Page 1

LBH-1790AN,1795AN

INSTRUCTION MANUAL

Page 2

CONTENTS

I. IMPORTANT SAFETY INSTRUCTIONS ..................................................... 1

II. SPECIFICATIONS ....................................................................................... 1

1. Specications .........................................................................................................................2

2. Standard sewing shape list ...................................................................................................3

3. Conguration .........................................................................................................................4

III. INSTALLATION .......................................................................................... 5

IV. PREPARATION BEFORE OPERATION .................................................. 15

1. Lubrication ...........................................................................................................................15

2. Inserting the needle ............................................................................................................. 16

3. Threading the needle-thread ...............................................................................................17

4. Threading the bobbin case .................................................................................................17

5. Adjusting the bobbin thread tension .................................................................................18

6. Installation of bobbin case ..................................................................................................18

7. Installing the knife ...............................................................................................................19

8. Checking the sewing machine in the delivered state ....................................................... 19

V. OPERATION OF THE SEWING MACHINE .............................................. 20

1. Explanation of the operation panel switch ........................................................................ 20

2. Basic operation of the sewing machine ............................................................................22

3. How to use the pedal ........................................................................................................... 24

4. Input of the presser type ..................................................................................................... 26

5. Performing pattern selection .............................................................................................. 27

6. Changing needle thread tension ........................................................................................28

7. Performing re-sewing .......................................................................................................... 29

8. Winding bobbin thread ........................................................................................................ 30

9. Using the counter ................................................................................................................31

10. Using the initial value pattern ........................................................................................... 33

11. Changing sewing data .......................................................................................................34

12. Method of setting sewing data with/without edit ............................................................ 36

13. Sewing data list .................................................................................................................. 37

14. Copying sewing pattern ....................................................................................................43

15. How to edit/check the data other than sewing data .......................................................44

16. Using parameter register key ...........................................................................................46

17. Performing continuous stitching .....................................................................................47

18. Performing cycle stitching ................................................................................................ 50

19. How to change the name of cycle/continuous sewing data ..........................................52

20. Explanation of plural motions of knife .............................................................................53

21. Method of changing memory switch data .......................................................................54

22. Memory switch data list ....................................................................................................55

23.

How to change the sewing speed while the sewing machine is engaged in sewing ......... 59

24. How to adjust the pedal variable resistor ........................................................................ 60

i

Page 3

25. How to adjust the contrast ................................................................................................ 61

26. How to set the key lock .....................................................................................................61

27. Communication .................................................................................................................. 62

28. Setting the irregular work .................................................................................................66

VI. MAINTENANCE ....................................................................................... 68

1. Adjusting the needle-to-hook relation ...............................................................................68

2. Adjusting the needle thread trimmer .................................................................................69

3. Adjusting the presser bar pressure ...................................................................................70

4. Adjustment of the bobbin presser unit ..............................................................................70

5. Thread tension .....................................................................................................................71

6. Replacing the fuse ............................................................................................................... 72

VII. GAUGE COMPONENTS ........................................................................ 73

1. Cloth cutting knife ...............................................................................................................73

2. Throat plate ..........................................................................................................................73

3. Presser .................................................................................................................................. 73

VIII. ERROR CODE LIST .............................................................................. 74

1. How to operate the sewing machine in the case an error is displayed .......................... 74

2. Operation procedure to be followed when a message is displayed ............................... 80

IX. TROUBLES AND CORRECTIVE MEASURES ....................................... 81

X. DRAWING OF THE TABLE ...................................................................... 83

XI. INITIAL VALUE DATA FOR EACH SHAPE TABLE ............................... 85

ii

Page 4

I. IMPORTANT SAFETY INSTRUCTIONS

1) Never operate the machine unless the oiling tank has been properly lubricated.

2) After the completion of a day's work, remove dust and dirt accumulating on the hook, bobbin thread

trimming knife section and lubricating hole of the oil tank. At this time, also check whether or not the oil

quantity is adequate.

3) Be sure to return the starting pedal to the home position after the machine has started to run.

4) This machine is provided with a machine head tilt detector so that it cannot be operated in the state

that the machine head is tilted. When operating this sewing machine, turn the power switch ON after

setting the sewing machine to the bed base properly.

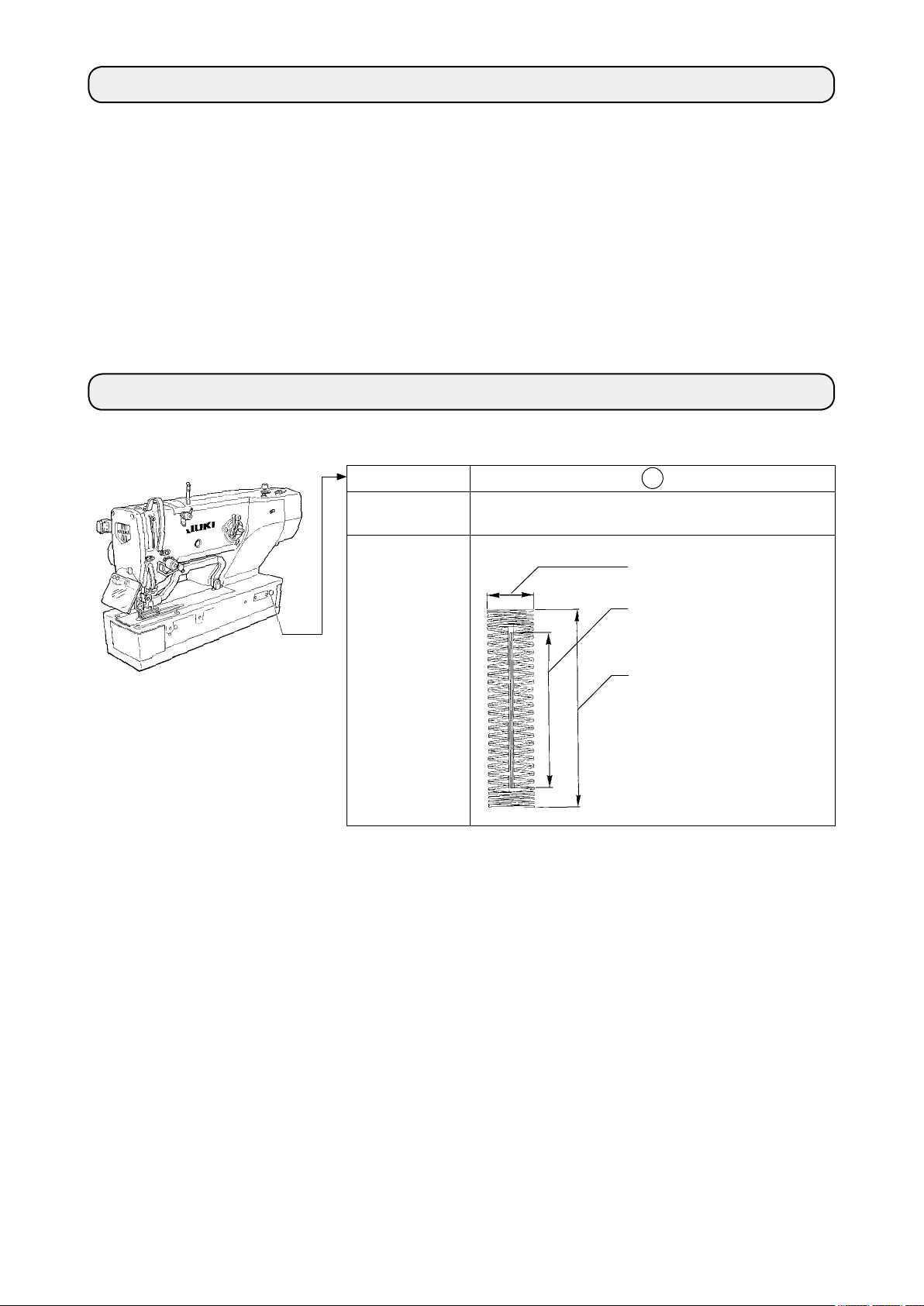

II. SPECIFICATIONS

Main specications of the LBH-1790AN, LBH-1795AN computer-controlled, lockstitch buttonholing machine.

Subclass S

Major application

Buttonholing size

Buttonholing of cloth such as men’s shirts, blouses,

work uniforms, ladies' wear, etc.

Standard : Max. 5 mm

Special type part : Max. 10 mm

Knife size used :

6.4 to 31.8 mm (1/4' to 1-1/4')

Buttonholing sewing length

Standard : Max. 41 mm

Special type part

: Max. 120 mm

– 1 –

Page 5

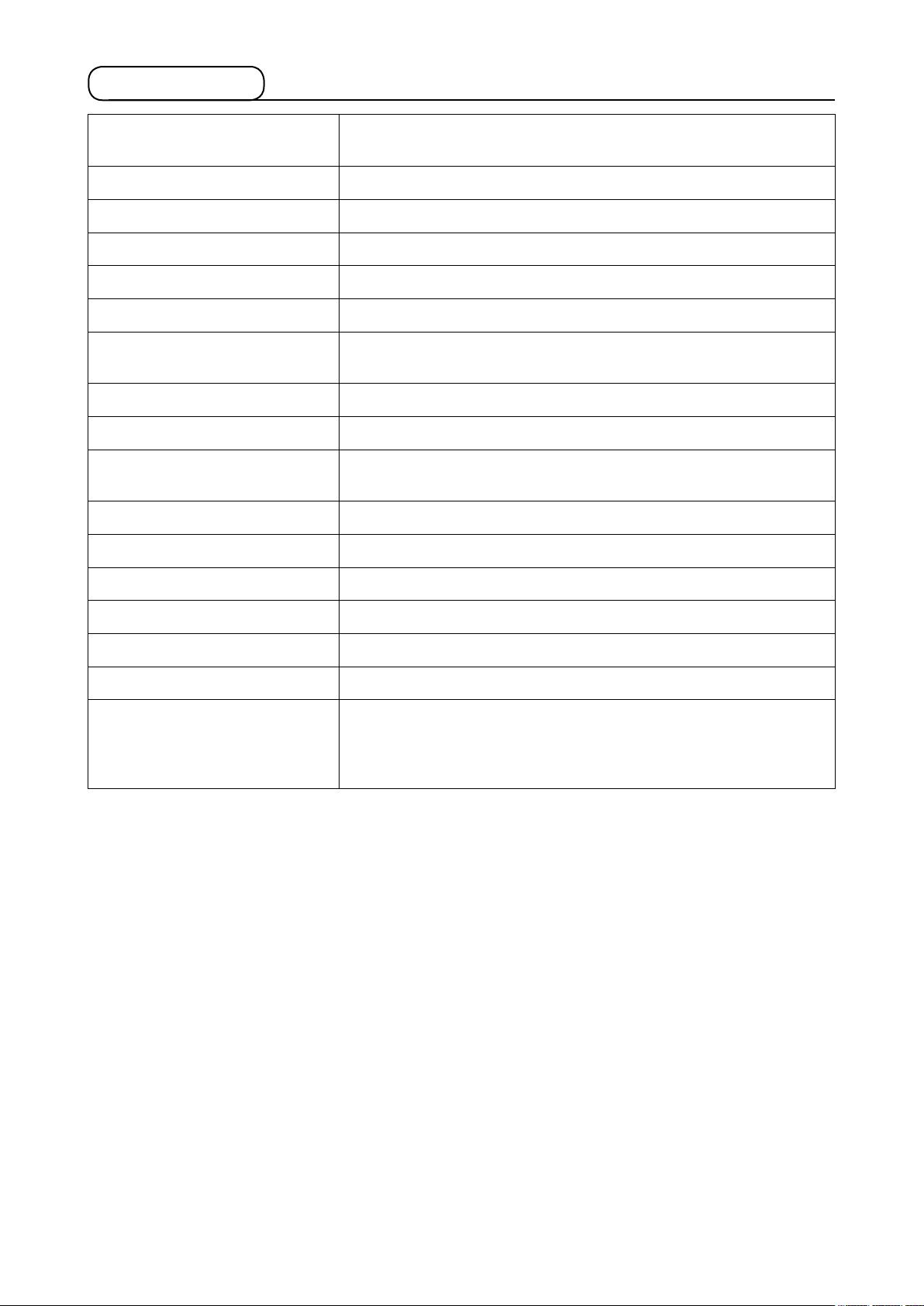

1. Specications

Sewing speed

Needle DP × 5 #11J to #14J

Hook DP type full-rotary hook

Needle rocking drive method Drive by stepping motor

Feed drive method Drive by stepping motor

Presser lifting drive method Drive by stepping motor

Lift of presser foot 14 mm (Optional setting available) Max. : 17 mm (At the time of nee-

Cloth cutting knife drive method Motor-driven crank system

Standard sewing shape 31 kinds

Number of patterns stored in

memory

Mass Machine head 55 kg, Control box 5.5 kg

Power consumption 370 VA

Standard speed : 3,600 sti/min (Max. : 4,200 sti/min) (Max. : 3,300 sti/

min when dry hook is used)

dle up by reverse run)

99 patterns

Operating temperature range 5 ˚C to 35 ˚C

Operating humidity range 35% to 85% (No dew condensation)

Line voltage Rated voltage ± 10% 50/60 Hz

Motor used 3-phase 200 to 240 V, 370 VA

Noise - Equivalent continuous emission sound pressure level (LpA) at the

workstation :

A-weighted value of 81.0 dB ; (Includes ; KpA = 2.5 dB) ; according

to ISO 10821- C.6.3 -ISO 11204 GR2 at 3,600 sti/min.

