Page 1

mJUICI

m

HIGH

SPEED,

SINGLE

NEEDLE,

ENGINEERING

LOCKSTITCH

INDUSTRIAL

SEWING

MANUAL

I •

Gl

H • UUKI

BARTACKING

MACHINE

TOKYO

JUKI

INDOSTRIAl

CO..

LTD

Page 2

•A

Page 3

MODEL

LK-280

CONTENTS

ENGINEERS

MANUAL

(STANDARD

(CORRECTIVE

(I)

(II)Thread

ADJUSTING

Thread

MEASURES

slippage

breakage

(III)Inadequate

(IV)

Needle

( V

)Cautions

(VI)

Inadequate

(CAUTIONS

(HOWTOTIGHTEN

(ADJUSTING

(I)

Adjusting

(II)

Adjusting

(III)

(IV)

Adjusting

Adjusting

breakage

ON

DISMANTLING

METHODOFVARIOUS

FIGURES) 1

FOR

thread

on sewing

thread

THE

RATTLE)

the

starting

the

pedal

the

thread

the

position

FAULTY

STITCHES)

trimming

synthetic

tension

OF PARTS) 22

DEVICES)

and

pressure

trimming

of

materials

stopping

decreasing

device

the

stop-motion

with

unit

synthetic

lever

thread

7 '

7

11

16

18

19

20

23

24

24

34

39

42

(V)

Adjusting

(VI)

Adjusting

(VII)

(VIII)

(IX)

(X)

(XI)

Adjusting

Adjusting

Adjusting

Adjusting

Adjusting

(XII) Adjustment

(XIII)

(XIV)

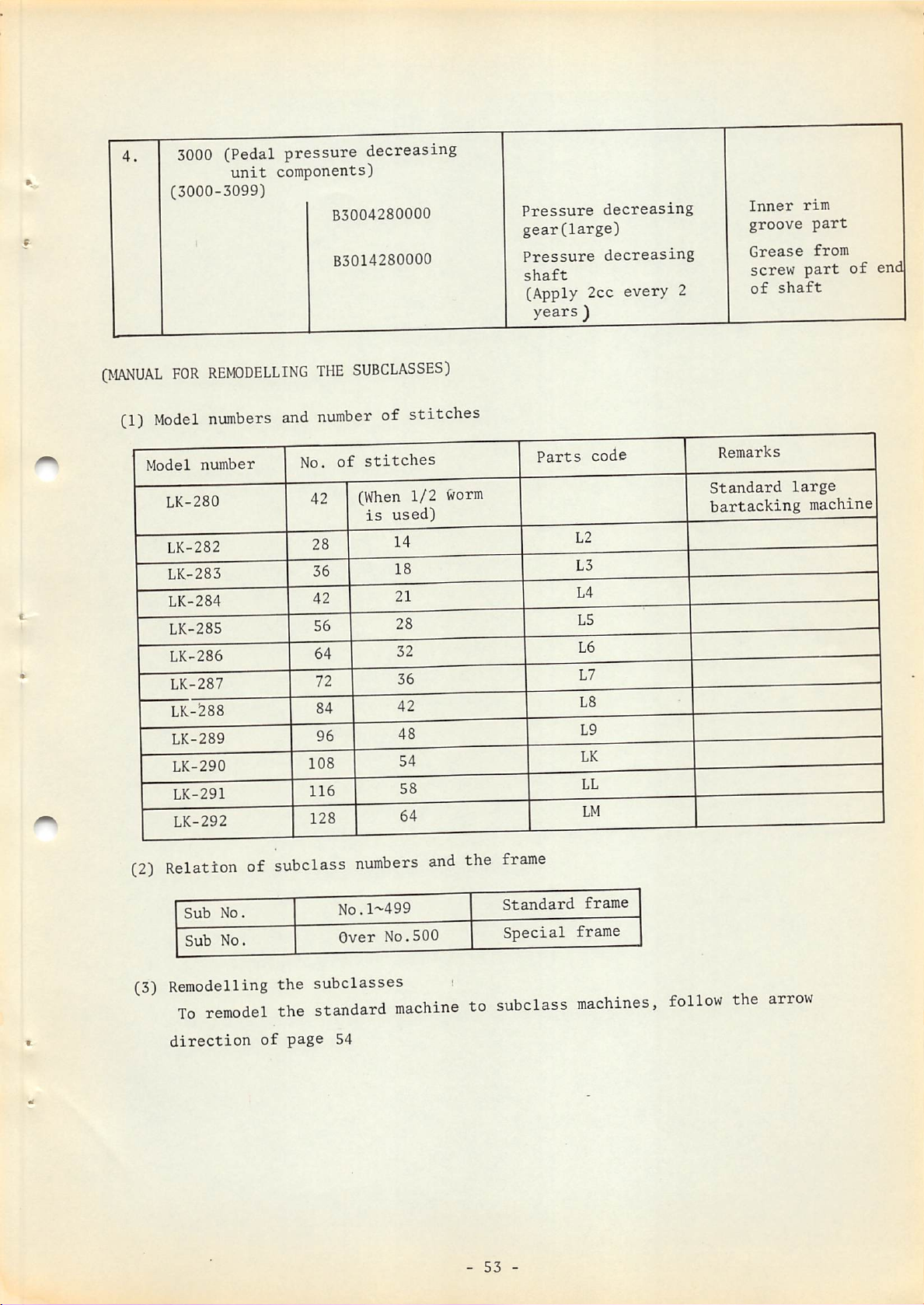

(MANUAL

AO-10

ENGINERS

Dismantling

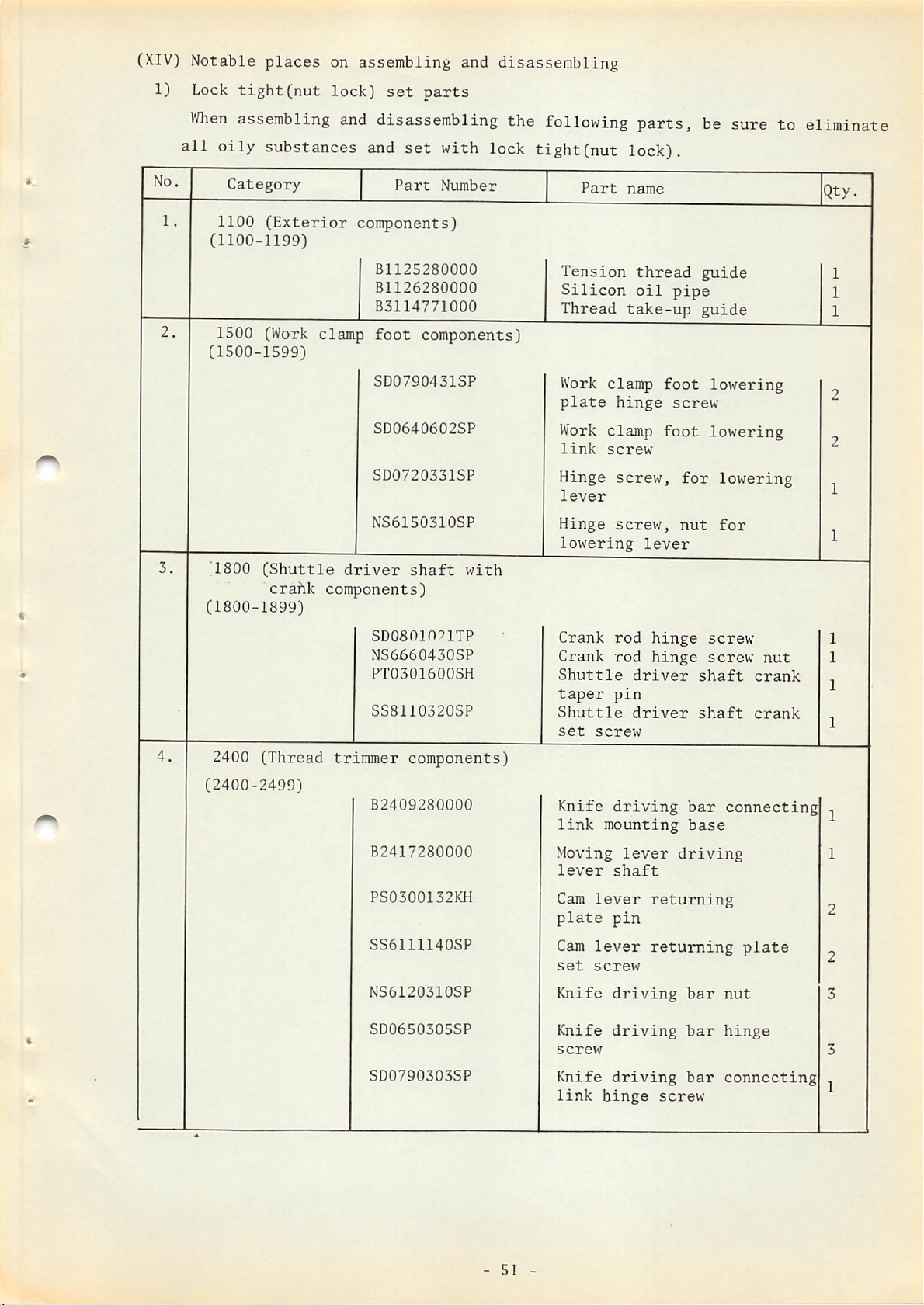

Notable

FOR

REMODELLING

UNIT

(ONE

MANUAL

the

thread

the

feed

the

shuttle

the

height

the

height

the

safety

the

bobbin

of

the

the

places

PEDAL

AO-11 64

on assembling and

FOR

tension

release

components 44

race

of

the

of

work clamp

the

wiper

foot

device

thread

winder

V-belt

silicon

oil

tank

disassembling

THE

SUBCLASSES)

LK-280) 60

42

46

47

47

48

49

50

50

51

53

Page 4

LK-280

ENGINEERS

MANUAL

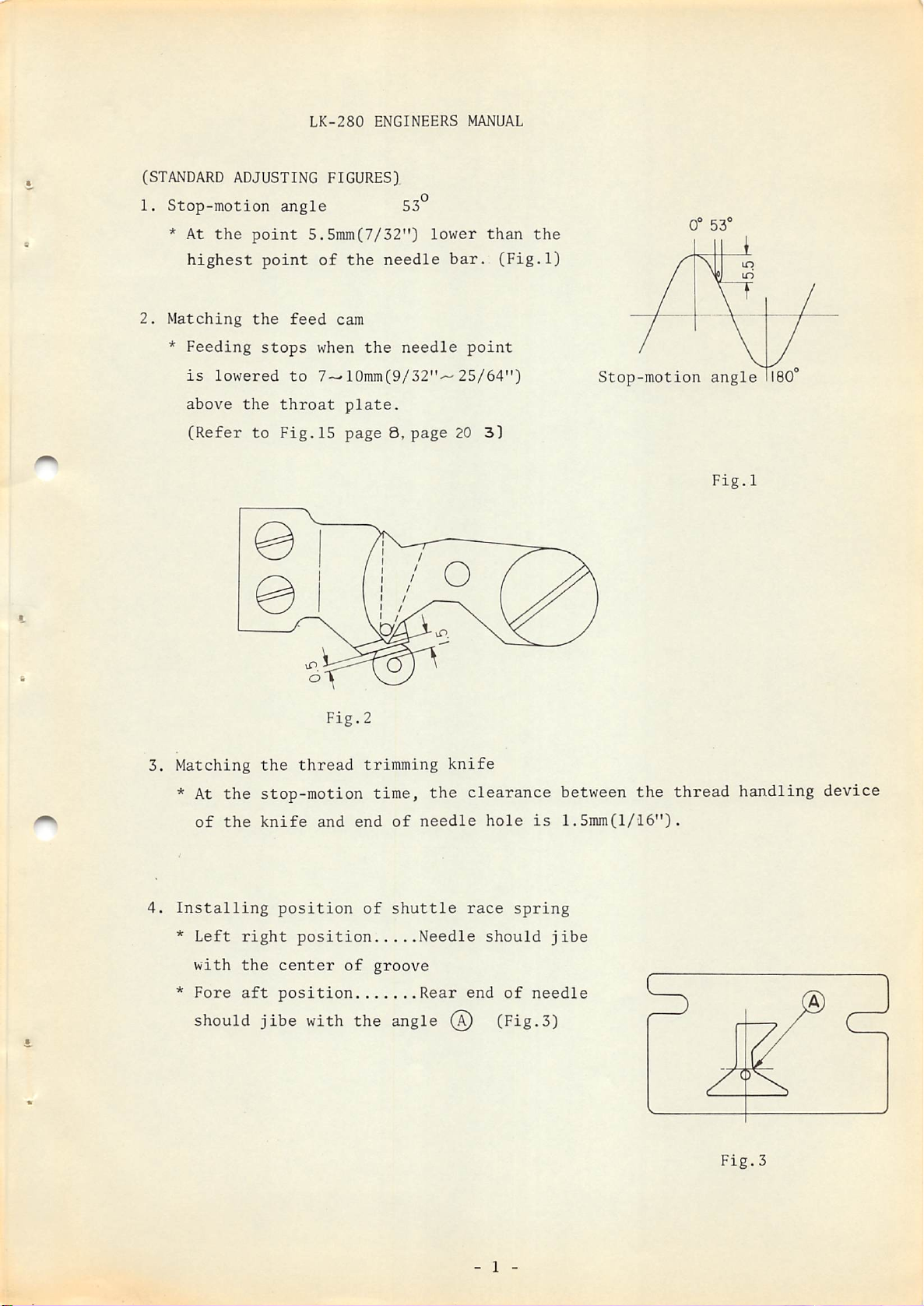

(STANDARD

ADJUSTING FIGURES).

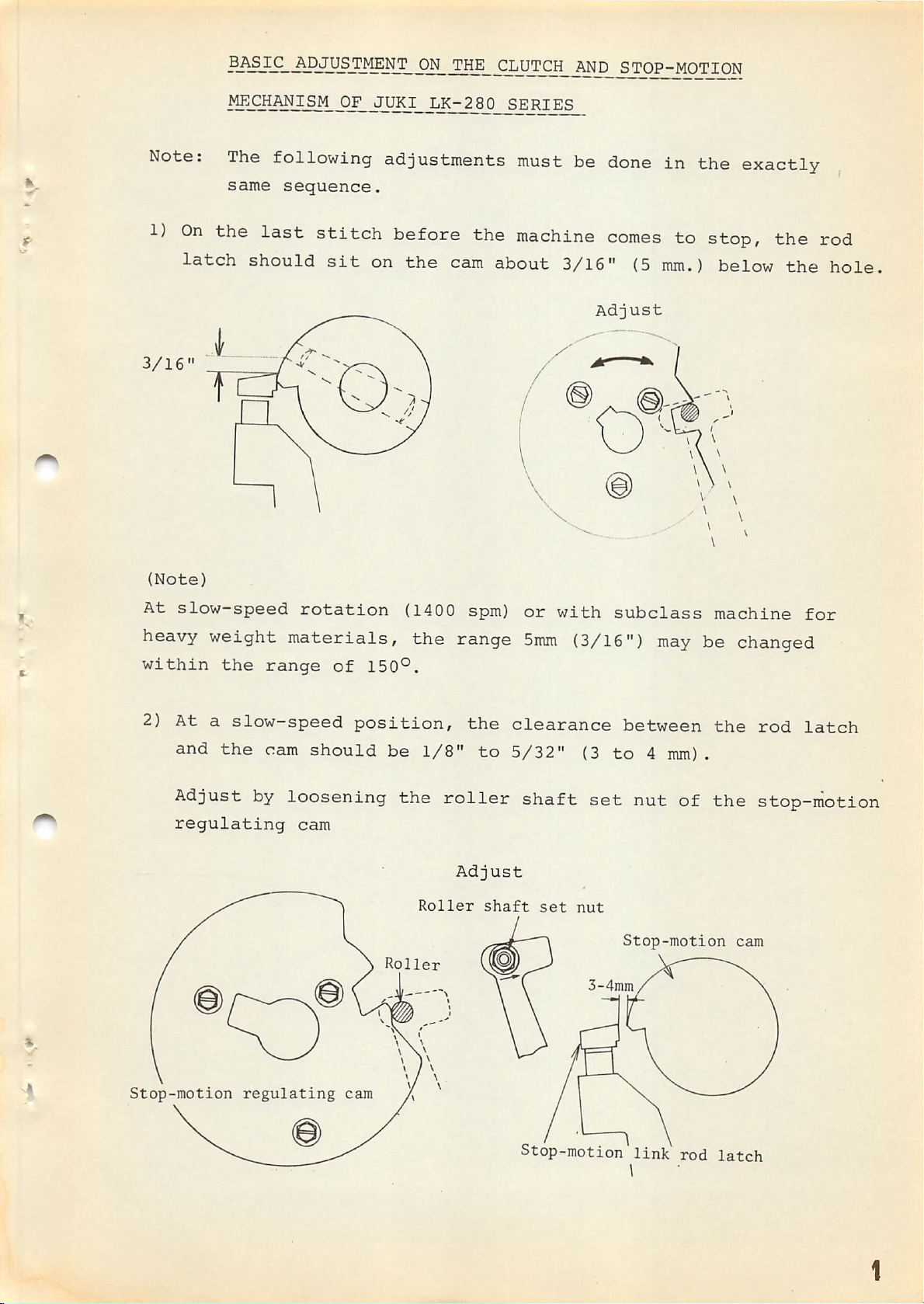

1. Stop-motion angle

* At

the

2.

Matching

highest

*

Feeding

is

above

(Refer

point

point

the

stops

lowered

the

to

5.5mm(7/32")

feed

to

throat

Fig.15

53°

lower

of

the

needle

cam

when

7—10mm(9/32"'~-25/64")

the

needle

plate.

page9,page

bar.

point

20

than

3)

the

(Fig.l)

Stop-motion

0-

53

angle

Fig.l

Fig.2

3.

Matching

* At

4.

