Johnson Systems JS-ICON User Manual

User Manual

JS-ICON™ Series

Dimmer/Relay Rack

JS-ICON™ 2410

JS-ICON™ 2413

JS-ICON™ 1220

JS-ICON™ 1210/620

JOHNSON SYSTEMS INC.

www.johnsonsystems.com

2002161

Contents

Warranty ..........................................................................................................2

For Technical Assistance .................................................................................2

Introduction ......................................................................................................3

Characteristics .................................................................................................4

Installation .......................................................................................................5

Power Supply Connection Details ...................................................................6

Ground Connection Details .............................................................................8

Dimmer Output ................................................................................................9

Control Input/Output ......................................................................................10

MADD-24 (Multiple Application Dimmer Driver) ............................................11

User Interface ................................................................................................12

System Status - LED Indicators.....................................................................13

System Status - LCD Display ........................................................................13

Quick Programming Reference to System Conguration Menu Items ..........15

Detailed Programming of System Conguration Menu Items........................16

Important Hard-key Information .....................................................................31

Troubleshooting Reference ...........................................................................32

Warranty

JS-ICON™ Series dimmer racks come with a standard 1 year limited

warranty. Extended warranties of up to 10 years are available at the time of

purchase. For details visit www.johnsonsystems.com/warranties.htm.

For Technical Assistance

1. Refer to your product user manual. The most current revision is

available online: www.johnsonsystems.com/literature.htm

2. Contact the “point-of-sale” dealer or distributor from which this product

was originally purchased, and ask for technical assistance.

3. If neither of the above can provide you with the necessary information,

please contact our factory via email (info@johnsonsystems.com)

or phone (403-287-8003) during business hours (Monday to Friday,

8:00AM to 5:00PM MST).

2

www.johnsonsystems.com

Introduction

JS-ICON™ Series wall-mount dimmer racks represent the ultimate

value in hi-performance dimming! Next generation “system-on-a-chip”

technology coupled with state-of-the-art inductor technology provides

unsurpassed quality in professional grade SCR dimming.

Advanced next generation hardware and software designs reduce

stand-by power consumption to less than 1 Watt, allowing for

compliance with the International Energy Agency’s “One Watt

Initiative” for standby power consumption. This makes JS-ICON™

Series the “greenest” dimmer racks available!

Available in a number of different sizes and congurations, JS-ICON™

Series dimmer racks are designed for side-by-side installation and

high density requirements. Intuitive LCD user interface combined with

dual DMX inputs, analog inputs and contact closure inputs allow for

industry wide application.

Removable cover allows for ease of installation and serviceability.

On demand “MagLev®” thermal management technology produces

superior cooling that is virtually silent making JS-ICON™ the natural

choice for “quiet space” dimming installations. Exclusive “lamp

warming” techniques extends lamp life considerably while maintaining

industry leading performance!

• Available in multiple sizes and congurations.

• Unique power saving “stand-by” mode reduces power

consumption to less than 1 Watt. Compliance with the “One Watt

Initiative”.

• Dims standard or low-voltage incandescent quartz lamps.

• Individual dimmer prole selection permits safe and silent nondim control of uorescent loads, HID lighting, motors, etc.

• Dual DMX512-A inputs with on-board protocol manager.

Optional wireless DMX receiver.

• Unique “lamp warming” feature extends lamp life.

• Analog and dedicated dry contact BMS inputs for interface with

HVAC, security and audio.

• LCD user interface for easy setup and monitoring.

• Over-heat and over-current protected.

• Non proprietary dimmer SCR’s are 200% rated.

• On-demand ‘MagLev®’ thermal management technology

produces superior cooling that is virtually silent.

• “Load Shed” inputs for power management and photocell

interface.

• Up to 10 year product warranty available!

www.johnsonsystems.com 3

Characteristics

• Maximum Feeder Capacity: 100 Amp 120/208 VAC 3Ø 5 wire. Max.

Rating 28.8kW. 100 Amp 120/240 VAC 1Ø 4 wire. Max. Rating 24.0kW.

• Power Termination: Power lug input. Terminal block output.

• Environment: Temperature Range: 23°F (-5°C) to 104°F (40°C) ambient.

Humidity Range: 0% to 90% non-condensing.

• Dimmer Load Type: Incandescent quartz lamps and electronic

(SCR dimmable) low voltage xtures.

• Relay Load Type: Any to maximum circuit rating.

• Switch Type: 200% rated, non-proprietary SCR solid state relay.

• Choke Type: High performance, copper wound, hybrid core toroidal

magnetic lter.

• Choke Rise Time: 2400W = 400µs; 1560W = 300µs; 1200W = 300µs.

• Physical: 30" x 17" x 6.8" (75 cm x 43 cm x 17 cm).

• Weight: All Models approximately 66 lbs. (30 Kg).

• Material: 18-gauge steel CRS.

• Finish: Textured ne black powder coat.

