Page 1

English – 1

SVENSKA

J O N S E R E D S E R V I C E

108 87 55-30

HT 2122T

HT 2126T

HT 2130

Owner's manual

Read these instructions carefully and make sure you

under-stand them before using the machine.

Bedienungsanleitung

Lesen Sie die Bedienungsanweisung sorgfältig durch

und machen Sie sich mit dem Inhalt vertraut, bevor

Sie die Maschine benutzen.

Manuel d'utilisation

Lire attentivement et bien assimiler le manuel

d'utilisation avant de se servir de la machine.

Istruzioni per l'uso

Prima di mettere in esercizio la macchina leggere

accuratamente le seguenti istruzioni.

Instruções para uso

Leia as instruções para o uso com toda a atenção e

compreenda o seu conteúdo antes de fazer uso da

máquina.

Instruções para uso

Leia as instruções para o uso com toda a atenção e

compreenda o seu conteúdo antes de fazer uso da

máquina.

Page 2

2 – English

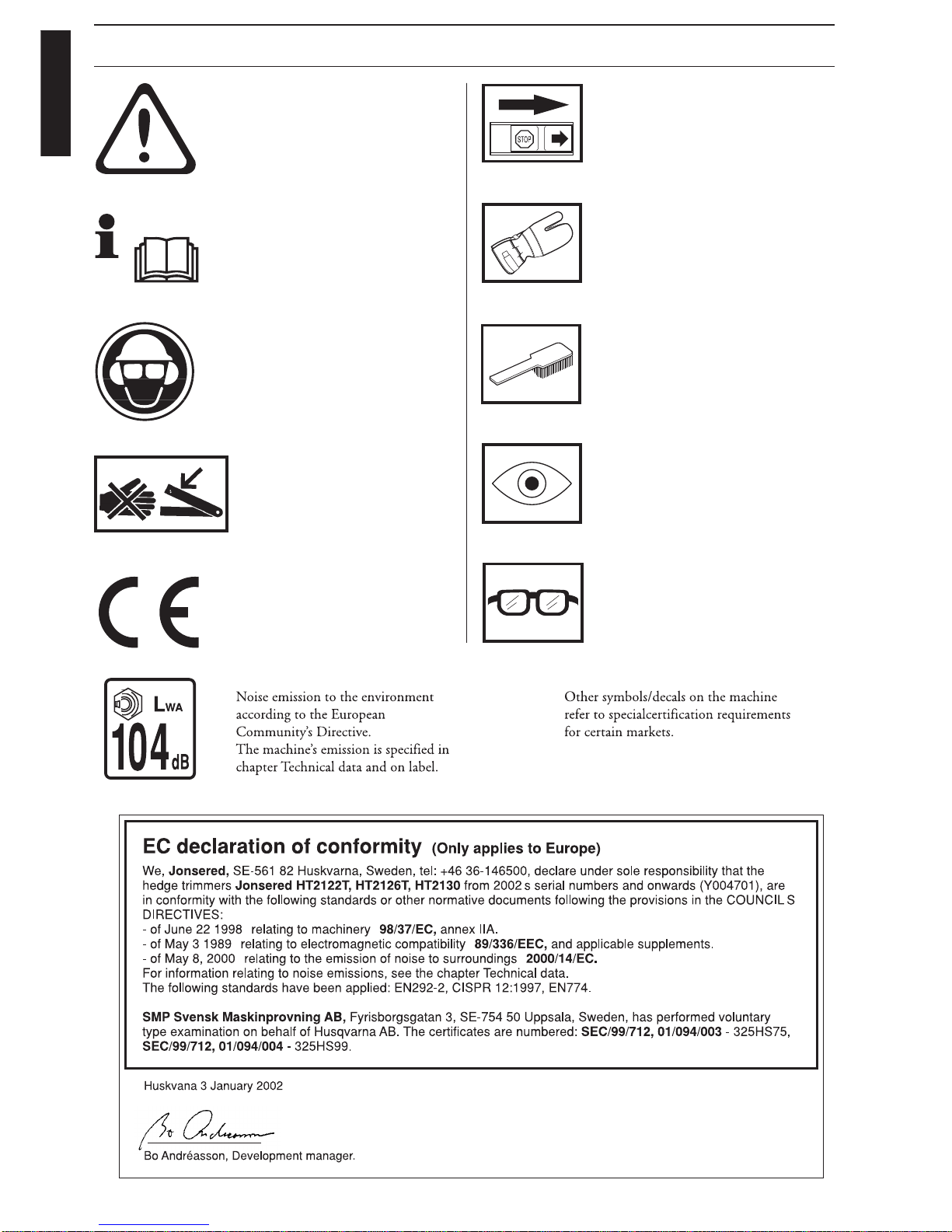

Key to symbols

Read the instructions carefully and

make sure you understand them

before using the machine.