Installing

*

*

of

Left

with

Fore

the

the

stop-motion

the

knife

right

the

aft

thread

and

position

position

center

position

trimming

time,

end

of

of

groove

the

of

needle

shuttle

Needle

Rear

knife

should jibe with the angle @ (Fig.3)

clearance

hole

race

spring

should

end

of

needle

between

is

1.5mm(l/i6").

jibe

the

thread

handling

Fig.3

device

- 1 -

Page 5

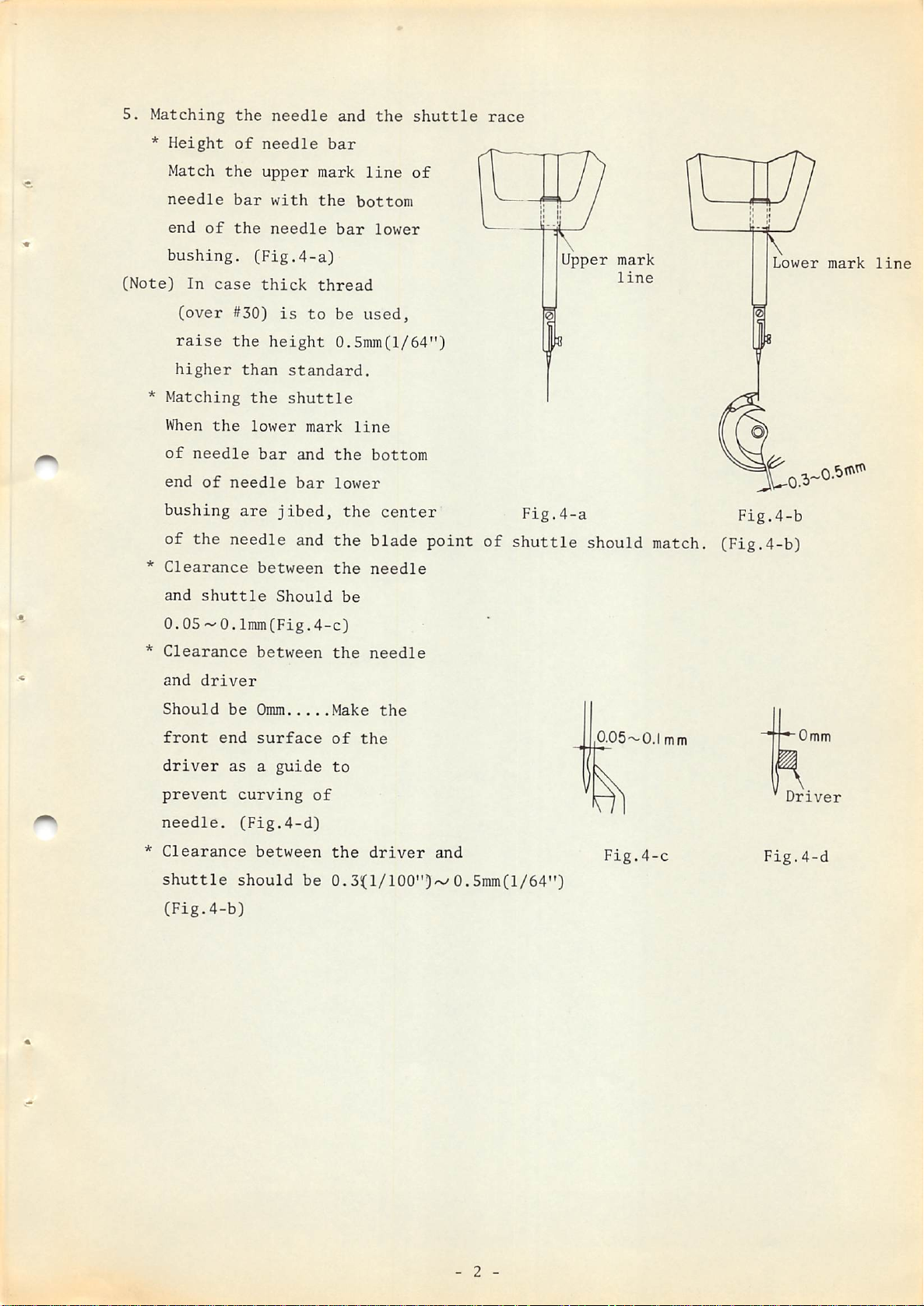

5.

Matching

*

Height

the

of

needle

needle

and

bar

the

shuttle

race

Match

needle

end

bushing.

(Note]

In

(over

raise

higher

*

Matching

When

of

end

bushing

of the needle

*

Clearance

and

of

case

the

needle

of

shuttle

the

bar

the

CFig.4-a)

#30)

the

thgin

the

lower

needle

are

upper

with

needle

thick

is

height

standard.

shuttle

bar

bar

jibed,

and

between

Should

mark

the

bar

line

bottom

lower

thread

to

be

used,

0.5mra(l/64")

mark

and

line

the

lower

the

bottom

center

the blade point

the

needle

be

of

of

Upper

Fig.4-a

shuttle

mark

line

Lower

Fig.4-b

should match. (Fig.4-b)

mark

line

0.050.

*

Clearance

and

Should

front

driver

prevent

needle.

*

Clearance

shuttle

(Fig.4-b)

lmm(Fig.4-c)

driver

be

end

as

curving

(Fig.4-d)

should

between

Omm

surface

a

guide

between

the

Make

of

the

to

of

the

be

0.3i(l/100"]-^

needle

the

driver

and

0.5mm(l/64")

0.05~0.l

Fig.4-c

mm

•Omm

Driver

Fig.4-d

- 2 -

Page 6

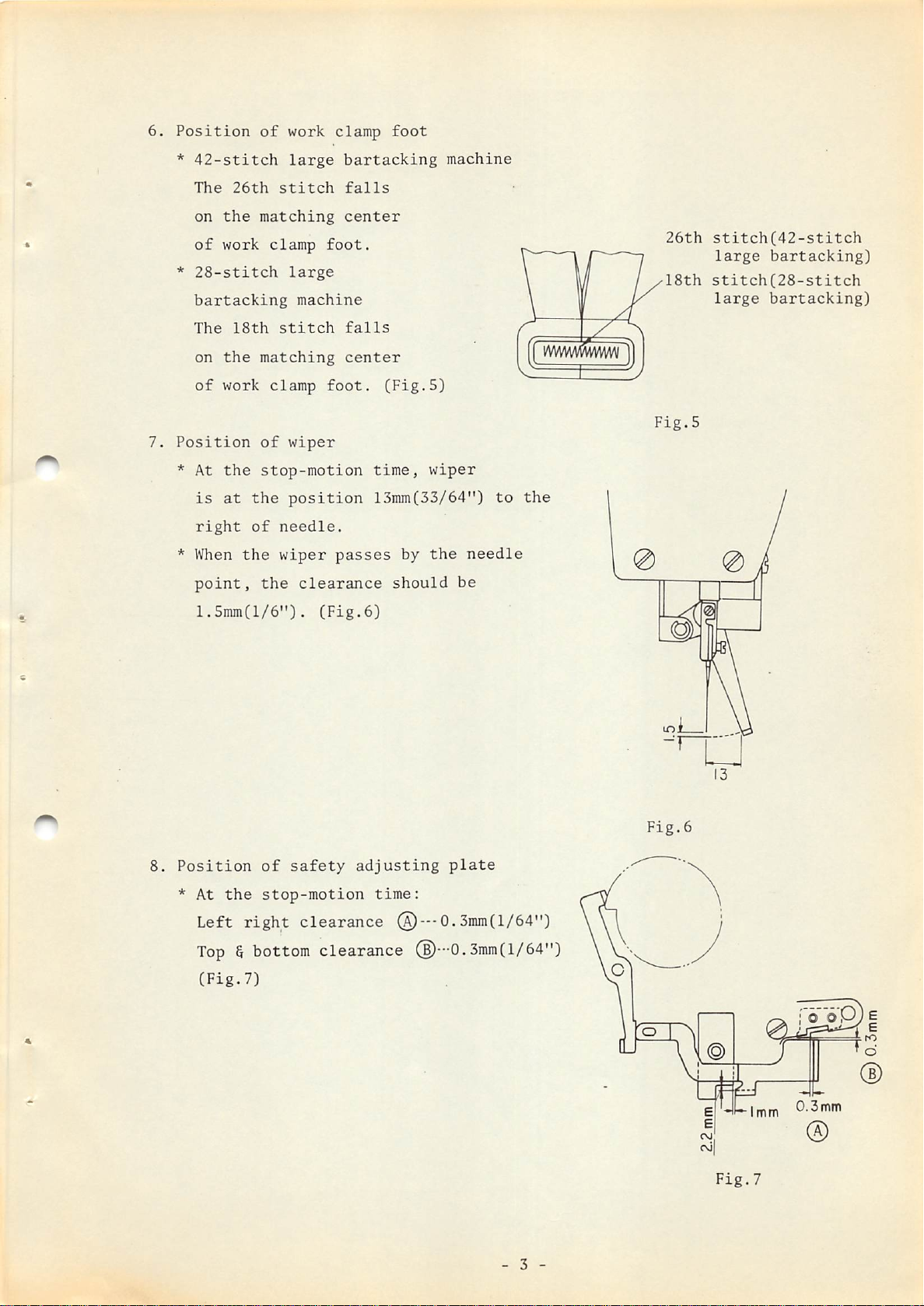

6.

7.

Position

*

42-stitch

The

on

the

of

work

*

28-stitch

bartacking

The

on

the

of

work

Position

26th

matching

18th

matching

of

of

stitch

clamp

stitch

clamp

work

large

large

machine

wiper

clamp

bartacking

falls

center

foot.

falls

center

foot.

foot

(Fig.5)

machine

mmviSww

26th

18th

Fig.5

stitch(42-stitch

large

stitch(28-stitch

large

bartacking)

bartacking)

8.

* At

* When

Position

* At

the

stop-motion

is

at

the

right

of

the

point,

1.5inm(l/6").

the

of

the

stop-motion

position

needle.

wiper

clearance

(Fig.6)

safety

time,

13inm(33/64")

passes

should

adjusting

time:

by

wiper

the

be

plate

to

needle

the

O

Fig.6

Left

right

Top&bottom

(Fig.7)

clearance ® —0.3nim(l/64")

clearance

®—0.3mm(l/64")

- 3 -

Fig.

0.3mm

©

7

Page 7

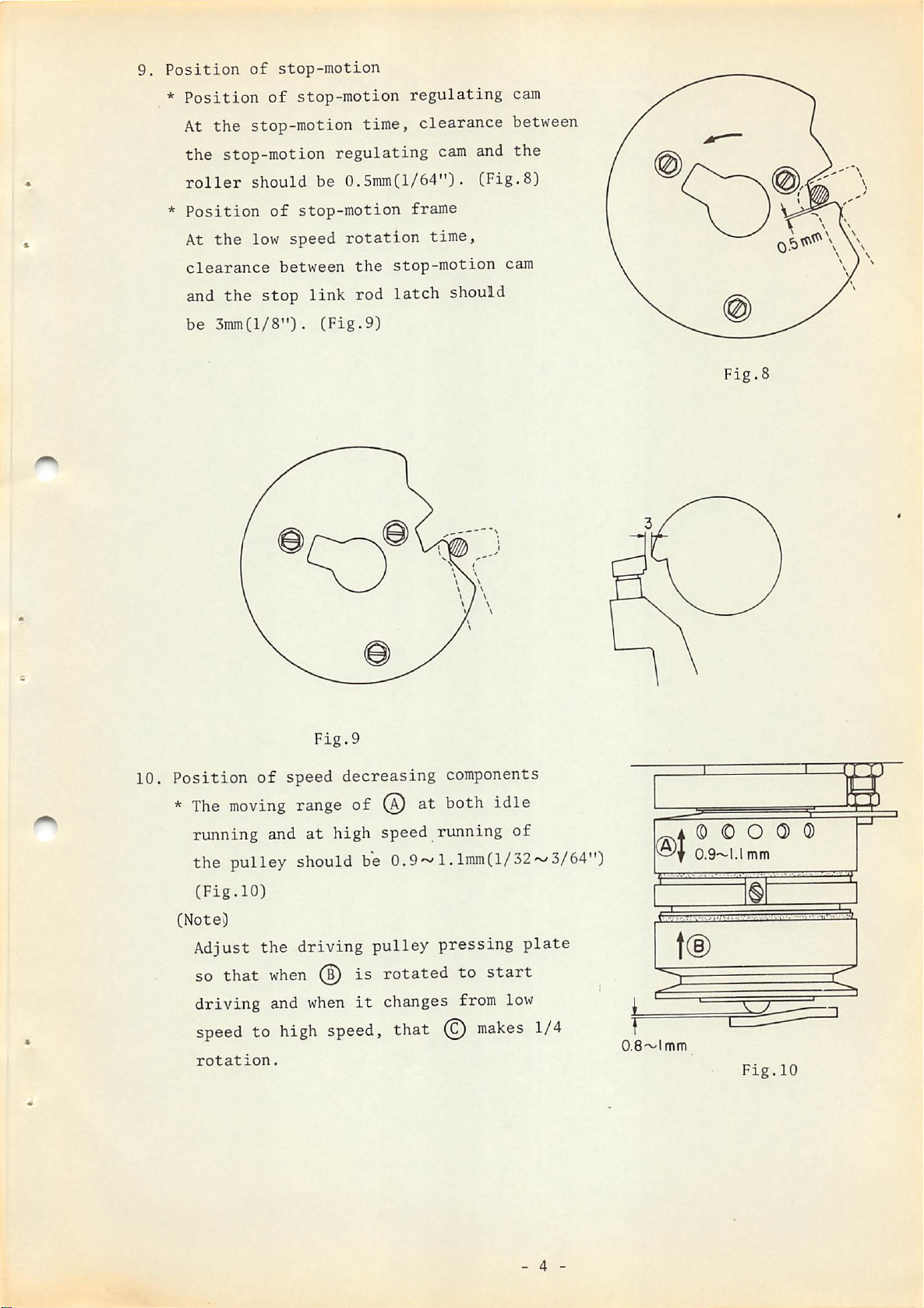

9.

Position

*

Position

At

the

of

stop-motion

of

stop-motion

stop-motion

time,

regulating

clearance

cam

between

the stop-motion

roller

*

Position

At

clearance

and

be

should

of

the

low

the

stop

3inmCl/8").

regulating

be

stop-motion

speed

between

link

(Fig.9)

cam

0.5mmCl/64")•

frame

rotation

the

rod

time,

stop-motion

latch

and

(Fig-S)

should

the

cam

Fig.

8

10.

Fig.9

Position

*

The

running and

of

moving

speed

range

at

the pulley should be

(Fig.10)

(Note)

Adjust

so

driving

speed

rotation.

that

to

the

when

and

driving

when

high

speed,

decreasing

components

of ® at both idle

high speed running

0.9*^

pulley

is

rotated

it

changes from low

1.lmm(l/32'^^3/64")

pressing

to

start

that ©

makes

of

plate

1/4

A © 0 O 0)

0.9-1.1

mm

.

...

Fig.10

Q)

-

_J

'

IT

- 4 -

Page 8

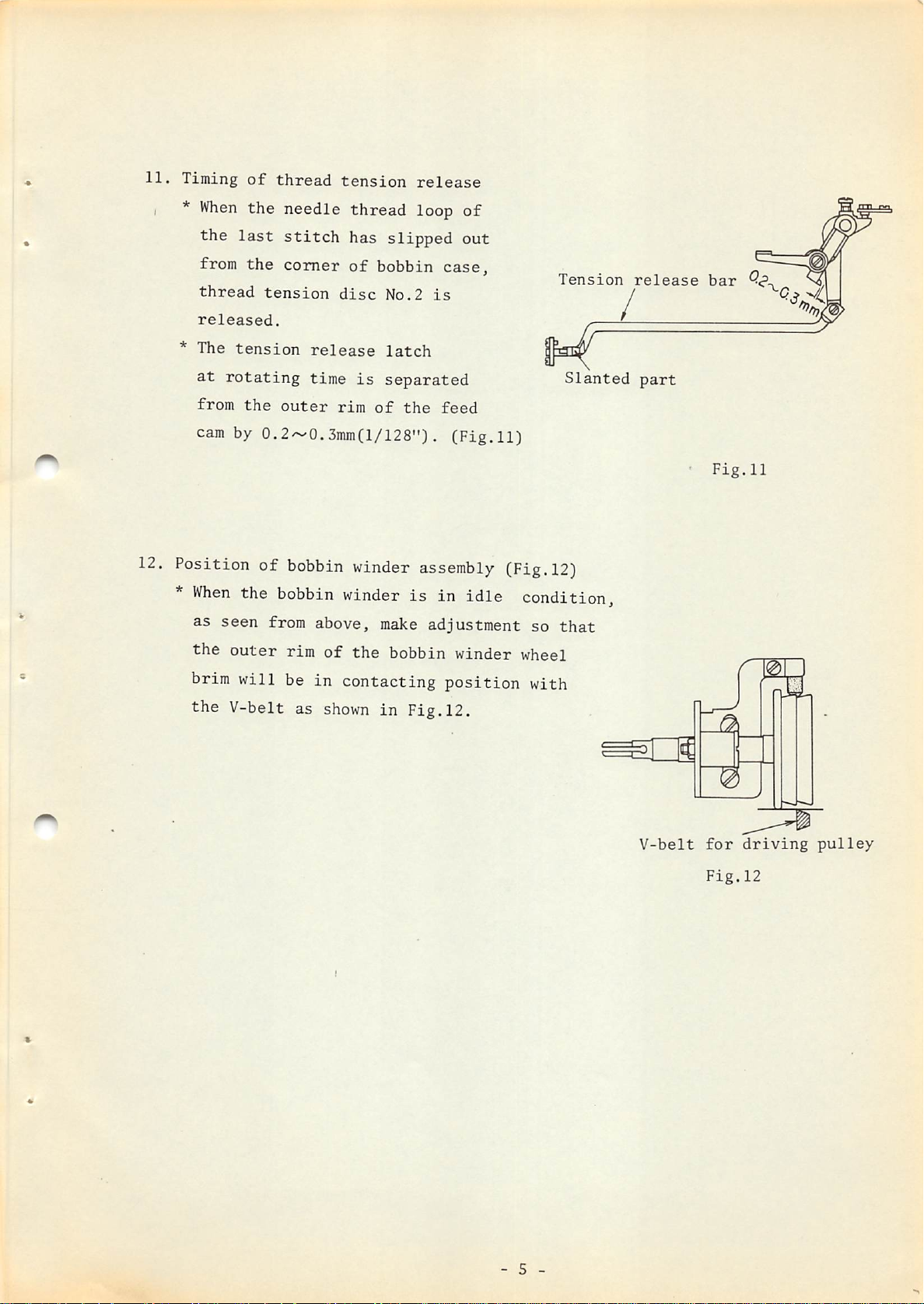

11.