4

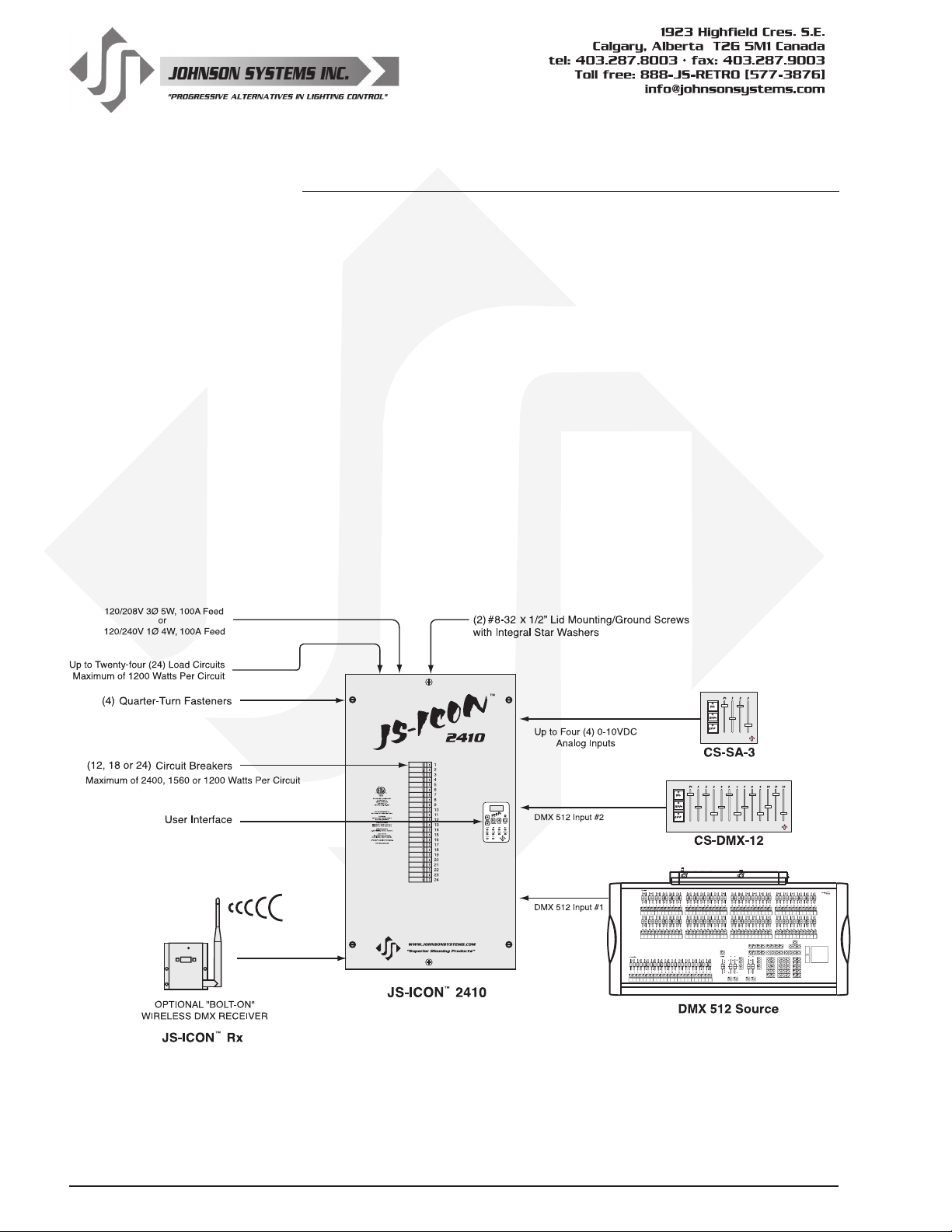

Typical System Installation

JS-ICON™ 2410 - Twenty-four (24) 10 AMP CCTS.

