Johnson Systems J-PACK User Manual

User Manual

J-PACK Series

Hi-Performance Dimmer Pack

JOHNSON SYSTEMS INC.

WWW.JOHNSONSYSTEMS.COM

Contents

Warranty ..........................................................................................................2

Introduction ......................................................................................................3

Characteristics .................................................................................................4

Installation .......................................................................................................6

Mounting Options ............................................................................................6

AC Power Supply Input Options ......................................................................8

Output Connector/Receptacle Options ..........................................................10

Output Connector/Receptacle Diagrams .......................................................12

Control Input ..................................................................................................12

MADD-6 (Multiple Application Dimmer Driver) Controller ..............................13

User Interface ................................................................................................14

System Status • LED Indicators ...................................................................15

System Status • LCD Display ........................................................................15

Quick Programming Reference to System Conguration Menu Items ..........17

Detailed Programming of System Conguration Menu Items........................18

Important Hard-key Information .....................................................................28

J-PACK Dimmer Pack (DP) Ordering Information .........................................29

Troubleshooting Reference ...........................................................................30

Warranty

J-PACK Series dimmer packs come with a standard one (1) year

limited warranty. Extended warranties of up to ten (10) years are

available at the time of purchase.

For details visit: www.johnsonsystems.com/warranties.htm

For Technical Assistance

1. Refer to your product user manual. The most current revision is

available online: www.johnsonsystems.com/literature.htm

2. Contact the “point-of-sale” dealer or distributor from which this product

was originally purchased, and ask for technical assistance.

3. If neither of the above can provide you with the necessary information,

please contact our factory via email (info@johnsonsystems.com)

or phone (403-287-8003) during business hours (Monday to Friday,

8:00AM to 5:00PM MST).

2

WWW.JOHNSONSYSTEMS.COM

J-PACK Series

Hi-Power Dimmer Pack

Introduction

J-PACK dimmers are a truly universal hi-performance series of 6 channel

dimmer packs. Designed for versatility in virtually any environment, these unique

and compact dimmer packs can be wall-mounted for permanent installations,

19” rack mounted, pipe mounted or used as portable units. Multiple units can be

easily “ganged” together for fast system expansion.

Next generation “system-on-a-chip” technology provides unsurpassed value

in SCR dimming. Stand-by power consumption of less than 1 Watt, allow

for compliance with the International Energy Agency’s “One Watt Initiative”

for standby power consumption. This makes J-PACK’s truly “green” with the

minimal possible impact on the environment!

Available in various sizes and congurations, J-PACK’s offer unique exibility

in professional grade dimming. Designed for modern lower wattage compact

lament dimming loads these dimmers are full rated at 1,560 Watts for constant

prolonged operation. Premium hydraulic magnetic circuit breakers offer safety

and eliminate the false tripping concern of competitive dimmers. Intuitive LCD

user interface combined analog inputs and contact closure inputs allow for

industry wide application.

On demand “MagLev®” thermal management technology produces superior

cooling that is virtually silent making J-PACK’s the natural choice for “quiet

space” dimming installations. Exclusive “lamp warming” techniques extends

lamp life considerably while maintaining industry leading performance!

Features

• Available in a range of voltage and output congurations.

• Unique power saving stand-by mode reduces power consumption to less

than 1 Watt, a “green” dimmer pack.

• Dim standard or low-voltage incandescent quartz lamps. Compatible with

SCR dimmable LED lamps and xtures.

• Individual dimmer prole selection permits safe and silent control of non-

dim lighting loads.

• DMX512 start addressable in single channel (offset) or individually (patch).

• DMX “snapshots” with scene playback.

• Unique “lamp warming” feature extends lamp life signicantly.

• Analog and dedicated dry contact BMS inputs for interface with HVAC,

security and audio.

• “Load Shed” inputs for power management and photocell interface.

• LCD user interface for easy setup and monitoring.

• Over-heat and over-current protected.

• Non-proprietary dimmer SCR’s are 300% rated.

• On-demand ‘MagLev®’ thermal management technology produces superior

cooling that is virtually silent.

• Up to 10 year product warranty available!

WWW.JOHNSONSYSTEMS.COM 3

Characteristics

• Maximum Feeder Capacity:

• Edison 15 Amp 120 VAC 1Ø 3 wire. Max. Rating 1,800W.

• 2 Circuits of Edison 15 Amp 120 VAC 1Ø 3 wire. Max. Rating 3,600W.

• 30 Amp 120/208 VAC 3Ø 5 wire. Max. Rating 9,000W.

• 40 Amp 120/240 VAC 1Ø 4 wire. Max. Rating 9,000W.

• Power Termination: Power lug input.

• Output selection of Terminal Block, Stage Pin, Edison, TLG or Socapex.

• Maximum output 1,560 Watts per circuit.

• Environment

• Temperature Range: 23°F (-5°C) to 104°F (40°C) ambient.

• Humidity Range: 0% to 90% non-condensing.

• Load Type: Incandescent quartz lamps and electronic (SCR dimmable) low voltage xtures.

• Switch Type: 300% rated, non-proprietary SCR solid state relay.

• Rise Time: 300uS.

