JUKI LH-4100 Instruction Manual

ENGLISH

CONTENTS

1. SPECIFICATIONS ........................................................................................................... 1

2. NAME OF EACH COMPONENT .................................................................................... 2

3. INSTALLATION ............................................................................................................... 3

3-1. Installing the bottom cover .................................................................................................................................. 3

3-2. Opening and closing of the control box (SC-910) .............................................................................................4

3-3. Adjusting the height of the knee lifter ................................................................................................................4

3-4. Installation of thread stand .................................................................................................................................. 5

3-5. Caution when installing the panel ...................................................................................................................... 5

3-6. Connecting the cord ............................................................................................................................................. 6

3-7. Managing the cord ................................................................................................................................................ 8

3-8. Adjusting the knee lifter detection seat (asm.) ................................................................................................ 10

4. PREPARATION OF THE SEWING MACHINE ............................................................. 11

4-1. Lubrication .......................................................................................................................................................... 11

4-2.Cleaningthelter ...............................................................................................................................................

4-3. Adjusting the amount of oil in the hook .......................................................................................................... 13

4-4. Attaching the needles ........................................................................................................................................13

4-5. How to take out the bobbin case ...................................................................................................................... 14

4-6. Inserting a bobbin in a bobbin case .................................................................................................................14

4-7. Threading the machine head ............................................................................................................................. 15

4-8. Thread tension .................................................................................................................................................... 16

4-9. Thread take-up spring ........................................................................................................................................ 16

4-10. Adjusting the stitch length ..............................................................................................................................17

4-11. Winding the bobbin thread ..............................................................................................................................18

4-12. Adjusting the needle stop position ................................................................................................................. 19

4-13. Pedal pressure and pedal stroke .................................................................................................................... 20

4-14. Adjustment of the pedal ................................................................................................................................... 20

12

5. OPARATION OF THE SEWING MACHINE .................................................................. 21

5-1. Pedal operation ................................................................................................................................................... 21

5-2. Hand lifter ............................................................................................................................................................ 22

5-3. Adjusting the pressure of the presser foot ...................................................................................................... 22

5-4. Thread tension release changeover when using the knee lifter ....................................................................23

5-5. Separately driven needle changeover switch (for LH-4168-7 and 4188-7) .................................................... 24

5-6. One-touch reverse feed switch lever (for touch-back) ................................................................................... 25

6. MAINTENANCE ............................................................................................................ 25

6-1. Changing procedure to bottom feed and the adjustment (LH-4128 without thread trimmer only)............. 25

6-2. Changing procedure to needle feed (for LH-4128 only) ................................................................................. 27

6-3. Adjusting the inner hook guide ......................................................................................................................... 28

6-4. Needle-to-hook relation ..................................................................................................................................... 29

6-5. Adjusting the height and the inclination of the feed dog ...............................................................................32

6-6. Adjusting the presser foot ................................................................................................................................. 32

6-7. Move (adjustment) of the hook shaft saddle when replacing the gauge ......................................................33

6-8. Lubricating route when changing the needle gauge size ............................................................................... 33

6-9. Adjusting the thread presser spring ................................................................................................................. 33

6-10. Adjusting the position of the moving knife .................................................................................................... 34

6-11. Replacing the bobbin thread slack preventer spring (for LH-4168-7 and 4188-7) ......................................35

6-12. Adjusting the hook needle guard .................................................................................................................... 35

6-13. Stop of the needle bars and angle of corners for corners stitching (for LH-4168-7 and 4188-7) ...............36

6-14. Caution when installing the gauge to the bed slide ...................................................................................... 36

6-15. Position of the wiper ........................................................................................................................................37

6-16.Replenishinggreasetothespeciedplaces(forLH-4168-7and4188-7) ...................................................

37

7. STITCH-TO-ANGLE TABLE BY GAUGE(PITCH AND mm CONVERSION TABLE) .. 39

8. GAUGE SETS ............................................................................................................... 40

9. TROUBLES AND CORRECTIVE MEASURES ............................................................ 45

iv

1. SPECIFICATIONS

Model name

Application

Hook

Thread trimmer

Separately

driven needle

bar mechanism

Max. sewing

speed

Needle

Gauge size

Lift of presser

foot

Lubrication

Noise

LH-4128

For light- and

medium-weight

materials

S type : standard, F type : foundation, G type : jeans

Small hook

Not provided

Not provided

4,000 rpm *

DP x 5 #9 to #16 (For S type), DP x 5 #9 to #11 (For F type), DP x 5 #16 to #22 (G type)

1/8" to 1-1/2"

3.2 to 38.1 mm

12 mm by knee lifter, 5.5 mm by hand lifter lever, 9 mm by knee lifter with wiper

Workplace-related

noise at sewing

speed

n = 4,000 min–1 :

Lpa

according to DIN

84 dB(A)

≦

Noise

measurement

45635-48-A-1.

LH-4128-7

(with automatic

thread trimmer)

For light-, medium-

and heavy-weight

materials

Small hook

Provided

Not provided

4,000 rpm *

5/32" to 1-1/4"

4 to 31.8 mm

New Defrix Oil No. 1

Workplace-related

noise at sewing

speed

n = 4,000 min–1 :

Lpa

according to DIN

84 dB(A)

≦

Noise

measurement

45635-48-A-1.

LH-4168-7

(with automatic thread

trimmer incorporating

corner stitching)

For light-, medium-

and heavy-weight

materials

Small hook

Provided

Provided

3,200 rpm

5/32" to 1"

4 to 25.4 mm

Workplace-related

noise at sewing

speed

n = 3,200 min–1 :

Lpa

according to DIN

84 dB(A)

≦

Noise

measurement

45635-48-A-1.

LH-4188-7

(with automatic thread

trimmer incorporating

corner stitching)

For medium- and

heavy-weight

materials

Large hook

Provided

Provided

3,200 rpm

5/32" to 1"

4 to 25.4 mm

Workplace-related

noise at sewing

speed

n = 2,700 min–1 :

Lpa

according to DIN

84 dB(A)

≦

Noise

measurement

45635-48-A-1.

* 3,500 rpm when the stitch length exceeds 4 mm.

