Page 1

BE98OOT0BOA

No.

00

V -

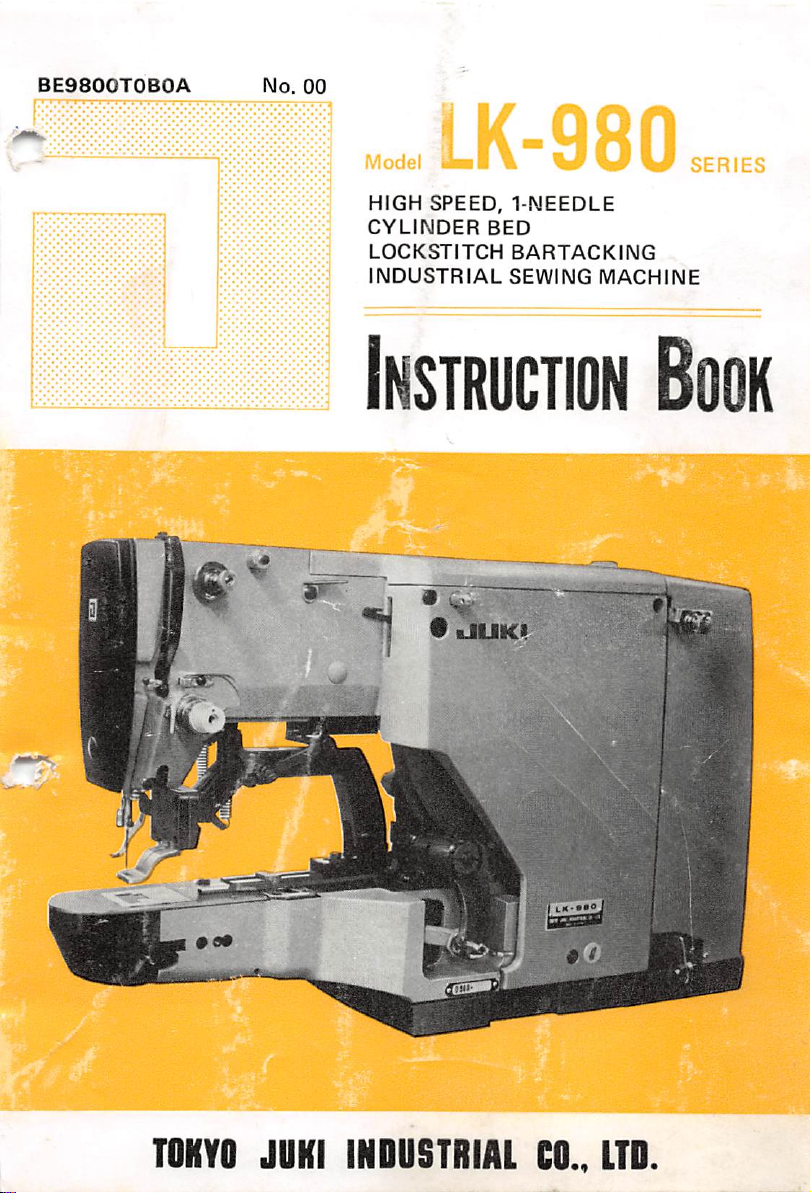

Model

HIGH

CYLINDER

LOCKSTITCH

INDUSTRIAL

INSTRUCTION

LK-980

SPEED,

t

BED

UUKU

1-NEEDLE

BARTACKING

SEWING

MACHINE

SERIES

Book

:V

ISmsu

-r

TOKYO

JUKI

INDUSTRIAL

CO.,

LTD.

Page 2

Page 3

CONTENTS

SPECIFICATIONS

GENERAL

Sewing

INSTALLATION

THREADING

NEEDLE

THREAD

ADJUSTING

ADJUSTING

ADJUST

ADJUSTING

RELATION

ADJUSTING

speed

AND

1. Assembling

2.

Mounting

3.

Howtoremove

4. Tilting

5.

6. Driving

1.

2.

3.

1.

2.

the

Lubrication

the

THE

TENSION

Needle

thread

Bobbin

thread

Thread

take-up spring 9

THE

LENGTHOFBARTACKING

THE

WIDTHOFBARTACKING

THE

FEED

THE

TENSION

BETWEEN

THE

STOP-MOTION

Stop-motion

Stop-motion

PREPARATION

the

machine

the

head

machine

the

table 3

and

the

motor

belt

cover

head

over the table 4

machine 5

MACHINE

tension

tension

TIMING

THE

RELEASE

NEEDLE

TIMINGOFTHE

AND

THE

MECHANISM

SHUTTLE

TENSION

DISC

regulating cam 13

frame

3. Driving pulley pressing plate 14

4. Brake ring

ADJUSTING

ADJUSTING

POSITIONING

ADJUSTING

ADJUSTING

ADJUSTING

ADDITIONAL

THICK

WHEN

WORK

TROUBLES

BAND-LOOP

KNIT

BUTTONHOLE

SMALL

OTHER

COTTON

SEWING

CLAMP

GOODS

BARTACKING

SUBCLASSES

stopper

THE

THREAD

THE

SAFETY ADJUSTING PLATE 16

THE

THE

POSITIONOFTHE

THE

WORK

THE

HEIGHTOFTHE

LUBRICATION

SYNTHETIC

FOOT

AND

THEIR

ATTACHING

BARTACKING

BARTACKING

SHUTTLE

CLAMP

THREADS

FOR

CORRECTIVE

MACHINES

TRIMMER

RACE

FOOT

NEEDED

MATERIALS

THE

KNITTED

MACHINES

MACHINES

MACHINES

SPRING

WIPER

WORK

CLAMP

FOR

THE

OR

USING

FABRICS

MEASURES

FOOT

USE

OF

SYNTHETIC

THREADS

No.2

. . . 11

...

1

1

2

3

4

5

7

8

9

9

10

10

10

12

14

15

16

16

I?

17

17

IS

18

18

19

22

24

24

26

26

Page 4

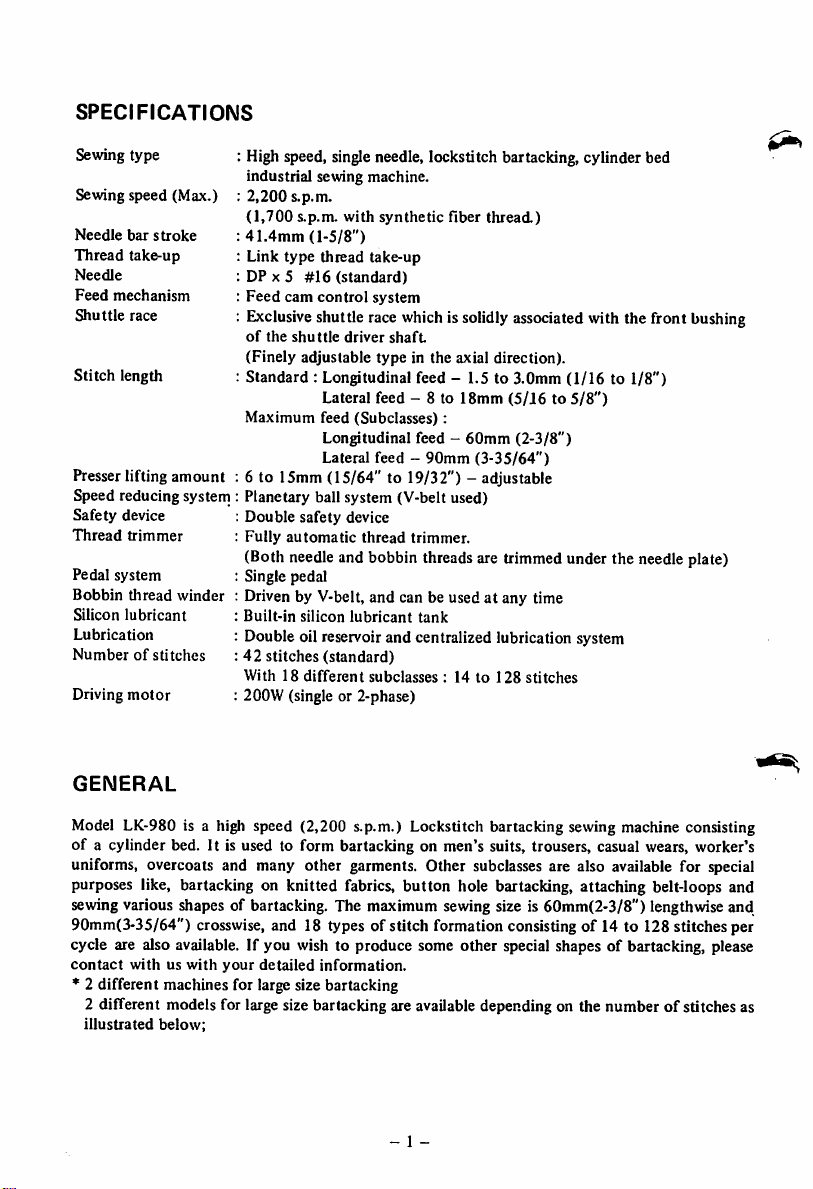

SPECIFICATIONS

Sewing

type

Sewing speed (Max.)

