Page 1

AC2-80ES

AIR COMPRESSOR

CAUTION

RISK OF INJURY! READ ENTIRE MANUAL BEFORE OPERATING!

THIS MANUAL IS AN IMPORTANT PART OF THE AIR COMPRESSOR

AND MUST REMAIN WITH THIS UNIT!

Stationary Electric Air Compressor Manual 1

Page 2

TABLE OF CONTENTS

Warning: This product contains lead, a

chemical known to the State of California

to cause birth defects or other reproductive

harm.

Wash your hands after handling this product.

INTRODUCTION ................................................................................................................3

IMPORTANT .................................................................................................................. 3

INSPECTION ......................................................................................................................3

IMPORTANT SAFETY INSTRUCTIONS ........................................................................... 4-7

RISK OF ELECTRIC SHOCK OR ELECTROCUTION ................................................4

RISK OF EXPLOSION OR FIRE .................................................................................5

RISK OF BURSTING ...................................................................................................5

RISK TO BREATHING .................................................................................................6

RISK OF BURNS .........................................................................................................6

RISK OF FLYING OBJECTS .......................................................................................6

RISK FROM MOVING PARTS .....................................................................................7

RISK FROM NEGLIGENCE............. ...........................................................................7

RISK OF AIR COMPRESSOR DAMAGE ....................................................................7

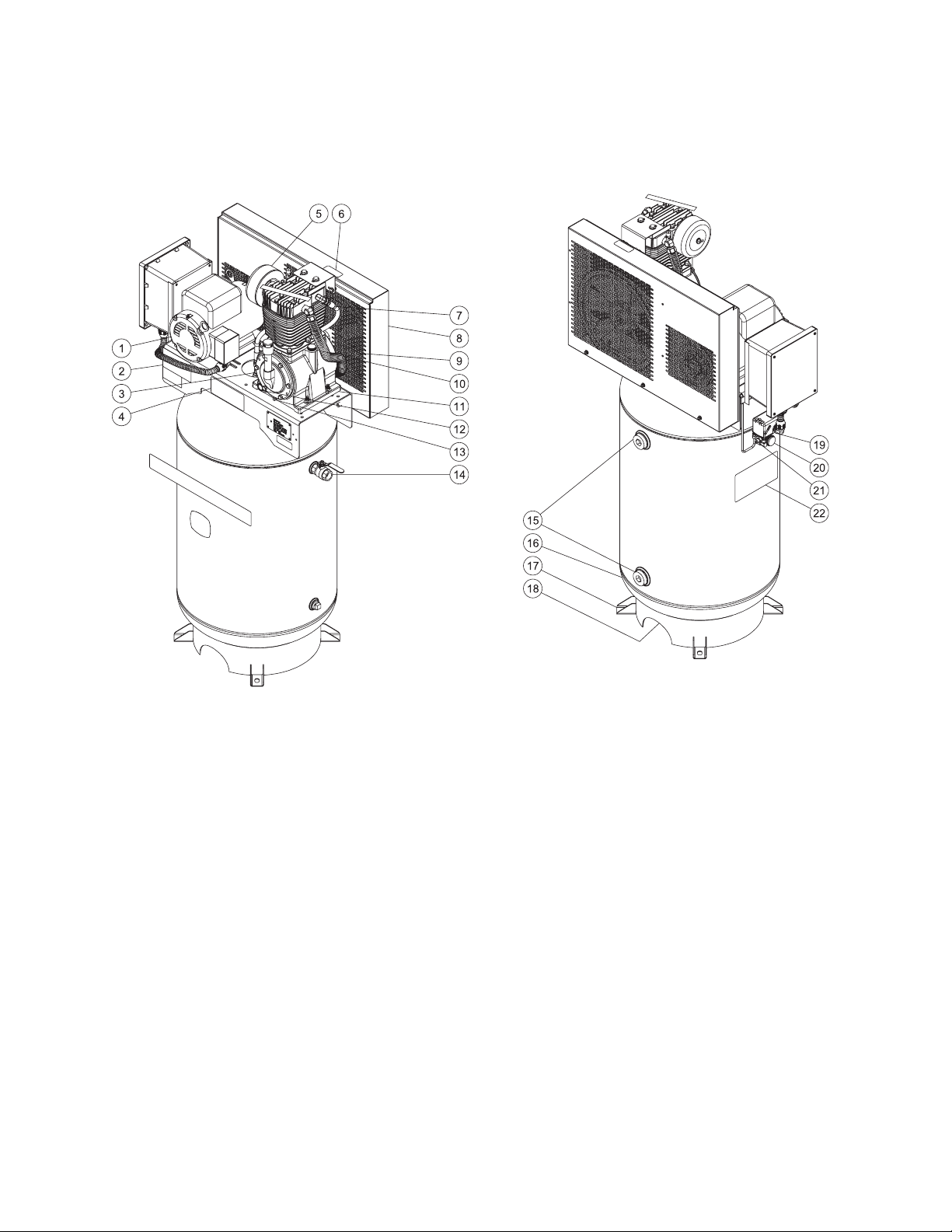

FEATURE DRAWINGS & REVIEW .............................................................................. 8-11

PREPARATION INSTRUCTIONS ...............................................................................12-13

INITIAL SET-UP .........................................................................................................12

LOCATION .................................................................................................................12

ELECTRICAL .............................................................................................................13

PRE-START CHECKLIST ..........................................................................................13

OPERATING INSTRUCTIONS ........................................................................................ 14

START-UP ..................................................................................................................14

SHUTDOWN ..............................................................................................................14

MAINTENANCE INSTRUCTIONS ...................................................................................14

TROUBLESHOOTING ................................................................................................15-17

WARRANTY .....................................................................................................................18

NOTES ..............................................................................................................................21

2 Stationary Electric Air Compressor Manual

Page 3

INTRODUCTION

Congratulations on the purchase of your new air compressor! You can be assured your air compressor was

constructed with the highest level of precision and accuracy. Each component has been rigorously tested by

technicians to ensure the quality, endurance and performance of this air compressor.

This operator's manual was compiled for your benet. By reading and following the simple safety, installation and

operation, maintenance and troubleshooting steps described in this manual, you will receive years of troublefree

operation from your new Air Compressor. The contents of this manual are based on the latest product information

available at the time of publication. The manufacturer reserves the right to make changes in price, color, materials

equipment, specications or models at any time without notice.

IMPORTANT!

A "DANGER, WARNING or CAUTION" safety warning will be surrounded by a "SAFETY ALERT BOX".

This box is used to designate and emphasize Safety Warnings that must be followed when operating this

air compressor. Accompanying the safety warnings are "Signal Words" which designate the degree or

level of hazard seriousness. The "Signal Words" used in this manual are as follows:

DANGER: Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided

MAY result in minor or moderate injury or damage to the air

compressor.

The symbols set to the left of this paragraph are "Safety Alert Symbols". These

symbols are used to call attention to items or procedures that could be dangerous

to you or other persons using this equipment.

ALWAYS PROVIDE A COPY OF THIS MANUAL TO ANYONE USING THIS EQUIPMENT. READ ALL

INSTRUCTIONS IN THIS MANUAL AND ANY INSTRUCTIONS SUPPLIED BY MANUFACTURERS OF

SUPPORTING EQUIPMENT BEFORE OPERATING THIS AIR COMPRESSOR AND ESPECIALLY POINT

OUT THE "SAFETY WARNINGS" TO PREVENT THE POSSIBILITY OF PERSONAL INJURY TO THE

OPERATOR.

Once the unit has been uncrated, immediately write in the serial number of your unit in the space provided

below.

SERIAL NUMBER_________________________________

Inspect for signs of obvious or concealed freight damage. If damage does exist, le a claim with the transportation

company immediately. Be sure that all damaged parts are replaced an that the mechanical and electrical problems

are corrected prior to operation of the unit. If you require service, contact your customer service.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

1. Model Number

2. Serial Number

3. Date and Place of Purchase

Please have the following information available for all service calls:

Stationary Electric Air Compressor Manual 3

Page 4

WARNING: When using this product basic precautions should always be observed, including the following:

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

IMPORTANT SAFETY INSTRUCTIONS

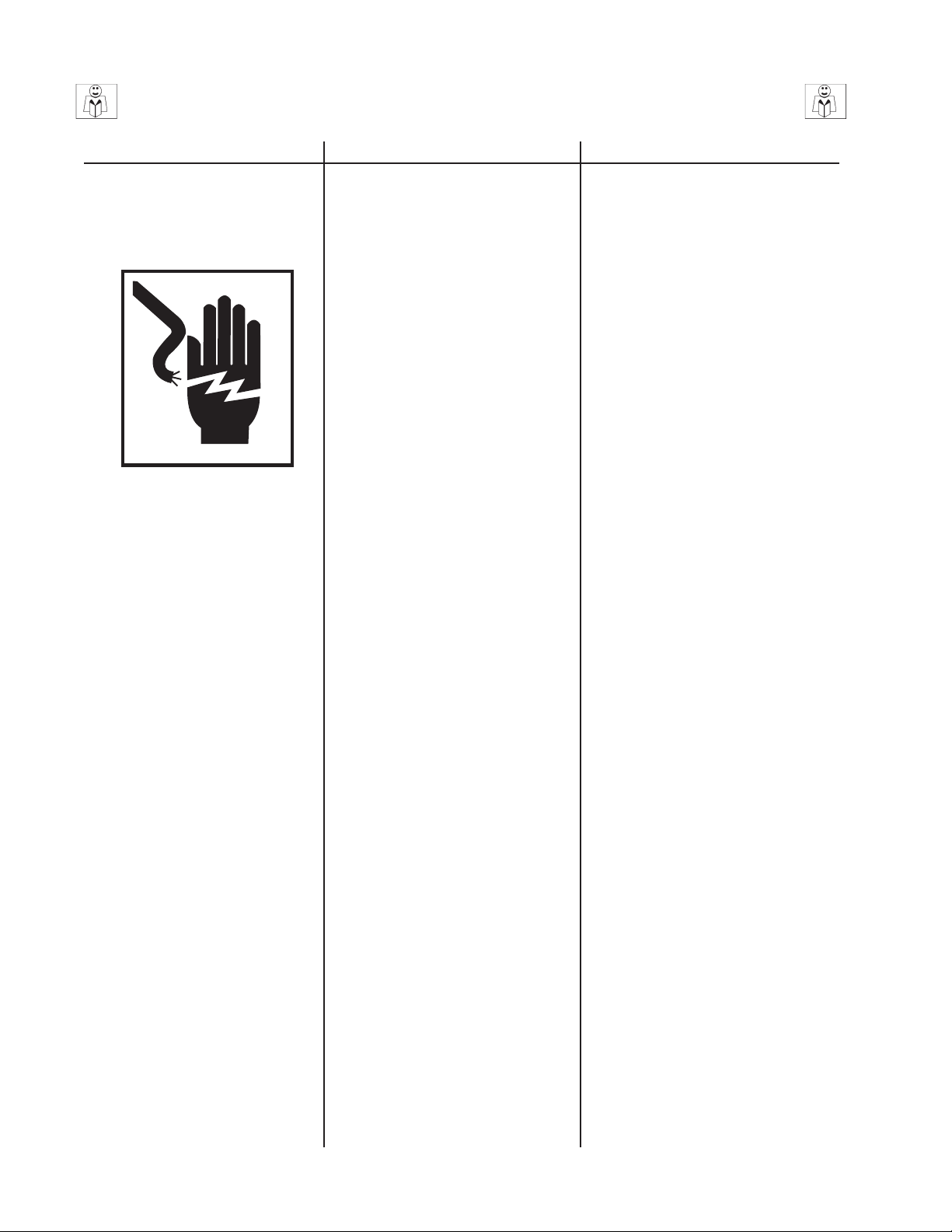

HAZARD

RISK OF ELECTRIC SHOCK

OR ELECTROCUTION

POTENTIAL CONSEQUENCE PREVENTION

Serious injury or death could occur

if the air compressor is not properly

grounded. Your air compressor is

powered by electricity and may cause

electric shock or electrocution if not

used properly.

Electrical shock may occur if the

air compressor is not operated

properly.

Serious injury or death may occur if

electrical repairs are attempted by

unqualied persons.

Installation of this unit, including all

electrical connections, must comply

with all local, state and national

codes.

This product must be grounded.

Connect to a GFCI circuit breaker

when available. If the unit should

malfunction or breakdown, grounding

provides a path of least resistance

for electric current to reduce the risk

of electric shock. Do not ground to a

gas supply line.

Improper connection of the equipmentgrounding conductor can result in a risk

of electrocution. Check with a qualied

electrician or service personnel if you

are in doubt as to whether the system

is properly grounded.

Always be certain the unit is receiving

proper voltage (+/- 5% of the voltage

listed on the nameplate). Before

installing electrical connections, be

certain the power switches are in the

"OFF" position.

Keep all connections dry and off the

ground.

Never operate air compressor in wet

conditions.

Never operate air compressor with

safety guards/covers removed or

damaged.

Any electrical wiring or repairs

performed on this air compressor

should be done by Authorized Service

Personnel in accordance with National

and Local electrical codes.

Bef ore opening an y electric al

enclosure, always shut off the air

compressor, relieve pressure and

unplug the air compressor from the

power source. Allow air compressor

to cool down. Never assume the air

compressor is safe to work on just

because it is not operating. It could

restart at any time! Service in a clean,

dry, at area.

4 Stationary Electric Air Compressor Manual

Page 5

IMPORTANT SAFETY INSTRUCTIONS

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

HAZARD

RISK OF

EXPLOSION OR FIRE

POTENTIAL CONSEQUENCE

Serious injury or death may occur

from normal electrical sparks in

motor and pressure switch

Serious injury may occur if any air

compressor ventilation openings

are restricted, causing the air

compressor to overheat and start

a re.

PREVENTION

Always operate air compressor in a

well ventilated area free of ammable

vapors, combustible dust, gases or

other combustible materials.

DO NOT SMOKE if spraying ammable

material. Locate the air compressor

at least 20 feet away from the spray

area. (An additional hose may be

required.)

Never place objects against or on

top of air compressor. Operate air

compressor at least 12 inches away

from any wall or obstruction that would

restrict proper ventilation.

RISK OF

BURSTING

Serious injury or death may occur

from an air tank explosion if air tanks

are not properly maintained.

Serious injury may occur from

an air compressor malfunction or

exploding accessories if incorrect

system components, attachments

or accessories are used.

Drain air tank daily or after each use

to prevent moisture buildup in the air

tank.

If air tank develops a leak, replace the

air tank immediately. Never repair, weld

or make modications to the air tank

or its attachments. Use only genuine

manufacturer repair parts for your air

compressor.

Never make adjustments to the factory

set pressures.

Neve r e x ceed manu f acture r s

maximum allowable pressure rating

of attachments.

Because of extreme heat, do not use

plastic pipe or lead tin soldered joints

for a discharge line.

Never use air compressor to inate

small, low pressure objects such as

toys.

Stationary Electric Air Compressor Manual 5

Page 6

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

HAZARD

RISK TO BREATHING

IMPORTANT SAFETY INSTRUCTIONS

POTENTIAL CONSEQUENCE

Serious injury or death could occur

from inhaling compressed air. The

air stream may contain carbon

monoxide, toxic vapors or solid

particles.

Sprayed materials such as paint,

paint solvents, paint remover,

insecticides, weed killers, etc. contain

harmful vapors and poisons.

Never inhale air from the air

compressor either directly or from

a breathing device connected to the

air compressor.

Operate air compressor only in

a well ventilated area. Follow all

safety instructions provided with the

materials you are spraying. Use of

a respirator may be required when

working with some materials.

PREVENTION

RISK OF BURNS

RISK FROM

FLYING OBJECTS

Serious injury could occur from

touching exposed metal parts.

These areas can remain hot for

some time after the air compressor

is shutdown.

Serious injury can occur from loose

debris being propelled at a high

speed from the compressed air

stream.

Soft tissue damage can occur from

the compressed air stream.

Never allow any part of your body

or other materials to make contact

with any exposed metal parts on the

air compressor.

Always wear safety glasses to shield

the eyes from ying debris.

Never point the air stream at any

part of your body, anyone else or

animals.

Never leave pressurized air in the air

compressor. Shut off air compressor

and relieve pressure when storing or

attempting maintenance.

Always maintain a safe distance from

people and animals while operating

the air compressor.

6 Stationary Electric Air Compressor Manual

Page 7

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

HAZARD

RISK FROM

MOVING PARTS

IMPORTANT SAFETY INSTRUCTIONS

POTENTIAL CONSEQUENCE

Risk of bodily injury from moving

parts. This air compressor cycles

(Starts/Stops) automatically when

the pressure switch is in the "On/

Auto" position.

Before performing maintenance,

always turn off air compressor.

Bleed pressure from the air hose and

disconnect from the electrical source.

All repairs to the air compressor

should be made by an Authorized

Service person. Never assume the

air compressor is safe to work on just

because it is not operating. It could

restart at any time!

Do not operate without protective

covers/guards. Always unplug the

air compressor before removing

any guard. Replace damaged

covers/guards before using the air

compressor.

PREVENTION

RISK FROM

NEGLIGENCE

RISK OF DAMAGE TO

AIR COMPRESSOR

Risk of injury from negligent use.

Risk of major repair.

Never allow children or adolescents

to operate this air compressor!

Stay alert-watch what you are doing.

Do not operate the air compressor

when fatigued or under the inuence

of alcohol or drugs.

Know how to stop the air compressor.

Be tho r o u g h ly familiar w i t h

controls.

Do not operate air compressor

without an air lter.

Do not operate air compressor in a

corrosive environment.

Always operate the air compressor

secured to a concrete surface to

prevent the air compressor from

falling.

Follow all maintenance instructions

listed in this manual.

! SAVE THESE INSTRUCTIONS !

Stationary Electric Air Compressor Manual 7

Page 8

ELECTRIC AIR COMPRESSOR FEATURES

TWO STAGE

(DOES NOT INCLUDE POWER CORD, POWER PLUG, PRESSURE REGULATOR)

AM2-SE05-80J FEATURES

Item Description

1 Electric Motor

2 Decal - Maintenance Instructions

3 Check Valve

4 Decal - Operating Instructions

5 Air Intake Filter

6 Decal - Warning: Hot Surface

7 Pump Discharge Line

8 Beltguard

9 Ventilation Openings

10 Oil Fill Port/vent

11 Air Compressor Pump

12 Oil Sight Glass

13 Oil Drain Plug

14 Outlet Fitting

15 Tank Inspection Openings

16 Air Tank Assembly

17 Foot

18 Air Tank Drain Valve

19 Motor Pressure Switch

20 Air Tank Pressure Gauge

21 Safety Relief Valve

22 Decal - Danger/warning/caution

8 Stationary Electric Air Compressor Manual

Page 9

EXPLODED VIEW & EXPLANATION OF AIR COMPRESSOR FEATURES

AIR TANK DRAIN VALVE: The drain valve is used to remove moisture from the

air tank(s) after the air compressor is shut off. NEVER attempt to open the drain valve

when more than 10 PSI of air pressure is in the air tank! To open the drain valve, turn

the knob counterclockwise.

OIL SIGHT GLASS: The Oil Sight Glass displays the oil level in the pump.

The oil level should be at the center of the Oil Sight Glass. If low, add SAE 30W

non-detergent oil.

OIL FILL PORT/VENT: Pour oil into the Oil Fill Port/Vent when required.