– 2 –

Page 6

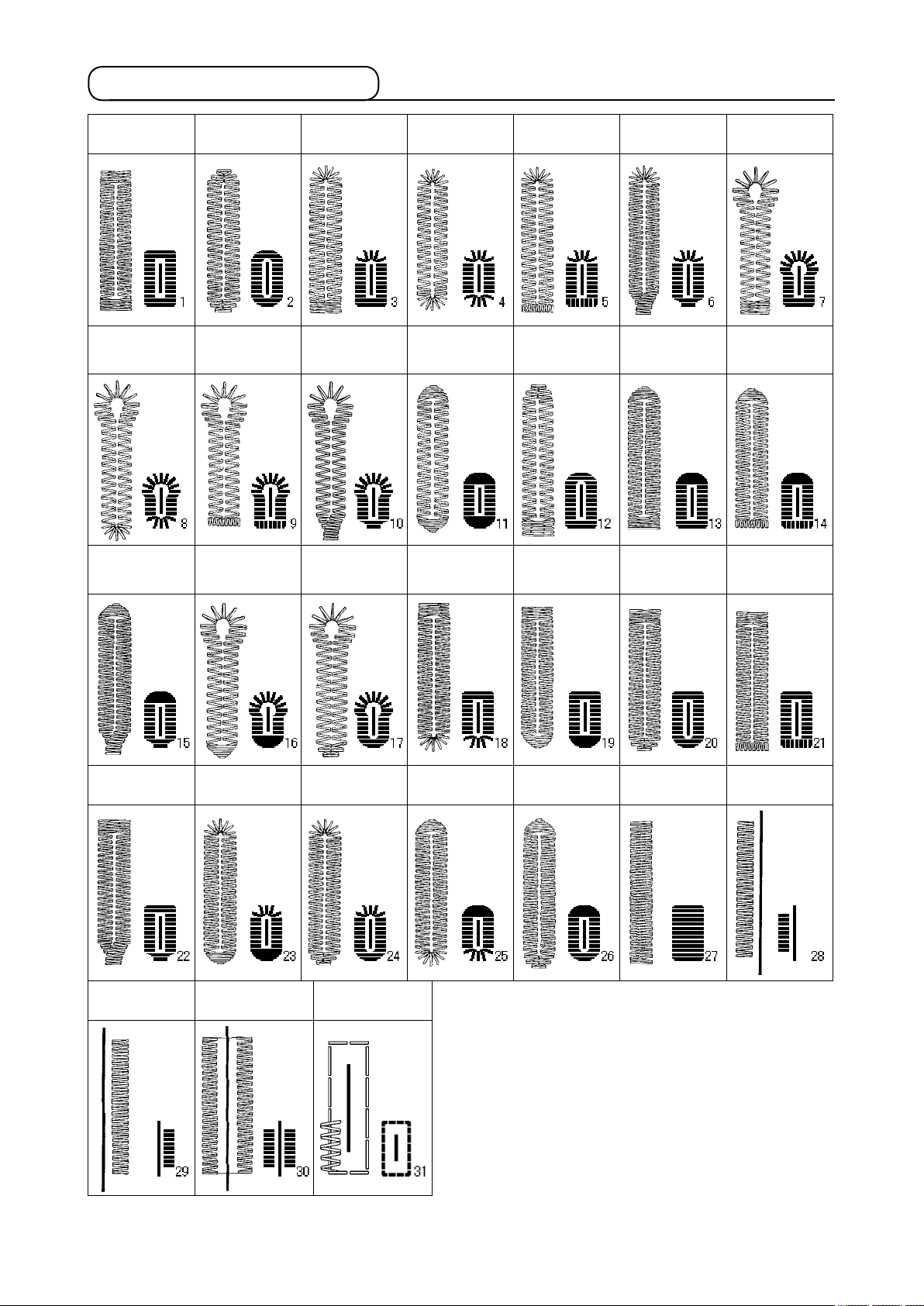

2. Standard sewing shape list

(1) Square type (2) Round type

PANEL

DISPLAY

(8) Eyelet radial

type

PANEL

DISPLAY

(15) Semilunar

taper bar-tacking

type

(9) Eyelet straight

bar-tacking type

(16) Eyelet semi-

PANEL

DISPLAY

PANEL

DISPLAY

lunar type

(3) Radial square

type

PANEL

DISPLAY

(10) Eyelet taper

bar-tacking type

PANEL

DISPLAY

(17) Eyelet round

type

(4) Radial type

PANEL

DISPLAY

(11) Semilunar

type

PANEL

DISPLAY

(18) Square radi-

al type

(5) Radial straight

bar-tacking type

PANEL

DISPLAY

(12) Round

square type

PANEL

DISPLAY

(19) Square

semilunar type

(6) Radial taper

bar-tacking type

PANEL

DISPLAY

(13) Semilunar

square type

PANEL

DISPLAY

(20) Square

round type

(7) Eyelet square

type

PANEL

DISPLAY

(14) Semilunar

straight bar-tack-

ing type

PANEL

DISPLAY

(21) Square

straight bar-tack-

ing type

PANEL

DISPLAY

(22) Square taper

bar-tacking type

PANEL

DISPLAY

(29) Bar-tacking,

left cut

PANEL

DISPLAY

PANEL

DISPLAY

(23) Radial semi-

lunar type

PANEL

DISPLAY

(30) Bar-tacking,

center cut

PANEL

DISPLAY

PANEL

DISPLAY

(24) Radial round

type

PANEL

DISPLAY

(31) Basting + Cloth

cutting knife

PANEL

DISPLAY

PANEL

DISPLAY

(25) Semilunar

radial type

PANEL

DISPLAY

PANEL

DISPLAY

(26) Semilunar

round type

PANEL

DISPLAY

PANEL

DISPLAY

(27) Bar-tacking

PANEL

DISPLAY

PANEL

DISPLAY

(28) Bar-tacking,

right cut

PANEL

DISPLAY

– 3 –

Page 7

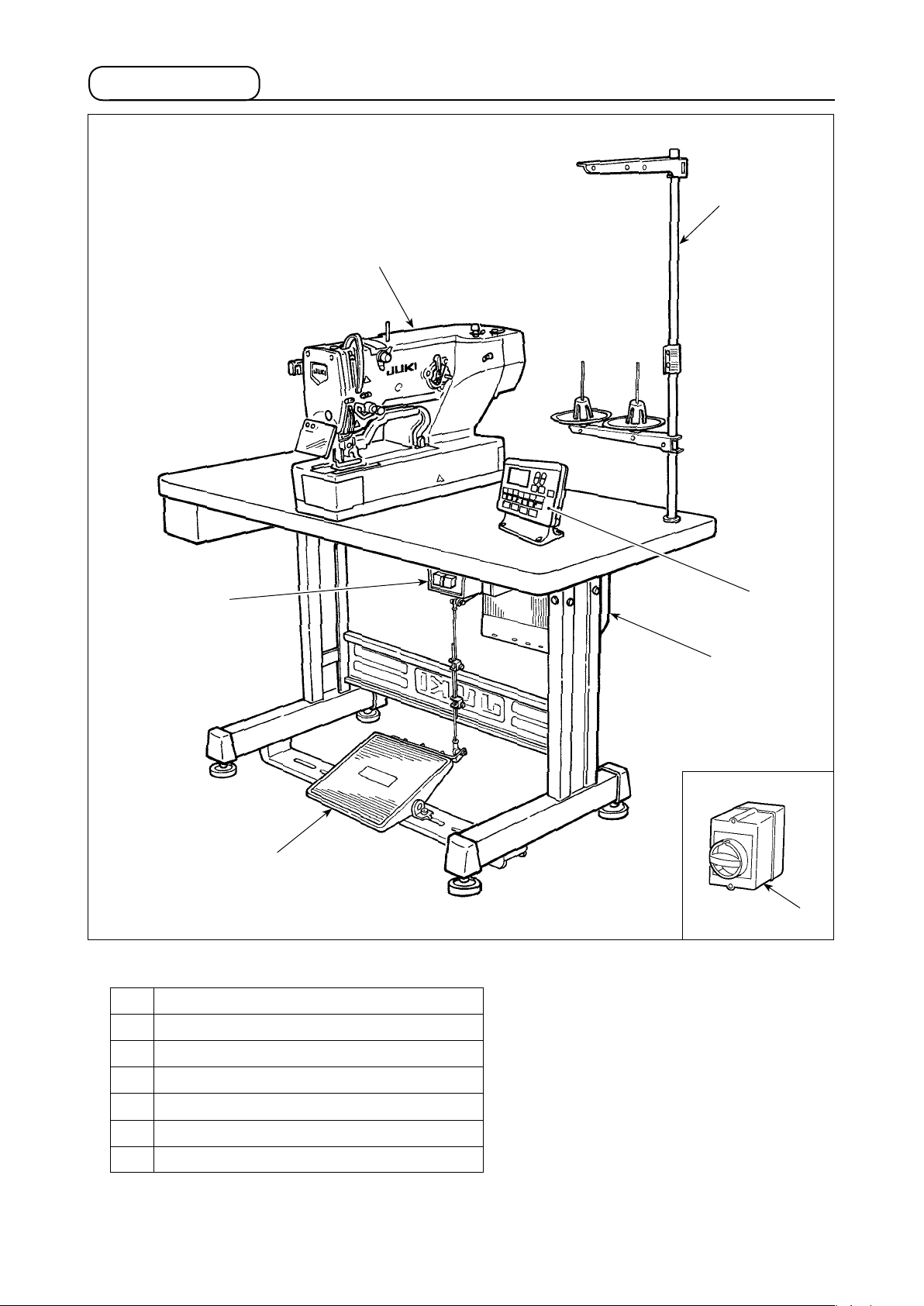

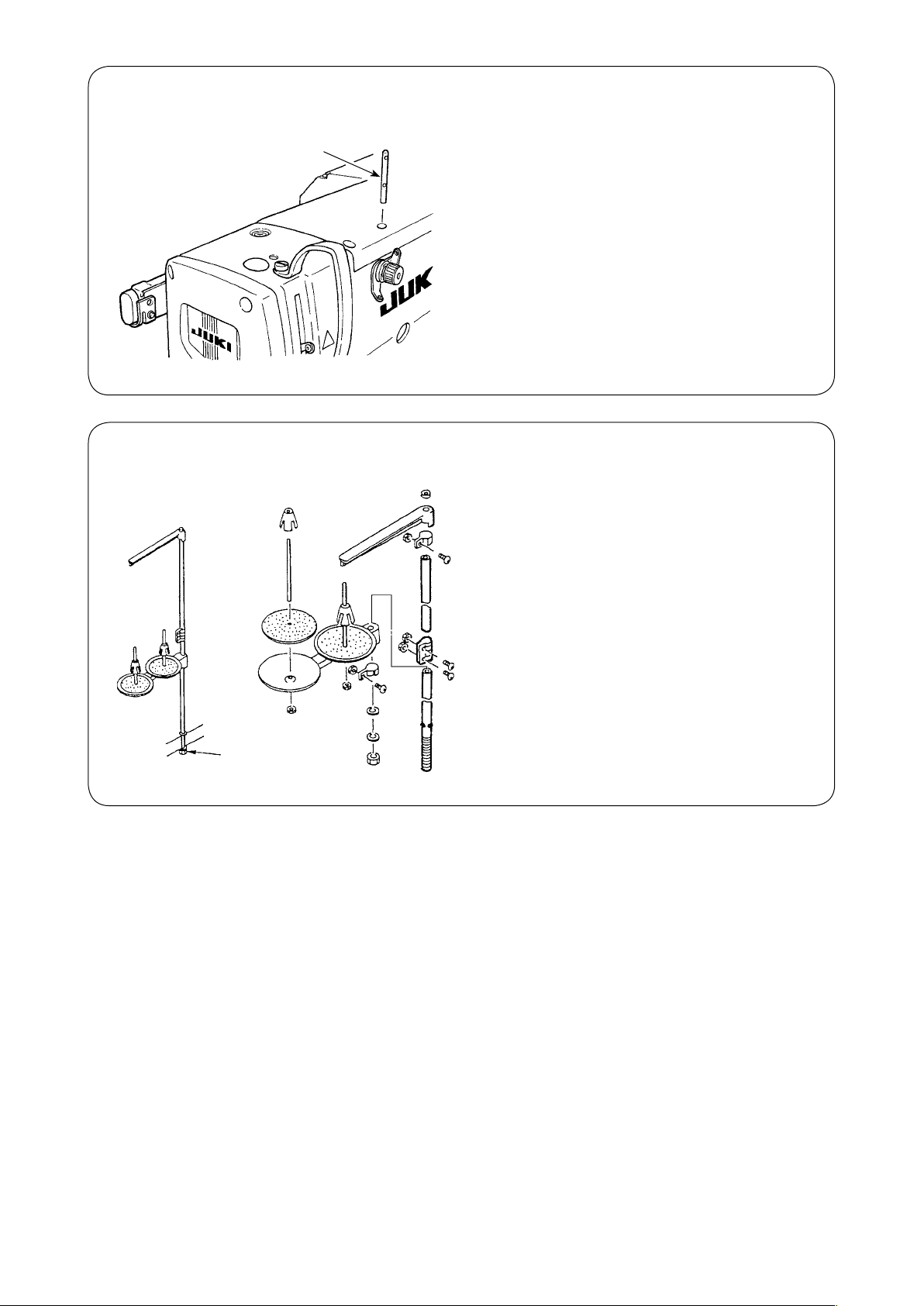

3. Conguration

LBH-1790AN, LBH-1795AN consists of the following components.

Power switch

Machine head (LBH-1790AN, LBH-1795AN)

Operation panel

Control box (MC-602)

Presser lifting and starting pedal

Thread stand device

Power switch (EU type)

– 4 –

Page 8

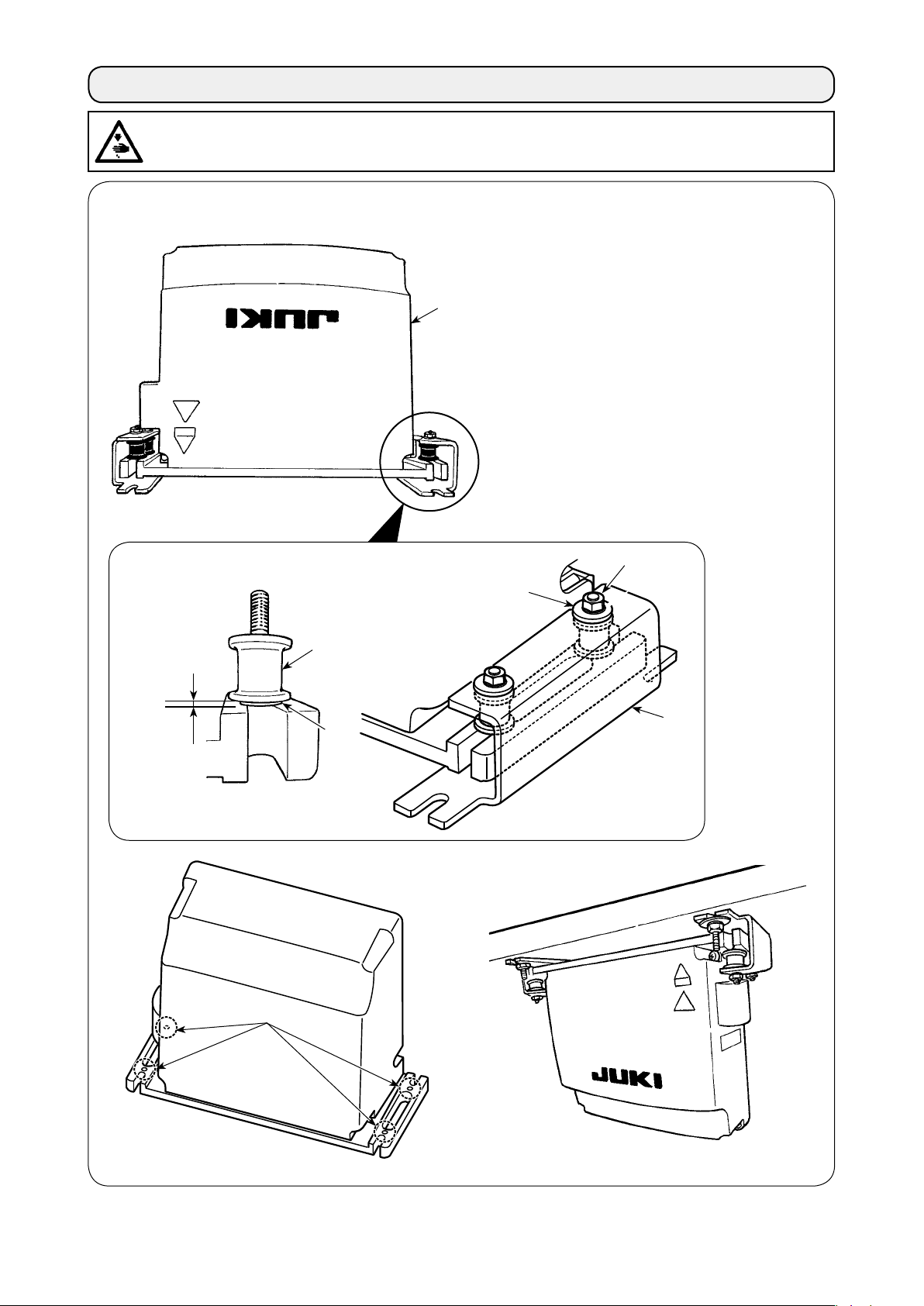

III. INSTALLATION

WARNING :

To prevent possible accidents caused by the fall of the sewing machine, perform the work by two

persons or more when the machine is moved.

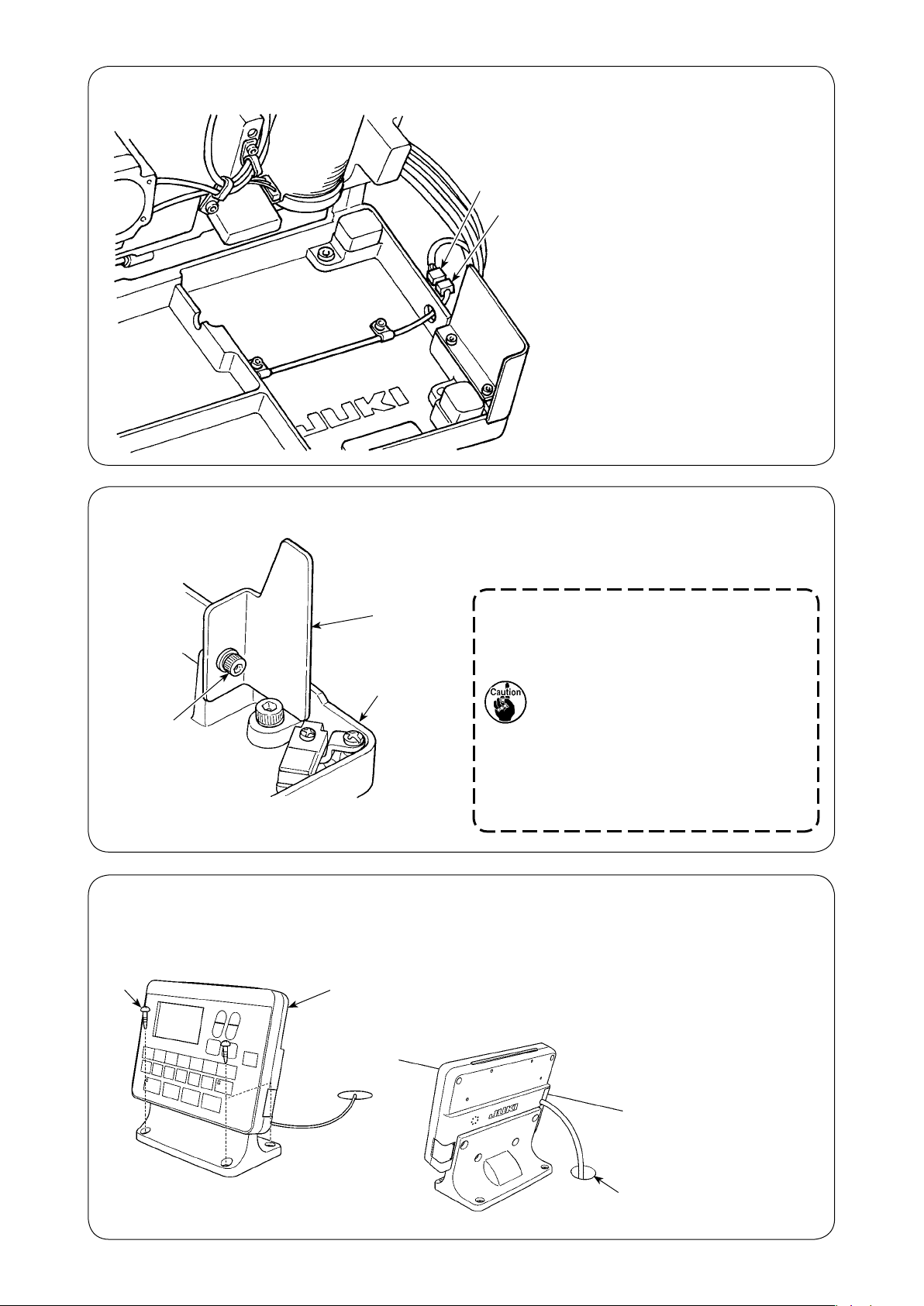

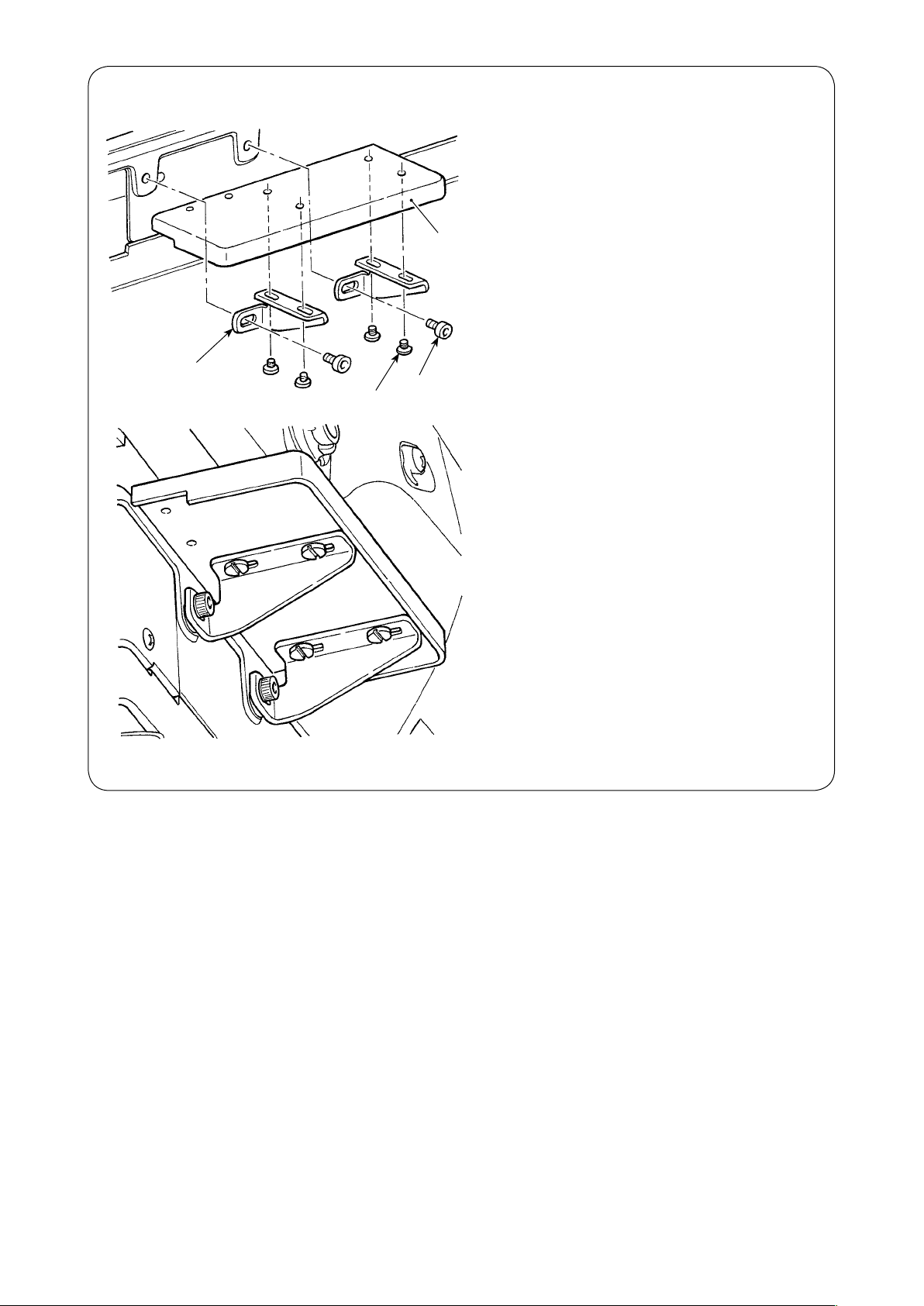

(1) Preparation for assembly of the control box

1) Fix toothed washers and rubber

cushions on control box . (At four

locations)

* Tighten the toothed washers so that their

height becomes 0.8 mm.