Needle

bar

stroke

Thread

take-up

Needle

Feed

mechanism

Shuttle

race

Stitch

length

device

trimmer

system

thread

lubricant

motor

amount

winder

Presser lifting

Speed reducing system

Safety

Thread

Pedal

Bobbin

Silicon

Lubrication

Numberofstitches

Driving

: High speed, single needle, lockstitch bartacking, cylinder bed

industrial sewing machine.

:

2,200

s.p.m.

(1,700

s.p.m.

with

:

41.4mm

: Link

: DP X 5

:

Feed

:

Exclusive

of

the

(1-5/8")

type

thread take-up

#16

(standard)

cam

control

system

shuttle race whichis solidly associated with the front bushing

shuttle

driver

synthetic

shaft

fiber

thread.)

(Finely adjustable type in the axial direction).

: Standard : Longitudinal feed - 1.5 to 3.0mm (1/16 to

Maximum feed

Lateral feed - 8 to

Longitudinal feed -

Lateral feed -

(Subclasses):

90mm

18mm

60mm

(3-35/64")

(5/J6to5/8")

(2-3/8")

1/8")

: 6 to 15mm (15/64" to 19/32") - adjustable

:

Planetary

:

Double

:

Fully

ball system (V-belt used)

safety

device

automatic

thread

trimmer.

(Both needleand bobbin threads are trimmed under the needle plate)

: Single pedal

: Driven by V-belt, and can be used at any time

:

Built-in

silicon

lubricant

tank

: Double oil reservoir and centralized lubrication system

:42stitches

With18different

(standard)

subclasses

: 14to128

stitches

: 200W (single or 2-phase)

GENERAL

Model LK-980 is a high speed (2,200 s.p.m.) Lockstitch bartacking sewing machine consisting

of a cylinder bed. It is used to form bartacking on men's suits, trousers, casual wears, worker's

uniforms, overcoats and many other garments. Other subclasses are also available for special

purposes like, bartacking on knitted fabrics, button hole bartacking, attaching belt-loops and

sewingvarious shapes of bartacking. The maximum sewing size is 60mm(2-3/8") lengthwiseand

90mm(3-35/64")

crosswise,

and 18 types of stitch formation consisting of 14 to 128 stitches per

cycle are also available. If you wish to produce some other special shapes of bartacking, please

contact

withuswith

your

detailed

information.

* 2 different machines for large size bartacking

2 different models for large size bartacking are availabledependingon the number of stitches as

illustrated

below;

- 1 -

Page 5

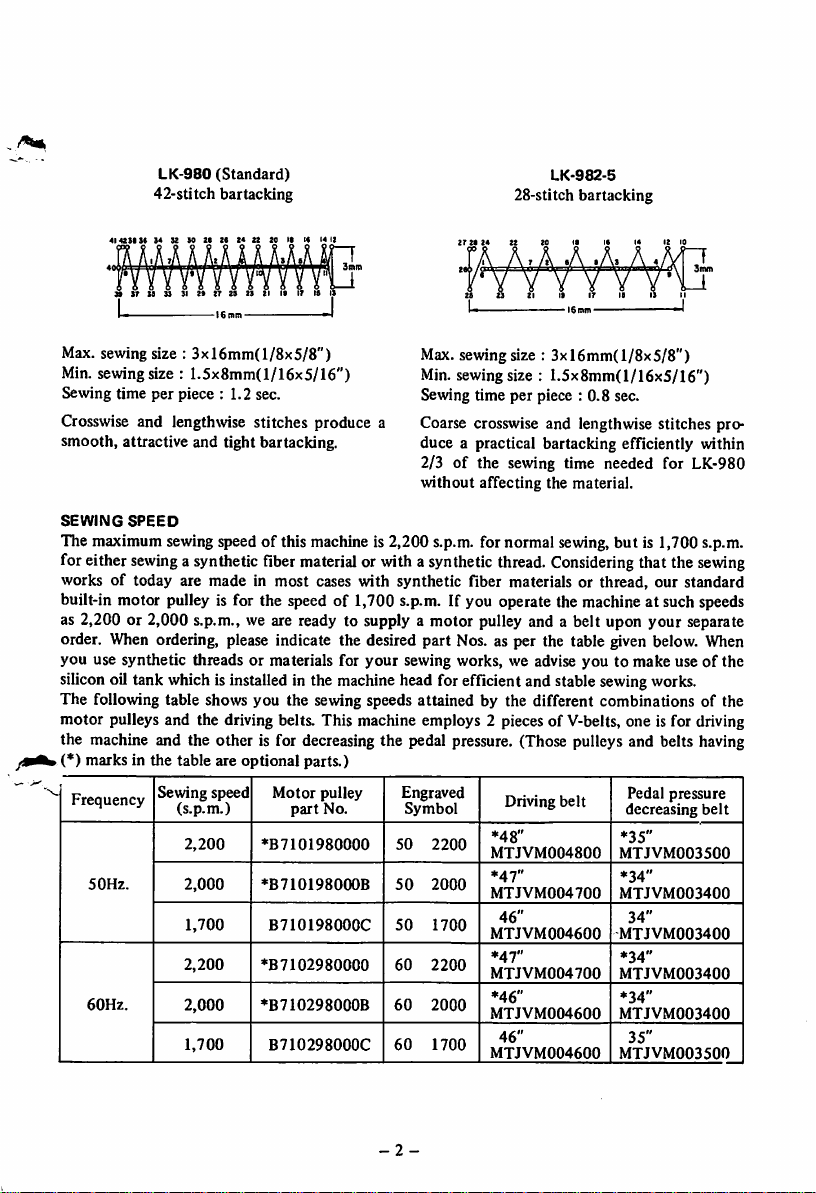

LK-980

(Standard)

42-stitch bartacking

272924

28-stitch

22

LK-982-5

bartacking

i6mtn

Max. sewing size :

Min. sewing size :

3xl6mm(l/8x5/8")

1.5x8mm(l/16x5/16")

Sewing time per piece : 1.2 sec.

Crosswise and lengthwise stitches produce a

smooth, attractive and tight bartacking.

Max. sewing size :

Min.sewingsize : 1.5x8mm(I/16x5/16")

Sewing time per piece : 0.8 sec.

Coarse crosswise and lengthwise stitches pro

duce a practical bartacking efficiently within

IGtnrn

3xl6mm(l/8x5/8")

2/3 of the sewing time needed for LK-980

without affecting the material.

SEWING

SPEED

The maximum sewing speed of this machine is 2,200 s.p.m. for normal sewing,but is 1,700 s.p.m.

for either

sewing

a synthetic fibermaterial or with a syntheticthread.

Considering

that the

sewing

works of today are made in most cases with synthetic fiber materials or thread, our standard

built-in motor pulley is for the speed of 1,700 s.p.m. If you operate the machine at such speeds

as 2,200 or 2,000 s.p.m., we are ready to supply a motor pulley and a belt upon your separate

When

order.

ordering, please indicate the desired part Nos. as per the table given below.

you use synthetic threads or materials for

your

sewing works, we advise you to make useofthe

When

siliconoil tank whichisinstalledin the machinehead for efficient and stable sewingworks.

The following table shows you the sewing speeds attained by the different combinations of the

motor pulleys and the driving belts. This machine employs 2 pieces of V-belts, one is for driving

the machine and the other is for decreasingthe pedal pressure. (Those pulleys and belts having

.(*) marks in the table are optional parts.)

Frequency

50Hz.

60Hz.

Sewing speed

(s.p.m.)

2,200

2,000

1,700

2,200

2,000

1,700

Motor

pulley

part

No.

♦B7101980000

»B7101980(K)B

B710198000C

♦B7102980000

♦B710298000B

B710298000C

Engraved

50

50

50

60

60

60

Symbol

2200

2000

1700

2200

2000

1700

Driving

belt

*48"

MTJVM004800

*47"

MTJVM004700

46"

MTJVM004600

*47"

MTJVM004700

*46"

MTJVM004600

46"

MTJVM004600

Pedal pressure

decreasing

*35"

MTJVM003500

*34"

MTJVM003400

34"

MTJVM003400

*34"

MTJVM003400

*34"

MTJVM003400

35"

MTJVM003500

belt

-2-

Page 6

INSTALLATION

AND

PREPARATION

1. Assembling

Paste

the

installation

Make

the installation holes with spot

the

attached

holes.

