Page 1

DDL-9000B Series

INSTRUCTION MANUAL

Page 2

CONTENTS

SPECIFICATIONS ................................................1

1. INSTALLATION ............................................2

2. ADJUSTING THE HEIGHT OF THE KNEE

LIFTER ..........................................................4

3. INSTALLING THE THREAD STAND ............4

4. LUBRICATION (DDL-9000B-S , -M ) ........5

5. ATTACHING THE NEEDLE ..........................6

6.

SETTING THE BOBBIN INTO THE BOB-

BIN CASE ........................................................ 6

7. ADJUSTING THE AMOUNT OF OIL (OIL

SPLASHES) IN THE HOOK

(DDL-9000B-S , -M ) ..................................7

(1) How to conrm the amount of oil (oil splash-

es) .................................................................... 7

(2) Sample showing the appropriate amount of oil 7

8. ADJUSTING THE AMOUNT OF OIL IN

THE HOOK (DDL-9000B-S , -M ) ..............8

9. THREADING THE MACHINE HEAD ............9

10. THREAD TENSION ......................................9

(1) Adjusting the needle thread tension ................ 9

(2) Adjusting the bobbin thread tension ............... 9

11. WINDING THE BOBBIN THREAD .............10

12. PRESSER FOOT PRESSURE ...................11

13. ADJUSTING THE STITCH LENGTH .........11

14.

ADJUSTING THE THREAD TAKE-UP

SPRING AND THE THREAD TAKE-UP

STROKE ...........................................................12

15. ADJUSTING THE NEEDLE STOP POSI-

TION ............................................................13

(1) Stop position after thread trimming ................ 13

(2) Adjusting procedure of the needle up/down

stop position .................................................. 13

16. PEDAL PRESSURE AND PEDAL

STROKE .....................................................14

(1) Adjusting the pressure required to depress

the front part of the pedal .............................. 14

(2) Adjusting the pressure required to depress

the back part of the pedal ............................. 14

(3) Adjusting the pedal stroke ............................ 14

17. ADJUSTMENT OF THE PEDAL ................14

(1) Installing the connecting rod .......................... 14

(2) Adjusting the pedal angle .............................. 14

18. PEDAL OPERATION ..................................15

19. NEEDLE-TO-HOOK RELATIONSHIP ........16

20. ONE-TOUCH TYPE REVERSE FEED

STITCHING MECHANISM ..........................17

21. ADJUSTING THE POSITION OF THE

WIPER (DDL-9000B- -WB, -0B) ..........18

22. COUNTER KNIFE .......................................19

23. HEIGHT AND TILT OF THE FEED DOG ....20

(1) Standard value of the height of the feed dog . 20

(2) Adjusting the height and tilt of the feed dog ...20

24. ADJUSTING THE FEED TIMING ...............21

25. THREAD TENSION RELEASE RELEAS-

ING MECHANISM .......................................21

26. MICRO-LIFTING MECHANISM OF THE

PRESSER FOOT ........................................22

27. SEWING CONDENSED STITCHES ...........23

28. FEED CONVERSION SPRING MECHA-

NISM (DDL-9000B-S , -M ) ......................23

29. CARE ..........................................................24

(1) Conrmation of the amount of oil in the hook

oil tank. .......................................................... 24

(2) Cleaning ....................................................... 24

30. APPLYING GREASE .................................. 25

(1) Sections to which grease is to be replen-

ished .............................................................. 25

(2) Releasing procedure of the grease-up warn-

ing for SC-920 ............................................... 26

i

Page 3

S : Micro-quantity lubrication

M : Semi-dry

D : Dry

SPECIFICATIONS

DDL-9000B-

S :

Medium-weight materials

H : Heavy-weight materials

A : Light weight materials

-SS -MS -DS -SH -MA

Max. sewing

speed

Thread trimming

speed

Stitch length 5 mm

Presser foot lift

(by knee lifter)

Needle

Lubricating oil

Noise

*2

JUKI NEW DEFRIX OIL No. 1

SS, MS, MA ;

'- Equivalent continuous emission sound pressure level (LpA) at the workstation:

A-weighted value of 77 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821- C.6.2 -ISO 11204

SH ;

'- Equivalent continuous emission sound pressure level (LpA) at the workstation:

A-weighted value of 77 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821- C.6.2 -ISO 11204

DS ;

'- Equivalent continuous emission sound pressure level (LpA) at the workstation:

A-weighted value of 79 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821- C.6.2 -ISO 11204

5,000sti/min 4,000 sti/min 4,500 sti/min 5,000 sti/min

500 sti/min (100 to 500 sti/min)

10 mm (standard) 15 mm (max.)

1738 Nm65 to 110

(DB×1 #9 to 18)

134 Nm65 to 110

(DP×5 #9 to 18)

or JUKI MACHINE OIL #7

GR2 at 4,000 sti/min.

GR2 at 4,000 sti/min.

GR2 at 4,000 sti/min.

*1

1738 Nm125 to 160

(DB×1 #20 to 23)

134 Nm125 to 160

(DP×5 #20 to 23)

- JUKI NEW DEFRIX OIL No. 1

or JUKI MACHINE OIL #7

1738 SAN10 Nm60 to 75

(DB×1 SF#8 to 11)

134 Nm60 to 75

(DP×5 #8 to 11)

*3

4mm

• The sewing speed will vary depending on the sewing conditions. The sewing speed preset at the time of shipping is 4,000sti/

min. The thread trimming speed can be changed within the range of ( ). The thread trimming speed preset at the time of

shipping is 420 sti/min.

1

*

: When stitch length exceeds 4 mm or more, set the max. sewing speed to 4,000 sti/min or less for use.

2

*

: Needle used depends on the destination.

3

*

: MA type is for light-weight materials. In the case the sewing machine is used with its speed of stitch set at 4,000 sti/min or

higher, the presser regulating spring and thread tension spring should be changed with S type ones.