2) Fix control box mounting plate with

plain washers and nuts . (At four

locations)

* Fix the mounting plate while tting the

screw in the U-groove in the mounting

plate.

0.8 mm

At four locations

– 5 –

Page 9

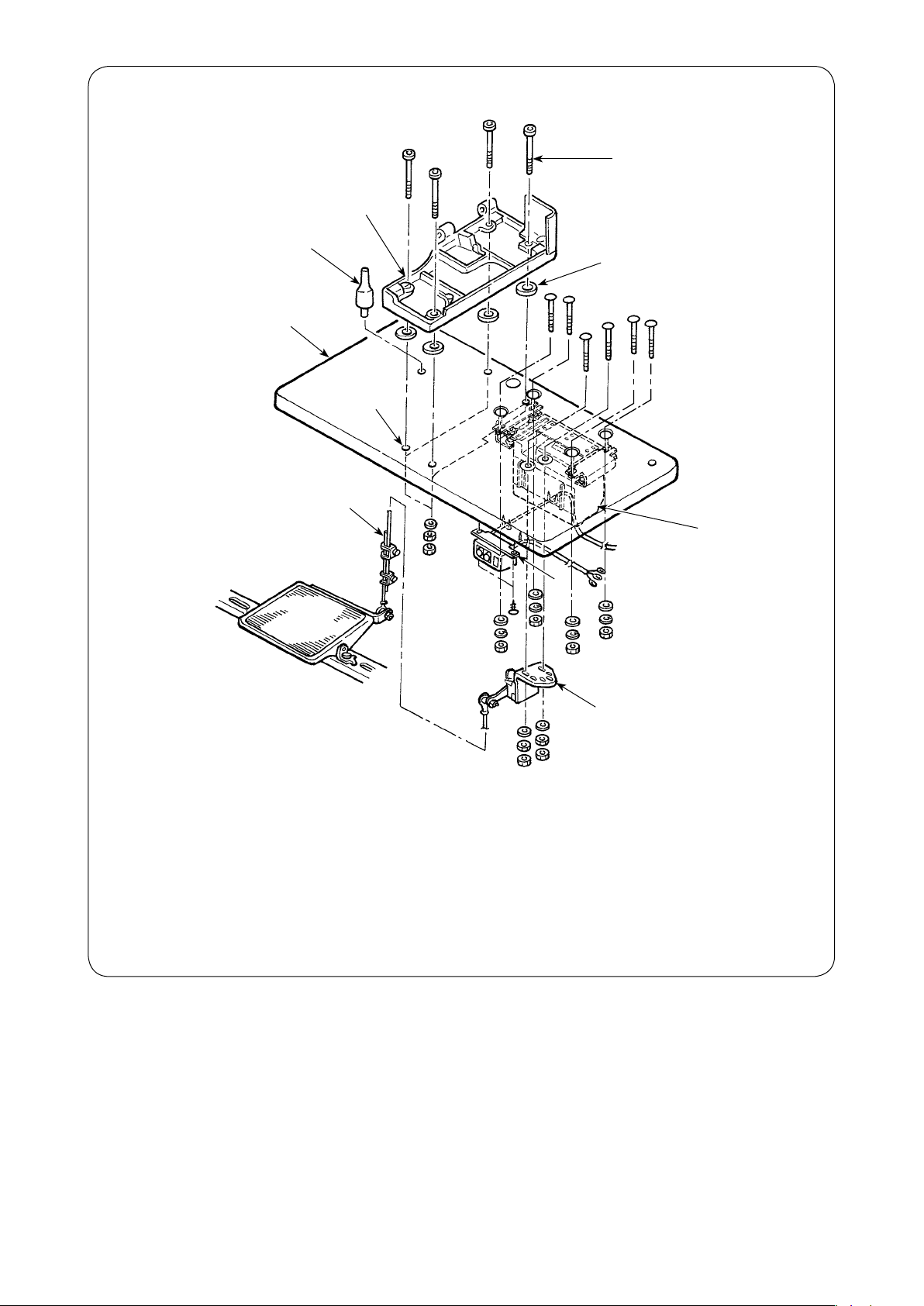

(2) Set-up of the table

1) Fix control box , power switch and pedal sensor on table .

2) Fix power switch with a staple.

3) Pass four bed base xed screws through bed base .

4) Set rubber cushions to holes (4 places) for xing bed base and x bed base .

5) Fix head support bar on table .

6) Place the main unit of the sewing machine on bed base . Then, connect the pedal and pedal sen-

sor with connecting rod supplied with the unit.

– 6 –

Page 10

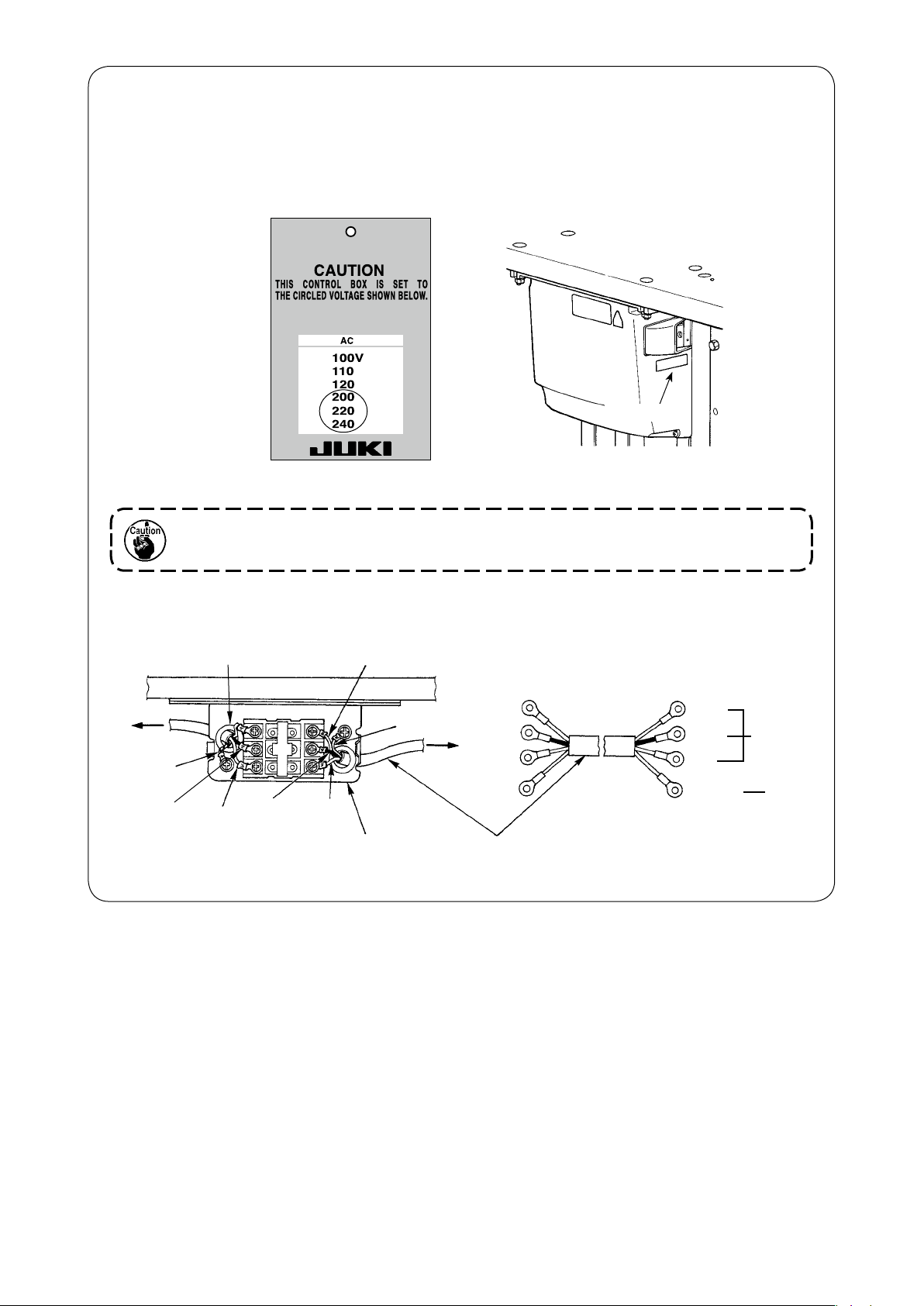

(3) Connecting the power source cord

• Connecting the power cable

Voltage specications are shown on the power indication tag attached on the power cable and on the

rating plate adhered on the power box. Connect the cable which matches the specications.

Power indication tag

Rating plate

(For example: In the

case of 200V)

Never use under the wrong voltage and phase.

• Connecting three phase 200V, 220V and 240V

Table

Control box

Green/Yellow

Black

White

Red

Black

White

Green /

Yellow

Red

Power switch

Plug

Power source cord

White

Black

Red

Green /

Yellow

AC200 V

AC220 V

AC240 V

GND

– 7 –

Page 11

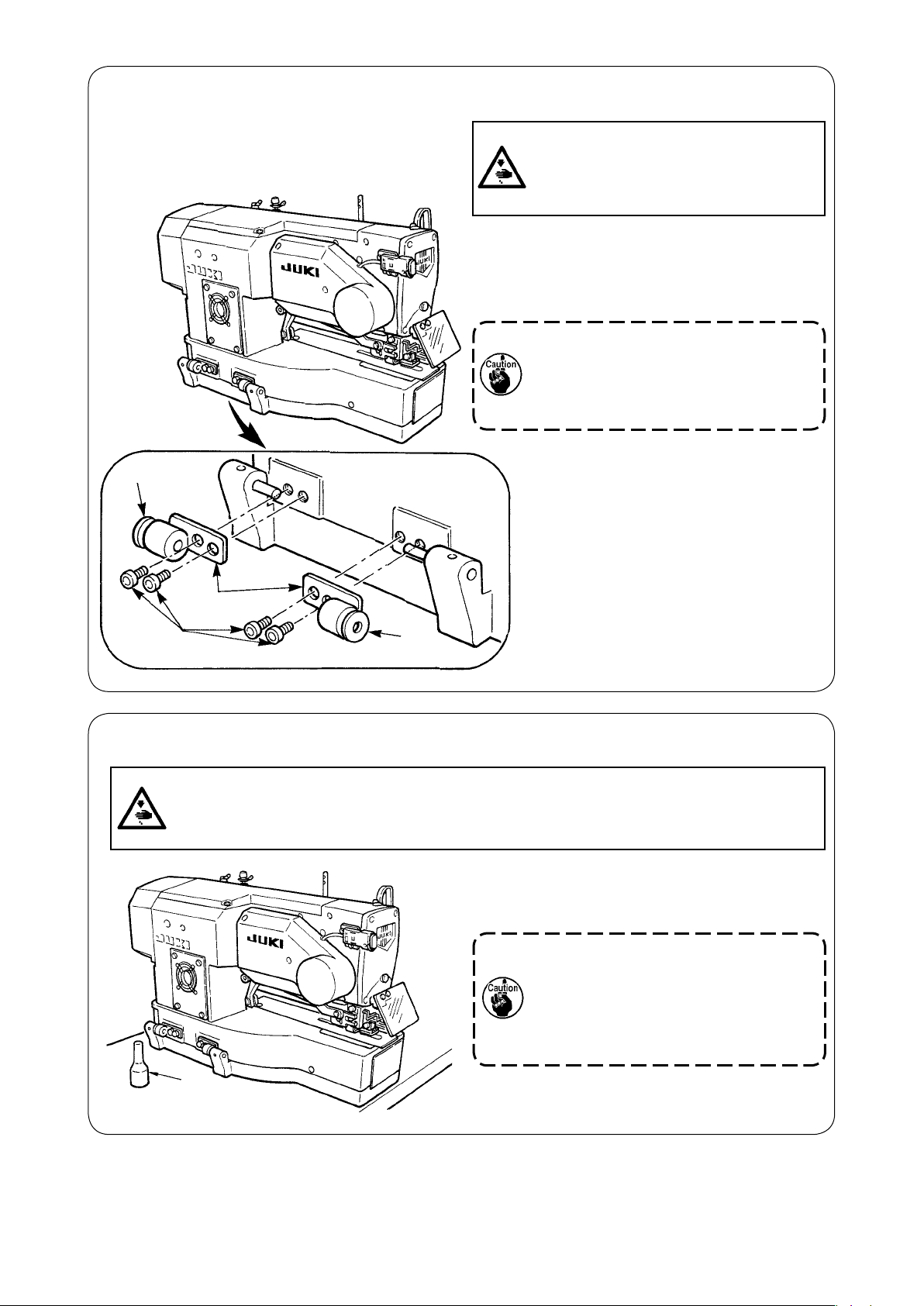

(4) Installing the sewing machine main unit

1) Place hinge plates and shaft bearings -1

-1 (rubber)

WARNING :

To prevent possible accidents caused by

the fall of the sewing machine, perform the

work by two persons or more when the

machine is moved.

(rubber) and -2 (metal) in two places on the

head base and x the hinge plates to the ma-

chine head with setscrews in two places.

When the rubber hinge and metal tting

hinge are installed in reverse order, it

is dangerous since the sewing machine

shakes when it is tilted. So, be careful.

(metal)

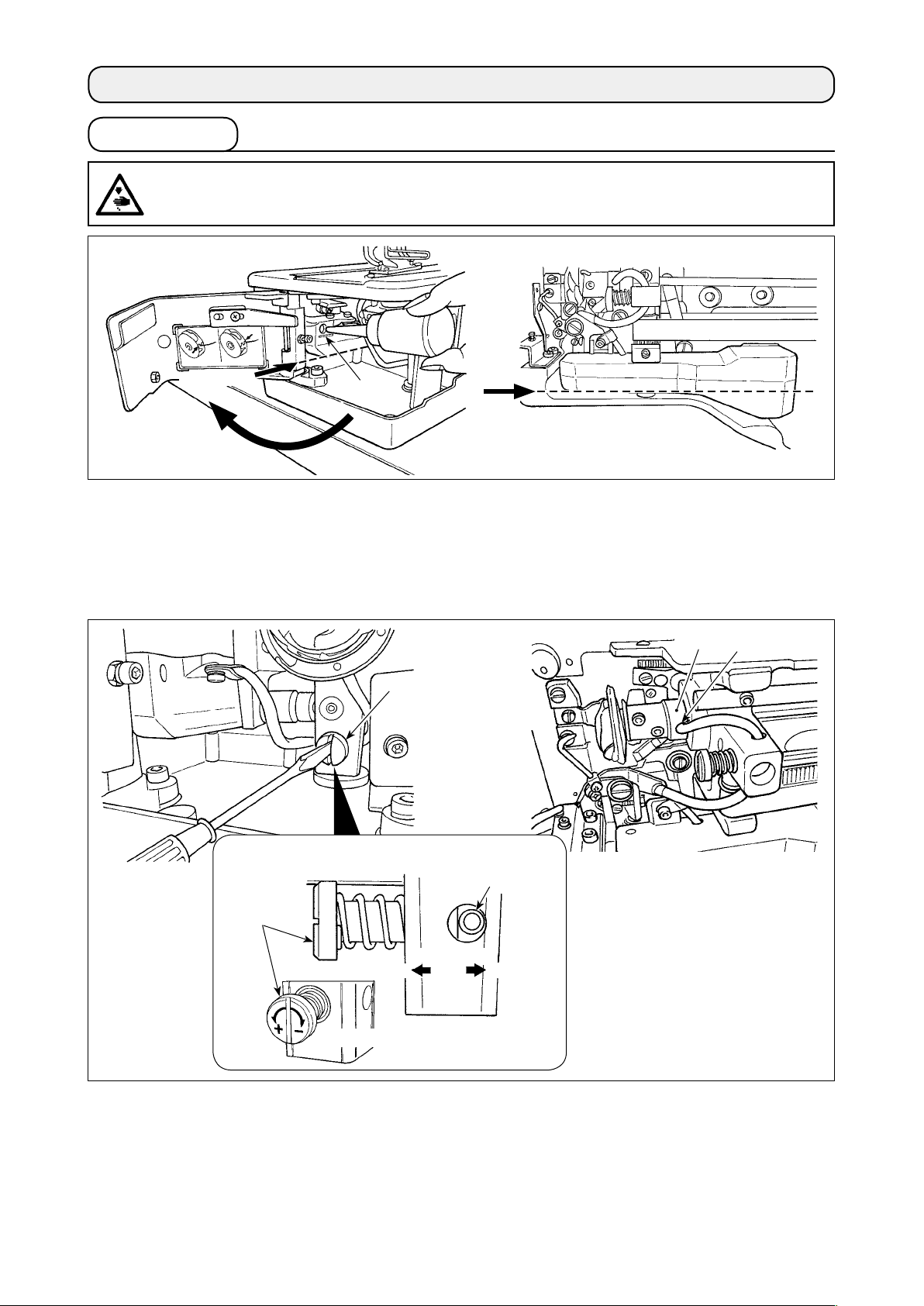

(5) Tilting the sewing machine head

WARNING :

When tilting/raising the sewing machine head, perform the work so as not to allow your ngers

to be caught in the machine. In addition, to avoid possible accidents caused by abrupt start of

the machine, turn OFF the power to the machine before starting the work.

-2

When tilting the sewing machine head, tilt quiet-

ly the sewing machine until head support bar

comes in contact with it.

1.