I *

Timing

When

the

of

the

last

thread

needle

stitch

tension

thread

has

release

loop

slipped

of

out

*

12.

Position of

*

brim

the

from

thread

released.

The

at

rotating

from

cam

When

as

seen

the

the

comer

tension

tension

the

outer

by 0.

bobbin

the

bobbin winder

from

outer

will

V-belt as

rim

be in contacting

of

bobbin

disc

release

time

is

rim

of

3mmCl/128")

winder

above,

of

the

shown

in

No.2

latch

separated

is

the

. (Fig.11)

assembly

is

in

make

adjustment

bobbin

Fig.12.

case,

feed

idle

winder

position

Tension

(Fig.12)

condition

so

that

wheel

with

Slanted

/

release

part

•

bar

Fig.11

V-belt

- 5 -

for

Fig.12

driving

pulley

Page 9

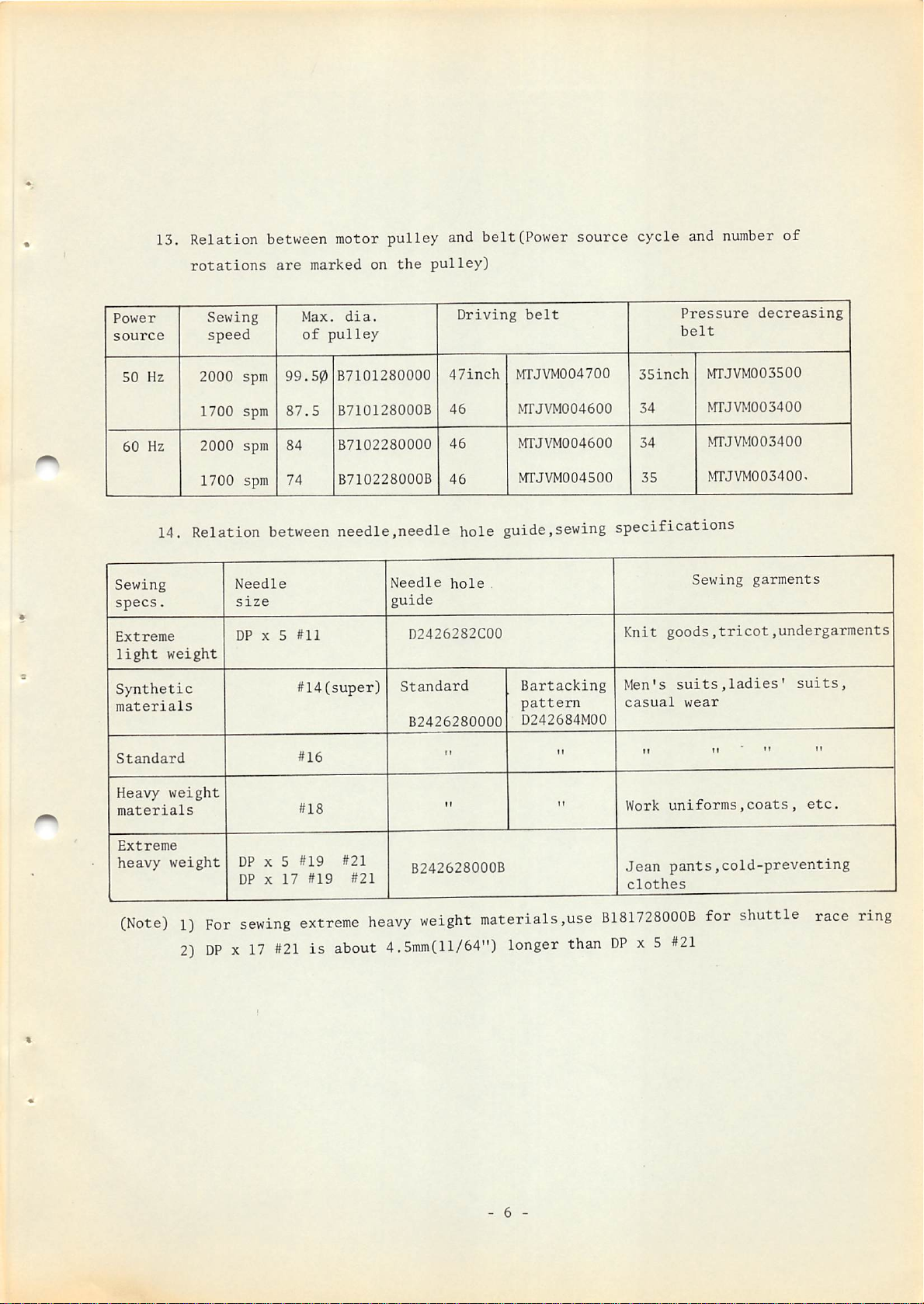

13. Relation between motor

rotations

are

marked

pulley

on

the

and belt(Power source cycle and

pulley)

number

o£

Power

source

50

Hz

60

Hz

14. Relation

Sewing

specs.

Extreme

light

Synthetic

materials

Standard

weight

Sewing

speed

2000

1700

2000

1700

spm

spm

spm

spm

between

Needle

size

DP X 5

Max.

of

pulley

99.50

87.5

84

74

B7101280000

B710128000B

B7102280000

B710228000B

needle,needle hole guide,sewing specifications

#11

#14(super)

#16

dia.

Needle

guide

D2426282C00

Standard

B2426280000

Driving

47inch

46

46

46

hole

r r

belt

MTJVM004700

MrJVM004600

MTJVM004600

OTJVM004500

.

Bartacking

pattern

D242684M00

Pressure

belt

35inch

34

34

35

Knit

Men's

casual

f T

II II

m'JVM003500

MTJVM003400

OTJVM003400

NfrJVM003400.

Sewing

goods,tricot,undergarments

suits,ladies'

wear

decreasing

garments

suits,

•• It

Heavy

materials

Extreme

heavy

weight

weight

(Note)1)For

2)

DPX17

DP X 5

DP X

17

sewing

#21isabout

#18

#19 #21

#19 #21

extreme

ft

B242628000B

heavy

weight

4.5mm(ll/64")

II

materials,use

longer

- 6 -

than

Work

uniforms,coats,

Jean

pants,cold-preventing

clothes

B181728000B

DP

x 5

for

#21

shuttle

etc.

race

ring

Page 10

(CORRECTIVE

MEASURES

FOR

FAULTY

STITCHES)

This

symptoms

breakage

(I)

Thread

*

*

*

1)

chapter

such

and

slippage

Faulty

needle

any

sewing

Principal

*

Stitches

*

Inadequate

*

Inadequate

*

Bobbin

Corrective

Prevent

*

Verify

If

not,

will

as

thread

inadequate

stitching

thread

shape

reasons

skip

length

adjustment

thread

measures

the

if

the

adjust

treat

on

slippage,thread

thread

symptoms

slips

is

at

is

out

formed.

the

first

of

the

too

short.

of

skip-stitching

shuttle

according

the

trimming.

from

trimmed

the

race

to

corrective

This

the

needle

stitch.

needle

thread

of

the

and

the

the

standard

measures

breakage,

is

a

faulty

at

thread.

take-up

first

needle

stitch.

on

skip-stitching,

condition

first

are

or

spring.

in

correcting

faulty

second

correct

procedure.

stitching

needle

by which

stitch

relationship.

the

before

*

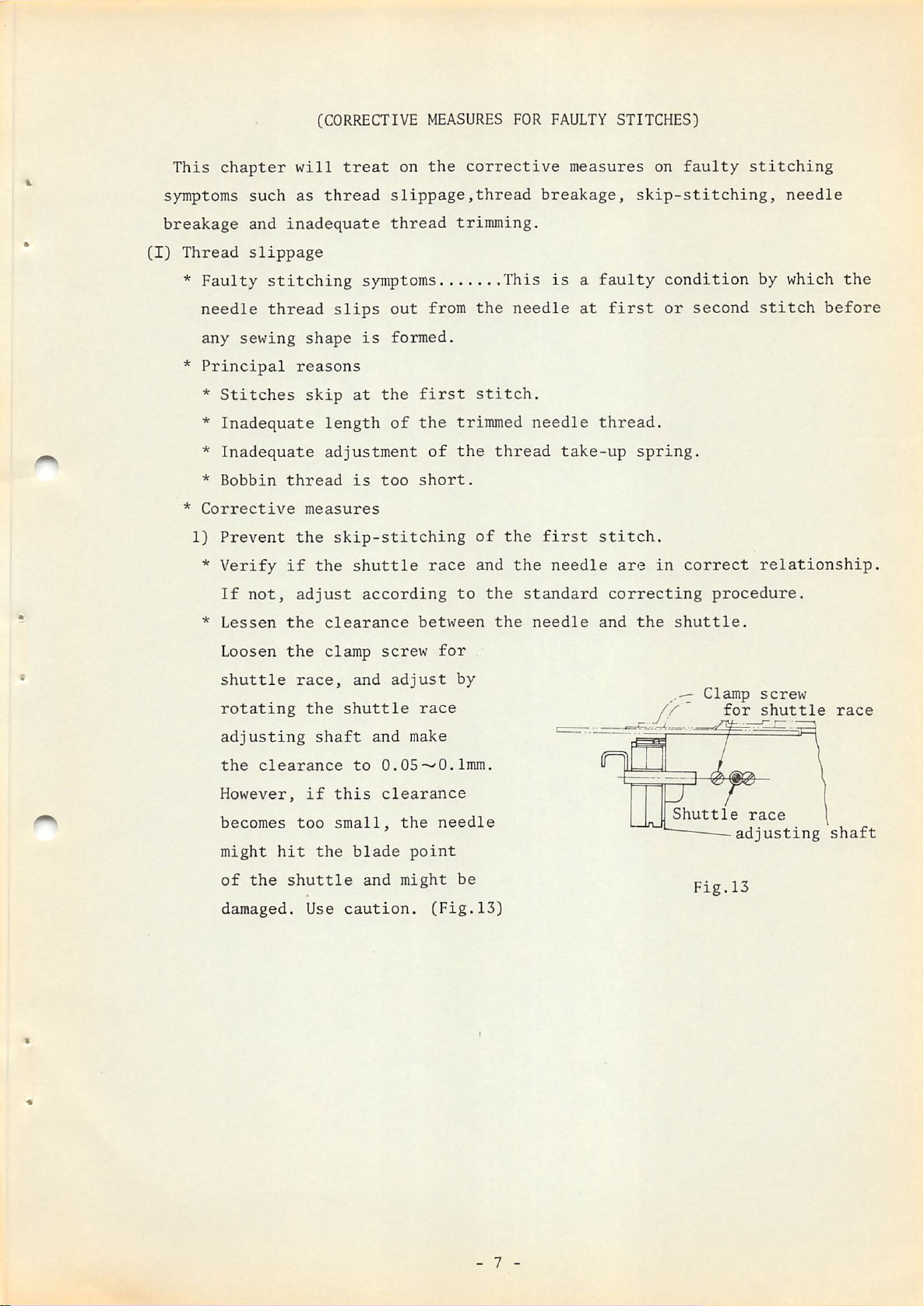

Lessen

Loosen

shuttle

rotating

adjusting

the

However,

becomes

might

of

damaged.

clearance

hit

the

the

the

race,

the

shaft

if

too

the

shuttle

Use

clearance

clamp

and

shuttle

to

this

small,

blade

and

caution.

between

screw

adjust

and

O-OS-^O.1mm.

clearance

race

make

the

point

might

for

needle

(Fig.13)

by

be

the

needle

and

the

shuttle.

.-j

n

Shuttle

Clamp

for

Fig.13

screw

shuttle

race

adjusting

race

shaft

- 7 -

Page 11

*

Inadequate

rotation

of

the

shuttle.

When

lap

it

Also,

the

surface

Watch

*

Prevent

sewing

To

prevent

would be

work clamp

and

the

a

convex

* Watch

Watch

has

started

"floating",

the

shuttle

well.

sometimes

of

carefully.

"concaving"

cloth.

these

best,

foot

work clamp

shapeC Q£| )

the

phase

carefully

to

loosen

does

thread

the

shuttle

and

faulty

normally,

with

a concave

foot

of

the

and

see

pierce

the

not

rotate

hards

race.

"convexing"

conditions,

to

process

lowering

as

shown

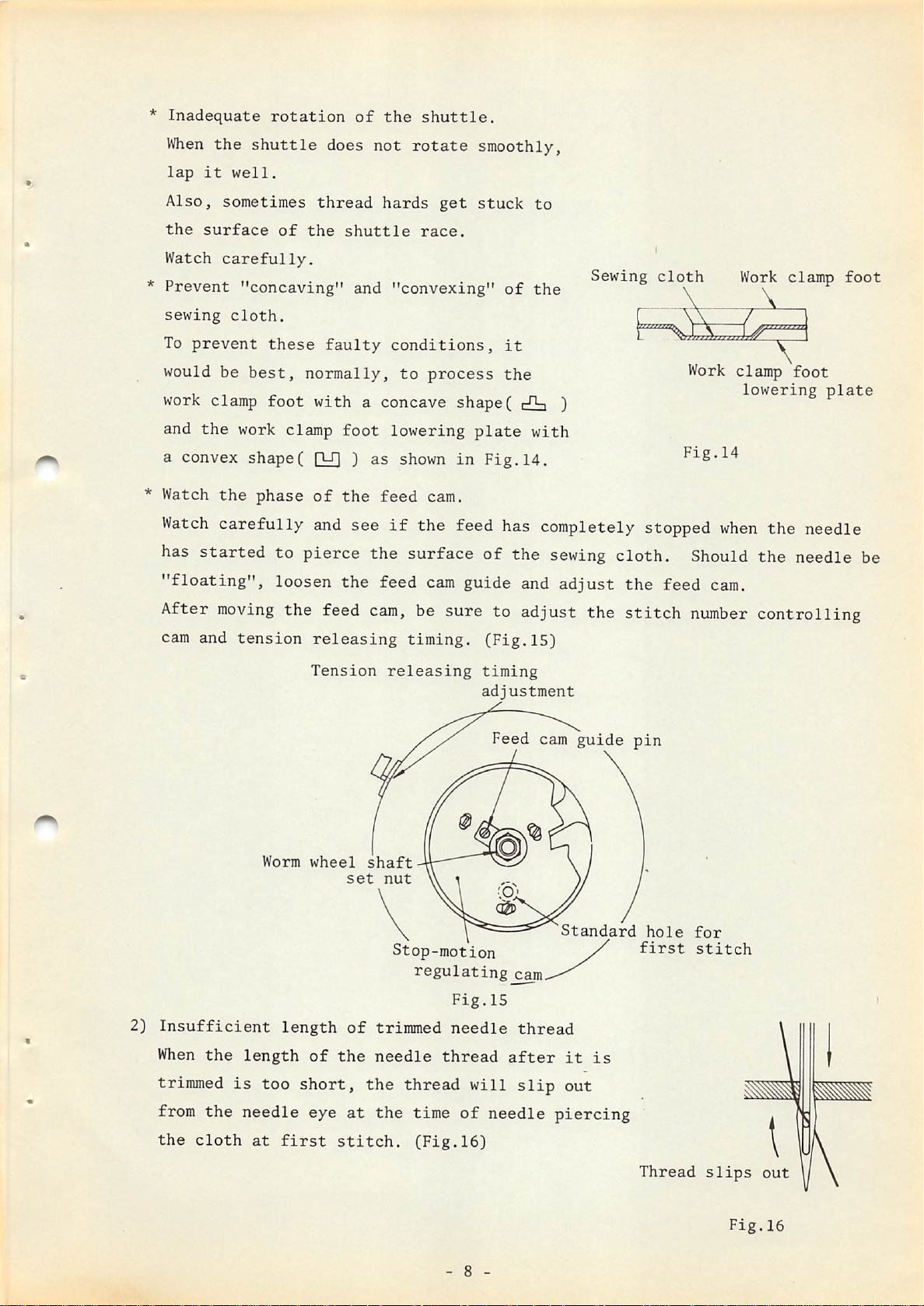

feed

the

feed

cam.

if

the feed has completely stopped

surface

cam

smoothly,

get

stuck

shape(

plate

in

Fig.14.

of

guide and

of

it

the

the

to

the

cHa

with

Sewing

)

sewing

adjust

cloth.

the

cloth

feed

Work

Fig.14

when

Should

cam.

Work

clamp

lowering

the needle

the

clamp

foot

foot

plate

needle be

After

cam and

2)

Insufficient

When

moving

tension

the

Worm

length

the feed

releasing

Tension

wheel

length

of

the

cam,

shaft

set

of

nut

trimmed

needle

be sure to adjust the

timing.

releasing

Stop-motion

regulating

Fig.15

needle

thread

(Fig.15)

timing

adjustment

Feed cam

cam

thread

after

guide

Standard

it

is

stitch

pin

hole

first

number

for

stitch

controlling

trimmed

from

the

the

cloth

is

too

needle

at

short,

first

eye

the

at

stitch.

the

thread

time

(Fig.16}

- 8 -

will

of

slip

needle

out

piercing

Thread

slips

Fig.16

Page 12

*

The

standard length

of

trimmed

needle thread

is

35'-40mmCl-3/8'-l-37/64")

* When

or

the

Adjust

(Refer

Conversely,

too

long.

