Page 1

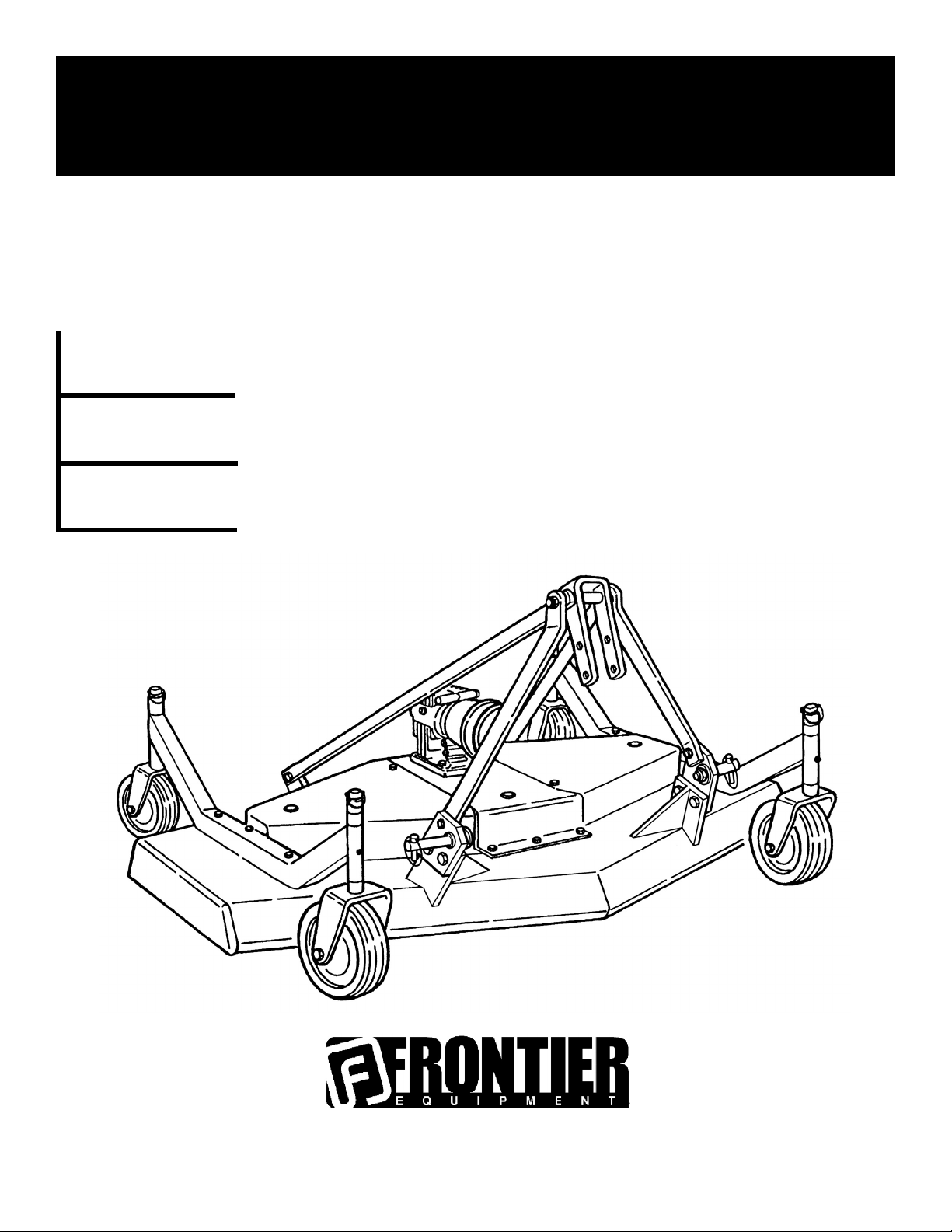

OPE R AT O R’S MAN U A L

GROOMING MOWERS

GM1048E

GM1060E

GM1072E

Manual 5BP960379B

Date 11/11/2010

Page 2

SAFETY

Take note! This safety alert symbol found throughout this manual is used to call your

attention to instructions involving your personal safety and the safety of others. Failure to

follow these instructions can result in injury or death.

This symbol means:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Signal Words

Note the use of the signal words DANGER, WARNING and CAUTION with the safety messages. The

appropriate signal words for each have been selected using the following guidelines:

DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in death or

serious injury, and includes hazards that are exposed when guards are removed. It may also be used

to alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, may result in minor or

moderate injury.

Page 3

INDEX

1 - GENERAL INFORMATION

2 - SAFETY PRECAUTIONS

3 - OPERATION

4

41.01 - General

41.02 - Warranty Information

51.03 - Model and Serial Number ID

51.04 - Assembly Instructions

71.05 - Quick Hitch Adapter Assembly and Operation

10

102.01 - Preparation

112.02 - Starting and Stopping

112.03 - Messages and Signs

14

143.01 - Operational Safety

163.02 - Set Up

173.03 - Cutting Height Adjustment

183.04 - Pre-Operational Check

183.05 - Attaching to the Tractor

193.06 - Start Up

4 - MAINTENANCE

5 - REPAIR PROCEDURES

203.07 - Working Speed

213.08 - Operating Techniques

223.09 - Uneven Terrain

233.10 - Removing Mower from the Tractor

233.11 - Transport

24

244.01 - Maintenance Safety

254.02 - Service

264.03 - Blade Maintenance

284.04 - Belt Tension

294.05 - Belt Replacement

304.06 - Driveline

33

335.01 - Gearbox

335.02 - Blade Spindle

335.03 - Suggested Spare Parts

345.04 - Storage

6 - TROUBLESHOOTING

7 - PRE-DELIVERY CHECKLIST

PARTS MANUAL

INDEX 3 FRONTIER

35

36

37

Page 4

GROOMING MOWERS OPERATOR’S MANUAL

1 - GENERAL INFORMATION

Thank you and congratulations for having chosen our implement. Your new grooming

mower is a technologically advanced machine constructed of high quality, sturdy

components that will fulfill your working expectations. Read this manual carefully. It will

instruct you on how to operate and service your mower safely and correctly. Failure to

do so could result in personal injury and/or in equipment damage.

1.01 - General

The implement described in this manual is to be used with tractors with PTO at 540 rpm

and clockwise rotation.

CAUTION: Always ensure that the coupling of the implement with the tractor is

done at the same PTO speed and direction of rotation. Do not operate this

implement at a PTO speed or direction of rotation other than that shown on the

implement. Serious damage can occur to the machine and/or the operator.

CAUTION: Unless otherwise specified, all hardware is metric. Use only metric

tools on metric hardware. Other tools that do not fit properly can slip and cause

injury.

CAUTION: Right hand and left hand sides of the implement are determined by

facing in the direction the implement will travel when going forward (see fig. 5).

1.02 - Warranty Information

Warranty coverage is provided by John Deere according to the terms of the

Agricultural/Commercial & Consumer Equipment Warranty Statement. Carefully read

the warranty statement on the back of your original purchase order for details on

coverage and limitations of this warranty.

Your Authorized Company Dealer has genuine parts in stock. Only these approved

replacement parts should be used.

GENERAL INFORMATION 4 FRONTIER

Page 5

GROOMING MOWERS OPERATOR’S MANUAL

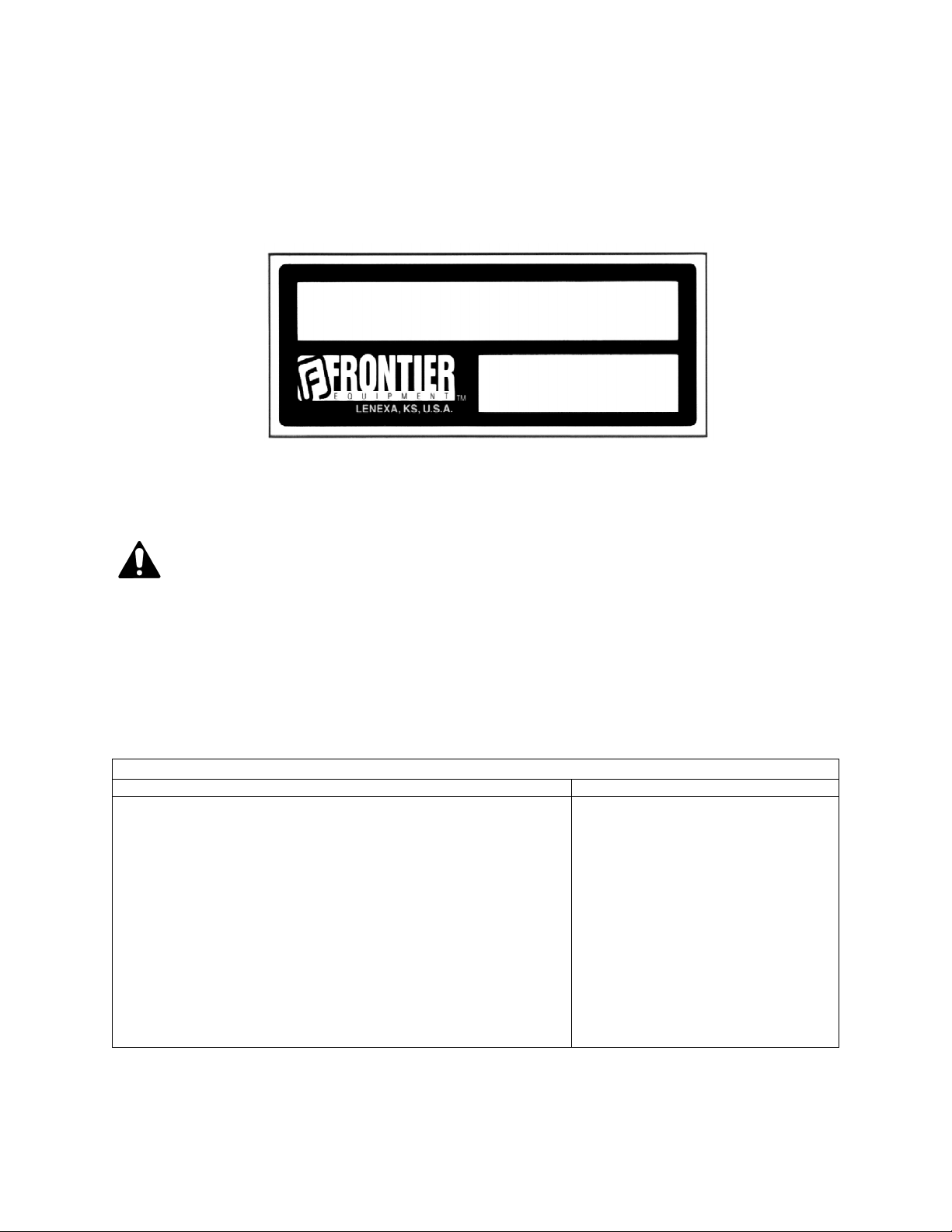

1.03 - Model and Serial Number ID

Attached to the frame is an ID plate showing the model and the serial number. Record

your implement model and serial number in the space provided below. Your dealer

needs this information to give you prompt, efficient service when you order parts.

1.04 - Assembly Instructions

CAUTION: Stand clear of bands when cutting as they could be under sufficient

tension to cause them to fly loose. Take care in removing bands and wire. They

often have extremely sharp edges and cut very easily.

Note: All hardware needed for assembly will be found in the hardware bag or on the

machine. Assembly will be easier if all parts are loosely assembled before tightening the

hardware.

