Page 1

ET -3507-J 1/2-INCH

HAMMER DRILL

CAUTION

RISK OF INJURY!

THIS MANUAL IS AN IMPORTANT PART OF THE HAMMER DRILL

AND SHOULD REMAIN WITH THIS UNIT WHEN YOU SELL OR RENT IT.

1/2-Inch Hammer Drill Operator's Manual 1

READ MANUAL BEFORE OPERATING!

Page 2

Introduction

Congratulations on the purchase of your new Hammer Drill! You can be assured your

hammer drill was constructed and designed with quality and performance in mind. Each

component has been rigorously tested to ensure the highest level of acceptance.

This operator's manual was compiled for your benefit. By reading and following the simple

safety, installation, operation, maintenance and troubleshooting steps described in this

manual, you will receive years of trouble-free operation from your new tool. The contents

of this manual are based on the latest product information available at the time of

publication. The manufacturer reserves the right to make changes in price, color, materials, equipment, specifications or models at any time without notice.

Once the unit has been removed from the box, immediately write in the serial number of your

unit in the space provided below.

SERIAL NUMBER_________________________________

Inspect for signs of obvious or concealed freight damage. If damage does exist, file a claim

with the transportation company immediately. Be sure that all damaged parts are replaced and

that the mechanical problems are corrected prior to operation of the unit. If you require service,

contact your Customer Service.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

Please have the following information available for all service calls:

1. Model Number

2. Serial Number

3. Date and Place of Purchase

WARNING

WEAR RESPIRAT ORY PROTECTION

Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contain chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-base paints,

• Crystalline Silica from bricks, cement and other masonry products, and

• Arsenic and Chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals, work in a well ventilated area and work

with approved safety equipment, such as those dust masks that are specially designed

to filter out microscopic particles.

2 1/2-Inch Hammer Drill Operator's Manual

Page 3

Table of Content

SAFETY .................................................................................................................. 4-8

GENERAL SAFETY RULES.................................................................. 4-8

FUNCTIONAL DESCRIPTION............................................................................... 9

MODEL................................................................................................... 9

NAME OF PARTS.................................................................................. 9

SPECIFICATIONS ................................................................................. 9

OPERATION........................................................................................................... 10-13

APPLICATIONS ..................................................................................... 10

PRE-OPERATION ................................................................................. 10-12

OPERATION .......................................................................................... 13

MAINTENANCE AND INSPECTION ..................................................................... 14

MAINTENAANCE AND INSPECTION................................................... 14

SERVICE AND REPAIRS...................................................................... 14

STANDARD ACCESSORIES ................................................................ 14

NOTES ................................................................................................................... 15

FRENCH ................................................................................................................. 16-29

SPANISH ................................................................................................................ 30-44

1/2-Inch Hammer Drill Operator's Manual 3

Page 4

Safety

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol on

your tool or in this manual, be alert to the potential for

personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A "DANGER, WARNING or CAUTION" safety warning will be

surrounded by a "SAFETY ALERT BOX." This box is used to

designate and emphasize Safety Warnings that must be

followed when operating this tool.

Accompanying the Safety Warnings are "signal words" which

designate the degree or level of hazard seriousness. The

"signal words" used in this manual are as follows:

DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, COULD result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided MAY result in minor or

moderate injury.

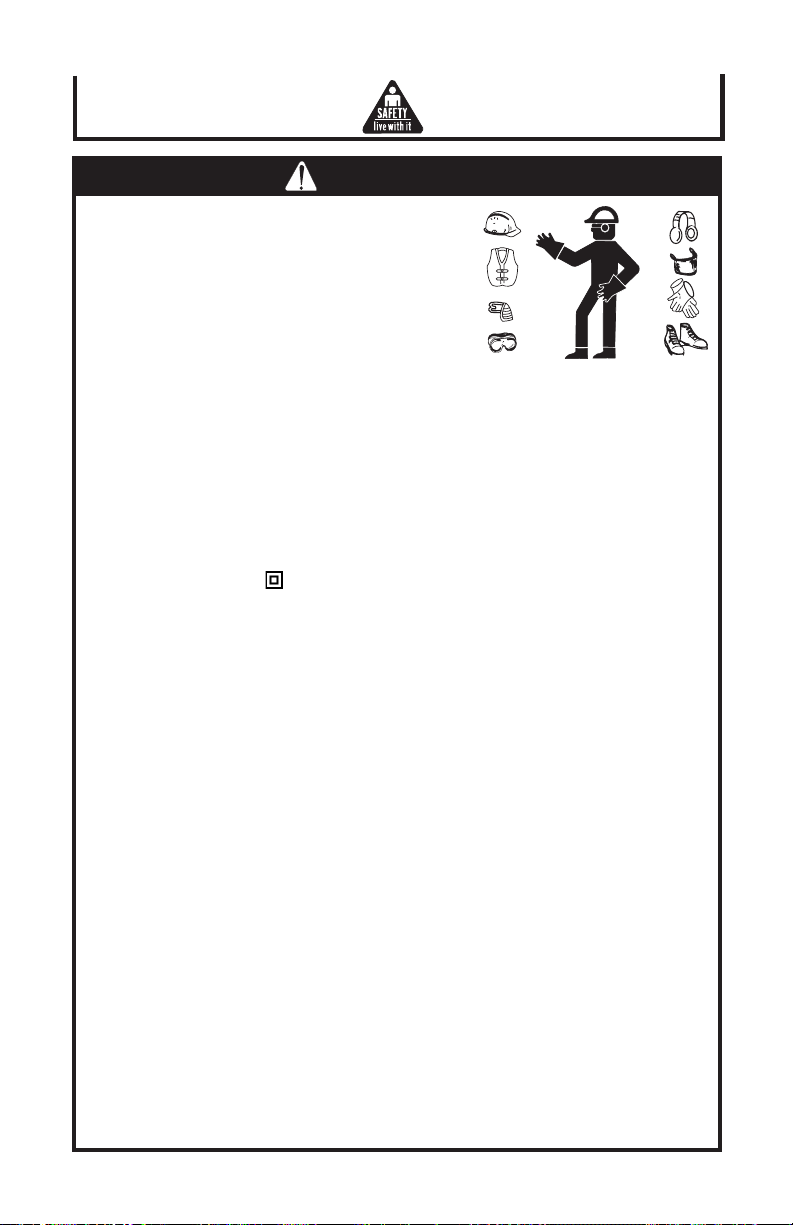

GENERAL SAFETY RULES

WARNING: Read and understand all

instructions.

Failure to follow all

instructions listed below, may

result in electric shock, fire and/

or serious personal injury.

SAVE THESE INSTRUCTIONS

4 1/2-Inch Hammer Drill Operator's Manual

Page 5

WARNING

KEEP YOUR WORK AREA CLEAN AND WELL LIT.

Cluttered benches and dark areas invite accidents.

DO NOT OPERATE POWER TOOLS IN EXPLOSIVE

ATMOSPHERES, SUCH AS IN THE PRESENCE OF

FLAMMABLE LIQUIDS, GASES, OR DUST. Power

tools create sparks which may ignite the dust of fumes.

KEEP BYSTANDERS CHILDREN, AND VISITORS

AWAY WHILE OPERATING A POWER TOOL.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

DOUBLE INSULATED TOOLS ARE EQUIPPED WITH

A POLARIZED PLUG (ONE BLADE IS WIDER THAN

THE OTHER.) THIS PLUG WILL FIT IN A POLARIZED OUTLET ONLY ONE WAY. IF THE PLUG DOES

NOT FIT FULLY IN THE OUTLET, REVERSE THE

PLUG. IF IT STILL DOES NOT FIT, CONTACT A

QUALIFIED ELECTRICIAN TO INSTALL A POLARIZED OUTLET. DO NOT CHANGE THE PLUG IN ANY

WAY. Double Insulation eliminates the need for the

three wire grounded power cord and grounded power

supply system.

AVOID BODY CONTACT WITH GROUNDED

SURFACES SUCH AS PIPES, RADIATORS, RANGES

AND REFRIGERATORS. There is an increased risk of

electric shock if your body is grounded.

DON'T EXPOSE POWER TOOLS TO RAIN OR WET

CONDITIONS. Water entering a power tool will

increase the risk of electric shock.

DO NOT ABUSE THE CORD. NEVER USE THE

CORD TO CARRY THE TOOLS OR PULL THE PLUG

FROM AN OUTLET. KEEP CORD AWAY FROM

HEAT, OIL, SHARP EDGES OR MOVING PARTS.

REPLACE DAMAGED CORDS IMMEDIATELY.

Damaged cords increase the risk of electric shock.

WHEN OPERATING A POWER TOOL OUTSIDE,

USE AN OUTDOOR EXTENSION CORD MARKED

“W-A” OR “W”. These cords are rated for outdoor use

and reduce the risk of electric shock.

1/2-Inch Hammer Drill Operator's Manual 5

Page 6

WARNING

PERSONAL SAFETY

STAY ALERT, WATCH WHAT YOU ARE DOING AND USE COMMON SENSE

WHEN OPERATING A POWER TOOL. DO NOT USE TOOL WHILE TIRED OR

UNDER THE INFLUENCE OF DRUGS, ALCOHOL, OR MEDICATION. A moment of

inattention while operating power tools may result in serious personal injury.

DRESS PROPERLY. DO NOT WEAR LOOSE CLOTHING OR JEWELRY. CONTAIN

LONG HAIR. KEEP YOUR HAIR, CLOTHING AND GLOVES AWAY FROM MOVING

PARTS. Loose clothes, jewelry, or long hair can be caught in moving parts.

AVOID ACCIDENTAL STARTING. BE SURE SWITCH IS OFF BEFORE PLUGGING

IN. Carrying tools with your finger on the switch or plugging in tools that have the

switch on invites accidents.

REMOVE ADJUSTING KEYS OR WRENCHES BEFORE TURNING THE TOOL ON.

A wrench or a key that is left attached to a rotating part of the tool may result in

personal injury.

DO NOT OVERREACH. KEEP PROPER FOOTING AND BALANCE AT ALL TIMES.

Proper footing and balance enables better control of the tool in unexpected situations.

USE SAFETY EQUIPMENT. ALWAYS WEAR EYE PROTECTION. Dust mask,

nonskid safety shoes, hard hat, or hearing protection must be used for appropriate

conditions.

TOOL USE AND CARE

USE CLAMPS OR OTHER PRACTICAL WAY TO SECURE AND SUPPORT THE

WORKPLACE TO A STABLE PLATFORM. Holding the work by hand or against your

body is unstable and may lead to loss of control.

DO NOT FORCE TOOL. USE THE CORRECT TOOL FOR YOUR APPLICATION.

The correct tool will do the job better and safer at the rate for which it is designed.

DO NOT USE TOOL IF SWITCH DOES NOT TURN IT ON OR OFF. Any tool that

cannot be controlled with the switch is dangerous and must be repaired.

DISCONNECT THE PLUG FROM THE POWER SOURCE BEFORE MAKING ANY

ADJUSTMENTS, CHANGING ACCESSORIES, OR STORING THE TOOL. Such

preventive safety measures reduce the risk of starting the tool accidentally.

STORE IDLE TOOLS OUT OF REACH OF CHILDREN AND OTHER UNTRAINED

PERSONS. Tools are dangerous in the hand of untrained users.

MAINTAIN TOOLS WITH CARE. KEEP CUTTING TOOLS SHARP AND CLEAN.

Properly maintained tools, with sharp cutting edges are less likely to bind and are

easier to control.

CHECK FOR MISALIGNMENT OR BINDING OF MOVING PARTS, BREAKAGE OF

PARTS, AND ANY OTHER CONDITION THAT MAY AFFECT THE TOOLS OPERATION. IF DAMAGED, HAVE THE TOOL SERVICED BEFORE USING. Many

accidents are caused by poorly maintained tools.

USE ONLY ACCESSORIES THAT ARE RECOMMENDED BY THE MANUFACTURER FOR YOUR MODEL. Accessories that may be suitable for one tool, may

become hazardous when used on another tool.