www.johnsonsystems.com

Installation

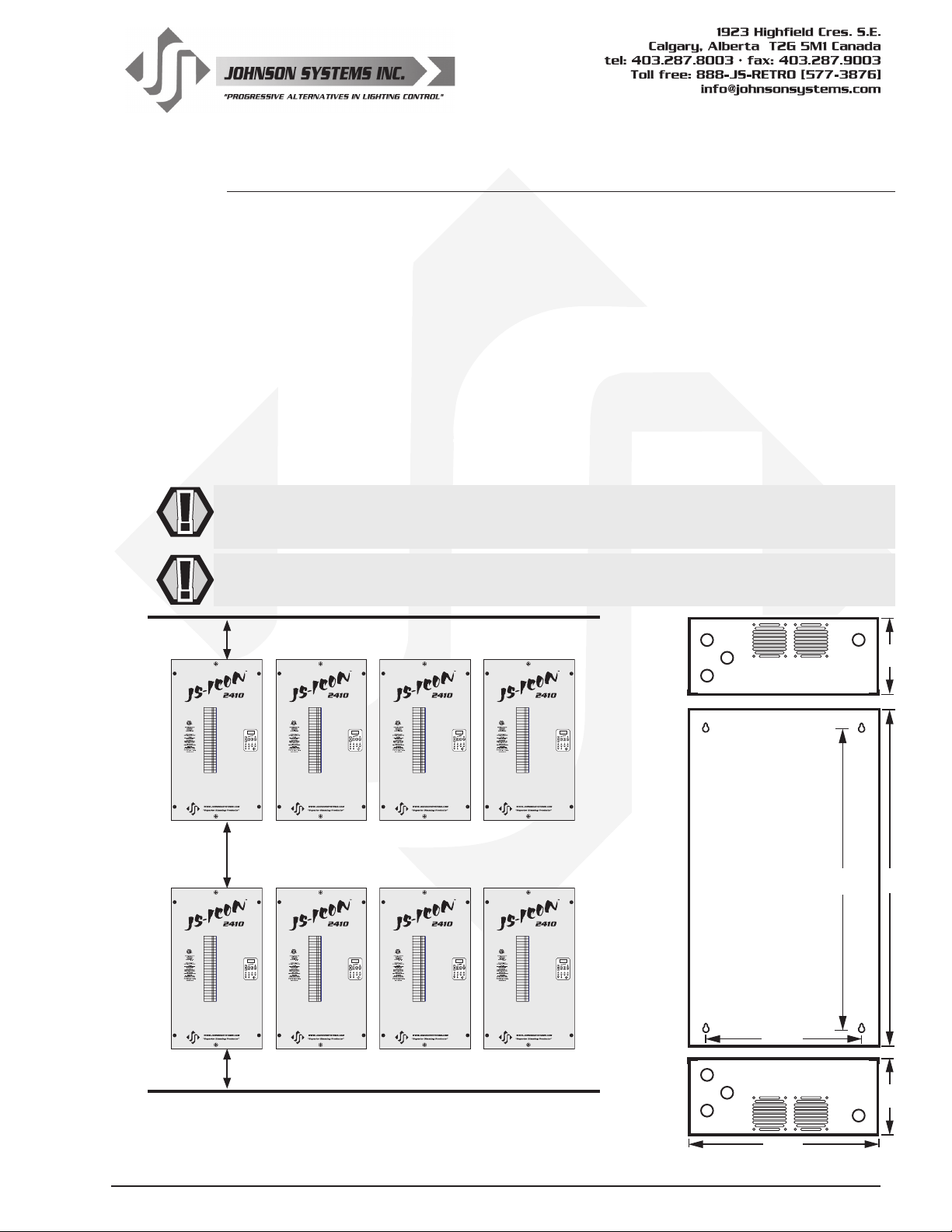

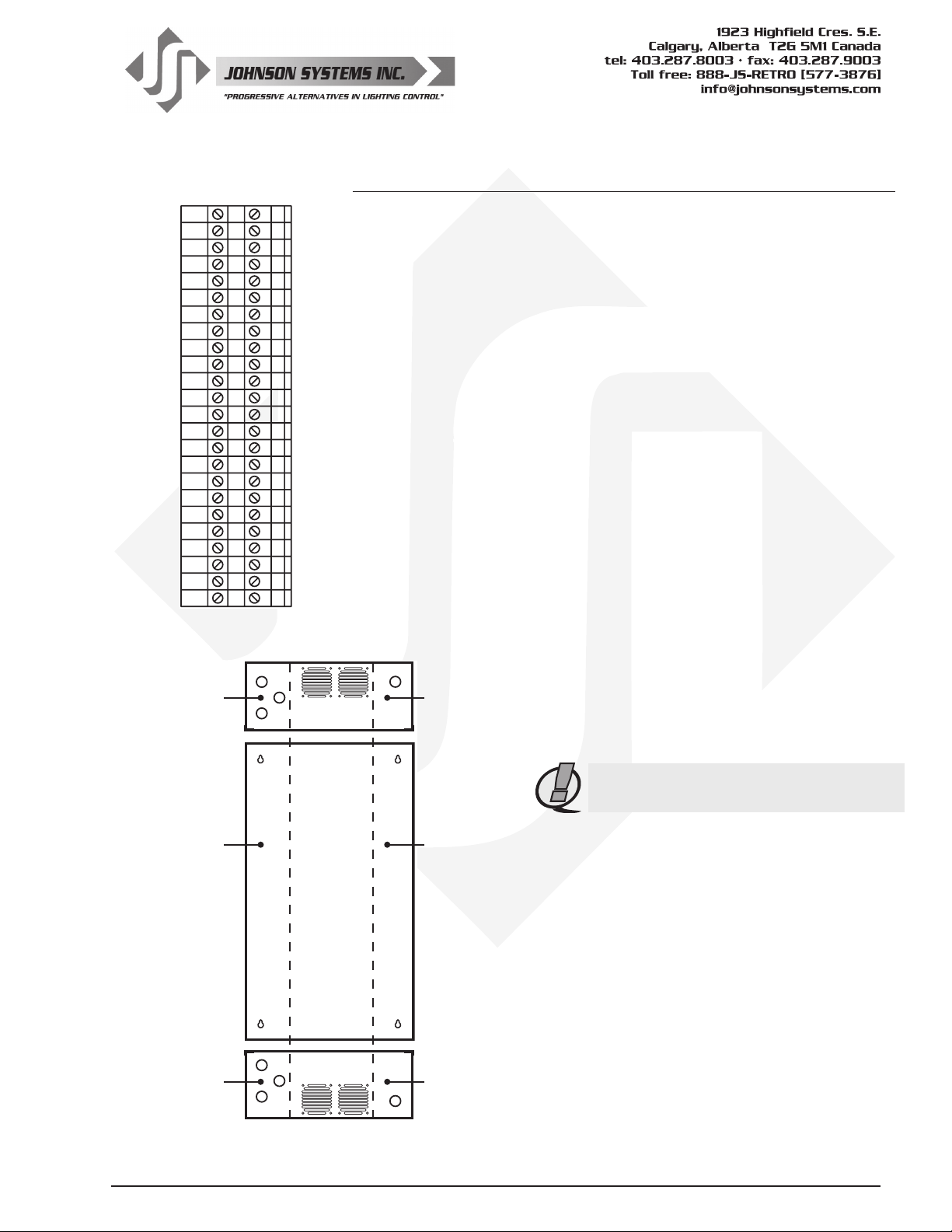

Mounting

The JS-ICON Series dimmer racks can be mounted to any wall surface capable of supporting

its weight of approximately 66 lbs (30 kg) for each rack. Four 1/4" (6mm) screws or bolts are

required to fasten the rack safely to the wall (see the drawing below for mounting locations and

dimensions). To access the mounting locations, simply remove the lid. The lid is secured by two

(2) #8-32 x 1/2" lid mounting/ground screws with integral star washers located at the top-center

and bottom-center of the lid, as well as four (4) quarter-turn fasteners located in each corner.

Use a #2 Philips screwdriver to remove the two (2) lid mounting/ground screws. To release the

four (4) quarter-turn fasteners, use a athead screwdriver to turn them a quarter-turn counter-

clockwise. Once the lid mounting/ground screws are removed and the fasteners are released,

the lid can be removed. When remounting the lid, it is very important to re-install and tighten the

two (2) mounting/ground screws to ensure ground continuity from the main chassis/enclosure to

the lid. The quarter-turn fasteners are easily locked into place by lining the slot up horizontally,

and pushing it in with a thumb.

WARNING: Risk of electrical shock. Before the power supply is turned on, ensure the lid is

securely fastened to the rack with the two (2) lid mounting/ground screws and four (4) quarterturn fasteners. Never remove the lid when the power supply is turned on.

WARNING: Mount the dimmer racks only as indicated below. Failure to comply may cause

thermal overheating.

12" Minimum Clearance for Hot Air Exhaust

6.80"

TOP VIEW

O/OFF

I/ON

1

O/OFF

2

O/OFF

I/ON

3

O/OFF

I/ON I/ON

4

O/OFF

I/ON

5

O/OFF

I/ON

6

O/OFF

7

2002161

O/OFF O/OFF

I/ON

8

O/OFF

I/ON I/ON

9

I/ON

10

O/OFF

I/ON

11

O/OFF O/OFF

12

I/ON I/ON

13

O/OFF

I/ON

14

O/OFF

I/ON

15

O/OFF

I/ON

16

O/OFF

I/ON

17

O/OFF

I/ON

18

O/OFF

I/ON

19

O/OFF

I/ON

20

O/OFF

I/ON

21

O/OFF

I/ON

22

O/OFF

I/ON

23

O/OFF

I/ON

24

O/OFF

I/ON

1

O/OFF

2

O/OFF

I/ON

3

O/OFF

I/ON I/ON

4

O/OFF

I/ON

5

O/OFF

I/ON

6

O/OFF

7

2002161

O/OFF O/OFF

I/ON

8

O/OFF

I/ON I/ON

9

I/ON

10

O/OFF

I/ON

11

O/OFF O/OFF

12

I/ON I/ON

13

O/OFF

I/ON

14

O/OFF

I/ON

15

O/OFF

I/ON

16

O/OFF

I/ON

17

O/OFF

I/ON

18

O/OFF

I/ON

19

O/OFF

I/ON

20

O/OFF

I/ON

21

O/OFF

I/ON

22

O/OFF

I/ON

23

O/OFF

I/ON

24

O/OFF

I/ON

1

O/OFF

2

O/OFF

I/ON

3

O/OFF

I/ON I/ON

4

O/OFF

I/ON

5

O/OFF

I/ON

6

O/OFF

7

2002161

O/OFF O/OFF

I/ON

8

O/OFF

I/ON I/ON

9

I/ON

10

O/OFF

I/ON

11

O/OFF O/OFF

12

I/ON I/ON

13

O/OFF

I/ON

14

O/OFF

I/ON

15

O/OFF

I/ON

16

O/OFF

I/ON

17

O/OFF

I/ON

18

O/OFF

I/ON

19

O/OFF

I/ON

20

O/OFF

I/ON

21

O/OFF

I/ON

22

O/OFF

I/ON

23

O/OFF

I/ON

24

2002161

18" Minimum Clearance KEEP CLEAR

O/OFF

I/ON

1

O/OFF

2

O/OFF

I/ON

3

O/OFF

I/ON I/ON

4

O/OFF

I/ON

5

O/OFF

I/ON

6

O/OFF

7

O/OFF O/OFF

I/ON

8

O/OFF

I/ON I/ON

9

I/ON

10

O/OFF

I/ON

11

O/OFF O/OFF

12

I/ON I/ON

13

O/OFF

I/ON

14

O/OFF

I/ON

15

O/OFF

I/ON

16

O/OFF

I/ON

17

O/OFF

I/ON

18

O/OFF

I/ON

19

O/OFF

I/ON

20

O/OFF

I/ON

21

O/OFF

I/ON

22

O/OFF

I/ON

23

O/OFF

I/ON

24

REAR VIEW

30"27"