– 1 –

Page 4

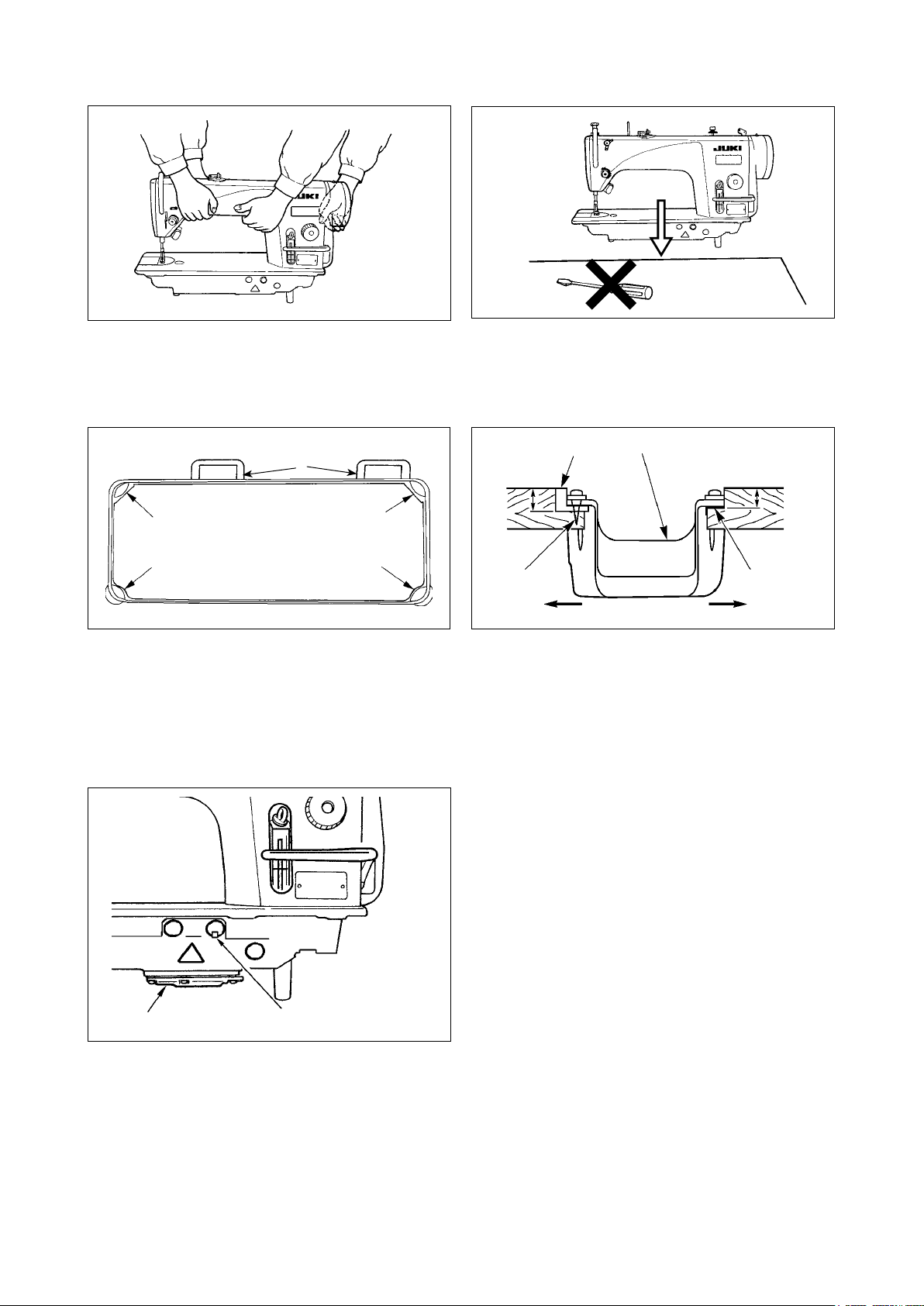

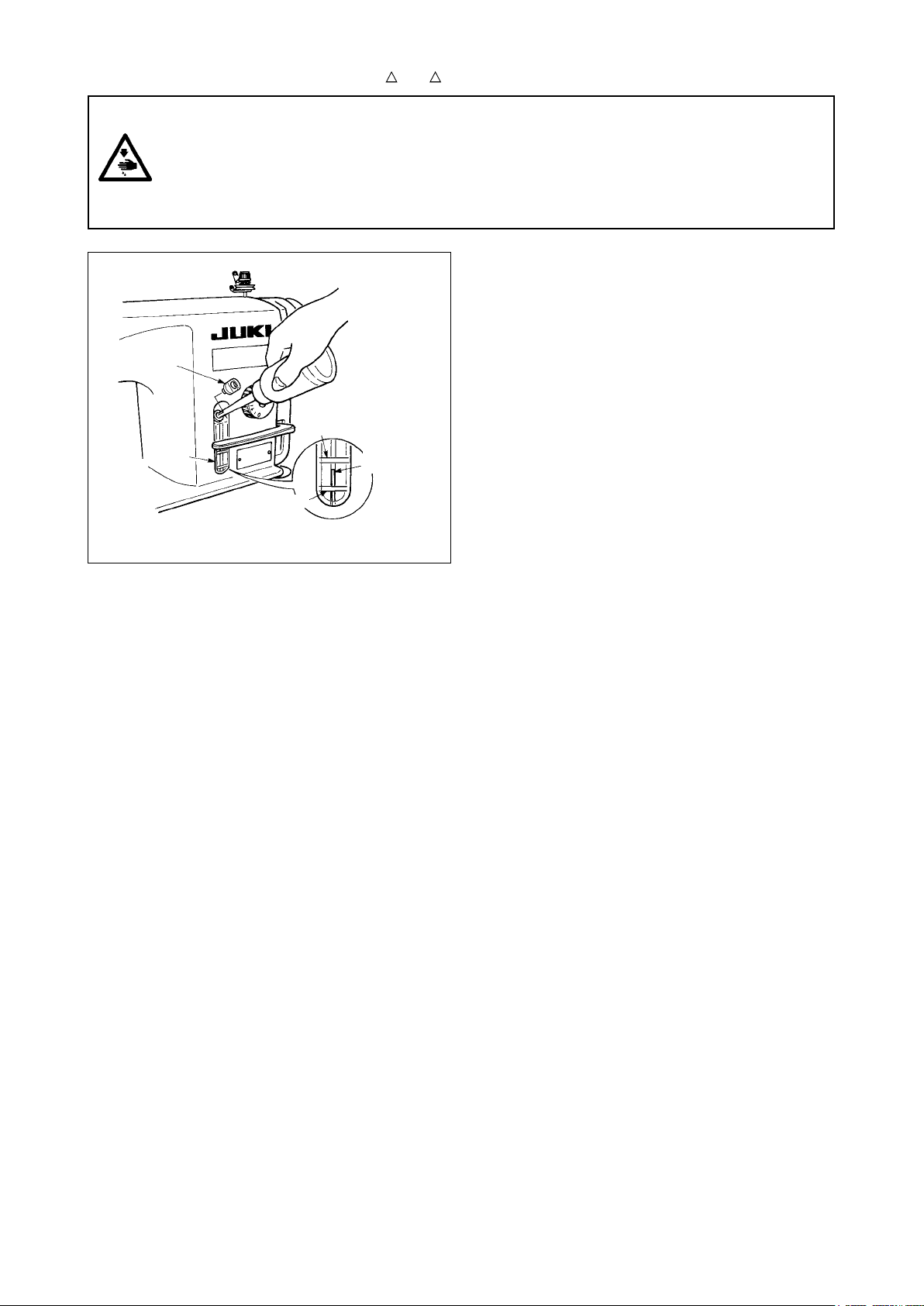

1. INSTALLATION

1) Carry the sewing machine with two persons as

shown in the gure above.

(Caution) Do not hold the handwheel.

❽

❸

❶

❸

❶

3) The under cover should rest on the four corners

of the machine table groove. Mount rubber hinge

seat ❽ on the table and x it on the table with a

nail.

2) Do not put protruding articles such as the screw-

driver and the like at the location where the sewing

machine is placed.

❶

23.5 mm

❷

❹

19.5 mm

❸

A

B

4) Fix two rubber seats ❶ on side A (operator’s

side) using nails ❷ as illustrated above. Fix two

cushion seats ❸ on side B (hinged side) using a

rubber-based adhesive. Then place under cover

❹ on the xed seats.

5) Remove air vent cap ❺ attached to the machine

bed.

(Caution)

1. If the sewing machine is operated without

removing air vent cap ❺, oil leakage from

gear box portion C may occur.

2. Be sure to attach cap ❺ when transporting

the machine head in the state that the ma-

chine head is removed from the machine

C

❺

table.