– 1 –

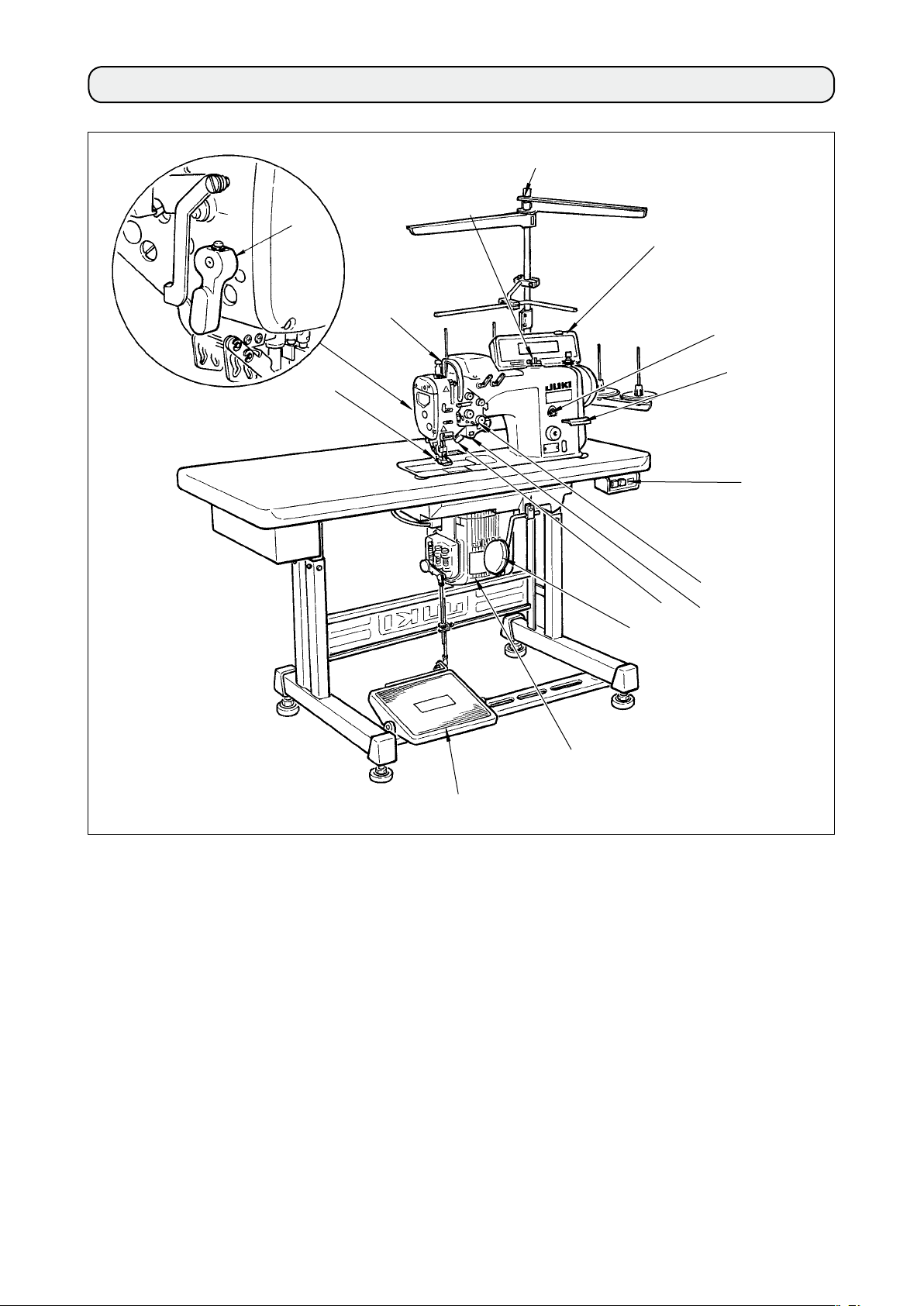

2. NAME OF EACH COMPONENT

!2

!5

3

2

!1

7

!0

9

!3

!4

8

4

1

Separately driven needle

1

changeover switch

Thread take-up cover

2

Finger guard

3

Thread tension controller

4

Control box

5

Pedal

6

Knee lifter lever

7

Power switch

8

Hand switch

9

Operation panel

!0

6

5

Bobbin winder

!1

Thread stand

!2

Oil supply opening

!3

Reverse feed control lever

!4

Hand lifter lever

!5

– 2 –

3. INSTALLATION

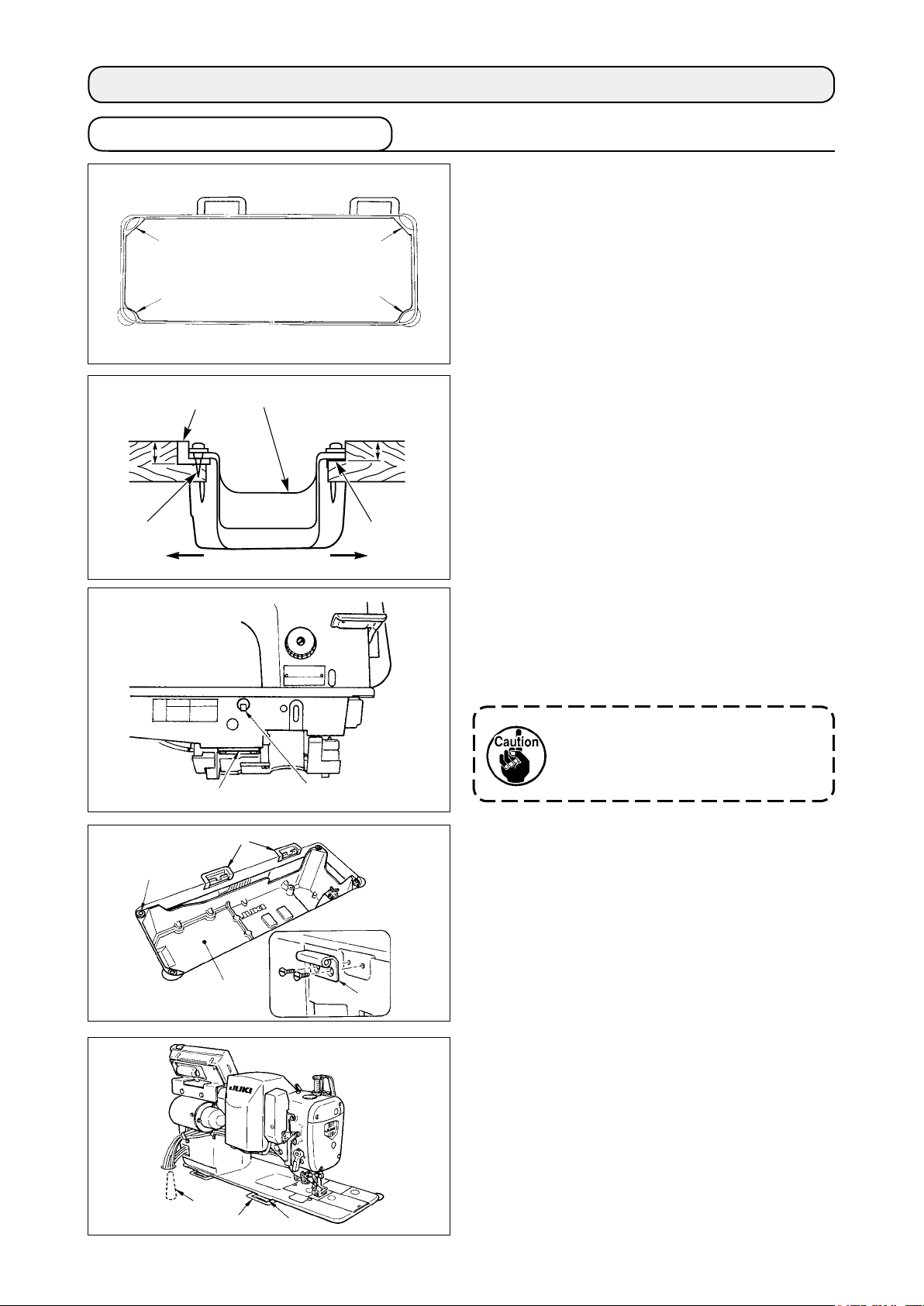

3-1. Installing the bottom cover

1) The bottom cover should rest on the four

corners of the machine table groove.

23.5 mm

2

3

1

1

A

4

B

3

1

19.5 mm

3

2) Fix two head support rubber seats

1

front side A to the protruding section of the

machine table using nails 2. Fix two machine

head cushion seats 3 on hinge side B using

a rubber-based adhesive, Then place bottom

cover 4 on the xed seats.

3) Remove air vent cap

attached to the

5

machine bed. (Be sure to attach cap 5 when

transporting the machine head in the state

that the machine head is removed from the

machine table.)

on the

8

C

4

7

5

6

If the sewing machine is operated

without removing air vent cap 5,

oil leakage from gear box portion

may occur.

C

4) Fit hinge

to the machine main body with

6

screws.

Fit the machine head to table rubber hinges

and place it on head cushions 8 on the

7

four corners.