Always wear:

• Hearing protection

• Eye protection

Switch off the engine by moving the

stop switch to the STOP position

before carrying out any checks or

maintenance.

Always wear safety gloves.

Regular cleaning is required.

Visual check.

Safety glasses or visor must be worn.

Do not touch the clippers

without first switching off the

engine.

This product is in accordance with

applicable CE directives.

WARNING!

Hedge trimmers can be danger-

ous!

Negligence or incorrect use can

result in serious, even fatal

injury.

ENGLISH

Page 3

English – 3

SVENSKA

Contents

Husqvarna AB has a policy of continuous

product development and therefore

reserves the right to modify the design

and appearance of products without prior

notice.

IMPORTANT!

A too lean carburettor adjustment significantly

increases the risk of an engine breakdown.

Insufficient care of the air filter will cause deposits

on the spark plug resulting in starting difficulties.

WARNING!

Under no circumstances may the design

of the machine be modified without the

permission of the manufacturer. Always

use genuine accessories. Non-authorised

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

Symbols explanation

Symbols _______________________________________ 2

Contents

Before using a new machine _______________________ 3

Contents ______________________________________ 3

Safety instructions

Personal safety equipment _________________________ 4

The machine’s safety equipment ____________________ 4

Control, maintenance and service of the machine’s safety

equipment _____________________________________ 6

Sharpening of the clippers _________________________ 7

Checking the clippers ____________________________ 7

General safety instructions_________________________ 7

General working instructions ______________________ 8

Basic safety precautions ___________________________ 8

Basic work technique _____________________________ 9

What is what?