– 2 –

Page 5

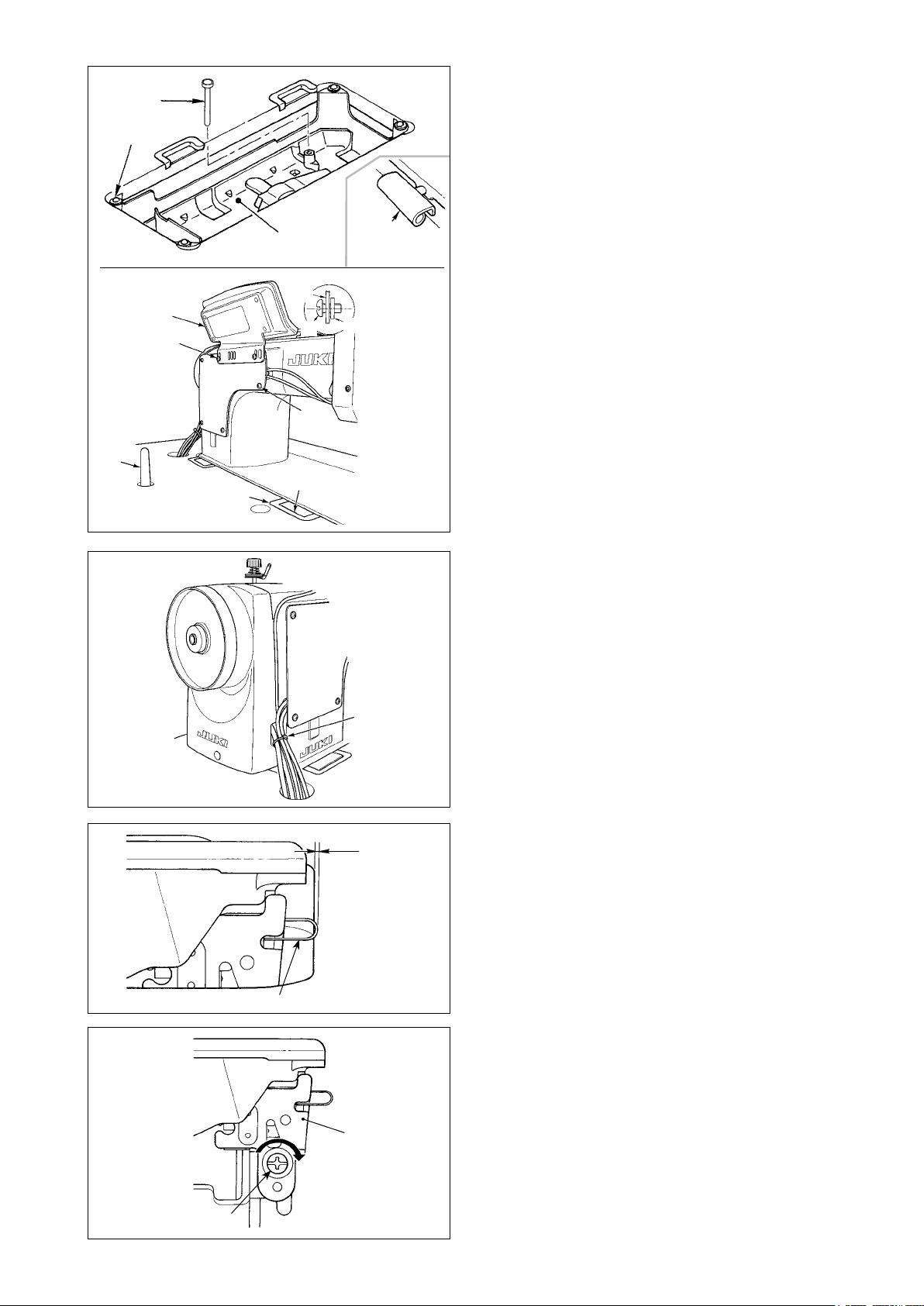

❾

❻

❽

❹

❼

❼

6) Fit knee lifter pressing rod ❻. Fit hinge ❼ into the

opening in the machine bed, and t the machine

head to table rubber hinge ❽ before placing the

machine head on cushions ❾ on the four corners.

7) Securely attach head support rod to the table

until it goes no further. Regarding the control

panel , remove two side plate xing screws ,

place the rubber packing , which is one of the

accessories of the control panel , between the

head section and control panel , then x them

together.

(Caution)

1. Do not use the screws supplied as accesso-

ries of control panel .

2.

Be sure to mount the machine head support

rod on the machine table so that its height

from the table surface becomes 55 to 60 mm.

For the sewing machine provided with the AK

device, be sure to mount the support rod

on the table so that its height from the table

surface becomes 38 to 43 mm.

8) Bundle cable clip band supplied as accessories

of the machine head at the root of the cable.

2.0 to 3.5 mm

9) Check to be sure that the table and the safety

switch arm are engaged with each other by 2.0

mm to 3.5 mm, with the sewing machine slightly

tilted.

(Caution) If the engagement between the table and

the safety switch arm is 2 mm or less, Error

302 may occur at the time of startup. Or, if the

aforementioned engagement is 3.5 mm or more,

safety switch arm may break.

10) If the engagement between the table and safety

switch arm is outside the range of 2.0 mm and

3.5 mm, loosen safety switch mounting screw

and tilt safety switch in the direction of the arrow

to adjust the engagement of safety switch arm

with the table.

– 3 –

Page 6

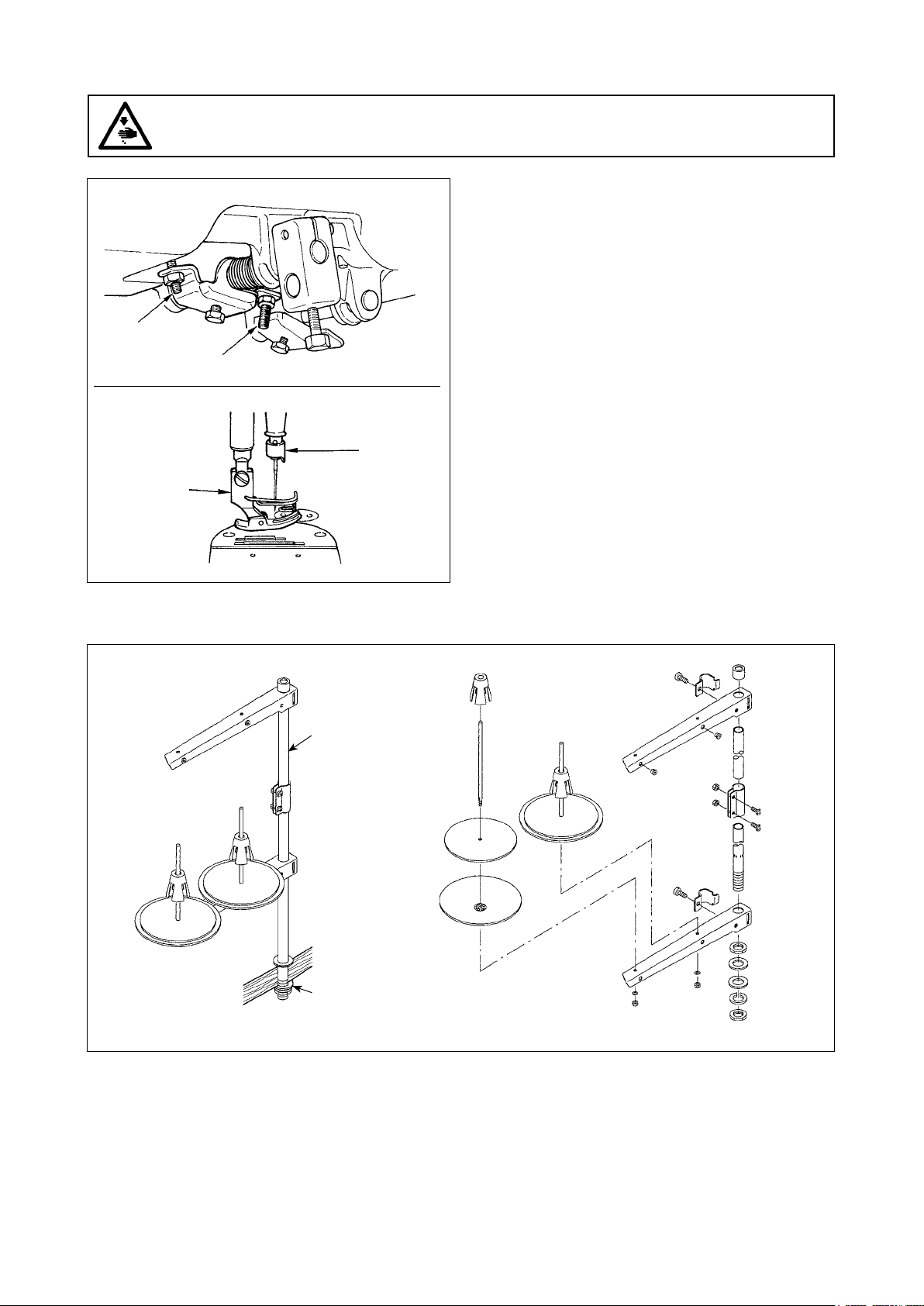

2. ADJUSTING THE HEIGHT OF THE KNEE LIFTER

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

The standard height of the presser foot lifted using the

knee lifter is 10 mm.

You can adjust the presser foot lift up to 15 mm using

knee lifter adjust screw ❶.

(Caution)

1. Do not operate the sewing machine in the

❹

❶

❷

❸

state that the presser foot ❸ is lifted by 10

mm or more since the needle bar ❷ comes

in contact with the presser foot ❸.

2. Knee lifter initial position

If the adjustment screw ❹ is over tightened,

the sewing machine will operate in a state

where the presser foot is lifted up, causing

defective sewing or noise.

3. INSTALLING THE THREAD STAND

❷

❶

1) Assemble the thread stand unit, and insert it in the hole in the machine table.

2) Tighten nut ❶.

3) For ceiling wiring, pass the power cord through spool rest rod ❷.

– 4 –

Page 7

4. LUBRICATION (DDL-9000B-S , -M )

WARNING :

1. Do not connect the power plug until the lubrication has been completed so as to prevent

accidents due to abrupt start of the sewing machine,

2. To prevent the occurrence of an inammation or rash, immediately wash the related portions if oil

adheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

❶

❸

❷

Upper

engraved

marker line

Upper

engraved

marker line

Fill the oil tank with oil for hook lubrication before op-

erating the sewing machine.

1) Remove oil hole cap ❶ and ll the oil tank with

JUKI NEW DEFRIX OIL No.1 (Part No. : MD-

FRX1600C0) or JUKI MACHINE OIL #7 (Part No.