Each unit is shipped in a crate as a kit that consists of the following:

Description

Hardware bag contains the following:

Parts used to assemble wheels:

Parts used to assemble wheel arm:

Q.ty

1Main frame assembly

2Top hitch arms

2Wheel arms w/yokes

4Wheels

1Driveline

4 Bolt HH M14-2.00x140 C8.8 Z P (#5BP0006615)

4 Nut PT M14-2.00 C6 Z TK (#5BP0030358)

4 Wheel spacer (#5BP0008528)

6 Bolt HH M10-1.50x90 C8.8 Z P (#5BP0026185)

6 Washer flat Ø11 W (#5BP0051776)

6 Washer flat Ø10 W (#5BP0002034)

6 Washer lock Ø10 Z (#5BP0001280)

6 Nut HH M10-1.50 C6 TK Z (#5BP0001279)

GENERAL INFORMATION 5 FRONTIER

Page 6

GROOMING MOWERS OPERATOR’S MANUAL

4

1

5

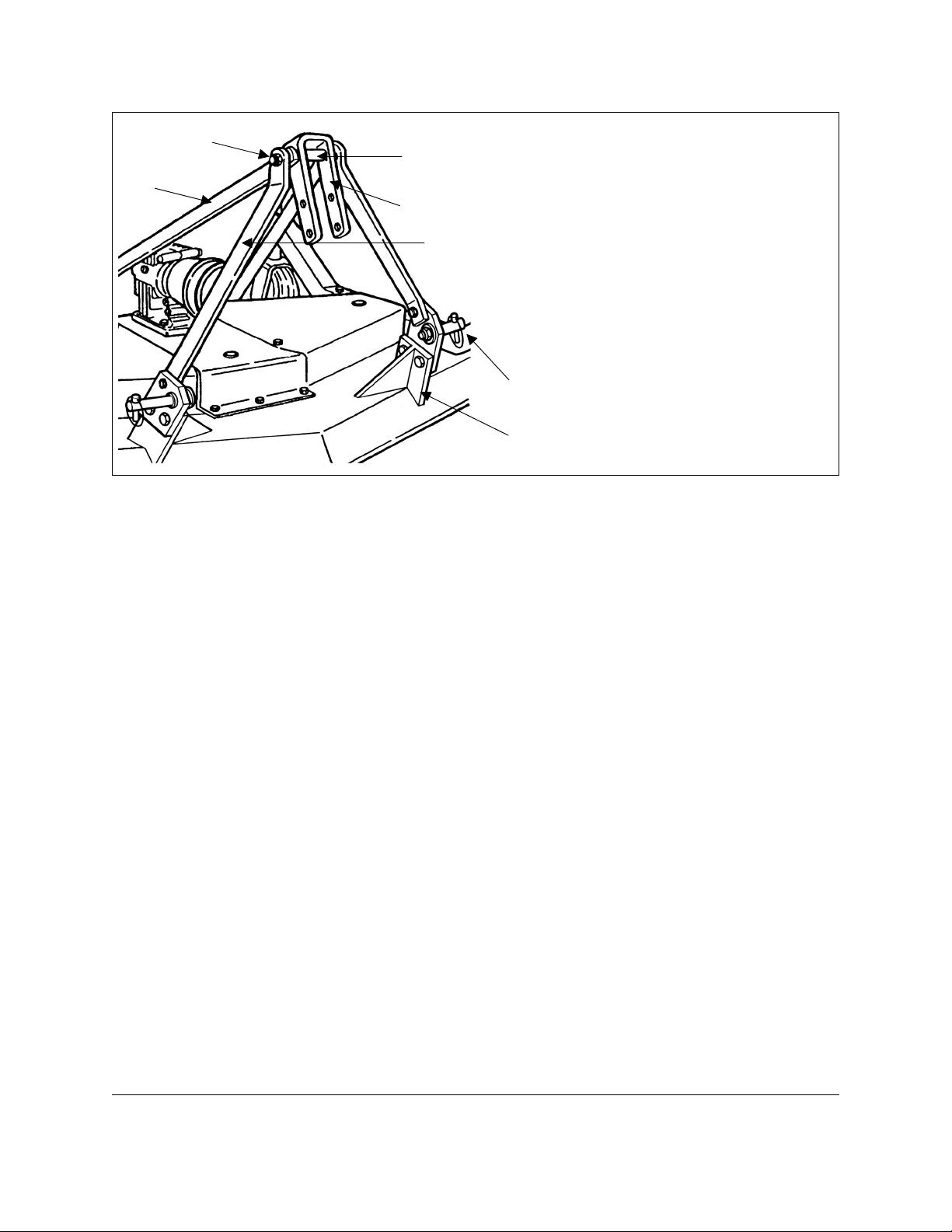

Fig. 2

1. inner spacer

2. top hitch plate

2

3. top hitch support

3

4. bolt

5. top hitch arm

6. linking plate

7. front support plate

6

7

To assemble the mower proceed as follows:

1. Unbolt the wheel arms and discard the mounting bracket.

2. Separate the wheel arms and remove the hardware bag secured between them.

3. IMPORTANT: Remove the belt shields to inspect around the belt area and

under the gearbox central plate to be sure the area is clear of packing material

such as blocks of wood, paper, etc.

4. Bolt the wheel arm assemblies to the mower deck with the flat washer and locknuts.

There is no difference between left/right or front/rear. Be sure both assemblies are

securely mounted.

5. Assemble each wheel to the yokes with one M14x140 bolt and one inner bushing.

Tighten down snugly. The wheel should turn freely but have no side to side

movement.

6. Replace the belt shields.

7. Bolt up the top hitch arms (see #5, fig. 2 & 3) to the outside of the rear support

plates on the rear of the mower (see #8, fig. 3).

8. Bolt up the top hitch supports (see #3, fig. 2 & 3) to the inside of the linking plates

(see #6, fig. 2) that are already bolted to the outside of the front support plates (see

#7, fig. 2).

9. Bolt up the top hitch plate (see #2, fig. 2 & 3) with the M16x140 bolt. It should be

bolted as follows: bolt, top hitch support, top hitch arm, top hitch plate, spacer, top

hitch plate, top hitch arm, top hitch support, locknut. Tighten the locknut down

securely, the top hitch plate should be able to swivel 360°.

10.Grease, wheel arms, and spindles. Check the gearbox for oil. It should be

approximately ½ filled.

11.Install driveline and ensure it has at least 2” from bottoming out in its shortest

working position and has the minimum 6” overlap in its longest working position.

Refer to Section 4.061 of this manual, if it is determined that the driveline is too long

1

GENERAL INFORMATION 6 FRONTIER

See Section 4.06 - Driveline, for instructions on how to determine correct driveline length and

Page 7

GROOMING MOWERS OPERATOR’S MANUAL

and needs to be shortened. Contact your local dealer if it is determined that the

driveline is too short for your tractor.

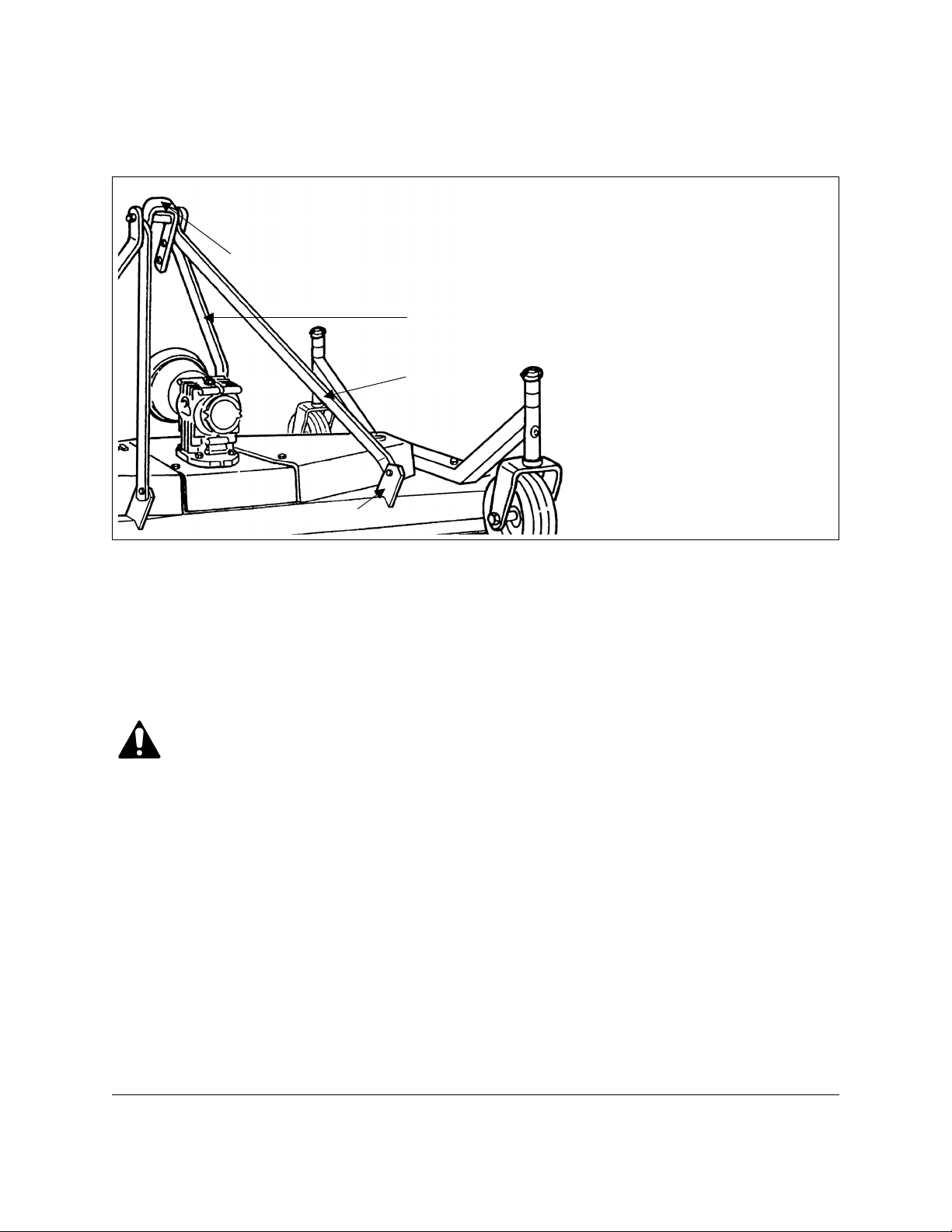

Fig. 3

2. top hitch plate

2

3. top hitch support

5. top hitch arm

3

8. rear support plate

5

8

1.05 - Quick Hitch Adapter Assembly and Operation

Using an iMatch/Quick Hitch system:

The GM1 series mowers can be used with an iMatch/Quick Hitch system, allowing for

quick and easy hookup, by installing an optional adapter. This optional adapter has

floating yokes that will allow the mower to follow the contour of the ground.

WARNING: When using an iMatch/Quick Hitch on a PTO driven implement always

ensure there is the proper driveline overlap prior to use. If there is not the

minimum 6” overlap do not use and contact your nearest dealer to purchase a

longer driveline.

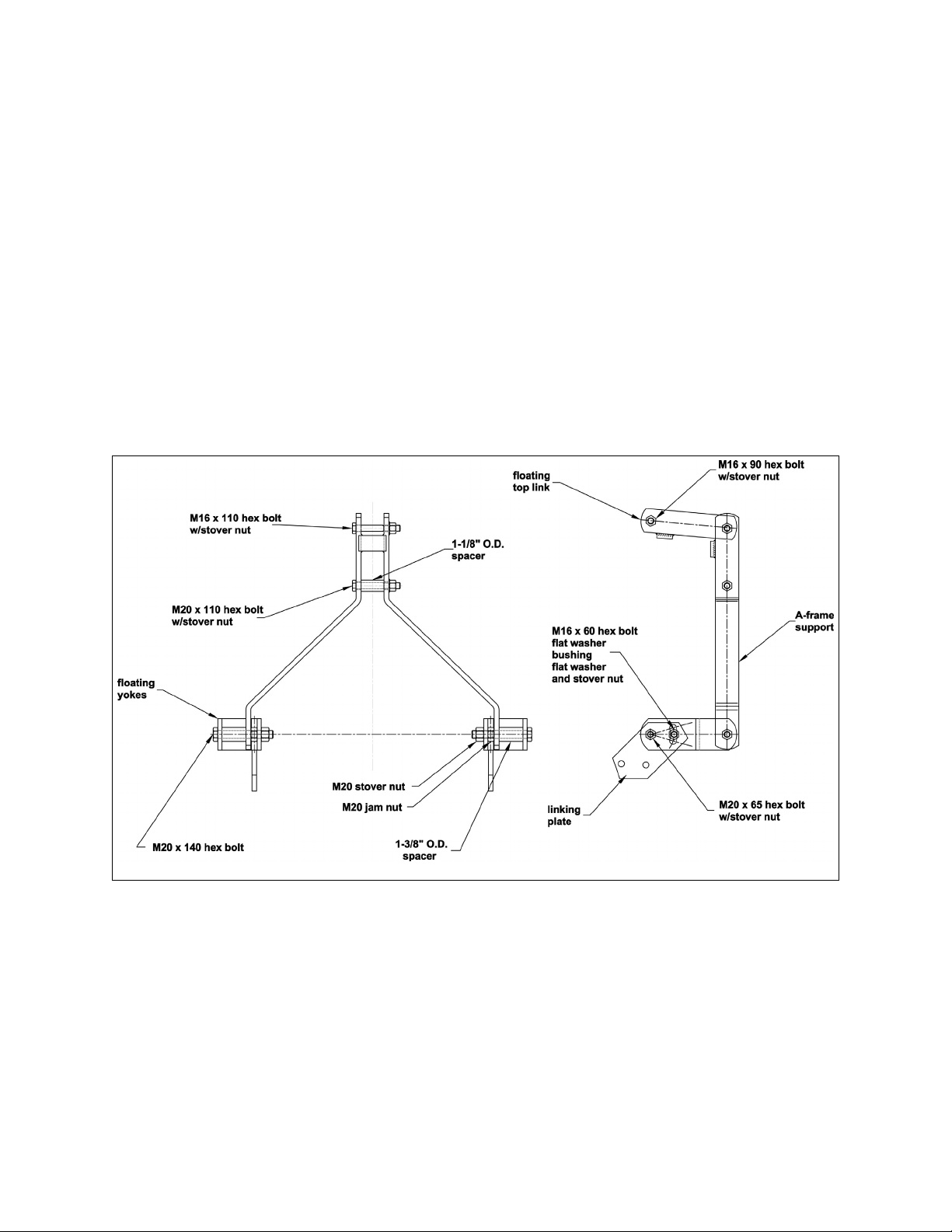

iMatch/Quick Hitch Adapter assembly (see fig. 4):

1. Remove hitch pins from grooming mower’s linking plates.

2. Remove M16x140 bolt on top of the three point hitch of the grooming mower.

3. Remove M20x45 bolts that hold the top hitch supports to the linking plates of the

mower.

