

8. Thread breaks at the

start of sewing after

thread trimming.

9. Stitch skipping occurs

at the start of sewing

after thread trimming.

Initial position of the moving

1

knife has been improperly

adjusted.

Bobbin thread tension is too low.

2

Position of the thread guide is

3

improper.

Torque at the time of cutting

4

thick thread is insufficient.

The needle thread is caught in

1

the hook.

Bobbin thread is not clamped

1

after thread trimming.

Position of the thread guide is

2

not proper.

Number of revolutions is too fast

3

and needle thread cannot catch

bobbin thread.

Bobbin thread tension is too low.

4

Refer to “Adjusting the initial position of

藺

the knife” in the Engineer’s Manual.

Increase the bobbin thread tension.

藺

Refer to

藺

position.”

When using thick thread equivalent to #4

藺

or #5, delay the UP stop position.

Refer to "Function No. 112" of the

Instruction Manual for SC-510.

Shorten the length of thread remaining

藺

on the needle after thread trimming.

Refer to

Check again the installing position of

藺

clamp spring.

When thread is thin,replace theclamp

藺

spring with one for thin thread.

Refer to

藺

position.”

Increase the number of stitches of soft

藺

start at the setting of motor.

Refer to "Instruction Manual for SC-510".

Increase the bobbin thread tension.

藺

“26. (6) Thread guide installing

“19. THREAD TENSION.”

“26. (6) Thread guide installing

− 33 −

Loading...

Loading...