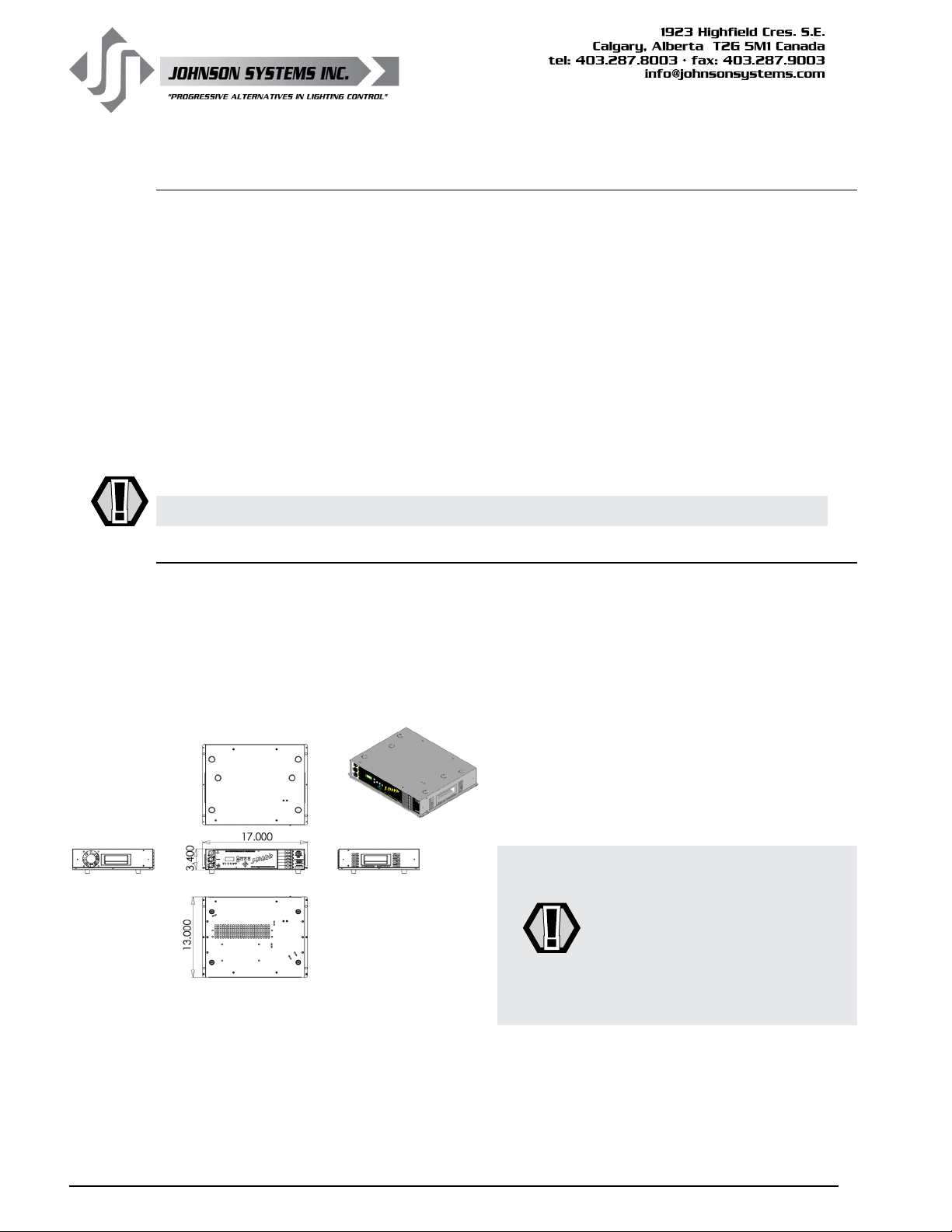

• Physical: 13" x 17" x 3.4" (33 cm x 43 cm x 8.5 cm).

• Weight: 22 - 23 lbs. (10.0 - 10.5 Kg) depending on model.

• Material: 18-gauge steel CRS.

• Finish: Hammer texture black powder coat.