O/OFF

I/ON

1

O/OFF

2

O/OFF

I/ON

3

O/OFF

I/ON I/ON

4

O/OFF

I/ON

5

O/OFF

I/ON

6

O/OFF

7

2002161

O/OFF O/OFF

I/ON

8

O/OFF

I/ON I/ON

9

I/ON

10

O/OFF

I/ON

11

O/OFF O/OFF

12

I/ON I/ON

13

O/OFF

I/ON

14

O/OFF

I/ON

15

O/OFF

I/ON

16

O/OFF

I/ON

17

O/OFF

I/ON

18

O/OFF

I/ON

19

O/OFF

I/ON

20

O/OFF

I/ON

21

O/OFF

I/ON

22

O/OFF

I/ON

23

O/OFF

I/ON

24

O/OFF

I/ON

1

O/OFF

2

O/OFF

I/ON

3

O/OFF

I/ON I/ON

4

O/OFF

I/ON

5

O/OFF

I/ON

6

O/OFF

7

2002161

O/OFF O/OFF

I/ON

8

O/OFF

I/ON I/ON

9

I/ON

10

O/OFF

I/ON

11

O/OFF O/OFF

12

I/ON I/ON

13

O/OFF

I/ON

14

O/OFF

I/ON

15

O/OFF

I/ON

16

O/OFF

I/ON

17

O/OFF

I/ON

18

O/OFF

I/ON

19

O/OFF

I/ON

20

O/OFF

I/ON

21

O/OFF

I/ON

22

O/OFF

I/ON

23

O/OFF

I/ON

24

O/OFF

I/ON

1

O/OFF

2

O/OFF

I/ON

3

O/OFF

I/ON I/ON

4

O/OFF

I/ON

5

O/OFF

I/ON

6

O/OFF

7

2002161

O/OFF O/OFF

I/ON

8

O/OFF

I/ON I/ON

9

I/ON

10

O/OFF

I/ON

11

O/OFF O/OFF

12

I/ON I/ON

13

O/OFF

I/ON

14

O/OFF

I/ON

15

O/OFF

I/ON

16

O/OFF

I/ON

17

O/OFF

I/ON

18

O/OFF

I/ON

19

O/OFF

I/ON

20

O/OFF

I/ON

21

O/OFF

I/ON

22

O/OFF

I/ON

23

O/OFF

I/ON

24

O/OFF

I/ON

1

O/OFF

2

O/OFF

I/ON

3

O/OFF

I/ON I/ON

4

O/OFF

I/ON

5

O/OFF

I/ON

6

O/OFF

7

2002161

O/OFF O/OFF

I/ON

8

O/OFF

I/ON I/ON

9

I/ON

10

O/OFF

I/ON

11

O/OFF O/OFF

12

I/ON I/ON

13

O/OFF

I/ON

14

O/OFF

I/ON

15

O/OFF

I/ON

16

O/OFF

I/ON

17

O/OFF

I/ON

18

O/OFF

I/ON

19

O/OFF

I/ON

20

O/OFF

I/ON

21

O/OFF

I/ON

22

O/OFF

I/ON

23

O/OFF

I/ON

24

14"

12" Minimum Clearance for Cool Air Intake

BOTTOM VIEW

6.80"

17"

www.johnsonsystems.com 5

∅A

∅B

∅C

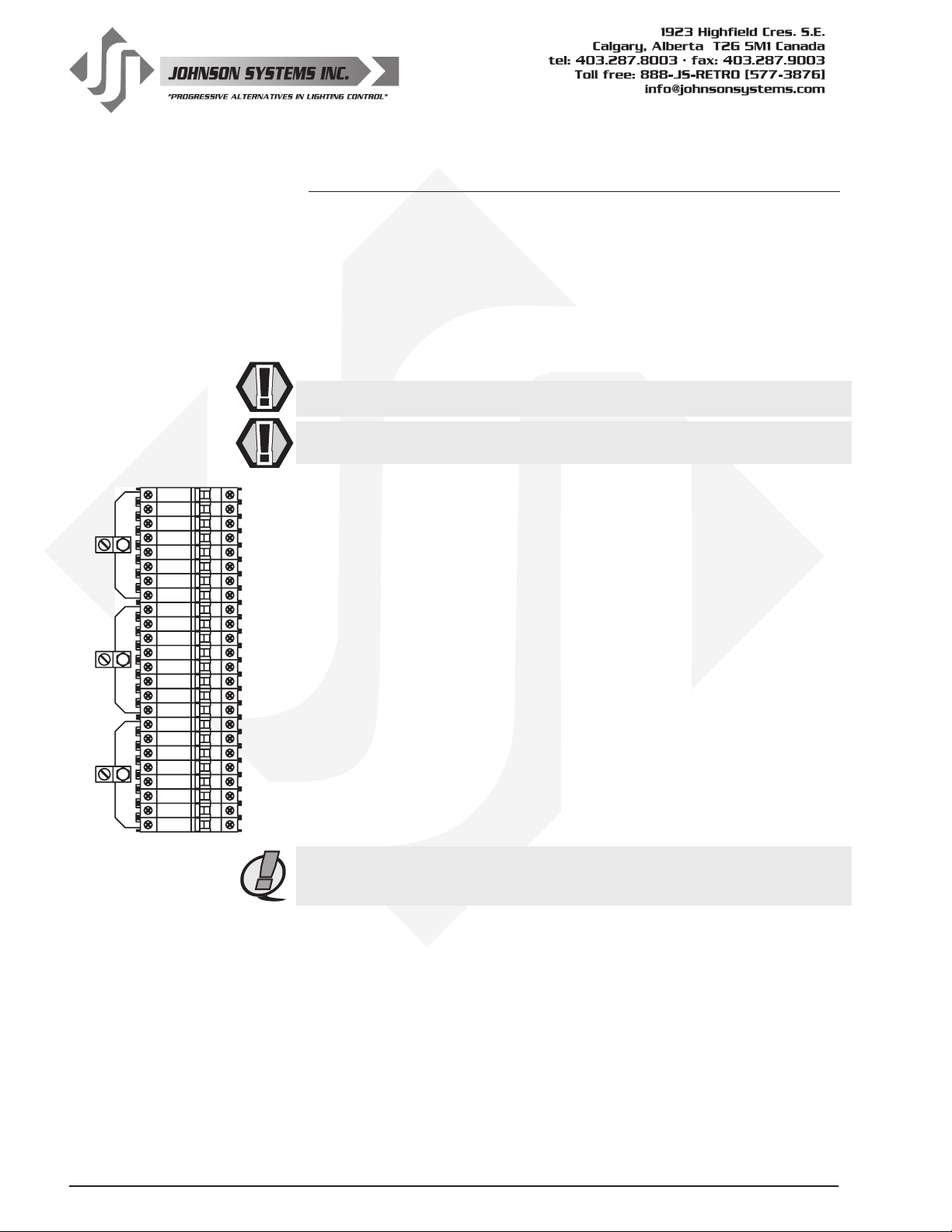

Power Supply Connection Details

The JS-ICON™ Series dimmer racks are capable of various 120V power

supply congurations. The contractor termination section is located on the

left-hand side. Knockouts on the top and bottom of the chassis are provided

for wire/conduit entry to the power terminals. The phase power terminals

are mounted directly onto copper bussbars, used to distribute current to

each dimmers circuit breaker. The power terminals may be rotated up to 180

degrees to facilitate top or bottom wire entry. To rotate the power terminals,

loosen the 1/4-20 x 1/2" mounting bolts (use a 7/16" wrench or socket), rotate

terminals into place, and tighten the mounting bolts to 45-50 IN-LBS (5.0-5.6 NM).

WARNING: Wiring termination must be done by qualied personnel only!

WARNING: Be sure all power connections are tightened to specication

before power supply is turned on.

Power Supply Configurations - Three Phase:

120/208 VAC, 3Ø, 5-Wire up to 100 Amps per phase. Maximum 28.8kW total.

Use wire size #14 to #1/0 AWG. Strip insulation length to 0.65" (16.5mm).

Torque power terminals (A, B, C) to 45-50 IN-LBS (5.0-5.6 NM).