: MML007600CA) using the oiler supplied with the

machine.

2) Fill the oil tank with the oil until the top end of oil

amount indicating rod ❸ comes between the upper

engraved marker line A and the lower engraved

marker B line of oil amount indicating window ❷.

If the oil is lled excessively, it will leak from the

air vent hole in the oil tank or proper lubrication

will be not performed. In addition, when the oil is

vigorously lled, it may overow from the oil hole.

So, be careful.

3) When you operate the sewing machine, rell oil if the top end of oil amount indicating rod ❸ comes down

to the lower engraved marker line of oil amount indicating window ❷.

(Caution)

1. When you use a new sewing machine or a sewing machine after an extended period of disuse,

use the sewing machine after performing break-in at 2,000 sti/min or less.

2. For the oil for hook lubrication, purchase JUKI NEW DEFRIX OIL No. 1 (Part No. : MDFRX1600C0)

or JUKI MACHINE OIL #7 (Part No. : MML007600CA).

3. Be sure to lubricate clean oil.

4. Do not operate the machine with the oil hole cap ❶ removed. Never remove cap ❶ from the oil

inlet in any case other than oiling. In addition, take care not to lose it.

– 5 –

Page 8

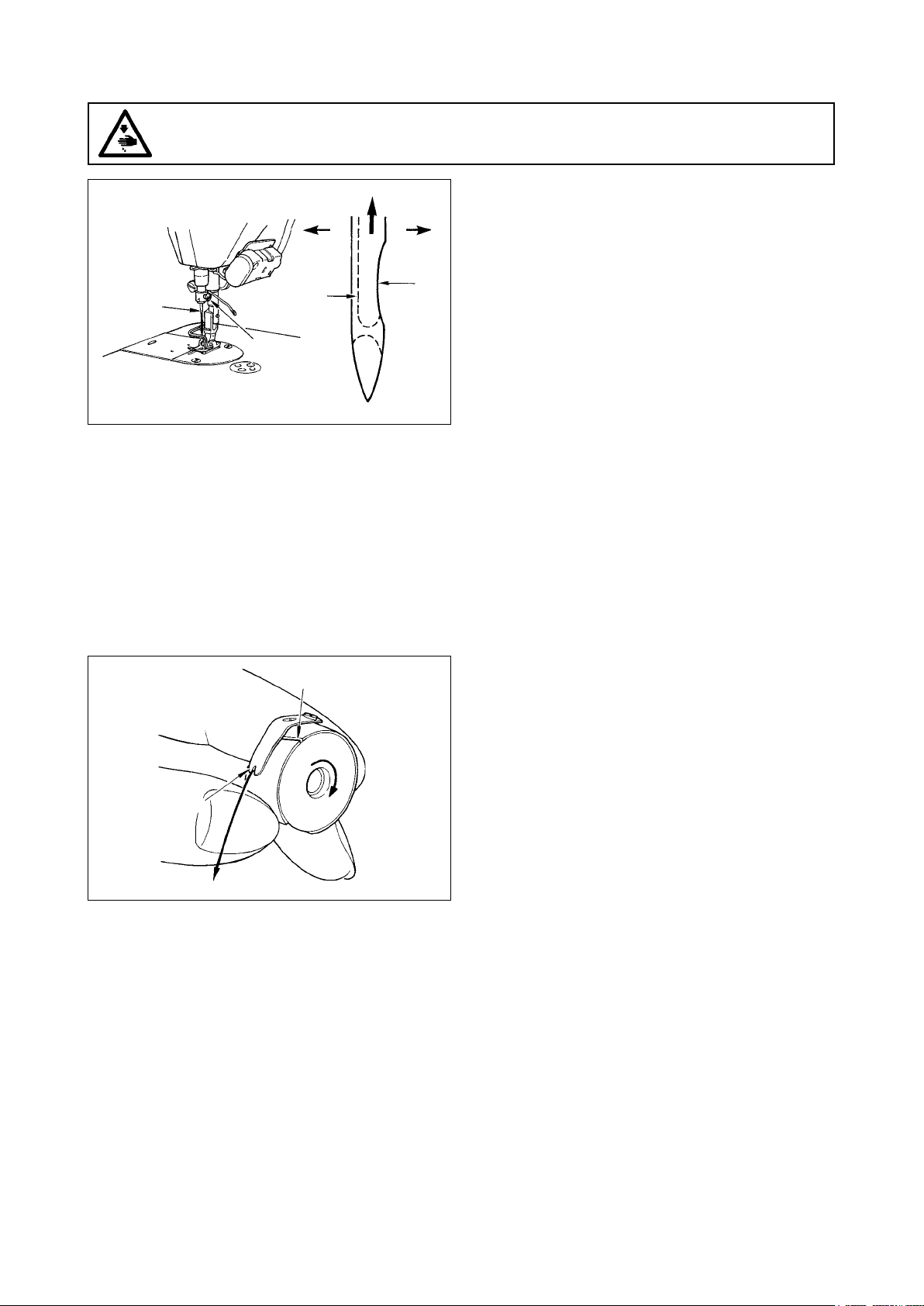

5. ATTACHING THE NEEDLE

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

Use the specied needle for the machine. Use the

proper needle in accordance with the thickness of

D

❶

❷

C

4) Securely tighten screw ❷.

5) Check that long groove C of the needle is facing exactly to the left in direction D.

(Caution) When polyester lament thread is used, if the indented part of the needle is tilted toward oper-

ator's side, the loop of thread becomes unstable. As a result, hangnail of thread or thread breakage

may occur. For the thread that such phenomenon is likely to occur, it is effective to attach the needle

with its indented part slightly slanting on the rear side.

B

A

thread used and the kinds of the materials.

1) Turn the handwheel until the needle bar reaches

the highest point of its stroke.

2) Loosen screw ❷, and hold needle ❶ with its

indented part A facing exactly to the right in direction B.

3) Insert the needle fully into the hole in the needle

bar in the direction of the arrow until the end of

hole is reached.

6.

SETTING THE BOBBIN INTO THE BOBBIN CASE

1) Install the bobbin in the bobbin case so that the

A

2) Pass the thread through thread slit A, and pull

B

C

3) Check that the bobbin rotates in the direction of

thread wound direction is clockwise.

the thread in direction C. By so doing, the thread

will pass under the tension spring and come out

from notch B.

the arrow when thread is pulled.

