User Manual

EDI-120

Control Retrofit for

Electronics Diversified Inc. (EDI)

Mark VII Dimmer Racks

JOHNSON SYSTEMS INC.

www.johnsonsystems.com

Contents

Warranty ..........................................................................................................2

Introduction ......................................................................................................3

Packaging & Contents .....................................................................................4

Dimensional Drawings .....................................................................................4

Installation .......................................................................................................5

OEM Connector Pinouts ................................................................................10

Control Input/Output Connections ................................................................. 11

EEPROM Memory Module ............................................................................13

User Interface ................................................................................................14

LCD Display...................................................................................................14

Programming Switches..................................................................................14

System Status • LED Indicators ....................................................................15

System Status • LCD Display ........................................................................15

Quick Programming Reference to System Conguration Menu Items ..........17

Detailed Programming of System Conguration Menu Items........................18

Important Hard-key Information .....................................................................33

Troubleshooting Reference ...........................................................................34

Warranty

The EDI-120 retrot control system comes with a standard one (1) year

limited warranty against defects in parts and workmanship. Extended

warranties of up to ten (10) years are available at the time of purchase.

For details visit http://www.johnsonsystems.com/warranties.htm

For Technical Assistance

1. Refer to your product user manual. The most current revision is

available online: www.johnsonsystems.com/literature.htm

2. Contact the “point-of-sale” dealer or distributor from which this product

was originally purchased, and ask for technical assistance.

3. If neither of the above can provide you with the necessary information,

please contact our factory via email (info@johnsonsystems.com)

or phone (403-287-8003) during business hours (Monday to Friday,

8:00AM to 5:00PM MST).

2

www.johnsonsystems.com

EDI-120

(Installed)

Introduction

The EDI-120 is a next generation retrot electronics

package designed specically for upgrading the

EDI Mark VII performance dimmer racks making

system replacement completely unnecessary. This

full-featured, ETL approved, state-of-the-art unit

provides a direct digital interface to most of today’s

modern lighting communication protocols.

Designed to install in minutes with only simple

hand tools, this compact and elegant package has

been designed for longevity and reliability with

the end-user in mind. Intuitive LCD user interface

combined with a single modular design makes

the EDI-120 extremely user-friendly and easily

serviceable. Advanced next generation hardware

and software designs reduce stand-by power

consumption to less than 1 Watt, allowing for compliance with the

International Energy Agency’s “One Watt Initiative” for standby

power consumption.

Rackmount Locations (x4)

Full featured, hi-resolution dimming with ultra-fast response.

Exclusive “lamp warming” techniques extends lamp life considerably.

An environmentally and nancially responsible solution that offers

unsurpassed high performance in a matter in minutes!

System Status LED Indicators

LCD Display

Programming Switches

www.johnsonsystems.com 3

Packaging & Contents

Each EDI-120 retrot control system is shipped in a custom designed box and packaging for

protection of the unit. It’s recommended to keep the box and packaging stored in a safe place. In

the unlikely event that the system needs to be returned to the JSI Factory, the packaging will help

prevent shipping damage and maintain warranty.

Each EDI-120 retrot control system includes all of the parts required to complete the retrot.

Parts included with the EDI-120 retrot control system:

• 10’ (3m) Belden 9829 (or equivalent) length of cable used to extend existing DMX cable(s).

• Two (2) 3-position breakaway connectors used to splice the existing DMX cable(s) to the

supplied DMX cable.

• Four (4) 1’ (30.5cm) extension ribbon cables used to extend the OEM P3, P4, P5 and P6

ribbon cables.

• 8’ (2.4m) #18 AWG green wire used to connect the EDI-120 retrot control system chassis to

earth ground.

• 5’ (1.5m) #18AWG yellow and brown wires used to connect the fan control wiring from the

OEM P1 connector to the fan SSR. Typical installations already contain the control wiring

within the OEM P1 connector wiring, and these wires are not required.

• 10’ (3m) yellow CAT 5e patch cable used to daisy-chain the DMX-A and DMX-B between

multiple EDI-120 retrot control systems. Only supplied when multiple EDI-120 retrot

control systems are purchased.

• Four (4) #10-32 x 3/8” mounting screws used to secure the EDI-120 retrot control system in

the EDI Mark VII dimmer rack.