AIR INTAKE FILTER: This lter is designed to clean air coming into the pump. To ensure

the pump continually receives a clean, cool, dry air supply this lter must always be clean and

ventilation opening free from obstructions. Replace lter element when necessary.

AIR COMPRESSOR PUMP: To compress air, the pistons move up and down in the cylinders. On the

downstroke, air is drawn in through the air intake valves while the exhaust valves remain closed. On the

upstroke, air is compressed, the intake valves close and compressed air is forced out through the exhaust

valves, into the discharge line, through the check valve and/or the pilot valve and into the air tank.

MOTOR/PRESSURE SWITCH: This switch is used to start or stop the air compressor. Moving the switch to the "Auto" (On) position will provide automatic power

to the pressure switch which will allow the motor to start when the air tank pressure is

below the factory set "cut-in" pressure. When in the Start/Stop Option, the pressure

switch stops the motor when the air tank pressure reaches the factory set "cut-out"

pressure. For safety purposes, this switch also has a pressure release valve located

on the side of the switch designed to automatically release compressed air from the

air compressor pump head and its discharge line when the air compressor reaches

"cut-out" pressure or is shut off. This allows the motor to restart freely. Moving the

switch to the "Off" position will remove power from the pressure switch and stop the

air compressor.

SAFETY RELIEF VALVE: This valve is designed to prevent system failures by

relieving pressure from the system when the compressed air reaches a predetermined

level. The valve is preset by the manufacturer and must not be modied in any way. To

verify the valve is working properly, pull on the ring. Air pressure should escape. When

the ring is released, it will reseat.

AIR TANK PRESSURE GAUGE: The air tank pressure gauge indicates the reserve air

pressure in the air tank.

STARTER: the Motor starter provides thermal overload protection. The starter is required from on motors 5 Hp and above.

Stationary Electric Air Compressor Manual 9

Page 10

NOTES

10 Stationary Electric Air Compressor Manual

Page 11

WARNING

THE FOLLOWING PAGES CONTAIN OPERATING

AND MAINTENANCE INSTRUCTIONS.

DO NOT ATTEMPT TO OPERATE THIS AIR

COMPRESSOR UNTIL YOU HAVE READ AND

UNDERSTOOD ALL SAFETY PRECAUTIONS

AND INSTRUCTIONS LISTED IN THIS MANUAL.

INCORRECT OPERATION OF THIS UNIT CAN

CAUSE SERIOUS INJURY!!

DO NOT ALTER OR MODIFY THIS EQUIPMENT

IN ANY MANNER!

Stationary Electric Air Compressor Manual 11

Page 12

PREPARATION INSTRUCTIONS

WARNING

RISK OF EXPLOSION OR FIRE

CAUSING SERIOUS INJURY

OR DEATH!

Do not allow the motor or Motor/

Pressure Switch to come in

contact with ammable vapors,

combustible dust, gases or other

combustible materials. An electric

spark may cause an explosion

or re.

When using the air compressor

for spray painting, place the air

compressor as far away from the

work area as possible.

INITIAL SET-UP:

1. Read safety warnings before setting-up air compressor.

2. Ensure the oil level in the air compressor pump is adequate. If low,

add SAE-30W non-detergent oil.

LOCATION:

1. In order to avoid damaging the air compressor, do not incline the air

compressor transversely or longitudinally more than 10°.

2. Place air compressor on a concrete surface at least 12 inches away from

obstacles that may prevent proper ventilation. Place the ywheel side

of the unit toward the wall. Do not place air compressor in an area:

-where there is evidence of oil or gas leaks.

-where ammable gas vapors or materials may be present.

-where air temperatures fall below 32°F or exceed 104°F.

-where extremely dirty air or water could be drawn into the air

compressor.

3. Distribute air compressor weight evenly. Excessive vibration can weaken

the air tank creating a hazard of explosion.

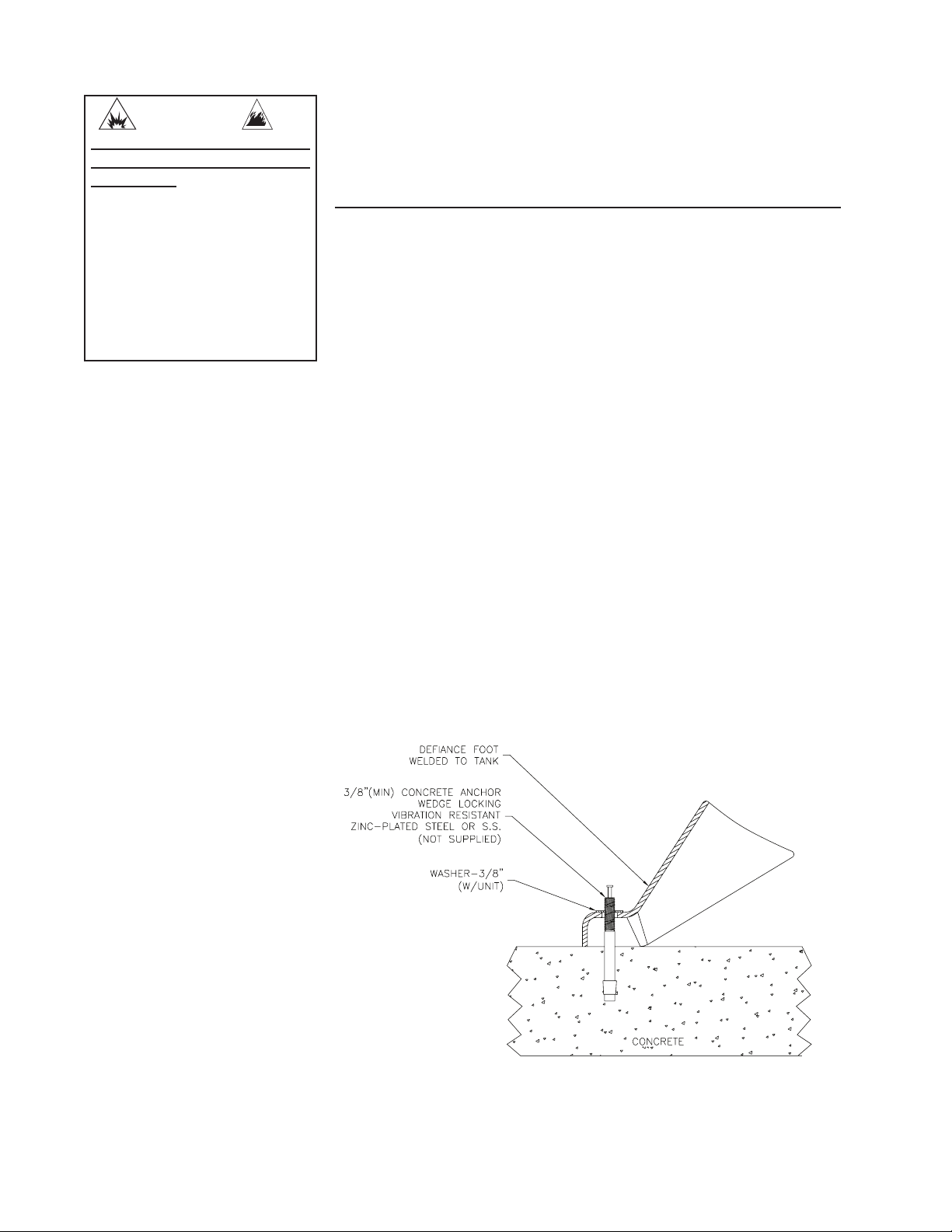

4. Bolt the air compressor to the concrete surface.

a. Mark the areas through the feet of the air compressor where anchor

bolts will be placed.

b. Move the air compressor and drill holes in the marked areas to

accept the anchor bolts.

c. With the nut attached, pound the anchor bolts into the pre-drilled

holes.

d. Remove the nuts and place the air compressor over the anchor

bolts.

e. Replace and tighten the nuts.

12 Stationary Electric Air Compressor Manual

ANCHOR-DCE

Page 13

PREPARATION INSTRUCTIONS

L1 L2 L3

G

L2

L1

Power

In

1 Phase

ELECTRICAL:

1. A qualied electrician MUST hook up the electrical system.

a. Verify the electrical supply at the power source is off.

b. Be certain all switches on the Control Panel are in the "OFF"

position.

c. Make connections to the terminal as shown below.

DANGER

RISK OF ELECTROCUTION!

Improp er conne ction of the

equipment-grounding conductor

can result in a risk of shock or

electrocution. Check with a

qualied electrician or service

personnel if you are in doubt as

to whether the outlet is properly

grounded. The wire with insulation

having an outer surface that is

green with or without yellow

stripes is the grounding wire.

WARNING

RISK OF ELECTRICAL SHOCK!

This product must be grounded. If

there should be a malfunction or

breakdown, grounding provides

a path of least resistance for

electric current to reduce the risk

of electric shock.

electric diagram_industrial line_1 Phase

PRE-START CHECKLIST:

1. Check oil level. Add if necessary.

2. Remove any moisture in the air compressor air tank. NEVER

attempt to open the Air Tank Drain Valve when more than 10

PSI is in the air tank! Remove excessive pressure with an air tool,

then open the Air Tank Drain Valve in the bottom of the air tank. Close

tightly when drained.

3. Make sure the Motor/Pressure Switch is in the "OFF" position.

4. Make sure the Safety Relief Valve is working correctly.

5. Make sure all guards and covers are in place and securely mounted.

WARNING

RISK OF BODILY INJURY!

Never attempt to open the Air

Tank Drain Valve when more

than 10 PSI of air pressure is in

the air tank!