machine table

pattern

paperonthe

surfaceoftable

facing

first, and then attach the

installing base,spoolholderbase,headsupport and tension

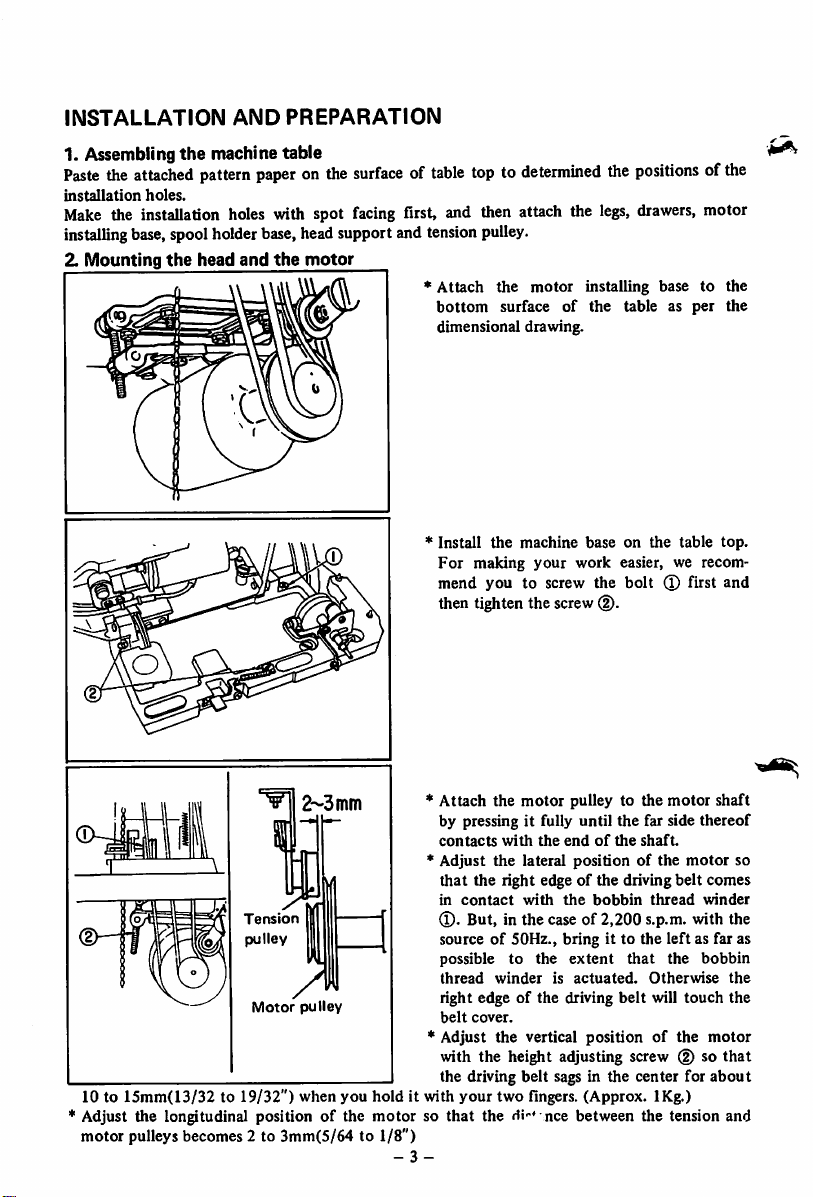

2.

Mounting

the

head

and

the

motor

* Attach the

bottom

dimensional drawing.

* Install

For

mend

then tighten the screw@.

toptodetermined

pulley.

motor

surface

the

making

you

machine

to screw the

installing base to the

of

the

base

your

work

the

positionsofthe

legs,

drawers,

table as

on the table

easier, we recom

bolt

® first and

motor

per

the

top.

z-^omm

* Attach the

motor

pulley to the

motor

by pressing it fully until the far side thereof

Tension

pulley

Motor

pulley

contacts

* Adjust

that

in

®.

sourceof50Hz., bring it to the

possible

thread

right edge of the driving

belt

* Adjust

with

the

the

endofthe

lateral position of

shaft.

the

the right edge of the driving

contact

with

the

bobbin

thread

But, in the case of 2,200 s.p.m. with the

left

to

the

extent

that

winderisactuated.

cover.

the

vertical

positionofthe

belt

the

Otherwise

will

with the height adjusting screw (D so

the driving belt sags in the center for

10 to 15mm(13/32 to 19/32") when you hold it with your two fingers. (Approx. IKg.)

Adjust the longitudinal positionofthe

motorsothat

the Hi-' nee between the tension and

motor pulleys becomes 2 to 3mm(5/64 to 1/8")

-

3-

motor

belt

as far as

touch

shaft

so

comes

winder

bobbin

the

the

motor

that

about

Page 7

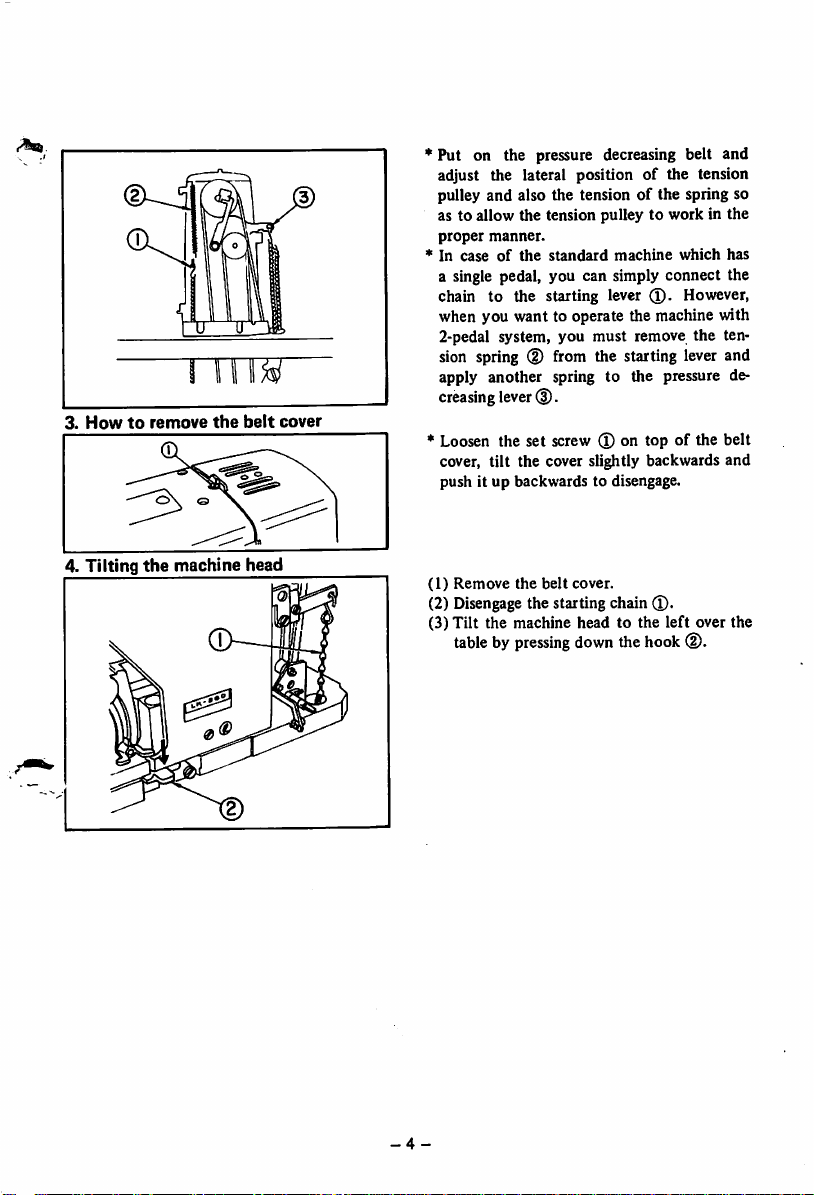

3.

Howtoremove

4.

Tilting

the

the

machine

belt

head

cover

* Put on the pressure decreasing belt and

adjust the lateral position of the tension

pulley and also the tension of the spring so

as to allow the tension pulley to work in the

proper

manner.

* In

caseofthe

standard

machine

which

has

a single pedal, you can simply connect the

chain to the starting lever However,

when you want to operate the machine with

2-pedal system, you must remove the ten

sion spring (D from the starting lever and

apply another spring to the pressure de

creasing

lever

d).

* Loosen the set screw (D on top of the belt

cover,

tilt

the cover slightly backwards and

push it up backwards to disengage.

(1)

Remove

(2)

Disengage

(3)

Tilt

tablebypressing

the

belt

cover.

the starting chain d).

the

machine

headtothe

down

thehook(D.