What is what? _________________________________ 10

Technical data

HT 2122 T, HT 2126 T _________________________ 10

HT 2130 _____________________________________ 11

Assembly

Assembly _____________________________________ 12

Fuel handling

Petrol ________________________________________ 12

Two-stroke oil _________________________________ 12

Mixture ______________________________________ 12

Fuelling ______________________________________ 13

Start and stop

Cold engine ___________________________________ 13

Varm engine __________________________________ 13

Start _________________________________________ 13

Stopping _____________________________________ 14

Maintenance

Carburettor setting _____________________________ 14

Air filter ______________________________________ 14

Spark plug ____________________________________ 14

Replacement of starter cord and/or return spring ______ 15

Silencer ______________________________________ 15

Blades _______________________________________ 16

Gear case _____________________________________ 16

Cooling system ________________________________ 16

Maintenance schedule ___________________________ 16

ENGLISH

Page 4

4 – English

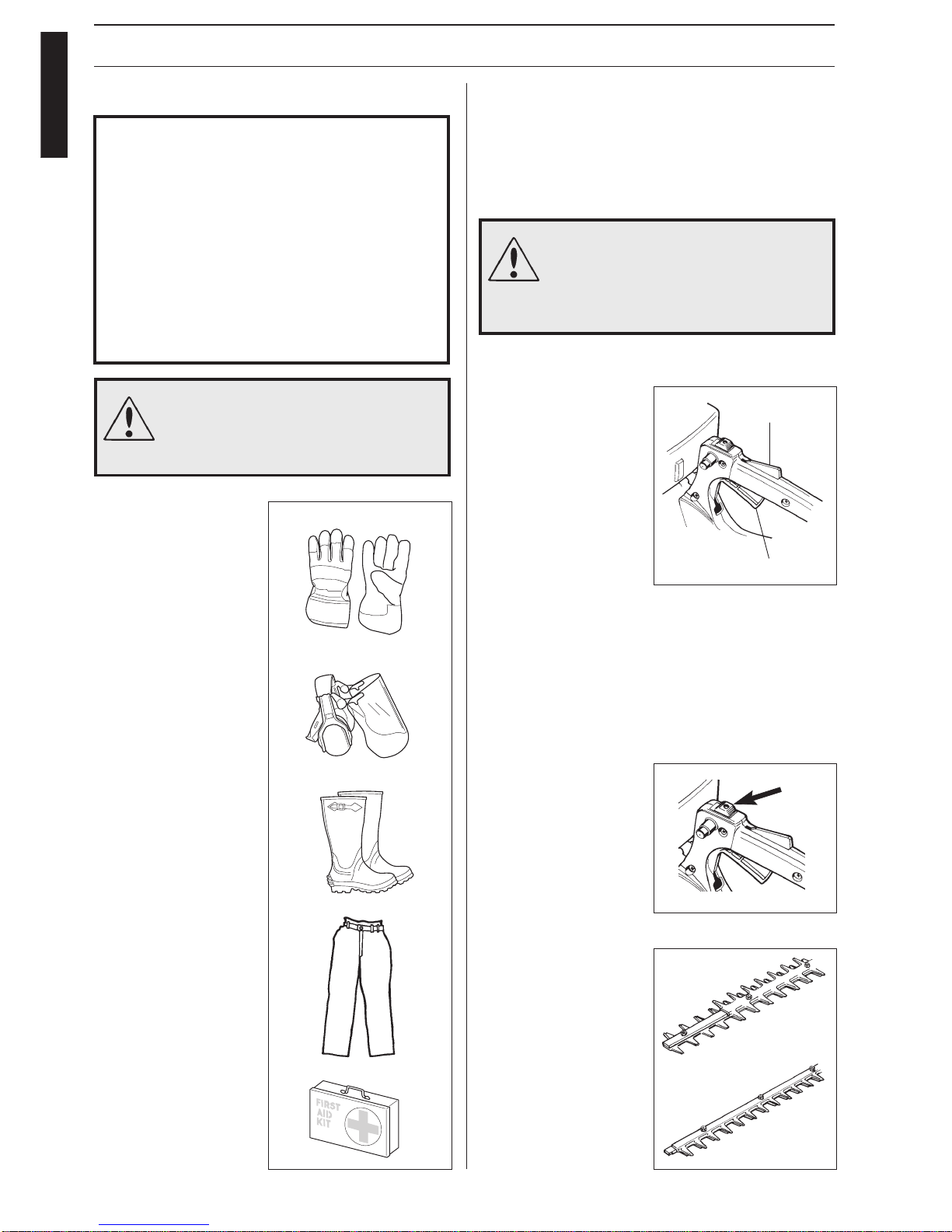

A

B

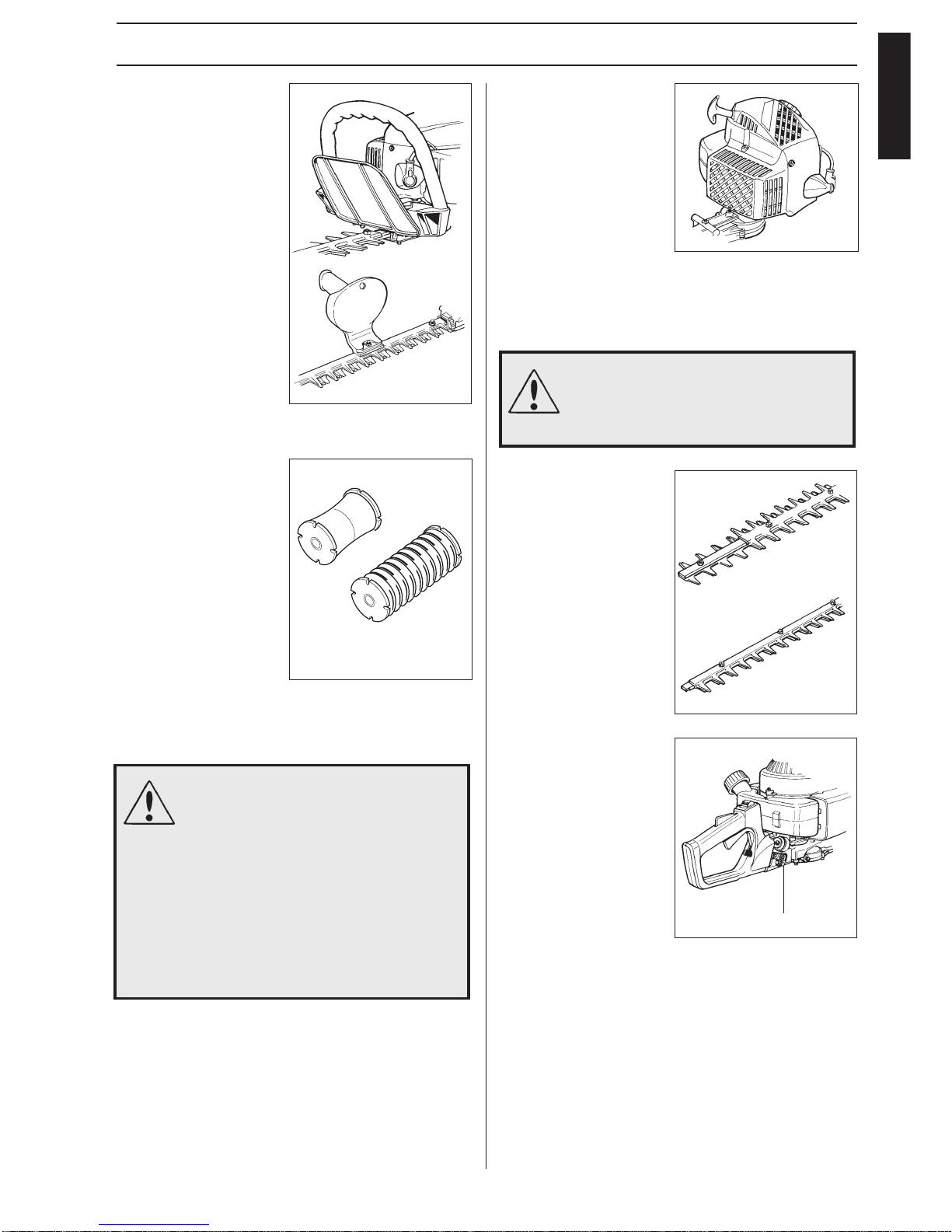

The machine‘s safety equipment

This section describes the machine‘s safety equipment, its

function and how checks and maintenance are carried out to

ensure that it operates correctly. (See the chapter “What is

what“ to locate where this equipment is positioned on your

machine.)

IMPORTANT INFORMATION

• Incorrect or careless use of this machine can

turn it into a dangerous tool that can cause

serious or even fatal injury.

It is extremely important that you read and

understand this manual.

• When using this machine the safety equipment

approved by the appropriate authorities must be

used. Personal safety equipment does not

eliminate the risk of accidents, however, it can

reduce the effects of an injury in the event of an

accident. Ask your dealer for help when choosing

safety equipment.

1. Throttle trigger

lock

The throttle trigger lock is

designed to prevent the

throttle from accidentally

being engaged. When the

trigger lock (A) is pressed

into the handle the throttle

(B) is released. When the

grip on the handle is

released the throttle and the

throttle trigger lock return

to their original positions.

This takes place via two

independent return spring

systems. This means that

the throttle is automatically

locked in its "idling"

position.

2. Stop switch

The stop switch should be

used to stop the engine.

3. Blad guard

Reduces the risk of the

hand coming in contact

with the clippers if it slides

off the handle.

WARNING!

Never use a machine with defective safety

equipment. Follow the control,