Make sure that sewing machine head

support bar is placed on the table

before tilting the sewing machine.

2. To protect fall-down, be sure to tilt

the sewing machine in a level place.

– 8 –

Page 12

(6) Connecting the machine head tilt detector

(7) Installing the hook oil shield plate

Connect machine head tilt detector with

connector located on the machine head

side.

(8) Installing the operation panel

Install hook oil shield plate onto bed base

with setscrew .

Attach hook oil shield plate to the

bed base with the sewing machine

raised.

In addition, check to be sure that the

sewing machine does not interfere

with hook oil shield plate when

tilting/raising the former.

Adjust the mounting of the hook oil

shield plate to prevent scattered

from the gap between the bed and

cover pot.

Fix operation panel on the table with four wood-

screws . Pass the cable through hole in the

table.

– 9 –

Page 13

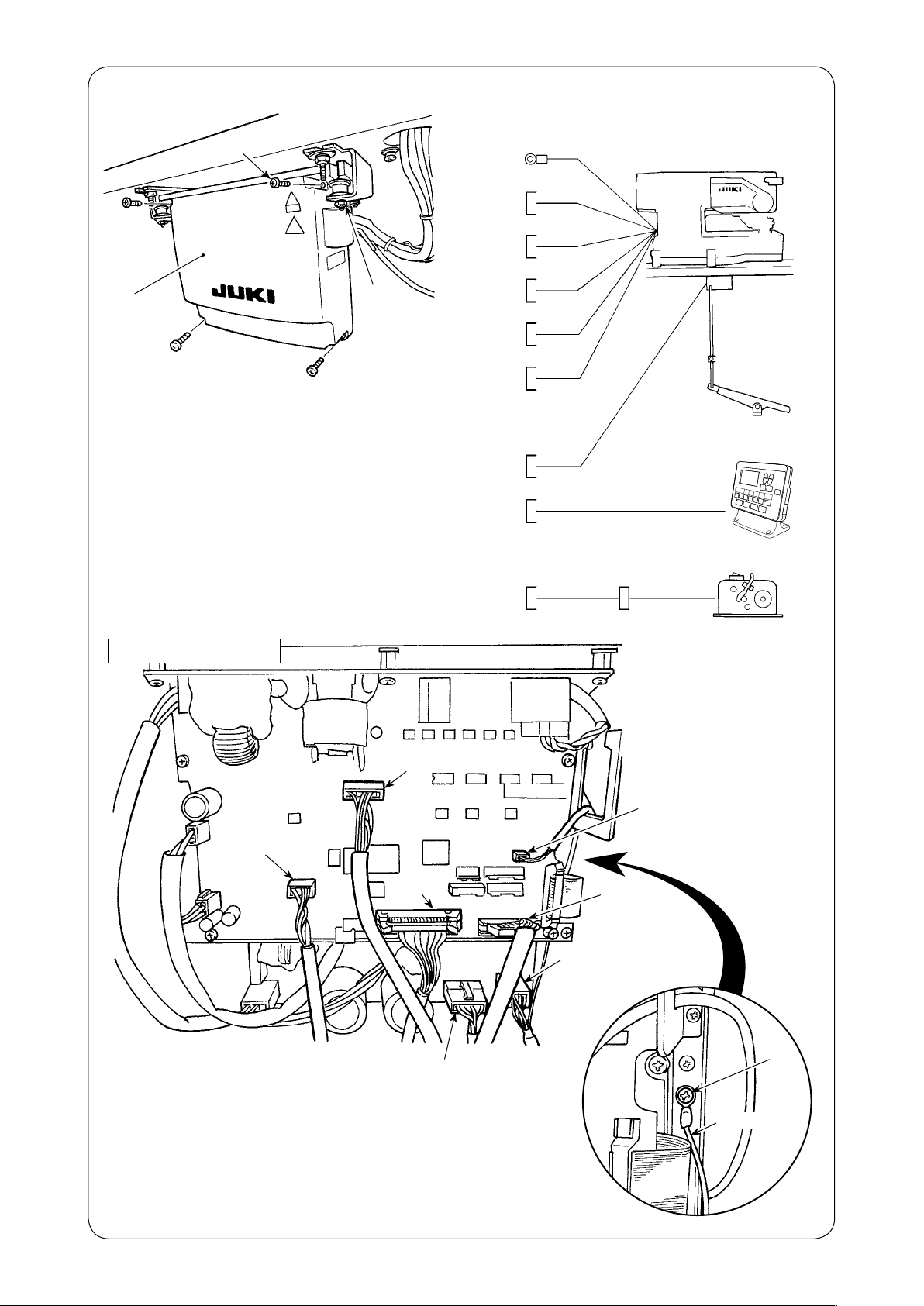

(9) Connecting the cords

1) Loosen four setscrews of control box cov-

er . Remove control box cover .

2) Connect the cord to the connector on the

MAIN PCB as illustrated in the gure below.

3) Fix the earth cord with setscrew .

4) Install control box cover .

5) Fix control box cover with the washers,

spring washers and nuts .

Earth cord

CN15

CN17

CN32

CN40

CN49

CN39

CN34

Sewing machine head

Operation panel

Electric bobbin winding device (optional)

MAIN circuit board

CN40

MAIN-INT C

CN32

MAIN-INT B

CN34

Panel

CN44

CN39

Pedal

CN49

MAIN-INT A

CN15

Main motor encoder

CN17

Main motor cord

– 10 –

Earth cord

Page 14

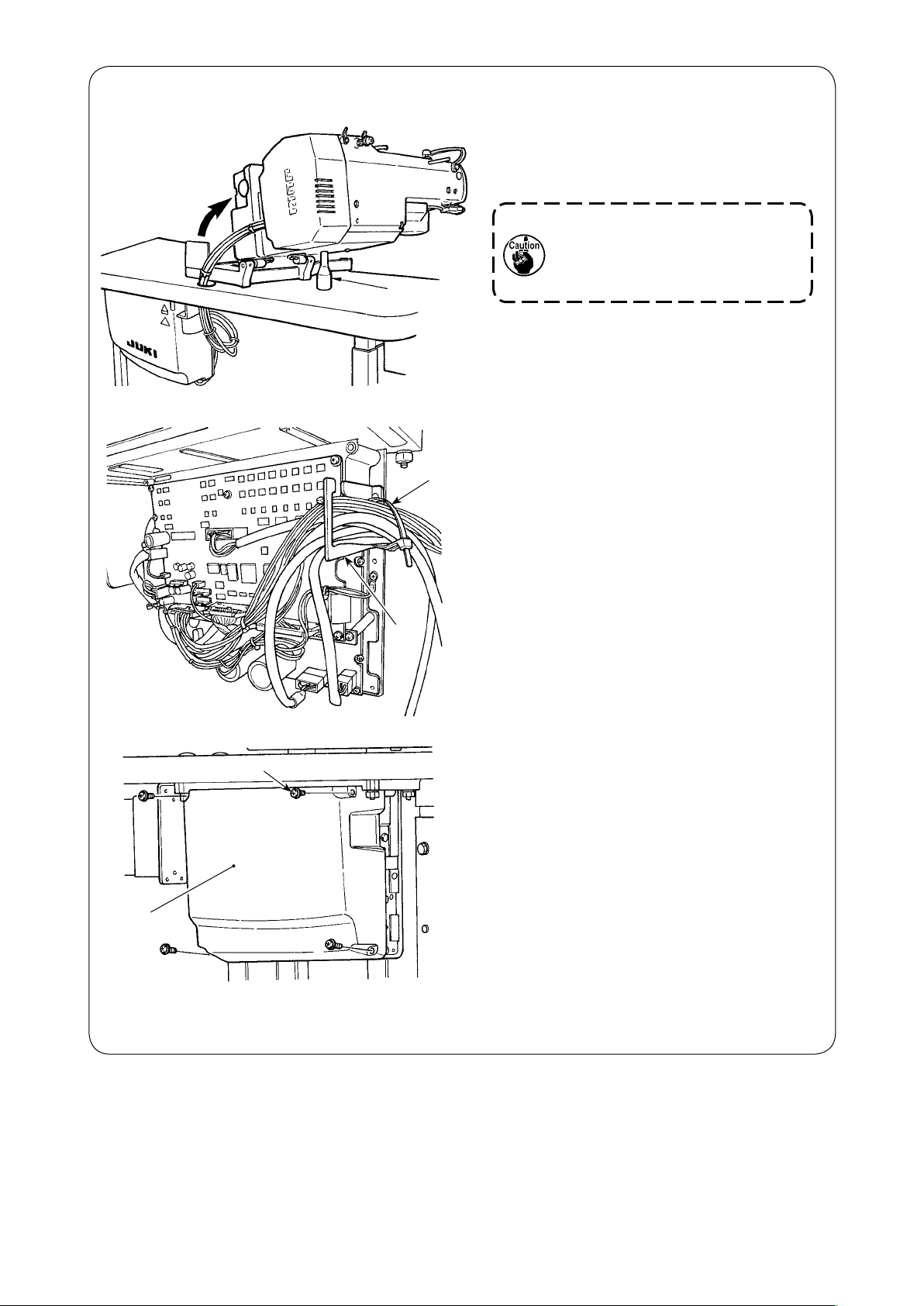

(10) Managing the cord

1) Slowly tilting the sewing machine, check

that the cords are not forcibly pulled.

When you tilt the sewing machine, make sure that the sewing

machine head support bar is

placed on the table.

2) Bring the cords under the table into the

control box.

3) Put the cord brought into the control box

through cord exit plate and fix cable

clip band .

4) Install control box lid with four set-

screws .

– 11 –

Page 15

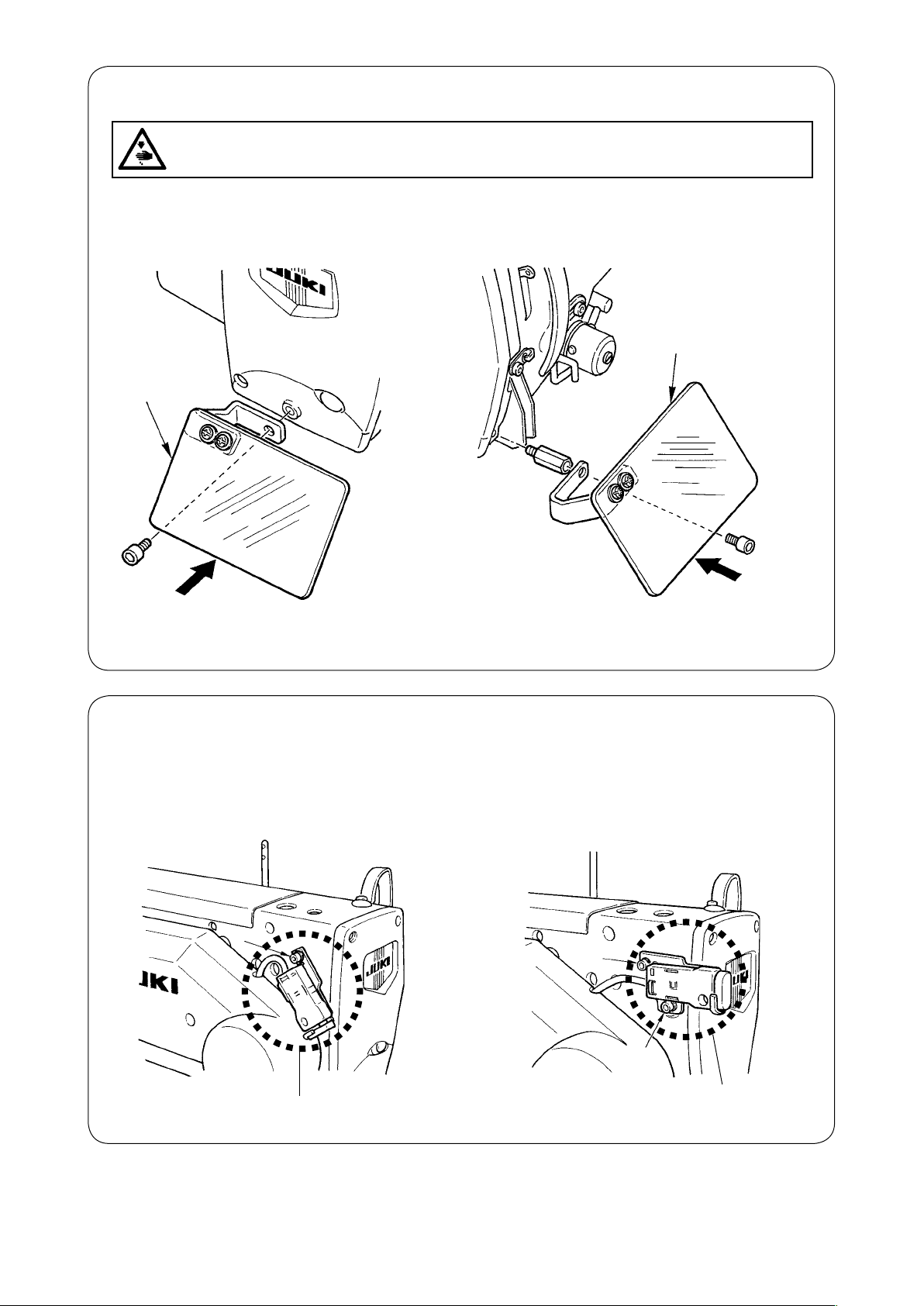

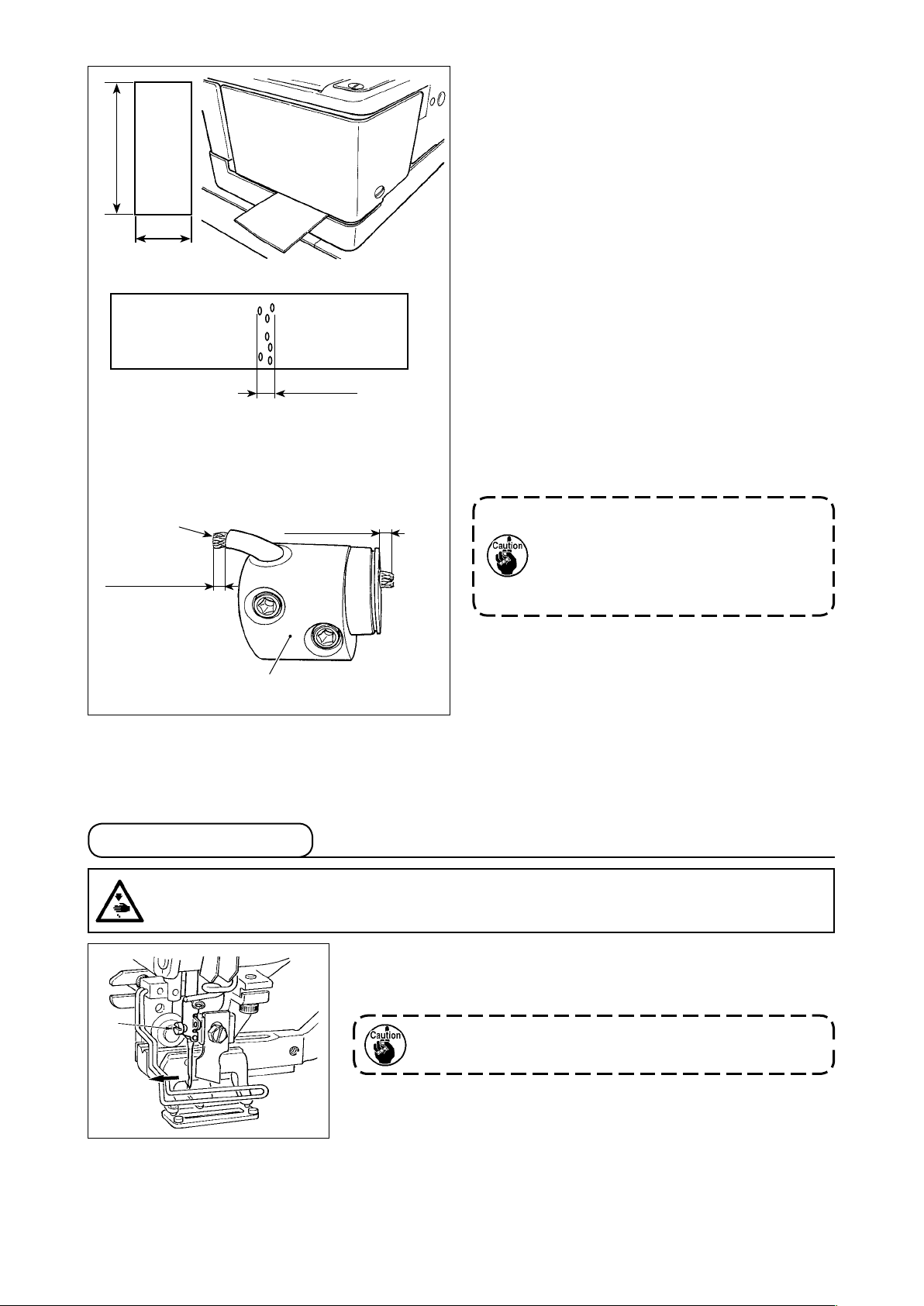

(11) Installing the eye protection cover

WARNING :

Be sure to attach this cover to protect the eyes from the disperse of needle breakage.

Be sure to install and use eye protection cover and use the sewing machine.

When placed longitudinally

Operator

When placed horizontally

Operator

(12) Fixing the temporary stop switch

The temporary stop switch has been in the state as shown in gure A at the time of delivery.

Loosen setscrew and set the switch in the state as shown in gure B, and x it with setscrew to-

gether with setscrew supplied with the machine.

A

B

– 12 –

Page 16

(13) Thread guide rod

Thread guide rod

(14) Installing the thread stand

Securely t the thread guide rod so that two side

holes in the thread guide rod face the thread

guide.

1) Assemble the thread stand, and set it in the

hole in the top right corner of the machine

table.

2) Tighten locknut to x the thread stand.

– 13 –

Page 17

(15) Installing the auxiliary table

1) Temporarily x two auxiliary table mount-

ing plates on auxiliary table with four

bolts .

2) Temporarily fix auxiliary table on the

sewing machine bed with two bolts .

3) Fix four bolts while removing a clear-

ance between the sewing machine bed

and auxiliary table .

4) Fix two bolts while aligning auxiliary

table with the top surface of the sewing

machine bed.

– 14 –

Page 18

IV. PREPARATION BEFORE OPERATION

1. Lubrication

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

Front side

Front

side

1) Lubricating oil to oiling tank

○ Fill the oiling tank with JUKI New Defrix Oil No.1 up to the level indicated by “MAX” .

(Caution) When supplying oil to the oil tank through the lubricating hole, take care not to allow

dust to enter the oil tank.

○ Supply oil in the case the oil cannot be visually observed from the front side of the oil tank.