left

over

the

-4

-

Page 8

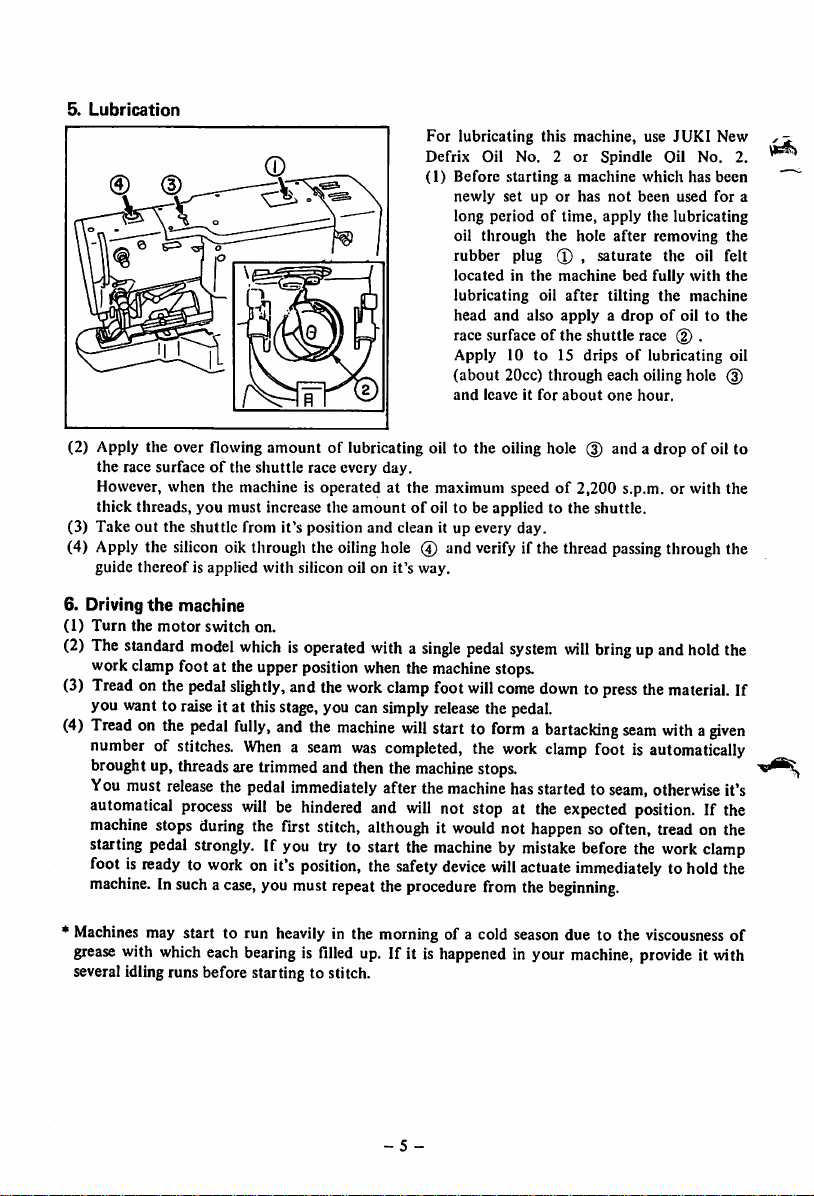

5.

Lubrication

For

lubricating this

Defrix

Oil No. 2

(1) Before

(2) Apply the over flowing amount of lubricating oil to the oiling hole (5) and a drop of oil to

the

race surfaceofthe

However, when the machine is operated at the maximum speed of 2,200 s.p.m. or with the

thick threads, you must increase the

out

(3) Take

(4) Apply the silicon oik through the oilinghole 0 and verify if the thread passingthrough the

guide

the shuttle from it's position and clean it up every day.

thereof

is applied

shuttle

with

race every

silicon oil on

day.

amountofoil to be applied to the shuttle.

it's

way.

startingamachine

newly

set uporhas

long

periodoftime,

through

oil

rubber

locatedinthe

lubricating oil

head

and

race

surfaceofthe

Apply

10 to 15 dripsoflubricating oil

(about

20cc)

and

leaveitfor

machine,

or

Spindle

apply

the

plug

hole

(l) ,

saturate

machine

after

also

applyadropofoil to

shuttle

through

about

use

which has

not

been

the lubricating

after

bed

fully

tilting

race

each

oiling

one

hour.

JUKI

Oil No. 2.

used

removing

the

oil

with

the

machine

(2) .

hole

New

been

for

the

felt

the

the

(3)

a

6. Driving

(1)

(2)

(3)

(^)

*

Machines

grease

several idling runs before starting to stitch.

the

machine

Turn

the

motor

switch

The

standard

work

Tread

you want to raise it at this stage, you cansimply

Treadonthe

model

clamp

footat theupper

on the

pedal

pedal

numberofstitches.

broughtup, threadsare

Youmust

automatical

machine

starting

foot is

release

process

stops

pedal

readytowork

machine.Insuchacase,

may start to run heavily in the morning of a cold season due to the viscousness of

with

which

on.

whichisoperated

slightly,

andthe

fully,

and

Whenaseam

trimmed

the

pedal

immediately

willbehindered

during

the first stitch,

strongly.Ifyou

on it's

you

must

each

bearingisfilled

position

work

the

machine

and then the

try to start the

position,

repeat

withasingle

when

the

machine

clamp

foot

release

will

was

starttoformabartacking

completed,

machine

after the

and

machine

will

not stop at the

althoughitwould

machinebymistake

the

safety

the

up. If it is

- 5 -

device

procedure

happened

pedal

stops.

will

come

the pedal.

the

stops.

not

will

from

system

will

downtopress

work

clamp

hasstarted to

expected

happen

actuate

the

beginning.

in your

machine,

bringupand

seam

foot is

seam,

hold

the

material.

withagiven

automatically

otherwise

position.

If the

so often, tread on the

before

the

work

clamp

immediatelytohold

provide

it with

the

If

it's

the

Page 9

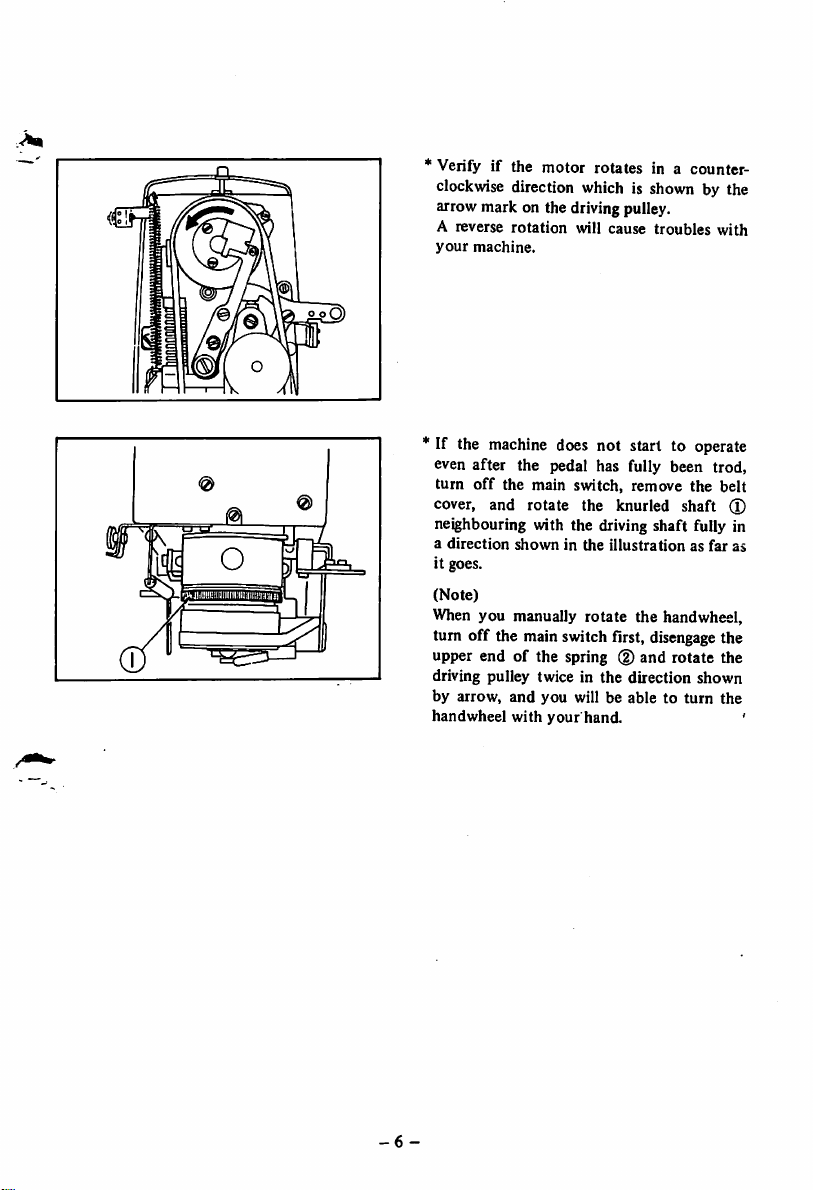

* Verify if the motor rotates in a counter

clockwise

direction

which

is shown by the

arrow mark on the driving pulley.

A reverse

your

machine.

rotation

will cause troubles

with

"If the

machine

does not start to operate

even after the pedal has fully been trod,

turn

off

cover, and

the main switch, remove

rotate

the knurled shaft

the

neighbouring with the driving shaft fully in

a

direction

it goes.

(Note)

showninthe

illustrationasfar

When you manually rotate the handwheel,

turn off the main switch first,

disengage

upper end of the spring (2)and rotate the

driving pulley twice in the direction shown

by arrow,

handwheel

and

with

you

your

will be

hand.

abletoturn

belt

(X)

as

the

the

'