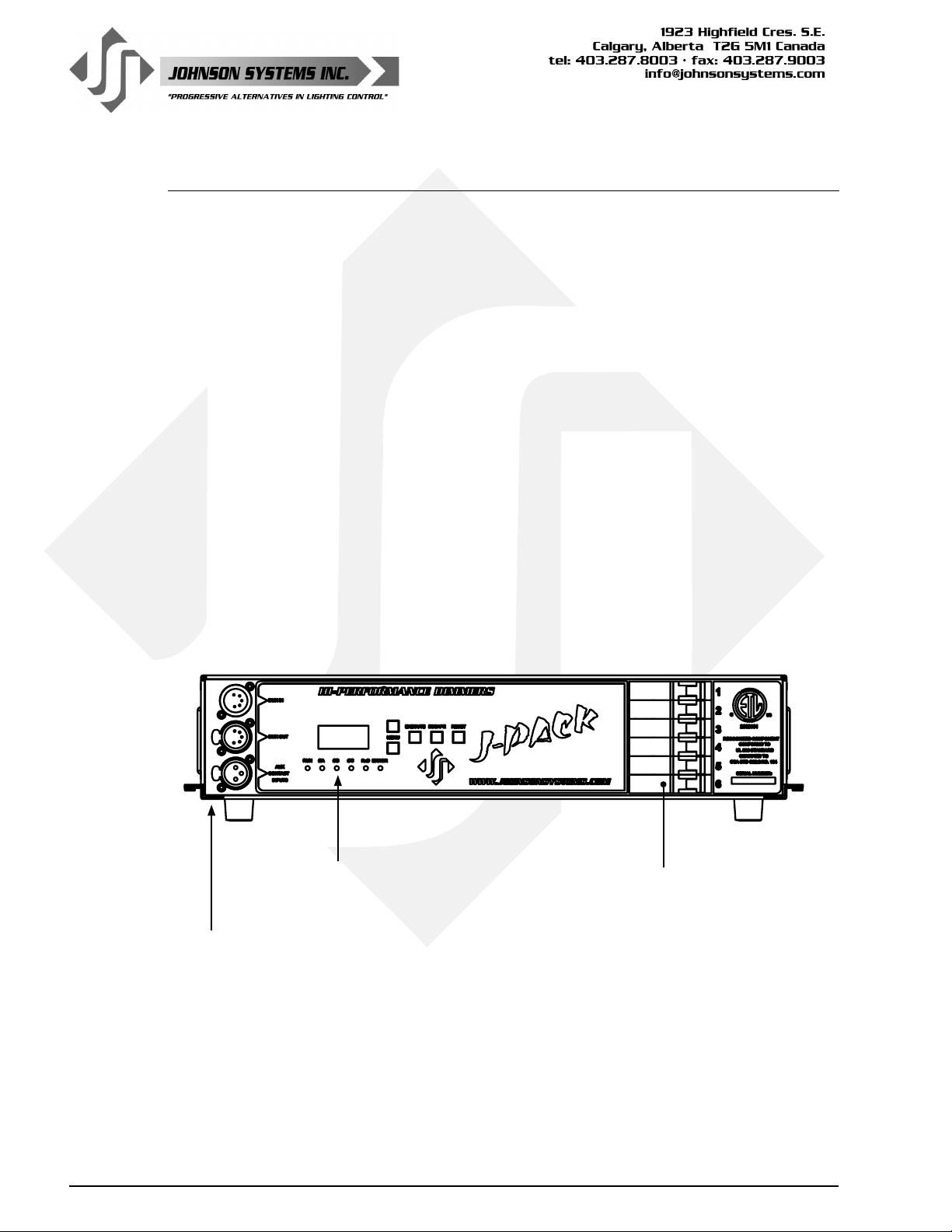

User Interface

Refer to page 14 for details

Control Input XLR Connectors

Refer to page 13 for details

Front View

Circuit Breakers

4

WWW.JOHNSONSYSTEMS.COM

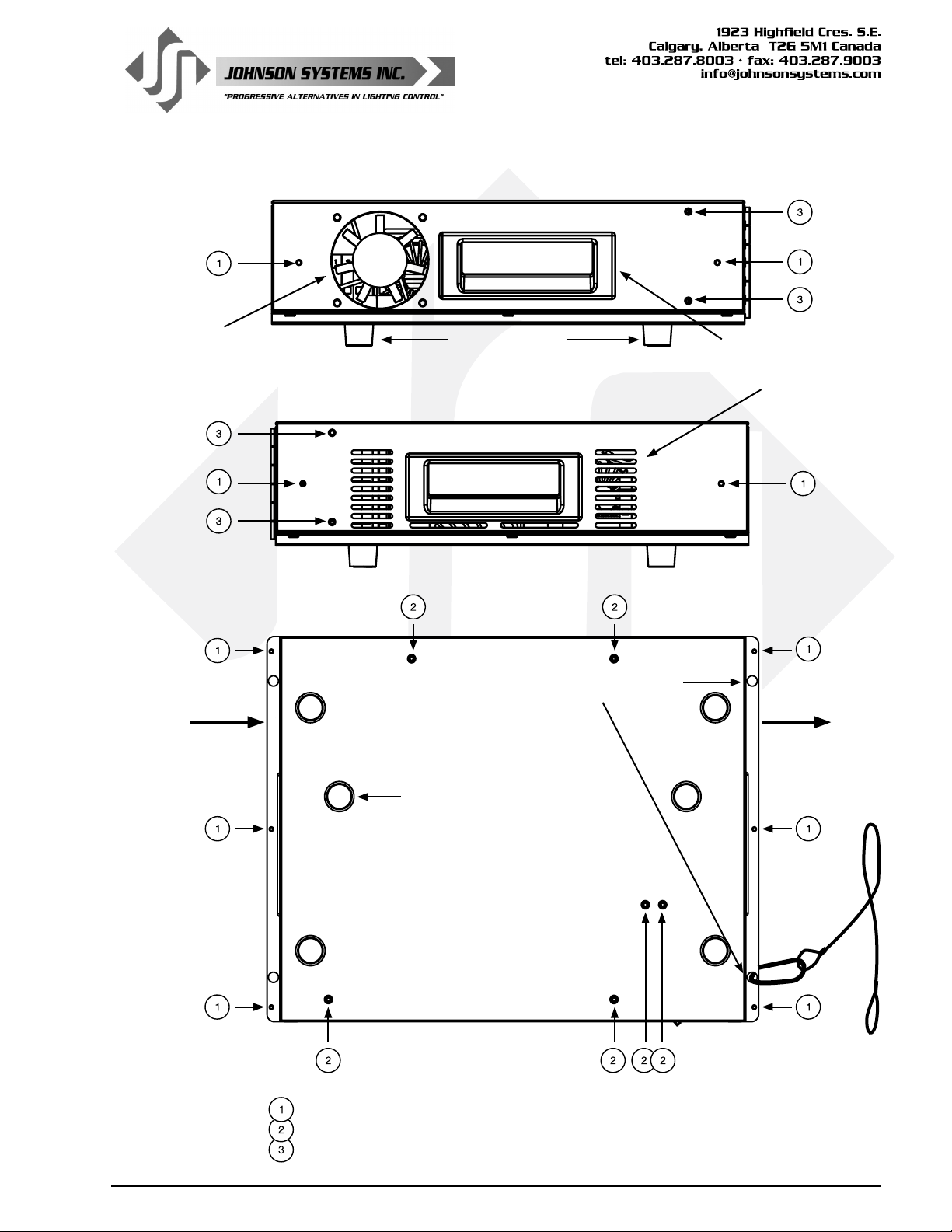

Left Side View

Air Intake Fan

Air

Intake

Rubber Feet

(For RF model only)