4. Attach the floating yokes of quick hitch adapter assembly to the linking plates of the

mower. Note: Two ½” long bushings for the floating yokes are provided in the

hardware bag of the quick hitch adapter kit. Ensure these spacers are installed onto

the M16x60 bolt.

procedures for shortening the driveline.

GENERAL INFORMATION 7 FRONTIER

Page 8

GROOMING MOWERS OPERATOR’S MANUAL

5. Attach the floating top link to the top hitch arms using the M16x90 bolt and stover

nut.

6. Attach the A-frame support to the floating top link using the M16x110 bolt with stover

nut.

7. Install the M20x110 bolt with the 1-1/8” spacer into the A-frame support.

8. Insert the M20x140 bolt into the floating yokes. The order should be as follows: bolt,

first half of floating yoke, 1-3/8” bushing, A-frame support, M20 jam nut, second half

of floating yoke, M20 stover nut. The two M20 jam nuts need to be jammed against

each side of the linking plates of the grooming mower. This will allow some motion in

the bushing.

9. Loosen the M16x40 bolts that secure the top hitch arms to the rear support plates of

the mower. Only loosen slightly. The arms must be able to move slightly up and

down.

10.Tighten all hardware, ensuring all bolts and nuts have enough play to allow quick

hitch adapter to move up and down.

Fig. 4 - Quick-Hitch Adapter assembly.

iMatch/Quick Hitch adapter operation:

After completing assembly of the adapter, the tractor lift arms should be raised and

locked in a position so the floating yokes are horizontal. Ensure that the M16x60 bolt is

approximately in the center of the slot on the floating yoke. Positioning the bolt in this

location allows the mower to have maximum float both up and down.

GENERAL INFORMATION 8 FRONTIER

Page 9

GROOMING MOWERS OPERATOR’S MANUAL

CAUTION: Improper setup of the quick hitch adapter can result in equipment

damage. A replacement driveline must generally be installed to prevent injury or

equipment damage when using the quick hitch adapter.

CAUTION: If the three point hitch of the tractor is set in the lowest position, the

driveline may bottom out against the quick hitch resulting in a bent driveline. If

the mower is lifted after the driveline has been bent, it may also damage the

gearbox, mounting plates and other hardware.

GENERAL INFORMATION 9 FRONTIER

Page 10

G

ROOMING MOWERS OPERATOR’S MANUAL

2 - SAFETY PRECAUTIONS

Safety is the primary concern in the design and manufacture of our products.

Unfortunately our efforts to provide safe equipment can be wiped out by a single

careless act of an operator.

In addition to the design and configuration of equipment, hazard control and accident

prevention are dependent upon the awareness, concern, prudence and proper training

of personnel involved in the operation, transport, maintenance and storage of

equipment. It is the operator’s responsibility to read and understand all safety and

operating instructions in the manual and to follow these.

Allow only properly trained personnel to operate the mower. Working with unfamiliar

equipment can lead to careless injuries. Read this manual, and the manual for your

tractor, before assembly or operation, to acquaint yourself with the machines. It is the

mower owner’s responsibility, if this machine is used by any person other than yourself,

is loaned or rented, to make certain that the operator, prior to operating, reads and

understands the operator’s manuals and is instructed in safe and proper use.

2.01 - Preparation

1. Before operating equipment read and understand the operator’s manual and the

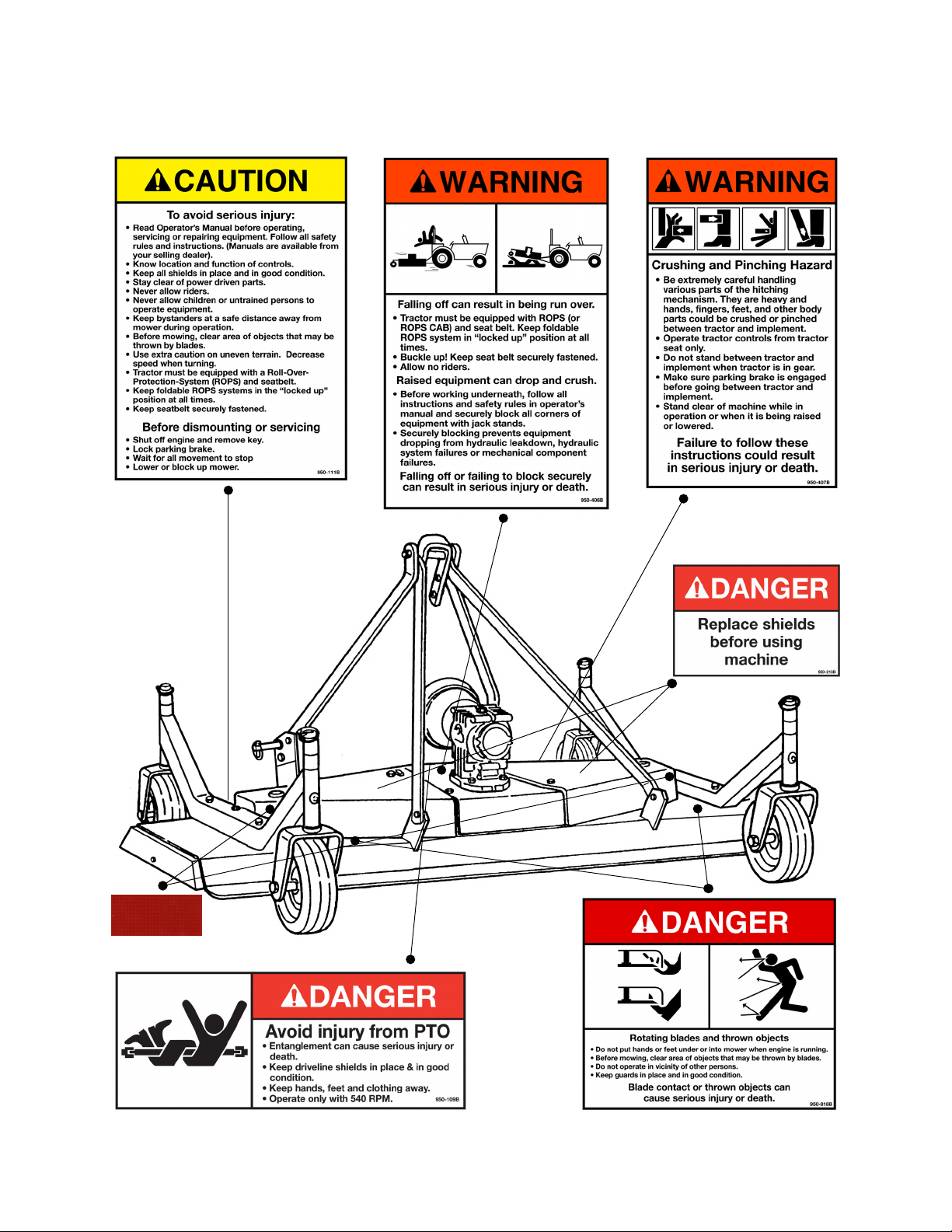

safety signs (see fig. 5).

2. Thoroughly inspect the implement before initial operation to assure that all

packaging materials, i.e. wires, bands, and tape have been removed.

3. Personal protection equipment including hard hat, safety glasses, safety shoes, and

gloves are recommended during assembly, installation, operation, adjustment,

maintaining and/or repairing the implement.

4. Operate the mower only with a tractor equipped with an approved

Roll-Over-Protective-System (ROPS). Always wear your seat belt. Serious injury or

even death could result from falling off the tractor.

5. Clear area to be cut of stones, branches or other debris that might be thrown,

causing injury or damage.

6. Operate only in daylight or good artificial light.

7. Ensure mower is properly mounted, adjusted and in good operating condition.

8. Ensure that all safety shielding and safety signs are properly installed and in good

condition.

SAFETY PRECAUTIONS 10 FRONTIER

Page 11

G

ROOMING MOWERS OPERATOR’S MANUAL

2.02 - Starting and Stopping

1. Be sure that no one is near the machine prior to engaging or while the machine is

working.

2. Be sure the tractor is in “Neutral” before starting engine.

3. Mower operating power is supplied from tractor PTO. Refer to your tractor manual

for PTO engagement and disengagement instructions. Always operate PTO at 540

rpm. Know how to stop the tractor and mower quickly in case of an emergency.

4. When engaging PTO, the engine rpm should always be low. Once engaged and

ready to start cutting, raise PTO speed to 540 rpm and maintain throughout cutting

operation.

5. Check the tractor master shield over the PTO stub shaft. Make sure it is in good

condition and fastened securely to the tractor. Purchase a new shield if old shield is

damaged or missing.

6. After striking an obstacle, disengage the PTO, shut the tractor down and thoroughly

inspect for damage before restarting.

7. Never engage the PTO until the mower is in the down position and resting on the

ground. Never raise the mower until all blades have come to a complete stop.

8. To park the vehicle safely, stop vehicle on a level surface (not on a slope),

disengage PTO, engage the parking brake, stop the engine, remove the key, and

wait for engine and all moving parts to stop before leaving the operator’s seat.

9. Stay clear of rotating drivelines. Entanglement in rotating driveline can cause serious

injury or death. Wear close fitting clothing. Stop the engine and be sure PTO

driveline is stopped before getting near it.

2.03 - Messages and Signs

1. Read and adhere to all safety and operating decals on this machine (see fig. 5).

2. Before dismounting tractor: Allow moving parts to stop, stop engine, set brake and

remove the key of unattended equipment.

3. Keep away from rotating blades and driveline.

4. Keep guards and shields in place and in good condition.

5. Do not mow with bystanders in area.

6. Allow no riders on tractor or mower.

7. Allow moving parts to stop before repair.

8. Securely support mower before working underneath.

Additional warning and operating decals are available at no extra charge. Please specify

model and serial number when ordering.

SAFETY PRECAUTIONS 11 FRONTIER

Page 12

G

ROOMING MOWERS OPERATOR’S MANUAL

Fig. 5 - Safety decals - implement; replace immediately if damaged.

left side

Red reflective decal

placed under belt shield

right side

SAFETY PRECAUTIONS 12 FRONTIER

Page 13

G

ROOMING MOWERS OPERATOR’S MANUAL

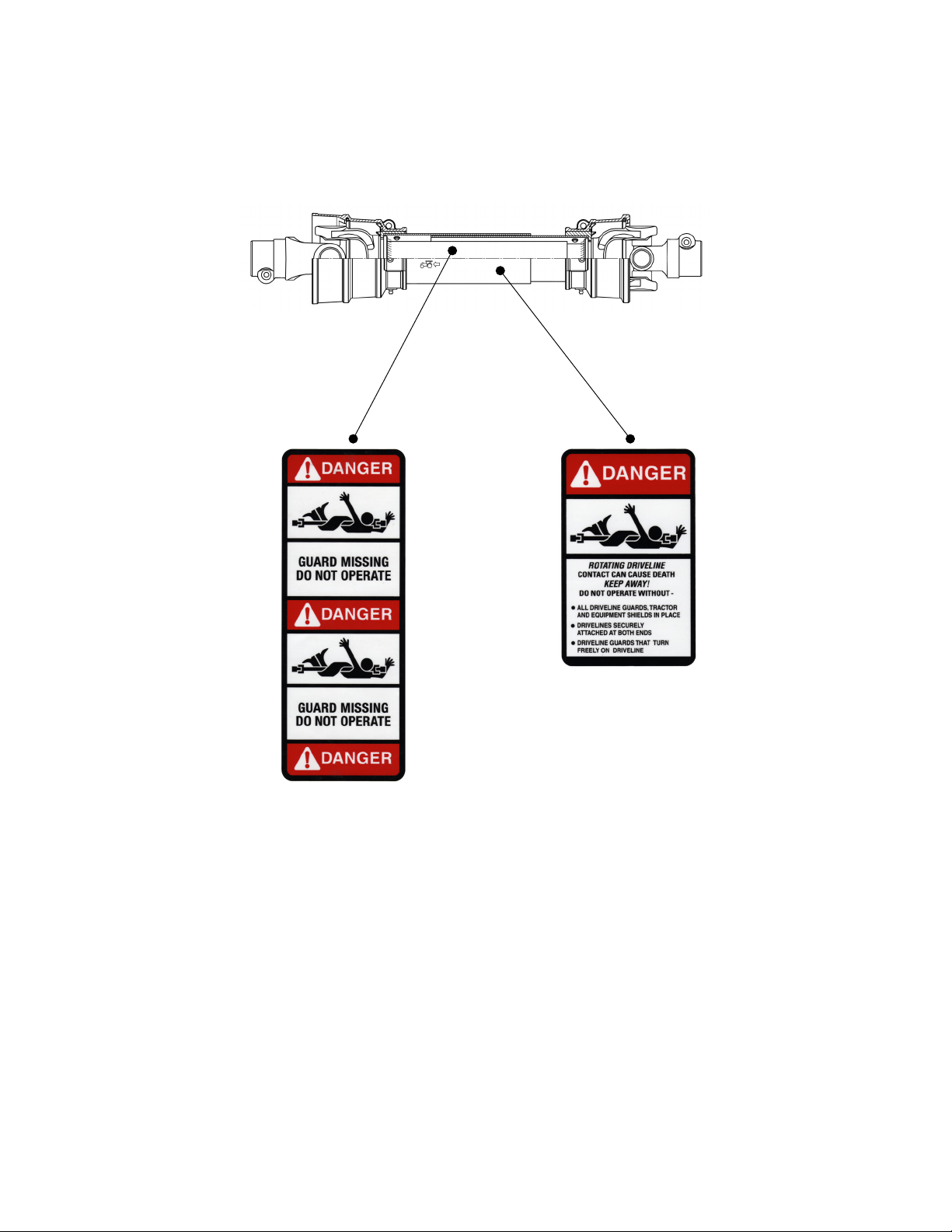

Safety decals - driveline; replace immediately if damaged.

placed on outer tube

placed on outer shield

SAFETY PRECAUTIONS 13 FRONTIER

Page 14

G

ROOMING MOWERS OPERATOR’S MANUAL

3 - OPERATION

You have purchased a three spindle mower designed especially for the mowing of

grassy areas where a highly professional cut is required without wasting time.