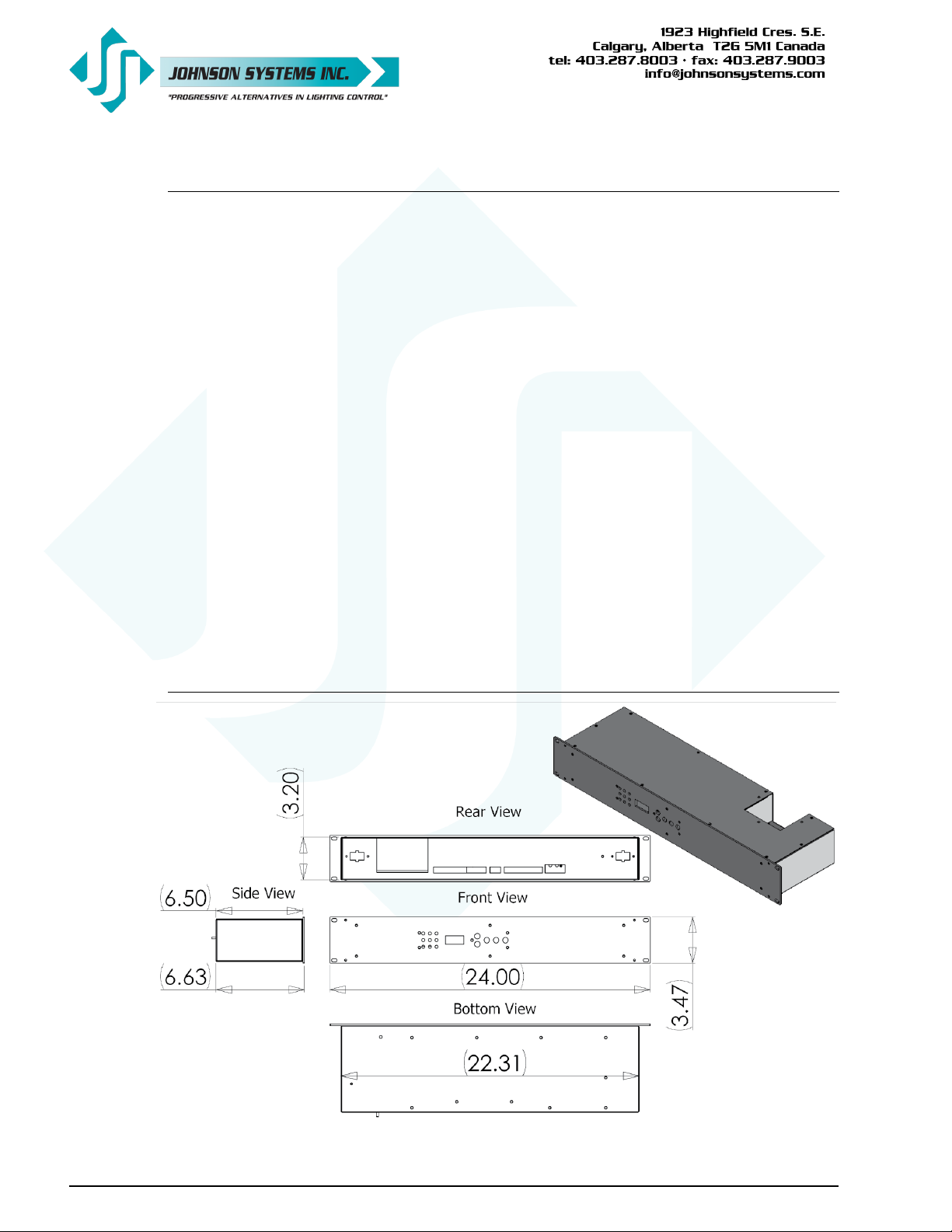

Dimensional Drawings

4

NOTE: All measurements are in inches.

www.johnsonsystems.com

Installation

•

Disconnect (turn off) the power supply to the EDI Mark VII dimmer rack(s).

WARNING! Verify all power is disconnected (turned off) before proceeding.

Removal of the old EDI Control Module

• Remove the four (4) mounting screws securing the EDI Mark VII control

module.

• Carefully pull the control module forward until all of the rear wiring

connections are visible. Do not disconnect any wiring at this point.

• If you are not familiar with the EDI Mark VII control module electronics

and wiring, it is strongly advised that you take a few minutes to inspect

the OEM (Original Equipment Manufacturer) wiring (P1 through P6). If

the cables aren’t already labeled, label them using a permanent marker

(Sharpie).

P1 contains the AC power supply conductors (Neutral, Phase A, Phase

B and Phase C) used to power the control module, as well as the low

voltage fan control wiring (positive DC voltage control and common).

Observe the location of the P1 connector and compare it to the location

of the P1 connector on the EDI-120 retrot. If the P1 connector is

located on the opposite side, refer to the installation of the new EDI-120

retrot system for details.

On some earlier versions of EDI Mark VII dimmer racks, the fan

control was sensed from the house control inputs, and the fan control

wiring does not come through the P1 connector. If this is the case, the

fan control will need to be rewired from the P1 connector to the fan

SSR. More information regarding this modication is provided in the

“Installation of the new EDI-120 retrot system” section of this manual.

P2 contains the eld wiring connections for DMX and analog control.

NOTE: The P2 connection is obsolete when the EDI-120 retrot control

module is installed, and all the eld wiring must be terminated

on the back of the EDI-120 retrot control module. Refer to the

installation of the new EDI-120 retrot system for more details.

P3 contains the PWM output control signals for dimmers 1 through 36.

P4 contains the PWM output control signals for dimmers 25 through 60.

P5 contains the PWM output control signals for dimmers 61 through 96.

P6 contains the PWM output control signals for dimmers 85 through 120.

• All of the internal OEM wiring must remain intact to complete the retrot.

Compare these connections to the ones on the back of the EDI-120

retrot control module. Do not disconnect any wiring until you are

completely satised with how easy this is going to be.

NOTE: Never pull directly on the wires to remove connectors.

www.johnsonsystems.com 5

• Disconnect the P1 power connector/cable. Carefully squeeze the

latches on each side of the connector together to release the connector

and then pull the connector out. Inspect the connector and the

termination of the wires in the connector. Be sure everything looks okay.