Stationary Electric Air Compressor Manual 13

Page 14

OPERATING INSTRUCTIONS

AC Ele. Maintenance Chart

MAINTENANCE CHART

PROCEDURE DAILY WEEKLY MONTHLY 1000 HOURS

Check pump oil level X

Oil leak inspection X

Drain condensation in air tank (s) X

Inspect guards/covers X

Check for unusual noise/vibration X

Check for air leaks X

Clean exterior of compressor X

Inspect air fi lter X

Inspect belt X

Check safety relief valve X

Change pump oil * X

Replace air fi lter X

START-UP:

1. Read safety warnings before performing operation.

2. Move the Motor/Pressure Switch to the "AUTO" position.

3. If you notice any unusual noise or vibration, stop the air compressor and refer

to "Troubleshooting".

SHUTDOWN:

1. To stop the air compressor, move the Motor/Pressure Switch to the "OFF"

position.

2. Drain air from the air tanks by releasing air with an attached air tool or by

pulling on the Safety Relief Valve.

3. Once the Air Tank Pressure Gauge registers under 10 pounds, open the Air

Tank Drain Valve under the air tank to drain any moisture.

4. Allow the air compressor to cool down, then wipe clean.

MAINTENANCE INSTRUCTIONS

Read the instruction manual before performing maintenance. The following

procedures must be performed when stopping the air compressor for maintenance

or service.

1. Turn off air compressor.

2. Open all drains after the tank gauge registers under 10 PSI..

3. Wait for the air compressor to cool before starting service.

WARNING

RISK OF BODILY INJURY!

Nev e r a s s ume the air

compressor is safe to work

on just because it is not

operating. It could restart at

any time!

*THE PUMP OIL MUST BE CHANGED AFTER THE FIRST 100 HOURS OF OPERATION AND EVERY 1000

HOURS OR 3 MONTHS, WHICHEVER COMES FIRST.

EVERY TWO YEARS, AN AUTHORIZED SERVICE TECHNICIAN SHOULD CHECK THE CHECK VALVE, INTAKE

VALVES AND DELIVERY VALVES.

14 Stationary Electric Air Compressor Manual

Page 15

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE REMEDY

Air compressor will not start.

Motor/Pressure Switch turned "OFF".

Motor Thermal Overload tripped on

air compressor.

Circuit breaker tripped or fuse blown

at power source.

Move Motor/Pressure Switch to

"AUTO" position.

Turn unit off, wait 5 minutes, then

press Motor Thermal Overload until

click is heard.

Reset circuit breaker or replace fuse if

necessary, using only "Fusetron" type

T fuses.

Check for low voltage conditions.

Disconnect any other electrical ap-

pliances from circuit or operate air

compressor on its own branch circuit.

Air compressor will not start,

but motor hums, then stops.

Motor voltage does not match power

source.

Air tank pressure achieved the "Maximum setting" or "Stop pressure" of

the Motor/Pressure Switch.

Pressure release valve on Motor/

Pressure Switch has not unloaded

pump head pressure.

Pilot valve's check valve stuck open.

Defective motor, or Motor/Pressure

Switch.

Low oil level (if unit is equipped with

Low Oil Sensor)

Loose electrical connection.

Too many appliances being operated on same circuit.

Incorrect voltage, incorrect sized

circuit breaker, fuse or motor. Defective motor.

Defective Check Valve or Motor/

Pressure Switch.

Contact your Customer Service.

The motor will start automatically

when air tank pressure drops down to

the "Cut-in" or "Start" pressure of the

Motor/Pressure Switch.

Bleed the line by moving the switch to

the "Off" position.

Remove and clean or replace.

Contact your Customer Service.

Add oil to pump

Contact qualied electrician.

Use another circuit or remove excess

appliances from circuit.

Contact qualied electrician.

Replace.

Air compressor does not stop

even though the maximum

pressure allowed has been

reached.

Stationary Electric Air Compressor Manual 15

Motor/Pressure Switch not operating correctly.

Replace.

Page 16

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE REMEDY

Noisy operation.

Loose motor pulley or pump ywheel.

Tighten pulley and or ywheel.

Pressure drop in air tank or

rapid pressure loss when air

compressor is shut off.

Insufcient pressure at air tool

or accessory.

Air leaks from Safety Relief

Valve.

Lack of oil in the pump.

Carbon deposits on pistons or valves.

Bearing, piston or connecting rod

failure.

Air leaks at connections. Allow the air compressor to build

Defective Check Valve or Pilot Valve.

Air leak in air tank.

Air leaks or restrictions.

Restricted air intake lter.

Pipe, hose or hose connections are

too small or long.

Air compressor is not large enough

for air requirement.

Slipping belt.

Restricted Pilot Valve.

Possible defective Safety Relief

Valve.

Excessive air tank pressure.

Add correct amount of oil.

Remove cylinder head and inspect.

Clean or replace valve plate.

STOP THE AIR COMPRESSOR!

Contact your customer service.

pressure to the maximum allowed.

Turn off and brush a soapy water solution onto all connections.

Check connections for air bubbles.

Tighten the connections where

leaks are present.

Remove, clean or replace.

Air tank must be replaced. Do not

attempt to repair air tank!

Check for leaks and repair.

Clean or replace.

Replace with larger pipe, hose or

connectors.

Use a smaller tool or larger air

compressor.

Tighten or replace.

Clean or replace.

Operate Safety Relief Valve manually

by pulling on ring. If it still leaks, it

should be replaced.

Replace Motor/Pressure Switch.

Clean, reset or replace Pilot Valve.

Air leaks at pump.

Air continues to leak at Motor/

Pressure Switch while motor is

running.

Air blowing from Air Intake

Filter.

16 Stationary Electric Air Compressor Manual

Defective gaskets.

Defective Motor/Pressure Switch.

Damaged inlet (reed) valve.

Torque head bolts to 19.5 ft./lbs.

for Single Stage & 33.2 for

2 stage.

Replace.

Remove cylinder head and

inspect. Clean or replace valve

plate.

Page 17

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE REMEDY

When in the Start/Stop Option,

motor runs continuously.

Motor/Pressure Switch does not

shut off motor when air compressor reaches "cut-out" pressure and

safety relief valve activates.

Move the Motor/Pressure Switch

to the "OFF" position. If the motor

does not shut off, remove power to

the machine. If the electrical contacts are welded together, replace

the pressure switch.

Moisture in discharge air.

Excessive oil consumption or oil in

hose.

Air compressor is incorrectly

sized.

Condensation in air tank caused

by high level of atmospheric humidity.

Restricted air intake lter.

Air compressor on unlevel surface.

Crankcase overlled with oil.

Wrong viscosity.

Plugged oil dipstick vent.

Oil leaks.

Worn piston rings or scored cylinder.

Limit the air usage to the capacity

of the air compressor. Either use a

smaller tool or a larger air compressor.

Drain air tank after every use.

Drain air tank more often in humid

weather and use an air line lter.

Clean or replace.

Do not incline the air compressor more than 10° in any direction

while running.

Drain oil. Rell to proper level with

SAE-30W non-detergent oil.

Drain oil. Rell to proper level with

SAE-30W non-detergent oil.

Clean.

Tighten pump bolts to torque stated

in Parts List, or replace gaskets.

Contact your customer service.

Oil has milky appearance. Water in oil due to condensation. Drain oil. Rell to proper level with

SAE-30W non-detergent oil.

Unit runs backward. Reversed wiring. Contact qualied electrician.

Stationary Electric Air Compressor Manual 17

Page 18

STATEMENT OF WARRANTY

The manufacturer warrants all parts, (except those referred to below), of your

new air compressor to be free from defects in materials and workmanship during

the following periods:

For Two (2) Years from the date of original purchase:

Compressor Pump Plumbing

Tank Assembly

For Six (6) Months from the date of original purchase:

Pressure Switch Regulator

Check Valve Pilot Valve

Copper/Stainless Steel Line

For Ninety (90) days from the date of original purchase:

Pressure Gauges Safety Relief Valves

Drain Valves

Defective parts not subject to normal wear and tear will be repaired or replaced

at our option during the warranty period. In any event, reimbursement is limited

to the purchase price paid.

EXCLUSIONS

1. Motor is covered under separate warranty by its respective manufacturer

and is subject to the terms set forth therein.

2. Normal wear parts:

Air Filter Isolators

3. This warranty does not cover parts damaged due to normal wear, abnormal

conditions, misapplication, misuse, accidents, operation at other than

recommended voltage, pressures or temperature, improper storage or

freight damage. Parts damaged or worn by operation in dusty environments

are not warranted. Failure to follow recommended operating and

maintenance procedures also voids warranty.

4. Labor charges, loss or damage resulting from improper operation, maintenance

(other than routine air tank draining and oil changes, if applicable) or

repairs made by persons other than a Manufacturer Authorized Service

Center.

5. The use of other than Genuine Manufacturer Repair Parts will void

warranty.Parts returned, prepaid to our factory or to an Authorized Service Center

will be inspected and replaced free of charge if found to be defective and subject to

warranty. Under no circumstances shall the manufacturer bear any responsibility

for loss of use of the unit, loss of time or rental, inconvenience, commercial

loss or consequential damages. There are no warranties which extend beyond

the description of the face hereof.

For Service or Warranty Consideration, contact

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

18 Stationary Electric Air Compressor Manual

Page 19

NOTES

Manuel Compresseur d'air électrique stationaire 21

Page 20

TABLE DES MATIÈRES

AVERTISSEMENT: Ce produit contient

du plomb, un produit chimique qui est

connu par l'état de Californie comme

étant la cause de cancer et de

malformations congénitales ou autres

effets nocifs de reproduction.

Laver vos mains après avoir manipulé ce produit.