This mower is perfect for the maintenance of parks, private lawns, industrial parks,

airports, hospital grounds, schools, highways, golf courses, sport complexes, etc. The

GM1 series, for tractors up to 30 HP, come in working widths of 4’, 5’ and 6’

respectively. The mower can be either tractor front or rear mounted. On your mower,

the tractor PTO transmits its power through a driveline to a speed multiplier gearbox. A

pulley is attached to the pinion gear shaft of the gearbox which, via high resistance

belts, transmits power to pulleys coupled to the three individual spindle shafts. Blades

are secured to these shafts which turn at a high blade tip speed to cut the grass.

Our grooming mowers comes equipped with 4 swivel wheels. Aside from regulating the

cutting height, the wheels are set in such a way as to allow the mower to follow the

contour of the terrain and give a precise level cut even in undulating conditions.

3.01 - Operational Safety

CAUTION: Our mowers are designed considering safety as the most important

aspect and are the safest available in today’s market. Unfortunately, human

carelessness can override the safety features built into our machines. Injury

prevention and work safety, aside from the features on our mowers, are very

much due to the responsible use of the equipment. It must always be operated

prudently following with great care, the safety instructions laid out in this manual.

1. The use of this equipment is subject to certain hazards which cannot be prevented

by mechanical means or product design. All operators of this equipment must read

and understand this entire manual, paying particular attention to safety and

operating instructions, prior to using.

2. Do not operate the tractor and mower when you are tired, sick or when using

medication.

3. Keep all helpers and bystanders at least several feet from a rotary mower. Only

properly trained people should operate this machine.

4. The majority of accidents involve entanglements on the driveline, injury of

bystanders by objects thrown by the rotating blades, and operators being knocked

off the tractor by low hanging limbs and then being run over by the mower. Accidents

are most likely to occur with machines that are loaned or rented to someone who

has not read the operator’s manual and is not familiar with a rotary mower.

OPERATION 14 FRONTIER

Page 15

G

ROOMING MOWERS OPERATOR’S MANUAL

5. Always stop the tractor, set brake, shut off the tractor engine, remove the ignition

key, lower implement to the ground and allow mower blades to come to a complete

stop before dismounting tractor. Never leave equipment unattended with the tractor

running.

6. Never place hands or feet under mower with tractor engine running or before you

are sure all motion has stopped. Stay clear of all moving parts.

7. Do not allow riders on the mower or tractor at any time. There is no safe place for

riders.

8. Do not operate unless all personnel, livestock and pets are several feet away to

prevent injury by thrown objects.

9. Before backing up, disengage the mower and look behind carefully.

10.Install and secure all guards and shields before starting or operating.

11.Keep hands, feet, hair and clothing away from moving parts.

12.This rotary mower is designed for use only on tractors with 540 rpm power take off.

13.Never operate tractor and mower under trees with low hanging limbs. Operators can

be knocked off the tractor and then run over by the rotating blades.

14.The rotating parts of this machine have been designed and tested for rugged use.

However, they could fail upon impact with heavy, solid objects such as steel guard

rails and concrete abutments. Such impact could cause the broken objects to be

thrown outward at very high velocities. To reduce the possibility of property damage,

serious injury, or even death, never allow the cutting blades to contact such

obstacles.

15.Frequently check mower blades. They should be sharp, free of nicks and cracks and

securely fastened.

16.Stop mower immediately upon striking an obstruction. Turn engine off, remove key,

inspect and repair any damage before resuming operation.

17.Stay alert for holes, rocks and roots in the terrain and other hidden hazards. Keep

away from drop-offs.

18.Use extreme care and maintain minimum ground speed when transporting on

hillside, over rough ground and when operating close to ditches or fences. Be careful

when turning sharp corners.

19.Reduce speed on slopes and sharp turns to minimize tipping or loss of control. Be

careful when changing directions on slopes. Do not start or stop suddenly on slopes.

Avoid operation on steep slopes.

20.When using a unit, a minimum 20% of tractor and equipment weight must be on

tractor front wheels. Without this weight, tractor could tip over, causing personal

injury or death. The weight may be attained with a front end loader, front wheel

weights, ballast in tires or front tractor weights. When attaining a minimum 20% of

tractor and equipment weight on the front wheels, you must not exceed the ROPS

weight certification. Weigh the tractor and equipment. Do not guess or estimate!

21.Inspect the entire machine periodically2. Look for loose fasteners, worn or broken

parts, and leaky or loose fittings.

22.Use only the driveline supplied with the mower. Do not use it if it is missing any

shield or safety protection.

2

OPERATION 15 FRONTIER

See Chapter 4 - Maintenance.

Page 16

G

6

ROOMING MOWERS OPERATOR’S MANUAL

23.Pass diagonally through sharp dips and avoid sharp drops to prevent “hanging up”

tractor and mower.

24.Avoid sudden starts and stops while traveling up or downhill.

25.Always cut down slopes; never across the face. Avoid operation on steep slopes.

Slow down on sharp turns and slopes to prevent tipping and/or loss of control.

3.02 - Set Up

Notice to dealer: Pre-delivery setup and service including lubrication is the

responsibility of the authorized dealer. It is up to him to assure that the machine is in

perfect condition and ready to be used. It is his responsibility to ensure that the

customer is aware of all safety aspects and operational procedures for the mower. He

must also fill out the Pre-Delivery Checklist3 prior to delivering the mower.

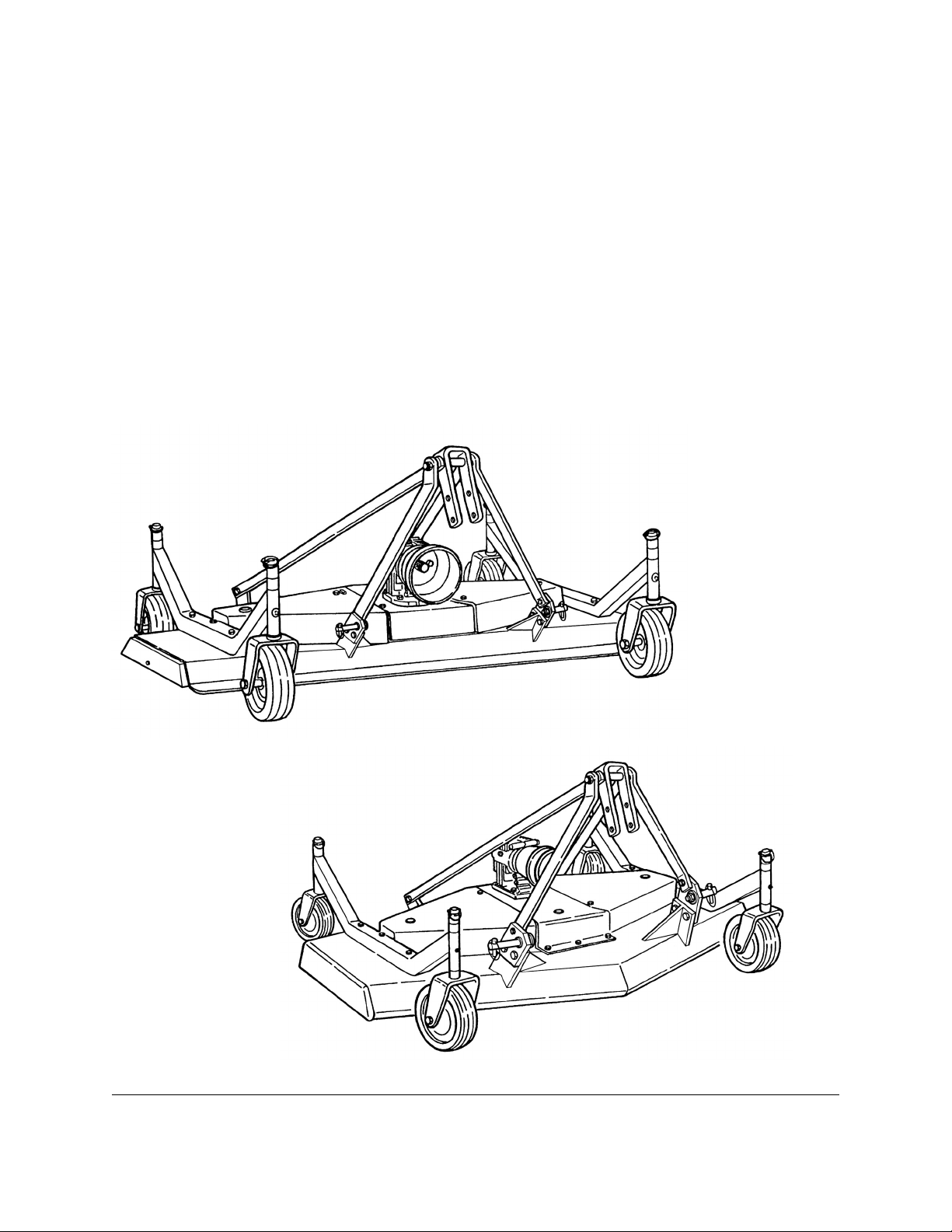

Fig.

Front mount mower.

Fig. 7

Rear mount mower.

3

OPERATION 16 FRONTIER

See Chapter 7 - Pre-Delivery Checklist.

Page 17

G

ROOMING MOWERS OPERATOR’S MANUAL

As mentioned above, all our grooming mowers may be either tractor front or rear

mounted. Changing our mowers from front mount to rear, or vice versa, can be easily

done at our authorized dealerships. This is accomplished by simply turning the three

point hitch and the gearbox 180 degrees (see fig. 6 & 7).

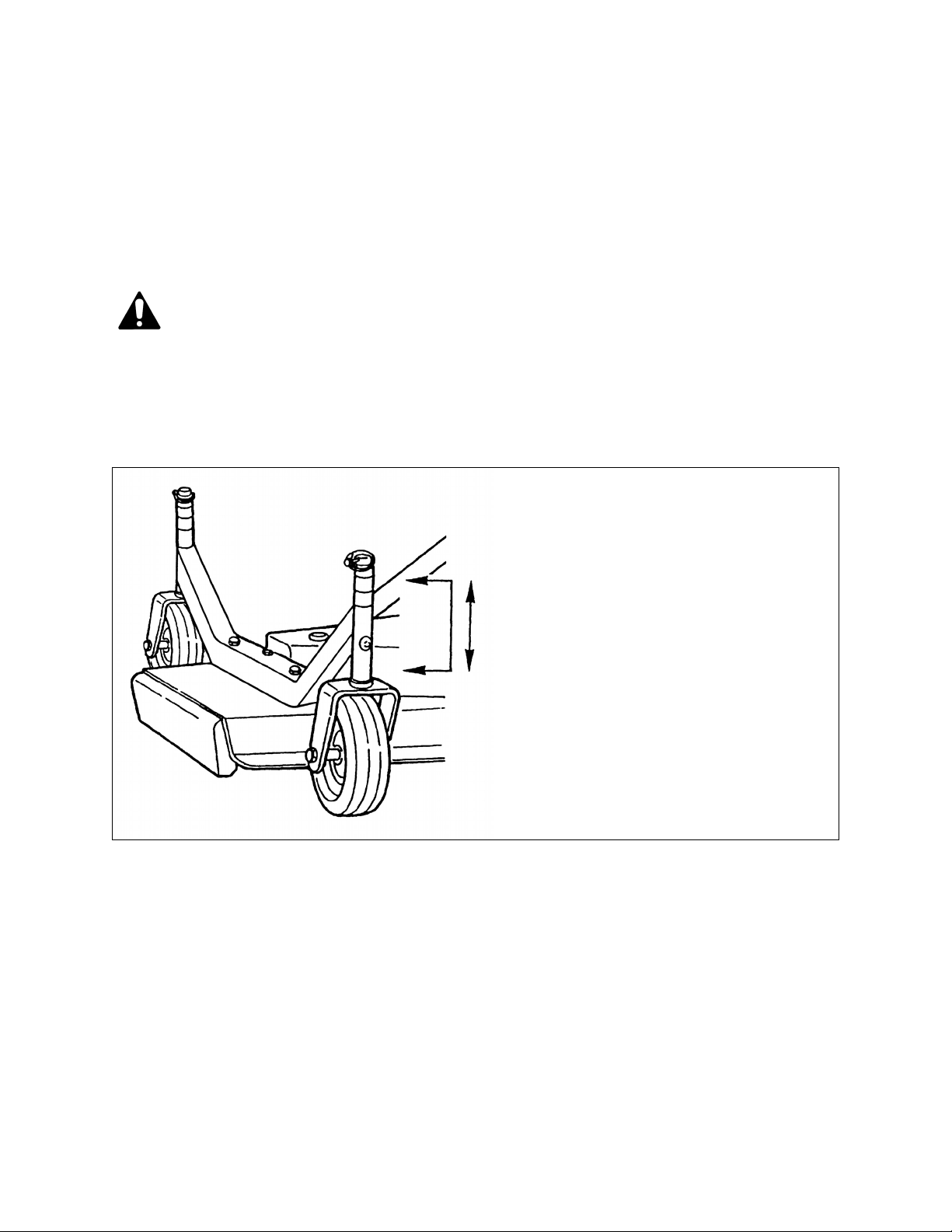

3.03 - Cutting Height Adjustment

WARNING: Keep hands and feet away from moving blades.