• Disconnect the P2 connector/cable. This cable will not be re-used on the

EDI-120 retrot, so once the old control module is removed, it should

be coiled up, wire-tied and carefully set aside inside the dimmer rack,

making sure it is isolated from any AC line voltage.

• Disconnect the P3, P4, P5 and P6 connectors/cables. Again, be sure

not to pull directly on the ribbon cable to remove the connector as this

may cause damage. Carefully pull the connectors straight out.

• The old control module should now be free and clear of all connections,

and can now be completely pulled out of the dimmer rack and set aside.

• With the old control module removed, it is a great opportunity to do

some preventative maintenance. The dimmer rack should be thoroughly

cleaned, vacuumed and sprayed out using compressed air. All of the

AC line and load connections should be inspected and tightened if

necessary.

• Inspect the fan blower and be sure it spins freely. If required,

replacement fans are available.

Installation of the new EDI-120 Retrofit Control System

• Remove your new EDI-120 retrot control system from the box.

• Take a look at the eld wiring connections on the back of the EDI-120

retrot. There is a connector for DMX-A input, a connector for DMX-A

thru, a connector for DMX-B input, a connector for DMX-B thru, a

connector for four (4) 0-10VDC analog inputs, a connector for dry

contact inputs and a connector for +12VDC to power peripheral devices.

All of the eld wiring terminates on these connectors.

• Refer to the “Control Input/Output Connections” section on page 11 and

12 for details.

• On the old EDI control module (Multi-Link), the DMX input came through

the P2 connector. Since this connection/cable is now obsolete, locate

the DMX input and thru (if applicable) cable(s) coming into the dimmer

rack from the eld. Once the cable(s) has been located, disconnect

it. Inspect the cable(s) and ensure it will be long enough to reach the

connectors on the EDI-120 retrot, once it is installed. Two (2) 3-position

breakaway connectors and a 10’ (3m) Belden 9829 (or equivalent)

length of cable is supplied for extending the cable(s) if it isn’t long

enough. The cable(s) can now be dressed out and terminated on the

DMX-A input and DMX-A thru (if applicable) breakaway connectors

provided. Be sure to isolate and protect all shield wires and comply with

standard RS-485 termination practices.

• On the old EDI control module, the 0-10VDC analog inputs came

through the P2 connector. Since this connection/cable is now obsolete,

locate the analog input cable(s) coming into the dimmer rack from

the eld. Note the EDI-120 retrot only has four (4) 0-10VDC analog

inputs, versus ten (10) on the old control module. Once the analog input

cable(s) have been located, disconnect them. If required, extend the

cables. The cable(s) can now be dressed out and terminated on the

analog input breakaway connector provided.

6

www.johnsonsystems.com

If more than four (4) analog inputs are required, additional equipment may be necessary to

facilitate them. Consult the factory for options and further information.

• Dress out and terminate any applicable connections for the input/output contacts on the

breakaway connector provided.

• Dress out and terminate any applicable +12VDC power supply connections on the

breakaway connector provided.

• The intention is for the DMX input receptacle (5-pin male XLR) on the front of the EDI

dimmer rack to be connected to the DMX-B input on the EDI-120 retrot. To do this, the

existing wires connected to the XLR must be disconnected, and an applicable length of the

supplied 10’ (3m) Belden 9829 (or equivalent) cable must be reconnected to the XLR on one

end, and terminated on the DMX-B input breakaway connector provided on the other end.

Be sure to isolate and protect all shield wires and comply with standard RS-485 termination

practices.

Alternatively, the DMX-B input and thru connectors can be used for other purposes.

• Conrm all applicable eld wiring is terminated on the breakaway connectors provided. For

future reference, be sure all cables are labeled using a permanent marker (Sharpie).

• Inspect the OEM P3, P4, P5 and P6 ribbon cables and determine if they are long enough

to easily connect to the EDI-120 retrot. Four (4) 1’ (30.5cm) extension ribbon cables have

been provided to extend the OEM ribbon cables for ease of installation. When connecting,

be sure the OEM ribbon cable connector is fully seated in the provided extension ribbon

cable connector.