INTRODUCTION .................................................................................................................................23

IMPORTANT ........................................................................................................................................ 23

INSPECTION ....................................................................................................................................... 23

IMPORTANTES CONSIGNES DE SÉCURITÉ ..............................................................................24-27

RISQUE DE DÉCHARGE ÉLECTRIQUE OU D'ÉLECTROCUTION ..................................... 24

RISQUE D'EXPLOSION OU D'INCENDIE ............................................................................25

RISQUE D'ÉCLATEMENT ...................................................................................................... 25

RISQUE DE PROBLÉMES RESPIRATOIRES ....................................................................... 26

RISQUE DE BRÛLURES ........................................................................................................ 26

RISQUE DE PROJECTION D'OBJETS .................................................................................. 26

RISQUE PROVENANT DE PIÈCES MOBILES ...................................................................... 27

RISQUE RÉSULTANT DE NÉGLIGENCE .............................................................................. 27

RISQUE DE DÉGATS AU COMPRESSEUR D'AIR ............................................................... 27

DESSINS ET REVUE DES COMPOSANTS .................................................................................28-29

NOTES ................................................................................................................................................ 30

INSTRUCTIONS DE PRÉPARATION ............................................................................................32-34

INSTALLATION INITIALE .......................................................................................................32

EMPLACEMENT ..................................................................................................................... 32

ELECTRIQUE ......................................................................................................................... 33

POINTS DE CONTRÔLE AVANT DÉMARRAGE ...................................................................33

INSTRUCTIONS D'UTILISATION ....................................................................................................... 34

MISE EN MARCHE ................................................................................................................. 34

MISE À L'ARRÊT .................................................................................................................... 34

INSTRUCTIONS D'ENTRETIEN ......................................................................................................... 34

DÉPANNAGE ...................................................................................................................................... 35

BON DE GARANTIE ........................................................................................................................... 39

22 Manuel Compresseur d'air électrique stationaire

Page 21

INTRODUCTION

Félicitations de l'achat de votre nouveau compresseur d'air! Vous pouvez être assuré que votre nouveau

compresseur a été construit avec le plus haut niveau de précision et de abilité. Chaque composant a été

rigoureusement testé par des techniciens pour assurer la qualité, la durabilité et la performance de ce compresseur

d'air.

Ce manuel opérateur a été dressé pour que vous en retiriez le meilleur parti. Par la lecture et l'application des

mesures simples de sécurité, d'installation et d'opération, d'entretien et de dépannage décrites dans ce manuel,

votre nouveau compresseur d'air fonctionnera sans faille pendant de nombreuses années. Le contenu de ce

manuel est basé sur la dernière information disponible du produit au moment de la publication. Le fabricant se

réserve le droit d'effectuer des changements de prix, de couleur, de matériaux, d'équipement, de caractéristiques

ou de modèles à tout moment sans communication préalable.

IMPORTANT!

Les avertissements de sécurité "DANGER, AVERTISSEMENTou ATTENTION" seront entourés par un

"ENCADRÉ ALERTE SÉCURITÉ". Cet encadré est utilisé pour indiquer et souligner les avertissements

de sécurité qui doivent être suivis en actionnant ce compresseur d'air. En plus des avertissements de

sécurité, des "mots d'alerte" sont utilisés pour indiquer le degré ou niveau de risque. Les "mots d'alerte"

utilisés dans ce manuel sont comme suit:

DANGER: Indique une situation au danger imminent qui, si elle n'est pas évitée,

ENTRAINERA la mort ou des blessures graves.

AVERTISSEMENT: Indique une situation potentiellement dangereuse qui, si elle n'est

pas évitée, POURRAIT entraîner la mort ou des blessures graves.

ATTENTION: Indique une situation potentiellement dangereuse qui, si elle n'est pas évitée,

PEUT entraîner des blessures mineures ou peu graves et des dégats au

compresseur.

Les symboles placés à gauche de ce paragraphe sont des "symboles d'alerte de sécurité". Ces symboles

sont utilisés pour souligner les points ou les procédures qui pourraient être dangeureuses pour vous

ou tout autre personne

utilisant cet équipement.

Fournisser toujours une copie de ce manuel à toute personne utilisant cet équipement. Lire toutes les

instructions dans ce manuel et toutes instructions fournies par les fabricants d'équipement de support

avant d'utiliser ce compresseur d'air et attirer spécialement l'attention aux "Avertissements de Sécurité"

pour empêcher la possibilité de blessures pour l'utilisateur.

Une fois l'appareil déballé, écrivez immédiatement le numéro de série de votre appareil dans l'espace çi-

dessous.

NUMERO DE SÉRIE________________________________

Assurez-vous qu'il n'y a pas de signes de dommages évidents ou cachés suite au transport. En cas de dommages,

remplissez immédiatement une réclamation avec la compagnie de transport. Assurez-vous que toutes les

pièces endommagées sont remplacees et les problémes mécaniques et électriques corrigés avant l'utilisation

de l'appareil. Si vous avez besoin d'assistance, entrez en contact avec votre service clientèle.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

du lundi au vendredi de 8h00 à 17h00, CST (heure centrale)

Veuillez avoir les informations suivantes disponibles pour toute intervention:

1. Numéro de modèle

2. Numéro de série

3. Date et lieu d'achat

Manuel Compresseur d'air électrique stationaire 23

Page 22

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ

AVERTISSEMENT: Lors de l'utilisation de ce produit, des précautions de base doivent toujours être

observées, incluant les suivantes:

LIRE TOUTES LES INSTRUCTIONS AVANT UTILISATION DU NETTOYEUR A PRESSION

RISQUE CONSEQUENCE POTENTIELLE PRÉVENTION

RISQUE DE DÉCHARGE

ÉLECTRIQUE OU

D'ÉLECTROCUTION

Des risques de mort ou de blessures

graves peuvent survenir si le

compresseur n'est pas relié à la terre

correctement. Votre compresseur

est alimenté à l'électricité et il y a

risque de décharge électrique ou

d'électrocution si l'appareil n'est pas

utilisé correctement.

Une décharge électrique peut se

produire si le compresseur n'est pas

utilisé correctement.

Des risques de m o rt ou de

blessures graves peuvent survenir

si des réparations électriques sont

effectuées par des personnes

incompétentes.

L'installation de cet appareil , ainsi que

tous les branchements électriques,

doivent respecter tous les codes

locaux et nationaux.

Cet appareil doit être mis à la terre.

Connecter le à un disjoncteur mis à

la terre si il y en a un de disponible.

Si l'appareil s'avére défectueux ou

tombe en panne, la mise à la terre

offre un trajet de moindre résistance

au courant électrique pour réduire le

risque de décharges électriques.

Ne pas mettre à la terre à une ligne

d'alimentation de gaz.

Une connexion inappropriée du

co nducteur d e m ise à l a te rre

d'équipement peut provoquer un

risque d'électrocution. Consulter un

électricien qualié en cas de doute sur

la mise à la terre du système.

Soyez toujours certain que l'appareil

reçoit un voltage correct (+/-5%

du voltage inscrit sur la plaque

du fabricant). Avant de faire des

raccordements électriques, soyez

certain que les interrupteurs sont en

position d'ARRET (OFF).

Garder tous les branchements au sec

et au dessus du sol.

Ne j amai s fair e fon ctio nner l e

compresseur dans des conditions

humides.

Ne j amai s fair e fon ctio nner l e

compresseur sans les gardes/caches

de sécurité ou si les gardes sont

endommagées.

Toutes réparations ou tout câblage

électrique effectués sur le compresseur

doivent être effectués par le personnel

d'un centre de service autorisé qualié

conformément aux codes d'électricité

locaux et nationaux.

Avan t d'ouvrir n'import e quel

boîtier électrique, s'assurer que le

compresseur est à l'arrêt, relâcher

la pr e s s i o n et débran c h e r le

compresseur de la source d'énergie.

Laisser le compresseur refroidir. Ne

parter pas du principe qu'il est sans

risque d'effectuer un travail sur le

compresseur alors qu'il est à l'arrêt. Il

pourrait se remettre en marche à tout

moment! Tout travail doit s'effectuer

dans un endroit propre, sec et plat.

24 Manuel Compresseur d'air électrique stationaire

Page 23

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ

LIRE TOUTES LES INSTRUCTIONS DE SÉCURITÉ AVANT UTILISATION

RISQUE CONSÉQUENCE POTENTIELLE

RISQUE D'EXPLOSION OU

D'INCENDIE

Des risques de mort ou de blessures

graves peuvent survenir à la suite

d'étincelles électriques normales

dans le moteur et l'interrupteur de

pression.

Toute obst ruct ion aux é vents

du compresseur peut provoquer

une sur chau ffe impo rtan te et

risque d'entraîner un incendie, et

également, en conséquence, des

blessures graves.

PREVENTION

Toujo u r s fai r e fonc t i o n n er l e

compresseur dans un endroit bien

ventilé, libre de vapeurs inammables,

de poussière combustible, de gaz, ou

d'autres matériaux combustibles.

NE PAS FUMER si vous pulvérisez

une matière inammable! Placer le

compresseur à au moins 20 pieds (6.09

M) de l'aire de vaporisation. (L'addition

d'un tuyau supplémentaire peut être

nécessaire.)

Ne jamais placer d'objets contre ou

sur le dessus du compresseur. An

d'éviter de nuire à la circulation d'air,

faire fonctionner le compresseur

dans un endroit ouvert d'au moins

12 pouces (30 cm) de tout mur ou de

toutes obstructions.

RISQUE D'ECLATEMENT

Des risques de mort ou de blessures

graves peuvent survenir à la suite

d'une explosion du réservoir d'air

si les réservoirs d'air ne sont pas

entretenus correctement.

Des blessures graves peuvent

survenir suite à une dysfonction

du compresseur ou à l'explosion

d'accessoires si des composants

du système, des rajouts ou des

accessoir e s incorrects so n t

utilisés.

Vider le réservoir d'air quotidiennement

ou après chaque utilisation an d'éviter

l'accumulation d'humidité.

Si le réservoir d'air présente une

fuite, le remplacer immédiatement.

Ne jamais faire de réparations, de

soudures ou de modifications au

réservoir d'air ou à ses accessoires.

N'utiliser que les pièces détachées

de votre concessionnaire John Deere

pour réparer votre compresseur.