Detailed diagram of oil amount adjusting section

Oil pipe

Increase

Increase

Oil amount

Decrease

Decrease

2) Adjusting the lubrication for the sewing hook

○ The amount of oil is adjusted with oil amount adjusting screw .

○ Amount of supplied oil is reduced when turning the screws clockwise.

○ When you rst operate your sewing machine after set-up or after an extended period of disuse, re-

move the bobbin case and apply a few drops of oil to the hook race. In addition, apply a few drops oil

from oiling hole in hook driving shaft front metal to soak the inside felt in oil.

– 15 –

Page 19

100 mm

40 mm

2 to 5 mm

* The adequate oil quantity is achieved when the

oil spots are made on paper within a range of 2 to

5 mm in width (oil spots should not be in the form

of lines).

3) How to check the hook oil quantity

1. In preparation for checking the hook oil quan-

tity, cut a sheet of paper to make a piece of

paper size of which is approximately 40 mm x

100 mm.

2. After the adjustment of the oil quantity, start

the sewing machine at a high speed (3,600

sti/min) by 100 times or more.

3. Insert the piece of paper prepared in Step 1

into the clearance provided between the hook

cover and the bed base so that it is placed

near the underside of the hook.

As a guide, insert the paper until it comes in

contact with the hook oil shield.

4. Supporting the paper with hand, run the sew-

ing machine by ve cycles using the standard

pattern (3,600 sti/min) and check the splash-

ing oil quantity.

Approximately

0.5 mm

2. Inserting the needle

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

Approximately

0.5 mm

Hold needle with its recessed part facing toward the operator side A,

insert the needle fully into the needle clamping hole, and tighten nee-

dle setscrew . Use a DPx5-(#11J, #14J).

In the case the oil quantity is too much

even after the oil controlling screw is

fully tightened, remove the hook shaft

coupling and cut off the excess of

oil wick .

When attaching the needle, turn OFF the power to the

motor.

A

– 16 –

Page 20

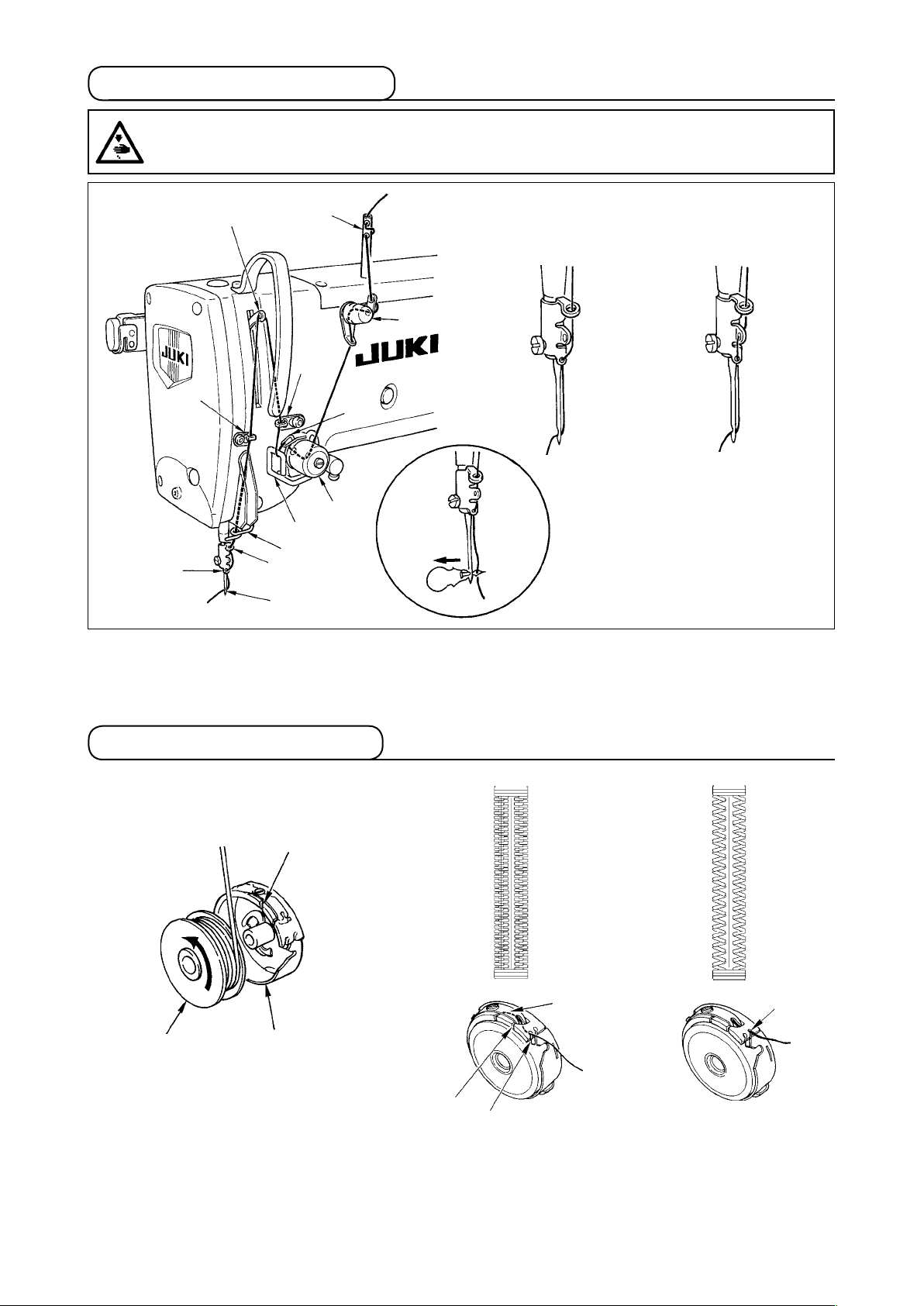

3. Threading the needle-thread

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

Cotton thread, spun thread

Synthetic lament thread

Pass the needle thread in the order to as shown in the gures.

The threading can be done easily by using the needle threader supplied with the machine.

Change the thread guide threading method according to the thread to be used.

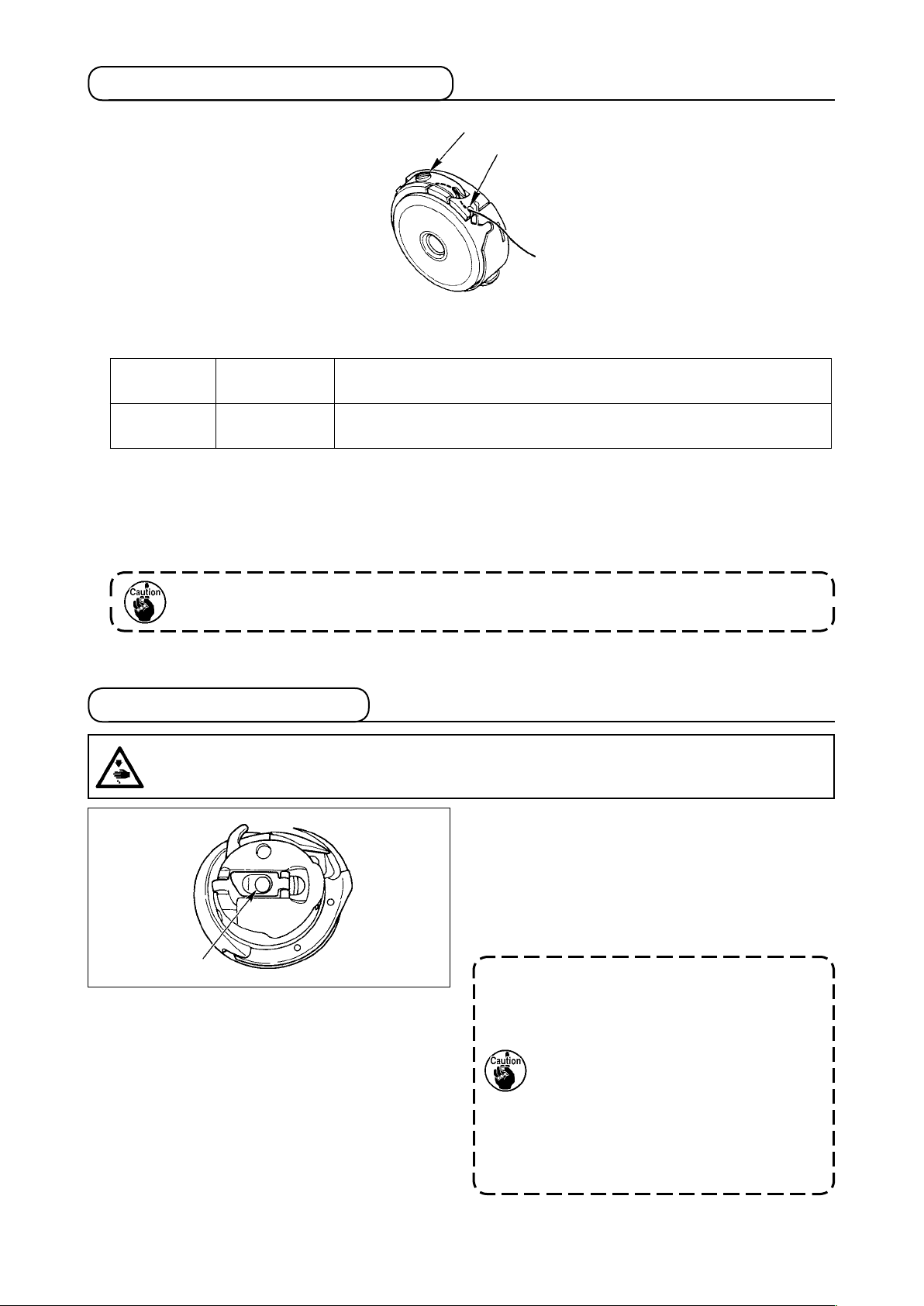

4. Threading the bobbin case

Whip stitchPurl stitch

Bobbin

Bobbin case

Rotating direction of bobbin and threading

1) Fit the bobbin so that it rotates in the direction of the arrow.

2) Pass the thread through thread slit , then through under the tension spring , again through thread

slit , and pull the thread from .

3) Threading at for purl stitching is different from that for whip stitching. So, be careful.

– 17 –

Page 21

5. Adjusting the bobbin thread tension

Adjust the bobbin thread tension as given below when the bobbin thread is pulled up at the position where

thread slit of bobbin case comes up.

Purl stitch 0.05 to 0.15N

Whip stitch 0.15 to 0.3N

Turning tension adjust screw clockwise will increase bobbin thread tension, and turning it counterclockwise will decrease the tension.

Adjust the bobbin thread tension to lower for synthetic lament thread, and to higher for spun thread. The

thread tension is higher by approximately 0.05N when the bobbin case is set to the hook since idle-prevention spring is provided.

When bobbin thread tension is adjusted, check the needle thread tension setting of the

memory switch. (Refer to "V-22. Memory switch data list" p.55.)

To such an extent that bobbin case quietly comes down when holding

thread end coming from bobbin case and shaking it quietly up and down.

To such an extent that bobbin case barely comes down when holding

thread end coming from bobbin case and shaking it somewhat strongly.

6. Installation of bobbin case

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

1) Lift up and hold bobbin case latch lever between

two ngers.

2) Push the bobbin case into the hook so that it is

supported by the hook shaft and then snap in

the latch lever.

Press the bobbin case until the predetermined

position is reached, and it will click.

1. If the bobbin case is out of the predetermined position, it can jump out

from the hook to cause the needle

thread to tangle on the hook shaft.

Check to be sure that the bobbin

case is properly installed in the correct position.

2. There is a difference in the shape of

bobbin case between the standard

hook and the dry one. They have

nothing in common with each other.

– 18 –

Page 22

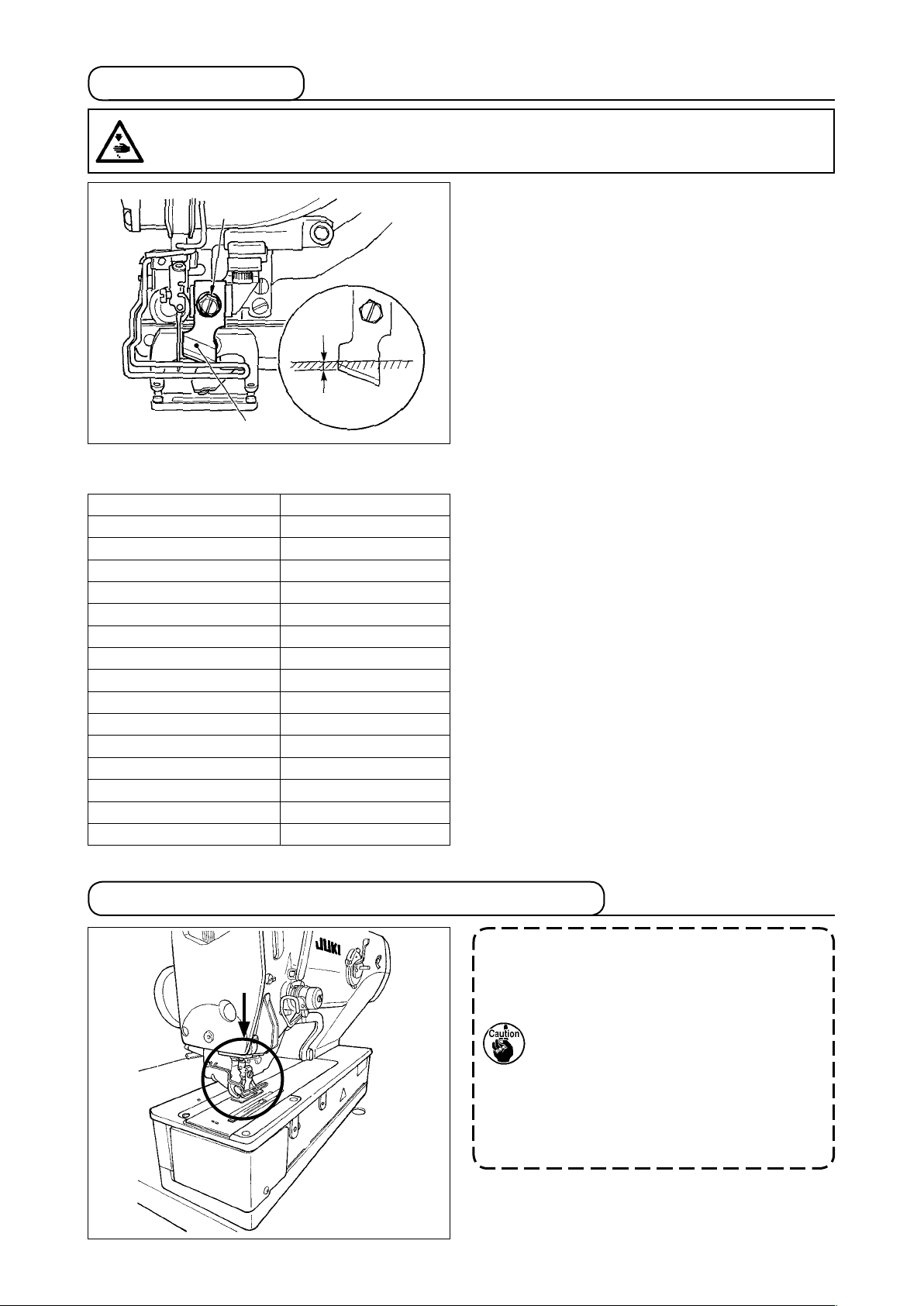

7. Installing the knife

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

1 to 2 mm

Inch mm CONVERSION TABLE

Knife size Indication of mm

1/4 6.40

3/8 9.50

7/16 11.10

1/2 12.70

9/16 14.30

5/8 15.90

11/16 17.50

3/4 19.10

13/16 20.60

7/8 22.20

1 25.40

1 1/8 28.60

1 1/4 31.80

1 3/8 34.90

1 1/2 38.10

When replacing the knife with a new one, perform as

follows.

1) Knife can be easily removed together with the

washer when removing knife retaining screw .

2) Lower the knife bar by hand. Now, push the knife

bar down so that the knife goes below the top

surface of the throat plate by 1 to 2 mm, as illus-

trated in the gure. In this state, place the wash-

er and tighten the setscrew.

When the cloth cutting knife you have is indicated in

inch, set the cloth cutting length (knife size) in mm

using the inch → mm conversion table. (Refer to

13. Sewing data list" p.37

.)

"V-

8. Checking the sewing machine in the delivered state

If the work clamp foot is the lifted state

before turning the power ON, lower it

rstly and turn ON the power to the

sewing machine.

When lowering the work clamp, take

care not to place your hands near the

knife.

If the power is turned ON with the work

clamp raised and the ready key is

pressed, "E998 Work clamp deviation

error" can occur.