-6-

Page 10

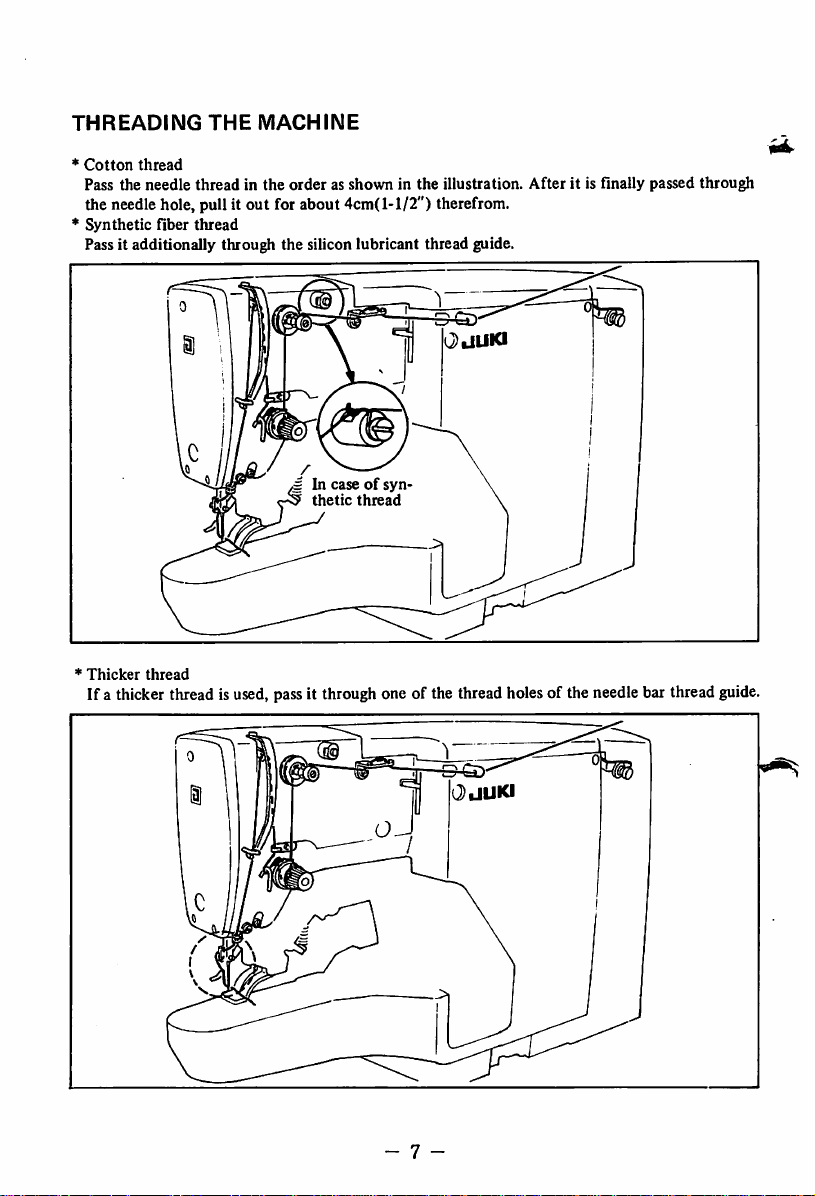

THREADING

*

Cotton

thread

Pass the

needle

THE

MACHINE

threadinthe

orderasshowninthe

illustration.

After

it is finally passed

the needlehole, pull it out for about 4cm(1-1/2") therefrom.

*

Synthetic

fiber

thread

Passit additionally through the silicon lubricant thread guide.

OldUKI

g In

caseofsyn

thetic

thread

*

Thicker

thread

If a thicker thread is used, passit throughone of the thread holesof the needlebar thread

through

guide.

- 7 -

Page 11

NEEDLE

iitnumi

*

Needles

Very light weight

material

Synthetic

material

Medium heavy weight

material

Heavy weight

material

(Note)

and

Sewing-cloth

fiber

For

sewing a very

material

> 1

#11

#14

SUPER

#16

#18

thick

material

lor?

Needle

(DPx5)

(DP

X 5

needle)

(DPX5)

(DP

X 5)

like denim, a subclass

*

Howtoattach

o DP X 5, No. 16 is

machine.

needle clamping

Insert

the

needle

the

standard

the

hole

needle

needle

fully

on the needle bar by

for

into

facing the long groove thereof towards you

and clamp

the

needle with a screw,

o If the needle thread forms such faulty

stitchesasshown

maybeeffectivetosolve

in the

above

illustration, it

themtoturn

needle slightly to the left,

o When you are going to sew a synthetic fiber

material

a

Needle hole guide

D2426-282-C00

B2426-280-000

B2426-280-000

B

2426-280-000

SUPER

(standard)

(standard)

(standard)

withasynthetic

needle.

Made-up goods

Knittedortricot

Men's

Men's

Working wears

overcoats

machine

LK-984-50 is available.

fiber thread,

and

ladies'

and

ladies'

and

attach

wears

suits

suits

this

the

the

• Winding

the

bobbin

@

thread

spindle.

(2)

Pass

around

direction

(3)

Push

the

starttowind.

wound

(4)

Normally

of

it's

(5)Ifthe

the

the

threadasillustrated

the

bobbin

shownbythe

the

bobbin

bobbin,

and

up, it will

the

capacity.

bobbiniswound

nut

(I) and turn the bobbin adjusting

screw (D clockwise.

(6)Ifthe

(7) Do

the

bobbin

the

not

threadisnot

bobbin,

winder

not

forget to

machine

attach

adjust

before

the

be guided properly to the

wheel and

wind

the

the

bobbin.

* Use genuine JUKI bobbin case and bobbin, or bobbin may idle or slip

-

8-

several

arrow

winder

trip

the

bobbin

As

soonasthe

automatically

bobbiniswound

too

wound

the

positionofthe

base

(3).

attach

the

driving it. If

belt

cover,

the

bobbin

mechanism

outofbobbin case.

and

wind

turnsinthe

mark.

latch

towards

thread

bobbin

stop.

about

much,

loosen

evenly

around

belt

cover to

you

belt

will

winder

may

fail to

it

will

is

80%

do

not

Page 12

THREAD

TENSION

No.1thiead

disc

\

Arm

thiead

guide

A

.Thread

No.2thread

tension

spring

take-up

disc

L

tension

1.

Needle

thread

tension

(1)

Thread

o This is mainly used

tension disc No. 1

of

the

thread

for

leftonthe

adjusting

needle

the

after

length

ming.

The

needle

thread

o

tension varies

depending

on its quality. Adjust the length of needle

thread

whichisleftonthe

trimmed by turning the tension disc

that

the

thread

but

can

does

not

becomesasshort

not

slip

outofthe needle.

get a satisfactory result from this

needle

afteritis

No.l

as possible

(If

adjustment, try to adjust it with the tension

disc

No.

2 as

(2)

o

This

needle

creases

2.

o Pull

on

Thread

disc

Bobbin

the

the

described

tension

No.2isused

thread

the

tension.

thread

bobbin

bobbin

disc

tension.

tension

thread

case for

later.)

No.2

about

for

adjusting

Oockwise

through

2.5cm(l")

turn

the

put the bobbin case into the shuttle race

ring.

o

The

bobbin

thread

by

turning

Clockwise

counterclockwise

the thread

turn

tension can be

tension

will

increase

turn

will

decrease

screw

the

adjusted

d).

tension

it.

trim

so

you

the

in

hole

and

and

Thread

spring

3.

Thread

The

normal

take-up

stroke

spring

of

the

thread take-up

spring is 6 to 8mm(15/64 to 5/16") and the

tensionatthe

oToadjust

(X)

and

starting

point

the

stroke,

rotate

the tension controller as

is 30to50g.

loosen

sembly to left or right,

o To

adjust

the

tension,

insert

the

screw

driver

into

the

small

tension

creaseorcounterclockwise

tension.

o

Synthetic

needle, if the

stroke

must

lessen

-9

-

post

and

turnitclockwise to in

flber

thread

thread

and

high tension. In this case,

the

tensionofthe

groove on

to

may

slip

take-up spring has large

spring.

the

set

bladeofa

decrease

outofthe

screw

the

the

you

Page 13

ADJUSTING

THE

LENGTH

OF

BARTACKING

Loosen the wing nut 0 to clamp the cross

wise feed regulator and move it downwards

for producing longer bartackings or upwards

for

shorter

after

bartackings.

adjustment

Ti^ten

the wing

nut

ADJUSTING

ADJUSTING

t ^

7—IOhuh

THE

THE

kfJli

Ul 1

WIDTH

FEED

f

V

/f

OF

BARTACKING

TIMING

1/

Loosen the lock

nut

0 on the feed regulator

and turn the adjusting knob ® counterclock

wise

for producing wider bartackings or clock

wise for narrow bartackings. Tighten the lock

nut 0 securely after

o A

cloth

feed

when

the

height of 7 to 10mm(9/32 to 25/64") above

the

top

o

o If

surfaceofthe

Better

thread

height is closer to 7mm(9/32").

loose

stitchisformed

thread,

it is

changing the said height closer to 10mm

(25/64").

adjustment

motion

mustbecompleted

needle

has

come

downtothe

throat

with

plate,

synthetic

this

tensionisobtainedasthe

effectivetosolve

said

fiber

trouble

by

-

10-

Page 14

ADJUSTING

DISC

No.2

Needle

thread

Too

long

Length is

form

Too

Thread

the

not

short

is snapped on

way

and

jumps

uni

THE

up

TENSION

Tension

release

Pushitup

Push it up

Pushitdown

Pushitdown

RELEASE

lever

TIMING

OF

THE

TENSION

(1) Position of the tension release latch trip

ping

segment

Adjust the position of the tension release

latch tripping segment (f) so that the

pointed end of the tension

release

latch

stays on top of (2) at the time of stop

motion.

(2) If the tension release timing at the tension

disc No.2 is incorrect, the length of thread

leftonthe

too

the

needle

short

or the thread may slip

needleatthe

startofbartacking.

after

trimming may be

out

The

vertical position of the tension release

lever (D must be properly adjusted by

loosening

tension

moment

the

hinge

disc

No.2isreleased

when the

screw

® so that the

top

endofthe thread

at

the

take-up leverhas gone up to coincide with

the engraved mark (5)after completion of

the

last

stitchofa bartacking.

Adjust the height of the tension release

lever in the following way in order to

obtain an ideal length of remaining thread

at

the

needle

after

trimming;

of

* Adjust the position of the pointedend of the

tension

release

latch ® by meansof the adjusting

screw(j) so that the said pointed end of ® is brought closerto but not into contact withthe

surface of feed cam ® during running.