SERVICE

TOOL SERVICE MUST BE PERFORMED ONLY BY QUALIFIED REPAIR PERSONNEL. Service or maintenance performed by unqualified personnel could result in a risk

of injury.

WHEN SERVICING A TOOL, USE ONLY IDENTICAL REPLACEMENT PARTS.

FOLLOW INSTRUCTIONS IN THE MAINTENANCE SECTION OF THIS MANUAL.

Use of unauthorized parts or failure to follow Maintenance Instruction may create a

risk of electric shock or injury.

NEVER TOUCH MOVING PARTS

Never place your hands, fingers or other body parts near the tool’s moving parts.

NEVER OPERATE WITHOUT ALL GUARDS IN PLACE.

Never operate this tool without all guards or safety features in place and in proper

working order. If maintenance or servicing requires the removal of a guard or safety

feature, be sure to replace the guard or safety feature before resuming operation of

the tool.

6 1/2-Inch Hammer Drill Operator's Manual

Page 7

WARNING

SPECIFIC SAFETY RULES AND SYMBOLS

1. HOLD TOOLS BY INSULATED GRIPPING SURFACES WHEN PERFORMING

AN OPERATION WHERE THE CUTTING TOOL MAY CONTACT HIDDEN

WIRING OR ITS OWN CORD. Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

2. Wear ear plugs when using the tool for extended periods. Prolonged exposure to

high intensity noise can cause hearing loss.

3. NEVER touch the tool bit with bare hands after operation.

4. NEVER wear gloves made of material liable to roll up such as cotton, wool, cloth

or string, etc.

5. ALWAYS attach the side handle and securely grip the Hammer Drill.

6. ALWAYS be careful with buried objects such as underground wiring. Touching

these active wiring or electric cables with this tool, you may receive an electric

shock.

Confirm if there are any buried objects such as electric cable within the wall, floor

or ceiling where you are going to operate here after.

7. Definitions for symbols used on this tool:

Volts = V

Hertz = Hz

Amperes = A

No load speed = n

Watt = W

Class II Construction =

Revolutions per minute = ---/min

o

CAUTION

USE RIGHT TOOL

Don’t force small tool or attachment to do the job of a heavy-duty tool. Don’t use tool for

purpose not intended —for example— don’t use circular saw for cutting tree limbs or logs.

NEVER USE A POWER TOOL FOR APPLICATIONS OTHER THAN THOSE

SPECIFIED

Never use a power tool for applications other than those specified in the Instruction

Manual.

HANDLE TOOL CORRECTLY

Operate the tool according to the instructions provided herein. Do not drop or throw the

tool. Never allow the tool to be operated by children, individuals unfamiliar with its

operation or unauthorized personnel.

KEEP ALL SCREWS, BOLTS AND COVERS TIGHTLY IN PLACE

Keep all screws, bolts, and plates tightly mounted. Check their condition periodically.

DO NOT USE POWER TOOLS IF THE PLASTIC HOUSING OR HANDLE IS CRACKED

Cracks in the tool’s housing or handle can lead to electric shock. Such tools should not

be used until repaired.

BLADES AND ACCESSORIES MUST BE SECURELY MOUNTED TO THE TOOL

Prevent potential injuries to yourself or others. Blades, cutting implements and accessories which have been mounted to the tool should be secure and tight.

KEEP MOTOR AIR VENT CLEAN

The tool’s motor air vent must be kept clean so that air can freely flow at all times. Check

for dust buildup frequently.

1/2-Inch Hammer Drill Operator's Manual 7

Page 8

CAUTION

OPERATE POWER TOOLS AT THE RATED VOLTAGE

Operate the power tool at voltages specified on its nameplate.

If using the power tool at a higher voltage than the rated voltage, it will result in

abnormally fast motor revolution and may damage the unit and the motor may burn

out.

NEVER USE A TOOL WHICH IS DEFECTIVE OR OPERATING ABNORMALLY

If the tool appears to be operating unusually, making strange noises, or otherwise

appears defective, stop using it immediately and arrange for repairs by a JOHN

DEERE AUTHORIZED DEALER.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF

Don’t leave tool until it comes to a complete stop.

CAREFULLY HANDLE POWER TOOLS

Should a power tool be dropped or struck against hard materials inadvertently, it may

be deformed, cracked, or damaged.

DO NOT WIPE PLASTIC PARTS WITH SOLVENT

Solvents such as gasoline, thinner benzine, carbon tetrachloride, and alcohol may

damage and crack plastic parts. Do not wipe them with such solvents.

Wipe plastic parts with a soft cloth lightly dampened with soapy water and dry

thoroughly.

DOUBLE INSULATION FOR SAFER OPERATION

To ensure safer operation of this power tool, JOHN DEERE has adopted a double

insulation design. “Double insulation “ means that two physically separated insulation

systems have been used to insulate the electrically conductive materials connected to

the power supply from the outer frame handled by the operator. Therefore, either the

symbol “ ” or the words and “Double insulation” appear on the power tool or on the

nameplate.

Although this system has no external grounding, you must still follow the normal

electrical safety precautions given in this Instruction Manual, including not using the

power tool in wet environments.

To keep the double insulation system effective, follow these precautions:

a. Only JOHN DEERE AUTHORIZED DEALER should disassemble

or assemble this power tool, and only genuine JOHN DEERE replacement

parts should be installed.

b. Clean the exterior of the power tool only with a soft cloth moistened with

Never use solvents, gasoline or thinner on plastic components; otherwise the plastic

may dissolve.

soapy water, and dry thoroughly.

SAVE THESE INSTRUCTIONS AND MAKE THEM AVAILABLE TO

OTHER USERS AND OWNERS OF THIS TOOL!

8 1/2-Inch Hammer Drill Operator's Manual

Page 9

Functional Description

NOTE: The information contained in this Instruction Manual is designed to assist

NEVER operate, or attempt any maintenance on the tool unless you have first read

and understood all safety instructions contained in this manual.

Some illustrations in this Instruction Manual may show details or attachments that

differ from those on your own power tool.

MODEL:

ET-3507-J 1/2-INCH HAMMER DRILL

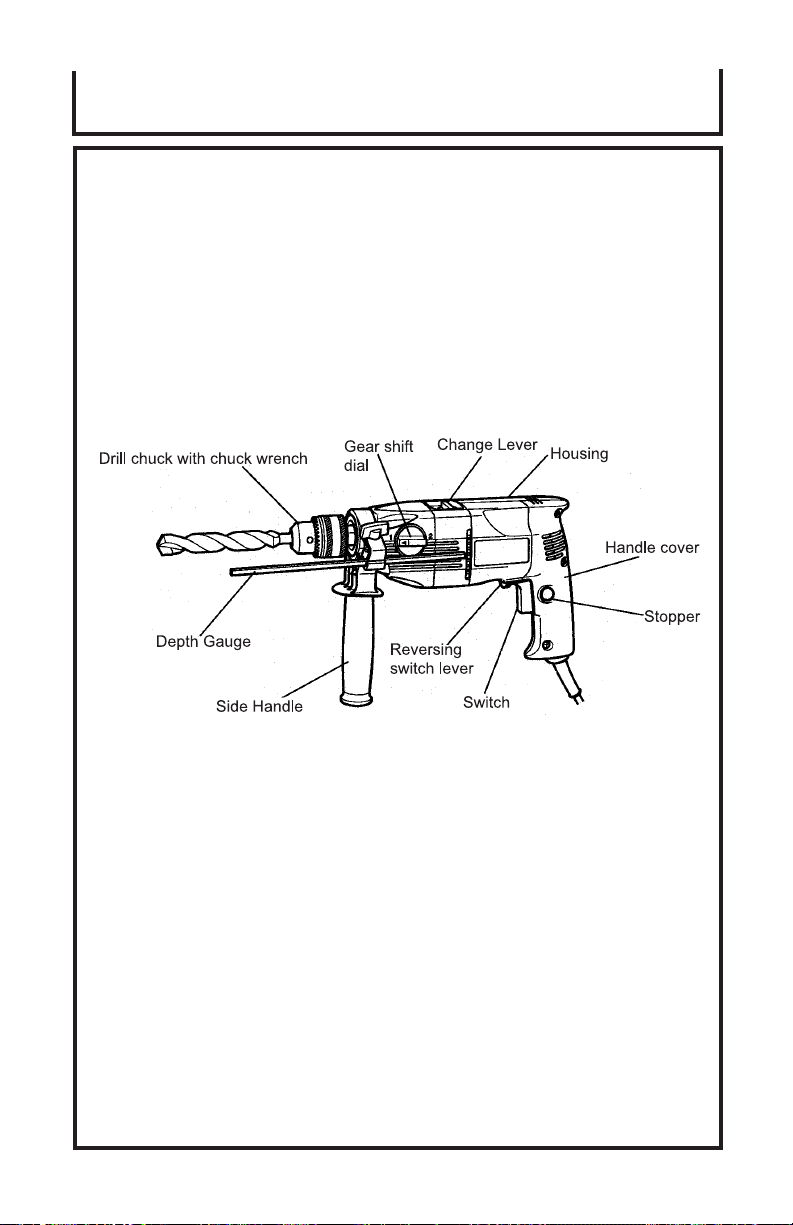

NAME OF PARTS:

you in the safe operation and maintenance of the power tool.

(Fig. 1)

SPECIFICATIONS:

Motor Single Phase, Series Commutator Motor

Power source Single Phase 115V AC 60 Hz

Current 6.8 A

Reversible Yes

Speed change 1 2

No-load speed 0–1100/min 0–2600/min

Drill chuck capacity: 1/2" (13mm)

Capacity:

Steel- 1/2" (13mm) 5/16" (8mm)

Concrete- 3/4" (20mm) 1/2" (13mm)

Wood- 1-9/16" (40mm) 1" (25mm)

No-load impact rate 14000/min 36000/min

Weight (Without Cord) 4.6 lbs (2.1 kg)

1/2-Inch Hammer Drill Operator's Manual 9

Page 10

Operation

APPLICATIONS:

By combined actions of ROTATION and IMPACT: Boring holes in hard surfaces

(concrete, marble, granite, tiles, etc.)

By ROTATIONAL action: Boring holes in metal, wood and plastic.

PRE-OPERATION:

1. Power source:

Ensure that the power source to be utilized conforms to the power source require

ments specified on the product nameplate.

2. Power switch:

Ensure that the switch is in the OFF position. If the plug is connected to a

receptacle while the switch is in the ON position, the power tool will start operating

immediately and can cause serious injury.

3. Extension cord:

When the work area is far away from the power source, use an extension cord of

sufficient thickness and rated capacity. The extension cord should be kept as short

as practicable.

WARNING: DAMAGED CORD MUST BE REPLACED OR REPAIRED.

4. Check the receptacle

If the receptacle only loosely accepts the plug, the receptacle must be repaired.

Contact a licensed electrician to make appropriate repairs.

If such a faulty receptacle is used, it may cause overheating, resulting in a serious

hazard.

5. Confirming condition of the environment:

Confirm that the work site is placed under appropriate conditions conforming to

prescribed precautions.

6. Selecting the appropriate drill bit:

a. When boring concrete or stone, use a masonry drill bit.

b. When boring metal or plastic, use an ordinary metalworking drill bit.

c. When boring wood, u se an ordinary woodworking drill bit. However, when

drilling 1/4" (6.5 mm) or smaller holes, use a metalworking drill bit.