Ne jamais modifier les pressions

établies en usine.

Ne jamais excéder la valeur maximale

de pression recommandée des

accessoires établi par le fabricant.

En raison de la chaleur extréme, ne

pas utiliser de tuyau en plastique ou

de joints soudés à l'étain/fer pour la

conduite de décharge.

Ne jamais utiliser le compresseur pour

goner de petits objets à faible pression

tels que les jouets d'enfants.

Manuel Compresseur d'air électrique stationaire 25

Page 24

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

RISQUE

RISQUE DE PROBLEME

RESPIRATOIRE

IMPORTANT SAFETY INSTRUCTIONS

POTENTIAL CONSEQUENCE

Respirer l'air comprimé peut entraîner

des blessures graves allant jusqu'à

la mort. Le jet d'air peut contenir

de l'oxyde de carbone, des vapeurs

toxiques, ainsi que des particules

solides.

Les matériaux pulvérisés tels que la

peinture, les solvants de peinture,

les décapants, les insecticides, les

désherbants et autre contiennent des

vapeurs nocives et toxiques.

Ne jamais inhaler l'air émis par le

compresseur, que ce soit directement

ou au moyen d'un dispositif respirateur

branché au compresseur.

N'utiliser l'appareil que dans unb

endroit bien aéré. Suiver toutes les

instructions de sécurité données avec

les matériaux que vous pulvérisez.

L'usage d'un masque respiratoire peut

être nécessaire quand vous travaillez

avec certains matériaux.

PREVENTION

RISQUE DE BRULURES

RISQUE DE PROJECTION

D'OBJETS

Le fait de toucher les surfaces de

métal exposées peut causer de

graves blessure. Ces surfaces

peuvent rester chaudes pendant

un certain temps aprés l'arrêt du

compresseur.

Des blessures graves peuvent être

provoquées par des débris solides

projetés à grande vitesse par le jet

d'air comprimé.

Le jet d'air comprimé peut causer

des lésions aux tissus de la peau

exposée.

Ne jamais laisser aucune partie de

votre corps ou autre matériaux entrer

en contact avec les surfaces de métal

exposées de votre compresseur.

Porter toujours des l u n e t t e s

protectrices an de vous protéger

les yeux contre les projections de

débris.

Ne jamais diriger le jet d'air vers

votre corps, d'autres individus ou

des animaux.

Ne jamais laisser d'air sous pression

dans le compresseur. Mettez vous à

la position arrêt et relâchez la pression

avant de ranger ou d'entamer

l'entretien de votre appareil.

Ecarter toute personne ou animal

de la zone d'utilisation quand le

compresseur fonctionne.

26 Manuel Compresseur d'air électrique stationaire

Page 25

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ

LISEZ TOUTES LES INSTRUCTIONS DE SÉCURITÉ AVANT UTILISATION

RISQUE

RISQUE PROVENANT DES

PIECES MOBILES

CONSÉQUENCE POTENTIELLE

Risque de blessures corporelles

causé par les pièces mobiles. Ce

compresseur fonctionne (démarre/

s'arrête) automatiquement quand

l'interrupteur pression est en position

"Marche/Auto". (On/Auto)

PRÉVENTION

Avant de procéder à l'entretien,

veuiller toujours éteindre l'appareil.

Purger la pression dans le tuyau d'air

et débrancher le cordon électrique

de la prise. Toutes les réparations

du compresseur d'air doivent être

effectuées par une agence agrée

de service aprés vente. Ne parter

pas du principe qu'il est sans

risque d'effectuer un travail sur le

compresseur alors qu'il est à l'arrêt.

Il pourrait se remettre en marche à

tout moment!

Ne jamais f aire fonctionn er le

compresseur sans gardes et caches

de protection. Débrancher toujours

le compresseur avant d'enlever toute

garde de protection. Remplacer les

gardes et caches de protection si

elles sont endommagées avant de

se servir du compresseur.

RISQUE CAUSE PAR DE LA

NEGLIGENCE

RISQUE DE DEGATS AU

COMPRESSEUR

Risque de blessure par utilisation

négligente.

Risque de réparations importantes.

Le compresseur est interdit aux

enfants et adolescents!

Rester vigilant et attentif à vos gestes.

Ne pas utiliser l'appareil sous l'effet de

la fatigue ou sous l'inuence d'alcool

ou de drogues.

Savoir arrêter le compresseur.

Connaître à fond son

fonctionnement.

N'utiliser jamais l'appareil sans ltre

à air.

Ne pas utiliser le compresseur dans

un environnement corrosif.

Ne faire fonctionner le compresseur

que lorsqu'il est xé sur une surface

en béton an d'éviter la chute de

l'appareil.

Veuillez lire toutes les instructions

d'entretien contenues dans ce

manuel.

! GARDER CES INSTRUCTIONS!

Manuel Compresseur d'air électrique stationaire 27

Page 26

COMPOSANTS DU COMPRESSEUR D'AIR ELECTRIQUE

STADE PAR DEUX

(Ne comprend pas le cordon de secteur, la prise électrique, le régulateur de pression)

AM2-SE05-80J FEATURES

1. Moteur électrique

2. Décalque-Instructions d'entretien

3. Soupape de retenue

4. Décalque-Instructions de

fonctionnement

5. Filtre d'admission d'air

6. Décalque-Avertissement: Surface

7. Conduite de décharge de la pompe

8. Carter de courroie

9. Ouvertures de ventilation

10. Orice de remplissage d'huile

11. Pompe du compresseur

12. Indicateur de niveau d'huile à vue

directe

28 Manuel Compresseur d'air électrique stationaire

13. Bouchon de vidange d'huile de la

pompe

14. Adaptateur de sortie

15. Ouvertures d'inspection du réservoir

16. Assemblage du réservoir d'air

17. Pied

18. Robinet de purge du réservoir

19. Interrupteur Moteur/Pression

20. Manométre du réservoir d'air

Chaude

21. Soupape de sûreté

22. Décalque-Danger/Avertissement/

Attention

Page 27

VUE DETAILLEE ET EXPLICATION DES COMPOSANTS DU COMPRESSEUR

ROBINET DE PURGE DU RESERVOIR D'AIR: Le rôle du robinet de purge est

d'évacuer l'humidité du/des réservoir(s) après l'arrêt de l'appareil. NE TENTER JAMAIS

d'ouvrir le robinet de purge du réservoir d'air quand la pression qu'il contient

dépasse 10 PSI (0.68 BAR)! Pour ouvrir le robinet de purge, tourner le bouton dans

le sens inverse des aiguilles d'une montre.

NDICATEUR DE NIVEAU D'HUILE A VUE DIRECTE: L'indicateur de niveau d'huile

à vue directe indique le niveau d'huile dans la pompe. Le niveau d'huile doit être

au centre de l'indicateur. Si le niveau d'huile est bas, ajouter de l'huile non détersive

SAE30.

ORIFICE DE REMPLISSAGE D'HUILE: Verser de l'huile dans l'orice de remplissage

d'huile quand cela sera nécessaire.

FILTRE D'ADMISSION D'AIR: Ce ltre est conçu pour nettoyer l'air qui entre dans

la pompe. Pour assurer que la pompe reçoit en permanence un air propre, frais et

sec, ce ltre doit toujours être propre et les ouvertures de ventilation libres de toute

obstruction. Remplacer l'element du ltre dès que nécessaire.

POMPE DU COMPRESSEUR D'AIR: Pour comprimer l'air, le piston se déplaçe de haut en bas dans le

cylindre. Dans la course descendante, l'air entre dans les soupapes d'admission d'air pendant que les

soupapes d'échappement d'air demeurent fermées. Dans la course ascendante, l'air est comprimé, la

soupape d'admission se ferme et l'air comprimé est poussé vers les soupapes d'échappement, passe par

la conduite de décharge puis, par la soupape de retenue et/ou la valve pilote pour nalement aboutir dans

le réservoir d'air.

INTERRUPTEUR MOTEUR/PRESSION: Cet interrupteur est utilisé pour démarrer

ou arrêter le compresseur. Mettre cet interrupteur en position de mise en marche

(ON) fournira une mise sous tension automatique à l'interrupteur de pression ce qui

permettra au moteur de démarrer quand la pression du réservoir d'air baissera sous

"la pression d'enclenchement" établie en usine. Quand l'interrupteur est en option

Marche/Arrêt, l'interrupteur arrête le moteur quand la pression du réservoir d'air

atteint "la pression de coupe-circuit" établie en usine. Par raison de sécurité, cet interrupteur a aussi un

détendeur de pression situé dans l'interrupteur et qui est conçu pour libérer automatiquement l'air comprimé

de la tête de la pompe du compresseur et de sa conduite de décharge lorsque le compresseur atteint "la

pression de coupe-circuit" ou qu'il est arrêté. Le détendeur de pression permet au moteur de redémarrer

sans problème. Appuyer sur l'interrupteur pour le mettre en position d'arrêt (OFF) coupera le courant de

l'interrupteur pression et arrêtera le compresseur d'air.

SOUPAPE DE SURETE: Cette soupape est conçue pour empêcher des pannes du systéme

en diminuant la pression du systéme quand l'air comprimé atteint un niveau prédeterminé.

La soupape est programmée par le fabricant et ne doit être modiée en aucune façon.

Pour vérier que la soupape marche correctement, tirer sur l'anneau. De l'air sous pres-

sion devrait s'échapper. Quand l'anneau est relaché, il se remet en place.

MANOMETRE DU RESERVOIR D'AIR: Le manomètre du réservoir d'air indique la

pression d'air en réserve dans le/les réservoir(s).

DÉMARRER: Le moteur assure la protection thermique de surcharge. Le démarreur

est exigé sur la puissance de cheval des moteurs 5 et ci-dessus.