-11-

Page 15

RELATION

Height of . Position of

«edleb^

BETWEEN

KbSl

ing

Upper indi

^

eating

Lower

gating

Needle

qm

line

indi

tin^

bar

THE

sewing

h^k

i>1

kCt

0.3~0.5

NEEDLE

AND

THE

SHUTTLE

Adjust the positionsofthe needle and the

shuttle in the following way; Switch

machine,

tread

on the

starting

pedal

the driving pulley manually until

bar

comes

down

to its

bottom

dead

* Howtoadjust

(1) Loosen

the

the

heightofthe

needle bar

clamp

and

the

point.

needle

screw.

off

rotate

needle

the

bar

(2) Bring the upper marking line on the

needle

bottom

bushing.

(3)

Tighten

*

Howtoadjust

bartothe

surface

the

same

of

needle bar

the

positionofthe

levelasthatofthe

the

needle

clamp

screw.

shuttle

bar

lower

(1) Rotate the driving pulley further until the

lower marking line on

the

agrees to

bushing.

bottom

the

needle bar

surfaceofthe

lower

(2) At this stage, loosen the shuttle driver

clamp

screw,

adjust

the

positionofthe

shuttle

point

so as to

meet

with

the

center

line of the needle and tighten the clamp

screw.

No

clearance

the needle

driver,

driver

to

because

actuates

prevent

and

it from being

(3) Loosen the shuttle race clamp screw

the

to

front

the

receive

mustbeleft

edgeofthe

front

edgeofthe

the

bent.

between

needle

said

and

©.

(4) Adjust the longitudinal position of the

shuttle

racebyturning

the

shuttle

race

adjusting shaft (D so that the clearance

between

becomes

0.00394").

(5) Tighten the clamp screw

the

0.05

needle

to

and

0.1mm

the

(T).

shuttle

(0.00197

point

to

*

Howtotake

out

the

shuttle

Disengage a pair of shuttle race latches ®

towards

them

and

Do it carefully

floor.

-12-

towards

shuttle

left

and

right respectively by pulling

you,

and

the

are

taken

nottodrop

out

shuttle

from

the

race

the

ring

positions.

shuttleonthe

Page 16

ADJUSTING

Stop-motion

lever

tension

spring

THE

STOP-MOTION

Driving-pulley

Stop-motion

cam

MECHANISM

1.

Stop-motion

While

the

wheel,

the

the

starting pedal. Disconnect the stop-

motion

anchor

and

rotating the driving pulley (D 2 to 3 turns

in

the

normal

Tread

on the pedal for

so astolet

cam coincide with the top edge of the

stop-motion

regulating

machineisoperatedbythe

safety

device

lever

tension

lower

the

direction.

cam

workstolock

spring (T)

work

clamp

starting

"A"

pointofthe

hook.

hand-

up

from

its

foot

by

the

machine

stop-motion

Stop-motion

Stop-motion notch

screw

Stop-motion

hook

Stop-motion

roller

regulating cam

By keeping this

motion

regulating cam idly in the direction

shown

by the

point

"B"

with the

camatthis

-

13

condition,

arrow

in figure

of the cam comes

stop-motion

position

roller and fix the

with

the

turn

cam

the stop-

until

into

set

the

contact

screw.

Page 17

1-1.

Stop-motion cam

Stop-motion

The timing to let the roller

the

stop-motion

cam

notch

after

drop

the last

and rest in

stitch

sewn is determined by the positionofthe

2nd

/ ^

screw. / -—s.

1st

screw

stop-motion

Provide the stop-motion notch with a proper

position by moving it up or down, according

to

the

notch.

sewing speeds as listed below, when

the last stitch is sewn and the top edge of

the

(Note)

Stop-motion

hook

In caseof1,700

s.p.m.

stop-motion

motion

cam.

Position of

At

1,700

At

2,000

At

2,200

s.p.m.

s.p.m. Between the 1st and the

s.p.m.

the

stop-motion

hook

touches the stop-

hook

Centerofthe

2nd

screws.

Centerofthe

2nd

screw.

1st screw.

The degreeofstop-motion shock depends also on the position of the stop-motion notch.

If the sewing machine carries an excessive rotational torque to reduce its sewing speed especially

in a cold season, shift the

the

counteraction.

notch

position counterclockwise along the circumference to increase

2.

Stop-motion

frame

Adjust the position of the roller shaft (f) on

No.2marking

No.1marking

line

line

the regulating cam so

surface of the brake ring and the 2nd

marking

coincide

speed

line on the stop-motion hook (D

with

running.

each

that

the circumferential

otheratthe

timeoflow-

3. Driving pulley pressing plate

At the

moment

the

stop-motion

circumferential

the driving clutch must be engaged to drive

the

machine.

ing the position of the driving pulley pressing

plate (J) by means of the adjusting screw (6).

Use a

spanner

for this adjustment. Tighten the nut in such a

wayasto

20 mm

tightened. Please note

runs

too

runs

too

heavier.

(Note)

Ensure always

and

brake

-

14

-

when

the

hook

surfaceofthe

Obtain

such

(9 x 10) in

turn

the

(25/32")

endofthe

after

fast, it will make

slow, it will

cork

that

the slow speed

ring ®

make

1st

marking

line

(5) coincides with

brake

ring (4),

functionbyadjust

the

accessory

spanner

it has been

that,

much

the

don't

further

properly

if the machine

noise and if it

starting

cork

ring (D

rotate during

box

pedal

is

on

the

Page 18

operationofthe driving pulley (§) while the

machine is suspended.

since it causes wearing

tion gear if the slow speed cork ring (g) and

Readjust

accidentsofthe

the

screw (6)

reduc

brake cork ring @ are rotating.

4.

Brake

ring

stopper

Adjust the brake ring stopper © so that the

0.3mm

brake cylinder

tionby0.3mm

run.

(Q)

moves in the arrow direc

when

the

machine

starts

Make sure that the screw (g) is firmly clamp

ing the brake ring stopper

(Note)

®.

For disassemblyand assembly of the slow speed cork ring (5) to lubricate greasereplace should be

done in the following order:

1.

Remove

the

driving

pulley

pressing

plate

(T)

and the

driving

pulley

(g)

and

remove

the C ring

(D with the tool (§) and the slow speed cork ring (5) is removed.

2.

Reinstall

after

couple

the

applying

the

slow speed

previously

grease,

usedclutch spring bracket

give

grease

ring

to the end

and

main

shaft

cork

(small)

(S)

surface

of the mainshaft thrust

thrust

washer

to the newslowspeedcork ring

washer

with

the

main

shaft.

® and

3. Replacealwaysthe C ring (D with new one and install it in the followingway:

1)

Widen

the C ring open enough to be inserted in the main shaft by means of a tool and place

if from the position

positionofthe C ring during operationofthe machine).

(g)

to (g). (If the C ring is widened too largebe careful to avoidoff-

2) Push the C ring from position (g) to the groove © of the main shaft in the direction of

arrow

3)

Asertain

(<-)byusing 2

whether the C ring fits into the

screw

drivers.

groove

© by

pulling

hard the slowspeed cork

ring (D by hand towards the directionofarrow (-»).

to

/i-C-Q

Page 19

ADJUSTING

THE

®(S)

THREAD

TRIMMER

At

the

timeofstop-motion,

between the rear end of the movingknife (l)

and the edge of the needle hole located on the

needle

holeguidemustbe 1.5mm(l/16").

Loosen

the

screw (3)

ing the moving knife.

and

adjust

the

clearance

it by position

ADJUSTING

ADJUSTING

Whilethe presser foot is raised at the time of

stop motion, move the safety adjusting plate

® in the arrow direction until it comes in

contact

with the safety plate (2)

_^,^^learance

^ (1/64") when the presser foot is brought

down. Fix the safety adjusting plate at such

a position.

between

THE

PLATE

0.3mtn

them

SAFETY

becomes

and

also the

0.3mm

POSITIONING

RACE

SPRING

THE

SHUTTLE

5

a

Lateral

position:

The center line of the groove must coin

cide

with

the

needle

center.

Longitudinal position:

The corner (g) must coincide with the rear

endofthe

needle.

—16—

Page 20

ADJUSTING

THE

POSITION

0

OF

THE

WIPER

* When you adjust

the

heightofthe

loosen the screw ® on the wiper installing-

plate

and adjust

the

heightofthe

wiper,

wiper

installing plate vertically along the adjust

able

screw

hole.

*

The

o

clearance

thatofthe

when

centerofthe

To

check

shaft

(page. 13) in

the

needle

dead

point

* During this adjustment, you

not

to allow it to hit either the work clamp

footorthe

between

needle

the

wiper has swung

needle.

this

clearance,

has

the tipofwiper and

mustbel.Smm(l/16")

rotate

the

normal

come

downtothe

at the time of stop-motion.

needle.

down

the

direction

must

be careful

to the

knurled

until

bottom

ADJUSTING

ADJUSTING

THE

WORK

26th

stitch

'

(42-stitch

largebartack-^

in^

18th

stitch

(28-stitch

large bartack-

in^

THE

HEIGHT

CLAMP

OF

FOOT

* In case of the 42-stitch bartacking: the 26th

stitch

mustbelocatedonthe-

work

clamp

foot

and

right wings).