– 6 –

Page 9

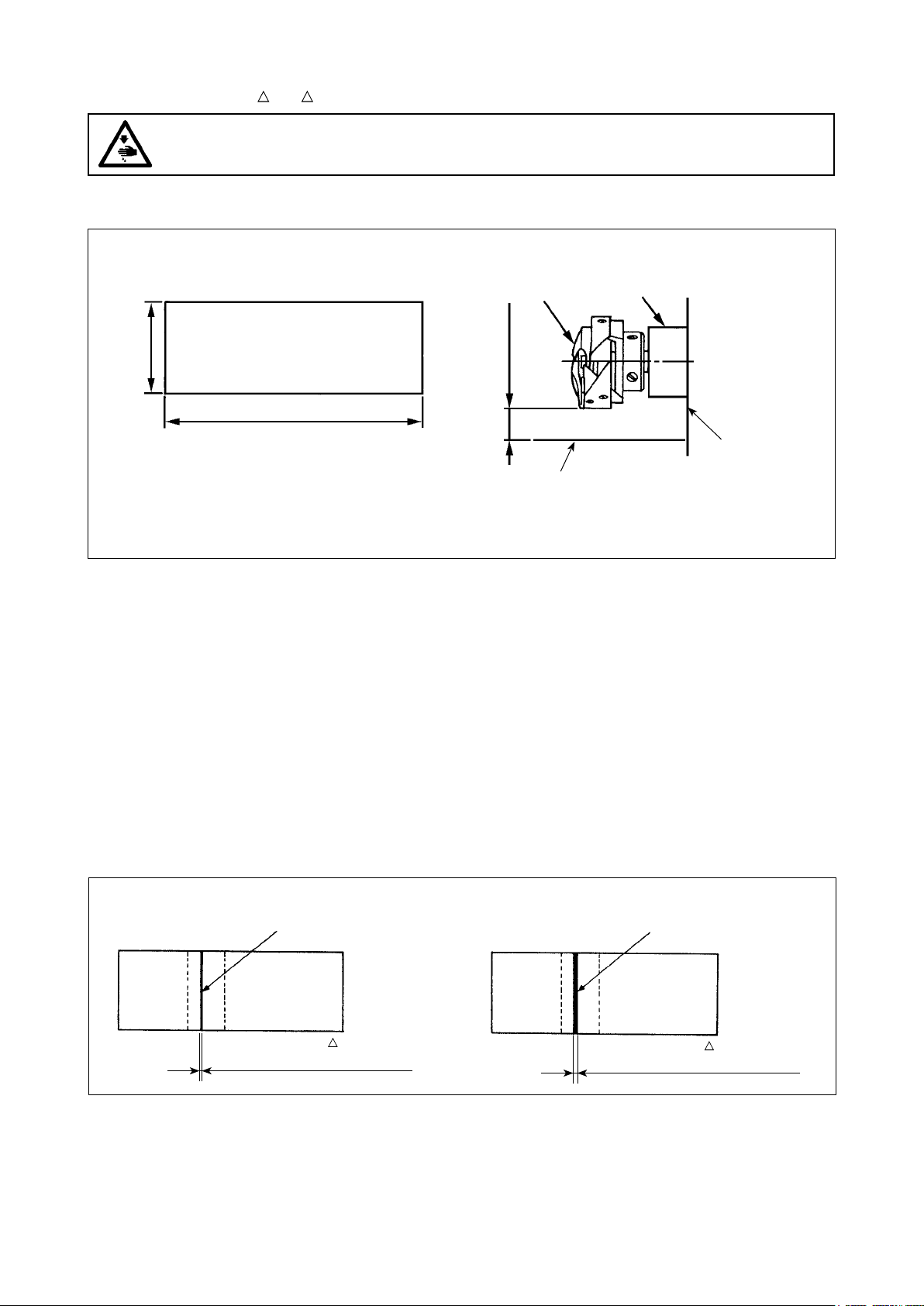

7. ADJUSTING THE AMOUNT OF OIL (OIL SPLASHES) IN THE HOOK

(DDL-9000B-S , -M )

WARNING :

Be extremely careful about the operation of the machine since the amount of oil has to be checked

by turning the hook at a high speed.

(1) How to conrm the amount of oil (oil splashes)

❶ Amount of oil (oil splashes) conrmation paper

Approx. 25 mm

Approx. 70 mm

* Use any paper available regardless of the material.

❷ Position to conrm the amount of oil (oil splashes)

Hook

3 - 10mm

Oil splashes conrmation paper

* Place the amount of oil (oil splashes) conrmation paper under

the hook and keep it from the hook by 3 to 10 mm to conrm

the amount.

Hook driving shaft front bushing

Bed

Closely fit the

paper against the

wall surface of

the bed.

* When carrying out the procedure described below in 2), conrm the state that the needle thread

from the thread take-up lever to the needle and the bobbin thread are removed, the presser foot is

lifted and the slide plate is removed. At this time, take extreme caution not to allow your ngers to

come in contact with the hook.

1) If the machine has not been sufciently warmed up for operation, make the machine run idle for approxi-

mately three minutes. (Moderate intermittent operation)

2) Place the amount of oil (oil splashes) conrmation paper under the hook while the sewing machine is in

operation.

3) Conrm that oil exists in the oil tank.

4) Conrmation of the amount of oil should be completed in ve seconds. (Check the period of time with a

watch.)

(2) Sample showing the appropriate amount of oil

Appropriate amount of oil (small)

Splashes of oil from the hook

• DDL-9000B-SS, -M : 0.5 to 1 mm

• DDL-9000B-SH : 1 to 3 mm

1) The state given in the gure above shows the appropriate amount of oil (oil splashes). It is necessary to nely

adjust the amount of oil in accordance with the sewing processes. However, do not excessively increase/de-

crease the amount of oil in the hook. (If the amount of oil is too small, the hook will be seized (the hook will be

hot). If the amount of oil is too much, the sewing product may be stained with oil.)

2) Check the oil amount (oil splashes) three times (on the three sheets of paper), and adjust so that it should

not change.

– 7 –

Appropriate amount of oil (large)

Splashes of oil from the hook

• DDL-9000B-SS, -M : 1 to 1.5 mm

• DDL-9000B-SH : 2 to 4 mm

Page 10

8. ADJUSTING THE AMOUNT OF OIL IN THE HOOK (DDL-9000B-S , -M )

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

❹

❸

❷

❶

Decrease

Increase

Tighten (turn clockwise) oil amount adjustment screw ❶ to increase the amount of oil in the hook, or loosen

(turn counterclockwise) to decrease it.

(Caution)

[When using RP hook (hook for dry head) for S or -M type]

1. Remove hook driving shaft oil wick setscrew ❷ and attach hook driving shaft stopper screw ❸

(Part No. : 11079506) and rubber ring ❹ (Part No. : R0036080200).

2. Loosen oil amount adjustment screw ❶ up to the minimum so as to reduce the oil amount in the

hook. However, do not completely stop the oil and be careful not to allow oil adjustment screw

❶ to come off.

3. Never drain the oil in the oil tank even when RP hook (hook for dry head) is used.

– 8 –

Page 11

9. THREADING THE MACHINE HEAD

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

❸

❾

❶

❷

❹

❽

❺

10. THREAD TENSION

B

❶

❻

❼

A

A

E

❸

(Note) Do not pass

this thread

through

section A.

F

❷

C

D

(1) Adjusting the needle thread tension

1) Turn thread tension No. 1 nut ❶ clockwise (in di-

rection A), to shorten the thread length remaining

on the needle after thread trimming or counter-

clockwise (in direction B), to lengthen the thread

length.

2)

Turn thread tension nut ❷ clockwise

C) to increase or counterclockwise (in direction D)

to reduce the needle thread tension.

(in direction

(2) Adjusting the bobbin thread tension

1)

Turn tension adjusting screw ❸ clockwise

direction E)

direction F)

– 9 –

to increase or counterclockwise

to reduce the bobbin thread tension.

(in

(in

Page 12

11. WINDING THE BOBBIN THREAD

❽

❸

B

❶

❷

❹

A

C

❻

❼

D

❻

E

❺

❻

1) Insert the bobbin deep into the bobbin winder

spindle ❶ until it will go no further.

2) Pass the bobbin thread pulled out from the spool

rested on the right side of the thread stand follow-

ing the order as shown in the gure on the left.

Then, wind clockwise the end of the bobbin thread

on the bobbin several times.

(In case of the aluminum bobbin, after winding

clockwise the end of the bobbin thread, wind coun-

terclockwise the thread coming from the bobbin

thread tension several times to wind the bobbin

thread with ease.)

3) Press the bobbin winder trip latch ❷ in the di-

rection of A and start the sewing machine. The

bobbin rotates in the direction of C and the bobbin

thread is wound up. The bobbin winder spindle ❶

automatically as soon as the winding is nished.

4) Remove the bobbin and cut the bobbin thread with

the thread cut retainer ❸.

5) When adjusting the winding amount of the bob-

bin thread, loosen setscrew ❹ and move bobbin

winding lever ❷ to the direction of A or B. Then

tighten setscrew ❹.

To the direction of A : Decrease

To the direction of B : Increase

6) In case that the bobbin thread is not wound evenly on the bobbin, remove the handwheel, loosen screw

❺ and adjust the height of bobbin thread tension ❽.

• It is the standard that the center of the bobbin is as high as the center of thread tension disk ❻.

• Adjust the position of thread tension disk ❻ to the direction of D when the winding amount of the bobbin

thread on the lower part of the bobbin is excessive and to the direction E when the winding amount of the

bobbin thread on the upper part of the bobbin is excessive.

After the adjustment, tighten screw ❺.

7) To adjust the tension of the bobbin winder, turn the thread tension nut ❼.

(Caution)

1. When winding the bobbin thread, start the winding in the state that the thread between the bobbin

and thread tension disk ❻ is tense.

2. When winding the bobbin thread in the state that sewing is not performed, remove the needle

thread from the thread path of thread take-up and remove the bobbin from the hook.

3. There is the possibility that the thread pulled out from the thread stand is loosened due to the

inuence (direction) of the wind and may be entangled in the handwheel. Be careful of the direc-

tion of the wind.

– 10 –

Page 13

12. PRESSER FOOT PRESSURE

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

B

C

A

❶

❷

1) Loosen nut ❷. As you turn presser spring regulator ❶ clockwise (in direction A), the presser foot

pressure will be increased.