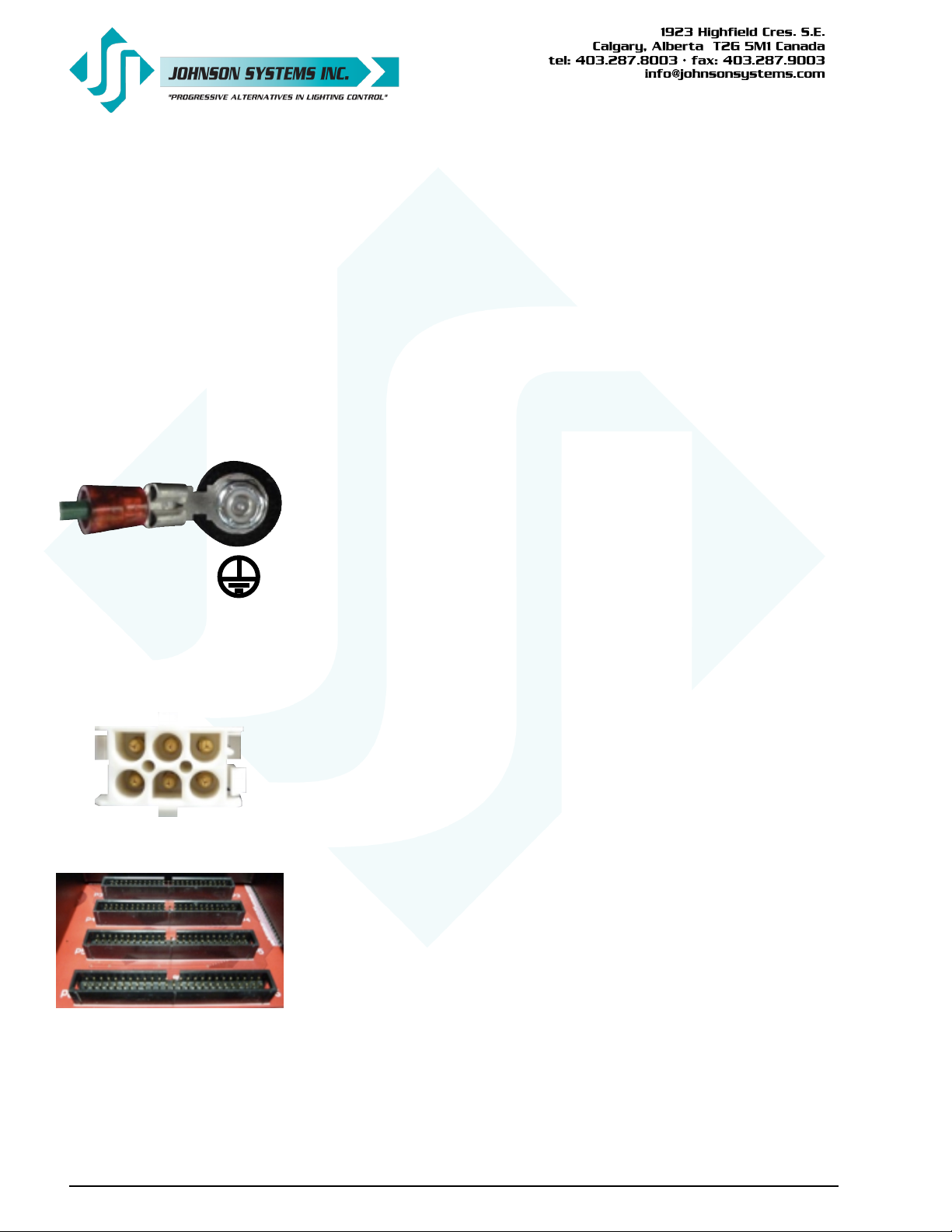

• An 8’ (2.4m) #18 AWG green wire has been provided for connection of earth ground to the

EDI-120 chassis. One end of the ground wire has a 0.250” female disconnect, and connects

to the male on the back of the EDI-120 retrot. Locate a place inside the dimmer rack

chassis to connect the other end of the ground wire. Cut the wire to length, dress it out and

connect (fasten) it to the dimmer rack chassis.

WARNING: Ensure chassis is connected to earth ground.

• On some earlier versions of EDI Mark VII dimmer racks, the fan control was sensed from the

house control inputs, and the fan control wiring does not come through the P1 connector. If

this is the case, the fan control will need to be rewired from the P1 connector to the fan SSR.

5’ (1.5m) #18AWG yellow and brown wires have been provided to implement fan control

from the EDI-120 retrot via the P1 connector to the fan SSR. For the yellow (fan control V+)

wire, the female pin on the one end inserts into pin 5 of the P1 connector and the other end

terminates to V+ on the fan SSR. For the brown (fan control V- (common)) wire, the female

pin on the one end inserts into pin 6 of the P1 connector and the other end terminates to V(common) on the fan SSR. Refer to page 10 for the P1 power connector pinout information.

• There are two (2) locations on the back of the EDI-120 retrot where the P1 power

connector/cable can be installed - one (1) on the right-hand side and one (1) on the left-hand

side. When looking at the EDI-120 from the rear view, the P1 connector is installed on the

left-hand side location (more common) by the factory. Have a look at which side the power

cable comes out in the dimmer rack and determine if the P1 connector needs to be moved to

the right-hand side location.

www.johnsonsystems.com 7

Ensure chassis is

connected to earth

ground.

POWER SUPPLY INPUT

120/208VAC, 3P4W, 1.3A, 60Hz

120/240VAC, 1P3W, 1.3A, 60Hz

EXTERNAL DISCONNECT REQUIRED

P1

If the connector needs to be moved, follow the following procedure:

First, remove the ten (10) #4-40 x 1/4” mounting screws that fasten the

lid onto the EDI-120 chassis. Remove the lid and set it aside, along

with the screws. Remove the metal cover plate on right-hand side P1

location by unscrewing the two (2) #4-40 x 1/4” mounting screws. Set

the cover plate aside, along with the screws. Release the P1 power

connector by carefully squeezing the tabs on each side of the connector

together and pushing the connector back. Cut and remove the wire-tie

securing the cable to the EDI-120 chassis via the bridge lance located

on the front-side of the chassis. The P1 connector/cable can now be

moved to the right-hand side location. Neatly route the cable and then

clip the P1 connector into place. Be sure the P1 connector is fully

seated and secure. Use a wire-tie to secure the cable to the chassis –

there is a bridge lance located above the power supply on the front-side

of the chassis. Reinstall the cover plate over the P1 connector opening

on the left-hand side of the chassis. Reinstall the lid.