* When

too

short.

* When

thread

needle

appropriate

0.1^0.

*

If

the

handling

thread

the

tension

thread

the

to

the

tension

the

counter

is

thread

ISmm.

clearance

device

will

will

timing

Fig.47,

if

the

trimmed

and

tolerance

become

release

by

page

disc

knife

at

the

of

of

slip

means

timing

No.l

the

bobbin

between

l.Smm

the

shorter.

timing

out

of

4-3

is

pressure

is

too

c£]ii

between

counter

from

tension

).

too

high,

part

thread

the

is

the

fast,

knife

late,

needle.

is

the

of

will

needle

the

is

the

release

the

too

thread

the

be

hole

end

widened,

thread

lever.

trimmed

strong,

moving

trimmed

guide

of

needle

will

will

length

the

be

knife,

short.

and

eye

the

thread

trimmed

so

the

and

length

be

trimmed

will

generally

The

counter

the

of

be

sporadic

will

before

most

thread

trimmed

too

be

both

knife

short

or

trimmed

the

is

needle

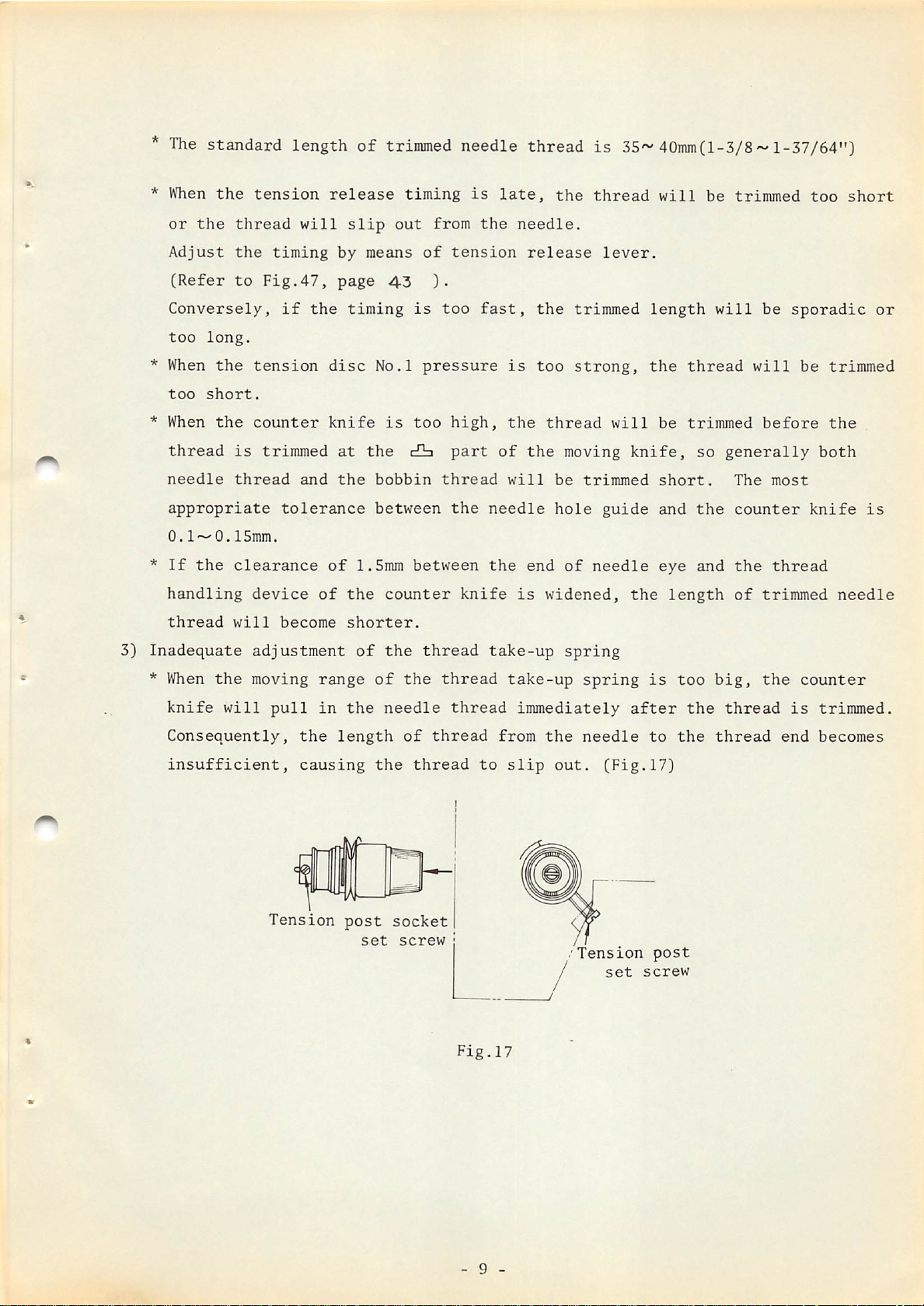

3)

Inadequate

*

adjustment

When

knife

Consequently,

insufficient,

the

will

moving

pull

the

causing

Tension

range

in

the

length

post

of

set

the

of

needle

the

socket

screw

thread

the

of

thread

thread

thread

thread

Fig.17

take-up

take-up

immediately

from

to

slip

spring

the

out.

.'Tension

spring

needle

(Fig.17)

set

is

after

to

post

screw

too

the

the

big,

thread

thread

the

counter

is

end

trimmed.

becomes

- 9 -

Page 13

*

When

the

moving

range

of

the

thread

take-up

spring

is

too

big,

loosen

the

*

(Note)

4)

Inadequate

*

*

thread

controller

When

insert

direction.

When

the

tension

the

a

the

tension

matching

return

If

from

can

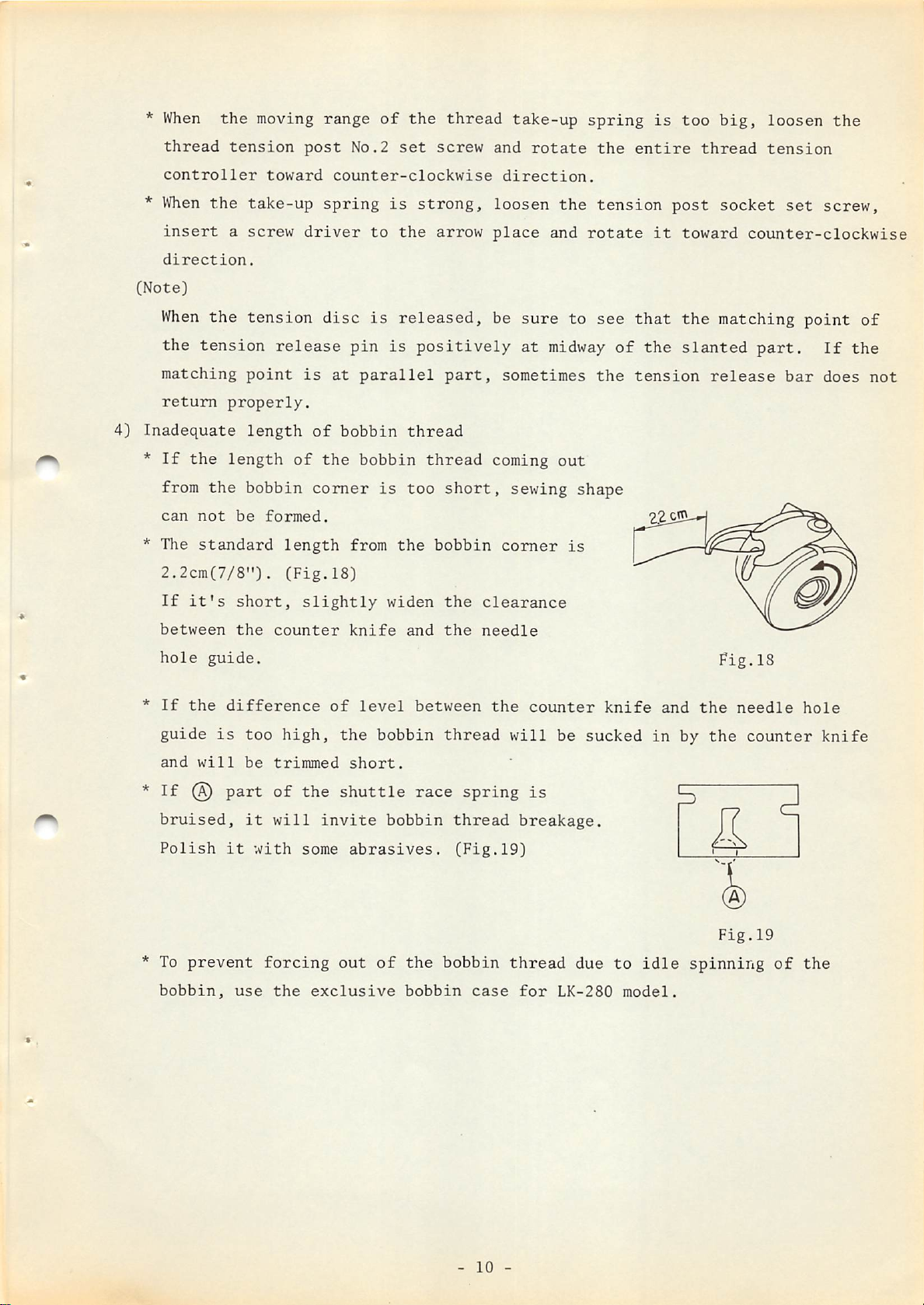

The

2.2cm(7/8").

If

properly.

the

length

the

not

standard

it's

be

short,

toward

take-up

screw

tension

release

point

length

of

bobbin

formed.

length

(Fig.18)

post

No.2

counter-clockwise

spring

driver

disc

to

is

pin

is

at

parallel

of

bobbin

the

bobbin

comer

from

slightly

set

is

strong,

the

released,

is

positively

thread

is

too

the

widen

screw

arrow

part,

thread

short,

bobbin

the

and

rotate

direction.

loosen

place

be

sure

at

sometimes

coming

sewing

comer

clearance

the

and

rotate

to

midway

out

shape

is

the

entire

tension

see

that

of

the

tension

it

the

thread

post

toward

the

slanted

tension

socket

set

counter-clockwise

matching

part.

release

bar

screw,

point

If

does

of

the

not

between

hole

*

If

guide

and

*

If

bruised,

Polish

* To

bobbin,

guide.

the

difference

is

will

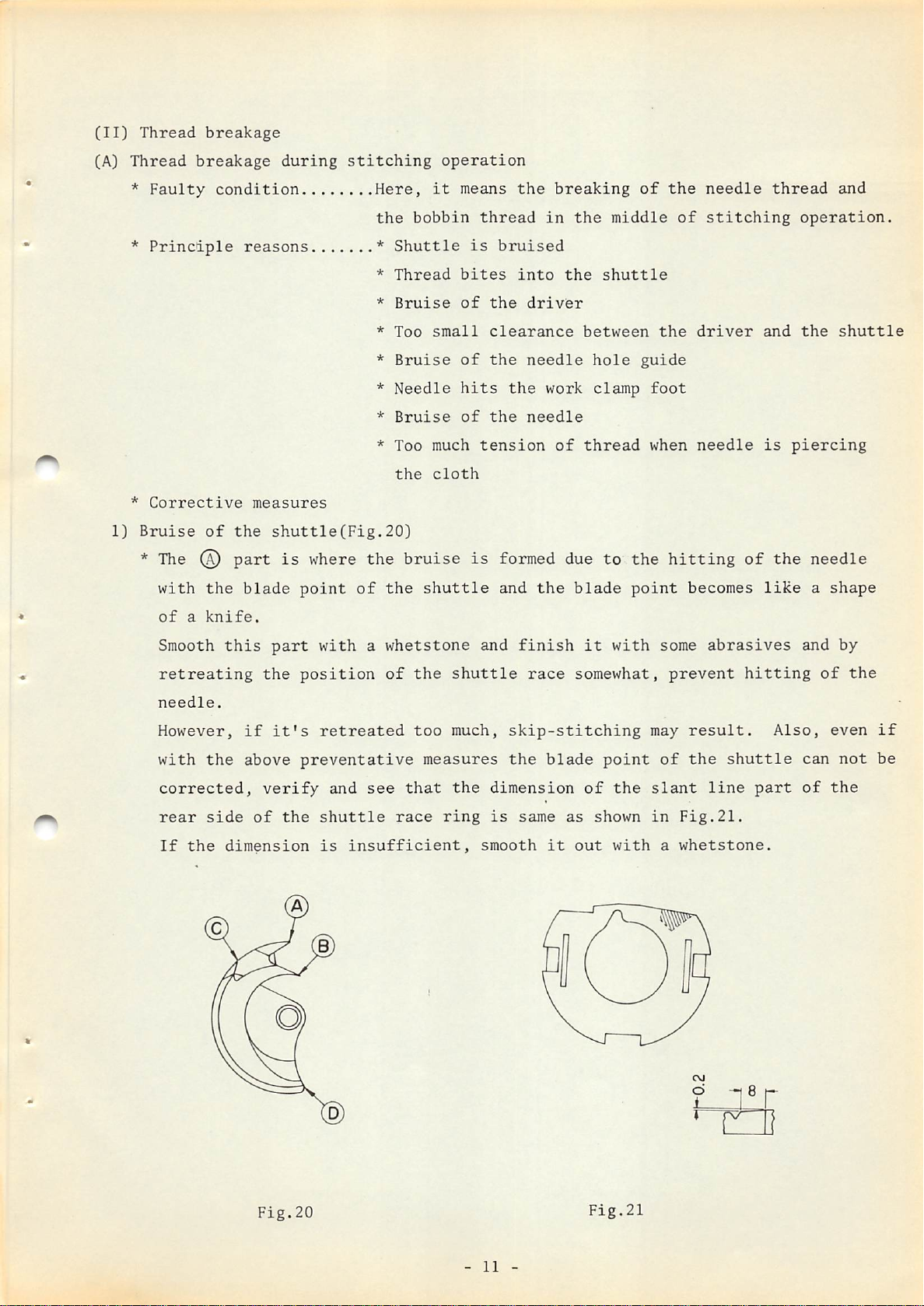

@

part

it

prevent

the

too

be

it

use

counter

high,

trimmed

of

will

with

forcing

the

of

the

the

shuttle

invite

some

out

exclusive

knife

level

and

bobbin

short.

bobbin

abrasives.

of

the

bobbin

the

between

thread

race

thread

(Fig.19)

bobbin

needle

the

spring

case

counter

will

be

is

breakage.

thread

for

LK-280

knife

sucked

due

to

model.

in

idle

and

by

spinning

Pig.18

the

the

Fig.19

needle

counter

of

hole

knife

the

-

10

-

Page 14

(II)

(A)

Thread

Thread

*

Faulty

*

Principle

breakage

breakage

condition

reasons

during

stitching

Here,

the

*

Shuttle

*

Thread

*

Bruise

*

Too

*

Bruise

*

Needle

*

Bruise

operation

it

bobbin

small

means

thread

is

bites

of

the

clearance

of

the

hits

of

the

the

bruised

into

driver

needle

the

needle

breaking

in

the

the

between

work

middle

shuttle

hole

clamp

of

the

guide

foot

the

of

needle

stitching

driver

thread

and

and

operation.

the

shuttle

*

Corrective

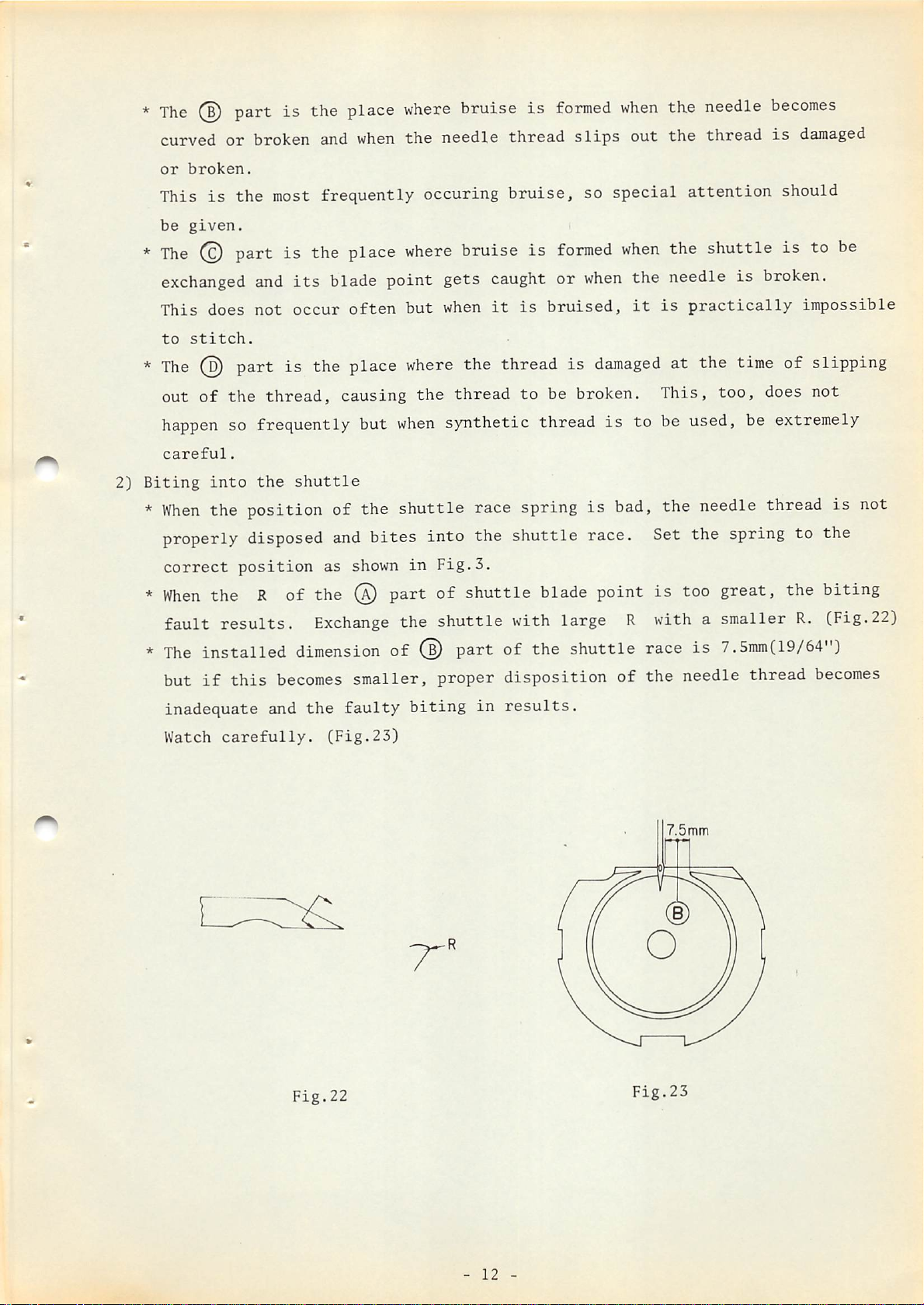

1)

Bruise

* The (a)

of

with

of

a

the

knife.