Be sure tractor engine is off, parking brake is locked, and key is removed before

making any adjustments.

Never rely on the tractor lift system. Install blocks or stands under the mower

deck to prevent it from falling.

Fig. 8

The cutting height is

adjusted by moving the

height adjustment spacers

on the wheel yokes above or

below the wheel arm.

The cutting height is the distance from the blades to the ground. The cutting height is

adjusted by moving the spacers on the wheel yokes. Placing spacers between the

wheel arm and the wheel yoke raises the cutting height by the size of the spacer.

Removing the spacers, lowers it by the same height (see fig. 8).

Be sure all wheel arms are adjusted equally. This is the only way to ensure a completely

uniform cut.

IMPORTANT: Very low cutting heights should be avoided. Damaging shock loads

occur when the blades strike the ground repeatedly. This can cause damage to

the mower.

OPERATION 17 FRONTIER

Page 18

G

ROOMING MOWERS OPERATOR’S MANUAL

Cutting lower than 2” under most circumstances should be avoided.

The cutting height is adjustable from 1” to 4”.

A front anti-scalp roller is also available upon request. This accessory is particularly

helpful when cutting over uneven terrain.

3.04 - Pre-Operational Check

IMPORTANT: Check each of the following, carefully, prior to engaging the equipment:

1. The spindle bearings have been greased.

2. The belts for proper tension.

3. The oil in the gearbox.

4. The driveline cross and bearings have been greased.

5. No wrappings or foreign objects are around the blades, belts or driveline.

6. The blades are properly installed and the blade bolts properly torqued4.

7. All hardware is tight.

8. The tractor, to ensure correct direction of PTO and rpm speed.

9. All safety shields and guards are in place and tightly attached.

10.No people or animals are in the work area.

11.When working, make sure the tractor hitch is in the “float” position, in order to allow

the mower to follow the contour of the ground.

DANGER: Stay clear of rotating driveline. Entanglement in rotating driveline can

cause serious injury. Disengage PTO, engage parking brake or place

transmission in “Park”, shut off the tractor and remove the key before working

around hitch, attaching or detaching driveline, making adjustments, servicing or

cleaning the machine.

3.05 - Attaching to the Tractor

Unit may be used on tractors ranging from 18 to 30 HP equipped with a standard PTO

and category 1 three point hitch5. Never use this mower with tractors over 30 HP.

CAUTION: Check the tractor PTO rpm to ensure it is set at 540 and turns

clockwise.

4

5

See Table 1, page 32.

See Table 2, page 32.

OPERATION 18 FRONTIER

Page 19

G

ROOMING MOWERS OPERATOR’S MANUAL

CAUTION: Always ensure that the tractor tire pressure is correct according to the

tractor operator’s manual.

DANGER: Failure to ensure a secure coupling of the implement to the tractor can

cause injury and damage to the implement or tractor.

To attach the mower to the tractor do the following:

1. Back the tractor up to the mower in order to slip the tractor hitch arms over the hitch

pins welded to the mower hitch arms. Turn off the tractor engine. Secure them in

place with the lynch pins.

2. Adjust the tractor sway blocks or chains to remove all side movement.

3. Attach the top link. Adjust tractor top link to allow the mower to follow the ground

contour and yet remain as level as possible when raised to transport position.

4. Install the shielded driveline to the tractor by first lining up the splines and

depressing the snap pin. Push the yoke onto the PTO shaft as far as it will go.

Release the pin and pull back slowly until the pin clicks in place. Repeat this

operation on the implement end.

5. Attach the driveline chains to the tractor and to the mower to keep the driveline

protection from turning. The chains should not be too tight.

3.06 - Start Up

DANGER: The mower must always be lowered to the ground before starting

tractor engine or engaging PTO lever.

Lower mower to the ground with the tractor rock shaft control lever. With the engine

idling, slowly engage the PTO drive. Move the throttle lever until the PTO speed

indicated on the mower is obtained.

The mower is set for a PTO speed of 540 rpm.

Shift the transmission to a slow speed gear and start forward, increase the ground

speed by shifting upward until the desired speed is obtained. Do not mow in reverse

unless absolutely necessary and only after careful observation of the area behind the

mower.

CAUTION: Do not operate this mower at a PTO speed or direction of rotation

other than that shown on the mower. Serious damage can occur to the machine

and/or the operator.

OPERATION 19 FRONTIER

Page 20

G

ROOMING MOWERS OPERATOR’S MANUAL

Before starting to mow, never forget that the operator is responsible for the following:

1. Safe and correct driving of the tractor and mower.

2. To learn precise safe operating procedures for both the tractor and the mower.

3. To ensure all maintenance and lubrication has been performed on the mower.

4. To have read and understood all safety aspects for the mower in the operator’s

manual.

5. To have read and understood all safety decals on the mower.

6. Checking the condition of the blades. Worn or damaged blades should be changed

before starting6.

7. Checking to ensure that the cutting edge is the leading edge of the blade7.

8. Checking that there is no wire, weed, grass or other material wrapped around

blades.

9. Checking to see if front weights need to be added to the tractor in order to maintain

balance.

10.Checking the tractor tires for the proper pressure in accordance with the tractor

operator’s manual.

11.Checking that the PTO shield, belt shields and all other shielding are on the

machine and securely in place.

12.Making sure the proper attire is worn. Avoiding loose fitting clothing which can

become entangled. Wearing sturdy, tough-soled work shoes and protective

equipment for eyes, hands, ears and head. Never operate tractor or implements in

bare feet, sandals or sneakers.

13.Checking area for stones, branches and other debris that might be thrown.

14.Ensuring proper lighting is available, sunlight or good artificial lighting.

3.07 - Working Speed

The mowing speed depends on ground conditions, tractor HP, mowing height, and

grass thickness. Only a test run will enable you to gauge the optimal working speed for

your conditions.

Under most conditions a 3 to 8 mph ground speed is best. As a rule of thumb, and if the

conditions permit, grass dispersion is increased by higher ground speeds.

In order to obtain the best cut possible, always keep the tractor rpm up to the speed

indicated on the mower. When increasing or decreasing mowing ground speed, always

use gear selection, not engine speed. This will maintain the constant maximum blade

speed necessary for a clean cut.

The mulching kit is an option available for the GM1 mowers. This kit, containing 3

multilevel cutting edge blades and add-on containment baffling which bolts to the

underside of the mower deck, mulches and pulverizes grass and leaves.

Another benefit of the mulching kit is safety. In fact, the kit greatly reduces the possibility

of thrown objects. This is particularly important when mowing around schools, public

parks and golf courses. If you are using a mulching kit, you need to reduce your

ground speed to under 2 mph (see fig. 9).

6

7

See Section 4.03 - Blade Maintenance.

See Section 4.03 - Blade Maintenance.

OPERATION 20 FRONTIER

Page 21

G

ROOMING MOWERS OPERATOR’S MANUAL

Fig. 9

The mulching kit is an

available option,

consisting in 3

multilevel cutting edge

blades and add-on

containment baffling

which bolts to the

underside of the mower

deck, to mulch and

pulverize grass and

leaves.

3.08 - Operating Techniques

All of the following factors are important in selecting the proper forward speed:

1. Height of grass.

2. Type of grass.

3. Density of grass.

4. Type of terrain.

5. Grass condition, wet or dry.

This mower has been designed to cut grass with heights from 4” to 8”. It is

recommended to avoid cutting grass taller than 10”. For the best results, try cutting the

grass at least once per week during growing season. Tall, dense grass should be cut at

low speed, while thin medium grass can be cut at a faster ground speed. For cleaner

cuts and efficient mowing, the blades must be kept sharp

Always operate PTO at 540 rpm. This is necessary to maintain proper blade speed and

obtain a clean cut.

Under certain conditions, tractor tires may roll some grass down and prevent it from

being cut at the same height as the surrounding area. If this occurs reduce the tractor

ground speed but maintain a 540 rpm engine speed. The lower ground speed will permit

the grass to at least partially rebound. Under some conditions grass will not rebound

enough to be cut evenly, resulting in an uneven appearance. In general, lower cutting

8

.

8

OPERATION 21 FRONTIER

See Sharpening Blades in section 4.03 - Blade Maintenance.

Page 22

G

ROOMING MOWERS OPERATOR’S MANUAL

height gives a more even cut with less tendency to leave tire tracks. If cut is still not

satisfactory, cut the area twice.

Mow extremely tall grass twice. On the first pass use a high cutting height. On the

second pass position the mower at the desired height and, when practical, mow at a

right angle in travel to the first pass.

Plan your pattern to travel straight forward whenever possible.

It is better to cut grass more often, than too short. Short grass deteriorates rapidly in hot

weather and invites weed growth during growing season.

If at any time the mower should jam resulting in belt slippage of 2 or more seconds,

raise the mower and continue for 2-3 minutes. This will allow the pulleys to cool and

prolong belt life.

DANGER: The mower blades can throw objects hundreds of feet which could

result in personal or property damage.

Pick up all rocks and other debris before mowing.

Enter new areas carefully. Cut grass higher at first, allowing mower to clear

hidden objects.

CAUTION: For emergency reasons learn how to stop the tractor and mower

quickly. On the finishing mowers always disengage the PTO, lock parking brake,

stop engine and allow the mower blades to come to a complete stop before

dismounting the tractor.

3.09 - Uneven Terrain

DANGER: Be careful of rollover when operating tractor and mower over uneven

ground.

The following precautions should always be observed when working on uneven terrain:

1. In extremely uneven terrain rear wheel weights, front tractor weights, and/or tire

ballast should be used to improve stability.

2. Observe the type of terrain and develop a safe working pattern.

3. Whenever traction or stability is doubtful, first test drive over the terrain with the PTO

disengaged.

4. Operate the implement up and down steep slopes, not across slopes, to prevent the

tractor from tipping. Avoid sudden stops and starts, and slow down before changing

directions on a slope.

5. Pass diagonally through sharp dips and avoid sharp drops to prevent hanging up the

tractor and implement.

OPERATION 22 FRONTIER

Page 23

G

ROOMING MOWERS OPERATOR’S MANUAL

6. Slow down on sharp turns and slopes to prevent tipping or loss of control.

7. Avoid tipping the mower while cutting.

8. Watch for holes, roots or other hidden objects. Do not use near the edge of a gully,

ditch or stream bank.

An anti-scalping roller is recommended for uneven ground contours. The roller

rides the nose of the mower over a mound to help keep the nose from bulldozing

or the blades from scalping the ground.

3.10 - Removing Mower from the Tractor

CAUTION: Disengage tractor PTO. Set parking brake. Stop engine and remove

key from ignition. Disconnect mower driveline from tractor PTO shaft. Collapse

driveline and store in appropriate place. Disconnect three point linkage and

carefully drive tractor away from mower.

3.11 - Transport

Before raising the mower for transport, the tractor top link must be adjusted so when

lifted, the rear of the machine is higher than the front (the mower’s nose is tilted

downward). To do this, shorten the tractor top link until the top hitch plate is locked

forward and no longer able to pivot. This will keep the mower locked in position and

minimize the shaking and bouncing during transport which can damage the hitch or

frame.

CAUTION: Make sure PTO is disengaged and blades have stopped turning before

raising mower to full transport position. Do not tow tractor and mower behind

other vehicles. Use a properly equipped trailer with heavy tie-downs for towing

operations.