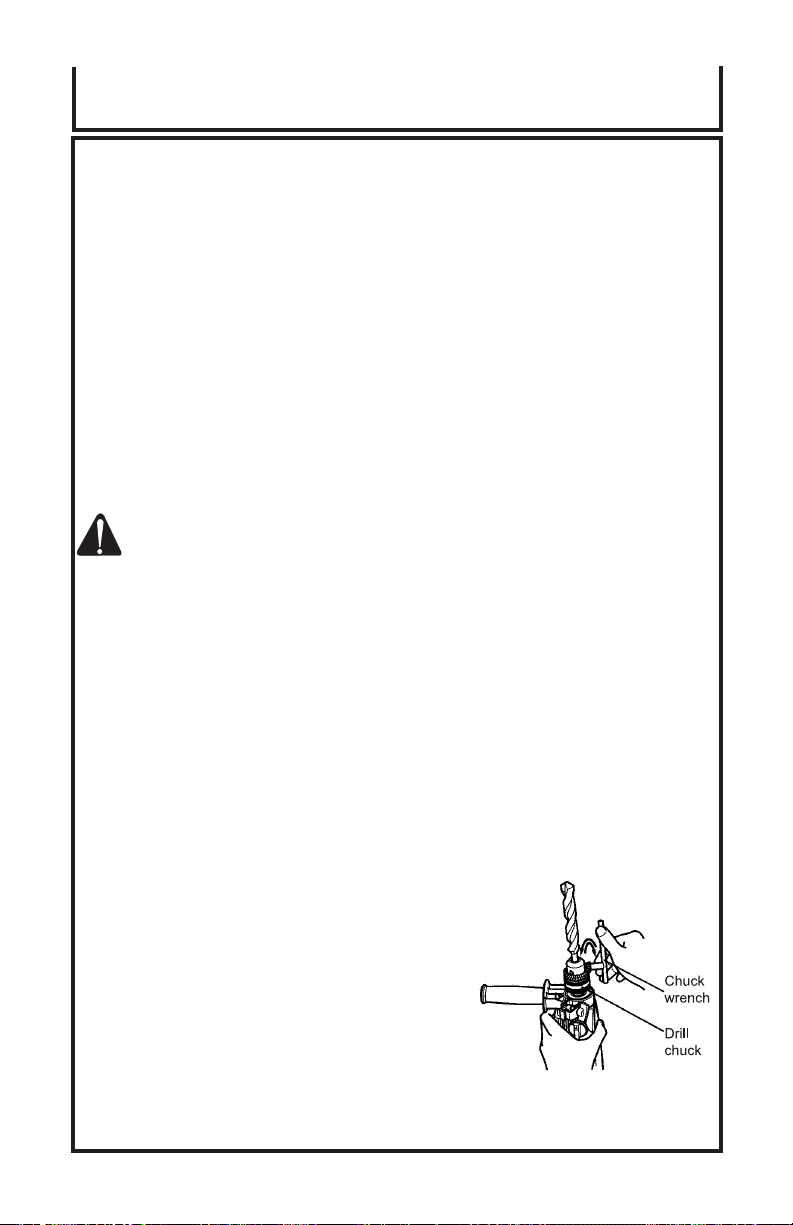

7. Mounting and dismounting of the bit. (Fig. 2)

Fit the drill bit into the chuck and use the chuck

wrench to secure it, tightening the chuck by each

of the three holes in turn.

(Fig. 2)

10 1/2-Inch Hammer Drill Operator's Manual

Page 11

Operation

PRE-OPERATION (CONTINUED):

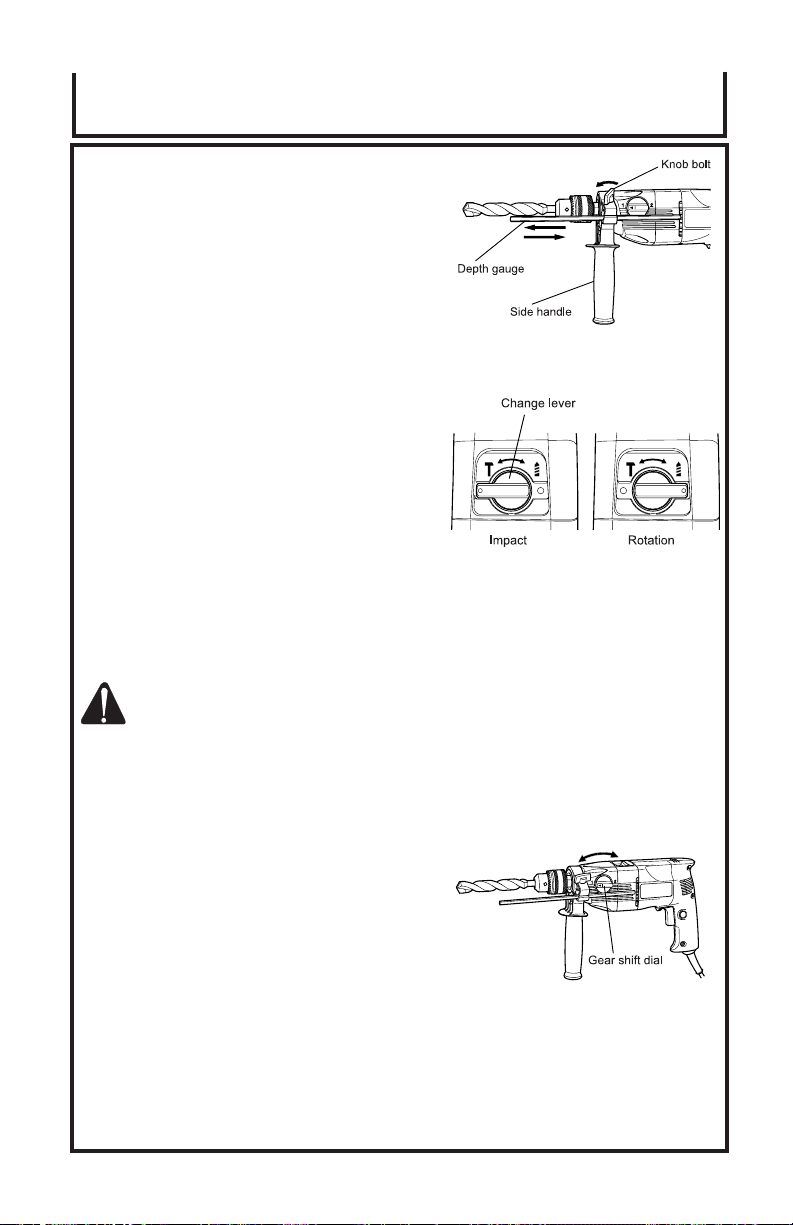

8. Fixing the side handle (Fig. 3):

Loosen the knob bolt on the side handle, and

attach the side handle to the gear cover in a

position convenient for drilling. Match the

projecting part of the handle to the groove on

the gear cover, and firmly tighten the knob bolt.

To remove the side handle, loosen the knob

bolt and rotate the handle.

To attach a depth gauge on the side handle,

insert the gauge into the U-shaped groove on

the side handle, adjust the position of the depth

gauge in accordance with the desired depth of

the hole, and firmly tighten the wing bolt.

9. IMPACT to ROTATION change over (Fig. 4):

The Hammer Drill can be switched from

IMPACT (impact plus rotation) to ROTATION

(rotation only) by rotating the change lever

(Fig. 1). When boring concrete, stone, tile or

similar hard materials, rotating the change lever

to IMPACT side. The drill head impacts against

the material while continuing to rotate.

When boring metal, wood or plastic, rotating

the change lever to ROTATION side. The drill

rotates as an ordinary electric drill.

CAUTION: DO NOT USE THE HAMMER

DRILL IN THE IMPACT

FUNCTION IF THE

MATERIAL CAN BE BORED

BY ROTATION ONLY. SUCH

ACTION WILL NOT ONLY

REDUCE DRILL EFFICIENCY,

BUT MAY ALSO DAMAGE THE

DRILL TIP.

NOTE: The change lever may not rotate smoothly

when changing from hammer drill mode to

drill mode (Fig. 4).

In this case, switch ON and operate the

machine for few seconds. The spindle

shaft will then be pushed forward, and the

change lever can be moved smoothly.

(Fig. 3)

(Fig. 4)

(Fig. 5)

10. High-speed/Low-speed change over:

To change speed, rotate the gear shift dial as indicated by the arrow in Fig. 5. The

numeral "1" engraved on the drill body denotes low speed, the numeral "2"

denotes high speed.

1/2-Inch Hammer Drill Operator's Manual 11

Page 12

Operation

PRE-OPERATION (CONTINUED):

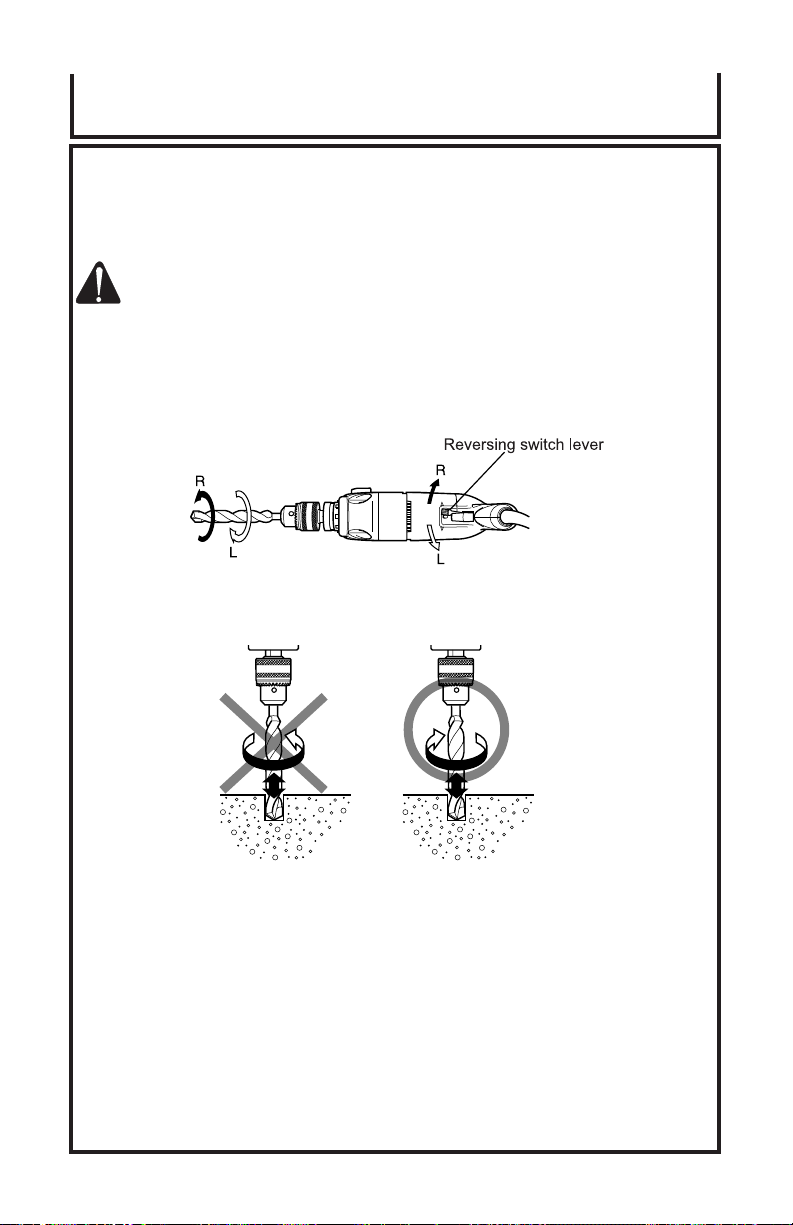

11. Confirm the direction of bit rotation:

The bit rotates clockwise (viewed from the rear side) by pushing the R-side of the

reversing switch lever.

The L-side of the lever is pushed to turn the bit counterclockwise. (Fig. 6)

CAUTION: NEVER CHANGE THE DIRECTION OF BIT ROTATION WHILE

OPERATING. TURN THE POWER SWITCH OFF BEFORE

CHANGING THE DIRECTION OF BIT ROTATION: OTHERWISE,

BURNING OF THE MOTOR WILL RESULT.

ALWAYS USE THE HAMMER DRILL WITH CLOCKWISE

ROTATION, WHEN USING IT AS A HAMMER DRILL. (FIG. 7)

(Fig. 6)

(Fig. 7)

12 1/2-Inch Hammer Drill Operator's Manual

Page 13

OPERATION:

Operation

CAUTION: TO PREVENT ACCIDENTS, MAKE SURE TO TURN THE SWITCH

1. Operation of switch:

a. The drill speed can be adjusted from O through full speed by regulating the

trigger-squeezing force. The more the trigger is squeezed, the faster the drill

rotates. When the trigger is squeezed fully, the speed is the maximum.

b. Pulling the trigger and pushing the stopper, it keeps the switched-on condition

which is convenient for continuous running. When switching off, the stopper

can be disconnected by pulling the trigger again.