Manuel Compresseur d'air électrique stationaire 29

Page 28

NOTES

30 Manuel Compresseur d'air électrique stationaire

Page 29

AVERTISSEMENT

LES PAGES SUIVANTES CONTIENNENT LES

CONSIGNES D'UTILISATION ET D'ENTRETIEN.

NE TENTER PAS DE FAIRE FONCTIONNER CE

COMPRESSEUR D'AIR AVANT D'AVOIR LU ET

COMPRIS TOUTES LES PRECAUTIONS ET

CONSIGNES DE SECURITE CONTENUES DANS

CE MANUEL.

L'UTILISATION INAPPROPRIEE DE CET

APPAREIL PEUT CAUSER DES BLESSURES

SERIEUSES!!

NE PAS ALTERER OU MODIFIER CET

EQUIPEMENT EN AUCUNE MANIERE!

Manuel Compresseur d'air électrique stationaire 31

Page 30

AVERTISSEMENT

PIED DE DÉFI

PIED DE DÉFI SOUDÉ

AU RÉSERVOIR

RONDELLE-3/8 POUCES (10 mm)

BÉTON

BOULON D'ANCRAGE POUR

BÉTON DE 3/8 POUCES (10 mm)

MINIMUM, RESISTANT AUX

VIBRATIONS, EN ACIER PLAQUÉ

ZINE OU EN INOX (N'EST PAS FOURNI)

INSTRUCTIONS DE PREPARATION

INSTALLATION INITIALE:

RISQUE D'EXPLOSION OU

D'INCENDIE ENTRAÏNANT

DES BLESSURES GRAVES OU

LA MORT!

Ne pas permettre au moteur ou

à l'interrupteur Moteur/Pression d'entrer en contact avec

des vapeurs inammables, des

gaz , de la poussière ou autres

matériaux combustibles. Une

étincelle pourrait entraîner un

incendie.

Quand le compresseur sert à

pulvériser de la peinture, le

placer aussi loin que possible

du champ de travail.

1. Lire les consignes de sécurité avant d'installer le compresseur.

2. S'assurer que le niveau d'huile dans la pompe du compresseur est

sufsant. Si il est bas, ajouter de l'huile non-détersive SAE .

EMPLACEMENT:

1. Pou r évit er d'ab îmer l e c ompr esseu r, n e pas l'i ncli ner

transversalement ou longitudinalement plus de 10°.

2. Placer le compresseur sur une surface en béton à une distance d'au

moins 12 pouces (0.30M) de tout obstacle qui pourrait empêcher une

bonne ventilation. Placer le coté du volant de l'appareil vers le mur.

Ne pas placer le compresseur dans un endroit:

-où il y a des traces d'huile ou de carburant.

-où des vapeurs ou des substances de gaz inammable peuvent être

présentes.

-où la température de l'air tombe en-dessous de 32°F (0°C) ou

dépasse 104°F (40°C).

-où de l'air ou eau très sales pourraient être aspirés dans le

compresseur.

3. Répartisser le poids du compresseur également. Une vibration excessive

peut affaiblir le réservoir d'air créant un risque d'explosion.

4. Boulonner le compresseur à une surface en béton:

a. Marquer les endroits à travers les pieds du compresseur où les

boulons d'ancrage seront placés.

b. Deplacer le compresseur et percer des trous dans les endroits

marqués où seront placés les boulons d'ancrage.

c. Marteler les boulons d'ancrage avec l'écrou attaché dans les trous

déjà percés.

d. Enlever les écrous et placer le compresseur au dessus des boulons

d'ancrage.

e. Remplacer et serrer les écrous.

32 Manuel Compresseur d'air électrique stationaire

Page 31

INSTRUCTIONS DE PREPARATION

L1 L2 L3

G

L2

L1

Power

In

1 Phase

ELECTRIQUE:

1. Un électricien qualié DOIT installer le systéme électrique.

a. Vérier que la source d'alimentation électrique est éteinte:

b. Etre certain que tous les interrupteurs sur le tableau de commande

sont en position "OFF" (Arrêt).

c. Faire les raccordements à la borne comme montré çi-dessous.

DANGER

RISQUE D'ELECTROCUTION

Un mauvais raccordement du

conducteur de masse peut

être la cause d'un risque de

décharge ou d'électrocution.

Vérier avec un électricien ou

un personnel de service qualié

si vous avez un doute quant au

raccordement de masse. Le l

recouvert d'une gaine isolante

dont la surface externe est verte

- avec ou sans rayures jaunes

est le l de terre.

AVERTISSEMENT

RISQ U E D E DECHAR G E

ELECTRIQUE!

Ce produit doit être raccordé à la

terre. Si un court circuit ou une panne

devaient survenir, la masse fournit un

circuit de résistance moindre pour le

courant électrique an de réduire le

risque de décharge.

POINTS DE CONTROLE AVANT DEMARRAGE:

1. Vérier le niveau d'huile. Ajouter de l'huile si nécessaire.

2. Enlever toute humidité du réservoir d'air du compresseur. NE

TENTER JAMAIS d'ouvrir le robinet de purge du réservoir d'air

quand la pression qu'il contient dépasse 10 PSI (0.68 BAR)! Enlever

la pression excessive avec un outil pneumatique, puis, ouvrir le robinet

de purge du réservoir d'air situé en bas du réservoir d'air. Bien fermer

une fois vidé.

3. S'assurer que l'interrupteur Moteur/Pression est dans la position "Arrêt"

(OFF).

4. S'assurer que la soupape de sûreté marche correctement.

5. S'assurer que toutes les gardes et caches de protection sont en place

et sont solidement assemblées.

Manuel Compresseur d'air électrique stationaire 33

AVERTISSEMENT

RIS Q U E DE BLESS U R ES

CORPORELLES!

NE TENTER JAMAIS d'ouvrir le

robinet de purge du réservoir

d'air quand la pression qu'il

contient dépasse 10 PSI (0.68

BAR)!

Page 32

AC Ele. Maintenance Chart French

TABLEAU D'ENTRETIEN

PROCÉDURES TOUS

LES

JOURS

TOUTES

LES

SEMAINES

TOUS LES

MOIS

TOUTES

LES 200

HEURES

Vérifier le niveau d'huile de la ompe X

Insection de fuite d'huile X

Evacuer la condensation de/des

réservoir (s) d'air

X

Inspection des gardes et caches de

protection

X

Vérifier si i l y a des bruits insolites ou

des vibrations

X

Rechercher d'é ventuelles fuites d'air X

Nettoyer l'extérieur du compresseur X

Inspecter le filter à air X

Inspecter la courroie X

Vérifier la soupape de sûreté X

Changer l'huile de pompe* X

Remplacer le filtre à air X

INSTRUCTIONS DE FONCTIONNEMENT

DEMARRAGE:

1. Lire les avertissements de sécurité avant de mettre le compresseur en

marche.

2. Tirer l'interrupteur Moteur/Pression vers le haut jusqu'à la position "AUTO".

3. Si vous remarquez des bruits insolites ou des vibrations, arrêtez le compresseur

et consulter la partie "Dépannage".

ARRET:

1. Pour arrêter le compresseur, pousser l'interrupteur Moteur/Pression jusqu'à

la position "Arrêt" (OFF).

2. Vider l'air des réservoirs d'air en relâchant l'air avec un outil pneumatique

attaché ou en tirant sur la soupape de sûreté.

3. Un fois que le manomètre du réservoir d'air enregistre moins de 10 livres (4.5

KG), ouvrir le robinet de purge du réservoir d'air sous chaque réservoir d'air

pour laisser échapper toute humidité.

4. Permettre au compresseur de refroidir, puis le nettoyer en l'essuyant.

INSTRUCTIONS D'ENTRETIEN

Lire le manuel d'instruction avant d'entretenir le compresseur. Les procédures

suivantes doivent être effectuées lors de l'arrêt de la machine pour l'entretien ou

la réparation:

1. Arrêter le compresseur d'air.

2. Ouvrir tous les orices de vidange.

4. Attendre que le compresseur refroidisse avant de l'entretenir.

*L'huile de pompe doit être changée aprés les premières 100 heures d'opération

et toutes les 1000 heures ou 3 mois, selon la limite qui est atteinte en premier.

Tous les 2 ans, un technicien de service autorisé doit vérier la soupape de retenue,

les soupapes d'approvisionnement et les soupapes de distribution.

34 Manuel Compresseur d'air électrique stationaire

AVERTISSEMENT

RISQUE DE BLESSURES

CORPORELLES!

NE PARTEZ PAS DU

PRINCIPE QU'IL EST SANS

RISQUES D'EFFECTUER

UN TRAVAIL SUR LE

COMPRESSEUR ALORS

QU'IL EST A L'ARRET! IL

POURRAIT SE REMETTRE

EN MARCHE A TOUT

MOMENT!

Page 33

DEPANNAGE

SYMPTOME CAUSE PROBABLE REMEDE

Le compresseur ne veut pas

démarrer.

Interrupteur Moteur/Pression est en

position d'arrêt (OFF). .

Déclencheur de surcharge thermique du moteur activé.

Disjoncteur déclenché ou fusible

grillé dans la boîte à fusibles.

Le voltage du moteur n'est pas égal

à la source d'énergie.

La pression du réservoir d'air a at-

teint le niveau de pression maximum

ou "arrêt" (Stop) de l'interrupteur

Moteur/Pression.

Tirer l'interrupteur Moteur/Pression

jusqu'à la position "ON".

Eteindre l'appareil, attendre 5 minutes, puis appuyer sur l'interrupteur

de Surcharge Thermique du moteur

jusqu'à ce que vous entendiez un

déclic.

Réarmer le disjoncteur ou remplacer

le fusible en utilisant seulement un

fusible de "Fusetron" genre T.

Vérier que la tension n'est pas trop

faible.

Débrancher tous les autres appareils

sur le circuit ou utiliser le compresseur sur son propre circuit.