Right Side View

Top View

Four (4) Safety Cable Mounting Holes

(For PM model only)

Handle

Air Exhaust

Ventilation

Air

Exhaust

Six (6) Indents

(For vertical stacking)

Ten (10) SEMS #6-32 x 3/8" Philips Pan Head, Top Panel (Lid) Mounting Screws

Six (6) #6-32 x 3/8" Philips Flat Head, Top Panel (Lid) Mounting Screws

Four (4) SEMS #6-32 x 3/8" Philips Pan Head, Rack Mount Bracket Mounting Screws

WWW.JOHNSONSYSTEMS.COM 5

Safety Cable supplied

on PM model

Installation

J-Pack Series dimmer packs are intended for indoor use only, in a controlled environment at a room

temperature.

• Mount in a suitable location.

Refer to the Mounting Options section on page 6 for applicable details.

• Connect the applicable AC power supply input.

Refer to the AC Power Supply Input Options section on page 8 for applicable details.

• Connect the relay output receptacles/terminals.

Refer to the Relay Output Connection Options section on page 10 for applicable details.

• Connect DMX and/or dry contact control input(s).

Refer to the Control Input section on page 12 for details.

• Program, setup, test and verify functionality.

Refer to the Detailed Programming of System Conguration Menu Items section

on page 18 for details.

WARNING: For indoor use only!

Mounting Options

J-PACK Series dimmer packs are capable of various mounting options to suit the application required.

A cooling fan mounted inside the dimmer pack is used to move air through the chassis and cool

the heat sink and chokes. The fan is temperature controlled via a temperature sensor mounted on

the heat sink. If the heat sink temperature is >=55ºC the fan is turned on to half speed. If the heat

sink temperature is >=70ºC the fan is turned full on. It is important to mount the dimmer pack in the

orientation intended with unobstructed ventilation to ensure adequate cooling.

RF = Rubber Feet

For portable applications, the dimmer pack

can be set on any at surface. Rubber feet are

mounted on the bottom of the dimmer pack,

with indents on the top cover panel to facilitate

vertical stacking of up to 6 units high.

WARNING: Never place the dimmer packs

side by side (horizontally) without

a minimum of 12" of clearance

between them. Always leave a

minimum of 6" of clearance from

the dimmer packs air intake and

exhaust. Failure to comply may

cause thermal overheating.