5) In case the AK-device is not provided, attach

head support rod

to the machine table.

9

9

7

6

– 3 –

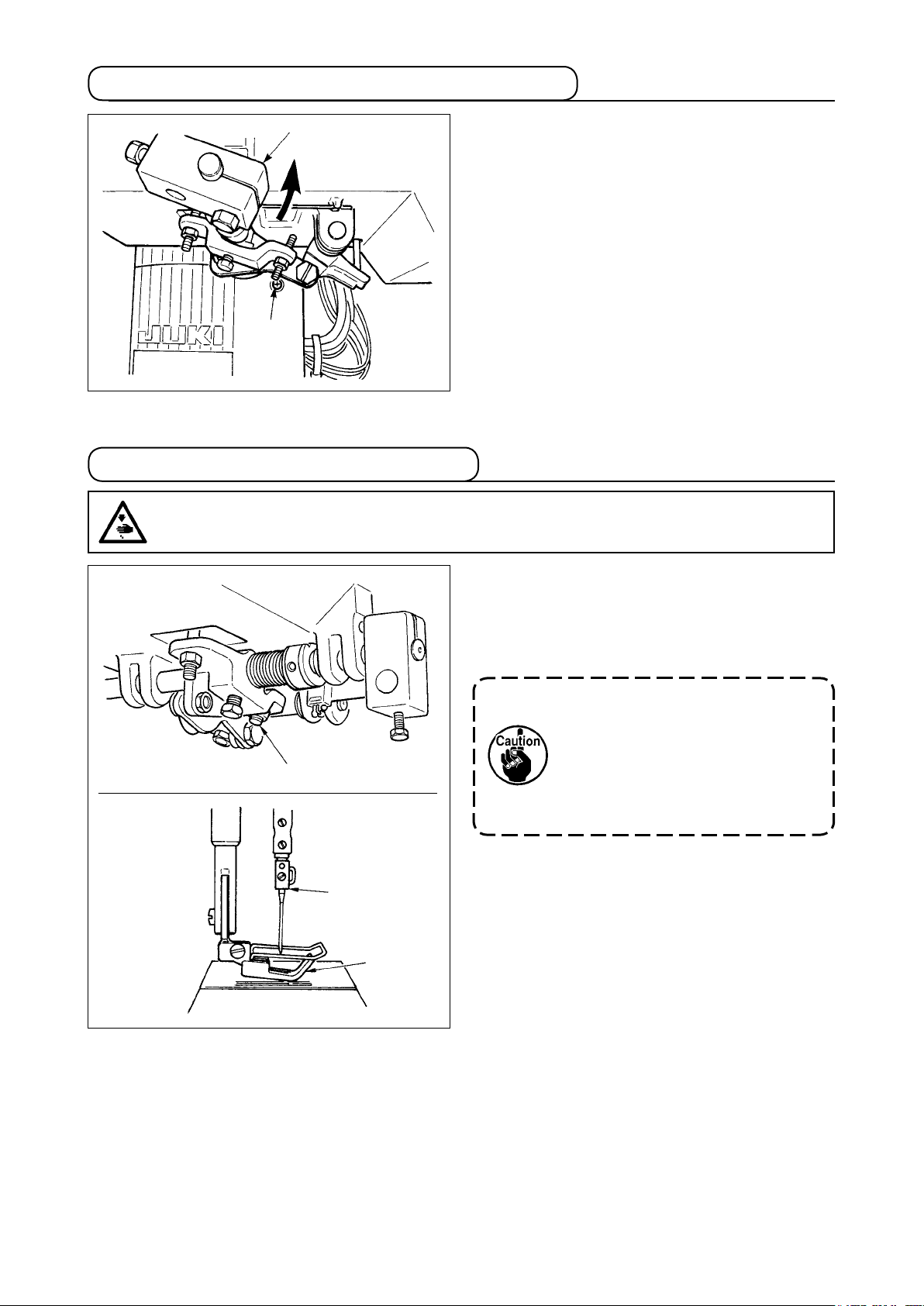

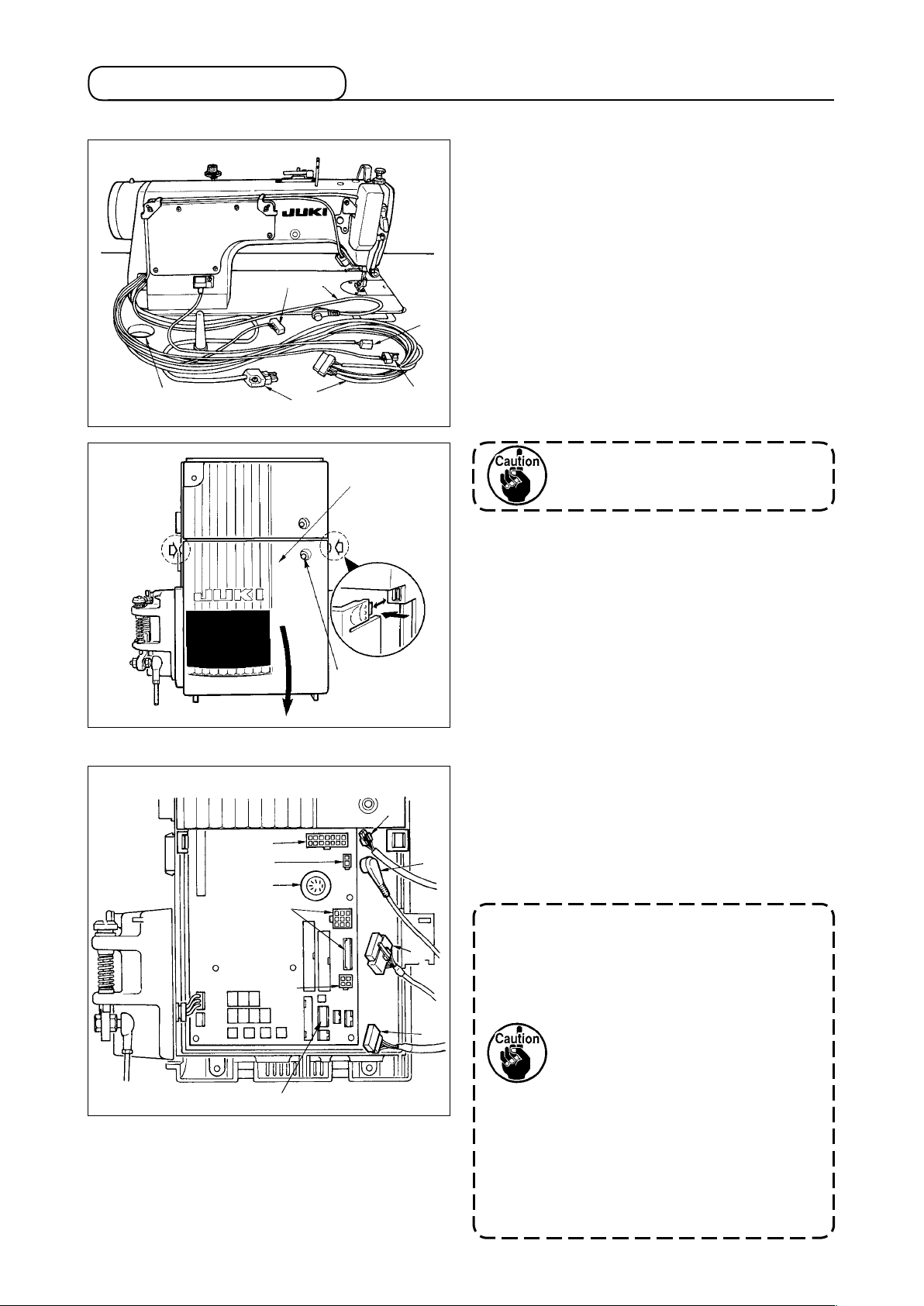

3-2. Opening and closing of the control box (SC-910)