(on the joining lineofleft

* In case of the 28-stitch bartacking; the 18th

stitch

work

mustbelocated

clamp

foot (on the

on

and right wings)

* Adjust it by moving the roller shaft

the

THE

direction

fllustration.

WORK

CLAMP

shownbyarrow

FOOT

The adjustment in the height of work clamp

foot ranges from 6mm( 15/64") to 15mm

(19/32") depending on the thickness of

materials.

centerofthe

the

centerofthe

joining

lineofleft

(T)

markonthe

in

17

-

Page 21

ADDITIONAL

COTTON

When a

thicker

not

enough to form well tightened stitches.

LUBRICATION

THREADS

thread

than

No.30orNo.20

NEEDED

are used, the

FOR

lubrication

THE

USE

to the

OF

shuttle

THICK

race

may

be

In such a case, we recommend you to lubricate the shuttle race manually 3 or 4 times a day in

ordertolessen

the

rotational

load from the

shuttle

andtoproduceabetter

sewing condition.

WHEN

THE

USING

SYNTHETIC

SYNTHETIC

MATERIALS

THREADS

OR

SEWING

We advise you to operate the machine in the following way when you use synthetic threads or

sew

chemicalorsynthetic

1) Replace the motor pulley with a special pulley for sewing synthetic materials.

sewing speed is 1,700 s.p.m.)

2) Use

the

silicon

lubricant

materials;

tank

additionally.

(Maximum,

Refer to the paragraph under the "Threading the machine".

3) Use a SUPER needle for

4) Lessen the

WORK

stroke

CLAMP

synthetic

from the thread take-up spring.

FOOT

FOR

fiber thread.

THE

KNITTED

FABRICS

The following optional work clamp feet are available for bartacking on the very light weight

materials, light weight materials or knitted fabrics;

Workclamp foot for the knitted fabrics (Right) B2551-280-00B

Work clamp foot for the knitted fabrics (Left) B2552-280-00B

Feed plate for the knitted fabrics B2519-280-008

-

18

Page 22

TROUBLES

No.

Troubles

1.

Needle

slips

outatthe

startofsewing.

2.

Thread

is

snapped

often

or

synthetic

thread

is

ravelling.

3.

Synthetic

threadisbrok

enorlorms

loose

stitches

at

the

start

sewing.

thread

very

AND

THEIR

Some

1.

the

2.

Needle

shortonthe

CORRECTIONS

Causes

stitches

start

of stitching.

threadisleft

thread trimming.

3.

Bobbin

threadistoo

4. Material is rippled.

5.

Tension

disc

high tension.

1.

Shuttleorshuttle

spring

has

surface.

scratchedonit's

2. Shuttle race spring has a

scratchonthe

3. Needle hole guide is bruised.

4. Needle hits the work clamp

foot.

5.

Mbrous

dust

grooveofshuttle

6.

Clearance

shuttle

shuttleistoo

7.

Thread

small.

between

driver

take-up

8. Stroke of the thread take-up

spring is too big.

1.

Duetothe

heatoffriction.

2. Timing of feed is

of

correct.

are

skipped

too

needle

after

short.

No.1has

driver

surface.

staysinthe

race.

the

and

the

small.

strokeistoo

not

Corrections

at

Adjust

the

needle

0.1mm

Referto"Needle

a

"Adjusting the tension release timing

of

Lessen

Increase

counter

clearance

and

the

shuttleto0.05mm

(0.00197"to0.039").

the

tension

disc

the

bobbin

the

clearance

knife

and

guide.

Refer to "Work clamp foot for the

knitted

fabrics".

too

Increase

the

strokeoftlic

take-up spring or decrease the tension

from

the

tension

disc

Poli.sh tho.se surfaces by meansofoil

stonesorbuffs.

Remove such scratch by buffing or

replace

it.

Polish it up with buffs, or replace it.

Refer to "Adjusting the work clamp

foot".

Take

out

the

shuttle

dust

from

the

shuttle

Bend

the

shuttle

driver

the clearance to 0.3 to

to

1/32")

Move the arm thread guide A to the

left.

Referto"Needle

Lessen

the

stroke.

Refer to "when sewing synthetic

materials or using synthetic threads."

Refer to "Adjusting the feed timing."

between

thread

No.2".

thread

between

the

needle

No.

and

race.

so astomake

0.5mm(l/64"

thread

the

tension"

tension.

hole

thread

1.

remove

tension."

the

and

any

to

,

19

-

Page 23

No.

Troubles

4.

Needleisbrok

en frequently.

5.

Threads

not

trimmed.

are

Causes

1. Needle is

2. Needle

foot.

hits

not

straight.

the

3. Timingoffeed is

correct

work

not

clamp

Replace

Refer to

foot.

Refer to "Adjusting the feed timing".

Corrections

the

needle.

"Adjusting

the

work

4. Wiper hooks the needle. Adjust the heightofwiper.

5.

Needleistoo

6.

Positionofthe

driverisnot

fine.

shuttle

correct.

1. Height of the counter knife

is

not

correct.

2.

Bladeofcounter

not

sharp.

3.

Differenceoflevel

the

needle

the

counter

knife

hole

guide

knifeisnot

between

and

Select a suitable needle according

the

typeofmaterial

Referto"Motionsofthe

the

shuttle".

Raise the blade edgeofcounter

0.5mm(0.0197")

level

is

Sharpen

the

knife.

Adjust it to 0.1 to 0.15mm(0.0039"

to

0.0059")

from the installation

enough.

4. Positionofthe moving knife

is

not

correct.

5.

Positionofthe

spring is

6.

The

last

not

stitch

shuttle

correct.

skips.

race

Refer to

trimmer."

Refer to "positioning the shuttle race

spring".

Referto"motionsofthe

the

shuttle

"Adjusting

race."

the

thread

needle

needle

clamp

to

and

knife by

and

Thread

ing length is

not

adequate.

6.

Stitches

very

trimm

often.

skip

1. Tension release timing

tension

disc

shuttle

and

No.2isnot

needle

are

not

between

the

shuttleistoo

properly

the

not

correct.

1.

Motionsofthe

the

synchronized.

2.

Clearance

needle

much.

3. Timingoffeed is

of

and

correct.

-20-

Refer to "Adjusting the tension release

timing of the tension disc No.2".

Referto"Relation

needle

and

Refertothe

the

shuttle

above.

betweenofthe

race."

Refer to "Adjusting the feed timing."

Page 24

No.

Troubles

7.

Needle

thread

comes

out

the

bottom

surfaceofthe

material.

8. Work clamp

foot

does

go

up.

9.

Machine

not

start.

not

does

Causes

4. Needle is

not

S. Material is rippled.

6. Bobbin thread is

1.

Needle

of

2.

thread

enough.

Tension

release

is

outoffunction.

3. Thread length

ming is

too

1. Positionofthe stop-motion

is

not

correct

2.

The

forceofinertiaisnot

enough.

3. Safety adjusting plate is

positioned

incorrectly.

4. Motor is running in the

reverse

direction.

5.

Motor

does

1.

The

forceofinertiaisnot

enough.

2. Clutch slips at the high

speed

operation.

3. Starting pedal is

early.

4. Positionofthe safety

adjusting plate is

5. Position of the stop-motion

hookisnot

correct.

6. Push down slide plate does

not

return

smoothly.

straight.

too

tensionisnot

mechanism

after

long.

not

run.

trod

not

tight.

trim

too

correct.

Correction

Replace the needle.

Refer to "Work clamp foot for the

knitted

fabric."

Lessen the bobbin thread tension. Keep

the

counter

knife

away

from

the

mating surface of the needle hole guide.

Adjust

the

Verifyifthe

tensionofthe

tension

release

needle

mechanism

thread.

is working during operation.

Refer to "Adjusting the tension release

timingofthe tension disc

Trytoidleitonce.

No.2".

Movethe stop-motion regulating cam

slightlytoit's

rotational

direction.

Refer to "Adjusting the safety adjust

ing plate".

Correct

it.

(normal

directionisshown

by arrow mark on the pulley.)

Motor must keep running continuously.

Movethe stop-motion regulating cam

slightly to

it's

rotational direction.

Refer to "Driving pulley pressing

plate".

Starting

pedal

work

clamp

mustbetrod

foot

has

come

after

the

downtoit's

position.

Refer to "Adjusting the safety adjusting

plate".

Refer to "Adjusting the stop-motion

mechanism."

Correct

it.

-21

Page 25

No.

10.

Stop-motion

makes

much

Troubles

too

noise.

Causes

1.

The

forceofinertiaistoo

great

2. Driving belt is

too

tight.

Correction

Move the stop-motion regulating cam

slightly in

rotation.

Adjust

it's

reverse

the

positionofthe

direction

motor

of

so

that the driving belt has proper tight

ness. (The

about

them with

belt

sags at the center for

10mm(13/32") when you hold

your

two fingers.)

BAND-LOOP

These

machines

trousers,

jeanpantsetc. but it can be

for producingseams

^ax.

sewing

standard

sewing size : 14mm(35/64")

ATTACHING

are

specially

similar

to bartacking.