Smooth

retreating

needle.

However,

with

the

corrected,

rear

side

If

the

measures

the

shuttle(Fig.20}

part

blade

this

part

the

if

it's

above

verify

of

dimension

is

where

point

with

position

retreated

preventative

and

the

shuttle

is

* Too much

the

the

bruise

of

the

a

whetstone

of

the

too

see

that

race

insufficient,

tension

cloth

is

shuttle

and

shuttle

much,

measures

the

ring

smooth

of

formed due

and

the

finish

race

skip-stitching

the

blade

dimension

is

same

it

thread

to

blade

it

with

somewhat,

point

of

the

as

shown

out

with

when

the

point

may

slant

in

needle

hitting

becomes

some

prevent

result.

of

the

Fig.21.

a

whetstone.

is

of

like

abrasives

hitting

shuttle

line

part

piercing

the

and

Also,

can

of

needle

a

shape

by

of

the

even

not

the

if

be

Fig.20

-

11

-

Fig.21

CM

d

1

Page 15

*

The

(D

part is

the

place

where

bruise

is

formed

when

the

needle

becomes

curved

or

broken.

This

be

*

is

given.

The

© part is the place

exchanged

This

does

to

stitch.

*

The

(d)

out

of

happen

careful.

2)

Biting

*

into

When

the position of the shuttle race spring

properly disposed

correct

or

broken and

the

most

and

not

part

the

thread,

its

occur

is

when

frequently occuring bruise, so special

blade point gets

often

the place

causing

so frequently but

the

shuttle

and

position

as shown

the

needle

where

but

where

when

bruise is

when

the thread is

the

thread

synthetic thread

bites into the

in

Fig.3.

thread

caught

it

is

to

shuttle

slips

out

the

thread

attention

formed

or

bruised,

be broken.

when

when

damaged

is

is

bad, the needle thread

the shuttle is to

the needle is broken.

it

is

practically

at the time of slipping

This,

to be used, be extremely

too,

race. Set the spring to the

is

damaged

should

impossible

does not

is

be

not

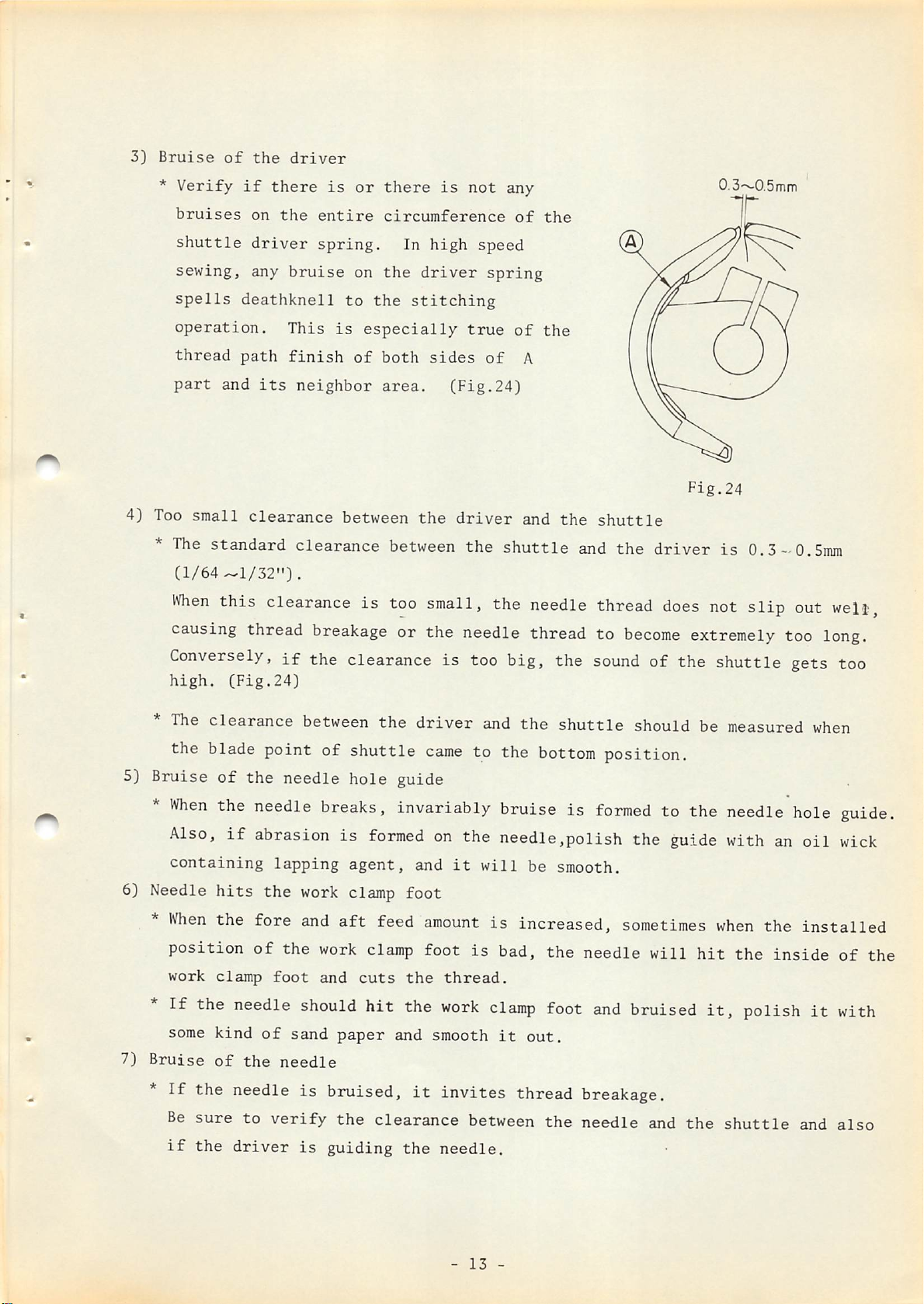

*

When

fault

*

The

but

inadequate

Watch

the R of the ® part of shuttle blade point

results.

installed

if

this

carefully.

dimension

becomes

and

the

Exchange

smaller,

faulty

(Fig.23)

the

shuttle

with large R with a smaller

of ® part of the shuttle race

proper

biting

disposition

in

results.

of

is

too great, the biting

is

7.Smm(19/64")

the

needle

7.5mtn

thread

R.

(Fig.22)

becomes

Fig.22

-

12

-

Fig.23

Page 16

3)

Bruise

*

Verify

of

if

the

driver

there

is

or

there

is

not

any

0.3~0.5mm

4) Too

*

Conversely,

high.

bruises

shuttle

sewing,

spells

operation.

thread

part

small

The

(1/64^1/32").

When

causing

on

driver

any

deathknell

path

and

clearance

standard

this

thread

(Fig.24)

the

entire

spring.

bruise

This

finish

its

neighbor

clearance

clearance

breakage

if

the clearance is too big, the

on

to

the

is

especially

of

both

area.

between

is

circumference

In

high

the

driver

stitching

true

sides

(Fig.24)

the

driver

between

too

the

small,

speed

spring

of

shuttle

the

of

of

the

A

and

needle

the

the

or the needle thread to

shuttle

and

thread

sound

Fig.24

the

driver

does

become

is

0.3-0.5mm

not

slip

extremely

too

of the shuttle gets too

out

welit,

long.

*

The

the blade point of shuttle

5) Bruise

*

When

Also,

containing

6) Needle

When

position

work

If

some

7)

Bruise

*

If

Be

if

clearance between

of

the needle

the

needle

if

abrasion is

lapping

hits

the

the fore

of

clamp

foot

the needle

kind

of

of

the

breaks, invariably bruise is

work

and

the

work

and

should

sand

needle

hole

formed

agent,

clamp

aft

clamp

cuts

hit

paper

the

feed

the needle is bruised,

sure

the

to

verify

driver

is

the

clearance between the needle and

guiding

driver

came

guide

on

and

foot

amount

foot

the

the

and smooth

it

the

and

the

shuttle

to the

bottom

the needle,polish the guide with

it

will

is

thread.

work

be

is

increased,

bad,

clamp

it

out.

smooth.

the

foot

invites thread breakage.

needle.

position.

formed

sometimes

needle

and

bruised

should be measured

to the

needle

an

will

when

hit

it,

the

the

the

polish

shuttle

inside

when

hole

oil

guide.

wick

installed

of

it

with

and

also

the

-

13

-

Page 17

8)

Tension

of

thread

when

needle

is

piercing

the

cloth

(B)

* Make

and

pulling.

Thread

*

Faulty

*

Principal

*

Corrective

the

also

breakage

condition

thread

make

reasons

measures

take-up

the

at

pressure

thread

spring's

of

trimming

the

stroke

spring

time

This

needle

at

is

the

forming

*

Defective

*

Moving

*

Height

*

Shuttle

*

Inadequate

surface

*

Position

to

to

a

thread

last

the

knife

of

small

about

faulty

stitching

normal

thread

counter

race

finish

of

needle

of

scale(6-^8mm)(15/64-^5/16")

30—50gr

condition

or

the

is

bruised

spring

moving

bobbin

thread

releasing

knife

of

hole

knife

time

is

thread

at

the

by

thread

without

trimming

timing

bruised

guide

start

which

path

of

the

is

cut

per

process.

of

lower

1)

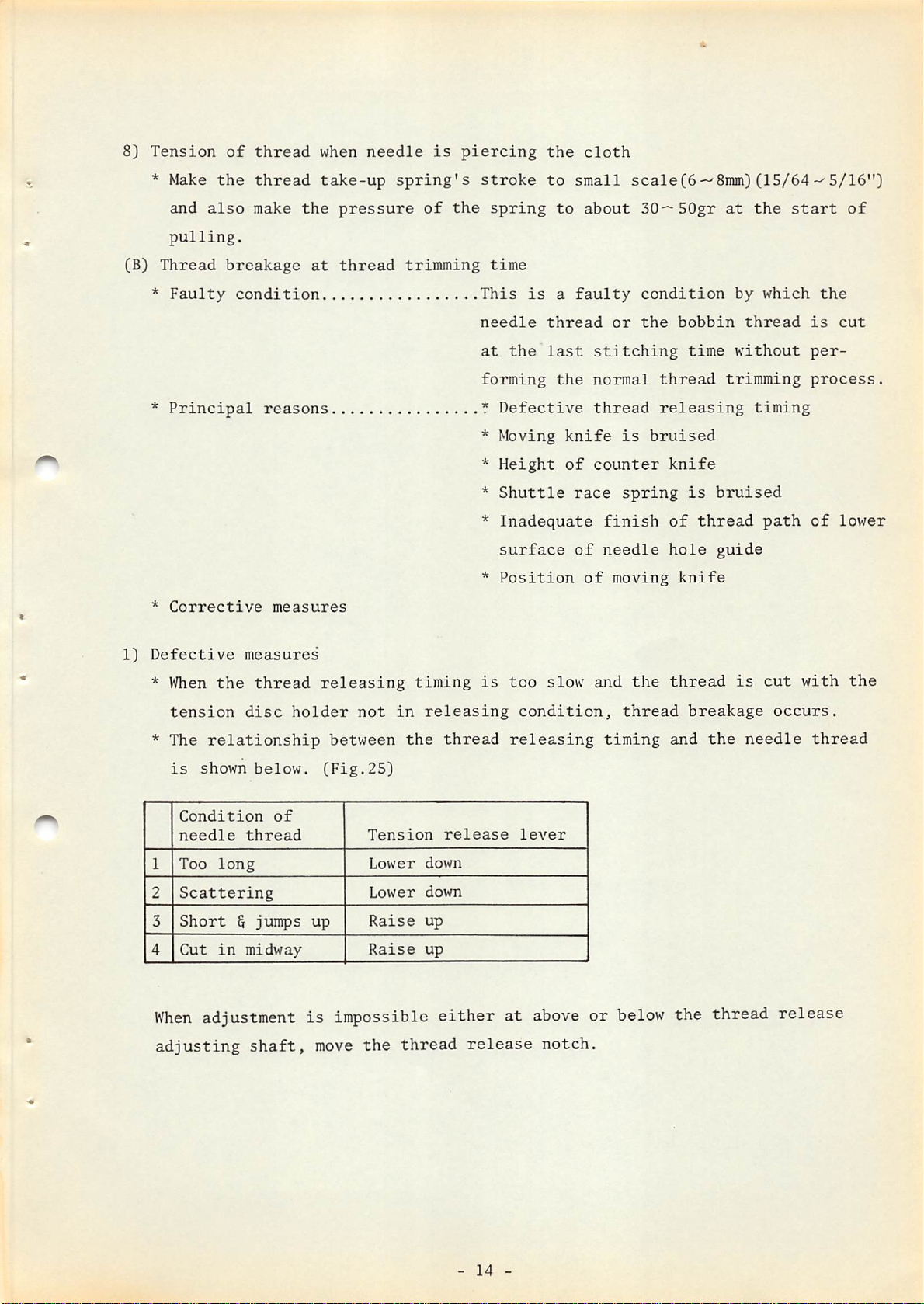

Defective

*

When

tension

* The

is

shown

Condition

needle

1

Too

2

Scattering

3

Short

4

Cut

When

adjustment

adjusting

measures

the

thread

disc

relationship

below.

of

thread

long

§

jumps

in

midway

shaft,

releasing

holder

(Fig.

up

is

move

not

in

between

25)

Tension

Lower

Lower

Raise

Raise

impossible

the

thread

timing

releasing

the

down

down

up

up

either

thread

release

release

is

at

too

slow

condition,

releasing

lever

and

thread

timing

the

above or below the

notch.

thread

breakage

and

is

the

needle

thread

cut

occurs.

release

with

thread

the

-

14

-

Page 18

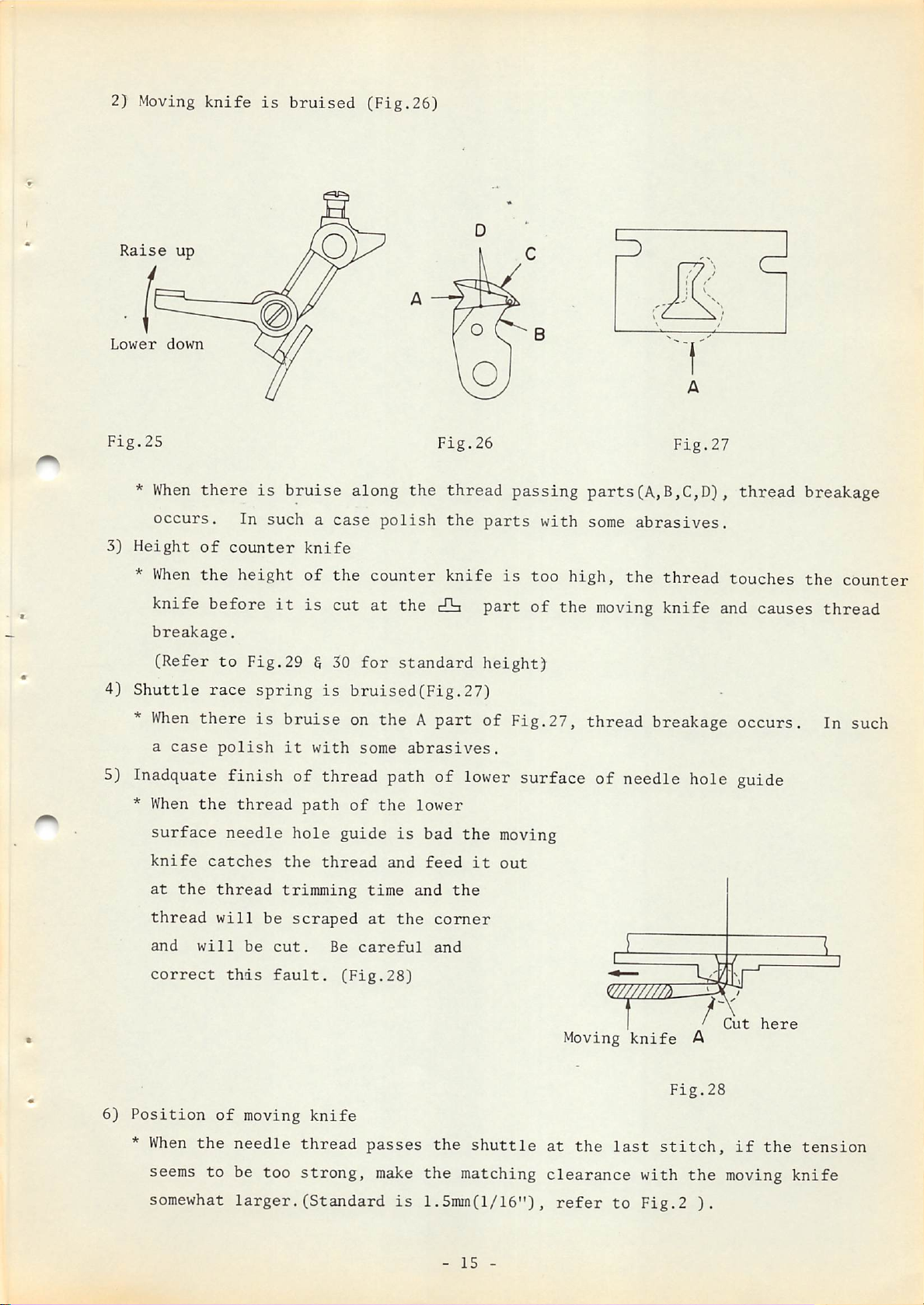

2) Moving

knife

is

bruised

(Fig.26)

Raise

Lower

Fig.25

*

3)

Height

*

4}

Shuttle

up

down

When

When

occurs.

there

of

the

In

counter

height

knife before

breakage.