2

1

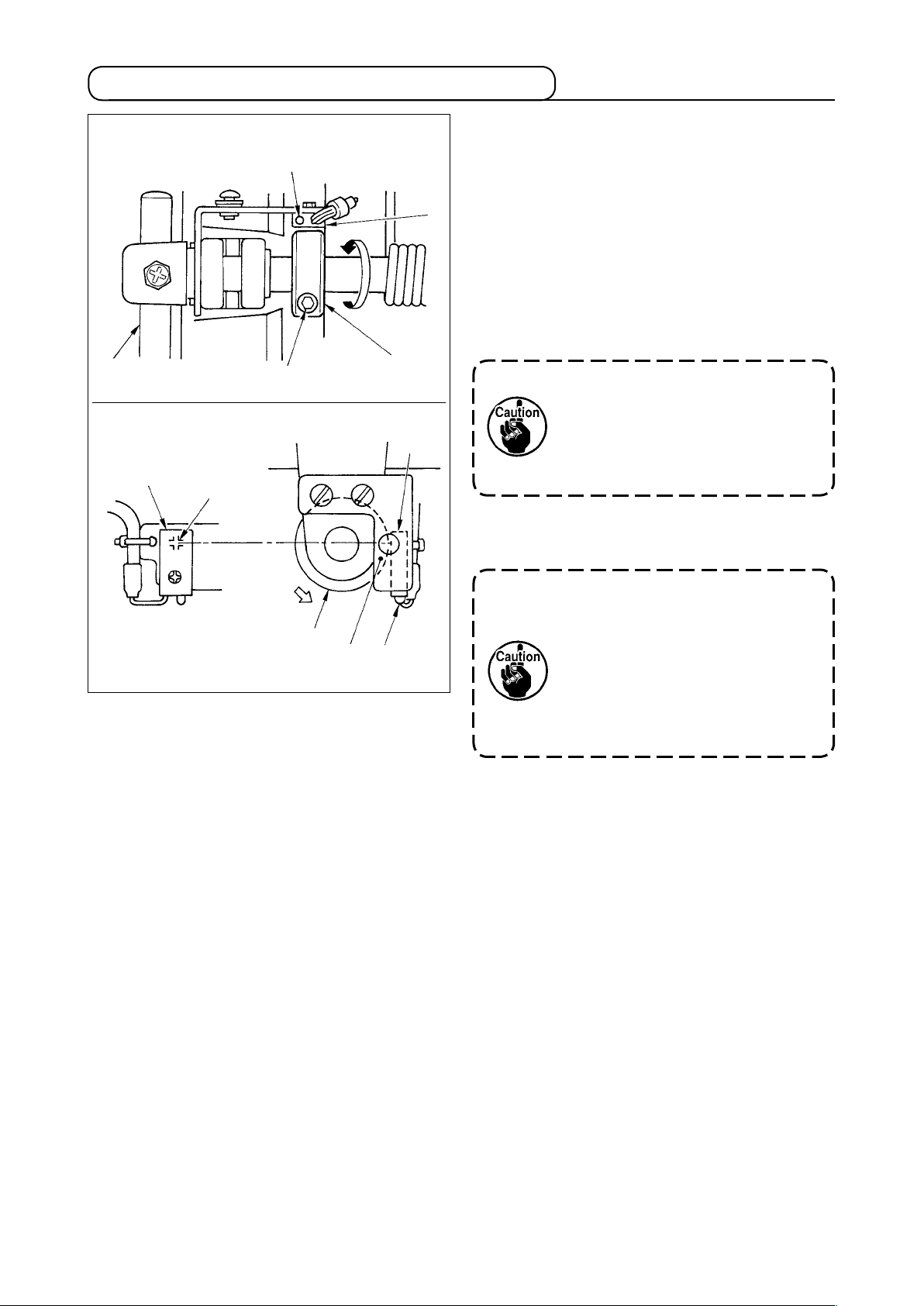

3-3. Adjusting the height of the knee lifter

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

When opening and closing the control box, move

th e knee lifter co mp onents 2 to the po sition

where screw hole 1 can be observed and perform

the work.

For the connection of the cords and setting of the

control box, refer to the Instruction Manual for

SC-910 together with this Instruction Manual.

1

2

3

1) The standard height of the presser foot lifted

using the knee lifter is 12 mm.

2) You can adjust the presser foot lift up to 13

mm using knee lifter adjust screw

1

.

D o no t o p e r a te t h e s ew i n g

mach i ne i n th e stat e th at the

presser foot 3 is lifted by 12 mm

or more since the needle bar 2

comes in contact with the presser

foot 3.

– 4 –

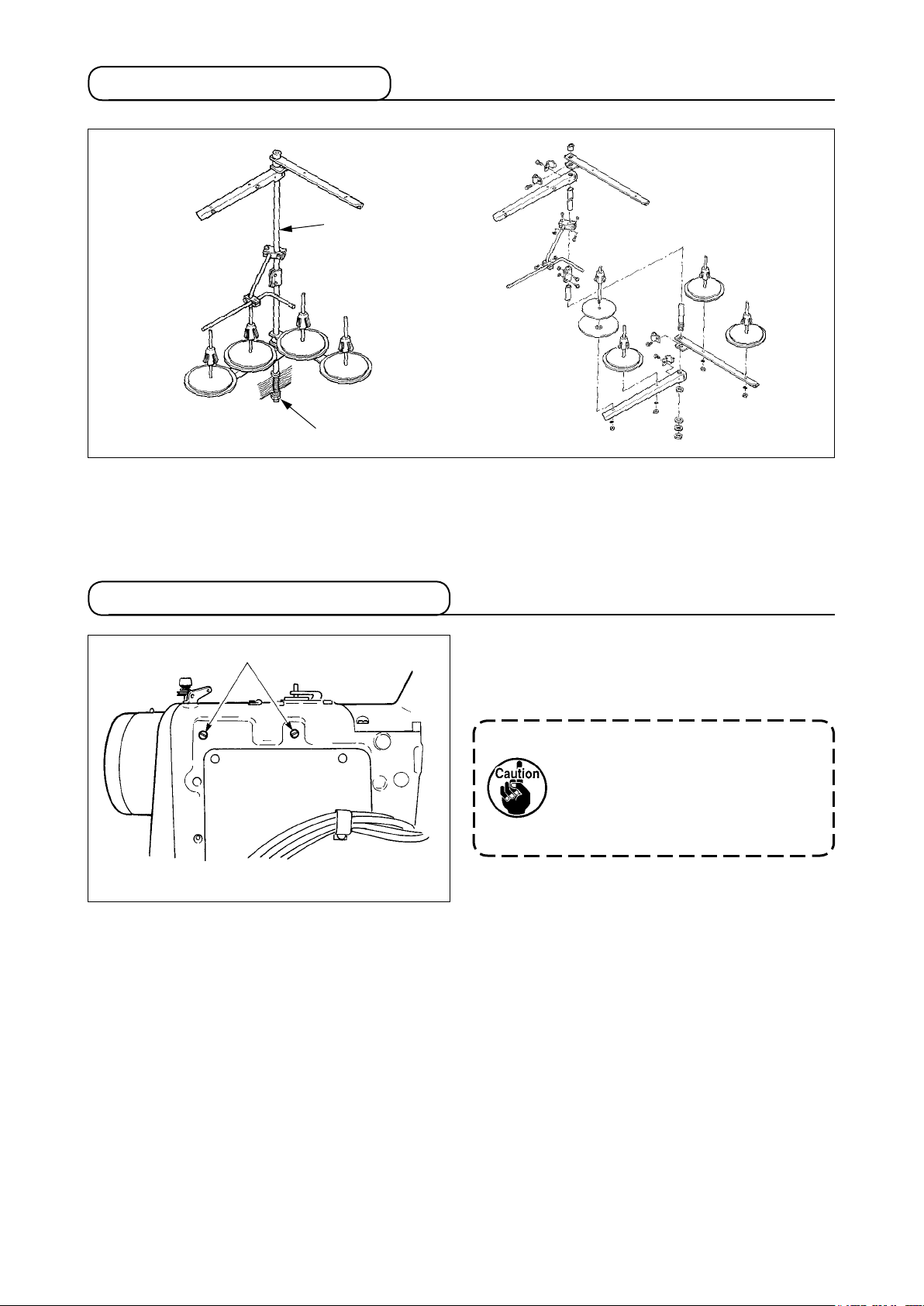

3-4. Installation of thread stand

2

1

Assemble the thread stand, set it up on the machine table using the installation hole in the table and