maintenance and service instructions

described in this section.

Gloves

Gloves should be worn

when necessary, e.g.,

when assembling cutting

equipment.

Ear protection

Ear protection offering

sufficient dampening

effect should be used.

Eye protection

Blows from branches or

objects thrown by the

rotating cutting

equipment can damage

the eyes.

Shoes or boots

Use anti-slip and sturdy

footwear.

Clothing

Wear clothes made of a

strong fabric and avoid

loose clothing that can

catch on shrubs and

branches. Always wear

heavy-duty long pants.

Do not wear jewellery,

shorts, sandals or go

barefoot. Secure hair so it

is above shoulder level.

First aid kit

A first aid kit should

always be carried by the

operator.

Safety instructions

Personal safety equipment

ENGLISH

WARNING!

Remove your hearing protection as soon

as you stop the engine, so that you can

hear any noises or warning signals.

Page 5

English – 5

SVENSKA

A

4. Hand guard

The guard is fitted in front

of the front handle (mod.

HT 2122 T and HT 2126

T) and has the purpose of

protecting the left hand

from injury, e.g. from twigs

and branches.

Model HT 2130 has a

similar guard.

Safety instructions

5. Vibration damp ing system

Your machine is equipped

with a vibration damping

system, which is designed to

give as vibration-free and

comfortable use as possible.

The machine‘s vibration

damping system reduces the

transfer of vibrations

between the engine unit/

cutting equipment and the

machine‘s handles.

6. Silencer

The silencer is designed to

give the lowest possible noise

level and to direct the

engine‘s exhaust fumes away

from the operator.

The engine‘s exhaust fumes

are hot and can contain

sparks, which can lead to the

outbreak of fire.

It is extremely important that the instructions for checking,

maintaining and servicing the silencer are followed. (See the

section "Control, maintenance and service of the machine's

safety equipment).

WARNING!

During use and for some time after the

silencer is very hot. Do not touch the

silencer if it is hot!

7. Clippers

Make sure that the clippers

are not damaged by cutting

steel wire, nails, or by

excessive force.

NOTE!

During transport and

storage the transport

guard should always

be fitted over the

clippers.

WARNING!

Over exposure to vibrations can result in

blood-vessel or nerve injury to persons

suffering with blood circulation problems.

Seek medical attention if you experience

physical symptoms that can be related to

over exposure to vibrations. Examples of

such symptoms are "numbness", lack of

feeling, "tickling", "pricking", "pain", lack

of or a reduction in normal strength,

changes in the colour of the skin or its

surfaces. These symptoms normally

appear in the fingers, hands or wrists.