(Refer

to

race

Fig.29

is

bruise

suchacase

knife

of

it

is

6 30

spring

is

along

the

cut

for

bruised(Fig.27)

the

polish

counter

at

the

standard

Fig.26

thread

the

knife

cO=t

passing

parts

is

part

height)

with

too

of

5

parts(A,B,C,D),

some

high,

the

abrasives.

the

moving

5

Fig.27

thread

thread

touches

knife and causes thread

breakage

the

counter

*

When

a

there

case

5) Inadquate

*

6)

When

surface

knife

at

thread

and

correct

Position

*

When

the

the

will

the

polish

finish

thread

needle

catches

thread

will

be

this

of

moving

needle

is

bruise

it

with

on

theApart

some

abrasives.

of Fig.27,

thread

breakage occurs. In such

of thread path of lower surface of needle hole guide

hole

the

trimming

be

scraped

cut.

fault.

path

of

guide

thread

Be

(Fig.28)

the

and

time

at

careful

is

the

lower

bad

feed

and

comer

and

the

the

it

moving

out

(^777777m

T '

knife

thread

passes

the

shuttle

Moving

at

the

knife

last

A

Fig.28

stitch,

v

f

J V

Cut

I—'

if

here

the

'

tension

seems

somewhat

to

be

too

strong,

larger.(Standard

make

is

the

matching

1.5mm(l/16"),

-

15

-

clearance

refer

to

with

Fig.2

the

).

moving

knife

Page 19

(Ill)

Inadequate

thread

trimming

Faulty condition

*

Principal

*

Corrective

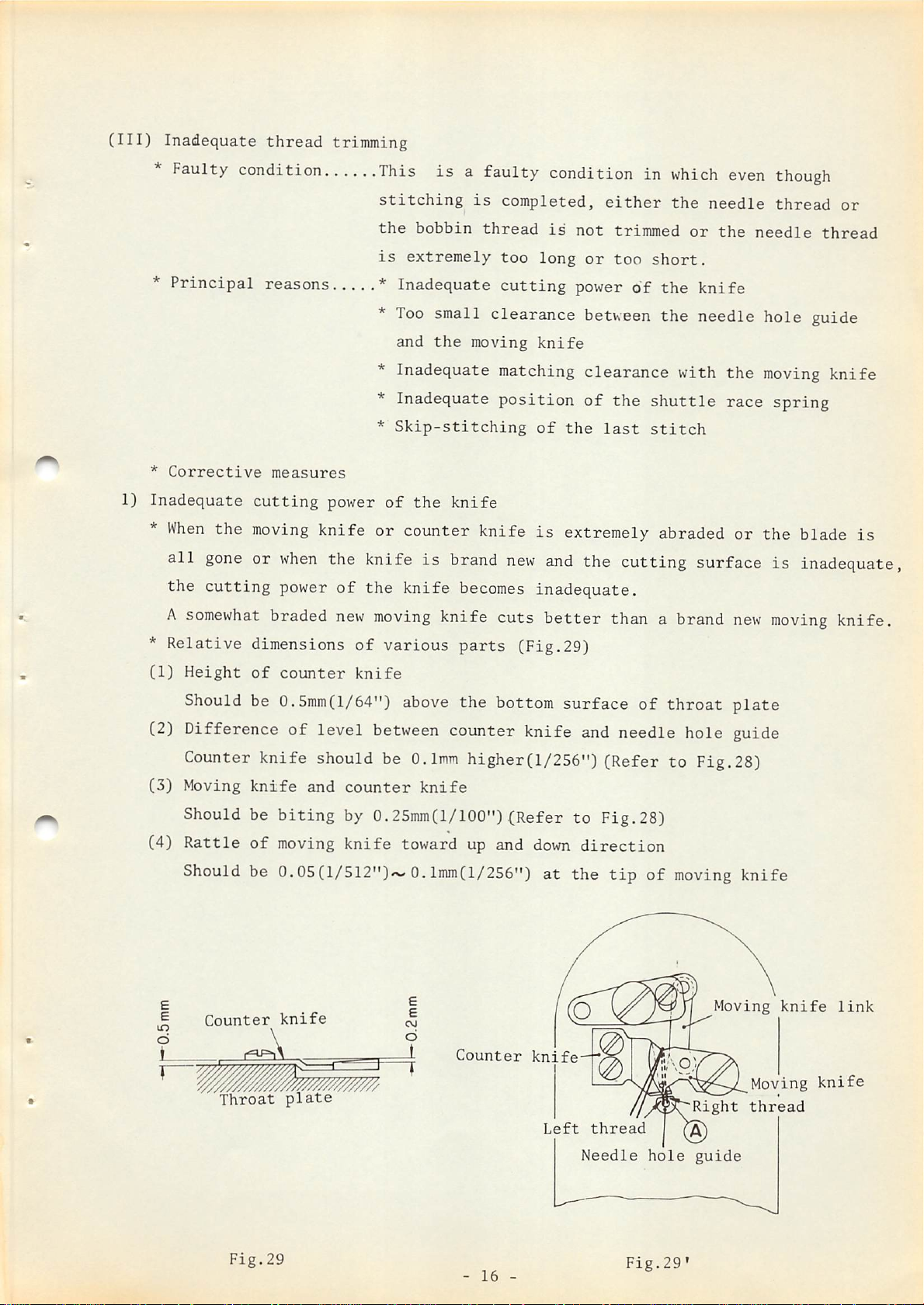

1) Inadequate

*

When

all

the

A

the

gone

cutting

somewhat

This

stitching

the

is

is

bobbin

extremely

reasons * Inadequate

*

Too

small clearance between

and

the

* Inadequate matching

* Inadequate

*

Skip-stitching

measures

cutting

moving

or

when

power

braded

power

of

the

knife

knife or counter knife

the knife is brand

of

the

knife

new

moving

knife cuts

a faulty condition in

is

completed,

thread

too

cutting

moving

position

new

becomes

is

long

knife

of

is

and

inadequate.

better

either

not

trimmed

or

too

power

of

clearance

of

the

the

last

extremely abraded or

the cutting surface is inadequate,

than a brand

which

the

or

short.

the

the

with

shuttle

stitch

even

needle

the

though

thread

needle

or

thread

knife

needle hole guide

the

race

new

moving

spring

the

moving

knife

blade

knife.

is

*

Relative

(1)

Height

Should be 0.5mm(l/64")

(2) Difference

Counter

(3)

Moving

Should be

(4)

Rattle

dimensions

of

counter

of

level

knife

knife

should be

and

biting

of

moving

of

various

knife

above

between counter knife and needle hole guide

0.1mm

counter

knife

by 0.2Smm(l/lQ0")(Refer

knife

toward up and

Should be 0. OS(l/512")'^-> 0. lmm(l/256")

Counter

Throat

knife

plate

parts

the bottom surface

(Fig.29)

of

throat

higher(1/256") (Refer to Fig,28)

to

Fig.28)

Counter

down

knife

at

Left

direction

the

tip

thread

of

moving

Moving

•Right

plate

knife

Moving

thread

knife

link

knife

Needle

Fig.29

-

16

-

Fig.29»

hole

guide

Page 20

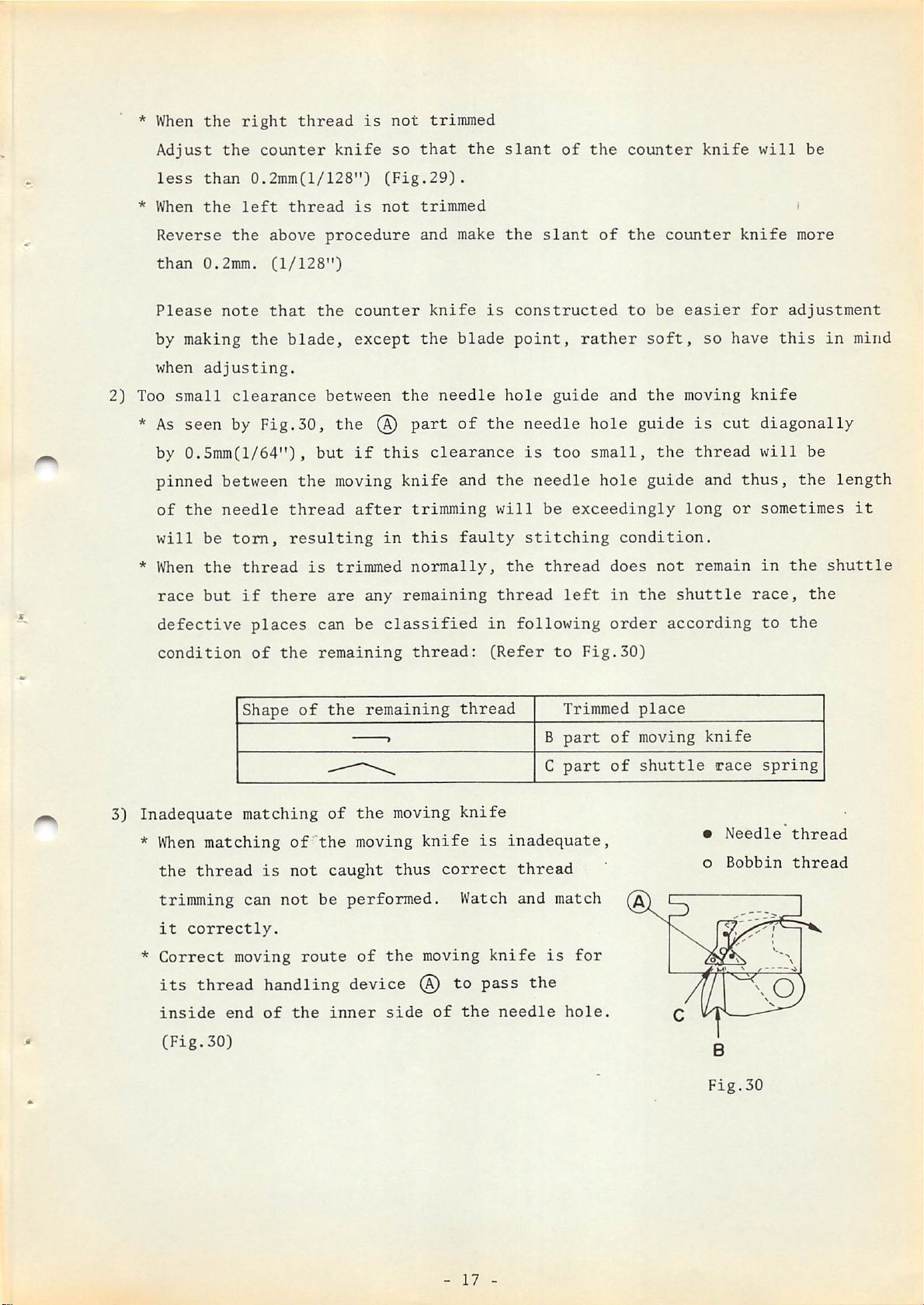

* When

the

right

thread

is

not

trimmed

*

2) Too

*

* When

Adjust

less

When

Reverse

than

Please

by

when

small

As

by

pinned

of

will

race

the

than

the

0.2mm(l/128")

left

the

0.2mm.

note

making

adjusting.

the

clearance

seen by Fig.30,

0.5mm(l/64"),

between

the

needle

be

torn,

the

thread

but

if

counter

thread

above

(1/128")

that

blade,

the

thread

resulting

there

knife

procedure

the

between

the

but

moving

is

trimmed

are

so

(Fig.29).

is

not

counter

except

@

if

this

after

in

any

that

trimmed

and

make

knife

the

blade

the

needle

part

of

clearance

knife

trimming

this

normally,

and

faulty

remaining

the

slant

the

is

point,

hole

of

slant

constructed

rather

guide

the

of

counter

the

to

and

the needle hole guide

is

too

small,

the

will

stitching

the

thread

needle

be

thread

hole

exceedingly

condition.

does

left

in

be

soft,

the

the

guide

not

the

knife

counter

easier

so

moving

is

thread

and

long

remain

shuttle

will

knife

for

have

knife

cut

diagonally

will

thus,

or

sometimes

in

race,

be

more

adjustment

this

in

be

the

the

shuttle

the

mind

length

it

3)

Inadequate

*

*

defective

condition

When

matching

the

thread

trimming

it

correctly.

Correct

its

thread

inside

(Fig.30)

places

of

Shape

matching

is

can

moving

the

of

of

not

not

route

can

remaining

the

of

"the

caught

be

handling device ®

end

of

the

inner

be

classified

thread:

remaining

»

^

the

moving

moving

thus

performed.

of

the

side

thread

knife

knife

correct

Watch

moving

to

of

the

in

following

(Refer

is

inadequate,

thread

and

knife

pass

needle

B

C

is

the

to

Fig.30)

Trimmed

part

part

match

for

hole.

order

place

of

moving

of

shuttle

according

knife

race

•

Needle

o

Bobbin

to

the

spring

thread

thread

-

17

-

Fig.30

Page 21

4)

Inadequate

position

of

the

shuttle

race

spring

5)

Skip-stitching

* When

ly.

Needle

*

*

* When

in

the

caught

Adjust

Faulty

Principal

the

the

case

proper

the

by

the

breakage

condition

position

of

inadequate

position

of

the

stitches

the

knife

needle

reasons....*

of

of

last

skip

and

and

the

shuttle

matching

the

shuttle

stitch

at

the

thus

the

shuttle.

This

means

operation

Insufficient

*

Inadequate

last

the

race

thread

the

timing

is

of

the

race

stitch,

(Fig.4)

needle

guide

bad,

moving

spring.

the

will

breaks

of

of

the

not

front

feed

same

knife

(Fig.3)

needle

be

in

faulty

occurs.

thread

trimmed.

the

surface

does

middle

of

condition

Adjust

not

of

sewing

the

driver

it

get

as

to

*

Corrective

1)

Insufficient

* As shown

the

shuttle

Therefore,

2j

Inadequate

*

When

and

adjust

The

point

in

driver,

to

timing

the

cloth

thus

needle

the

standard

has

measures

guide

Fig.4-d,

the

cause

adjust

feed

adjustment

come

*

*

*

of

front

unless

needle

needle

so

that

of

feed

feed

movement does

starts

timing.

down

to

Bruise

Needle

Inadequate

may

breakage.

on

hits

surface

the

be

curved

the

needle

needle

assembling

of

needle

not

to

"flow",

is

to

needle

match so

7'^10mm(9/32'^

the

the

when

will

25/64")

hole

work

driver

is

stop

breakage

that

guide

clamp

of

guided

it

pierces

be

guided

before

the

above

foot

moving

at

the

by means

the

occurs.

feeding

the

knife

front

the

needle

stops

throat

cloth

Refer

end

and

of

the

pierces

to

when

plate.

surface

hits

driver.

the

Fig.15

the

of

the

cloth

and

needle

-

18

-

Page 22

3)

Needle

* A

hole

needle,

guide

once

broken,

sometimes

bruises

inside

suface

of

the

needle

hole

4)

Hits

*

5)

Inadequate

guide

the

point

The

bruise

with

Also,

are

please

use

the

If

the

foot,

when

extreme

or

due

needle

will

needle

so

a

new

as

there

available

refer

correct

work

needle

needle

changing

caution.

assembling

to

hole

be

caught

hole

easily,

one.

depending

to

ones.

clamp

hits

breakage

are

the

the

guide.

is

heat-treated

but

many

page

foot

the

stitch

curving

of

Unless

again

in

by

case

kinds

on

the

6 No.14 and

work

occurs,

of

clamp

size,

moving

the

this

the

harder

it

of

usage,

so

apply

knife

needle

bruise

bruise

is

bruised

needle

when

causing

than

hole

piercing

is

smoothly

needle

the

needle

toagreater

guide

in

the

cloth,

removed,

breakage.

and

so

it

degree,

combination

Moving

connecting

may

the

needle

should

exchange

with

knife

bruise

not

it

needles

link

(V)

1)

* When

if

the

knife

and

will

needle

knife

CFig.31)

Cautions

Extreme

materials

Thread

removing

installation

connecting

the

needle

hit

the

to

will

on sewing

caution

with

breakage

moving

be

broken

be

should

synthetic

the

knife

link

is

dropped,

bruised.

synthetic

due

to

components,

of

the

is

knife

or

the

be

exercised

thread

heat

moving

forgotten

the

causing

moving

Be

careful.

materials

as

needle

the

for

under:

with

sewing

synthetic

synthetic

Fig.31

thread

or

mixed

synthetic

Due

to

the

to

should

cause

be

the

taken:

resistance

cloth

to

of

be

the

cut

cJoth

or

stick

at

-

19

piercing

by

melting,

-

time,

following

the

needle

corrective

gets

over-heated

measures

Page 23

*

Change

to a

pulley

for

synthetic

materials(SOHz

B710128000B,

60Hz

B710228000B).

Sewing speed

*

Use

silicon

machine", page 5 and No,7, page 4)

*

Use

super needle for

*

If

a fine needle

effective.