tighten nut

When you use power supplied by the overhead power line, pass the power supply cord through hollow

spool rest rod

gently.

1

2

.

3-5. Caution when installing the panel

1

Use washers, toothed lock washers, and screws

mounted on the machine head when installing

1

the panel.

The screws attached to the panel

may d amag e th e screw hole s

since the pitch of the screws is

different from that of the machine

head.

– 5 –

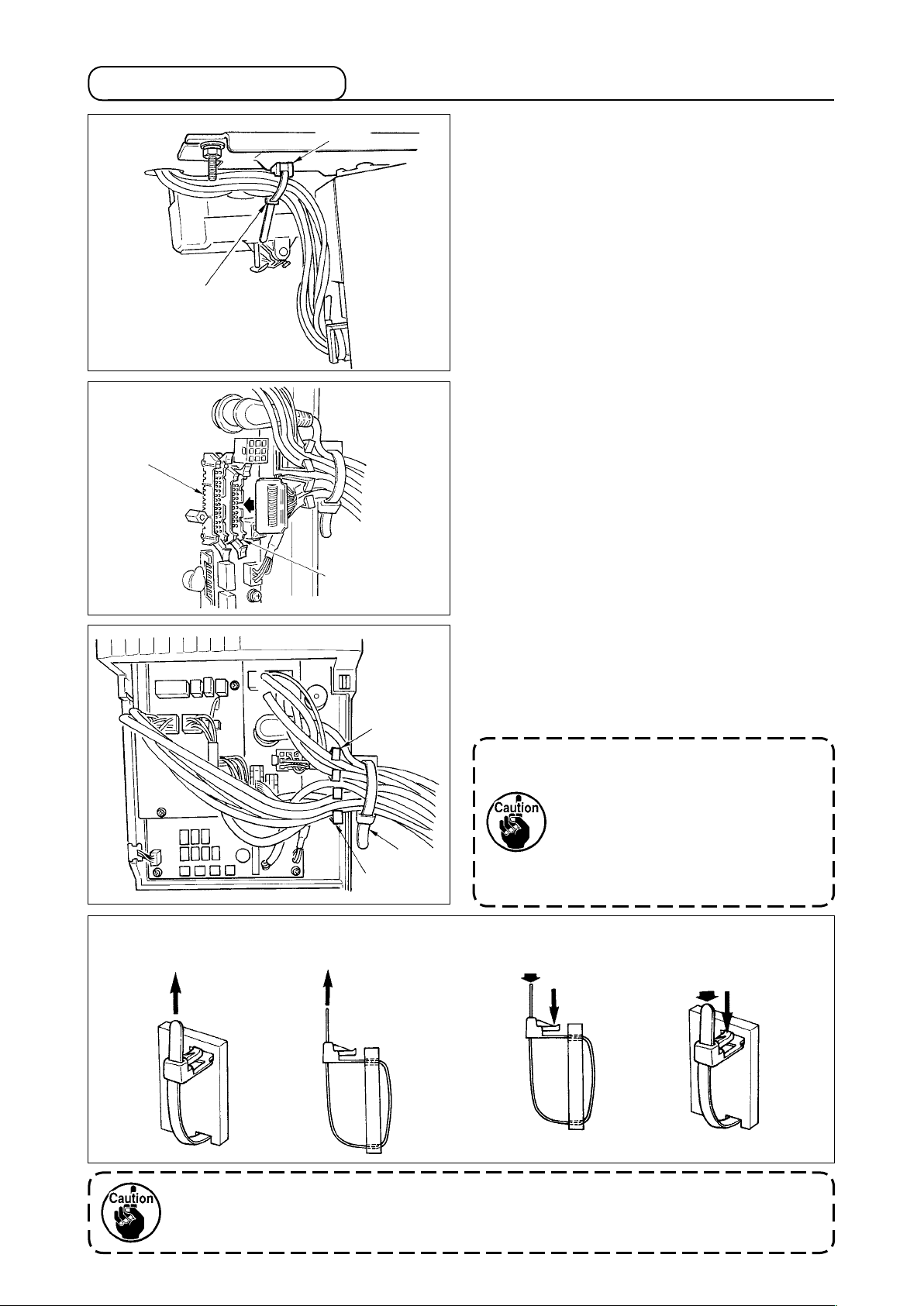

3-6. Connecting the cord

(1) LH-4128,4128-7,4168-7,4188-7

2

5

4

1) Pass the cords

of the thread trimming

笊

solenoid, reverse-stitching solenoid, etc.,

and the cords of the synchronizer 笆, safety

switch 笳, machine head 4P connector 笘,

motor signal 笙, motor output 笞through hole

A in the table to route them down under the

machine table.

2) Loosen setscrew

A

6

1

3

3) Pressing the side of front cover

direction of the arrow, open the front cover

in front cover

!2

!5

in the

!5

.

toward you.

Be sure to open / close the front

!5

4) Connect 14P code

machine head to connector

cover with your hands.

coming from the

1

(CN46).

7

5) Connect 4P connector coming from the

machine head

6) Connect 4P connector

to connector 笨 (CN31).

笘

(safty switch

笳

connector) coming from the machine head to

!2

connector

(CN48).

笶

7) Connect 7P connector

machine head to connector

8) Connect connector

笙

machine head to connector

coming from the

笆

(CN30).

筐

coming from the

(CN38, CN39).

筺

(Connect 8P connector to CN38 and in case

7

!0

@0

!1

!9

2

3

of 9Pconnector, connect to CN39.)

9) When the optional AK125 device is attached,

connect 2P connector

device to connector

coming from the AK

筴

(CN40).

筧

Be su re to secur ely inser t t he

r e s p e c t i v e connectors af ter

8

1

9

4

5

checking the inserting directions

sin ce all con nec tor s h ave the

inserting directions. (When using a

type with lock, insert the connectors

until they go to the lock.)

The sewing machine is not actuated

$5

unless the connectors are inserted

properly. In addition, not only the

problem of error warning or the

like occurs, but also the sewing

machine and the control box are

damaged.

– 6 –

(2) 4168-7,4188-7

Optional unit A

@3

@6

#2

@5

#0

#1

@4

@2

@1

In addition to “3-6. (1)”, connect the cords below.

1) Pass separately driven needle changeover switch cord

and separately driven needle sensor cord @3 through hole A in the table to route them down

@2

, separately driven needle solenoid cord

@1

under the machine table.

2) Connect 10P connector

Connect 8P connector @2 coming from the machine head to connector @5 (CN129).

3)

Connect 6P connector @3 coming from the machine head to connector @6 (CN128).