Before transporting:

1. Always select a safe ground speed that is appropriate for the terrain.

2. Beware of traffic on public roads. Install a SMV (Slow Moving Vehicle) sign when

traveling on roads or streets. Comply with all federal, state and local laws.

3. Reduce ground speed when turning and take care that the implement does not strike

obstacles such as trees, fences or buildings.

4. Always disengage PTO before raising the implement to transport position.

5. When raising the mower be sure the PTO driveline does not hit either the mower or

the tractor.

6. During transport the mower should not be lifted over 14” to 16” from the ground.

OPERATION 23 FRONTIER

Page 24

G

ROOMING MOWERS OPERATOR’S MANUAL

4 - MAINTENANCE

DANGER: Stop engine, lock parking brake and remove key before performing any

service or maintenance.

Never rely on the tractor lift system. Install blocks or stands under the mower

deck to prevent it from falling.

Always use personal protection devices, such as glasses or gloves when

performing maintenance.

Keep fingers out of slots to prevent injury.

4.01 - Maintenance Safety

1. Good maintenance is your responsibility.

2. Keep service area clean and dry. Be sure electrical outlets and tools are properly

grounded. Use adequate light for the job at hand.

3. Make sure there is plenty of ventilation. Never operate the engine of the towing

vehicle in a closed building. The exhaust fumes may cause asphyxiation.

4. Make no repair or adjustments with the tractor engine running. Before working on

the machine, disengage the PTO, shut off the engine, set the brakes, and remove

the ignition key.

5. Be certain all moving parts on attachment have come to a complete stop before

attempting to perform maintenance.

6. Never work under equipment unless it is blocked securely.

7. Always use personal protection devices such as eye, hand and hearing protectors,

when performing any service or maintenance.

8. Frequently check mower blades. They should be sharp, free of nicks and cracks and

securely fastened.

9. Periodically tighten all bolts, nuts and screws and check that all cotter pins are

properly installed to ensure unit is in a safe condition.

10.When completing a maintenance or service function, make sure all safety shields

and devices are installed before placing unit in service.

11.Do not attempt to mount a tire unless you have the proper equipment and

experience to do the job.

12.Inflating or servicing tires can be dangerous. Whenever possible, trained personnel

should be called to service and/or mount tires.

13.After servicing, be sure all tools, parts and service equipment are removed.

MAINTENANCE 24 FRONTIER

Page 25

G

ROOMING MOWERS OPERATOR’S MANUAL

14.Never replace hex bolts with less than grade five bolts unless otherwise specified,

i.e. shear bolts9.

15.Where replacement parts are necessary for periodic maintenance and servicing,

genuine replacement parts must be used to restore your equipment to original

specifications. The company will not claim responsibility for use of unapproved parts

and/or accessories and other damages as a result of their use.

16.Unauthorized modifications to the machine may impair the function and/or safety of

the machine and reduce its life. If equipment has been altered in any way from

original design, the manufacturer does not accept any liability for injury or warranty.

4.02 - Service

The accompanying illustrations show lubrication points. The chart gives the frequency of

lubrication in hours, based on normal operating conditions. Severe or unusual

conditions may require more frequent lubrication.

Use a good quality SAE multipurpose type grease for all locations shown. Be sure to

clean fittings thoroughly before using grease gun.

Use 90 wt. gear oil in gearbox.

Hourly:

1. Check the condition of mower blades for nicks or dull edges. Sharpen if necessary.

2. Replace bent or damaged blades

10

.

3. Also check blades for damage after hitting an obstruction.

4. Clean foreign material from mower deck and belt area.

Fig. 10

Wheel yokes lubrication.

Every 8 hours:

1. Lubricate the driveline and the wheel yokes: Apply two or three shots of grease

to the driveline cross and bearings and the telescoping shafts; apply the same

9

10

MAINTENANCE 25 FRONTIER

Refer to Table 1 - Torque Specifications, page 32.

See Section 4.03 - Blade Maintenance.

Page 26

G

ROOMING MOWERS OPERATOR’S MANUAL

amount to the wheel arm grease fittings (see fig. 10). See the driveline manufacturer

operator’s manual for further information on the driveline.

2. Gearbox oil level: Check gearbox oil level, it should be between 1/2 and 2/3 full. If

needed add either SAE 90 wt. or SAE 140 wt. gear oil.

Every 25 hours: Check hardware tightness; mower vibrations can loosen bolts.

Check tightness of the hardware periodically, using Table 1 as a guide11.

Every 50 hours:

1. Lubricate the three spindles with two or three shots of multipurpose grease (see fig.

11). The top grease fittings are easily accessible from the top of the deck by simply

removing the plastic dust guards.

2. Check belt tension12.

Fig. 11

Lubrication of the spindle

shafts easily accessible from

the top of the deck.

4.03 - Blade Maintenance

WARNING: To avoid possible injury always wear proper eye and hand protection

when servicing mower blade.

In order for the mower to work properly, and to always obtain a precision cut with lower

HP requirements thus keeping cost down, proper blade maintenance is important.

Blades must be kept sharp, at their original length and corners maintained. A blade

must be replaced if, due to wear or damage, its original shape has been distorted.

11

12

MAINTENANCE 26 FRONTIER

See Table 1 - Torque Specifications, page 32.

See Section 4.04 - Belt Tension.

Page 27

G

ROOMING MOWERS OPERATOR’S MANUAL

Installing or removing blades

If the mower blades need to be installed, do the following:

1. The blade turns in a counter clockwise direction when viewed from the bottom of

the deck. The cutting edge must be towards the direction of rotation. The lift wing of

the blades is closest to the deck and the cutting edge away from it (see fig. 12).

2. Install the cup washer (see fig. 12) over the blade bolt and secure the blade in place

as described above.

3. With a wrench, block the spindle and tighten the bolt to 103 lb. ft. (see fig. 13).

4. To remove the blades reverse the procedure.

1

2

3

4

5

6

7

8

9

11

10

Fig. 12 - Spindle assembly.

1. grease fitting

2. hexagonal nut

3. pulley

4. rotor support

5. cover

7. blade

8. cup washer

9. blade bolt

10. cutting edge close to ground

11. lift wing

Ground

6. shaft

WARNING: Do not substitute blades or any bolt for the blade retaining bolt.

Company blades and blade retaining bolts are specially made for this application.

Using non original parts can effect the quality of cut and may also cause damage

to the mower.

MAINTENANCE 27 FRONTIER

Page 28

G

ROOMING MOWERS OPERATOR’S MANUAL

DANGER: Proper torque must be used when tightening the blade retaining bolt. If

these safety precautions are not followed, the blade could come off during

operation and be thrown hundreds of feet from the mower.

Sharpening Blades

Blade sharpening is extremely important in order to get the best cutting results. Sharp

blades permit a high quality cut and also reduce HP thus lowering cost.

To sharpen blades, first remove them following the above instructions.

Place the blade in a vise and sharpen them by using a hand file or grinder. Do not

sharpen the blades to a sharp cutting edge. The cutting edge should be between 1/64”

to 1/32” to prevent excessive pitting and dulling of the blades. Sharpen both ends of the

blade equally for balance and always maintain corners. Always keep all three blades

sharpened equally in order to maintain balance.

1

2

Fig. 13

3

1. spindle

2. blade

3. blade bolt

CAUTION: Unbalanced or warped blades can cause damage to the mower and/or

personal injury. Replace damaged blades before operating the mower. Sharpen

both ends of the mower blades equally or until the blade is balanced.

4.04 - Belt Tension

Belt tension control

Check the belt tension by applying a force of 12-15 lb. pushing against the belt halfway

between the pulleys. The belt deflection should be between

MAINTENANCE 28 FRONTIER

5

/16”-3/8”.

Page 29

G

ROOMING MOWERS OPERATOR’S MANUAL

Belt tension adjustment

The mower has an automatic belt tensioner. The tension is created by a spring

connecting a tensioner pulley to a fixed hitch plate with 3 positions (see fig. 14). Upon

delivery, the spring is located in the first position. When the belt stretches after use,

adjust the tension by relocating the spring in the other two holes. If the belt has

stretched to the point that the belt is not tight enough even in the last hole, then it is

necessary to replace the belt.

123

Fig. 14

1. tensioner

2. belt

3. pulley

4. spring

5. hitch plate

4

5

4.05 - Belt Replacement

If the belt has been stretched or damaged to the point where the proper tension cannot

be obtained it must be changed.

Fig. 15

2

6

7

3

5

4

3

1. drive pulley

2. central pulley

3. side pulley

4. belt

5. belt tensioner

6. hitch plate

5

MAINTENANCE 29 FRONTIER

1

7. spring

Page 30

G

ROOMING MOWERS OPERATOR’S MANUAL

To replace the belt do the following:

1. Remove belt shields. Clean foreign material from the mower deck and belt area.

2. Release spring tensioner to loosen belt.

3. Loosen rear nuts holding central plate (do not remove them).

4. Remove front nuts holding central plate (see fig. 14).

5. Lift the front of the central plate and remove old belt.

6. Replace new belt starting from the right spindle pulley (see fig. 15).

7. Lower central plate. Replace front nuts. Tighten front and rear nuts holding down

central plate.

8. Replace spring tensioner.

9. Check belt for proper tension.

10.Reinstall the belt shields.

4.06 - Driveline

DANGER: Only use the original driveline supplied with this mower and always

with the safety shielding. Carefully read and file away the driveline operator’s

manual supplied by the manufacturer. The following does not substitute the

information found in the driveline manual.

IMPORTANT: Always check driveline length during initial setup and when connecting to

a different tractor.

In the collapsed position the driveline should be approximately 2” from bottoming out to

prevent possible damage to the tractor or implement. When the driveline is in the

maximum extended position, the ideal minimum overlap of the two halves should be

approximately 6” (see fig. 16).

Fig. 16

min. 6"

MAX.

min. 2"

MIN.

MAINTENANCE 30 FRONTIER

Page 31

G

ROOMING MOWERS OPERATOR’S MANUAL

If determined that the driveline is too long, follow these procedures to adjust the length:

1. Separate the two driveline halves. Connect one half to the tractor PTO and the other

half to the mower.

2. Raise and lower the mower with the 3 point hitch to find the position where the

driveline is shortest. Hold the half shafts side by side and mark the desired length on

the outer female tube guard leaving a 1½” gap between the end of the guard tube

and bell guard.

3. Cut off both guard tubes the same amount as marked in step 2.

4. Shorten both drive tubes the same amount as guard tubes.

5. De-burr and clean filings from drive tubes and apply grease to outside of inner

telescoping tube.

6. Reassemble the driveline halves and connect to tractor and mower. Raise and lower

mower again to be sure driveline does not bottom out in its shortest position and has

a minimum overlap of 6” in the longest position.

7. Install both driveline safety chains. One should be hooked in a hole on the outer

driveline yoke shield and to the tractor to restrict outer shield rotation. The second

one should be hooked in a hole on the inner driveline yoke shield and to the

implement to restrict inner shield rotation.

If determined that the driveline is too short for your tractor, contact your local dealer.

CAUTION: Always work with the driveline as straight as possible. This will

prolong its life and that of its components. It is advised, not to work at an angle

greater than 15 degrees.

MAINTENANCE 31 FRONTIER

Page 32

G

ROOMING MOWERS OPERATOR’S MANUAL

TABLE 1 - TORQUE SPECIFICATIONS

Metric (ISO)

treaded

bolts head

marking

Bolt

Thread

size

mm

When using lock washers with nuts, increase torque values by 5%.

mm

0.8M5

1M6

1.25M8

1M8

1.5M10

1.25M10

1M10

1.75M12

1.5M12

1.25M12

2M14

1.5M14

2M16

1.5M16

2.5M18

2M18

1.5M18

2.5M20

1.5M20

2.5M22

1.5M22

3M24

2M24

3M27

2M27

3.5M30

2M30

4M36

Class 8.8Class 5.8

Class 10.9

ft-lbN.mft-lbN.mft-lbN.m

794634

111571046

273618251216

283819261317

527135482331

557538512433

587839532635

9112362844054

9412864874156

9813366904459

144195981336284

1542091051426994

22330215220697131

236320161218104141

310421218295133181

443229311145196

327

343465241327150203

437592306415189256

476646335454212288

595807418567254344

644873452613281381

7501017526714327444

8081095567769360488

110314967741050484656

117615948251119530719

1499203310471420668906

16592250118016007381000

260735351830248211311534

Inch (SAE)

treaded

bolts head

marking

Thread

Bolt

inch

size

inch

tpi

201/4”

281/4”

185/16”

245/16”

163/8”

243/8”

147/16”

207/16”

131/2”

201/2”

129/16”

189/16”

115/8”

185/8”

103/4”

163/4”

97/8”

147/8”

81”

121”

71-1/8”

121-1/8”

71-1/4”

121-1/4”

61-3/8”

121-3/8”

61-1/2”

121-1/2”

Grade 8Grade 5Grade 2

ft-lbN.mft-lbN.mft-lbN.m

121681157

1419101368

241115

397539

253317

273719261317

445931422027

496735472331

709549673243

7810655753648

106144751024866

120163851155575

1542081091477095

17123212116479106

21228715020397132

240325170230110149

376509266361172233

420569297403192261

606822430582167226

668906473642184249

9091232644873250339

9951348704955273371

128817467941077354480

144519588911208

1817246311201519500677

2012272812411682553750

2382323014691992655888

27123677167322687461011

31614286194926438691179

35574823219429749781326

TABLE 2 - GM1 GROOMING MOWERS - TECHNICAL FEATURES

Series GM1, Rear Discharge, for tractors up to 30 HP, PTO 540 rpm, 3 point hitch cat. 1

HPModel

Working

width

Overall

width

Weight

lb.