• A 10’ (3m) yellow CAT 5e patch cable is supplied to daisy-chain the

DMX-A and DMX-B between multiple EDI-120 retrot systems, in multirack installations and racks containing more than 120 dimmer circuits. If

applicable, route the cable into place.

• Everything should now we prepared and ready for nal installation of the

EDI-120 retrot.

• Put the EDI-120 retrot into a position where all the eld wiring and

OEM wiring can be plugged in.

• Connect (plug in) in the green ground wire onto the EDI-120 chassis

connector.

• If applicable, connect (plug in) in the yellow CAT 5e patch cable.

• Connect (plug in) the prepared DMX input and thru connectors.

• Connect (plug in) the prepared input/output contacts connector.

• Connect (plug in) the prepared analog input connector.

• Connect (plug in) the prepared +12VDC power supply connector.

• Connect (plug in) the OEM P1 power connector.

• Connect (plug in) the OEM P3, P4, P5 and P6 ribbon cable connectors.

• All of the eld wiring and OEM cables should now be connected

(plugged in).

• Be sure all connections are secure and fully seated.

• Slide the EDI-120 retrot along the guide rails and into place. Be sure

not to pinch any of the cables.

On some earlier versions of EDI Mark VII dimmer racks, the guide rail

opening for the EDI-120 retrot may be much narrower. If this is the

case, the guide rails will need to be removed. Once the guide rails are

removed, the EDI-120 retrot will need to held in place and secured

using the mounting screws provided.

• Secure the EDI-120 retrot using the four (4) #10-32 x 3/8” mounting

screws provided.

8

www.johnsonsystems.com

Turn on and test the new EDI-120 Retrofit System

• Connect (turn on) the power supply to the EDI Mark VII dimmer rack.

• Verify the operation of the system status LED indicators, LCD display

and programming switches.

• Refer to the programming section of this manual for system

conguration.

• Test the system thoroughly to ensure all wiring terminations are

functioning.

• Verify all of the dimmer control outputs have the correct phase

referencing. If a dimmer control output is patched to the incorrect phase

reference, the dimmer will not dim correctly and will go to full output at

around 1% DMX input. The factory conguration for EDI-120 retrot

systems is for 3-phase applications, with the dimmer phase reference

patch set at AABBCCAABBCC... For true single-phase applications

with the phases 180° out of phase from each other, set the default

(DEFAULT) menu phase patch to phase patch 2 (ØPATCH2). The

phase patch (Ø-PATCH) menu must be used to congure non-standard

applications or for single-phase applications with the phases 120° out of

phase from each other.

• Verify the fan blower is operating properly. The fan blower should turn

on with between 6-7% DMX or analog control - when DMX or analog

control drops below 6-7%, there is a 5 minute timeout on the fan blower

blower to ensure the dimmers have been cooled sufciently.