4)

Remove the cord extending from #2 (COM) from #0 (BNC) and connect it to #1 (LH).

5)

@1

ing from the machine head to connector @4 (CN125).

com

$4

$2

$3

$0

Remove setscrew $0 located on the left-hand

6)

side of the power switch, and place the point

of earth cord (asm.)

lifter detecting sensor plate (asm.)

coming from knee

$3

$2

setscrew. Then tighten the setscrew.

When the earth cord has not been

connected, malfunction will be

caused.

7) Connect knee lifter detection sensor

connector

– 7 –

to connector $5 (CN32).

$4

to the

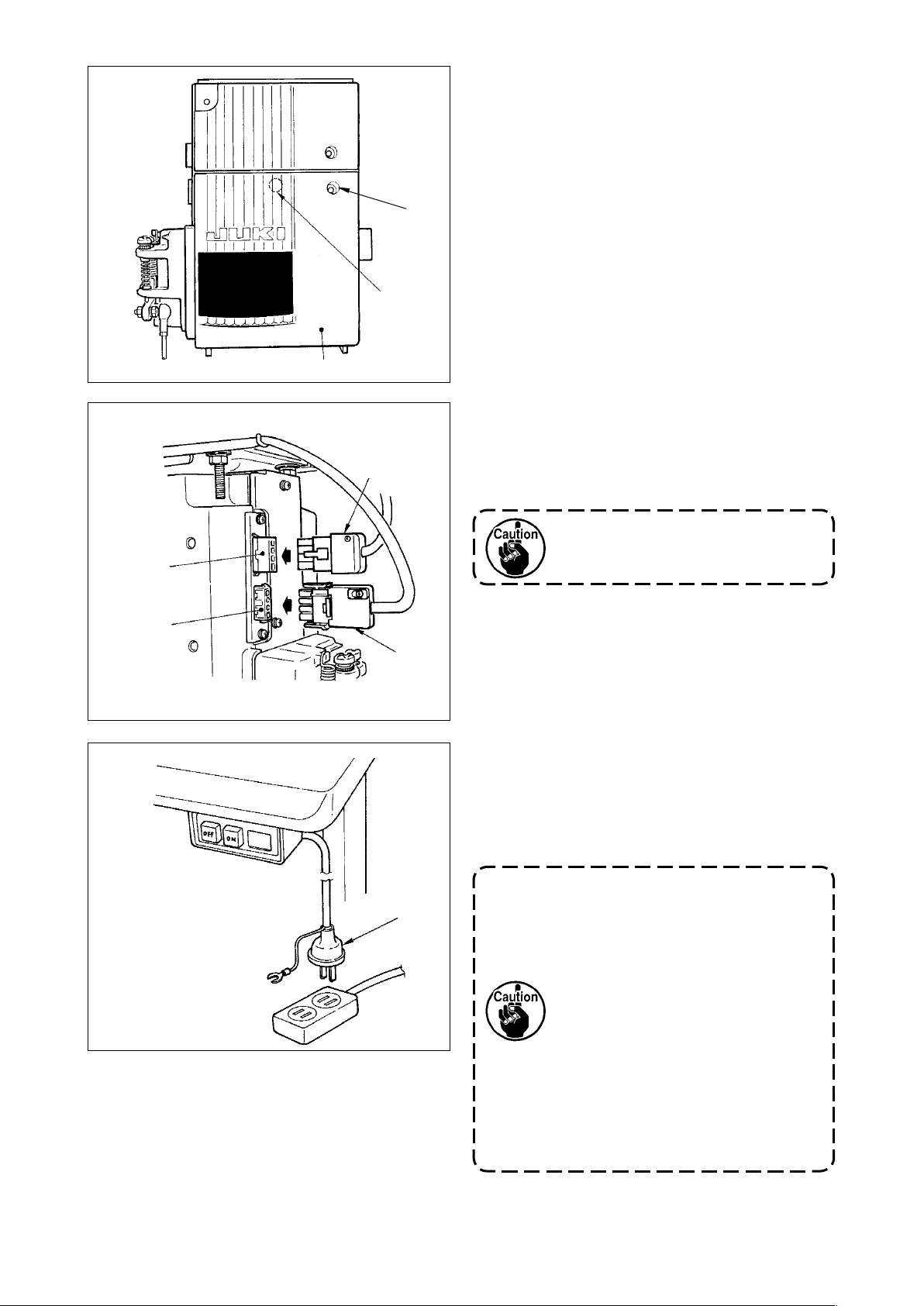

3-7. Managing the cord

B

@3

A

!4

@5

1) Fix all cables coming from the machine head

with cable clip band

.

綏

attached to tie-mount

絽

[Connection of the connector for CP panel]

Exclusive connectors are prepared for connection

of the connector for CP-160.

Paying attenti o n t o the o r i e n t ation of th e

connector, connect it to connector

located on

笋

the circuit board. After connecting, securely lock

the connector.

[Connecting for IP panel]

The connector for connecting IP-100 and IP-110

are prepared.

When connecting, insert the connector until it is

locked to

筬

.

2) After inserting the connector, put all cords

together with cable clip band

located on

!3

the side of the box. At this time, bundle the

cords (connector CN46) of thread trimming

solenoid, reverse feed solenoid, etc., AK

cord (connector CN40) and motor signal cord

(connector CN39) to wire saddle

, bundle

@5

detector cord (connector CN30) above wire

saddle

(connector CN32) between wire saddles

and

, knee lifter detection sensor cord

@5

and other cords to wire saddle

@6

@6

@5

.

1. Fix the cord clamp and the

cable clip band following the

attaching procedure.

2. When removing the connector,

!3

@6

remove it from the wire saddle

and remove it while pressing

the hook of the cable clip band.

Howtoxcableclipband

Pull

筍

Pull

How to remove cable clip band

Push

Push

Pushing the hook portion, push the band to remove it.

Push the hook.

1. Fixthecableclipbandfollowingtheattachingprocedureasshowninthegure.

2. To remove the cable clip band, push the cable clip band until it comes off while pressing

thehookofthebandfollowingtheremovingprocedureasshowninthegure.

– 8 –

筌

絽

笄

3) Close front cover

while paying attention to

筌

pinching of the wire.

Lightly press portion 絽 and insert front cover

with “click”.

筌

4) After that, x it with the screw

笄

.

筅

筥

笞

筵

5) Connect motor output cord

to connector

笞

located on the side of the box.

6) Connect connector 4P

to connector

筥

.

of the power switch

筵

Route the motor output cord from

the front face of the box.

7) Make sure that the power switch is turned

OFF and insert power supply cord

coming

筰

from the power switch into the power plug

socket. (Illustration is for the japanese

specication 100V type.)

筅

筰

1. Top end of power supply cord

varies in accordance with

destination or supply voltage.

Check again the supply voltage

and the voltage designated on

the control box when installing

the switch.

2. Prepare the power switch

conformed to the safety

standard.

3. Be sure to connect the ground

wire (green / yellow).

– 9 –

3-8. Adjusting the knee lifter detection seat (asm.)

1) Turn ON the power.

Conditions : LED starts lighting at presser

foot lift of 5 mm.

7

3

Detection section

LED

!3

To align

edges

4

3

3

2) Press knee p

foot by 5 mm from the top surface of throat

plate.

3) Turn knee lifter detection seat (asm.)

direction of the arrow and x it at the position

where LED of knee lifter detection sensor

starts lighting with setscrew

align the edge of detection seat (asm.)

with that of knee lifter detection sensor

Whe n t he edges of k nee li fter

4) Conrm that LED goes out when knee pad

plate

ad plate

and lift

7

the presser

4

. At this time,

!3

det ecti on s enso r 3 a nd k nee

lifter detection seat (asm.) 4 are

not aligned, detection trouble will

be caused.

is released.