On Mod. HT 2122 T and

HT 2126 T the rear grip can

be turned to ensure a good

working position for the

hand, when for example

trimming the side of a

hedge.

NOTE!

Check that the nut (A)

is well tightened after

adjusting the grip.

ENGLISH

Page 6

6 – English

A

B

Safety instructions

Control, maintenance and service of

the machine's safety equipment

IMPORTANT INFORMATION

• All service and repairs to the machine require

special training.

• This applies especially to the machine's safety

equipment. If the machine does not meet any of

the controls listed below you should contact your

service workshop.

• The purchase of one of our products guarantees

that professional repair and servicing will be

carried out on it. If the point of purchase is not

one of our servicing dealers, please ask for

details of the closest service workshop.

1. Throttle trigger

lock

• Check that the throttle

(B) is locked in the

“idling position“ when

the throttle trigger lock

is in its original position.

• Press in the throttle

trigger lock (A) and

make sure it returns to

its original position

when released.

• Ensure that the throttle

and throttle trigger lock

move easily and that

their return spring

systems function.

• Start the machine and

apply full throttle.

Release the throttle and

check that the cutting

equipment stops and

remains at a standstill. If

the cutting equipment

rotates with the throttle

in the idling position

then the carburettor‘s

idling setting must be

checked. See chapter

“Maintenance“.

3. Vibration damping system

• Check the vibration

damping elements

regularly for material

cracks and distortion.

• Check that the vibration

damping elements are

securely attached

between the engine unit

and the cutting

equipment.

4. Silencer

• Never use a machine that

has a defective silencer.

• Check regularly that the

silencer is secure.

5. Cutting equipment

This section describes how through correct maintenance and

through using the right type of cutting equipment you can:

• Ensure maximum clearing capacity.

• Increase the service life of the cutting equipment.

A. Only use the

recommended clippers!

B. Keep the clippers well

oiled and correctly

maintained! Insufficient

oiling increases wear.

C. Check that the screws

which hold the clippers

together are always tight.

2. Stop switch

• Start the engine and

make sure that the

engine stops when the

stop switch is moved to

the stop position.

ENGLISH

Page 7

English – 7

SVENSKA

45°

6. Blade and hand guard

Sharpening of

the clippers

It is important that the

clippers are always sharp to

ensure full cutting capacity

and clean cuts.

Dismantle the blade guard

and use a plain file to

sharpen the teeth. The filing

angle should be 45°.

Safety instructions

WARNING!

Never use a machine with defective safety

equipment. The safety equipment should

be maintained as described in this section.

If your machine does not meet any of

these controls you should contact your

service workshop.

Check the clippers each time

they are used for:

• Damage and wear to the

the teeth.

• Wear on the blade’s

guide slots, screws and

washers.

• Warping of the blade.

• Oiling of the blade and

gear case.

See chapter ”Maintenance”

for appropriate measures.

Checking the clippers

WARNING!

Defective clippers can increase the risk of

accidents.

IMPORTANT INFORMATION

• The machine is only designed for cutting hedges.

• The only accessories to be used with the engine

as a drive source are the cutting units we

recommend.

• Never use the machine if you are tired, if you

have consumed alcohol, or if you are taking

medicines that can affect your sight, your

judgement or the control of your body.

• Use personal safety equipment. See the section

"Personal safety equipment".

• Never use a machine that has been modified so

that it no longer corresponds with the original

design.

• Never use a machine that is faulty. Follow the

maintanence, control and service instructions

in this Operator's Manual.

Some maintenance and service actions should

be carried out by trained and qualified

specialists. See the chapter

"

Maintenance"..

• All covers and guards must be fitted before

starting the machine. Check that the spark plug

cap and HT lead are not damaged, otherwise

you could get an electric shock.

General safety instructions

Check that the blade guard

is secure and not damaged.

Check that the left and right

hand guard are in good

condition without visible

defects, e.g. cracking.

ENGLISH

Page 8

8 – English

Safety instructions

A. Start

• Never start the engine indoors. The toxic exhaust gases are

hazardous to inhale.

• Make sure that there is no risk of people or animals coming

in contact with the clippers.

• Place the machine on the

ground and make sure that

the clippers are free from

branches and stones.

Press the engine to the

ground with the left hand.

Grip the start handle with

the right hand and slowly

pull out until a resistance

is felt (start hooks engage).

Now give a quick and

strong pull.

B. Fuel safety

• Always use a fuel contai-

ner with an anti-spill

valve.

• Never fill the machine

while the engine is

running.

• Provide good ventilation

when filling or mixing

fuel.

• Move the machine at least

3 m from the filling

position before starting.