2. When using as a Drill or a Hammer Drill:

a. Pressing force of the drill:

You cannot drill holes more quickly even if you press the drill with a stronger

force than necessary. It not only damages tip of drill bits and decreases the

efficiency of operation, but also shortens the life of the drill.

b. In case of penetrating holes:

Drill bits can be broken when the material being drilled is penetrated. It is

important to decrease pressing force just before penetrating.

CAUTION: IN CONTINUOUS OPERATION, CONDUCT NO-LOAD

c. When a thick drill bit is used.

Your arm is subjected to larger reaction force when a thicker drill bit is used.

Be careful not to be moved by the reaction force. For this, establish a foothold,

hold the unit tightly with both hands perpendicularly to the material being

drilled.

OFF AND DISCONNECT THE PLUG FROM THE RECEPTACLE

WHEN THE DRILL BITS AND OTHER VARIOUS PARTS ARE

INSTALLED OR REMOVED. THE POWER SWITCH SHOULD

ALSO BE TURNED OFF DURING A WORK BREAK AND AFTER

WORK.

OPERATION FOR FIVE SECONDS AFTER COMPLETING A

DRILLING JOB.

1/2-Inch Hammer Drill Operator's Manual 13

Page 14

Maintenance and Inspection

MAINTENANCE AND INSPECTION:

WARNING: BE SURE TO SWITCH POWER OFF AND DISCONNECT THE

1. Inspecting the drill bits:

Since use of a dull tool will cause motor malfunctioning and degraded efficiency,

replace the drill bit with a new one or resharpening without delay when abrasion is

noted.

2. Inspecting the mounting screws:

Regularly inspect all mounting screws and ensure that they are properly tightened.

Should any of the screws be loosened, retighten them immediately.

WARNING: USING THIS HAMMER DRILL WITH LOOSENED SCREWS IS

3. Keeping after use:

When not in use, the Power tool should be kept in a dry place out of the reach of

children.

4. Inspecting the carbon brushes:

For your continued safety and electrical shock protection, carbon brush inspection

and replacement on this tool should ONLY be performed by a JOHN DEERE

AUTHORIZED DEALER.

5. Maintenance of the motor:

The motor unit winding is the very “heart”’ of the power tool. Exercise due care to

ensure the winding does not become damaged and/or wet with oil or water.

SERVICE AND REPAIRS:

All quality power tools will eventually require servicing or replacement of parts because

of wear from normal use. To assure that only authorized replacement parts will be used,

all service and repairs must be performed by a JOHN DEERE AUTHORIZED DEALER,

ONLY.

PLUG FROM THE RECEPTACLE DURING MAINTENANCE AND

INSPECTION.

EXTREMELY DANGEROUS.

WARNING: ACCESSORIES FOR THIS POWER TOOL ARE MENTIONED IN

STANDARD ACCESSORIES:

-Plastic Carrying Case 1

-Side Handle 1

-Depth Gauge 1

-Chuck Wrench (Spec. only for chuck with chuck wrench) 1

NOTE: Accessories are subject to change without any obligation on the part of

JOHN DEERE.

14 1/2-Inch Hammer Drill Operator's Manual

THIS INSTRUCTION MANUAL. THE USE OF ANY OTHER

ATTACHMENT OR ACCESSORY CAN BE DANGEROUS AND

COULD CAUSE INJURY OR MECHANICAL DAMAGE.

Page 15

Notes

1/2-Inch Hammer Drill Operator's Manual 15

Page 16

Introduction

Félicitations de l'achat de votre nouveau la clé à outil! Vous pouvez être assuré que votre

nouveau la outil a été construit avec le plus haut niveau de précision et de fiabilité. Chaque

composant a été rigoureusement testé par des techniciens pour assurer la qualité, la durabilité

et la performance de ce outil.

Ce manuel opérateur a été dressé pour que vous en retiriez le meilleur parti. Par la lecture

et l'application des mesures simples de sécurité, d'installation et d'opération, d'entretien et

de dépannage décrites dans ce manuel, votre nouveau outil. Fonctionnera sans faille

pendant de nombreuses années. Le contenu de ce manuel est basé sur la dernière

information disponible du produit au moment de la publication. Félicitations se réserve le

droit d'effectuer des changements de prix, de couleur, de matériaux, d'équipement, de

caractéristiques ou de modèles à tout moment sans communication préalable.

Une fois l'appareil déballé, écrivez immédiatement le numéro de série de votre appareil dans

l'espace çidessous.

NUMÉRO DE SÉRIE_________________________________

Assurez vous qu'il n'y a pas de signes de dommages évidents ou cachés suite au transport.

En cas de dommage, remplissez immédiatement une réclamation avec la compagnie de

transport. Assurez vous que toutes les pièces endommagées sont remplacees et les

problémes mécaniques et électriques corrigés avant l'utilisation de l'appareil. Si vous avez

besoin d'assistance, entrez en contact avec votre service clientèle.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068-0050

Tél.: JD-KLEEN (1-877-535-5336) Fax 563-556-1235

du lundi au vendredi de 8h00 à 17h, CST (heure centrale)

Veuillez avoir les informations suivantes disponibles pour toute intervention:

1. Numéro de modèle

2. Numéro de série

3. Date et lieu d'achat

ADVERTISSEMENT

LE PORT D’UNE PROTECTION RESPIRATOIRE EST RECOMMANDÉ

Certaines poussières produites par le sablage, le sciage, le broyage, le perçage, et

autres activités de construction contiennent des produits chimiques connus par l'Etat de

Californie pour cause de cancer, de défauts de naissance ou de problèmes de

reproduction. Des exemples de ces produits chimiques sont:

• Du plomb provenant de peintures à base de plomb.

• De la silice de Crystalline provenant de briques, de ciment et d’autres produits de

maçonnerie.

• De l’arsenic et du chrome provenant de bois de charpente traité chimiquement.

Votre risque de ces contacts varie selon le temps passé à faire ce genre de travail.

Pour réduire votre exposition à ces produits chimiques, travailler dans un endroit bien

aéré et avec un équipement de sécurité approuvé tels que les masques de poussière

conçus spécialement pour filtrer les particules microscopiques.

16 Manuel Opérateur

Page 17

Table Des Matieres

SÉCURITÉ.............................................................................................................. 18-23

DESCRIPTION FONCTIONNELLE ....................................................................... 24

UTILISATION ......................................................................................................... 25-28

ENTRETIEN ET INSPECTIONS ............................................................................ 29

SIGNIFICATION DES MOTS D’AVERTISSEMENT ............................. 18-23

MAQUETTE ........................................................................................... 24

NOM DES PARTIES .............................................................................. 24

UTILISATIONS....................................................................................... 24

SPECIFICATIONS ................................................................................. 24

UTILISATIONS....................................................................................... 25

AVANT L'UTILISATION ......................................................................... 25-27

UTILISATION ......................................................................................... 28

ENTRETIEN ET INSPECTIONS ........................................................... 29

ENTRETIEN ET RÉPARATION ............................................................ 29

ACCESSORIES STANDARD ................................................................ 29

Manuel Opérateur 17

Page 18

Sécurité

RECONNAÎTRE LES SYMBOLES DE MISE EN

GARDE

Voici le symbole de mise en garde. Lorsqu'il apparaît sur la

outil ou dans la présente publication, c'est pour prévenir d'un

risque potentiel de blessure.

Respecter tous les conseil de sécurité ainsi que les

consignes générales de prévention des accidents.

COMPRENDRE LES TERMES DE MISE EN

GARDE

Les avertissements de sécurité "DANGER,

AVERTISSEMENT ou ATTENTION" seront entourés par

un "ENCADRE ALERTE SECURITE".Cet encadré est utilisé

pour indiquer et souligner les avertissements de sécurité qui

doivent être suivis en actionnant d'outils. En plus des

avertissements de sécurité, des "mots d'alerte" sont utilisés

pour indiquer le degré ou niveau de risque. Les "mots

d'alerte" utilisés dans ce manuel sont comme suit:

DANGER: Indique une situation au danger

imminent qui, si elle n'est pas évitée,

ENTRAINERA la mort ou des blessures

graves.

AVERTISSEMENT: Indique une situation

potentiellement dangereuse qui, si elle

n'est pas évitée, POURRAIT entraîner la

mort ou des blessures graves.

DANGER

AVERTISSEMENT

ATTENTION

ATTENTION: Indique une situation

potentiellement dangereuse, qui, si elle

n'est pas évitée, PEUT entraîner des

blessures mineures ou peu graves et des

dégats au compresseur.

REGLES GENERALE DE SECURITE

AVERTISSEMENT: Lire et

coxmprendre toutes les instructions. Un

non respect de toutes les intrucitons

ci-dessous peut entraîner une

électrocution, un incedie et/ou de

sérieuses blessures personnelles.

CONSERVER CES INSTRUCTIONS

18 Manuel Opérateur

Page 19

AVERTISSEMENT

GARDER LA ZONE DE TRAVAIL PROPRE ET BIEN

ÉCLAIRÉE. Les établis mal rangés et les zones

sombres invitent aux accidents.

NE PAS UTILISER LES OUTILS MOTORISÉS DANS

UNE ATMOSPHÈRE EXPLOSIVE, TELLE QU’EN

PRÉSENCE DE LIQUIDES INFLAMMABLES, DE GAZ

OU DE POUSSIÈRES. Les outils motorisés créent des

étincelles qui risquent d’enflammer la poussière ou les

vapeurs.

TENIR LES SPECTATEURS, LES ENFANTS ET LES

VISITEURS ÉLOIGNÉS, LORS DE L’UTILISATION DE

L’OUTIL MOTORISÉ. Une distraction peut faire perdre

le contrôle de la machine.

SÉCURITÉ ÉLECTRIQUE

LES OUTILS À DOUBLE ISOLATION SONT ÉQUIPÉS

D’UNE FICHE POLARISÉE (UNE LAME EST PLUS

LARGE QUE L’AUTRE). CETTE FICHE NE

PÉNÉTRERA DANS UNE PRISE SECTEUR

POLARISÉE QUE DANS UN SENS. SI LA FICHE NE

RENTRE PAS COMPLÈTEMENT DANS LA PRISE, LA

RETOURNER. SI ELLE NE RENTRE TOUJOURS PAS,

CONTACTER UN ÉLECTRICIEN QUALIFIÉ POUR

INSTALLER UNE PRISE POLARISÉE. Ne pas modifier

la fiche d’aucune façon. La double isolation élimine

le besoin d’un cordon d’alimentation à trois fils et d’un

système d’alimentation avec mises à la terre.

EVITER TOUT CONTACT CORPOREL AVEC LES

SURFACES MISES À LA TERRE TELLES QUE LES

CANALISATIONS, LES RADIATEURS, LES

RÉCHAUDS ET LES RÉFRIGÉRATEURS. Il y a un

risque accru d’électrocution si son corps est mis à la

terre.

NE PAS EXPOSER LES OUTILS MOTORISÉS À LA

PLUIE OU À L’HUMIDITÉ. De l’eau pénétrant à

l’intérieur de l’outil motorisé augmente le risque

d’électrocution.

NE PAS MALTRAITER LE CORDON

D’ALIMENTATION. NE JAMAIS UTILISER LE

CORDON POUR PORTER LES OUTILS OU TIRER

SUR LA FICHE DU RÉCEPTACLE. GARDER LE

CORDON À L’ÉCART DE LA CHALEUR, DE L’HUILE,

DES ARÊTES COUPANTES OU DES PIÈCES EN

MOUVEMENT. REMPLACER LES CORDONS

ENDOMMAGÉS IMMÉDIATEMENT. Des cordons

endommagés augmentent le risque d’électrocution.

LORS DE L’UTILISATION D’UN OUTIL MOTORISÉ,

UTILISER UN CORDON DE RALLONGE EXTÉRIEUR

MARQUÉ “W-A” OU “W”. Ces cordons sont prévus

pour une utilisation extérieure et réduisent les risques

d’électrocution.