www.johnsonsystems.com 9

OEM Connector Pinouts

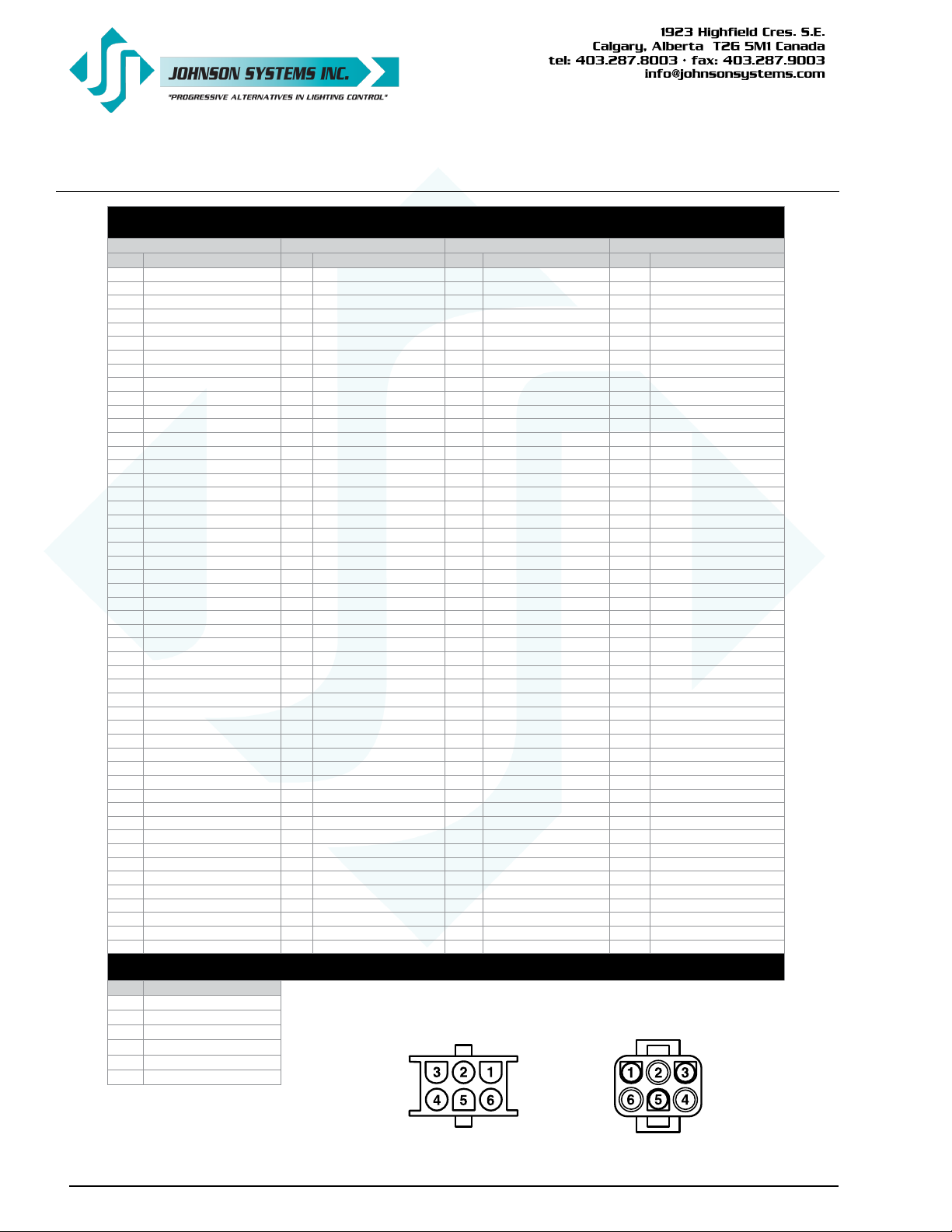

OEM P3, P4, P5 and P6 Dimmer (PWM) Control Cable Pinout

P3 Connector P4 Connector P5 Connector P6 Connector

PIN FUNCTION PIN FUNCTION PIN FUNCTION PIN FUNCTION

1 Dimmer (PWM) 1 1 Dimmer (PWM) 25 1 Dimmer (PWM) 61 1 Dimmer (PWM) 85

2 Dimmer (PWM) 2 2 Dimmer (PWM) 26 2 Dimmer (PWM) 62 2 Dimmer (PWM) 86

3 Dimmer (PWM) 3 3 Dimmer (PWM) 27 3 Dimmer (PWM) 63 3 Dimmer (PWM) 87

4 Dimmer (PWM) 4 4 Dimmer (PWM) 28 4 Dimmer (PWM) 64 4 Dimmer (PWM) 88

5 Dimmer (PWM) 5 5 Dimmer (PWM) 29 5 Dimmer (PWM) 65 5 Dimmer (PWM) 89

6 Dimmer (PWM) 6 6 Dimmer (PWM) 30 6 Dimmer (PWM) 66 6 Dimmer (PWM) 90

7 Dimmer (PWM) 7 7 Dimmer (PWM) 31 7 Dimmer (PWM) 67 7 Dimmer (PWM) 91

8 Dimmer (PWM) 8 8 Dimmer (PWM) 32 8 Dimmer (PWM) 68 8 Dimmer (PWM) 92

9 Dimmer (PWM) 9 9 Dimmer (PWM) 33 9 Dimmer (PWM) 69 9 Dimmer (PWM) 93

10 Dimmer (PWM) 10 10 Dimmer (PWM) 34 10 Dimmer (PWM) 70 10 Dimmer (PWM) 94

11 Dimmer (PWM) 11 11 Dimmer (PWM) 35 11 Dimmer (PWM) 71 11 Dimmer (PWM) 95

12 Dimmer (PWM) 12 12 Dimmer (PWM) 36 12 Dimmer (PWM) 72 12 Dimmer (PWM) 96

13 Dimmer SSR +12VDC 13 Dimmer SSR +12VDC 13 Dimmer SSR +12VDC 13 Dimmer SSR +12VDC

14 Dimmer Overtemp 14 Dimmer Overtemp 14 Dimmer Overtemp 14 Dimmer Overtemp

15 DC Common 15 DC Common 15 DC Common 15 DC Common

16 DC Common 16 DC Common 16 DC Common 16 DC Common

17 Dimmer (PWM) 13 17 Dimmer (PWM) 37 17 Dimmer (PWM) 73 17 Dimmer (PWM) 97

18 Dimmer (PWM) 14 18 Dimmer (PWM) 38 18 Dimmer (PWM) 74 18 Dimmer (PWM) 98

19 Dimmer (PWM) 15 19 Dimmer (PWM) 39 19 Dimmer (PWM) 75 19 Dimmer (PWM) 99

20 Dimmer (PWM) 16 20 Dimmer (PWM) 40 20 Dimmer (PWM) 76 20 Dimmer (PWM) 100

21 Dimmer (PWM) 17 21 Dimmer (PWM) 41 21 Dimmer (PWM) 77 21 Dimmer (PWM) 101

22 Dimmer (PWM) 18 22 Dimmer (PWM) 42 22 Dimmer (PWM) 78 22 Dimmer (PWM) 102

23 Dimmer (PWM) 19 23 Dimmer (PWM) 43 23 Dimmer (PWM) 79 23 Dimmer (PWM) 103

24 Dimmer (PWM) 20 24 Dimmer (PWM) 44 24 Dimmer (PWM) 80 24 Dimmer (PWM) 104

25 Dimmer (PWM) 21 25 Dimmer (PWM) 45 25 Dimmer (PWM) 81 25 Dimmer (PWM) 105

26 Dimmer (PWM) 22 26 Dimmer (PWM) 46 26 Dimmer (PWM) 82 26 Dimmer (PWM) 106