Below is the dimmer phasing for each JS-ICON™ Series dimmer rack model:

JS-ICON™ 2410 and JS-ICON™ 2413 (Example shown to the left)

• Dimmers 1 to 8 are powered from Phase A.

• Dimmers 9 to 16 are powered from Phase B.

• Dimmers 17 to 24 are powered from Phase C.

JS-ICON™ 1220

• Dimmers 1 to 4 are powered from Phase A.

• Dimmers 5 to 8 are powered from Phase B.

• Dimmers 9 to 12 are powered from Phase C.

JS-ICON™ 1210/620

• Dimmers 1 to 8 are powered from Phase A.

• Dimmers 9 to 14 are powered from Phase B.

• Dimmers 15 to 18 are powered from Phase C.

NOTE: Power supply requires an external disconnect.

NOTE: For connection use copper wire only, rated 167°F (75°C) minimum.

6

www.johnsonsystems.com

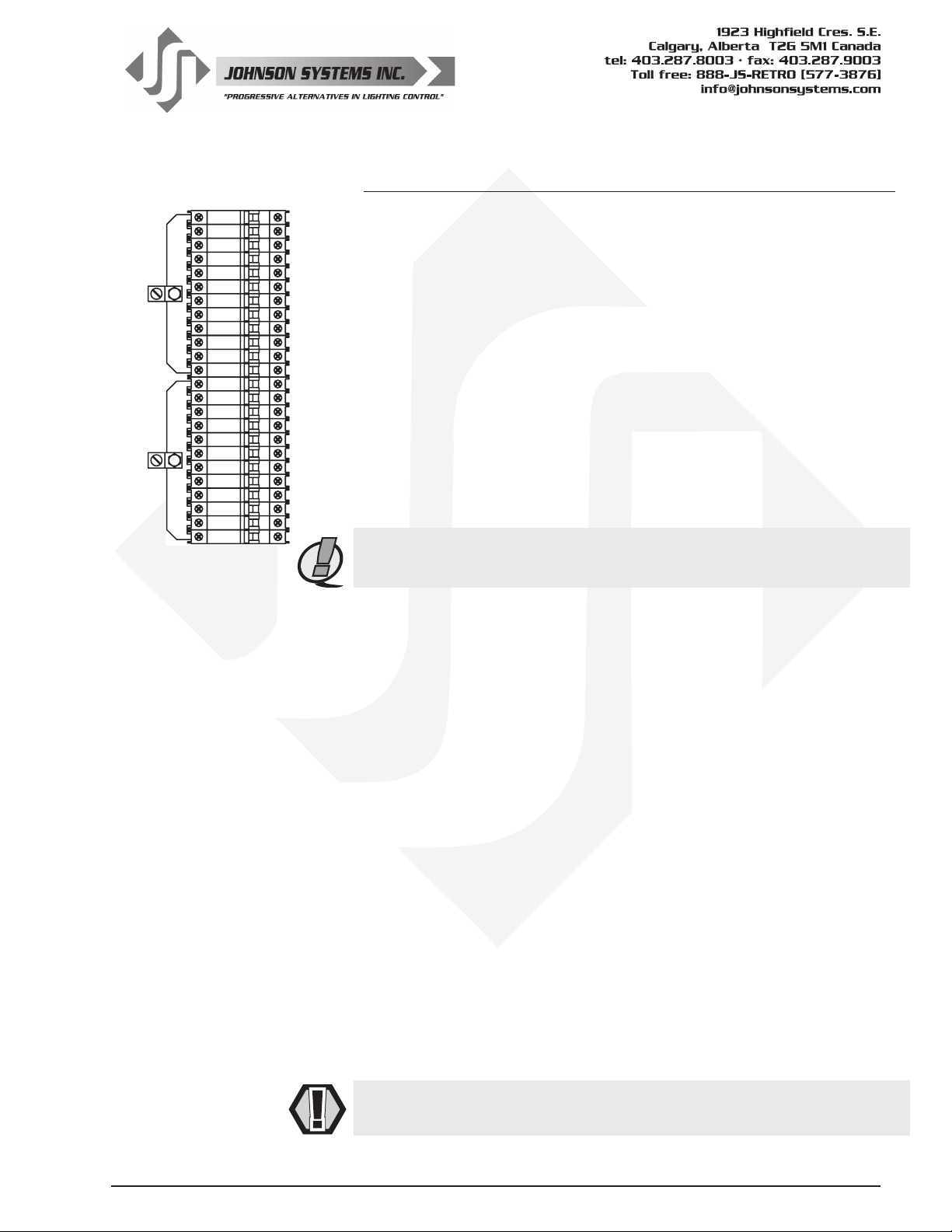

Power Supply Connection Details

Power Supply Configurations - Single Phase:

120/240 VAC, 1Ø, 4-Wire up to 100 Amps per phase. Maximum 24.0kW total.

Use wire size #14 to #1/0 AWG. Strip insulation length to 0.65" (16.5mm).

Torque power terminals (A, B, C) to 45-50 IN-LBS (5.0-5.6 NM).

∅A

∅B

Below is the dimmer phasing for each JS-ICON™ Series dimmer rack model:

JS-ICON™ 2410 and JS-ICON™ 2413 (Example shown to the left)

• Dimmers 1 to 12 are powered from Phase A.

• Dimmers 13 to 24 are powered from Phase B.

JS-ICON™ 1220

• Dimmers 1 to 6 are powered from Phase A.

• Dimmers 7 to 12 are powered from Phase B.

JS-ICON™ 1210/620

• Dimmers 1 to 12 are powered from Phase A.

• Dimmers 13 to 18 are powered from Phase B.

NOTE: Power supply requires an external disconnect.

NOTE: For connection use copper wire only, rated 167°F (75°C) minimum.

Three-Phase to Single-Phase Conversion

JS-ICON™ Series dimmer racks are normally shipped for three-Phase

operation unless otherwise specied at the time of purchase. Please contact

your supplier for a single-phase conversion kit if required. The following steps

will need to be followed to convert the JS-ICON™ dimmer rack from three-

phase to single-phase operation.

1. Remove the three-phase copper bussbars by loosening all of the screws

terminals (use a medium sized #2 Philips or Flathead screwdriver) on

the left-hand side of the circuit breakers.

2. Insert the supplied single-phase copper bussbars, and tighten all of the

circuit breaker screw terminals to 20 IN-LBS (2.26 NM).

3. Reconnect the black #18 AWG wire (underneath) to the Phase A

bussbar.

4. Reconnect the red #18 AWG wire (underneath) to the Phase B bussbar.

5. Tape off or use a marette to isolate the blue #18 AWG wire.

6. Remove two (2) of the phase power terminals (use a 7/16" wrench or

socket) from the old three-phase bussbars, and fasten them to the new

single-phase bussbars. Use the original mounting bolts and tighten to

45-50 IN-LBS (5.0-5.6 NM).

7. Note that the default phase patch will need to be recongured when the

system is powered up. For more information, see “DEFAULTS” menu

item on page 30.

WARNING: Be sure all power connections are tightened to specication

before power supply is turned on.

www.johnsonsystems.com 7

Load Circuit Neutral

Output Terminals

Power Supply Connection Details

Neutral Power Distribution Block

Neutral Input Terminal

• Use wire size #14 to #1/0 AWG. Strip insulation length to 0.65" (16.5mm).