2)

To

prevent the thread

*

During

thread

3) Thread

*

When

the

For

the

guideAtoward

releasing

thread

feed.

adjustment,

adjustmentsothat

4) Bruise on the

*

In

sewing

should

oil

be

lubricant.(Refer to

synthetic

is

used, piercing resistance will be less

from

sewing,ifthe

left

at

start

releasing

occurs

refer to

the

shuttle

synthetic

driver

materials,

1,700

s.p.m.

splitting

thread

and

of sewing

at

the

chapter

feed

stops

spring

INSTRUCTION

materials.

finely

should

make

the

the

start of

on

near

bruise

is

BOOKon"How

split

thread

finely

take-up

sewing,

"Matching

the

10mmC25/64")

liable

the

to

and

or

breaks,

lever

adjust

feed

cam"

rangetobe

be

formedonthe

to thread the

will be

move

stroke

the

timing

and

more

the

bigger.

of

make

effective.

tail

frame

end

of

the

thread

carefully.

5)

Smooth

To

following

*

*

*

* Needle

* Needle

(VI) Inadequate

*

1)

Adjust

out

enable

Shuttle

Shuttle

Shuttle

In

case

the

the

the

parts:

driver

race

hole

bar

thread

of

timing

slipping

When

this

thread

thread

spring

spring

guide

thread

inadequate

guide B1405280000

tension

of

out

happens,

path

to

pass

thread

feed

side

of

the

smooth

smoothly,

B1813280000

B1818280000

B1815280000

B2426280000

tension

shuttle

this out

smooth

out

driver

with

the

spring,

buff, etc.

thread

path

so

watch

of

the

Within

the

effective.

the

range

describedonthe

timingoffeedsothat

Then,

the thread tension

the

chapteron"Matching

feed

-

stops

20

will

-

nearer

become

the

better.

the

feed

7mmC9/32")

cam",

rangetobe

adjust

Page 24

2) Tension

disc

No.2 and

thread

tension

spring

Make

become

*

1)

Adjusting

Install

left.

Be

When

careful.

the

tension

better.

the

the

the

However,

needle

facing

needle

of

thread

if

both

of

about

it's

of

these

is

intersecting

the

needle

10°

rotated

Intersecting

parts

toward

too

much,

Fig.32

and

left

here

it

the

than

might

tension

the

invite

of

the

standard

skip-stitching.

thread

by

rotating to

will

-

21

-

Page 25

(CAUTIONSONDISMANTLINGOFPARTS)

1}

Howtoremove

*

When

pulling out the shuttle driver shaft,

for

shuttle

the

driver

shuttle

shaft

driver

with

shaft

crank.

with crank

do

not ever pull out the

knock

2)

This

driver

is

because needle bearings are used

shaft

with

crank

and

will

damage

for

the

the

needle

In pulling out the shuttle driver shaft with crank,

and

the

How

*

The

Remove

main

plate,

pull

When

the

cam,

oscillating

to

remove

main

the

shaft

can

the counterweight, feed

shaft

them

speed

knock

thrust

and

stop-motion

out

toward

decreasing device

pin

screw

as the stop-motion

main

rock

shaft

shaft

hinge

be pulled out without

cam

driving

collar,

tension

rear.

brake

must

release

spring

be

then insert a thick

cam

is

set

tight

pin

and

removing

worm,

cam

and

by

removed

screw

with

roller,

tapping

for

rear

bushing

bearing.

pull

remove

them

the

speed

shuttle

the shuttle driver

out toward

decreasing device.

drive connecting rod,

driving pulley pressing

the

rear

some

driver

an

adhesive agent, then

reason,

between

the stop-motion

of

the

rear.

bushing

first

shuttle

lightly,

remove

remove

it

3)

When

Be

sure

become

the

speed decreasing device

to

remove

damaged.

the

needle

as

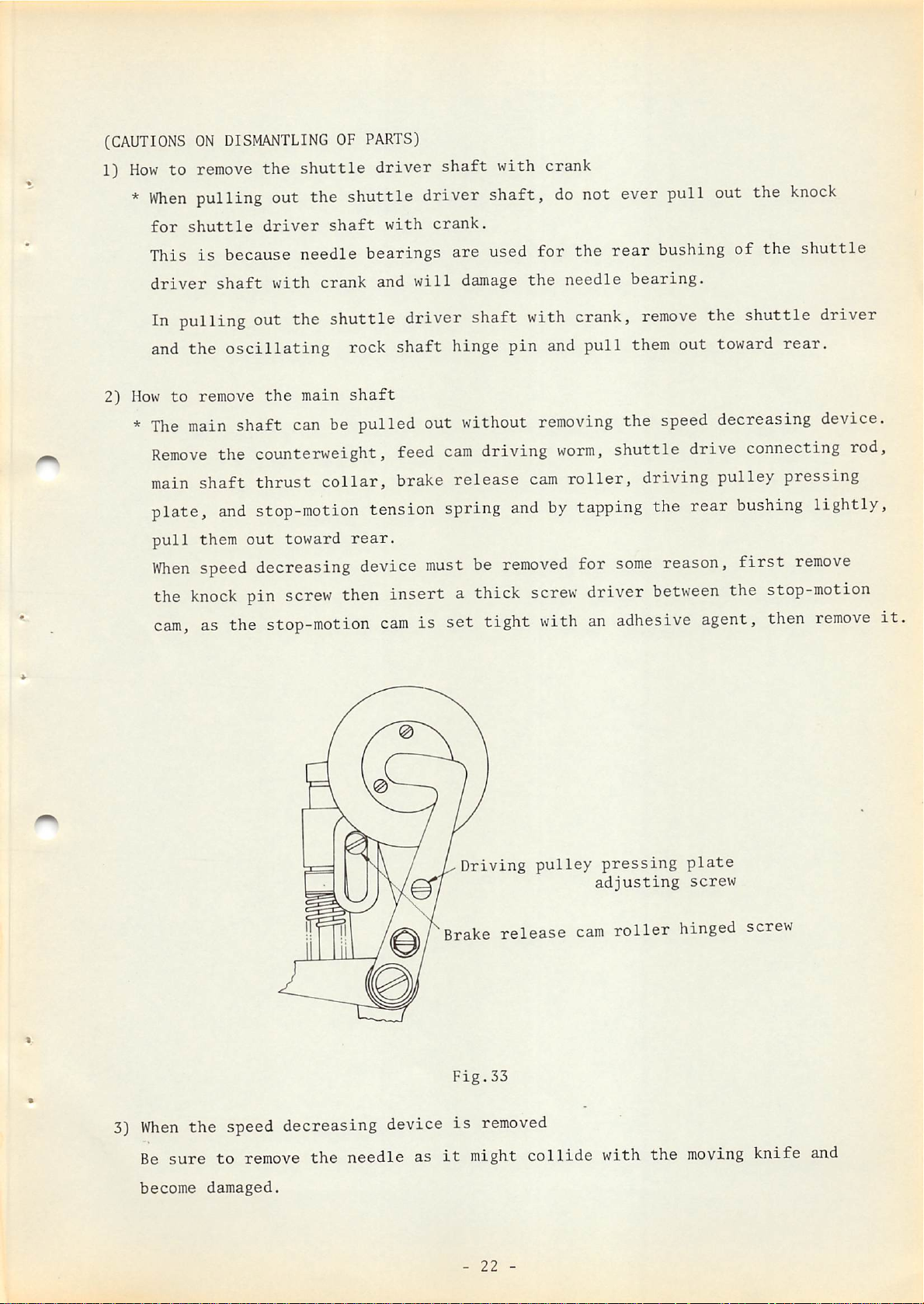

Driving

Brake

Fig.33

is

it

might

-

removed

22

pulley

release

collide

-

pressing

adjusting

cam

with

roller

plate

screw

hinged screw

the

moving

knife

and

Page 26

(HOWTOTIGHTEN

1)

How

to

eliminate

THE

RATTLE)

the

rattle

of

the

Feed

main

cam

0

shaft

2)

*

When

the

direction

greatly

thrust

toward

* Most

* After

tension

How

to eliminate the

wheel

*

When

tension

of

the

To

eliminate

affected.

collar

the

appropriate

tightening

releasing

rattle

releasing

main

Main

shaft

thrust

machine becomes

of

the

main

shaft,

To

tighten

toward the

arrow

direction.

rattle

the

rattle,

timing.

rattle

is

formed

shaft.

this

on the feed

timing

rattle,

collar

Fig.34

old

arrow

(Fig.34)

toward

of feed

will

remove

and

rattle

the feed

and

eliminate

direction

the

main

re-adjust

cam

cam

be

greatly

the

begins

and

while

shaft

the feed

driving

driving

affected

to

be formed toward

the tension releasing timing

this

rattle,

rotating

direction

cam,

worm

worm

and

parts,

just

move

the feed

should

stitch

feed

in

the

the

the

shaft

will

the

main

cam

be 0.01'^0.04mm.

regulating

cam

driving

feed and

case

shaft

strongly

cam

the

of

the

be

and

worm

rattle

driving

Then,

*

the

between

shaft

worm

of

be

cover

and

rotate

of

the

loosen

worm.

press

the

arrow

will

the

eliminated.

direction

the

will

move

main

the

down

feed

main

not

shaft

top

2

become

toward

(Fig.35)

surface

screws

the

cam

shaft

and

of

feed

driving

so

that

and

wrong.

the

the

of

cam

rear

rattle

the

the

worm

the

the

frame

feed

shaft

toward

relation

feed

Then,

bushing

will

-

23

cam

and

cam

the

-

r1

1

—

0

Fig.35

X

w

])

J

Page 27

After

adjustment,

be

sure

to

tighten

the:

set

screws.

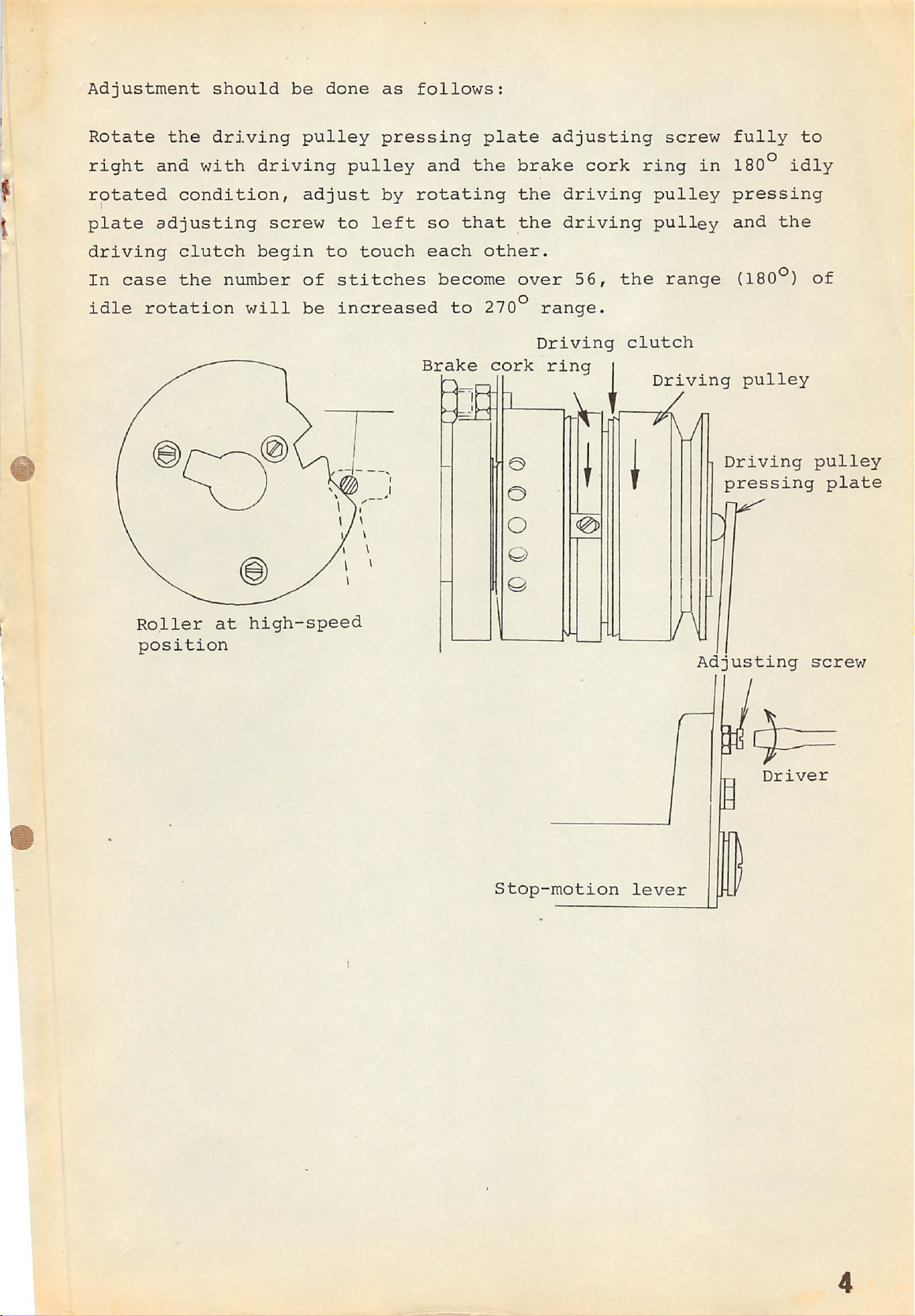

(ADJUSTING

(I)

Adjusting

(A)

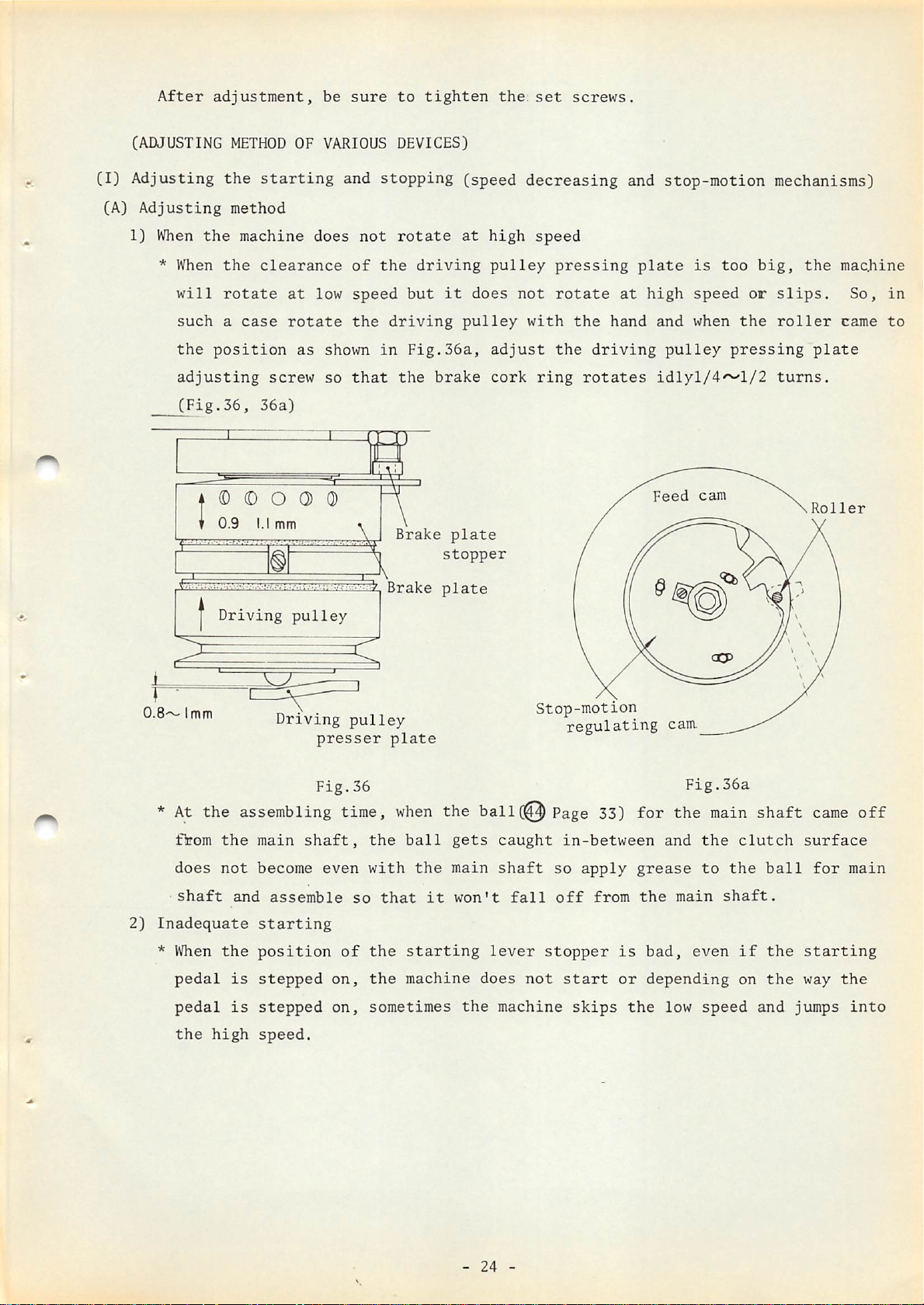

1)

Adjusting

When

*

When

will

suchacase

the

adjusting

(Fig.36,

i:

METHOD

the

method

the

the

rotate

position

(D

9 I.I

machine

OF

starting

does

clearance

at

low

rotate

as

screw

36a)

O O O 0

mm

VARIOUS

and

not

of

speed

the

shown

so

that

X Brake

DEVICES)

stopping

rotate

the

driving

but

driving

in

Fig.36a,

the

brake

Brake

(speed

at

it

does

pulley

plate

stopper

plate

decreasing

high

pulley

not

adjust

cork

speed

with

ring

pressing

rotate

the

the

driving

rotates

and

at

hand

stop-motion

plate

high

is

speed

and

when

pulley

idlyl/4^1/2

Feed

cam

too

or

the

pressing

mechanisms)

big,

the

slips.

roller

plate

turns.