2) As you turn the presser spring regulator counter-clockwise (in direction B), the pressure will be

decreased.

3) After adjustment, tighten nut ❷.

The standard value of the addition C of the height of

presser spring regulator is as follows :

• S type : 31.5 to 29 mm (Approximately 40 to 45N/4

to 4.5kg)

• H type : 31.5 to 28 mm (Approximately 50 to 60N/5

to 6kg)

• A type : 22 mm (Approximately 20N/2kg)

13. ADJUSTING THE STITCH LENGTH

A

❶

❷

B

❸

* The dial calibration is in millimeters.

1) Turn stitch length dial ❶ in the direction of the

arrow, and align the desired number to marker

dot A on the machine arm.

2) To change over the feed scale mark from "large"

to "small", turn stitch dial ❶ while pressing feed

lever ❷ in the direction of the arrow and pressing

stopper ❸ in the direction of arrow B (toward the

back of the arm).

3)

To change over the feed scale mark from "small"

to "large", turn stitch dial ❶ while pressing stopper

❸

in the direction of arrow B (toward the back of

the arm).

4) Release stopper ❸ to x stitch dial ❶.

– 11 –

Page 14

14.

ADJUSTING THE THREAD TAKE-UP SPRING AND THE THREAD TAKE-UP STROKE

❹

❺

[DDL-9000B- S, -MA]

❾

❽

C

[DDL-9000B-SH]

❽

D

❾

❶

F

G

H

E

❻

A

B

❶

❸

❷

❻

A

B

❶

❸

❷

(1) Adjusting the stroke of thread take-up spring ❶

1) Loosen setscrew ❷.

2) Turn tension post ❸ clockwise (in direction A), the stroke of the thread take-up spring will be increased,

and turn the post ❸ counterclockwise (in direction B), the stroke will be decreased.

(2) Adjusting the pressure of thread take-up spring ❶

1) Loosen setscrew ❷, and remove thread tension (asm.) ❺.

2) Loosen tension post setscrew ❹.

3) Turn tension post ❸ clockwise (in direction A), the pressure will be increased, and turn the post ❸ counter-

clockwise (in direction B), the pressure will be decreased.

* Standard state of the thread take-up spring

The engraved marker line ❻ on the machine arm is almost aligned with the top of thread take-up spring.

(It is necessary to adjust in accordance with materials and processes.)

(Caution) For the Model DDL-9000B- DS, the fully-dry hook is adopted. Comparing with the sewing machine

using the existing hook, the sewing machine tends to be affected by the adjustment of the thread take-up

spring. If the thread take-up spring does not work sufciently, thread running increases. As a result, thread

breakage, balloon stitching, etc. may occur.

To check how the thread take-up spring works, draw out the needle thread in direction F after having

adjusted the thread take-up spring pressure to check whether the thread take-up spring exerts force to

the thread up to the last moment (state G) just before the thread comes out from E. If the spring fails to

exert force to the spring until the last moment (state H), decrease the thread take-up spring pressure. In

addition, the stroke of the thread take-up spring is excessively small, the spring does not work properly.

For the general fabrics, a stroke of 10 to 13 mm is proper.

(3) Adjusting The Thread Take-up Stroke

1) When sewing heavy-weight materials, move thread guide ❽ to the left (in direction C) to increase the length

of thread pulled out by the thread take-up.

2) When sewing light-weight materials, move thread guide ❽ to the right (in direction D) to decrease the

length of thread pulled out by the thread take-up.

* Standard state of the thread guide

・ - S, -MA: Marker line ❾ on the thread guide aligns with the center of the setscrew.

・ -SH: Marker line ❾ on the thread guide aligns with the center of the marker line on the machine arm.

– 12 –

Page 15

15. ADJUSTING THE NEEDLE STOP POSITION

WARNING :

1. Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

2. Do not perform switch operations other than those described in the following explanations.

3. Be sure to re-turn the power switch ON after one second or more has passed. If the power is turned ON

immediately after turning it OFF, the sewing machine may not work normally. In this case, turn ON the

power again.

(1) Stop position after thread trimming

1) The standard needle stop position is obtained by

D

A

B

C

* For the details, refer to the Instruction Manual for

aligning marker dot A on the pulley cover with

white marker dot B on the handwheel

the control box together.

(2) Adjusting procedure of the needle up/down stop position

* When the panel other than CP-18 is used, refer to the explanation of each panel.

F

❺

❶

E

❷

❸

❹

5) Specify the setting contents F within the range of -15 to 15 with switch ❸ or switch ❹.

(Standard is "0". The numeric of set value indicates the approximate rotating angle.)

When the numeric is set to the "+" direction, the needle UP stop position is lowered. (Direction C)

When the numeric is set to "–" direction, the needle UP stop position is raised. (Direction D)

6) After completion of the setting, press switch ❶ or switch ❷ to determine the updated value. (When turning

OFF the power to the machine before performing this work, the contents are not updated.)

7) After completion of the operation, turn OFF the power to the machine. The normal operation can be performed

by turning ON the power to the machine again.

1) Turn OFF the power to the machine.

2) Turn the power ON while pushing the switch ❺

on the operation panel.

3) The screen display E indicates the setting No.

96 and F indicates the number of revolution.

(When the screen display is not changed, operate

again steps 1) and 2).

4) Update the setting No. by switch ❶ or switch ❷.

Setting No. 121 : Needle UP stop position

Setting No. 122 : Needle DOWN stop position

– 13 –

Page 16

16. PEDAL PRESSURE AND PEDAL STROKE

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

Upper side

❷

❶

Lower side

❹

❸

(1) Adjusting the pressure required to depress the front part of the pedal

1) When the pedal pressure spring ❶ is hooked to the lower side, the pedal pressure will decrease, and when

hooked to the upper side, the pedal pressure will increase.

(2) Adjusting the pressure required to depress the back part of the pedal

1) The pressure increases as you turn reverse depressing regulator screw ❷ in, and decreases as you turn

the screw out.

(3) Adjusting the pedal stroke

1) The pedal stroke decreases when you insert connecting rod ❸ into the left hole ❹.

17. ADJUSTMENT OF THE PEDAL

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

(1) Installing the connecting rod

1) Move pedal ❸ to the right or left as illustrated

by the arrows so that motor control lever ❶ and

connecting rod ❷ are straightened.

❶

❷

(2) Adjusting the pedal angle

❷

❹

❸

1) The pedal tilt can be freely adjusted by changing

the length of the connecting rod ❷.

2) Loosen adjust screw ❹, and adjust the length of

connecting rod ❷.

– 14 –

Page 17

18. PEDAL OPERATION

A

B

C

D

E

The pedal is operated in the following four steps:

1) The machine runs at low sewing speed when you

lightly depress the front part of the pedal. B

2) The machine runs at high sewing speed when

you further depress the front part of the pedal. A

(If the automatic reverse feed stitching has been

preset, the machine runs at high speed after it

completes reverse feed stitching.)

3) The machine stops (with its needle up or down)

when you reset the pedal to its original position.

C

4) The machine trims threads when you fully depress

the back part of the pedal. E

* When the auto-lifer (AK device) is used, one more

operating switch is provided between the sewing

machine stop switch and thread trimming switch.

The presser foot goes up when you lightly depress

the back part of the pedal D, and if you further de-

press the back part, the thread trimmer is actuated.

When starting sewing from the state that the

presser foot has been lifted with the Auto-lifter

and you depress the back part of the pedal, the

presser foot only comes down.

• If you reset the pedal to its neutral position during

the automatic reverse feed stitching at seam start,

the machine stops after it completes the reverse

feed stitching.

• The machine will perform normal thread trimming

even if you depress the back part of the pedal

immediately following high or low speed sewing.

• The machine will completely perform thread

trimming even if you reset the pedal to its neutral

position immediately after the machine started

thread trimming action.

– 15 –

Page 18

19. NEEDLE-TO-HOOK RELATIONSHIP

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

❶

C

D

A

B

0.04 to 0.1 mm

❹

❺

A

❸

A

❷

B

Adjust the timing between the needle and the hook

as follows :

1) Adjusting the needle bar height. Turn the hand-

wheel to bright the needle bar down to the lowest

point of its stroke, and loosen setscrew ❶.

2) Adjusting the needle bar height. Align marker line

(For a DB needle : marker line A, For a DA needle

: marker line C) on needle bar ❷ with the bottom

end of needle bar lower bushing ❸, then tighten

setscrew ❶.