• Torque neutral terminal(s) to 45-50 IN-LBS (5.0-5.6 NM).

Capable of single or dual rated neutral termination. The neutral terminal may be

mounted on the top or bottom of the distribution block to facilitate top or bottom

wire entry. To change the position of the neutral terminal, remove the 1/4-20 x

1/2" mounting bolt (use a 7/16" wrench or socket), move into place, and tighten

the mounting bolt to 45-50 IN-LBS (5.0-5.6 NM).

Load Circuit Neutral Output Terminals

• Use wire size #14 to #8 AWG. Strip insulation length to 0.315" (8mm).

• Torque load circuit neutral terminals to 20-25 IN-LBS (2.3-2.8 NM).

Models JS-ICON™ 2410, JS-ICON™ 2413 and JS-ICON™ 1210/620 are supplied

with 25 load

NOTE: For connection use copper wire only, rated for 167°F (75°C) minimum.

circuit

neutral terminals, while Model JS-

ICON™ 1220 is supplied with 12.

Load Circuit Neutrals

Ground Input

Load

Circuit

Grounds

Ground Connection Details

Ground Input Terminal

• Use wire size #14 to #1/0 AWG. Strip insulation length to 0.65" (16.5mm).

• Torque ground terminal to 45-50 IN-LBS (5.0-5.6 NM).

The ground input terminal may be rotated up to 360 degrees to facilitate top or

bottom wire entry. To rotate the ground terminal, loosen the 1/4-20 lock-nut (use

a 7/16" wrench or socket), rotate terminal into place, and tighten the lock-nut to

45-50 IN-LBS (5.0-5.6 NM).

Load Circuit Ground Output Terminals

• Use wire size #14 to #8 AWG. Strip insulation length to 0.315" (8mm).

• Torque load circuit ground terminals to 20-25 IN-LBS (2.3-2.8 NM).

Models JS-ICON™ 2410, JS-ICON™ 2413 and JS-ICON™ 1210/620 are supplied

with 25 load circuit ground terminals, while model JS-

NOTE: For connection use copper wire only, rated for 167°F (75°C) minimum.

ICON™ 1220 is supplied with 12.

8

www.johnsonsystems.com

Load Output

Terminal Blocks

12 345 6789101311 12 14 15 16 17 18 19 20 21 22 23 24

Line Voltage

AC Wire / Conduit

Entry

Dimmer Output

JS-ICON™ 2410 24 x 10 Amp (1200 Watt) dimmers.

JS-ICON™ 2413 24 x 13 Amp (1560 Watt) dimmers.

JS-ICON™ 1220 12 x 20 Amp (2400 Watt) dimmers.

JS-ICON™ 1210/620 12 x 10 Amp (1200 Watt) and

6 x 20 Amp (2400 Watt) dimmers.

JS-ICON™ Series dimmer racks are designed for high performance dimming of

standard incandescent, quartz, and dimmable (SCR/Leading-Edge) electronic

low-voltage xtures. The dimmer outputs may be congured for non-dimmed

applications when switched (relay controlled) load outputs are required.

Knockouts on the top and bottom of the chassis are provided for wire/conduit

entry to the power terminals.

Load (Hot) Output Connection Details

Load output connections are terminated via DIN rail mounted terminal blocks.

Models JS-ICON™ 2410 and JS-ICON™ 2413

• Use wire size #14 to #10 AWG. Strip insulation length to 0.315" (8mm).

• Torque load output terminal blocks to 5-7 IN-LBS (0.6-0.8 NM).

Model JS-ICON™ 1220

• Use wire size #14 to #8 AWG. Strip insulation length to 0.4" (10mm).

• Torque load output terminal blocks to 13-16 IN-LBS (1.5-1.8 NM).

Model JS-ICON™ 1210/620

• For load output terminal blocks 1 to 12, use

Low Voltage

DC Wire / Conduit

Entry

TOP VIEW

same specication as Model JS-ICON

2410.

• For load output terminal blocks 13 to 18,

use same specication as Model JS-

ICON™ 1220.

™

Line Voltage

AC Contractor

Termination

Section

Line Voltage

AC Wire / Conduit

Entry

REAR VIEW

BOTTOM VIEW

NOTE: For connection use copper wire

only, rated for 167°F (75°C) minimum.