27 Dimmer (PWM) 23 27 Dimmer (PWM) 47 27 Dimmer (PWM) 83 27 Dimmer (PWM) 107

28 Dimmer (PWM) 24 28 Dimmer (PWM) 48 28 Dimmer (PWM) 84 28 Dimmer (PWM) 108

29 Dimmer SSR +12VDC 29 Dimmer SSR +12VDC 29 Dimmer SSR +12VDC 29 Dimmer SSR +12VDC

30 Dimmer Overtemp 30 Dimmer Overtemp 30 Dimmer Overtemp 30 Dimmer Overtemp

31 DC Common 31 DC Common 31 DC Common 31 DC Common

32 DC Common 32 DC Common 32 DC Common 32 DC Common

33 Dimmer (PWM) 25 33 Dimmer (PWM) 49 33 Dimmer (PWM) 85 33 Dimmer (PWM) 109

34 Dimmer (PWM) 26 34 Dimmer (PWM) 50 34 Dimmer (PWM) 86 34 Dimmer (PWM) 110

35 Dimmer (PWM) 27 35 Dimmer (PWM) 51 35 Dimmer (PWM) 87 35 Dimmer (PWM) 111

36 Dimmer (PWM) 28 36 Dimmer (PWM) 52 36 Dimmer (PWM) 88 36 Dimmer (PWM) 112

37 Dimmer (PWM) 29 37 Dimmer (PWM) 53 37 Dimmer (PWM) 89 37 Dimmer (PWM) 113

38 Dimmer (PWM) 30 38 Dimmer (PWM) 54 38 Dimmer (PWM) 90 38 Dimmer (PWM) 114

39 Dimmer (PWM) 31 39 Dimmer (PWM) 55 39 Dimmer (PWM) 91 39 Dimmer (PWM) 115

40 Dimmer (PWM) 32 40 Dimmer (PWM) 56 40 Dimmer (PWM) 92 40 Dimmer (PWM) 116

41 Dimmer (PWM) 33 41 Dimmer (PWM) 57 41 Dimmer (PWM) 93 41 Dimmer (PWM) 117

42 Dimmer (PWM) 34 42 Dimmer (PWM) 58 42 Dimmer (PWM) 94 42 Dimmer (PWM) 118

43 Dimmer (PWM) 35 43 Dimmer (PWM) 59 43 Dimmer (PWM) 95 43 Dimmer (PWM) 119

44 Dimmer (PWM) 36 44 Dimmer (PWM) 60 44 Dimmer (PWM) 96 44 Dimmer (PWM) 120

45 Dimmer SSR +12VDC 45 Dimmer SSR +12VDC 45 Dimmer SSR +12VDC 45 Dimmer SSR +12VDC

46 Dimmer Overtemp 46 Dimmer Overtemp 46 Dimmer Overtemp 46 Dimmer Overtemp

47 DC Common 47 DC Common 47 DC Common 47 DC Common

48 DC Common 48 DC Common 48 DC Common 48 DC Common

49 No Connection 49 No Connection 49 No Connection 49 No Connection

50 No Connection 50 No Connection 50 No Connection 50 No Connection

OEM P1 Power Connector Pinout

PIN FUNCTION

1 Phase A

2 Phase B

3 Phase C

4 Neutral

5 Fan Control V+

6 Fan Control V- (Common)

P1 Chassis Connector

with male pins

P1 Cable Connector

with female pins

10

www.johnsonsystems.com

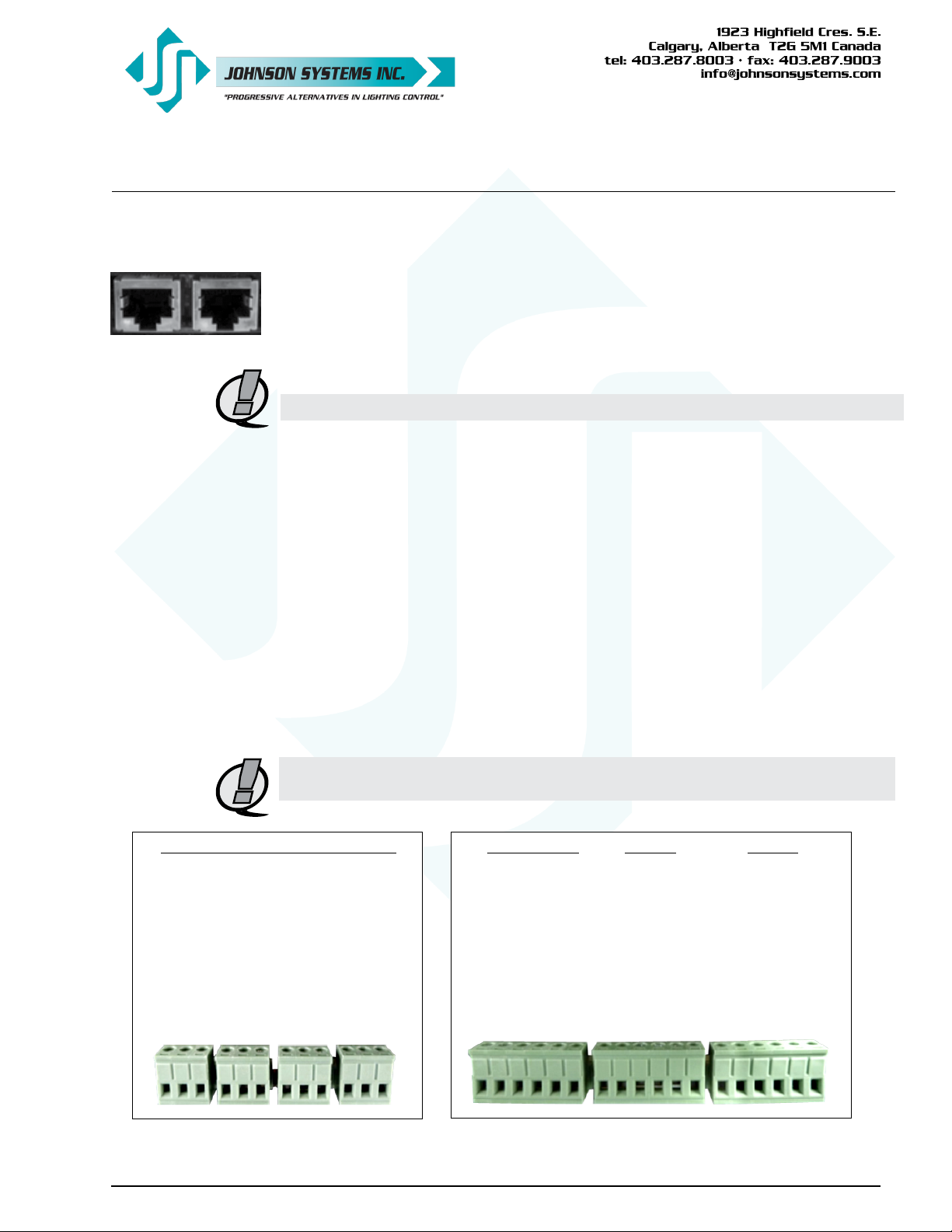

Control Input/Output Connections

DMX-A AND DMX-B

INPUT AND THRU

DAISY-CHAIN MULTI-

RACK INSTALLATIONS

All EDI-120 retrot control systems come with a variety of control input and output (I/O)