3) Position the needle and the hook A.

Loosen the three hook setscrews, turn the hand-

wheel in normal rotation and align marker line (For

a DB needle : marker line B, For a DA needle :

marker line D) on ascending needle bar ❷ with

the bottom end of needle bar lower bushing ❸.

4) In this state, align hook blade point ❺ with the

center of needle ❹. Provide a clearance of 0.04

mm to 0.1 mm (reference value) between the

needle and the hook, then securely tighten the

three hook setscrews.

(Caution) If the clearance between the blade point

of hook and the needle is smaller than the

specied value, the blade point of hook will

be damaged. If the clearance is larger, stitch

skipping will result.

• RP hook (dry hook) is used for the hook of

DDL-9000B-DS type. When replacing, use the

part No. described below. There are two kinds

of Part Nos. of the hooks classied by the

regions.

22890206

22890404 (For Europe)

(Caution) Periodically clean RP hook (dry hook) since the hook rolls up thread waste or cloth waste and

failure of the machine or defective sewing may be caused.

(Caution) Because the needle bar ❷ of DDL-9000B-MS and DS is black colored, sometimes it is hard to

see the engraved lines. Make the working area bright by bringing a light or by other method.

– 16 –

Page 19

20. ONE-TOUCH TYPE REVERSE FEED STITCHING MECHANISM

The moment switch lever ❶ is pressed, the machine

performs reverse feed stitching.

The machine resumes normal feed stitching the mo-

ment the switch lever is released.

❷

❶

WARNING :

Turn OFF the power before starting the

work so as to prevent accidents caused

by abrupt start of the sewing machine.

[Adjusting the position of switch]

1) Loosen setscrew ❷ and move the switch itself up

and down to adjust the height.

❸

2) Switch ❶ can be used in two positions by turning

it.

3) In addition, when you desire to lower the position

❹

of switch ❶, loosen setscrew ❸ located in the

back of the machine head and lower switch base

❹.

The following functions can be performed by one-touch operation using optional switch (23632656) ❺.

Optional switch (separately-available)

1. Needle up/down compensating stitching

... Every time the switch is pressed, needle up/

down compensating stitching is performed.

2. Back compensating stitching

... Every time the switch is pressed, reverse feed

❺

stitching is performed at low speed. (It is effective only when a constant-dimension stitching

pattern is selected on the panel.)

3. Function to cancel once reverse feed stitching at

the end of sewing

... When the switch is pressed, the next automatic

❼

reverse feed stitching at the end of sewing only

can be canceled once.

❻

❾

❽

4. Thread trimming function

... When the switch is pressed, thread trimming

is performed.

5. Presser lifting function

... When the switch is pressed, automatic presser

lifting can be executed.

6. One stitch compensating stitching ... Every time the switch is pressed, one stitch compensating stitching

is performed.

* When using the optional switch, it is necessary to set the function with the control box. For the

details, see the Instruction Manual for the control box.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

[Connection of the optional switch]

Insert the cord of the optional switch into ❼ and ❽ of 4P connector ❻ coming from the machine head. (There

is no polarity.)

The pin is provided with the inserting direction. Insert it with protruding portion ❾ upward.

– 17 –

Page 20

21. ADJUSTING THE POSITION OF THE WIPER (DDL-9000B- -WB, -0B)

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

Adjust the position of the wiper ❻ according to the

thickness of the material sewn.

1) Turn the handwheel in the normal direction of rota-

❸

❷

❶

tion to align white marker dot ❶ on the handwheel

with marker dot ❷ on the machine arm.

2) Adjust so that a clearance of 1 mm is provided

between the at section of the wiper and the side

face of the needle. Tighten wiper adjust screw ❸

so that the wiper ❻ is pressed and xed by wiper

collar ❹.

❹

❻

2mm

1mm

* When there is no need to use the wiper, set the wiper operation OFF according to the following procedure.

This setting can be made while the power is being turned ON. (One touch setting function.)

1) Keep pushing switch ❺ for 2 seconds. The display

E

F

will change to the function setting mode.

2) Change the setting No. E to using switch ❼

or switch ❽.

3) Change the setting of F from “ ” to “ ” using

switch ❾ or switch .

4) In order to return to normal sewing state, push

switch ❺.

(Caution) When switch ❺ is pushed, the setting

❼

❽

❾

❺

made will be conrmed.

– 18 –

Page 21

22. COUNTER KNIFE

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

[DDL-9000B-SS, -DS, -M ]

A

C

❶

B

4 mm

B

[DDL-9000B-SH]

A

B

❶

6 mm

A

B

A Moving knife

B Center of needle

❶

A

If the knife does not cut thread sharply, immediately re-sharpen counter knife ❶ as illustrated in Fig. C and

re-install it properly.

1) If the mounting position of the counter knife is moved in direction A from the standard mounting position,

the thread length after thread trimming will be increased accordingly.

2) If the mounting position is moved in direction B, the thread length will be decreased accordingly.

(Caution) When sharpening again the knife blade, extra special care must be taken on the handling of

the knife.

– 19 –

Page 22

23. HEIGHT AND TILT OF THE FEED DOG

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

❻

b

9000B- S,9000B-MA :

a

b

❶

a

Feed dog at

the time of

b

❷

delivery

Position of engraved marker

dot of feed bar

rocker shaft

B1613012I00

(- S, -MA)

D1613155W00

(-MA)

0.8mm

9000B-SH : 1.2mm

23614506

(- S)

11403003, 11062601

(-SH)

a

❸

A

B

❹

❺

❼

A

B

(1) Standard value of the height of the feed dog

Standard feed dog height, when it is lifted to the highest from the top surface of the throat plate, :

9000B- S and 9000B-MA : 0.8 mm

9000B-SH : 1.2 mm

Adjust the feed dog height in accordance with processes and materials.

(Caution) Adjust the directions of the engraved marker dot of feed bar driving shaft ❶ and the engraved

marker dot of feed bar rocker shaft ❸ on the right side (operator side).

(2) Adjusting the height and tilt of the feed dog

1) Loosen setscrew ❷ in feed bar driving shaft ❶ and setscrew ❹ in feed bar rocker shaft ❸.

2) Height and tilt of the feed dog will change by turning both shafts ❶ and ❸ with a screwdriver.

3) For the relation between the rotating direction of each shaft and tilt of feed bar ❻, refer to the gure above.

* Standard delivery state : The engraved marker dot of feed bar rocker shaft ❸ is adjusted to engraved

marker lines ❽ and ❾ of the feed dog of each type and the height of feed dog is adjusted with feed bar

driving shaft ❶.

4) After the adjustment, securely tighten the setscrews. (Tighten setscrews ❷ and ❹ in the state that shafts

❶

and ❸ are pushed against the handwheel side.)

(Caution)

1. If the tilt of the feed dog is adjusted with one shaft only, the height of the feed dog changes. Be

sure to adjust it with both shafts.

2. Movement position of the feed dog may be shifted depending on the adjusting position of the shaft.

At this time, loosen setscrew ❺ in feed rocker shaft arm ❼ and adjust the movement position.

3. The feed dog may interfere with the thread trimmer unit due to the adjustment of height or tilt of

the feed dog. So, be careful.

– 20 –

Page 23

24. ADJUSTING THE FEED TIMING

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

❶

❷

❹

❸

DDL-9000B- S

DDL-9000B-MA

DDL-9000B-SH

❺

❸

Timing of the feed dog can be adjusted by changing the stop position of vertical feed cam ❶. Adjusting procedure is as described below.

1) Tilt the sewing machine head and loosen two setscrews ❷ in vertical feed cam ❶.

2) Turn vertical feed cam ❶ to change the timing of the feed dog. Align graduation ❸ on the feed bar driving

arm with engraved marker line ❹ on the feed driving shaft.

• Turn vertical feed cam ❶ in the direction of ( + )

→Increases the feed timing.

• Turn vertical feed cam ❶ in the direction of ( – )

→Decreases the feed timing.

* Standard value of the engraved marker line on the feed eccentric cam

The position of graduation ❸ in the standard state : 9000B- S and 9000B-MA : Engraved marker line ❹

9000B-SH : Engraved marker line ❺ (+20°)

25. THREAD TENSION RELEASE RELEASING MECHANISM

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

By means of the thread tension release releasing

❷

❶

2) Fix screw ❶ on the top of thread tension release changeover plate ❷.

The thread tension disk does not rise even when the presser foot is lifted, and the needle thread tension

is not loosened. (The thread tension disk rises only when thread trimming is performed.)