Manuel Opérateur 19

Page 20

AVERTISSEMENT

SÉCURITÉ PERSONNELLE

RESTER SUR SES GARDES, REGARDER CE QUE L’ON FAIT ET UTILISER SON

SENS COMMUN LORS DE L’UTILISATION D’UN OUTIL MOTORISÉ. NE PAS

UTILISER UN OUTIL EN ÉTAT DE FATIGUE OU SOUS L’INFLUENCE DE

DROGUES, D’ALCOOL OU DE MÉDICAMENTS. Un moment d’inattention lors de

l’utilisation de l’outil motorisé peut entraîner de sérieuses blessures personnelles.

S’HABILLER CORRECTEMENT. NE PAS PORTER DES VÊTEMENTS LARGES OU

DES BIJOUX. ATTACHER LES CHEVEUX LONGS. TENIR SES CHEVEUX,

VÊTEMENTS ET SES GANTS ÉLOIGNÉS DES PARTIES MOBILES. Les vêtements

larges, les bijoux et les cheveux longs peuvent se prendre dans les parties mobiles.

EVITER TOUT DÉMARRAGE ACCIDENTEL. S’ASSURER QUE LE

L’INTERRUPTEUR D’ALIMENTATION EST SUR LA POSITION D’ARRÊT AVANT

DE BRANCHER LA MACHINE. Transporter l’appareil avec les doigts sur l’interrupteur

d’alimentation ou brancher un outil avec l’interrupteur sur la position marche invite aux

accidents.

RETIRER LES CLEFS D’AJUSTEMENT OU LES COMMUTATEURS AVANT DE

METTRE L’OUTIL SOUS TENSION. Une clef qui est laissée attachée à une partie

tournante de l’outil peut provoquer une blessure personnelle. NE PAS TROP

PRÉSUMER DE SES FORCES. GARDER EN PERMANENCE UNE POSITION ET

UN ÉQUILIBRE CORRECT. Une position et un équilibre correct permettent un

meilleur contrôle de l’outil dans des situations inattendues.

UTILISER UN ÉQUIPEMENT DE SÉCURITÉ. TOUJOURS PORTER DES LUNETTES DE PROTECTION. Un masque à poussière, des chaussures de sécurité

antidérapantes, un chapeau dur et des bouchons d’oreille doivent être utilisés dans

les conditions appropriées.

UTILISATION DE L’OUTIL ET ENTRETIEN

UTILISER UN ÉTAU OU TOUTES AUTRES FAÇONS DE FIXER ET MAINTENIR LA

PIÈCE À USINER SUR UNE PLATE-FORME STABLE. Tenir la pièce avec la main

ou contre son corps est instable et peut conduire à une perte de contrôle de l’outil.

NE PAS FORCER SUR L’OUTIL. UTILISER L’OUTIL CORRECT POUR

L’APPLICATION SOUHAITÉE. L’outil correct réalisera un meilleur et plus sûr travail

dans le domaine pour lequel il a été conçu. NE PAS UTILISER UN OUTIL S’IL NE SE

MET PAS SOUS OU HORS TENSION AVEC UN INTERRUPTEUR. Un outil qui ne

peut pas être commandé avec un interrupteur est dangereux et doit être réparé.

DÉCONNECTER LA FICHE DE LA SOURCE D’ALIMENTATION AVANT DE

RÉALISER TOUT AJUSTEMENT, CHANGEMENT D’ACCESSOIRES OU POUR

RANGER L’OUTIL. De telles mesures de sécurité réduisent le risque que l’outil ne

démarre accidentellement.

RANGER LES OUTILS INUTILISÉS HORS DE LA PORTÉE DES ENFANTS ET DES

AUTRES PERSONNES INEXPÉRIMENTÉES. Les outils sont dangereux dans les

mains de personnes inexpérimentées. CONSERVER LES OUTILS AVEC SOIN.

GARDER LES OUTILS DE COUPE AIGUISÉS ET PROPRES. Des outils bien

entretenus, avec des lames coupantes aiguisées risquent moins de se gripper et sont

plus faciles à contrôler.

VÉRIFIER LES DÉFAUTS D’ALIGNEMENT OU GRIPPAGE DES PARTIES MOBILES, LES RUPTURES DES PIÈCES ET TOUTES LES AUTRES CONDITIONS

QUI PEUVENT AFFECTER LE FONCTIONNEMENT DES OUTILS. EN CAS DE

DOMMAGE, FAIRE RÉPARER L’OUTIL AVANT DE L’UTILISER. Beaucoup

d’accidents sont causés par des outils mal entretenus. UTILISER UNIQUEMENT LES

ACCESSOIRES RECOMMANDÉS PAR LE FABRICANT POUR LE MODÈLE

UTILISÉ. Des accessoires qui peuvent convenir à un outil, peuvent devenir dangereux

lorsqu’ils sont utilisés avec un autre outil.

20 Manuel Opérateur

Page 21

AVERTISSEMENT

RÉPARATION

LA RÉPARATION DE L’OUTIL NE DOIT ÊTRE RÉALISÉE UNIQUEMENT PAR UN

RÉPARATEUR QUALIFIÉ. Une réparation ou un entretien réalisé par un personnel non

qualifié peut entraîner des risques de blessures.

LORS DE LA RÉPARATION D’UN OUTIL, UTILISER UNIQUEMENT DES PIÈCES DE

RECHANGE IDENTIQUES. SUIVRE LES INSTRUCTIONS DE LA SECTION

D’ENTRETIEN DE CE MODE D’EMPLOI. L’utilisation de pièces non autorisées ou un

non respect des instructions d’entretien peut créer un risque d’électrocution ou de

blessures.

NE JAMAIS TOUCHER LES PARTIES MOBILES

Ne jamais placer ses mains, ses doigts ou toute autre partie de son corps près des

parties mobiles de l’outil.

NE JAMAIS UTILISER L’OUTIL SANS QUE TOUS LES DISPOSITIFS DE SÉCURITÉ

NE SOIENT EN PLACE

Ne jamais faire fonctionner cet outil sans que tous les dispositifs et caractéristiques de

sécurité ne soient en place et en état de fonctionnement. Si un entretien ou une

réparation nécessite le retrait d’un dispositif ou d’une caractéristique de sécurité,

s’assurer de bien remettre en place le dispositif ou la caractéristique de sécurité avant

de recommencer à utiliser l’outil.

REGLES DE SECURITE SPECIFIQUES ET SYMBOLES

1. TENIR LES OUTILS PAR LES SURFACES DE GRIPPAGE LORS DE LA

RÉALISATION D’OPÉRATION OÙ L’OUTIL DE COUPE RISQUE D’ENTRER EN

CONTACT AVEC DES CÂBLES CACHÉS OU SON PROPRE CORDON. Un

contact avec un fil “sous tension” mettra les parties métalliques de l’outil “sous

tension” et électrocutera l’utilisateur.

2. Porter des bouchons d’oreille lors de l’utilisation de l’outil pendant de longues

périodes. Une exposition prolongée à un son de forte intensité peut endommager

l’ouïe de l’utilisateur.

3. NE JAMAIS toucher la mèche avec des mains nues après l’utilisation.

4. NE JAMAIS porter de gants faits d’une matière qui risque de s’enrouler, comme

du coton, de la laine, de la toile ou de la ficelle, etc.

5. TOUJOURS fixer la poignée latérale et tenir le marteau perforateur solidement.

6. TOUJOURS vérifier s’il y a des objets encastrés par exemple des fils électriques.

Le fait de toucher avec l’outil un fil ou un câble électrique sous tension encastré

dans le mur risque de provoquer une décharge électrique.

Vérifier s’il y des objets encastrés, par exemple un câble électrique, dans le mur,

le plancher ou le plafond avant d’y commencer le travail.

7. Définitions pour les symboles utilisés sur cet outil:

V volts

Hz hertz

A ampères

novitesse sans charge

W watt

Construction de classe II

---/min tours par minute

Manuel Opérateur 21

Page 22

ATTENTION

UTILISER L’OUTIL CORRECT

Ne pas forcer sur un petit outil ou accessoire pour faire le travail d’un outil de grande

puissance. Ne pas utiliser un outil pour un usage pour lequel il n’a pas été prévu: par

exemple, ne pas utiliser une scie circulaire pour couper des branches d’arbre ou des

bûches.

NE JAMAIS UTILISER UN OUTIL MOTORISÉ POUR DES APPLICATIONS AUTRES

QUE CELLES SPÉCIFIÉES

Ne jamais utiliser un outil motorisé pour des applications autres que celles spécifiées

dans le mode d’emploi.

PRECAUCIÓN

MANIPULER L’OUTIL CORRECTEMENT

Utiliser l’outil de la façon indiquée dans ce mode d’emploi. Ne pas laisser tomber ou

lancer l’outil. Ne jamais permettre que l’outil soit utilisé par des enfants, des personnes

non familiarisées avec son fonctionnement ou un personnel non autorisé.

MAINTENIR TOUTES LES VIS, TOUS LES BOULONS ET LES COUVERCLES

FERMEMENT EN PLACE

Maintenir toutes les vis, tous les boulons et les couvercles fermement montés. Vérifier

leurs conditions périodiquement.

NE PAS UTILISER LES OUTILS MOTORISÉS SI LE REVÊTEMENT DE PLASTIQUE

OU LA POIGNÉE EST FENDU

Des fentes dans le revêtement ou la poignée peuvent entraîner une électrocution. De

tels outils ne doivent pas être utilisés avant d’être réparé.

LES LAMES ET LES ACCESSOIRES DOIVENT ÊTRE FERMEMENT MONTÉS SUR

L’OUTIL

Eviter les blessures potentielles personnelles et aux autres. Les lames, les instruments

de coupe et les accessoires qui ont été montés sur l’outil doivent être fixés et serrés

fermement.

GARDER PROPRES LES ÉVENTS D’AIR DU MOTEUR

Les évents d’air du moteur doivent être maintenus propres de façon que l’air puisse

circuler librement tout le temps. Vérifier les accumulations de poussière fréquemment.

UTILISER L’OUTIL MOTORISÉ À LA TENSION NOMINALE

Utiliser l’outil motorisé à la tension spécifiée sur sa plaque signalétique.

Si l’on utilise l’outil motorisé avec une tension supérieure à la tension nominale, il en

résultera une rotation anormalement trop rapide du moteur et cela risque

d’endommager l’outil et le moteur risque de griller.

NE JAMAIS UTILISER UN OUTIL DÉFECTUEUX OU QUI FONCTIONNE

ANORMALEMENT

Si l’outil n’a pas l’air de fonctionner normalement, fait des bruits étranges ou sans cela

paraît défectueux, arrêter de l’utiliser immédiatement et le faire réparer par un centre de

service JOHN DEERE autorisé.

22 Manuel Opérateur

Page 23

PRECAUCIÓN

NE JAMAIS LAISSER FONCTIONNER L’OUTIL SANS SURVEILLANCE. LE

METTRE HORS TENSION.

Ne pas abandonner l’outil avant qu’il ne soit complètement arrêté.

MANIPULER L’OUTIL MOTORISÉ AVEC PRÉCAUTION

Si un outil motorisé tombe ou frappe un matériau dur accidentellement, il risque d’être

déformé, fendu ou endommagé.

NE PAS ESSUYER LES PARTIES EN PLASTIQUE AVEC DU SOLVANT

Les solvants comme l’essence, les diluants, la benzine, le tétrachlorure de carbone et

l’alcool peuvent endommager et fissurer les parties en plastique. Ne pas les essuyer

avec de tels solvants. Essuyer les parties en plastique avec un chiffon doux légèrement

imbibé d’une solution d’eau savonneuse et sécher minutieusement.