7

in the

3

4

.

3

4

Magnet

* For explanation, the figure above omits knee pad

plate and the like.

LED

It is adjus ted s o that the kn ee

lifting motion is detected when

presser f oot is lifted by 5 mm.

When using it with the lift amount

of less tha n 5 mm, r edu ce the

standard adjustment value and

re-adjust according to step 3).

5) When the magnet of knee lifter detection seat

(asm.)

comes near the detection section

4

(+ mark section) of knee lifter detection

sensor

, it detects that knee lifting has been

3

performed and LED lights up.

– 10 –

4. PREPARATION OF THE SEWING MACHINE

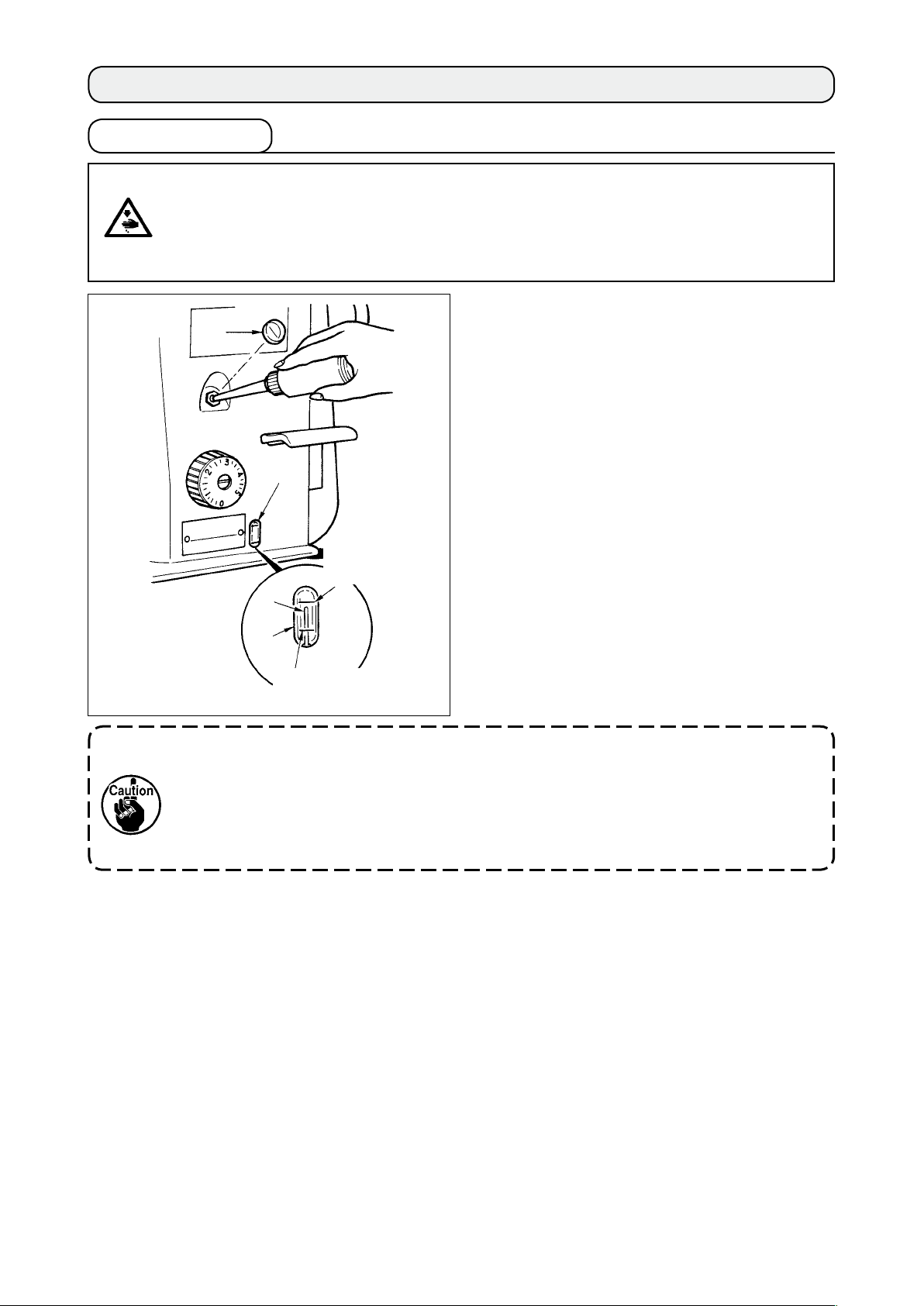

4-1. Lubrication

WARNING :

1. Do not connect the power plug until the lubrication has been completed so as to prevent

accidents due to abrupt start of the sewing machine,

2. Topreventtheoccurrenceofaninammationorrash,immediatelywashtherelatedportionsif

oil adheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

Fill the oil tank with oil for hook lubrication before

1

2

Upper engraved

marker line

3

2

Lower engraved

marker line

operating the sewing machine.

1) Remove oil hole cap 1 and fill the oil tank

with JUKI New Defrix Oil No. 1 using the oiler

supplied with the machine.

2) Fill the oil tank with the oil until the top end

of oil amount indicating rod 3 aligns with

the upper engraved marker line of oil amont

indicating window 2.

If the oil is lled excessively, it will leak from

the air vent hole in the oil tank or proper

lubrication will be not perform ed. So, be

careful.

3) When you operate the sewing machine, rell

oil if the top end of oil amount indicating rod

comes down to the lower engraved marker

3

line of oil amount indicating window

2

.

• When you use a new sewing machine or a sewing machine after an extended period

of disuse, use the sewing machine after performing break-in at 3,000 rpm or less.

• For the oil for hook lubrication, purchase JUKI New Defrix Oil No. 1 (Part No. :

MDFRX1600C0).

• Do not use again the oil gathered in the bottom cover since it will cause the trouble

of lubrication.