Low Voltage

DC Contractor

Termination

Section

Low Voltage

DC Wire / Conduit

Entry

www.johnsonsystems.com 9

J24

J23

J18

J17

J33

J30

J29

J28

J27

J26

J21

J20

J19

J16J15

PS1

J1

J3

J2

J6

J4

J8J7 J10J9

J12

J5

J11

J14J13

J32

INPUT

VAC26485

WATTS15DCVOLTS12SUPPLYPOWER

TO

AUX

SCTY

FIRE

OCOP

+12V

COM

ANA4

ANA3

ANA2

ANA1

COM

BCN

CMD-D+CMD-D+CMD-D+CMD+

DMX A I/ODMX B I/O

BUMP

REMOTE

LCD AND LED STATUS

D-

A

1+

1-

2+

2-

A-

B-

C-

D-

++

UAD

SSR1

UAD

SSR2

DUAL

SSR1

DUAL

SSR2

UAD

SSR3

FAN1 FAN2

-

1+

1-

2+

2-

A-

B-

C-

D-

++

1+

1-

2+

2-

A-

B-

C-

D-

++

1+

1-

2+

2-

A-

B-

C-

D-

++

1+

1-

2+

2-

A-

B-

C-

D-

++

1+

1-

2+

2-

A-

B-

C-

D-

++

TERMO

TEMP

SENSOR

-STAT

LM35DT

+

-

FAN3 FAN4

+

-

UAD

SSR4

UAD

SSR5

UAD

SSR6

DUAL

SSR3

DUAL

SSR4

DUAL

SSR5

DUAL

SSR6

DUAL

SSR4

DUAL

SSR5

DUAL

SSR6

1210 620

NO

1+

1-

2+

2-

1+

1-

2+

2-

1+

1-

2+

2-

1210 6201210 620

Signal Distribution Board

SWITCH CONT

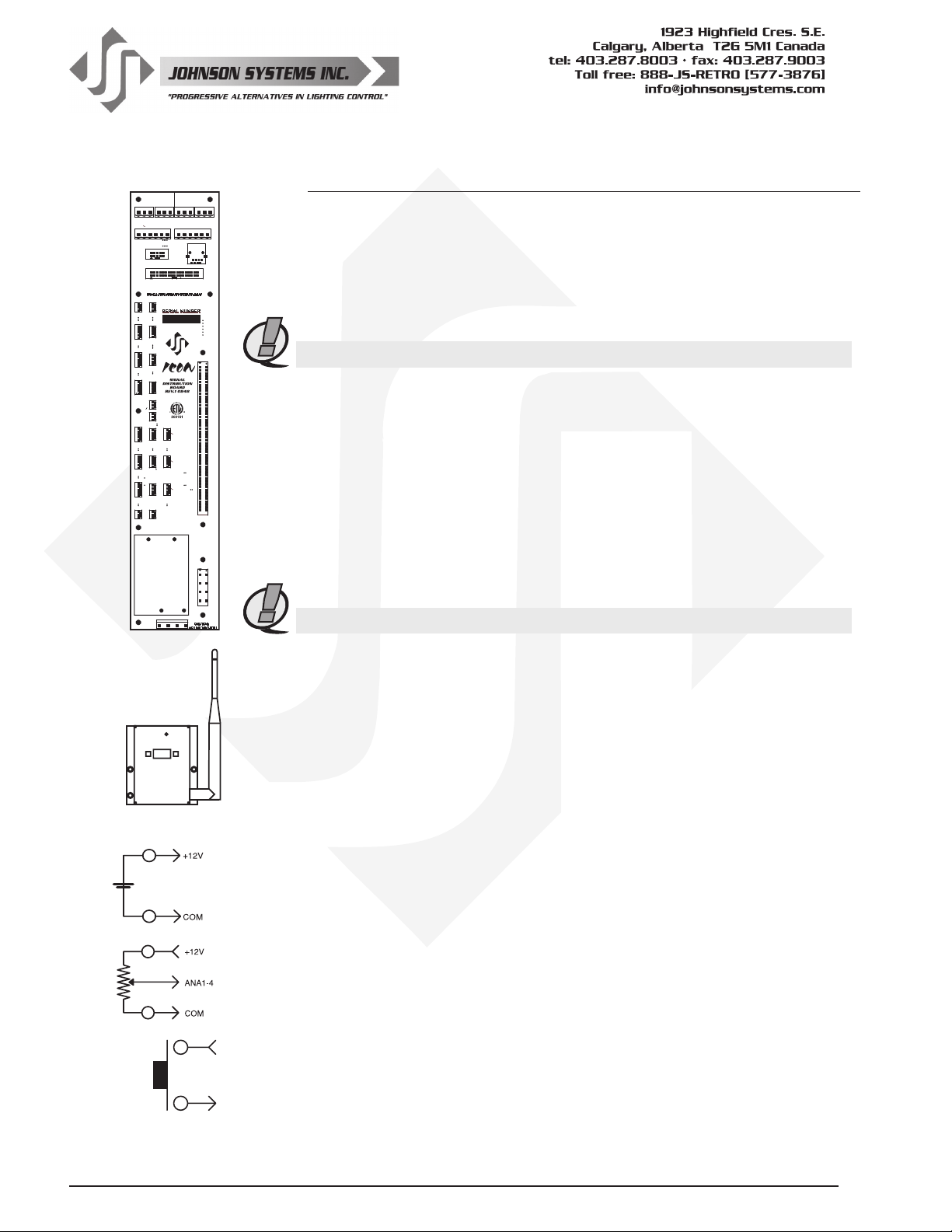

Control Input/Output

JS-ICON™ Series dimmer racks come with a variety of control input and output

(I/O) capabilities. All I/O connections are terminated on the Signal Distribution

Board, located on the right-hand side of the dimmer rack.

Breakaway type connectors are supplied for all I/O connections.

• Use wire size #28 to #12 AWG. Strip insulation length to 0.3" (7.5mm).

• Torque terminations to 3.6 IN-LBS (0.4 NM).

NOTE: For connection use copper wire only, rated for 167°F (75°C) minimum.

Dual DMX Input and Through

• DMX A terminates to J7 and J8 connectors.

• DMX B terminates to J9 and J10 connectors.

• Complies with USITT DMX512-A (ANSI E1.11 - 2008), Standard protocol

for digital data control.

• Recommended cable is Belden 9829, 9842, Cat 5 or equivalent

(low-capacitance, twisted pair).

• Wiring must follow a daisy-chain topology.

• Maximum of 32 receiving devices on a single DMX line.

• Maximum cable length is 1,500 feet (455 meters).

• For more information, Google DMX, or visit:

http://old.usitt.org/DMX512FAQ.aspx

NOTE: Ensure only the last (end-of-line) DMX receiving device is terminated!

MAINTAINED

NORMALLY OPEN

JS-ICON™ Rx

ACT

+12V

ANA1-4

Models JS-ICON™ Rx and JS-ICON™ Tx

Wireless DMX is optional for all JS-ICON™ Series dimmer racks. SHoW DMX

receiver (JS-ICON™ Rx) and transmitter (JS-ICON™ Tx) is sourced from City

Theatrical, and has been selected for its reliability and ease of use. The JSICON™ Rx is specically designed for easy adaptation to all JS-ICON™ products.

The JS-ICON™ Rx comes complete with a wiring harness and mounting

hardware. For more information visit:

http://www.johnsonsystems.com/JS-ICON_Rx_Manual_by_City_Theatrical.pdf.

+12VDC Power Supply Output

• A regulated +12VDC power supply is available for powering external

devices.

• Terminate on +12V and COM of J12 connector.

• External devices should not exceed the maximum combined current draw

of 200mA.

0-10VDC Analog Inputs or Load Shed Contact Inputs

• Four (4) analog inputs terminate on J12 connector.

• AN1=Analog Input 1, AN2=Analog Input 2, AN3=Analog Input 3,

AN4=Analog Input 4.

• Inputs can be congured for normal or load shed mode of operation.

• Inputs can be patched to any combination of dimmer output circuits.

•

Programmed in the “ANA MODE” and “ANA PTCH” menus. See page 22 for details.

10

www.johnsonsystems.com

MAINTAINED

SWITCH CONT

O/T

EEPROM

NORMALLY OPEN

ACT

MAX

FIRE

SCTY

AUX

COM

Over-Temperature Input (Normally Open)

• Terminate (O/T) on J11 connector.

• Disables all dimmer outputs when contact/switch is closed.

• Controlled via a maintained contact/switch to low-voltage common (COM).

Fire Alarm Input (Normally Open)

• Terminate (FIRE) on J11 connector.

• Triggers selected channels to turn on when contact/switch is closed.

• Controlled via a maintained contact/switch to low-voltage common (COM).

• Programmed in the “F-ALARM” menu. See page 25 for details.

Security Alarm Input (Normally Open)

• Terminate (SCTY) on J11 connector.

• Triggers selected channels to cycle on and off at a 1 Hertz rate.

• Controlled via a maintained contact/switch to low-voltage common (COM).

• Programmed in the “S-ALARM” menu. See page 24 for details.

Auxiliary Input (Normally Open)

• Terminate (AUX) on J11 connector.

• Triggers 1 of 24 presets when contact/switch is closed.

• Controlled via a maintained contact/switch to low-voltage common (COM).

• Programmed in the “AUX IN” menu. See page 24 for details.

Open Collector Output

• Terminate (OCOP) on J11 connector.

• Sink up to 100mA.

• Trigger Solid State Relays (SSR) or other external devices.

• Controlled via DMX and/or Analog Input 4.

• Programmed in the “OC MODE” menu. See page 23 for details.