capabilities. All I/O connections are terminated on the connectors located at the rear of

the EDI-120 chassis.

Breakaway type connectors are provided for all I/O connections.

• Use wire size #28 to #12 AWG.

• Strip wire insulation length to 0.28” (7mm).

• Use a 1/8” (3.2mm) at head screwdriver to tighten connections.

• Torque connections to 3.5 IN-LBS (0.4 NM).

NOTE: For connection use copper wire only, rated for 167°F (75°C) minimum.

Isolated Dual DMX Input and Thru

• DMX-A (SHIELD/COMMON, DATA-, DATA+) input and thru is terminated on the two 3-position breakaway

connectors provided.

• DMX-B (SHIELD/COMMON, DATA-, DATA+) input and thru is terminated on the two 3-position breakaway

connectors provided.

• For multi-rack EDI-120 installations, a 10’ (3m) CAT 5e patch cable is supplied. This cable is used to daisychain the DMX-A and DMX-B between systems. The CAT 5e patch cable plugs into the RJ45 connectors

located at the rear of the EDI-120 chassis.

• Complies with USITT DMX512-A (ANSI E1.11 - 2008), standard protocol for digital data control.

• Recommended cable is Belden 9829, 9842, Cat 5 or equivalent (low-capacitance, twisted pair).

• Wiring must follow a daisy-chain topology.

• Maximum of 32 receiving devices on a single DMX line.

• Maximum cable length is 1,500 feet (455 meters).

• For more information, Google DMX, or visit: http://old.usitt.org/DMX512FAQ.aspx

NOTE: Ensure only the last (end-of-line) DMX receiving device is terminated! Refer to

menu items “DMXA TRM” and “DMXB TRM” on page 21 for further details.

ISOLATED DUAL DMX INPUT AND THRU

DMX-A

INPUT

SHIELD / COMMON

DMX-A

THRU

DATA -

DATA +

DMX-B

INPUT

SHIELD / COMMON

DATA -

DATA +

SHIELD / COMMON

DATA -

DMX-B

THRU

DATA +

SHIELD / COMMON

DATA -

INPUT/OUTPUT

CONTACTS

COMMON

OVERTEMP INPUT (N.O)

FIRE ALARM (N.O)

SECURITY ALARM (N.O)

DATA +

AUXILIARY INPUT (N.O)

0-10VDC

ANALOG INPUTS

OPEN COLLECTOR OUTPUT

COMMON

+ 12 VDC

ANALOG INPUT 1

+12 VDC

POWER SUPPLY

2 AMPS MAXIMUM

ANALOG INPUT 2

ANALOG INPUT 3

ANALOG INPUT 4

COMMON

COMMON

COMMON

+ 12 VDC

+ 12 VDC

+ 12 VDC

www.johnsonsystems.com 11

Loading...

Loading...