• Never start the machine.

a) If you have spilt fuel on

it:

Wipe up all spillage.

b) If you have spilt fuel on

yourself or your clotches:

Change your clotches.

c) If there is a fuel leak:

Replace damaged parts.

Make regular checks for

leakage from the fuel cap

and the fuel supply pipes.

C. Storage

• Store the machine and fuel so that any leakage or fumes

do not risk coming into contact with sparks or naked

flames. For example, electric machines, electric motors,

electrical switches/power switches, heaters or the like.

• When storing fuel approved containers intended for this

purpose must be used.

• When storing the machine for long periods the fuel tank

must be emptied. Contact your local petrol station to find

out how to dispose of excess fuel.

• The guard over the clippers should always be fitted when

the machine is not in use.

WARNING!

Exercise great care when handling fuel.

Bear in mind the risk of fire, explosions

and inhaling fumes.

IMPORTANT INFORMATION

• This section takes up the basic safety precautions.

• If you encounter a situation where you are

uncertain how to proceed you should ask an

expert. Contact your dealer or your service

workshop.

• Avoid all usage which you consider to be beyond

your capability.

1. Observe your surroundings.

• To ensure that people,

animals or other things

cannot affect your

control of the machine.

• To ensure that the above

mentioned do not come

into contact with the

cutting equipment or

objects that can be

thrown by the cutting

equipment.

WARNING!

Never use a machine without the

possibility of calling for help in the

event of an accident.

General working instructions

Basic safety precautions

ENGLISH

Page 9

English – 9

SVENSKA

15–30°

A

Safety instructions

2. Avoid usage in unfavourable weather conditions. For

example, thick fog, heavy rain, strong winds or extreme

cold, etc. To work in bad weather conditions is tiring and

can create dangerous circumstances, e.g. slippery surface.

3. Make sure you can walk

and stand safely Look

out for any obstacles

with unexpected

movement (roots,

stones, branches, pits,

ditches, etc.). Take great

care when working on

slopin ground.

When trimming the top of a

hedge the clippers should be

held so that the blade is at

an angle of between 15° and

30° to the horizontal plane.

Swing the clippers in an arch

over the hedge so that cut

branches are swept off.

To ensure a good working

position for the hand when

trimming hedge sides the

rear grip can be turned on

mod. HT 2122 T and HT

2126 T.

Release the nut (A) and turn

the handle 90° in either

direction.

NOTE!

Remember to tighten

the nut well after

making the adjustment.

When trimming the sides of

the hedge hold the blade

vertically and swing the

clippers in an arch.

4. When moving over longer distances and transporting the

transport guard should be used.

5. Never put the machine down with the engine running

unless you have good sight of it.

6. Never allow children to use the machine.

Basic working technique

• Always cut with the engine at full throttle.

• Let the engine idle after each work phase. Full revs without

loading the engine can seriously damage the engine.

• Observe great caution when working close to power lines

and wire fencing.

ENGLISH

Page 10

10 – English

What is what? – Technical data

Owner's manual

ENGLISH

18

HT 2122 T

HT 2126 T

Page 11

English – 11

SVENSKA

What is what? – Technical data

Owner's manual

ENGLISH

HT 2130

Page 12

12 – English

Petrol

• Use unleaded or quality

leaded petrol.

• The lowest recommended

octane rating is 90. If you

run the engine on a petrol

with a lower octane rating

than 90 so-called

"knocking" can occur.

This leads to an increased

engine temperature,

which can result in a

serious engine breakdown.

• When working at

continuous high revs a

higher octane rating is

recommended.

Assembly – Fuel handling

Assembly

WARNING!

The hedge trimmers must only be used

with the clippers which are fitted on the

original machine.

Model HT 2122 T and HT

2126 T is delivered assembled

and ready for use.

Model HT 2130 is delivered

with the front handle loose.

Fit it on the appropriate screw

on the bar. Use the screw and

the hole in the handle which

gives the best working

position.

WARNING!

The machine is fitted with a two-stroke

engine and must always be run on a

mixture of petrol and two-stroke oil. To

ensure the correct mixture proportions it

is important to measure the quantity of oil

accurately. When mixing small amounts of

fuel small discrepancies in the amount of

oil has a great bearing on the proportions

of the fuel mixture. Always provide good

ventilation when handling fuel.

Two-stroke oil

• For the best results use Jonsered two-stroke oil. Mixing

ratio 1:50 (2%).

• If Jonsered two-stroke oil is not available you can se a high

quality two-stroke oil intended for air cooled engines.

Contact your dealer when selecting an oil.

Mixing ratio: 1:33 (3%).

• Never use two-stroke oil intended for water cooled

outboard motors, so-called outboard motor oil.