Roller

machine

So,

in

came

to

0.8'^'

*

2)

Inadequate

*

I

imm

At

flrrom

does

shaft

When

pedal

pedal

the

the

high

Driving

pulley

Driving

assembling

the

not

the

is

is

main

become

and

shaft,

assemble

starting

position

stepped

stepped

speed.

pulley

presser

Fig.36

time,

even

so

of

on,

on,

plate

when

the

ball

with

the

that

it

the

starting

the

machine

sometimes

Stop-motion

regulating

the ball(@Page

gets

main

won't

the

caught

shaft

lever

does

machine

fall

so

off

stopper

not

in-between

start

skips

33)

apply

from

for the

grease

the

is

bad,

or

depending

the

cam.

Fig.36a

and

main

low

main

the

to

even

speed

clutch

the

shaft.

if

on

shaft

ball

the

the

and

came

surface

for

starting

way

jumps

off

main

the

into

-

24

-

Page 28

Adjust

the

position

of

the

starting

lever

stopper

so

that

at

the

low

speed

sewing,

the

stop-motion

to

function

clearance

regulating

effectively.

between

cam

roller

(Fig.37)

the

stop-motion

comes

to

lmm(

Starting

regulating

3/64'*)

lever

cam

to

enable

stopper

and

the

the

stopper

* When

so

the

clearance

the

roller

they

might

or

make a "bump-bump"

make

(Fig.38)

the

is

big

catch

clearance

between

at

each

the

stop-motion

other

noise

to

O.Smm.(1/64")

Fig.37

the

stop-motion

at

starting

sometimes,

time,

time

Stop-motion

regulating

latch

cam

groove

and

Fig.38

-

25

-

•Fig.

Stop-motion

38»

cam

Page 29

*

If

an

unusual

torque

should

bear

on

the

machine

during

running, the

machine

might

speed

machine.

3)

When

*

When

the brake clutch

stop

running

running.

the

machine

the floating

when

Adjust

does not run

the

the

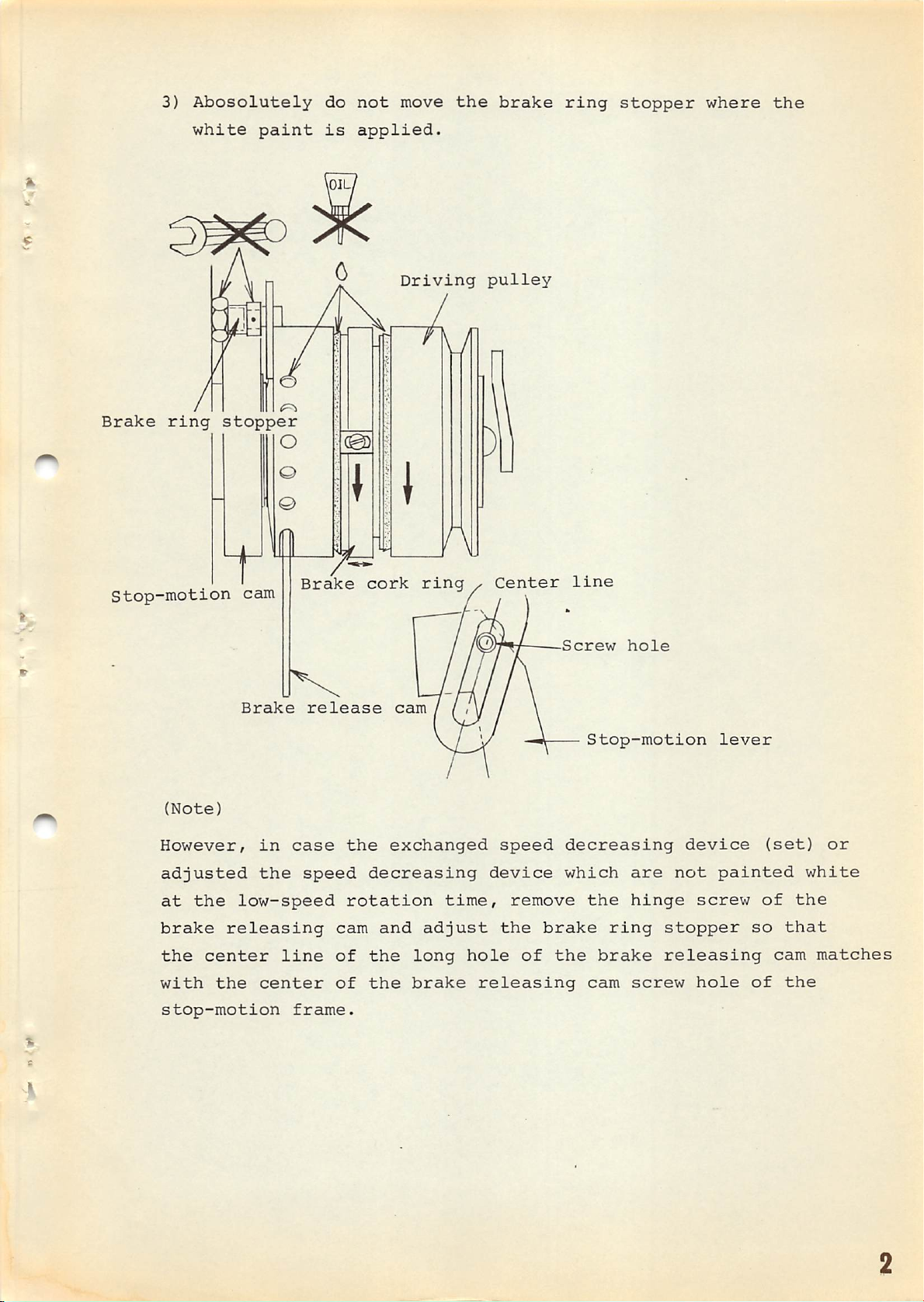

amount(rise)

becomes

inadequate

So, adjust the brake plate stopper so

running

amount

brake cork ring fore

idly

stop-motion

When

of driving

machine

If

the

or at

of

all

high

parts

speed

even.

and

whenitreaches the

time.

the

brake

is

brake

cork

and

af

running

cork ring

ring

stop-motion

at

low

running

And,

aft

extreme

is

speed.

is

too far

low

speed

machinesothat

at

low

of the

running

speed

brake

and

that

is to

no

unusual

plate is

slips.

the floating

comesto1.5mmCl/16")

after

so

that

observed to be stopping

time, the

that,

as

shown

the stop-motion latch begins to rotate

outer

worn

rim

of the stop-motion

brake

is perfectly functioning

out to be adjusted,

be

switched

torque

too

big, the biting of

amount

and

make

over

is

borne

at

either

the floating

to

by

in Fig.38', adjust the

cam

at the

momentarily

at the

start

and

exchange

it

with a

high

the

idle

the

new

one.CFig.36,

*

In

height

*

Whem

will

case the

oil

not

brake

of

the spring to

and

grease

enter

into

to driving clutch also in

(Note)

*

slipping

Do

not use thinner or trichlorothane as they

brake

When

driving clutch

In such a

the

main

sound.

cork.

the returning

does

case,

shaft

and

the driving belt is too strong,

the

tension

Generation of unusual noise

*

When

the clearance of the pulley pressing plate

of

the

Fig.38')

spring

etc. are sticking to the

is

8mmC5/16")

low

speed, so

too

which

weak,

case

it

or exchange

wipe

if

too will

them

brake

off

slip,

it

with a

cork

with alcohol. This holds

oily matter sticks to

impede

power

not separate

either

of the spring for the the

and

the

machine

exchange

the

spring

or

main

will not rotate at

insert

adjust the strength of the spring. Also,

sometimes

belt.

the spring will not return,

is

too narrow, the driving

so either adjust the

new

one.

ring

it

might

it,

it

produces

slip

the function of the

shaft is

weak,

low

a washer

into

if

the hole

the tension of

so

true

the

speed.

adjust

and

of

a

t

clutch

bearing

will

at high speed,

will

to

slip

generate

enter

during

refer

out.

at

low speed running, causing the

As a

idle

to 1) of

result,

running.

this

-

the

Therefore,

chapter

26

-

ball

and

will-be

when

make

outer

bruised

the

proper adjustment.

ring

and

machine

inside

unusual

is

to

the

be

noise

run

Page 30

*

Unusual

When

of

like

To

the

*

The

*

The

correct

the

cork

a

squeaky

cause

cause

noise

surface

this

is

of

of

from

of

small

sound

this

this

unusual

the

cork

the

and

generates.

sound

sound

cork

when

at

at

sound,

of

the

starting

starting

stopping

remove

clutch

is

time

time

the

is

oscillating,

stopped,

is

is

723

cork

and

sometimes

38

of

rof

with

the

Fig.39-1.

Fig.39-1.

a

sand

contacting

an

unusual

paper

make

area

noise

the

contacting

* Even

the

Use

grease

* Even though

timing

main

stop-motion

bruised

refer

5)

Generation

*

If

the

pulley

refer

and

is

big

surface

if

dust

gets

ball

will

of

lithium

the

is

such

shaft

is

cam

and

the

to

page 26 3) and make

of

unusual

floating

and

at

to para.3) of

make

proper adjustment. This

and in

wider.

into

be

bruised.

group

stop-motion

that

the

trying

to

is

interlocked

sound

of

heat

amount

high speed

this

this

case

the

grease

So

consistency

hook

brake

rotate

speed

proper

of

the

running,

chapter on

refer

or

be

careful

is

caught

plate

at

to

is

low

the

decreasing

adjustment.

brake

is

this

"When

also

to

the above

the

quality

when

No.2

biting

speed,

assembling.

for

this

in

the

into

it

hook and thus

device

not

uniform

unusual

heat

the machine does not run

happens

when

para,

of

grease

purpose.

stop-motion

the

cork,

can

not

rotate

the

ball

becomes

at

both

generates.

the

oscillation

on "Unusual

has

loud.

idle

become

cam,

then

even

because

bearing

In such a

running

In such a

noise

if

will

at

of

from

inferior,

the

if

the

the

be

case,

of

the

case,

low

speed"

the cork

the cork"

and

*

If

hard

generates

very

capacity

*

How

Refer

6)

Stop-motion

correct

too

much

grease(high

also.

lightly

of

to

apply

to

the

sound

this

defect.

grease

consistency

In such a

to

the

the

driving

grease

following

is

is

outer

big

poured

ring

ring

chapter

(Fig.39)

into

the

number)

case,

apply grease

inside

long holeCS

on "Assembling

ball

is

the

bearing

used

ball

places).

for

at

assembling

of

lithium

decreasing

time,

group consistency

the

unusual

bearing and apply about 1/5

the

speed

decreasing

unit".

speed

heat

or

No.2

of

-

27

-

Page 31

* When

the

clearance

between

the

stop-motion

lever

and

the

stop

ring

rod

latch

is

small,

by

the

ring

*

Correct

cam

so

stop-motion

*

Also,

into

para.3)

adjustment.

the

stop

stop-motion

rod

latch

stop-motion

that,

at

at

the

low speed

above on

link

and

and

the

at

the

the

same

end

of

step,

"When

Stop-motion

rod

latch

generates

stop-motion

timing

last

stitch,

time

sewing,

thus

the

into

hits

sound,

lever

can be

the

as

obtained

the

it

passes

high

generating

machine does

goes

action

the

stop-motion

so

to

stop

ring

the

speed

adjust

14mm(9/16").

by

adjusting

stop

running

rod

lever

the

clearance

latch

ring

suddenly

the

rod

shock sound. In such a

not

run

at

low

speed"

Stop-motion

cam

by

the

stop-motion

cam

part

latch.

stops

case,

and make

shock

between

enters

without

refer

produced

the

stop

regulating

into

entering

to

the

proper

Stop-motion latch

Fig.39

Stop-motion

lever

-

28

-

Page 32

(B)

Assembling

the

speed

decreasing

unit

This

of

chapter

parts,

refer

treats

to

only

the

the

parts

assembling

list

for

order,

LK-280

and

so

for

the

construction

names,

construction

diagram.

etc,

that

grease

to

ring.

grease

much

that

balls

Cautions

all

and

grease

carefully.

there

Assembling

ordei

1.

2.

3.

1.

Note

Apply

Refer

thrust

Apply

capacity

2.

If

N)

CO

3.

too

so

watch

Verify

in

the

on

parts

to

Fig.39-1

the

are

needle

to8long

set

the

is

are

or

inside

assembling

concentric.

bearing

for

inserting

holes

balls.

applied,

no

dust

and

outside

to

heat

or

parts

about

foreign

rings.

the

will

1/5

generate,

matter

1.

2.

Cautions

Verify

the

If

something

with

balls

new

that

and

ones.

on

dismantling

there

inside

is

wrong,

are

no

and

exchange

bruises

outside

on

rings.

them

1.

Put

the

2.

3.

pushing

clipped

Watch

Verify

through

lower

in-between

out

that

the

for

end

push

the

all

shaft)

parts

on

top

of

in(2) . ( ^

byaplier).

balls

which

are

the

base

and

and

@

may

jump

concentric.(Pass

may

out.

by

be

them

1.

By

pushing

(T)

and by gouging between

Q) and (y) , with a screw

2.

remove

Watch

jump

out

out.

©•

for

the

balls

driver

which

might

Page 33

♦

•>

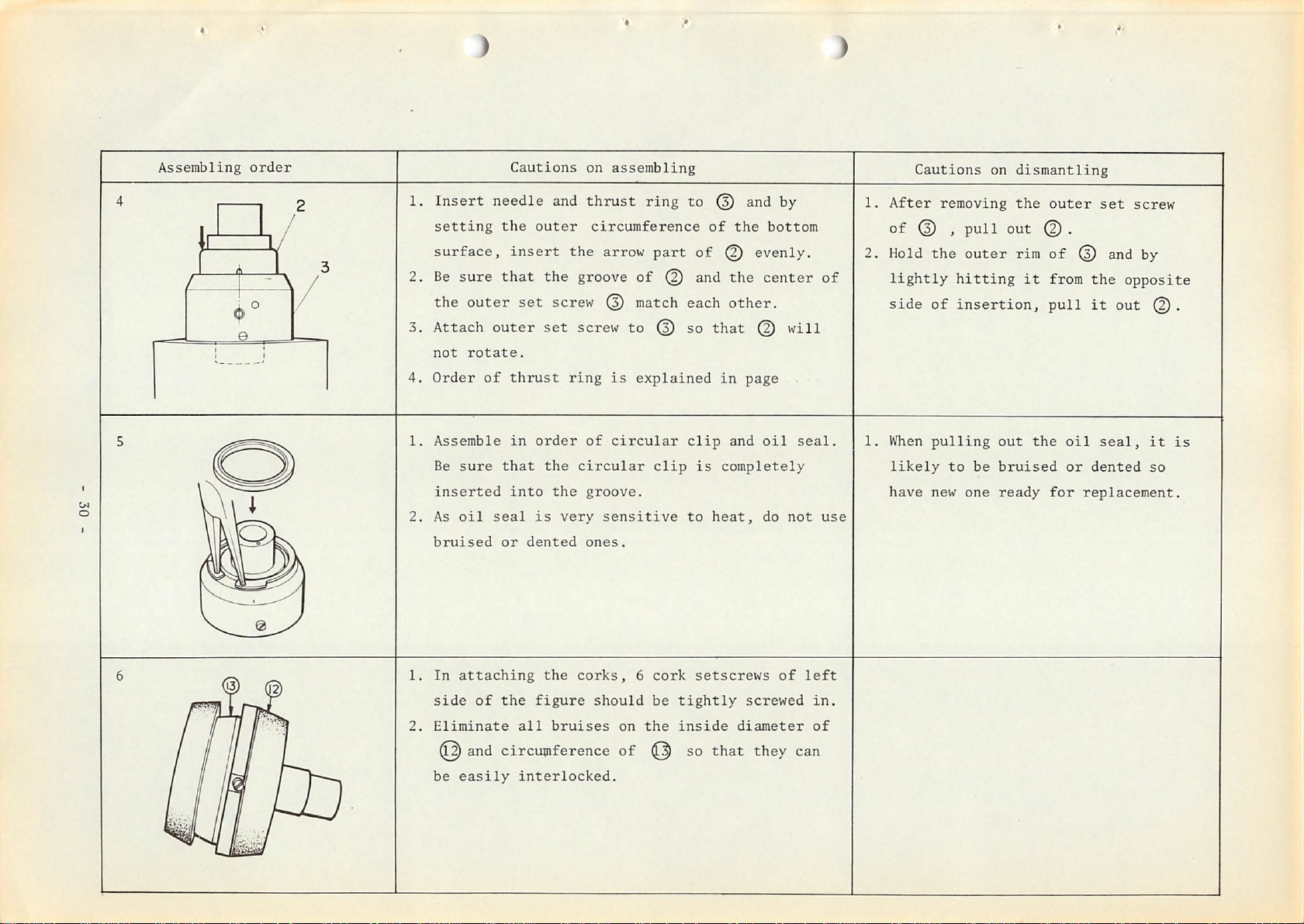

Assembling

C/l

o

order

1.

Insert

setting

surface,

2.

Be

sure

the

outer

3. Attach

not

rotate.

4.

Order

1.

Assemble

Be

sure

inserted

2.

As

oil

bruised

Cautions

needle

the

insert

that

outer

of

thrust

in

that

into

seal

or

set

dented

on

and

thrust

outer

circumference

the arrow

the

groove

screw

set

screw to © so

ring

order

is

the

the

very

of

circular

groove.

sensitive

ones.

assembling

ring

part

of

© and

match

is

explained

circular

clip

to

@ and by

of

of

^ evenly.

each

that

in

clip

is

completely

to

heat,

the

the

other.

page

and

bottom

center

©

will

oil

do

not

seal.

of

use

Cautions

1.

After

of

removing

© )

2. Hold the

lightly

side

of

1.

When

pulling

likely

have

new

on

poll

outer

hitting

insertion,

out

to

be

bruised

one

ready

dismantling

the

outer

out © .

rim

of

it

from

pull

the

for

set

© and by

the