Rotor

rpm/min

Blades tip

speed ft/min

#

Blades

Cutting

height

# Belts

& type

MAINTENANCE 32 FRONTIER

# Wheels &

size

Driveline

1

ASAE 2

ASAE 2

ASAE 2

3

/8”

nd.

cat4 - 8.4”x3.2”1 BX1” - 4”313,1883,03734051”48”16-30GM1048E

nd.

cat4 - 8.4”x3.2”1 BX1” - 4”314,7632,80337562”60”16-30GM1060E

nd.

cat4 - 8.4”x3.2”1 BX1” - 4”314,5662,27844074”72”16-30GM1072E

Page 33

G

ROOMING MOWERS OPERATOR’S MANUAL

5 - REPAIR PROCEDURES

CAUTION: All repair procedures must be done by authorized dealerships. It is not

recommended that untrained individuals perform any repair work. The following

operations are detailed for qualified personnel only.

5.01 - Gearbox

To remove the gearbox:

1. Remove the belt13 (see fig. 14).

2. Remove the nut holding the pulley to the gearbox pinion shaft.

3. Remove the pulley.

4. Remove the nuts holding the gearbox to the central plate.

5. Remove the gearbox.

If it is necessary to replace any part on the inside of the gearbox, it is important to

replace oil seals or gaskets to ensure a tight fit when reassembling.

To replace the gearbox, follow the above instructions in reverse order.

5.02 - Blade Spindle

To remove a blade spindle:

1. Remove the belt14.

2. Remove the nut holding the pulley to the spindle shaft (see fig. 12).

3. Remove the blades15.

4. Unbolt the bolts holding the rotor support to the mower deck.

5. If necessary remove and replace the bearings from the rotor using presses or

extractors.

6. Reassemble in reverse order ensuring that the nut securing the top pulley (see

fig. 12) is tightened to 118 lb. ft.

5.03 - Suggested Spare Parts

It is suggested that the following spare parts be kept on hand for the mower at all times

to prevent a minor problem from delaying work.

13

14

15

REPAIR PROCEDURES 33 FRONTIER

See Section 4.05 - Belt Replacement.

See Section 4.05 - Belt Replacement.

See Section 4.03 - Blade Maintenance.

Page 34

G

ROOMING MOWERS OPERATOR’S MANUAL

QuantityDescription

3Blades

3Blade bolts

3Washers

1Belts

5.04 - Storage

After seasonal use it is important to perform the following for prolonged storage:

1. Wash the mower carefully.

2. Inspect the mower and replace worn or damaged parts.

3. Tighten all hardware.

4. Grease all areas indicated under Maintenance

5. Loosen the belts if the mower is to be stored for an extended length of time.

6. Cover the mower from the elements in order to have it in perfect condition for the

start of the next season.

16

.

16

REPAIR PROCEDURES 34 FRONTIER

See Chapter 4 - Maintenance.

Page 35

G

ROOMING MOWERS OPERATOR’S MANUAL

6 - TROUBLESHOOTING

WARNING: Be sure tractor engine is off, parking brake is locked, and key is

removed before making any adjustments.

SOLUTIONPOSSIBLE CAUSEPROBLEM

Uneven cutting.

cutting.

Belt slippage.

Mower vibrates.

Grass build up at exit.

Cup washer not between

blade and bolt.

Ground speed too fast.

Blades need sharpening.

Caster wheels uneven.

Direction of blades is wrong.Blades turning but not

Lack of tension.

Object clogging mower.

Debris in pulleys.

Object wrapped around blade.

Belt damaged.

Wet grass.

Grass too high.

Tractor rpm too slow.

Check washer location at all 3

spindles.

Shift to lower gear.

Sharpen blades.

Adjust wheel position.

Blade should turn CCW when

you face deck bottom. See

Blades Maintenance section.

Tighten belt.

Remove object.

Clean pulleys.

Remove object.

Replace belt.

Tighten belt.Belt slipping.Belt squeal.

Allow grass to dry.

Raise mower, shift to lower

gear, make two passes over

grass. Mow grass high 1st pass,

2nd pass cut to desired height.

Increase tractor rpm, check

engine and PTO speeds.

Belts are tight when

installing.

Streaking conditions

in swath.

Wrong belt size.

Installed belts incorrectly.

Too wet to mow.

Blades cannot cut grass

pressed down by wheels.

Dull blades.

Check belt size.

See Belts Replacement section.

Allow grass to dry.

Maintain engine speed and shift

to lower gear.

Sharpen blade. See Blades

Maintenance section.

Blades worn down, preventing

Change blades.

overlap.

Cut grass windrows.

Ground speed too low.

Tractor rpm too slow.

Increase ground speed.

Increase tractor rpm, check

engine and PTO speeds.

TROUBLESHOOTING 35 FRONTIER

Page 36

G

ROOMING MOWERS OPERATOR’S MANUAL

7 - PRE-DELIVERY CHECKLIST

To the dealer: Inspect the machine thoroughly after assembly to assure it is

functioning properly before delivering it to the customer. The following checklist

is a reminder of points to cover. Check off each item as it is found satisfactory or

after proper adjustment is made.

Gearbox oil level.

Guards and shield properly fastened.

Lubrication of grease fittings.

All hardware properly tightened.

All decals properly located and readable (see fig. 5).

Blades properly installed, blade bolts and nuts tightened.

Overall condition (touch up scratches, clean and polish).

Test run, check for excessive vibration or overheating of bearings.

Operator’s Manual.

Review the Operator’s Manual with the customer. Explain the following:

Warranty.

Safe operation and service.

Correct machine installation and operation.

Daily and periodic lubrication, maintenance and inspections.

Troubleshooting.

Operational procedures and storage.

Parts and service.

Fill out the Pre-Delivery Checklist and the on-line Warranty Registration form.

Give customer the Operator’s Manual and encourage the customer to read the

manual carefully.

IMPORTANT: The dealer must complete the Warranty Registration, located on the

Frontier website. Warranty claims will be denied if the Warranty Registration has

not been completed.

Model Number: __________ Serial Number: __________

Delivery Date: __________ Dealer’s Signature: __________

PRE-DELIVERY CHECKLIST 36 FRONTIER

Page 37

PAR T S MA N U A L

GROOMING MOWERS

GM1048E

GM1060E

GM1072E

Note: Serial #’s with the XF prefix are subsequent to serial numbers with the BC prefix. For example: A

reference to “serial # BC… 739197 & above” will also include all serial numbers with an XF prefix.

Frontier ECO-R48, R60, R72 (US)

Printed on January 12, 2011

ECO-R48, ECO-R60, ECO-R72 Ver. F

Parts Manual 11/2010

Page 38

GROOMING MOWERS FRAME OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

ARTS MANUAL 38 FRONTIER

P

06/2007

Page 39

GROOMING MOWERS FRAME OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

Qty.DescriptionPart #Ref.

5BP0151501P1

5BP0251501P

5BP0351501P

17

18

19

1Frame 4’ rear discharge; GM1048E #BC…844971 & above

1Frame 5’ rear discharge; GM1060E #BC…844971 & above

1Frame 6’ rear discharge; GM1072E #BC…844971 & above

2Belt shield 4’ frame; GM1048E5BP01088173

2Belt shield 5’ frame; GM1060E5BP0208817

2Belt shield 6’ frame; GM1072E5BP0308817

1Central plate 4’ frame; GM1048E5BP00515814

1Central plate 5’ frame; GM1060E5BP0051583

1Central plate 6’ frame; GM1072E5BP0051585

3Cap5BP00066475

2Rear protection 5’ frame, outer; GM1060E5BP00518587

2Rear protection 6’ frame, outer; GM1072E5BP0051859

2Rear protection, inner5BP00518568

2Bolt HH M10-1.50x110 C8.8 Z F5BP00088189

2Nut ES M10-1.50 Z TK5BP001410610

-Washer fender Ø10 Z5BP003015711

-Bolt HH M10-1.50x25 C8.8 Z F5BP003317612

-Washer flat Ø10 W5BP000203413

-Nut PT M10-1.50 C6 TK Z5BP0030156 14

2Washer lock Ø10 Z5BP000128015

4Nut HH M10-1.50 C6 TK Z5BP000127916

-Bolt HH M10-1.50x20 C8.8 Z F5BP000634917

2Nut ES M10-1.50 Z TN5BP001523718

4Washer lock Ø12 Z5BP000107719

4Nut HH M12-1.75 C6 Z TK5BP000303820

-Cap5BP005157022

17

18

replacing frame.

19

replacing frame.

P

06/2007

Serial #BC…844970 & below must also order two (2) linking plates (5BP0051817) when replacing frame.

Serial #BC…844970 & below must also order two (2) linking plates (5BP0051817) when replacing frame.

Serial #BC…307418 & below must also order two (2) linking plates (5BP0051817) & two (2) belt shields (5BP0208817) when

Serial #BC…844970 & below must also order two (2) linking plates (5BP0051817) when replacing frame.

Serial #BC…307418 & below must also order two (2) linking plates (5BP0051817) & two belt (2) shields (5BP0308817) when

ARTS MANUAL 39 FRONTIER

Page 40

GROOMING MOWERS THREE POINT HITCH & WHEEL ARMS OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

ARTS MANUAL 40 FRONTIER

P

07/2009

Page 41

GROOMING MOWERS THREE POINT HITCH & WHEEL ARMS OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

Qty.DescriptionPart #Ref.

2Top hitch support 5BP00518221

2Top hitch arm GM1048E5BP00518242

2Top hitch arm GM1060E5BP0051826

2Top hitch arm GM1072E5BP0051828

1Spacer 5BP00068293

1Top hitch plate 5BP00068284

1Bolt HH M16-2.00x140 C8.8 Z P5BP00068915

7Nut PT M16-2.00 C6 Z TK5BP00055816

2Bolt HH M16-2.00x40 C8.8 Z F5BP00326877

4Bolt HH M16-2.00x45 C8.8 Z F5BP00065788

2Bolt HH M20-2.50x45 C8.8 Z F5BP00095389

2Nut PT M20-2.50 C6 TK Z5BP000550710

2Hitch pin 5BP000555011

2Lynch pin Ø11x455BP001826612

2Spacing disc5BP005184913

2Washer lock Ø20 Z5BP000535114

2Nut HH M20-1.50 C6 Z MD5BP000554215

4Wheel yoke 5BP000878516

4Cotter pin5BP000878317

4Spacer5BP000852818

4Bolt HH M14-2.00x140 C8.8 Z P5BP000661519

4Nut PT M14-2.00 C6 Z TK5BP003035820

2Wheel arm 4’ frame; GM1048E5BP005177221

2Wheel arm 5’ frame; GM1060E5BP0051781

2Wheel arm 6’ frame; GM1072E5BP0051783

4Grease fitting M10-1.005BP000106522

8Spacer, height adjustment 1”5BP000658623

8Spacer, height adjustment ½”5BP000658724

6BOLT HH M10-1.50x90 C8.8 Z P5BP002618525

6Washer flat SP Ø10 W5BP005177626

6Washer flat Ø10 W5BP000203427

6Washer lock Ø10 Z5BP000128028

6Nut HH M10-1.50 C6 TK Z5BP000127929

2Linking plate, #BC…844971 & above 5BP005181736

4Wheel hard tire, complete5BP000852637

8Bushing, hard tire (not shown)5BP0006613

4Wheel 9” air tire, complete (option)5BP0008797

8Steel retainer, air tire (not shown)5BP0006969A

8Bearing needle, air tire (not shown)5BP0006968

ARTS MANUAL 41 FRONTIER

P

07/2009

Page 42

GROOMING MOWERS TRANSMISSION & SPINDLE OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

ARTS MANUAL 42 FRONTIER

P

07/2009

Page 43

GROOMING MOWERS TRANSMISSION & SPINDLE OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

Qty.DescriptionPart #Ref.