6

WWW.JOHNSONSYSTEMS.COM

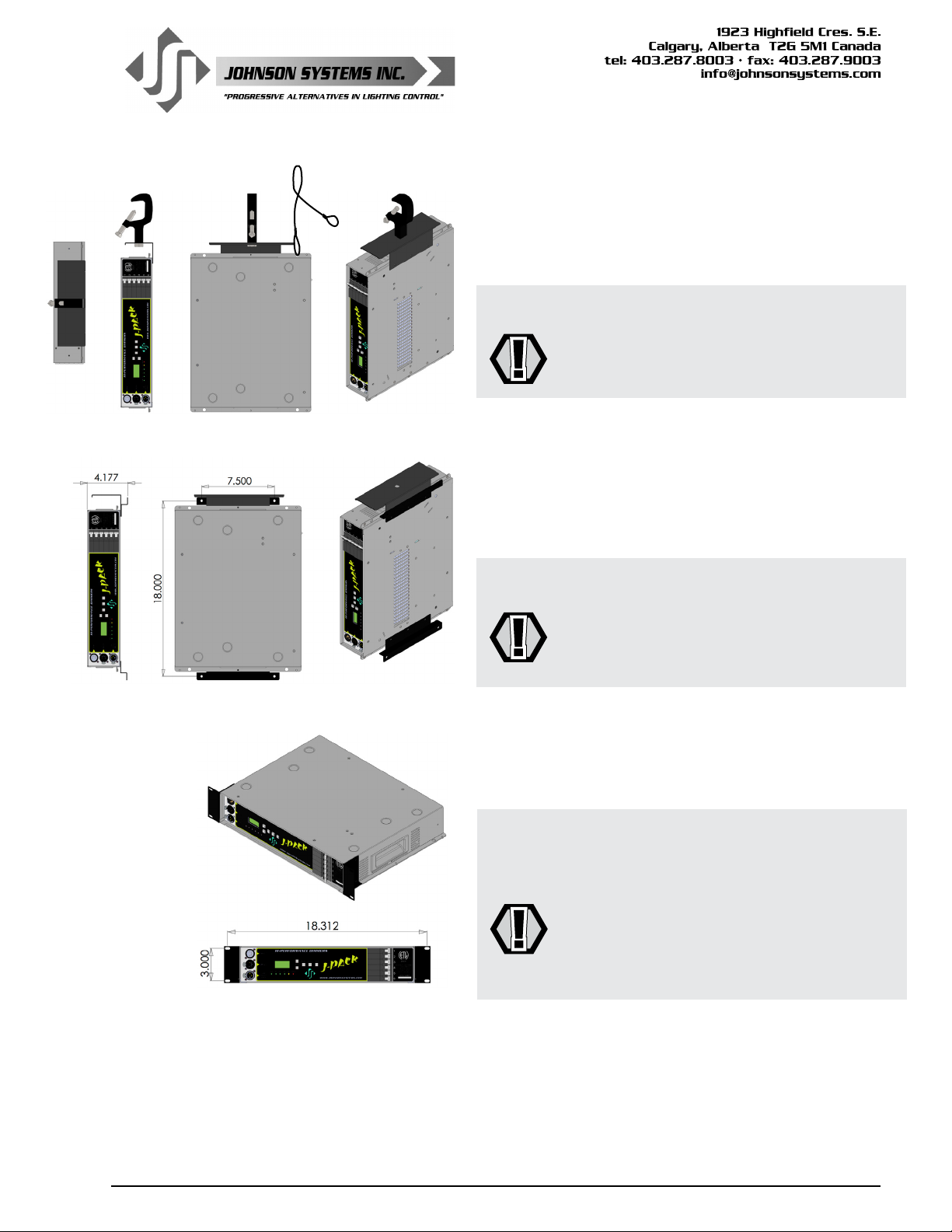

PM = Pipe Mount

For pipe mounting, a bracket, C-clamp and safety cable are

provided and must be used to secure the dimmer pack to

standard pipe sizes from 1" to 2" (1.25" to 2.375" outside

diameter).

WARNING: Ensure the pipe is secure and rated adequately

for local rigging codes.

Ensure the safety cable is fastened correctly to

secure the dimmer pack.

WM = Wall Mount

For permanent applications, the dimmer pack can be mounted

to any wall surface capable of supporting its weight. Using the

four (4) mounting holes provided, 1/4" (6mm) screws or bolts

are required to fasten and secure the rack safely to the wall.

WARNING: Never mount the dimmer packs side by

side (vertically) without a minimum of 12"

of clearance between them. Always leave a

minimum of 6" of clearance from the dimmer

packs air intake and exhaust. Failure to comply

may cause thermal overheating.

RM = Rack Mount

For rack mounting, brackets are provided and used to secure

the dimmer pack in a standard 19" rack.

WARNING: Ensure there is sufcient ventilation provided

when mounting multiple dimmer packs within a

19" rack. The internal ambient temperature of

the rack must not exceed 104°F (40°C). Failure

to comply may cause thermal overheating.

Ensure there is adequate rear support provided

to maintain the dimmer pack position inside the

19" rack.

WWW.JOHNSONSYSTEMS.COM 7

AC Power Supply

Input Terminals

AC Power Supply Input Options

J-PACK Series dimmer packs are capable of various 120VAC power supply input

congurations.

Remove the top panel (lid) of the dimmer pack chassis to access the contractor

termination area, where the required AC power supply input terminals are

located. To remove the top panel (lid), remove the ten (10) SEMS #6-32 x 3/8"

Philips pan head mountings screws located on the sides and the six (6) #6-

32 x 3/8" Philips at head mounting screws located on the top, using a Philips

#2 screwdriver, and carefully lift the lid up. The cooling fan is mounted on the

lid, so be careful not to strain the fan wiring cable. If the fan cable needs to

be disconnected, carefully cut off the strain relief wire tie and unplug the fan

connector from the J10 PCB connector. Be sure to save the mounting screws to

secure the top panel (lid) once the AC power supply input wiring termination is

complete.

A 1.109" knockout (suitable for 0.75" conduit) located on the rear panel of the

relay pack chassis is provided for wire/conduit entry to the AC power supply

input terminals. Ensure an adequate tting is used to secure the conduit to the

rear panel. Only use wire rated for the specications provided. Route the wire

directly from the conduit entry into the power terminals. Use a 3/16" athead

screwdriver to torque the power terminals to the specications provided.

Once the AC power supply input wiring termination is complete, carefully

reinstall the top panel (lid). If the cooling fan cable was disconnected, be sure

to reconnect it to the J10 PCB connector, and install a wire tie for strain relief.

Carefully slide the lid down into place, making sure the fan cable does not get

pinched in the metalwork. Secure the lid using the mounting screws previously

removed. To ensure ground continuity between all chassis panels, be sure to use

the SEMS mounting screws with integral star washers on the sides.

WARNING: All wiring must comply with local electrical codes and be

completed by qualied personnel only!

WARNING: For connection use copper wire only, rated for 167ºF (75ºC)

minimum!

WARNING: All AC power supply input options require an external disconnect!

WARNING: Ensure the AC power supply external disconnect is turned off and

locked out while wiring terminations are completed!

WARNING: For permanent installations, the external disconnect must be

located adjacent to the equipment.

AVERTISSMENT: Pour les installations permanentes, le débrancher externe

doit être trouvé adjacent à l'équipement.