• Never use oil intended for four-stroke engines.

Mixture

• Always mix petrol and oil in a clean container intended for

petrol

• Always start by filling half the quantity of petrol required.

Then add the entire oil quantity. Mix (shake) the fuel

mixture. Fill the remaining quantity of petrol

• Mix (shake) the fuel mixture carefully before filling in the

machine's fuel tank.

• Do not mix fuel for more than approx. 2 months use.

• If the machine is not used for a long period of time, the

fuel tank should be emptied and cleaned.

Petrol Oil

Lit. Lit.

2 % (1:50) 3 % (1:33)

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

NOTE!

Do not tighten the screw so tightly that the blade is clamped

tight. See chapter "Maintenance" for information on blade

adjustment.

ENGLISH

Model HT 2130 can be

fitted with a collector plate

for cut material, fitted on

the cutter member.

Remove the three main nuts

on the cutter member.

Tighten the bolts and then

unscrew them a half turn.

Place the plate over the bolts

and tighten the nuts. Make

sure that the bolts do not

turn when tightened!

Page 13

English – 13

SVENSKA

1

1

2

SVENSKA

3

Fuel handling

Start and stop

Cold engine

1. Push the short-circuiting

switch (1) to "ON"

(forwards).

2. Push the choke control

to closed position (2).

3. Press in the air purge(3)

3 – 4 times.

Varm engine

Use the same starting

procedure as for the cold

engine, but do not set the

choke control in the choke

position.

Start

Grip the starter handle and

slowly pull out the starter

cord until a resistance is felt

(starter prawl engages).

Now give a quick and strong

pull.

NOTE!

Do note pull the starter cord

out completely and do not

release the starter cord from

the fully extended position.

This can damage the

machine.

Move the choke control

back to the initial position

immediately when the

engine fires, and make

repeated attempts to start

until the engine starts.

Fuel handling – Start and stop

Fuelling

WARNING!

The following precautions reduce the

risk of fire:

Do not smoke or place any source of

heat in the vicinity of the fuel.

Never refuel when the engine is running.

Open the fuel cap slowly when fuelling

so that any over pressure is released

slowly.

Tighten the fuel cap carefully after

refuelling.

Always move the machine from the

fuelling place before starting.

WARNING!

• Always move the machine from the

filling position before starting.

• Place the hedge trimmers on a firm

surface and make sure that you

are standing in a well-balanced

position before starting the engine.

• Make sure that no unauthorised

persons are in the working area.

• Check before starting that the

clippers cannot bite into any

object.

WARNING!

Beware of the moving cutting blades

when the engine is started.

• Clean around the fuel

cap. Contamination in

the tank can disrupt

operations.

• Ensure that the fuel is

well mixed by shaking

the container before

filling the tank.

ENGLISH

Page 14

14 – English

0,5 mm

Start and stop – Maintenance

Stopping

The engine is stopped by

switching off the ignition.

Move the stop switch

backwards to the STOP

position.

Carburettor setting

In the carburettor, fuel is

mixed with air. When the

engine is test run at the

factory, the carburettor is

basically adjusted. A further

adjustment may be required,

according to climate and

altitude. The carburettor has

one adjustment possiblity:

T = Idle speed adjustment

screw ”IDLE”.

Adjustment (T) ”IDLE”

Check that the air filter is clean.

When the idle speed is correct, the cutter will not move.

If adjustment is required, close (clockwise) the T-screw, with

the engine running, until the cutter starts to move . Open

(counter-clockwise) the screw until the cutter stops. You have

reached the correct idle speed when the engine runs smoothly

in all positions well below the rpm when the cutter starts to

move.

If the cutter still moves after idle speed adjustment, contact

your service workshop.

WARNING!

When the engine is idling the cutter must

under no circumstances move.

Air filter

The air filter must be

cleaned from dust and dirt

in order to avoid:

• Carburettor malfunctions.

• Starting problems.

• Engine power reduction.

• Unnecessary wear on the

engine parts.

• Abnormal fuel

consumption.

Cleaning/changing the air filter

Clean the filter after every 25 hours or more regularly if

operating conditions are exceptionally dusty.

Dismantle the air filter cover and remove the air filter. Wash

in clean, warm soapy water.

Ensure that the filter is dry before refitting.

An air filter used for a long period of time can never be

cleaned completely. Therefore it is necessary to replace the

filter from time to time with a new filter. A damaged air filter

must always be replaced.

Spark plug

The condition of the spark

plug is affected by:

• An incorrect carburettor

setting.

• An incorrect fuel mixture

(too much oil).

• A dirty air filter.

These factors cause deposits

on the spark plug electrode

that may result in

malfunction or starting

difficulties.