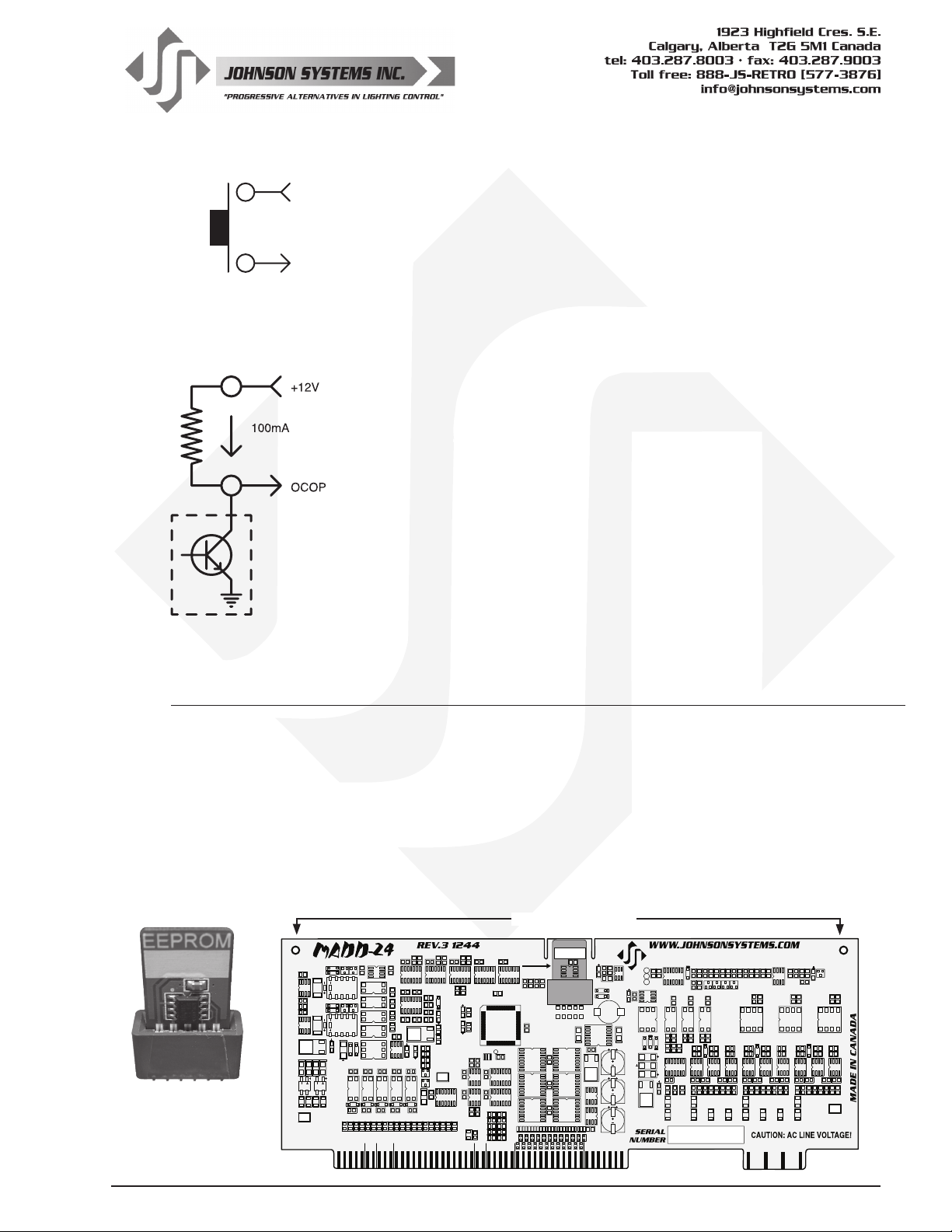

MADD-24 (Multiple Application Dimmer Driver)

The MADD-24 is the central electronic control system (aka brain) for all JS-ICON™ Series dimmer racks.

The MADD-24 is located on the right-hand side of the dimmer rack, and mounts into card edge connectors

located on the Signal Distribution Board. The MADD-24 can easily be removed by unscrewing two #440 mounting screws (use a small sized #1 Philips screwdriver) located on the top corners, and pulling

it forward using both hands. When re-installing a MADD-24, be sure it is fully seated into the card edge

connectors, and the two mounting screws are screwed in tight.

Located on the MADD-24 is a removable EEPROM memory module. The EEPROM memory module

slides into the PORT1 connector located on the upper center of the board. The EEPROM memory module

is used to backup important conguration settings and may be removed for safe storage. The EEPROM

memory module can also be used for rmware updates. Refer to menu items “EEPROM”, “FW-LOAD”,

“RESTORE” and “BACKUP” on page 27 to 29 for further details.

Mounting Screws

EEPROM

1

MEMORY

R127 R126

C79

C78

MODULE

U50

U49

C61

R87

R86

R85

R121

U28

C65 C64

C63

X1

R68

R69

C80

U37

C81

U38

R66 R67

R75

R76

C89

R77

F5

R78

R84

PORT1

BACKUP &

FIRMWARE

C62

UPDATE

U29

TP4

C58

U33

U30

R79 R74

C59

R80

C60

U31

PWM

R81

R82

R83

R89 R88

TPA

TPB

C68

TPC

U51

CALIBRATE

D27

D28

C34

C33

T3

L1

D18

D17

U32

VR3

C53

Q7

U52 U53

U34

DC/FAN

C1

C2

C3

C54

C55

C57

C56

D26

U18

R134

R133

R132

R131

R130

C84

C83

R128

R129

U17

R52 R53

R54

U11

U13

U12

D2

D1

D3

R43 R46

U1

R3

C4

VR1

R1 R2

R51

R47

R48

R49

R50

R42

C24

R45

R44

C25

D6

U8

U9

C5

C26

C27

C28

R34

R5

R4

R38

R37

R36

R35

R33 R32

R31

C85

R141

R140

R139

R138

R137

R136

R135

Q11 Q10 Q9 Q8

C37

R57

U16

R29

C32 C31

C15

C16

C30

D5

U5

U6

U10

C17

C18

C29

R21

R22

R24

R23

R41

R40

R39

R18

R19 R20

R30

C87

U19

R145

R144

R143

R142

C86

C19

R25

VR5

C88

C36

R56

C35

U14

U15

R16

C6

C14 C13

C7

C21

C22 C23

U7

R26

R17

C12

D4

U2

U4

U3

C8

C9

C10

C20

R8

R9

R14

R13

R12

R11

R10

R28

R27

R7 R6

TP1

EDGE1

EEPROM

Memory Module

U20

U21

VR2

C40

R58

R59

C41

D9 D10 D11

F1 F2 F3 F4

RLY1

R60

Q4 Q3

D15

D16

R61

C38

C39

D12

BR2 BR1

TP3

1 BUMP REM

EDGE2

R63

U26 U25 U24 U23

RLY2

D7

D8

T5

U40

U41

U42

U43

D22

D21

D20

R108 R107

R106

C73

R95

R94

C72

R93

R92

C71

R91

R90

ANA I/O DMX LCD LED SWITCH

C42

C43

U22

Q1 Q2

D13

D14

C75

U46

R62

U45

R64 R65

R70 R71 C52

U27

R96

R122 R123

R124 R125

C76

C77

U47

U48

C51 C50

R146

R120

C67

R72 R73

C49 D25

C44

C46

C45

R115 R114 R113 R112 R111

U44

D23

D24

R110 R109

C74

R97

C66

C47 C48

VR4

R116

R117

R118

R119

TP2

Q6

Q5

U35

C69 C70

D19

C82

U39

U36

R99

R98

R105

R104

R103

R102

R101

R100

R55

C11

R15

www.johnsonsystems.com 11

Loading...

Loading...