DOUBLE ISOLATION POUR UN FONCTIONNEMENT PLUS SUR

Pour assurer un fonctionnement plus sûr de cet outil motorisé, JOHN DEERE a

adopté une conception à double insolation. “Double isolation” signifie que deux

systèmes d’isolation physiquement séparés ont été utilisés pour isoler les matériaux

conducteurs d’électricité connectés à l’outil motorisé à partir du cadre extérieur

manipulé par l’utilisateur. C’est pourquoi, le symbole “ ” ou les mots “Double

insulation” (double isolation) apparaissent sur l’outil motorisé ou sur la plaque

signalétique. Bien que ce système n’ait pas de mise à terre extérieure, il est quand

même nécessaire de suivre les précautions de sécurité électrique données dans ce

mode d’emploi, y-compris de ne pas utiliser l’outil motorisé dans un environnement

humide.

Pour garder le système de double isolation effectif, suivre ces précautions:

a. Seuls les CENTRES DE SERVICE AUTORISES JOHN DEERE peuvent

démonter et remonter cet outil motorisé et uniquement des pièces de

rechange JOHN DEERE garanties d’origine doivent être utilisées.

b. Nettoyer l’extérieur de l’outil motorisé uniquement avec un chiffon doux

légèrement imbibé d’une solution savonneuse et essuyer minutieusement.

Ne jamais utiliser des solvants, de l’essence ou des diluants sur les parties en

plastique; sinon le plastique risquerait de se dissoudre.

CONSERVER CES INSTRUCTIONS ET LES METTRE A LA DISPOSITION DES

AUTRES UTILISATEURS DE CET OUTIL!

Manuel Opérateur 23

Page 24

Description Fonctionnelle

NOTE: Les informations contenues dans ce mode d’emploi sont conçues

NE JAMAIS utiliser ni entreprendre une révision de l’outil sans avoir d’abord lu et

compris toutes les instructions de sécurité contenues dans ce manuel.

Certaines illustrations dans ce mode d’emploi peuvent montrer des détails ou des

accessoires différents de ceux de l’outil motorisé utilisé.

MAQUETTE:

ET-3507-J

NOM DES PARTIES:

pour assister l’utilisateur dans une utilisation sans danger et un

entretien de l’outil motorisé.

(Fig. 1)

SPECIFICATIONS:

Moteur Moteur série monophasé à collecteur

Source d’alimentation Secteur, 115V 60 Hz, monophasé

Courant 6,8 A

Rotation en sens inverse Oui

Changement de vitesse 1 2

Vitesse sans charge 0–1100/min 0–2600/min

Capacité de mèche 1/2" (13mm)

Capacité:

Acier 1/2" (13mm) 5/16" (8mm)

Béton 3/4" (20mm) 1/2" (13mm)

Bois 1-9/16" (40mm) 1" (25mm)

Vitesse de percussion 14000/min 36000/min

Poids (sans fil) 4,6 lbs (2,1 kg)

24 Manuel Opérateur

Page 25

Utilisation

UTILISATIONS:

By combined actions of ROTATION and IMPACT: Boring holes in hard surfaces

(concrete, marble, granite, tiles, etc.)

By ROTATIONAL action: Boring holes in metal, wood and plastic.

AVANT L’UTILISATION:

1. Source d’alimentation

S’assurer que la source d’alimentation qui doit être utilisée est conforme à la

source d’alimentation requise spécifiée sur la plaque signalétique du produit.

2. Interrupteur d’alimentation

S’assurer que l’interrupteur est sur la position OFF (arrêt). Si la fiche est connectée

sur une prise alors que l’interrupteur est sur la position ON (marche), l’outil

motorisé démarrera immédiatement risquant de causer de sérieuses blessures.

3. Cordon prolongateur

Quand la zone de travail est éloignée de la source d’alimentation, utiliser un cordon

prolongateur d’épaisseur et de capacité nominale suffisante. Le cordon

prolongateur doit être aussi court que possible.

AVERTISSEMENT: TOUT CORDON ENDOMMAGÉ DEVRA ÊTRE

4. Vérifier la prise

Si la prise reçoit la fiche avec beaucoup de jeu, elle doit être réparée. Contacter un

électricien licencié pour réaliser les réparations nécessaires.

Si une telle prise défectueuse est utilisée, elle peut causer une surchauffe

entraînant des dangers sérieux.

5. Vérification des conditions d’environnement

Vérifier que l’état de l’aire de travail est conforme aux précautions.

6. Choix du foret de perçage correct

a. Pour perçage dans béton ou pierre

Utiliser les forets de perçage maçonnique.

b. Pour perçage dans métal ou plastique

Utiliser un foret de perçage ordinaire pour métal.

c. Pour perçage dans bois

Utiliser un foret de perçage ordinaire pour bois.

Toutefois, pour percer des trous de 1/4" (6,5 mm)

ou plus petits, utiliser un foret de perçage pour métal.

7. Montage et démontage des forets. (Fig. 2):

Fixer le foret de perçage dans le mandrin et

utiliser la clef à mandrin pour le serrer, en

serrant le mandrin par ses trois trous.

REMPLACÉ OU RÉPARÉ.

(Fig. 2)

Manuel Opérateur 25

Page 26

Utilisation

AVANT L’UTILISATION:

8. Fixation de la poignée latérale (Fig. 3):

Desserrer le boulon à oreilles sur la poignée

latérale et attacher la poignée latérale au

boîtier de l’engrenage dans une position propre

au perçage. Faire coincider la partie dépassant

de la poignée avec la rainure sur le boîtier de

l’engrenage, et resserrer le boulon à oreillies à

fond.

Pour retirer la poignée latérale, desserrer le

boulon à oreilles et faire tourner la poignée.

Pour attacher un témoin de profondeur sur la

poignée latérale, introduire le témoin dans la

rainure en U sur la poignée latérale, régler la

position du témoin en fonction de la profondeur

souhaitée pour le trou, et resserrer le boulon à

oreilles à fond.

9. Commutation: fonctionnement en

PERCUSSION/fonctionnement en ROTATION

(Fig. 4):

La visseuse perceuse à percussion peut être

commutée de PERCUSSION (percussion plus

rotation) à ROTATION (rotation seulement) en

tournant le levier (Fig. 1) entièrement dans le

sens des aiguilles d’une montre. La tête de la

perceuse percute contre le matériau tout en

continuant de tourner. Lors du perçage de

métal, de bois ou de matières plastiques, ou

pour le serrage de vis, tournez le levier de

changement à fond dans le sens antihoraire.

Le perceuse ROTATION tournera alors en tant

que perceuse électrique ordinaire.

(Fig. 3)

(Fig. 4)

ATTENTION: NE PAS UTILISER LA

PERCEUSE À PERCUSSION EN

FONCTIONNEMENT PERCUSSION SI

LE MATÉRIAU PEUT ÊTRE PERCÉ PAR

SIMPLE ROTATION. CE

FONCTIONNEMENT RÉDUIRAIT D’UNE

PART L’EFFICACITÉ DE PERÇAGE ET

ABÎMERAIT AUSSI LA POINTE DE

PERÇAGE.

NOTE: Lorsque l’on passe du mode de perceuse à

percussion au mode de perceuse (Fig. 4), il se

peut que le levier de changement ne tourne

pas aisément. Dans ce cas, mettre l’outil sous

tension et le faire fonctionner pendant quelques

secondes. La tige de l’axe est alors poussée

vers l’avant, facilitant ainsi le déplacement du

levier.

26 Manuel Opérateur

Page 27

Utilisation

AVANT L’UTILISATION:

10. Commutation grande vitesse/faible vitesse:

Pour changer de vitesse, faire tourner le

bouton de changement de vitesse comme

indiqué par la flèche sur la Fig. 5. Le numéro

“1” gravé sur le corps de la perceuse indique

la vitesse faible, le numéro “2” indique la

grande vitesse.

11. Verifiez la direction de rotation de la mèche:

La mèche tourne dans le sens horaire (vu de

l’arrière) quand on appuie sur côté-R du

levier de contact.

En appuyant sur cIoté-L du levier la mèche

tourne dans le sens anti-horaire. (Fig. 6)

ATTENTION: UTILISEZ TOUJOURS LA

VISSEUSE/PERCEUSE À

PERCUSSIONS DANS LE

SENS HORAIRE DE

ROTATION, QUAND

VOUS L’UTILISEZ EN TANT

QUE PERCEUSE À

ROTATION. (FIG. 7)

(Fig. 6)

(Fig. 5)

(Fig. 7)

Manuel Opérateur 27

Page 28

UTILISATION:

Utilisation

ATTENTION: POUR ÉVITER TOUT RISQUE D’ACCIDENT, BIEN

1. Fonctionnement de l’interrupteur:

a. Le vitesse de la perceuse peut être réglée de O à vitesse maximale, en

réglant la force de pression du trigger. Plus on presse le trigger, plus la

perceuse tourne rapidement. Quand le trigger est pressé á fond, la vitesse est

maximale.

b. Tirez l’interrupteur-trigger et poussez l’arrêtoir; ceci maintient l’interrupteur en

position de marche quand un fonctionnement continu est requis. Lors de la

mise en arrêt, l’arrêtoir peut être relâché en tirant ànouveau le trigger.

2. Utilisation en tant que perceuse ordinaire ou perceuse à percussions:

a. Force d’appui:

Vous ne pourrez pas percer les trous plus vite simplement en appliquant une

force d’appui plus grande que nécessaire. Ceci non seulement endommagera

la pointe de la mèche et diminueral l’efficacité de rendement, mais raccourcira

aussi la durée de vie de la perceuse.

b. Perçage de trous

Les mèches peuvent se casser lors du perçage du matériel. Il est important de

diminuer la force de pression juste avant le perçage.

ATTENTION: POUR LE FONCTIONNEMENT CONTINU, EFFECTUEZ UNE

COUPER LE CONTACT ET DÉBRANCHER LA FICHE DE LA

PRISE SECTEUR LORS DE L’INSTALLATION OU DU RETRAIT

DES MÈCHES ET DES AUTRES PIÈCES. IL FAUDRA

ÉGALEMENT COUPER LE CONTACT LORS D’UNE

INTERRUPTION DE TRAVAIL ET LORSQUE LE TRAVAIL EST

TERMINÉ.

MARCHE À VIDE PENDANT 5 SECONDES APRÈS AVOIR

TERMINÉ UN TRAVAIL DE PERÇAGE.

c. Utilisage d’une mèche épaisse:

Dans ce cas votre bras sera soumis à une force de réaction plus grande.

Faites attention de ne pas vous laisser entraîner par cette force. Pour ce faire,

maintenez une bonne prise de pied, tenez l’outil fermement avec les deux

mains et perpendiculairement par rapport au matériel de travail.

28 Manuel Opérateur

Page 29

Entretien et Inspection

ENTRETIEN ET INSPECTION:

AVERTISSEMENT: S’ASSURER DE METTRE L’INTERRUPTEUR

1. Vérification de la mèche:

L’utilisation continue d’une mèche usée et ou endommagée réduira l’efficacité de `

perçage et peut gravement surcharger le moteur de la perceuse. Vérifiez

fréquemment la méche et remplacez la dès que nécessaire.

2. Inspection des vis de montage:

Inspecter régulièrement toutes les vis de montage et s’assurer qu’elles sont

correctement serrées. Si l’une des vis était desserrée, la resserrer immédiatement.

AVERTISSEMENT: UTILISER LA MARTEAU PERFORATEUR AVEC DES VIS

3. Après usage:

Lorsqu’on ne se sert pas de l’outil électrique, le ranger dans un lieu sec et hors de

portée des enfants.

4. Inspection des balais en carbone:

Pour assurer à tout moment la sécurité et la protection contre les chocs électrique,

confier l’inspection et le remplacement des balais en carbone de l’outil

EXCLUSIVEMENT à un centre de service après-vente agréé par JOHN DEERE.

5. Entretmoteur:

Le bolde l’ensemble moteur est le “cœur” mêmeutil électro-portatif. Veiller

soigneusement à ce bobinage ne soit pas endommagé et/ou par de l’huille ou de

l’eau.

ENTRETIEN ET RÉPARATION:

Tous les outils motorisés de qualité auront éventuellement besoin d’une réparation ou du

remplacement d’une pièce à cause de l’usure normale de l’outil. Pour assurer que

seules des pièces de rechange autorisées seront utilisées, tous les entretiens et les

réparations doivent être effectués uniquement par UN CENTRE DE SERVICE JOHN

DEERE AUTORISE.