If the machine is low on power, difficult to start or runs

poorly while idling always check the spark plug first.

If the spark plug is dirty, clean it and at the same time check

that the electrode gap is 0.5 mm. The spark plug should be

changed after about one month of operation or earlier if

necessary.

NOTE!

Always use the recommended type of spark plug. An incorrect

spark plug can damage the cylinder/piston.

ENGLISH

Page 15

English – 15

SVENSKA

3 r

4 r

3 r

Maintenance

WARNING!

• The return spring is tensioned in the

starter housing and can with negligent

handling spring out and cause injury.

• Observe care when replacing the starter

spring or starter line. Use protective

glasses.

Replacement of

starter cord and/

or return spring

1. Remove the 4 screws

which hold the starter

device, and lift off.

2. Make sure that the

return spring is

untensioned and

dismantle the screw

which holds the pulley.

Lift off the pulley.

3. Remove the defective

return spring replace

with a new one.

WARNING!

The spring can with negligent handling

spring out and cause injury. Use

protective glasses.

Lubricate the spring with

thin motor oil.

1. Insert a new starter cord

through the hole in the

starter and anchor it in

the pulley and starter

handle with a knot.

2. Wind 4 turns on line on

the pulley anti-clockwise.

3. Place the pulley over the

journal and make sure

that the return spring

grips in the pulley. Fit

the centre screw with the

accompanying washer.

4. Lift up the cord in the

recess on the pulley and

turn the wheel about 3

turns anti-clockwise to

tension the return spring.

5. Check that the pulley

can be turned an

additional 1/2 turn when

the starter cord is fully

withdrawn.

6. Fit the starter by first

pulling out the starter

cord a little and then

placing the starter in

position against the

crankcase. Now release

the starter cord slowly so

that the start hooks grip

in the pulley.

7. Tighten the screws which

hold the starter.

Silencer

The silencer is designed to

dampen the noise level and

to direct the exhaust fumes

away from the user. The

exhaust fumes are hot and

can contain sparks, which

can result in fire if the

exhaust fumes are directed

towards a dry or

inflammable material.

NOTE!

Never use a machine with a

defective silencer.

ENGLISH

Page 16

16 – English

1/2 r

1

2

1

1

4

2

3

Blades

The blades have been fitted

in the blade guide with four

resp. five screws. These

screws must be tightened so

that the clearance is

sufficient for the blades to

move freely.

When there is not

enough clearance:

The blades cannot move

freely. There is too much

friction on the sliding

surfaces.

When there is too

much clearance:

The blades do not cut

efficiently.

Adjusting the

clearance:

1. Release the nuts on the

blades.

2. Tighten the screws as far

as possible, and then

release the screws a half

turn.

3. Tighten the nuts without

turning the screws.

Replace the screws in the

blade guide as soon as they

have been worn or damaged.

Replace the blades as soon as

they have been damaged.

NOTE!

Lubricate the sliding surfaces

of the blades with machine

oil.

Maintenance

Cooling system

To maintain as low an

operating temperature as

possible the engine is

equipped with a cooling

system.

The cooling system consists

of:

1. An air intake on the

starte unti.

2. Cooling fins on the

flywheel.

3. Cooling fins on the

cylinder.

4. Cylinder cover (leads

cold air onto the

cylinder).

WARNING!

Gloves should always be worn when

handling the blades.

Gear case

Apply a good quality lithium

based grease through the

grease fitting until a small

amount comes out between

the cutter blades and the gear

case. Lubrication shold be

applied at 50 hour intervals

and more frequent at heavy

use.

Clean the cooling system using a brush at least once a week,

in difficult conditions more often.

A dirty or blocked cooling system leads to the

engine overheating resulting in damage to the

cylinder and piston.

Maintenance schedule

Below you will find some general maintenance instructions.

For futher information please contact your service dealer.

Daily maintenance

• Clean the exterior of the hedge trimmer.

• Check the blade guard and hand guard for damage or

cracking.

• Check that the teeth on the blades are sharp and

undamaged.

• Check that the blade nuts are sufficiently tightened.

• Check that nuts and screws are sufficiently tightened.

Weekly maintenance

• Check the starter, especially cord and return spring.

• Clean the exterior of the spark plug.

• Remove the spark plug and check the electrode gap. Adjust

it to 0.5 mm, or change the spark plug.

• Clean the cooling fins on the cylinder and check that the

air intake at the starter is not clogged.

• Clean the air filter.

• Check that the gear case is filled with grease.

Monthly maintenance

• Rinse the fuel tank with gasoline.

• Clean the exterior of the carburettor and the space around

it.

• Clean the fan and the space around it.

ENGLISH

Loading...

Loading...