– 19 –

Page 23

V. OPERATION OF THE SEWING MACHINE

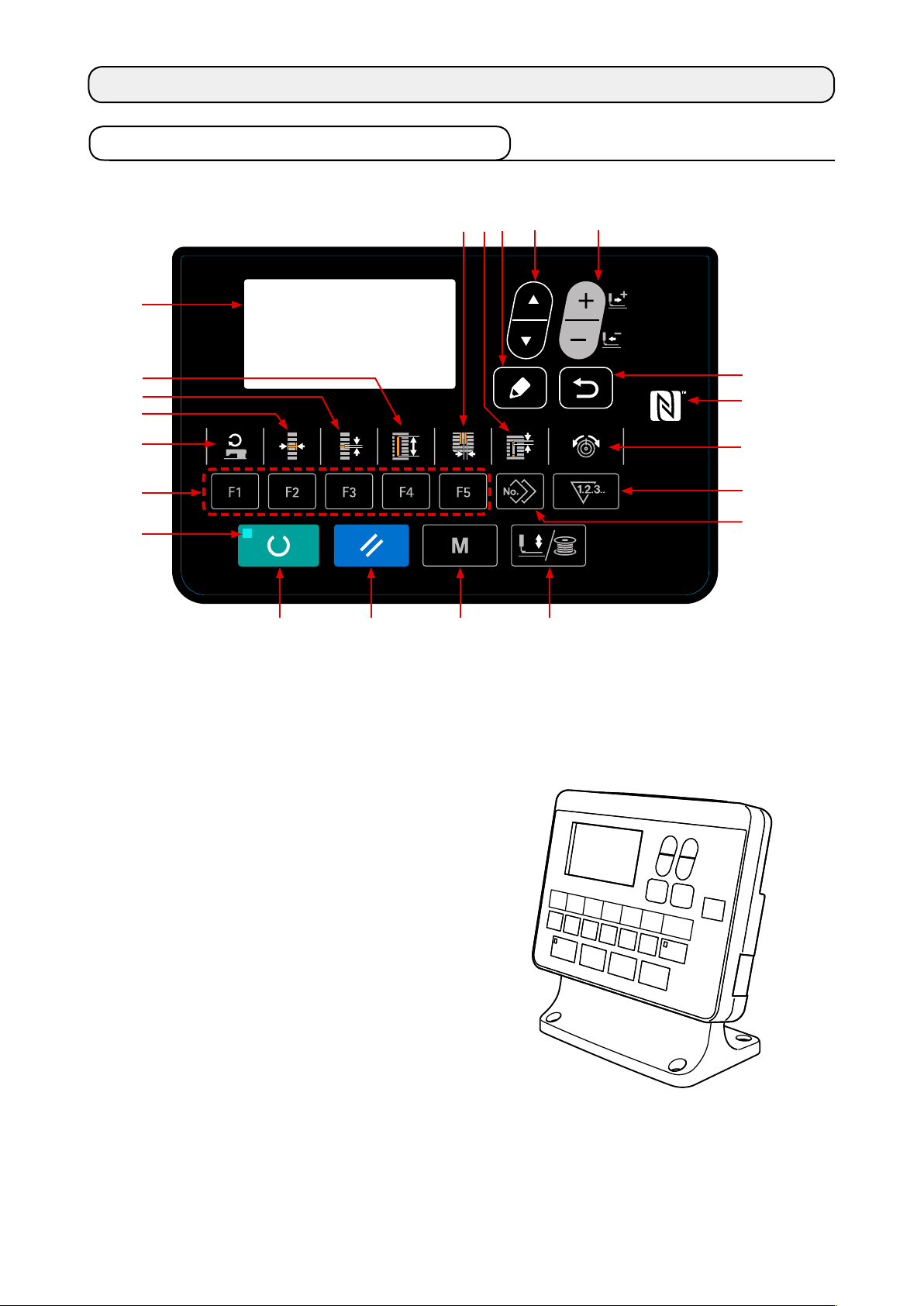

1. Explanation of the operation panel switch

– 20 –

Page 24

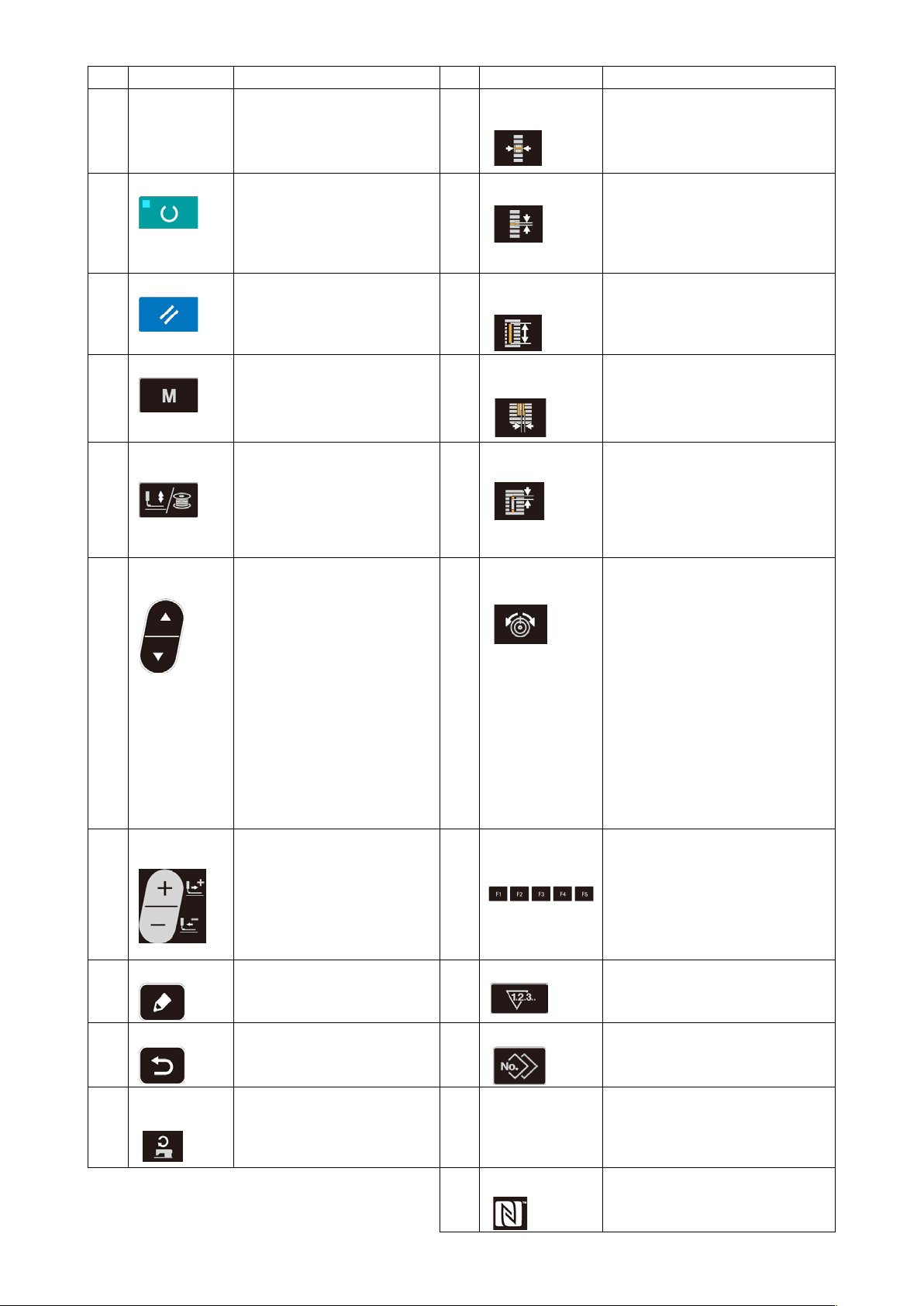

No. NAME FUNCTION No. NAME FUNCTION

LCD display Various data such as pattern

READY key Press this key when starting

RESET key Press this key when releasing

No., shape, etc. are displayed.

sewing.

Every time this key is pressed,

change-over of sewing ready

set state and data set state can

be performed.

error, travelling the feed mechanism to its initial position,

counter resetting, etc.

OVEREDGING

WIDTH key

PITCH key

CLOTH CUT

LENGTH key

This key selects overedging width

display.

Every time this key is pressed,

S005 and S006 are displayed alternately.

This key selects pitch of parallel

section.

Every time this key is pressed,

S007 and S021 are displayed alternately.

This key selects cloth cut length

display.

MODE key This key is used for displaying

PRESSER and

WINDER key

ITEM SE-

LECT key

DATA

CHANGE key

EDIT key This key is used to display the

the mode screen.

This key lifts or lowers the presser. When the presser goes up,

the needle bar travels to the origin and when it comes down, the

needle bar travels to the right.

This key is pressed when performing bobbin winding.

This key is used to select the

data No. and other kinds of

data.

This key is used to change the

pattern No. and other kinds of

data.

This key is used to move the

feed forward on a stitch-bystitch basis.

edit screen, to select the item

or to display the detail screen.

KNIFE GROOVE

WIDTH key

CLEARANCE

key

THREAD TEN-

SION key

PARAMETER

REGISTRATION

key

COUNTER key This key selects counter display.

This key is used to select the knifegroove width correction display.

Every time this key is pressed,

S003 (right) and S004 (left) are

displayed alternately.

This key selects clearance display.

Every time this key is pressed,

S022 (rst clearance) and S023

(second clearance) are displayed

alternately.

This key is used to select the

thread tension display.

Every time this key is pressed, the

display item is changed over as

described below:

S052 Thread tension at the right

parallel section

S053 Thread tension at the left

parallel section (rst cycle of

double stitching)

S054 Thread tension at the right

parallel section (rst cycle of

double stitching)

S055 Thread tension at the rst

bartacking section

S056 Thread tension at the second

bartacking section

This is a short cut key that parameter registration is available. Registration of shortcut to setting display

of an optional pattern, sewing

parameter or adjustment data is

possible. For the setting procedure,

Refer to

register key" p.46

"V-16. Using parameter

.

RETURN key This key is used to return the

SEWING

SPEED key

screen to the previous one.

This key is used to display the

parameter edit items related to

the sewing speed.

– 21 –

COPY key Press this key when copying pat-

tern.

SET READY

LED

It lights up under the sewing mode.

NFC mark Bring the tablet or smartphone

close to the NFC mark when

carrying out communication.

Page 25

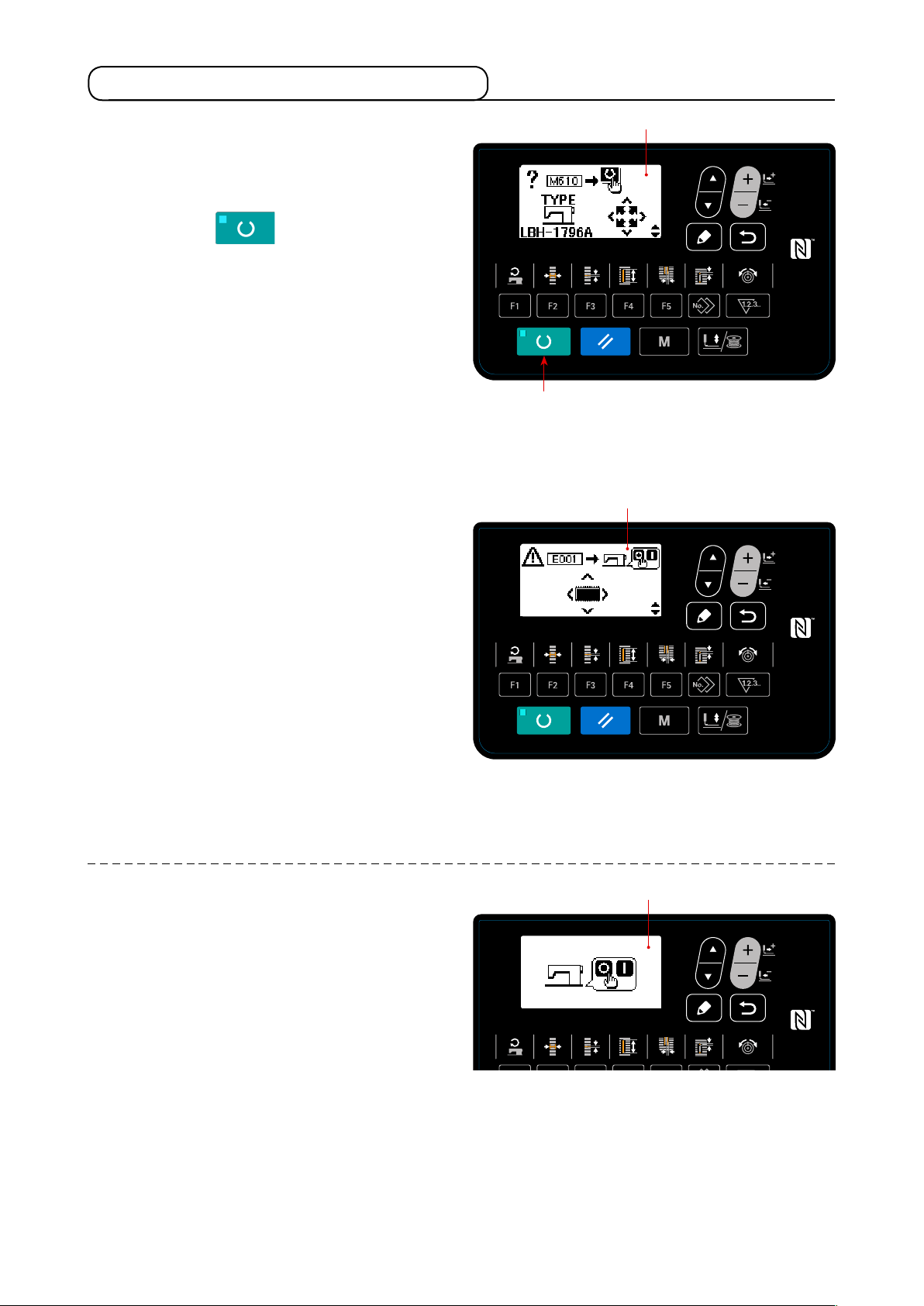

2. Basic operation of the sewing machine

1) Select the model of your sewing machine.

When you turn the power ON for the first time

after the purchase of your sewing machine, the

model confirmation screen is displayed. Press

READY key .

When Error E001 screen B is displayed, turn the

power OFF.

A

B

* In the case the power-OFF screen C is dis-

played after the completion of procedure de-

scribed in 1), turn the power OFF once. Then,

carry out the procedure described 1) again.

– 22 –

C

Page 26

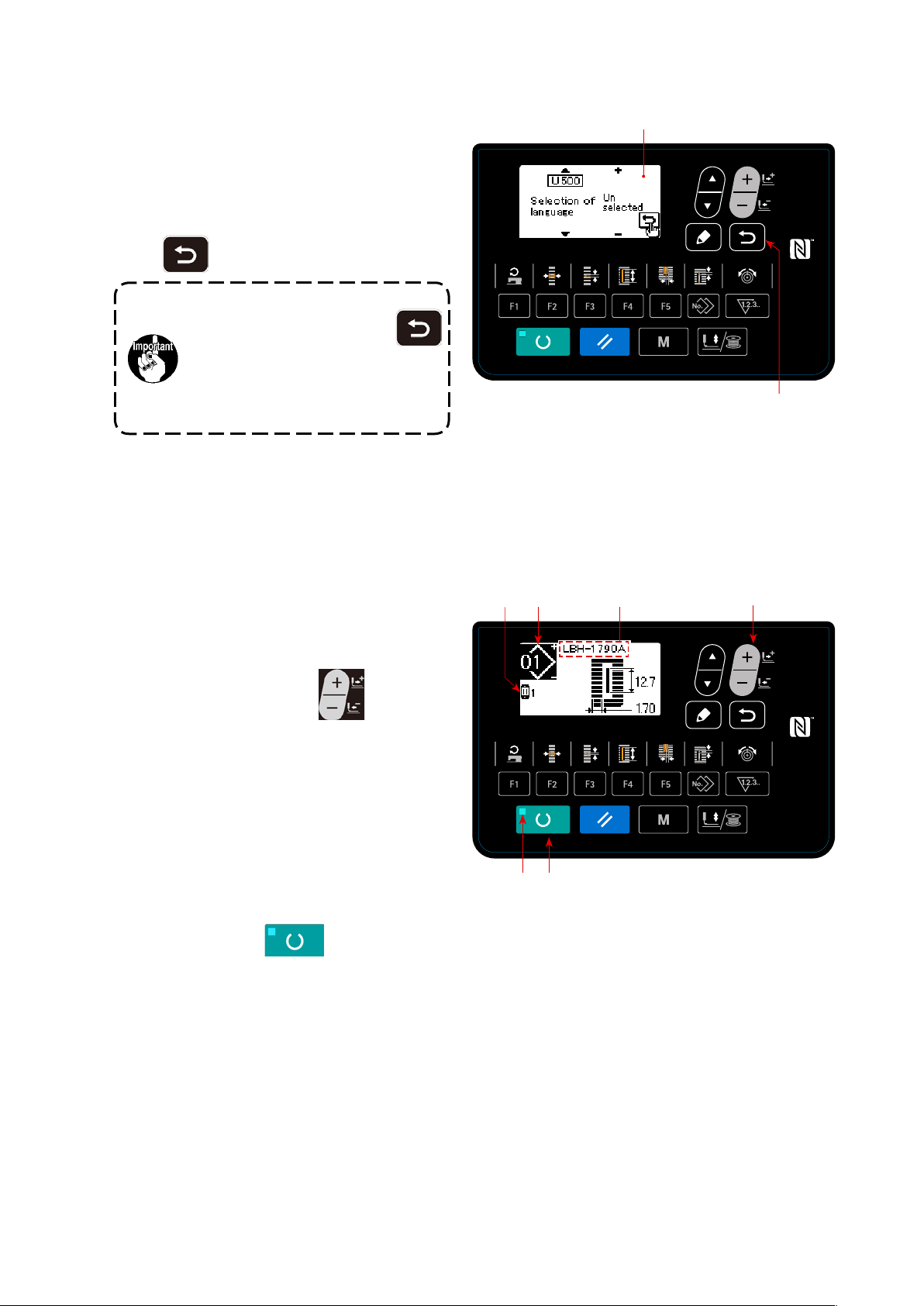

2) Turn ON the power switch.

When you turn ON the power to the sewing

machine for the rst time after the purchase, the

language selection screen A is displayed. Select

the language to be displayed, then press return

key .

If you terminate the language selec-

tion by pressing return key

without selecting the language, the

language selection screen will be

displayed every time you turn ON the

power to the sewing machine.

First, check that presser type B which has been

set is the same as that of the presser actually

mounted. For checking and setting procedures,

refer to

"V-4. Input of the presser type" p.26.

3) Select the pattern No. you desire to

sew.

When the power is turned ON, the pattern No. C

and pattern data name D are displayed.

When you want to change the pattern number,

A

CB

D

press DATA CHANGE key and select

the number you want to use for sewing.

When you purchase the sewing machine, pattern

No. 1 to 10 described in

ing data" p.34

the pattern No. you sesire to sew from among

these numbers. (The No. with which the pattern

has not been registered is not displayed.)

have been registered. Select

"V-11. Changing sew-

4) Set the sewing machine to sewing possible state.

When READY key is pressed, SET READY LED lights up to show that the sewing is en-

abled.

5) Start sewing.

Set the sewing product to the presser portion, and operate the pedal to start the sewing machine, and

sewing starts. The pedal type of the sewing machine has been factory-set to the 1-pedal type at the time

of shipment. However, the pedal operation method can be selected from among four different ones.

Select the operating procedure you desire and use the sewing machine. → Refer to

the pedal" p.24

.

"V-3. How to use

– 23 –

Page 27

3. How to use the pedal

For this sewing machine, the pedal operation method to be used can be selected from among the four dif-

ferent ones as described on the next page. Select the operating procedure you desire for working efcien-

cy and use the sewing machine.

(1) Setting procedure of the pedal type

1) Call the pedal type setting parameter.

Keep MODE key held pressed for

three seconds under the input mode where SET

READY LED goes out. Then, the MEMORY

switch (level 2) is displayed on the menu.

Select the target item with ITEM SELECT key

and press EDIT key . Then, the

memory switch (level 2) edit screen A is dis-

played.

When the pedal type selection parameter

is not displayed, press ITEM SELECT key

to select the pedal type.

2) Select the pedal type.

Press DATA CHANGE key and the pic-

A B

ture is changed as shown in the illustration below.

Select the pedal type B you desire.