3Pulley SPB 120x1; GM1048E5BP00085311

3Pulley SPB 130x1; GM1060E5BP0008666

3Pulley SPB 160x1; GM1072E5BP0008881

2Pulley, belt tensioner 5BP00085612

1Belt BX 98; GM1048E5BP00086303

1Belt BX 112 ½; GM1060E5BP0008670

1Belt BX 140; GM1072E5BP0008950

1Spring 5BP00517404

1Pulley SPB 250x15BP00086235

1Support, belt tensioner; #BC…631791 & below5BP00085636

1Support, belt tensioner; GM1048E #BC…631792 & above5BP0051741

5BP0051745

1Support, belt tensioner; GM1060E, GM1072E #BC…631792 &

above

1Hitch plate; #BC…631791 & below5BP00085717

1Hitch plate; GM1048E #BC…631792 & above5BP0008571

1Hitch plate; GM1060E #BC…631792 & above5BP0051755

1Hitch plate; GM1072E #BC…631792 & above5BP0051757

1Bolt HH M10-1.50x35 C8.8 Z F; #BC…631791 & below5BP00912818

1Bolt belt tensioner SP M10-1.50; #BC…631792 & above5BP0051751

1Washer fender Ø10 Z; #BC…631791 & below5BP00301579

1Washer flat Ø16 W; #BC…631792 & above5BP0051753

14Nut PT M10-1.50 C6 TK Z5BP0030156 10

1Bolt HH M10-1.50x35 C8.8 Z F5BP009128111

1Nut HH M10-1.50 C6 TK Z5BP000127912

1Bolt HH M20-2.50x65 C8.8 Z F5BP000857613

1Nut HH M20-2.50 C6 Z MD5BP000550814

4Washer flat Ø20 Z5BP004655515

2Nut PT M20-2.50 C6 TK Z5BP000550716

3Nut SP M25-1.50 Z5BP000669817

3Grease fitting Ø8, press in5BP002903618

12Bolt HH M10-1.50x30 C8.8 Z F5BP000127819

3Bolt blade SP M14-1.50x325BP000665920

3Washer conical spring Ø18 Z5BP000856021

3Blade standard 4’ frame; GM1048E5BP000679522

3Blade standard 5’ frame; GM1060E5BP0006641

3Blade standard 6’ frame; GM1072E5BP0006845

3Blade mulching 4’ frame; GM1048E (option)5BP0006795M

3Blade mulching 5’ frame; GM1060E (option)5BP0006641M

3Blade mulching 6’ frame; GM1072E (option)5BP0006845M

3Blade high lift 4’ frame; GM1048E (option)5BP0006795B

3Blade high lift 5’ frame; GM1060E (option)5BP0006641B

3Blade high lift 6’ frame; GM1072E (option)5BP0006845B

3Blade flat 4’ frame; GM1048E (option)5BP0006795F

3Blade flat 5’ frame; GM1060E (option)5BP0006641F

3Blade flat 6’ frame; GM1072E (option)5BP0006845F

3Blade gator 4’ frame; GM1048E (option)5BP0006795G

3Blade gator 5’ frame; GM1060E (option)5BP0006641G

3Blade gator 6’ frame; GM1072E (option)5BP0006845G

ARTS MANUAL 43 FRONTIER

P

07/2009

Page 44

GROOMING MOWERS TRANSMISSION & SPINDLE OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

ARTS MANUAL 44 FRONTIER

P

07/2009

Page 45

GROOMING MOWERS TRANSMISSION & SPINDLE OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

Qty.DescriptionPart #Ref.

3Spindle shaft5BP000855723

3Key 8x7x255BP000663924

3Cover5BP000663625

3Shim Ø25x35x25BP000660626

3Bearing 6205-ZZ5BP0006626A27

3Support, spindle shaft5BP000853828

3Spacer5BP000853629

3Bearing 6205-Z5BP0006634A30

- Spindle assembly5BP000853331

ARTS MANUAL 45 FRONTIER

P

07/2009

Page 46

GROOMING MOWERS FRONT ROLLER AND MULCHING KIT (OPTION)OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

ARTS MANUAL 46 FRONTIER

P

06/2010

Page 47

GROOMING MOWERS FRONT ROLLER AND MULCHING KIT (OPTION)OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

Qty.DescriptionPart #Ref.

6Nut HH M12-1.75 C6 Z TK5BP000303811

1Roller pin5BP000892918

1Front roller 3”5BP006735819

1Pin split Ø4x50 Z5BP011208720

1Roller support, right5BP000892321

1Roller support, left5BP020892422

-Bolt HH M10-1.50x20 C8.8 Z F5BP000634923

4Washer flat Ø10 W5BP000203424

-Nut PT M10-1.50 C6 TK Z5BP003015625

2Bolt HH M10-1.50x35 C8.8 Z F5BP009128126

-Washer fender Ø10 Z5BP003015727

1Baffling, front 4’ frame; GM1048E5BP000875528

1Baffling, front 5’ frame; GM1060E5BP0115824

1Baffling, front 6’ frame; GM1072E5BP0008759

1Baffling, rear 4’ frame; GM1048E5BP000875629

1Baffling, rear 5’ frame; GM1060E5BP0115825

1Baffling, rear 6’ frame; GM1072E5BP0008760

3Blade mulching 4’ frame; GM1048E5BP0006795M30

3Blade mulching 5’ frame; GM1060E5BP0006641M

3Blade mulching 6’ frame; GM1072E5BP0006845M

4Bolt HH M10-1.50x25 C8.8 Z F5BP003317631

ARTS MANUAL 47 FRONTIER

P

06/2010

Page 48

GROOMING MOWERS IMATCH/QUICK-HITCH ADAPTER (OPTION)OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

ARTS MANUAL 48 FRONTIER

P

06/2007

Page 49

GROOMING MOWERS IMATCH/QUICK-HITCH ADAPTER (OPTION)OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

Qty.DescriptionPart #Ref.

1A-frame support5BP503753B1

1Floating top link5BP503754B2

2Floating yoke5BP00519413

2Spacer 1-3/8”5BP503755B4

1Spacer 1-1/8”5BP503756B5

1Bolt HH M16-2.00x110 C8.8 Z P5BP00703466

4Nut PT M16-2.00 C6 Z TK5BP00055817

1Bolt HH M20-2.50x110 C8.8 Z P5BP00519538

2Bolt HH M20-2.50x140 C8.8 Z P5BP00519549

2Bolt HH M20-2.50x65 C8.8 Z F5BP000857610

2Bolt HH M16-2.00x60 C8.8 Z P5BP000657711

5Nut PT M20-2.50 C6 TK Z5BP000550712

4Washer flat Ø16 W5BP000856813

2Bushing5BP503757B14

1Bolt HH M16-2.00x90 C8.8 Z P5BP000802915

2Nut HH M20-2.50 C6 Z TN5BP001568616

5BP005181717

5BP000657818

5BP000558119

20

21

22

2Linking plates

4Bolt HH M16-2.00x45 C8.8 Z F

4Nut PT M16-2.00 C6 Z TK

5BP006750

23

1Quick-Hitch adapter complete (field conversion kit)

1Assembly manual, quick-hitch adapter5BP971378B

20

with serial #BC…844970 & below do not need the linking plates to attach the quick hitch adapter.

21

hitch adapter kit.

22

hitch adapter kit.

23

of the mower will be changed to part number 5BP0500404.

P

06/2007

The linking plates (5BP0051817) come with the mower and are not part of the quick hitch adapter kit. Mowers

The four (4) bolts (5BP0006578) and (4) nuts (5BP0005581) come with the mower and are not part of the quick

The four (4) bolts (5BP0006578) and (4) nuts (5BP0005581) come with the mower and are not part of the quick

When ordering the quick hitch adapter together with the GM1060E or the GM1048E mower, the original driveline

ARTS MANUAL 49 FRONTIER

Page 50

GROOMING MOWERS GEARBOX 540 RPM OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

ARTS MANUAL 50 FRONTIER

P

08/2010

Page 51

GROOMING MOWERS GEARBOX 540 RPM OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E

Qty.DescriptionPart #Ref.

1Oil seal 40.68.105BP00101921

2Bearing 62085BP0012149A2

1Input shaft5BP00088923

1Cap5BP00086094

8Nut HH M08-1.25 C6 Z TK5BP00018065

1Breather cap; #BC…304739 & below5BP00085986

1Breather cap; #BC…304740 & above5BP0010177

1Gasket, breather cap5BP00086017

8Bolt SC M08-1.25x50 C8.8 Z P5BP00101718

5BP33001019

24

2Housing, gearbox w/center fill hole; #BC…304739 & below

1Housing, gearbox w/o fill hole; #BC…304740 & above5BP0051891

4Nut HH M12-1.75 C6 Z TK5BP000303810

4Washer lock Ø12 Z5BP000107711

1Pinion gear5BP005019212

2Bearing 62075BP0025332A13

1Spacer5BP001019614

1Shim Ø35x45x2.55BP003419615

1Snap ring, outer Ø355BP004212216

1Oil seal 35.62.105BP000229517

1Central plate 4’ frame; GM1048E5BP005158118

1Central plate 5’ frame; GM1060E5BP0051583

1Central plate 6’ frame; GM1072E5BP0051585

1Key 8x7x355BP000668819

1Pulley SPB 250x15BP000862320

1Nut SP M25-1.50 Z5BP000669821

1Ring gear 5BP000889322

2Bolt HH M10-1.50x120 C8.8 Z P5BP001526324

4Washer flat Ø10 W5BP000203425

2Nut PT M10-1.50 C6 TK Z5BP003015626

1Housing, gearbox w/fill hole; #BC…304740 & above5BP005189227

5BP0500620

25

1Gearbox complete 540 rpm; #BC…304739 & below

1Gearbox complete 540 rpm; #BC…304740 & above5BP0500647

24

need to be replaced with part # 5BP0051891 and part # 5BP0051892.

25

P

08/2010

A limited quantity of these gearbox housings is available, after which both left and right housings (# 5BP3300101)

Gearbox no longer available should be replaced with gearbox part # 5BP0500647.

ARTS MANUAL 51 FRONTIER

Page 52

GROOMING MOWERS DRIVELINE OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E; #XF…276188 & BELOW

PARTS MANUAL 52 FRONTIER

04/2009

Page 53

GROOMING MOWERS DRIVELINE OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E; #XF…276188 & BELOW

Qty.DescriptionPart #Ref.

2PTO yoke5BP1022010C1

2Cross w/bearing5BP1002020C2

1Outer tube w/yoke; GM1048E5BP1942045NC3

1Outer tube w/yoke; GM1060E5BP1942055NC

1Outer tube w/yoke; GM1072E5BP1942070NC

1Inner tube w/yoke; GM1048E5BP1952047NC4

1Inner tube w/yoke; GM1060E5BP1952057NC

1Inner tube w/yoke; GM1072E5BP1952072NC

1Locking ring, outer tube; #XF…276188 & below5BP1782210C5

1Rigid cone, outer tube; #XF…276188 & below5BP1784201C6

1Standard cone (tractor end); #XF…276188 & below5BP1784203C7

2Pin; #XF…276188 & below5BP1784212C8

2Chain, anti-rotation5BP1006065C9

1Shield, outer tube; GM1048E5BP1773043C10

1Shield, outer tube; GM1060E5BP1773053C

1Shield, outer tube; GM1072E5BP1773068C

1Shield, inner tube; GM1048E5BP1872043C11

1Shield, inner tube; GM1060E5BP1872053C

1Shield, inner tube; GM1072E5BP1872068C

1Long cone (implement end); #XF…276188 & below5BP1784205C12

2Stiffening ring; #XF…276188 & below5BP1213233C13

1Rigid cone, inner tube; #XF…276188 & below5BP1784202C14

1Locking ring, inner tube; #XF…276188 & below5BP1782211C15

5BP90SL2043C16

5BP90SL2053C

5BP90SL2068C

26

27

28

1Shield, complete; GM1048E

1Shield, complete; GM1060E

1Shield, complete; GM1072E

1Decal “DANGER - Rotating driveline, keep away” outer shield5BP950463B17

1Decal “DANGER - Guard missing, do not operate” outer tube5BP950464B18

-Driveline, complete; GM1048E5BP0500402

-Driveline, complete; GM1060E5BP0500403

-Driveline, complete; GM1072E5BP0500404

26

27

28

Complete shield is interchangeable with part # 5BP96SL2043C.

Complete shield is interchangeable with part # 5BP96SL2053C.

Complete shield is interchangeable with part # 5BP96SL2068C.

PARTS MANUAL 53 FRONTIER

04/2009

Page 54

GROOMING MOWERS DRIVELINE OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E; FROM #XF…276189 TO #XF...286013

ARTS MANUAL 54 FRONTIER

P

11/2010

Page 55

GROOMING MOWERS DRIVELINE OPERATOR’S MANUAL

GM1048E, GM1060E, GM1072E; FROM #XF…276189 TO #XF...286013

Qty.DescriptionPart #Ref.

5BP1022010C1

5BP1002020C2

5BP1942045NC3

5BP1942055NC

5BP1942070NC

5BP1952047NC4

5BP1952057NC

5BP1952072NC

29

30

31

32

33

34

35

36

2PTO yoke

2Cross w/bearing

1Outer tube w/yoke; GM1048E

1Outer tube w/yoke; GM1060E

1Outer tube w/yoke; GM1072E

1Inner tube w/yoke; GM1048E

1Inner tube w/yoke; GM1060E

1Inner tube w/yoke; GM1072E

1Locking ring, outer tube; from #XF…276189 to XF...2860135BP1782710C5