8

WWW.JOHNSONSYSTEMS.COM

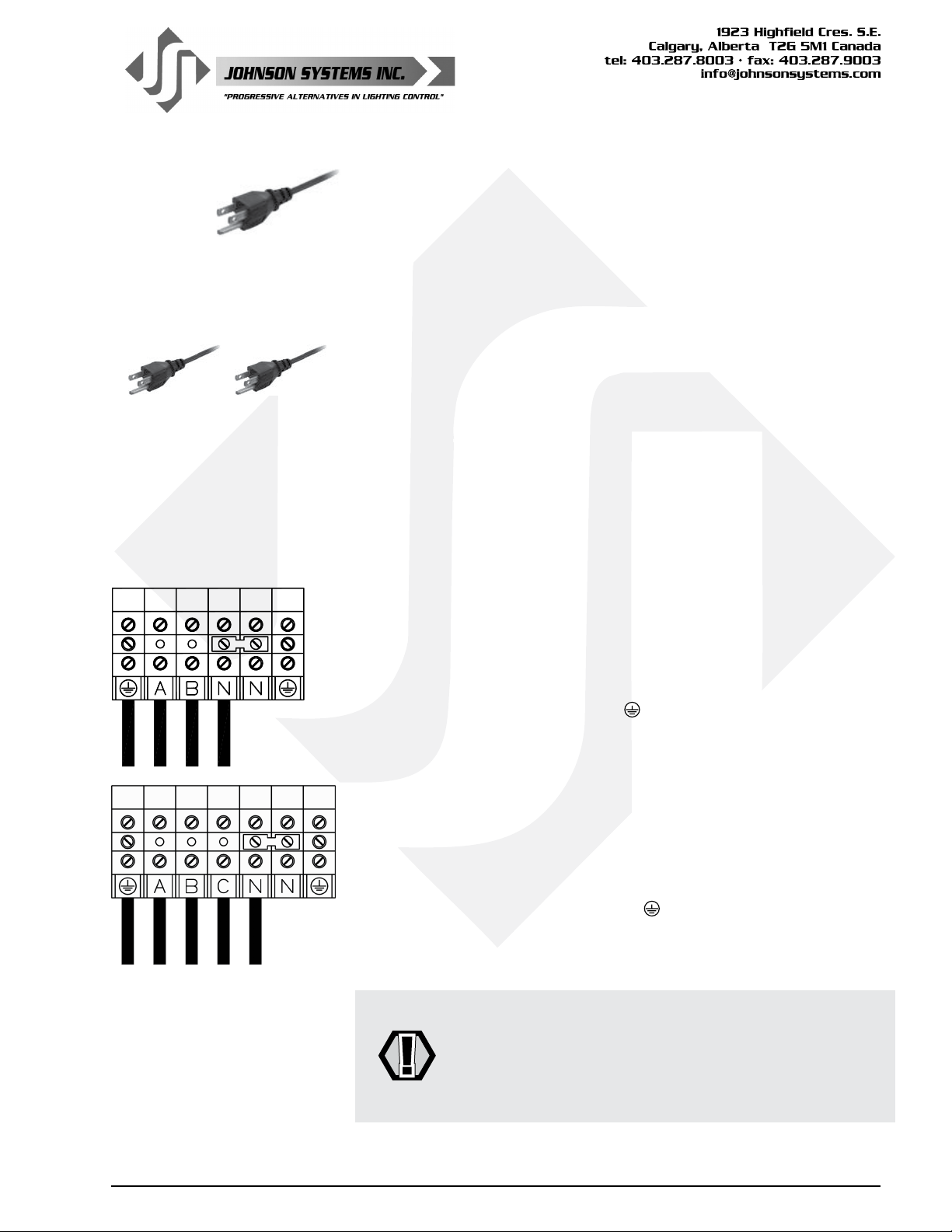

120 = 120VAC 1Ø 3-Wire via a Single 5' Edison Power Cord

Includes a single factory installed 5' (1.5m) Edison power cord. Connect the

cables to a standard Edison (NEMA 5-15) receptacle, protected with a circuit

breaker rated at a maximum of 15 Amps.

• Up to 15 Amps – maximum 1,800W total.

• Internal electrical wiring termination is not required.

• Available only with Duplex Edison output connectors/receptacles.

120 = 120VAC 1Ø 3-Wire via Dual 5' Edison Power Cord

Includes two (2) factory installed 5' (1.5m) Edison power cords. Connect the

cables to standard Edison (NEMA 5-15) receptacles, each protected with a

circuit breaker rated at a maximum of 15 Amps.

• 2 circuits of up to 15 Amps – maximum 3,600W total.

• Internal electrical wiring termination is not required.

• Dimmers 1, 3 and 5 are powered from a single power cord.

• Dimmers 2, 4 and 6 are powered from a single power cord.

• Available only with Duplex Edison (NEMA 5-15) output connectors/

receptacles.