(Caution) Do not use screw ❶ at any position other than the top or bottom position of the thread tension

release changeover plate.

* The screw has been factory-set to the bottom position at the time of delivery.

* In case of the machine with wiper, remove the wiper unit (two setscrews) to adjust.

mechanism, sewing can be performed without slackening the needle thread tension even when the presser

foot is lifted during sewing.

(Even when the presser foot is slightly lifted at the thick

overlapped section by the knee lifter, this mechanism

can prevent the thread tension from being

changed. )

[How to release]

1) Remove the cap in the machine head and loosen

thread tension release changeover screw ❶ using

a hexagon wrench.

– 21 –

Page 24

26. MICRO-LIFTING MECHANISM OF THE PRESSER FOOT

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

When sewing velvet or the like which is uffy, slippage

❶

Approx. 9 mm

❷

of material or damage of material is reduced by using screw ❶ for presser foot micro-lifting. Lower the

presser foot and set the state that the feed dog is lower

than the throat plate.

Gradually tighten screw ❶ for presser foot micro-lifting

in the state that nut ❷ is loosened, nely adjust the

position of the presser foot until it matches the material,

and x it with nut ❷.

(Caution) When the presser foot micro-lifting mech-

anism is not used, adjust the height of screw

❶ so that it is higher by approximately 9 mm

than the sewing machine. If the sewing machine

is operated in the state that the micro-lifting

mechanism is working, sufcient feed force

cannot be obtained.

For DDL-9000B, the presser foot micro-lifting mechanism is provided as standard. When it is frequently used,

however, it is convenient to use the micro-lifting device (separately available) which can be adjusted without

using tools.

Presser foot micro-lifter (asm.) [40056622] (Separately available)

❹

❻

❷

❸

❺

❶

22908552

Hand lifter cam (mounted

on the machine head is

used)

B1521555000

Hand lifter setscrew

(mounted on the machine

head is used)

Presser foot micro-lifter components

No. Part No. Description Q’ty

1 23611106 Hand lifter 1

2 23610504 Stopper base 1

3 23610652 Stopper screw 1

4 D5119206K0K Collar 2

5 23610702 Nut 1

6 SL6053592TN Setscrew 1

– 22 –

Page 25

27. SEWING CONDENSED STITCHES

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

❶

❷

It is possible to change the stitch length of the normal

feed pitch by operating switch ❶ or reverse feed control lever ❷ during sewing.

1) Tilt the machine head, and loosen three xing

screws ❹ of the reverse feed solenoid ❸.

2) Slide reverse feed solenoid ❸ in the direction of

the arrow to adjust so that the center of screw ❹

is aligned with engraved marker line ❺ represent-

ing the condensation stitch length. Then x the

solenoid with setscrews ❹.

3)

To return the stitch length back to the initial setting

(to reset), slide reverse feed solenoid ❸ in the

direction of arrow A until it comes in contact with

the end face of slit in bed strut B ❻. Then, x the

solenoid at that position with setscrews ❹.

Sewing direction

A

Condensed stitch

❸

❹

28. FEED CONVERSION SPRING MECHANISM (DDL-9000B-S , -M )

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

Sewing direction

Shorter

Direction of reverse

feed stitching

Shorter

Sewing direction

❸

Shorter

Direction of reverse

feed stitching

Shorter

❹

B

A

❷

❻

❺

❶

In automatic reverse stitching, in case the forward and the reverse stitches do not match, a rough correction

can be made by adjusting the feed adjustment spring hook ❶.

* To make a ne correction, the correction of timing of the reverse feed stitching solenoid is necessary

by adjusting Function Setting Nos. 51, 52 and 53. Refer to the Instruction Manual for the control

box (SC-920) for details of adjustment procedure.

1) In case the stitch does not match the target as shown in ❸, loosen feed adjustment spring hook xing

screw ❷, make ❶ slide in A direction, and x using the screws ❷.

2) In case the stitch does not match the target as shown in ❹, loosen feed adjustment spring hook xing

screw ❷, make ❶ slide in B direction, and x using the screws ❷.

– 23 –

Page 26

29. CARE

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

Perform the maintenance below every day for longer use of your machine.

(1) Conrmation of the amount of oil in the hook oil tank.

Conrm that the top of oil amount indicating rod ❶

is between the upper engraved marker line and the

lower engraved marker line of the oil amount indicating

window. (For the details, refer to “4. LUBRICATION”.)

❶

(2) Cleaning

1) Remove needle ❷, presser foot ❸ and throat

plate ❹.

❸

❺

❷

❹

❻

2) Remove dust adhered to feed dog ❺ and thread

trimmer unit ❻ with a soft brush or cloth.

3) Tilt the machine head and wipe out the dirt of bob-

bin case and the like with soft cloth, and conrm

that there is no scratch. Wipe out with the cloth

dust and hook oil drained in the under cover near

the hook.

– 24 –

Page 27

30. APPLYING GREASE

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

(Caution)

1. When the machine needs replenishment of grease, an alarm sounds. Once the alarm sounds,

replenish grease. In the case the machine is used under harsh environment, it is recommended

to replenish grease once a year for ensuring effective greasing.

2. Do not apply oil to the sections which are lubricated with grease.

3. Be aware that grease can leak from the thread take-up cover and needle bar if the amount of

grease is excessive.

4. Be sure to use JUKI GREASE A TUBE (part number: 40006323) supplied with the machine head.

(1) Sections to which grease is to be replenished

Replenishment of exclusive grease

❶

■ Needle bar lower bushing (DDL-9000B-M , B-DS type)

(Caution) Carry out greasing with the needle bar

1) Remove the face plate.

2) Remove grease lling screw ❷.

❷

3) Remove the cap of exclusive grease tube ❶.

At this time, add grease until it overows the oil

4) Push overowing exclusive grease with the oil

5) Wipe the excess of grease off the area around the

❶

installed.

Insert its tip into the oil hole and replenish grease

from exclusive grease tube ❶.

hole.

lling screw into the oil hole.

oil hole.

– 25 –

Page 28

■ Presser bar bushing (all models)

❸

1) Put the tip of exclusive grease tube ❶ into tapped

hole ❸ to replenish grease.

2) Push overowing exclusive grease with the oil

lling screw into the oil hole.

3) Wipe the excess of grease off the area around the

oil hole.

❶

(2) Releasing procedure of the grease-up warning for SC-920

❺

❶

❻

❷ ❸ ❹ ❼

When the time of grease-up has come,

screen display of LED ❺ on the left-

hand gure becomes "E220".

The screen display can be reset by

pressing switch ❼.

Error E220 (Grease-replenishment

warning) will be displayed every time

the power is re-turned ON.

If the machine is further used for a certain period of time without replenishing grease, Error E221 (Grease-re-

plenishment error) will be displayed. In this case, the error cannot be reset by pressing switch ❼ and the

sewing machine will be inoperative.

Error E221 can be reset by carrying out the steps of procedure described below.

– 26 –

Page 29

WARNING :

To avoid possible personal injuries caused by movement other than that you desired, do not operate

the switches in the procedure other than those required, as described below, to specify the functions.

❶

❻

❷ ❸ ❹

❻

❺

❺

1) Turn OFF the power to the unit.

2) Pressing switch ❹, turn ON

the power to the unit.

3) When the screen is displayed,

keep switch ❹ held pressed

for three seconds until the buzzer

sounds twice.

4) Set the setting No.❻ to "118".

When you want to advance the

setting No.❻, press switch

❷ to advance the setting No.❻

When you want to return the set-

ting No.❻, press switch ❶ to

return the setting No.❻

❶

❷ ❸ ❹

(Caution) Keep pressing switch ❷ or switch ❶, and the setting No. ❻ will advance (return)

continuously. If the setting No. ❻ is moved forward (or backward), the previous (or subsequent)

content of the setting is conrmed. Be careful when the content of a setting is changed (when the

up / down switch is touched).

❻

❺

5) When setting No. ❻ is adjusted

to "118", the current set value is

displayed on LED ❺. Then Press

switch ❹ (switch ❸) to

change to "1".

6) When the change has been complet-

ed, press switch ❷ or ❶

to specify the changed value.

❶

❷ ❸ ❹

(Caution) When turning OFF the power before performing this work, the contents which have been

changed are not updated.

After completion of the operation, turn the power OFF and re-turn it ON to restore the normal operation.

– 27 –

Loading...

Loading...