Contacter service clientèle.

Le moteur démarrera automatiquement quand la pression du réservoir

d'air redescendra au niveau de "pression d'enclenchement" ou la pression

"Start" de l'interrupteur Moteur/Pres-

sion.

Le compresseur d'air ne

démarre pas, mais le moteur

ronronne puis s'arrête.

La soupape de sûreté de pression

sur l'interrupteur Moteur/Pression

bloquée en position ouverte ne peut

libérer la pression de la tête.

Le clapet de retenue de la valve

pilote est bloqué en position ouverte.

Moteur ou interrupteur Moteur/Pression défectueux.

Mauvais contact.

Trop d'appareils marchent sur le

même circuit.

Tension incorrecte, ou disjoncteur,

fusible ou moteur de la mauvaise

taille.

Soupape de retenue ou interrupt-

eur Moteur/Pression défectueux.

Purger la ligne en mettant

l'interrupteur Moteur/Pression en position "Arrêt" (OFF).

Enlever et nettoyer ou remplacer.

Contacter votre service clientèle.

Contacter un électricien qualié.

Se servir d'un autre circuit ou

enlever les appareils en trop du

circuit.

Contacter un électricien qualié.

Remplacer.

Manuel Compresseur d'air électrique stationaire 35

Page 34

DEPANNAGE

SYMPTOME CAUSE PROBABLE REMEDE

Le compresseur ne s'arrête

pas bien que la pression

maximale permise soit at-

teinte.

Fonctionnement bruyant

Interrupteur Moteur/Pression ne

fonctionne pas correctement.

Poulie du moteur ou volant de la

pompe desserrées.

Manque d'huile dans la pompe.

Dépôts de carbone sur les pistons

ou les soupapes.

Remplacer.

Resserrer la poulie et/ou le volant.

Ajouter une quantité correcte d'huile.

Vérier si il y a des dommages aux

paliers.

Enlever la tête du cylindre et

l'inspecter. Nettoyer ou remplacer le

siège de la soupape.

Perte de pression dans le

réservoir d'air ou perte de pression rapide quand le compres-

seur est mis à l'arrêt.

Pression insufsante pour faire

fonctionner les outils pneuma-

tiques ou les accessoires.

Panne des paliers, pistons ou

ensemble de bielle.

Fuite d'air aux raccords. Laisser le compresseur accumuler

Soupape de retenue ou valve

pilote défectueuses.

Fuite d'air dans le réservoir.

Fuites d'air ou restrictions d'air.

Filtre d'admission d'air bouché.

Les conduites, tuyaus ou raccords

de tuyau sont trop petits ou longs.

Le compresseur n'est pas assez

gros pour les exigences d'air.

ARRETER LE COMPRESSEUR!

Contacter service clientèle.

le maximum de pression permis.

Eteindre et passer un coup de

brosse à l'eau savonneuse sur

tous les raccords. Rechercher

d'éventuelles bulles d'air aux raccords. Resserrer les raccords là où

se trouvent les fuites.

Enlever, nettoyer ou remplacer.

Le réservoir d'air doit être remplacé.

N'essayer pas de réparer le réservoir.

Rechercher les fuites et réparer.

Nettoyer ou remplacer le ltre.

Remplacer par des conduites, tuy-

aus ou des raccords plus gros.

Servez-vous soit d'un outil plus petit

ou d'un compresseur plus grand.

La courroie glisse.

Valve pilote obstruée.

Fuite d'air à la soupape de

sûreté.

36 Manuel Compresseur d'air électrique stationaire

Possibilité d'une soupape de sûreté

défectueuse.

Pression excessive du réservoir

d'air.

Resserrer ou remplacer.

Nettoyer ou remplacer.

Faire fonctionner la soupape de

sûreté manuellement en tirant sur

l'anneau. Si elle fuit toujours, elle

devrait être remplacée.

Remplacer l'interrupteur Moteur/Pression. Nettoyer, réinitialiser ou rem-

placer la valve pilote.

Page 35

DEPANNAGE

SYMPTOME CAUSE PROBABLE REMEDE

Fuite d'air à la pompe.

De l'air continue de fuire

au niveau de l'interrupteur

Moteur/Pression lorsque le

moteur marche.

Soufement d'air provenant

du ltre d'admission d'air.

Le moteur marche sans arrêt

quand il est en position "Marche/

Arrêt" (Start/Stop).

Joints défectueux.

Interrupteur Moteur/Pression défectueux.

Soupape (reed) d'admission

défectueuse.

L'interrupteur moteur/pression

ne coupe pas le moteur quand le

compresseur atteint "la pression

de coupe-circuit" et la soupape de

sûreté s'active.

Couple de serrage des boulons:

Etage unique= 17 ft./lbs (23N.m).

Double Etage= 33 ft./lbs (45N.m).

Remplacer.

Enlever la tête du cylindre et inspecter. Nettoyer ou remplacer le

siège de la soupape.

Mettre l'interrupteur Moteur/Pression en position d'arrêt (OFF). Si le

moteur ne s'arrête pas, débrancher

le compresseur. Sil les contacts

électriques sont soudés ensemble,

remplacer l'interrupteur de pression.

Le compresseur est de la mauvaise taille.

Humidité dans l'air de décharge. Condensation dans le réser-

voir causée par un haut niveau

d'humidité atmosphérique.

Consommation excessive d'huile

ou huile dans le tuyau.

Filtre d'admission d'air obstrué.

Le compresseur n'est pas sur une

surface plane.

Le carter déborde d'huile.

Mauvaise viscosité.

Limiter la pression d'air proportio-

nellement à la capacité du compresseur. Servez-vous soit d'un

outil plus petit ou d'un compresseur

plus grand.

Purger le réservoir après chaque

utilisation.

Purger le réservoir d'air encore

plus souvent quand le temps est

humide et se servir d'un ltre à air

dans le tuyau.

Nettoyer ou remplacer.

Ne pas incliner le compresseur

plus de 10° dans aucune direction

pendant qu'il fonctionne.

Purger l'huile. Remplir jusqu'au

bon niveau avec de l'huile non-détersive SAE-30W.

Purger l'huile. Remplir jusqu'au

bon niveau avec de l'huile non-détersive SAE-30W.

Orice de la jauge d'huile bouché.

L'huile fuit.

Segments usés ou cylindre rayé.

Manuel Compresseur d'air électrique stationaire 37

Nettoyer.

Resserrer les boulons de pompe à

un serrage de couple comme indiqué dans le manuel des pièces de

rechange, ou remplacer les joints.

Contacter service clientèle.

Page 36

DEPANNAGE

SYMPTOME CAUSE PROBABLE REMEDE

L'huile a un aspect laiteux. Présence d'huile dans l'eau at-

tribuable à la condensation.

Purger l'huile. Remplir jusqu'au bon

niveau avec de l'huile non-détersive

SAE-30W.

L'appareil fonctionne à l'envers. Circuit électrique est inversé. Contacter un électricien qualié.

38 Manuel Compresseur d'air électrique stationaire

Page 37

BON DE GARANTIE

Le fabricant garantit toutes les pièces (à l'exception de celles stipulées çi-dessous)

de votre nouveau compresseur d'air en cas de défauts de matériaux et de fabrication

pendant les pèriodes suivantes:

Pendant deux (2) année à partir de la date d'achat initiale:

Pompe du compresseur Tuyauterie

Assemblage du réservoir

Pendant de six (6) mois à partir de la date d'achat initiale:

Interrupteur de pression Régulateurs

Soupape de retenue Valve Pilote

Conduite de en cuivre/inoxydable

Pendant quatre vingt dix (90) jours à partir de la date d'achat initiale:

Manomètres Soupapes de sûreté

Soupapes de vidange

Les pièces défectueuses non sujettes à l'usure normale seront réparées ou

remplacées à notre choix pendant la période de garantie. Quoi qu'il arrive, le

remboursement est limité au prix d'achat.

EXCLUSIONS

1. Le moteur est couvert sous une garantie séparée par son fabricant respectif et

est sujet aux conditions mises en place à cet égard.

2. Usure normale des pièces:

Isolateurs Filtre à air

3. Cette garantie ne couvre pas les pièces endommagées par l’usure normale, des

conditions anormales, une application erronée, une mauvaise utilisation, un accident,

un fonctionnement autre qu'aux tensions, pressions et températures recommandées,

un stockage inapproprié ou des dégats de transport. Les pièces endommagées ou

usées par le fonctionnement dans des environnements poussiéreux ne sont pas

garanties. La garantie ne couvre pas les dégâts provoqués par un mauvais suivi

des procédures de fonctionnement et d’entretien .

4. Les coûts de main d'oeuvre, pertes ou dommages résultant d'une mauvaise

utilisation, l'entretien (autre que la vidange routine du réservoir d'air et les

changements d'huile si applicable) ou les réparations faites par des personnes

autre qu'un centre de service agréé du fabricant.

5. L'utilisation de toute pièce autre que des pièces de réparation authentiques de

votre concessionnaire agréé annulera la garantie. Les pièces renvoyées en port

payé, à notre usine ou à un centre de service agréé seront inspectées et remplacées

gratuitement si elles sont jugées déféctueuses après estimation, et couvertes par

la garantie. Le fabricant n’est en aucun cas responsable de la perte d'utilisation

de l'appareil, du temps perdu ou de la perte de location de l'appareil, des ennuis,

des pertes commerciales ou des dommages indirects. Il n’existe aucune garantie

prolongeant les dates d’expiration stipulées çi-dessus.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

du lundi au vendredi de 8h00 à 17h00, CST (heure centrale)

Manuel Compresseur d'air électrique stationaire 39

Page 38

40 Manuel Compresseur d'air électrique stationaire

37-0619-E/F-010809

©Copyright 2005, John Deere

Manufactured for Deere & Company

Moline, Illinois 61265

Operator’s Manual

Loading...

Loading...