AVERTISSEMENT: NE JAMAIS UTILISER D’ACCESSOIRES AUTRES QUE

ACCESSOIRES STANDARD:

-Mallette de transport en plastique 1

-Poignée latérale 1

-Jauge de profondeur 1

-Clef pour mandrin (Spéc. uniquement pour mandrin

avec clé de serrage) 1

D’ALIMENTATION SUR LA POSITION OFF ET DE

DÉCONNECTER LA FICHE DE LA PRISE SECTEUR AVANT

L’ENTRETIEN ET L’INSPECTION DE LA MEULEUSE.

DESSERRÉES EST EXTRÊMEMENT DANGEREUX.

CEUX QUI SONT MENTIONNÉS CI-DESSOUS.

L’UTILISATION DE TOUT AUTRE ÉQUIPEMENT OU

ACCESSOIRE, PAR EXEMPLE UNE MEULE-BOISSEAU OU

UNE MEUIE À FRONÇONNER, ETC., POURRAIT ÊTRE

DANGEREUSE ET PROVOQUER DES BLESSURES OU DES

DOMMAGES DU MATÉRIEL.

NOTE: Les spécifications sont sujettes à modification sans aucune obligation de la

part de JOHN DEERE.

Manuel Opérateur 29

Page 30

Introduccion

¡Felicitaciones por la compra de su nueva herramienta! Puede estar seguro que de

herramienta fue construida con el nivel más alto de precisión y exactitud. Cada

componente ha sido probado rigurosamente por técnicos para asegurar la calidad, la

resistencia y el rendimiento de esta unidad.

Este manual del operador fue compilado para su beneficio. Leyendo y siguiendo los pasos

simples de seguridad, instalación, operación, mantenimiento y localización de fallas

descritos en este manual ayudará a prolongar aun más la operación libre de fallas que

usted puede esperar de su nueva herramienta. El contenido de este manual está basado

en la información actualizada disponible al momento de la publicación. Fabricante se

reserva el derecho de efectuar cambios en precio, color, materiales, equipo,

especificaciones o modelos en cualquier momento sin previo aviso.

Escriba el número de serie de su unidad en el espacio provisto abajo, una vez que la

unidad haya sido desempacada.

NUMERO DE SERIE___________________________

Inspeccione por daño el contenido de la caja. Si algo parece dañado, NO LA DEVUELVA

AL LUGAR DE COMPRA. Llame a su representante de servicio al cliente.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

Telefone gratis en los EE. UU.: 877-535-5336 / Fax 563-556-1235

Por favor tenga disponible la información siguiente para todas las llamadas de servicio:

Telefono: 1-877-JD-KLEEN

Lunes - Viernes 8:00 a.m. - 5:00 p.m. CST

1. Número de modelo

2. Número de serie

3. Fecha y lugar de compra

ADVERTENCIA

USE PROTECCIÓN RESPIRATORIA

Alogunos polvos creados por el lijado mecámico, el aserrado, el esmerilado, el

taladrado y otras actividades de construcción contienen sustancias químicas conocidas

por le Estado de California como agentes cancerígenos, defectos congénitos y otros

daños reproductores. Algunos ejemplos de estas sustancias químicas son:

- El plomo de las pinturas a base de plomo,

- El sílice cristalino de los ladrillos y cemento y otros productos de mampostería, y

- El arsénico y el cromo de la madera tratada químicamente.

El riesgo resultante de la exposición varía según la frecuencia con que se realiza este

tipo de trabajo. Para reducir la exposicíon a esta sustancias químicas: trabaje en un

lugar bien ventilado y realice el trabajo utilizando el equipamiento apropiado, tal como

las máscares para el polvo especialmente diseñados para eliminar las partículas

minúsculas.

30 Manual del Operador

Page 31

Tabla de Materias

SEGURIDAD .......................................................................................................... 32-37

DESCRIPCIÓN FUNCIONAL ................................................................................ 38

OPERACIÓN .......................................................................................................... 40-42

MAINTENIMIENTO E INSPECCIÓN ..................................................................... 43

INSTRUCCIONES IMPORTANTES DE SEGURIDAD ......................... 32-37

MODELO ................................................................................................ 38

NOMENCLATURA ................................................................................. 38

ESPECIFICACIONES............................................................................ 38

APLICACIONES..................................................................................... 38

ANTES DE LA OPERACIÓN ................................................................. 40-41

OPERACIÓN.......................................................................................... 42

MAINTENIMIENTO E INSPECCIÓN..................................................... 43

MANTENIMIENTO Y REPARACIÓN .................................................... 43

ACCESORIOS ESTÁNDAR .................................................................. 43

Manual del Operador 31

Page 32

Seguridad

PELIGRO

ADVERTENCIA

PRECAUCION

INFORMATION DE SÉCURITÉ RECONOCER

El símbolo indicado a “Símbolo de Alerta de Seguridad”. Este

símbolo se usa para alertarlo acerca de artículos o

procedimientos que podrían ser peligrosos para usted u otras

personas usando este equipo.

PALABRAS DE ALERTA QUE ENTIENDO

Estos párrafos están rodeados por una “CASILLA DE

ALERTA DE SEGURIDAD”. Esta casilla se usa para

designar y enfatizar las Advertencias de Seguridad que

deben seguirse al operar esta herramienta.

Acompañando a las Advertencias de Seguridad están las

“palabras de alerta” que designan el grado o nivel de

seriedad de riesgo. Las “palabras de alerta” usadas en este

manual son las siguientes:

PELIGRO: Indica una situación inminente riesgosa la cual, si no se evita,

ADVERTENCIA: Indica una situación potencialmente riesgosa la cual, si no se

PRECAUCION: Indica una situación potencialmente riesgosa la cual, si no se

RESULTARA en la muerte o en lesiones graves.

evita, PODRIA resultar en la muerte o en lesiones graves.

evita PUEDE resultar en lesiones menores o moderadas.

NORMAS GENERALES DE SEGURIDAD

ADVERTENCIA: Lea y entienda todas las

instrucciones. Si no sigue las

instrucciones indicadas a continuación,

pueden producirse descargas eléctricas,

ìncendios, y/o lesiones serias.

GUARDE ESTAS INSTRUCCIONES

32 Manual del Operador

Page 33

ADVERTENCIA

MANTENGA EL ÁREA DE TRABAJO LIMPIA Y BIEN

ILUMINADA. Los bancos de trabajo desordenados y las

áreas obscuras pueden conducir a accidentes.

NO UTILICE LA HERRAMIENTA EN ATMÓSFERAS

EXPLOSIVAS, COMO EN PRESENCIA DE LÍQUIDOS

INFLAMABLES, GASES, O POLVO. La herramienta

eléctrica crea chispas que pueden incendiar polvo o

gases.

MANTENGA ALEJADAS A OTRAS PERSONAS, NIÑOS

O VISITANTES, CUANDO UTILICE LA HERRAMIENTA

ELÉCTRICA. Las distracciones pueden hacer que pierda

el control de la herramienta.

SEGURIDAD ELÉCTRICA

LAS HERRAMIENTAS ELÉCTRICAS CON

AISLAMIENTO DOBLE POSEEN UN ENCHUFE

POLARIZADO (UNA CUCHILLA ES MÁS ANCHA QUE

LA OTRA.) ESTE ENCHUFE ENCAJARÁ EN UN

TOMACORRIENTE POLARIZADO DE UNA SOLA

FORMA. SI EL ENCHUFE NO ENTRA

COMPLETAMENTE EN EL TOMACORRIENTE,

INVIERTA SU SENTIDO DE INSERCIÓN. SI SIGUE SIN

ENTRAR, PÓNGASE EN CONTACTO CON UN

ELECTRICISTA CUALIFICADO PARA QUE LE INSTALE

UN TOMACORRIENTE POLARIZADO. NO CAMBIE

NUNCA EL ENCHUFE. El aislamiento doble elimina

la necesidad de un cable de alimentación de tres

conductores, uno para puesta a tierra, y del sistema de

alimentación con puesta a tierra.

EVITE EL CONTACTO CON SUPERFICIES CON

PUESTA A TIERRA, TALES COMO TUBOS,

RADIADORES, HORNOS, Y REFRIGERADORES. Si

toca tierra, existe el peligro de que reciba una descarga

eléctrica.

NO EXPONGA LA HERRAMIENTA ELÉCTRICA A LA

LLUVIA NI A LA HUMEDAD. La entrada de agua en la

herramienta eléctrica aumentará el riesgos de descargas

eléctricas.

NO MALTRATE EL CABLE DE ALIMENTACIÓN. NO

UTILICE NUNCA EL CABLE DE ALIMENTACIÓN PARA

TRANSPORTAR LA HERRAMIENTA NI PARA

DESCONECTARLA DEL TOMACORRIENTE.

MANTENGA EL CABLE ALEJADO DEL CALOR,

ACEITE, BORDES CORTANTES, O PARTES MÓVILES.

REEMPLACE INMEDIATAMENTE CUALQUIER CABLE

DAÑADO. Un cable dañado puede ser la causa de

descargas eléctricas.

CUANDO UTILICE LA HERRAMIENTA ELÉCTRICA EN

EXTERIORES, UTILICE UN CABLE PROLONGADOR

MARCADO CON “W-A” O “W”. Estos cables han sido

diseñados para utilizarse en exteriores y reducir el riesgo

de descargas eléctricas.

Manual del Operador 33

Page 34

ADVERTENCIA

SEGURIDAD PERSONAL

ESTÉ SIEMPRE ALERTA Y UTILICE EL SENTIDO COMÚN CUANDO UTILICE LA

HERRAMIENTA ELÉCTRICA. NO UTILICE LA HERRAMIENTA CUANDO ESTÉ

CANSADO O BAJO LA INFLUENCIA DE MEDICAMENTOS NI DE ALCOHOL. Un

descuido al utilizar la herramienta eléctrica puede resultar en una lesión seria.

VÍSTASE ADECUADAMENTE. NO UTILICE ROPA FLOJA NI JOYAS. SI TIENE

PELO LARGO, RECÓJASELO. MANTENGA SU PELO, ROPA, Y GUANTES

ALEJADOS DE LAS PARTES MÓVILES. La ropa floja, las joyas, o el pelo largo

pueden engancharse en las partes móviles.

EVITE LA PUESTA EN MARCHA ACCIDENTAL. CERCIÓRESE DE QUE LA

ALIMENTACIÓN DE LA HERRAMIENTA ELÉCTRICA ESTÉ DESCONECTADA

ANTES DE ENCHUFARLA EN UNA TOMA DE LA RED. Si lleva la herramienta

eléctrica con el dedo colocado en el interruptor, o si la enchufa con dicho interruptor

cerrado, es posible que se produzcan accidentes.

QUITE LAS LLAVES DE AJUSTE Y ABRA LOS INTERRUPTORES ANTES DE

PONER EN FUNCIONAMIENTO LA HERRAMIENTA. Una llave dejada en una parte

móvil de la herramienta podría resultar en lesiones.

NO SOBREPASE SU ALCANCE. MANTENGA EN TODO MOMENTO UN BUEN

EQUILIBRIO. El conservar en todo momento el equilibrio le permitirá controlar mejor

la herramienta en situaciones inesperadas.

UTILICE EQUIPOS DE SEGURIDAD. PÓNGASE SIEMPRE GAFAS

PROTECTORAS. Para conseguir las condiciones apropiadas, utilice una mascarilla

contra el polvo, zapatos no resbaladizos, un casco duro, y tapones para los oídos.

UTILIZACIÓN Y CUIDADOS DE LA HERRAMIENTA

UTILICE ABRAZADERAS U OTRA FORMA PRÁCTICA DE ASEGURAR Y SUJETAR

LA PIEZA DE TRABAJO SOBRE UNA PLATAFORMA ESTABLE. La sujeción de la

pieza de trabajo con la mano o contra su cuerpo puede ser inestable y conducir a la

pérdida del control.