2-pedal

1-pedal

(Without intermediate

position)

1-pedal

(With intermediate

position)

1-pedal

(With a depress on the

back part of the pedal)

– 24 –

Page 28

(2) Explanation of pedal motion

2-pedal type

Initial position

Presser : Intermediate

position or Cloth

setting position

1) Setting of

sewing product

Presser goes up as

high as the pedal toe

down amount of the

left side pedal.

2) Start of Sewing

Sewing starts when

the right side pedal is

depressed.

3) End of sewing

Presser automatically

goes up to Intermediate position .

1-pedal

(Without intermediate

position)

Initial position

Presser : Maximum

position

1) Setting of sewing

product

2) Conrmation of

setting of sewing

product

Presser comes down

to Cloth setting position

when the rst step of

the pedal is depressed.

3) Start of Sewing

Sewing starts when

the second step of the

pedal is depressed.

4) End of sewing

Presser automatically

goes up to Maximum

position .

1-pedal

(With intermediate

position)

Initial position

Presser : Maximum position

1) Setting of sewing

product

2) Conrmation of

setting of sewing

product

Presser comes down to

Intermediate position

when the rst step of the

pedal is depressed.

3) Conrmation of

start of sewing

Presser comes down to

Cloth setting position

when the second step of

the pedal is depressed.

4) Start of Sewing

Sewing starts when the

third step of the pedal is

depressed.

5) End of sewing

Presser automatically

goes up to Maximum

position .

1-pedal

(With a depress on the

back part of the pedal)

Initial position

Presser : Intermediate

position

1) Setting of sewing

product

2) Conrmation of

setting of sewing

product

When the back part of

the pedal is depressed,

the presser foot goes up

to Maximum position .

When the pedal is depressed to the rst step of

its stroke, the presser foot

comes down to Intermediate position . When the

pedal is depressed to the

second step of its stroke,

the presser foot comes

down to Cloth setting position .

3) Start of Sewing

Sewing starts when the

third step of the pedal is

depressed.

4) End of sewing

Presser automatically

goes up to Intermediate

position .

* Height of the respective positions of to

described on the left side can be set or changed

by the memory switches.

Refer to

Cloth

•

Pedal switch setting (In the case the optional 2-pedal switch

switch data" p.54

"V-21. Method of changing memory

.

(part number: 40003491) is used)

– 25 –

Page 29

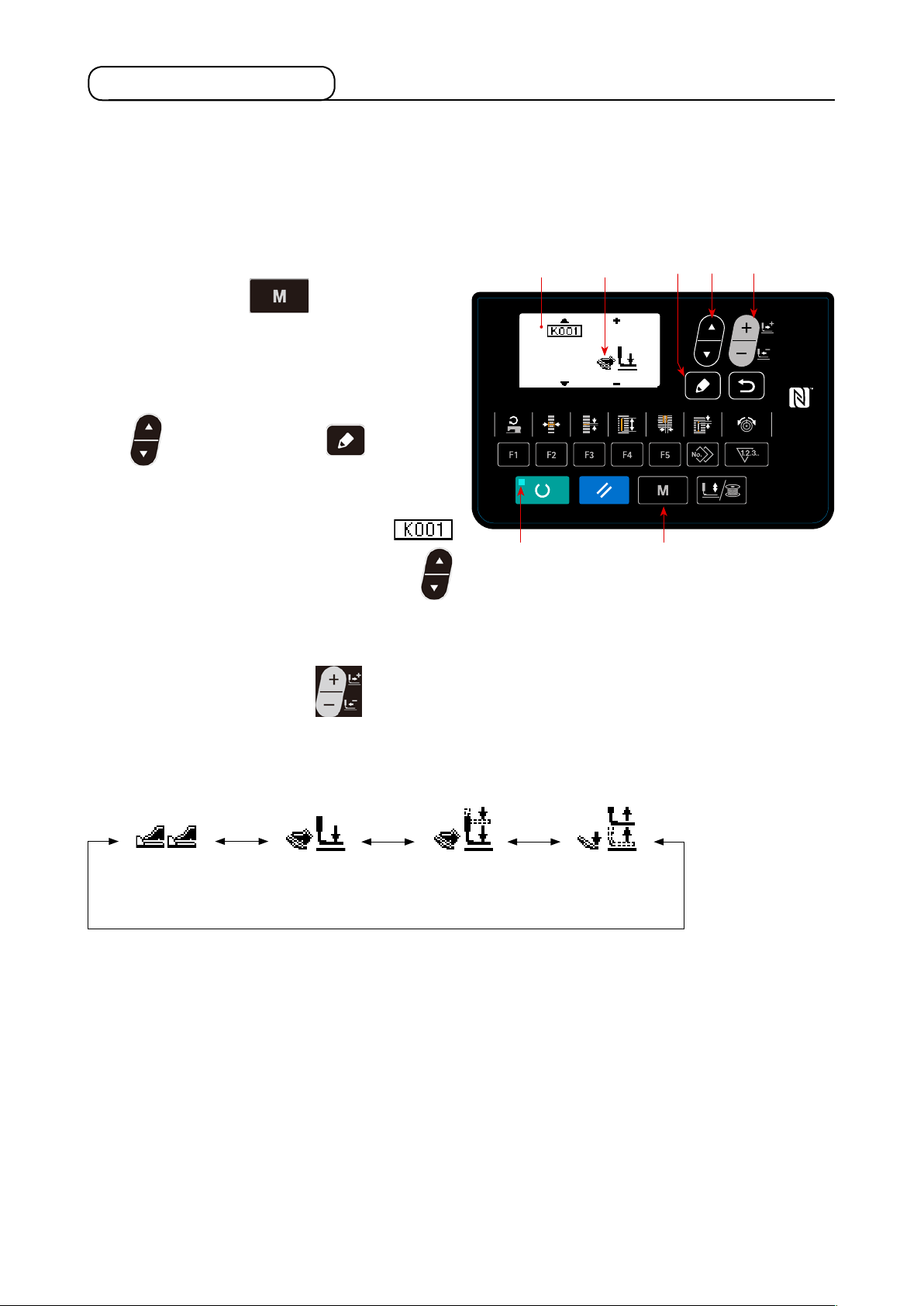

4. Input of the presser type

(1) Setting procedure of the presser type

1) Call the presser type setting parameter.

When MODE key is pressed, the

memory switch (level 1) edit screen A is dis-

played.

2) Select the presser type.

Press DATA CHANGE key , and the

picture is changed as shown in the illustration

below. Set the presser type B actually mounted

on the sewing machine referring to

presser type

Type 1 Type 2 Type 3 Type 5 *

below.

(2) Table of

A B

(2) Table of presser type

Set the number in the frame of engraved part number of presser to the type of presser.

Type Part No. of presser foot

Type 1 B151177 1 000 *

Type 2 B151177 2 000 *

* Set type 5 when using the presser other than

Type 3 B151177 3 000 *

Type 5 * —

type 1 to 3. Change Presser size

width and Presser size length of the

memory switch (level 1) to adjust to the press-

er to be used.

Refer to "V-21. Method of changing mem-

ory switch data" p.54.

* When using type 5 with stitch width of 6 mm

or more and 41 mm or more in length, it is

necessary to replace components such as

presser arm, feed plate, etc.

– 26 –

Page 30

5. Performing pattern selection

(1) Selection from the pattern selection screen

1) Set the mode to the input mode.

Under the input mode where SET READY LED

goes out, pattern selection is enabled.

If the current mode is the sewing mode, press

READY key to change over the mode

to the input mode.

2) Call the pattern selection screen.

Pattern No. A which is currently selected is

displayed.

3) Select the pattern.

Press DATA CHANGE key , and the

patterns which have been registered are changed

over in order and displayed. Here, select the No.

you desire to sew.

(2) Selection by means of the register key

For this sewing machine, it is possible to register a desired pattern No. to the PARAMETER REGISTER

key.

When the pattern is registered once, pattern selection can be performed by pressing only the switch.

Refer to

→

"V-16. Using parameter register key" p.46

.

– 27 –

Page 31

6. Changing needle thread tension

Needle thread tension can be changed while performing trial sewing since the data related to the needle

thread tension can be set by the sewing mode as well.

1) Call thread tension at parallel section

setting data.

When THREAD TENSION key is pressed,

the sewing data edit screen A is displayed.

2) Change thread tension at parallel

section.

Press DATA CHANGE key , and set

value B goes up or comes down and the thread

tension can be changed. The relation between the

nish of sewing and the set value is as shown in

the illustration below. Set the value referring to the

illustration.

3) Call thread tension at bar-tacking

section setting data.

When THREAD TENSION key is pressed

again, the sewing data edit screen C is displayed.

4) Changing the needle thread tension at

bar-tacking section.

B

A

12

D

C

34

Press DATA CHANGE key , and set

value D goes up or comes down and the thread

tension can be changed. The relation between the

nish of sewing and the set value is as shown in

table below. Set the value referring to the table.

* For the tension other than that at parallel section

and bar-tacking section, refer to

ing sewing data" p.34

and

"V-11. Chang-

"V-21. Method of

changing memory switch data" p.54.

Set value of tension at parallel section and bar-tacking section

Set value on panel

Initial value

Purl stitch

Whip stitch

Tension at parallel

section

Bar-tacking tension Thread tension

Tension at parallel

section

Bar-tacking tension Thread tension

Crest is

lowered.

is decreased.

Thread tension

is decreased.

is decreased.

120

35

60

60

Crest is raised.

Thread tension is

increased.

Thread tension is

increased.

Thread tension is

increased.

For the eyelet

radial shape, set

the bar-tacking

tension rst to

approximately 120

and make the balance of stitches.

Purl stitch and Whip stitch

Purl stitch

Whip stitch

Whip stitch

Purl stitch

When applying higher tension to the needle thread to permit it to pass straight

through fabric, the purl stitch is formed by the bobbin thread which is pulled

over from both sides to the center line.

Whip stitch

The whip stitch is formed in zigzag showing the needle thread only on top of

fabric, and the bobbin thread on the bottom.

– 28 –

Page 32

7. Performing re-sewing

When stop switch A is pressed during sewing

operation, the sewing machine interrupts sewing

and stops. At this time, error display screen B is

displayed to inform that the stop switch is pressed.

A

To continue performing sewing from

some point in sewing

Sewing motion stop status

Error display screen B is displayed.

1) Release the error.

Press RESET key to release the error.

Then step motion screen C is displayed.

2) Return the presser.

-2

-1

and the

and the

Press BACKWARD key

presser returns stitch by stitch.

Press FORWARD key

presser advances stitch by stitch. Return the

presser to the re-sewing position.

3) Start sewing again.

Depress the right side pedal and sewing starts again.

Error No. Error pictograph

E CD

-1

B

-2

To perform re-sewing from the start

Sewing motion stop status

Error display screen B is displayed.

1) Release the error.

Press RESET key to release the error.

Then step motion screen C is displayed.

2) Return the presser to the sewing

product setting position.

Press again RESET key and the

presser returns to the sewing product setting

position.

3) Perform again the sewing work from

the start.

* Existing number of stitches/total number of stitches

are displayed in section D.

* Existing sewing command is displayed in section E.

Kinds of commands are :

Sewing

command

Thread trimmer

command

– 29 –

Jump feed

command

Knife command

Page 33

8. Winding bobbin thread

(1) Winding the bobbin

In the case you wind the bobbin using presser and winder key , remove the thread from

the thread take-up lever and detach the bobbin from the hook.

1) Set the bobbin.

Fit a bobbin fully onto the bobbin winder shaft.

Take the thread from the spool and pass it through

the guides in the numerical order as shown in

the gure, and wind the end of the thread several

times around the bobbin. Then push the bobbin

winding lever in the direction of the arrow mark.

2) Set the mode to the bobbin winding

mode.

Under the input state, press PRESSER and

WINDER key . In this state, press

ITEM SELECT key .

3) Start bobbin winding.

Depress the pedal, and the sewing machine ro-

tates and starts winding bobbin thread.

4) Stop the sewing machine.

Once the bobbin is wound with the predetermined

amount of thread, bobbin winding lever is

released. Press PRESSER and WINDER key

or depress the pedal to stop the sewing

machine. Then remove the bobbin and cut bobbin

thread with thread trimmer retaining plate .

• Press PRESSER and WINDER key

, and the sewing machine stops and returns to

the normal mode.

• Depress the pedal and the sewing machine

stops while the bobbin thread winding mode

stays as it is. Use this way when winding bob-

bin thread around plural bobbins.

B

A

(2) Adjusting the amount to be wound on

a bobbin.

To adjust the winding amount of the bobbin

thread, loosen setscrew and move the bobbin

winding lever to the direction of A or B. Then,

tighten setscrew .

To the direction of A : Decrease

To the direction of B : Increase

– 30 –

Page 34

9. Using the counter

(1) Setting procedure of the counter value

1) Call counter setting screen.

When COUNTER key is pressed

under the input mode where SET READY LED

goes out, the counter screen A is displayed to

enable setting of the counter.

Setting of the counter value can be performed

only with the input mode.

In case of the sewing mode, press READY key

to set the mode to the input mode.

2) Selection of kinds of counters.

Press ITEM SELECT key to display the

pictograph B which indicates the counter type in

reverse video.

Press DATA CHANGE key , and select

the counter you desire from among the kinds of

counters below.

A B D C

3) Change of counter set value.

Press ITEM SELECT key to display the set value C of the counter in reverse video.

Press DATA CHANGE key and input the set value until count-up is reached.

4) Change of existing counter value.

Press ITEM SELECT key to display the current value D of the counter in reverse video.

Press RESET key and the value on the way of counting can be cleared.

In addition, it is possible to edit the numerical value with DATA CHANGE key .

The counter has been factory-set to " Sewing UP counter" at the time of delivery. This counter has

been factory-set so that it stops counting after the number of times of start of sewing machine has

reached 100. Set this counter according to your conditions of use.

– 31 –

Page 35

(2) Kind of counter

Sewing UP counter

Every time the sewing of one shape is performed, the existing value is counted up.

When the existing value is equal to the set value, count-up screen is displayed.

Sewing DOWN counter

Every time the sewing of one shape is performed, the existing value is counted down.

When the existing value is reached to "0", count-up screen is displayed.

No. of pcs. UP counter

Every time one cycle or one continuous stitching is performed, the existing value is counted up.

When the existing value is equal to the set value, count-up screen is displayed.

No. of pcs. DOWN counter

Every time one cycle or one continuous stitching is performed, the existing value is counted

down. When the existing value is reached to "0", count-up screen is displayed.

Counter not used

(3) Count-up releasing procedure

When count-up condition is reached during

sewing work, the whole count-up screen E ashes

on and off. Press RESET key to reset

the counter, and the mode returns to the sewing

mode. Then the counter starts counting again.

E

– 32 –

Page 36

10. Using the initial value pattern

This sewing machine has the initial value to perform the optimum sewing for the sewing shapes (31 shapes).

Refer to

→

When creating sewing data newly, it is convenient to create it by copying the initial value pattern.

"XI. INITIAL VALUE DATA FOR EACH SHAPE TABLE" p.85

.

1) Set the mode to the input mode.

Under the input mode where SET READY LED

goes out, pattern change is enabled. If the current

mode is the sewing mode, press READY key

to change over the mode to the input

A

2

mode.

2) Call initial value pattern.

The currently-selected pattern No. A is displayed.

Press DATA CHANGE key to select

initial value pattern .

3) Select shape.

The shape selection screen B is displayed to

shown the currently-selected shape C.

Select shape C to sew with DATA CHANGE key

. It is possible to select the shape from

among 12 shapes at the time of your purchase.

However, it is possible to select the shape from

among maximum 31 shapes by increasing the

shape selection level (K004).

Refer to

switch data" p.54

"V-21. Method of changing memory

.

B

3

C

4) Perform trial sewing.

Press READY key to set the mode to

the sewing mode. Then it is possible to perform

sewing and the selected shape can be sewn.

* The initial-value pattern can be edited only with respect to the data on needle thread tension and

sewing speed. Be aware that the edited data will return to the initial value(s) when the pattern shape is

changed or re-call of the pattern is carried out.

5) Copy initial value pattern.

Copy the pattern which has been selected and conrmed through the steps above to the normal pattern

and use it.

Copying procedure

Refer to

"V-14. Copying sewing pattern" p.43

– 33 –

.

Page 37

11. Changing sewing data

(1) Initial sewing data at the time of your purchase

Patterns from 1 to 10 have been already registered at the time of your purchase. Initial values of the

square type, the cloth cutting length of which only is different from each other, have been inputted in the

sewing data. → Refer to

"XI. INITIAL VALUE DATA FOR EACH SHAPE TABLE" p.85

.

Pattern No. Cloth cutting length

1 6.4 mm

2 9.5 mm

3 11.1 mm

4 12.7 mm

5 14.3 mm

6 15.9 mm

7 17.5 mm

8 19.1 mm

9 22.2 mm

10 25.4 mm

(2) Changing procedure of sewing data

1) Set the mode to the input mode.

Under the input mode where SET READY LED

goes out, sewing-data change is enabled.

If the current mode is the sewing mode, press

READY key to change over the mode

to the input mode.

(1/4”)

(3/8”)

(7/16”)

(1/2”)

(9/16”)

(5/8”)

(11/16”)

(3/4”)

(7/8”)

(1”)

Pictograph showing data item

Data item No.

A

2) Call sewing data edit screen.

When EDIT key is pressed, the sewing

data edit screen A for the currently-selected pat-

tern No. is displayed.

3) Select sewing data to be changed.

Press ITEM SELECT key , and select the

data item you desire to change.

Data item which is not used according to the

shape and data item which is set without function

are skipped and not displayed. So, be careful.

Refer to

→

data with/without edit" p.36

"V-12. Method of setting sewing

.

4) Change data.

For the sewing data, there are data item which changes numerical value and that which selects pictograph.

No. such as is attached to the data item which changes numerical value. Increase or decrease the

set value with DATA CHANGE key to change the value.

No. such as is attached to the data item which selects pictograph. Pictograph can be selected with

DATA CHANGE key .

For the details of sewing data, refer to

→

"V-13. Sewing data list" p.37

– 34 –

.

Page 38

5) Changing the name of pattern data.

Select "S500 Pattern data name" and press EDIT

key to enable change of the pattern data

name.

When you press ITEM SELECT key , the

edit point will move in sequence. The character

placed between "+" and "-" is the edit position

under selection.

Press DATA CHANGE key while the

character is being selected, the character can be

selected. Press RESET key to delete

the character which is being selected. When you

keep RESET key held pressed for one

second, the data name can be deleted.

Change the pattern data name by carrying out the

aforementioned procedure in repetition.

The characters that can be used for the

pattern name

A - Z, 0 - 9, ., +, -, /, #, (blank)

– 35 –

Page 39

12. Method of setting sewing data with/without edit

This sewing machine has been set so as not to be capable of editing sewing data items which are less

frequently used at the time of your purchase. When you desire to set the data more closely in accordance

with the sewing products, set the sewing data item to the edit possible state and use the machine.