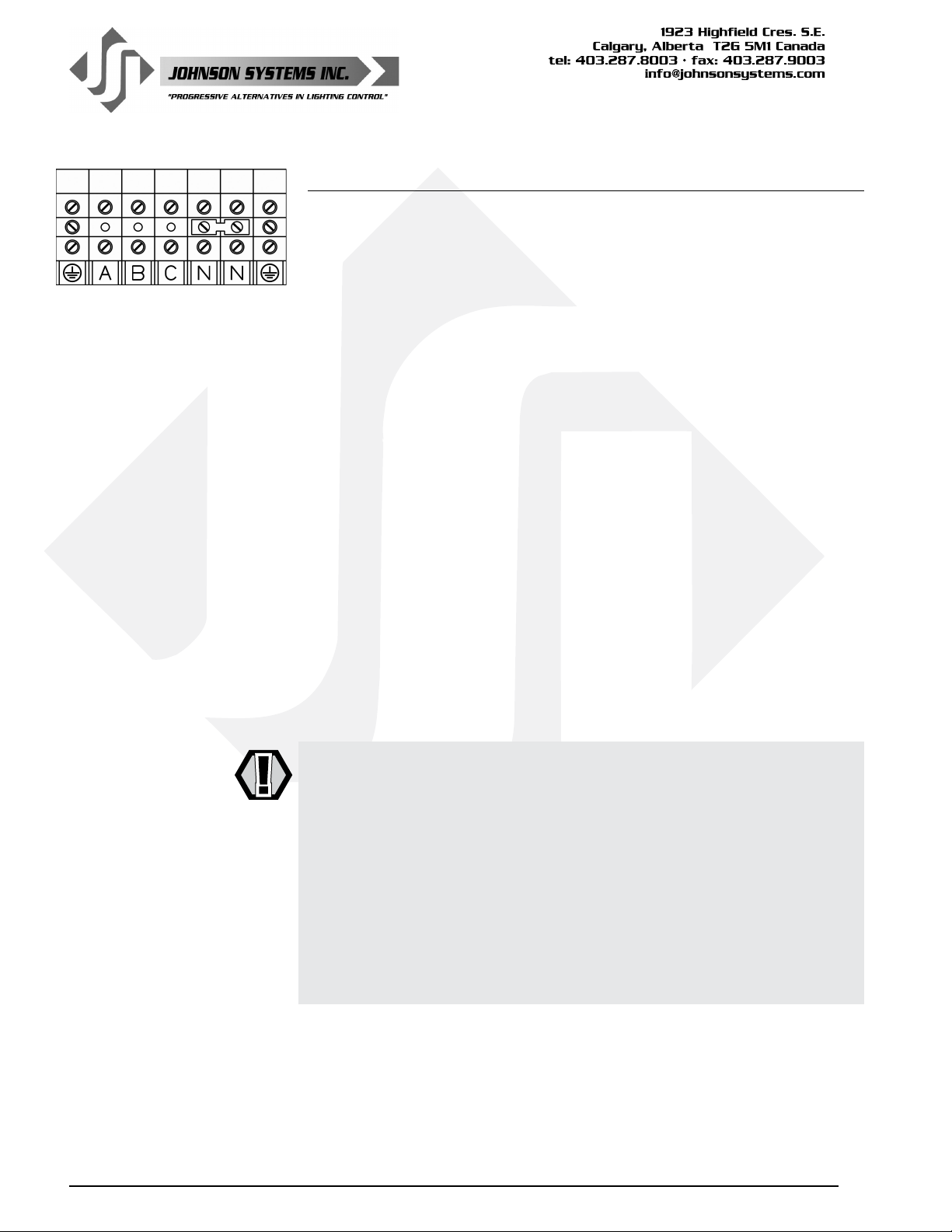

120/240 = 120/240VAC 1Ø 4-Wire Terminal Block

• Up to 40 Amps per phase – maximum 9,000W total.

• Use wire size #12 to #4 AWG copper wire only, rated for 167°F (75°C)

minimum.

• Strip insulation length to 0.44" (11mm).

• Torque power terminals (A, B, N, ) to 10.5 IN-LBS (1.2 NM).

• Dimmers 1, 3 and 5 are powered from Phase A.

• Dimmers 2, 4 and 6 are powered from Phase B.

120/208 = 120/208VAC 3Ø 5-Wire Terminal Block

• Up to 30 Amps per phase – maximum 9,000W total.

• Use wire size #12 to #4 AWG copper wire only, rated for 167°F (75°C)

minimum.

• Strip insulation length to 0.44" (11mm).

• Torque power terminals (A, B, C, N, ) to 10.5 IN-LBS (1.2 NM).

• Dimmers 1 and 4 are powered from Phase A.

• Dimmers 2 and 5 are powered from Phase B.

• Dimmers 3 and 6 are powered from Phase C.

WARNING: Ensure all AC power supply connections are tightened to the

torque specication provided, before turning on the AC power

supply!

Ensure all chassis panels are secure before turning on the AC

power supply!

WWW.JOHNSONSYSTEMS.COM 9

Output Connector/Receptacle Options

J-PACK Series dimmer packs are designed for high performance dimming of standard

incandescent, quartz, and dimmable (SCR/Leading-Edge) electronic low-voltage xtures. The

dimmer outputs may be congured for non-dimmed applications when switched (relay controlled)

load outputs are required. Six (6) 1,560 Watt dimmer output circuits are fully protected by

premium 13 Amp hydraulic magnetic circuit breakers. Each of the dimmer outputs are connected

via various optional output connectors/receptacles.

120VAC Operation with Factory Installed Single or Dual Edison Power Cord

Capable of dimming six (6) 1,560 Watt dimmer output circuits, fully protected by premium 13 Amp

hydraulic magnetic circuit breakers. Powered with single or dual 120VAC 1Ø 3-Wire, each hot leg

is dimmed independently through six (6) Solid State Relays (SSR). J-PACK Series dimmer packs

supplied with a factory installed single (1) Edison power cord are capable of dimming a total of

1,800 Watts shared between the six (6) Duplex Edison output connectors. J-PACK Series dimmer

packs supplied with factory installed dual (2) Edison power cords are capable of dimming a total

of 3,600 Watts shared between the six (6) Duplex Edison output receptacles.