NO FUERCE LA HERRAMIENTA. UTILICE LA HERRAMIENTA CORRECTA PARA

SU APLICACIÓN. Con la herramienta correcta realizará mejor el trabajo y ésta será

más segura para la velocidad para la que ha sido diseñada.

NO UTILICE LA HERRAMIENTA SI EL INTERRUPTOR DE ALIMENTACIÓN DE LA

MISMA NO FUNCIONA. Cualquier herramienta que no pueda controlarse con el

interruptor de alimentación puede resultar peligrosa, y deberá repararse.

DESCONECTE EL ENCHUFE DEL CABLE DE ALIMENTACIÓN ANTES DE

REALIZAR CUALQUIER AJUSTE, CAMBIAR ACCESORIOS, O GUARDAR LA

HERRAMIENTA. Tales medidas preventivas de seguridad reducirán el riesgo de que

la herramienta se ponga en funcionamiento accidentalmente.

GUARDE LAS HERRAMIENTAS QUE NO VAYA A UTILIZAR FUERA DEL

ALCANCE DE NIÑOS Y DE OTRAS PERSONAS NO ENTRENADAS. Las

herramientas son peligrosas en manos de personas inexpertas.

REALICE EL MANTENIMIENTO CUIDADOSO DE LAS HERRAMIENTAS.

MANTENGA LAS HERRAMIENTAS AFILADAS Y LIMPIAS. Las herramientas

adecuadamente mantenidas, con los bordes cortantes afilados, serán más fáciles de

utilizar y controlar.

COMPRUEBE QUE LAS PIEZAS MÓVILES NO ESTÉN DESALINEADAS NI

ATASCADAS, QUE NO HAYA PIEZAS ROTAS, Y DEMÁS CONDICIONES QUE

PUEDAN AFECTAR LA OPERACIÓN DE LAS HERRAMIENTAS. EN CASO DE

QUE UNA HERRAMIENTA ESTÉ AVERIADA, REPÁRELA ANTES DE UTILIZARLA.

Muchos de los accidentes se deben a herramientas mal cuidadas.

UTILICE SOLAMENTE LOS ACCESORIOS RECOMENDADOS POR EL

FABRICANTE PARA SU MODELO. Los accesorios adecuados para una herramienta

pueden ser peligrosos cuando se utilicen con otra.

34 Manual del Operador

Page 35

ADVERTENCIA

SERVICIO DE REPARACIÓN

EL SERVICIO DE REPARACIÓN DEBERÁ REALIZARLO SOLAMENTE PERSONAL

CUALIFICADO. El servicio de mantenimiento o de reparación realizado por personal

no cualificado podría resultar en el riesgo de lesiones.

PARA EL SERVICIO DE MANTENIMIENTO O REPARACIÓN DE UNA

HERRAMIENTA, UTILICE SOLAMENTE PIEZAS DE REPUESTO IDÉNTICAS.

Siga las instrucciones de la sección de mantenimiento de este manual. La utilización

de piezas no autorizadas, o el no seguir las indicaciones del Manual de instrucciones

puede crear el riesgo de descargas eléctricas u otras lesiones.

NO TOQUE NUNCA LAS PIEZAS MÓVILES

No coloque nunca sus manos, dedos, ni demás partes del cuerpo cerca de las piezas

móviles de la herramienta.

NO UTILICE NUNCA LA HERRAMIENTA SIN LOS PROTECTORES COLOCADOS EN

SU LUGAR

No utilice nunca esta herramienta sin los protectores de seguridad correctamente

instalados. Si el trabajo de mantenimiento o de reparación requiere el desmontaje de

un protector de seguridad, cerciórese de volver a instalarlo antes de utilizar la

herramienta.

NORMAS Y SÍMBOLOS ESPECÍFICOS DE SEGURIDAD

1. SUJETE LAS HERRAMIENTAS POR LAS SUPERFICIES DE EMPUÑADURA

AISLADAS CUANDO REALICE UNA OPERACIÓN EN LA QUE LA

HERRAMIENTA DE CORTE PUEDA ENTRAR EN CONTACTO CON CABLES

OCULTOS O CON SU PROPIO CABLE DE ALIMENTACIÓN. El contacto con un

conductor “activo” “activará” las partes metálicas de la herramienta y el operador

recibirá una descarga eléctrica.

2. Cuando tenga que utilizar la herramienta durante mucho tiempo, colóquese

tapones en los oídos. la exposición prolongada a ruido de gran intensidad puede

causar la pérdida del sentido del oído.

3. No toque NUNCA una broca de la herramienta con las manos desnucas después

de la operación.

4. NUNCA utilice guantes hechos de material que pueda quedar pillado en la

herramienta, como algodón, lana, paño, cuerda, etc.

5. Fije SIEMPRE la empuñadunral lateral del martillo roto-percutor y sujétela con

seguridad.

6. Tenga cuidado SIEMPRE con los objetos que puedan estar enterrados o

emparedados, tales como cables eléctricos.

Si tocase un cable activo con esta herramienta, podría recibir una descarga

eléctrica.

Confirme que no haya ningún objeto enterrado o emparedado, como cables

eléctricos, en el suelo, el techo, o en las paredes en los que vaya a trabajar.

7. Definiciones para los símbolos utilizados en esta herramienta:

V voltios

Hz hertzios

A amperios

novelocidad sin carga

W vatios

Construcción de clase II

---/min revoluciones por minuto

Manual del Operador 35

Page 36

PRECAUCIÓN

UTILICE LA HERRAMIENTA CORRECTA

No fuerce herramientas ni accesorios pequeños para realizar un trabajo pesado.

No utilice las herramientas para fines no proyectados, por ejemplo, no utilice esta

amoladora angular para cortar madera.

NO UTILICE NUNCA UNA HERRAMIENTA ELÉCTRICA PARA APLICACIONES QUE

NO SEAN LAS ESPECIFICADAS

No utilice nunca una herramienta eléctrica para aplicaciones no especificadas en este

Manual de instrucciones.

MANEJE CORRECTAMENTE LA HERRAMIENTA

Maneje la herramienta de acuerdo con las instrucciones ofrecidas aquí. No deje caer

ni tire la herramienta. No permita nunca que los niños ni otras personas no autorizadas

ni familiarizadas con la operación de la herramienta utilicen ésta.

MANTENGA TODOS LOS TORNILLOS, PERNOS, Y CUBIERTAS FIRMEMENTE

FIJADOS EN SU LUGAR

Mantenga todos los tornillos, pernos, y cubiertas firmemente montados. Compruebe

periódicamente su condición.

NO UTILICE HERRAMIENTAS ELÉCTRICAS SI LA CARCASA O LA EMPUÑADURA

DE PLÁSTICO ESTÁ RAJADA

Las rajas en la carcasa o en la empuñadura de plástico pueden conducir a descargas

eléctricas. Tales herramientas no deberán utilizarse mientras no se hayan reparado.

LAS CUCHILLAS Y LOS ACCESORIOS DEBERÁN MONTARSE CON SEGURIDAD

EN LA HERRAMIENTA

Evite lesiones personales y de otras personas. Las cuchillas, los accesorios de corte, y

demás accesorios montados en la herramienta deberán fijarse con seguridad.

MANTENGA LIMPIO EL CONDUCTO DE VENTILACIÓN DEL MOTOR

El conducto de ventilación del motor limpio para que el aire pueda circular libremente

en todo momento. Compruebe frecuentemente y limpie el polvo acumulado.

UTILICE LAS HERRAMIENTAS ELÉCTRICAS CON LA TENSIÓN DE

ALIMENTACIÓN NOMINAL

Utilice las herramientas eléctricas con las tensiones indicadas en sus placas de

características.

La utilización e una herramienta eléctrica con una tensión superior a la nominal podría

resultar en revoluciones anormalmente altas del motor, en el daño de la herramienta, y

en la quemadura del motor.

NO UTILICE NUNCA UNA HERRAMIENTA DEFECTUOSA O QUE FUNCIONE

ANORMALMENTE

Si la herramienta parece que funciona anormalmente, produciendo ruidos extraños,

etc., deje inmediatamente de utilizarla y solicite su arreglo a un centro de reparaciones

autorizado por JOHN DEERE.

NO DEJE NUNCA LA HERRAMIENTA EN FUNCIONAMIENTO DESATENDIDA.

DESCONECTE SU ALIMENTACIÓN

No deje sola la herramientas hasta mientras no se haya parado completamente.

36 Manual del Operador

Page 37

PRECAUCIÓN

MANEJE CON CUIDADO LAS HERRAMIENTAS ELÉCTRICAS

Si una herramienta eléctrica se ha caído o ha chocado inadvertidamente contra

materiales duros, es posible que se haya deformado, rajado, o dañado.

NO LIMPIE LAS PARTES DE PLÁSTICO CON DISOLVENTE

Los disolventes, como gasolina, diluidor de pintura, bencina, tetracloruro de carbono,

y alcohol pueden dañar o rajar las partes de plástico. No las limpie con tales

disolventes.

Limpie las partes de plástico con un paño suave ligeramente humedecido en agua

jabonosa y después séquelas bien.

AISLAMIENTO DOBLE PARA OFRECER UNA OPERACIÓN MÁS SEGURA

Para garantizar una operación más segura de esta herramienta eléctrica, JOHN

DEERE ha adoptado un diseño de aislamiento doble. “Aislamiento doble” significa

que se han utilizado dos sistemas de aislamiento físicamente separados para aislar

los materiales eléctricamente conductores conectados a la fuente de alimentación del

bastidor exterior manejado por el operador. Por lo tanto, en la herramienta eléctrica o

en su placa de características aparecen el símbolo “ ” o las palabras “Double

insulation” (aislamiento doble).

Aunque este sistema no posee puesta a tierra externa, usted deberá seguir las

precauciones sobre seguridad eléctrica ofrecidas en este Manual de instrucciones,

incluyendo la no utilización de la herramienta eléctrica en ambientes húmedos.

para mantener efectivo el sistema de aislamiento doble, tenga en cuenta las

precauciones siguientes:

a. Esta herramienta eléctrica solamente deberá desensamblar y ensamblarla

un CENTRO DE REPARACIONES AUTORIZADO POR JOHN DEERE, y

solamente deberán utilizarse con ella piezas de reemplazo genuinas de

JOHN DEERE.

b. Limpie el exterior de la herramienta eléctrica solamente con un paño suave

humedecido en agua jabonosa, y después séquela bien.

No utilice disolventes, gasolina, ni diluidor de pintura para limpiar las partes

de plástico, ya que podría disolverlas.

GUARDE ESTE MANUAL DE INSTRUCCIONES DONDE

PUEDAN LEERLO OTRAS PERSONAS QUE VAYAN A UTILIZAR ESTA

HERRAMIENTA!

Manual del Operador 37

Page 38

Descripción Funcional

NOTA: La información contenida en este Manual de instrucciones ha sido diseñada

NUNCA haga funcionar ni efectúe el mantenimiento de la herramienta antes de leer y

comprender todas las instrucciones de seguridad contenidas en este manual.

Algunas ilustraciones de este Manual de Instrucciones pueden mostrar detalles o

accesorios diferentes a los de la propia herramienta eléctrica.

MODELO:

ET-3507-J 1/2" HAMMER DRILL

NOMENCLATURA:

para ayudarle a utilizar con seguridad y mantener esta herramienta

eléctrica.

(Fig. 1)

ESPECIFICACIONES:

Motor Motor conmutador en serie monofásico

Fuente de alimentación 115V CA, 60 Hz, monofásica

Currient 6,8 A

Reversible Yes

Alteración de velocidad 1 2

Velocidad de marcha 0–1100/min 0–2600/min

Capacidad del portabrocas 1/2" (13mm)

Capacidad

Acero 1/2" (13mm) 5/16" (8mm)

Concreto 3/4" (20mm) 1/2" (13mm)

Madera 1-9/16" (40mm) 1" (25mm)

Velocidad de percusión 14000/min 36000 /min

Peso (sin cable) 4,6 lbs (2,1 kg)

38 Manual del Operador

Page 39

Operación