LK-984-10

(21

stitches)

size:I4mm(35/64")

MACHINES

designed

practically

Min. sewing size : 6mm( 15/64")

In order to attach the band-loops firmly, this

model

is designed to form

more

stitches

the both ends of a loop than the central part

thereof.

for

on

attaching

band-loopstomen's

used

also

for

attaching

LK-982-20

various

3 2 I

(28

trousers,

cords,

stitches)

Max.sewing size : 16mm(5/8")

Standard sewingsize : 14mm(35/64")

Min. sewing size : 7mm(9/32")

To reinforce the band-loops, this model forms

more

stitches

evenly

than

thatofother

and also is capable of attaching wider loops

forjean pants ski'ing pants etc.

The

following

parts are to be used for

a size of 14 to 16mm(35/64 to 5/8").

D2519-L2A-F00 Feed plate

D2551-L2A-FOO Workclamp foot

working

labels

model

sewing

and

-22-

Page 26

LK-982-30

(28

stitches)

LK-984-40

(42

stitches)

—©a—

Max. sewing size : 25mm(63/64")

Standard sewing size : 25mm(63/64")

Min. sewing size : 13mm(33/64")

This model is used for sewing longer stitches

than

thatofmodel

-tK

—

LK-9

29m

82-20.

—<P—

O a

?

Max. sewing size : 35mm(1-3/8")

Standard sewing size : 25mm(63/64")

Min. sewing size : 18mm(45/64")

This model is used for

attaching

larger band-

loops securely.

The following parts are to be used for sewing

a size of 25 to

D2519-L4A-R00

D2551-L4A-R00

35mm(63/64

Feed

Work

to 1-3/8")

plate

clamp

foot

* In addition to the above 4 models for band-loop attaching machines, the following models, of

which the work clamp foot is operated with the pedal system, are also available;

LK-984P-10

LK-982P-20

*

Needles

UseDPX 5

No.14to

No.16needles

and DP x 5 No.18 to No.21 needles for jean pants and working wears etc.

LK-982P-30

LK-984P-40

for

such

soft

materialsasmen's

trousers

and

knitted

For

sewing synthetic

fabrics

materials with synthetic threads, we recommend you to make use of the SUPER needles and

also silicon

*

Dimensionsofthe

lubricant

table

for

efficient

sewing works.

Refer to the separate demensional drawing of table for setting up the machine head thereoj

m

*

Notes

for

The

ed

installation

band-loop

from

the

attaching

sideofthe

machineisoperat

machine

head.

Apply the attached pedal connecting rod,

and

you

will

easily.

operate

-

23

-

the

machine

more

Page 27

KNIT

GOODS

BARTACKING

MACHINES

These machines are designed to be used

for

forming bartackings on

the

knitted

materials,

but

they are also capable of producing fine and stable bartacking on light weight materials.

LK-984-6

Max.

sewingsize : 3 x 8mm(l/8 x 5/16")

(21

stitches)

Standard sewingsize : 2 x 6.5mm(5/64 x 1/4")

Min. sewingsize : 1.3 x 4mm(3/64 x 5/32")

Time saving bartacking with coarse stitches.

*

Needles

Use DP X5, No. 11 needles.

BUTTONHOLE

These machines are

BARTACKING

designed

for bartacking the tail of eyelet buttonholes of men's suits, over

MACHINES

LK-982-3

Max. sewing size : 3 x

Standard sewing size : 2 x

Min. sewingsize : 1.3 x 4mm(3/64 x 5/32")

Fine and smooth bartacking is formed with

lengthwise

stitches.

(28

1524222018

10 12 14

252321

8mm(l/8x5/16")

stitches)

6.5mm(5/64x1/4")

coats, raincoats, etc. In order not only to reinforce the physical strength of the buttonholes but

to increase visualeffect, these modelsemploy a specialsystem to start to bartack either from the

gathered

closed.

end or the side of the buttonhole? automatically so that thebuttonholeis

The

gathered

LK-984-4

20 2117 15 13 II 9

width

canbeadjusted

(21

stitches)

between

the

range

of0 to

4mm(0

LK-982-1

2724222018 16 14 12 10 8

(28

to5/32").

stitches)

steadily

kept

25

23

:

8mm

Max. sewing size : 3 x

8mm(l/8

x 5/16")

Standard sewingsize : 2.5 x 8mm(3/32 x 5/16")

Min. sewing size : 1.3 x 4mm(3/64 x 5/32")

Stitch is coarse,

formed

withinashort

but

bartacking is efficiently

time.

Max.sewingsize : 3 x 8mm(l/8 x 9/32")

Standard sewingsize : 2.5 x 8mm(3/32 x 5/16")

Min.

sewing

This bartacking consists of many lengthwise

stitches

and

9 17 5 13

size: 1.3x 4mm(3/64 x 5/32")

forms

smooth

and

fine

seams.

In addition to the standard buttonhole bartacking machines equipped with the single pedal

system,

available;

the

following

LK-984P-4

models

which

has 2

-

pedals

24

-

to control the

LK-982P-1

work

clamp

foot, are

also

Page 28

Procedure

for

operation

1) Place the eyelet buttonhole part under the work clamp foot, bring the work clamp foot

down and match the

buttonhole

exactly with the center

partofthe work clamp foot.

2) After the position of the first stitch was determined, tread on the starting pedal. Then, the

work clamp foot will be automatically closed together the slit of the

3)

machine

The

will

machine

starttorun.

will be

automatically

stopped

after

a sewing cycle has

2.

Adjusting

foot

When

you

of the

work

want

clamp

the

to lessen

buttonhole

been

performed.

openingofwork

the

gathering

foot

depending

on the size

and the

clamp

width

of buttonholes, loosen the hinge screw (1)and

move the work clamp foot regulator @ to the

0

0

direction

On

the gathering

foot

As this regulator assembly is

posed to

securely tighten

3.

If the pressing force of the work clamp

not

ping

shownbythe

the

other

hand,ifyou

width,

regulator (2) to the reverse direction.

the

operating

Adjusting

work

clamp

enoughtoprevent

outofthe position,

the

the

foot

pressing

arrow

wanttoincrease

move

the

vibration,

hinge screw.

forceofthe

the

material

take

mark.

work

repeatedly

out

the

clamp

you

foot

from

pressure

ex

must

slip

spring (3) regulating shaft from it's position

by pushing upwards and move (2) regulating

nuts (2) slightly upwards as shown by the

arrow

mark.

is

4. Detaching

the

work

clamp

When you take out the work clamp

remove the pressure spring by pushing

upward,

pull

out

the

block

fixed by a snap ring, remove the

of

the work clamp

you can

detach

5.

Adjusting

connecting

When

the

nearest

positiontoyou,

work

the

the

work

rod

clamp

foot

connecting rod, and

work

clamp

clamp

foot

has

loosen

which sets the stop-motion frame connecting

plate

and

adjust

the said

platesothat

work clamp foot driver lever stationing latch

(2) and the

hookofthe

work

bearing backet ® are engaged with ejiph

other.

-

25

shaft

foot

foot

cotter

foot

come

the

clamp

foo'f

which is

pin

assembly.

to the

screw

the

foot

Page 29

SMALL

BARTACKING

MACHINES

This machine is suitable to produce bartackings on mens' suits, overcoats etc. where fine appear

anceisrequired.

LK-984-11

20

9 17

Max. sewing size : 3 x

Standard sewing size : 2.5 x 8mm(3/32 x

Standard sewingsize : 2.5 x 8mm(3/32 x 5/16") Standard sewing size : 2.5 x 8mm(3/32 x 5/16")

Min. sewing size : 1.5 x

For

making small bartacking on various goods.

*

Needles

: DP x 5, No. 16

OTHER

Many

SUBCLASSES

other

subclass machines are involved in LK-980 series depending on their sewing shapes and

have been practically used by our

to introduce all those models in this instruction book. Therefore, please do

inquire us

Two

about

examples

LK-984-8

Label sewing machine

(21

stitches)

IS

13

II

9

-8mm

8mm(l/8x5/16")

4inm(l/16x5/32")

customers

your

specific applications which you can

are

shown

below;

(21

stitches)

LK-982.2

28

2724222018 16 14 12 10 8

2S2321 19 17 IS 13 II 9

L-

Max. sewing size : 3 x

Min. sewing size : 1.5 x

(28

stitches)

8mm

8mm(l/8x5/16")

4mm(l/16x5/32")

For making smooth and fine bartacking.

*

for

Needles:

labour

DP x 1or5, No. 16

saving purposes. We are

not

find herein.

LK-984-12(42

sUtches)

Crescent shape sewing machine

J

not

in a position

not

hesitate to

^ Movingdirection

iZ 15 (4 15 « 17

(•

Moving direction

MM57M5S54S5

92

5l5025ttrM

Max. sewing size : 0 x 34mm

(Ox

Standard sewing size : 0 x

Min.

sewingsize : 0 x 24mm(0 x 15/16")

Needles

: DP x 5, No. 14

1-11/32")

34mm

(Ox

1-11/32")

Applications : sewing various kinds of

labels,

etc.

19

37

-lOmm

Standard

sewing size : 7 x

10mm

(9/32x25/64")

Needles : DP x 5, No. 11

Applications : attaching cords and strapsto

ladies'

under

-

26

-

17

garment.

7 mm

2mm

Page 30

MEMO

i,

Page 31

Page 32

TOKYO

JUKI

II I 'II II.I:

IIIlllloll I'lllllll

l,|.,I.1

IIII.NIIlllll.lilillll

""iiiininiijiiiiiHiniiiuiiiiiiiiiuoiiiiuiiiiiiiiillli

r.TiPrinted in Japan(T)

Loading...

Loading...