120VAC Output Receptacle with Factory Installed Single or Dual Edison Power Cord

• ED = 15A Duplex Edison (NEMA 5-15)

120VAC Operation

Capable of dimming six (6) 1,560 Watt dimmer output circuits, fully protected by premium 13 Amp

hydraulic magnetic circuit breakers. Powered with 120/240VAC 1Ø 4-Wire or 120/208VAC 3Ø

5-Wire, each hot leg is dimmed independently through six (6) Solid State Relays (SSR). Capable

of dimming a total of 9,000 Watts shared between the six (6) output connectors/receptacles.

120VAC Output Connector/Receptacle Options

• SP = 20A Stage Pin (Bates)

• TL = 20A Twist Lock Ground (TLG) (NEMA L5-20R)

• SO = 19-Pin Socapex

• TB = Terminal Block

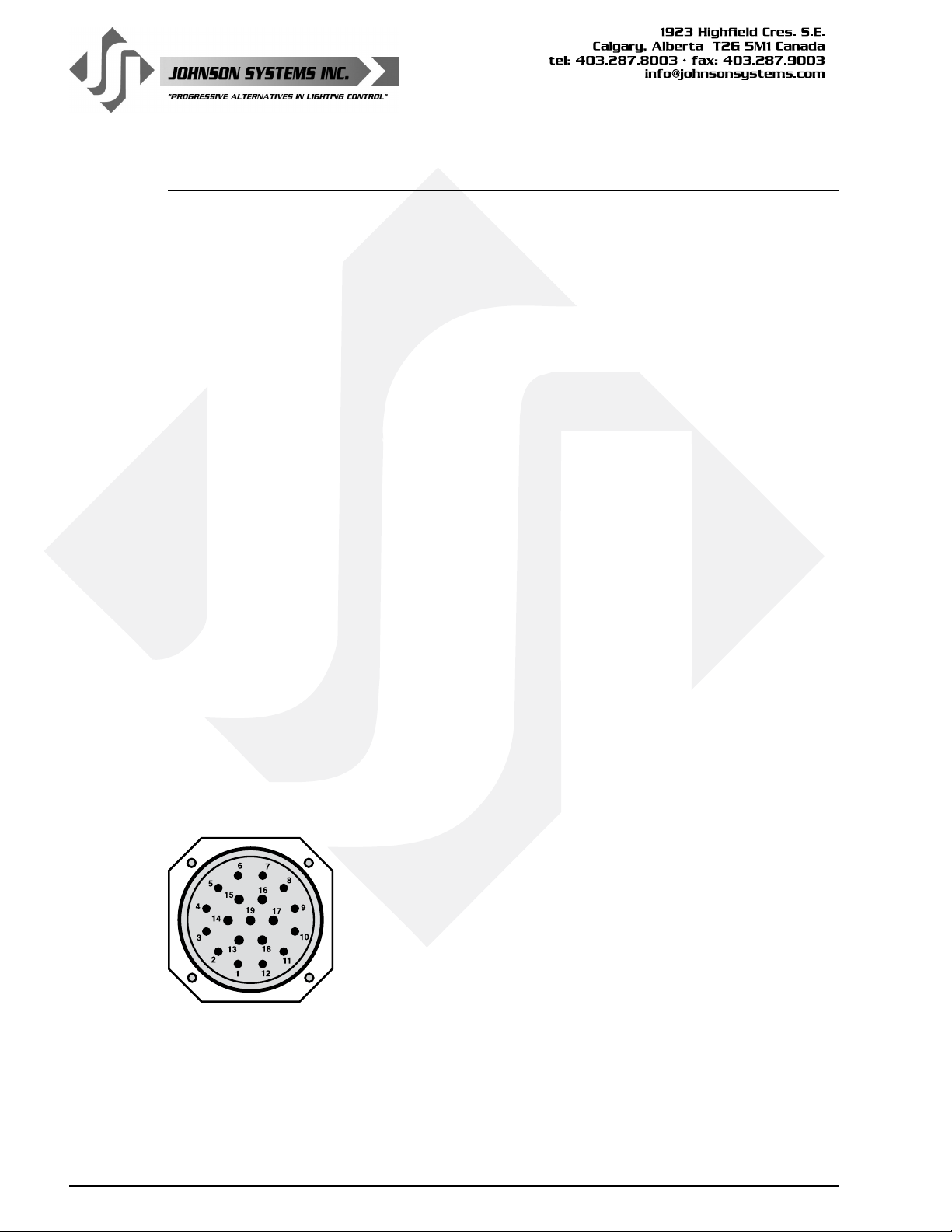

19-Pin Socapex Connection Details (Pinout)

Pin 1 = Circuit 1 Hot

Pin 2 = Circuit 1 Neutral

Pin 3 = Circuit 2 Hot

Pin 4 = Circuit 2 Neutral

Pin 5 = Circuit 3 Hot

Pin 6 = Circuit 3 Neutral

Pin 7 = Circuit 4 Hot

Pin 8 = Circuit 4 Neutral

Pin 9 = Circuit 5 Hot

Pin 10 = Circuit 5 Neutral

Pin 11 = Circuit 6 Hot

Pin 12 = Circuit 6 Neutral

Pin 13 = Circuit 1 Ground

Pin 14 = Circuit 2 Ground

Pin 15 = Circuit 3 Ground

Pin 16 = Circuit 4 Ground

Pin 17 = Circuit 5 Ground

Pin 18 = Circuit 6 Ground

Pin 19 = Not Used

10

WWW.JOHNSONSYSTEMS.COM

Loading...

Loading...