* For the setting of sewing data with/without edit, when S052, right parallel section tension is set to

without edit, sewing is performed with the data of S051 left parallel section tension. When S056, 2nd

bar-tacking tension is set to without edit, sewing is performed with the data of S055, 1st bar-tacking

section.

When the sewing data items other than the above ones are set to without edit, the data to be referred

are the initial value data.

1) Set the mode to the input mode.

Under the input mode where SET READY LED

goes out, data setting is enabled.

If the current mode is the sewing mode, press

READY key to change over the mode

A

to the input mode.

2) Call sewing data with/without edit

changeover screen.

Press MODE key . Select

Sewing parameter edit select"

enable/disable changeover screens A and B are

displayed.

"05

. Then, data edit

3) Select sewing data you desire to

change over.

Press ITEM SELECT key

sewing data item C you desire to change over.

At this time, changeover possible item only can

be selected.

, and select

4) Changeover of with/without edit.

When DATA CHANGE key is pressed,

the pictograph display C for the currently-selected

sewing data is changed over.

Non-reverse display : With edit

Reverse display : Without edit

Return to step 3), and plural sewing data items

can be changed over.

(With edit)

B

(Without edit)

C

5) Save data which have been set.

When RETURN key

changed-over state is saved and the screen

returns to the mode screen. When RESET key

previous screen.

is pressed, the screen returns to the

is pressed, the

– 36 –

Page 40

13. Sewing data list

Sewing data are those that can be inputted to 99 patterns from pattern 1 to 99 and can be inputted to

☆

each pattern. The sewing machine has been set in the state that the data which is necessary to set “With/

without edit” cannot be selected at the time of your purchase. Change over the function to “With edit” if

necessary for the use. → Refer to

No. Item Setting range Edit unit Remarks

S001

Sewing shape

Select a desired pattern shape from among 31 sewing shapes

stored in the sewing machine.

"V-12. Method of setting sewing data with/without edit" p.36

1 to 31 1 –

.

S002

S003

S004

–

* Only 12 kinds of standard sewing shapes can be selected

at the time of your purchase. When increasing the kinds of

shapes, perform setting of

leve

l of memory switch data. → Refer to

switch data list" p.55

Refer to "II-2. Standard sewing

shape list" p.3.

K004 Sewing shape selection

"V-22. Memory

.

Cloth cut length

This item sets the length of cloth that is cut by cloth

cutting knife. However, in case of bar-tack shape (Nos.

27, 28, 29, and 30 of S001), sewing length is set.

By making effective

tions of cloth cutting knife

make the plural motions of knife by the knife size set

in the item

sewing product is cut. → Refer to

switch data list" p.55

U018 Cloth cutting knife size

U019 Function of plural mo-

of memory switch data,

, and the

"V-22. Memory

.

Knife groove width, right

This item sets the clearance between cloth cutting

knife and right parallel section.

Knife groove width , left

This item sets the clearance between cloth cutting

knife and left parallel section.

3.0 to 119.60 0.1 mm –

-2.00 to 2.00 0.05 mm –

-2.00 to 2.00 0.05 mm –

S005

S006

S007

S008

S009

Overedging width, left

This item sets the overedging width of left parallel

section.

Ratio of right and left shapes

This item sets enlargement/reduction ratio of right

side shape making the knife position as the center.

Pitch at parallel section

This item sets sewing pitch of left and right parallel

sections.

2nd bar-tacking length

This item sets length of bar-tacking on the front side.

Bottom

of square

type

Bottom of

straight

bar-tacking

Bottom

of taper

1st bar-tacking length

This item sets length of bar-tacking on the rear side.

Top of

square

type

0.10 to 5.00 0.05 mm –

50 to 150 1% –

0.200 to 2.500 0.025 mm –

0.2 to 5.0 0.1 mm –

0.2 to 5.0 0.1 mm –

– 37 –

Page 41

No. Item Setting range Edit unit Remarks

S010

Compensation of bar-tacking width, right

-1.00 to 1.00 0.05 mm –

This item adjusts right side outer shape of bar-tacking section in terms of overedging section. It is corrected 1st and 2nd bar-tacking together.

Top of

square

type

Bottom

of square

type

Bottom of

straight

bar-tacking

S011

S012

S013

S014

S015

S016

Compensation of bar-tacking width, left

This item adjusts left side outer shape of bar-tacking

section in terms of overedging section.

Top of

square

type

Bottom

of square

type

Bottom of

straight

bar-tacking

Taper bar-tacking offset, left

This item sets length to form bar-tacking section of

taper bar-tacking shape.

Taper bar-tacking offset, right

This item sets length to form bar-tacking section of

taper bar-tacking shape.

Eyelet shape length

This item sets upper side length from center of eyelet of eyelet shape.

Number of stitches of eyelet shape

This item sets number of stitches in the upper 90˚ of

eyelet shape.

Eyelet width

This item sets crossuise size of the inside of eyelet

shape. Actual needle entry point is the dimension to

S004 Knife groove width, left

which

is added.

-1.00 to 1.00 0.05 mm –

0.00 to 3.00 0.05 mm

0.00 to 3.00 0.05 mm

1.0 to 10.0 0.1 mm

1 to 8 1

1.0 to 10.0 0.1 mm

*1

*1

*1

*1

*1

S017

Eyelet length

1.0 to 10.0 0.1 mm

*1

This item sets lengthwise size of the inside of eyelet

shape.

S018

Round type shape length

1.0 to 5.0 0.1 mm

*1

This item sets upper length from the center of round

type shape.

Top of

semilunar

type

Bottom of

semilunar

type

1 to 8 1

*1

S019

Top of

round

type

Bottom

of round

type

Top of

Radial

type

Bottom

of radial

type

Number of stitches of radial shape

This item sets number of stitches in the upper 90˚ of

radial shape.

S020

Reinforcement of radial shape

– –

*1, *2

This item sets with/without reinforcement stitching of radial

shape.

: With : Without

*1 : Displayed according to the shape

*2 : Displayed when it is set to with edit. Refer to "V-12. Method of setting sewing data with/without edit" p.36.

*3 : Displayed when the function is selected.

– 38 –

Page 42

No. Item Setting range Edit unit Remarks

S021

Pitch at bar-tacking section

0.200 to 2.500 0.025 mm –

This item sets sewing pitch of bar-tacking section.

S022

S023

S031

S032

Top of

square

type

Bottom

of square

type

Top of

round

type

Bottom

of round

type

Top of

semilunar

type

Bottom of

semilunar

type

Bottom of

straight bar-

tacking

Bottom of

taper bar-

tacking

1st clearance

This item sets the clearance between 1st bar-tacking

and knife groove. This item is applied to all shapes.

2nd clearance

This item sets the clearance between 2nd bar-tack-

ing and knife groove.This item is applied to all

shapes.

Single/double stitching

This item selects single or double stitching.

Single

stitching

Double

stitching

Double stitching cross selection

This item selects overlapping stitching or cross stitching at the

needle entry of parallel section when setting double stitching.

: Double stitching

: Cross stitching

0.0 to 4.0 0.1 mm –

0.0 to 4.0 0.1 mm –

– – –

– –

*3

S033

S034

S035

S036

S037

S038

S039

Compensation of double stitching width

This item sets amount to narrow overedging width of

1st cycle when setting double stitching.

Number of times of basting

This item sets number of times of basting.

: Without basting : With basting

(Setting of number of times)

Basting pitch

This item sets pitch at the time of performing basting.

Rolling length of basting

This item sets rolling length of needle thread when

performing basting.

Rolling pitch of basting

This item sets rolling pitch of needle thread when

performing basting.

Rolling width of basting

This item sets rolling width of needle thread when

performing basting.

Lengthwise compensation of needle entry

of basting

This item sets the amount to move needle entry po-

sition back and forth when performing basting more

than two cycles.

0.0 to 2.0 0.1 mm

0 to 9 1 time –

1.0 to 5.0 0.1 mm

2.0 to 20.0 0.1 mm

0.2 to 5.0 0.1 mm

0.0 to 4.0 0.1 mm

0.0 to 2.5 0.1 mm

*3

*3

*3

*3

*3

*2, *3

*1 : Displayed according to the shape

*2 : Displayed when it is set to with edit. Refer to "V-12. Method of setting sewing data with/without edit" p.36.

*3 : Displayed when the function is selected.

– 39 –

Page 43

No. Item Setting range Edit unit Remarks

S040

Crosswise compensation of needle entry

0.0 to 1.0 0.1 mm

*3

of basting

This item sets the amount to move needle entry

position to the right or left when performing basting

more than two cycles.

S041

S042

S044

S051

S052

S053

S054

Compensation of left side position of basting

This item sets the amount to move the sewing

reference position of basting from the center of left

overedging to the right or left.

Compensation of right side position of

basting

This item sets the amount to move the sewing

reference position of basting from the center of right

overedging to the right or left.

Speed setting of basting

This item sets speed of basting.

Left parallel section tension

This item sets needle thread tension at left parallel

section.

Right parallel section tension

This item sets needle thread tension at right parallel

section.

Left parallel section tension (1st cycle of

double stitching)

This item sets needle thread tension at left parallel

section of 1st cycle at the time of double stitching.

Right parallel section tension (1st cycle of

double stitching)

This item sets needle thread tension at right parallel

section of 1st cycle at the time of double stitching.

-2.0 to 2.0 0.1 mm

-2.0 to 2.0 0.1 mm

400 to 4200 100 sti/min

0 to 200 1 –

0 to 200 1

0 to 200 1

0 to 200 1

*2, *3

*2, *3

*3

*2

*2, *3

*2, *3

S055

S056

S057

Tension at 1st bar-tacking section

This item sets needle thread tension at 1st bar-tack-

ing section.

Tension at 2nd bar-tacking section

This item sets needle thread tension at 2nd

bar-tacking section.

Setting of needle thread tension at the

0 to 200 1 –

0 to 200 1

0 to 200 1 –

*2

start of sewing

This item sets needle thread tension of tie stitching

at the start of sewing.

S058

S059

Setting of needle thread tension of basting

This item sets needle thread tension of basting.

ACT timing adjustment at the start of 1st

0 to 200 1

-5 to 5 1 stitch

*3

*2

bar-tacking

This item adjusts needle thread tension output start

timing at 1st bar-tacking section.

*1 : Displayed according to the shape

*2 : Displayed when it is set to with edit. Refer to "V-12. Method of setting sewing data with/without edit" p.36.

*3 : Displayed when the function is selected.

– 40 –

Page 44

No. Item Setting range Edit unit Remarks

S060

ACT timing adjustment at the start of right

-5 to 5 1 stitch

*2

overedging

This item adjusts needle thread tension output start

timing at right overedging section.

S061

S062

S063

S064

S065

S066

ACT timing adjustment at the start of 2nd

bar-tacking

This item adjusts needle thread tension output start

timing at 2nd bar-tacking section.

Number of stitches of tie stitching at the

start of sewing

This item sets number of stitches of tie stitching at

the start of sewing.

Sewing pitch of tie stitching at the start of

sewing

This item sets sewing pitch pf tie stitching at the

start of sewing.

Tie stitching width at the start of sewing

This item sets tie stitching width at the start of sew-

ing.

Lengthwise compensation of tie stitching

at the start of sewing

This item sets start position of tie stitching in length-

wise direction at the start of sewing.

Crosswise compensation of tie stitching at

the start of sewing

This item sets start position of tie stitching in cross-

wise direction at the start of sewing.

-5 to 5 1 stitch

0 to 8 1 stitch –

0.00 to 0.70 0.05 mm

0.0 to 3.0 0.1 mm –

0.0 to 5.0 0.1 mm

0.0 to 2.0 0.1 mm

*2

*2

*2

*2

S067

S068

S069

S070

S081

S083

Tie stitching width at the end of sewing

This item sets tie stitching width at the end of sew-

ing.

Number of stitches of tie stitching at the

end of sewing

This item sets number of stitches of tie stitching at

the end of sewing.

Lengthwise compensation of tie stitching

at the end of sewing

This item sets start position of tie stitching in length-

wise direction at the end of sewing.

Crosswise compensation of tie stitching at

the end of sewing

This item sets start position of tie stitching in cross-

wise direction at the end of sewing.

Knife motion

This item sets "With/without motion" of normal cloth cutting knife.

: Normal knife

motion OFF

: Normal knife

motion ON

Knife motion at 1st cycle of double stitching

This item sets "With/without motion" of cloth cutting knife at 1st

cycle when double stitching is performed.

0.1 to 1.5 0.1 mm –

0 to 8 1 –

0.0 to 5.0 0.1 mm

0.0 to 3.0 0.1 mm

– – –

– –

*2, *3

*2

*2

: Normal knife

motion OFF

: Normal knife

motion ON

*1 : Displayed according to the shape

*2 : Displayed when it is set to with edit. Refer to "V-12. Method of setting sewing data with/without edit" p.36.

*3 : Displayed when the function is selected.

– 41 –

Page 45

No. Item Setting range Edit unit Remarks

S084

S086

S087

Maximum speed limitation

This item sets max. speed limitation of the sewing

machine. The maximum value of data edit is equal

to the number of revolutions of

speed limitation

Refer to

→

p.55

.

of the memory switch data.

"V-22. Memory switch data list"

K007 Maximum

Pitch of going

This item sets sewing pitch of going side of

bar-tacking shape (Shape Nos. 27, 28, 29 and 30 of

S001).

Width of going

This item sets width of going side of bar-tacking

shape (Shape Nos. 27, 28, 29 and 30 of S001).

400 to 4200 100 sti/min –

0.200 to 2.500 0.025 mm –

0.1 to 10.0 0.05 mm –

S088

S089

S090

S500

Pitch of coming

This item sets sewing pitch of coming side of

bar-tacking shape (Shape Nos. 27, 28, 29 and 30 of

S001).

Width of coming

This item sets width of coming side of bar-tacking

shape (Shape Nos. 27, 28, 29 and 30 of S001).

Presser foot pressure

Used to set the pressure to clamp the material.

When the set value is 25, the presser foot pressure

is approximately 4 kg. When the set value is 80, the

presser foot pressure is approximately 10 kg.

Pattern data name

Used for changing the name of pattern data.

0.200 to 2.500

0.1 to 10.0 0.05 mm –

20 to 80 1 –

– – –

0.025 mm –

– 42 –

Page 46

14. Copying sewing pattern

Data of pattern No. which has been already registered can be copied to pattern No. which has not been

used. Overwriting copy of the pattern is prohibited. When you desire to overwrite, perform it after erasing

the pattern once.

1) Set the mode to input mode.

Under the input mode where SET READY LED

goes out, copy is enabled.

If the current mode is the sewing mode, press

READY key to change over the mode

to the input mode.

Pattern No. of

copy source

Pattern No. (B) of

copy destination

A

2) Select pattern No. of copy source.

Press ITEM SELECT key to select the

source pattern No.

Refer to

→

p.27

When creating pattern data quite newly. it is

convenient to copy the initial value pattern.

Refer to

→

tern" p.33

"V-5. Performing pattern selection"

"V-10. Using the initial value pat-

3) Call copy screen.

Press COPY key , and copy screen A is

displayed.

4) Select pattern No. of copy destination.

Pattern No. B which is not used is displayed.

Press DATA CHANGE key to select a

number to be used for copying. When you desire

to erase the pattern, select the garbage can .

5) Start copying.

When READY key is pressed, the copy starts. Then, the screen returns to the input screen on

which the pattern No. which is created by copying is selected.

When RETURN key is pressed, the screen returns to the previous screen without performing

copying.

* In addition, cycle data and continuous stitching data can be copied by the same method.

– 43 –

Page 47

15. How to edit/check the data other than sewing data

The screen for editing/checking the various data is invoked by selecting the menu on the mode screen.

1) Set the mode to input mode.

Under the input mode where set ready LED

goes out, the mode screen can be called. If the

current mode is the sewing mode, press READY

key to change over the mode to the

input mode.

2) How to invoke the mode screen.

Press MODE key

screen (operator level).

Then, keep MODE key

for three seconds to display the mode screen

(service level).

On each level mode screen, the menu items listed

in the table below are displayed.

Display level Menu on the mode screen

to display the mode

held pressed

Operator level Memory switch 1

Version display

Communication

Regist. of parmtr key

Sewing parameter edit selection

Maintenance personnel

level

USB format

Check program

Pedal VR adjustment

Adjustment of contrast

Memory switch 2

Key lock

– 44 –

Page 48

3) Selecting the menu.

Items which can be registered on the key are displayed. Press ITEM SELECT key

to select the

target menu. When you press EDIT key during the menu selection, the following screens can be

invoked.

1. Memory switch 1

→

Refer to

2.

Version display

Version of the system software is displayed.

"V-21. Method of changing memory switch data" p.54

for details.

3. Communication

→

Refer to

"V-27. Communication" p.62

for details.

4. Regist. of parmtr key

→

Refer to

"V-16. Using parameter register key" p.46

for details.

5. Sewing parameter edit selection

→

Refer to

"V-12. Method of setting sewing data with/without edit" p.36

for details.

6. USB format

→ Refer to the Engineer's Manual for details.

7. Check parogram

Refer to the Engineer's Manual for details.

→

8. Pedal VR adjustment

→

Refer to

"V-24. How to adjust the pedal variable resistor" p.60

9. Adjustment of contrast

→

Refer to

"V-25. How to adjust the contrast" p.61

10. Memory switch 2

→

Refer to

"V-22. Memory switch data list" p.55

11. Key lock

→

Refer to the Engineer's Manual for how to enable selection of the key lock from the mode screen

and how to set the key lock.

For the functions which are not described in this manual, only the maintenance personnel is

allowed to operate while referring to the Engineer's Manual since operating those functions can

lock up the sewing machine or can cause unforeseen accidents.

for details.

for details.

for details.

– 45 –

Page 49

16. Using parameter register key

Register parameters which are frequently used with parameter register key and use them.

Parameters which have been registered can be selected by pressing only the parameter register key

under the input mode.

(1) Method of register

1) Set the mode to the input mode.

Under the input mode where SET READY LED

goes out, parameter registration is enabled.

If the current mode is the sewing mode, press

READY key to change over the mode

to the input mode.

A B

2) Call parameter register screen.

Press MODE key to display the mode

screen. Select the parameter key registration

on this screen. Then, the parameter registration

screen A is displayed.

When you press EDIT key on the screen,

the parameter registration key setting screen is

displayed.

The parameter registration key setting screen

can also be displayed by keeping the parameter

registration key you want to edit held pressed.

3) Select parameter.

Item B which can be registered to the key is displayed. Press ITEM SELECT key to select the