– 11 –

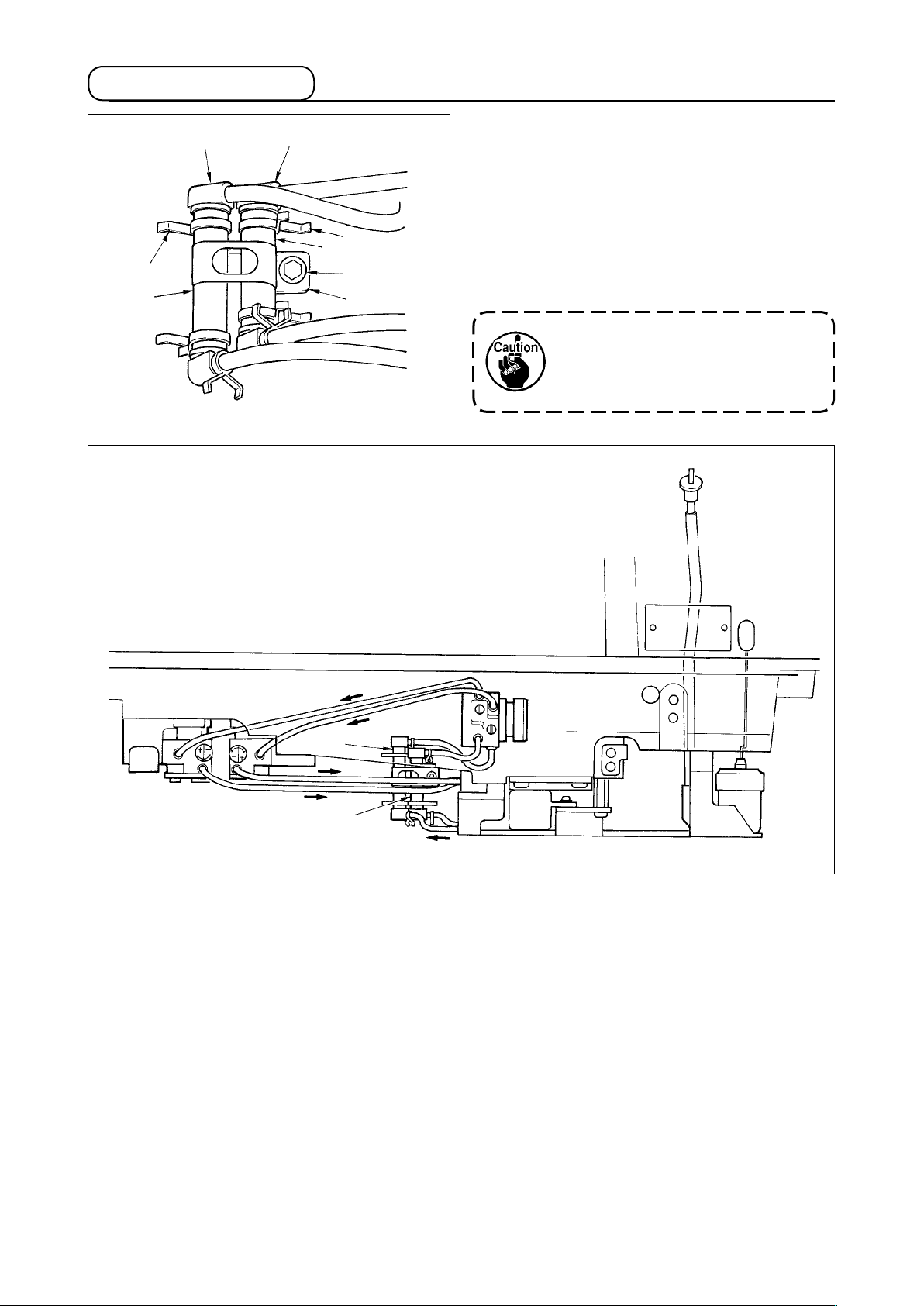

4-2.Cleaningthelter

8

9

!0

!0

9

8

7

6

Periodically clean filter sections

and 5 (2

4

places) (approximately once in three months).

1) Loosen setscrews

of oil tube holder 6

7

and remove and remove the lter from the

machine bed.

2) Loosen pipe stopper

and joint

!0

.

, and remove tube 9

8

3) After removing dust adhered to the net section

of joint

, return the lter to its home position.

!0

Whentheltersclogwithdustor

the like, trouble of lubrication

occurs and trouble of the sewing

machine will be caused.

Lubrication to hook

Circulation

4

5

Lubrication

– 12 –

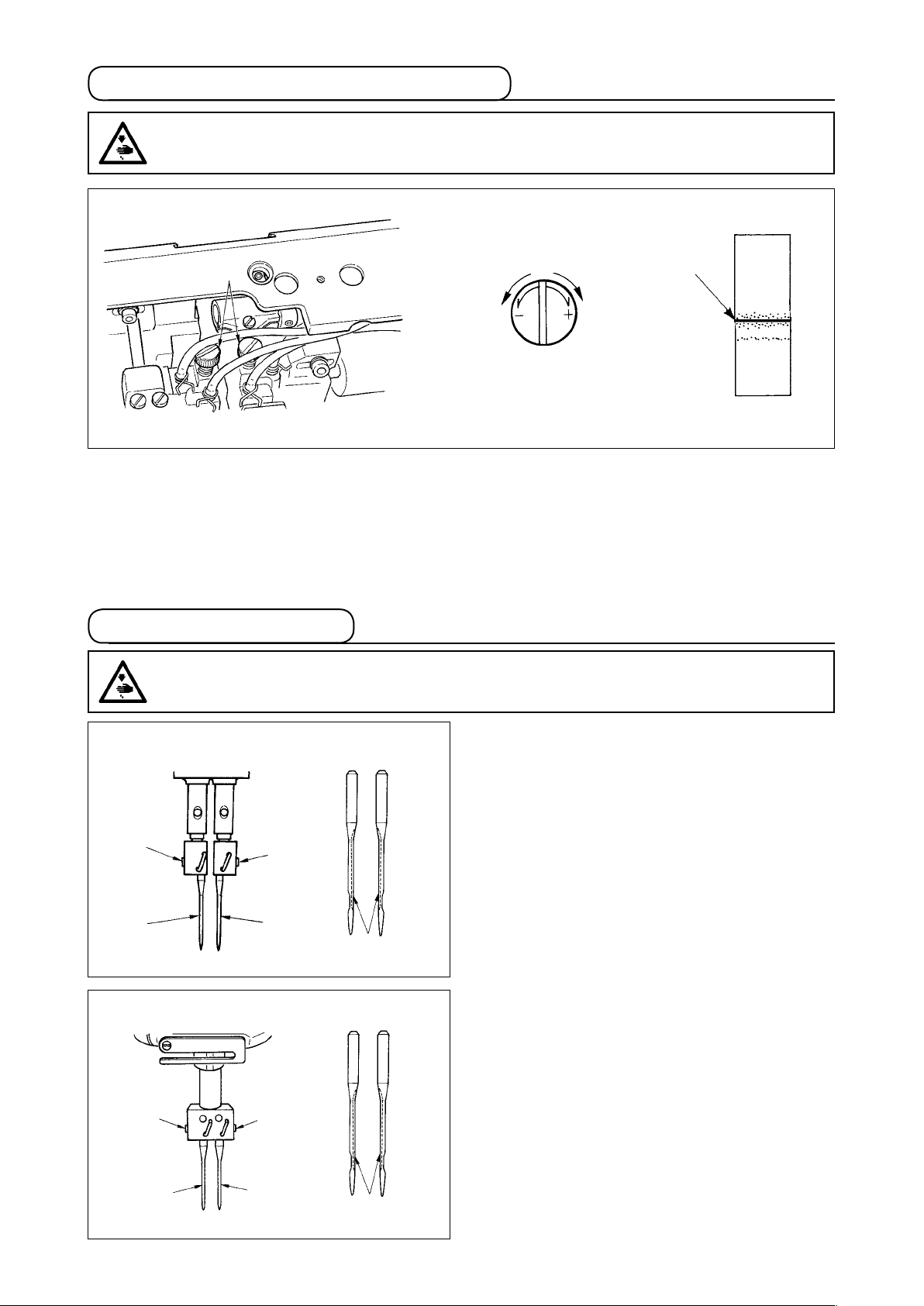

4-3. Adjusting the amount of oil in the hook

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

1

Oil amoun t

decreases

Oil splashes

Oil amount

increases

Adjust the amount oil using adjusting screw 1. Turn screw 1 clockwise to increase the amount of oil

in the hook or counterclockwise to decrease it. Measure the amount of oil in ve seconds. When the

amount of oil is excessively decreased, break-down will be caused. So, be careful.

4-4. Attaching the needles

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

LH-4168-7, 4188-7

2

1

LH-4128, 4128-7

2

2

1

2

3

Switch "off" the motor.

Use DPx5 needles.

1) Turn the handwheel until the needle bar has

come up to the highest point of its stroke.

2) Loosen needle clamp screws 2 and pick up

two needles 1 in the way that their grooves

are facing outwards.

3

3) Insert the needles into the needle clamp as

far as they will go.

4) Tighten needle clamp screws 2 rmly.

1

1

3

– 13 –

Loading...

Loading...